Stator punching sheet storage and transportation device

A transportation device and stator punching technology, which is applied in the field of mechanical processing, can solve the problems of confusion on site, inability to be used universally, and low utilization rate of tooling, and achieve the effects of high degree of generalization, convenient access and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

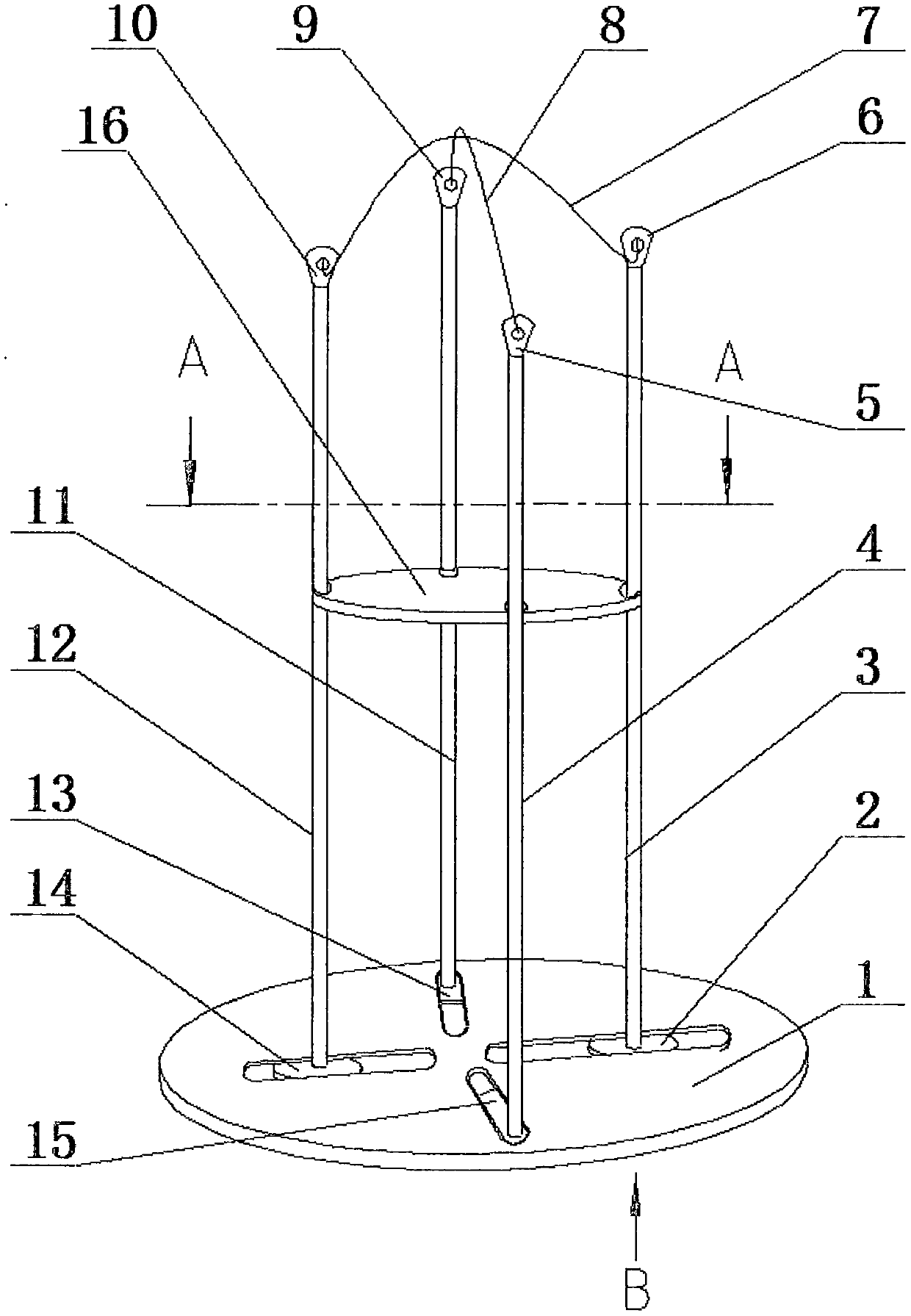

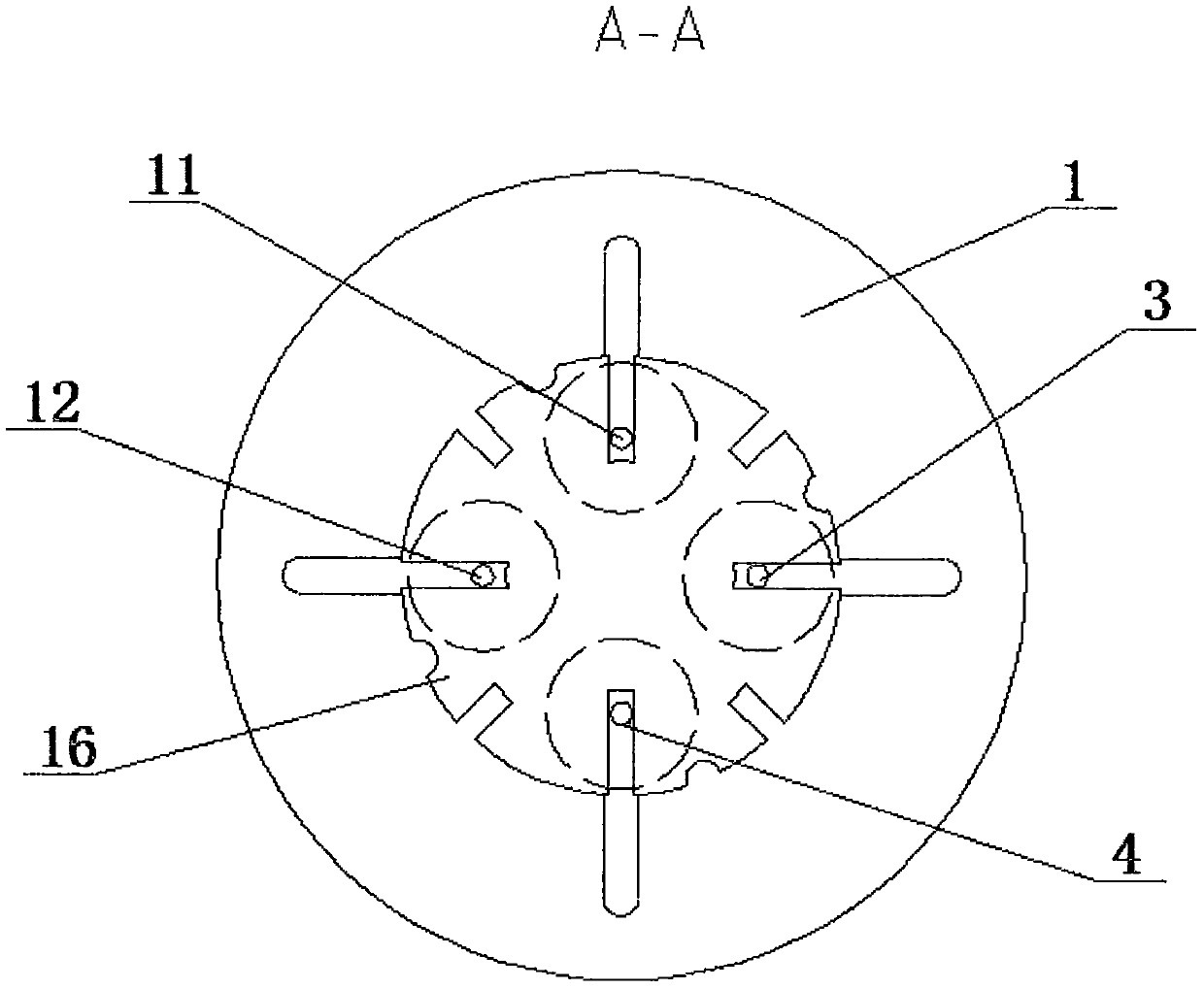

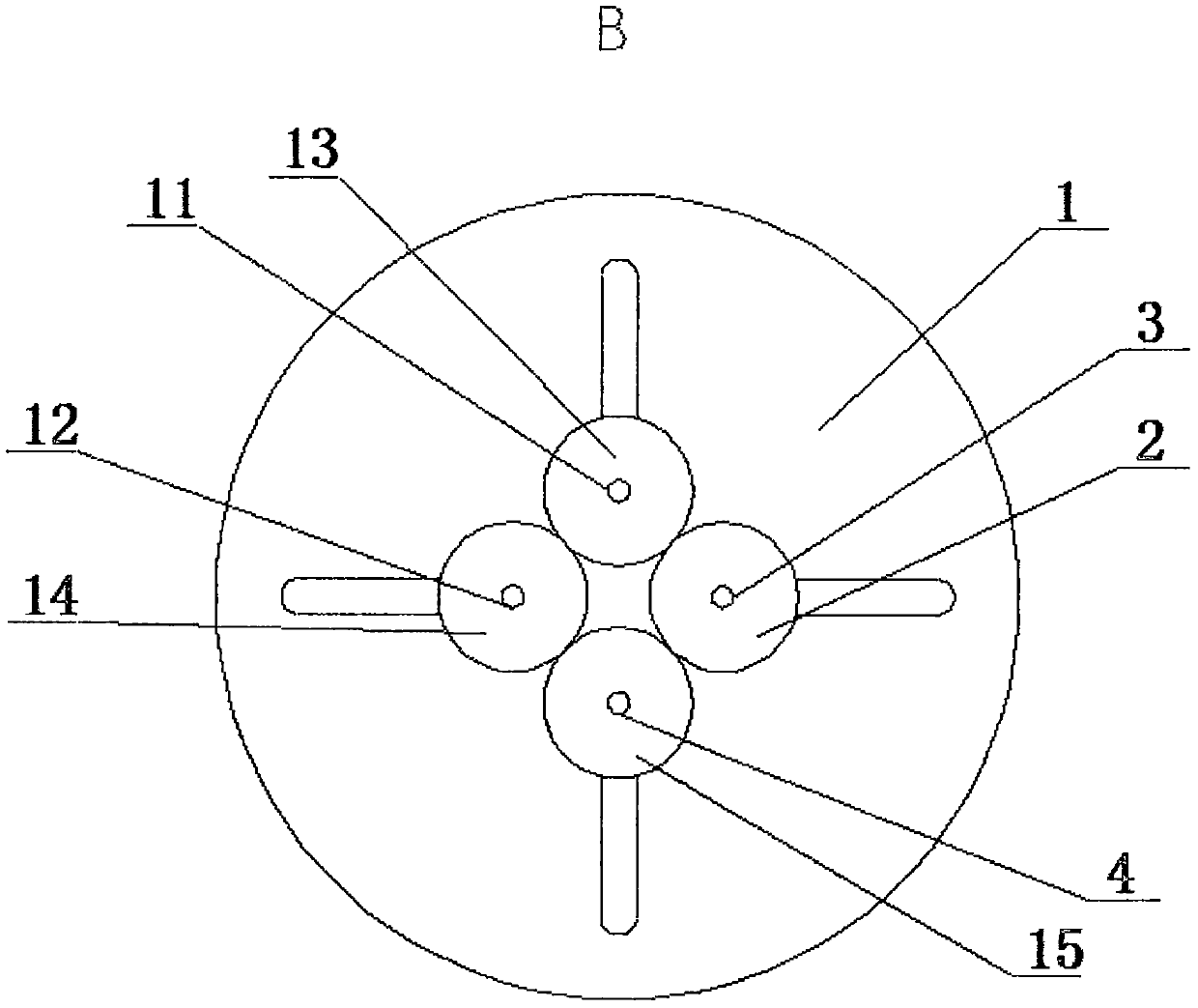

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a stator punch storage and transportation device includes a chassis 1 and a chuck 16. The chassis 1 is a circular thin-walled part, and the chassis 1 is provided with 4 oblong holes. The 4 The four oblong holes are arranged in a cross shape, the