Patents

Literature

147results about How to "Small shock and vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

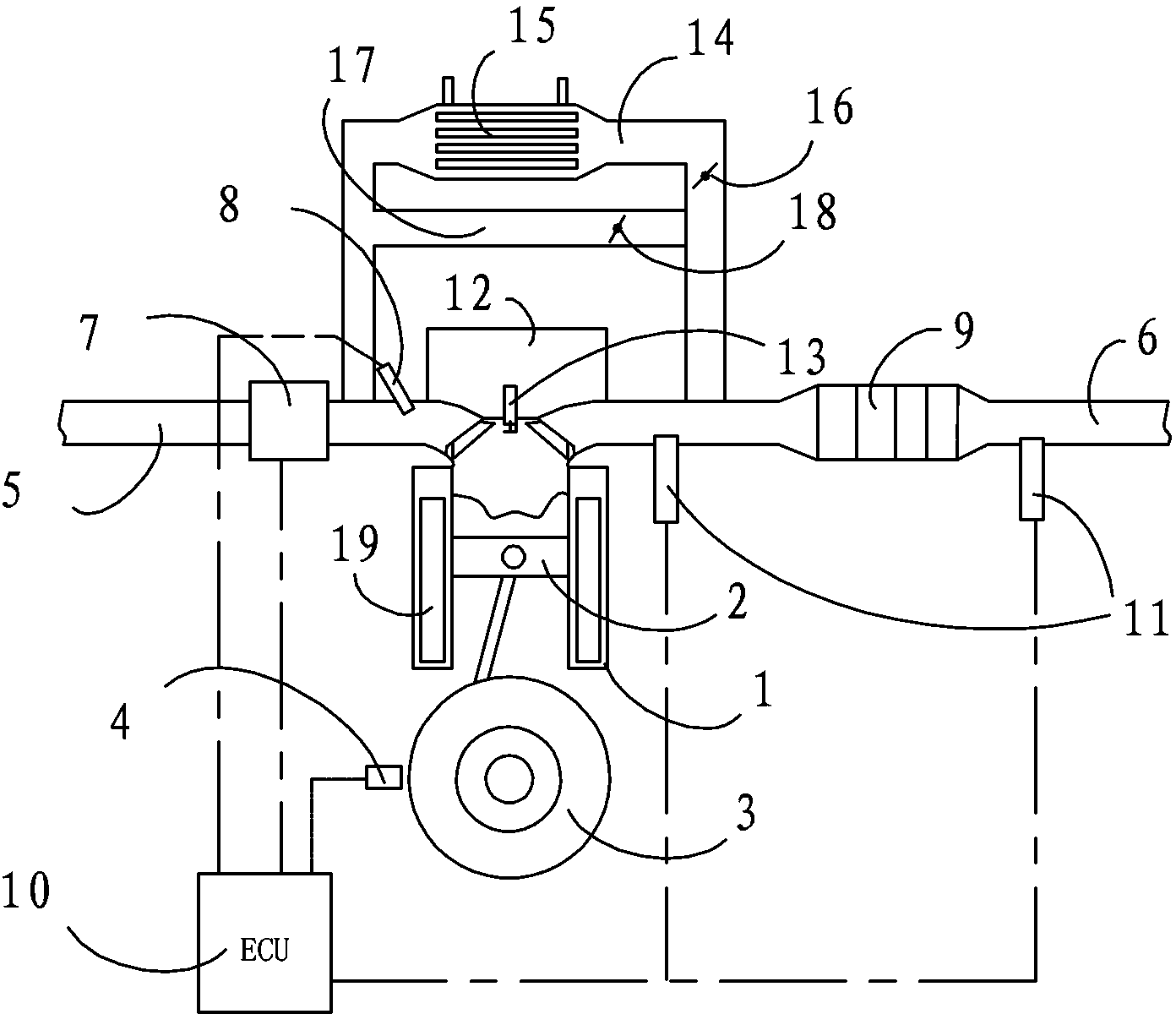

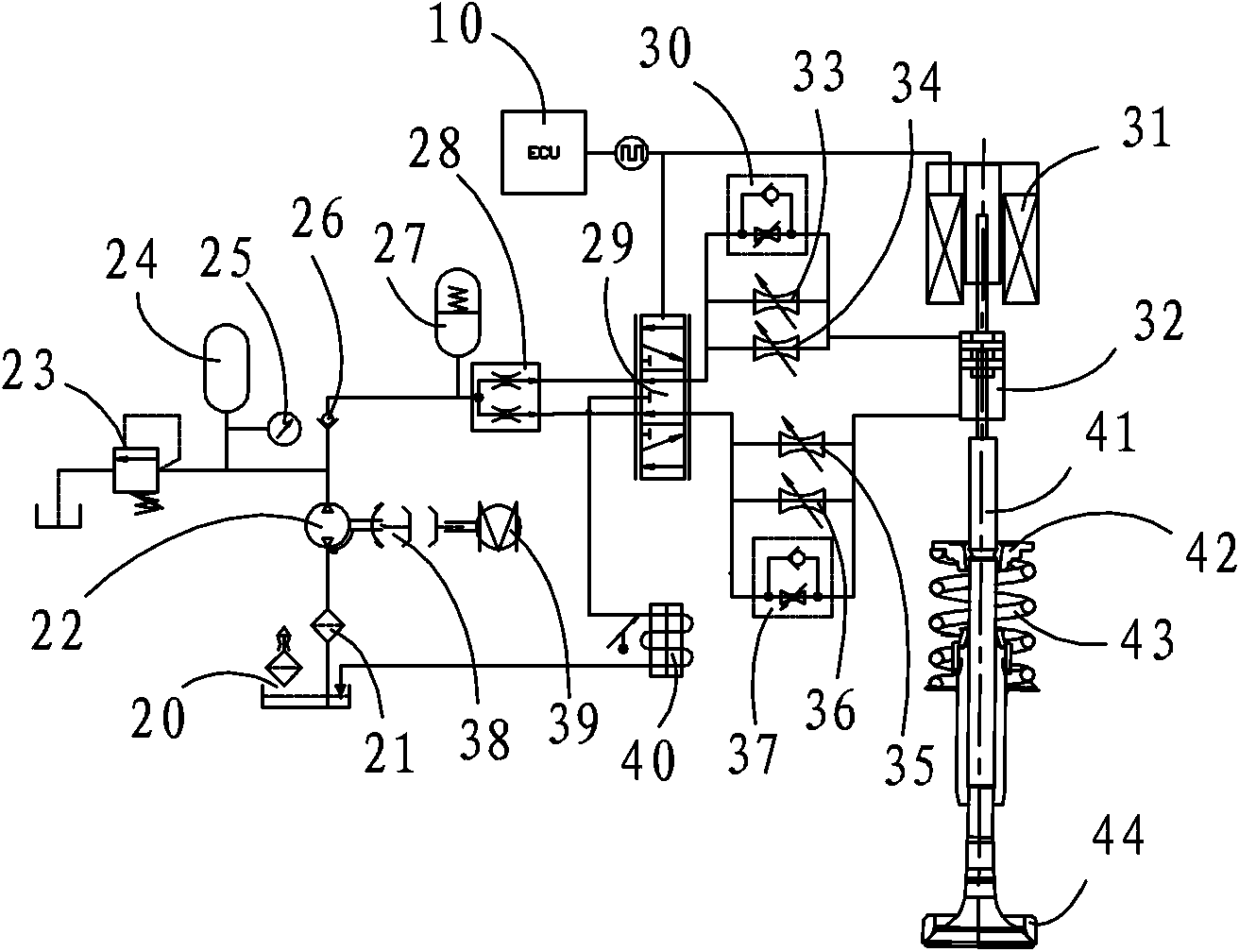

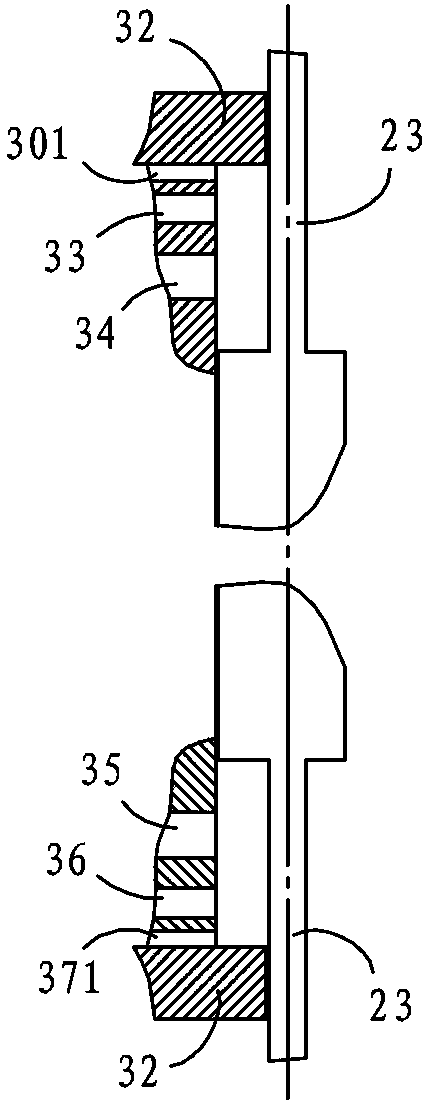

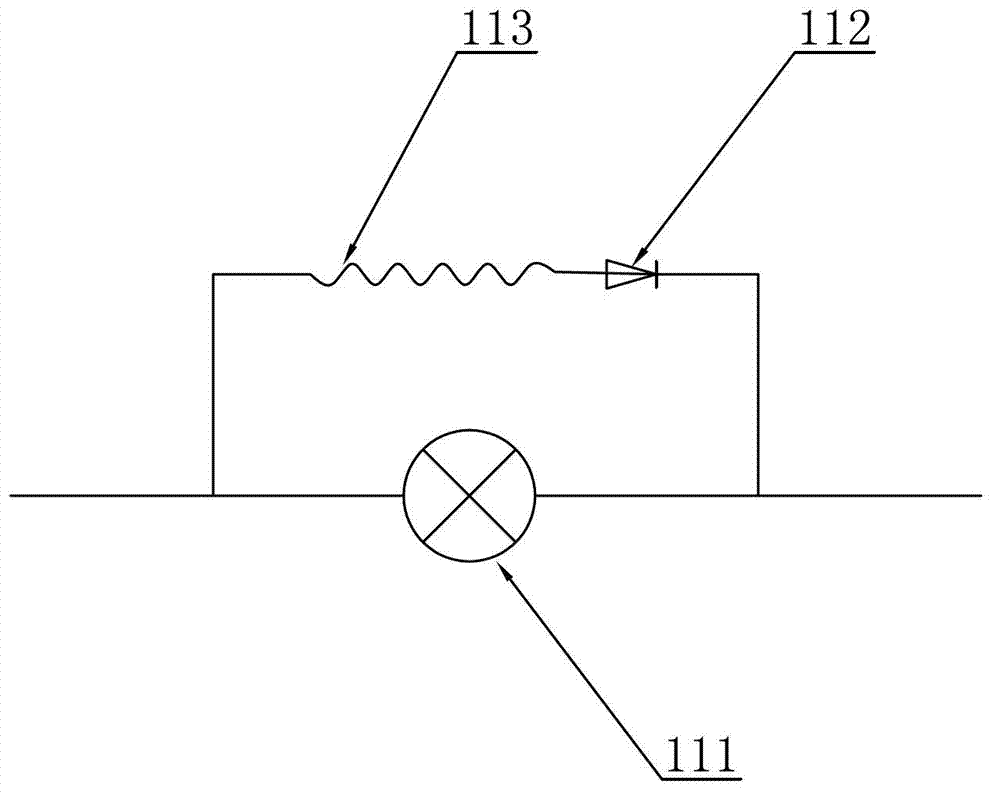

Full variable valve engine and control method thereof

ActiveCN104018902ASmall shock and vibrationReduce noiseValve arrangementsInternal combustion piston enginesInlet channelCombustion

The invention relates to a full variable valve engine which comprises an air cylinder with an air inlet channel and an exhaust channel. A piston is arranged in the air cylinder. The bottom end of the piston is connected with a crank-link mechanism. A sparking plug is arranged in the air cylinder. A throttle valve and an oil sprayer are arranged on the air inlet channel. A tail gas processing unit is arranged on the exhaust channel. Full variable valve mechanisms are arranged at the communication portions of the air inlet channel, the exhaust channel and the air cylinder. An EGR channel with a cooler is arranged between the air inlet channel and the exhaust channel in a connecting mode. An EGR valve is arranged on the EGR channel. The engine further comprises an ECU control unit which can control the spark plug, the oil sprayer, the EGR valve and the full variable valve structures to make the engine operate. The invention further relates to a full variable valve engine control method. The shortcoming of an existing electric control hydraulic and electric control magnetic force driving mode can be overcome, the engine can be controlled to operate under various combustion modes, and the fuel economy and the emission performance of the engine are further improved.

Owner:长城汽车股份有限公司平湖分公司

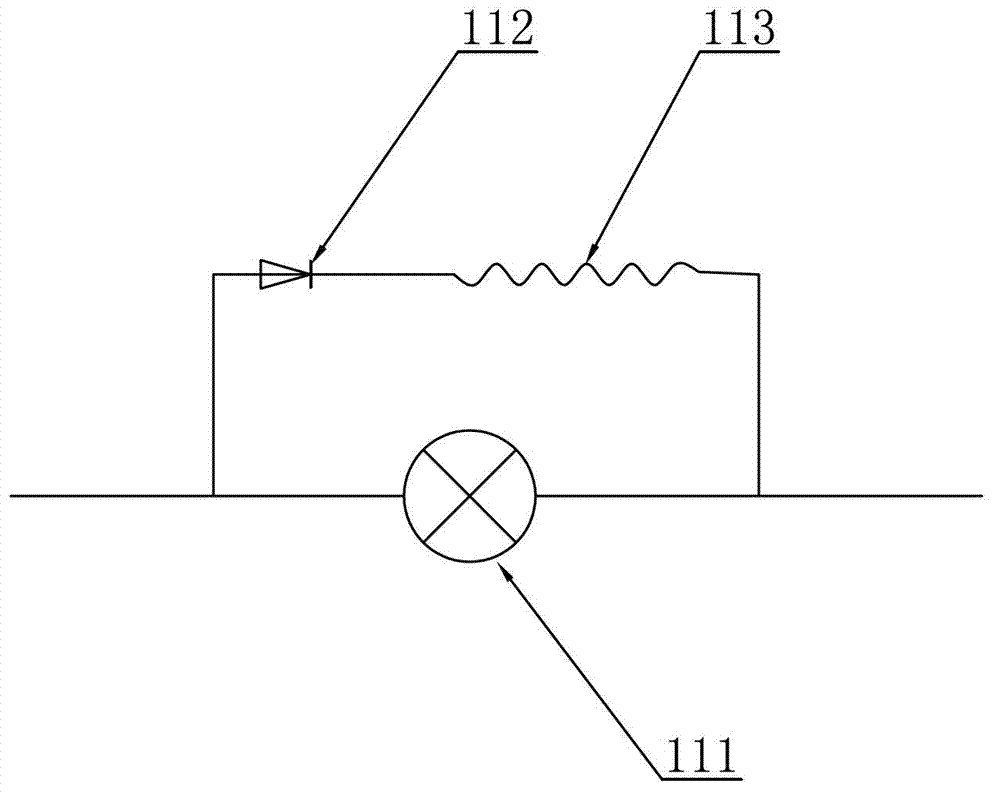

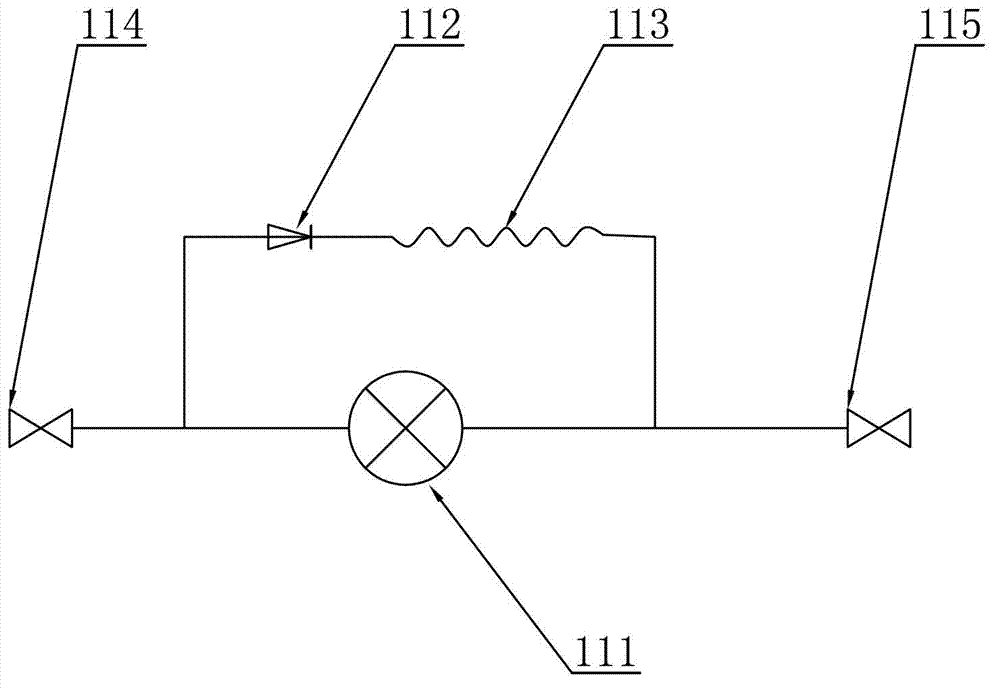

Throttling device and air conditioner adopting same

InactiveCN102767923AImprove sound qualityReduce cavitation effectsNoise suppressionEfficient regulation technologiesCavitationSound quality

The invention discloses a throttling device, which includes an electronic expansion valve, and is characterized in that a one-way valve and a capillary tube are connected to form a bypass over the electronic expansion valve; the one-way valve and the capillary tube are connected in series, so as to form a capillary tube one-way valve assembly. The invention further discloses an air conditioner including the throttling device, which is characterized in that an indoor unit of the air conditioner includes a blower system, and an evaporator component welded on a public pipeline of the throttling device. According to the invention, the one-way valve is closed when the throttling device is used for refrigeration, and is conducted when the throttling device is used for heating; the by-pass capillary tube is adopted to reduce the partial pressure difference of a cooling medium, and reduce the phase change speed of the cooling medium and the cavitation degree, so that ear-piercing noise and cooling medium impulsive vibration caused by the cavitation effect of the cooling medium can be reduced, and the sound quality during the operation of the air conditioner is greatly improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD

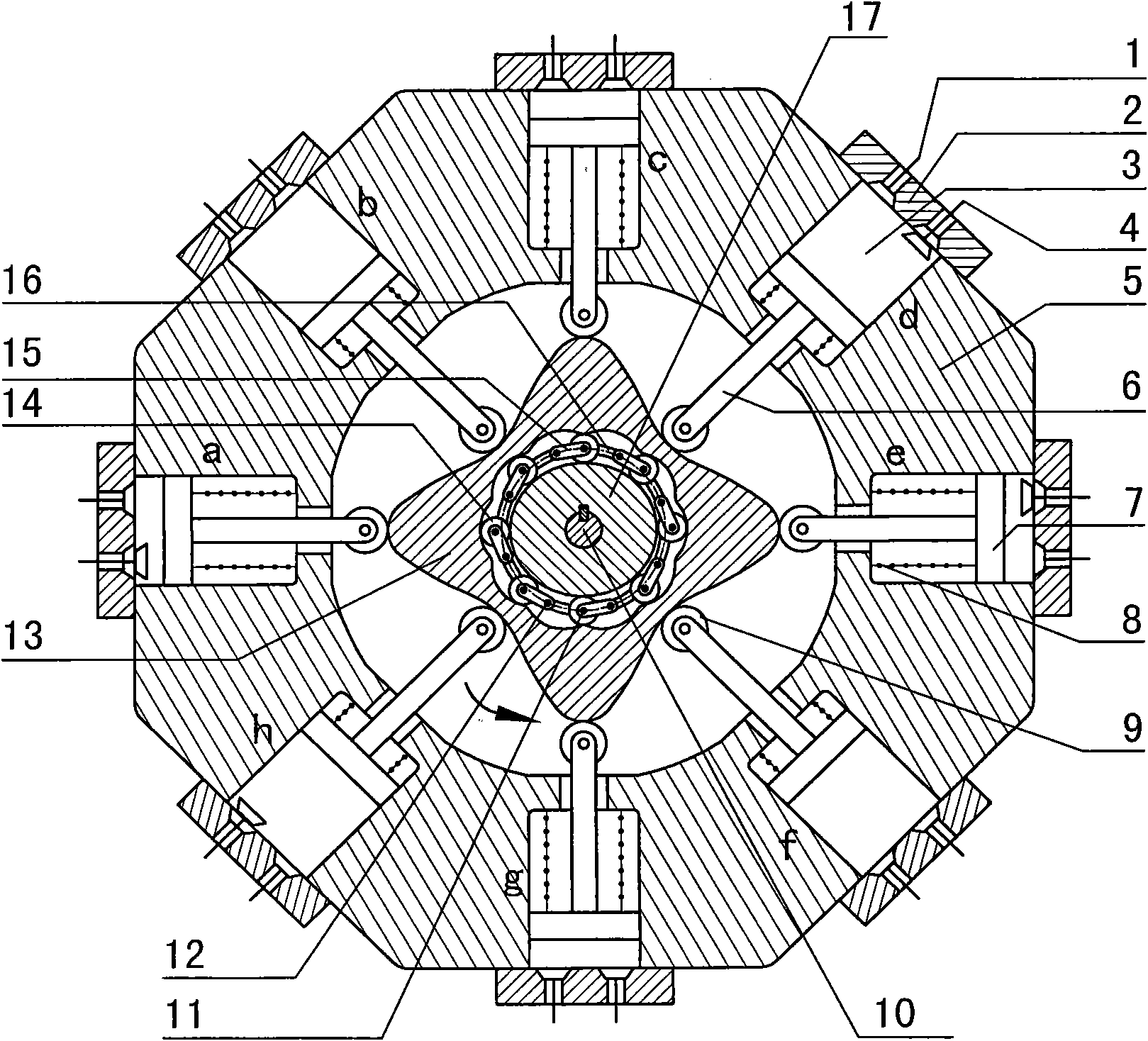

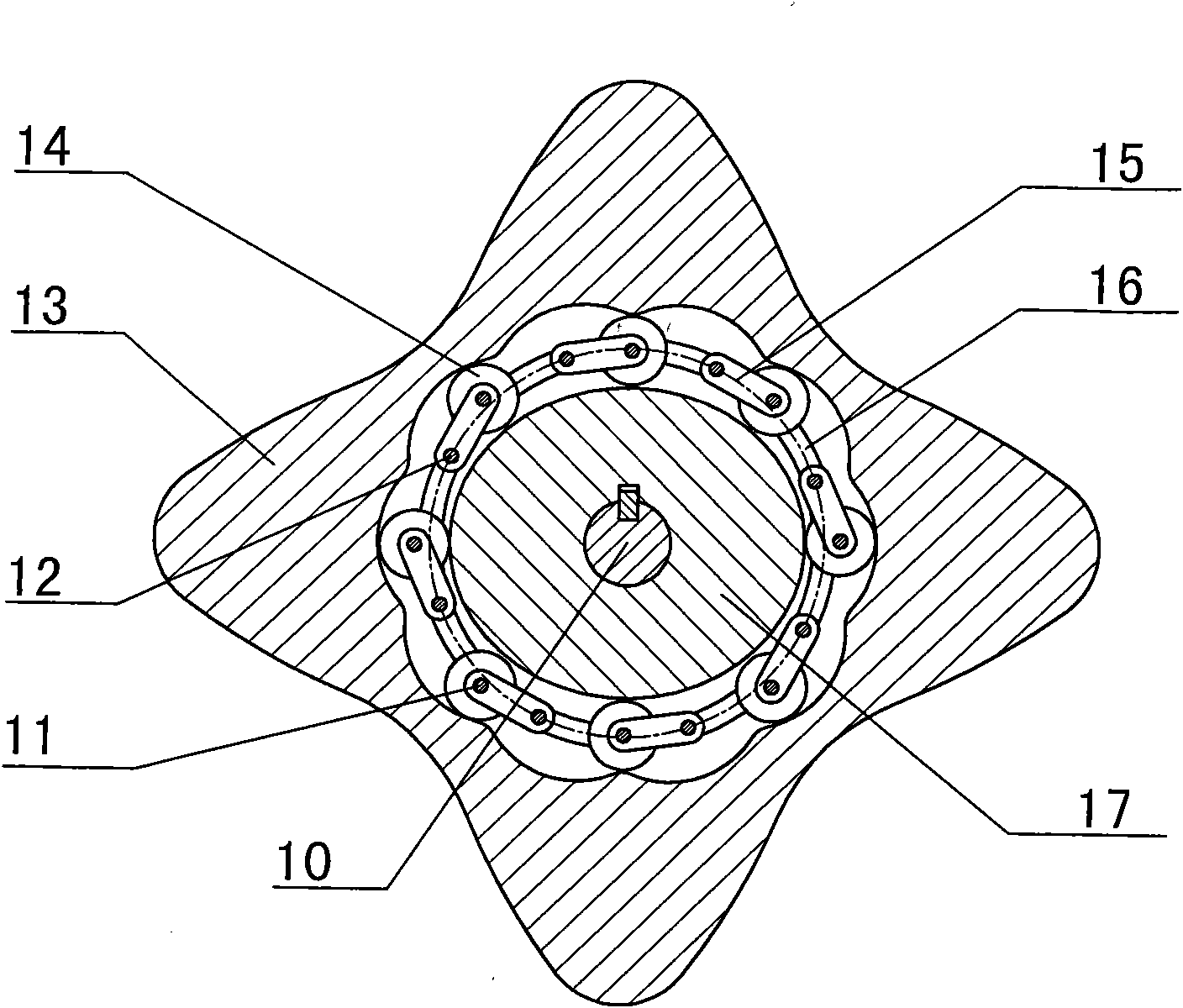

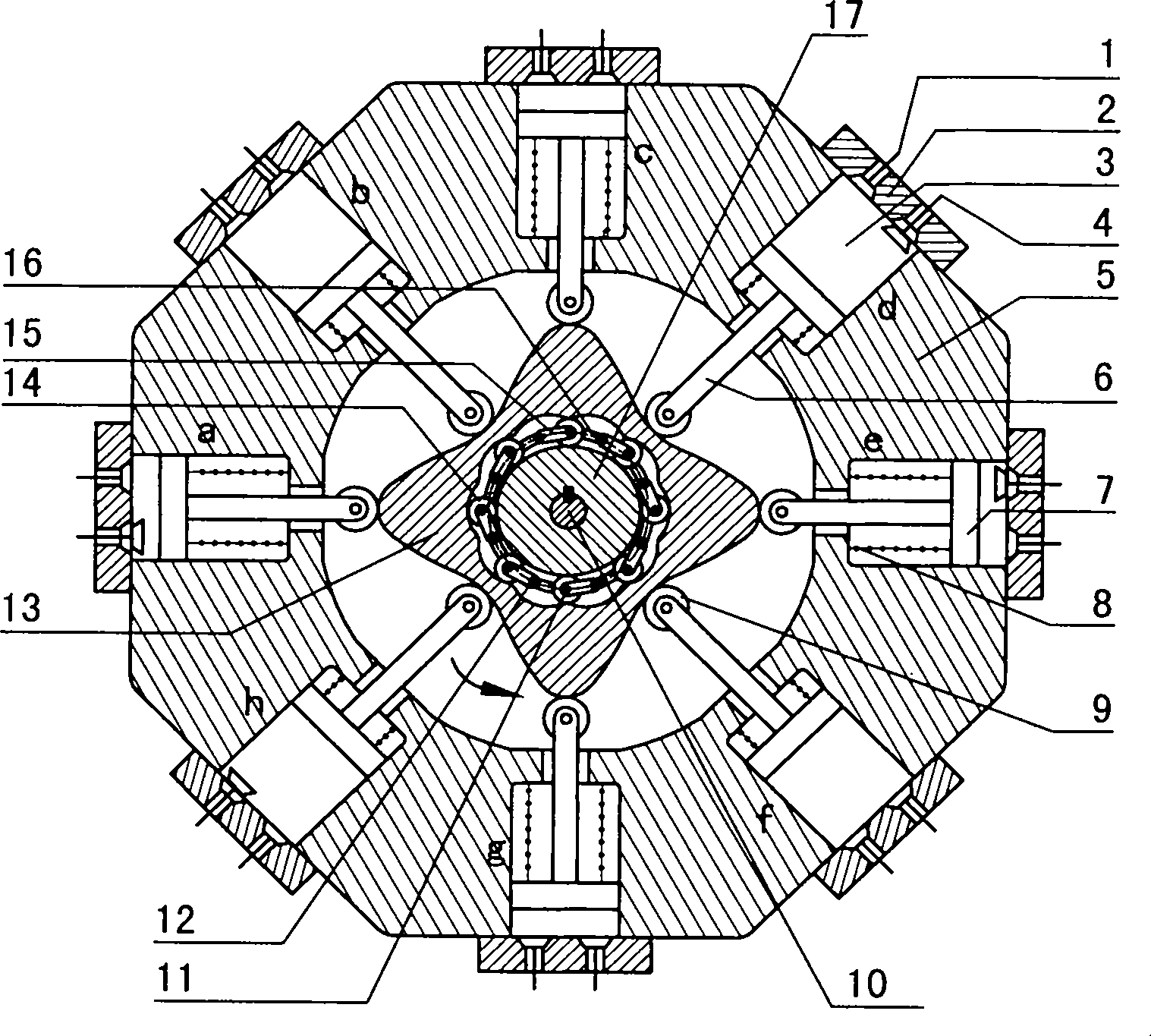

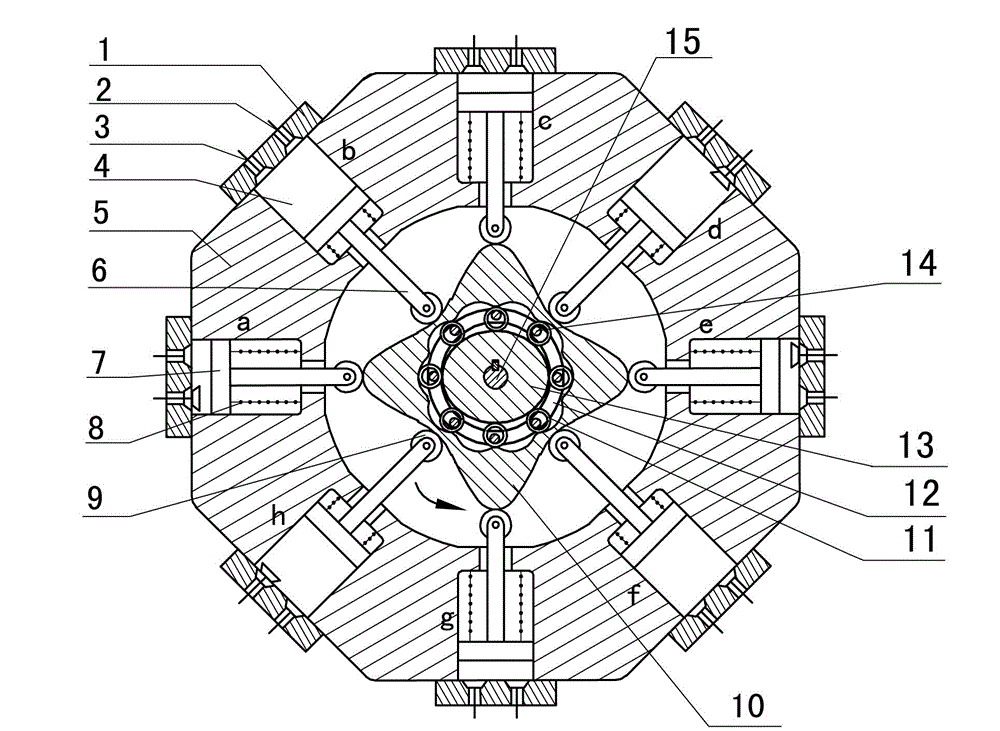

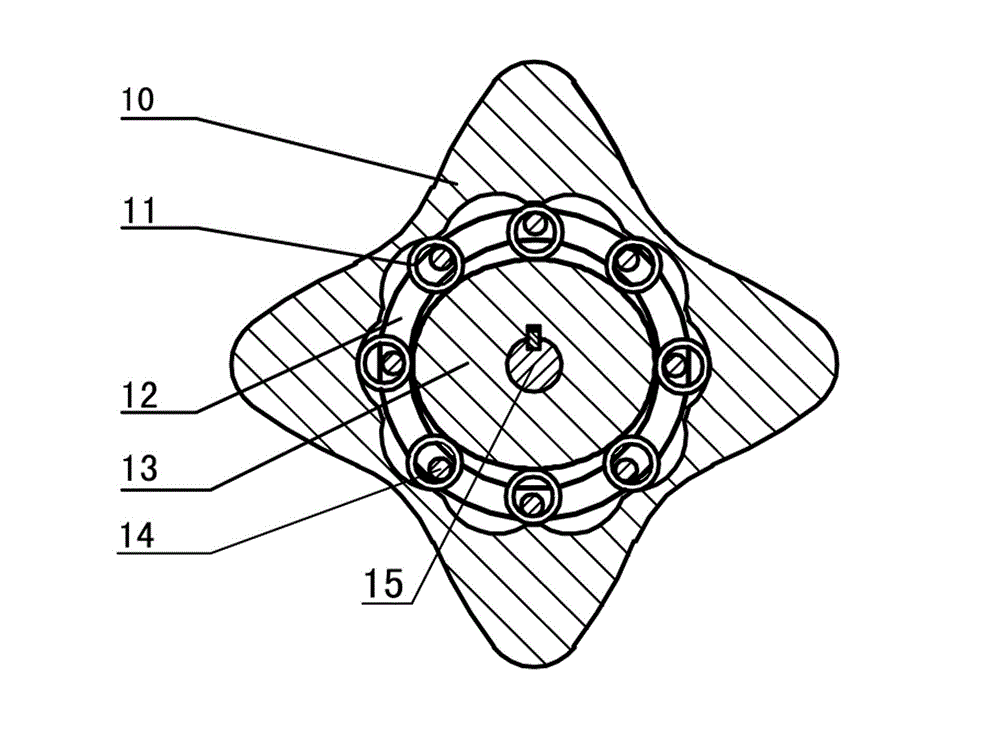

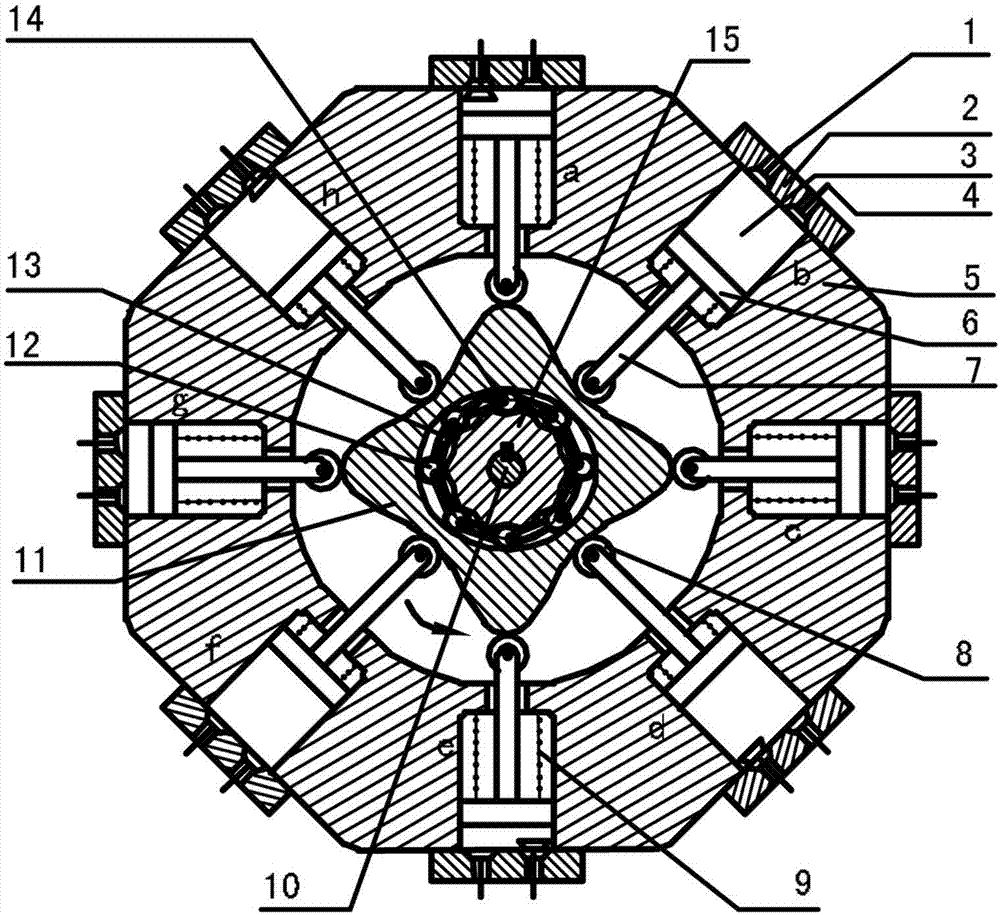

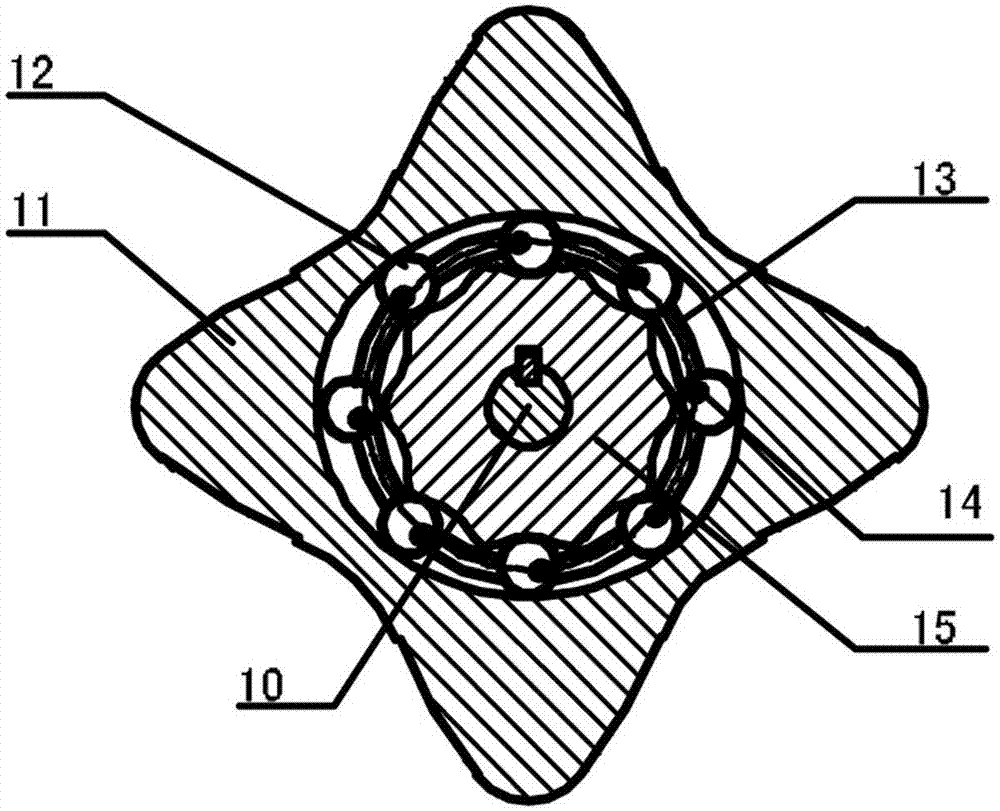

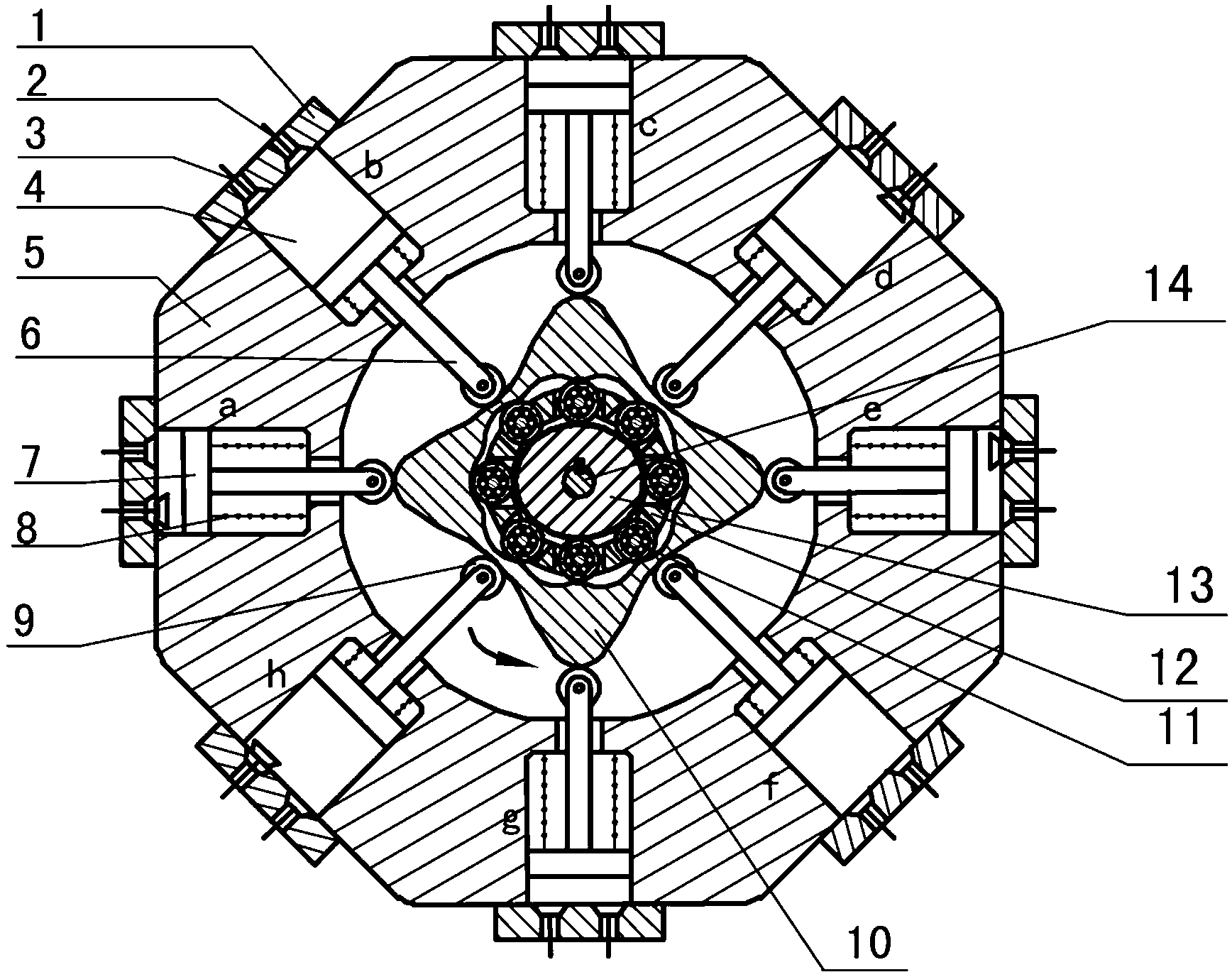

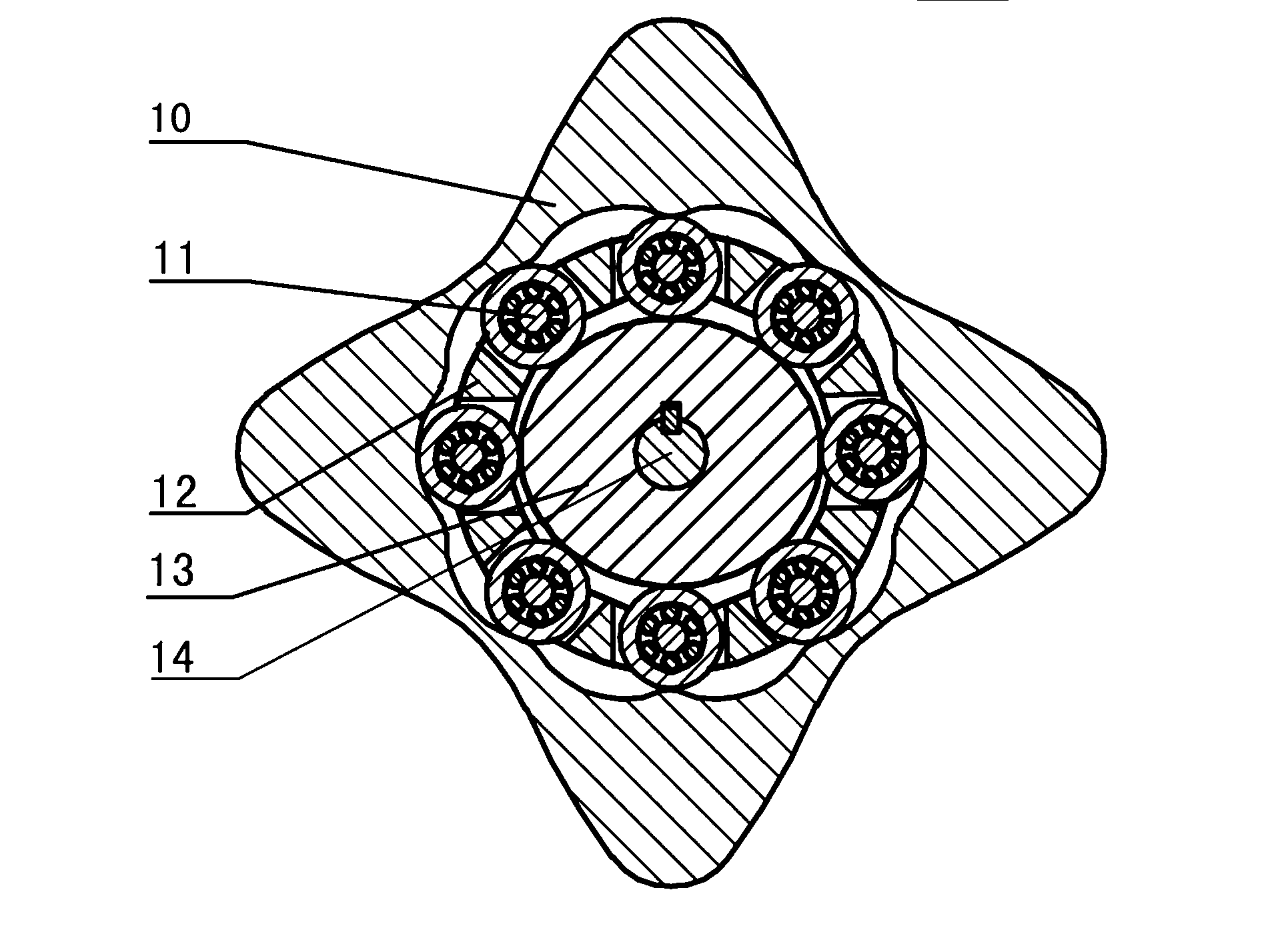

Double-phase shock wave swing rod type high-speed internal combustion engine

InactiveCN102094710ASmall shock and vibrationReduce noiseValve drivesMachines/enginesShock waveDouble phase

The invention discloses a double-phase shock wave swing rod type high-speed internal combustion engine, and relates to the field of fuel gas power. The invention provides a novel internal combustion engine, wherein eight cylinders are annularly, symmetrically and uniformly distributed around a convex inner central wheel, so that the resultant force borne by the convex inner central wheel is zero; cylinder pistons directly act on the convex inner central wheel through push rods; and the power is transmitted to an output shaft connected with a double-phase shock wave wheel key from the convex inner central wheel through a movable tooth transmission of a double-phase shock wave swing rod. In the internal combustion engine, a connecting rod and a crankshaft in the traditional internal combustion engine are omitted; and a double-phase shock wave swing rod transmission mechanism in the convex wheel has no eccentric mass and has the advantage of automatic balance of inertia force and working load. The revolution speed of the output shaft depends on the transmission rate of the movable tooth transmission; if a movable tooth rack is fixed, the double-phase shock wave wheel outputs power at a high speed; the internal combustion engine can be widely applied to the fields in need of high revolution speed, such as small generators, helicopter engines and the like; and when the output revolution speed is regular, the emission of harmful gases can be reduced. The internal combustion engine has the advantages of simple and compact structure, small axial size, automatic stress balance and stability in operation.

