Patents

Literature

181 results about "Finish line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

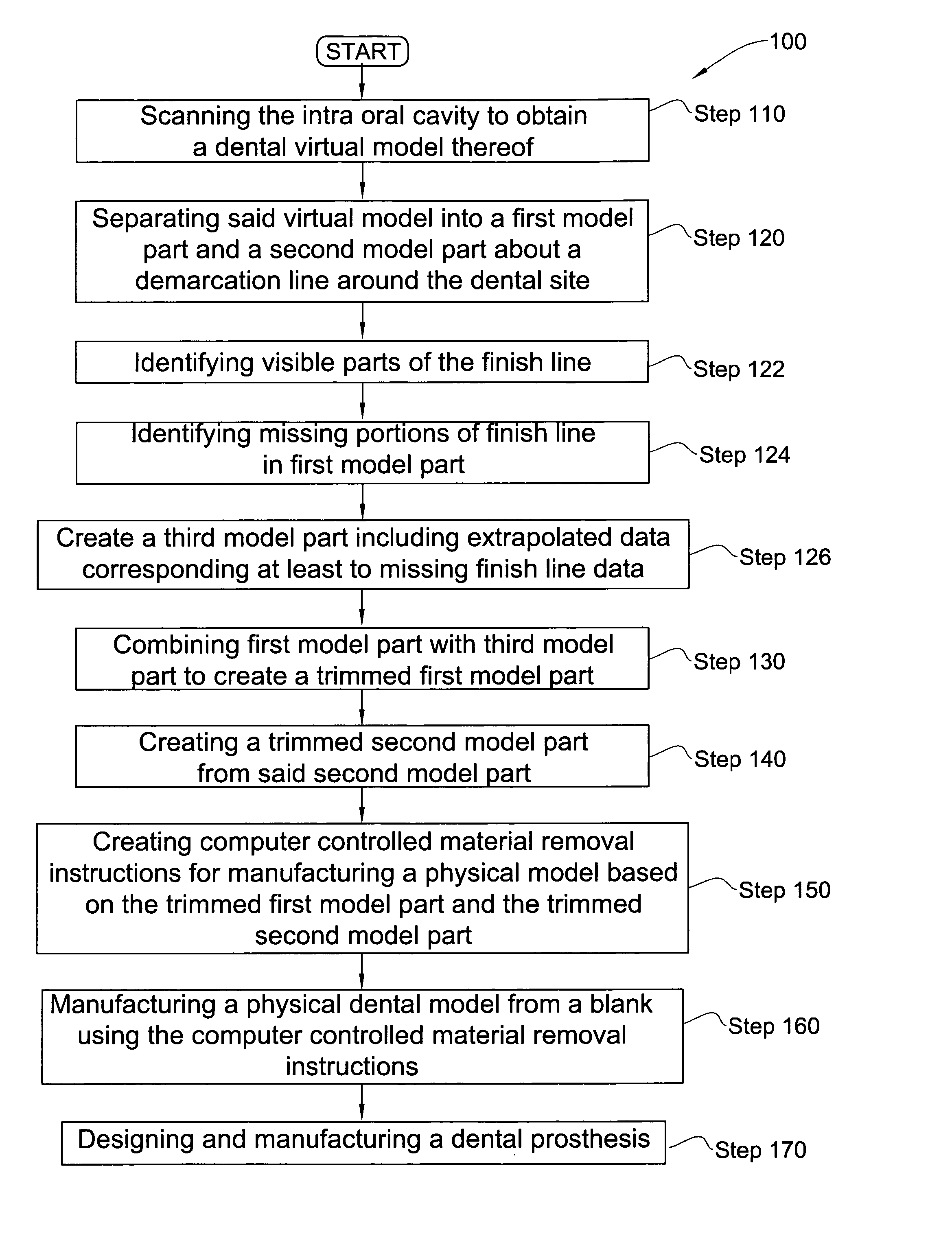

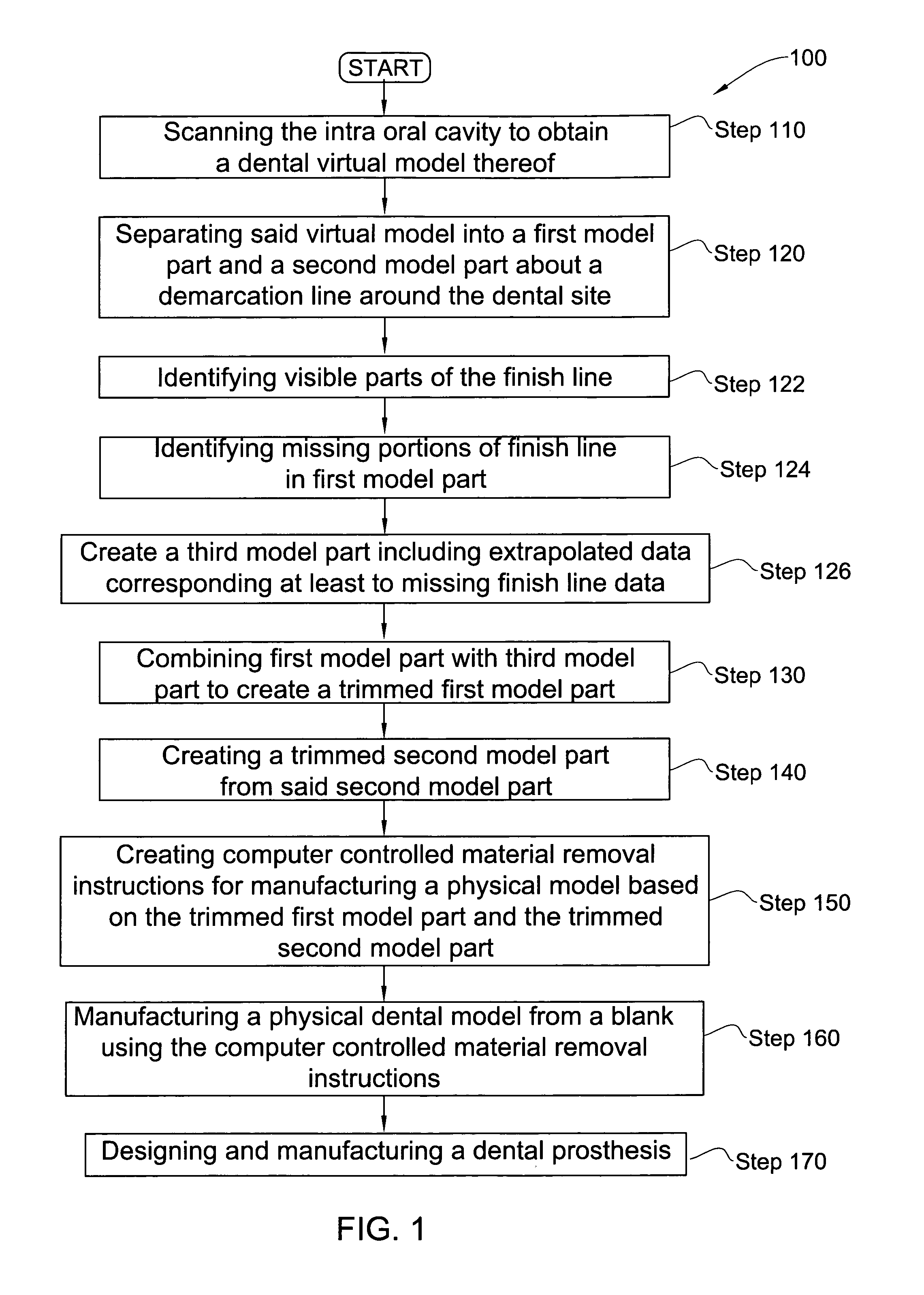

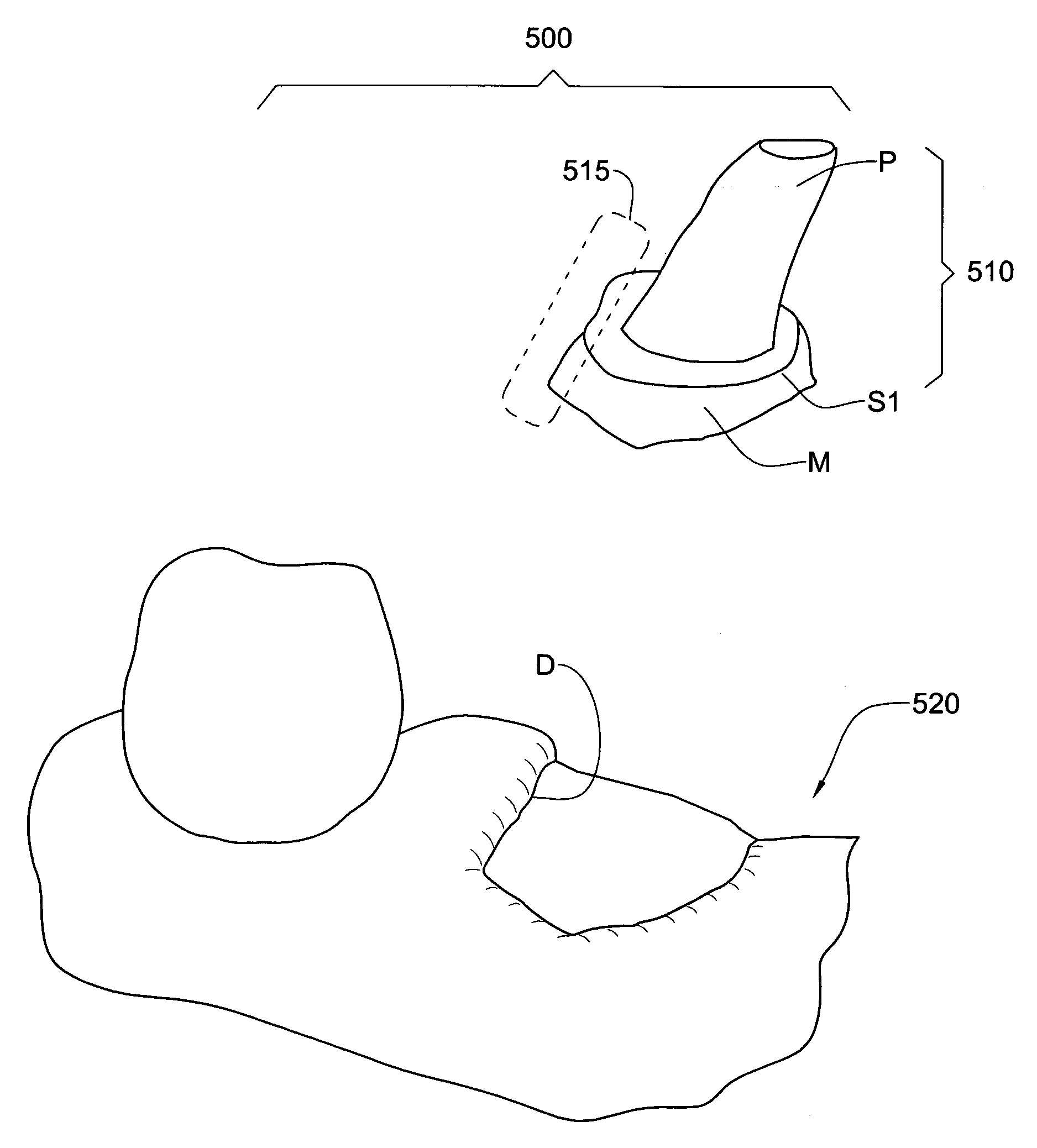

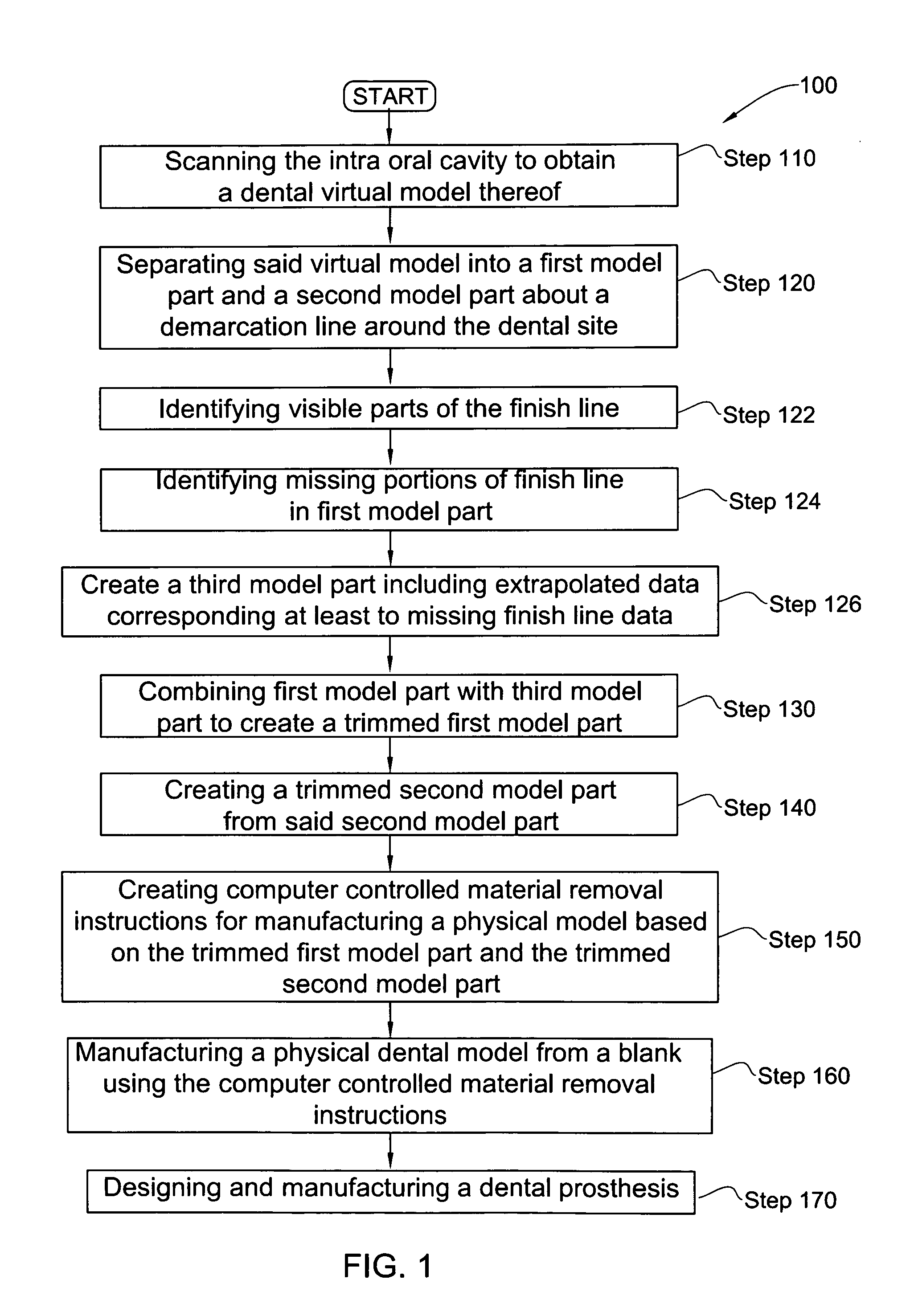

Method for manipulating a dental virtual model, method for creating physical entities based on a dental virtual model thus manipulated, and dental models thus created

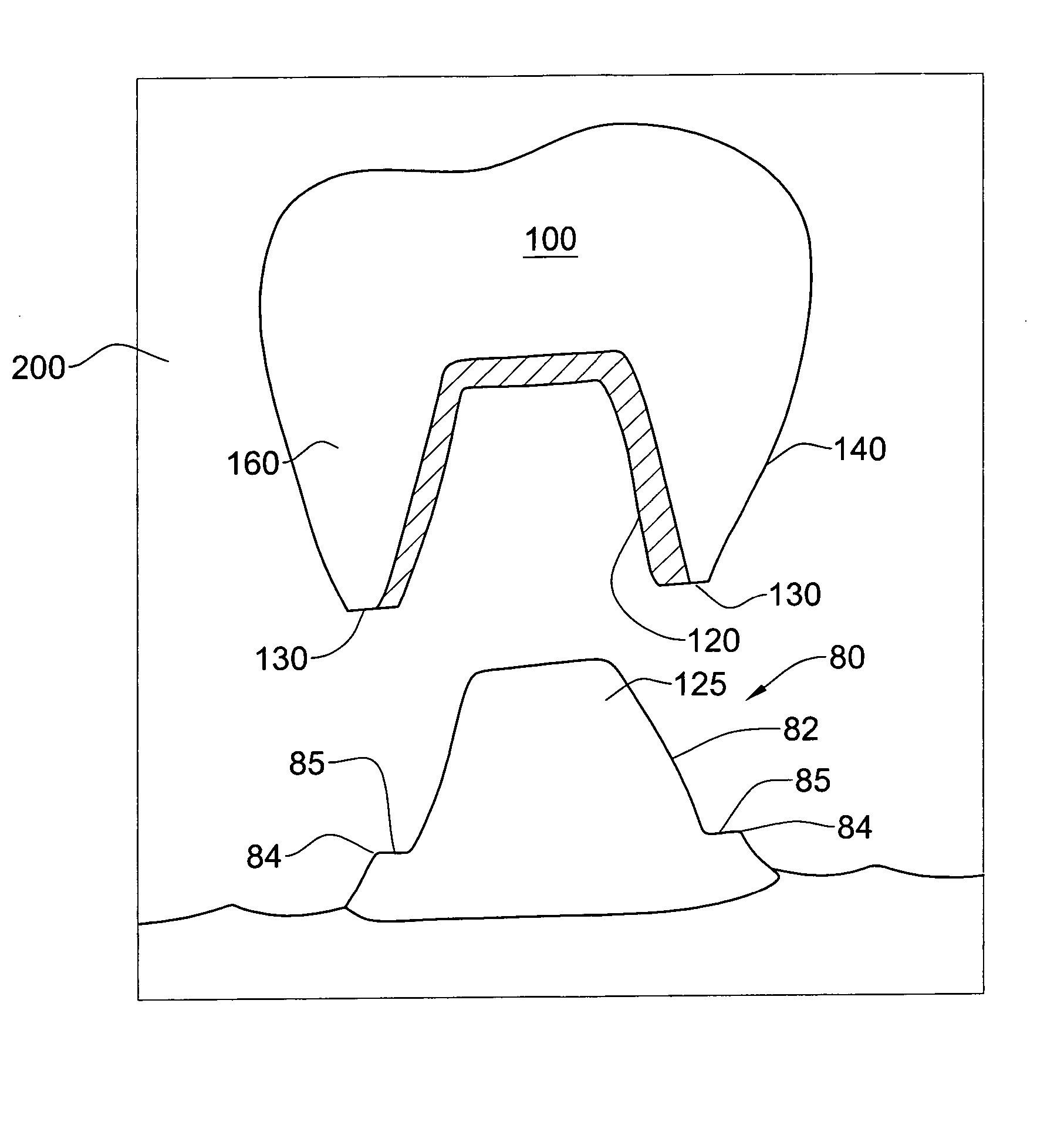

A 3D virtual model of an intra oral cavity in which at least a part of a finish line of a preparation is obscured is manipulated in virtual space by means of a computer or the like to create, recreate or reconstruct finish line data and other geometrical corresponding to the obscured part. Trimmed virtual models, and trimmed physical models, can then be created utilizing data thus created. The virtual models and / or the physical models may be used in the design and manufacture of copings or of prostheses.

