Patents

Literature

141 results about "Manufacturing services" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing as a service is the shared use of a networked manufacturing infrastructure to produce goods. In other words, manufacturers use the internet to share manufacturing equipment in order to reduce costs and make better products.

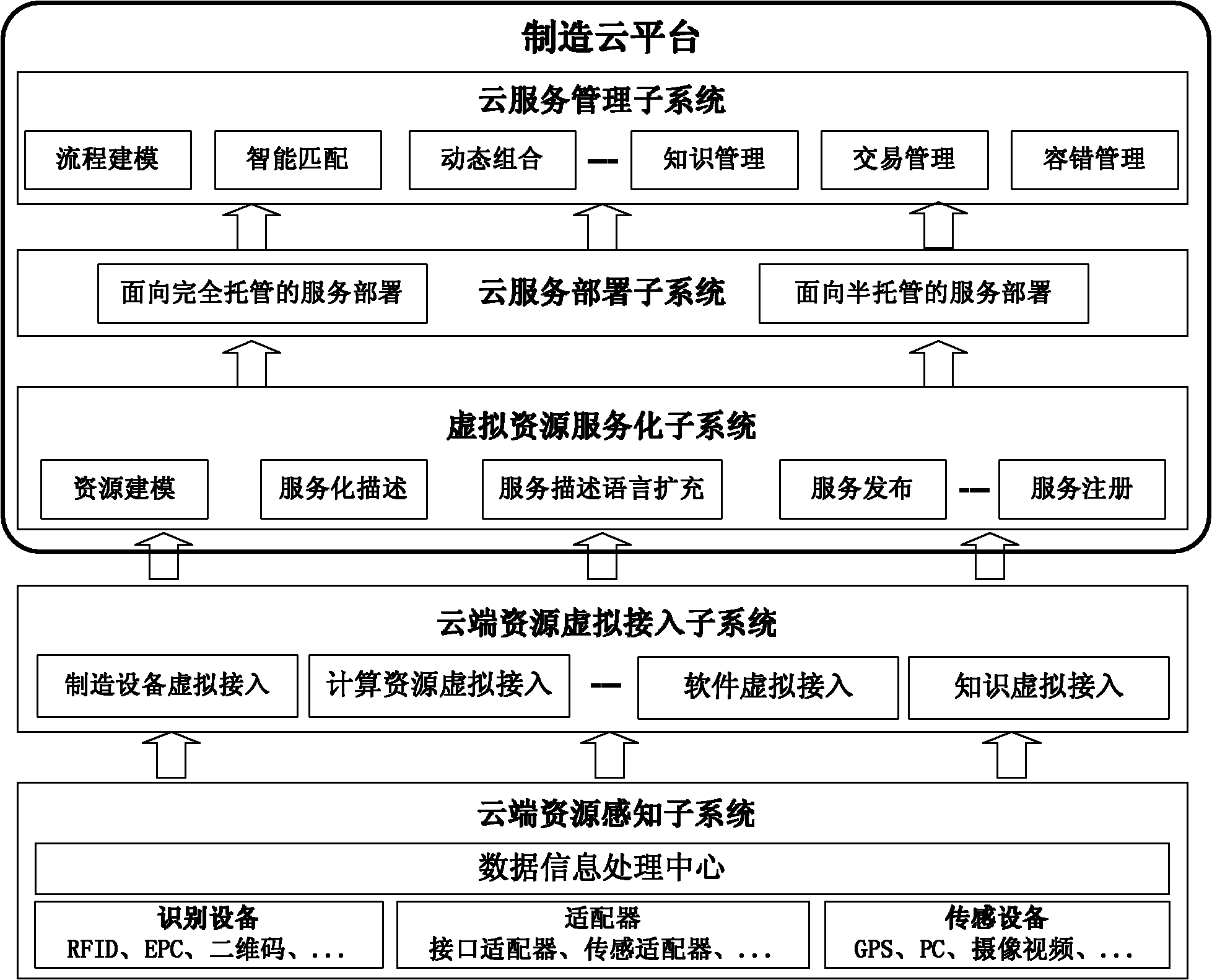

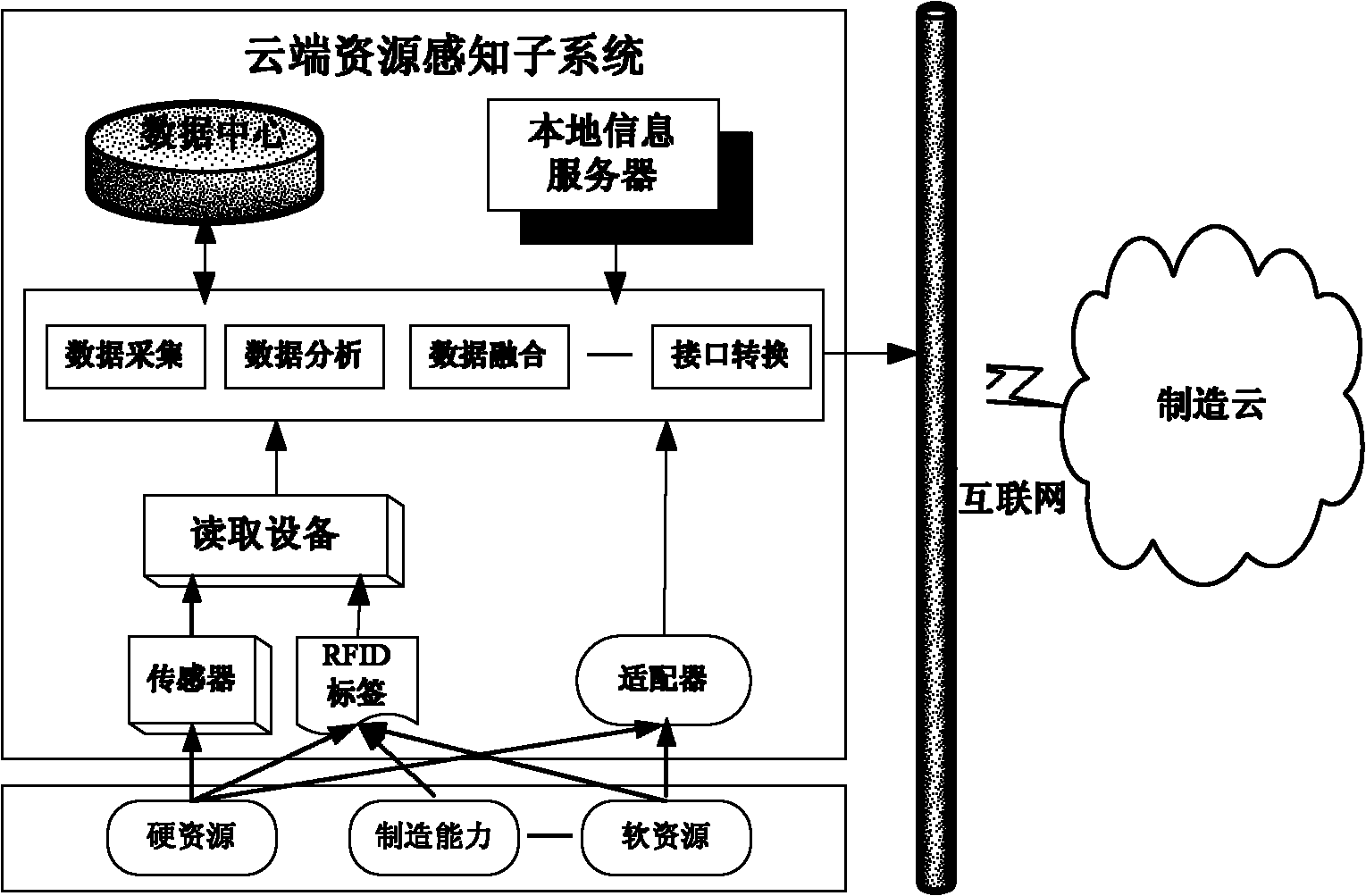

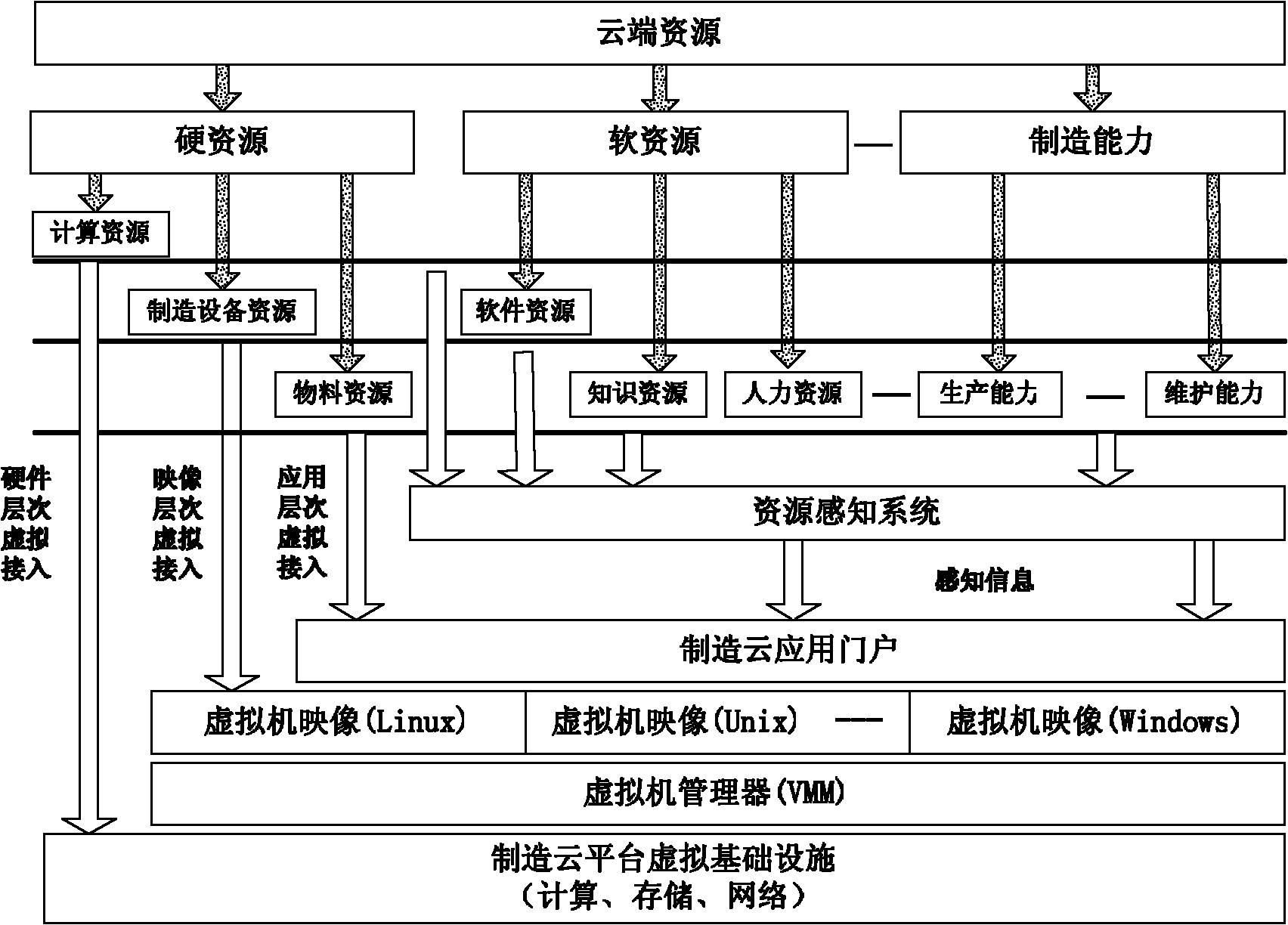

Manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities

InactiveCN102176723ARealize analysisAchieving processing powerTransmissionSoftware simulation/interpretation/emulationInformatizationResource utilization

The invention provides a manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities, which is used for solving the problems that the use ratio of resources is low, the sharing of the manufacturing capacities is insufficient, effective business operation management measures are short and the like in the process of manufacturing enterprise informatization in China. Aiming at the characteristics of the manufacturing resources and the actual demands of an enterprise for a cloud manufacturing service platform, and according to the lifeline of a cloud service life cycle, the manufacturing resources and the manufacturing capacity in the manufacturing cloud system are designed and stated in five system modules namely intellisense, virtual access, virtual resource servicesation, deployment of cloud services, and integrated management of the cloud services, thus meeting the demand of the on-demand use and the dynamic collaboration of the manufacturing resources and the manufacturing capacities. The manufacturing cloud system has the advantages that the intellisense, the servicesation of the manufacturing capacities and service life cycle demands which are accessed to the manufacturing resources are supported, the intelligence is supported, the services are shared on demand, the system structure is flexible, the levels are distinct, and the expandability is strong.

Owner:BEIHANG UNIV

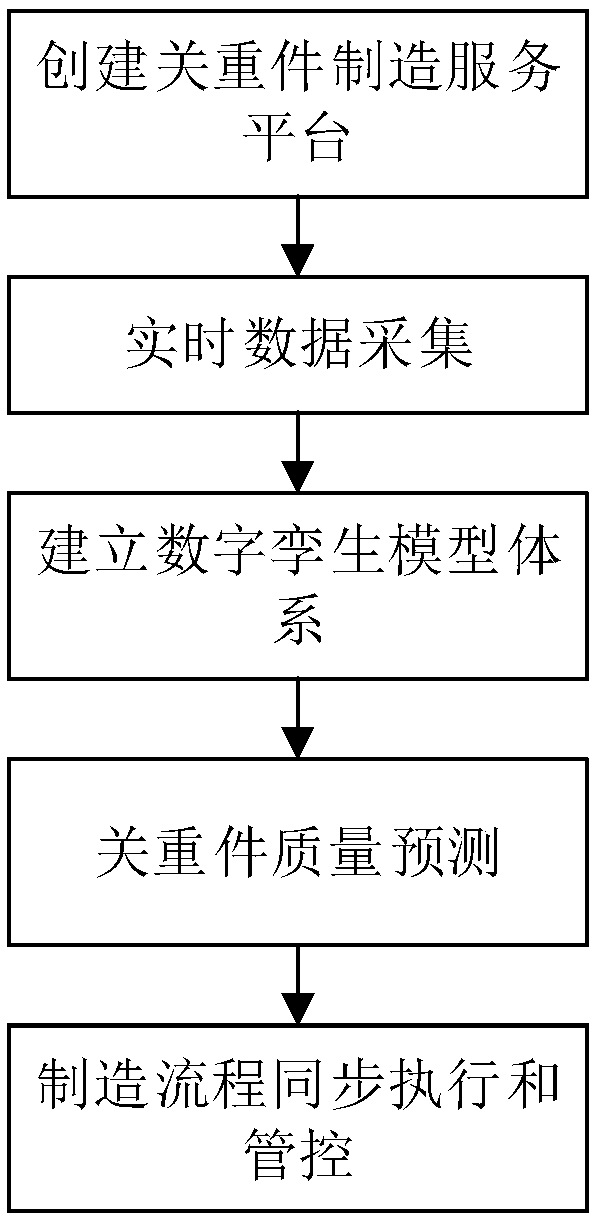

Control method for manufacturing process of key parts of marine diesel engine based on digital twin

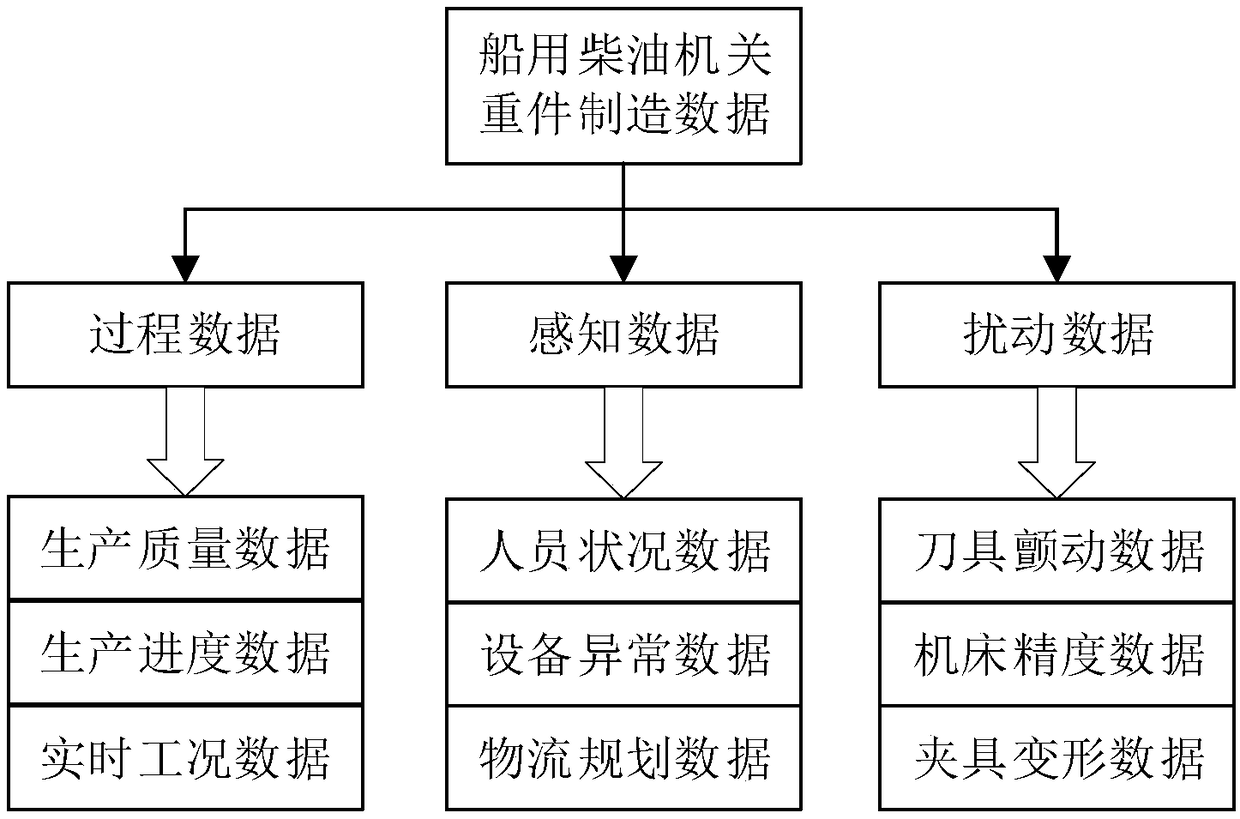

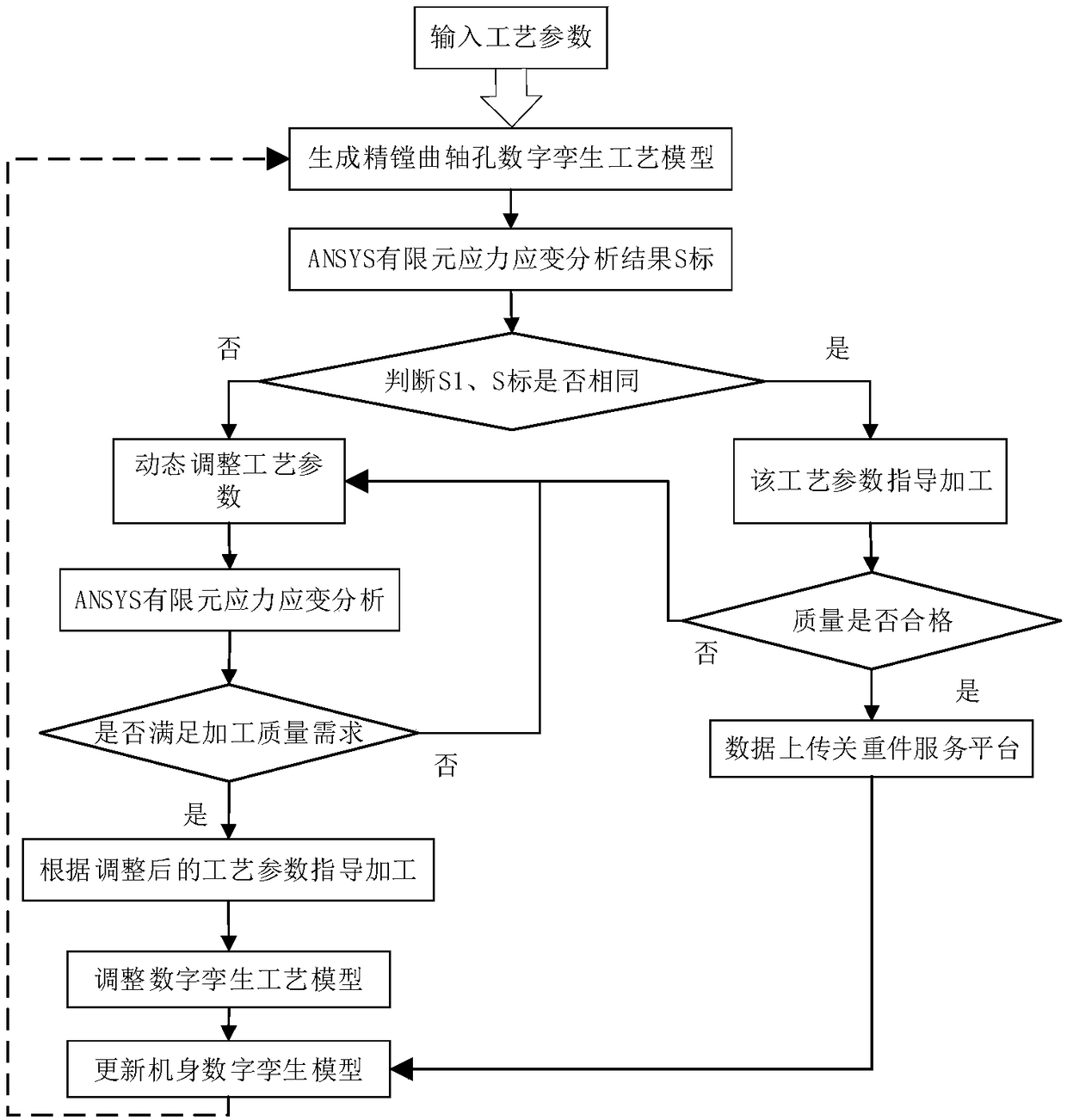

ActiveCN109270899AMonitor Disturbance FactorsDisturbing factors are eliminated in timeTotal factory controlProgramme total factory controlInformation spaceFull cycle

The invention discloses a control method for the manufacturing process of key parts of a marine diesel engine based on digital twin. The method comprises the following steps: (1) creating a manufacturing service platform for the key parts; (2) performing real-time data acquisition; (3) establishing a digital twin model system; (4) performing quality prediction; and (5) performing synchronous execution and control of the manufacturing process. Through quality control for key part manufacturing of the marine diesel engine, the quality data of workpiece processing and manufacturing based on a digital twin technology can be monitored dynamically and visually in real time. Process parameters are optimized by real-time simulation of a digital twin model, and an actual processing process is controlled with optimized parameters. Meanwhile, real mapping of an information space and a physical space is utilized effectively, and real-time and full-cycle management and control of the quality of thekey parts and the stability of processing resources and equipment in the manufacturing process are realized. The method is of great significance to improve the quality of the key parts and the utilization rate of resources, as well as to improve the production efficiency.

Owner:JIANGSU UNIV OF SCI & TECH

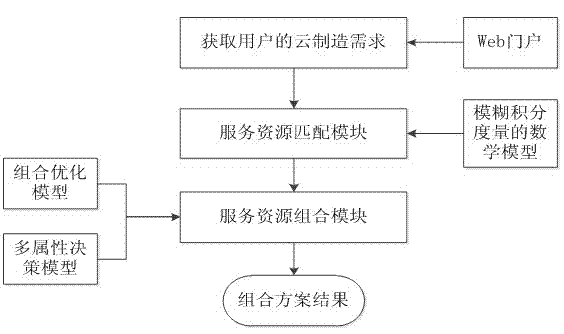

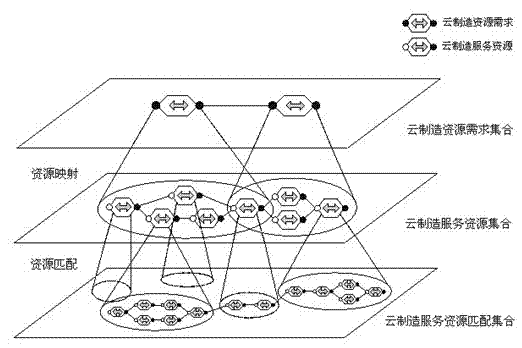

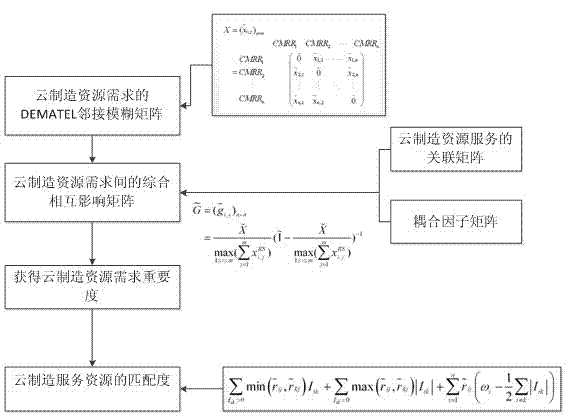

Cloud manufacturing service resource match and combination method based on performance fusion

The invention discloses a cloud manufacturing service resource match and combination method based on performance fusion. According to a relationship between cloud manufacturing service resources and cloud manufacturing resource requirements of users, a cloud manufacturing service resource combination is divided into two stages of match and combination, a performance fusion model of the match and the combination is constructed, and combination schemes are evaluated and sequenced by means of a dynamic multi-attribute decision-making method to filter an optimal cloud service resource combination scheme. According to the cloud manufacturing service resource match and combination method based on performance fusion, the problem that current networking manufacturing resource match methods can't be directly used for achieving cloud manufacturing service match; and simultaneously, idle manufacturing cloud can be used for automatic rent-seeking on a cloud platform and is convenient, fast, safe and cheap for customers to use, a many-to-many mapping relationship of requirements and services is n:1:m, and by means of the many-to-many mapping relationship, a multi-layer and three-dimensional manufacturing service is provided for manufacturing industries.