Owner:SICHUAN UNIV

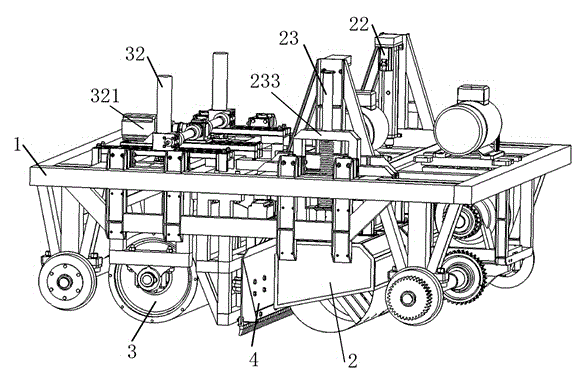

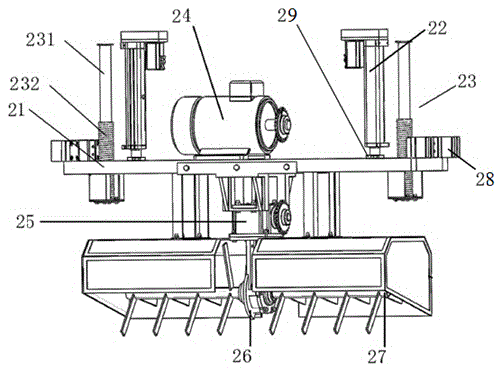

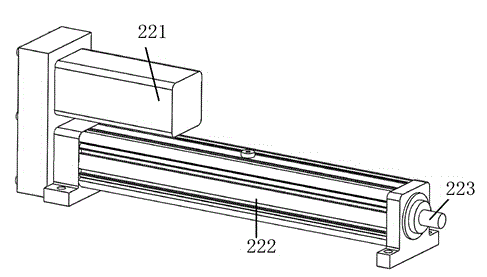

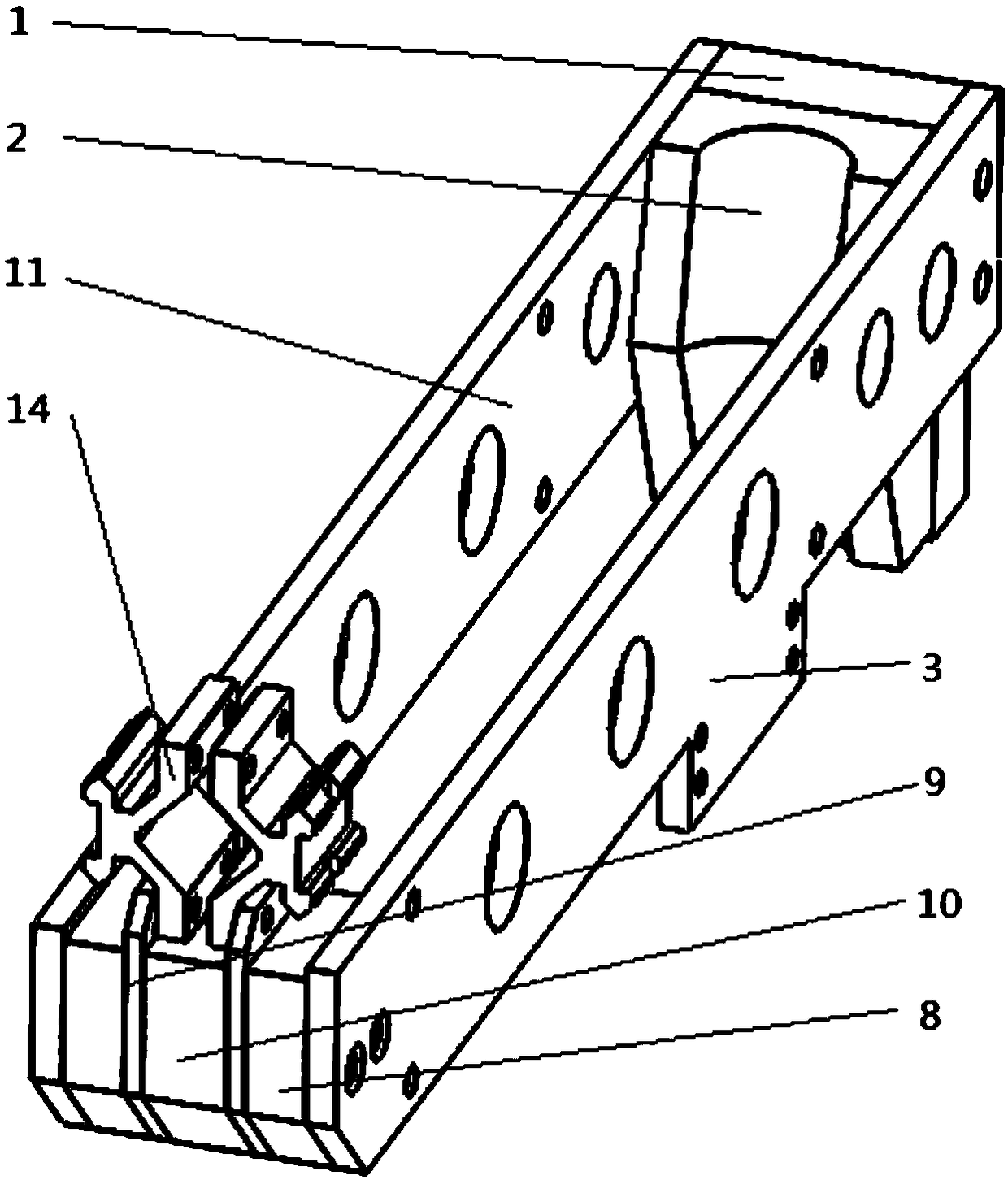

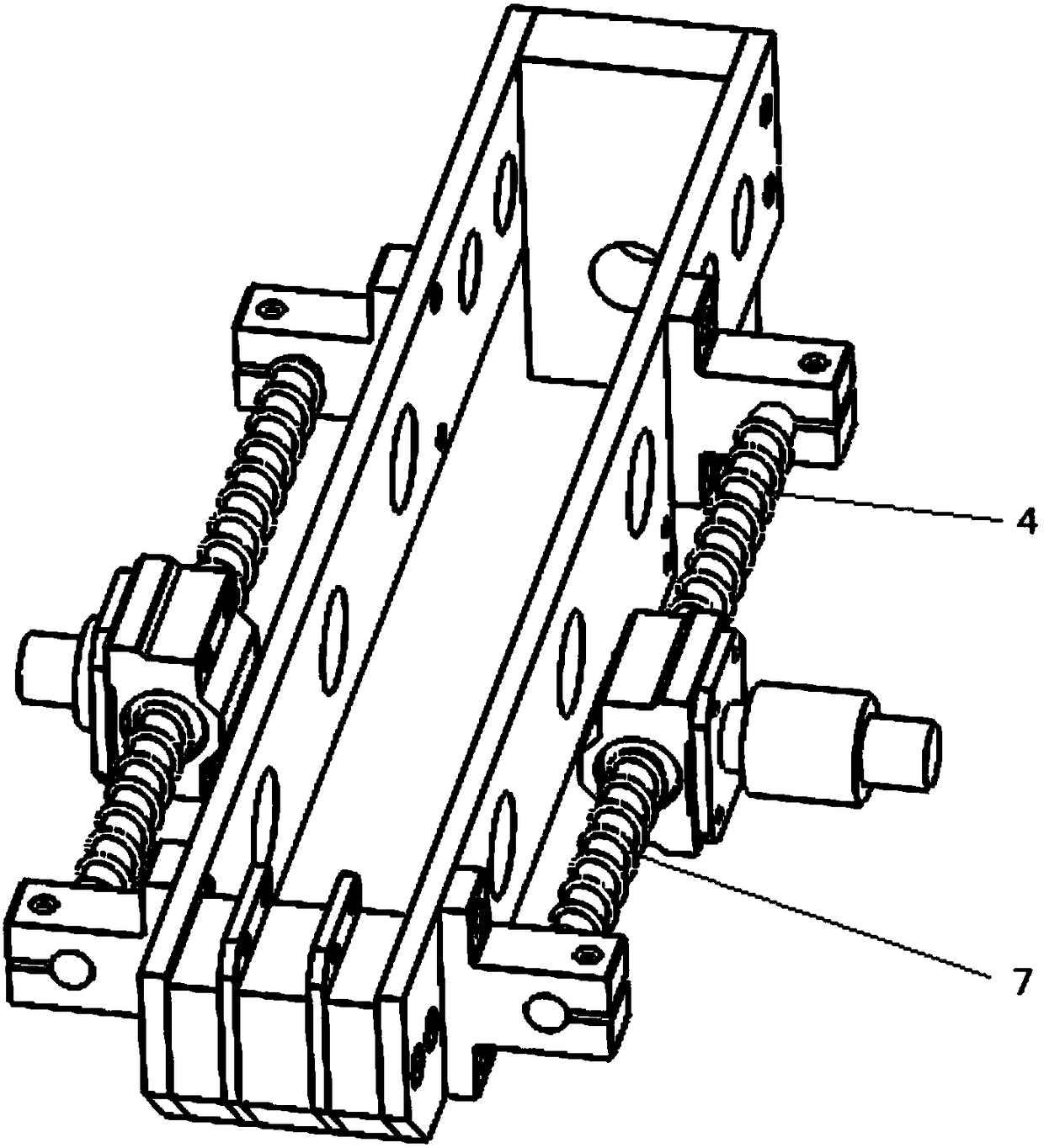

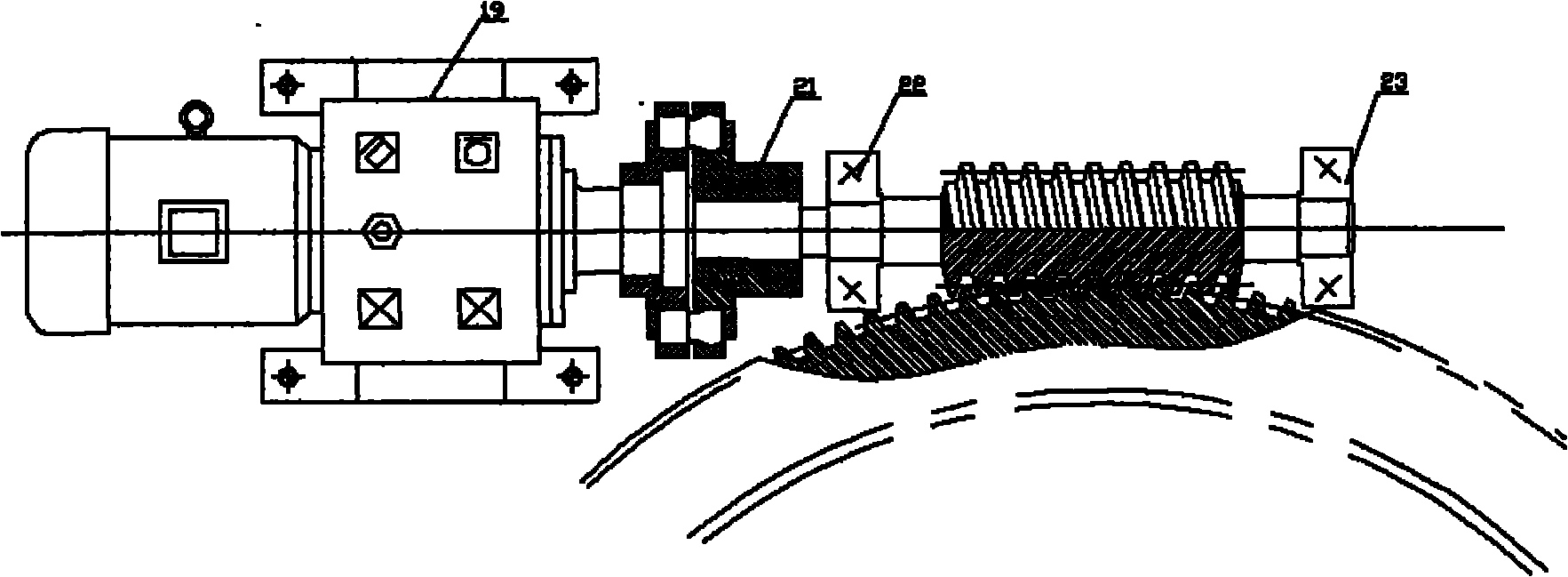

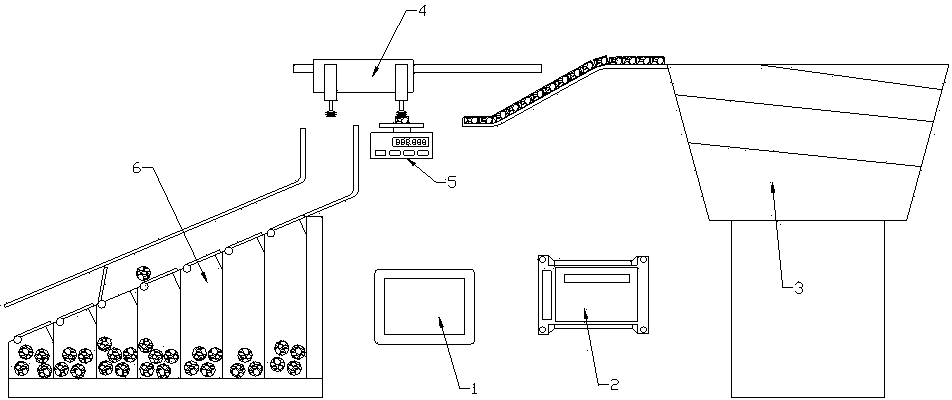

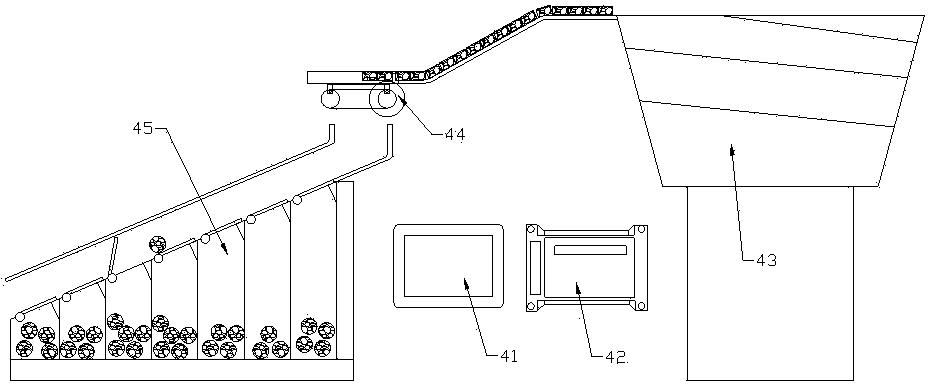

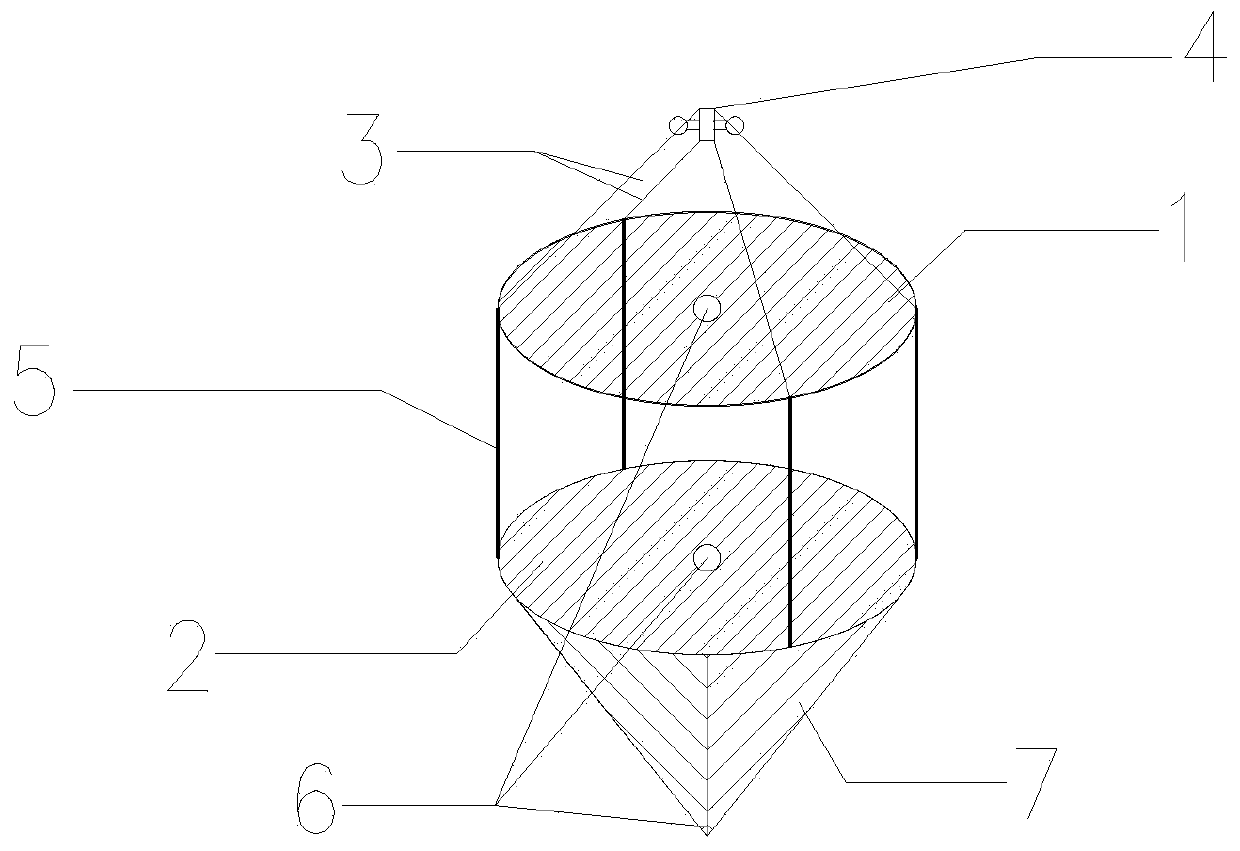

Small multifunctional trolley based on soil bin testbed

InactiveCN104568420AShort response timeHigh adjustment accuracyMachine part testingEngineeringTillage

The invention discloses a small multifunctional trolley based on a soil bin testbed. The small multifunctional trolley comprises a testbed rack, a rotary tillage system, a soil compaction system and a soil leveling system. The rotary tillage system is arranged at the front end of the trolley rack. The soil compaction system is arranged at the rear end of the trolley rack. The soil leveling system is arranged on the trolley rack and located between the rotary tillage system and the soil compaction system. The small multifunctional trolley is an important component of the testbed, integrates rotary tillage, leveling and compaction functions and is assisted by a soil bin and capable of conducting soil bin tests of multiple kinds of working modes, and test results can provide important test data and technological means for soil cultivation component design, selection and failure mode analysis and can provide test conditions for combined rotary tillage component research.

Owner:CHONGQING UNIV OF TECH

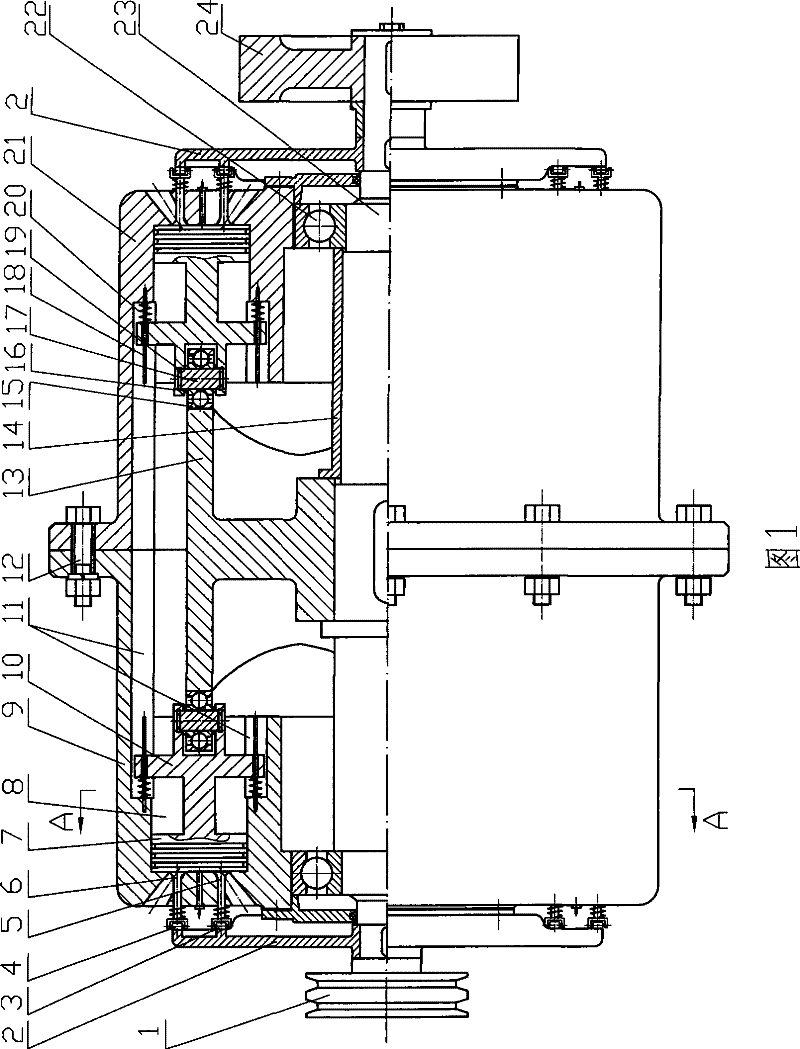

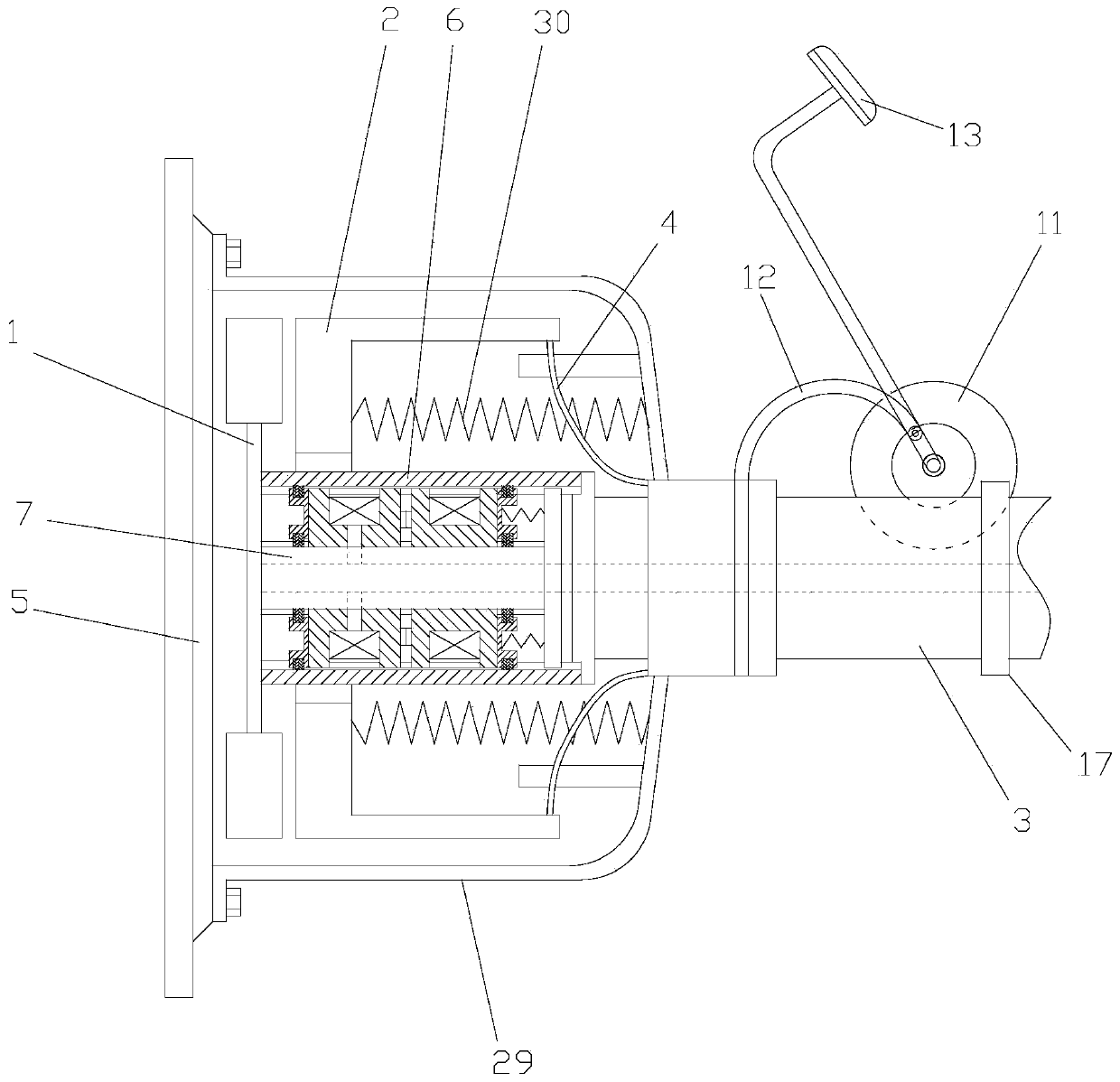

Electromagnetic torque clutch

ActiveCN107725631AMeet stability requirementsGuaranteed reliabilityMagnetically actuated clutchesElectromagnetic clutchDrivetrain

The invention provides an electromagnetic torque clutch. The electromagnetic torque clutch comprises an input shaft, an input wheel, an electromagnetic coil, an output shaft and an output wheel fixedto the output shaft. The input wheel is provided with a plurality of radial long grooves extending in the radial direction. A swing rod is arranged in each radial long groove. A spherical fulcrum is fixedly arranged in the middle of each swing rod. One end of each swing rod penetrates through a guide ball. The other end of each swing rod is fixedly provided with a permanent magnet. The output shaft and the input shaft are arranged coaxially. The output wheel is closely attached to the input wheel. The radial long grooves face the output wheel. The surface, facing the input wheel, of the outputwheel is provided with a plurality of grooves. Each groove is opposite to the corresponding radial long groove to form a track groove allowing the corresponding guide ball to roll in. Under the action of an electromagnetic field of the electromagnetic coil, the functions of connection and disconnection of dynamic power in an automobile power transmission system are achieves through left-right swinging of the swing rods, and the requirement for the stability of dynamic torque transmission of the automobile power transmission system is met.

Owner:SHANGHAI GKN DRIVE SYST

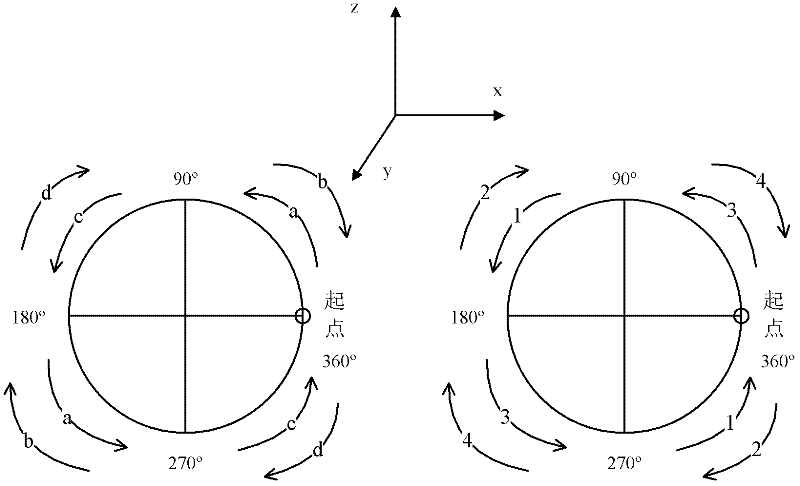

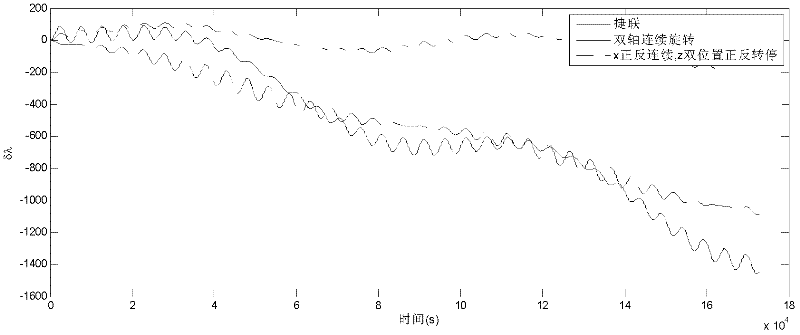

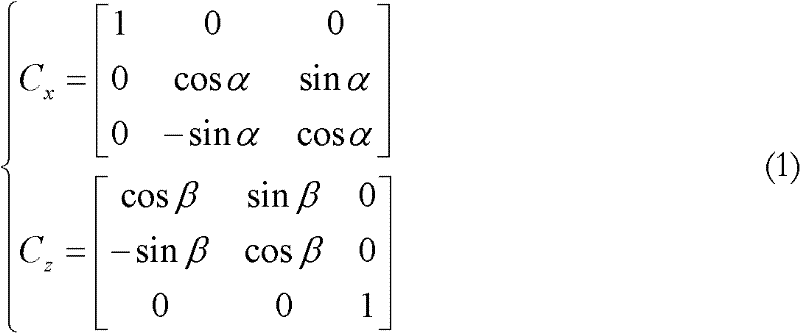

Rotating method of modulation type inertial navigation system with double-axis rotating continuously

InactiveCN102538789AHigh precisionReduce complexityNavigational calculation instrumentsNavigation by speed/acceleration measurementsRotation methodRotation velocity

The invention belongs to the field of inertial navigation, aiming to solve the optimization problem of a modulation method during double-axis rotating. The invention provides a rotating method of a modulation type inertial navigation system with double-axis rotating continuously. In the rotating method, the rotating speed of azimuth axis omegaz and pitch axis omegax is needed to preset to meet a condition of omegaz=2omegax. The periodical rotating method of the inertial navigation system based on the condition improves the precision of the inertial navigation system and ensures the stability of the carrier by modulating the error of inertial apparatuses in three sensitive axis (azimuth axis, pitch axis and horizontal axis) directions of the inertial navigation system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Two-phase outer cam sleeve type high-rotational-speed internal-combustion engine

InactiveCN102877942AHigh speed outputReduce axial sizeGearingMachines/enginesEngineeringInternal combustion engine

The invention discloses a two-phase outer cam sleeve type high-rotational-speed internal-combustion engine, and relates to the field of power of fuel gas. The invention provides a novel internal-combustion engine. Eight cylinders are annularly, symmetrically and uniformly distributed around an outwards convex inner gear ring, so that resultant force from which the outwards convex inner gear ring is suffered is zero; pistons of the cylinders directly act on the outwards convex inner gear ring through push rods; and power is transferred to an output shaft connected with a symmetric two-phase cam through a key by the outwards convex inner gear ring through the drive of a two-phase outer cam type sleeve oscillating tooth. By using the internal-combustion engine, a connecting rod and a crankshaft in a conventional internal-combustion engine are omitted; a two-phase outer cam sleeve driving mechanism of the outwards convex inner gear ring of the internal-combustion engine does not have an eccentric mass; the internal-combustion engine has the characteristic of the self balancing of inertia force and a working load; the rotational speed of the output shaft depends on the drive ratio of the drive of the oscillating tooth; if a dowel pin frame is fixedly arranged, the symmetric two-phase cam carries out output at a high speed; the internal-combustion engine can be widely applied to the field of high rotational speeds, such as engines of helicopters, and miniature engines; and when an output rotational speed is constant, the emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, small in axial dimension and self-balancing in stress, and is stable to run.

Owner:SICHUAN UNIV

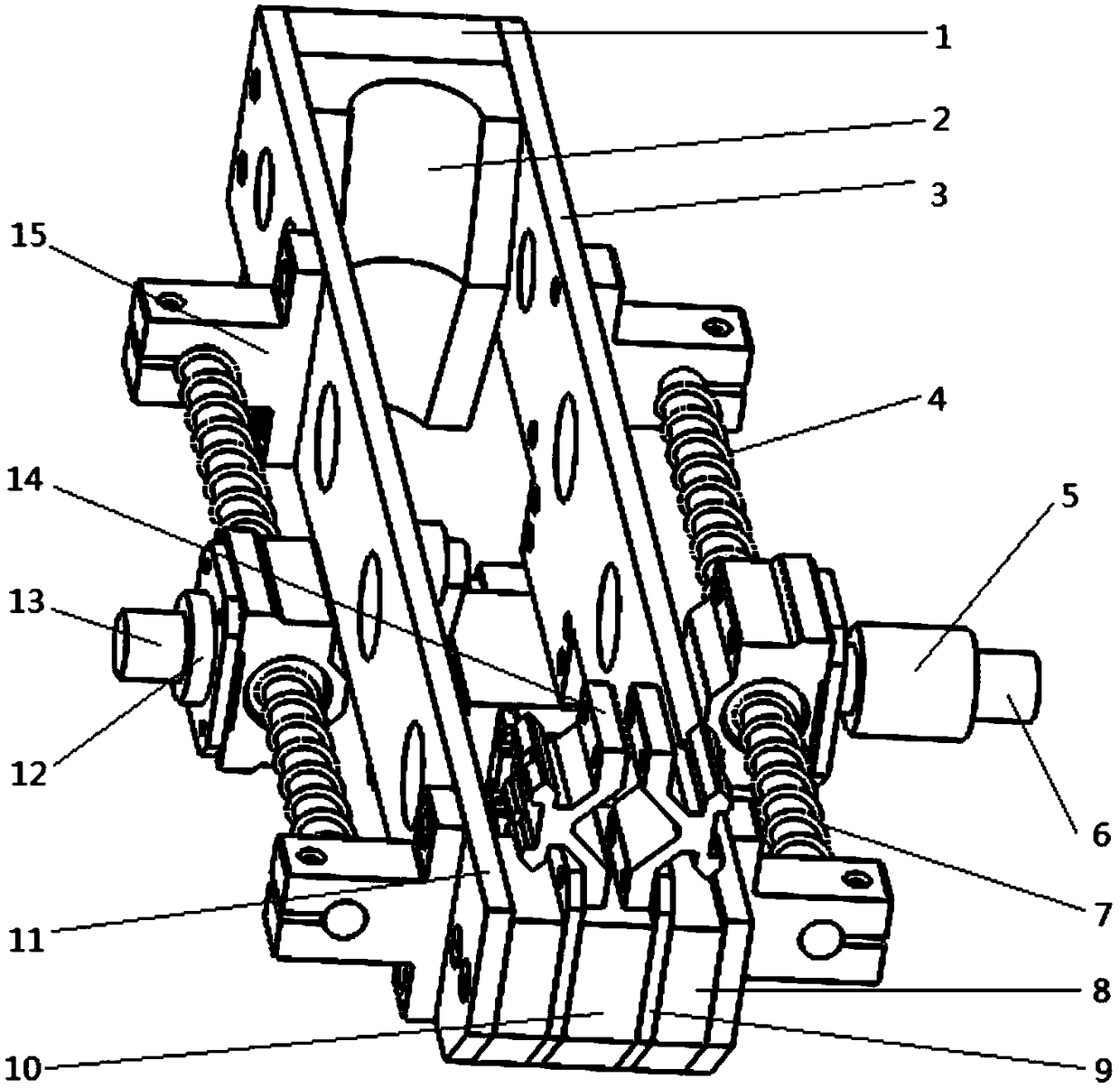

Gun clamping mechanism assembled to unmanned aerial vehicle and provided with spring buffer device

ActiveCN108195227AStable positionSuccinct structureWeight reductionGun mountingsEngineeringMechanical engineering

The invention discloses a gun clamping mechanism assembled to an unmanned aerial vehicle and provided with a spring buffer device. The gun clamping mechanism comprises a gun clamping sub-mechanism, afiring mechanism, a first cylindrical boss, a second cylindrical boss and two spring buffer mechanisms. The two spring buffer mechanisms are symmetrically arranged on the two sides of the gun clampingsub-mechanism. The firing mechanism is fixed to the bottom of any side of the gun clamping sub-mechanism. The first cylindrical boss and the second cylindrical boss are fixed to the outer sidewalls of the two spring buffer mechanisms correspondingly. The first cylindrical boss and the second cylindrical boss are used for pan-tilt cascade connection. The gun clamping mechanism is concise in overall structure and small in mass. Limiting springs and buffer springs are adopted to be connected in series, so that a gun is stable in position before firing and is buffered both in the recoiling process and in the counter-recoiling process, and unnecessary impact vibration is reduced.

Owner:NANJING UNIV OF SCI & TECH

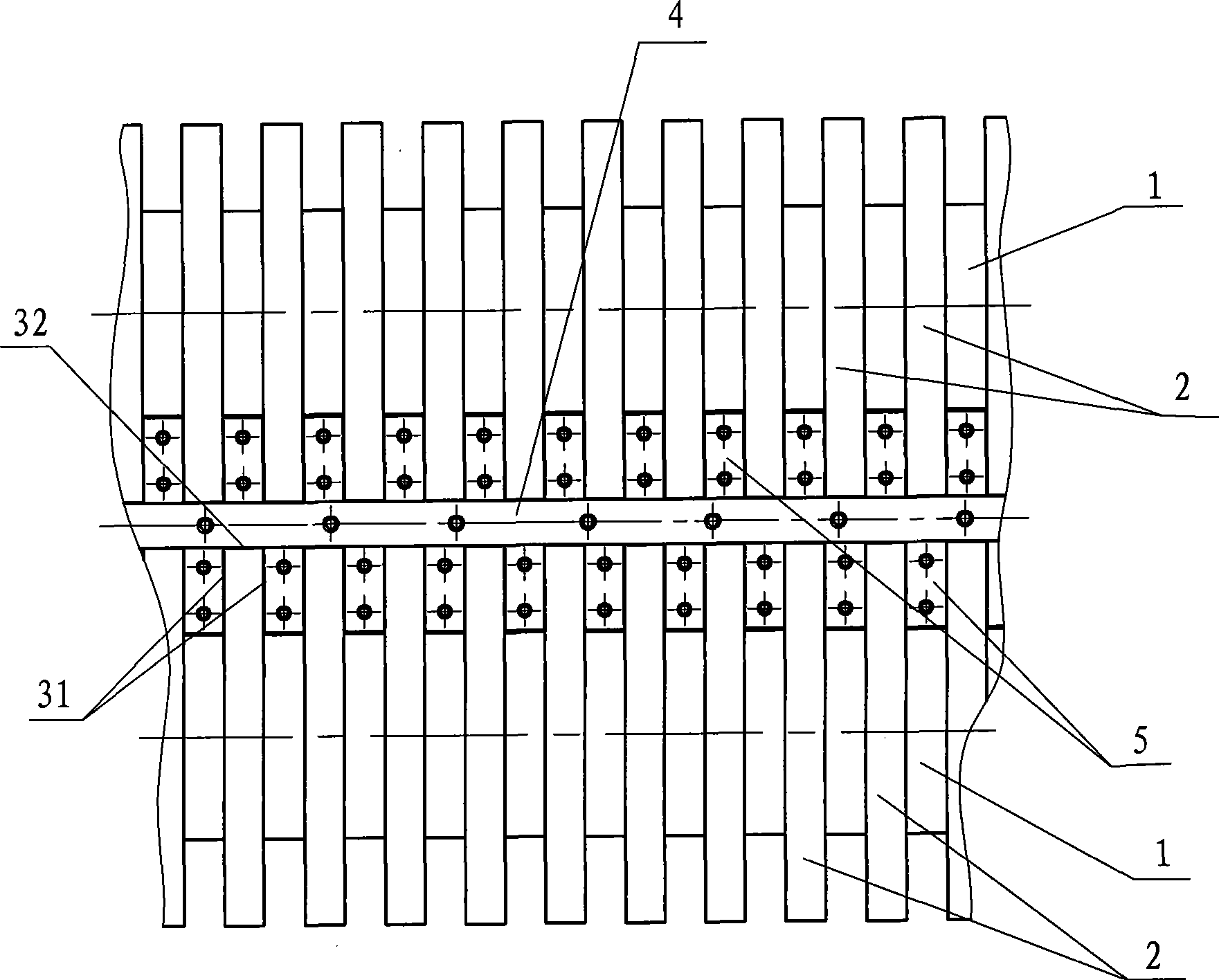

Straw crushing device with combined bed knife

The present invention relates to a crushing processing device which is used for plant stalk in the industries of papermaking, clean energy, etc. Specifically the invention relates to a combined dead knife straw crusher. The device comprises at least one rotatable knife roll which is arranged with a plurality of knife discs. The circumferences of knife discs are uniformly installed with a plurality of fly knife blades. The edges of two sides of each fly knife blade are provided with transverse cutting edges. The radial outer margin of each fly knife blade is provided with a longitudinal cutting edge. The side part of knife roll is fixed with a longitudinal dead knife in longitudinal direction. The rotation track of longitudinal cutting edge of fly knife blade is next to the longitudinal edge of longitudinal dead knife so that the longitudinal cutting edge and the longitudinal dead knife can execute relative shearing movement. The side of knife roll next to the longitudinal is also fixedly installed with a plurality of transverse dead knifes which are transversely installed and are positioned in the clearance between the adjacent knife discs, so that the transverse cutting edges of fly knife blades and the transverse dead knifes can execute relative shearing movement. The crushing processing device of the invention greatly increases the homogeneity of crushing and simultaneously has the advantages of smooth crashing process, little impact vibration and high reliability.