Owner:ALIGN TECH

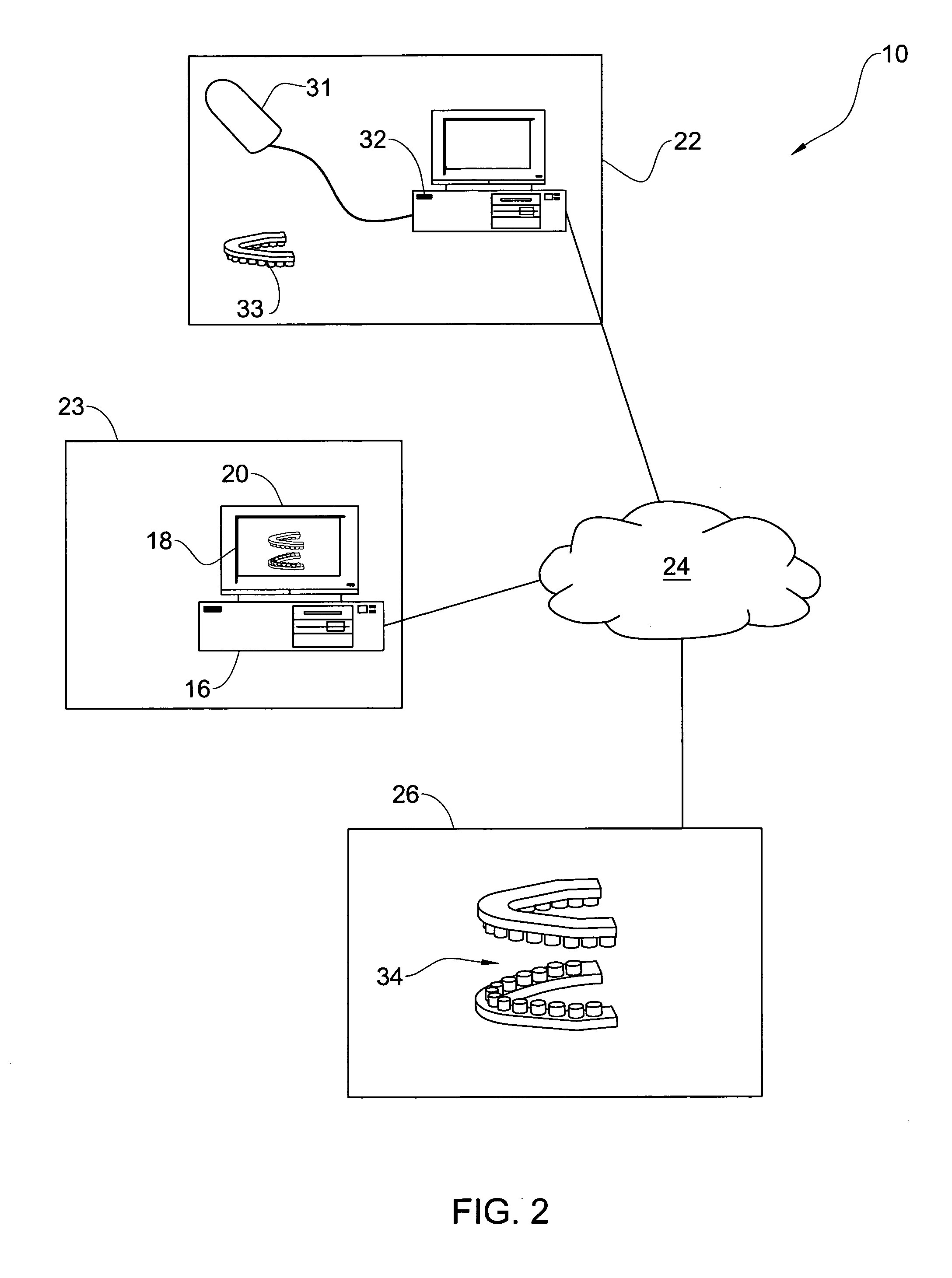

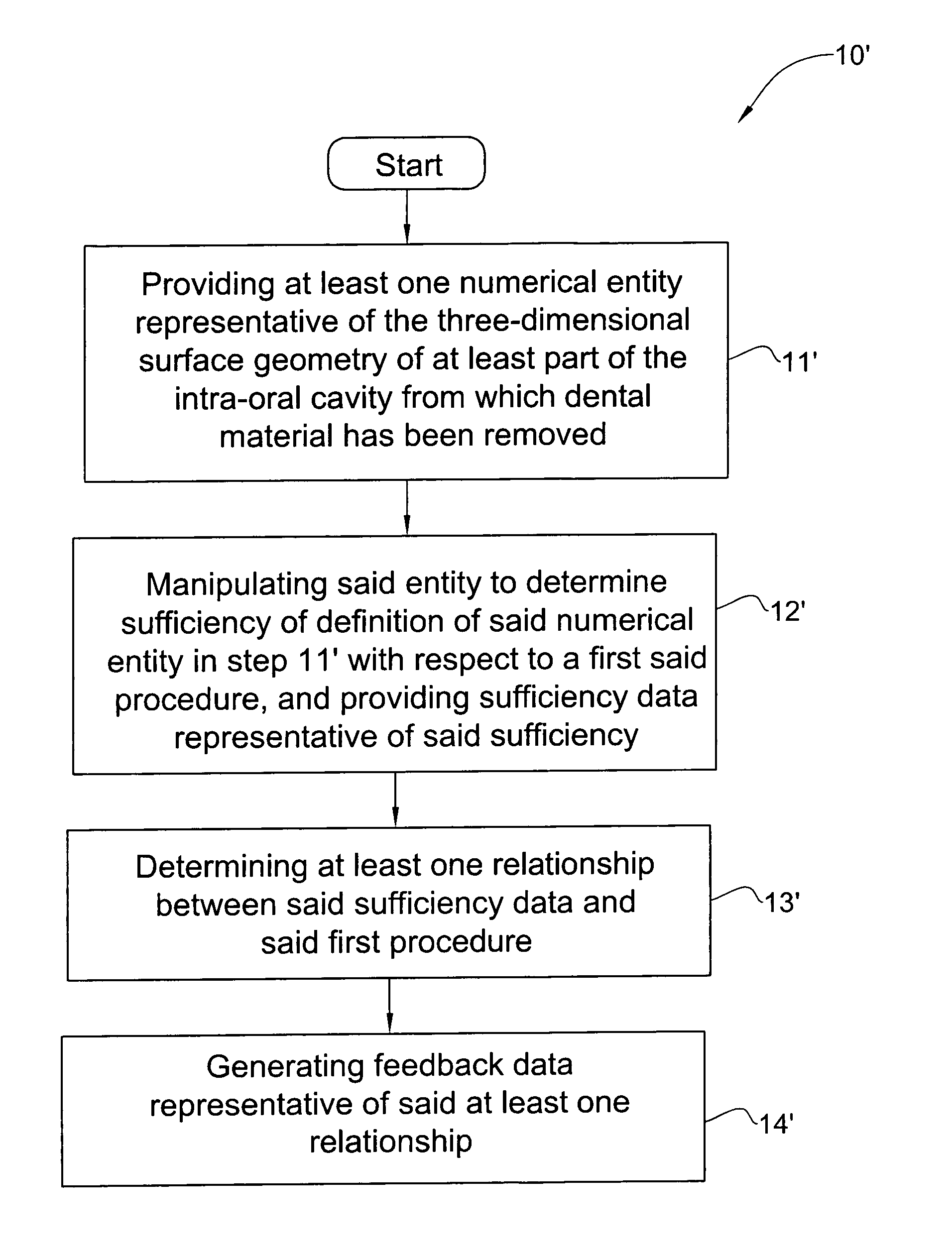

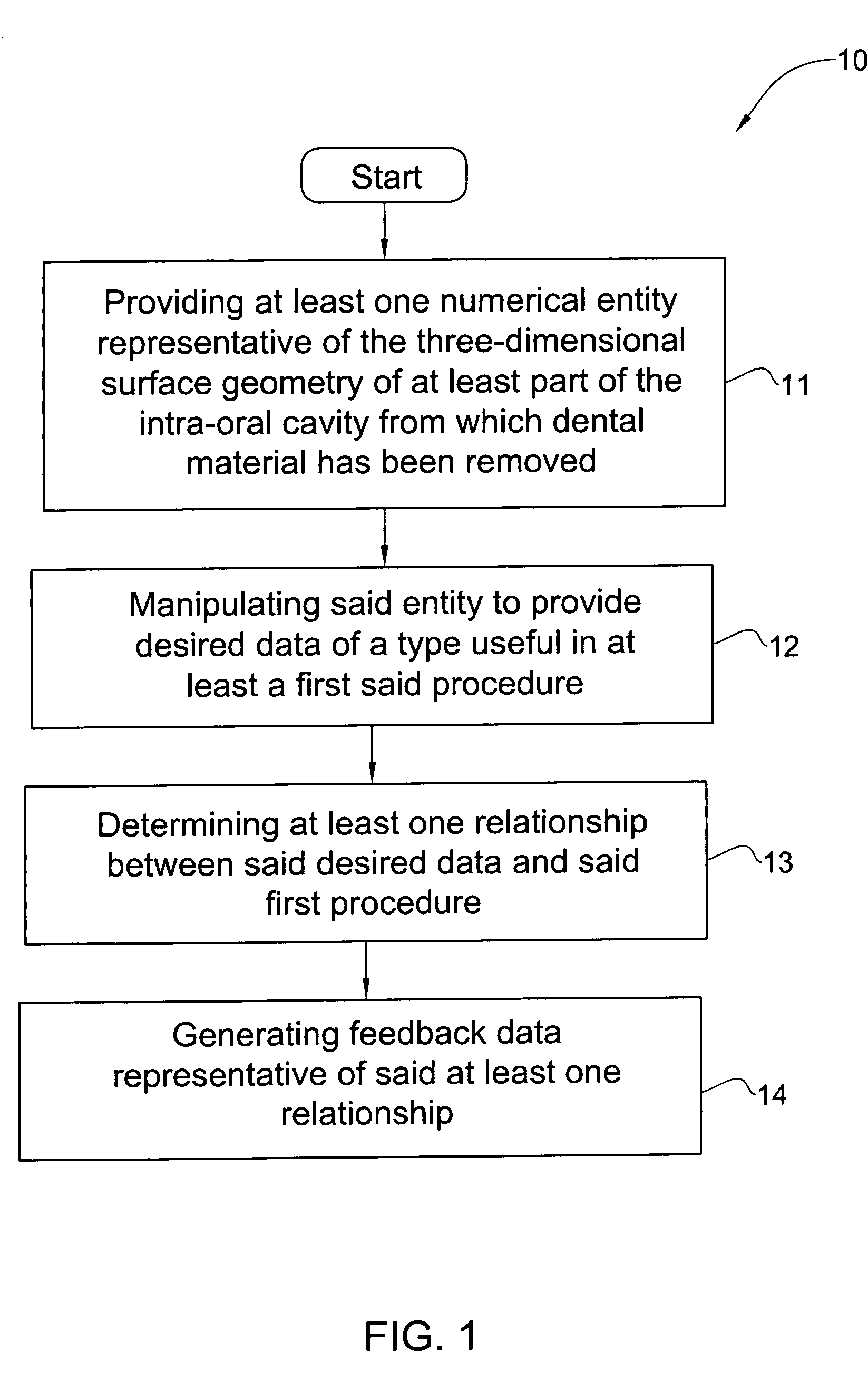

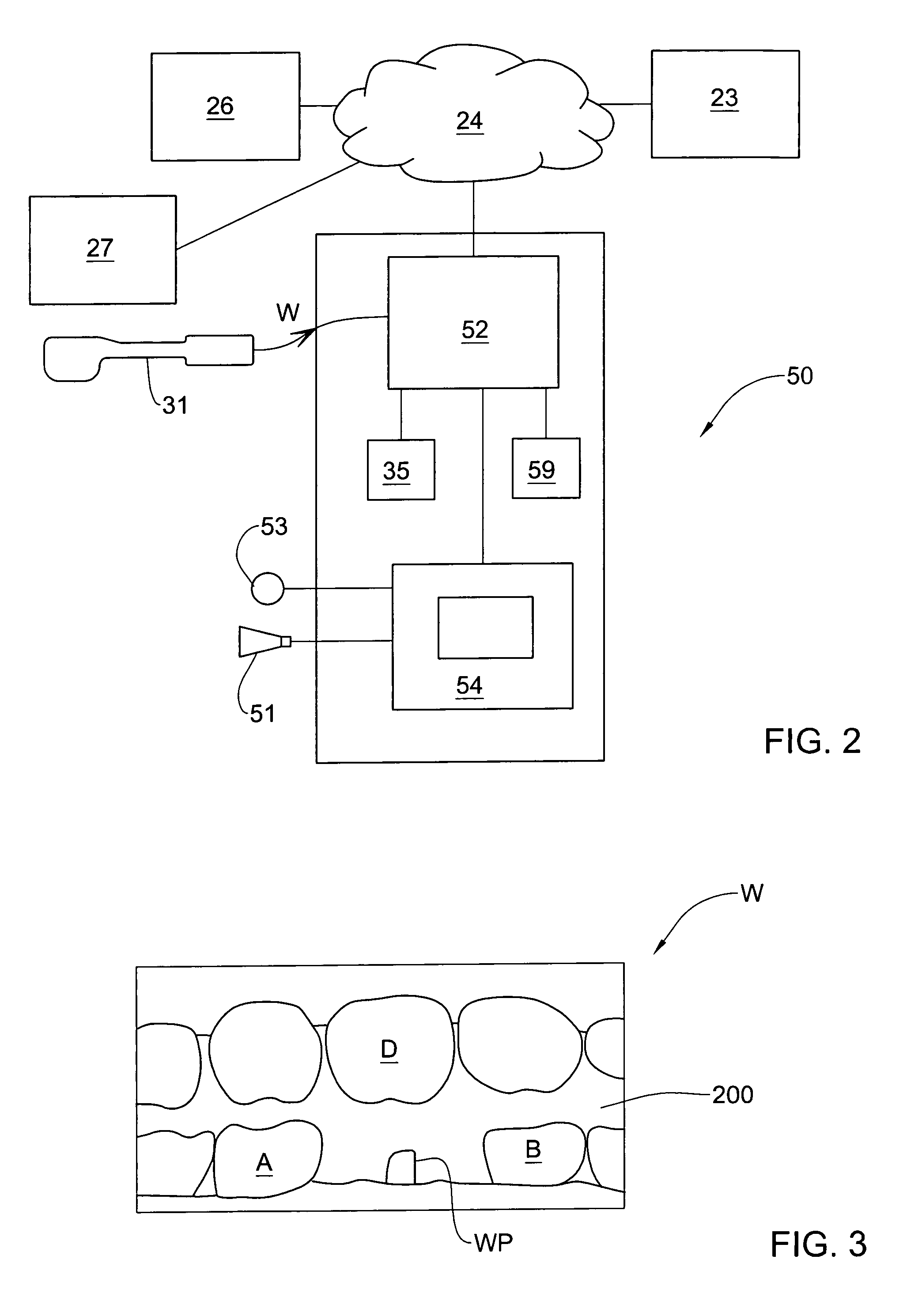

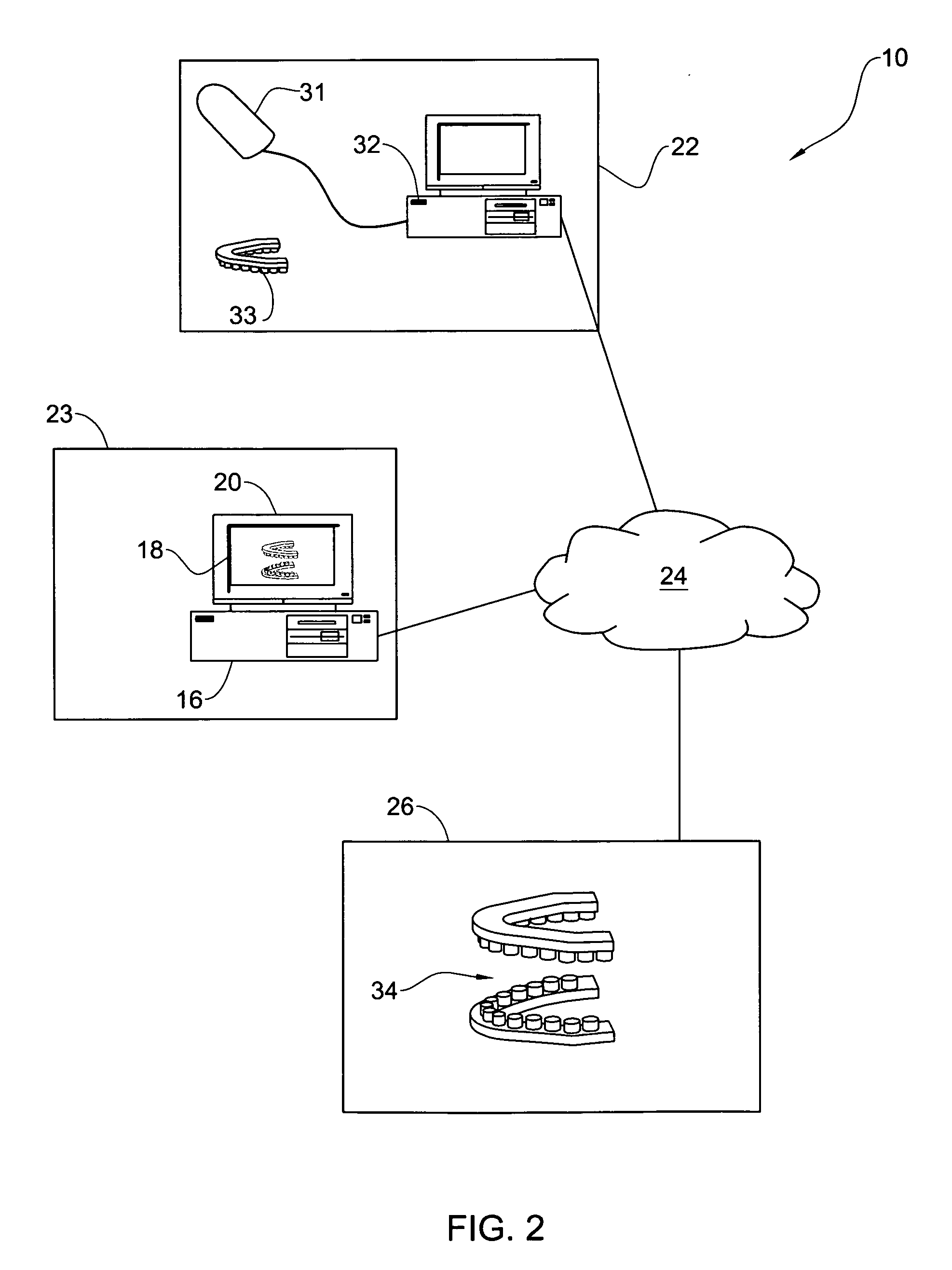

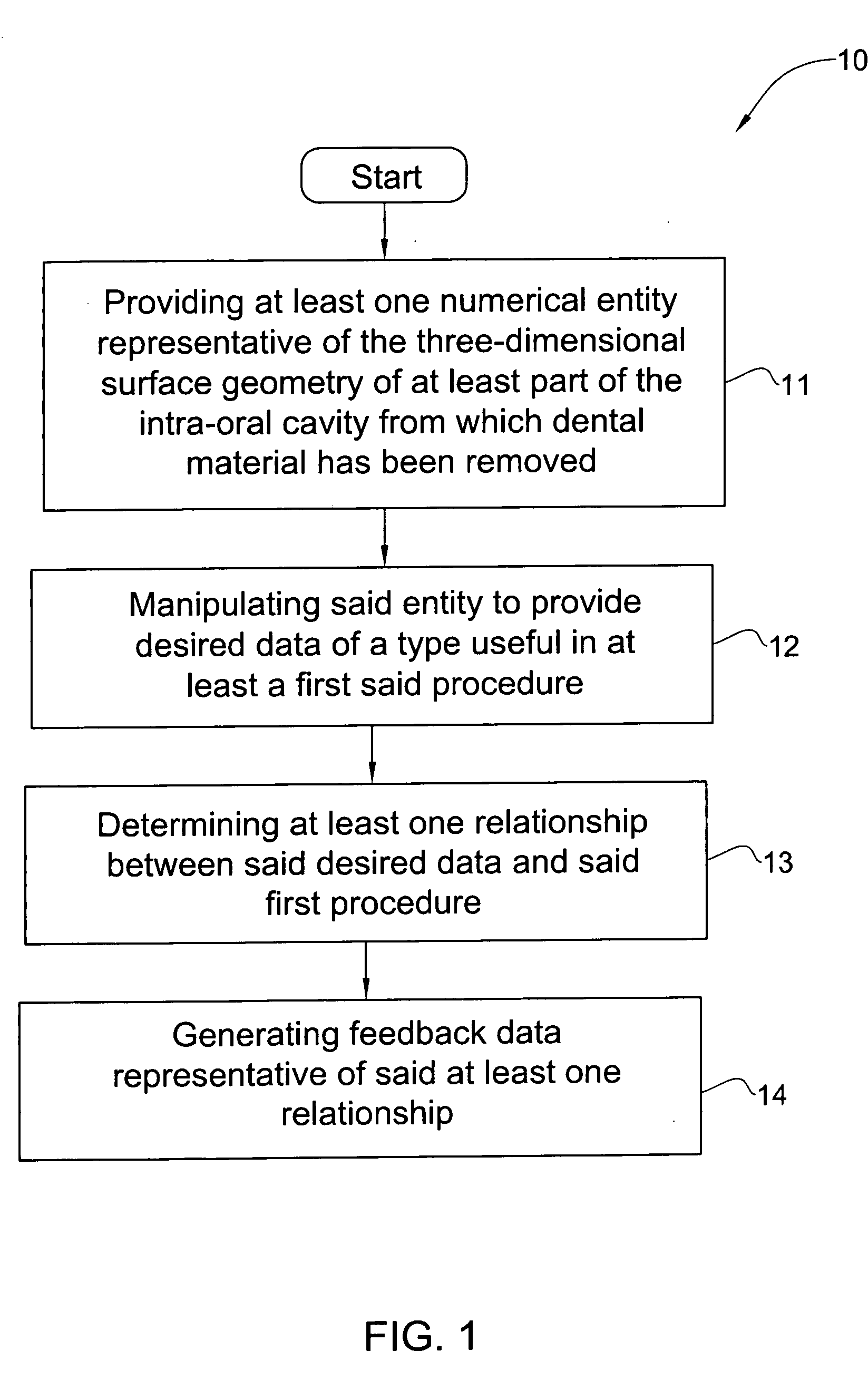

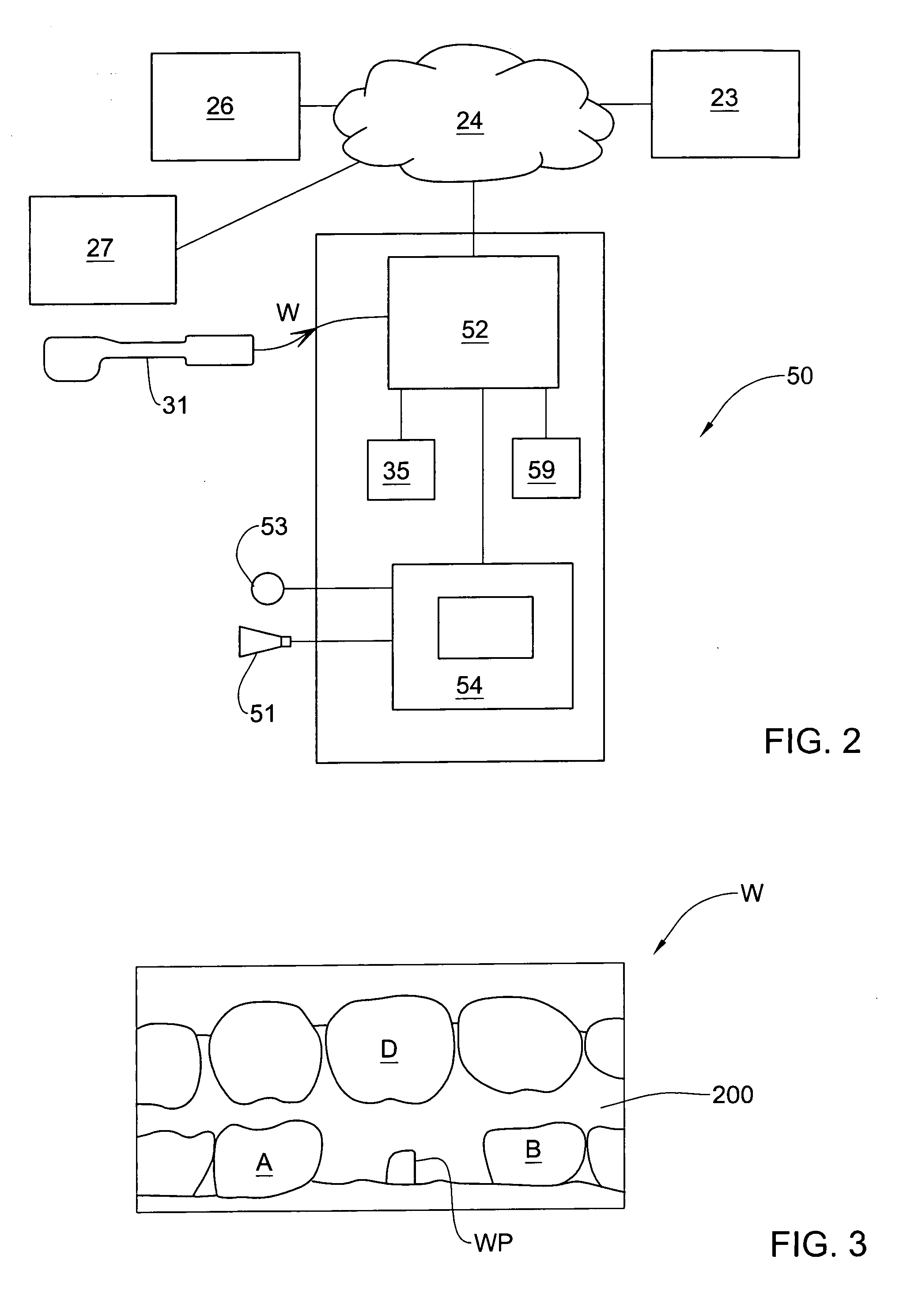

Method and system for providing feedback data useful in prosthodontic procedures associated with the intra oral cavity

ActiveUS7862336B2Impression capsMechanical/radiation/invasive therapiesNumerical modelsComputer science

Feedback data useful in prosthodontic procedures associated with the intra oral cavity is provided. First, a 3D numerical model of the target zone in the intra oral cavity is provided, and this is manipulated so as to extract particular data that may be useful in a particular procedure, for example data relating to the finish line or to the shape and size of a preparation. The relationship between this data and the procedure is then determined, for example the clearance between the preparation and the intended crown. Feedback data, indicative of this relationship, is then generated, for example whether the preparation geometry is adequate for the particular type of prosthesis.

Owner:ALIGN TECH

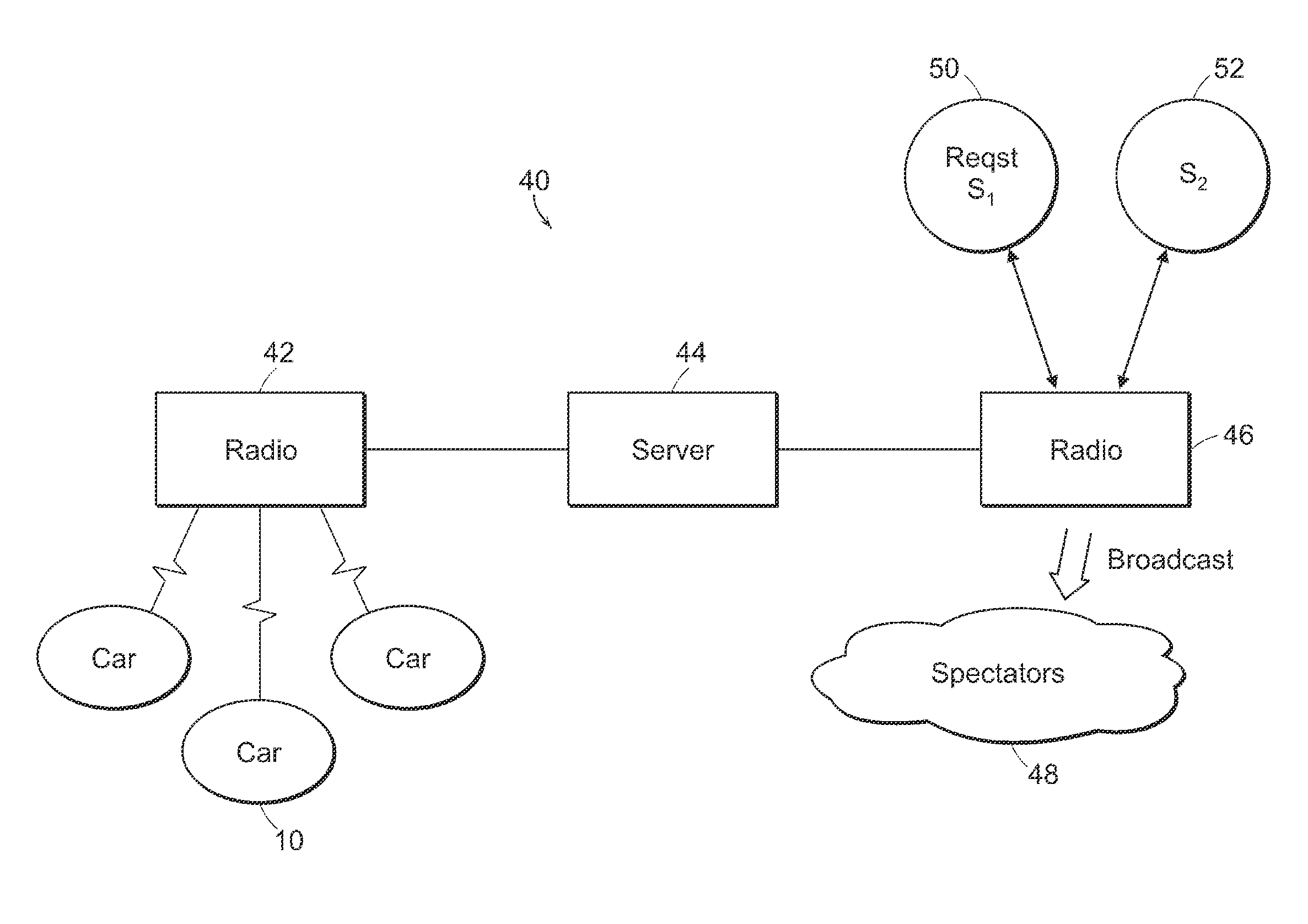

GPS Based Spectator and Participant Sport System and Method

ActiveUS20070015586A1Improve accuracyAchieve accuracyTelevision system detailsGymnastic exercisingMovement systemComputer science

A spectator sport system and method that displays different views of a sporting event and, in particular, uses the spectator's GPS position to assist in displaying a view from the spectator's position. The spectator, using a personal device, can zoom, pan, tilt and change the view, as well as change the view to another position, such as a finish line, goal, or a participant position. Vital information on the sporting event or a participant can be appended to the view. In some forms, augmented reality can be used, such as a finish line or goal, to enhance the experience. Additional service requests can be made from the personal device.

Owner:SPATIAL REALITY LLC

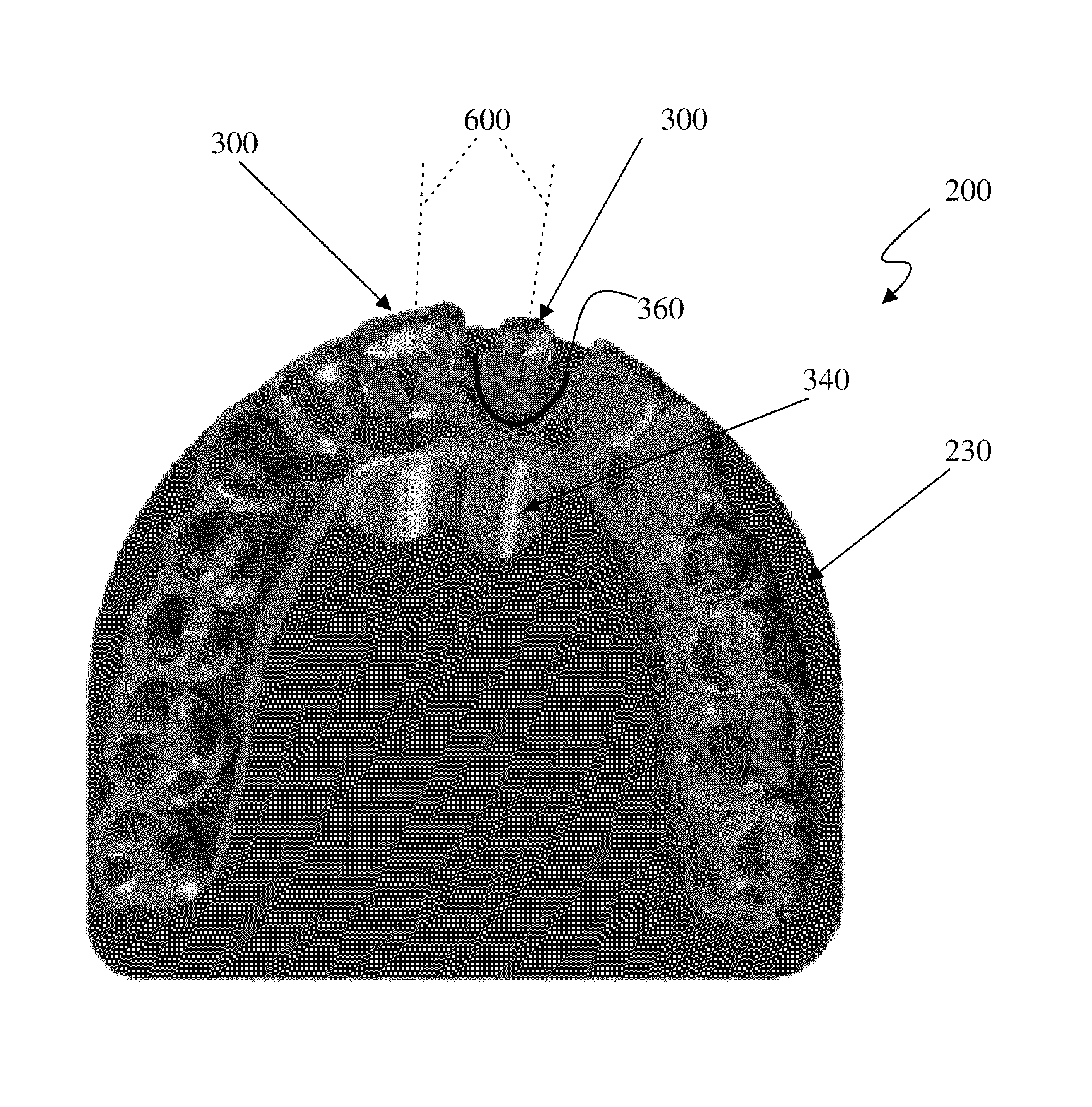

Method for manipulating a dental virtual model, method for creating physical entities based on a dental virtual model thus manipulated, and dental models thus created

ActiveUS20080300716A1Impression capsAnalogue computers for chemical processesVirtual spaceProsthesis

A 3D virtual model of an intra oral cavity in which at least a part of a finish line of a preparation is obscured is manipulated in virtual space by means of a computer or the like to create, recreate or reconstruct finish line data and other geometrical corresponding to the obscured part. Trimmed virtual models, and trimmed physical models, can then be created utilizing data thus created. The virtual models and / or the physical models may be used in the design and manufacture of copings or of prostheses.

Owner:ALIGN TECH

Method and system for providing feedback data useful in prosthodontic procedures associated with the intra oral cavity

ActiveUS20060115793A1Improve performanceImpression capsMechanical/radiation/invasive therapiesNumerical modelsIntra oral

Feedback data useful in prosthodontic procedures associated with the intra oral cavity is provided. First, a 3D numerical model of the target zone in the intra oral cavity is provided, and this is manipulated so as to extract particular data that may be useful in a particular procedure, for example data relating to the finish line or to the shape and size of a preparation. The relationship between this data and the procedure is then determined, for example the clearance between the preparation and the intended crown. Feedback data, indicative of this relationship, is then generated, for example whether the preparation geometry is adequate for the particular type of prosthesis.

Owner:ALIGN TECH

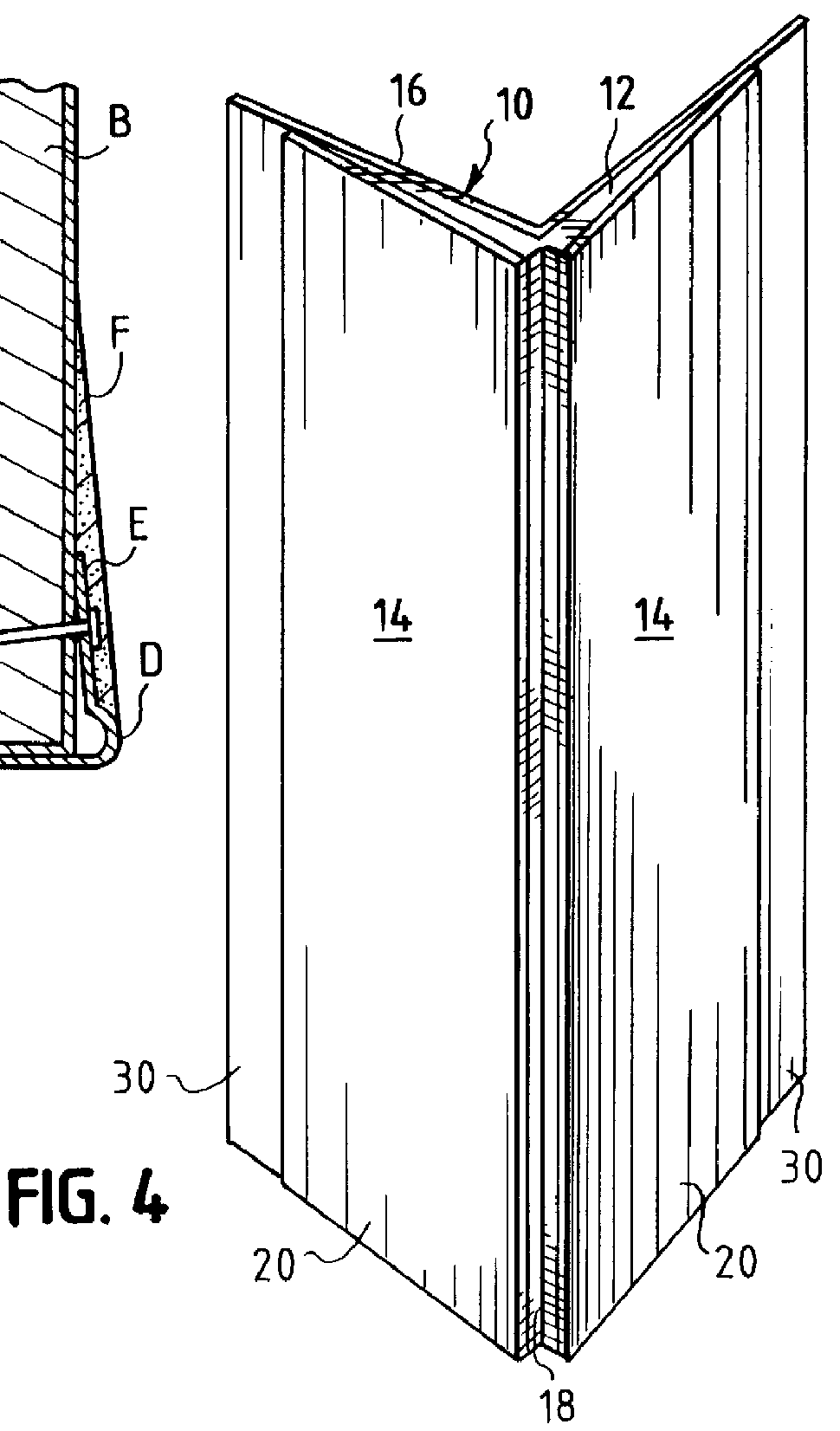

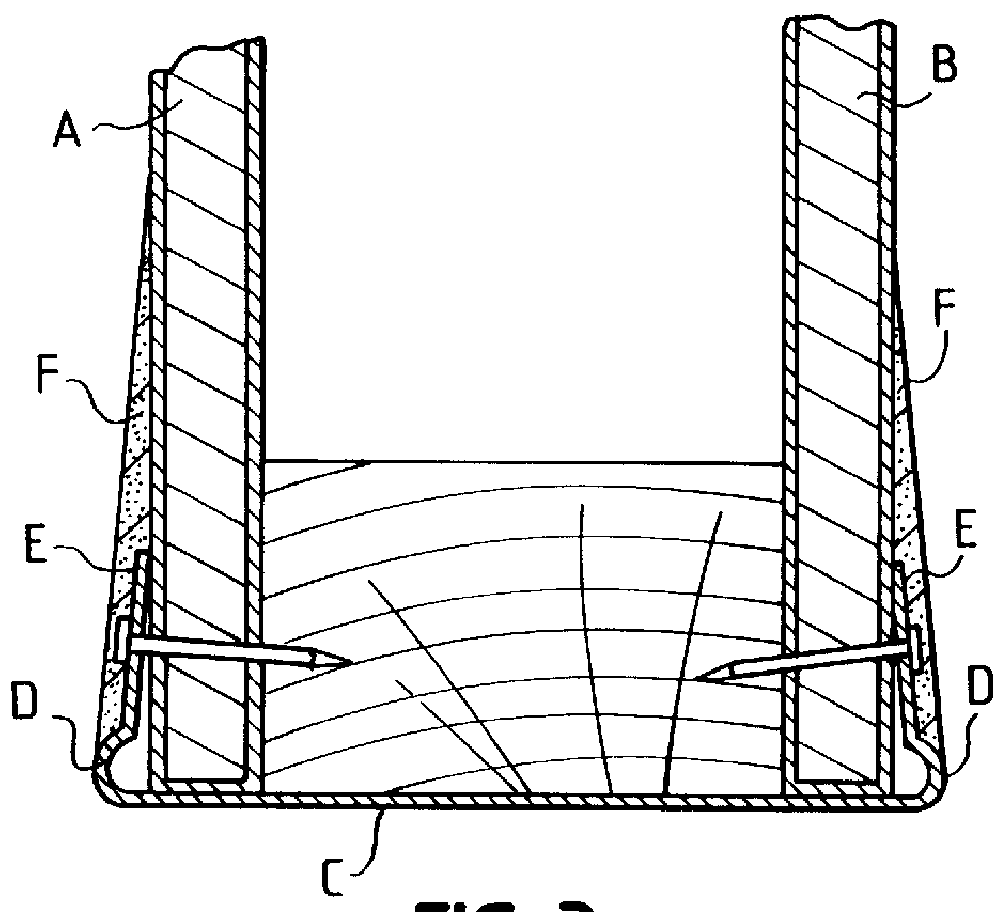

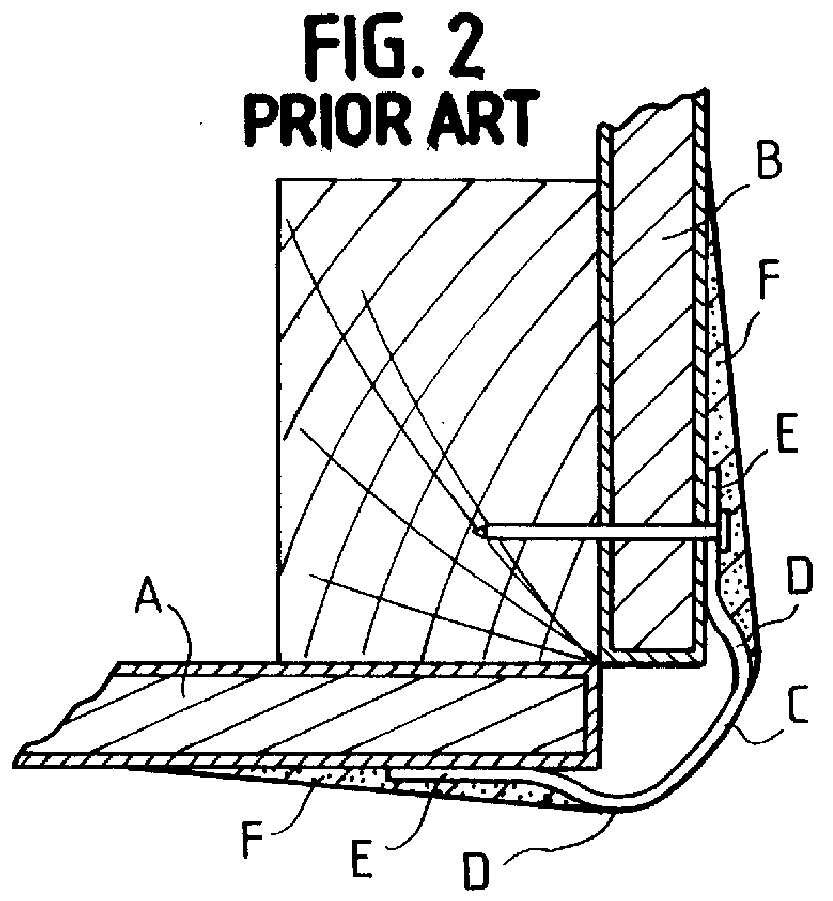

Non coatable drywall finishing system

A drywall finishing system for finishing 1) normal inside and outside corners of any angle, 2) stub wall or closet corners, 3) window wrap corners, and 4) L-metal for window sills and areas where drywall ends against some other surface like brick. The finishing system comprises a preformed trim piece comprising a semi-rigid member that is relatively thick in the center and tapers laterally to a thin edge. A layer of paper is bonded to the inside surface of the semi-rigid member for receiving joint compound to continuously bond the trim piece to the dry wall. A layer of finishing material is bonded to the exterior surface of the semi-rigid member. To install one of the pieces, it is selected from stock and cut to length. A flat coat of mud is applied to both sides of an exterior or interior angle, and the trim piece is placed over the mud and smoothed into place. Since it is preformed, the piece makes a straight line at the required angle. Once, the piece is in place, the edges are feathered once with a small amount of mud and a wide blade. At that point the corner is complete except for drying. It generally does not need to be sanded or touched up or at most, requires very little sanding or touching up. The finish material on the exterior surface can be directly textured or painted. Most of the intense labor associated with prior art methods is eliminated since none of the parts need to be coated with mud or sanded. In addition, the parts form straight, finished lines and angles as soon as they are installed.

