Patents

Literature

66results about How to "Eliminate inertial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

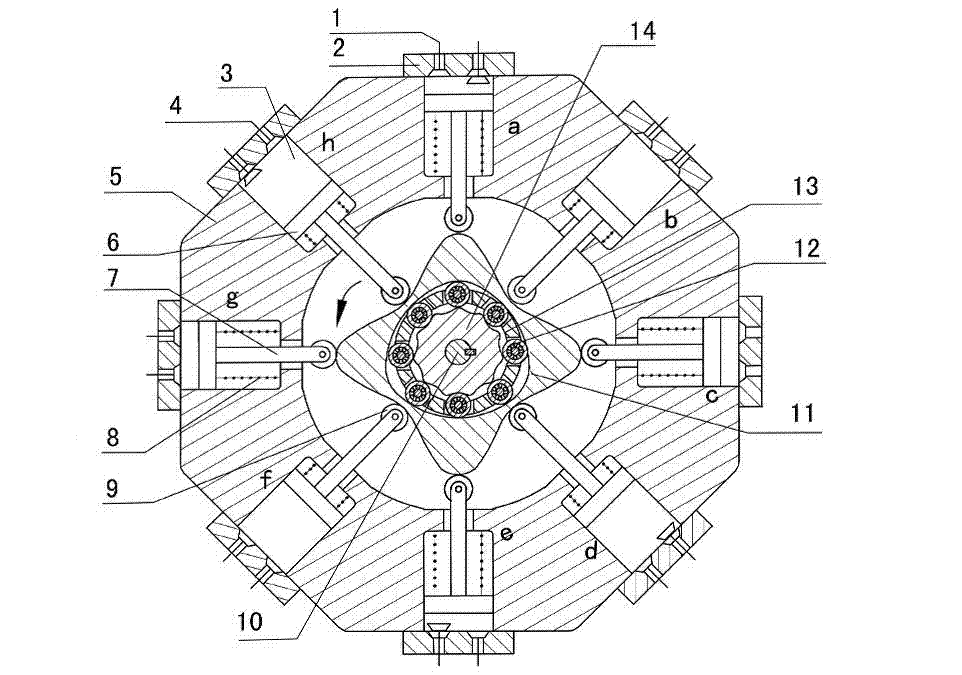

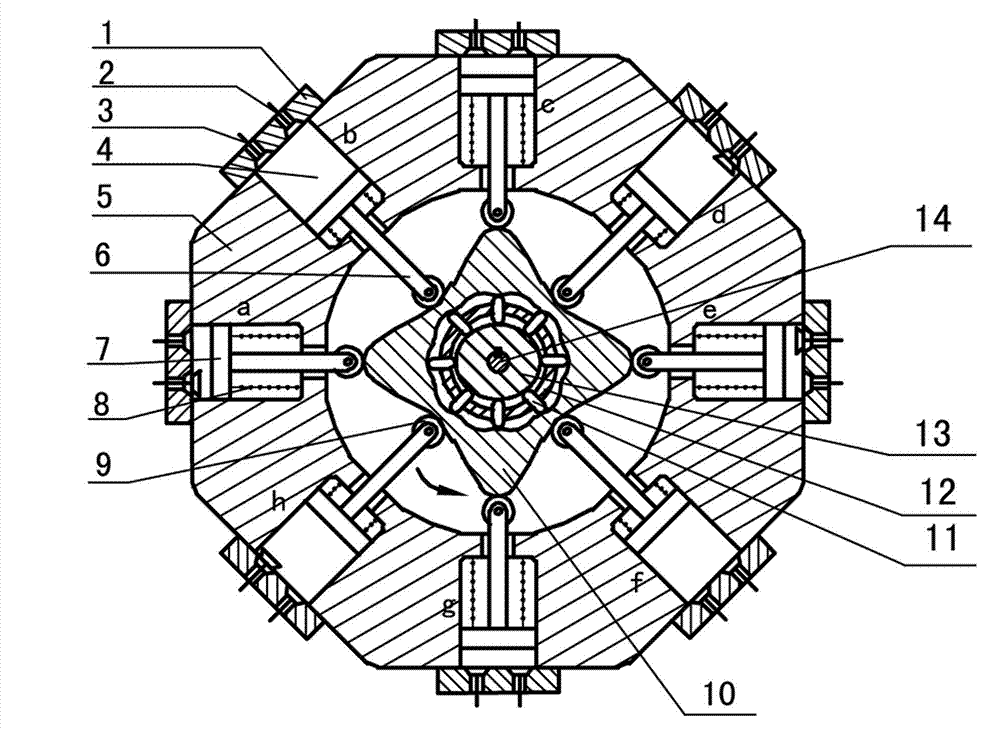

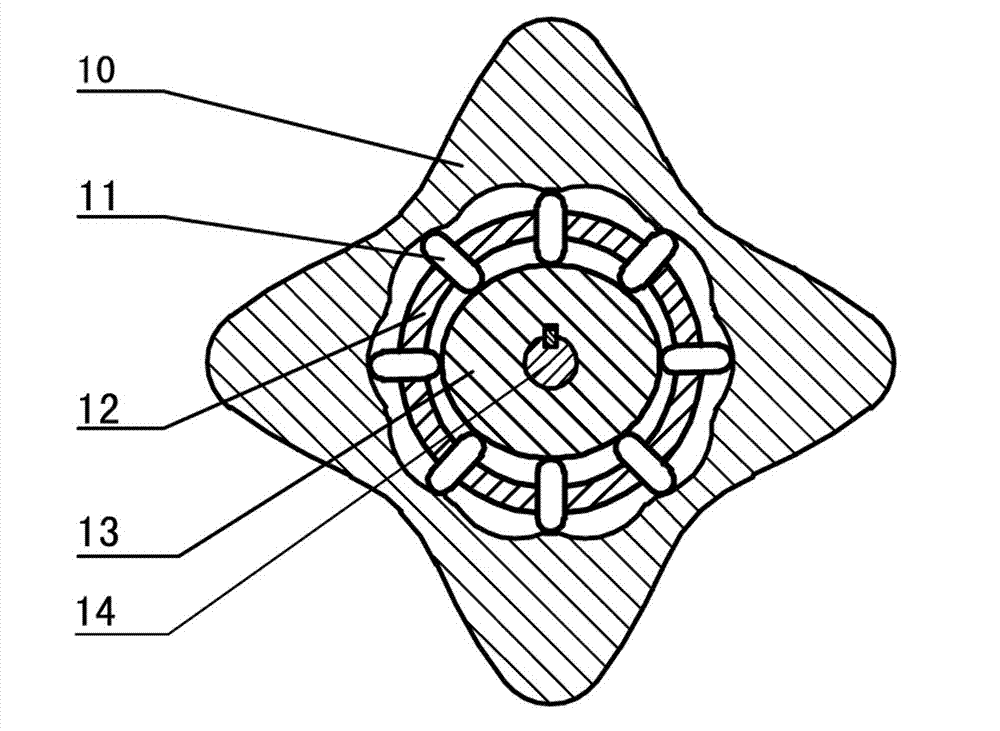

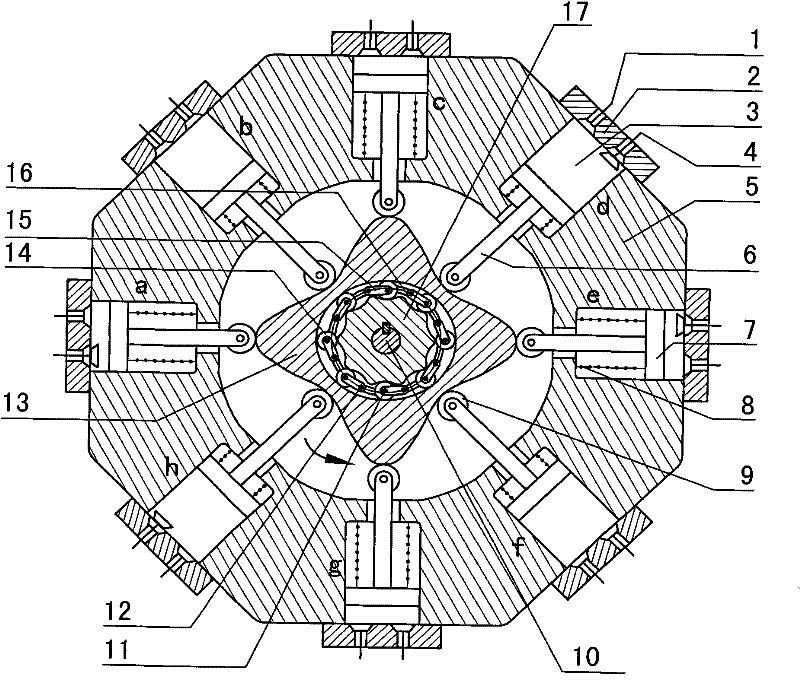

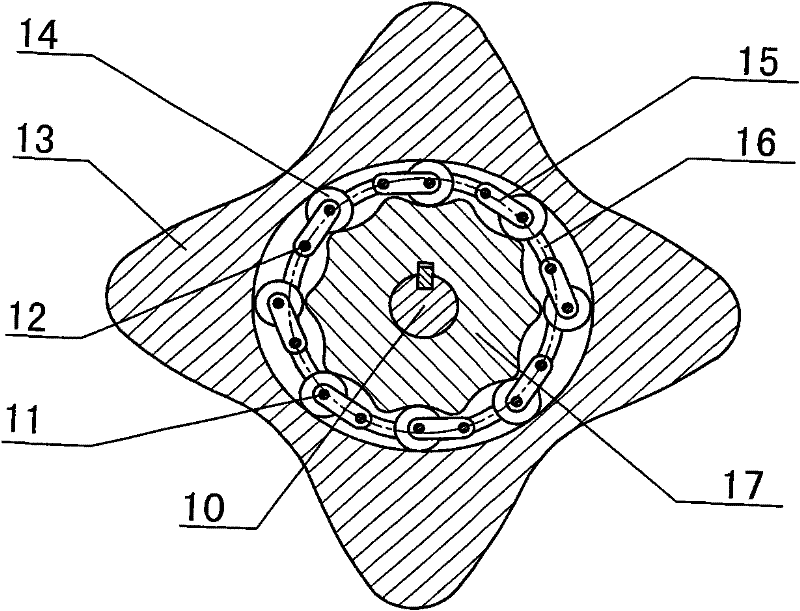

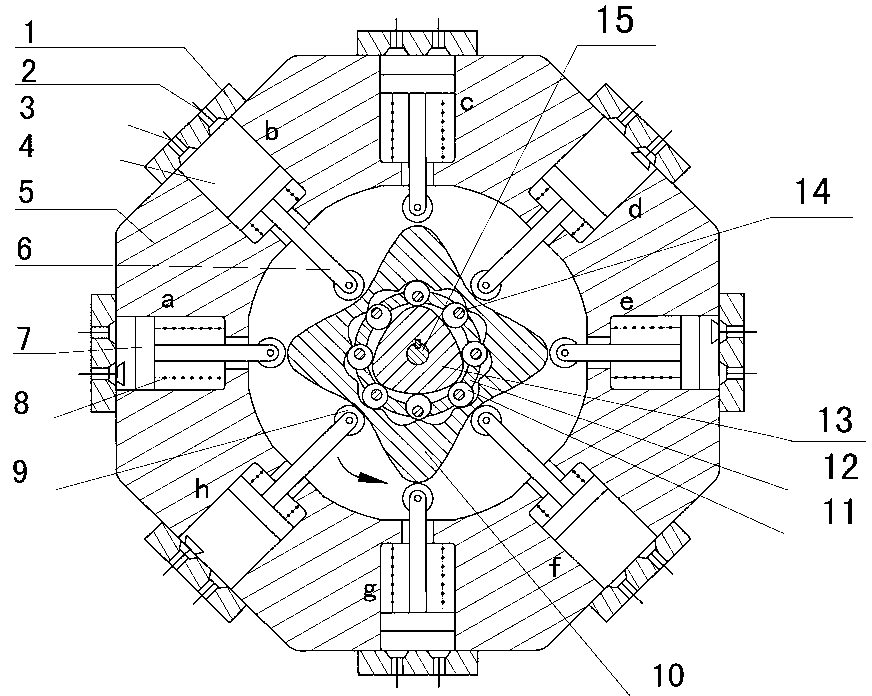

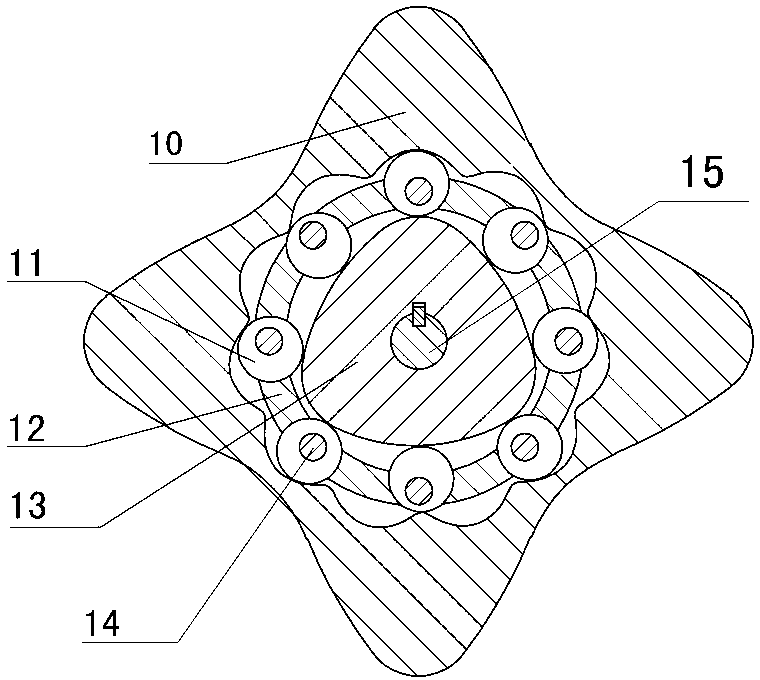

Crankshaft-free cam planetary transmission combustion engine

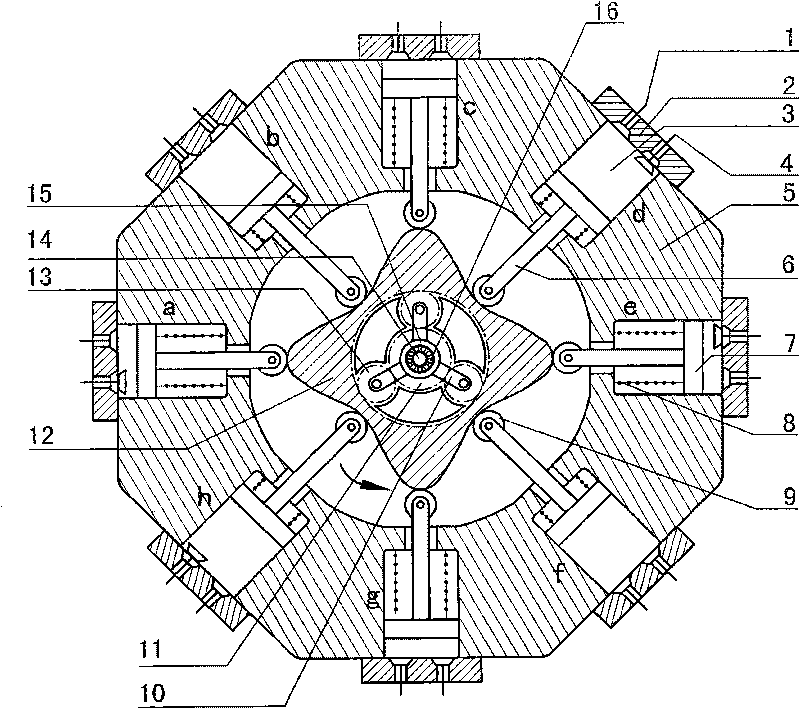

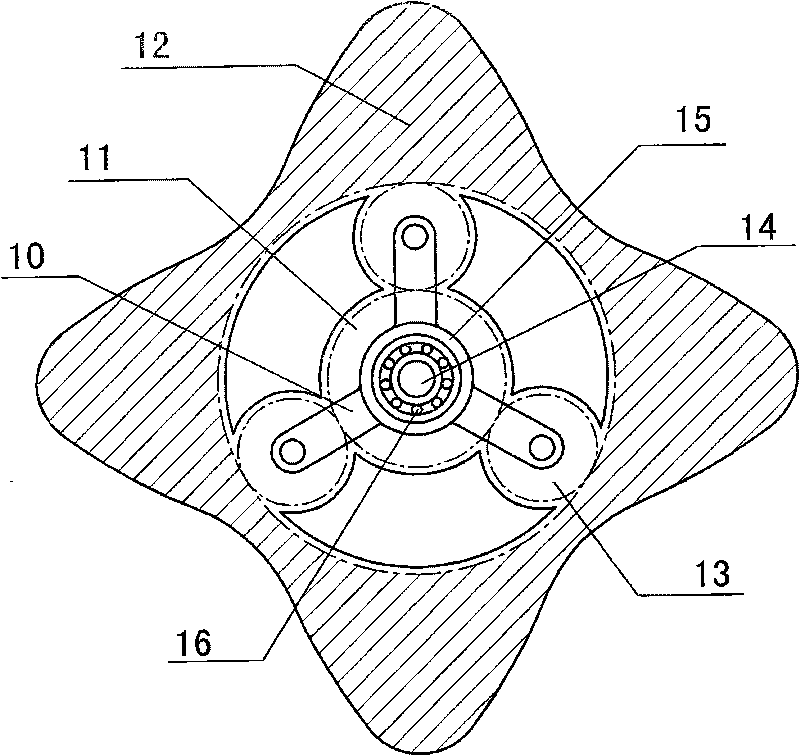

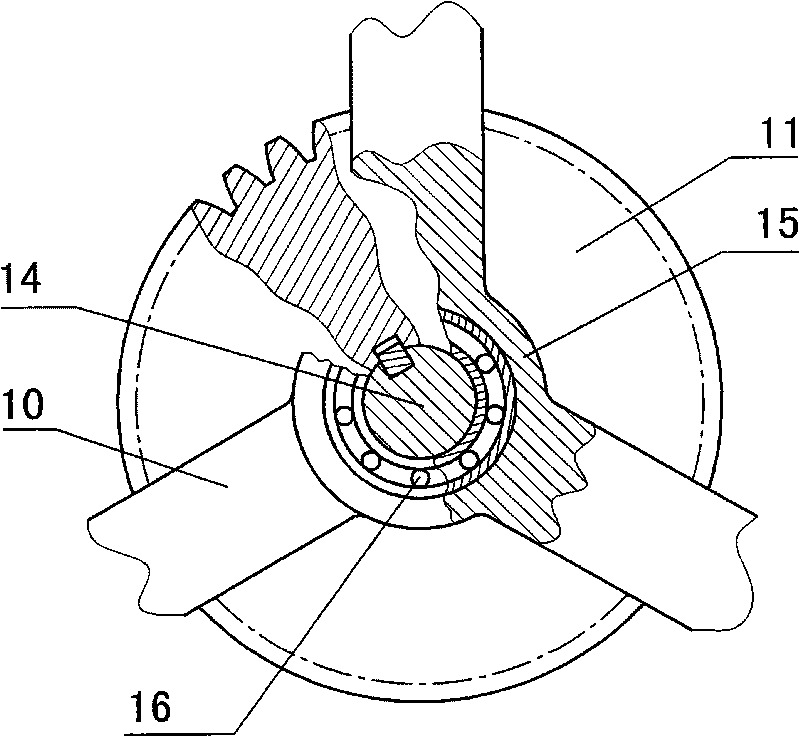

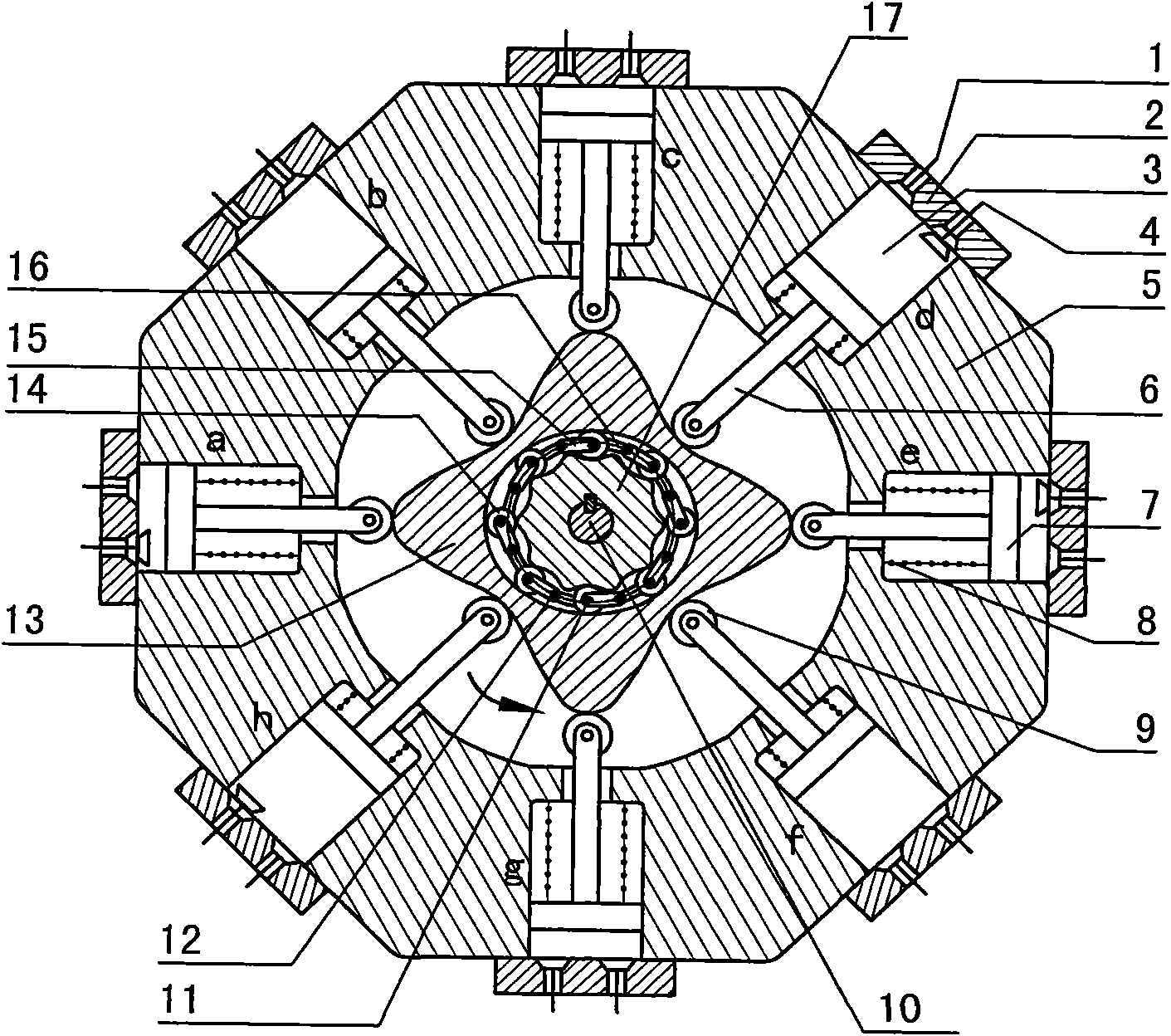

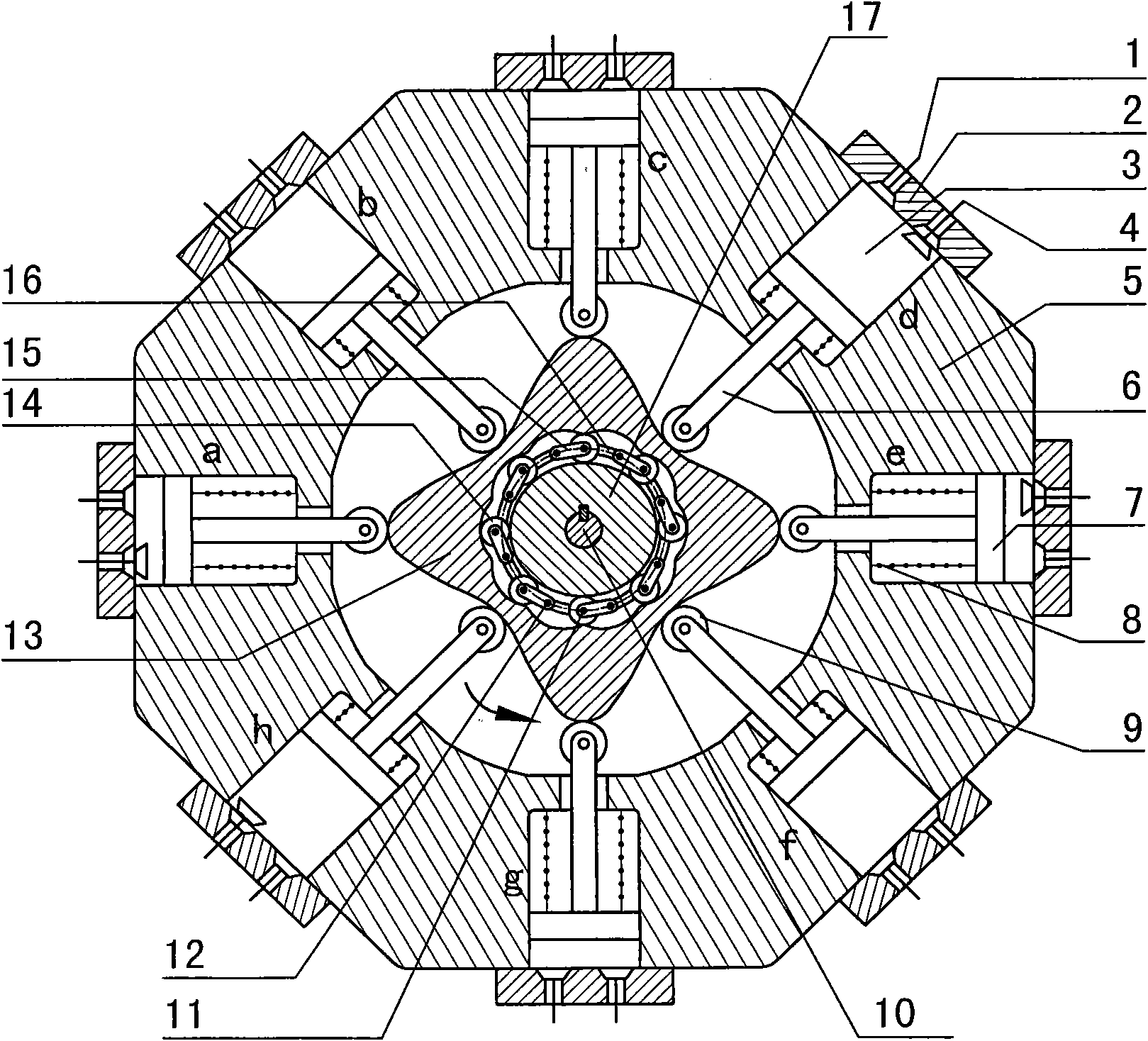

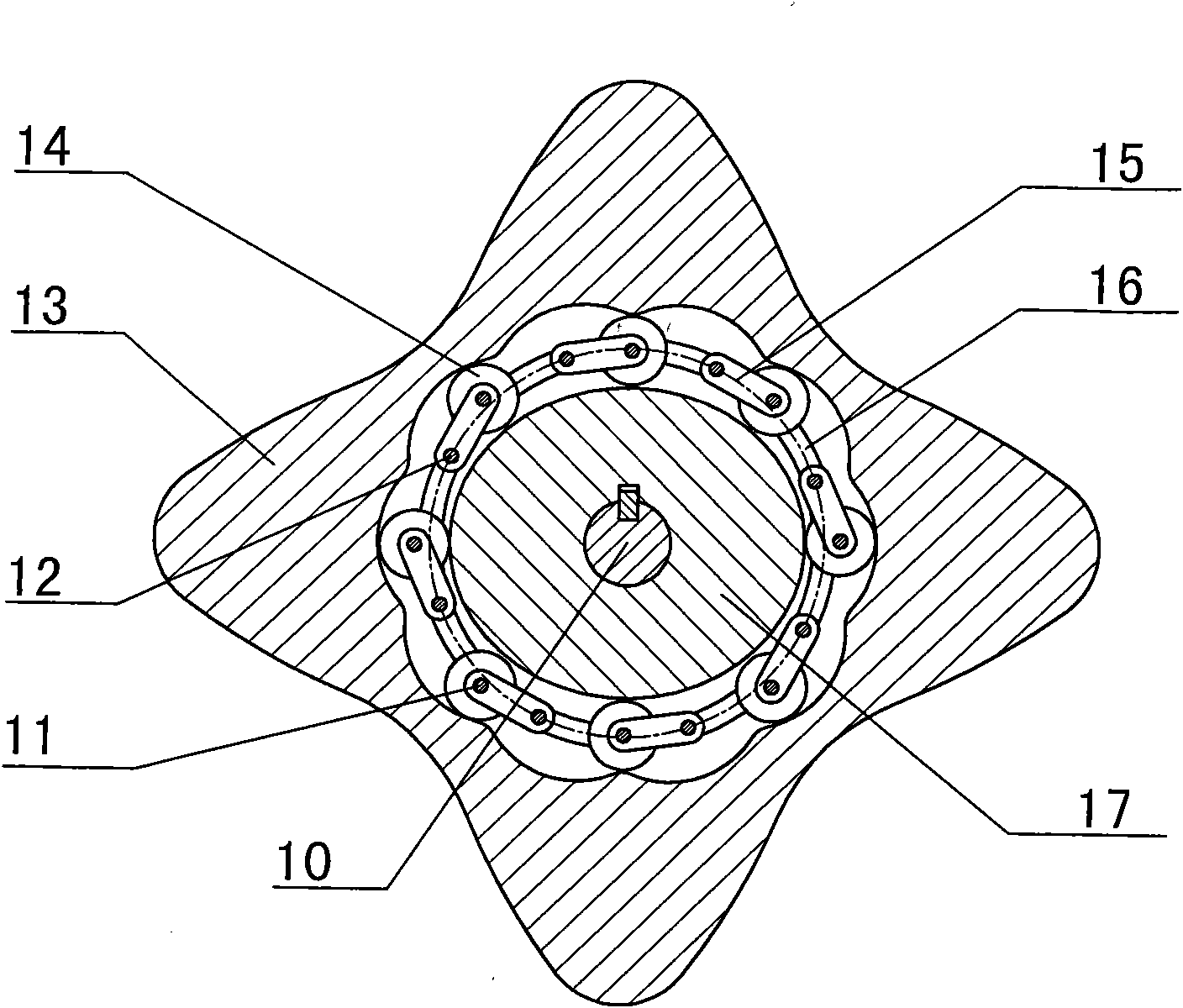

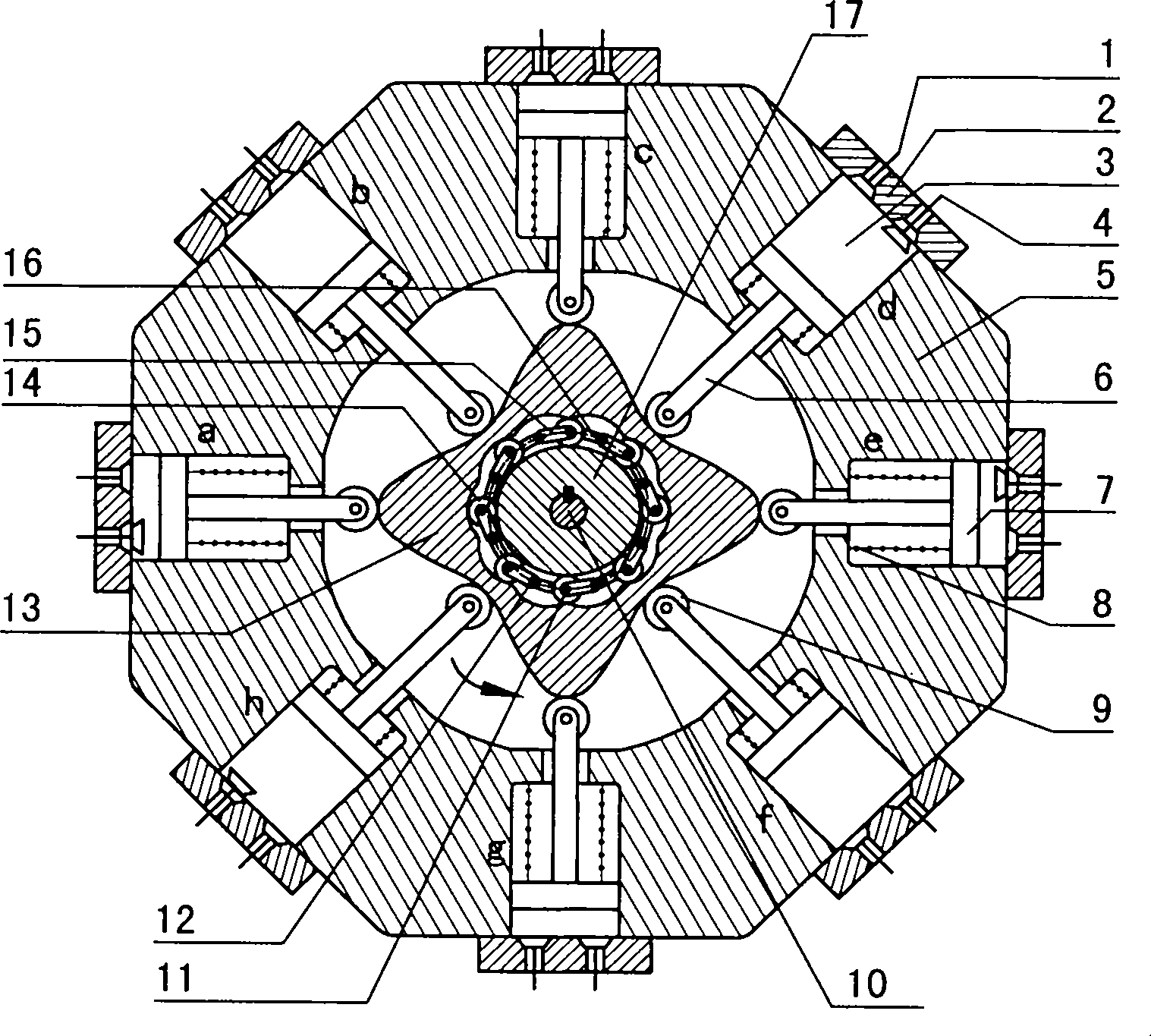

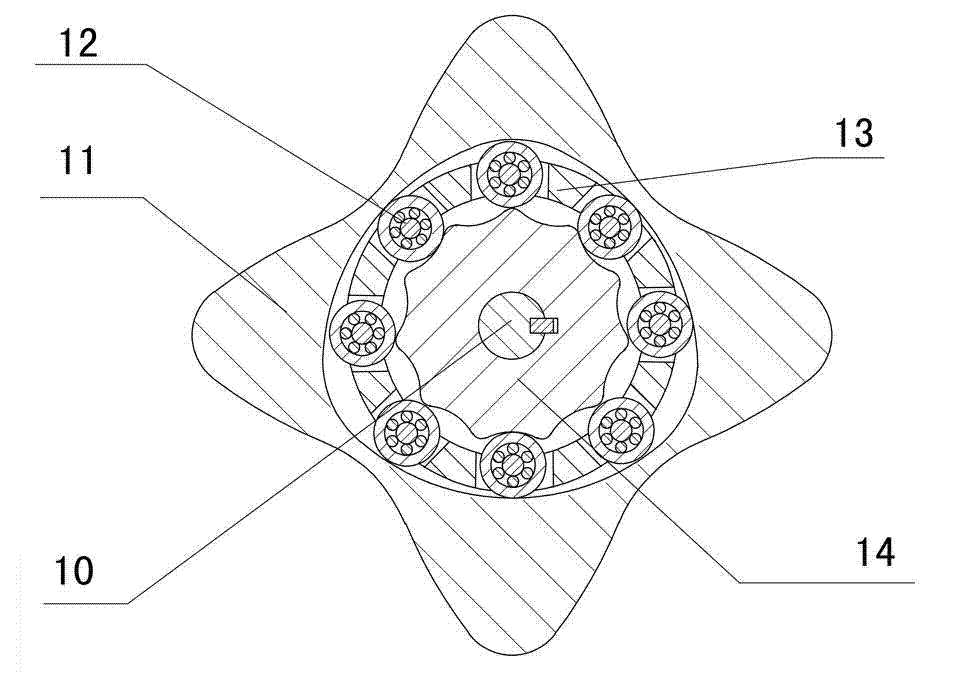

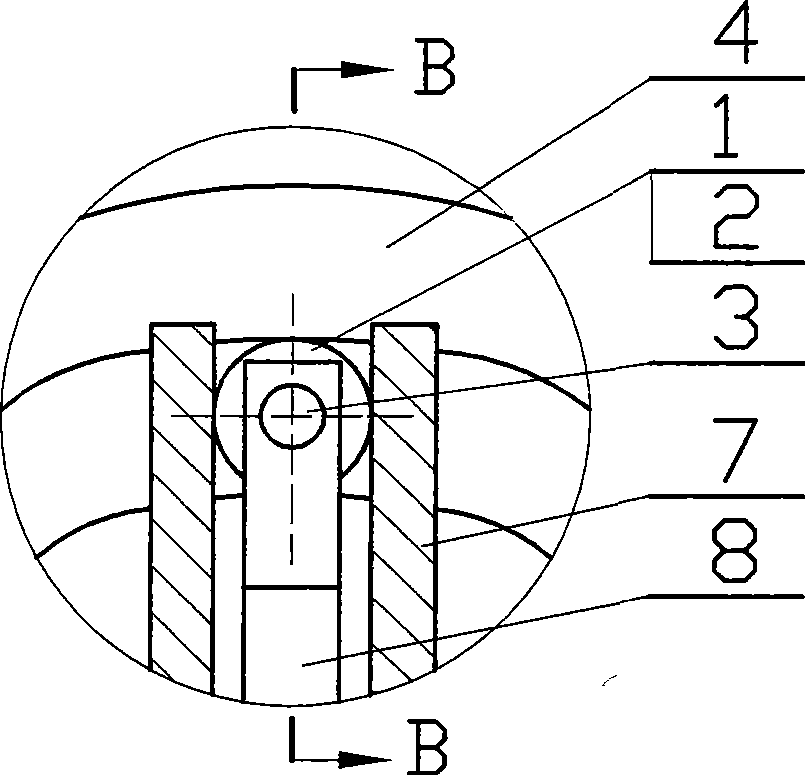

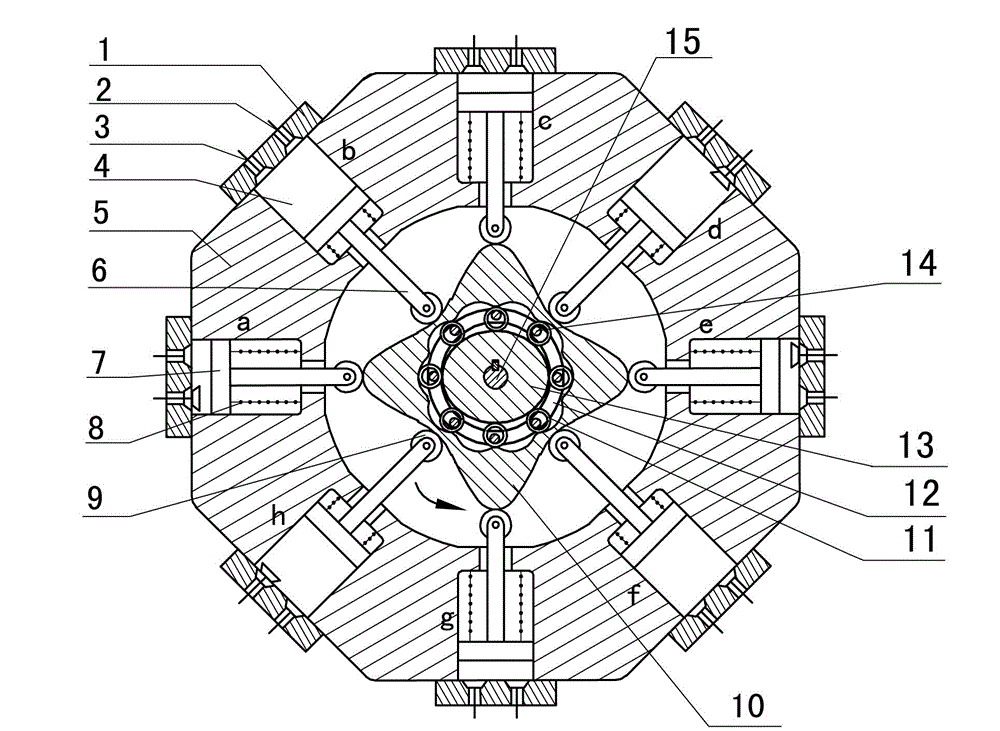

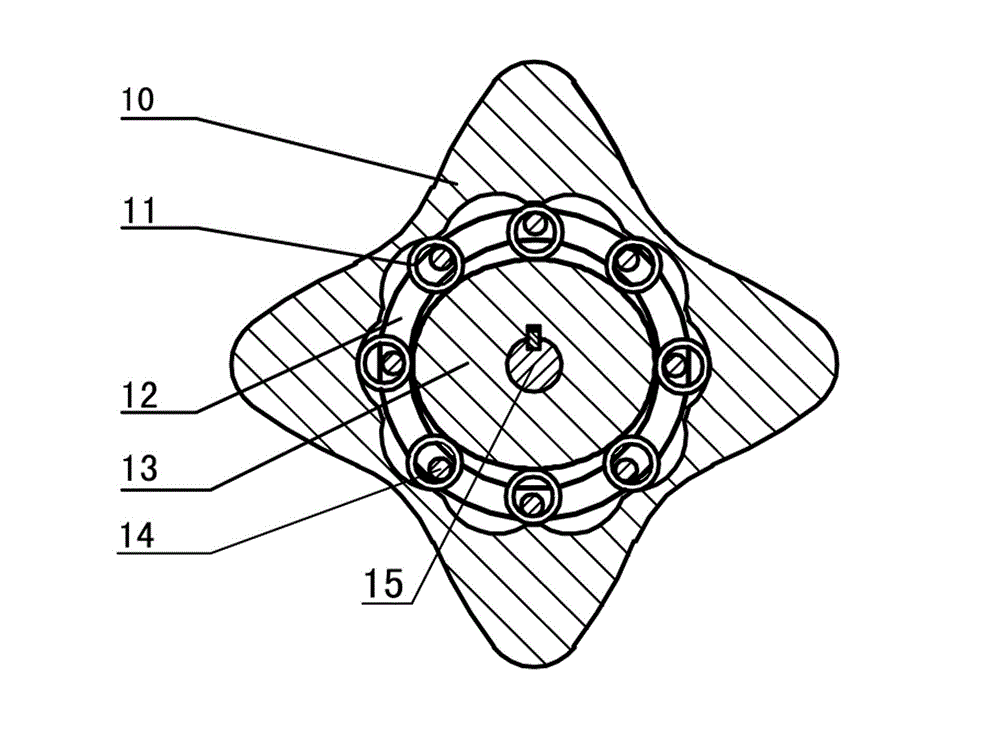

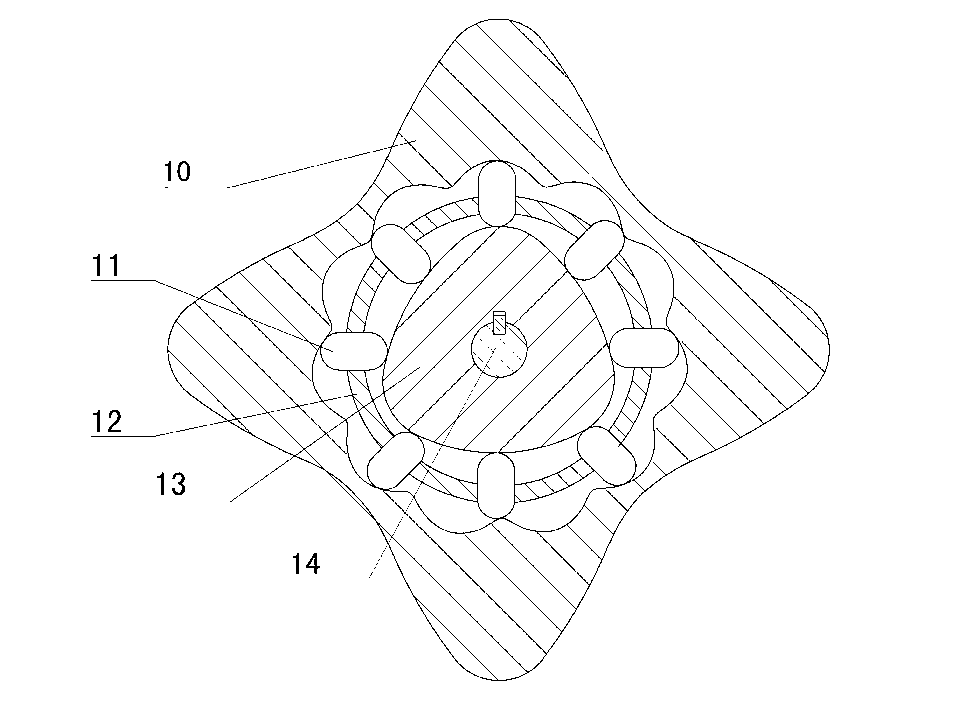

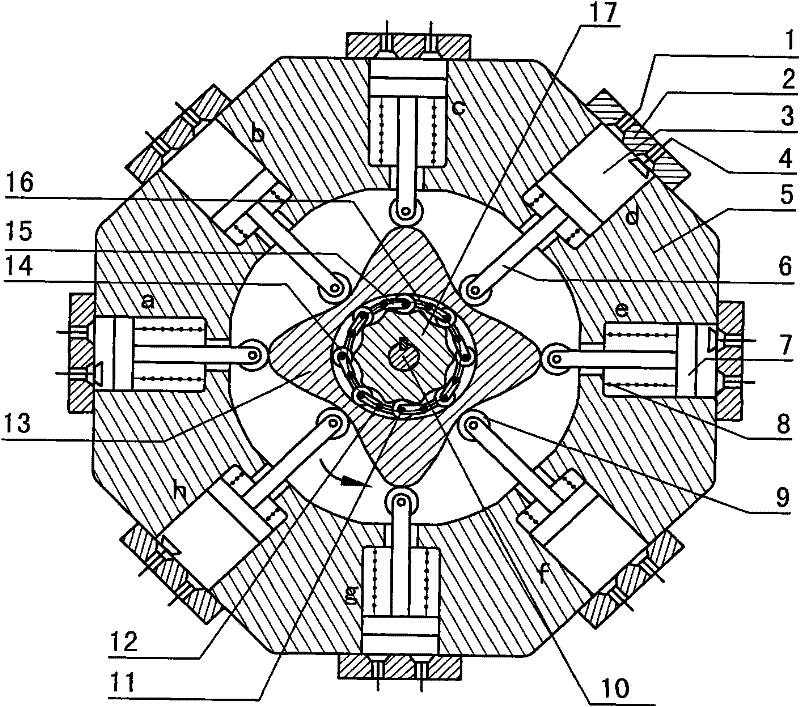

The invention discloses a crankshaft-free cam planetary transmission combustion engine, relating to the field of gas power and belonging to a multi-cylinder internal combustion engine. In the novel combustion engine, eight cylinders are evenly distributed around a cam sun wheel in a ring-shaped symmetrical way to lead the resultant force of the cam sun wheel to be zero, cylinder pistons act on the cam sun wheel through a push rod directly, the power is transmitted to an output shaft through planetary transmission by the cam sun wheel for outputting, and a sun wheel or a tie bar can be used as an outputting piece. The combustion engine saves a connecting rod and a crankshaft in the traditional combustion engine, each cylinder completes two work cycles each circle of the cam sun wheel; the rotation speed of the