Patents

Literature

396results about How to "High degree of generalization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent high-voltage management system of electric car

InactiveCN105774557AImprove securityImprove convenienceElectric devicesElectric vehicle charging technologyIntelligent lightingPre-charge

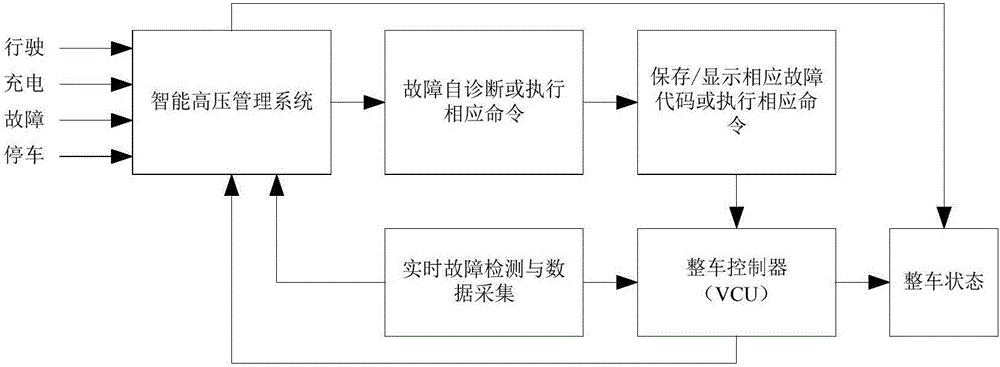

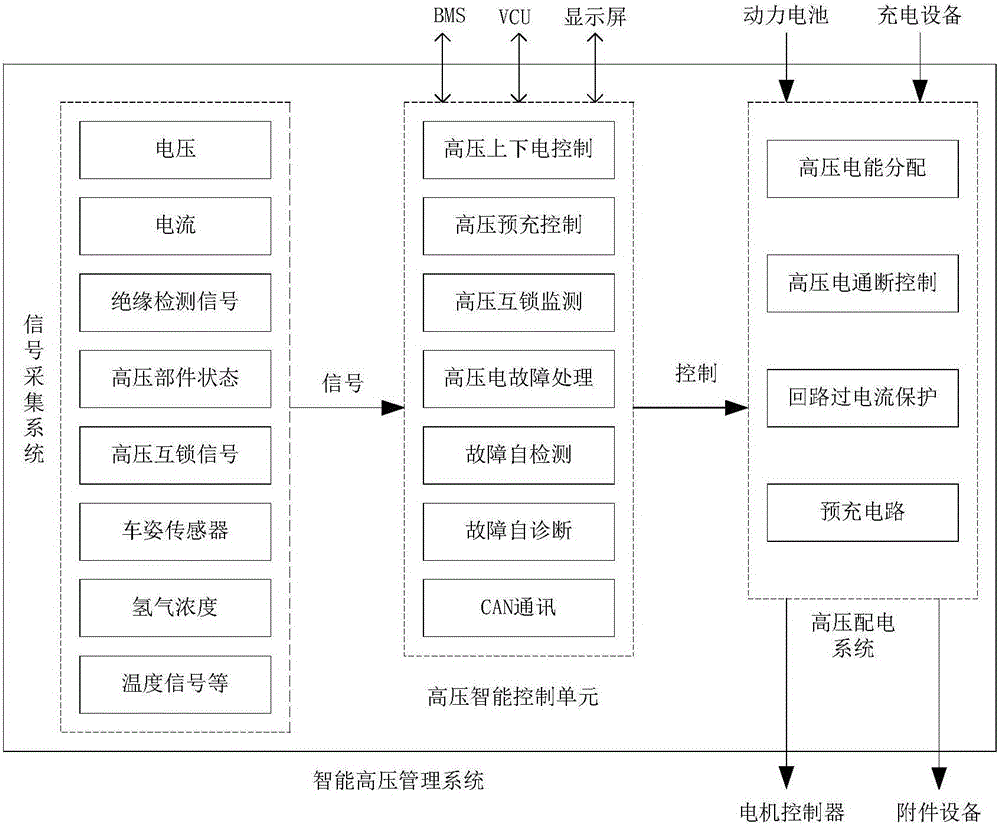

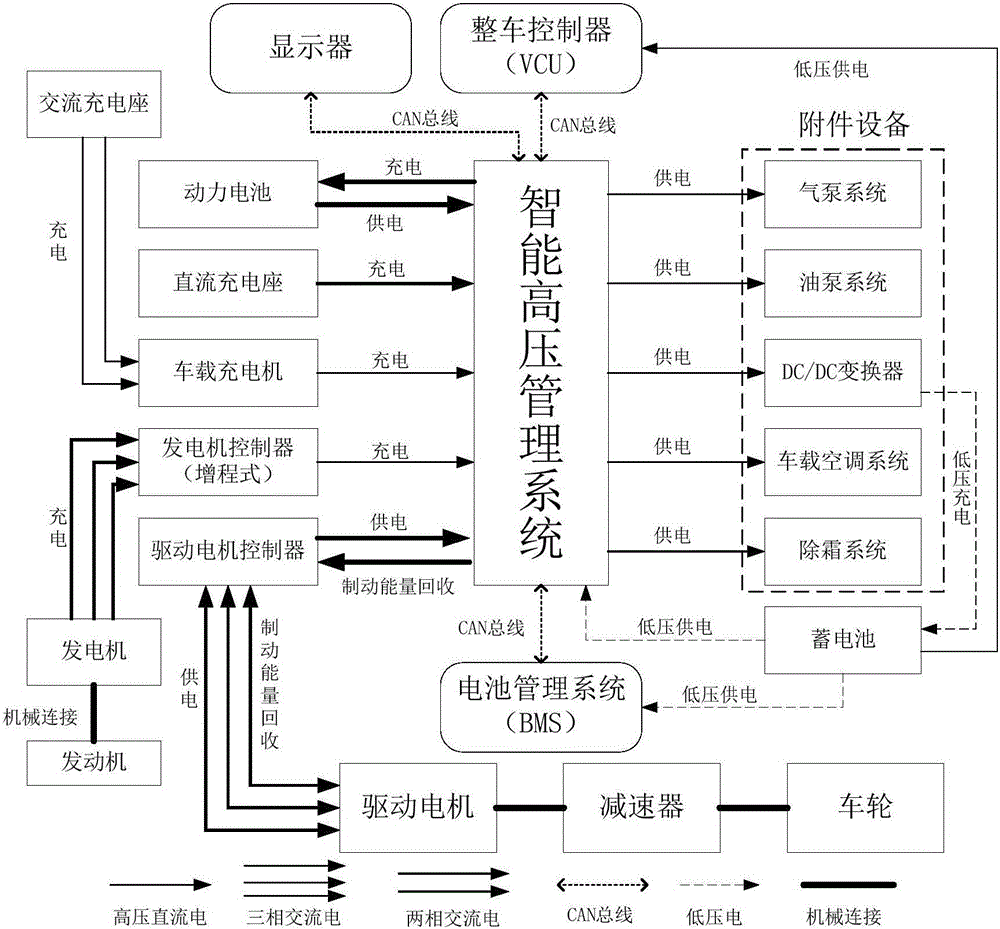

The invention provides an intelligent high-voltage management system of an electric car. According to the intelligent high-voltage management system of the electric car, a signal collecting system collects the car operation state, failure detection object state and car posture state in real time; an intelligent high-voltage control unit receives an instruction of a vehicle control unit (VCU) and / or a battery management system (BMS), enables a high-voltage electricity distribution system to normally distribute electricity to vehicle high-voltage equipment and feeds back the execution result to the VCU and / or the BMS; meanwhile, fault diagnosis and detection are carried out on the high-voltage electricity distribution system according to collected data and received vehicle real-time interaction data; the fault type is determined according to a preset fault database, the high-voltage electricity distribution system is made to execute the high-voltage electricity on-off control logic under the preset fault types, and the diagnosis result is stored and sent; the high-voltage electricity distribution system caries out high-voltage electricity distribution, high-voltage electricity on / off control, circuit overcurrent protection and high-voltage pre-charging on all high-voltage devices of the car according to the instruction of the intelligent high-voltage control unit. The intelligent high-voltage management system of the electric car realizes intelligent management of high-voltage electricity of the whole car, and better improves the high-voltage safety of the electric car.

Owner:WUHAN UNIV OF TECH

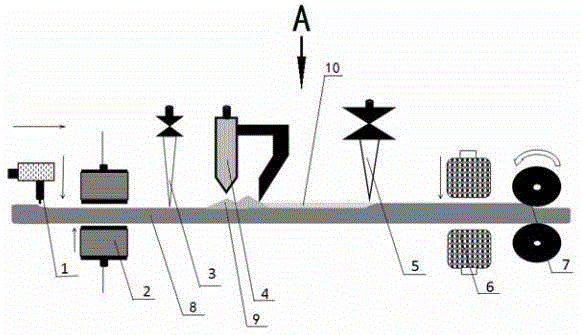

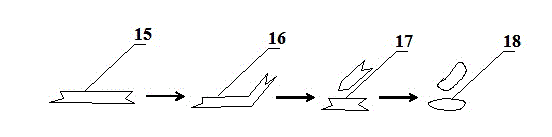

Direct forming manufacturing method of metal-based multilayer/gradient composite board and process unit of direct forming manufacturing method

ActiveCN105643215AHigh bonding strengthEliminate surface stressRoll force/gap control deviceMetal rolling arrangementsHigh energyBound property

The invention discloses a direct forming manufacturing method of a metal-based multilayer / gradient composite board and a process unit of the direct forming manufacturing method. Scale, corrosion materials and other impurities on the joint surface of a base board are removed through chemical cleaning, the cleaned surface is subjected to gradient power electromagnetic induction heating or laser bombardment surface treatment, all phases near the joint surface are fully dissolved, a solid solution is enhanced, toughness and corrosion resistance are improved, the surface stress of the board is eliminated, and surface laser treatment is conducted to improve the binding property of a composite layer; raw materials of the composite layer are added and injected through powder laying, a high-energy heat source is adopted for irradiation or induction heating to melt powder, metallurgical bonding is formed between the composite layer and a base, and control over the final shape of a cold / hot-rolled board is conducted. The obtained multilayer / gradient composite board is compact in surface structure, bonding between the composite layer and the base and between layers is good, and the interlayer bonding performance of the composite board is remarkably improved. The process is high in flexibility, and the production period of the metal-based composite board can be greatly shortened after the process is combined with an existing continuous casting technology.

Owner:SHANGHAI UNIV

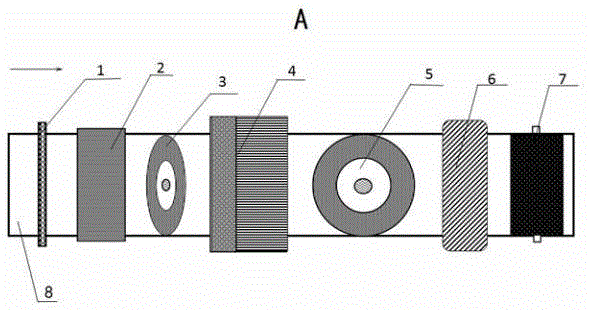

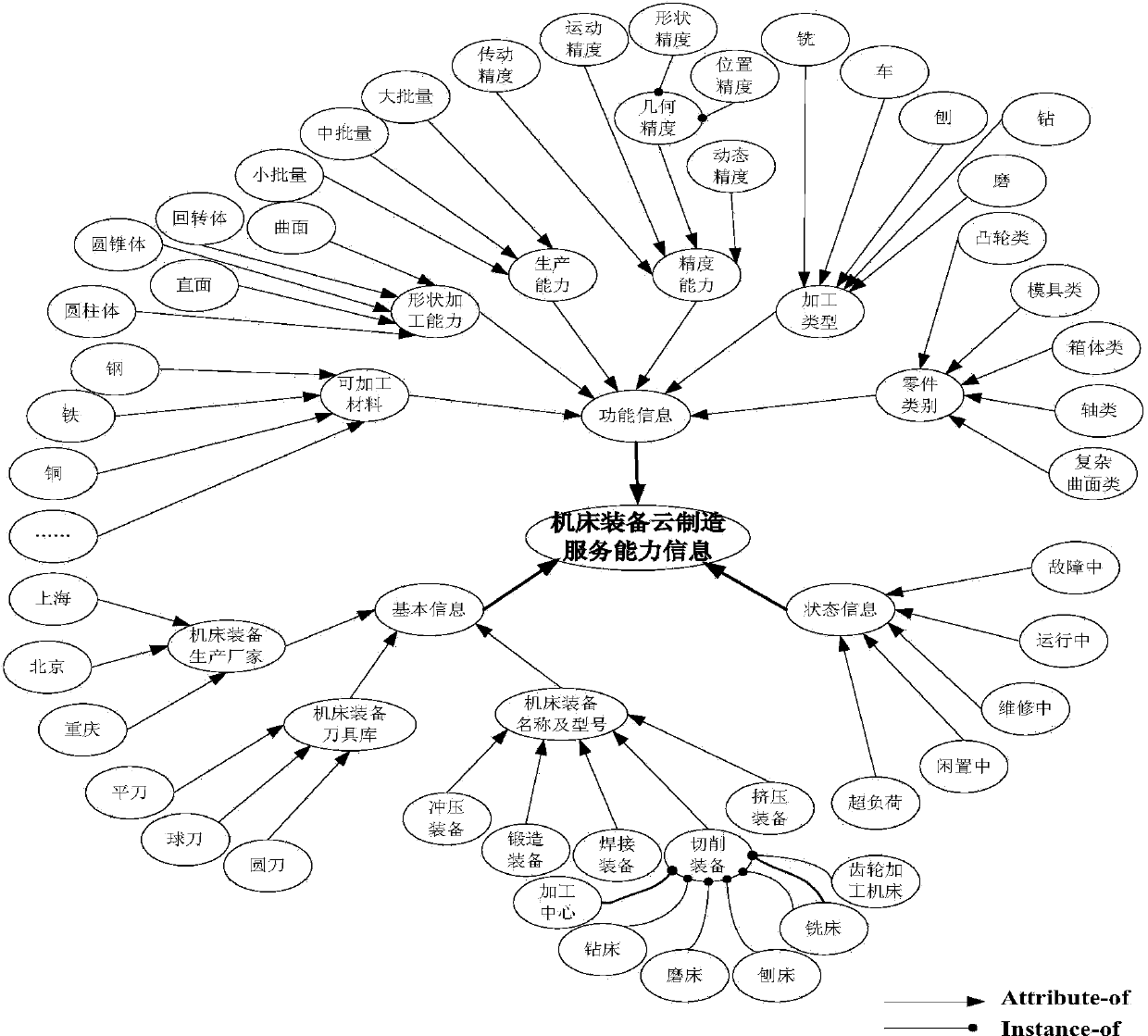

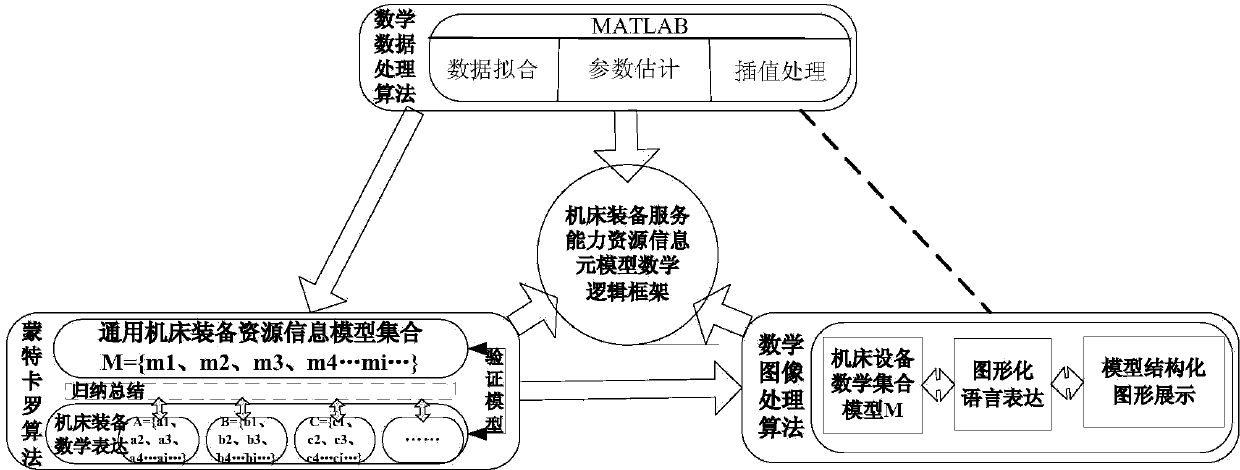

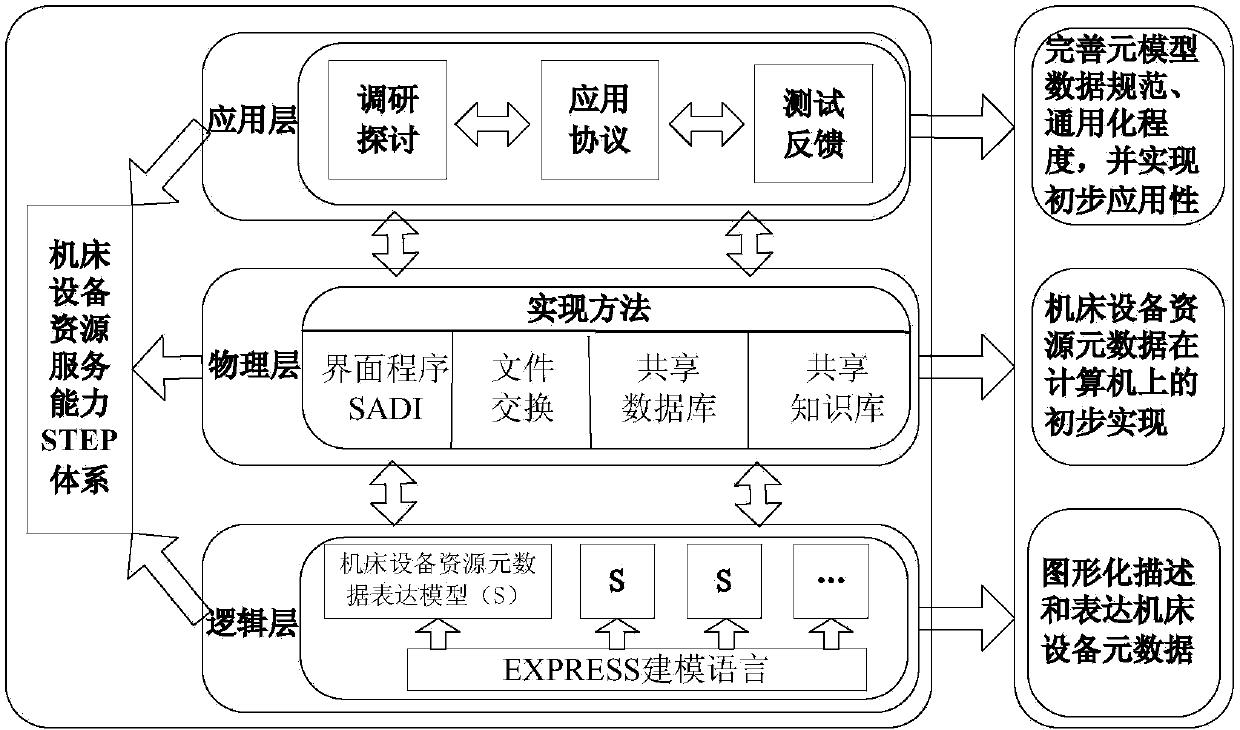

Machine tool equipment service capability modeling method in cloud manufacturing environment

InactiveCN103473407ASolve the problem of how to display graphicallyImprove data normalizationSpecial data processing applicationsPersonalizationVirtualization

The invention relates to a machine tool equipment service capability modeling method in a cloud manufacturing environment, and belongs to the technical field of information. The machine tool equipment service capability modeling method is a machine tool equipment information standardization description method including a substance information analyzing and extracting method, a mathematical modeling technique and an STEP (standard for the exchange of product model data) technique. The machine tool equipment service capability modeling method includes creating a uniform machine tool equipment cloud manufacturing service capability model through analyzing and extracting, logic framework building and virtual standardization describing of machine tool equipment information, and configuring model information parameters in an individualized way. The machine tool equipment service capability modeling method can lay a foundation for realization of techniques like visualized packaging and displaying of machine tool equipment, establishing of machine tool equipment resource libraries and intelligent semantic-based matching of machine tool equipment resources in the cloud manufacturing environment. The machine tool equipment service capability modeling method has the advantages of high virtualized simulation degree, high universality and good expandability; by the machine tool equipment service capability modeling method, service enterprises can be effectively supported to provide cloud manufacturing services conveniently and users can be effectively supported to find and match better resources intelligently.

