Patents

Literature

1236results about "Variable capacity containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

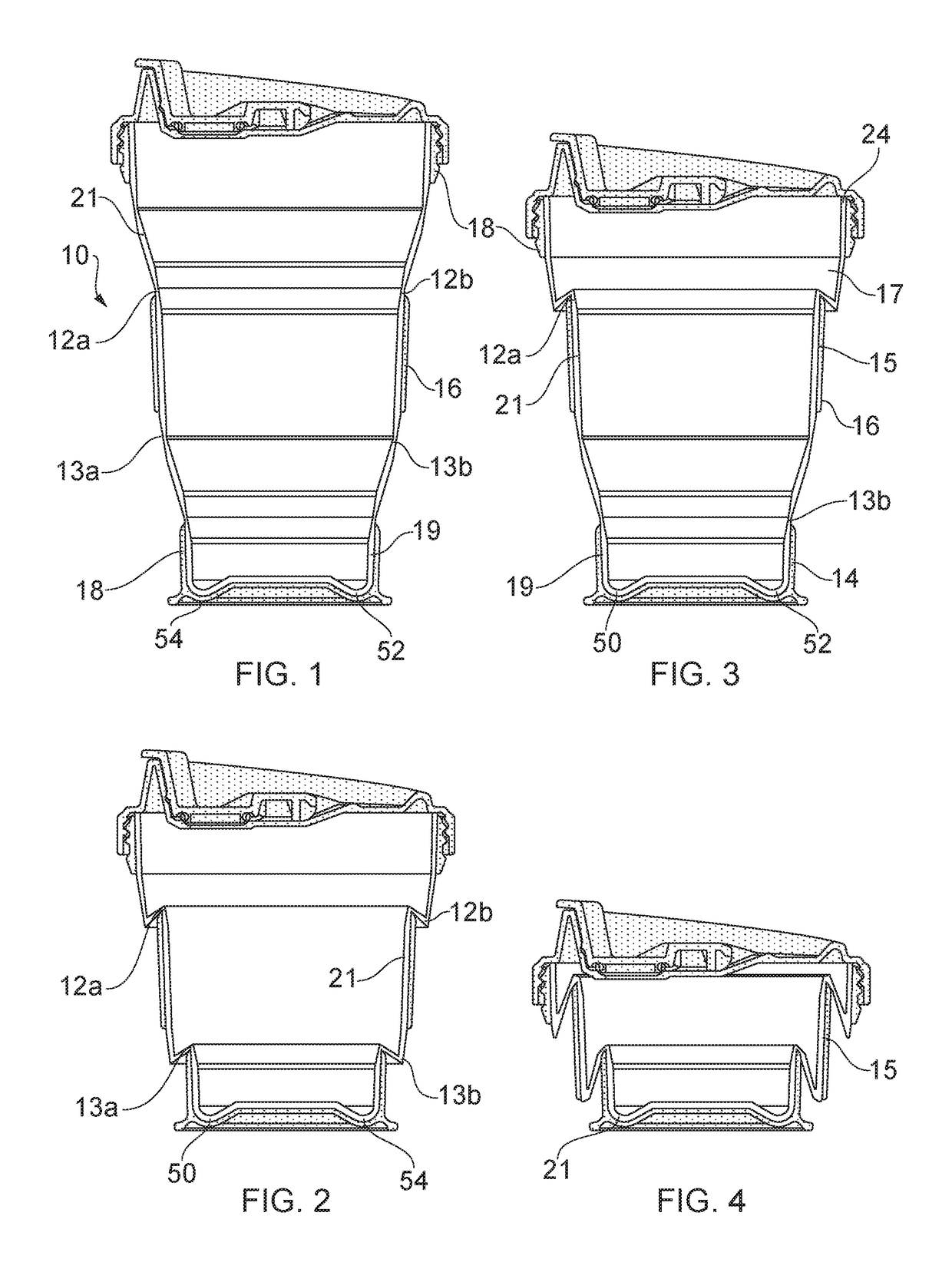

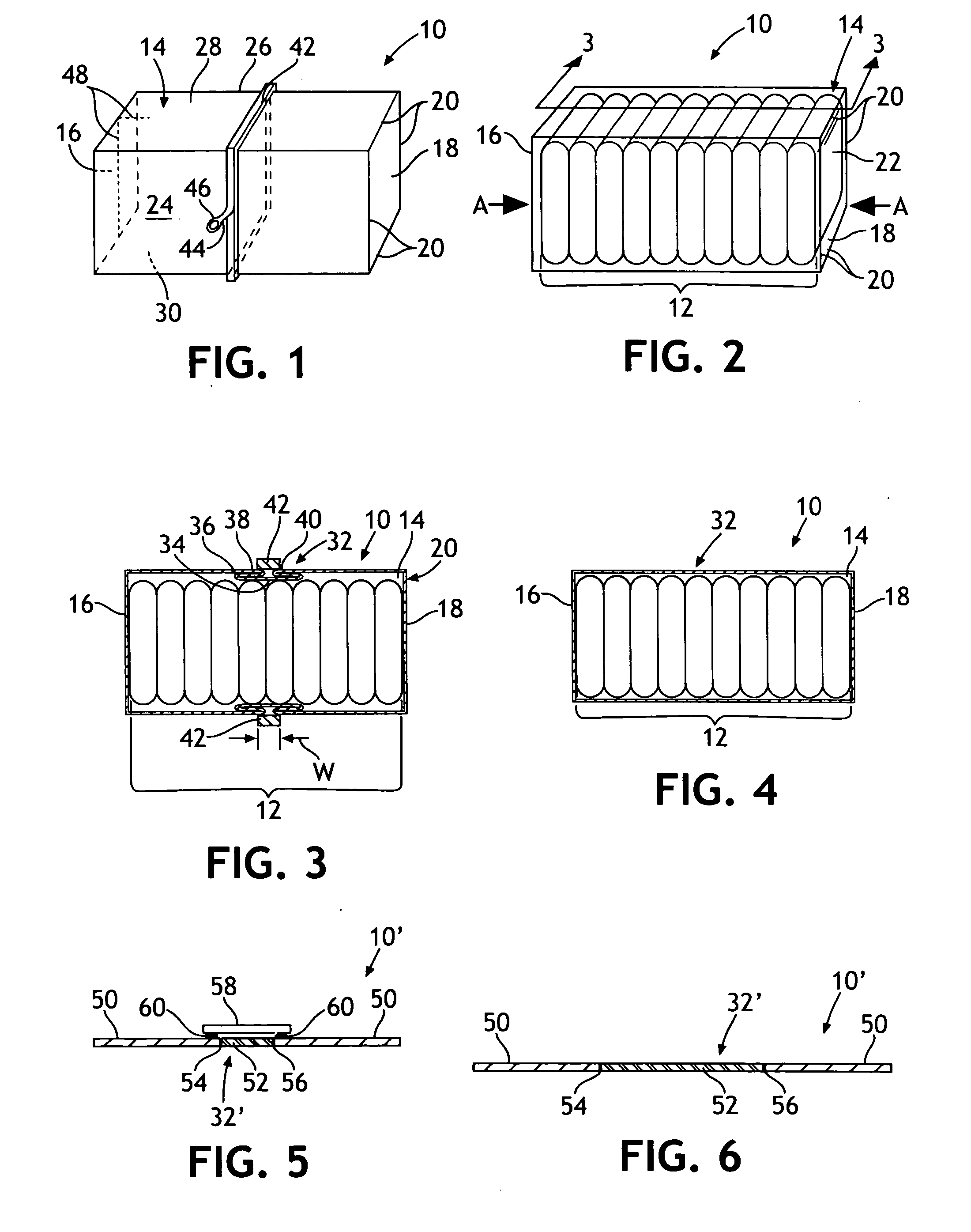

Collapsible container

ActiveUS20050127073A1Compact configurationMaximize available spaceLarge containersVariable capacity containersEngineeringMechanical engineering

Owner:DART IND INC

Collapsible container

InactiveUS20050127074A1Compact configurationBig economyVariable capacity containersEngineeringMechanical engineering

