Patents

Literature

33 results about "CAR disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

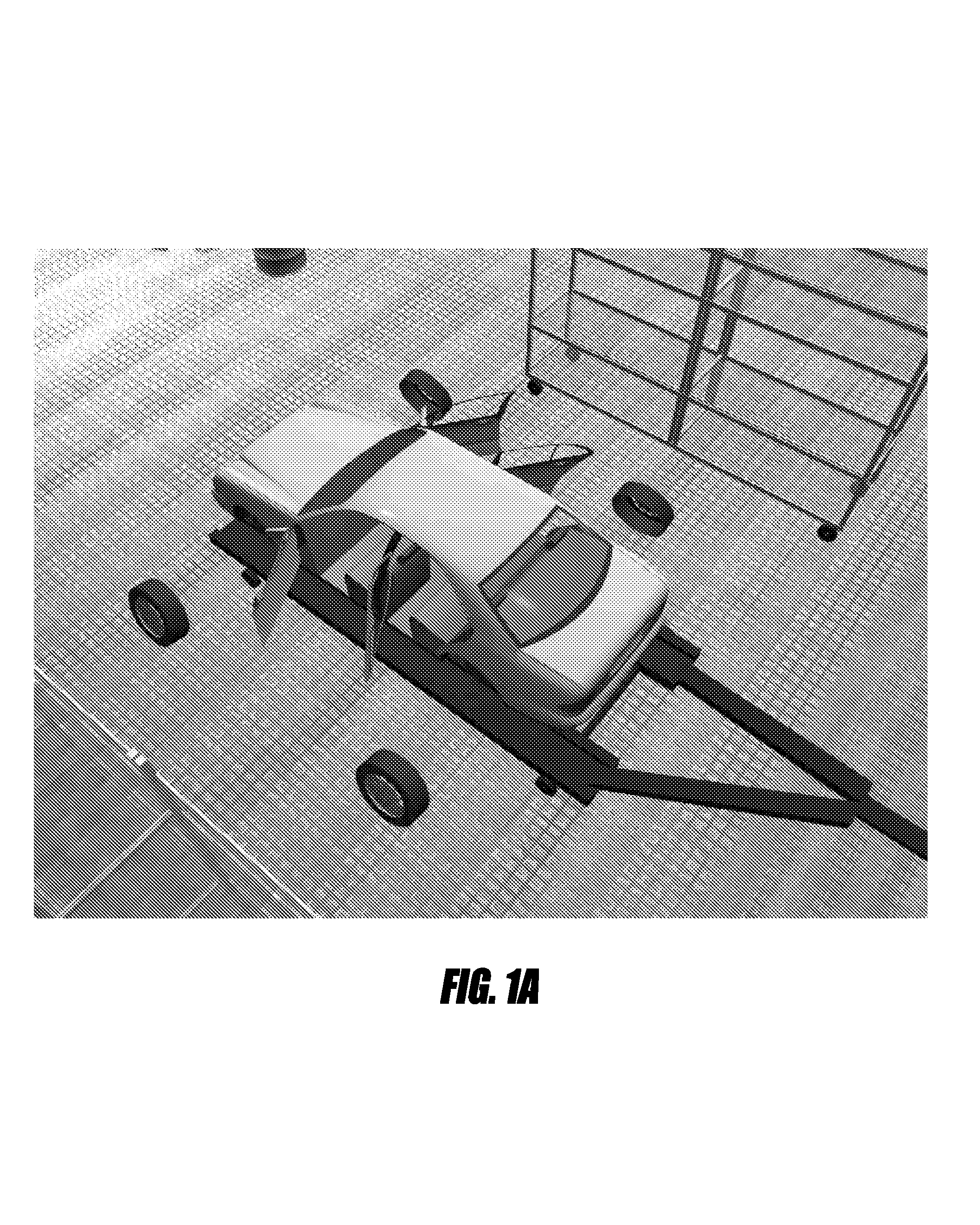

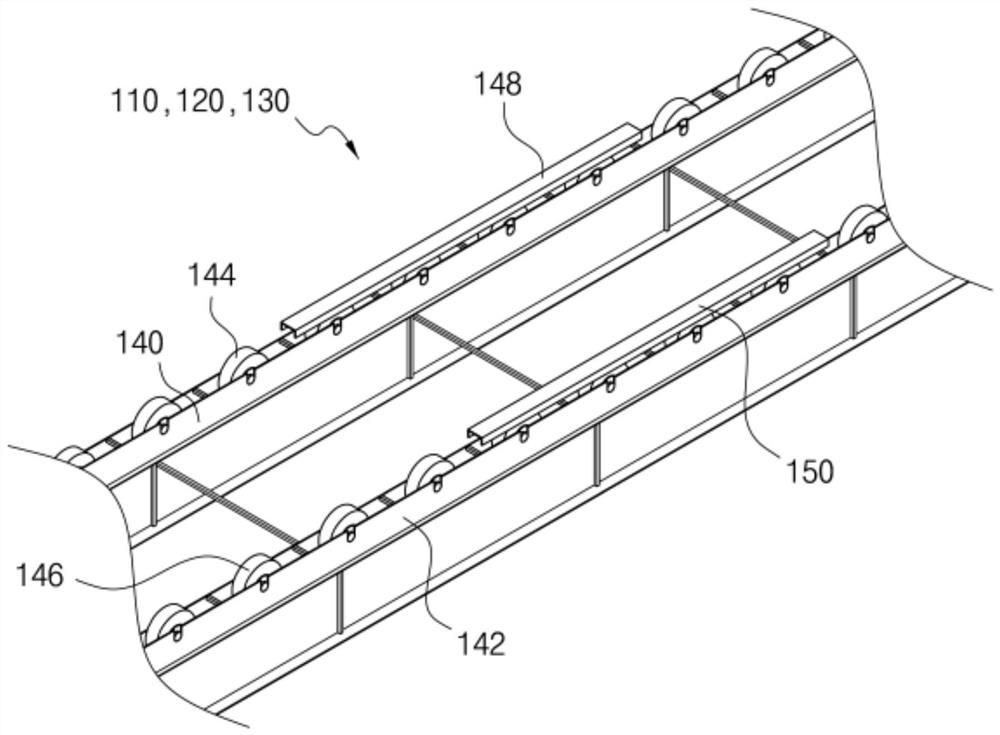

Suspended automobile disassembly line

InactiveUS20050193541A1Automatic control devicesVehicle dissasembly recoveryCAR disassemblyRange of motion

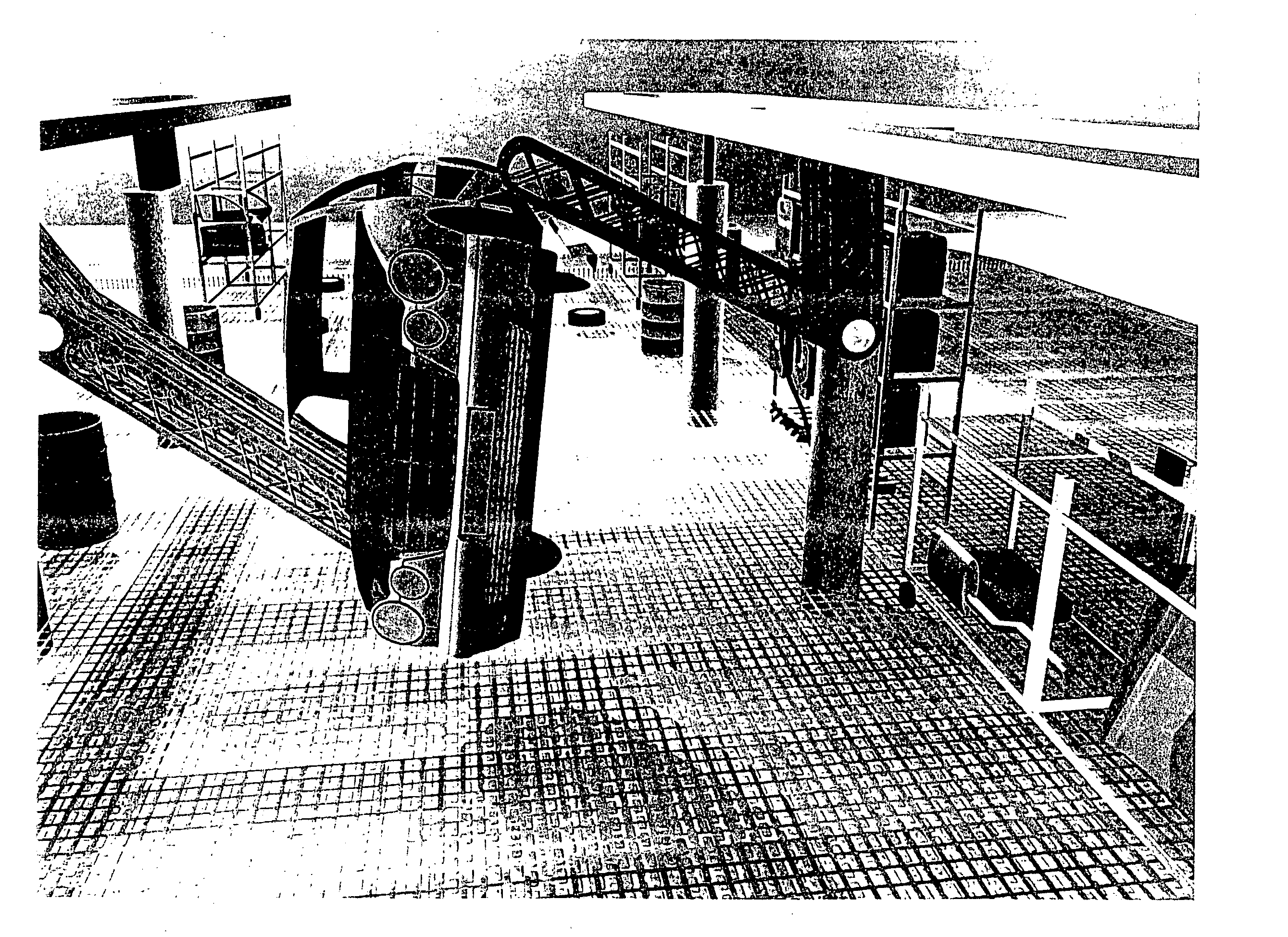

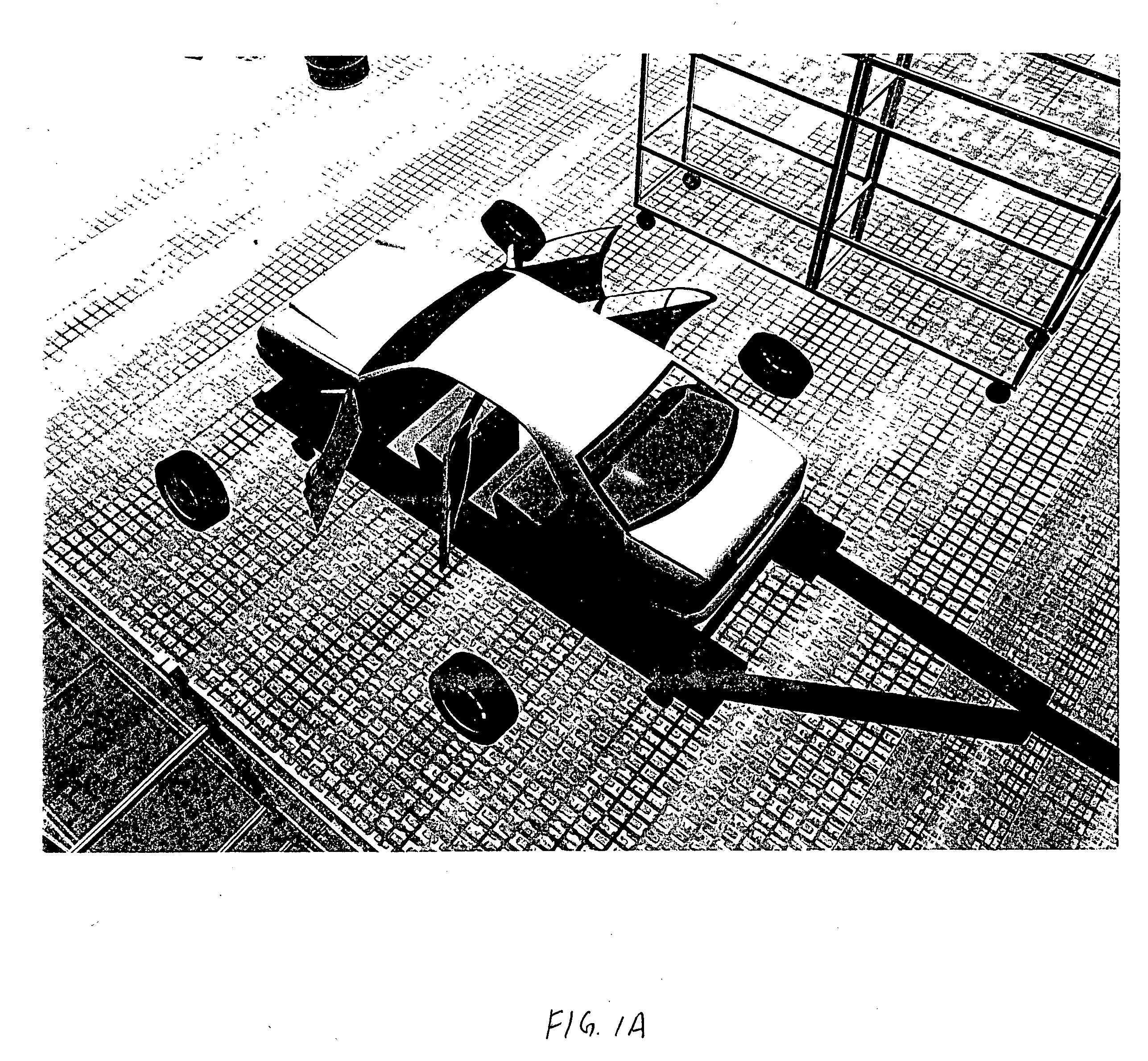

A suspended automobile disassembly line that does not utilize any hydraulically operated equipment is provided. The disassembly line utilizes a plurality of electrically operated lift system to stabilize and suspend an automobile while at various stages of disassembly. Since the automobile is suspended throughout the disassembly line, human handling is reduced and efficiency of the disassembly process is improved. The lift system includes a plurality of grabber arms that provide a wide range of motion adapted to move and tilt a vehicle into various positions during disassembly.

Owner:DAVIDYAN ROBERT

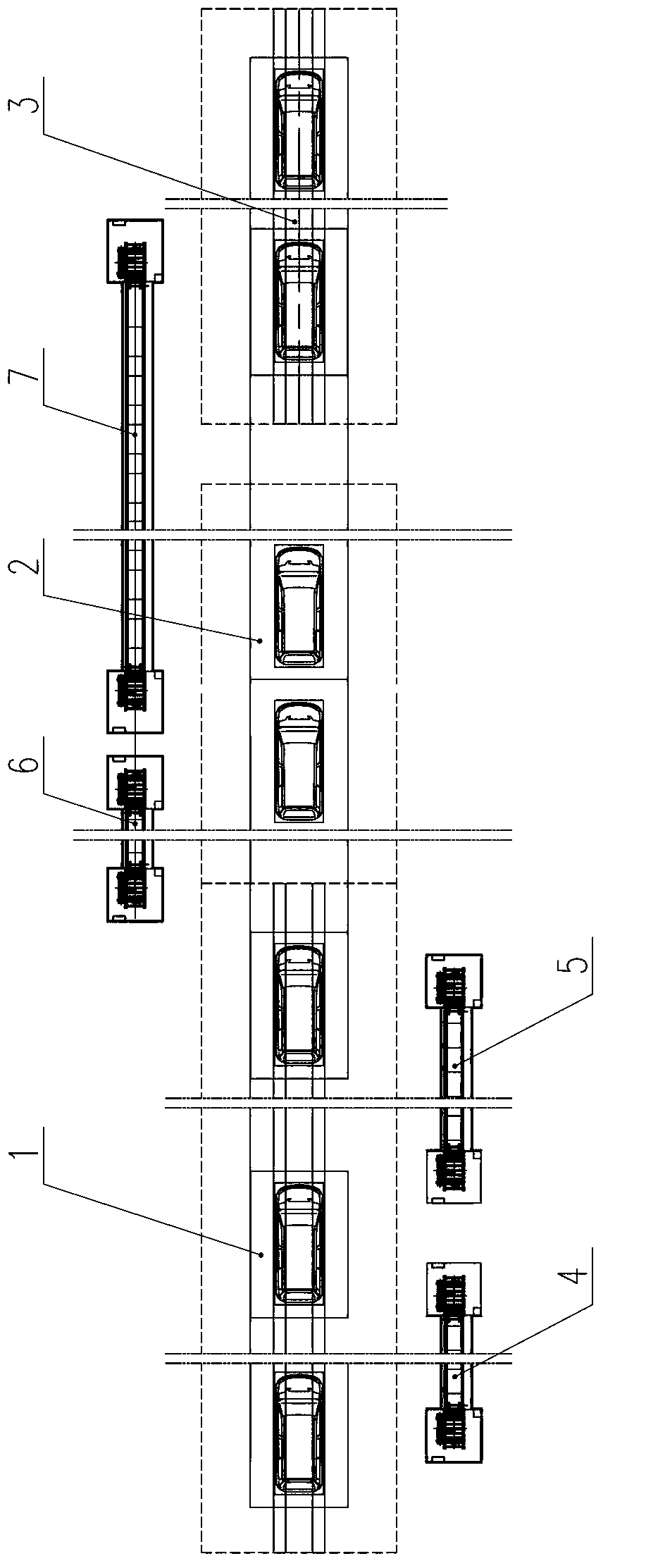

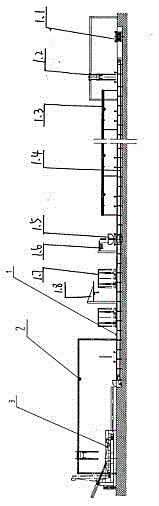

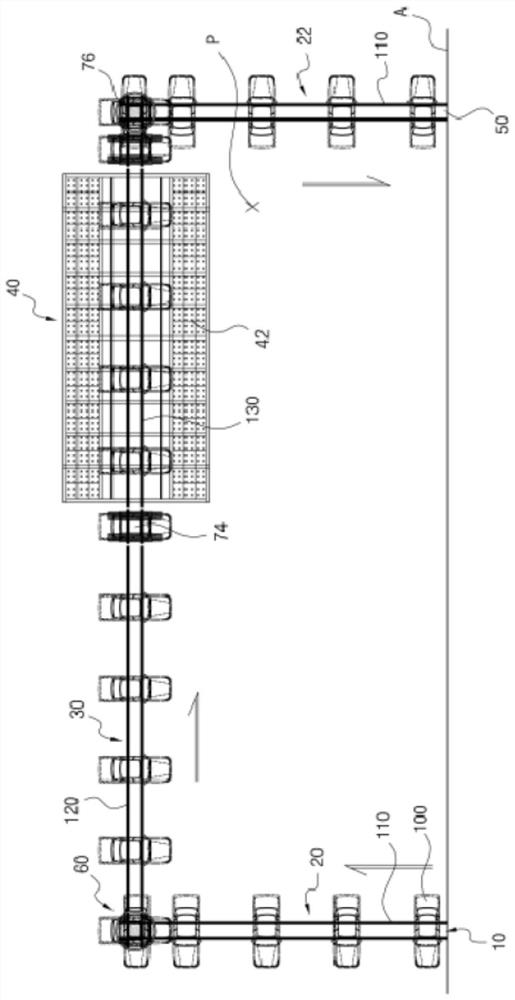

Scraped car disassembly production line

ActiveCN103101585AReduce labor intensityIncrease productivityVehicle dissasembly recoverySolid waste disposalCAR disassemblyProduction line