Owner:CERTAINTEED GYPSUM & CEILING MFG INC

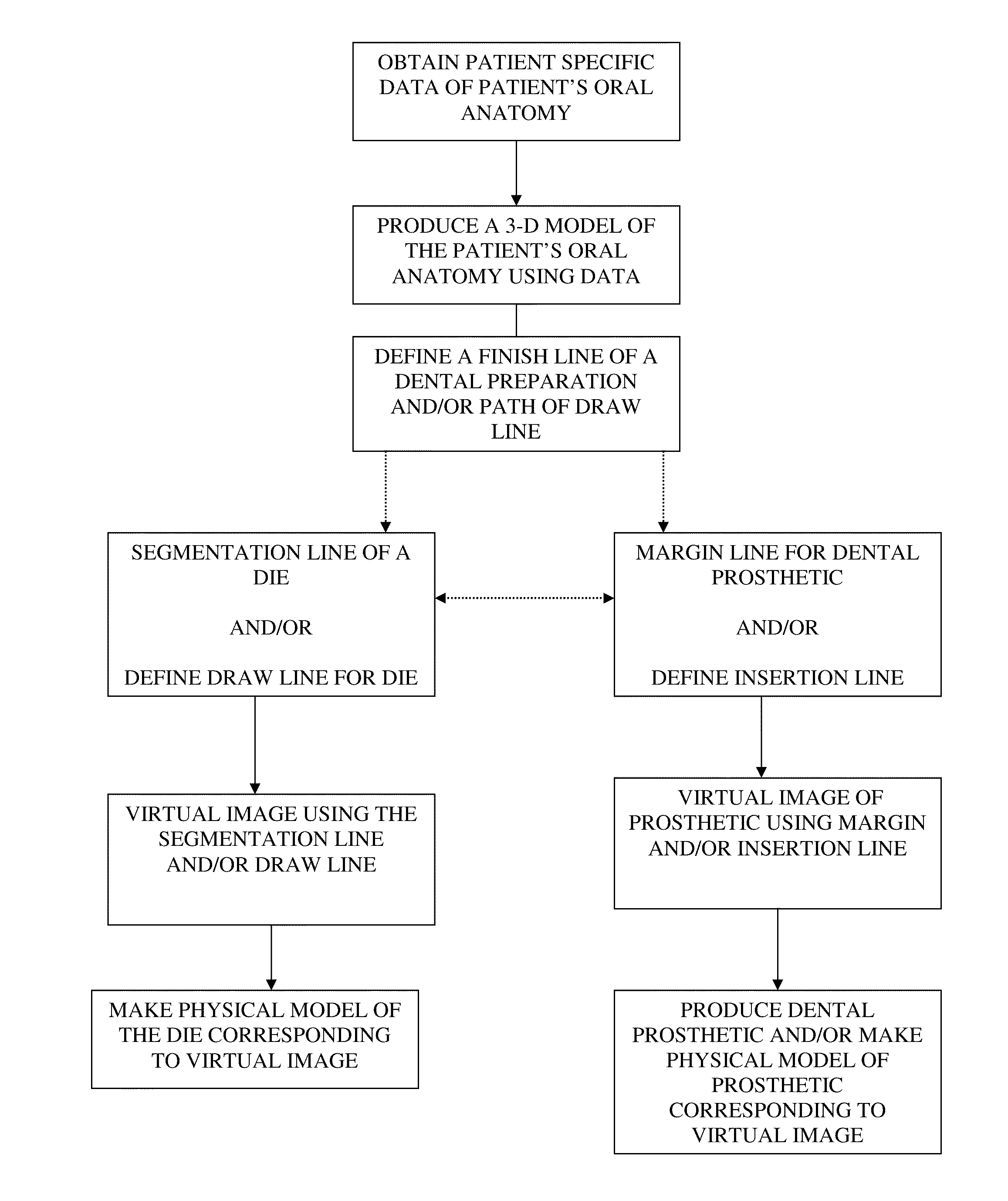

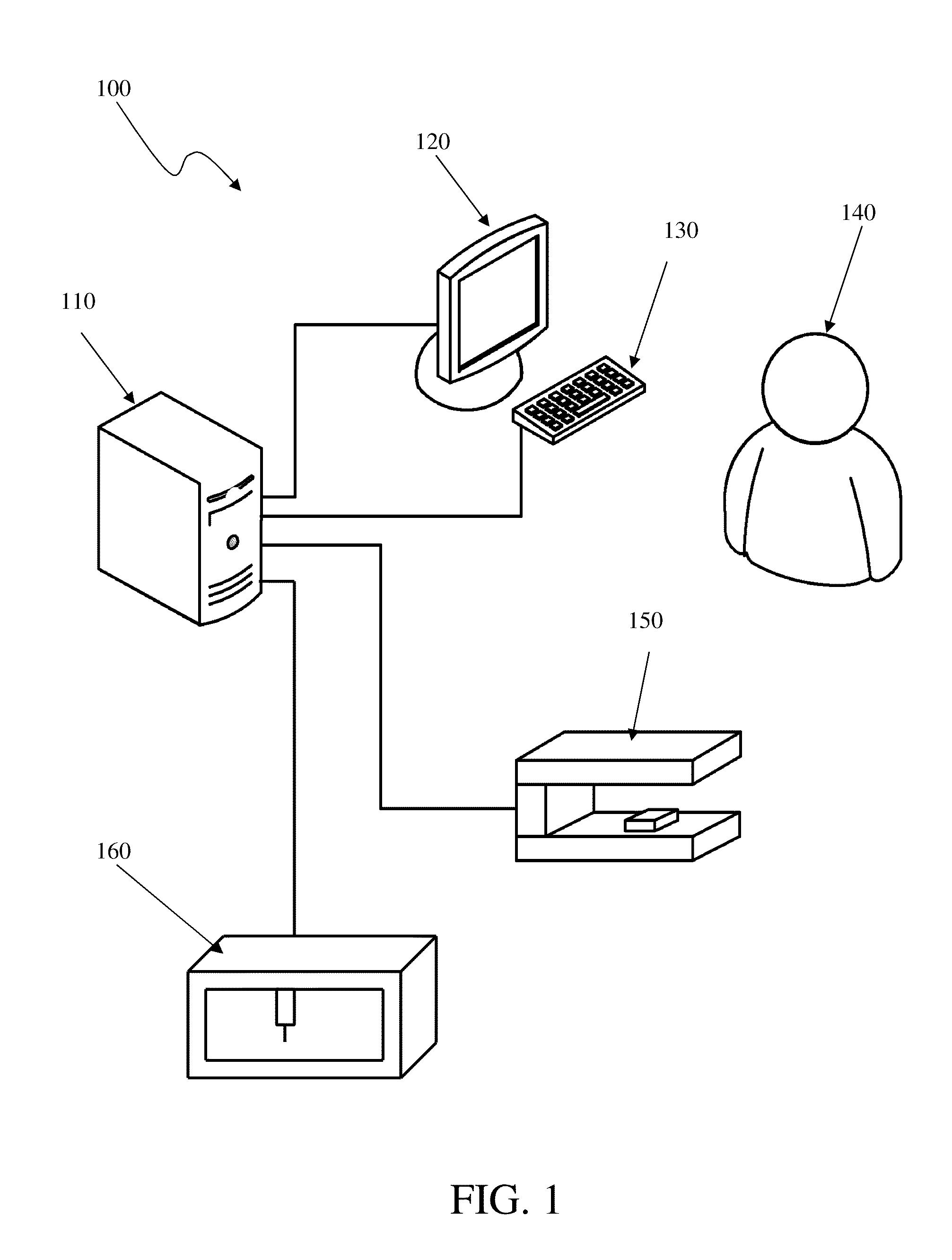

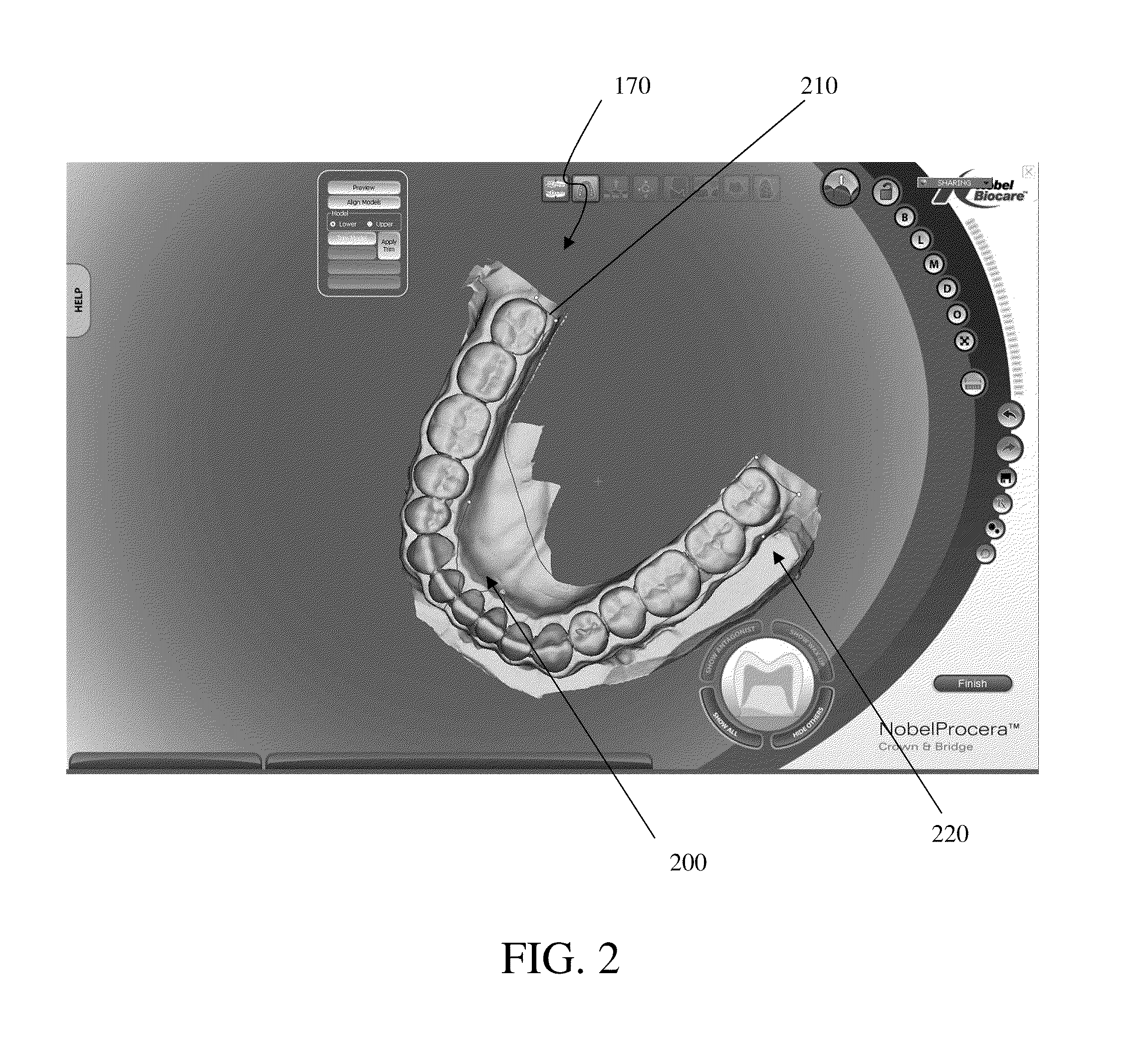

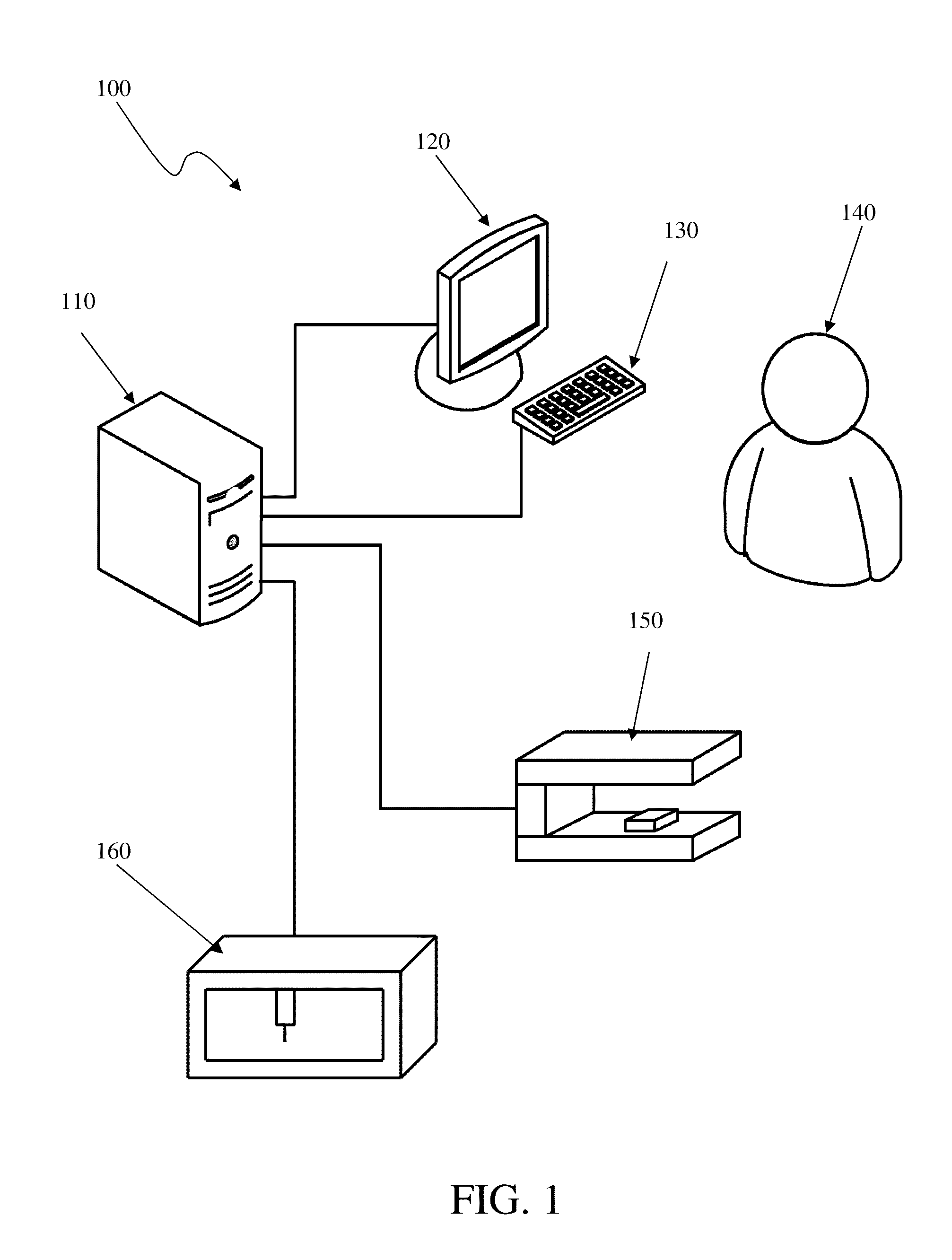

Method for planning a dental component

Presented herein are methods and devices for designing dental components, such as physical models of a patient's anatomy, crowns and bridges. An operator of a prosthetic designing system can receive information, such as from a scanner, which provides information on the topology of the patient's dentition. The operator can use this information to design a custom prosthetic to fit the patient. Part of the designing process involves using a finish line defined for a preparation as a segmentation line for a physical die corresponding to the preparation, and using a path of draw line as an insertion axis line for a dental prosthetic.

Owner:BIOCAD MEDICAL

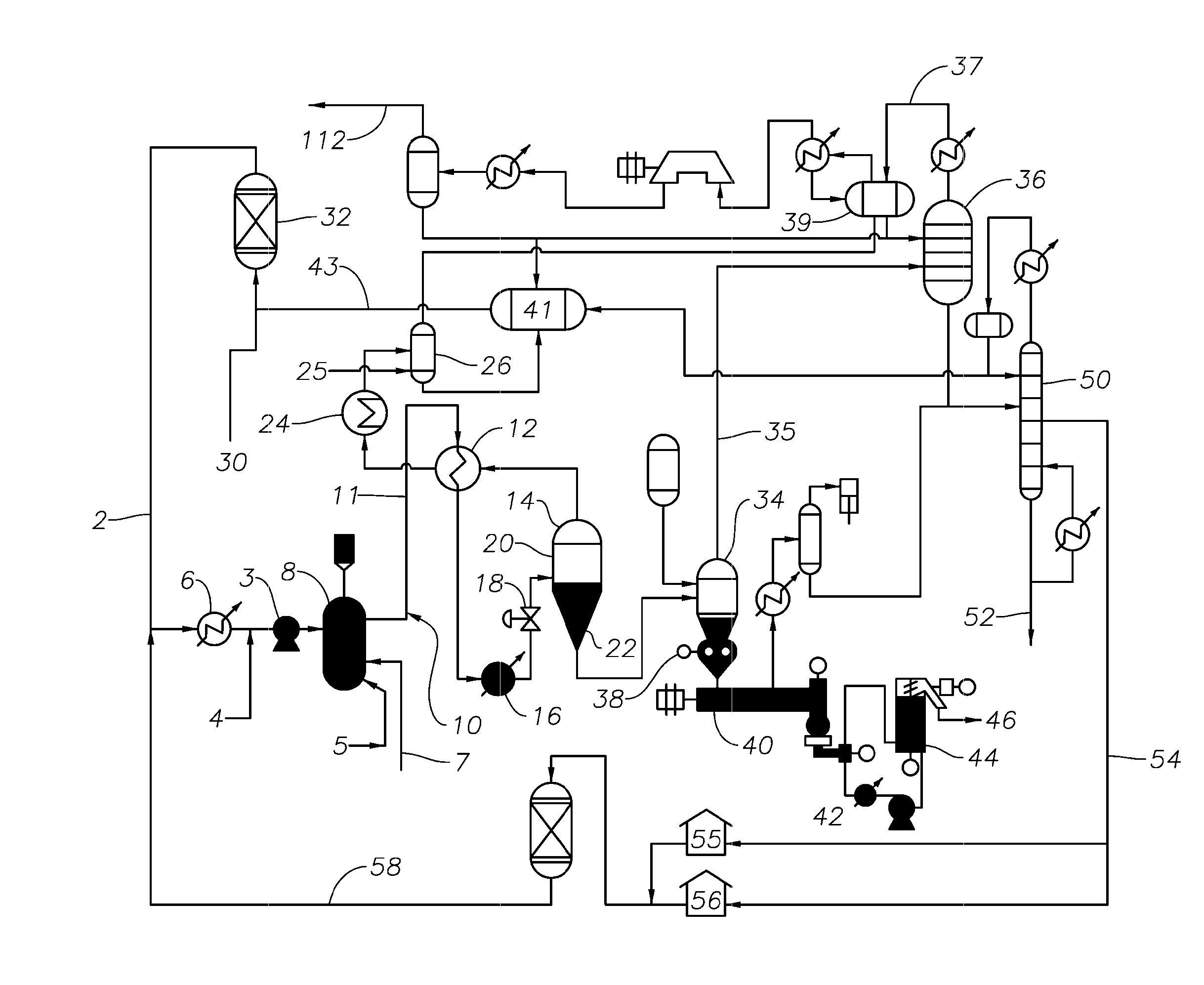

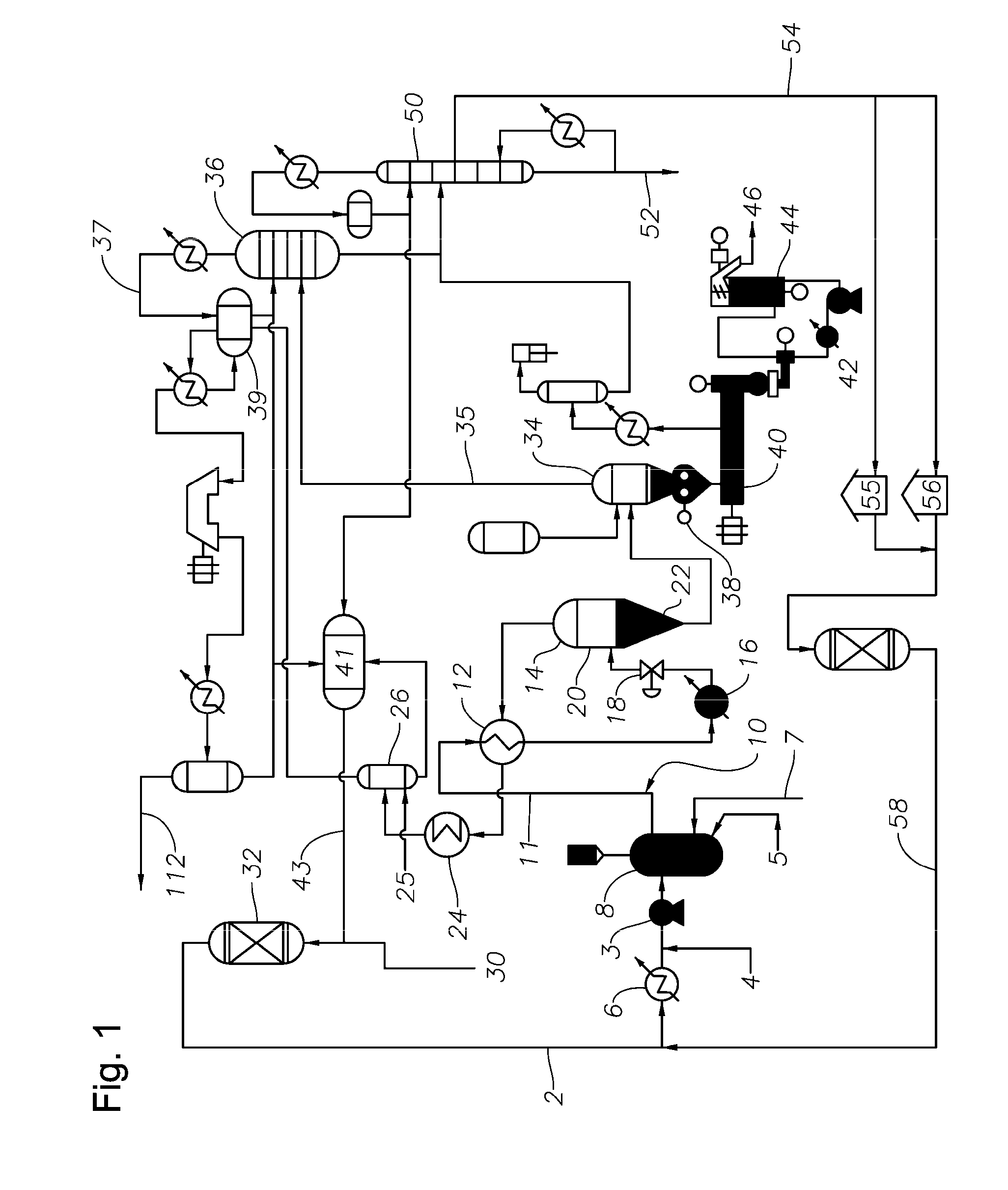

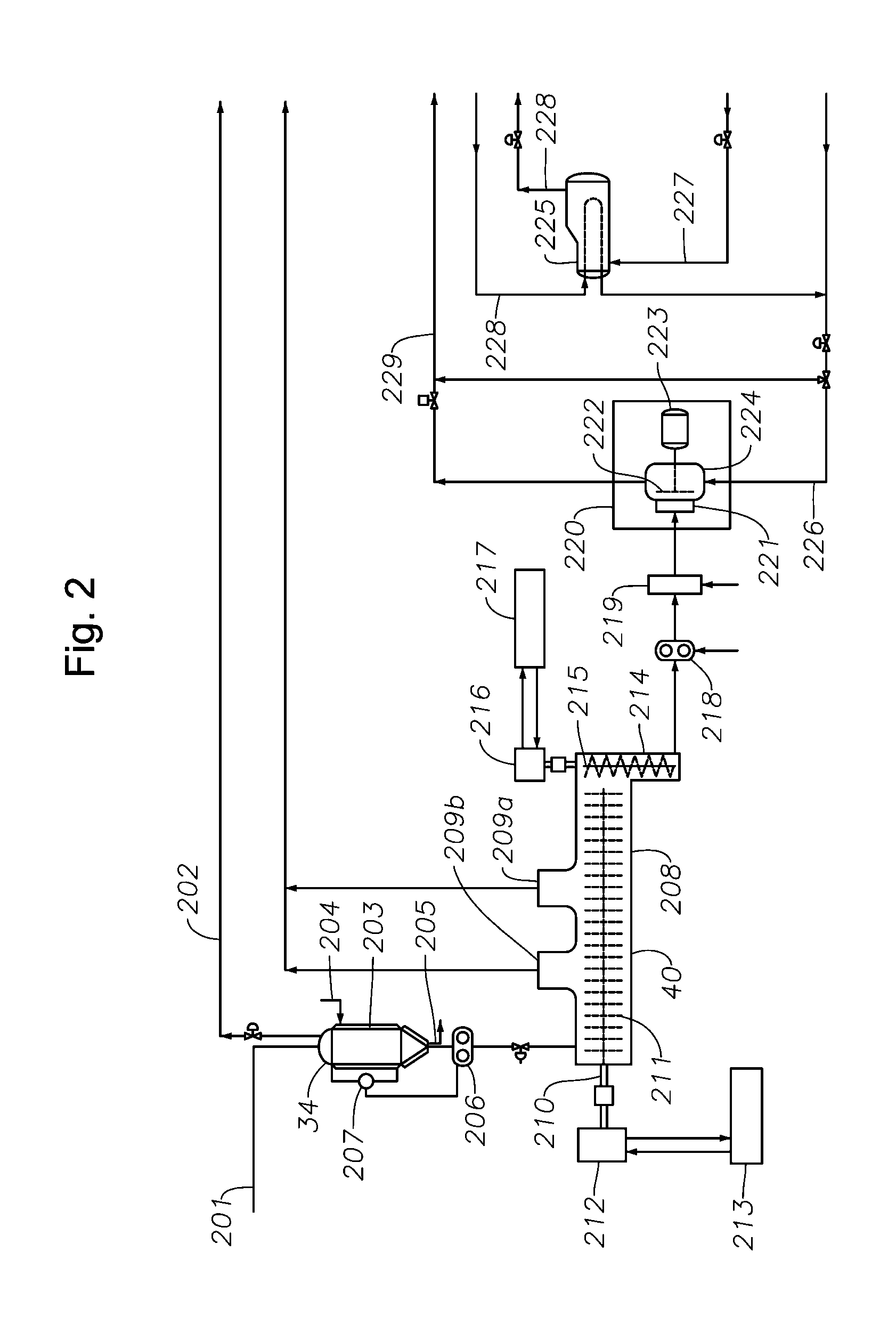

Processes And Apparatus For Polymer Finishing And Packaging

ActiveUS20110172382A1Process control/regulationCleaning heat-transfer devicesSolution polymerizationResidence time

Provided are apparatus and methods relating to the finishing line of a continuous solution polymerization plant. In one aspect, an apparatus includes a pelletizer having cooling liquid, e.g., water or aqueous solution, into which is added a pelletization aid. In another aspect, the apparatus comprises means to remove residual polymer particles from the pelletizer cooling liquid. In a further aspect, the apparatus comprises conduits of at least 50 m in length for carrying propellant cooling liquid from the pelletizer to a drying apparatus. The residence time of the pellets in the cooling liquid may be 10 seconds or more. In a further aspect, a drying apparatus is provided for the pellets which comprises first and second drying zones. In a further aspect, a pneumatic conveyor is provided for carrying pellets to a packaging apparatus. In a further aspect, a packaging apparatus is provided comprising a blender silo.

Owner:EXXONMOBIL CHEM PAT INC

GPS Based Spectator and Participant Sport System and Method

ActiveUS20080198230A1Improve accuracyAchieve accuracyDirection finders using radio wavesClosed circuit television systemsData setDriver/operator

A spectator sport system and method that displays different views of a sporting event and, in particular, uses a position selected by the spectator to assist in displaying a view from the selected position. The spectator, using an internet device, can zoom, pan, tilt and change the view, as well as change the view to another position, such as a finish line, goal, or a participant position (e.g. Driver of car #3 or Tiger Wood's position). The starting position can be specified, as well as the target position or orientation from the starting position. Vital information on the sporting event or a participant can be appended to the view. In some forms, augmented reality or any geographic referenced datasets can be used and combined, such as 3D imagery or 3D renderings, to enhance the experience.

Owner:SPATIAL REALITY LLC

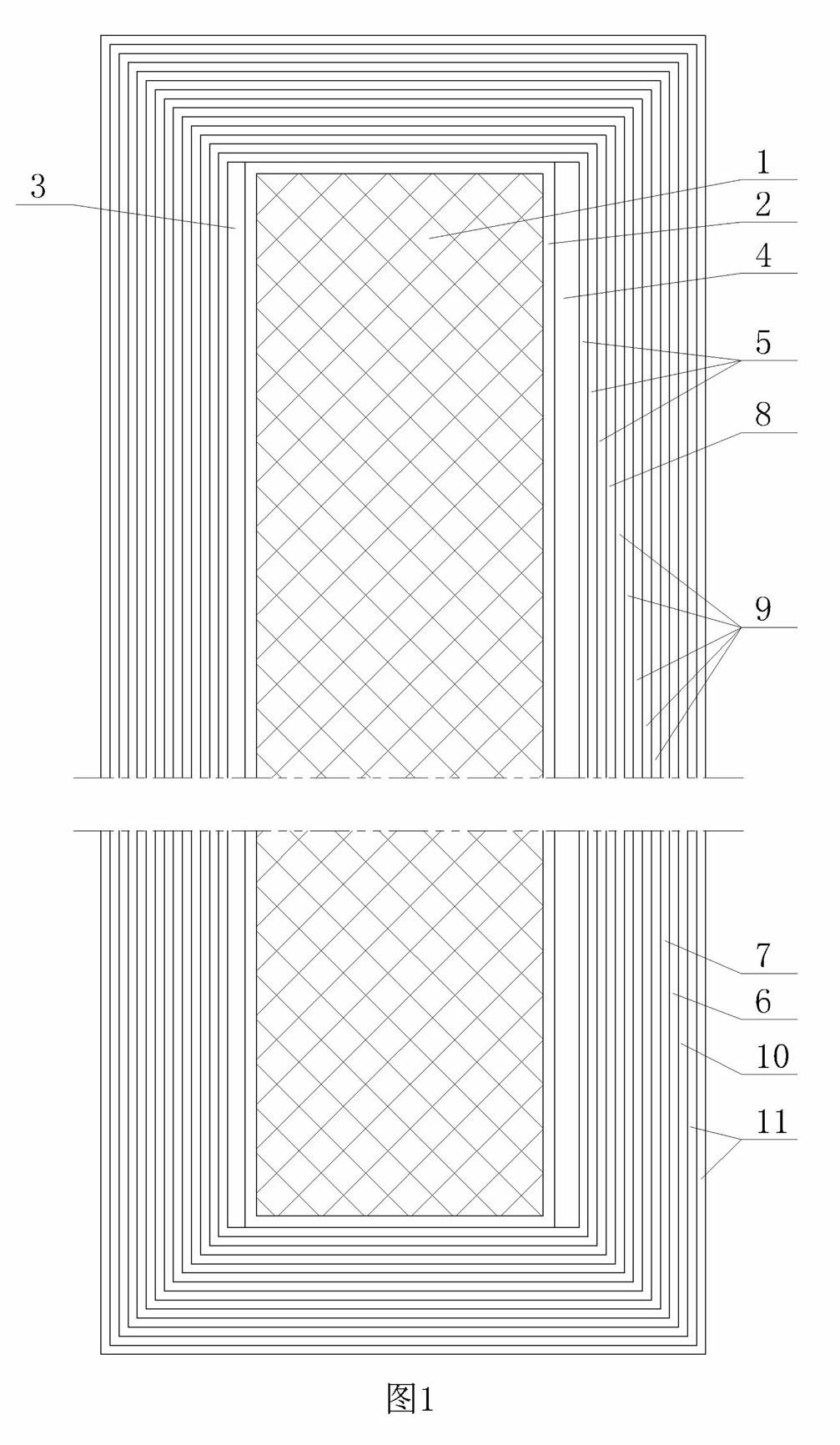

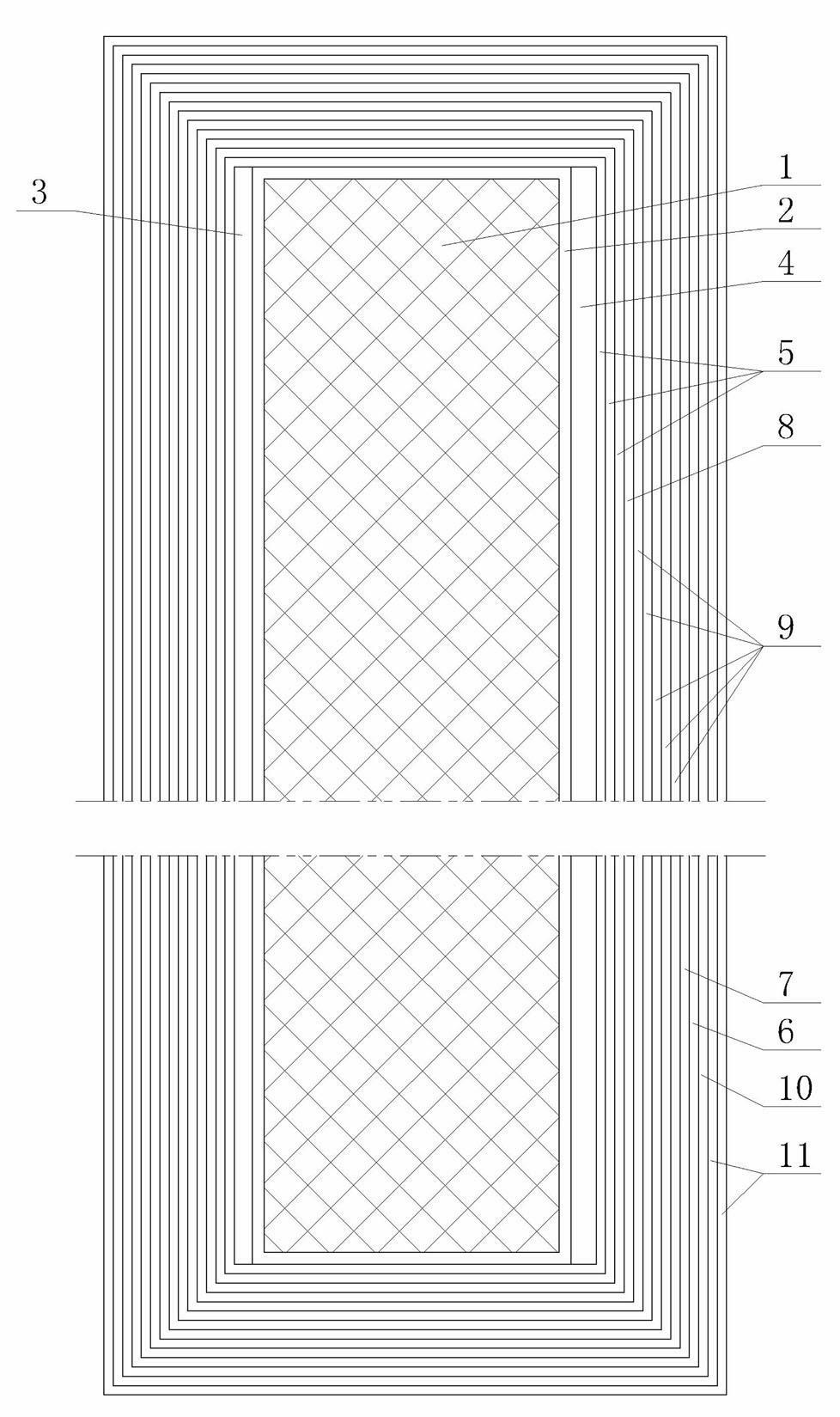

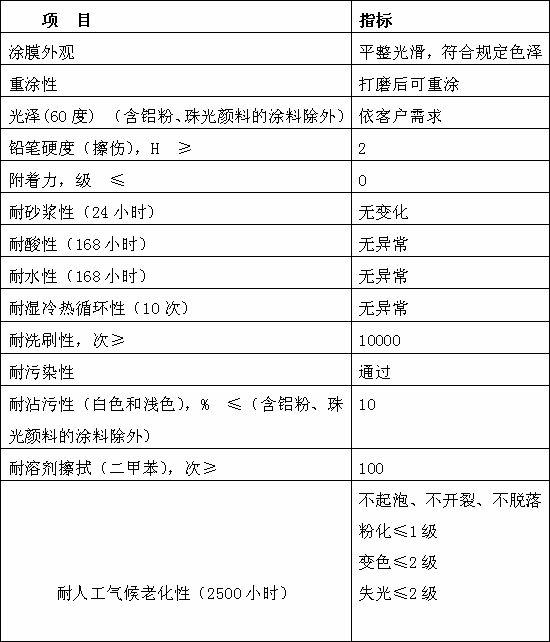

Building inner and outer wall decorating plate and manufacturing method thereof

ActiveCN102425284ASolve Adhesion ProblemsSolve the problems of transfer printing technologyCovering/liningsPretreated surfacesCalcium silicateCross-link

The invention discloses a method for building inner and outer wall decorating plate, which comprises two flows, each flow including steps of: a primer line processing flow: (1) thickness sanding and dedusting, (2) roller painting back seal coat and curing into a first UV seal coat layer, (3) roller painting UV penetrant twice, (4) leveling by infrared ray, (5) coating UV putty at the front and UV curing and generating a UV putty layer, (6) roller painting the UV seal coat for three times and respectively curing and generating three second UV seal coat layers, (7) fine sanding; and a roller painting finish line flow: (1) dedusting, (2) roller painting UV glue and generating a first UV glue layer, (3) coating the UV finish for five times and curing and generating five UV finish layers. The decorating plate can solve the problems that a UV curing penetrating agent is strongly, quickly and deeply penetrated into a fiber reinforced calcium silicate slab or a fiber cement slab, deeply cured to form a film and subjected to stereo chemical netlike cross-linking reaction with UV putty and UV sealing paint, and thoroughly solves the problem of adhesive force between the decorative surface layer and a substrate.

