Patents

Literature

142results about How to "Smooth lifting movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

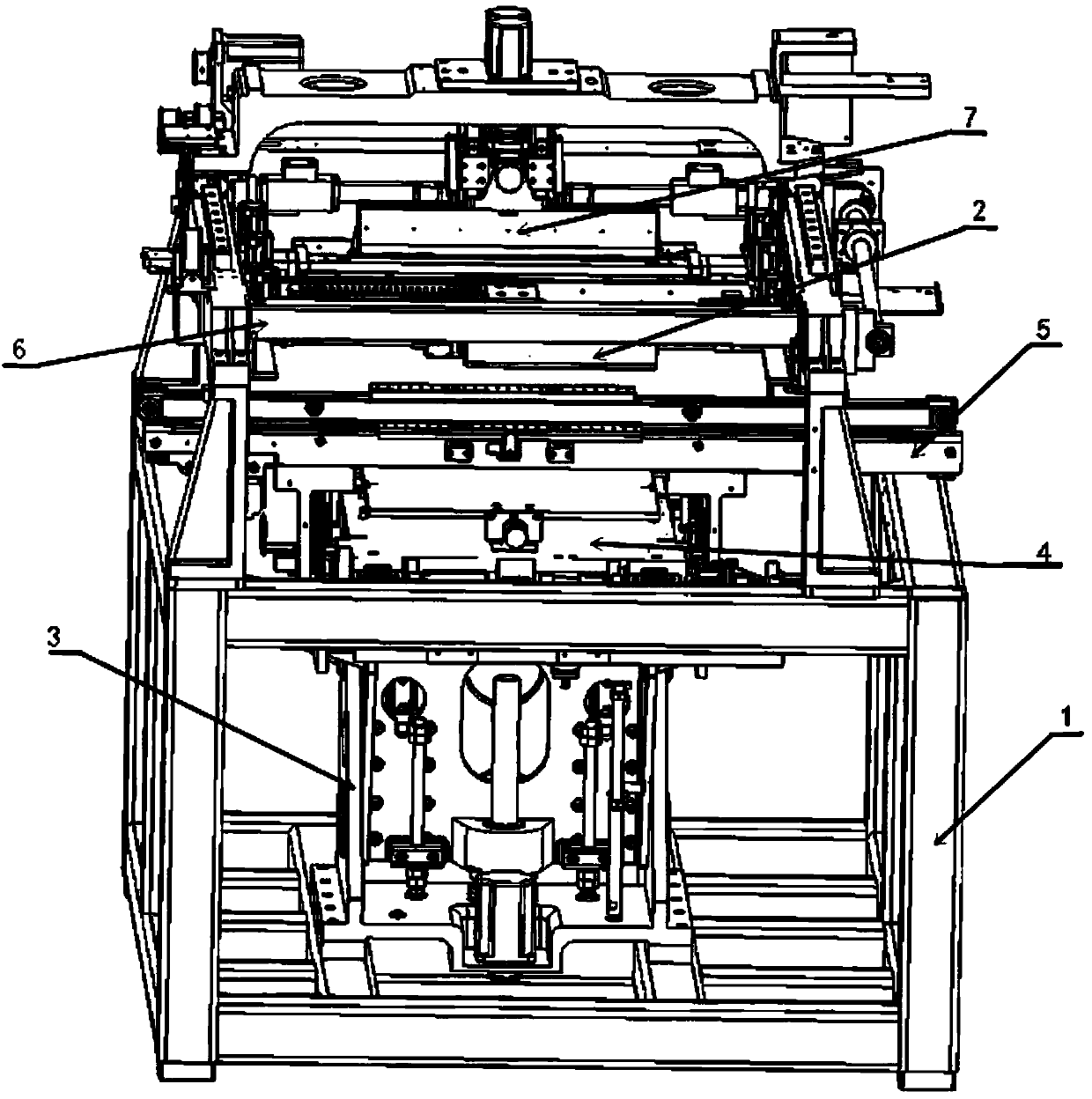

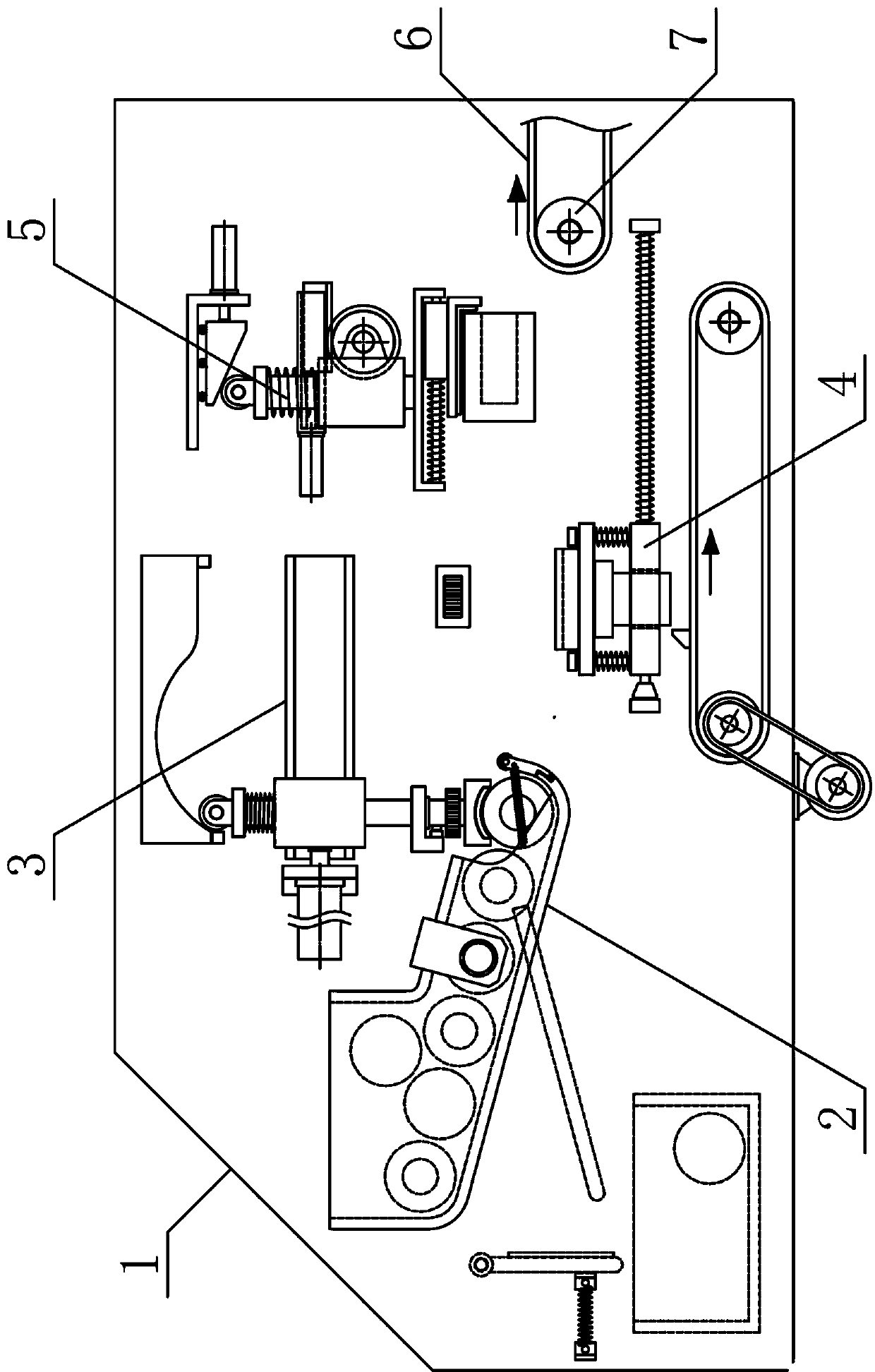

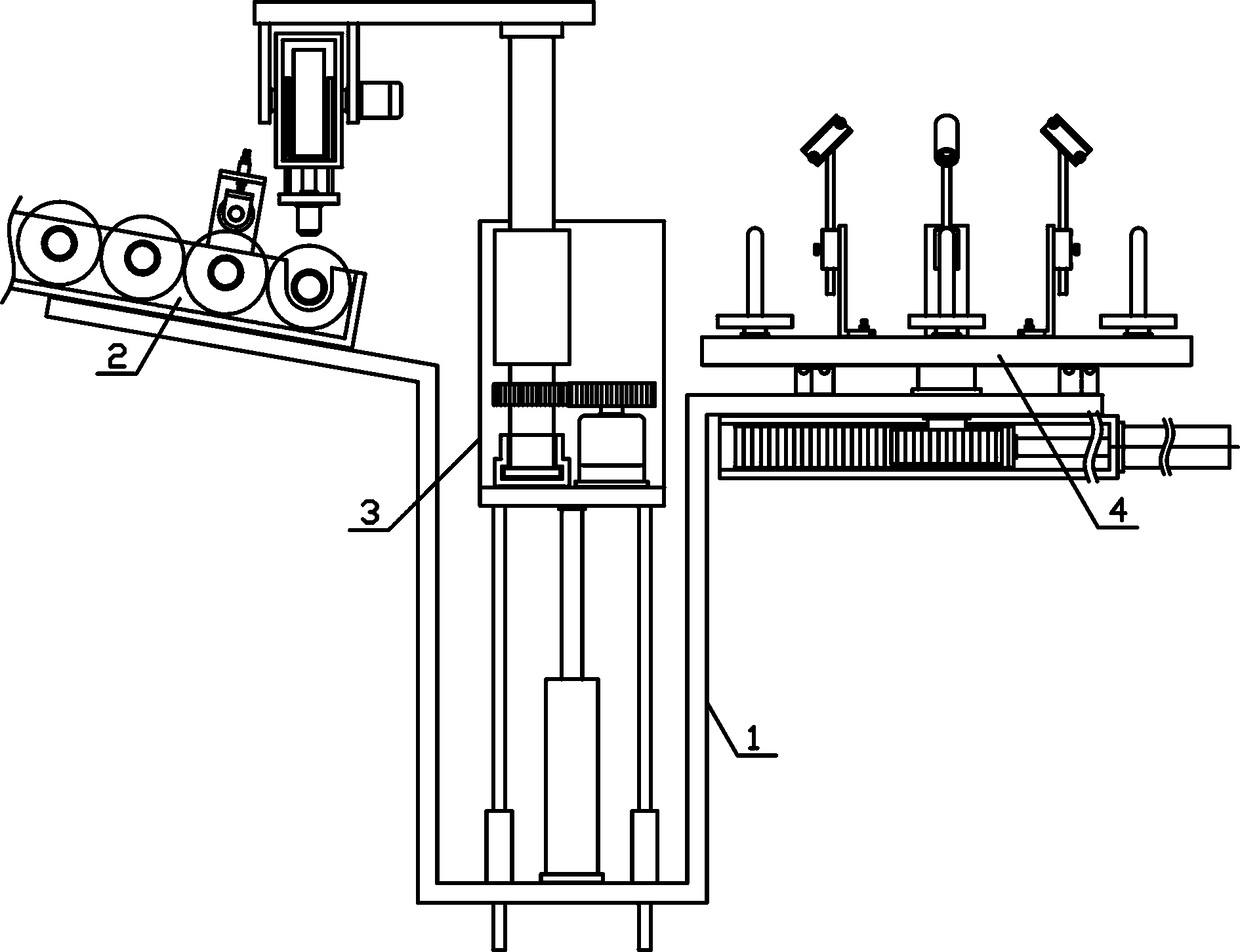

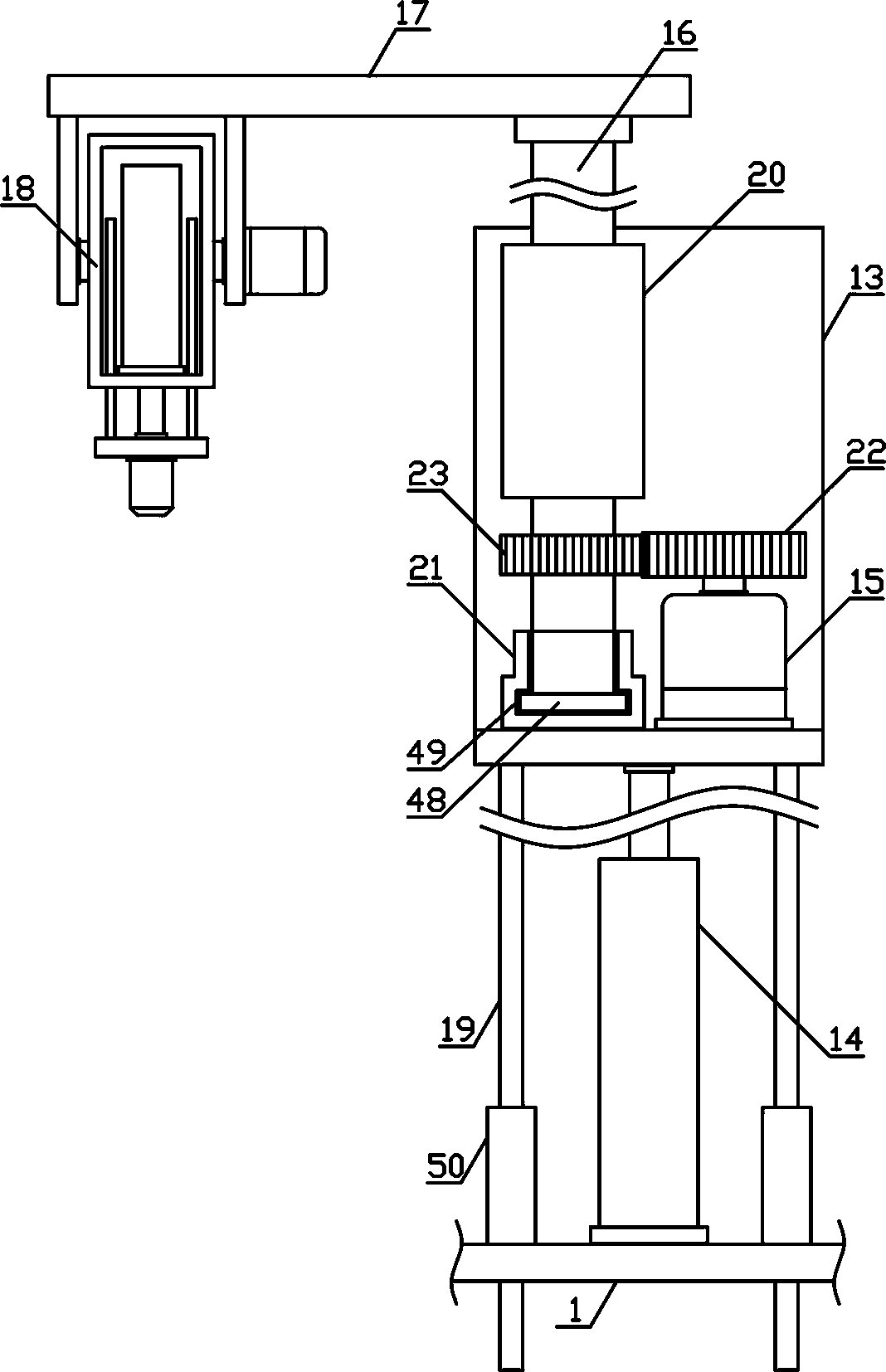

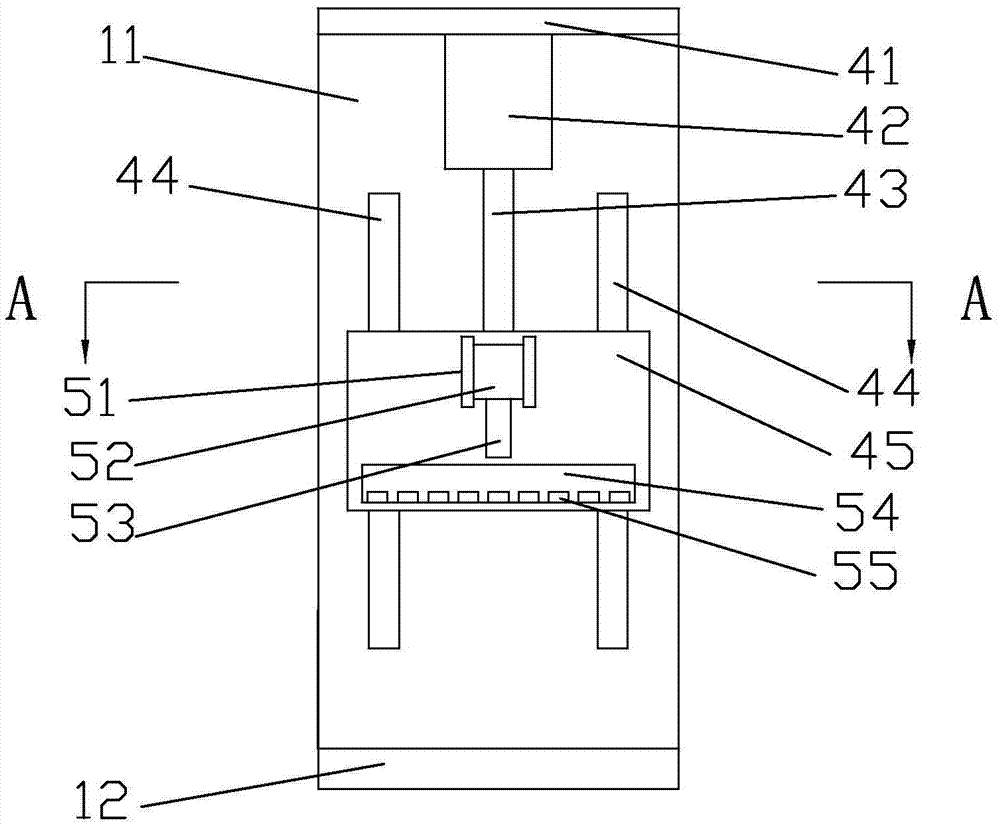

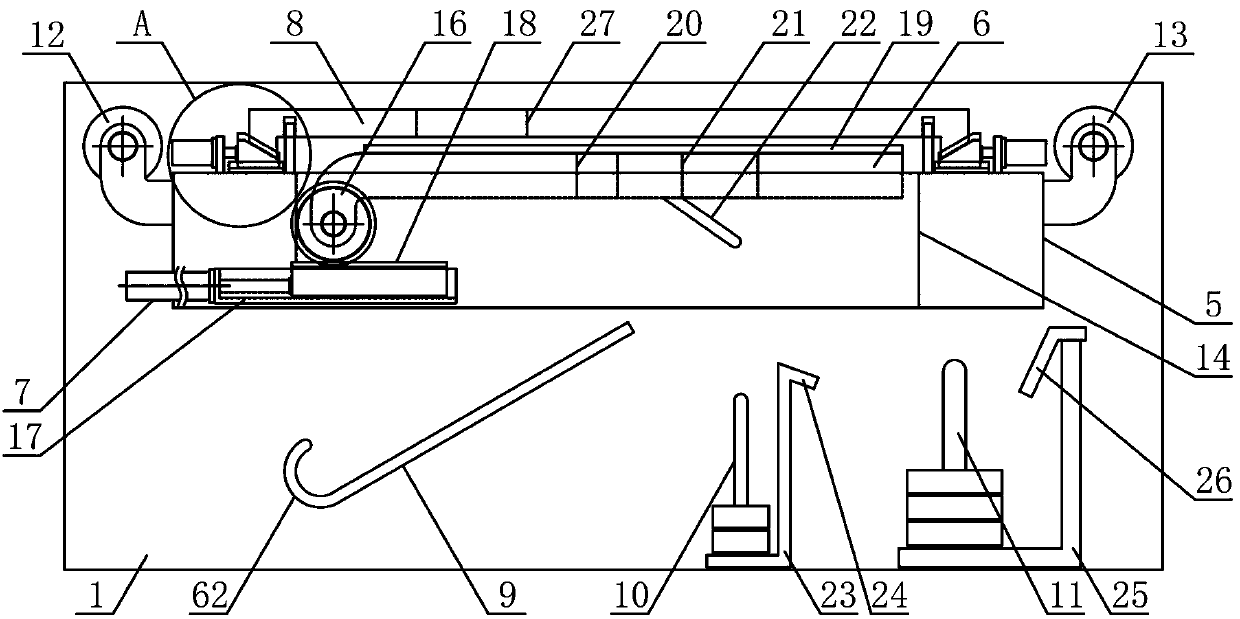

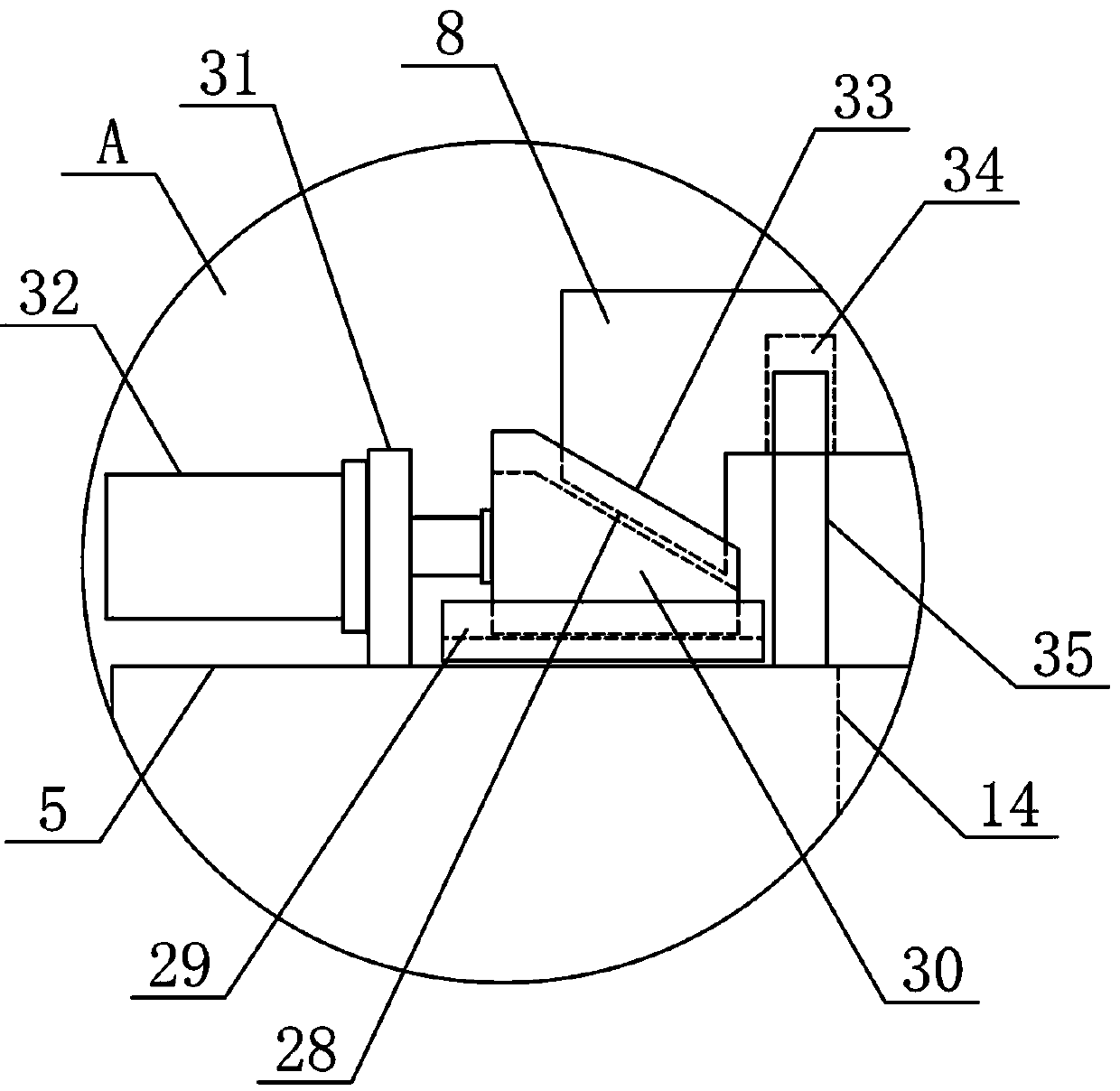

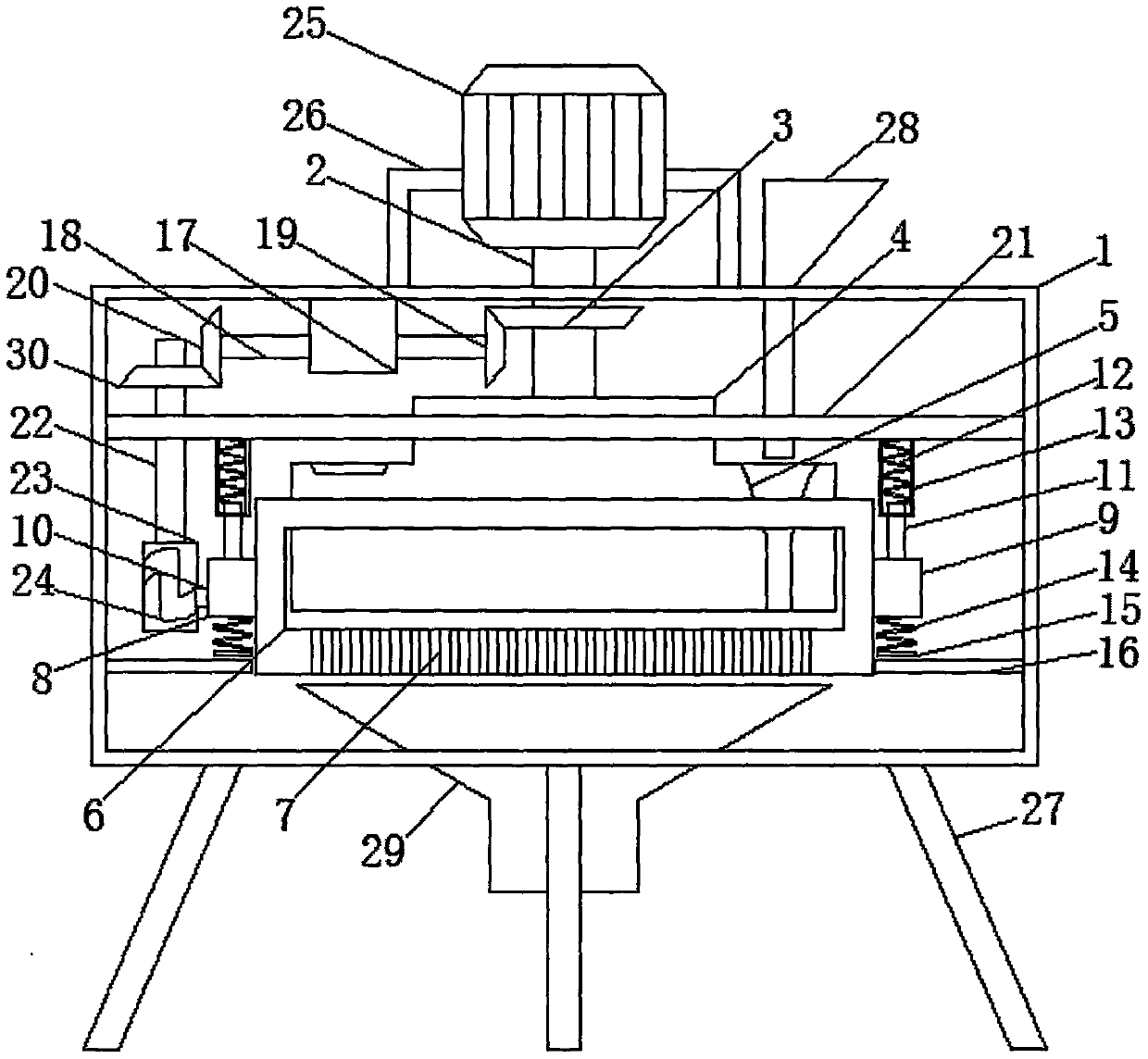

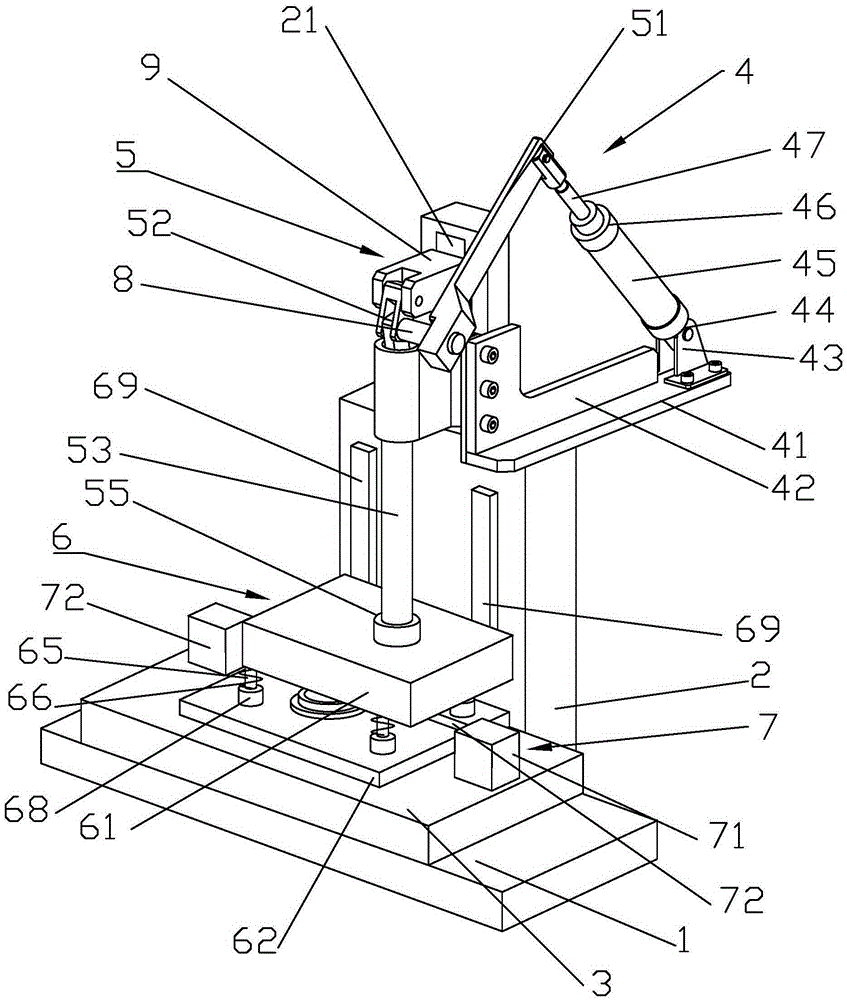

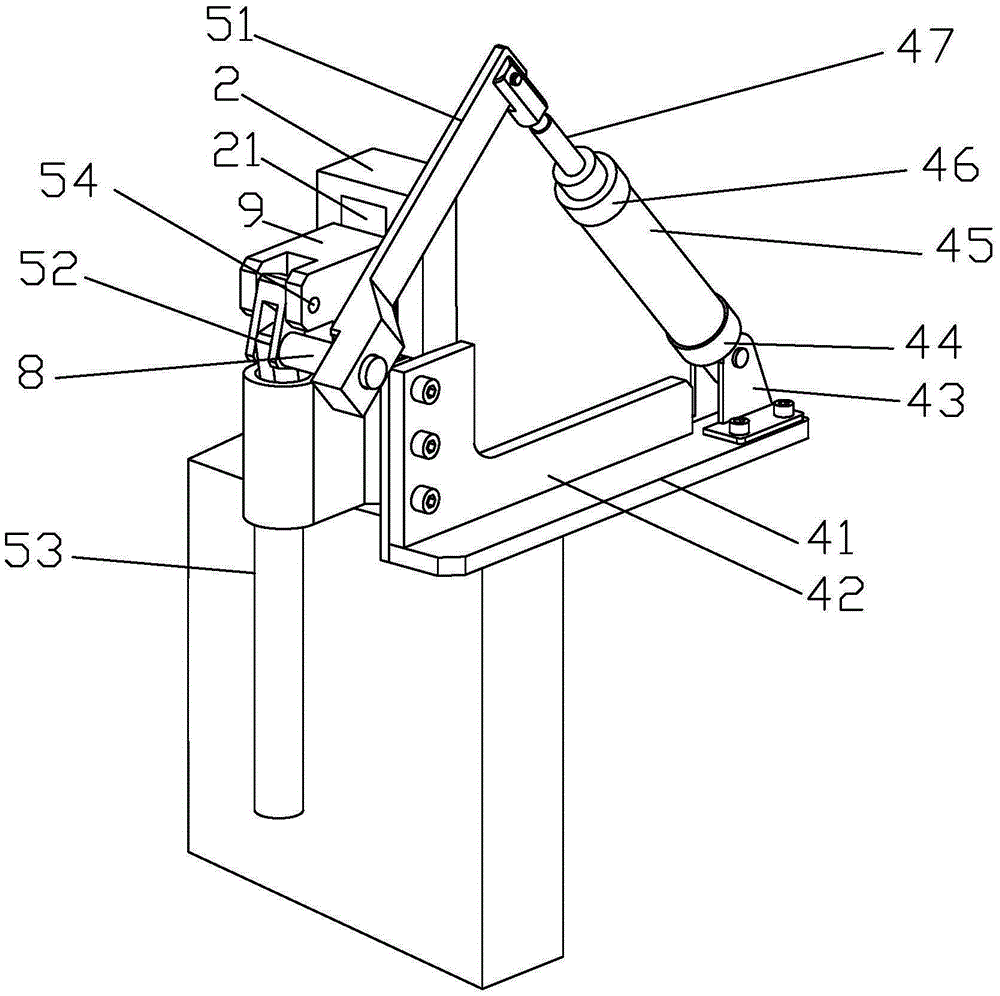

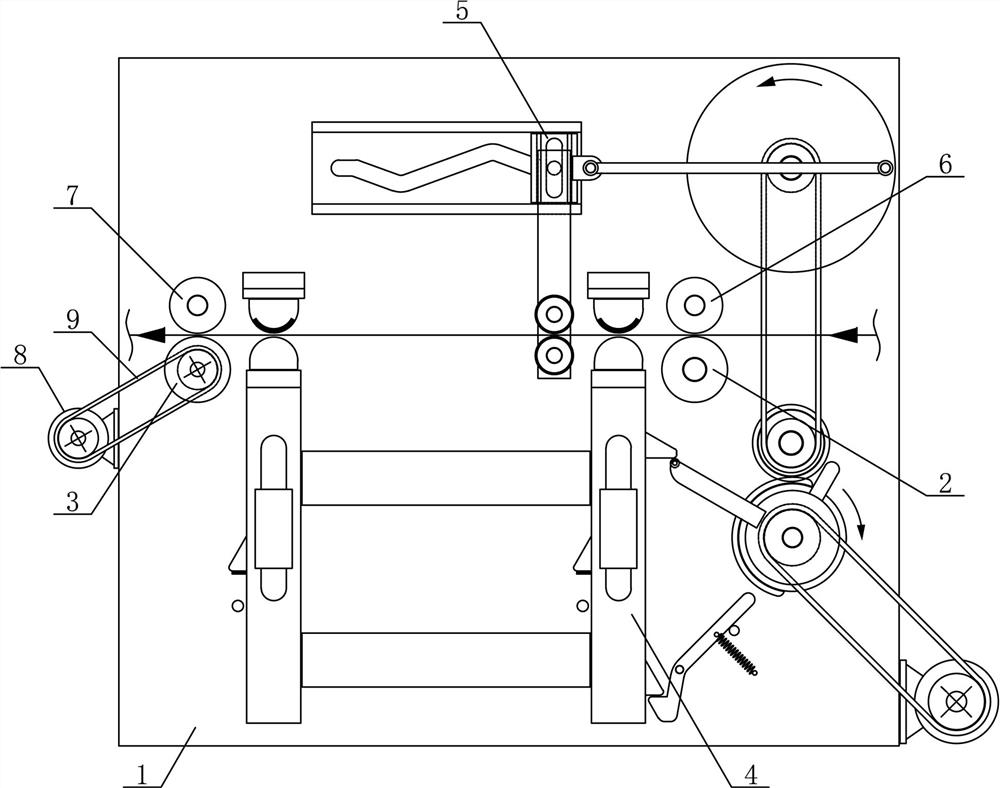

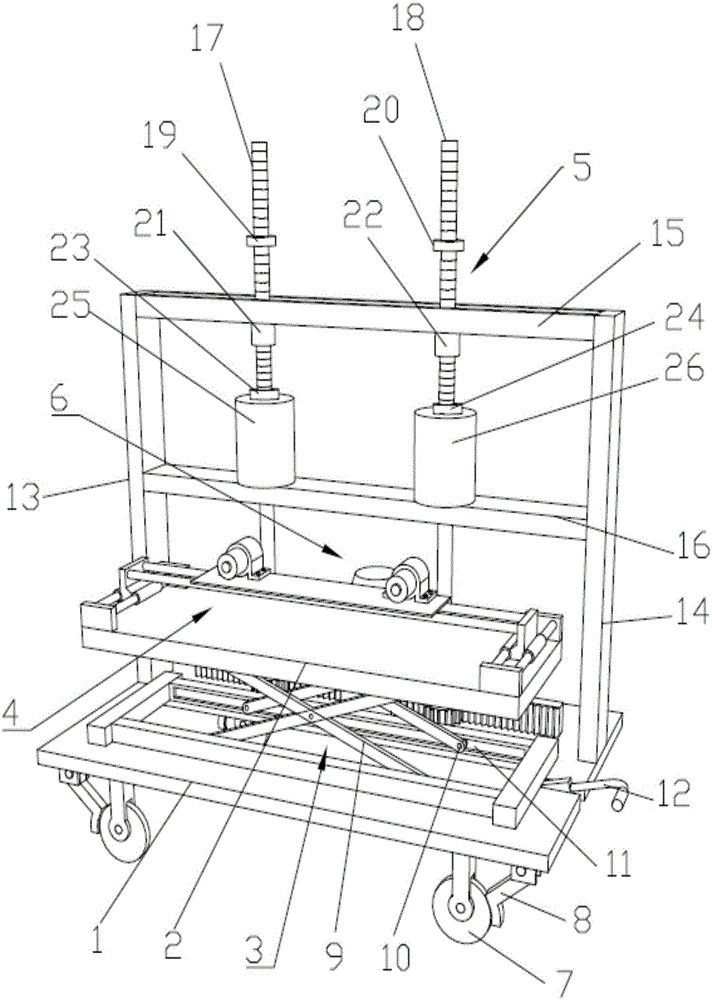

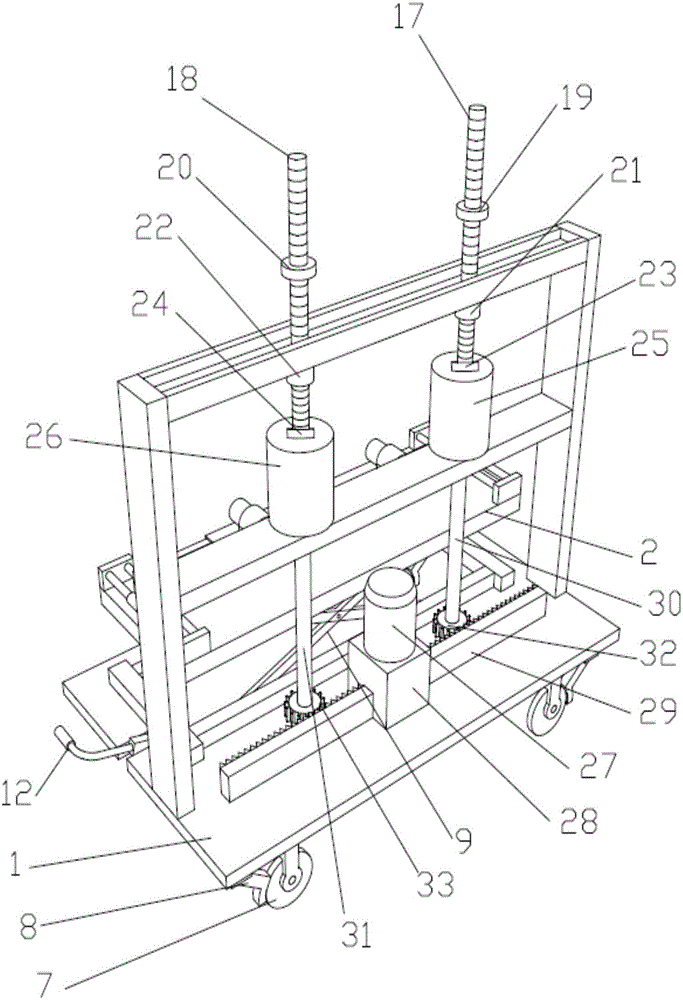

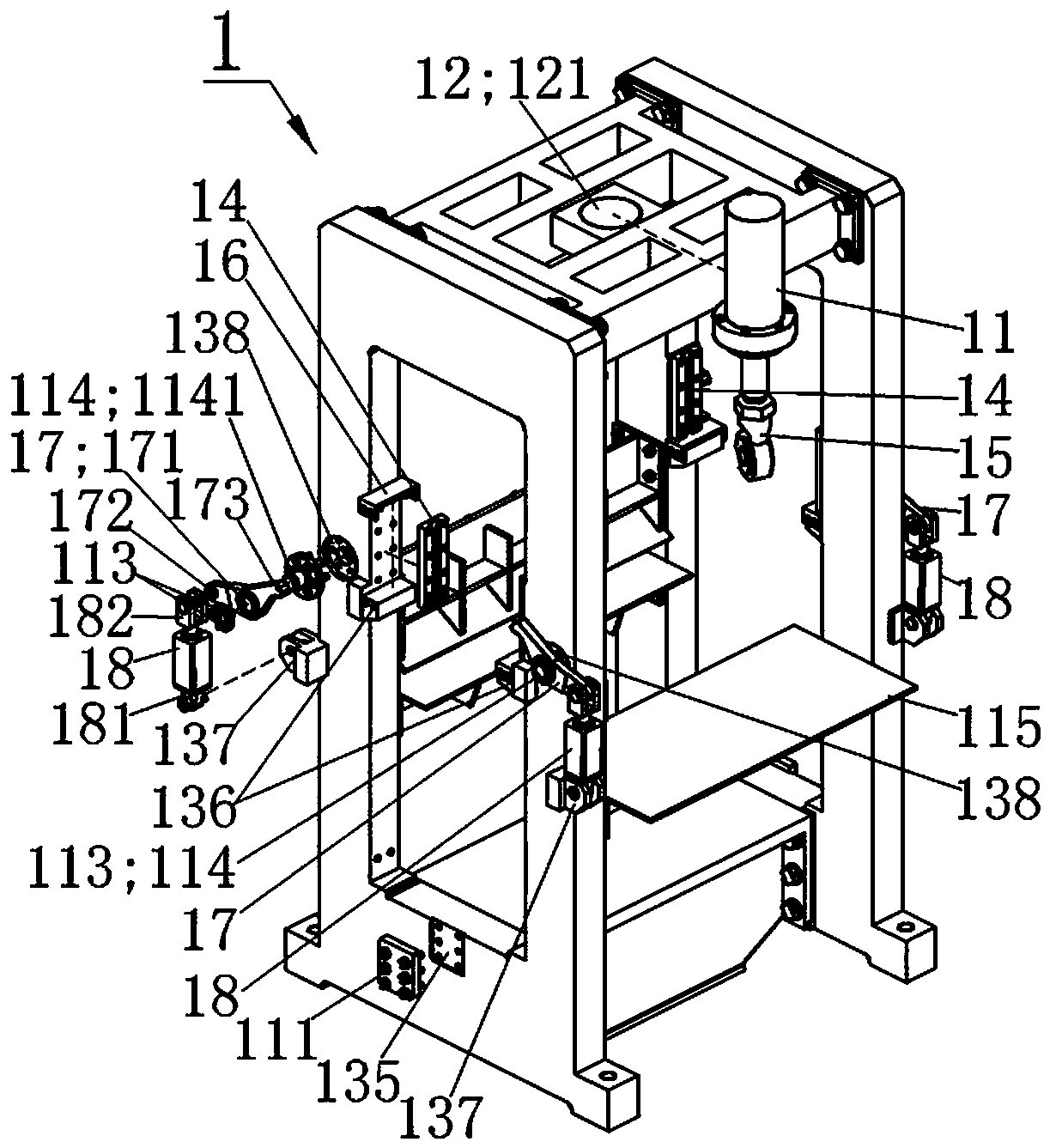

Full-automatic solder paste printer

ActiveCN104191808AEasy to cleanControl pressureScreen printersPrinting press partsPrinting pressSolder paste

The invention discloses a full-automatic solder paste printer. The full-automatic solder paste printer comprises a rack subassembly, wherein a Z-axis lifting system is installed at the bottom end of the rack subassembly, and a platform correcting system is installed at the top end of the Z-axis lifting system and provided with a guide rail transporting system; the rack subassembly is provided with a steel screen frame clamping system, a scraper blade printing system and an automatic cleaning system; the Z-axis lifting system makes lifting movement stable and positioning fast and accurate and solves the problem that responding speed is low because large-inertia lifting control is low in positioning accuracy; the difficult problem that manual PCB correction is not accurate is solved through the platform correcting system, and printing quality is improved; a steel screen frame is cleaned in any combination mode of a drying cleaning mode, a wet cleaning mode and a vacuum cleaning mode, so that the cleaning effect of the steel screen frame is greatly improved, manual cleaning time is shortened, and labor intensity is relieved; through the scraper blade printing system, pressure of a scraper blade can be accurately controlled and regulated, and the problem that the scraper blade pressure of a traditional printer cannot be controlled is solved.