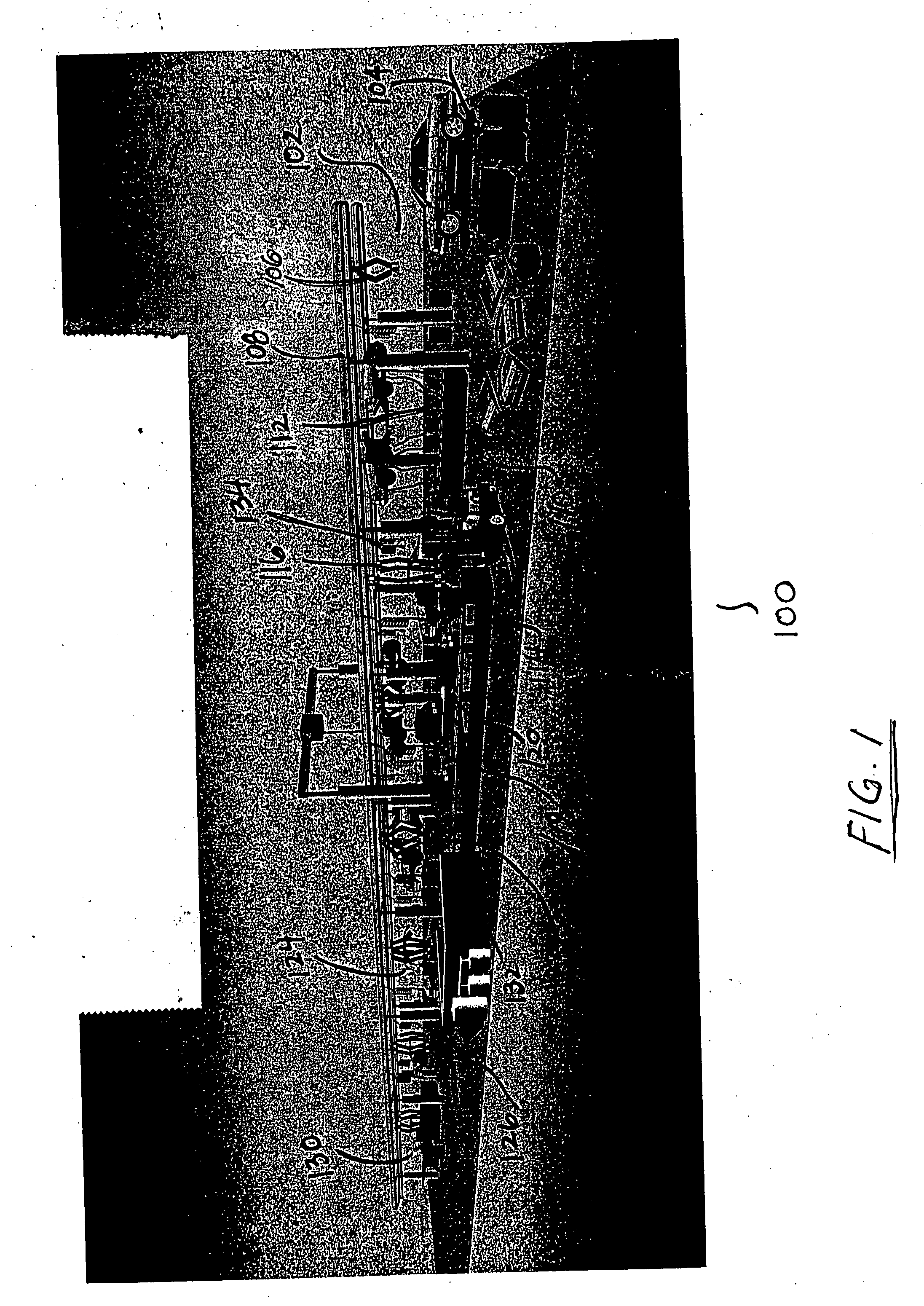

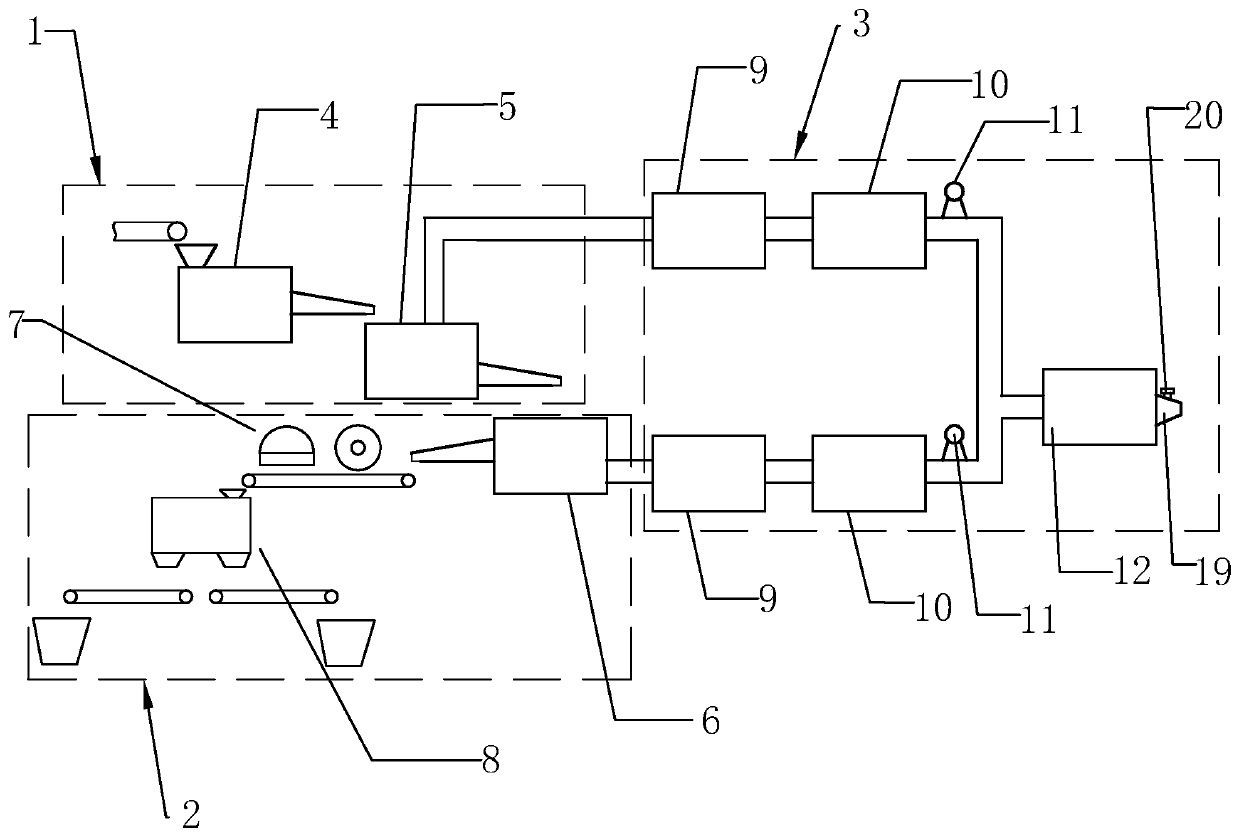

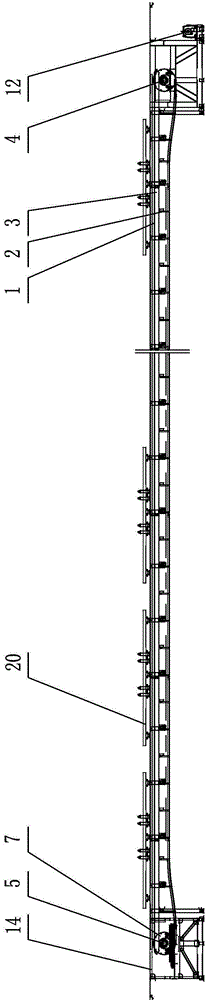

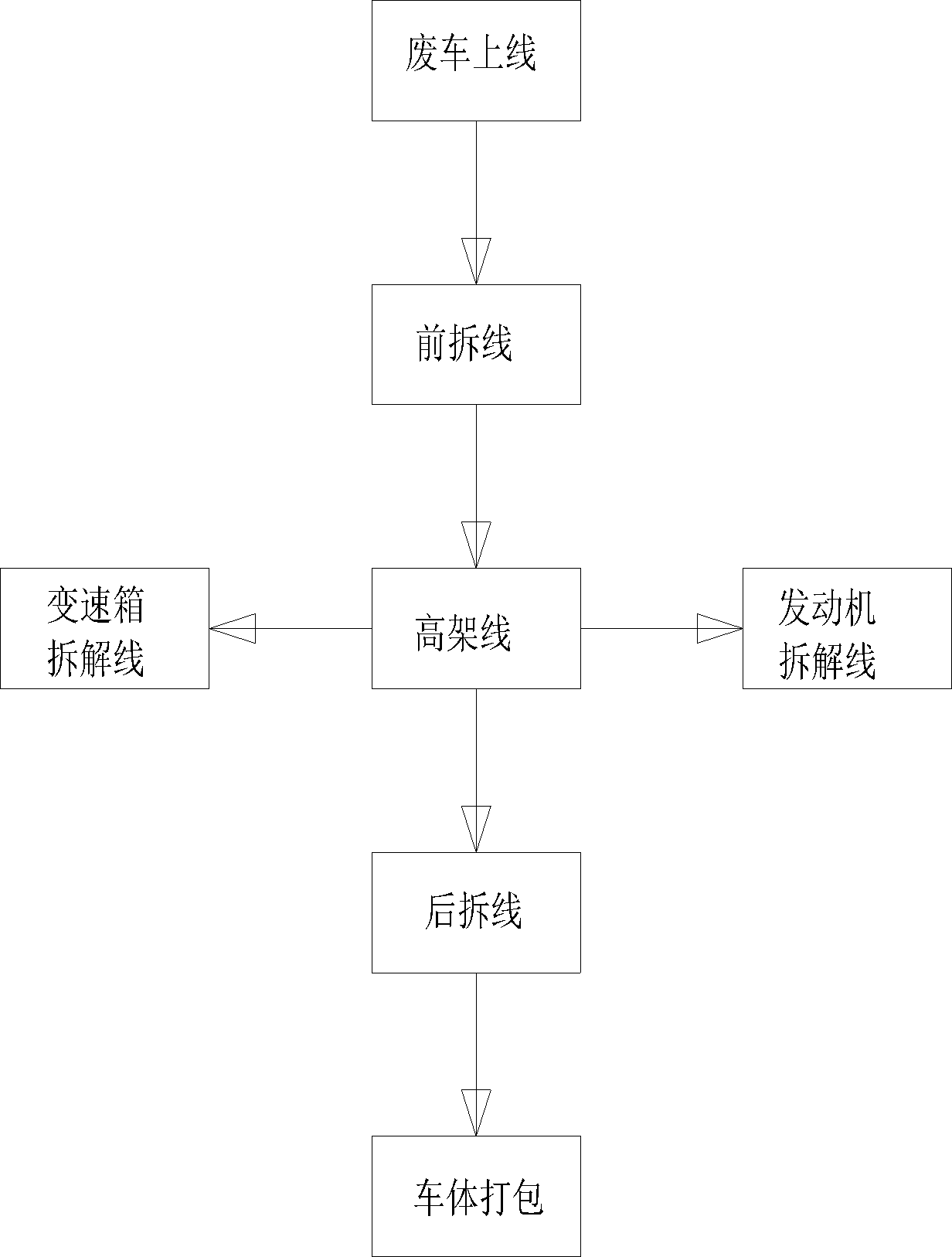

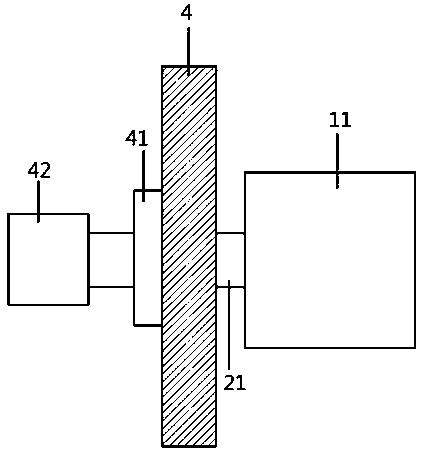

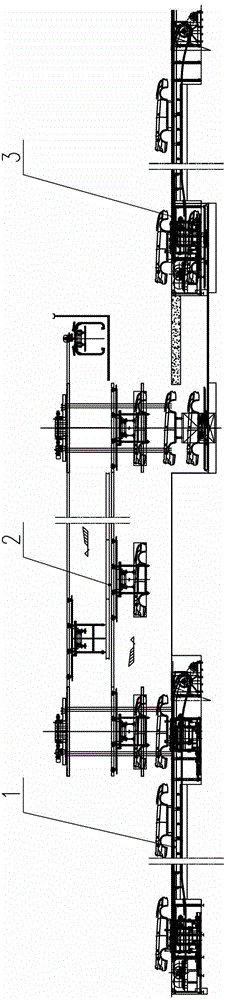

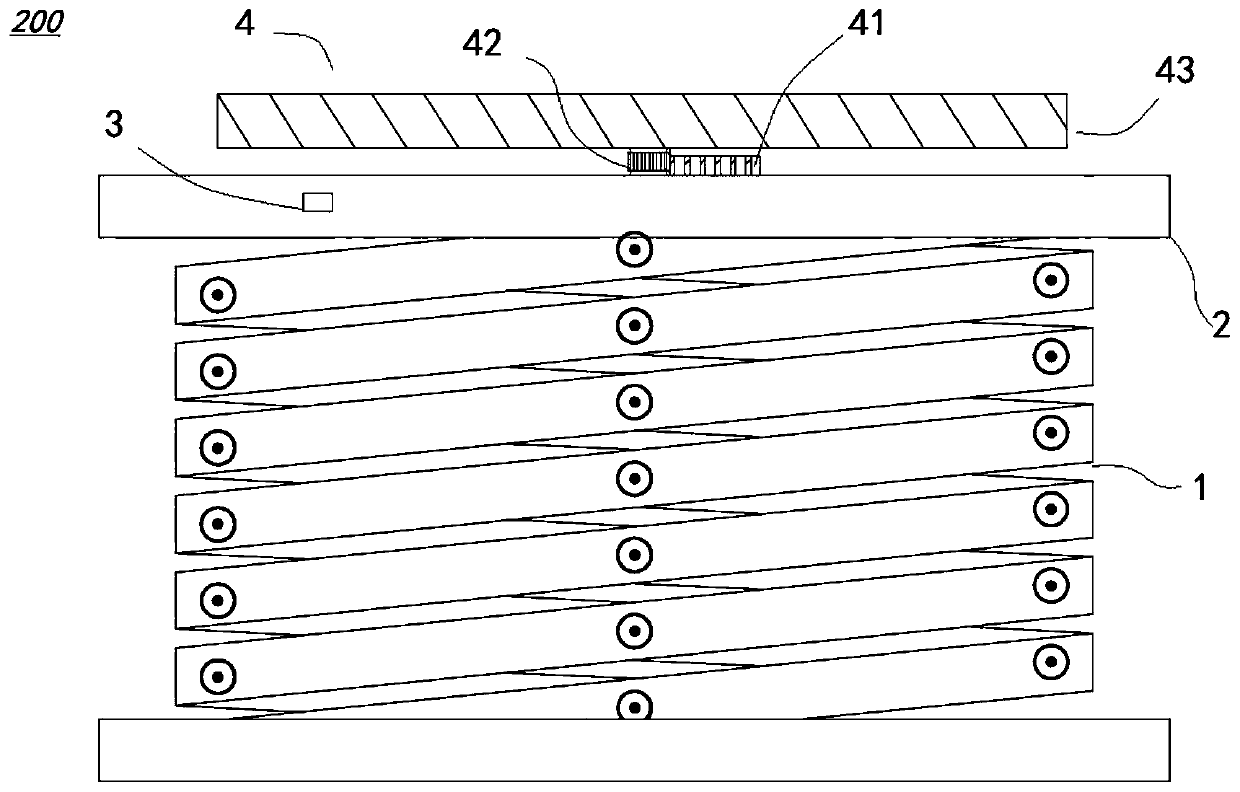

The invention relates to a scraped car disassembly production line which comprises a main line and an assembly dismantling line. The main line comprises an environment-friendly pre-processing and ground disassembly line, an overhead chassis disassembly line and a ground finish line which are arranged in sequence. The environment-friendly pre-processing and ground disassembly line adopts a double-plate-chain structure, the overhead chassis disassembly line adopts an electronic manufacturing service (EMS) self-propelled trolley type conveying structure, and the ground finish line adopts a double-plate-chain structure. The assembly dismantling line comprises a car door dismantling line, an instrument board dismantling line, a car suspension frame dismantling line and an engine auxiliary dismantling line which respectively adopt accumulation type maneuvering roller way conveying structures, wherein the assembly dismantling line is located on the lateral face of the main line. The scraped car disassembly production line adopts an advanced automated logistic system, achieves mechanical and automatic production of car disassembly operation, remarkably improves the production efficiency, reduces labor intensity of workers, saves manpower resources and reduces safety accident occurrence rate.

Owner:MIRACLE AUTOMATION ENG CO LTD

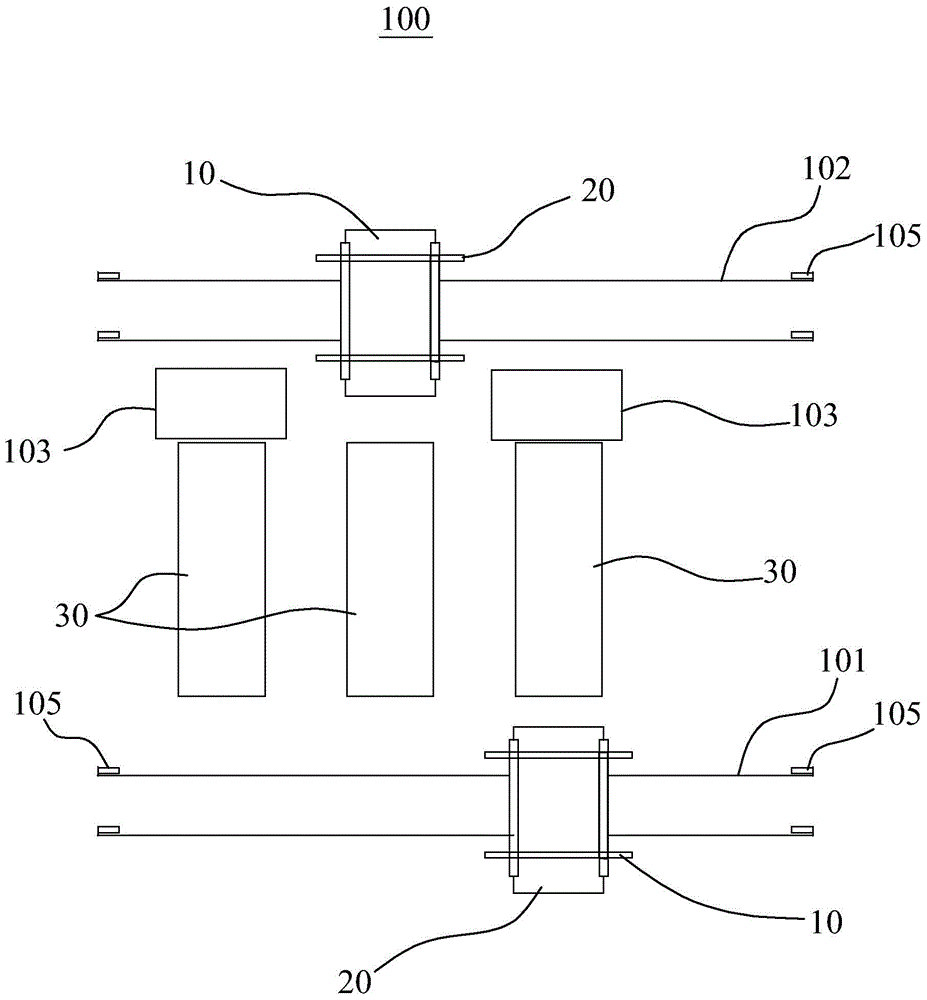

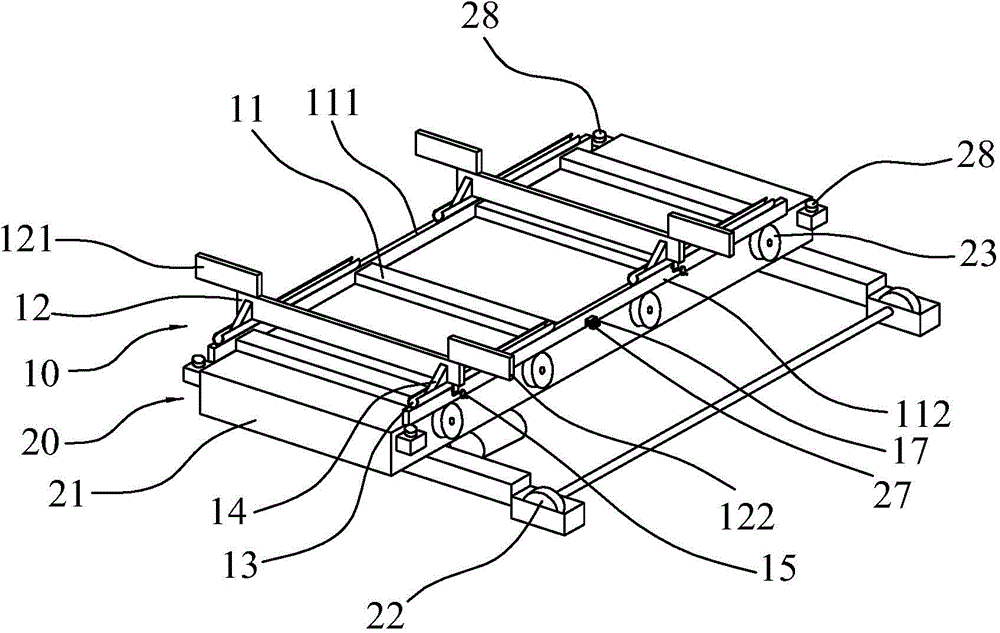

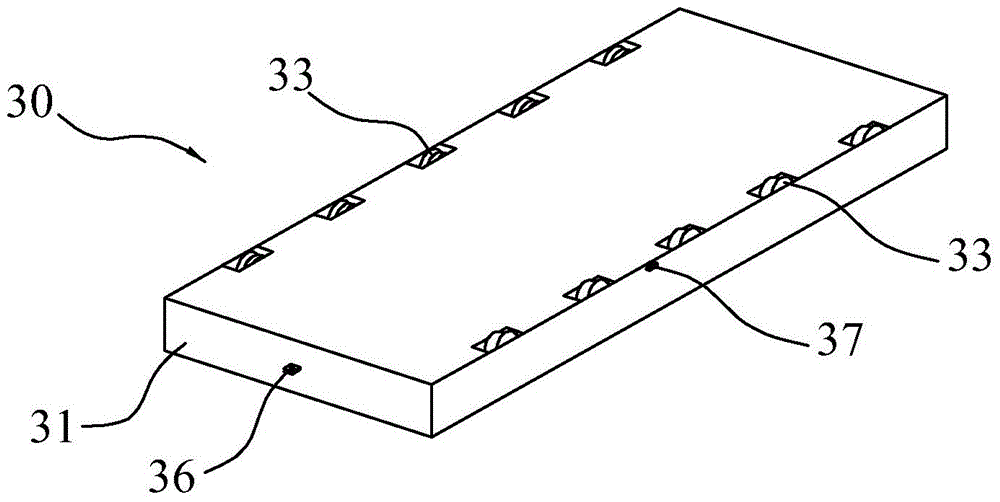

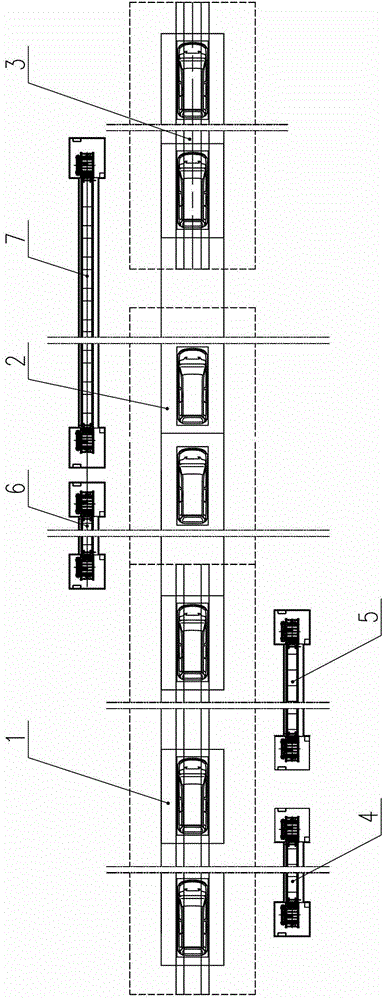

Online system for disassembling scraped car

ActiveCN104527842AImprove the efficiency of dismantling and recyclingLow costVehicle dissasembly recoverySolid waste disposalCAR disassemblyEngineering

An online system for disassembling a scraped car comprises a loading device and a conveying device, wherein the loading device comprises runners, the conveying device comprises at least two guide rails, moving machines and rolling beds, wherein the moving machines slide on the guide rails, the rolling beds are located on the side edges of working positions, the guide rails are located at two sides of the rolling beds in two rows, at least one moving machine is arranged on each guide rail, the runners are located on the moving machines, each moving machine is provided with a first slide driving structure which can drive the runners to slide on the moving machines, second slide driving structures which can drive the runners to slide on the rolling beds are arranged on the rolling beds, the moving machine on the guide rail on a disassembly working position is used for conveying the runners carrying the scraped car to the rolling beds, and the moving machine on the guide rail on the other side of the disassembly working position is used for receiving and sending the empty runners returned by the rolling beds. Therefore, the runners can be recycled, the car can be disassembled continuously, cars are conveyed in order rapidly, the car disassembly recycle efficiency is improved, and the cost is reduced.

Owner:GEM TIANJIN URBAN MINING RECYCLING IND PARK DEV CO LTD +3

Scraped car resource recovery system with dust-removal device

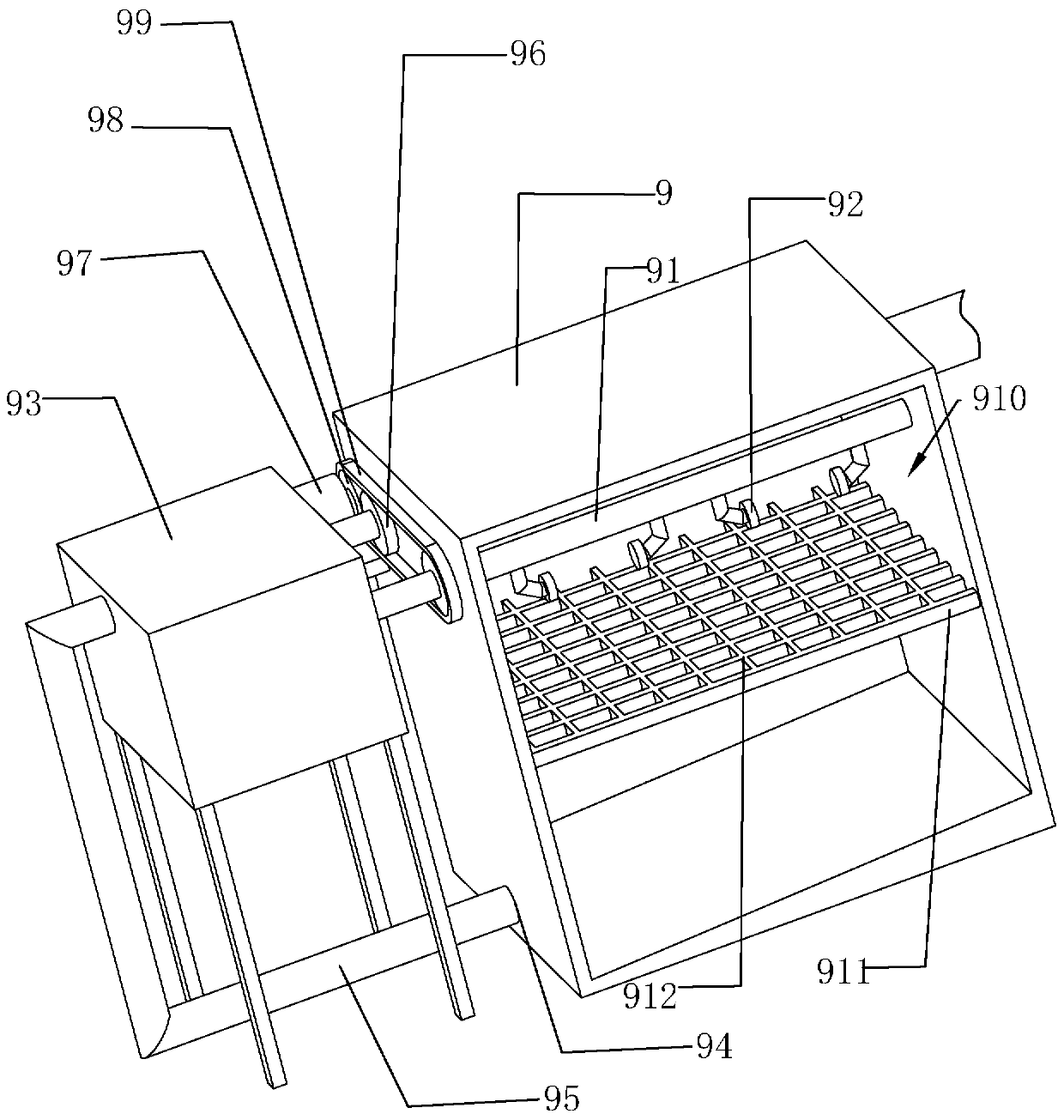

InactiveCN111229775AImprove working environmentImprove the effect of dust suppressionCombination devicesUsing liquid separation agentCAR disassemblyResource recovery

The invention discloses a scraped car resource recovery system with a dust-removal device, and relates to the technical field of scraped car disassembly. According to the technical key point, the scraped car resource recovery system comprises a crushing unit and a screening unit, and the dust-removal mechanism crushing unit comprises a double-shaft shredding machine and a crusher; the dust-removalmechanism screening unit comprises a sieve shaker, a magnetic separator and an eddy current sorting machine which are sequentially connected; dust-removal mechanisms are arranged on one sides of thedust-removal mechanism sieve shaker and the dust-removal mechanism crusher; the dust-removal mechanisms comprise settling chambers, one sides of the two settling chambers are correspondingly connectedto the dust-removal mechanism sieve shaker and the dust-removal mechanism crusher; and dust-removal towers are connected to the other sides of the dust-removal mechanism settling chambers, and a tailgas tower is connected to the side, away from the dust-removal mechanism settling chambers, of the dust-removal mechanism dust-removal towers through draught fans. By arranging the dust-removal mechanisms, the settling chambers and the dust-removal towers with a dust-removal structure are used for absorbing and processing dust generated in the working process of the sieve shaker and the crusher,so that the dust in a working environment of a factory is reduced, and the good working environment is provided for operators.

Owner:陕西省报废汽车回收拆解有限公司

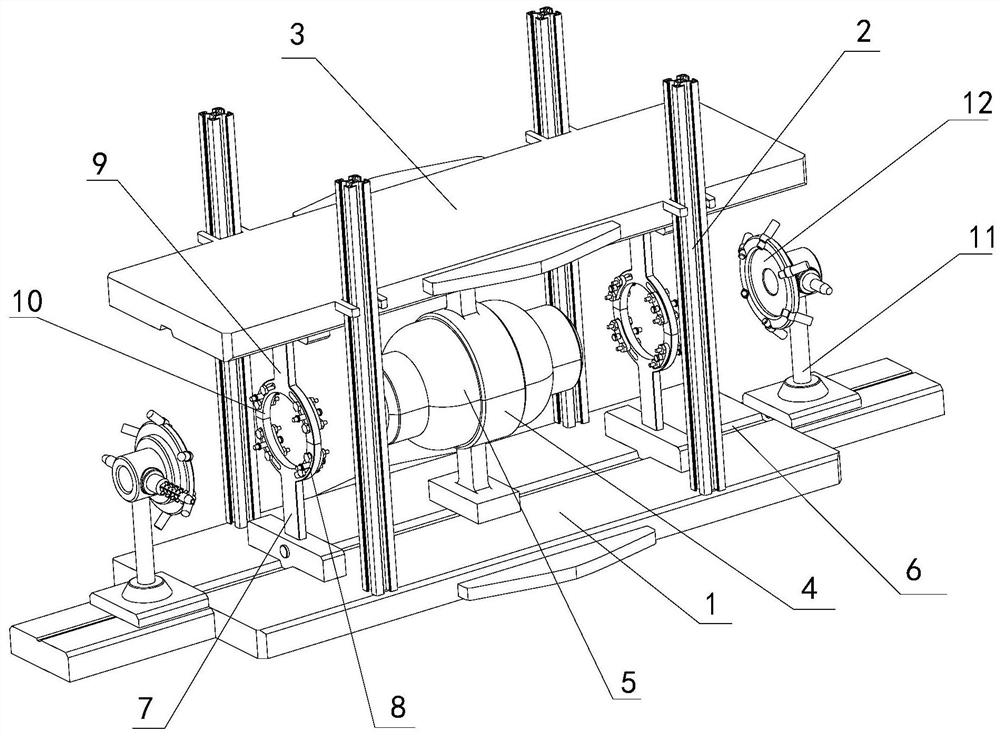

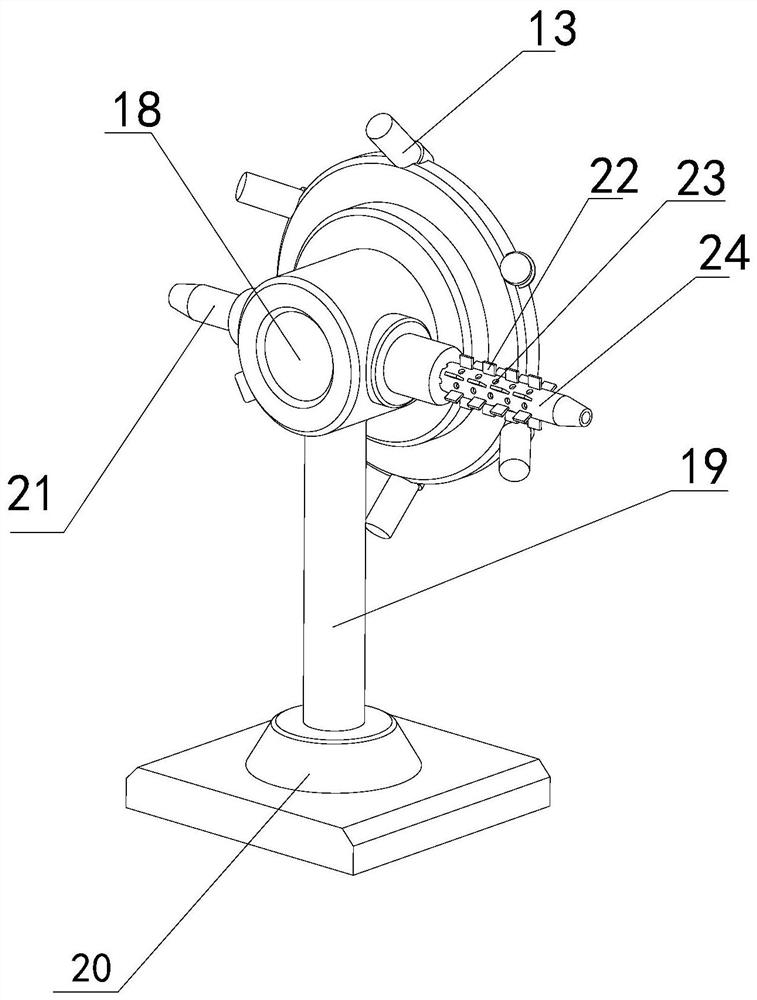

Dismantling control method for waste vehicles

The invention discloses a dismantling control method for waste vehicles and belongs to the technical field of car disassembly. The dismantling control method is based on a vehicle disassembly turningmachine; the vehicle disassembly turning machine includes a chassis locking mechanism, a turning mechanism, a lifting mechanism, a car body limitation mechanism and a disassembly platform; the car body limitation mechanism includes a car body clamping component and a car top limitation component; the chassis locking mechanism comprises two chassis locking components which are spaced and of the same structure; and each chassis locking component includes a fixing frame, a material transferring component and two symmetrically arranged pressing components. Different types of car bodies can be fixed through the car body limitation mechanism so as not to shake during the process of rotation and lifting, and thus the needs of different types of cars are met. In addition, the car body limitation mechanism can clamp and lift a car shell, and the chassis locking mechanism can lock a chassis of a car body so as to assist workers in dismantling the car shell.