Owner:JIANGSU DATANG MACHINERY

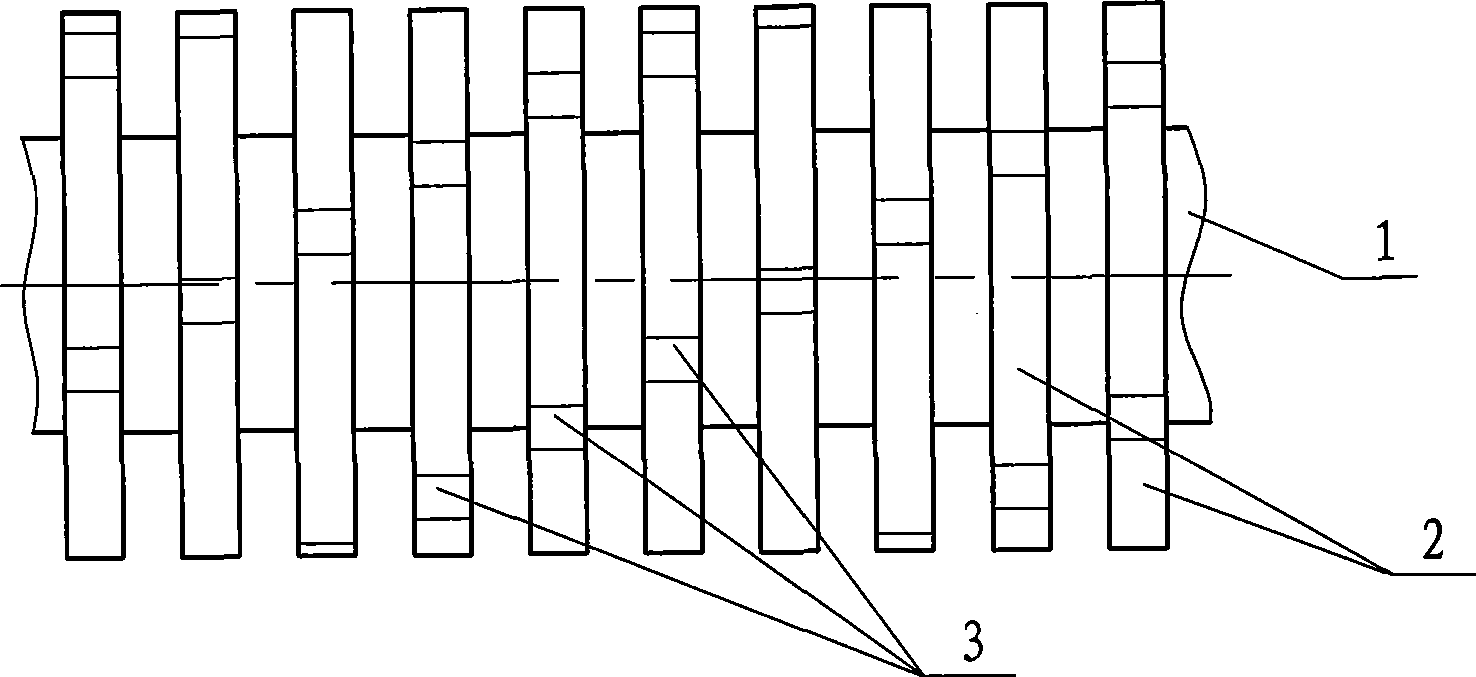

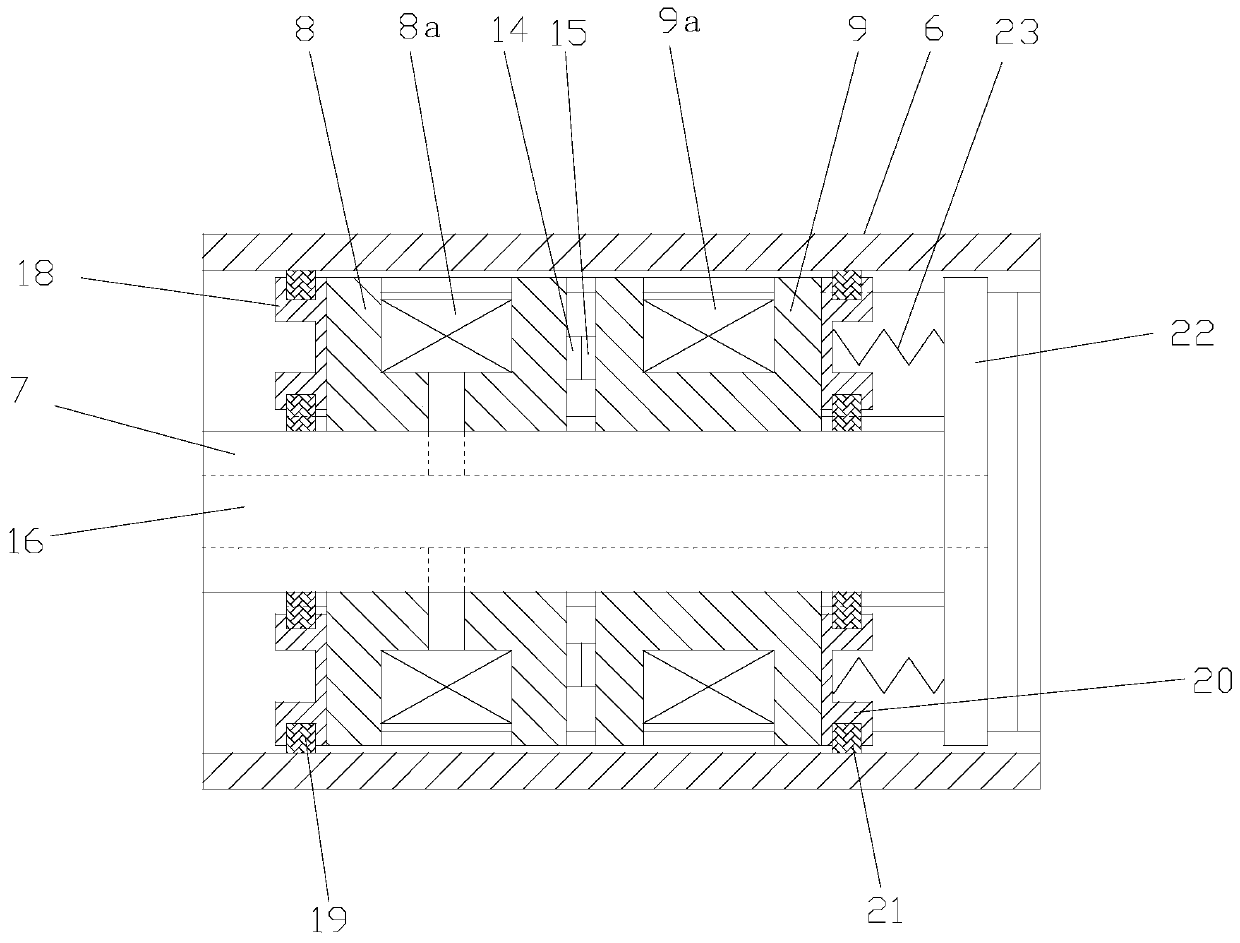

Two-phase inner cam type swinging transmission internal combustion engine

InactiveCN102828824AForce self-balancingLarge transmission ratioGearingMachines/enginesLow speedEngineering

The invention provides a two-phase inner cam type swinging transmission internal combustion engine, which relates to the field of gas motive power and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, eight air cylinders are annularly, symmetrically and uniformly distributed around an outer convex inner two-phase inner cam, the resultant force of the outer convex inner two-phase inner cam is zero, an air cylinder piston directly acts on the outer convex inner two-phase inner cam through a push rod, and the motive power is transferred to an output shaft connected with a center wheel key through a two-phase inner cam type swinging movable tooth via the outer convex inner two-phase inner cam. The internal combustion engine has the characteristics that a connecting rod and a crankshaft in the traditional internal combustion engine are omitted, and an outer convex inner two-phase inner cam type swinging transmission mechanism does not have the eccentric mass, and has the inertia force and work load self balance characteristic. The rotating speed of the output shaft depends on the transmission ratio of the movable tooth transmission, when the movable tooth frame is fixed, a center wheel realizes low-speed and large-torque output, and the internal combustion engine can be widely applied to engineering machinery, armored car and the like with high-powder requirements. The internal combustion engine has the advantages that the structure is simple and compact, the axial dimension is small, the self balance of the stress is realized, and the operation is stable.

Owner:SICHUAN UNIV

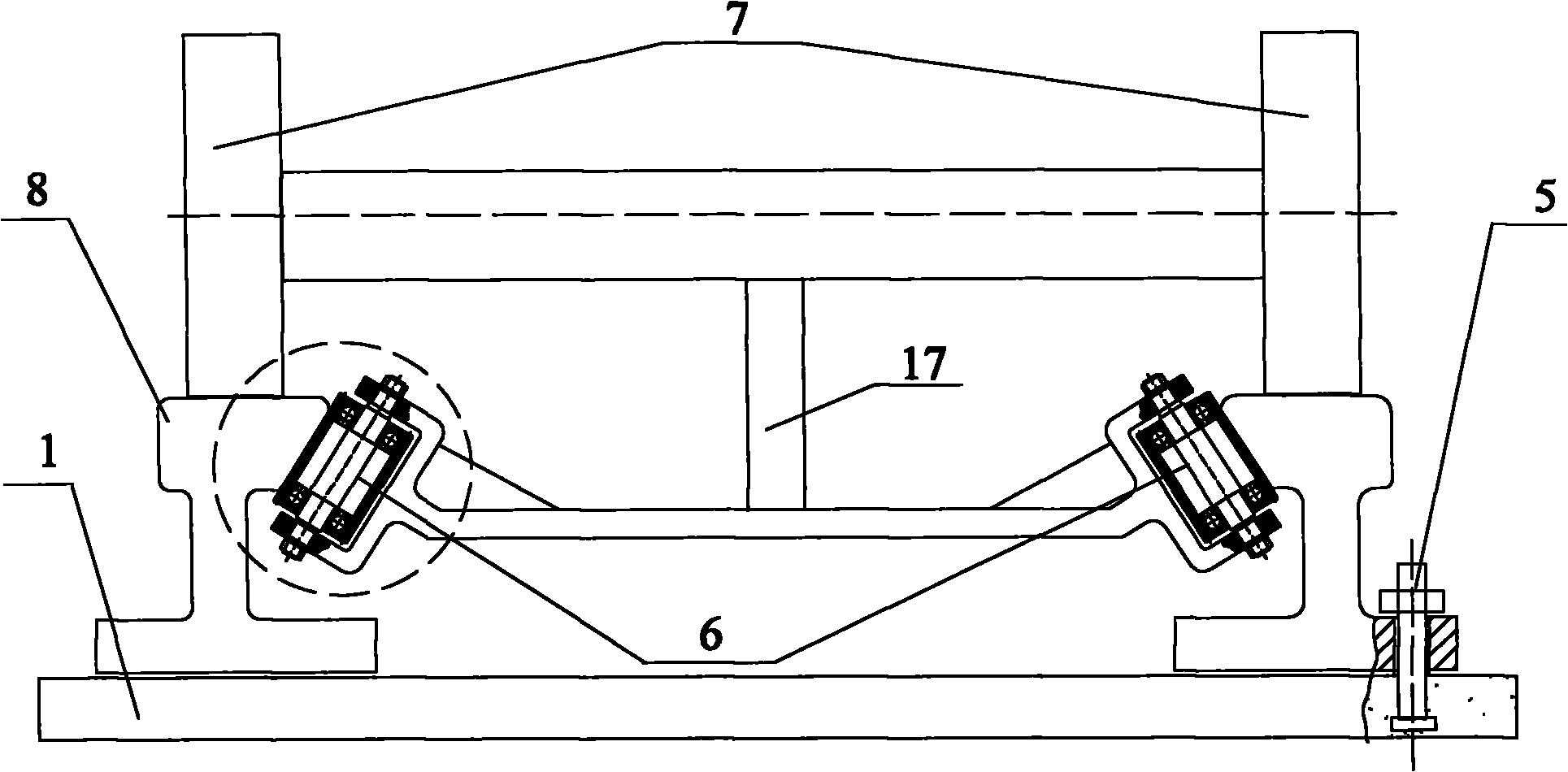

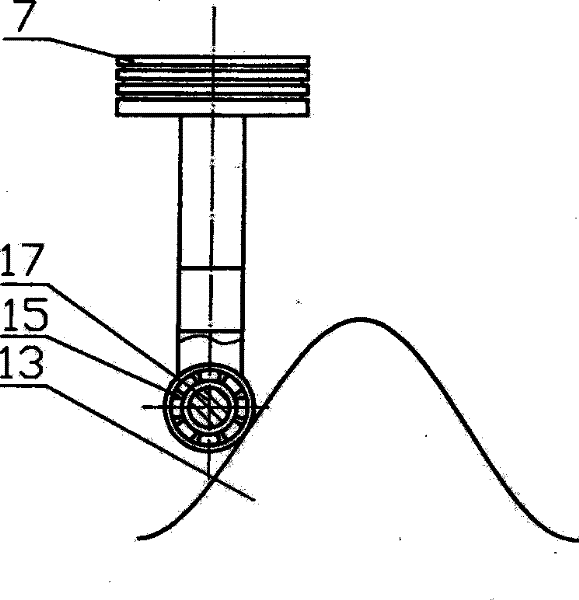

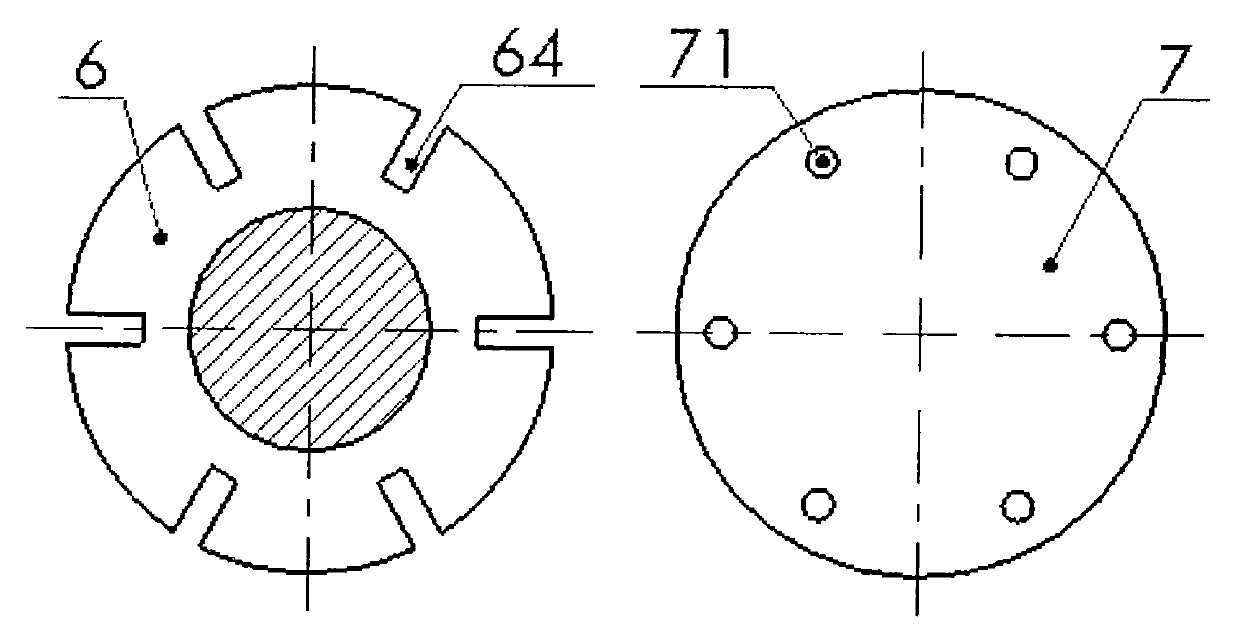

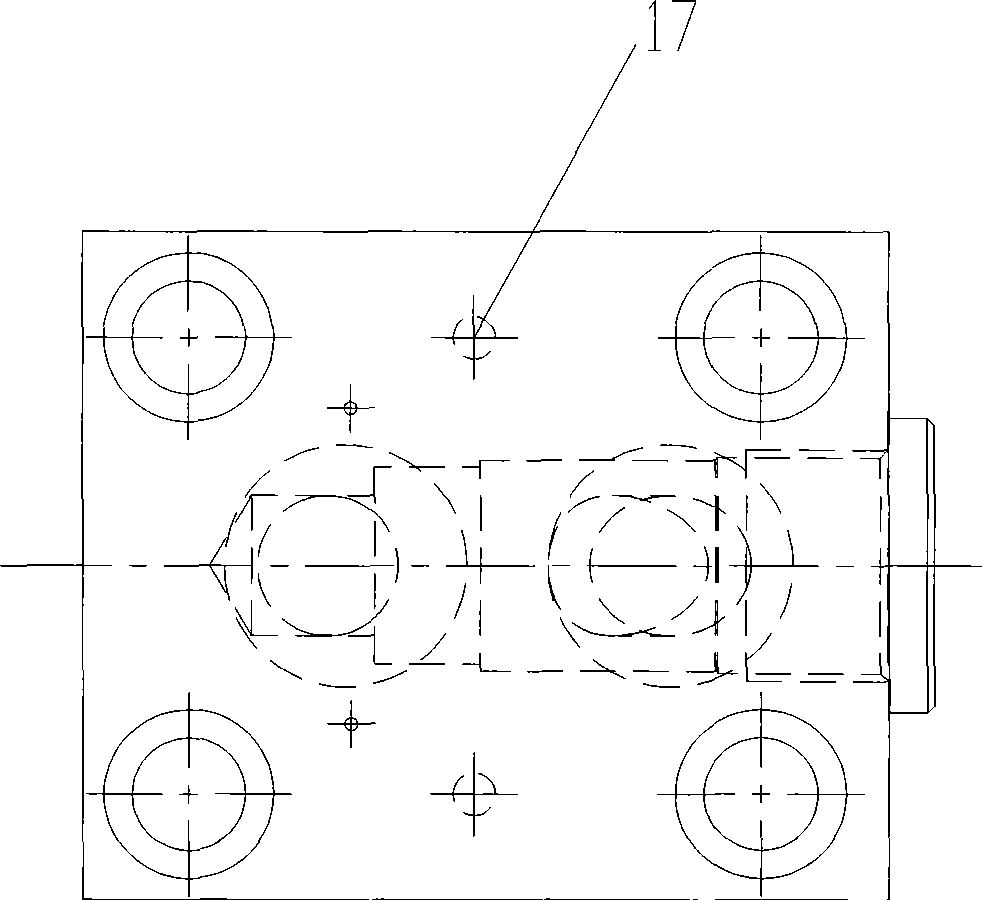

Pure rolling contact structure with low noise and low abrasion loss for rail transit wheel and guiding rail

InactiveCN102049965ASafe and reliable structureAvoid disadvantagesRail-engaging wheelsRailway componentsLow noiseEngineering

The invention discloses a pure rolling contact structure with low noise and low abrasion loss for a rail transit wheel and a guiding rail. The pure rolling contact structure comprises column-shaped wheels (7) and rolling guiding components (6), wherein, the outer round surfaces of the column-shaped wheels (7) are in contact with the upper surface of the guiding rail; the rolling guiding components (6) are assembled on a bracket (17) fixedly connected with a vehicle chassis and / or a wheel shaft; and the rolling guiding components (6) are in rolling contact with the inner side surfaces of the guiding rail. In the invention, the sliding contact between the wheels and the guiding rail is changed into the rolling contact, so that the structure is safer, and beneficial to overcome the defects such as high noise, high abrasion and the like in the existing contact manners.

Owner:GUANGDONG IND TECHN COLLEGE

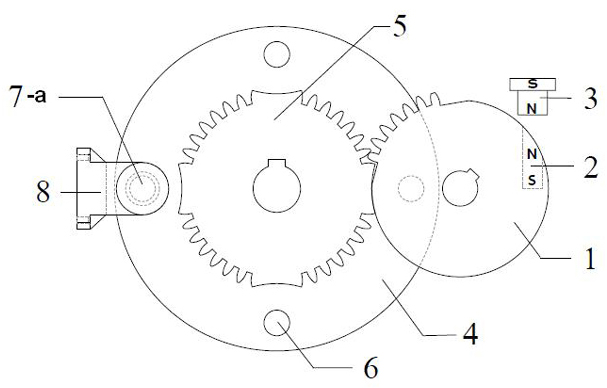

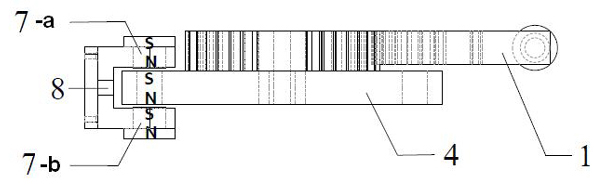

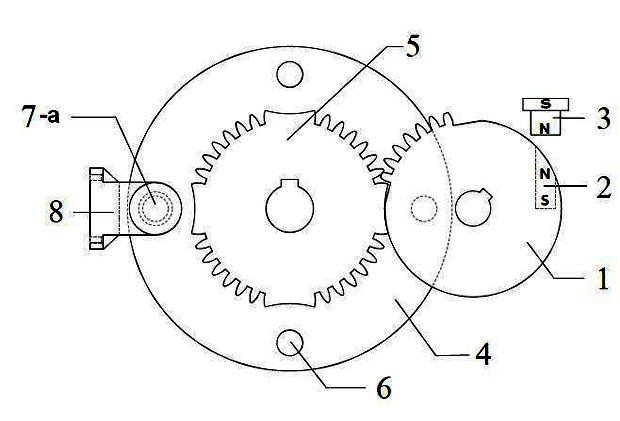

Magnetic vibration damping and positioning incomplete gear

InactiveCN101963218AReduce transient shock vibrationProtection gear pairGearingPortable liftingMagnetEngineering

The invention discloses a magnetic vibration damping and positioning incomplete gear, relating to the field of intermittent drive mechanisms. The magnetic vibration damping and positioning incomplete gear comprises an incomplete gear drive wheel (1), an index plate (4), an incomplete gear driven wheel (5), a positioning frame (8), a stand, a vibration damping magnet A (2), a vibration damping magnet B (3), a magnetic positioning pin (6) and a positioning magnet. Compared with the prior art, the invention greatly improves the reliability and the stability and has the advantages of simple mechanism structure and long service life.

Owner:JIANGSU UNIV

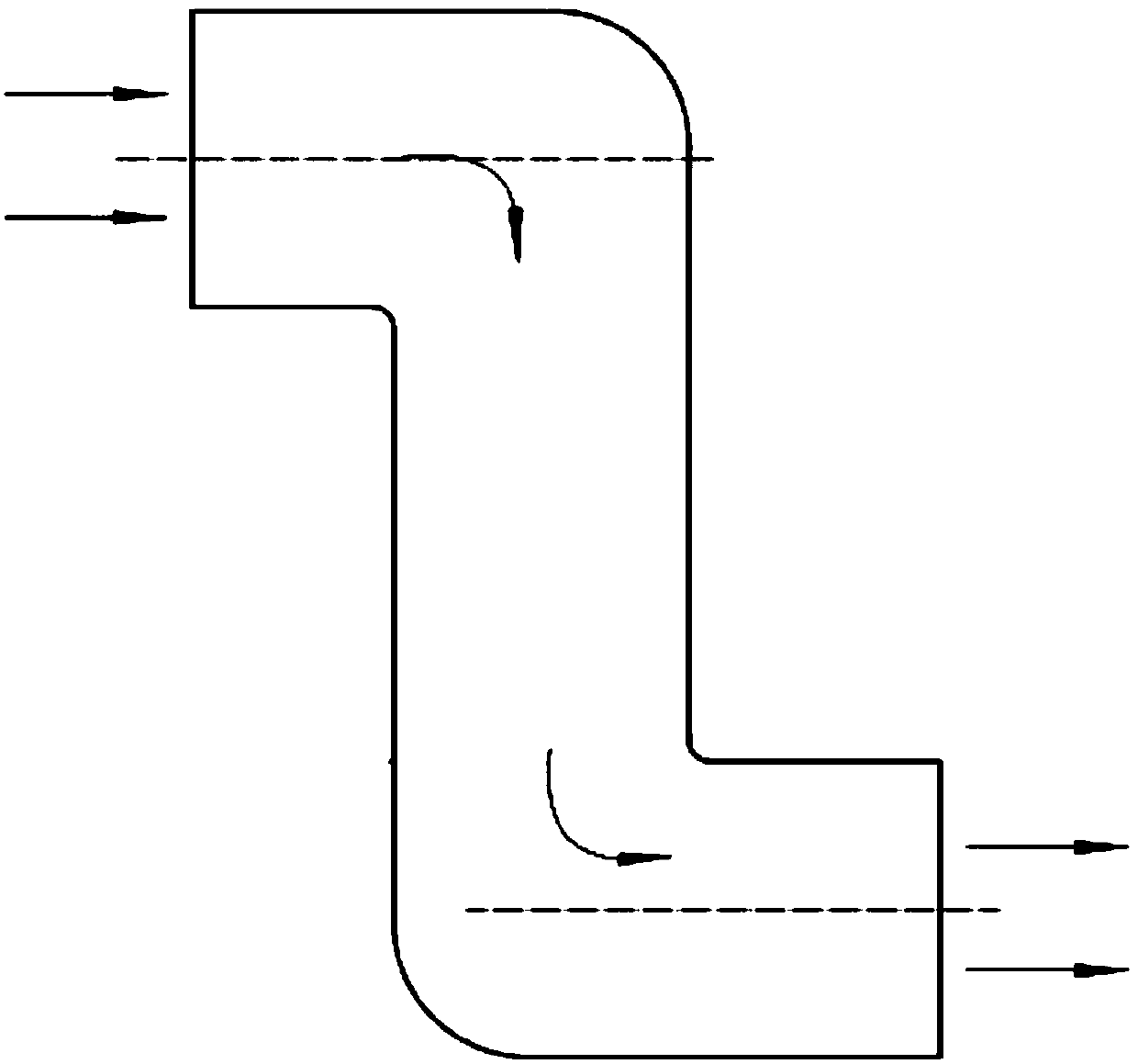

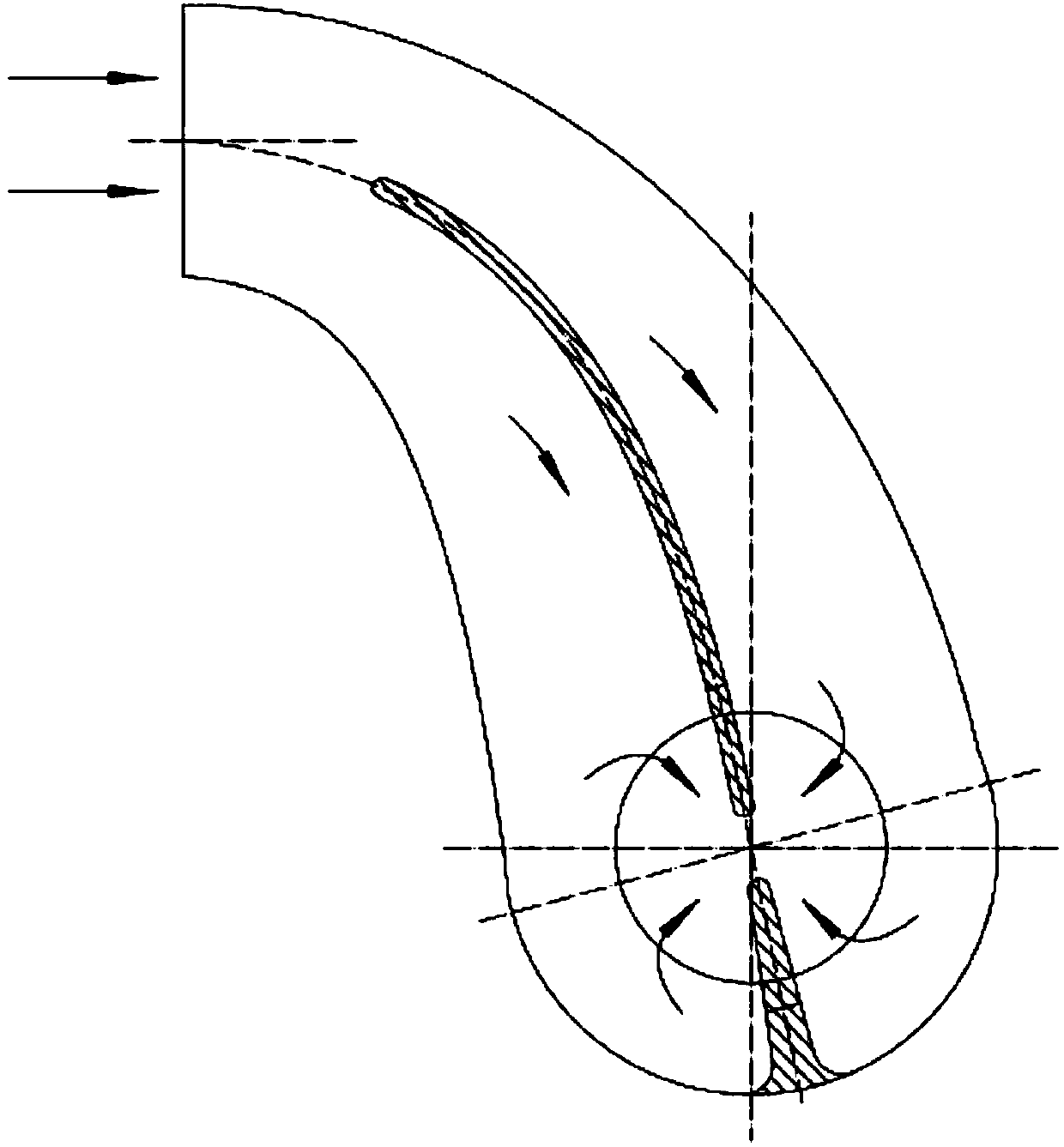

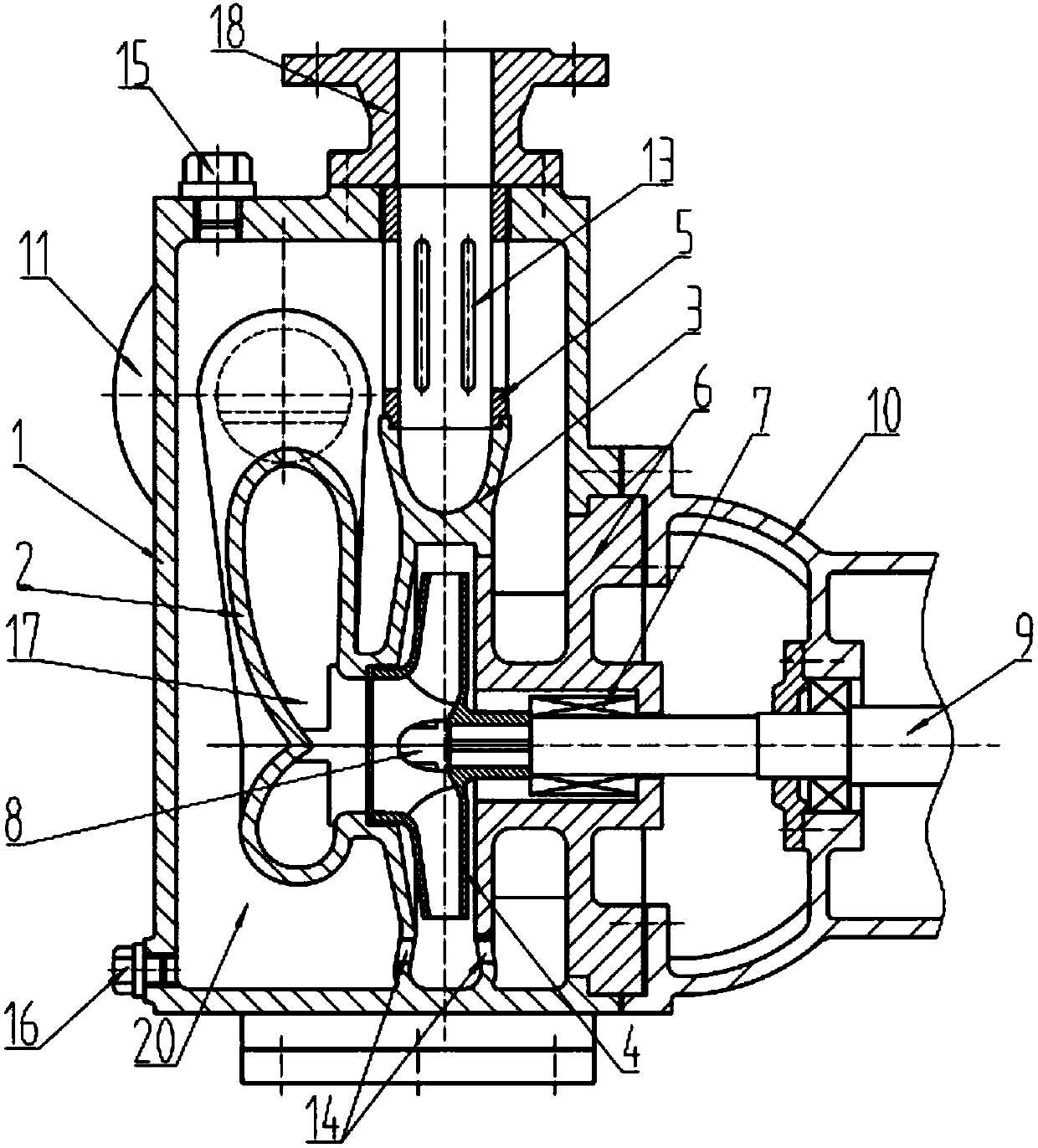

Double-outlet multipurpose external mixing type self-priming pump with quasi-spiral suction chamber