Owner:ZHEJIANG UNIV

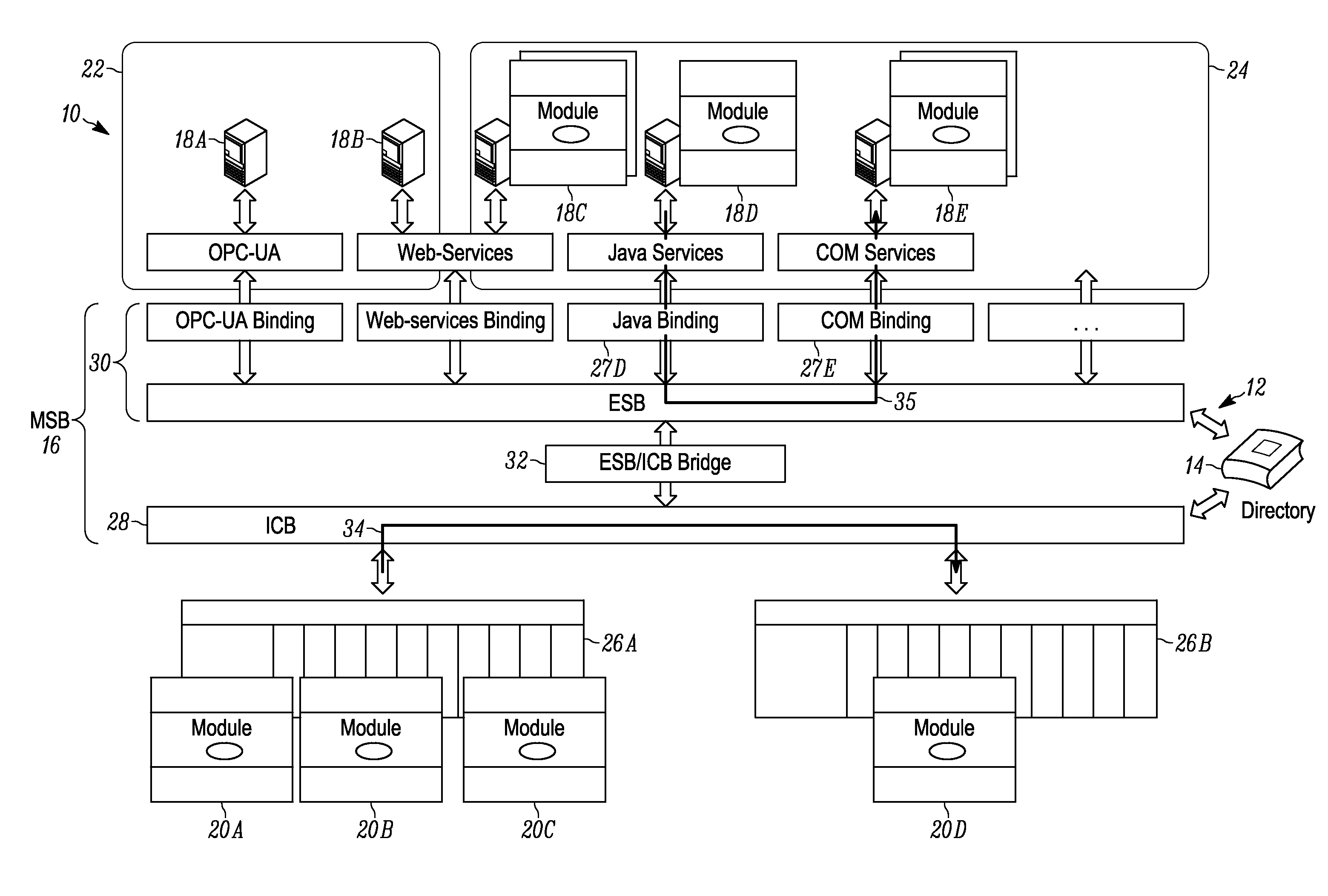

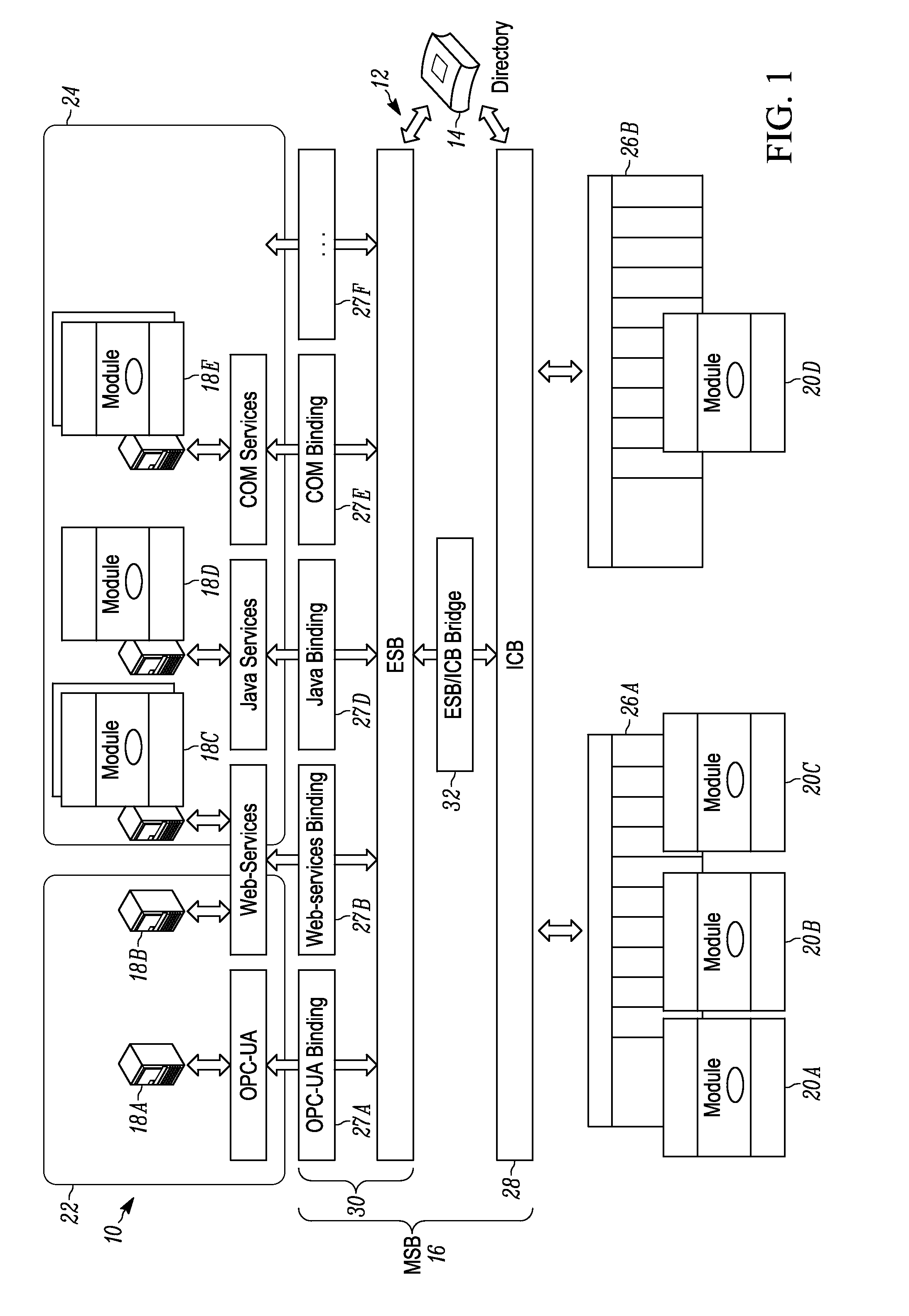

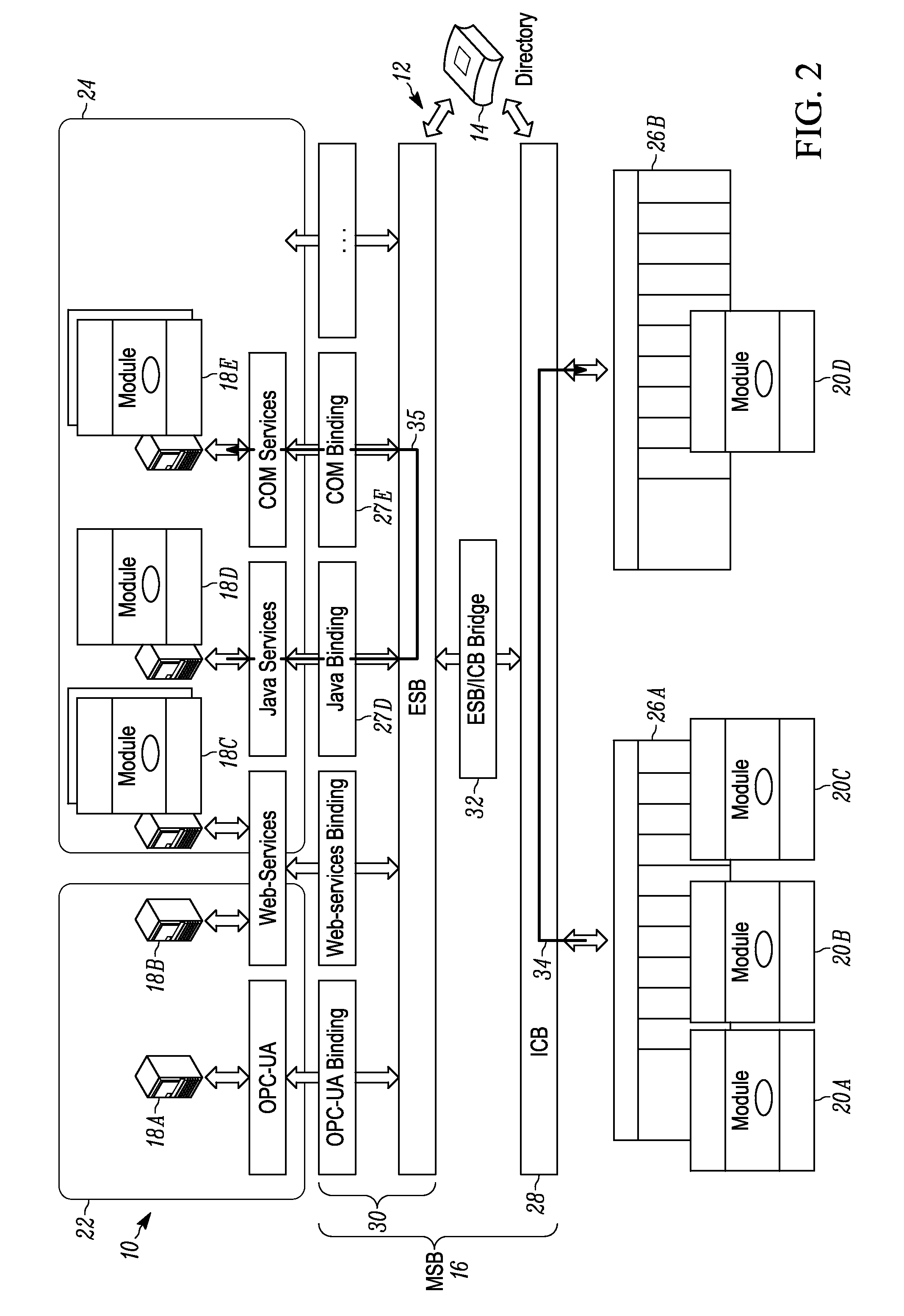

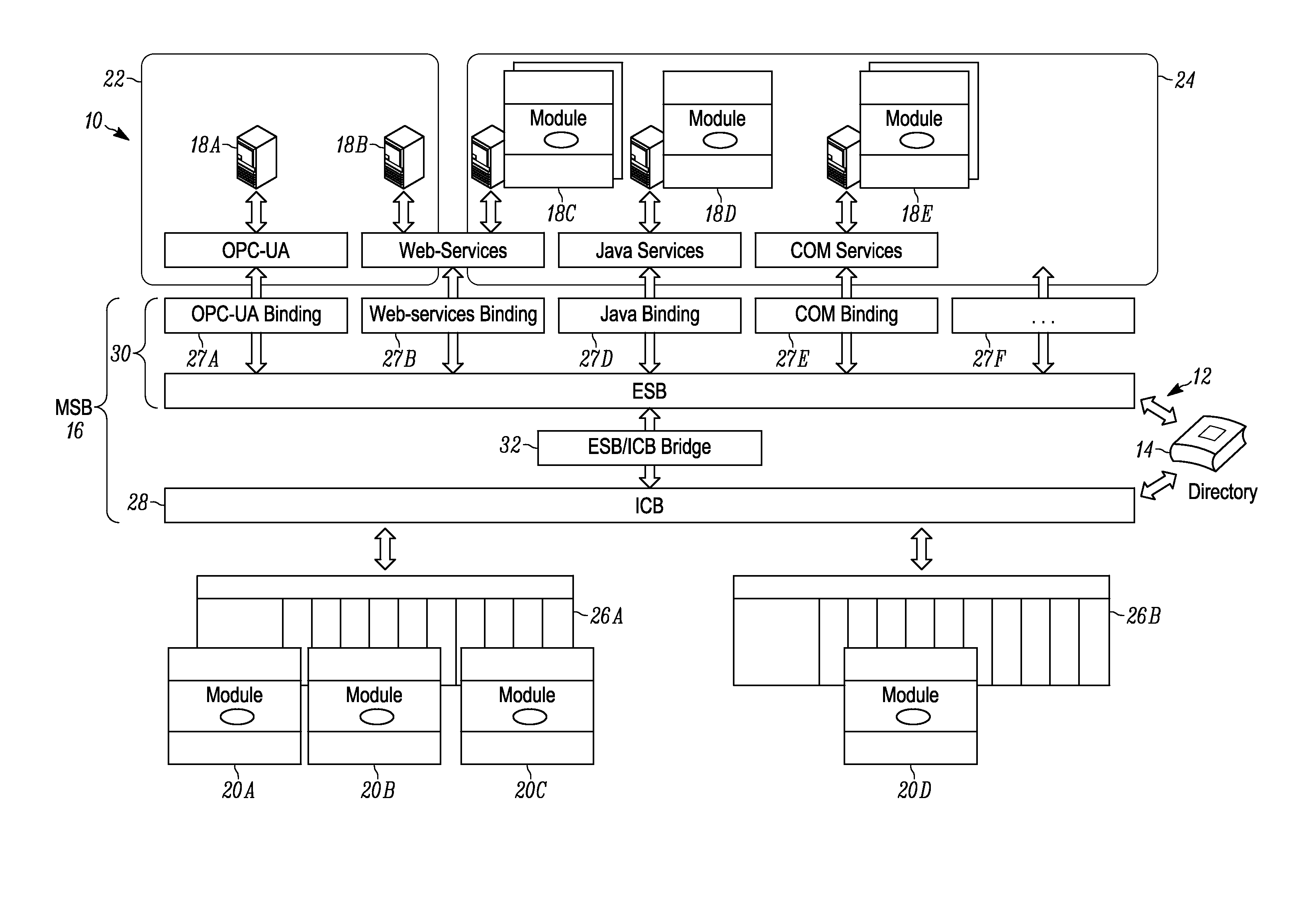

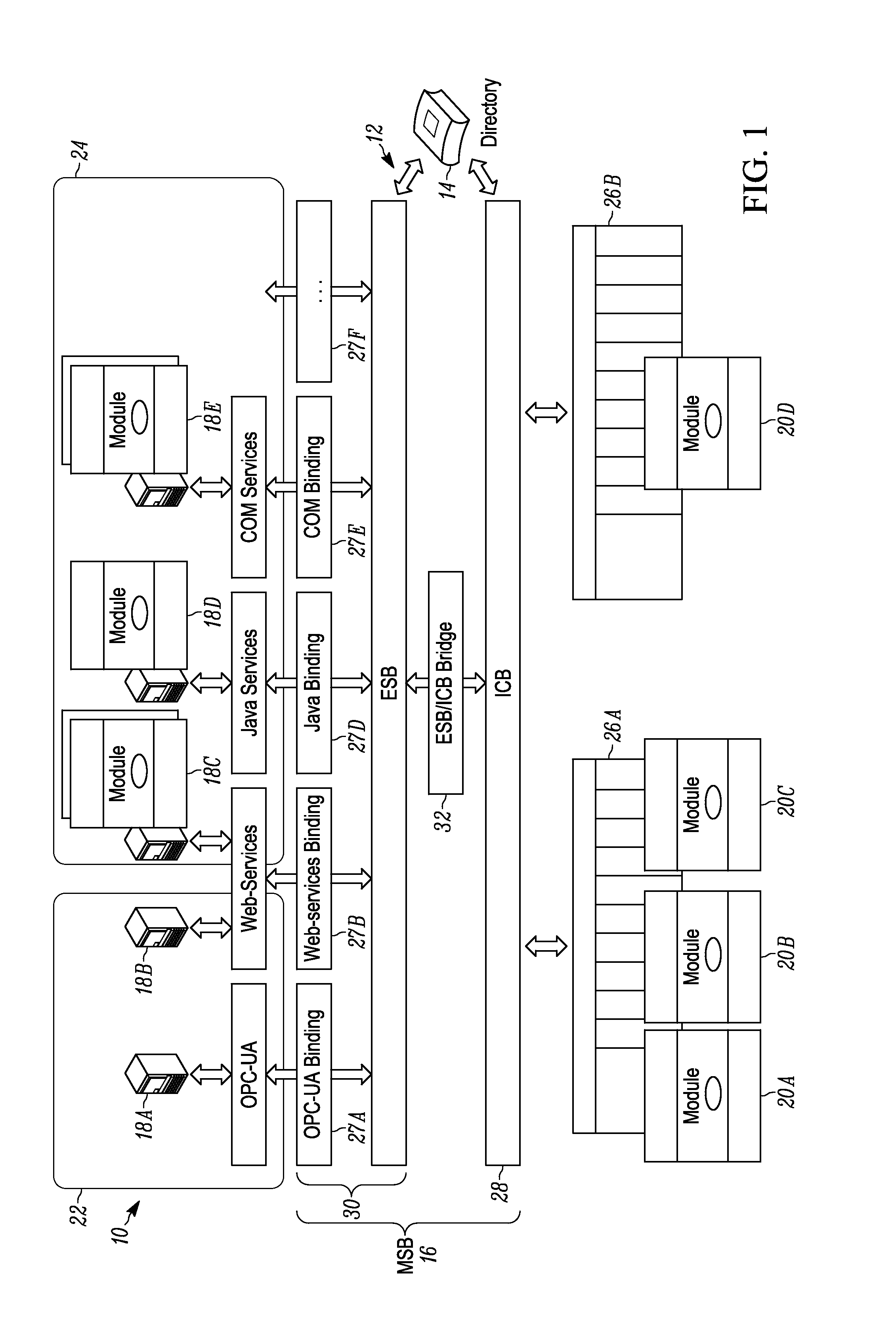

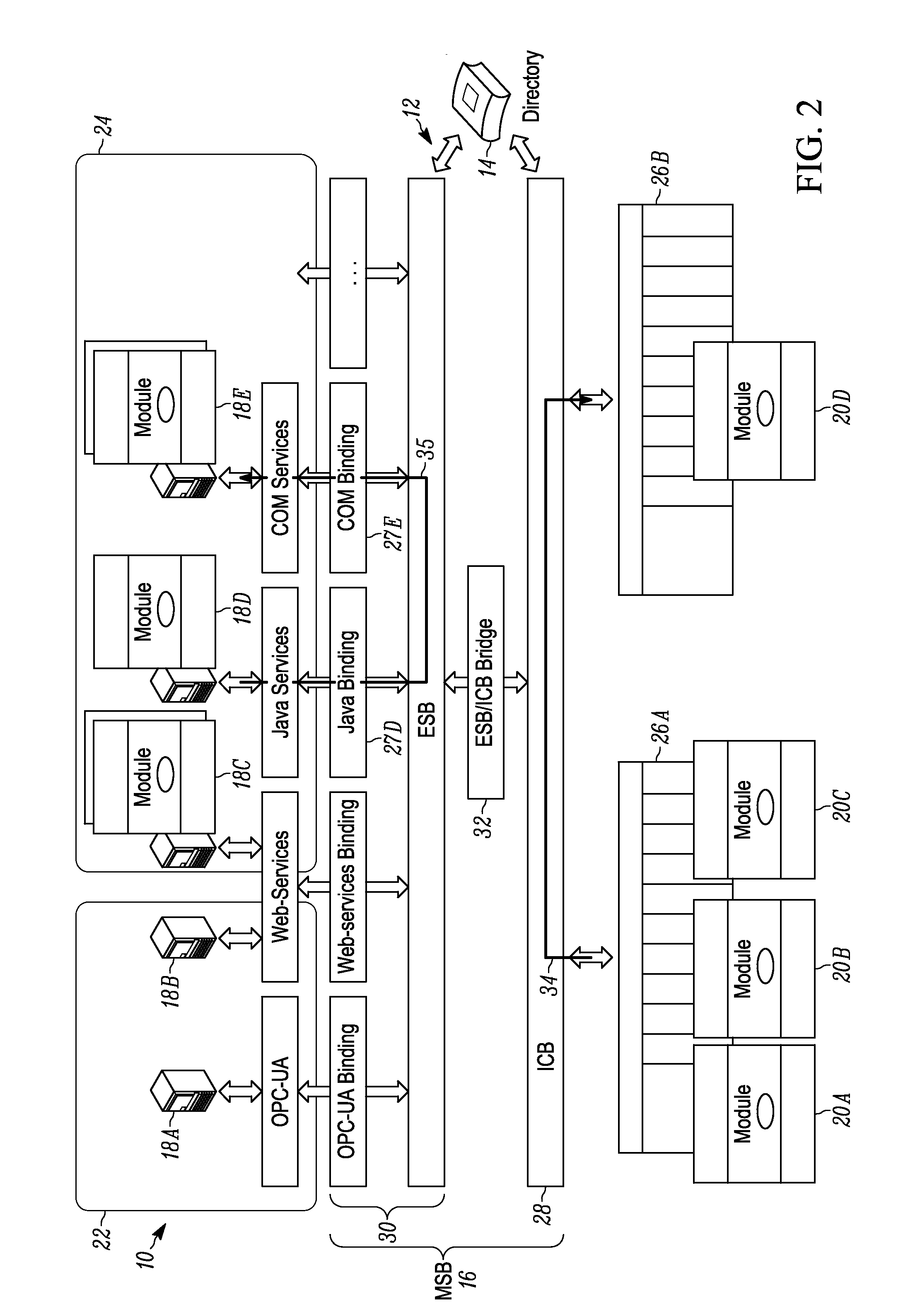

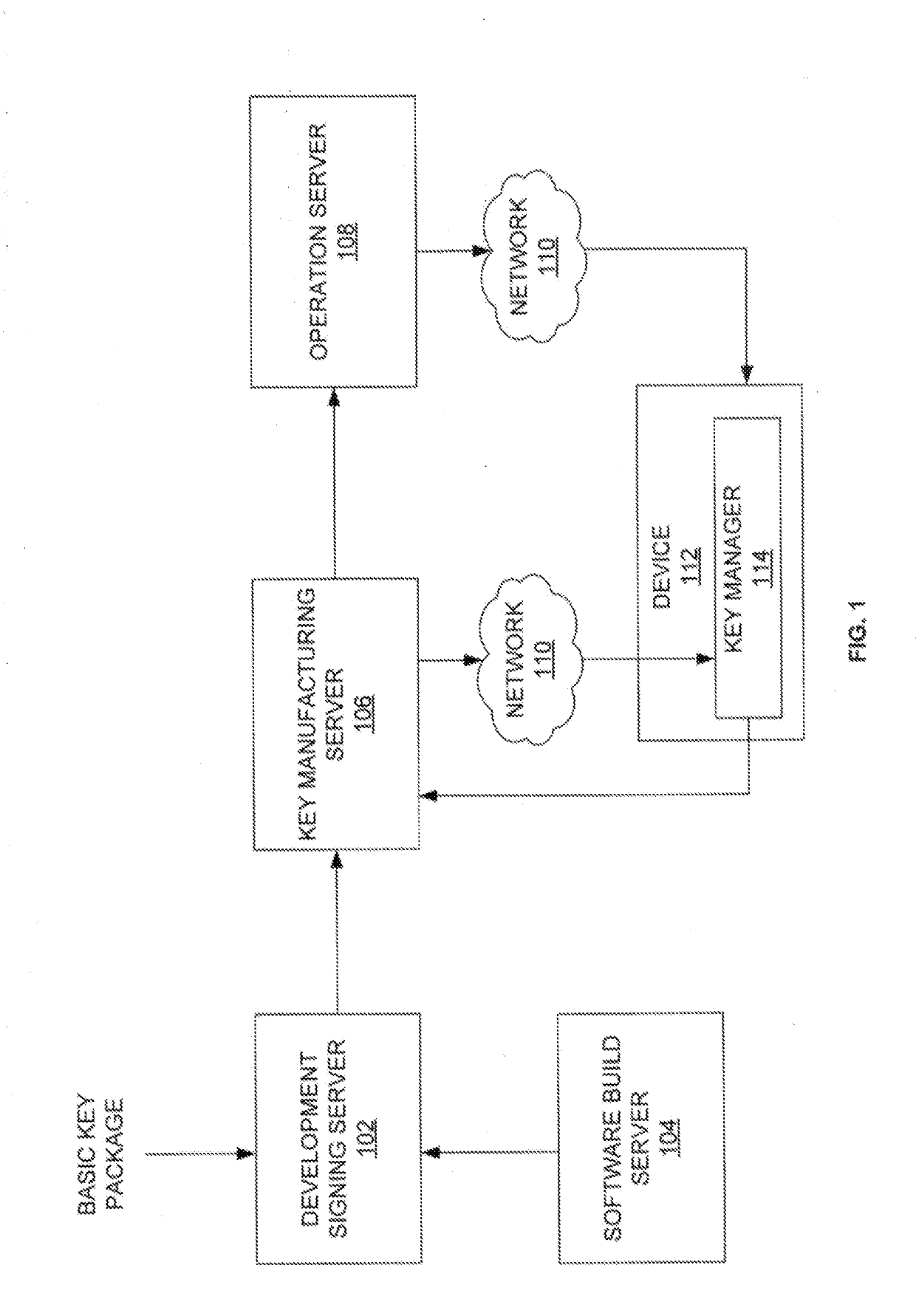

Systems and methods for conducting communications among components of multidomain industrial automation system

ActiveUS20110258262A1Overcome disadvantagesMultiprogramming arrangementsMultiple digital computer combinationsCommunications systemComputer module

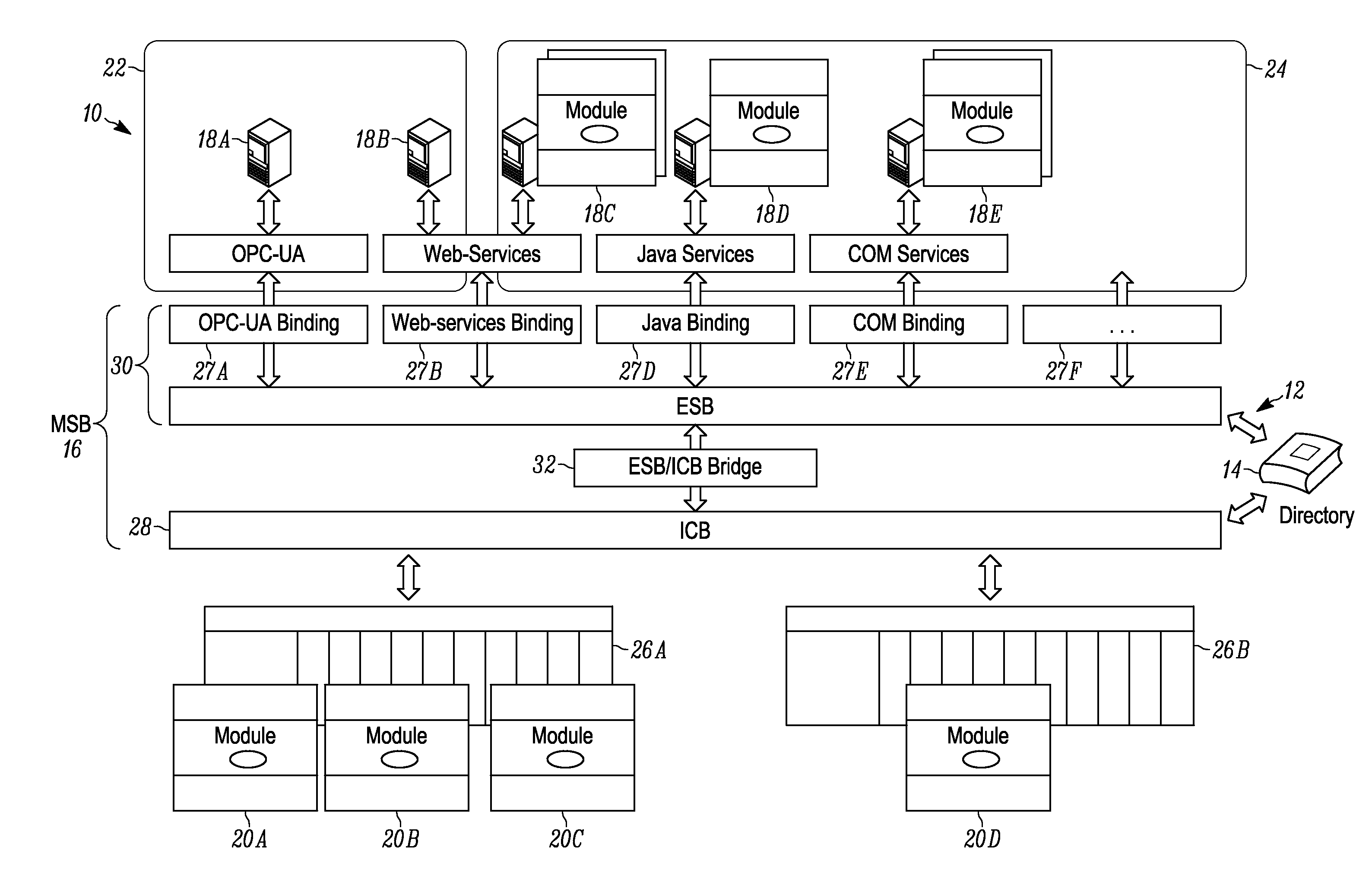

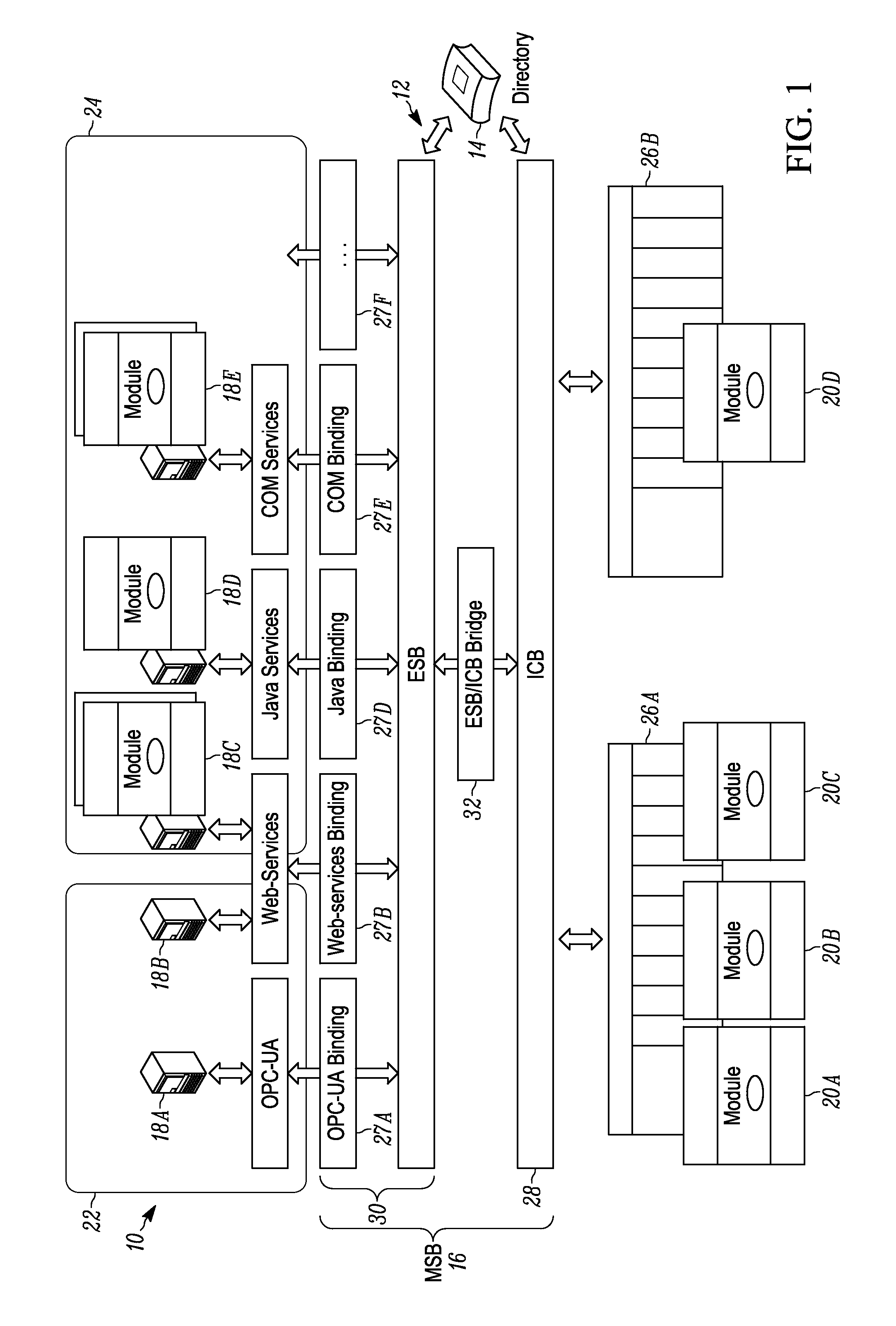

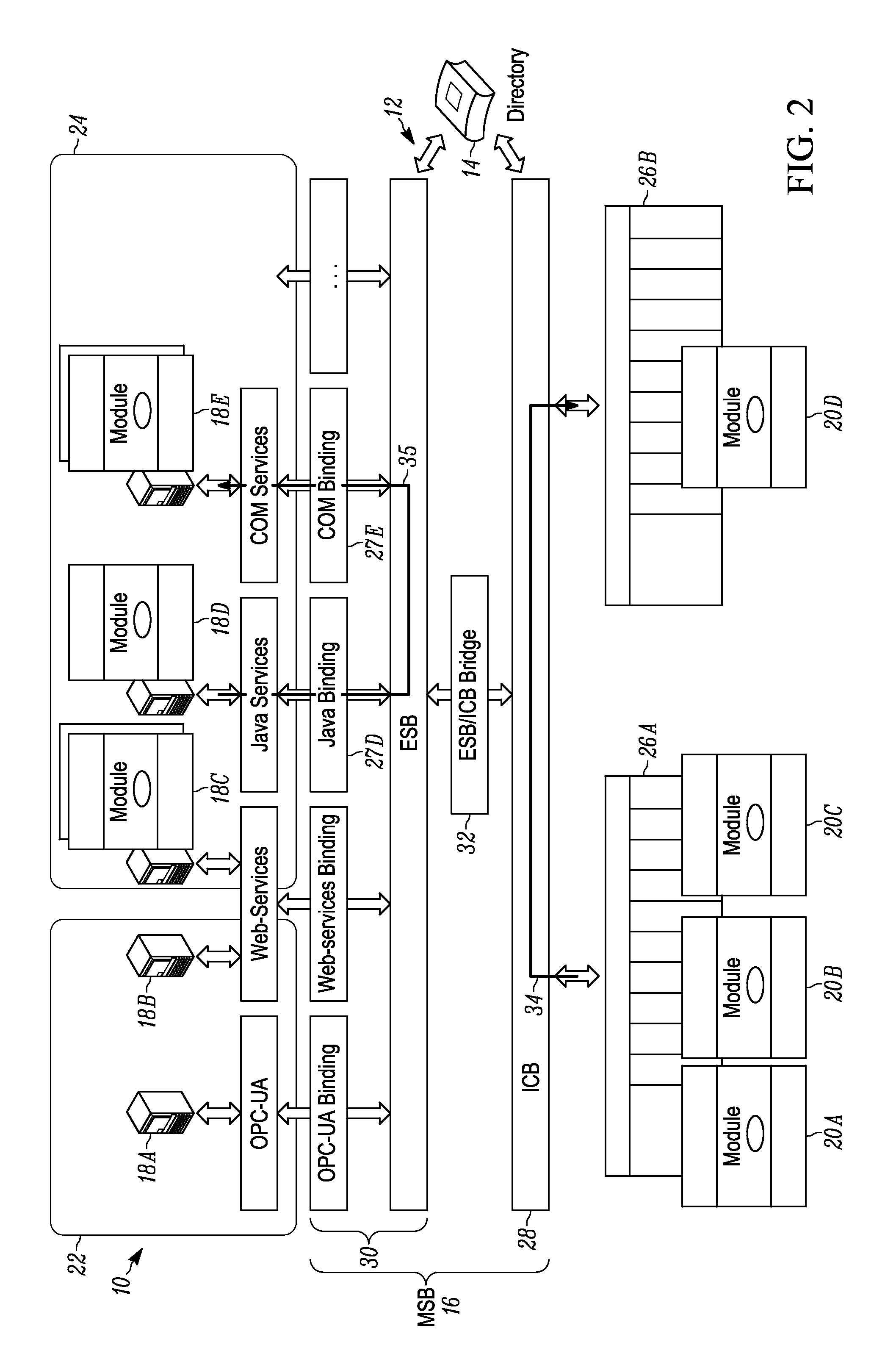

An improved industrial automation system and communication system for implementation therein, and related methods of operation, are described herein. In at least some embodiments, the improved communication system allows communication in the form of messages between modules in different control or enterprise domains. Further, in at least some embodiments, such communications are achieved by providing a communication system including a manufacturing service bus having two internal service busses with a bridge between the internal busses. Also, in at least some embodiments, a methodology of synchronous messaging is employed.