Owner:江苏好道商务科技有限责任公司

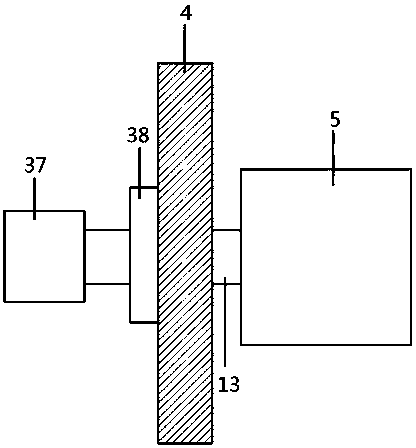

Wide plate chain conveying system of scraped car disassembly line

The invention relates to a wide plate chain conveying system of a scraped car disassembly line. The wide plate chain conveying system of the scraped car disassembly line is characterized in that a main support, a driving mechanism, a conveying mechanism and a tensioning mechanism are included, the driving mechanism and the tightening mechanism are located in a driving framework and a tensioning frame which are located at the two ends of the main support respectively, and the conveying mechanism is arranged on the main support; the conveying mechanism comprises a driving shaft installed on the driving framework and a driven shaft installed on the tensioning frame, multiple driving chain wheels are installed on the driving shaft through bearings, and multiple driven chain wheels are installed on the driven shaft through bearings; the upper side and the lower side of the main support are provided with upper tracks and lower tracks respectively, and the upper tracks and the lower tracks are parallel to each other; panels are arranged on the main support, the inner sides of the panels are connected with dragging chains through screws, and the dragging chains are slidably installed on the upper tracks and the lower tracks and wound on the driving chain wheels and the driven chain wheels. According to the wide plate chain conveying system of the scraped car disassembly line, the production efficiency can be significantly improved, the labor intensity of workers can be lowered, manpower resources can be saved, and the safety accident occurrence rate can be decreased.

Owner:MIRACLE AUTOMATION ENG CO LTD

Dust removal and noise reduction device for disassembling scraped car

ActiveCN111469955AEasy to assistEasy to moveVehicle dissasembly recoverySolid waste disposalCAR disassemblyDust control

The invention relates to a dust removal and noise reduction device for disassembling a scraped car, and relates to the technical field of scraped car disassembly. The device comprises a disassemblingsliding rail, a moving platform and a hoisting crane, wherein a plurality of storage racks and a cleaning pool are arranged on the two sides of the disassembling sliding rail, carrying sliding rails and a carrying platform are symmetrically arranged on the two sides of the disassembling sliding rail, disassembling covers are arranged on the carrying platform, a plurality of sliding side plates arevertically arrayed on the carrying sliding rails, sliding assemblies are arranged at the bottom ends of the sliding side plates, the disassembling covers abut against the sliding side plates, and thedisassembling sliding rail is divided into a plurality of disassembling stations through the sliding side plates and the disassembling covers. The carrying sliding rails are moved to promote the twodisassembling covers and the sliding side plates to be folded, a disassembling station is formed, and the disassembling station is arranged on the periphery of the moving platform. Meanwhile, a sliding assembly is arranged, the sliding side plates can be promoted to slide along the sliding assembly, the carrying platform is facilitated to move, disassembling equipment can be arranged on the two sides of the disassembling sliding rail, the disassembling equipment are not hindered by the disassembling covers and the sliding side plates, and dust, smoke and noise in the disassembling process arereduced in the whole process.

Owner:陕西欣辉报废汽车回收拆解有限公司

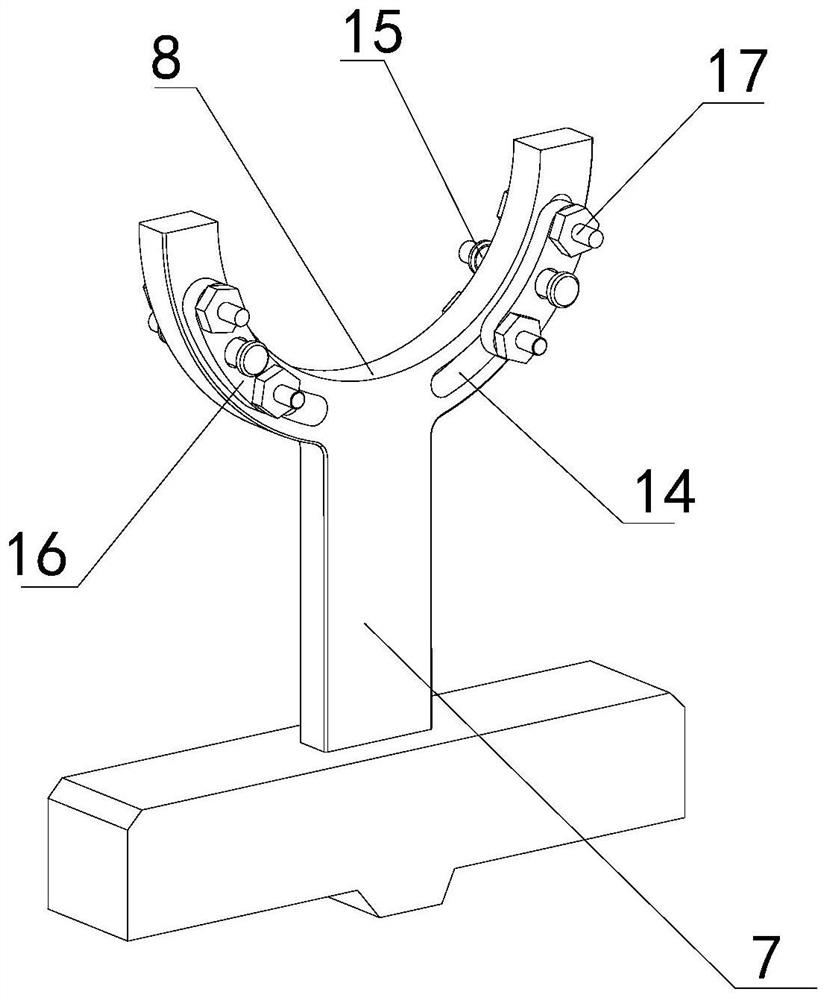

Automobile rear axle disassembling device

InactiveCN111347236AEasy to clean manuallyEasy maintenanceCleaning using toolsVehicle componentsCAR disassemblyDrive shaft

The invention discloses an automobile rear axle disassembling device, and belongs to the field of automobile disassembly. The automobile rear axle disassembling device comprises a base, machine frames, a connecting frame and a first driving mechanism; the machine frames are arranged at two ends of the base, the connecting frame is horizontally arranged above the base, the connecting frame is slidably connected with the machine frames, and the first driving mechanism can drive the connecting frame to move up and down; the two ends of each second supporting part are correspondingly connected with the two ends of each first supporting part to surround a half bridge portion of a rear axle; and electric screwdrivers and electric wrenches are fixedly mounted on each of the first supporting partsand the second supporting parts. Compared with the prior art, according to the automobile rear axle disassembling device, the end part of a half bridge driving shaft can be quickly removed, manpoweris saved, and the disassembling efficiency is improved.

Owner:杨唯巍

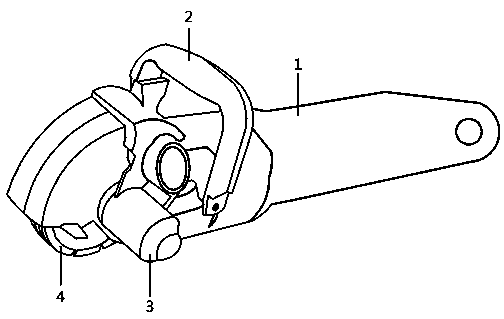

Car bumper disassembling device

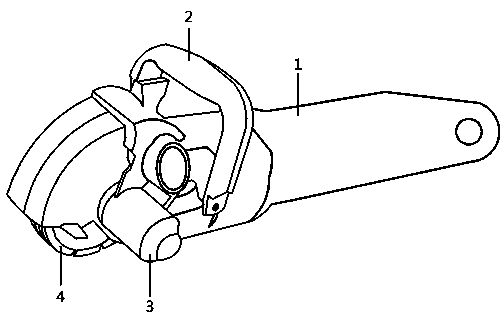

ActiveCN103723212AReduced dismantling timeReduce the consumption of manpower and material resourcesVehicle dissasembly recoverySolid waste disposalCAR disassemblyHydraulic cylinder

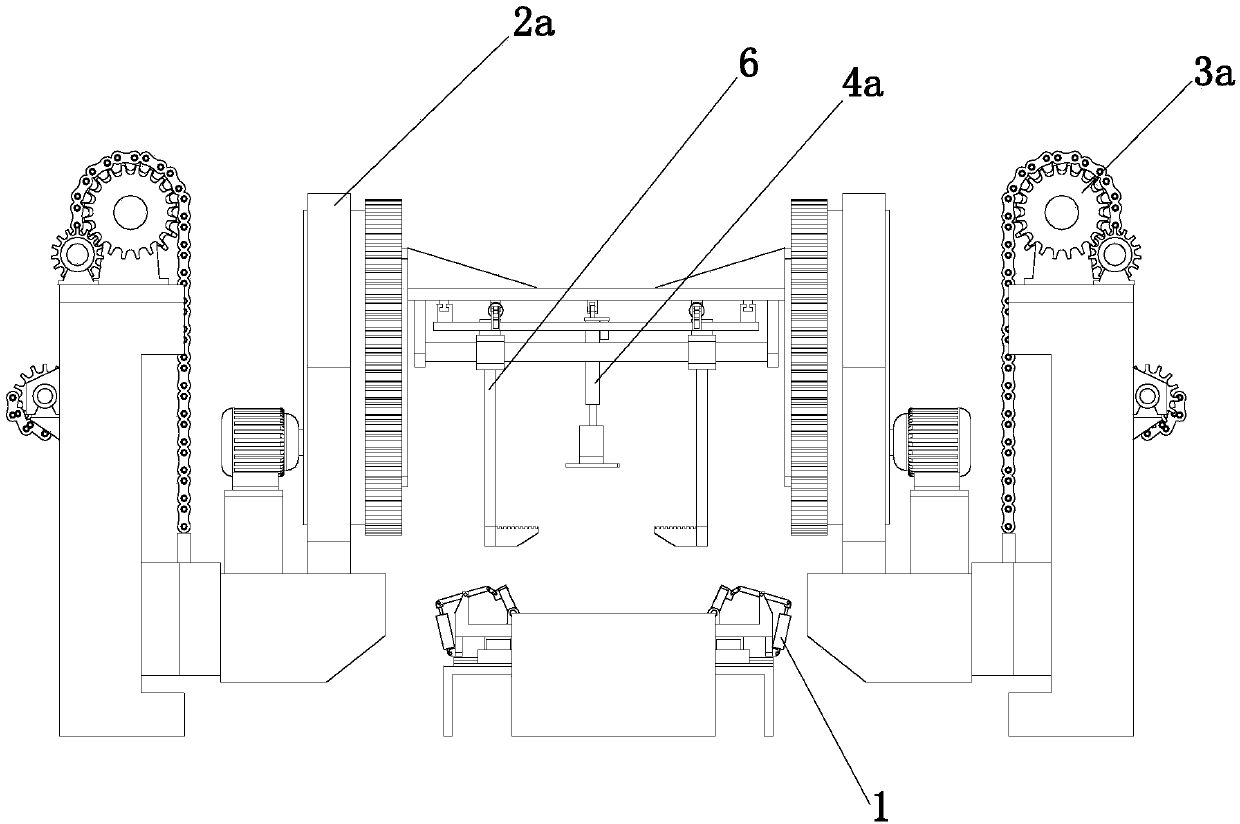

The invention discloses a car bumper disassembling device. The car bumper disassembling device is provided with a supporting plate and two disassembly boxes, wherein the disassembly boxes are respectively provided with a mechanical arm. Each mechanical arm is provided with a perpendicular lead screw, a lifting motor driving the perpendicular lead screw to rotate, a movable frame capable of moving on the perpendicular lead screw, a supporting arm movably connected to the movable frame, a pressing arm in pin joint with the front end of the upper portion of the movable frame, a grabbing arm in pin joint with the front end of the pressing arm, a supporting arm hydraulic cylinder which is connected to the movable frame and drives the supporting arm to move, a pressing arm hydraulic cylinder which is connected to the supporting arm and drives the pressing arm to swing and a grabbing arm hydraulic cylinder which is connected to the pressing arm and drives the grabbing arm to swing. Two pairs of adjusting wheels which move leftwards and rightwards are arranged at the bottom of each disassembly box. Two horizontal guide rails are arranged on the upper surface of the supporting plate and correspond to the adjusting wheels. Two pairs of walking wheels which walk forwards and rearwards are arranged on the bottom surface of the supporting plate. The car bumper disassembling device saves disassembly time, reduces consumption of labor and resources, greatly improves disassembly efficiency, and is particularly suitable for an automatic car disassembly production line.

Owner:JIANGSU UNIV OF TECH

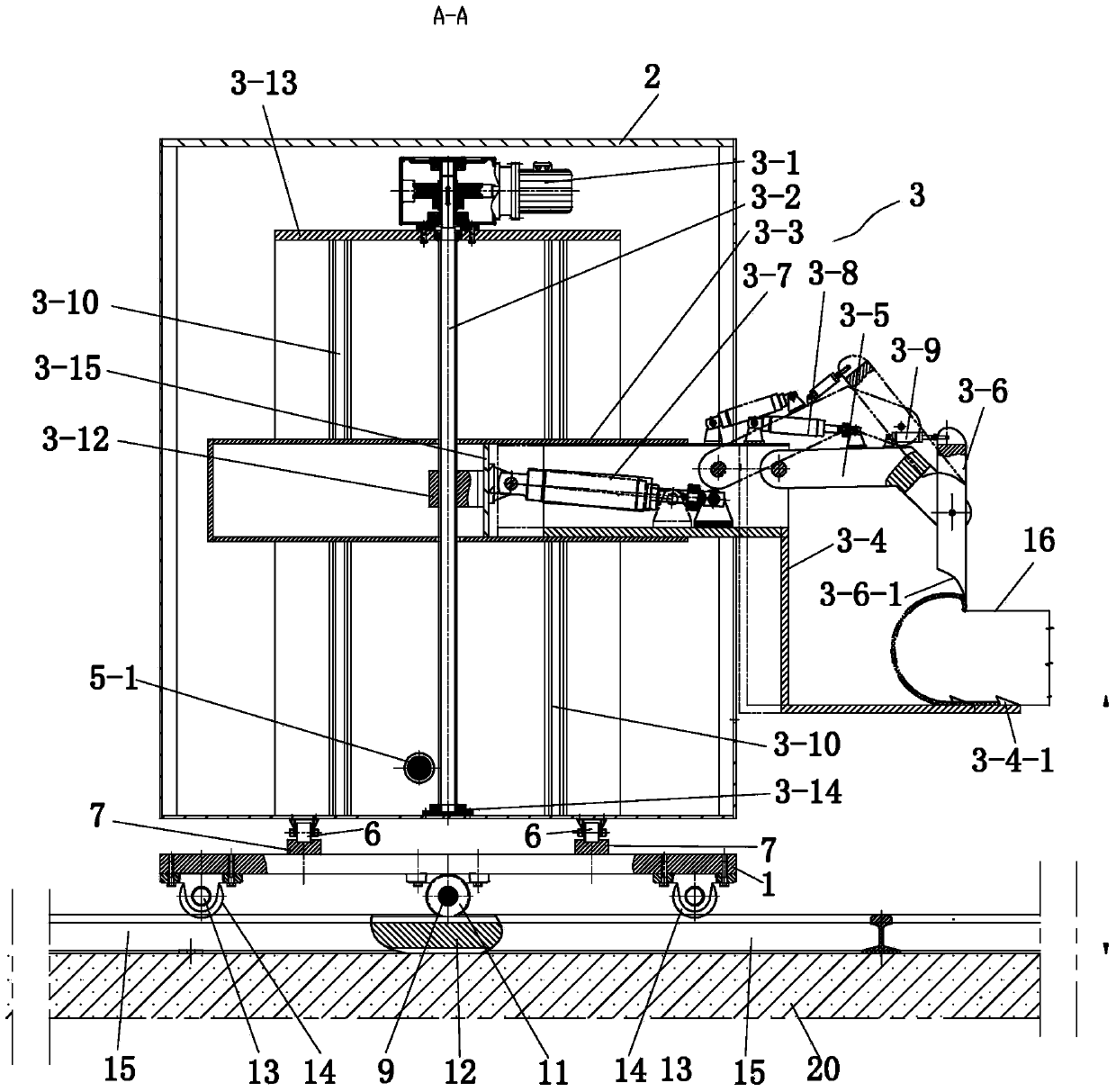

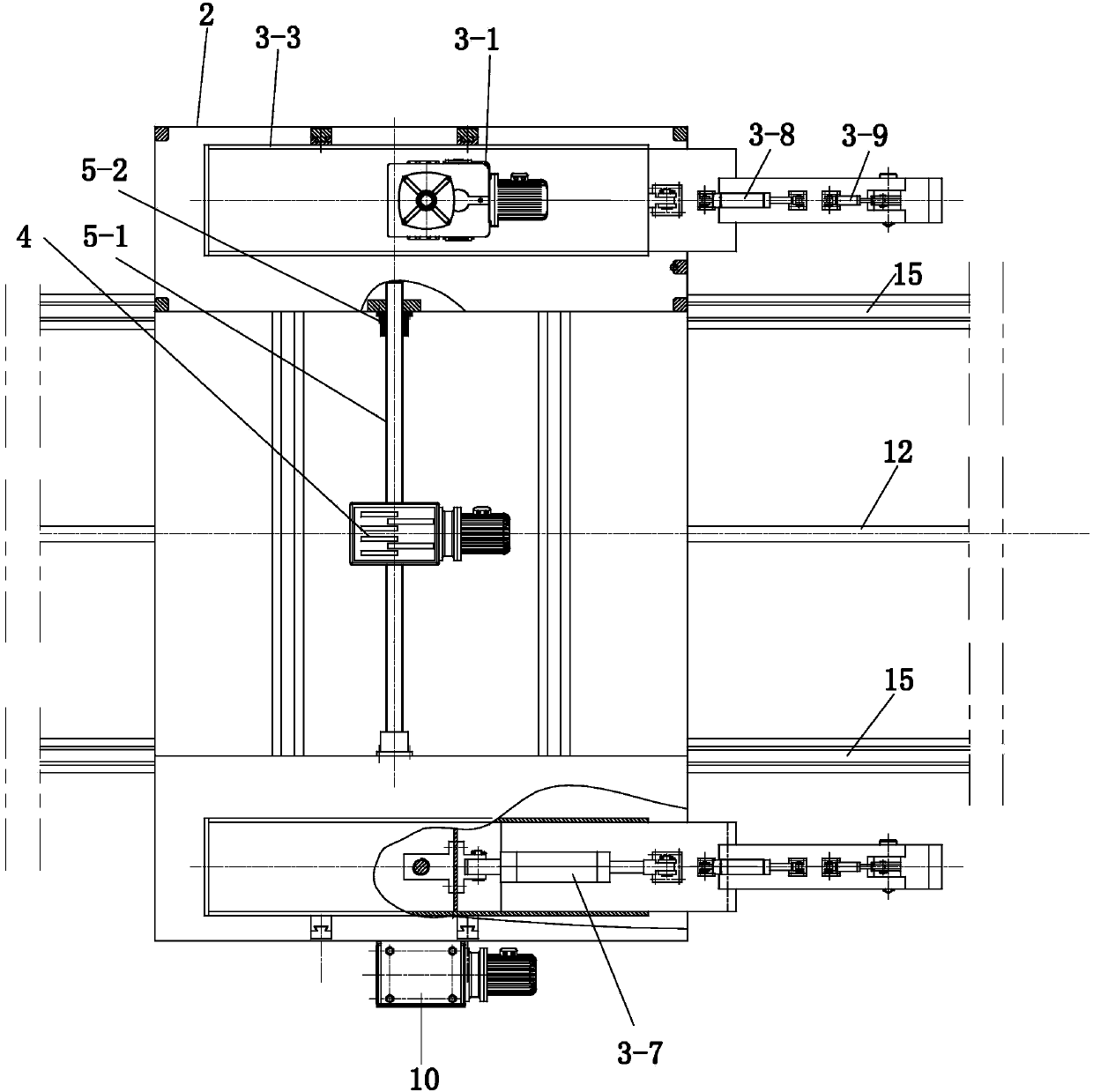

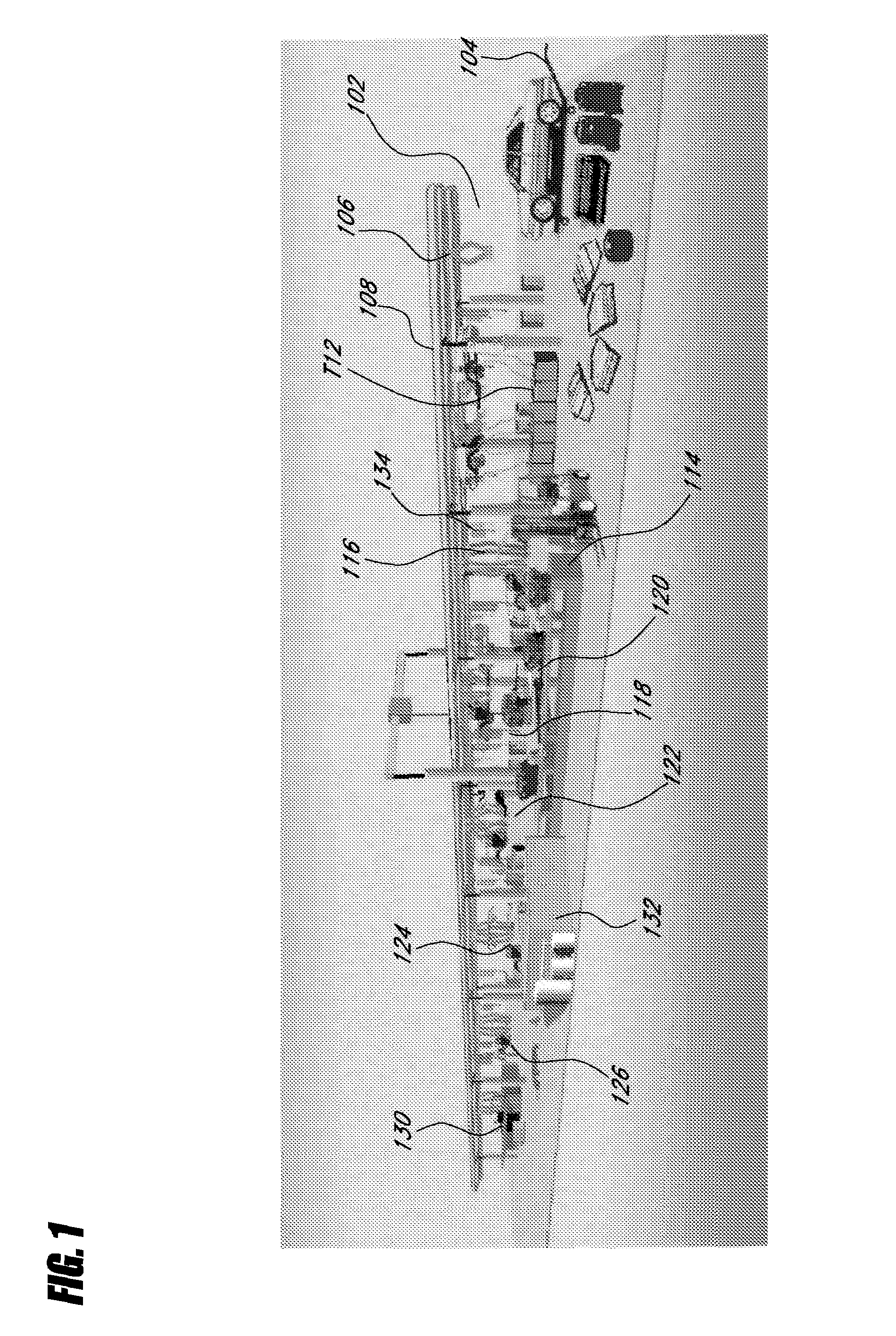

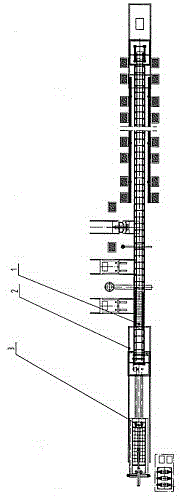

End-of-life vehicle disassembly line

InactiveCN102556216BOptimize layoutImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalCAR disassemblyProgrammable logic controller

The invention discloses a scrapped car disassembly line. Along the conveying direction of scrapped cars, the scrapped car disassembly line is structurally characterized in that a feeding system is used for conveying the scrapped cars to a pre-disassembly conveying system, the pre-disassembly conveying system is used for completing preparations required by chassis disassembly and conveying the scrapped cars to an overhead conveying system, the overhead conveying system is used for disassembling the scrapped cars and conveying the disassembled scrapped cars to a post-disassembly conveying system which is used for packaging the scrapped cars, and the feeding system, the pre-disassembly conveying system, the overhead conveying system and the post-disassembly conveying system are connected with a PLC (programmable logic controller) module. The scrapped car disassembly line adopting the technical scheme has the advantages of mechanized operation, PLC module control, dynamic automated disassembly and higher disassembly efficiency, the subsystems facilitate arrangement of the whole disassembly line and are clear in division of responsibilities, corresponding parts are sequentially disassembled along with conveyance of the scrapped cars, disassembly efficiency is high, and management and adjustment are facilitated.

