Outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine

A technology of internal combustion engine and movable tooth transmission, which is applied in the direction of machines/engines, mechanical equipment, etc., and can solve problems such as large impact, large mechanical wear, and large unbalanced centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

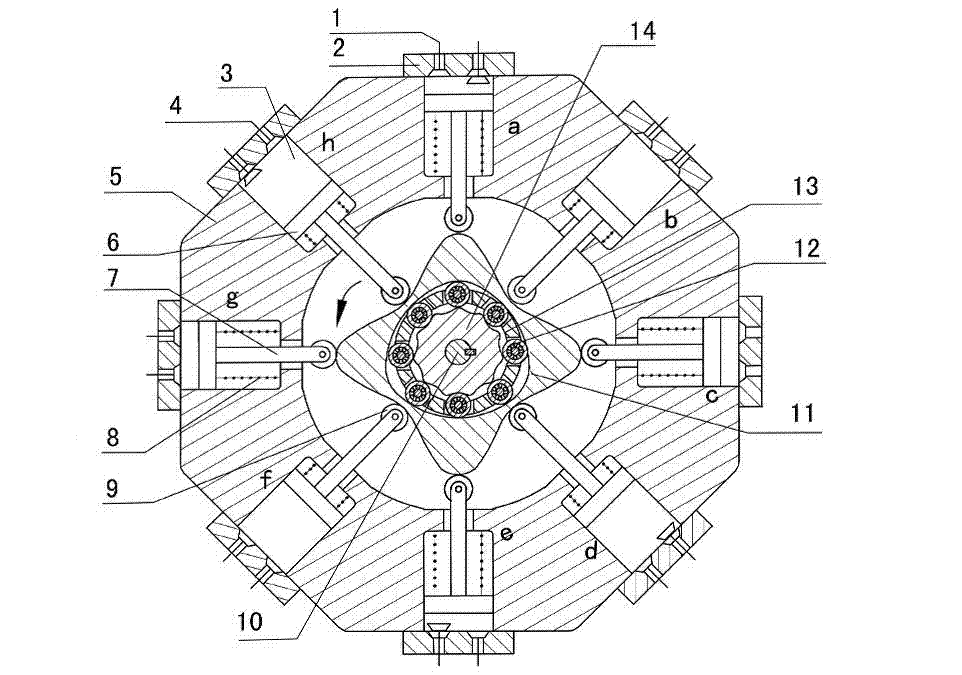

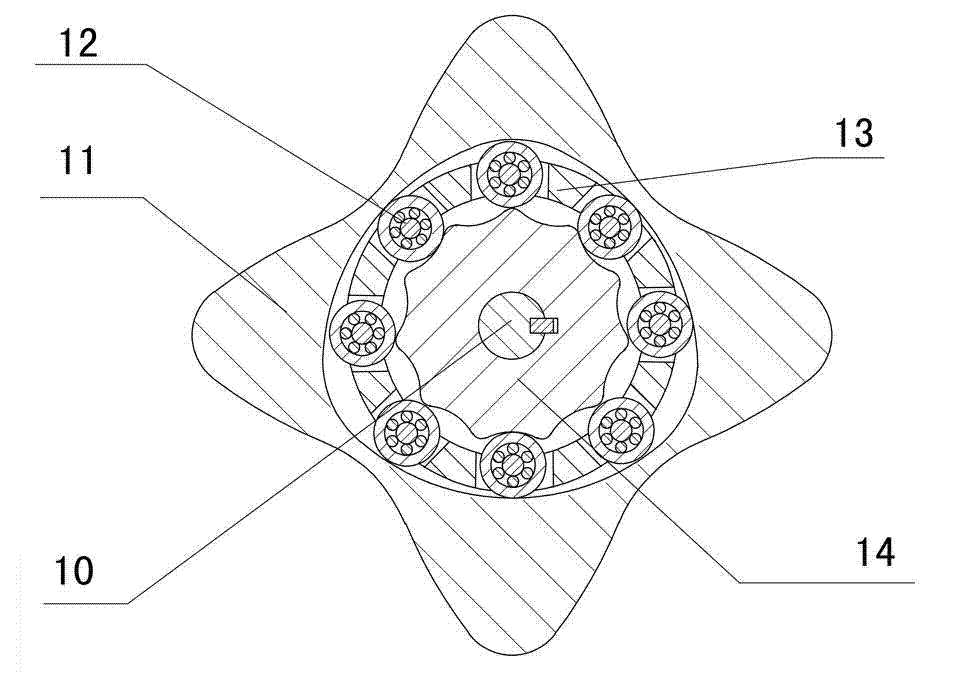

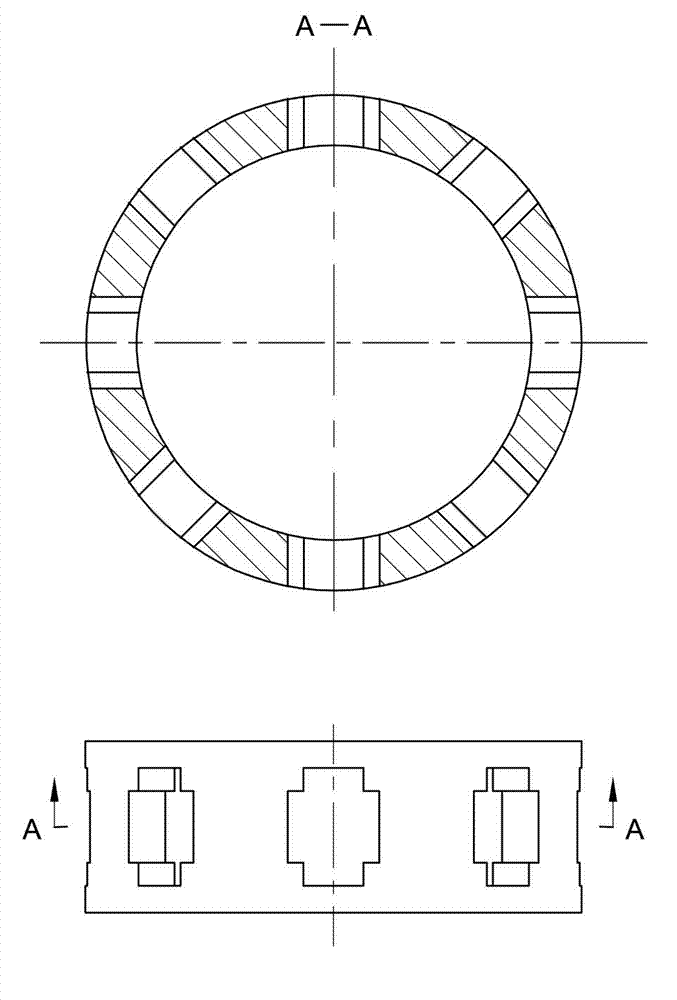

[0041] Figure 1~Figure 5 The cam rolling transmission internal combustion engine with any tooth difference inside the outer convex shown is composed of exhaust valve (1), cylinder head (2), cylinder (3), intake valve (4), cylinder block (5), piston (6) , push rod (7), spring (8), roller (9), output shaft (10), convex inner multi-phase inner cam (11), rolling movable tooth (12), movable gear rack (13), Center wheel (14) etc. are formed. Eight air cylinders (3) are evenly and symmetrically distributed in a circular shape around the outer convex inner multiphase inner cam (11), and the angle between two adjacent air cylinders is 45°. There is a piston (6) in each cylinder (3), one end of the push rod (7) is solidified with the piston (6), and the other end is equipped with a roller (9), and the push rod (7) is connected with the outer convex inner The multi-phase inner cams (11) change from sliding friction connection to rolling friction connection through rollers (9). One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com