Owner:CHONGQING UNIV

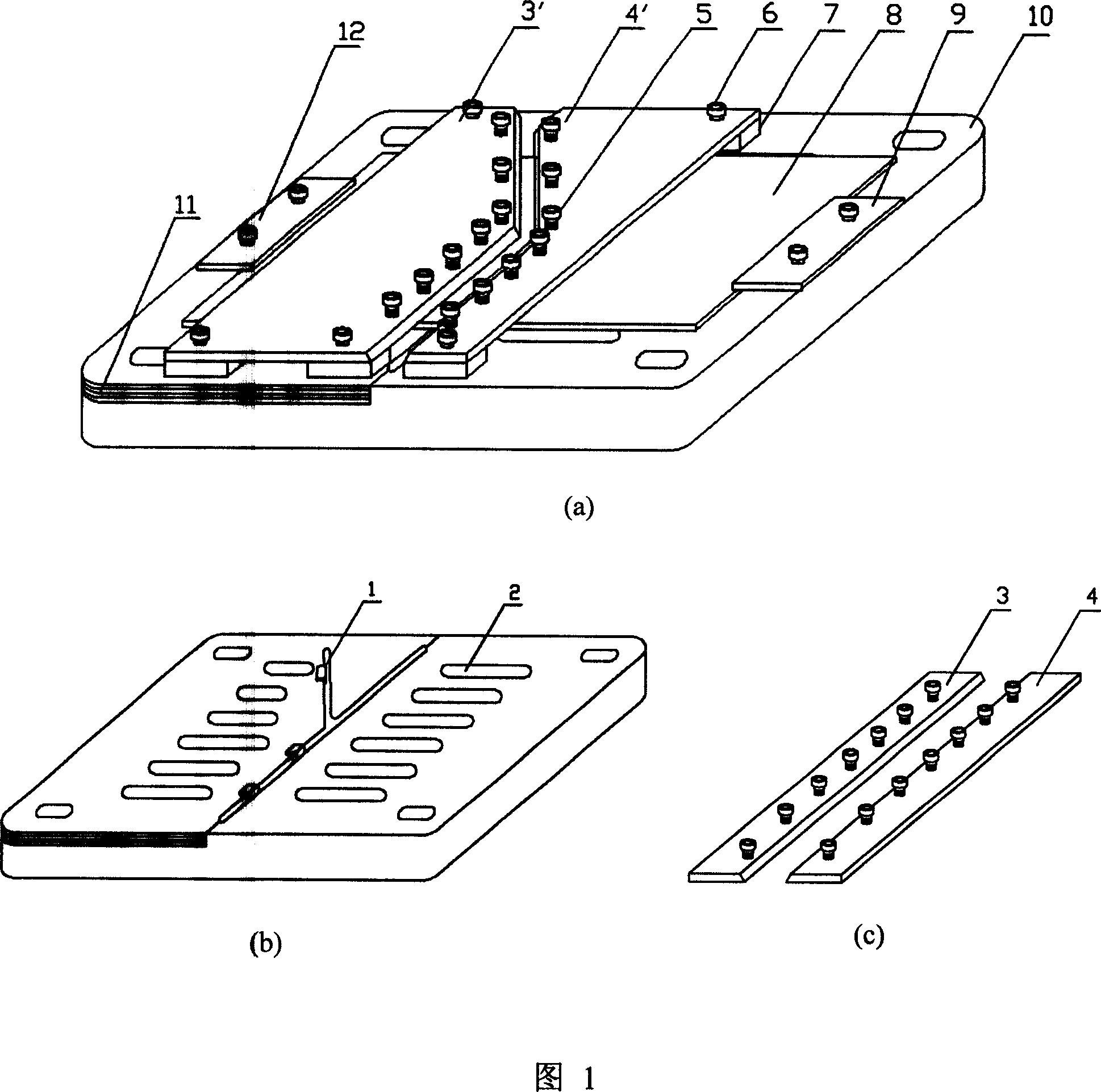

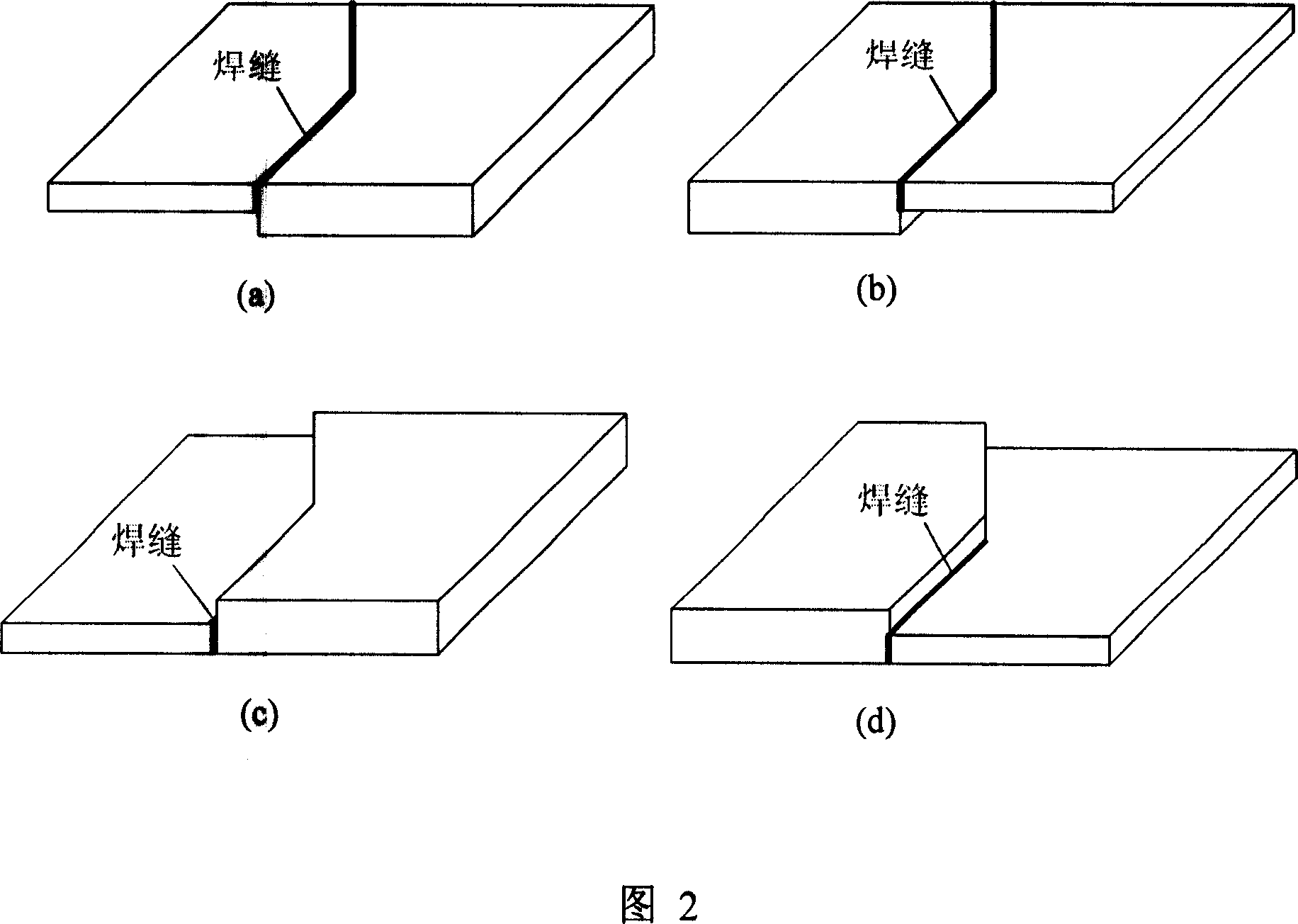

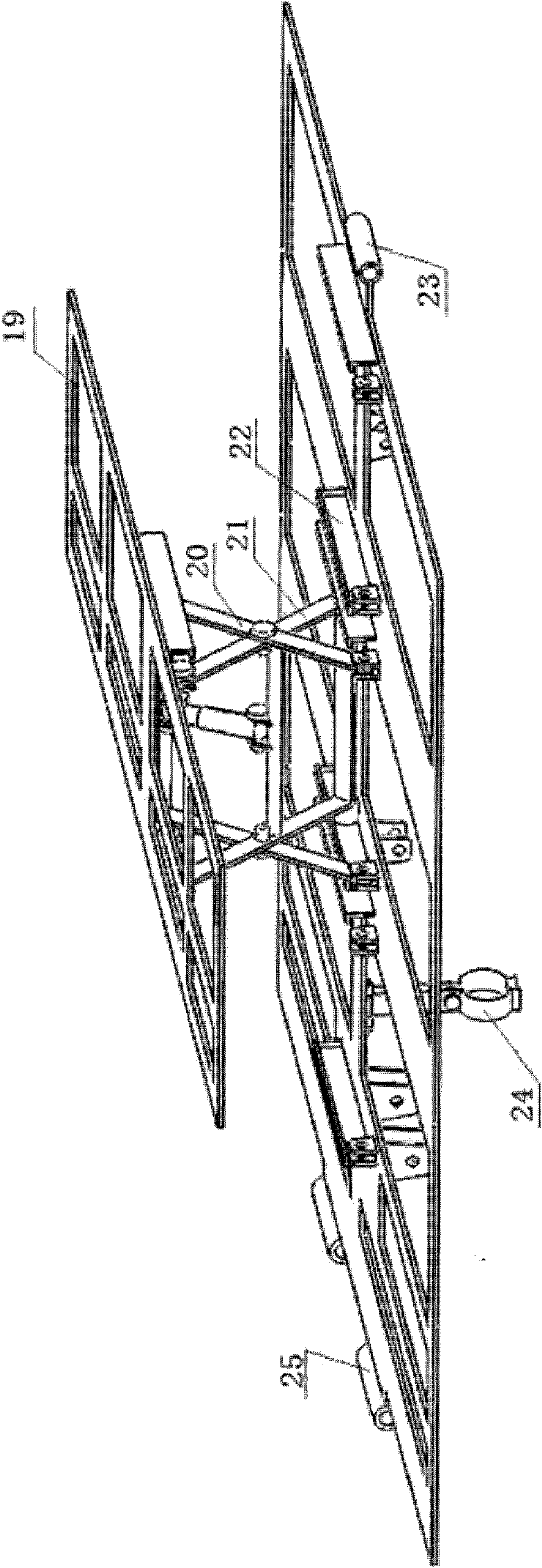

Deformable welding fixture for plate splicing welding with linear and curved weld seams

InactiveCN101020281AEasy clampingAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

The present invention is a double-purpose deformable welding fixture for welding linear and curved weld seams, and the fixture has linear welding slot and curved welding slot integrated onto one pedestal to reach the double-purpose aim. The double-purpose deformable welding fixture consists of one pedestal height difference structure comprising one thickness difference step and one height regulating tab for fitting different welding thickness, and one clamping screw mechanism comprising right and left pressing boards with screw holes and corresponding cap screws. It can regulate clamping force and control welding deformation by means of novel flexible location mode, and is suitable for linear and curved welding of common steel plate, high strength steel plate, aluminum plate, etc of different sizes.

Owner:JIANGSU UNIV

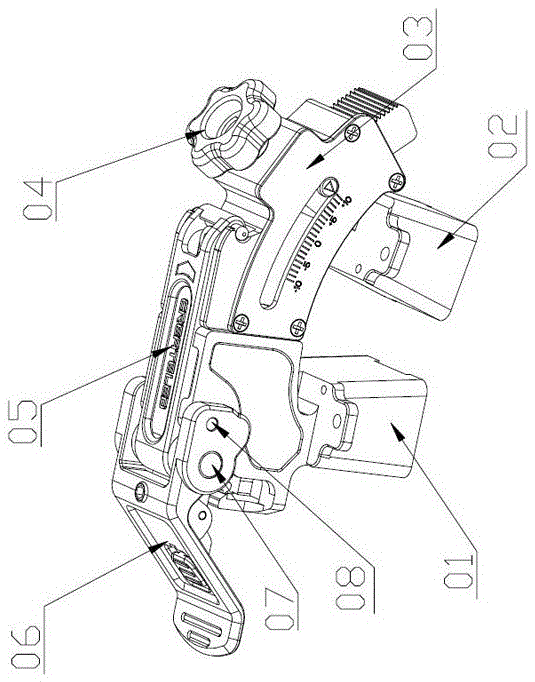

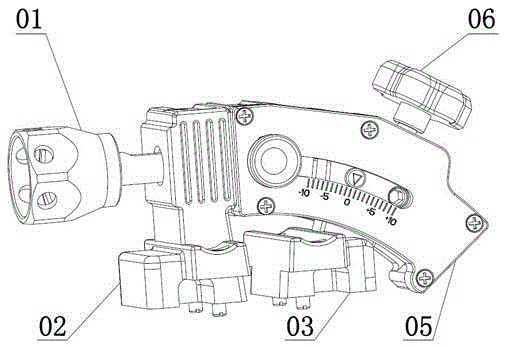

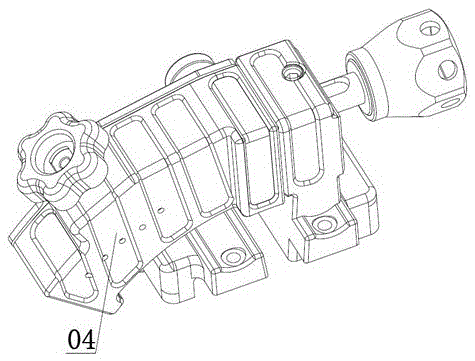

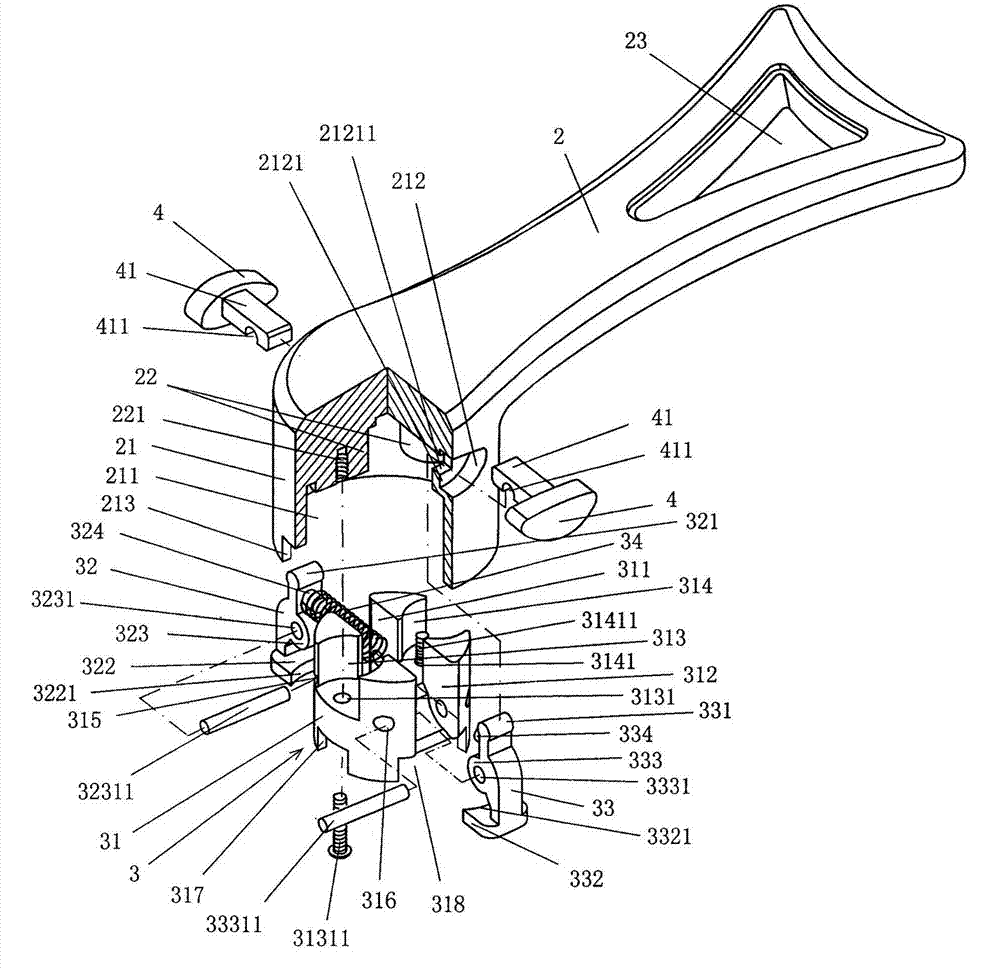

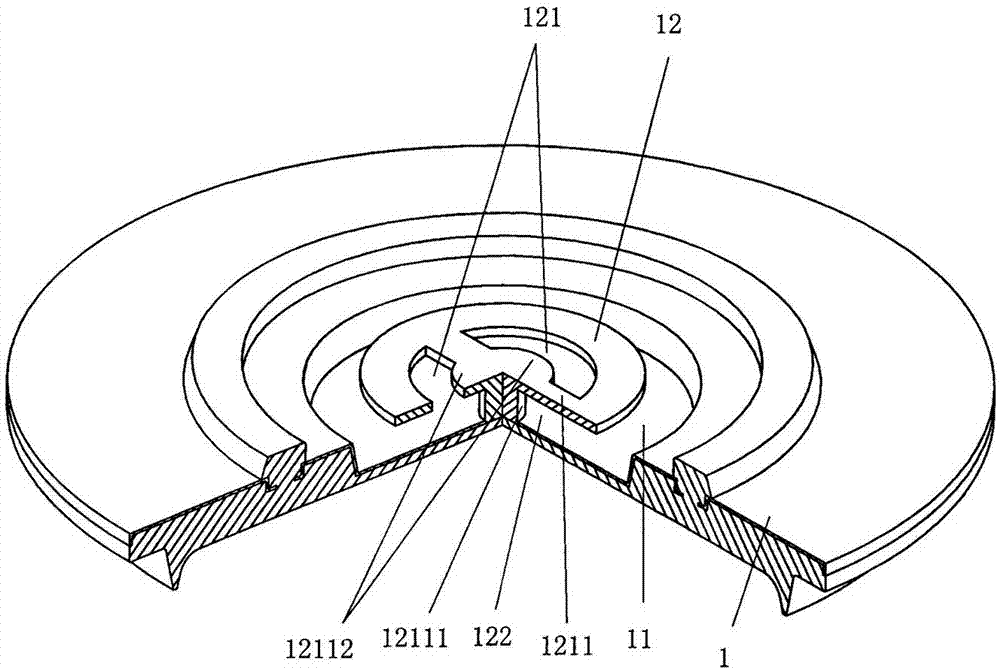

Adjusting module based on variable curvature and arc-shaped LED display screen spliced from adjusting module

ActiveCN105575273AAvoid defectsHigh degree of generalizationIdentification meansLED displayComputer science

The invention discloses an adjusting module based on variable curvatures and an arc-shaped LED display screen spliced from the adjusting module. The adjusting module comprises a first part and a second part, wherein the first part consists of angle adjusting components; the second part consists of positioning and locking components; the first part comprises a sliding set and a fixed angle set; the second part comprises a buckle set and a safety anti-loosing set. The invention further discloses the arc-shaped LED display screen based on the variable curvatures. The arc-shaped LED display screen comprises a plurality of unit boxes and a plurality of adjusting modules based on the variable curvatures. A right fixing block on the first part and a left fixing block on the second part are respectively mounted on adjacent sides of each unit box body, the adjusting module is adopted for angle adjustment and locking and positioning on adjacent unit box bodies, and the arc-shaped LED display screen of which the angle can be randomly varied within the range of 10 degrees can be formed. The adjusting module has the advantages of high universalization degree, applicability to multiple mounting situations, convenience in assembly and disassembly, high bearing capacity and solidness, adjustable radian and seamless splicing.

Owner:CREATELED ELECTRONICS

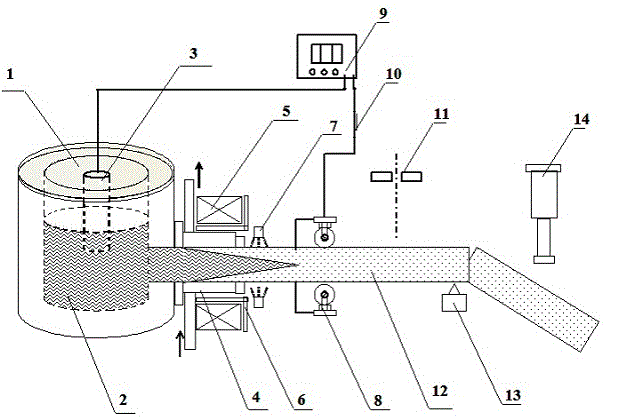

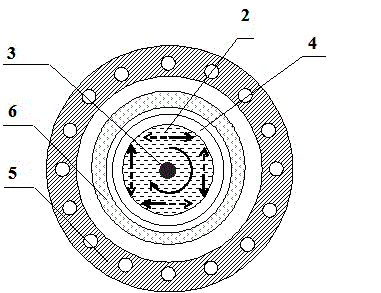

Method for controlling metal solidification phase texture in combined mode through external rotating magnetic field and current and fusion casting device of method

The invention discloses a method for controlling metal solidification phase texture in a combined mode through an external rotating magnetic field and current and a fusion casting device of the method. In a metal solidification process, firstly, the rotating magnetic field is exerted on a metal melt area on the front edge of a metal melt solidification interface, and meanwhile the current is exerted on metal melt nearby a solid-liquid interface area of a whole continuously cast bloom through an external power supply. Under the combined action of the rotating magnetic field and the current, electromagnetic combined stirring is conducted on metal liquid nearby the metal melt solidification interface, so that collision, friction and scour occur among primary grains of the metal melt and between the primary grains and the metal melt, fragmentation of the primary grains can be caused, and therefore the solidification texture of the continuously cast bloom is refined. The method is used for preparing high-quality metal materials.

Owner:SHANGHAI UNIV

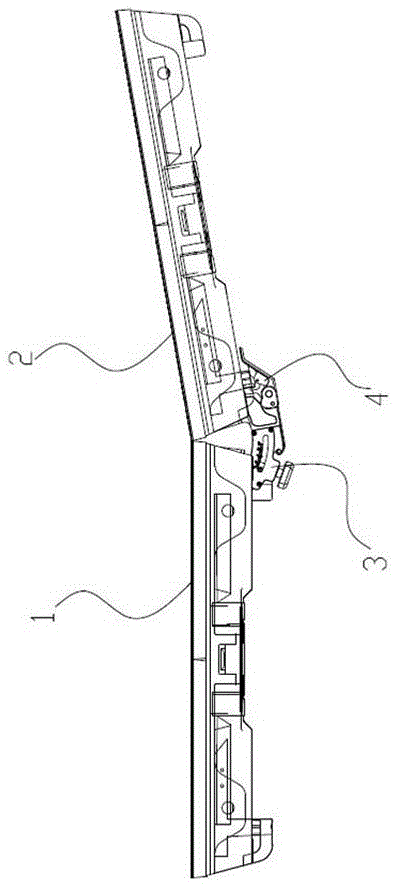

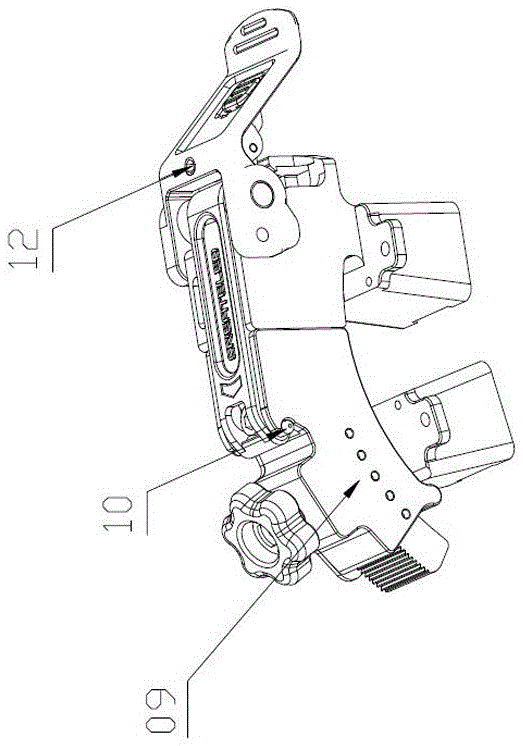

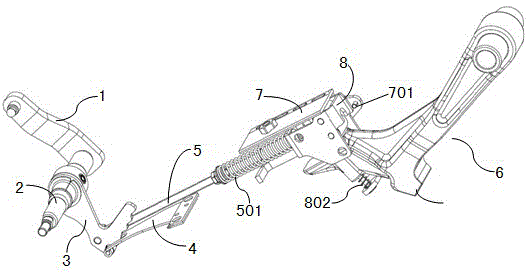

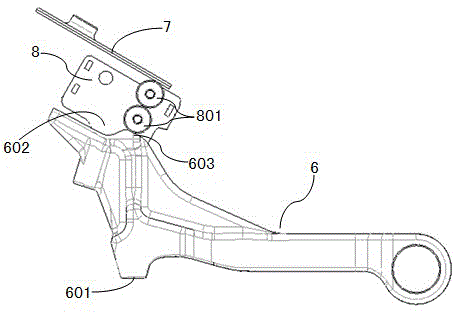

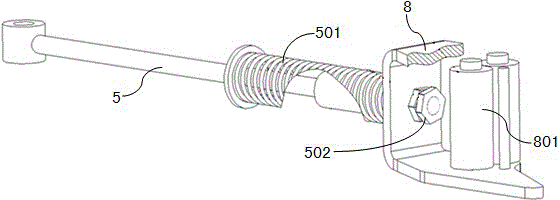

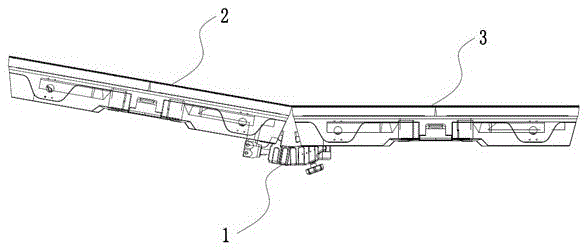

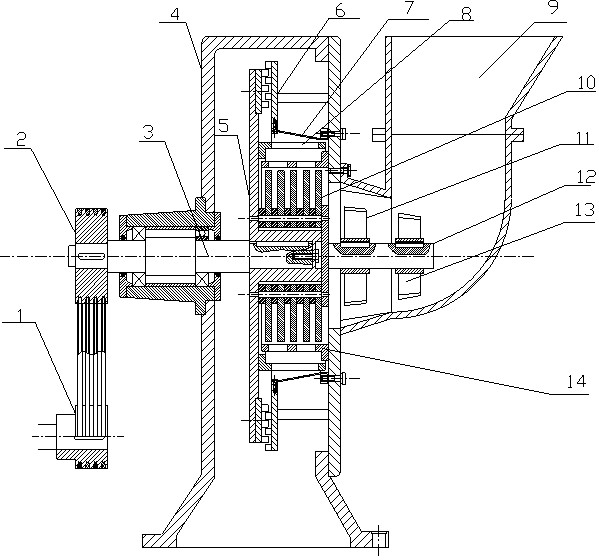

Parking locking mechanism for automatic transmission

InactiveCN104534087AReasonable structureCompact structureGearing controlAutomatic transmissionLocking mechanism

The invention discloses a parking locking mechanism for an automatic transmission. The parking locking mechanism for the automatic transmission comprises a shifting rocker arm, a parking gear and a parking pawl; the shifting rocker arm is fixed on a shifting shaft and drives the parking pawl to move through a driving assembly; the driving assembly comprises a parking rocker arm, a parking pushing rod and a roller seat; the parking rocker arm is fixed on the shifting shaft; one end of the parking pushing rod is hinged to the parking rocker arm and while the other end of the parking pushing rod is mounted to the roller seat; a roller is arranged on the roller seat; a returning spring is arranged between the roller seat and the parking pawl. The parking locking mechanism is reasonable and compact in structure, and reliable in performance.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

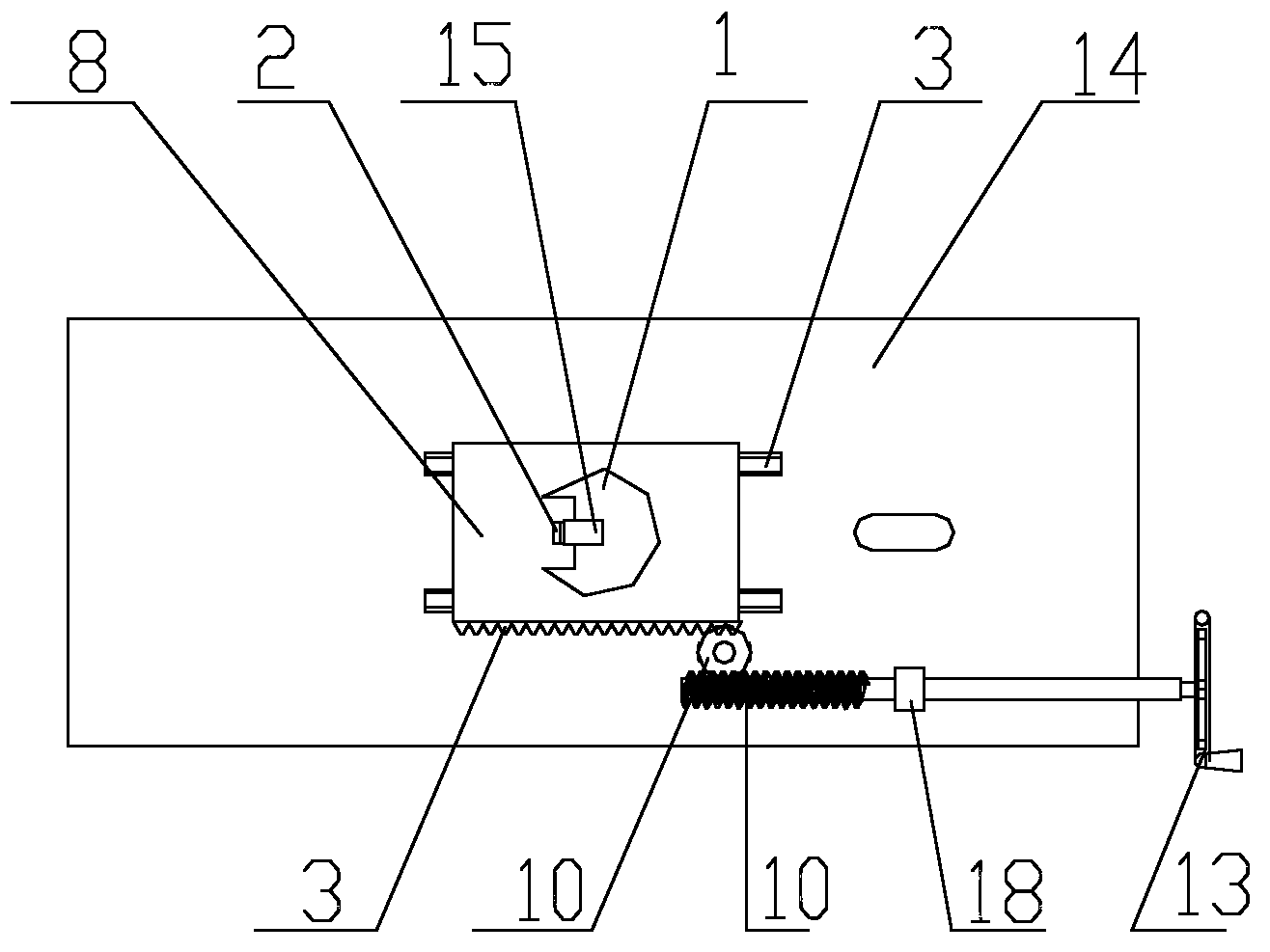

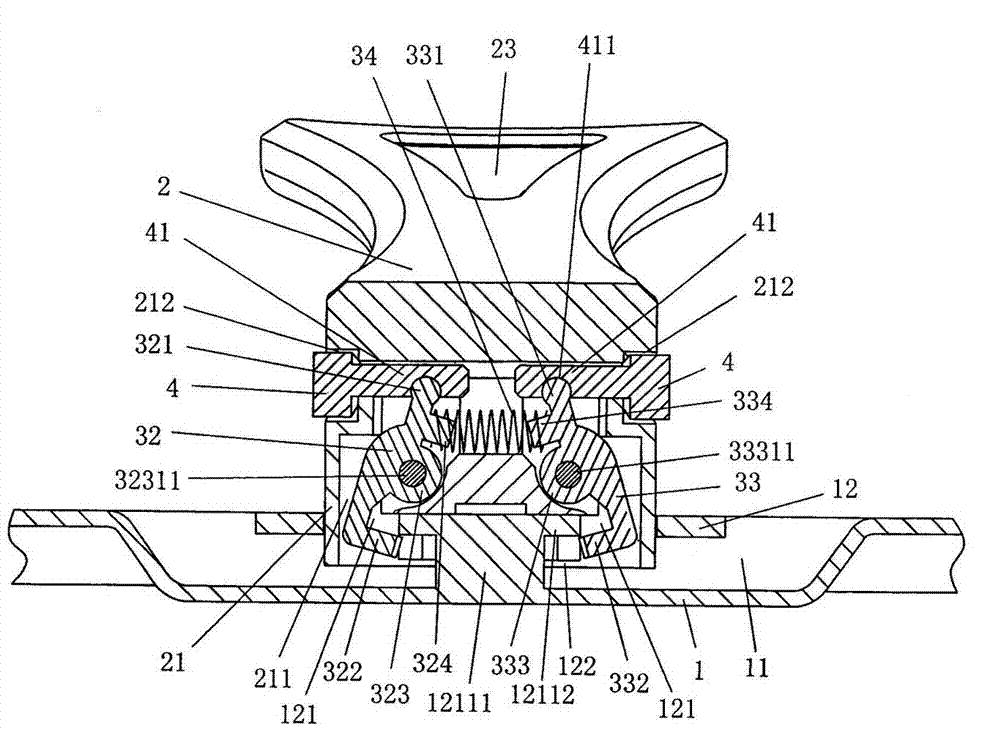

LED (Light-Emitting Diode) display screen assembling component and arc-shaped LED display screen

InactiveCN105575272AOvercoming can only be assembled into a planeOvercoming revealingIdentification meansLED displayLight-emitting diode

The invention discloses an LED (Light-Emitting Diode) display screen assembling component. The LED display screen assembling component comprises a locking rod, a left fixing block, a right fixing block, a pressing block, an arc-shaped groove, a positioning handle, a locking handle and a pushing block, wherein the left fixing block is locked with the arc-shaped groove through the locking rod and the locking handle; an arc-shaped sliding block which is integrally formed with the right fixing block is accommodated in the arc-shaped groove and sealed in the arc-shaped groove through the pressing block; the pushing block is connected onto the positioning handle; the pushing block is in meshing connection with the arc-shaped sliding block; the handheld part of the positioning handle is screwed tightly to fix the arc-shaped sliding block in the arc-shaped groove to form a relative radian between the left fixing block and the right fixing block. The invention further discloses an arc-shaped LED display screen. The defect that the conventional LED display screens can only be assembled into a flat LED screen or fixed-radian arc-shaped LED screen is overcome; the LED display screen assembling component and the arc-shaped LED display screen have the advantages of high universality degree, adaptability to installation in a plurality of places, high convenience in assembling and disassembling, high loadbearing capacity and stability, capacity of adjusting radian randomly within a certain angle range, and capacity of realizing seamless assembling.