Owner:SHENZHEN GRANDSEED TECH DEV

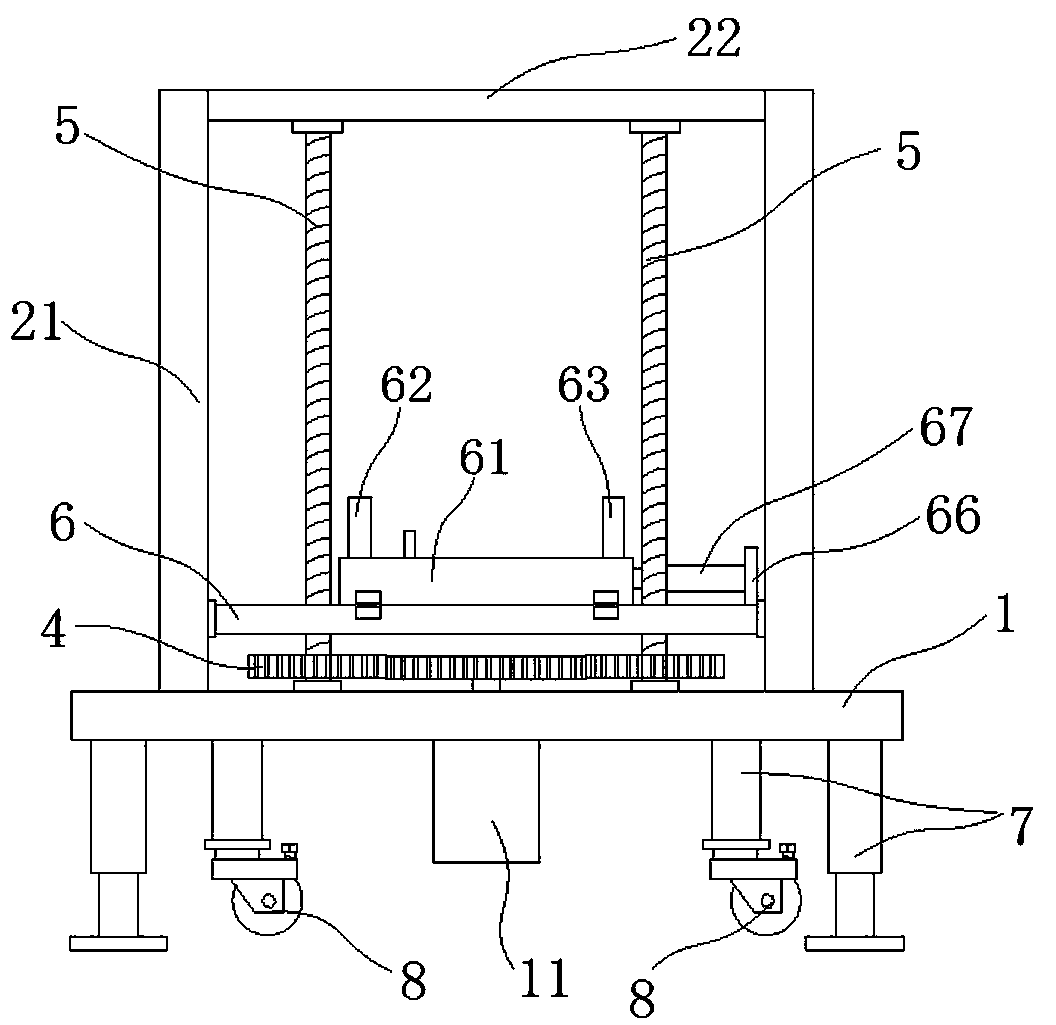

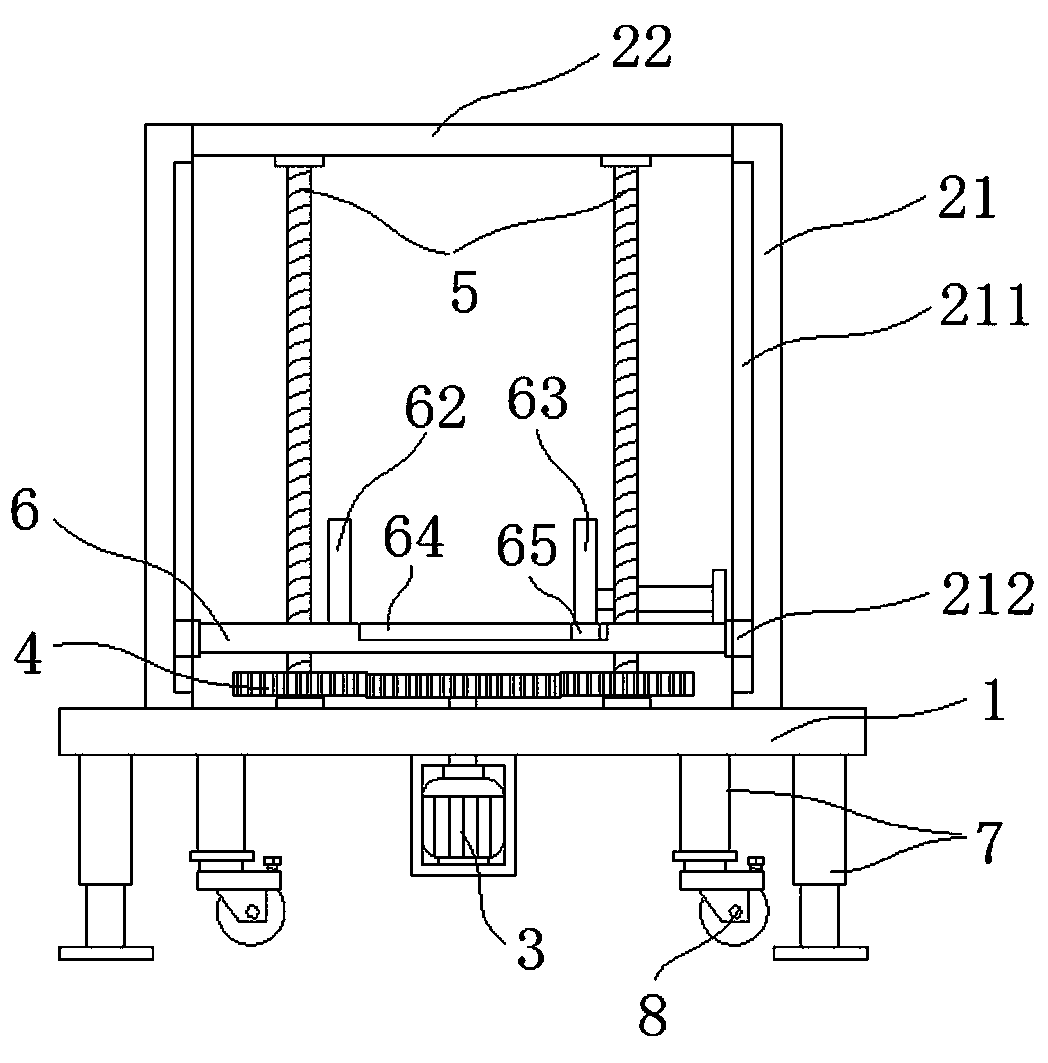

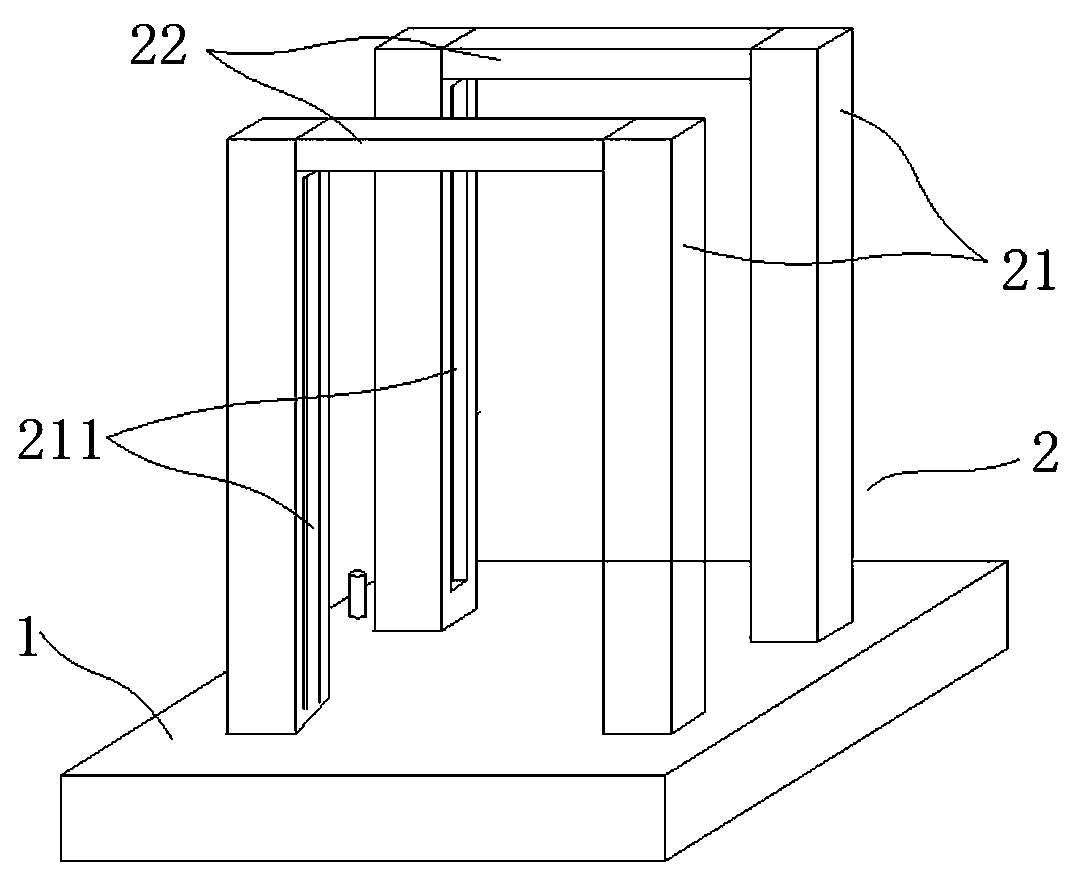

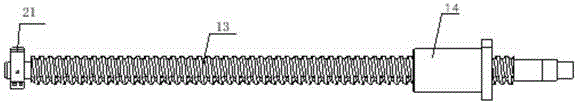

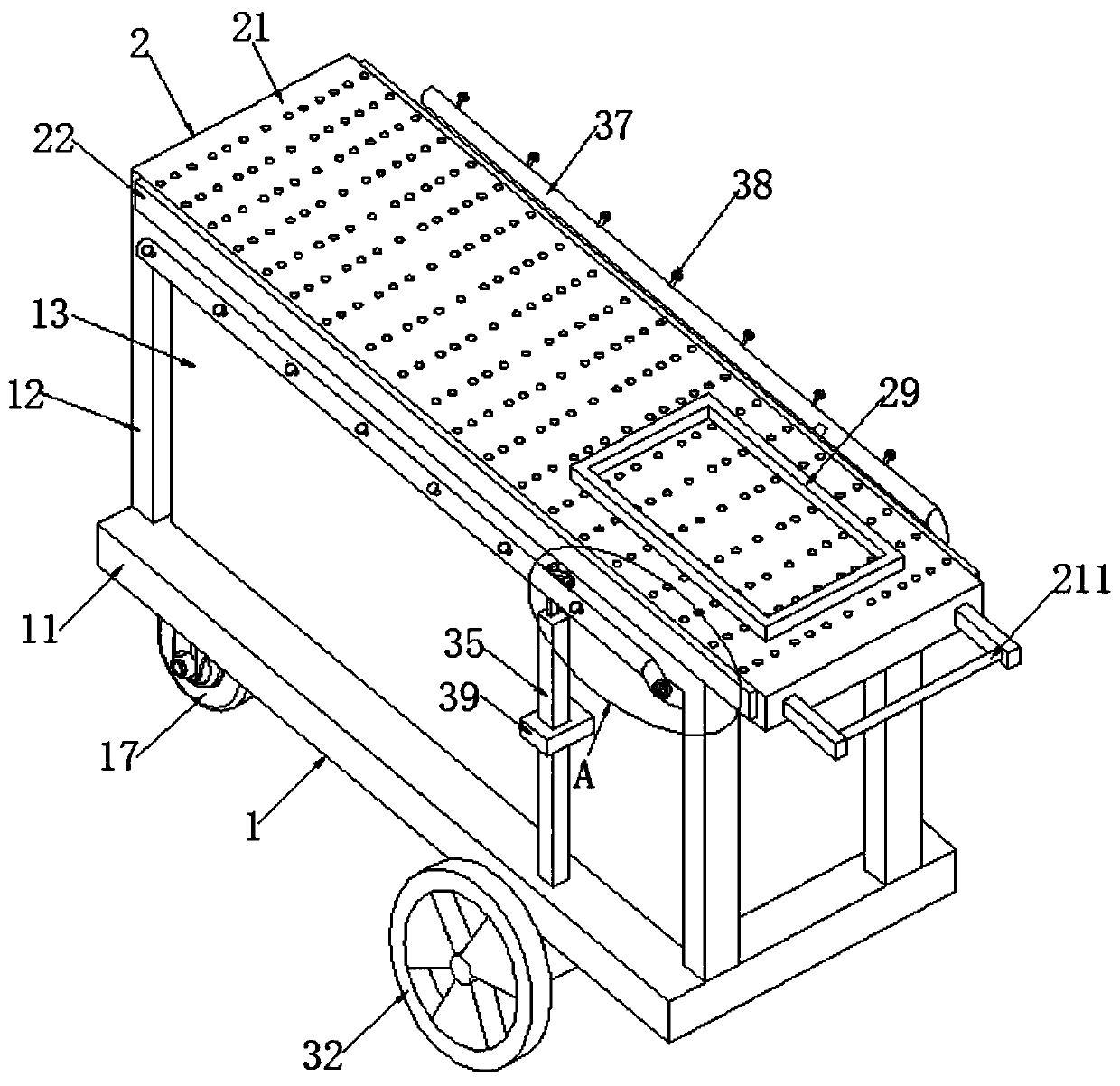

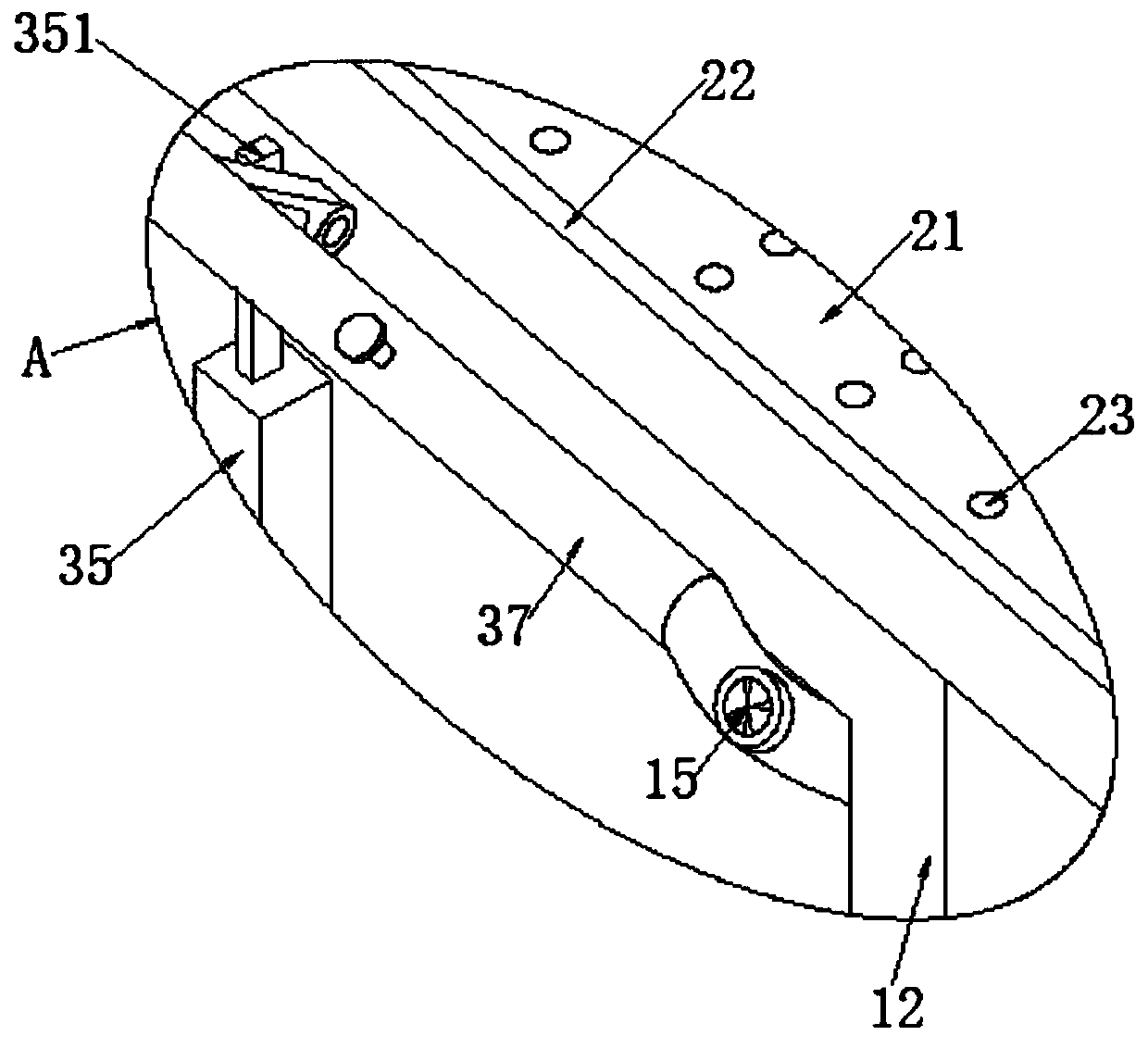

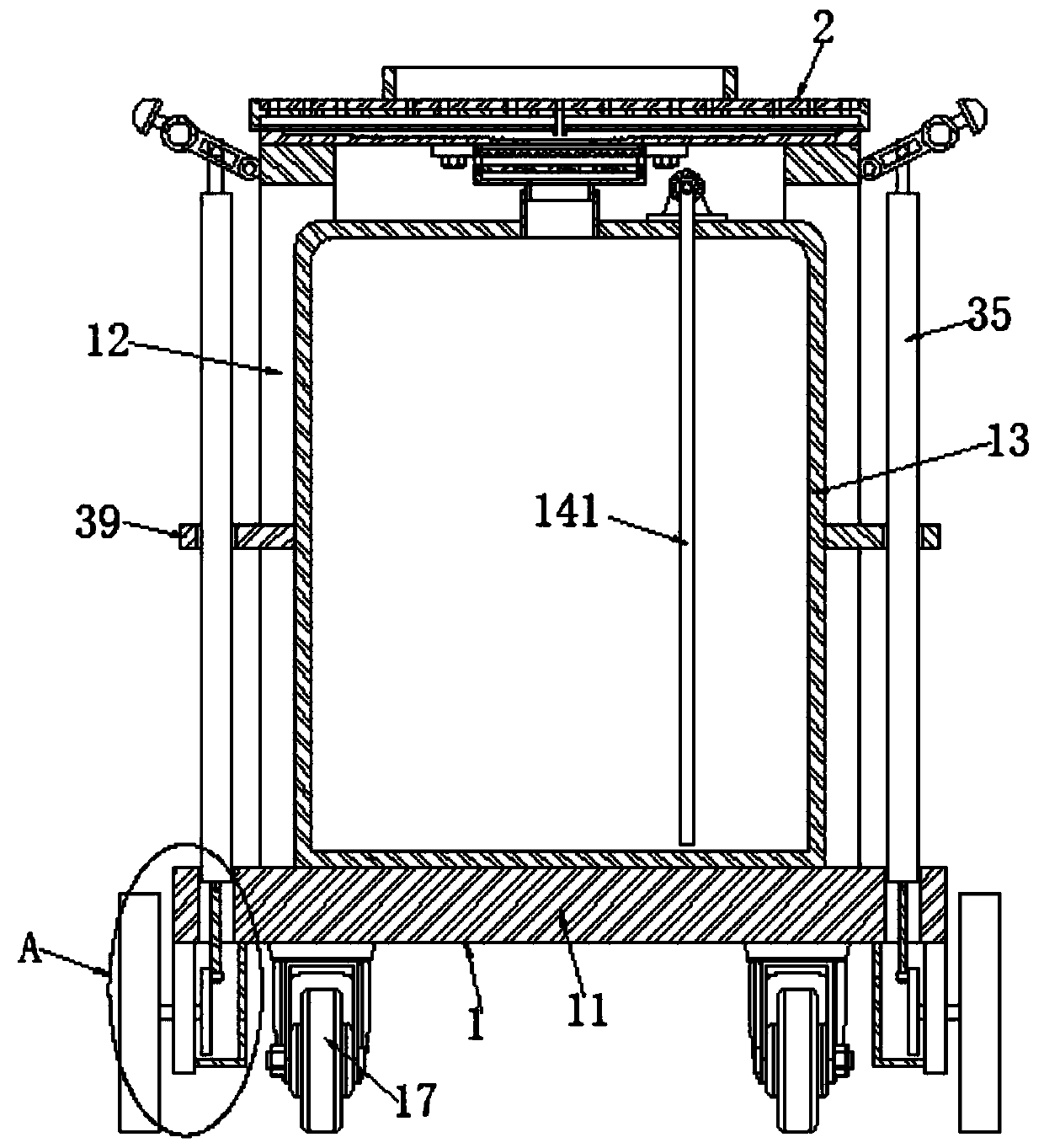

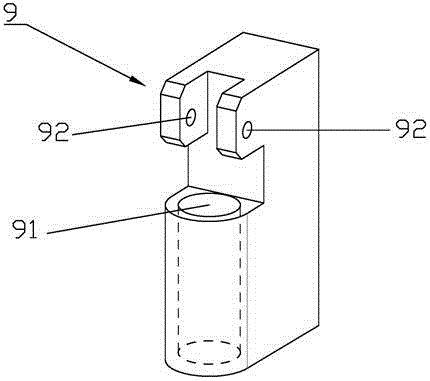

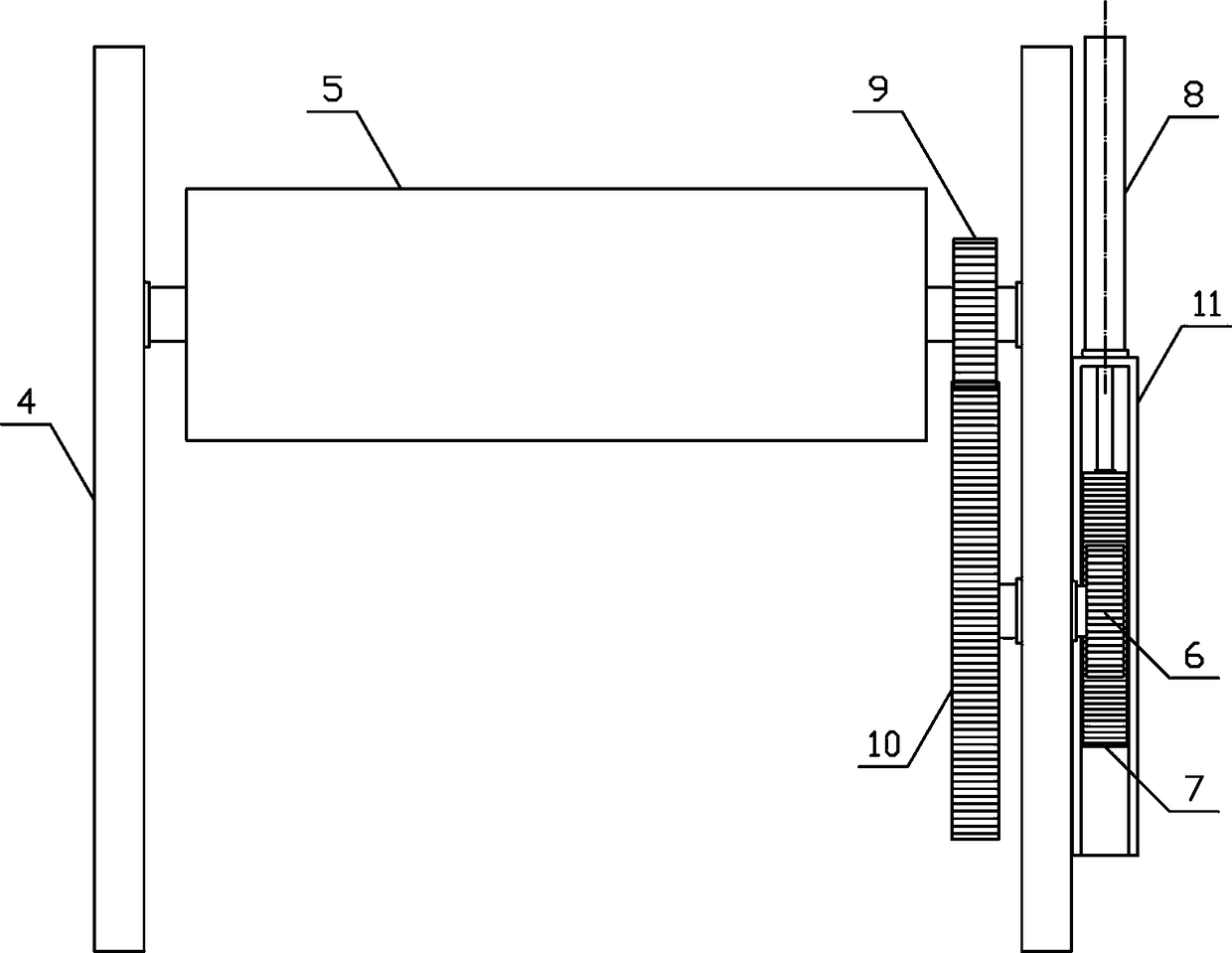

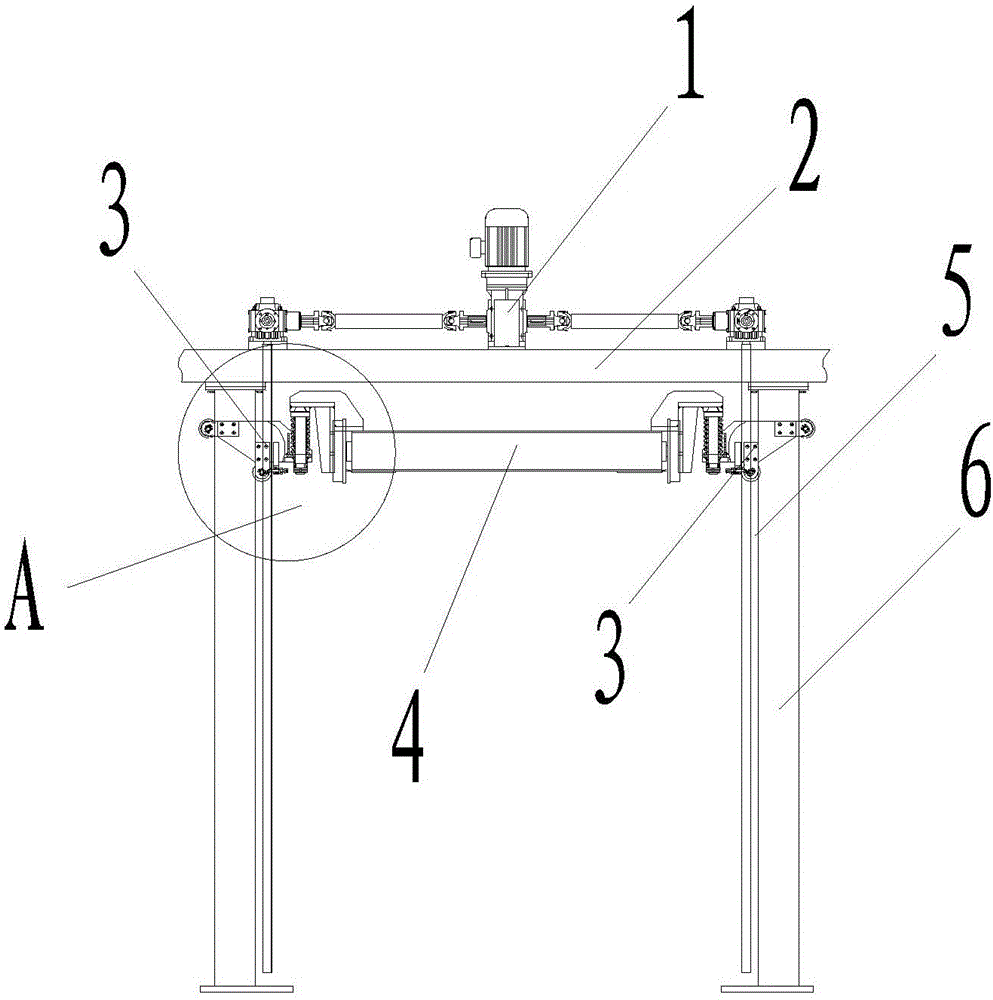

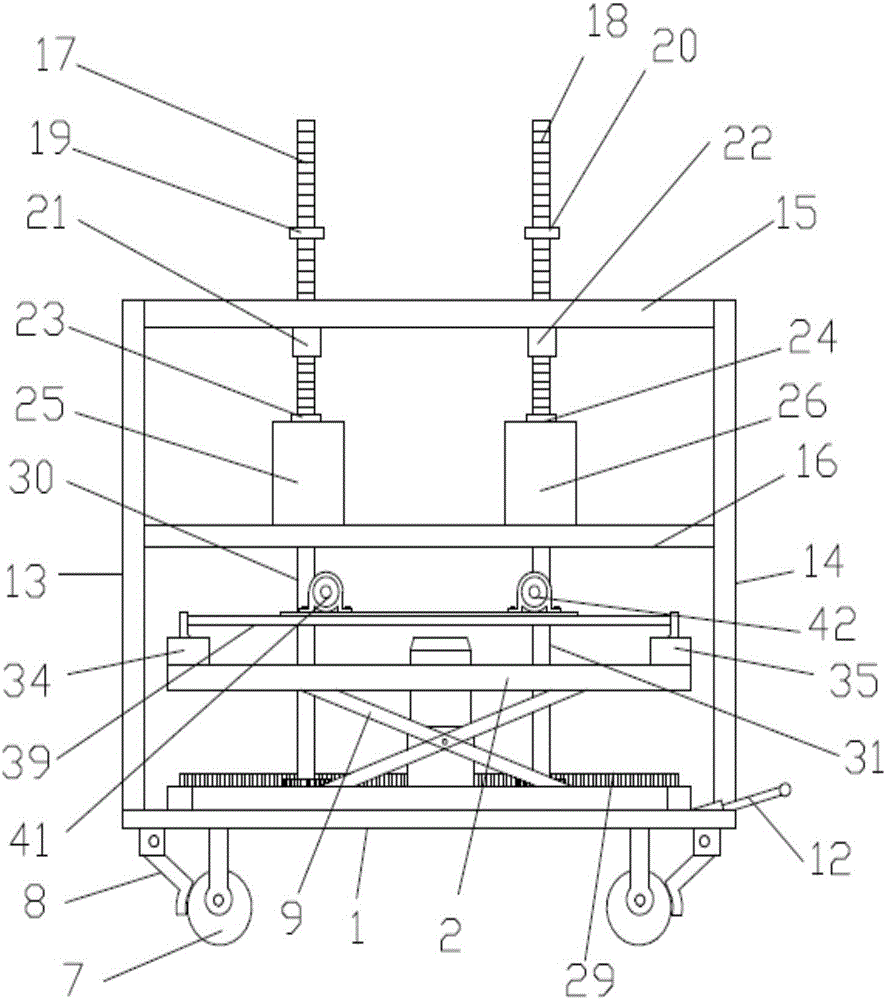

Power equipment maintenance and transportation lifting device

PendingCN109599776ASmooth lifting movementProtective equipmentLifting framesSwitchgearPower equipmentSupport plane

The invention relates to the technical field of power equipment maintenance, in particular to a power equipment maintenance and transportation lifting device. The power equipment maintenance and transportation lifting device comprises a base, a support frame, a motor, a transmission gear, at least two screw rods and a carrier plate, wherein the support frame is fixed on the base; the screw rod isvertically arranged; one end of the screw rod is rotationally connected to the base, and the other end is rotationally connected to the support frame; the carrier plate is provided with a mounting hole corresponding to the screw rod; the carrier plate is connected with the screw rod through the mounting hole; the motor is fixed on the base; and the transmission gear is connected with the screw rodand the motor respectively. The device solves the problem of poor stability of the lifting device during lifting. Meanwhile, clamping and protection functions are added, thereby avoiding accidents, facilitating movement, improving flexibility, lowering maintenance cost, improving transportation efficiency and facilitating use.

