Patents

Literature

190results about How to "Wide transmission ratio range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

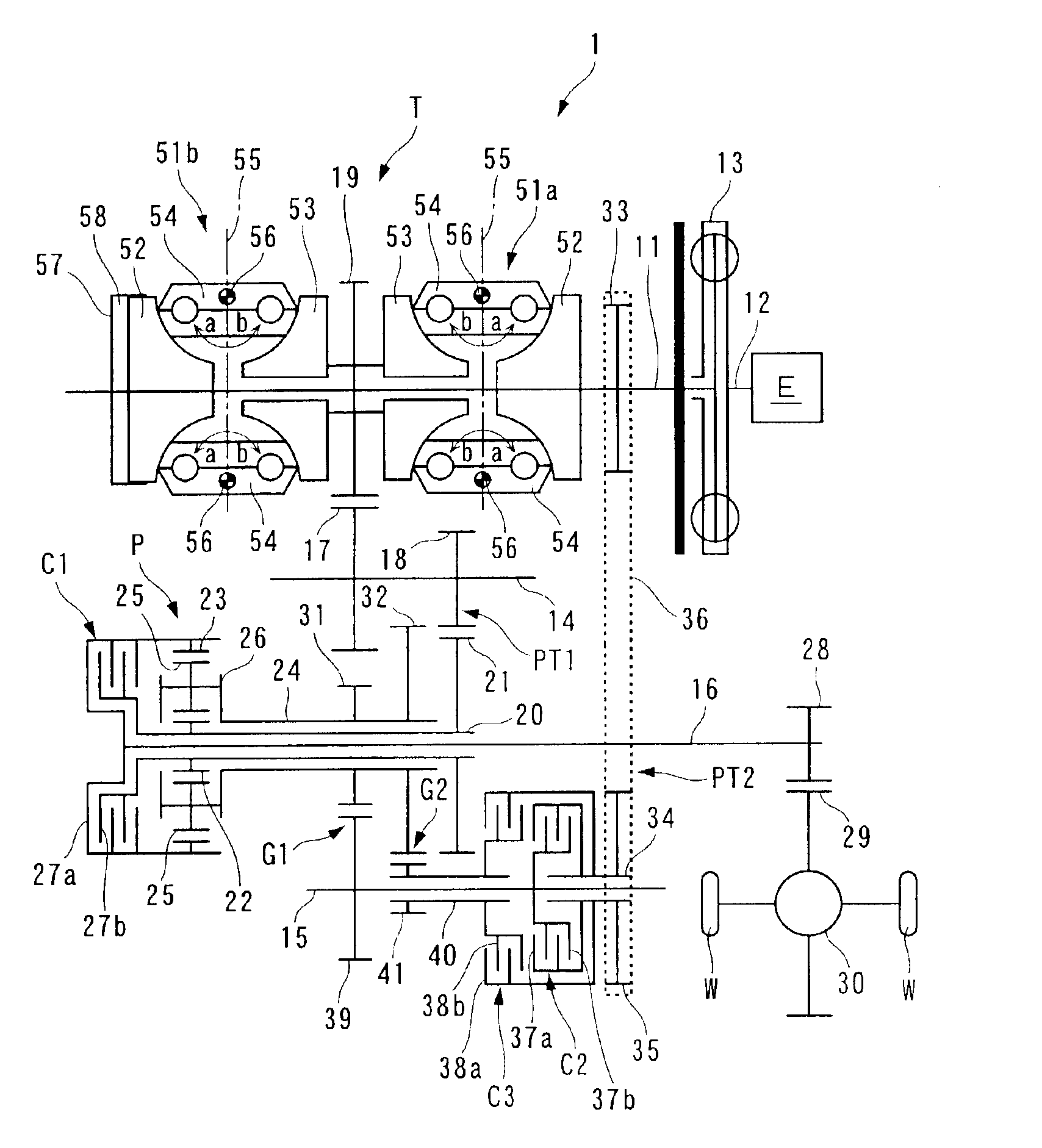

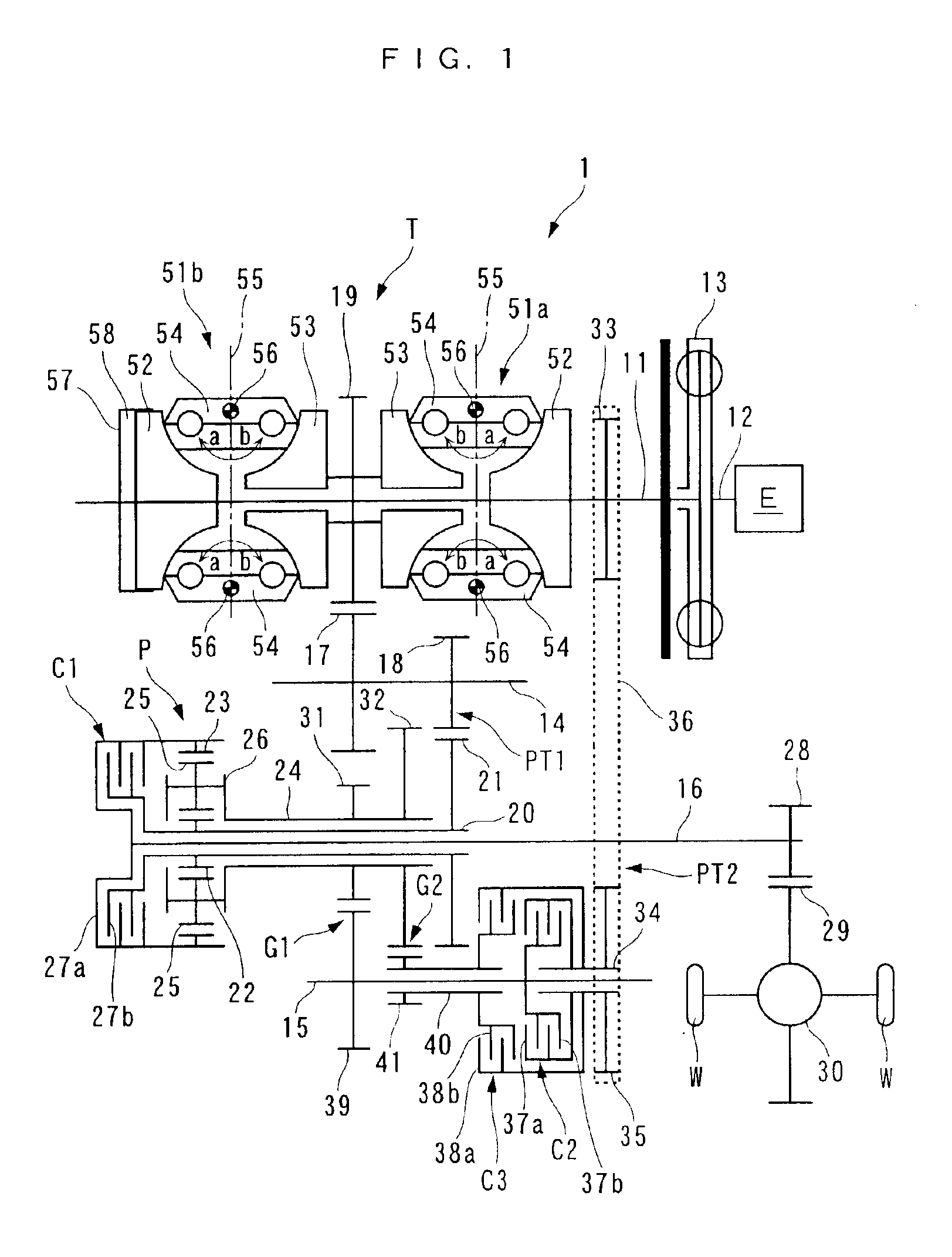

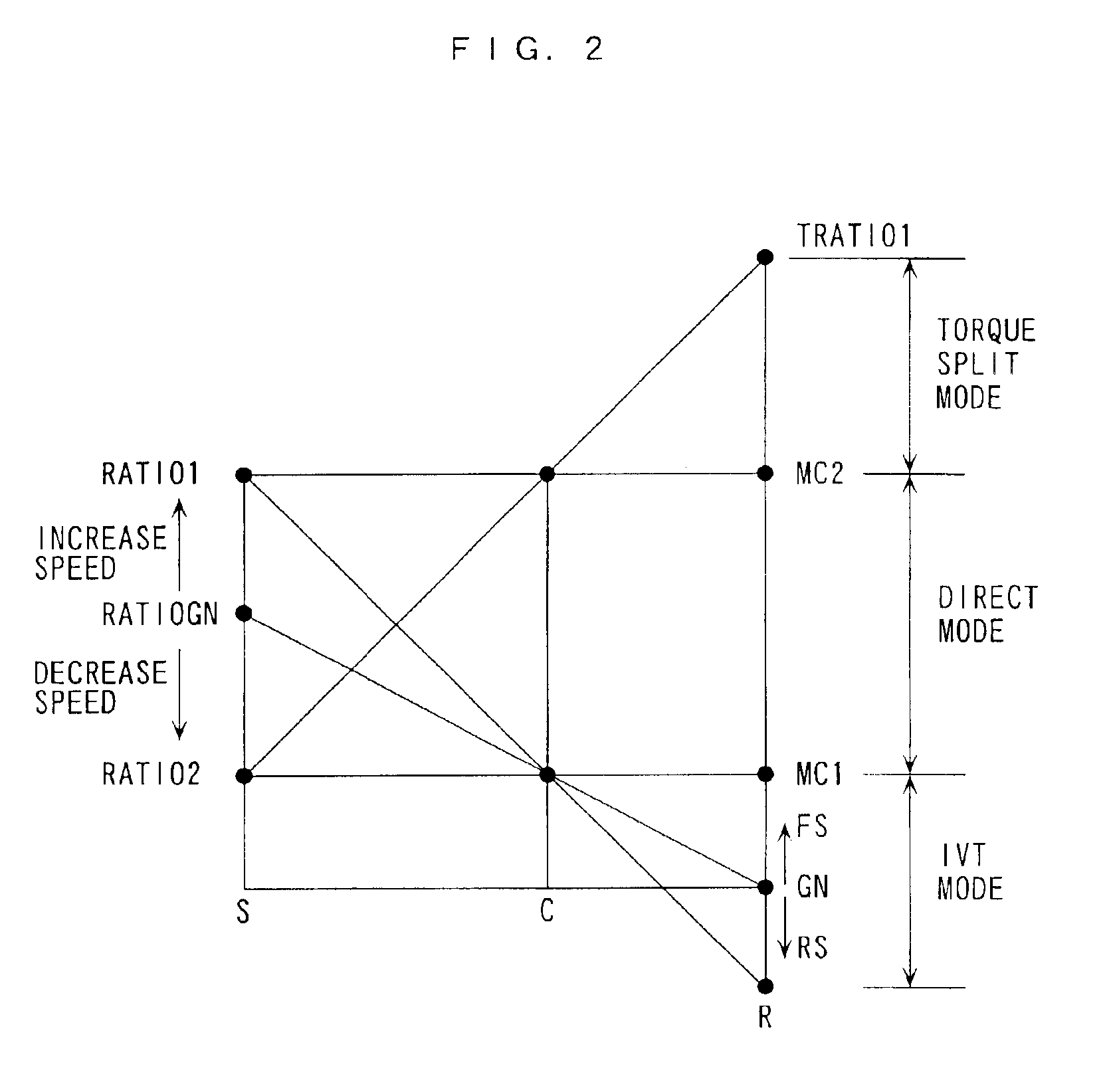

Continuously variable transmission system for vehicles

A continuously variable transmission system designable compact in size and manufacturable at a reduced cost by reducing the number of component parts and securing a maximum transmission ratio width. A toroidal continuously variable transmission has an input member connected to an output shaft of a prime mover, and an output member for outputting rotation of the input member at a continuously variable transmission ratio. A planetary gear mechanism has a first element connected to the output member, a second element connected to drive wheels, and a third element. A first clutch establishes and releases connection between the first element and the second element. A first gear train and a second gear train having a larger gear ratio, are arranged between the output shaft and the third element in parallel. Second and third clutches establish and release respective connections of first and second gear trains.

Owner:HONDA MOTOR CO LTD

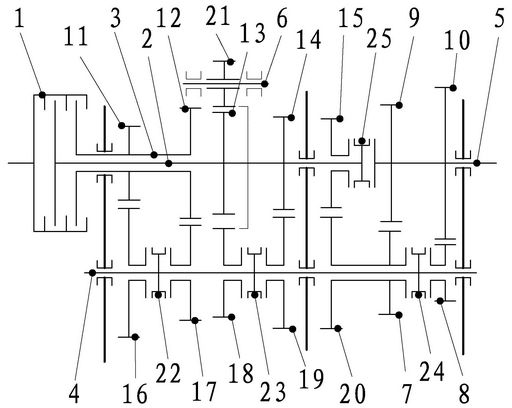

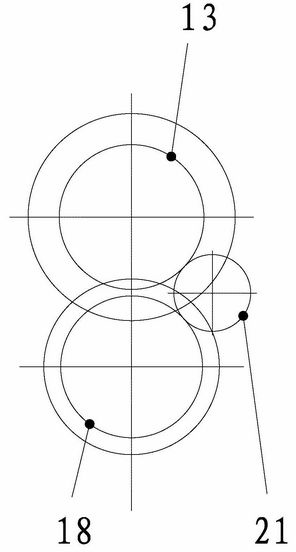

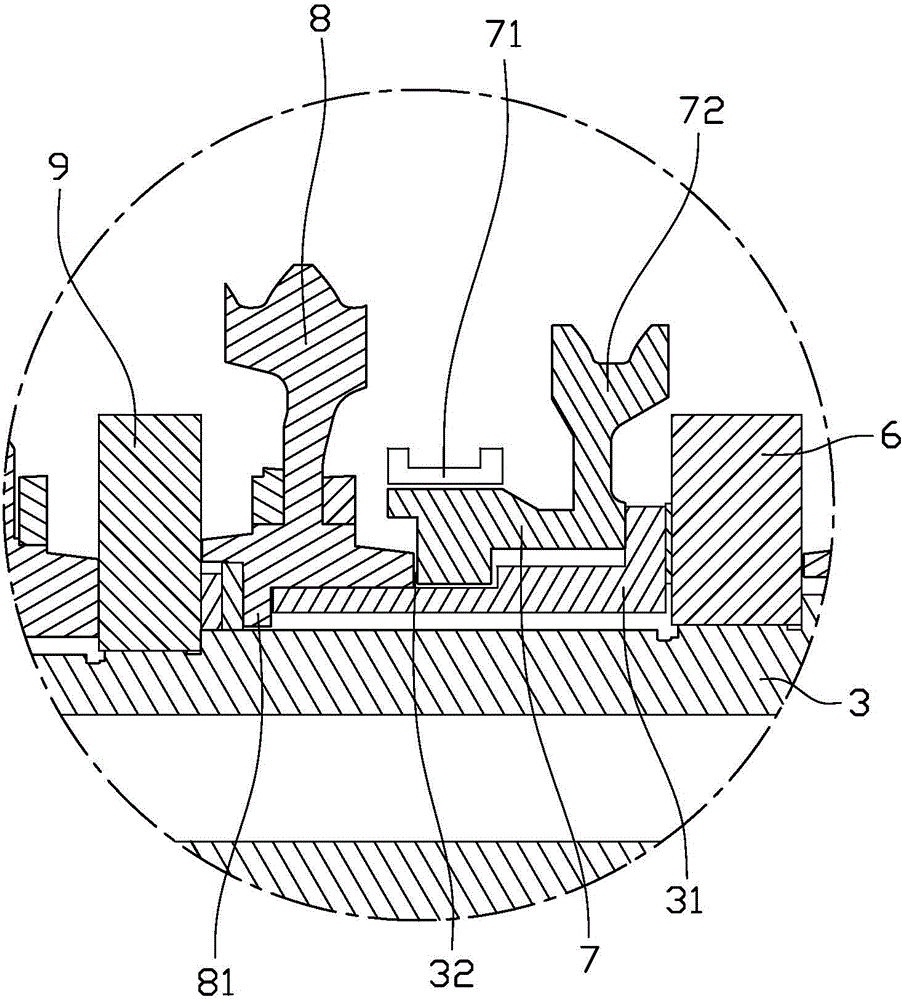

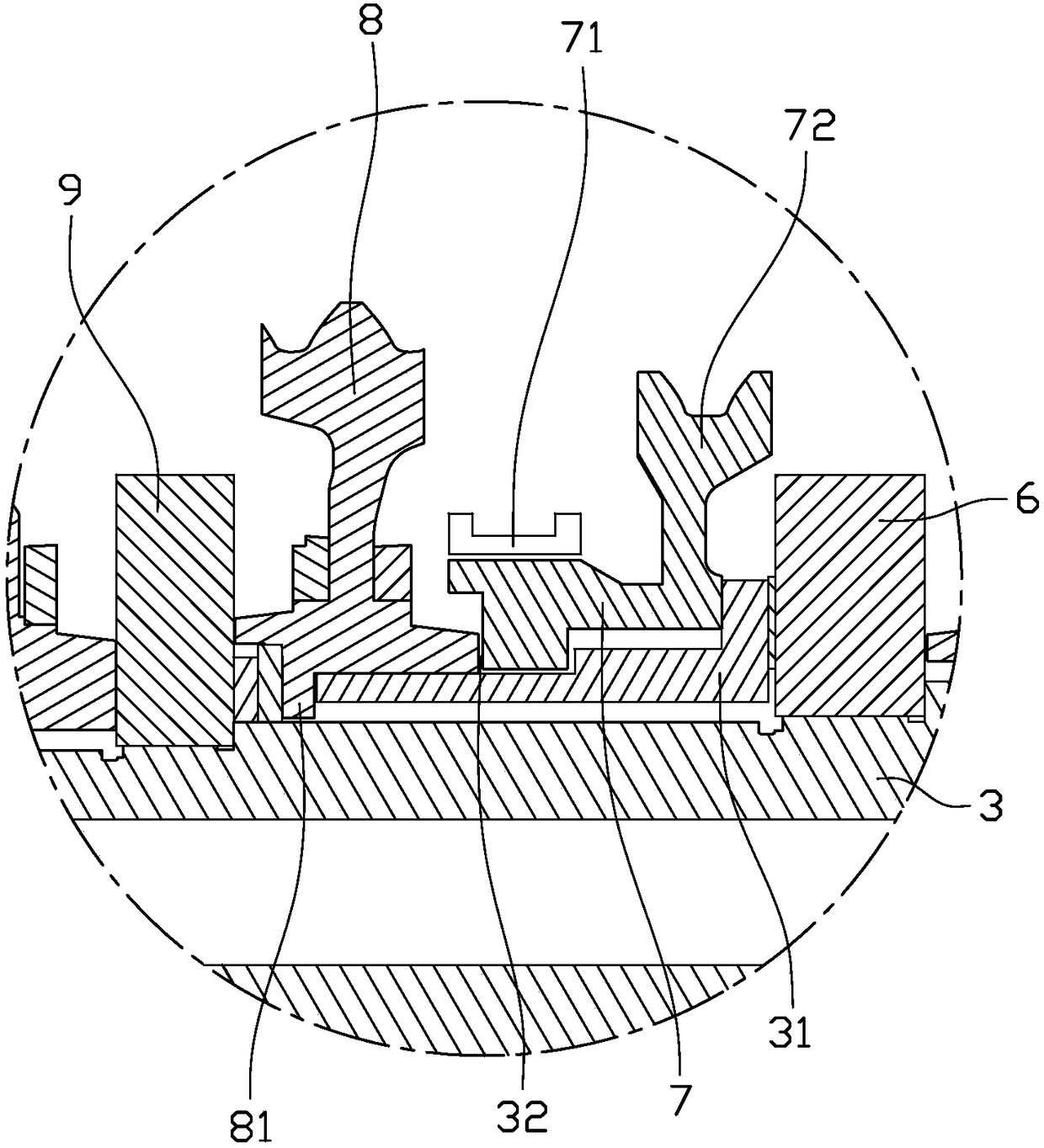

Double clutch type automatic gearbox

ActiveCN101713459AReduce length dimensionCompact structureToothed gearingsGearing controlAutomatic transmissionEngineering

The invention discloses a double clutch type automatic gearbox, which comprises a shell of the gearbox, first and second input shafts, and first and second automatic clutches which selectively transmit the rotation of a motor to the first or second input shaft; two sides of the first and second input shafts are provided with first and second output shafts basically parallel to the first and second input shafts; driving gears arranged on the input shafts are meshed with driven gears capable of rotatably sleeved on the first output shaft and / or the second output shaft; and at least one driving gear in the driving gears arranged on the first input shaft or the second input shaft is simultaneously two driven gears on the first and second output shafts. The driving gears are shared, so the arrangement mode of the gear transmission group is changed into a parallel arrangement mode, the length of the gearbox can be greatly shortened, the gearbox can be provided with eight gears on the premise of maintaining the same dimension as a five- or six-gear gearbox, and the dynamic property, the economical efficiency and the grade of the whole vehicle are obviously improved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

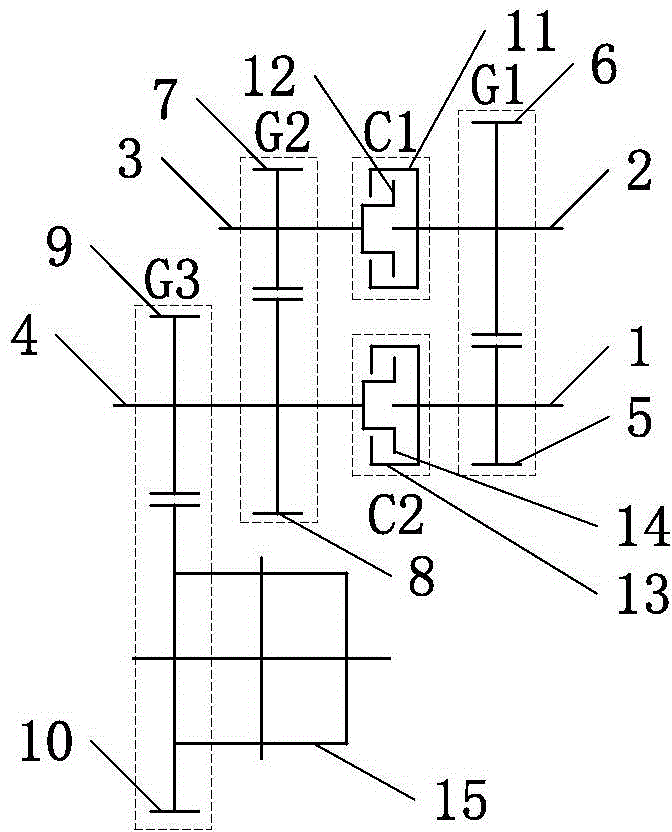

Automatic two-gear transformer for pure electric automobile

InactiveCN104595450ACompact structureLight in massElectric propulsion mountingToothed gearingsElectricityAutomatic transmission

An automatic two-gear transformer for a pure electric automobile comprises an input shaft, a first middle shaft, a second middle shaft, a third middle shaft, a first cylindrical gear pair, a second cylindrical gear pair, a third cylindrical gear pair, a first torque transmission device, a second torque transmission device and a differential assembly; rotation center lines of the input shaft, the third middle shaft and the differential assembly are mutually parallel. According to the automatic two-gear transformer for the pure electric automobile, automatic two-gear speed change is adopted, the transmission ratio range is expanded, the performance requirement on a drive motor can be reduced greatly, an efficient and light drive motor is allowed to be used, and the total size, the total mass and the total cost of an electric drive system of the pure electric automobile are further reduced.

Owner:BEIHANG UNIV

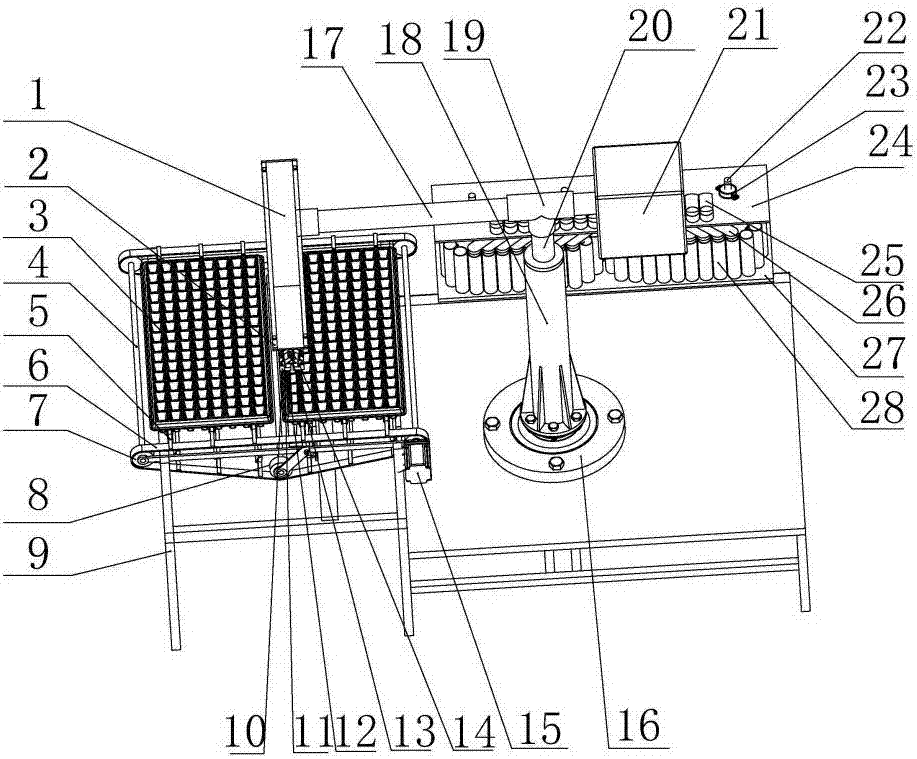

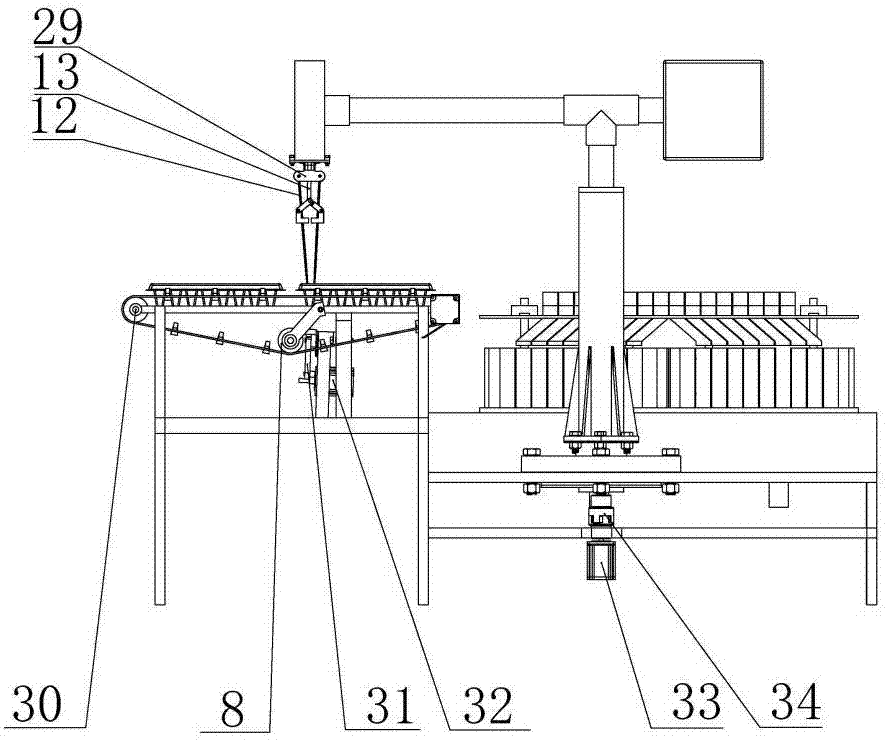

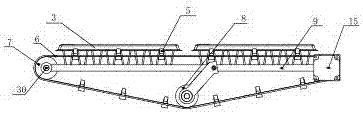

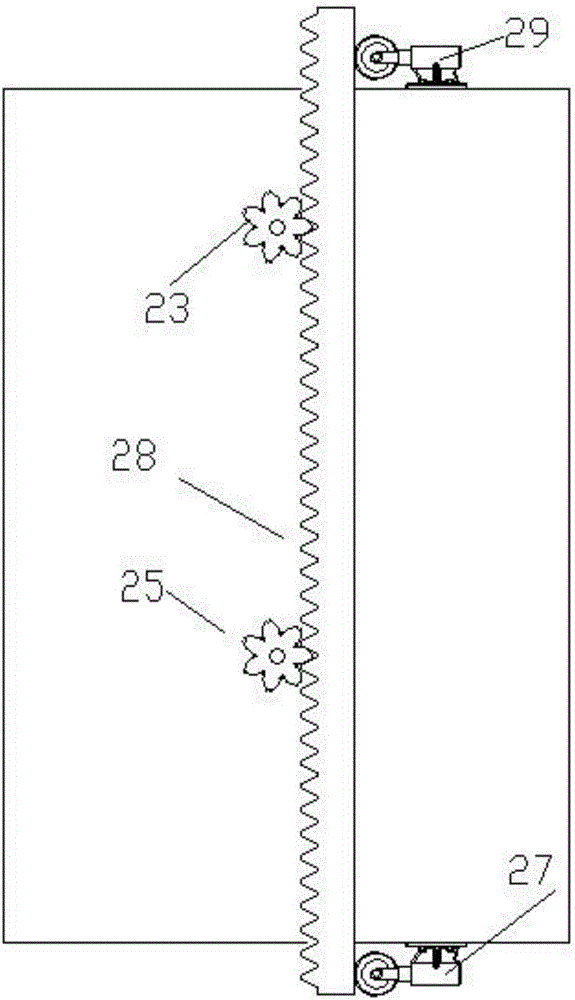

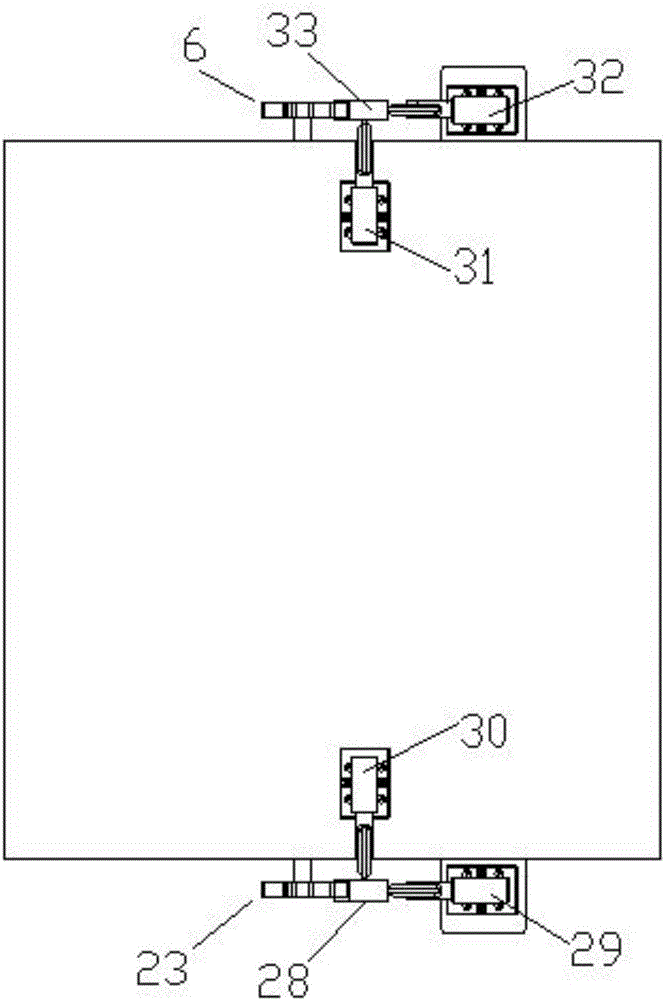

Novel transplanting machine automatic feeding device

PendingCN106973602AImprove transmission efficiencyCompact structureTransplantingAgricultural engineeringFully automated

The invention discloses a novel transplanting machine automatic feeding device, which consists of a seedling disc step displacement device, a seedling taking device, a seedling jacking device, a pot seedling conveying device and a rotary seedling collecting device. The novel transplanting machine automatic feeding device is mainly used for realizing the mechanical fully automatic seedling taking in the agricultural transplanting process; the labor requirements on the transplanting are reduced; the planting quality is improved; the yield and income increase of farmers are promoted. In the work process of the device, the seedling jacking device jacks out pot seedlings in the seedling taking position, then, the whole line pot seedling clamping is performed by the seedling taking device from the seedling taking position; then, the pot seedling conveying device rotates for 90 degrees to reach the seedling putting position and puts the whole row of pot seedlings into a seedling collecting hopper of the rotary seedling collecting device; in addition, under the operation condition of the rotary seedling collecting device, the pot seedlings are separated into two lines to be put into a planting device one by one; finally, the pit disc seedlings are planted into the soil through the planting device.