Owner:CREATELED ELECTRONICS

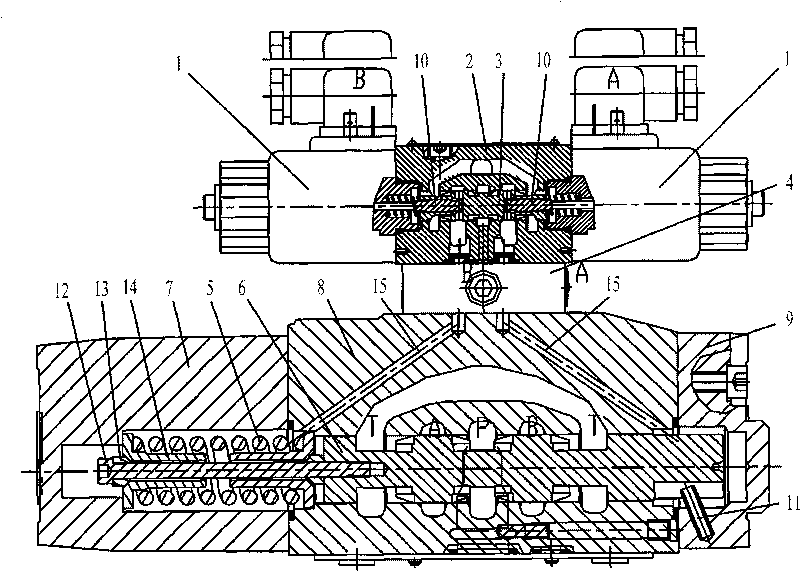

Pilot proportional reversing valve

InactiveCN101713420AHigh work pressureAffects left and right movementServomotor componentsEngineeringControl valves

The invention discloses a pilot proportional reversing valve, which comprises a main valve body and a pilot control valve arranged on the main valve body, wherein both ends of the main valve body are provided with a left end cover and a right end cover; and a main valve core and a main spring are arranged in the main valve body. The pilot proportional reversing valve is characterized in that: the pilot control valve comprises a pilot valve body and a left and a right proportion electro-magnets arranged at both ends of the pilot valve body; and a proportional reducing valve is arranged between the main valve body and the pilot valve body. The pilot proportional directional valve has the advantages of simplified structure, low cost, reduction of extravasation link, good spring guidance, high reliability and strong capability of resisting oil pollution.

Owner:SHANGHAI LIXIN HYDRAULIC

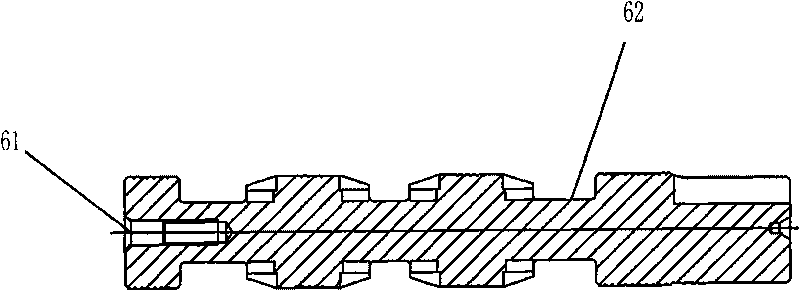

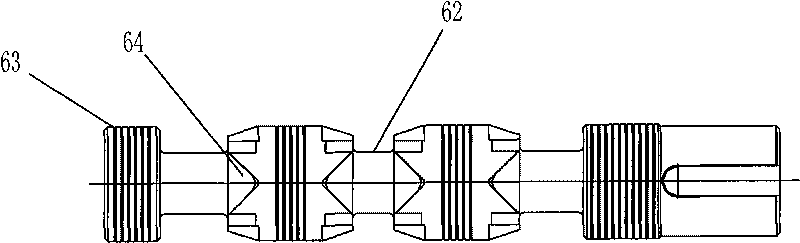

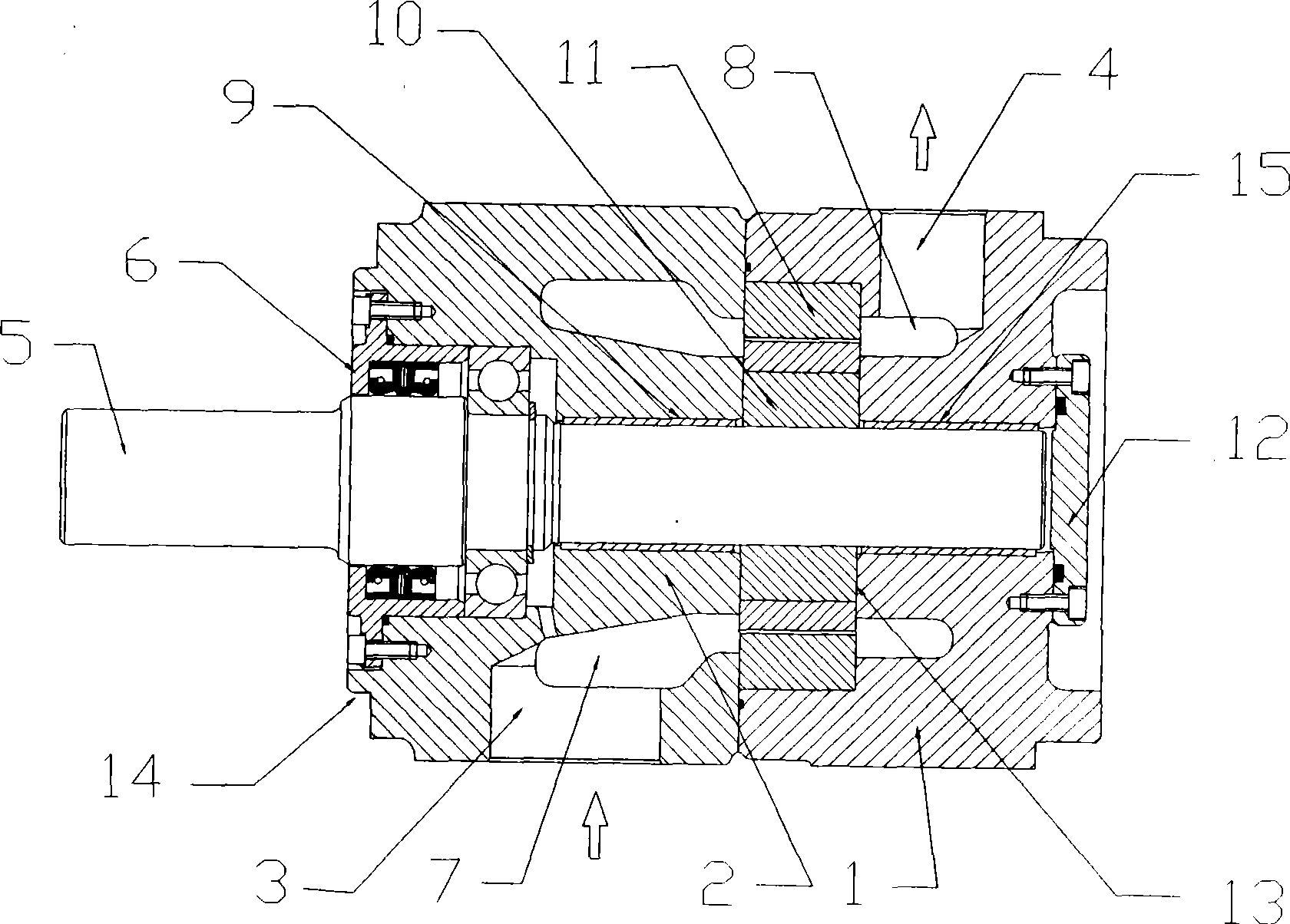

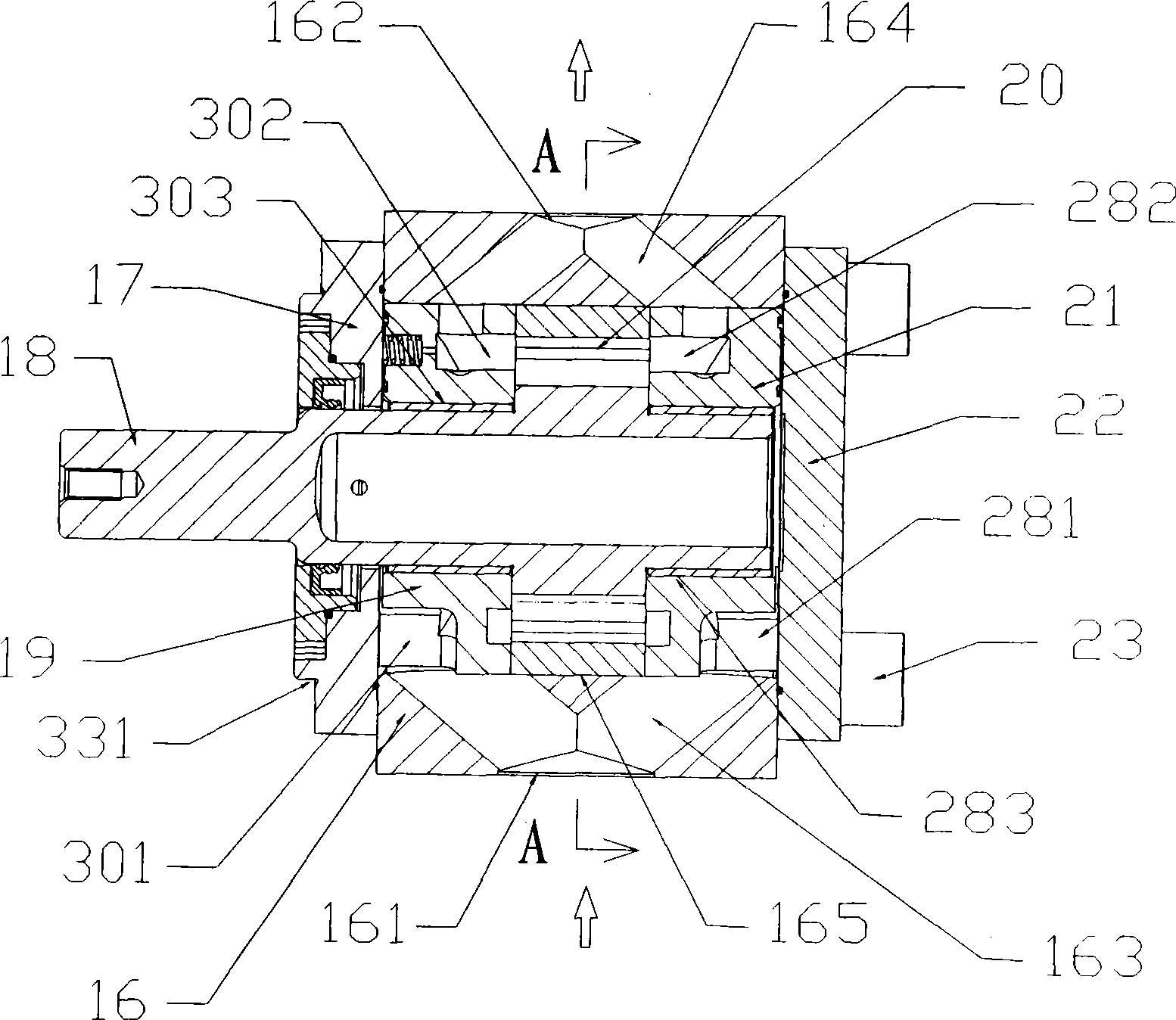

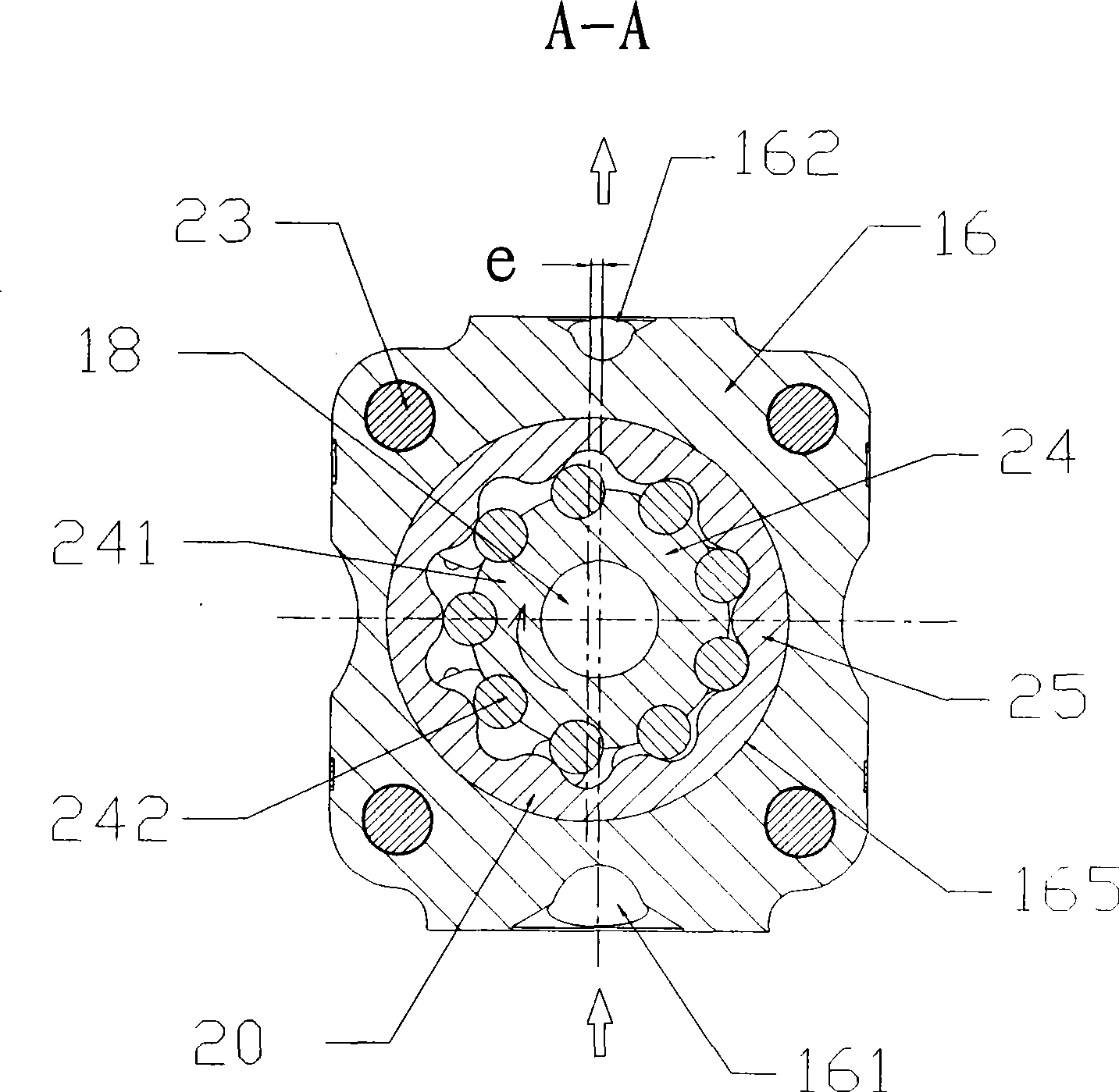

Modular internal gear pump or modular motor

InactiveCN101446286AGeneralizationReduce inventory requirementsEngine of intermeshing engagement typeRotary piston pumpsGear pumpModularity

The invention discloses a modular internal gear pump or a modular motor, comprising a plurality of generalized components such as a shell, an internal gear pair, an input shaft, a fixed shaft tray component, a floating shaft tray component, a flange cover component, a rear cover component and the like, so as to form a barbell type combined structure connected in series, thus realizing modularization of functions, combination of structures and universalization of parts. The invention has the advantages of good universalization of parts, flexible and simple assembly and excellent adaptability of structures, thus achieving the beneficial effects of reducing inventory of parts, shortening the cycle of production and goods delivery and reducing operation cost of products.