Owner:山东鲁泰装配式装修材料有限公司

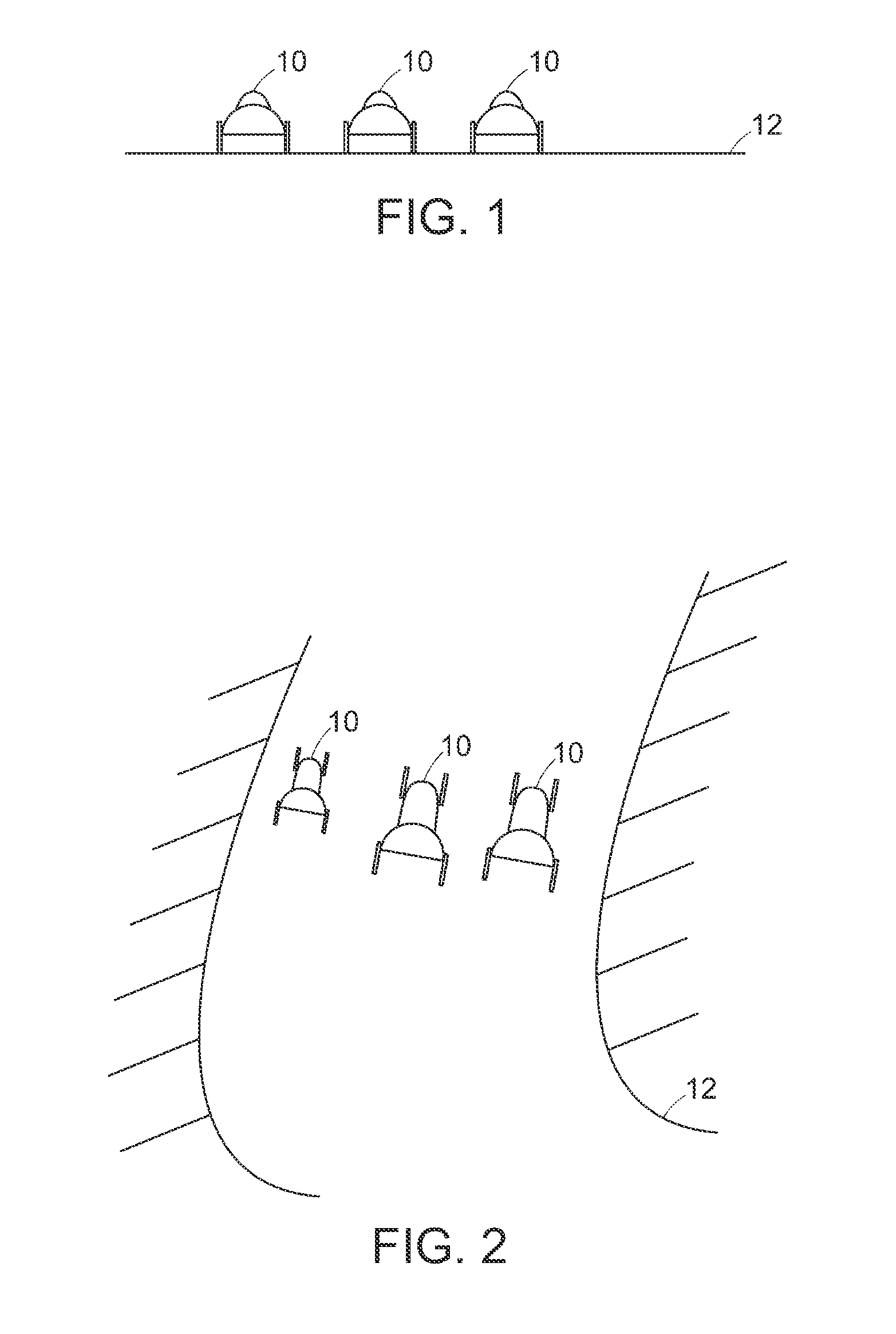

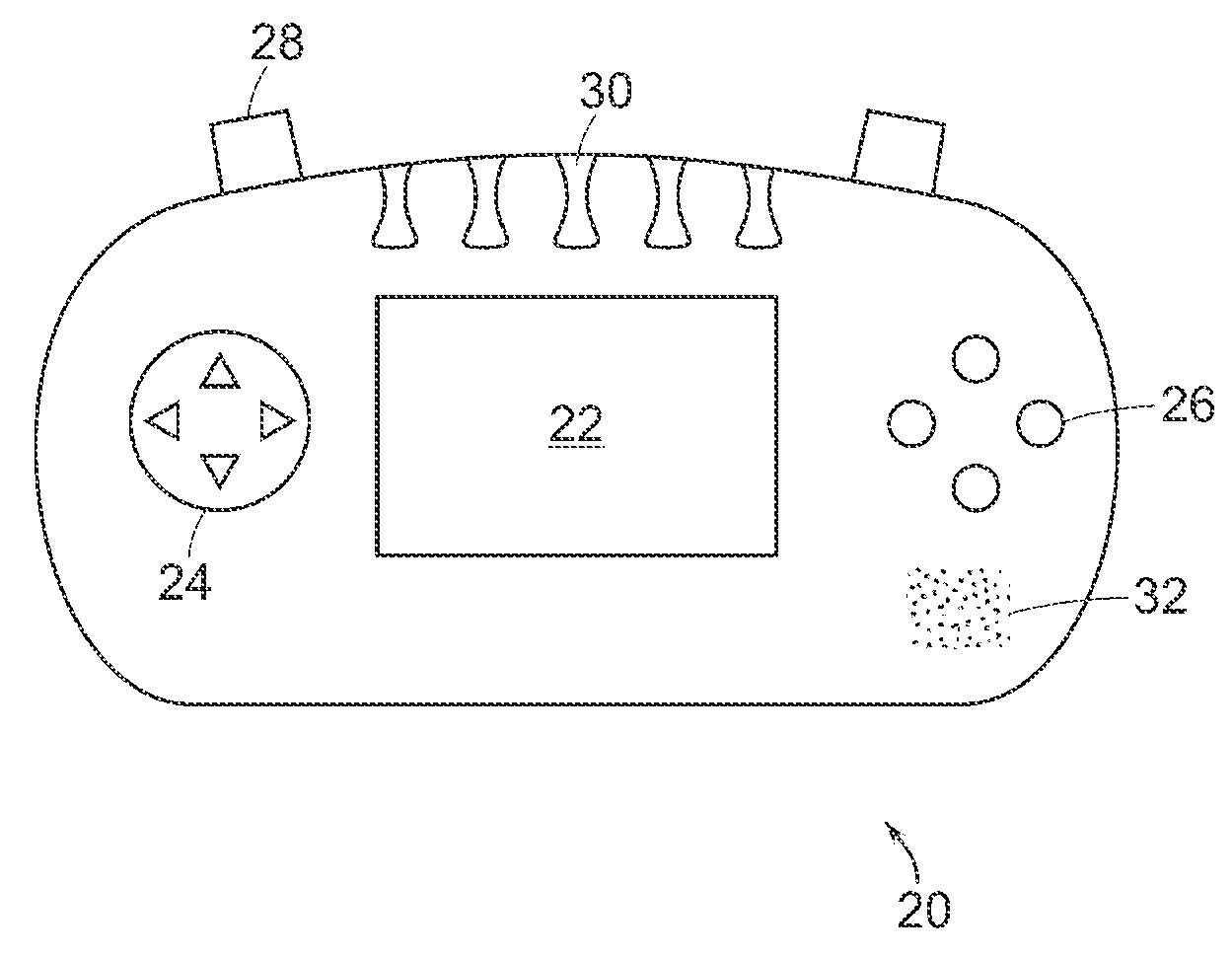

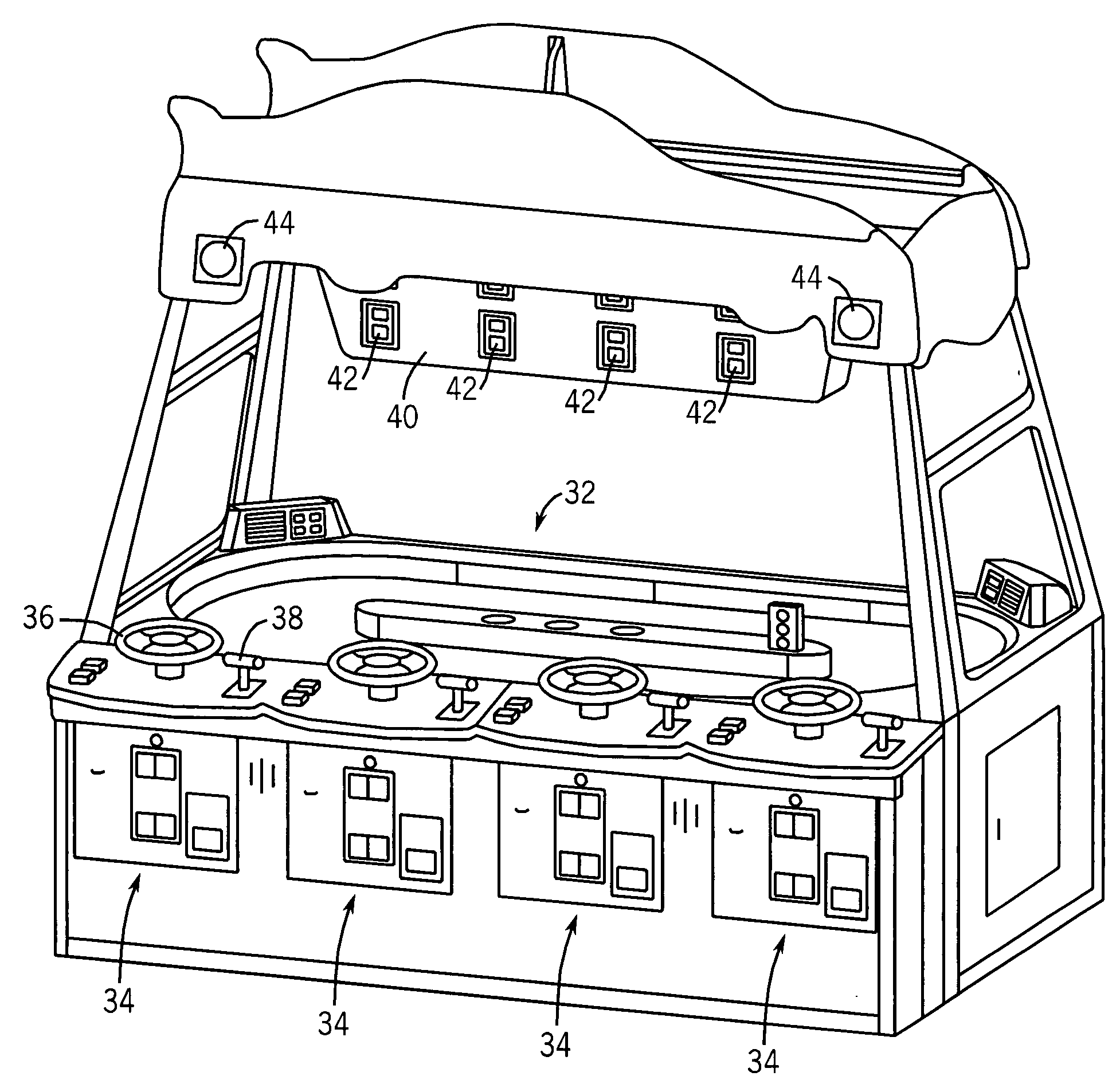

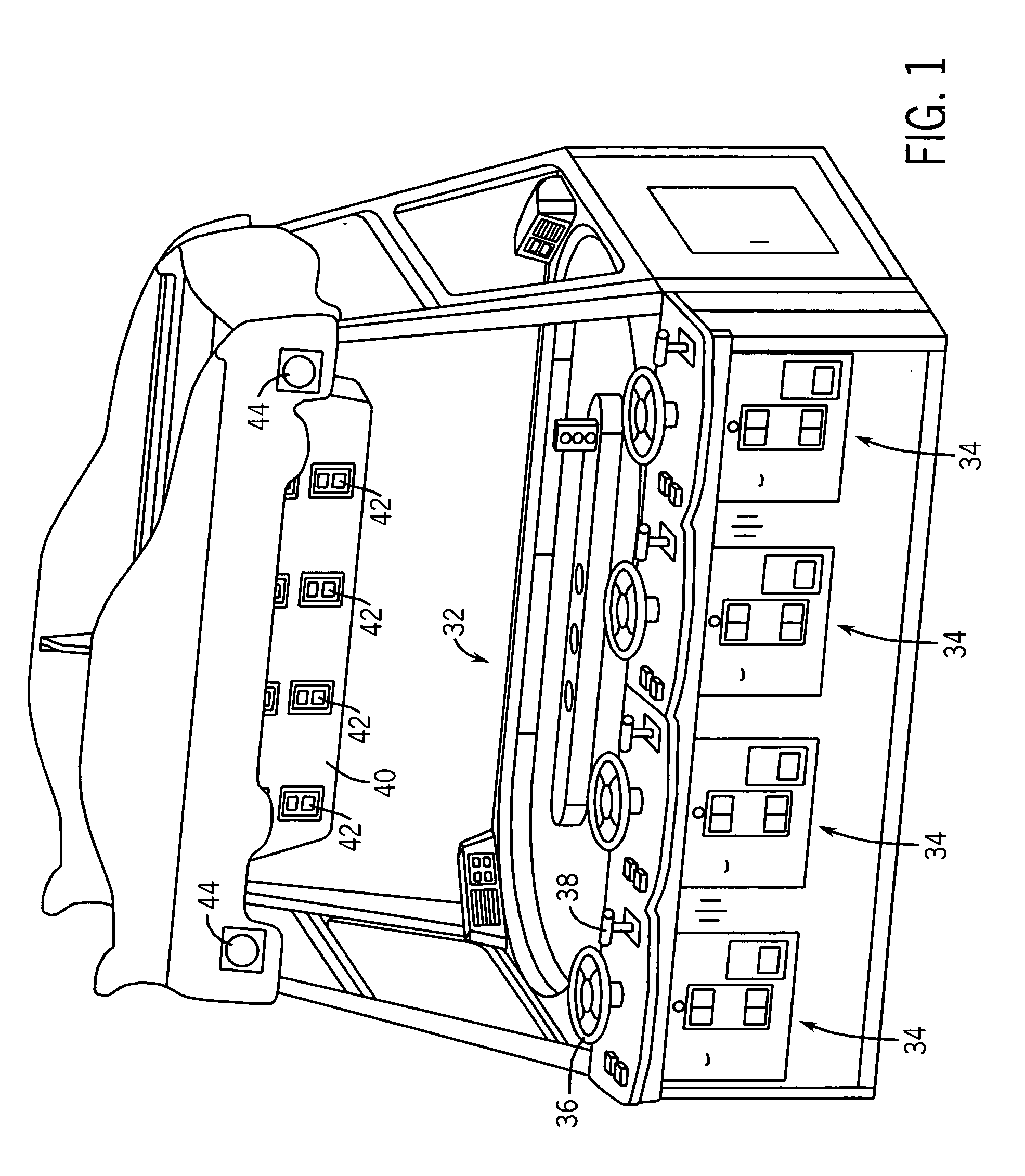

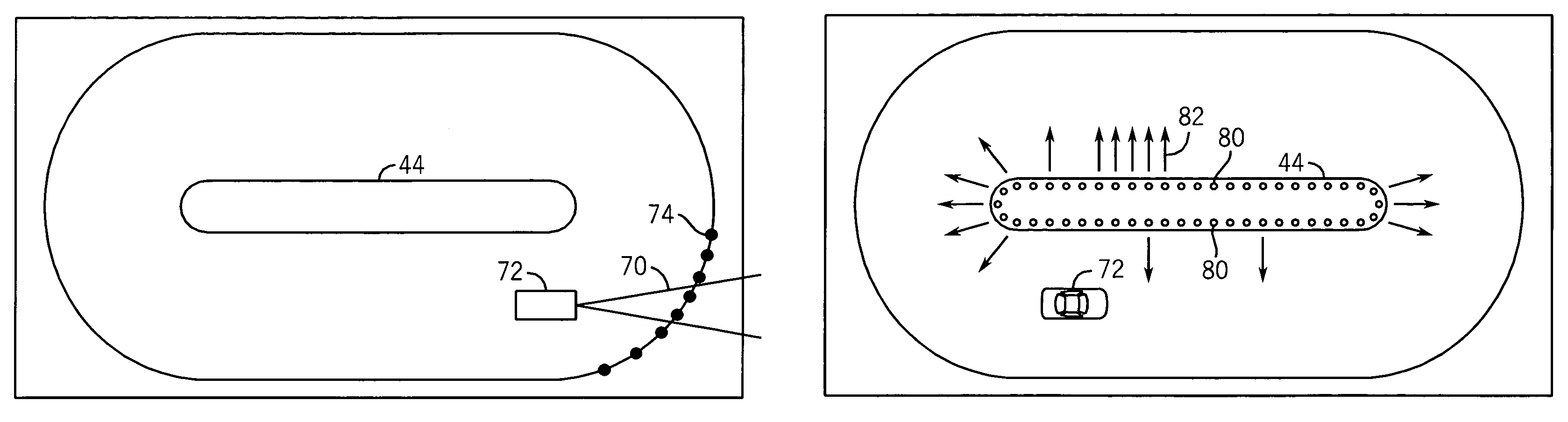

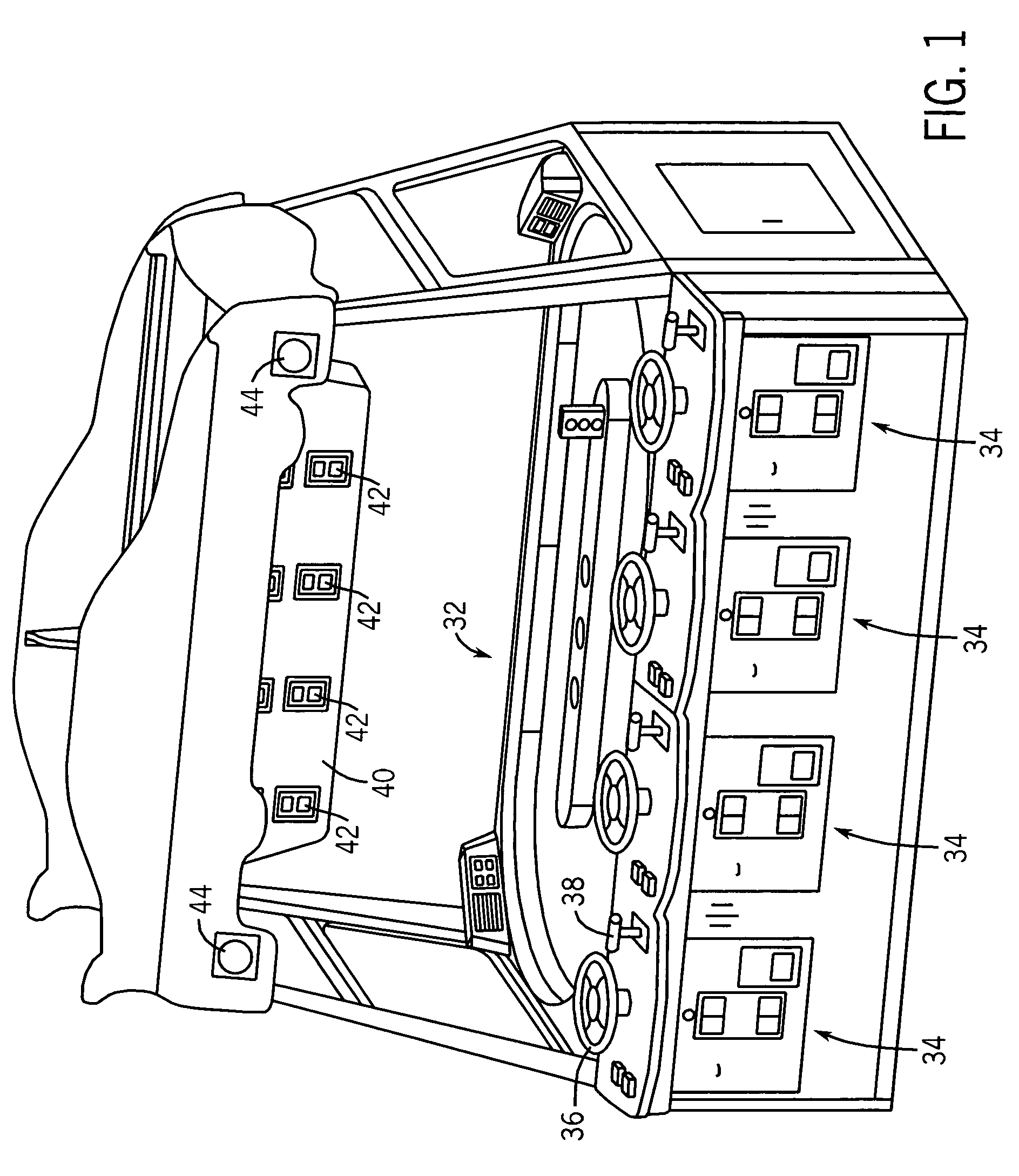

Computer controlled car racing game

InactiveUS20050215327A1Eliminate needMinimization requirementsIndoor gamesSpecial data processing applicationsSteering wheelSimulation

A computer controlled toy car racing game that can be played by a plurality of players. If less than a maximum number of players is present at the beginning of a race, a computer controller operates the remaining race cars such that each race includes all of the race cars. The racing game includes numerous sensors positioned above the racing course that relay control commands to each of the race cars. If a race car is computer controlled or computer assisted, the control commands are created by the computer controller. If the race car is controlled by a player, the control commands include information from a throttle and steering wheel used by the player. Upon completion of a race, the computer controller controls each of the race cars to bring the race cars back to a point on the race course near the start / finish line.

Owner:BAY TEK GAMES

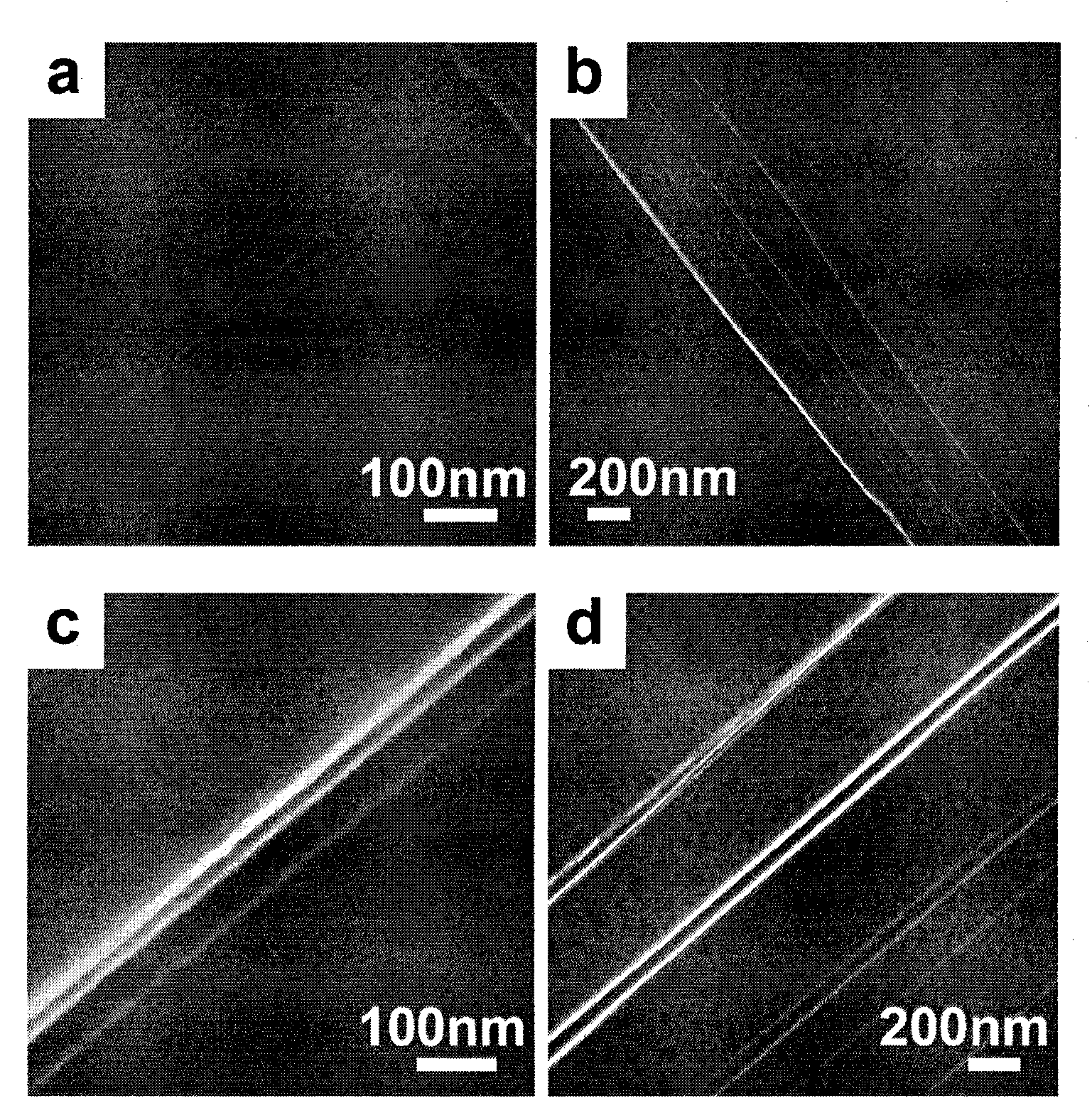

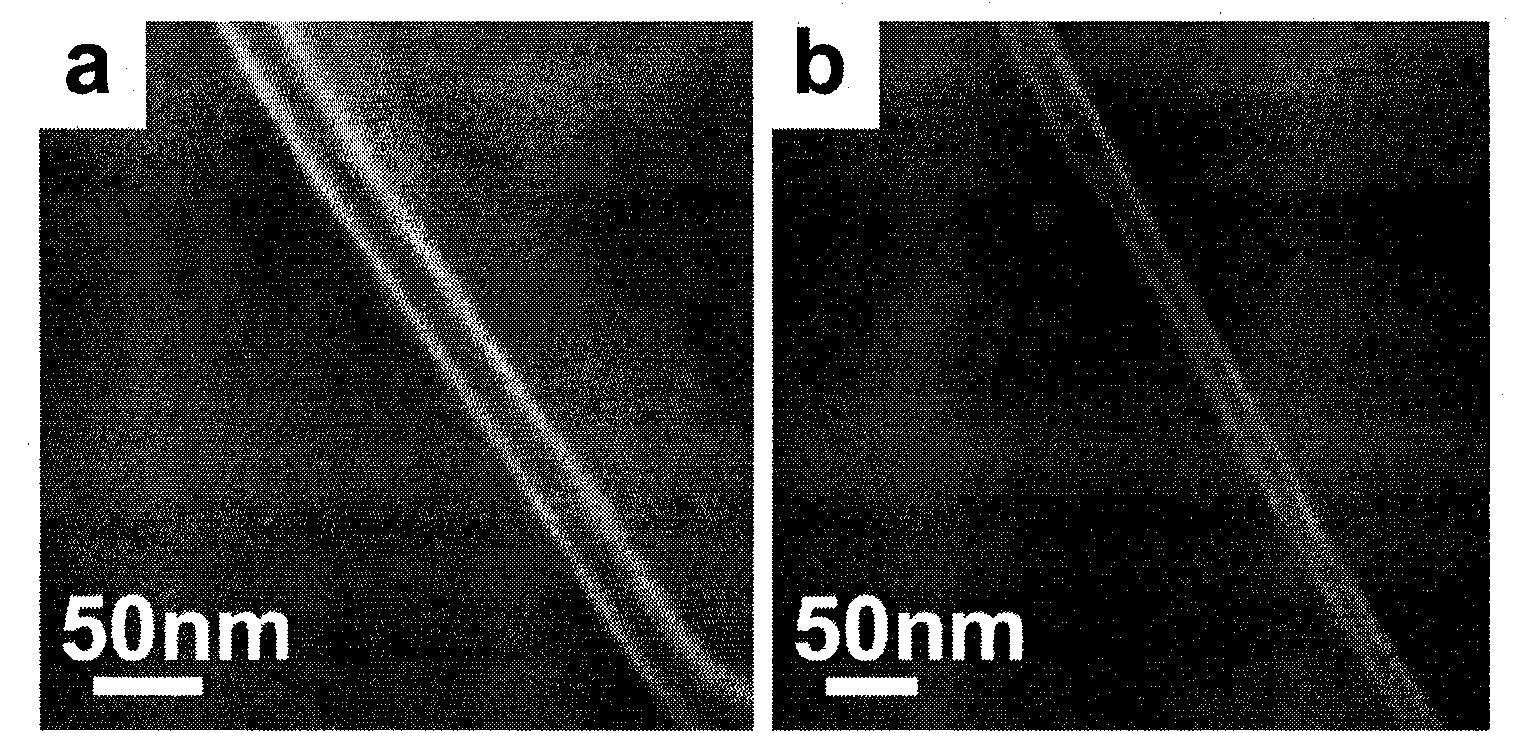

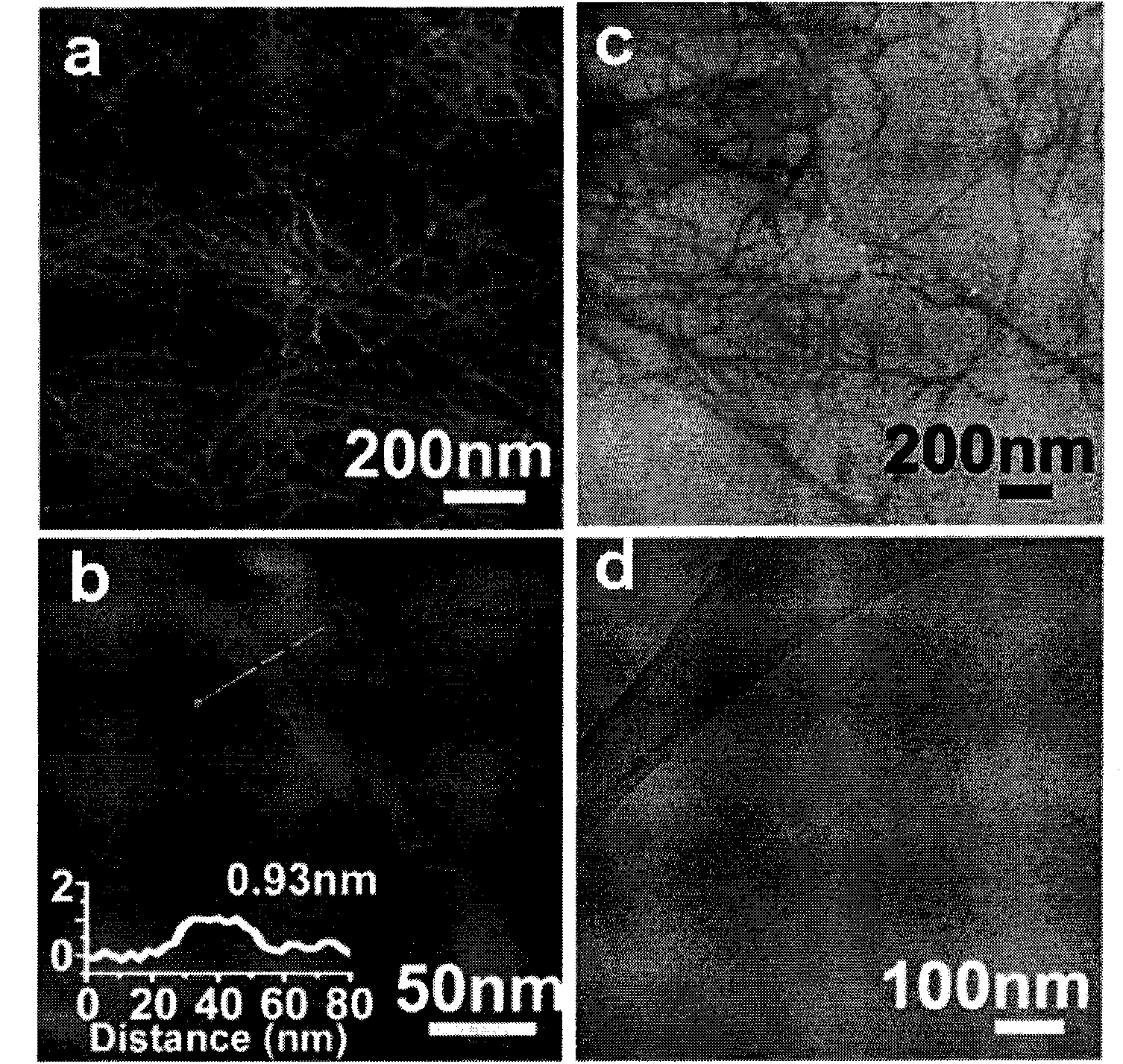

Method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme

The invention relates to a technology for producing graphene belts, in particular to a method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme. The method comprises the following steps of: firstly obtaining oxidized graphite in a Hummers method, selectively finishing line defects on the surface of the oxidized graphite by utilizing the oxygen-containing functional group in the process of oxidizing the graphite, and producing grapheme with surface line defects by combining high-temperature rapid expansion and peeling, thermal reduction, solvent dispersion and centrifugal separation; then cutting the graphene and recovering the structure of the graphene by utilizing ultrasonic shearing and chemical reduction; and finally removing large pieces of incompletely cut grapheme in a high-speed centrifuging method to further produce the graphene belt with controllable layer number and width. The method can be used for producing the graphene belt with controllable layer number, width and boundary by controlling the key cutting process parameters, such as graphite raw material variety, oxidization process, peeling process, reduction process, dispersion process and centrifugal treatment process, and the method is easy to operate and has low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

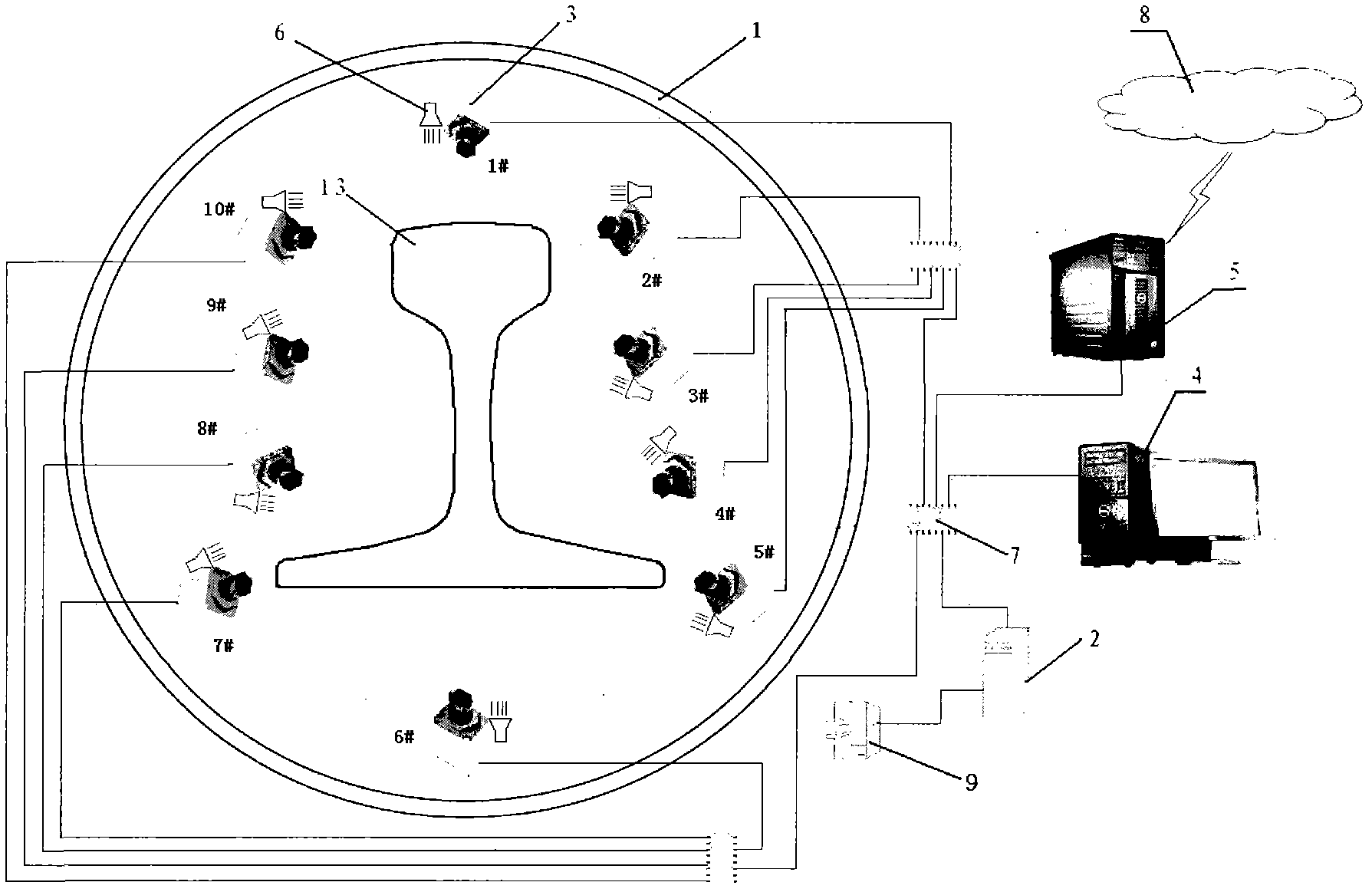

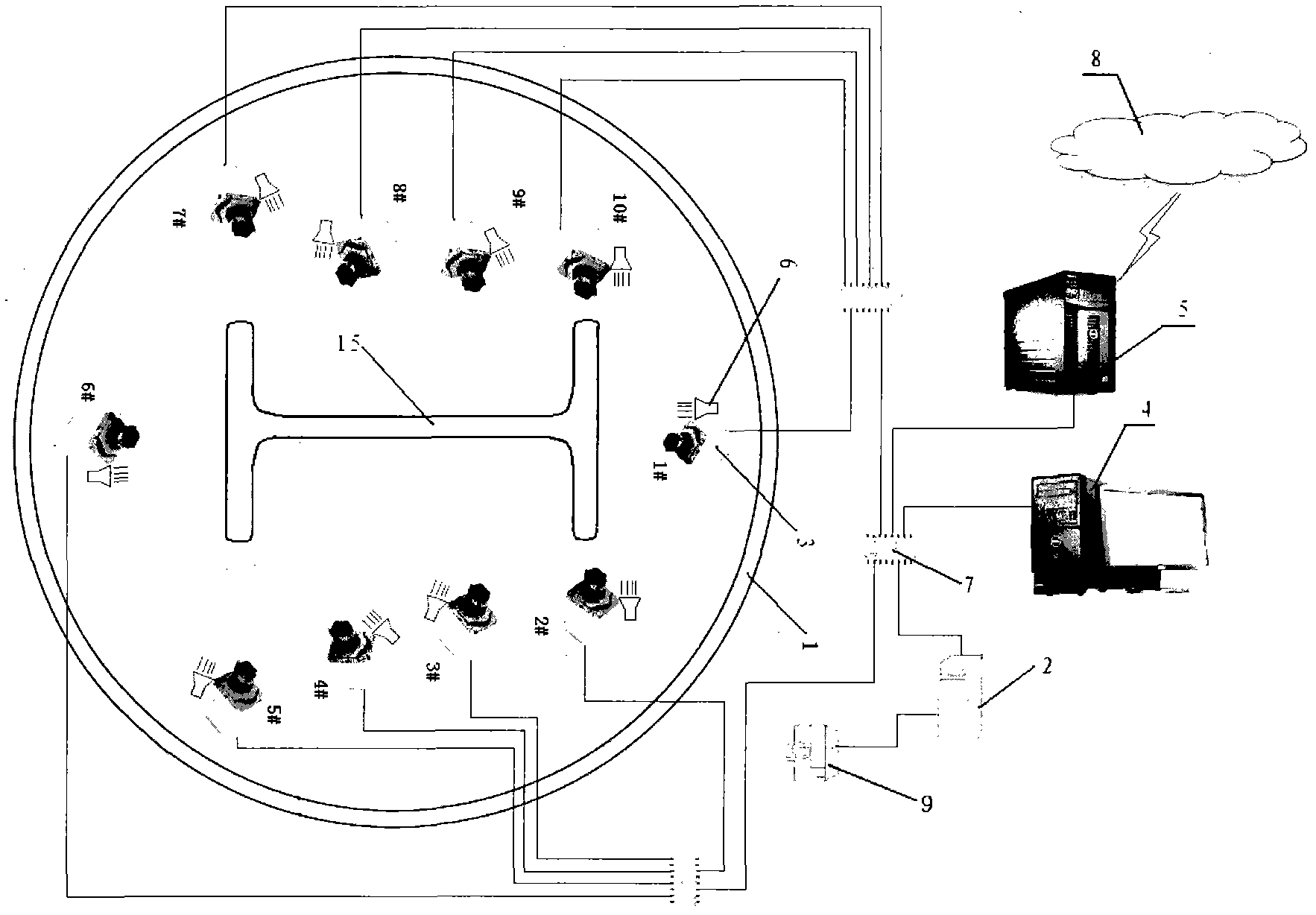

Surface defect automatic detecting device for section bars

InactiveCN102384910ARun at high speedAutomatic identification and strong adaptabilityOptically investigating flaws/contaminationInformation processingEngineering

The invention relates to a surface defect automatic detecting device for production process of a section bar rolling mill production line, which comprises a fixing device, a control device, video cameras, an image collecting computer, an information processing server, a light-emitting diode (LED) light source, a local area network, a process control network system, a spraying device, a pinch roll, a conveying roller way, stripper rubber and compressed air. The surface defect automatic detecting device for production process of the section bar rolling mill production line is characterized in that the number of the video cameras is determined according to the maximum number of the video cameras needed in the most complex surfaces of all varieties of the section bars to be detected. The surface defect automatic detecting device achieves automatic detection of surface defect of section bars (including varieties of heavy rails, H-shaped steel, joint steel, channel steel, steel angle and the like) by controlling and adjusting focal distance and angle of the video camera and the number of the video cameras. The surface defect automatic detecting device for production process of the section bar rolling mill production line is strong in adaptability, the same configuration can be applied to heavy rail processing lines and profile steel finishing lines, and accordingly software, hardware and spare parts of the device are universal, and manufacture and maintenance cost of equipment can be saved.