Owner:GUANGDONG POWER GRID CO LTD +1

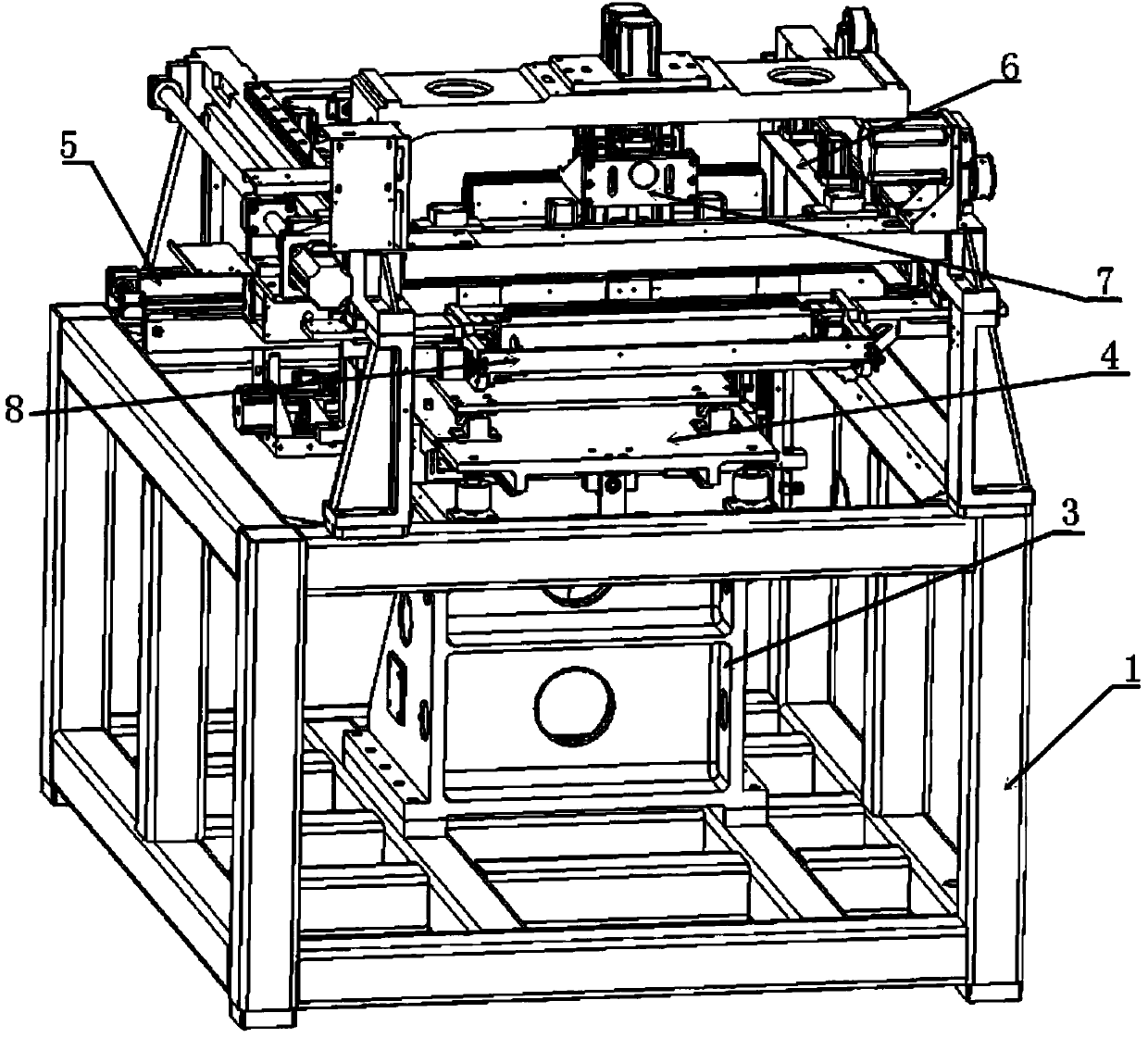

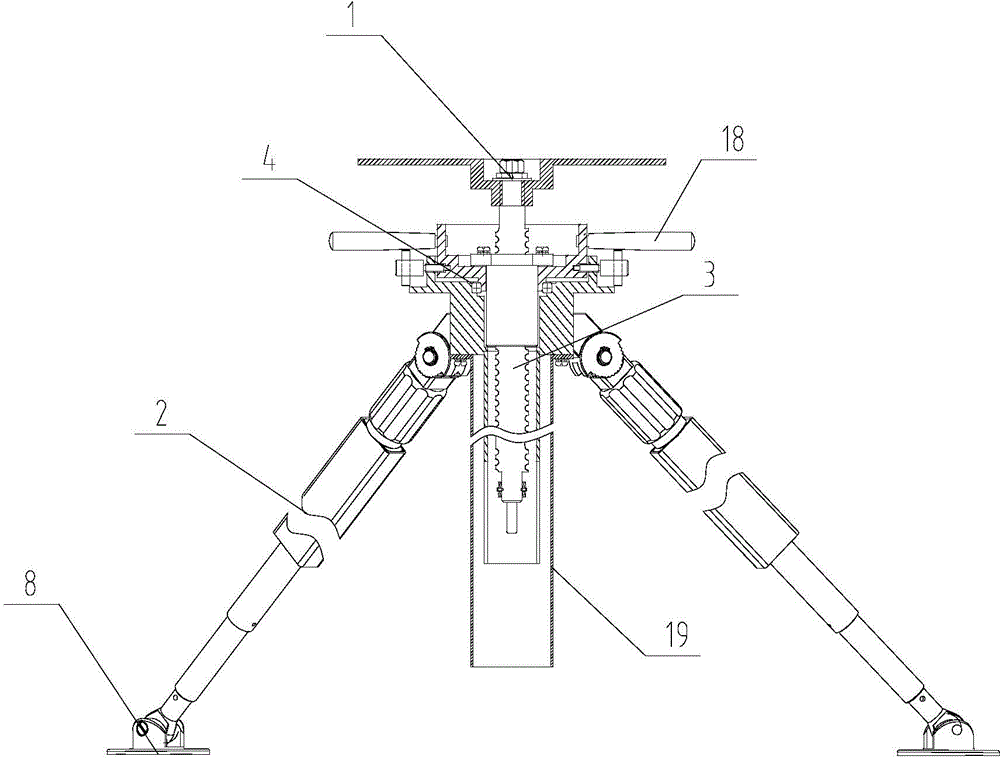

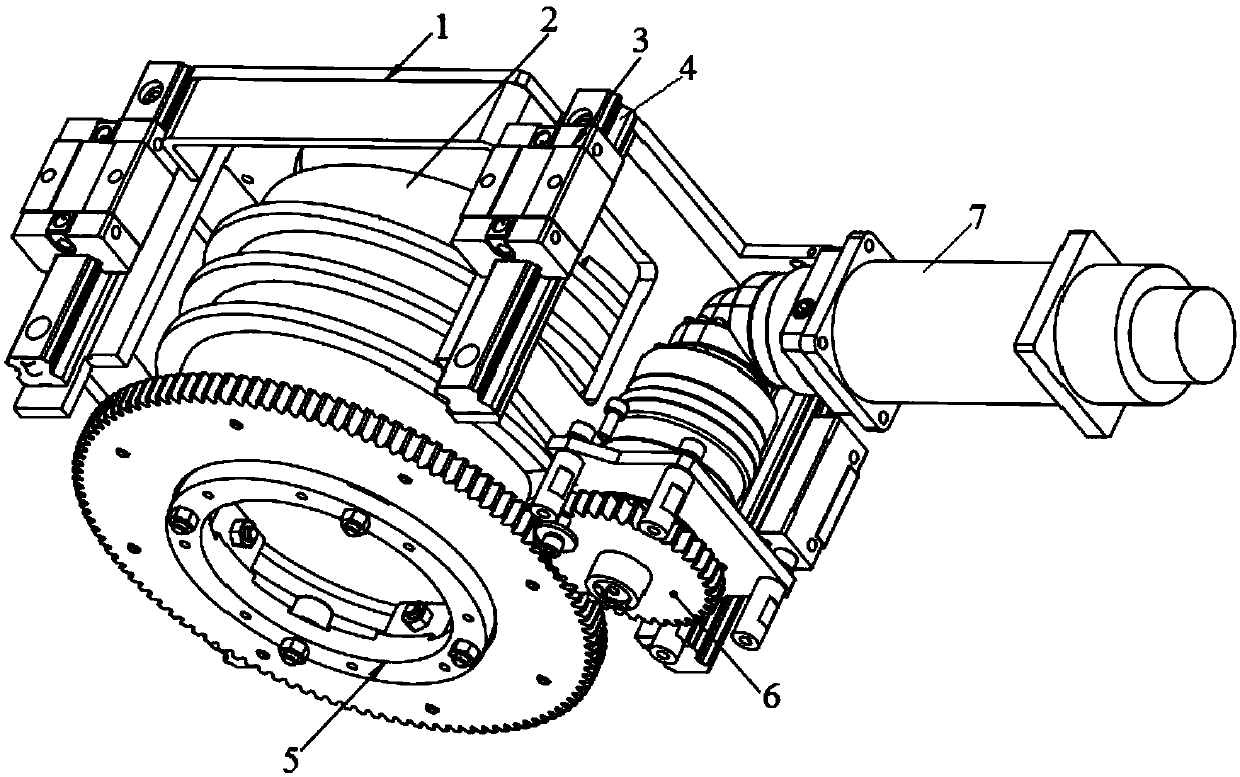

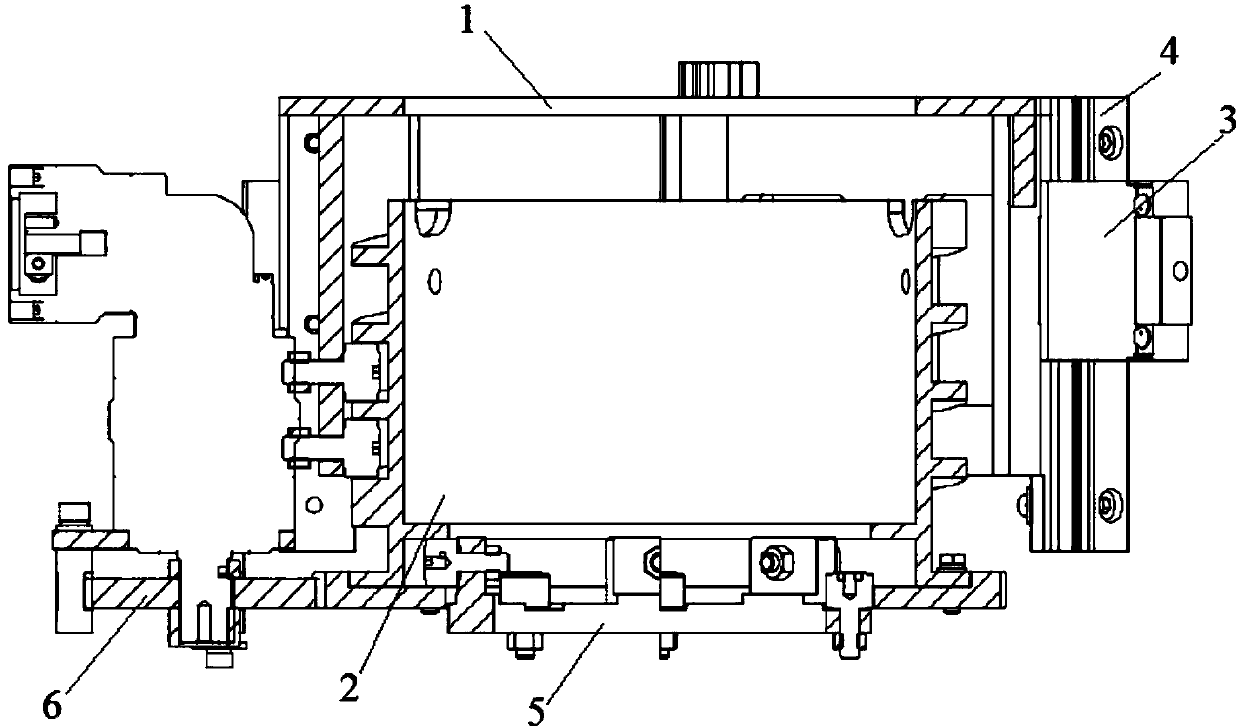

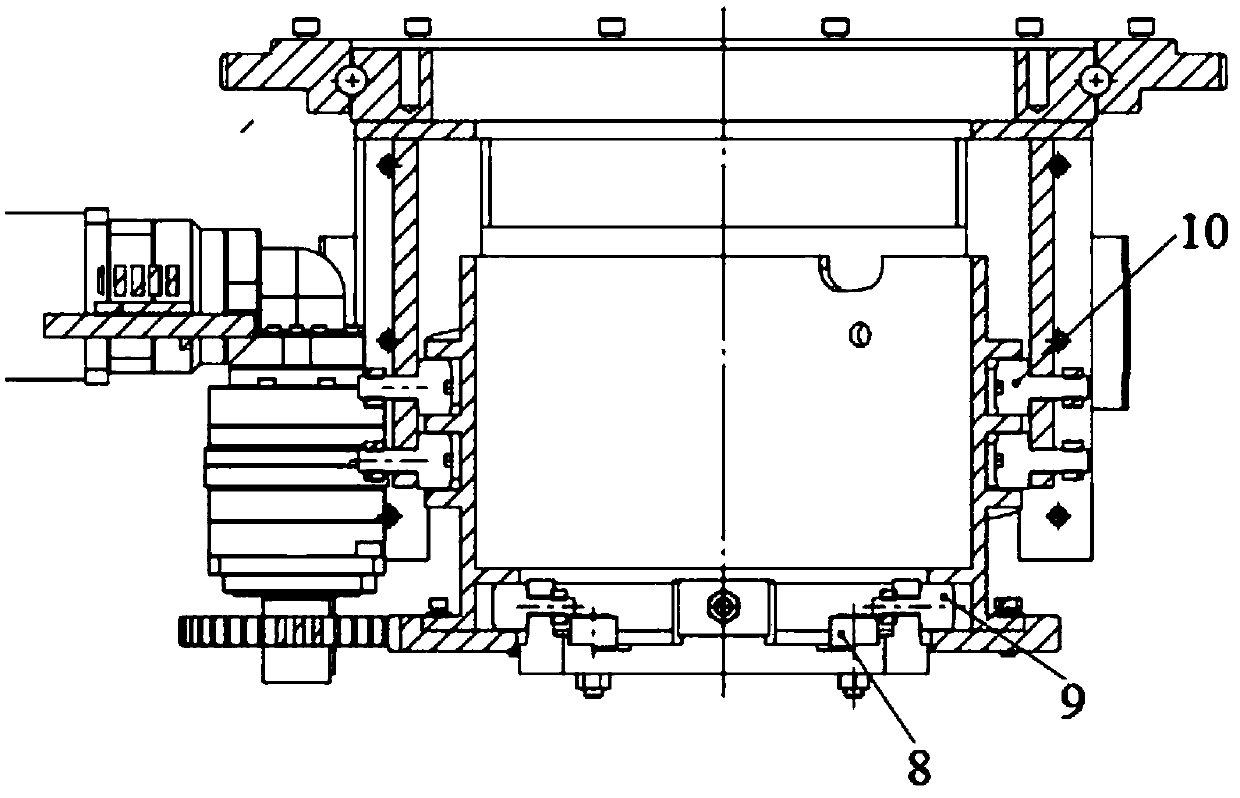

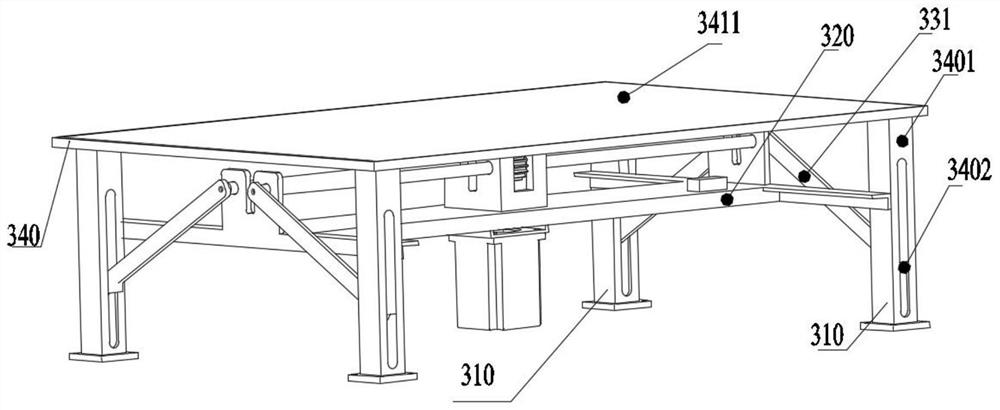

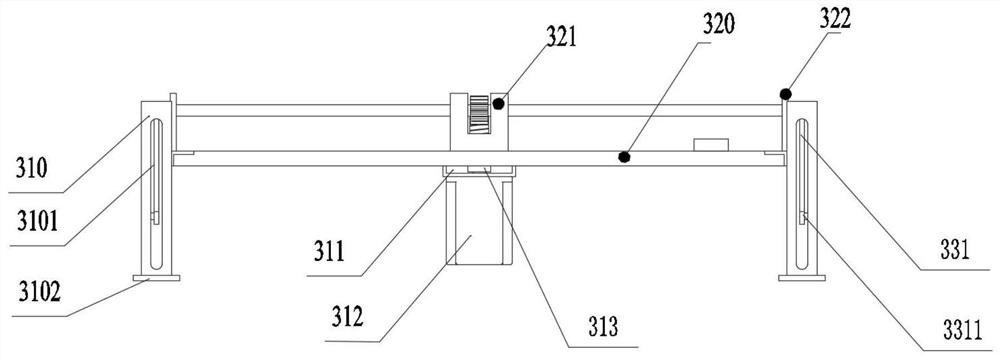

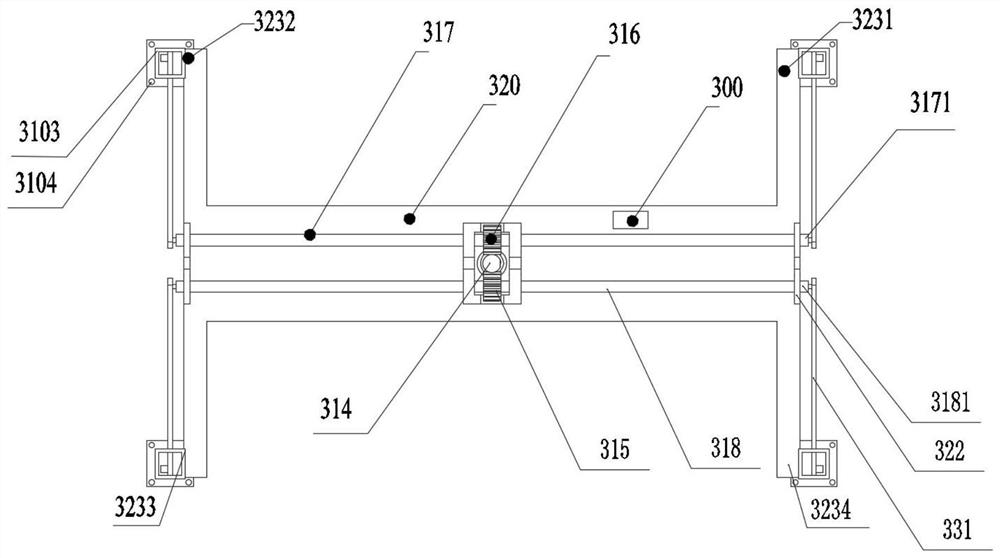

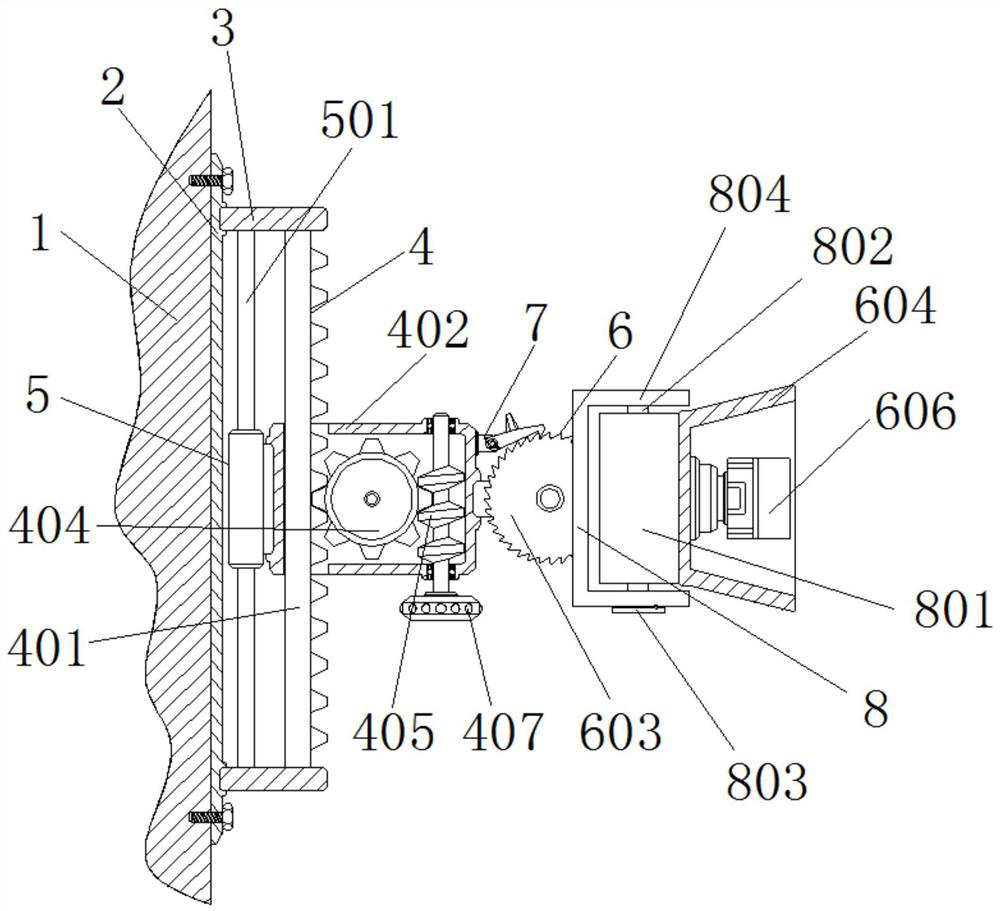

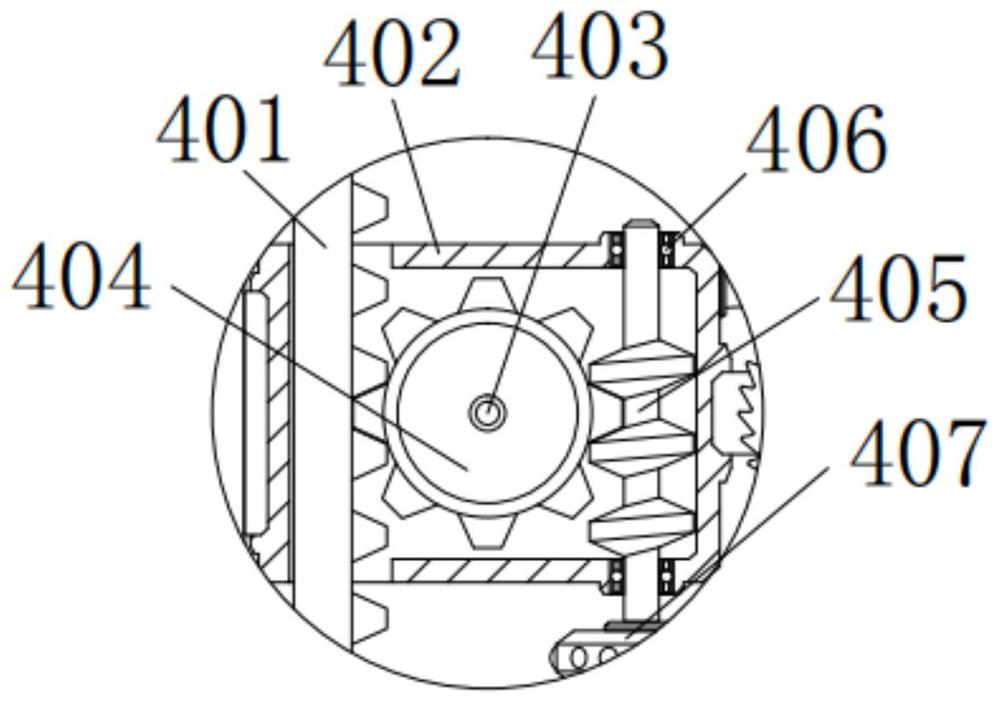

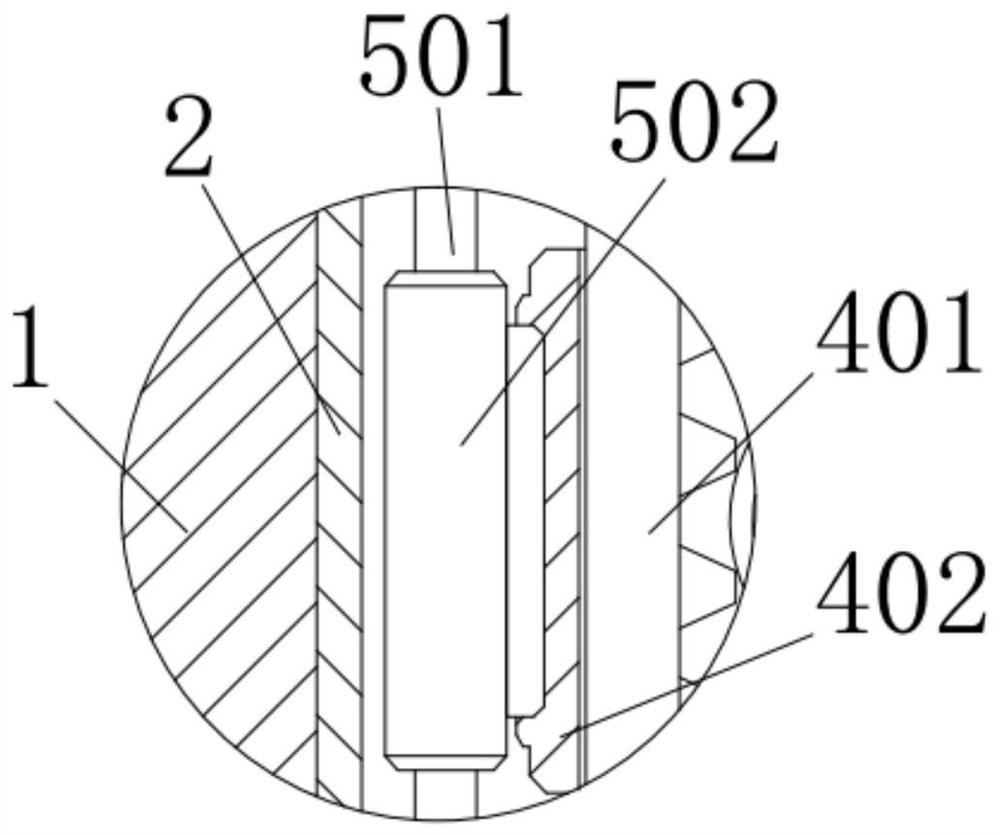

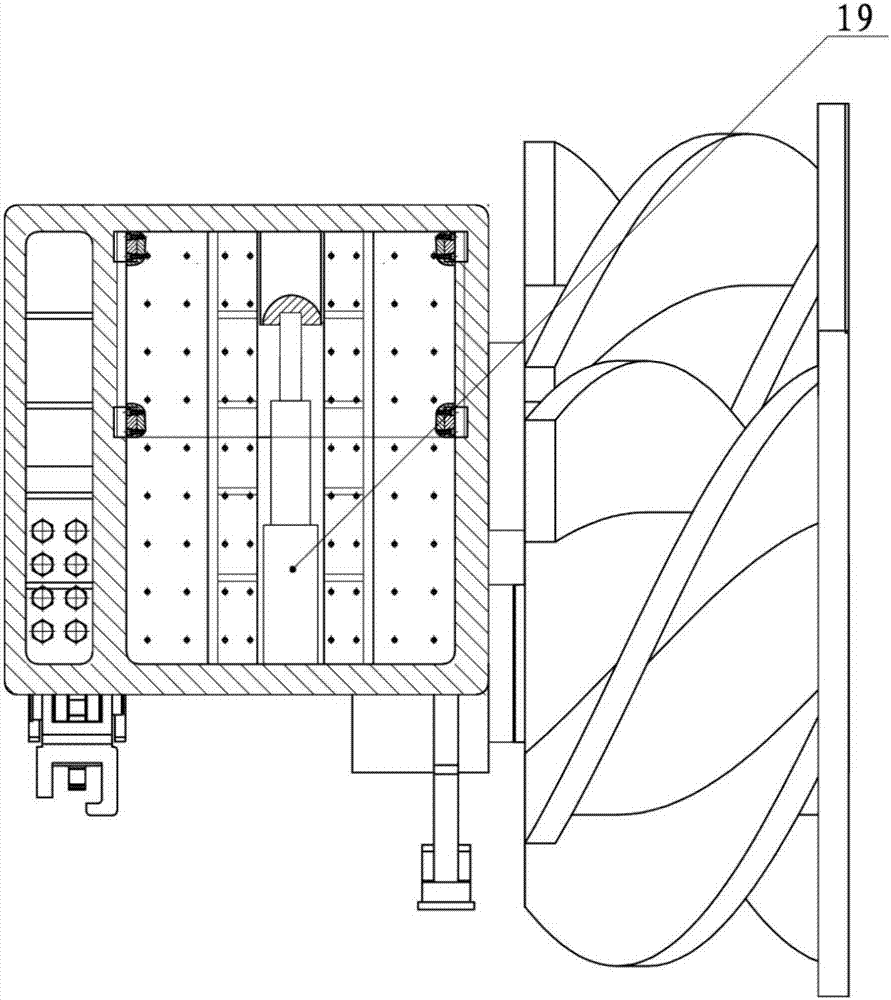

Vibration exciter fixed mounting device and using method thereof

The invention discloses a vibration exciter fixed mounting device which mainly comprises a vibration exciter fixing platform assembly, supporting foot assemblies, a screw rod sliding assembly and a rotary table assembly. The vibration exciter fixing platform assembly is fixed at one end of the screw rod sliding assembly by a nut; the screw rod sliding assembly is arranged on the rotary table assembly; the supporting foot assemblies are connected with the rotary table assembly so as to support the vibration exciter fixing platform assembly. The vibration exciter fixed mounting device is flexible to regulate, is reliable to fix, is simple to mount, has a compact structure, has a lighter weight, is convenient to use in the external field and has better adaptability.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

Multifunctional assistive device for lower limb rehabilitation training

InactiveCN102743261ASmooth lifting movementReduce noiseGymnastic exercisingChiropractic devicesDaily livingLife quality

The invention provides a multifunctional assistive device for lower limb rehabilitation training, comprising a moving part, a lifting part and a seat part, wherein the lifting part is installed on the moving part; and the seat part is installed on the lifting part. The multifunctional assistive device for the lower limb rehabilitation training is simple to operate, convenient to use, and people-oriented; based on ergonomics theories, rehabilitation training and daily living activities are flexibly combined together in an assistive way; a user can perform corresponding actions according to needs without the help of other people, so that a sufferer achieves the best assistance and rehabilitation training effect at the psychological and physical aspects; and therefore, the living quality of the lower limb disabled is effectively improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