Owner:安徽韦尔汽车科技有限公司

Method of disassembling an automobile

InactiveUS7493683B2Automatic control devicesVehicle dissasembly recoveryCAR disassemblyRange of motion

A suspended automobile disassembly line that does not utilize any hydraulically operated equipment is provided. The disassembly line utilizes a plurality of electrically operated lift system to stabilize and suspend an automobile while at various stages of disassembly. Since the automobile is suspended throughout the disassembly line, human handling is reduced and efficiency of the disassembly process is improved. The lift system includes a plurality of grabber arms that provide a wide range of motion adapted to move and tilt a vehicle into various positions during disassembly.

Owner:DAVIDYAN ROBERT

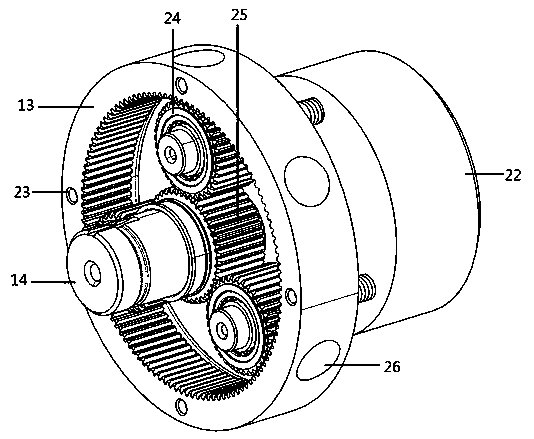

Pressing type scrapped automobile disassembling device

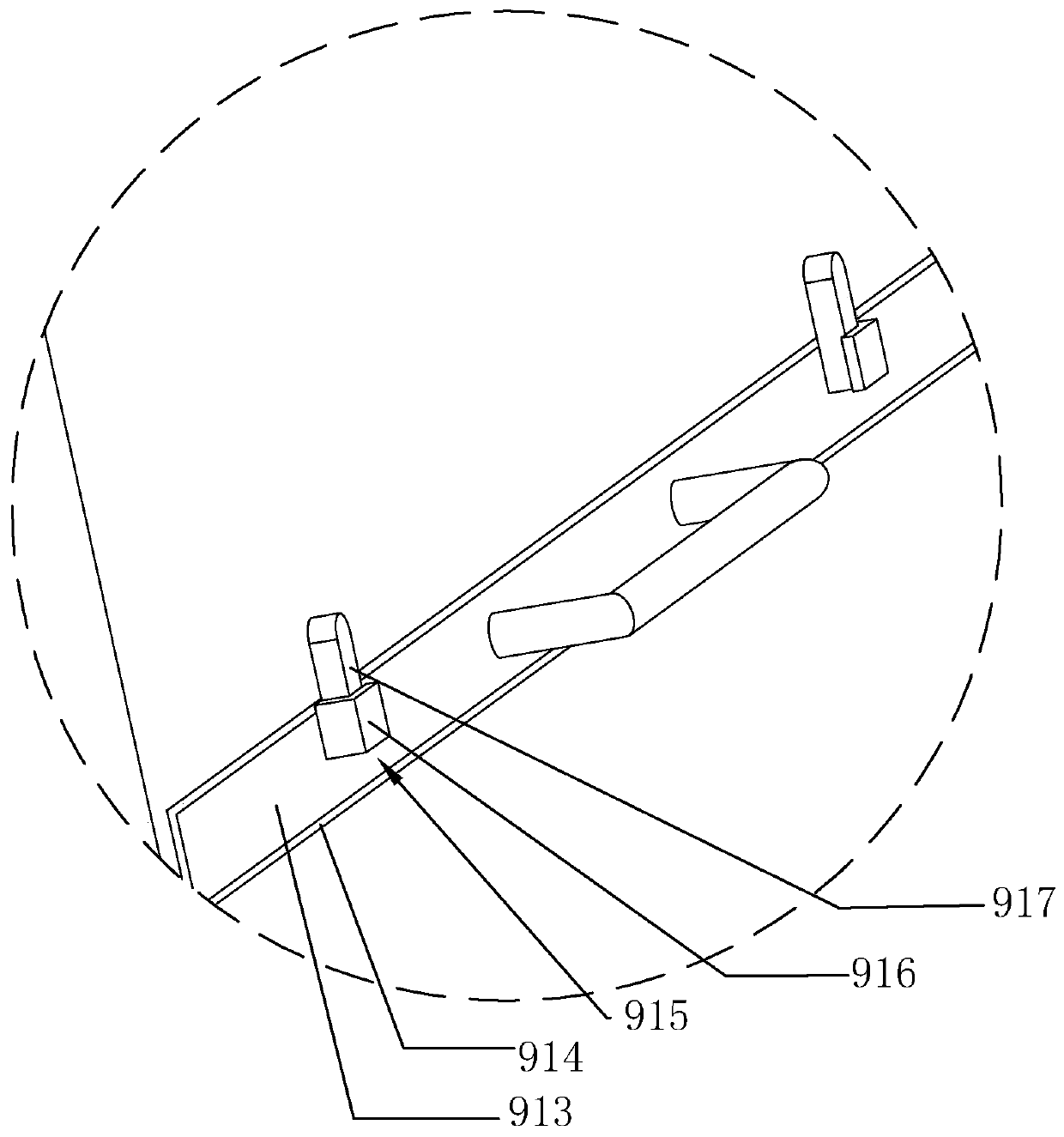

ActiveCN110834690AExtended service lifeSimple structureVehicle dissasembly recoverySolid waste disposalCAR disassemblyGear wheel

The invention relates to a pressing type scrapped automobile disassembling device. The device comprises a disassembling device body, the disassembling device body is provided with a transmission device, the transmission device comprises a mounting cylinder, an inner gear ring is rotationally arranged in the mounting cylinder, a driving gear is arranged at the axis of the inner gear ring, the periphery of the driving gear meshes with three driven gears, inner bearings are fixedly mounted on the inner sides of the three driven gears, the axes of the right side surface of the three driven gears are connected with a transmission base through three connecting rod devices, when the device is inadvertently detached from a hand of an operator, a jacking spring pushes the transmission base to moverightwards, a brake disc makes contact with a friction ring and performs friction braking on the transmission base, a cutter is stopped to avoid danger, and a sliding block pulls a semi-spherical clamping head to be disengaged from a semi-spherical clamping groove through an anti-abrasion rope, so that an inner clamping ring can rotate to perform force unloading on torque, a motor driving device is protected, the device is simple in structure, easy to install, safer and more intelligent, and the service life of a motor is prolonged.

Owner:王盈盈

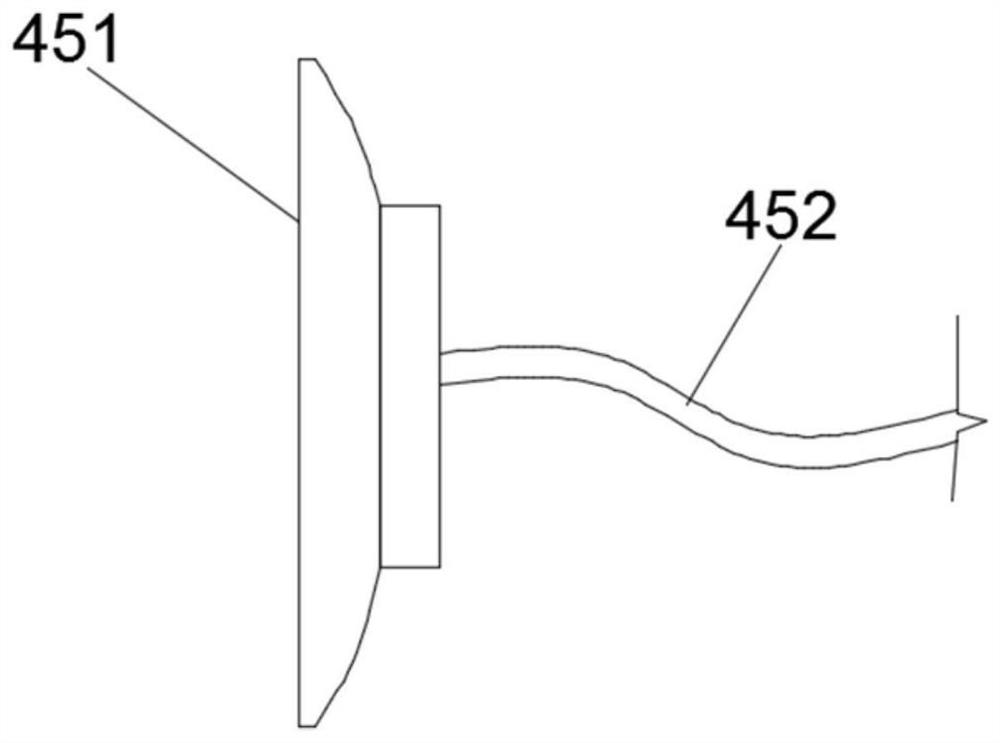

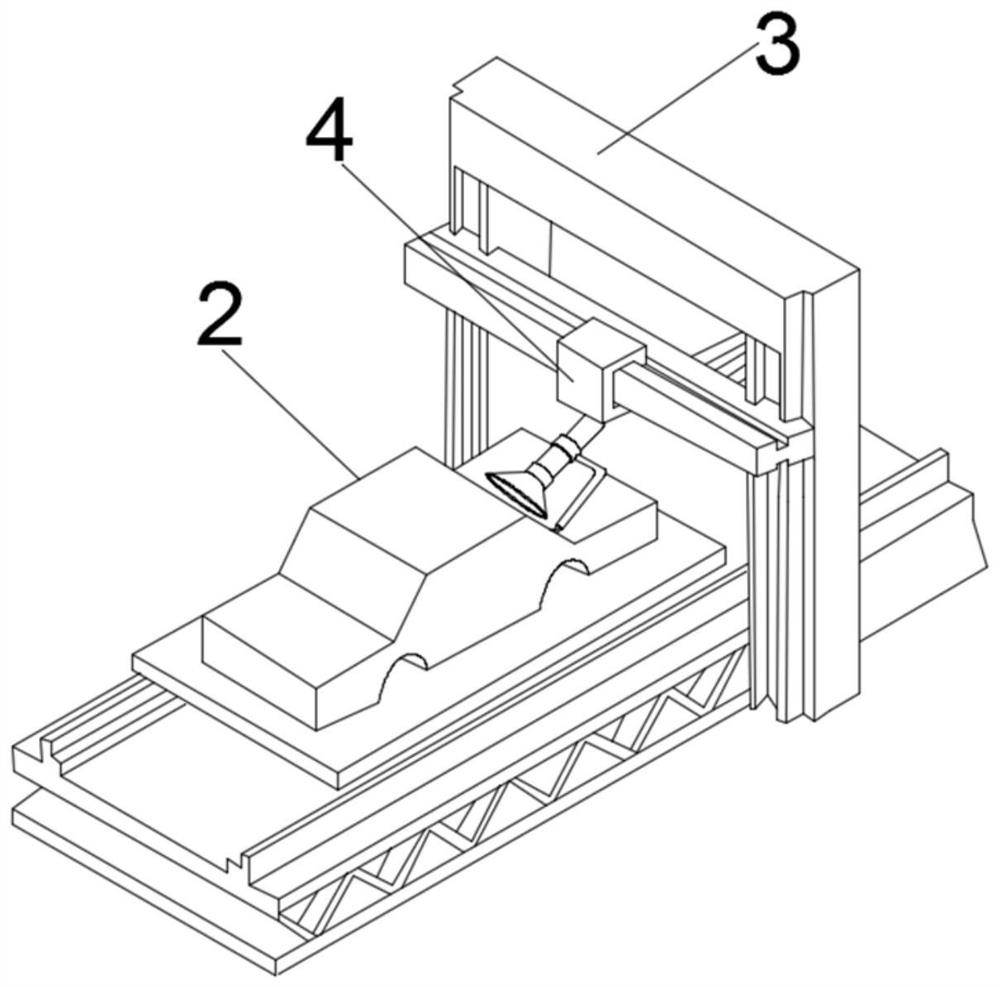

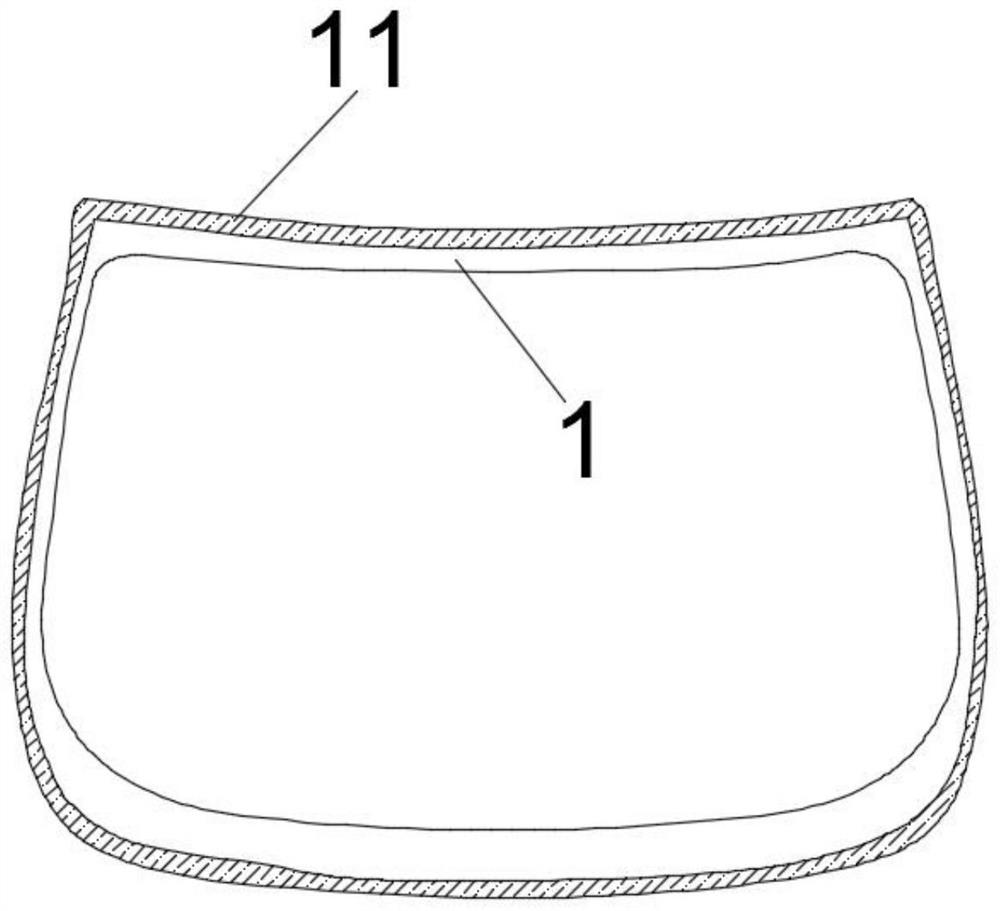

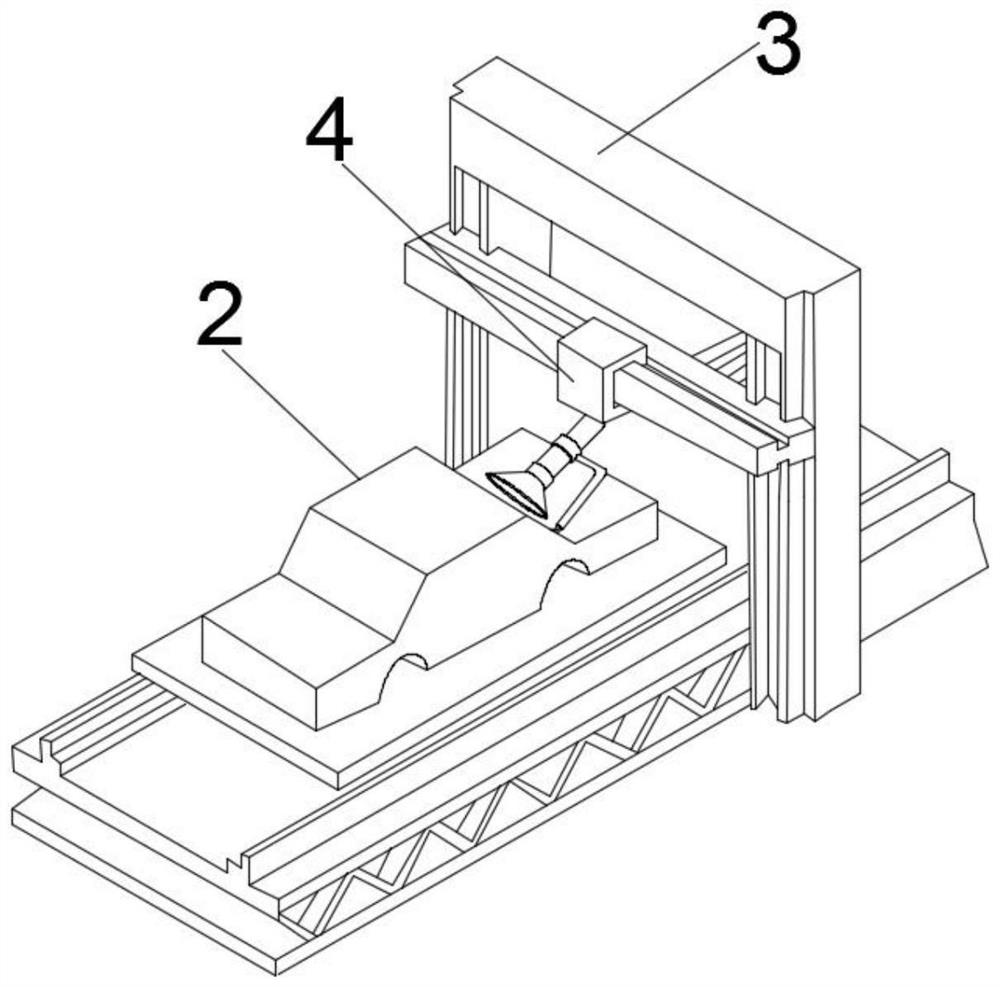

Non-destructive disassembling device for windshield glass of scrapped automobile

ActiveCN111976867AAvoid damageImprove adsorption capacityVehicle dissasembly recoverySolid waste disposalCAR disassemblyTransmission belt

The invention discloses a non-destructive disassembling device for a windshield glass of a scrapped automobile. The non-destructive disassembling device comprises an automobile disassembling frame, wherein the scrapped automobile is fixed on a transmission belt on the lower side of the automobile disassembling frame; a guide assembly is arranged on the automobile disassembling frame; an automobilewindshield glass disassembling device body is arranged on the guide assembly; and the windshield glass disassembling device body moves on the automobile disassembling frame along with the guide assembly to nondestructively disassemble an automobile windshield glass. According to the non-destructive disassembling device, a cutting assembly and a fixing assembly of the waste automobile glass are designed on the same device, when in use, the automobile glass can be fixed and cut at the same time, the situation that automobile glass subjected to nondestructive cutting falls to be broken due to the fact that binding force between the automobile glass and surrounding parts is lost is avoided, and thus the disassembled automobile glass is protected; and the non-destructive disassembling device has the characteristics that nondestructive disassembling of the automobile glass can be completely achieved so as to protect the automobile glass, the use is convenient, and the structural design is reasonable.

Owner:CHONGQING COLLEGE OF HUMANITIES SCI & TEHNOLOGY

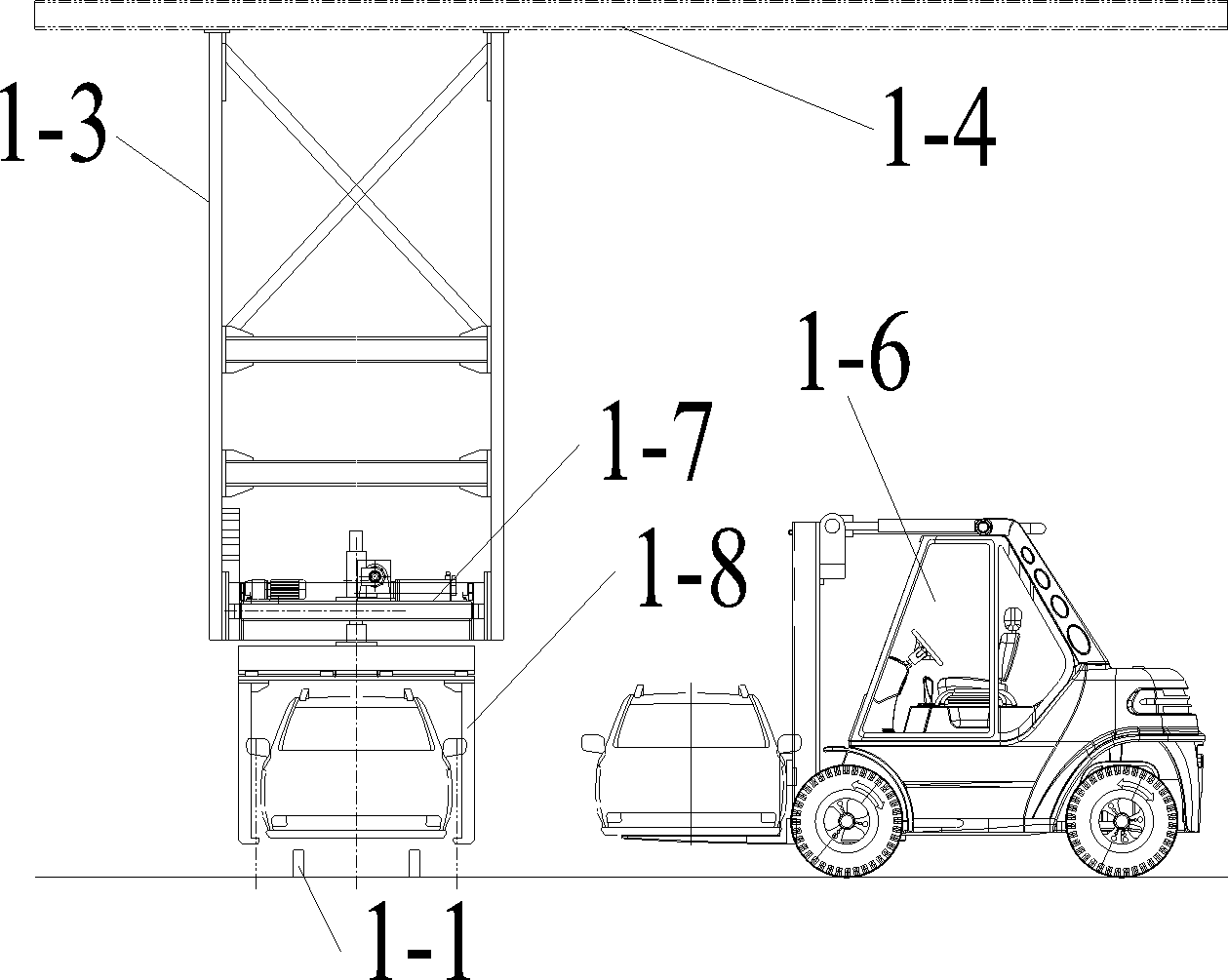

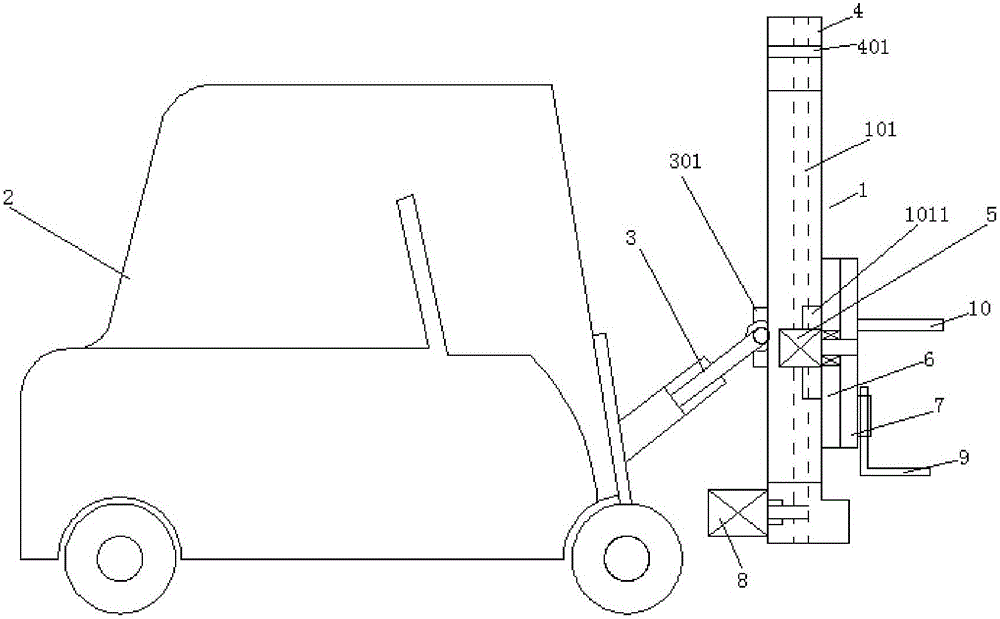

Forklift for disassembling automobile

The invention discloses a forklift for disassembling an automobile. The forklift comprises a forklift body and a material receiving fixing frame. The material receiving fixing frame is arranged on the front side of the forklift. The two sides of the front end face of the forklift body are provided with hydraulic telescopic supporting columns. The front ends of the telescopic supporting columns are connected to the material receiving fixing frame through hinge connection pieces in a hinged mode. The fixing frame is provided with a transmission chain capable of being closed at the first place. The upper end and the lower end of the transmission chain are provided with transmission gears respectively. The transmission gears are fixed to the material receiving fixing frame through fixing shafts. The transmission gear fixing shaft at the lower end is connected with a drive device. The transmission chain is provided with a fixing beam. The fixing beam is provided with a fixing disc and a rotating disc. The rotating disc is arranged on the fixing disc in a rotating mode. The rotating disc is provided with a drive shaft. The rear end of the drive shaft is connected with a drive motor. The rotating disc is provided with a pair of symmetrical material receiving forks. According to the forklift, an existing material receiving mechanism for a forklift is improved, so that material receiving forks of the forklift can be rotated at a certain angle, and the use range and purpose of the forklift in an automobile disassembling line can be broadened.

