No-rocker roller vertical-lifting-type comprehensive coal cutter

一种垂直升降、采煤机的技术,应用在截割机械、土方钻采、分切机械等方向,能够解决传动系统可靠性降低、截割传动系统冗杂、摇臂结构失效破坏等问题,达到承载能力增强、避免直接接触、减小冲击破坏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

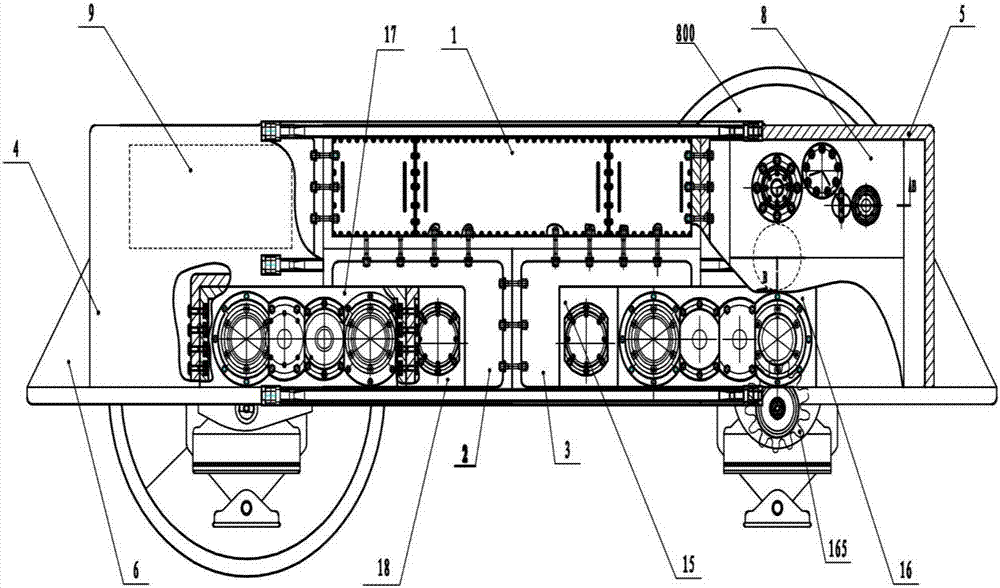

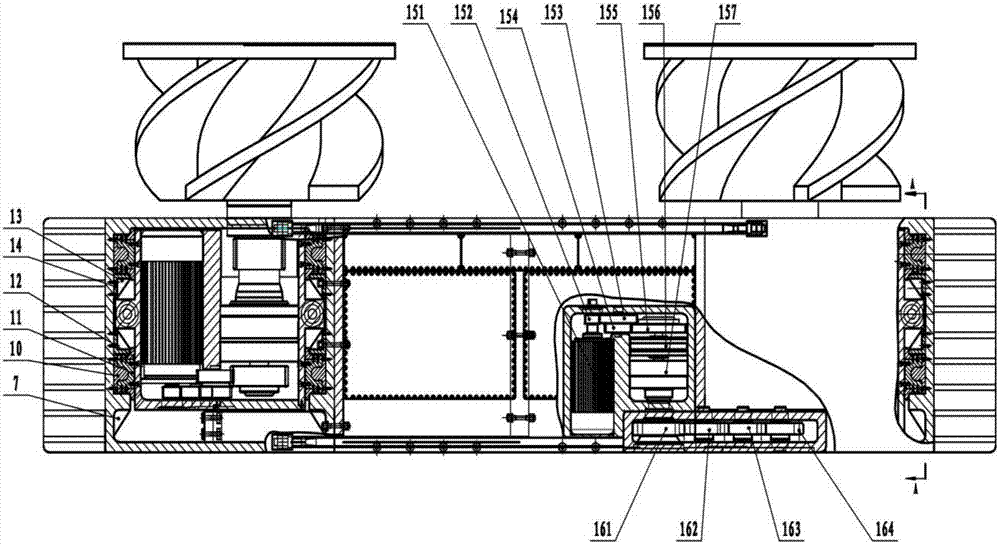

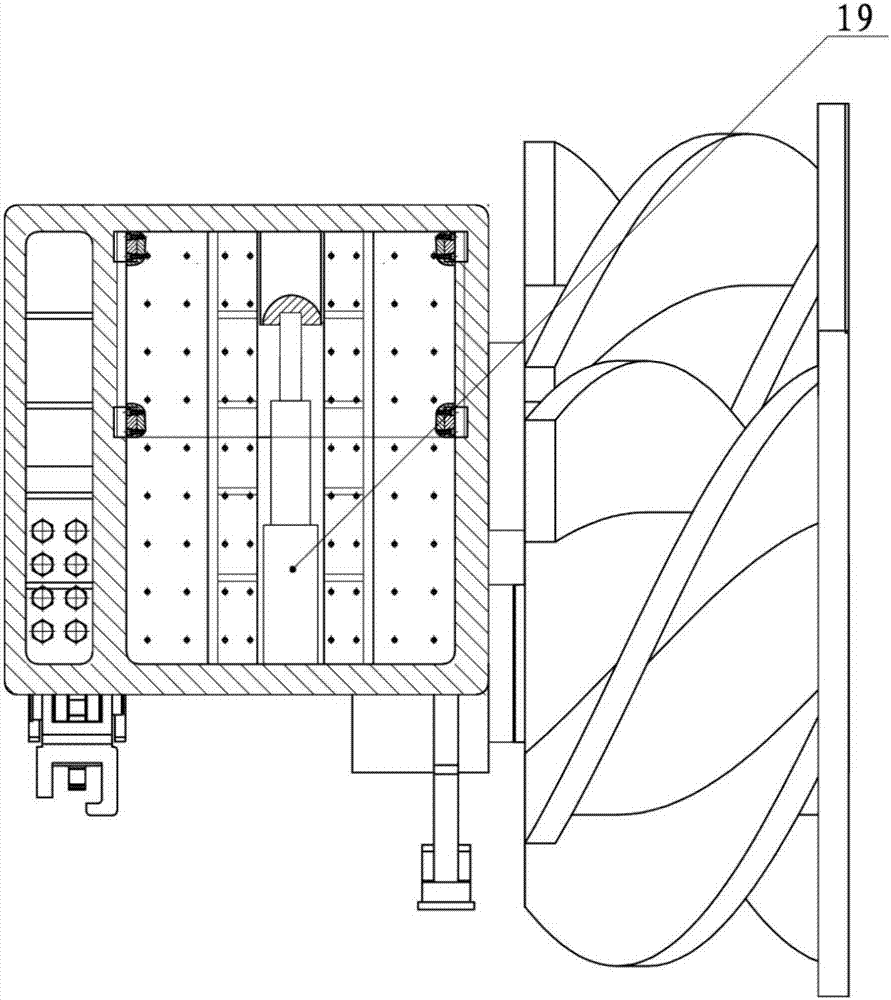

[0024] Such as figure 1 and figure 2 As shown, a kind of rocker-arm drum vertical lift type comprehensive shearer provided by the present invention is suitable for the mining of medium-thick and long-wall coal seams with a coal seam inclination angle less than 30°, medium-hard coal quality, and hard coal seam, which includes a central control box 1 , the left support box 2, the right support box 3, the left side guide rail fixed box 4, the right side guide rail fixed box 5, the left travel gear box 17 and the right travel gear box 16. The left support box 2 and the right support box 3 are symmetrically arranged below the central control box 1, and the left guide rail fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com