Owner:DART IND INC

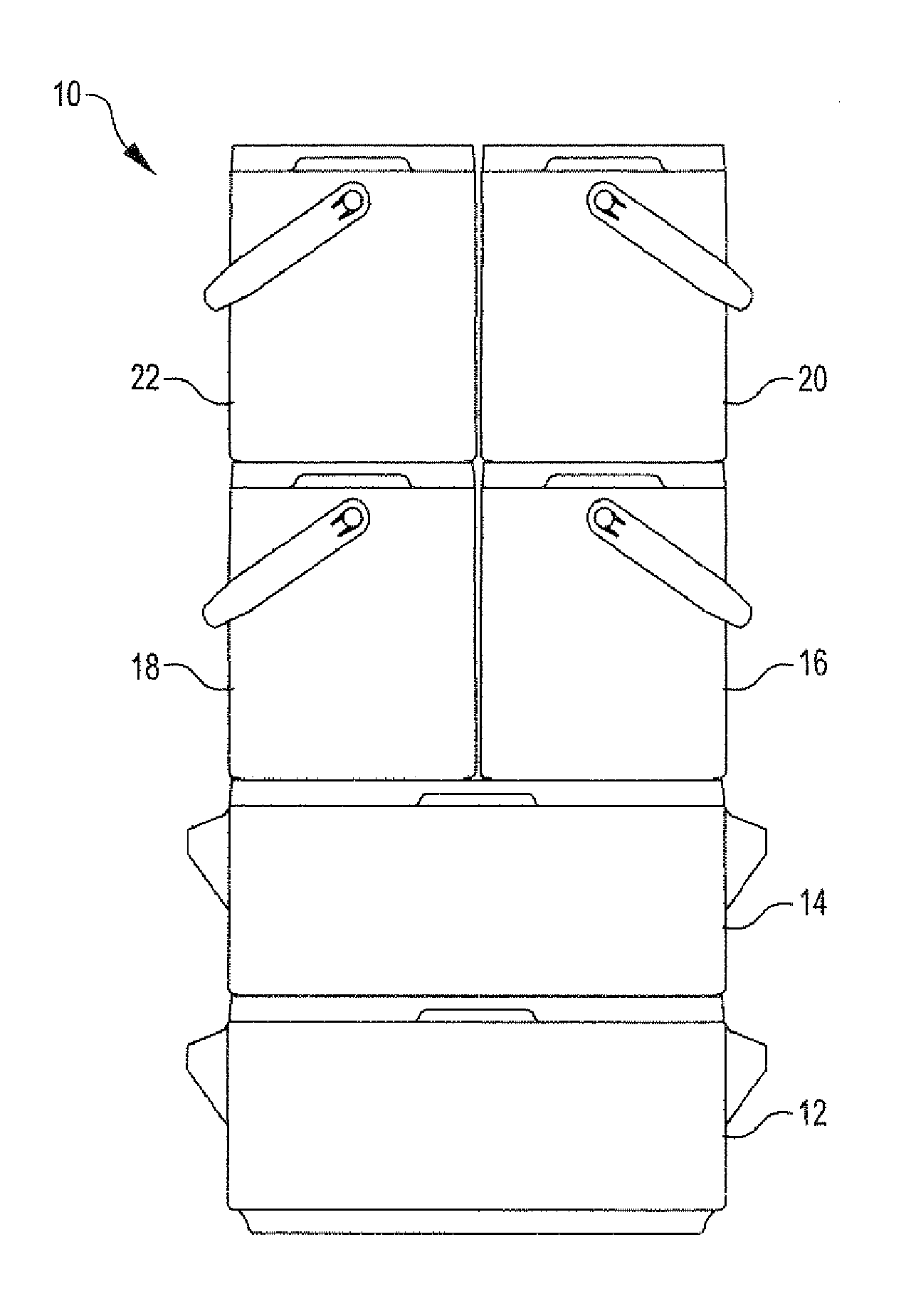

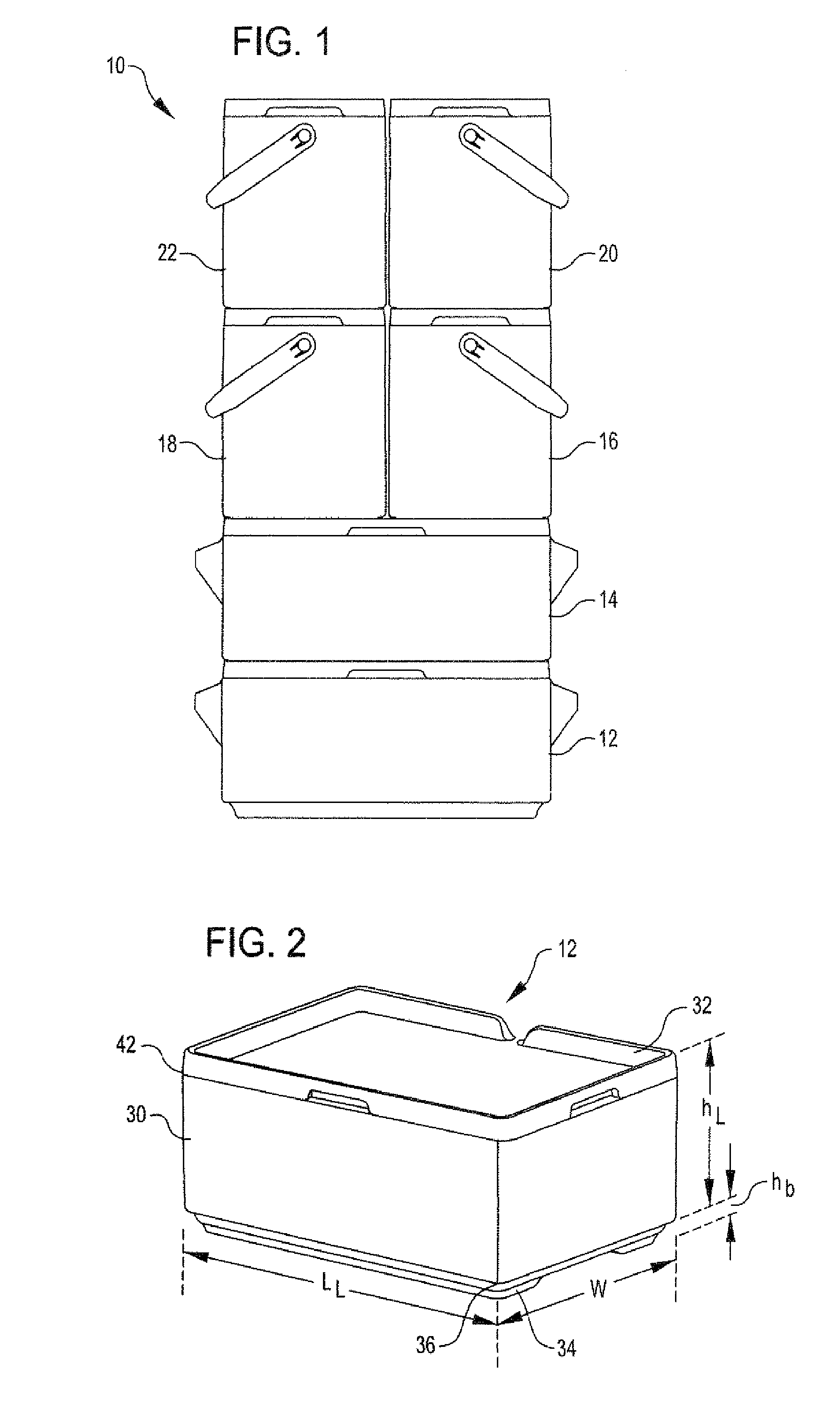

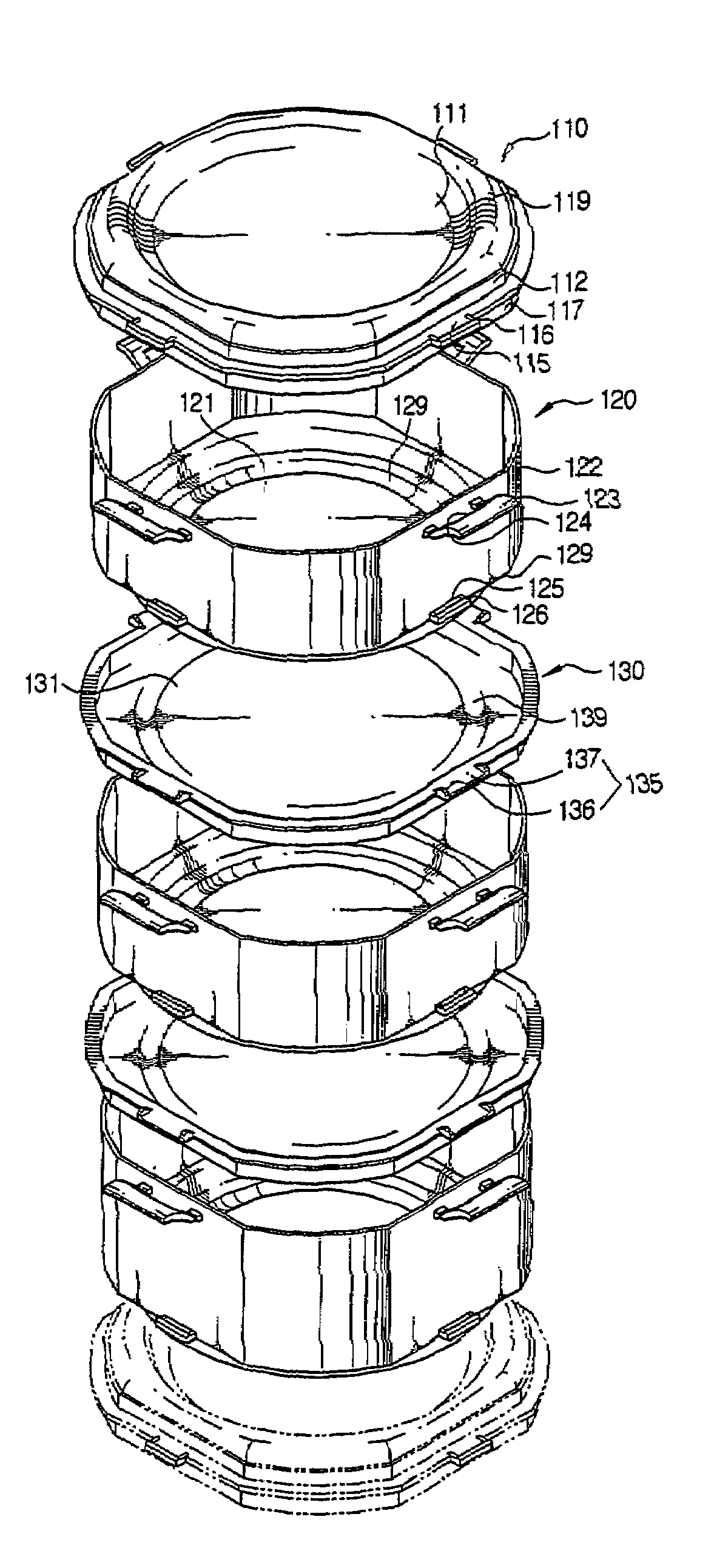

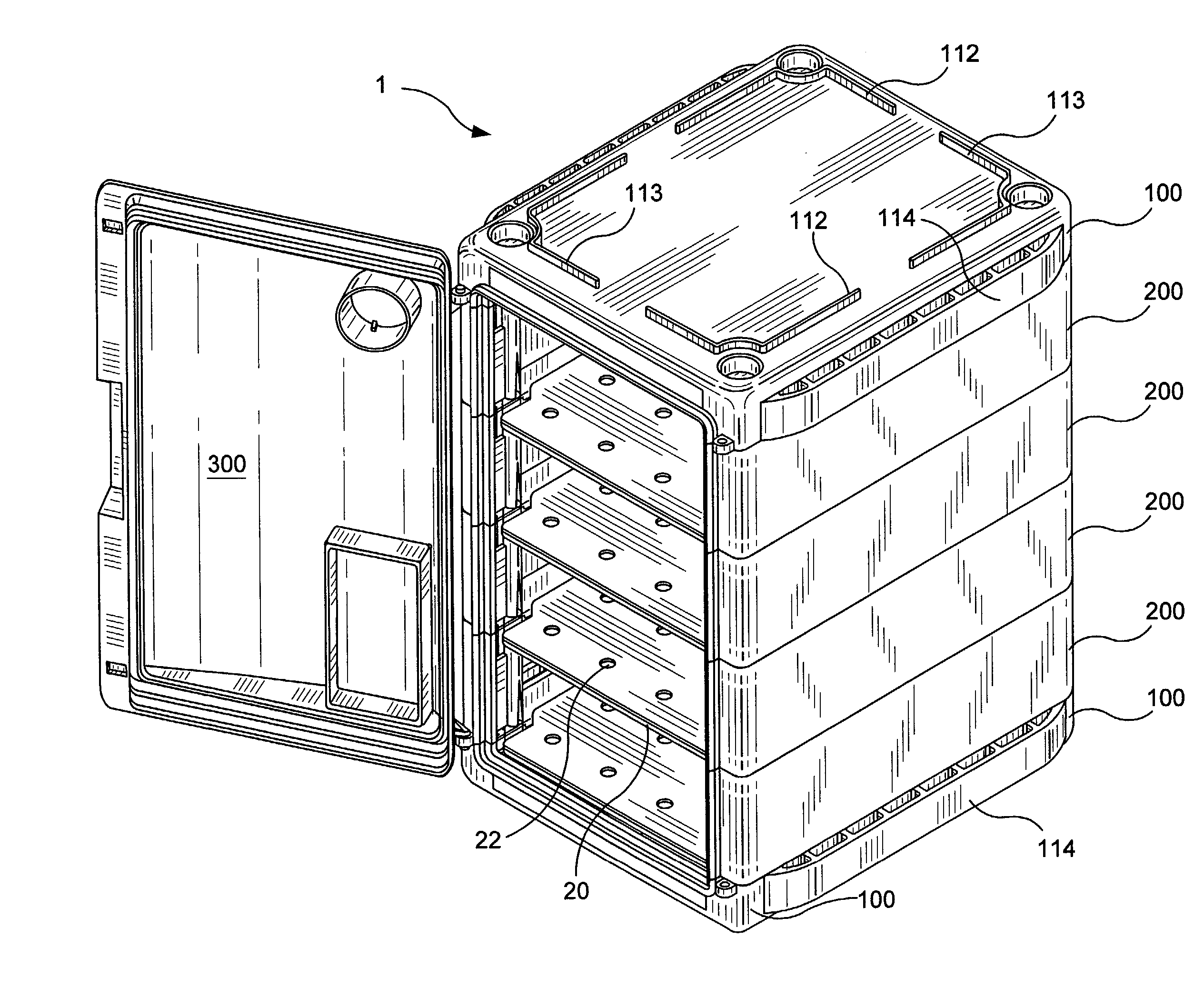

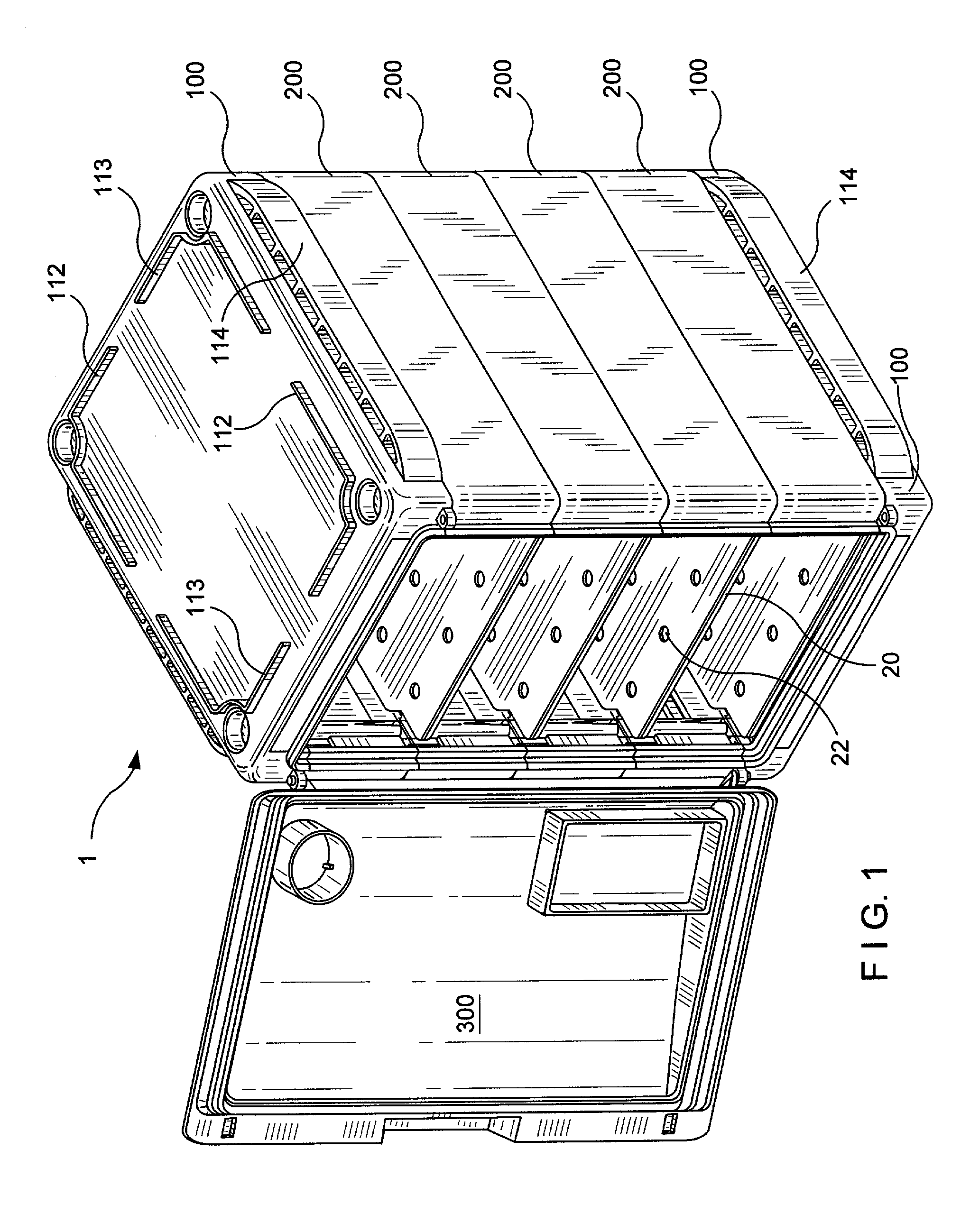

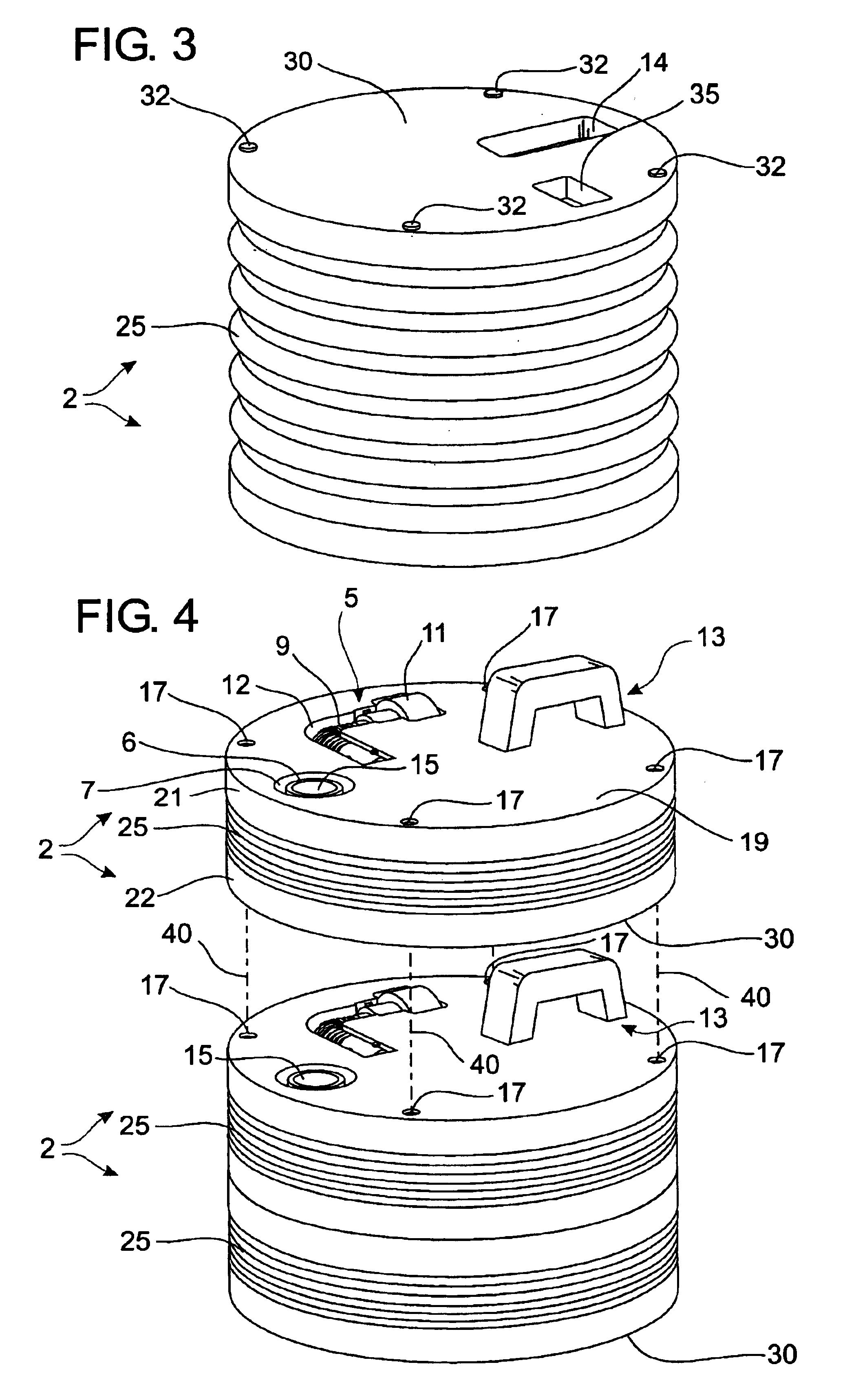

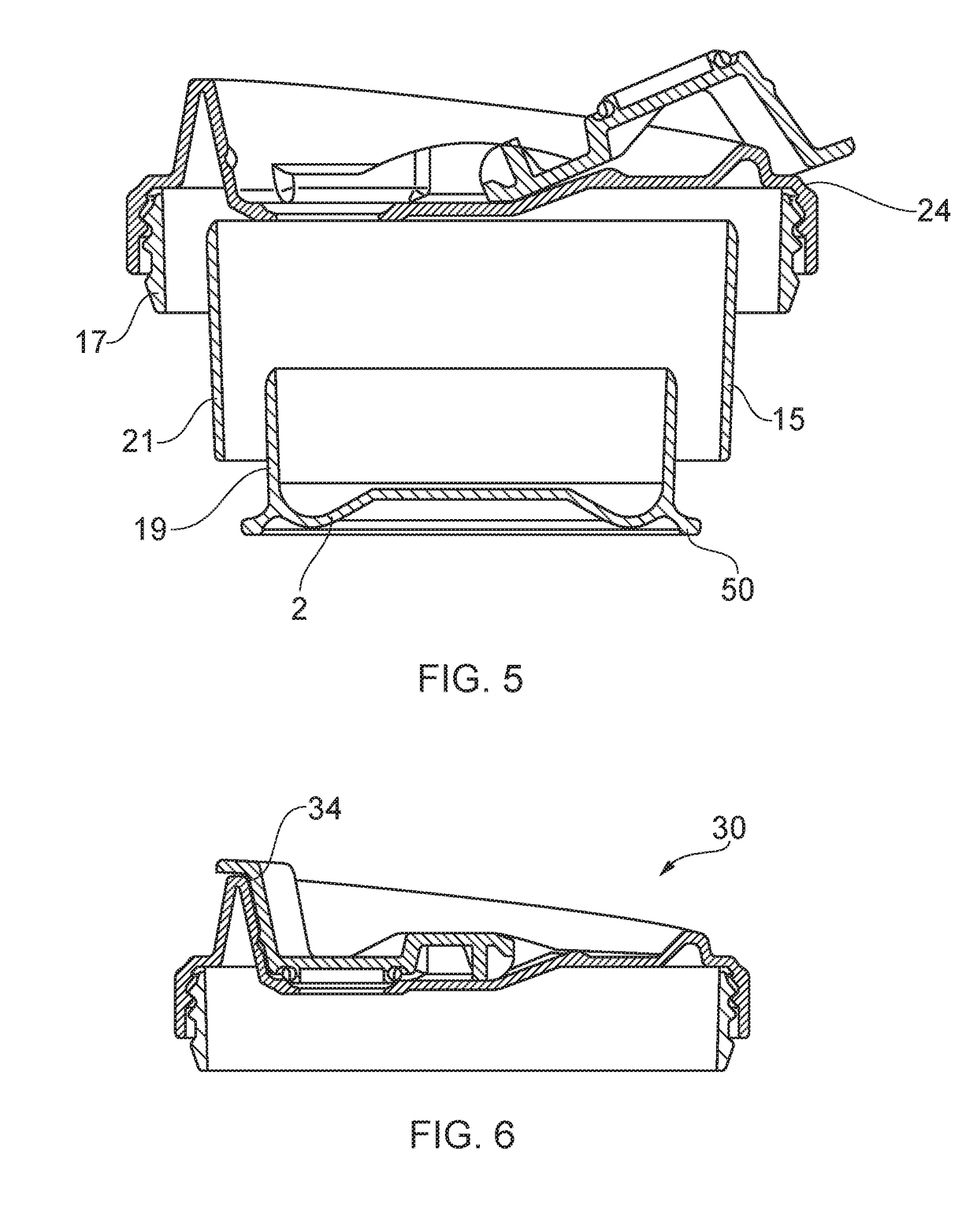

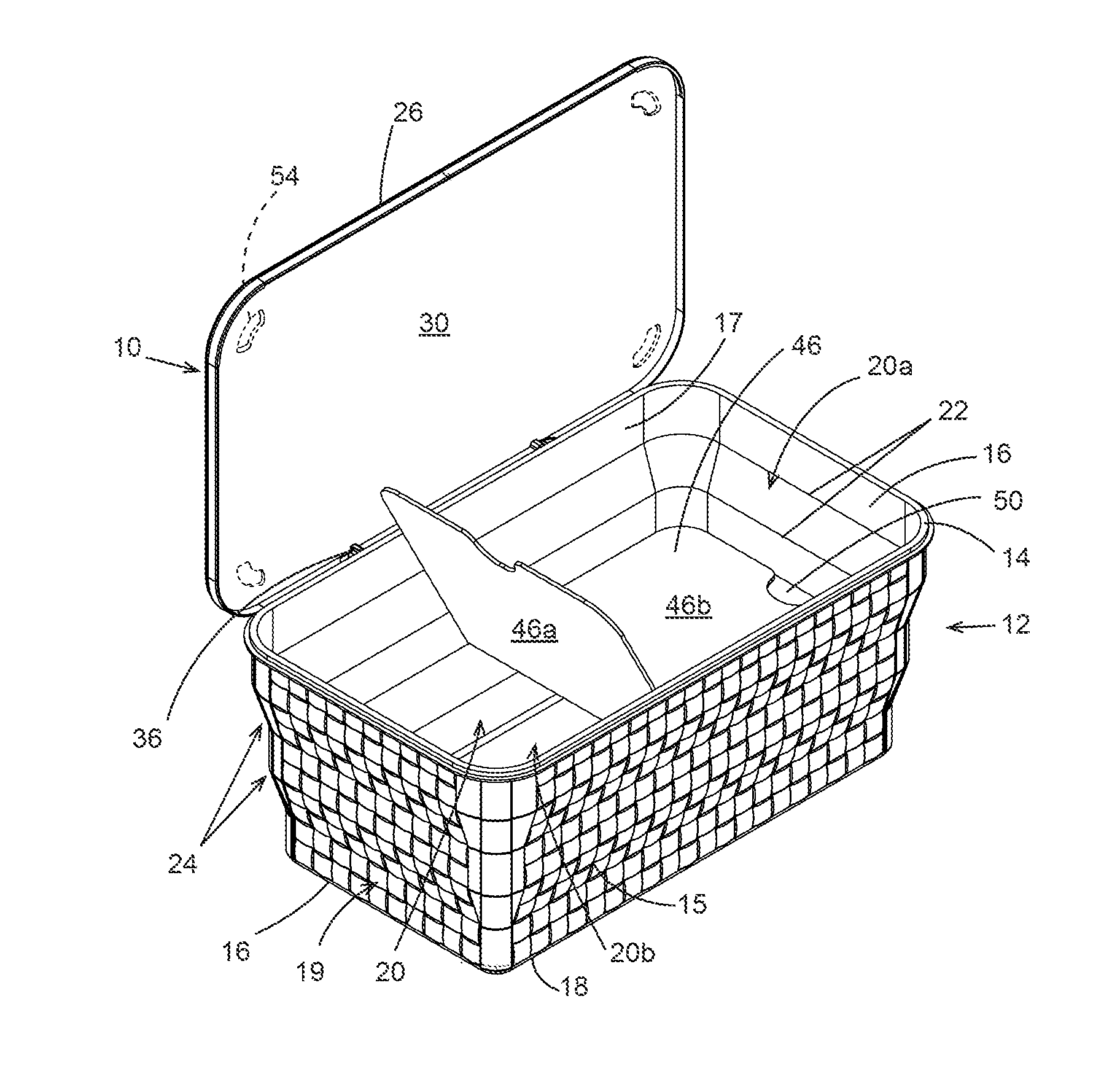

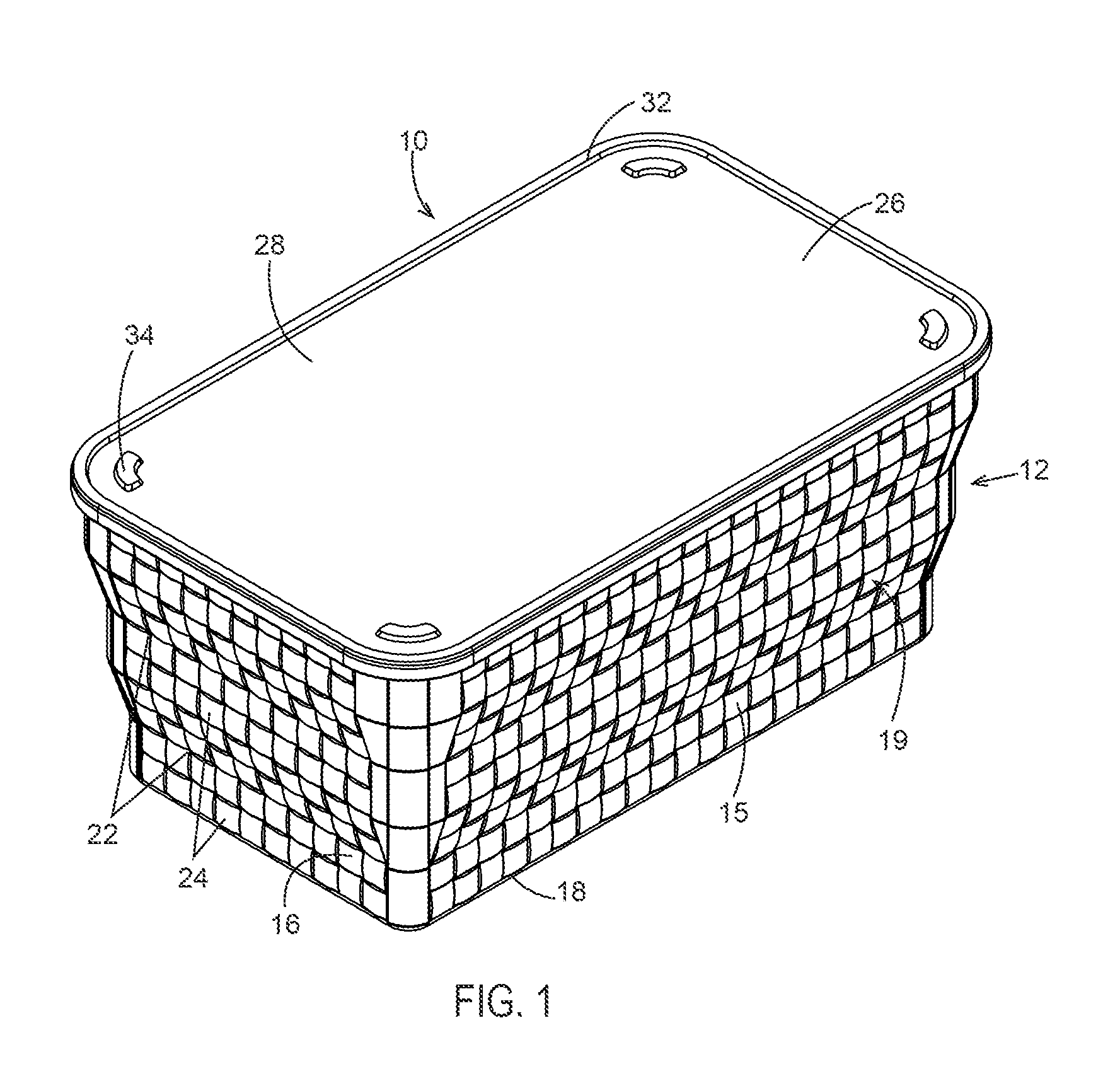

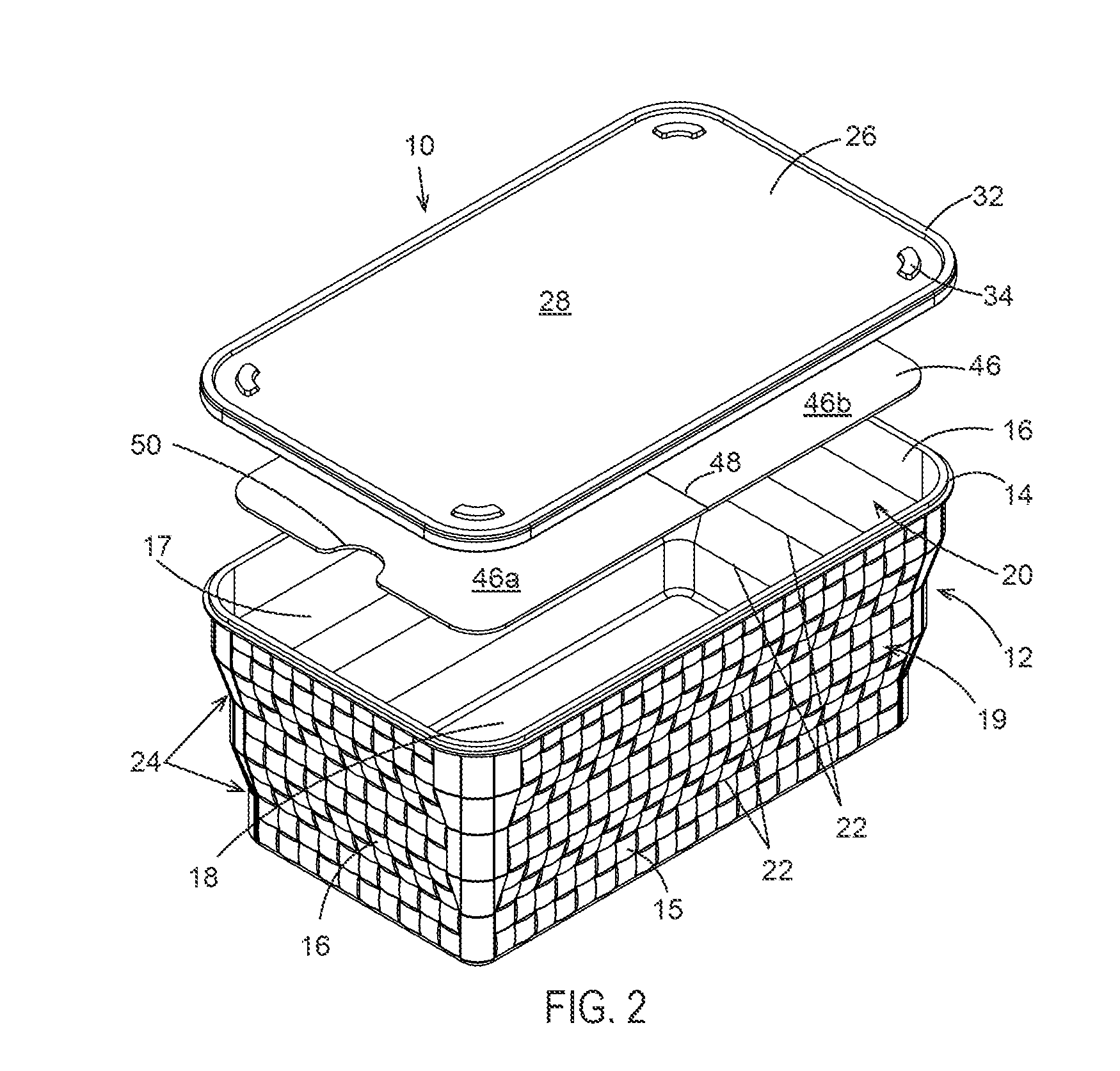

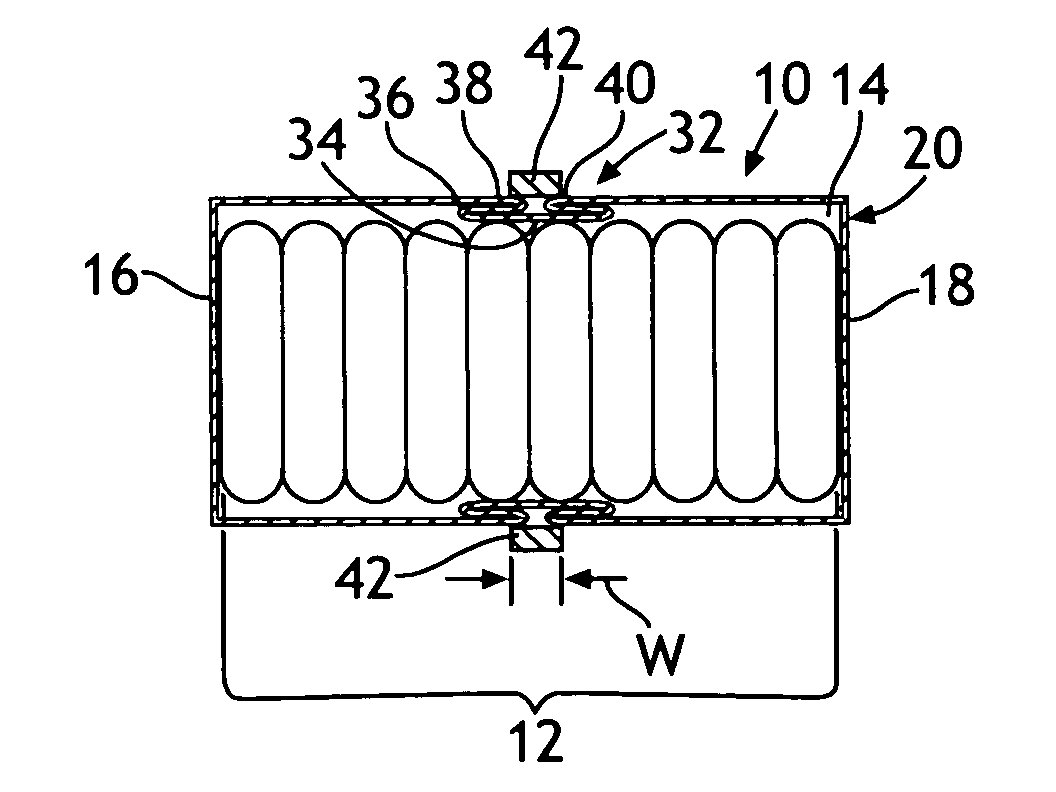

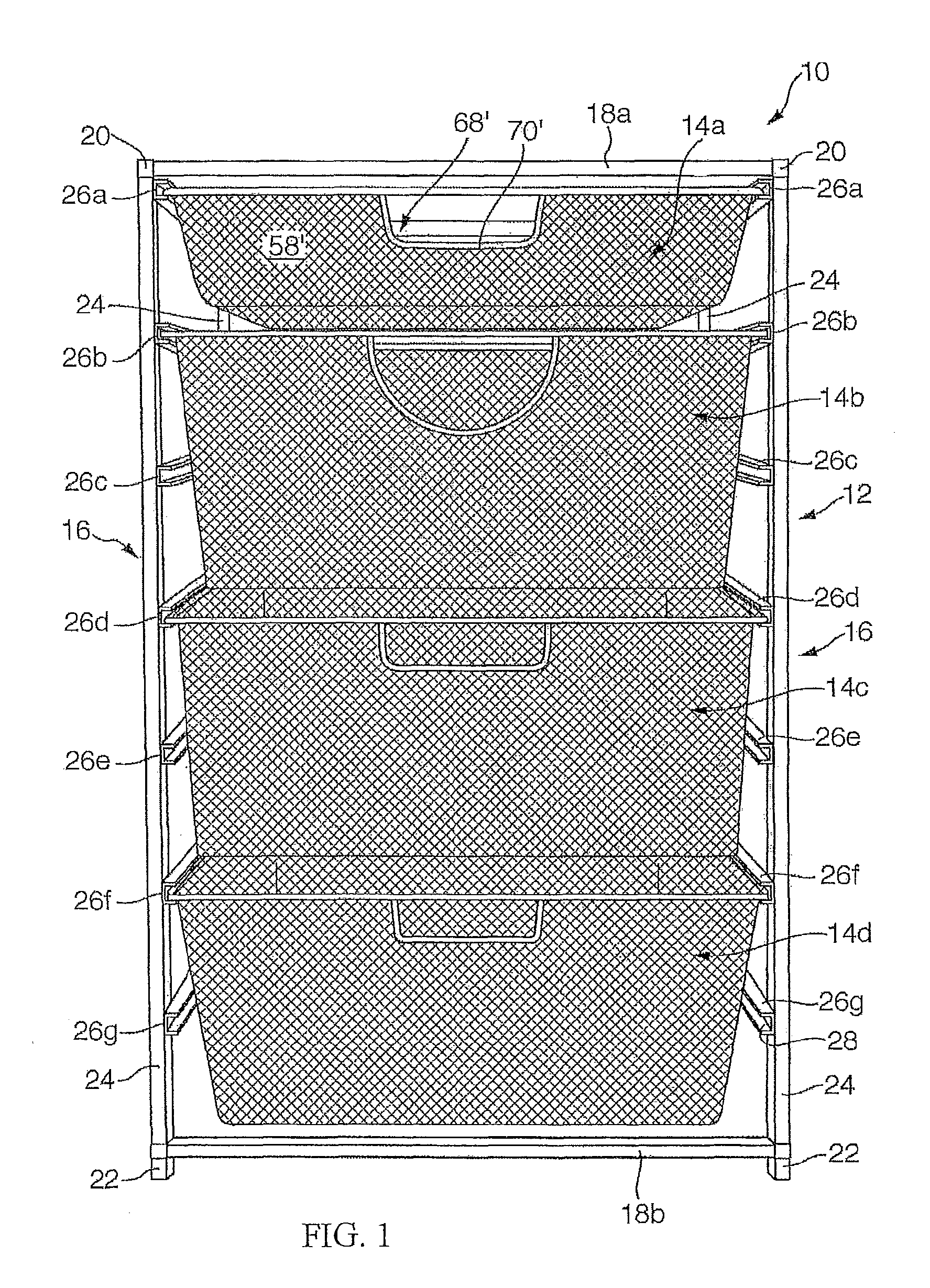

Stackable portable cooler system

InactiveUS20110220531A1Limit widthwise horizontal movementLimit horizontal movementLighting and heating apparatusVentilationEngineeringChiller

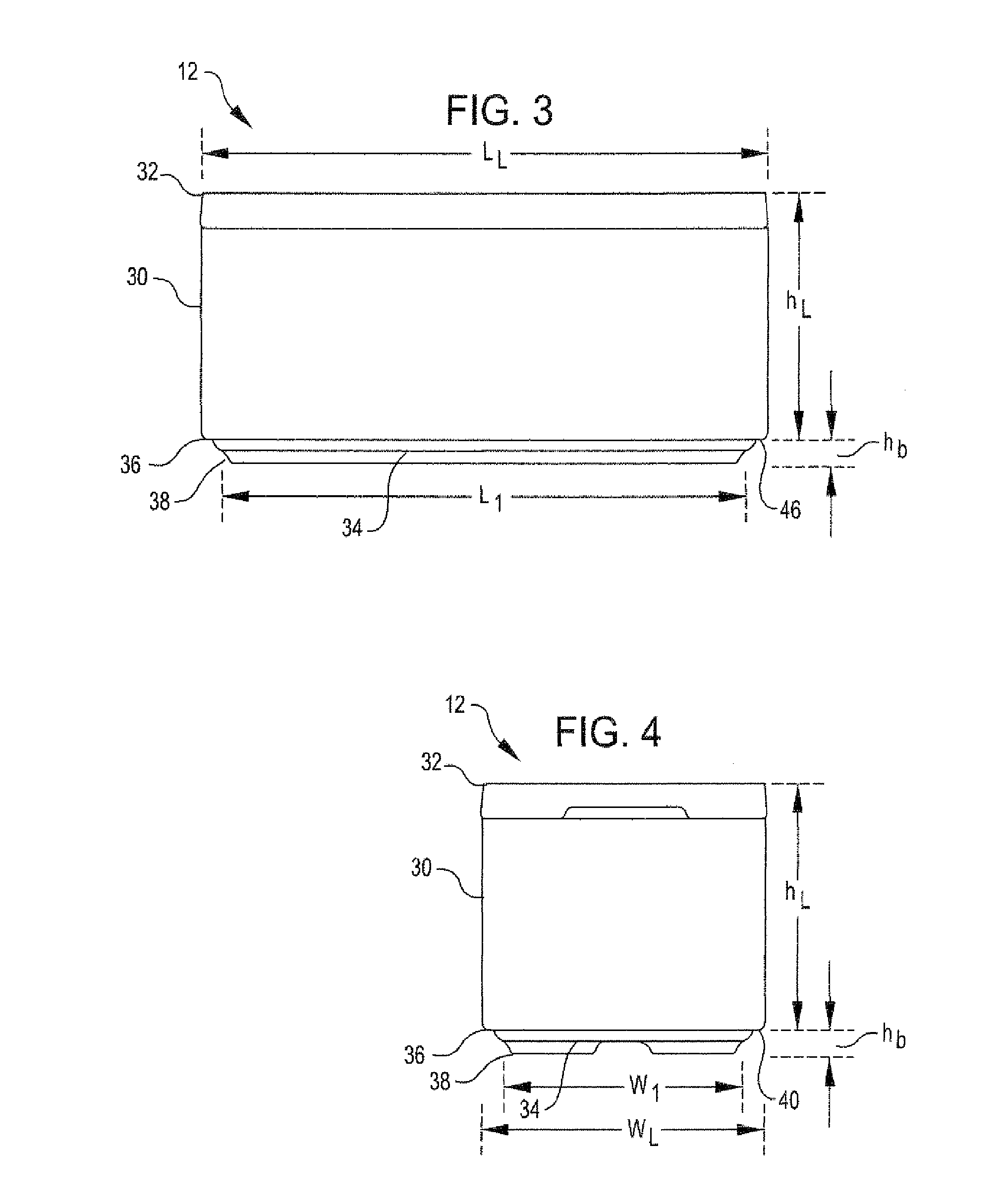

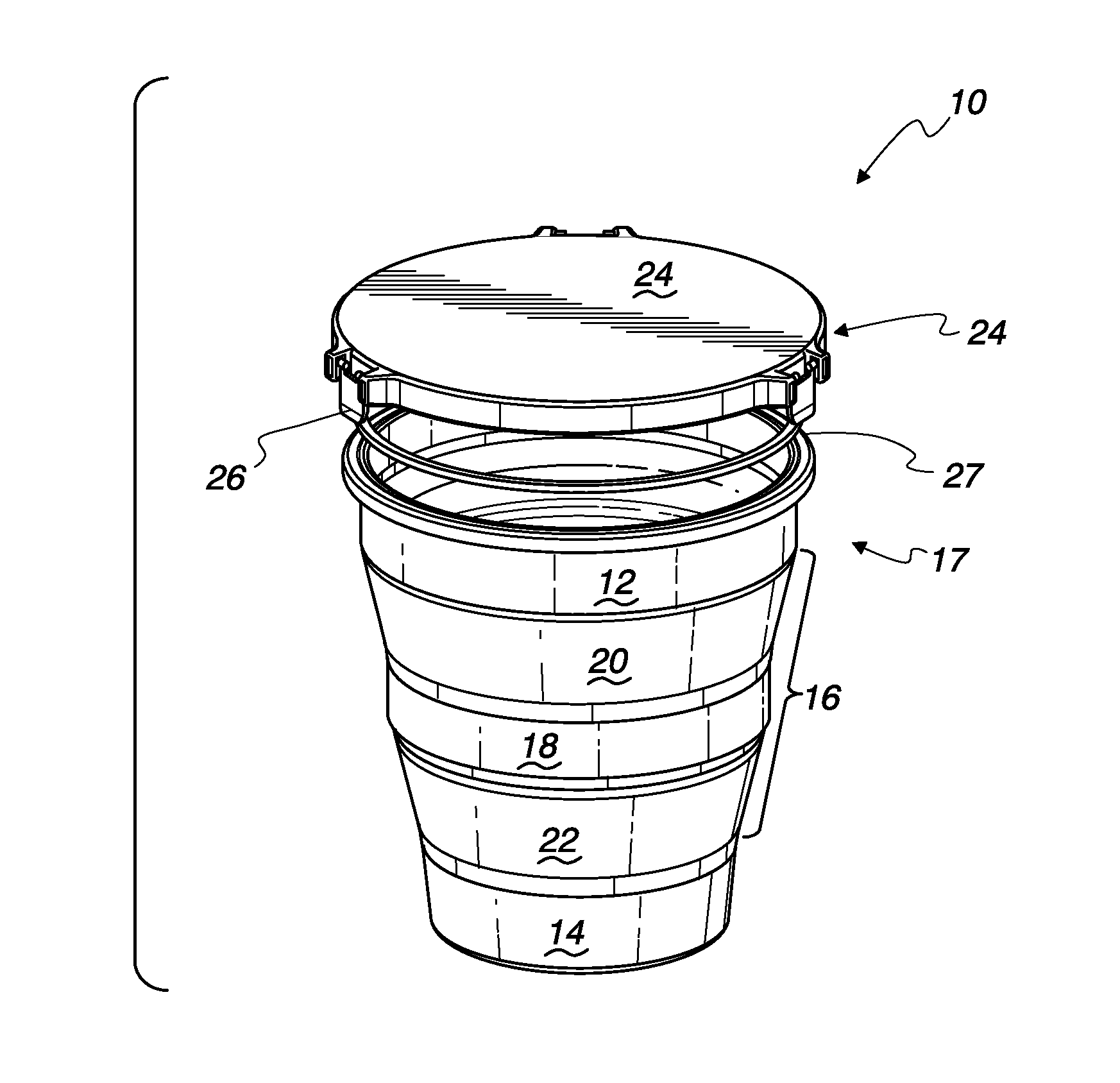

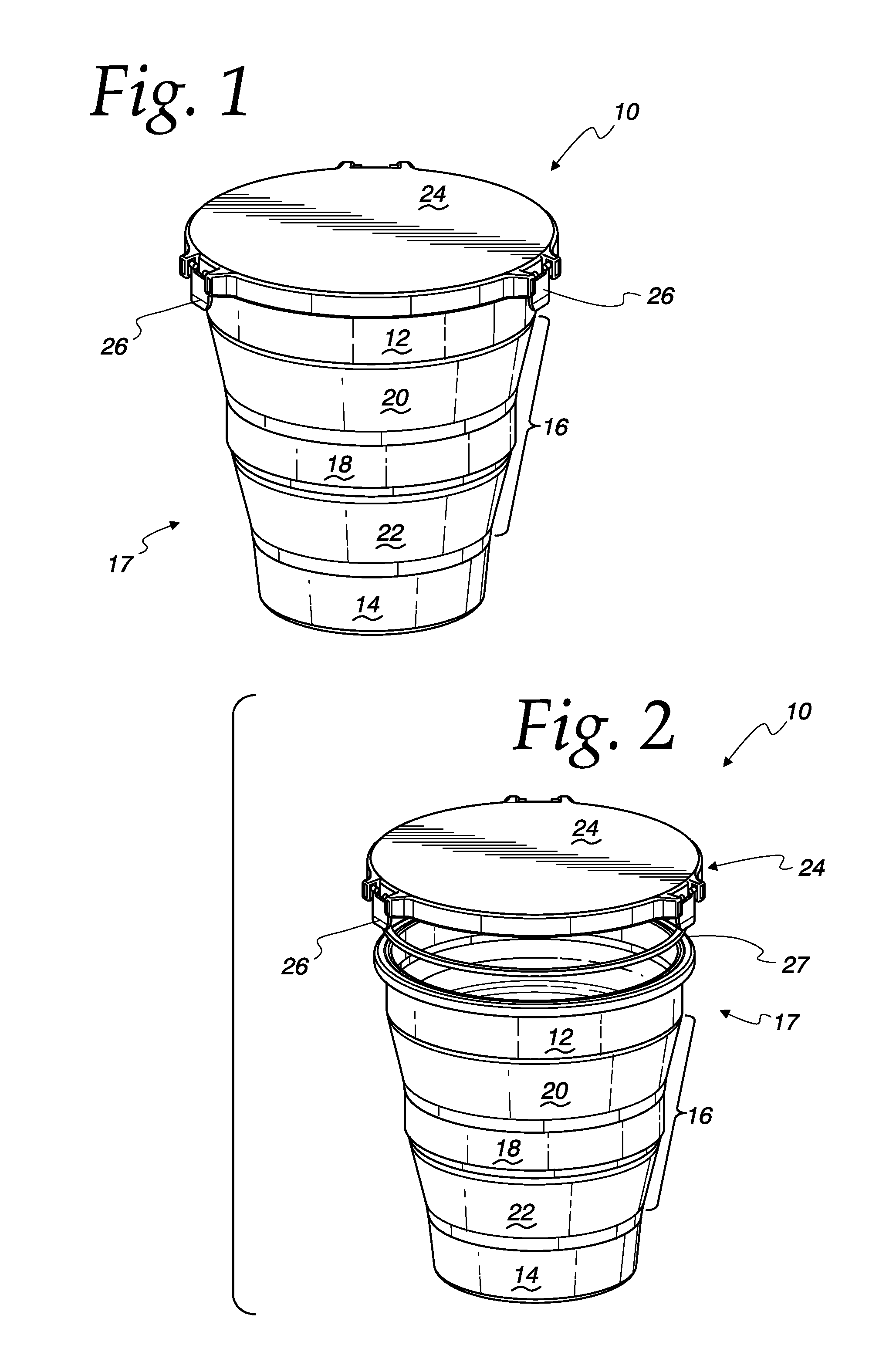

A portable cooler stacking system is provided, where portable coolers of different shapes and sizes can be optimally and stably stacked. The cooler system can include a first cooler having a first size and a second cooler having a second size, where the first and second sizes are different. A pair of second coolers can be stacked on the first cooler, where the second coolers are positioned widthwise along the length of the lid of the first cooler. In this manner, an inner length of the top surface of the lid of the first cooler is slightly greater then the width of a lower portion the second coolers and the inner width of the top surface of the lid of the first cooler is greater then two times the width of the lower portion of the second coolers. As such, two second cooler can be positioned widthwise along the length of the lid of the first cooler. The adjacent position of the second coolers and the interlocking surfaces substantially limit the horizontal movement of the pair of second coolers on the lid of the first cooler.

Owner:THE COLEMAN CO INC

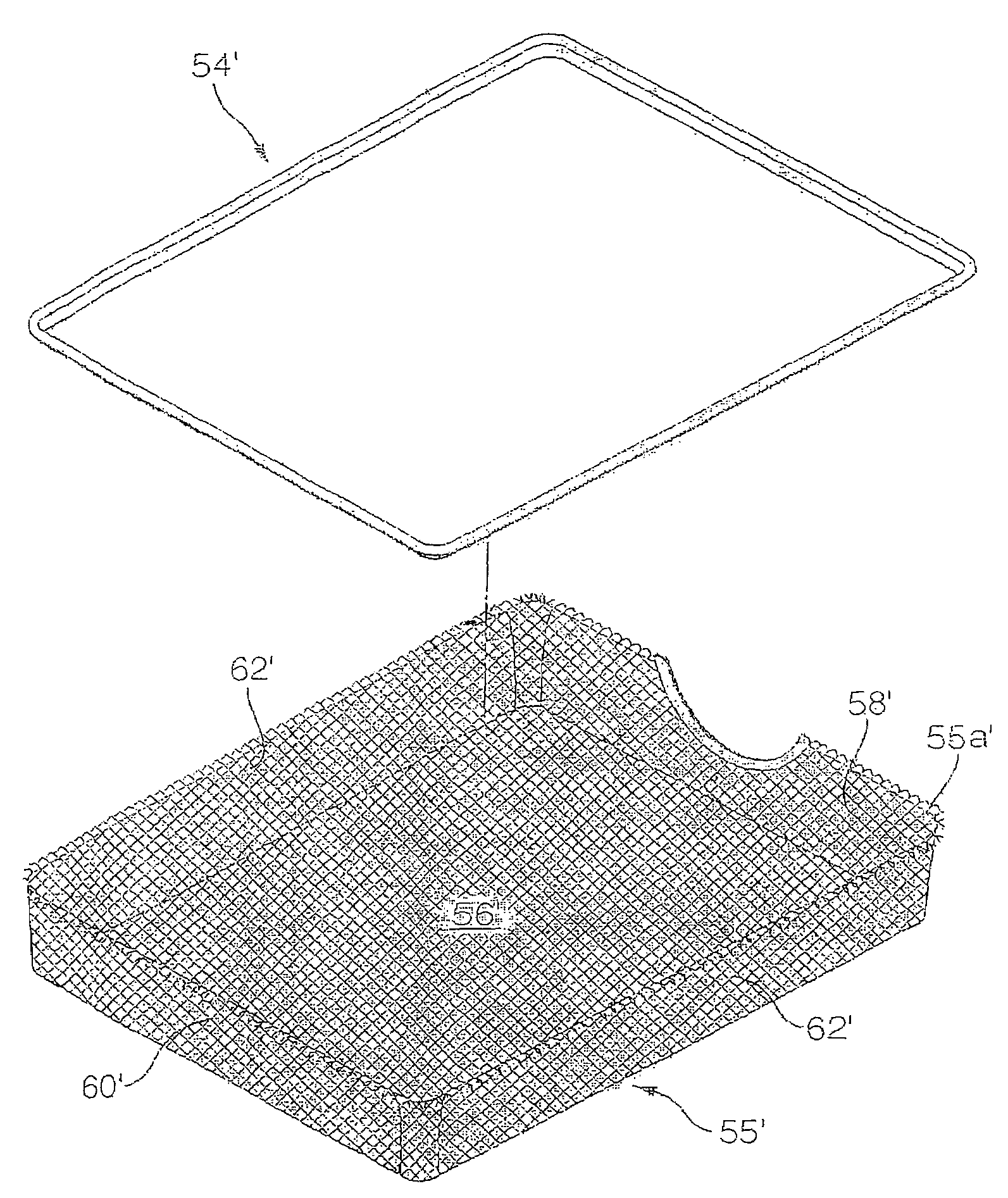

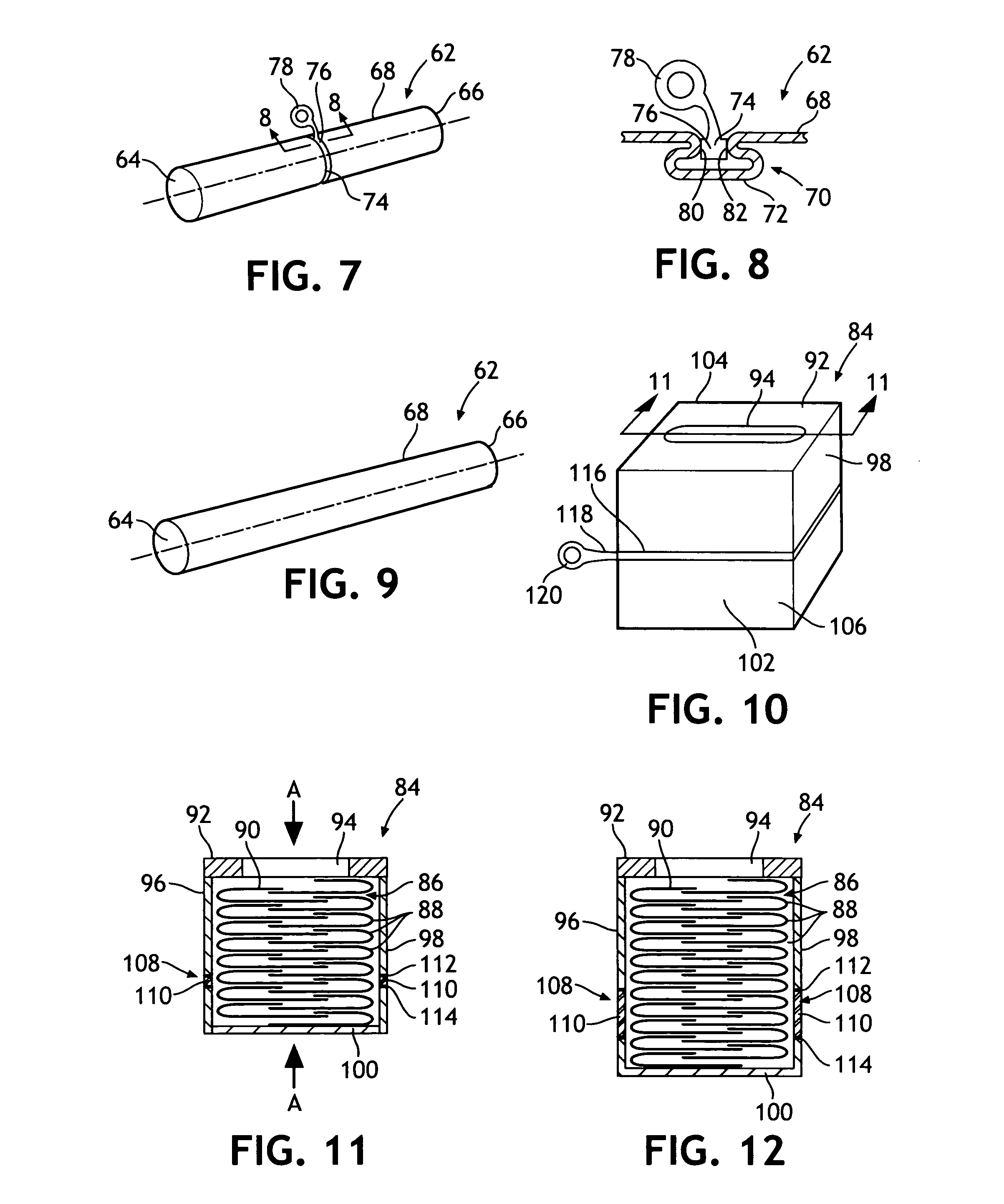

Collabsible Bottle, Method Of Manufacturing A Blank For Such Bottle And Beverage-Filled Bottle Dispensing System

InactiveUS20120097634A1Increase stiffnessIncrease resistanceEnvelopes/bags making machineryBoxes/cartons making machineryEngineeringBottle