Owner:魏卿轩

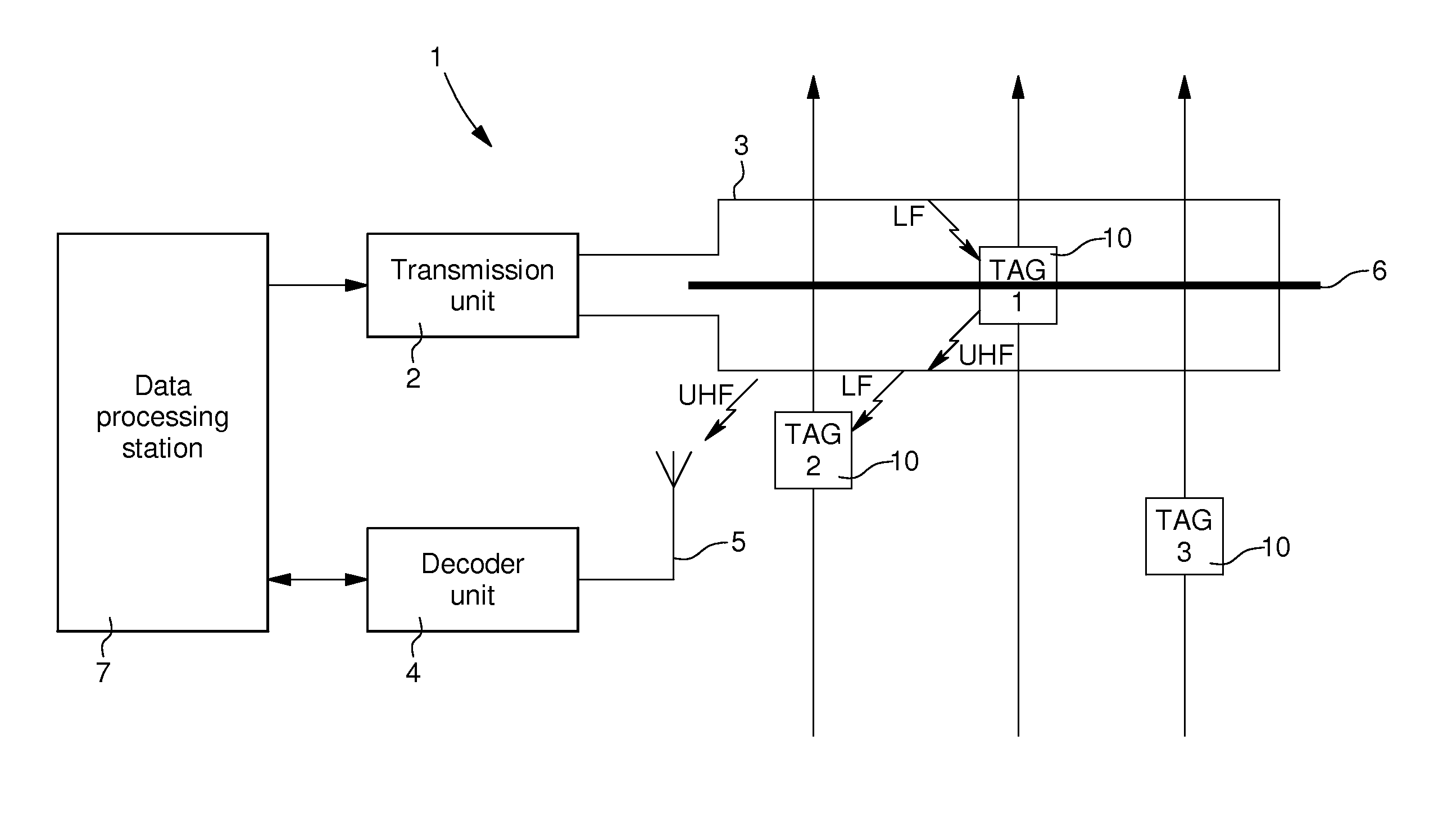

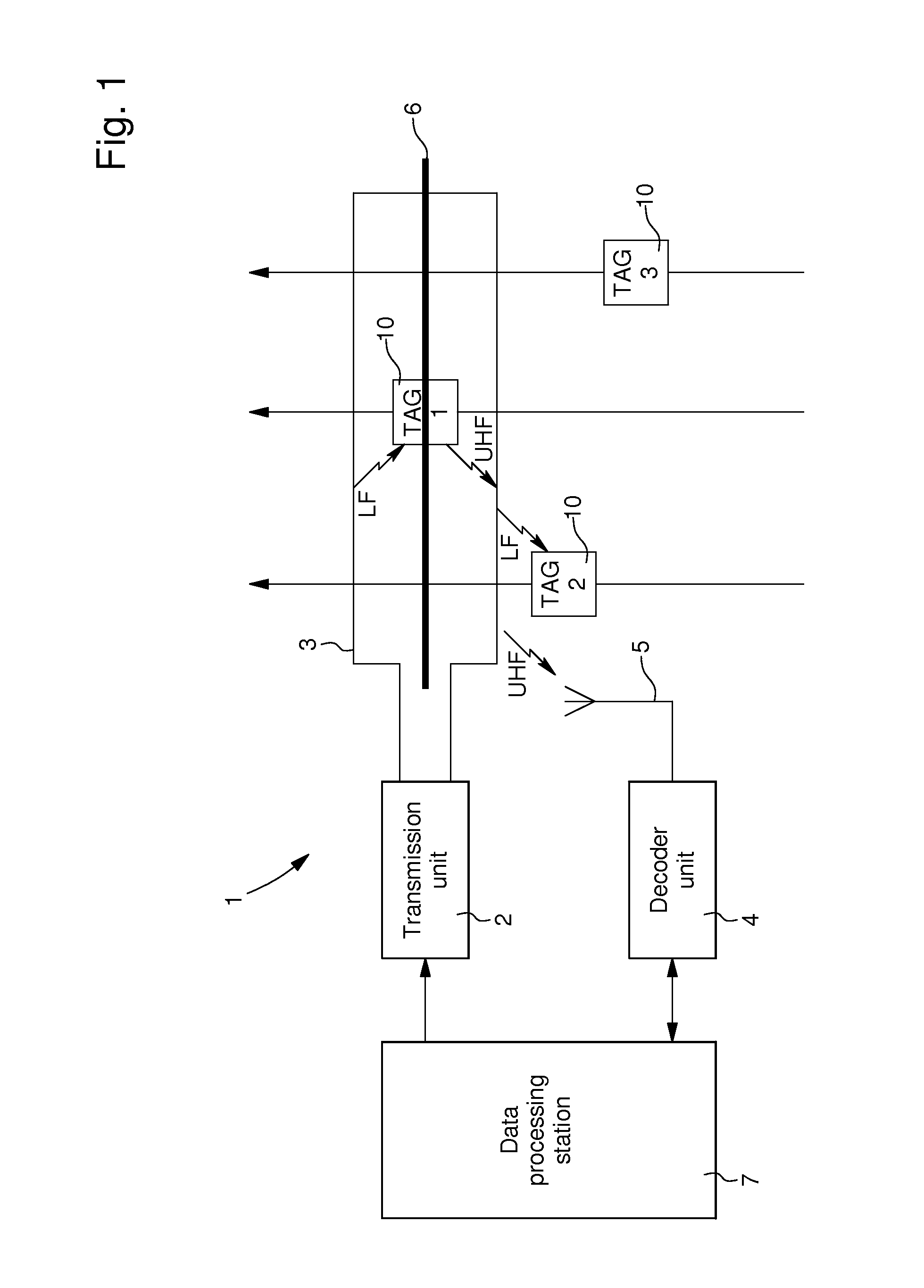

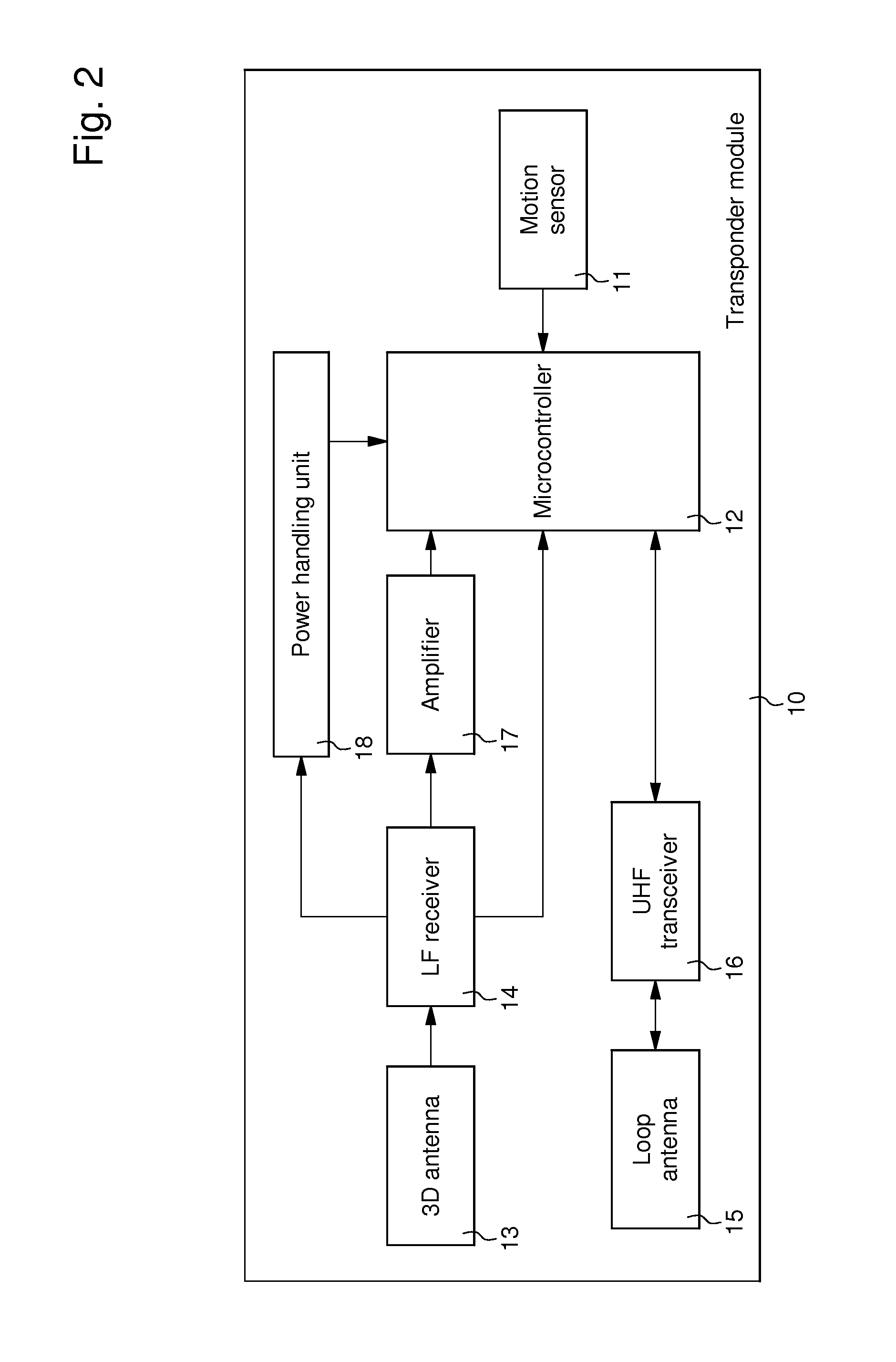

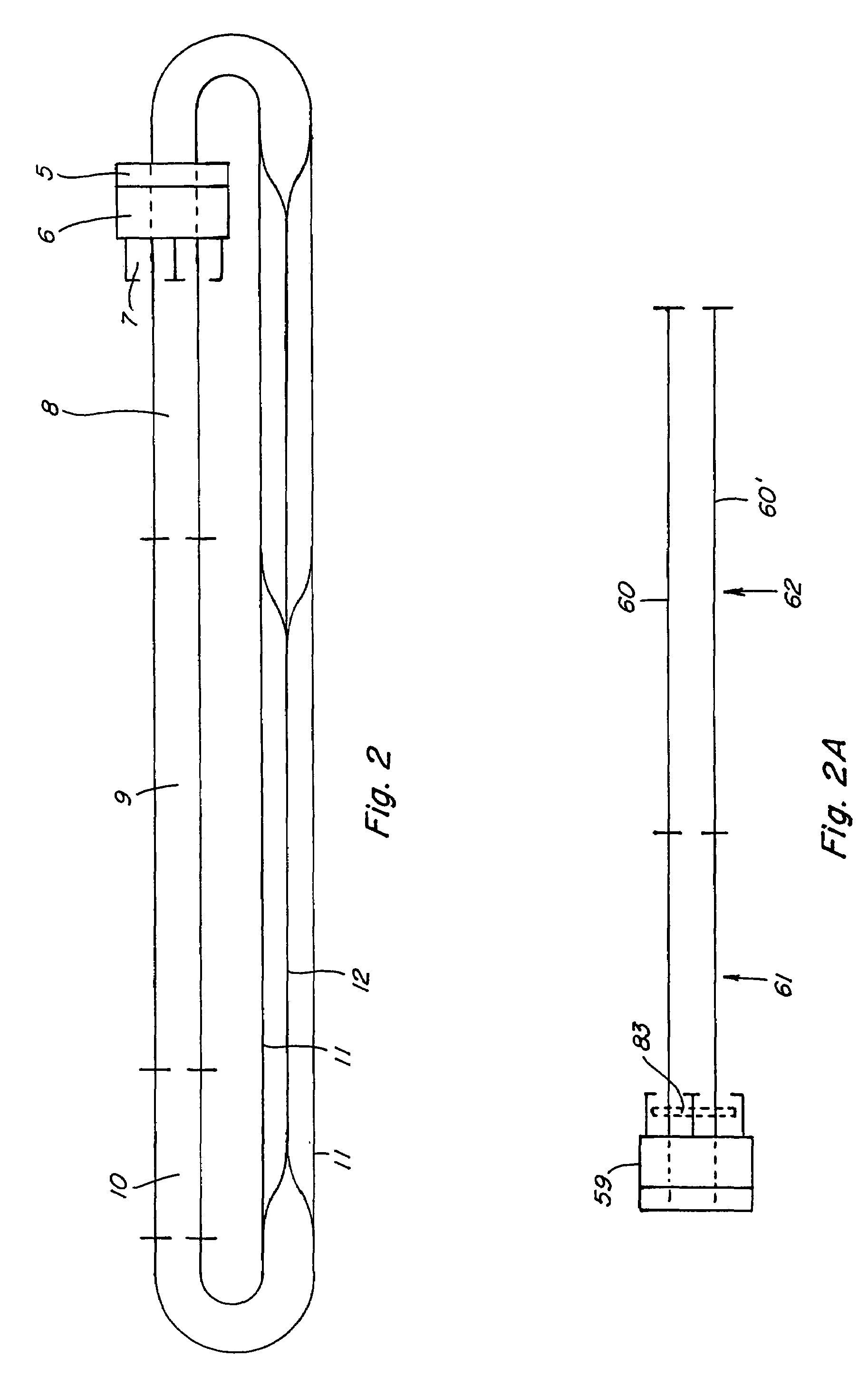

Method of measuring a time in a sports competition using a transponder module, and transponder module for implementing the method

ActiveUS20140169140A1Accurate detectionIncreased complexityRegistering/indicating time of eventsElectromechanical unknown time interval measurementEngineeringMotion sensors

The invention concerns a method of measuring at least one time or an elapsed period of a competitor in a sports competition via a transponder module which is personal to the competitor and accompanies the competitor throughout the competition in a measuring system. The personalised transponder module is activated at the start of the competition or in intermediate positions or at the finish line of the competition (6). Detection of at least one variation in motion or vibration level is effected by a motion sensor (11) integrated in the transponder module. The transponder module transmits data related to the detection effected by the motion sensor on the competition route or in intermediate positions or at the finish line of the competition, to a decoder unit (4) of the measuring system to check a time or elapsed period related to the detection of the competitor's motion sensor.

Owner:SWISS TIMING

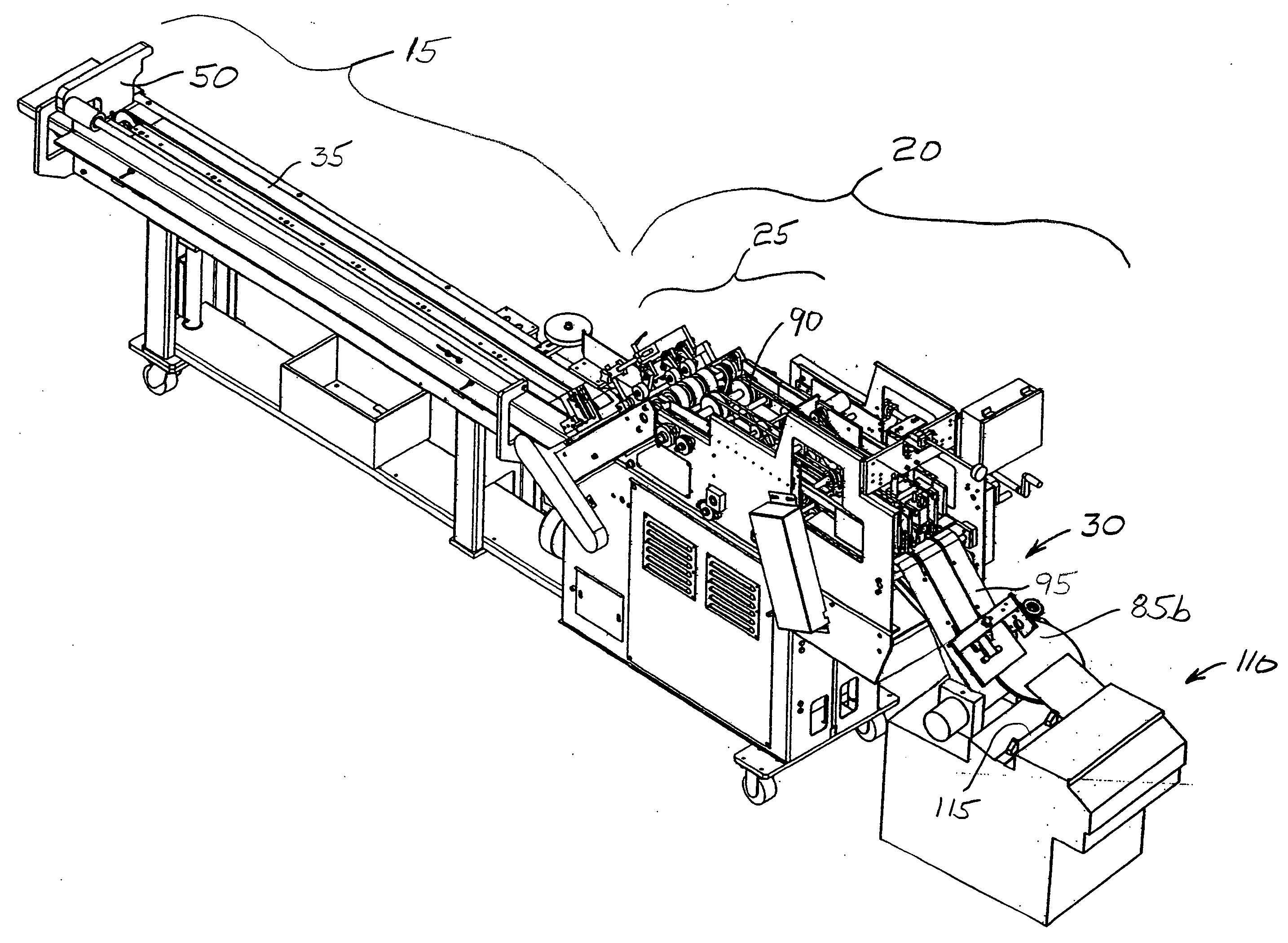

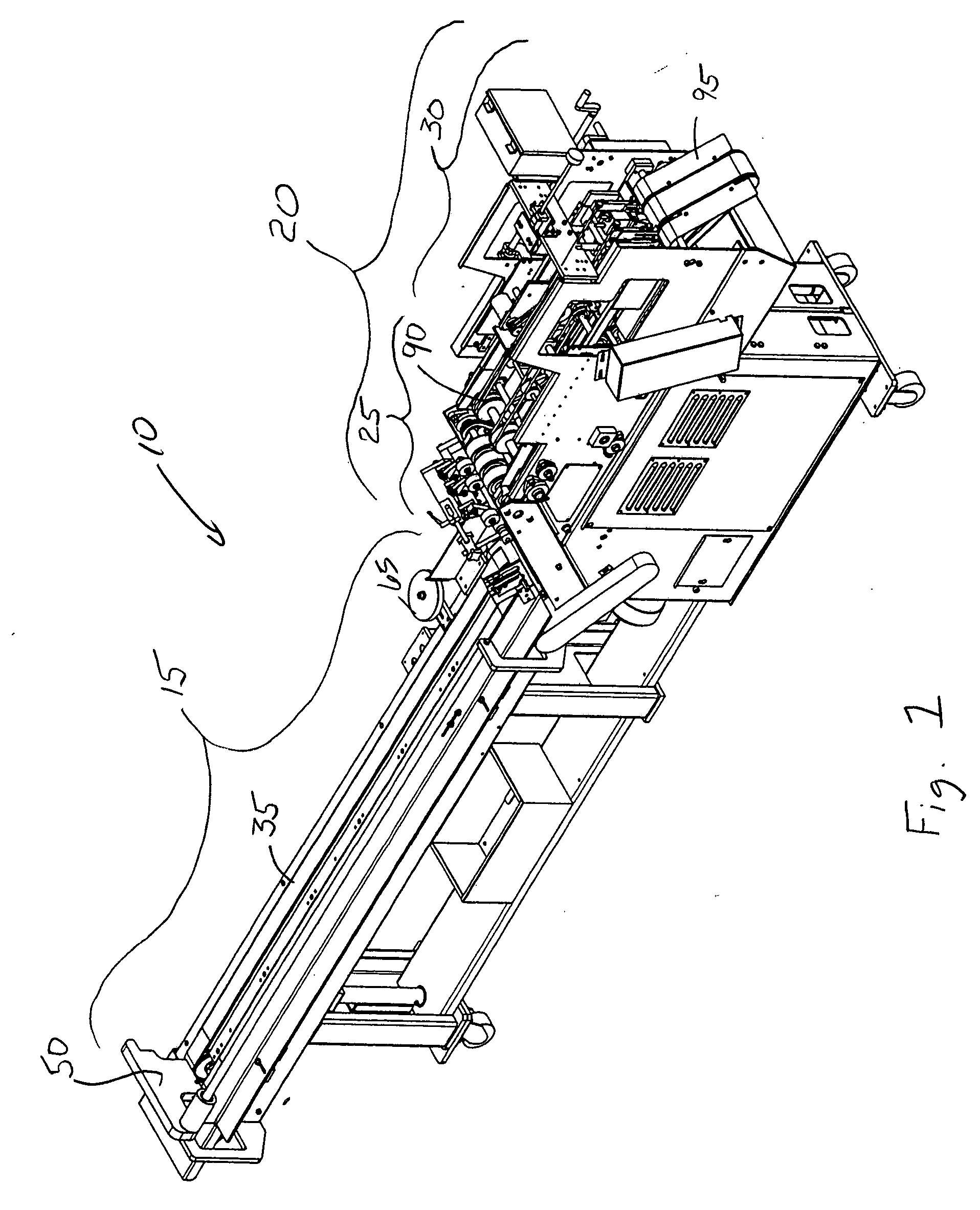

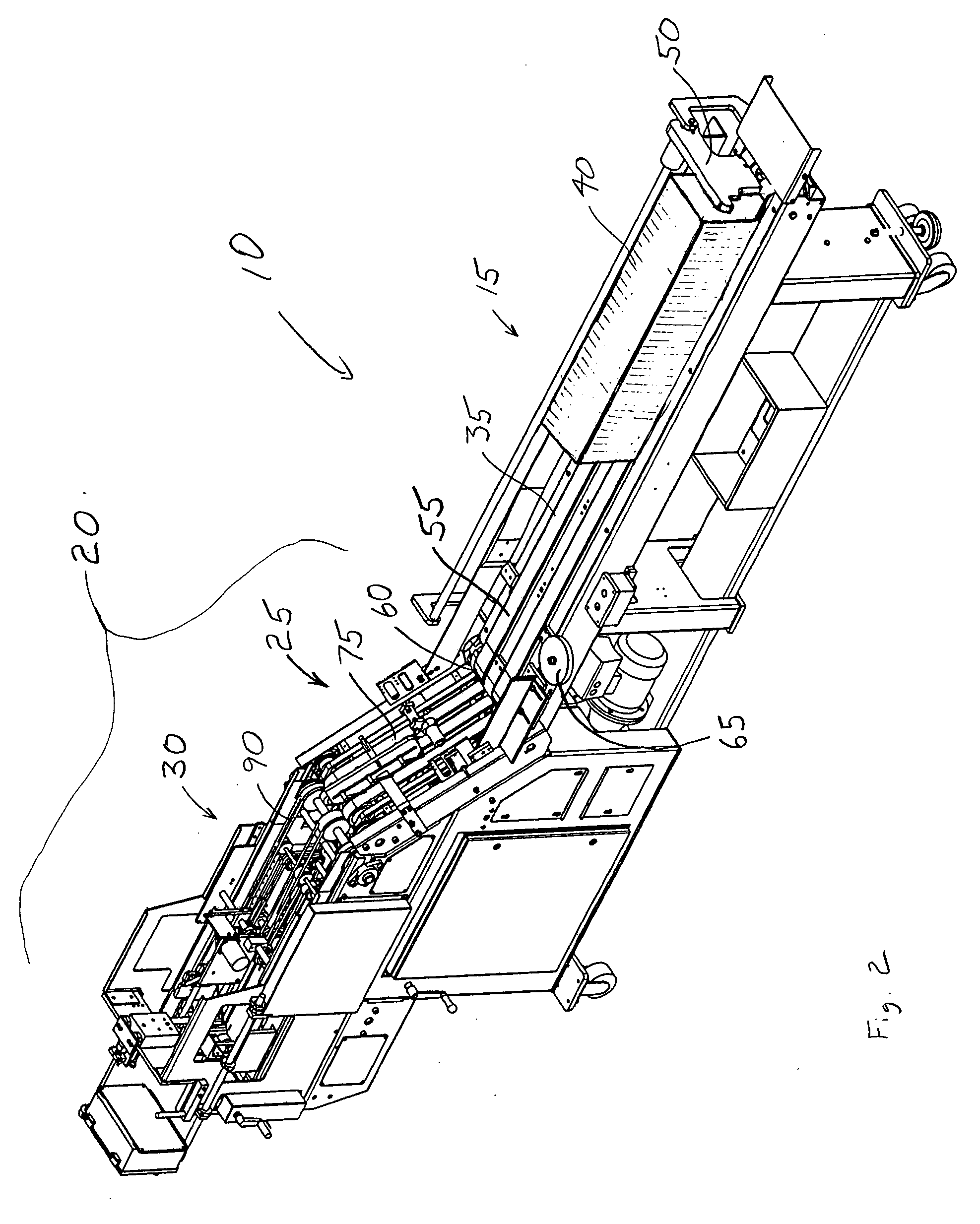

Product delivery loader and its use

A loader operable to deliver product to a process line. The loader including a buffer section operable to support a printed product and a transfer section operable to receive printed product from the buffer section. One of a plurality of interchangeable nose sections is coupled to the transfer section to receive the printed product and deliver the printed product to the process line. The loader is engageable with a support post of a finishing line to align the loader with respect to the finishing line and / or to supply production support to the loader.

Owner:QUAD GRAPHICS

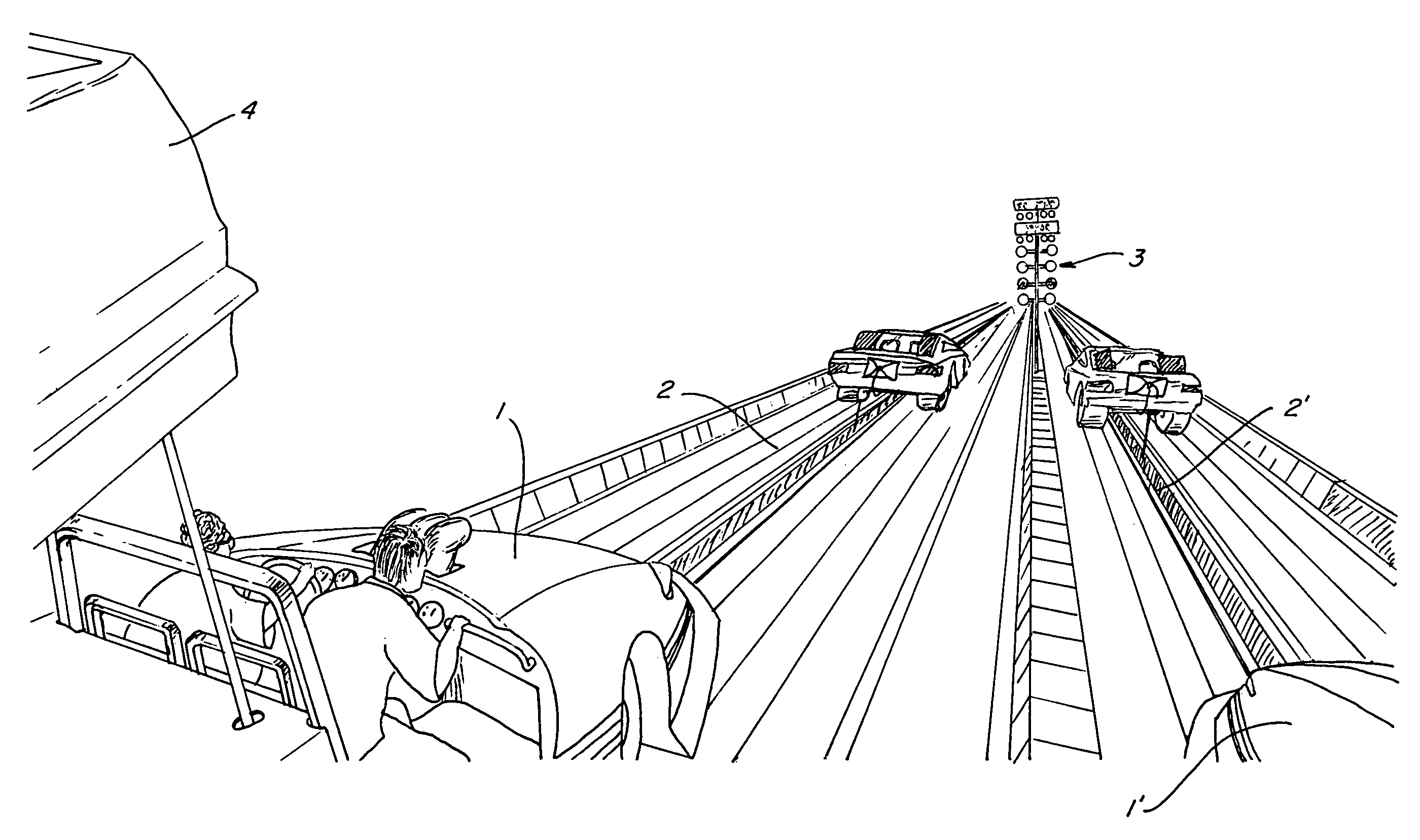

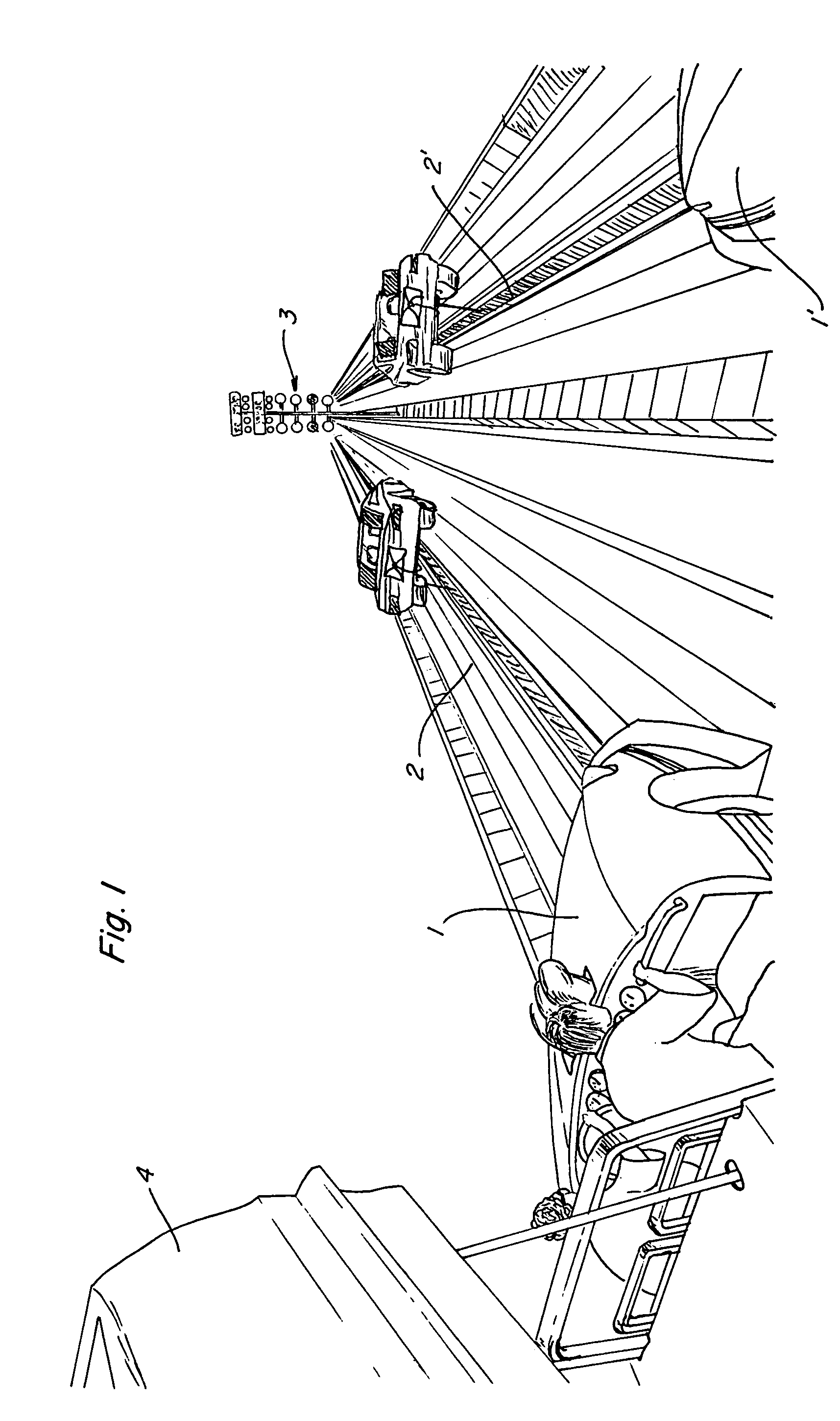

Real-size simulated pneumatic drag strip ride

A real-size simulated drag strip ride is presented which recreates the physical and visual sensations of a drag race. A pair of real-size dragsters are positioned along specified and controlled parallel linear tracks. The occupant is positioned inside the driver's compartment, with a full safety harness securing him in place in an adjustable seat. The invention includes audio sounds of ignition, “burn-out” and acceleration simulating a drag strip race, as well as simulated smoke from the “burn out” portion of the race preparation. Once the simulated light tower signals that the dragster is set to race, each driver of two, side-by-side vehicles pushes the acceleration pedal to accelerate the vehicle through an initial acceleration zone. The dragsters are propelled by use of a pneumatically powered piston attached to a cable located out of sight underneath the vehicle. The race is finished when the cars pass the finish line. Speeds and the winner are displayed on the starting line tower. The cars are then returned to the loading and unloading area for the next riders.

