Non-destructive disassembling device for windshield glass of scrapped automobile

A technology for scrapping cars and windshields, which is used in vehicle scrapping and recycling, solid waste removal, and motor vehicles. , Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

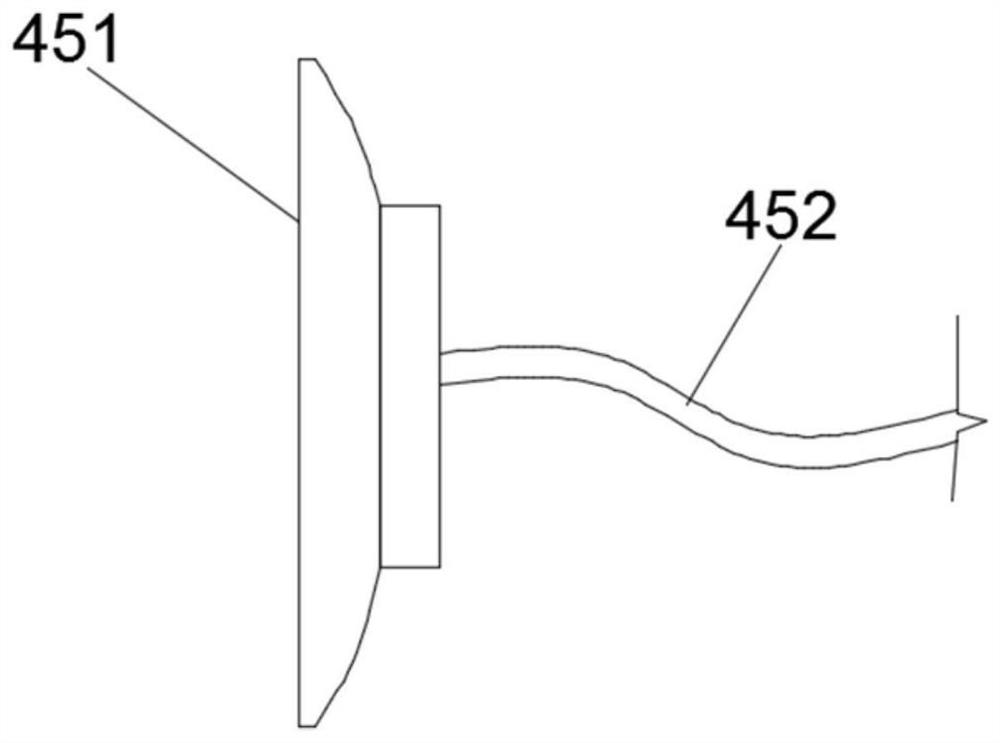

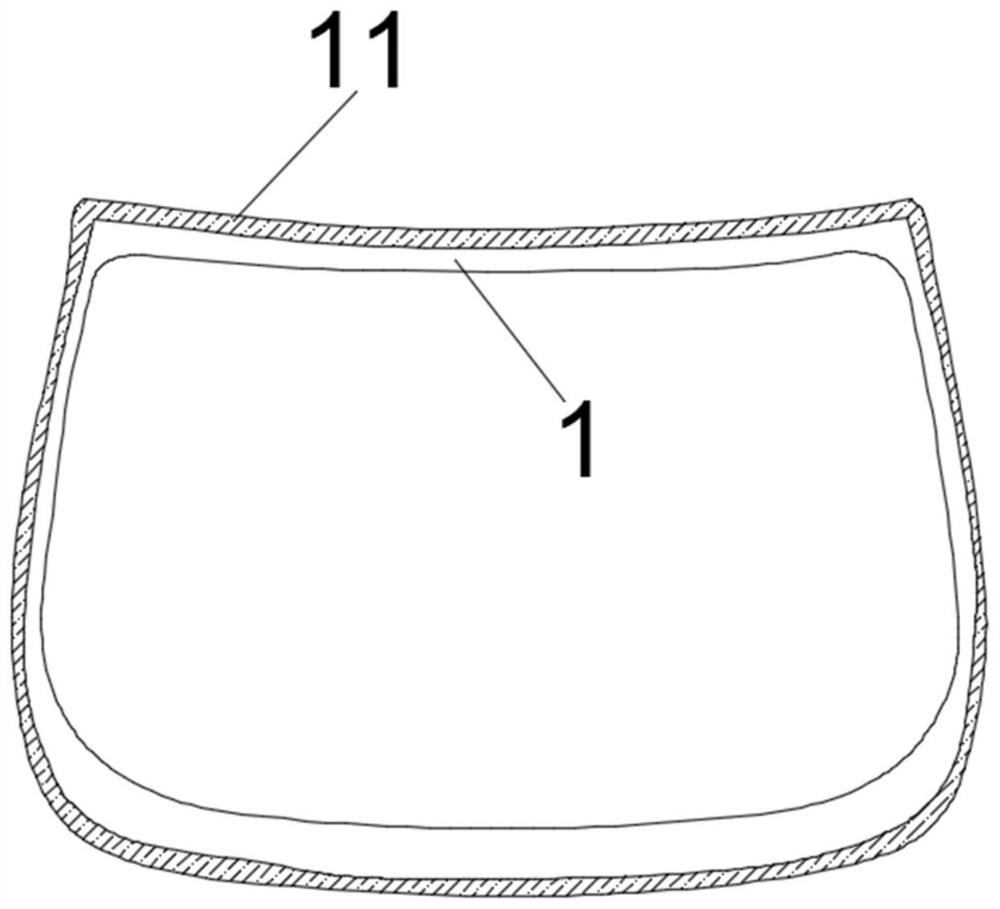

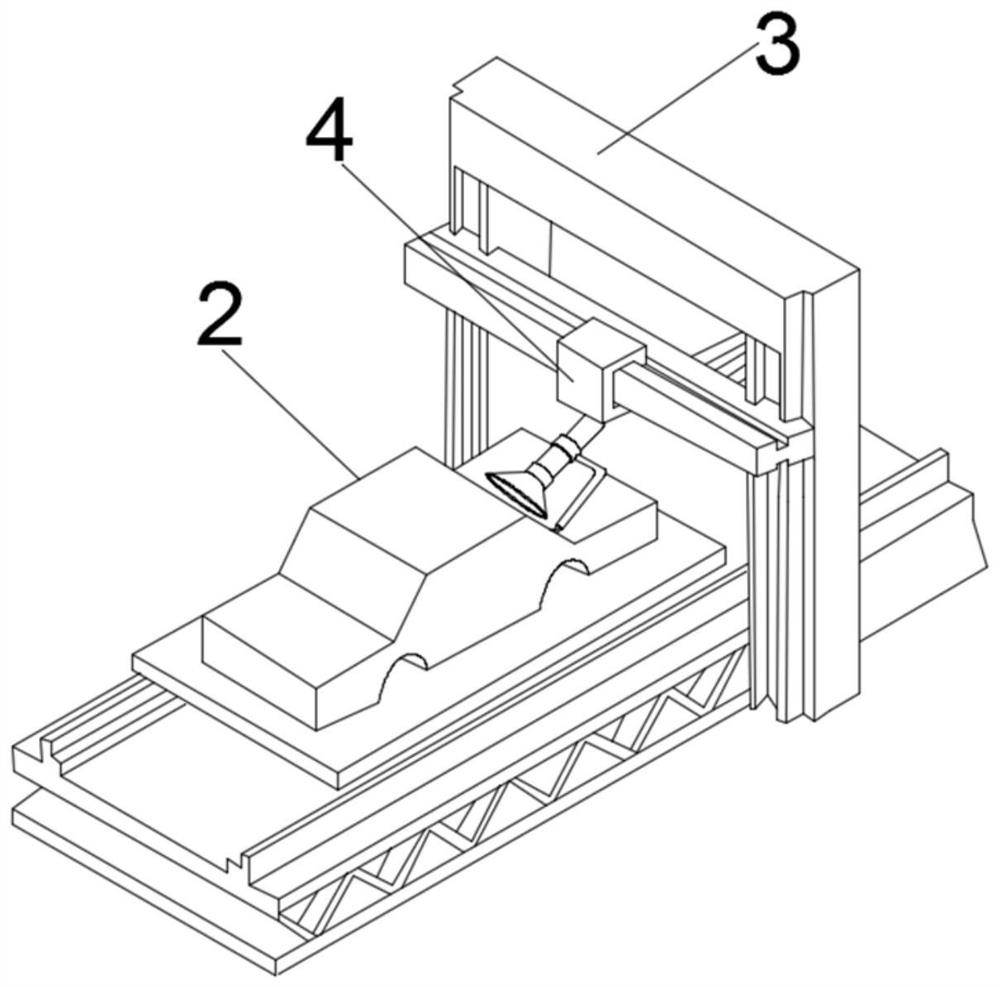

[0050] Refer to the attached Figure 1-26 A nondestructive dismantling device for a windshield glass of a scrapped car as shown includes a car dismantling frame 3, the scrapped car 2 is fixed on the transmission belt on the lower side of the car dismantling frame 3 for transmission, and the car dismantling frame 3 is provided with The guide assembly is provided with an automobile windshield dismantling device 4 , and the windshield dismantling device 4 moves on the automobile disassembly frame 3 along with the guide assembly to disassemble the automobile windshield without damage.

[0051] Preferably, the guide assembly includes a longitudinal guide rod 31 and a lateral guide rod 32 arranged on the vehicle dismantling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com