Owner:ZHENJIANG DALI HYDRAULIC MOTOR

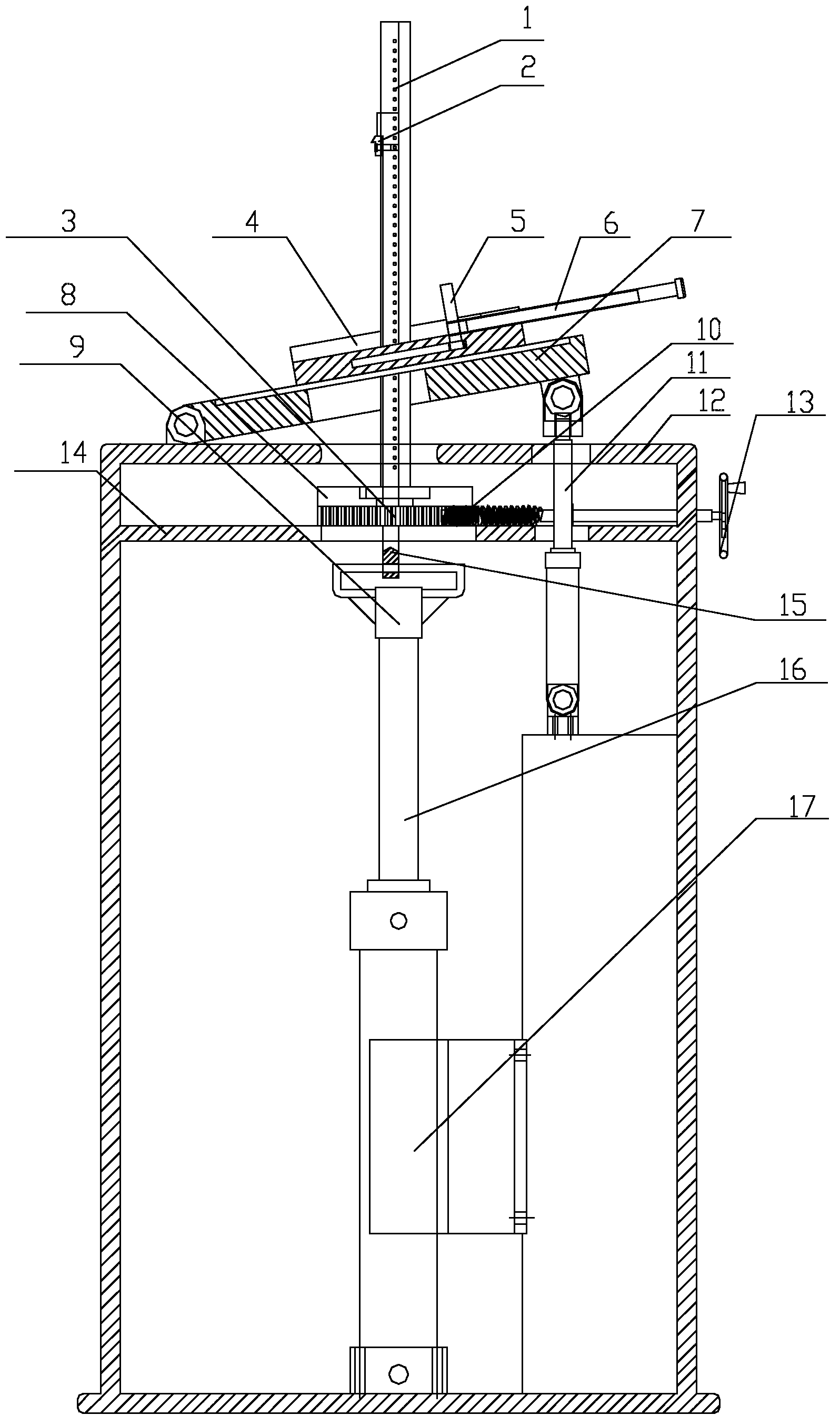

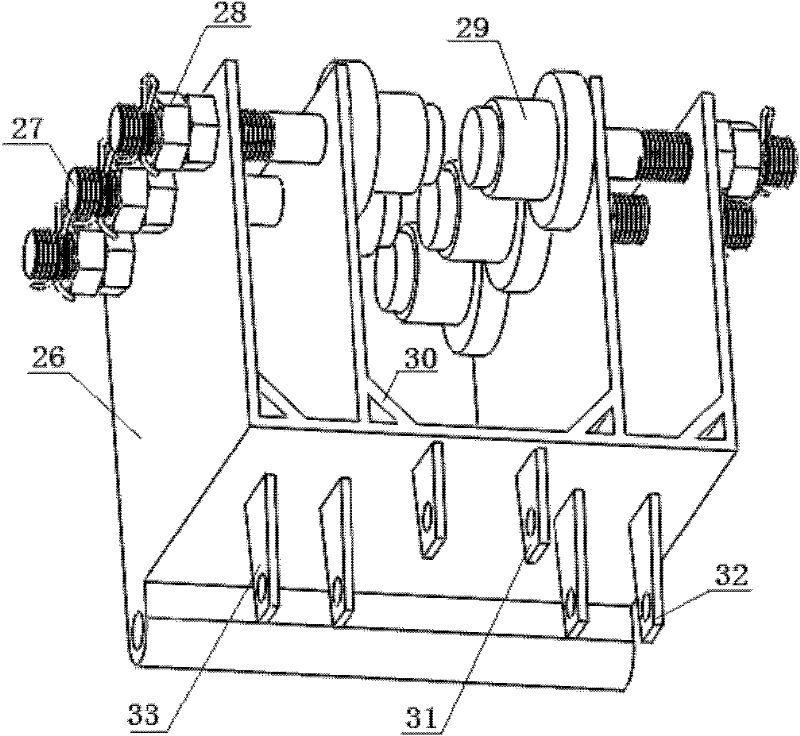

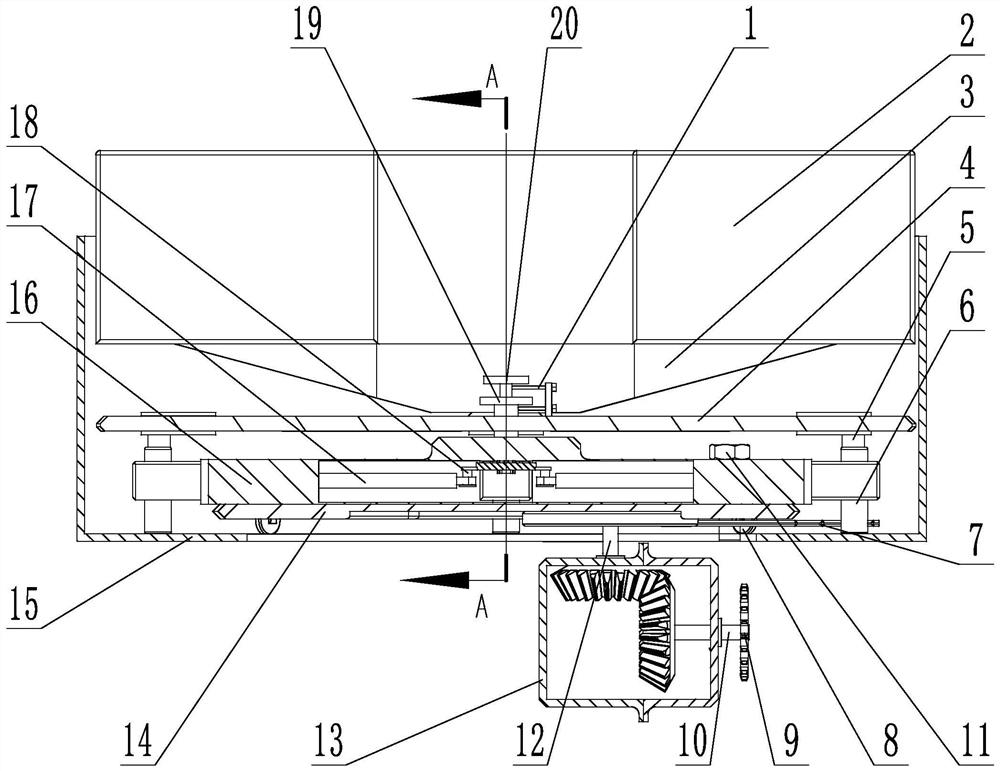

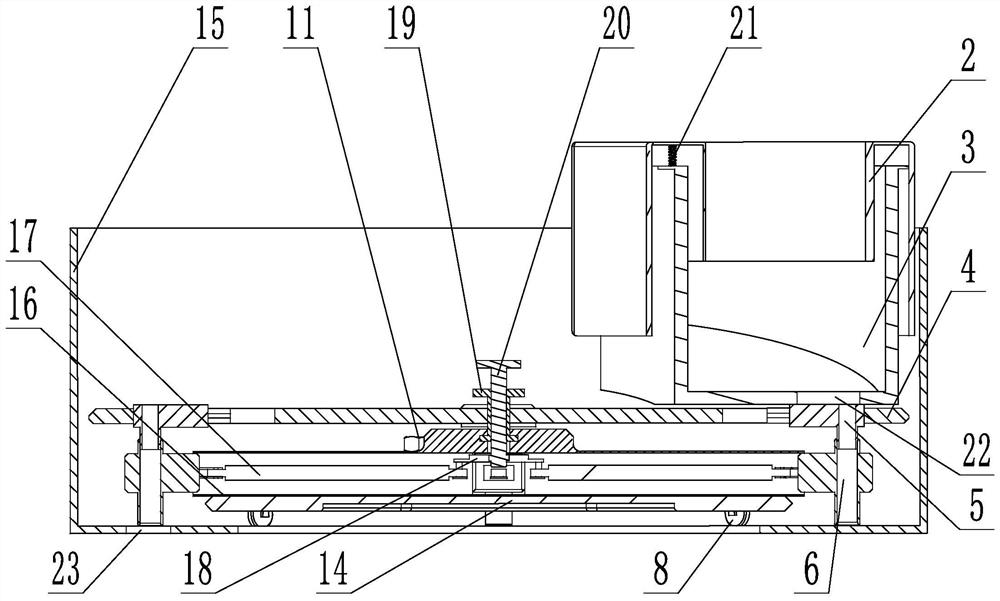

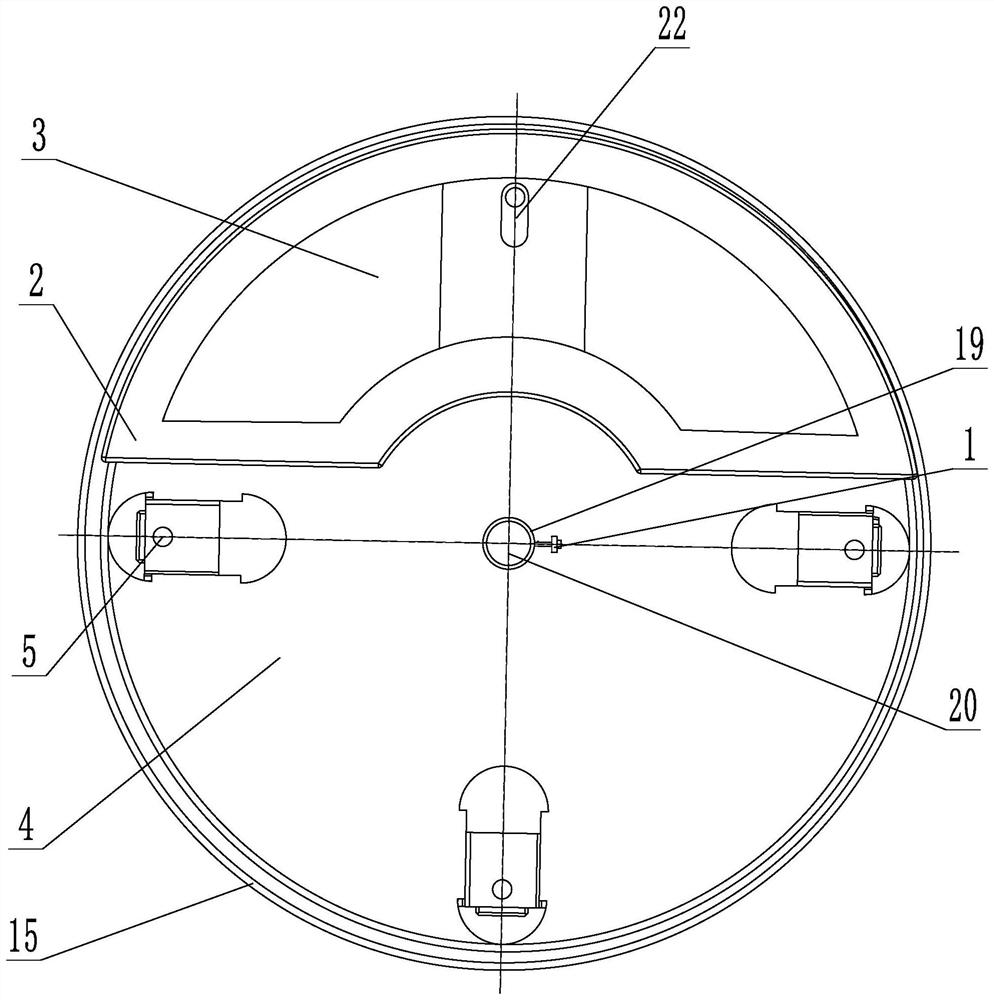

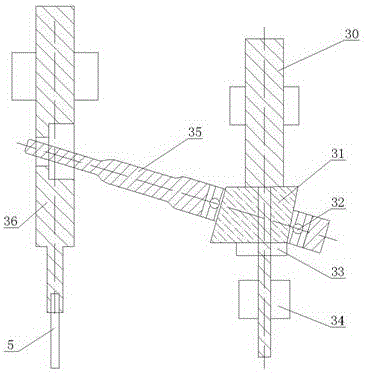

Processing device of internal keyway of tapered hole of large workpiece

InactiveCN103240460AImprove machining accuracyHigh precisionLarge fixed membersBroaching machinesHydraulic cylinderEngineering

The invention discloses a processing device of an internal keyway of a tapered hole of a large workpiece. The processing device comprises a guide rod, a broach sheet, rack guide rails, a fixture body, a locating pin, a locating rod, a worktop, a feed workbench, a coupling mechanism, a worm and gear, a hydraulic cylinder, a machine tool body, a hand feed device, a broach rod, a primary motion hydraulic cylinder, a fixing device and a bearing pedestal, wherein one end of the worktop used for placing and locating the workpiece is connected with the machine tool body by a fixed hinged support, and the upper end of the hydraulic cylinder is articulated with the other end of the worktop. The processing device can process the internal keyway of the tapered hole of the large workpiece, is simple in structure, convenient to mount and high in practicability, and has the characteristics that a small mechanism can process the large workpiece and the processing precision is high; and parts and components are high in standardization degree and universalization degree.

Owner:JIANGSU UNIV OF SCI & TECH

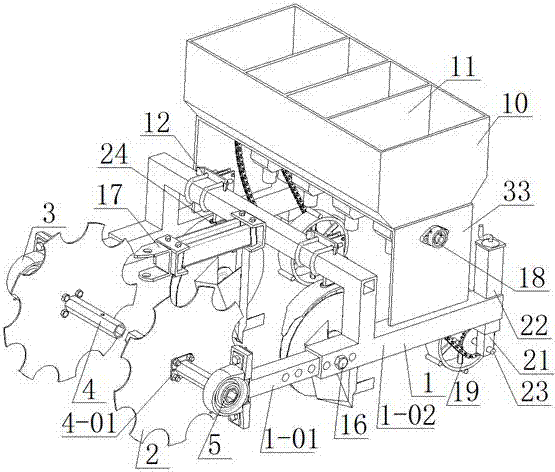

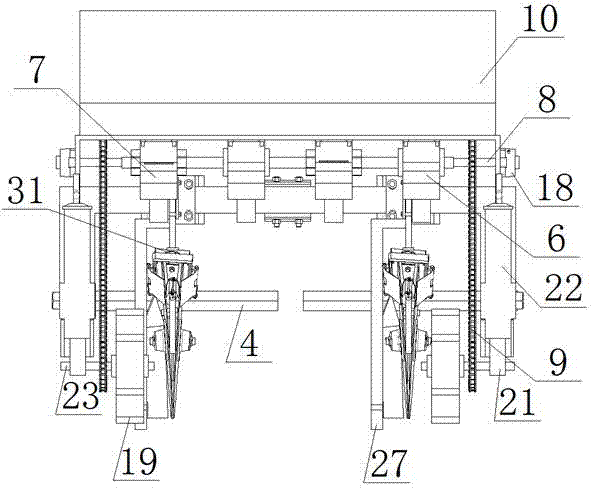

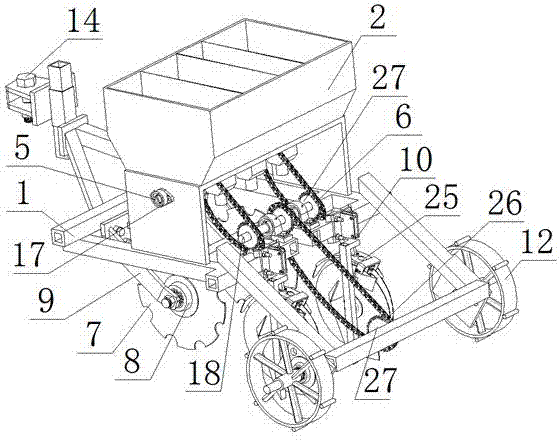

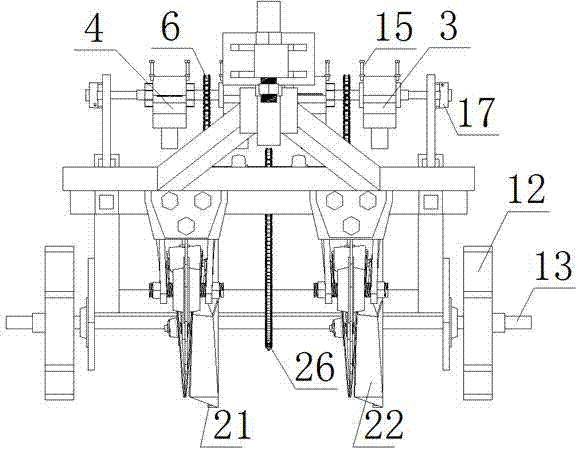

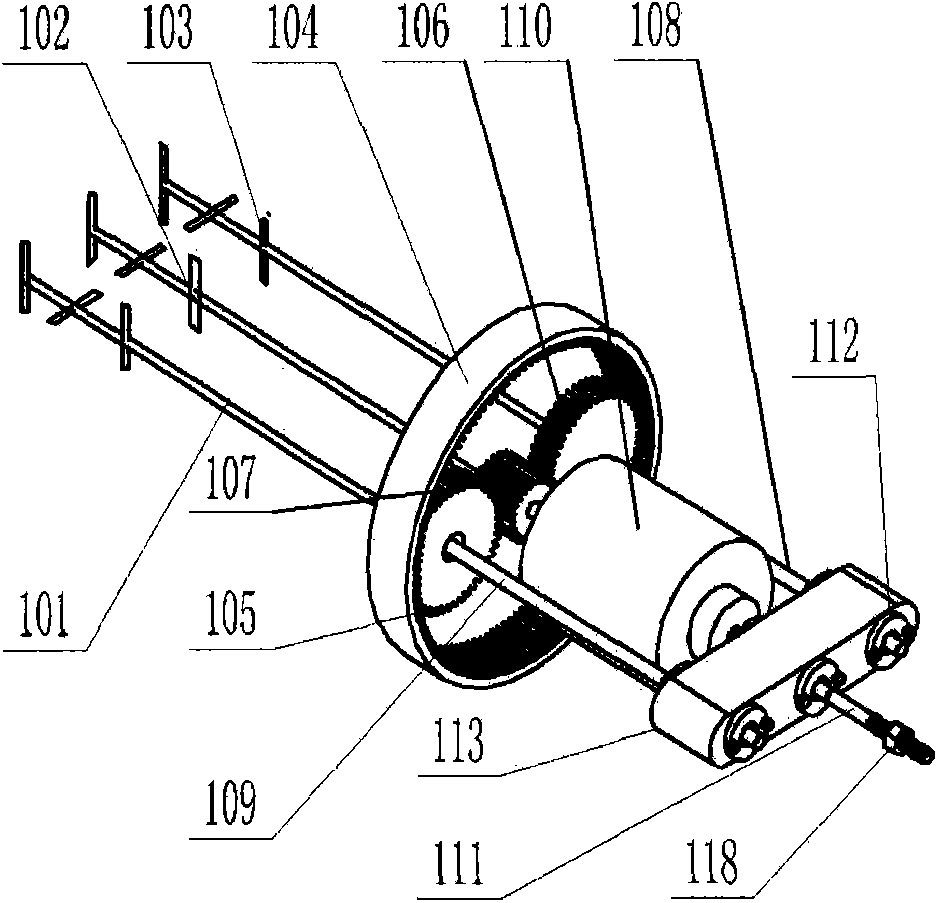

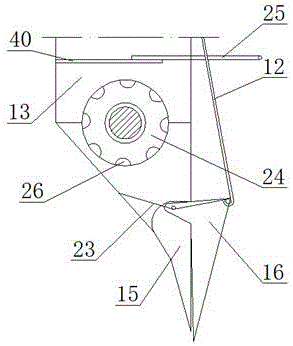

No-tillage seeder matching with micro-tiller

ActiveCN107027394AIncrease profitSimple structurePlantingAgriculture gas emission reductionAgricultural engineeringSprocket

The invention relates to a no-tillage seeder matching with a micro-tiller, and belongs to the field of agricultural machine design. The no-tillage seeder comprises a frame, notched discs, bearing seats I, hexagonal tubes, a shaft sleeve, seed sowing devices, fertilizer discharging devices, a seed sowing and fertilizer discharging driving mechanism, a seed sowing and fertilizer discharging transmitting mechanism, a seed and fertilizer box, U-shaped tube clamps, a sprocket wheel I, seed sowing and fertilizer discharging fixed bolts, seed sowing and fertilizer discharging connecting plates, bolts, a hook support, bearing seats II, land wheels, a rocking rod, lifting tubes, a connecting hollow tube, a connecting shaft, double-disc trench digging, seed sowing and fertilizer applying mechanisms, sprocket wheels II and a supporting rack, and every double-disc trench digging, seed sowing and fertilizer applying mechanism comprises a disc, a shovel handle, a fertilizer discharging tube, a protection plate, a baffle plate, a soil scraping plate, a seed sowing tube mouth, a cutterhead shaft, a seed sowing plate and a fixed seat. The no-tillage seeder has the advantages of simple structure, convenience in operation, increase of the utilization rate of fertilizers and land, reduction of the labor intensity, and strict meeting design requirements of agricultural machines.

Owner:KUNMING UNIV OF SCI & TECH

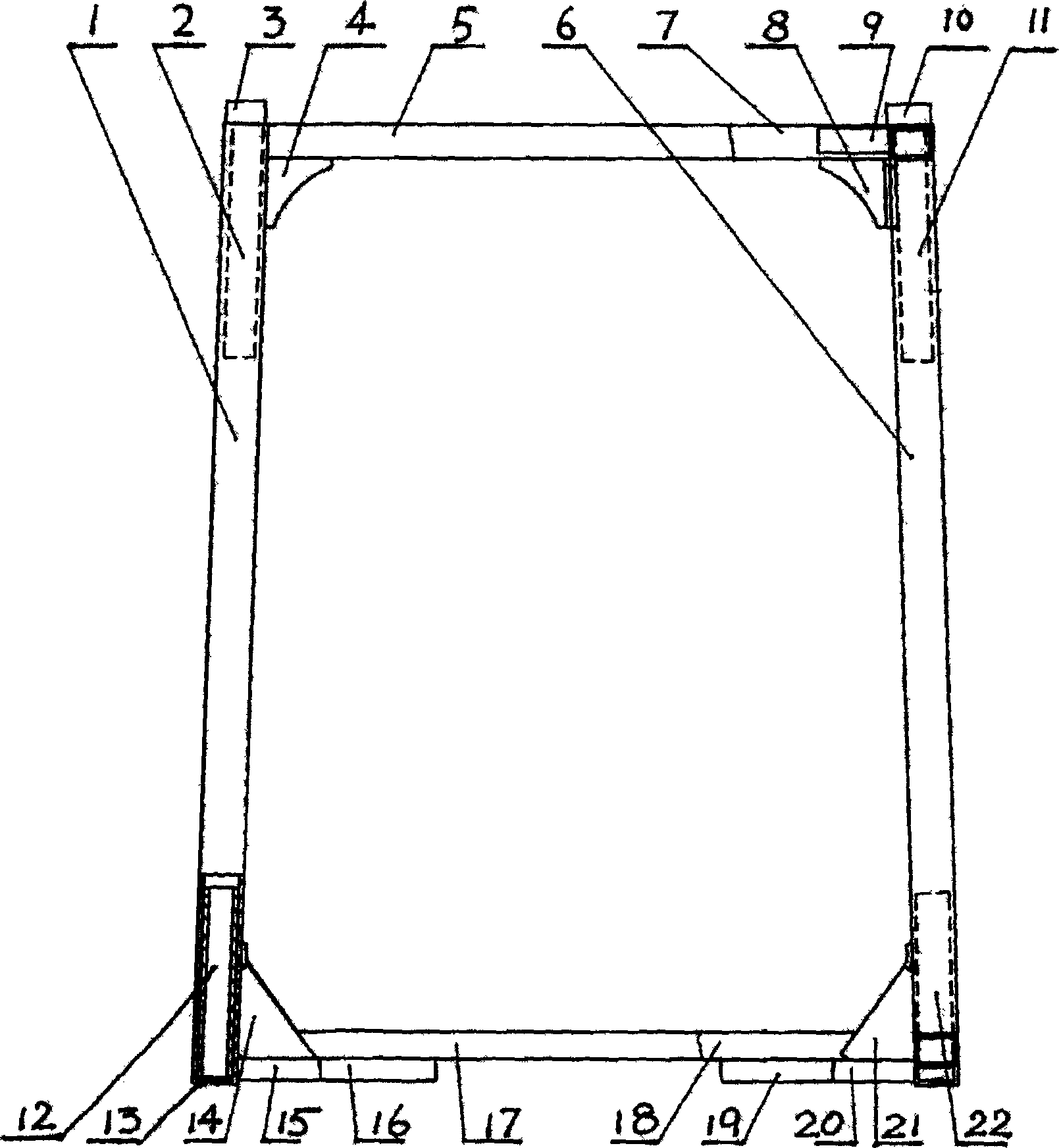

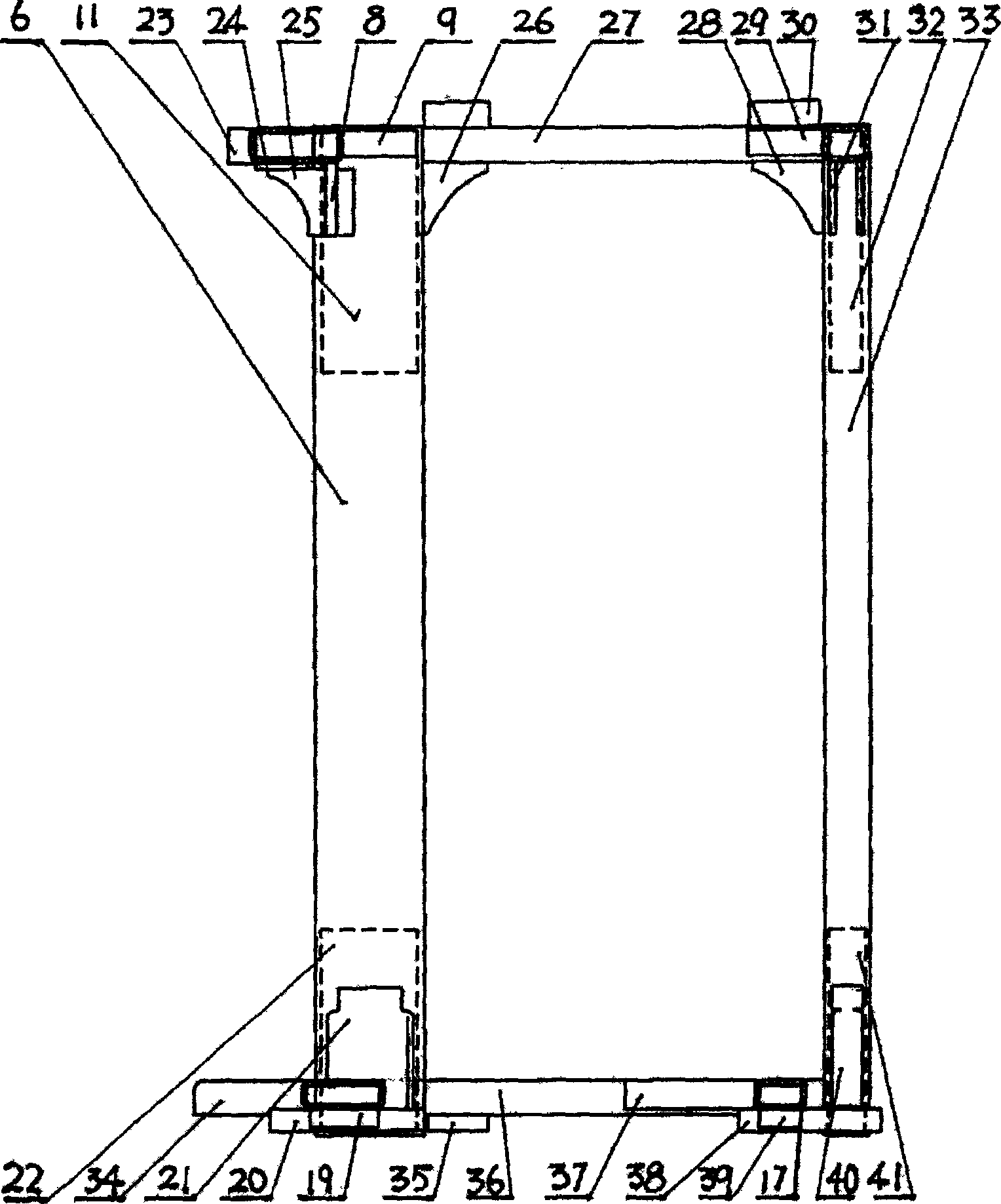

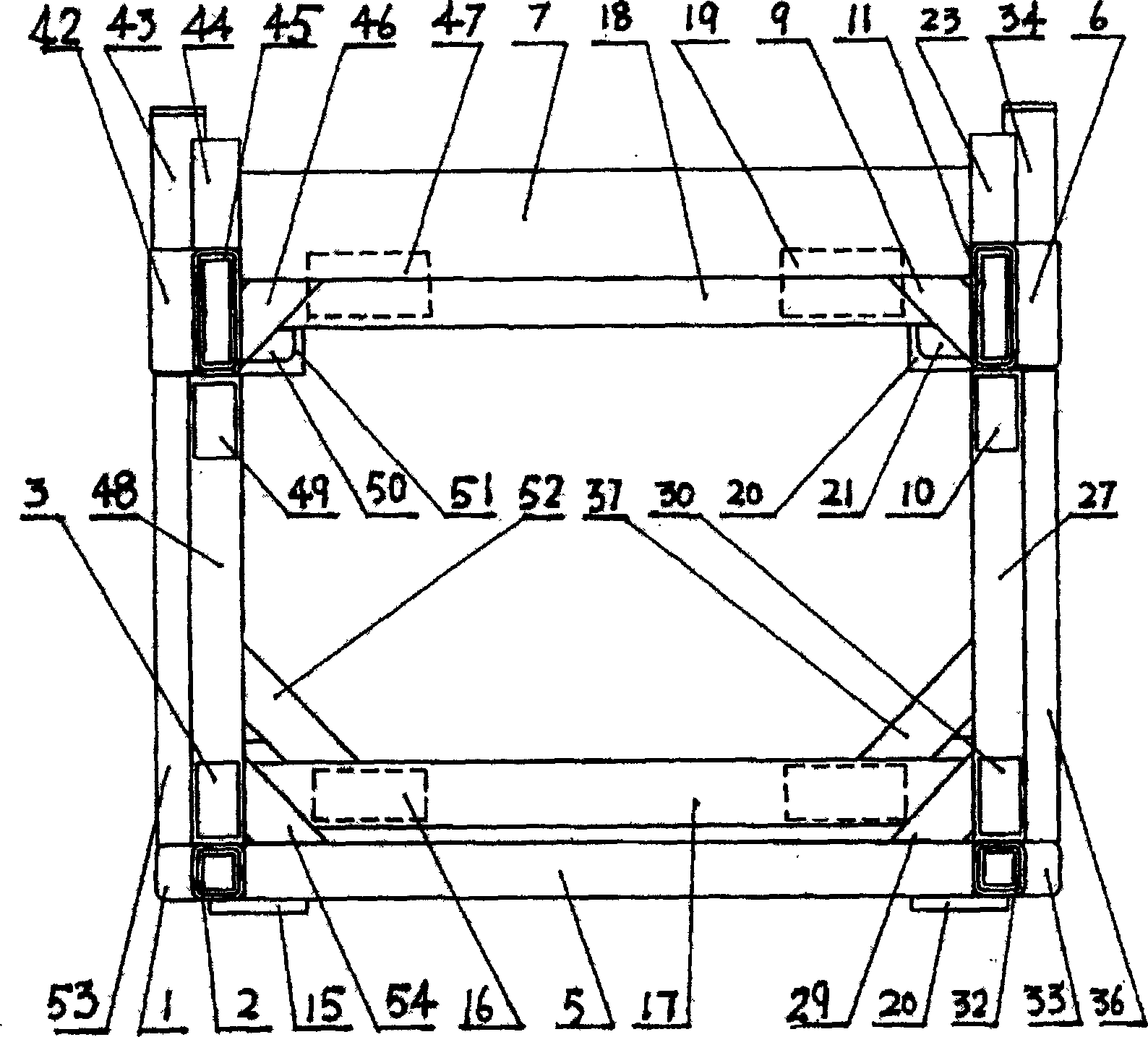

Machineshop truck driver's cab with reinforced turnover protection device

InactiveCN1775607AHigh degree of generalizationReduced Shock Concussion DamagePedestrian/occupant safety arrangementLoading-carrying vehicle superstructuresMachine shopEnergy absorption

The invention discloses a machine-shop truck cab with reinforced turnover protector, characterized in that the special structural positions of the cab framework are added with combined beams for raising plastic deforming force, i.e. the upper and lower ends of each of the front, rear, left and right pillars are added with combined beams, separately, changing the bearing force of the pillars, and making the invention have ROPS protector and able to largely improve the universal degree of machine-shop truck cab and as the vehicle turns over, the ROPS component can bear the impact force of the ground plane, assuring any part of the deformed ROPS and the ground plane do not enter in human body limit safety region and simultaneously the ROPS has a certain energy absorbing ability to reduce impact and vibration damage to the driver. The invention has the characters of simple structure and convenient application and use.