Owner:ROCKWELL AUTOMATION TECH

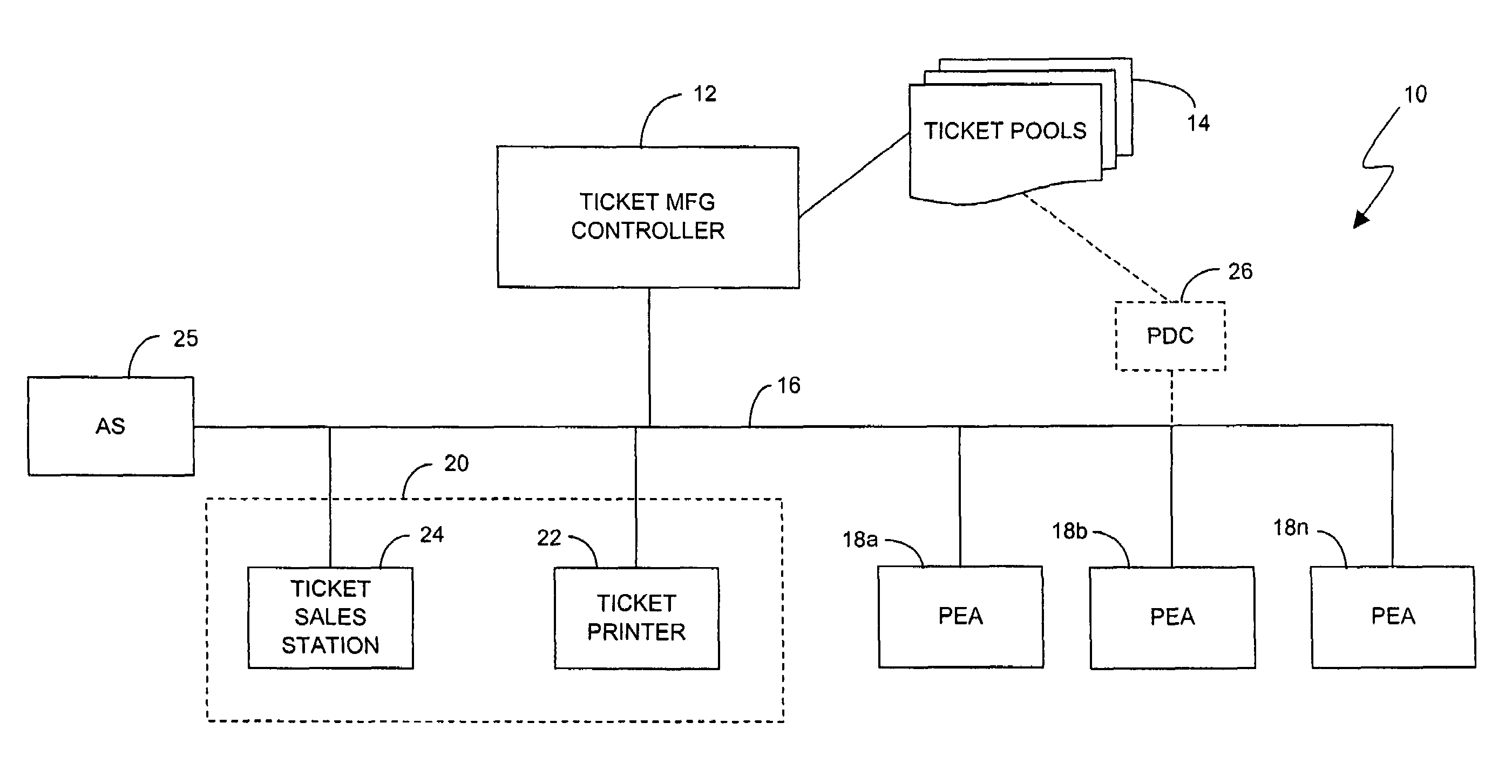

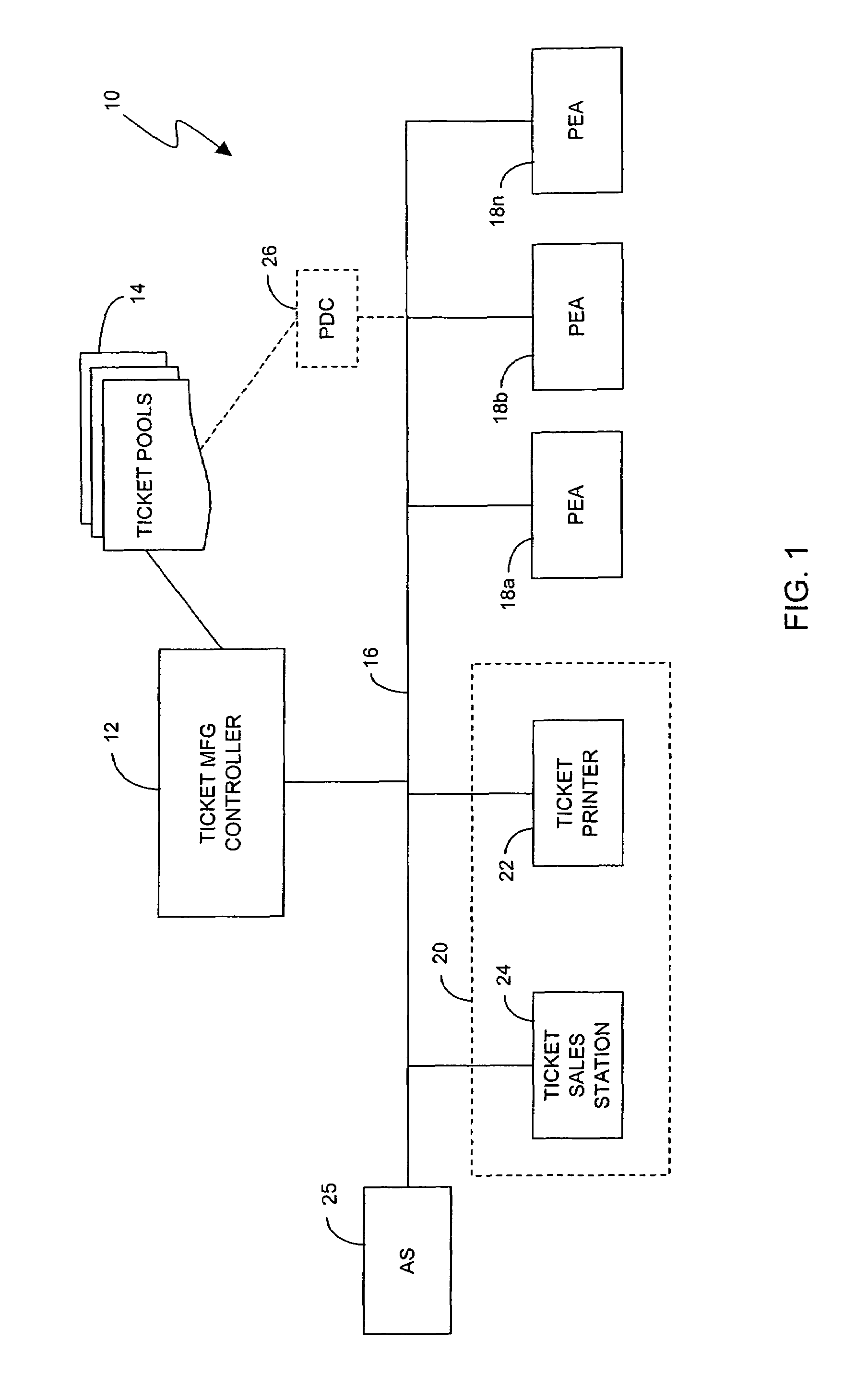

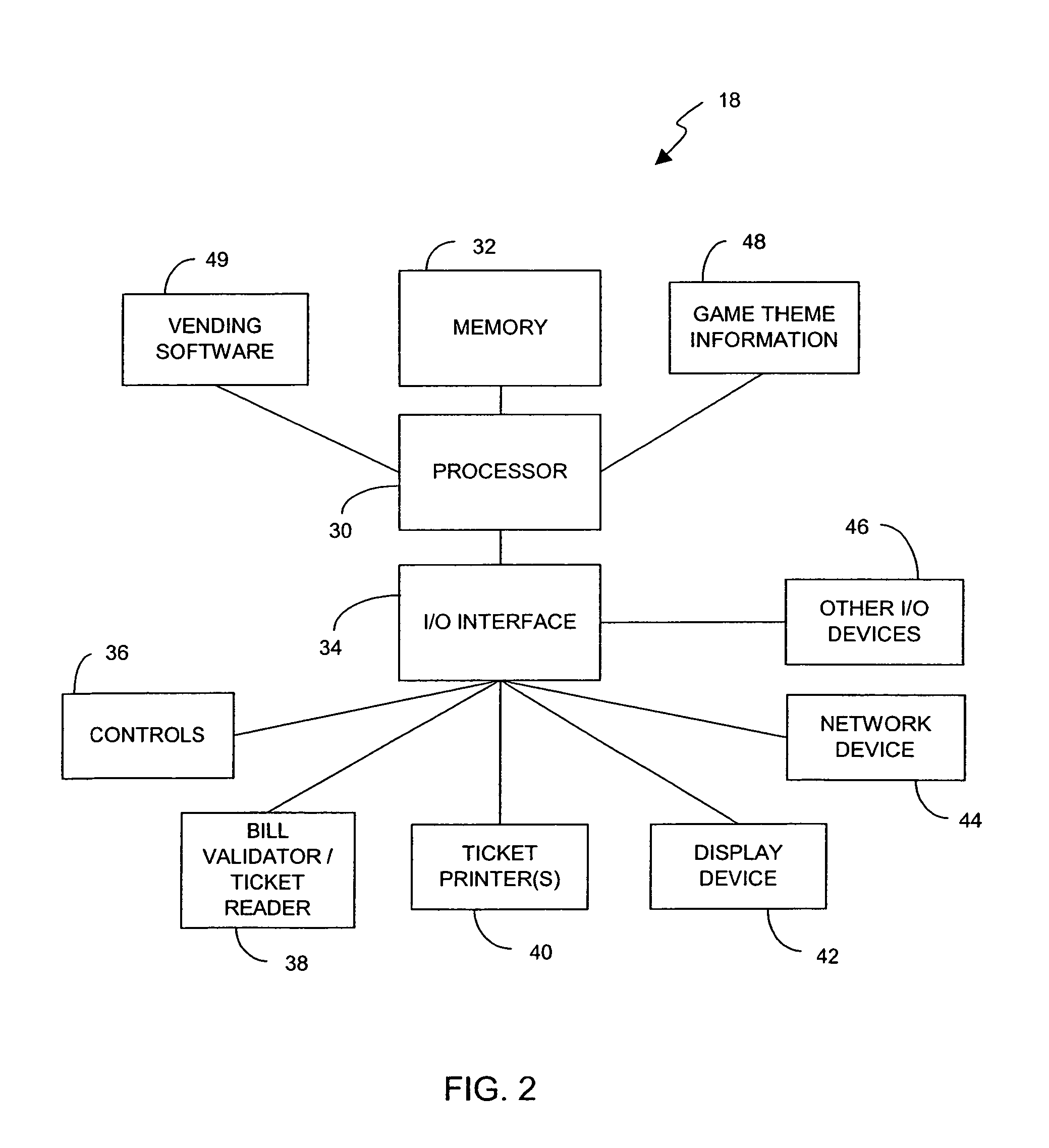

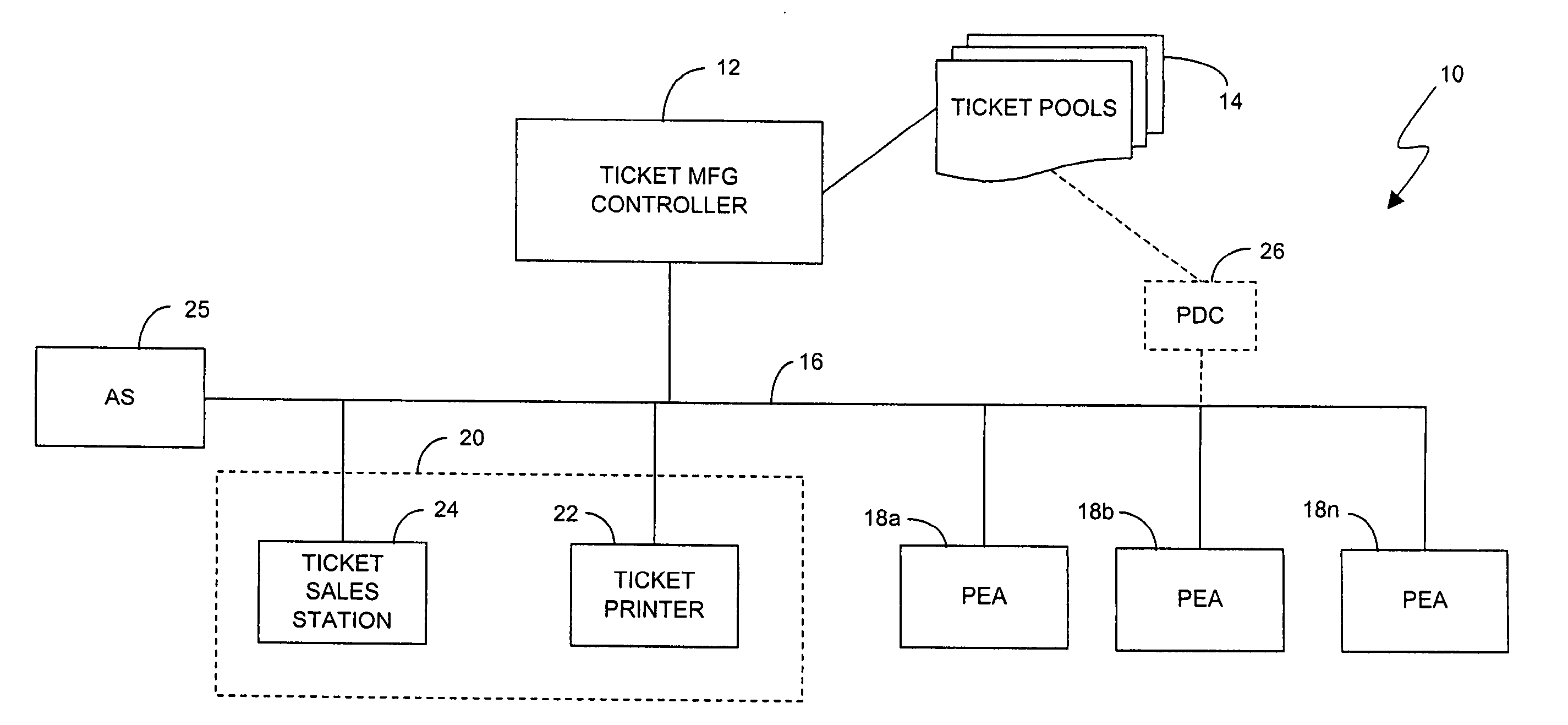

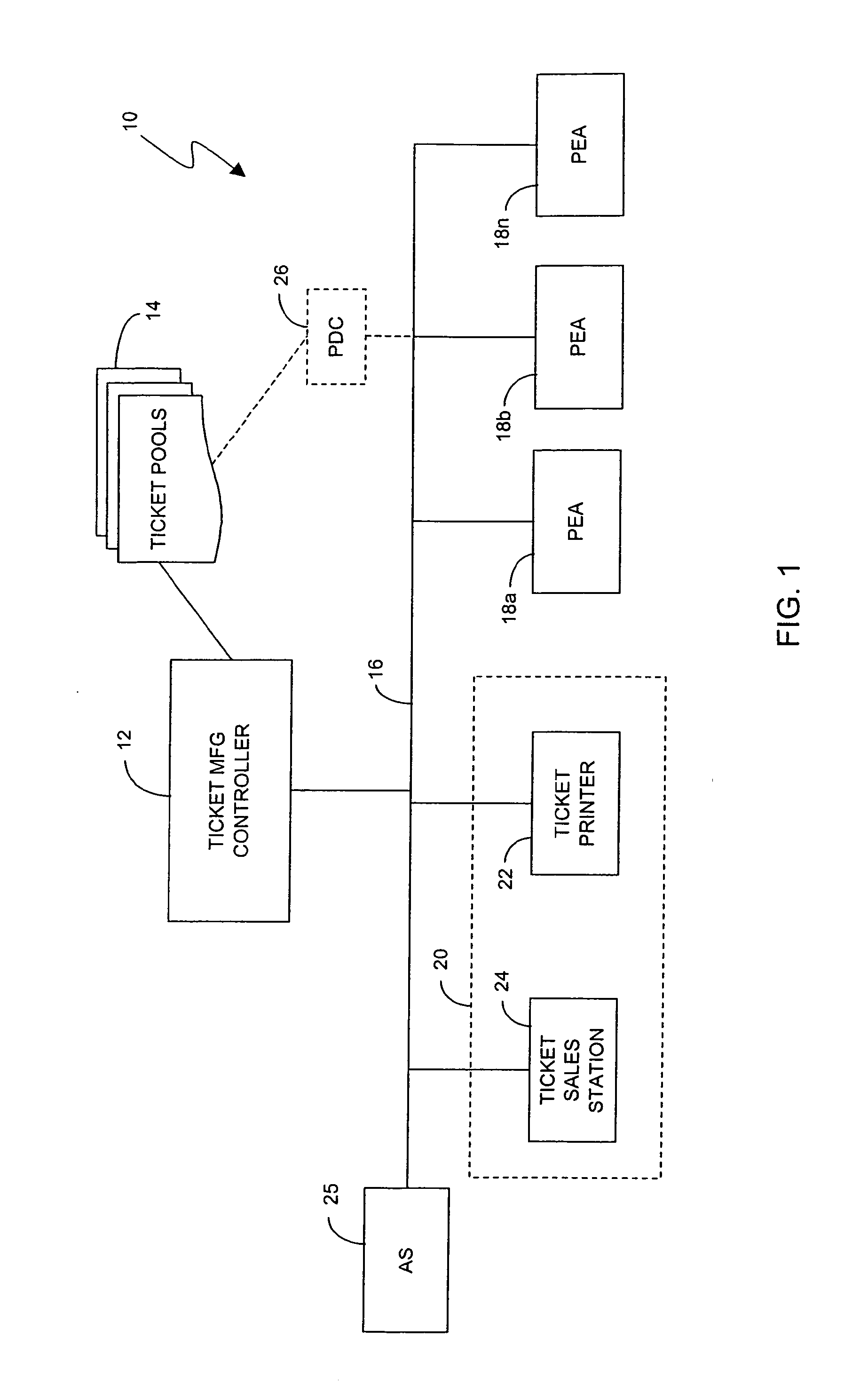

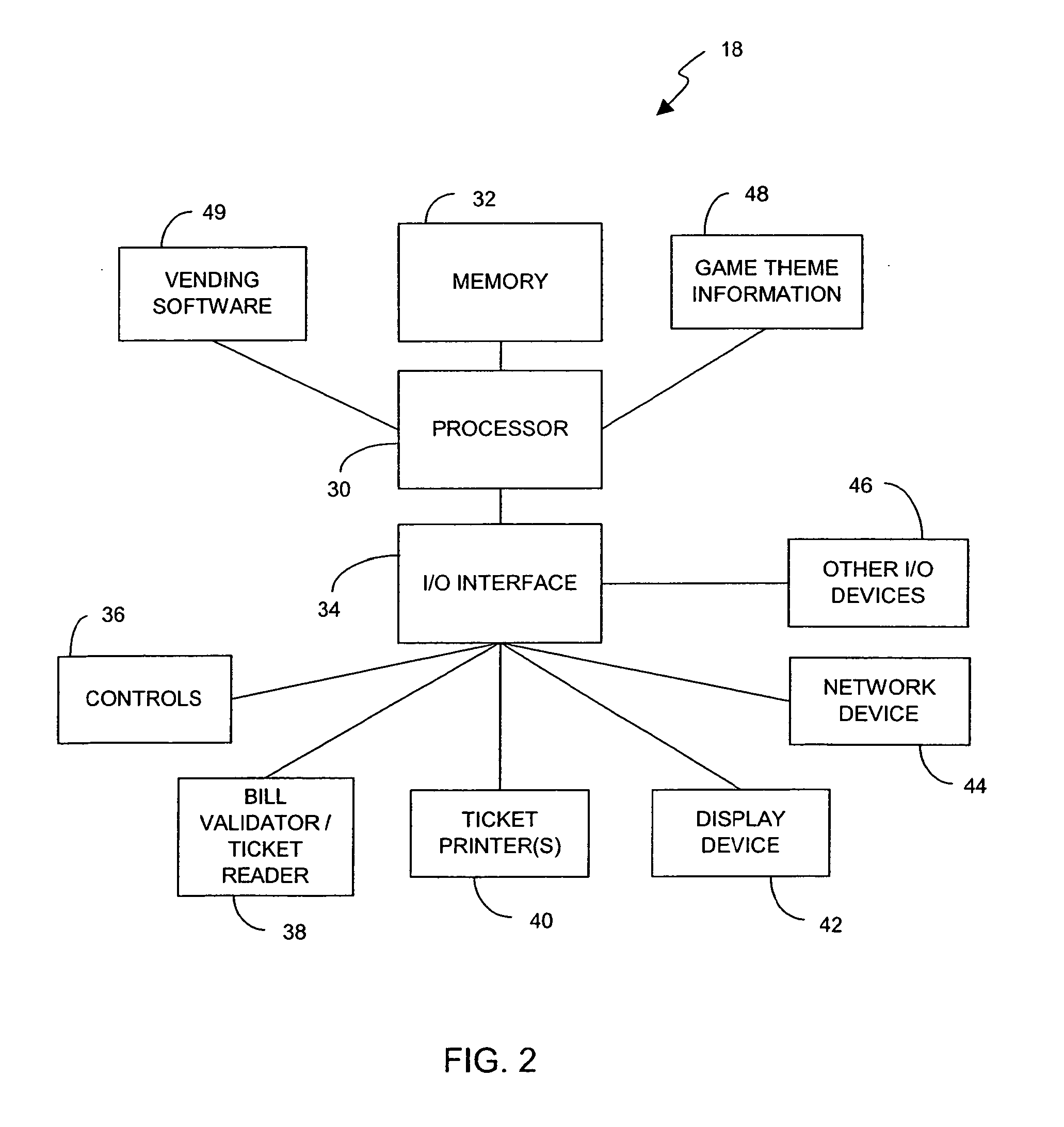

On-demand ticket system

A distributed manufacturing and distribution process for lottery tickets is disclosed. The manufacturing / vending system comprises a ticket manufacturing server and one or more vending devices located at remote sites. Each vending device is operatively coupled for communication with the server, normally via a network connection. Each vending devices is further equipped with blank media and printing means, so that a customer is able to purchase on-demand tickets from a vending device in communication with the server. Additionally, the vending devices may be configured as electronic aid to display the results of the purchased lottery tickets in entertaining ways to the customer.

Owner:BALLY GAMING INC

Systems and methods for conducting communications among components of multidomain industrial automation system

ActiveUS20110258637A1Programme controlDigital data processing detailsCommunications systemComputer module

An improved industrial automation system and communication system for implementation therein, and related methods of operation, are described herein. In at least some embodiments, the improved communication system allows communication in the form of messages between modules in different control or enterprise domains. Further, in at least some embodiments, such communications are achieved by providing a communication system including a manufacturing service bus having two internal service busses with a bridge between the internal busses. Also, in at least some embodiments, a methodology of synchronous messaging is employed.

Owner:ROCKWELL AUTOMATION TECH

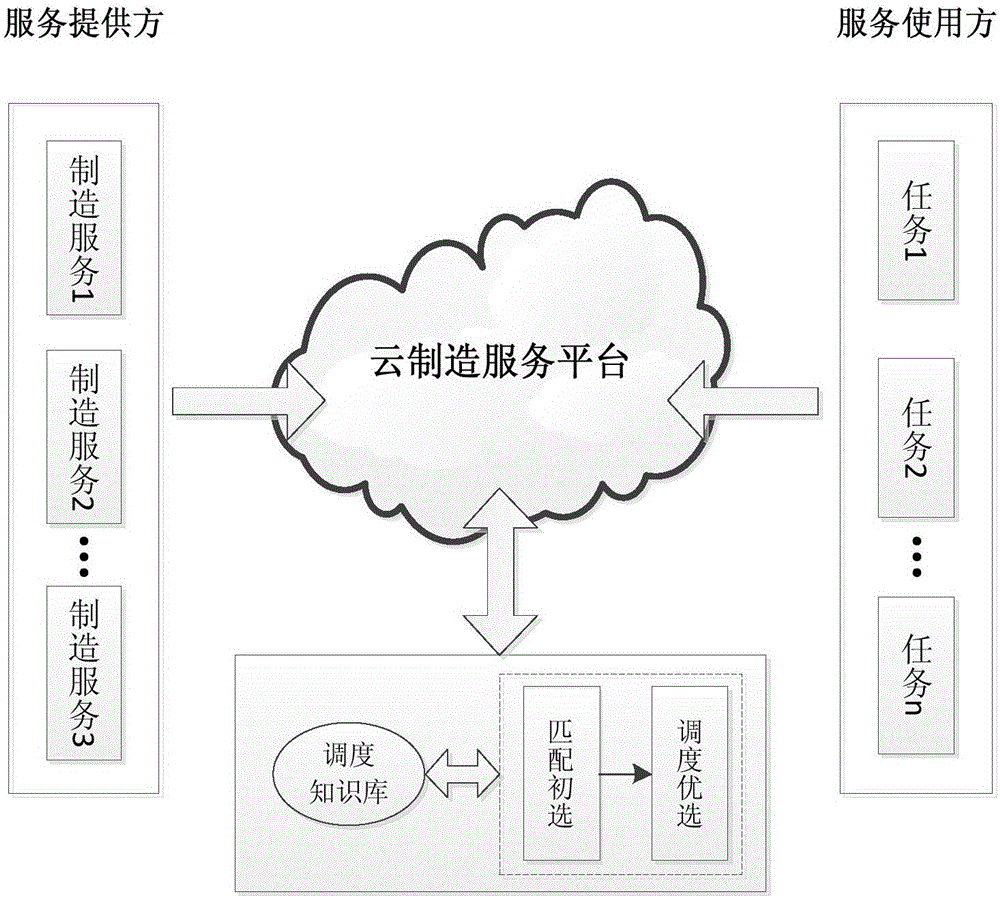

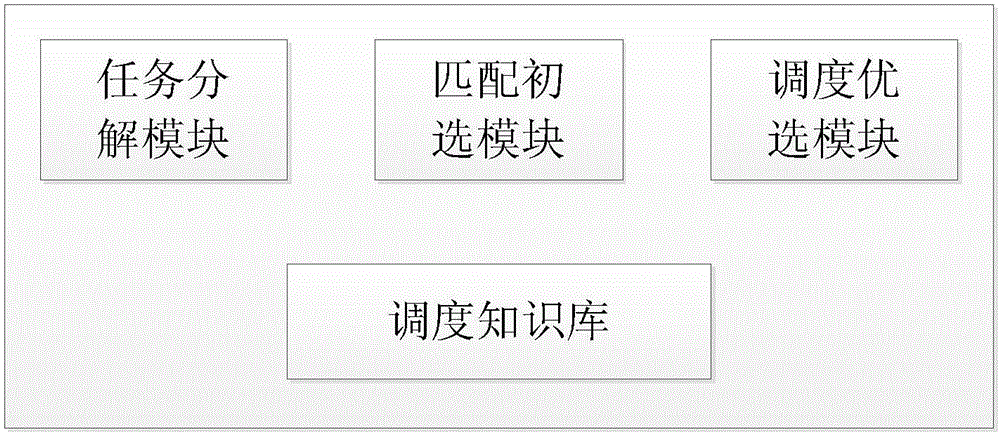

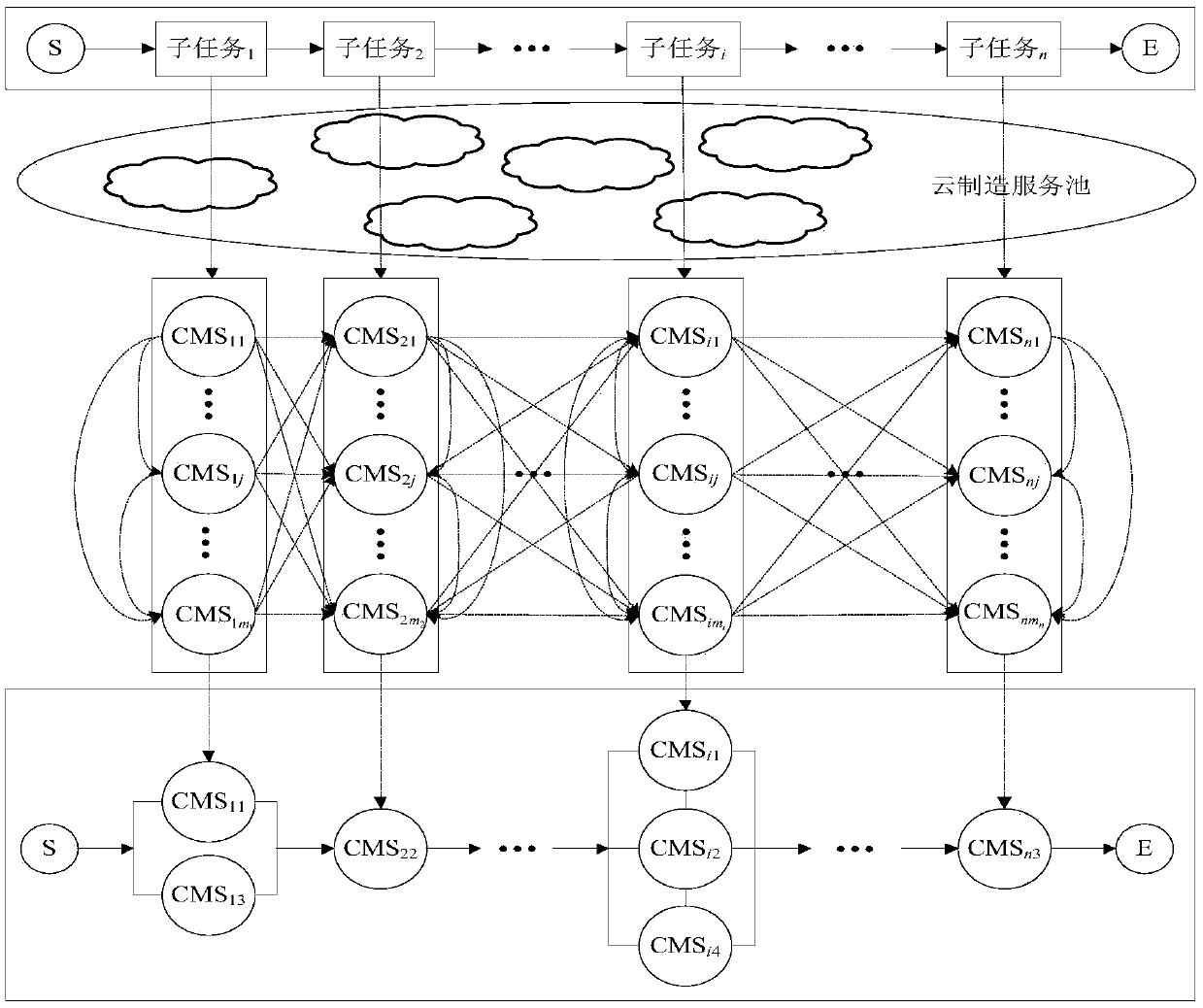

Cloud manufacturing service scheduling method and system

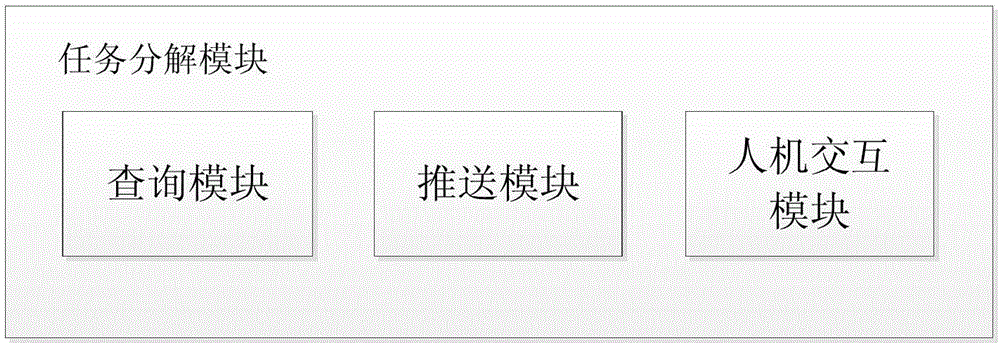

The invention provides a cloud manufacturing service scheduling method and system. A service use direction cloud manufacturing service platform submits a manufacturing task. A task decomposition module in the cloud manufacturing service platform acquires all subtasks corresponding to the task type from the subtask database in a scheduling knowledge base according to the task name and the task type. All subtasks of the task type are pushed to a service consumer on a human-computer interaction interface. The service consumer selects subtasks according to the requirements. Each subtask comprises the subtask name and the subtask identifier. A matching primitive selection module finds a manufacturing service matching the subtask identifier in the scheduling knowledge base according to the subtask identifier, so that each subtask has a separate manufacturing service set. A scheduling optimization selection module carries out optimization selection on manufacturing services in each manufacturing service set according to the restriction condition submitted by the service consumer, so as to complete scheduling finally. The scheduling knowledge base updates manufacturing services registered on the cloud manufacturing service platform according to a service provider.

Owner:SUNWAVE COMM

Systems and methods for conducting communications among components of multidomain industrial automation system

ActiveUS20110258359A1Facilitate communicationEasy to set upProgramme controlWireless commuication servicesCommunications systemEngineering

An improved industrial automation system and communication system for implementation therein, and related methods of operation, are described herein. In at least some embodiments, the improved communication system allows communication in the form of messages between modules in different control or enterprise domains. Further, in at least some embodiments, such communications are achieved by providing a communication system including a manufacturing service bus having two internal service busses with a bridge between the internal busses. Also, in at least some embodiments, a methodology of synchronous messaging is employed.