PendingCN107588008AImprove self-priming performanceImprove hydraulic performancePump componentsPriming pumpAgricultural irrigationPetrochemical

The invention provides a double-outlet multipurpose external mixing type self-priming pump with a quasi-spiral suction chamber. The double-outlet multipurpose external mixing type self-priming pump mainly comprises an inlet flange, a pump body, an impeller, an air-liquid separating pipe, a rear cover, a suspension body part, an outlet flange and a flange cover, wherein the pump body is formed by the quasi-spiral suction chamber, a spiral compression chamber and a liquid storage chamber through integral casting and is provided with double outlets and the like. The hydraulic performance of the pump is effectively improved while the self-priming performance of the self-priming pump is improved, the flow losses of fluid media in a suction chamber and a water compressing chamber are remarkablyreduced, and the double-outlet multipurpose external mixing type self-priming pump has the advantages of being high in efficiency and reliability, compact in structure, convenient to install and maintain and multipurpose, serving as a pipeline self-priming pump accessed horizontally only by slightly adjusting an installing mode and the like, is suitable for the fields of agricultural irrigation and drainage, river and pond breeding, municipal drainage, petrochemical metallurgy and the like and can be installed on a movable pump truck for fire-fighting operation and the like.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

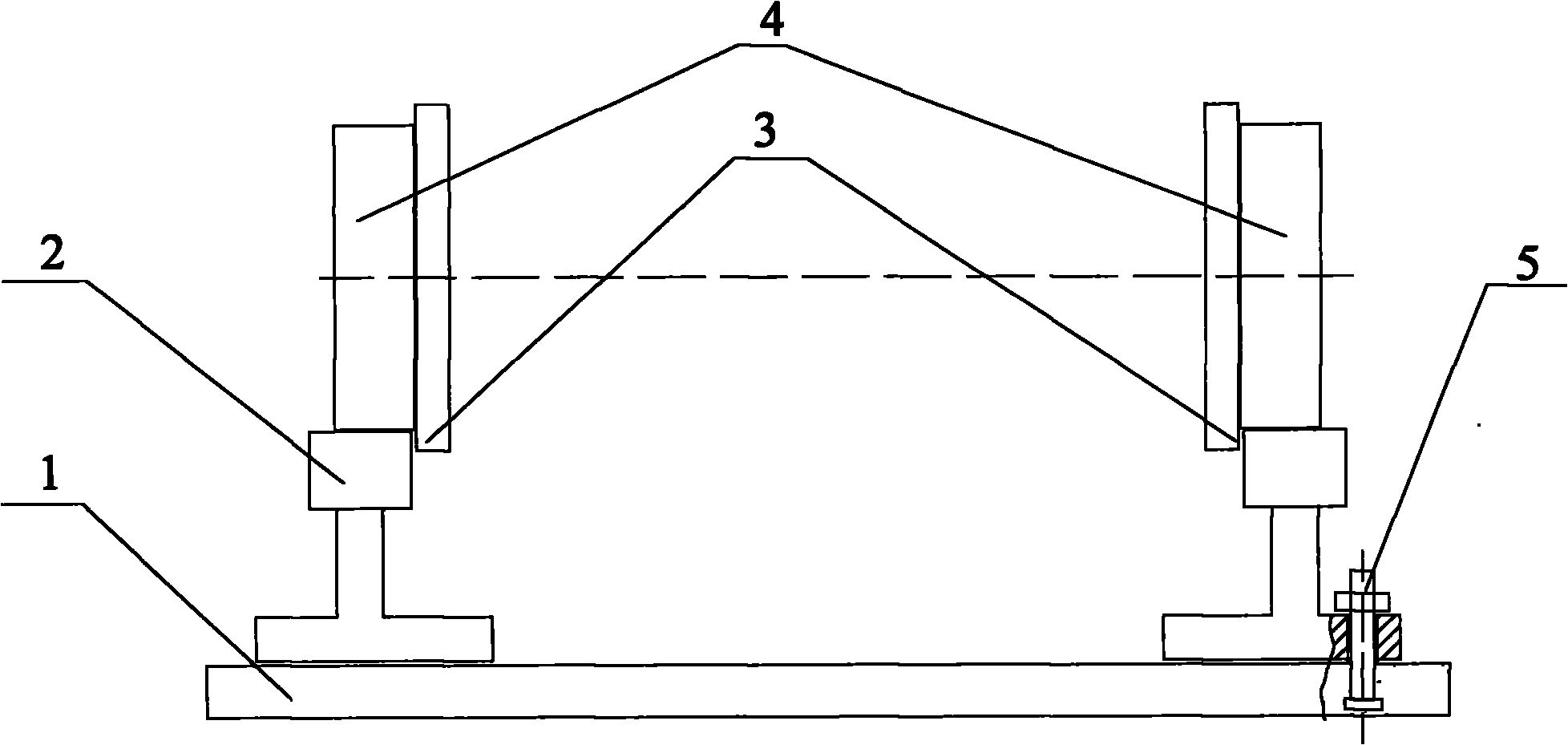

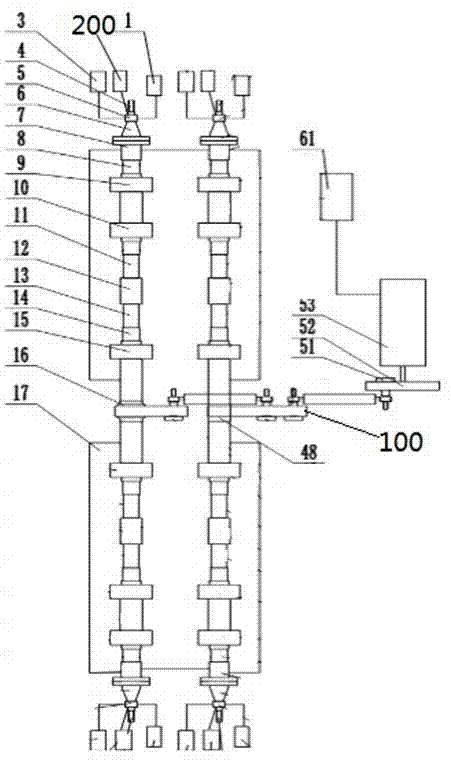

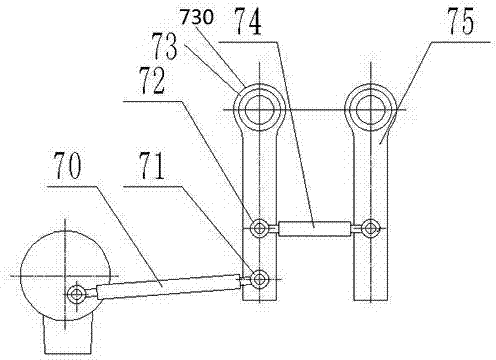

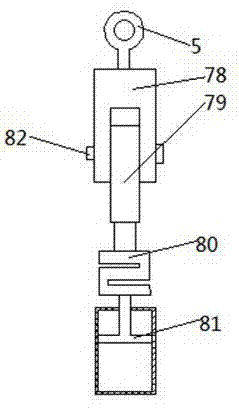

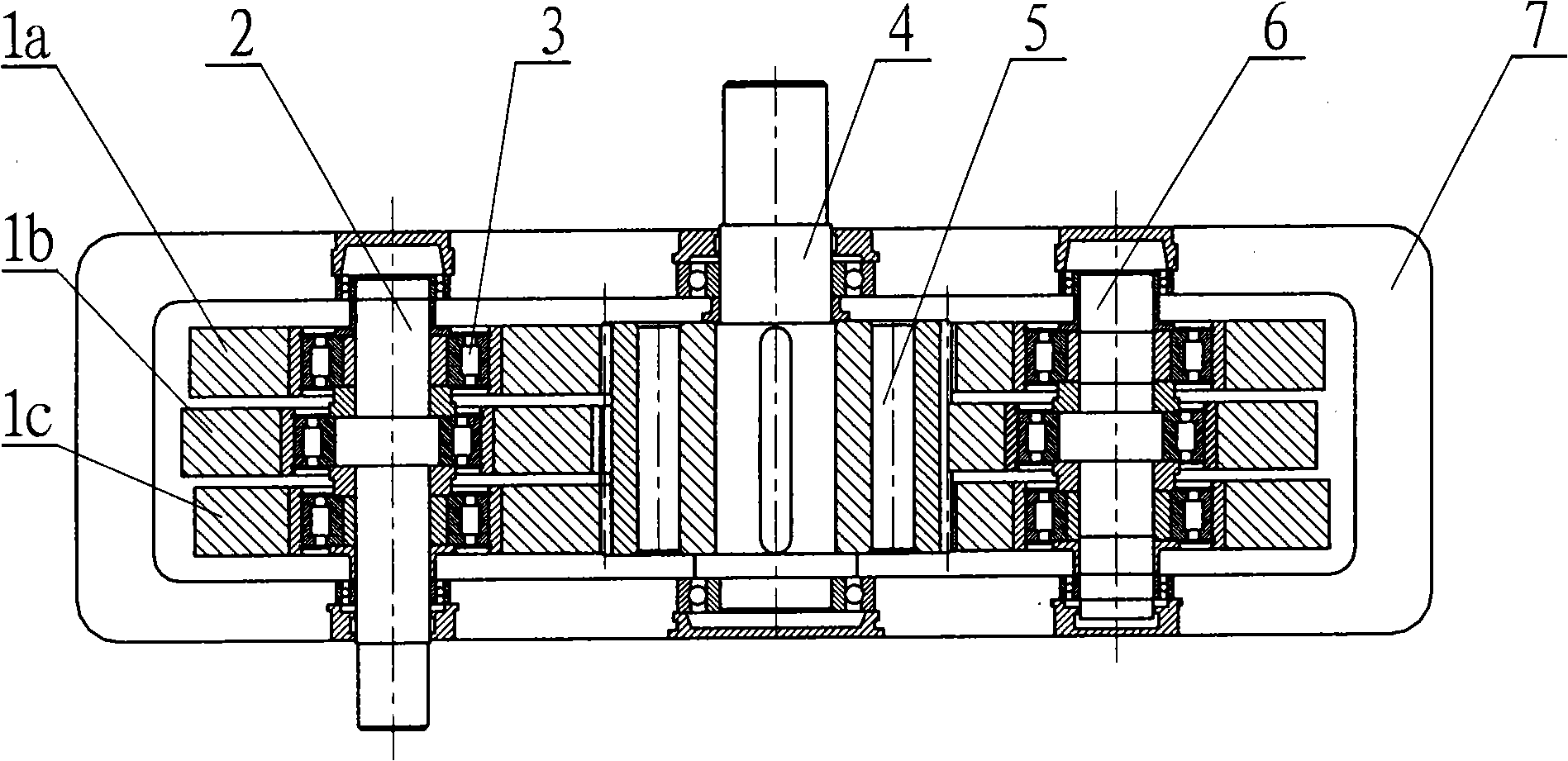

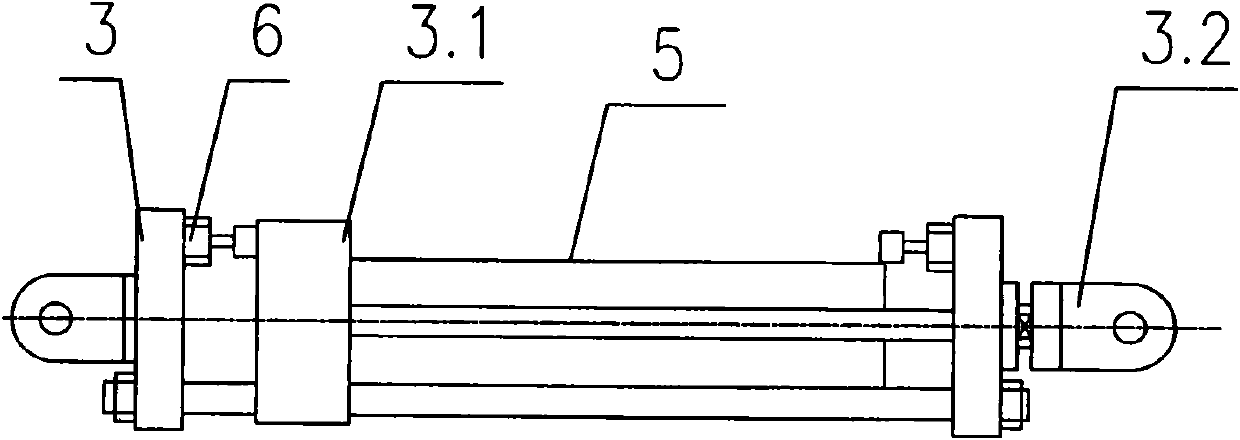

Dynamic performance testing machine of joint bearing and transmission shaft rotation drive unit thereof

The invention provides a dynamic performance testing machine of a joint bearing and a transmission shaft rotation drive unit thereof. The testing machine comprises at least two transmission shafts that are arranged in parallel and are used for driving an inner ring or outer ring of a to-be-tested bearing; and the transmission shafts are driven by a transmission shaft rotation drive unit to make synchronous rotation. The transmission shaft rotation drive unit includes a parallel connecting rod structure. The parallel connecting rod structure contains a plurality of drive oscillating rods that extend in parallel and are fixedly connected with the transmission shafts in a one-to-one correspondence mode and transmission connecting rods hinged between the adjacent drive oscillating rods; and one drive oscillating rod serves as a driving oscillating rod driven by a power mechanism. The power mechanism consists of a drive motor and a driving crank in transmission connection with a power output shaft of the drive motor; and the driving crank uses a drive connecting rod to drive the driving oscillating rod to make oscillation. One end of the drive connecting rod is hinged with the driving crank and the other end is hinged with the driving oscillating rod. The driving crank, the driving oscillating rod, and the driving oscillating rod form a crank rod-oscillating mechanism. The structure is simple, the impact vibration is low, and the noises are low.

Owner:台州科锦轴承有限公司

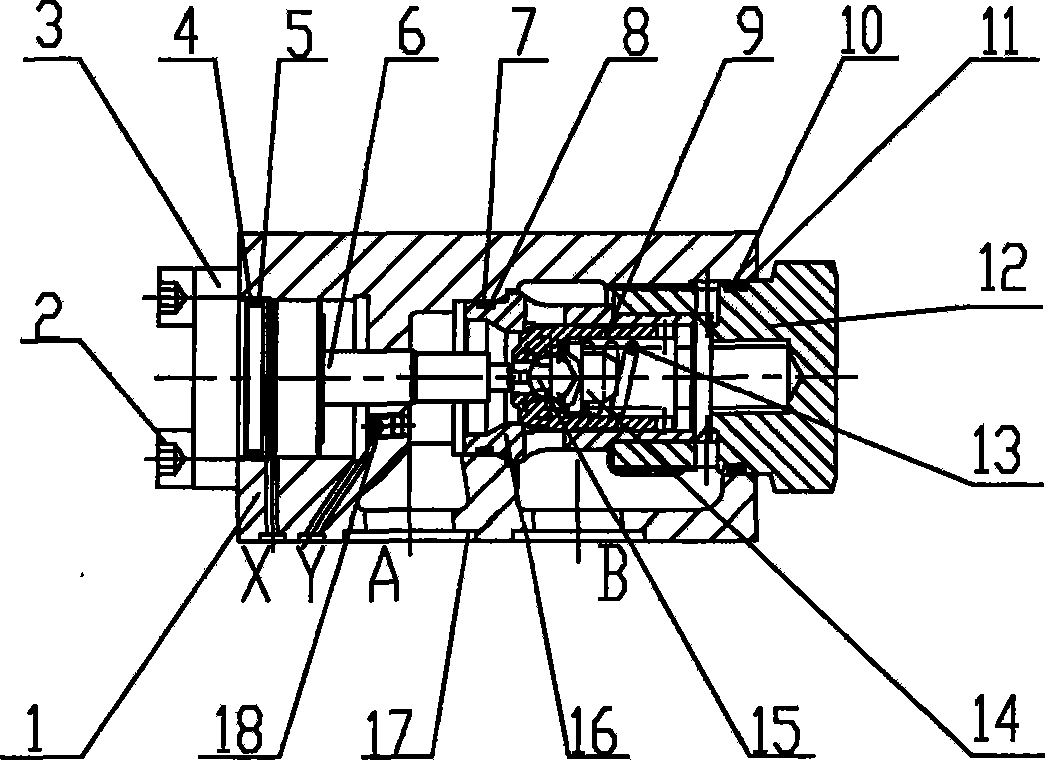

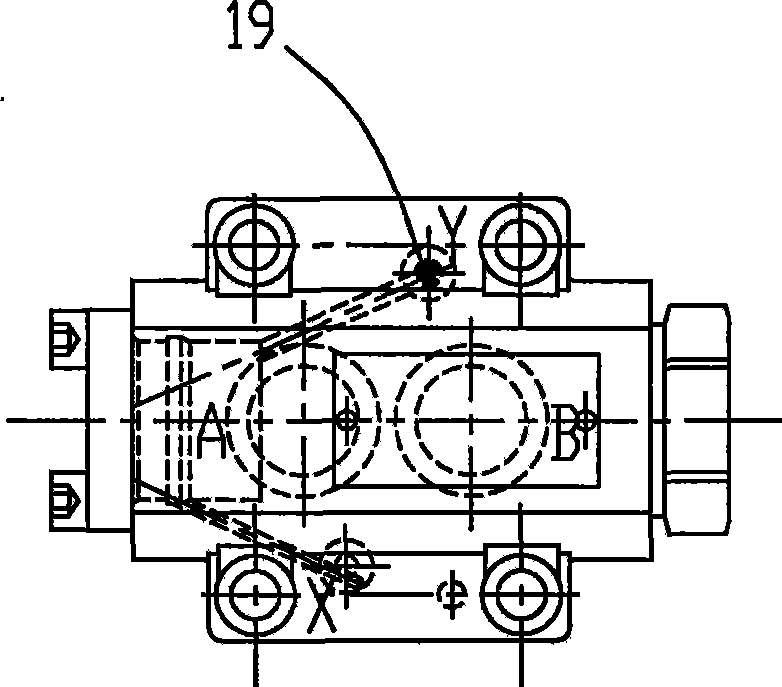

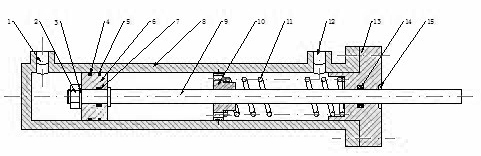

Liquid-controlled non-return valve

InactiveCN101435445AWide applicabilitySmall pressure dropServomotor componentsEngineeringScrew thread

The invention discloses a hydraulic control one way valve and relates to a hydraulic control valve. The hydraulic control one way valve is characterized in that the middle of the hydraulic control one way valve is provided with a main hole; the underside is provided with an oil inlet hole A and an oil outlet hole B; free flow can be formed between the hole A and the hole B; and a hydraulic control port X and an oil drain port Y are also arranged on a valve body. Two sides of the valve body are closed by an end cover and a valve cover; and pressure oil between the end cover and the valve body and between the valve cover and the valve body is kept unleaked outside through a sealing ring and a retaining ring. The inside of the valve body is manufactured with two main flow passage holes by a foundry method in order that the hole A and the hole B are communicated with the main hole respectively. The hydraulic control one way valve has the advantages that the hydraulic control one way valve is optimized and is added with opening pressure in order that the valve has wider application; a right end cover adopts screw thread connection so as to simplify a structure; the structure can increase the oil control cubage and greatly increase oil through amount; and the pre-opening function of the valve can effectively reduce impact vibration and improve the smoothness of motion so as to increase the service life of the valve.

