Seven-speed double-clutch type automatic transmission

A technology of automatic transmission and double clutch, which is applied to the transmission device, transmission device parts, gear transmission device, etc. It can solve the difficulty of increasing the arrangement of the gear shift actuator, the inability to pre-engage the first gear and the reverse gear at the same time, and the difficulty of assembling the transmission system, etc. problem, to achieve the effect of reasonable transmission ratio distribution, favorable weight reduction and reasonable layout of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

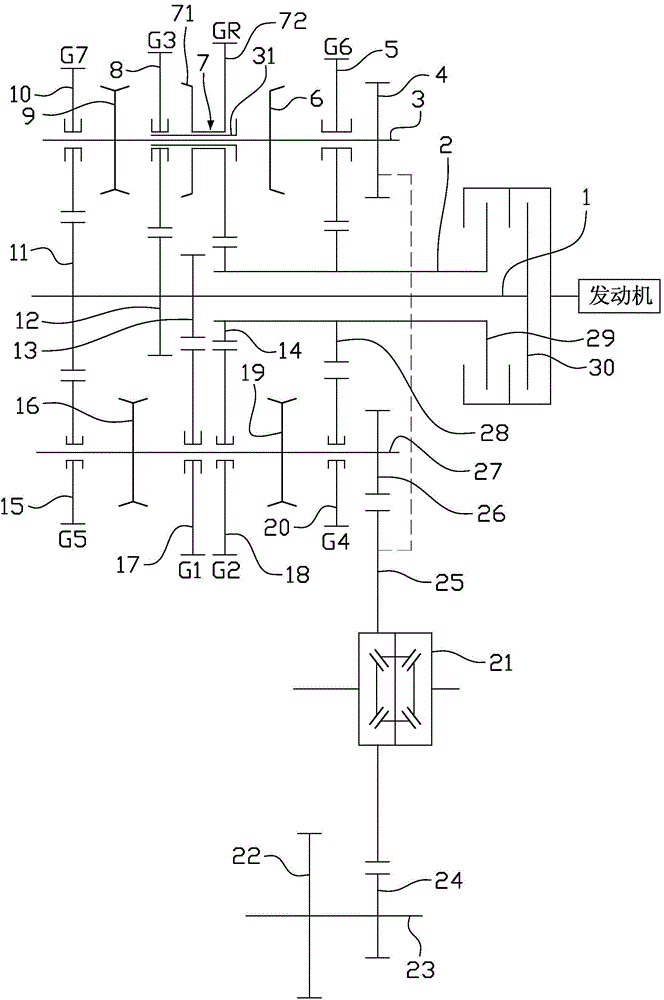

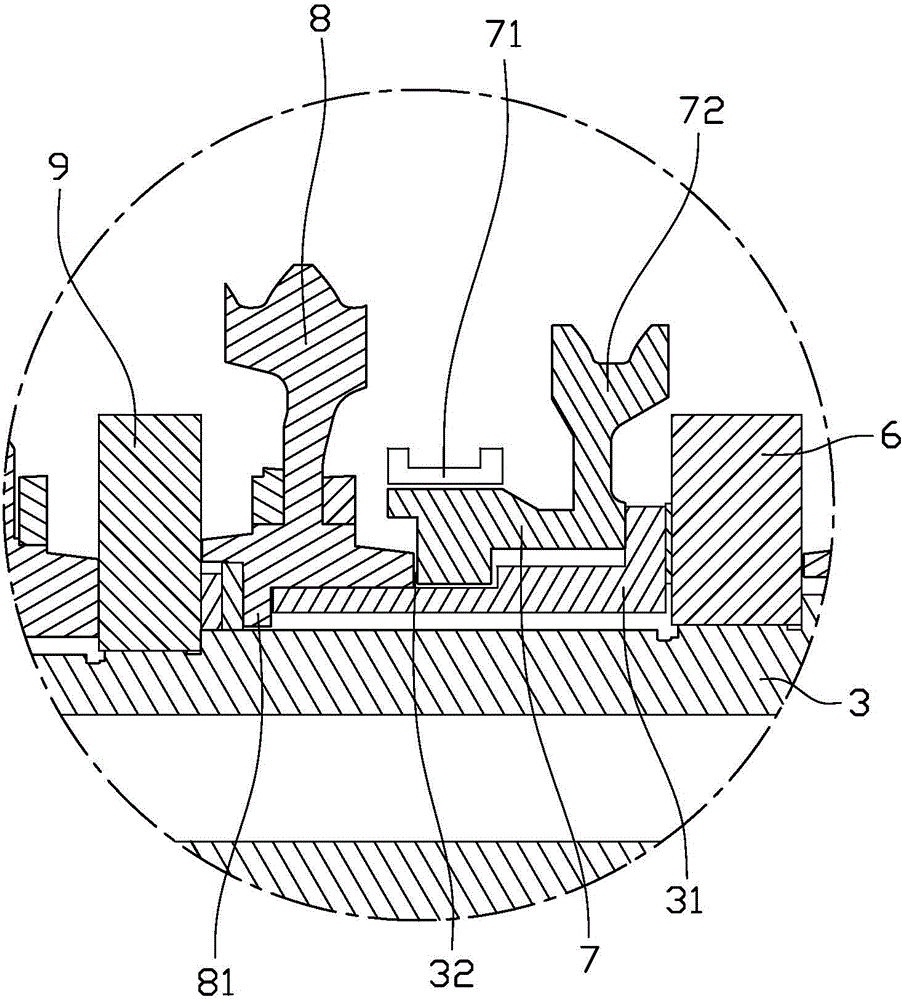

[0041] figure 1 It is a schematic structural diagram of the seven-speed dual-clutch automatic transmission according to the first embodiment of the present invention, please refer to figure 1 , the automatic transmission of this embodiment includes: a first input shaft 1, a second input shaft 2, a second output shaft 3, a second main reduction gear 4, a sixth-speed driven gear 5, a sixth-speed synchronizer 6, a reverse gear Component 7, third gear driven gear 8, third and seventh gear synchronizer 9, seventh gear driven gear 10, fifth and seventh gear driving gear 11, third gear driving gear 12, first gear driving gear 13, second reverse gear driving gear 14, Fifth-speed driven