On-line model of motor starting time of bar finishing line separating plate and braking plate

A technology of motor starting and separating plates, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems that are prone to steel punching accidents in the cooling bed, the inability to achieve the best operating state of the cooling bed steel delivery system, and the failure to achieve the best Optimum coordination and other issues to achieve the effect of reducing manual intervention, improving yield and production efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

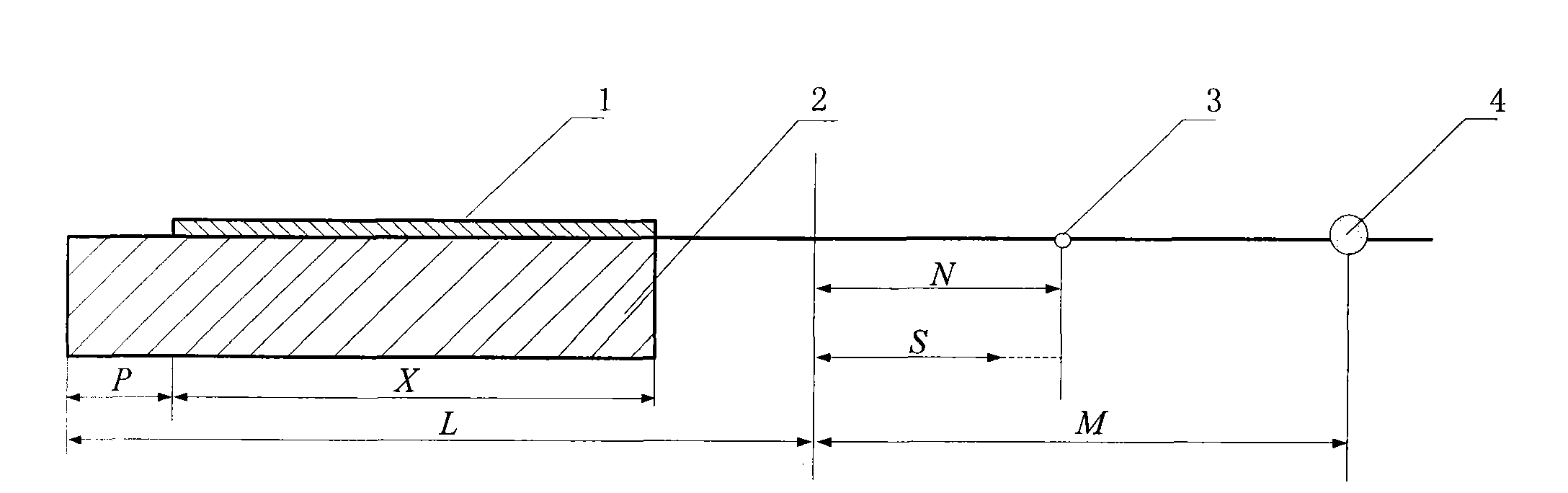

[0056] An online model of the start-up time of the separating plate and braking plate motors in a bar finishing line. Such as figure 1 Shown: the effective length L of the cooling bed 2 is 118 meters; the distance M from the flying shear 4 to the cooling bed 2 is 81 meters; the length X of the double-foot steel 1 is 97.5 meters; the double-foot steel 1 to the head of the cooling bed 2 The head-to-head distance P is 6 meters; the maximum length of double-foot steel 1 is X max is 110 meters.

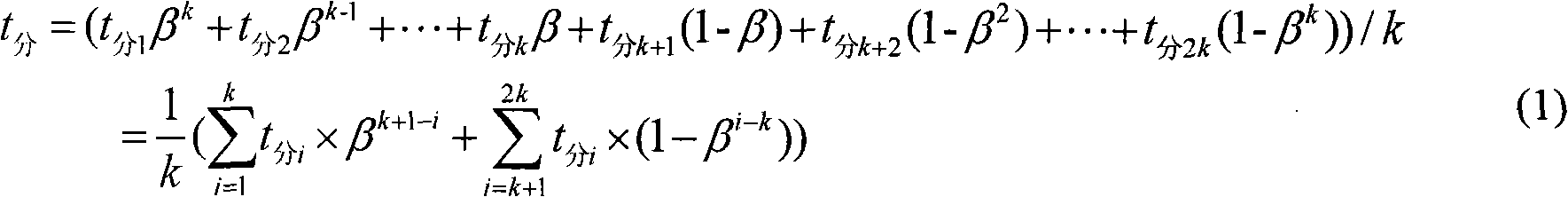

[0057] First collect the latest 2k action time data t when the separation plate and the brake plate fall from the high position to the low position 分i and t 制i , i=1, 2, ..., 2k, using the weighted mean filtering algorithm, to obtain the predicted value of the time when the separation plate falls from the high position to the low position next time:

[0058]

[0059] In the formula (1): the weighting coefficient β is taken as 0.5, k=5,

[0060] t 分i -Measurement time for the separat...

Embodiment 2

[0126] An online model of the start-up time of the separating plate and braking plate motors in a bar finishing line. Such as figure 1 Shown: the effective length L of the cooling bed 2 is 118 meters; the distance M from the flying shear 4 to the cooling bed 2 is 81 meters; the length X of the double-foot steel 1 is 83 meters; the double-foot steel 1 to the head of the cooling bed 2 The head-to-head distance P is 10 meters; the maximum length of double-foot steel 1 is X max It is 98 meters.

[0127] First collect the action time data t of the latest 2k separation plates and brake plates respectively 分i and t 制i , i=1, 2, . . . , 2k, using a weighted mean filtering algorithm. The predicted value of the time when the separation plate falls from the high position to the low position next time is obtained respectively:

[0128]

[0129] In the formula (1): the weighting coefficient β is taken as 0.35, k=4,

[0130] t 分i -Measurement time of the separation plate falling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com