Scraped car disassembly production line

A kind of scrapped automobile and assembly line technology, applied in the direction of scrapped vehicle recycling, motor vehicle, solid waste removal, etc., can solve the problems of irregular operation process, few professional technicians in automobiles, low degree of mechanization, etc., so as to reduce the incidence of safety accidents. , the effect of reducing the labor intensity of workers and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

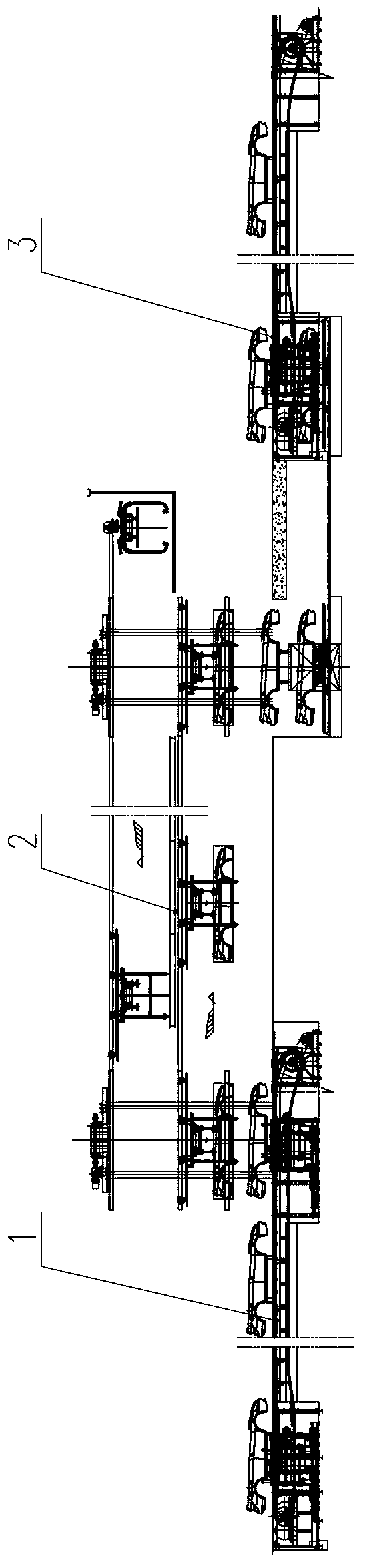

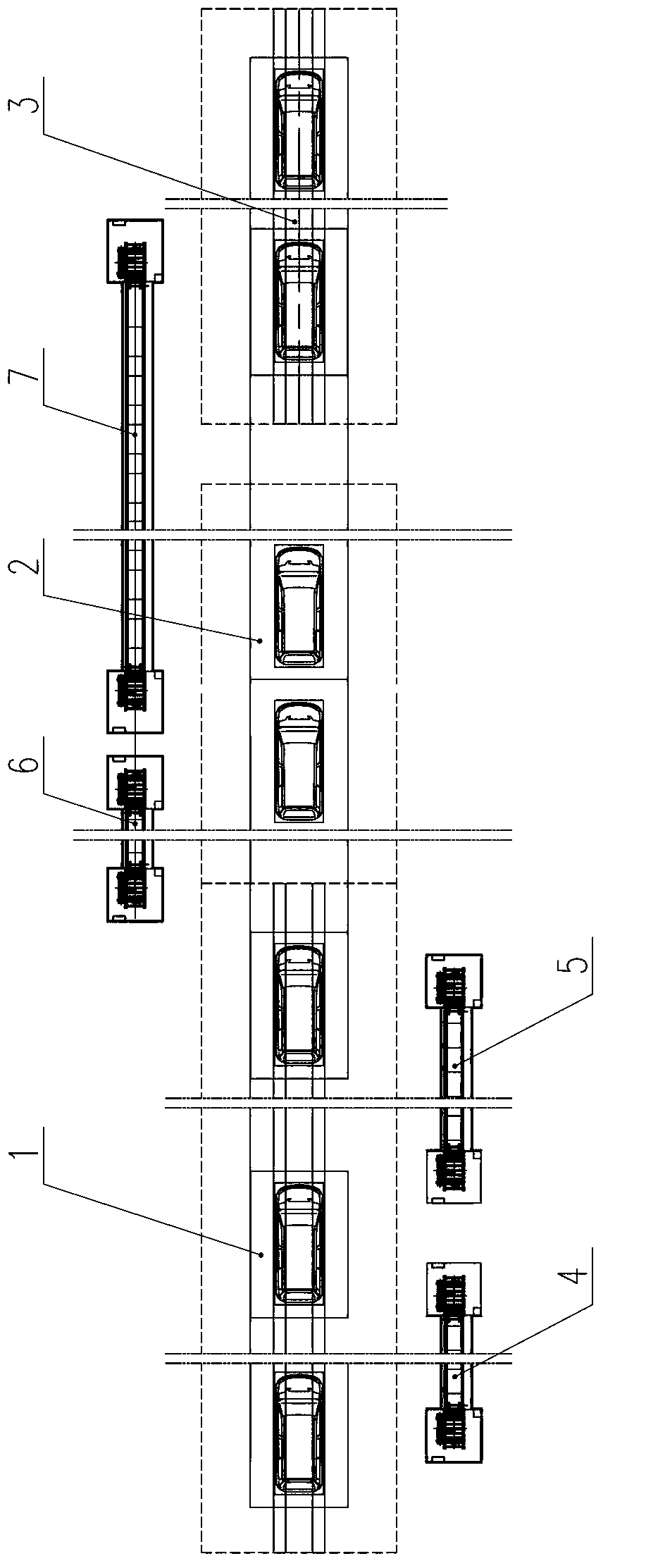

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] figure 1 , figure 2 Among them, including environmental protection pretreatment and ground dismantling line 1, aerial chassis dismantling line 2, ground completion line 3, door dismantling line 4, instrument panel dismantling line 5, vehicle suspension dismantling line 6, engine subframe Split line 7 etc.

[0012] Such as figure 1 , figure 2 As shown, the present invention is a dismantling assembly line for scrapped automobiles, including a main line and an assembly line for dismantling.

[0013] The main line includes environmental protection pretreatment and ground dismantling line 1, aerial chassis dismantling line 2 and ground completion line 3 arranged in sequence. There are transfer stations between the environmental protection pretreatment and ground dismantling line 1 and the aerial chassis dismantling line 2, and betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com