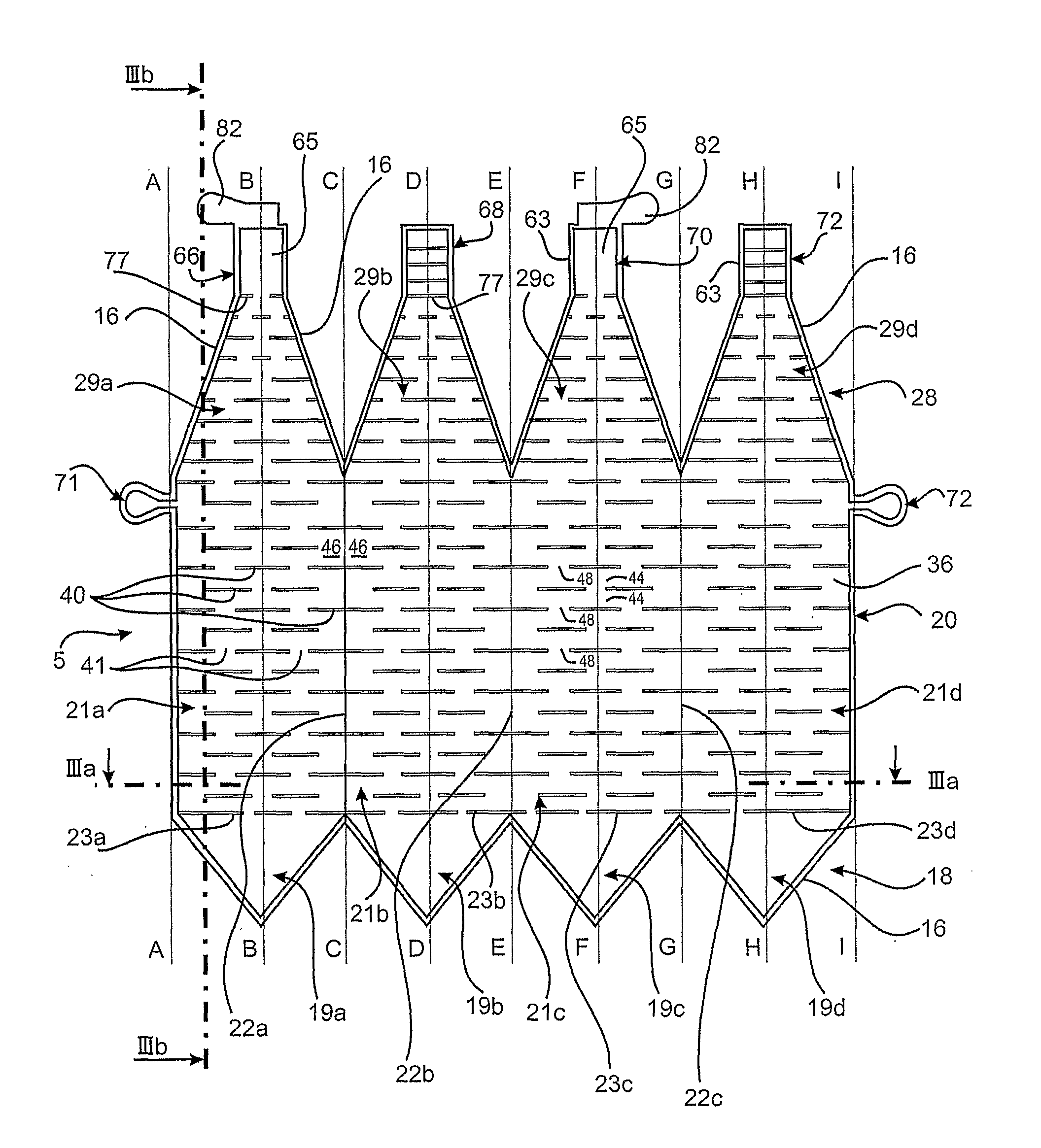

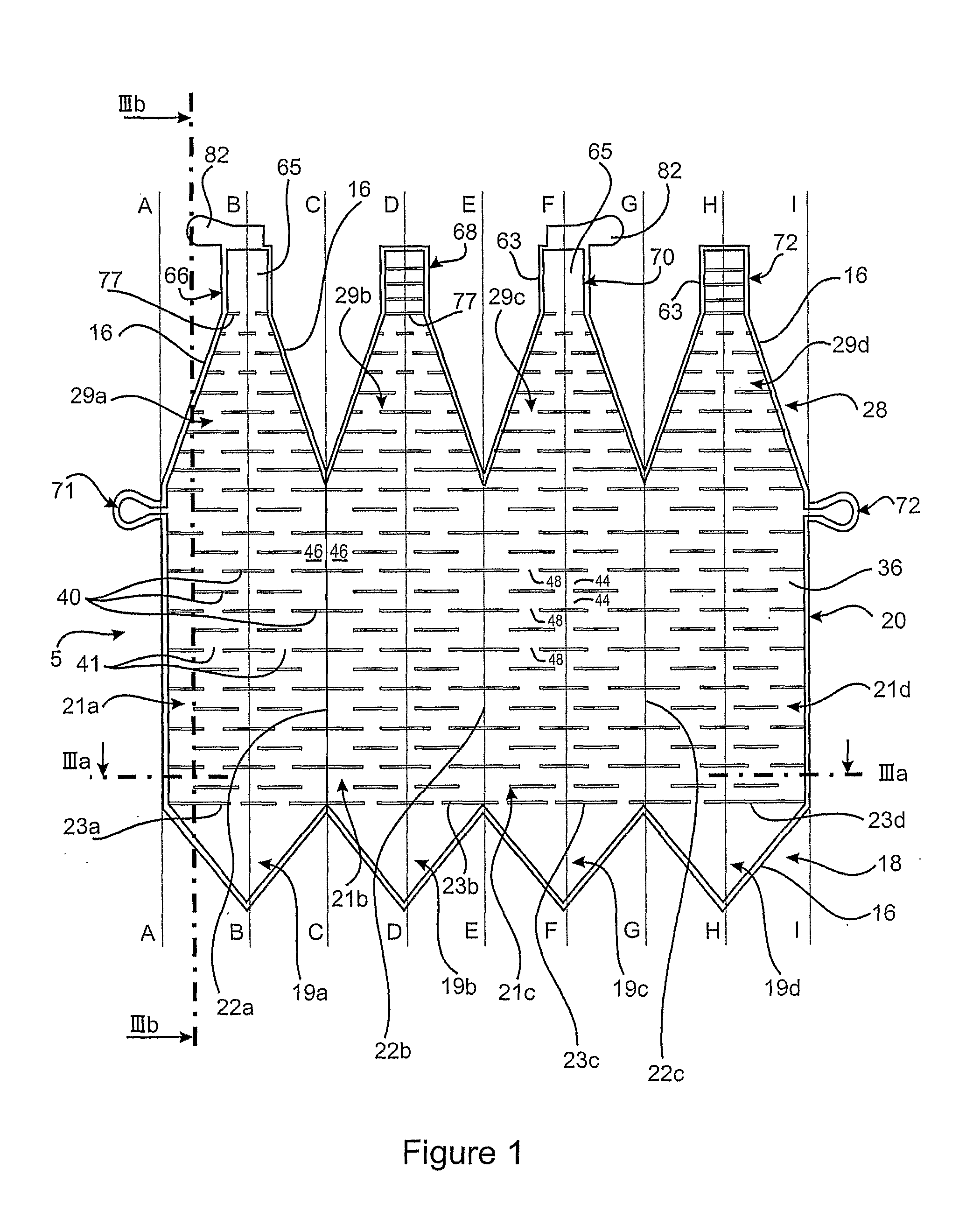

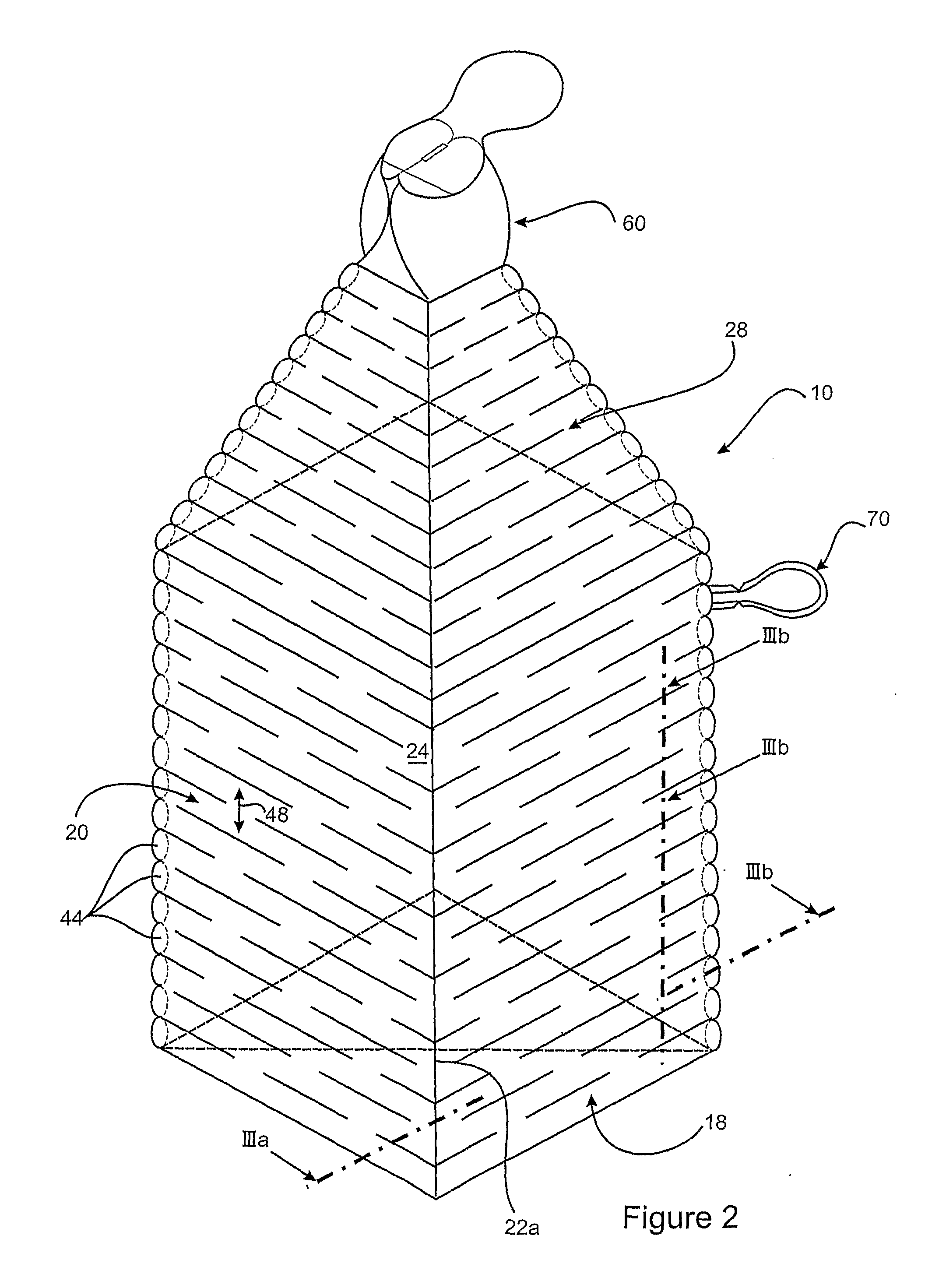

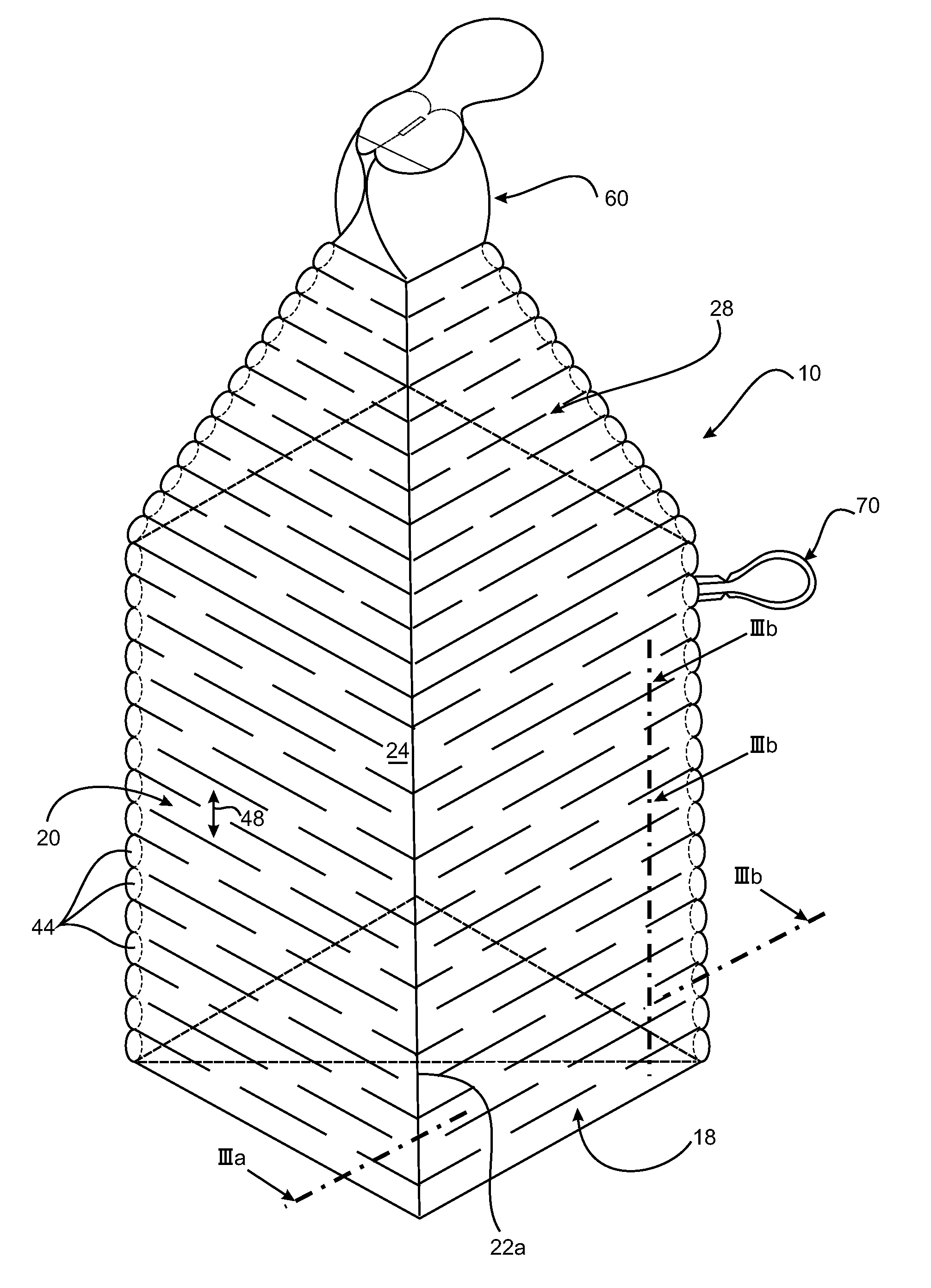

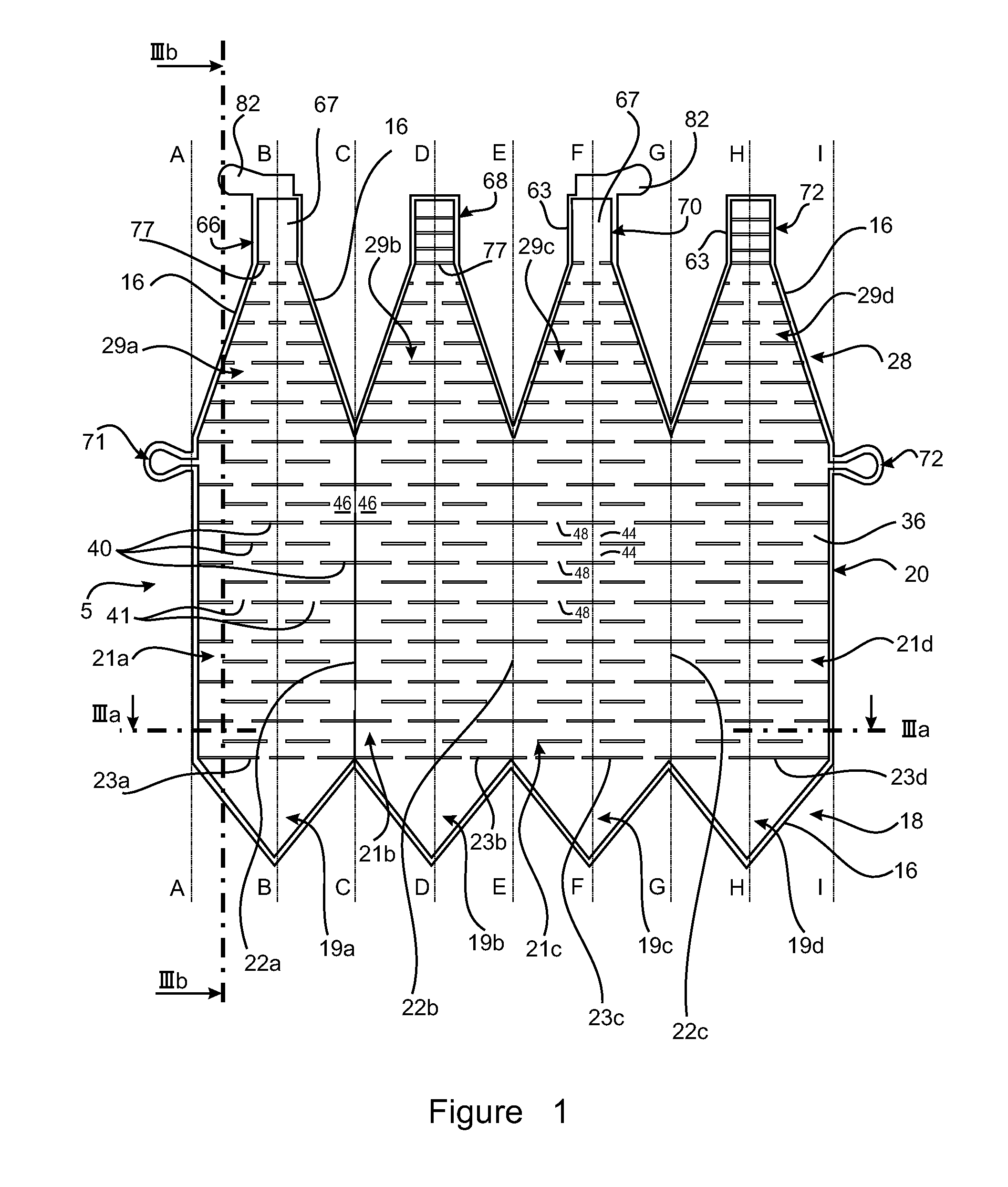

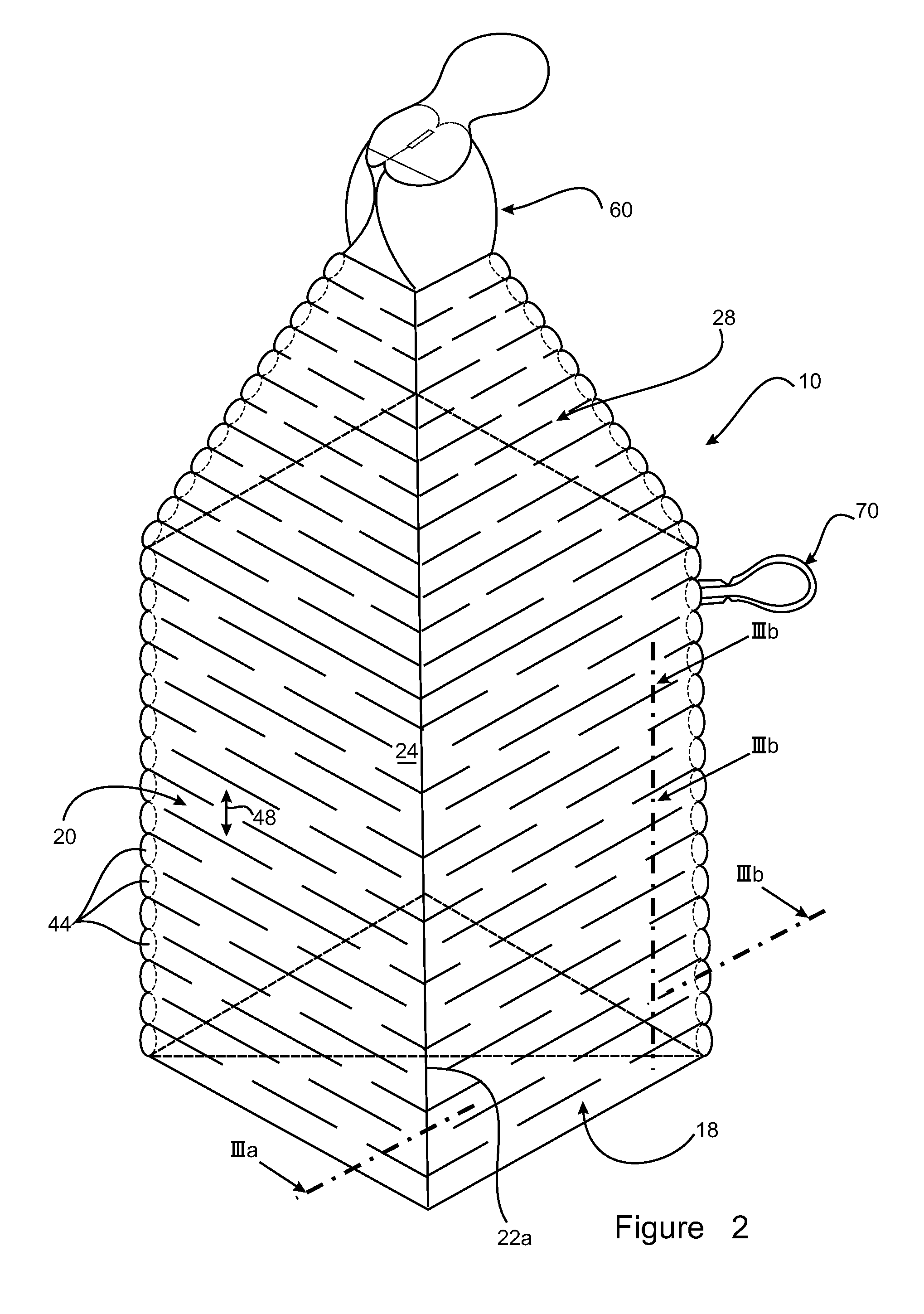

The present invention concerns a double-skinned inflatable bottle blank and its method of manufacturing which comprises: (i) stacking two sheets of liquid impermeable, flexible foil material, preferably in coplanar arrangement; (ii) blanking the sheets to create respective, preferably shape-congruent blanks having each a contoured perimeter edge; (iii) bonding the two blanks along joining seams that follow the contoured perimeter edges, but for at one or more inflation locations, thereby to define a double skinned blank into which an inflating fluid can be introduced through the inflation location; (iv) additionally bonding the two blanks at a plurality of discrete stiffening seams which are arranged in a predetermined grid or pattern thereby defining a grid-work of intersecting, inflatable stiffener structures in at least such part of the double skinned blank which will provide an upstanding peripheral wall of the bottle when erected through inflation; (v) folding the double skinned blank; and (vi) selectively bonding together portions of the joined perimeter edge of the double skinned blank, but for at a predetermined filling / dispensing location, to define a double-skinned, inflatable bottle blank with an internal cavity surrounded by a bottom wall for standing the bottle upright, said peripheral wall and a top wall, the filling / dispensing location located preferentially in the top wall such as to define a dispensing orifice for filling and dispensing liquid into and from the internal cavity, the inflatable stiffener structures providing an exoskeleton about the internal cavity when inflated.

Owner:RIEDL JOHN THOMAS

Collapsible bottle, method of manufacturing a blank for such bottle and beverage-filled bottle dispensing system

InactiveUS8540094B2Increase stiffnessIncrease resistanceBoxes/cartons making machineryLayered productsBottleInflatable

A double-skinned inflatable bottle blank is manufactured by: (i) stacking two sheets of liquid impermeable, flexible foil material; (ii) blanking the sheets; (iii) bonding the two blanks along joining seams that follow contoured perimeter edges to define a double skinned blank which can be inflated through an inflation location; (iv) additionally bonding the two blanks at in a predetermined grid of seams to provide an upstanding peripheral wall with intersecting, inflatable stiffener structures; (v) folding the double skinned blank; and (vi) selectively bonding together portions of the joined perimeter edge of the double skinned blank to define a double-skinned, inflatable bottle blank with an internal cavity surrounded by a bottom wall, peripheral wall and top wall with a dispensing orifice, the inflatable stiffener structures between the seams providing an exoskeleton about the internal cavity when inflated.

Owner:RIEDL JOHN THOMAS

Collapsible container

ActiveUS7654402B2Maximize available spaceLarge containersVariable capacity containersElectrical and Electronics engineeringEngineering

Owner:DART IND INC

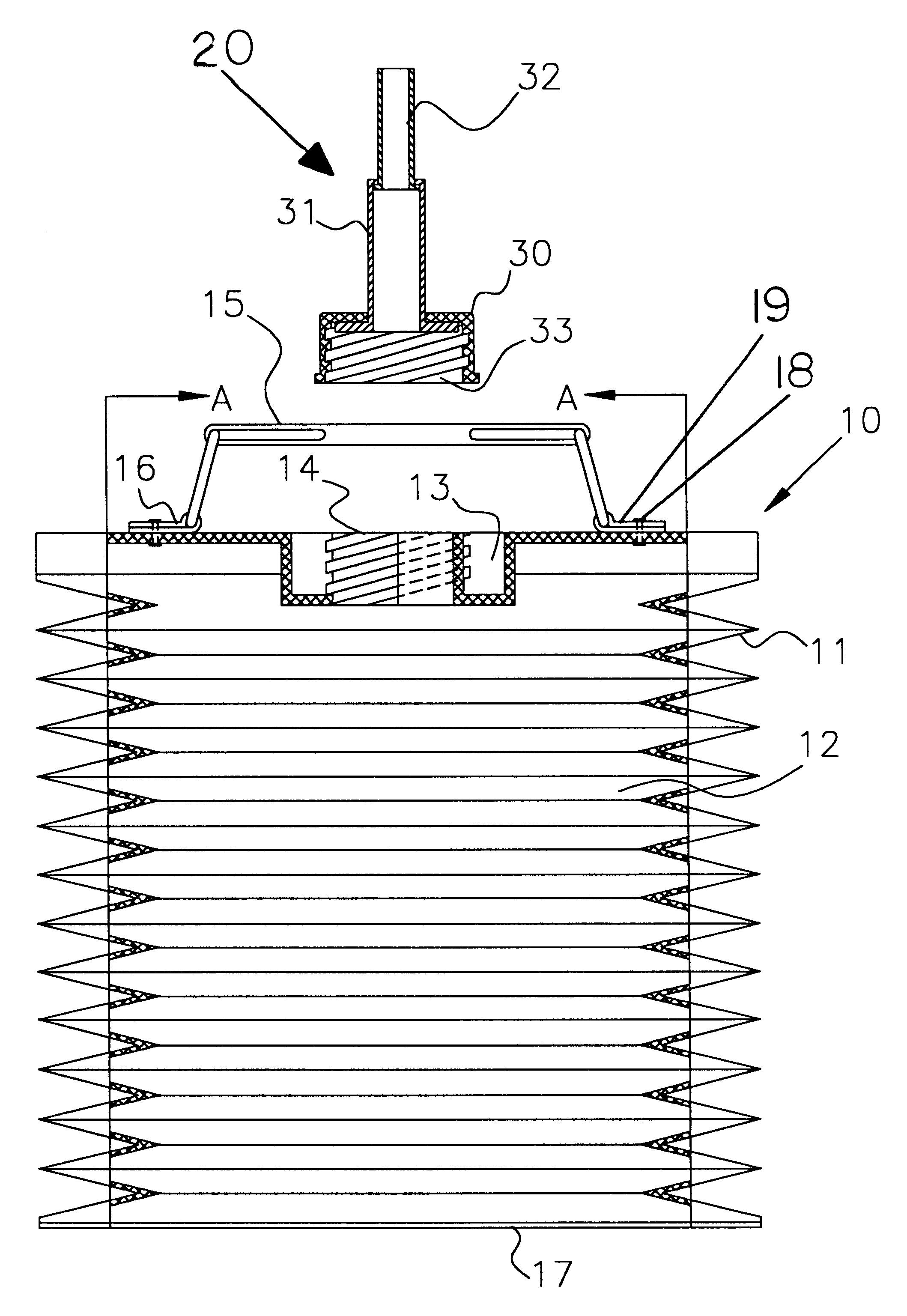

Foldable ovenware container and method of production

A foldable or collapsible ovenware container that maintains a rigid shape while in use and can be folded into a smaller size for storage. The ovenware container includes rigid top and bottom portions separated by a flexible middle portion. The flexible middle portion includes thick and thin wall sections. Pressure applied to the top portion causes the flexible middle portion to collapse in an orderly manner toward the bottom portion, with the middle portion folding at each of the thin wall sections to create a plurality of folds or pleats in the middle portion in the collapsed configuration.

Owner:FUNG DUNCAN C

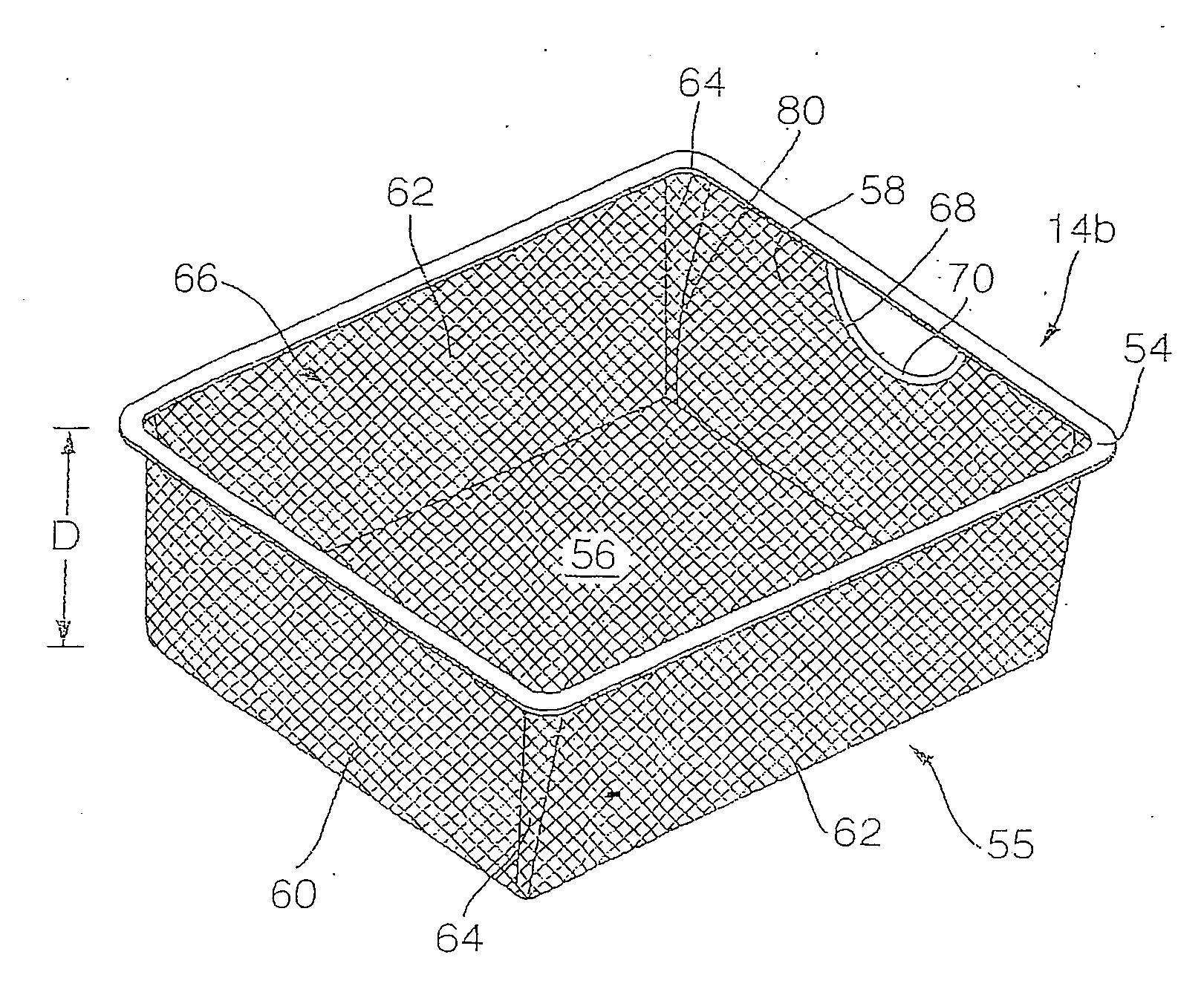

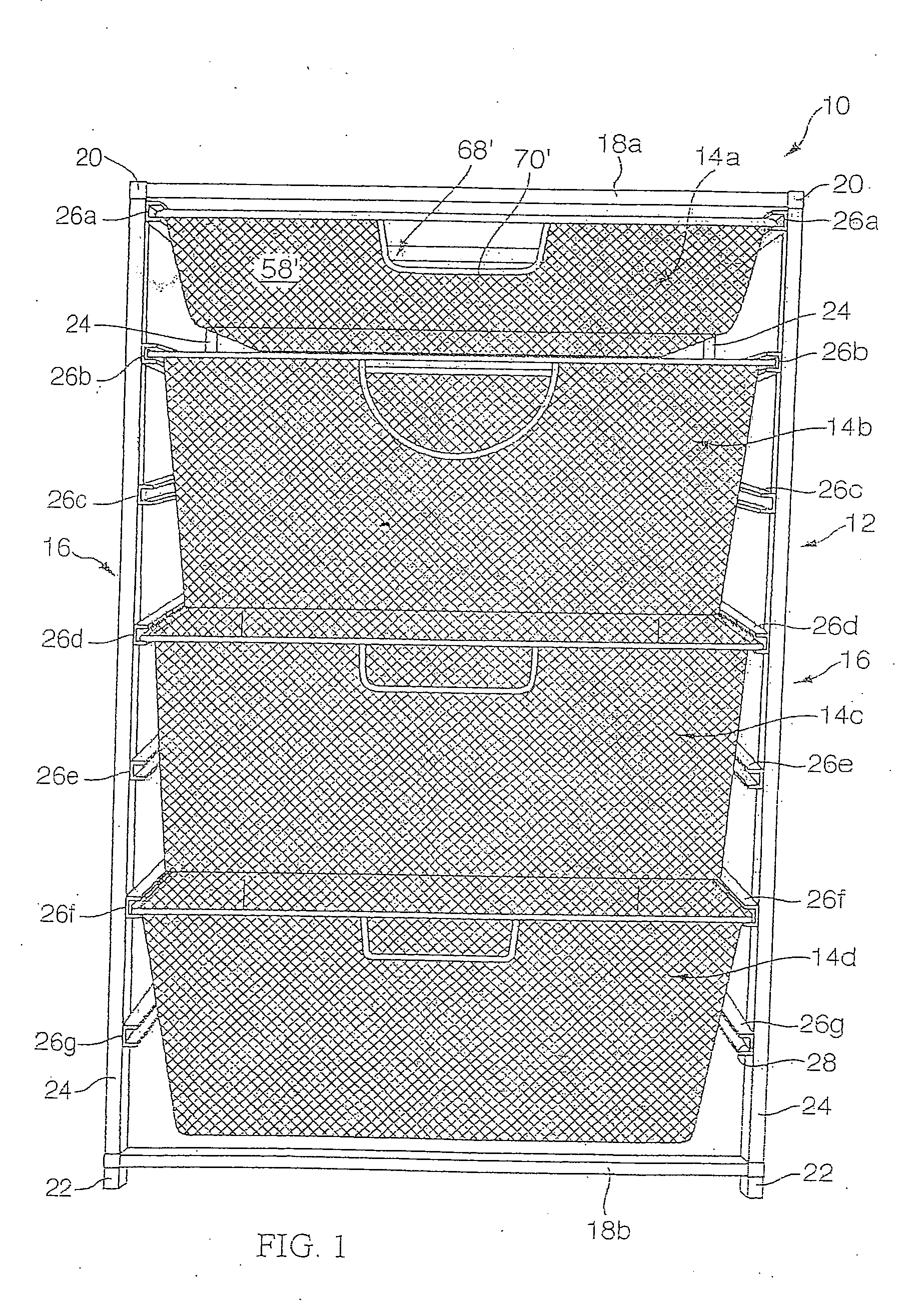

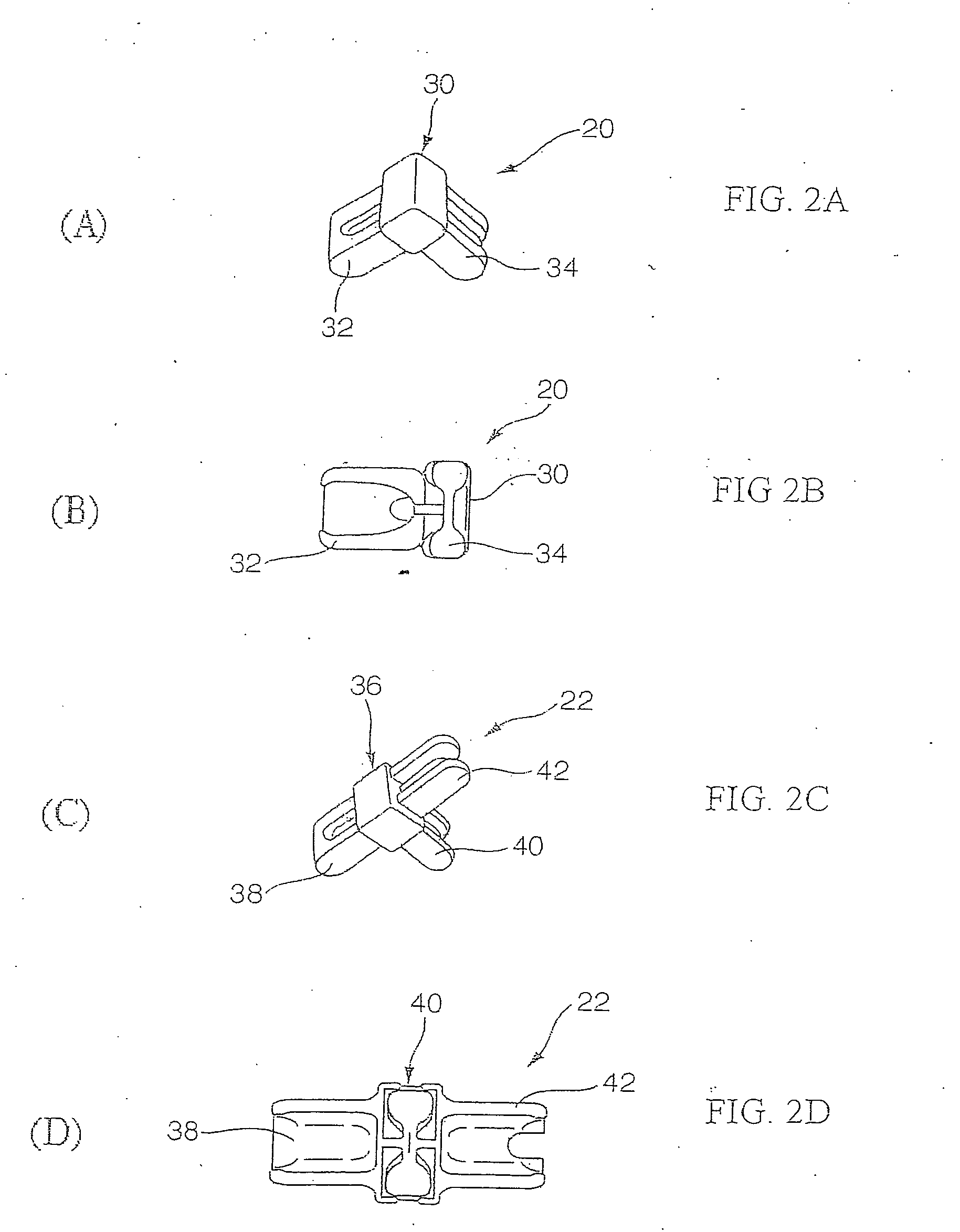

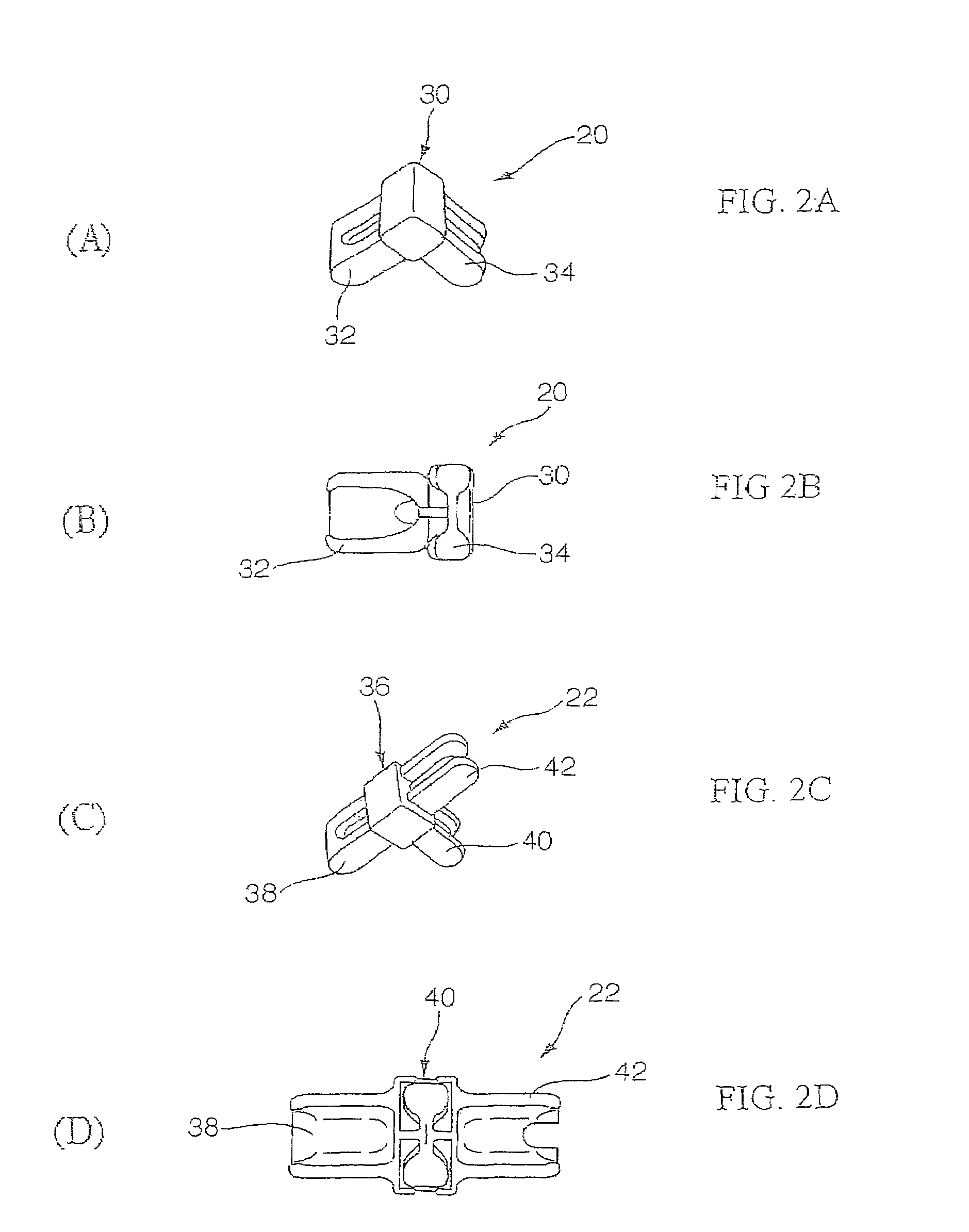

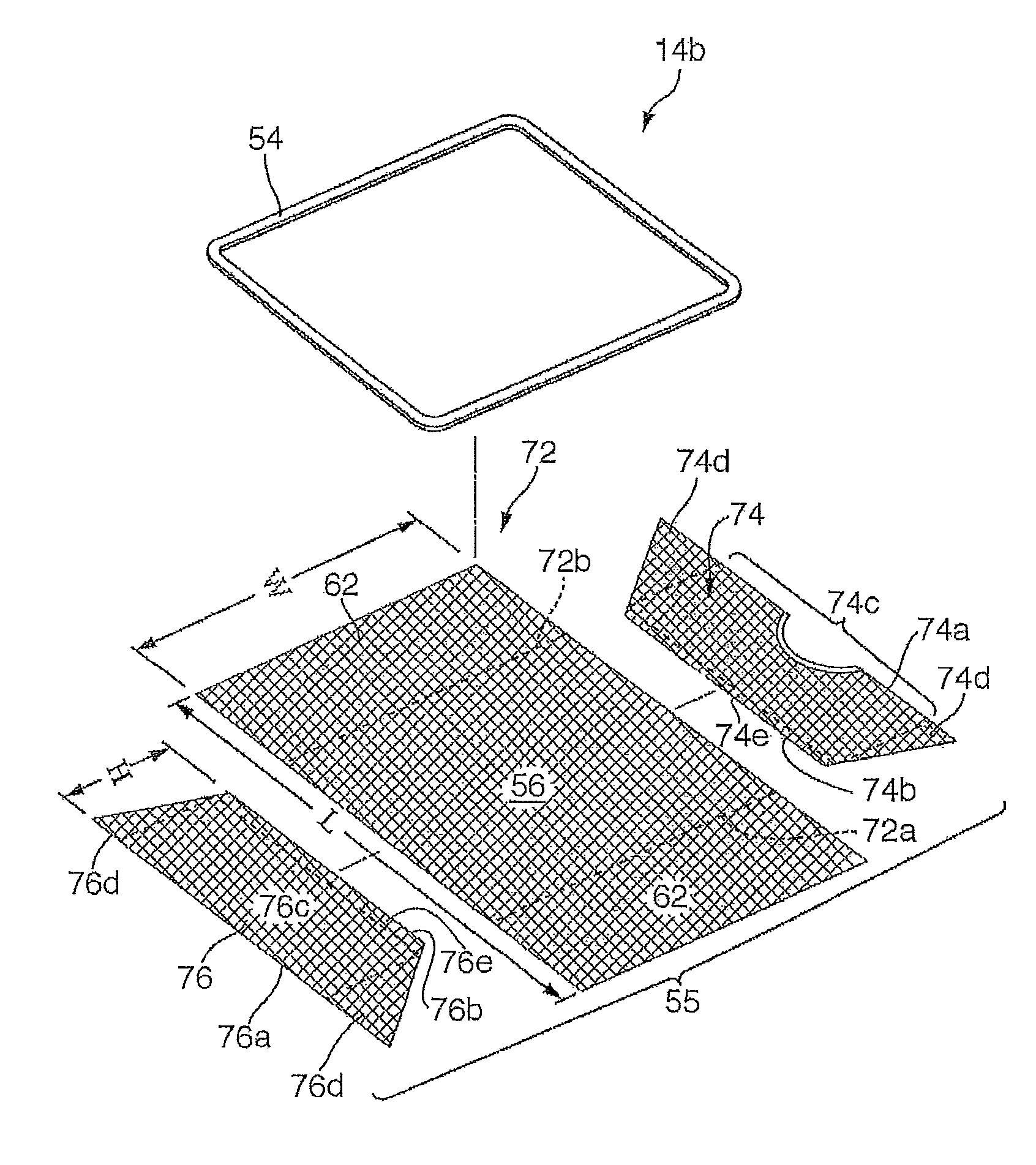

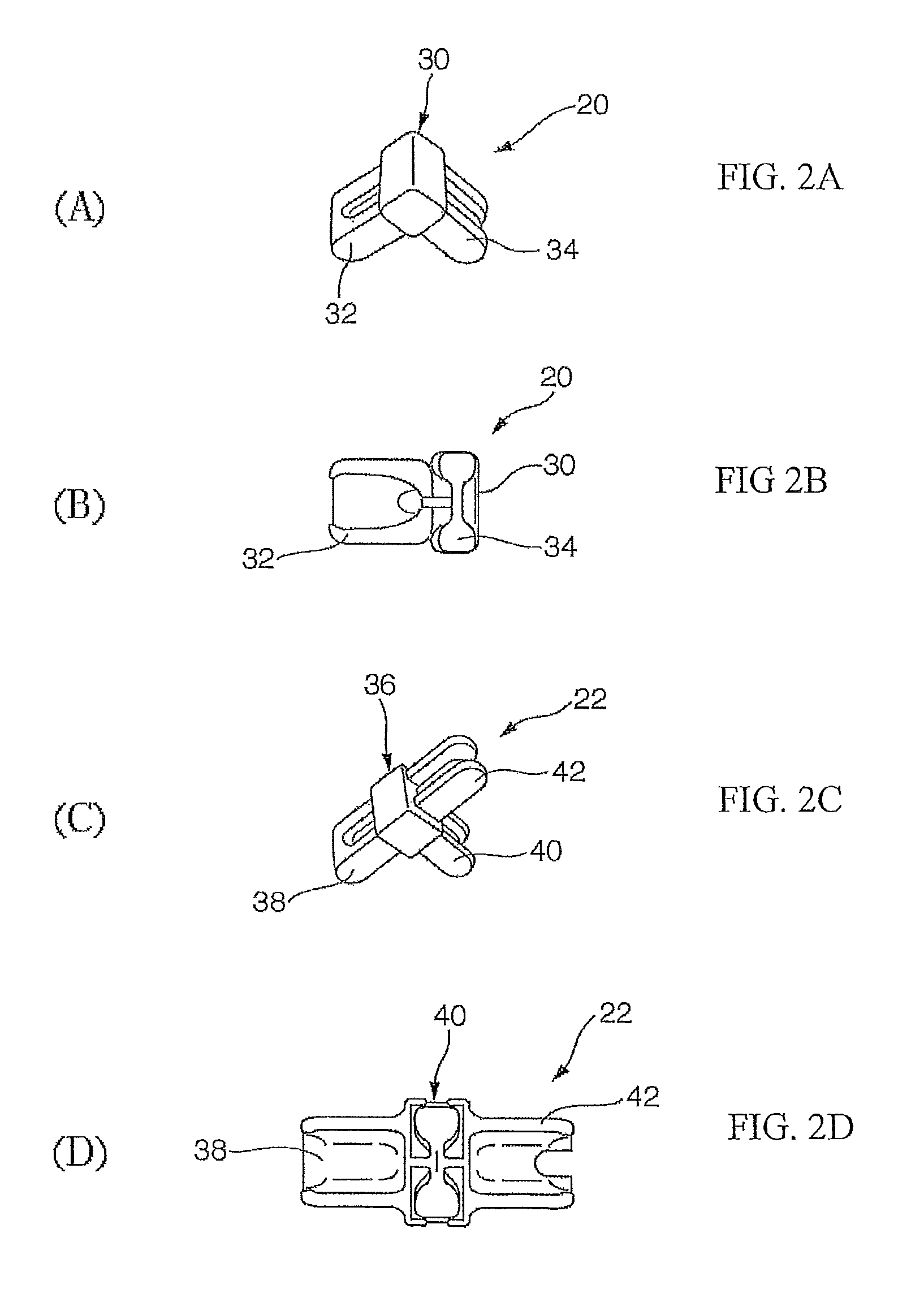

Method for making mesh containers with a rail and mesh container formed therefrom

The present invention is directed to a method of forming a container comprising forming a basket portion of metal mesh material and a rail connected to the basket portion. The rail extends substantially outwardly from the outer surface of the basket portion and the rail extends continuously around the outer surface of the basket portion. In one example, the method includes forming the rail so that it does not contain or surround a free edge of the basket portion. In another example, the method includes forming the rail so that it includes an opening for containing or surrounding a free edge of the basket portion. The method may also include forming a lower rail. The present invention is also directed to a container formed by such method.

