Piezoelectric direct-driven fuel injector with rotation type valve core

A technology of spool rotation and fuel injectors, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., to achieve fast response, fewer components, and lower costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

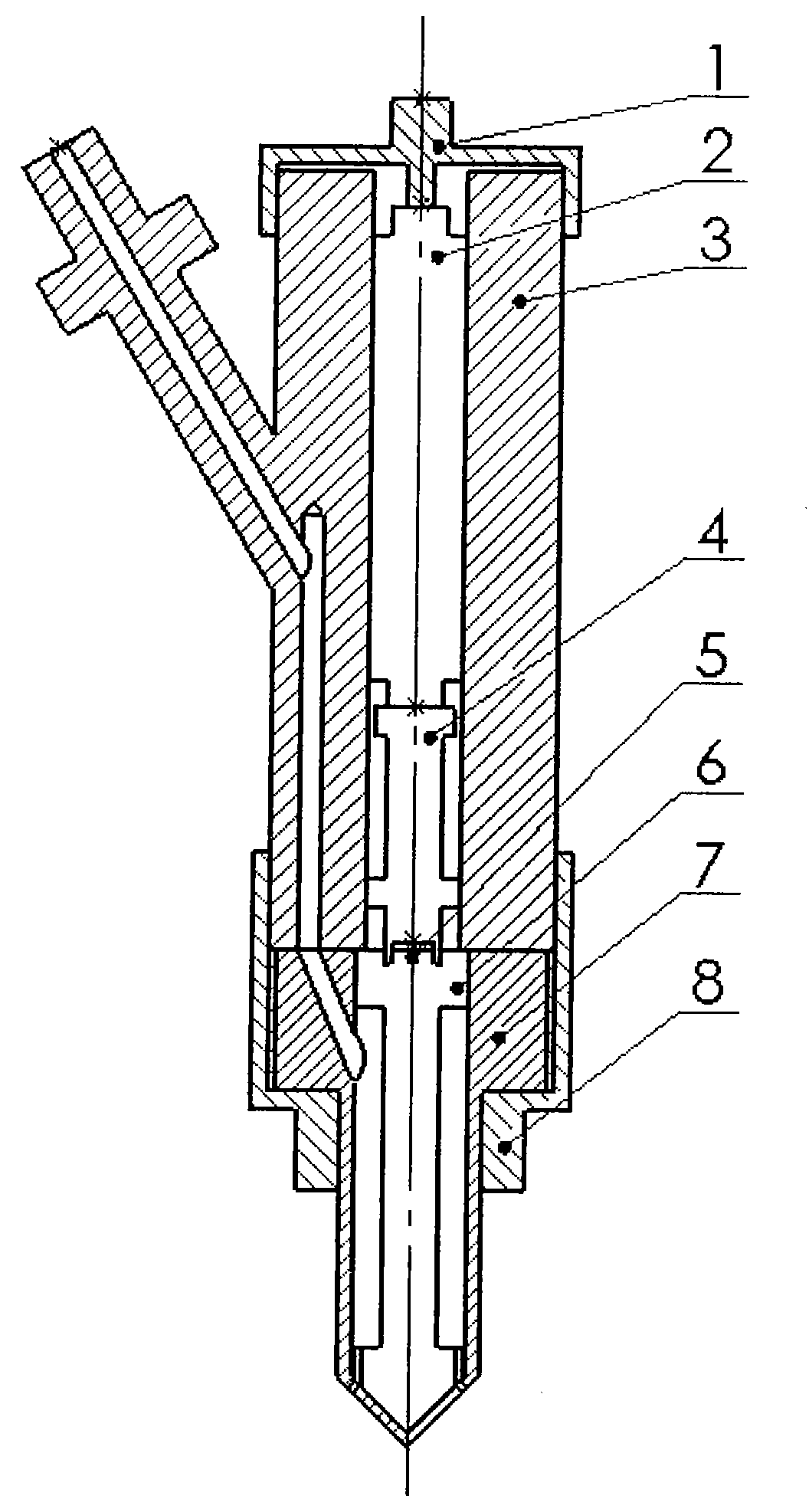

[0020] The present invention provides a piezoelectric direct-drive fuel injector that utilizes the electric displacement of the ceramic piezoelectric stack to directly drive the rotation of the valve core of the fuel injector to realize the opening and closing of the fuel injection. The present invention will be further described in conjunction with the accompanying drawings and specific embodiments below. .