Owner:SHIHEZI UNIVERSITY

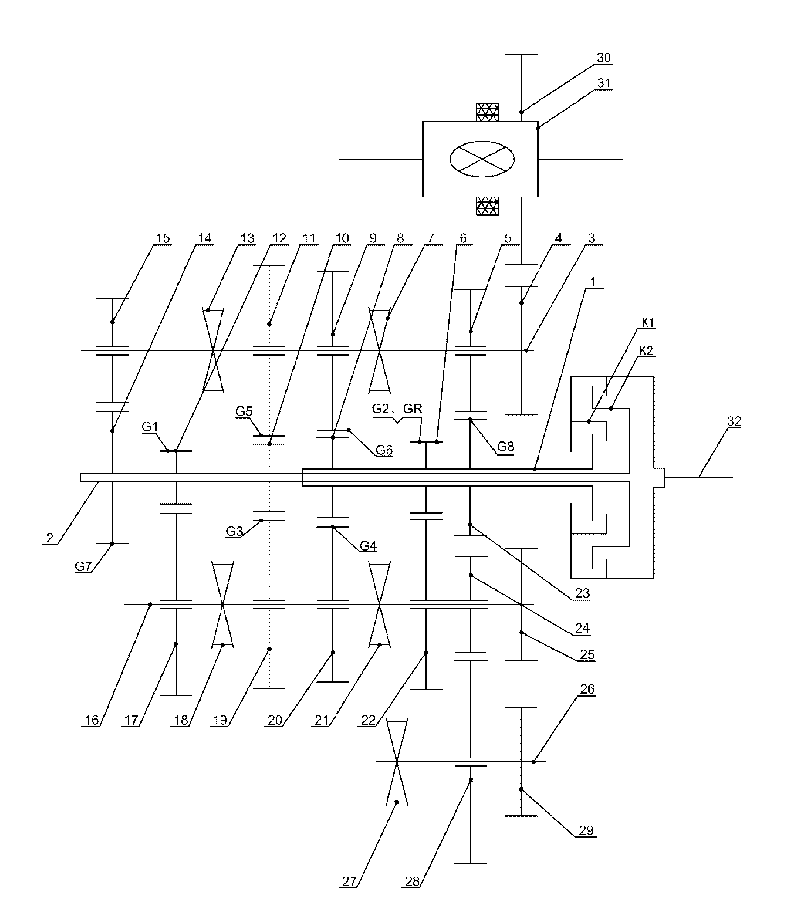

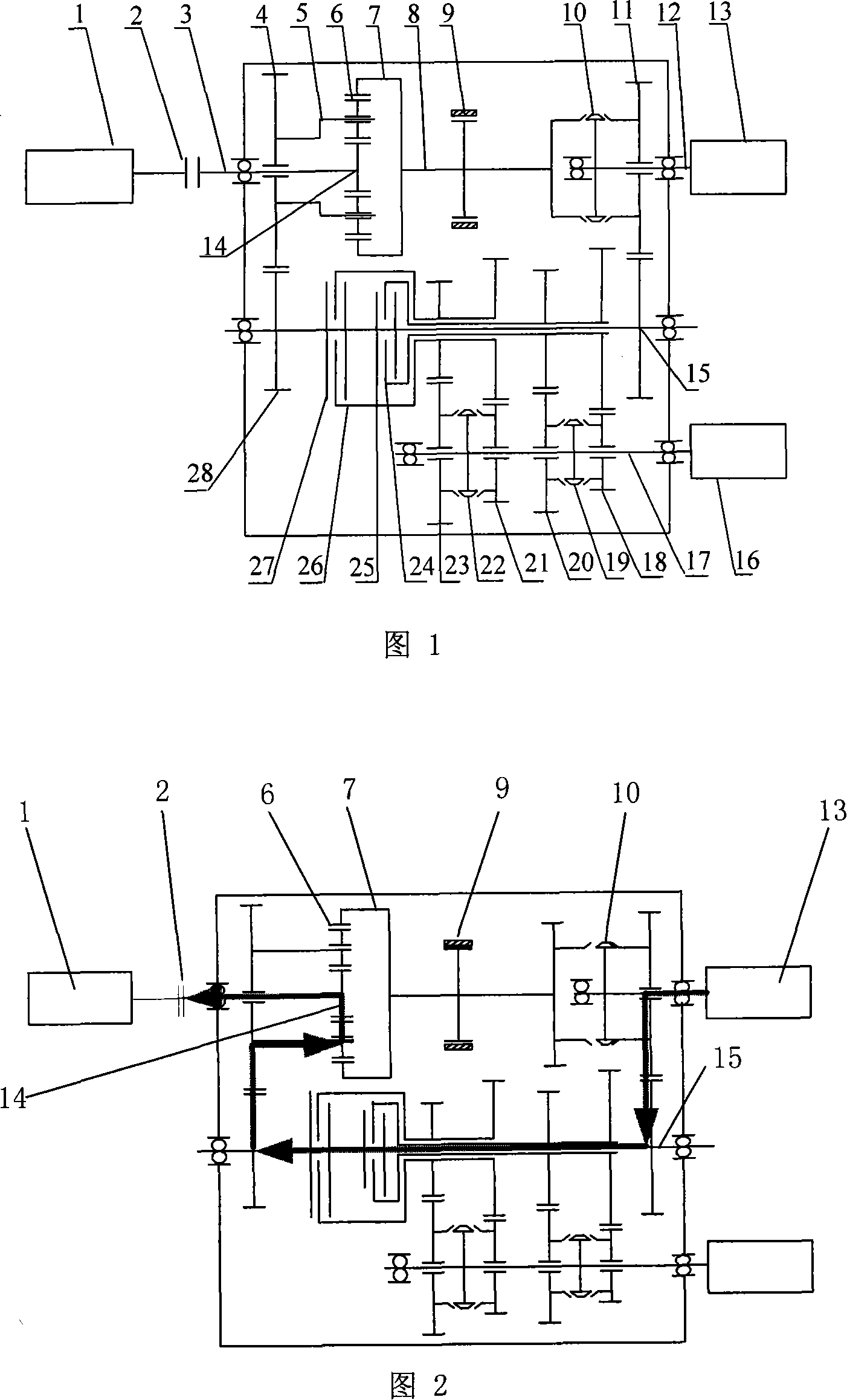

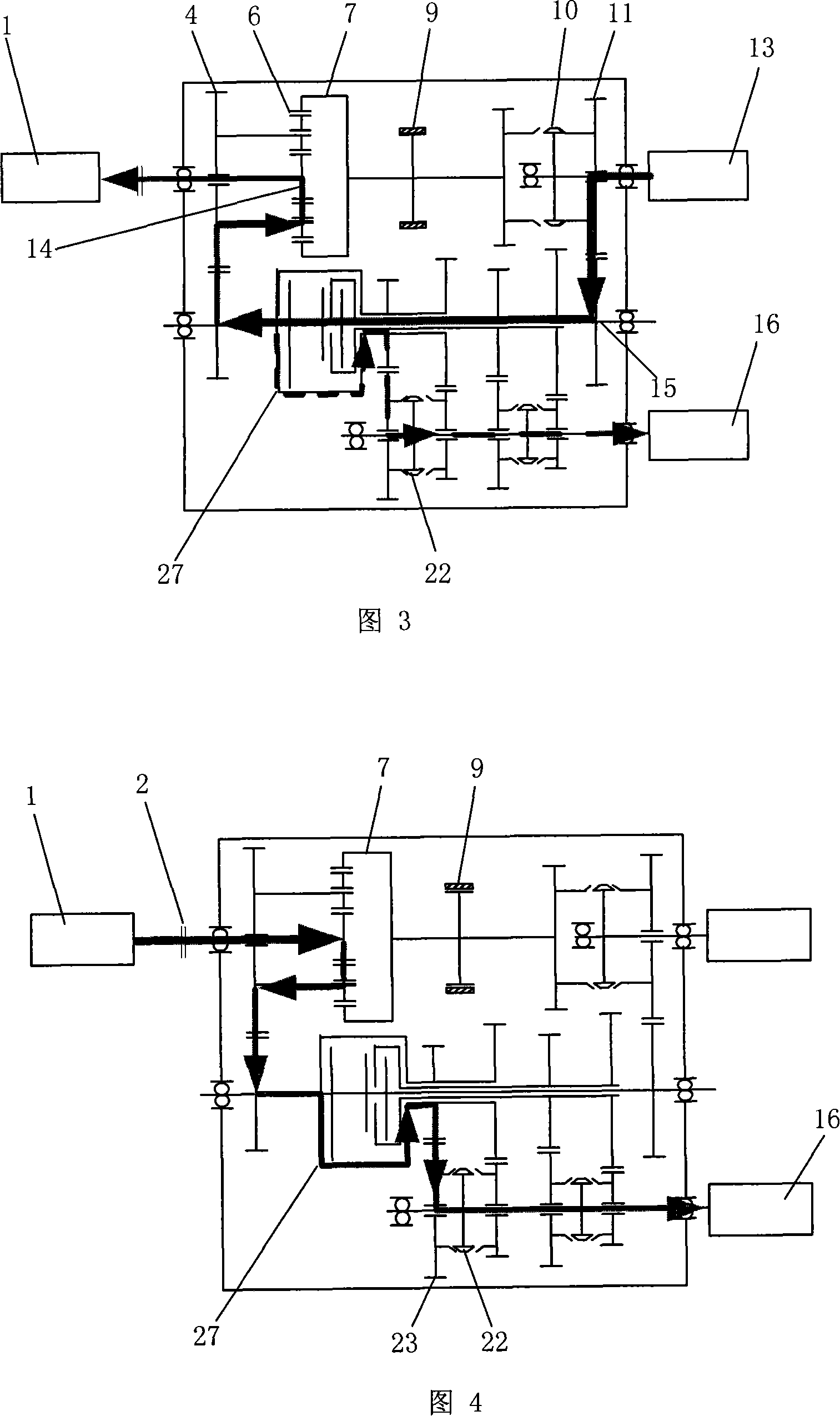

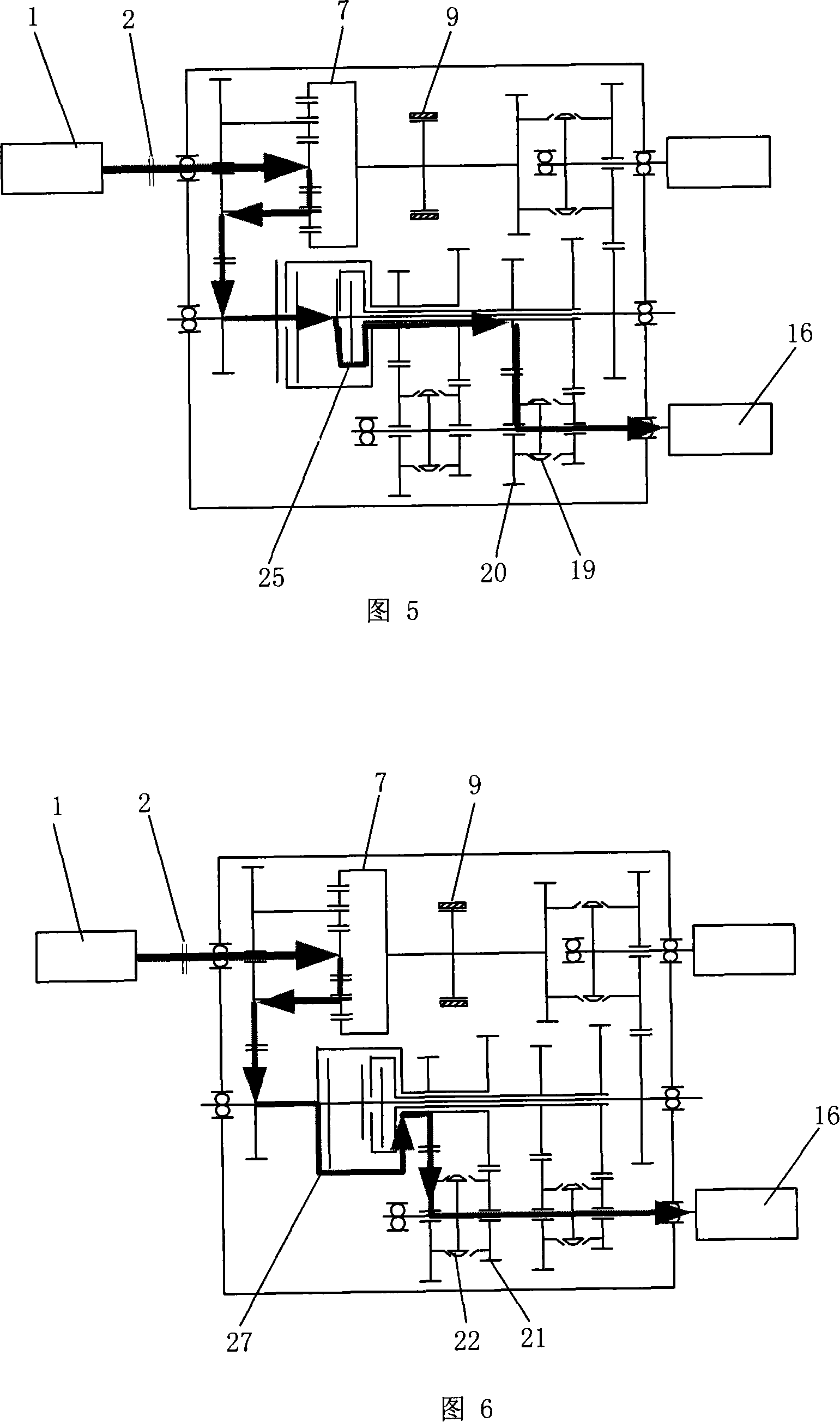

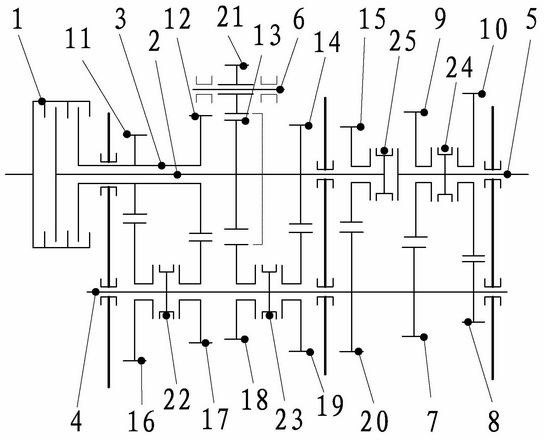

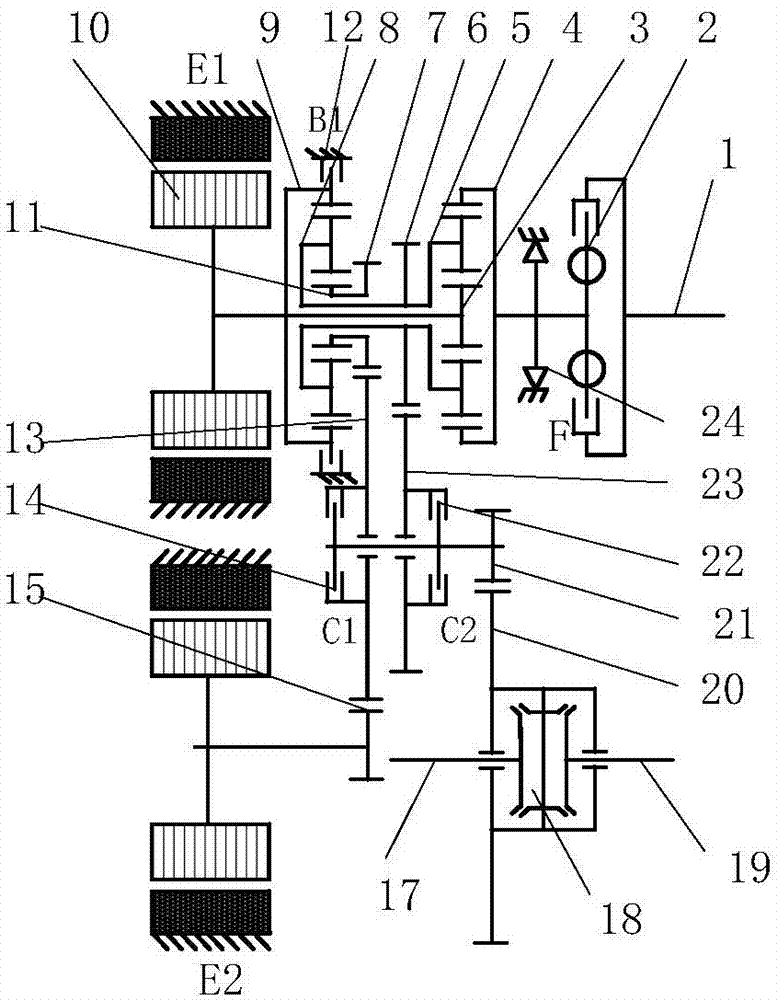

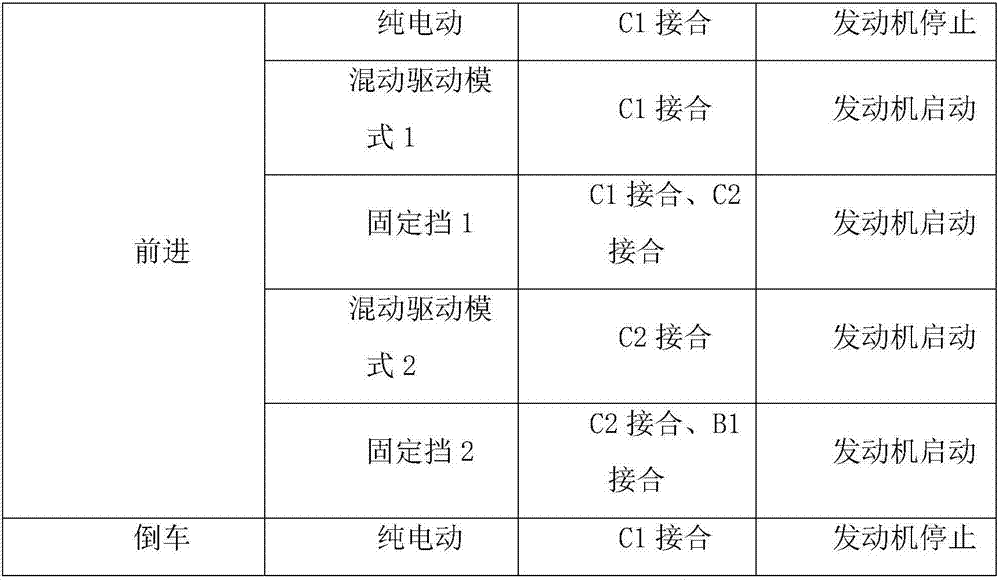

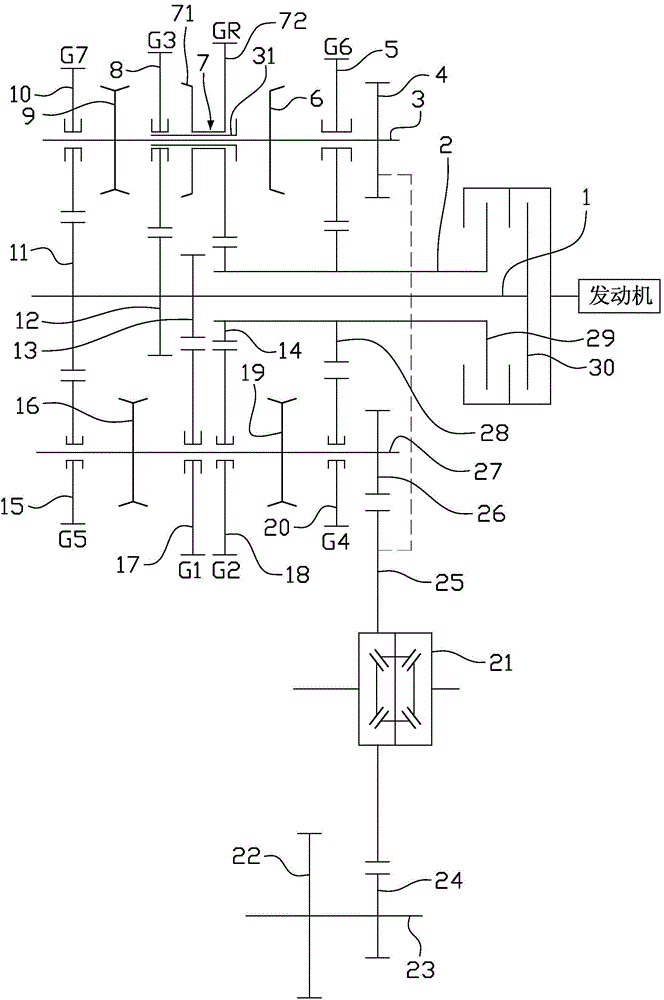

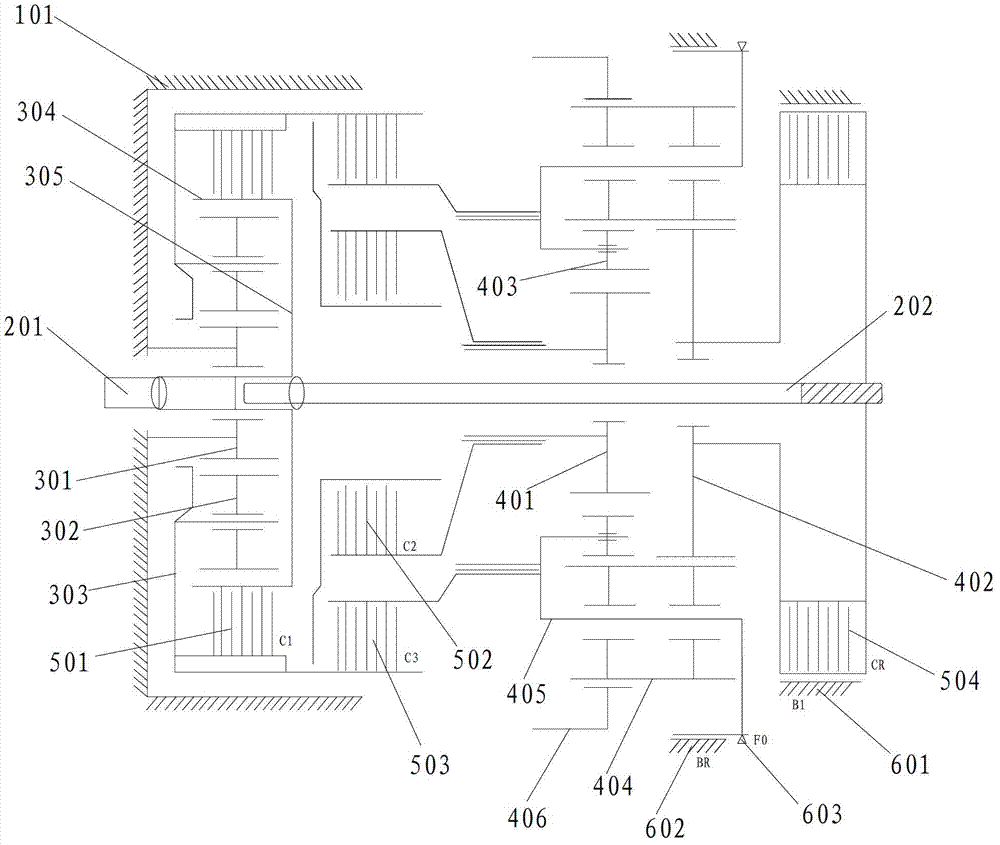

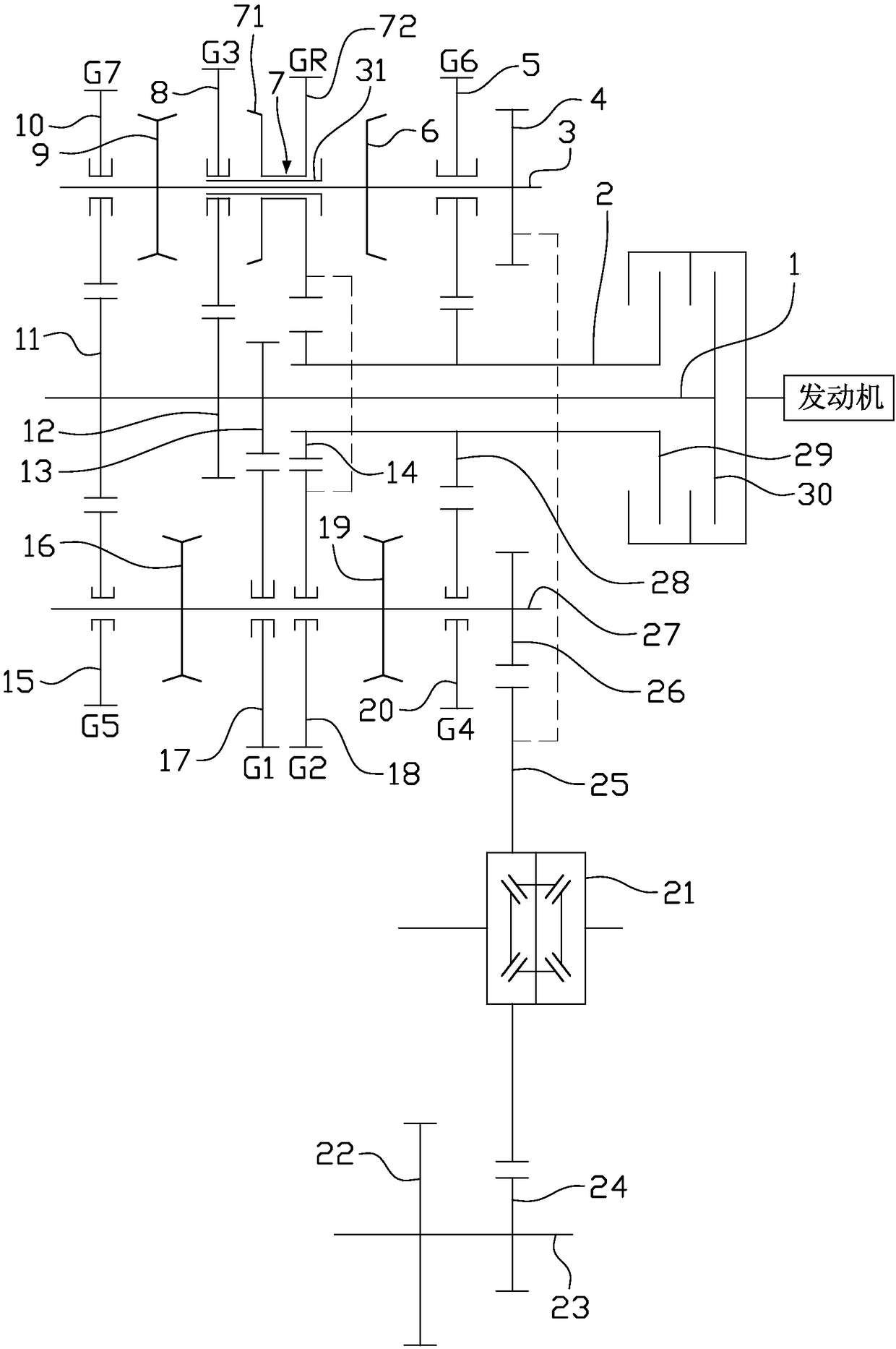

Hybrid power drive device based on double clutch automatic speed-changer

ActiveCN101149095AImprove economyImprove comfortToothed gearingsGearing controlAutomatic transmissionGear wheel

The mixed power drive unit based on double clutch automatic speed variator has one planet gear train, one double clutch automatic speed variator, three synchronizers and one brake. The planet gear train includes a planet gear, an outer gear and a sun gear; the double clutch automatic speed variator includes four shafts, two DCT clutches, four gear meshing pairs and two synchronizers. The present invention has the advantages of power synthesis between the engine and the motor with single planet gear rank, the combination with DCT, relatively broad transmission ratio range of stepless speed change and capacity of expanding the use range of engine.