Owner:TIANJIN LIUGONG MACHINERY

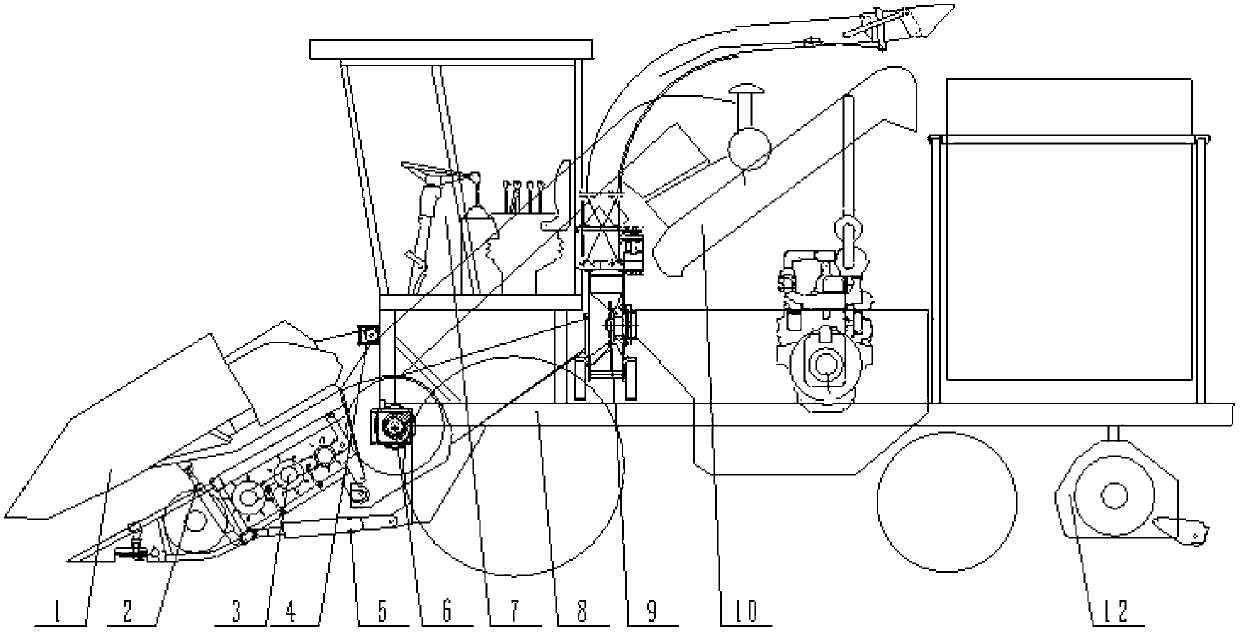

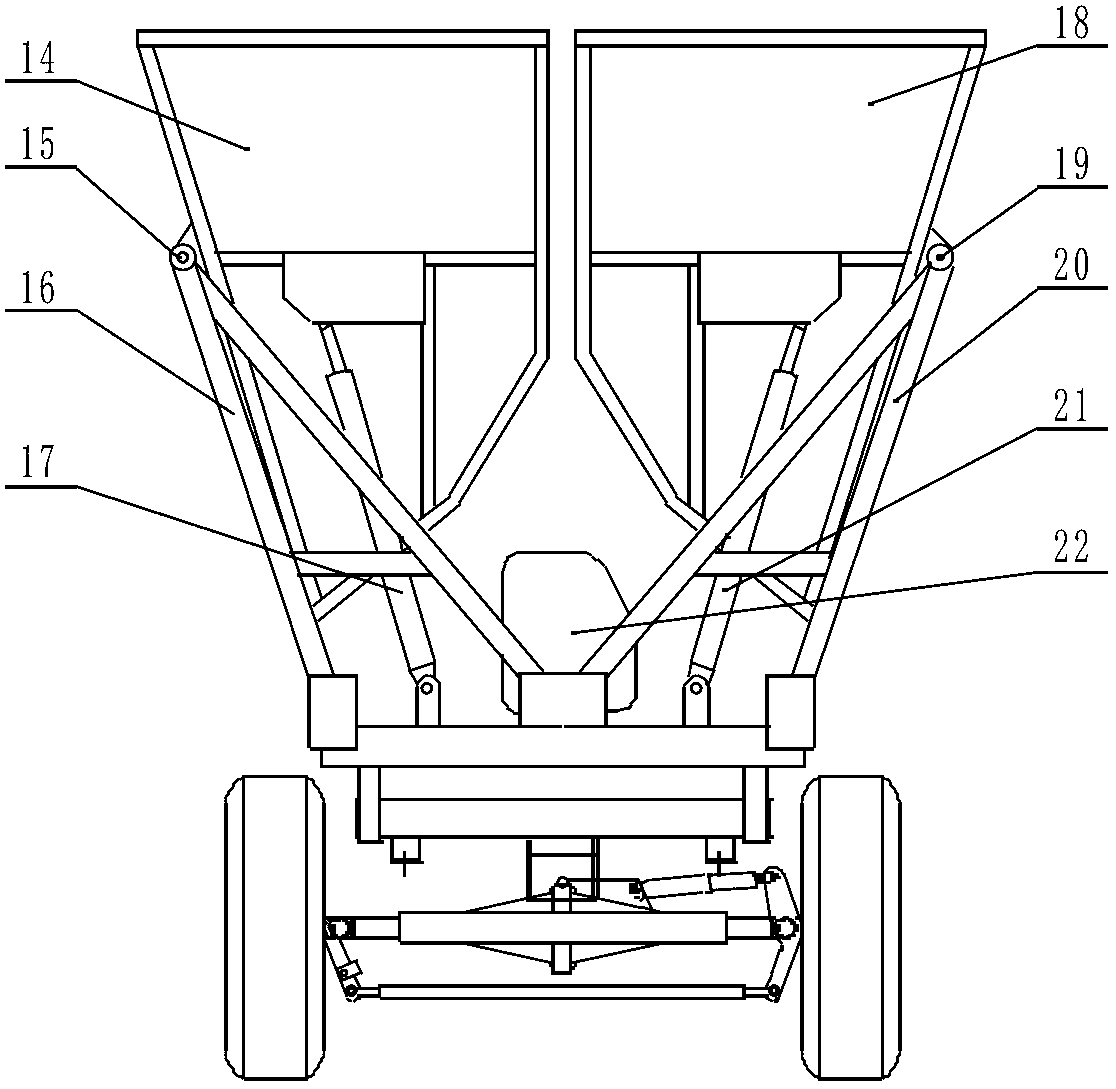

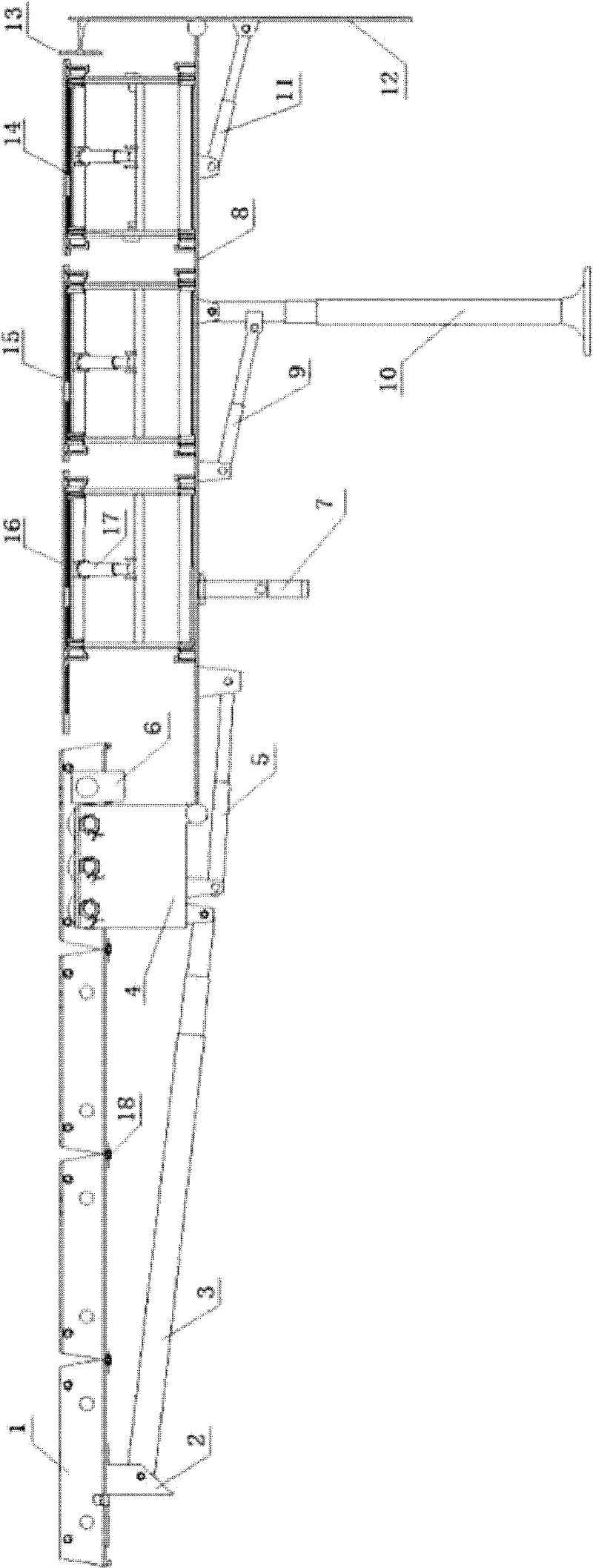

Small and medium size self-propelled corncob-stem both-gaining corn combine harvester

The invention discloses a small and medium size self-propelled corncob-stem both-gaining corn combine harvester which comprises a walking base disc. The walking base disc is provided with an upper layer header, a lower header, a drive cab, a fruit-corncob conveyer, an engine, a grass chamber, a crop chamber, an oil chamber, a dialing wheel assembly, a straw feeding device and a kicker. One end of the upper layer header is connected with an installing base of the upper layer header in a hanging mode. A lower end is connected with the lower layer header through an oil cylinder of the upper layer header. The lower layer header is located below the upper layer header. One end of the upper layer header is connected with an installing base of the lower layer header in a hanging mode. The lower end of the lower layer header is connected with the walking base disc through an oil cylinder of the upper layer header. The installing base of the lower layer header and the installing base of the upper layer header are respectively connected with the walking base disc. The dialing wheel assembly, the straw feeding device and the kicker are connected with the front portion of the walking base disc. The small and medium size self-propelled corncob-stem both-gaining corn combine harvester can be used for completing corn harvest in the field, corn straw cutting, chopping, collecting and stubble cleaning operations in one time. The small and medium size self-propelled corncob-stem both-gaining corn combine harvester can not only harvest corn corncobs and straws, but also avoid resource wasting and environment pollution brought from straw burning.

Owner:SHANDONG AGRI MACHINERY RES INST

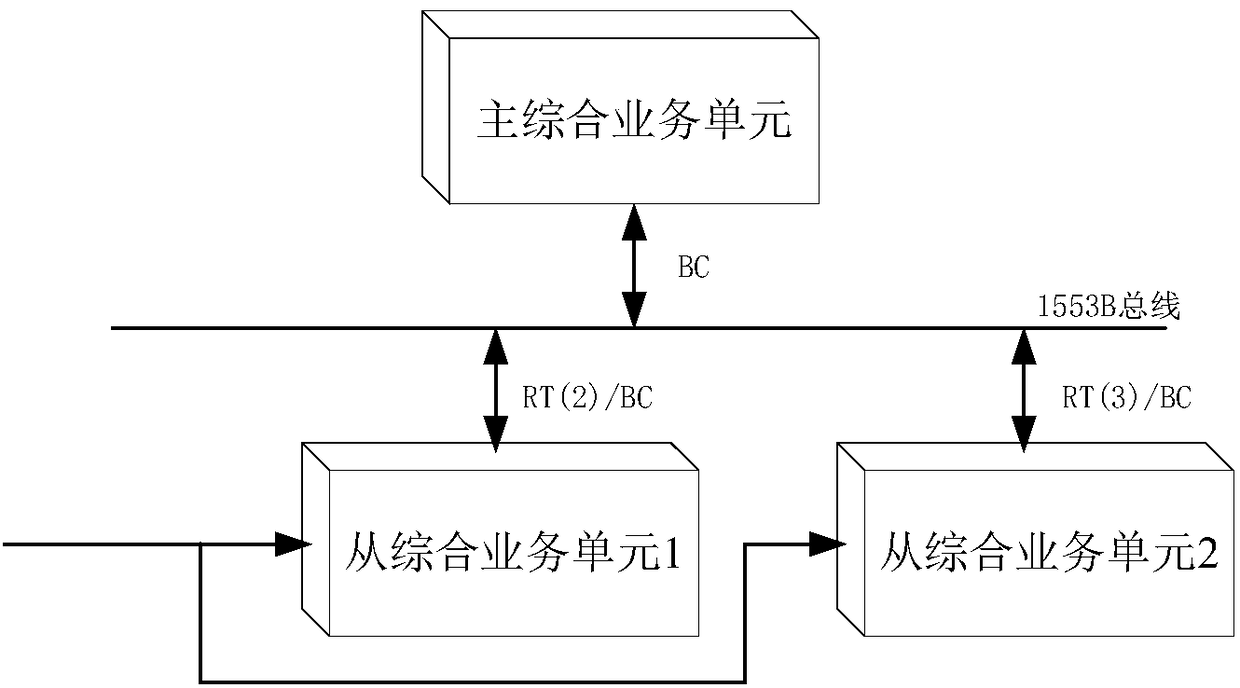

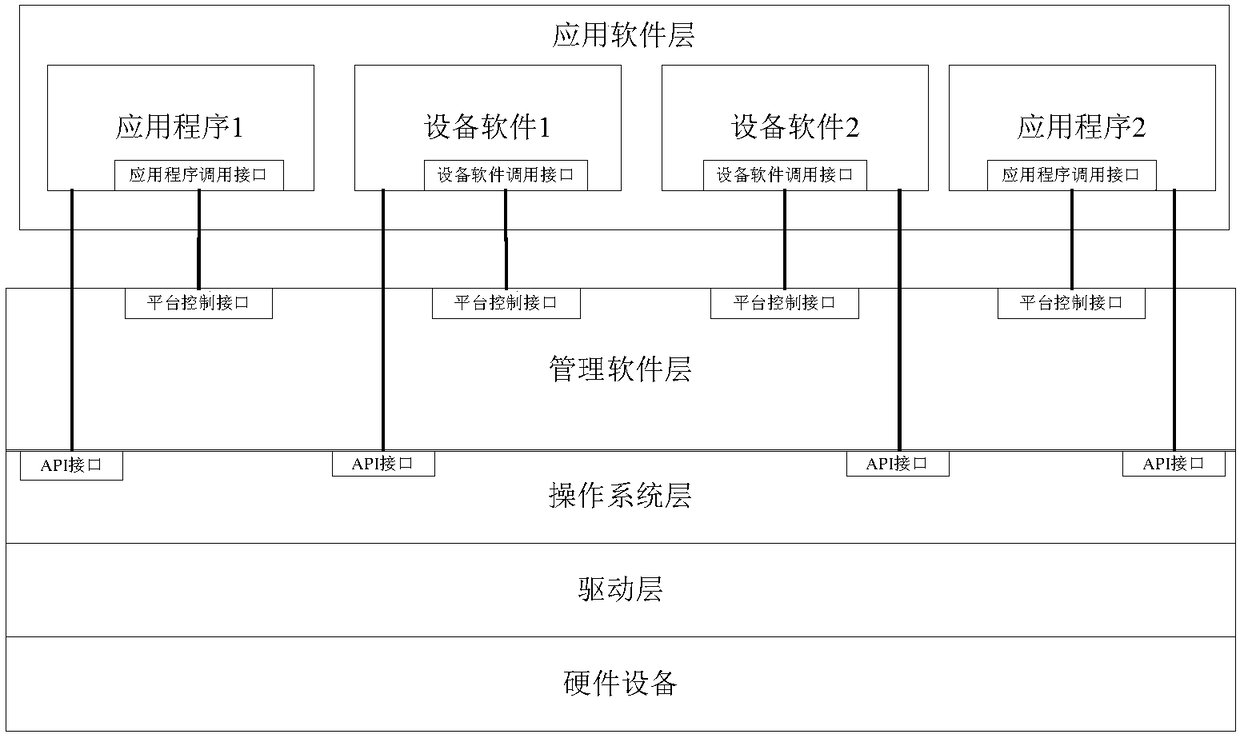

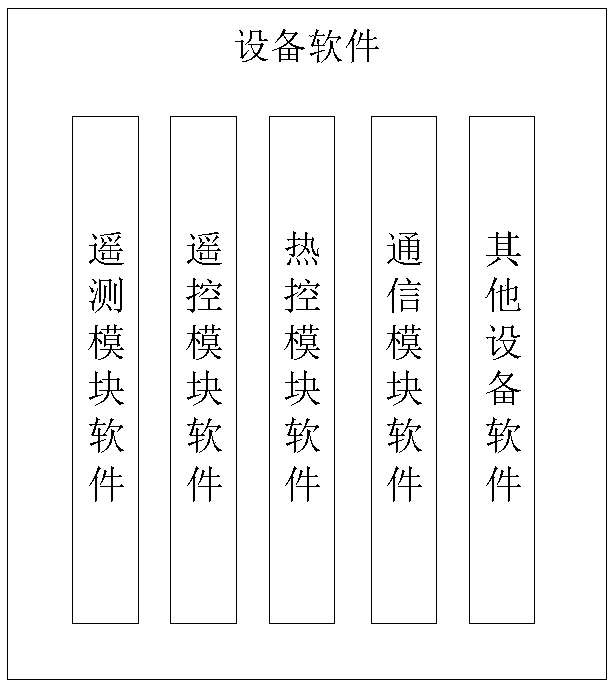

Reconfigurable satellite integrated electronic system

ActiveCN108199939AReduce wasteRapid refactoringRadio transmissionHigh level techniquesElectronic systemsBus mastering

The invention discloses a reconfigurable satellite integrated electronic system, which can realize fast reconfiguration of the system, improves fault-tolerant capability of the system, reduces power consumption and weight of the whole satellite and reduces waste of calculating resources. The system comprises more than two integrated service units and a 1553B bus. The more than two integrated service units are connected through the 1553B bus; one of the integrated service units serves as a bus controller BC of the 1553B bus, and the other integrated service units serve as remote terminals RT ofthe 1553B bus. The BC is configured to execute an integrated control task of on-satellite in-orbit data; one RT is configured to execute one on-satellite independent electronic function task; and when the current BC fails, one RT is switched to a new BC of the 1553B bus, and the new BC executes the integrated control task of the on-satellite in-orbit data.

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH

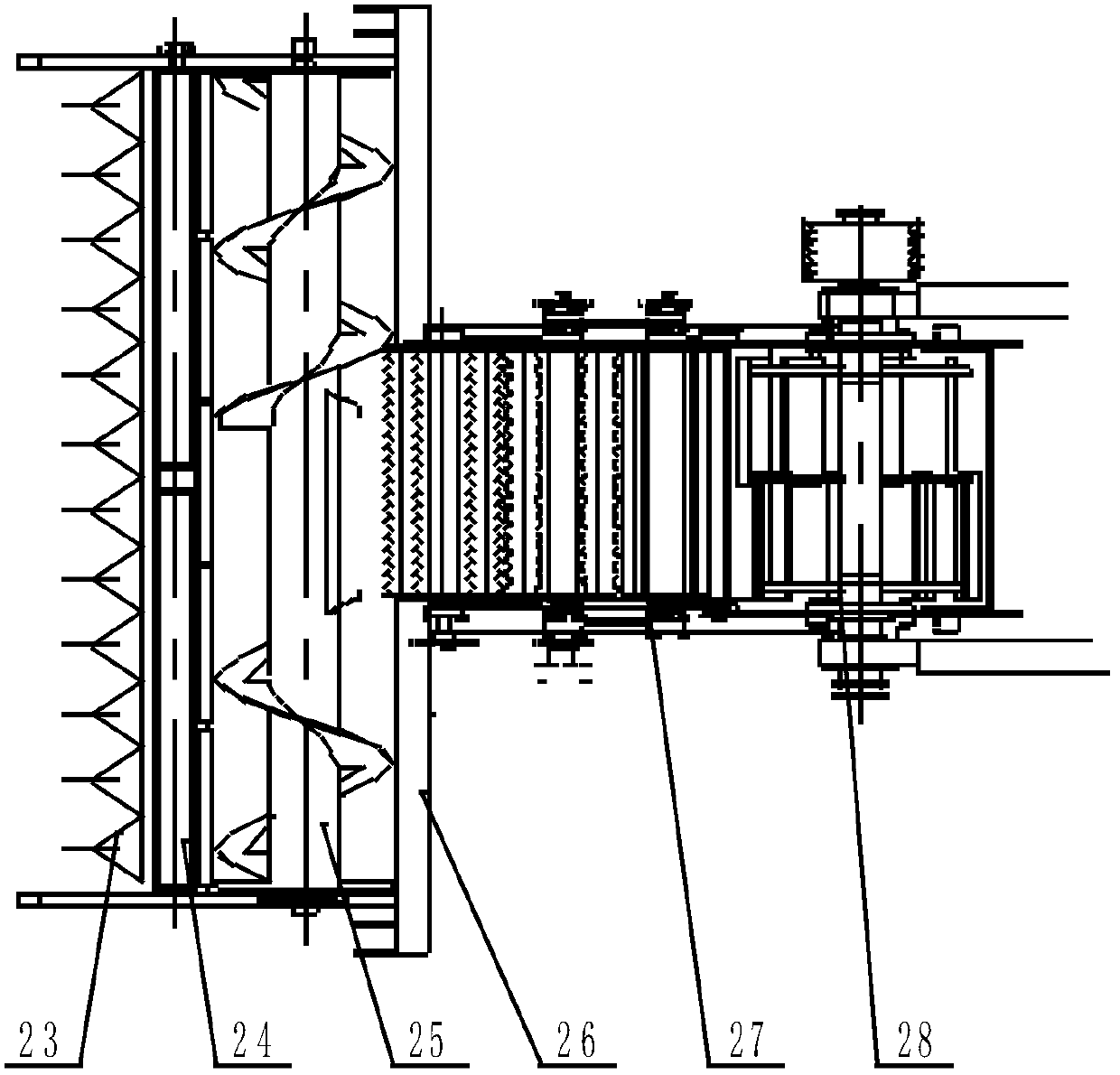

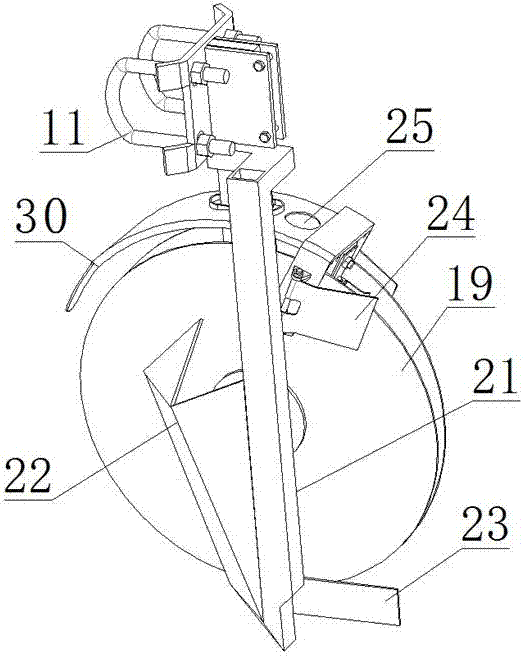

Corn sowing and fertilization machine

InactiveCN107046877AImprove the level of farmingSolve the problem of deep fertilizationFertiliser and seeding apparatusCircular discAgricultural engineering

The invention relates to a corn sowing and fertilization machine, and belongs to the field of agricultural machinery design. The corn sowing and fertilization machine comprises a rack, a seed and fertilizer box, seed sowing devices, fertilization devices, a seed sowing and fertilization driving mechanism, a seed sowing and fertilization transmission mechanism, a notched disk, bearing seats I, a bracket, a double-disk furrowing sowing and fertilization mechanism, a U-shaped pipe clip, land wheels, a land wheel driving mechanism, a connecting pin, a seed sowing and fertilization fixing bolt, a seed sowing and fertilization connecting plate, bearing seats II, a chain-driving transmission middle-end driving mechanism and a wheel-driving transmission mechanism, wherein the double-disk furrowing sowing and fertilization mechanism comprises a disk, a shovel handle, a fertilization pipe, a protection plate, a baffle, a soil scraping plate, a pipe opening of a seed sowing pipe, a cutterhead shaft, a seed sowing plate and a fixed seat. By adopting the corn sowing and fertilization machine, manual dibbling is replaced, and the level of a corn planting industry is improved; straws which cause blocking can be separated, and distances between seeds and chemical fertilizer can keep 3cm or more, so that the problem of difficultly realizing deep fertilization for sowing narrow-row crops in a cultivation process is effectively solved.