output shaft depends on the transmission ratio of the planetary transmission, when the sun wheel is fixed, the tie bar outputs with low speed and large torque, and can be widely applied to the fields such as engineering machinery; when the tie bar is fixed, the sun wheel outputs with high speed, and can be used as the power source of small generators and the like, and higher rotation speed can reduce the emission of harmful gas. The combustion engine has variable speed, simple and compact structure, small axial dimension, large power and stable operation.

Owner:SICHUAN UNIV

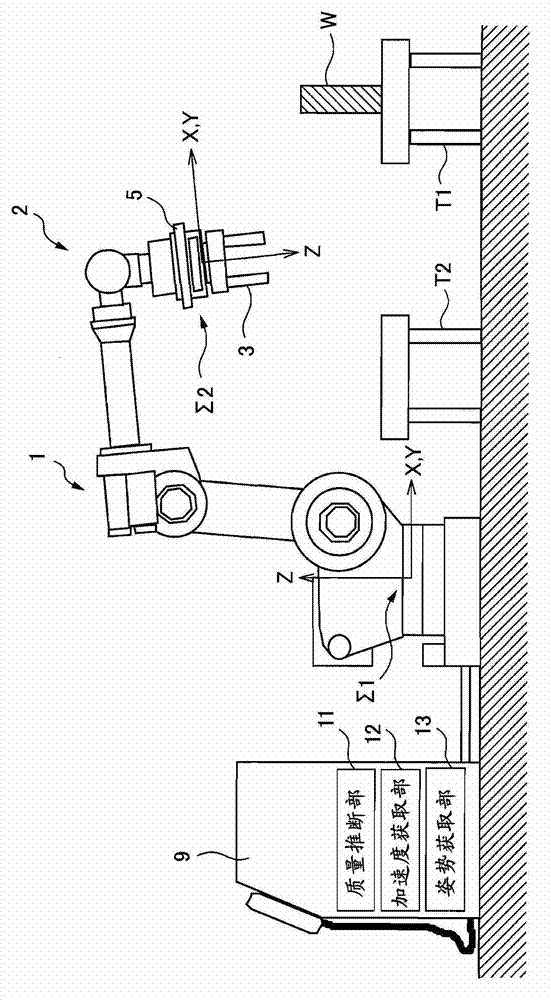

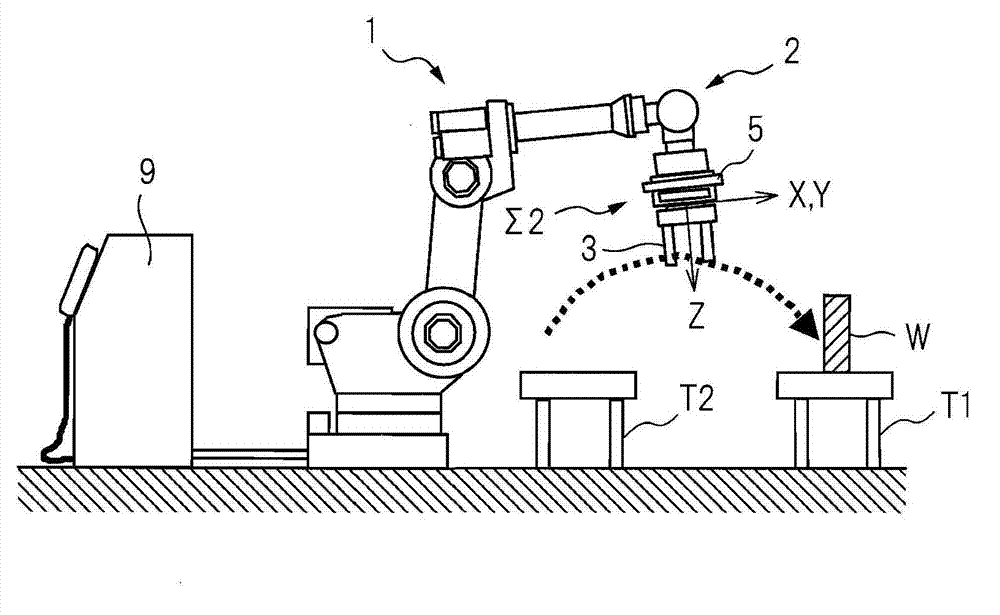

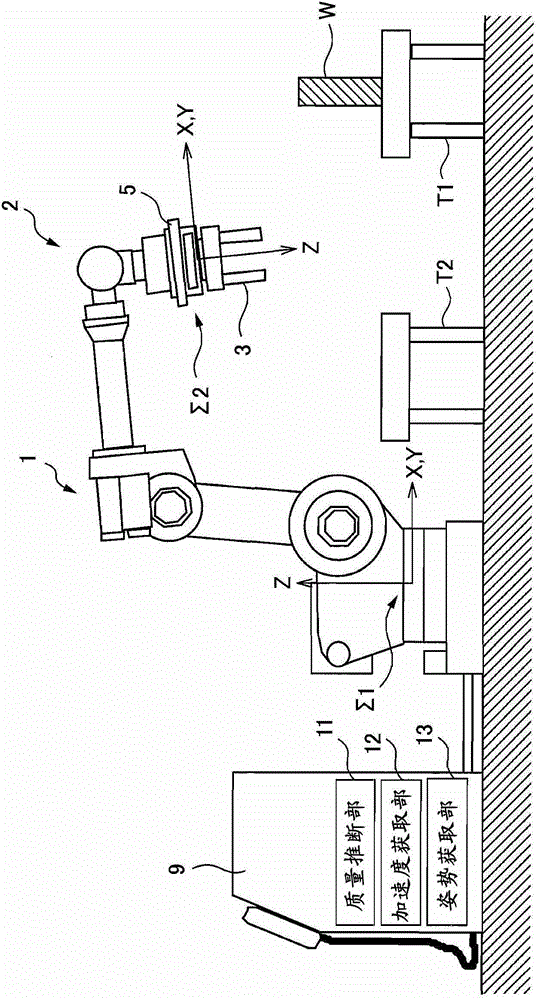

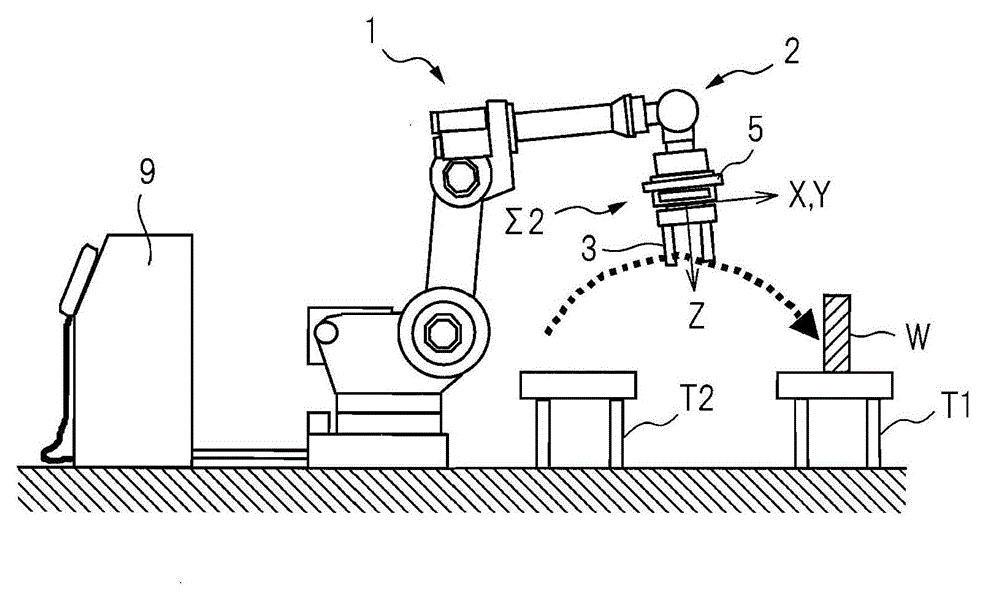

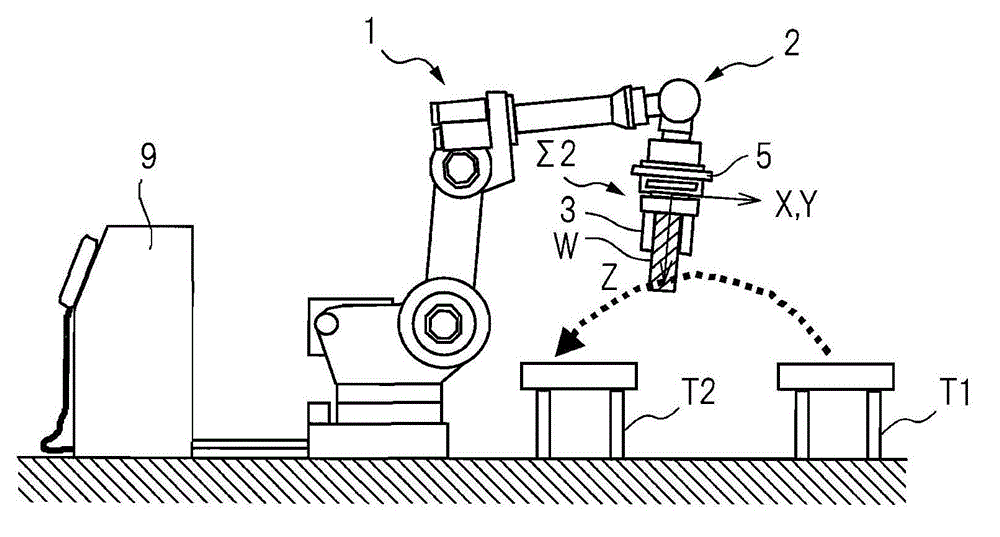

Robot having workpiece mass measurement function

ActiveCN102990642ALong cycleSimple structureProgramme controlProgramme-controlled manipulatorEngineeringMass measurement

The invention provides a robot having workpiece mass measurement function. Workpiece mass can be correctly obtained, even during operating. A robot (1) having a workpiece mass measurement function for measuring the mass of a workpiece that is held, includes a force measurement unit (5) that measures the force that is applied to the tip part (2) of the mechanism part of the robot (1), and a mass estimation unit (11) that estimates the mass of the workpiece that is held by the robot (1), based on information about the force acquired by the force measurement unit (5) while the robot (1) is moving. Workpiece mass can be correctly obtained, even during operating. Preferably, force measurement unit (5) estimates the mass of the workpiece according to a force measured value measured when the workpiece is held and a force measured value measured when the workpiece is not held.

