Dry separation device for stainless steel in scraped car disassembly tailings

A sorting device and a technology for scrapped cars, which are applied in the direction of separating solids from solids with airflow, solid separation, magnetic separation, etc., can solve the problems of increased manufacturing costs, inconsistent sizes of stainless steel materials, etc., and improve the separation efficiency , The structure of the equipment is simple, the effect of convenient and quick recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

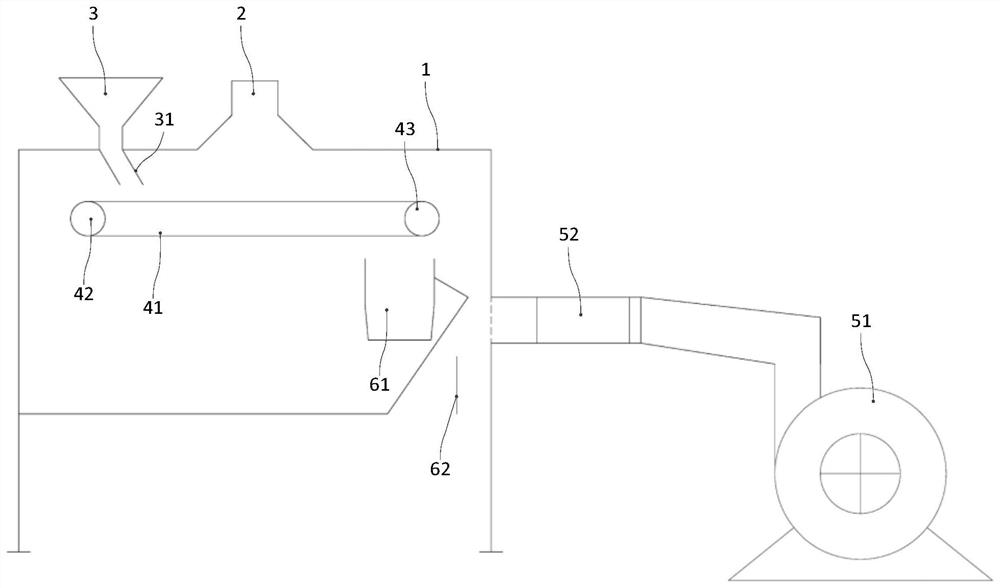

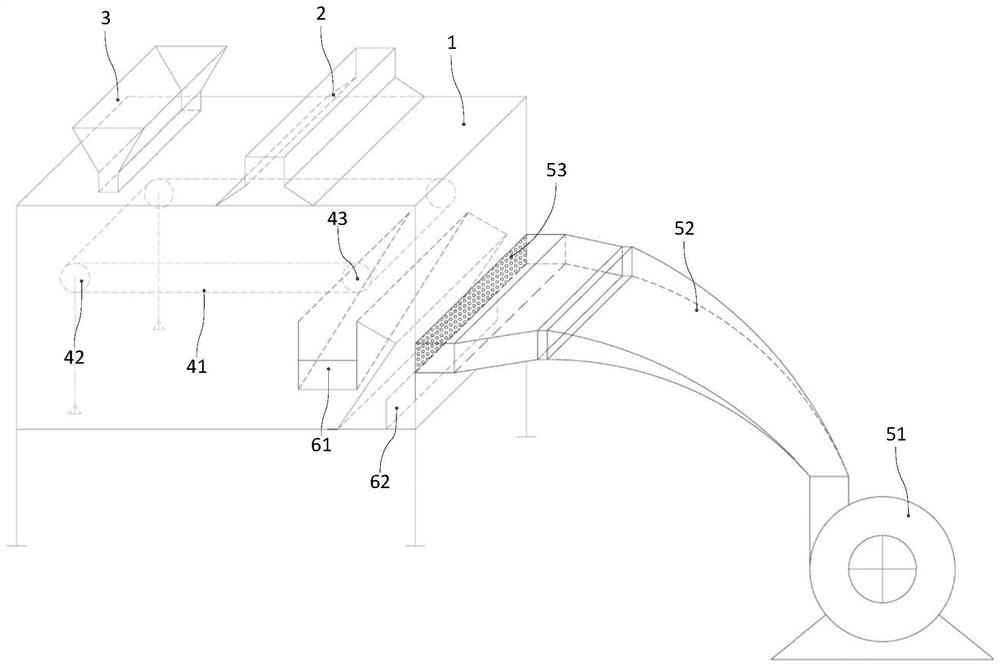

[0024] The stainless steel dry separation device in the waste car dismantling tailings of the present invention, such as figure 1 , figure 2 As shown, it includes a box body 1, and the top side of the box body 1 is provided with a feeding port 3; the box body 1 is also provided with a dust collection channel 2, which can suck away the dust generated in the box body 1, and carry out Dust removal.

[0025] Described box body 1 is mainly provided with sorting conveyer belt 41, and one end of described sorting conveyer belt 41 is arranged on the driving roller 42, and the other end of described sorting conveyer belt 41 is provided with magnetic roller 43, and described magnetic There are rare earth permanent magnets with ultra-high magnetic flux in the roller 43, which can attract small pieces of stainless steel; however,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com