Owner:RACING ATTRACTIONS

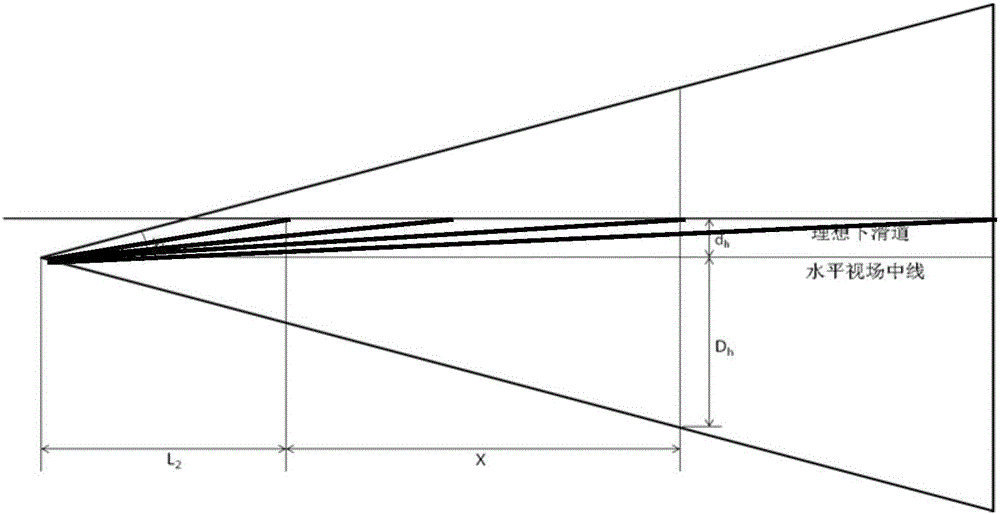

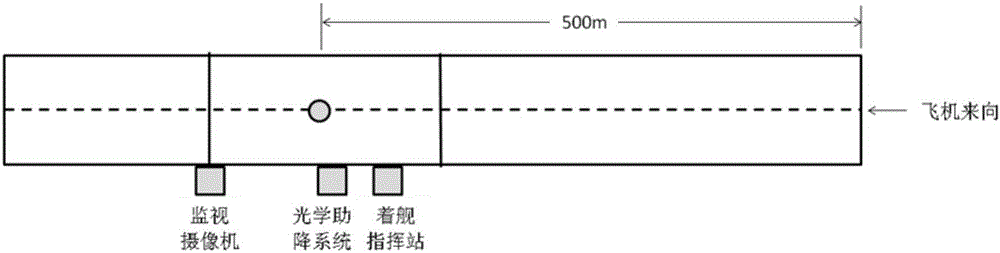

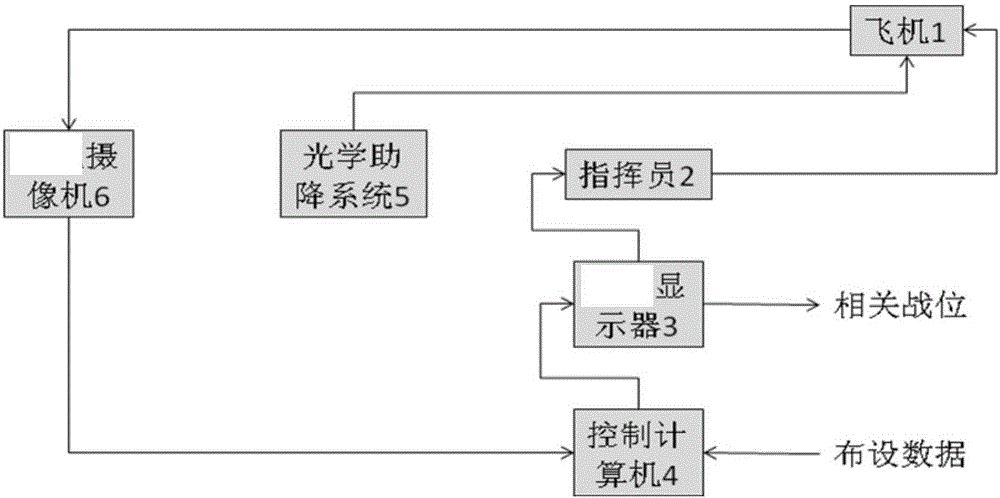

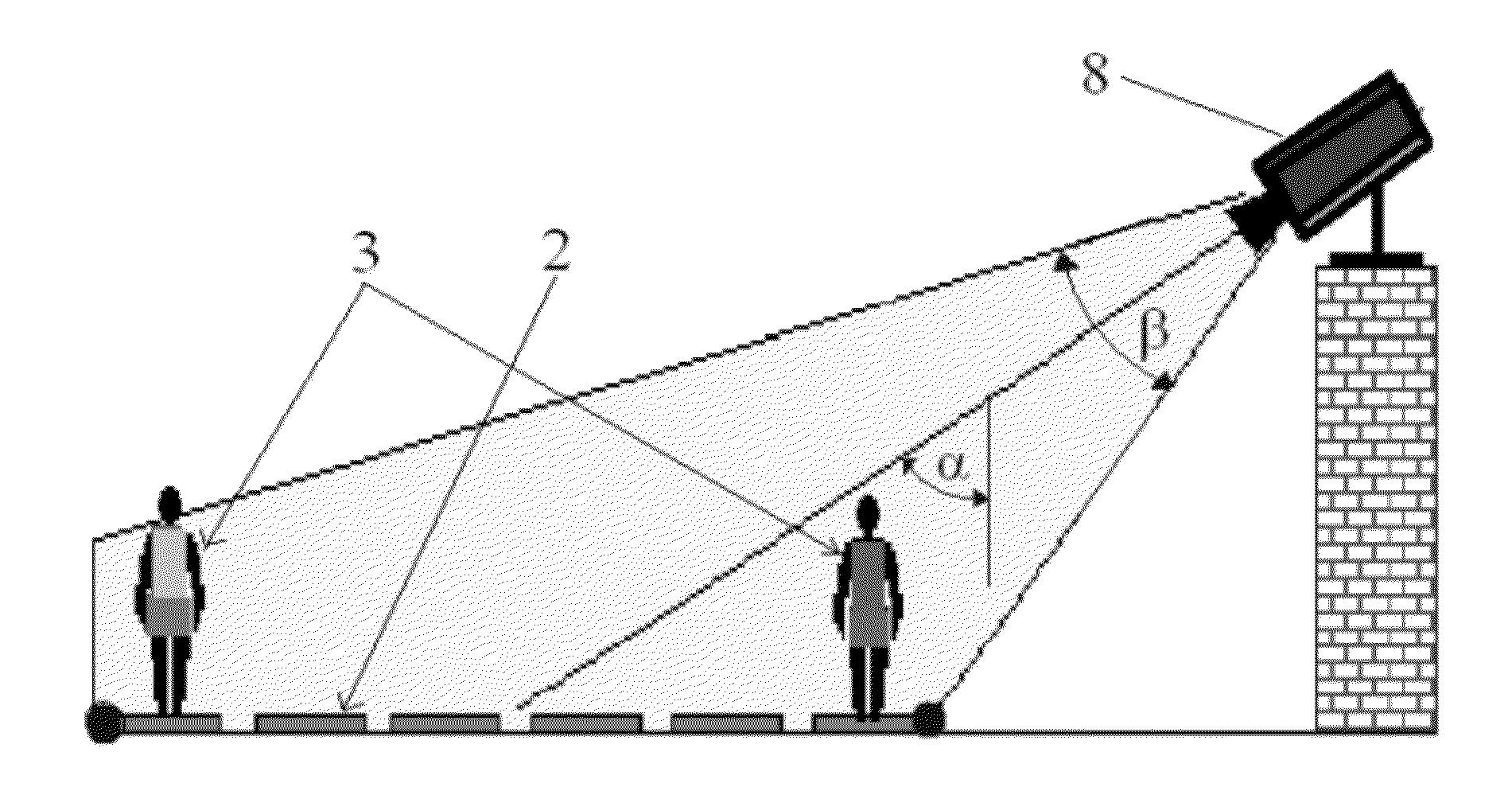

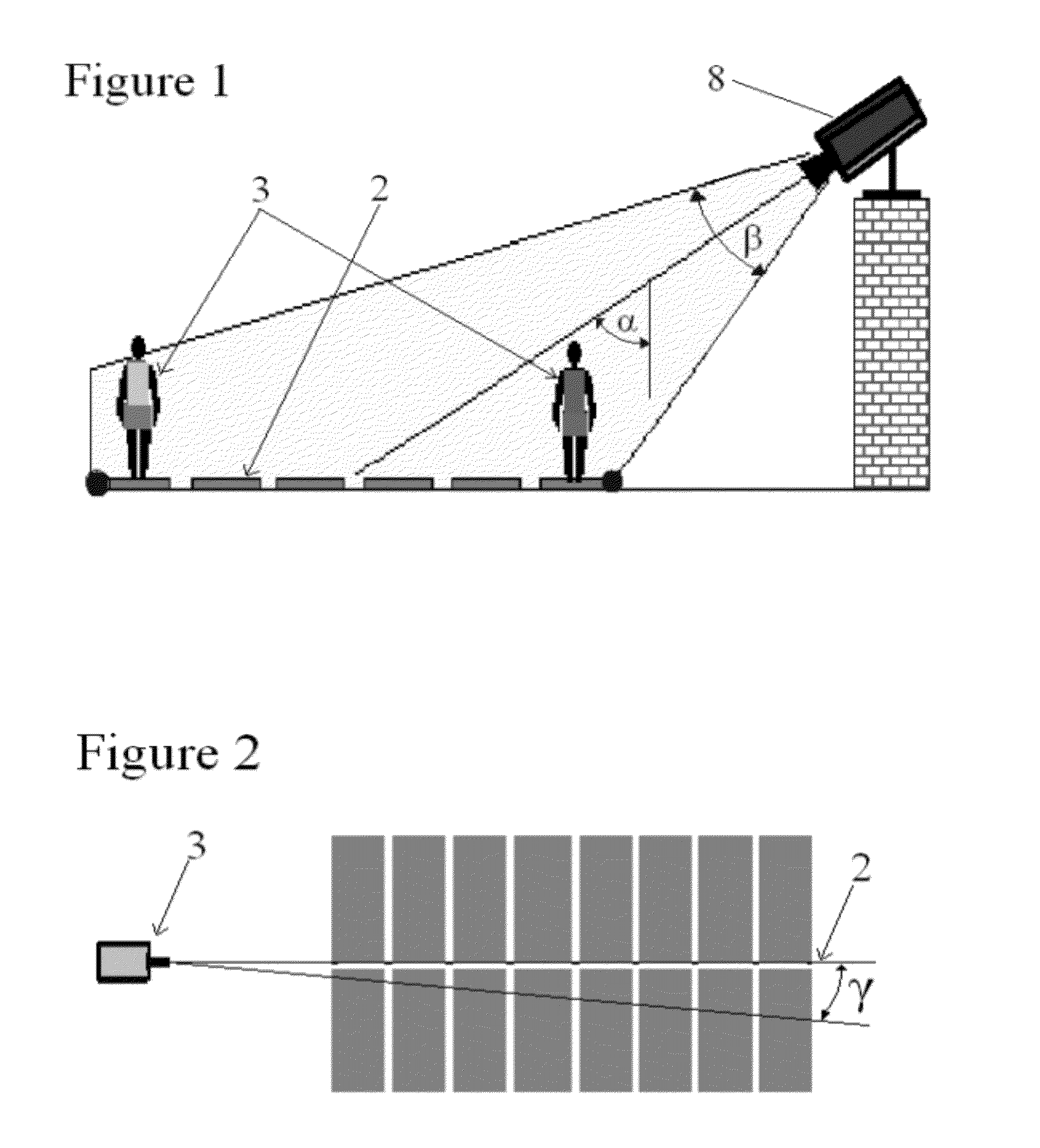

Aircraft landing monitoring guiding system

ActiveCN106781709AEasy maintenanceEasy to assemble and disassembleAutomatic aircraft landing aidsAircraft landingGliding flight

The invention relates to an aircraft landing monitoring guiding system. According to the aircraft landing monitoring guiding system, firstly, an ideal landing point, a stern line and a runway finishing line are set on a runway; secondly, a camera (6) is selected and is mounted outside the runway at one side of a transverse line of the runway finishing line, a view center of the third camera (6) aligns a far-end point of an ideal glide path; an optical landing assisting system (5) is mounted outside the runway at a same side as the camera (6); a commander (2) and a monitor (3) are at same side of the runway as the camera (6) and the optical landing assisting system (5); the camera (6) is connected with a control computer (4) and a monitor (3) through signal wires; a whole flight process of an aircraft (1) along the ideal glide path is observed by the commander (2), images of the aircraft (1) during gliding flight are acquired from the monitor (3); high-low and left-right deviation of the aircraft (1) is determined by the commander (2), and a pilot is prompted to land the aircraft (1).

Owner:NAVAL AVIATION UNIV

Computer controlled car racing game

InactiveUS7402106B2Pleasant experienceEliminate needIndoor gamesTransmission systemsSteering wheelSimulation

A computer controlled toy car racing game that can be played by a plurality of players. If less than a maximum number of players is present at the beginning of a race, a computer controller operates the remaining race cars such that each race includes all of the race cars. The racing game includes numerous sensors positioned above the racing course that relay control commands to each of the race cars. If a race car is computer controlled or computer assisted, the control commands are created by the computer controller. If the race car is controlled by a player, the control commands include information from a throttle and steering wheel used by the player. Upon completion of a race, the computer controller controls each of the race cars to bring the race cars back to a point on the race course near the start / finish line.

Owner:BAY TEK GAMES

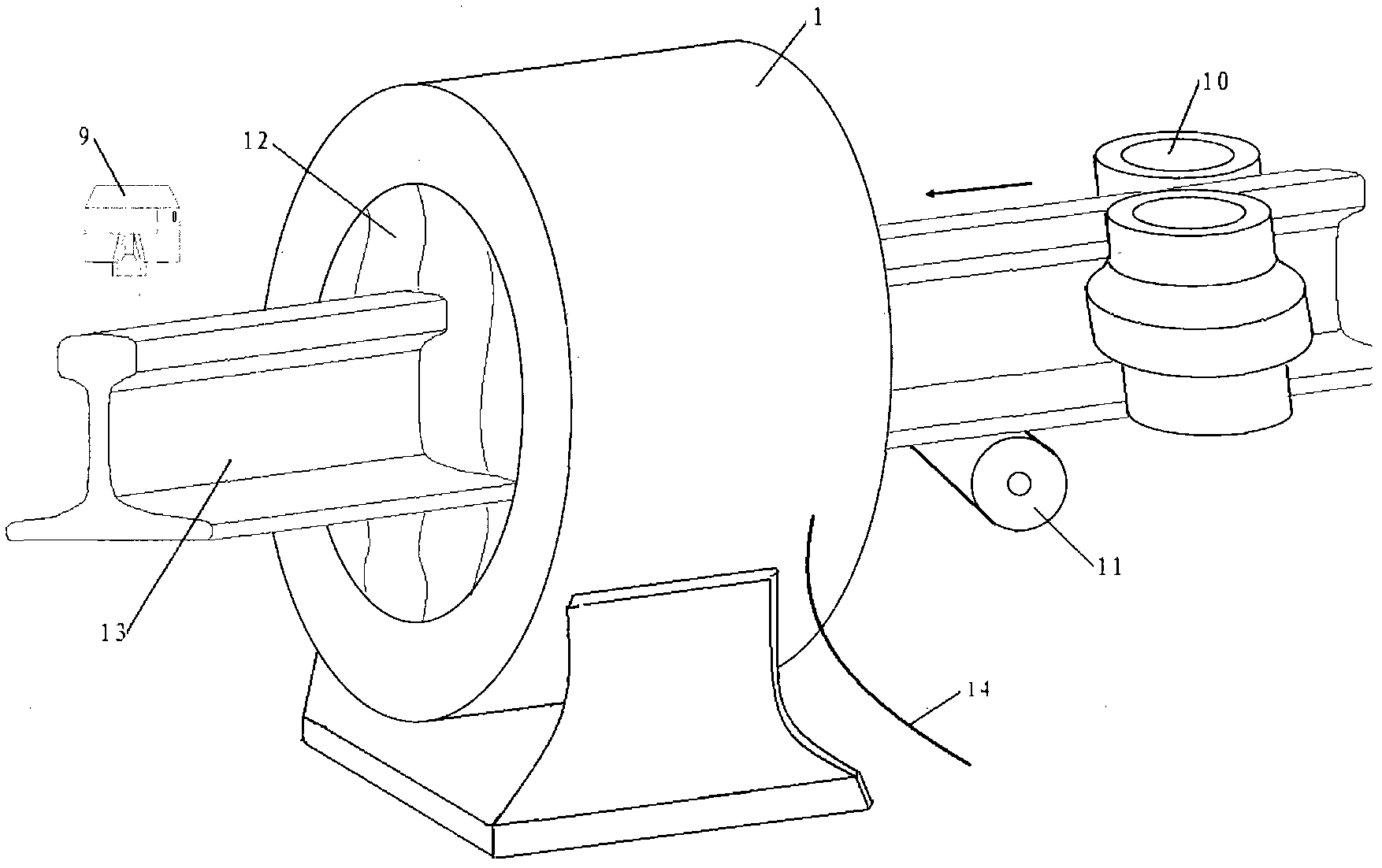

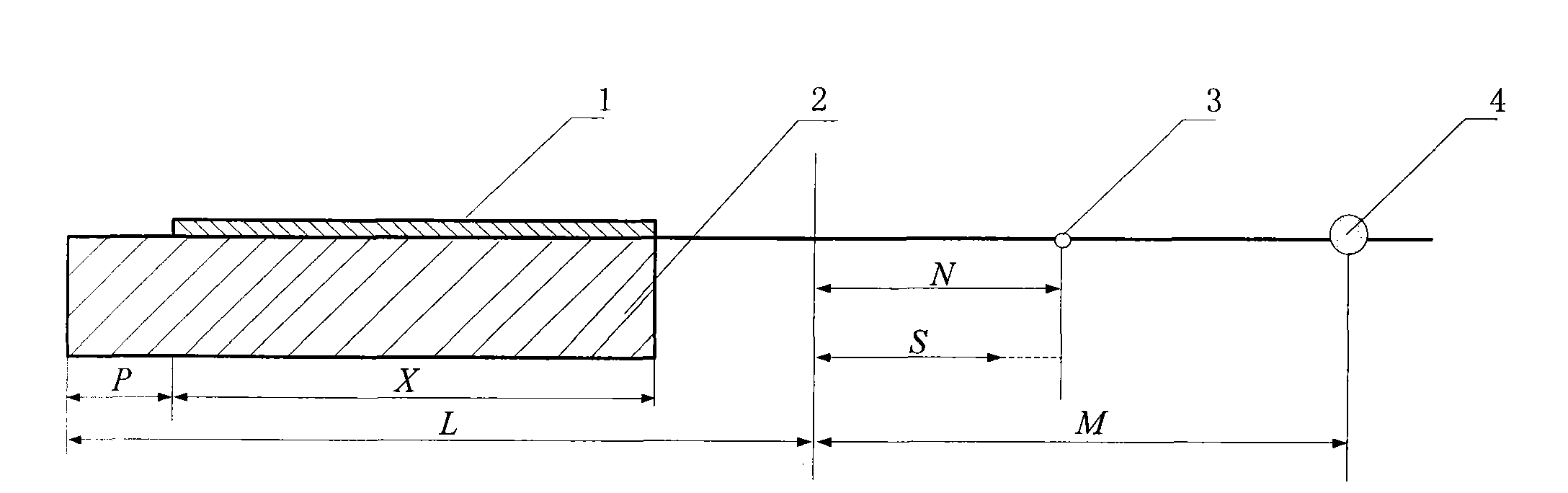

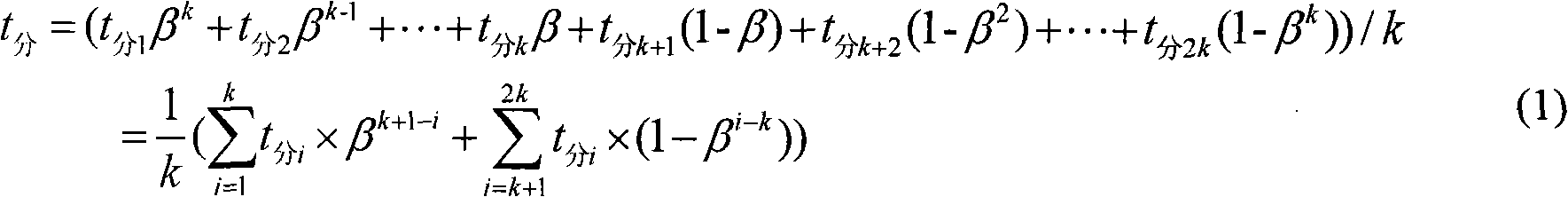

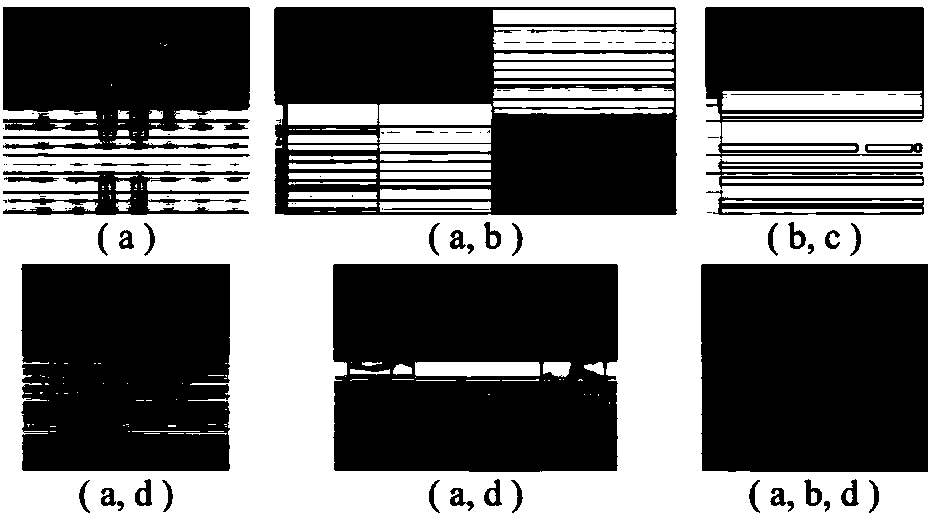

On-line model of motor starting time of bar finishing line separating plate and braking plate

InactiveCN101983786AHigh yieldIncrease productivityRoll mill control devicesMetal rolling arrangementsStart timeFilter algorithm

The invention relates to an on-line model of motor starting time of a bar finishing line separating plate and a braking plate, which has the following scheme: firstly, acquiring the latest 2k time data of the separating plate and the braking plate falling from a high position to a low position, and acquiring a time predicted value of the separating plate and the braking plate falling from the high position to the low position for the next time by adopting a weighted mean value filtering algorithm; on the basis of the moving process of multiple-length steel (1) on the separating plate and the braking plate, according to the effective length and the multiple length of a cooling bed (2) and the requirement for flushing of the multiple-length steel (1), establishing a distance model between a steel splitting point (3) and the cooling bed (2); then, establishing a motor starting time model of the separating plate and the braking plate after shearing of a flying shear (4); after shearing of the flying shear (4), respectively delaying T separating time and T braking time, and starting the motors of the separating plate and the braking plate; and acquiring the acting time of the separating plate and the braking plate, and repeating the computation method. The model established in the invention is relatively accurate, can continuously approach the requirements of working conditions, and can be used for computer control to improve the degree of automation of the system of the bar cooling bed (2).

Owner:WUHAN UNIV OF SCI & TECH

Manufacturing method of soft fine-creased artificial super-fiber leather

InactiveCN104389192AImprove wrinkle problemWrinkle fine and naturalPolyurea/polyurethane coatingsSpecial surfacesProduction lineWork in process

The invention relates to the technical field of super-fiber leather, in particular relates to a manufacturing method of a soft scabriculous artificial super-fiber leather. The invention provides a manufacturing method of a soft finely crinkled artificial super-fiber leather which is soft, fine in crease and has hand-feeling approaching to genuine leather. The manufacturing method comprises the following process steps in order: enabling non-woven fabric to pass through a soaking trough, dipping in a PU resin solution in a certain proportion, then coating a layer of PU resin solution, solidifying, washing and drying to obtain super-fiber rough blank; enabling the super-fiber rough blank to pass through a methylbenzene extraction production line, performing high-temperature decrement to manufacture super-fiber base cloth semi-finished product; and enabling the super-fiber base cloth semi-finished product to pass through a piece of super-fiber base cloth after-finishing line (oiling and drying, puffing and accurately grinding) to manufacture the super-fiber base cloth; enabling a piece of release paper to orderly pass through a first coating head, a second coating head and a third coating head, orderly coating a layer of shell fabric, a middle material layer and an adhesion layer on the surface of the release paler; pre-heating the release paper coated with the shell fabric, the middle material and the adhesion layer, and then combining the manufactured super-fiber base cloth with the release paper coated with the shell fabric and the backing material, drying through a drying oven, separating to obtain the semi-finished product; and performing surface genuine leather treatment on the surface of the semi-finished product to obtain the finished product.

Owner:FUJIAN TOPSUN MICROFIBER

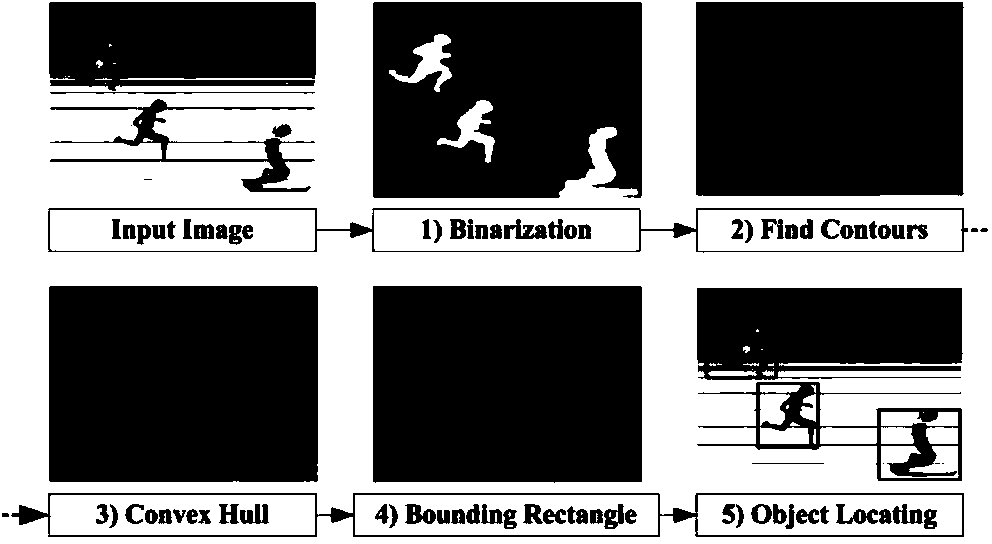

Human-body trunk identification device and method, and terminal-point image detection method and device

ActiveCN104036231AEliminate distractionsAccurate identificationCharacter and pattern recognitionMinimum bounding rectangleImage detection

The invention proposes a human-body trunk identification device which includes a target extraction module used for obtaining a body-shape contour of a line dashing image and determining a minimum external-connection rectangle of the body-shape contour so as to obtain a target area in the line dashing image; a body-shape segmentation module used for segmenting a body shape from the target area; and an identification module used for identifying a trunk part from the body shape. The device accurately positions the target area and effectively eliminates interferences of lower limbs, arms and a head and the like through body shape segmentation and thus a human body trunk part of the line dashing image can be identified rapidly and accurately. The invention also proposes a human-body trunk identification method, and a finish-line detection device and system.

Owner:SHENZHEN FAIRPLAY SPORTS DEV

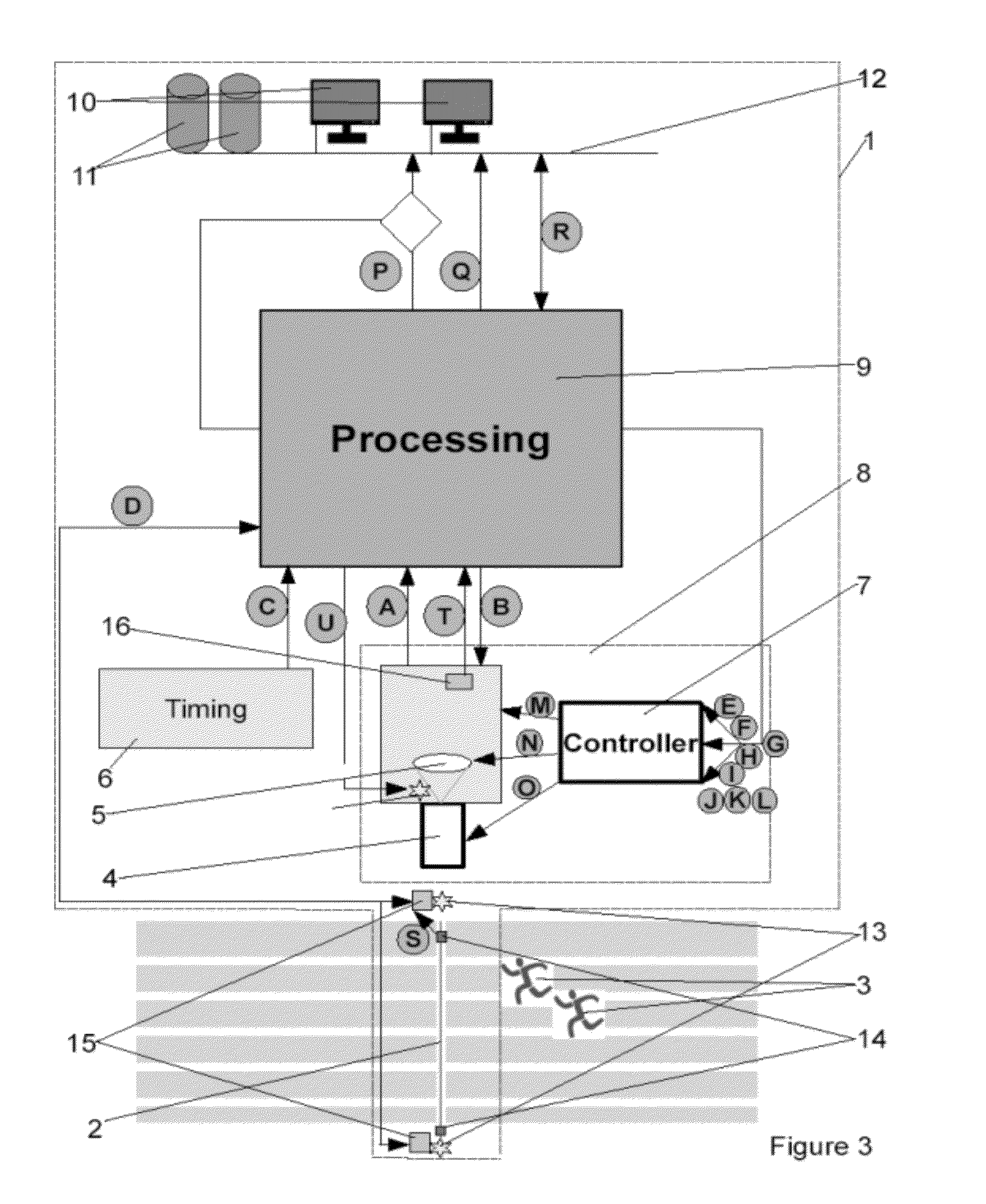

System and method of calibrating a system

ActiveUS20120188381A1Improve performanceThreshold value can be loweredRegistering/indicating time of eventsTelevision systemsComputer scienceFinish line

The system measures time of at least one object on the basis of passing a finish line and includes a camera with a photosensitive sensor and a lens for registering an image of the line. The image is sent to a processor for processing. Timing means deliver a timing signal to the processor. The system is at least partially automatically aligned. It thereto comprises a first active optical indicator that is located at a predefined location with reference to the line of passage, which indicator is detected as part of the image registered by the camera so as to obtain detection data. The system further includes a camera adjustment arrangement for adjustment of the orientation of a center axis of the camera, said adjustment being specified by the processor on the basis of the detection data.

Owner:TIMETRONICS

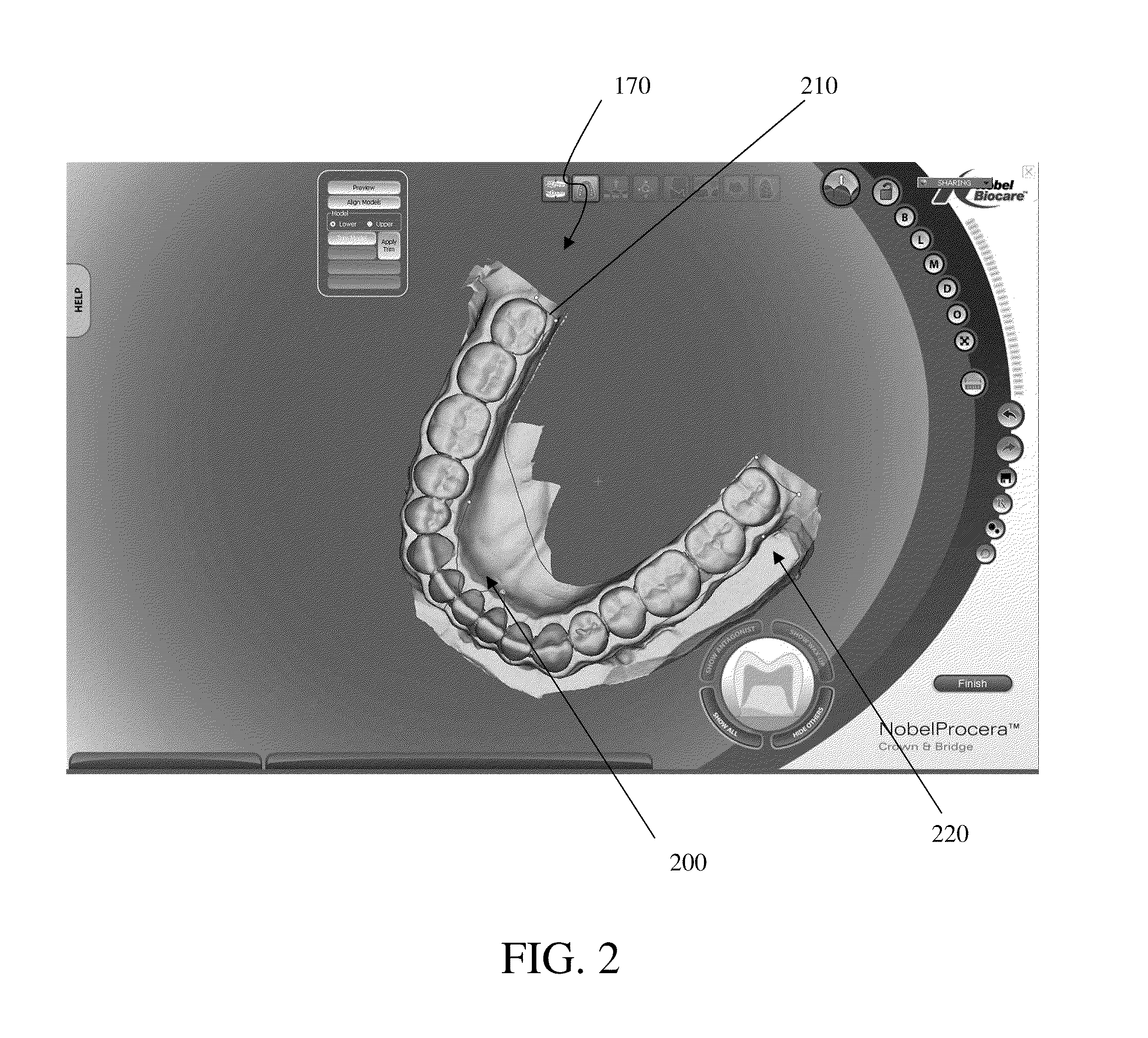

Method for planning a dental component

Presented herein are methods and devices for designing dental components, such as physical models of a patient's anatomy, crowns and bridges. An operator of a prosthetic designing system can receive information, such as from a scanner, which provides information on the topology of the patient's dentition. The operator can use this information to design a custom prosthetic to fit the patient. Part of the designing process involves using a finish line defined for a preparation as a segmentation line for a physical die corresponding to the preparation, and using a path of draw line as an insertion axis line for a dental prosthetic.

Owner:NOBEL BIOCARE CANADA INC

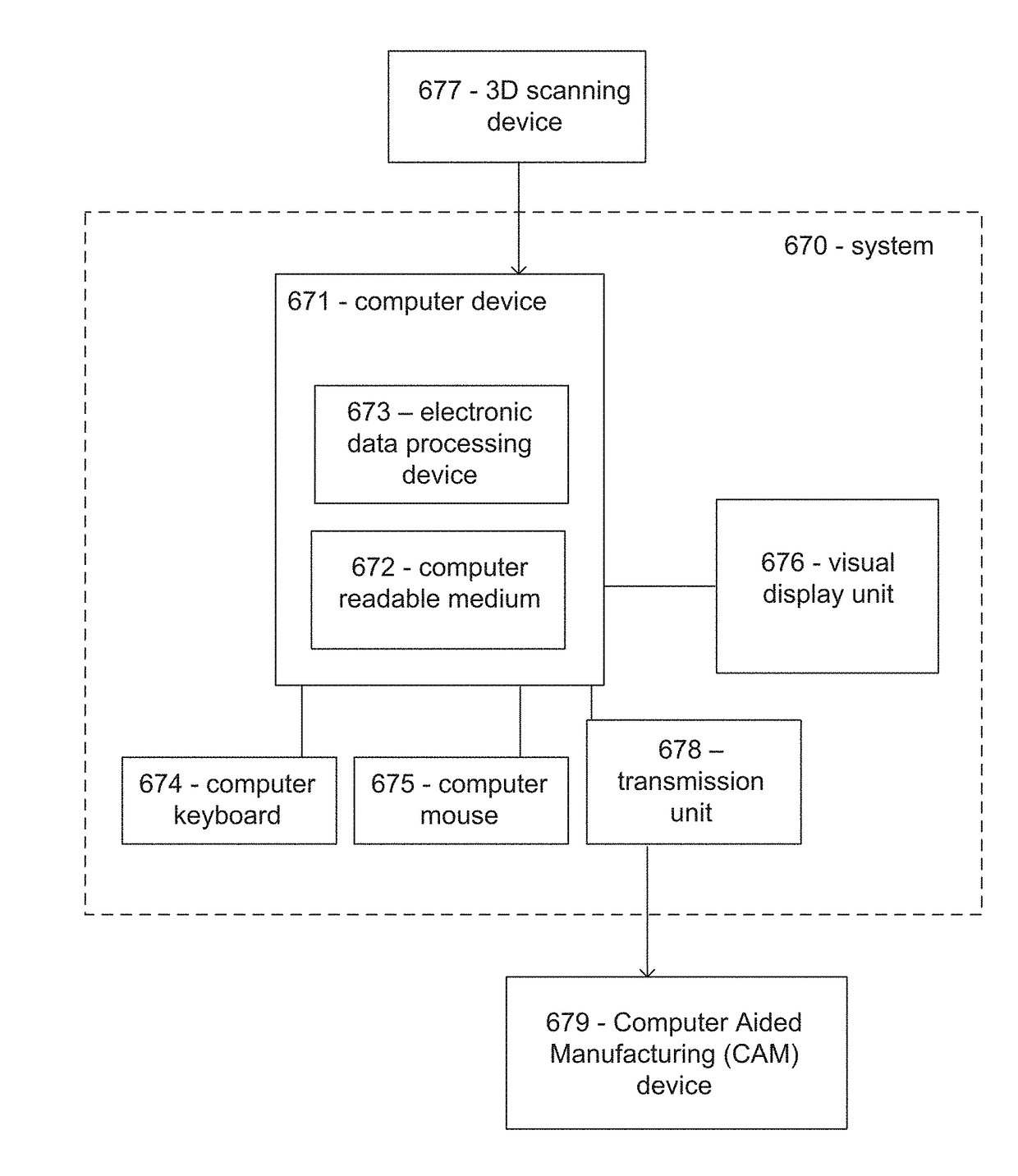

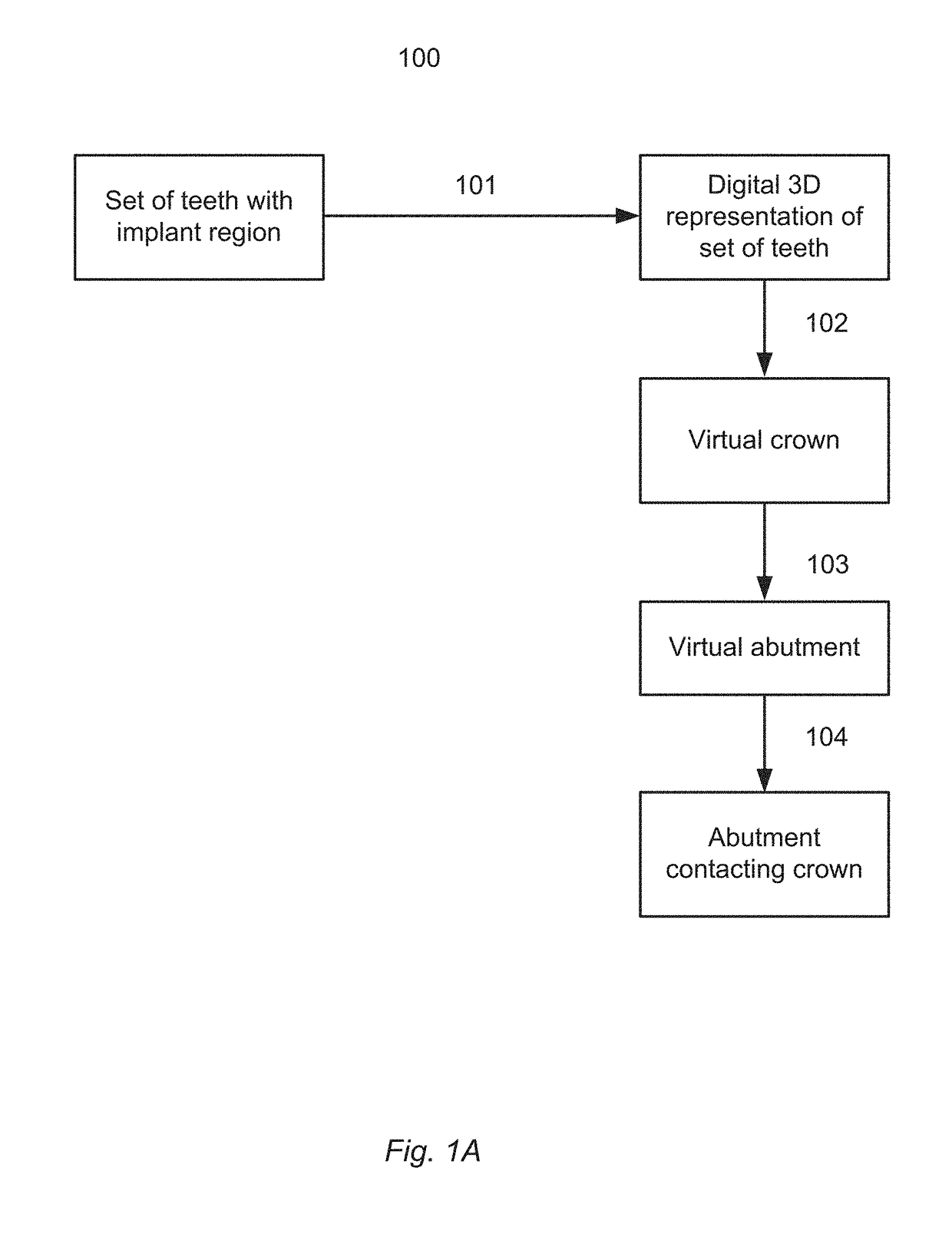

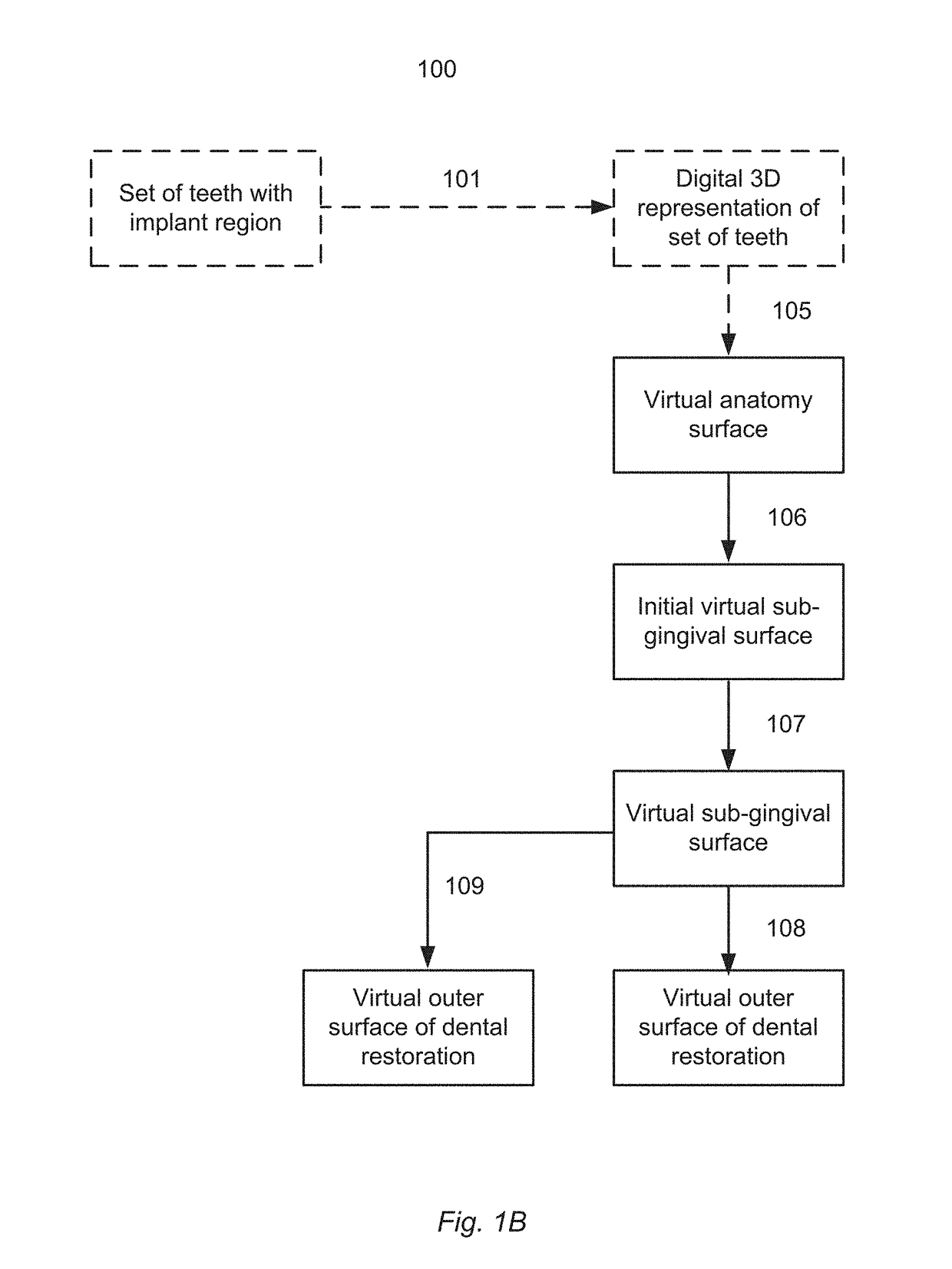

Designing a dental restoration

A method for designing a virtual abutment for manufacturing an abutment part of a dental restoration for a patient, the dental restoration further including a crown configured for being seated at the abutment, wherein the method includes loading a virtual anatomy surface into an electronic data processing device, the virtual anatomy surface expressing a target shape of the crown portion of the dental restoration; loading an obtained virtual abutment including a virtual abutment finish line into the electronic data processing device; and modifying the obtained virtual abutment by executing one or more computer implemented algorithms using the electronic data processing device, where the algorithms are configured to adapt the shape of the obtained virtual abutment such that the virtual abutment finish line of the modified virtual abutment is aligned with the virtual anatomy surface.