Owner:SHANGHAI LIXIN HYDRAULIC

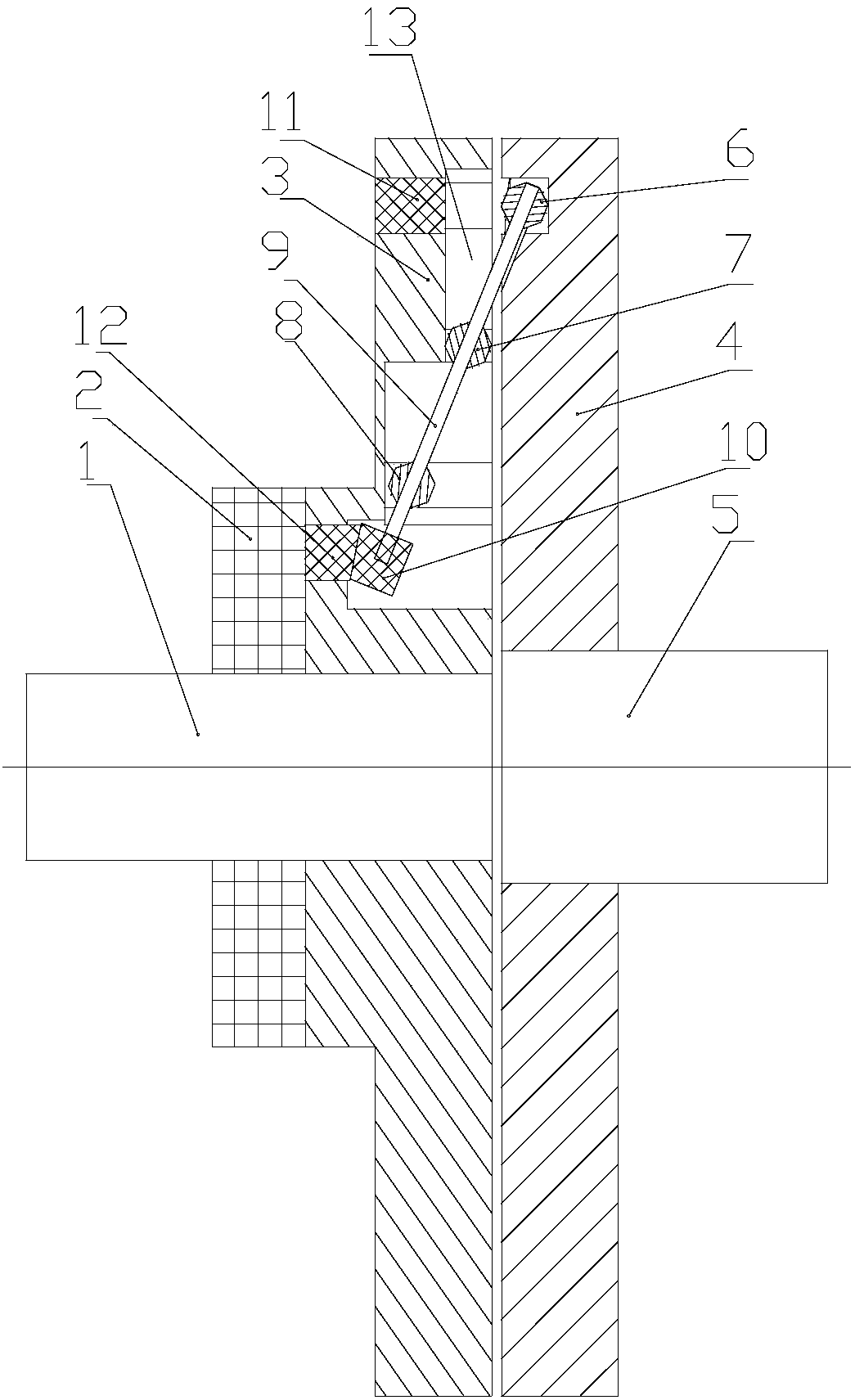

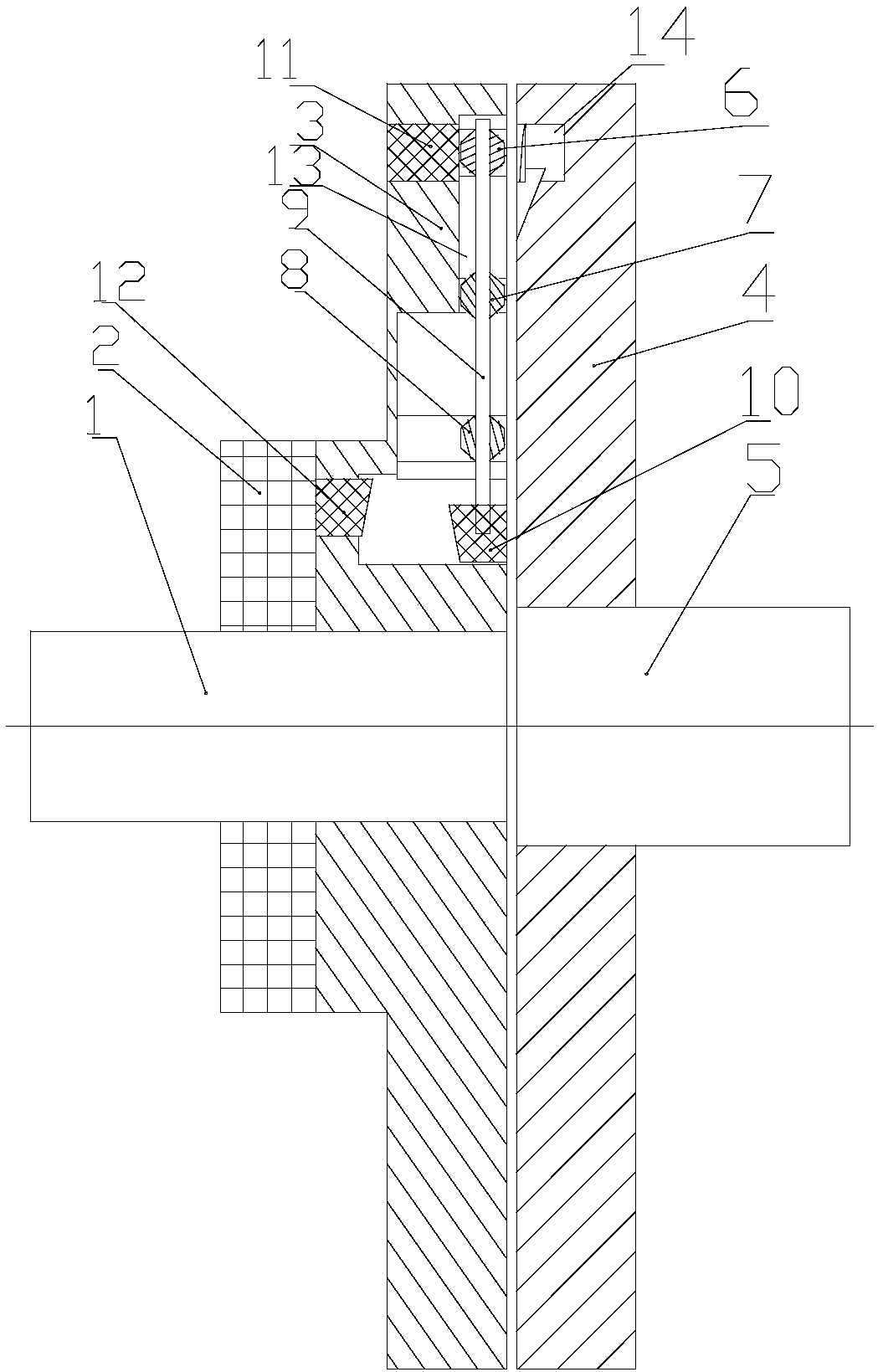

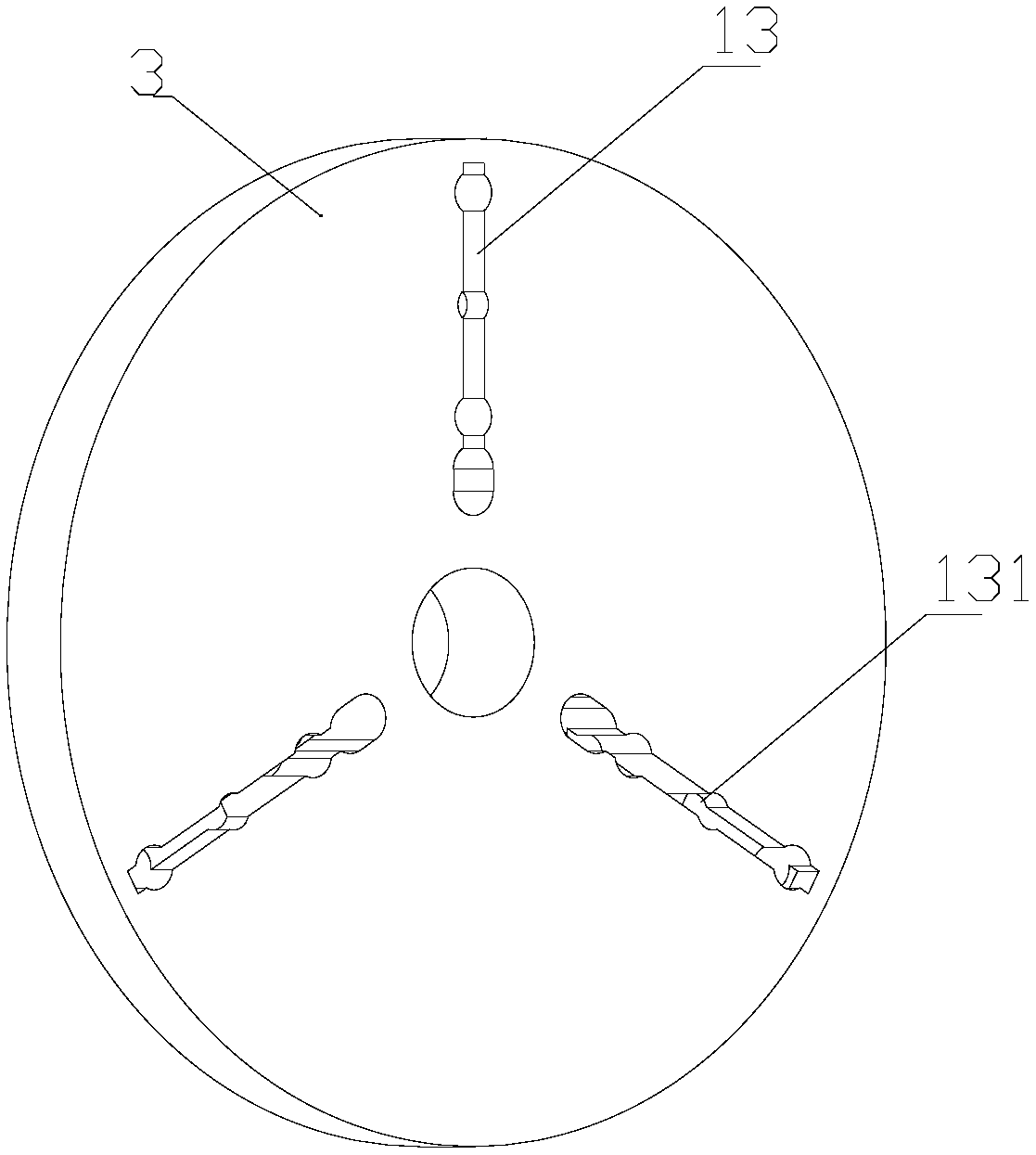

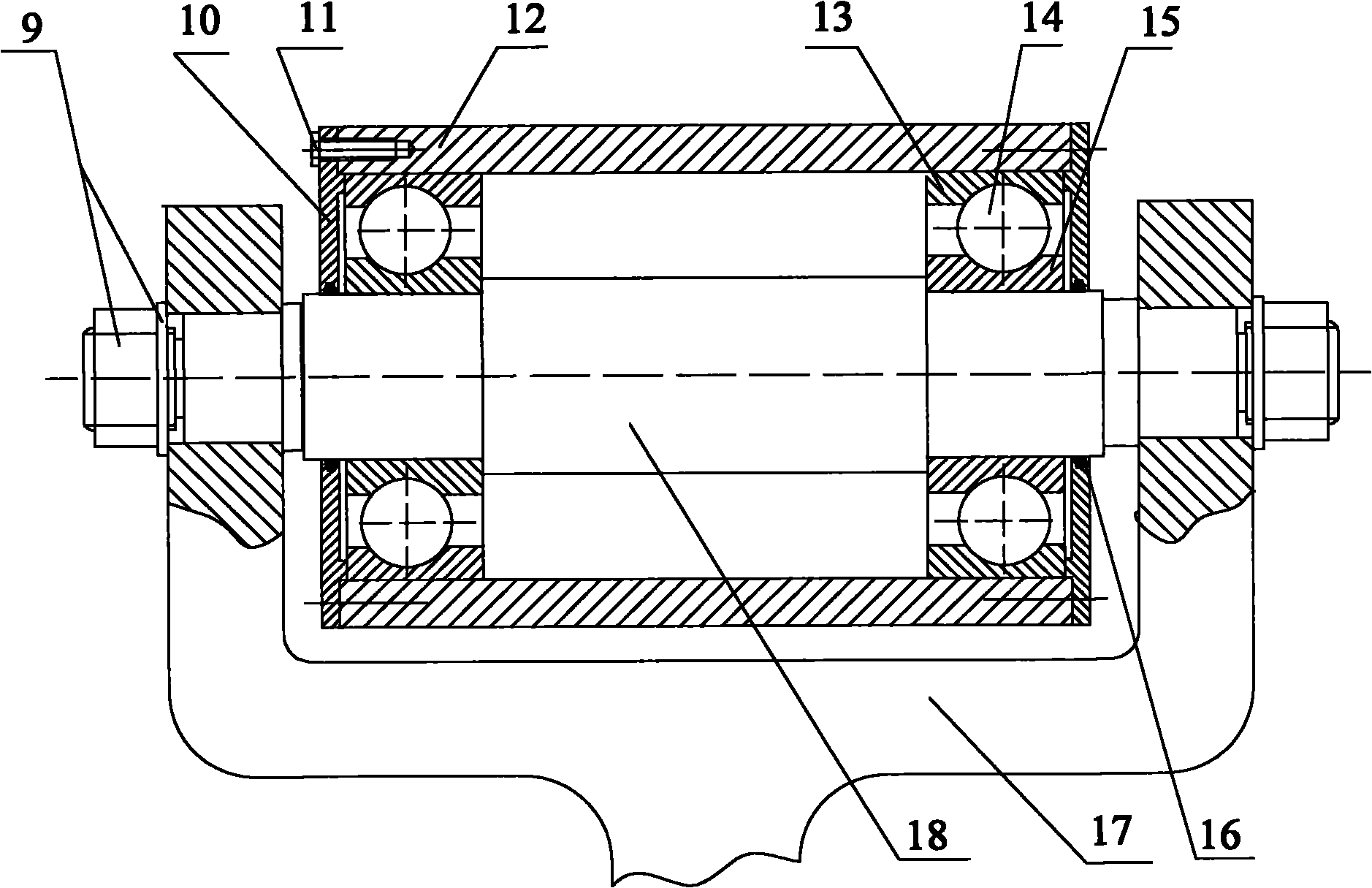

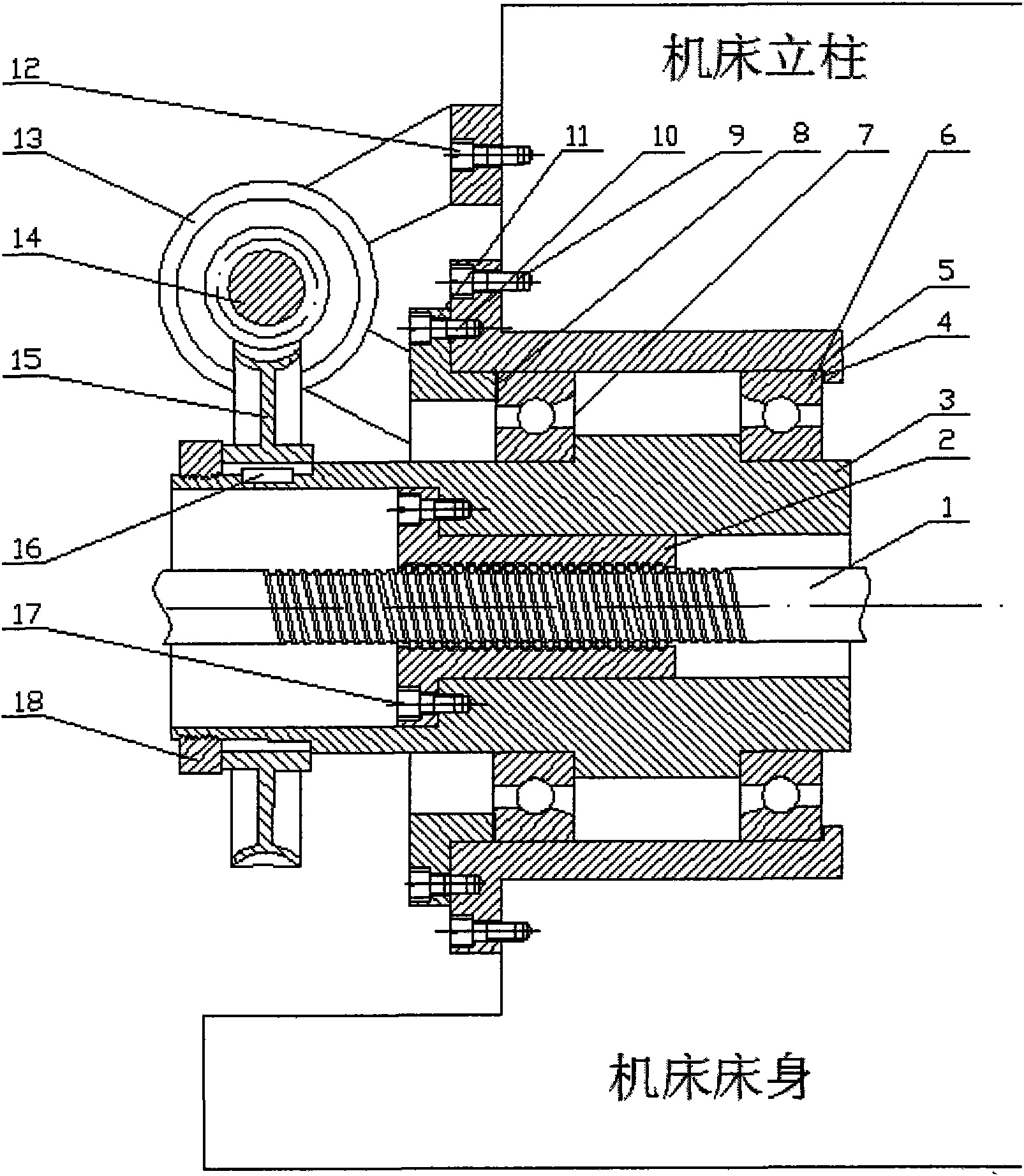

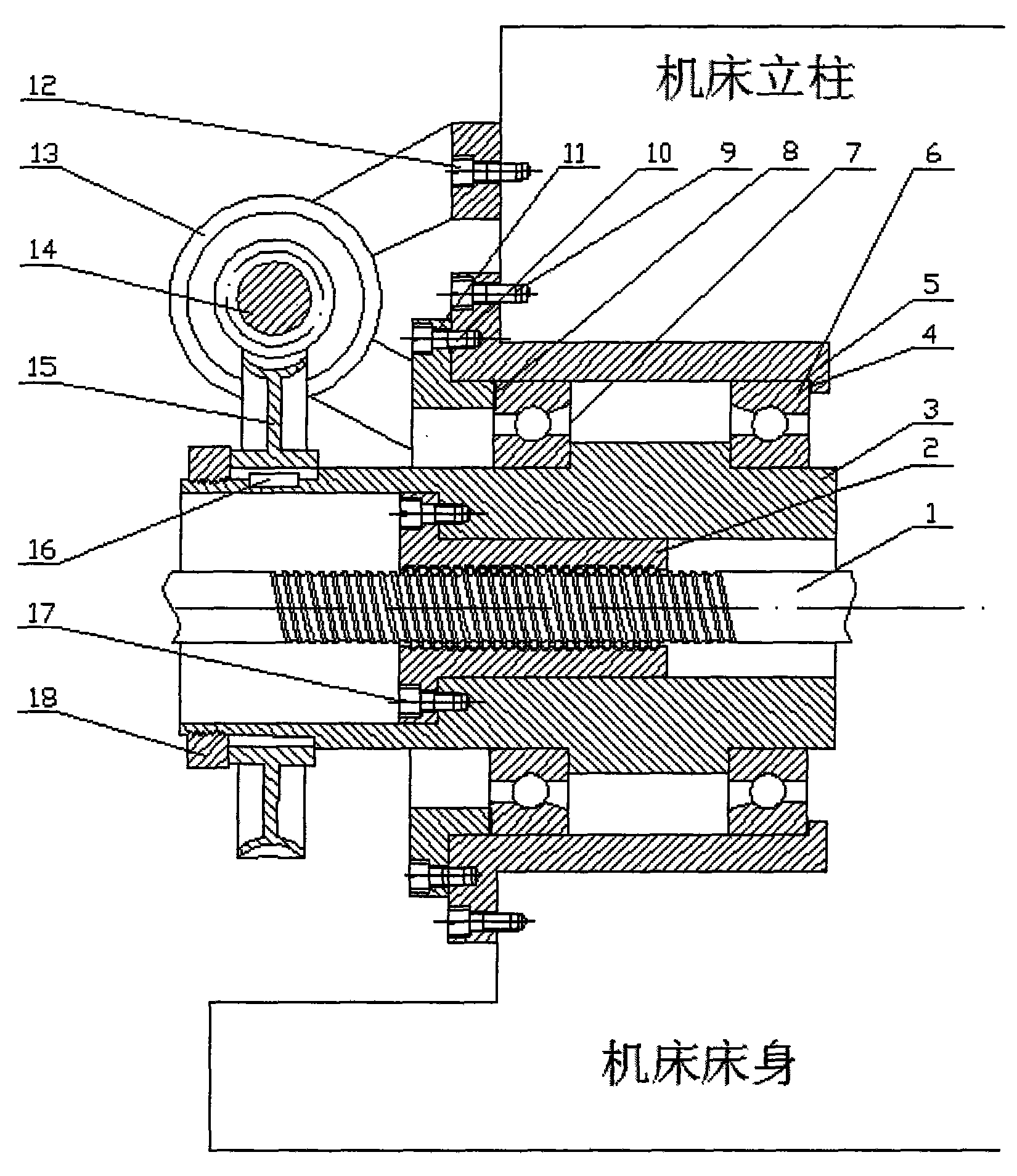

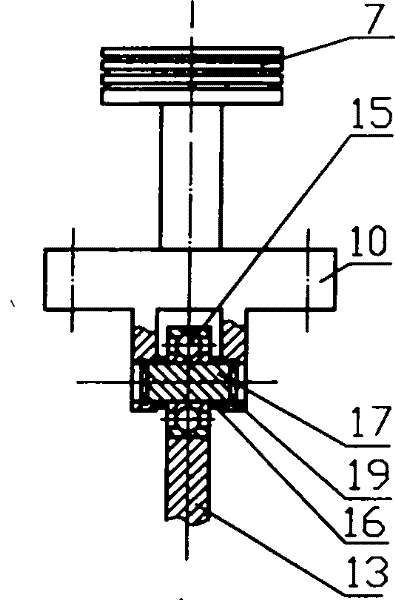

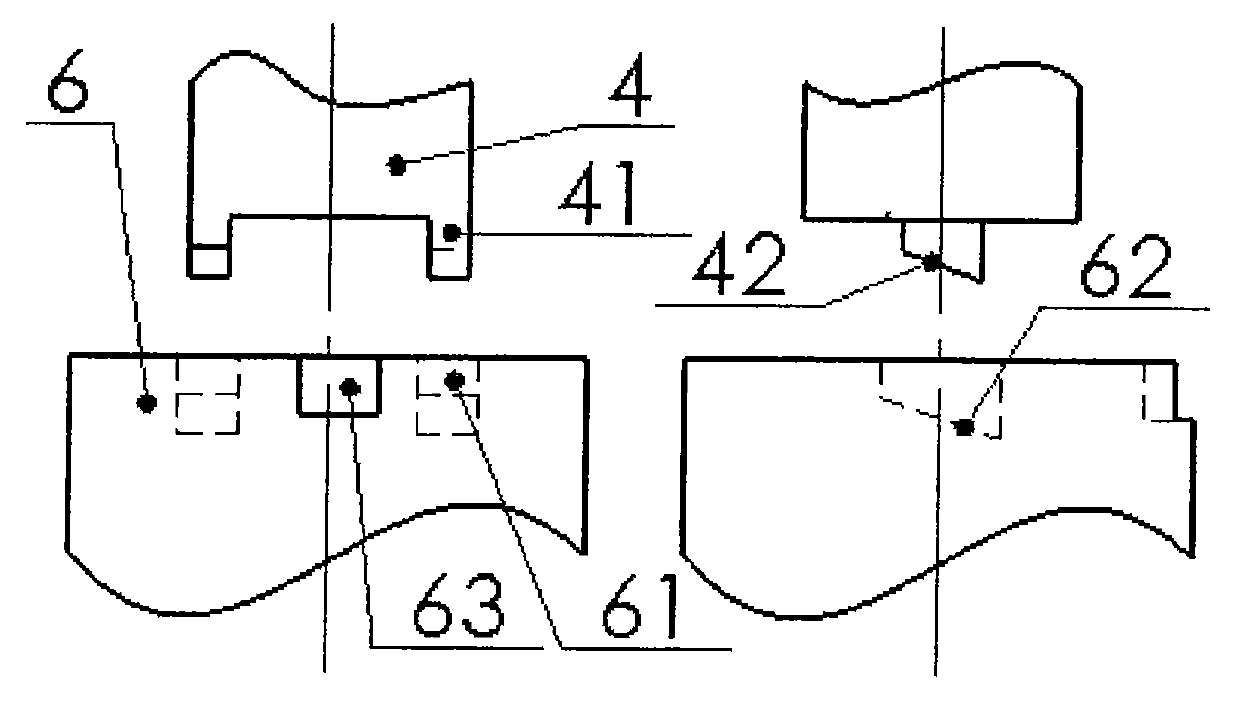

Thermal error differential screw compensating device and using method thereof

ActiveCN101791771AImprove versatilityImprove anti-interference abilityOther manufacturing equipments/toolsDifferential screwReduction drive

The invention discloses a thermal error differential screw compensating device comprising a screw rod nut drive system, a worm gear compensating system, and a fastening nut (18), wherein the screw rod nut (2) is fixedly connected with a first sleeve (3) by six first attachment screws (17) which are evenly distributed on the circumstance; a right bearing (6) and a left bearing (7) are installed on the first sleeve (3) to bear radial load and unidirectional axial load; the left bearing (7) utilizes the shaft shoulder of the first sleeve (3) and a second sleeve (11) to realize axial positioning; the right bearing (6) utilizes a third sleeve (5) and the shaft shoulder to realize axial positioning; the third sleeve (5) is connected with a machine tool stand column by six third attachment screws (9) which are evenly distributed on the circumferential direction; the second sleeve (11) is installed on the first sleeve (3) and is connected with the third sleeve (5) by six second attachment screws (10); a worm gear (15) in the worm gear compensating system is connected with the first sleeve (3) by a flat key (16); a motor coupled-type reducer engine base (13) is connected with the stand column by four fourth attachment screws (12); a motor coupled-type reducer (19) is connected with a worm (14) by a coupler (20); the motor directly drives the worm (14) to drive the worm gear (15) to rotate; and the fastening nut (18) are sued for axially positioning the worm gear (15) through screw thread.

Owner:CHONGQING UNIV +1

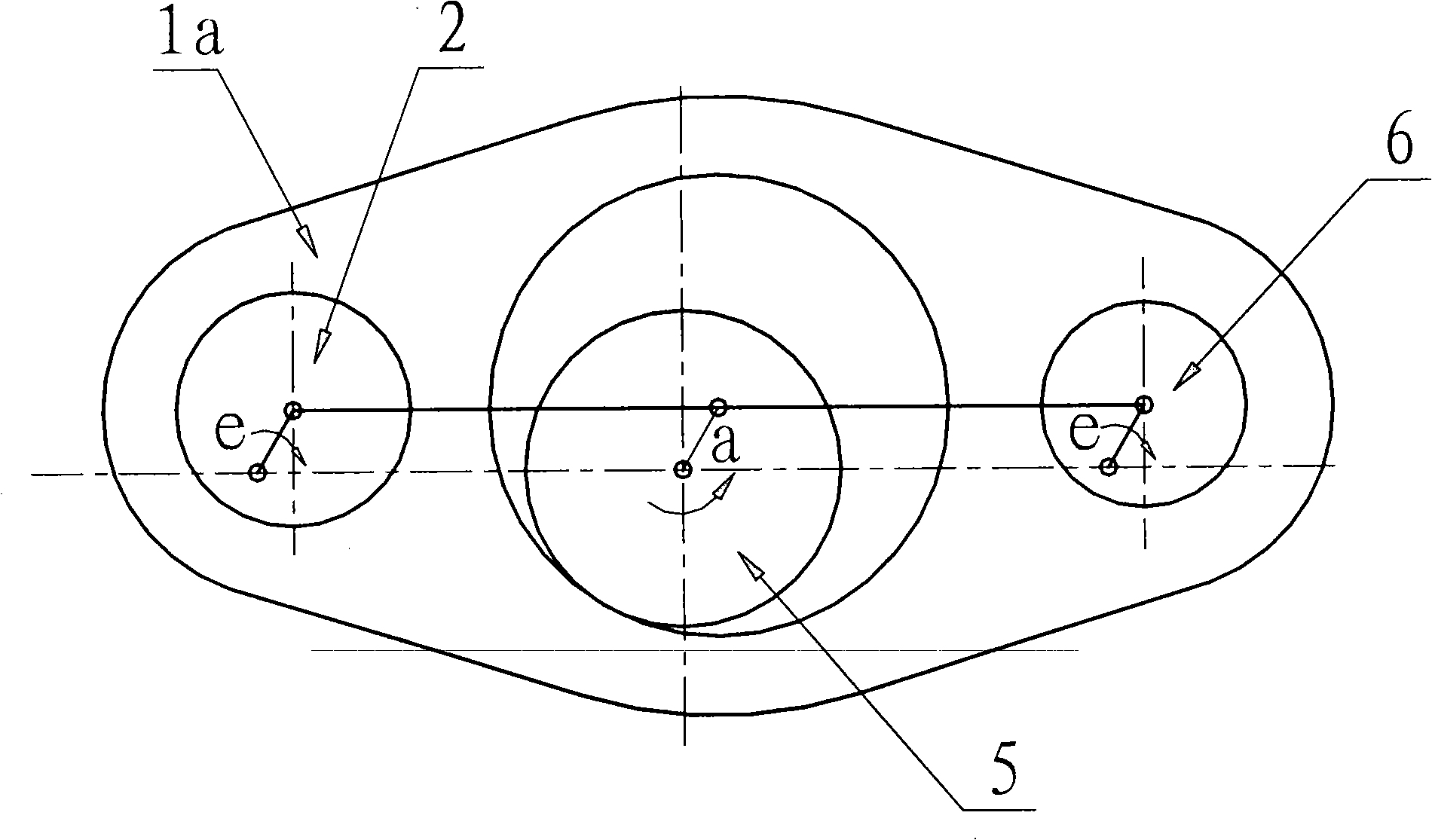

Method for eliminating three-ring speed reducer gear engagement impact

InactiveCN101324266ADoes not affect transfer efficiencyReduce dead center impactGearingGear wheelReduction drive

The invention discloses a method for eliminating the gear engagement impact of a three-ring gear reducer. The method comprises the steps of drawing a mechanism principle graph of the engagement course of an inner toothed ring plate and an outer toothed ring plate according to the dimensions and position relation of the three-ring gear reducer; finding out the engagement region of the inner toothed ring plate and the outer toothed ring plate on the mechanism principle graph; determining the dead centre position of the engagement of the inner toothed ring plate and the outer toothed ring plate; calculating the corresponding angle of the engagement of the inner toothed ring plate; and repairing inner teeth of the corresponding angle of the engagement region of the inner toothed ring plate. The method has the advantages that the impact of the three-ring gear reducer generated by engaging force is eliminated or reduced; dead centre impact of mechanism is effectively reduced through the repair of the engagement region of the dead centre position of the inner toothed ring plate; the operation is stable; the impact vibration is reduced; the transmission speed ratio of the mechanism is not affected; the service life of a bearing is prolonged by 40 percent; and the service lives of sealing parts in the gear reducer are also prolonged. The three-ring gear reducer has less noise, thereby reducing noise pollution and improving working environment.

Owner:TIANJIN TIANZHONG ZHONGZHI TECH ENG CO LTD

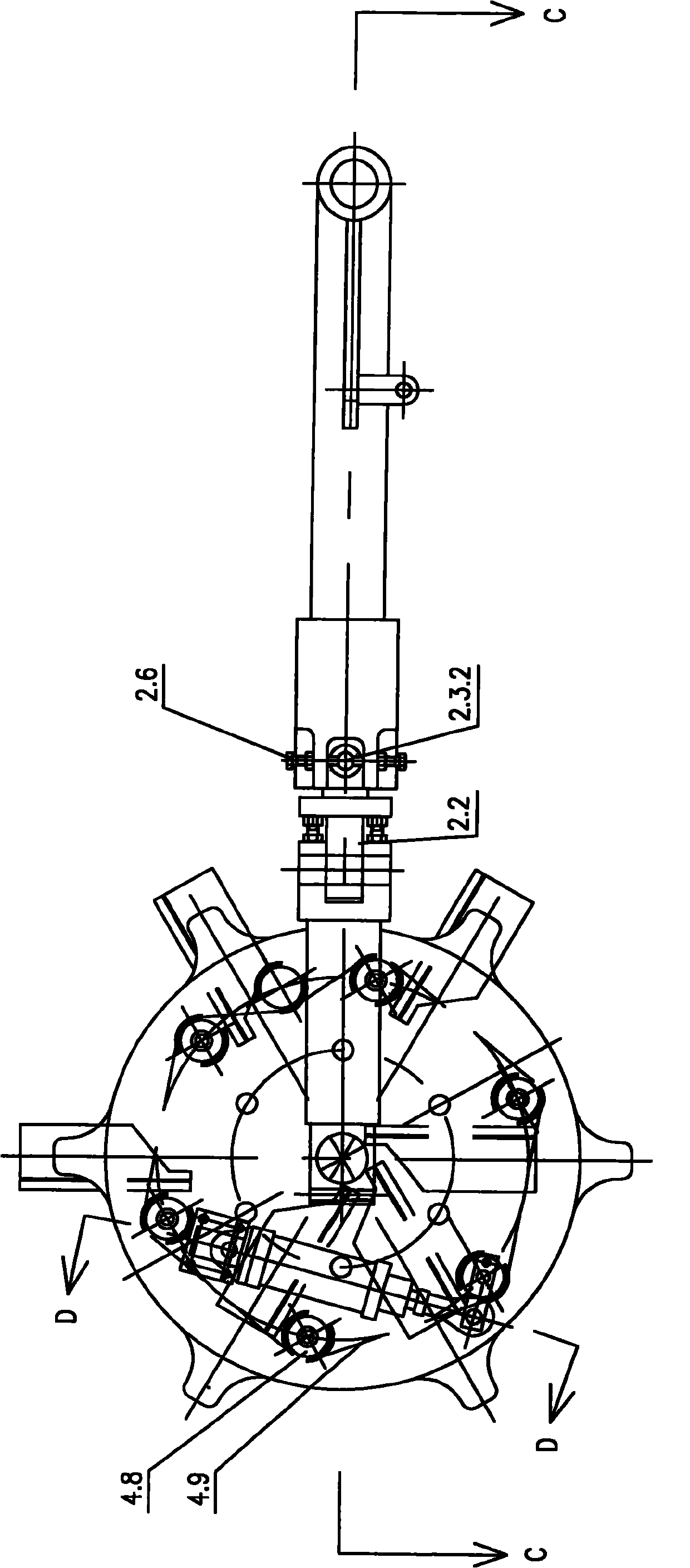

Tyre gripping device of hydraulic tyre forming vulcanizer

The invention relates to a tyre gripping device of a hydraulic tyre forming vulcanizer, which is mainly used for automatically fetching tyres and releasing tyres. The tyre gripping device of the hydraulic tyre forming vulcanizer comprises a tumbler (2) and a tyre gripping machine (4) and is characterized in that the tumbler (2) comprises a regulating bracket (2.1), a connecting rod (2.2) and a support arm (2.3), wherein one end of the connecting rod (2.2) is fixed with the regulating bracket (2.1) by a locking bolt (2.7), and the other end is connected with the support arm (2.3); and the tyregripping machine (4) comprises an opening and closing cylinder (4.1), an upper gripping disk (4.2), a lower gripping disk (4.3), a gear (4.4), a spline (4.5), a junction plate (4.6), a clavus (4.7), a chain wheel (4.8), a chain (4.9), a linear guide rail (4.10) and a transmission plate (4.11). In the invention, the tumbler can be directionally adjusted, each clavus of the tyre gripping machine still keeps same roundness, tyre gripping radius can be adjusted, and the invention has small volume, small weight, good concentricity and small mechanical shock.

Owner:江苏晟林科技有限公司

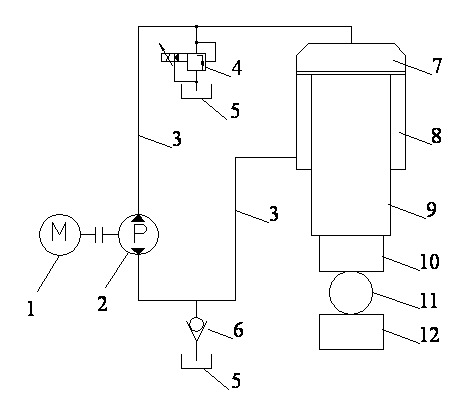

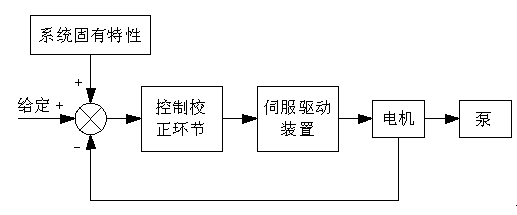

Rapid forging press servo direct-drive hydraulic system

InactiveCN103861983AQuick responseGuaranteed uptimeForging press drivesFluid-pressure actuator componentsEngineeringControl theory

The invention discloses a rapid forging press servo direct-drive hydraulic system, and belongs to the field of rapid forging press hydraulic transmission control. The rapid forging press servo direct-drive hydraulic system mainly comprises a main cylinder, a bidirectional quantitative pump, a servo motor, an overflow valve, a one-way valve, a hydraulic pipeline, a rodless cavity and a rod cavity of a main press cylinder and the like, an oil outlet and an oil inlet of the bidirectional quantitative pump are connected to the rodless cavity and the rod cavity respectively, the servo motor directly drives the bidirectional quantitative pump to run, a hydraulic actuating mechanism is directly driven by a servo motor and quantitative pump set so that a press continuously runs, the servo direct-drive hydraulic system controls the motor instead of controlling a control object (the valve or pump) in an original press hydraulic system, and the operating mode of the motor is improved into an intermittent operating mode from a continuous operating mode. By the aid of the rapid forging press servo direct-drive hydraulic system, unit efficiency can be effectively improved, energy consumption is reduced, the production environment is improved, so that the press more accurately and stably runs in a more energy-saving and environment-friendly manner, and the technical level of Chinese forging press equipment is integrally improved.