Owner:ROCKWELL AUTOMATION TECH

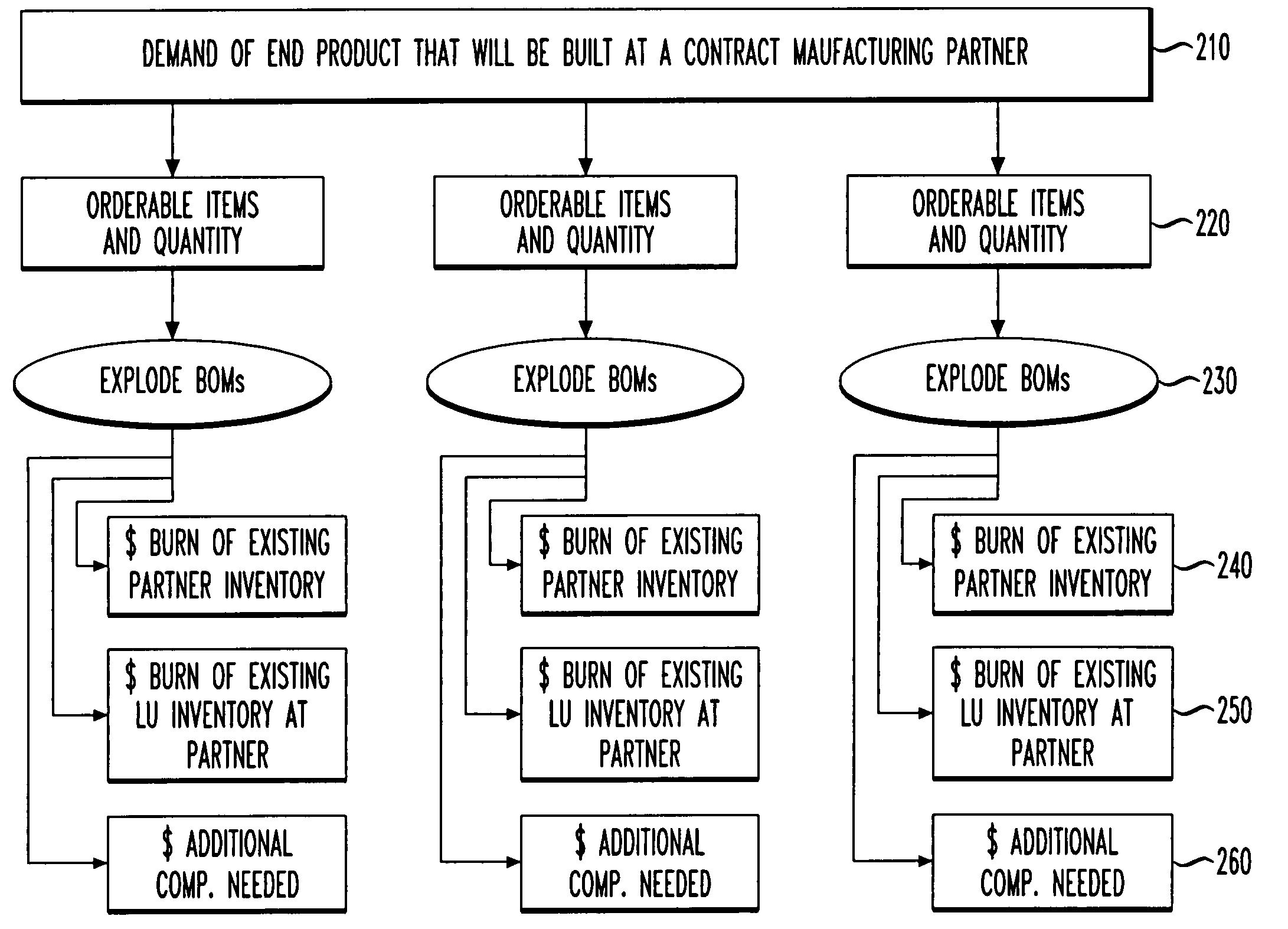

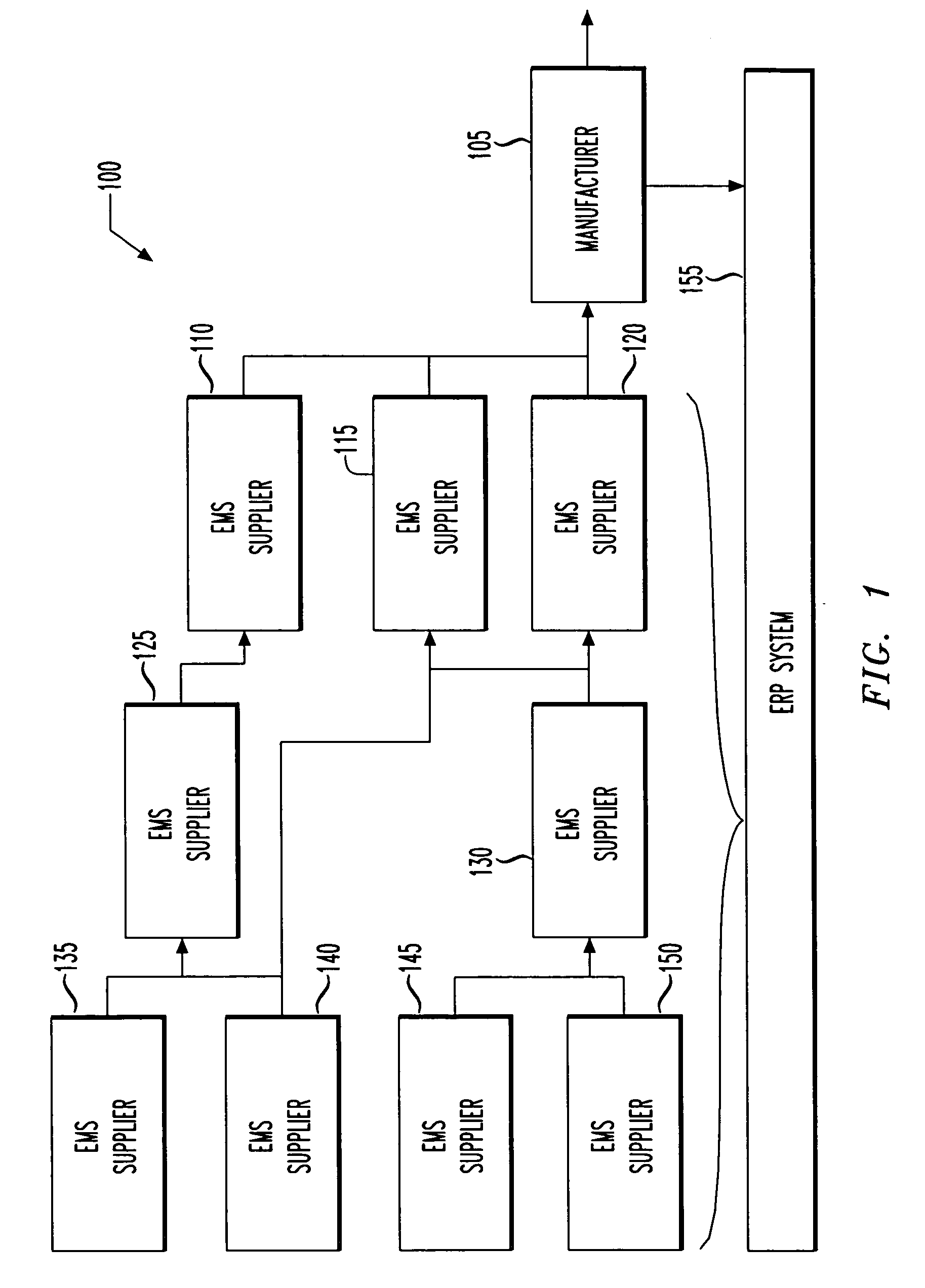

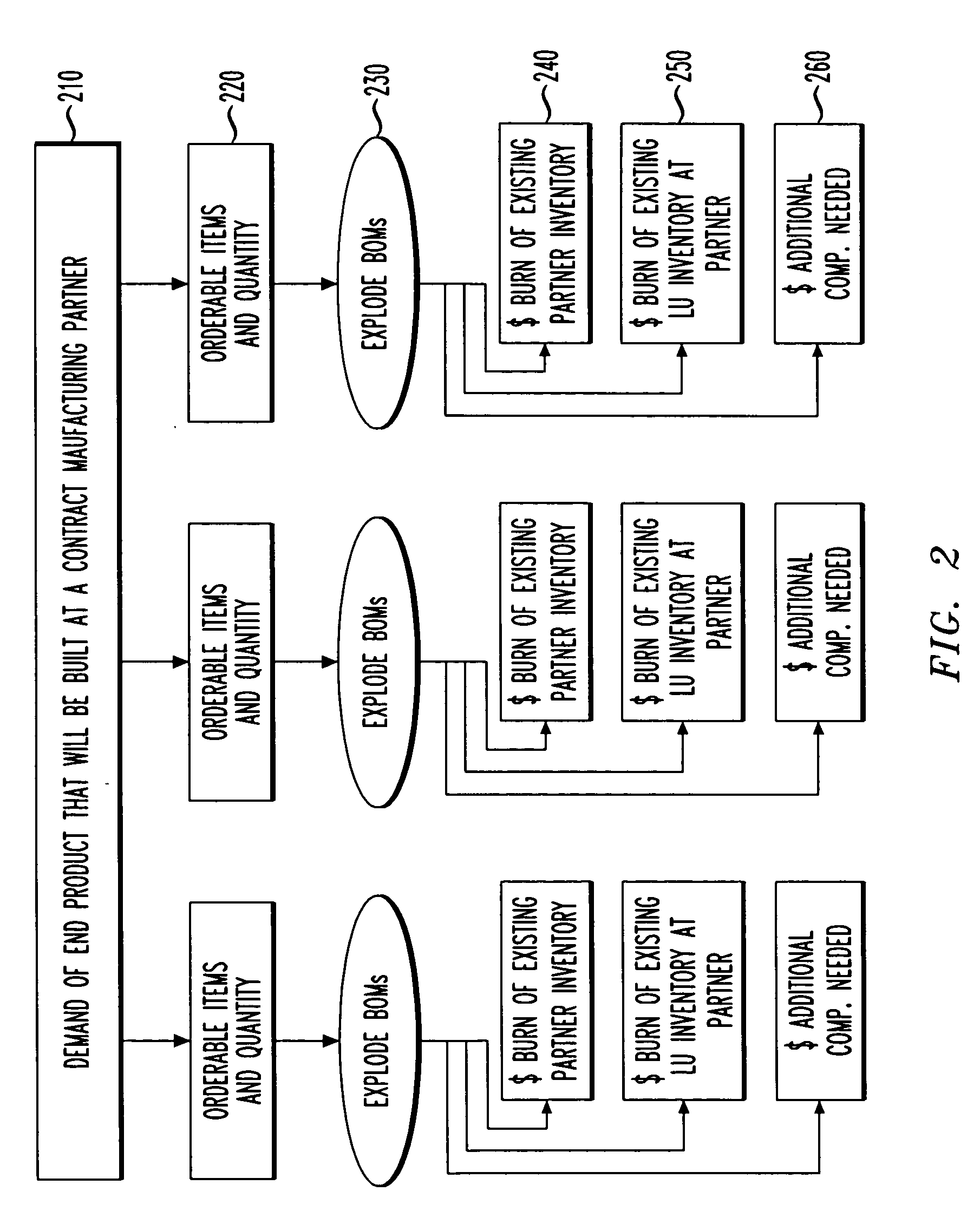

System and method for mitigating inventory risk in an electronic manufacturing services-based supply chain management and manufacturing execution system

InactiveUS20050288979A1Reduce riskReduce inventory riskSpecial data processing applicationsManufacture execution systemEnterprise resource planning

A system and method for mitigating inventory risk and an enterprise resource planning (ERP) system incorporating such system or method. In one embodiment, the system includes: (1) a uniqueness factor calculator configured to assign, to parts in an associated production database, uniqueness factors that are a function of a number of different products into which said parts go and (2) a risk report generator associated with said uniqueness factor calculator and configured to generate a report of risks associated with said products and based on said uniqueness factors.

Owner:LUCENT TECH INC

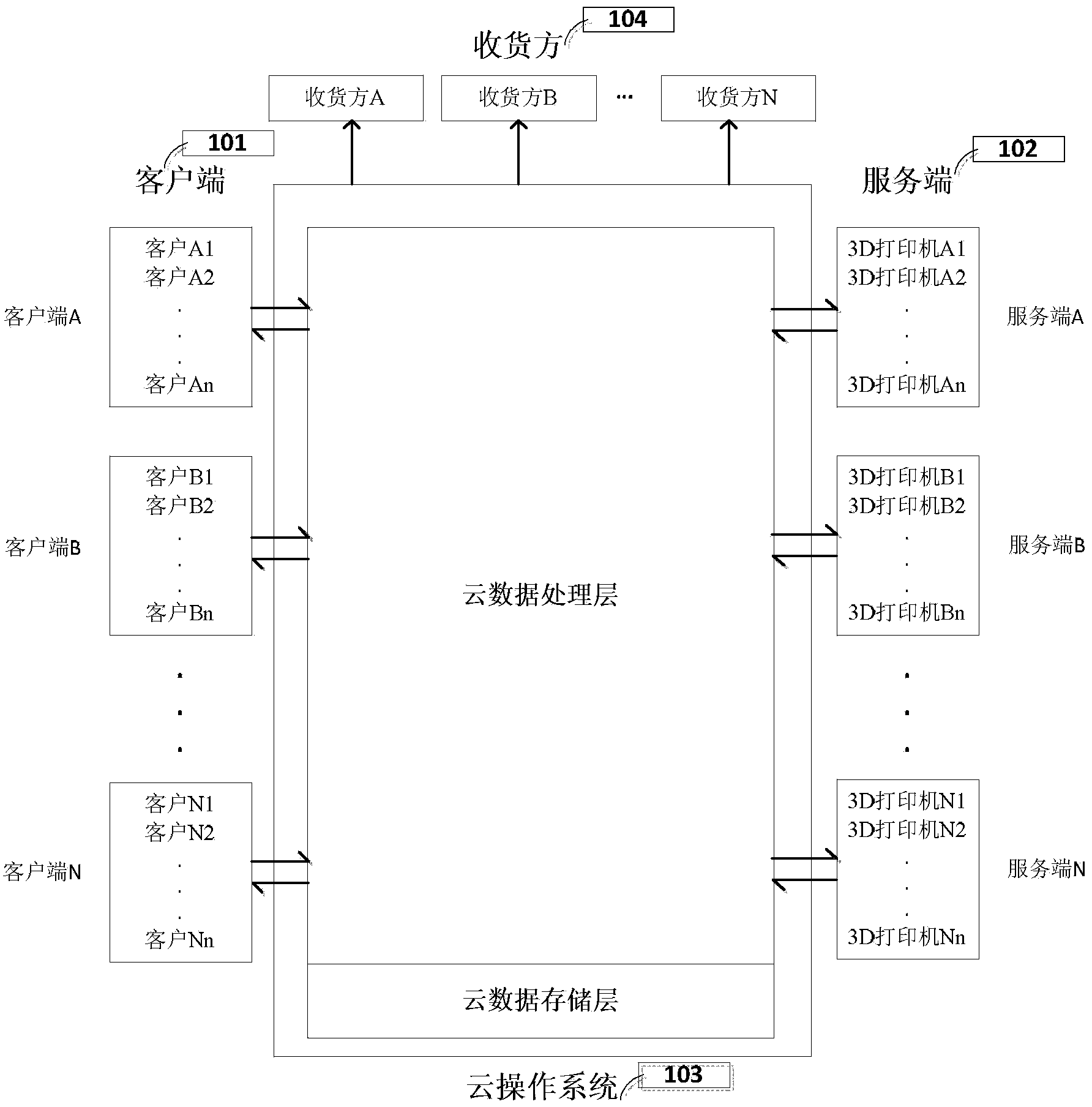

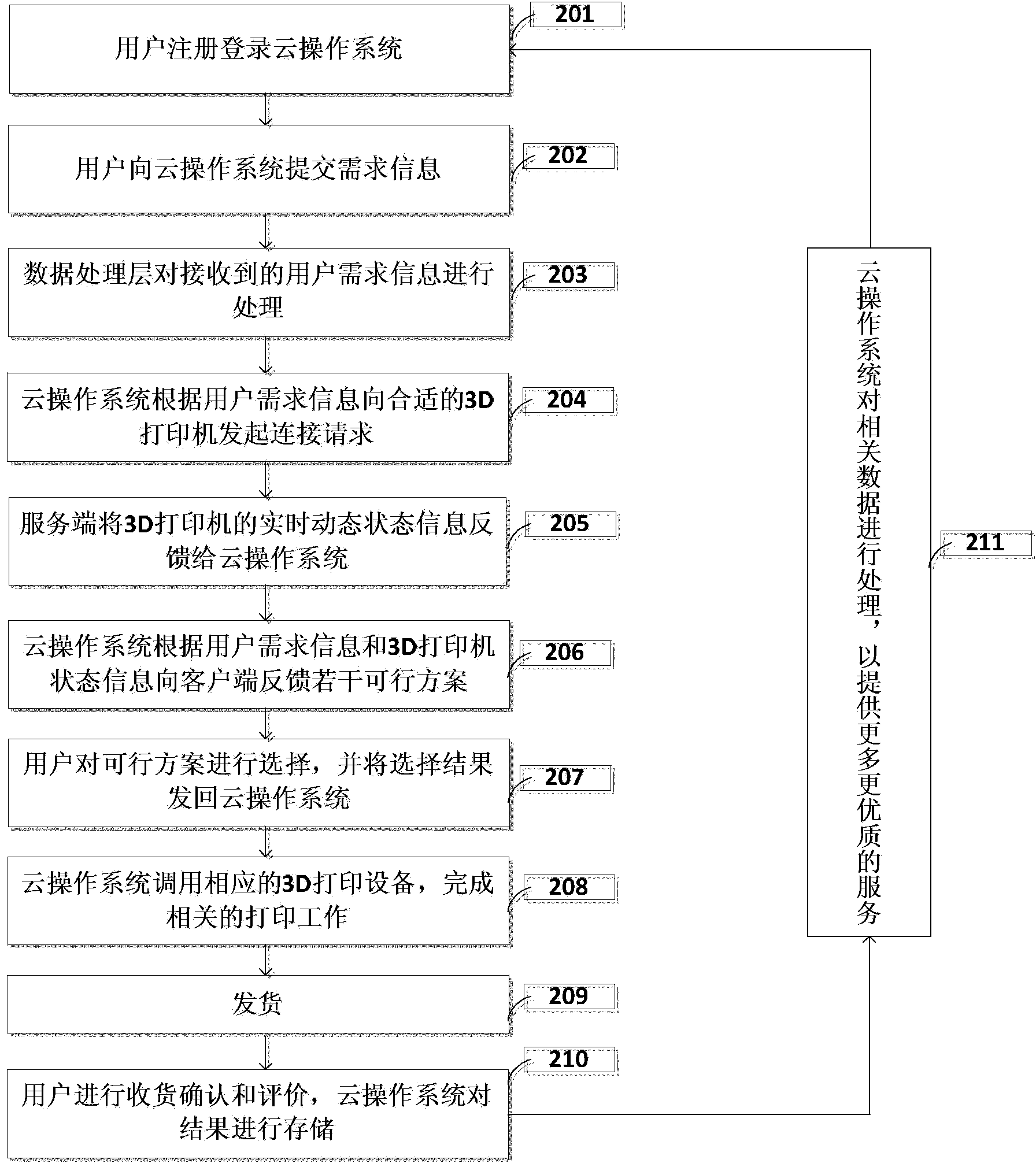

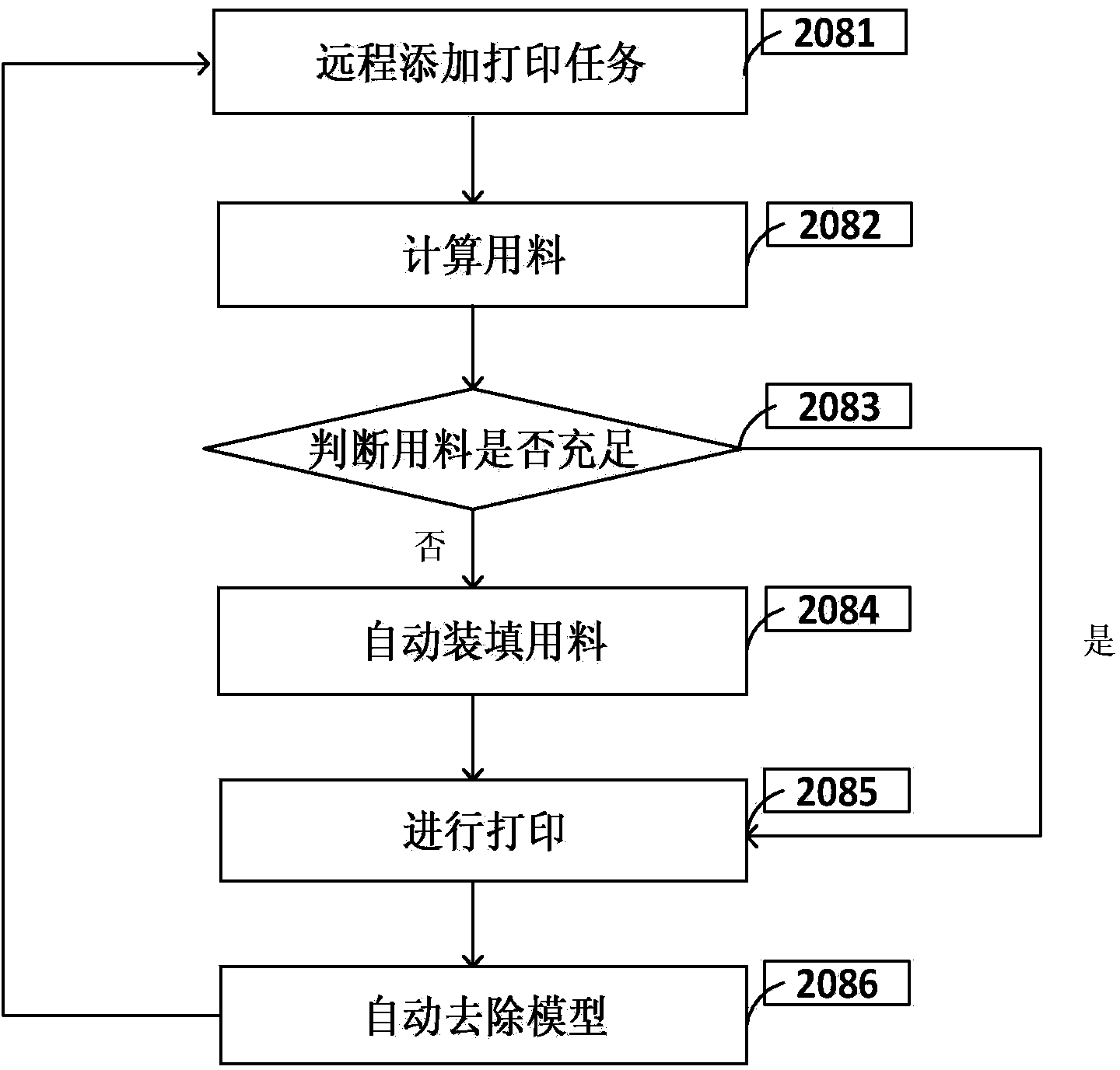

Additive manufacturing resource dispatching system based on cloud computing and corresponding method

ActiveCN103414792ARealize scheduling optimizationReduce sizeTransmissionLimited resourcesResource utilization

The invention discloses an additive manufacturing resource dispatching system based on cloud computing and a corresponding method. The system comprises a client for requiring an additive manufacturing task and receiving feedback information from a cloud operating system, a service end for executing the additive manufacturing task and receiving the additive manufacturing request from the cloud operating system as well as sending a manufactured product to a receiving party, the cloud operating system for coordinating work between the client and the service end, and the receiving part for receiving the product obtained by an additive manufacturing service. The invention further discloses an additive manufacturing resource dispatching method. According to the invention, automatic packing materials and automatic removing model of a 3D printer are realized by remotely controlling a computer based on cloud computing technology, different parts printed in a same place are automatically assembled according to a client demand, and the resource dispatching optimization problem of existing additive manufacturing industries with 3D printing as a representative, so that a 3D printer is networked from the original single printer, thereby, optimizing the utilization ratio of limited resources.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Method for Manufacturing On-Demand Lottery Tickets

A distributed manufacturing and distribution process for lottery tickets is disclosed. The manufacturing / vending system comprises a ticket manufacturing server and one or more vending devices located at remote sites. Each vending device is operatively coupled for communication with the server, normally via a network connection. Each vending devices is further equipped with blank media and printing means, so that a customer is able to purchase on-demand tickets from a vending device in communication with the server. Additionally, the vending devices may be configured as electronic aid to display the results of the purchased lottery tickets in entertaining ways to the customer.

Owner:BALLY GAMING INC

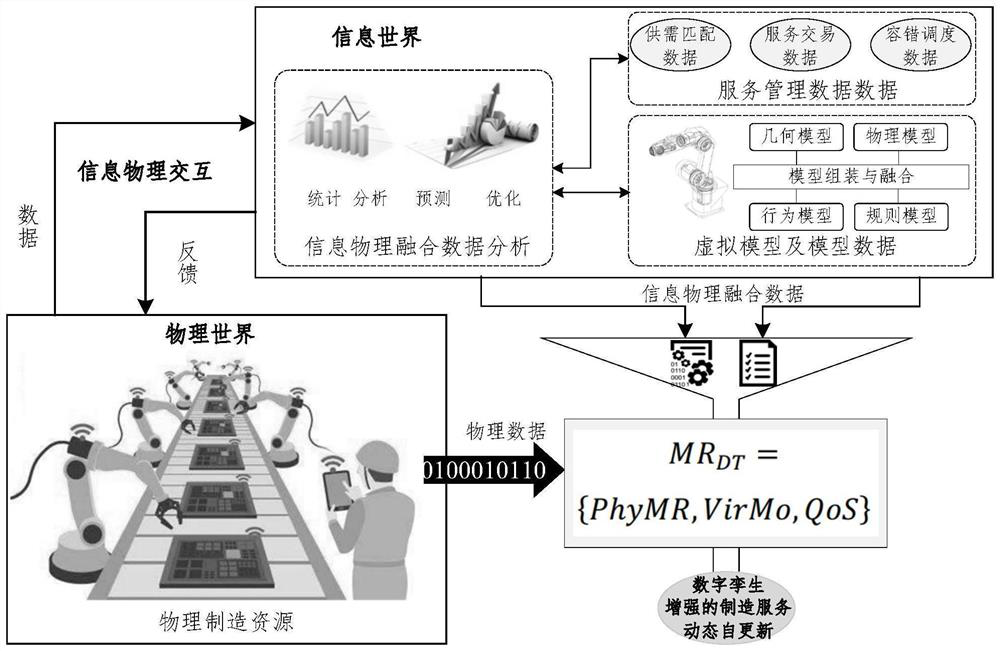

Digital twinning enhanced manufacturing service information physical fusion method

ActiveCN112101899AAchieve integrationRealize dynamic self-updateDesign optimisation/simulationOffice automationService informationVirtual model

The invention discloses a digital twinning enhanced manufacturing service information physical fusion method, which comprises the following steps of designing a digital twinning enhanced manufacturingresource servitization packaging module, firstly, establishing a high-fidelity virtual model for physical manufacturing resources, establishing a unified description template; packaging the virtual and real information of the physical manufacturing resources into a manufacturing service at the same time to form a digital twin enhanced manufacturing service; designing a service information physical fusion module, when a service is called, firstly calling a virtual model to simulate a manufacturing task demand to obtain a feasible optimal scheme, then calling physical resources to execute a task, and performing synchronous interaction and real-time coordination in the execution process; information physical fusion of services is realized based on fusion analysis of data in a virtual-real space, and dynamic updating of the services is realized through feedback of fusion data. According to the method, the accuracy of manufacturing resource service in the twin workshop can be improved to acertain extent, and the evolution of the manufacturing service caused by sequential extension and external environment change at any time is described.

Owner:BEIHANG UNIV

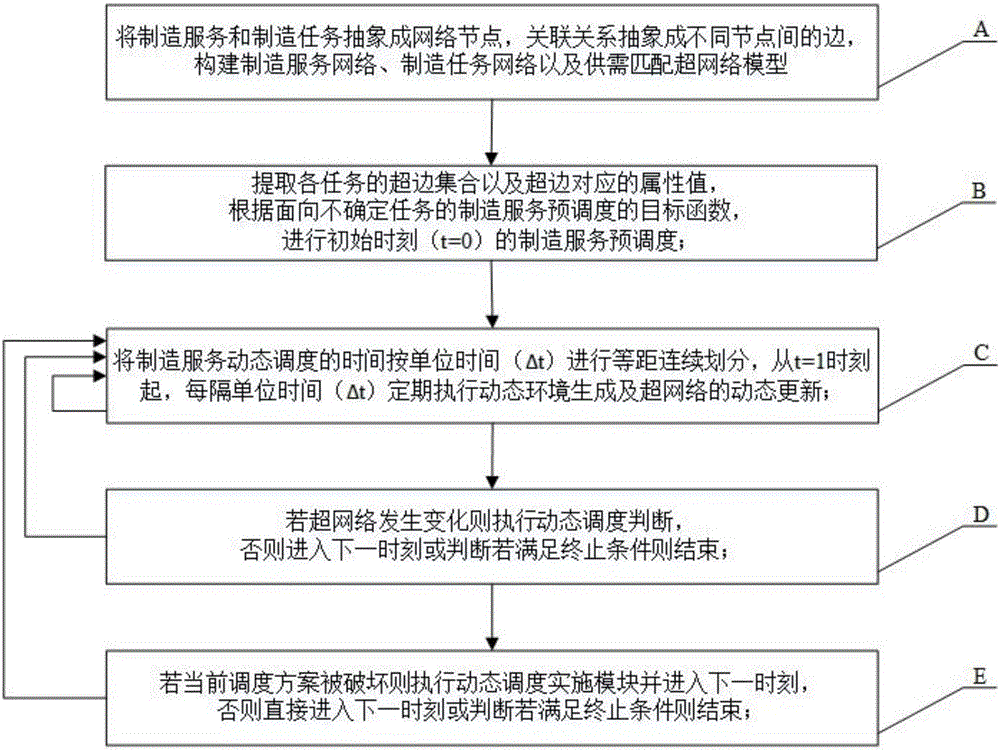

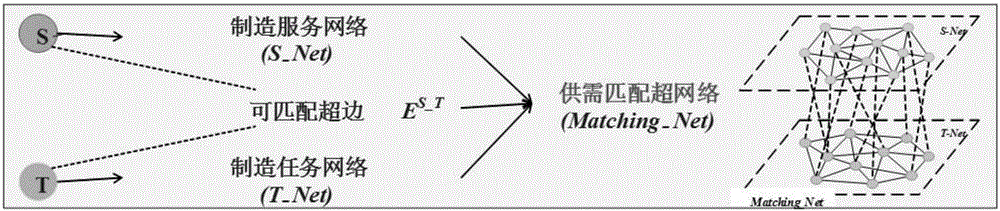

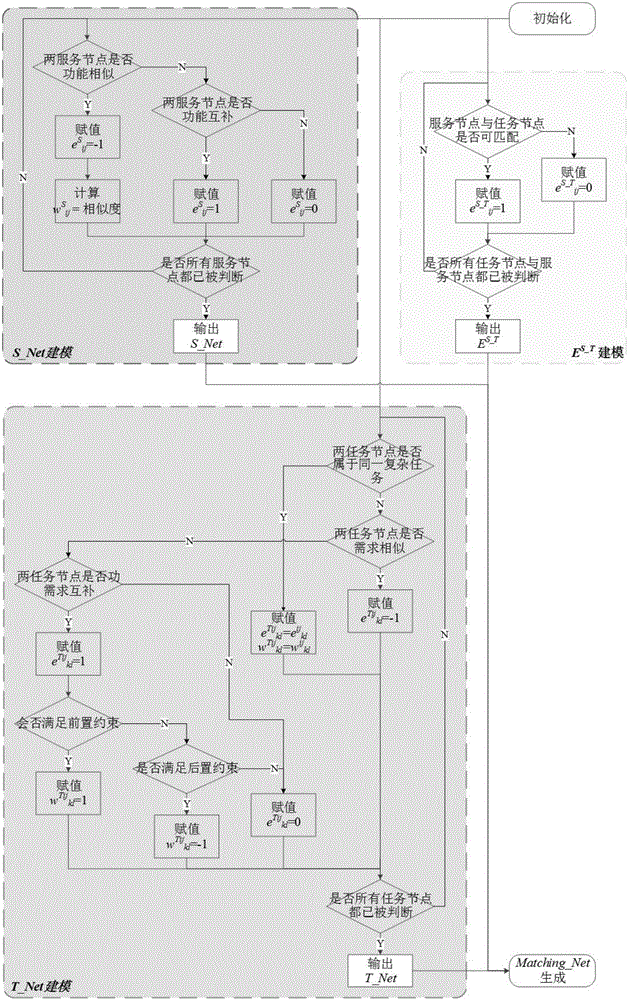

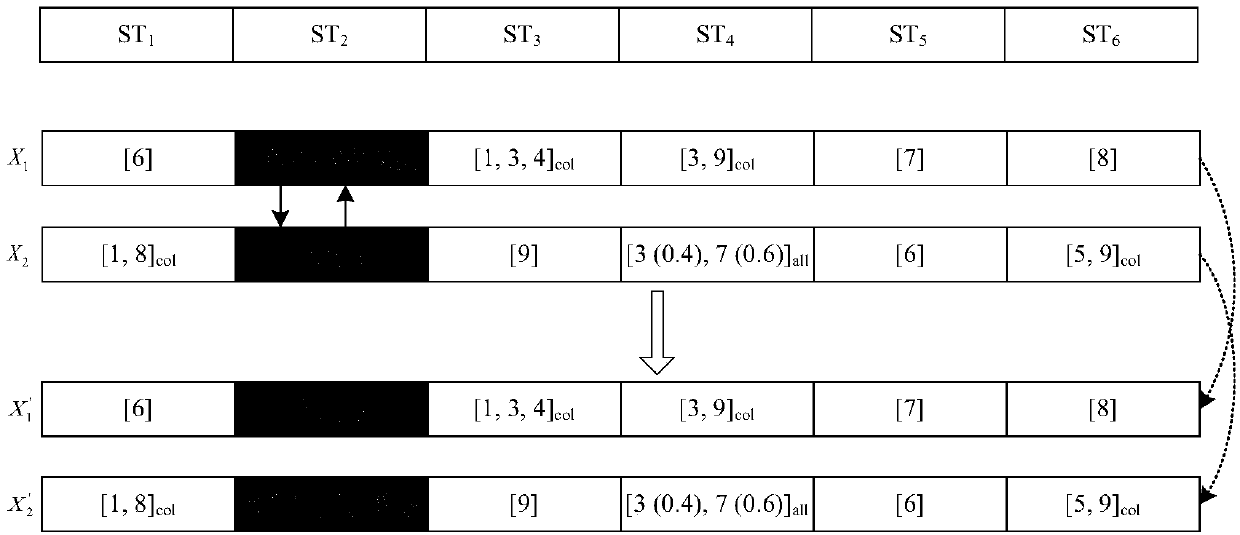

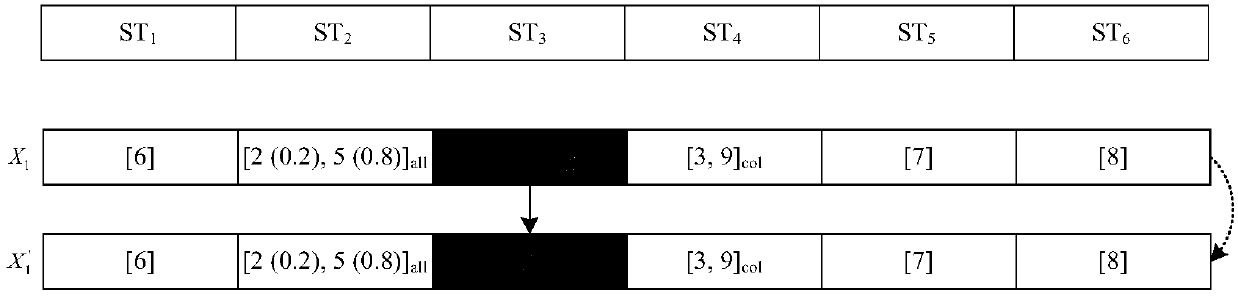

Supply-demand matching and dynamic scheduling method of manufacturing service based on hypernetwork

InactiveCN105959401AScalableMultiple assignment methodsGeometric CADTransmissionService-orientationDependability

This invention relates to a supply-demand matching and dynamic scheduling method of manufacturing service based on a hypernetwork. The method comprises the following steps: A, constructing a supply-demand matching hypernetwork model of the manufacturing service; B, before a task is executed actually, pre-scheduling the manufacturing service of an initial time; C, performing isometric and continuous division to the dynamic scheduling time of the manufacturing service according to units of unit time; from the time unit t=1, periodically generating a dynamic environment and executing the update of the hypernetwork at the interval of each unit of the unit time; D, if the hypernetwork changes, executing dynamic scheduling judge; otherwise, entering the next time unit, or finishing if the judge meets a stopping criterion; E, and if the current scheduling scheme is destroyed, executing dynamic rescheduling to generate a new scheduling scheme. The method provided by the invention can effectively reflect the dynamic environment in the service-oriented manufacturing system, and can ensure the validity of the dynamic scheduling of the manufacturing service and higher cooperation reliability of participant enterprises.

