Battery module and cooling device for battery module

A technology for battery modules and unit cells, applied in secondary batteries, secondary battery manufacturing, batteries, etc., can solve problems such as uneven heat dissipation, reduced charging and discharging efficiency of battery modules, and uneven cooling air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

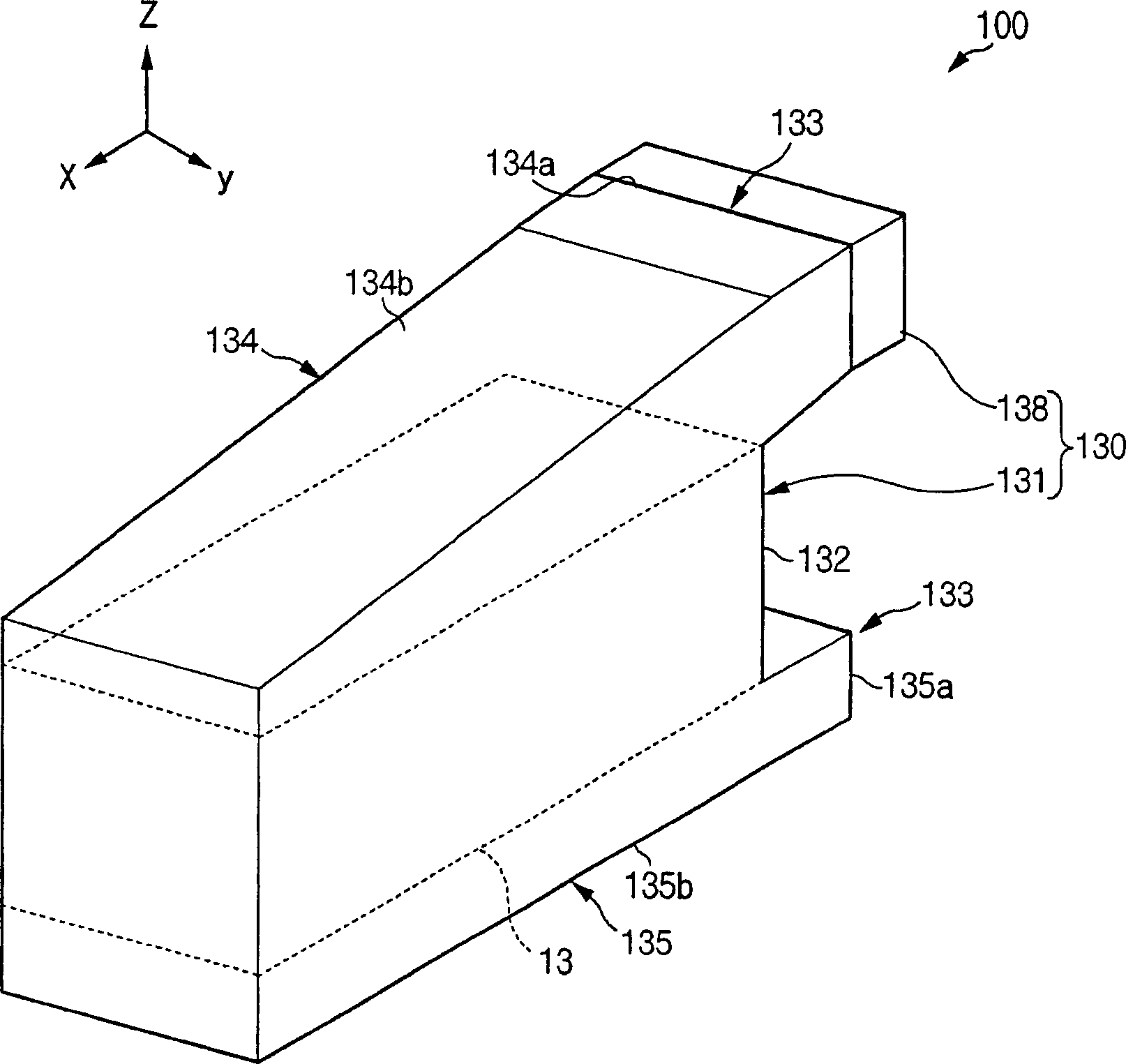

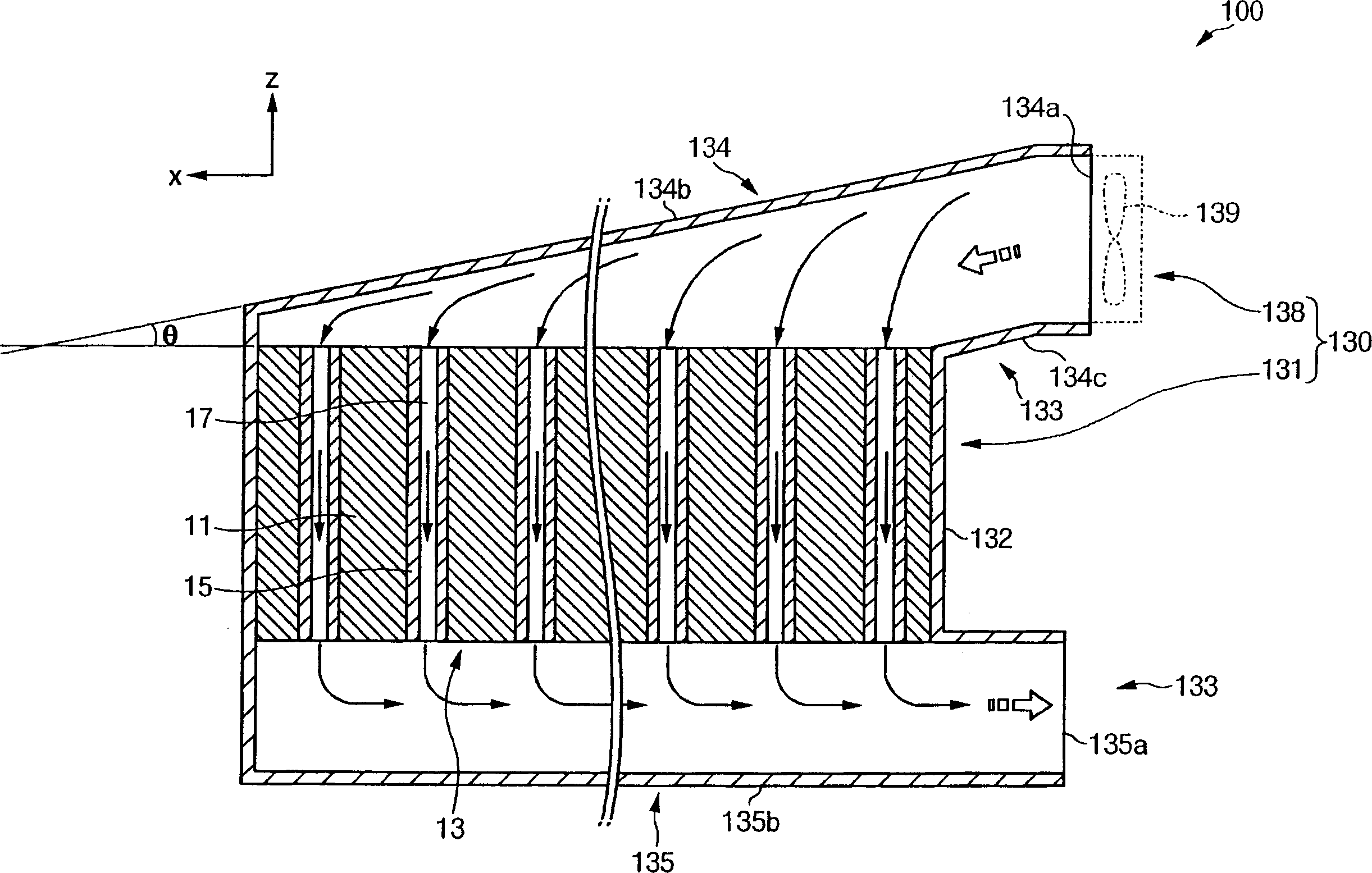

[0040] Such as figure 1 and 2 As shown, the battery module 100 of this embodiment is a high-capacity battery module, which includes a plurality of unit cells 11 arranged in series and separated from each other.

[0041] In this embodiment, each unit cell has a secondary battery including an electrode assembly including a positive electrode plate and a negative electrode plate inserted with a separator for charging and discharging.

