Elevating lift dispenser and container for foodstuffs

a technology of lift dispenser and foodtuff, which is applied in the direction of instruments, apparatus for dispensing discrete objects, and de-stacking objects, etc., can solve the problems of shaking the container, difficulty in manually extracting chips after a portion has been previously removed, and difficulty in grasping chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

and Some Common Features

[0034] General Configuration

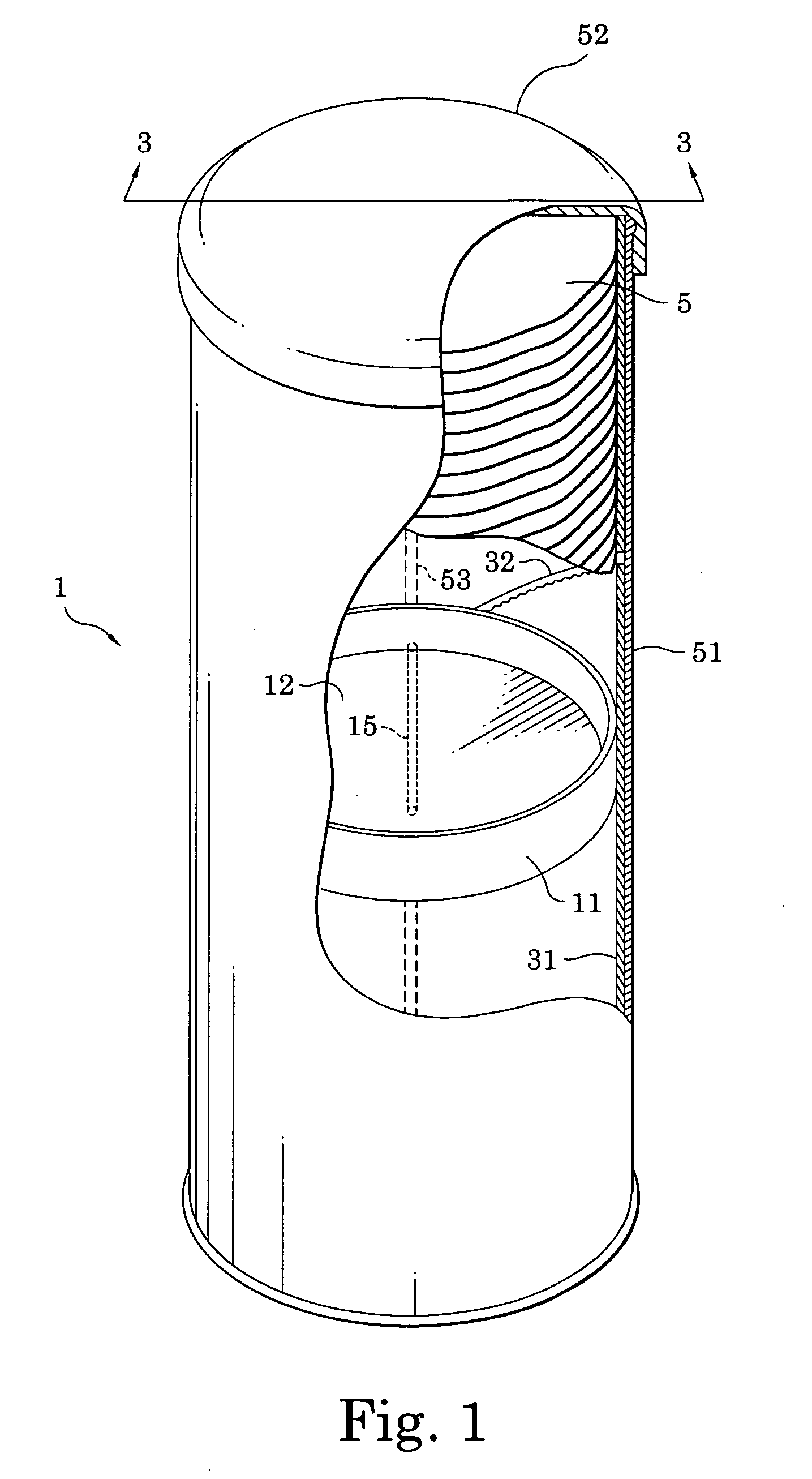

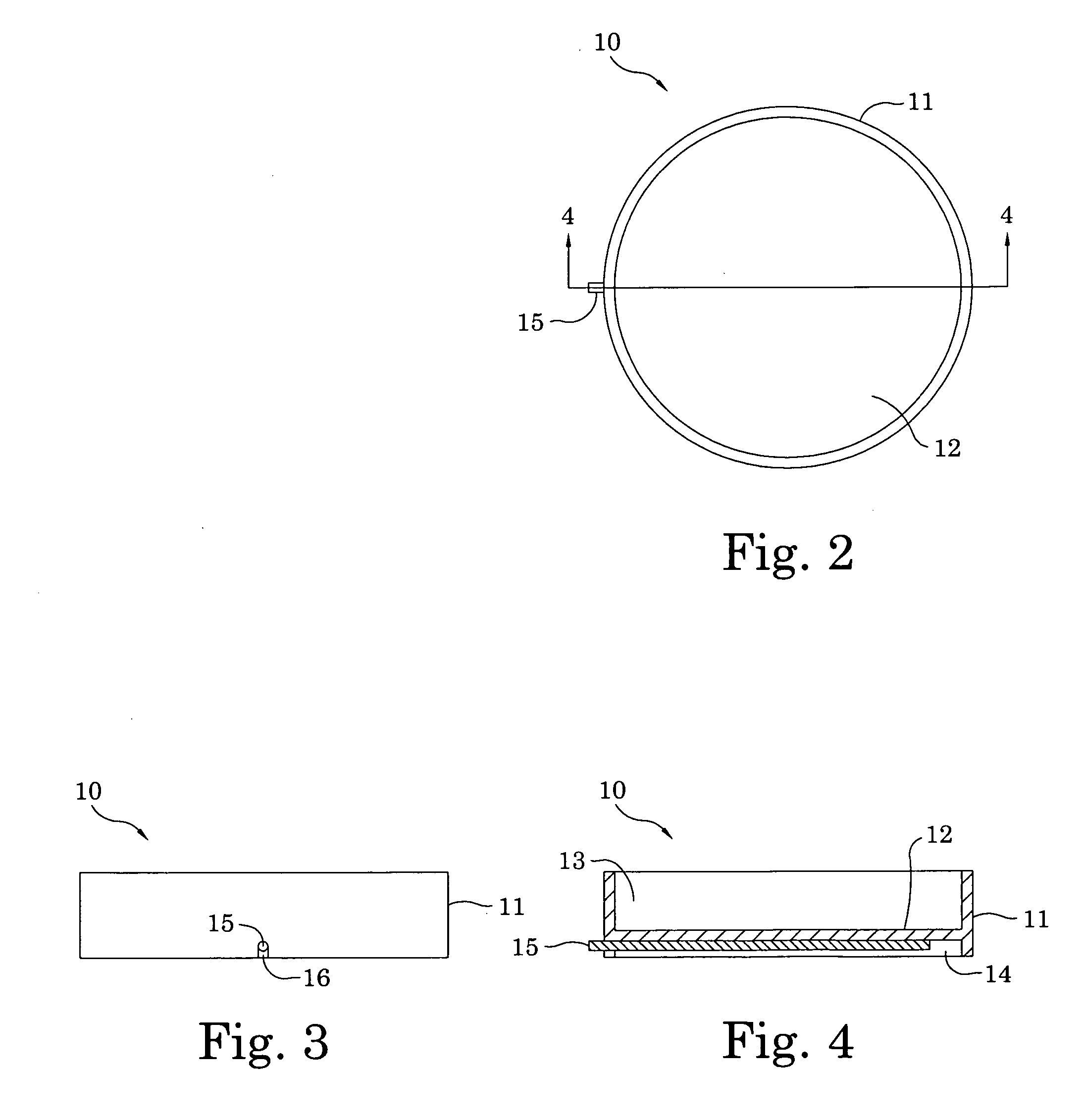

[0035]FIG. 1 shows a preferred embodiment of apparatus or assembly 1 according to some of the inventions set out herein. Apparatus 1 is used for both containing and elevating contents held within a container body to form a combined container and dispenser apparatus. This apparatus is generally referred to by the reference number 1.

[0036] The assembly has an outer piece which forms a container body or canister 51 and a removable cap or other suitable closure 52. The cap or other closure preferably snaps onto and off of the open end of the container body or canister. Alternatively, other types of closures having threads, bayonet features or other means adapted for securing the closure to the canister. Additionally, there may be a safety seal (not shown) applied after packing the canister to assure the consumer that the product has not been opened and contents removed, tampered with or adulterated in any manner.