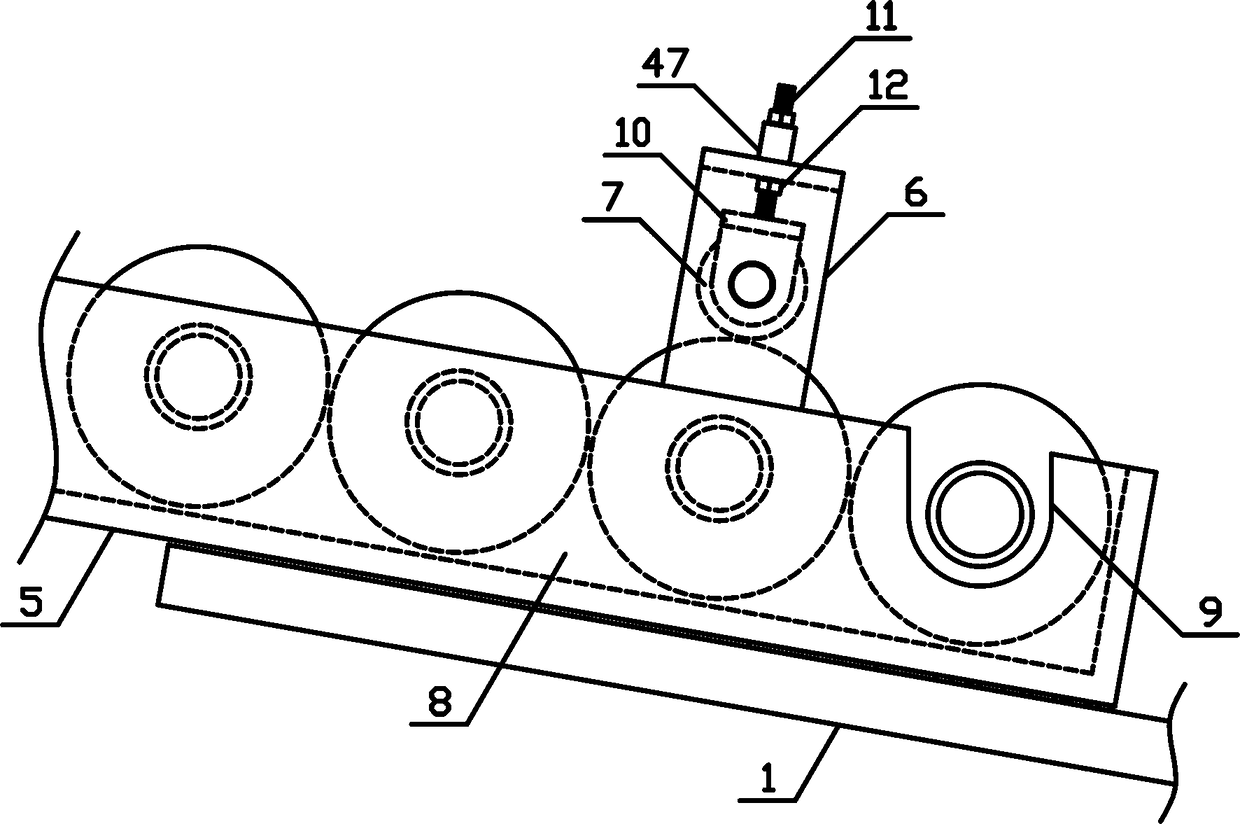

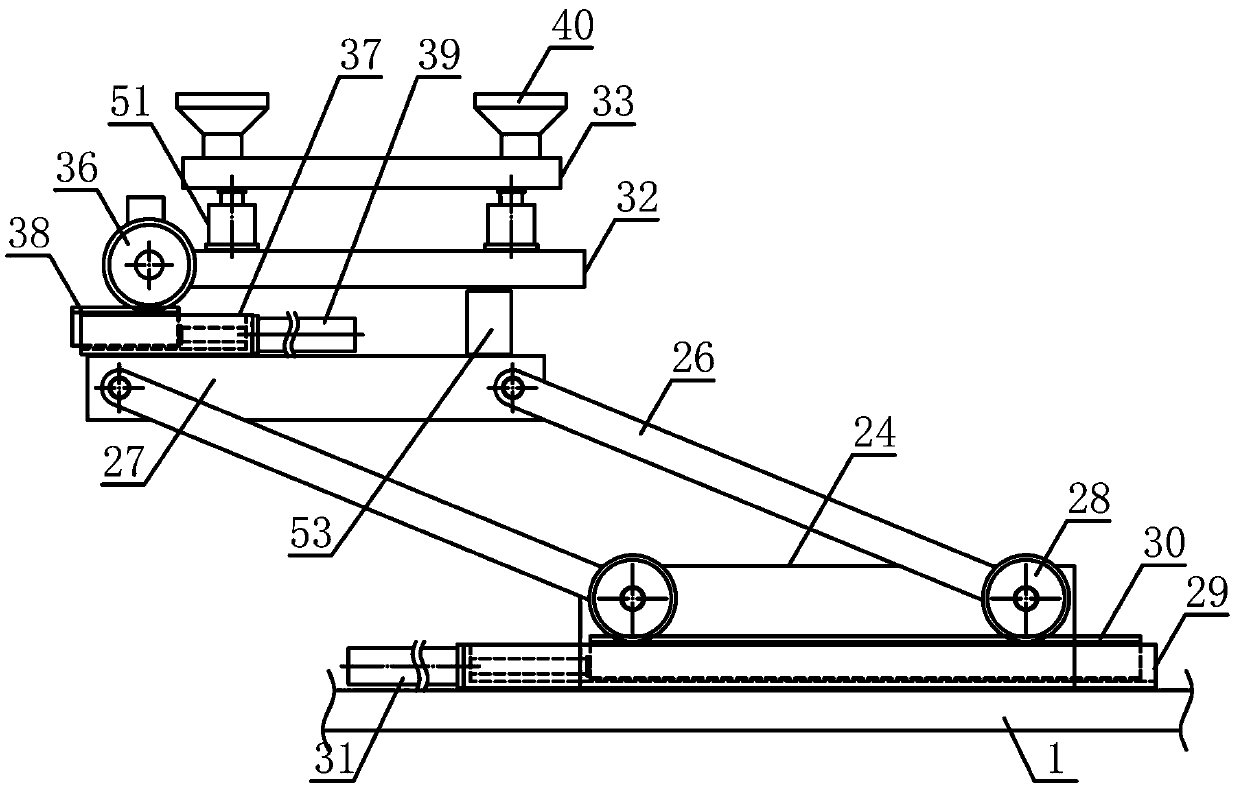

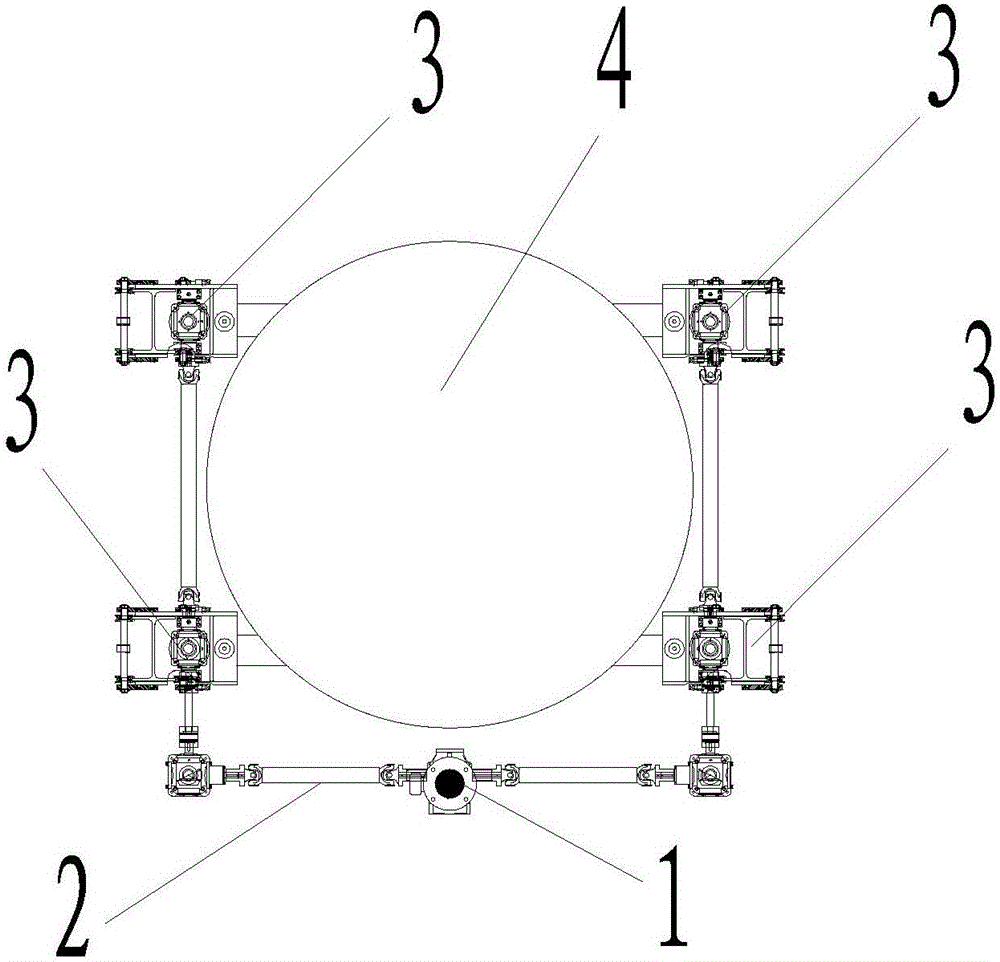

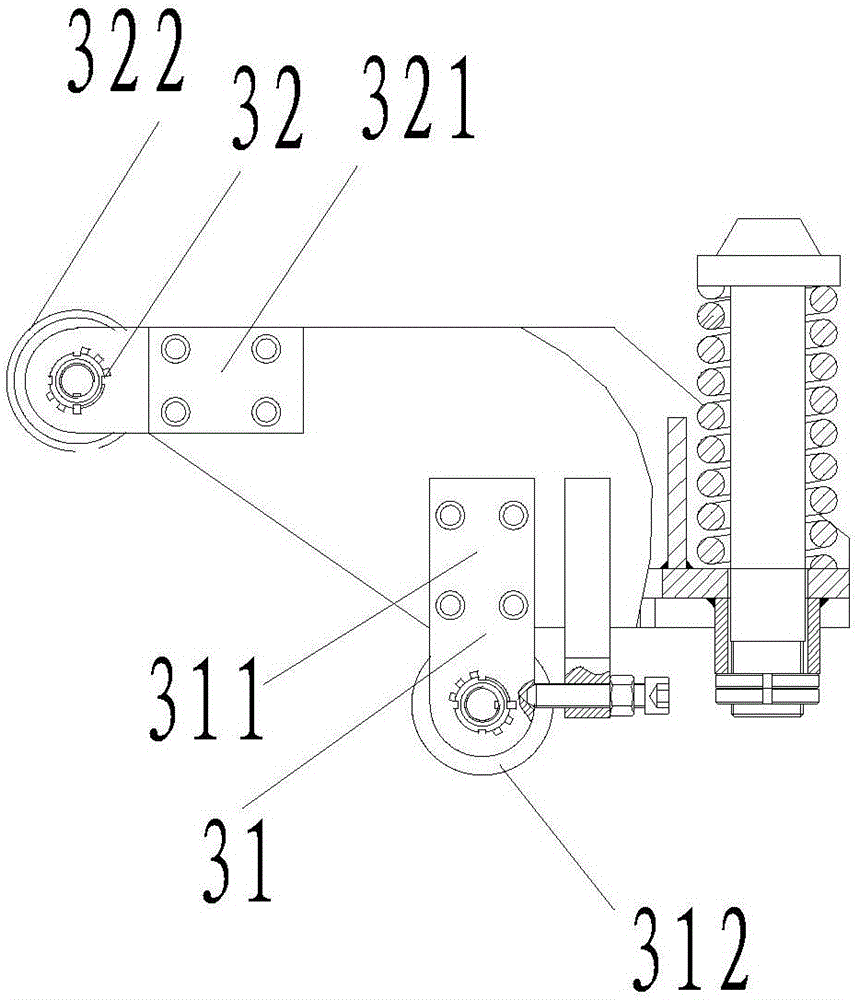

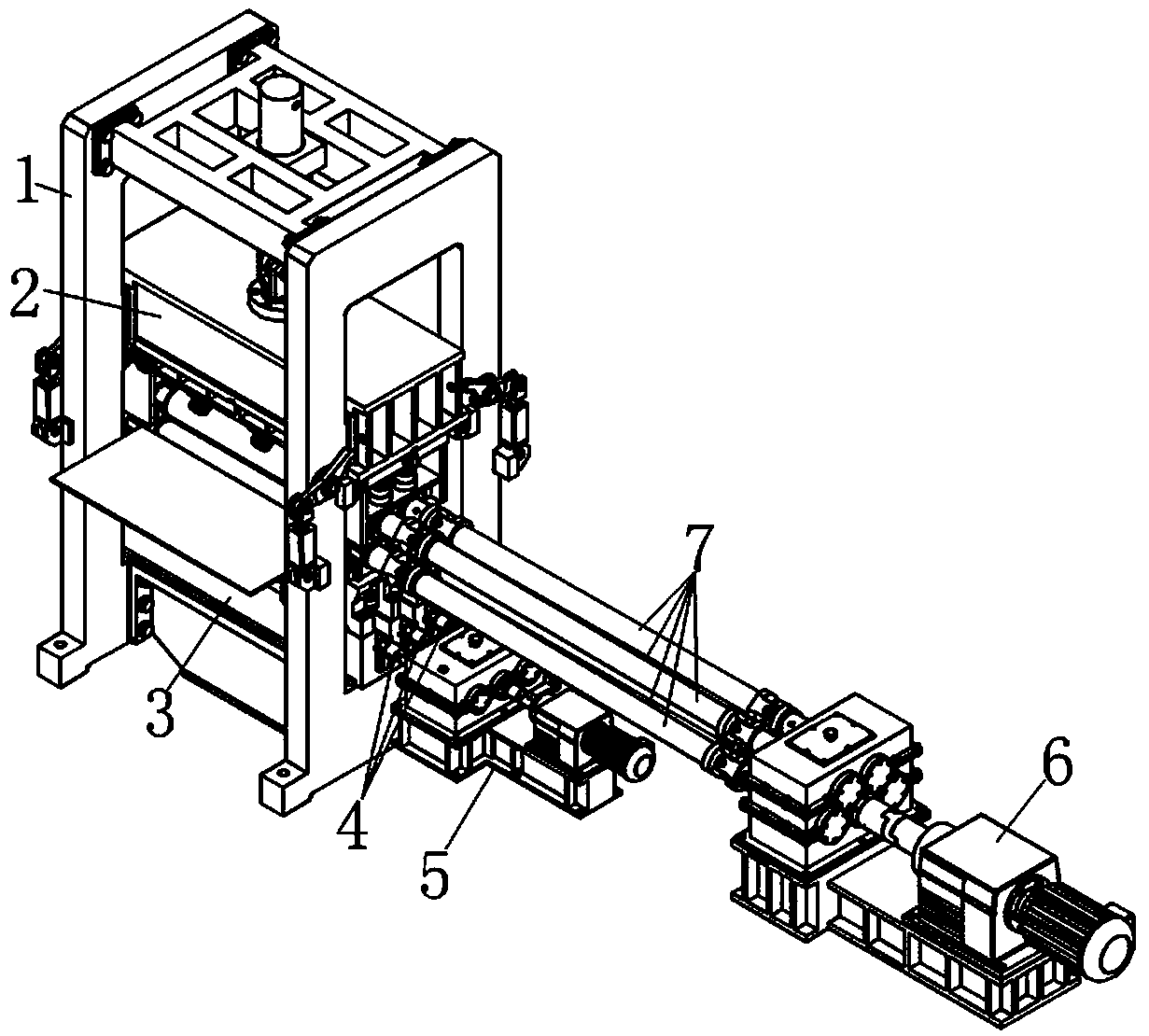

Automatic transfer device for tubular workpiece processing

InactiveCN111332743AReasonable structural designEven contactConveyorsMetal working apparatusMechanical equipmentAutomation

The invention discloses an automatic transfer device for tubular workpiece processing, and belongs to the field of workpiece conveying and processing mechanical equipment. A workpiece guide mechanism,a workpiece shifting mechanism and a workpiece overturning mechanism of the device are arranged on the upper side of a workpiece conveying bracket in sequence in the horizontal direction; a workpiececonveying mechanism is horizontally arranged a workpiece conveying bracket on the lower side of the middle of the workpiece shifting mechanism and the workpiece overturning mechanism; the workpiece conveying bracket on one side under the workpiece overturning mechanism is horizontally and rotatably connected to a workpiece transfer rotating roller; a workpiece transfer belt is horizontally woundon the workpiece transfer rotating roller; and the lower side of a workpiece storage hopper aslant communicates to a guide feeding pipe. The device is reasonable in structural design, can convenientlyand smoothly guide and shift tubular workpieces one by one, and can stably and accurately overturn the tubular workpieces to adjust a conveying station, so that the workpiece transfer automation degree is improved, efficient conveying and processing of the tubular workpieces are implemented, and the production and use demands are met.

Owner:费建国

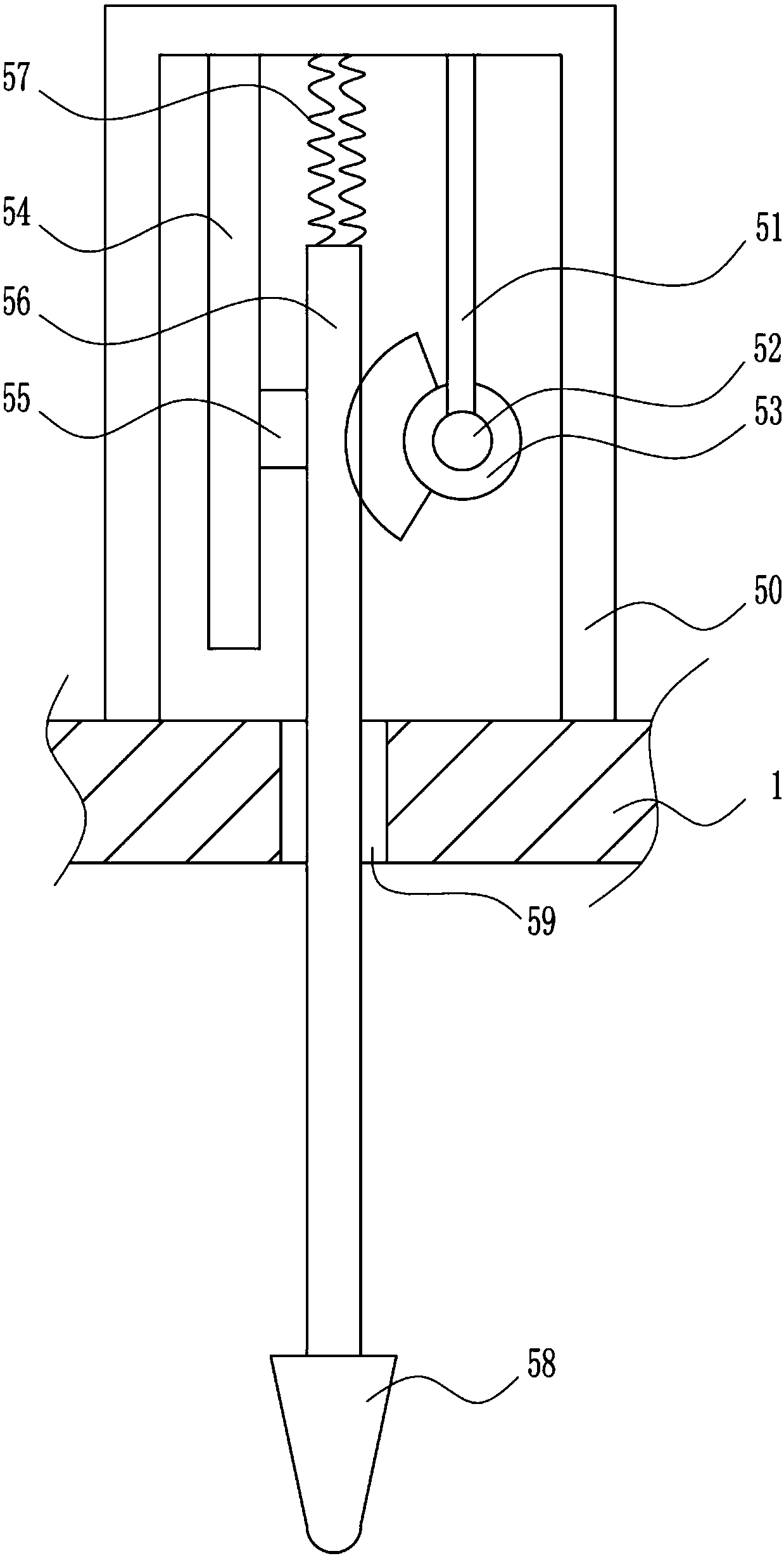

Chemical fiber bobbin yarn transferring and placing mechanism

InactiveCN109205393ARealize continuous feedingEasy and efficient replacementFilament handlingYarnFiber

The invention discloses a chemical fiber bobbin yarn transferring and placing mechanism, and belongs to the field of chemical fiber conveying and processing machine equipment. A bobbin transferring mechanism is vertically arranged on a fixing support between a bobbin guiding mechanism and a yarn placing mechanism. A discharging material pipe is obliquely downwards arranged on the upper side of thefixing support. The output end of a lifting air cylinder is vertically and fixedly provided with a lifting support. A bobbin transferring rotation rod is vertically and rotationally connected to a rotation rod sleeve. One end of the lower side of a reciprocating rotating plate is fixedly connected with the upper end of the bobbin transferring rotation rod. A bobbin taking mechanism is fixedly arranged at the other end of the lower side of the reciprocating rotation plate. A plurality of bobbin placing circular plates are evenly arranged at the outer end of the upper side of a yarn guiding rotation disc. A plurality of yarn guiding mechanisms are evenly arranged on the upper side of the yarn guiding rotation disc. The bobbin placing circular plates and the yarn guiding mechanism are sequentially arranged in the radial direction of the yarn guiding rotation disc from exterior to interior. The chemical fiber bobbin yarn transferring and placing mechanism is reasonable in structural design, a plurality of chemical fiber bobbin yarns can be continuously transferred and replaced conveniently and efficiently, a plurality of strands of chemical fiber filaments can be stably, accurately and synchronously conveyed, the automation degree is high, and the production and usage requirements are met.

Owner:桐乡市宏力纺织股份有限公司

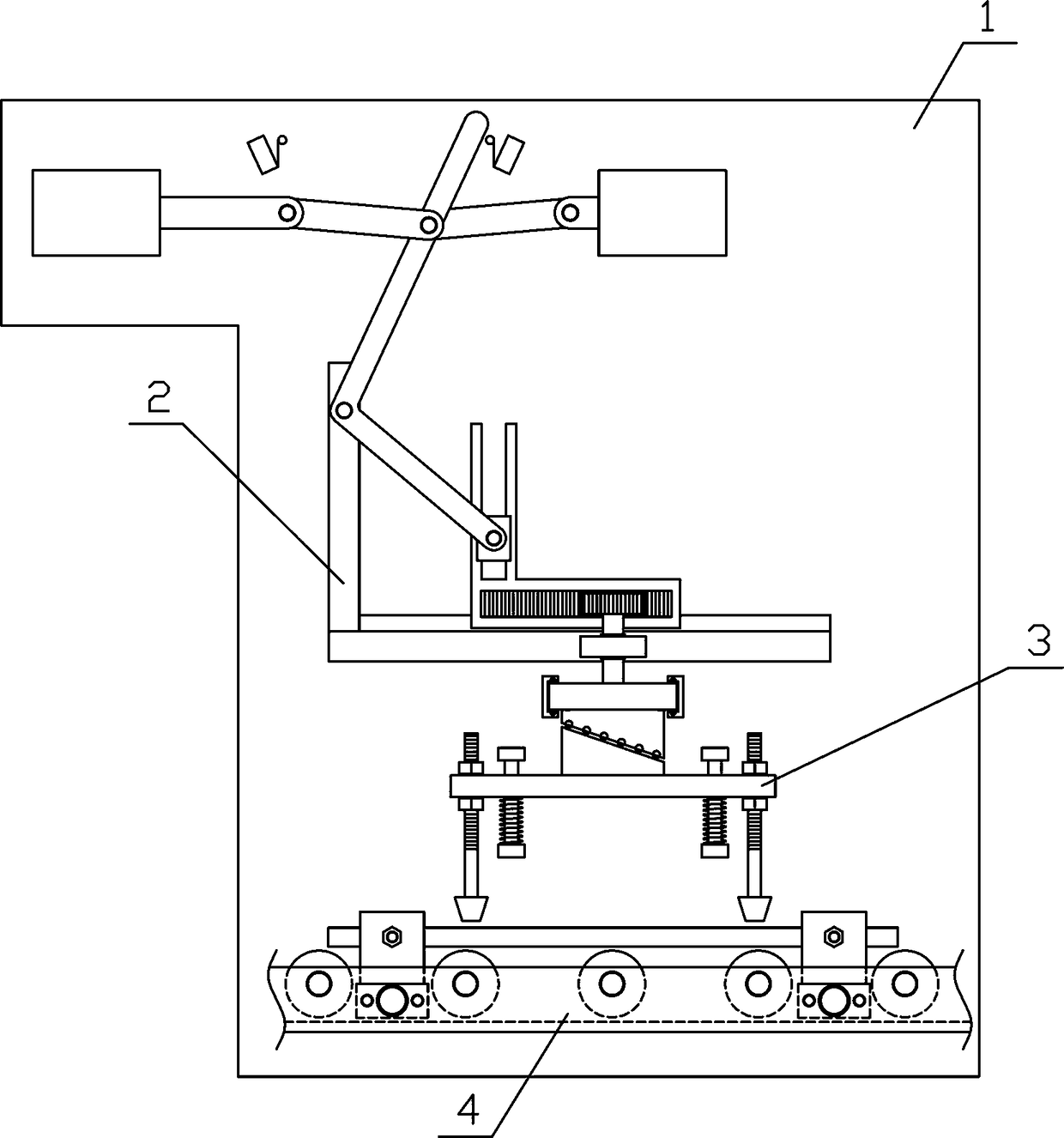

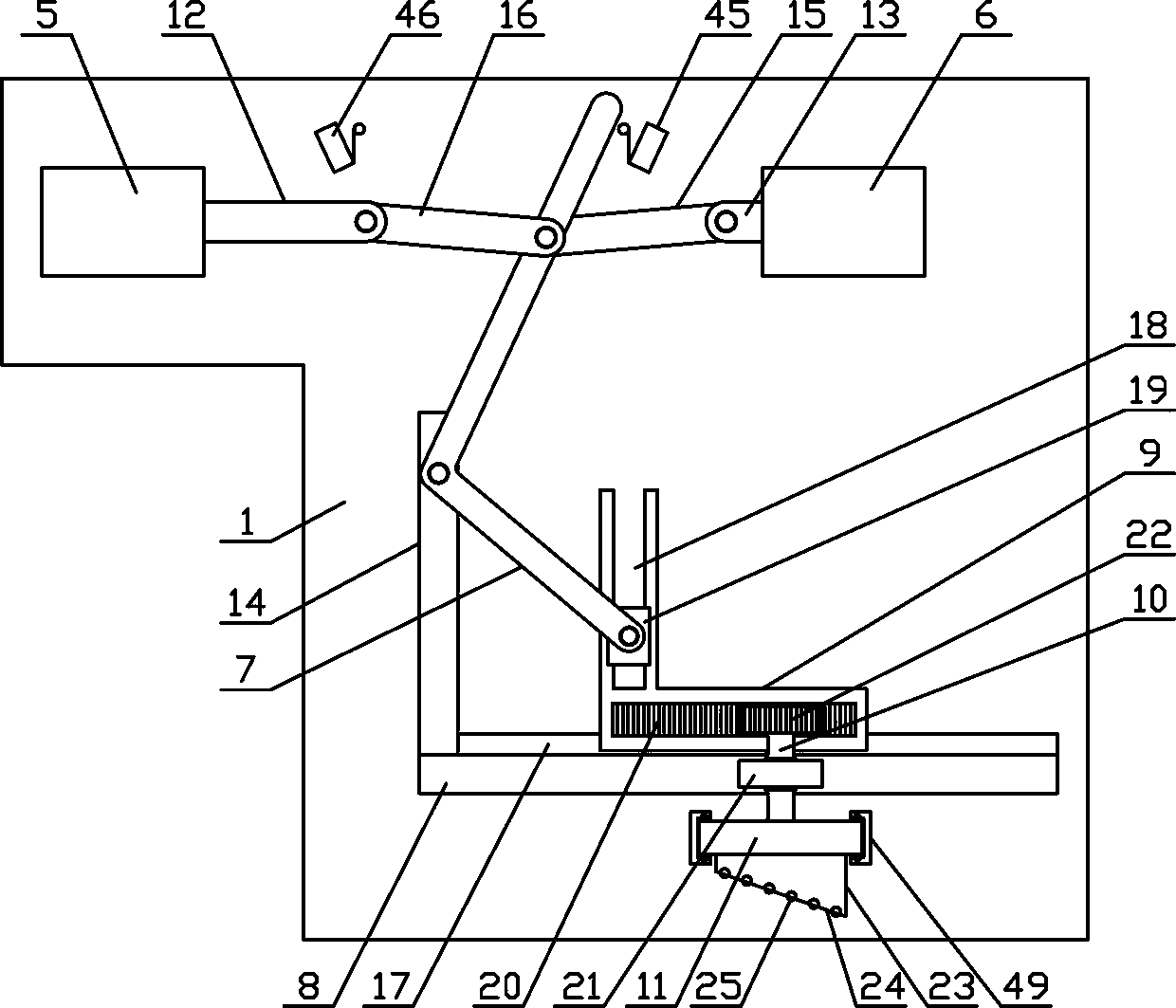

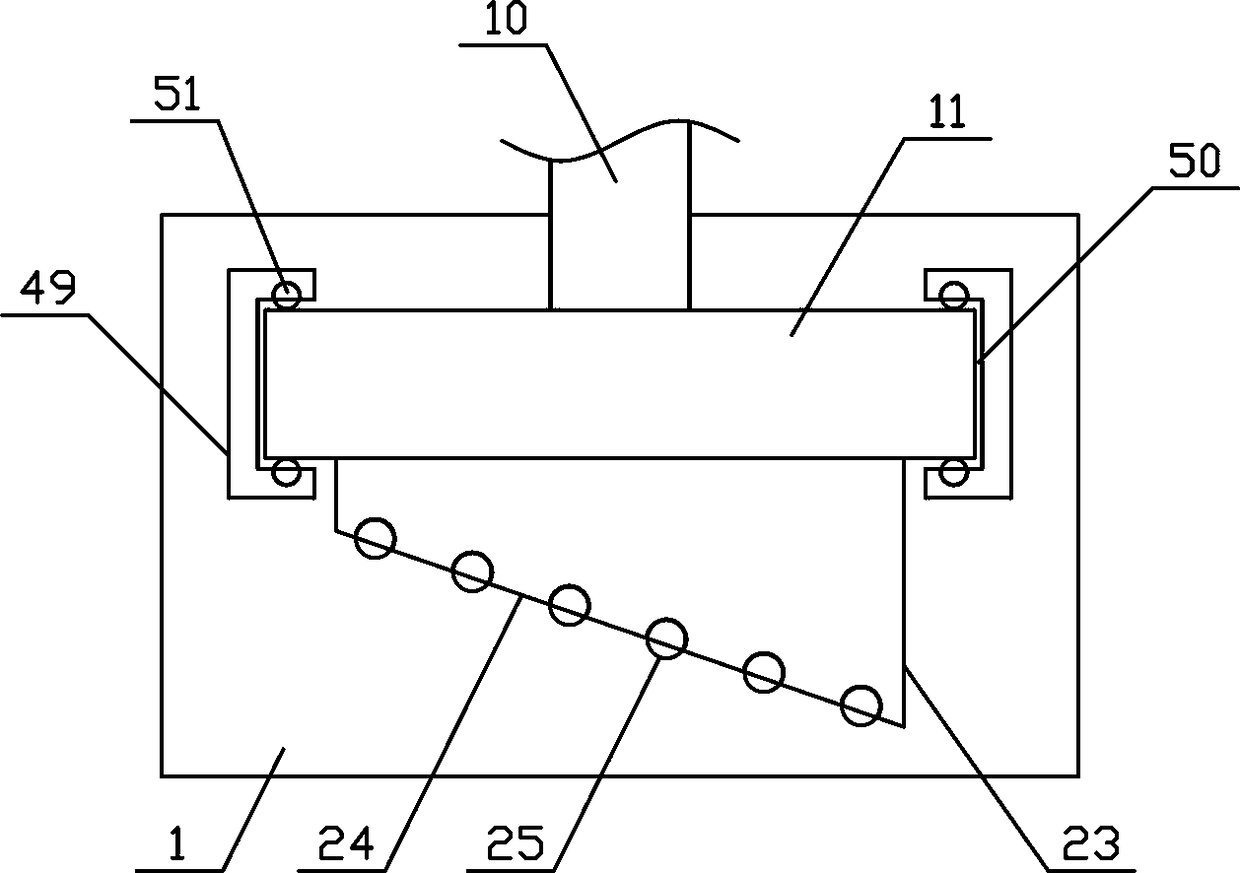

Blanking detection equipment applied to metal workpieces

ActiveCN105438780ASolve the problem of blanking inspectionReduce laborConveyorsOptically investigating flaws/contaminationEngineeringConveyor belt

The invention discloses blanking detection equipment applied to metal workpieces. The blanking detection equipment comprises a rack and a blanking platform, wherein the blanking platform is located on the rack; a conveyor belt is arranged in the blanking platform; a detection device is arranged on the inner side of the blanking platform; the detection device comprises a detection bottom plate, a detection vertical frame, a shooting component and a lifting detection mechanism; the detection bottom plate is arranged on the blanking platform; the detection vertical frame is arranged on the detection bottom plate; the detection vertical frame is provided with the lifting detection mechanism; the lifting detection mechanism is connected with the shooting component; a material baffling device is arranged on the outer side of the blanking platform; the material baffling device comprises a material baffling mechanism, a material baffling transmission mechanism and a material baffling positioning mechanism; the material baffling mechanism is arranged on the outer side of the blanking platform; the material baffling transmission mechanism is connected with the material baffling mechanism; the material baffling mechanism is located below the material baffling mechanism; and the material baffling positioning mechanism is arranged on the lower end of the blanking platform. The blanking detection equipment is simple in structure, high in pertinency and high in automation degree, and is scientific and convenient; and the blanking detection problem after the metal workpieces are machined is well solved.

