Cylinder double-face cam axial piston type crankless internal combustion engine

A double-sided cam and camshaft technology, applied in the direction of pistons, mechanical equipment, engine components, etc., can solve the problems of large impact, large unbalanced centrifugal force, large side pressure, etc., and achieve simplified valve mechanism, small radial size, smooth work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

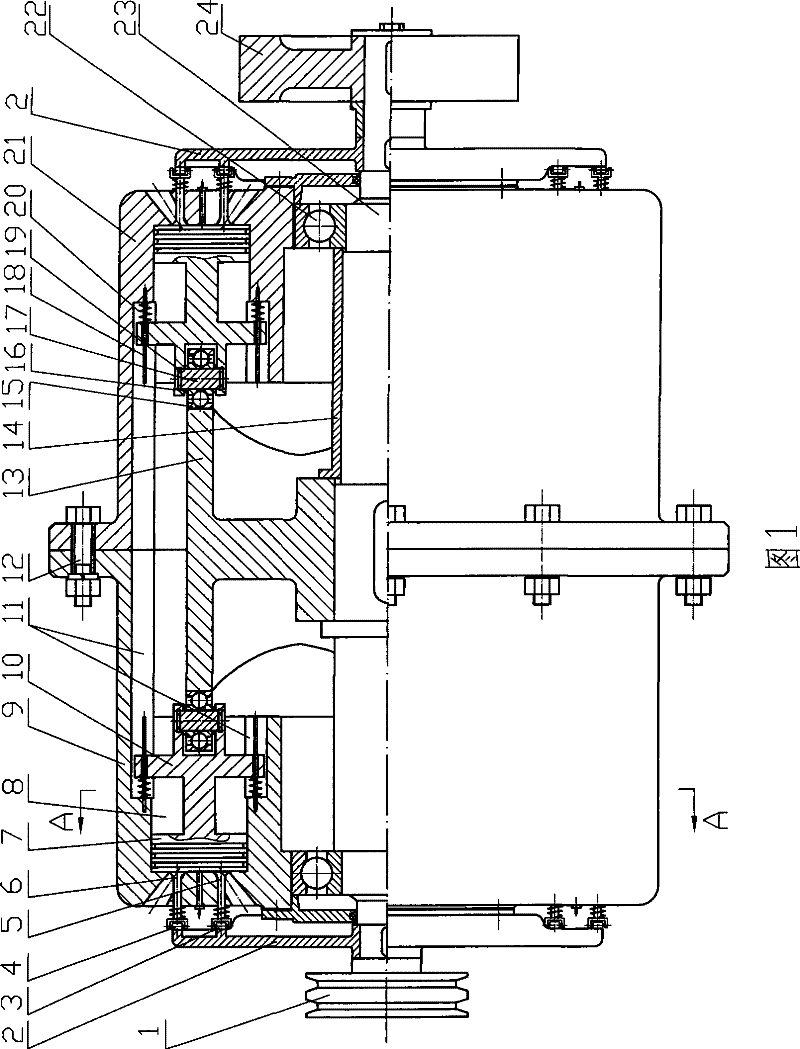

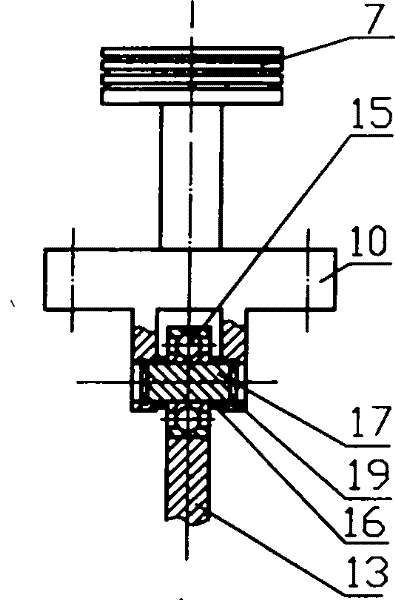

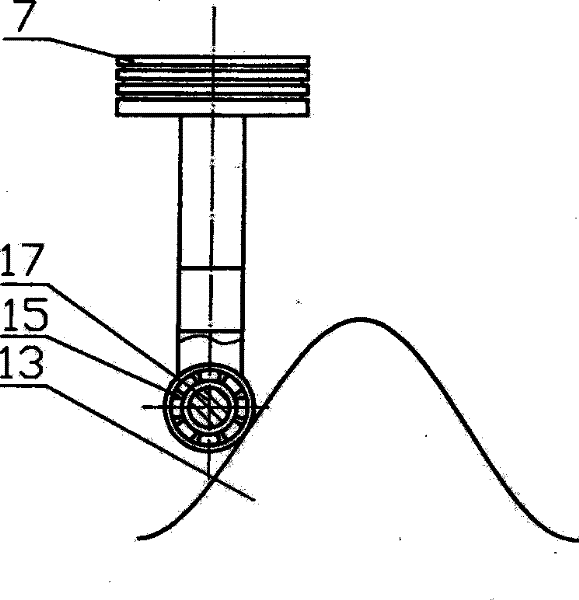

[0032] Embodiment 1: Cylinder double-sided cam axial piston type crankshaftless internal combustion engine with four cylinders

[0033] See attached Figure 1 to Figure 9 :exist Figure 1 to Figure 6 In the cylinder double-sided cam axial piston type internal combustion engine without crankshaft shown with four cylinders, the left cylinder block (9) and the right cylinder block (21) are connected into a whole with bolts (12), and the symmetry of the whole body is The center passes through a main shaft (23), and the main shaft (23) is respectively supported in the left cylinder block (9) and the right cylinder block (21) by two left and right bearings (22). (23) fixed connection, two cylinders (8) are respectively set in the left cylinder block (9) and the right cylinder block (21), and the axis lines of four cylinders (8) are all connected with the axis lines of the main shaft (23) Parallel, two cylinders (8) on each cylinder block are arranged symmetrically at intervals of ...

Embodiment 2

[0039] Embodiment 2: A cylinder double-sided cam axial piston type crankshaftless internal combustion engine with eight cylinders