symmetrical center of the four oblong holes is the center of the chassis 1, and the oblong holes are sequentially provided with column A3, column C11, column D12 and column B4 in the counterclockwise direction. The head of the column A3 is provided with a hook A6, the bottom surface of the column A3 is provided with a disk A2, the head of the column B4 is provided with a hook B5, and the bottom surface of the column B4 is provided with a disk B15. The head of the column C11 is provided with a hook C9, the bottom surface of the column C11 is provided with a disk C13, the head of the column D12 is provided with a hook D10, and the bottom surface of the column D12 i...

Embodiment 2

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a stator punch storage and transportation device includes a chassis 1, a chuck 16 and a chuck 20, the chassis 1 is a circular thin-walled part, and the chassis 1 is provided with 4 oblong holes, The four oblong holes are arranged in a cross shape, the symmetrical center of the four oblong holes is the center of the chassis 1, and the oblong holes are sequentially arranged with column A3, column C11, column D12 and column B4 in the counterclockwise direction , the head of the column A3 is provided with a hook A6, the bottom surface of the column A3 is provided with a disc A2, the head of the column B4 is provided with a hook B5, and the bottom surface of the column B4 is provided with a disc B15 , the head of the column C11 is provided with a hook C9, the bottom surface of the column C11 is provided with a disc C13, the head of the column D12 is provided with a hook D10, and the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com