Owner:TONGJI UNIV

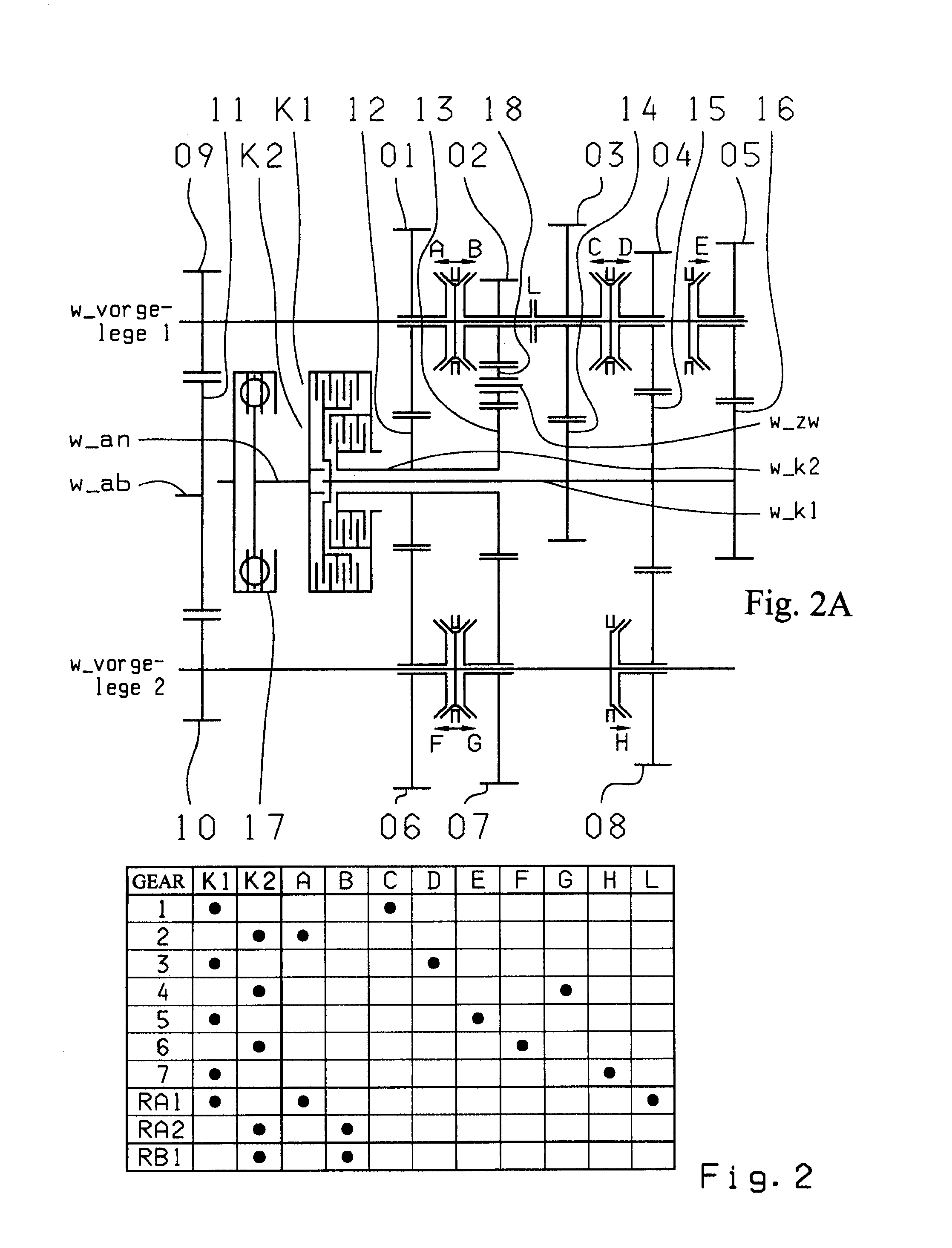

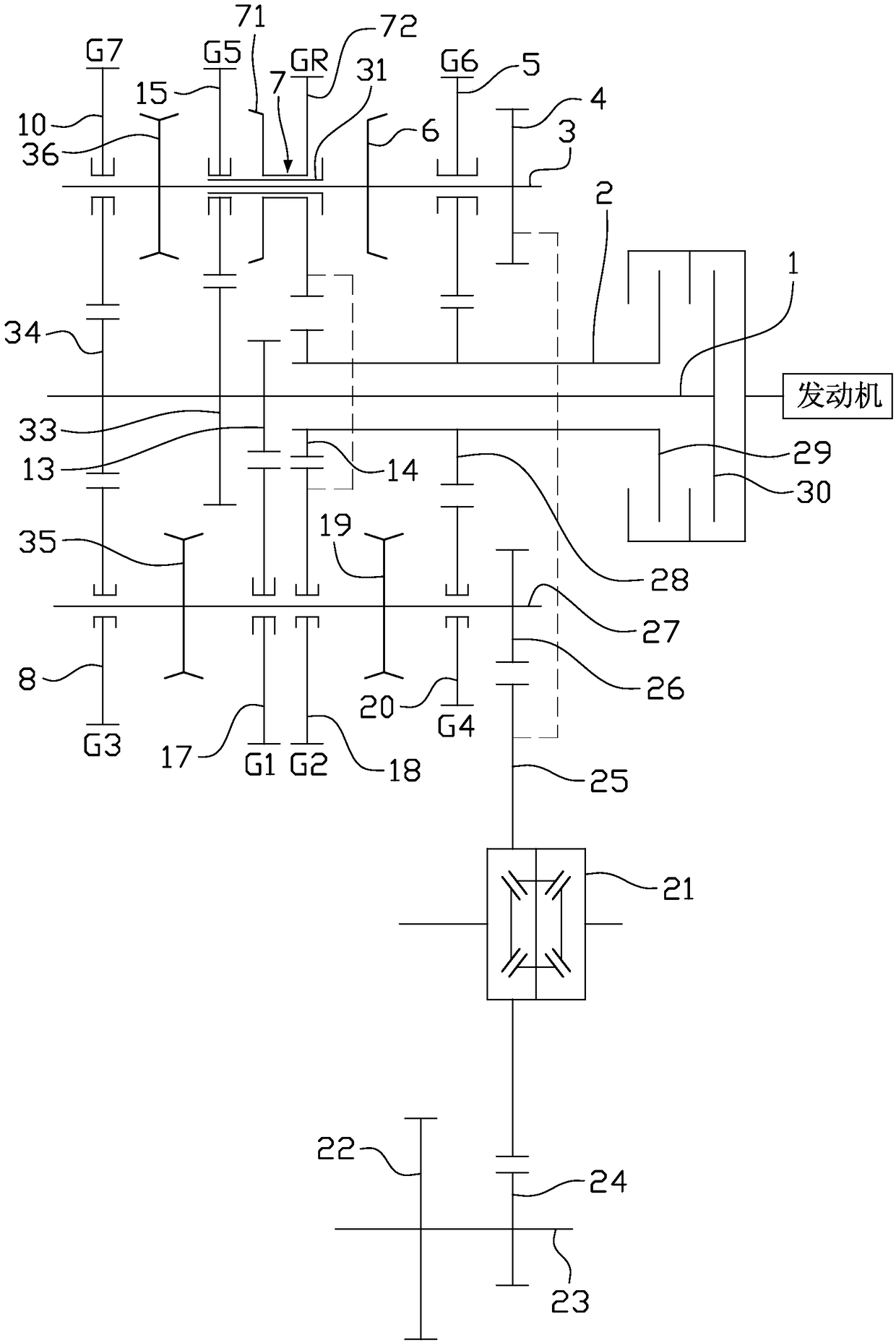

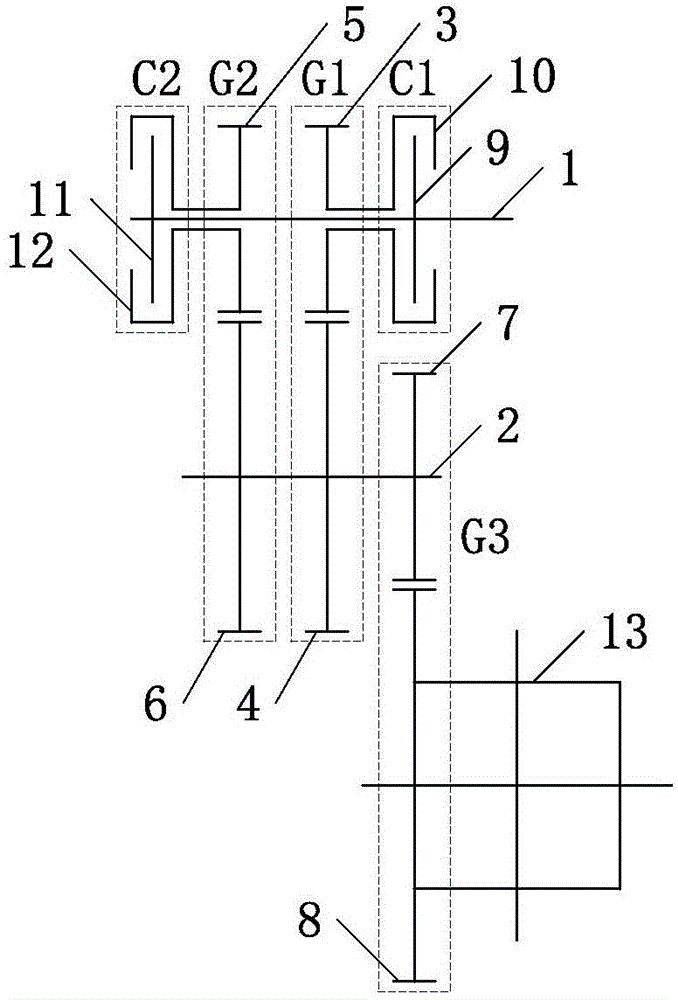

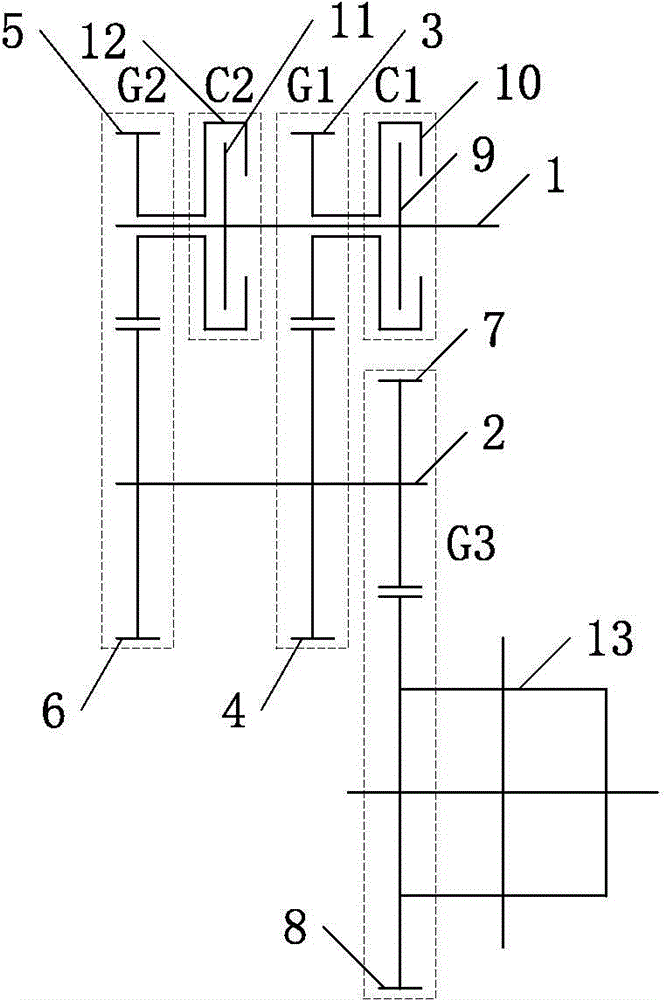

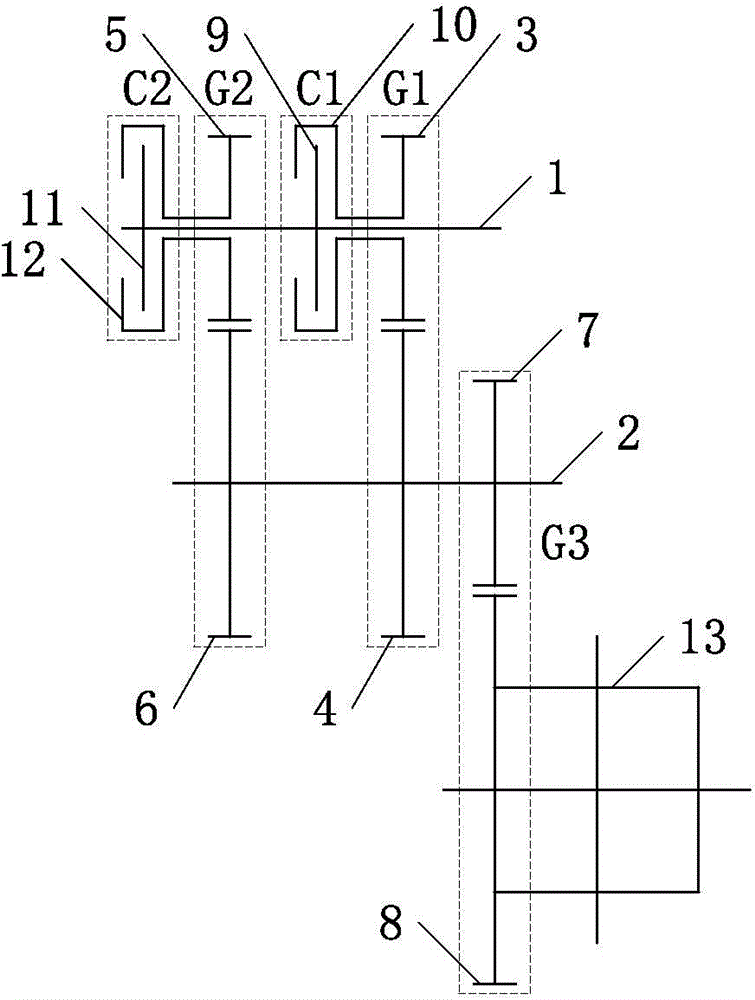

Multi-gear vertical dual clutch transmission

The invention discloses a multi-gear vertical dual clutch transmission, which comprises a nesting shaft, an intermediate shaft, an output shaft and a reverse gear shaft, wherein the intermediate shaft, the output shaft and the reverse gear shaft are parallel with each other; the nesting shaft and the output shaft are collinear; the solid input shaft of the nesting shaft is provided with a dual clutch; all gears of gear pairs are respectively arranged on a hollow input shaft and the intermediate shaft, or the solid input shaft and the intermediate shaft; the intermediate shaft and the output shaft are provided with a high-speed gear pair, a low-speed gear pair, a first synchronizer and a second synchronizer; the output shaft is provided with a fourth synchronizer; and a third synchronizer is arranged on the intermediate shaft and is located between a high-speed driving gear and a low-speed driving gear, or is arranged on the output shaft and is located between a high-speed driven gear and a low-speed driven gear. In the multi-gear vertical dual clutch transmission, the implementation of all gears needs to be completed by the joint participation of 1-2 synchronizers; on the premise of not increasing the number of meshing gear pairs, through the joint utilization of all the gears of the gears and the alternating action of the four synchronizers, multi-gear drive and a wider drive ratio range are realized, and the number of the gears and the synchronizers is reduced, so that the layout of the vertical transmission is more compact, the manufacturing cost is saved, and the lightweight requirement of a whole vehicle is met. The multi-gear vertical dual clutch transmission of the vehicle can realize eight forward gears and two reverse gears at most.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

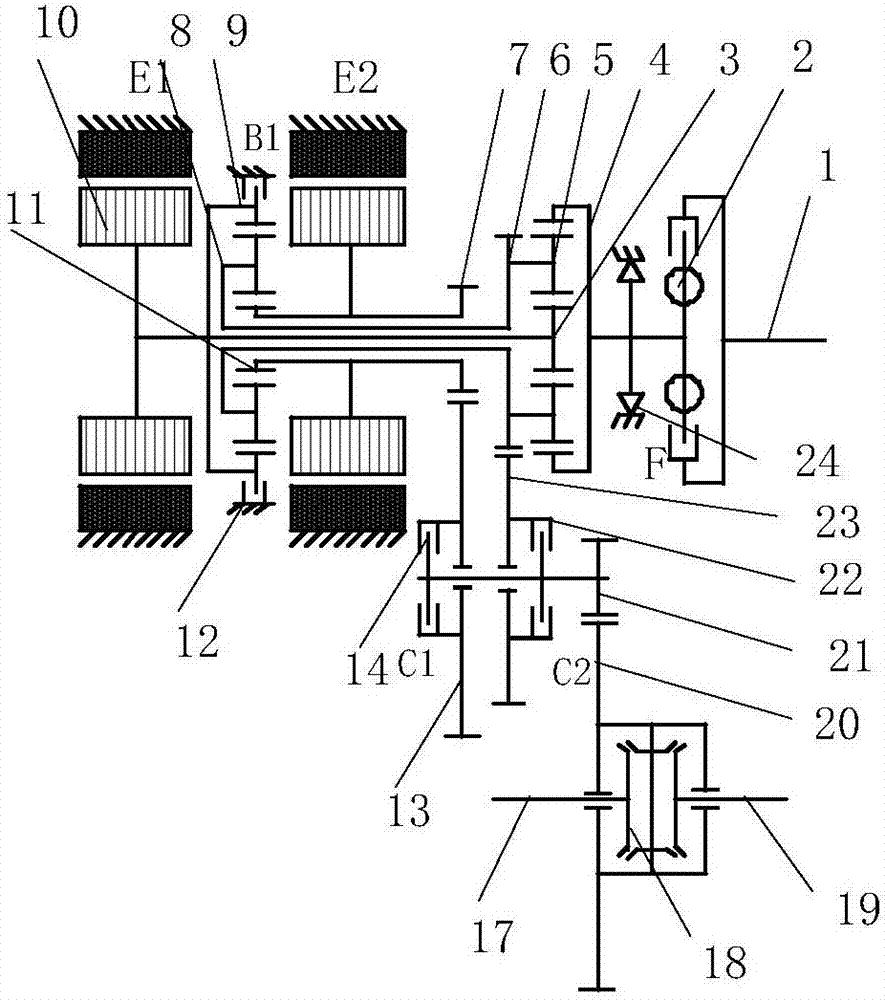

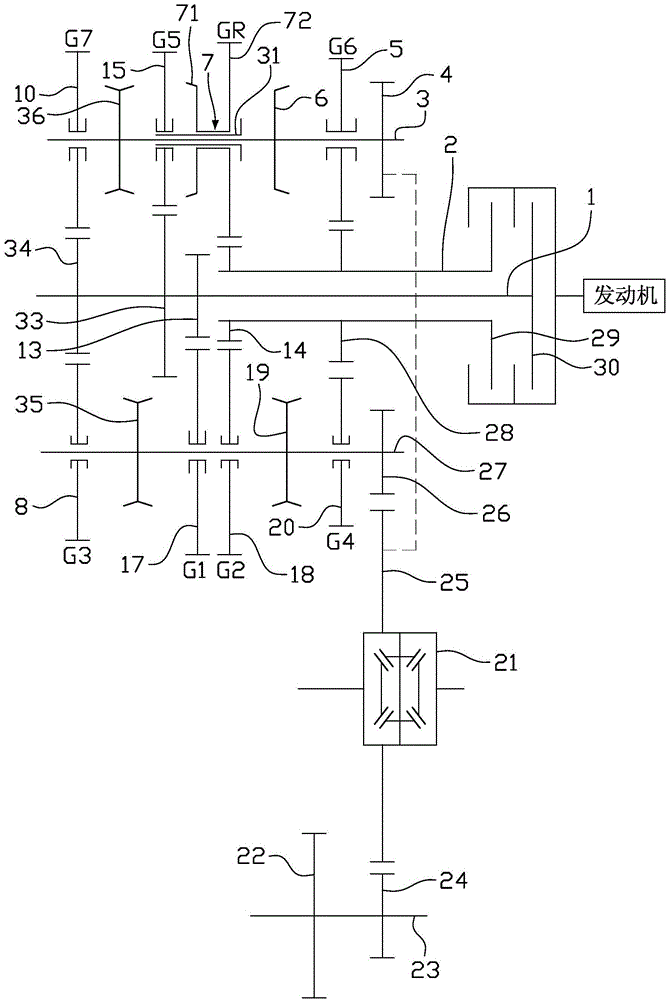

Dual-mode hybrid power transmission device of front-wheel drive car

ActiveCN106882032AReduce torqueReduced Power RequirementsElectric propulsion mountingGas pressure propulsion mountingPower splitDual mode

The invention belongs to the technical field of hybrid power cars, and particularly relates to a hybrid power transmission device. According to the technical scheme, the dual-mode hybrid power transmission device of a front-wheel drive car comprises an engine input shaft, torsion dampers, a dual planetary mechanism, a first gear, a second gear, a first motor, a first brake, a third gear, a first clutch, a second motor, a first output shaft, a differential mechanism, a second output shaft, a fifth gear, a sixth gear, a second clutch, a seventh gear and a one-way clutch. The dual-mode hybrid power transmission device is compact in structure, mode switching is conducted through the two clutches, and the clutches are arranged on the other shaft so that the overall axial length can be shortened. Power split is conducted through the dual planetary mechanism, and dual-mode power split can be achieved in the cooperation of the two switching clutches so that torque and power requirements of the two motors can be reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

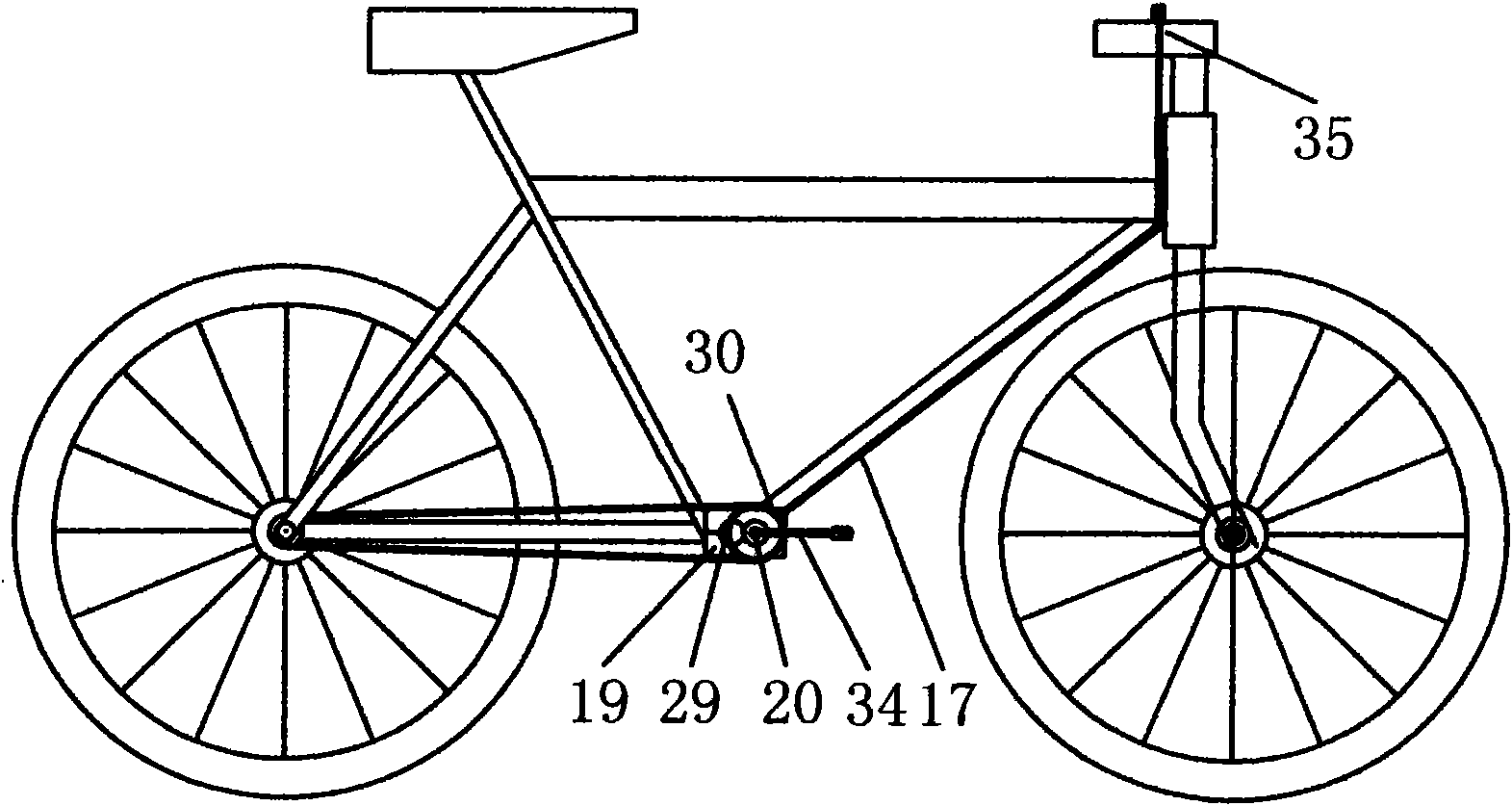

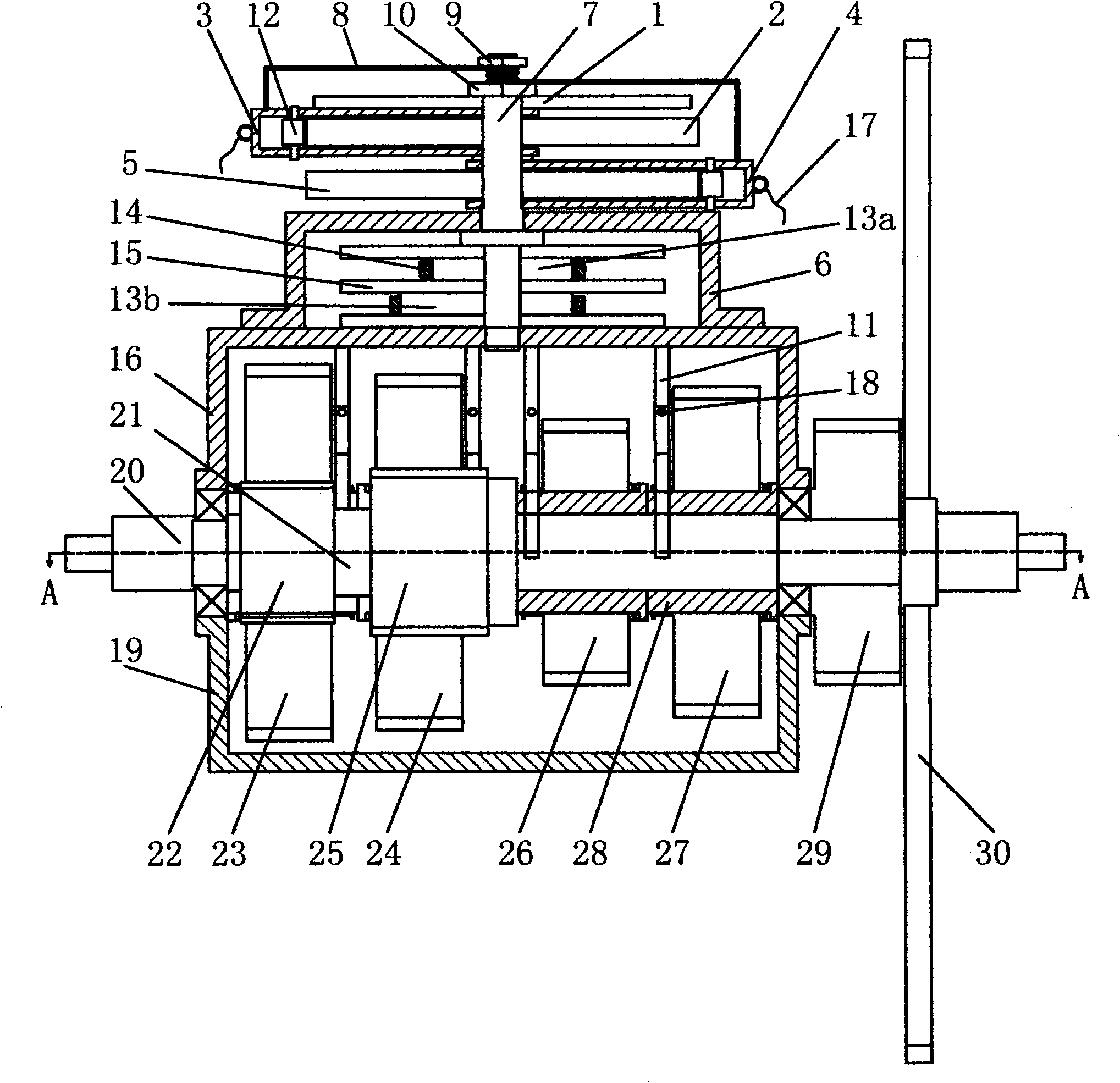

Bicycle with miniature box transmission on middle axle

ActiveCN101979273ASimple shiftingUnique designWheel based transmissionCycle control systemsAgricultural engineeringRoad condition

The invention discloses a bicycle with a miniature box transmission on a middle axle. The bicycle comprises a frame device, a transmission device, a moving device and a safety device and is characterized in that: the middle axle of the frame device is provided with the miniature box transmission consisting of a box speed transformation device and a shifting device; the middle axle and an auxiliary axle are arranged in a box; a clutch sleeve and a driving gear are fixedly arranged on the middle axle; the right outer end of the middle axle is in movable fit with a middle axle driven gear and a chain wheel; a clutch sleeve and a driven gear are fixedly arranged on the auxiliary axle; and an auxiliary axle driving gear is fixedly arranged at the right outer end of the auxiliary axle and engaged with the middle axle driven gear. The bicycle has a small and compact structure, large transmission ratio range, high climbing capability, high level road speed, low production cost and high popularization value, is convenient to use, flexible and rapid to shift, easy to manufacture and easy to accept by bicycle enthusiasts and can particularly realize quick shifting under various road conditions.