Owner:滁州市洪武报废汽车回收拆解利用有限公司

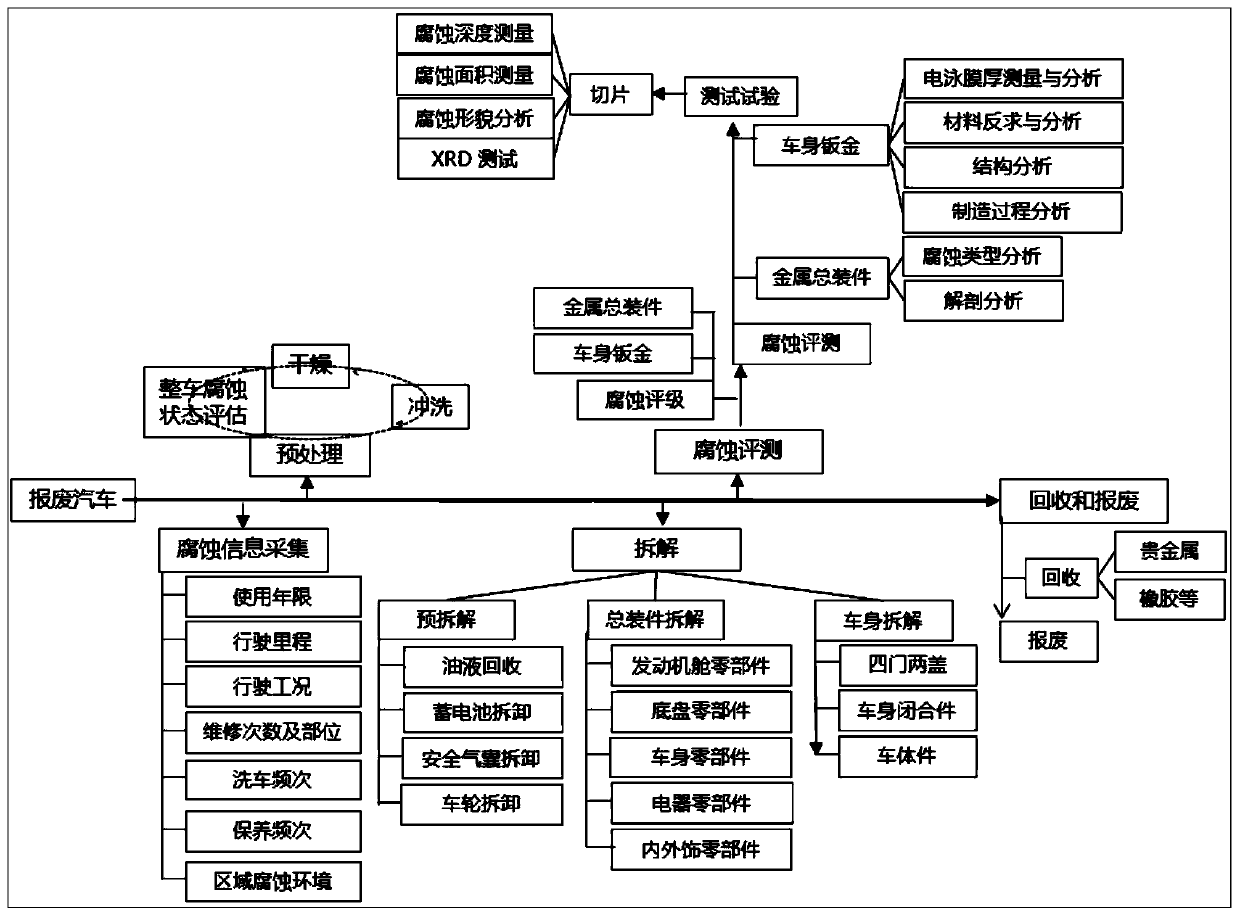

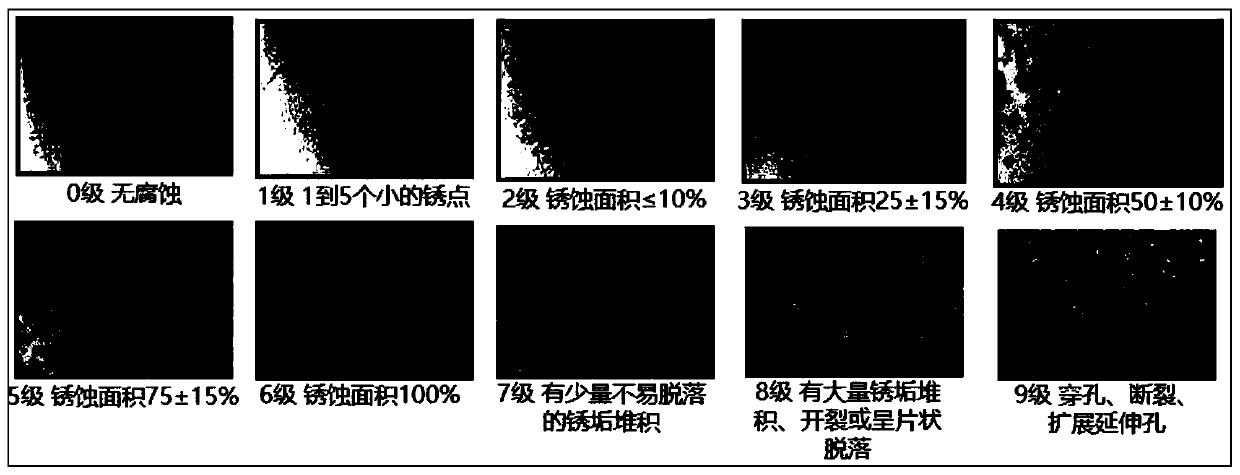

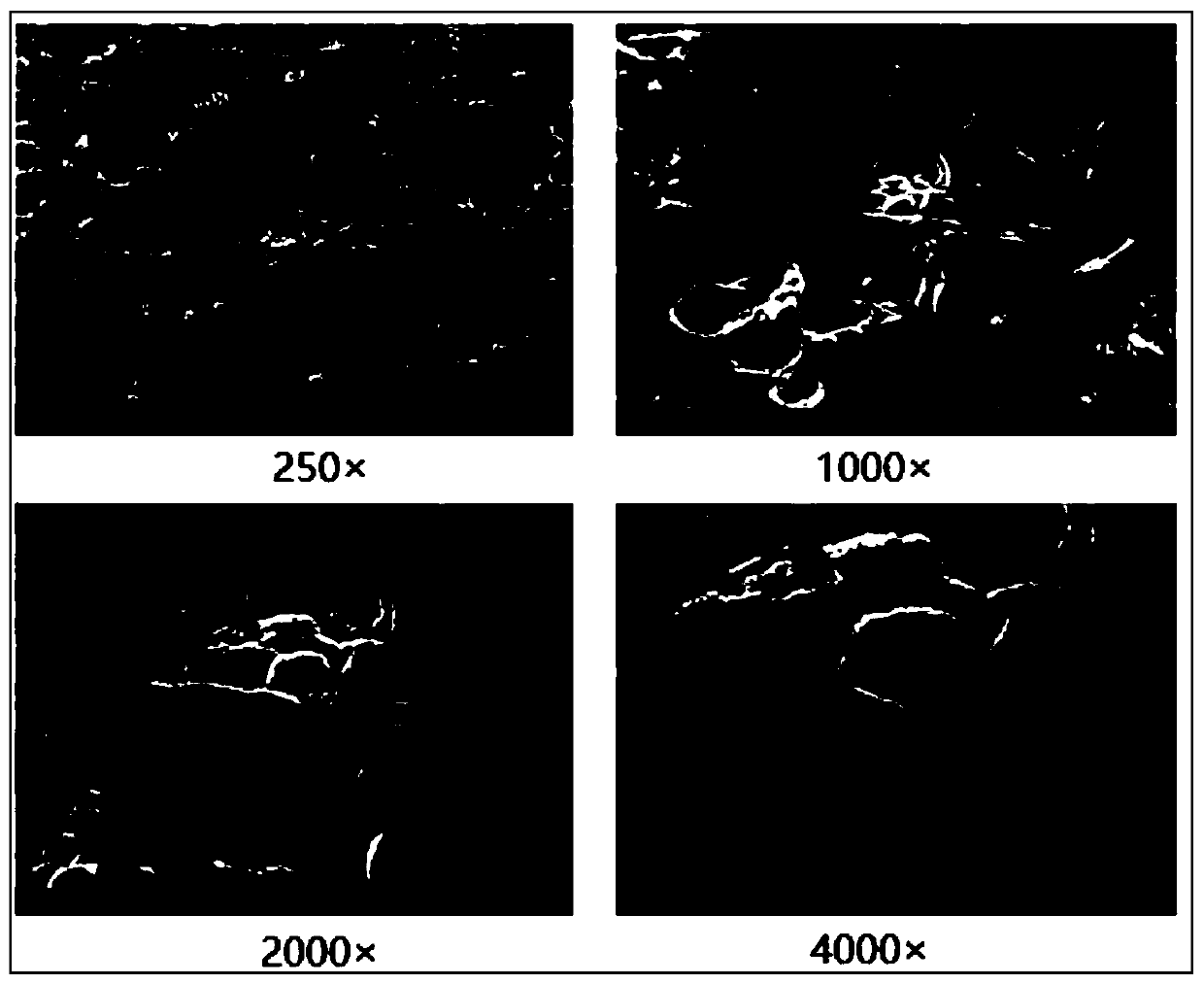

Corrosion evaluation method for scraped car disassembly

InactiveCN110889168AUnderstanding CorrosionUnderstanding the State of Market CorrosionGeometric CADCAR disassemblyForeign matter

The invention discloses a corrosion evaluation method for scraped car disassembly. The corrosion evaluation method comprises the following steps: (1) collecting basic information related to scraped car corrosion; (2) washing the scraped car, removing floating rust, mud ash and foreign matters on the surface of the scraped car, drying, and evaluating the corrosion state of the whole car before disassembly; (3) disassembling the scraped car, including pre-disassembling, final assembly disassembling and car body disassembling; and (4) carrying out corrosion rating on the disassembled metal finalassembly and the disassembled automobile body metal plate, and then carrying out corrosion evaluation, which comprises three aspects: the metal final assembly: corrosion type analysis, and anatomicalanalysis on parts with internal corrosion; vehicle body sheet metal: performing vehicle body manufacturing process corrosion evaluation, including electrophoretic film thickness, material, structure and manufacturing process; and testing: slicing the rusted area, and carrying out corrosion depth, corrosion area, corrosion morphology and XRD tests. Through qualitative corrosion evaluation and quantitative corrosion evaluation, reverse reference is provided for development and design of new products.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A non-destructive dismantling device for windshield glass of scrapped cars

ActiveCN111976867BAvoid damageImprove adsorption capacityVehicle dissasembly recoverySolid waste disposalCAR disassemblyTransmission belt

The invention discloses a windshield glass non-destructive dismantling device for scrapped cars, which comprises a car dismantling frame, scrapped cars are fixed on the transmission belt on the lower side of the car dismantling frame, a guide assembly is arranged on the car dismantling frame, and a guide assembly is installed on the guide assembly Automobile windshield dismantling device, the windshield glass dismantling device moves on the automobile dismantling frame with the guide assembly, and disassembles the automobile windshield glass without damage; Designed on the same device, when in use, it can fix and cut the car glass at the same time, ensuring that the car after non-destructive cutting will not fall and break because it loses its binding force with the surrounding parts, and protects the removed car glass , has the characteristics of fully realizing the non-destructive disassembly of automobile glass, protecting the automobile glass, convenient use and reasonable structure design.

Owner:CHONGQING COLLEGE OF HUMANITIES SCI & TEHNOLOGY

A car rear axle dismantling device

InactiveCN111347236BEasy to clean manuallyEasy maintenanceCleaning using toolsVehicle componentsCAR disassemblyDrive shaft

The invention discloses an automobile rear axle dismantling device, which belongs to the field of automobile disassembly. An automobile rear axle dismantling device, comprising: a base, a frame, a connecting frame and a first drive mechanism; the frame is arranged at both ends of the base, and the connecting frame is arranged horizontally above the base, the The connecting frame is slidably connected with the frame, and the first driving mechanism can drive the connecting frame to move up and down; wherein, the two ends of the second supporting member are respectively engaged with the two ends of the first supporting member , around the half bridge part of the rear axle; the first support member and the second support member are fixedly equipped with an electric screwdriver and an electric wrench Compared with the prior art, the automobile rear axle disassembly device of the present application can quickly Dismantling the end of the drive shaft of the half bridge saves manpower and improves disassembly efficiency.