Owner:DESIGN IDEAS

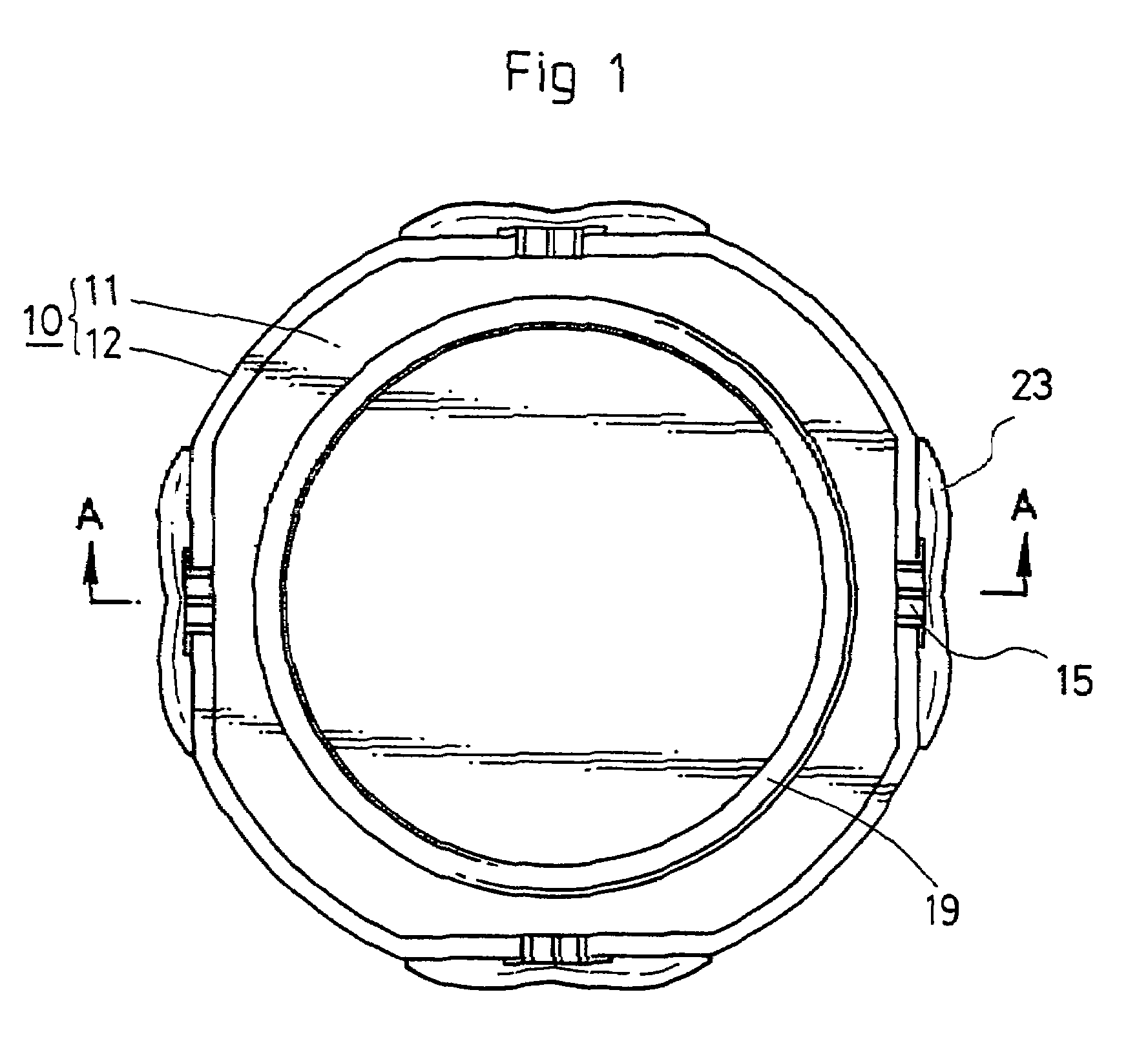

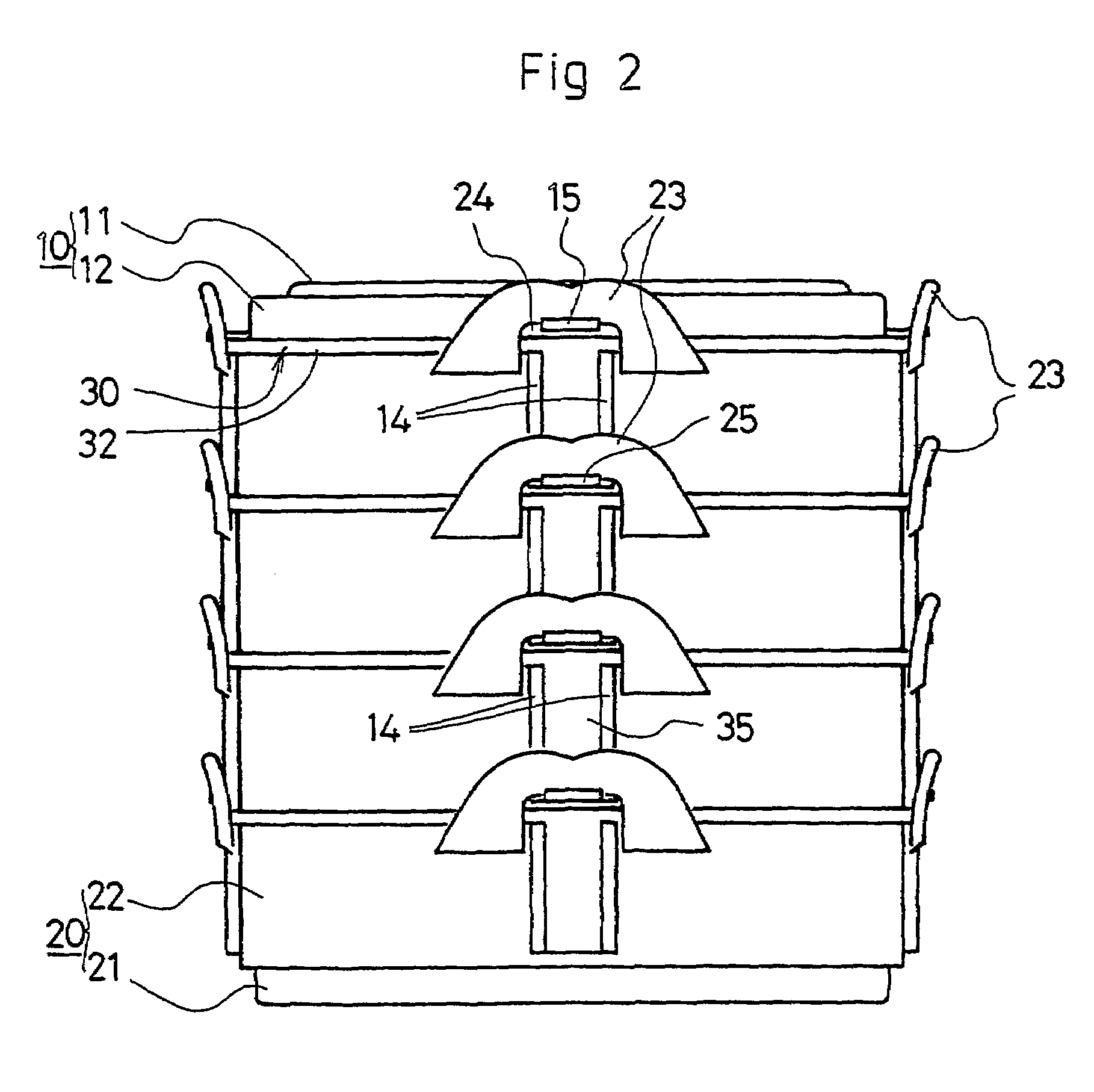

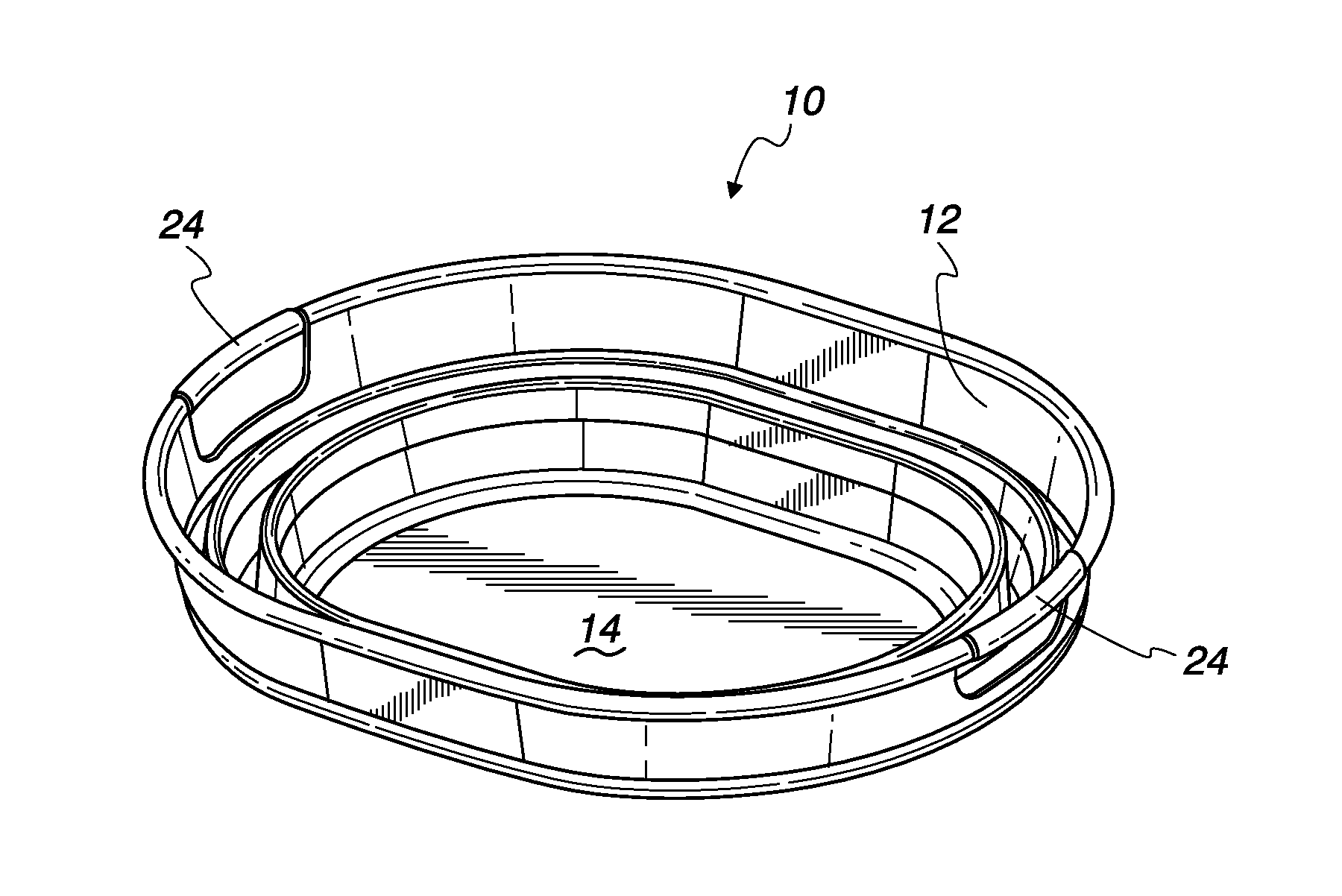

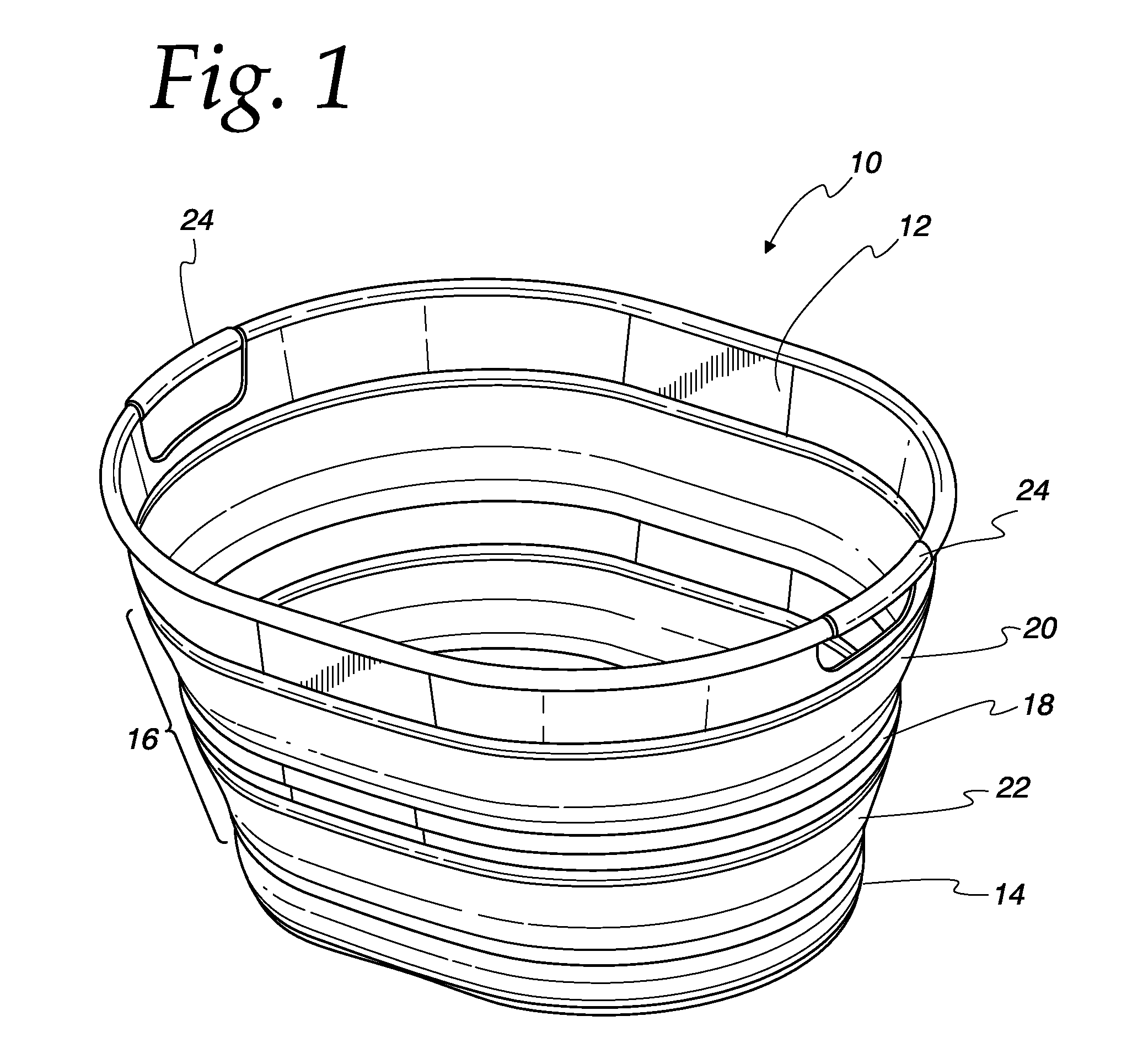

Collapsible container

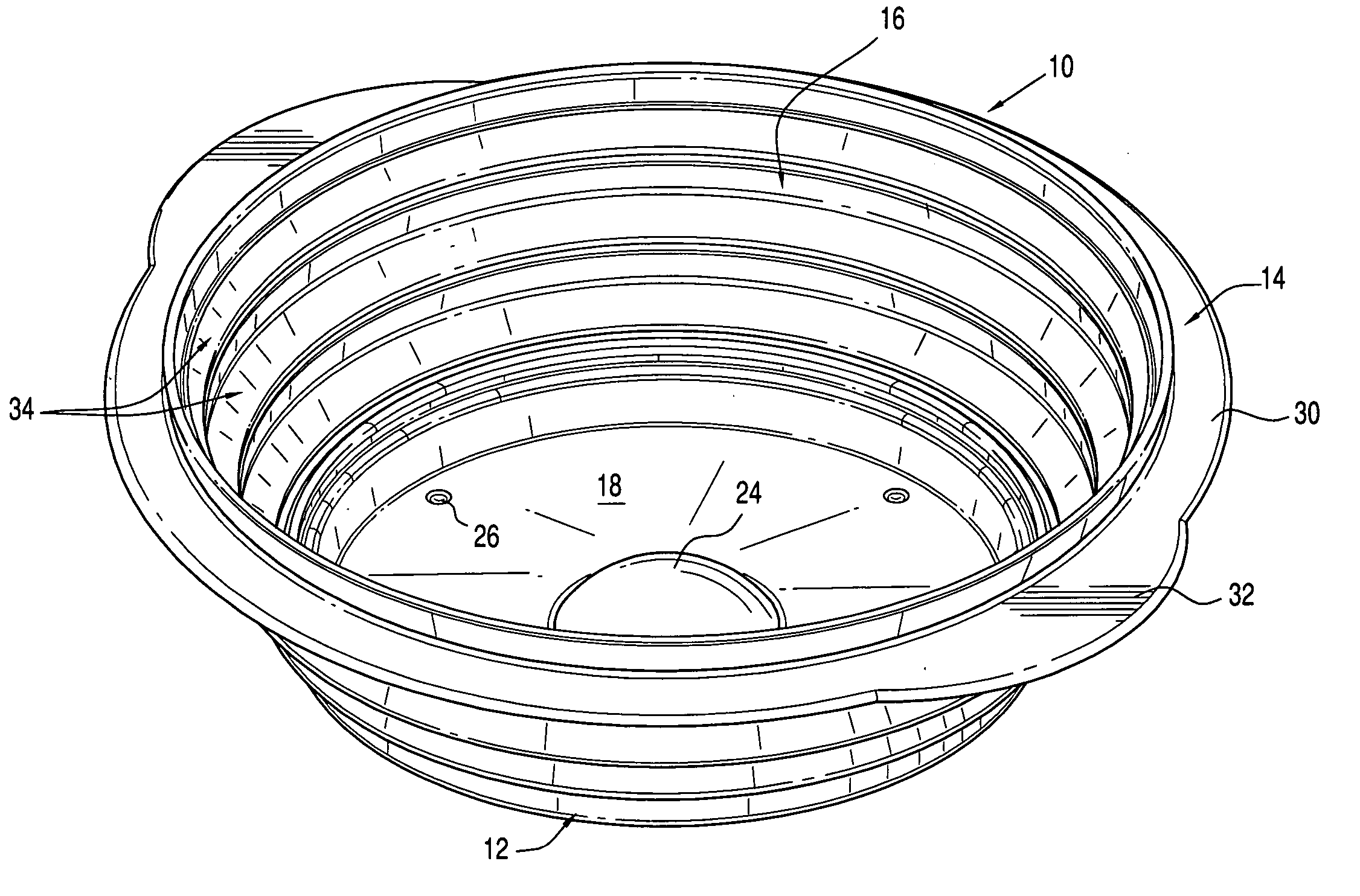

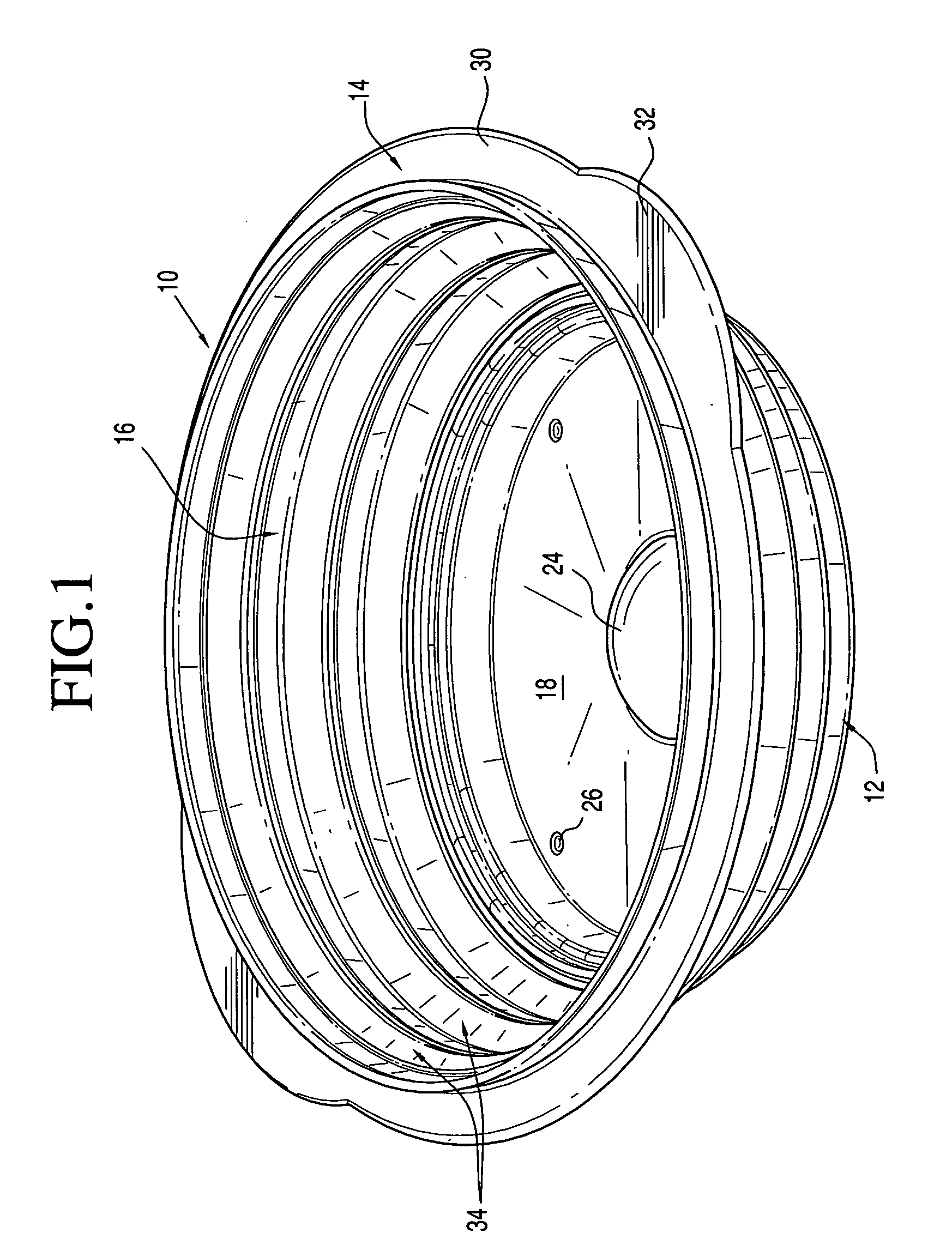

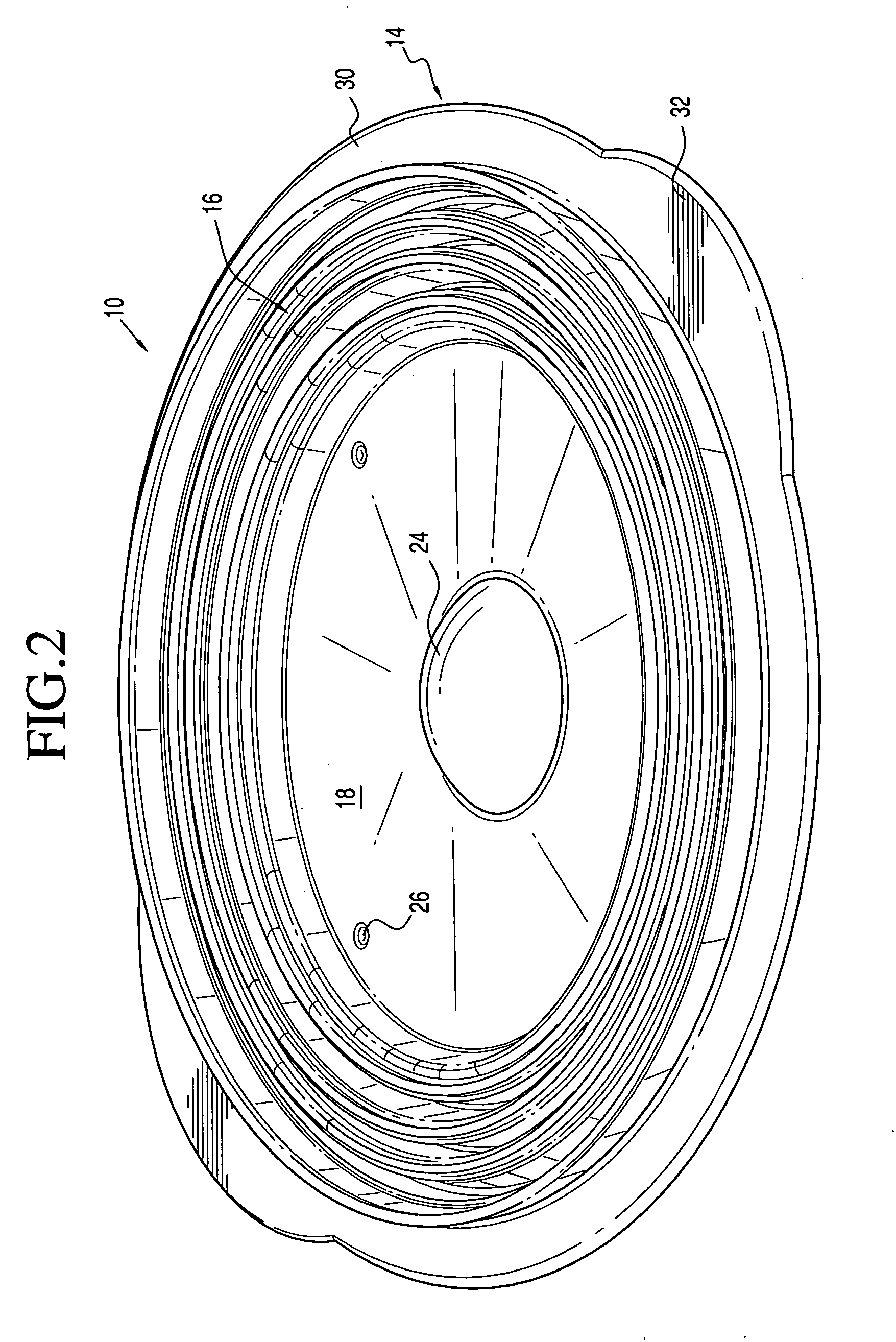

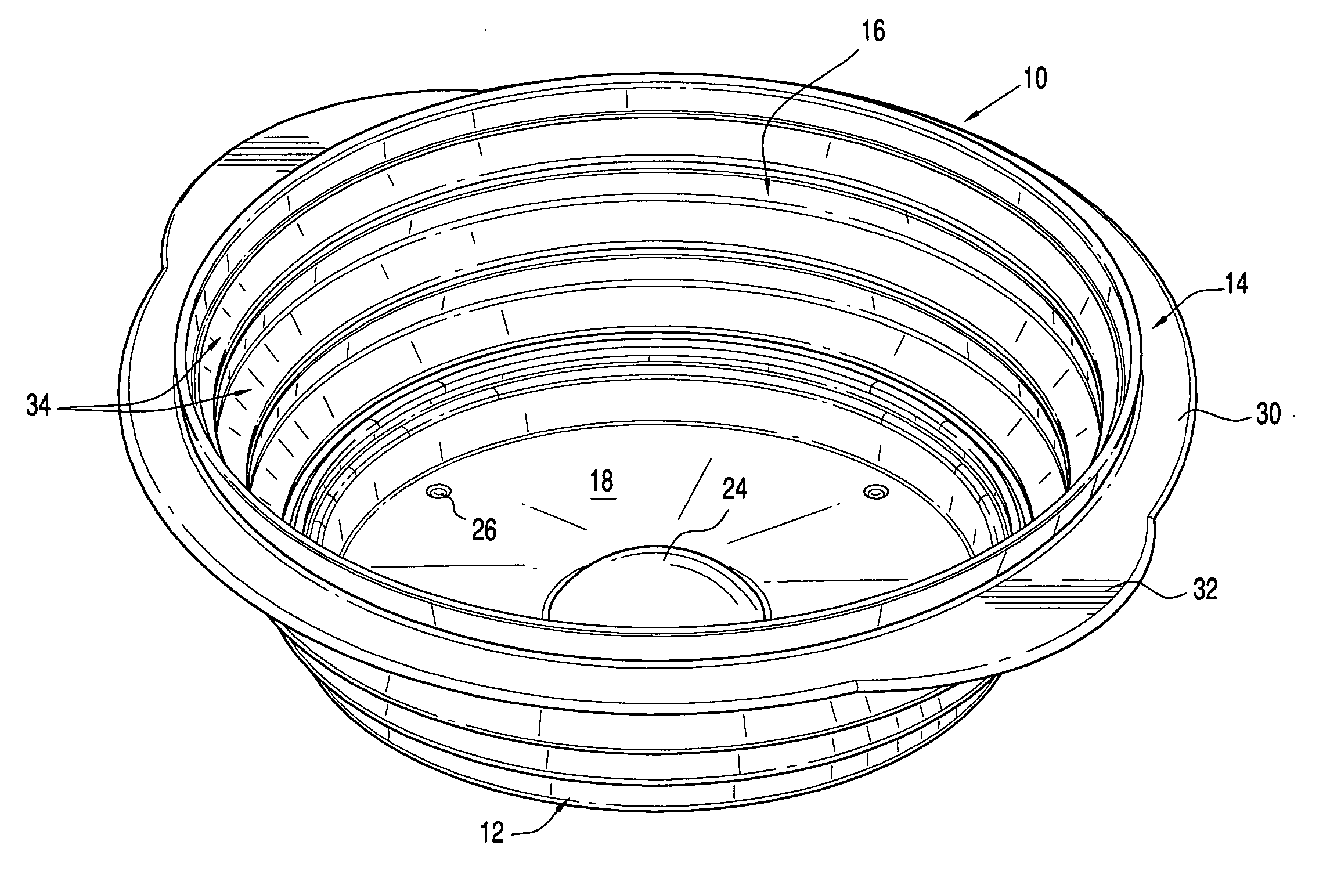

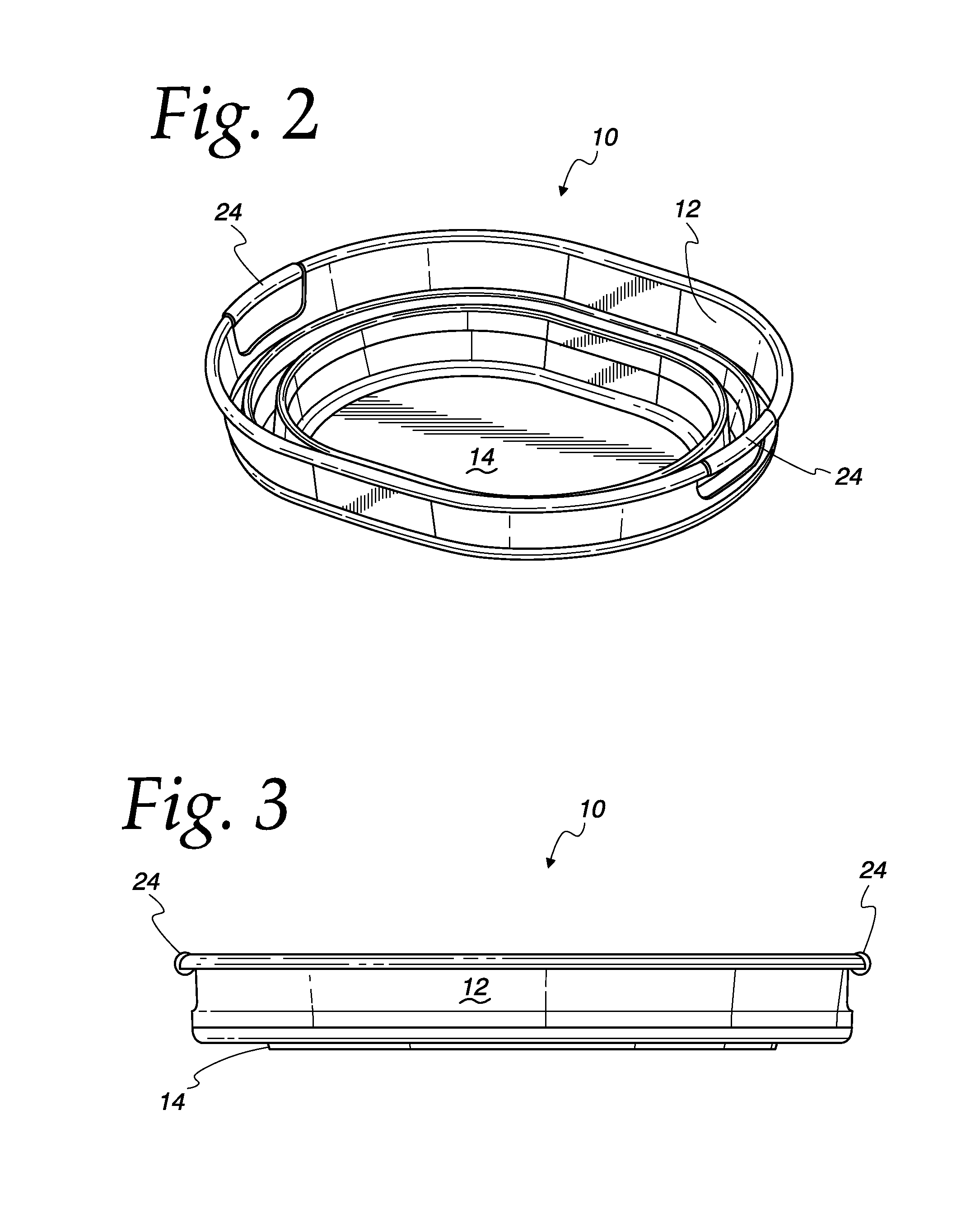

ActiveUS20130277364A1Compact configurationLess forceTravelling sacksCeramic shaping apparatusEngineeringMechanical engineering