Owner:BEIHANG UNIV

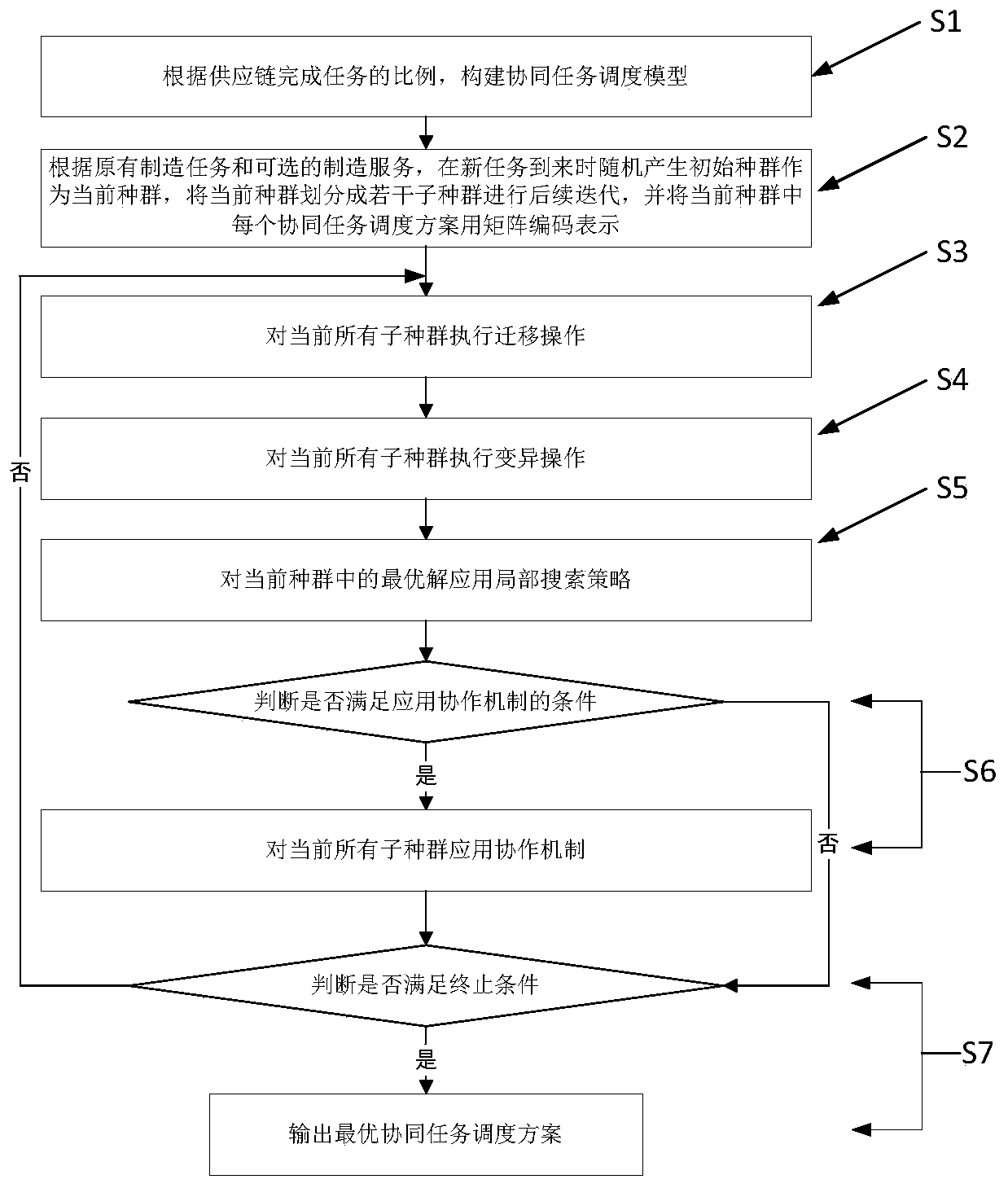

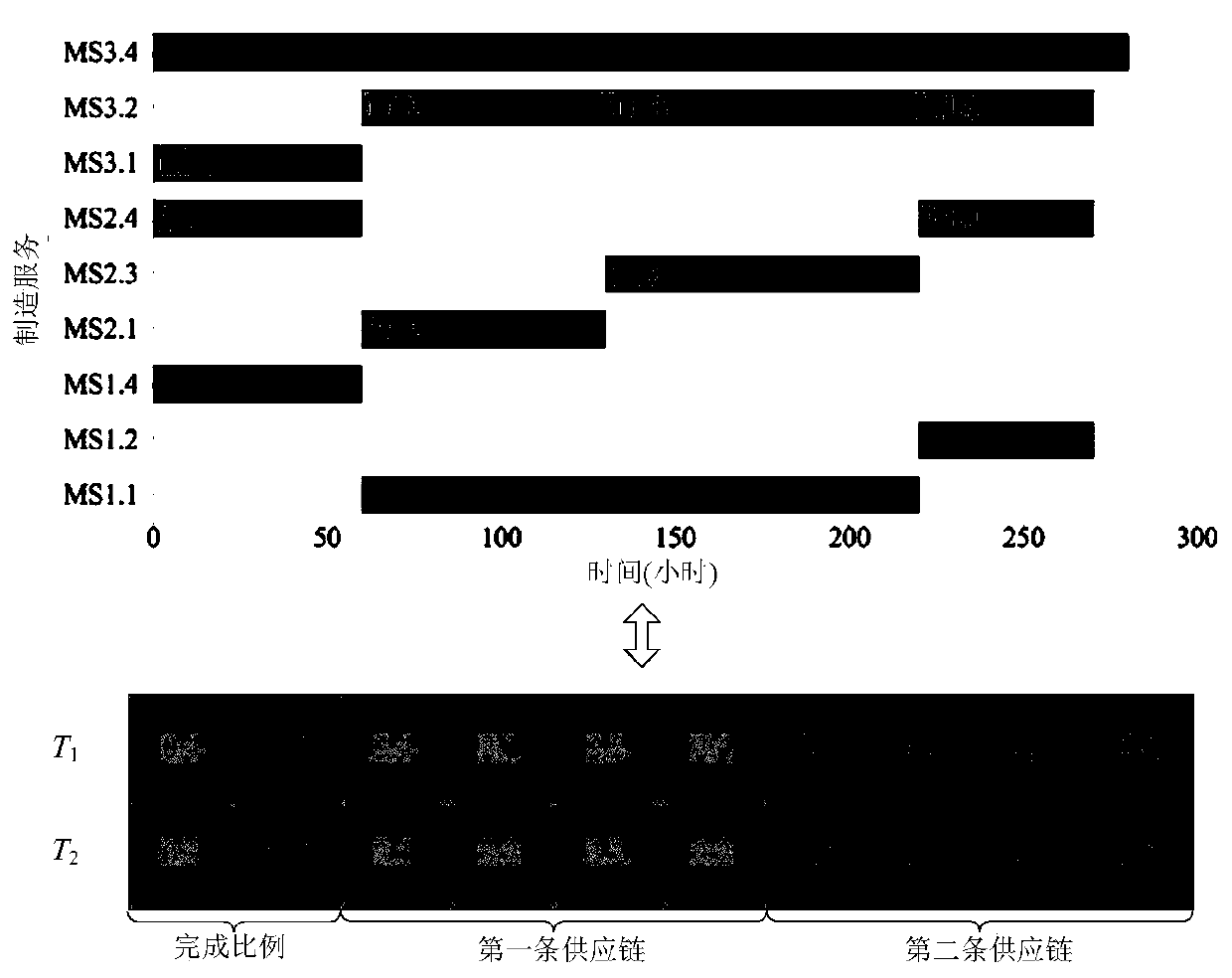

A dynamic task perception-oriented cloud manufacturing collaborative task scheduling method

InactiveCN109816243AImproving Performance in Solving Task Scheduling ProblemsOptimal Scheduling SchemeGenetic modelsForecastingSub populationsBiogeography

The invention discloses a dynamic task perception-oriented cloud manufacturing collaborative task scheduling method, which comprises the following steps of firstly, constructing a collaborative task scheduling model according to the proportion of tasks completed by a supply chain; generating an initial population as a current population when a new task arrives according to an original manufacturing task and an optional manufacturing service, dividing the current population into a plurality of sub-populations for subsequent iteration, and representing each collaborative task scheduling scheme in the current population by using matrix coding; and finally, solving is performed through an improved multi-population biogeography optimization algorithm, and fusing a multi-population strategy, a local search strategy and a cooperation mechanism, so that the task scheduling problem solving performance of the algorithm is improved. According to the method, a better scheduling scheme can be obtained in the scheduling stage and the re-scheduling stage.

Owner:ZHEJIANG UNIV OF FINANCE & ECONOMICS

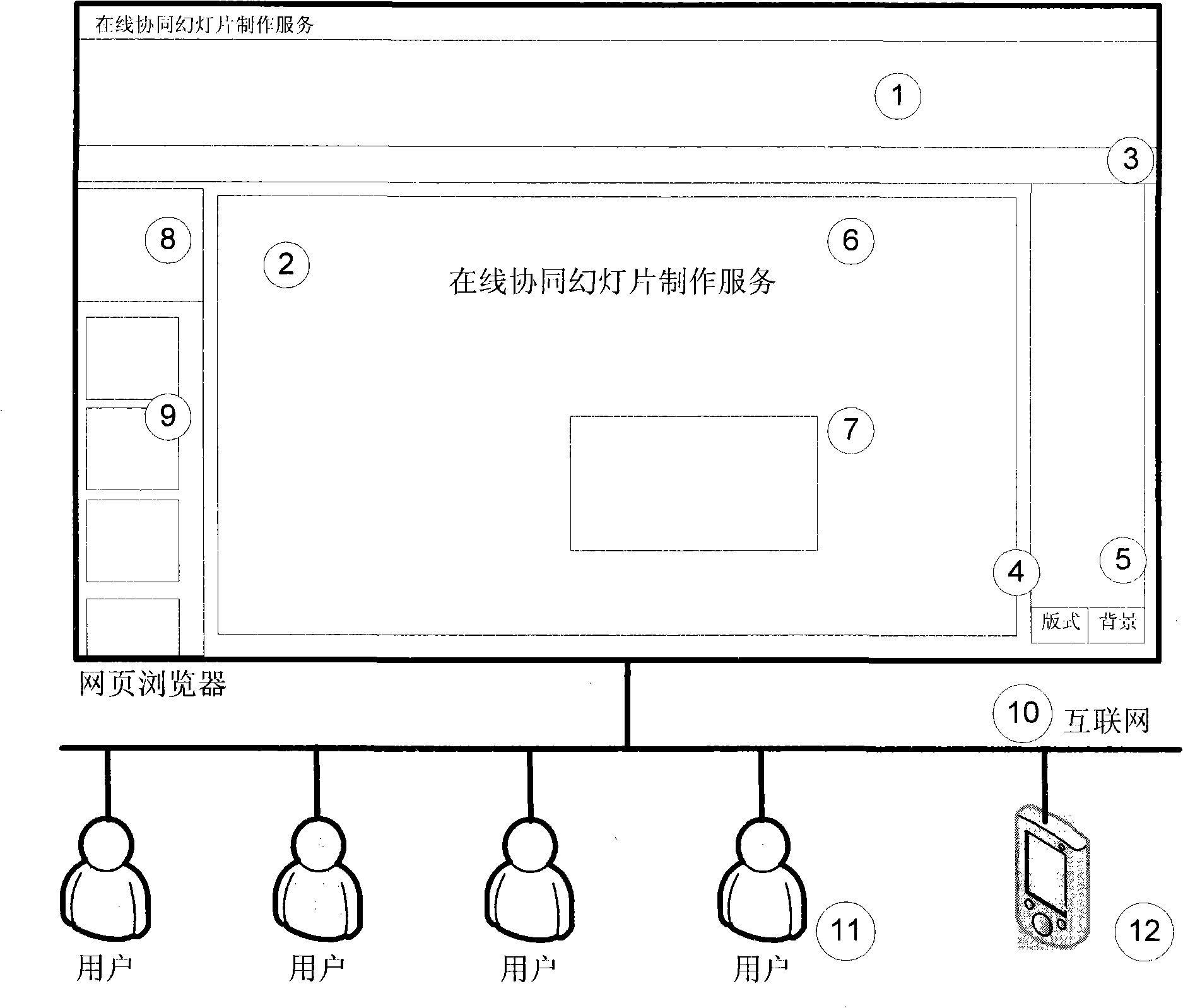

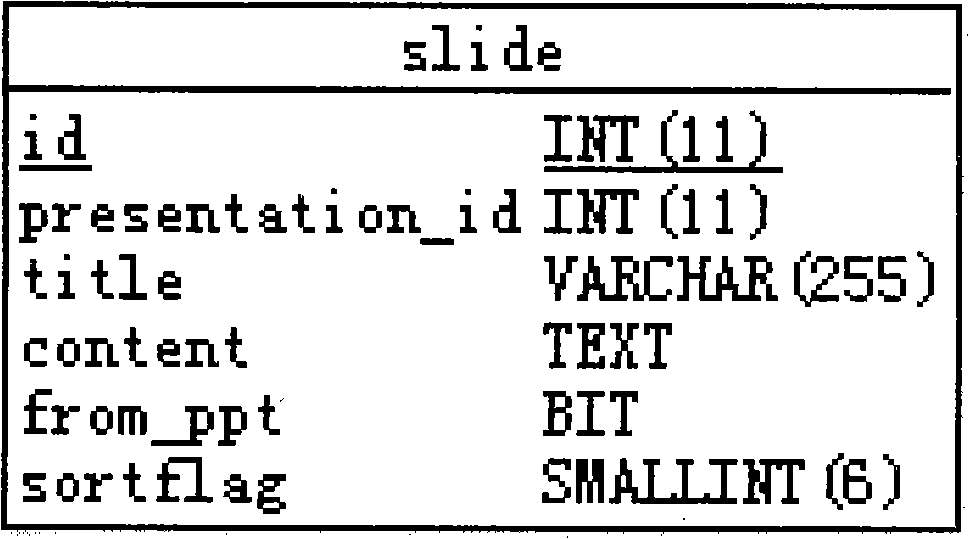

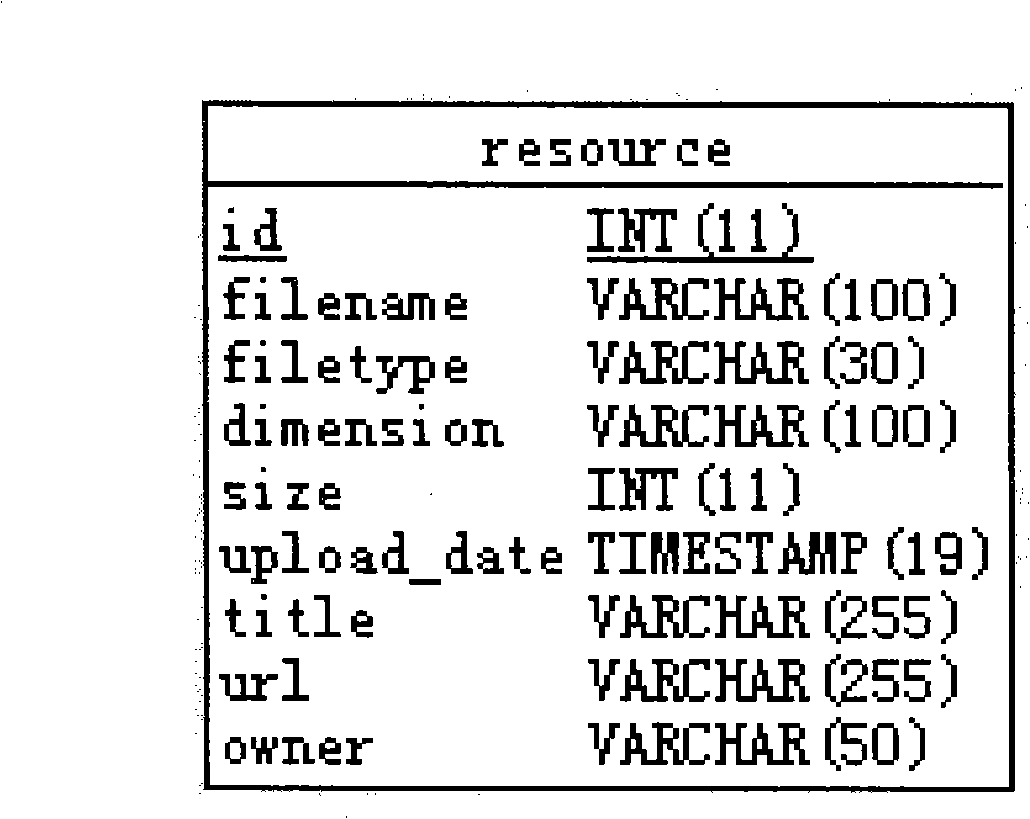

On-line cooperating lantern slide manufacturing service system

InactiveCN101299250AEasy to manufactureEasy to uploadSpecial data processing applicationsAnimationInternet users

The invention relates to an on-line synergy slides preparing service system, which can automatically switch the microsoft slides power point files, and the Open office slides into the slides format suitable for the present system. The system includes at least one web page server for providing the on-line synergic preparing of the slides, the web page server is connected to the Internet to provide the on-line demonstration slides files for the on-line lecture preparing o the Internet users, which has a perfect synergic preparing function and permits users to implement multiple person synergic completing a slides preparing and finalizing work through Internet. The on-line synergy slides preparing service system of the invention integrates a powerful demonstration instrument, thereby users can conveniently prepare on-line, upload and modify the lecture slides, can display any video and animation data to the audience through the system.

Owner:深圳市华飚企业管理有限公司

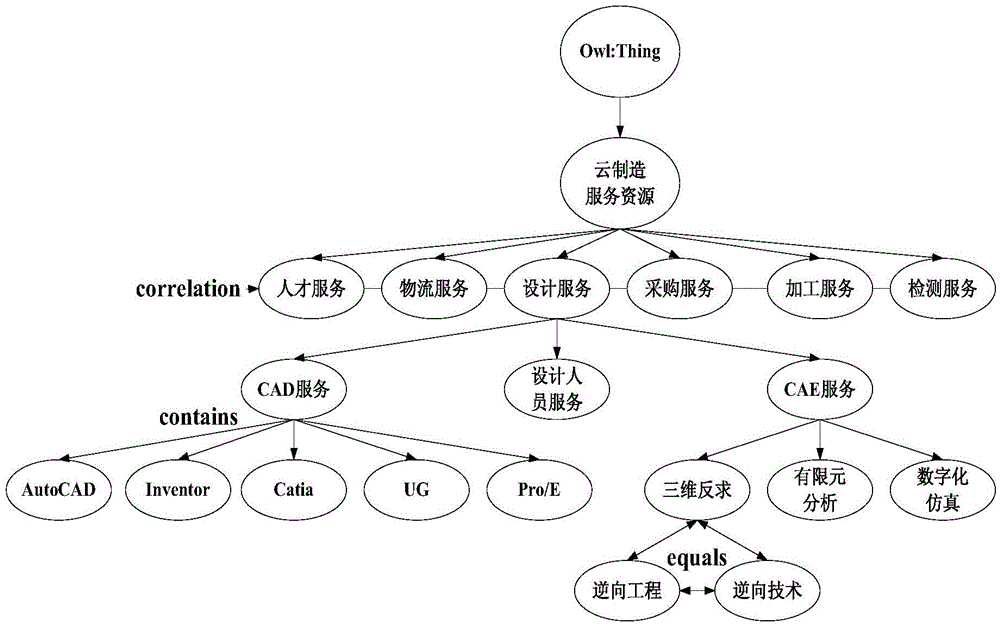

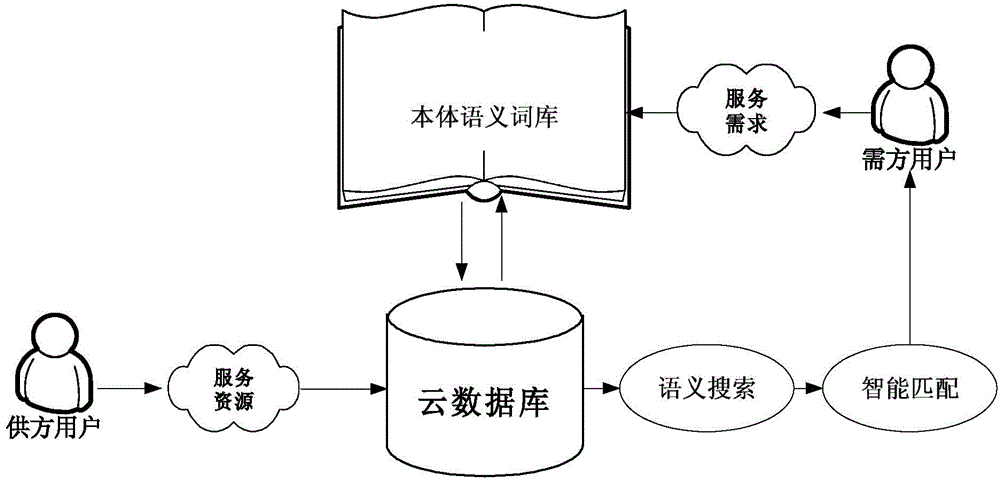

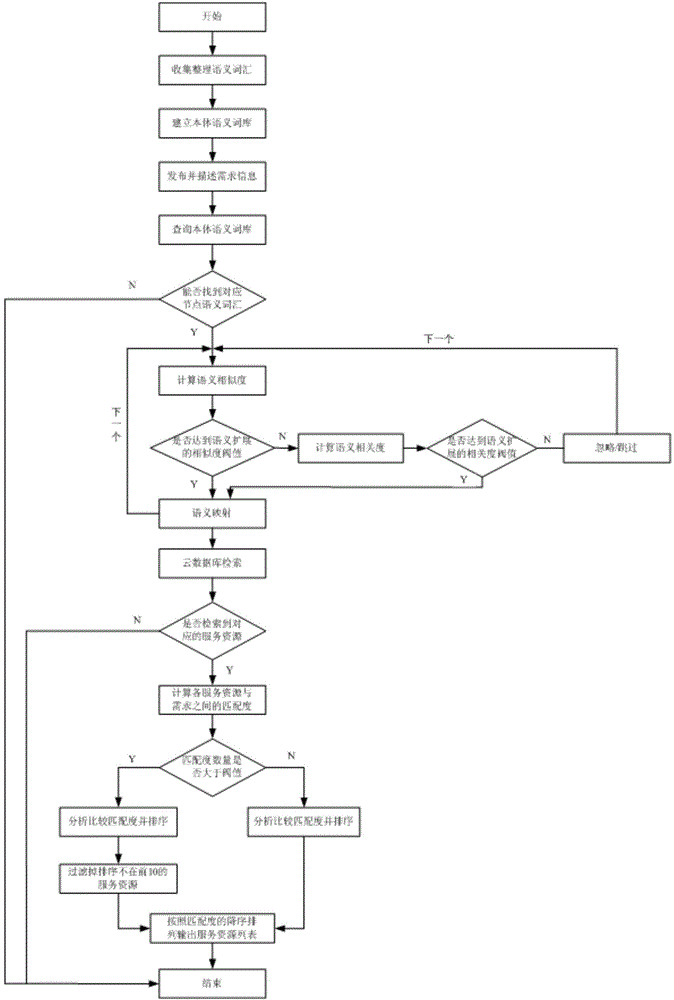

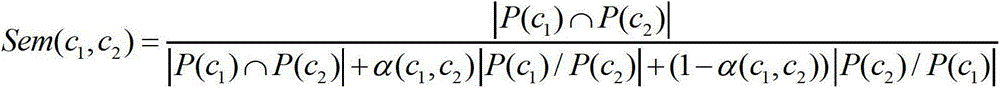

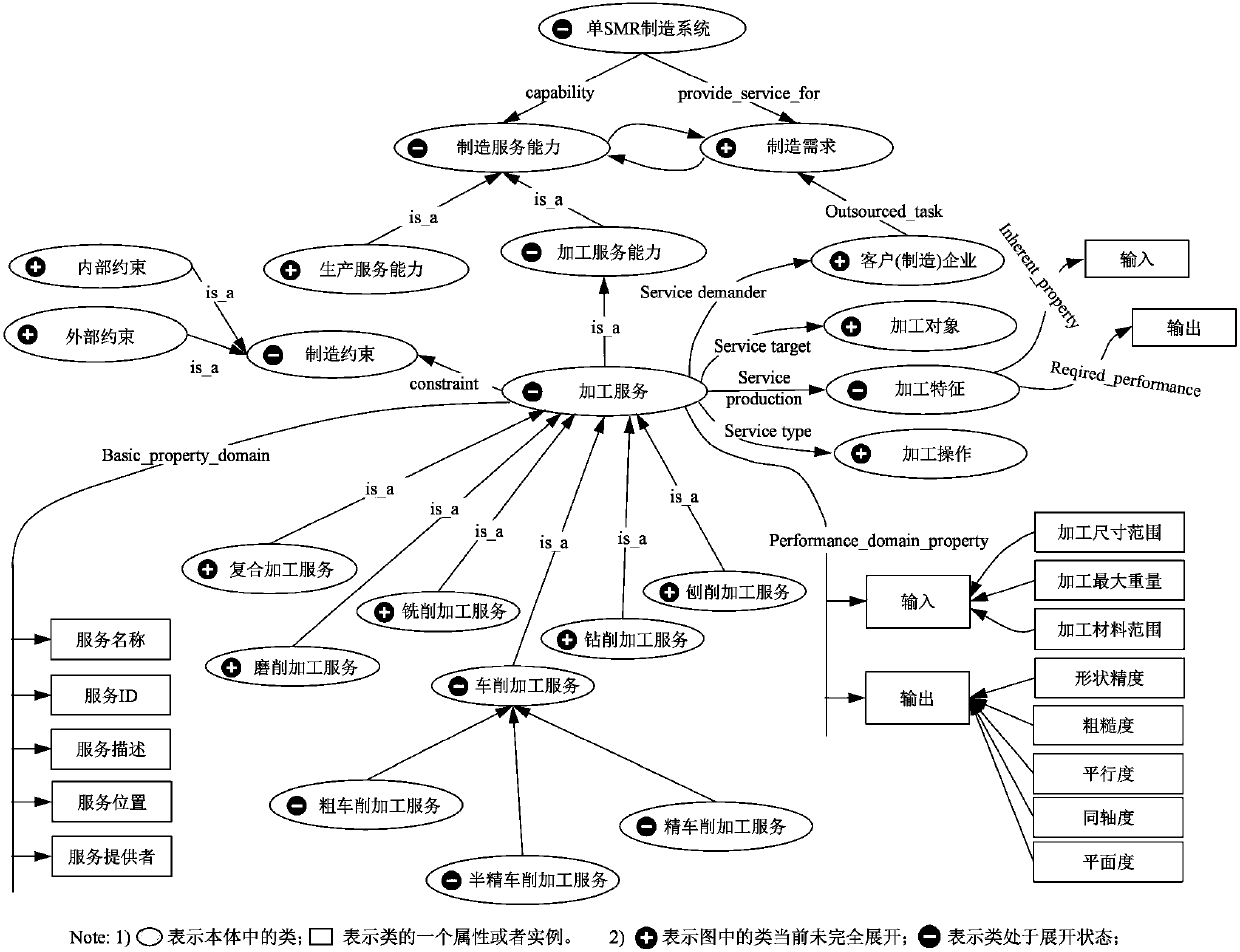

Ontology semantics-based supply and demand matching method for cloud manufacturing service

InactiveCN103984714AFast and Efficient Semantic SearchEfficient configurationTransmissionSpecial data processing applicationsSemanticsSemantic search

The invention provides an ontology semantics-based supply and demand matching method for cloud manufacturing service. Particularly, according to the method, a manufacturing service resource ontology semantic word library which is expanded longitudinally and vertically by establishing a cloud manufacturing service resource ontology with semantic relations; quick and high-efficiency service resource semantic search is realized; finally, the intelligent supply and demand matching of the cloud manufacturing service is realized by a comprehensive matching algorithm so as to support the high-efficiency configuration of service resource and the impartiality and the reliability of the cloud manufacturing service. The ontology semantics-based cloud manufacturing service supply and demand matching method supports semantic extended search, service resource management, and intelligent supply and demand matching.