Owner:南京大目信息科技有限公司

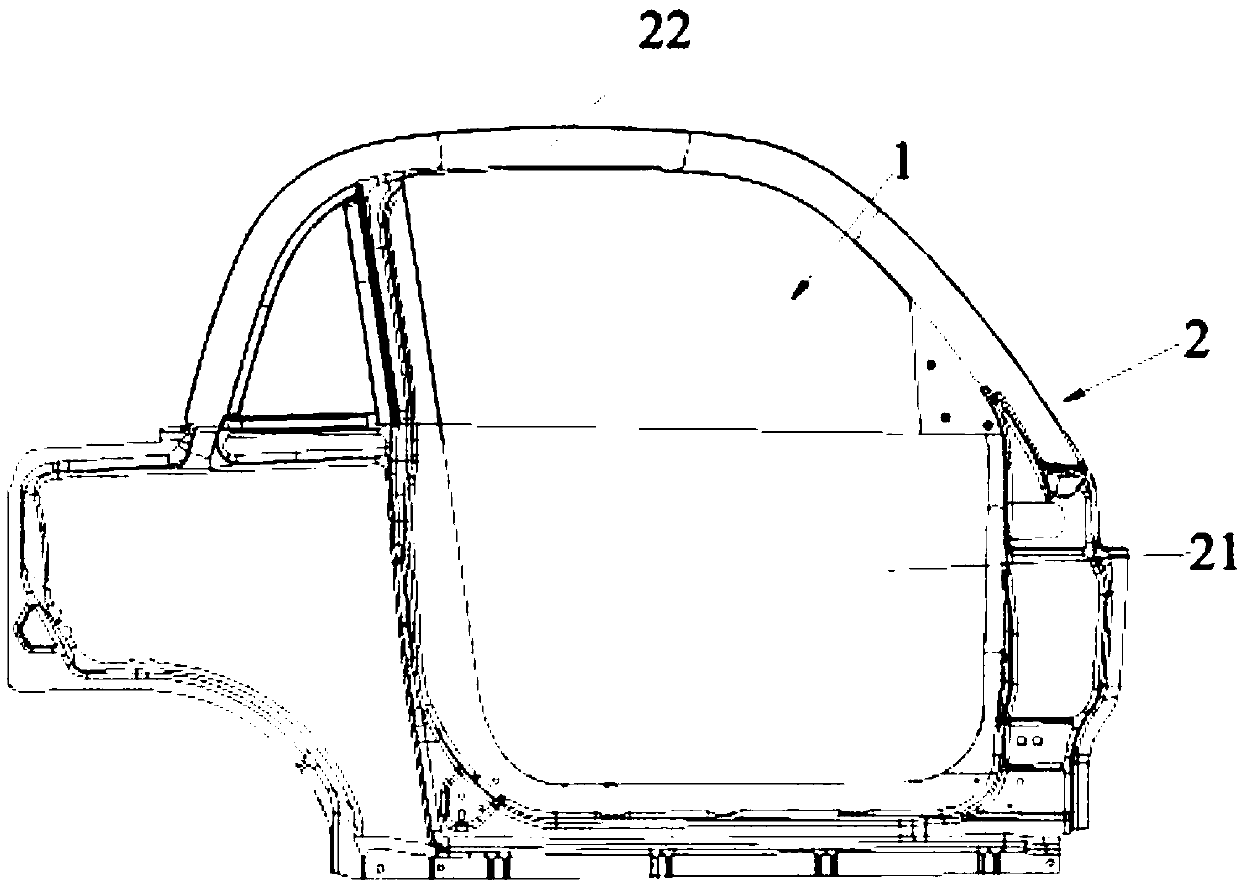

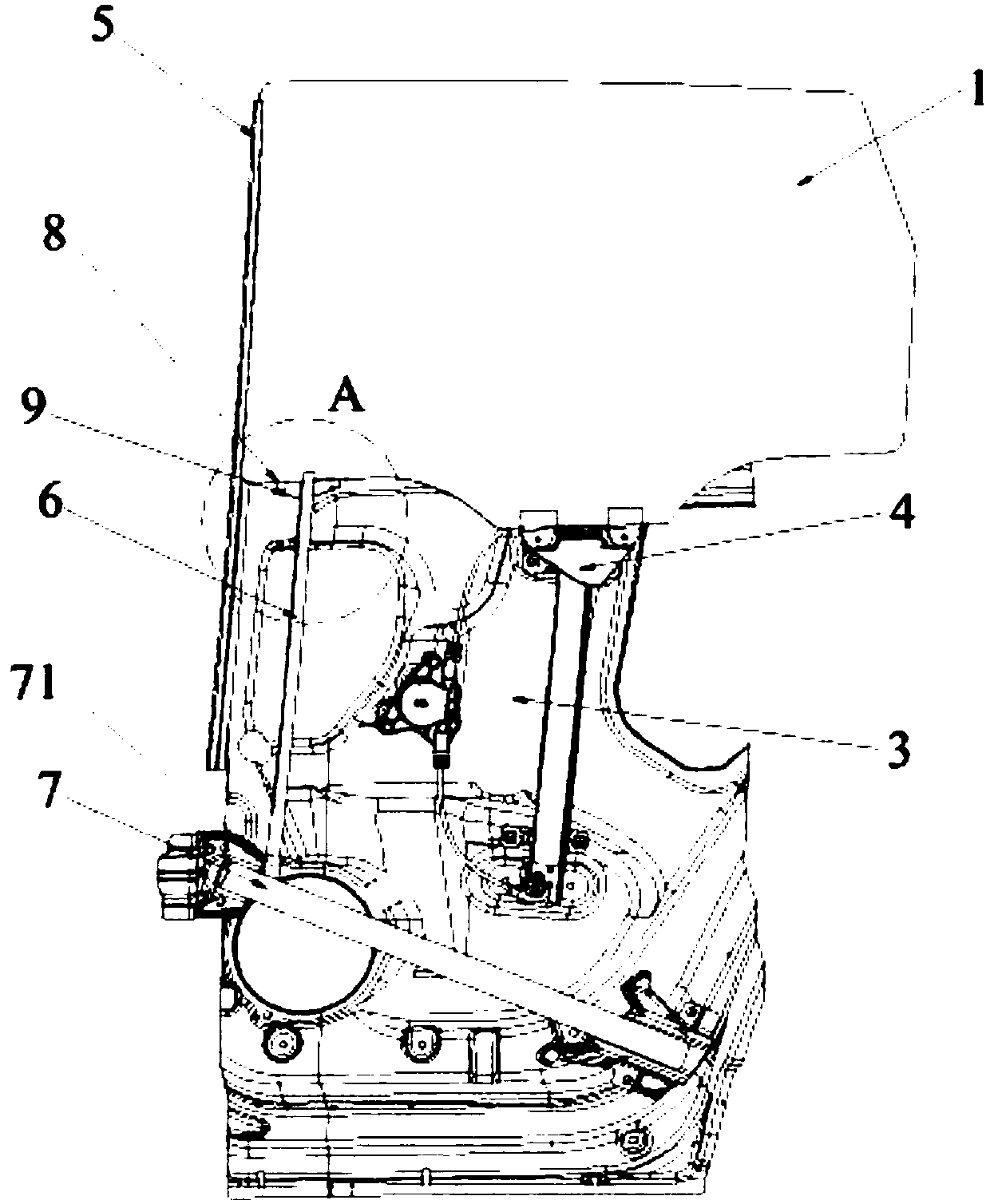

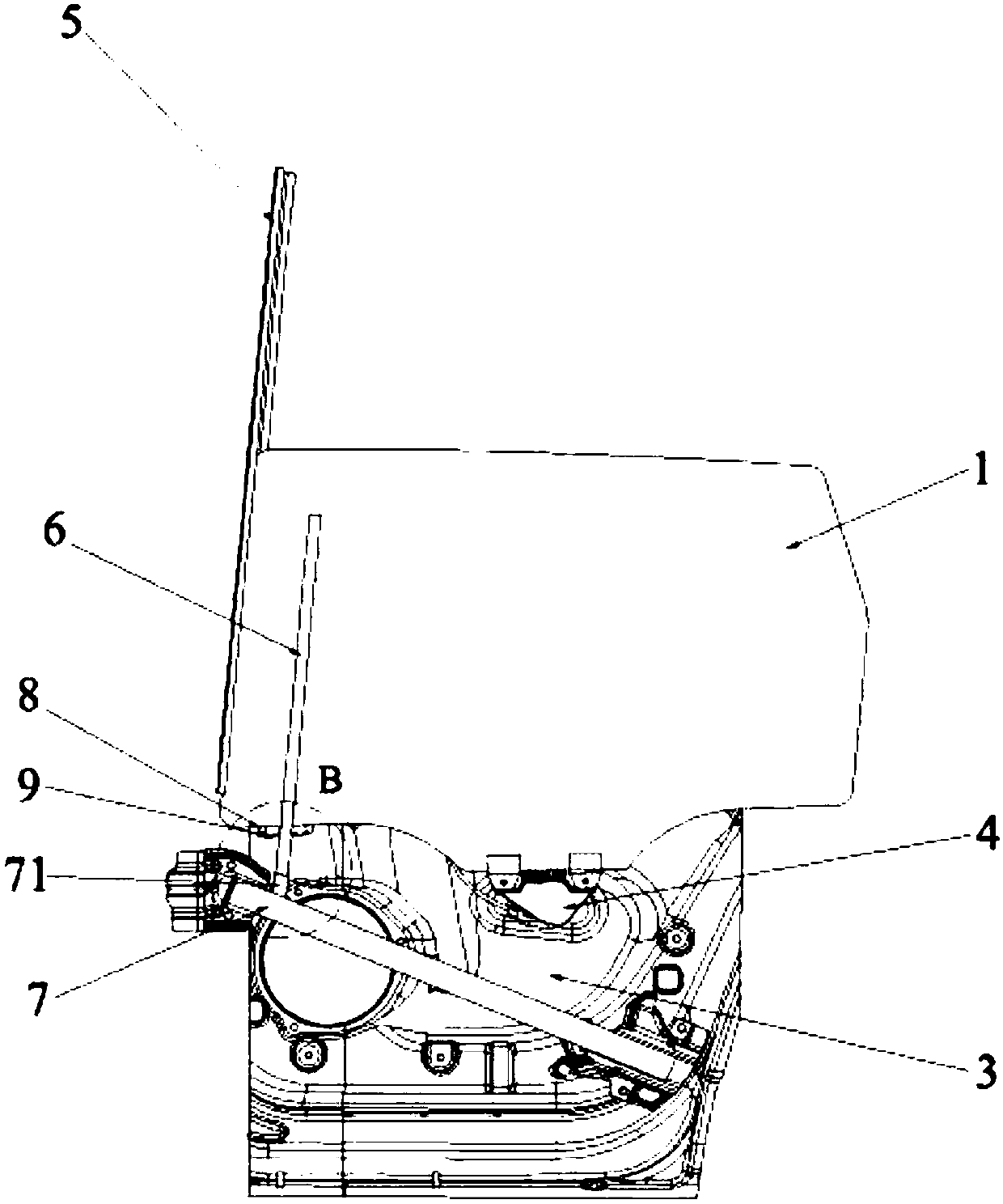

Power supply wire arrangement device of functionalized vehicle door glass

The invention discloses a power supply wire arrangement device of functionalized vehicle door glass. The power supply wire arrangement device comprises the functionalized glass, a guide pipe, a general cable pipe and a wire, wherein the functionalized glass is assembled on a vehicle door in a lifting mode; the guide pipe extends in the lifting direction of the functionalized glass and comprises aglass lifting groove and a connecting part; the general cable pipe is fixed to a vehicle door metal plate and provided with a branch pipe, the inner diameter of the branch pipe is equal to the outer diameter of the connecting part, the extending direction of the branch pipe is identical to that of the general cable pipe, and the connecting part is detachably connected to the branch pipe; and one end of the wire is connected to a functional layer, and the other end of the wire is inserted in the guide pipe, is guided into the general cable pipe through the guide pipe and joins a whole vehicle wire harness. Power supply and signal transmission can be conducted on the glass through the wire regardless of the lifting state of the glass, it is guaranteed that the situation that the glass is clamped on the vehicle door metal plate in the lifting process is avoided, extra supporting and fixing devices do not need to be arranged for wire arrangement of the wire, and the wire is arranged simply.

Owner:FUYAO GLASS IND GROUP CO LTD

Sheet material processing pressing mechanism

InactiveCN108772726AStable and precise rotationAccurate and efficient rotationMachine tool componentsPositioning apparatusSheet materialEngineering

The invention discloses a sheet material processing pressing mechanism, and belongs to the field of sheet material processing machinery and equipment. A driving mechanism, a pressing-down mechanism and a material conveying mechanism of the sheet material processing pressing mechanism are sequentially and horizontally arranged on one side of a fixing bracket from top to bottom, and a horizontal moving connecting plate is slidably disposed at a reciprocating guide rod in the horizontal direction. A horizontal moving rack is horizontally and fixedly arranged on one side of the horizontal moving connecting plate, and rotating pressing plates of a circular arc structure are vertically and symmetrically arranged on both sides of the lower part of a pressing disc. A lifting pressing plate is slidably disposed at lifting guide rods in the vertical direction, and a plurality of pressing lead screws are vertically arranged on the outer side of the lifting pressing plate. Pressing round platformsare fixedly arranged at the lower ends of the pressing lead screws, and a material conveying bracket is horizontally and rotatably connected with a plurality of material conveying rotating rollers inthe horizontal direction in sequence. The sheet material processing pressing mechanism is reasonable in structure design, can horizontally and accurately convey sheet materials according to the needs, can conveniently and smoothly press and fix the sheet materials in the conveying process, and can be applied to the sheet materials of different sizes and specifications to meet the needs of sheet material processing and using.

Owner:嘉兴汉羿文化传播有限公司

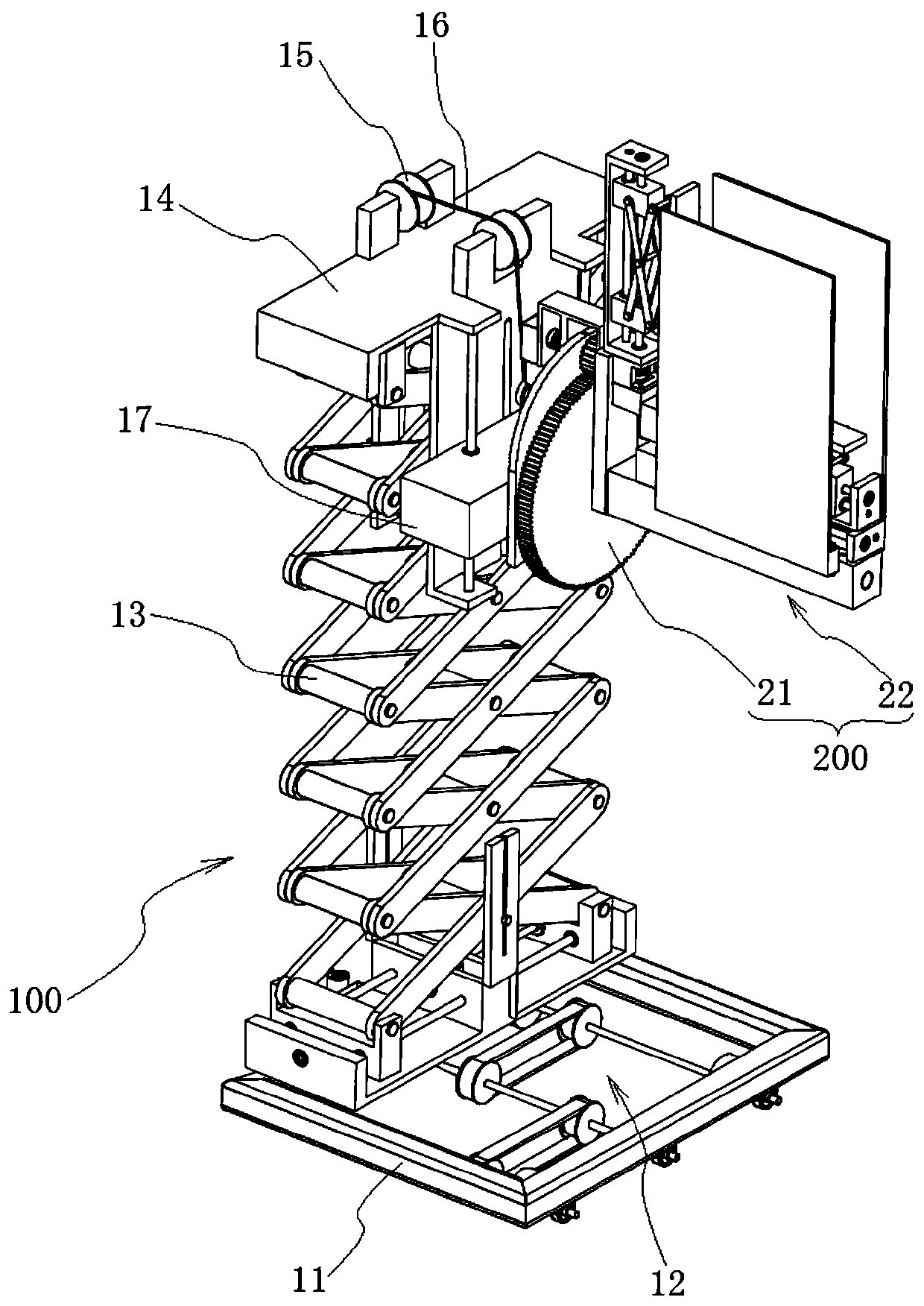

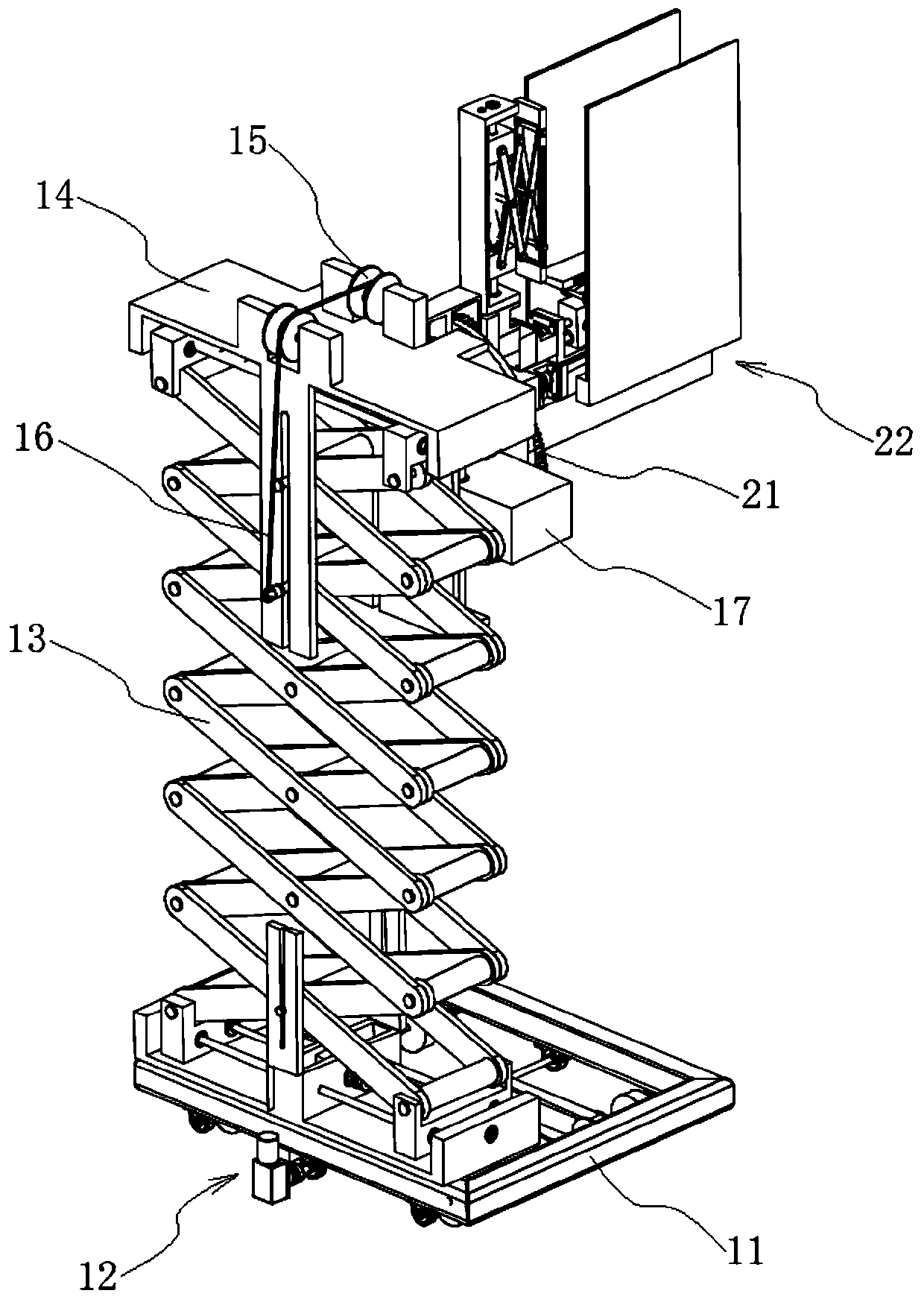

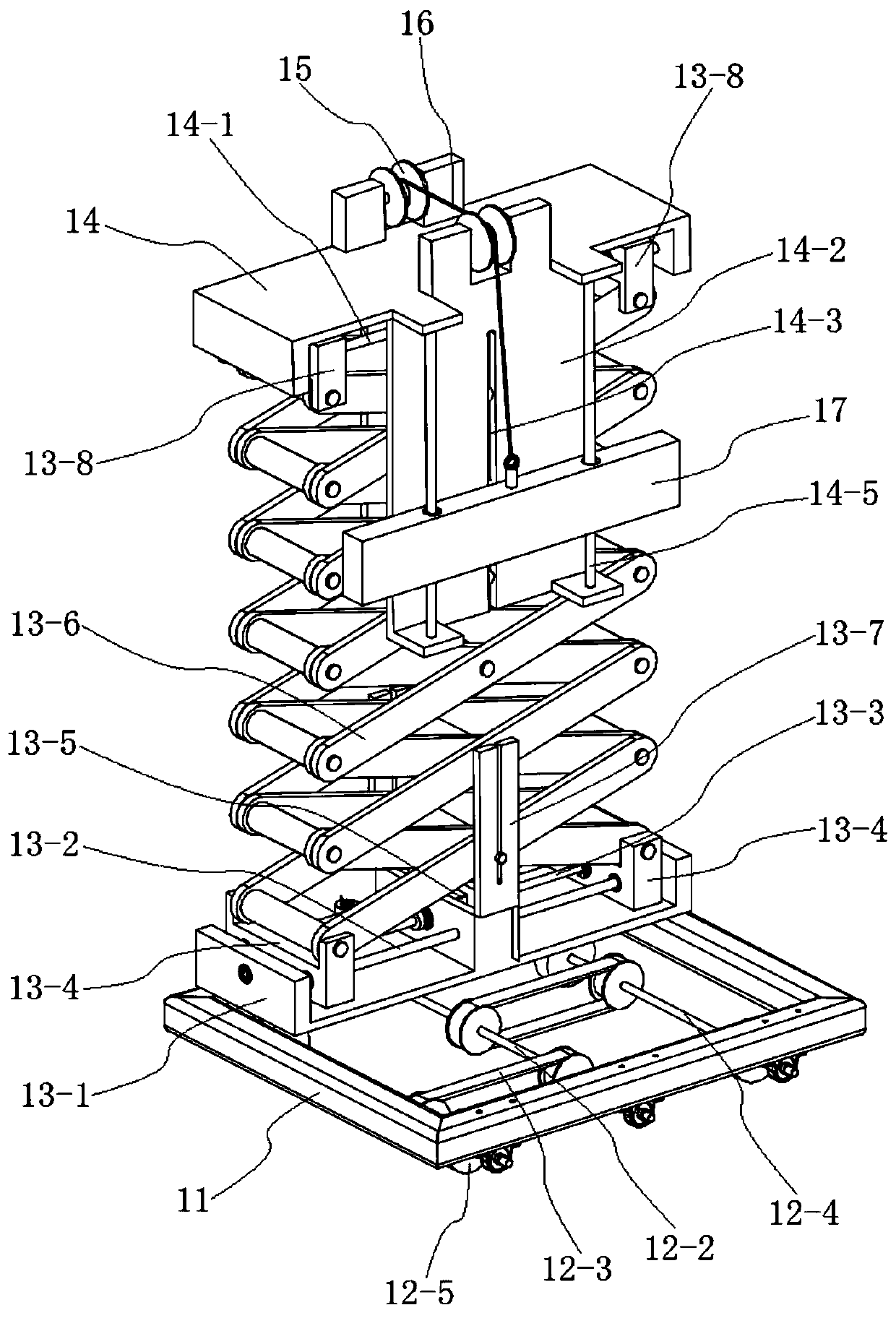

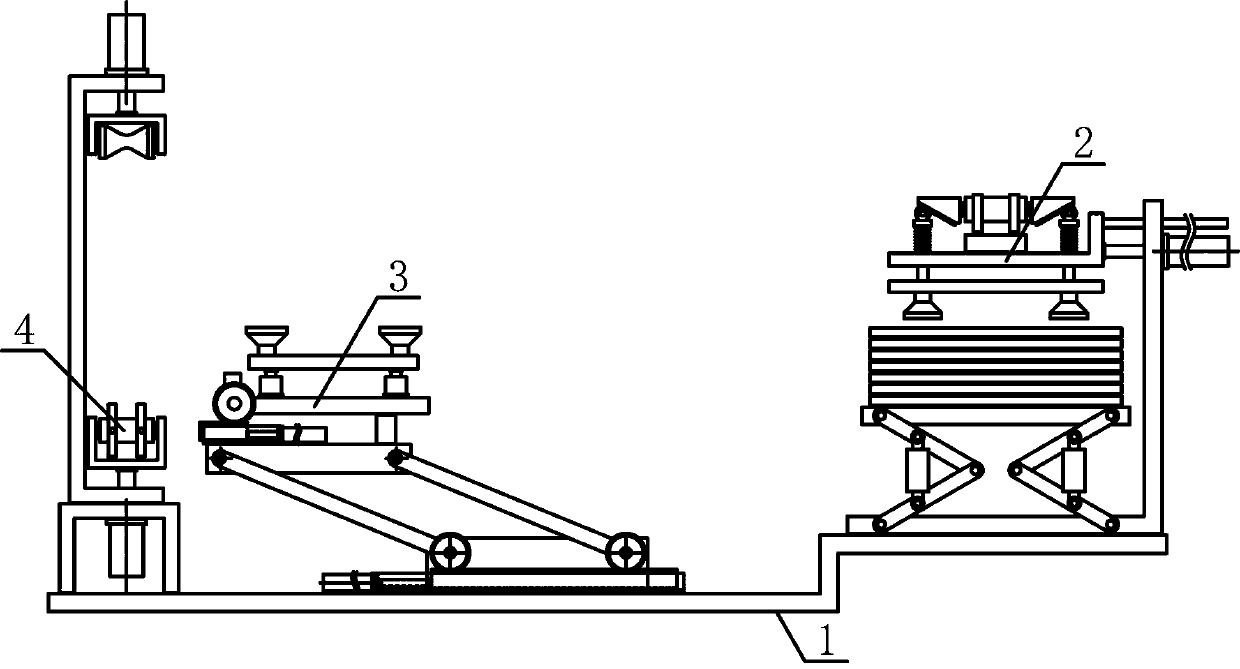

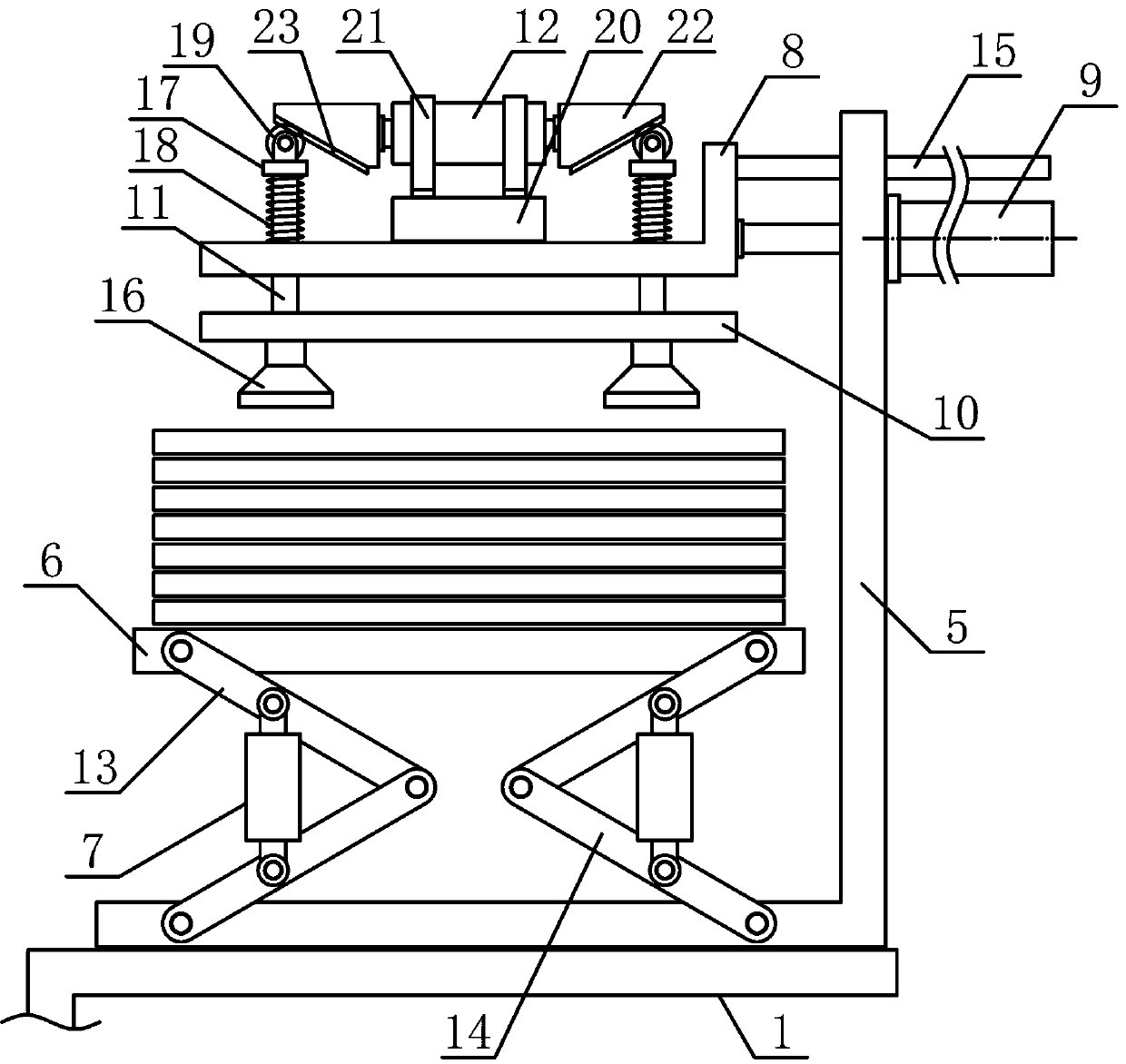

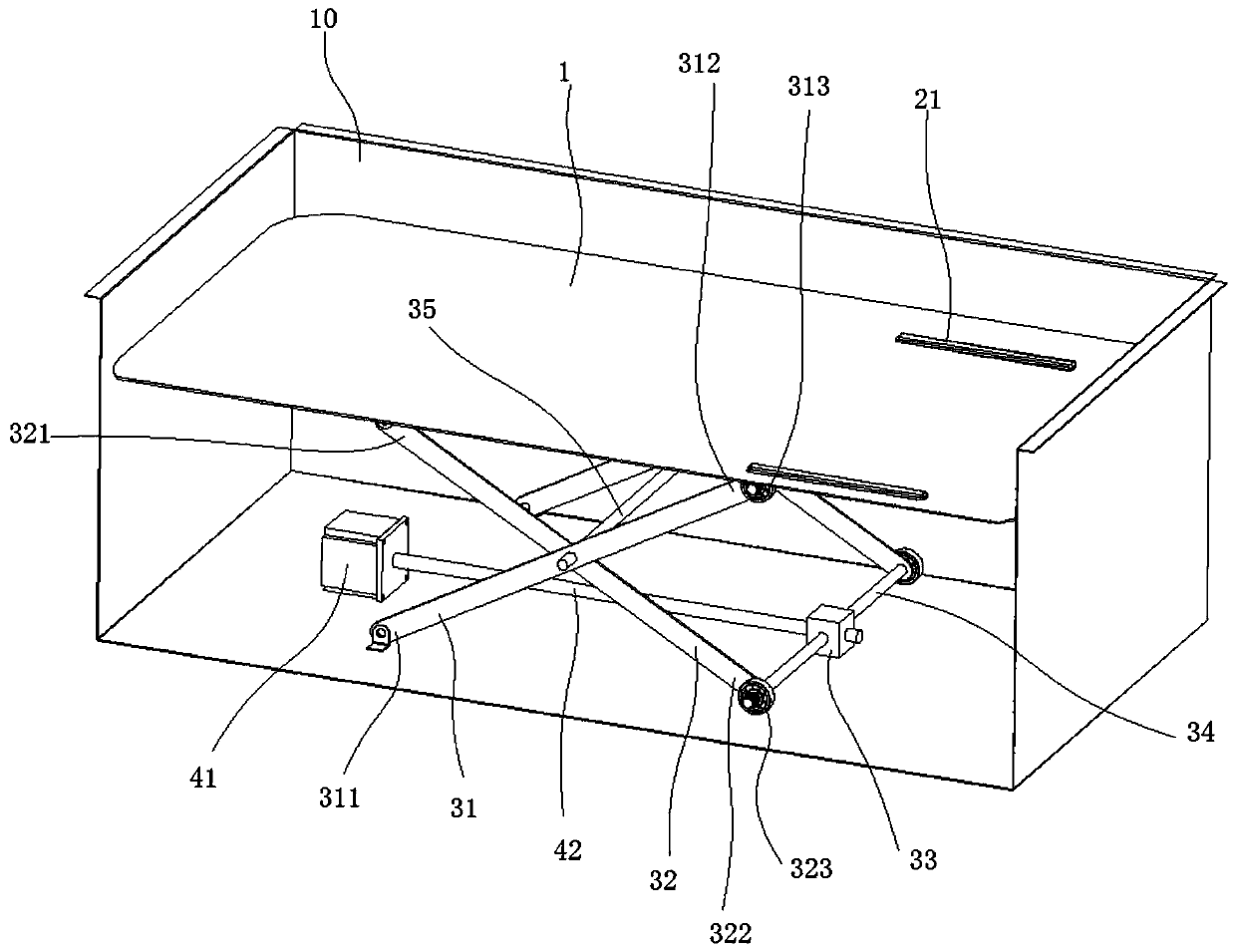

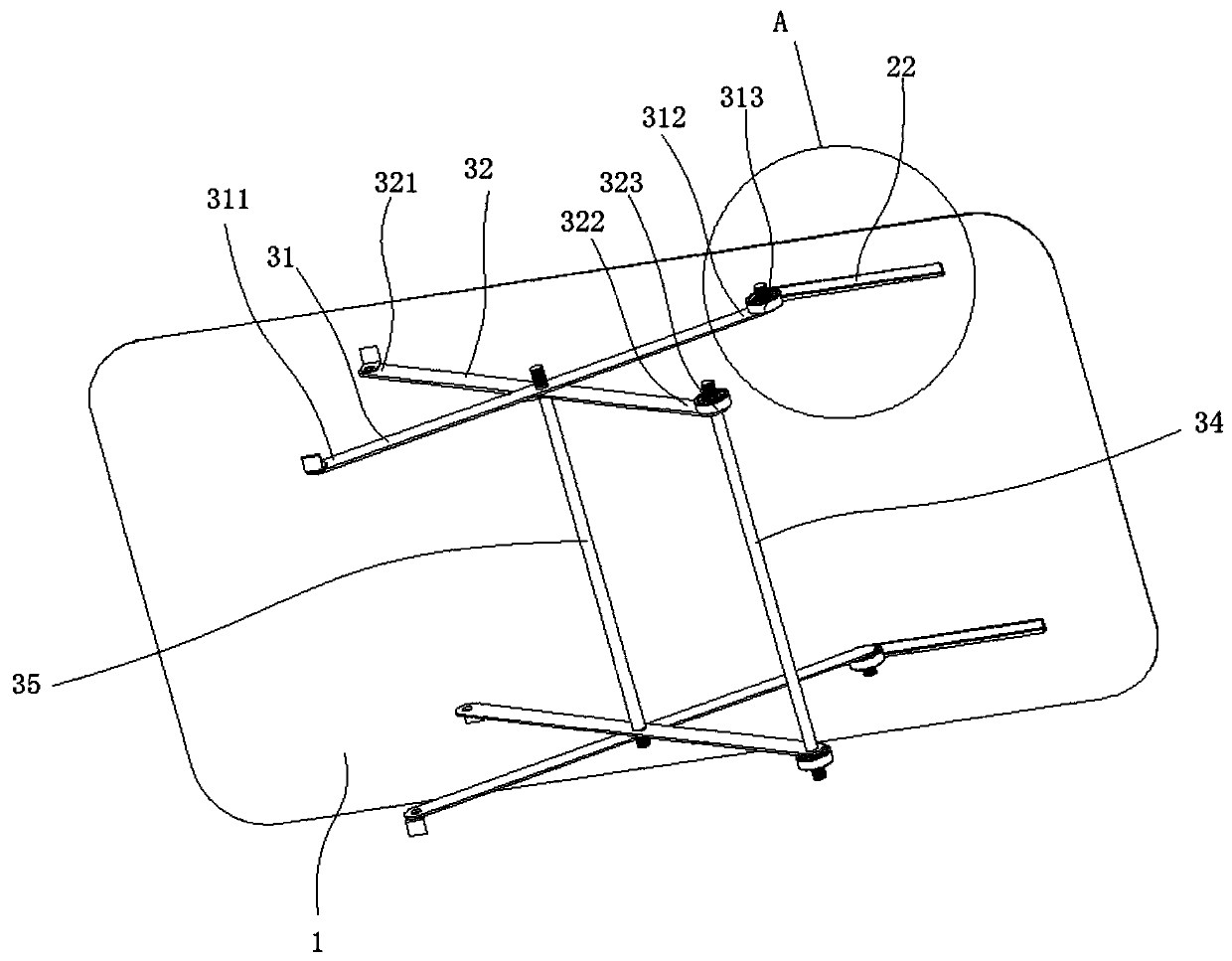

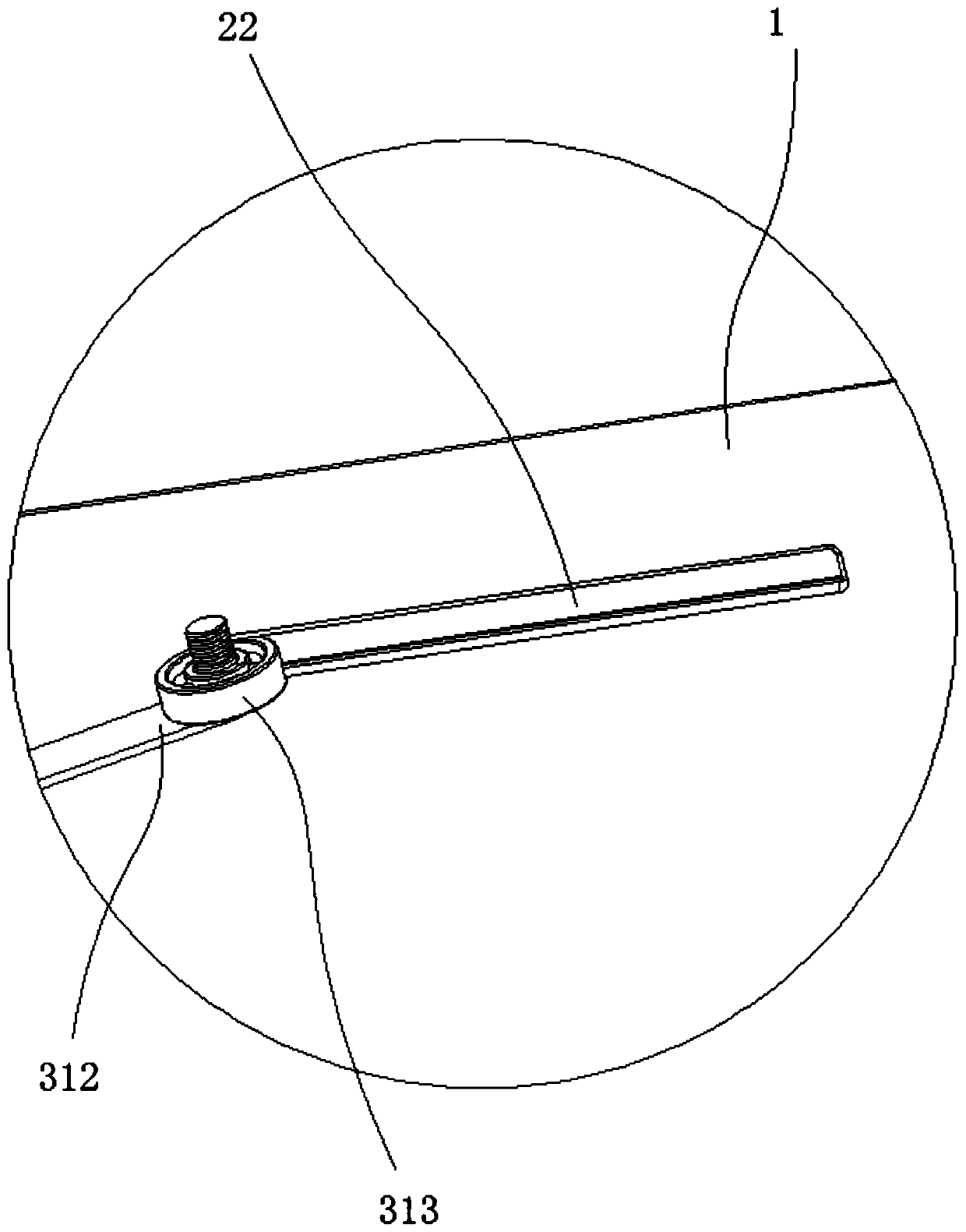

Intelligent bookshelf book grabbing device based on shear type lifting

InactiveCN111017796AImprove lifting stabilityImprove reliabilityLifting framesManipulatorEngineeringMechanical engineering

The invention discloses an intelligent bookshelf book grabbing device based on shear type lifting, and belongs to the field of intelligent bookshelves. The intelligent bookshelf book grabbing device is characterized in that a book grabbing mechanical arm is mounted at the upper part of a shear type telescopic mechanism in a sliding manner through a lifting sliding seat; the shear type telescopic mechanism drives the book grabbing mechanical arm to do lifting motion by utilizing a traction pull rope; the book grabbing mechanical arm can further ascend and descend relative to the upper portion of the shear type telescopic mechanism; the lifting motion stroke of the book grabbing mechanical arm is further expanded on the telescopic motion stroke of the shear type telescopic mechanism, it is guaranteed that the book grabbing mechanical arm can grab books on the bottom layer of an intelligent book shelf, and the highest ascending position of the book grabbing mechanical arm is increased; moreover, the shear type telescopic mechanism as short as possible is used for achieving lifting movement with a larger stroke, the lifting stability and reliability of the shear type telescopic mechanism are further improved, and the book grabbing device is simpler and more compact in structure and convenient to control intelligently.