Owner:杨唯巍

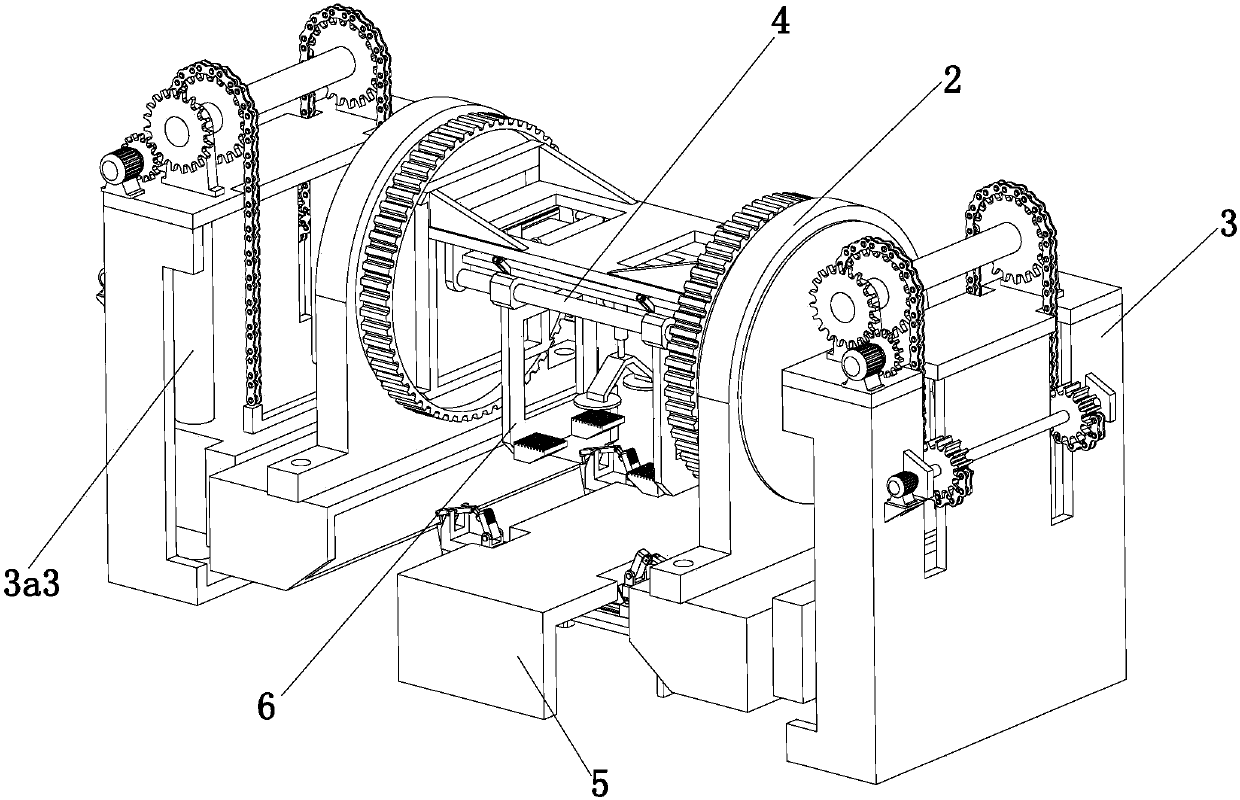

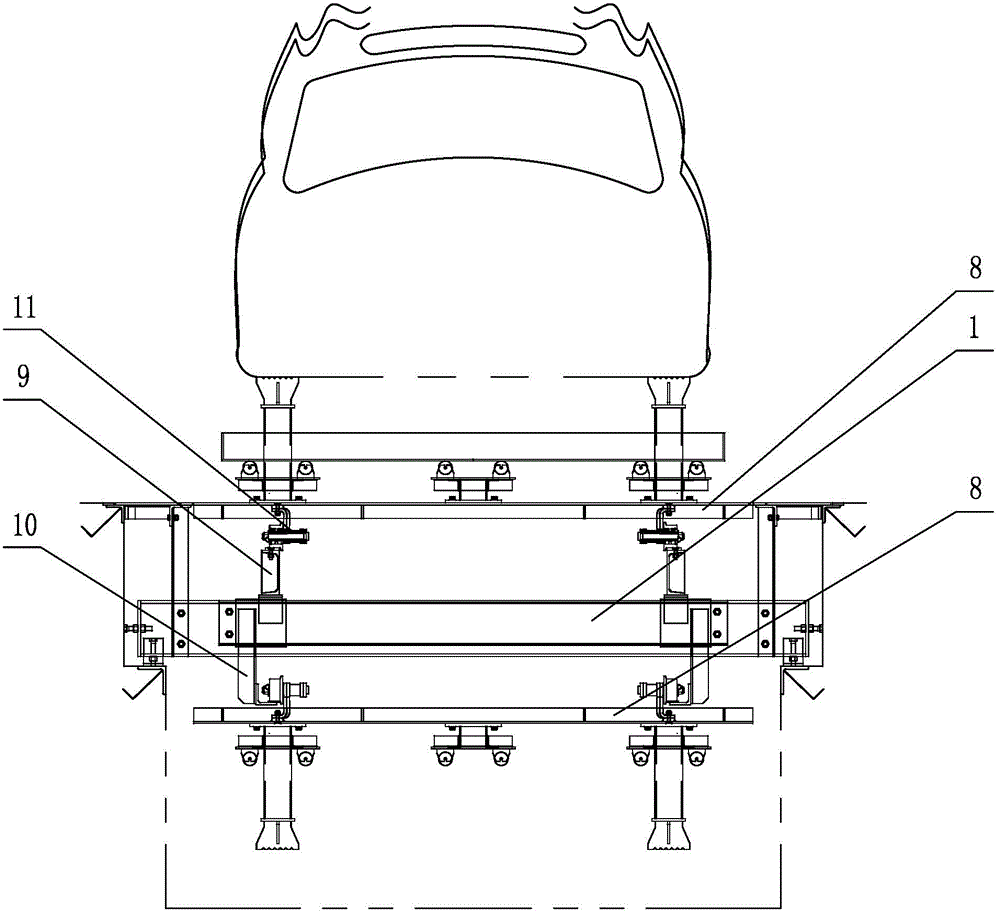

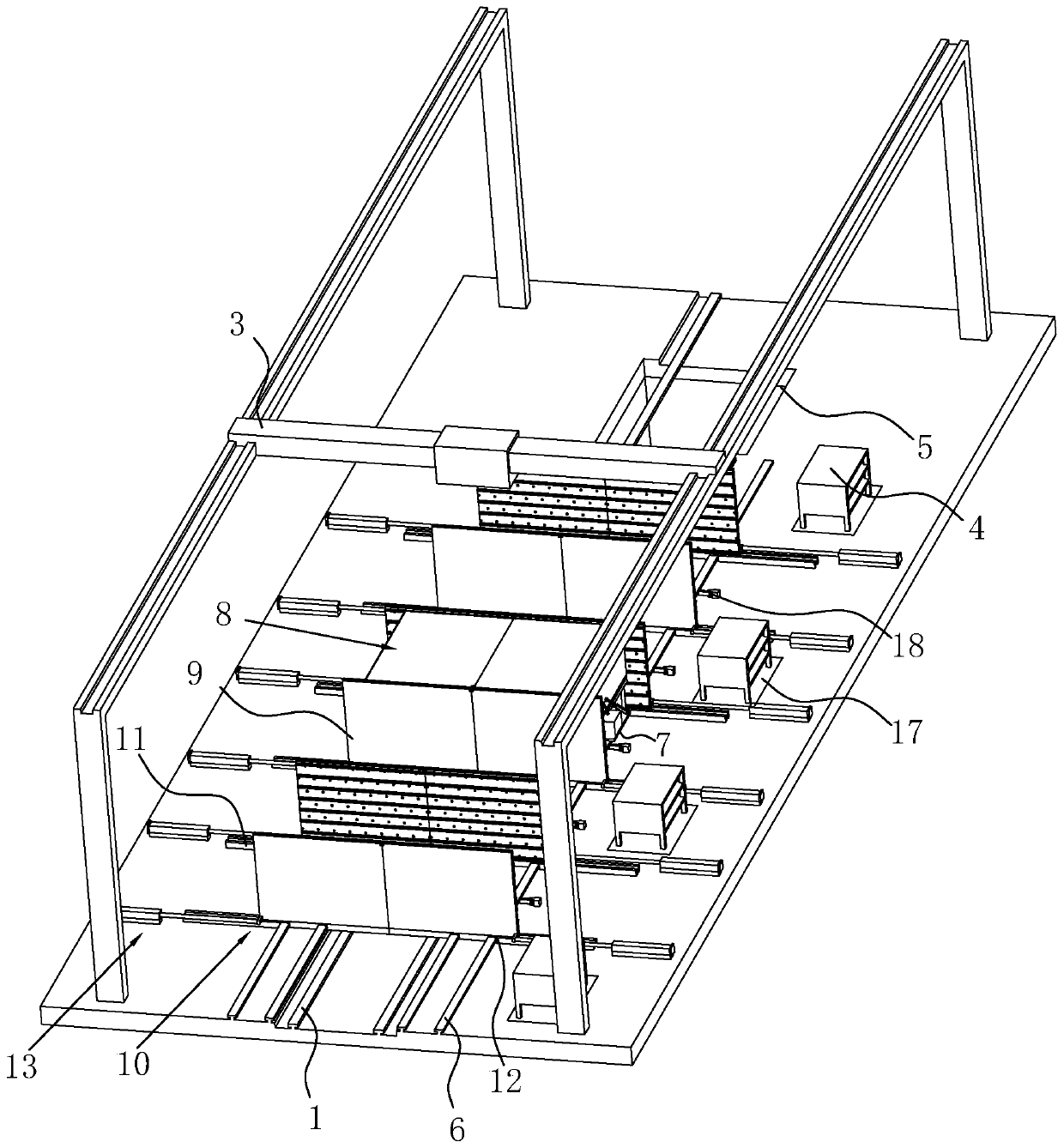

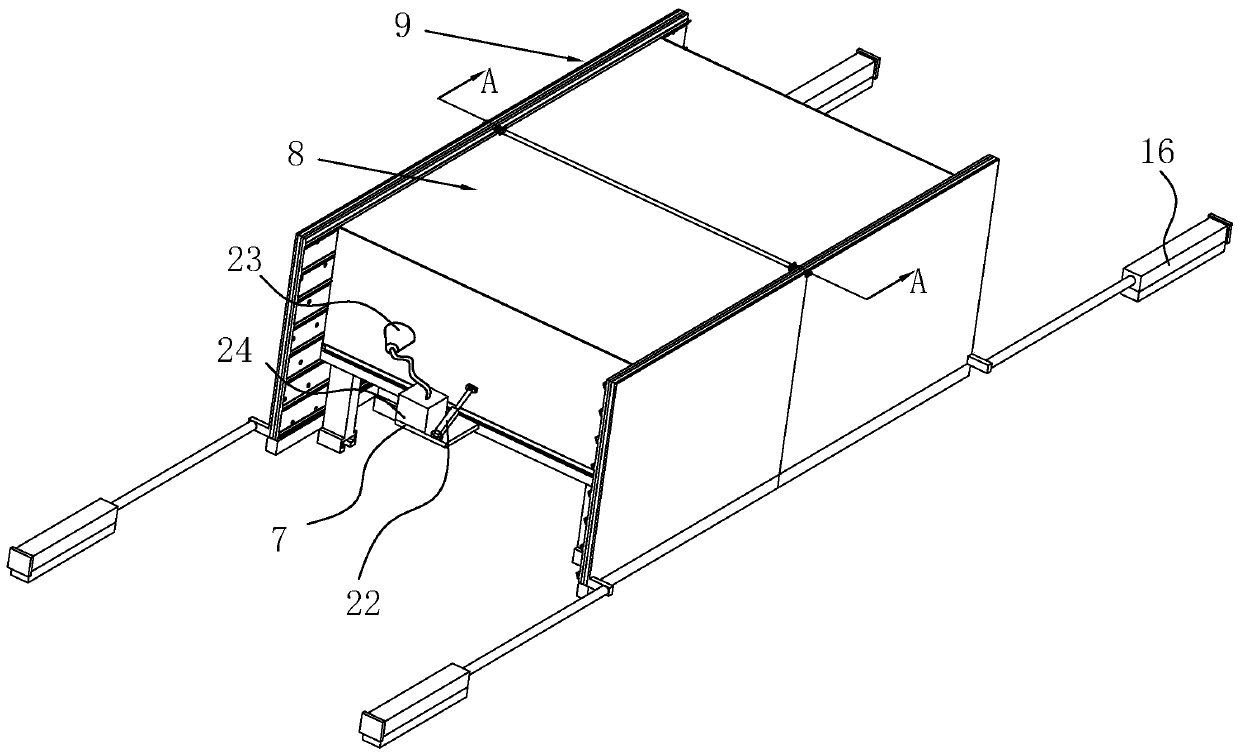

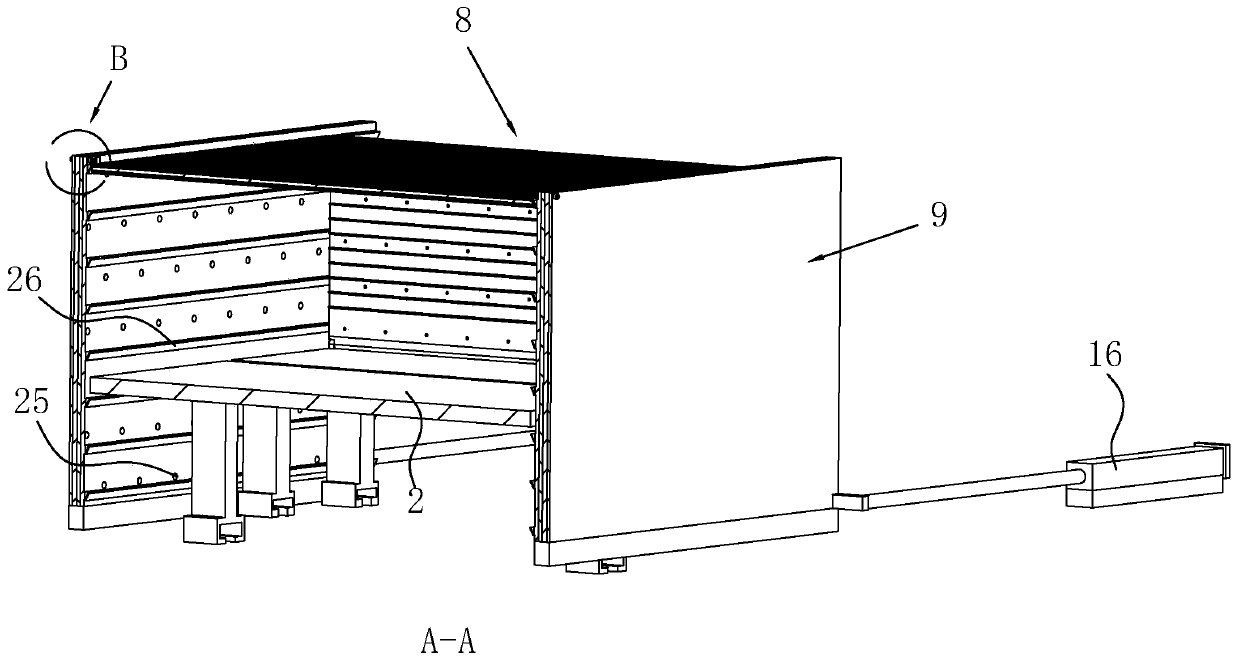

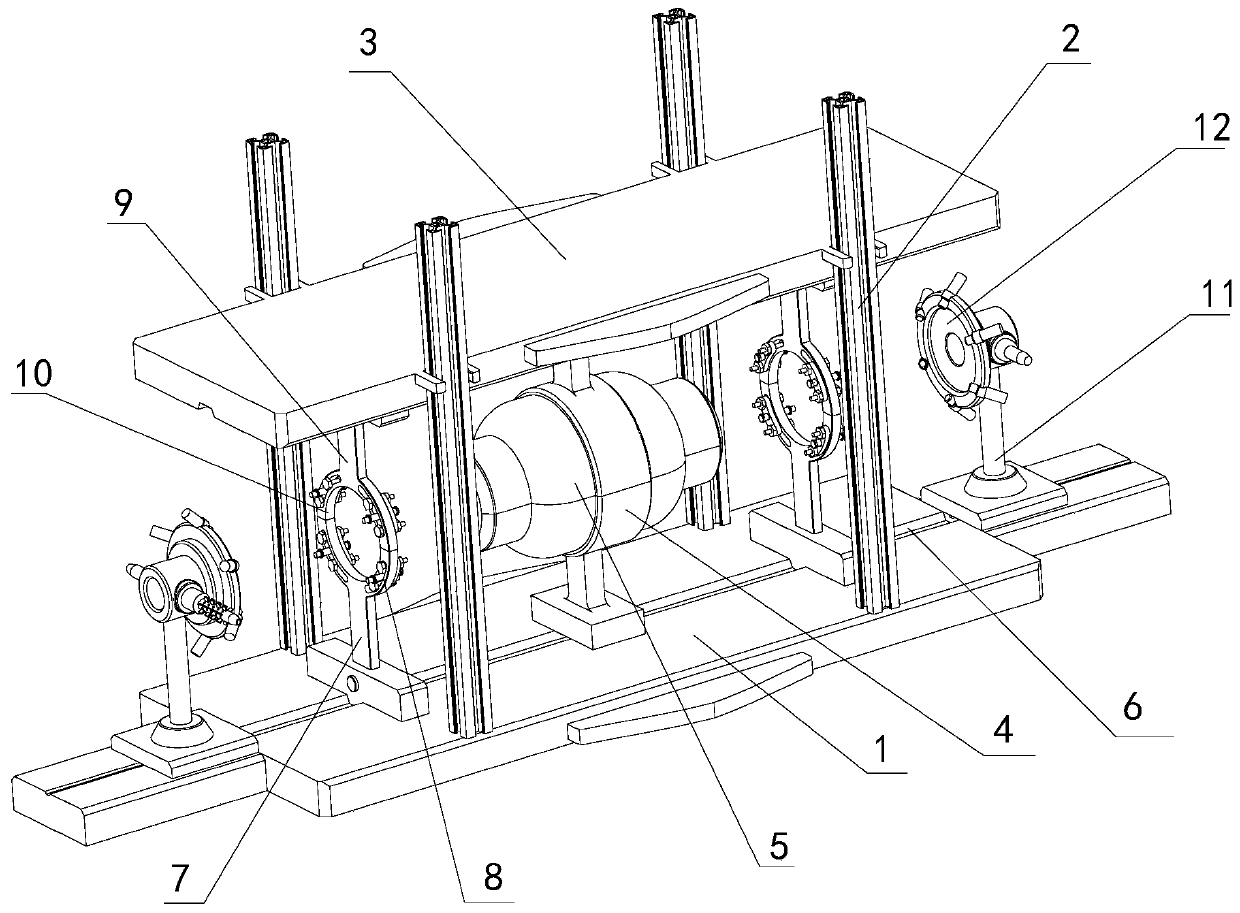

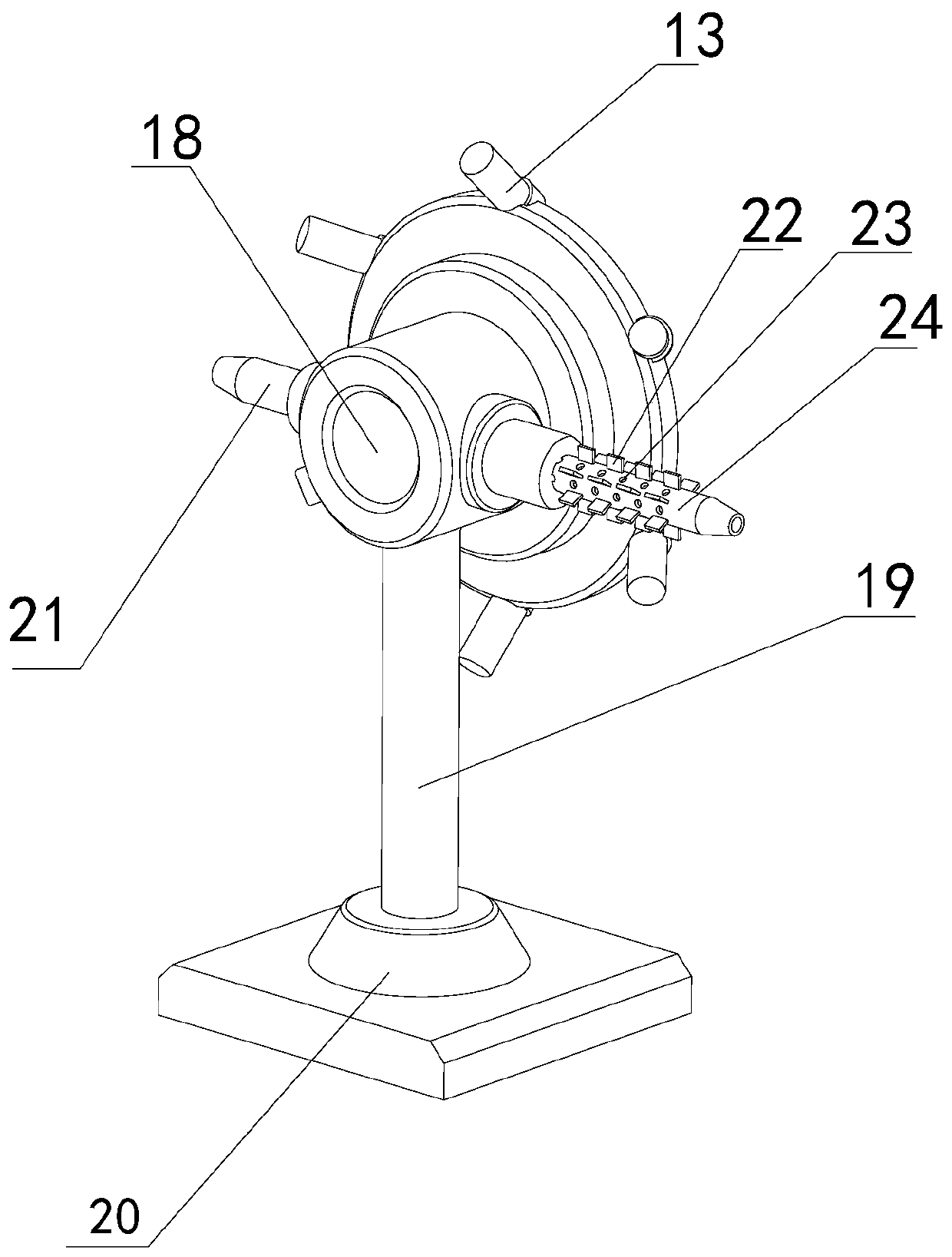

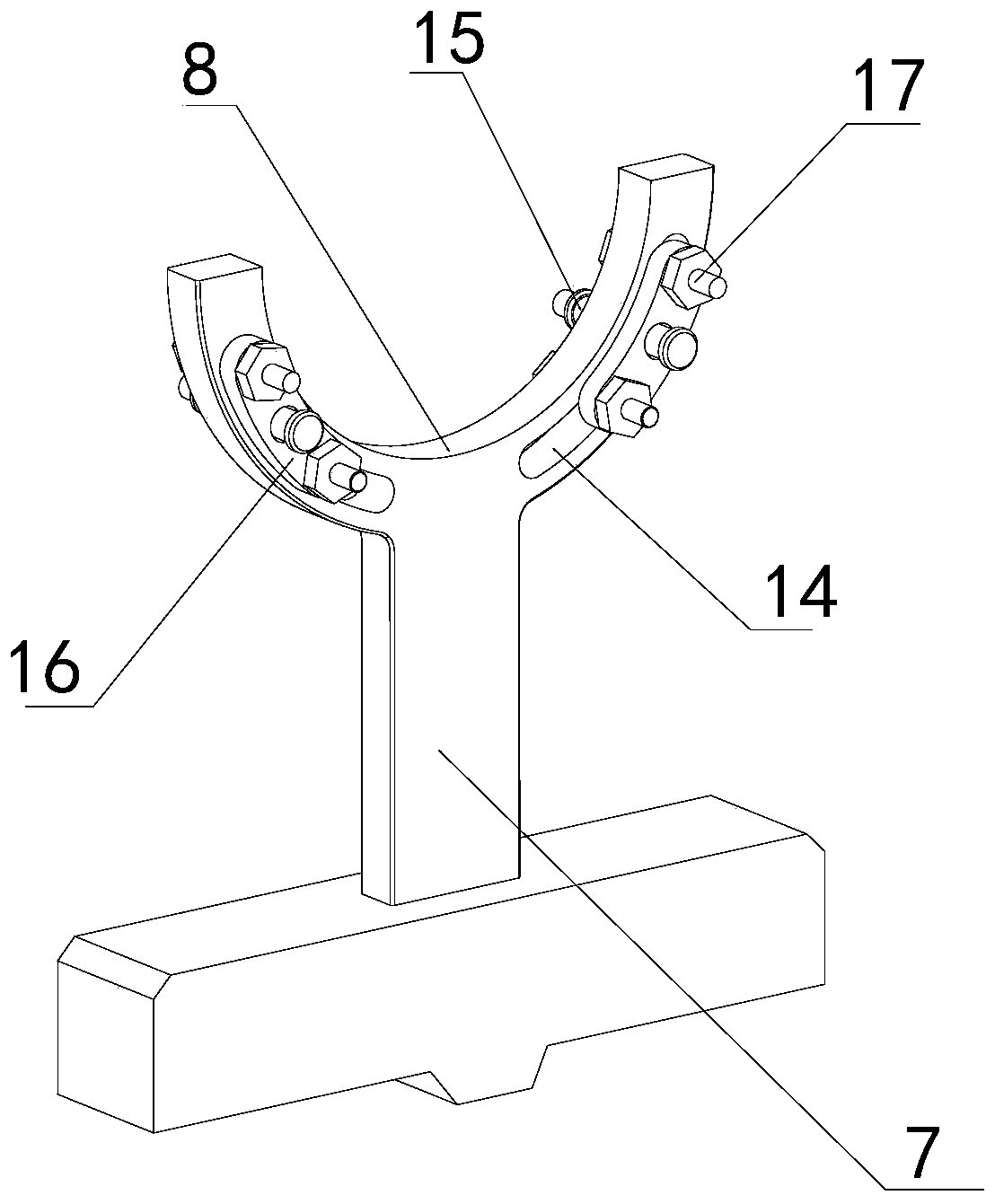

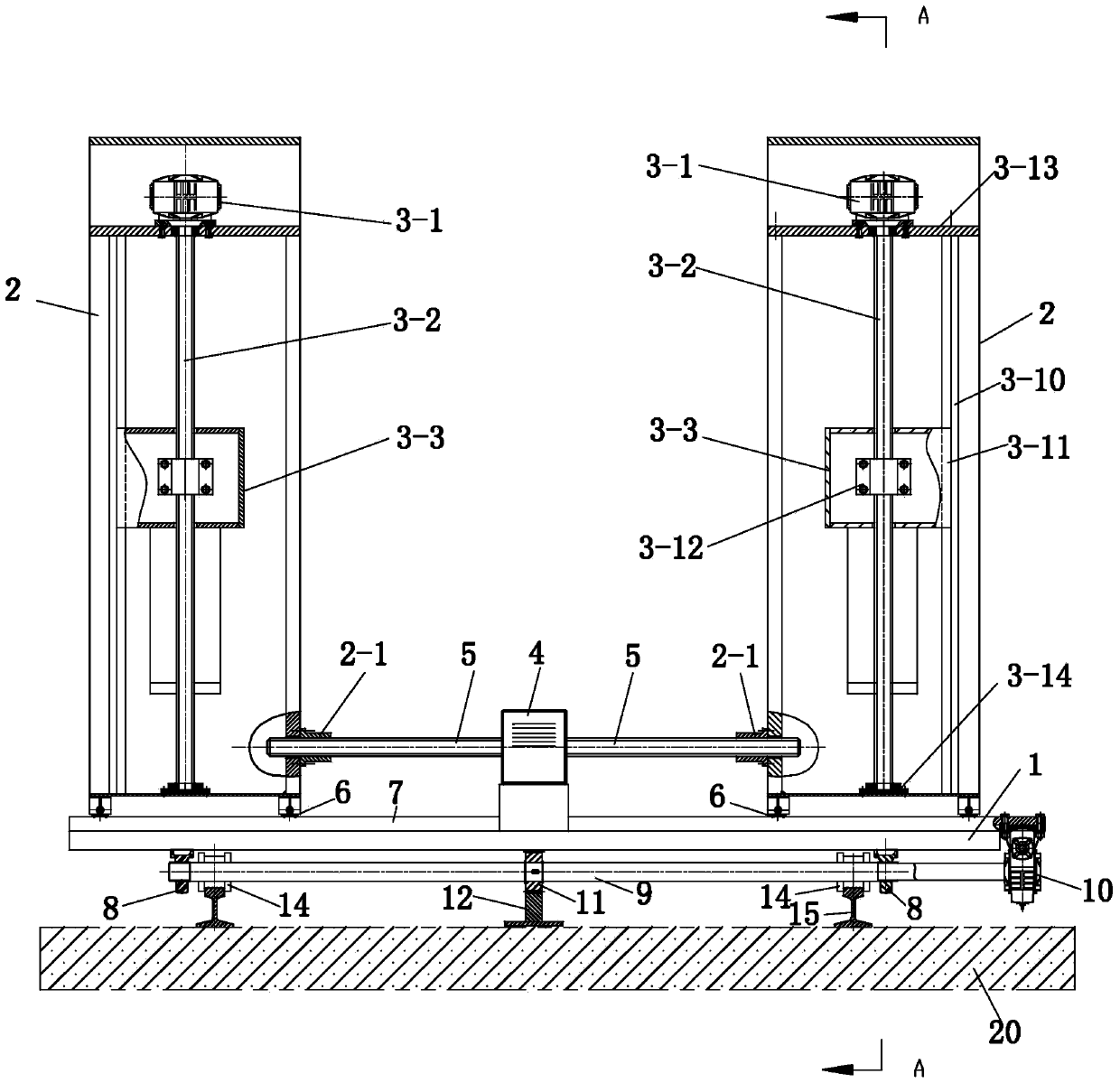

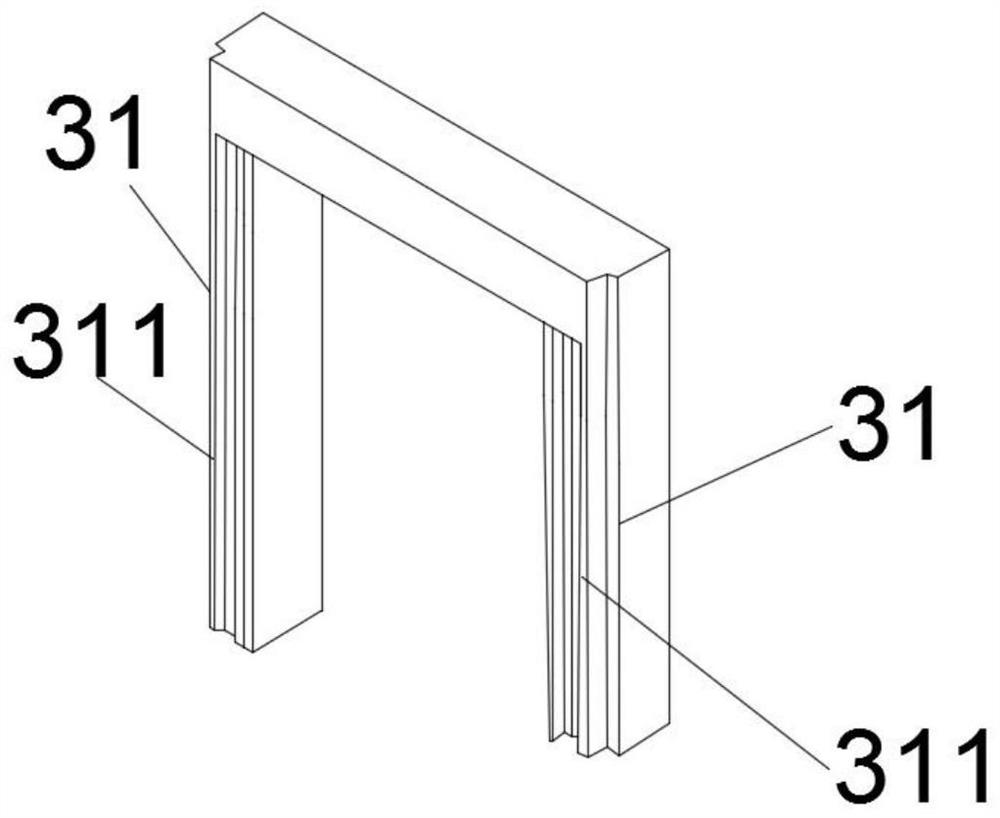

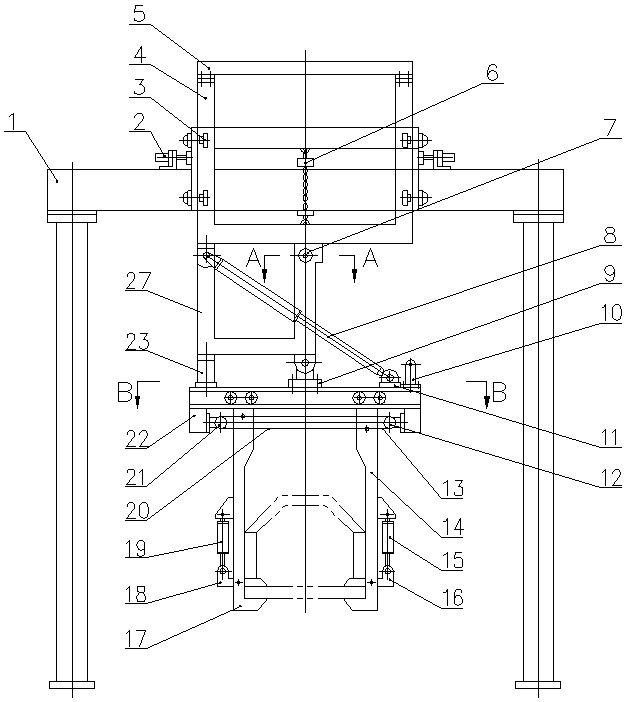

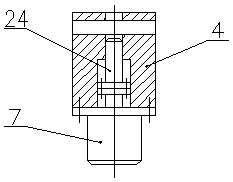

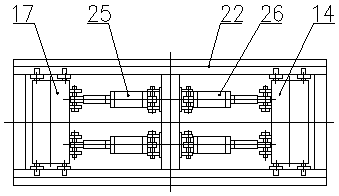

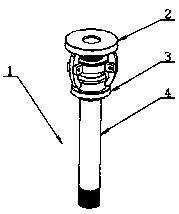

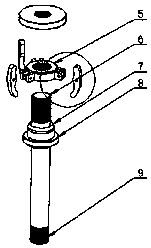

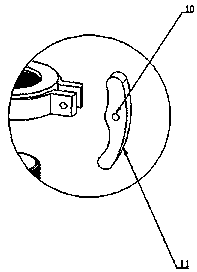

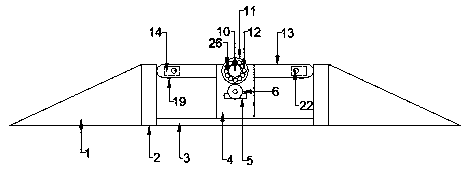

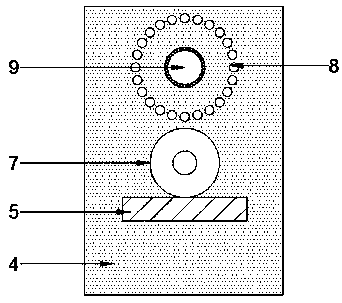

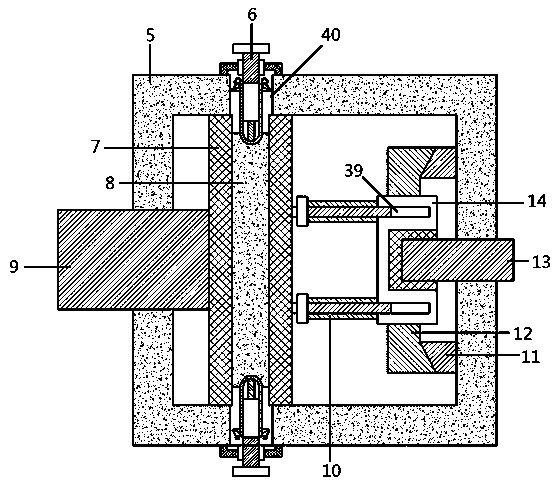

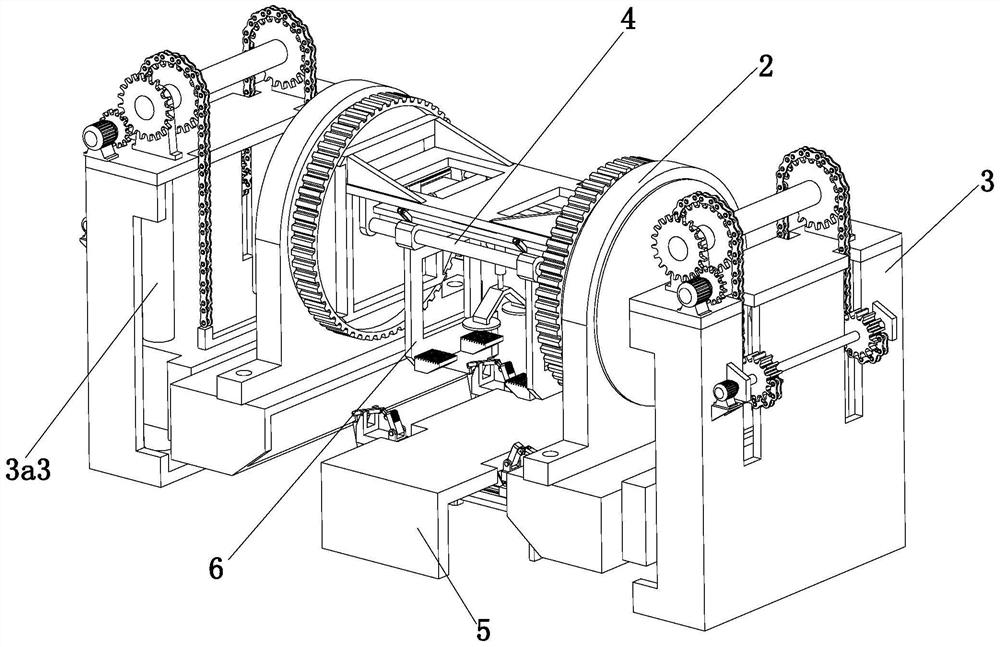

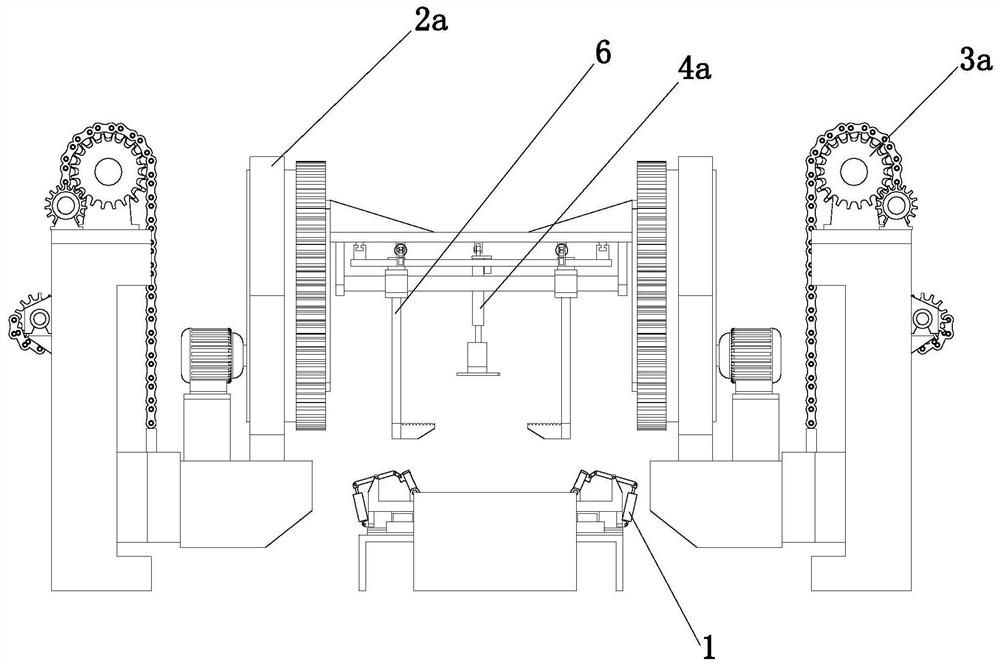

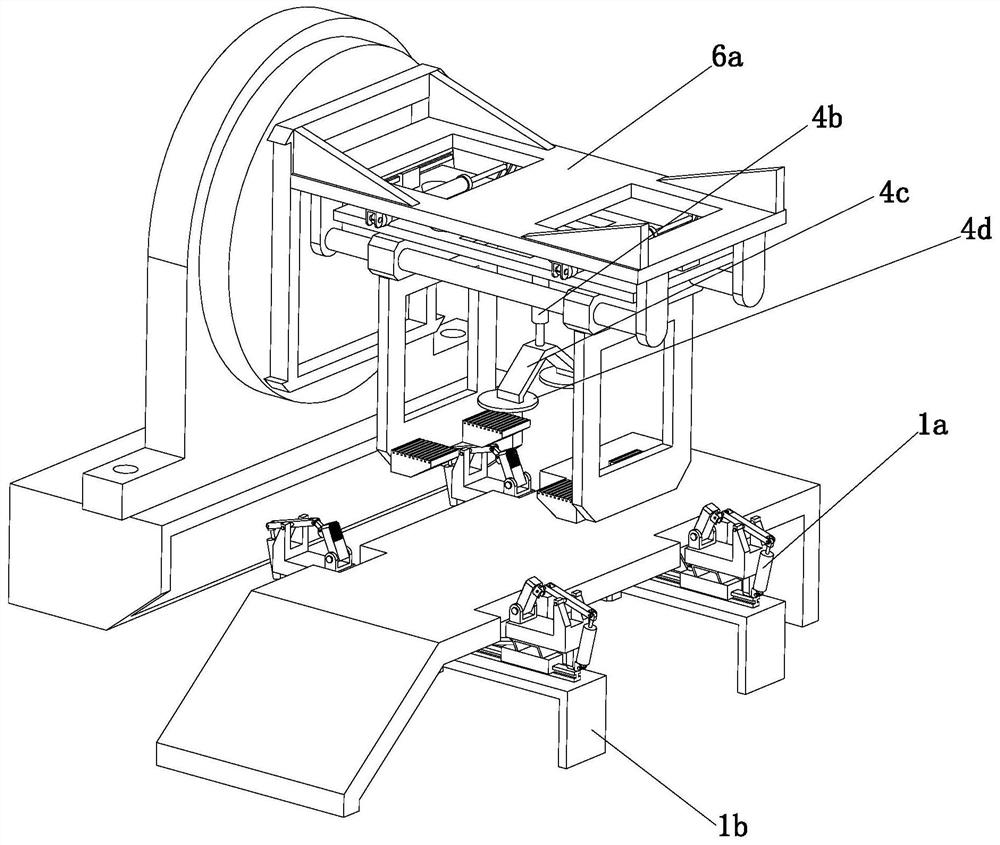

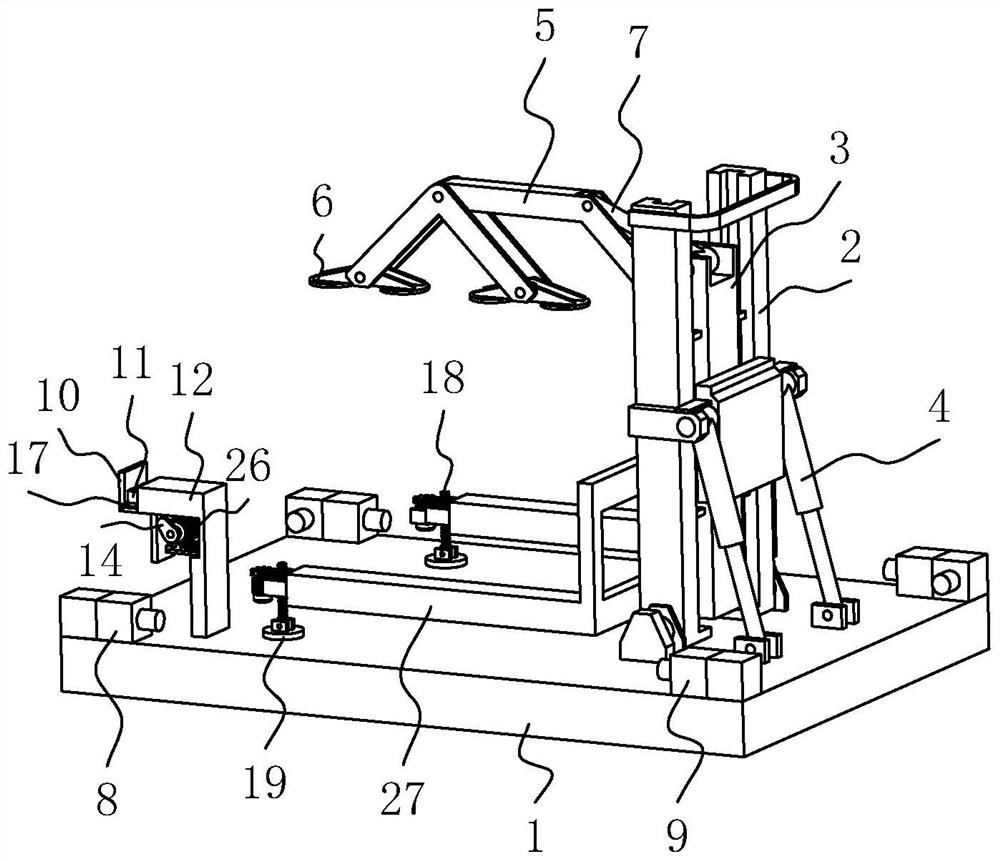

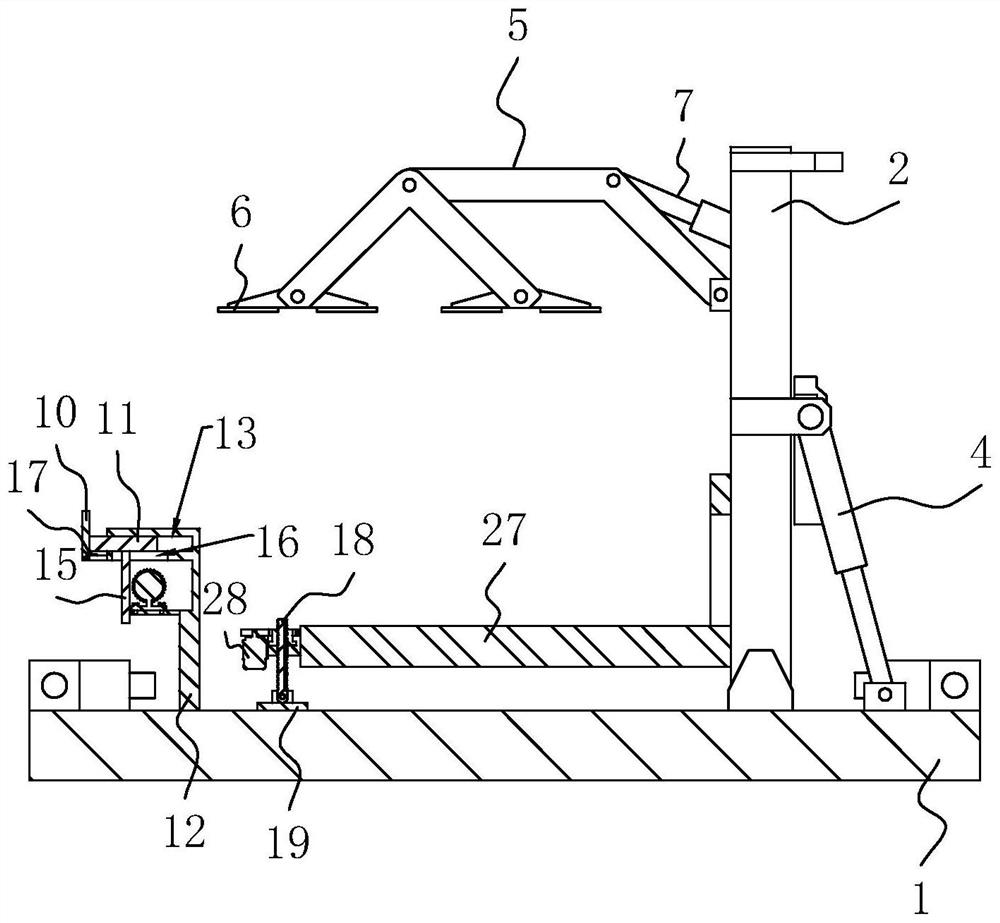

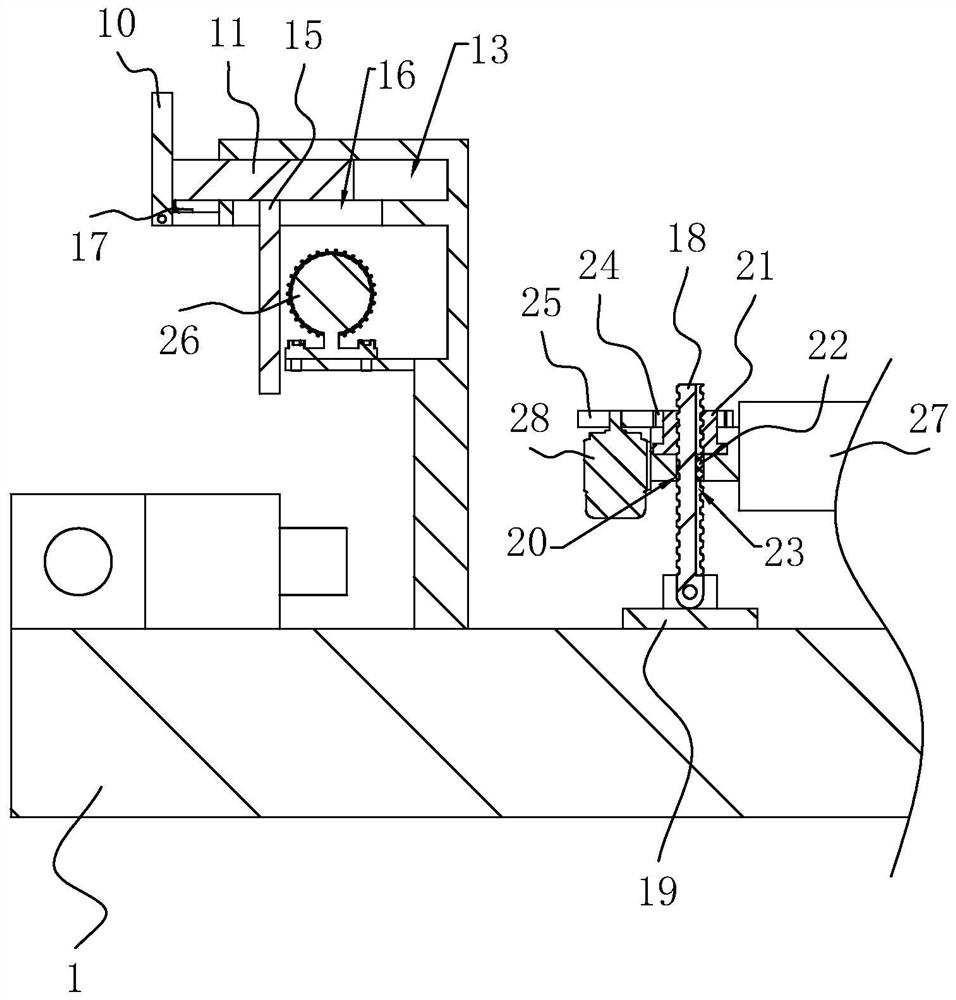

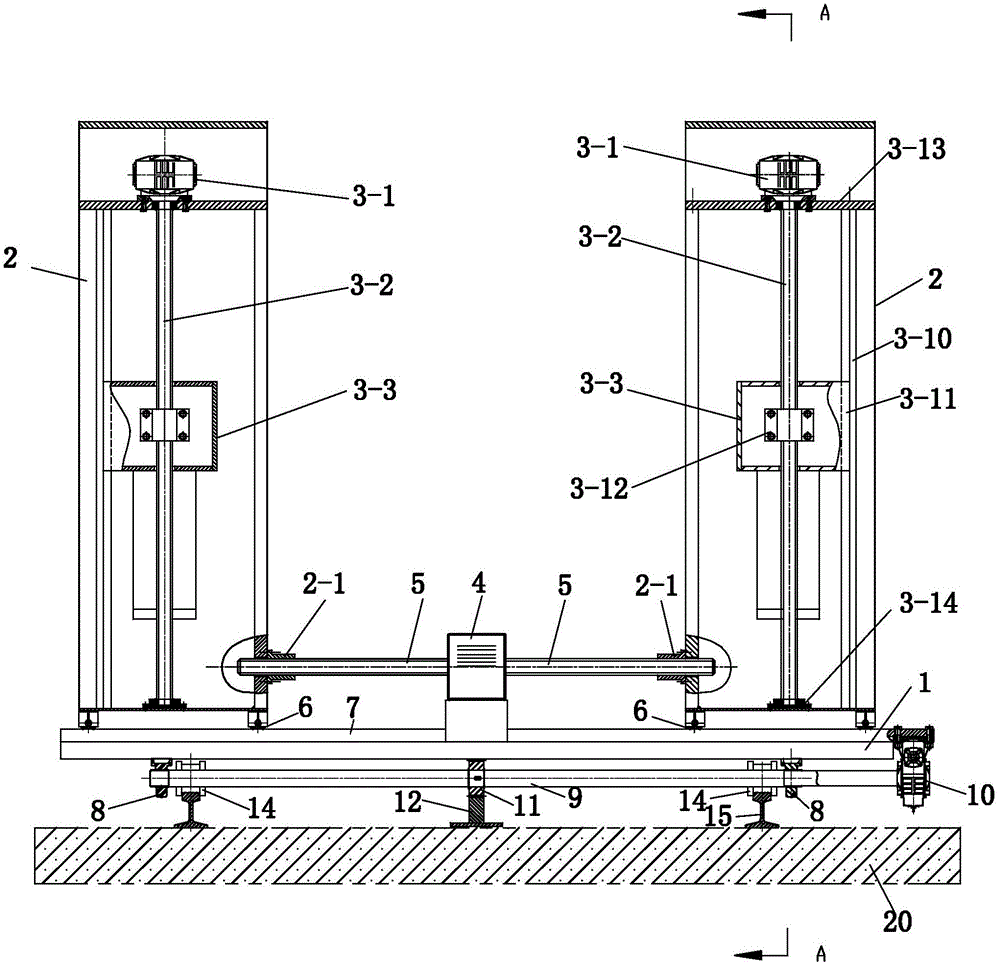

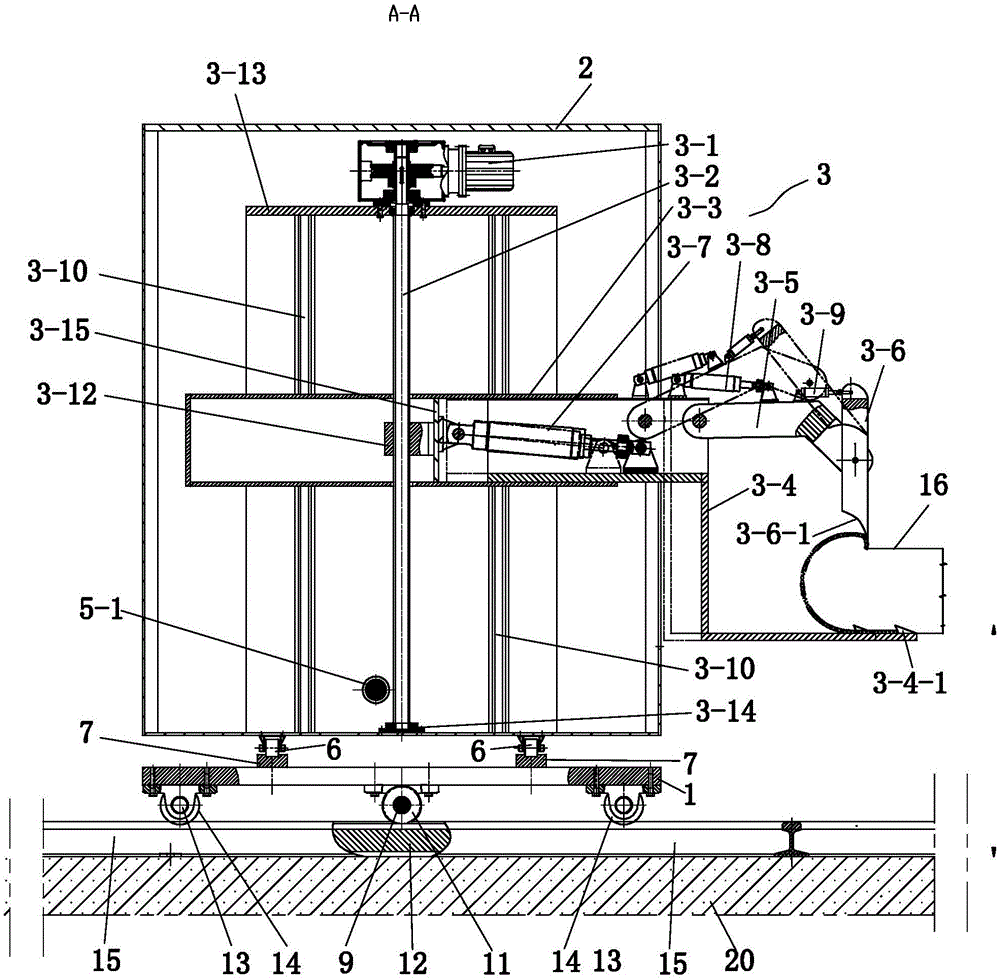

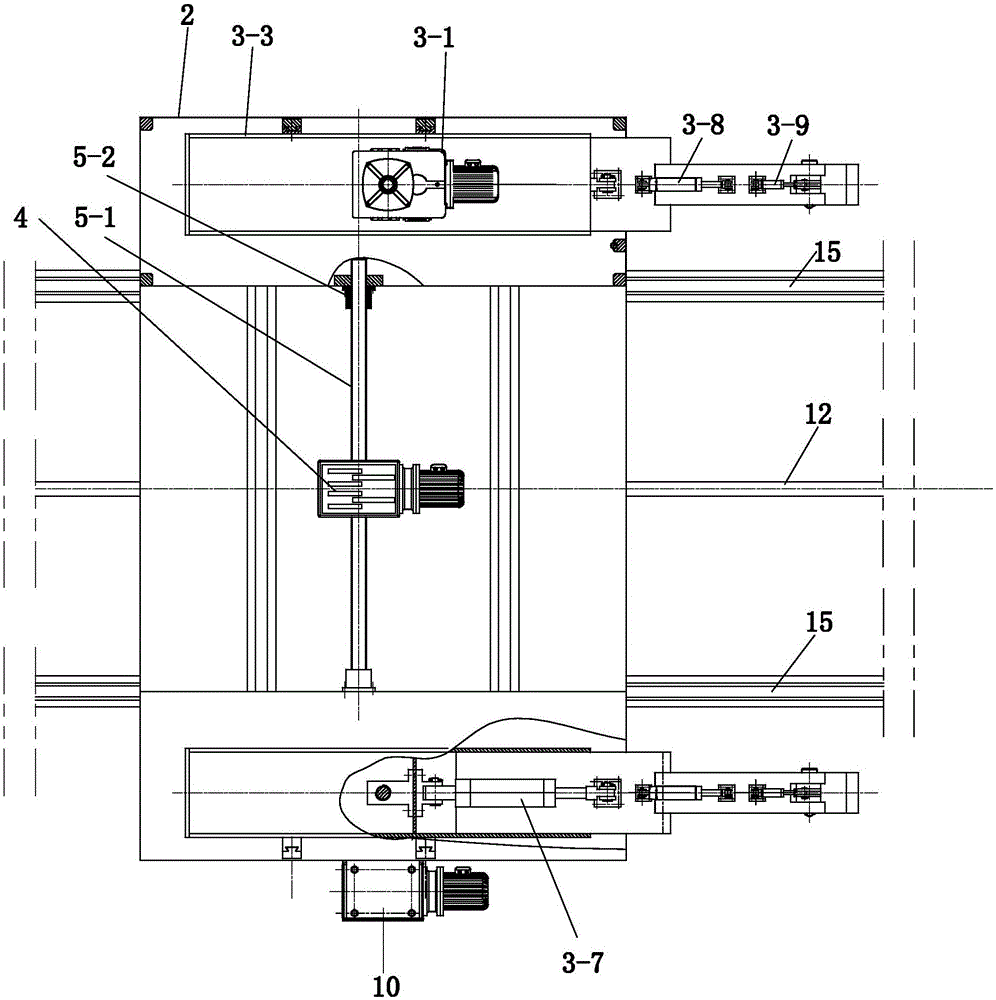

Lifting and flipping machine for scrapped car dismantling

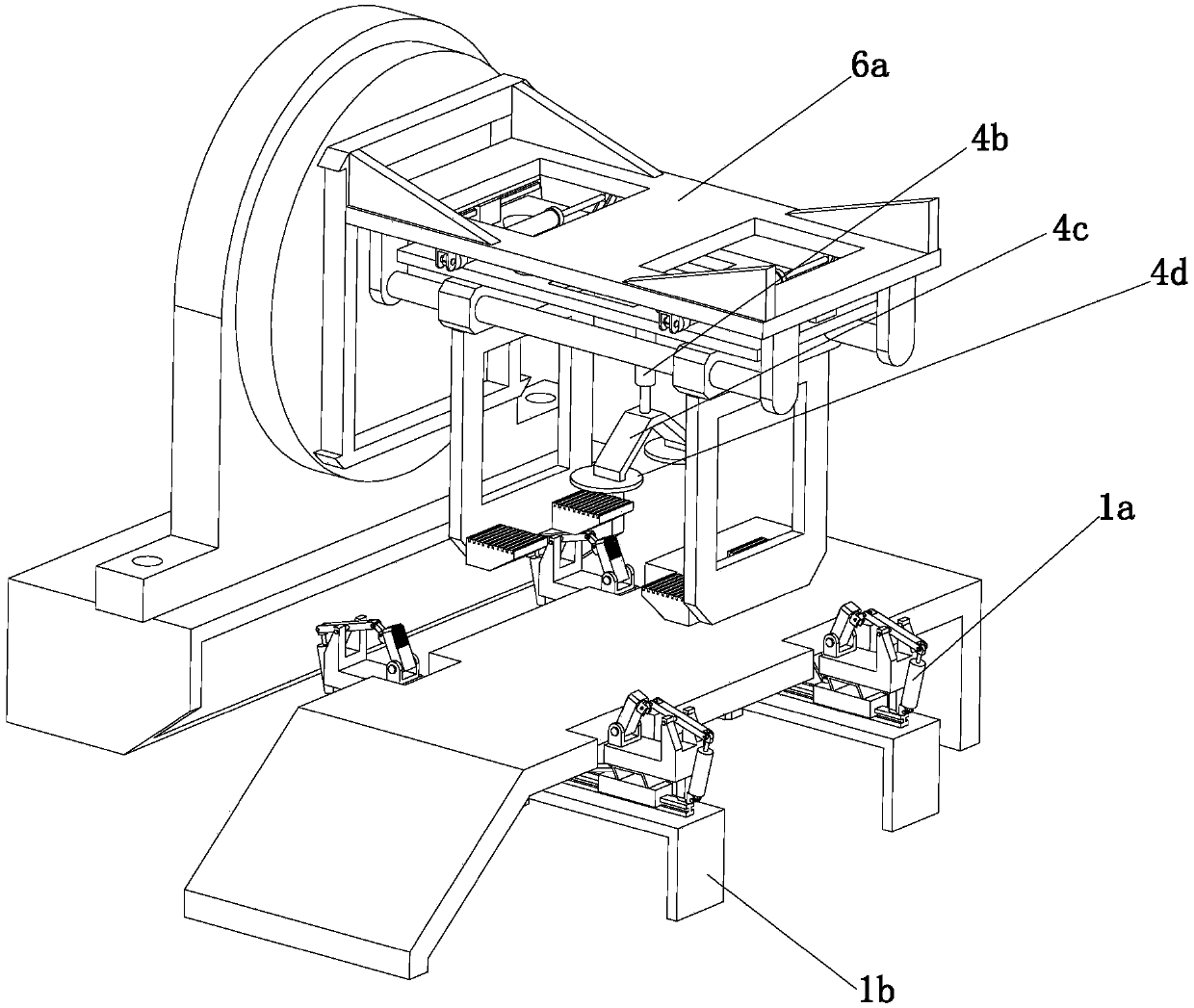

ActiveCN106672829BReasonable structureWith lifting functionLoad-engaging elementsCranesCAR disassemblyEngineering

The invention relates to a lifting and overturning two-purpose machine for scrapped car dismantling. The lifting and overturning two-purpose machine is characterized by comprising a rack (1), a lifting frame (4), an overturning locking cylinder (7), an overturning cylinder (8), a first support seat (9), an overturning locking tongue (10), a second support seat (11), a right hanging foot assembly (14), a right pressing foot cylinder (15), a right pressing foot (16), a left hanging foot assembly (17), a left pressing foot (18), a left pressing foot cylinder (19), an overturning frame (22), a limiting seat (23), a locking pin (24) and a connecting frame (27). The lifting and overturning two-purpose machine for scrapped car dismantling has the beneficial effects of being reasonable in structure, capable of achieving the lifting function as well as the overturning function, suitable for fixed-point type dismantling, also suitable for the assembly line dismantling manner and good in universality.

Owner:JIANGSU HUAHONG TECH STOCK

Connecting device for easy disassembly of automobile bearings

InactiveCN109253171ASimplify the installation processSimple and fast operationShaftsBearing unit rigid supportCAR disassembly