Owner:兰州兰石重工有限公司

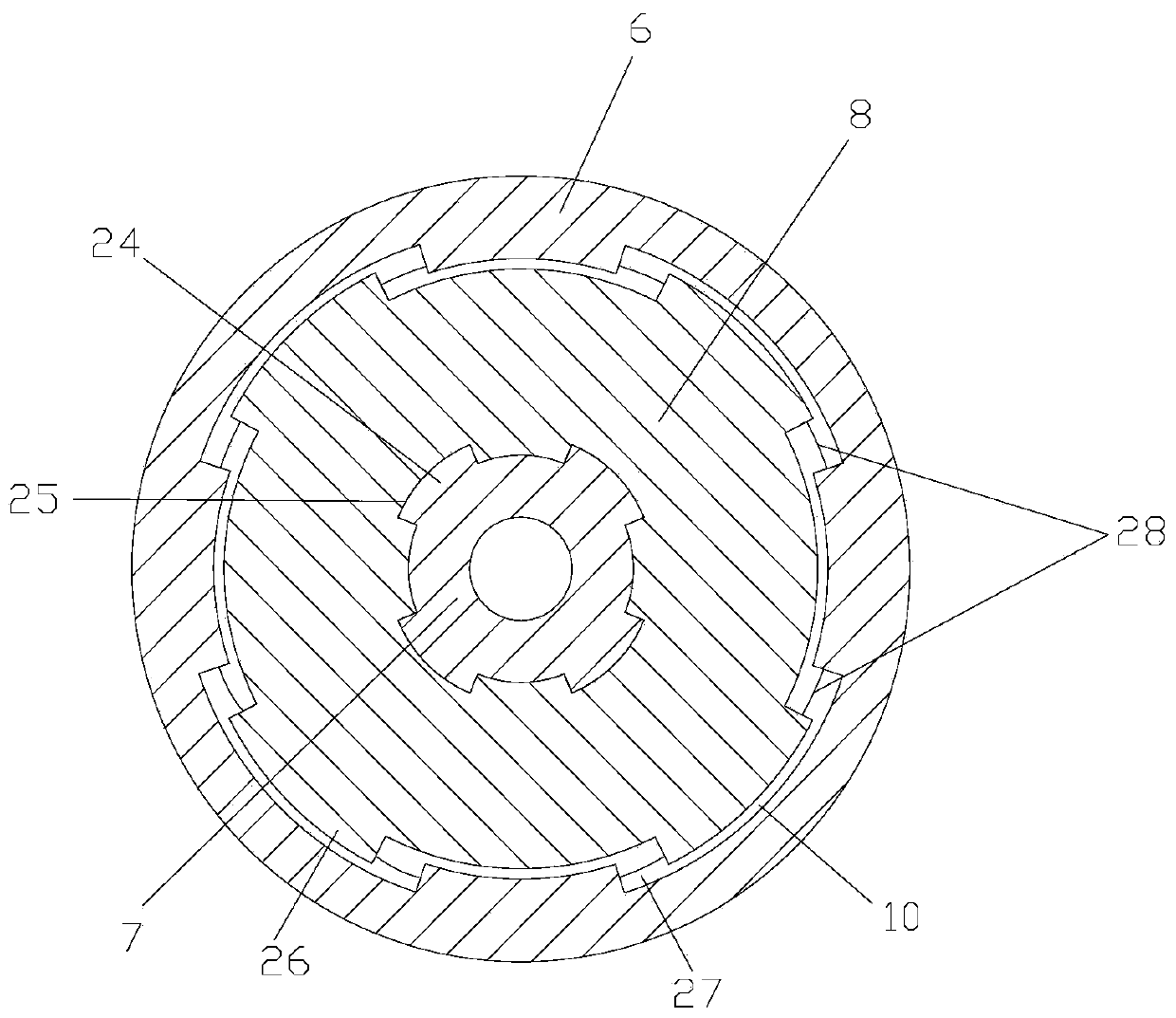

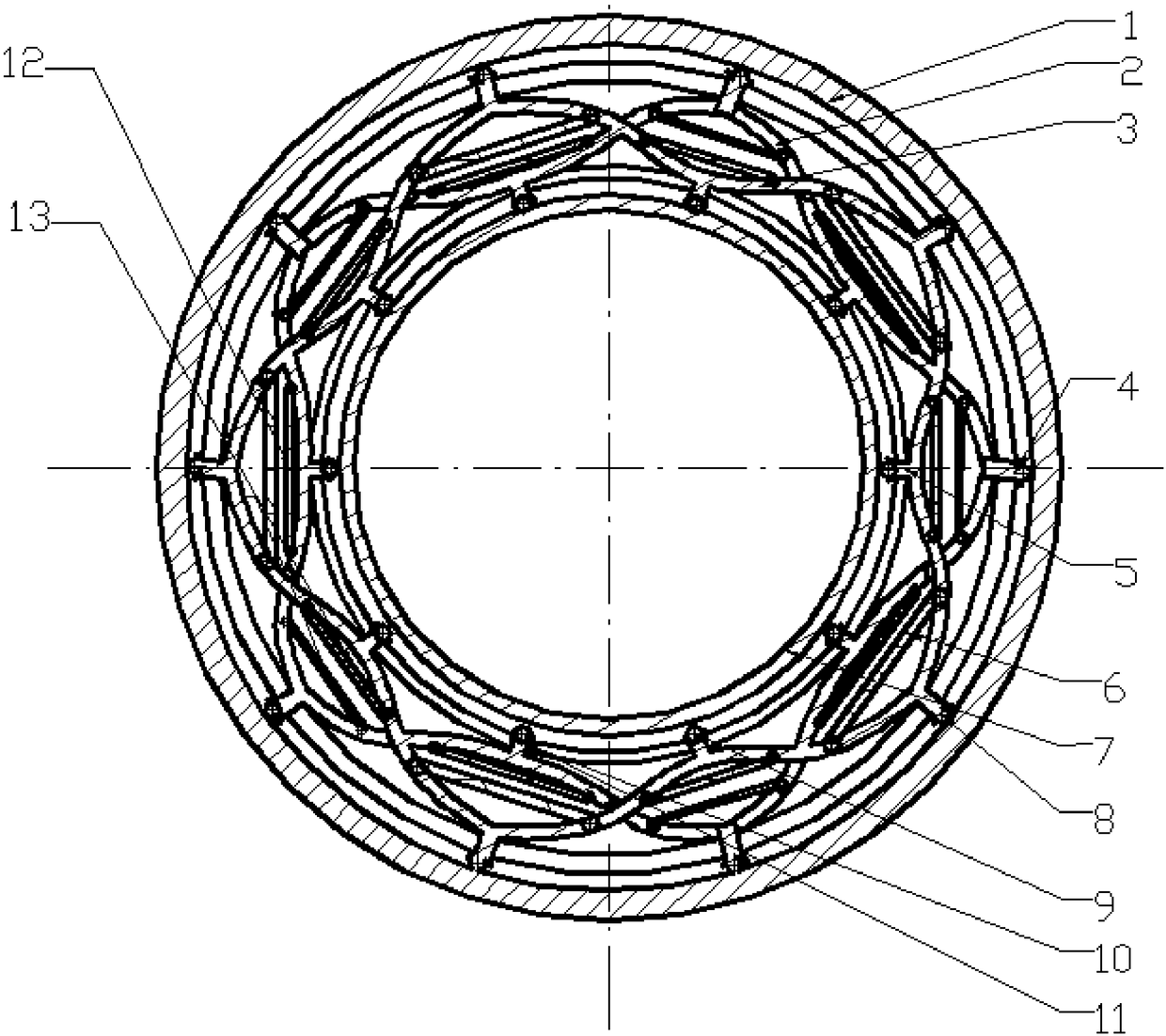

Two-phase outer cam shock wave rolling transmission internal combustion engine

InactiveCN102937048AReduce axial sizeCompact structureValve drivesMachines/enginesShock waveExternal combustion engine

The invention provides a two-phase outer cam shock wave rolling transmission internal combustion engine and relates to the field of gas power. According to the novel internal combustion engine, eight cylinders are annularly symmetrically evenly distributed around a convex inner tooth ring, the resultant force which the convex inner tooth ring is subjected to is zero, and a cylinder piston directly acts on the convex inner tooth ring through a push rod, power is transmitted to an output shaft connected with a two-phase outer cam key by two-phase outer cam shock wave rolling oscillating tooth transmission through the convex inner tooth ring. According to the internal combustion engine, a connecting rod and a crankshaft in a traditional internal combustion engine are not required, a convex inner two-phase shock wave rolling transmission mechanism does not have eccentric mass and has the advantages of self balancing of inertia force and working load, and the rotating speed of the output shaft depends on the transmission ratio of oscillating tooth transmission. If an oscillating tooth brace is fixed, a two-phase outer cam performs high-speed output and can be widely applied to the fields requiring for high rotating speeds, such as helicopter engines and small generators, and discharge of harmful gas can be reduced when the output rotating speed is fixed. The internal combustion engine is simple and compact in structure, small in axial dimensions self-balancing in stress and runs stably.

Owner:SICHUAN UNIV

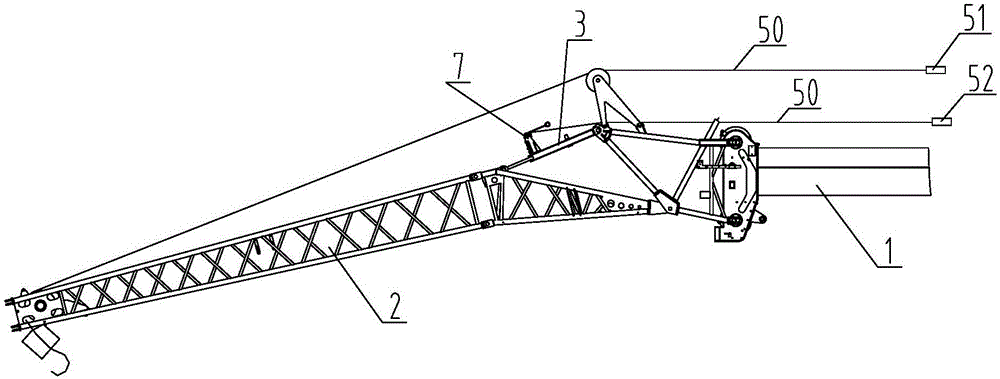

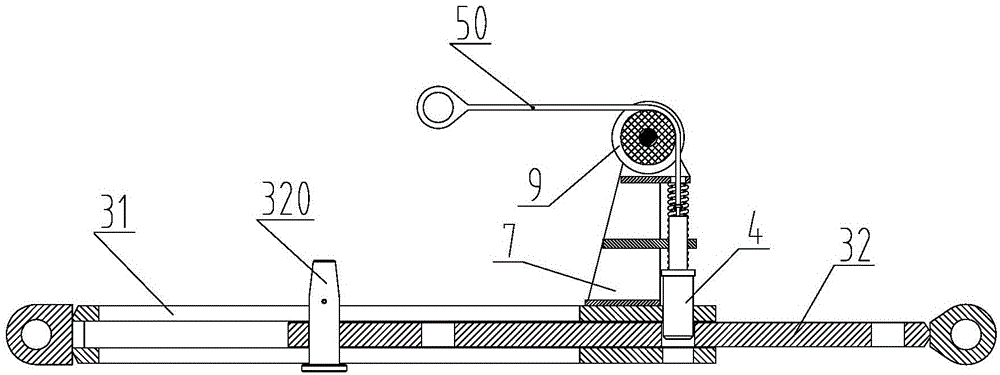

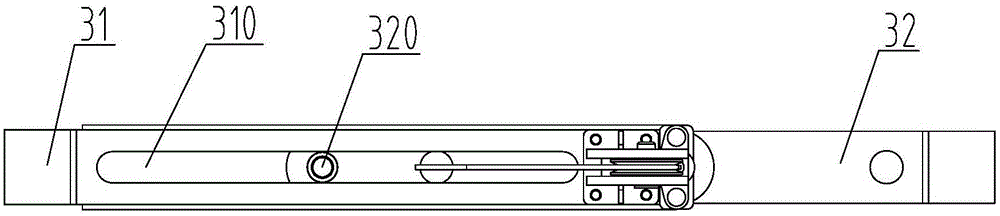

Crane boom mechanism and crane

The invention discloses a crane boom mechanism and a crane. The crane boom mechanism comprises a main boom and a vice boom. The vice boom is arranged at the tail end of the main boom in a swing mode. The crane boom mechanism further comprises an extensible component, a first winch and a second winch. One end of the extensible component is connected with the main boom, and the other end of the extensible component is connected with the vice boom. The extensible component is provided with a bolt used for locating. A rope of the first winch is used for drawing and releasing the vice boom. A rope of the second winch is connected with the bolt. The bolt is further provided with an elastic component. The elastic component exerts elastic force on the bolt, and the elastic force makes the bolt to penetrate into the extensible component. According to the crane boom mechanism and the crane, automatic adjustment of an angle between the main boom and the vice boom can be achieved. The crane boom mechanism is simple in structure, low in production cost, and applicable to the crane with a long vice boom structure.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

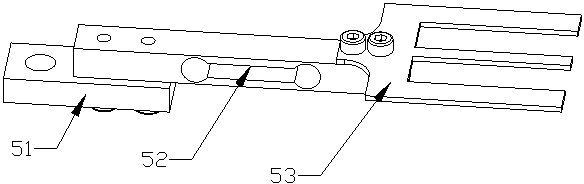

Weighing and sorting machine for cork sheet of badminton ball head

InactiveCN104190636AEfficient automatic weighing and sortingStable automatic weighing and sortingSortingSynchronous motorEngineering

The invention discloses a weighing and sorting machine for a cork sheet of a badminton ball head. The weighing and sorting machine comprises a vibration plate feeding device, a weighing device and a chute valve blanking device; the weighing device comprises a base plate, a weighing mechanism and a cork sheet transfer component, wherein the weighing mechanism and the cork sheet transfer component are arranged on the base plate; the weighing mechanism comprises a weighing sensor base fixed with the base plate, a weighing sensor arranged on the weighing sensor base and a weighing support frame connected with the weighing sensor; the cork sheet transfer component comprises a material pushing mechanism and a material moving mechanism; the material moving mechanism comprises a synchronous motor, a first shaft and a second shaft, wherein the first shaft and the second shaft are fixedly arranged on the base plate through a bearing pedestal; the tail ends of the first shaft and the second shaft are respectively connected with a first connecting rod and a second connecting rod; the tail ends of the first connecting rod and the second connecting rod are respectively connected with the two ends of a handling connecting rod. The invention provides the weighing and sorting machine for the cork sheet of the badminton ball head, which is efficient and stable.

Owner:YANTAI NANSHAN UNIV

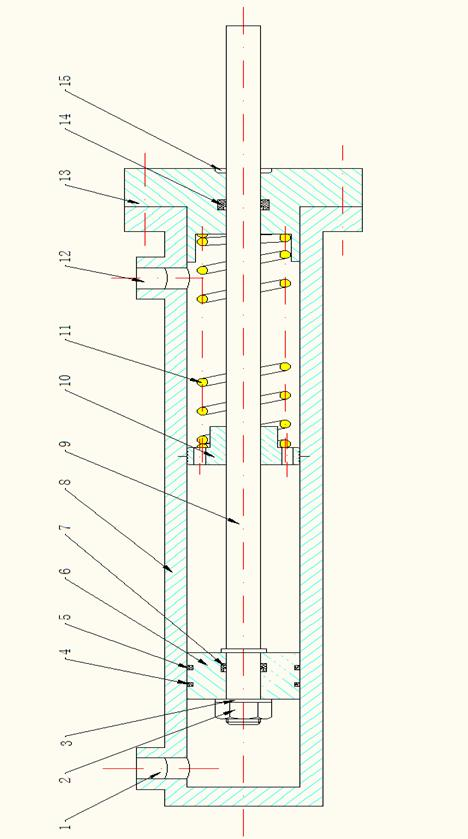

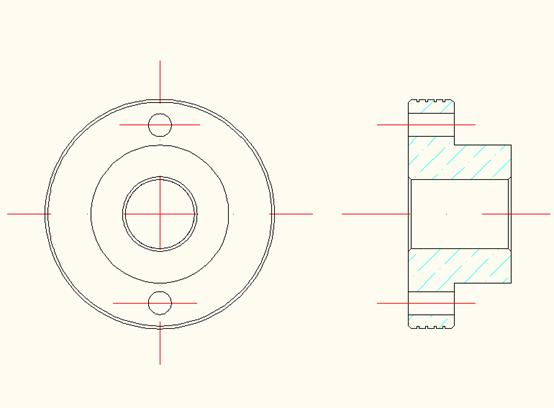

Floating guide hydraulic cylinder

InactiveCN102207116AIncrease stiffnessSolve the problem of friction and scratchingFluid-pressure actuatorsHydraulic cylinderCylinder head

The invention relates to a novel hydraulic cylinder with a floating guide sleeve. The hydraulic cylinder comprises a piston, a piston rod and the floating guide sleeve which are arranged in the hydraulic cylinder, and a spring for connecting the floating guide sleeve with a cylinder head. When the piston rod in the cylinder is long, the floating guide sleeve can have a good bearing guide position under the action of the spring, so that the rigidity of the piston rod is effectively improved; and the floating guide sleeve has automatic centering capability, and achieves a composite guide effect with the piston rod and the cylinder head, so that friction scratches between the piston and the inner wall of a cylinder barrel, and between the piston rod and the cylinder head are reduced, and leakage is reduced. The invention has the advantages that: the hydraulic cylinder has high guide property, sealing property and stability, the rigidity of the hydraulic cylinder is effectively improved, the material consumption of the hydraulic cylinder is reduced, and the like.

Owner:SICHUAN UNIV

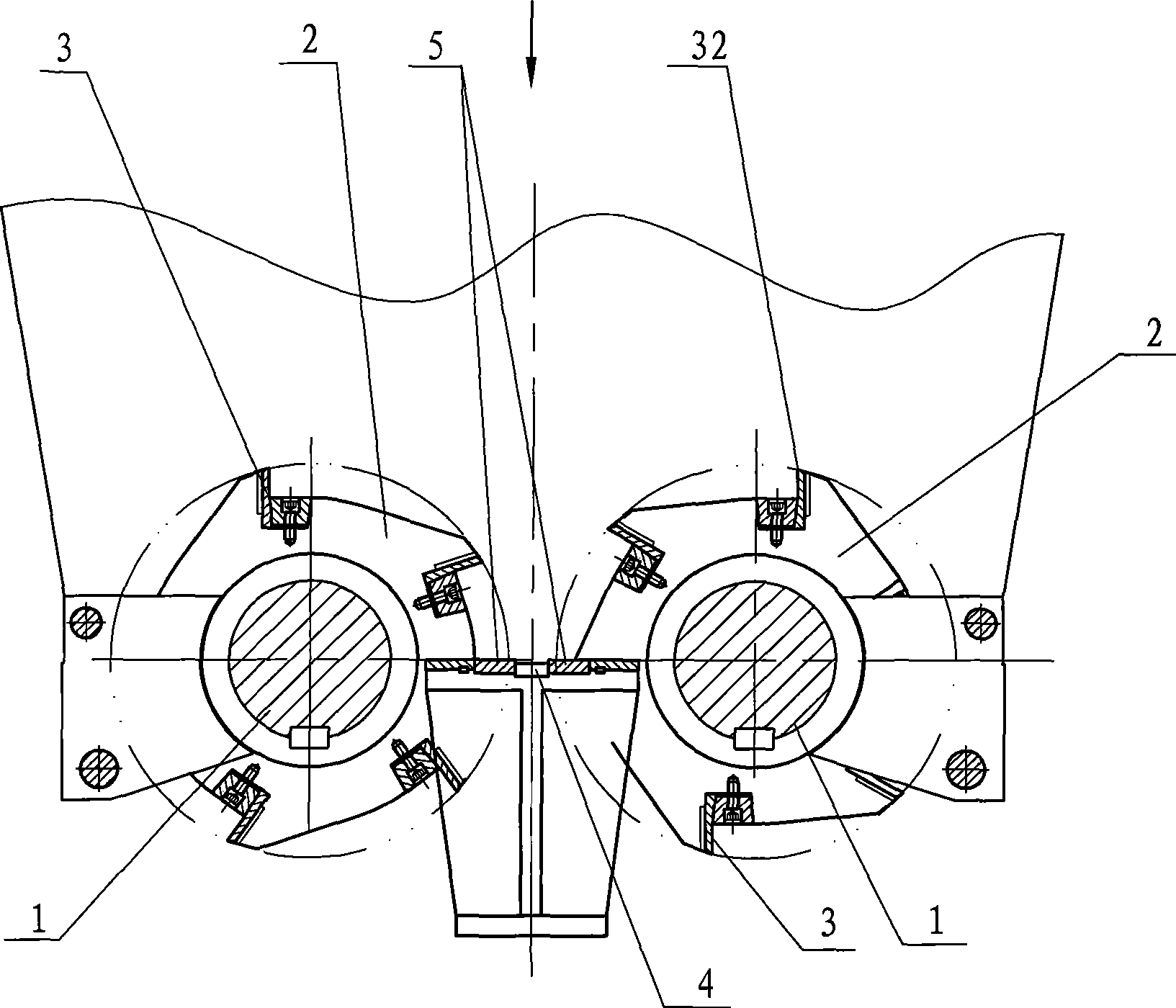

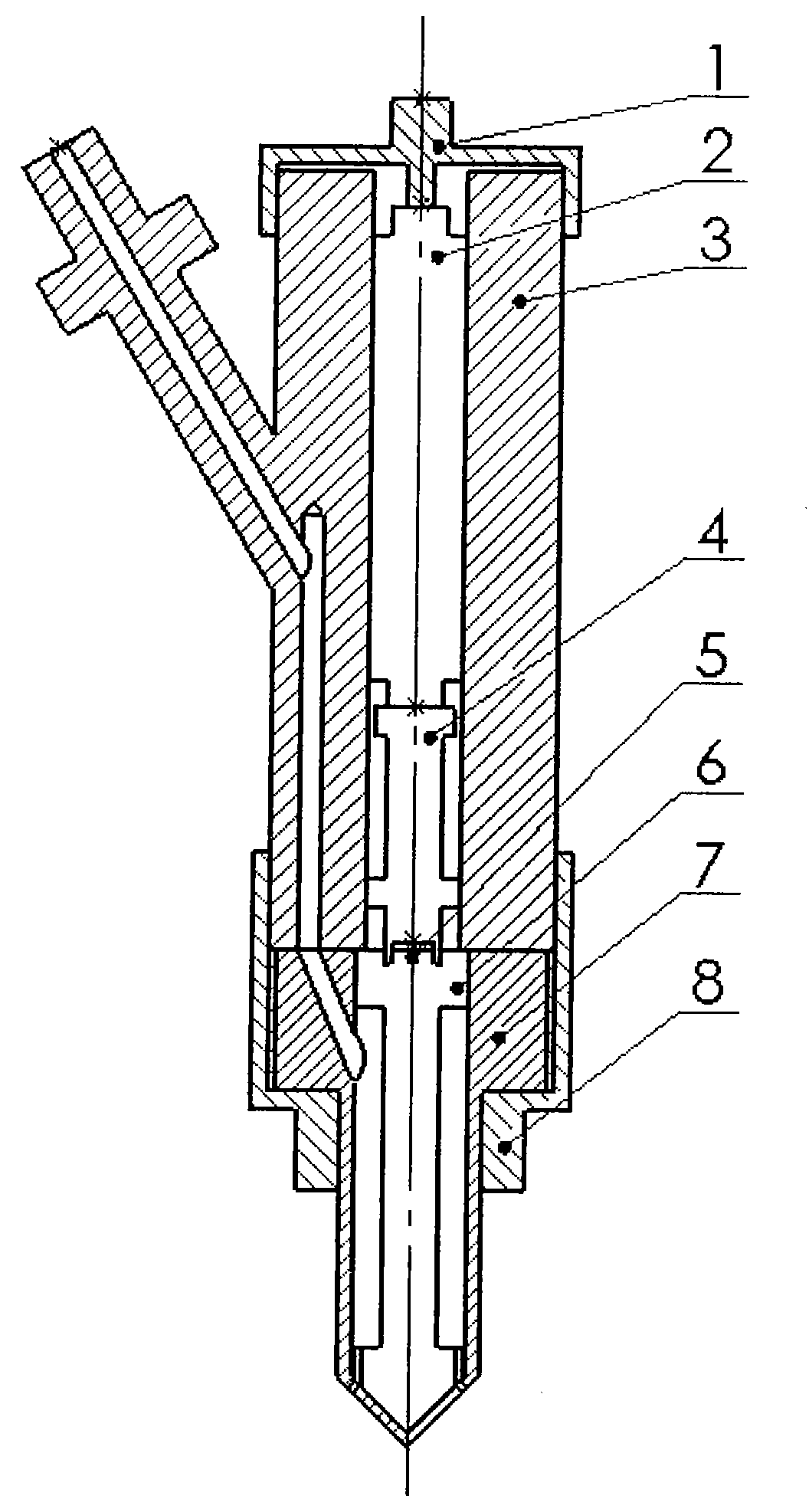

Cylinder double-face cam axial piston type crankless internal combustion engine

InactiveCN101392684BReduce noiseSmall shock and vibrationValve drivesMachines/enginesExhaust valveCombustion

The invention discloses a cylindrical double-track cam axial piston type crankless internal combustion engine, which relates to the technical field of internal combustion engines and is a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine; when pistons drive rollers arranged on the bottoms of the pistons for reciprocating movement, the rollers push a double-track cam fixed on a main shaft to rotate, and the power is output from the double-track cam through the main shaft. Outlines of two end surfaces of the double-track cam are in the form that wave crests correspond to wave crests, wave troughs correspond to wave troughs, and the two end surfaces are circumferentially symmetrical. Two groups of cylinders are symmetrically arranged at bothends of the double-track cam, and axis lines of the cylinders have equal distance to an axis line of the main shaft and are parallelly, circularly and evenly distributed. The pistons which have the same axis line and are symmetrically arranged with the spacing of 180 DEG C have the same working state, which ensures that the axial and radial composite force of the double-track cam and the main shaft are zero. A sliding rod at the bottom of each piston slides in a guide groove, which ensures that the side pressure of the piston is zero. Intake and exhaust valves of all the cylinders are intensively controlled by two distributing cams. The internal combustion engine has the characteristics of simple and compact structure, small volume, small impact vibration, steady operation, high power, long service life and so on.