Owner:CHANGZHOU INST OF TECH

Panel transferring and overturning mechanism

InactiveCN109625955ASmooth transmissionImprove efficiencyConveyorsConveyor partsMechanical equipmentEngineering

The invention discloses a panel transferring and overturning mechanism, and belongs to the field of plate conveying and machining auxiliary mechanical equipment. A lifting bearing plate is horizontally arranged on one side of a material bearing support, an adsorption connecting plate is horizontally arranged on the lower side of a horizontal movement connecting plate, a plurality of plate moving suckers are uniformly arranged on the lower side of the adsorption connecting plate, and a transferring bearing plate is horizontally arranged on the upper side of a fixing base, a overturning connecting plate is arranged on the upper side of the transferring bearing plate, and a material bearing connecting plate is arranged on one side of the overturning connecting plate; and a plurality of overturning suckers are arranged on the upper side of the material bearing connecting plate, a material guide support is vertically and fixedly arranged on the upper side of a material guide base, the upperside of the bearing plate support at the output end of a material bearing air cylinder is sequentially and rotationally connected with a plurality of bearing plate rotating rollers, and the lower side of a guide support at the output end of a guide air cylinder is sequentially and rotationally connected with a plurality of guide rotating rollers. According to the mechanism, the structural designis reasonable, the panels can be transferred and fed one by one, the panels can be stably and accurately overturned, the material loading and conveying automation degree of the panels is improved, andthe requirement for machining and using is met.

Owner:桐乡市川泰纺织科技有限公司

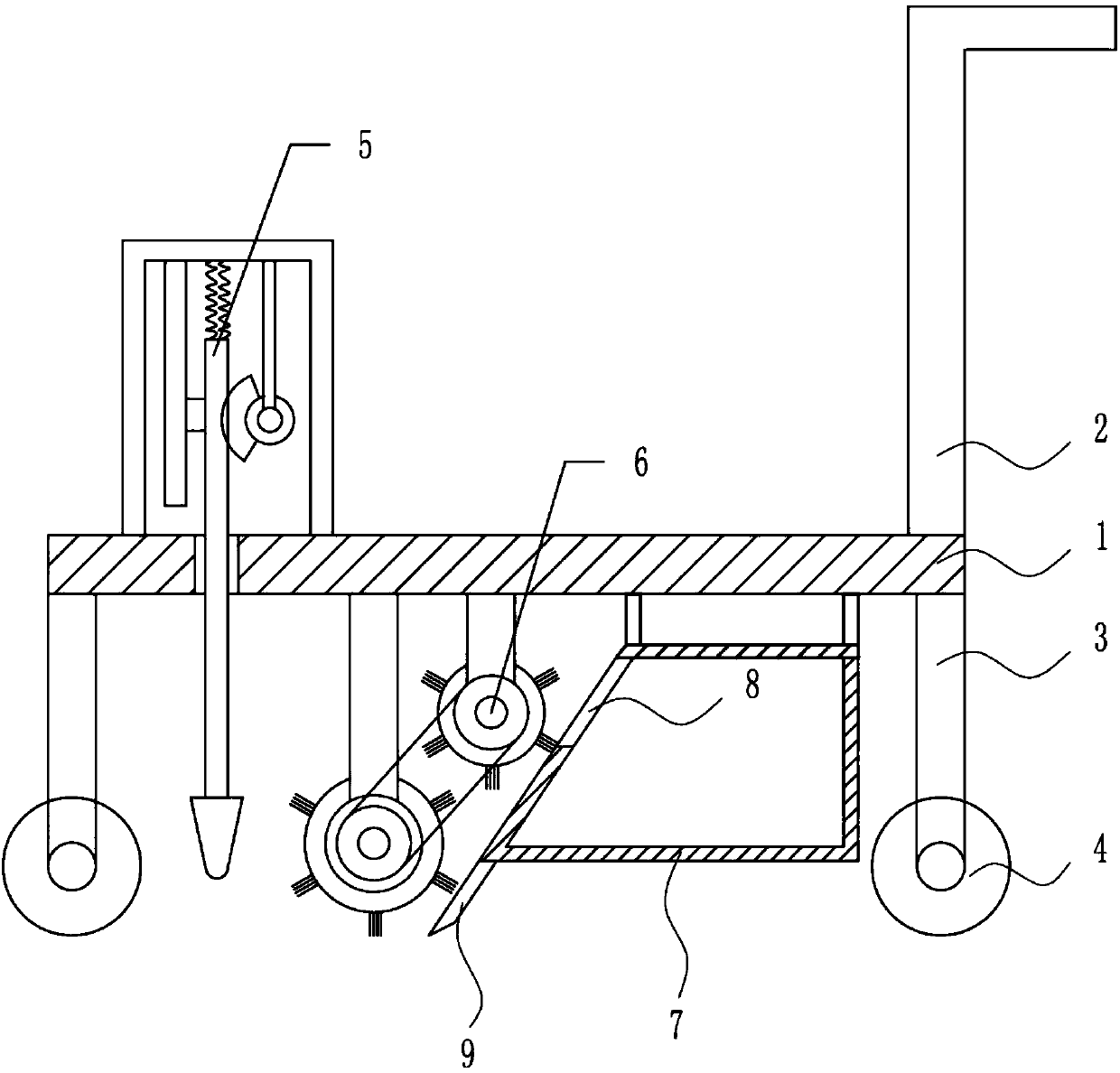

Floor cleaning device for engineering

InactiveCN107837042ASmooth lifting movementExpand the range of water sprayCarpet cleanersFloor cleanersEngineeringBilateral symmetry

The invention relates to a floor cleaning device, in particular to a floor cleaning device for engineering. The technical problem to be solved by the invention is to provide a floor cleaning device which has fast cleaning speed, clean sweeping and convenient movement for engineering. In order to solve the above technical problem, the invention provides such a floor cleaning device for engineeringwhich comprises a bottom plate, a pusher, a wheel carrier, a wheel, a percussion device, a sweeping device, a collection box and a baffle, wherein the pusher is arranged on the top of the right side of the bottom plate, the percussion device is arranged on the top of the left side of the bottom plate, the wheel carrier in bilateral symmetry is arranged at the bottom of the bottom plate, the wheelis arranged at the bottom of the wheel carrier, the collection box is arranged on the right side of the bottom of the bottom plate, a feeding inlet is formed in the upper part of the left side of thecollection box, and the baffle is arranged on the left side of the bottom of the collection box. The floor cleaning device for engineering achieves the effects of high cleaning speed, clean sweeping and convenient movement. The device adopts manual control of sweeping, so that the sweeping is cleaner, the sweeping speed is faster, the accuracy is high, and the operation is relatively simple.

Owner:饶胜智

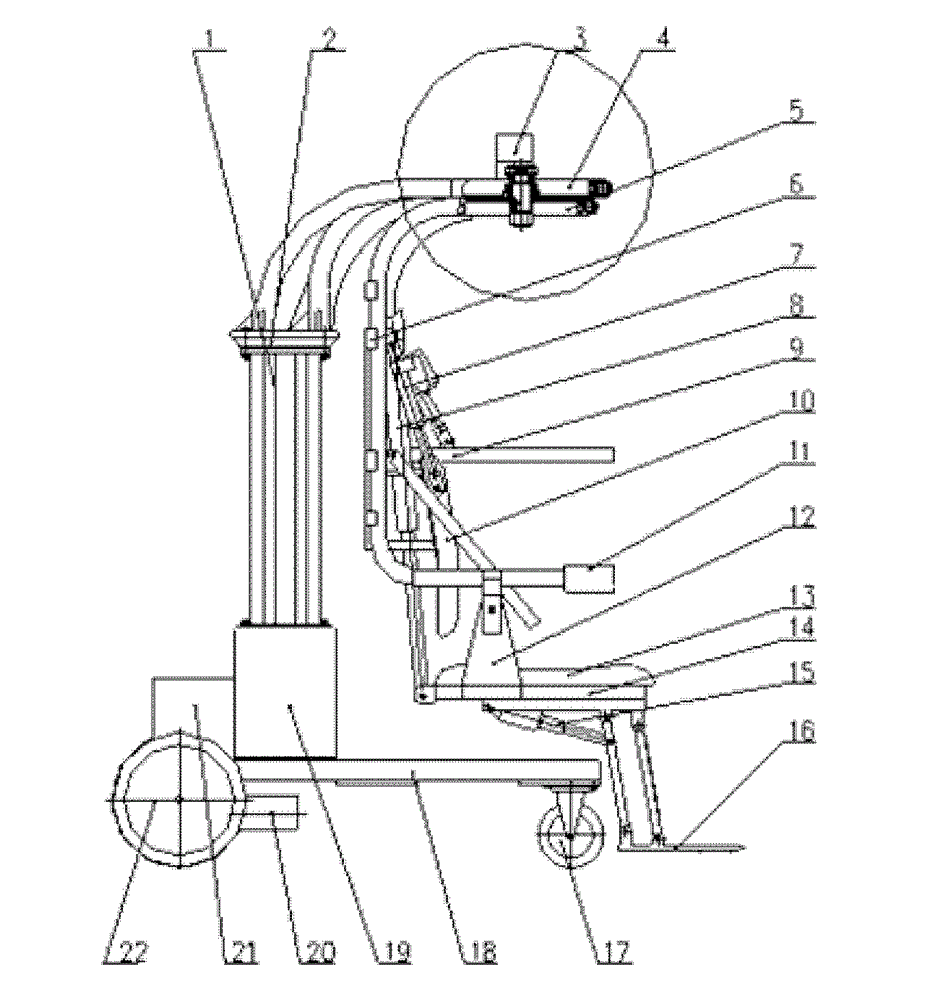

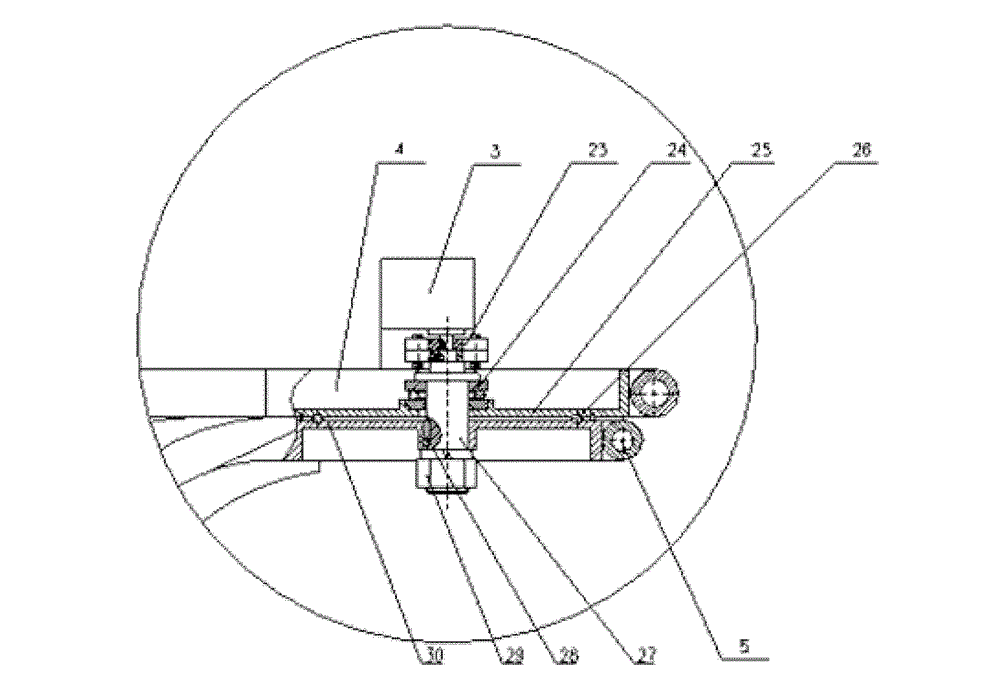

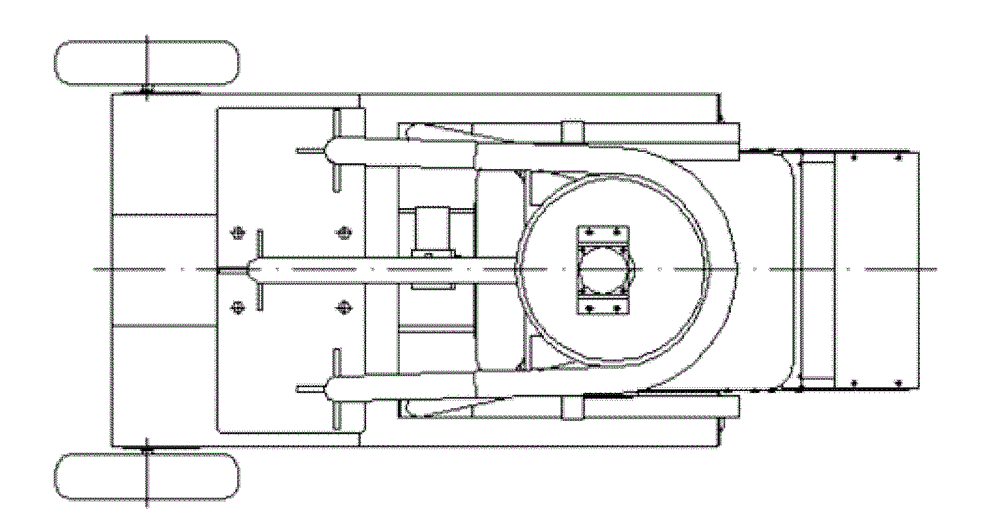

Lifting mechanism of AGV and AGV

InactiveCN110155906ASmooth lifting movementPlay a limiting roleLifting framesMechanical engineeringEngineering

The invention discloses a lifting mechanism of an AGV and the AGV. The lifting mechanism of the AGV comprises a tray, a rotating barrel and a rotary lifting rolling wheel, wherein the tray is used forbearing articles, the rotating barrel is rotationally arranged, a spiral guide groove is formed in the outer peripheral surface of the rotating barrel, the rotary lifting rolling wheel is arranged onthe tray and moves along the spiral guide groove, and the tray is driven by the rotary lifting rolling wheel to ascend and descend in the vertical direction. According to the lifting mechanism of theAGV, the lifting movement of the tray in the vertical direction is realized by virtue of the cooperation between the rotary lifting rolling wheel and the spiral guide groove formed on the rotating barrel, in the movement process, the upper side wall and the lower side wall of the spiral guide groove play a role in limiting the movement of the rotary lifting rolling wheel, so that the lifting movement of the tray is more stable. The spiral guide groove of the lifting mechanism is arranged on the outer peripheral surface of the rotating barrel, so that the motion working process of the liftingmechanism is easier to monitor, and then maintenance and repair are facilitated.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

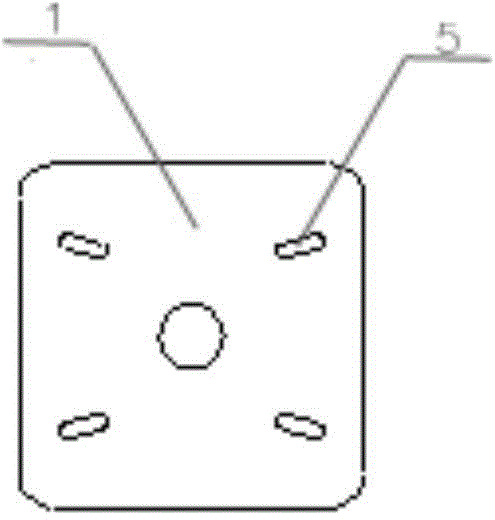

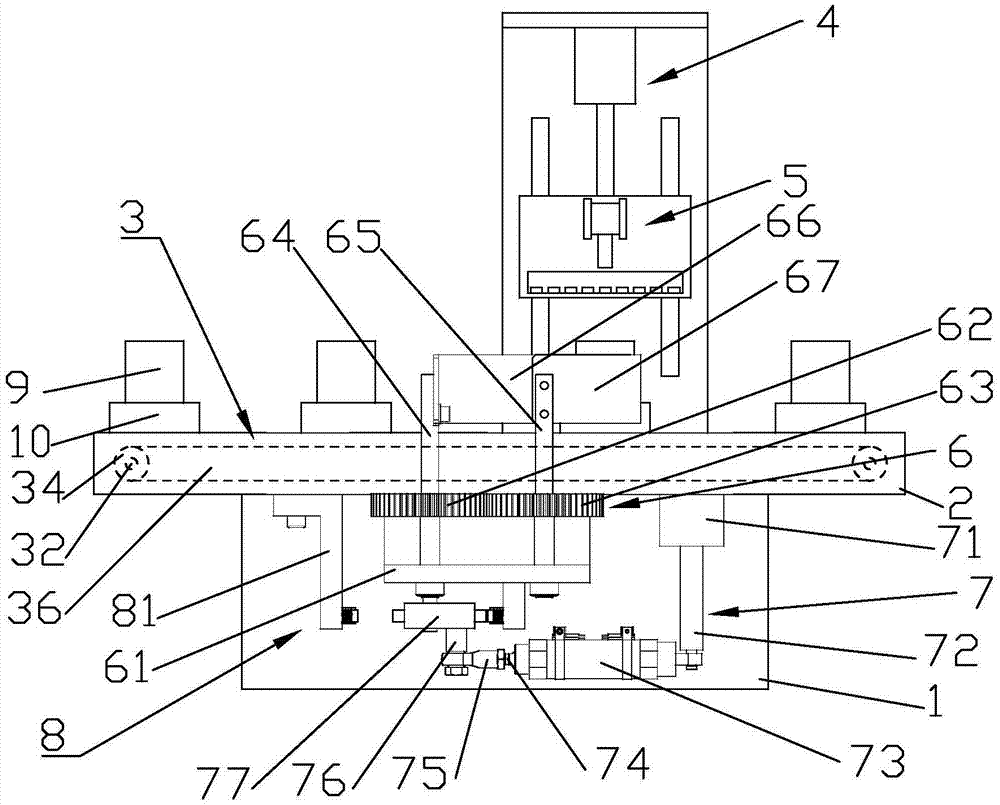

Automatic arranging mechanism for punched and sheared workpieces

ActiveCN110479847AHigh degree of processing automationSmooth and smooth separation and finishingMetal-working feeding devicesPositioning devicesFixed bearingPunching

The invention discloses an automatic arranging mechanism for punched and sheared workpieces and belongs to the field of workpiece processing mechanical devices. A plate feeding guide roller and a plate discharging guide roller are separately, horizontally and rotationally connected to the two sides of an arranging bracket; a guide rotating plate is rotationally arranged in an arranging rotating hole; a punching and shearing die plate is horizontally and fixedly arranged on the upper side of the arranging bracket; a punching and shearing die head matched with a punching and shearing pressure hole is fixedly arranged in the middle of the lower side of a lifting punching plate; translation guide rods are arranged on a reciprocating guide plate in the horizontal direction in a sliding manner;an output end of a plate pushing cylinder is fixedly connected with one side of the reciprocating guide plate; a lower pressure plate is fixedly arranged on the upper side of a fixed bearing plate atthe lower end of one side of the reciprocating guide plate in a horizontal laminating manner; and an upper pressure plate is arranged on the lower side of one end of a rotating pressure plate. The automatic arranging mechanism is reasonable in structural design, can conveniently, efficiently and continuously perform punching and shearing processing to produce workpieces, and annular workpieces formed through synchronous punching and shearing processing are stably and smoothly separated and arranged, so that the workpiece processing automatic degree is improved, and the processing and using requirements are met.

Owner:乳山吾星纤维有限公司

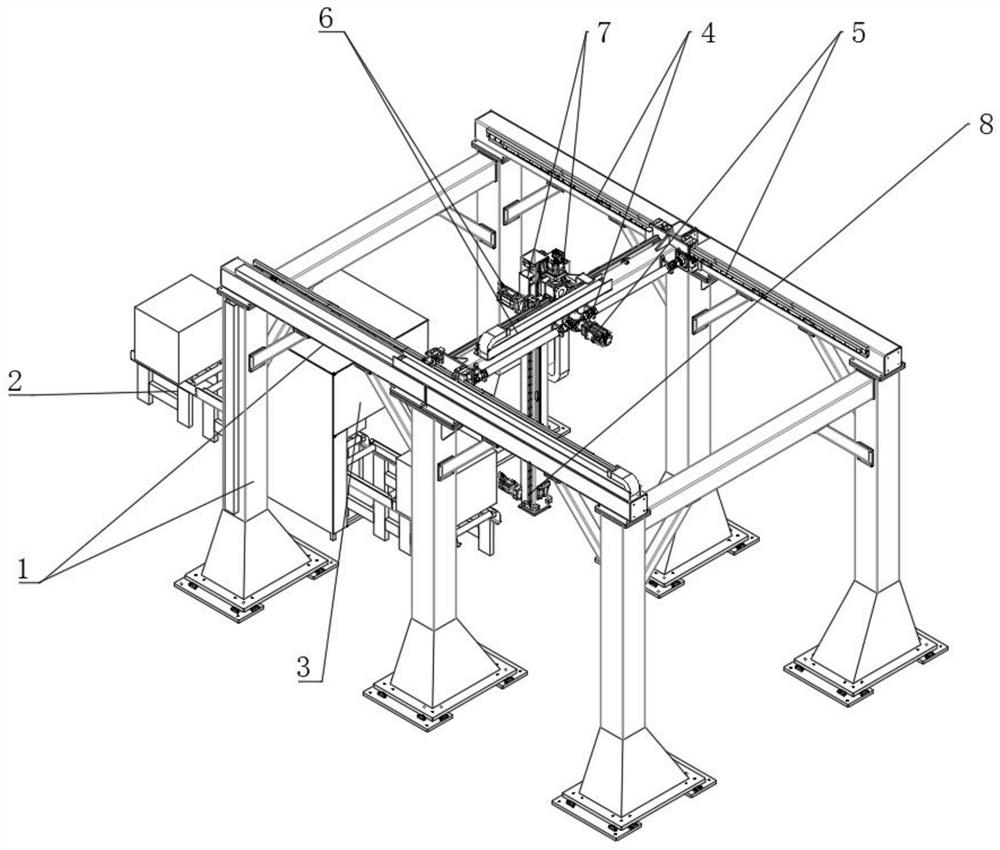

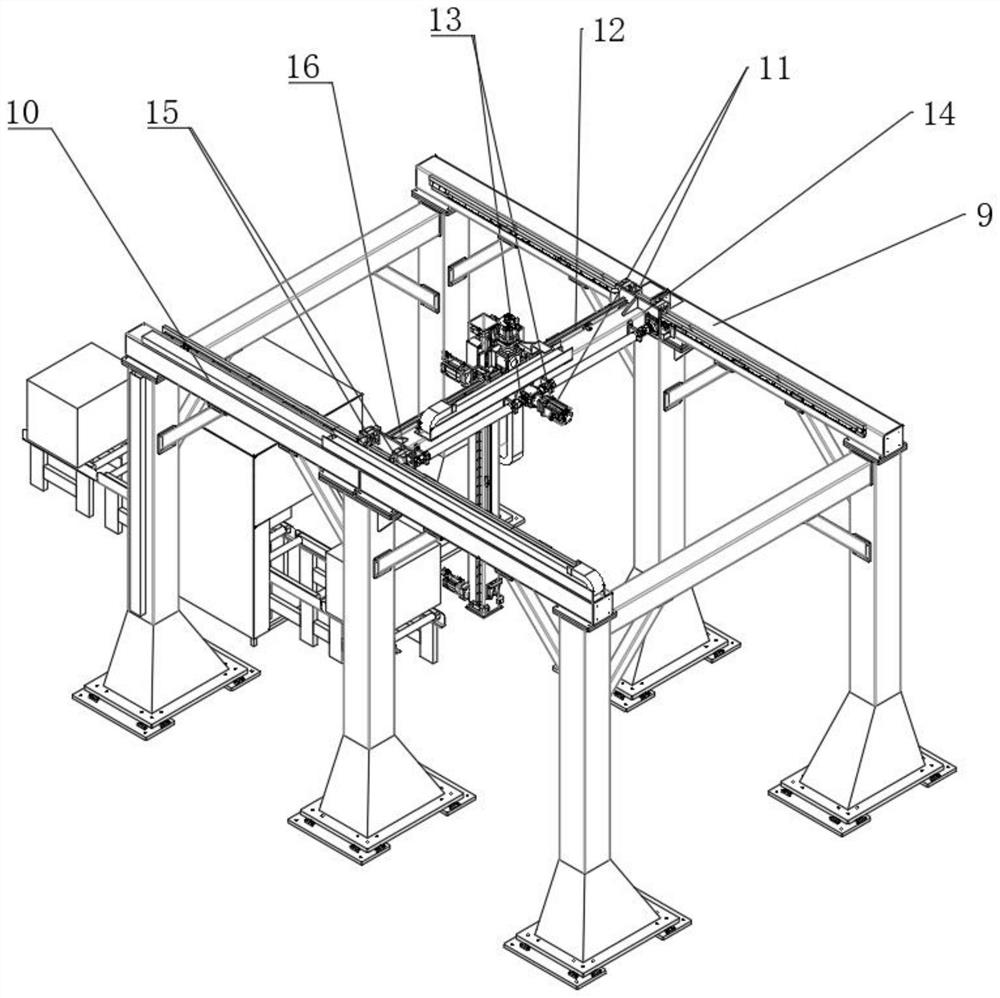

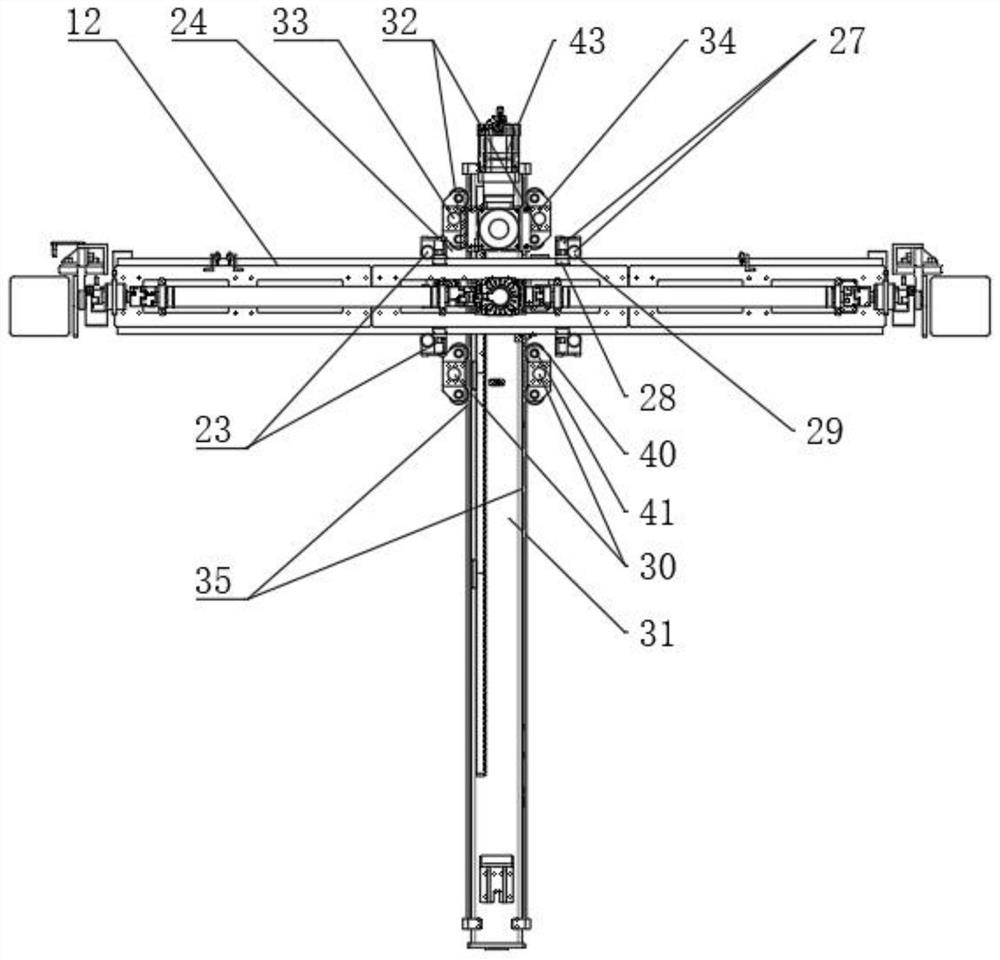

Truss robot with multi-degree-of-freedom stable motion function

PendingCN112894777AExtended service lifeGuaranteed stabilityProgramme-controlled manipulatorEngineeringStructural engineering

The invention discloses a truss robot with a multi-degree-of-freedom stable motion function, and belongs to a truss robot in the technical field of truss robot. The truss robot comprises a frame, a conveyor and a camera assembly, the conveyor and the camera assembly are arranged at the lower end of the frame, a multi-degree-of-freedom motion assembly is arranged on the frame, the multi-degree-of-freedom motion assembly comprises a transverse shaft motion mechanism moving in the length direction of the frame, a longitudinal shaft motion mechanism moving in the length direction of the transverse shaft motion mechanism and a vertical shaft motion mechanism arranged on the longitudinal shaft motion mechanism, and an A-axis motion pair is arranged at the bottom of the vertical shaft motion mechanism; According to the truss robot with the multi-degree-of-freedom stable motion function, the motion assemblies moving in the X-axis direction, the Y-axis direction and the Z-axis direction are arranged on the frame, stable motion control over the multi-degree-of-freedom motion assemblies is achieved, and therefore fixed-point operation of the truss robot in space is achieved.

Owner:YUNNAN KELAIZHONGCHENG INTELLIGENT EQUIP CO LTD

Flour grinding machine for rice noodle processing

InactiveCN109647578AEasy to GrindEfficient grindingCocoaGrain treatmentsGear wheelComputer engineering

The invention discloses a flour grinding machine for rice noodle processing. The lower portion of the left side of a first connection block is fixedly connected with a slider; the tops of the first connection block and a second connection block are each fixedly connected with an inserting rod; the tops of the inserting rods are fixedly connected with first springs; the outer sides of the insertingrods are sleeved with hollow columns; the bottoms of the first connection block and the second connection block are each fixedly connected with a second spring; the bottoms of the second springs areeach fixedly connected with a rubber block; the two sides of a first rotating shaft are sleeved with a second conical gear and a third conical gear correspondingly; the top of a second rotating shaftpenetrates through a supporting plate and is sleeved with a fourth conical gear; the bottom of the second rotating shaft penetrates through the supporting plate and is fixedly connected with a rotating column; and the outer side of the rotating column is provided with a slide groove. According to the flour grinding machine for rice noodle processing, due to use of the rotating column, the slide groove, a slider, the inserting rods, the first springs and hollow columns, the grinding efficiency of the flour grinding machine for rice noodle processing is high.