gear 15, first-fifth-speed synchronizer 16, first-speed driven gear 17, second-speed driven gear 18, second-fourth-speed synchronizer 19, fourth-speed driven gear 20, differential 21, parking gear 22. Parking shaft 23, third main reduction gear 24, differential ring gear 25, first main reduction gear 2...

no. 2 example

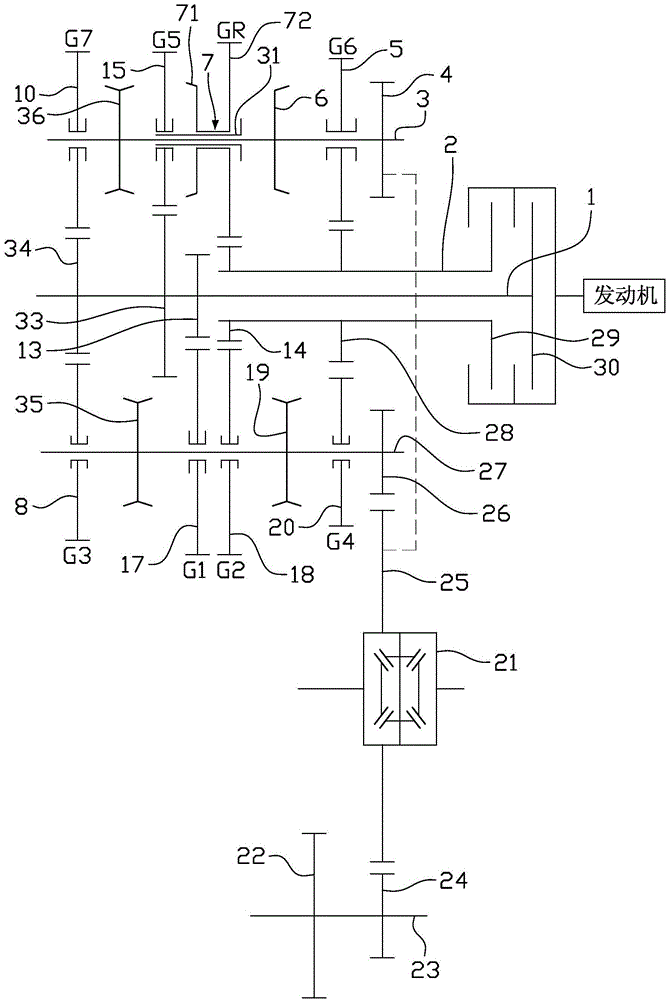

[0062] image 3 It is a schematic structural diagram of the seven-speed dual-clutch automatic transmission according to the second embodiment of the present invention, please refer to image 3 The difference between the automatic transmission of this embodiment and the automatic transmission of the first embodiment is that the third gear and the fifth gear are interchanged. Therefore, the first input shaft 1 is fixed on the first input shaft 1 from the end close to the engine. The driving gear 33 and the third and seventh gear driving gear 34, the second input shaft 2 is fixed with the fourth and sixth gear driving gear 28 and the second reverse driving gear 14 from the end close to the engine, and the first output shaft 27 is empty from the end close to the engine The fourth-speed driven gear 20, the second-speed driven gear 18, the first-speed driven gear 17 and the third-speed driven gear 8 are covered, and the second output shaft 3 is covered with a sixth-speed driven gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com