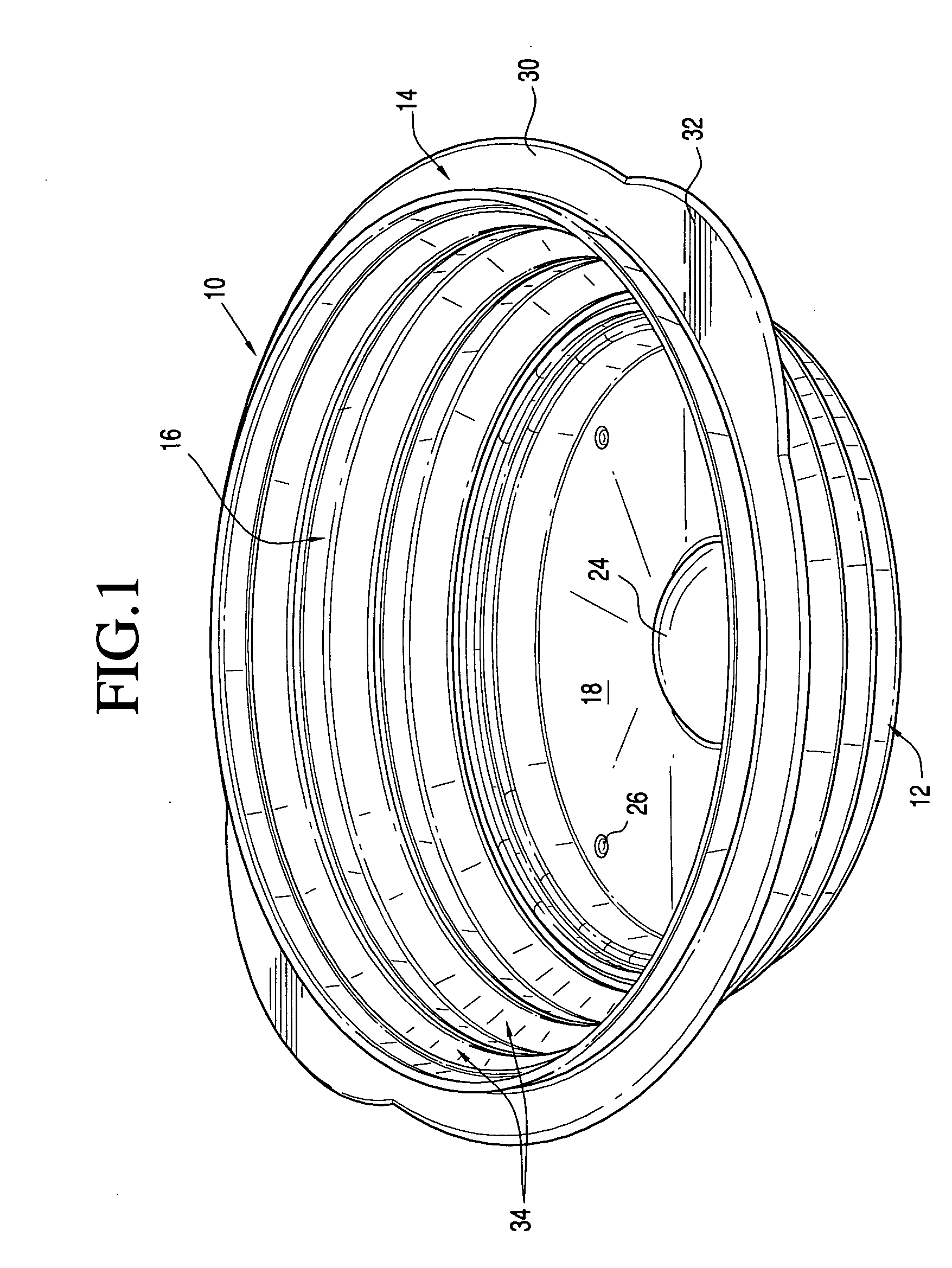

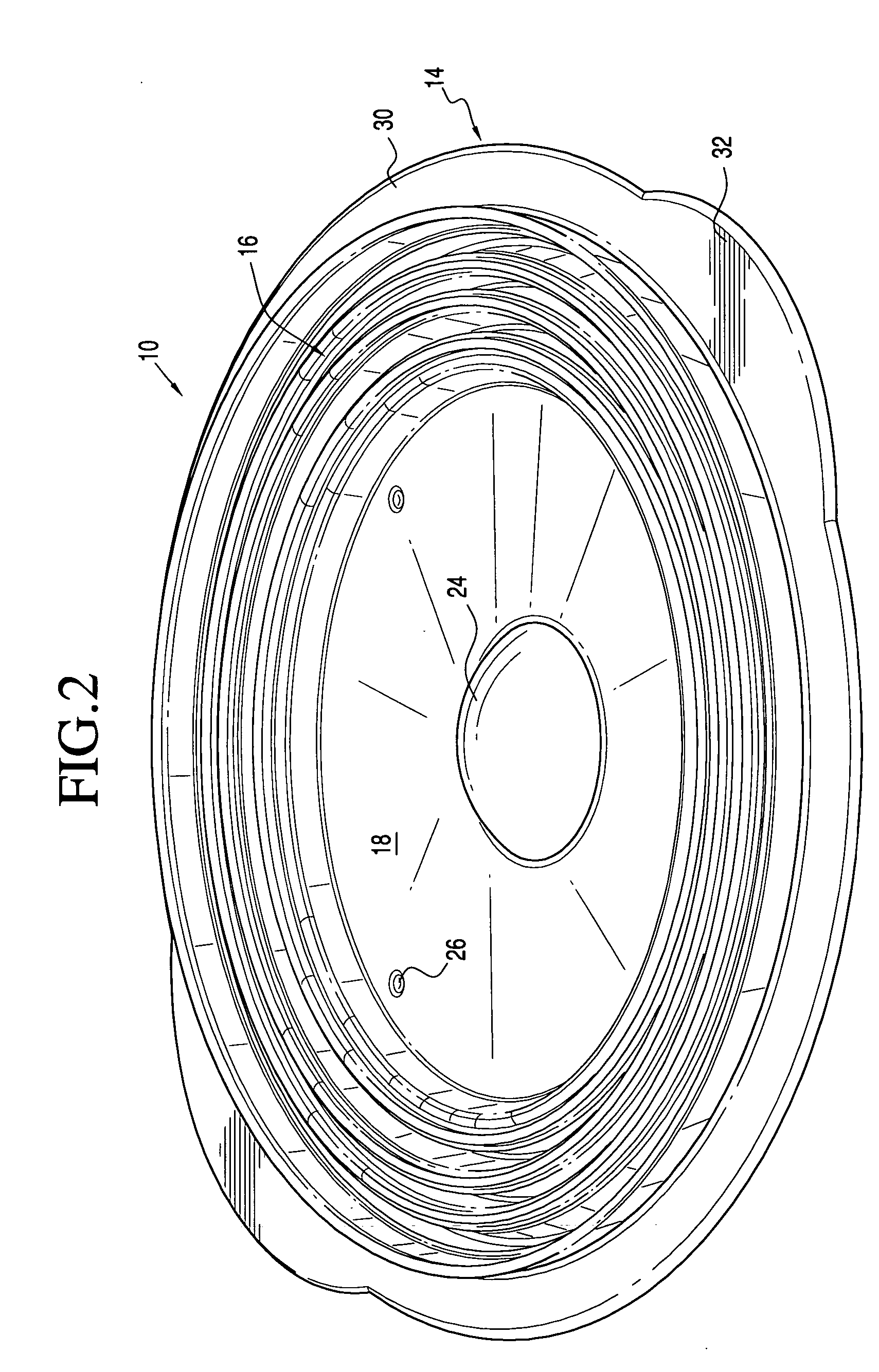

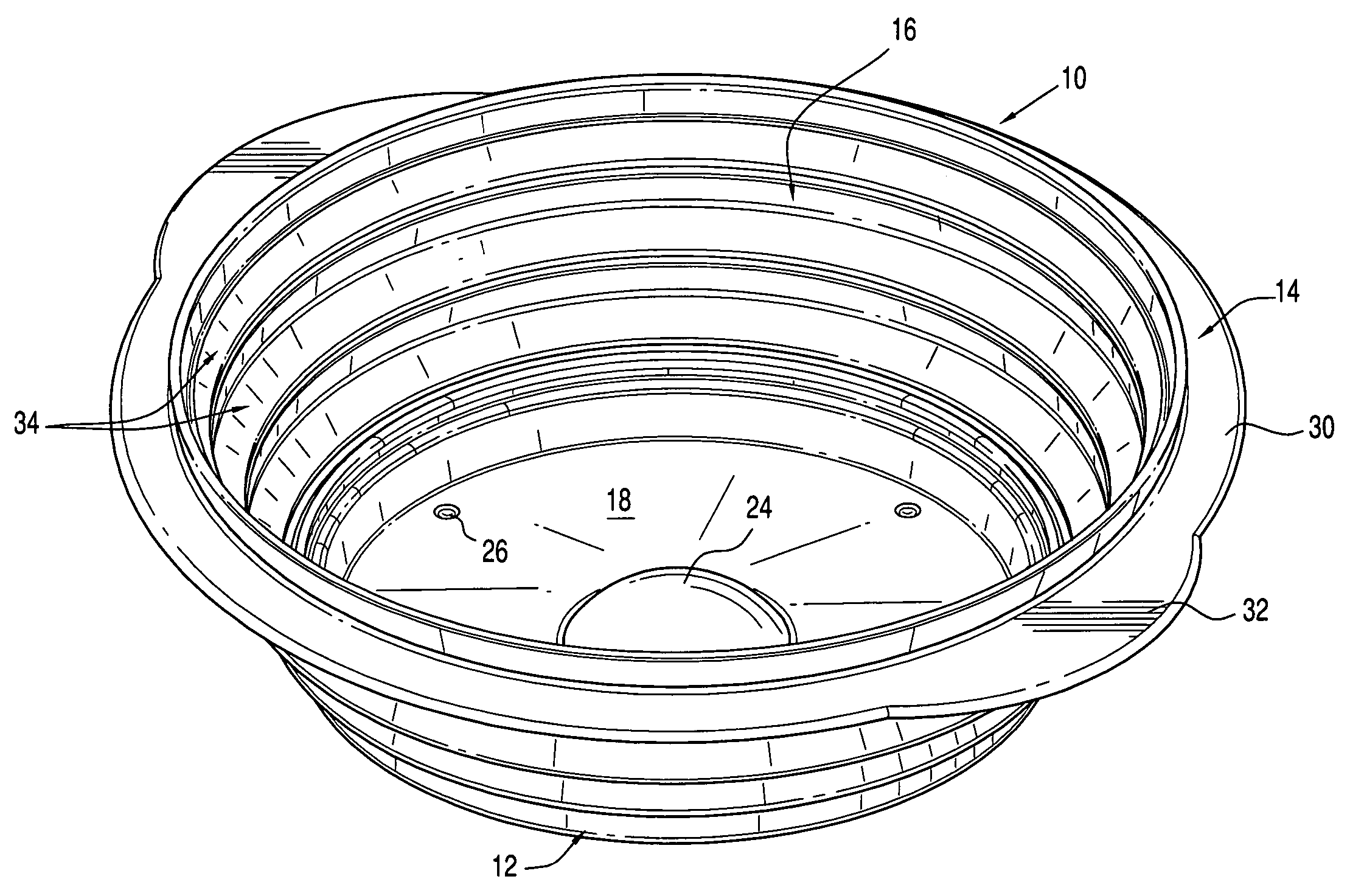

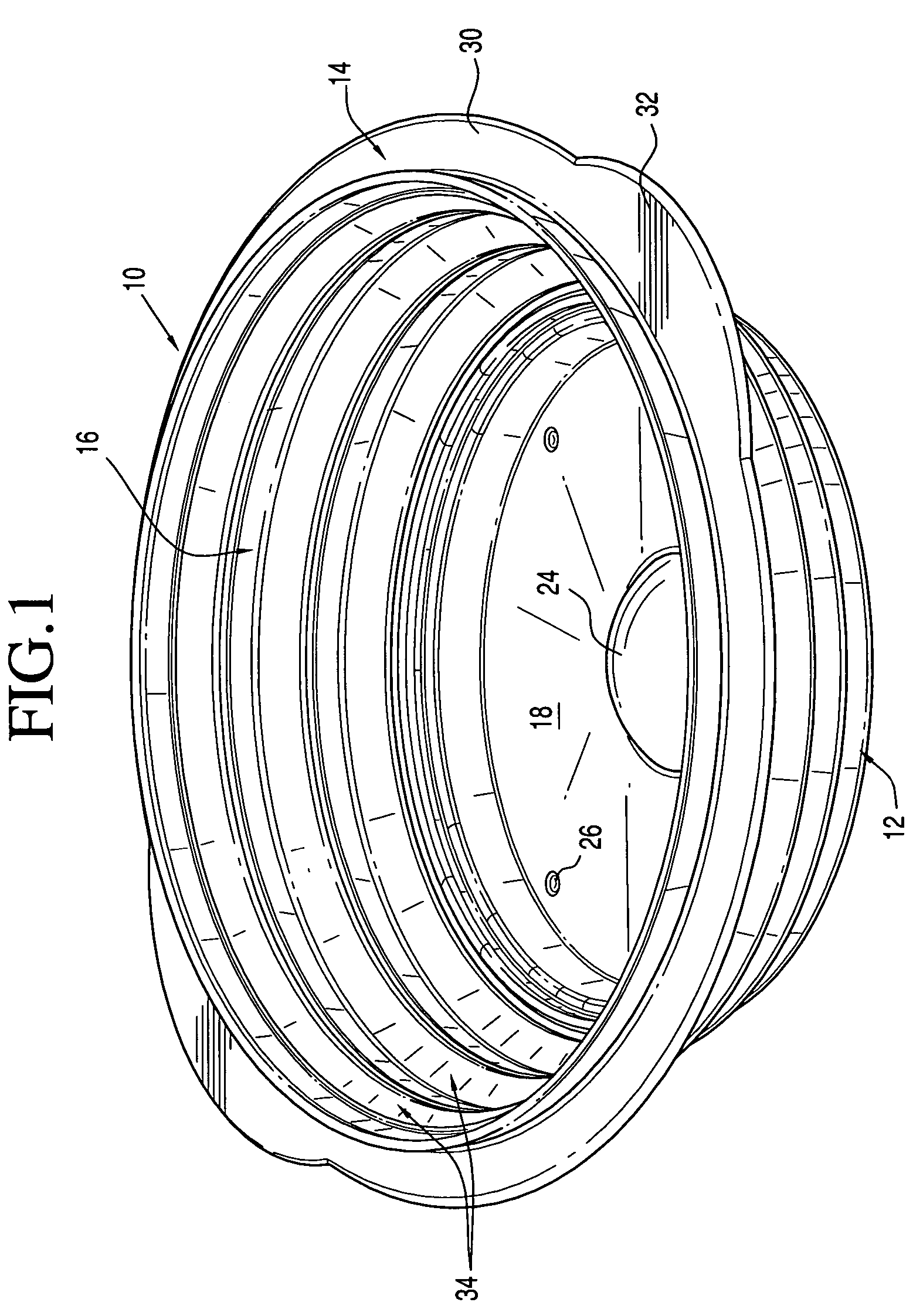

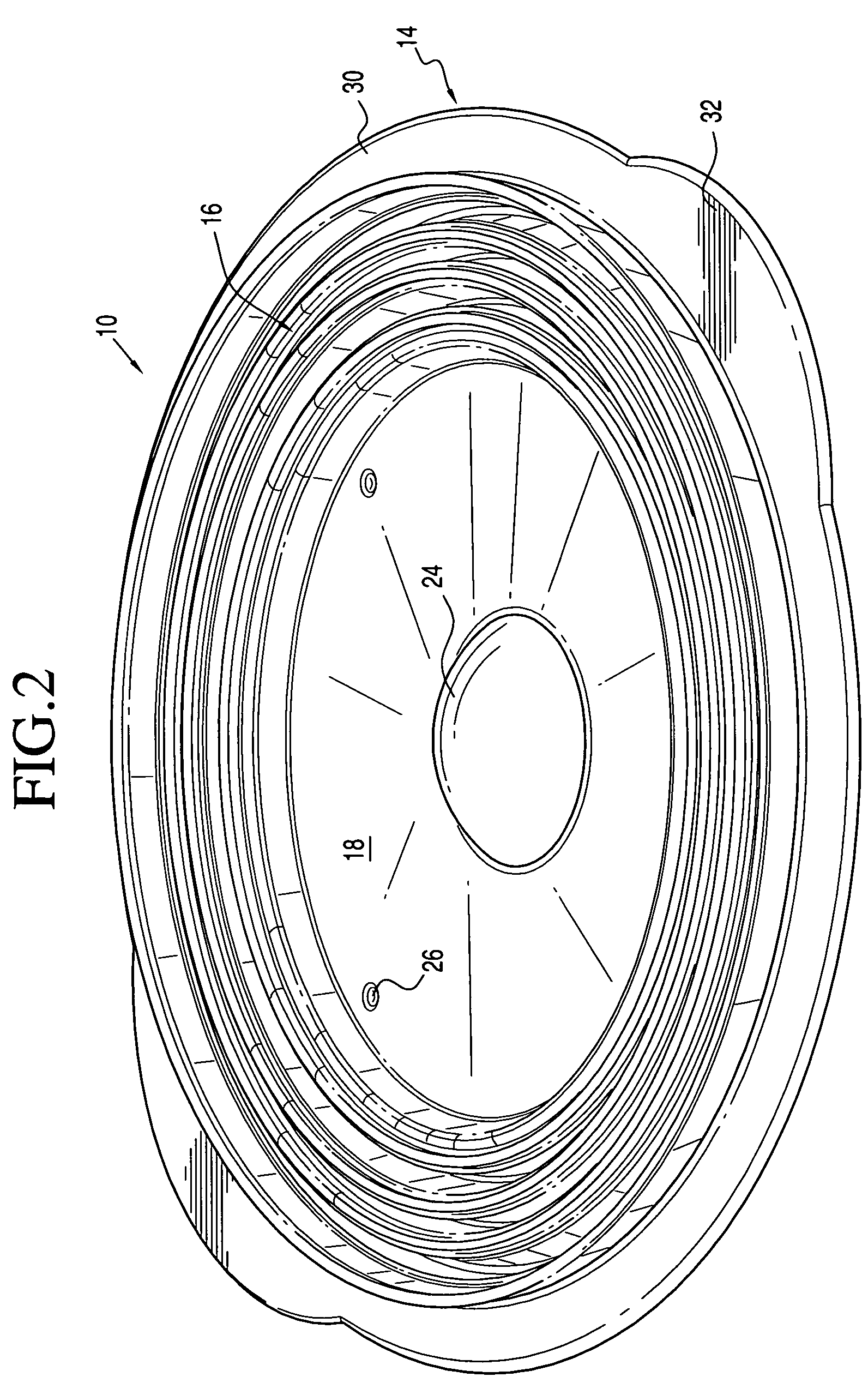

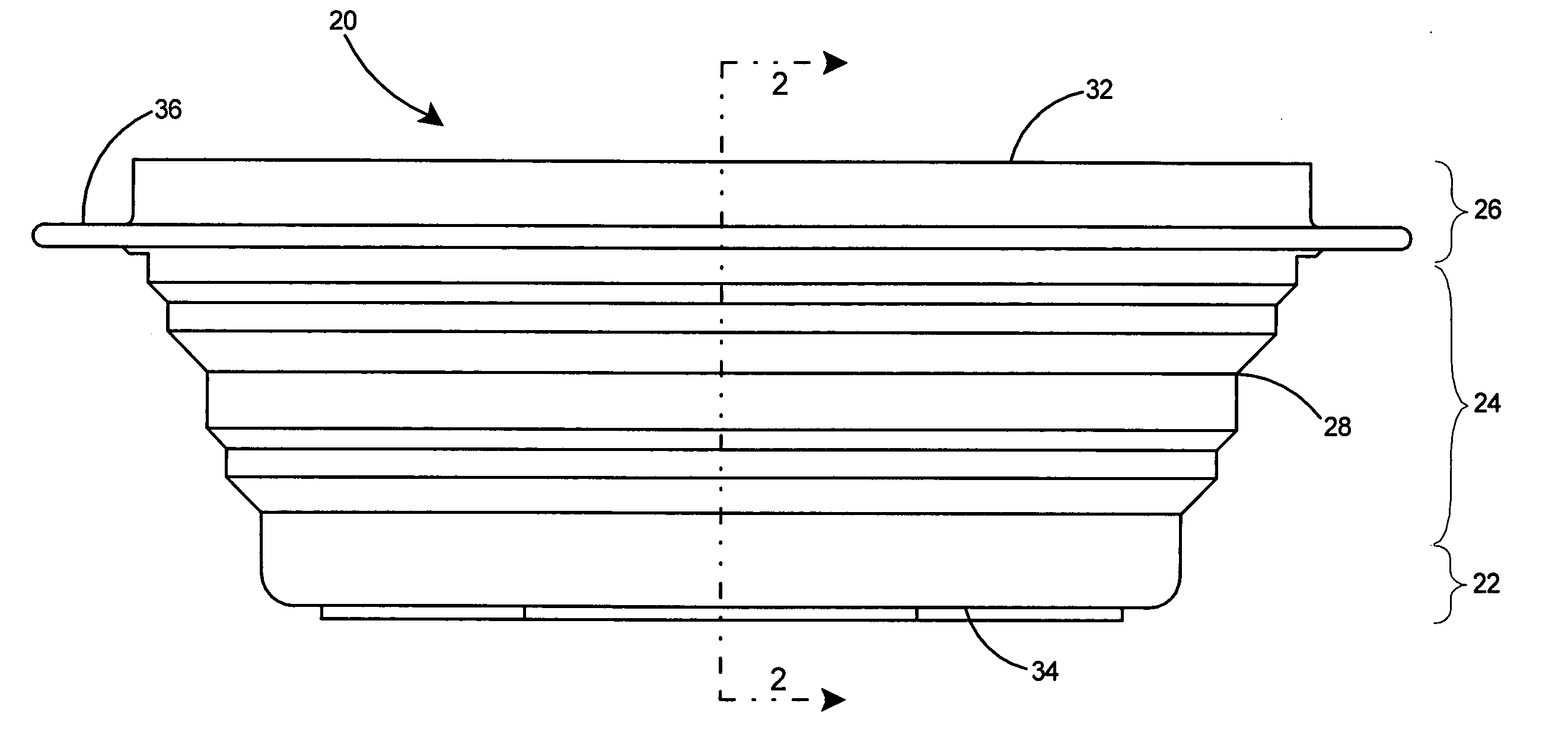

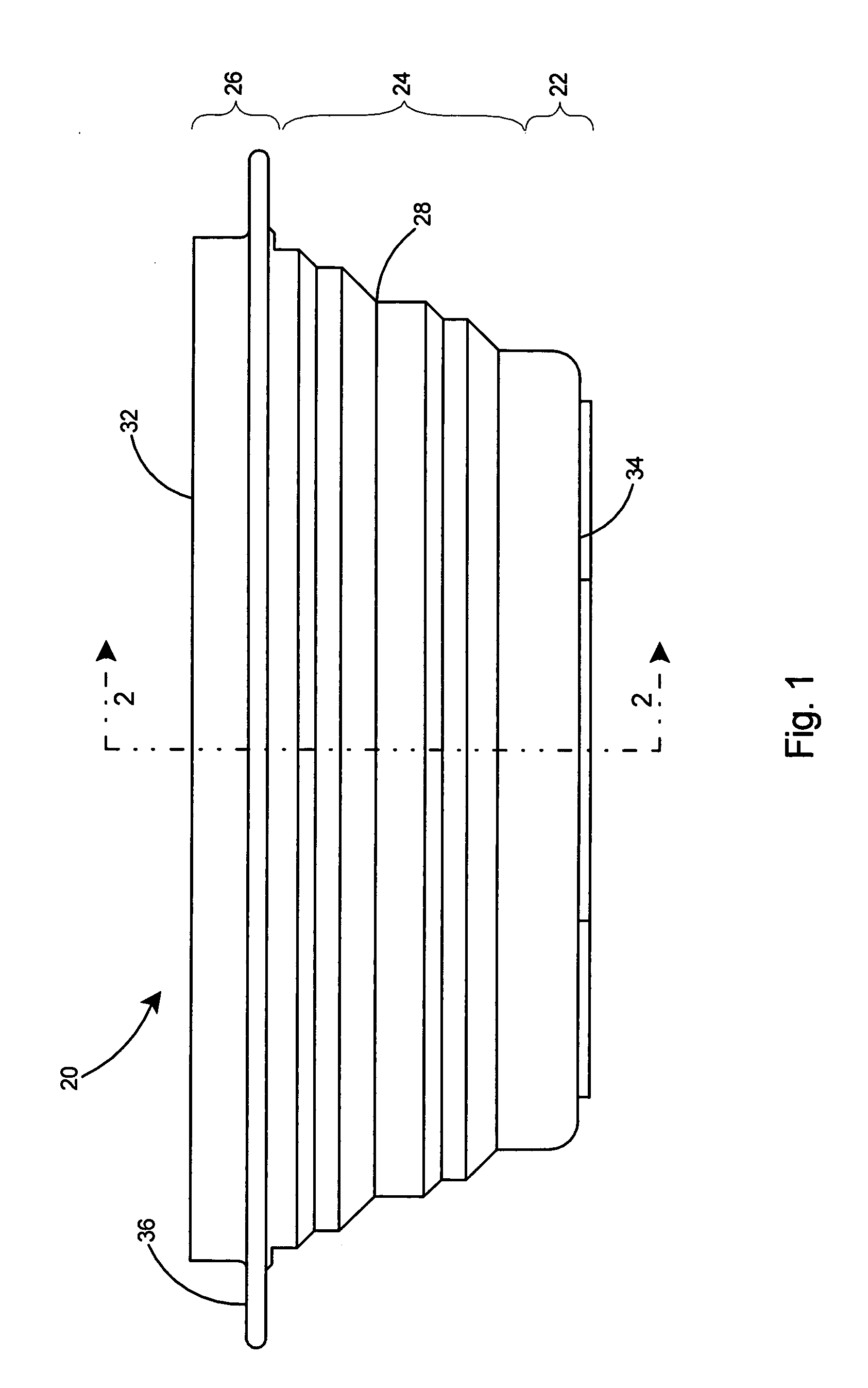

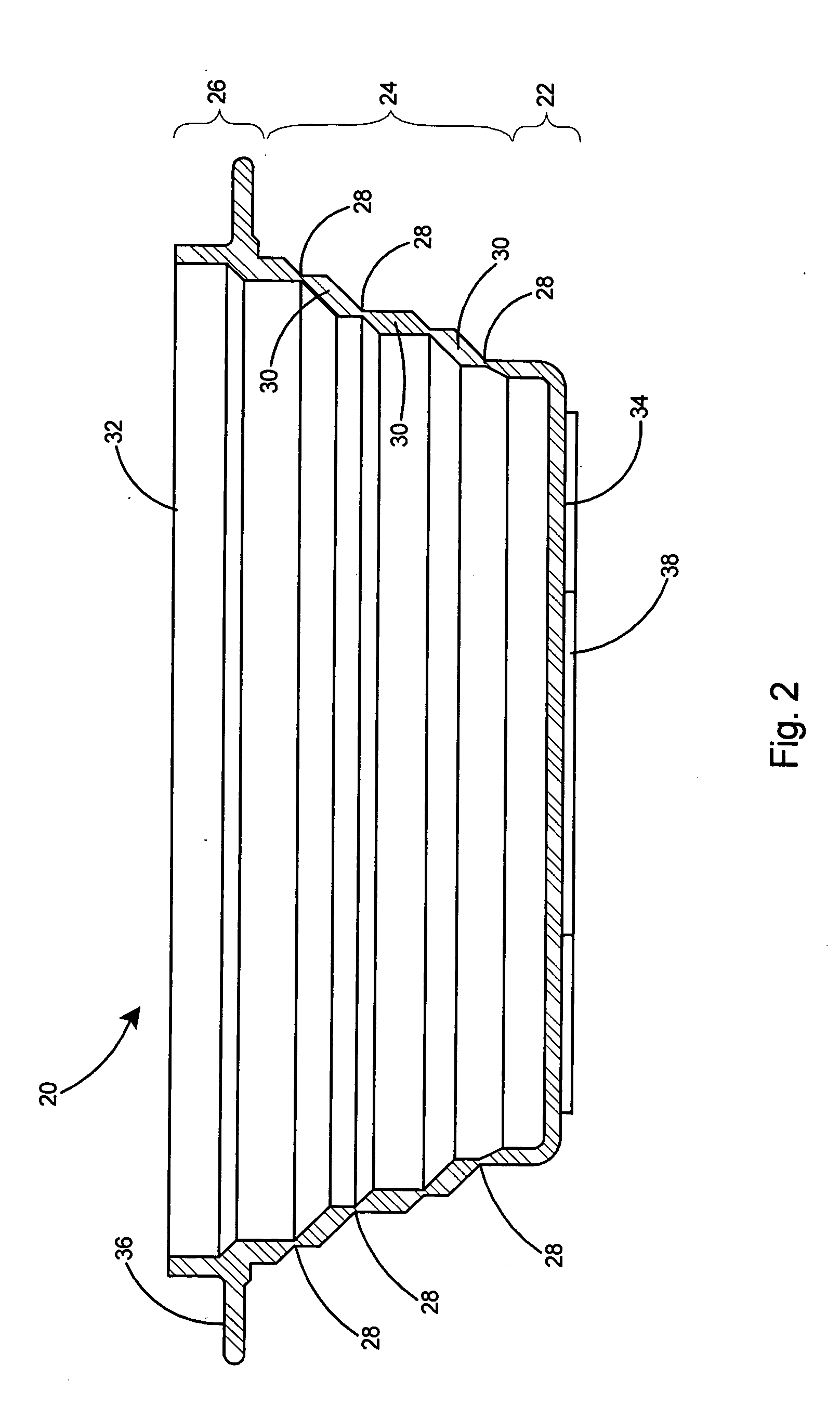

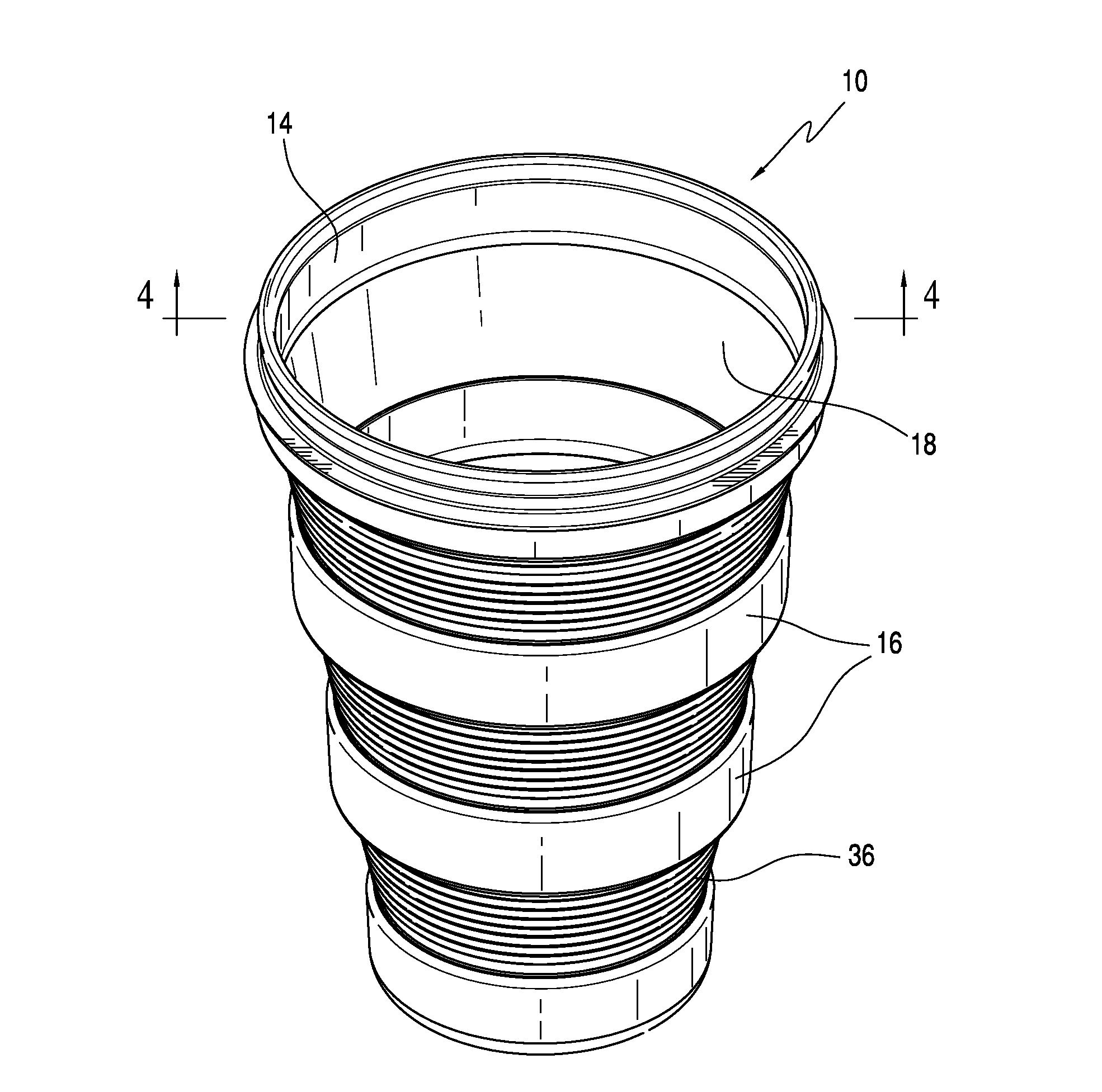

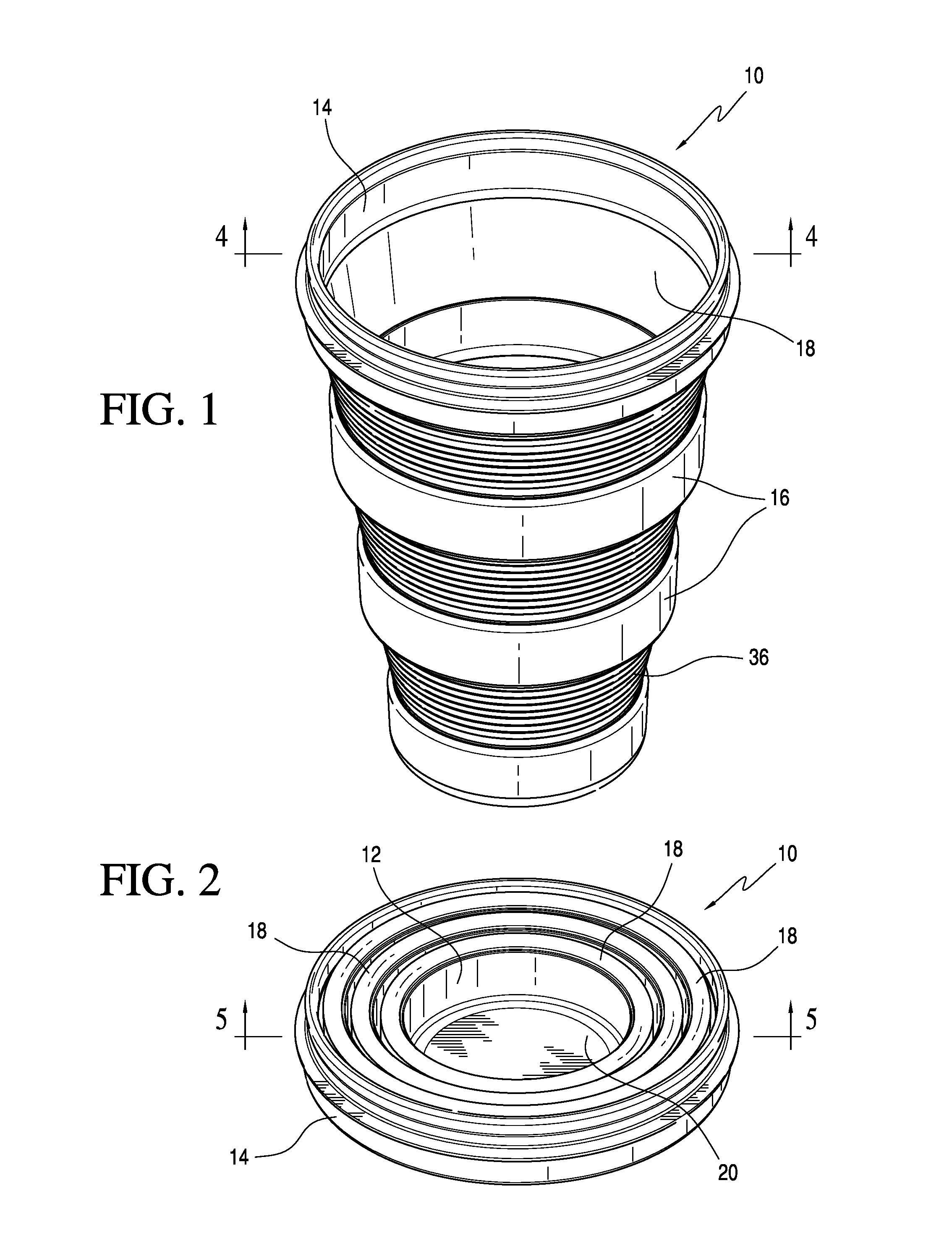

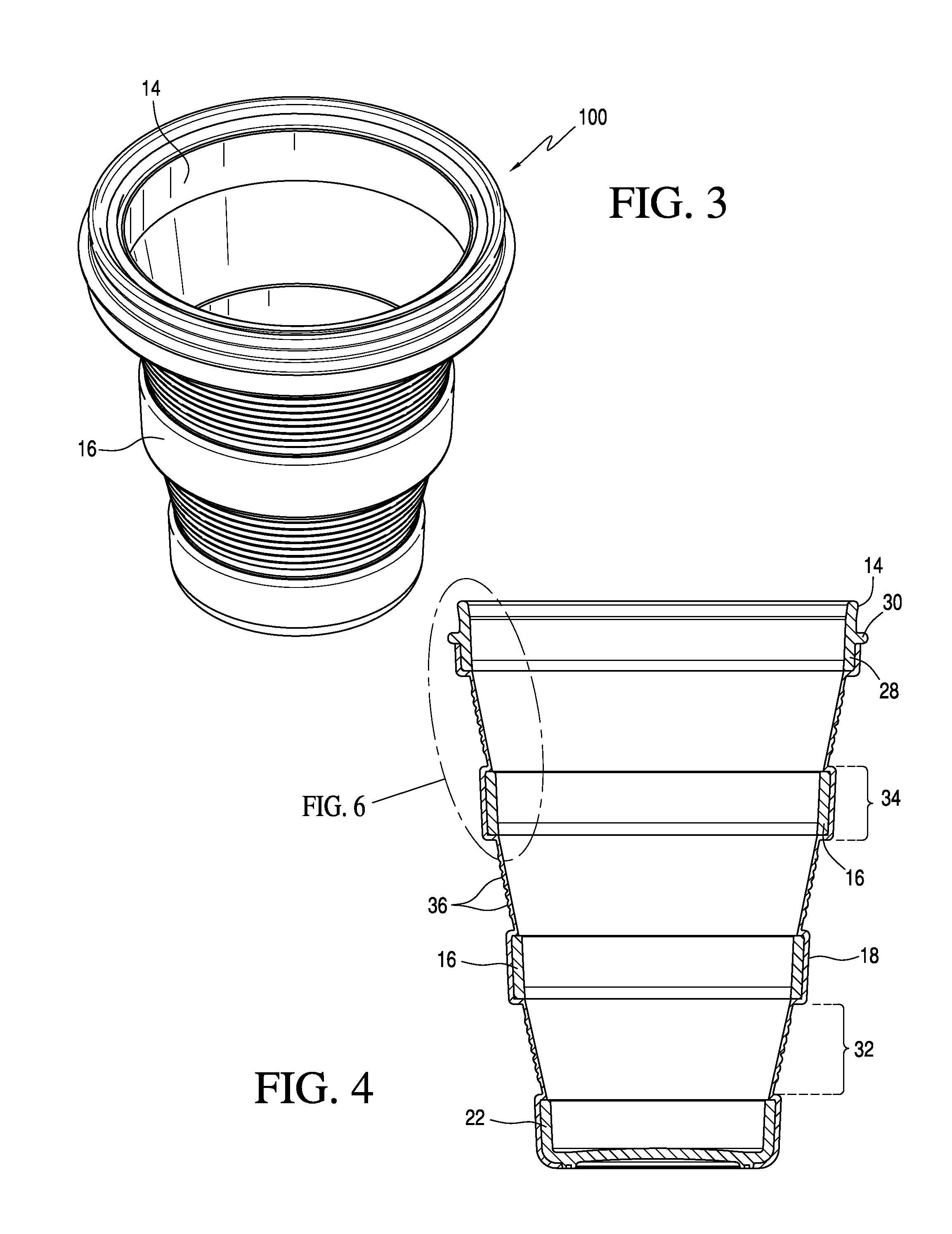

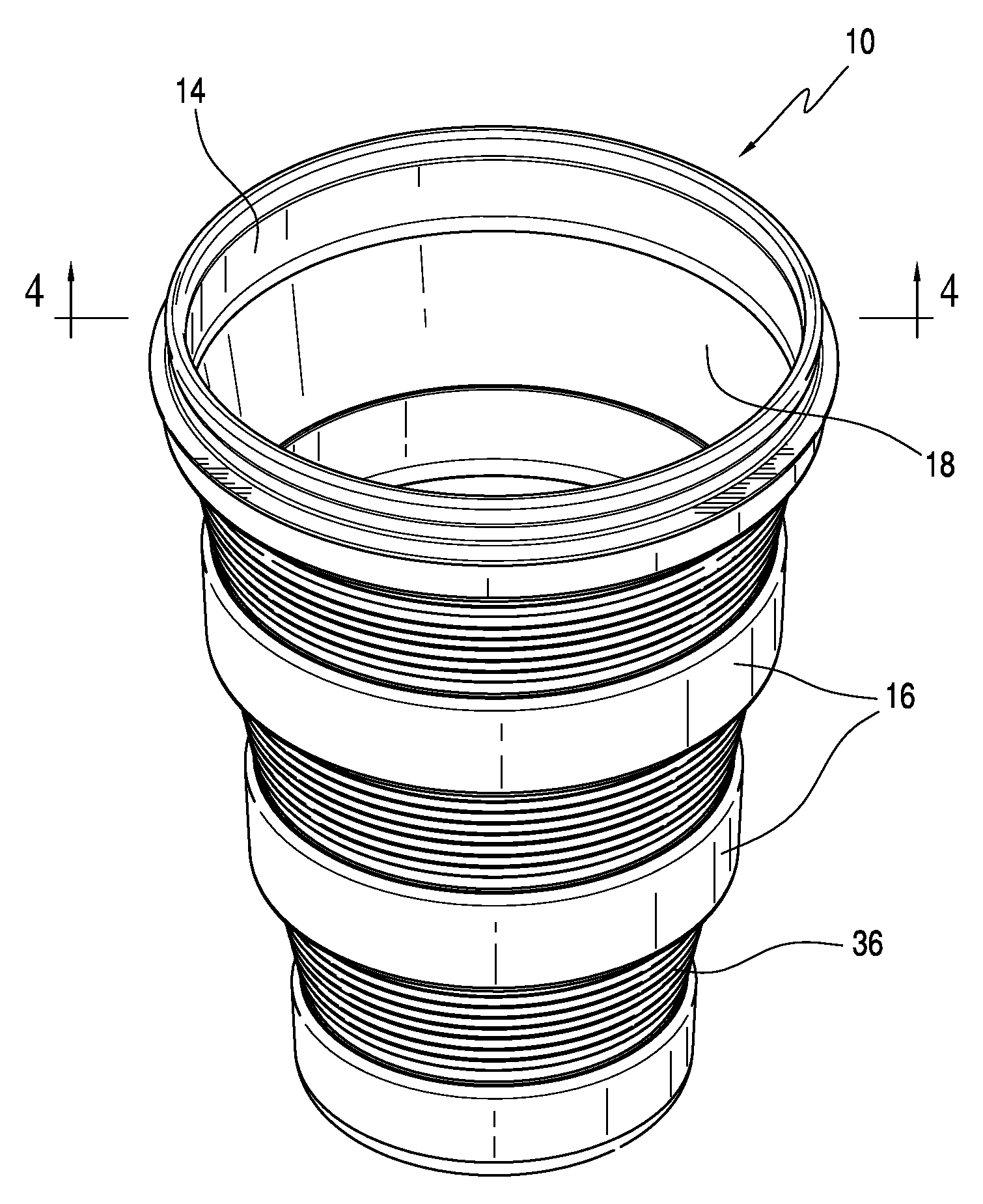

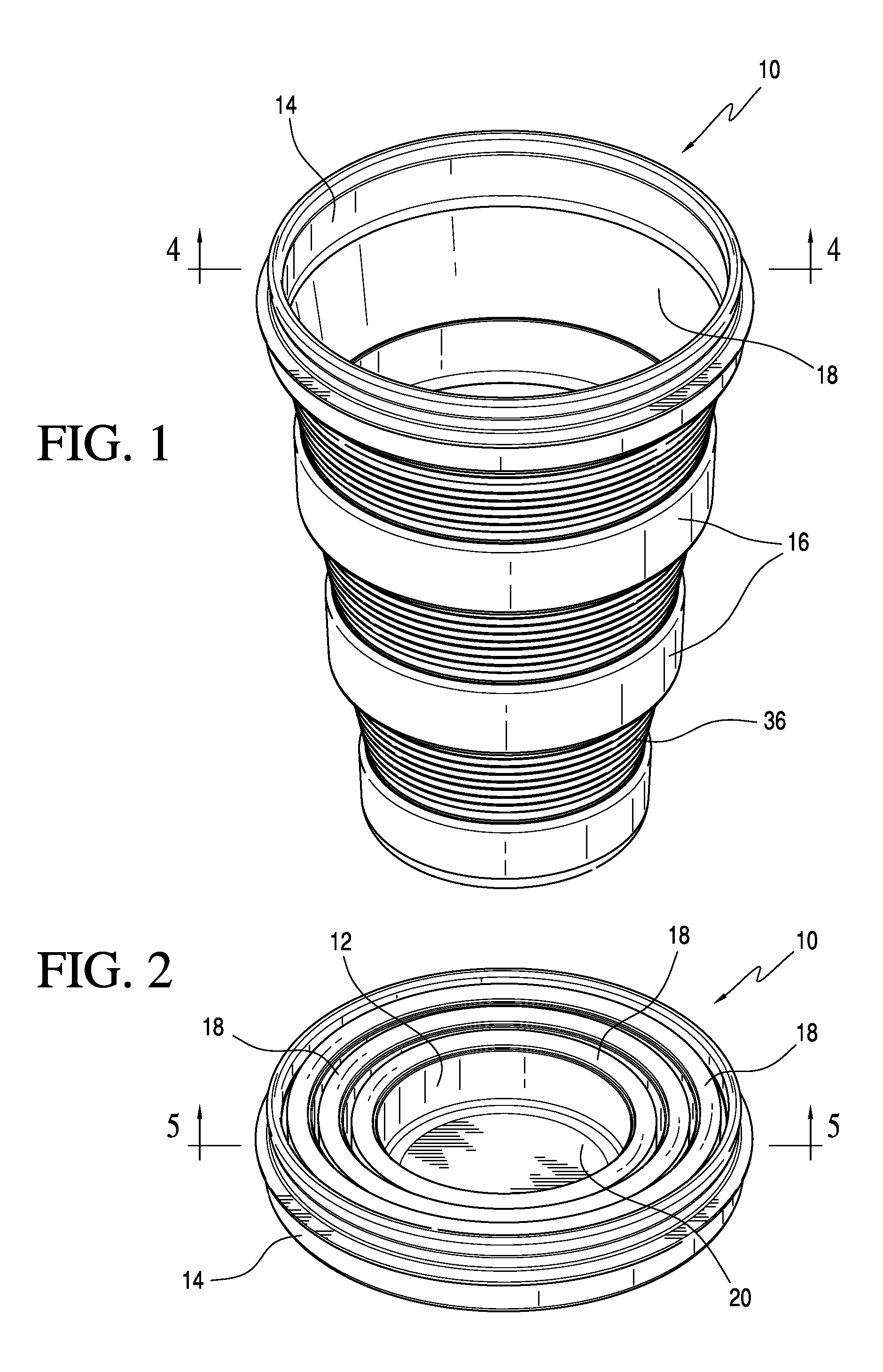

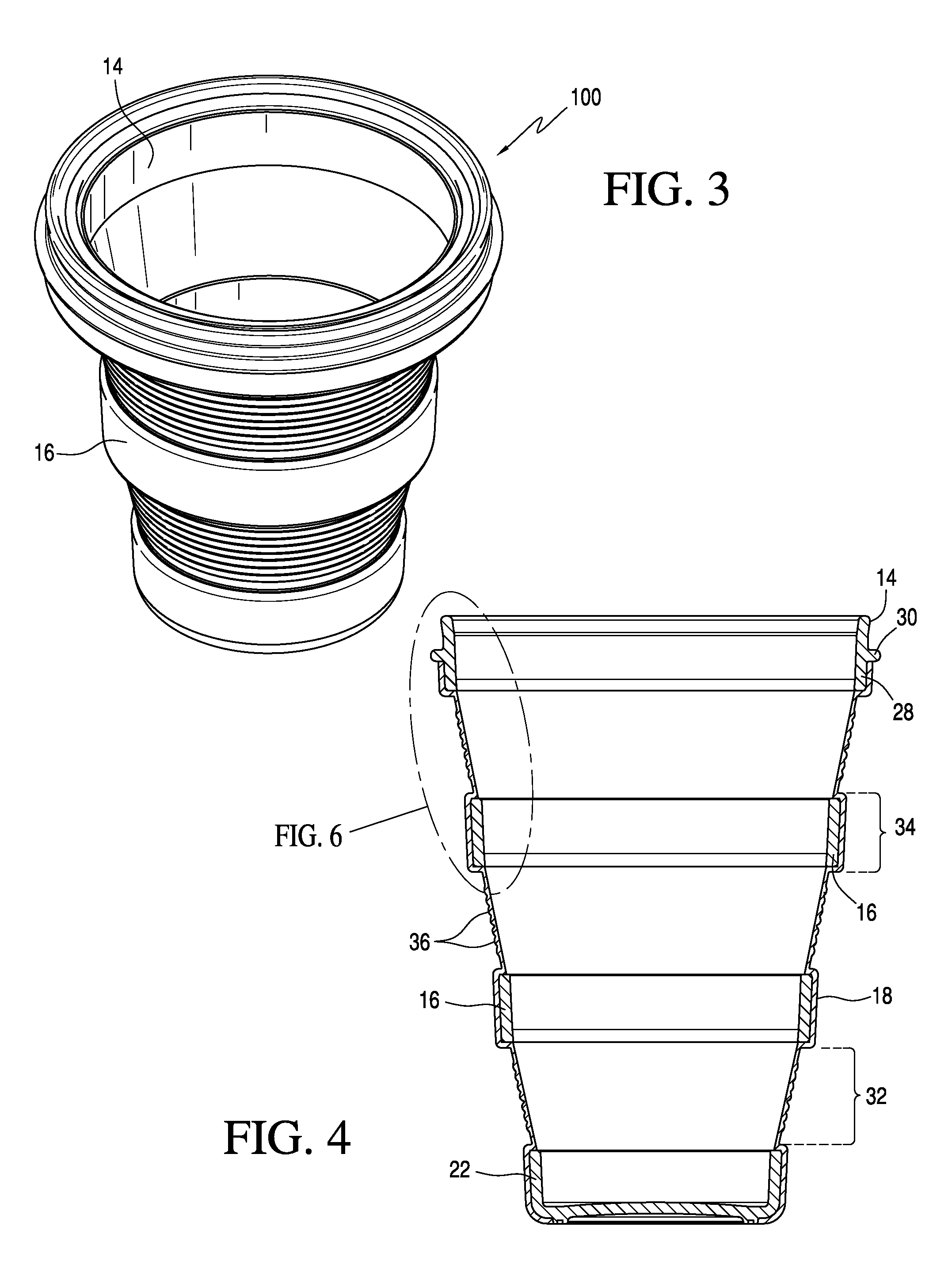

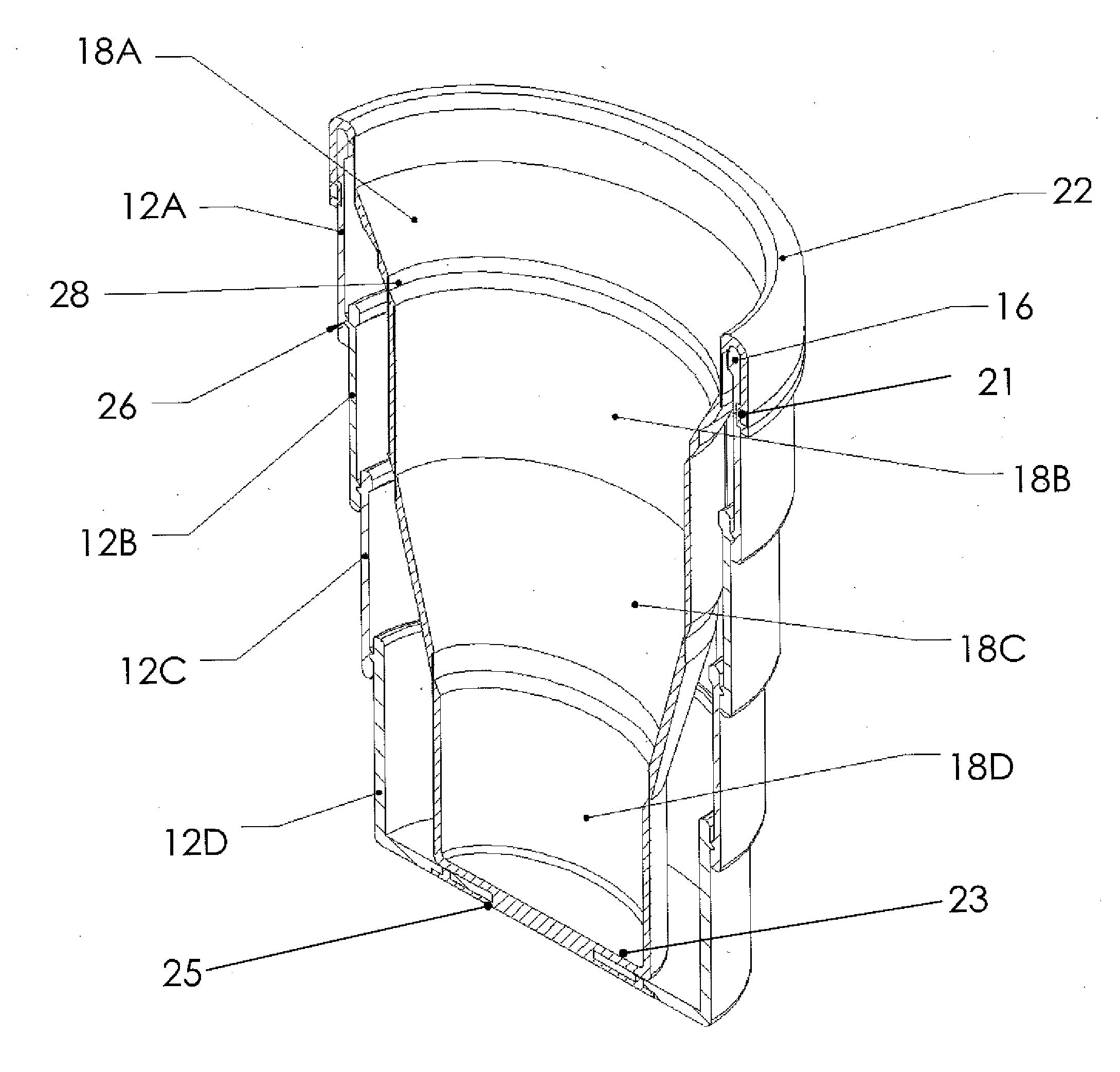

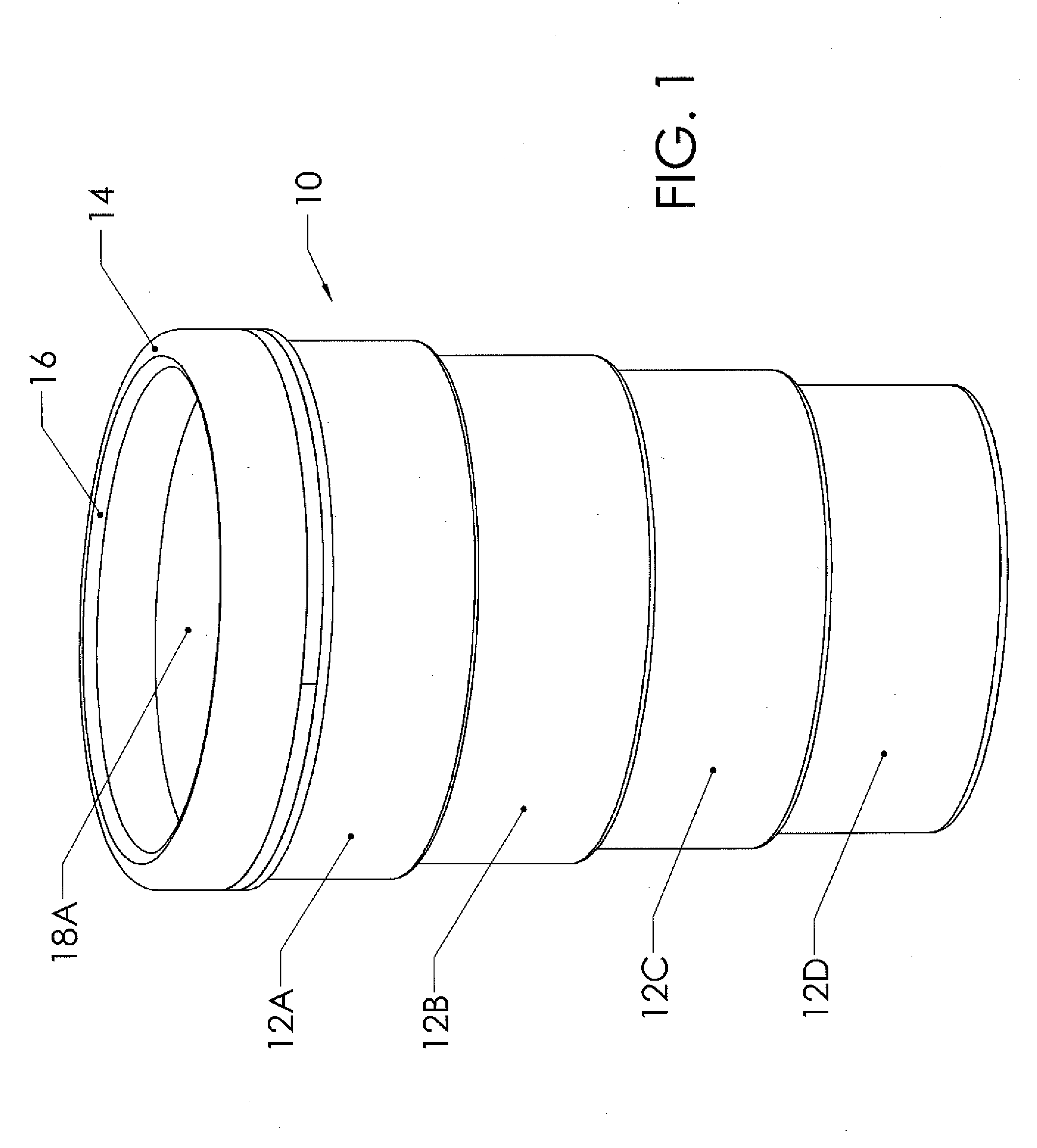

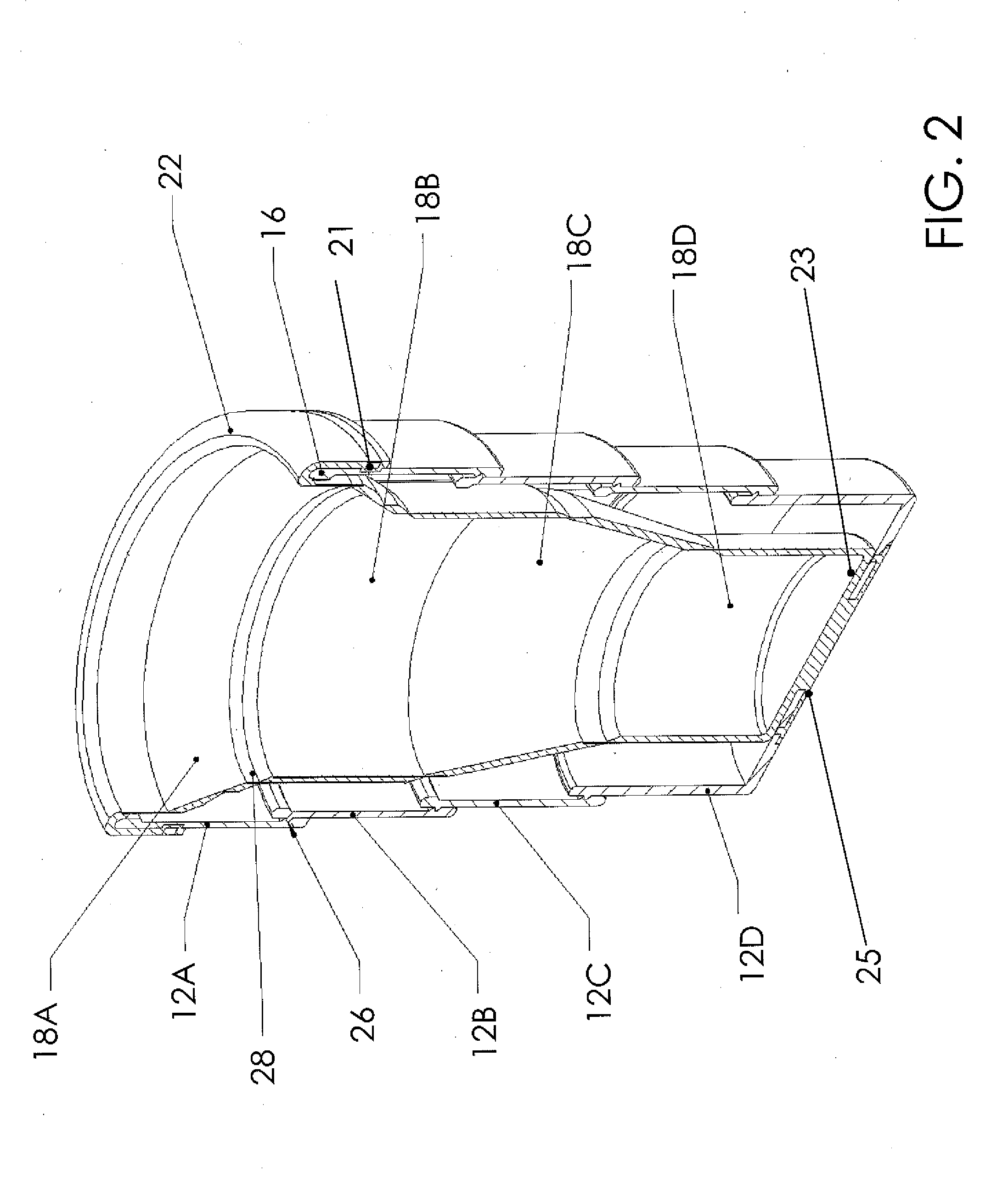

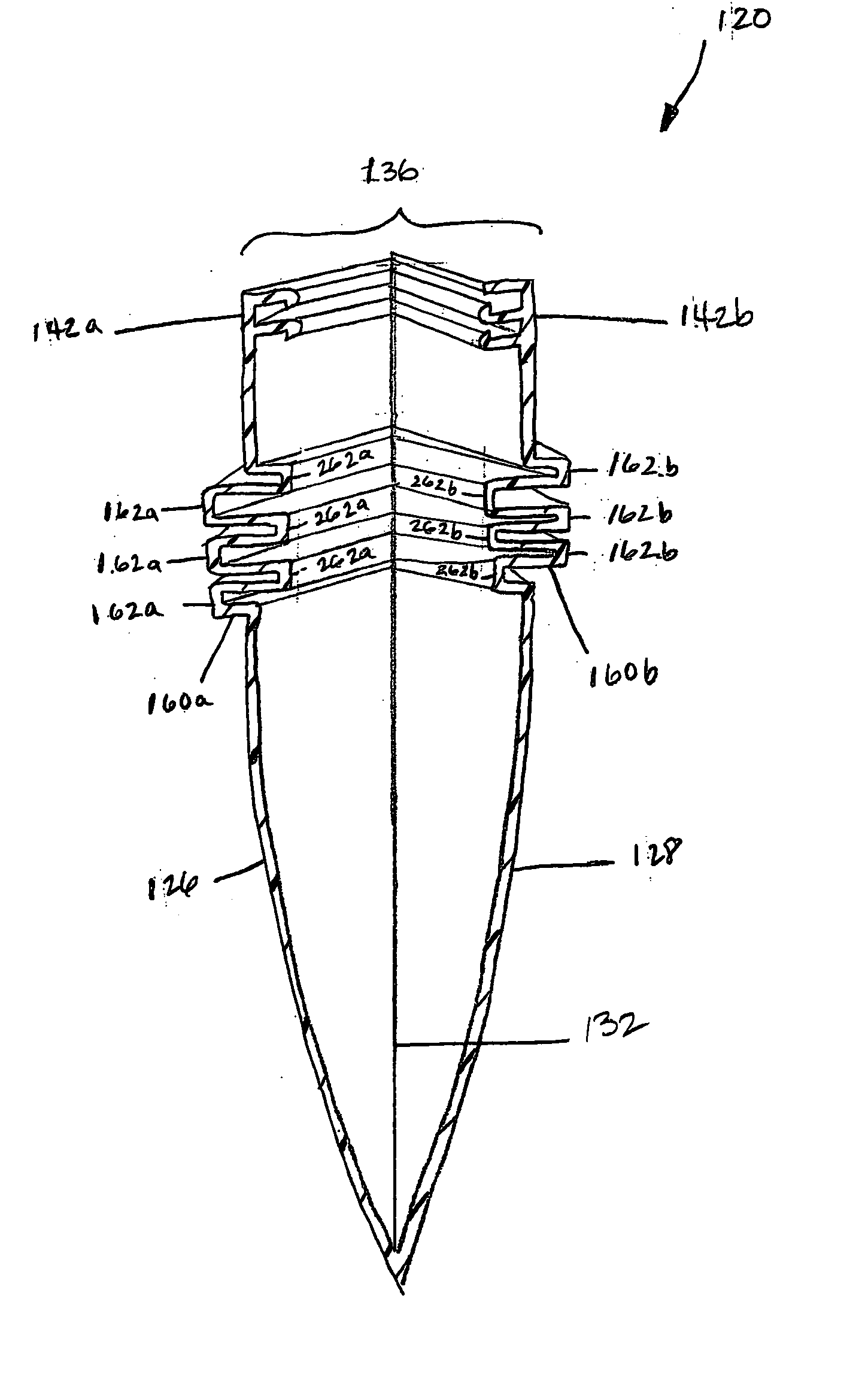

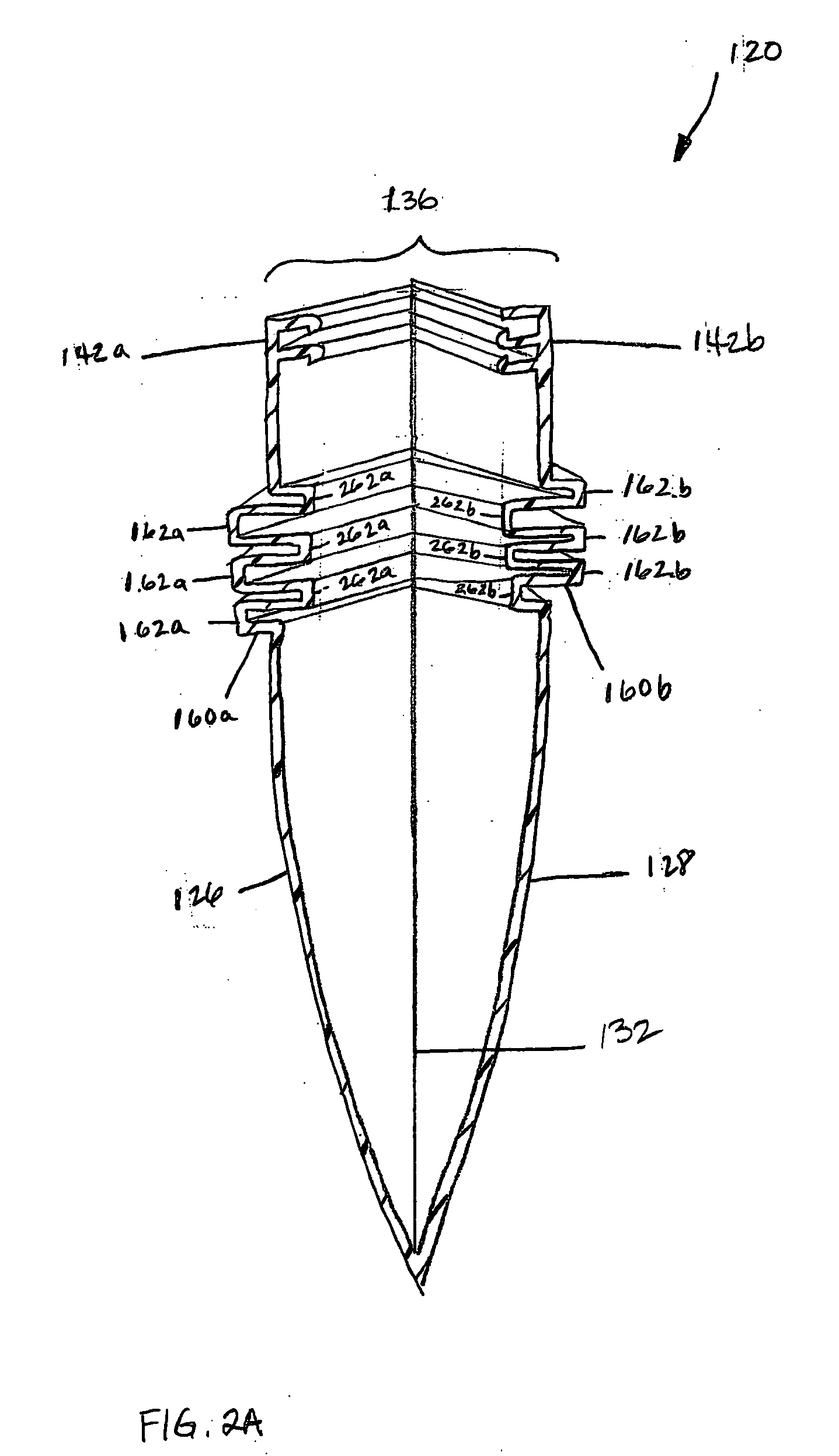

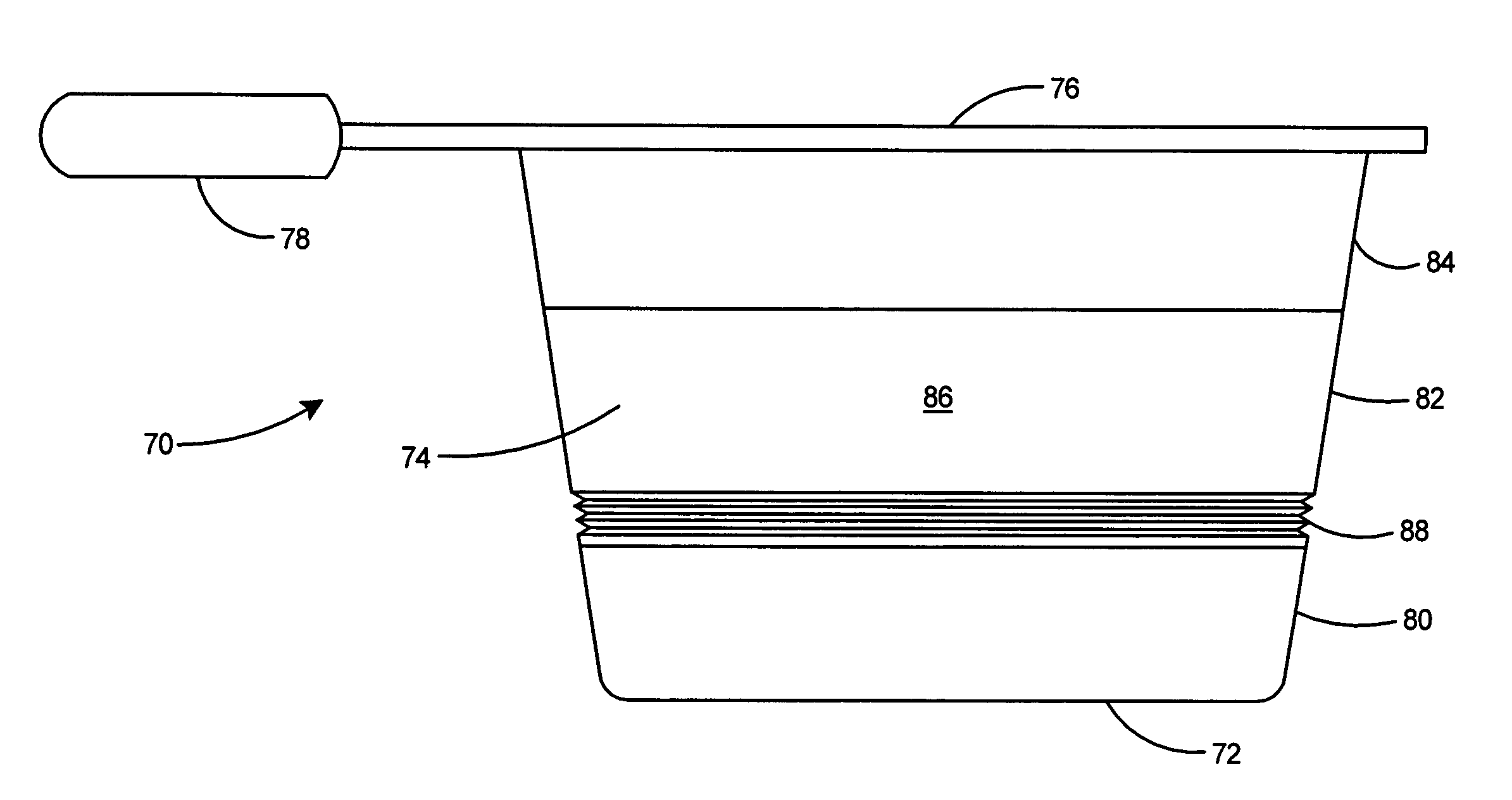

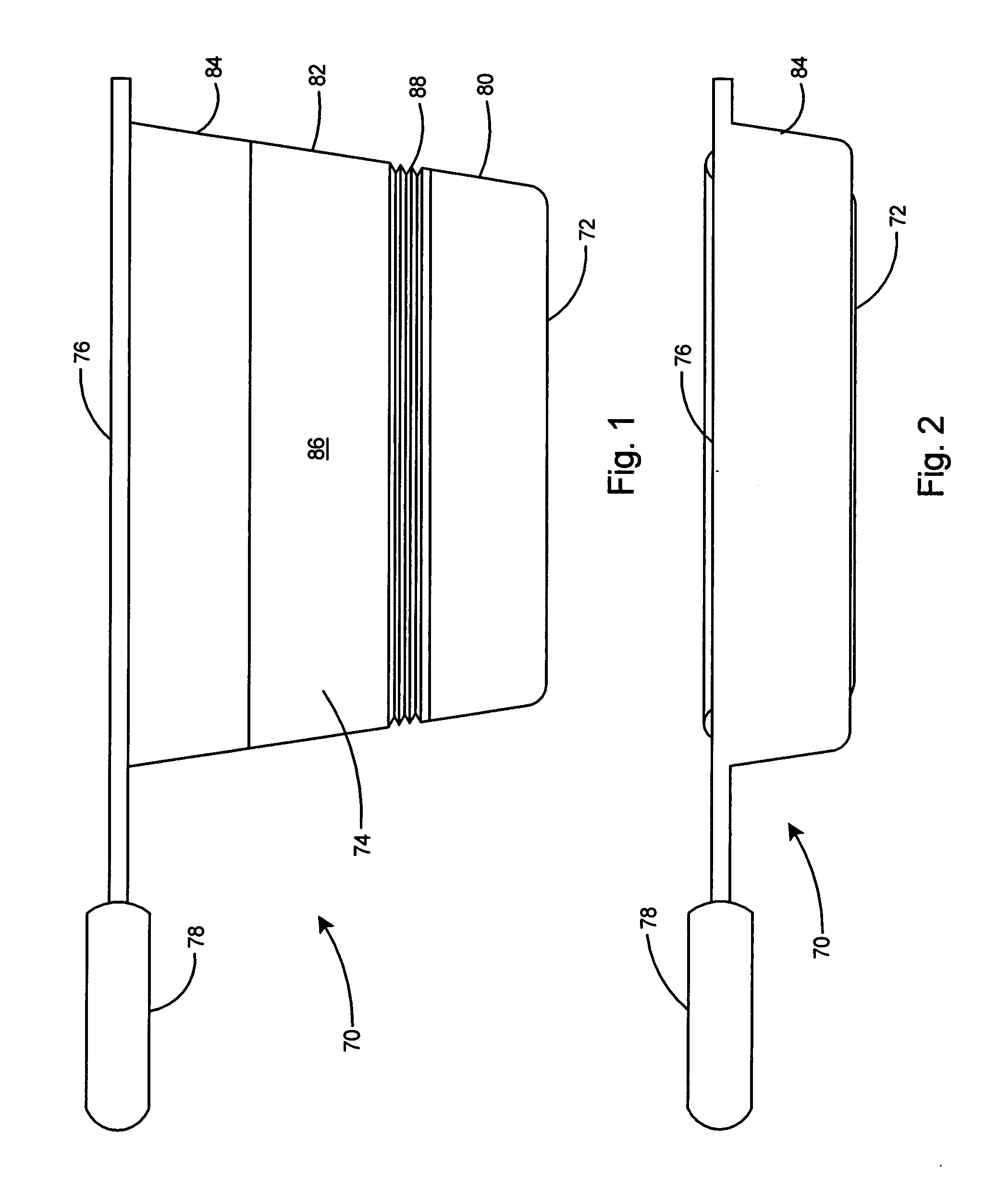

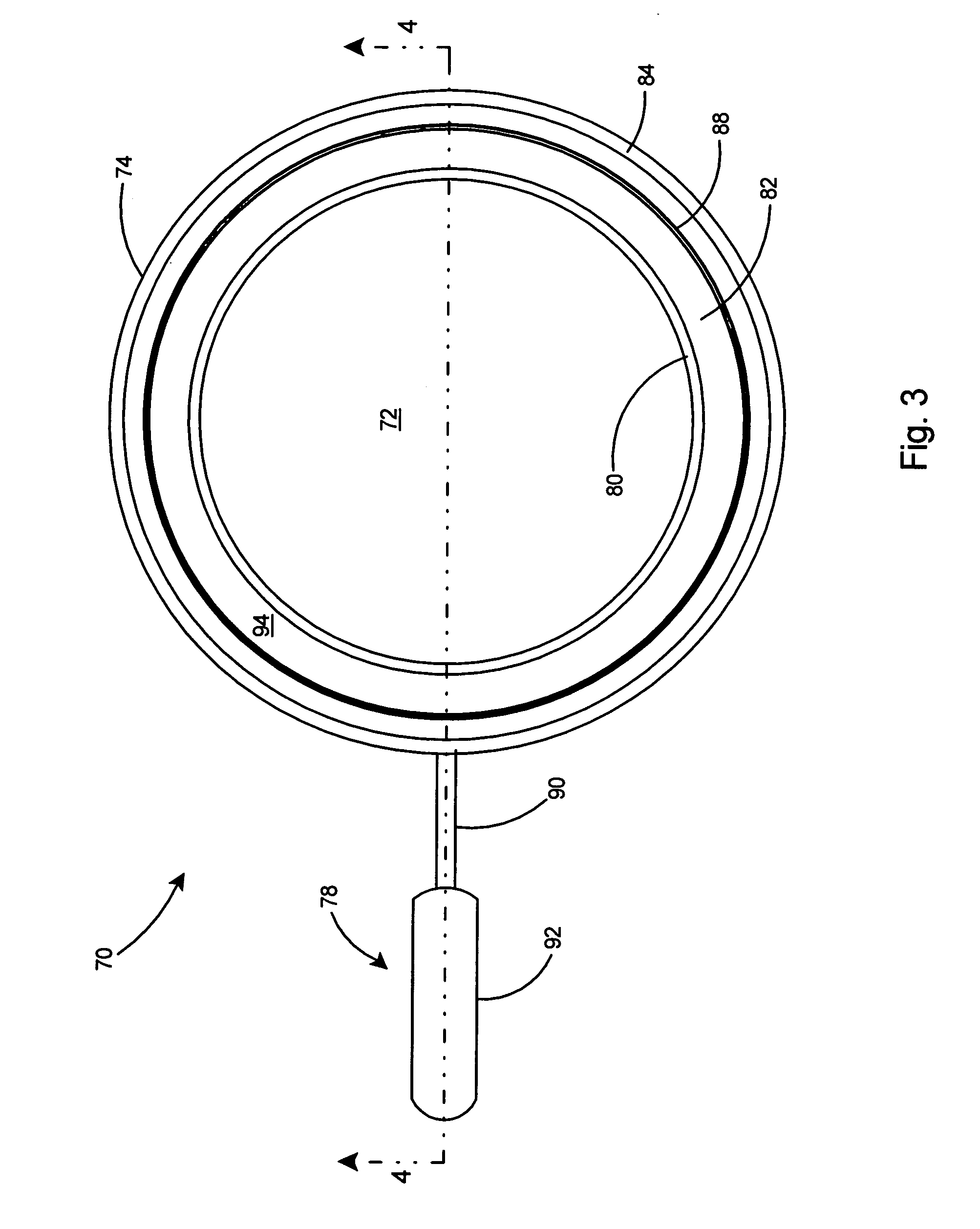

A collapsible container having a rigid base, a rigid top ring, and rigid intermediate rings extending therebetween. A flexible peripheral wall is intimately bonded to the base, top ring, and intermediate rings, to form wall sections having alternating sections of flexible material and flexible material intimately bonded to the intermediate rings, whereby the container is adjustable between an expanded position with the top ring spaced upward from said base and forming a container interior, and a collapsed position with said top ring surrounding said base in outwardly spaced substantially concentric relation thereto.

Owner:DART IND INC

Collapsible container

ActiveUS9044082B2Less forceMaximize available spaceTravelling sacksCeramic shaping apparatusEngineeringMechanical engineering