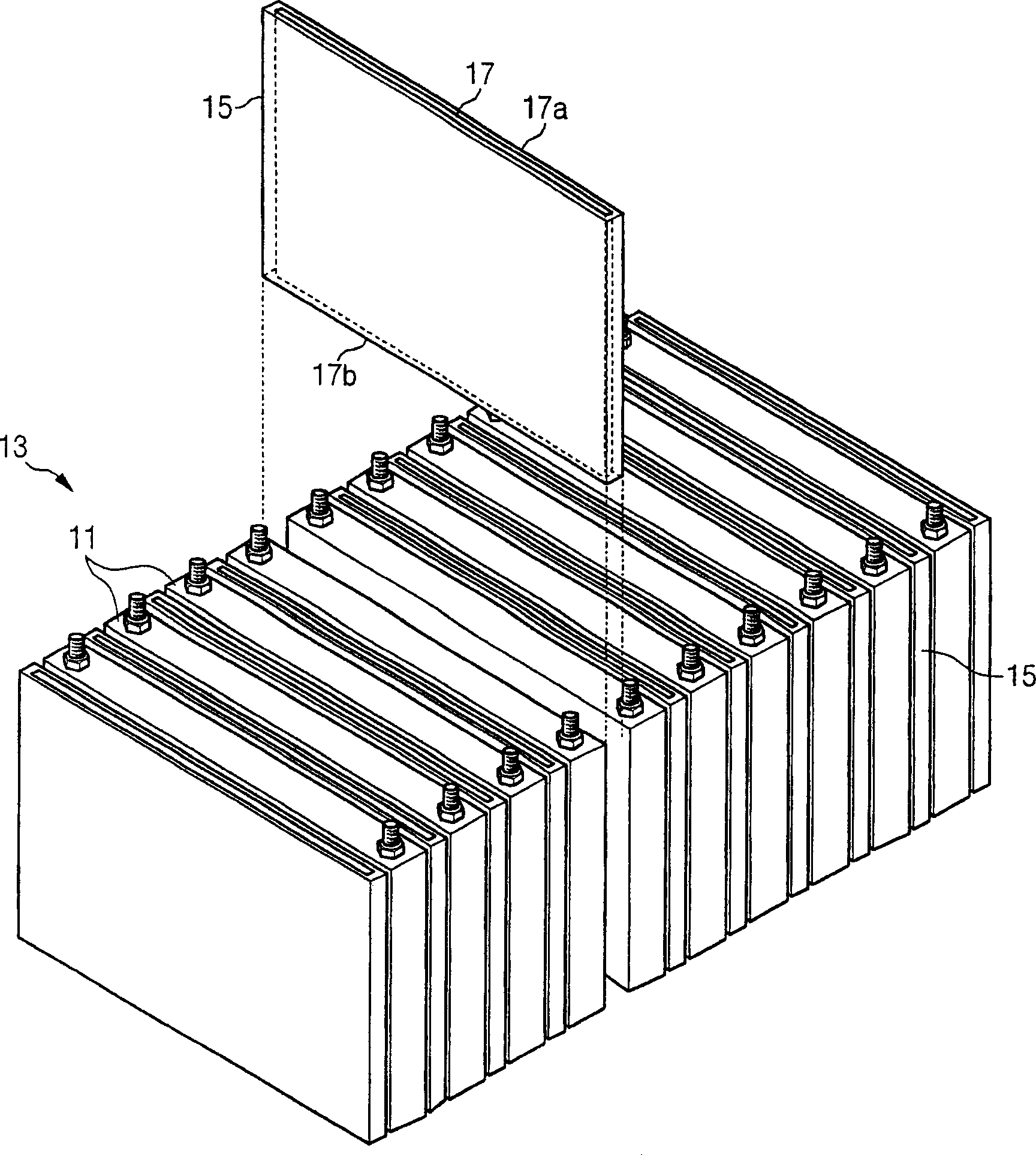

[0042] The battery separator 15 is provided between adjacent unit cells 11 and between the outermost unit cells 11 and the wall of the case 131 to maintain the distance between the unit cells 11 and to support the side of each unit cell 11. wall. An air ventilation passage 17 is formed on each battery separator 15 to allow cooling air having a lower temperature to flow through the unit cells 11 .

[0043] Such as image 3 As shown, at least one through hole extending from the edge 17a to the edge 17b of the battery separator 15 may be formed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com