Dust removal and noise reduction device for disassembling scraped car

A technology for scrapped cars and noise reduction, applied in the direction of scrapped vehicles, removal of solid waste, motor vehicles, etc., can solve problems such as large environmental impact, loud noise and dust, achieve a high degree of automation, reduce noise and smoke, reduce Effects of dust and smoke and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

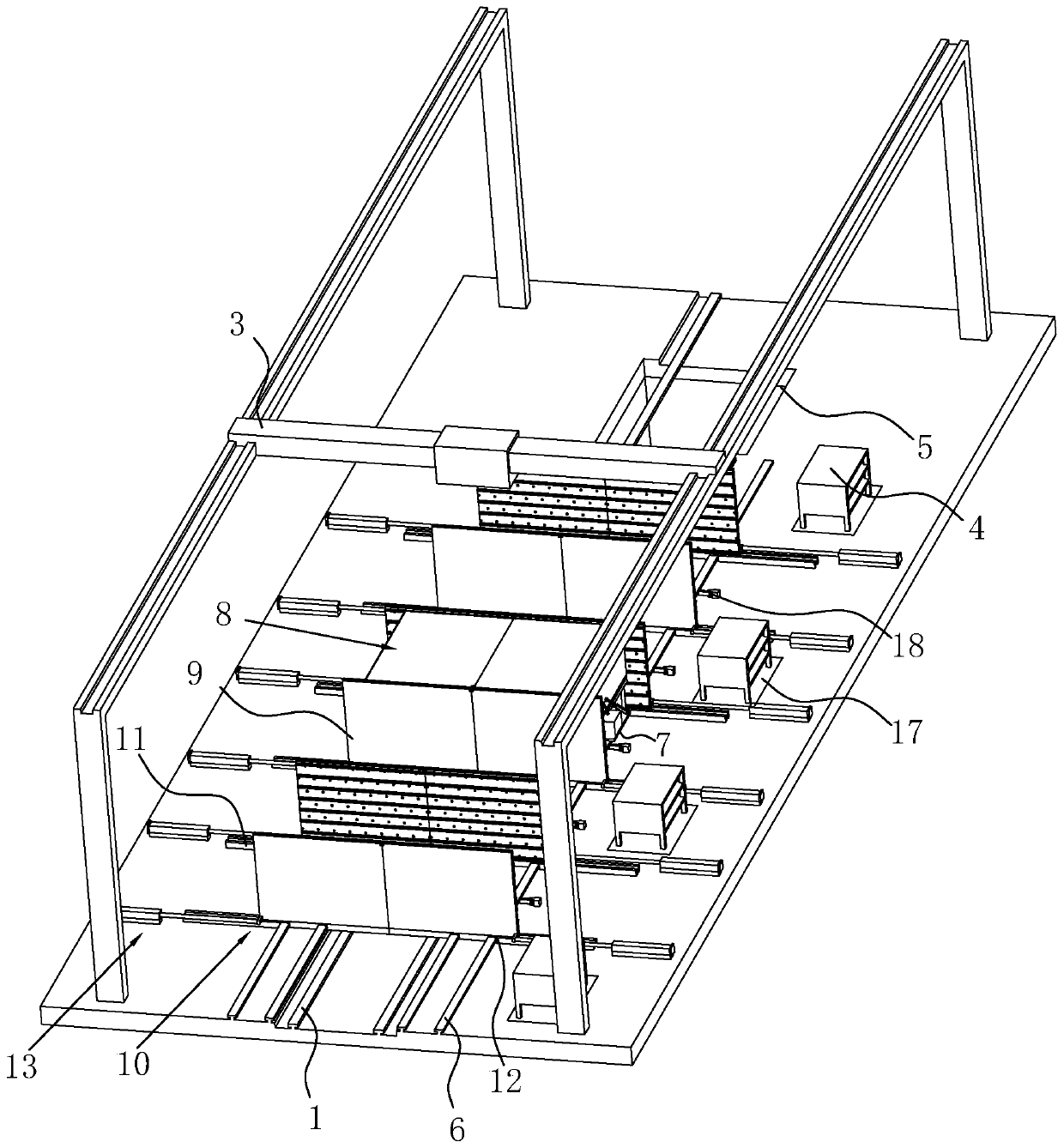

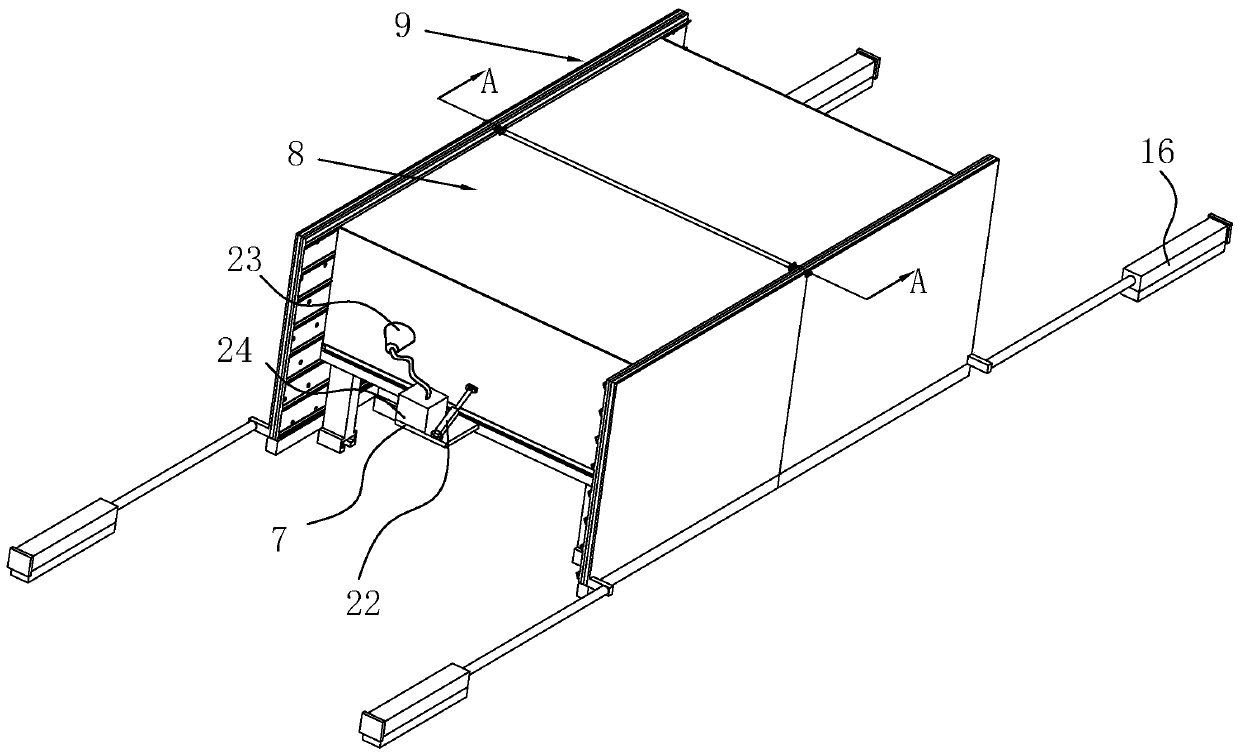

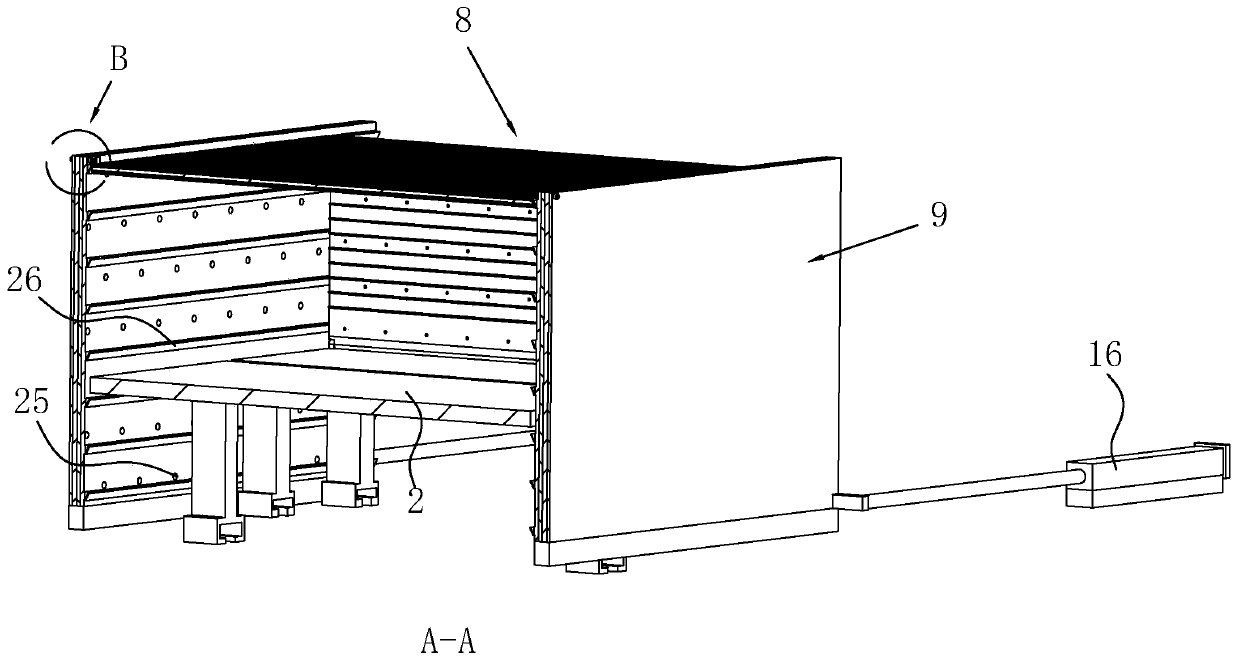

[0032] refer to figure 1 and image 3, is a dust removal and noise reduction device for dismantling scrapped automobiles disclosed by the present invention, which reduces the noise and dust pollution generated by automobile dismantling, and includes a dismantling slide rail 1 and a mobile platform 2, and dismantling slide rails 1 are provided on both sides Equipment, above the dismantling slide rail 1, a hoisting crane 3 is arranged in parallel, on both sides of the dismantling slide rail 1, several storage racks 4 are arranged, and a cleaning pool 5 is also arranged on the dismantling slide rail 1, and the two sides of the dismantling slide rail 1 are symmetrical A loading slide rail 6 is provided, a loading platform 7 is arranged on the loading sliding rail 6, a disassembly cover 8 is arranged on the loading platform 7, a plurality of sliding side plates 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com