A collapsible container having a rigid base, a rigid top ring, and rigid intermediate rings extending therebetween. A flexible peripheral wall is intimately bonded to the base, top ring, and intermediate rings, to form wall sections having alternating sections of flexible material and flexible material intimately bonded to the intermediate rings, whereby the container is adjustable between an expanded position with the top ring spaced upward from said base and forming a container interior, and a collapsed position with said top ring surrounding said base in outwardly spaced substantially concentric relation thereto.

Owner:DART IND INC

Collapsible Multi-Purpose Containers

ActiveUS20150253055A1Increase in sizeSmall sizeLighting and heating apparatusRemovable lids/coversEngineeringMechanical engineering

Owner:TSUI SAM TUNG

Collapsible container

InactiveUS20150291309A1Lower the volumeSecurely holdCooking-vessel materialsTravelling sacksEngineeringWall segment

Owner:MCGREGOR ROB ROY

Multi-layered container with intermediate lid

InactiveUS7510096B2Increase coupling and contact forceAvoid problemsTable equipmentsRemovable lids/coversEngineeringFlange

Owner:KOREA ALPHALINE CO LTD

Modular laboratory cabinet

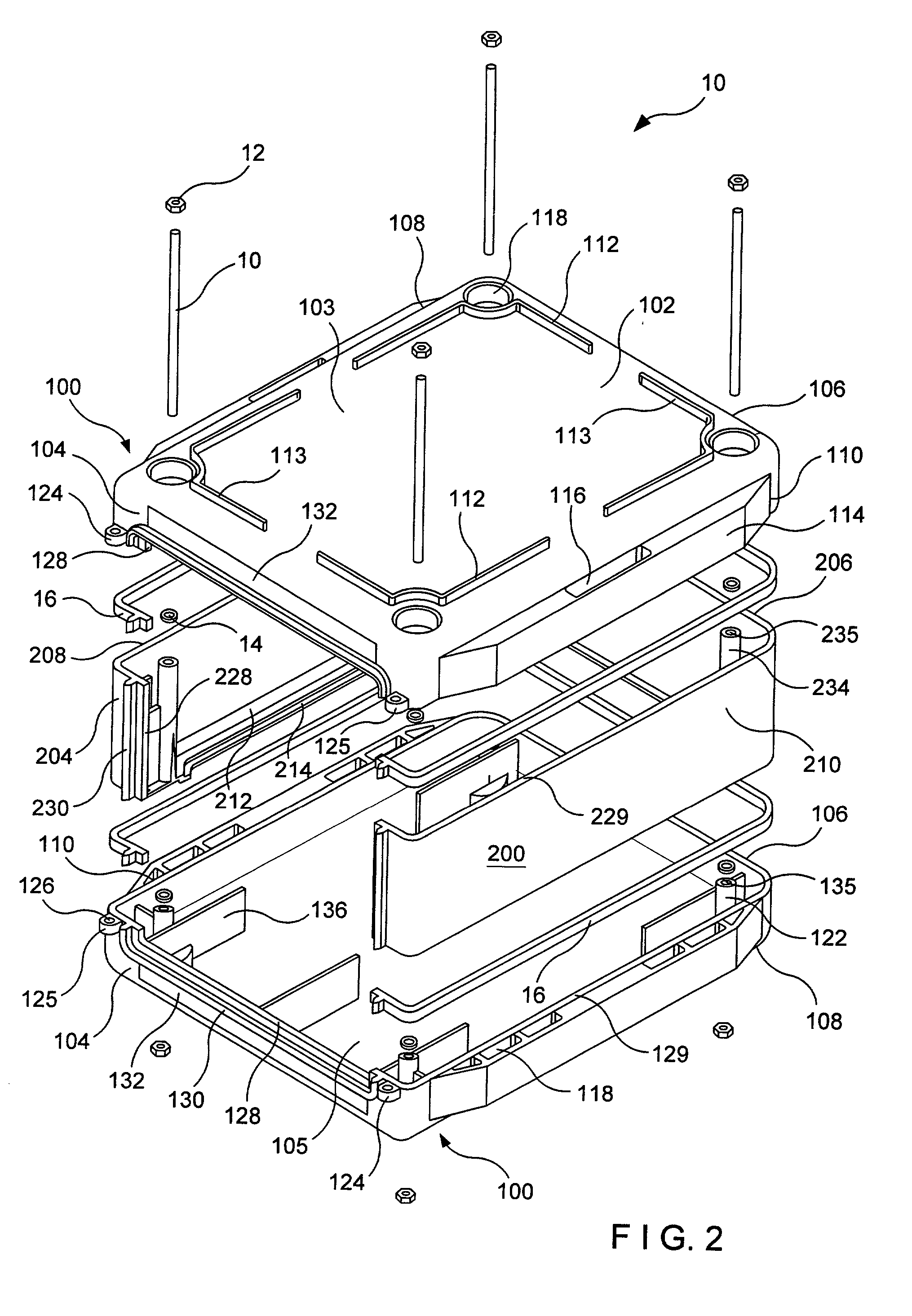

InactiveUS20020125799A1Efficient use ofLightweight and simple and low cost constructionDiagnosticsAir-pressure/air-lock chambersComputer moduleModularity

A modular laboratory cabinet assembly includes a pair of end units in inverted relation to one another, and at least one intermediate module interposed therebetween. A door is pivotably attached to the end units. Each end unit having a plurality of elongated supporting members and the intermediate module is formed with a plurality of columns. In the assembled condition, the supporting members and columns are aligned to form a continuous air-tight passage extending through the entire assembly.