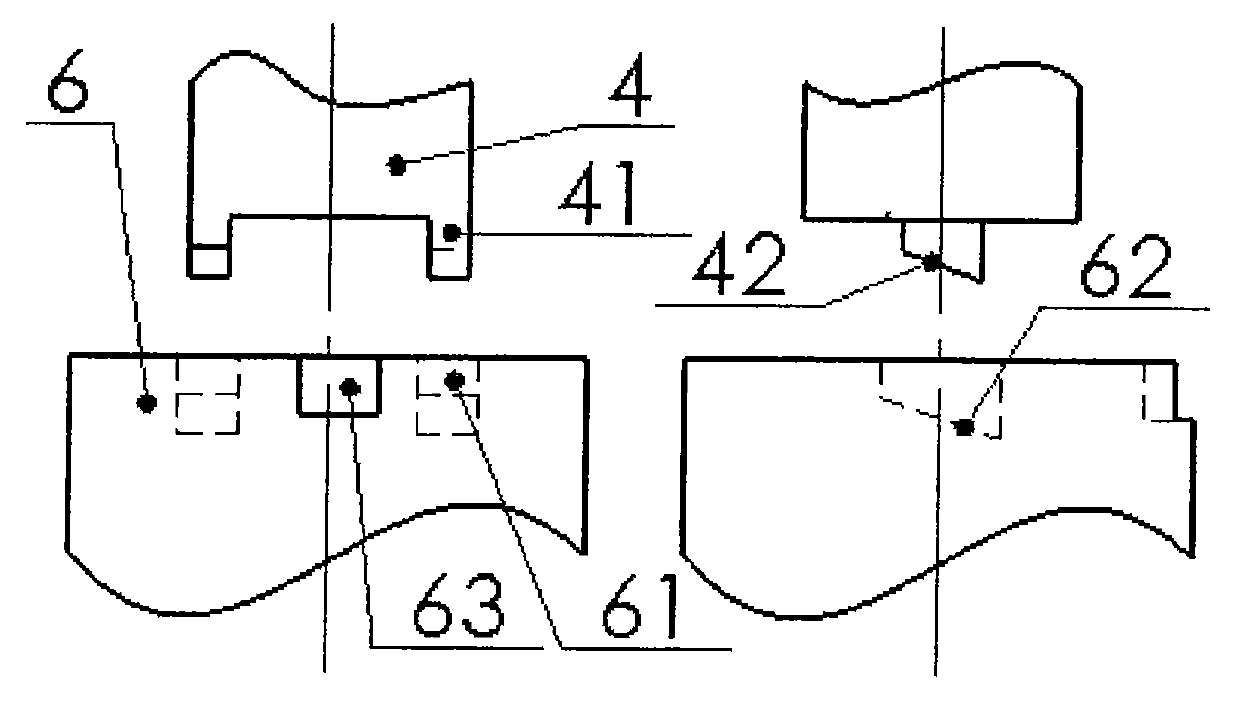

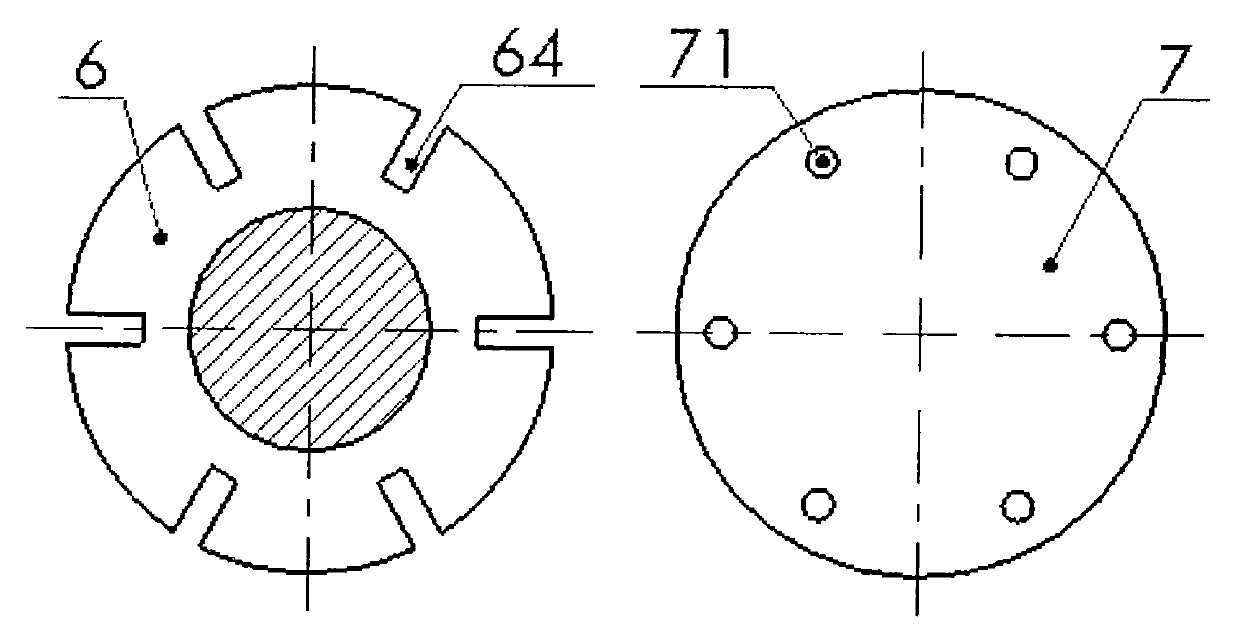

[0021] 1. in figure 1 In the shown embodiment, the valve core (4) is placed in the valve seat (7), the return spring (5) is installed to determine its initial axial position, and the ejector rod (4) is loaded into the valve body (3); Attach the top surface of the valve seat (7) to the bottom surface of the injector body (3), align the axes, and make sure that the wedge (41) of the ejector rod (4) and the groove (61) of the valve core (6) are relatively aligned. After position, use the sealing nut (8) to tighten the seal; install the piezoelectric actuator (2) in the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com