Owner:石幸运

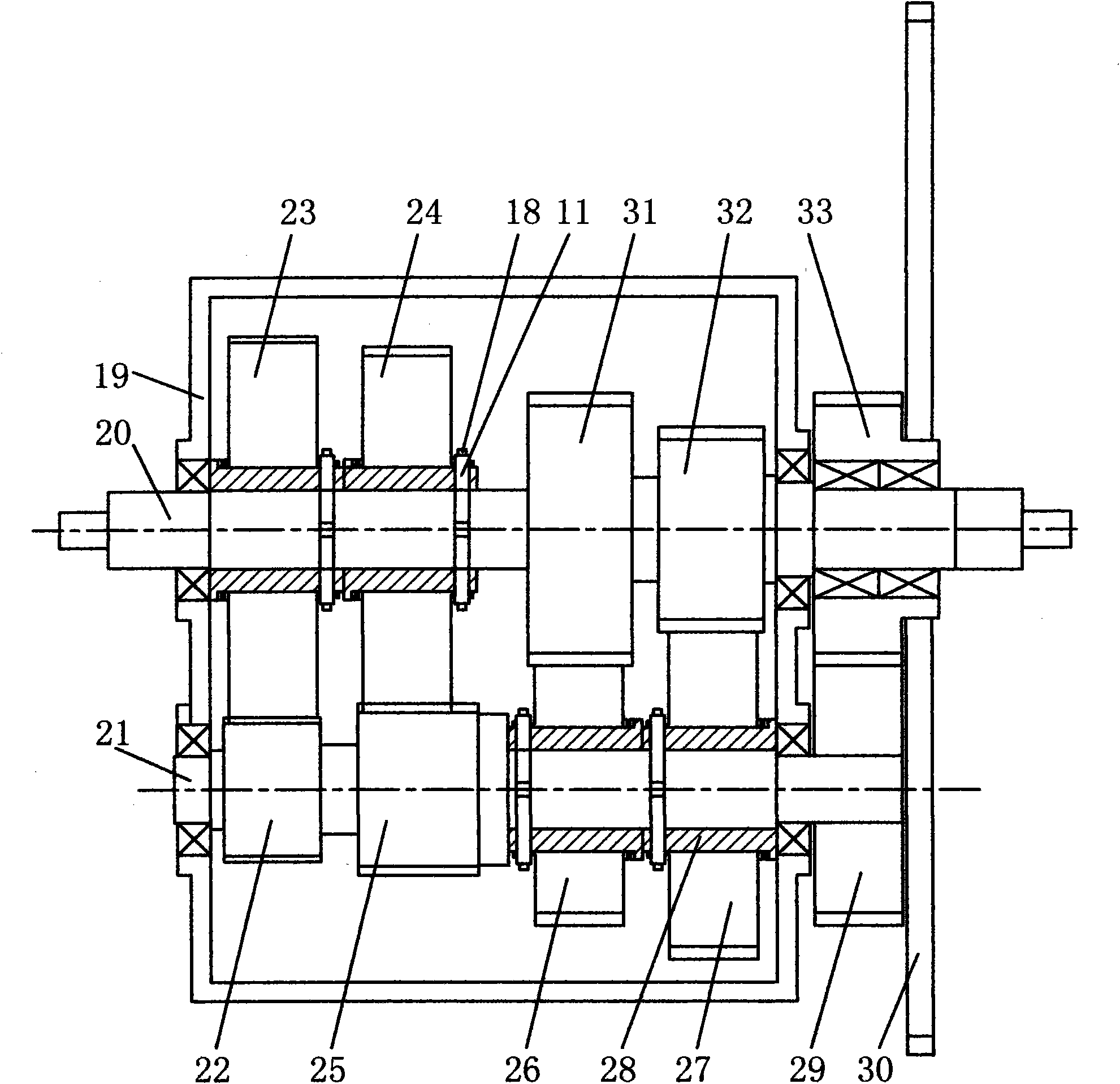

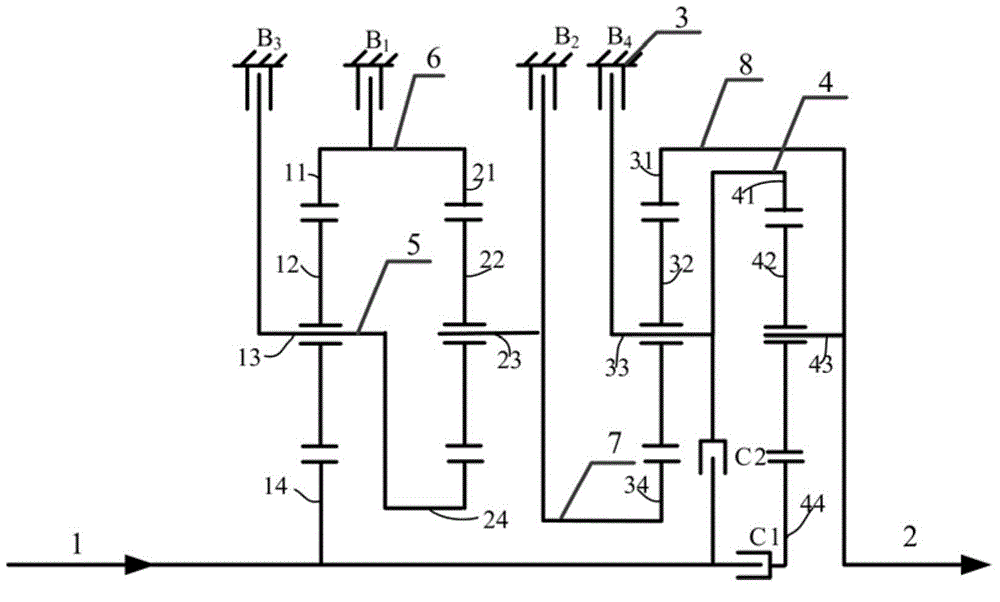

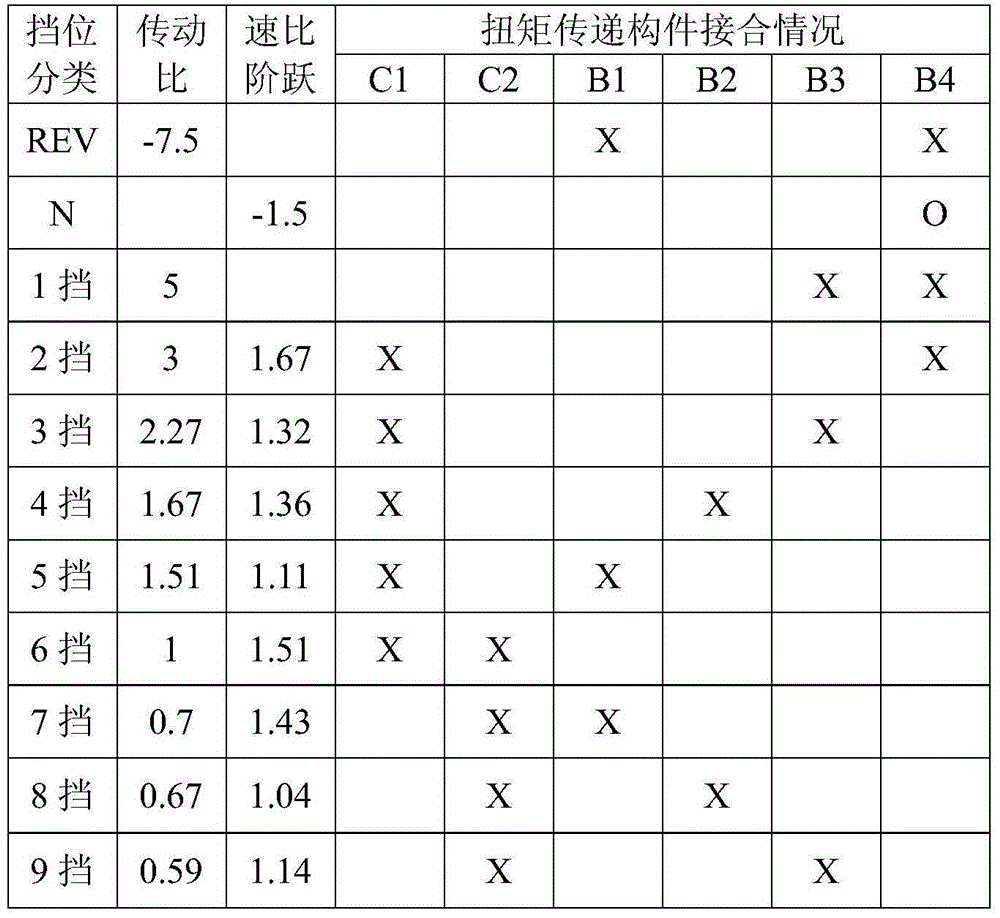

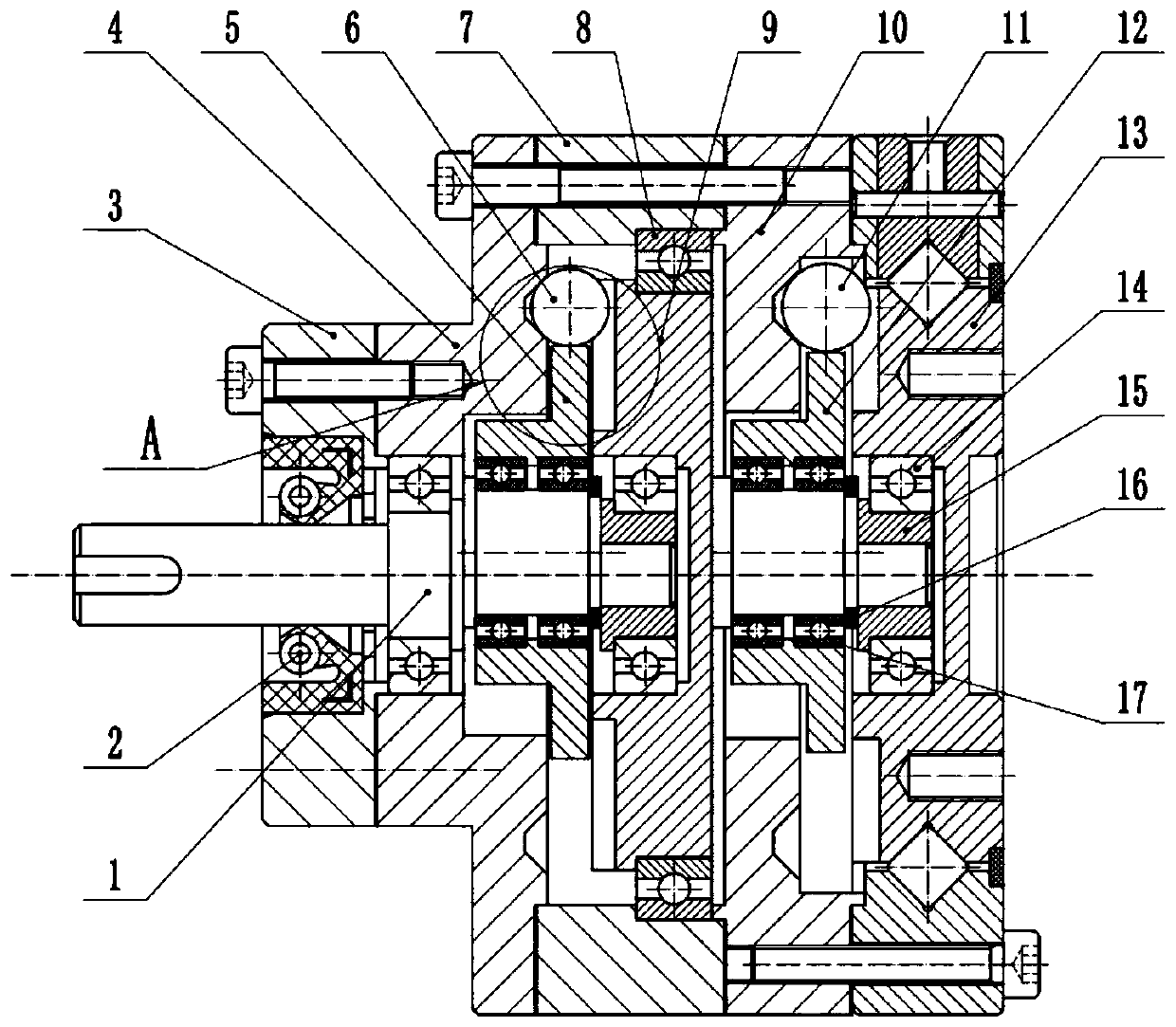

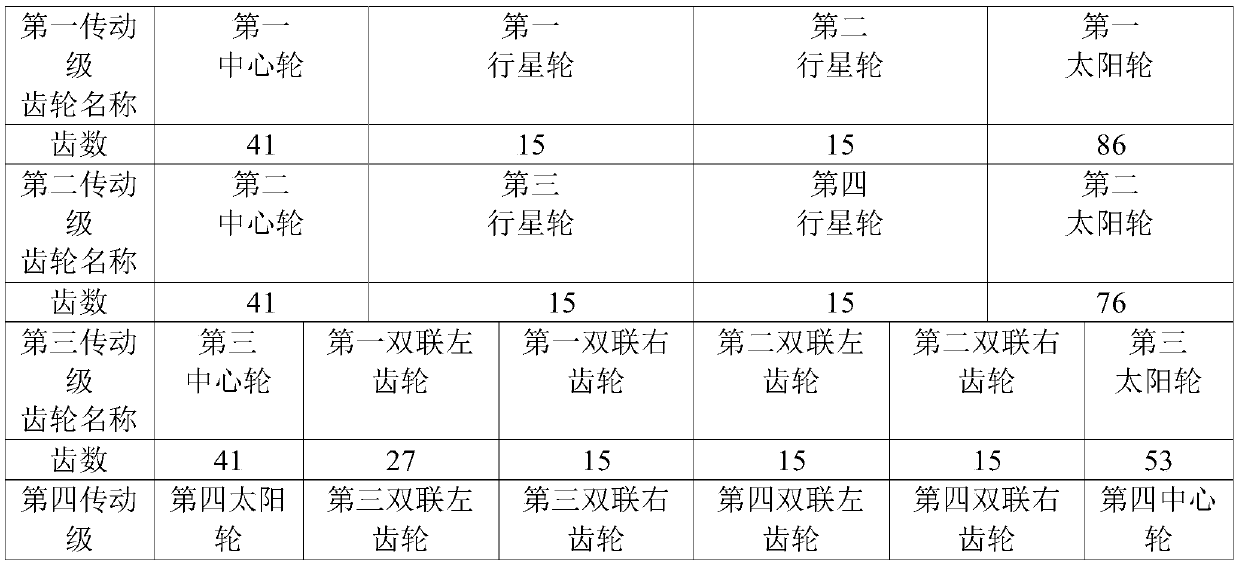

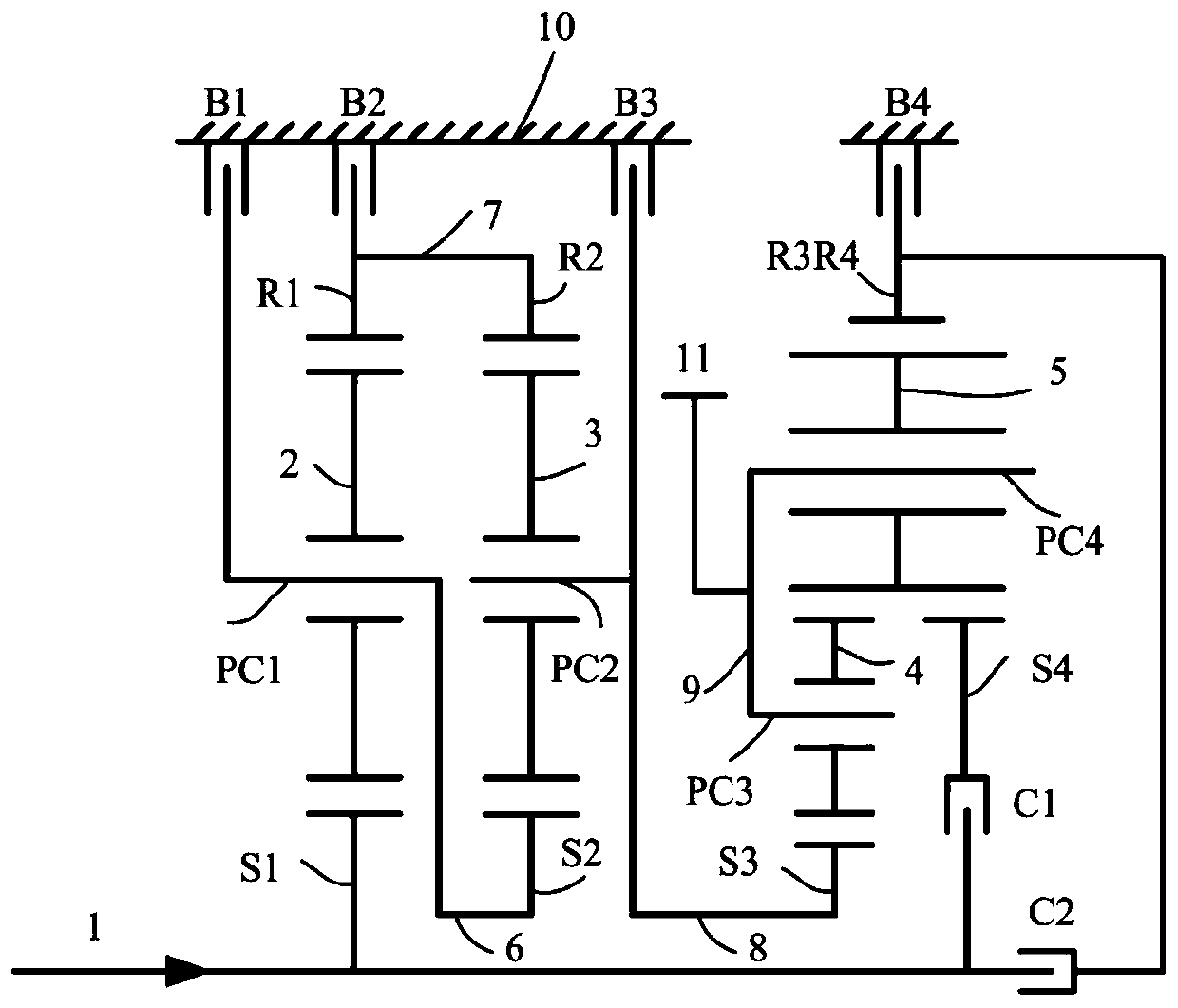

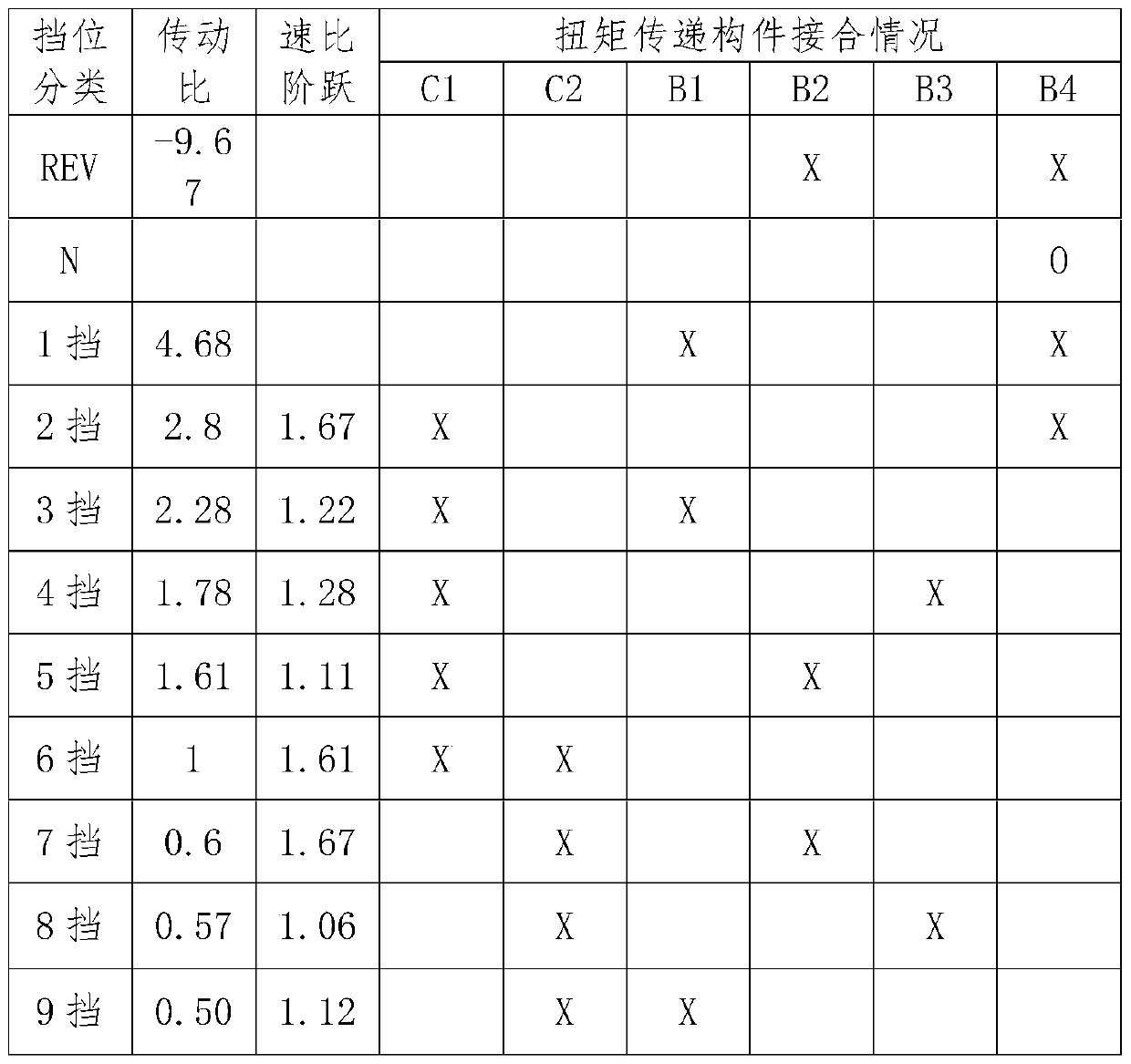

Nine-gear speed changer

InactiveCN105090394ASmall modulusCompact structureToothed gearingsTransmission elementsTorque transmissionGear train

The invention provides a nine-gear speed changer. The nine-gear speed changer mainly comprises an input shaft, an output shaft, planet gear rows, connecting members and torque transmission devices, which are all arranged in a speed changer housing, wherein each planet gear row comprises a sun gear, a planet carrier, a planet gear and a gear ring; the torque transmission devices include two clutches and four brakes; the two clutches and the four brakes are engaged selectively so as to rotate or fix the sun gears, the planet carriers, the gear rings or one of the five connecting members; the torque transmission devices can be engaged selectively in a combining form of at least two torque transmission devices so as to build the speed ratios of nine forward gears and the speed ratio of one reverse gear between the input shaft and the output shaft; and the nine forward gears include five deceleration gears, one direct gear and three overspeed gears. The speed changer provided by the invention is compact in structure, light in weight, small in size and easy to arrange on an automobile, and speed ratio steps between the transmission ratios of the gears of the speed changer meet the requirements of the speed changer.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