Owner:KUNMING UNIV OF SCI & TECH

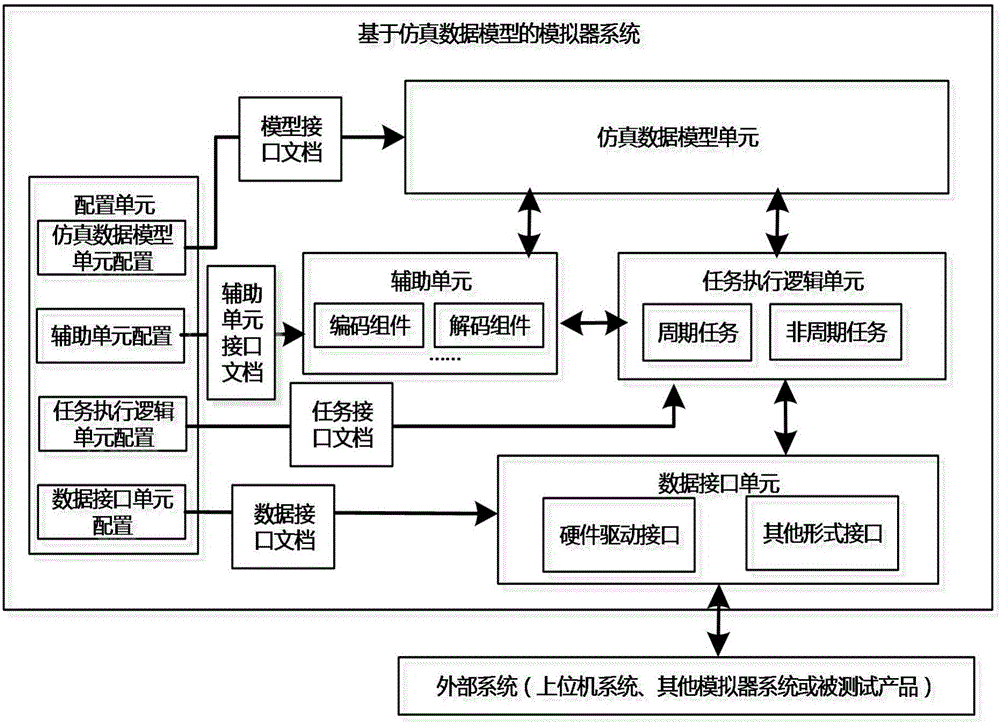

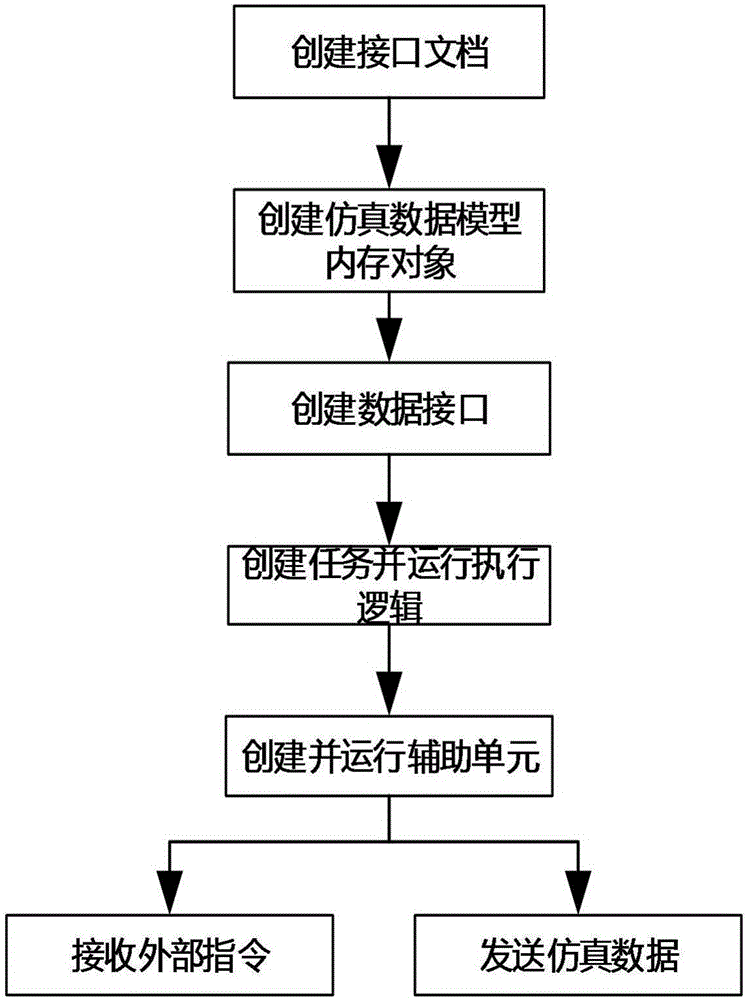

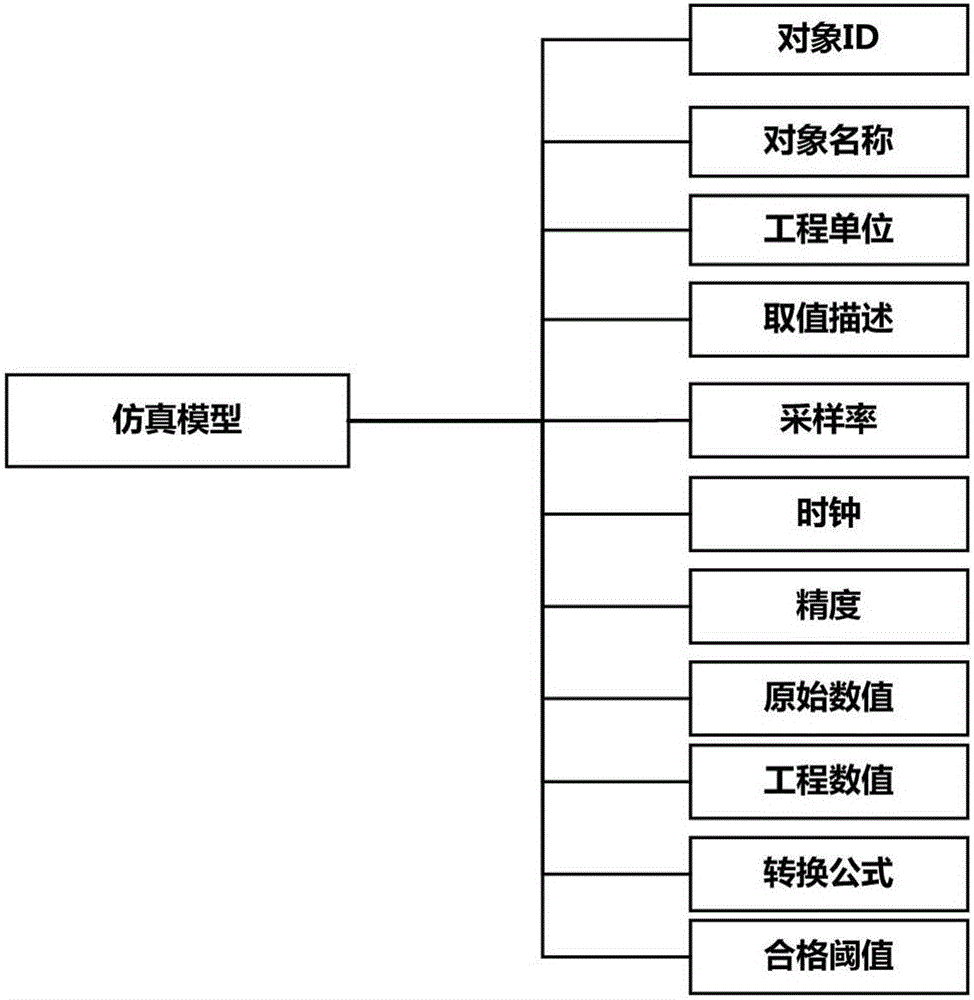

Simulator system and method based on simulation data model

ActiveCN106250308AHigh degree of standardizationHigh degree of generalizationSoftware testing/debuggingData sourceMemory object

The invention discloses a simulator system based on a simulation data model. The simulator system comprises a configuration unit, a simulation data model unit, a task execution logical unit, a data interface unit and an auxiliary unit. The invention further discloses a method for implementing the system. The method comprises the steps of creating an interface document, creating a simulation data model memory object, creating and connecting a data source, creating tasks and operating execution logic, crating and operating the auxiliary unit, receiving an external instruction and sending simulation data and the like. Through the interface document and the execution logic, the requirements of various simulation service logics can be met; and through the data interface unit, multi-type data interfaces (including a hardware driving interface and interfaces of other forms) can be matched. The standardization and universalization degree of a simulator are greatly improved, risks caused by service alterations are reduced, and users' investments are protected.

Owner:北京赛博智通信息技术有限责任公司

Suspension type driftage temporary supporting device and use method thereof

The invention discloses a suspension type driftage temporary supporting device and a use method thereof. The device comprises an I-shaped steel suspending beam, a supporting platform, a lifting platform, a moving frame and a plurality of hydraulic cylinders. The components are used for realizing the quick and continuous driftage, reducing the sinking and layering of a top tray, reducing the accidents of head-on roof caving and deviation, and reducing the labor intensity.

Owner:ANHUI UNIV OF SCI & TECH

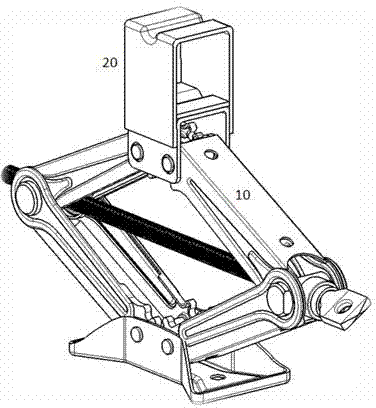

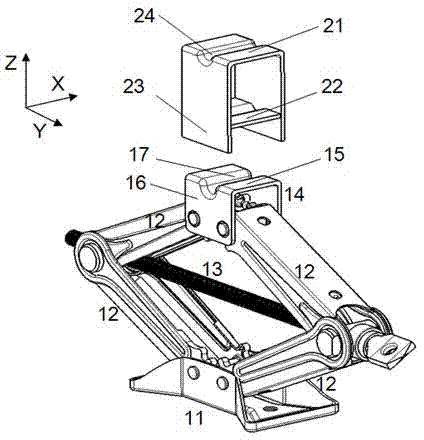

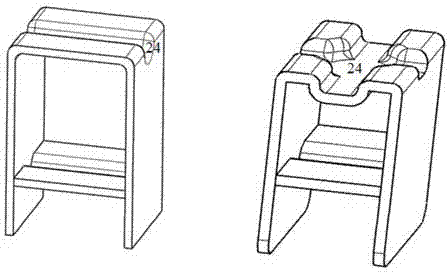

Automobile jack and lifting method thereof

ActiveCN103693580AHigh degree of generalizationMeet the lifting height requirementsLifting devicesAutomotive engineering

Owner:CHERY AUTOMOBILE CO LTD

Pot cover structure

InactiveCN103610396AReduce in quantityHigh degree of generalizationCooking-vessel lids/coversEngineeringMechanical engineering

The invention discloses a pot cover structure, and belongs to the technical field of cooking utensils. The pot cover structure comprises a pot cover body and a handle body. The pot cover structure is characterized in that the central position of one upward side of the pot cover body is provided with a concave cavity, wherein a pot cover lifting plate is arranged in the concave cavity, the pot cover lifting plate is provided with a pair of connecting seat matching cavities, the space between the pot cover lifting plate and the bottom wall of the concave cavity forms a clamping jaw moving and rising cavity, and a lifting plate fixing column is arranged at the middle position of a partition plate of the matching cavities and on the side facing the bottom wall of the concave cavity; a pot cover clamping and releasing mechanism connecting seat is arranged at one end of the handle body, wherein the central position of the pot cover clamping and releasing mechanism connecting seat is provided with a latch hook seat cavity, a pot cover clamping and releasing mechanism is arranged in the latch hook seat cavity, the pot cover clamping and releasing mechanism connecting seat is provided with a pair of buttons in a matched mode, and the buttons are distributed in a face-to-face state and extend into the latch hook seat cavity to be matched with the pot cover clamping and releasing mechanism. According to the pot cover structure, the number of handle bodies is reduced, resources are saved, and the pot cover structure is convenient to use and store in a standby state.

Owner:CHANGSHU KASMAIN

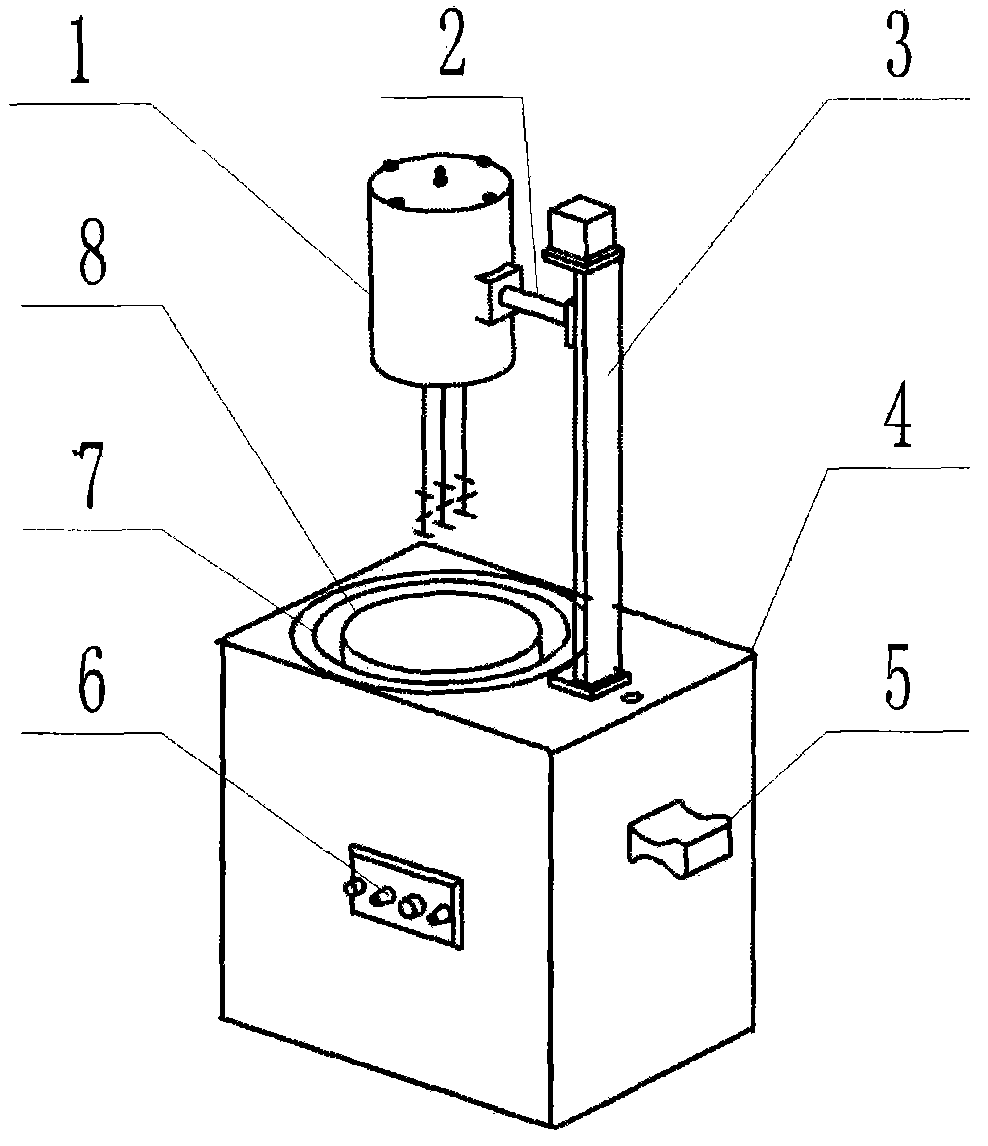

Ultrasonic temperature-controlled reinforced mixer

InactiveCN103623734AWith emulsificationWith decentralizationShaking/oscillating/vibrating mixersMixer accessoriesMicrocontrollerInterference fit

The invention provides a reinforced mixer with ultrasonic dispersion and temperature control functions. The mixer mainly comprises a planetary gear stirring mechanism, a lead screw sliding table, a case mechanism, an inner container, a heating ring, an ultrasonic vibration head, a beaker, a temperature sensor, a one-chip microcomputer and a control panel. An inner gearing big gear wheel of the planetary gear stirring mechanism is connected with a sleeve to form one body through interference fit; a revolution fixing mechanism controls stable rotation of a planetary gear; a driving motor drives running of a planetary gear train to realize a stirring function; a screw joint at the end part of a fixed axle balances torque of the planetary gear train, and the screw joint and a butt nut bear the weight of the planetary gear train and the stirring mechanism together. The side surface of the sleeve is provided with a fixed rod connected with a slide block of the lead screw sliding table; a stepping motor controls rotation of a lead screw so as to realize elevation and falling of the stirring mechanism; the inner container is embedded into the upper surface of a case, the ultrasonic vibration head is adhered on the lower transverse plane of the inner container, and the heating ring is fixed at the lower end of the inner container, thereby achieving heating, ultrasonic dispersion and mechanical reinforced stirring functions.

Owner:ANYANG INST OF TECH

Stem block plant smashing device

The invention discloses a stem block plant smashing device. The stem block plant smashing device comprises a motor for providing power and a machine body, wherein the motor drives a main shaft to move through a belt transmission device, and one end of the main shaft is sleeved with a moving tooth disc; a hammer is sleeved on the moving tooth disc, a rotating screen drum is arranged outside the hammer, and a coarse screen drum is arranged between the rotating screen drum and the hammer; a fine screen drum with a taper is arranged outside the rotating drum; one end of the fine screen drum is fixed on the machine body, and the other end of the fine screen drum is fixed on a fixed tooth disc; the disc surface of the moving tooth disc is provided with spike teeth; spike teeth meshed with the moving tooth disc in a staggered way are arranged on the fixed tooth disc; the moving tooth disc is connected with a cutter bar through a clamp device; and the cutter bar is provided with a first tool and a second tool in the sequence from outside to inside. The stem block plant smashing device provided by the invention has the advantages that the smashing for a stem block plant is divided into four stages, the use ratio of the stem block plant is greatly improved through ultrafine processing in four stages, more amylum in the equal stem block is extracted, resources are saved, and the stem block plant smashing device has popularization and application values.

Owner:JIANGSU UNIV OF SCI & TECH

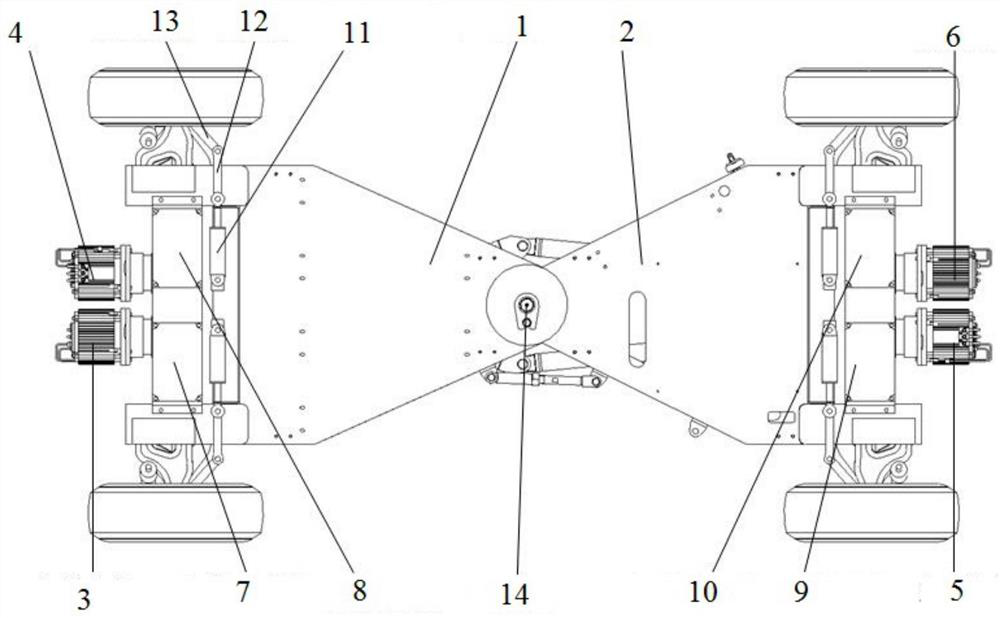

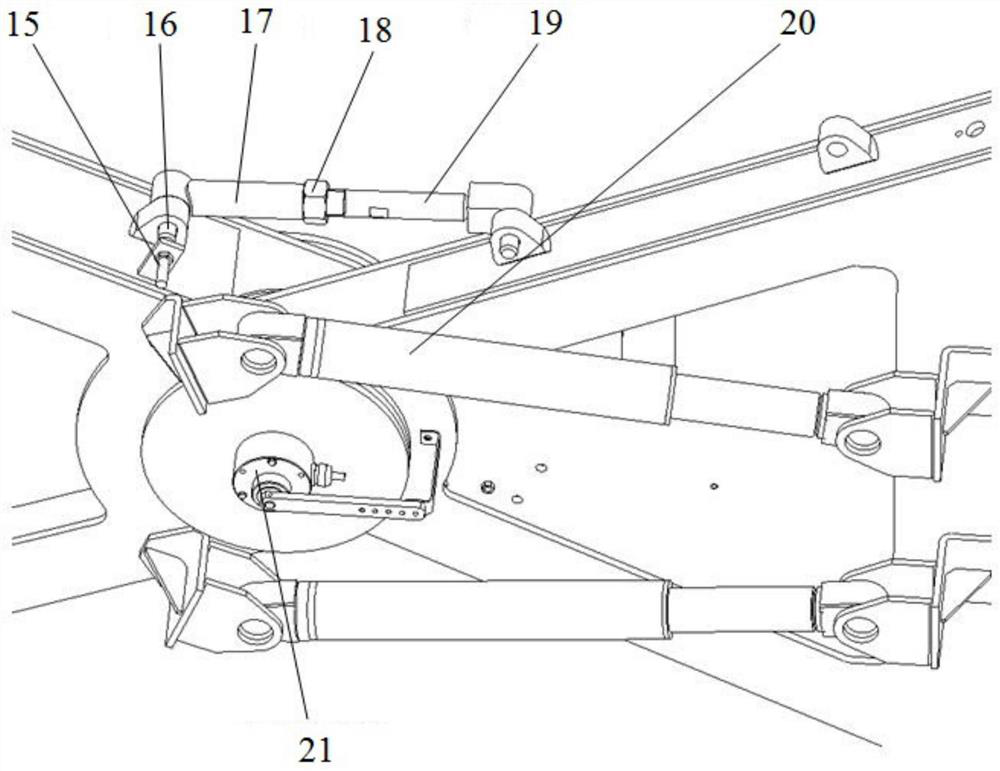

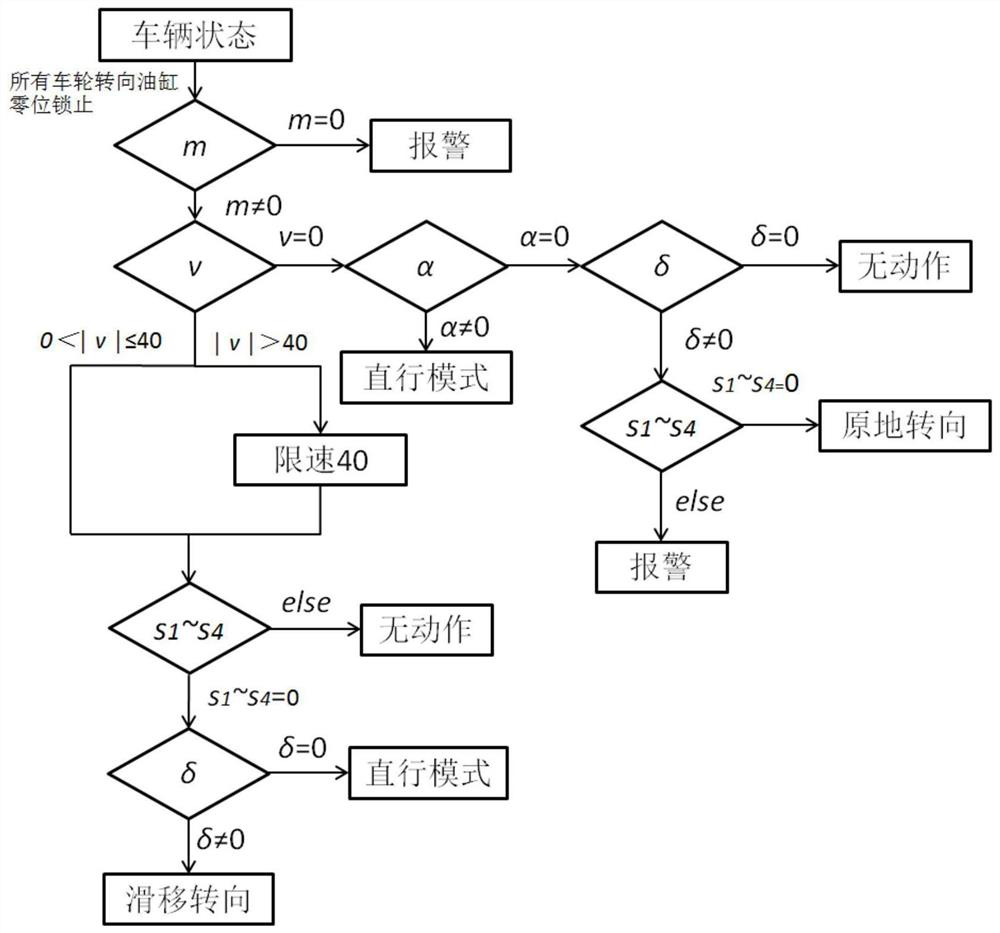

Multi-mode composite steering chassis and engineering machinery vehicle

ActiveCN111845931AImprove steering performanceImprove passabilityFluid steeringDeflectable wheel steeringVehicle frameControl theory

The invention discloses a multi-mode composite steering chassis and an engineering machinery vehicle. The multi-mode composite steering chassis comprises a front vehicle frame, a rear vehicle frame, aplurality of wheels arranged on the front vehicle frame and the rear vehicle frame respectively, driving devices corresponding to the wheels, wheel steering devices corresponding to the wheels, and avehicle control unit. The multi-mode composite steering chassis has the advantages that high-speed and low-speed driving and various steering modes can be achieved, the universalization degree is high, the modular design is achieved, the design period of new products can be shortened to a certain extent, and the purchasing cost is reduced; a manual mode and an automatic mode are adopted to selecta steering mode so that a smaller turning radius at a low rotating speed and the steering running stability of the vehicle at a high rotating speed can be realized, and the steering capacity and thepassing capacity of the vehicle are improved; and meanwhile, mechanical limiting and sensor signal acquisition are added so that the driving safety is improved.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

Seeding quantity adjustment and seeding grain distance adjustment dual-adjustment combined seed-metering device

PendingCN114175895ANovel structureAdaptableSeed depositing seeder partsAgricultural engineeringControl theory