Owner:FANUC LTD

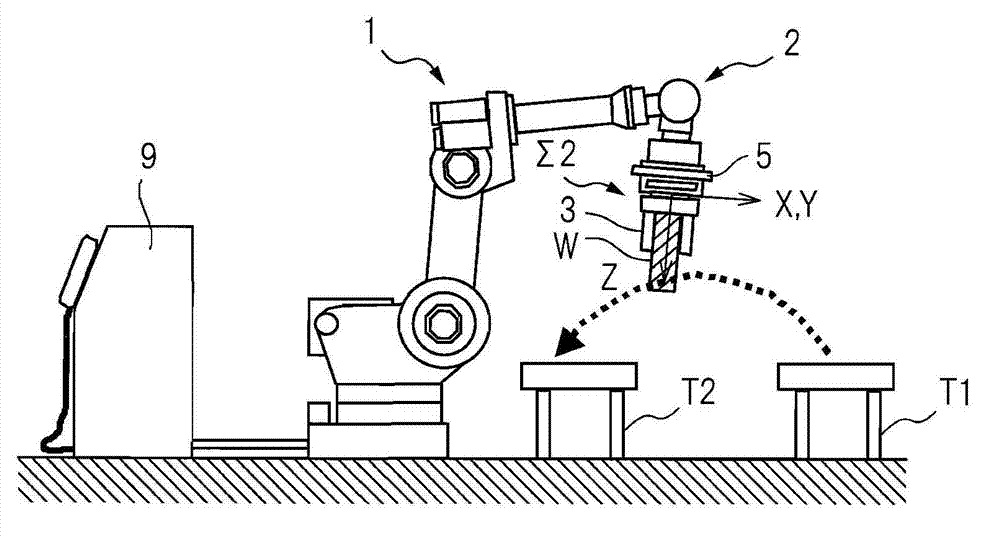

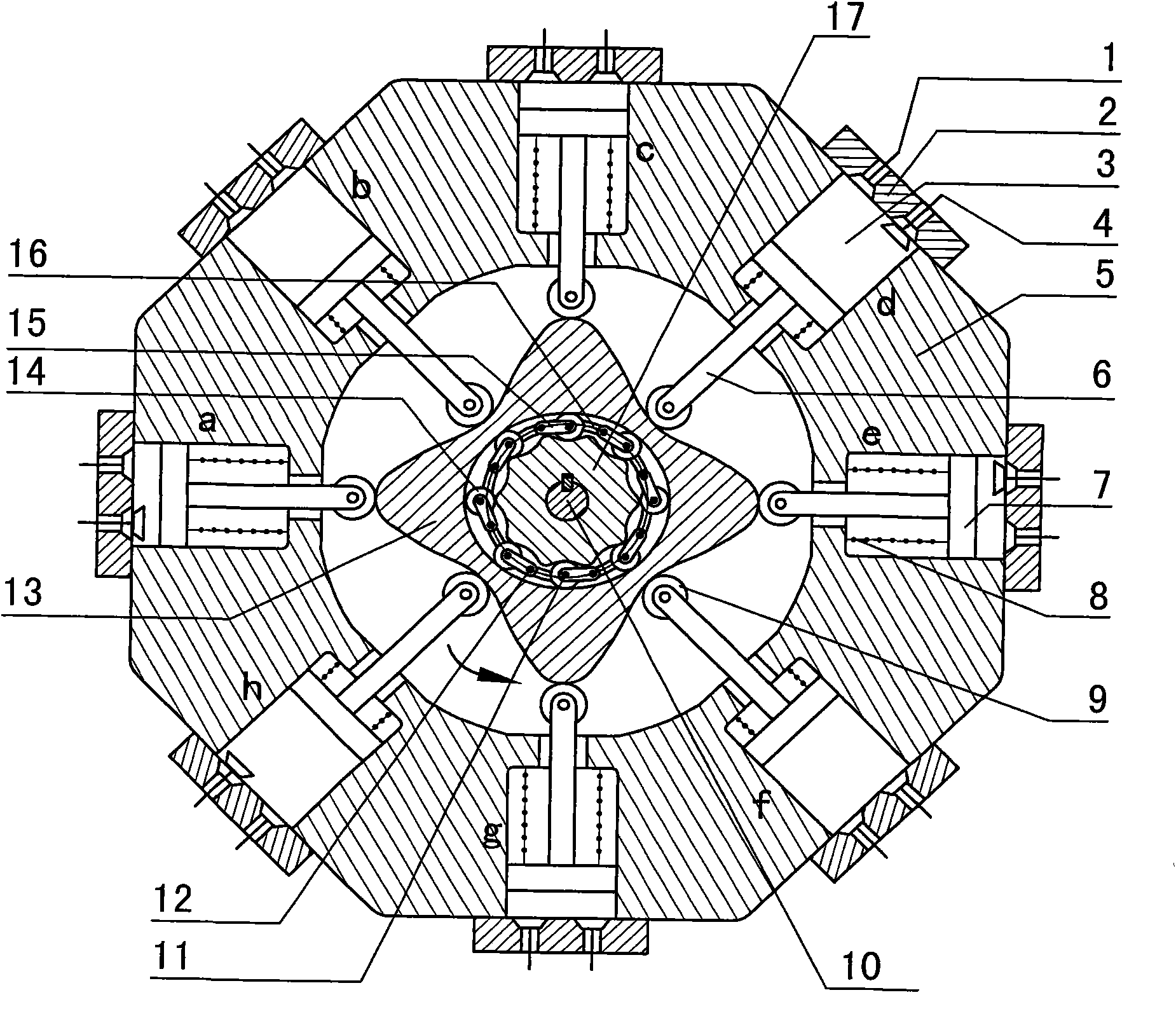

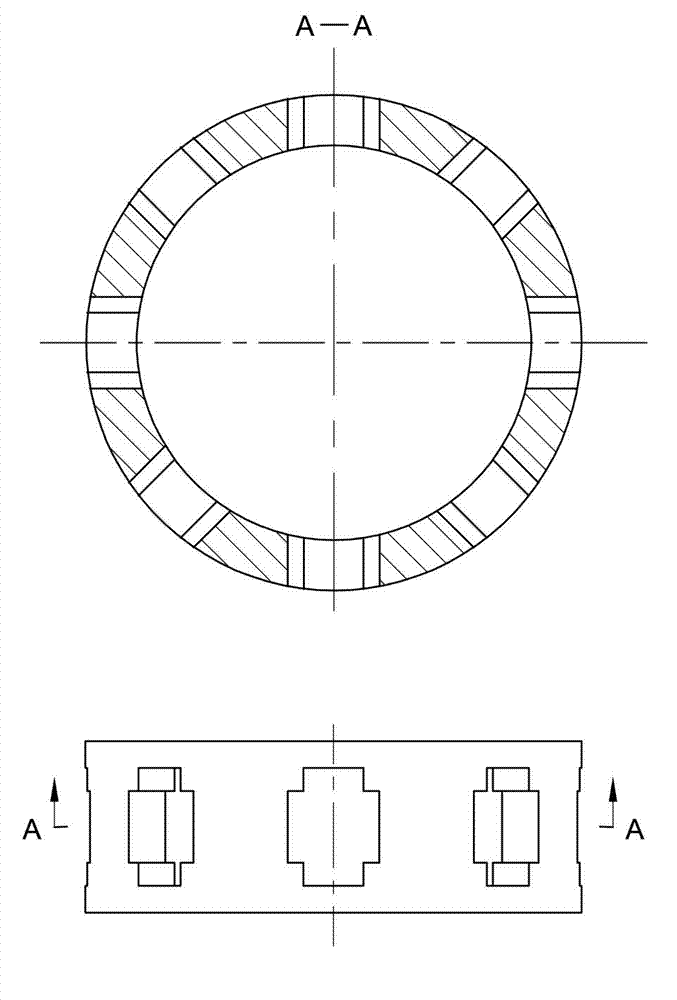

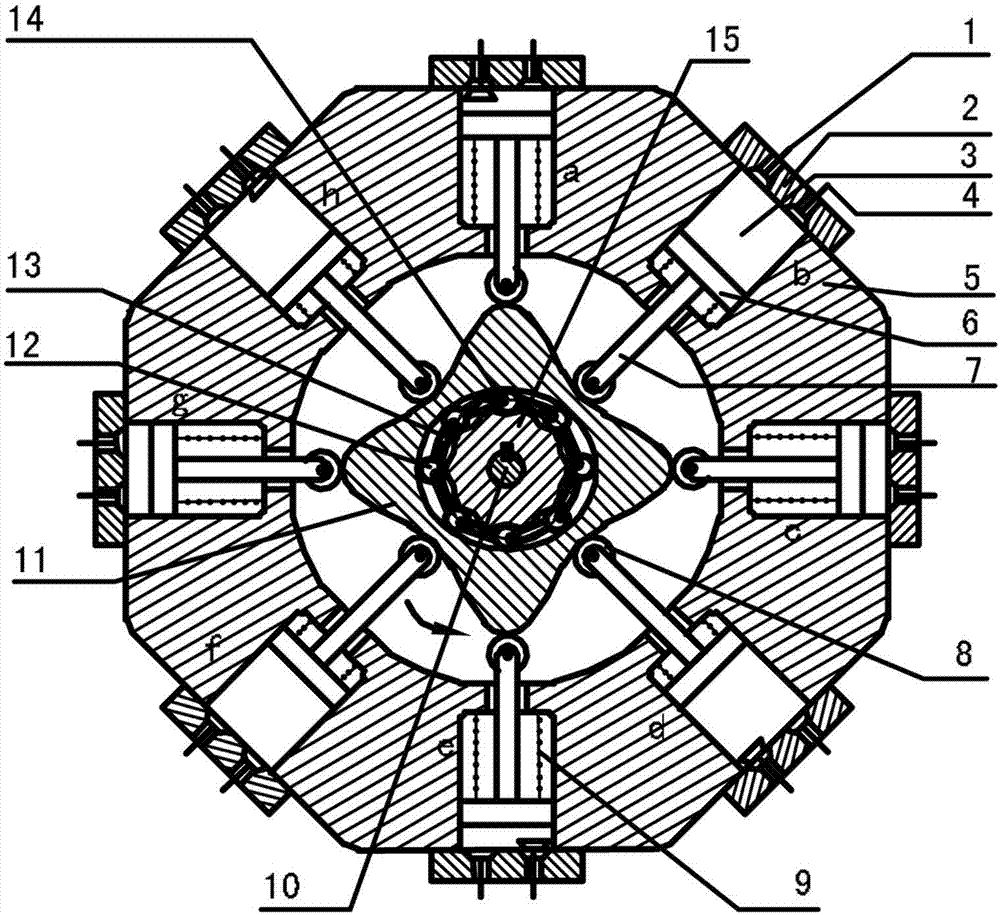

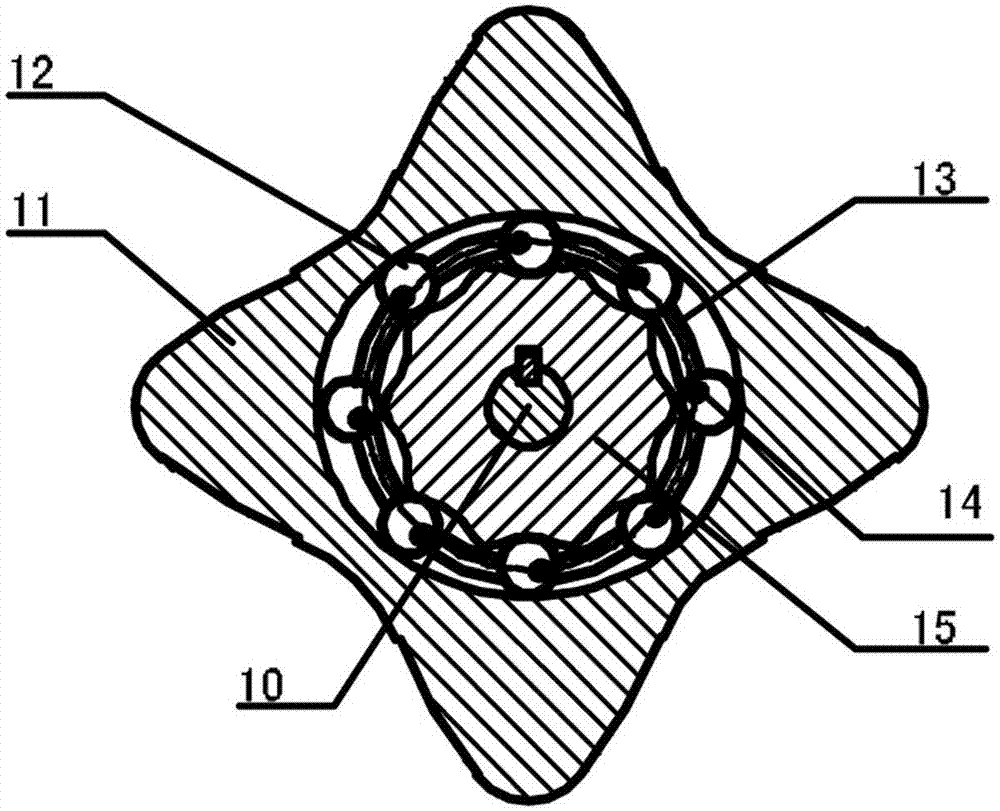

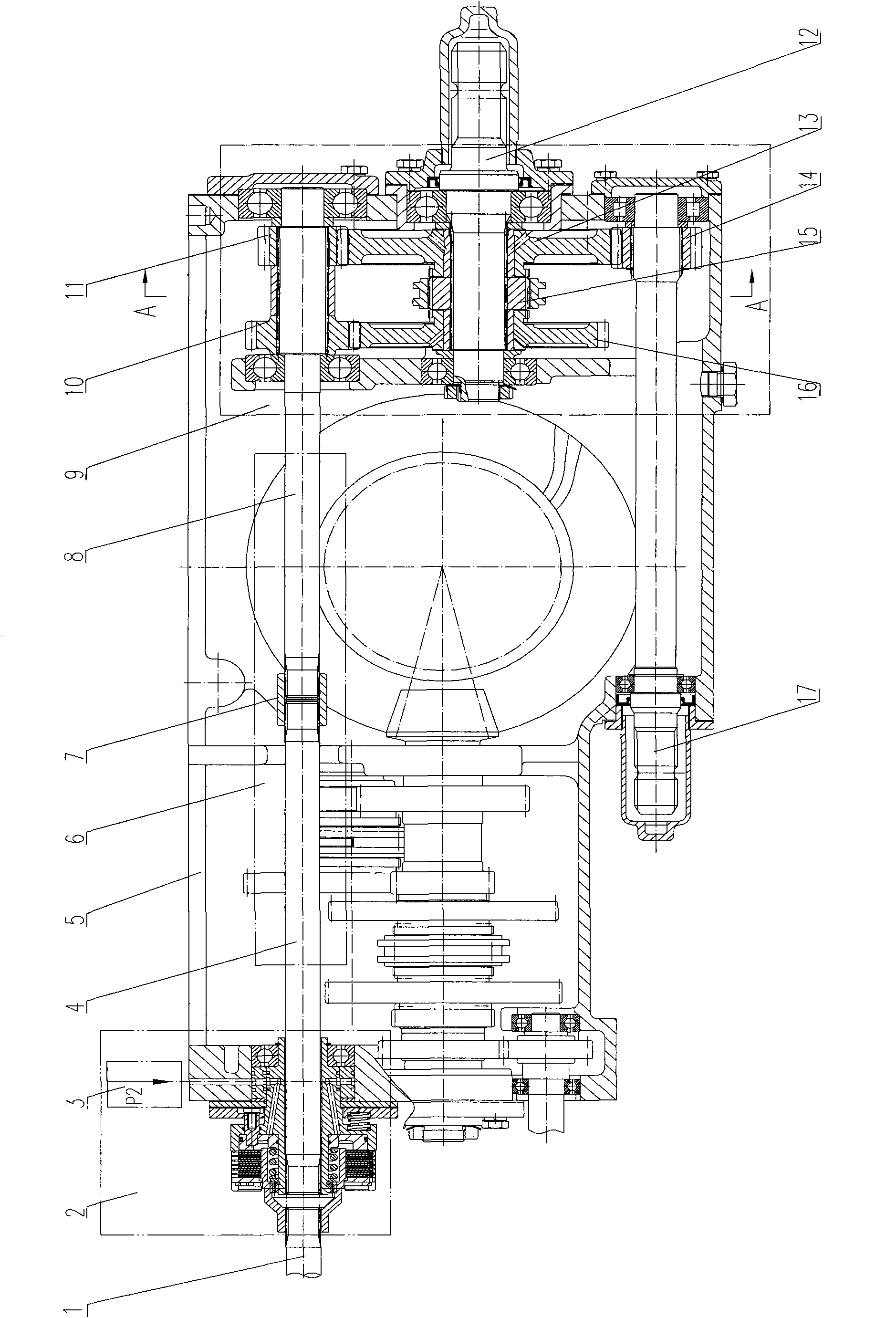

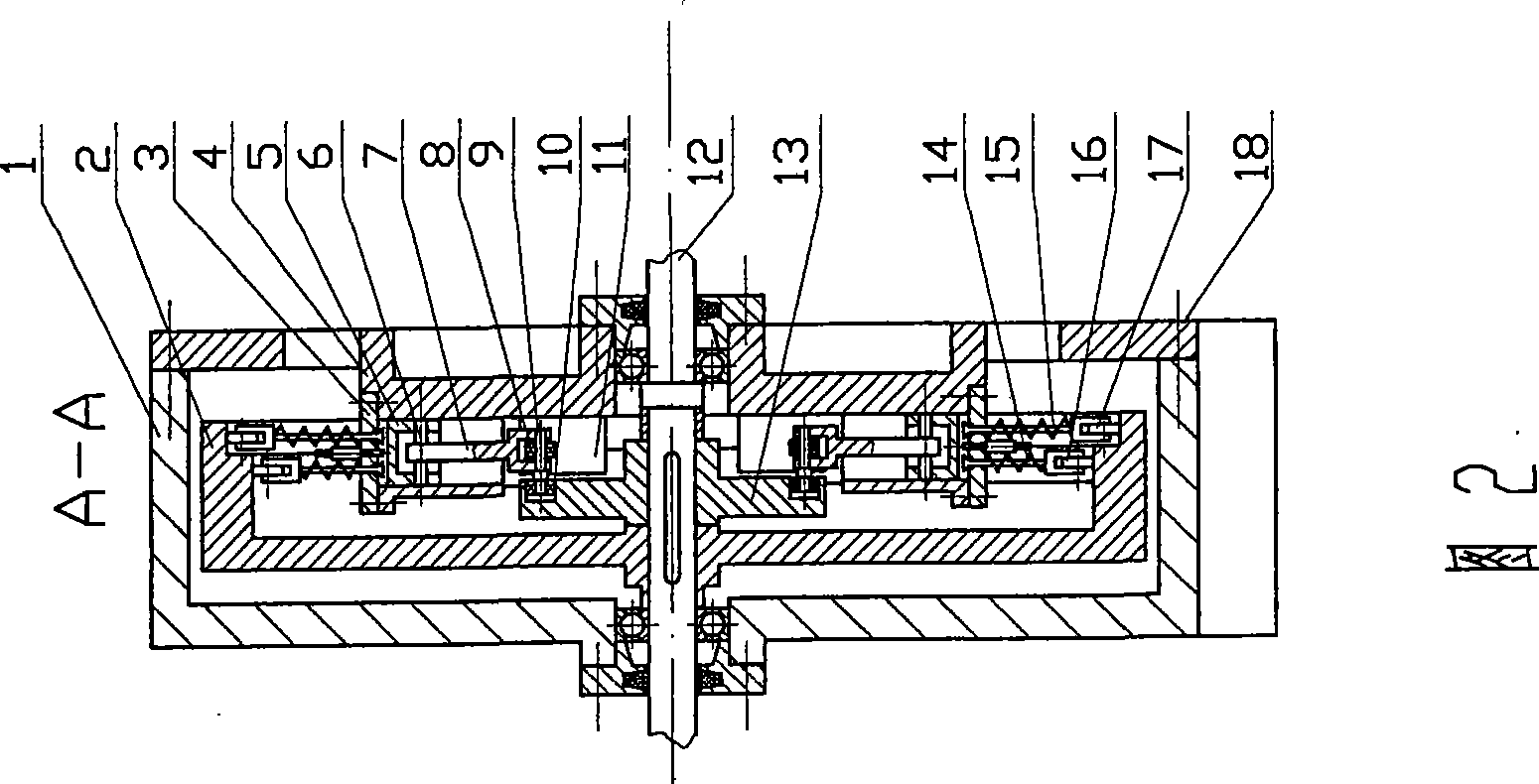

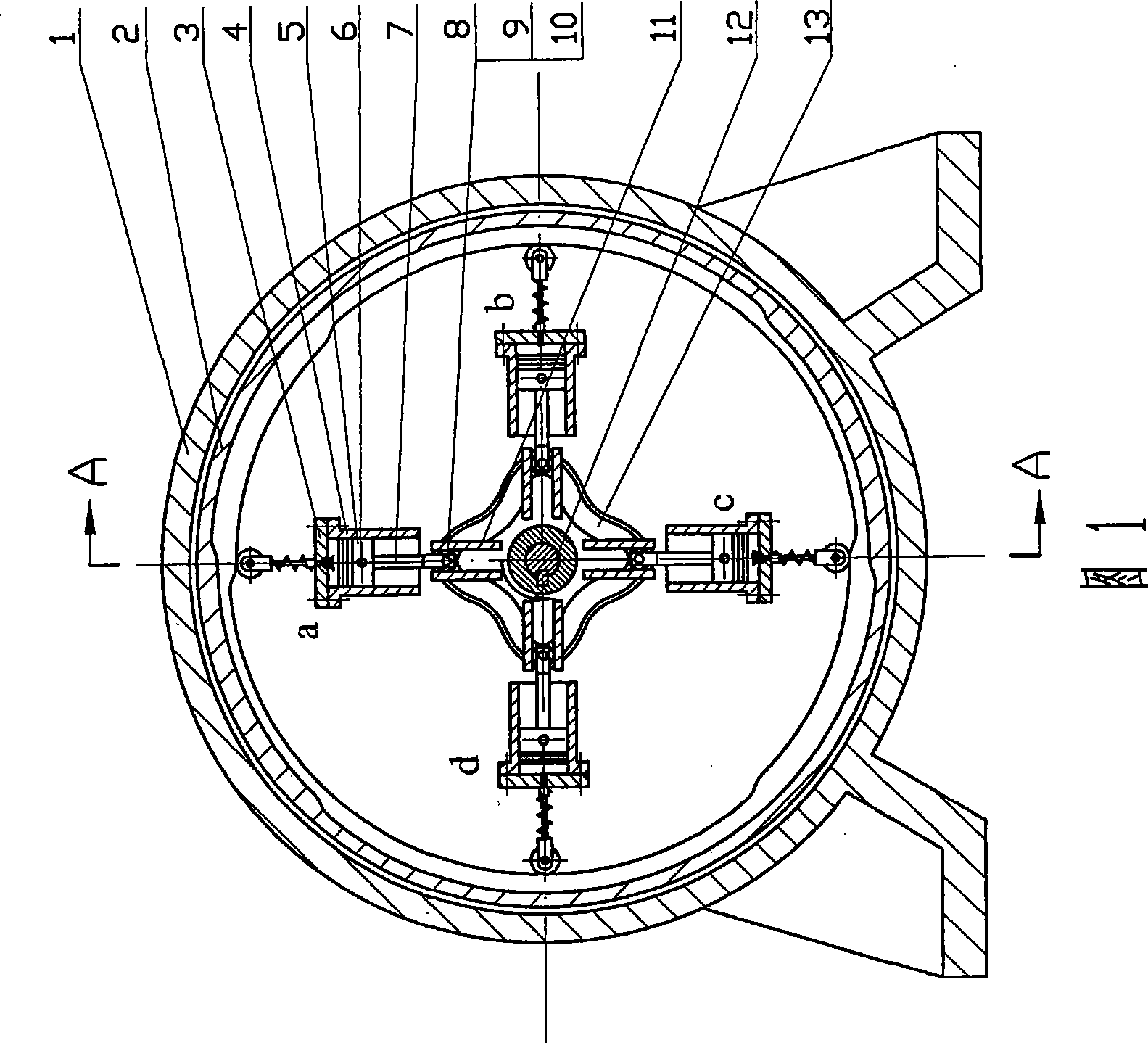

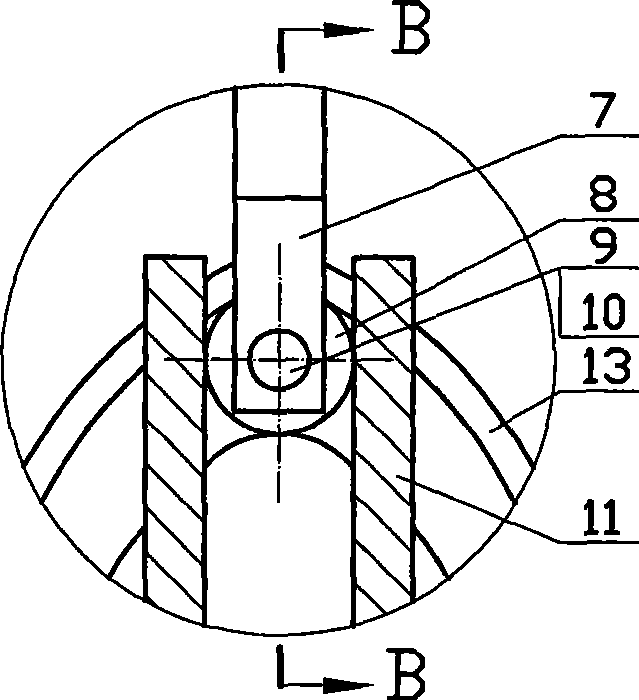

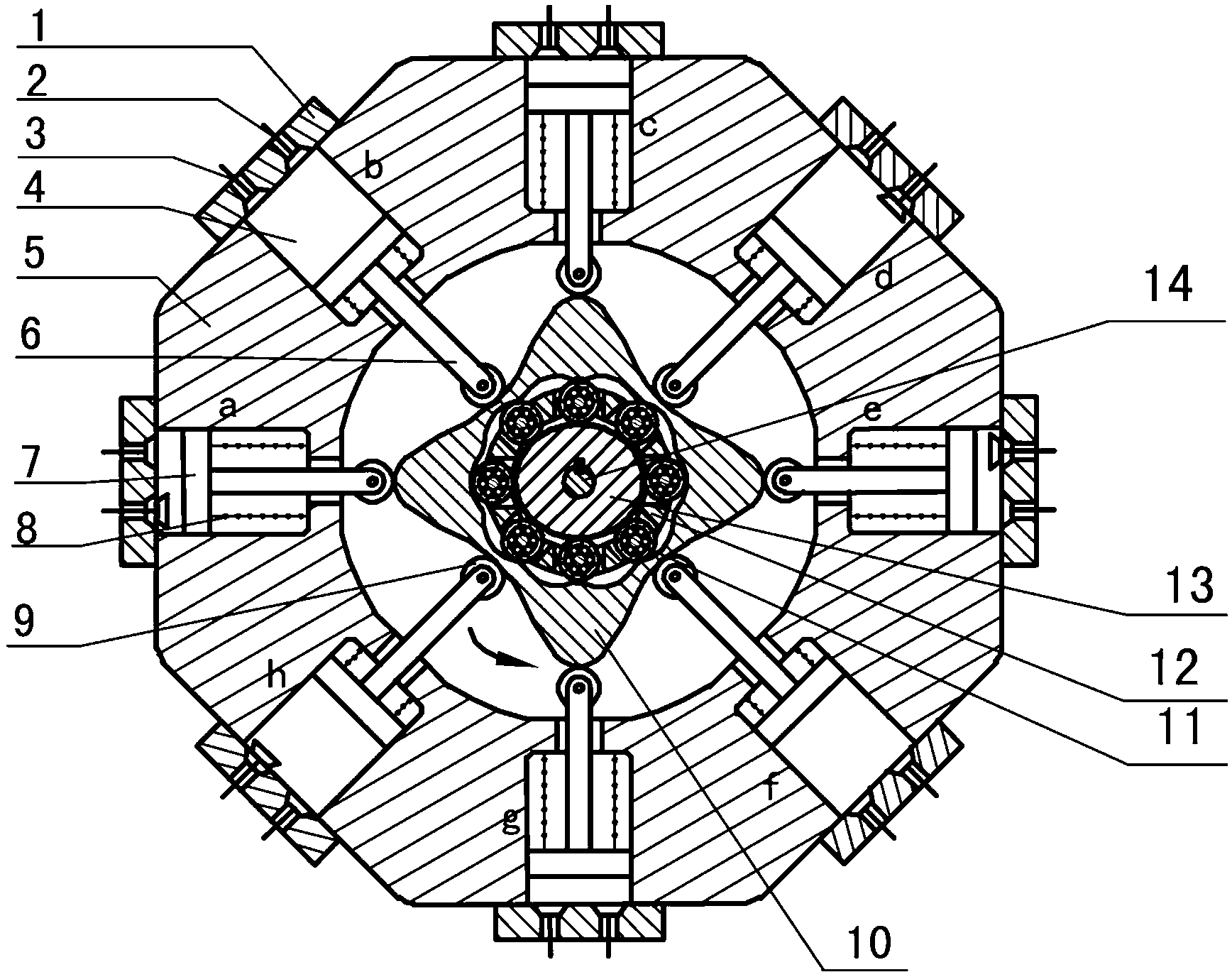

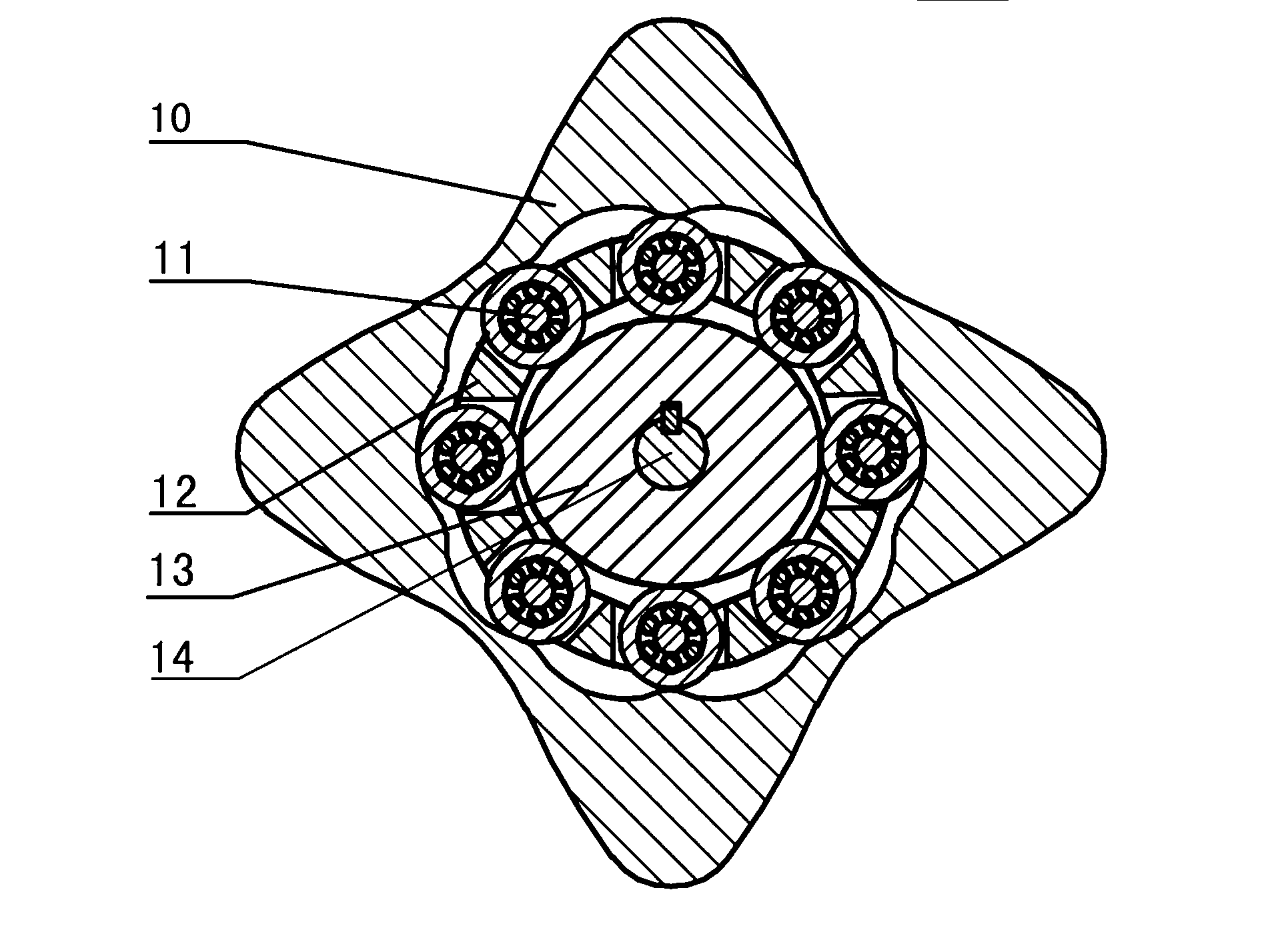

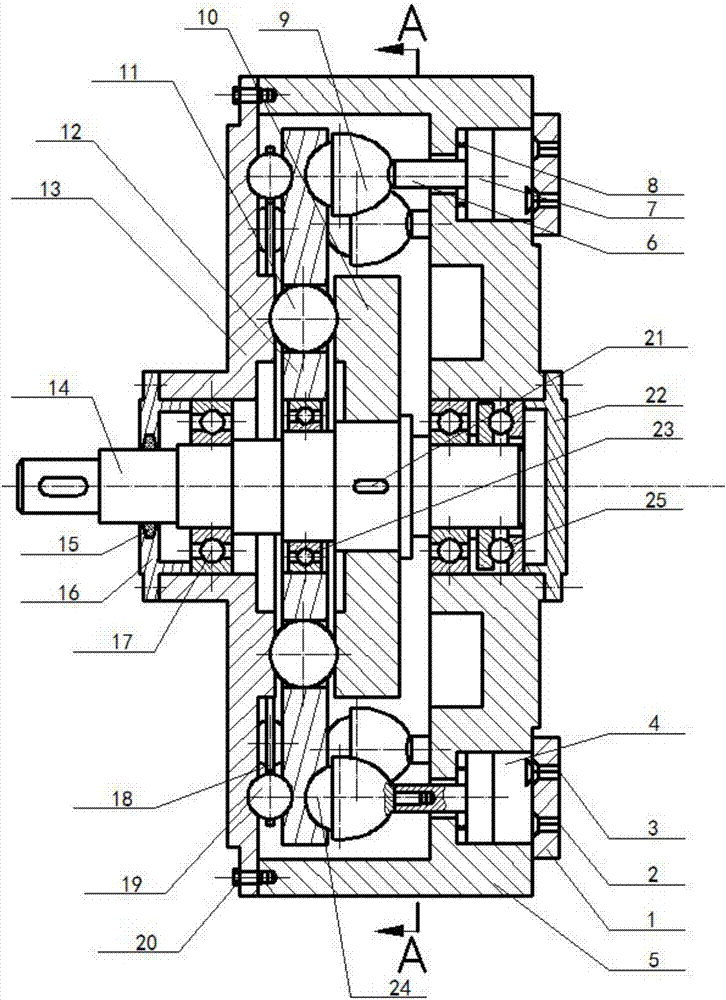

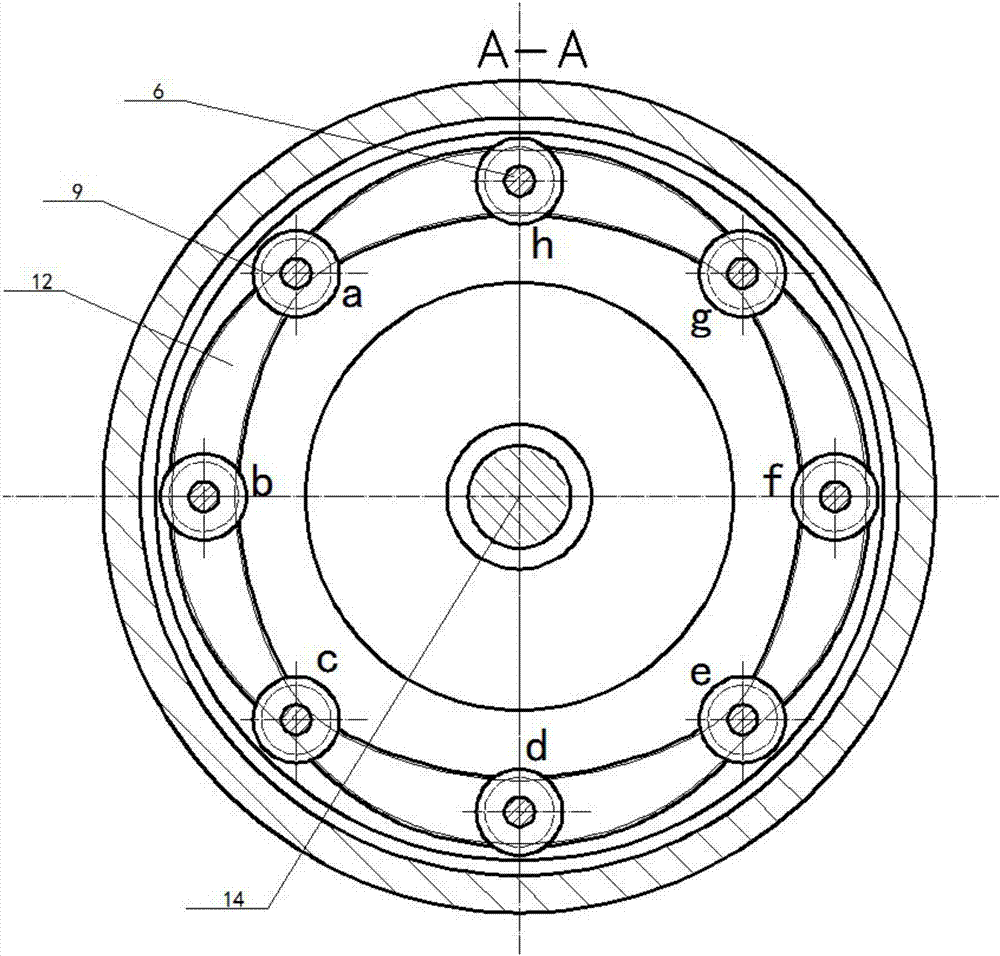

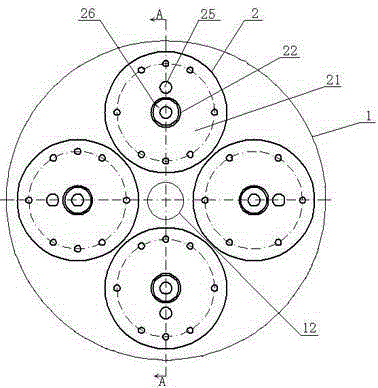

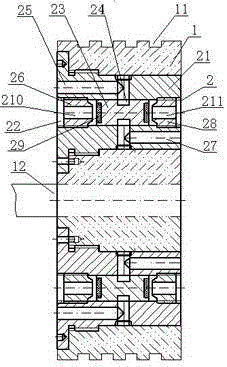

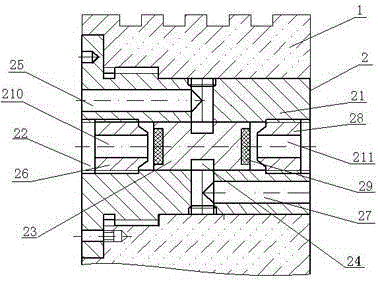

Internal dual-phase shockwave swing link transmission type internal combustion engine

InactiveCN101979853ACompact structureReduce axial sizeValve drivesMachines/enginesPistonResultant force

The invention discloses an internal dual-phase shockwave swing link transmission type internal combustion engine, relates to the field of gas power, and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, wherein eight cylinders are annularly, symmetrically and uniformly distributed around a convex internal dual-phase shockwave wheel, so that a resultant force stressed on the convex internal dual-phase shockwave wheel is zero; a cylinder piston directly acts on the convex internal dual-phase shockwave wheel through a push rod; and power is transferred to an output shaft which is connected with a wavelike wheel through keys from the convex internal dual-phase shockwave wheel through internal dual-phase shockwave swing link movable teeth. In the internal combustion engine, a connecting rod and a crank shaft in the conventional internal combustion engine are saved, and an external cam internal dual-phase shockwave swing link transmission mechanism of the conventional internal combustion engine does not have eccentric mass and has the advantage of self-balancing the inertial force and the working load. The rotation speed of the output shaft is determined by the transmission ratio of the transmission of the movable teeth; if a movable tooth frame is fixed, the wavelike wheel outputs low speed and large torque; and the internal combustion engine can be widely applied to the fields of military affaires and national defense needing high power, such as tanks, armored vehicles, engineering machinery and the like. The internal combustion engine has the advantages of simple and compact structure, small axial dimension and self-balanced stressing and operates stably.

Owner:SICHUAN UNIV

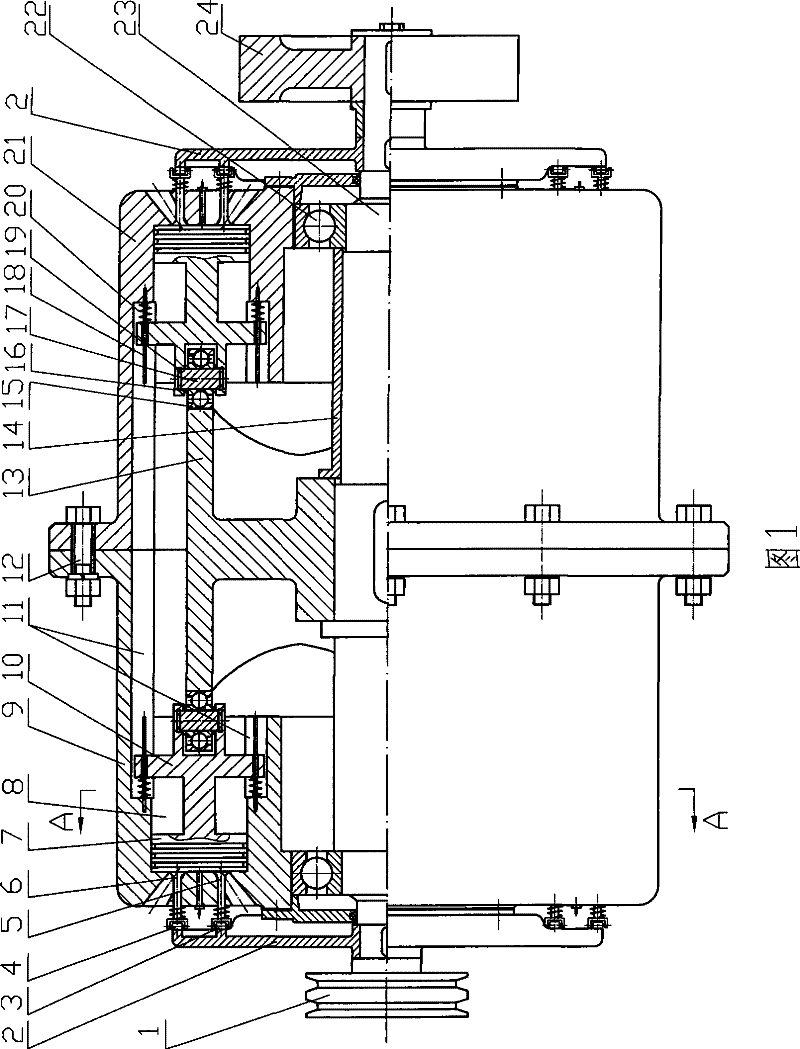

Double-phase shock wave swing rod type high-speed internal combustion engine

InactiveCN102094710ASmall shock and vibrationReduce noiseValve drivesMachines/enginesShock waveDouble phase

The invention discloses a double-phase shock wave swing rod type high-speed internal combustion engine, and relates to the field of fuel gas power. The invention provides a novel internal combustion engine, wherein eight cylinders are annularly, symmetrically and uniformly distributed around a convex inner central wheel, so that the resultant force borne by the convex inner central wheel is zero; cylinder pistons directly act on the convex inner central wheel through push rods; and the power is transmitted to an output shaft connected with a double-phase shock wave wheel key from the convex inner central wheel through a movable tooth transmission of a double-phase shock wave swing rod. In the internal combustion engine, a connecting rod and a crankshaft in the traditional internal combustion engine