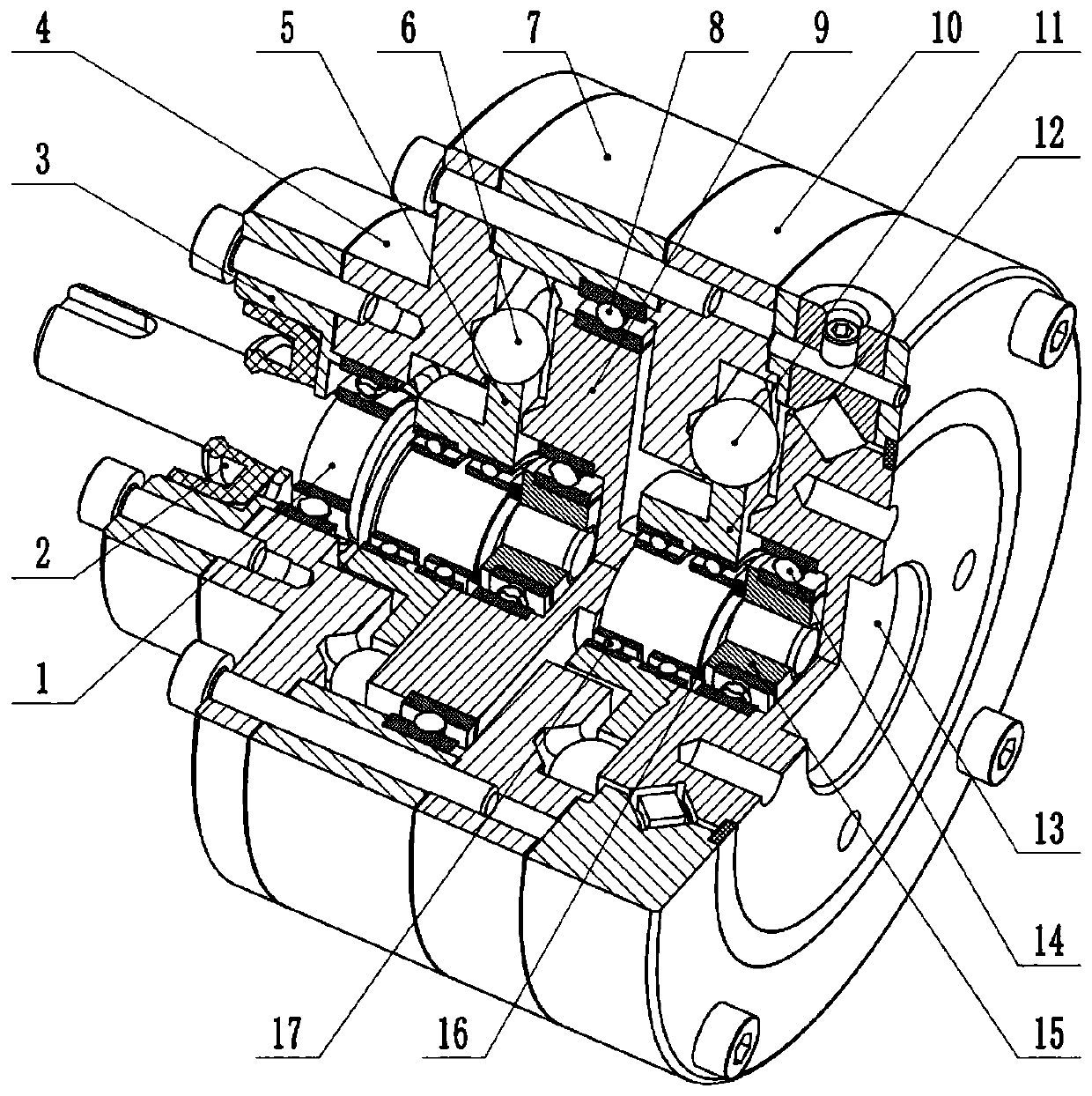

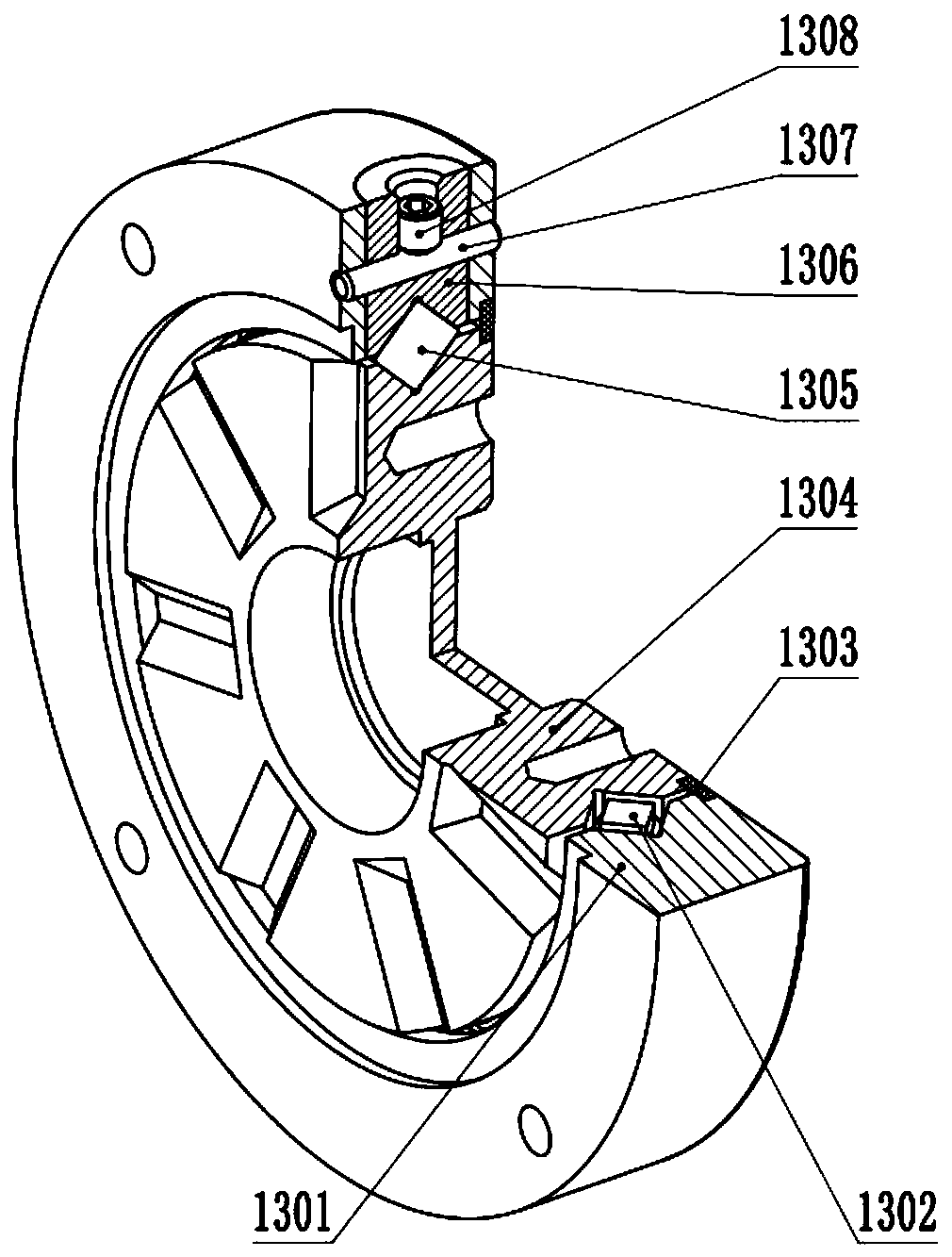

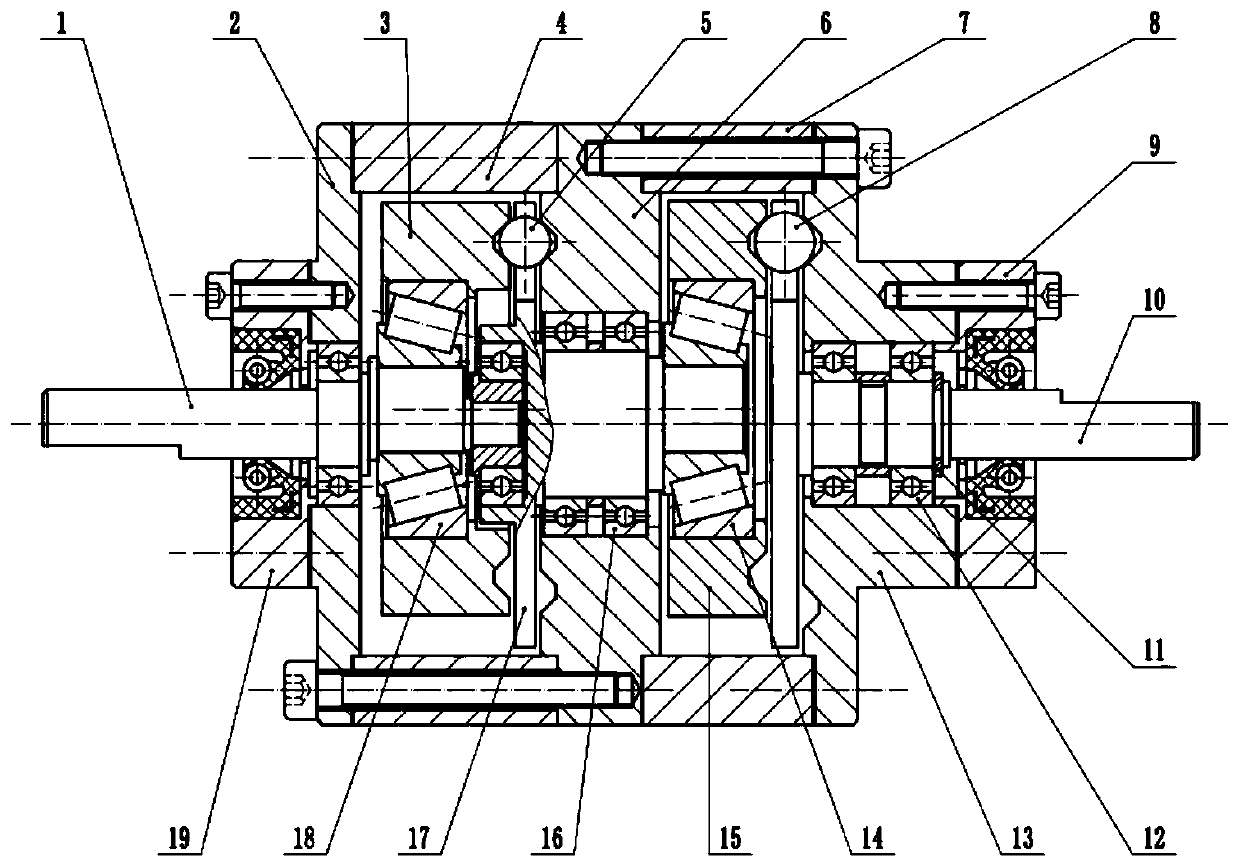

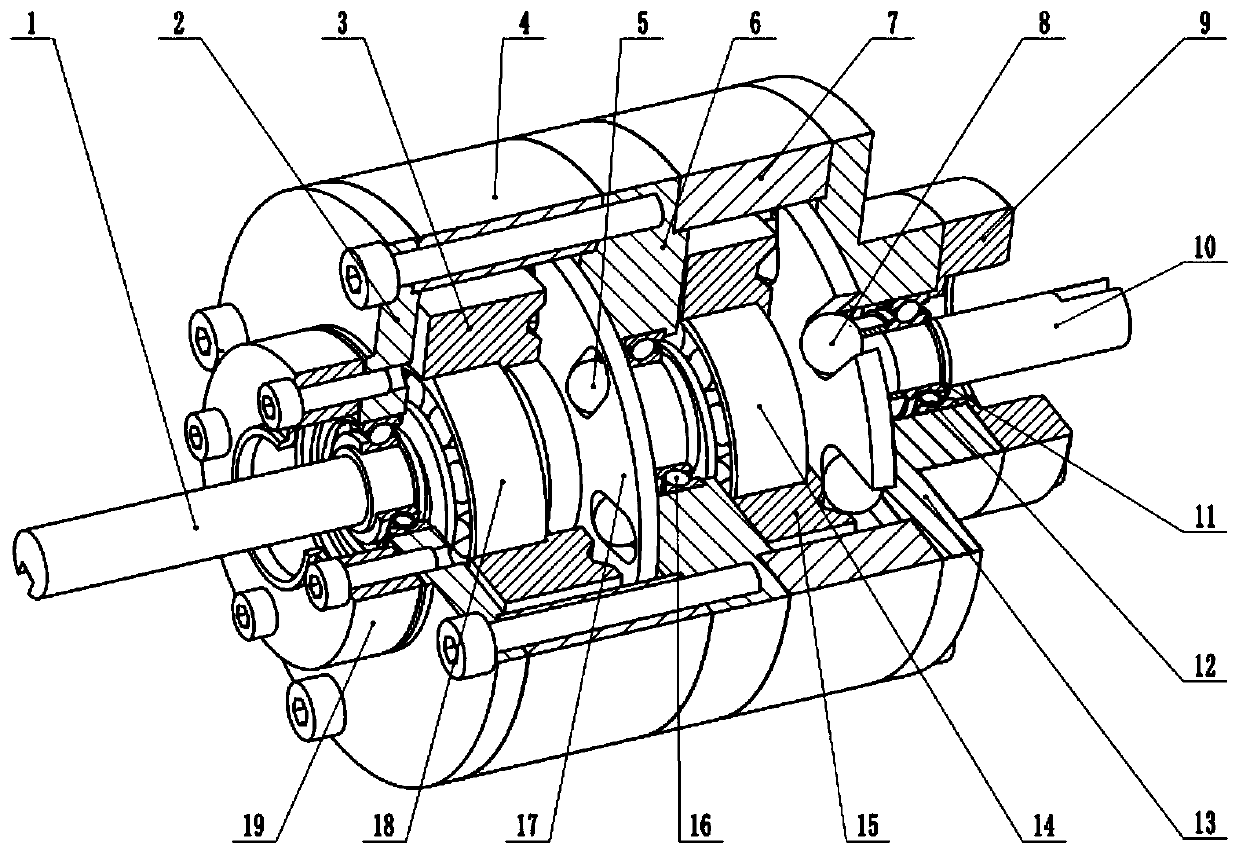

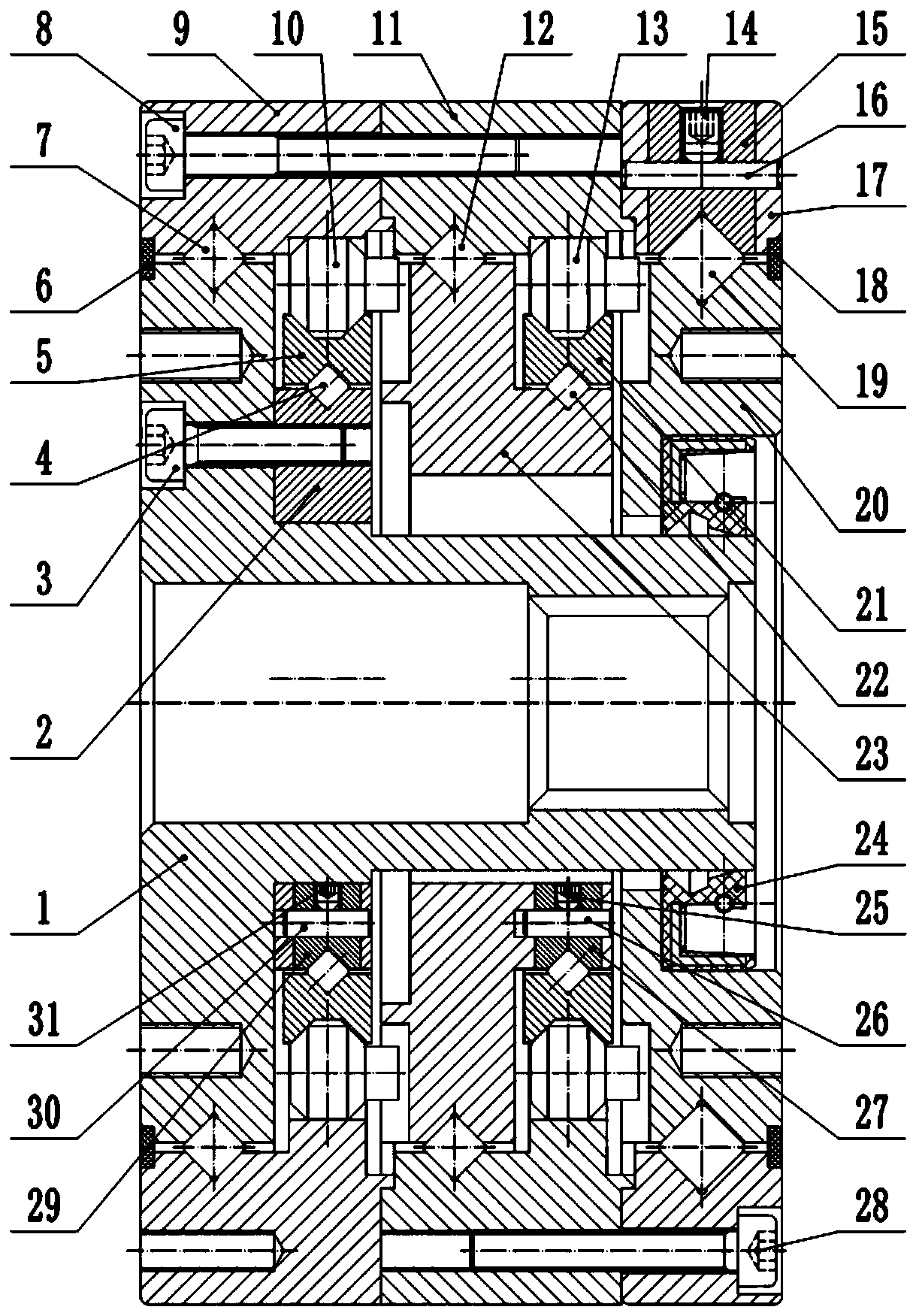

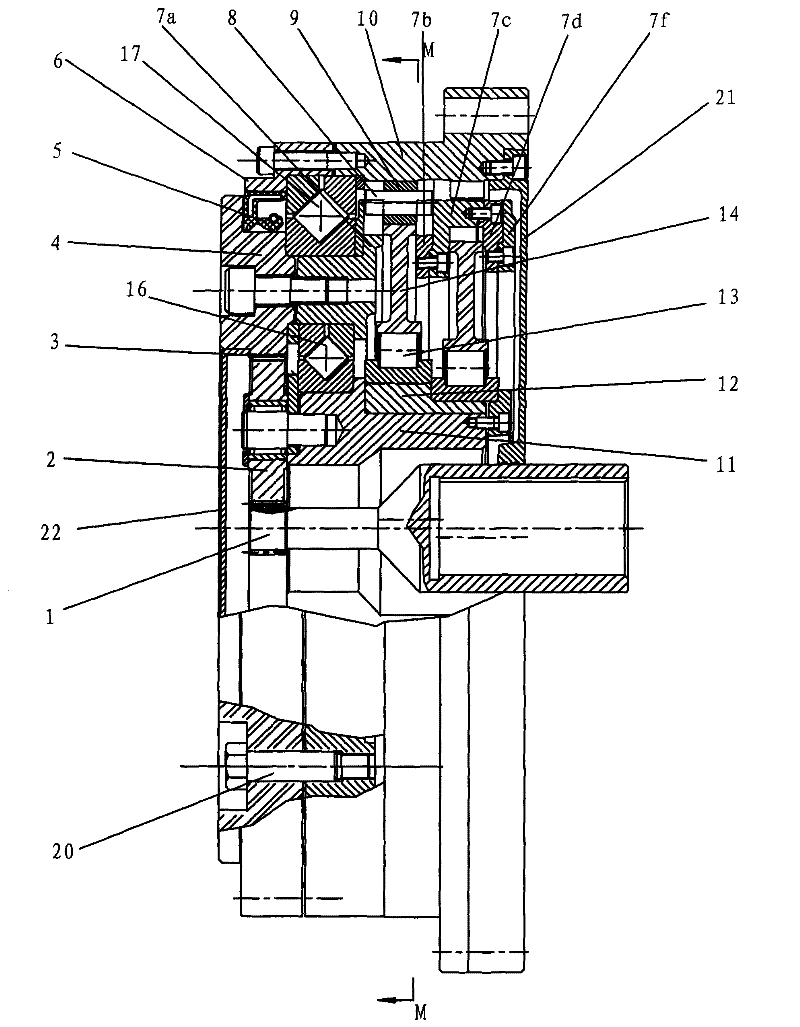

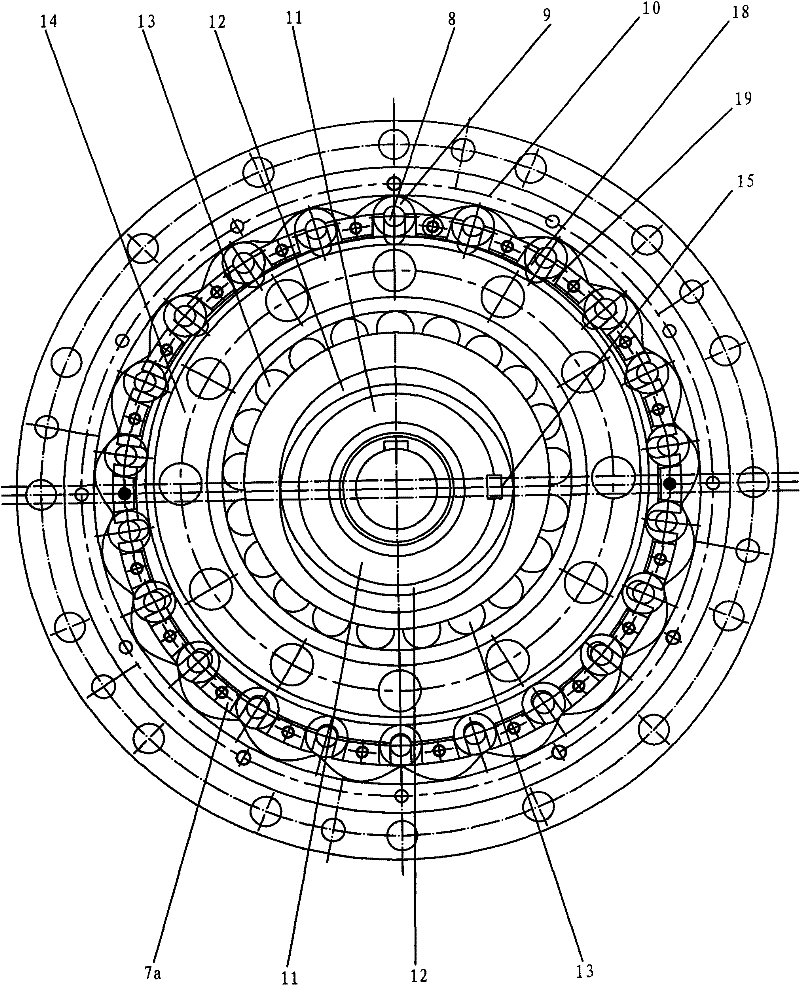

Cam shock wave type two-stage planar steel ball reducer

The invention provides a cam shock wave type double-stage planar steel ball reducer. The cam shock wave type double-stage planar steel ball reducer comprises an input shaft, a lip type sealing ring, aleft end cover, a first-stage center wheel, a first-stage shock wave cam, a first-stage steel ball, a shell, a first thin-wall bearing, a first-stage guide frame, a second-stage center wheel, a second-stage steel ball, a second-stage shock wave cam, a cross roller bearing, a deep groove ball bearing, a sleeve cup, a check ring and a second thin-wall bearing. The first-stage shock wave cam and thesecond-stage shock wave cam are hinged to the corresponding shaft section through the second thin-wall bearing, the right side of the second thin-wall bearing is limited through the check ring, the left end cover is connected to the left end of the first-stage center wheel through screws, the right end of the first-stage center wheel and the shell are fixedly arranged at the left end of the second-stage center wheel through screws, and the cross roller bearing and the right end of the second-stage center wheel are fixedly connected. The cam shock wave type double-stage planar steel ball reducer has the advantages of being simple and compact in structure, high in transmission efficiency, wide in transmission ratio range, large in bearing capacity and the like, can be subjected to parameterization and serialized design and is suitable for wide application.

Owner:YANSHAN UNIV

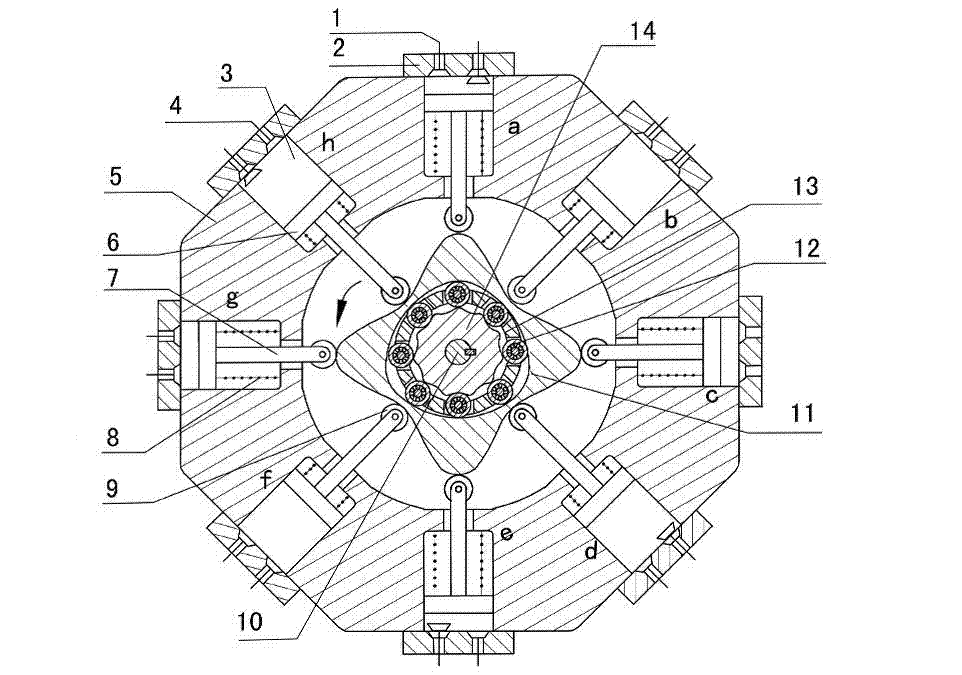

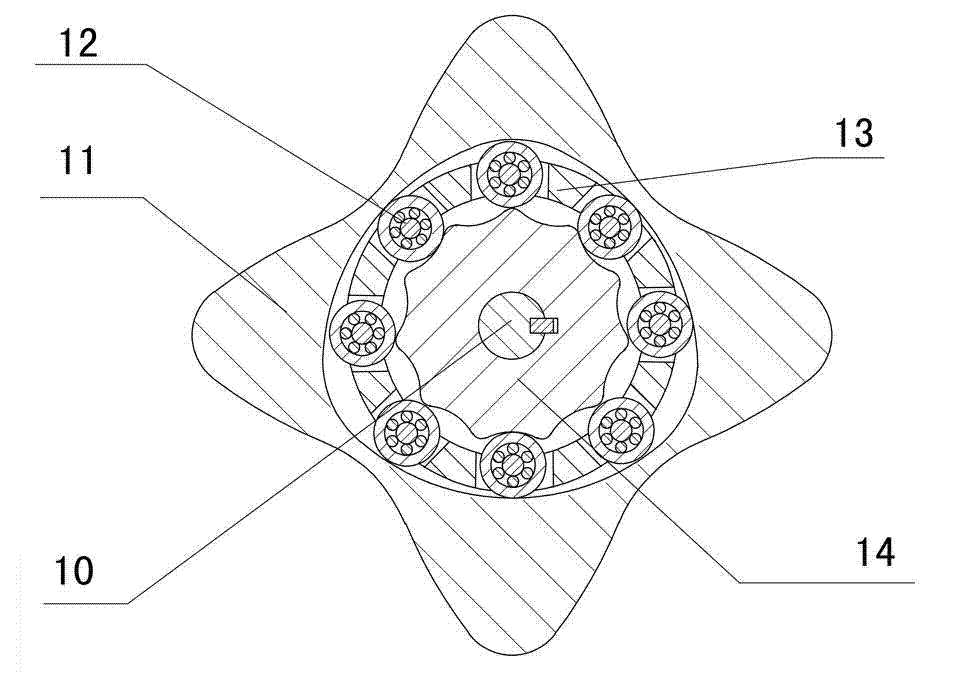

Outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine

The invention discloses an outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine, relating to the field of fuel gas power and belonging to a multi-cylinder internal-combustion engine. The invention provides a novel internal-combustion engine; eight cylinders are distributed on the periphery of an outer convex inner multiphase inner cam symmetrically in a ring shape, so that a resultant force of the outer convex inner multiphase inner cam is zero; each cylinder piston directly acts on the outer convex inner multiphase inner cam through a push rod; and power is transmitted to an output shaft connected with a central wheel key by the outer convex inner multiphase inner cam through arbitrary gear difference inner cam rolling moving movable gear transmission. With the adoption of the internal-combustion engine, a connecting rod and a crank shaft in the traditional internal-combustion engine are saved; an outer convex multiphase inner cam rolling moving transmission mechanism has the characteristics of having no eccentric mass, and having an inertia force and working load self-balancing; the rotating speed of the output shaft depends on transmission ratio of movable gear transmission; when a movable gear frame is fixed, output by a central wheel is in low speed and large torque; and the internal-combustion engine can be widely applied to the fields of high-power engineering machinery and military and the like, such as excavators and armored cars. The internal-combustion engine is simple and compact in structure, small in axial size, self-balancing in stress, and stable in rotating.

Owner:SICHUAN UNIV

Two-gear automatic gearbox for pure electric vehicle

ActiveCN104565226ACompact structureLight in massElectric propulsion mountingToothed gearingsElectricityAutomatic transmission

The invention relates to a two-gear automatic gearbox for a pure electric vehicle. The two-gear automatic gearbox comprises an input shaft, a first middle shaft, a second middle shaft, a first cylinder gear pair, a second cylinder gear pair, a third cylinder gear pair, a first torque transferring device, a second torque transferring device and a differential mechanism assembly, wherein the rotating central lines of the input shaft, the second middle shaft and the differential mechanism assembly are parallel to one another. The two-gear automatic transmission is adopted by the two-gear automatic gearbox, so that the driving ratio scope is widened, the performance demand on a driving motor is greatly reduced, the high-efficiency and light driving motor is allowed to be adopted, and the total volume, the total mass and the total cost of the two-gear automatic gearbox for the pure electric vehicle are further reduced.

Owner:绿传(北京)汽车科技股份有限公司

Seven-speed double-clutch type automatic transmission

ActiveCN105202123AQuick responseMiniaturizationToothed gearingsGearing detailsAutomatic transmissionEngineering

The invention provides a seven-speed double-clutch type automatic transmission which comprises two input shafts and two output shafts. The two input shafts are arranged in a nested mode. The automatic transmission is provided with seven forward gears and one reverse gear. Odd-gear driving gears are arranged on the first input shaft. Even-gear driving gears and reverse-gear driving gears are arranged on the second input shaft. Two reverse gears, the fourth gear, the sixth gear, the fifth gear and the seventh gear (or the third gear and the seventh gear) share the driving gears. A plurality of driven gears are arranged on the first output shaft. A reverse gear assembly and a plurality of driven gears are arranged on the second output shaft. The reserve gear assembly and the adjacent driven gear are designed into a dual-gear structure capable of being switched. As different clutches are used in the first gear and the reverse gear respectively, and in the neutral position starting process, the first gear and the reverse gear can be engaged in advance at the same time; as the reverse gear assembly and the adjacent driven gear are joined, reverse gear power transmission can be achieved, and a reverse gear shaft is omitted; by sharing the driving gears, the axial length of the automatic transmission is reduced.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

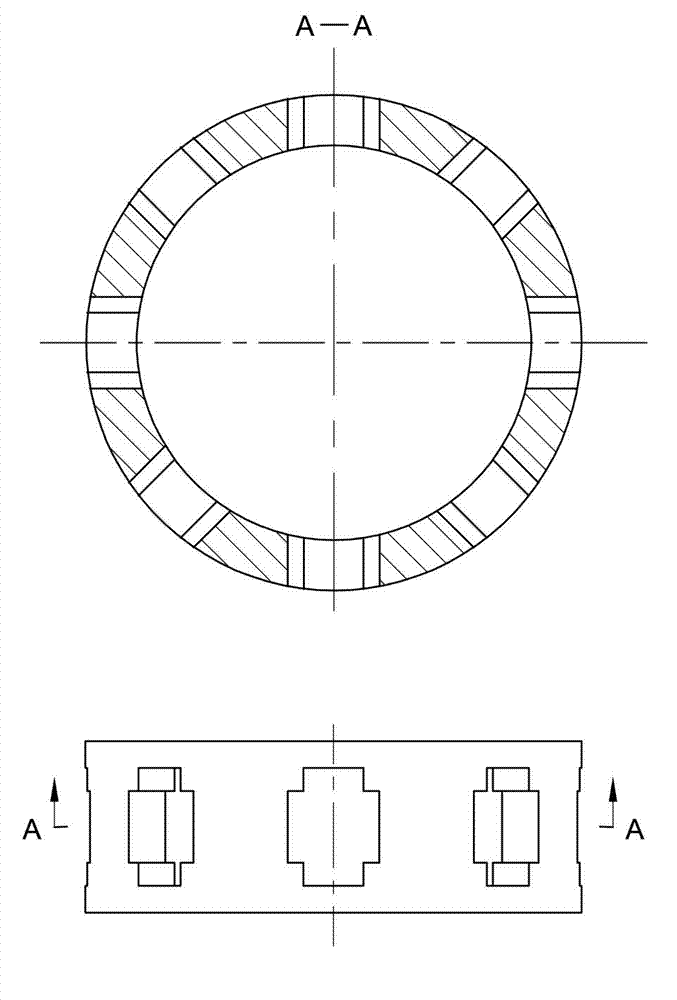

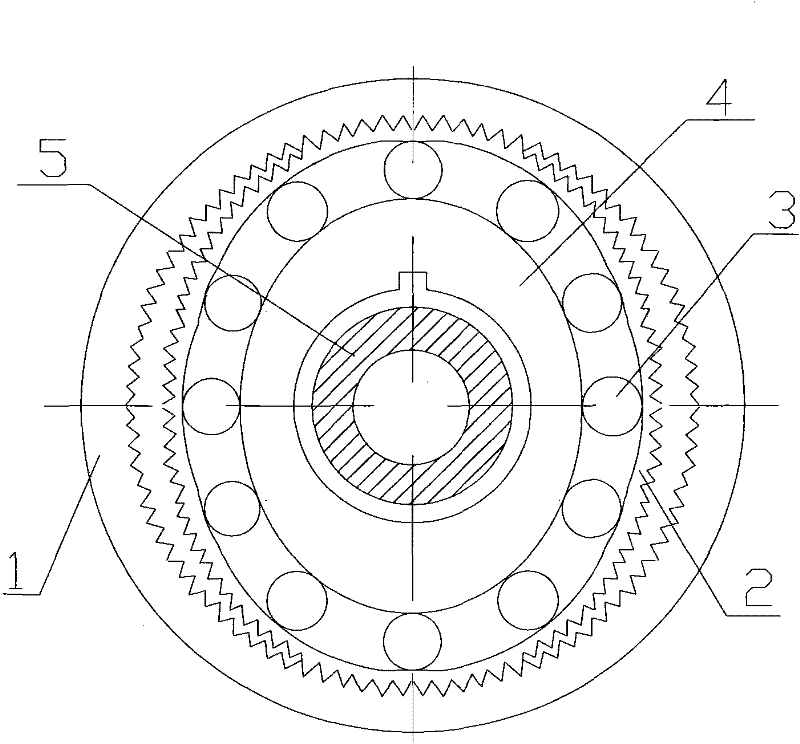

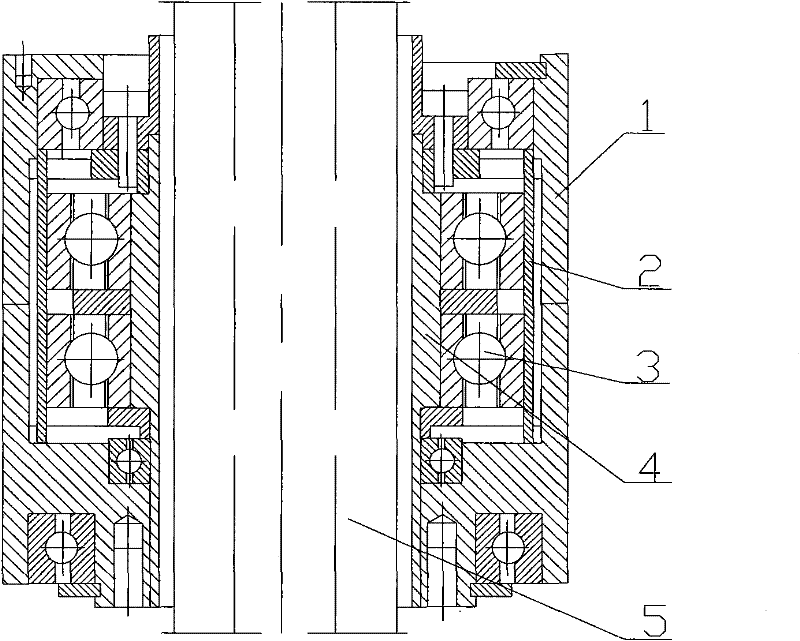

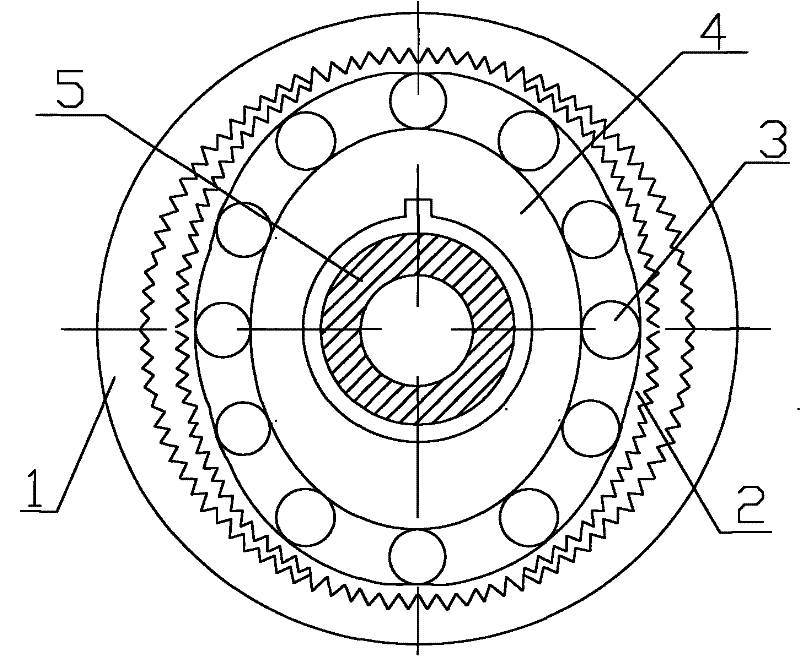

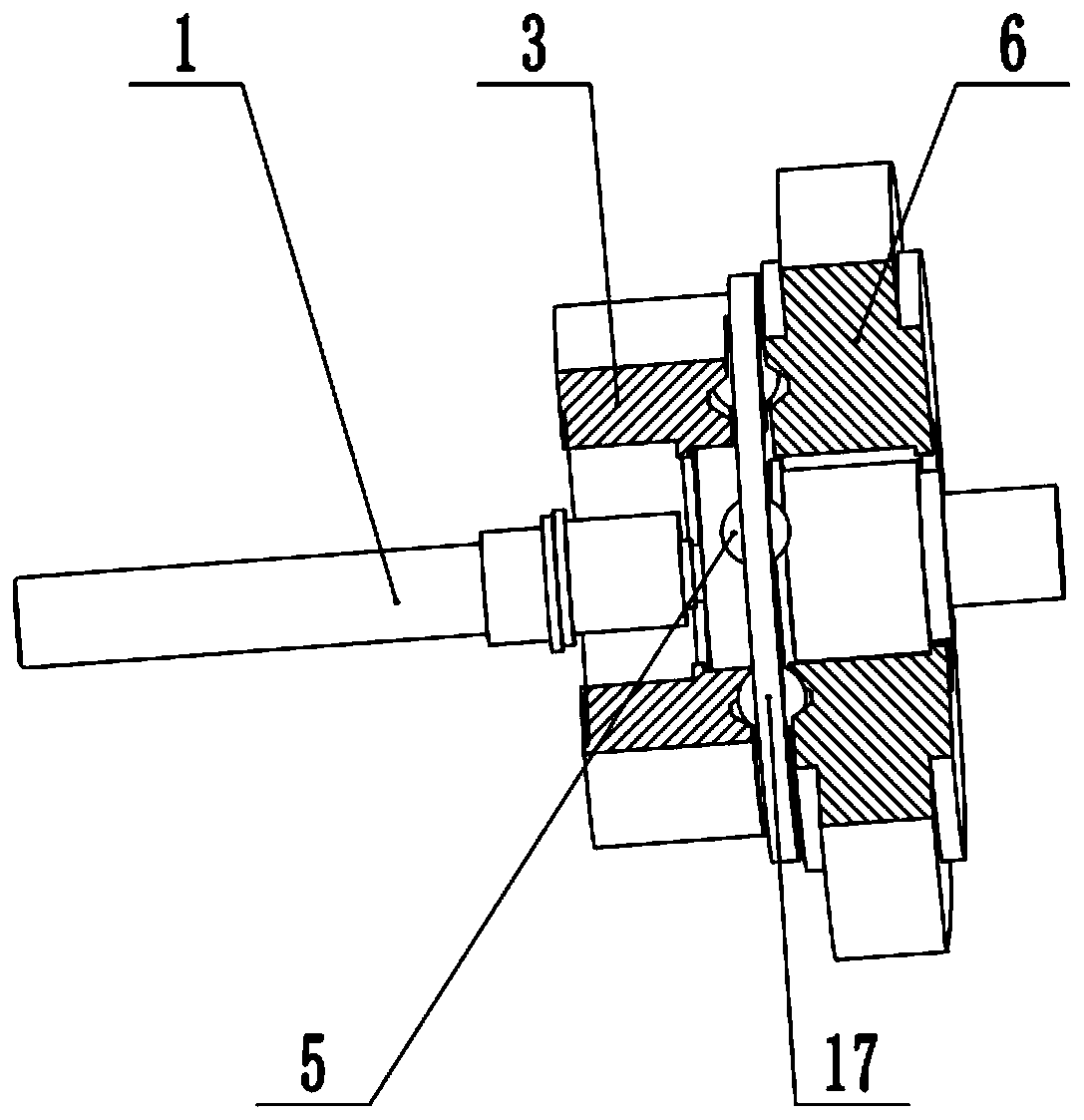

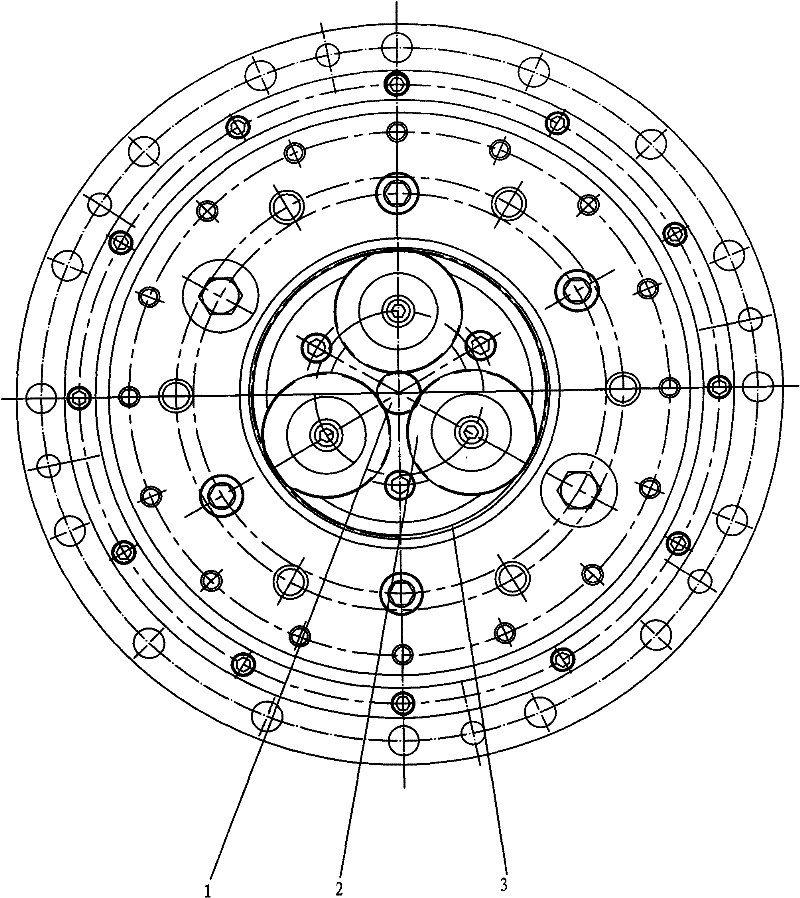

Petroleum drilling trajectory-controlled harmonic gear transmission device

The invention relates to a petroleum drilling trajectory-controlled harmonic gear transmission device. The device is characterized by being provided with a rigidity gear (1), a flexible gear (2), a bearing (3), a wave generator (4) and a hollow shaft (5), wherein the rigidity gear (1) is provided with an inner gear ring; the flexible gear (2) is provided with an outer gear ring; the wave generator (4) is provided with an elliptic cam and is arranged on the hollow shaft (5); the bearing (3) is between the wave generator (4) and the flexible gear (2); the rigidity gear (1) is arranged on the outer ring of the flexible gear (2); the flexible gear (2) is provided with two less teeth than the rigidity gear (1); and the flexible gear (2) is formed by processing a 30 chromium magnesium silicon material. The harmonic gear transmission device has small size, light weight and high transmission efficiency, can be suitable for a narrow underground space, is transmitted stably, and is operated safely and reliably; and the flexible gear is made of flexible gear materials with high fatigue resistance, so that the service life of the device is greatly prolonged.