Owner:HUBEI UNIV OF TECH

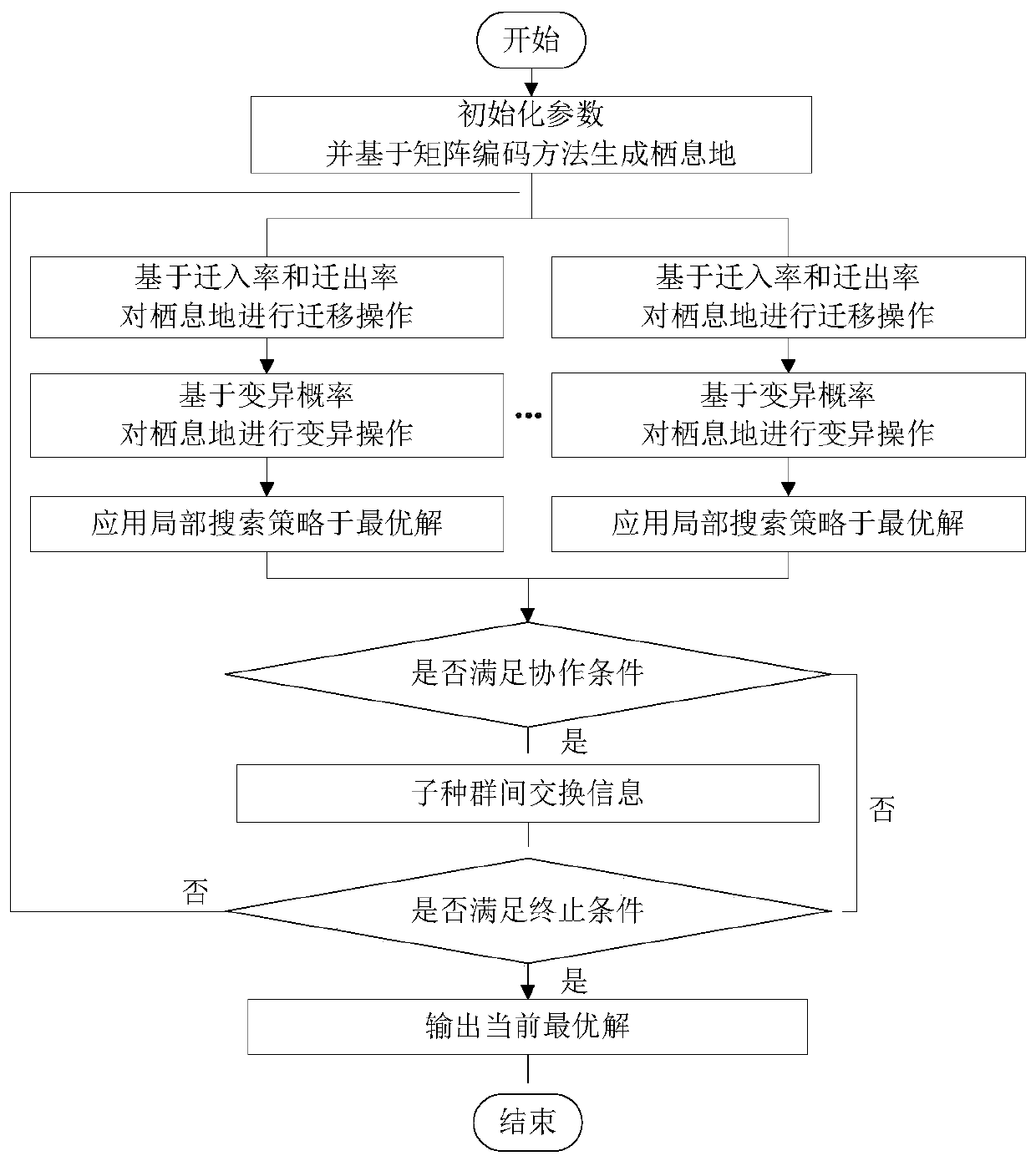

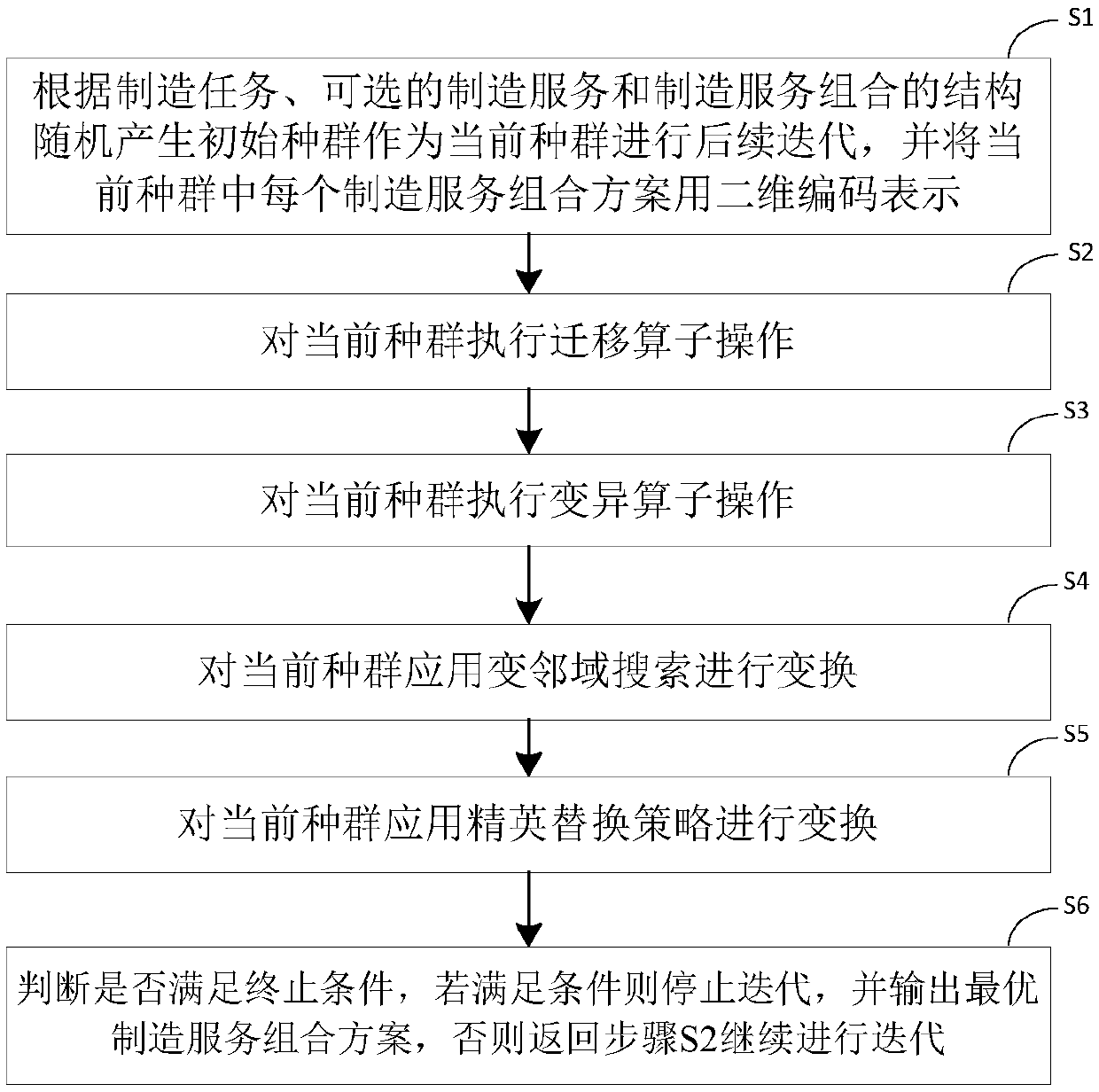

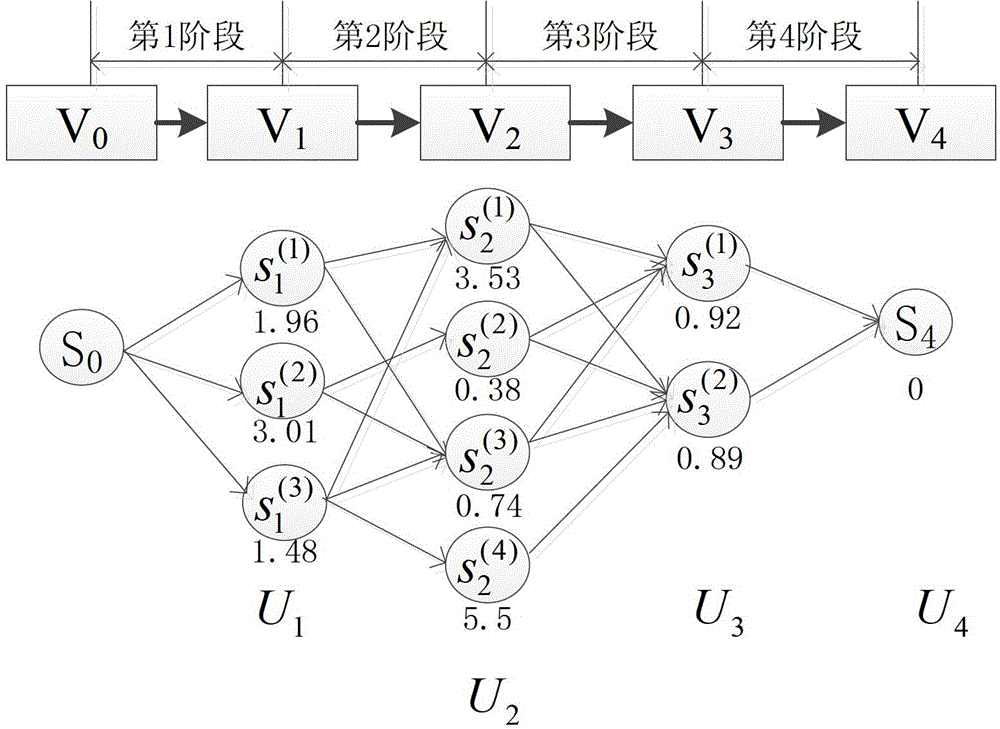

Cloud manufacturing service optimization method

ActiveCN108681789AIncrease spaceFast convergenceForecastingArtificial lifeService compositionMutation operator

The invention discloses a cloud manufacturing service optimization method. The method includes the following steps: first, according to a structure of a manufacturing task, optional manufacturing services and manufacturing service combinations, randomly generating an initial population as a current population for subsequent iteration, and representing each manufacturing service combination schemein the current population with a two-dimensional code; then executing transfer operator operation and mutation operator operation on the current population and applying variable neighborhood search tothe current population to perform transformation; and then judging whether an end condition is satisfied, if the condition is satisfied, stopping the iteration, and outputting the optimal manufacturing service composition scheme, otherwise returning to continue the iteration. The method provided by the invention has superior performance in solving the service combination problem.

Owner:ZHEJIANG UNIV OF FINANCE & ECONOMICS

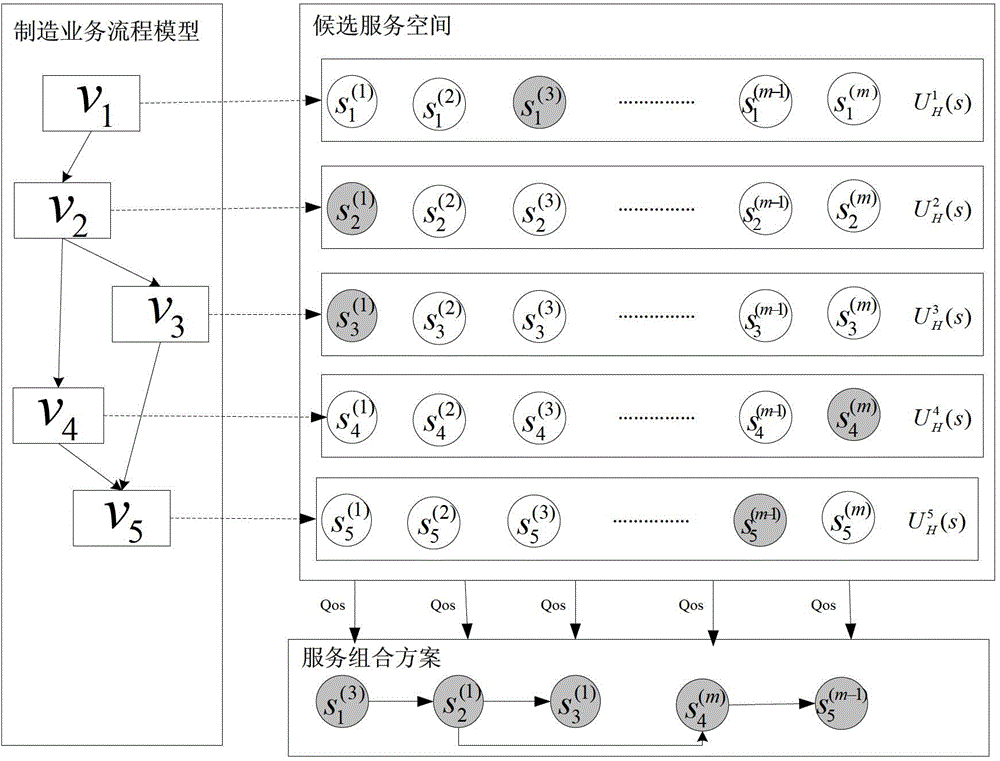

Semanteme service combination method based on dynamic planning

InactiveCN103149840AImprove enforceabilityHigh degree of automationAdaptive controlService compositionDynamic planning

The invention provides a semanteme service combination method based on dynamic planning. The semanteme service combination method based on the dynamic planning comprises firstly, decomposing a manufacturing service process model through a workflow engine, extracting requirements of each active node, and then obtaining all services which satisfy the active node through a service find matching process, and at last, selecting an appropriate candidate service from the services to generate a service combined scheme according to a certain strategy, achieving mapping a specific semanteme onto a task, and using a manufacturing service process which is described in a workflow model to translate a generating process of the semanteme service combined scheme into a dynamic evolution multistage decision process by combining characteristics of a networked manufacturing mode, using a data semanteme relationship between services as restraint, using comprehensive quality of the combined scheme as an optimization target, and using a dynamic planning method to generate a combined scheme which is globally optimum. The semanteme service combination method based on the dynamic planning has the advantages of enabling confirmation of a globally optimum solution to be easy, saving computing amount, being beneficial for providing abundant combined scheme results for a user, and improving performability of the combined scheme and automation degree of a combining process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

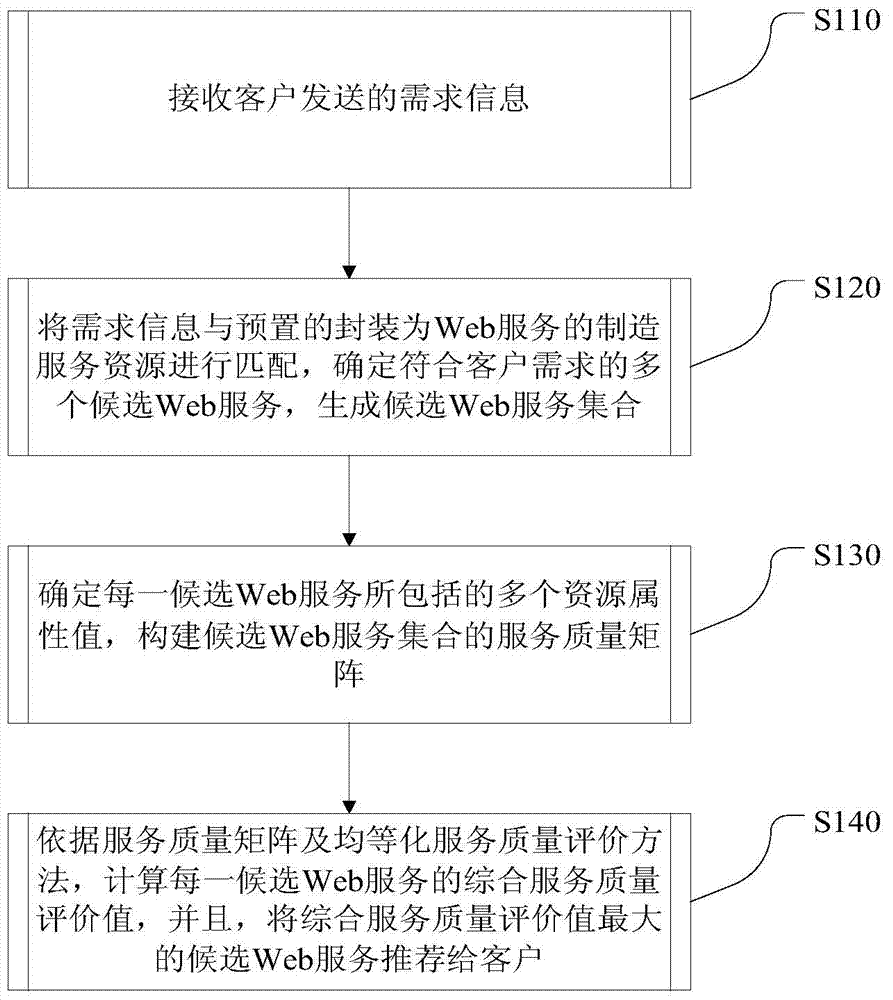

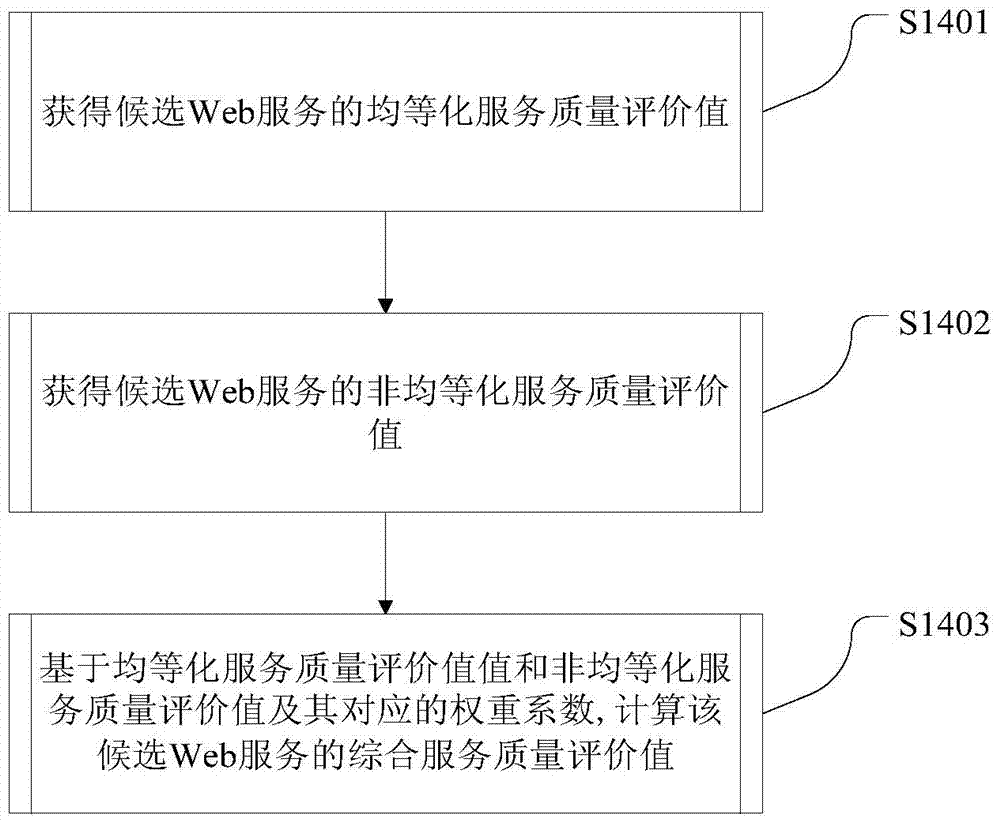

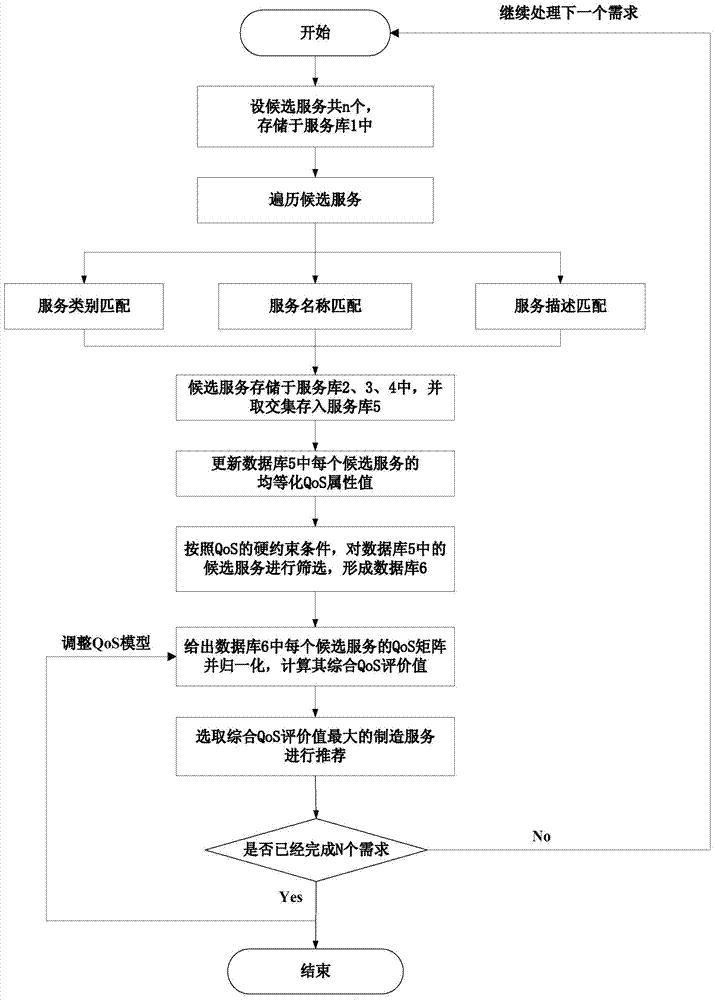

Manufacturing resource recommendation method and system on basis of Web services

InactiveCN103942283AImprove satisfactionImprove utilization efficiencyData processing applicationsResource allocationComposite servicesPersonalization

The invention discloses a manufacturing resource recommendation method and system on the basis of Web services. The manufacturing resource recommendation method includes the steps of receiving demand information sent by a client; matching the demand information with preset manufacturing service resources encapsulated to the Web services, determining multiple candidate Web services according to demands of the client, and generating an candidate Web service set; determining multiple resource attribute values included by each candidate Web service, and constructing a service quality matrix of the candidate Web service set; calculating the comprehensive service quality evaluation value of each candidate Web service according to the service quality matrix and an equalization service quality evaluation method, and recommending the candidate Web service with the maximum comprehensive service quality evaluation value to the client. The information technology is used for the method and system, information gaps between supply and demand of the services are eliminated, and equalization deployment of service resources can be achieved as far as possible on the premise that personalized demands of different clients are met.

Owner:HENAN POLYTECHNIC UNIV

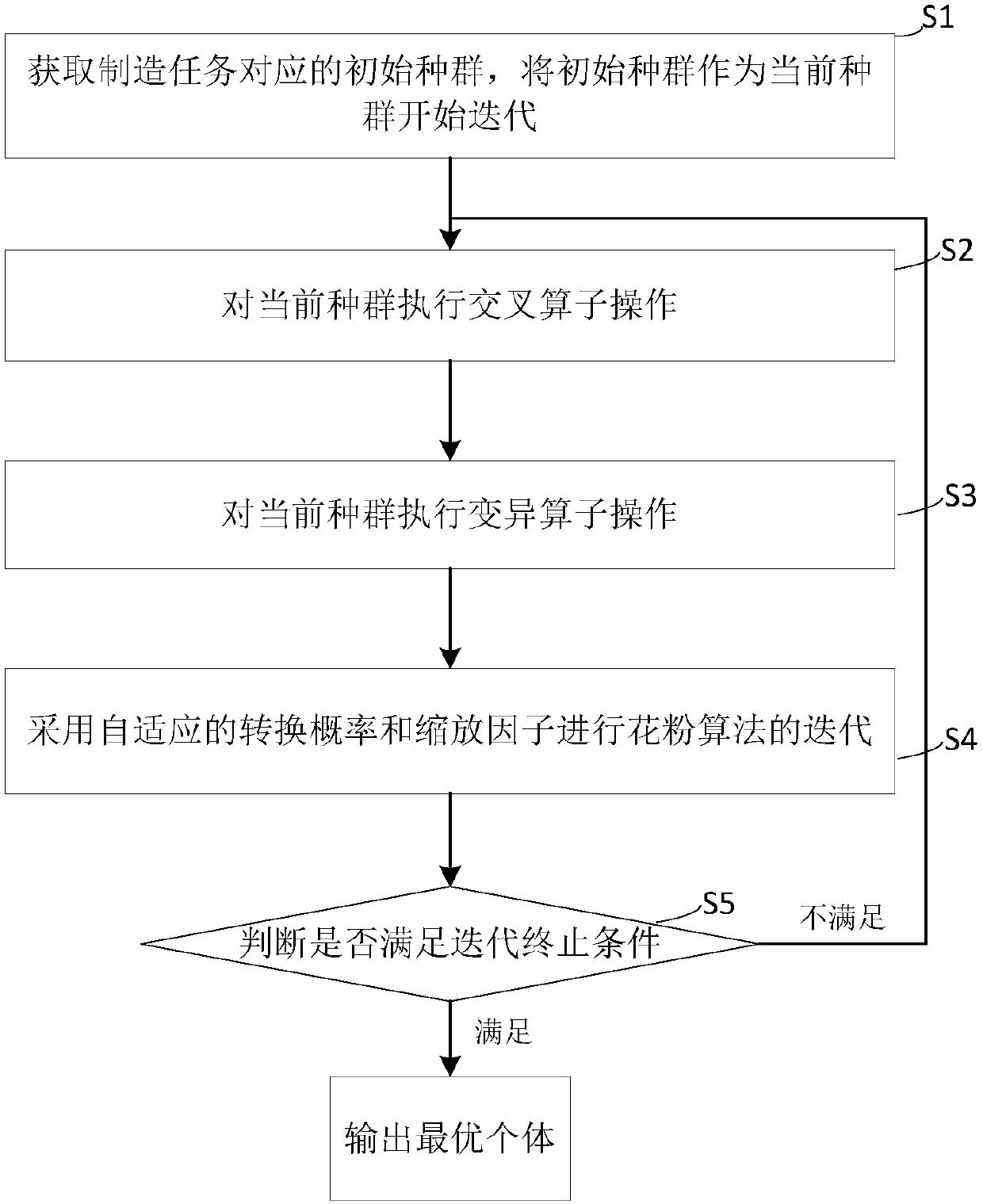

Manufacturing service supply chain optimization method based on service relevance

The invention discloses a manufacturing service supply chain optimization method based on service relevance. Firstly, an initial population corresponding to manufacturing tasks is acquired, and is used as a current population to start iteration; in iteration, firstly, crossover operator operations and mutation operator operations are executed on the current population, and then a self-adaptive transition probability and a scaling factor are adopted for iteration of a flower pollination algorithm (FPA); and whether an iteration termination condition is met is judged after one time of iteration,if yes, stopping iteration, and outputting an optimal individual, and otherwise, continuing iteration until the iteration termination condition is met. According to the method of the invention, the basic-type flower pollination algorithm and a crossover operator and a mutation operator of a genetic algorithm (GA) are fused, and performance of the algorithm is improved, and is superior to that ofthe genetic algorithm, that of differential evolution (DE) and that of the basic-type flower pollination algorithm when the manufacturing service supply chain optimization problem is solved.

Owner:ZHEJIANG UNIV OF FINANCE & ECONOMICS

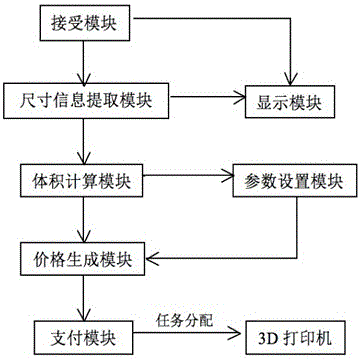

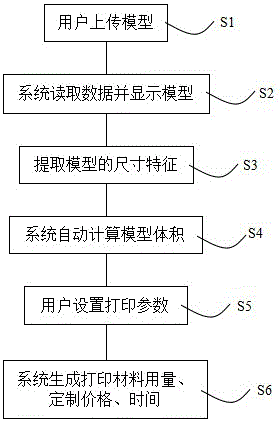

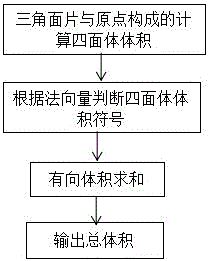

Online 3D printing customization system and method

InactiveCN106709793AOvercome the disadvantage of slow calculation speedSave storage spaceAdditive manufacturing apparatusBuying/selling/leasing transactionsPaymentMaterial type

The invention relates to the field of the 3D printing manufacturing service, and provides an online 3D printing customization system comprising a receiving module, a display module, a size information extraction module, a volume calculation module, a parameter setting module, a price generation module, a payment module and a 3D printer. The printing customization method of the system comprises the following steps that 1) a user uploads a 3D model file, 2) the system automatically reads and displays the model, 3) the system automatically extracts the size characteristics of the model, 4) the system automatically calculates the volume of the model, 5) the user selects the material type, and 6) the system automatically generates material utilization amount, customization price and production time at a cloud side so as to generate an order and complete printing after payment of the user. According to the 3D printing customization system and method, the problems that the 3D printing product customization process is complex, the price has no fixed standard and the transaction flow is complex can be effectively solved.