are omitted; and a double-phase shock wave swing rod transmission mechanism in the convex wheel has no eccentric mass and has the advantage of automatic balance of inertia force and working load. The revolution speed of the output shaft depends on the transmission rate of the movable tooth transmission; if a movable tooth rack is fixed, the double-phase shock wave wheel outputs power at a high speed; the internal combustion engine can be widely applied to the fields in need of high revolution speed, such as small generators, helicopter engines and the like; and when the output revolution speed is regular, the emission of harmful gases can be reduced. The internal combustion engine has the advantages of simple and compact structure, small axial size, automatic stress balance and stability in operation.

Owner:SICHUAN UNIV

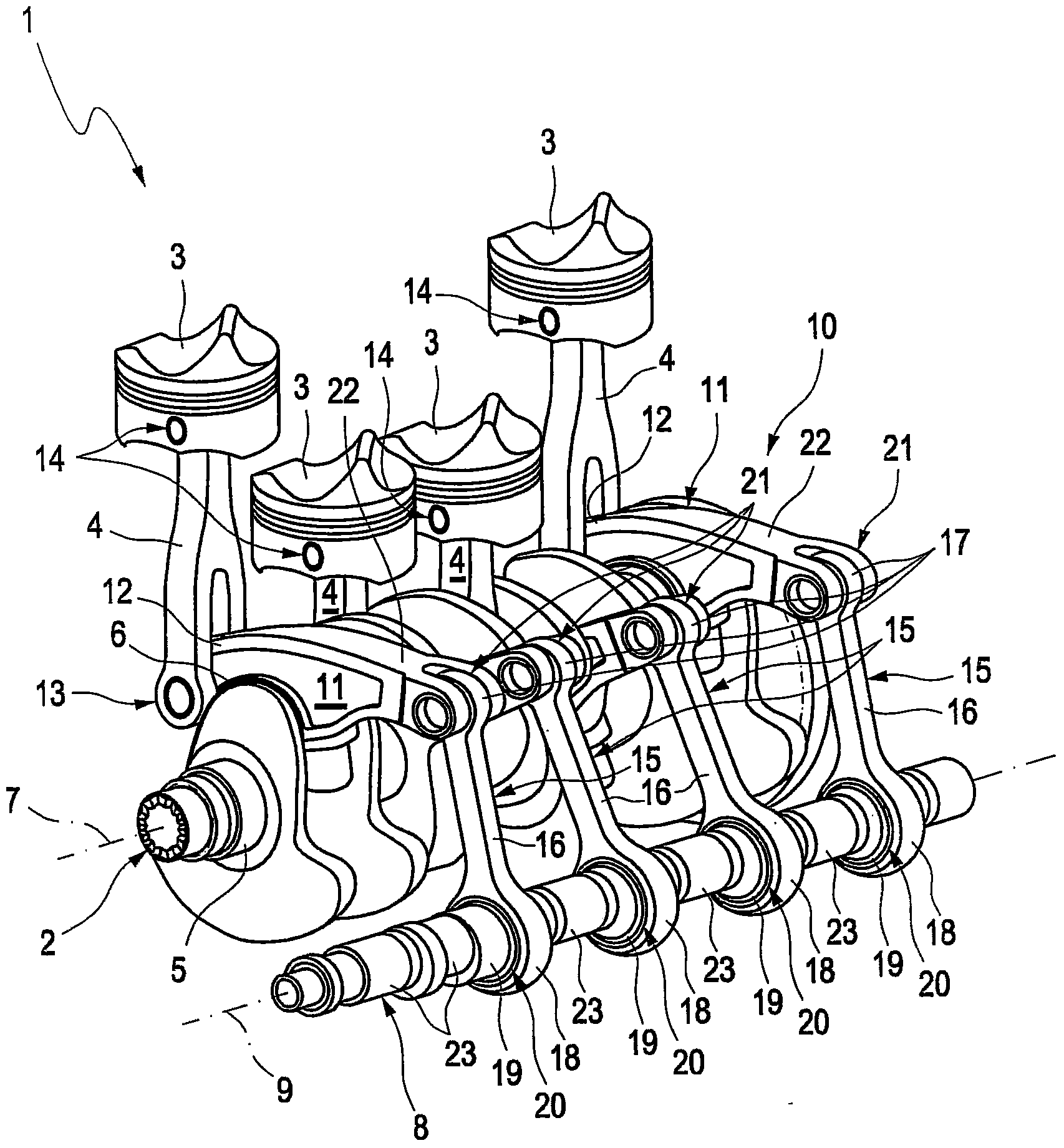

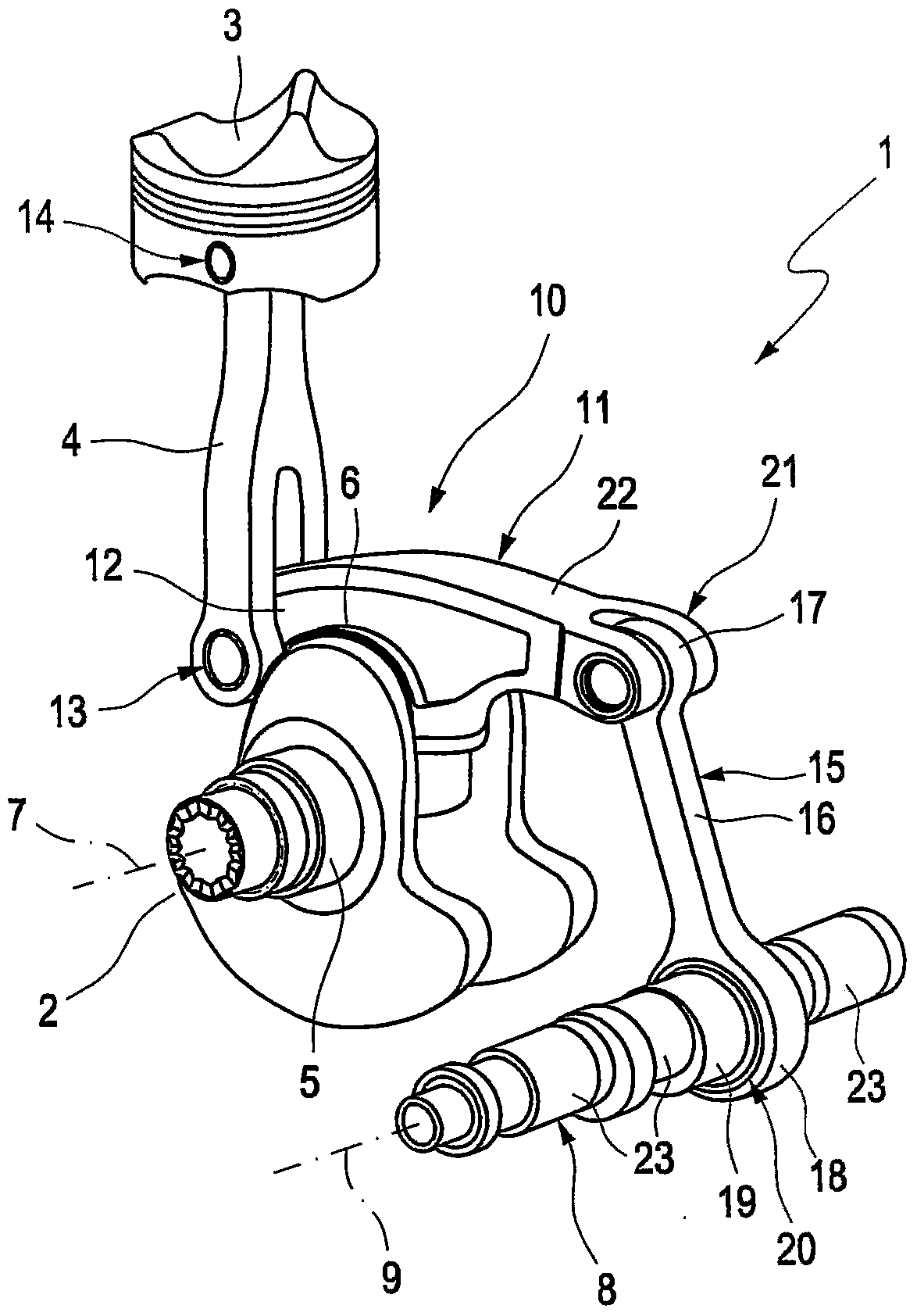

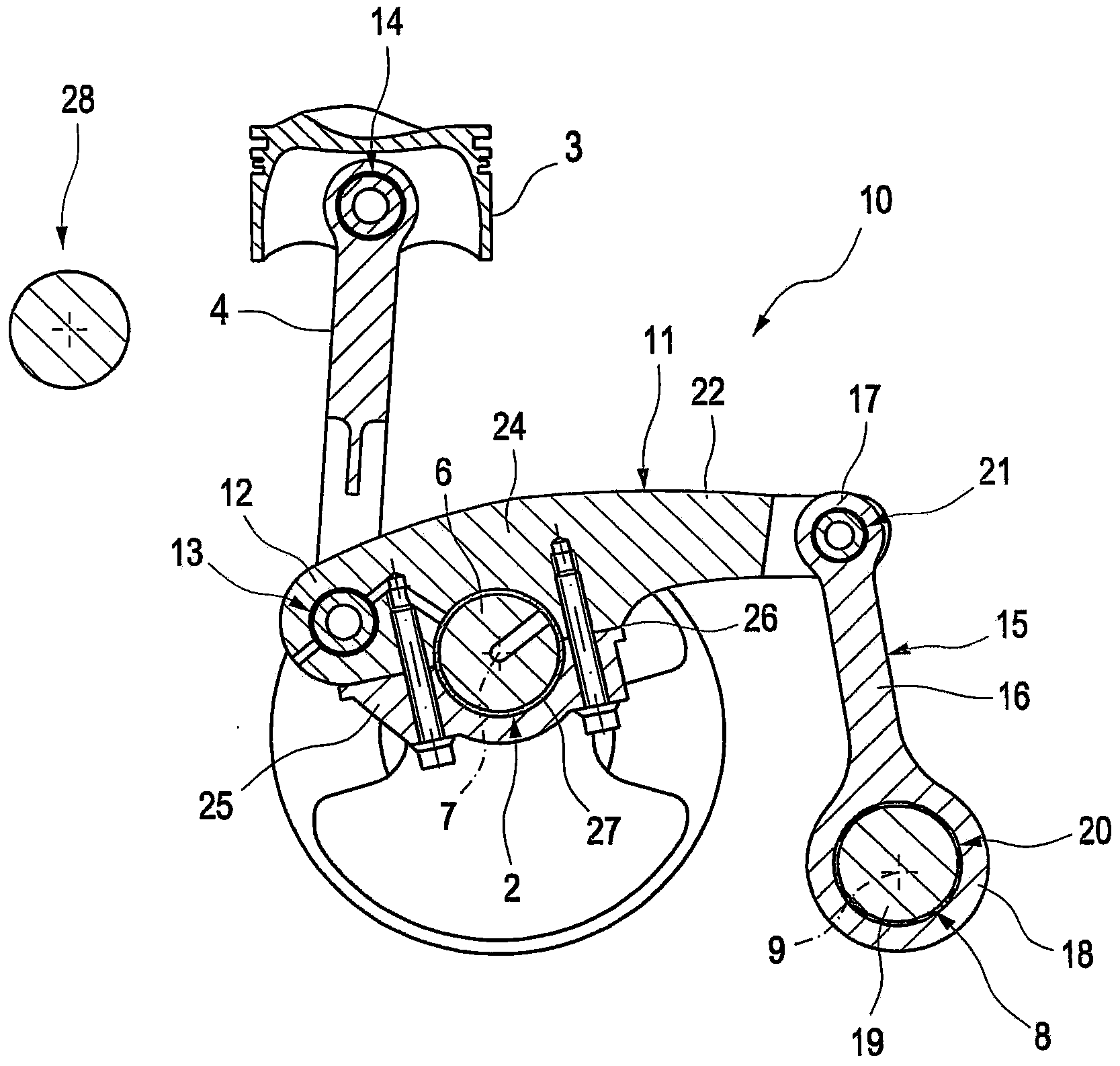

Internal combustion engine

ActiveCN103765040AImprove acoustic performanceEliminate inertial forceValve arrangementsInertia force compensationEngineeringInternal combustion engine

The invention relates to an internal combustion engine (1) having a multi-joint crank drive (10), said multi-joint crank drive (10) comprising a plurality of coupling members (11) rotatably mounted on crank pins (6) of a crankshaft (2) and a plurality of articulated connecting rods (15) rotatably mounted on crank pins (19) of an eccentric shaft (8), wherein each of the coupling members (11) is pivotably connected to a piston connecting rod (4) of a piston (3) of the internal combustion engine (1) and to one of the articulated connecting rods (15). A balance shaft (28), which is driven by a crankshaft (2) via a phase adjuster, is provided in order to at least partially dampen second-order mass forces occurring in the internal combustion engine (1).

Owner:AUDI AG

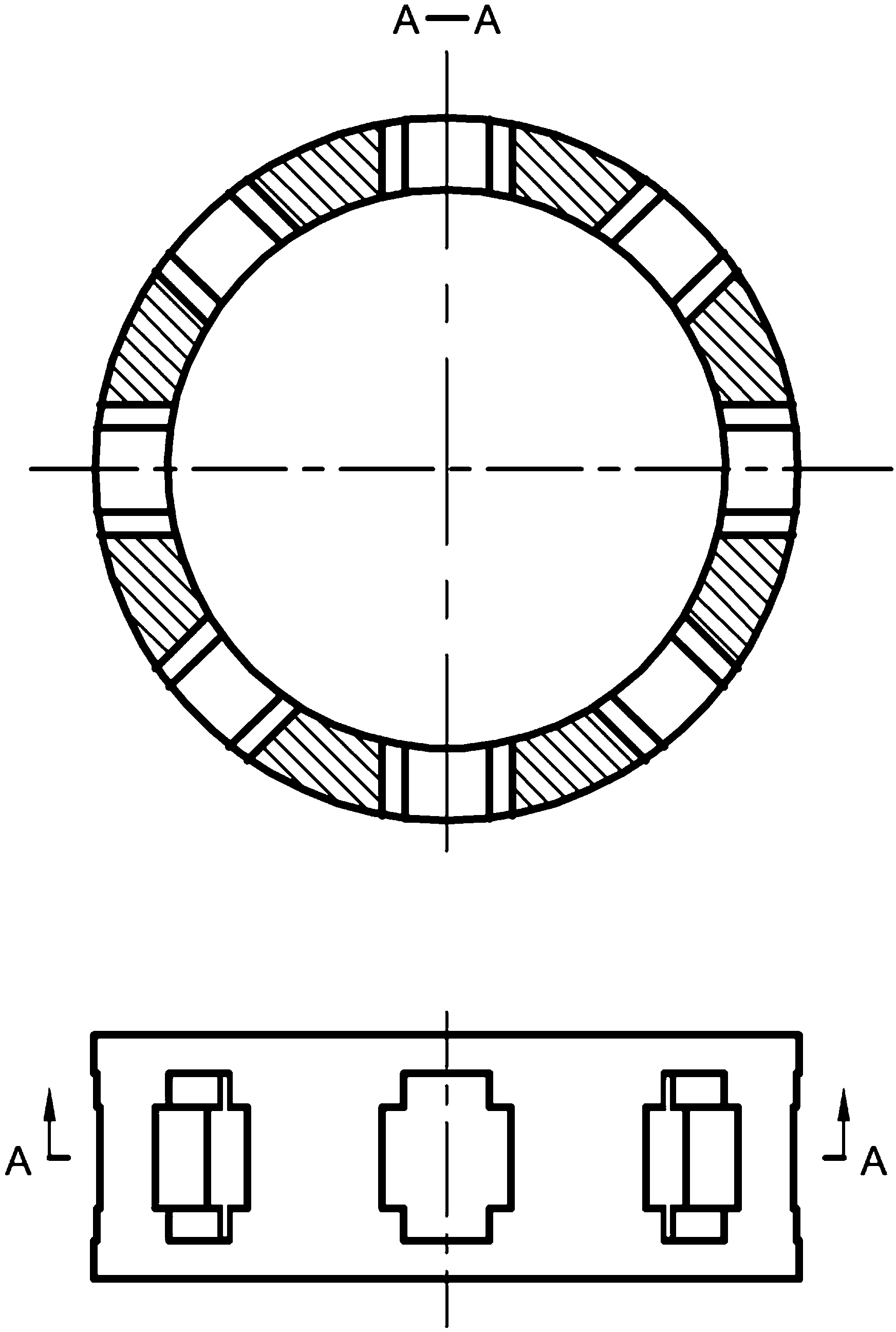

Outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine

The invention discloses an outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine, relating to the field of fuel gas power and belonging to a multi-cylinder internal-combustion engine. The invention provides a novel internal-combustion engine; eight cylinders are distributed on the periphery of an outer convex inner multiphase inner cam symmetrically in a ring shape, so that a resultant force of the outer convex inner multiphase inner cam is zero; each cylinder piston directly acts on the outer convex inner multiphase inner cam through a push rod; and power is transmitted to an output shaft connected with a central wheel key by the outer convex inner multiphase inner cam through arbitrary gear difference inner cam rolling moving movable gear transmission. With the adoption of the internal-combustion engine, a connecting rod and a crank shaft in the traditional internal-combustion engine are saved; an outer convex multiphase inner cam rolling moving transmission mechanism has the characteristics of having no eccentric mass, and having an inertia force and working load self-balancing; the rotating speed of the output shaft depends on transmission ratio of movable gear transmission; when a movable gear frame is fixed, output by a central wheel is in low speed and large torque; and the internal-combustion engine can be widely applied to the fields of high-power engineering machinery and military and the like, such as excavators and armored cars. The internal-combustion engine is simple and compact in structure, small in axial size, self-balancing in stress, and stable in rotating.