Owner:YANGTZE UNIVERSITY

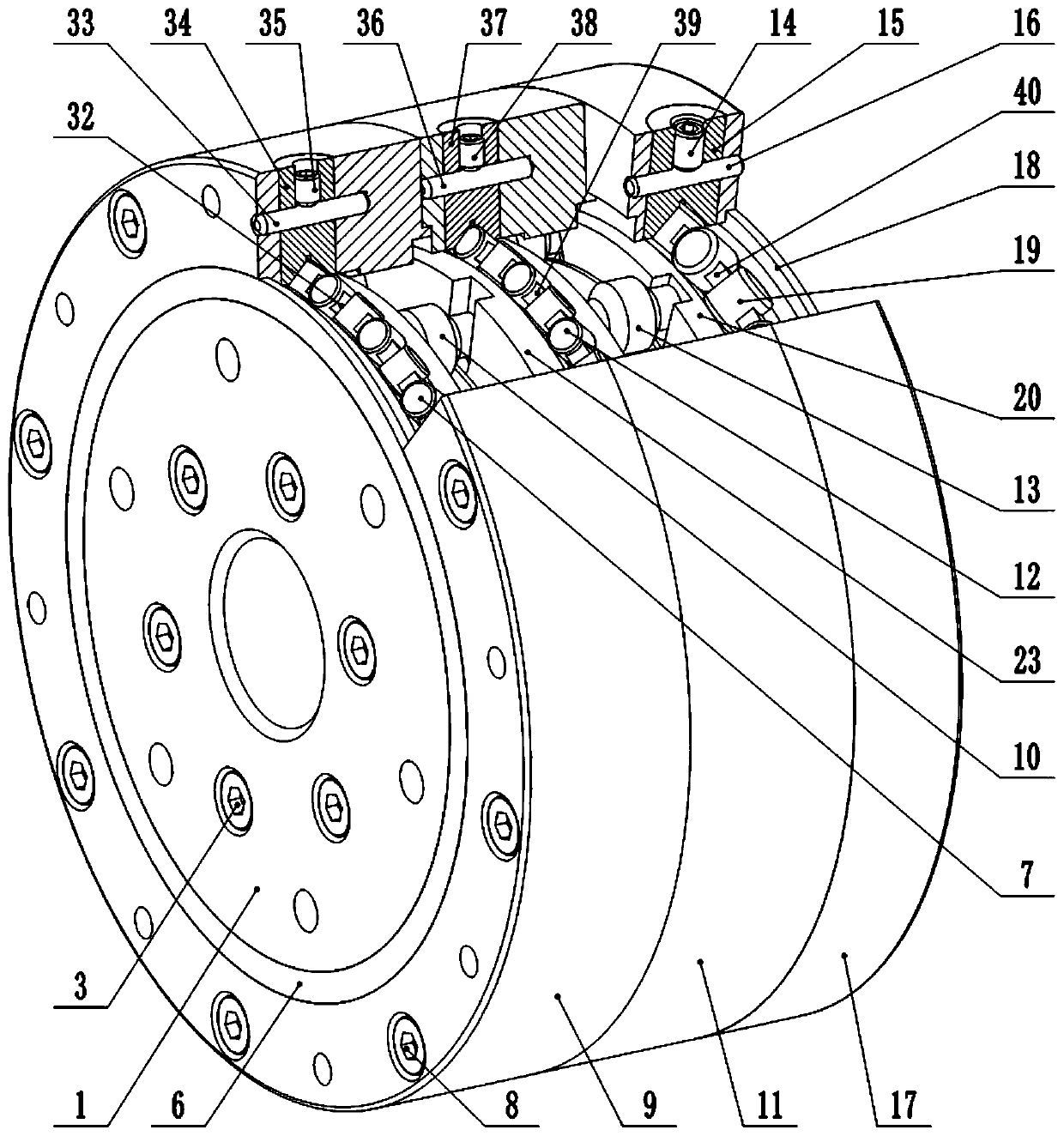

Speed reducer for eccentric driving and double-stage planar oscillating tooth gear

ActiveCN110513443ACompact structureEliminate backlash in mating pairsToothed gearingsGearing detailsShock wave deviceDouble stage

The invention relates to a speed reducer for an eccentric driving and double-stage planar oscillating tooth gear. The speed reducer comprises a driving shaft, shock wave devices, oscillating tooth gear frames, central wheels and an output shaft. In a first-stage transmission system, a first-stage central wheel is fixed, the first-stage central wheel and a first-stage shock wave device are connected to the eccentric section of the driving shaft through a first-stage tapered roller bearing, a first-stage steel ball moves in guide grooves of a first-stage oscillating tooth gear frame through thecommon constraint of a rolling path of the first-stage shock wave device and a rolling path of the first-stage central wheel, and power is output by the first-stage oscillating tooth gear frame; and in a second-stage transmission system, a second-stage central wheel is fixed, the output of the first-stage oscillating tooth gear frame is used as the input of the second-stage transmission system, asecond-stage shock wave device is connected to the eccentric section of the first-stage oscillating tooth gear frame through a second-stage tapered roller bearing, a second-stage steel ball moves in atooth gear groove of the output shaft through the common constraint of a rolling path of the second-stage shock wave device and the a rolling path of the second-stage central wheel, and power is output by the output shaft. According to the speed reducer for the eccentric driving and double-stage planar oscillating tooth gear, the first-stage oscillating tooth gear frame adopts an integrated structure, the structure is simple and compact, a transmission ratio range of the speed reducer is wide, the application range is wide, and the transmission efficiency is high.

Owner:YANSHAN UNIV

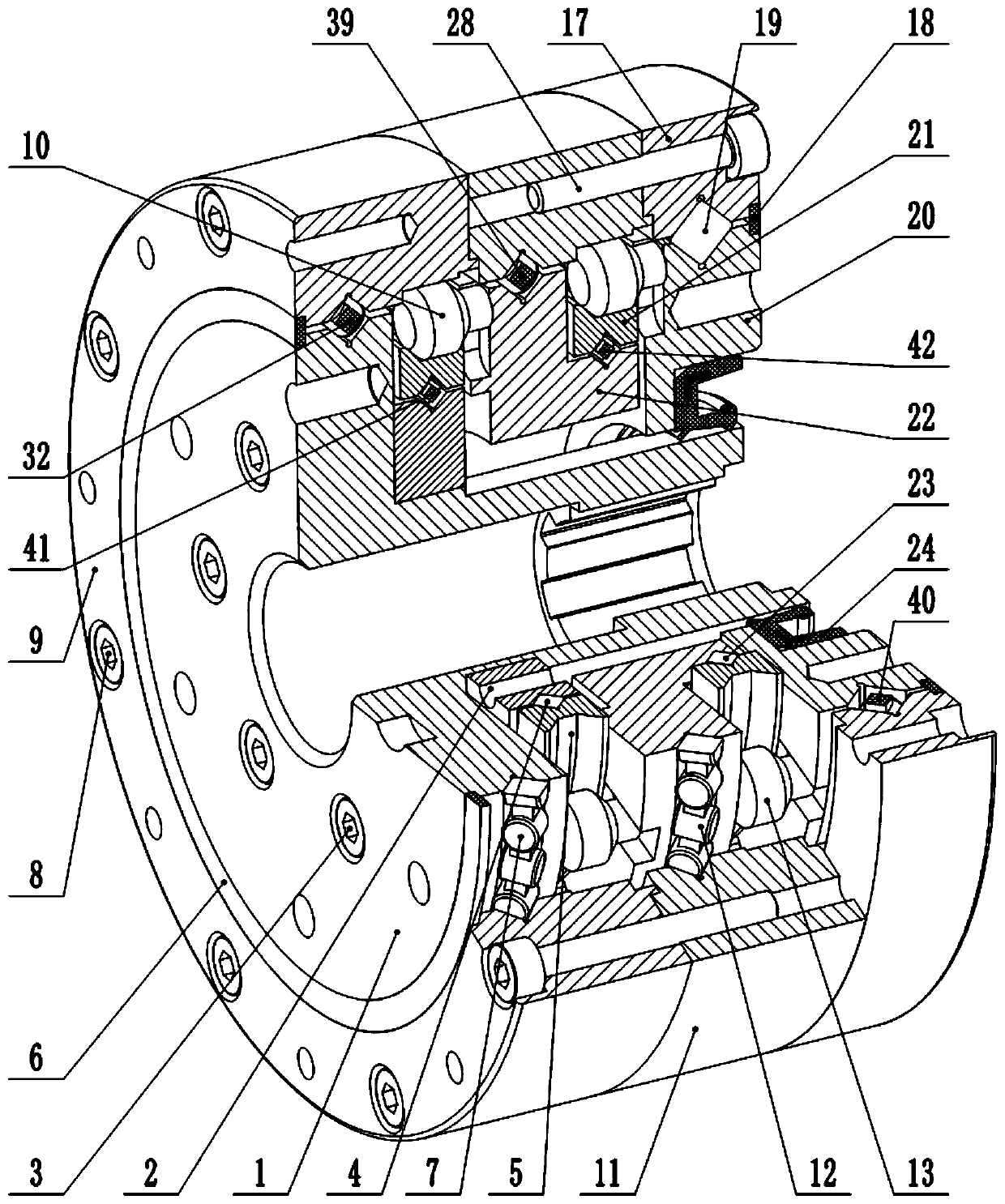

Two-stage sine hammer-shaped pin roller movable tooth reduction gear

ActiveCN111022608AIncrease stiffnessShortened axial structureGearingGearing detailsReduction driveStructural engineering

The invention discloses a two-stage sine hammer-shaped pin roller movable tooth reduction gear which mainly comprises an input shaft, a first-stage wave generator inner ring, a first-stage wave generator outer ring, a first shell, first-stage hammer-shaped pin roller movable teeth, a second shell, second-stage hammer-shaped pin roller movable teeth, a third shell, a second-stage movable tooth frame, a second-stage wave generator outer ring, a first-stage movable tooth frame, a frame seal ring and the like. The reduction gear has the advantages of a pin roller movable tooth reduction gear and the advantages of a steel ball movable tooth reduction gear, and a wave generator and a central wheel in transmission with the pin roller movable teeth and the movable tooth frame in transmission withsteel ball movable teeth are ingeniously combined together through the hammer-shaped pin roller movable teeth; by means of five composite integrated type specially-made crossed roller bearings, the whole reduction gear has the smaller draw ratio, lighter weight and lower machining and manufacturing difficulty and meanwhile has the higher structural rigidity, higher bearing capacity and higher transmission efficiency; and the reduction gear can be designed in a parameterization and serialization mode, can be applied to various fields and helps the rapid rising of intelligent manufacturing, 5G communication and other industries.

Owner:YANSHAN UNIV

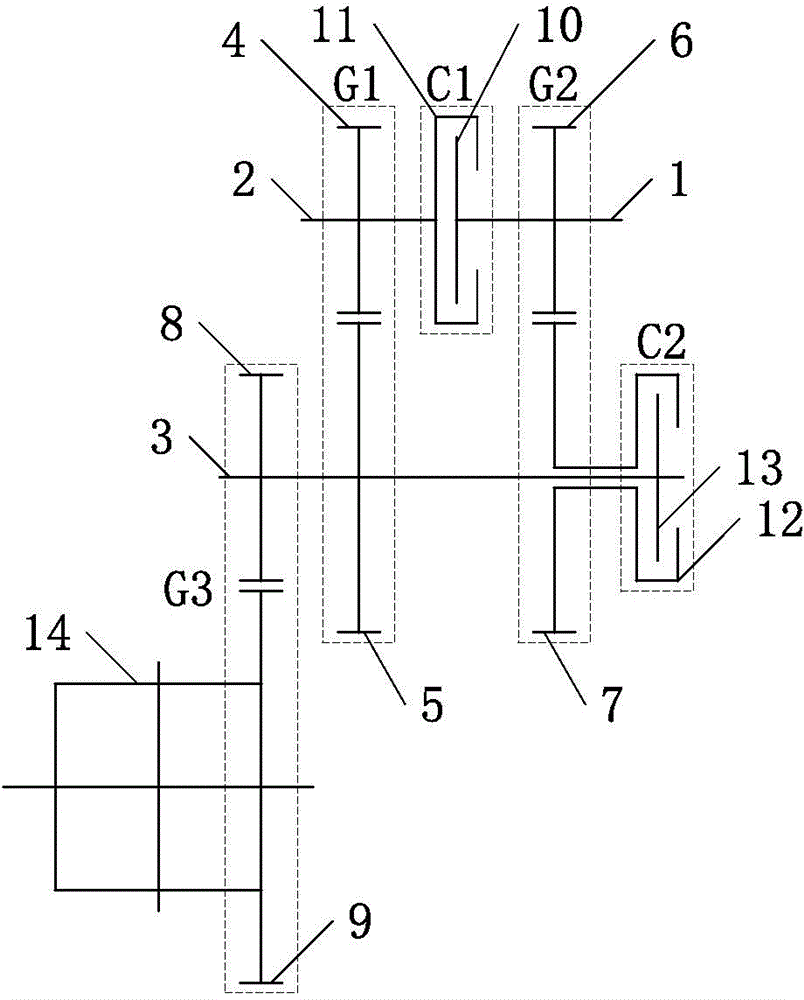

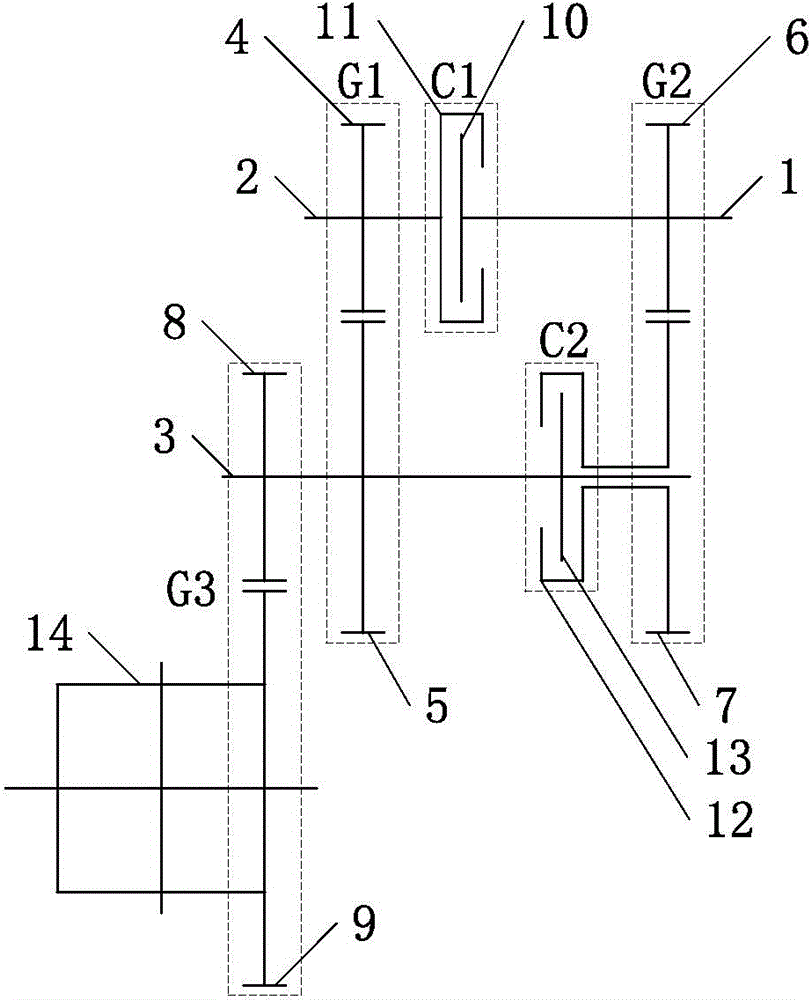

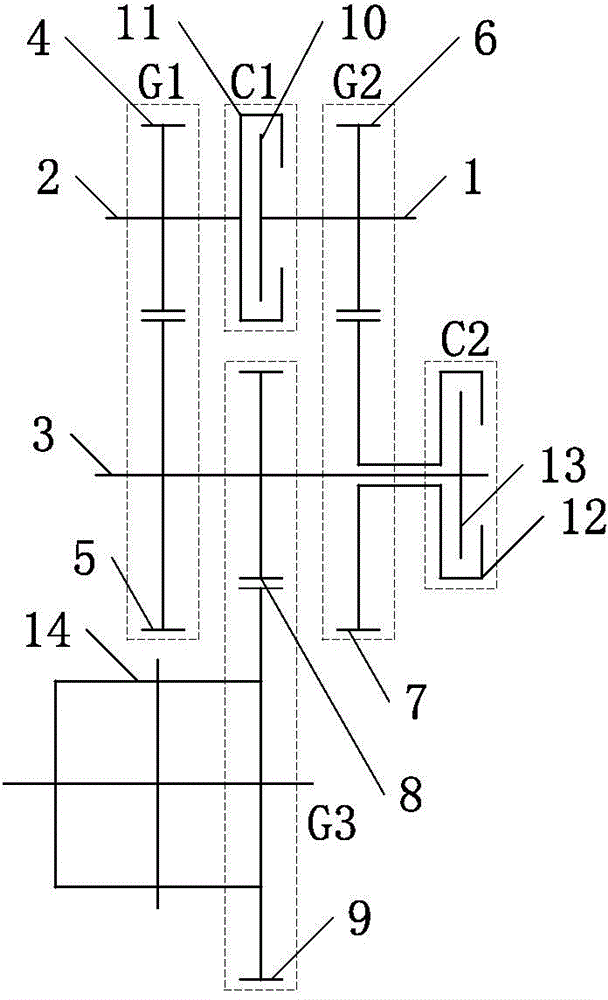

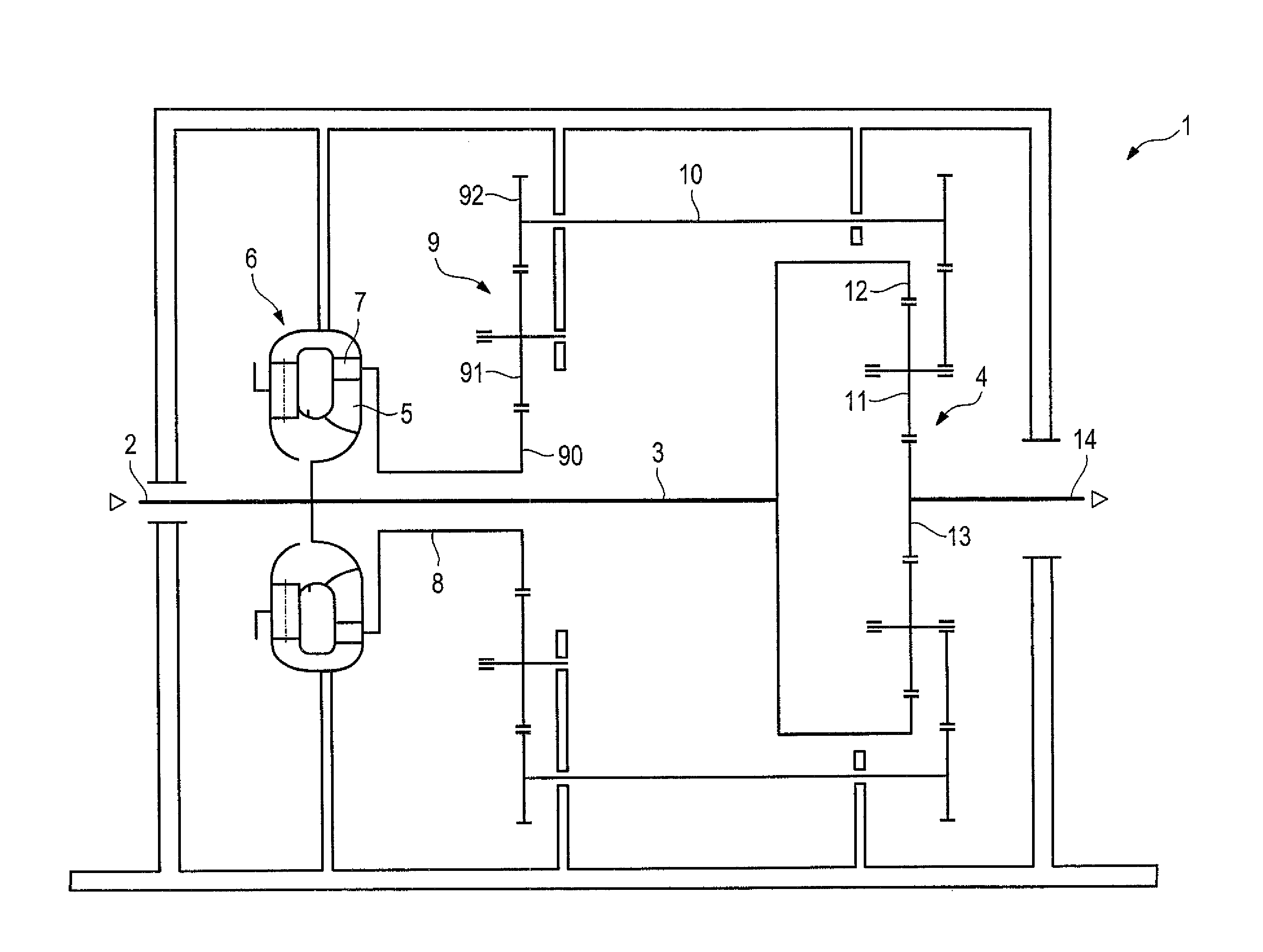

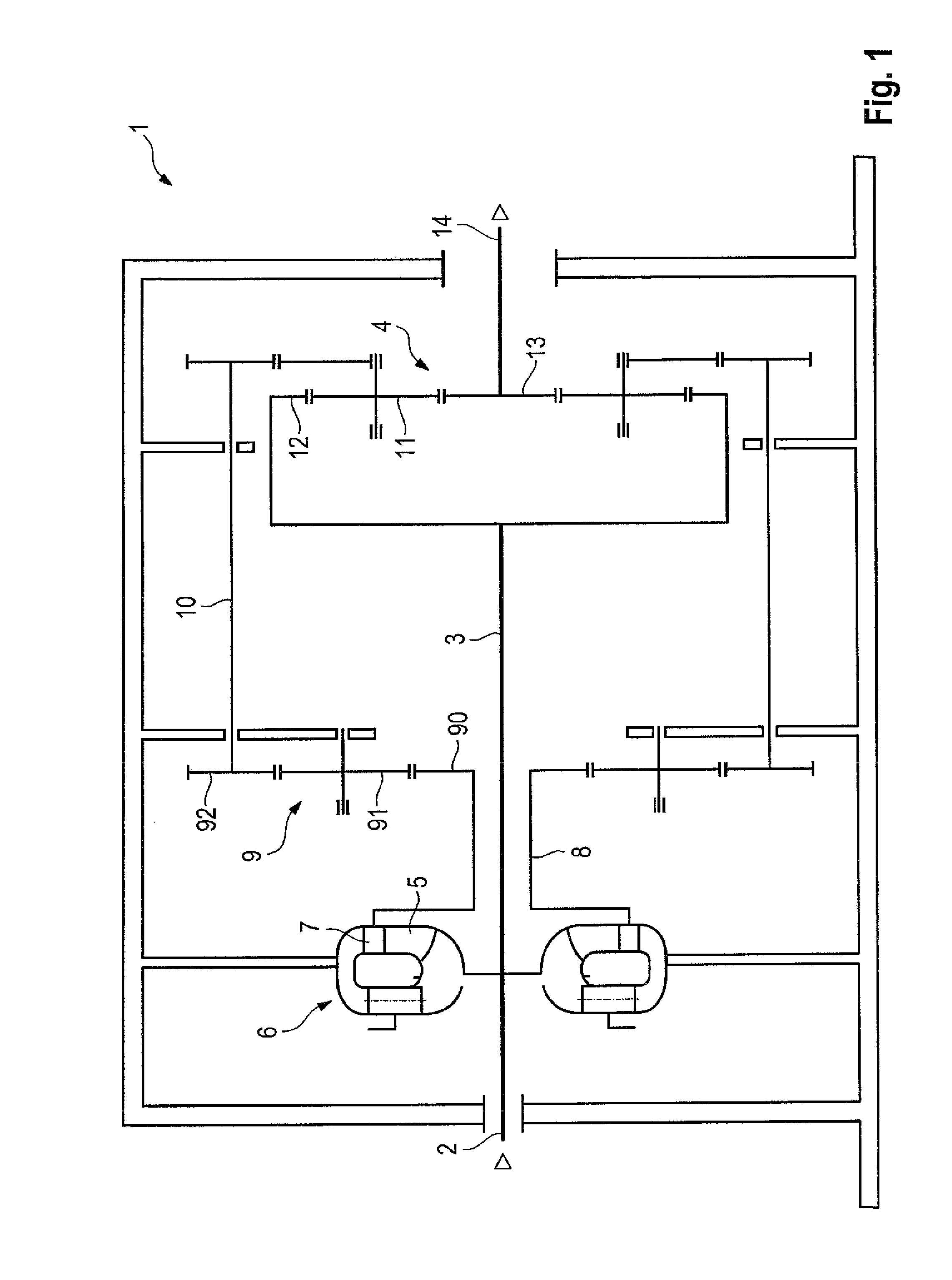

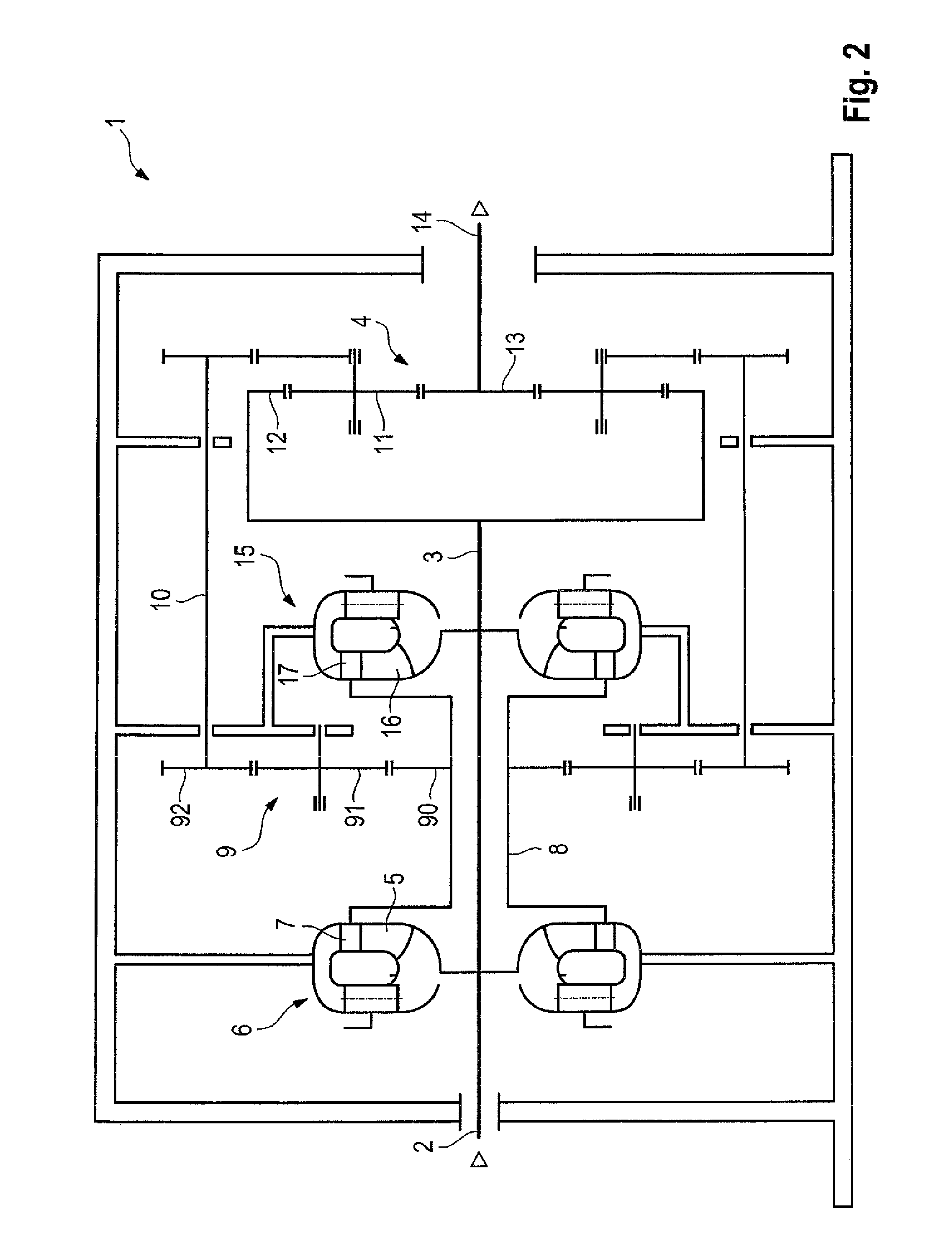

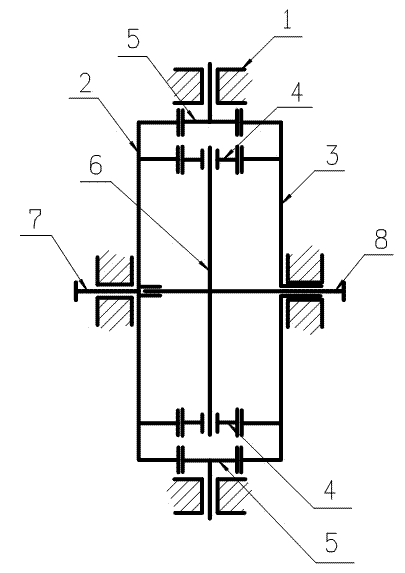

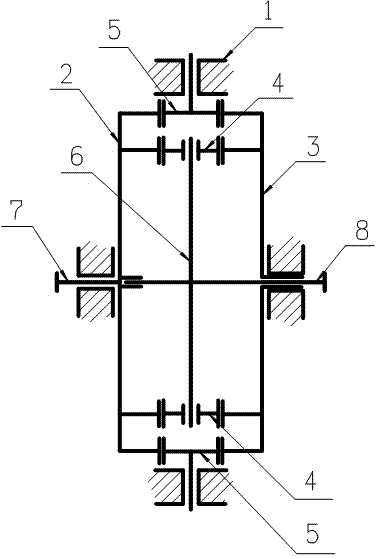

Superimposed transmission having coupling shafts

ActiveUS8663047B2High start resistanceStart moreToothed gearingsDifferential gearingsVariatorImpeller

A superimposed transmission for driving a rotational speed-variable work machine having the following design: an input shaft (2) is connected to an intermediate shaft (3); a pump wheel (5) of a hydrodynamic converter (6) rotates with the intermediate shaft (3); a turbine wheel (7) of the hydrodynamic converter (6) rotates with a superposition means; the intermediate shaft (3) and the transmission means are connected to an output shaft (14) by means of a differential gear (4); and the transmission means is designed as at least one coupling shaft (10), which connection the turbine wheel (7) of the hydrodynamic converter (6) to the differential gear (4). The at least one coupling shaft (10) runs parallel to the intermediate shaft (3). An additional hydrodynamic converter (15) can be present and / or the coupling shaft (10) can be connected in an engageable manner directly to the input shaft (2) by means of an additional transmission (18) for starting the transmission.