Owner:3SHAPE AS

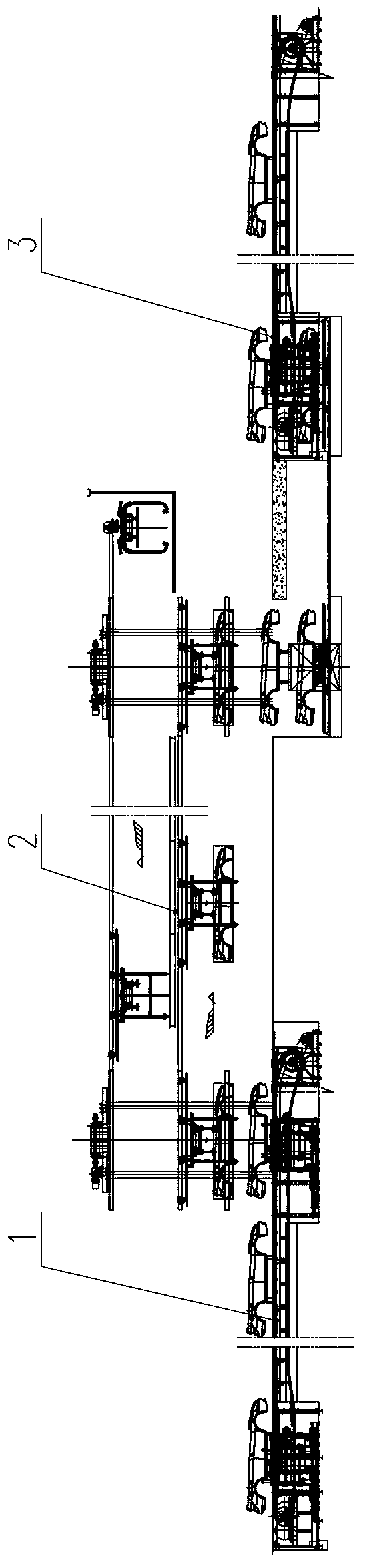

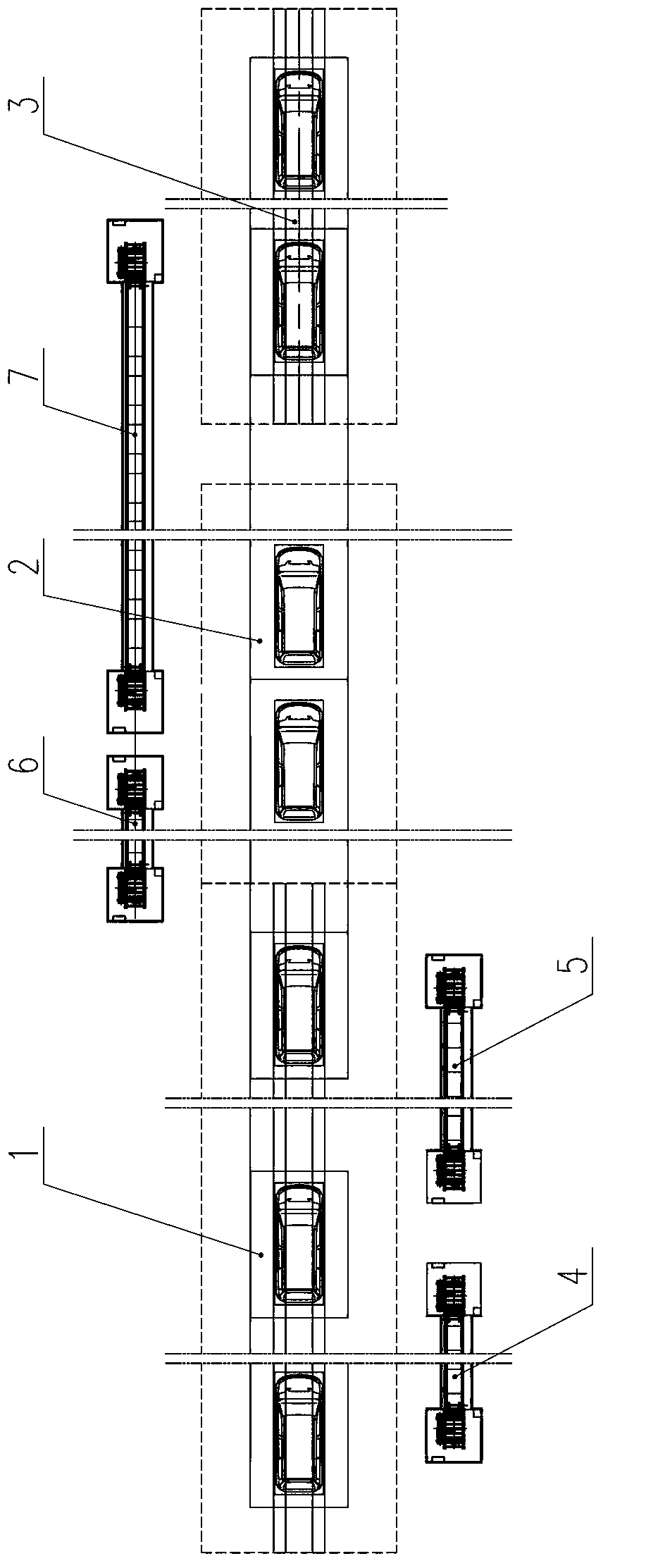

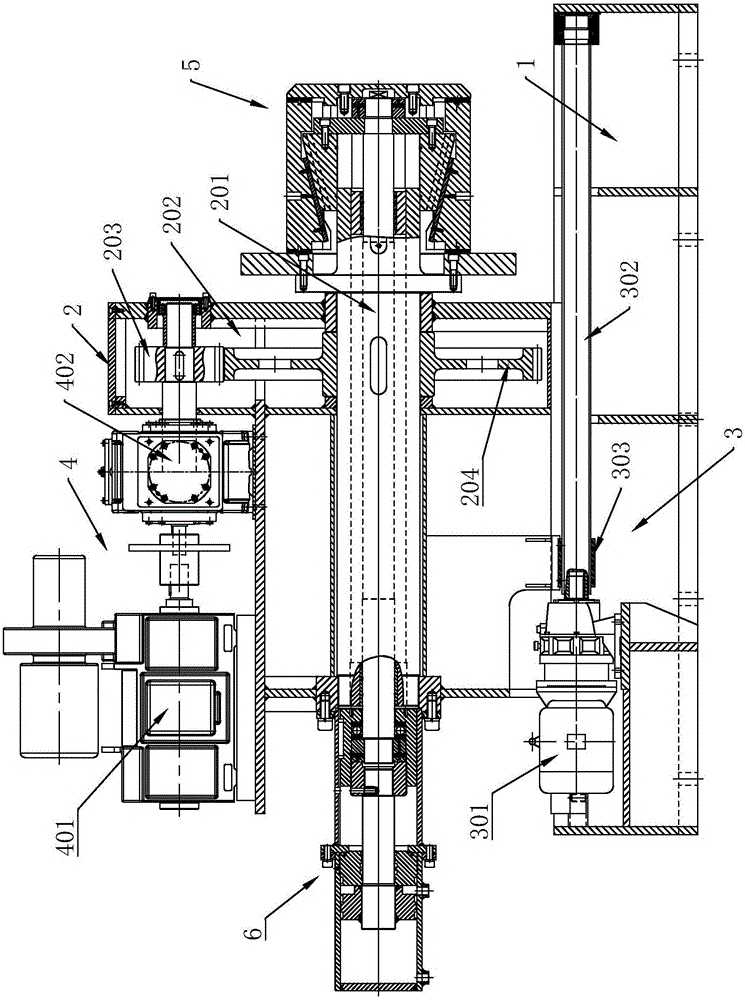

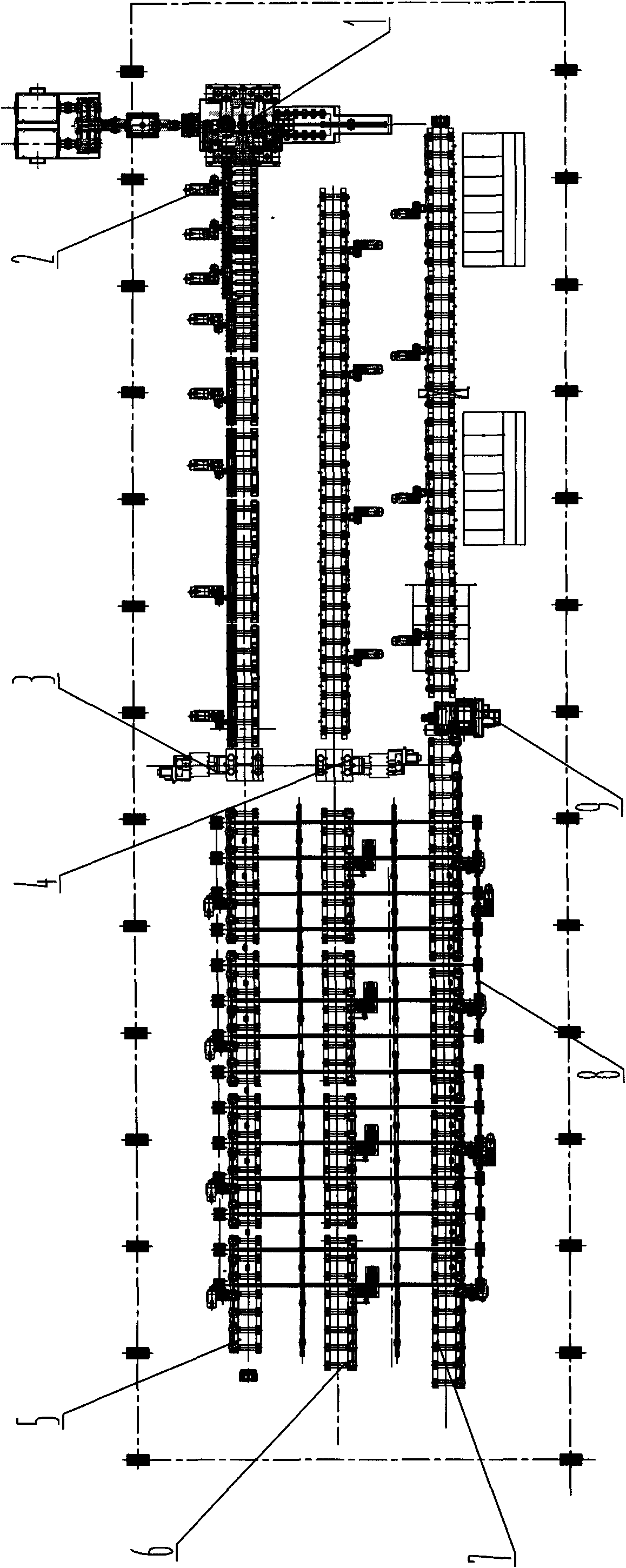

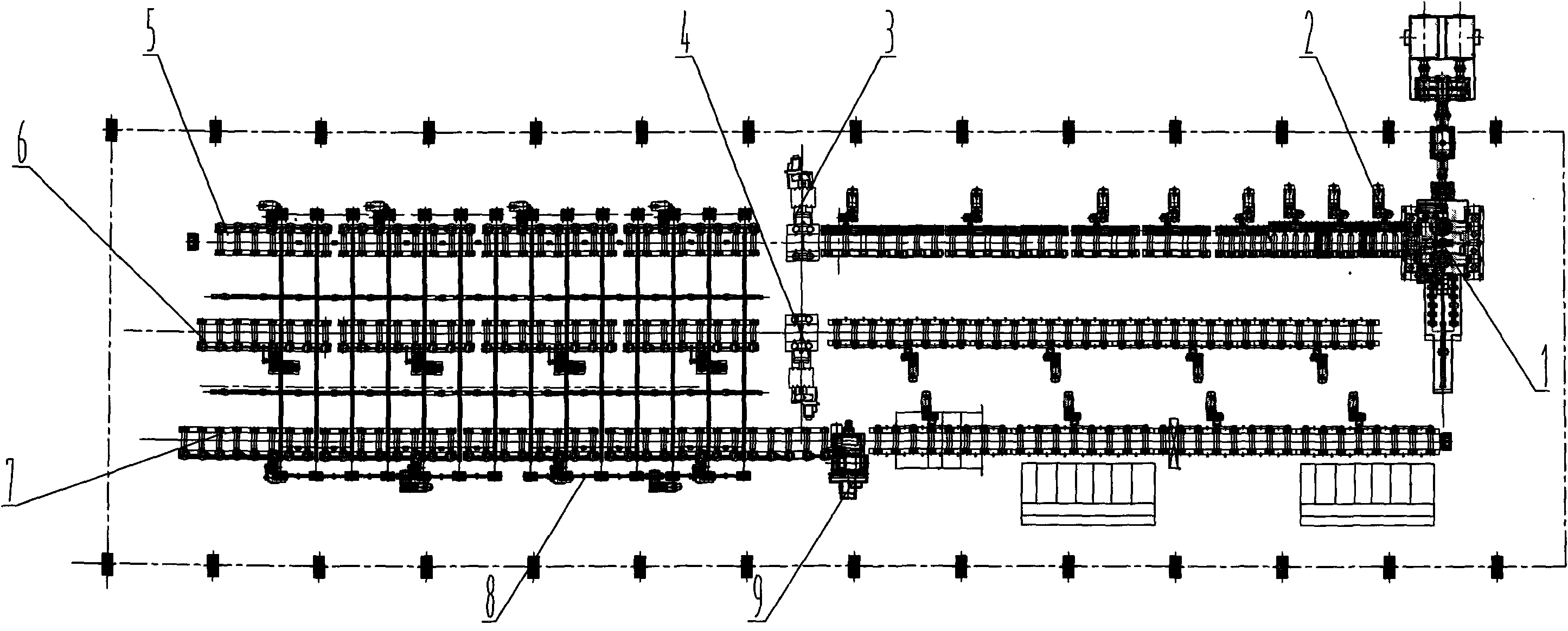

Scraped car disassembly production line

ActiveCN103101585AReduce labor intensityIncrease productivityVehicle dissasembly recoverySolid waste disposalCAR disassemblyProduction line

The invention relates to a scraped car disassembly production line which comprises a main line and an assembly dismantling line. The main line comprises an environment-friendly pre-processing and ground disassembly line, an overhead chassis disassembly line and a ground finish line which are arranged in sequence. The environment-friendly pre-processing and ground disassembly line adopts a double-plate-chain structure, the overhead chassis disassembly line adopts an electronic manufacturing service (EMS) self-propelled trolley type conveying structure, and the ground finish line adopts a double-plate-chain structure. The assembly dismantling line comprises a car door dismantling line, an instrument board dismantling line, a car suspension frame dismantling line and an engine auxiliary dismantling line which respectively adopt accumulation type maneuvering roller way conveying structures, wherein the assembly dismantling line is located on the lateral face of the main line. The scraped car disassembly production line adopts an advanced automated logistic system, achieves mechanical and automatic production of car disassembly operation, remarkably improves the production efficiency, reduces labor intensity of workers, saves manpower resources and reduces safety accident occurrence rate.

Owner:MIRACLE AUTOMATION ENG CO LTD

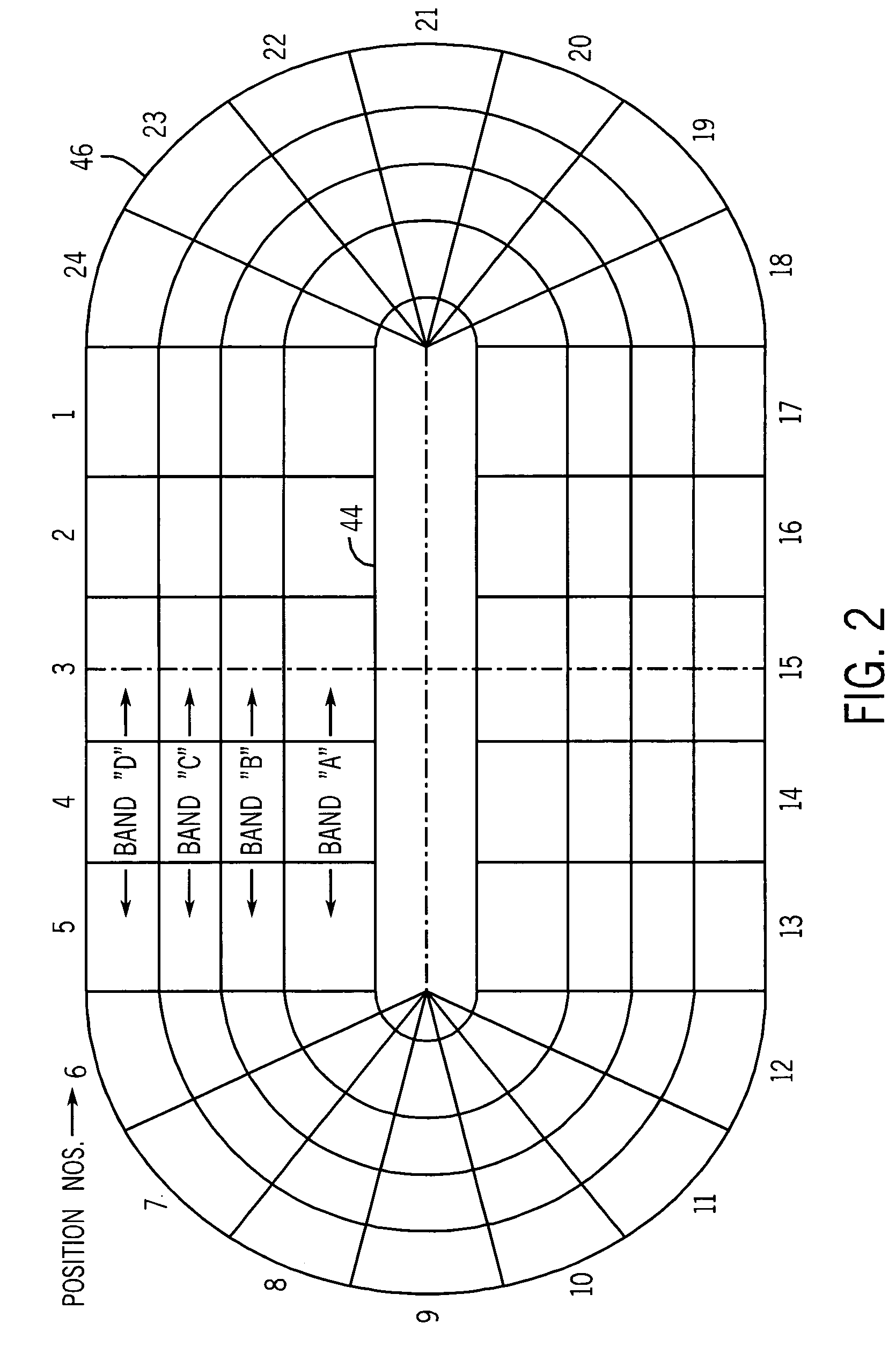

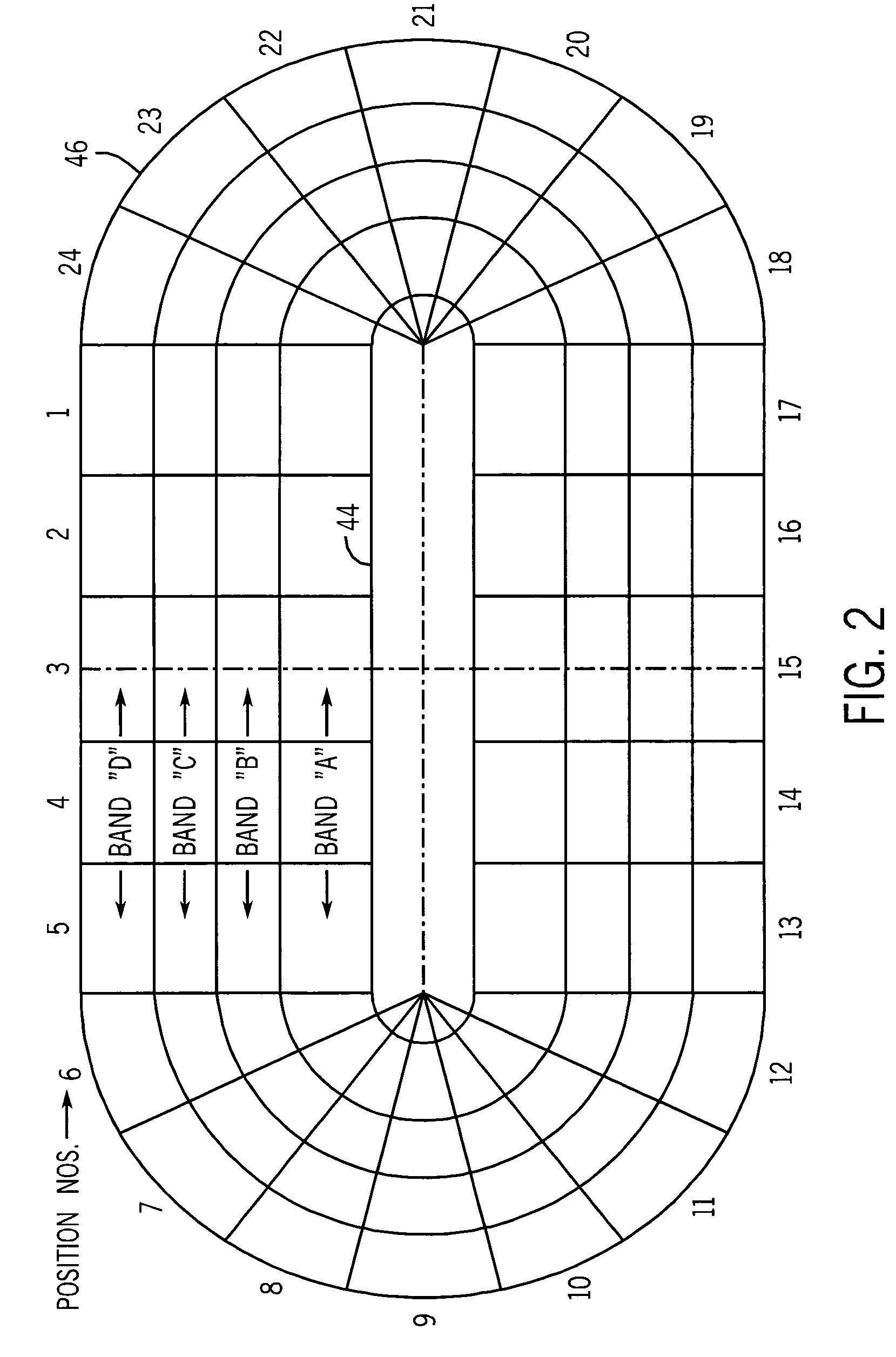

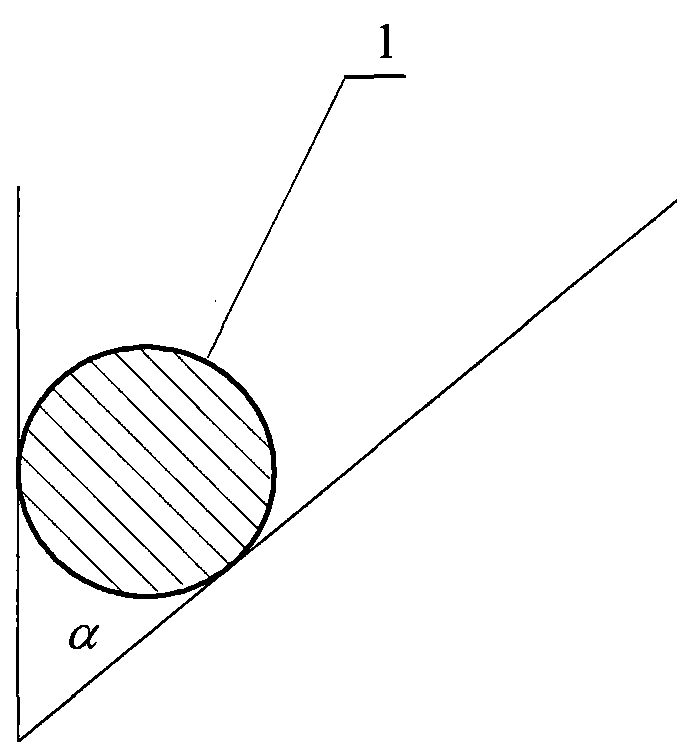

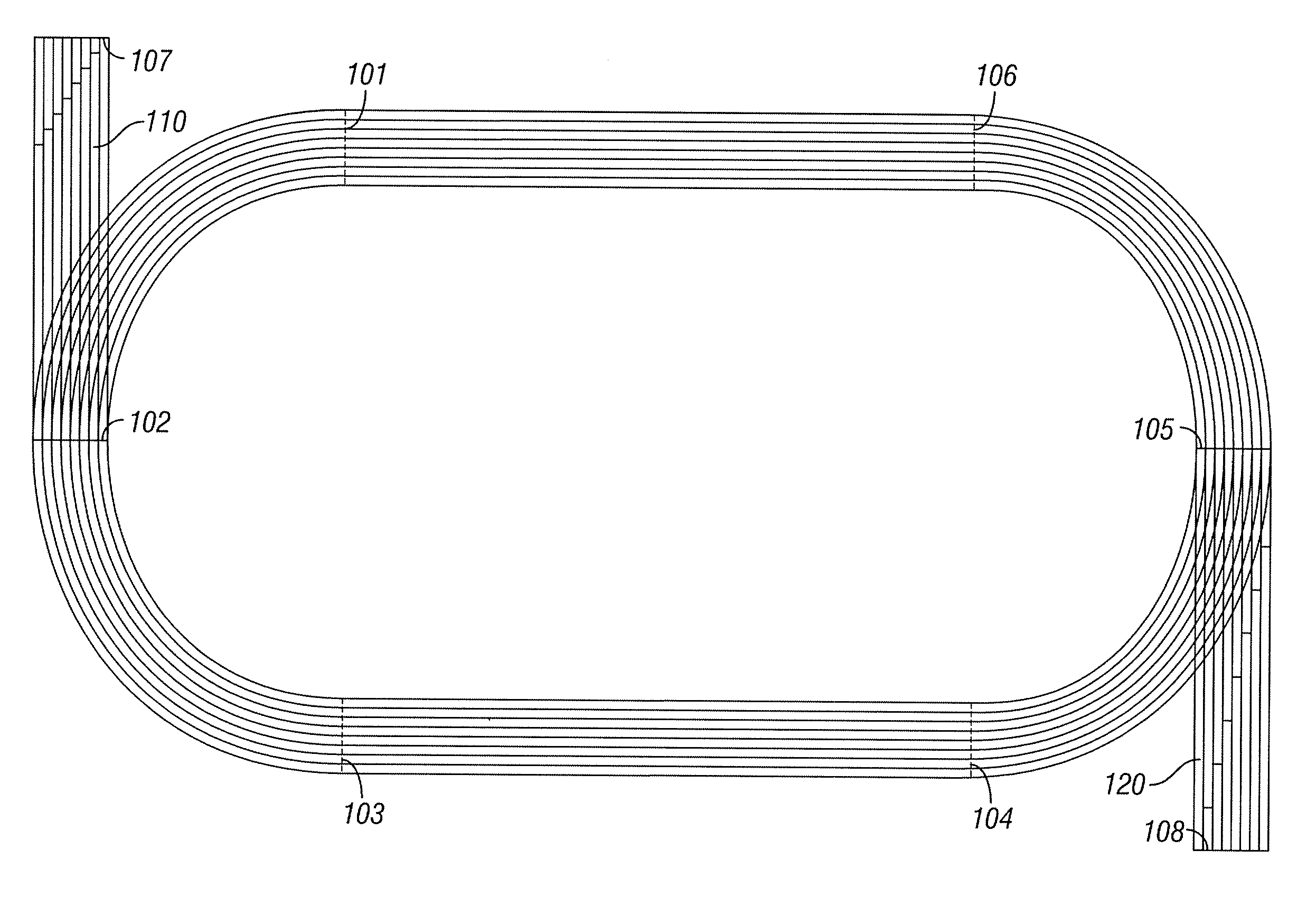

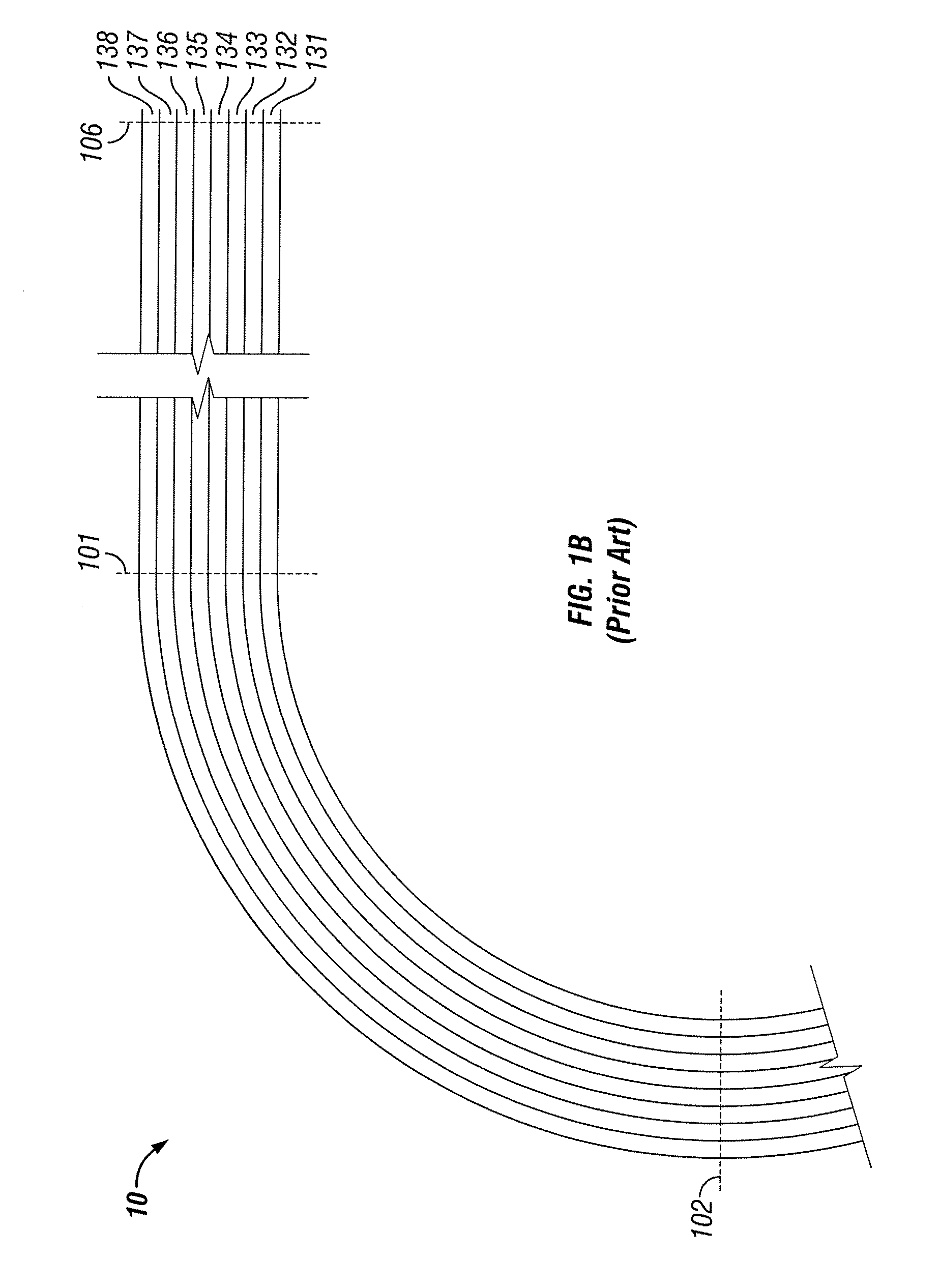

Proposed running track design for fairer 200 m and 400 m races

InactiveUS20070123360A1Eliminates effect of centrifugal forceEliminate the effects ofSki bindingsPublic buildingsTrackwayEngineering

The present invention is directed to a system and method for conducting a more fair race around an oval track by having runners in each lane run equal arc angles. Such a configuration eliminates the disproportionate effect of centrifugal force on competitors running in different lanes. Embodiments of the invention provide for the addition of a straight section to a standard oval track extending from a curved section perpendicular to the existing straightaway section. Runners in each lane start at staggered locations on the straight section. The staggered starting locations are chosen such that each runner travels an equal distance from the starting location to a common finish line. A single straight section may be employed to conduct races covering the entire length and half the length of the oval track or two straight sections may be employed to allow finishes for both races at a common finish line.