Owner:BEL ART PRODS

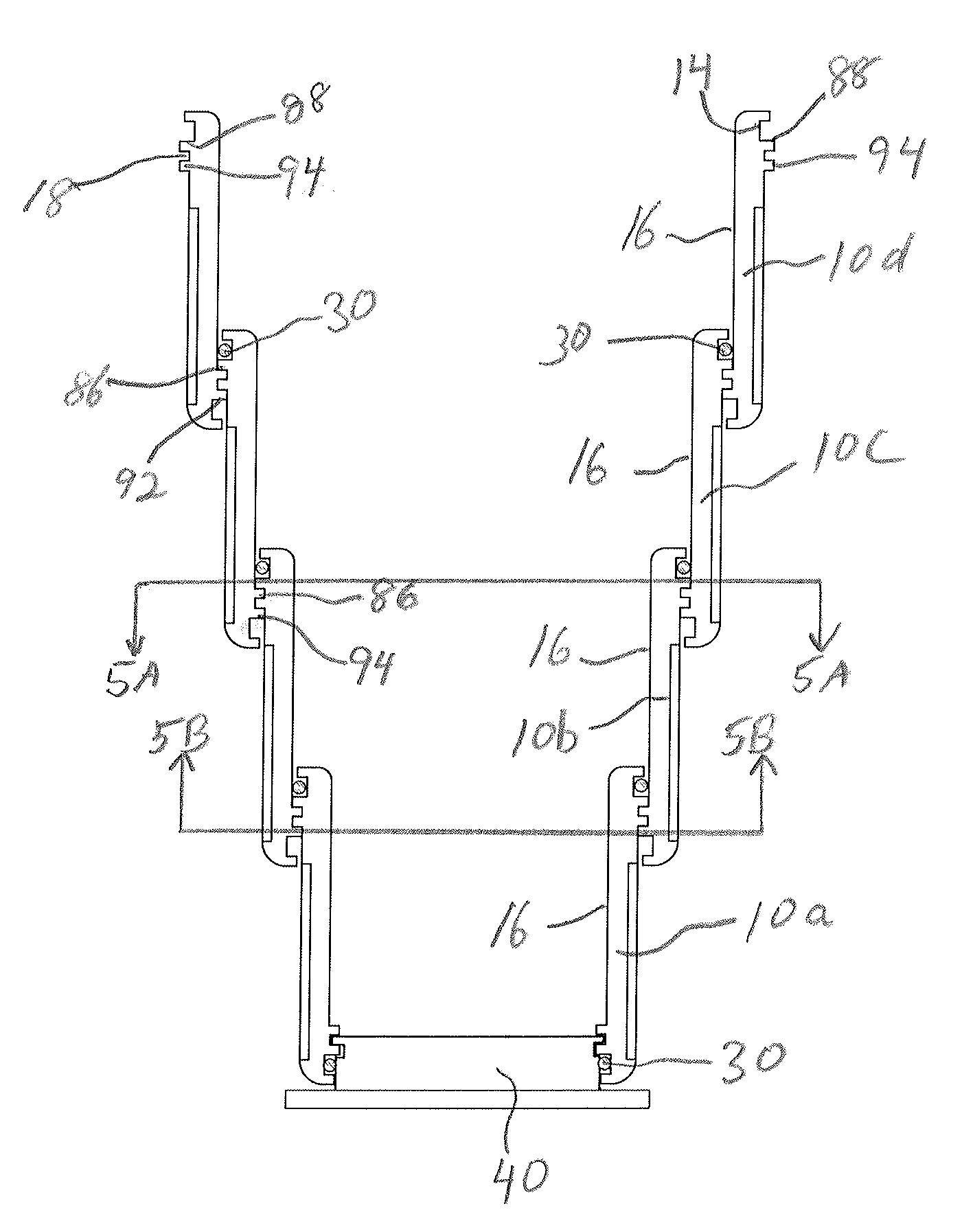

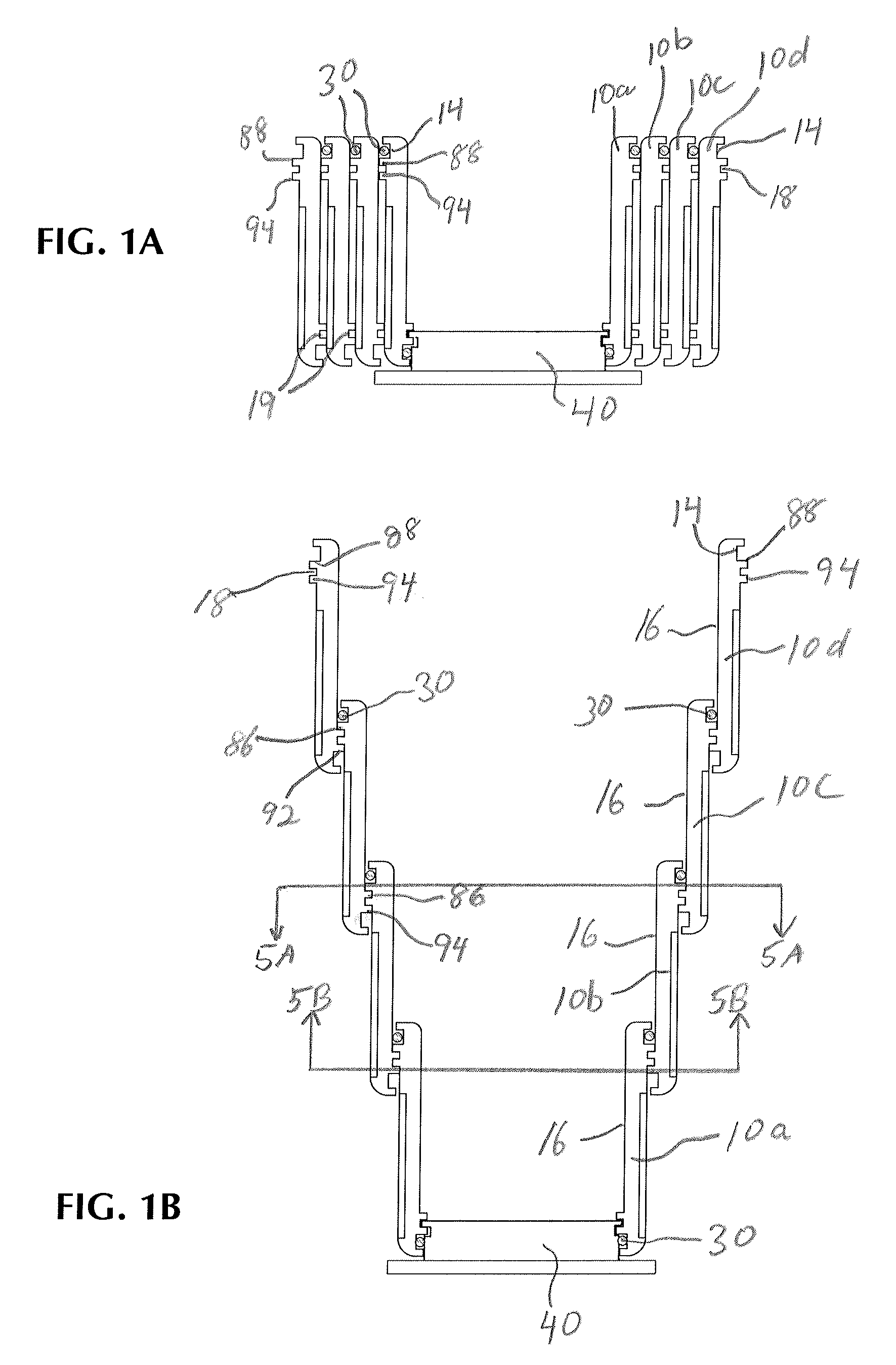

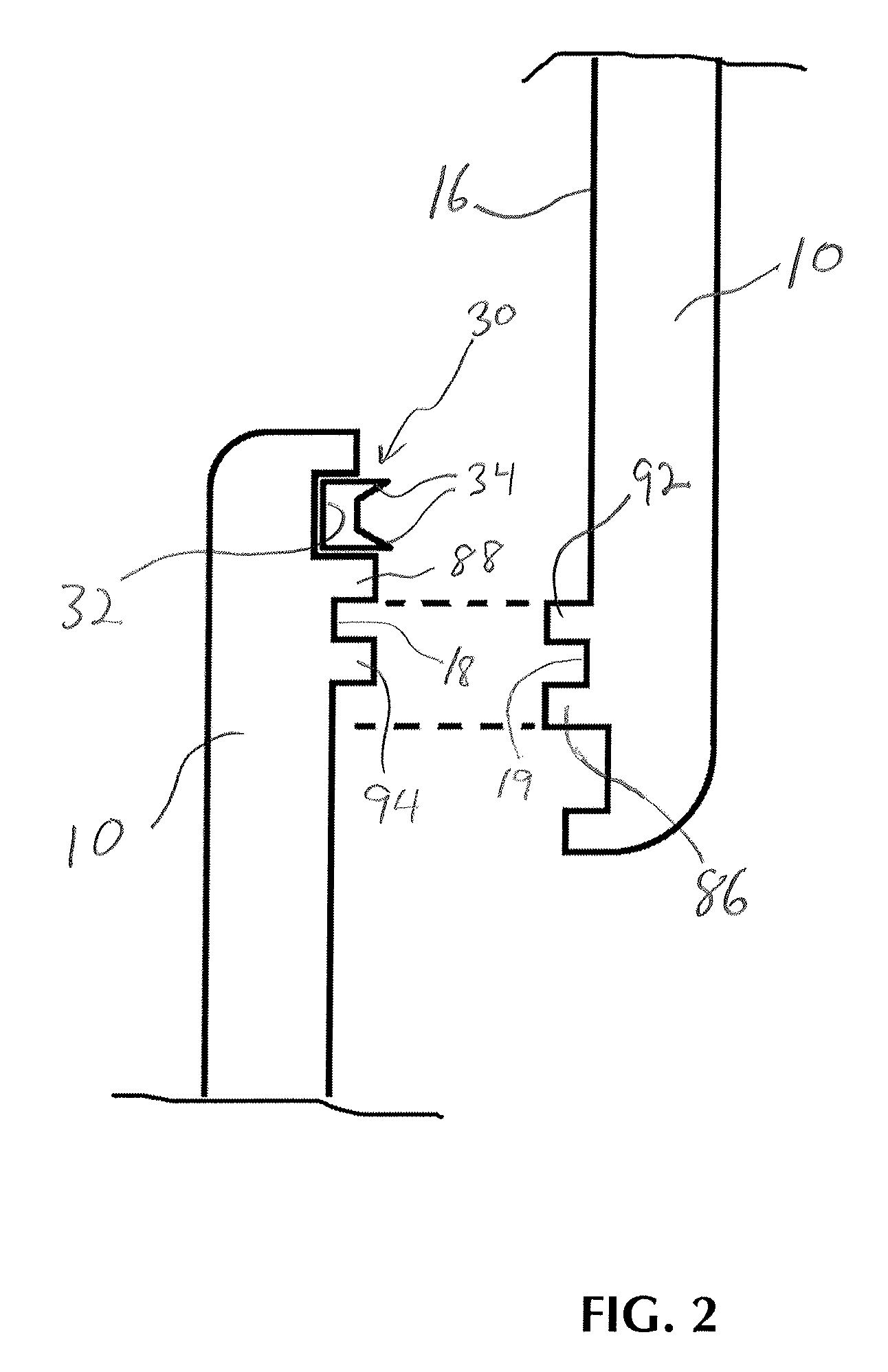

Collapsible cup

A collapsible beverage container has a plurality of co-axially oriented, concentric cylindrical wall sections of progressively different diameters. The wall sections are extendable from a collapsed position wherein the wall sections substantially completely overlap in an axial direction to an extended position wherein the wall sections only partially overlap in an axial direction. The collapsible beverage container includes one or more elastomeric gaskets between adjacent cylindrical wall sections, each gasket providing a liquid-tight seal along the entire extension of the adjacent cylindrical wall sections between the extended and collapsed positions.

Owner:FARIS ENTERPRISES

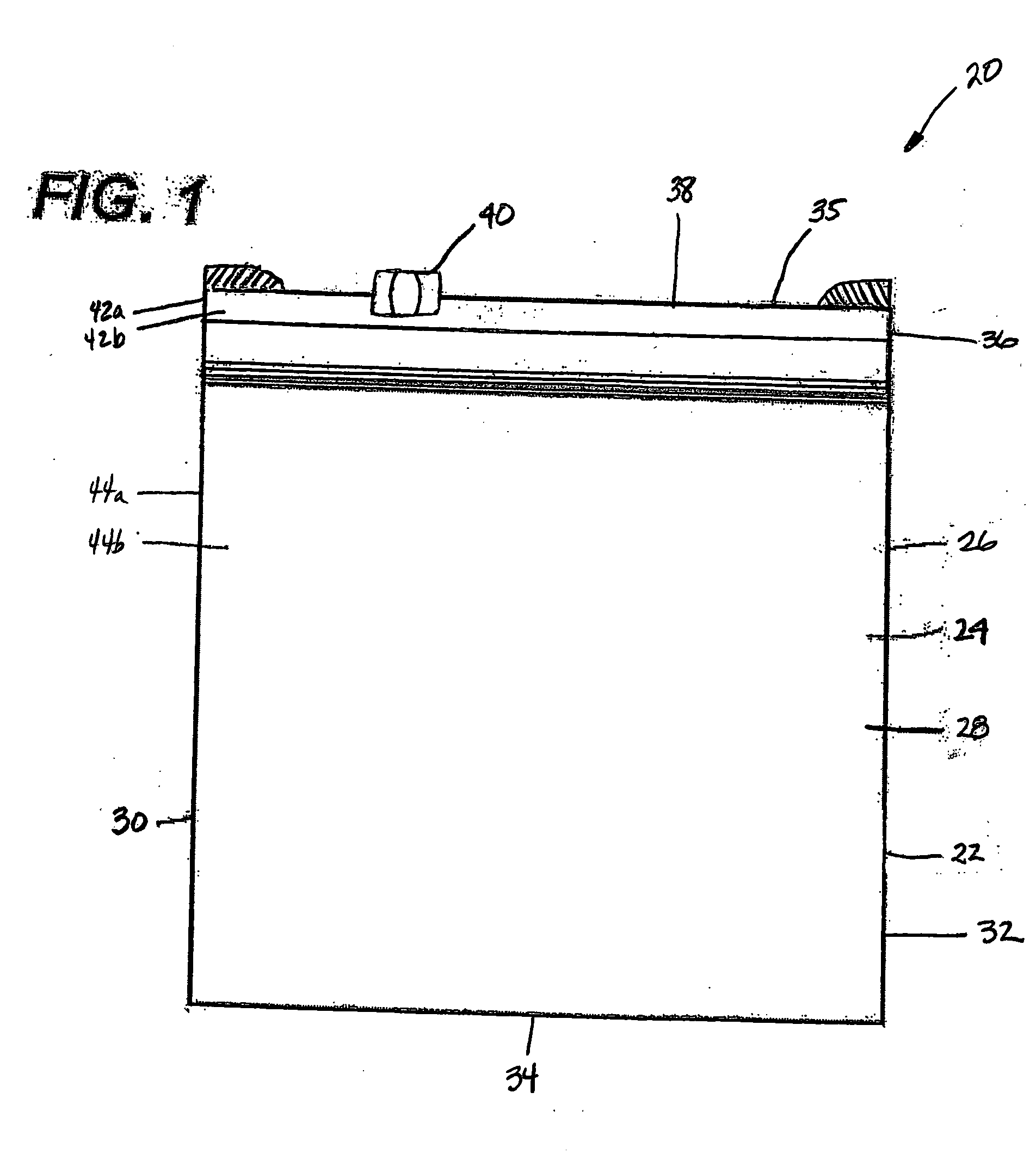

Pouch having at least one pleat

A pouch includes first and second opposing walls, a closure mechanism disposed between the opposing walls and at least one pleat disposed laterally across the pouch between the first and second side portions of the pouch, wherein the pleat is adapted to expand the pouch in a direction transverse to an axis of the opposing walls.

Owner:TURVEY ROBERT R

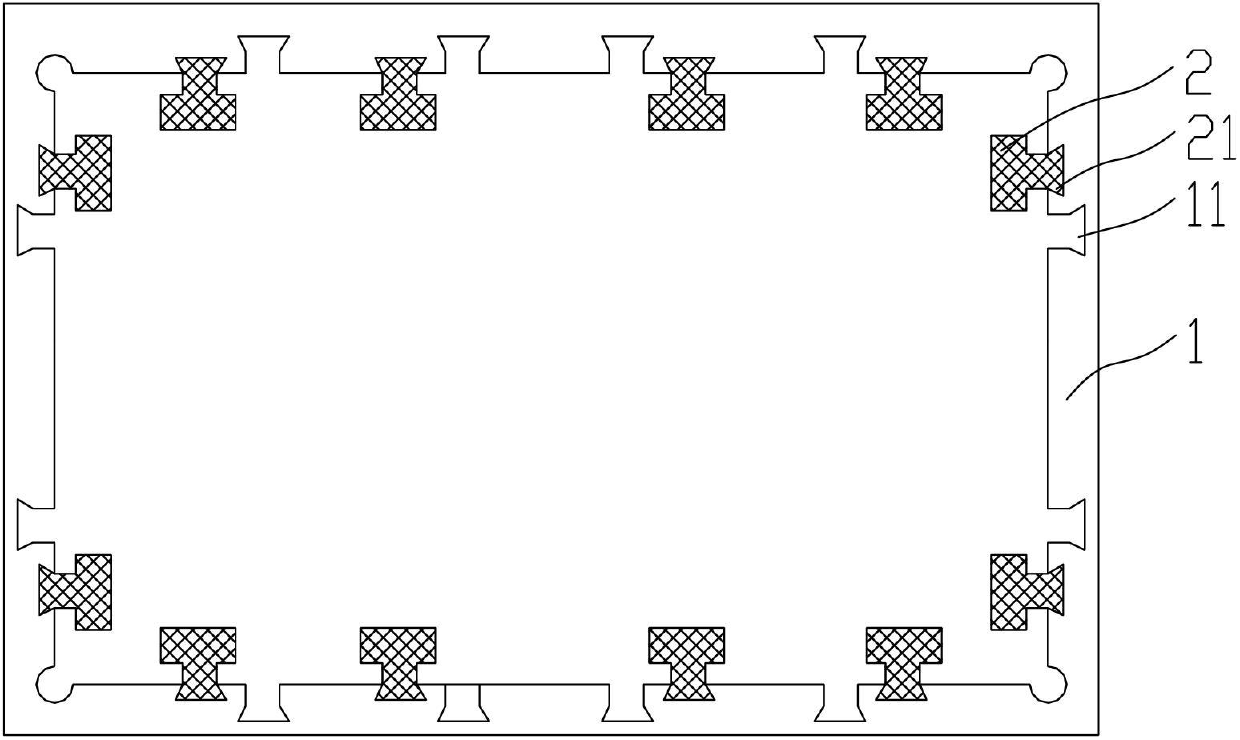

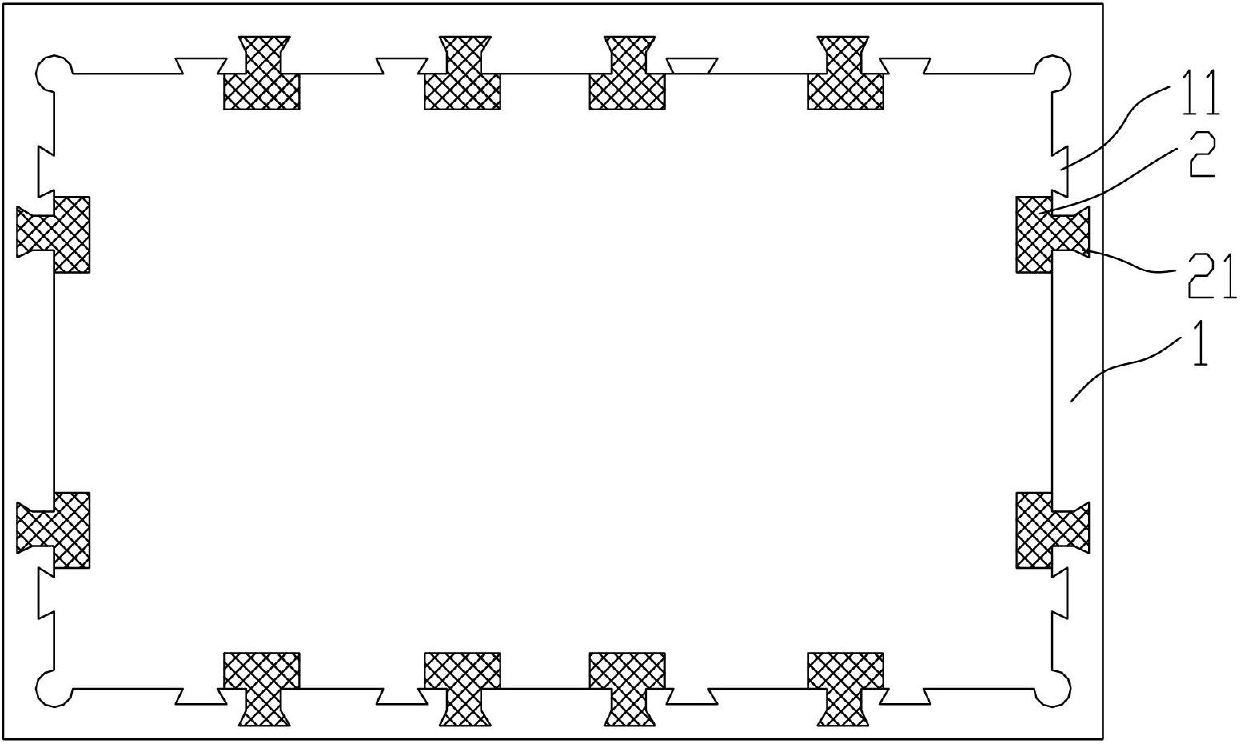

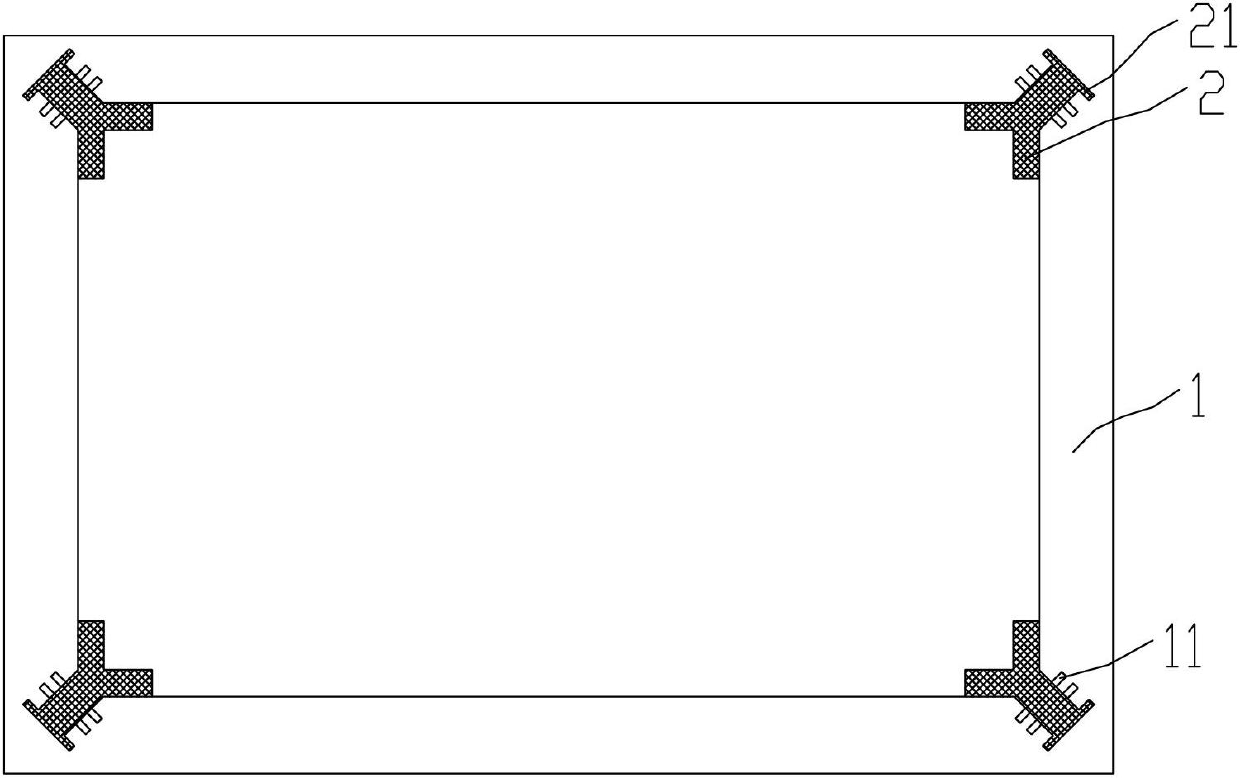

Liquid crystal glass packaging box

InactiveCN102673905AFlexible packagingReduce packaging costsContainers to prevent mechanical damageVariable capacity containersLiquid-crystal displayEngineering

The invention belongs to the field of packaging, and particularly relates to a liquid crystal glass packaging box, which comprises a box body and a buffer component. The buffer component is arranged on the inner surface of the sidewall of the box body and at least can be fixed in two different positions on the box body, and the accommodating dimensions of the packaging box differ when the buffer component is fixed in different positions. Since the liquid crystal glass packaging box adopts a split structure and comprises the box body and the buffer component, the buffer component is arranged on the inner surface of the sidewall of the box body and at least can be fixed in two different positions on the box body, and the accommodating dimensions of the packaging box differ when the buffer component is fixed in different positions, at least two packaging boxes of different dimensions can be formed via assembly of only one group of buffer components with one box body so as to adapt to packaging demands of liquid crystal glass or liquid crystal glass components of different dimensions, the packaging box can be shared by liquid crystal glass of different dimensions, flexible packaging can be realized, and the packaging cost can be reduced effectively.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

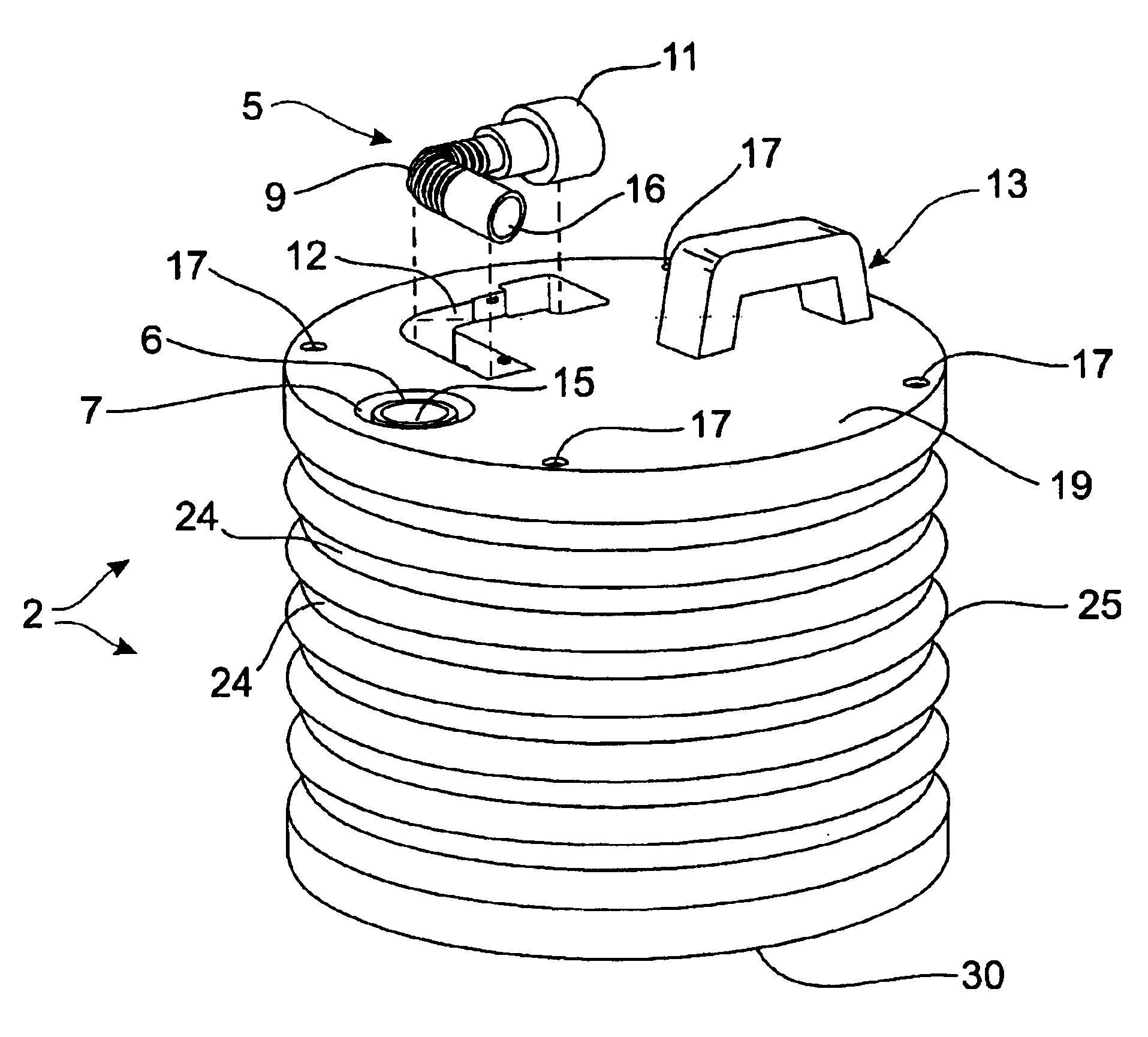

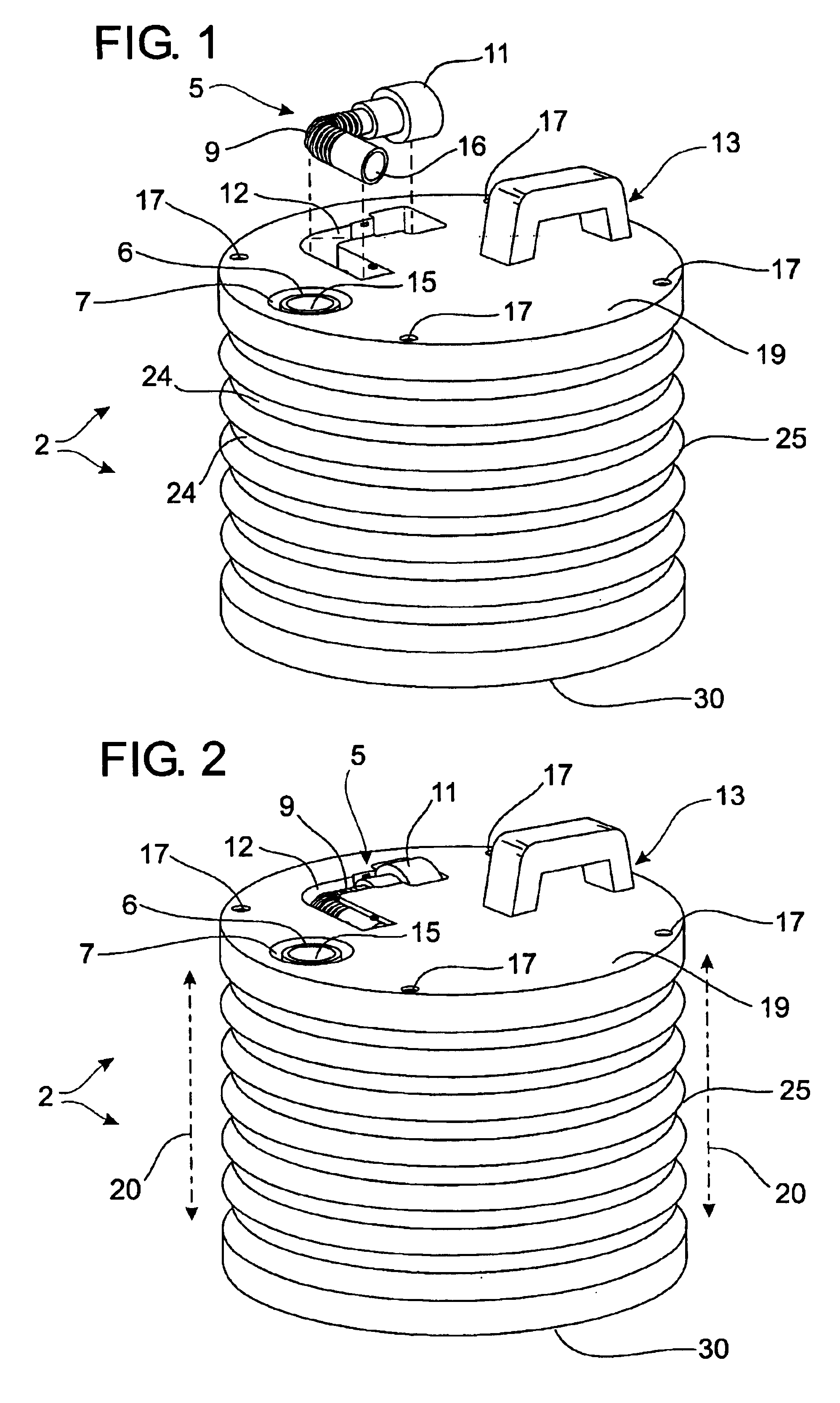

Single use collapsible liquid containment vessel

An expandable single use liquid containment vessel that can fit into restricted spaces such as the trunk or glove compartment of a passenger transport vehicle. The vessel contains a top and bottom wall integrally connected via an outer wall embodying accordion type pleats to allow for vessel compression and expansion. A single piece pouring nozzle is permanently attached to the containment vessel subsequent to introduction of a fluid the containment vessel's interior portion. One end of the filling nozzle secures the nozzle to the containment vessel. At the second end of the nozzle is an exiting orifice which has been dimensioned to preclude insertion therein of publicly accessible fueling nozzles commonly associated with motor vehicle refueling stations.

Owner:HUDKINS BRUCE ERIC

Method for making mesh containers with a rail and mesh container formed therefrom

The present invention is directed to a method of forming a container comprising forming a basket portion of metal mesh material and a rail connected to the basket portion. The rail extends substantially outwardly from the outer surface of the basket portion and the rail extends continuously around the outer surface of the basket portion. In one example, the method includes forming the rail so that it does not contain or surround a free edge of the basket portion. In another example, the method includes forming the rail so that it includes an opening for containing or surrounding a free edge of the basket portion. The method may also include forming a lower rail. The present invention is also directed to a container formed by such method.

Owner:DESIGN IDEAS LTD

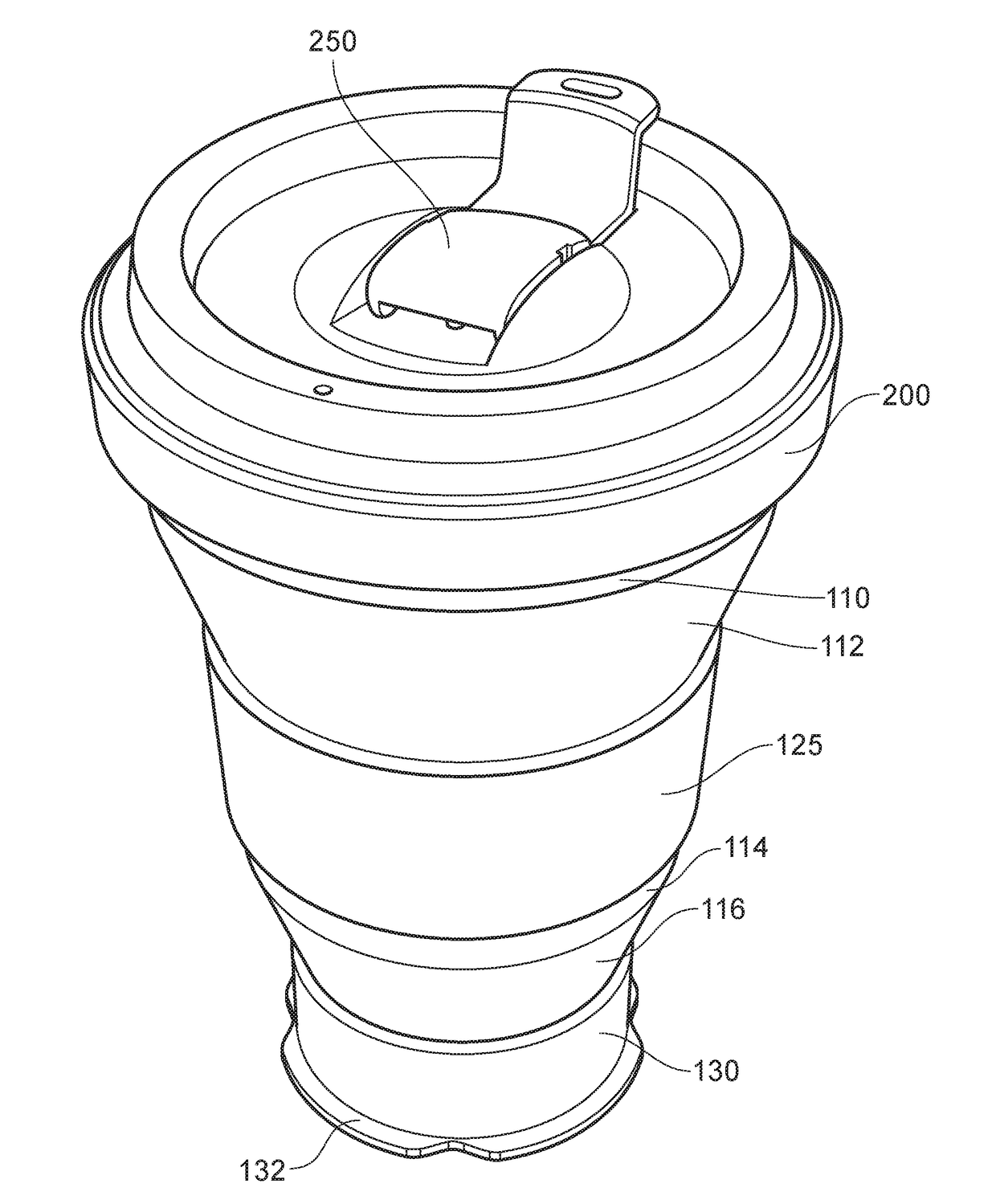

Reusable Cup

ActiveUS20180194517A1Easy to holdEasy to deployTravelling sacksPackage recyclingEngineeringMechanical engineering

The present invention relates to a reusable cup comprising a cup body formed from a liquid impervious, flexible material, the cup having an upper portion, a middle portion and a base portion, and having foldable pre-forms arranged so as to define at least a first folding hinge around a first circumferential location interposed between the middle portion and the upper portion, and a second folding hinge around a second circumferential location, separate from the first circumferential location, interposed between the base portion and the middle portion, an outer peripheral band is formed around the middle portion of the cup to provide a central band, wherein the cup body is foldable into itself, at the circumferential locations, so as to adopt a nested, concentric form.

Owner:POCKET ENTERPRISES

Collapsible Household Containers

ActiveUS20150251808A1Increase in sizeSmall sizeTravelling sacksKitchenware cleanersEngineeringMechanical engineering

Collapsible household containers having a foldable wall section with shape-retaining characteristics are disclosed. In particular, collapsible laundry baskets, buckets, colanders, dish drainers, and cups are provided. The folding region may include foldable tiers of a flexible material, each tier having at least one stable, relatively expanded position and at least one stable, relatively collapsed position; and an intervening, non-folding tier composed of a different, relatively rigid material.

Owner:TSUI SAM TUNG

Collapsible storage container

Owner:PATIKAS BRYANT BERNETTA

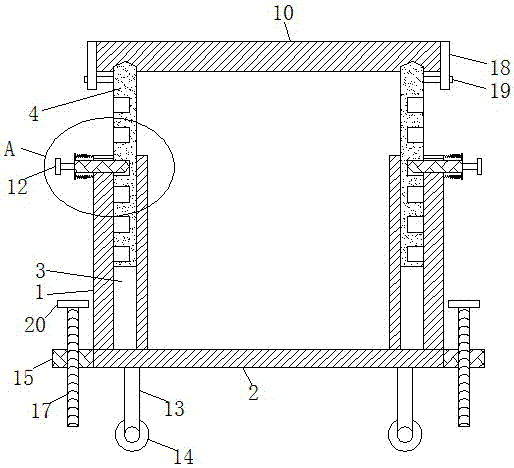

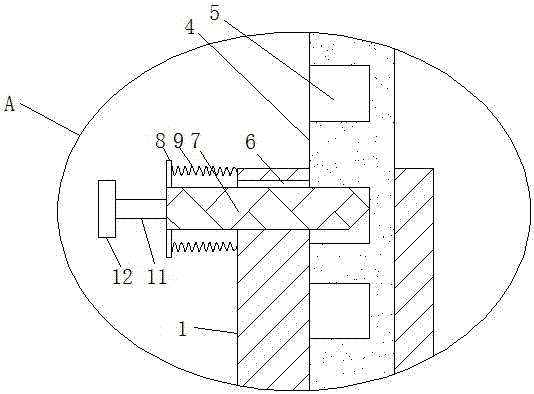

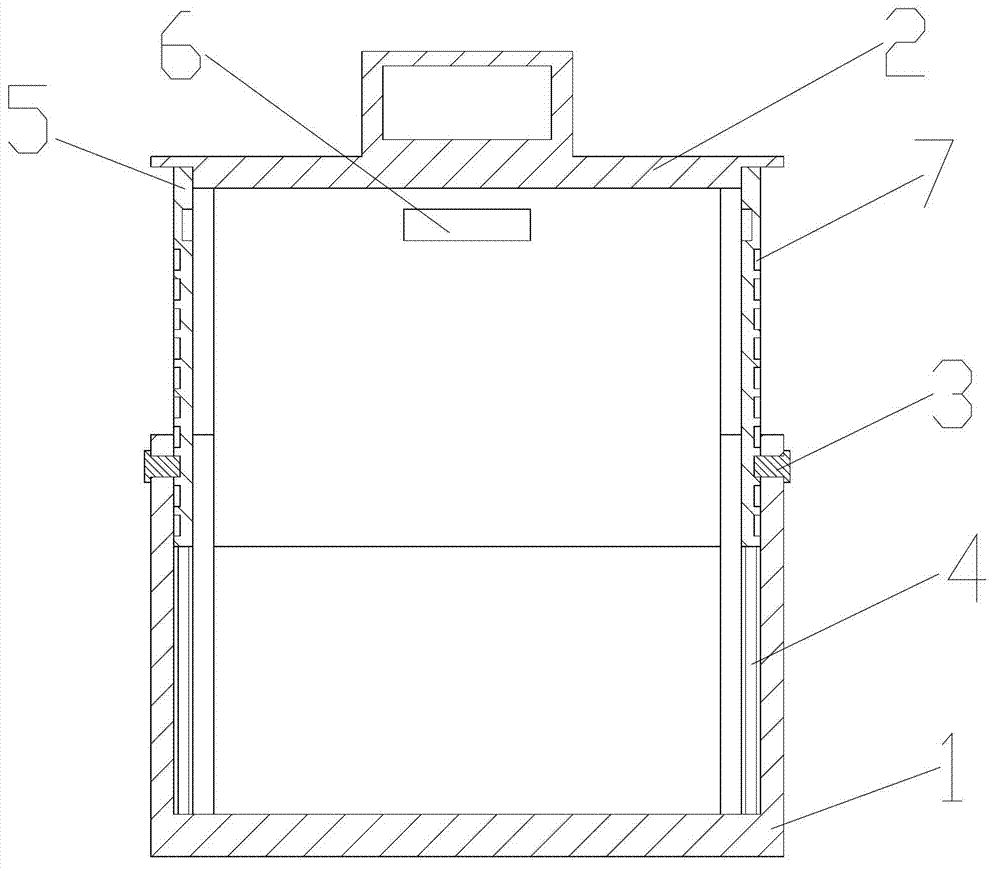

High-adjustment-capacity storage box for logistics equipment

ActiveCN107010305AImprove applicabilityEasy to operateVariable capacity containersLogistics managementEngineering

The invention discloses a high-adjustment-capacity storage box for logistics equipment. A bottom plate is welded to the bottom ends of first square tubes. A vertical annular cavity is formed in each first square tube. A second square tube is inserted into each annular cavity. The left and right sidewalls of each second square tube are both provided with insertion and connection slots. The tops of the left and right sidewalls of each first square tube are both provided with insertion and connection holes. The inner ends of insertion and connection rods penetrate through the insertion and connection holes and are inserted into the insertion and connection slots. Vertical plates are welded to the upper and lower ends of the outer side of each insertion and connection rod. A spring is welded to the inner end of each vertical plate. The inner ends of the springs are fixedly welded to the outer walls of the corresponding first square tubes. A mobile device and a positioning device are arranged below the bottom plate. The size of the high-adjustment-capacity storage box for the logistics equipment can be set according to actual demands. The high-adjustment-capacity storage box for the logistics equipment is easy to operate, convenient to adjust and move, fast in positioning and suitable for large-scale popularization.