Owner:SICHUAN UNIV

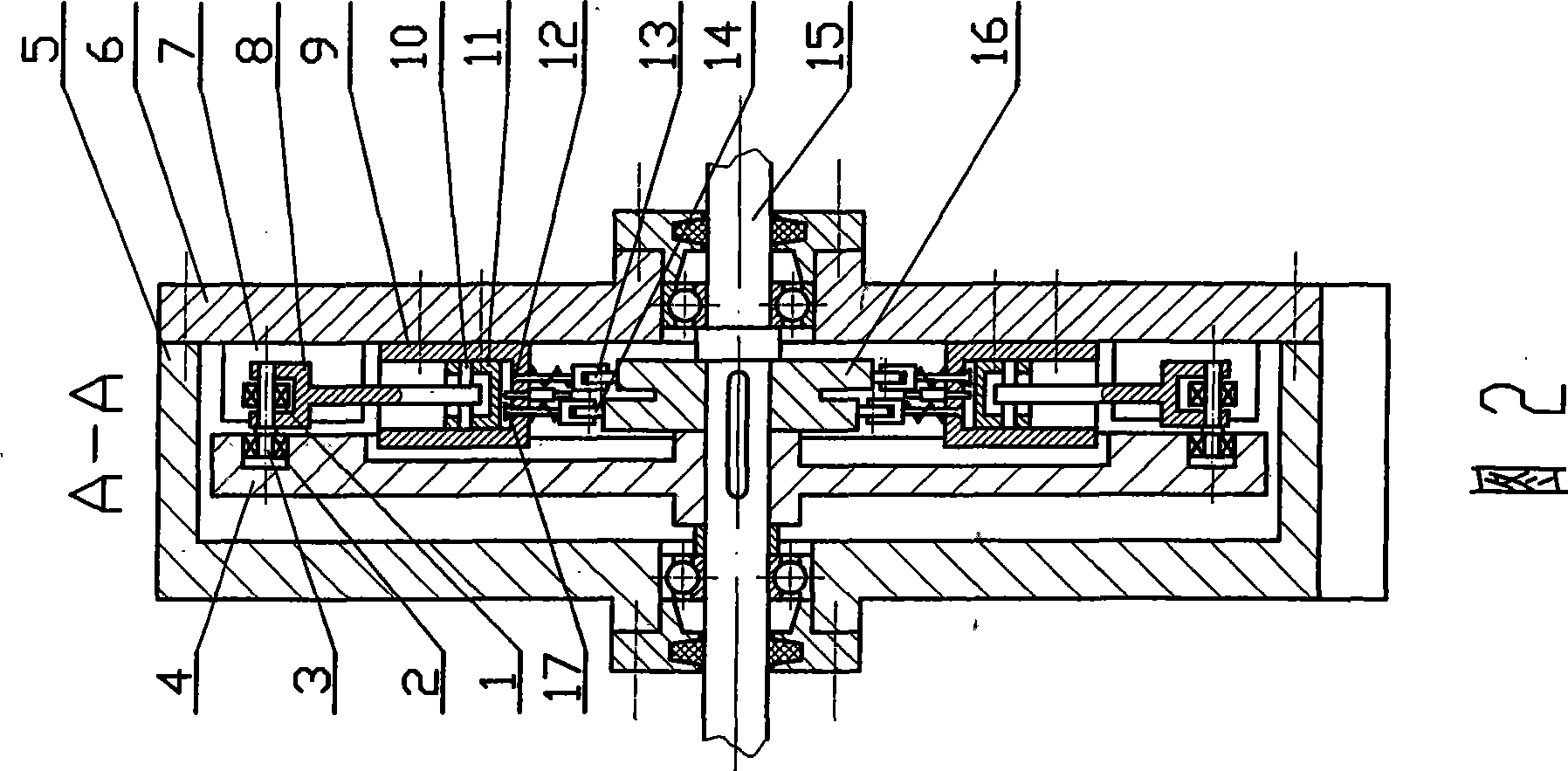

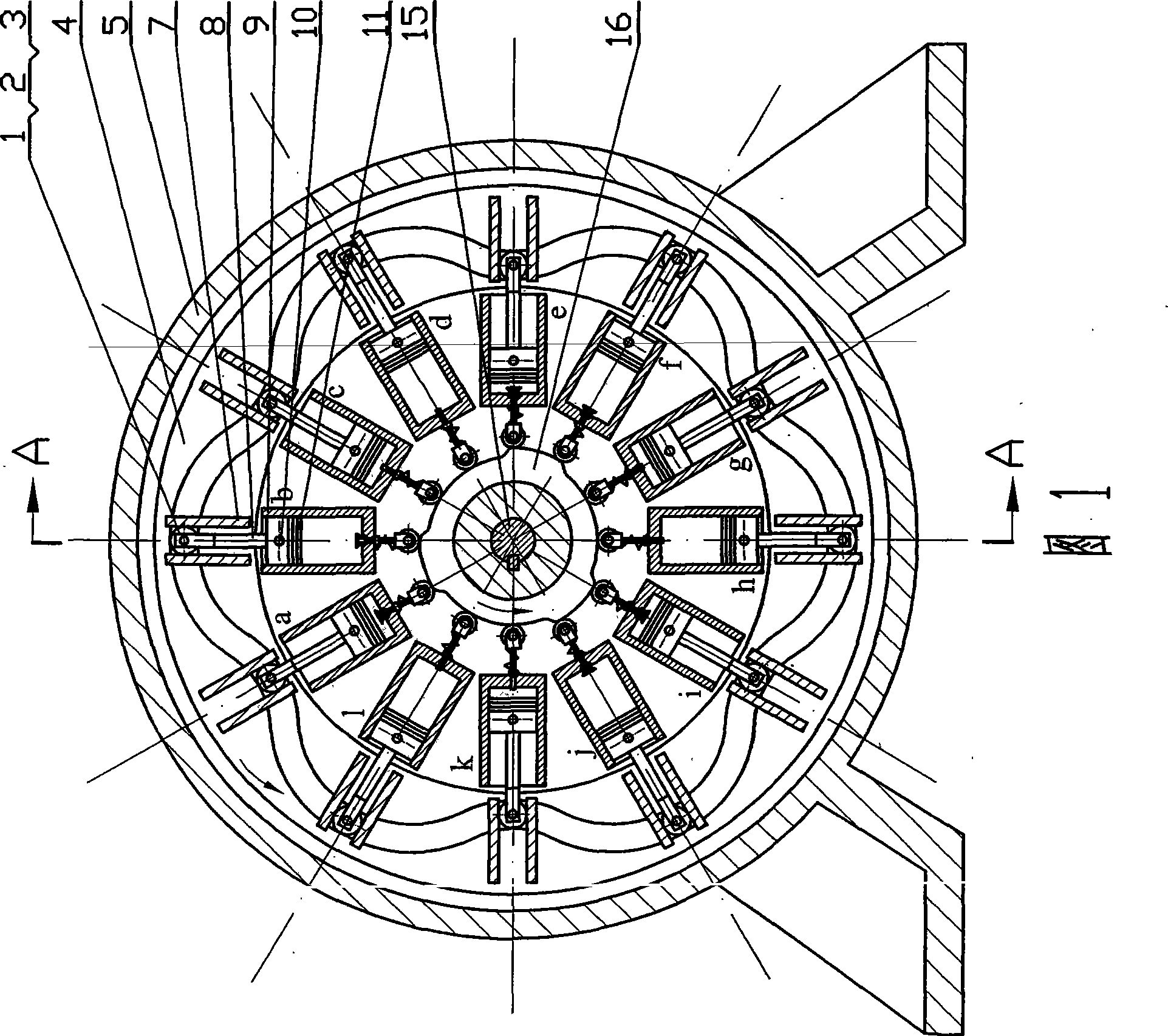

Internal wave type non-crankshaft internal combustion engine

InactiveCN101435363ACompact structureReduce the numberValve drivesMachines/enginesExhaust valveExternal combustion engine

The invention discloses an internal wave type crankshaft-free internal combustion engine. An internal wave wheel and a dual cascade valve cam are both fixed on an output shaft. Twelve cylinders are axially, symmetrically, annularly and evenly arranged on the circumference of the dual cascade valve cam inside the internal wave wheel. One end of a push rod is hinged with pistons; the other end of the push rod has a cam roller and a push rod roller; and the cam roller is inserted into a shape groove of the internal wave wheel, and the push rod roller is arranged in a guide groove. The driving force of the pistons is transmitted to the internal wave wheel and the output shaft by the push rod and is outputted, thereby saving a crankshaft and a connecting rod in the prior internal combustion engine. The guide groove bears a circumferential component force of the force given to the push rod by the internal wave wheel, thereby bringing about zero side pressure between the pistons and the cylinder walls. All acting forces of the pistons on the internal wave wheel are completely balanced. The dual cascade valve cam controls the intake and exhaust valves of all cylinders without a valve timing driving mechanism. The internal combustion engine is characterized by compact and simple structure, no side pressure, small axial size, low vibration, stable running, high outputted torque and power, high efficiency, long service life, and the like.

Owner:SICHUAN UNIV

Two-phase outer cam sleeve type high-rotational-speed internal-combustion engine

InactiveCN102877942AHigh speed outputReduce axial sizeGearingMachines/enginesEngineeringInternal combustion engine

The invention discloses a two-phase outer cam sleeve type high-rotational-speed internal-combustion engine, and relates to the field of power of fuel gas. The invention provides a novel internal-combustion engine. Eight cylinders are annularly, symmetrically and uniformly distributed around an outwards convex inner gear ring, so that resultant force from which the outwards convex inner gear ring is suffered is zero; pistons of the cylinders directly act on the outwards convex inner gear ring through push rods; and power is transferred to an output shaft connected with a symmetric two-phase cam through a key by the outwards convex inner gear ring through the drive of a two-phase outer cam type sleeve oscillating tooth. By using the internal-combustion engine, a connecting rod and a crankshaft in a conventional internal-combustion engine are omitted; a two-phase outer cam sleeve driving mechanism of the outwards convex inner gear ring of the internal-combustion engine does not have an eccentric mass; the internal-combustion engine has the characteristic of the self balancing of inertia force and a working load; the rotational speed of the output shaft depends on the drive ratio of the drive of the oscillating tooth; if a dowel pin frame is fixedly arranged, the symmetric two-phase cam carries out output at a high speed; the internal-combustion engine can be widely applied to the field of high rotational speeds, such as engines of helicopters, and miniature engines; and when an output rotational speed is constant, the emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, small in axial dimension and self-balancing in stress, and is stable to run.

Owner:SICHUAN UNIV

Two-phase inner cam type swinging transmission internal combustion engine

InactiveCN102828824AForce self-balancingLarge transmission ratioGearingMachines/enginesLow speedEngineering

The invention provides a two-phase inner cam type swinging transmission internal combustion engine, which relates to the field of gas motive power and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, eight air cylinders are annularly, symmetrically and uniformly distributed around an outer convex inner two-phase inner cam, the resultant force of the outer convex inner two-phase inner cam is zero, an air cylinder piston directly acts on the outer convex inner two-phase inner cam through a push rod, and the motive power is transferred to an output shaft connected with a center wheel key through a two-phase inner cam type swinging movable tooth via the outer convex inner two-phase inner cam. The internal combustion engine has the characteristics that a connecting rod and a crankshaft in the traditional internal combustion engine are omitted, and an outer convex inner two-phase inner cam type swinging transmission mechanism does not have the eccentric mass, and has the inertia force and work load self balance characteristic. The rotating speed of the output shaft depends on the transmission ratio of the movable tooth transmission, when the movable tooth frame is fixed, a center wheel realizes low-speed and large-torque output, and the internal combustion engine can be widely applied to engineering machinery, armored car and the like with high-powder requirements. The internal combustion engine has the advantages that the structure is simple and compact, the axial dimension is small, the self balance of the stress is realized, and the operation is stable.

Owner:SICHUAN UNIV

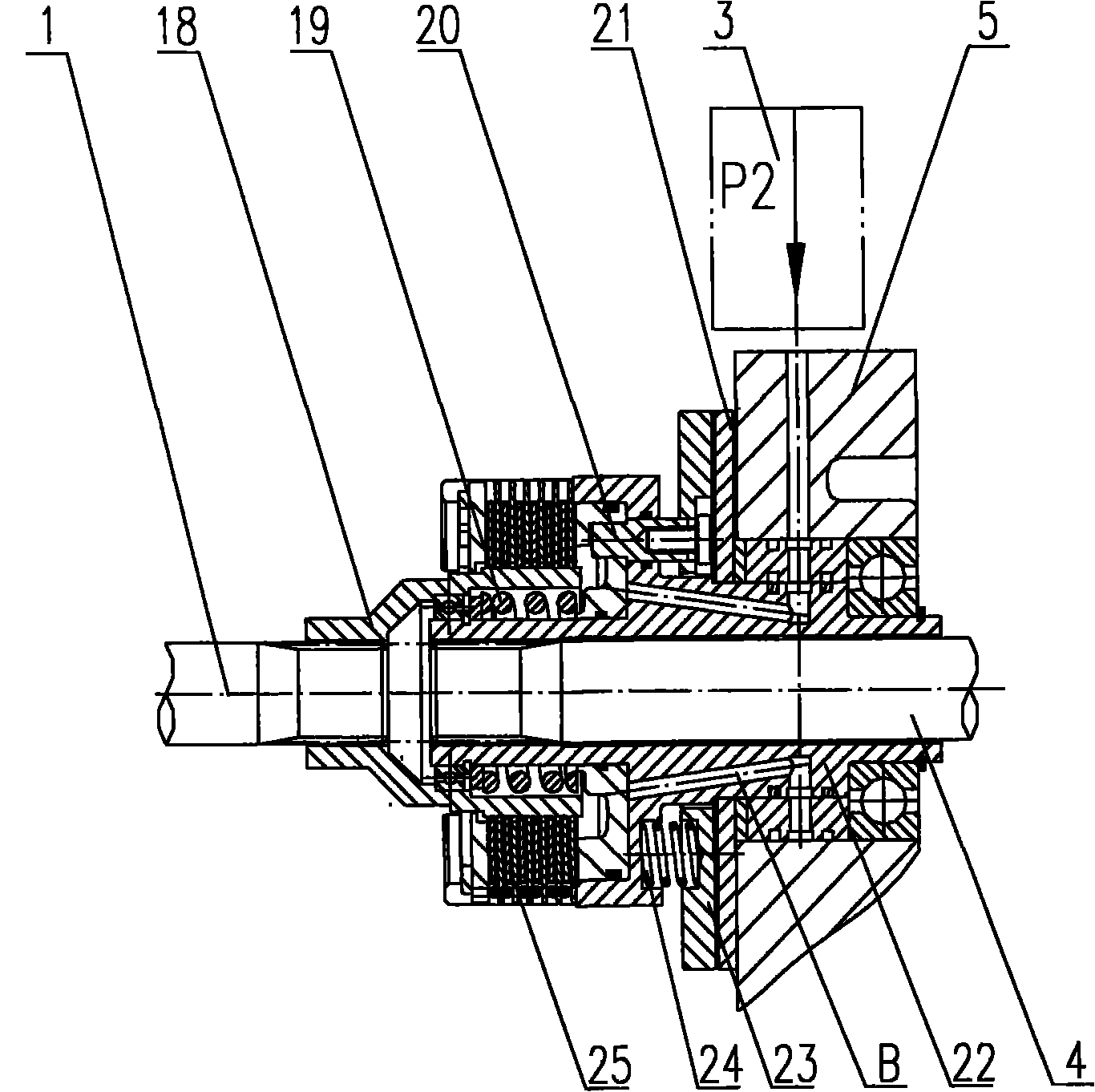

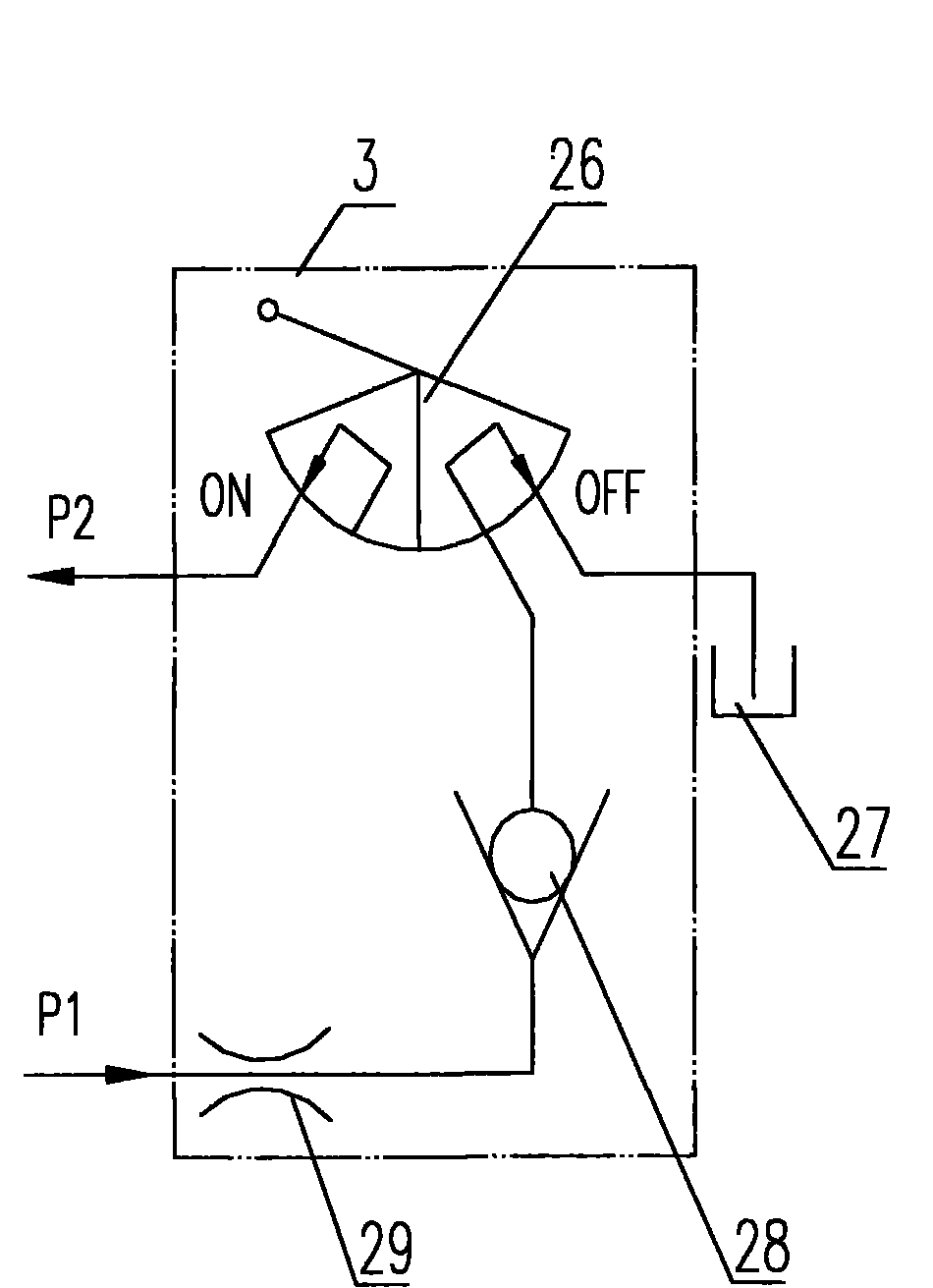

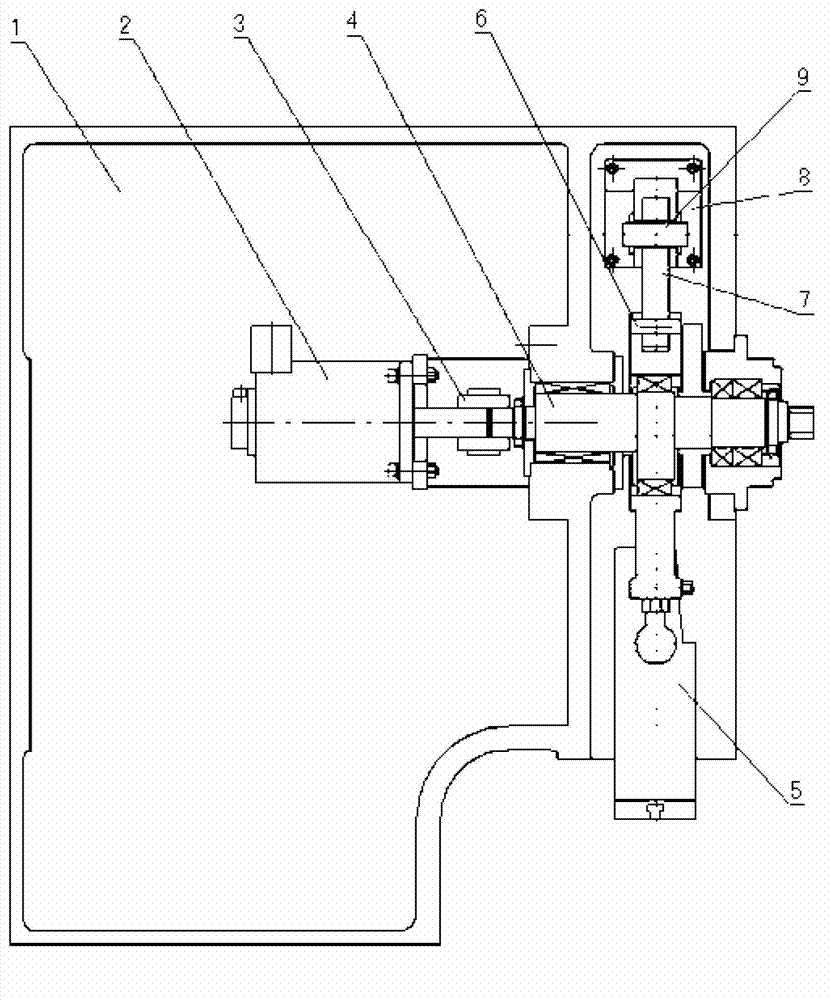

Central power output and rear power output device of tractor

The invention discloses a central power output and rear power output device of a tractor, which is controlled by adopting a hydraulic controlled type power output clutch, has reasonable design and simple and direct structure and comprises a power input shaft, a power output clutch, a hydraulic control valve, a rear axle shell, a power transmission shaft, a transmission gear set, a rear power output shaft, a central power output shaft and a rear power output shift operating device. The hydraulic controlled power output clutch is adopted to eliminate the inertia force generated when a driven farm machinery is separated, and the power output clutch is internally provided with a special braking component, so once the power output clutch is separated, the braking element can come into play so as to enable the power output shaft to rapidly stop rotation, thus preventing the power output shaft from being damaged while lifting. Therefore, the central power output and rear power output device can meet the structural requirement on the tractor to be matched with various farm machinery, favorably solves the key technology of central power output of the tractor and improves the complete machine performance and application scope of the tractor.

