Multi-gear vertical dual clutch transmission

A dual-clutch transmission, vertically mounted technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of large assembly size and weight, large number of parts, high manufacturing cost, etc., and achieve compact layout , wide transmission ratio range, and the effect of reducing the number of gears and synchronizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

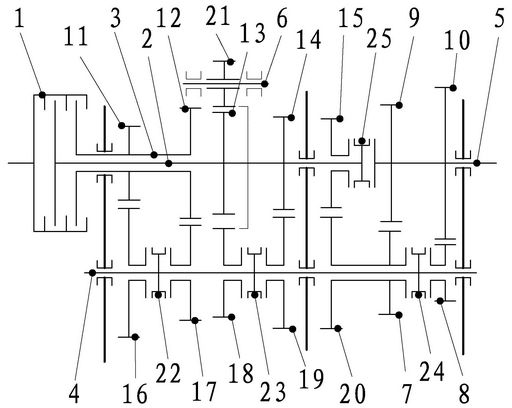

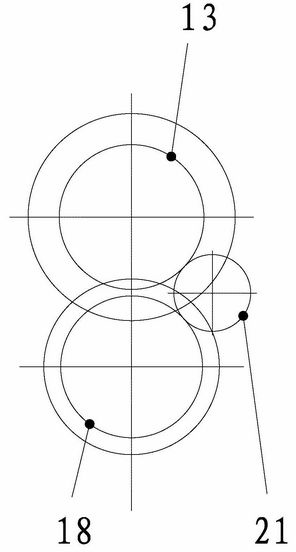

[0024] figure 1 and figure 2 Shown is a multi-gear longitudinal dual-clutch transmission, including a dual-clutch 1, a nested shaft, and three parallel shafts including an intermediate shaft 4, an output shaft 5, and a reverse gear shaft 6.

[0025] The nested shaft is a double input shaft structure composed of a hollow input shaft 3 and a solid input shaft 2 . The axis of the output shaft 5 is collinear with the axis of the nesting shaft. The double clutch 1 is arranged at one end of the solid input shaft 2 .

[0026] The common driving gear 11 for the first and fifth gears and the common driving gear 12 for the third and seventh gears are arranged on the hollow input shaft 3;

[0027] The output shaft 5 is provided with a high-speed driven gear 9 and a low-speed driven gear 10, which are constant mesh output gears, and mesh with the high-speed driving gear 7 and the low-speed driving gear 8 on the intermediate shaft 4 respectively.

[0028] The common driven gear 16 for...

Embodiment 2

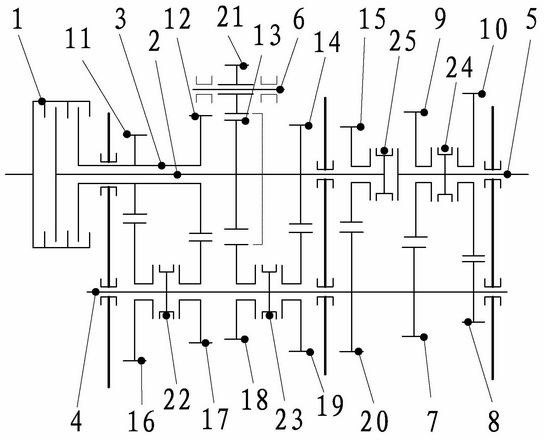

[0065] image 3 and Figure 4 Shown is a multi-gear longitudinal dual-clutch transmission, including a dual-clutch 1, a nested shaft, and three parallel shafts including an intermediate shaft 4, an output shaft 5, and a reverse gear shaft 6.

[0066] The nested shaft is a double input shaft structure composed of a hollow input shaft 3 and a solid input shaft 2 . The axis of the output shaft 5 is collinear with the axis of the nesting shaft. The double clutch 1 is arranged at one end of the solid input shaft 2 .

[0067] The shared driving gear 11 of the second and sixth gears, the shared driving gear 12 of the fourth and eighth gears are arranged on the hollow input shaft 3;

[0068] The output shaft 5 is provided with a high-speed driven gear 9 and a low-speed driven gear 10, which are constant mesh output gears, and mesh with the high-speed driving gear 7 and the low-speed driving gear 8 on the intermediate shaft 4 respectively.

[0069] Second and sixth gears shared dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com