Owner:陈丽贞

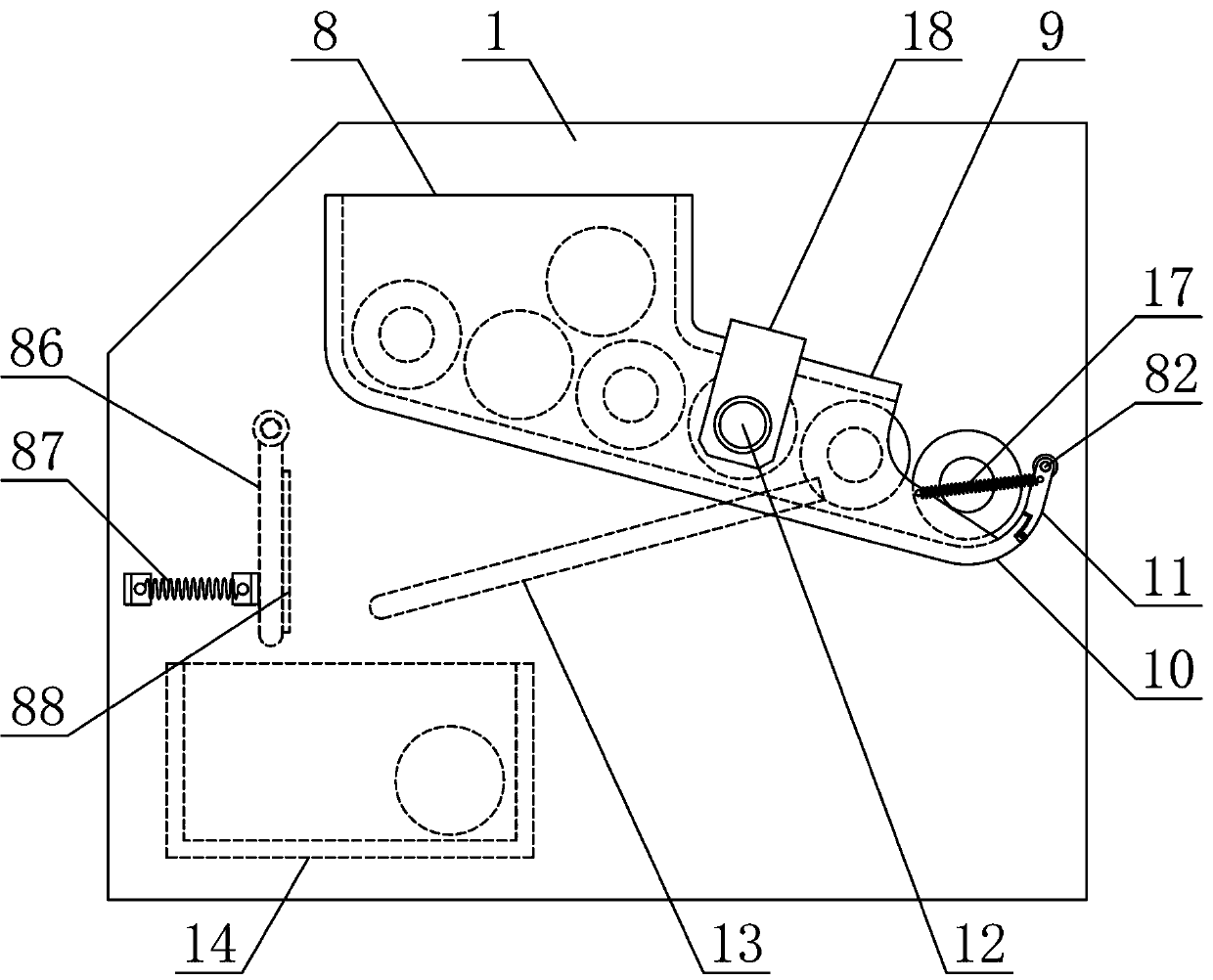

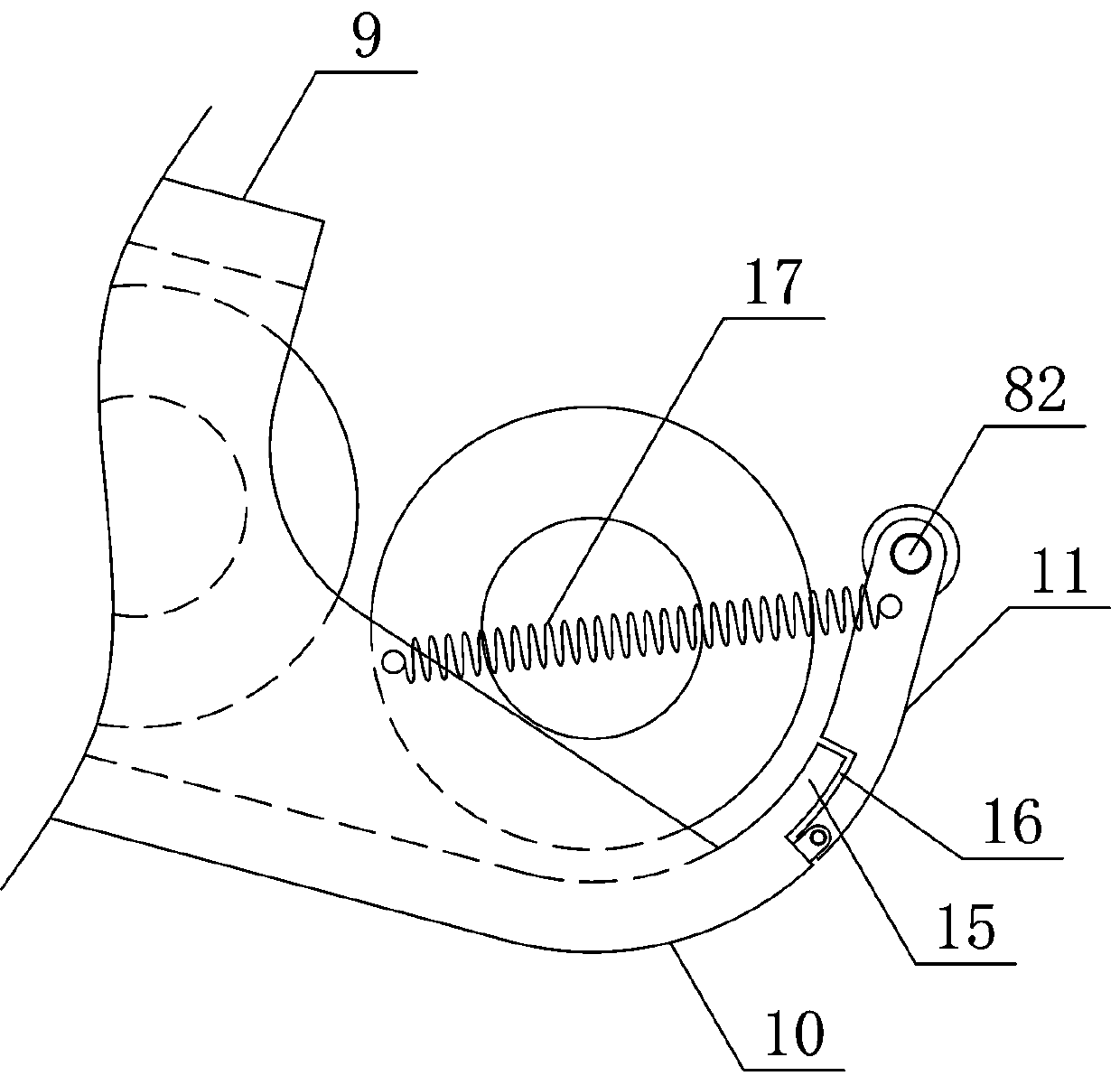

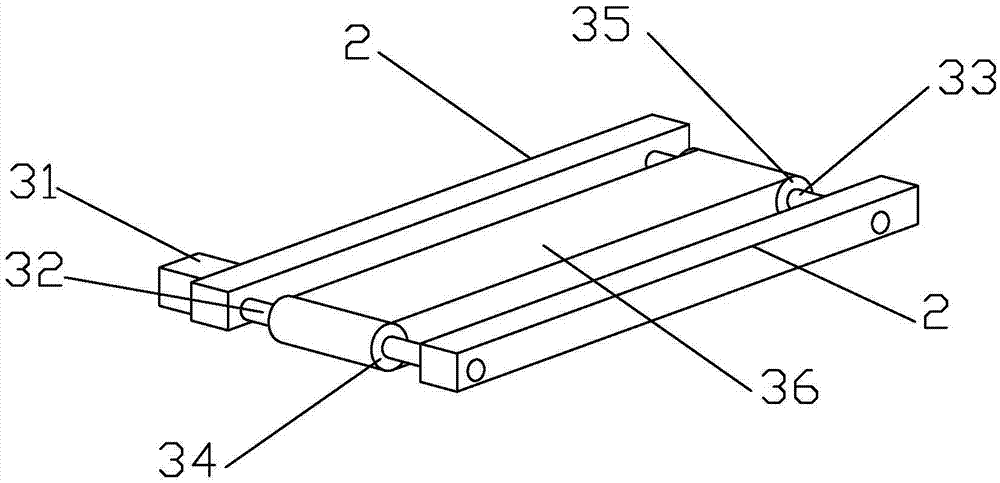

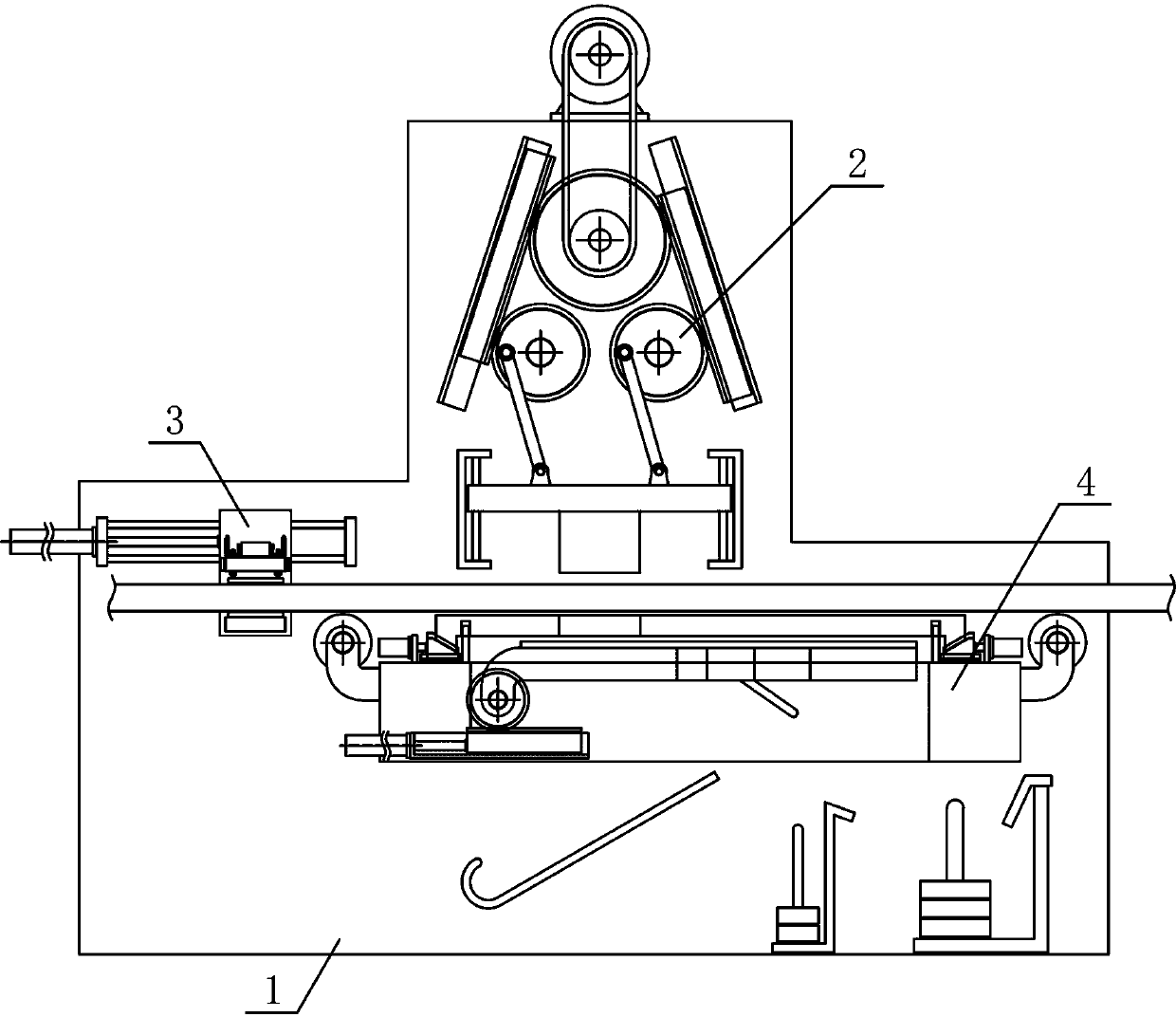

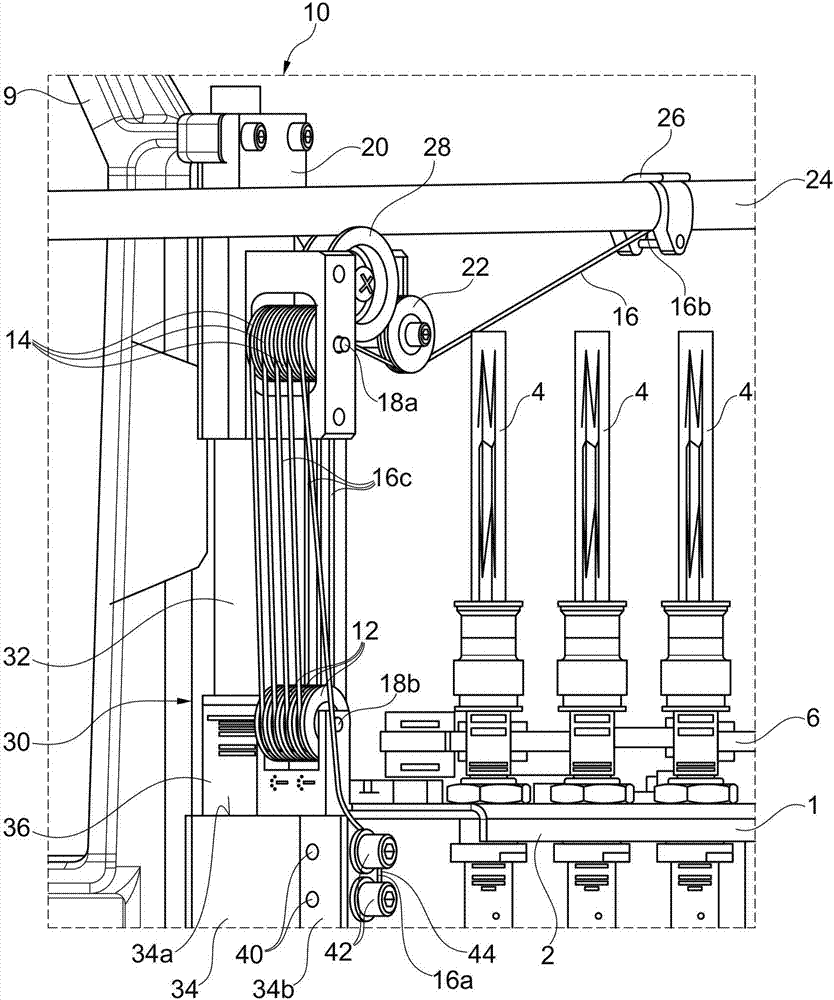

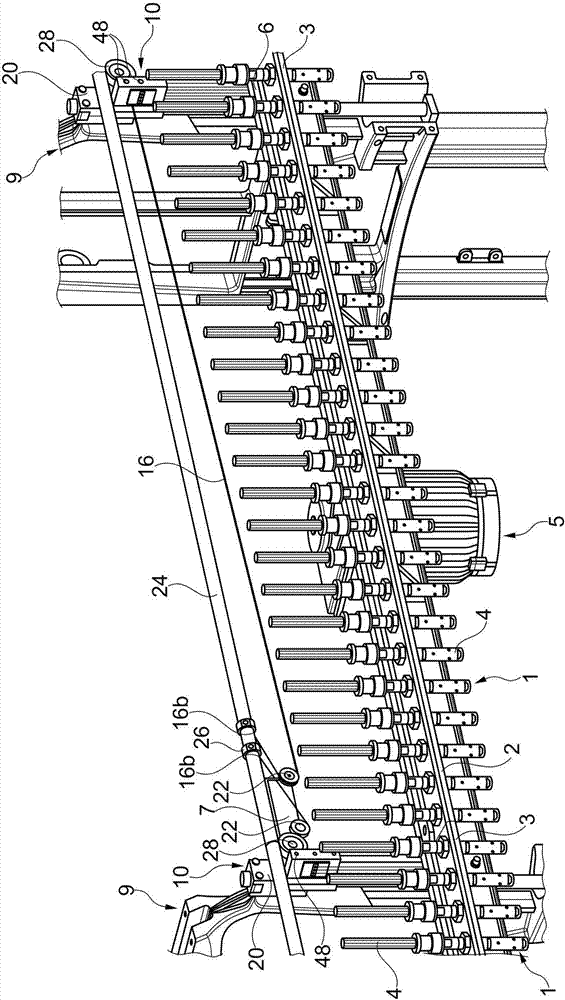

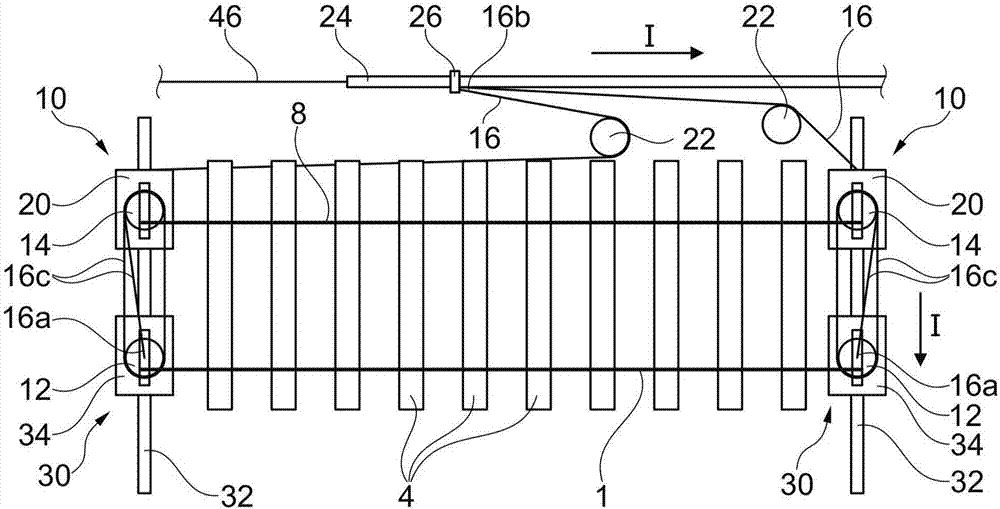

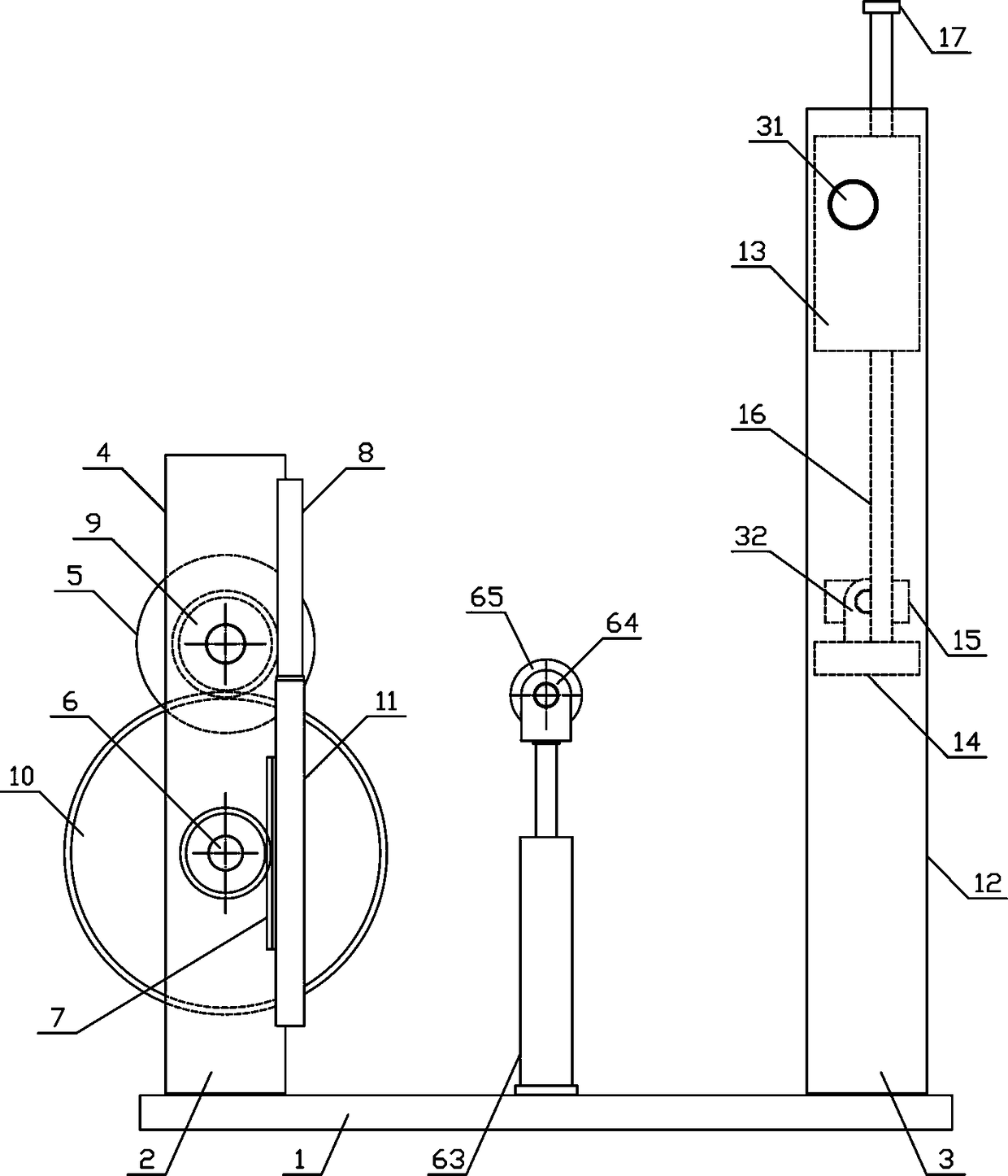

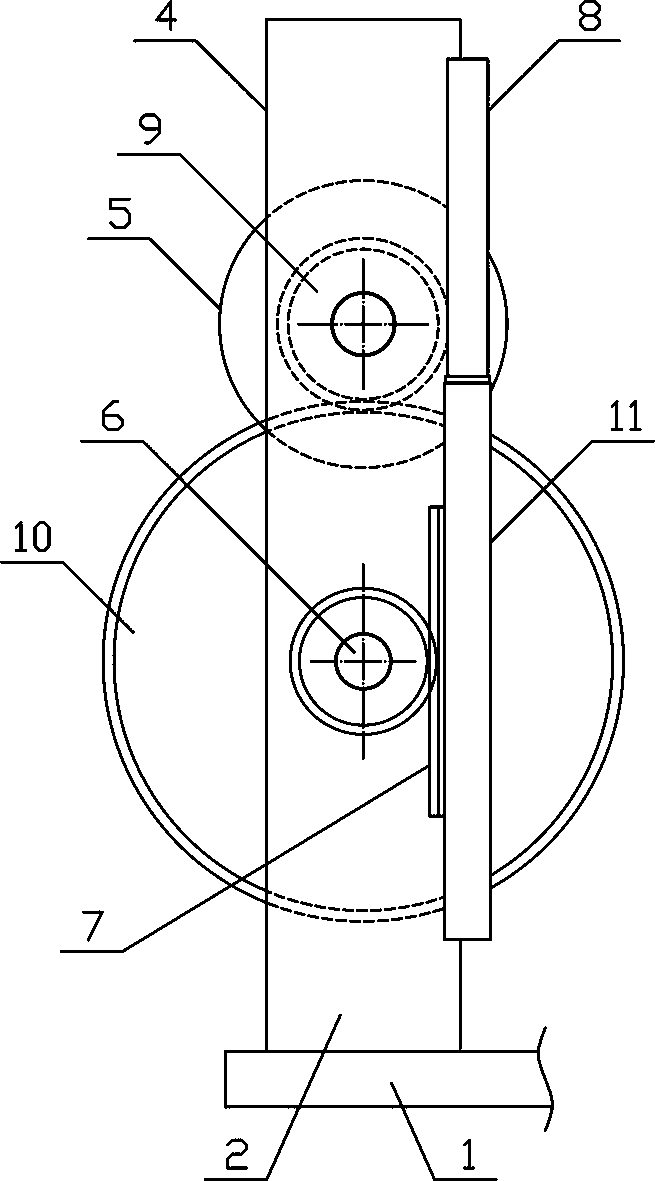

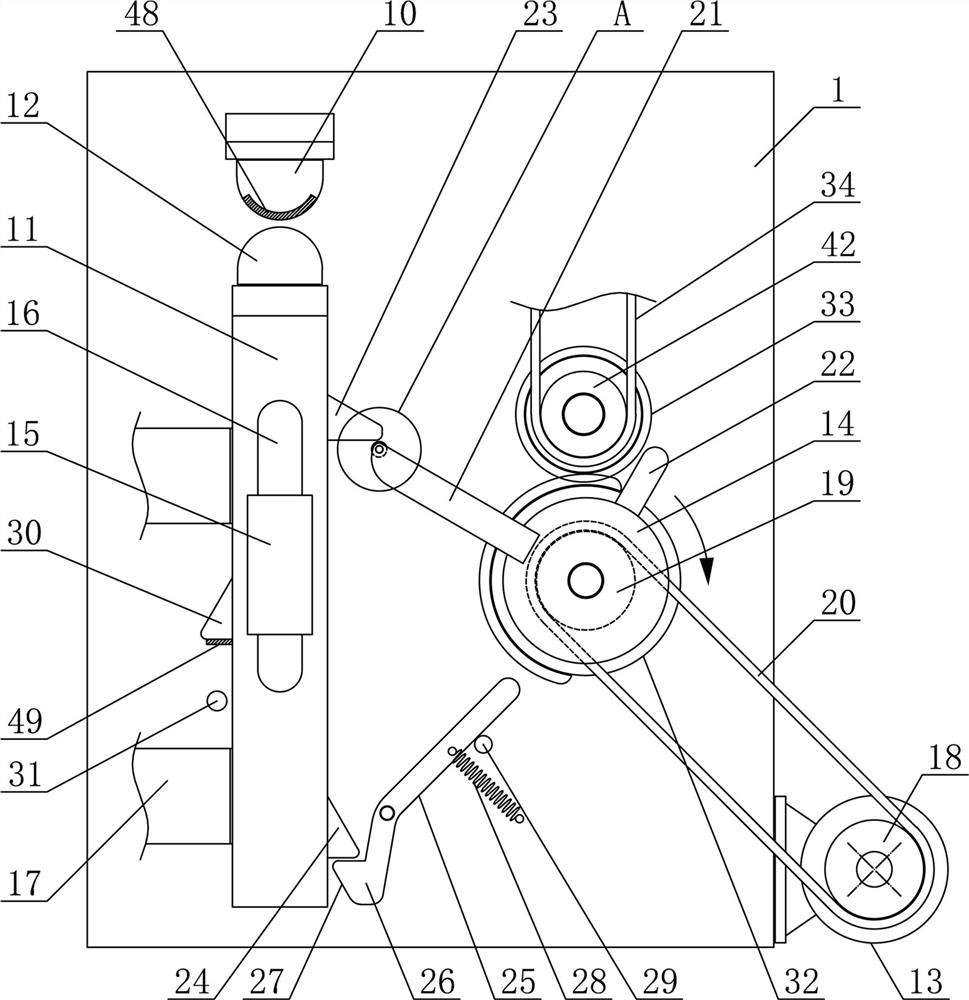

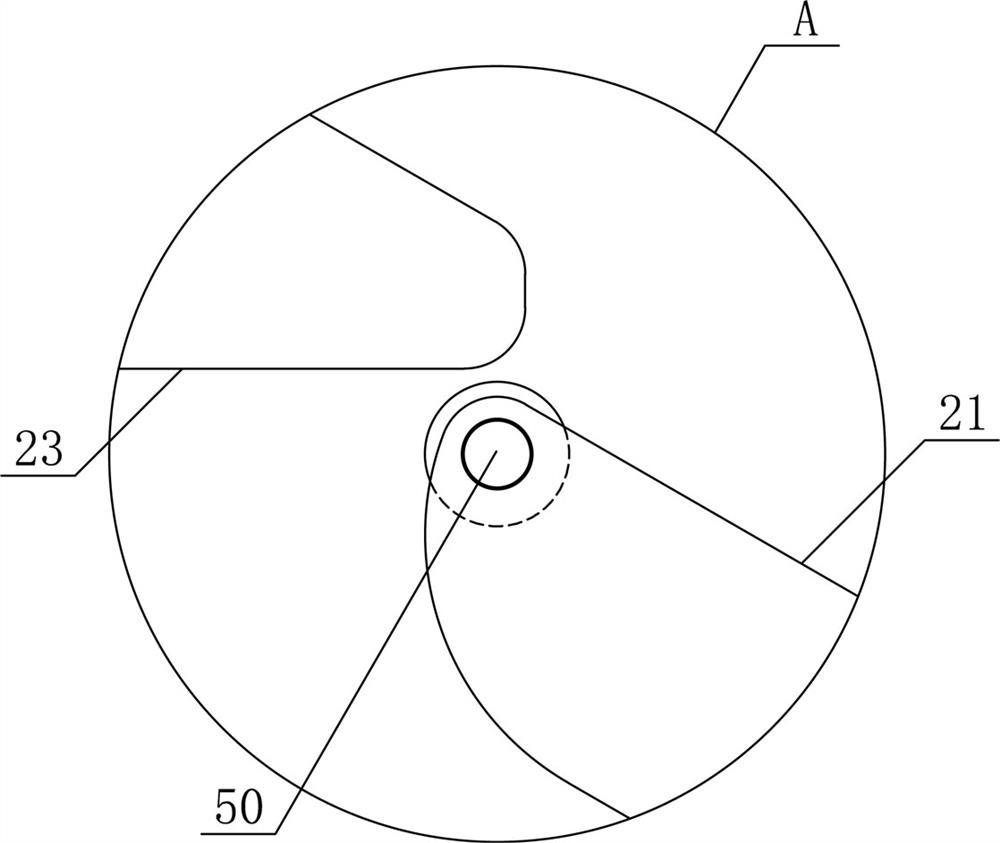

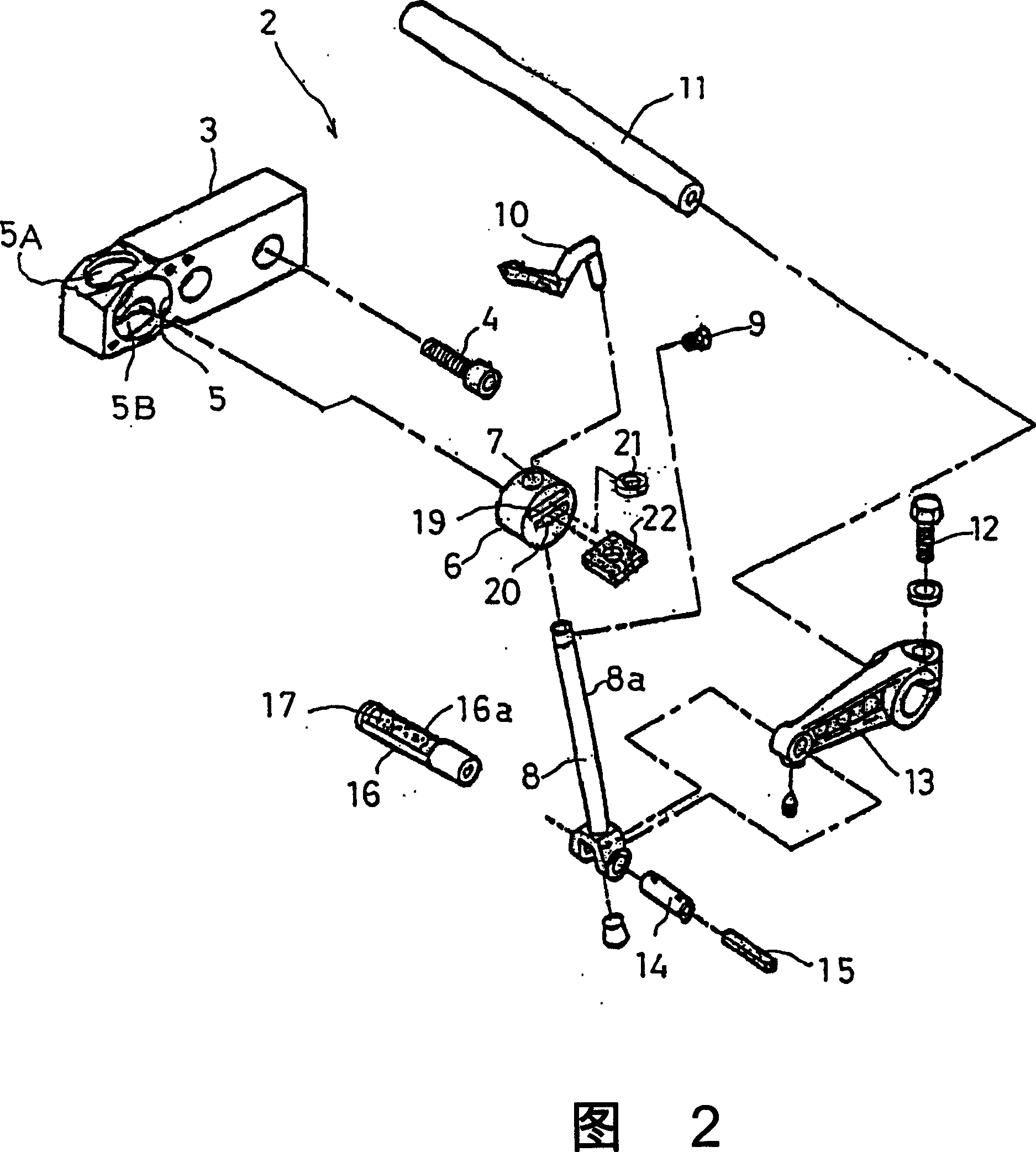

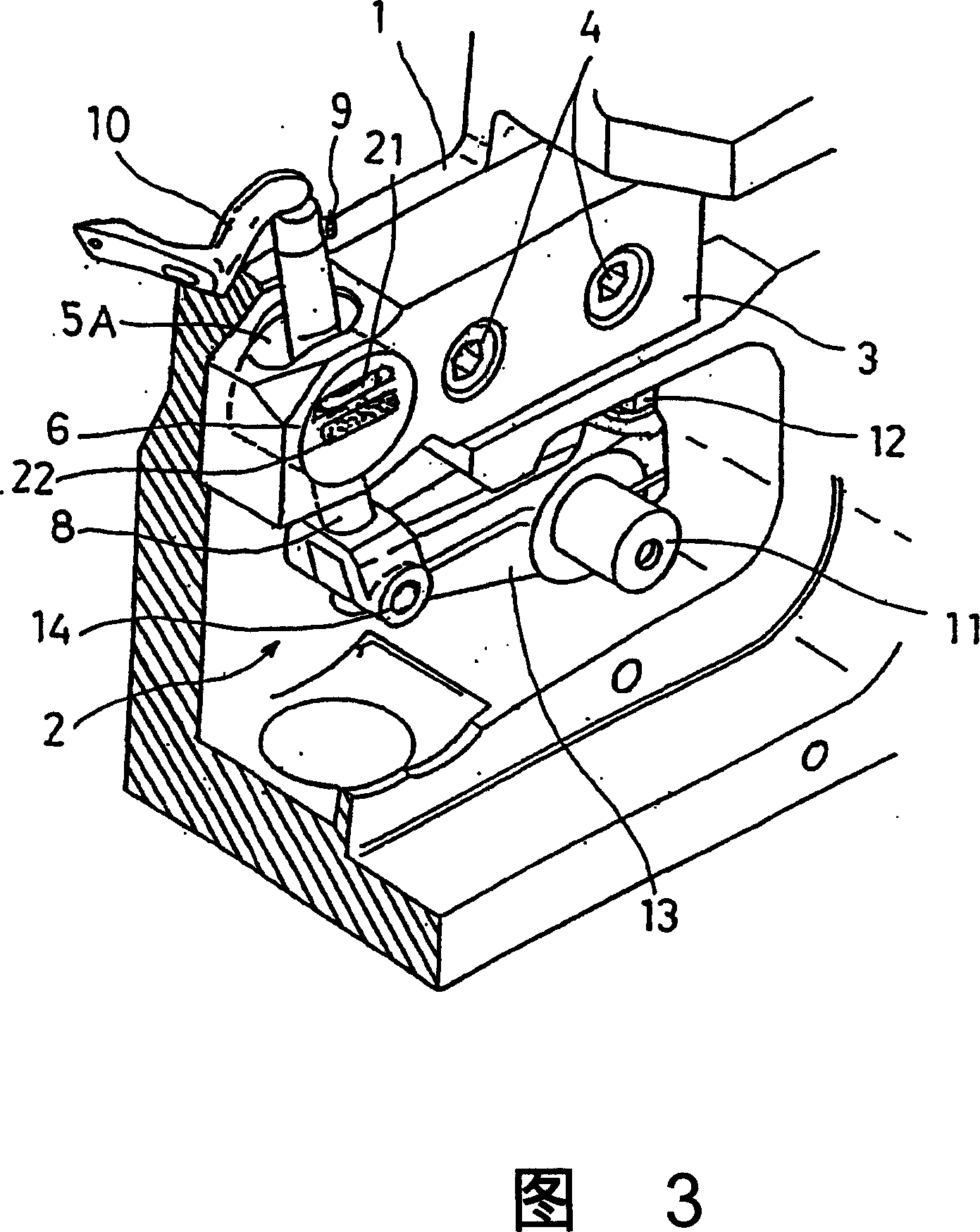

A spinning machine or a twister with a spindle rail capable of performing lifting motion

ActiveCN106939452AShorten the lengthEasy to installContinuous wound-up machinesBlock and tackleEngineering

The invention relates to a spinning machine or a twister with a spindle rail capable of performing lifting motion. The spinning machine or twister comprises a support base and at least one spindle rail (1) which is held by the support base in a manner of capable of performing lifting motion along at least one guide mechanism (30). The spinning machine or twister is characterized in that the support base holds a pulley block mechanism (10) which comprises a tying belt (16) which is guided to pass by at least one moving wheel (12) and at least one fixed wheel (14) alternately, wherein the at least one moving wheel (12) is connected with the spindle rail (1) in a position-changeable manner, and the at least one fixed wheel (14) is connected with the support base in a position-fixed manner; when a first end (16a) of the tying belt is installed in a position-fixed manner, the numbers of the fixed wheels (14) and the moving wheels (12) which the tying belt pass by before reaching a position-changeable second tying belt end (16b) are the same, or when the first end (16a) of the tying belt (16) is fixed in a manner of being movable along with the spindle rail (1), the tying belt pass by more fixed wheels (14) than moving wheels (12) during extending.

Owner:SAURER GERMANY GMBH & CO KG

Intelligent lifting shelf and refrigerator

InactiveCN111664650ASmooth lifting movementThe problem of gravity eccentricity is not affectedLighting and heating apparatusCooling fluid circulationIceboxElectric machinery

The invention discloses an intelligent lifting shelf and a refrigerator, wherein mounting grooves are formed in the upper surfaces of upright posts; rectangular channels are respectively arranged on the two opposite side surfaces of each mounting groove; a motor is arranged in the middle of a chassis; a lead screw is arranged on the motor through a coupler; a first transmission rod and a second transmission rod are movably arranged on a bearing block; crankshaft connecting rods are respectively arranged at the two ends of the first transmission rod and the second transmission rod; and the lower end of each crankshaft connecting rod passes through the rectangular channel and is connected with the lifting platform. According to the intelligent lifting shelf and the refrigerator in the invention, CCD cameras are arranged in the refrigerator in an array manner, so that the sizes of the stored objects are intelligently identified and judged, the required lifting height is calculated, the storage space of the objects to be stored is automatically adjusted and adapted, and intelligent lifting can be realized without manual lifting or manual reminding; bottom feet are driven to lift in theupright posts through the cooperation of the motor, the transmission rods and the crankshaft connecting rods, and a shelf board is driven to lift; and the lifting motion of the shelf is smooth and synchronous, the gravity eccentricity problem of the objects is basically not influenced, and the operation is stable.

Owner:CHANGHONG MEILING CO LTD

Environment-friendly rainwater collecting device for garden landscapes and irrigation device thereof

InactiveCN111576547ASolve the costSolve usabilityGeneral water supply conservationWatering devicesRainwater harvestingMechanical engineering

The invention discloses an environment-friendly rainwater collecting device for garden landscapes and an irrigation device thereof, and relates to the technical field of the garden landscapes. The environment-friendly rainwater collecting device comprises a connecting mechanism and a rainwater collecting mechanism, the rainwater collecting mechanism for collecting rainwater is fixedly arranged atthe top of the connecting mechanism, the connecting mechanism comprises a fixing plate, supporting tables are fixedly arranged on the upper surface of the fixing plate, a water tank is fixedly arranged on the upper surface of the fixing plate, and a water pump is fixedly arranged on one side of the water tank. By arranging the rainwater collecting mechanism and the irrigation device, the rainwateris collected into the water tank through a collecting plate and extending plates, the device is pushed, the water pump is started, driving wheels drive adjusting rods and spray heads to swing up anddown, and meanwhile the water pump conveys the rainwater to the spray heads for irrigation, and therefore the problems that when a conventional rainwater collecting and irrigation mode is adopted, themanufacturing cost is high, and flexible use cannot be achieved are solved; and the device is low in use energy consumption, energy-saving, environment-friendly and flexible in irrigation mode, and the usability of the device is improved.

Owner:河南积著信息技术有限公司

Stamping equipment applied to motor stator and rotor sheet production

ActiveCN105429385AIncrease productivitySimple structureManufacturing stator/rotor bodiesEngineeringUltimate tensile strength

The invention discloses stamping equipment applied to motor stator and rotor sheet production. The stamping equipment comprises a stamping engine base and a stamping engine body; a stamping apparatus comprises a stamping driving mechanism, a stamping transmission mechanism and a stamping assembly; the stamping driving mechanism is connected with the stamping transmission mechanism; the stamping transmission mechanism is connected with the stamping assembly; the stamping assembly comprises a stamping base, a stamping plate, a telescopic spring and a telescopic rod; the stamping base is glidingly mounted on the stamping engine body; the stamping plate is positioned below the stamping base; the stamping plate is mounted on a stamping platform; the telescopic rod is arranged between the stamping base and the stamping plate; and the telescopic spring is arranged on the telescopic rod. The stamping apparatus drives the whole equipment to move through the stamping driving mechanism; the stamping operation is performed by the stamping assembly under the drive of the stamping transmission mechanism; and the stamping equipment is simple in structure, good in stamping effect, safe, reliable and capable of improving the production efficiency of the stator and rotor sheet processing, lowering the labor intensity of workers and greatly improving the quality of products.