Owner:FIRST TRACTOR

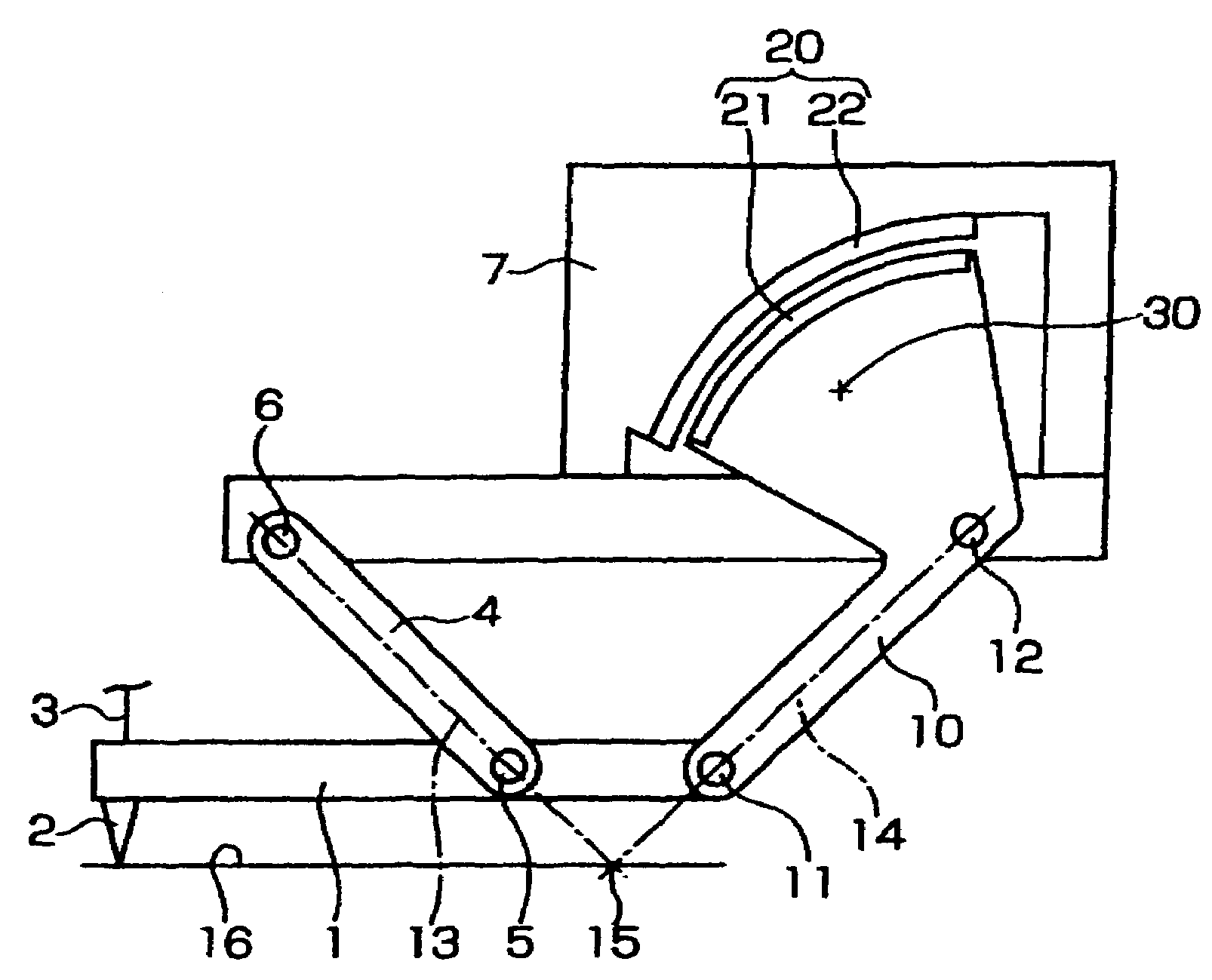

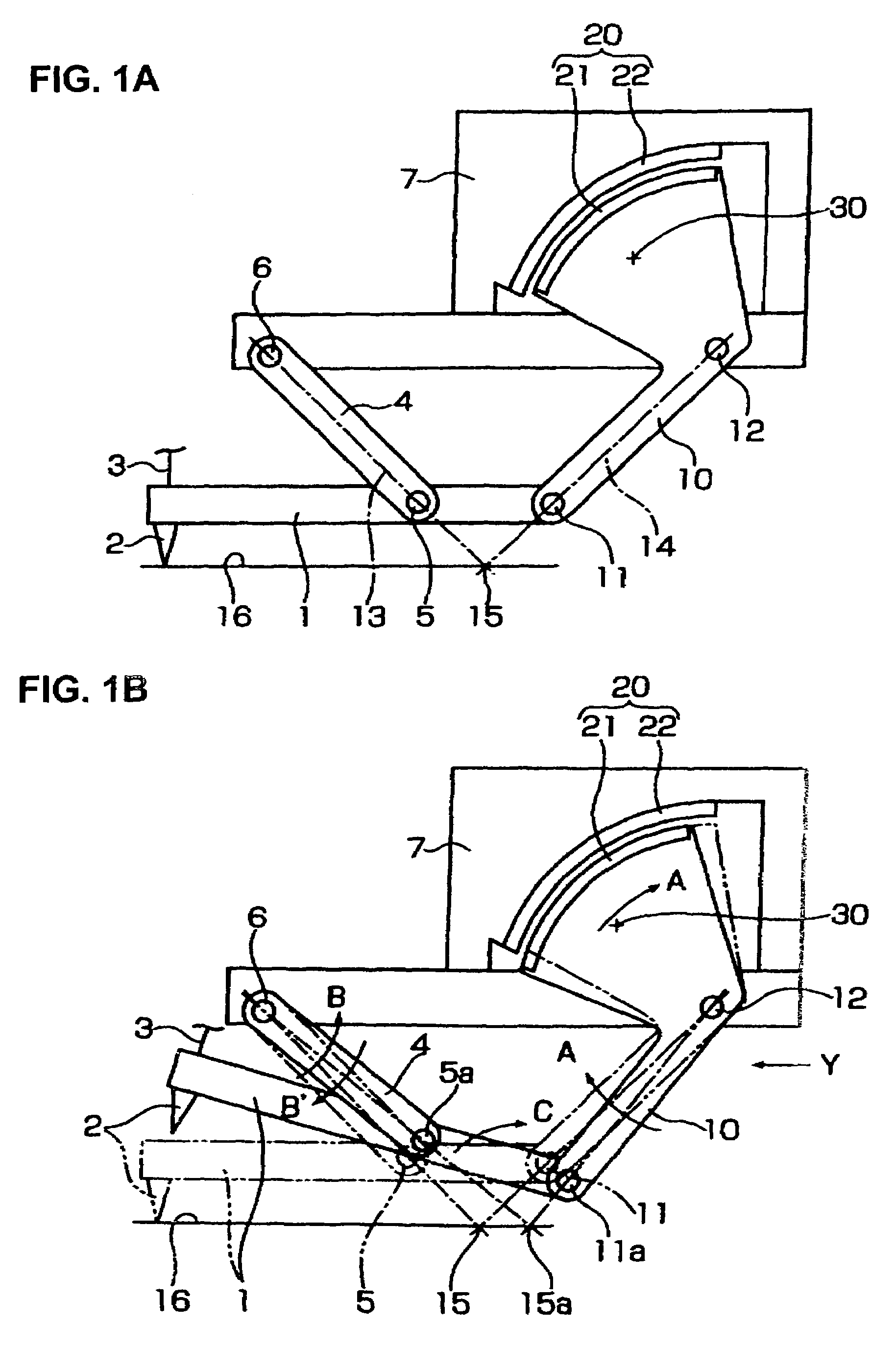

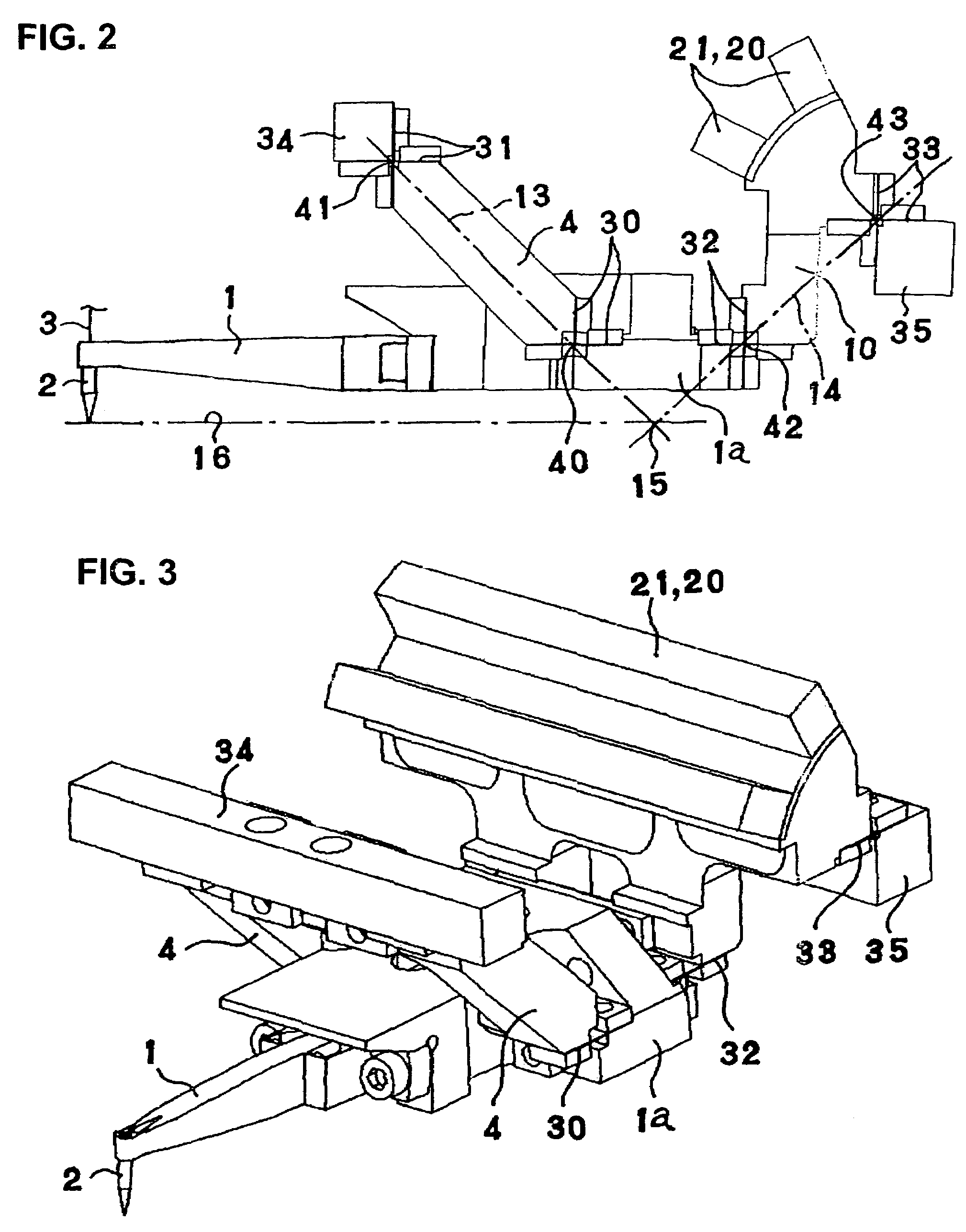

Bonding apparatus

InactiveUS7306132B2Improve bindingEliminate inertial forceWelding/cutting auxillary devicesSolid-state devicesEngineeringElectric motor

Owner:SHINKAWA CO LTD

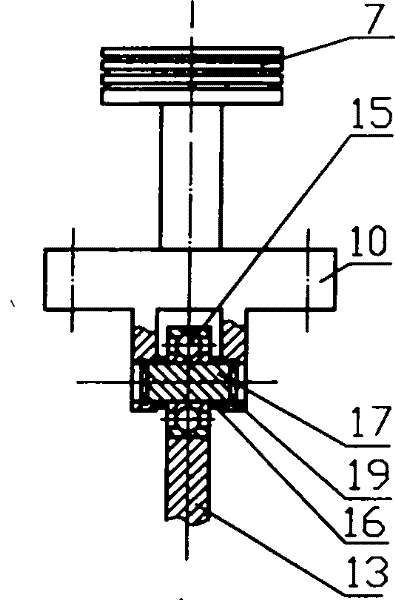

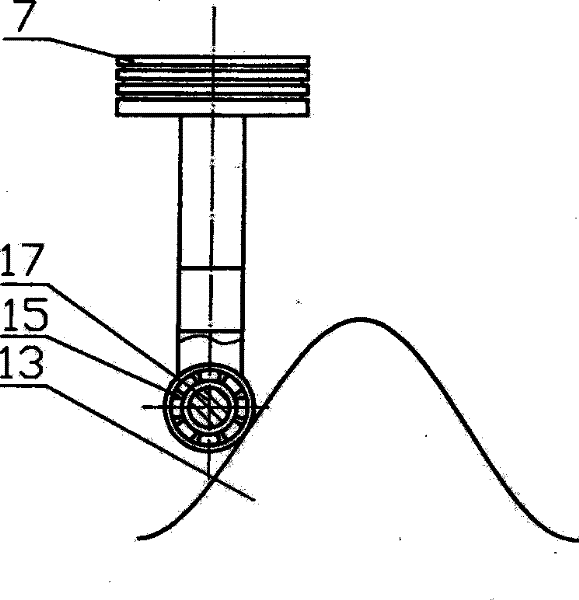

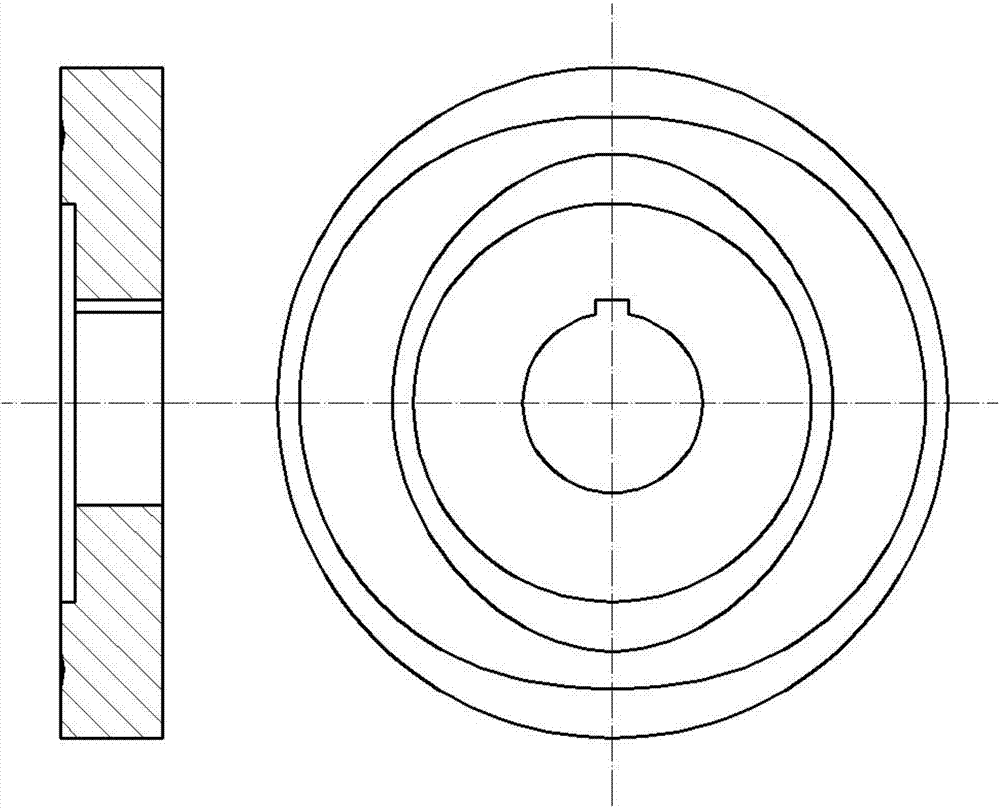

Push cam type internal combustion engine without side pressure

The invention relates to a non-side pressure push rod cam combustion engine, which transmits power of pistons to a main cam fixed on a main shaft by a push rod for output, wherein one end of the push rod is connected with hinges of the pistons, and the other end of the push rod is provided with a cam roller and a push rod roller; the cam roller is inserted into a cam-shaped groove on the main cam; the push rod roller is arranged inside a guide groove, so as to drive the push rod to move along the guide groove and make the guide groove bear the circumferential component force of the acting force of the main cam on the push rod, thereby the side pressure between the pistons and the cylinder walls is zero; cylinders are uniformly distributed on the circumference of the main cam and symmetrical with the axle center of the main cam; the acting force of all the pistons on the main cam is completely balanced; and a duplex inner cam which is fixed on the main shaft is used for controlling inlet valves and exhaust valves of all the cylinders. Compared with the prior combustion engine, the non-side pressure push rod cam combustion engine saves a crank-link mechanism, a distribution timing gear mechanism and so on, and has the characteristics of simple structure, small axial dimension, no side pressure, small abrasion, long service life, low vibration and noise, stable operation, large power, high transmission efficiency and so on.

Owner:SICHUAN UNIV

Design method of double-rotor internal-rotation constant pressure pump

InactiveCN101737322ASolving the challenge of being a monolithic structureSolve the sealing problemRotary piston pumpsRotary piston liquid enginesLow noiseEngineering

The invention relates to a design method of a double-rotor internal-rotation constant pressure pump, which is characterized in that the inner surface of a pump body (1) is provided with two groups of spiral grooves with opposite rotary directions, the normal sections of the spiral grooves are rectangular, and two eccentric sleeves (4) with opposite eccentric directions are sleeved on the axial surface of an eccentric shaft (5); two groups of spiral groove bodies (2) with opposite rotary directions are sleeved between the pump body (1) and the eccentric shaft (5), and two circular tracks (6) are respectively fixed on end covers at the outer end faces of the two groups of spiral groove bodies (2) with opposite rotary directions; a liquid inlet is respectively arranged at both ends of the pump body (1) and a liquid outlet is arranged at the middle part of the pump body (1) between the two groups of spiral groove bodies (2); and the inner surfaces of the spiral groove bodies (2) and the outer surface of the eccentric sleeve (4) are connected by arcs, the eccentric shaft (5) is connected with an end cover body of the pump body (1) by a bearing, and a liquid inlet and a liquid outlet are arranged at both ends of the pump body (1) or on the end cover body. The invention has high output pressure, good internal sealing effect, small volume, low noise and low energy consumption, can change the flow rate at constant pressure and can carry out the mixed output of liquid and gas.

Owner:张中元

Two-phase outer cam shock wave rolling transmission internal combustion engine

InactiveCN102937048AReduce axial sizeCompact structureValve drivesMachines/enginesShock waveExternal combustion engine

The invention provides a two-phase outer cam shock wave rolling transmission internal combustion engine and relates to the field of gas power. According to the novel internal combustion engine, eight cylinders are annularly symmetrically evenly distributed around a convex inner tooth ring, the resultant force which the convex inner tooth ring is subjected to is zero, and a cylinder piston directly acts on the convex inner tooth ring through a push rod, power is transmitted to an output shaft connected with a two-phase outer cam key by two-phase outer cam shock wave rolling oscillating tooth transmission through the convex inner tooth ring. According to the internal combustion engine, a connecting rod and a crankshaft in a traditional internal combustion engine are not required, a convex inner two-phase shock wave rolling transmission mechanism does not have eccentric mass and has the advantages of self balancing of inertia force and working load, and the rotating speed of the output shaft depends on the transmission ratio of oscillating tooth transmission. If an oscillating tooth brace is fixed, a two-phase outer cam performs high-speed output and can be widely applied to the fields requiring for high rotating speeds, such as helicopter engines and small generators, and discharge of harmful gas can be reduced when the output rotating speed is fixed. The internal combustion engine is simple and compact in structure, small in axial dimensions self-balancing in stress and runs stably.

Owner:SICHUAN UNIV

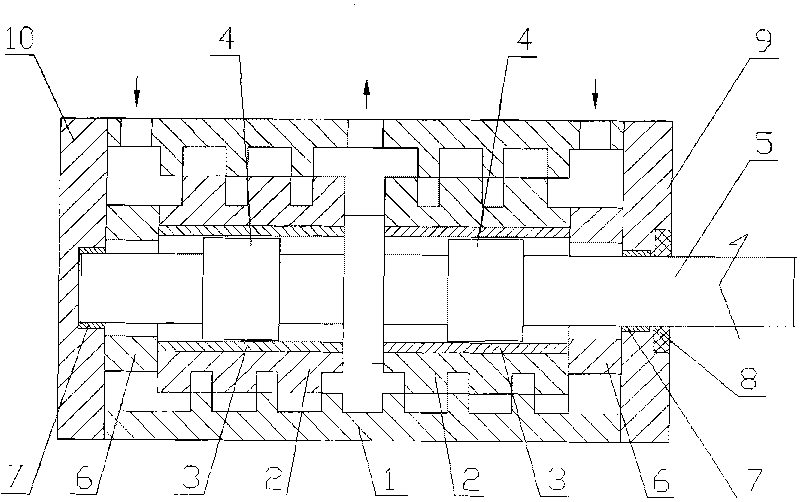

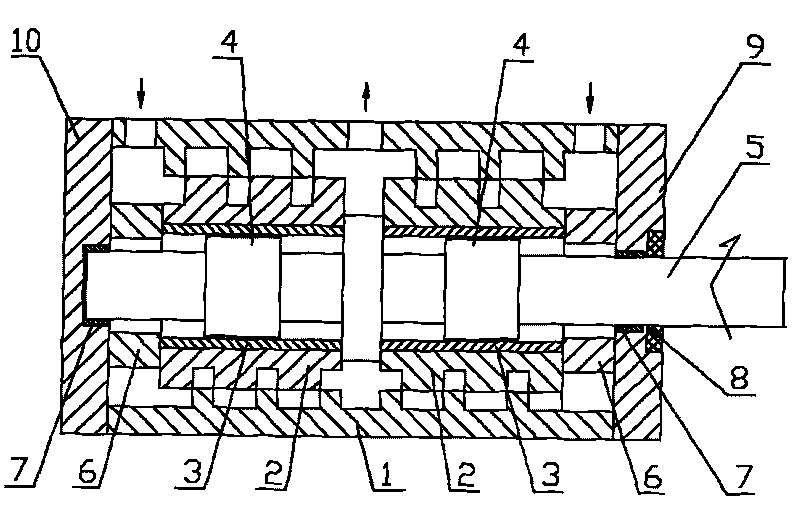

Cylinder double-face cam axial piston type crankless internal combustion engine

InactiveCN101392684BReduce noiseSmall shock and vibrationValve drivesMachines/enginesExhaust valveCombustion

The invention discloses a cylindrical double-track cam axial piston type crankless internal combustion engine, which relates to the technical field of internal combustion engines and is a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine; when pistons drive rollers arranged on the bottoms of the pistons for reciprocating movement, the rollers push a double-track cam fixed on a main shaft to rotate, and the power is output from the double-track cam through the main shaft. Outlines of two end surfaces of the double-track cam are in the form that wave crests correspond to wave crests, wave troughs correspond to wave troughs, and the two end surfaces are circumferentially symmetrical. Two groups of cylinders are symmetrically arranged at bothends of the double-track cam, and axis lines of the cylinders have equal distance to an axis line of the main shaft and are parallelly, circularly and evenly distributed. The pistons which have the same axis line and are symmetrically arranged with the spacing of 180 DEG C have the same working state, which ensures that the axial and radial composite force of the double-track cam and the main shaft are zero. A sliding rod at the bottom of each piston slides in a guide groove, which ensures that the side pressure of the piston is zero. Intake and exhaust valves of all the cylinders are intensively controlled by two distributing cams. The internal combustion engine has the characteristics of simple and compact structure, small volume, small impact vibration, steady operation, high power, long service life and so on.

Owner:SICHUAN UNIV

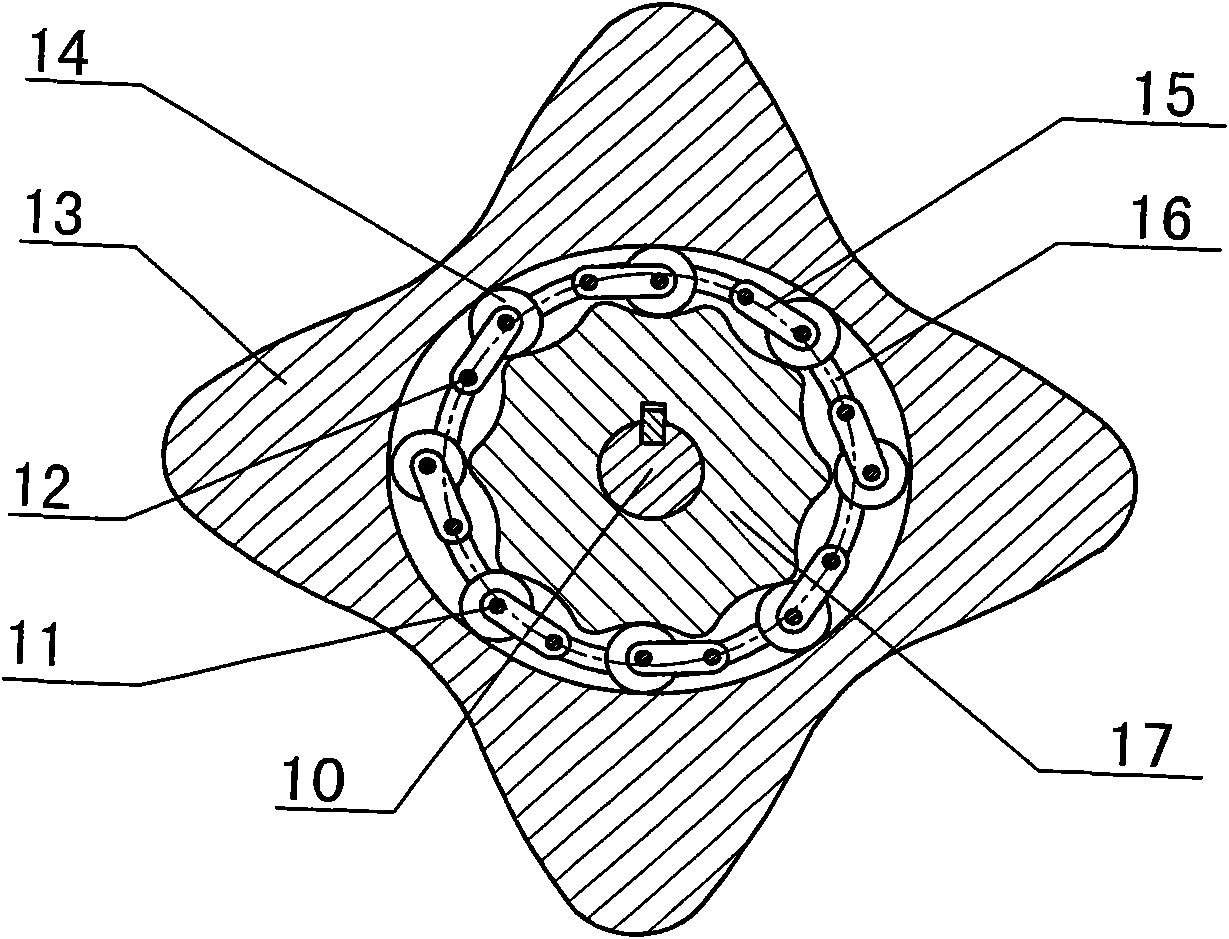

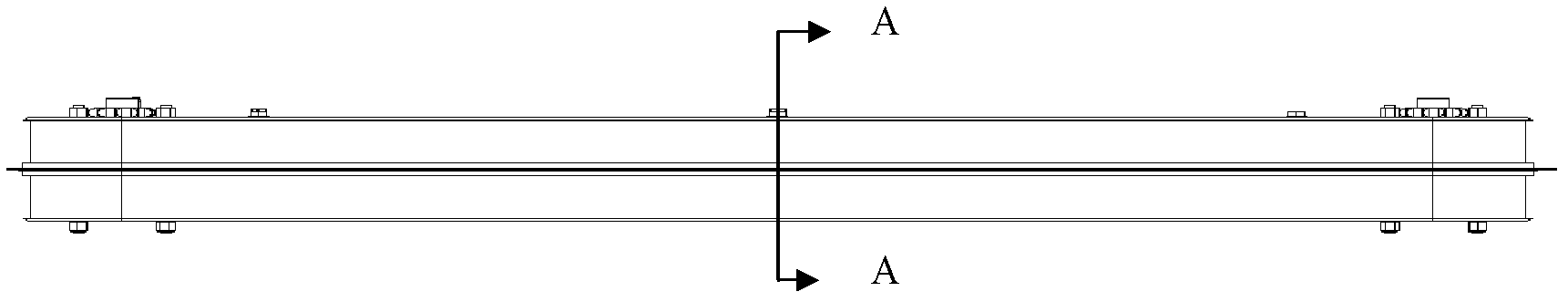

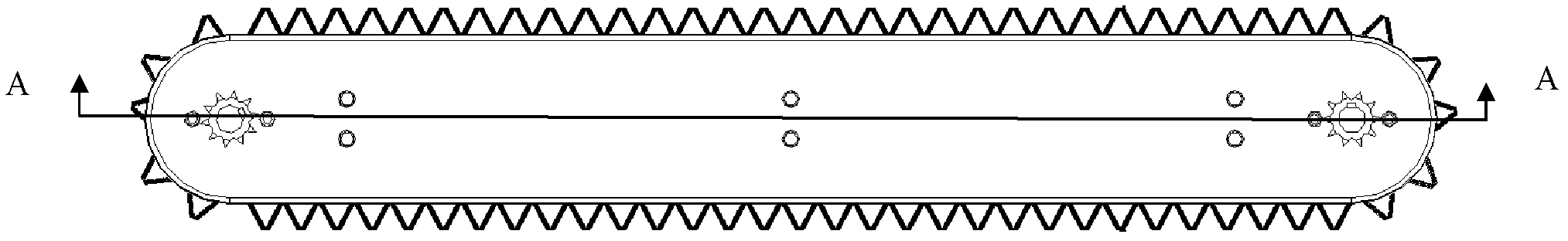

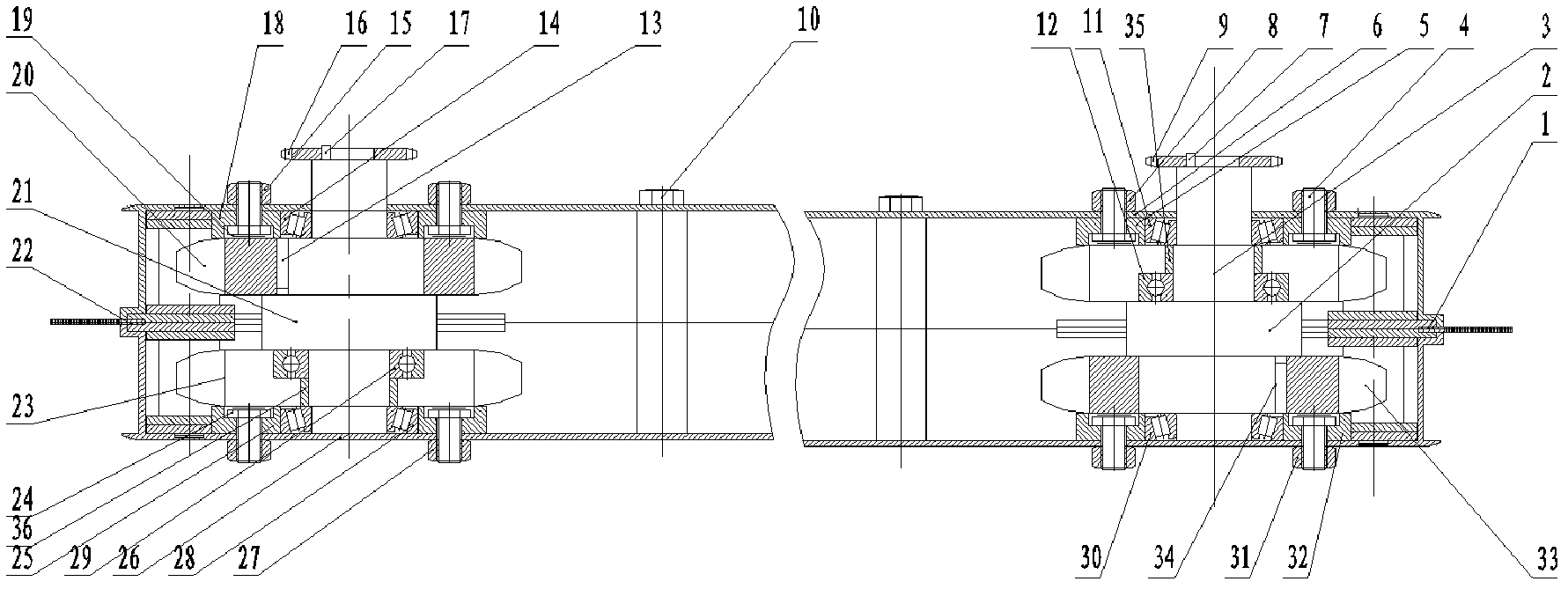

Chain-type double knife cutter

The invention belongs to the technical field of agricultural machineries, specifically to a chain-type double knife cutter for a mower, which has the advantages of high speed like rotary mower and low consumption like reciprocating mower, small vibration, low noise and stable cutting, comprising an upper chain knife (1) and a lower chain knife (22), wherein one end of the upper chain knife (1) surrounds a driving sprocket (20) of the upper chain knife to be located; the other end surrounds a driven sprocket (3) of the upper chain knife to be located; one end of the lower chain knife (22) surrounds a driving sprocket (33) of the lower chain knife to be locate; the other end surrounds a driven sprocket (23) of the lower chain knife to be located; the driving sprocket (20) of the upper chainknife is connected with a left input shaft (21); the driven sprocket (23) of the lower chain knife is supported on the left input shaft (21); the driving sprocket (33) of the lower chain knife is connected with a right input shaft (2); the driven sprocket (3) of the upper chain knife is supported on the right input shaft (2); the rotation directions of the left input shaft (21) and the right input shaft (2) are opposite and the rotation speeds are the same.

