Power supply wire arrangement device of functionalized vehicle door glass

A door glass and wiring device technology, applied to windshields, electrical components, vehicle parts, etc., can solve the problems of door sheet metal wear, wire breakage, and wires stuck on the door sheet metal, etc. The effect of jitter and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

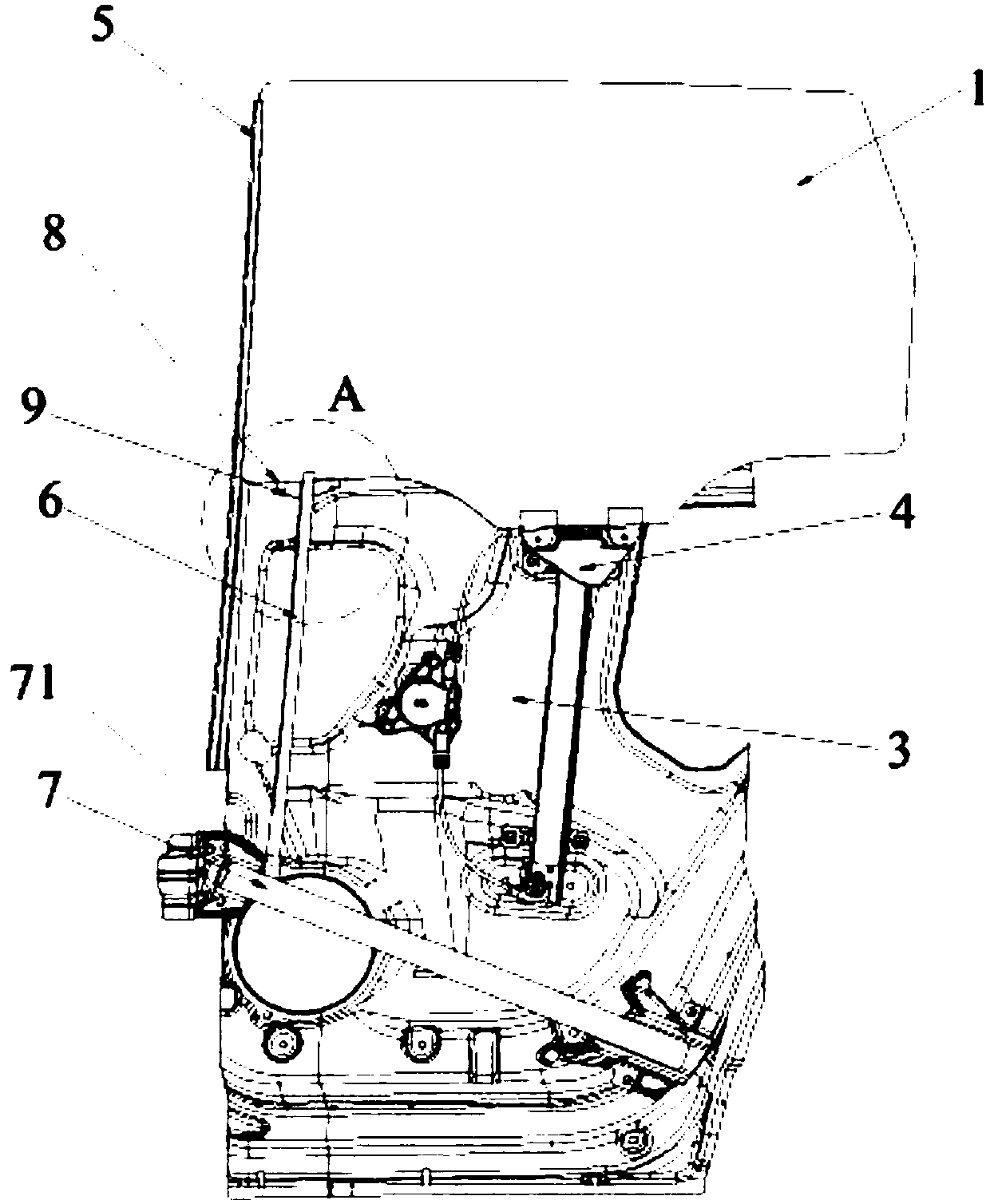

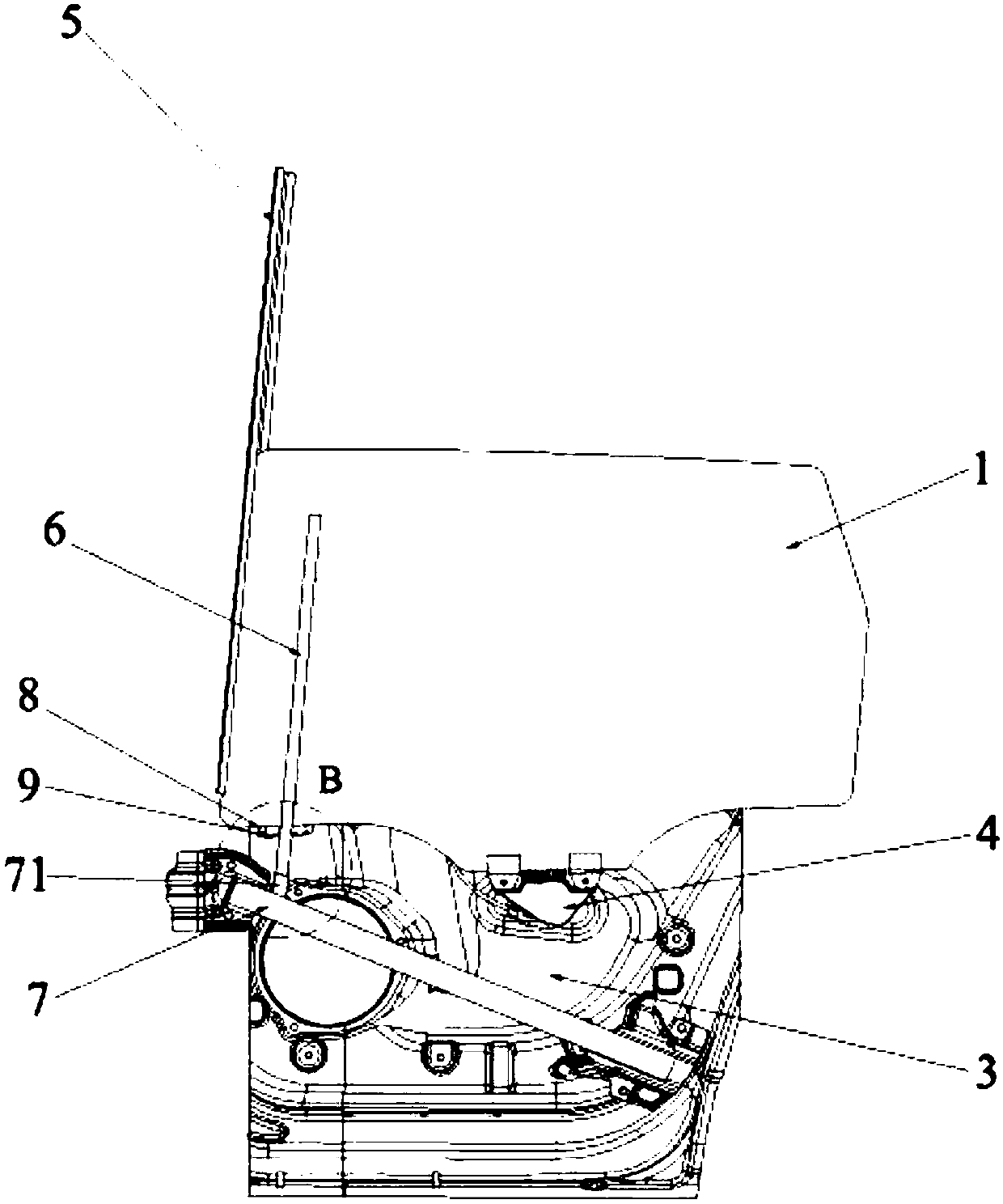

[0035] Such as Figure 1 to Figure 4 As shown, the power supply wiring device of the functionalized car door glass of the present invention includes:

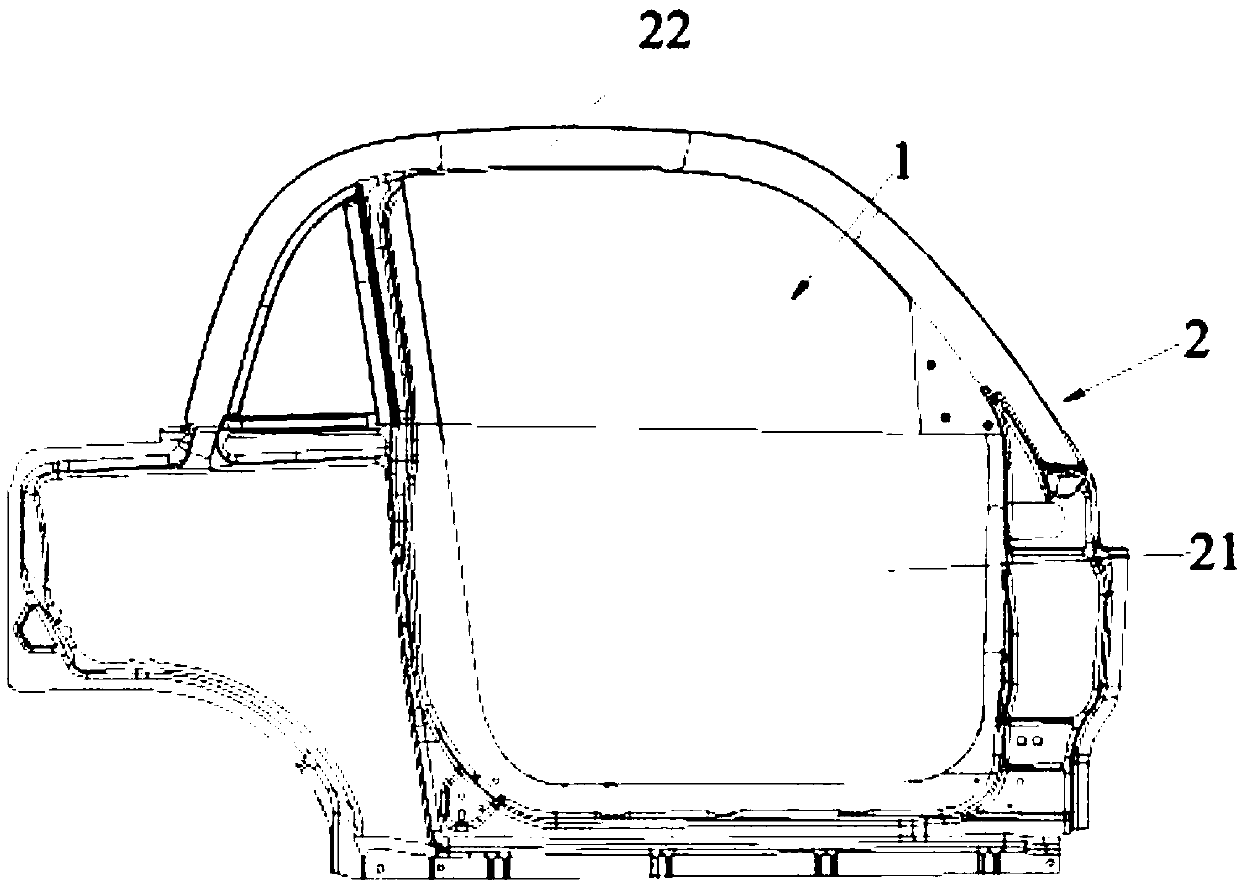

[0036] Functionalized glass, select the dimmable glass 1 whose functional layer is the liquid crystal layer and install it on the rear door window frame 22 of the rear door 2, and drive the dimmable glass 1 to lift electrically on the guide rail 5 through the glass lifting device 4 in the door component , the glass lifter 4 and the guide rail 5 are installed on the door sheet metal 3 placed in the door component 21 .

[0037] The conduit 6 extends in the lifting direction of the dimmable glass 1 and is made of a PVB plastic tube with an outer diameter of 4mm, including a glass lift groove 61 and a connecting por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com