Owner:SICHUAN UNIV

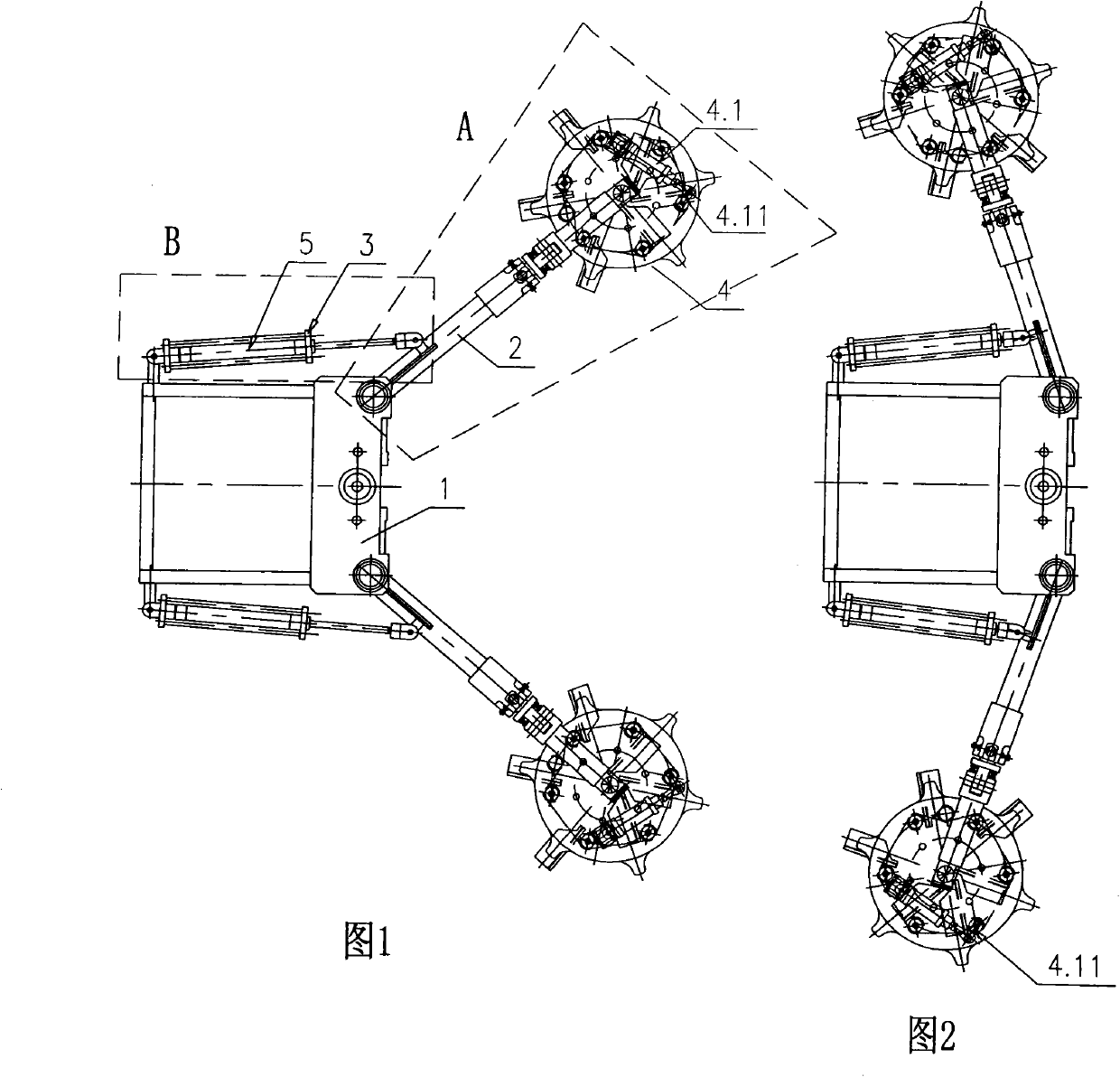

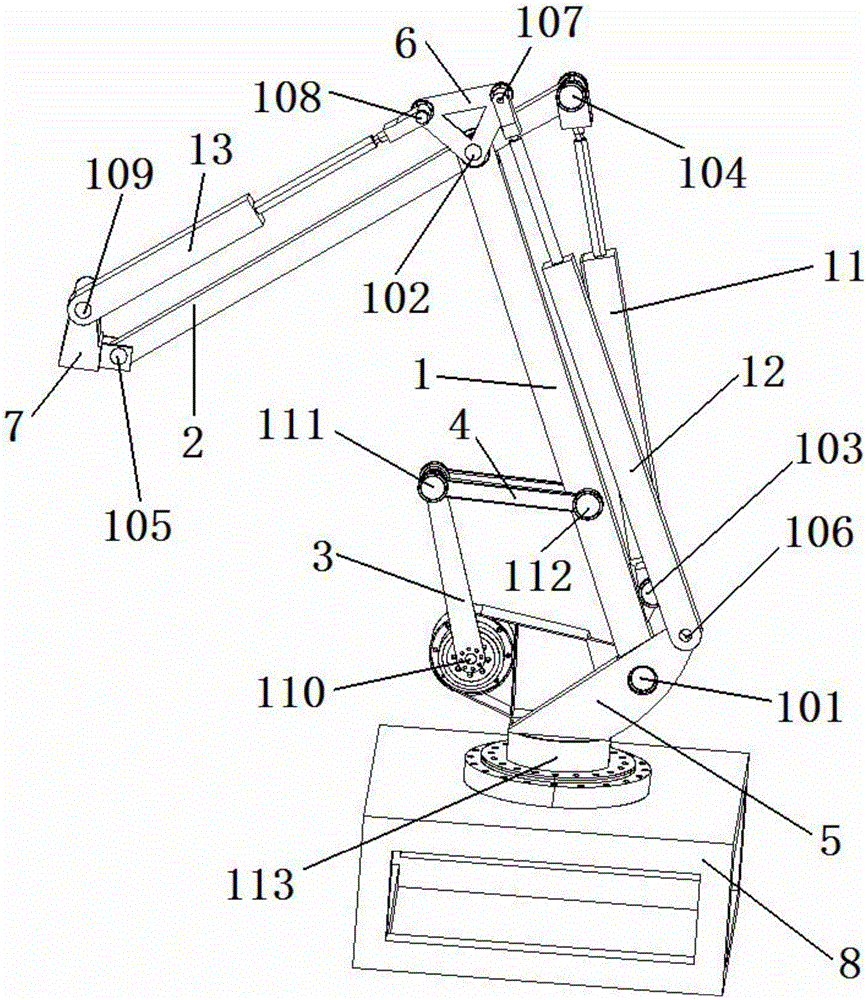

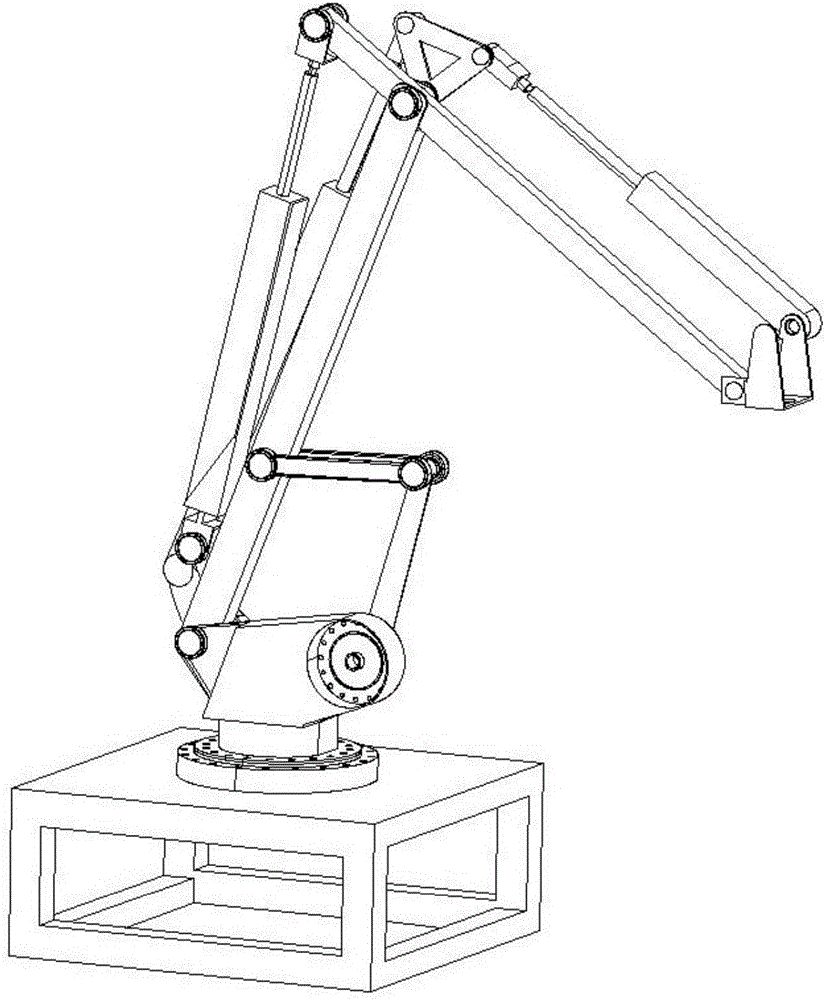

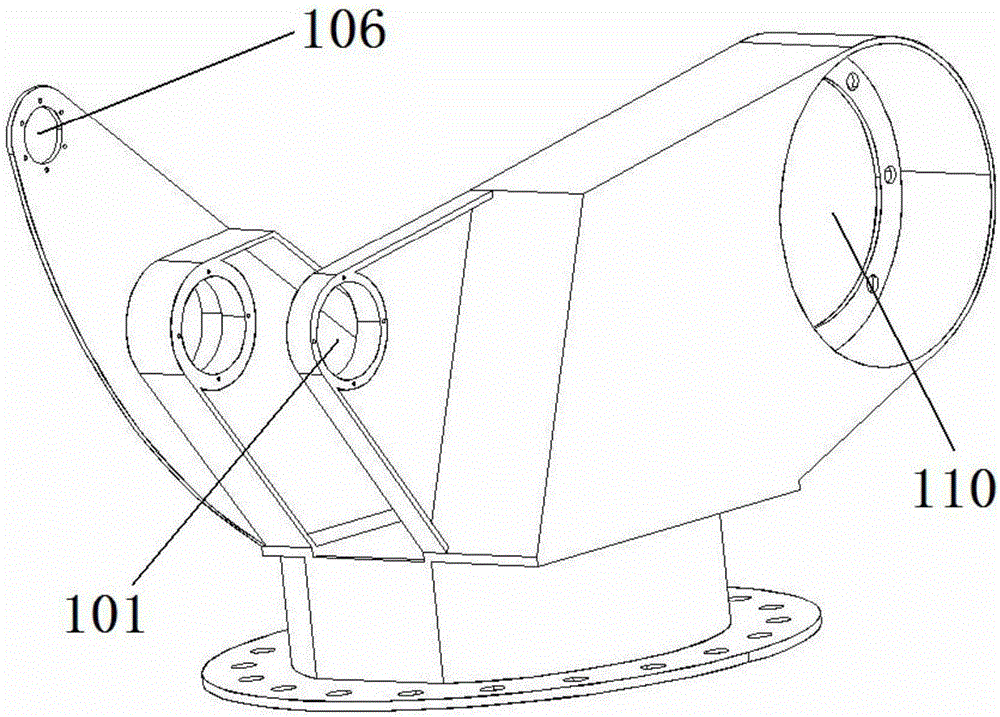

Controllable mechanism type stacking robot driven by electric push cylinders

InactiveCN106625588ANo pollutionNo pollution in the processProgramme-controlled manipulatorStacking articlesEngineeringWorking space

A controllable mechanism type stacking robot driven by electric push cylinders is characterized in that one end of a connecting rod I is connected with a frame; the other end of the connecting rod I is connected with a connecting rod II; one end of an electric push cylinder I is connected with the connecting rod I; the other end of the electric push cylinder I is connected with one end of the connecting rod II; the other end of the connecting rod II is connected with an executing terminal; one end of an electric push cylinder II is connected with the frame; the other end of the electric push cylinder II is connected with the first angle of a triangular connecting plate; the second angle of the triangular connecting plate is connected with one end of an electric push cylinder III; the other end of the electric push cylinder III is connected with the executing terminal; one end of a connecting rod III is connected with the frame; the other end of the connecting rod III is connected with one end of a connecting rod IV; the other end of the connecting rod IV is connected with the connecting rod I; and the frame is connected with a base. The stacking robot maintains a series of advantages such as simple structure, low manufacturing cost, large working space and compact structure and is improved in transmission efficiency compared with a traditional mechanism; and meanwhile the stacking robot is reduced in rotational inertia and increased in movement stability and reliability and is free of pollution.

Owner:GUANGXI UNIV

Controllable automobile clutch based on magnetorheology

PendingCN109737153AAdjustable binding forceReduce operator fatigueNon-rotating vibration suppressionElectrically actuated clutchesEngineeringDrive motor

The invention discloses a controllable automobile clutch based on magnetorheology. The controllable automobile clutch comprises a driven plate, a pressure plate, a transmission input shaft, a diaphragm spring connected with the pressure plate and a pushing device for pushing the diaphragm spring; the driven disk is in transmission connection with the transmission input shaft through a magnetorheological damper; the magnetorheological damper comprises a sleeve, a rotating shaft, a coil drum I and a coil drum II; the pushing device comprises a driving motor and a transmission mechanism for transmitting driving force of the driving motor to a diaphragm spring, a motor switch of the driving motor is arranged on the coil drum 1 and the coil drum II, and when the coil drum II moves towards the coil drum I to a set value, the motor switch is started. The controllable automobile clutch can adjust the magnitude of the magnetic field by changing the magnitude of the current, damping parameters are changed, the vibration damping control is achieved, and the control fatigue of a driver can be reduced.

Owner:CHONGQING VOCATIONAL INST OF ENG

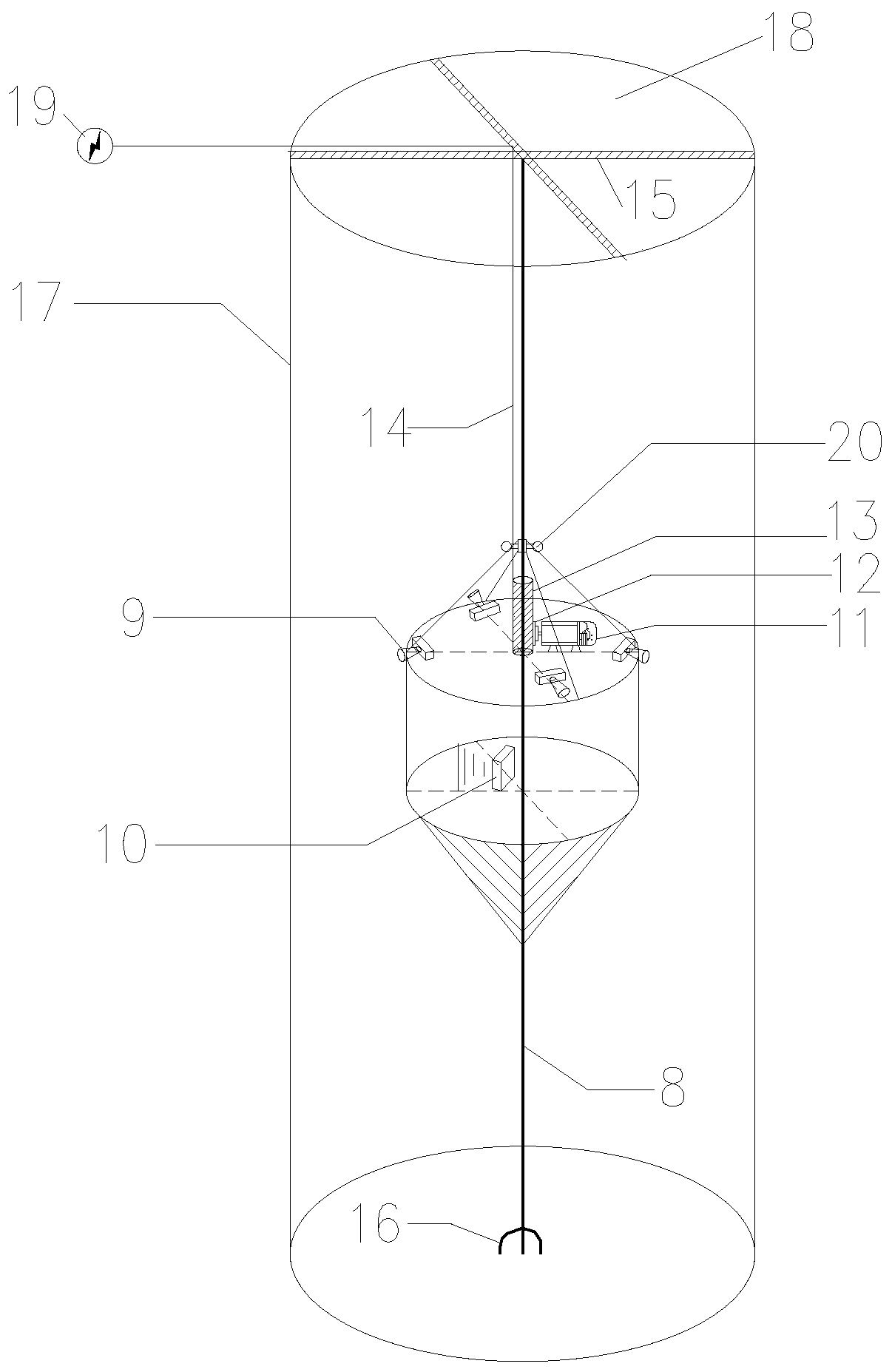

Traffic tunnel vertical shaft inspection system

ActiveCN111510640ADoes not take up spaceReduce volumeTelevision system detailsChecking time patrolsControl engineeringEngineering

The invention provides a traffic tunnel vertical shaft inspection system, which comprises a guide rope, an inspection platform, a lifting power device, a detection instrument and a control processingdevice, wherein the guide rope is a metal rope with a rough surface and is used for guiding and dragging the ascending and descending of the inspection platform; the lifting power device is connectedwith the inspection platform, is mounted on the guide rope, is used for fixing the inspection platform on the guide rope, and is also used for providing ascending and descending power for the inspection platform; the detection instrument is arranged on the inspection platform and is used for detecting the structural condition of the vertical shaft; the control processing device is electrically connected with the lifting power device and the detection instrument and used for controlling the lifting power device to drive the inspection platform to ascend and descend, and is also used for controlling the detection instrument to detect, receive and store detection data. The technical problems that a vertical shaft inspection system is complex in structure, high in system manufacturing cost andcomplex in system processing image recognition operation during inspection can be solved.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Piezoelectric direct-driven fuel injector with rotation type valve core

InactiveCN103470419AQuick responseGood repeatabilityFuel injection apparatusMachines/enginesElectricityLinear motion

The invention belongs to the field of a fuel injector of a fuel injection system of an internal combustion engine and particularly relates to a piezoelectric direct-driven fuel injector which directly drives the valve core of a fuel injection nozzle to realize the turn-on or turn-off of fuel injection by utilizing the electrogenerated displacement of a ceramic piezoelectric stack. According to the piezoelectric direct-driven fuel injector with the rotation type valve core, displacement is amplified by a mechanical type displacement amplifier through the utilization of a characteristic of a piezoelectric ceramic material that the displacement is generated in the power-on state, and linear motion is changed to rotary motion so that the valve core is driven to control the opening or closing of an injection hole; the piezoelectric direct-driven fuel injector mainly comprises a fuel injector body, a piezoelectric actuator, an ejection rod, the valve core, a valve seat, a return spring, a fine adjustment nut, a sealing nut and the like. By the adoption of the piezoelectric direct-driven fuel injector with the rotation type valve core, the direct driving of the valve core by the piezoelectric actuator is realized through the rotation type valve core; the structure is simple; the response is sensitive; the impact vibration is weak; the effect of energy conservation and emission reduction is quite good.

Owner:浙江展途动力科技有限公司

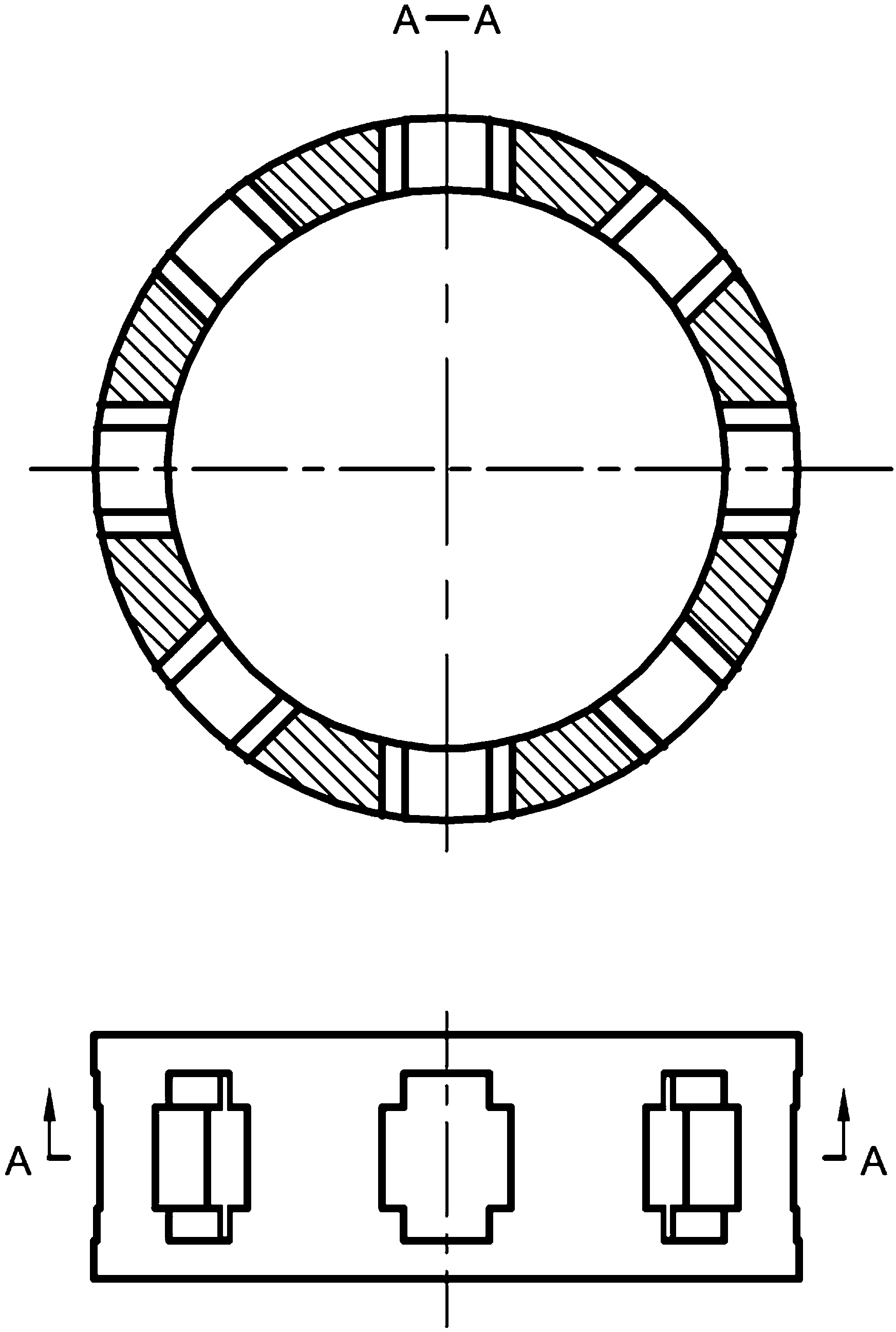

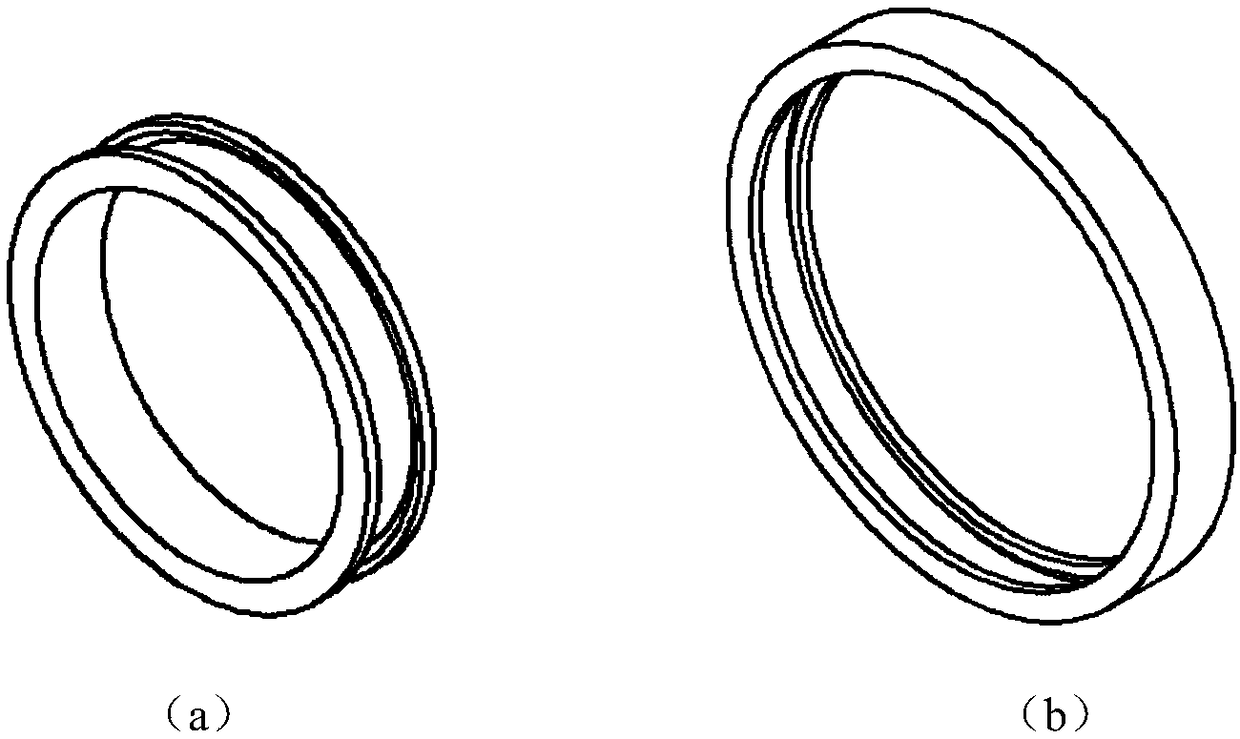

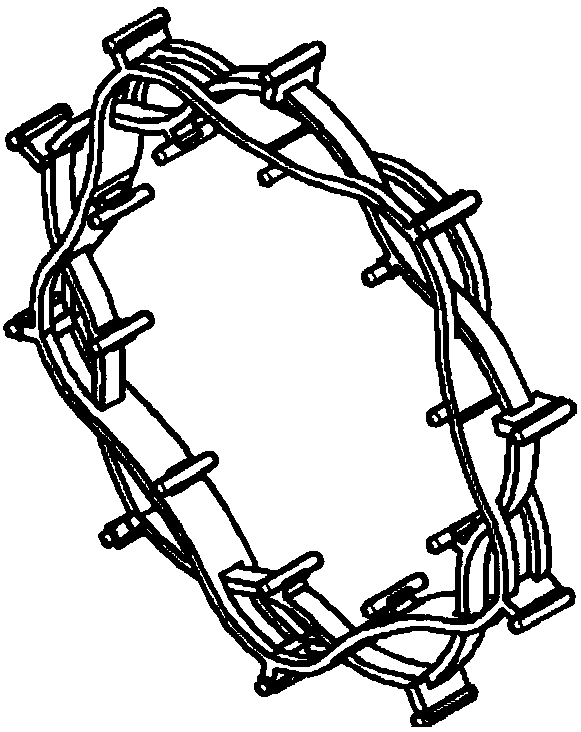

Elastic bearing based on double retainers

The invention discloses an elastic bearing based on double retainers. The elastic bearing comprises an outer ring, an inner ring, the first retainer and the second retainer. A first groove raceway isarranged on the inner wall of the outer ring. A second groove raceway is arranged on the outer wall of the inner ring. The inner ring and the outer ring are arranged concentrically. The first retainerand the second retainer both are circular-ring elastic bodies in a wave shape and are arranged in a staggered manner so that the wave crest and the wave trough on the first retainer can correspond tothe wave crest and the wave crest on the second retainer one by one. Clamping mechanisms which are provided with cylindrical rollers and matched with the first groove raceway are correspondingly arranged outwards on the wave crests of the first retainer and the second retainer, and clamping mechanisms which are provided with cylindrical rollers and matched with the second groove raceway are correspondingly arranged inwards on the wave troughs of the first retainer and the second retainer. The elastic bearing based on the double retainers is convenient to use, the radial bearing capacity of the bearing is improved, and the impact load received by a bearing seat is lowered greatly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

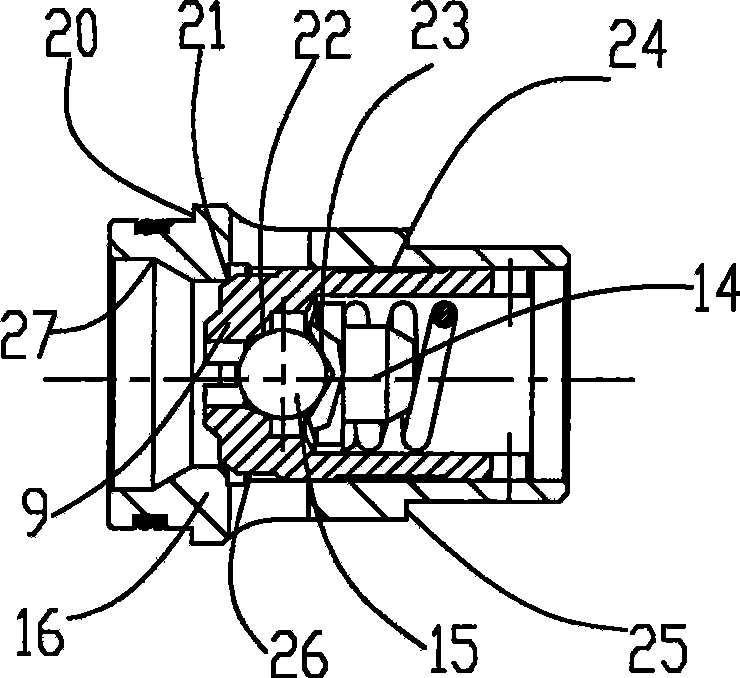

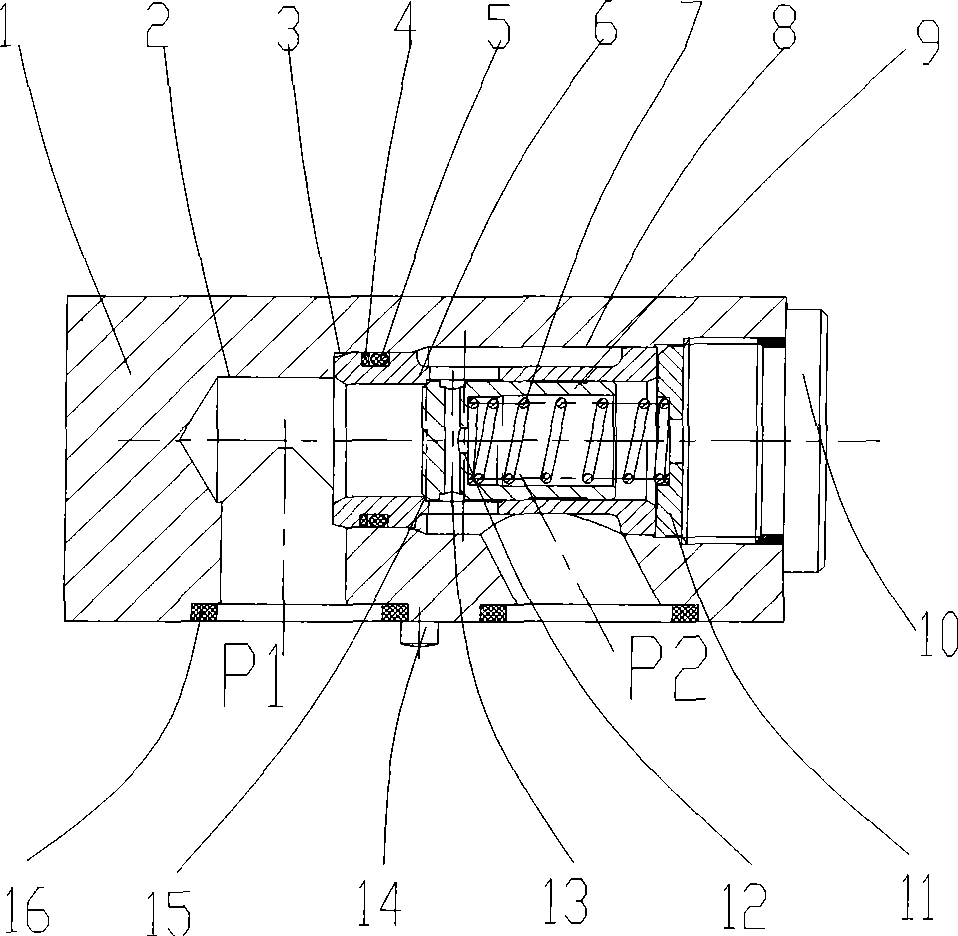

Non-return valve with valve housing

InactiveCN101469786ASmall shock and vibrationExtend your lifeServomotor componentsCheck valvesInternal cavityCheck valve

A check valve with a valve pocket, relating to the field of hydraulic control valve, comprises a valve body, a main hole is opened in the center of the valve body, the right end of the main hole of the valve body is sealedly fixed by using a screw plug, characterized in that, an oil inlet P1 and an oil outlet P2 are opened on the bottom of the valve body and communicated with the main hole, the valve pocket is arranged in the main hole, and between the oil inlet P1 and the oil outlet P2, the inner cavity of the valve pocket is arranged with a valve core the inner cavity of which is sleeved with a spring, one end of the spring is connected with the inner wall of the valve core, the other end of which is fixed on a spring base which is connected with the screw plug for sealing at the right end of the valve body. The check valve with a valve pocket has the beneficial effect that, due to connect the valve body and the valve core through the valve pocket, the impact vibration force is directly applied on the valve pocket, the impact vibration to the valve body is reduced, so the service life of the valve body is prolonged. The structure of the valve core is changed from the cone valve to cone pocket, the contact area in the movement process of the valve core is increased, thereby improving the movement stability of the valve core.

Owner:SHANGHAI LIXIN HYDRAULIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com