Owner:CHINA AGRI UNIV

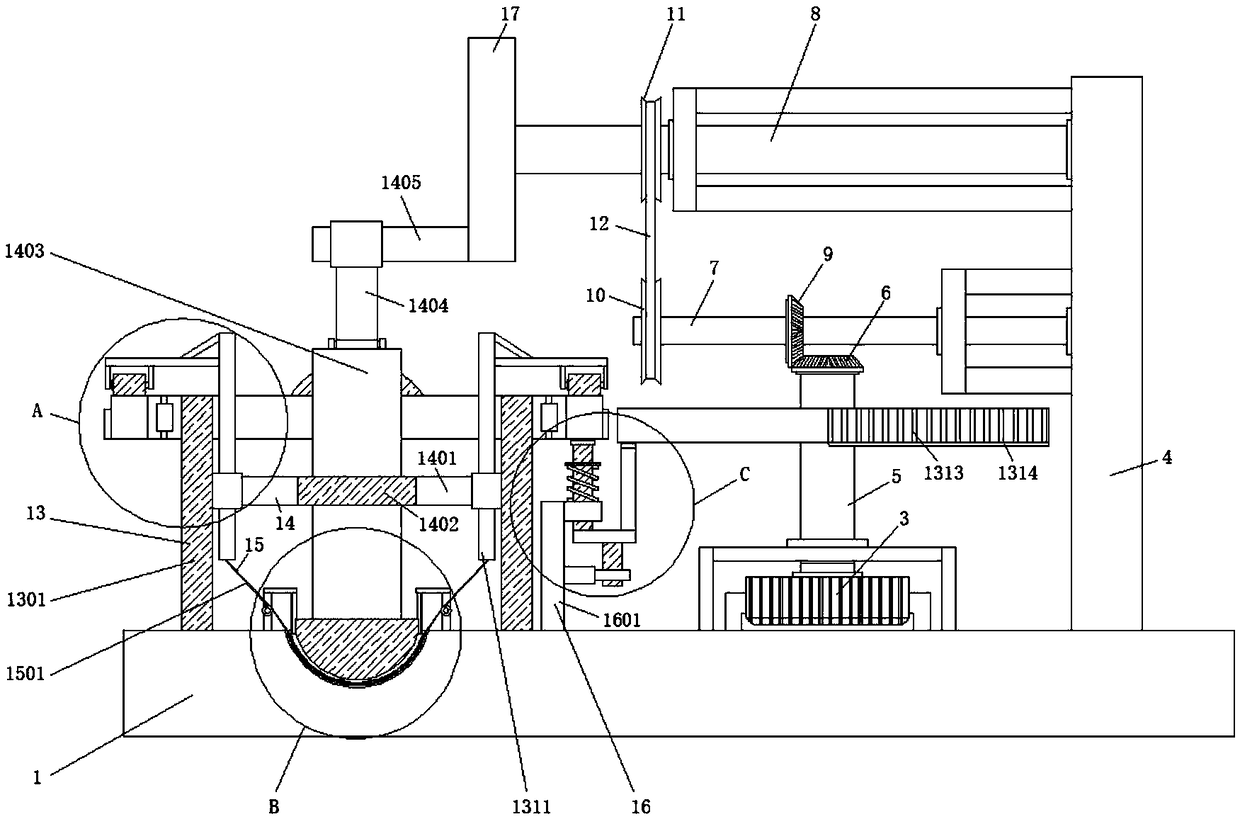

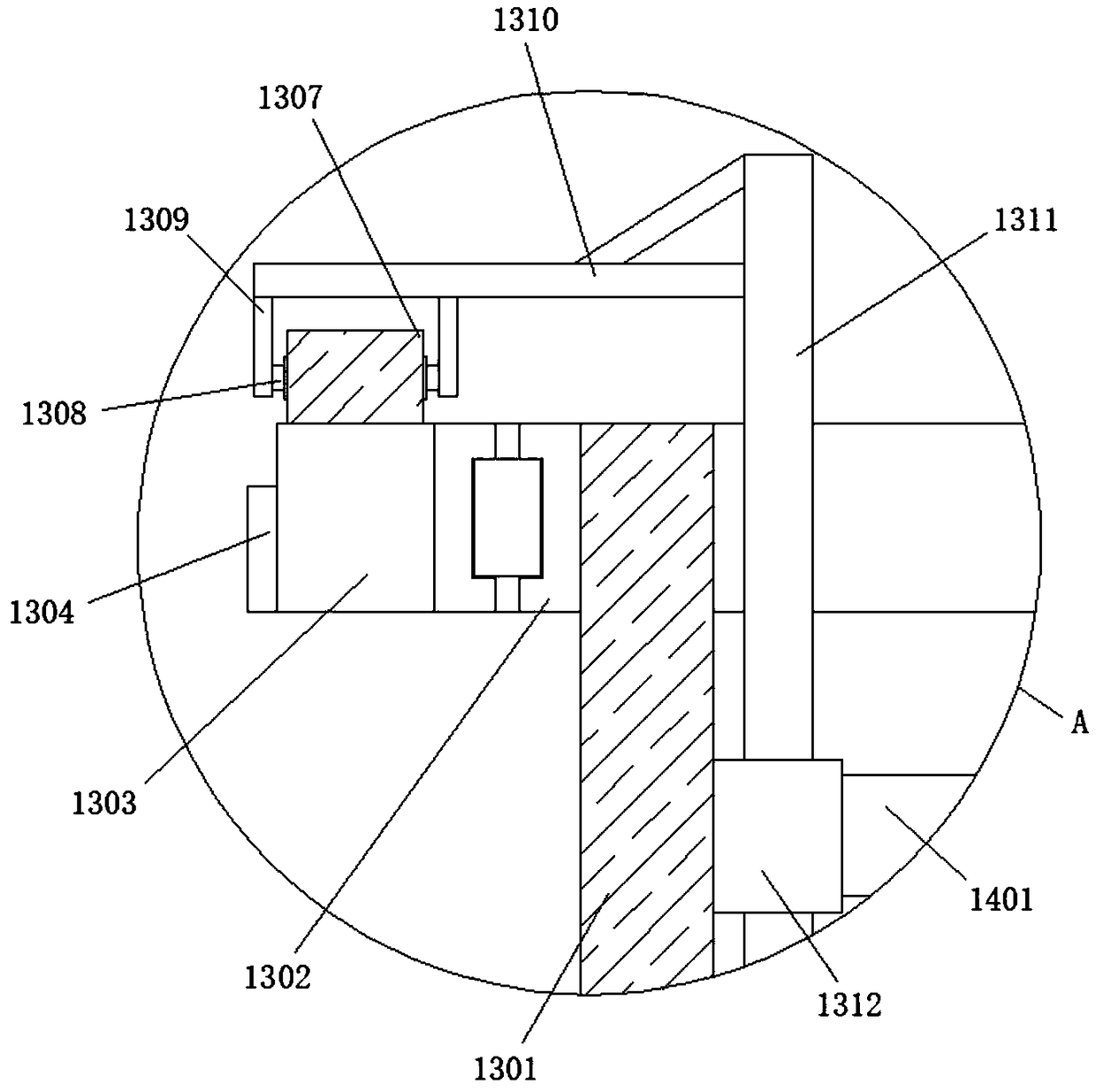

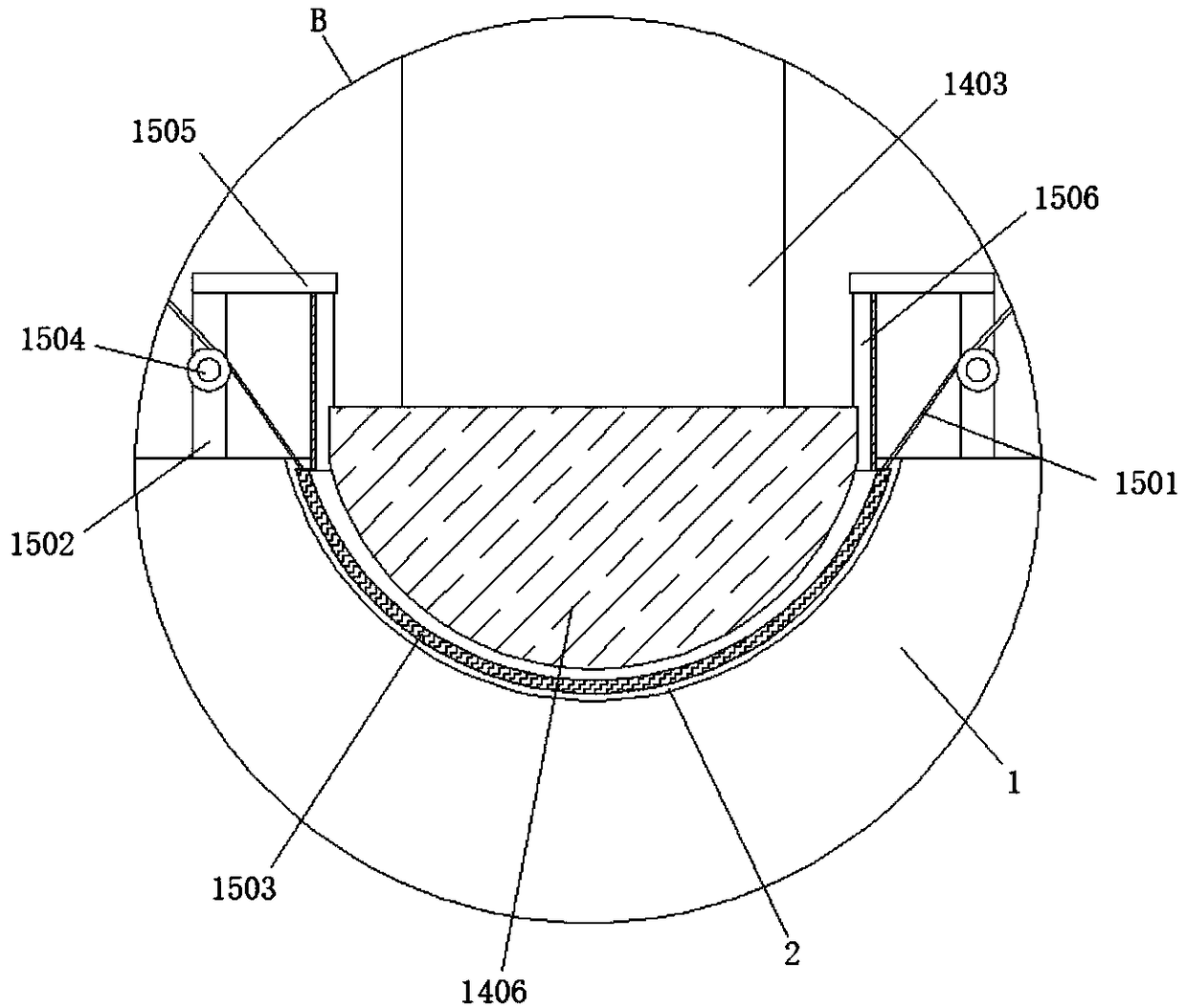

Initial stage processing device for production of special conventional snack

ActiveCN108812827AConsistent working frequencyBeat evenlyMeat processingElectric machineryDrive motor

The invention relates to the technical field of food production equipment, in particular to an initial stage processing device for production of a special conventional snack, and aims to solve the technical problems that when pork wonton wrappers are made, human resource consumption is high, and the production efficiency is low. In order to solve the technical problems, the invention provides theinitial stage processing device for production of a special conventional snack. The initial stage processing device comprises a bearing base, wherein a material placing groove is formed in the top ofthe bearing base; a driving motor and a first fixing plate are respectively and fixedly connected to the top of the bearing base from left to right; a first rotating shaft is fixedly connected to thetop of an output shaft of the driving motor; and a first helical tooth bevel gear is fixedly connected to the top of the first rotating shaft. According to the initial stage processing device for production of a special conventional snack disclosed by the invention, a wire bracing device, a meat hammering device and a meat overturning device are utilized, so that meat blanks can be automatically beaten, in the beating course, the meat blanks can be continuously overturned, and the beating of the meat blanks can be more uniform.

Owner:SHANDONG JINQIU AGRI & ANIMAL HUSBANDRY TECH

Any-tooth-difference movable type high rotation speed internal combustion engine

InactiveCN103047008ACompact structureReduce axial sizeGearingMachines/enginesThrough transmissionElectric generator

The invention provides an any-tooth-difference movable type high rotation speed internal combustion engine and relates to the field of combustion gas power. Eight cylinder are annularly and evenly distributed around an outward-protruding inner gear to enable the outward-protruding inner gear to be subjected to zero stress, cylinder pistons directly act on the outward-protruding inner gear through pushing rods, and power is transferred to an output shaft connected with a multiple-phase shock wave cam key through transmission of the outward-protruding inner gear and a multiple-phase cam type moving oscillating teeth. A connecting rod and a crankshaft in a traditional internal combustion engine are omitted, an outward-protruding inner multiple-phase cam type moving transmission mechanism has the advantages of being free of eccentric mass and having inertia force and working load self balance, the rotating speed of the output shaft depends on the transmission ratio of the oscillating teeth, if an oscillating tooth frame is fixed, a multiple-phase shock wave cam performs high-speed output, and the high rotation speed internal combustion engine can be widely applied to the field of machines needing high rotation speed, such as a helicopter engine, a small power generator and the like. When the output rotation speed is fixed, emission of harmful gas can be reduced. The any-tooth-difference movable type high rotation speed internal combustion engine is simple and compact in structure, small in axial size, self-balancing in stress and stable in operation.

Owner:SICHUAN UNIV

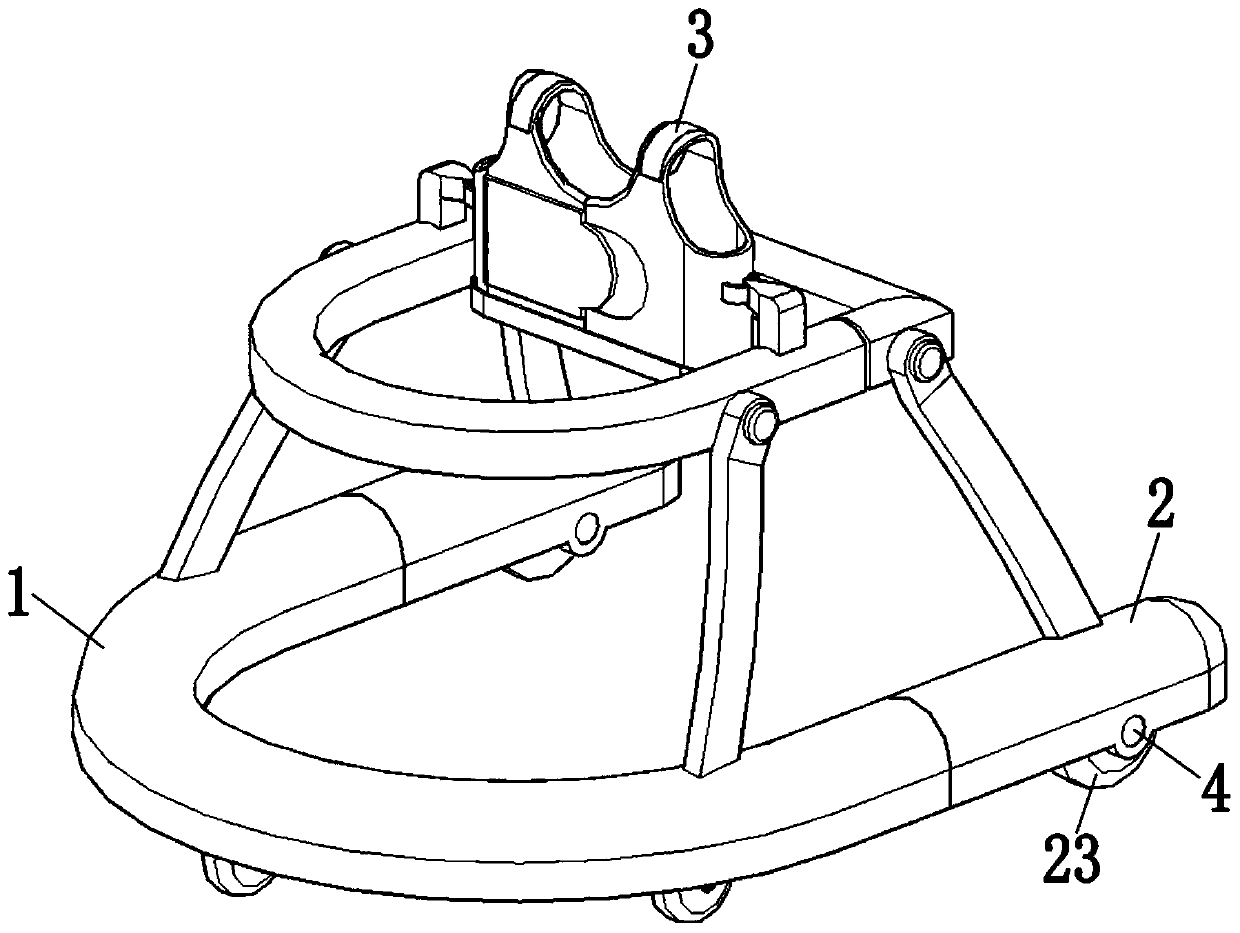

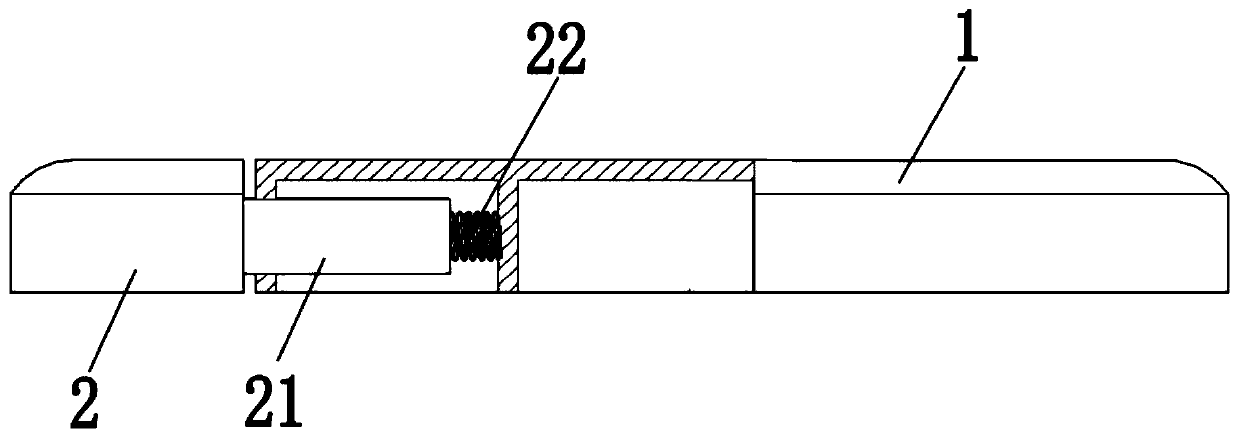

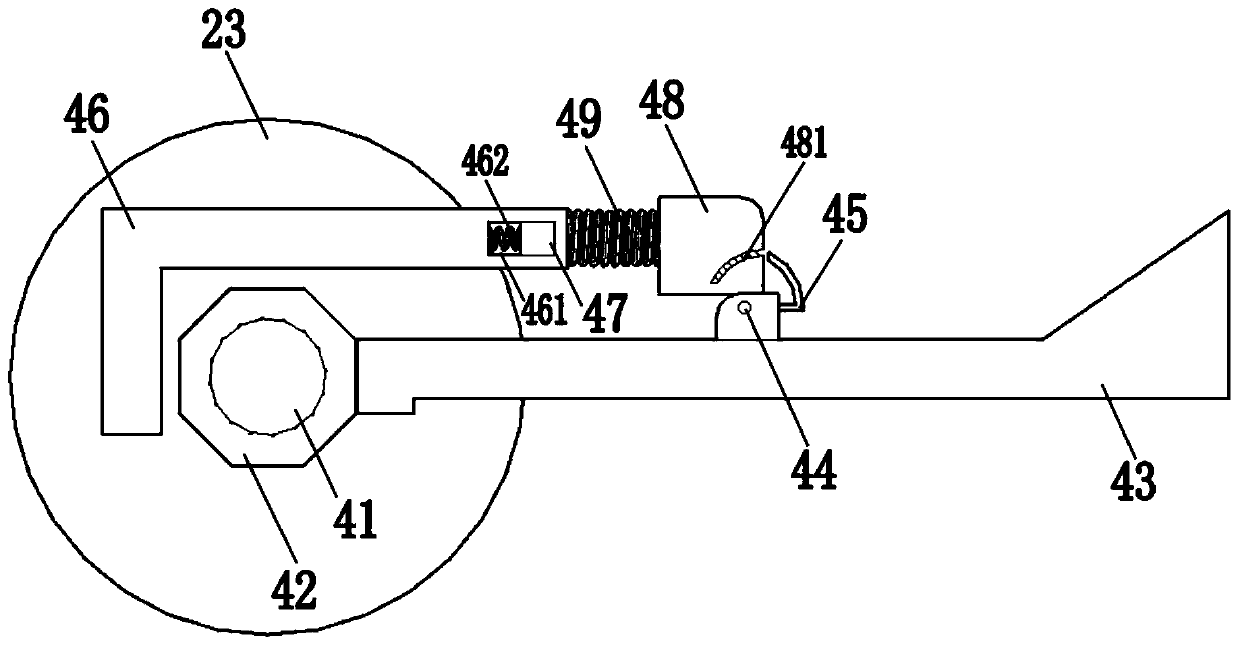

Movable baby walker

The invention belongs to the field of baby products, and particularly relates to a movable baby walker. The movable baby walker comprises a first body, a second body, a binding coat and two locking wheel devices; the first body and the second body are connected in a front-back mode; the binding coat is arranged at the upper end of the inner circumference of the first body; and the two locking wheel devices are connected with rear wheels. Through the locking wheel devices, a baby is prevented from gliding in the baby walker, the baby walker is prevented from having an accident in gliding, and the inertia force of the baby walker is eliminated, so that the baby does not walk faster and faster in the baby walker, and the baby can learn to walk at a constant speed in the baby walker; and the chest of the baby is wrapped with the binding coat to support the body of the baby, so that two legs are prevented from being forcedly separated in the walking process to form bowlegs.

Owner:安徽冠东科技有限公司

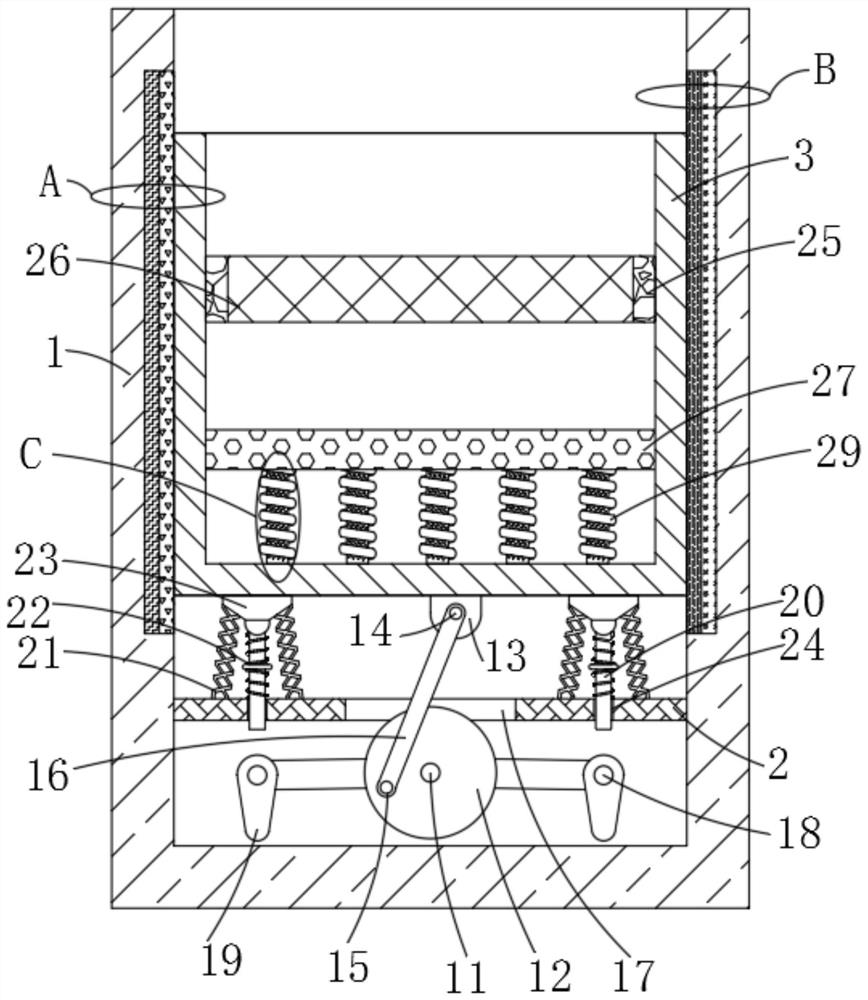

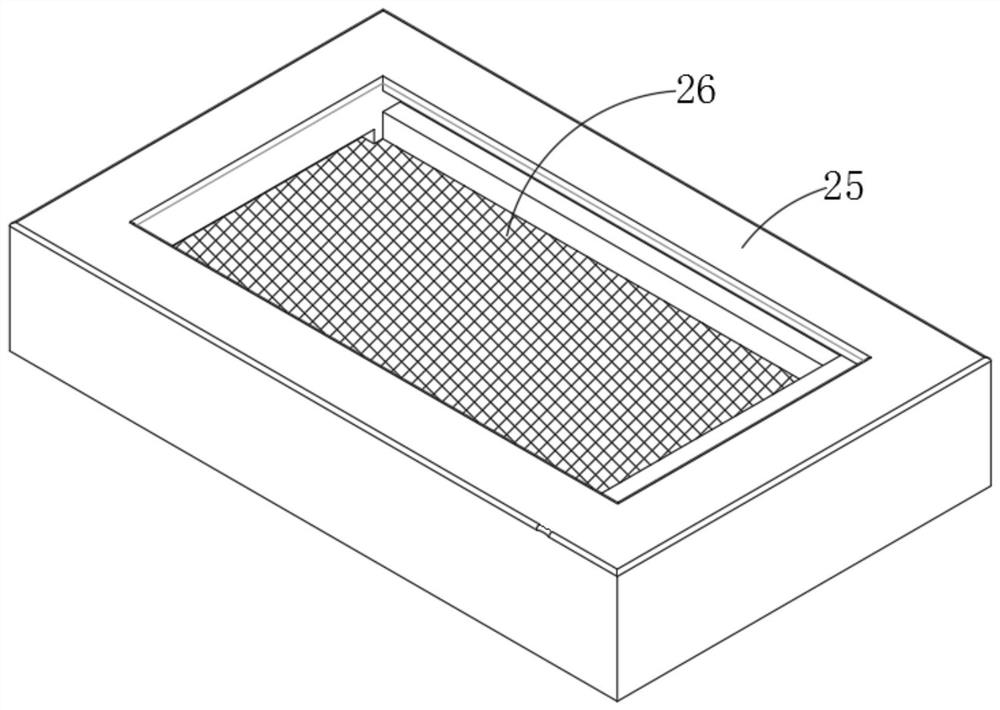

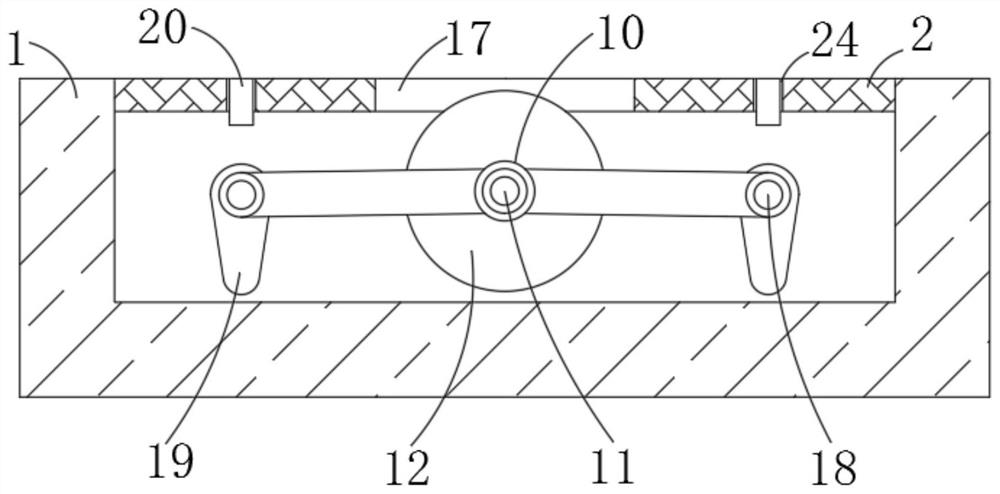

Rocker arm type vibrating trough

ActiveCN112588573ARealize the reciprocating functionImprove power sourceSievingElectrostatic separationClassical mechanicsElectric machinery

The invention discloses a rocker arm type vibrating trough comprising a machine barrel, and a bearing plate is fixedly installed in the machine barrel; a vibrating trough body is arranged above the bearing plate, and slidably connected with the inner walls of the two sides of the machine barrel; and a first adsorption assembly is arranged in the inner wall of the left side of the machine barrel, and a second adsorption assembly is arranged in the inner wall of the right side of the machine barrel. According to the rocker arm type vibrating trough, through arrangement of a driving mechanism, asubdivision mechanism, the first adsorption assembly, the second adsorption assembly, a power assembly and an auxiliary reset assembly, one motor is used for driving a plurality of components to achieve rocker arm type reciprocating vibration of the vibration groove, and the problems that an existing vibrating through operation system is too complex and high in operation cost are solved; multi-layer material screening treatment can be completed through twisting of triangular crushing pieces on springs, dust particles generated through separation can be adsorbed and collected through positive charges and negative charges generated in the up-down vibration process; and environmental pollution is avoided.