Owner:ALPHADEV

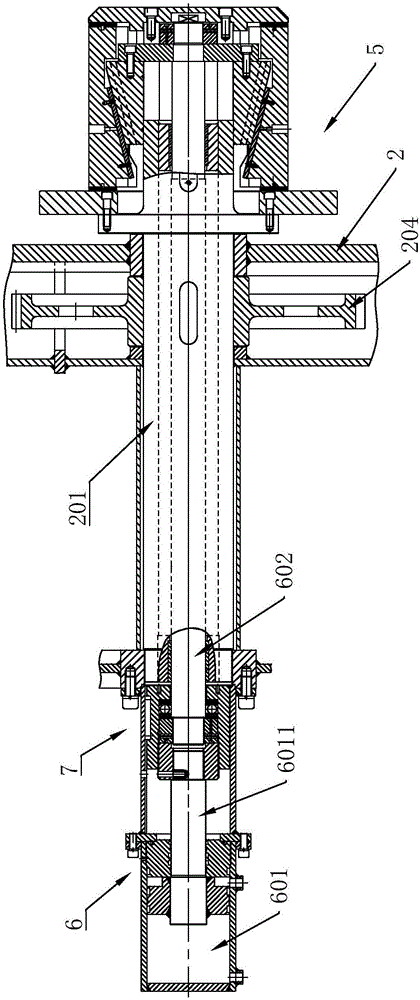

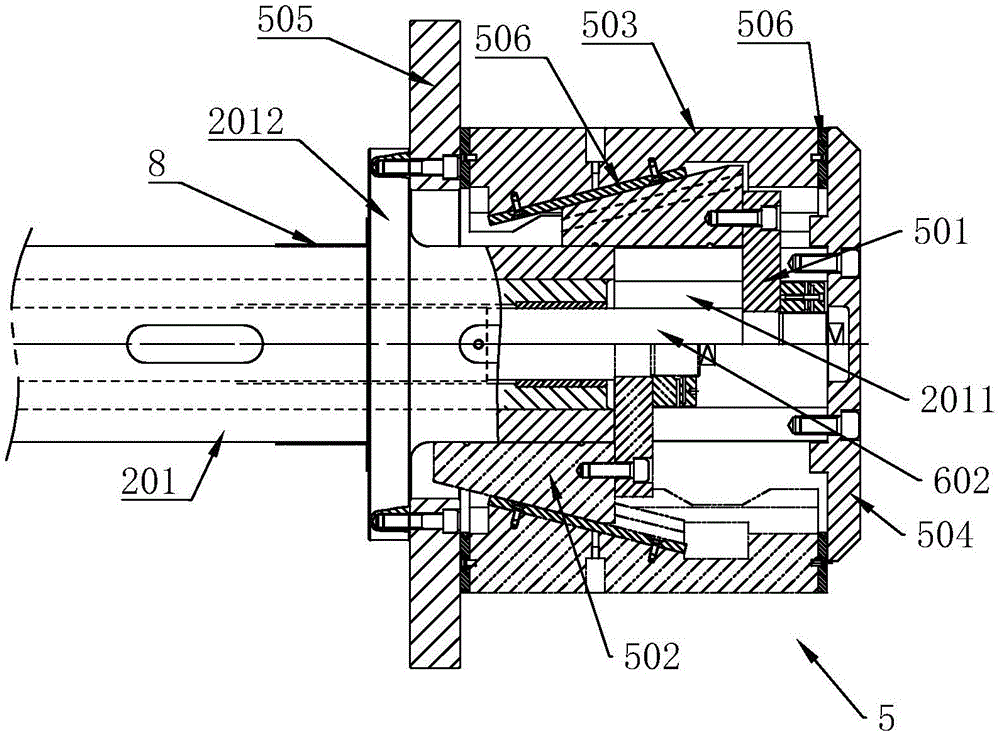

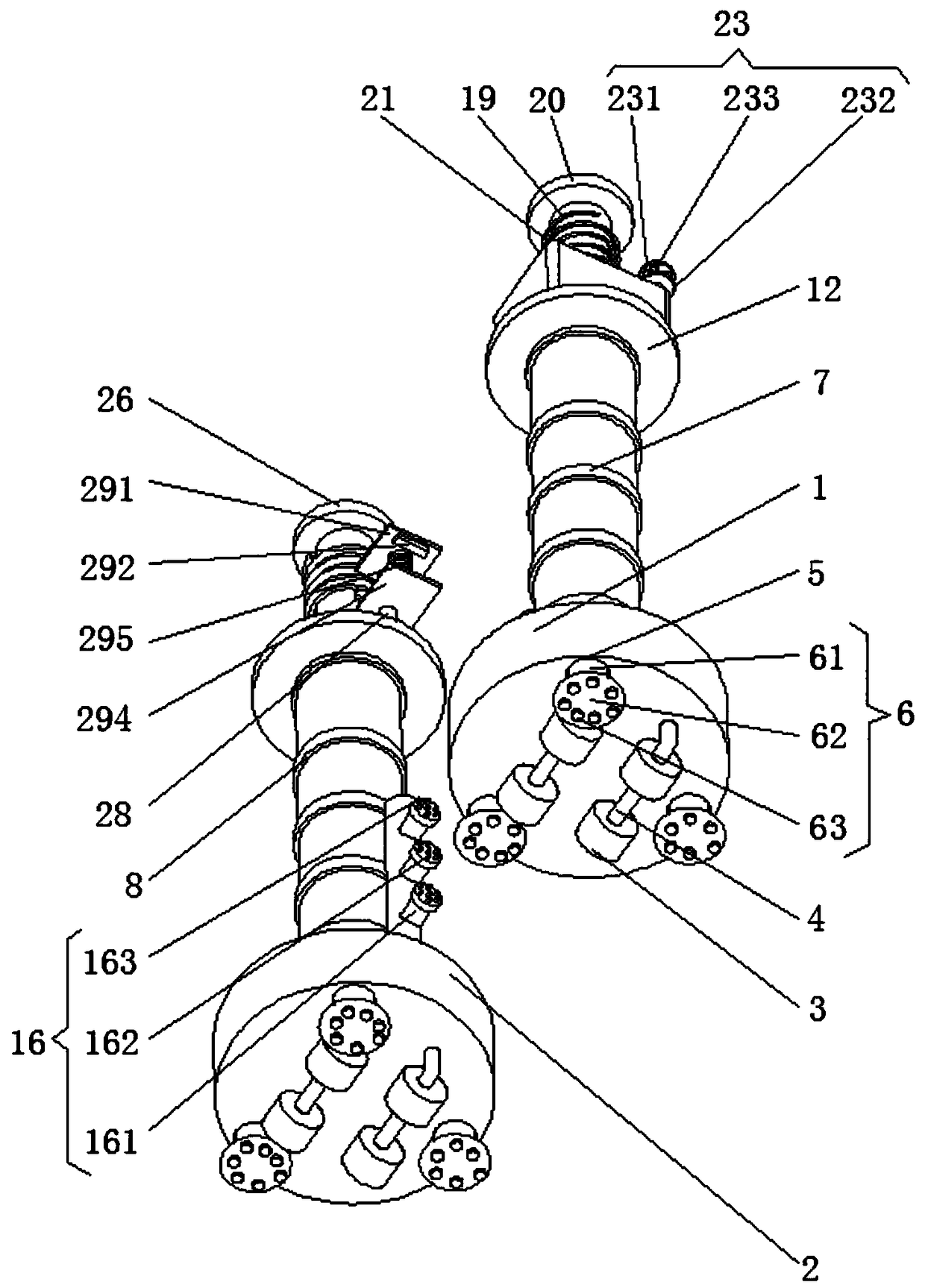

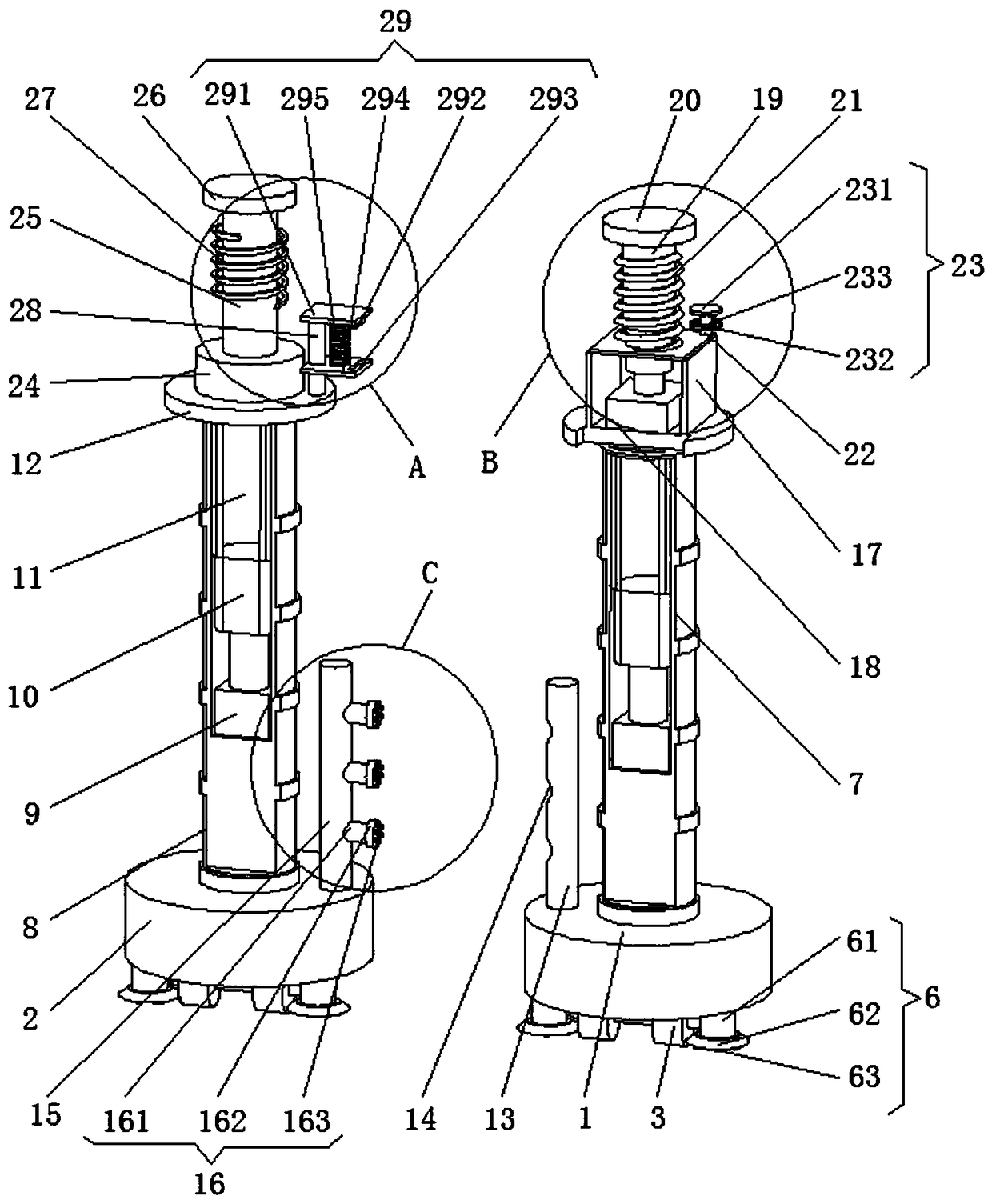

Uncoiler

The invention discloses an uncoiler which comprises a base. A spindle box is slidably installed on the base. A spindle driven by a first drive device is rotatably installed in the spindle box. An expanding and shrinking device is arranged at one end of the spindle. A second drive device connected with the expanding and shrinking device is arranged in the position, at the other end of the spindle, of the spindle box. The second drive device penetrates through the inside of the spindle and transversely drives the expanding and shrinking device. By adoption of the uncoiler, steel coil finishing lines and steel plate finishing lines can be mixed together, the situation that both steel coils and steel plates can be subjected to finishing on a production line can be achieved, and interference does not occur when the steel coils and the steel plates are switched; compared with conventional two production lines, investment cost is greatly saved, and the occupation area and the space occupancy rate are greatly lowered; meanwhile, the production usage rate is effectively increased; and further, the uncoiler is simple in structure, low in manufacturing cost, high in structural strength and long in service life.

Owner:山东亚盛重工股份有限公司

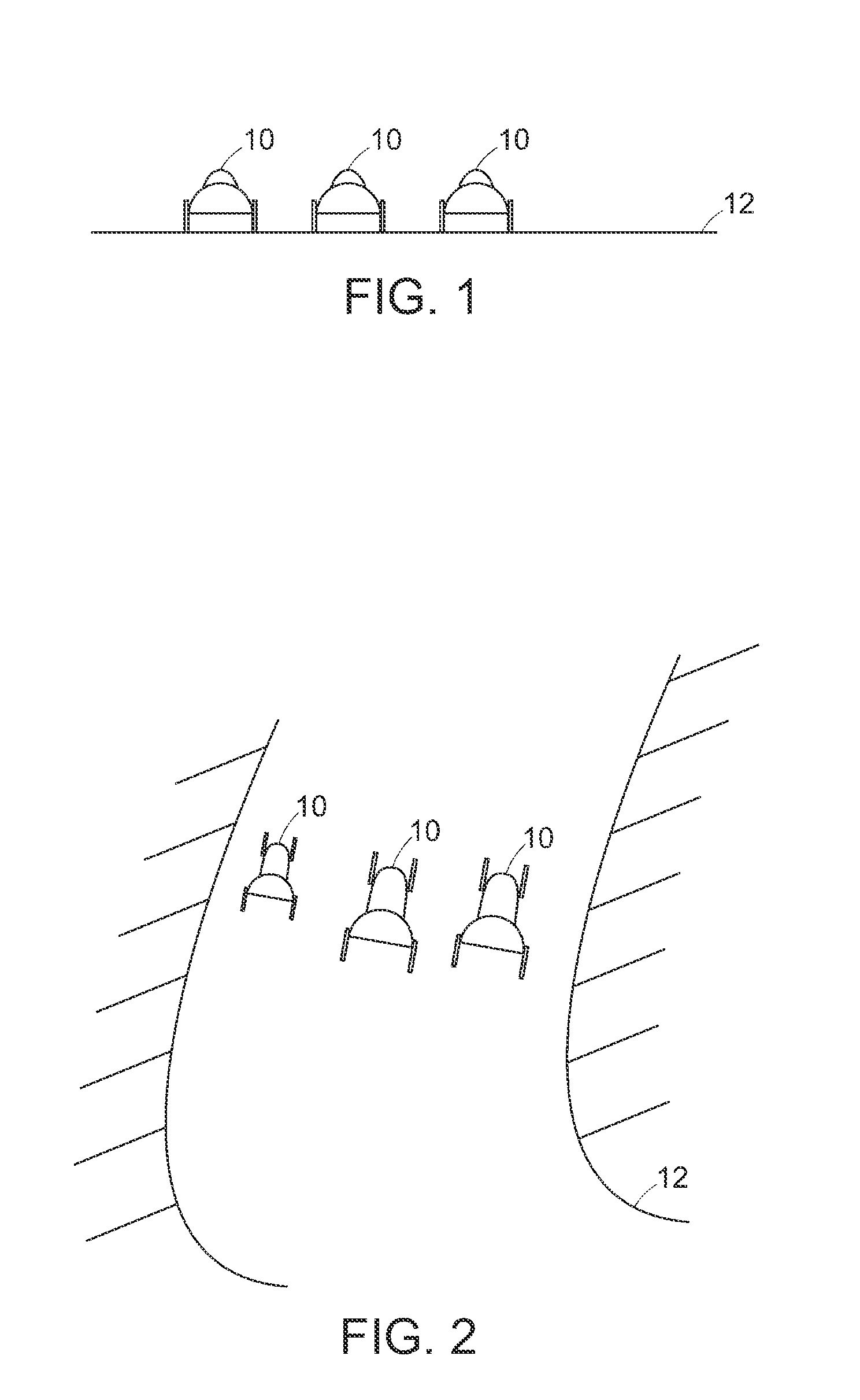

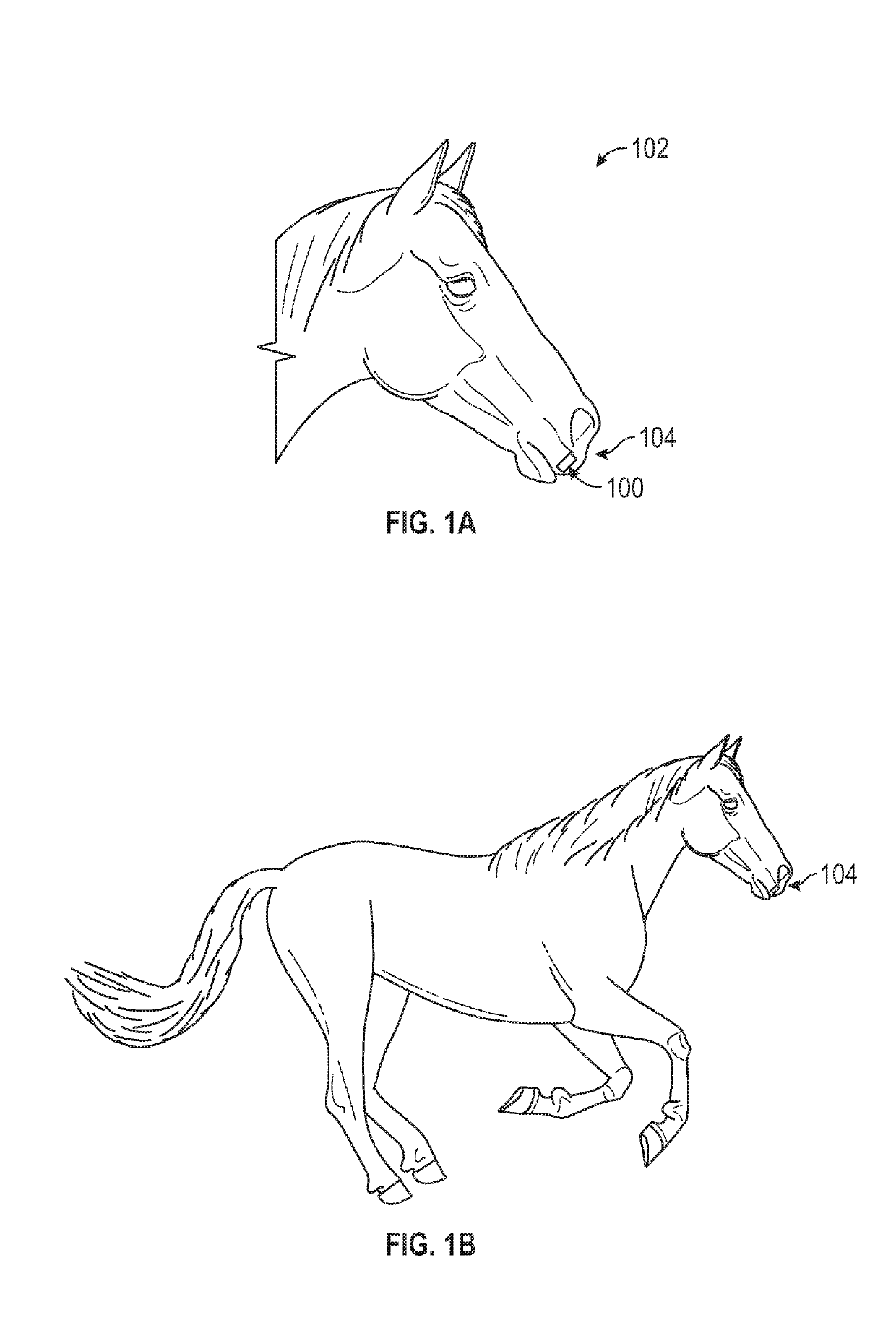

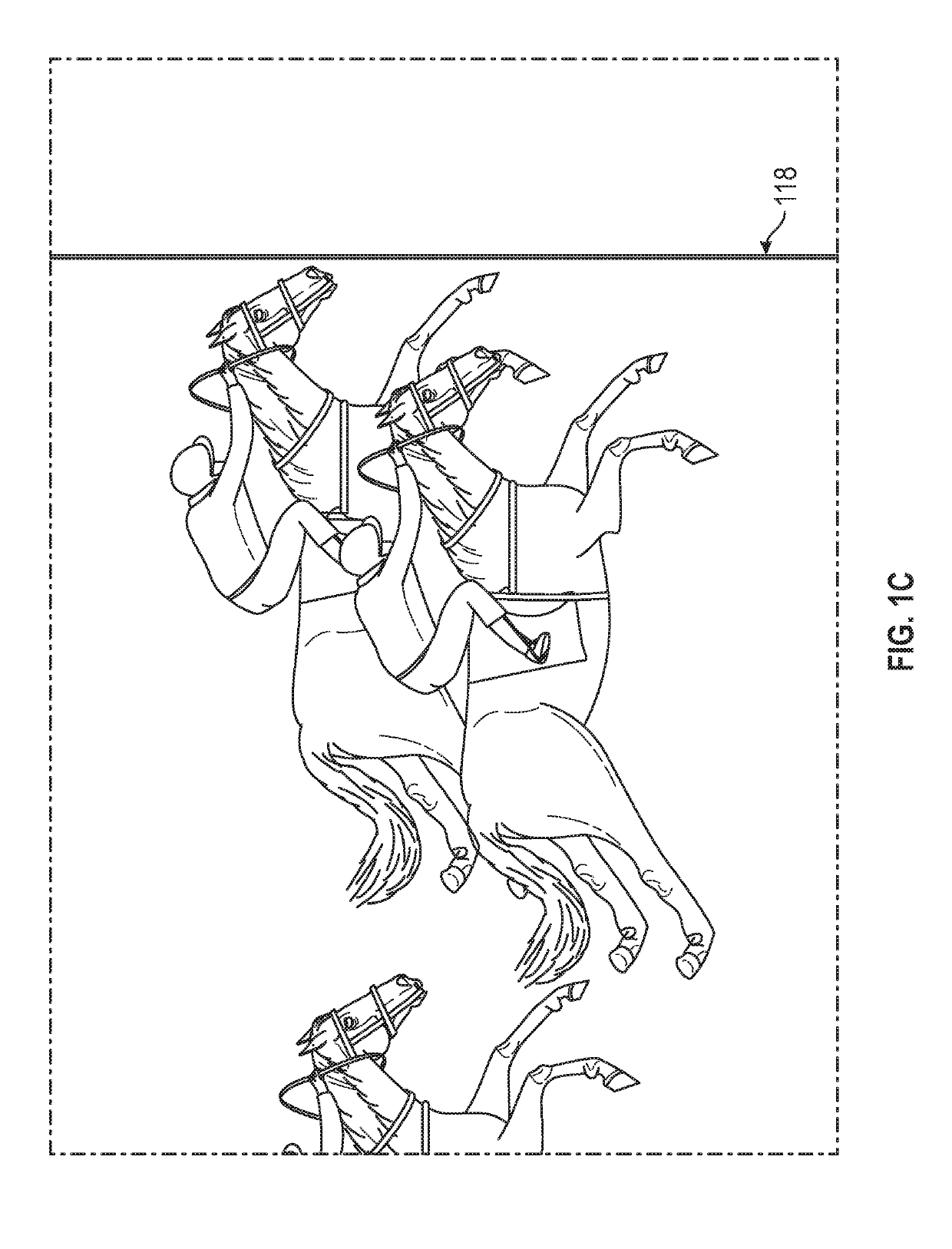

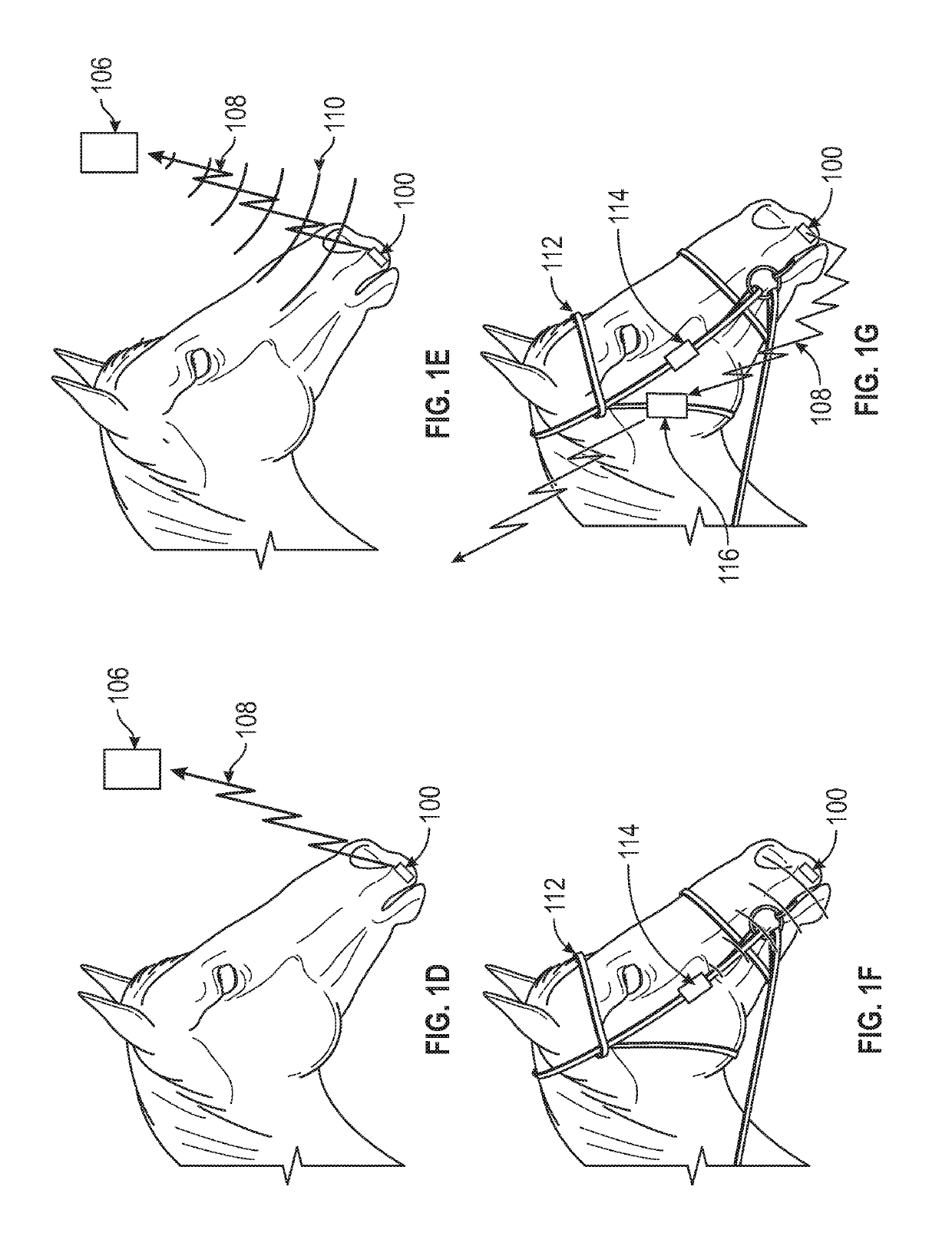

Method, System, and Apparatus for Determining Location of Animals in Competitive Environments

ActiveUS20190159428A1Easy maintenanceThermometer detailsRegistering/indicating time of eventsEngineeringHuman judgment

A tag is implanted in the forwardmost part of an animal to determine the location of the animal for competitive and security purposes. The tag is implanted such that it is inserted in the first part of an animal to cross a finish line. By using the tag to determine the when an animal has reached a predetermined location, the method and system can evaluate the results of the race, negating the need for human judgment. Further, the invention allows for tracking of the animal in transit and when at a race grounds.

Owner:LIP CHIP LLC

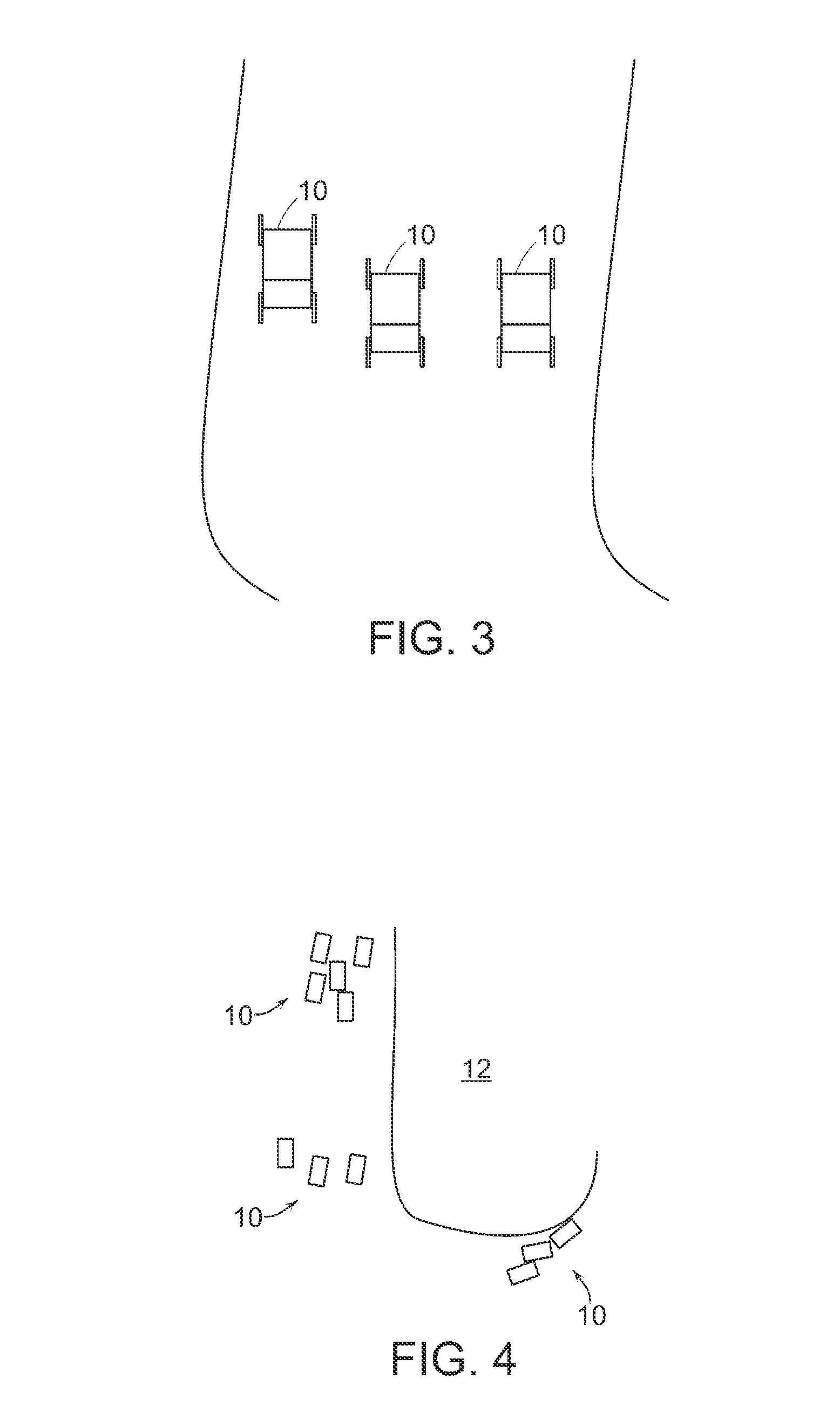

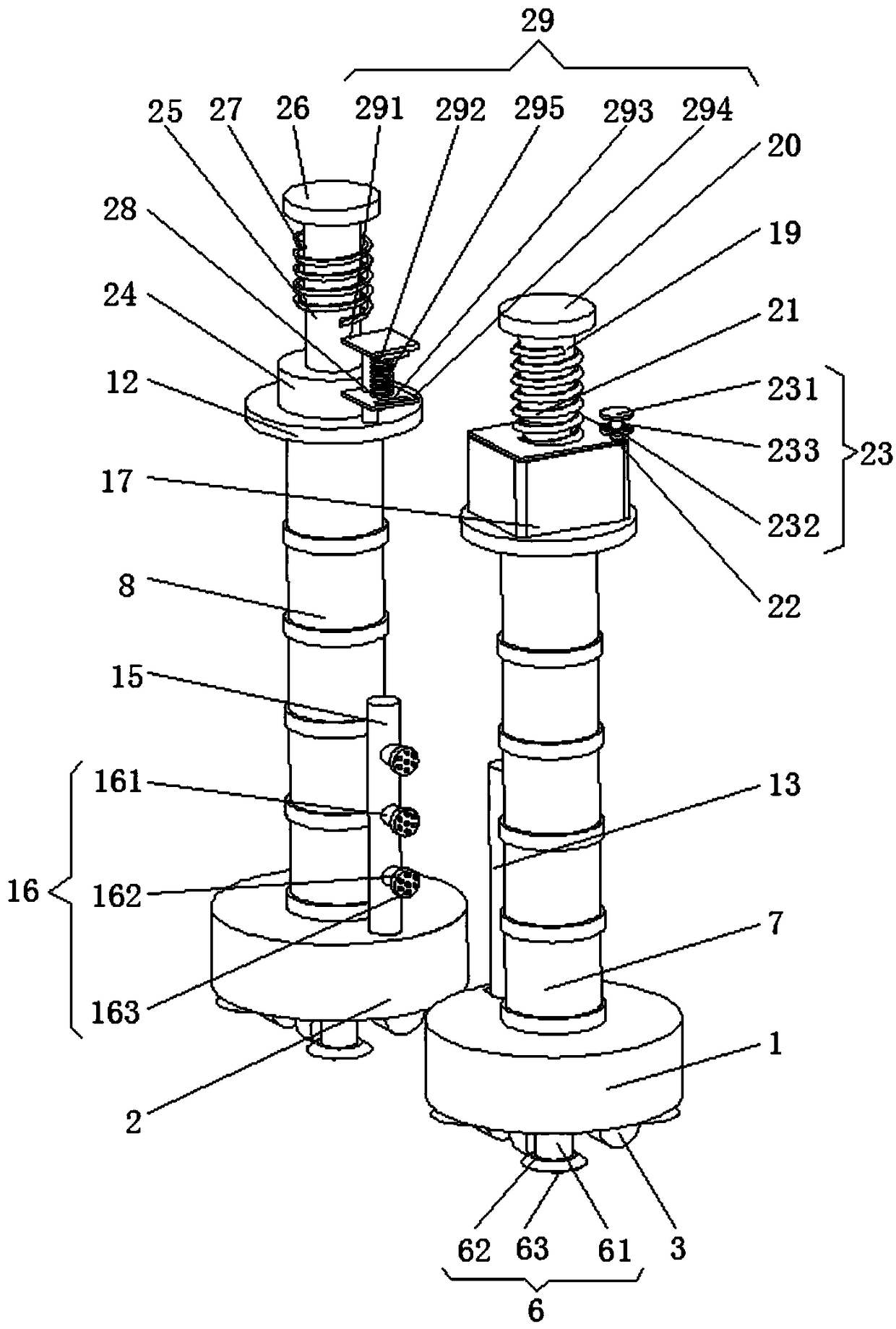

Hands-free finishing line indicating device for sports competition

InactiveCN108211320AEffective immobilizationImprove stabilitySport apparatusSports equipmentEngineering

The invention relates to the technical field of sports equipment and discloses a hands-free finishing line indicating device for sports competition. The hands-free finishing line indicating device comprises a first fixing base plate and a second fixing base plate and is characterized in that moving wheels are arranged at the bottom of each of the first fixing base plate and second fixing base plate, rotary shafts are rotatably connected to the middles of the moving wheels, the lateral sides of the moving wheels are provided with limit grooves located in the bottoms of the first fixing base plate and the second fixing base plate, and limit fixing devices are fixedly mounted in the middles of the limit grooves. The hands-free finishing line indicating device has the advantages that the hands-free finishing line indicating device can be conveniently moved to an appointed position by the combination of the moving wheels and the rotary shafts, and the problems that staff need to hold a finishing line during traditional track events, unnecessary manpower is consumed, and the sprint process of the track events has great potential safety hazards are solved.

Owner:HUNAN UNIV OF ARTS & SCI

Online double-straightener short-flow finishing line arrangement method in steel plate production

The invention discloses an online double-straightener short-flow finishing line arrangement method in steel plate production, wherein a finished steel plate rolling mill, a rollgang, two straighteners, a shearing machine and three rows of steel transmission roller beds are arranged in a workshop; the finished steel plate can enter into the straighteners after the tail part comes off the rolling mill for a certain distance; the other straightener and the shearing machine are sequentially and transversely arranged at intervals at the straightener side along the workshop, and the straighteners and the shearing machine can be arranged in a staggered way for saving space; the three rows of steel transmission roller beds are respectively longitudinally arranged along the workshop corresponding to the straighteners and the shearing machine; and a steel transmission mechanism stretches over the three rows of steel transmission roller beds for communicating the three rows of steel transmission roller beds and transmitting the steel plates for straightening and shearing. The invention has the advantages of realizing the compact arrangement of the double-straightener short-flow finishing line, thereby being capable of realizing short-flow compact arrangement in common 21-30m span workshops.

Owner:郑州新华重型机器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com