The invention discloses a connecting device for easy disassembly of automobile bearings, wherein the connecting device comprises a bracket and a functional seat. The bracket is composed of a close ring and a baffle ring; the baffle ring is arranged below the close ring; a bearing is arranged on the inner side of the bracket; a shaft head is arranged at the top of the bearing, and a shaft tail is arranged at the bottom of the bearing; the functional seat is arranged above the bracket; a rotary knob thread is arranged on the inner side of the functional seat, and a plurality of fixing clips arearranged on the outer side of the functional seat; a matching hole is arranged in the middle part of each fixing clip, and a dialing strip is arranged in the middle part of each fixing clip; a movablehole is arranged in the middle part of each dialing strip, and a connecting disc is arranged above the functional seat. According to the device, by operation of the dialing strips, a fixed extrusionforce is provided for the connecting disc after the shaft head is screwed and connected with the connecting disc, the connecting disc rotates to be divorced from the bearing after the rotary knob is arranged. The principle is simple, the operation is convenient and the practicability is high.

Owner:丁茂明

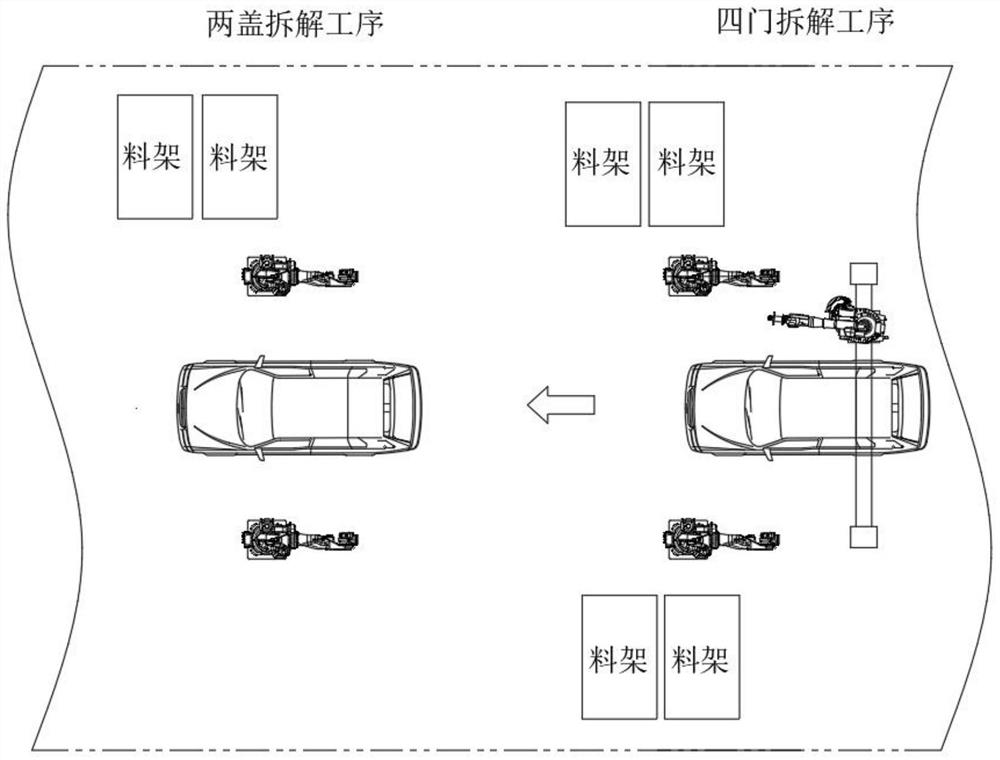

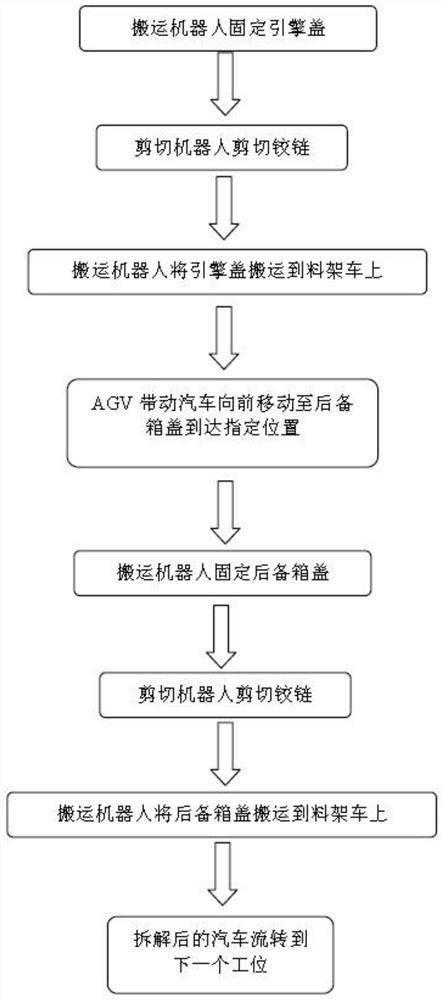

Automatic robot for disassembling two covers of automobile and control system of automatic robot

InactiveCN112874661AEasy to disassembleHigh degree of automationVehicle dissasembly recoverySolid waste disposalCAR disassemblyControl system

The invention relates to the technical field of scraped car disassembly, and discloses an automatic robot for disassembling two covers of an automobile and a control system of the automatic robot. The automatic robot comprises a door opening and code scanning station and a two-cover disassembling station, and the door opening and code scanning station conducts door opening and code scanning manually; and the two-cover disassembling station is used for disassembling an engine cover and a trunk cover of the automobile. According to the automatic robot for disassembling the two covers of the automobile and the control system of the automatic robot, the two-cover disassembling station is arranged, the two-cover disassembling station is used for disassembling an engine cover and a trunk cover of the automobile, and the two-cover disassembling station comprises two robots, a walking shaft, a hydraulic shearing device and an electromagnetic tooling, wherein one robot shears hinges of the engine cover and the trunk cover through the hydraulic shears, the other robot fixes and carries the engine cover and the trunk cover to the rack car through the electromagnetic tooling, and the engine cover and the trunk cover of the car can be disassembled conveniently through the arrangement of the station.