Owner:山东虎运食品股份有限公司

Compressed package having an expansion mechanism

InactiveUS20050077200A1Enclosed compartment will be enlargedFlexible coversWrappersEngineeringMechanical engineering

A package is disclosed having an enclosed compartment with a pair of oppositely aligned walls and a perimeter. An array of compressible articles is retained in the enclosed compartment. The package also includes an expansion mechanism for allowing the enclosed compartment to be enlarged. The expansion mechanism includes a pliable member positioned about the perimeter. A release strip is positioned across the expansion mechanism. The release strip is capable of being at least partially removed to allow the enclosed compartment to be enlarged as the pliable member expands or stretches. The package can also contain an opening mechanism for allowing the package to be opened so that the articles can be removed from the enlarged compartment.

Owner:KIMBERLY-CLARK WORLDWIDE INC

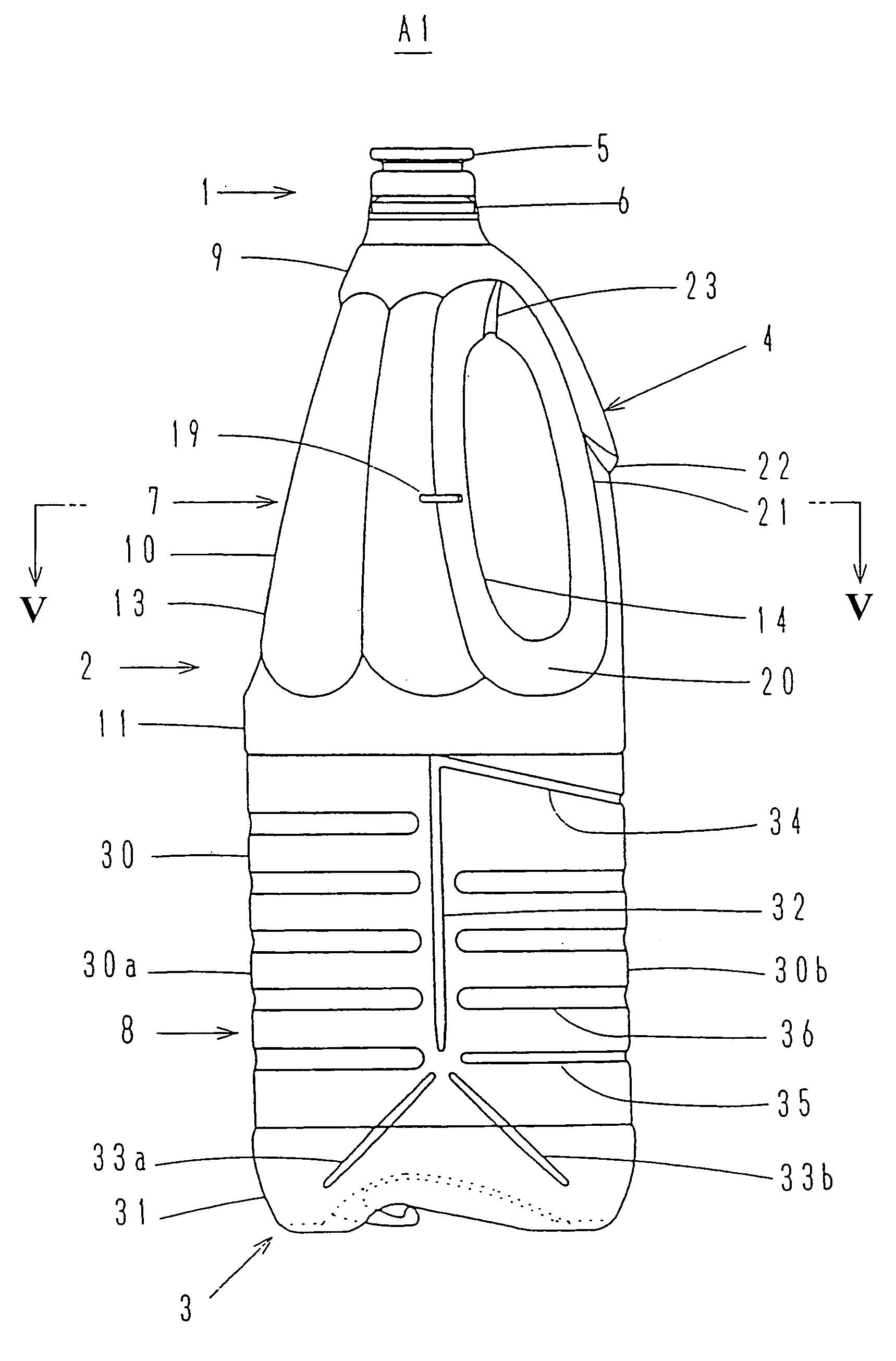

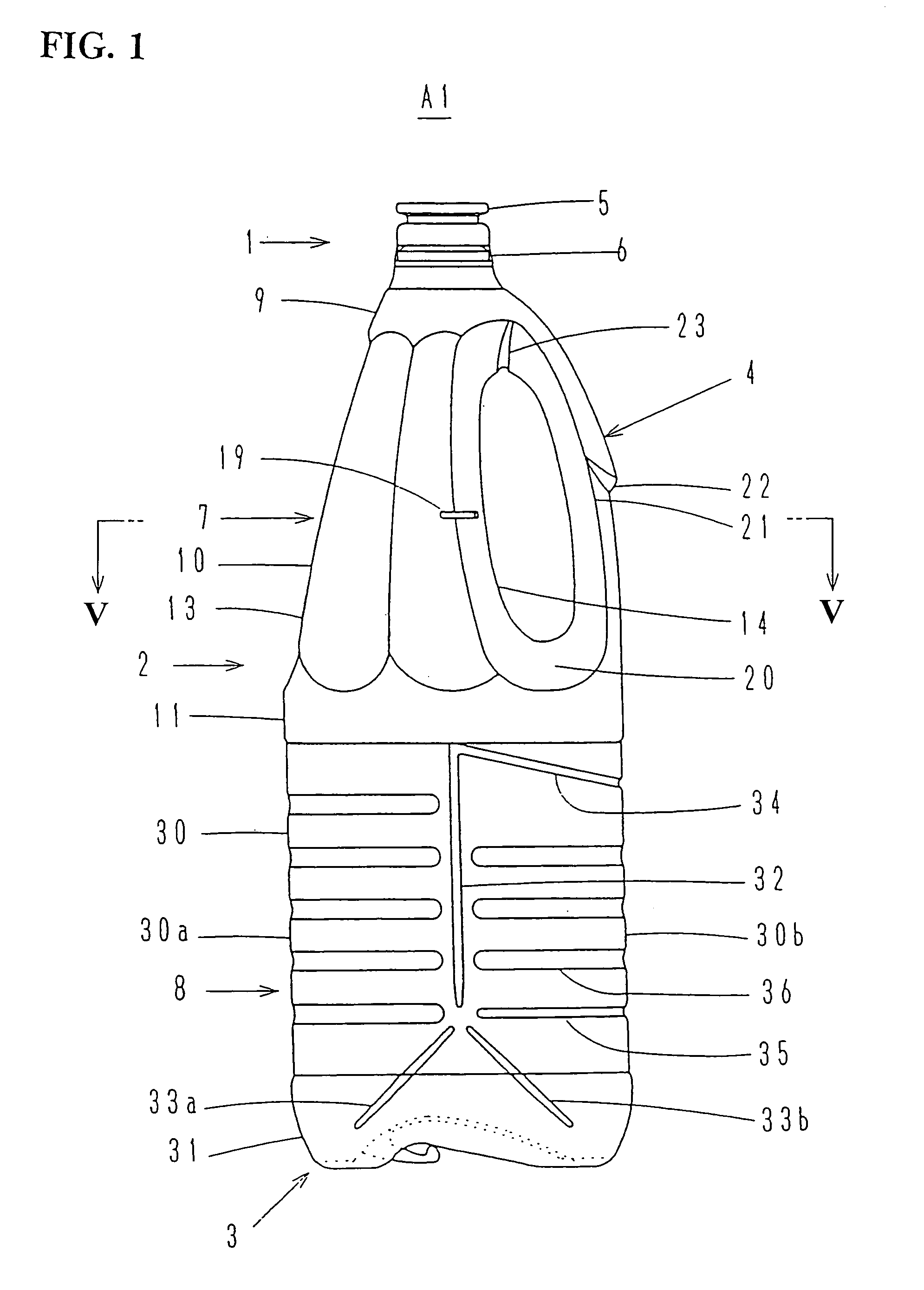

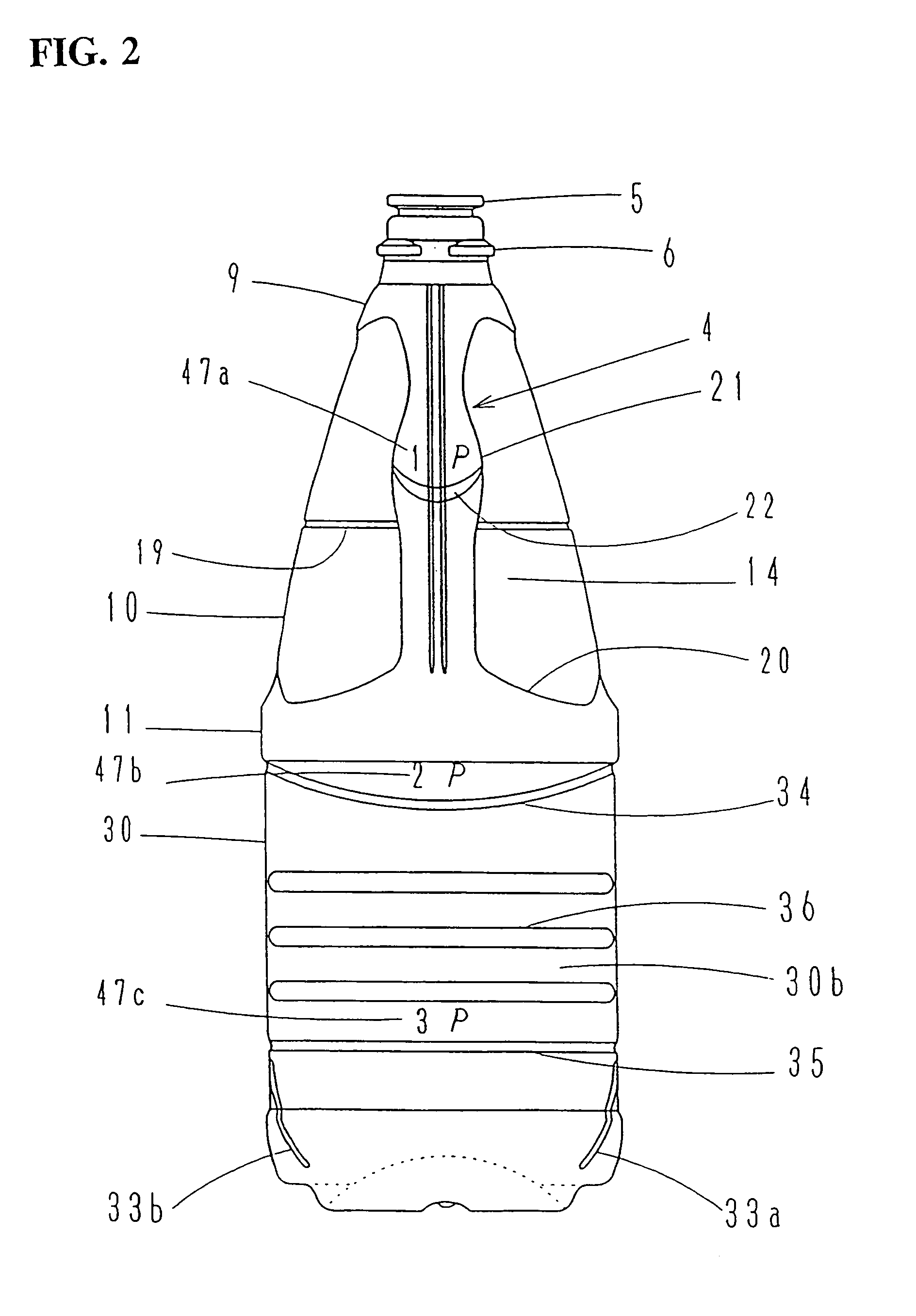

Plastic bottle with handle

A squeezable plastic bottle with a handle which is bendable by forming a bending deformation portion in the handle. The bending deformation portion of the handle can be a bending portion formed in the middle portion of the longitudinal direction of the handle. Further a bending rib can be formed between the handle and the body wall surface. The body may be squeezable and deformable by forming a bending rib in the bottle body.

Owner:YOSHINO KOGYOSHO CO LTD

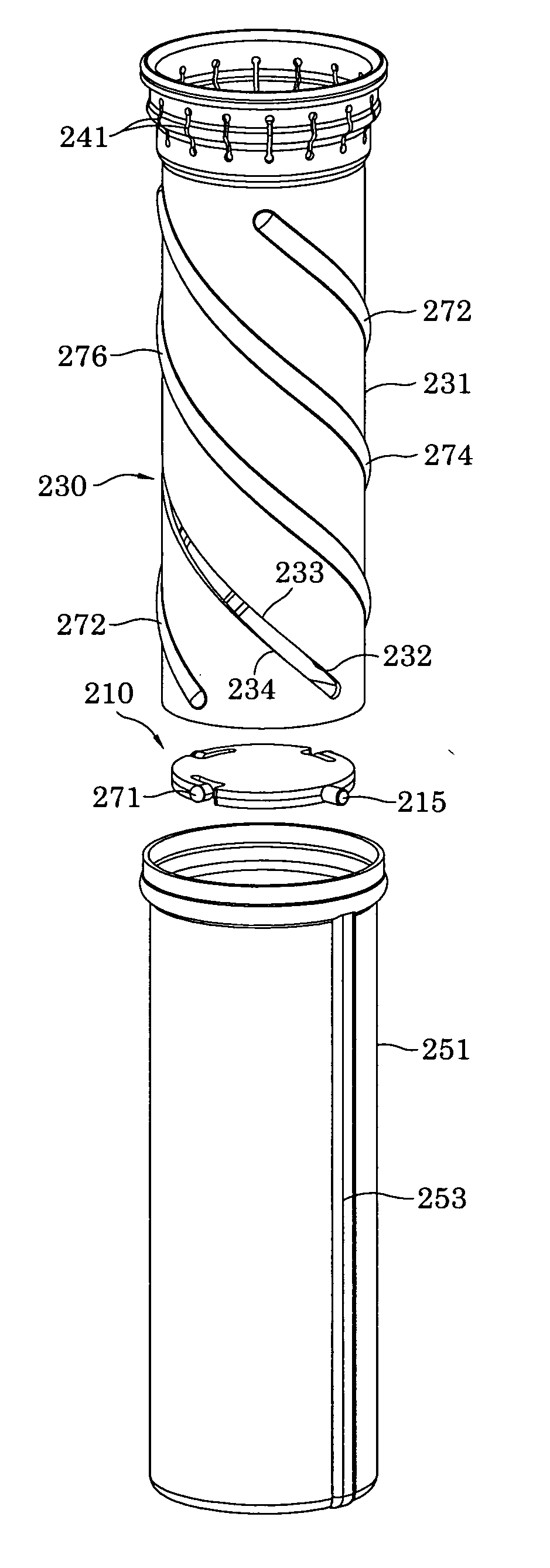

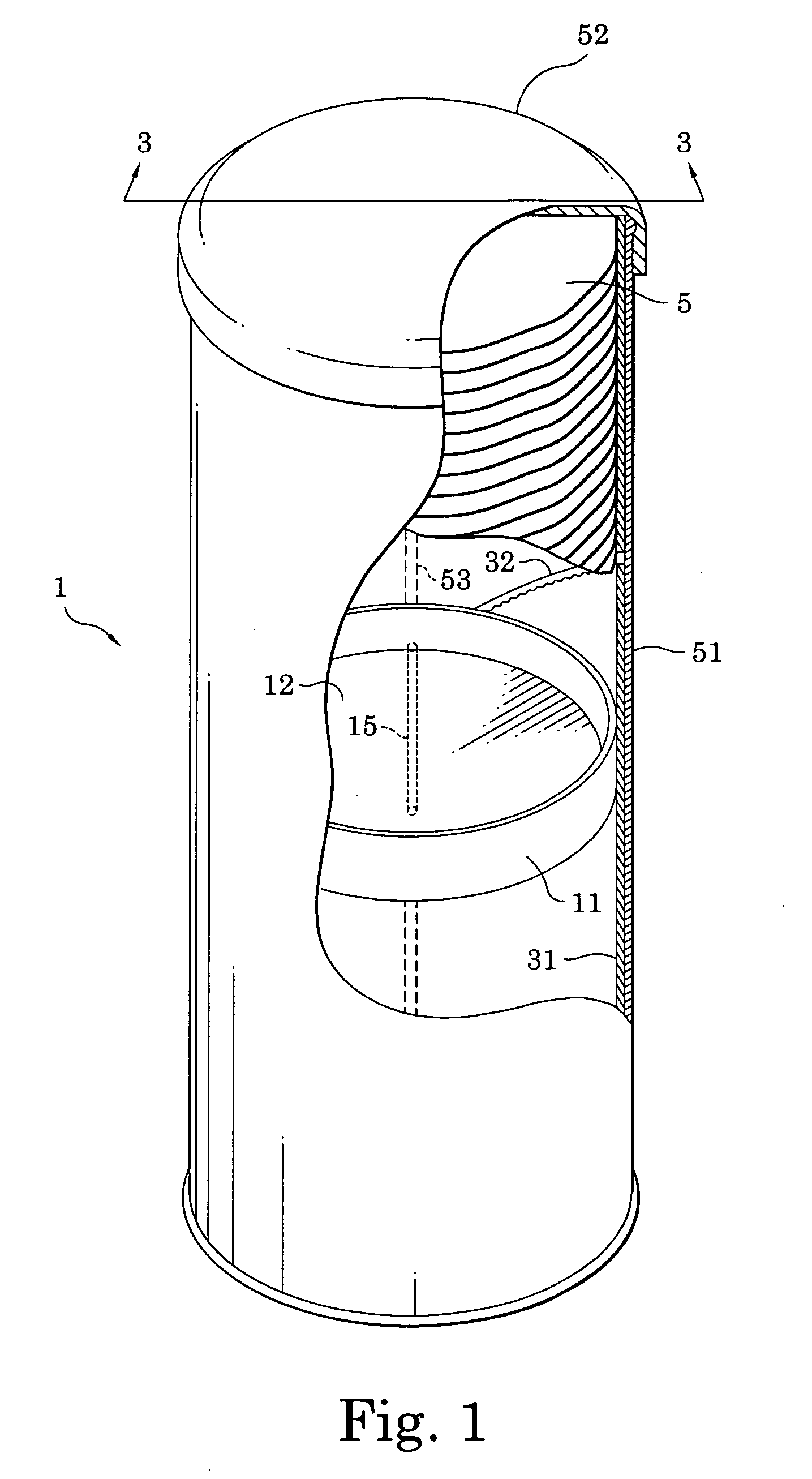

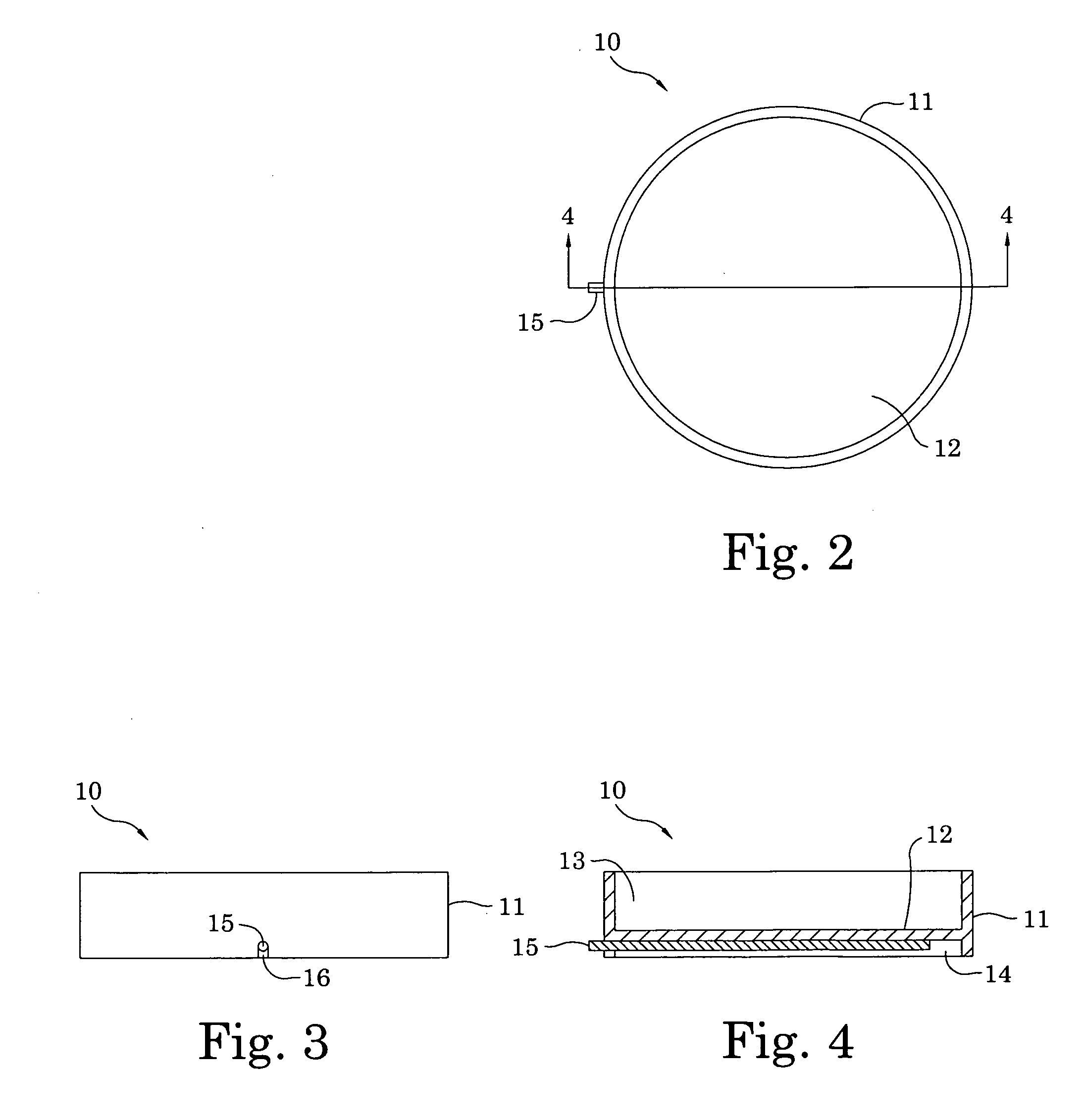

Elevating lift dispenser and container for foodstuffs

InactiveUS20080110922A1Dispensing apparatusCoin-freed apparatus detailsEngineeringMechanical engineering

Containers for foodstuffs which are resealable and have an elevating lift therein. The lift is preferably operated by an operator that fits within the container to prevent loss of freshness of the foodstuff or other contents. One operator uses a slot or groove which winds at least partially around a tubular operator which is engaged by a follower that extends from the elevator lift. The follower may also engage with a feature on an inside wall of the container to prevent rotation of the lift and provide relative longitudinal motion between the lift platform upon which chips or other foodstuffs are supported so that the contents can be adjusted for easy access. A removable lid allows controlled opening and closing or resealing of the container to keep the foodstuff contents fresh when not being dispensed.

Owner:SINES RANDY D

Method for making mesh containers with a rail and mesh container formed therefrom

The present invention is directed to a method of forming a container comprising forming a basket portion of metal mesh material and a rail connected to the basket portion. The rail extends substantially outwardly from the outer surface of the basket portion and the rail extends continuously around the outer surface of the basket portion. In one example, the method includes forming the rail so that it does not contain or surround a free edge of the basket portion. In another example, the method includes forming the rail so that it includes an opening for containing or surrounding a free edge of the basket portion. The method may also include forming a lower rail. The present invention is also directed to a container formed by such method.

Owner:DESIGN IDEAS LTD

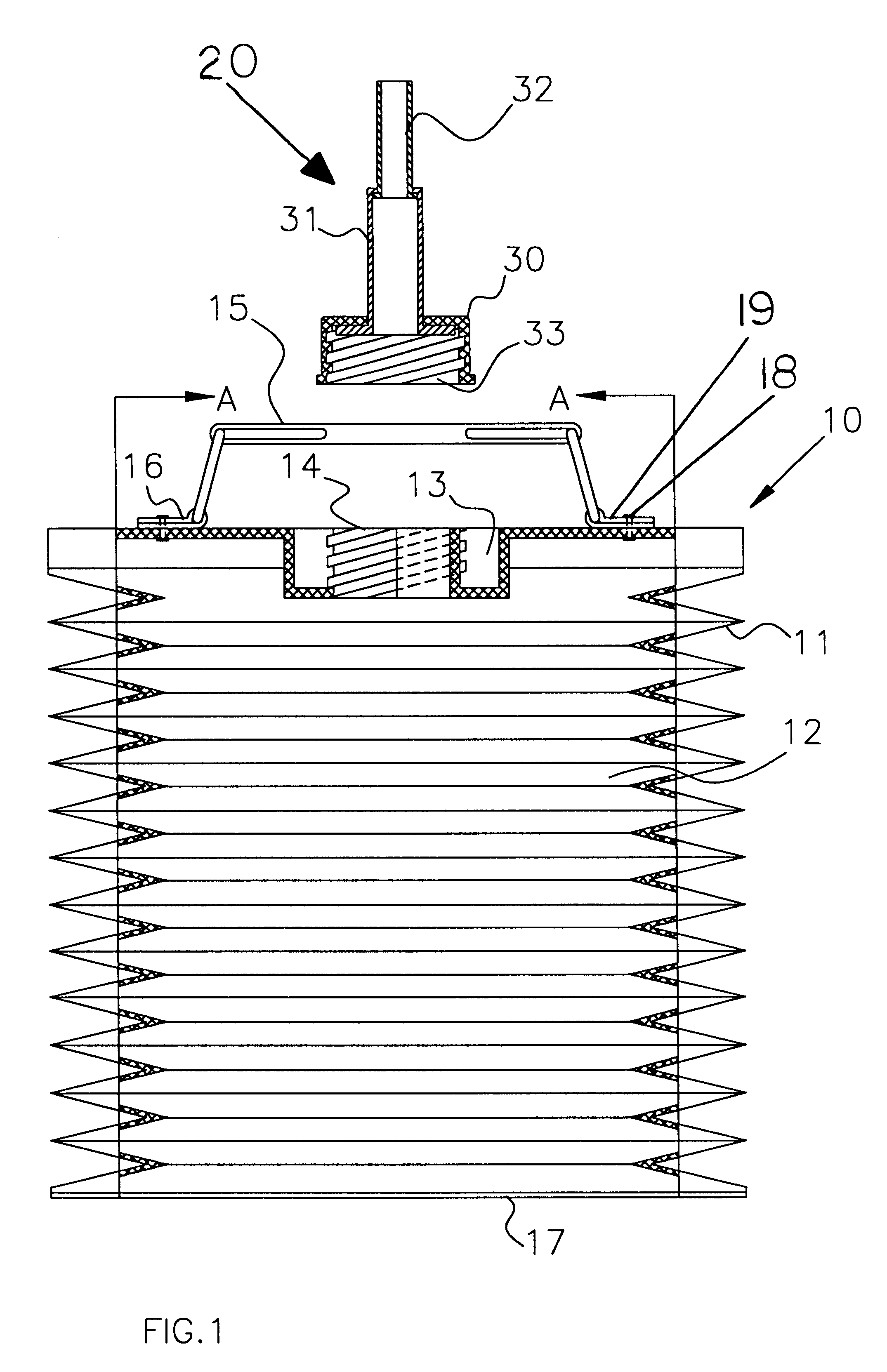

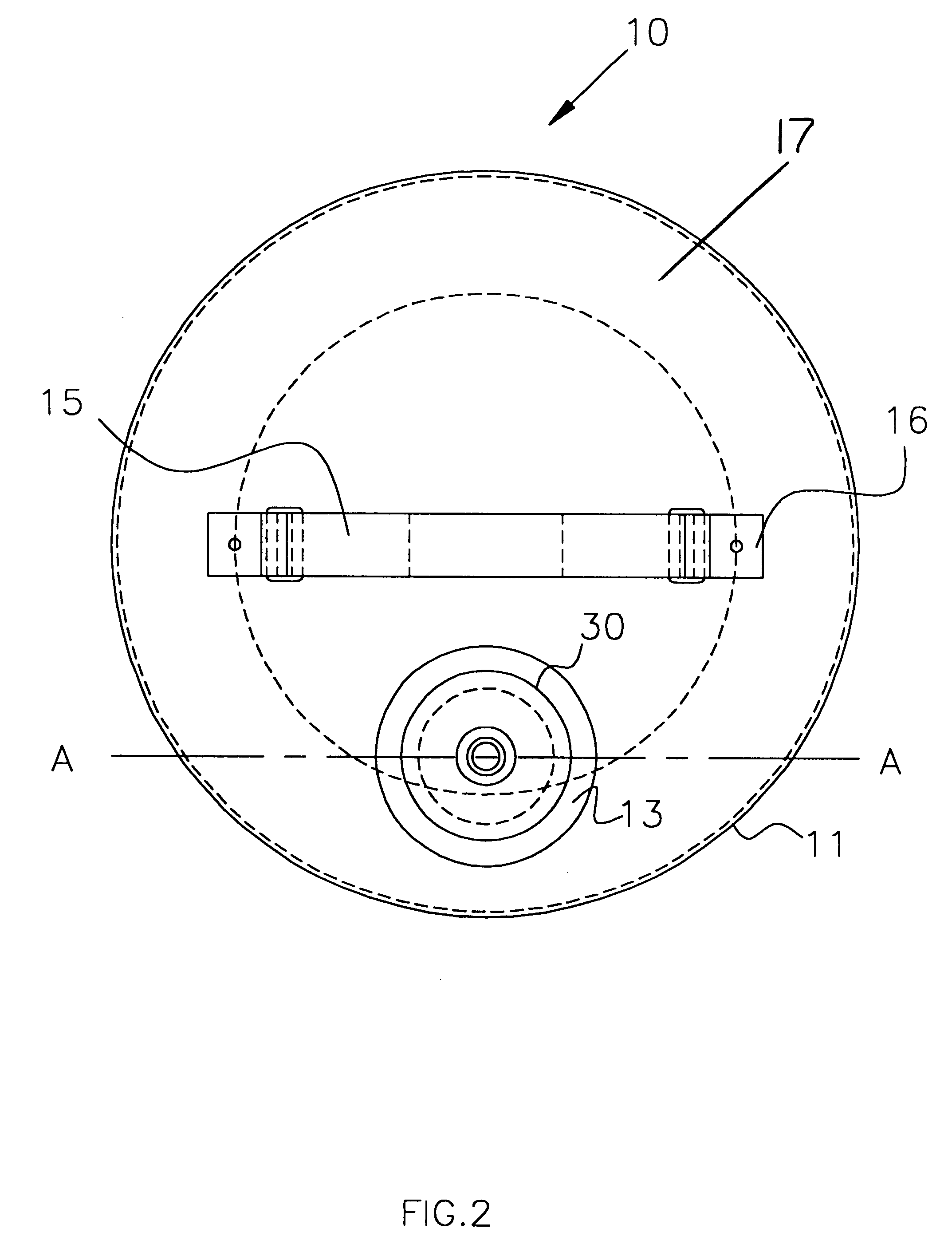

Collapsible container

The instant invention is a foldable plastic container consisting of accordion type pleats, a top having a circular depression for filling / emptying the container, a folding handle fastened to the top, and a telescoping nozzle which may be nested and contained in the cover or expanded for pouring a liquid.

Owner:ABBONDANDOLO ROBERT

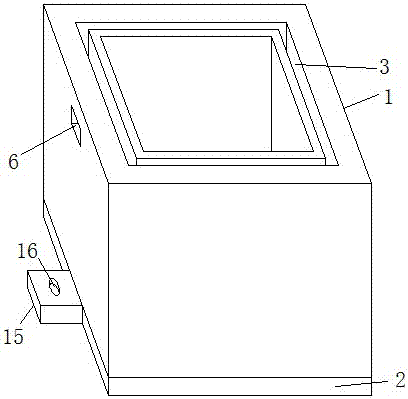

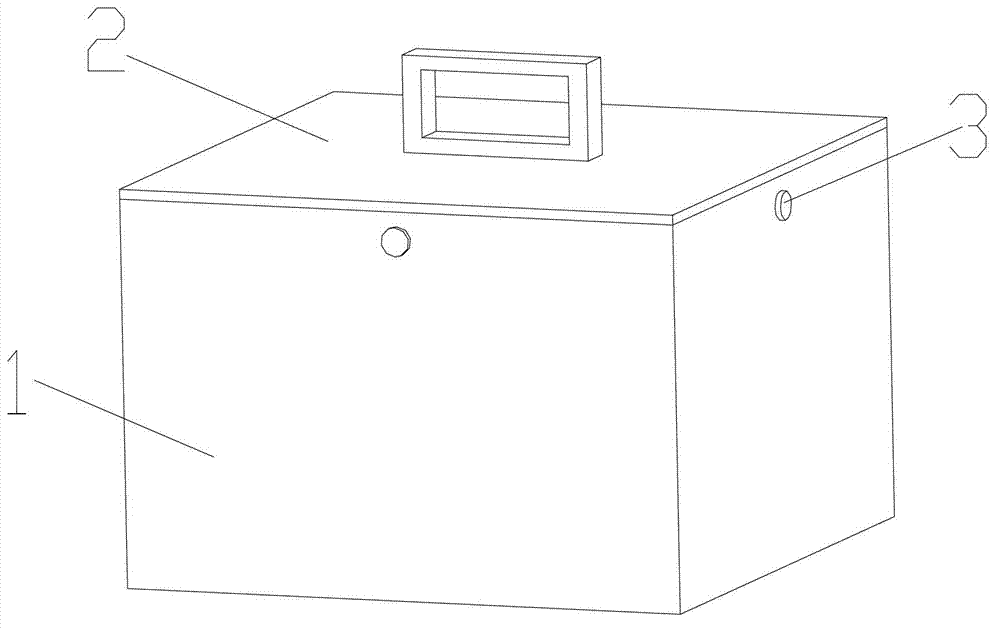

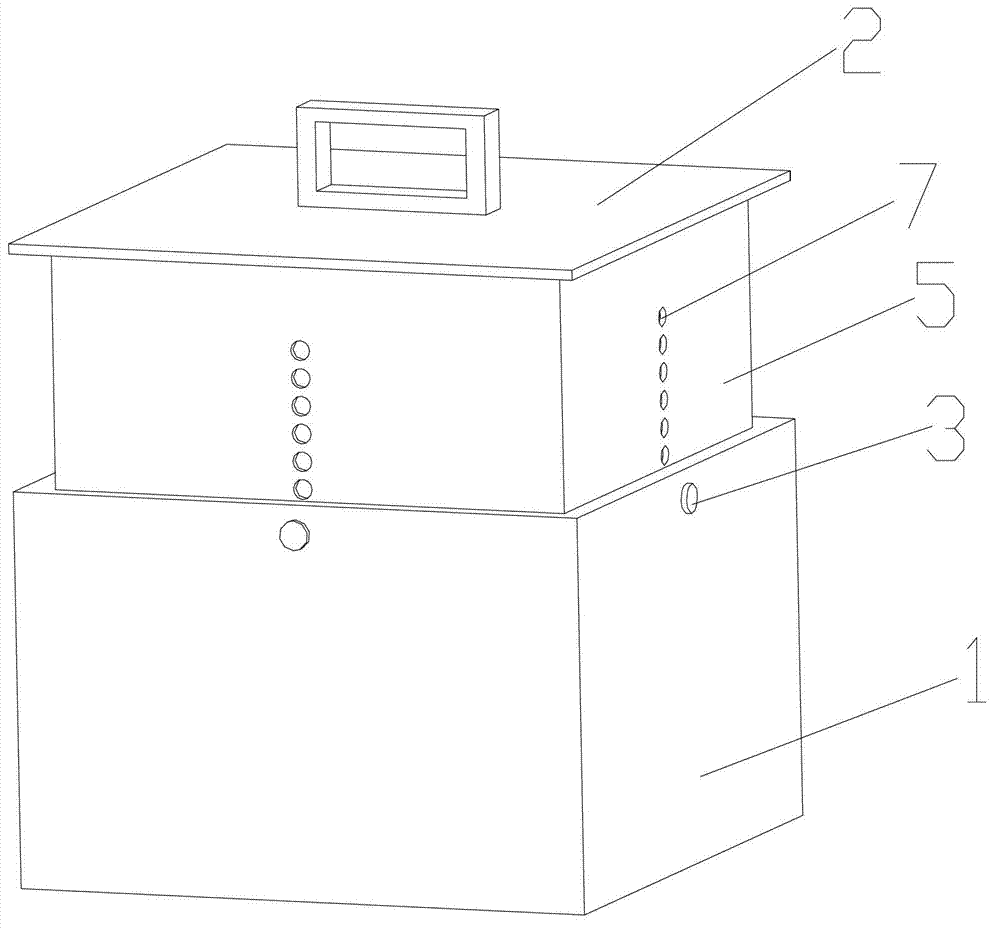

Stretchable containing box

InactiveCN102815442ABig spaceReasonable useVariable capacity containersComputer engineeringBlind hole

The invention discloses a stretchable containing box, including a box body and a box cover. A positioning hole is arranged on the outside surface of the box body and a sliding groove is arranged on the inside surface of the box body; a inside casing in the box body is arranged on the sliding groove; the inside surface of the inside casing is equipped with a groove and the outside surface of the inside casing is equipped with a plurality of equidistant positioning blind holes; moving in the sliding groove, the inside casing can be fixed by a fixing pin inserted both the positioning hole and the positioning blind hole. The invention enlarges the space of the box by the equipment of the inside casing to place more articles with the same area, which utilizes the space more reasonable; with a plurality of equidistant positioning blind holes arranged on the outside surface of the inside casing, the space of the box can be adjusted according to the real need, which is more user-friendly; because of the designed groove, the stretch and draw of the inside casing is easy for the hand to control: the fixing pin is inserted after adjustment; with the humanized overall design, the stretchable containing box can meet different demands by utilizing space fully and reasonably.

Owner:SUZHOU DONGLI MACHINERY

Foldable stovetop cookware and method of production

A foldable or collapsible stovetop container that maintains a rigid shape while in use and can be folded into a smaller size for storage. The stovetop container includes rigid top and bottom portions separated by a flexible middle portion. The flexible middle portion includes thin wall sections that form predetermined bend areas. Pressure applied to the top portion causes the flexible middle portion to collapse in an orderly manner toward the bottom portion, with the middle portion folding at each of the predetermined bend areas to create one or more folds or pleats in the middle portion in the collapsed configuration. The foldable stovetop container may be used on residential stovetops for the heating and cooking of food.

Owner:FUNG DUNCAN C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com