Owner:杭州纽带科技有限公司

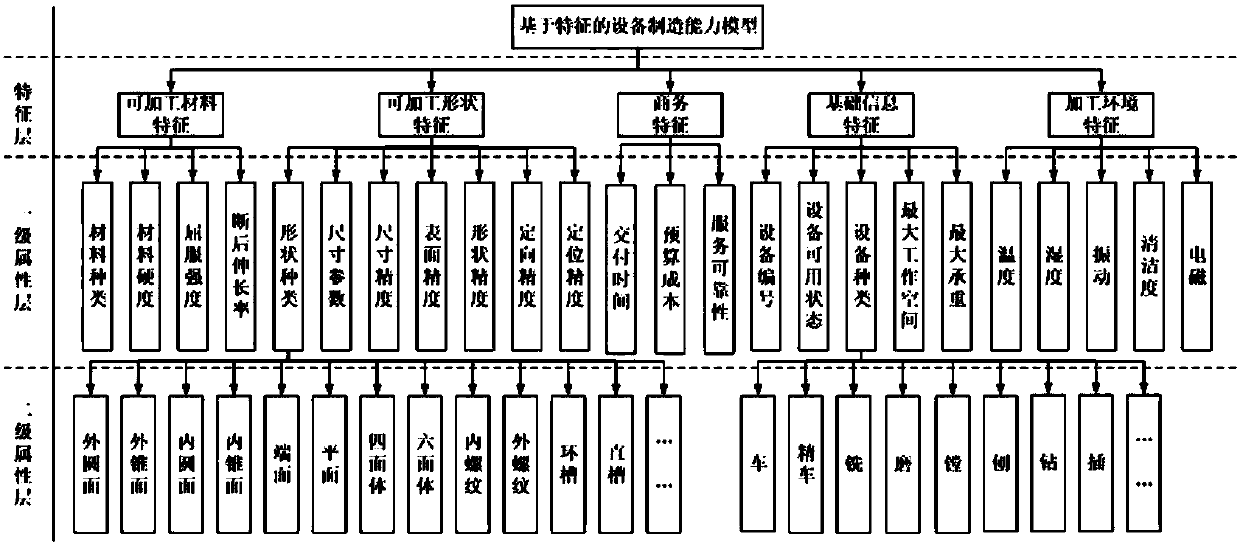

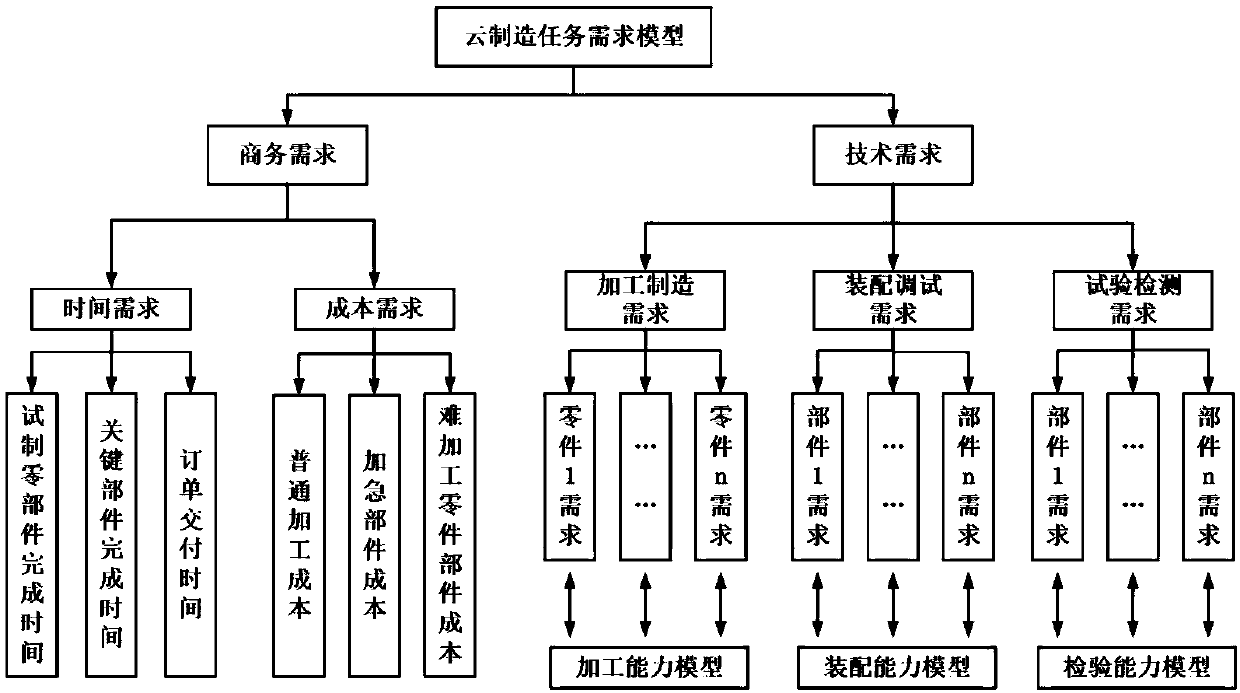

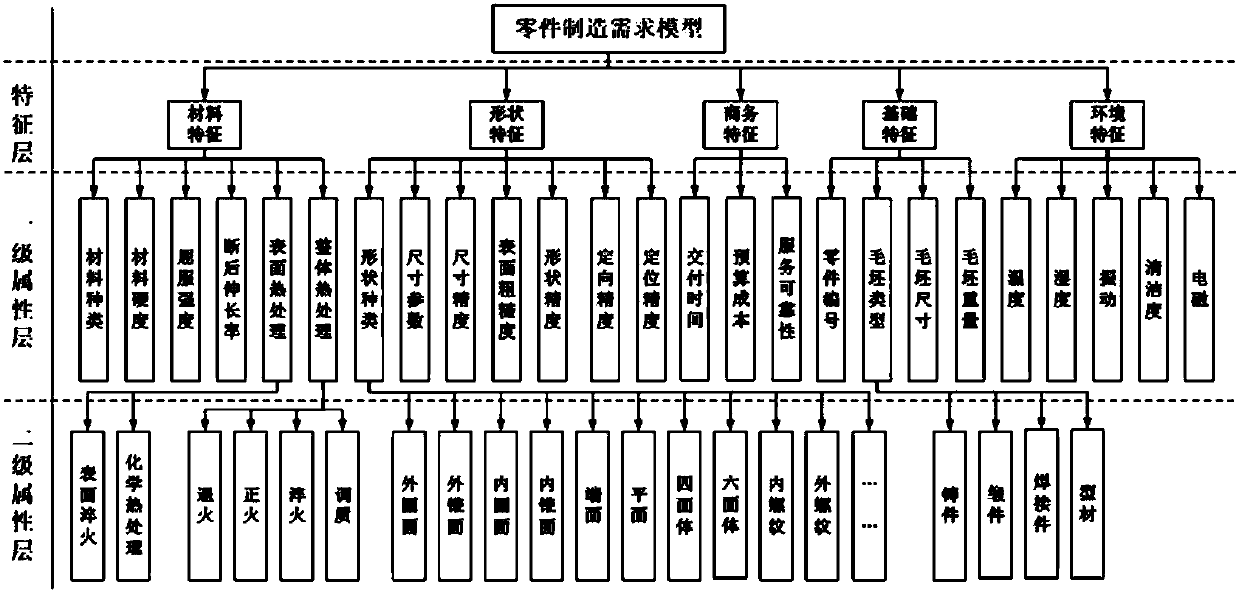

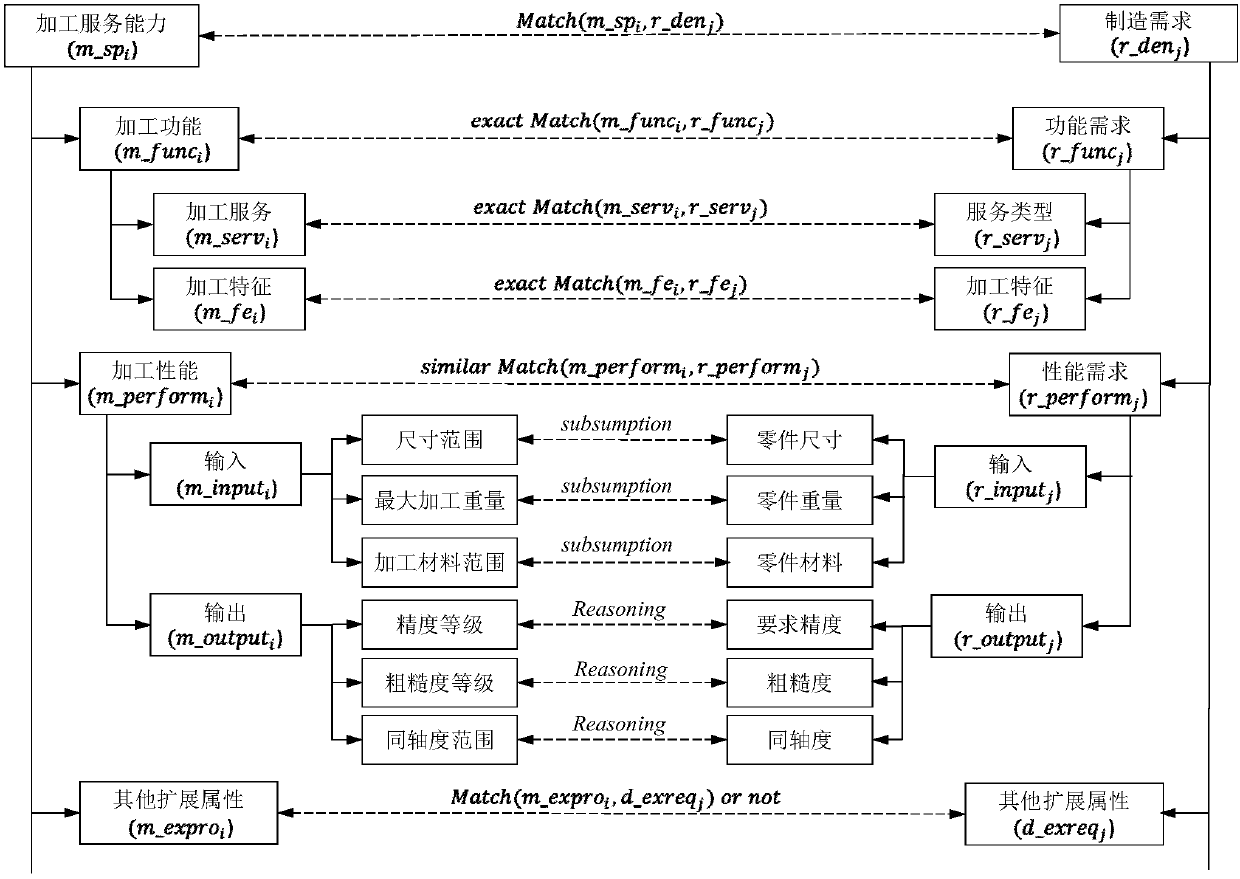

Method of manufacturing demand and device capability normalization modeling facing cloud manufacturing

ActiveCN107944698AGuaranteed validityAchieve matchingOffice automationResourcesManufacturing cost reductionNormalization model

A method of manufacturing demand and device capability normalization modeling facing cloud manufacturing provided by the invention comprises the steps of: introducing a feature process route on the basis of establishing a device manufacturing capability model and a part manufacturing demand model, employing an intuitionistic fuzzy algorithm to perform matching of a device source set and a cloud task manufacturing demand, and constructing a manufacturing demand and device capability normalization model facing cloud manufacturing. Through combination of features of cloud manufacturing, the method of manufacturing demand and device capability normalization modeling facing cloud manufacturing integrally considers diversity of parts and devices, complexity of the manufacturing process, manpowerparticipation factors and quantifiable factors of the resource capability, performs feature modeling of the demand and the capability, and establishes a mapping relation of the cloud manufacturing task and the device capability, so that the efficiency and the capability of subsequent manufacturing resource intelligent search and cloud manufacturing service combination optimization matching, a cloud manufacturing service platform can rapidly and effectively select manufacturing resources satisfying the manufacturing demand from lots of manufacturing resources, and therefore, the manufacturingcost is reduced, product quality is improved, and efficient sharing and optimization configuration of the manufacturing resources are achieved.

Owner:CHONGQING UNIV

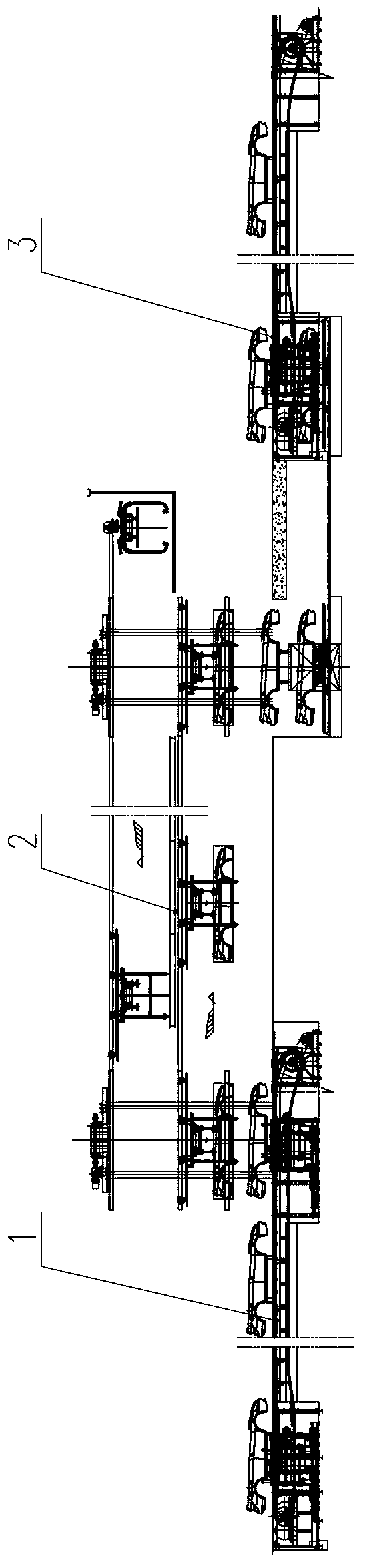

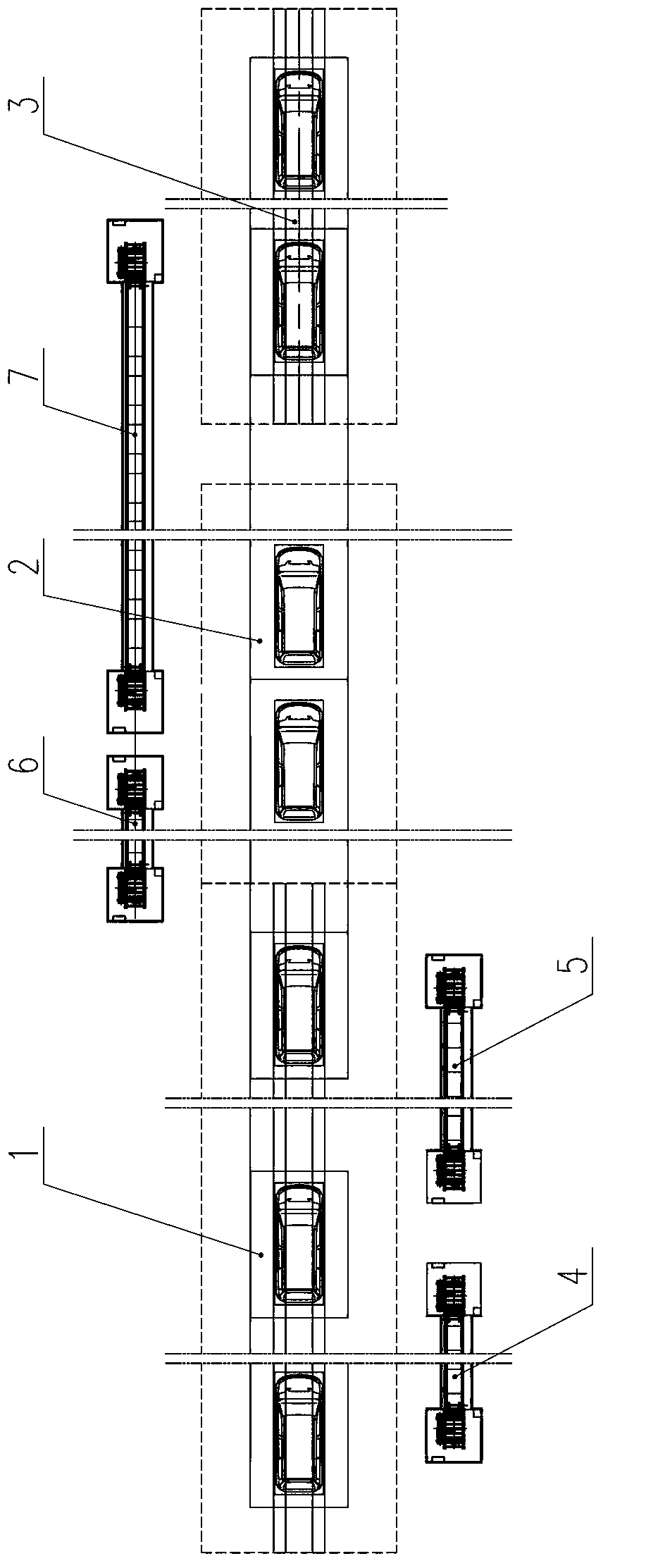

Scraped car disassembly production line

ActiveCN103101585AReduce labor intensityIncrease productivityVehicle dissasembly recoverySolid waste disposalCAR disassemblyProduction line

The invention relates to a scraped car disassembly production line which comprises a main line and an assembly dismantling line. The main line comprises an environment-friendly pre-processing and ground disassembly line, an overhead chassis disassembly line and a ground finish line which are arranged in sequence. The environment-friendly pre-processing and ground disassembly line adopts a double-plate-chain structure, the overhead chassis disassembly line adopts an electronic manufacturing service (EMS) self-propelled trolley type conveying structure, and the ground finish line adopts a double-plate-chain structure. The assembly dismantling line comprises a car door dismantling line, an instrument board dismantling line, a car suspension frame dismantling line and an engine auxiliary dismantling line which respectively adopt accumulation type maneuvering roller way conveying structures, wherein the assembly dismantling line is located on the lateral face of the main line. The scraped car disassembly production line adopts an advanced automated logistic system, achieves mechanical and automatic production of car disassembly operation, remarkably improves the production efficiency, reduces labor intensity of workers, saves manpower resources and reduces safety accident occurrence rate.

Owner:MIRACLE AUTOMATION ENG CO LTD

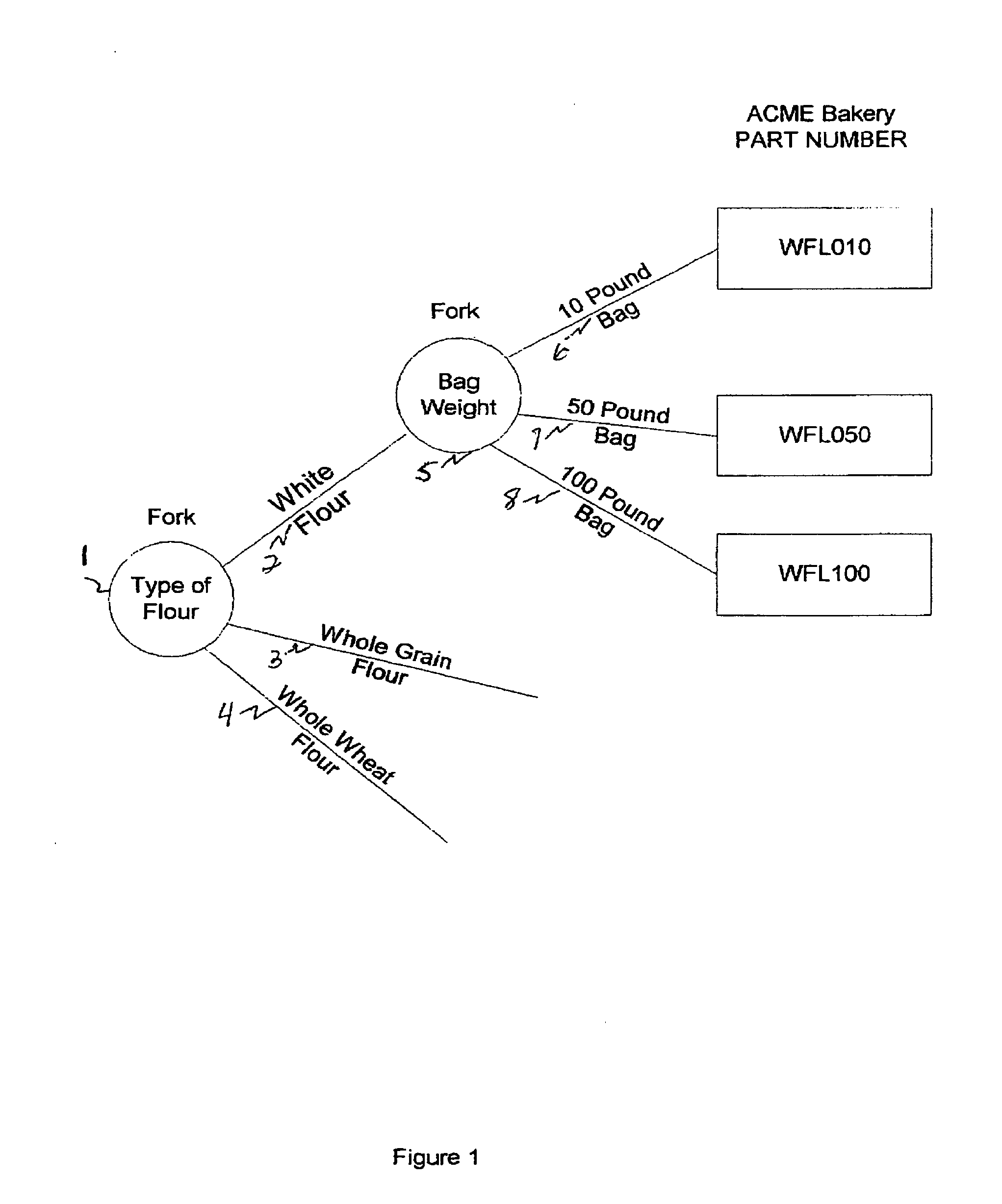

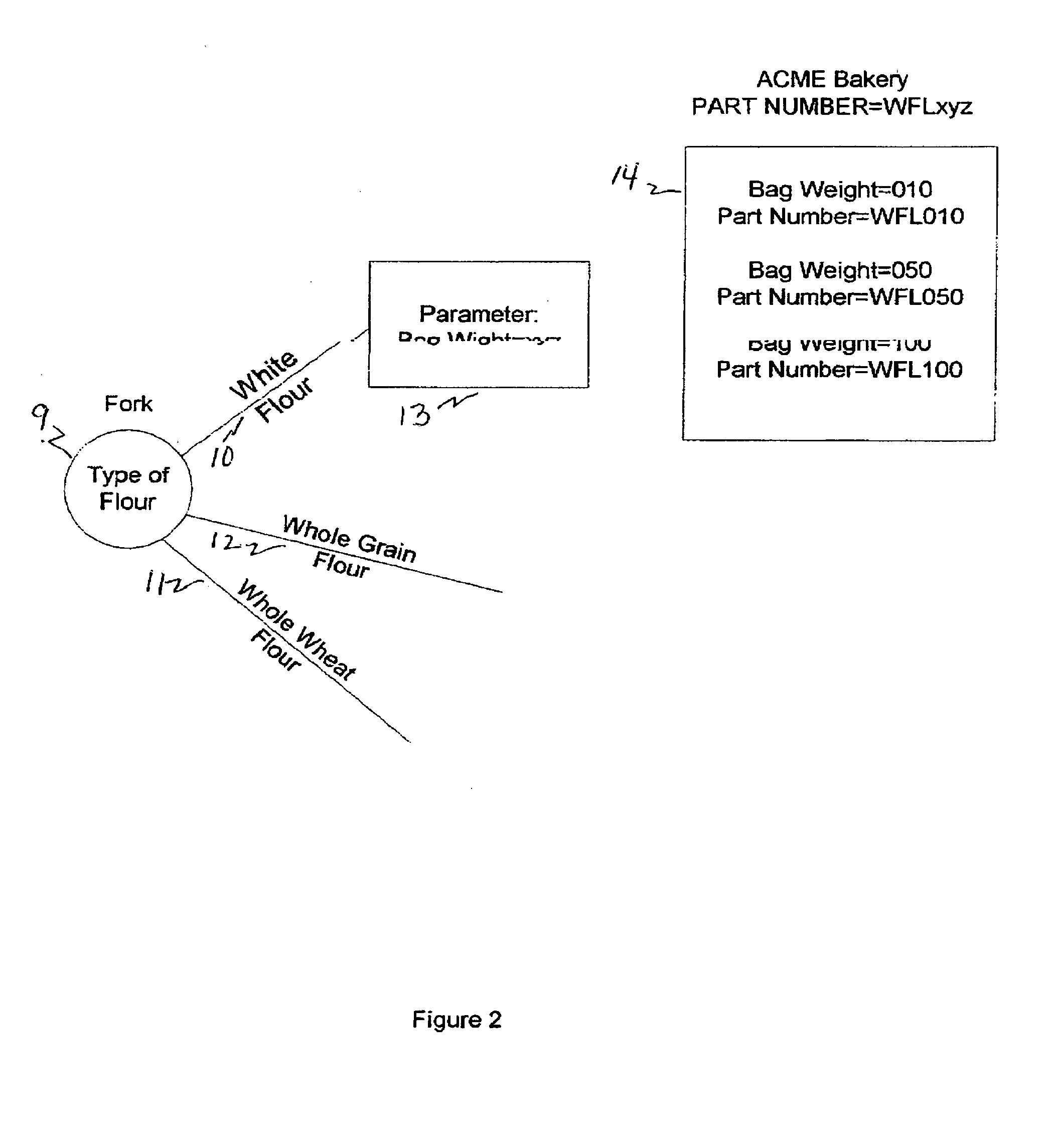

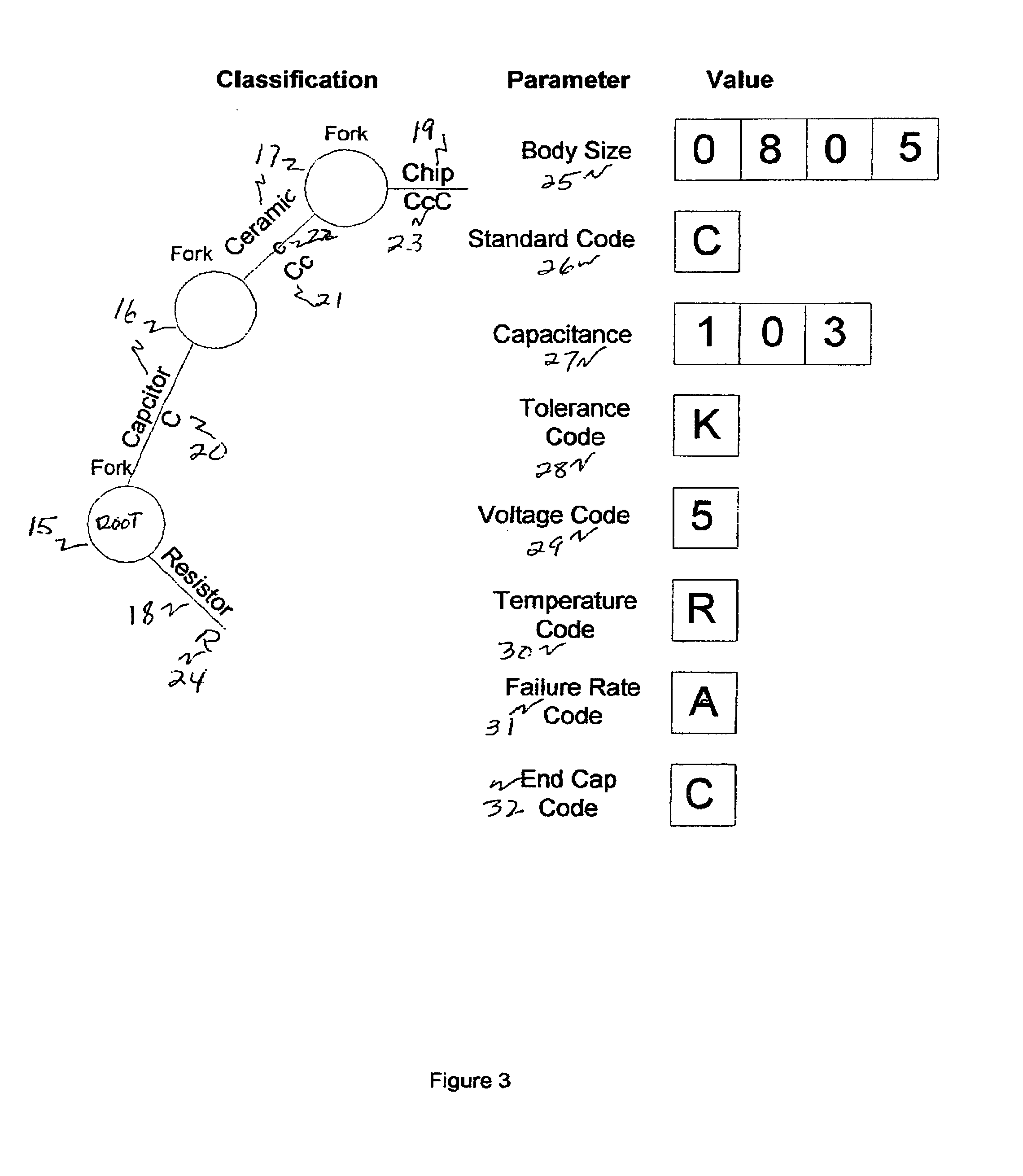

Compact item descriptor, catalog system and item part number validation

InactiveUS7680704B2Reduce time delayReduce in quantityAnimal feeding devicesBuying/selling/leasing transactionsService provisionBill of materials

In the present invention, items are described with a compact item descriptor where two items with the same compact item descriptor are interchangeable. The compact item descriptor can be generated for an item using a classification process and a set of parameters with values that describe the item.An organization assigns an identifier, a part number, to an item. The compact descriptor for the part number is stored in the item description field of the materials planning system and in the Approved Manufacturing List, AML. The AML identifies the supplier and supplier part number that may be ordered as the item. The Bill of Materials, BoM, for a product, is the parts list to build the product. The AML is used to identify the suppliers and supplier part number to purchase items needed to build the product The AML may contain errors and must be validated by the contract manufacturing company, called an EMS, Electronic Manufacturing Service provider. The EMS can use the compact item descriptor to validate or change the AML for a product quotation, for the ordering parts or components on the BoM.

Owner:OUCHI NORMAN KEN

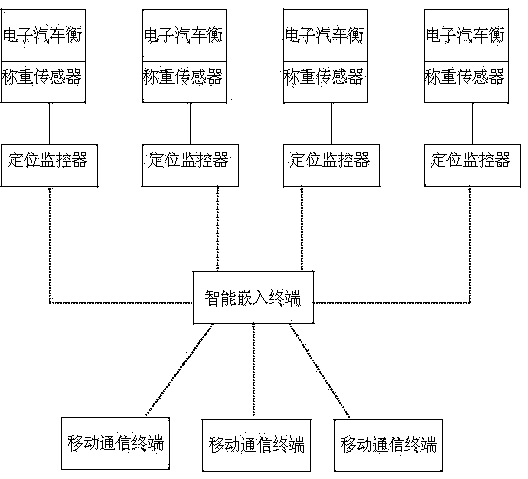

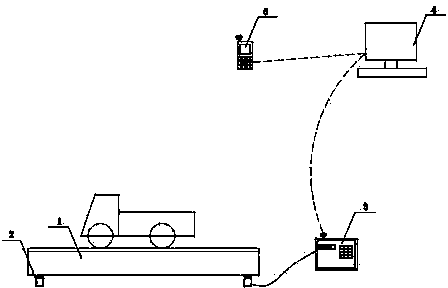

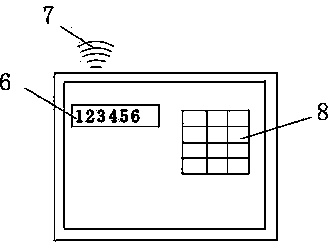

Intelligent truck scale internet-of-things system

InactiveCN103542923AAvoid lostImprove controlWeighing apparatus testing/calibrationTotal factory controlThe InternetComputer terminal

The invention provides an intelligent truck scale internet-of-things system which comprises electronic truck scales provided with weighing sensors. Each electronic truck scale is connected with one positioning monitor through an interface. A plurality of positioning monitors are connected with an intelligent embedded terminal at a manufacturer servicer through a mobile communication network. The intelligent embedded terminal is connected with a mobile communication terminal through a wireless network. The intelligent truck scale internet-of-things system can carry out real-time monitoring and analyzing on operation of equipment through the utilization of the internet-of-things technology, and various faults causing weighing inaccuracy can be found in the first time and initiatively reported to a manufacturer terminal remotely, so that the manufacturer can inform users of the faults of the truck scales in the first time and quickly solve the faults. Therefore, loss, caused by the weighing inaccuracy, of the users is prevented. Meanwhile, the innovation that the electronic truck scales are upgraded from passive 'anti-cheating' to initiative 'against-cheating' is achieved.