The invention discloses a double-adjustment combined seed-metering device for adjusting the seeding quantity and the seeding grain distance, and belongs to agricultural machinery. A supporting plate, an upper disc, an arc-shaped seed box and a seed box limiting cover cylinder are sequentially assembled in an annular frame from bottom to top in a supported mode through rollers, a track disc is fixedly installed on the lower end face of the supporting plate through bolts, a seeding quantity adjusting knob is inserted in the center of the upper disc and the center of the supporting plate, and a grain distance adjusting knob is inserted in the center of the seeding quantity adjusting knob. A grain distance adjusting disc fixedly installed at the lower end of a grain distance adjusting knob is hinged to a lower seed containing pipe through a connecting rod, an upper seed containing pipe and the lower seed containing pipe are assembled on an upper disc and a supporting plate respectively in a radial moving mode, the upper seed containing pipe is inserted into the lower seed containing pipe in a vertically moving mode, and a power frame is arranged on the lower portion of a track disc. A power output shaft of the bevel gear transmission box is fixedly mounted with the power frame; according to the device, the seeding quantity and the seeding grain distance can be adjusted on one seed-metering device, and the device is unique and reasonable in structure, wide in application range, high in adaptability and simple and convenient to adjust and operate.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

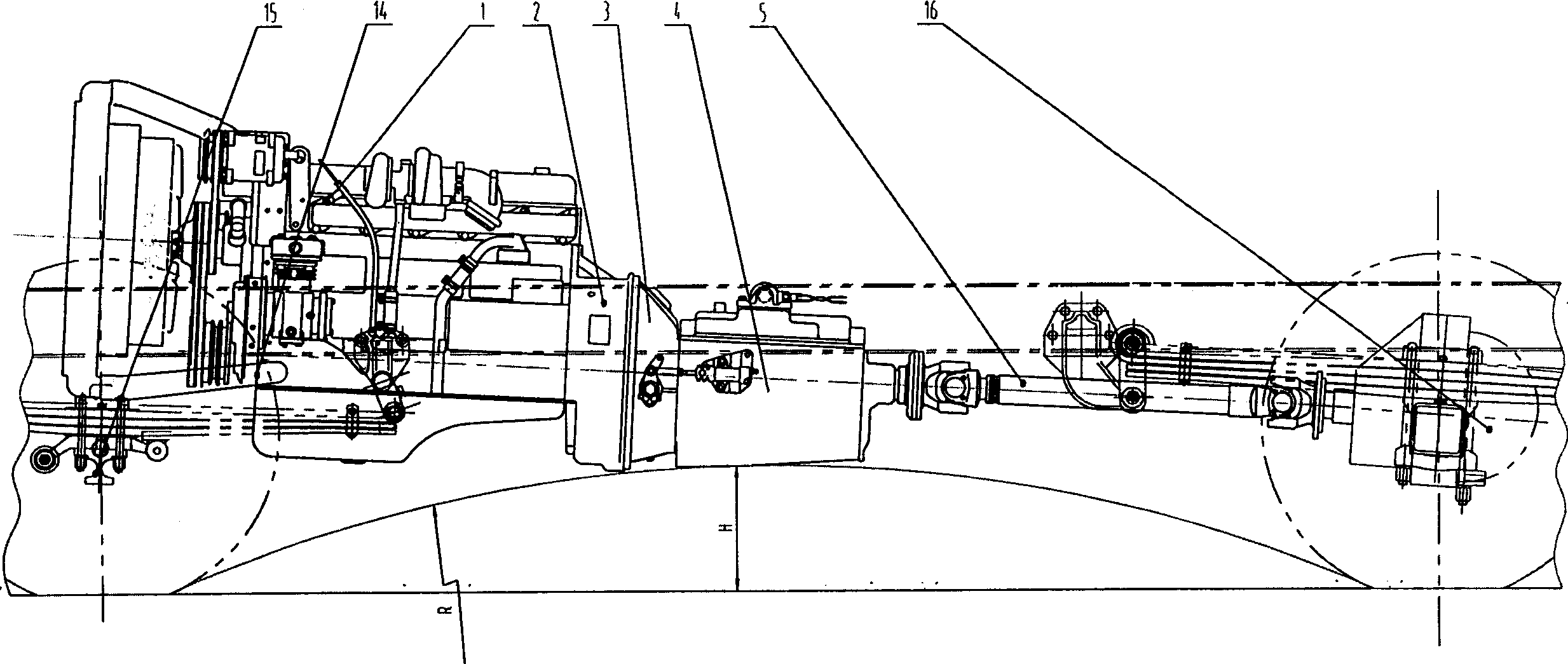

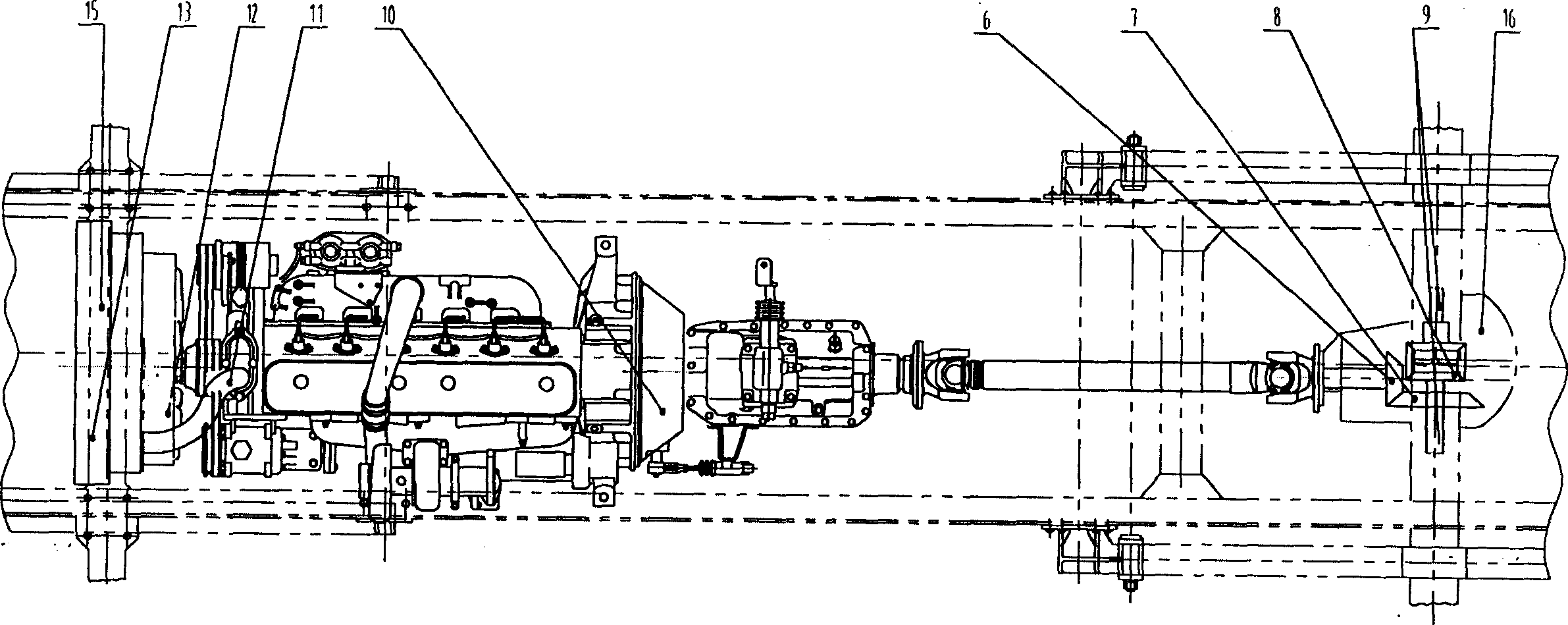

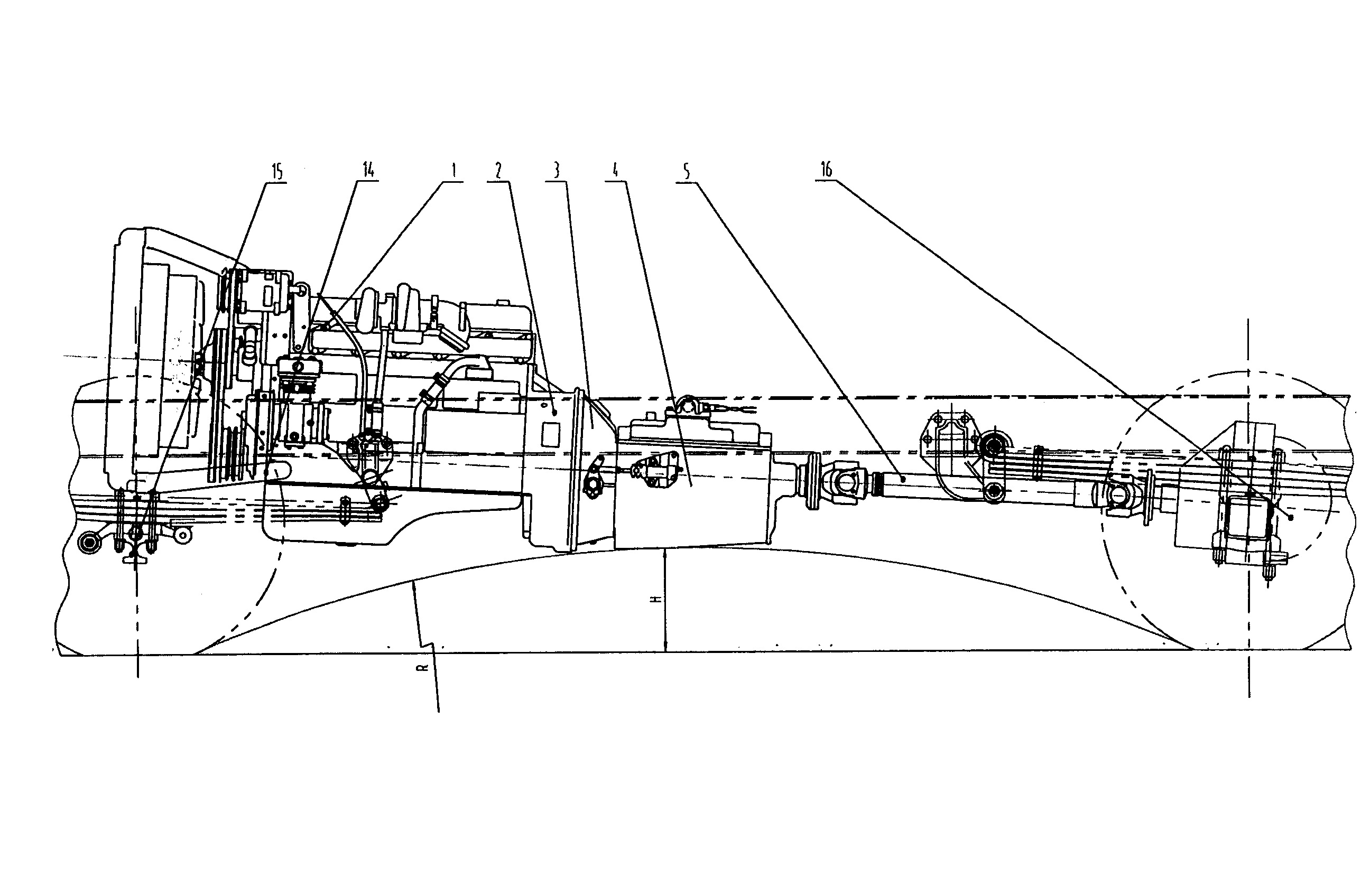

Arrangement for fixing engine with front air cooling of passenger car in middle position

A method for arranging the engine at the position behind the middle bridge of coach and using the front air inflow to cool the engine is disclosed. The engine is connected to the shell of clutch. The power of engine is transmitted to the drive shaft via clutch and the output shaft of speed variator and in turn to the wheels on back bridge via input flange, drive gear, driven gear, differential gear and semi-axle. Its advantages are flat floor, low noise and easy maintenance.

Owner:ZHENGZHOU YUTONG BUS CO LTD

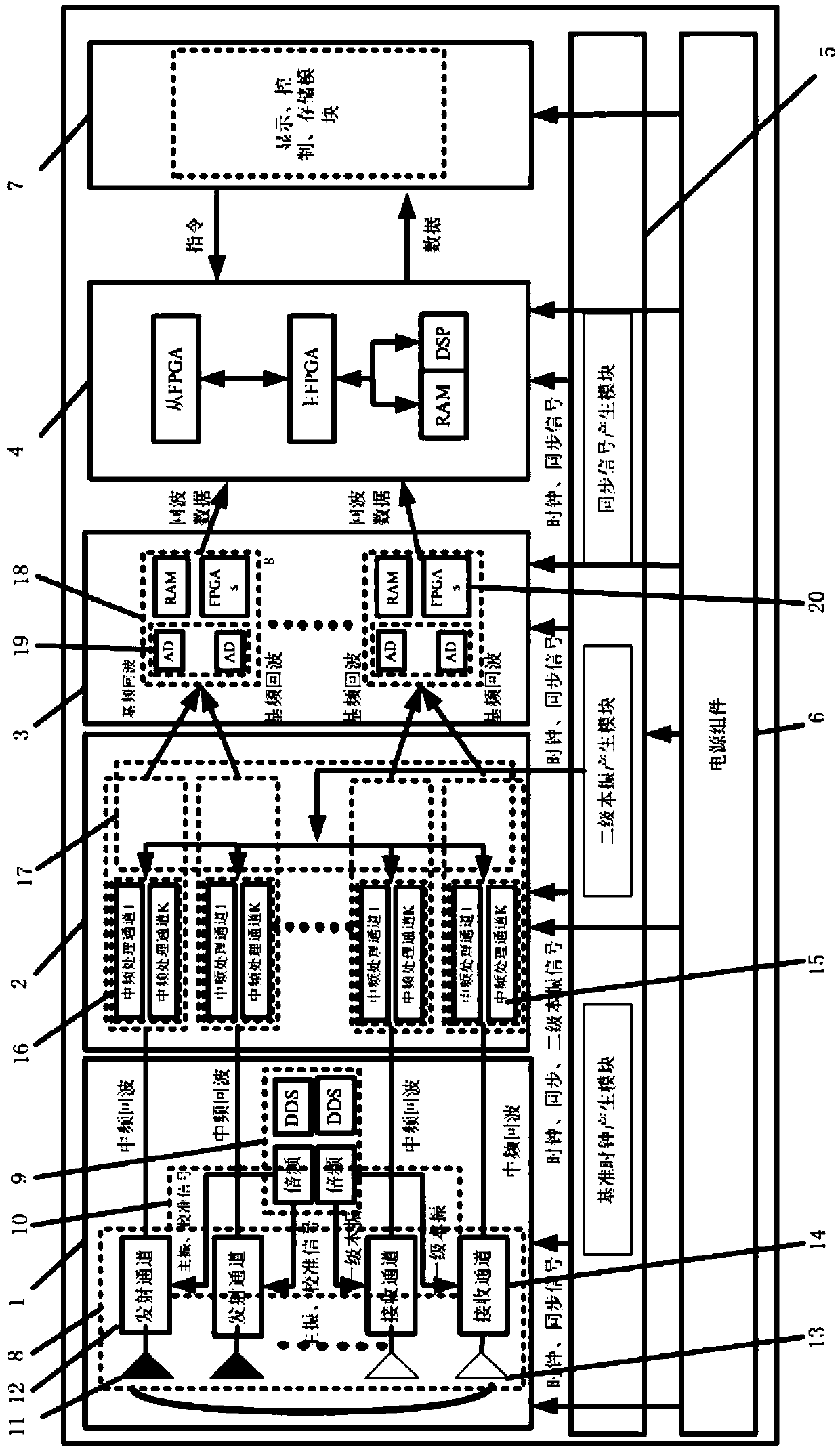

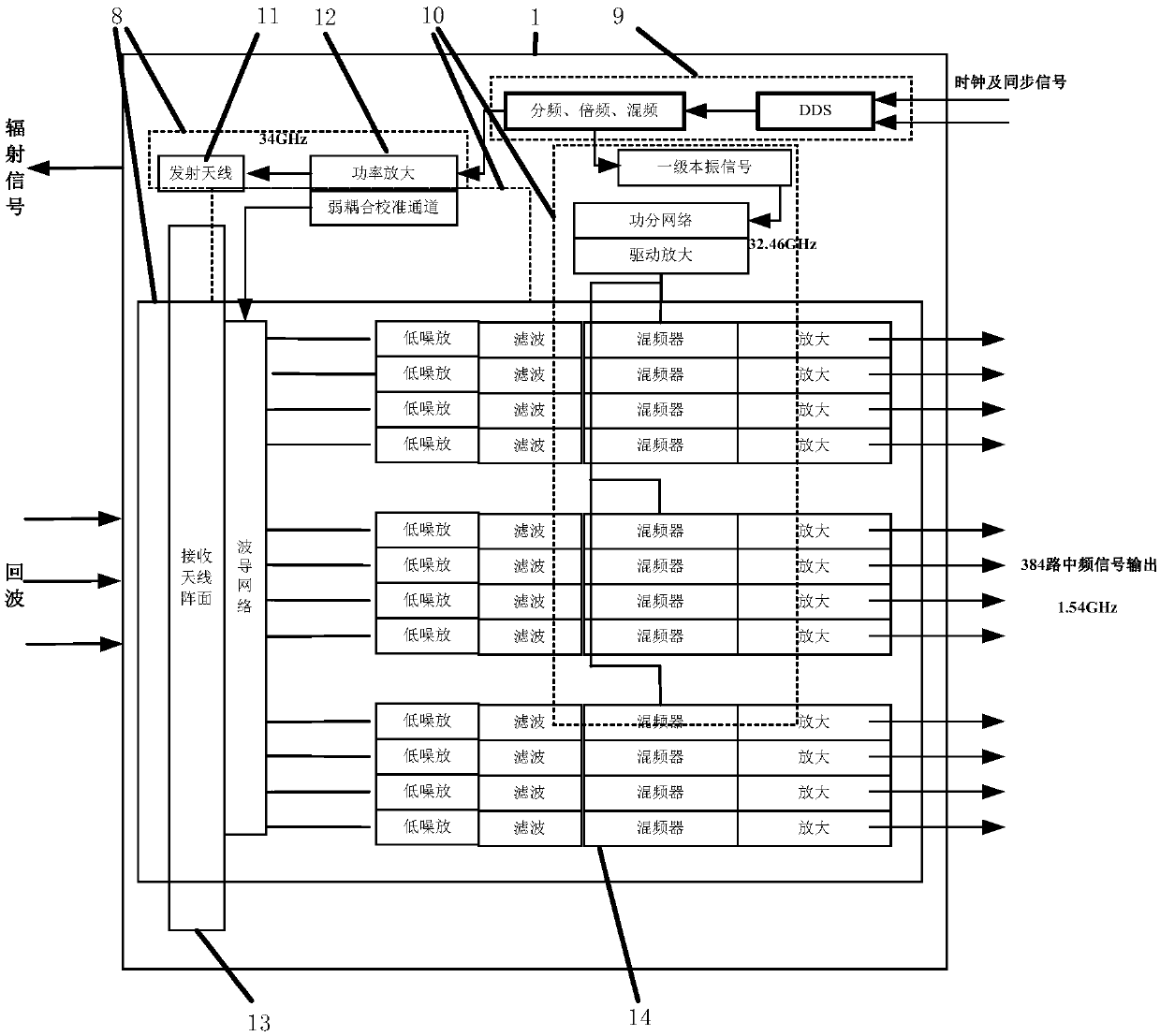

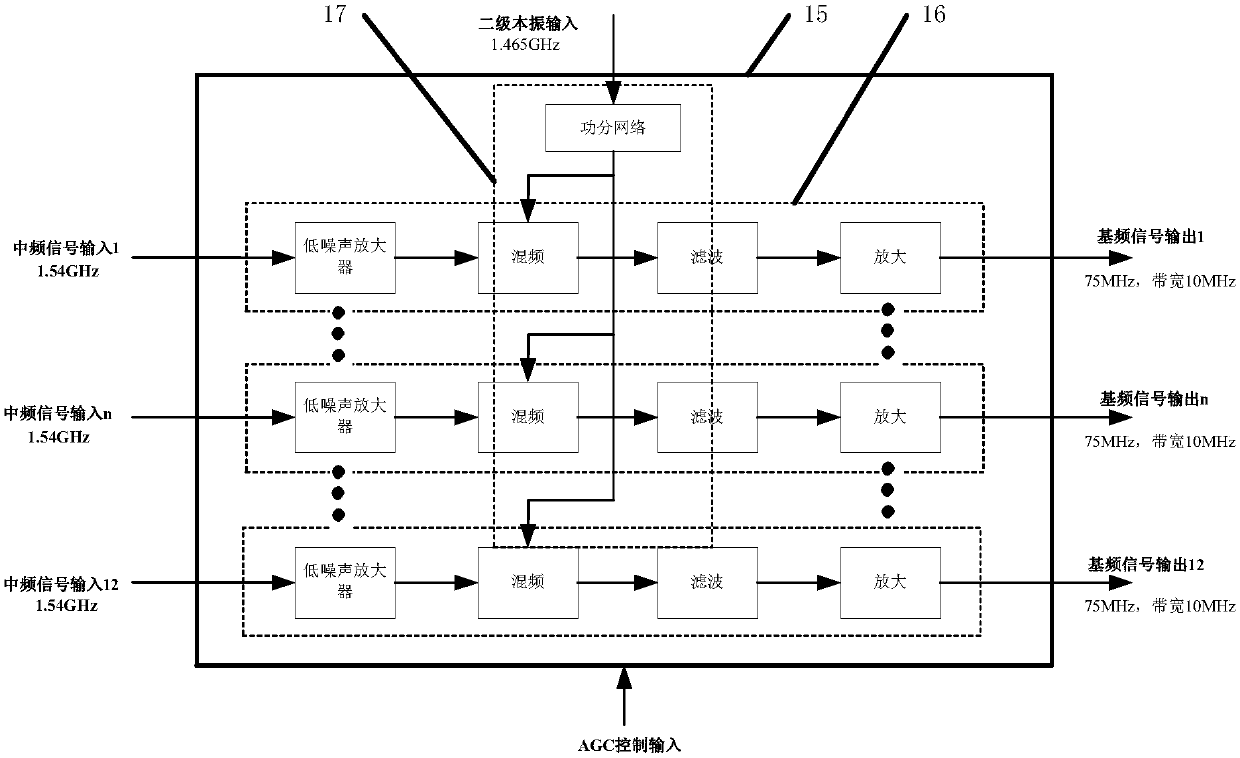

High-performance universal multi-channel radar system

ActiveCN109655797AImprove versatilityReduce acquisition bandwidthWave based measurement systemsLocal oscillator signalRadar systems

A high-performance universal multi-channel radar system comprises a millimeter wave short-range imaging high-frequency front-end assembly, an intermediate frequency processing assembly, a data acquisition assembly, a comprehensive signal processing assembly and a microwave source assembly. The high-frequency front-end assembly comprises a radio frequency and local oscillator signal generation module, a signal distribution and calibration network module, an antenna and a radio frequency channel array module, and realizes generation of radio frequency and primary local oscillator signals, and reception, amplification, filtering and primary down-conversion of echo signals. The intermediate frequency processing assembly realizes amplification, filtering and secondary down-conversion of echo signals. The data acquisition assembly is used for realizing echo signal acquisition and signal preprocessing. Real-time imaging of echo data is achieved through the comprehensive signal processing assembly. The microwave source assembly realizes generation of a clock reference signal, a synchronous signal and a secondary local oscillator signal. Resource waste caused by repeated design and development under same requirement or similar requirement is avoided, the design efficiency is effectively improved, and universality and flexibility are enhanced.

Owner:SHANGHAI RADIO EQUIP RES INST

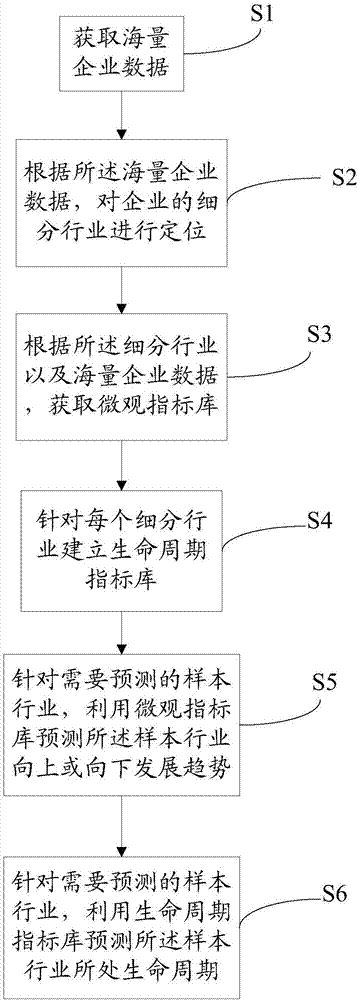

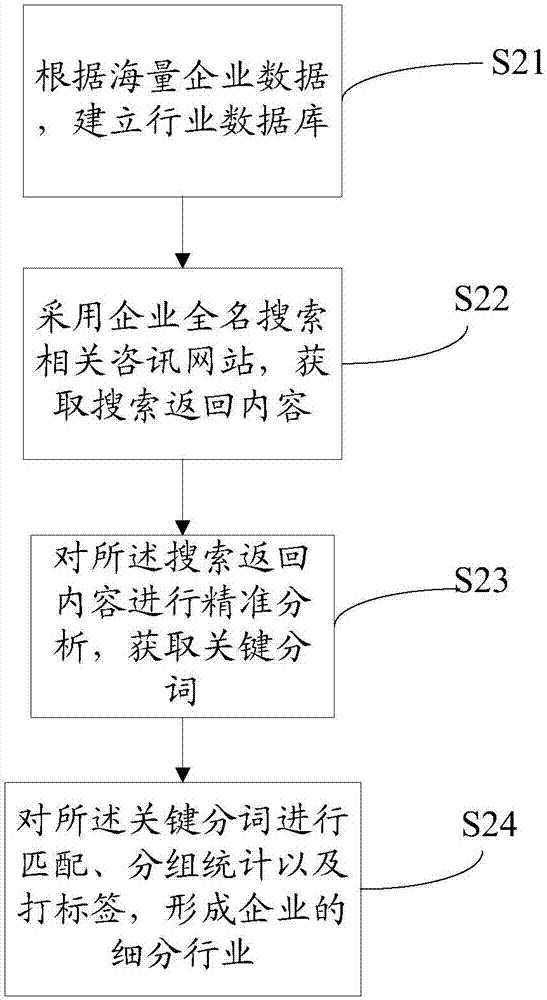

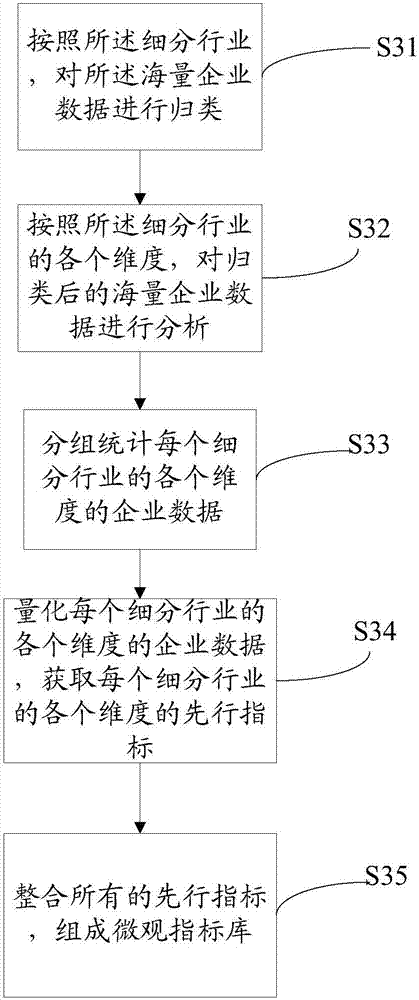

Big data-based industry trend accurate prediction method and system

InactiveCN107301471AClosing the gap in predictive analyticsImprove accuracyForecastingPredictive analyticsBig data

The invention relates to a big data-based industry trend accurate prediction method and system. The method comprises the steps of obtaining massive enterprise data; according to the massive enterprise data, locating subdivided industries of enterprises; according to the subdivided industries and the massive enterprise data, obtaining a micro-index library; establishing a life cycle index library for each subdivided industry; for a sample industry needed to be predicted, predicting an upward or downward development trend of the sample industry by utilizing the micro-index library; and for the sample industry needed to be predicted, predicting a life cycle in which the sample industry is located by utilizing a life cycle index library. According to the method and the system, the massive enterprise data is obtained; in combination with accurate locating of the subdivided industries of the industry, the micro-index library is formed for predicting the upward or downward development trend of the industry; the life cycle index library is established for predicting the life cycle of the industry; the accuracy of prediction and analysis is improved; certain industries can be separately controlled; the defects of macroscopic industry prediction analysis can be made up for; and the universality degree is high.