[0040] See attached Figure 1 ~ Figure 4 , Figure 7 ~ Figure 11 :exist Figure 1 ~ Figure 4 , Figure 10 and Figure 11 In the cylinder double-sided cam axial piston type internal combustion engine without crankshaft shown with eight cylinders, the left cylinder block (9) and the right cylinder block (21) are connected into a whole with bolts (12). The center passes through a main shaft (23), and the main shaft (23) is respectively supported in the left cylinder block (9) and the right cylinder block (21) by two left and right bearings (22). (23) fixed connection, four cylinders (8) are respectively arranged on the left cylinder body (9) and the right cylinder body (21), and the axis lines of eight cylinders (8) are all parallel to the axis of the main shaft (23) and The axes of the main shaft (23) are equidistantly arranged circularly and e...

Embodiment 3

[0043] Embodiment 3: cylinder double-sided cam axial piston type internal combustion engine without crankshaft with sixteen cylinders

[0044] See attached Figure 1 ~ Figure 4 , Figure 7 ~ Figure 9 , Figure 12 and Figure 13 :exist Figure 1 ~ Figure 4 , Figure 12 and Figure 13 In the cylinder double-sided cam axial piston type internal combustion engine without crankshaft shown with sixteen cylinders, the left cylinder block (9) and the right cylinder block (21) are connected into a whole with bolts (12). The center of symmetry passes through a main shaft (23), and the main shaft (23) is supported respectively in the left cylinder block (9) and the right cylinder block (21) by the left and right two bearings (22), and the double-sided cam (13) passes through the key and The main shaft (23) is fixedly connected, and eight cylinders (8) are respectively arranged on the left cylinder body (9) and the right cylinder body (21), and the axis lines of sixteen cylinders (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com