Owner:VOITH PATENT GMBH

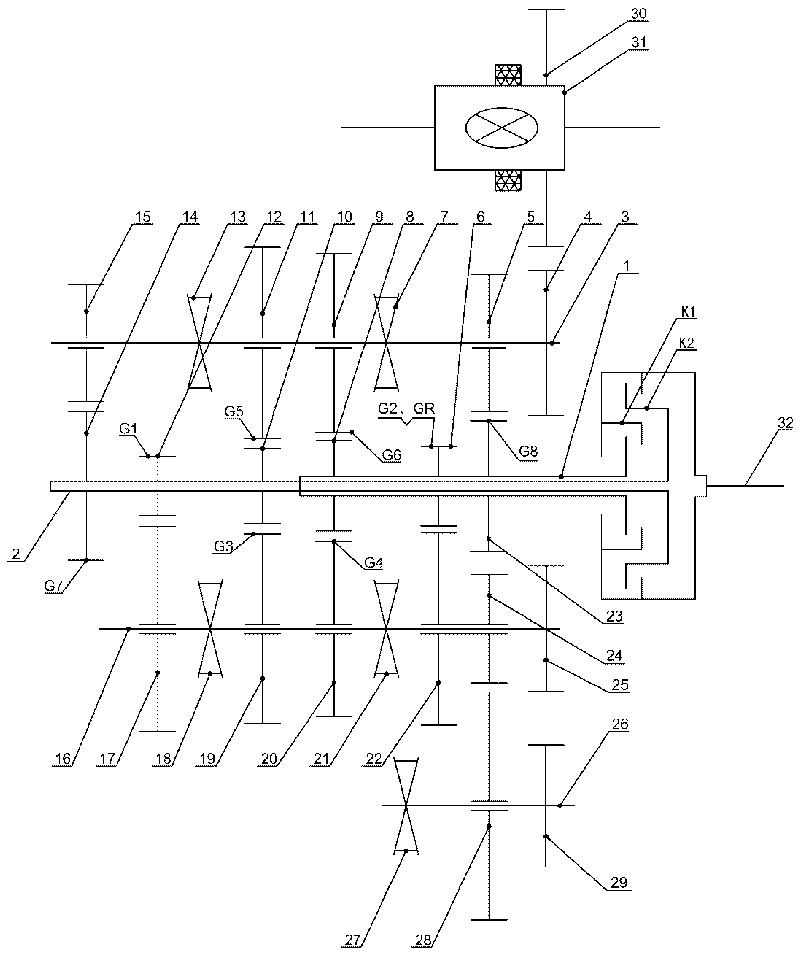

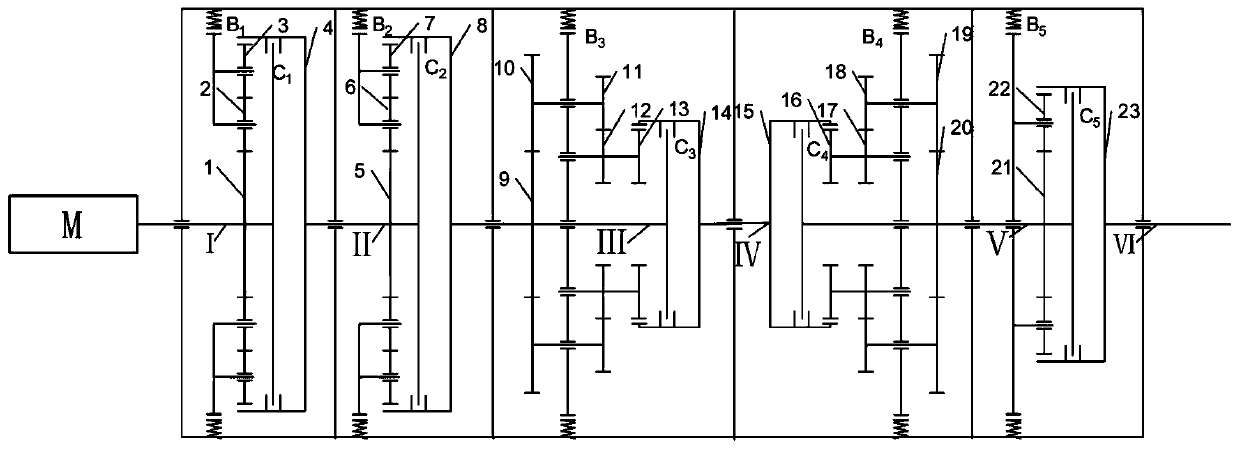

Sixteen-speed automatic transmission based on single-planetary gear train modular design

ActiveCN110345210ACompact structureReduce volumeToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention discloses a sixteen-speed automatic transmission based on single-planetary gear train modular design. The sixteen-speed automatic transmission based on single-planetary gear train modular design is characterized by mainly comprising a motor, a planetary gear train, an ordinary gear train, a clutch, brakes, a duplicate gear and a shell, wherein the first brake, the second brake, the third brake, the fourth brake, and the fifth brake are in a parallel type structure, and the conversion of respective gear trains is realized through the respective engagement. The sixteen-speed automatic transmission based on the single-planetary gear train modular design has 16 front speeds and 16 reverse gears, has flexible transmission ratio design, not only can be used for improving the fuel economy of a car, but also can be applied to gearboxes of trucks and heavy trucks, provides a new scheme reference for the structures of existing large-sized vehicle power transmission systems, and hasrelatively high use value and good application prospect.

Owner:HEFEI UNIV OF TECH

Automatic transmission and vehicles with same

The invention discloses an automatic transmission and vehicles with the same. The automatic transmission comprises a shell, an input shaft, a single-row single-stage planetary gear train, a Ravigneaux planetary gear train, a big sun wheel brake and a braking device. The single-row single-stage planetary gear train comprises a sun wheel, a planet wheel, a planet carrier and an annular gear, wherein the sun wheel is fixed on the shell, the annular gear rotates along the input shaft, and a first clutch is arranged between the annular gear and the planet carrier. The Ravigneaux planetary gear train comprises a big sun wheel, a small sun wheel, a long planet wheel, a short planet wheel, a shared planet carrier and a shared annular gear, a second clutch is arranged between the planet carrier and the small sun wheel, a third clutch is arranged between the planet carrier and the shared planet carrier, and a reverse gear clutch is arranged between the input shaft and the big sun wheel. The big sun wheel brake is used for braking the big sun wheel, and the braking device is used for braking the shared planet carrier. With the automatic transmission, eight-speed changing function is realized and transmission efficiency is high.

Owner:GREAT WALL MOTOR CO LTD

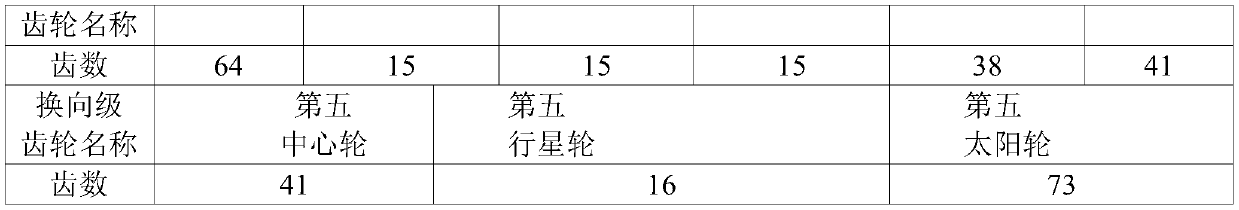

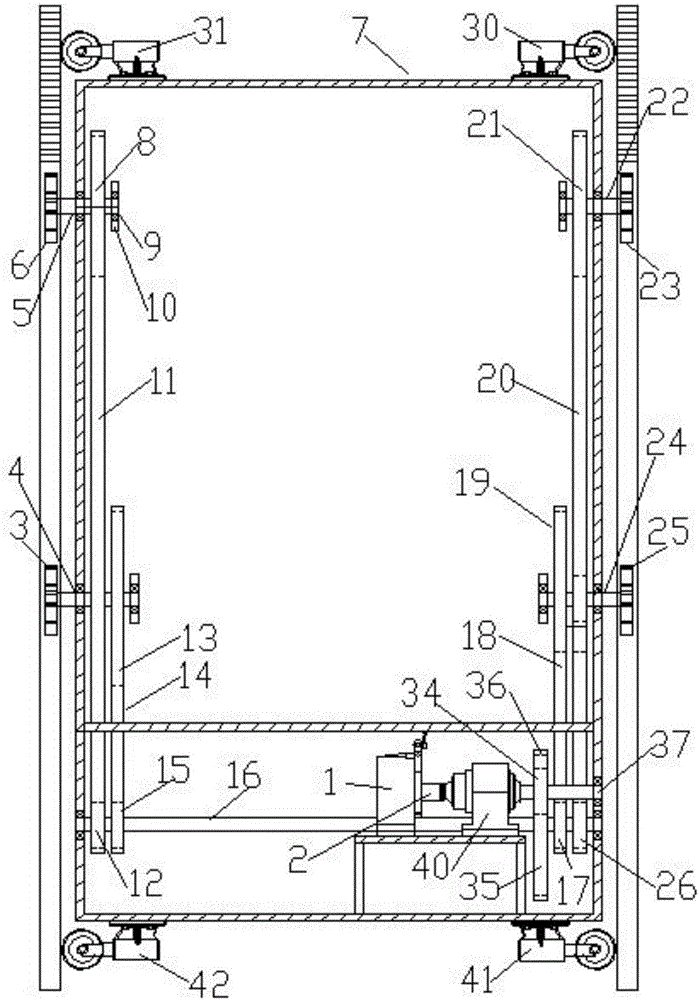

Pinion-and-rack driven elevator using planetary gear reducer

InactiveCN106241573AReduce volumeReduce weightMechanical energy handlingElevatorsAutomotive engineeringDrivetrain

A pinion-and-rack driven elevator using a planetary gear reducer is characterized in that a power transmission system includes a planetary gear reducer and a synchronous belt transmission system; an electric traction system is a motor system including a permanent magnet direct current motor system or a permanent magnet alternating current synchronous motor system; a right lower drive gear and a right upper drive gear are engaged with a right rack fixed in the vertical direction, and a left lower drive gear and a left upper drive gear are engaged with a left rack fixed in the vertical direction; rolling guide shoe rollers are elastically pressed against non-tooth-shaped guide rail surfaces of the left rack and the right rack and drive an elevator car to move upward or downward; a power loss band-type brake is arranged on a brake wheel coaxial to the motor, and a dual-backup structure is adopted; and an electric interlocked and mechanical interlocked outage star-connection unit circuit is arranged in an electrical control system.

Owner:廖忠民

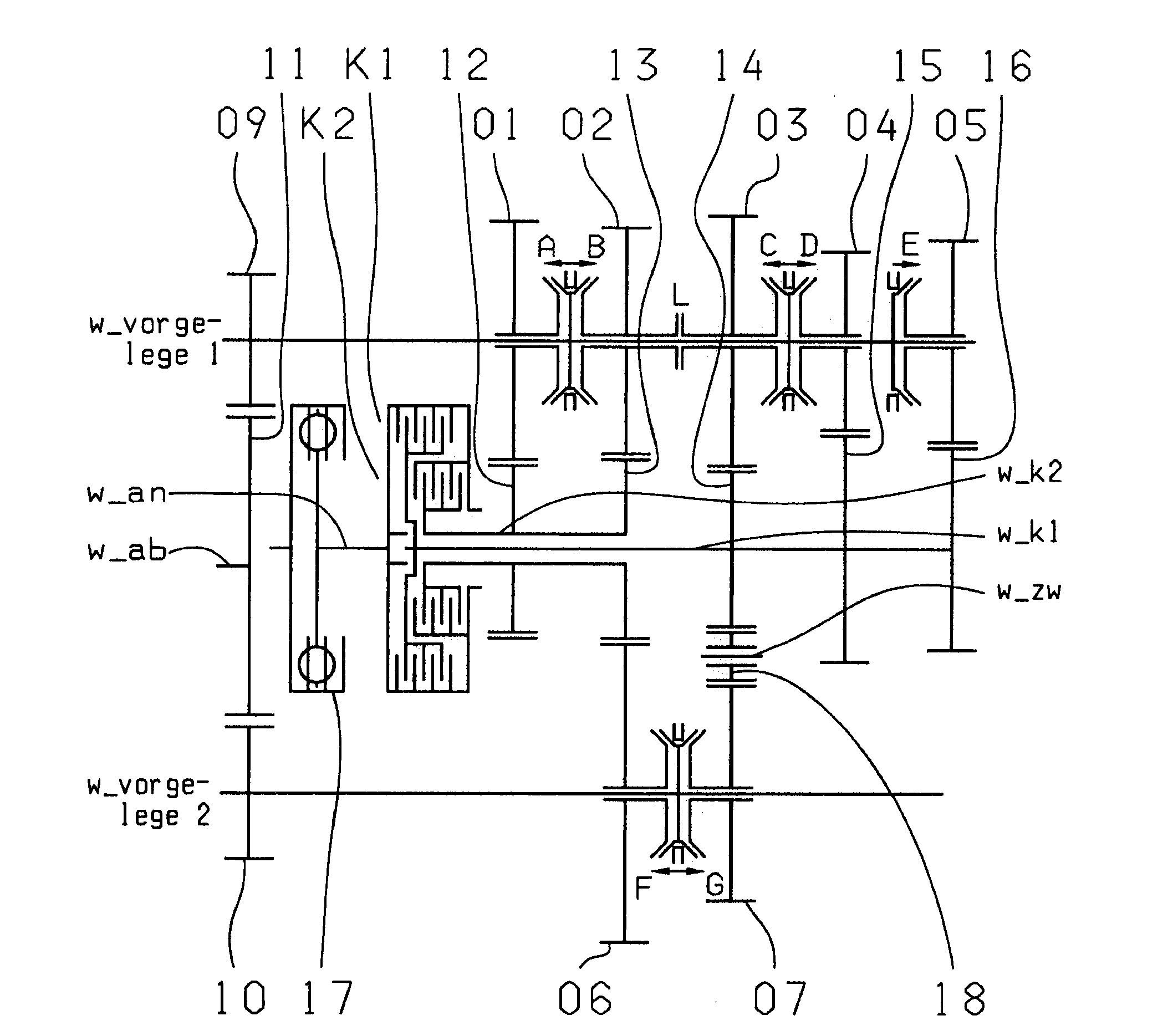

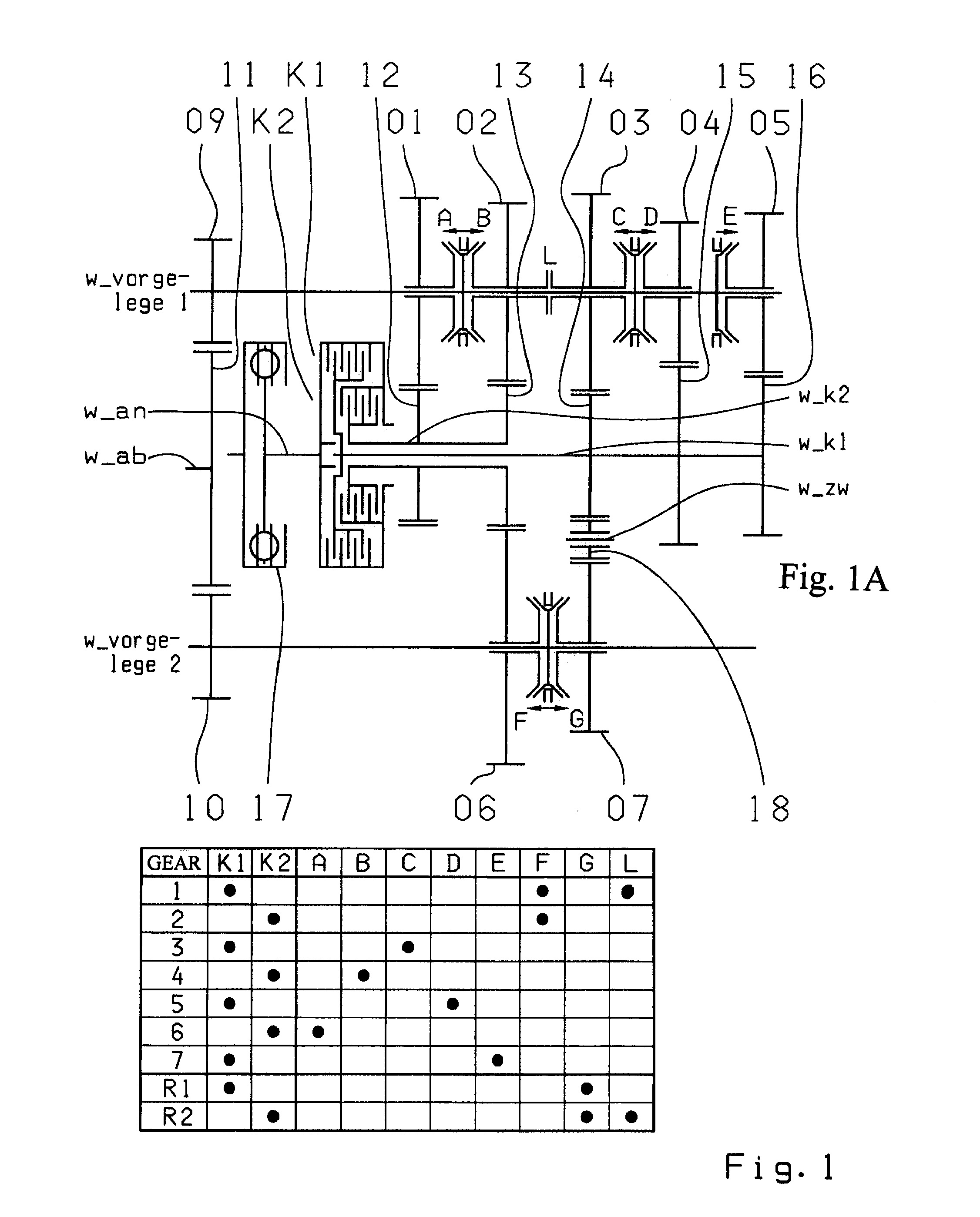

Dual clutch transmission

InactiveUS20100206105A1Reduce manufacturing costLess gear planesToothed gearingsTransmission elementsDrive shaftGear wheel

A double clutch transmission with two clutches connected to a drive shaft and to one of two transmission input shafts. Fixed gears are coupled to the input shafts and engage idler gears. Several coupling devices connect the idler gears to a countershaft which have an output gear that couple gears of an output shaft such that at least seven power shift forward gears and at least one reverse gear can be shifted, and four gear wheel planes are arranged in such a way that at least one power shift winding-path gear can be shifted via the shifting device, such that at least seven power shift forward gears and at least one reverse gear can be shifted, and five gear planes are positioned in such a way that at least one power shift winding-path gear can be shifted via a shifting device.

Owner:ZF FRIEDRICHSHAFEN AG

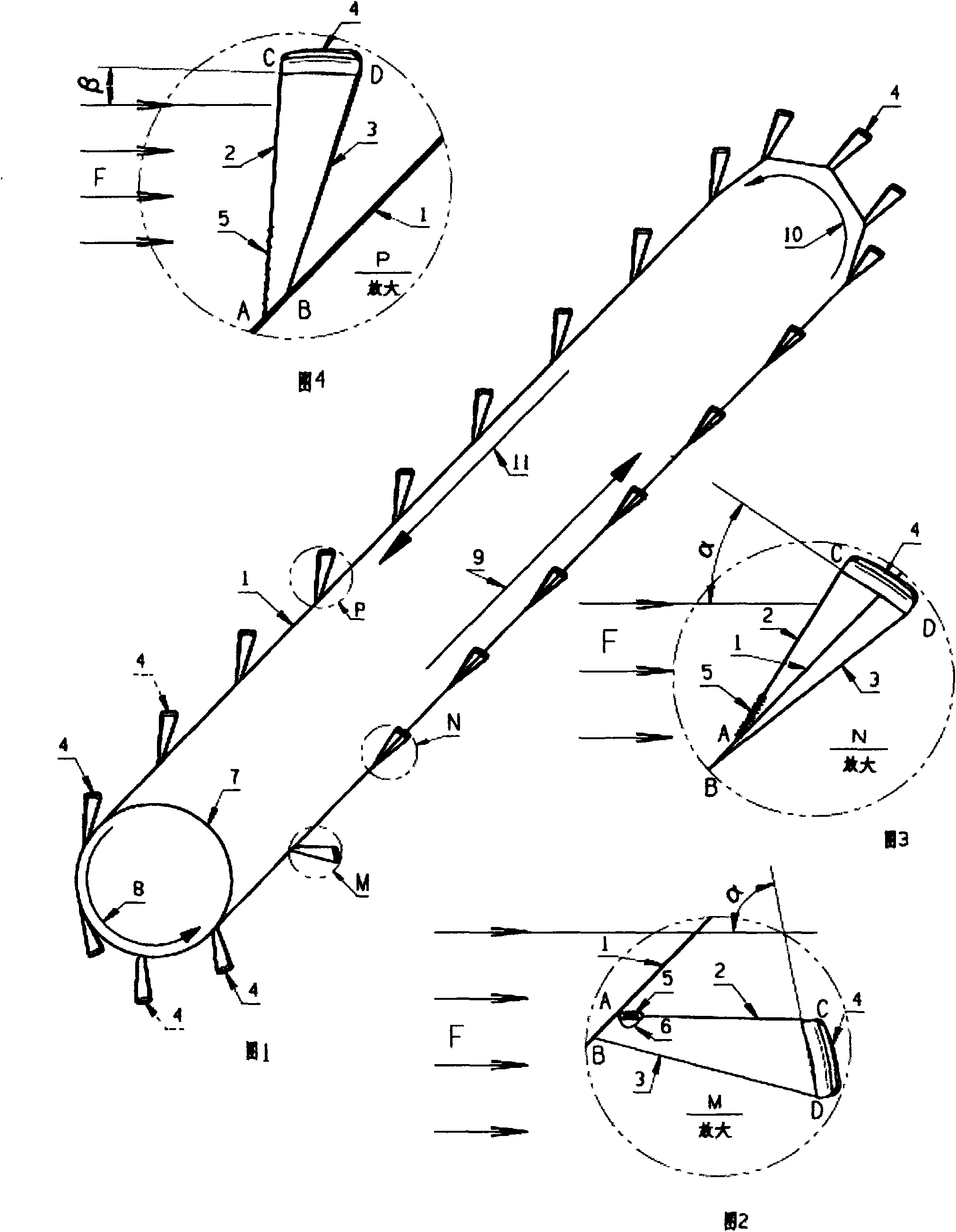

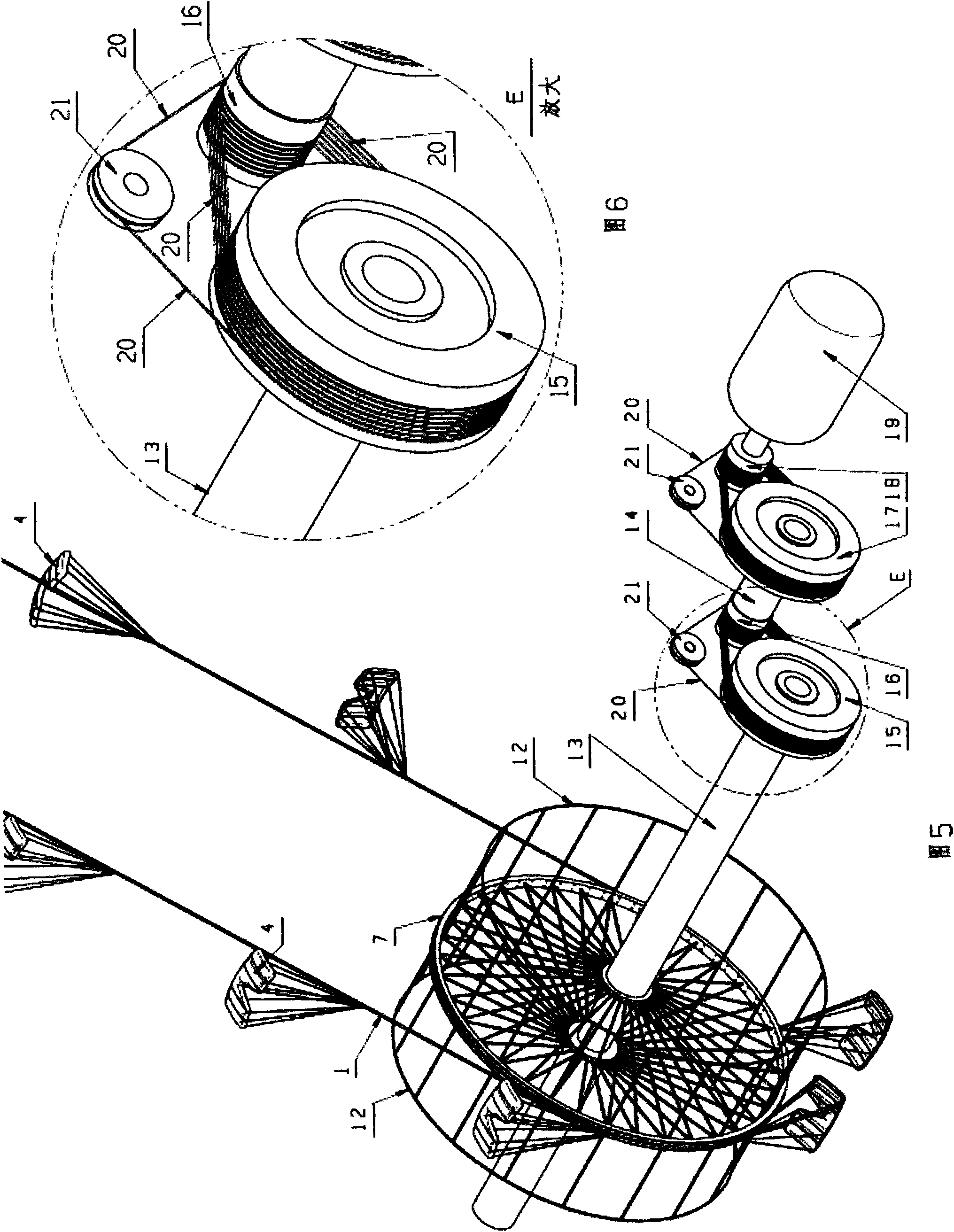

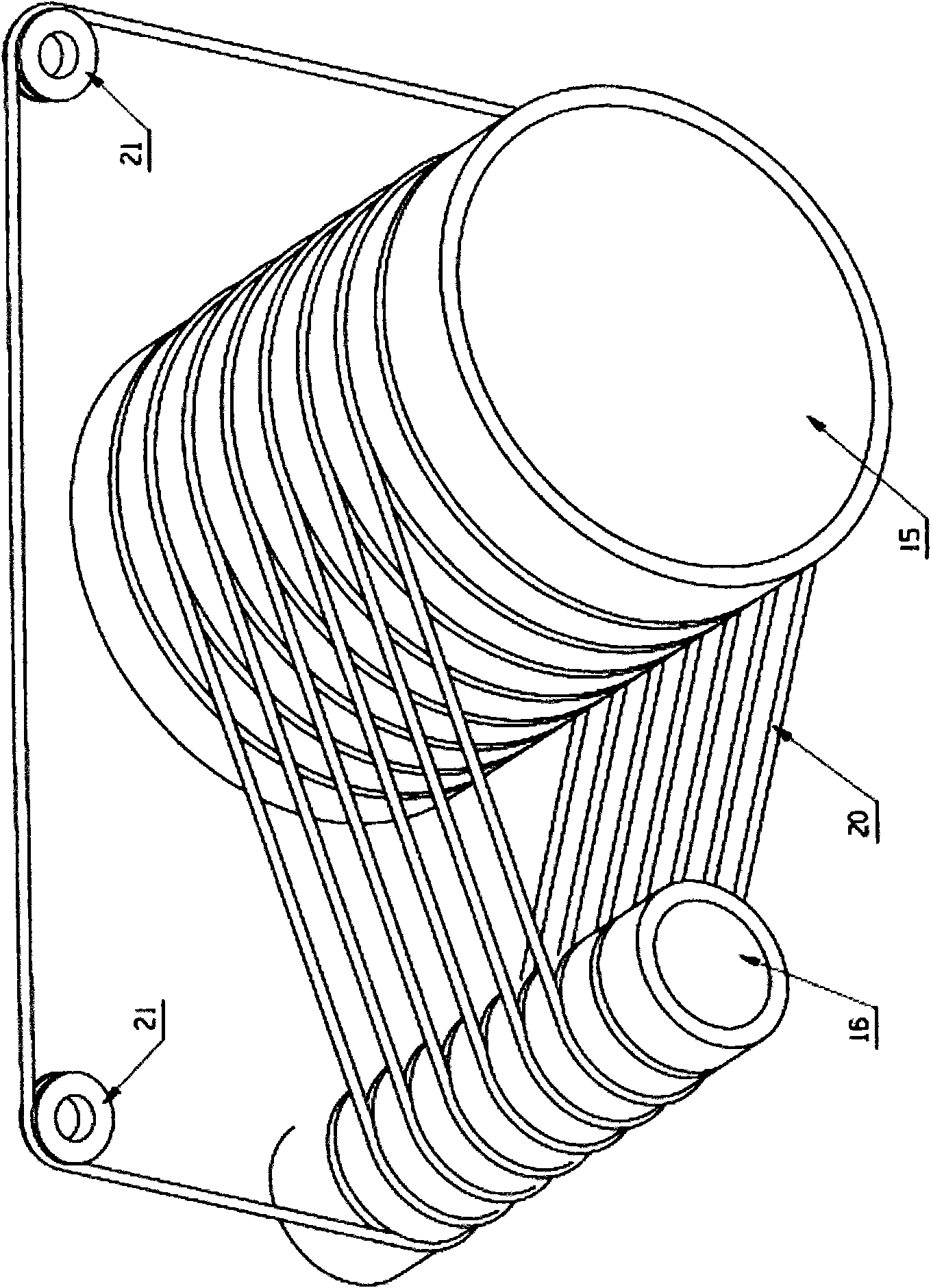

Self-control kite group generator

InactiveCN102654102ASimple organizationAutomatic smooth operationWind motor controlWind motor supports/mountsGreek letter betaAutomatic control

The invention relates to a device for utilizing wind energy, which is characterized by comprising at least ten kites capable of automatically controlling windward angles, a circularly-operated cableway combination and a multi-rope and multi-roller transmission device, wherein one end of a pulling-up wire (2) is intensively connected with a point A of a cableway (1) and the other end of the pulling-up wire is connected with the upper end of each kite body (4); one end of a pulling-down wire (3) is intensively connected with a point B of the cableway (1) and the other end of the pulling-down wire is connected with the lower end of each kite body (4); a point C is an upper end point of a central line of each kite body (4) and a point D is a lower end point of the central line of each kite body (4); a hinged four-rod mechanism is formed by an AB connecting line, an AC connecting line, a CD connecting line and a BD connecting line; according to a movement principle of the hinged four-rod mechanism, a windward angle alpha of the kite (N) at an acting state is greater than a windward angle beta of the kite (P) at a returning state; wind acting force of the kite (N) at the acting state is more than wind acting force of the kite (P) at the returning state; the cableway (1) drives a large transmission wheel (7), a transmission shaft (13), a multi-rope transmission device and a generator (19) to generate power along a direction indicated by an arrow (9).