Owner:江西辽燚环保产业有限公司

Scraped car disassembly production line

ActiveCN103101585BReduce labor intensityIncrease productivityVehicle dissasembly recoverySolid waste disposalCAR disassemblyProduction line

Owner:MIRACLE AUTOMATION ENG CO LTD

Automobile part disassembly platform

InactiveCN108789291AImprove efficiencyReduce labor intensityWork benchesOther workshop equipmentCAR disassemblyEngineering

Owner:昆山弗莱吉电子科技有限公司

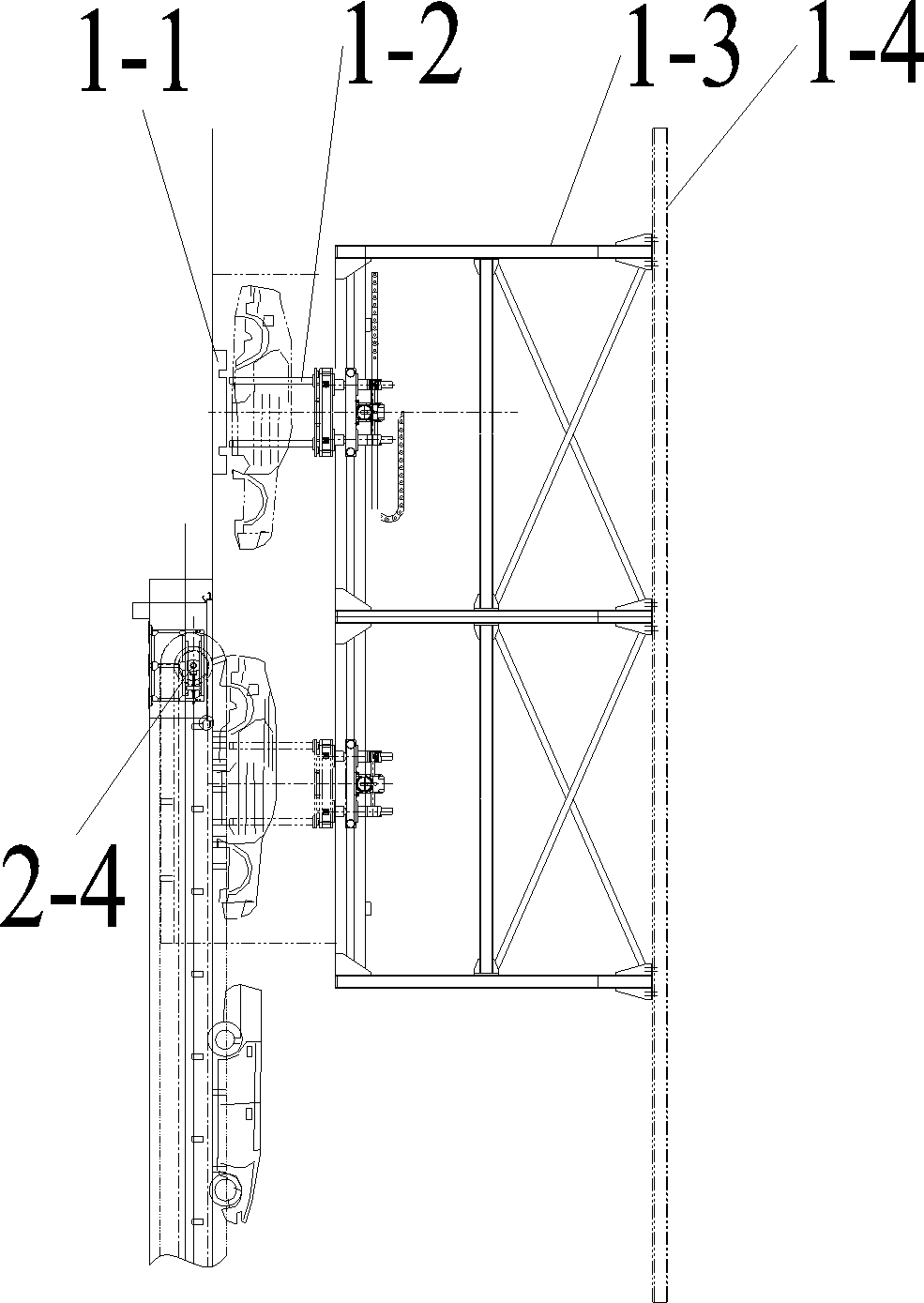

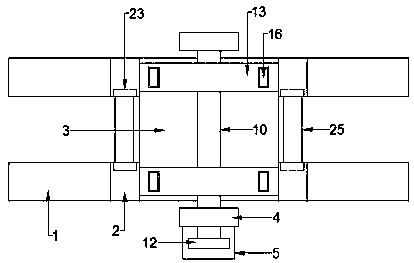

Scrapped car dismantling-body packing line

ActiveCN104044663BIncrease productivitySave storage spaceVehicle dissasembly recoverySolid waste disposalCAR disassemblyProduction line

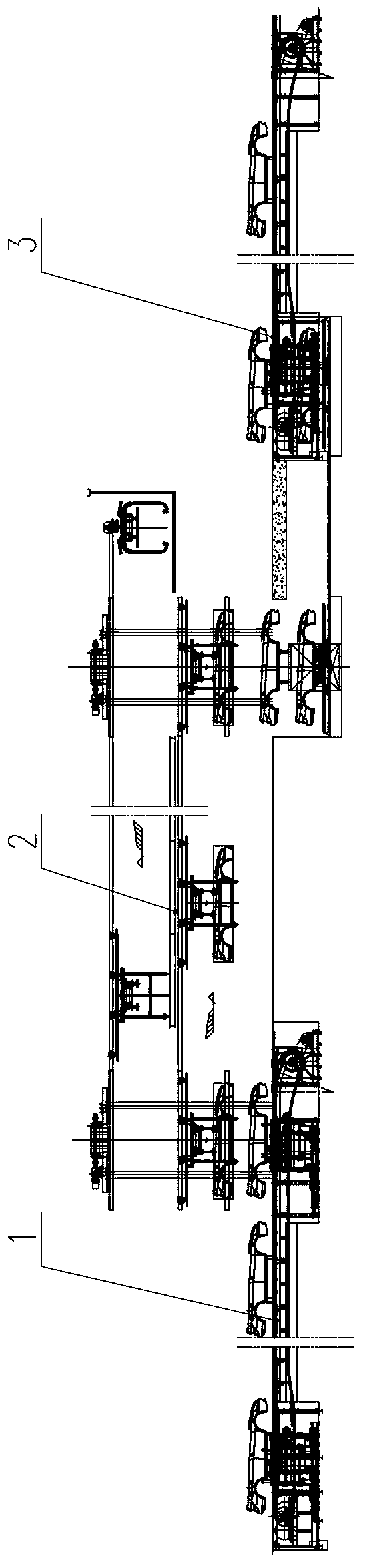

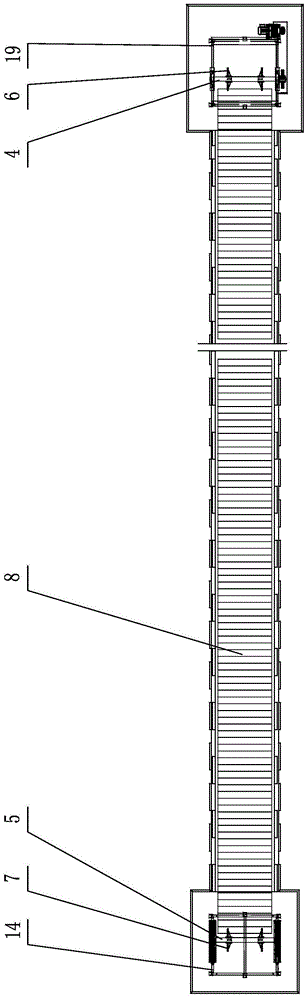

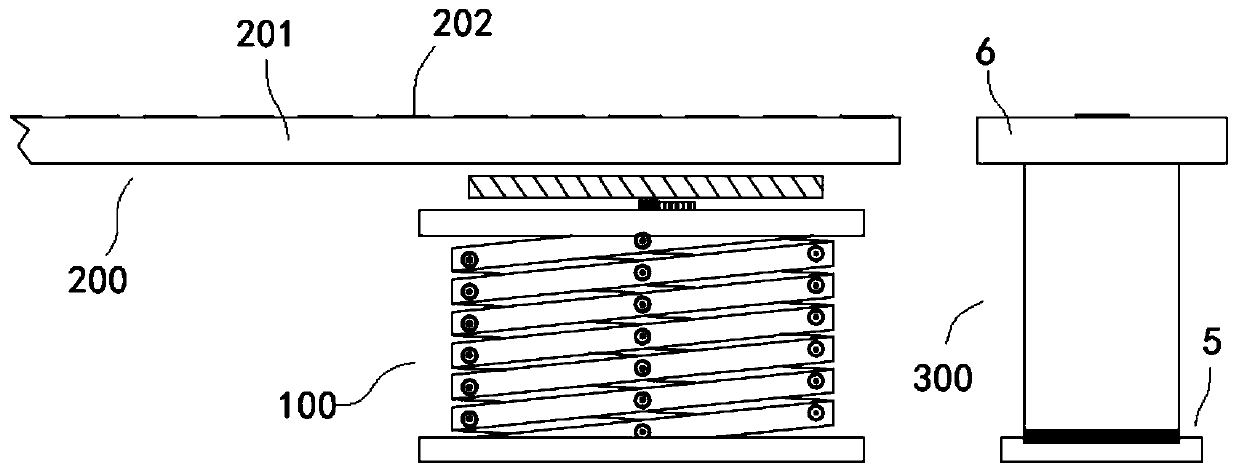

The invention relates to a disassembly-body packaging production line of a scrapped automobile. The disassembly-body packaging production line is characterized by comprising a disassembly line (1), a lifting, conveying and discharging machine (2) and a packer (3). According to the disassembly-body packaging production line, after the finished automobile is disassembled, a body is compressed and packaged. The disassembly-body packaging production line has the advantages that production efficiency is high, the compressed and packaged body occupies small storage space, transportation cost is reduced, and economical benefits are improved.

Owner:JIANGSU HUAHONG TECH STOCK

Adjustable anti-locking scraped car disassembly machine

ActiveCN110834691AExtend your lifeEnsure safetyVehicle dissasembly recoverySolid waste disposalElectric machineryCAR disassembly

The invention discloses an adjustable anti-locking scraped car disassembly machine. The adjustable anti-locking scraped car disassembly machine comprises a disassembly device body, the disassembly device body is provided with a transmission device, the transmission device comprises an installation cylinder, an inner gear ring is rotationally arranged in the installation cylinder, a driving gear isarranged in the axis of the inner gear ring, an input shaft is fixedly connected to the axis of the left side face of the driving gear, and a transmission base is slidably arranged on the right sideof the driving gear. When a cutter tool in the device is locked, torque transmitted by the input shaft makes a locking pin totally separated from a hemispherical clamping groove, an inner clamping ring is loosened, and an output shaft rotates to drive the inner clamping ring to rotate, so that a motor driving device is protected. A user can adjust the maximum locking force of the locking pin by changing the pressure of a sliding rod on the locking pin, a brake disc makes the transmission base frictionally braked or released through automatic left and right movement of the transmission base, the safety of an operator is effectively ensured, when the device is clamped, the torque is discharged, and the service life of a motor is effectively prolonged.

Owner:王盈盈

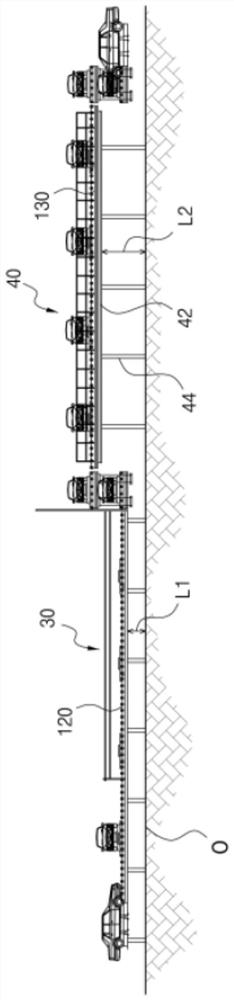

Scrap car dismantling system

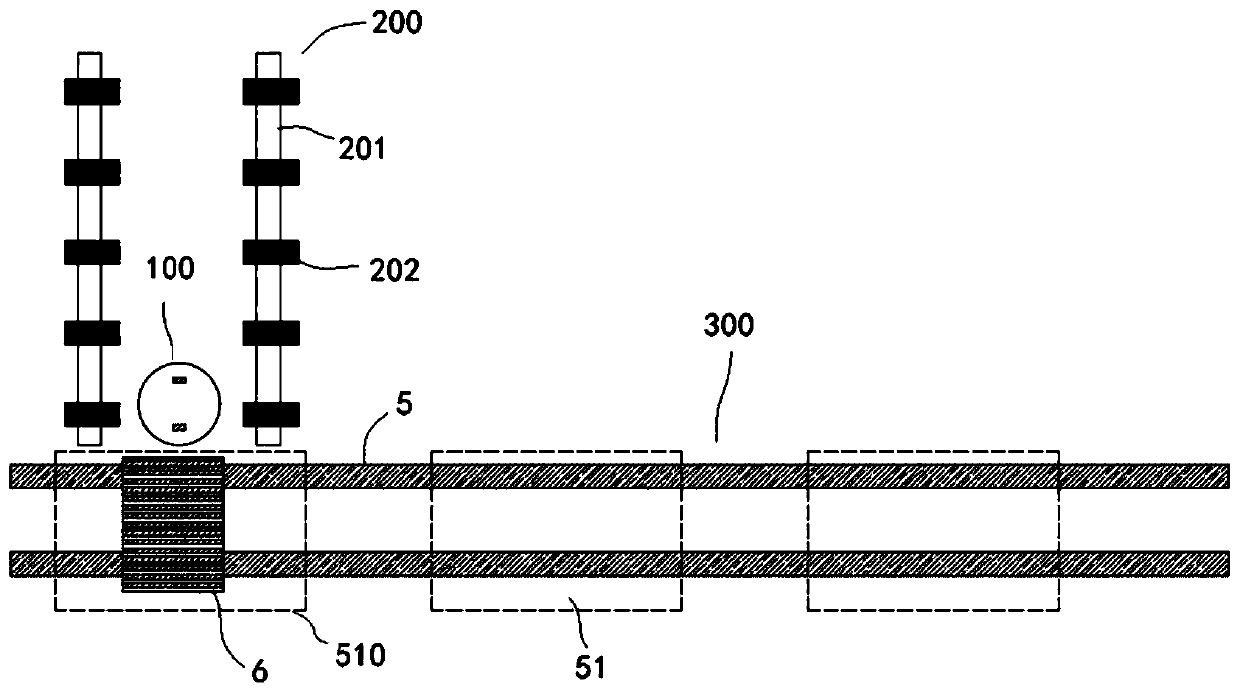

ActiveCN110539826BMobile Route MinimizationEasy to put inVehicle dissasembly recoverySolid waste disposalCAR disassemblyScrap

The scrapped car dismantling system of the present invention includes: a scrapped car input unit for inputting scrapped cars; Parts are disassembled during the moving process; the middle dismantling department makes the parts disassembled during the movement of the scrapped vehicle along the second transfer track configured in a manner higher than the above-mentioned first transfer track; A high-level dismantling section for dismantling parts while scrapped vehicles are moving along the third transfer rail arranged at a height higher than the second transfer rail; and a body discharge section for discharging disassembled The body of the parts can be disassembled in a scrapped car at a suitable height, so the operation becomes convenient and safe.

Owner:INSUN MOTORS

A method for controlling the dismantling of scrapped vehicles

The invention discloses a dismantling control method for waste vehicles and belongs to the technical field of car disassembly. The dismantling control method is based on a vehicle disassembly turningmachine; the vehicle disassembly turning machine includes a chassis locking mechanism, a turning mechanism, a lifting mechanism, a car body limitation mechanism and a disassembly platform; the car body limitation mechanism includes a car body clamping component and a car top limitation component; the chassis locking mechanism comprises two chassis locking components which are spaced and of the same structure; and each chassis locking component includes a fixing frame, a material transferring component and two symmetrically arranged pressing components. Different types of car bodies can be fixed through the car body limitation mechanism so as not to shake during the process of rotation and lifting, and thus the needs of different types of cars are met. In addition, the car body limitation mechanism can clamp and lift a car shell, and the chassis locking mechanism can lock a chassis of a car body so as to assist workers in dismantling the car shell.

Owner:江苏好道商务科技有限责任公司

Scraped car turnover device

PendingCN114179940ATo achieve the effect of flippingRealize the warning effectVehicle dissasembly recoverySolid waste disposalCAR disassemblyWorkbench

The invention relates to a scraped car turnover device, and relates to the field of car disassembly, the scraped car turnover device comprises a workbench and a support installed on the workbench, the support is provided with a supporting frame in a lifting mode, and the supporting frame is provided with a supporting table used for placing a car and a clamping mechanism used for clamping the car. The automobile turnover protection device is characterized in that a plurality of sets of induction mechanisms used for surrounding an automobile turnover protection area are arranged on the outer edge of the working table, the working table is provided with a warning mechanism used for warning workers, the supporting table is provided with a reinforcing mechanism used for stabilizing the supporting table, and the induction mechanisms are in control connection with the warning mechanism. The automobile turnover device has the effect of warning workers, and the safety performance in the automobile turnover operation process is ensured.

Owner:陕西省报废汽车回收拆解有限公司

Car bumper dismantling device

ActiveCN103723212BReduced dismantling timeReduce the consumption of manpower and material resourcesVehicle dissasembly recoverySolid waste disposalCAR disassemblyHydraulic cylinder

The invention discloses a car bumper disassembling device. The car bumper disassembling device is provided with a supporting plate and two disassembly boxes, wherein the disassembly boxes are respectively provided with a mechanical arm. Each mechanical arm is provided with a perpendicular lead screw, a lifting motor driving the perpendicular lead screw to rotate, a movable frame capable of moving on the perpendicular lead screw, a supporting arm movably connected to the movable frame, a pressing arm in pin joint with the front end of the upper portion of the movable frame, a grabbing arm in pin joint with the front end of the pressing arm, a supporting arm hydraulic cylinder which is connected to the movable frame and drives the supporting arm to move, a pressing arm hydraulic cylinder which is connected to the supporting arm and drives the pressing arm to swing and a grabbing arm hydraulic cylinder which is connected to the pressing arm and drives the grabbing arm to swing. Two pairs of adjusting wheels which move leftwards and rightwards are arranged at the bottom of each disassembly box. Two horizontal guide rails are arranged on the upper surface of the supporting plate and correspond to the adjusting wheels. Two pairs of walking wheels which walk forwards and rearwards are arranged on the bottom surface of the supporting plate. The car bumper disassembling device saves disassembly time, reduces consumption of labor and resources, greatly improves disassembly efficiency, and is particularly suitable for an automatic car disassembly production line.

Owner:JIANGSU UNIV OF TECH

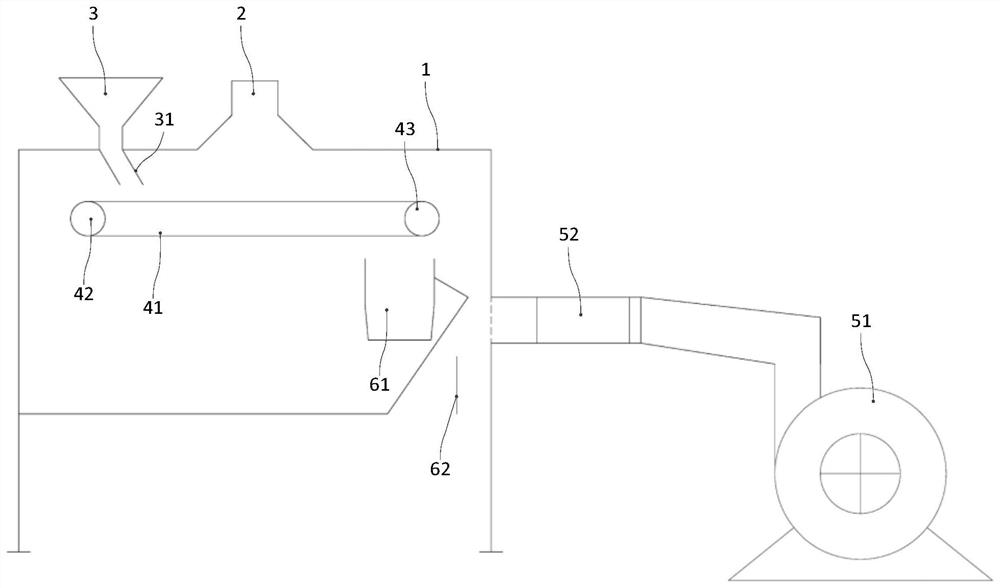

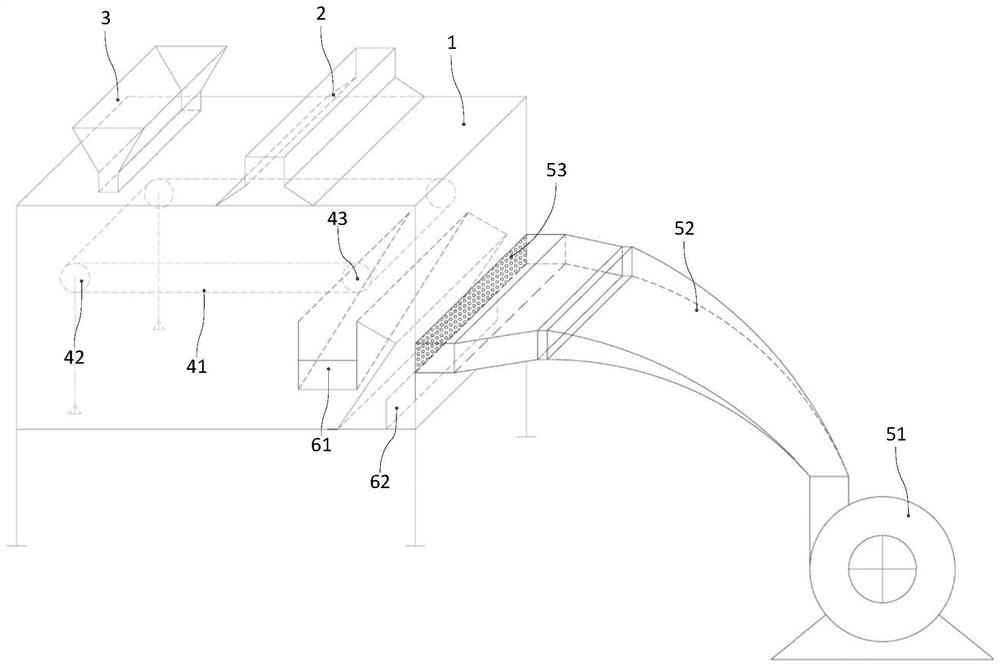

Dry separation device for stainless steel in scraped car disassembly tailings

PendingCN112657674AEasy to recycleSimple structureGas current separationDirt cleaningCAR disassemblyProcess engineering

The invention relates to a dry separation device for stainless steel in scraped car disassembly tailings. The dry separation device comprises a box body, a conveying magnetic separation device and a longitudinal blowing separation device; the conveying magnetic separation device and the longitudinal blowing separation device are respectively arranged in the box body; the conveying magnetic separation device is located in the middle of the box body, is horizontally arranged and comprises a separation conveying belt, a driving roller and a magnetic roller; the magnetic roller is arranged at one end of the separation conveying belt; the longitudinal blowing separation device is positioned in front of the conveying magnetic separation device; the longitudinal blowing separation device comprises a fan; and the draught fan is connected to the side face of the box body through an air pipe, and the air outlet of the air pipe is horizontally or obliquely arranged below the separation conveying belt. According to the dry separation device for the stainless steel in the scraped car disassembly tailings, the stainless steel existing in the scraped car disassembly tailings is conveniently and rapidly recycled, the equipment structure is simple, and the separation efficiency is greatly improved.

Owner:JIANGSU HUAHONG TECH STOCK +1

Multi-selection path conveying device for automobile disassembly

InactiveCN110171684APrevent slowing down productionRealize automated productionControl devices for conveyorsMechanical conveyorsCAR disassemblySingle line

The invention discloses a multi-selection path conveying device for automobile disassembly. The multi-selection path conveying device comprises an automobile body conveying line, a rotary lifting device and automobile body discharging line, wherein the rotary lifting device is arranged on the automobile body conveying line, the rotary lifting device comprises an induction device, a rotary base body and a controller, and the rotating base body can be selectively protruded out of the automobile body conveying line and can be controlled by the controller to move in the vertical direction and to rotate in the horizontal direction; the automobile body discharging line comprises a second conveying part and a third conveying part, wherein the second conveying part is divided into a plurality of pause stations along the length direction, the first pause station and the automobile body conveying line are collinear, the third conveying part can be selectively fixed on any pause station, and theconveying direction of the third conveying part is perpendicular to the second conveying part. An automobile body can be automatically selected to rotated by an angle by the rotary lifting device in the moving process on the automobile body conveying line, the automobile body can be discharged by different pause stations, so that the single-line discharging is prevented to slow down the production.

Owner:回收哥(武汉)互联网有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com