Online double-straightener short-flow finishing line arrangement method in steel plate production

A double leveler and leveler technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increased process length and increased investment in production workshops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

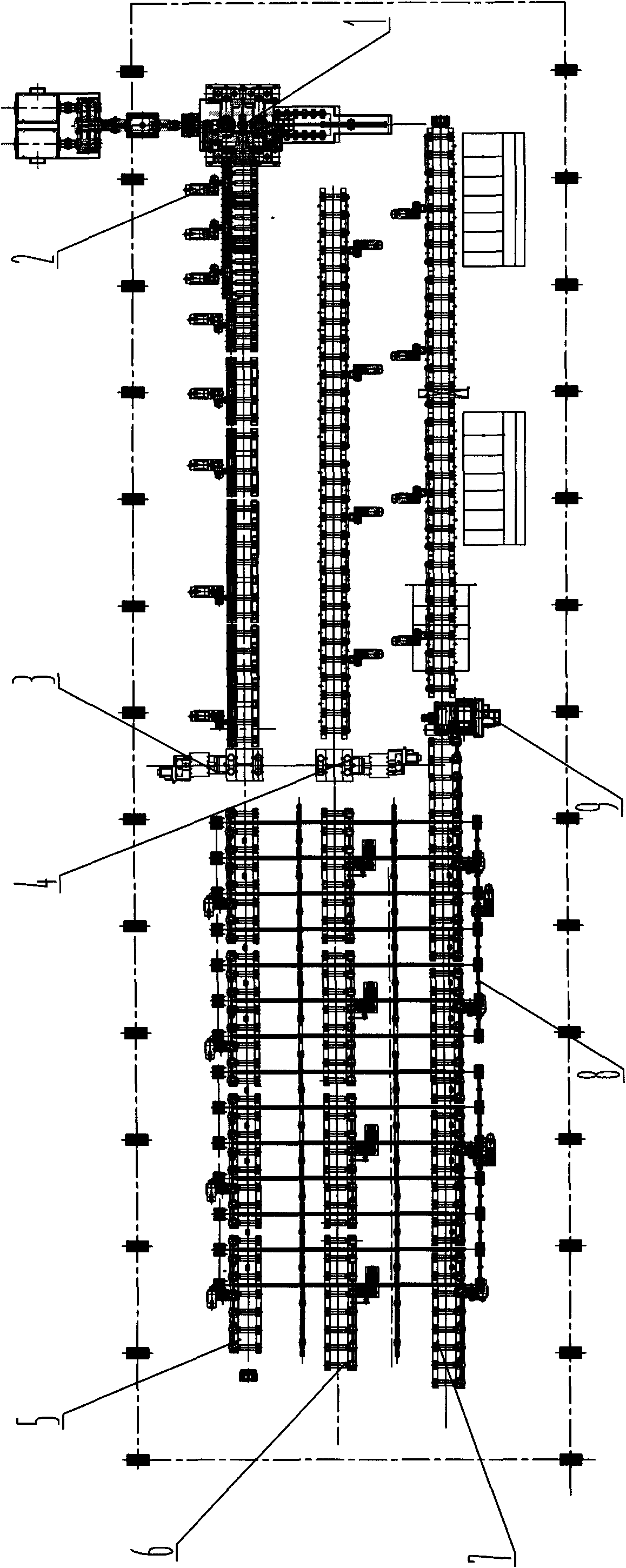

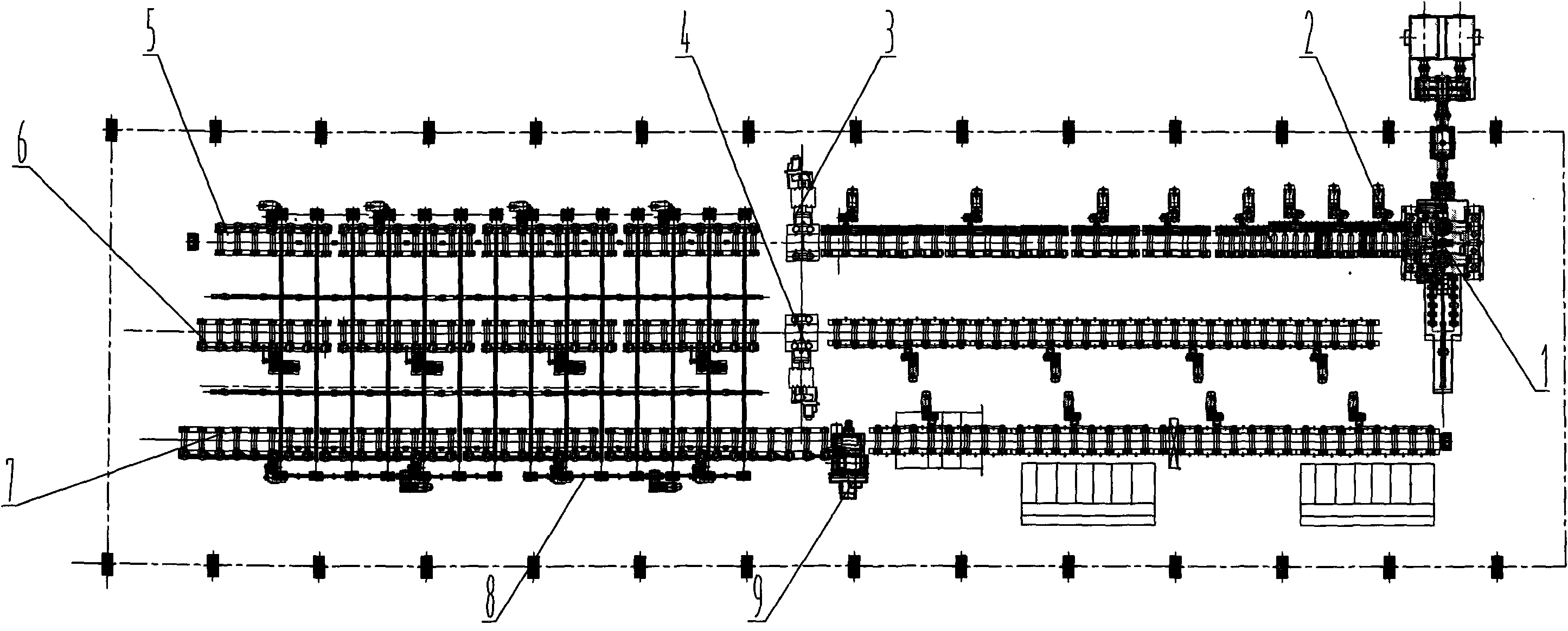

[0019] Such as figure 1 As shown, the layout method of the double straightening machine short-process finishing line on the steel plate production line of the present invention includes a finished steel plate rolling mill 1, a conveying roller table 2, two straightening machines 3, 4, Shearing machine 9, three shifting steel roller tables 5, 6, 7; at the position of 2m-3m at the exit of the conveying roller table 2 of the finished steel plate rolling mill 1, a straightening machine 3 is installed longitudinally in the workshop, The second straightening machine 4 and shearing machine 9 are successively installed on one side of the straightening machine 3 along the transverse interval of the workshop; and the shearing machine 9 are installed longitudinally along the workshop; across the three rows of shifting steel rollers 5, 6, 7, a steel shifting mechanism 8 composed of chains and claws is arranged to communicate with the three rows of shifting steel rollers 5, 6, 7. Transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com