Owner:南通捷越机电有限公司

Plate adjusting and locking mechanism

InactiveCN108748756ATranslational teleportation implementationEfficient and accurate processingMulti-purpose machinesWorking accessoriesLocking mechanismEngineering

The invention discloses a plate adjusting and locking mechanism, belonging to the field of construction material processing machinery and equipment. A guide plate mechanism and a clamping plate mechanism are vertically and fixedly arranged on the two sides of the upper part of a fixed base respectively, and the two ends of a guide plate roller are rotationally connected with the upper ends of guide plate supports on the two sides of the upper part of the fixed base respectively. The output end of a lifting cylinder is fixedly connected with upper end of a lifting rack. The clamping plate mechanism comprises a clamping plate support, an adjusting support, a lifting support, a rotary clamping plate and a locking mechanism. The lifting support is horizontally arranged on the lower side of theadjusting support, and lifting guide rods are vertically and fixedly arranged on the two sides of the upper part of the lifting support respectively and are arranged on the adjusting support in a sliding mode along a vertical direction. The middle parts of the two sides of the rotary clamping plate are respectively hinged with a rotary support seat, and the locking mechanism is horizontally and fixedly arranged on the upper side of the adjusting support. The plate adjusting and locking mechanism has a reasonable structural design, can stably and accurately convey a plate, can also conveniently and efficiently adjust the oblique angle of the plate, thereby meeting the needs of processing and use.

Owner:张帼威

Adjustable LED lamp lighting device

InactiveCN112325186AScientific and reasonable structureEasy to useLighting support devicesSemiconductor devices for light sourcesRatchetLED lamp

The invention discloses an adjustable LED lamp lighting device which comprises a wall body, a vertical plate is arranged on the right side of the wall body, a rack is arranged on the inner sides of two transverse plates, the top and the bottom of the rack are fixedly connected to the bottom of a top transverse plate and the top of a bottom transverse plate correspondingly, a box body is in clearance fit with the outer wall of the rack, and a worm wheel is arranged on the inner wall of the box body; the worm wheel is provided with a worm, the outer wall of the worm is meshed with the outer wallof the worm wheel, and the bottom of the worm wheel is fixedly connected with a handle. According to the novel LED lamp lighting device, the LED lamp can stably ascend and descend on the outer wall of the rack through rotation of the worm wheel and sliding connection of the sliding sleeve and the sliding rod, so that the LED lamp can rotate on the box body through the ratchet wheel, the ratchet wheel can drive the LED lamp to be subjected to angle adjustment, and the clamping rod can limit clockwise rotation of the ratchet wheel; and after the ratchet wheel drives the LED lamp to be subjectedto angle adjustment, the LED lamp can be stably placed.

Owner:黄铁山

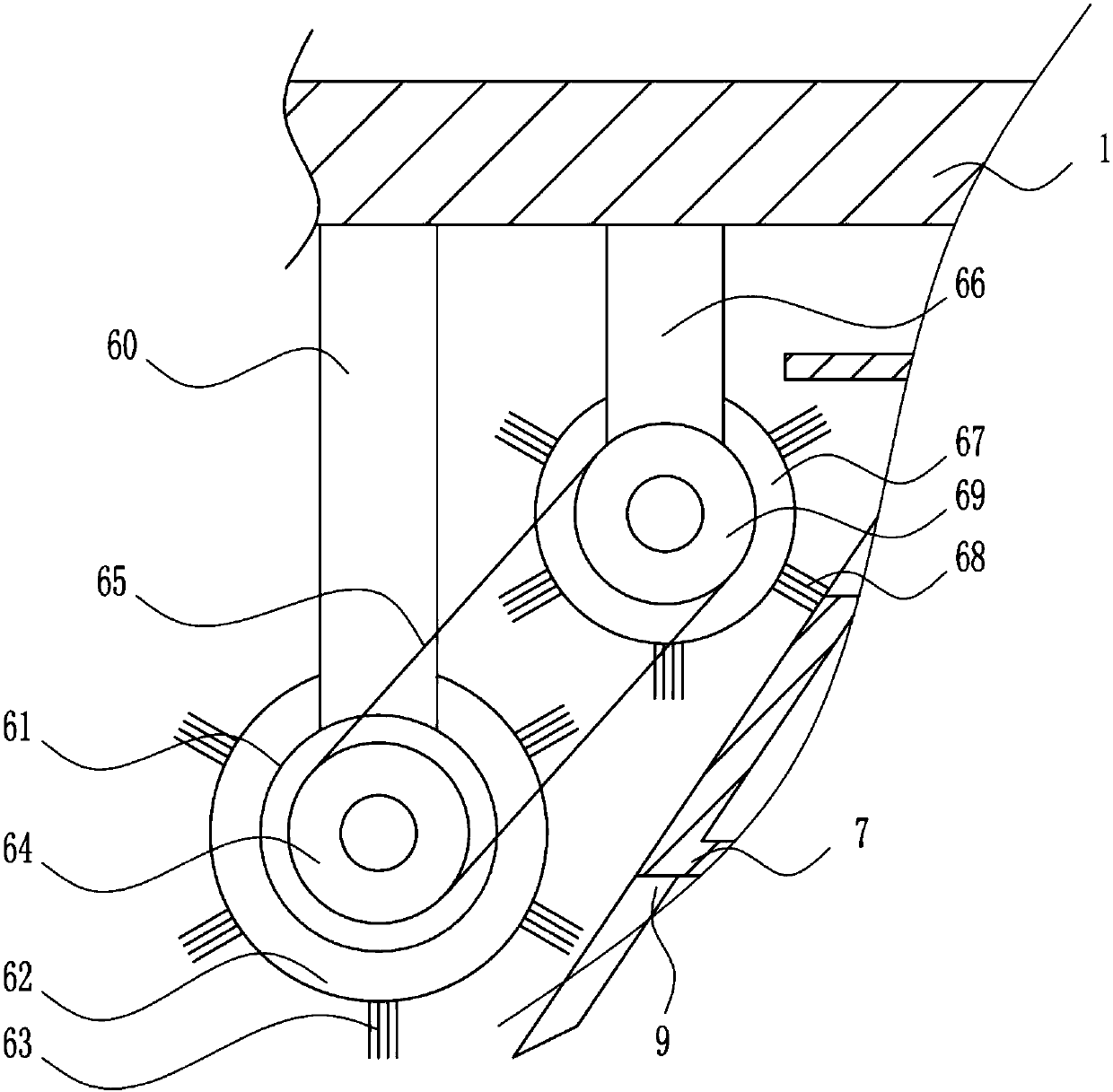

Impurity removing device for wool fiber and mint fiber blended yarn production

InactiveCN112410951ASmooth lifting movementEfficient and stable compressionFibre cleaning/openingYarnEngineering

The invention discloses an impurity removal device for wool fiber and mint fiber blended yarn production, and belongs to the field of textile production and processing mechanical equipment. A reciprocating impurity sticking mechanism and a yarn pressing mechanism are sequentially arranged on a yarn processing support from top to bottom; two yarn bearing fixing plates are adjacently arranged on a front yarn pressing rotary roller and a rear yarn pressing rotary roller on the corresponding sides correspondingly; a lifting yarn pressing plate parallel to the yarn bearing fixing plates is fixedlyarranged on the upper side of a reciprocating lifting guide plate; a translation impurity sticking guide plate is slidably arranged on a reciprocating translation support; an impurity sticking reciprocating connecting rod is arranged between an impurity sticking rotating disc and the translation impurity sticking guide plate; and the lower side of an impurity sticking lifting connecting plate is sequentially and horizontally connected with an upper impurity sticking rotating roller and a lower impurity sticking rotating roller in a rotating mode from top to bottom. The impurity removing deviceis reasonable in structural design, impurity removing processing can be continuously, stably and sequentially conducted in a segmented mode in the wool fiber and mint fiber blended yarn conveying process, the yarn processing automation degree is high, the processing quality is good, and the production and use requirements are met.

Owner:嘉兴厚亿纺织股份有限公司

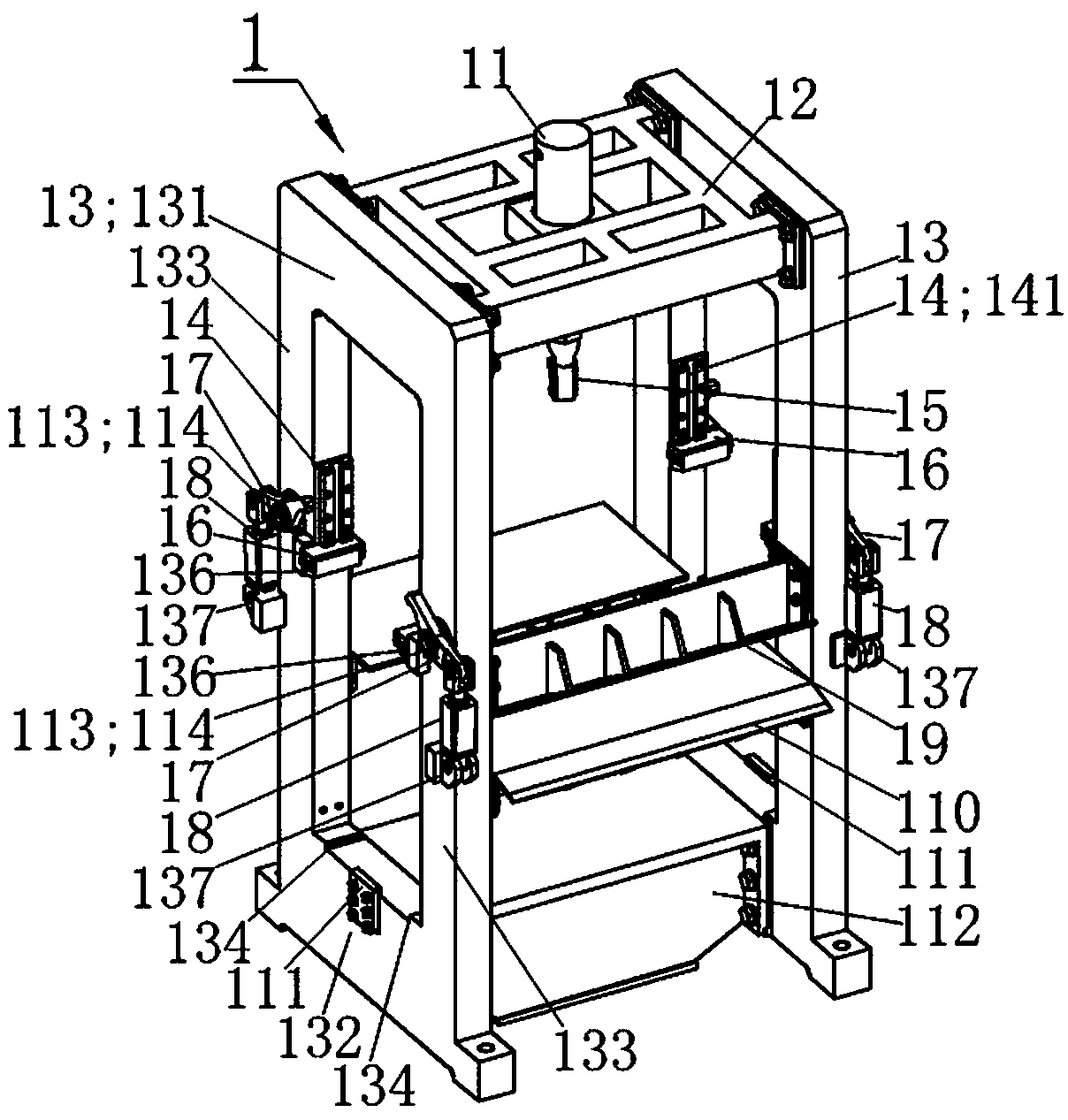

Lifting equipment

InactiveCN106477481ASmooth lifting operationSolve the problem of easy bending and deformationLifting framesEngineeringLifting equipment

The invention discloses lifting equipment which comprises a power device, a bracket, nut guide devices, a material loading device and lead screws and further comprises guide pillars. The guide pillars are perpendicularly arranged on the ground, and the tops of the guide pillars are connected with the bracket. The nut guide devices are arranged on the guide pillars in a sleeved manner and provided with first guide mechanisms and second guide mechanisms, wherein the first guide mechanisms are perpendicular to the second guide mechanisms. The first guide mechanisms are parallel to the horizontal plane and are in sliding connection with the outer side walls, close to the material loading device, of the guide pillars. The second guide mechanisms are perpendicular to the horizontal plane and are in sliding connection with the outer side walls, away from the material loading device, of the guide pillars. According to the lifting equipment, the guide pillars and the guide mechanisms matched with the guide pillars are adopted, and the problem that the lifting process is unsteady due to bending deformation of the lead screws can be reduced.

Owner:ADVANCED FOR MATERIALS & EQUIP

Carving machine applied to woodwork processing

PendingCN107521272ASolving Engraving ProblemsSimple structureOther artistic work equipmentsModel makingEconomic benefitsWorkbench

The invention discloses a carving machine applied to woodwork processing. The carving machine comprises a base, a workbench and a supporting frame. The workbench is located on the front side of the base, the supporting frame is located on the rear side of the base, an air cylinder lifting device is arranged between the base and the workbench, a carving device is arranged on the workbench and comprises a slide bar assembly and a transmission assembly, the transmission assembly comprises transmission motors and a transmission plate, the transmission motors include the first transmission motor and the second transmission motor, the first transmission motor is mounted on the left side of the transmission plate, the second transmission motor is mounted on the right side of the transmission plate, a positioning tool is arranged on the first transmission motor, a cutting tool is arranged on the second transmission motor, a rotating device is arranged on the lower portion of the supporting frame, and a fixing and adjusting device is arranged on the supporting frame. The machine is simple in structure, scientific, convenient, high in pertinence, high in automation degree, high in practicability, low in manufacturing cost and remarkable in economic benefit, and carving applied to woodwork processing is well achieved.

Owner:HANGZHOU DIANZI UNIV

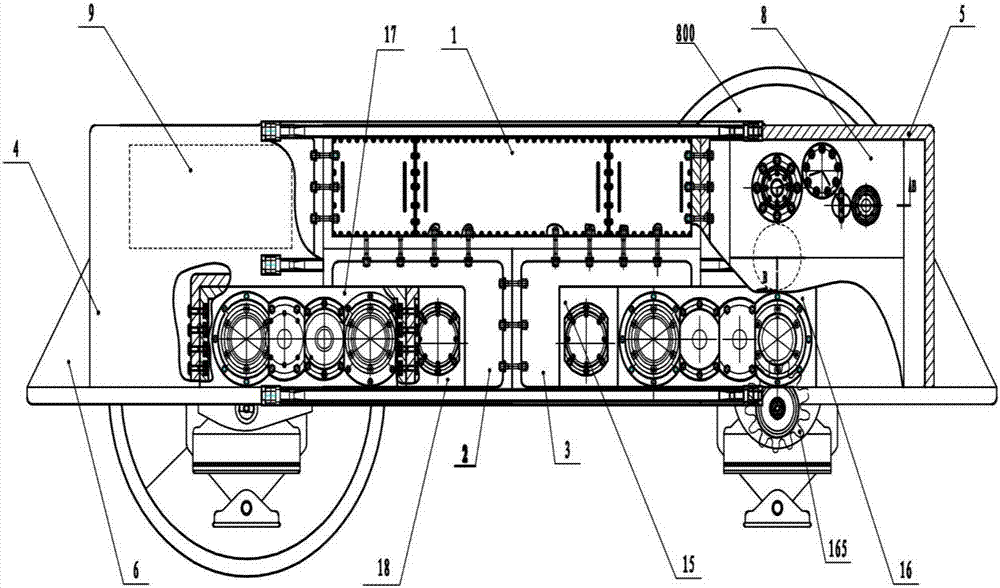

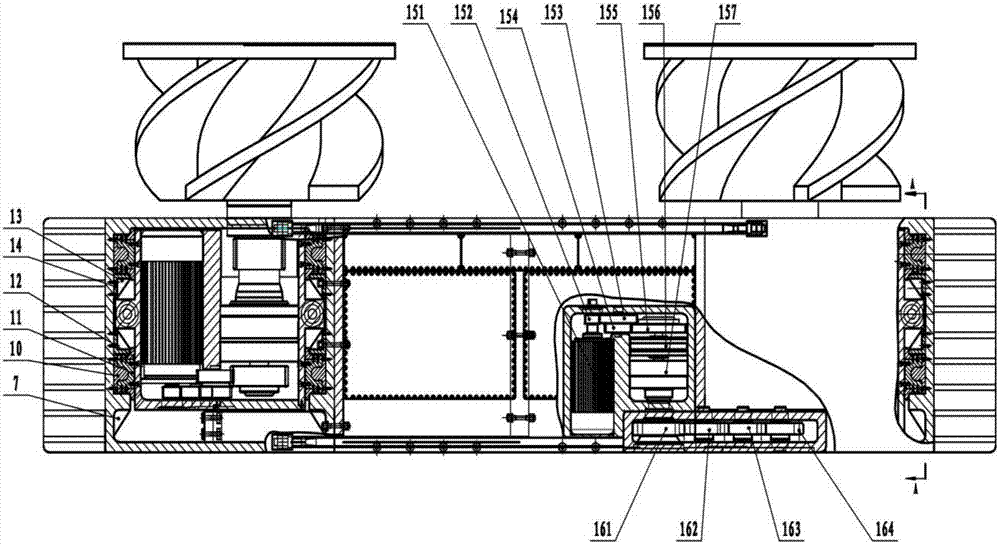

No-rocker roller vertical-lifting-type comprehensive coal cutter

ActiveCN107476804AReduce mechanical vibrationStable jobDriving meansPropulsionEngineeringIdler-wheel

The invention provides a no-rocker roller vertical-lifting-type comprehensive coal cutter. The no-rocker roller vertical-lifting-type comprehensive coal cutter is suitable for mining of a hard medium thick long wall coal seam with coal seam dip less than 30 degrees and medium thick coal quality and comprises a central control box, a left cutting lifting reduction gearbox, a right cutting lifting reduction gearbox, a left side guiding rail fixed box, a right side guiding rail fixed box, a left traction reduction gearbox, a right traction reduction gearbox, a left walking gear box and a right walking gear box. The left cutting lifting reduction gearbox and the right cutting lifting reduction gearbox are provided with sideways which are matched with lifting guiding rails of the left side guiding rail fixed box and the right side guiding rail fixed box. The left cutting lifting reduction gearbox and the right cutting lifting reduction gearbox are driven to do lifting movement by using lifting oil cylinders, and meanwhile, cutting motors of the left cutting lifting reduction gearbox and the right cutting lifting reduction gearbox drive a spiral roller to rotate through a cutting gear reduction mechanism. The left traction reduction gearbox and the right traction reduction gearbox drive the left walking gear box and the right walking gear box, and then left and right traction movement of the whole machine is driven. According to the no-rocker roller vertical-lifting-type comprehensive coal cutter, a cutting gear reduction mechanism adopts two-level gear transmission and two-level planetary gear transmission, a plurality of sets of idle wheel sets do not existed, and a transmission chain is simple; and by using matching of the lifting guiding rails and the sideways, the whole machine is compact in structure, and the reliability and stability of operation are improved.

Owner:张义民

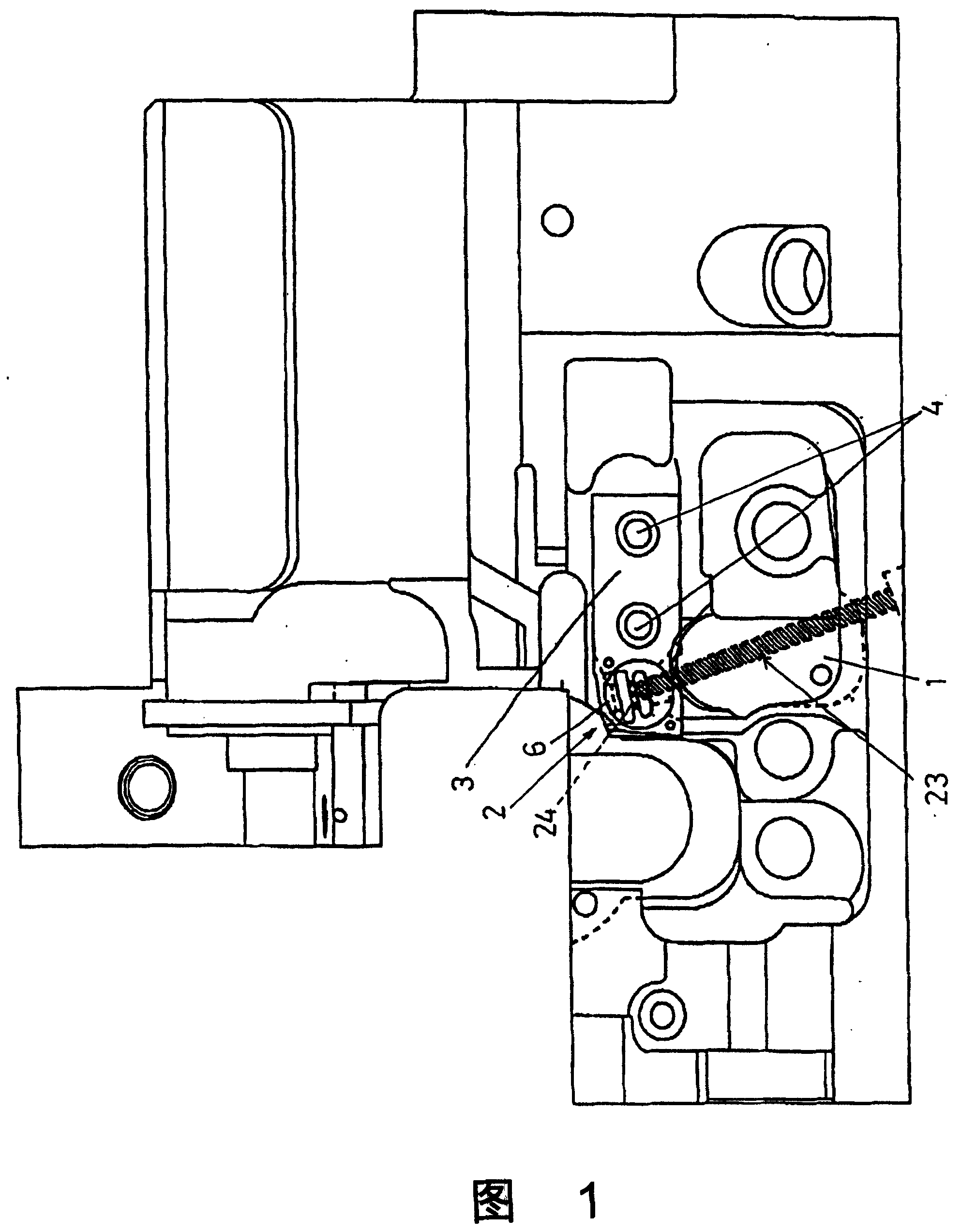

Anti-oil leakage device of top bend needle mechanism

InactiveCN1782167BSmooth lifting movementReliable scraping actionLubrication/cooling devicesEngine sealsEngineeringLubrication

To make a scraping off function for a surplus lubricant to be certainly and excellently exerted, to enable the long and stable maintenance of a prescribed oil leakage prevention capacity by avoiding the mixing of dust in the surplus lubricant and to enable the reuse of the surplus lubricant for the maintenance of the lubrication capacity for a vertical motion of an upper looper table. Two upper penetrating slot holes perpendicularly intersecting a penetration hole for the upper loop table to slidingly go up and down are bored in a cylindrical upper looper guiding body which is engaged and supported in a circular hole bored in an upper looper guiding member fixed to a sewing machine frame to be rotatable around the center of the circle, and an oil seal ring with an elastic lip which elastically touches by sliding a peripheral surface of the upper looper table and scrapes off the surplus portion of the lubricant attached to the peripheral surface and an oil absorbent ring which can absorb and keep the scraped surplus lubricant are respectively engaged with the upper penetration long hole and the lower penetration slot hole.

Owner:YAMATO SEWING MASCH MFG CO LTD

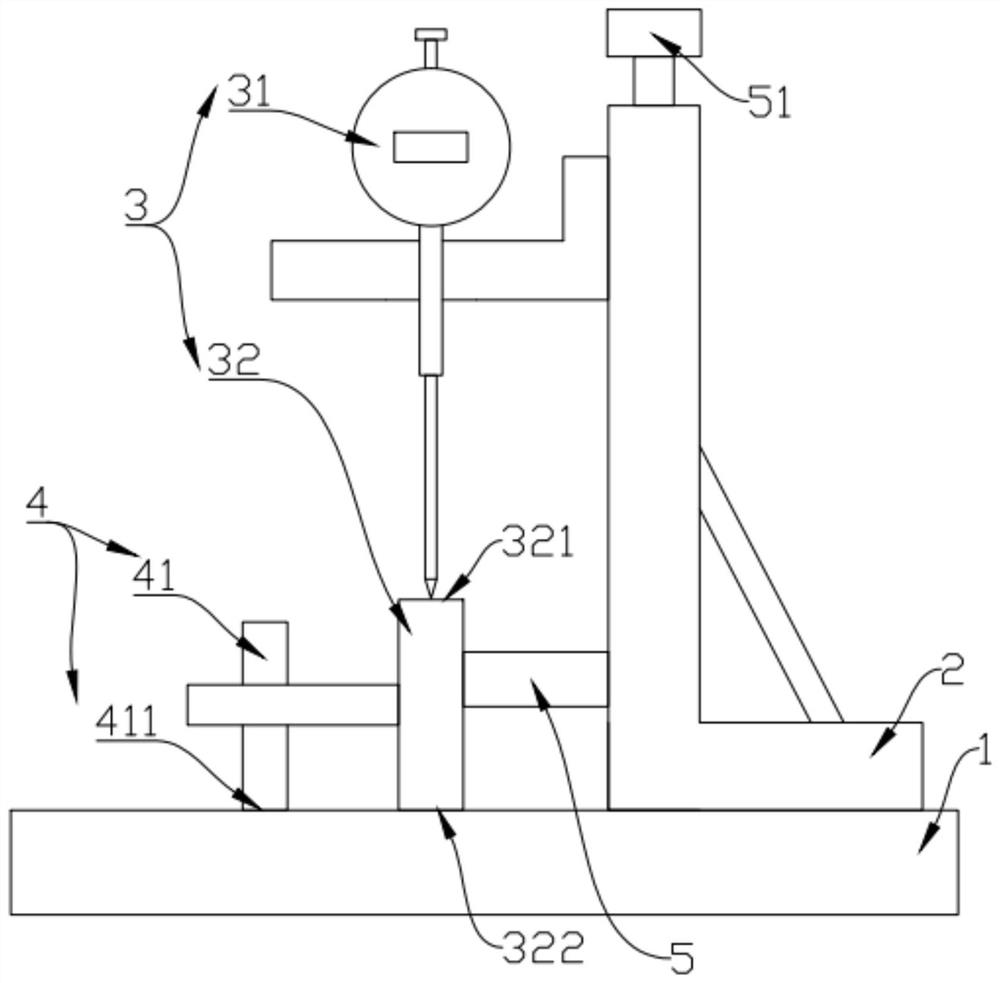

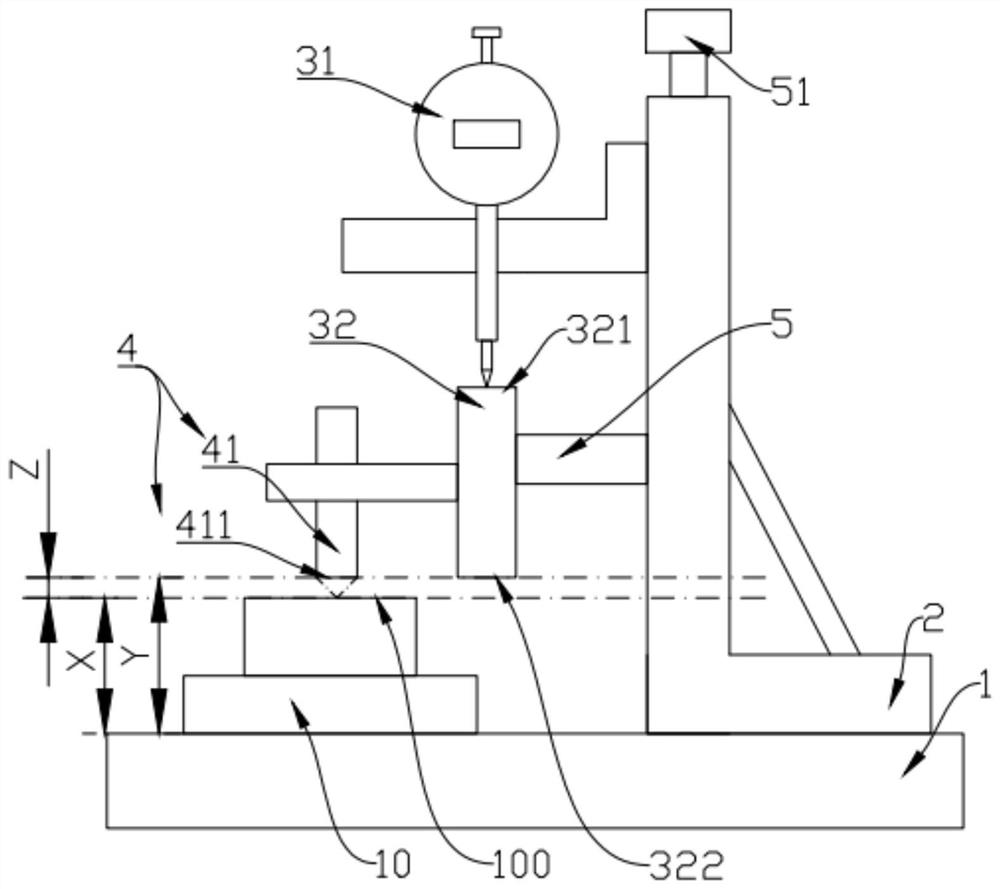

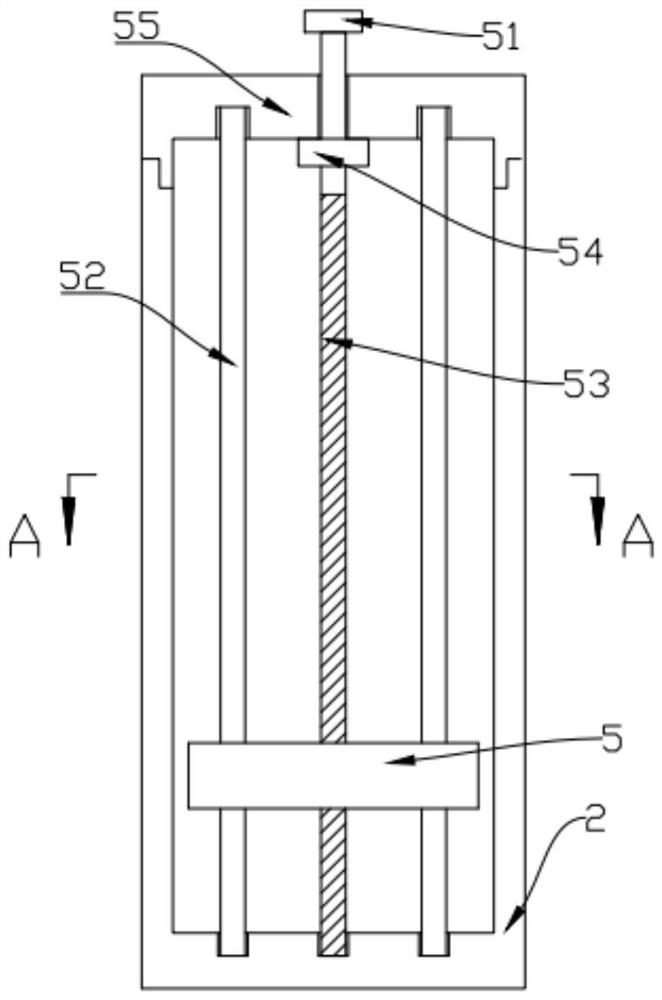

Non-contact precision measuring instrument

ActiveCN112504069AEasy to operateHigh precisionNuclear energy generationUsing optical meansMeasuring instrumentEngineering

The invention discloses a non-contact precision measuring instrument, which comprises a measuring platform used for placing a to-be-measured piece and a measuring tool, wherein the measuring tool comprises an upright post arranged on the measuring platform, and a coarse measuring tool and a fine measuring tool which are connected in series on the upright post, and the size of the to-be-measured piece is the reading difference of the coarse measuring tool and the fine measuring tool; the coarse measuring tool comprises a lifting block and a dial indicator arranged at the upper part of the lifting block, and when the bottom surface of the lifting block is arranged on the measuring platform, a dial indicator thimble is contacted with the top surface of the lifting block and displays that thereading is zero; and the fine measuring tool comprises a non-contact measuring tool fixed with the lifting block, and the measuring zero point position of the non-contact measuring tool is matched with the bottom surface position of the lifting block. The non-contact precision measuring instrument is simple to operate, wide-range, high-precision and non-contact measurement can be realized, and thesurface quality of a product is not influenced on the premise of ensuring the measurement precision.

Owner:HEFEI I TEK OPTOELECTRONICS CO LTD

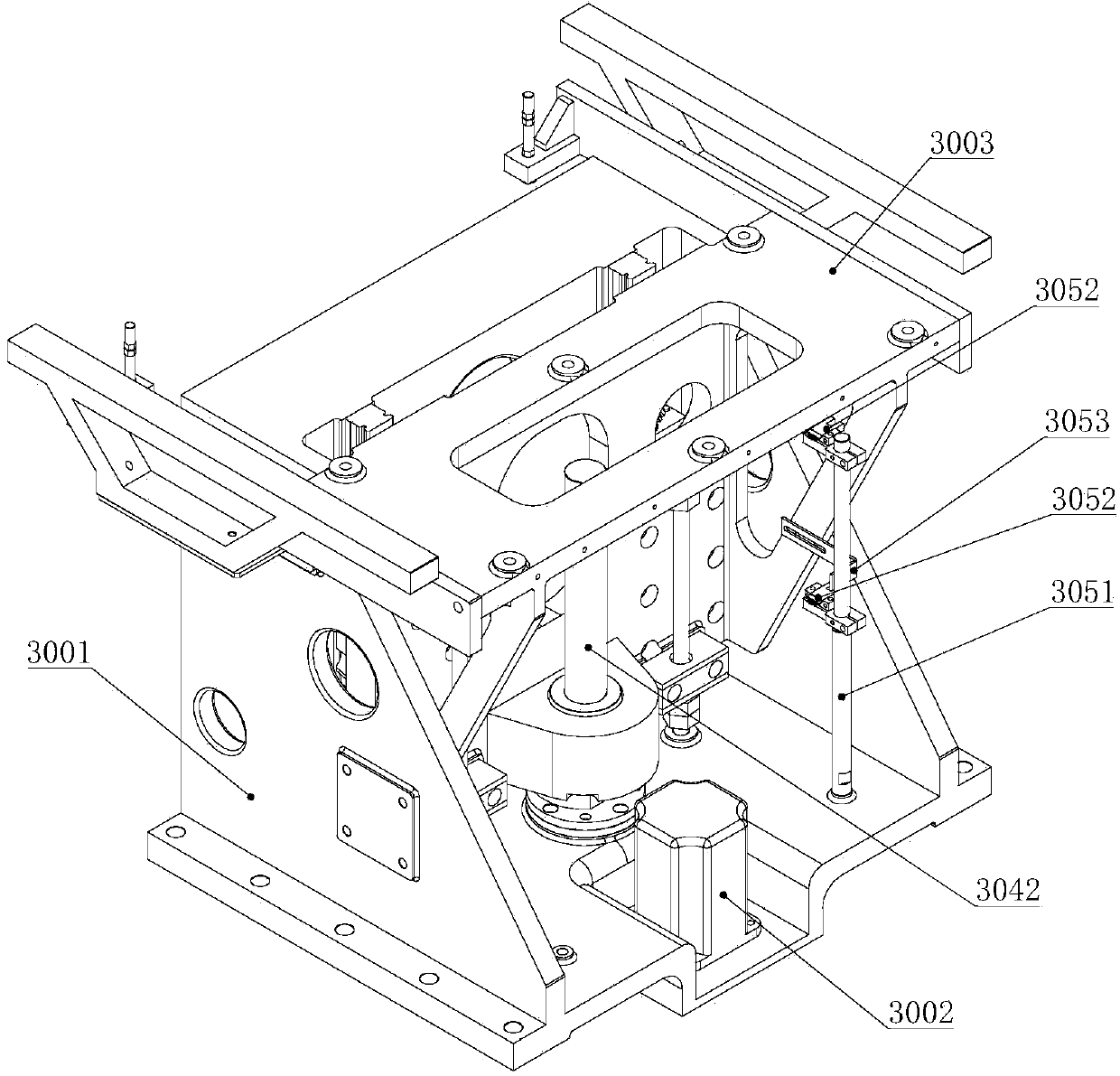

Hot rolled steel plate five-roll straightening machine

The invention discloses a hot rolled steel plate five-roll straightening machine and aims to provide hot rolling steel plate finishing machinery equipment in metallurgical industry. The hot rolled steel plate five-roll straightening machine has a function of straightening a hot rolled steel plate. The machine is provided with a base device, an upper roller device, a lower roller device, a rollinggap adjustment driving device, a straightening roller driving device and other main components; according to the technical scheme, the upper roller device can make lifting movement stably and reliablyas the upper roller device is limited during the lifting motion; a clamping mechanism is arranged at a work station of the upper roller device, so that the upper roller device is secure, reliable andsmall in vibration in the straightening process; a rolling gap is adjusted by combining a spiral pair and a wedge mechanism, so that the adjustment is reliable and the self-locking performance is good; and the rolling gap can be automatically adjusted by a driving line switching mechanism and a controlling device. The machine is simple in structure, easy to manufacture, convenient to repair and good in economical efficiency.

Owner:KUNMING UNIV

Lifting device of gas stove and gas stove

InactiveCN110207183AReduce usageLow costStoves/ranges foundationsDomestic stoves or rangesEngineeringGas stoves

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com