Owner:周振文

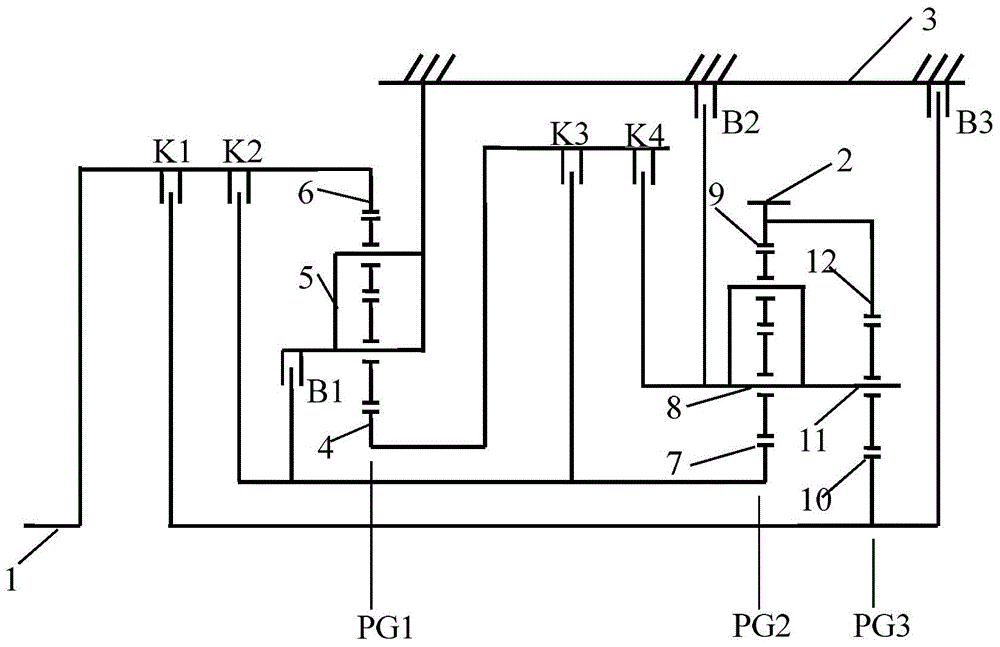

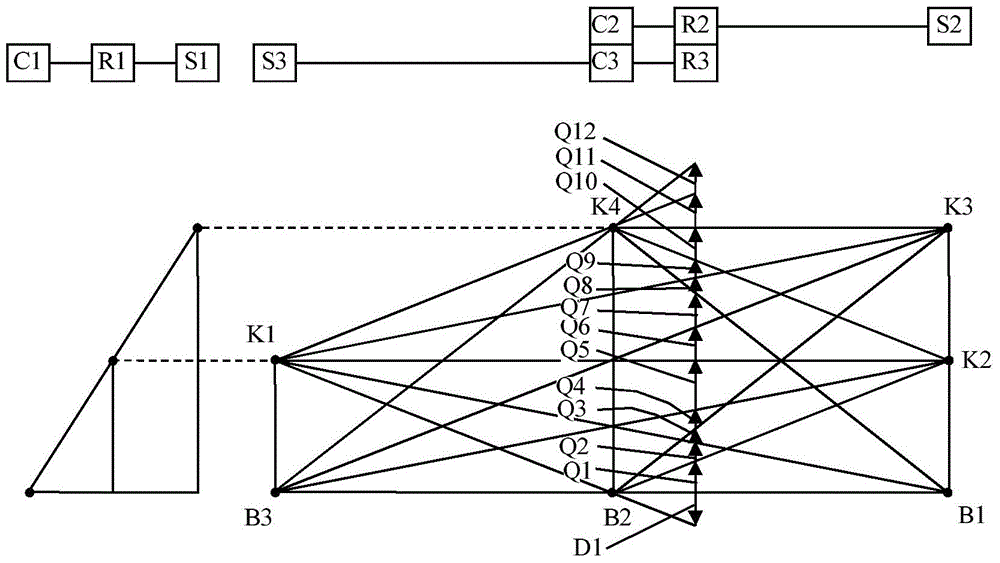

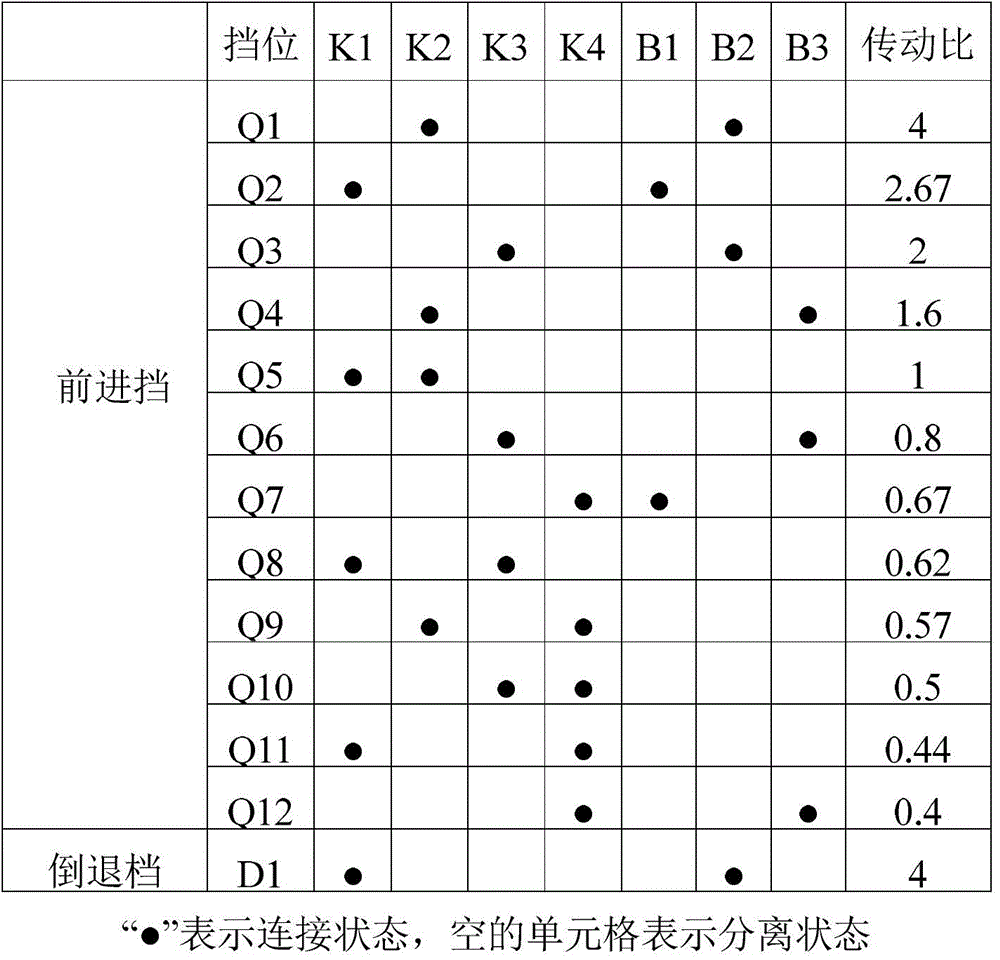

Automatic gearbox

InactiveCN104896041AReduce complexitySimple designToothed gearingsTransmission elementsAutomatic transmissionEngineering

The invention discloses an automatic gearbox which comprises an input shaft, a first planetary gear mechanism, a second planetary gear mechanism, a third planetary gear mechanism, an output shaft, a first clutch, a second clutch, a third clutch, a fourth clutch and a second brake. A first gear ring is connected with the input shaft, a first planetary frame is fixedly connected with a gearbox shell, a second planetary frame is fixedly connected with a third planetary frame, the output shaft is fixedly connected with a second gear ring and a third gear ring and parallel to the input shaft, the first clutch is freely connected with the input shaft and a third sun gear, the second clutch is freely connected with the input shaft and a second sun gear, the third clutch is freely connected with a first sun gear and the second sun gear, the fourth clutch is freely connected with the first sun gear and the second planetary frame, the second planetary frame is freely fixed to the gearbox shell by the aid of the second brake, and transmission gears are determined according to the connecting state of two fastening mechanisms. The automatic gearbox is more compact in structure and wider in speed ratio range, and is provided with more gears and at most provided with twelve forward gears and one reverse gear.

Owner:NANNING UNIV

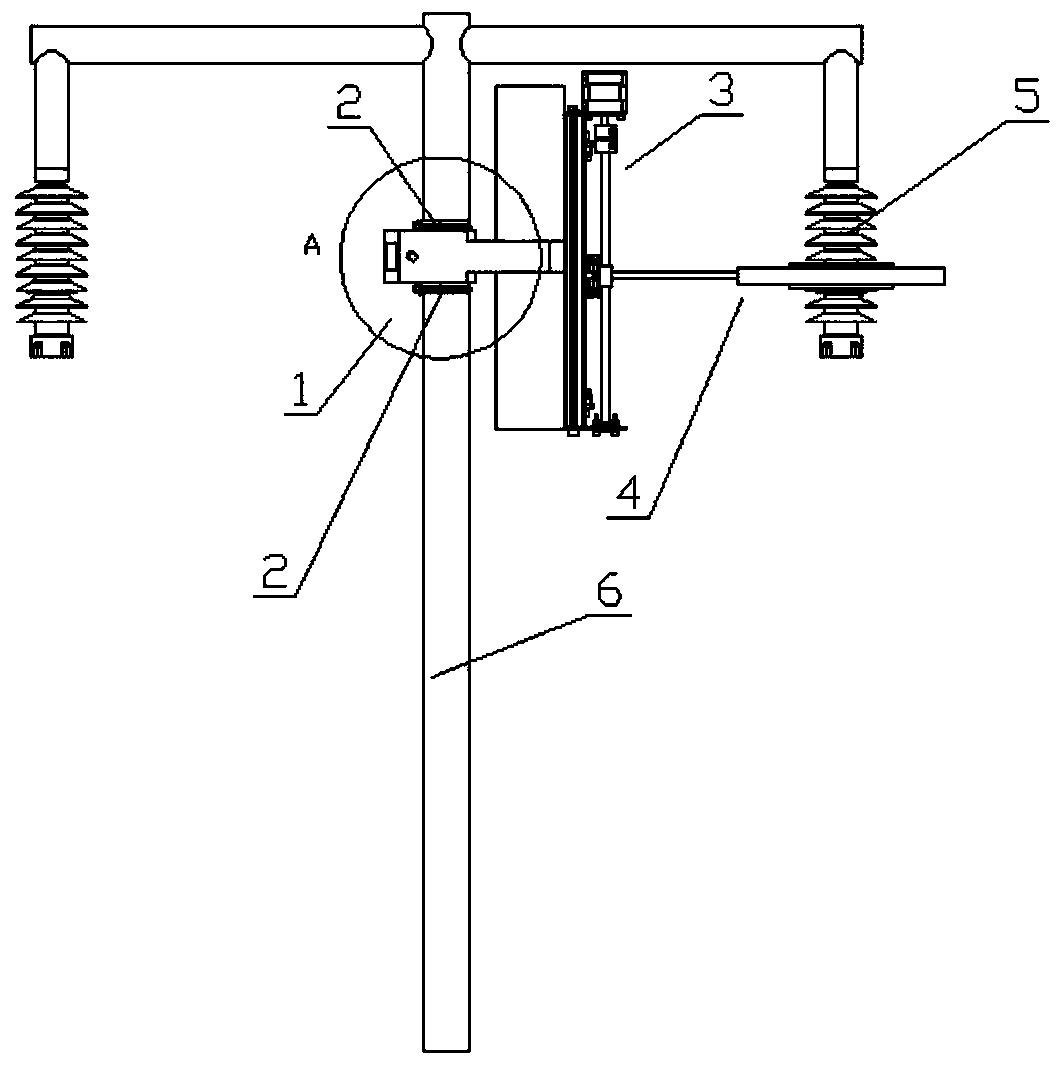

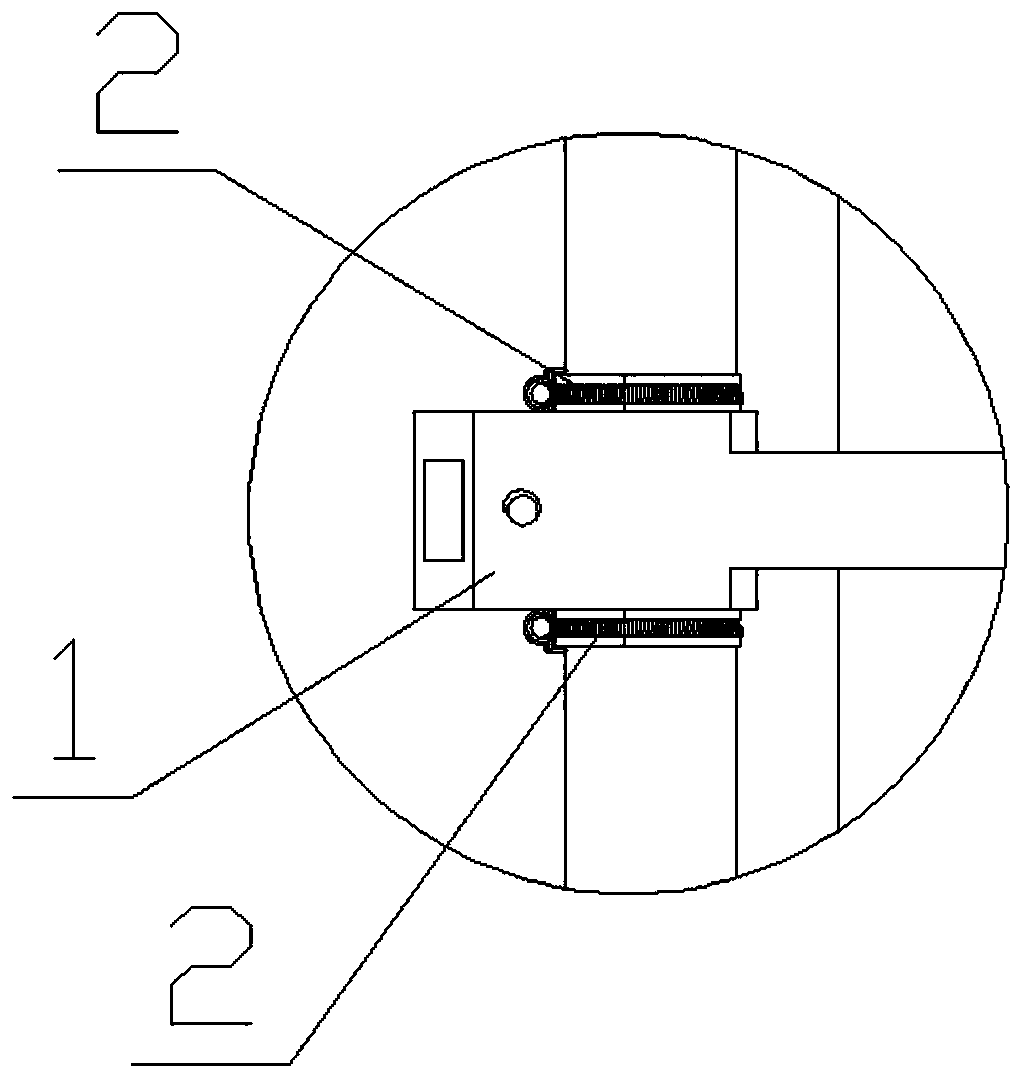

Power transmission line cleaning device

ActiveCN110125063AImprove stabilityReduce the risk factorCleaning using toolsEngineeringSafety coefficient

The invention provides a power transmission line cleaning device, and belongs to the technical field of power supply equipment. According to the technical scheme, the cleaning device comprises a clamping mechanism, a hose clamp is arranged on the upper side and the lower side of the clamping mechanism respectively, the hose clamps are used for controlling the clamping mechanism to move downwards along an electric pole, the clamping mechanism comprises a left end, a middle end and a right end, a clamping part is arranged at the middle end, a control mechanism for driving the clamping part to open and close is arranged at the left end, a connecting part is arranged at the right end, a lifting mechanism is arranged on the connecting part, the direction of the lifting mechanism is parallel tothe axis direction of the electric pole, a cleaning mechanism is vertically arranged on the lifting mechanism, and the cleaning mechanism is erected between the lifting mechanism and an insulator. Thepower transmission line cleaning device has the beneficial effects that an operator do not need to go to the top of the electric pole, the body of the operator do not need to extend out for cleaningthe insulator, and the safety coefficient is improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Double-clutch transmission

PendingCN108397523AMiniaturizationOptimize layoutToothed gearingsTransmission elementsEngineeringClutch

The invention discloses a double-clutch transmission. The double-clutch transmission comprises an inner input shaft, an outer input shaft and two output shafts, wherein the inner input shaft and the outer input shaft are coaxially embedded. The transmission is provided with seven forward gears and one reverse gear, odd gear driving gears are arranged on the inner input shaft, even gear driving gears are arranged on the outer input shaft, the second gear and the reverse gear share a driven gear, the fourth and sixth gears and the fifth and seventh gears (or the third and seventh gears) share the driving gears. A plurality of driven gears are arranged on a first output shaft, a reverse gear assembly and the driven gears are arranged on a second output shaft, and the reverse gear assembly andthe adjacent driven gears are designed to a double-gear structure which can be switched. Because different clutches are used in the first gear and the reverse gear separately, the first gear and thereverse gear can be pre-hung at the same time when a neutral gear starts; the double-gear structure is formed by joining of the reverse gear assembly with the adjacent driven gears, thus the transmission of reverse power is realized, and a reverse shaft is cancelled; and the axial length of the transmission can be reduced by sharing the driving gears or the driven gears.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Ninth-gear transmission

The invention discloses a ninth-gear transmission. The ninth-gear transmission comprises a transmission outer shell, an input shaft, an output shaft, a planetary gear row set, a coupling component setand a torque transmitting device, wherein the input shaft, the output shaft, the planetary gear row set, the coupling component set and the torque transmitting device are installed in the transmission outer shell; each planetary gear row comprises a gear ring, a sun gear, a planetary frame and a planetary gear supported by the corresponding planetary frame; the torque transmitting device comprises two clutches and four brakes, the two clutches and the four brakes are connected selectively to enable one of the sun gears, the planetary gears, the gear rings or four coupling components to rotateor be fixed; and the torque transmitting device can be selectively connected by at least two combination modes to establish nine forward gear speed ratios and one reverse gear speed ratio between theinput shaft and the output shaft, wherein the nine forward gear ratios comprise five reduction gears, one direct gear and three over drives. The ninth-gear transmission is compact in structure, lightin weight, small in size, is easy to arrange on a vehicle, and phase steps of the speed ratios between the transmission ratios of the gears of the transmission meet the requirement of the transmission.

Owner:YANSHAN UNIV

Composite rolling active-tooth transmission device and method for performing transmission by using the same

InactiveCN102691752AImprove power densityIncrease stiffnessToothed gearingsGearing detailsShock waveGear wheel

The invention relates to a composite rolling active-tooth transmission device and a method for performing transmission by using the same. The transmission device comprises an active-tooth transmission wheel train, a planetary gear train and outer transmission disks. Planetary gears of the planetary gear train are rotationally arranged on end faces of a shock shaft of the active-tooth transmission wheel train. A first crossed roller bearing is arranged between an active-tooth semi-disc of the active-tooth transmission wheel train and a fixed gear of the active-tooth transmission wheel train, and a second crossed roller bearing is arranged between the active-tooth semi-disc and the shock shaft. The outer transmission disks are connected with an active-tooth semi-disc, and internal teeth engaged with the planetary gears are arranged on the outer transmission disks. A central gear of the planetary gear train is supported and positioned by a prime mover, or a bearing is arranged in the shock shaft and the central gear is arranged on a central shaft passing through the bearing. According to the invention, not only the density of transmitted power is increased, the size is reduced, and the whole rolling active-tooth transmission structure is more compact, but also stiffness and precision of the transmission system are improved, and manufacturing and processing cost is greatly reduced.

Owner:陈仕贤

Face gear-type planetary reduction gearbox

InactiveCN102230519ASimple box structureLow installation accuracy requirementsToothed gearingsDrive shaftGear wheel

The invention discloses a face gear-type planetary reduction gearbox. A planetary reduction mechanism which is connected between two transmission shafts of the reduction gearbox in a transmission mode comprises two face gear groups, wherein the two face gear groups are rotationally arranged on a gearbox body respectively and formed by coaxially and fixedly connecting internal gear rings which are close to an axis and external gear rings which are far away from the axis; the gear faces of the two face gear groups are opposite to each other; a planetary frame is connected between two corresponding internal gear rings in the transmission mode; a fixed shaft gear is meshed between two corresponding external gear rings in the transmission mode; one face gear group is coaxially connected with a first transmission shaft; and the other face gear group is coaxially connected with a second transmission shaft by the planetary frame. Compared with the conventional cylindrical gear-type planetary reduction gearbox, the face gear-type planetary transmission mechanism has the advantages of high transmission ratio, compact structure, good load balancing effect and the like, and is stably operated, and the carrying capability of the unit gearbox of the face gear-type planetary transmission mechanism is 20 percent higher than that of the cylindrical gear-type planetary reduction gearbox.

Owner:HENAN UNIV OF SCI & TECH

Two-gear automatic transmission for battery electric vehicle

InactiveCN104633015ACompact structureLight in massElectric propulsion mountingToothed gearingsManufacturing cost reductionAutomatic transmission

A two-gear automatic transmission for a battery electric vehicle comprises an input shaft, an intermediate shaft, a first cylindrical gear pair, a second cylindrical gear pair, a third cylindrical gear pair, a first torque transfer device, a second torque transfer device and a differential assembly. The rotating central lines of the input shaft, the intermediate shaft and the differential assembly are mutually parallel. A driving motor, an automatic transmission and a driving bridge are integrated to form a whole, a transmission ratio range is widened, the performance requirement of the driving motor is remarkably reduced, the two-gear automatic transmission is simple and compact in structure, light in weight, stable in transmission and wide in transmission ratio range and has very high power transfer efficiency, energy consumption level is reduced, the power performance and economical efficiency of the whole vehicle are improved, and manufacturing cost is remarkably reduced.

Owner:BEIHANG UNIV

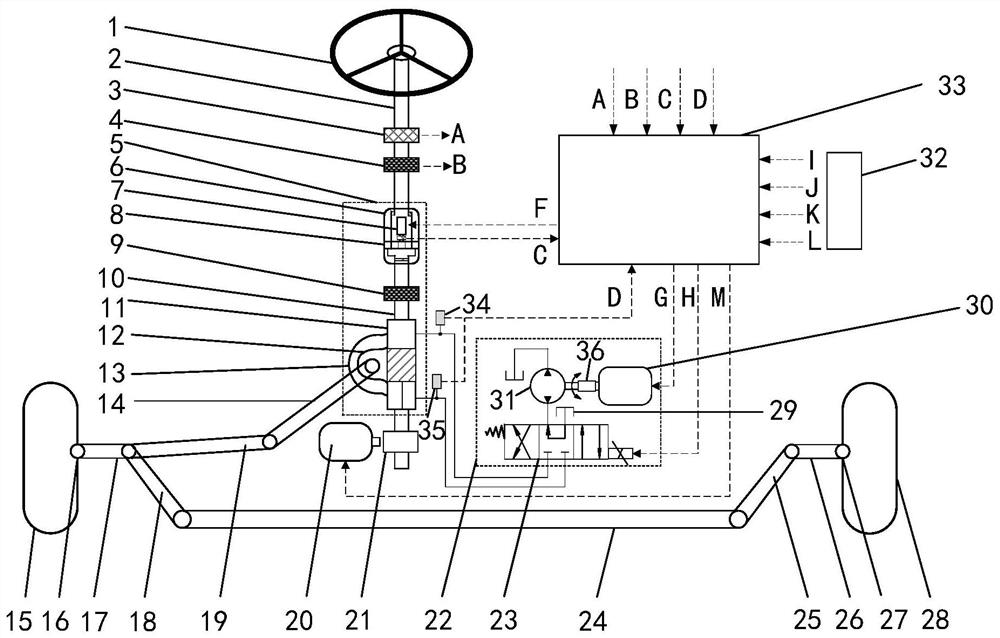

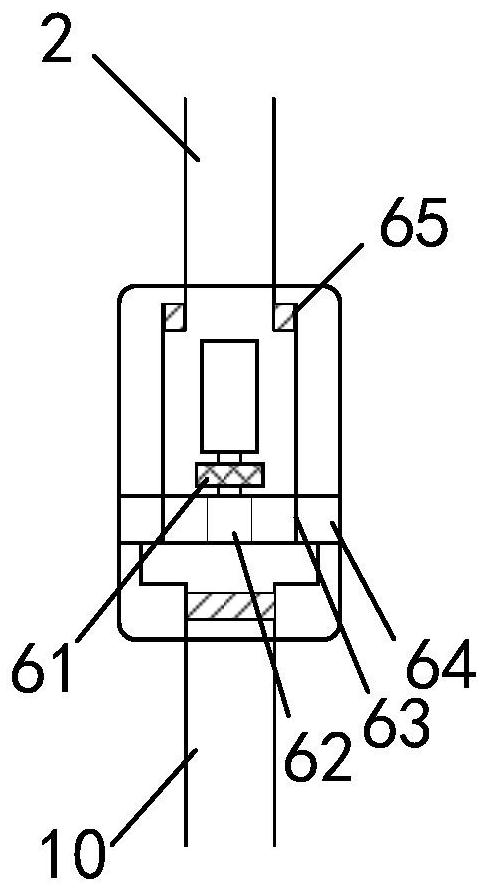

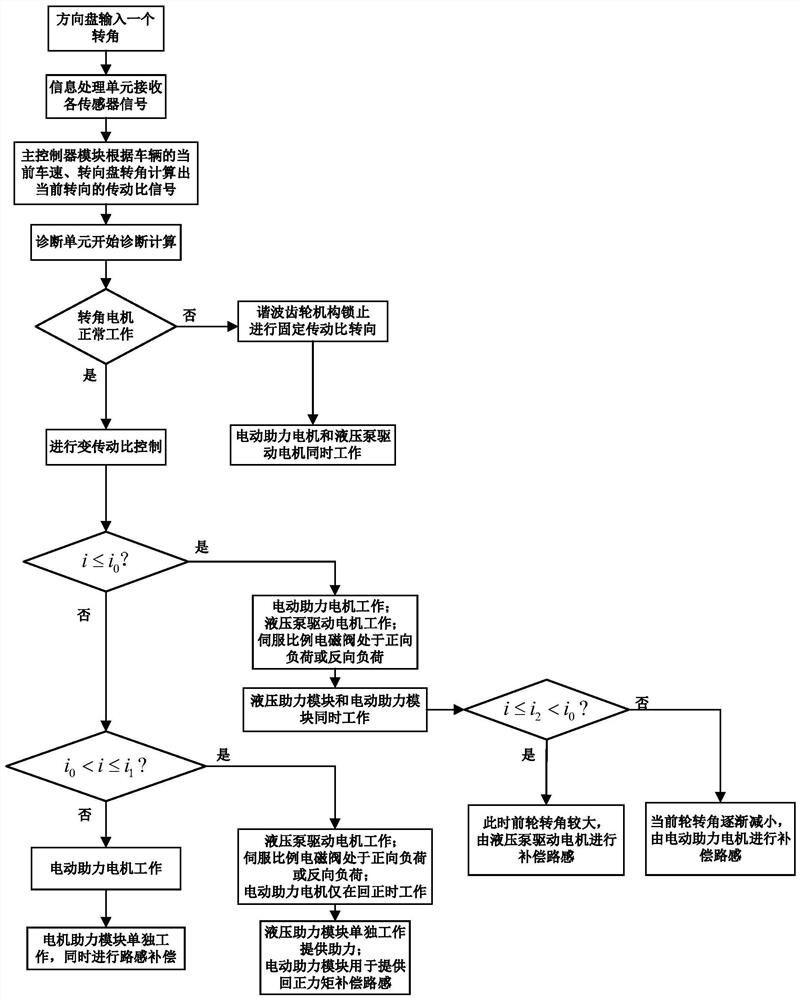

Variable-transmission-ratio circulating ball type electro-hydraulic steering system and control method thereof

ActiveCN113212543ARealize variable transmission ratio functionImprove active safetySteering linkagesMechanical steering gearsSteering wheelElectric machinery

The invention discloses a variable-transmission-ratio circulating ball type electro-hydraulic steering system and a control method thereof. The variable-transmission-ratio circulating ball type electro-hydraulic steering system comprises a steering wheel module, a variable-transmission-ratio hydraulic power assisting module, a mechanical transmission module, a motor power assisting module and a main controller module. According to the electro-hydraulic steering system, different motor power-assisted modes can be selected according to transmission ratio signals of different working conditions, steering is controlled through coordination of the hydraulic power-assisted motor and the electric power-assisted motor, the magnitude of steering power can be adjusted along with the transmission ratio signals of harmonic rotation angles, the three advantages of fast electric response, large hydraulic assistance and good variable transmission ratio stability are fused, the response speed is increased, the anti-interference capability is enhanced, and the overall energy consumption is reduced to a certain extent.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com