[0037] An operator 3...

second embodiment

[0050] Generally

[0051]FIGS. 12 and 13 show a second preferred embodiment according to the inventions hereof. Corresponding features used in container and dispenser apparatus 101 are labeled using reference numbers that are the same as used in the first embodiment with an added 100. Thus, such common features to both apparatuses 1 and 101 will not be repeated for sake of brevity. Significantly differing features included in apparatus 101 will now be described in greater.

[0052] Canister

[0053] Canister 151 is similar to canister 51 but modified by providing a canister groove or furrow 161 that preferably extends about the periphery. As shown, this is implemented by placing the furrow 161 near the upper portion of the canister. The function of this modification is further described below.

[0054] Canister 151 also has a guide 153 which is also described in further detail below.

[0055] Cap or Closure

[0056]FIGS. 12 and 13 show that the cap 152 or other suitable closure is somewhat diff...

third embodiment

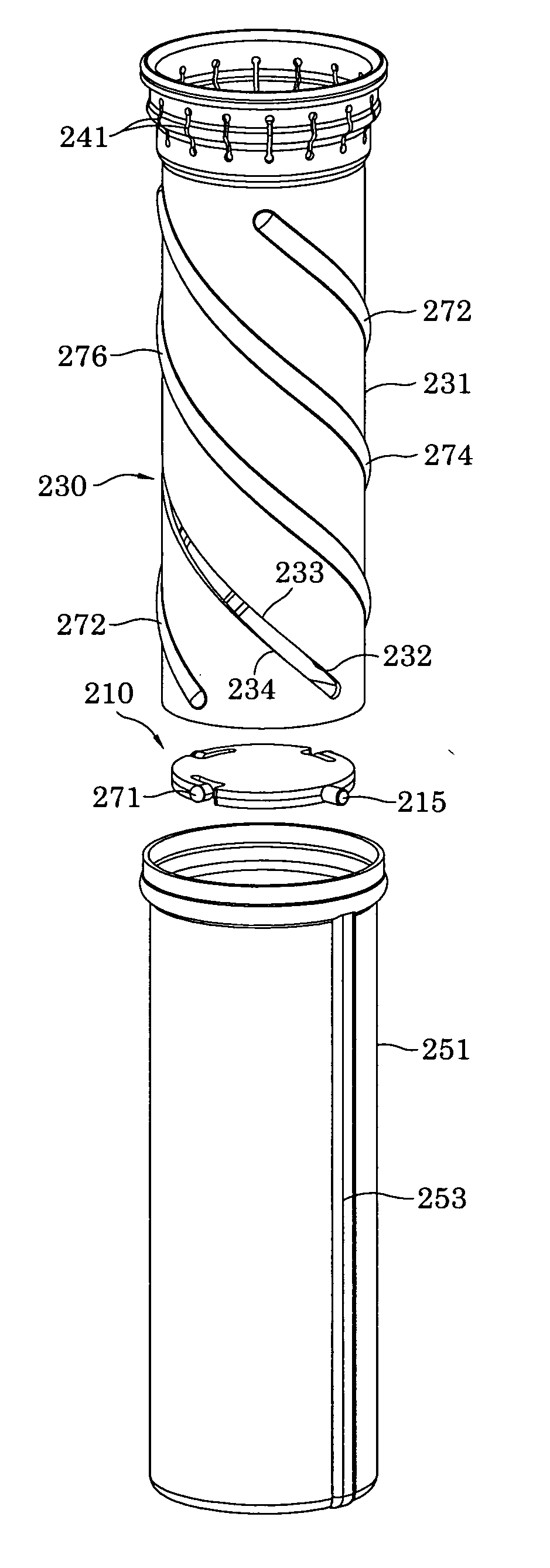

[0067] Plural Camming or Operating Features

[0068]FIGS. 14-16 illustrate a third preferred embodiment according to inventions described herein. Apparatus 201 is constructed in most respects similar to the second embodiment 101. Similar features with other embodiments are numbered similarly except they have 200 added thereto and therefore not repeated in their description.

[0069] The primary differences are with regard to having a plurality of camming features. The plural camming features are used to aid or improve in balanced operation of the lift assembly.

[0070] As shown, apparatus 201 has not only a camming or operating slot 232, but also one or more camming or operating features 272, 274 and 276. The features 272, 274 and 276 are in the form of grooves which receive the alignment projections 271, 273 and 275 which are on lift 210. The projection 215 extends through a slot 232 which is open through the operator tube. As the operator is rotated or otherwise moved, then force is tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com