Owner:前海梧桐(深圳)数据有限公司

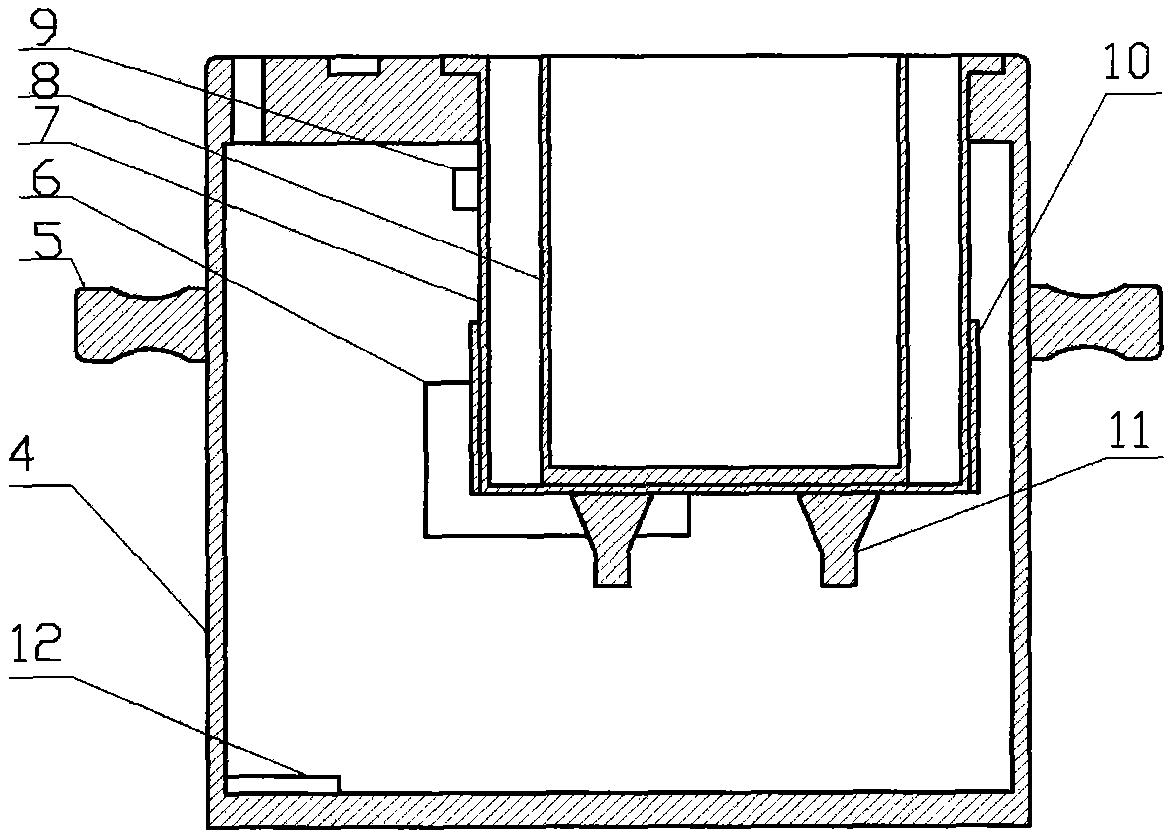

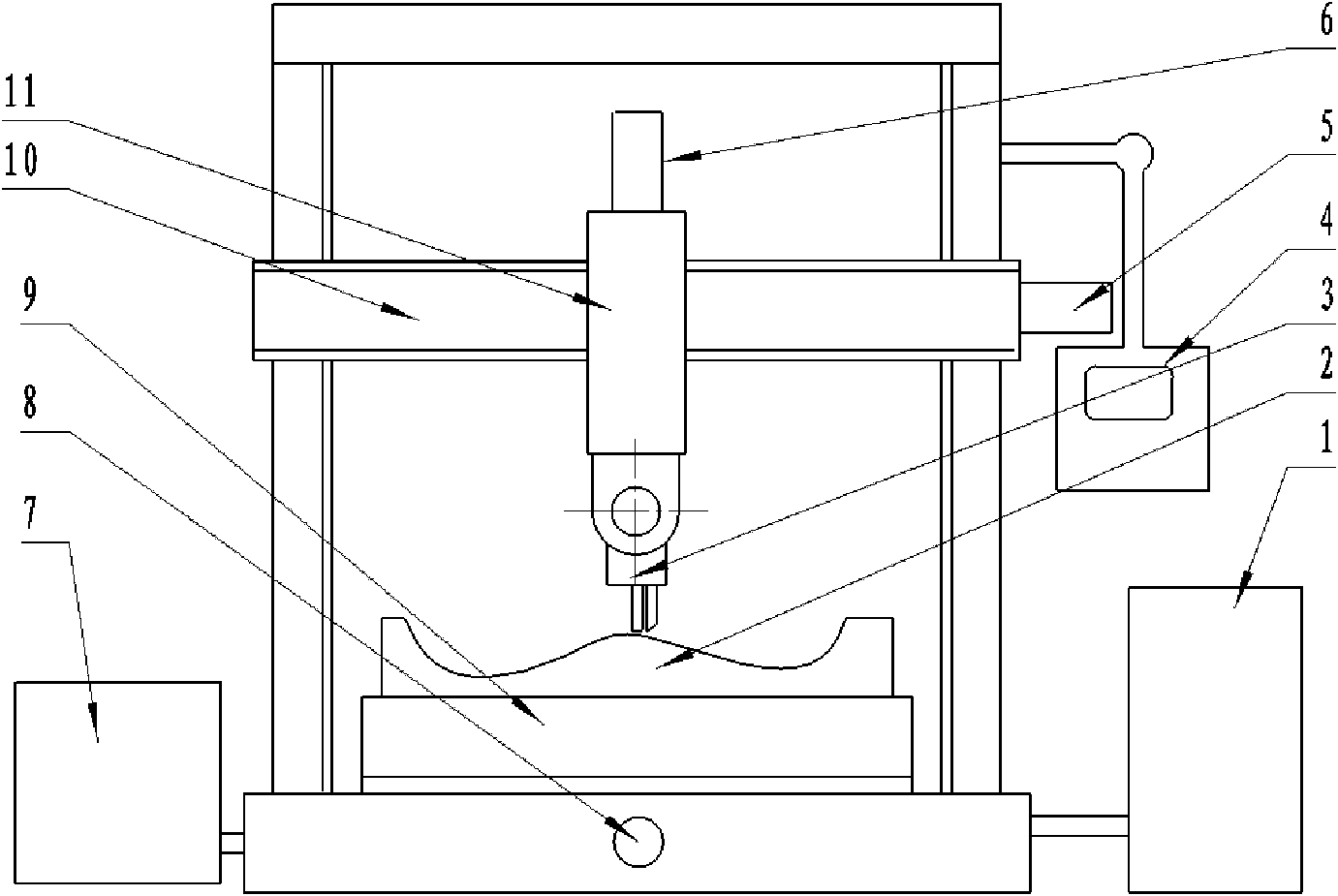

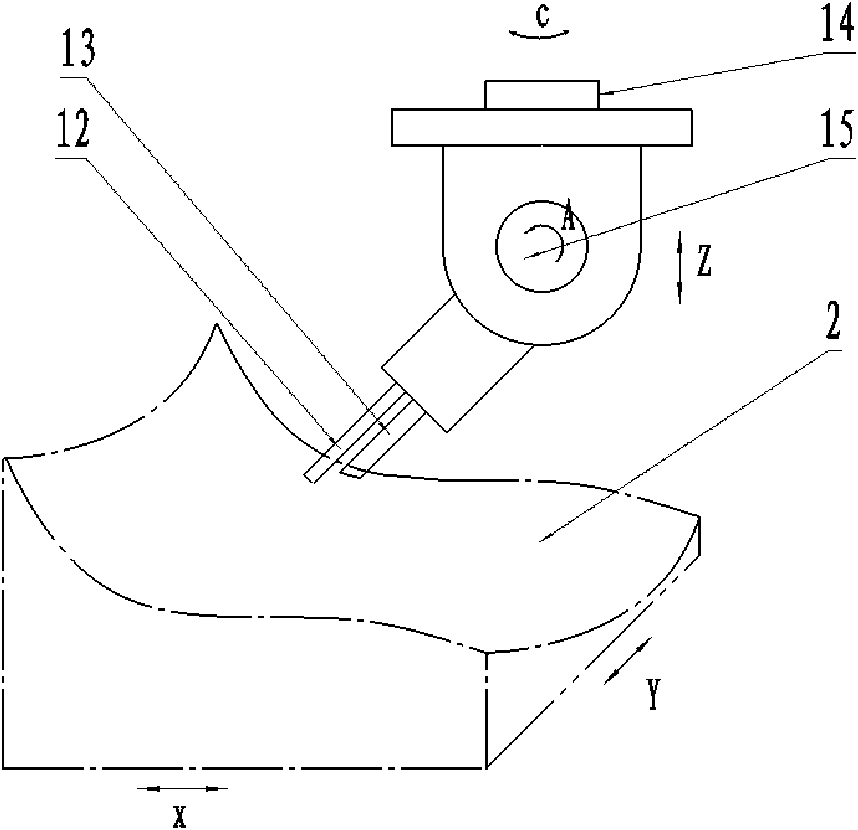

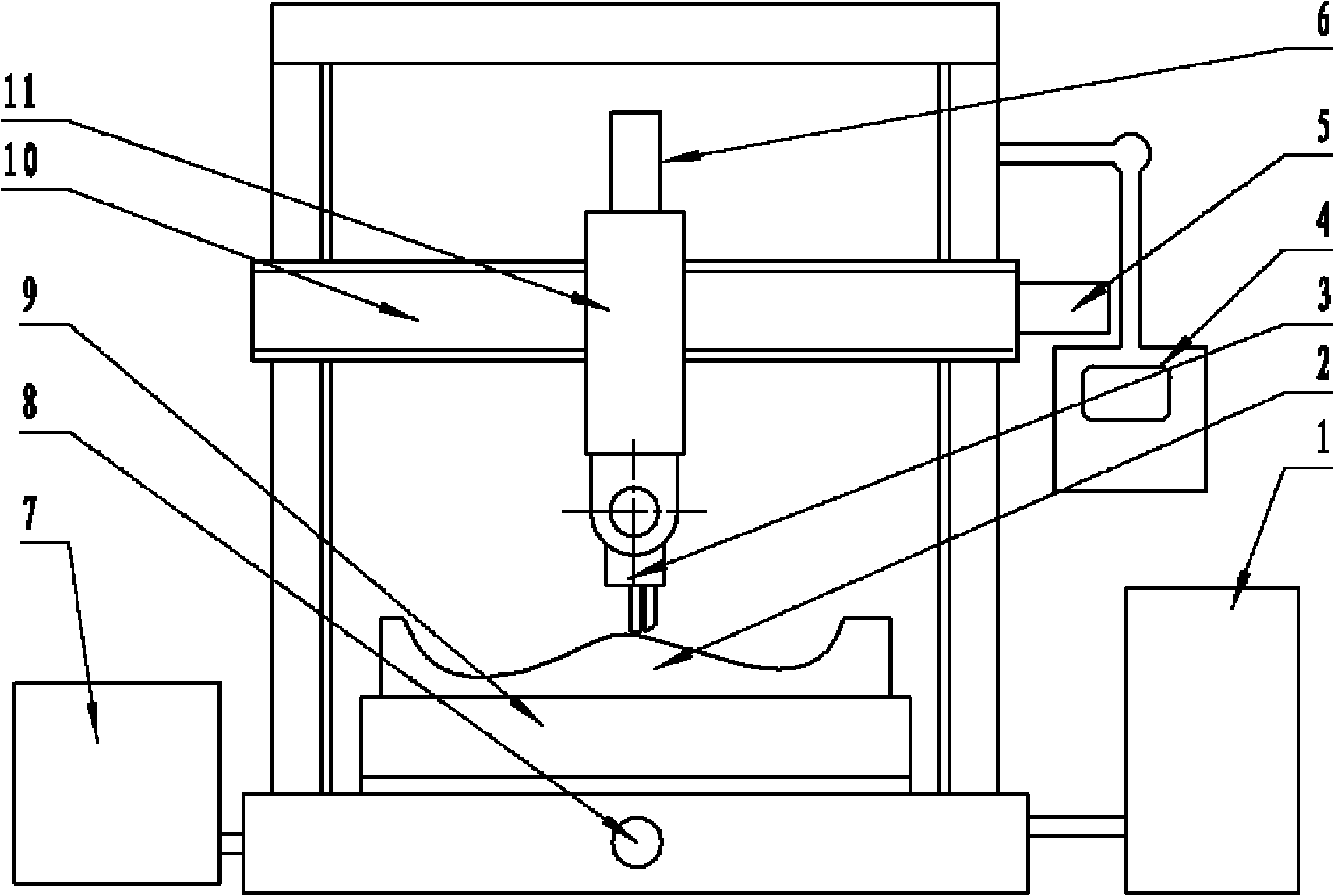

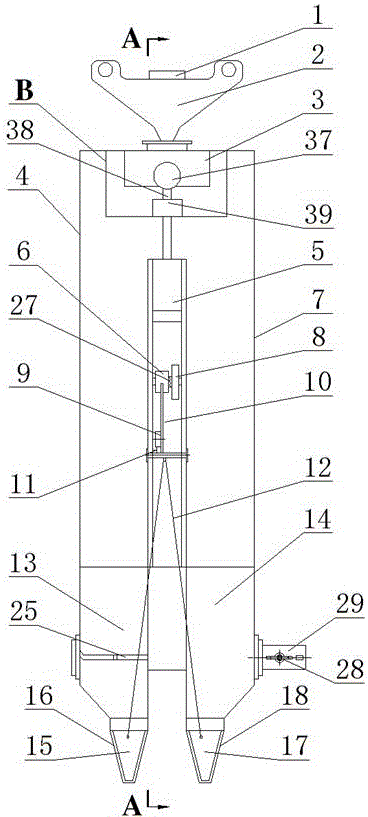

Complex-space curved-surface dot-motion induction heating hardening device and method

ActiveCN102051451AQuenching strengtheningLow powerIncreasing energy efficiencyHeat treatment process controlMaterial typeInduction heater

The invention relates to a complex-space curved-surface dot-motion induction heating hardening device and method. The complex-space curved-surface dot-motion induction heating hardening device mainly comprises a numerical control system (4), a five-axis servo mechanism, an induction heater (12) and a cooling liquid sprayer (13), wherein the numerical control system (4) and the five-axis servo mechanism are arranged on a frame; the induction heater (12) and the cooling liquid sprayer (13) are driven by the five-axis servo mechanism to respectively make a three-dimensional continuous motion along the complex-space curved surface of a part; after the induction heater heats the surface of the part to austenite transition temperature, the cooling liquid sprayer sprays out a cooling medium to cool the surface of the part, thereby realizing the hardening reinforcing treatment of the surface of the part. By utilizing the device, the method is realized in a way that: the current frequency, motion speed and route of an induction power source (1) is selected according to the material type and heat treatment technique of the treated part, and the process of heating and cooling on the surface of the part is completed while the induction heater and the cooling liquid sprayer respectively make a three-dimensional continuous dot motion on the surface of the part. The invention can accurately control the depth of hardening layer, and has the advantages of high work efficiency, low loss of heat energy, no pollution and the like; and the surface structure after hardening is uniform.

Owner:HUBEI TRI RING FORGING

Electric portable fertilizer-and-seeder

ActiveCN106134583AImprove work efficiencyIncrease profitSaving energy measuresFertiliser and seeding apparatusSeederGear wheel

The invention relates to an electric portable fertilizer-and-seeder and belongs to the field of agricultural machinery. The electric portable fertilizer-and-seeder comprises a switch, a grip, a storage battery, a seed case, a drive rod, a gear, a manure box, a flywheel, a rolling wheel, a duckbill connecting rod, a cam, a triangular pull rod, a seed collection box, a manure collection box, a fixed seeding duckbill, a movable seeding duckbill, a fixed fertilizing duckbill, a movable fertilizing duckbill, a sector gear, a connecting shaft, a connecting rod, a shifting fork, a reset spring, a planting wheel, a grain number adjusting control board, a seed collection pit, a ratchet, a motor, a coupler, an electric transmission mechanism and a butt strap; the electric transmission mechanism comprises a rotatable spindle, an eccentric block, a bearing I, a fixing block, a bearing II, an oscillating rod and a guide rod. By the arrangement, working efficiency in agriculture mechanization production is greatly improved, land fertilization can be performed according to cultivation of different crops and different seasons, and the utilization rate of fertilizer can be increased.

Owner:KUNMING UNIV OF SCI & TECH

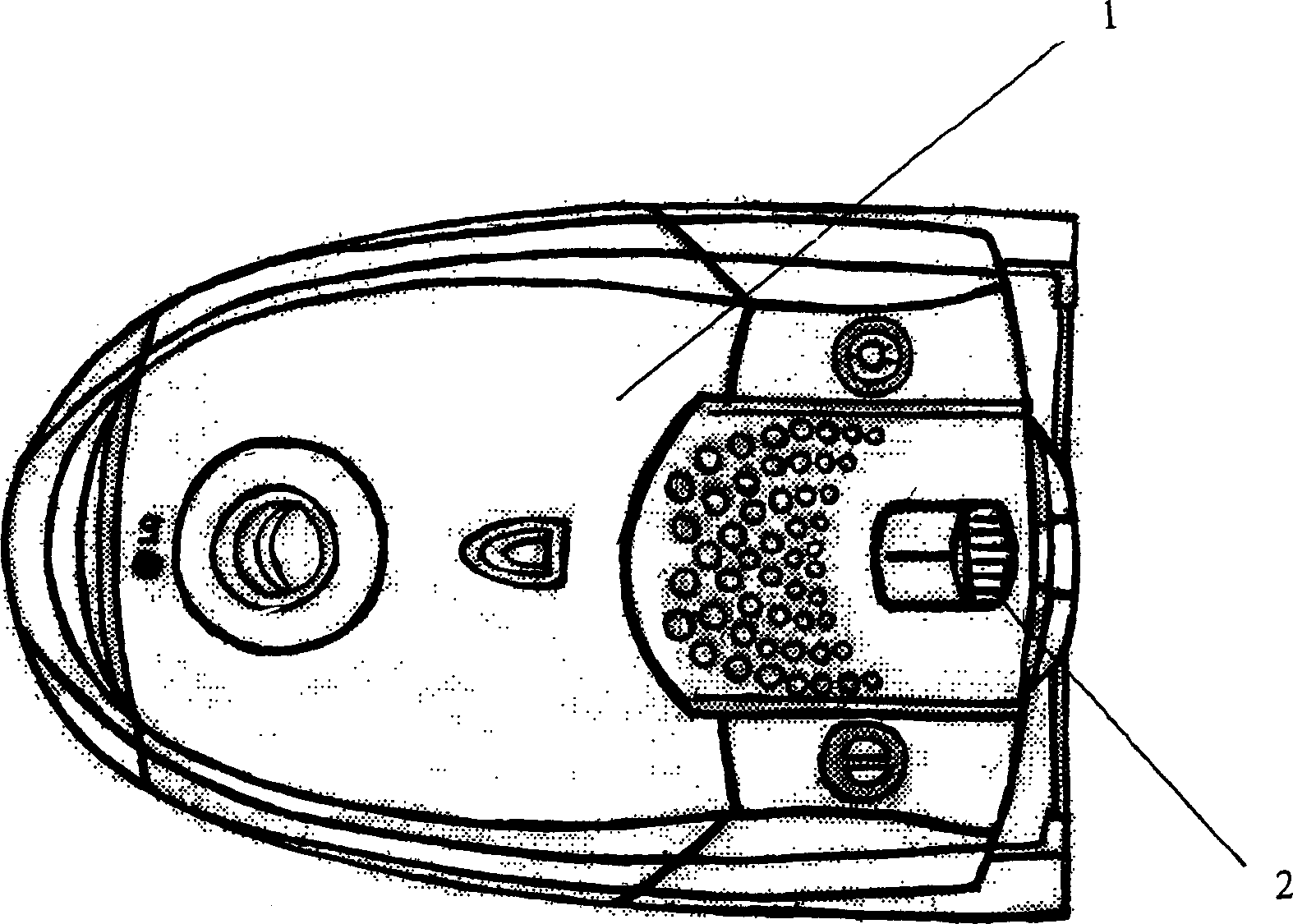

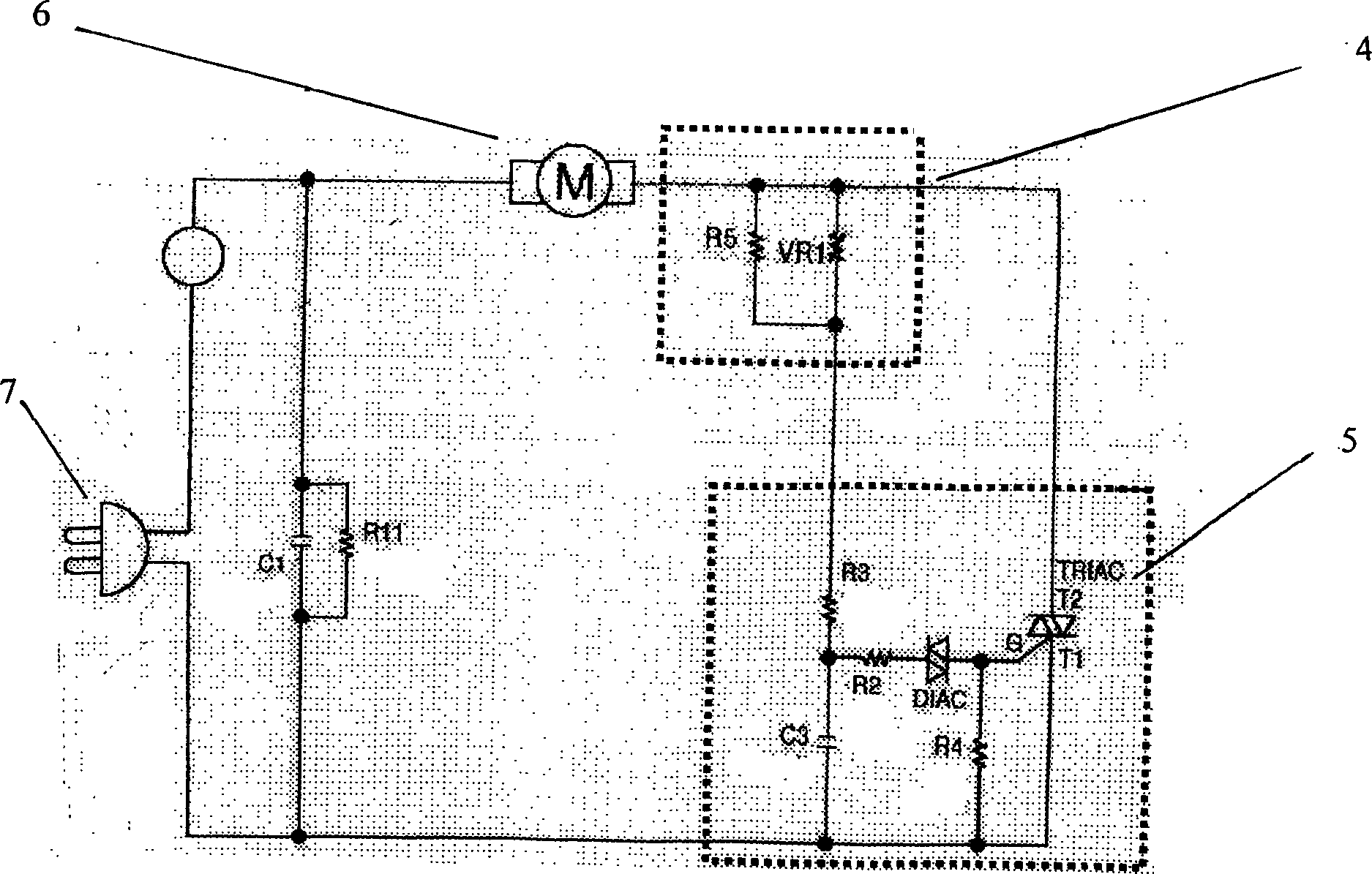

Touching type induction regulator for vacuum cleaner

InactiveCN1860983AHigh degree of generalizationMeet comfortAC motor controlElectric equipment installationDriver circuitEngineering

A touch induction type speed regulator of cleaner is composed of an operation knob arranged on the casing of cleaner and consisting of an acceleration piece and a deceleration piece and a speed regulating circuit connected to said two pieces for regulating the speed of motor and consisting of input buffer, phase lock ring, state and phase angle memory, digital comparator, driver and SCR.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com