Owner:德清鸿捷铸机有限公司

Robot having workpiece mass measurement function

ActiveCN102990642BLong cycleSimple structureProgramme controlProgramme-controlled manipulatorEngineeringMass measurement

A robot (1) having a workpiece mass measurement function for measuring the mass of a workpiece that is held, includes a force measurement unit (5) that measures the force that is applied to the tip part (2) of the mechanism part of the robot (1), and a mass estimation unit (11) that estimates the mass of the workpiece that is held by the robot (1), based on information about the force acquired by the force measurement unit (5) while the robot (1) is moving.

Owner:FANUC LTD

Can movable tooth frame two-phrase swinging-plate type internal combustion engine

InactiveCN107023388AReduce vibrationReduce noiseGearingMachines/enginesExternal combustion engineSteel ball

The invention provides a can movable tooth frame two-phrase swinging-plate type internal combustion engine, relates to the field of fuel gas power and belongs to a multi-cylinder internal combustion engine. According to the novel internal combustion engine provided by the invention, pistons act on a can movable tooth frame through push rods and universal ball assemblies, and power is transmitted to an output shaft in key linkage with a two-phrase swinging-plate wave generator through a slot-type two-phrase swinging-plate movable tooth transmission mechanism and is output. The can movable tooth frame integrates the internal combustion engine and a can movable tooth frame swinging-plate mechanism, and the internal combustion engine does not need to be additionally equipped with a speed increaser. A crankshaft connecting rod system in a crankshaft connecting rod type internal combustion engine is omitted, no eccentric mass exists in the internal combustion engine, all types of internal force are balanced automatically, steel ball movable teeth and left-cover-end gears are in multi-tooth engagement, the can movable tooth frame and the two-phrase swinging-plate wave generator are also in multi-tooth engagement, and all air cylinders are axially arranged. The internal combustion engine is simple and compact in structure, small in size, large in overlapped degree and high in bearing capacity and can be widely applied to the fields in need of a high rotation speed and large power, such as small generators and helicopter engines.

Owner:SICHUAN UNIV

Two-phase shock wave movable type high-rotation speed internal combustion engine

InactiveCN102900524AReduce axial sizeCompact structureMachines/enginesExternal combustion engineInternal combustion engine

The invention discloses a two-phase shock wave movable type high-rotation speed internal combustion engine, relates to the field of fuel gas power and provides a novel internal combustion engine. According to the internal combustion engine, eight cylinders are symmetrically arranged at the periphery of an externally raised inner gear ring uniformly, so that resultant force applied to the externally raised inner gear ring is zero; pistons of the cylinders directly act on the externally raised inner gear ring through push rods; and power is transmitted by the externally raised inner gear ring through a two-phase shock wave movable teeth transmission mechanism to an output shaft which is in keyed connection with a two-phase shock wave device. By the internal combustion engine, connection rods and crank shafts in the conventional internal combustion engine are eliminated, so that an externally raised inner two-phase shock wave movable transmission mechanism does not have eccentric mass, and the internal combustion engine has the characteristics that inertia force and working load are self-balanced; the rotation speed of the output shaft depends on a movable teeth transmission ratio; if movable teeth frames are fixed, the two-phase shock wave device outputs power at high speed; the internal combustion engine can be widely applied to field such as helicopter engines and small engines in which high rotation speed is required; when the output rotation speed is fixed, emission of harmful gas can be reduced; and besides, the internal combustion engine is simple and compact in structure, has a small axial size and stably runs, and stress is self-balanced.

Owner:SICHUAN UNIV

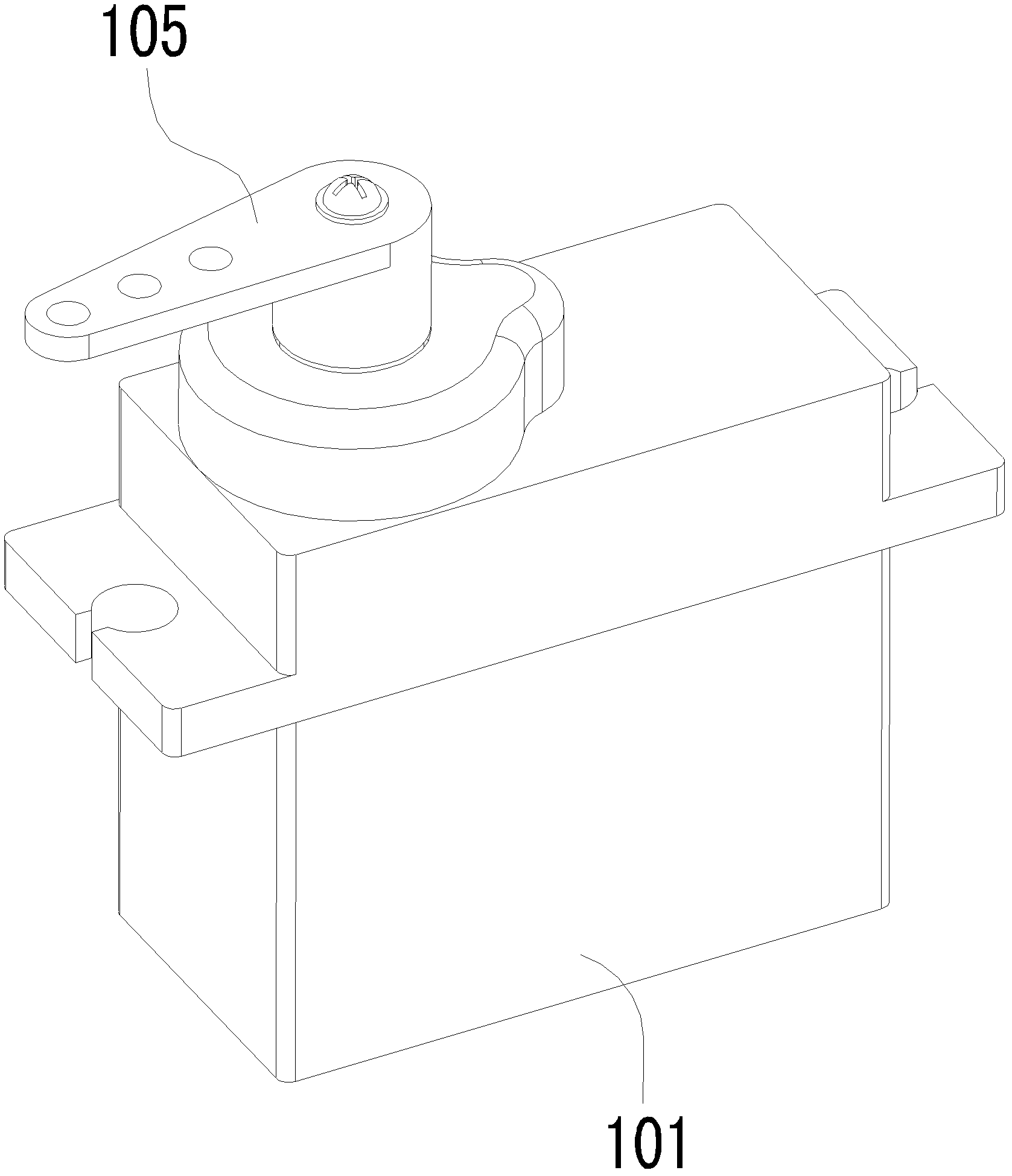

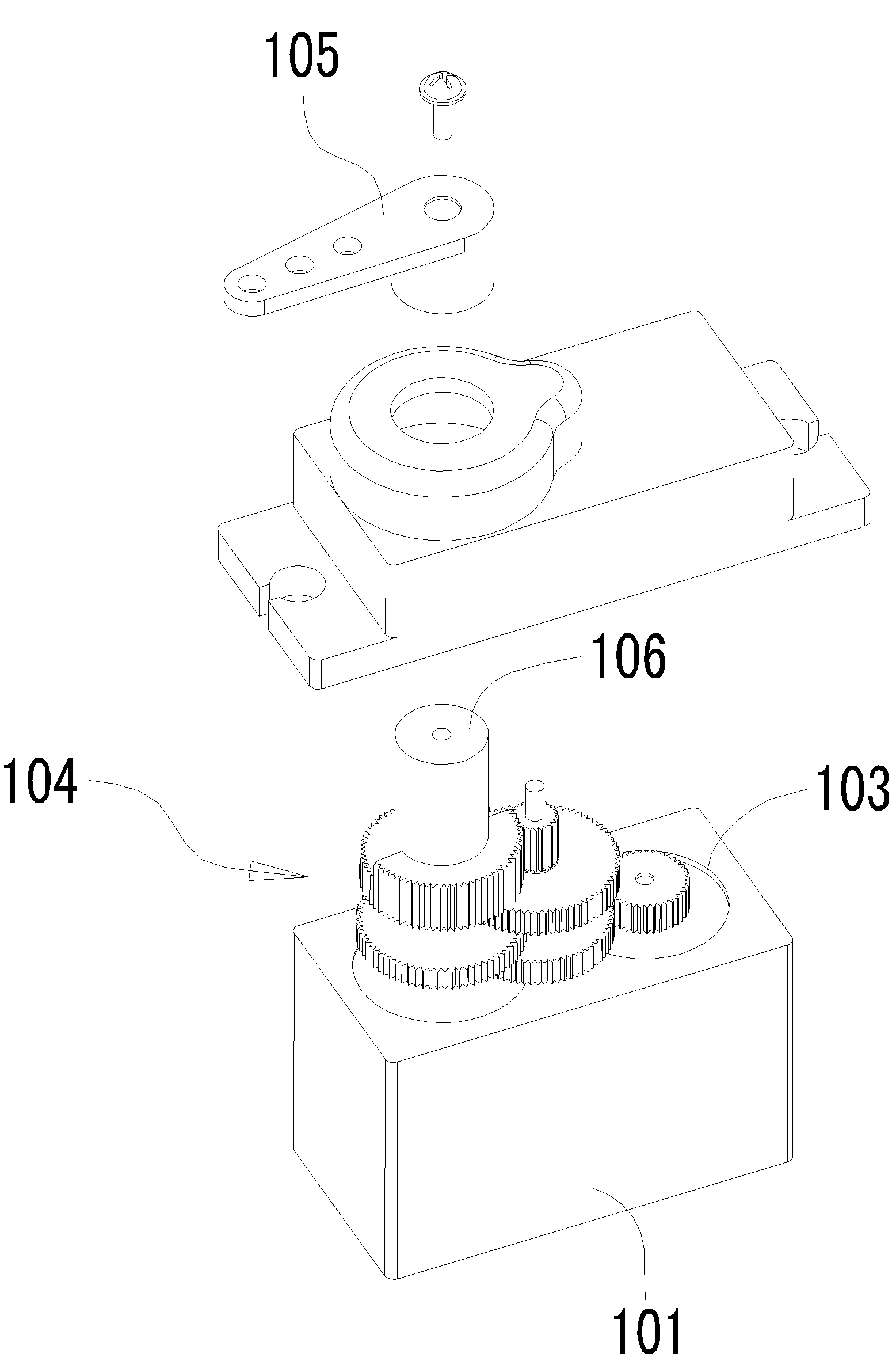

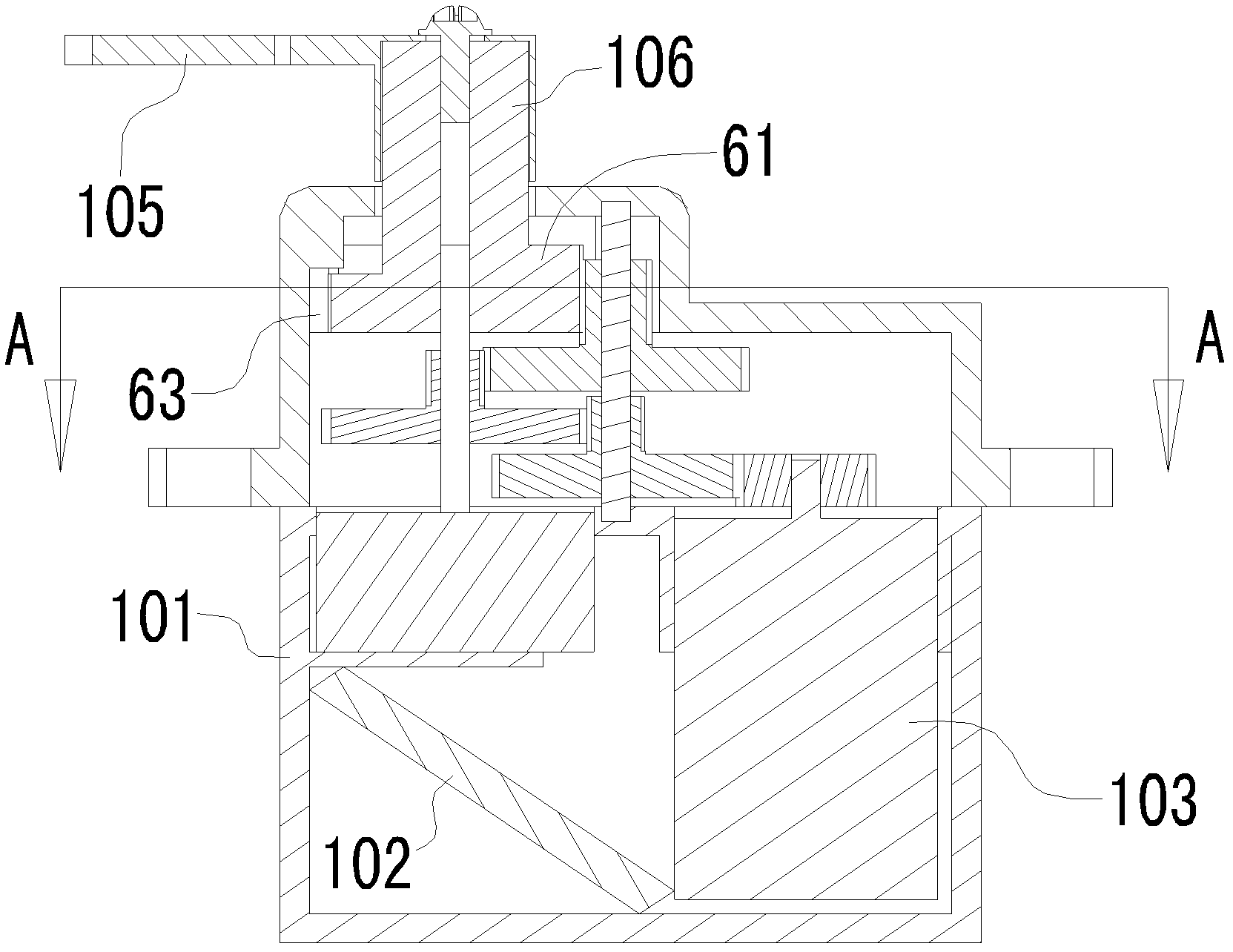

Buffering mechanism on output shaft of power output device and servo motor comprising same

ActiveCN102624144BGuaranteed normal operationEliminate inertial forceMechanical energy handlingGenerators/motorsMagnetic polesEngineering

The invention relates to a buffering mechanism on an output shaft of a power output device and a servo motor comprising the same. The buffering mechanism is connected with a load connector and comprises a first rotation part and a second rotation part which are laminated, and the output shaft drives the buffering mechanism to drive the load connector to move. The first rotation part is fixedly mounted on the output shaft, the second rotation part is rotationally mounted on the output shaft, the second rotation part is connected with the load connector, the first rotation part is provided with one or multiple first magnets, the second rotation part is provided with second magnets, the second magnets and the first magnets correspond to each other in positions, and magnetic poles thereof are reversed and attracted each other. The buffering mechanism is applied on an output shaft of the servo motor. The buffering mechanism is simple in structure, capable of effectively eliminating inertia force of the load connector at two critical points of starting and stopping of the servo motor, and gears on a speed reduction mechanism are protected.

Owner:ZHONGSHAN DAGU HI TECH ELECTRONICS

Internal dual-phase shockwave swing link transmission type internal combustion engine

InactiveCN101979853BReduce shockReduce vibrationValve drivesMachines/enginesLow speedExternal combustion engine

The invention discloses an internal dual-phase shockwave swing link transmission type internal combustion engine, relates to the field of gas power, and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, wherein eight cylinders are annularly, symmetrically and uniformly distributed around a convex internal dual-phase shockwave wheel,so that a resultant force stressed on the convex internal dual-phase shockwave wheel is zero; a cylinder piston directly acts on the convex internal dual-phase shockwave wheel through a push rod; andpower is transferred to an output shaft which is connected with a wavelike wheel through keys from the convex internal dual-phase shockwave wheel through internal dual-phase shockwave swing link movable teeth. In the internal combustion engine, a connecting rod and a crank shaft in the conventional internal combustion engine are saved, and an external cam internal dual-phase shockwave swing link transmission mechanism of the conventional internal combustion engine does not have eccentric mass and has the advantage of self-balancing the inertial force and the working load. The rotation speed of the output shaft is determined by the transmission ratio of the transmission of the movable teeth; if a movable tooth frame is fixed, the wavelike wheel outputs low speed and large torque; and the internal combustion engine can be widely applied to the fields of military affaires and national defense needing high power, such as tanks, armored vehicles, engineering machinery and the like. The internal combustion engine has the advantages of simple and compact structure, small axial dimension and self-balanced stressing and operates stably.

Owner:SICHUAN UNIV

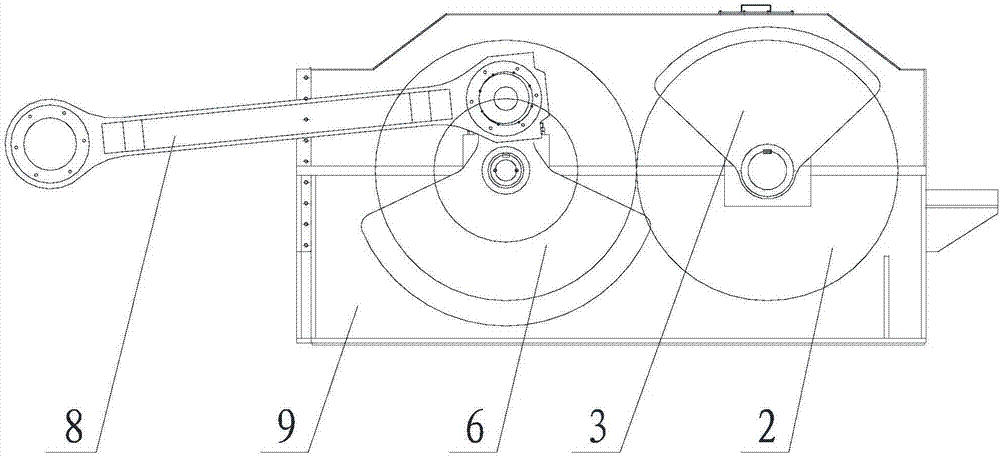

Slider balance mechanism for full servo notching machine

The invention discloses a slider balance mechanism for a full servo notching machine, comprising a notching machine body. The notching machine body is provided with an AC servo motor and a slider. The output shaft of the AC servo motor is connected with an eccentric crank shaft which is provided with the slider through a coupler. The notching machine body is provided with a balance member which is connected with a connecting rod block through a swinging shaft, the lower end of the connecting rod block is connected with a connecting rod through a small shaft, and the lower end of the connecting rod is fixedly arranged on the slider. The slider balance mechanism is compact in structure, wherein the inertia force of the slider in movement is eliminated, the body vibration is reduced, the notching noise is reduced, die wear is reduced, the frequency stroke of the slider is greatly improved, production efficiency is increased and the punching accuracy is improved.

Owner:WUHU ELECTROTECHN MACHINERY

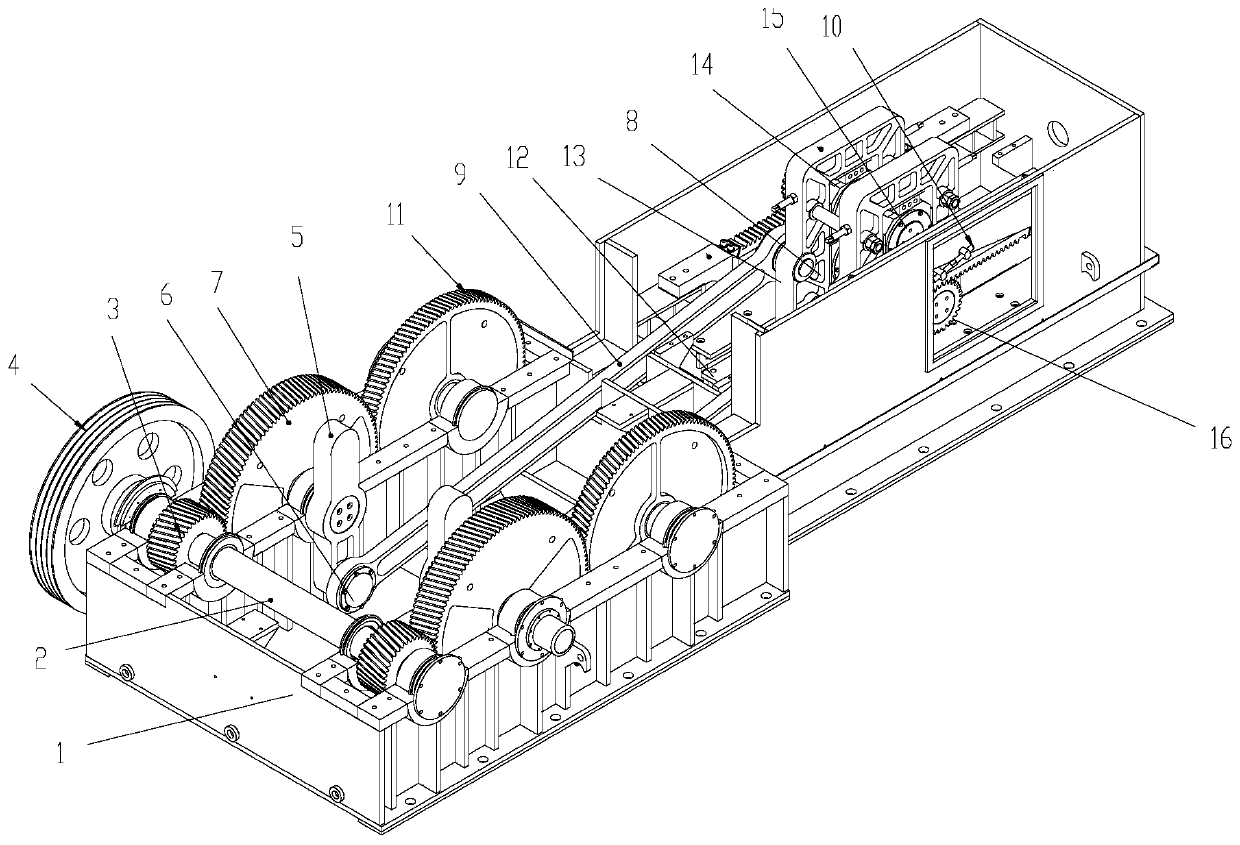

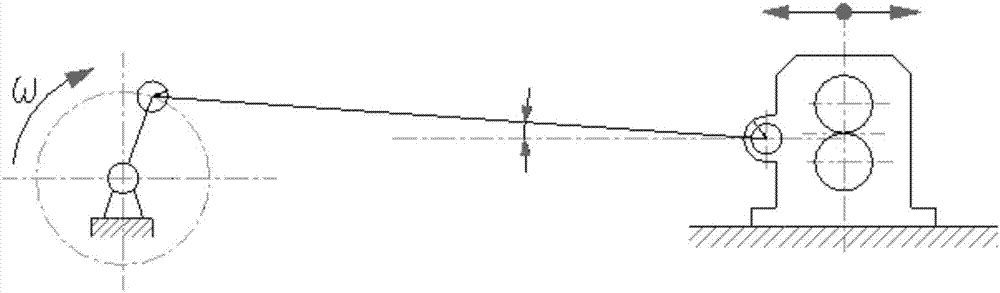

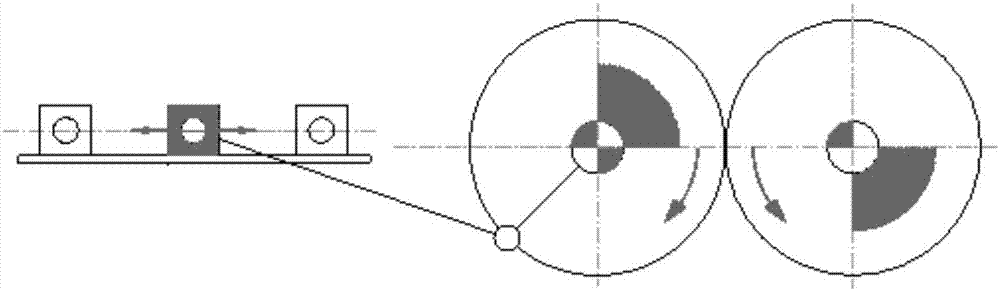

Roller reciprocating driving mechanism of high-speed cold pipe mill

PendingCN110404976AEliminate inertial forceReduce weightRolling mill drivesMetal rolling arrangementsDrive shaftEngineering

The invention discloses a roller reciprocating driving mechanism of a high-speed cold pipe mill. The roller reciprocating driving mechanism of the high-speed cold pipe mill comprises a main machine seat; a driving shaft is horizontally arranged at one end of the main machine seat; a pair of driving gears are symmetrically distributed on the driving shaft; a belt pulley is fixedly arranged at one end of the driving shaft; two sides of the main machine seat are respectively provided with two transmission gears engaged with the driving gears; the inner ends of gear shafts of the transmission gears are provided with connecting rod arms, mounting long grooves are formed in the connecting rod arms; one ends of the connecting rods are movably connected with the connecting rod arms through movablerods movably embedded in the mounting long grooves; fan-shaped notches are symmetrically formed in the positions, on two sides of the portion where the connecting rod arms are provided with the mounting long grooves, of the transmission gears; balance gears engaged with the transmission gears are arranged at the positions, on one side, away from the driving shaft, of the transmission gears, of the main machine seat; fan-shaped inner concaves are formed in the balance gears; a group of linear guide rails are arranged at the bottom of the other end in the main machine seat in parallel; a rollerseat is arranged on the linear guide rails; and two sides of the front end of the roller seat are movably connected with the other ends of the connecting rods through connecting shafts.

Owner:张家港恒立机械有限公司

Cold-rolling pipe mill transmission device with mass balance mechanism

ActiveCN107377628AHigh speedAvoid bending forceRolling mill drivesMetal rolling arrangementsCrankDrive shaft

The invention discloses a cold-rolling pipe mill transmission device with a mass balance mechanism. The cold-rolling pipe mill transmission device comprises a driving shaft, driving gears, first sector-shaped blocks, driven shafts, driven gears, second sector-shaped blocks, rotary shafts and connecting rods. The two first sector-shaped blocks are mounted on the driving shaft. The middle portions of the second sector-shaped blocks are symmetrically mounted at the opposite ends of the two driven shafts. The two rotary shafts are symmetrically mounted at the ends of the two second sector-shaped blocks. Due to the fact that the two symmetrical driven shafts, the two second sector-shaped blocks and the two rotary shafts form two symmetrical crank throws, an existing crankshaft is replaced with the two crank throws, the production cost is lowered, and the production cycle is shortened; the two crank throws drive the corresponding connecting rods to rotate, the bending force and twisting force generated when the two connecting rods are not synchronous are avoided, and the service life of parts is prolonged; and the first sector-shaped blocks and the second sector-shaped blocks are arranged in a staggered manner, the inertia force can be effectively eliminated, the speed of the cold-rolling pipe mill transmission device is increased, and accordingly the production efficiency is improved.

Owner:广东科莱博科技有限公司

hydraulic cylinder piston

ActiveCN103925259BEliminate inertial forceExtended service lifeFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a hydraulic cylinder piston, which includes a piston body provided with at least one buffer mechanism; the buffer mechanism is mainly composed of a buffer housing arranged in the piston body, a pressure relief valve, and first and second screw plugs , the buffer shell is provided with a pressure relief hole, and the left and right end faces of the buffer shell are respectively provided with diversion holes leading to the inside of the pressure relief hole, the two diversion holes in the pressure relief hole correspond to each other, and the pressure relief There is an annular pressure relief groove on the middle circumference of the valve, which is assembled in the pressure relief hole. The width of the pressure relief groove corresponds to the diameter of the diversion hole in the pressure relief hole. The first and second screw plugs are respectively provided with pressure introduction holes. The first and second screw plugs are assembled at both ends of the pressure relief hole, the diversion hole and the pressure relief valve in the pressure relief hole are between the first and second screw plugs, and the gap between the first and second screw plugs is The pressure relief hole forms the reciprocating space of the pressure relief valve, and when the pressure relief valve is at the stroke end in the reciprocating space, the pressure relief groove is blocked. Under load, it decelerates to zero when it reaches the end of the stroke, and works reliably.

Owner:SICHUAN ENG TECHN COLLEGE

Optional tooth difference swing type high-rotation-speed internal-combustion engine

An optional tooth difference swing type high-rotation-speed internal-combustion engine relates to the field of gas power. The tooth difference swing type high-rotation-speed internal-combustion engine is characterized in that eight air cylinders are annularly evenly distributed on the periphery of a protruding inner gear ring to allow resultant force borne by the inner gear ring to be zero. An air cylinder piston directly acts on the protruding inner gear ring through a push rod. Power is transmitted by protruding inner gear ring to an output shaft connected with a multi-phase shock wave wheel key through transmission of a multi-phase cam swing movable tooth. A connecting rod and a crankshaft in traditional internal-combustion engines are omitted, and the protruding inner multi-phase cam swing transmission mechanism has no eccentric weight, and has the advantages that self-balancing of inertia force and work load. Rotation speed of the output shafts depends on transmission ratio of movable tooth transmission. If a movable tooth frame is fixed, high-speed output of the multi-phase shock wave wheel is achieved. The internal-combustion engine is widely applicable to fields, which need high rotation speed, such as helicopter engines and small power generators. When rotation speed is fixed, emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, low in axial size, self-balancing in stress, and stable in operation.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com