Owner:JIANGSU SANLY SCALE

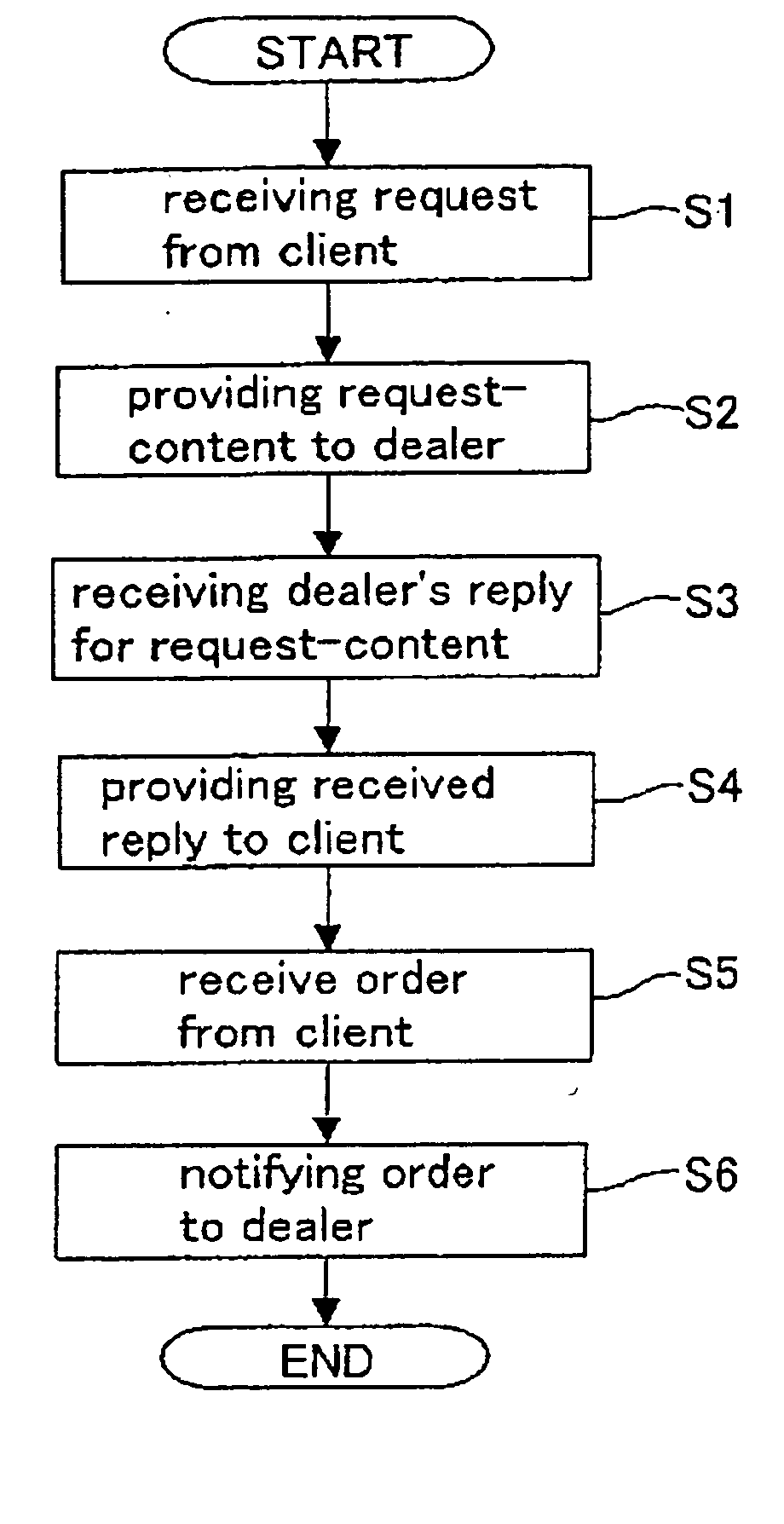

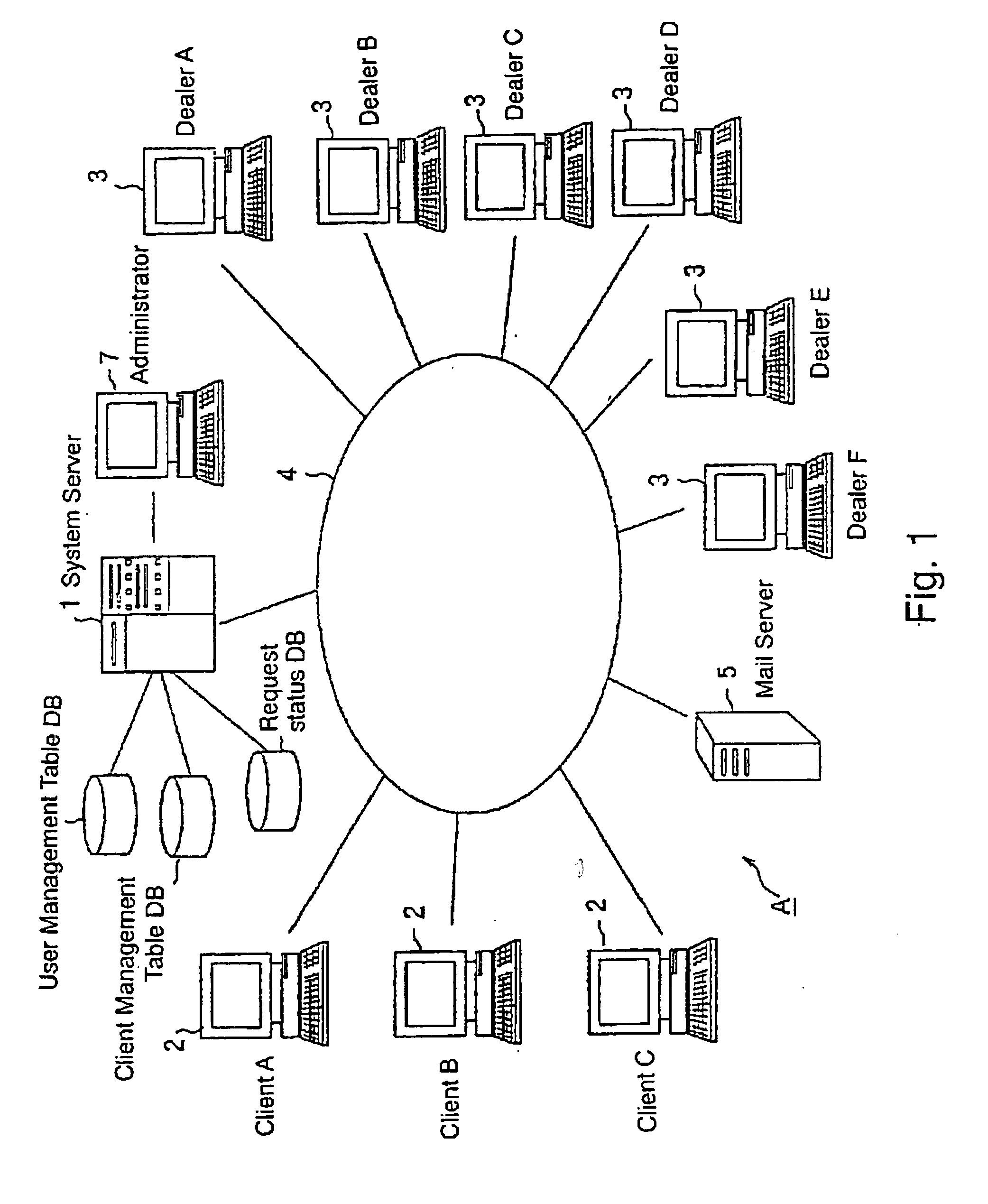

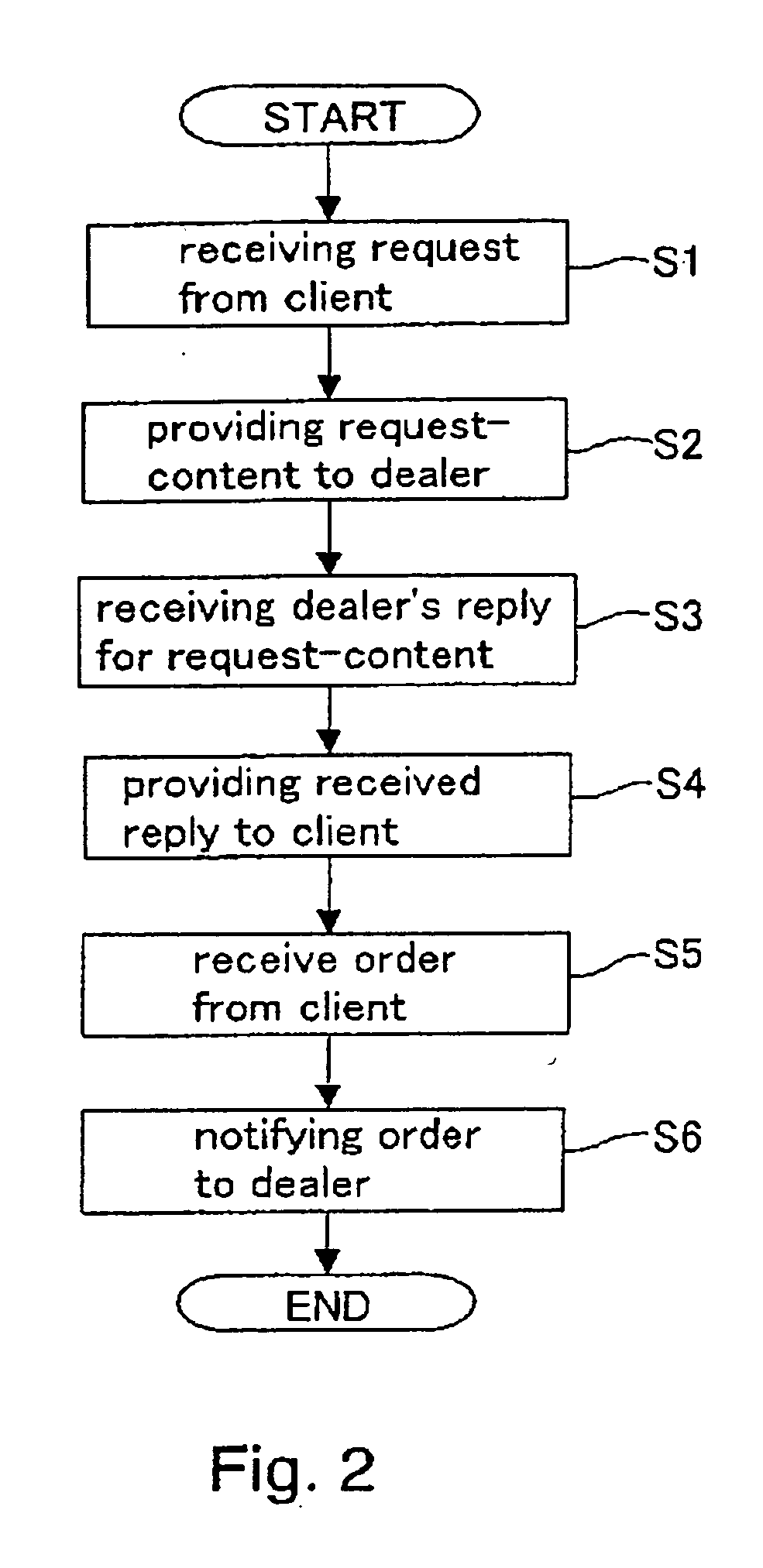

Information providing system, information providing method, information providing device, and recording medium

InactiveUS20050010480A1Printed circuit manufactureBuying/selling/leasing transactionsComputer networkEngineering

The present invention provides an information service method for providing information about a circuit-board inspection service, circuit-board manufacturing service or the like to clients and dealers to support and facilitate transactions therebetween. The information service method comprises the steps of receiving a board-specification information defining a specification of a circuit board from the client, providing the received board-specification information to the dealers, receiving information about products providable from the dealers, and providing the received product information to the client. Thus, the information from each dealer can be provided to the client.

Owner:OHT

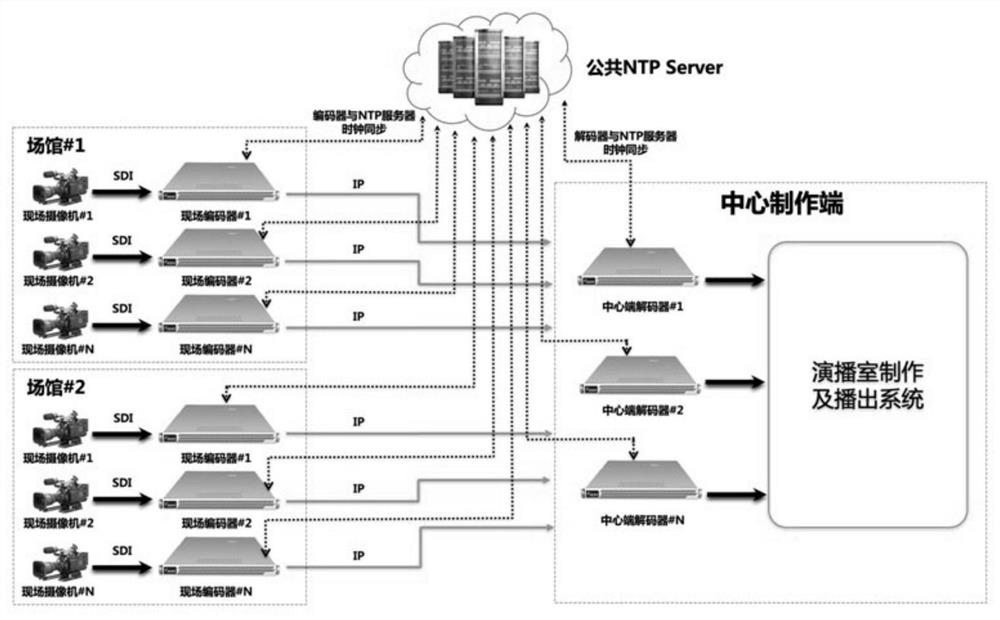

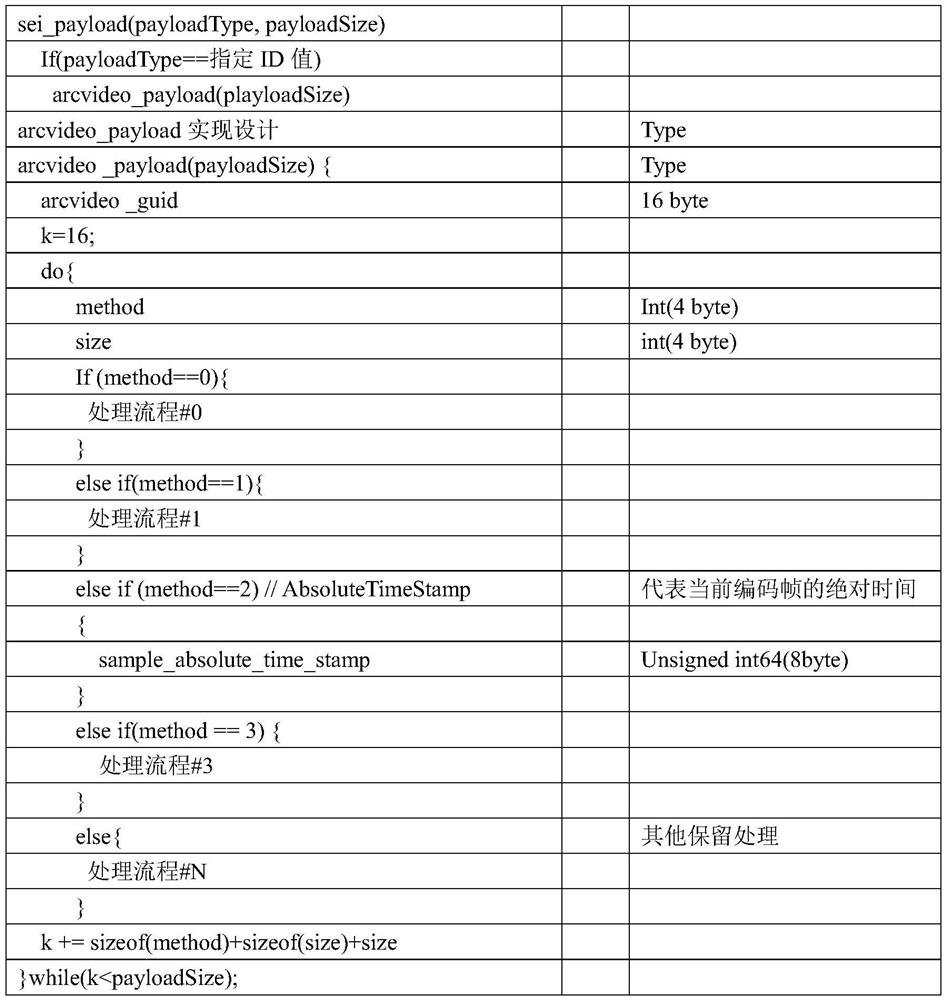

Multi-camera image synchronization method based on IP live streaming

InactiveCN112004102AAchieving Synchronous AccuracyLow costSelective content distributionComputer hardwareCamera image

The invention discloses a multi-camera image synchronization method based on IP live streaming. The multi-camera image synchronization method specifically comprises the following steps of: deploying apublic NTP server as a reference synchronous clock of encoders and decoders; connecting all encoders on site and all decoders at a central side with the public NTP server to ensure that reference clocks of all equipment are synchronously aligned; when the field encoders encode, writing the current absolute time into SEI information of an encoding layer; and receiving and decoding each IP live broadcast stream by means of the decoders at the central side, extracting absolute time in the SEI information, synchronously outputting SDI baseband signals according to time marks, and entering back-end manufacturing. The multi-camera image synchronization method has the advantages that strict frame synchronization among multiple cameras is achieved, the purpose of remote synchronous manufacturingis achieved, the frame synchronization precision of the broadcast level is achieved, low-cost and diversified remote live broadcast manufacturing services can be achieved, manufacturing modes are enriched, more service scenes are expanded, and a larger value-added effect is achieved.

Owner:HANGZHOU ARCVIDEO TECHNOLOGY CO LTD

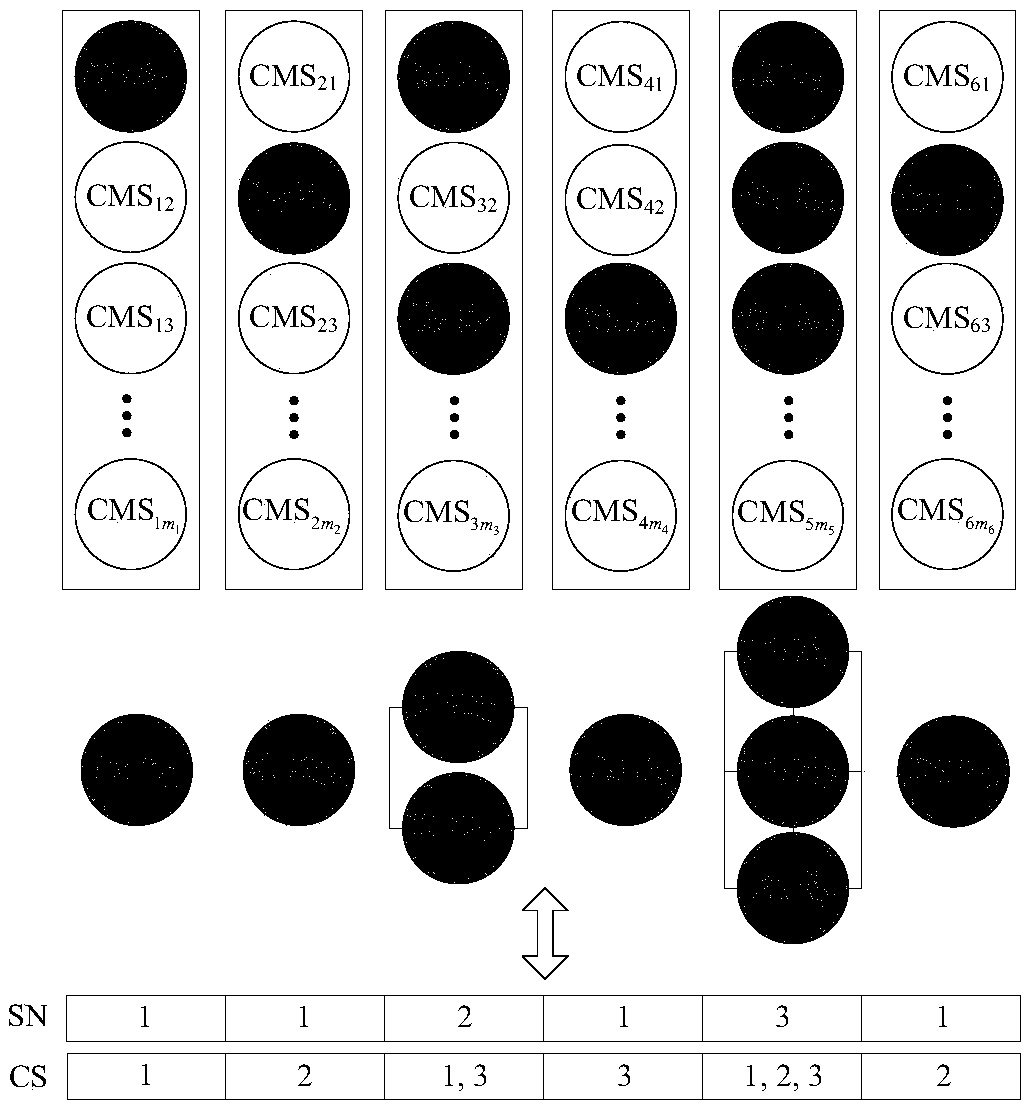

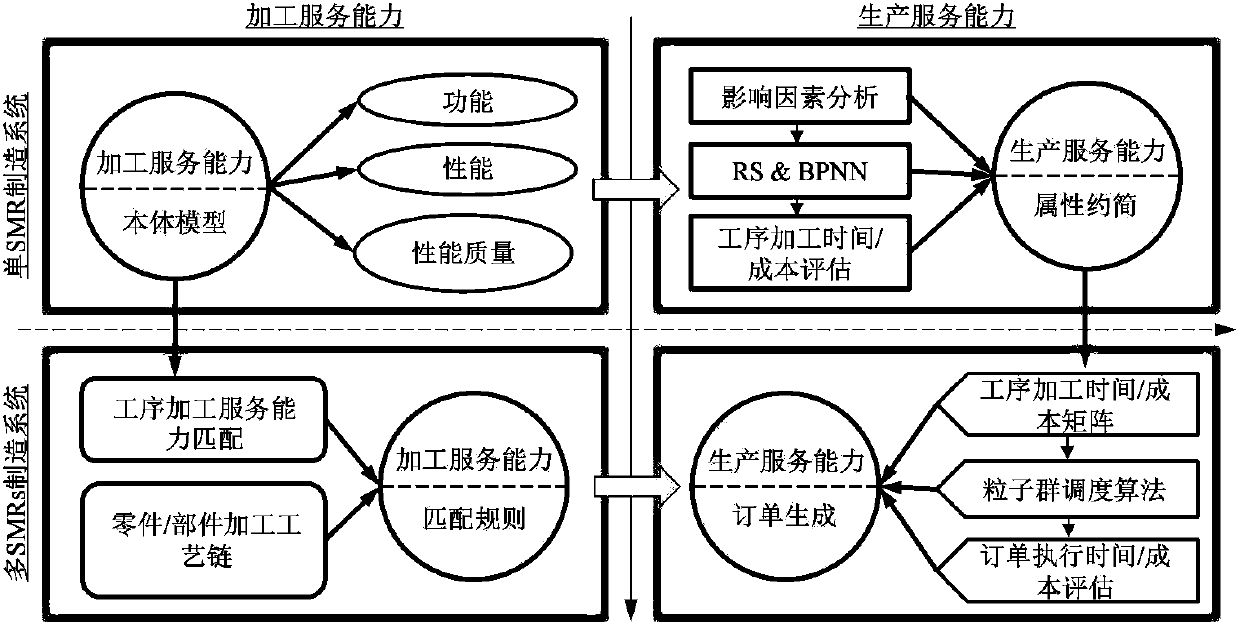

Method for evaluating manufacturing service capability of socialized manufacturing system for order demand

InactiveCN108053138AFulfilling demand for manufacturing ordersResourcesManufacturing computing systemsOrder formManufacturing systems

The invention provides a method for evaluating the manufacturing service capability of a socialized manufacturing system (SMS) for order demand. The manufacturing service capability of the SMS is divided into processing service capability and production service capability, and the processing service capability and production service capability of a single-socialized manufacturing resource (SMR) manufacturing system and a multi-SMR manufacturing system are studied separately. The service capability evaluation method presented by the invention can provide theoretical support for the automatic creation of manufacturing orders in the SMS. The method not only can describe what the SMS can process / produce from a qualitative point of view, but also can describe how much the SMS can process / produce in unit time from a quantitative point of view. The method is a basis for the description and release of SMR, an important index for the automatic searching and matching of resources and requirements, and an important evidence for order creation based on manufacturing service capability.

Owner:HUAQIAO UNIVERSITY

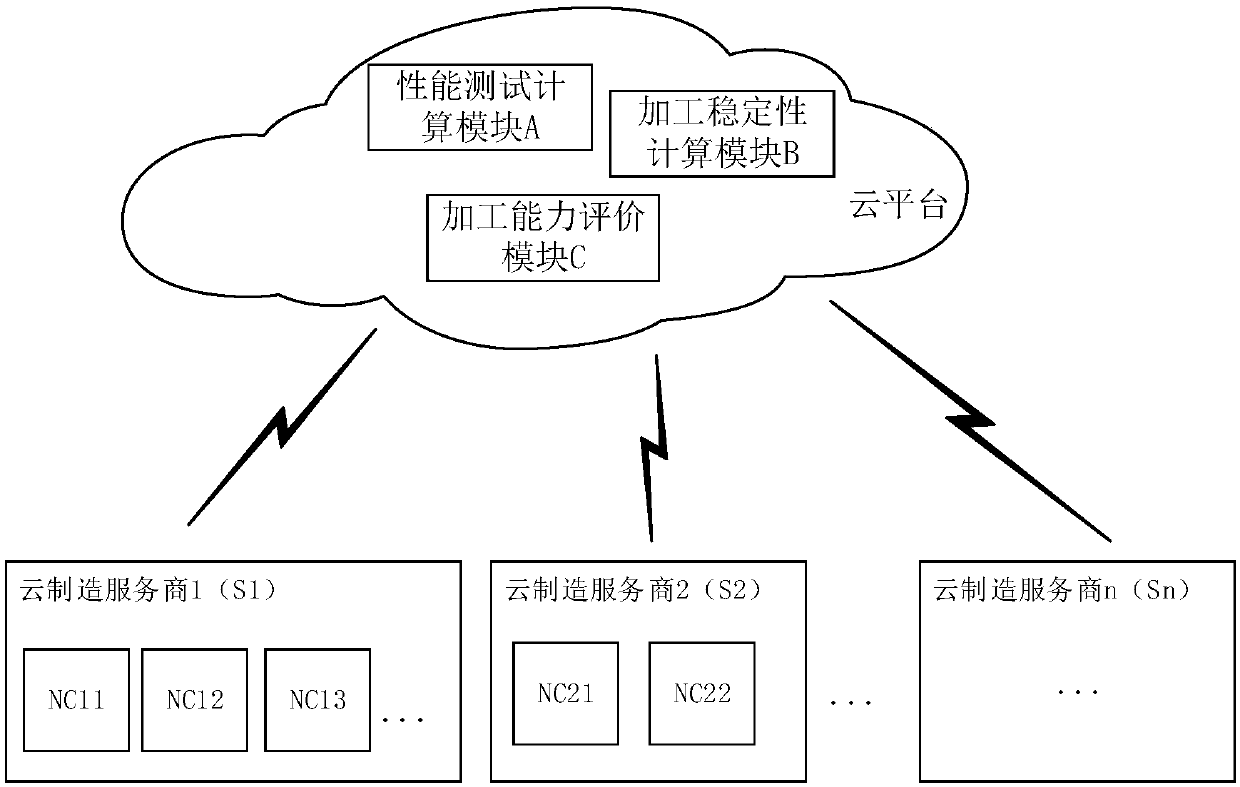

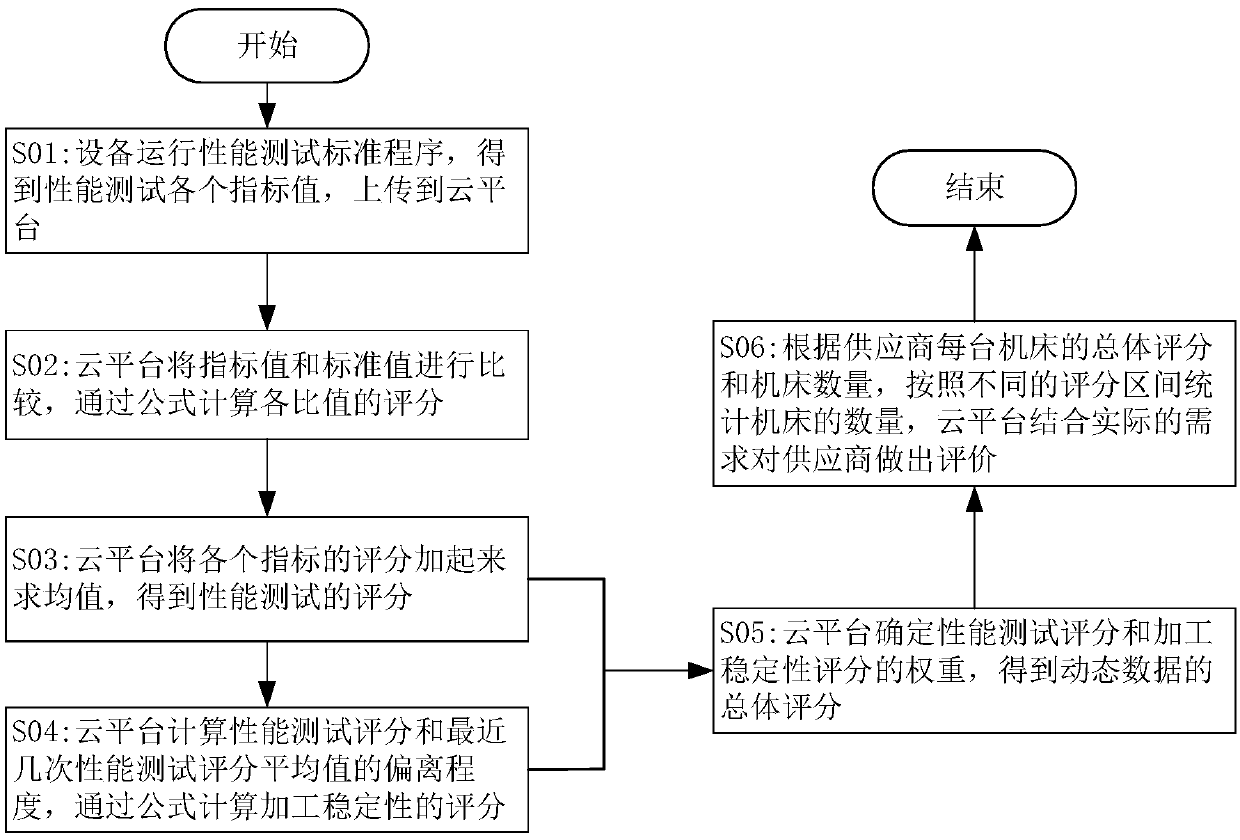

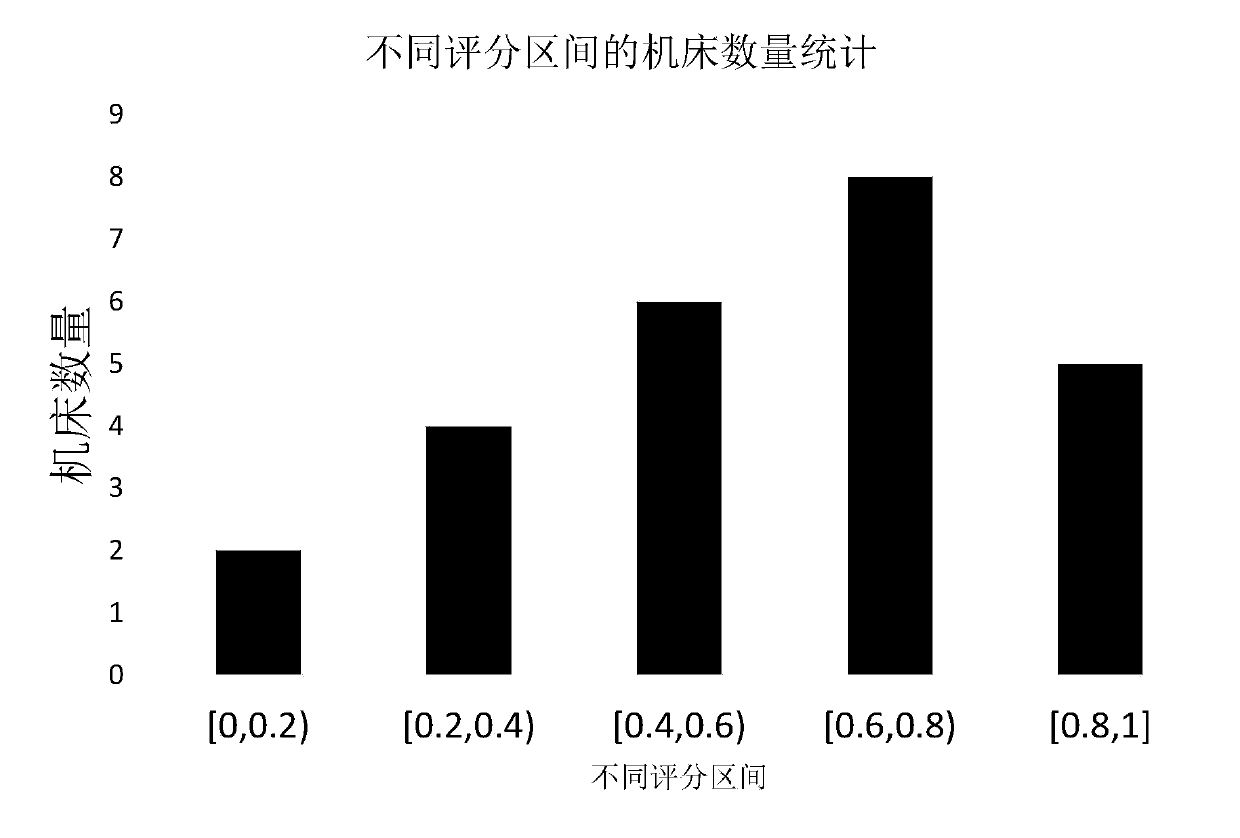

Cloud manufacturing service provider service capability online evaluation method and system

PendingCN109657920ADynamic AdjustmentMask processing capabilityResourcesManufacturing computing systemsData miningDatabase

The invention relates to a cloud manufacturing service provider service capability online evaluation method and system. The method comprises the steps that S01, a cloud platform obtains all index values of a cloud manufacturer machine tool performance test online; S02, the cloud platform compares the index values with standard values to obtain scores of the ratio of the index values to the standard values; S03, the cloud platform adds the scores and obtains an average value to obtain a performance test score; S04, the cloud platform obtains a score of the processing stability by using the performance test score and the mean value thereof; S05, a scoring weight by the cloud platform is set, and an overall score is calculated; And S06, the cloud platform counts the number of the overall scores of the machine tool according to different scoring intervals, and makes an evaluation. The system is composed of a cloud platform and related modules of a cloud manufacturing service provider, andthe cloud platform comprises a performance test calculation module A, a processing stability calculation module B and a processing capability evaluation module C. Compared with the prior art, the system has the advantage of timely and dynamically evaluating the service capability of the supplier.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com