Double-clutch transmission

A dual-clutch transmission and clutch technology, which is applied to vehicle gearboxes, gear transmissions, transmission components, etc., can solve the problems of unfavorable transmission space layout compactness, complex reverse gear transmission path, and large number of gear meshes, etc., to achieve transmission The effects of reasonable ratio distribution, shortened axial length and variable transmission ratio range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

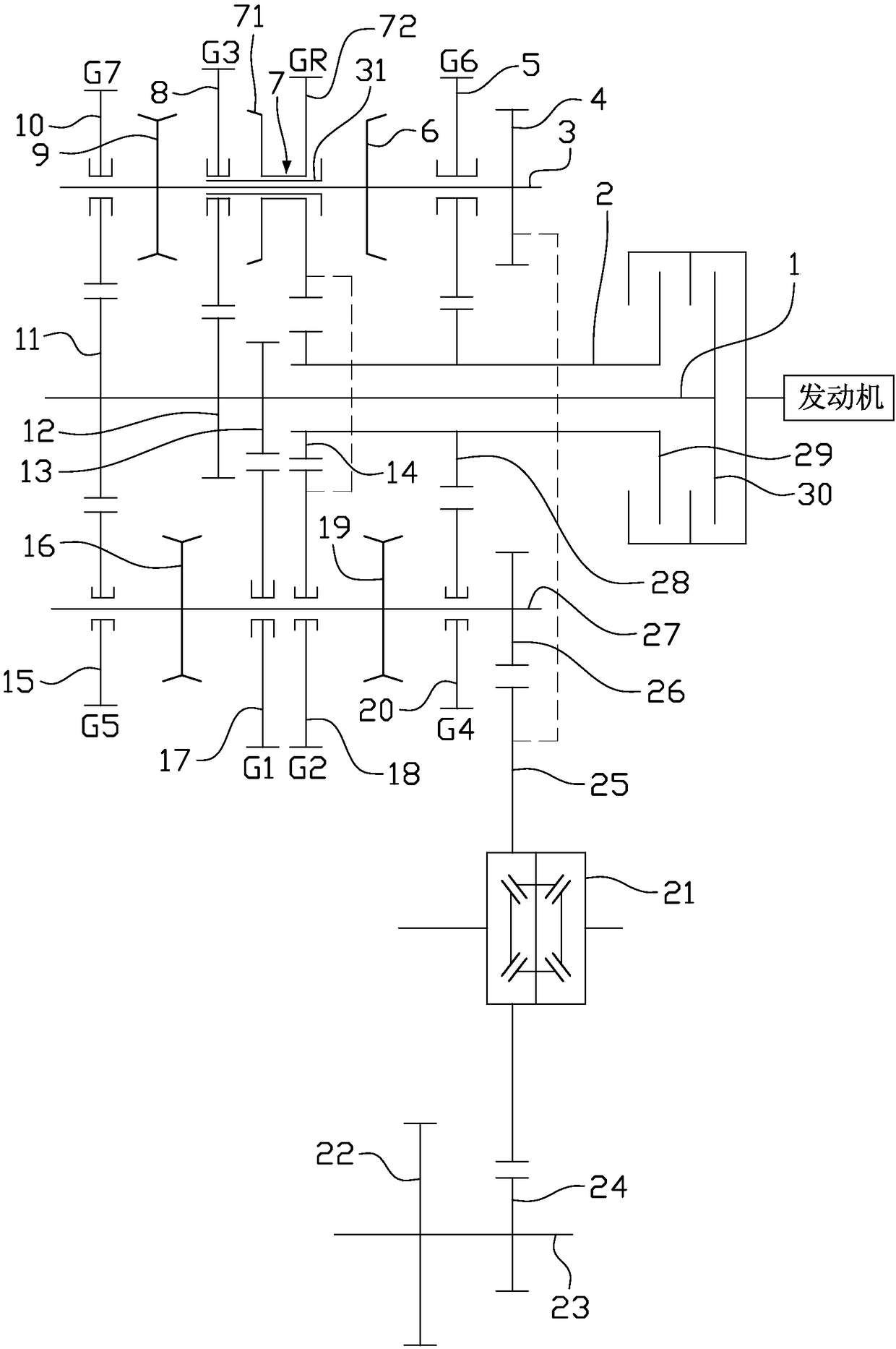

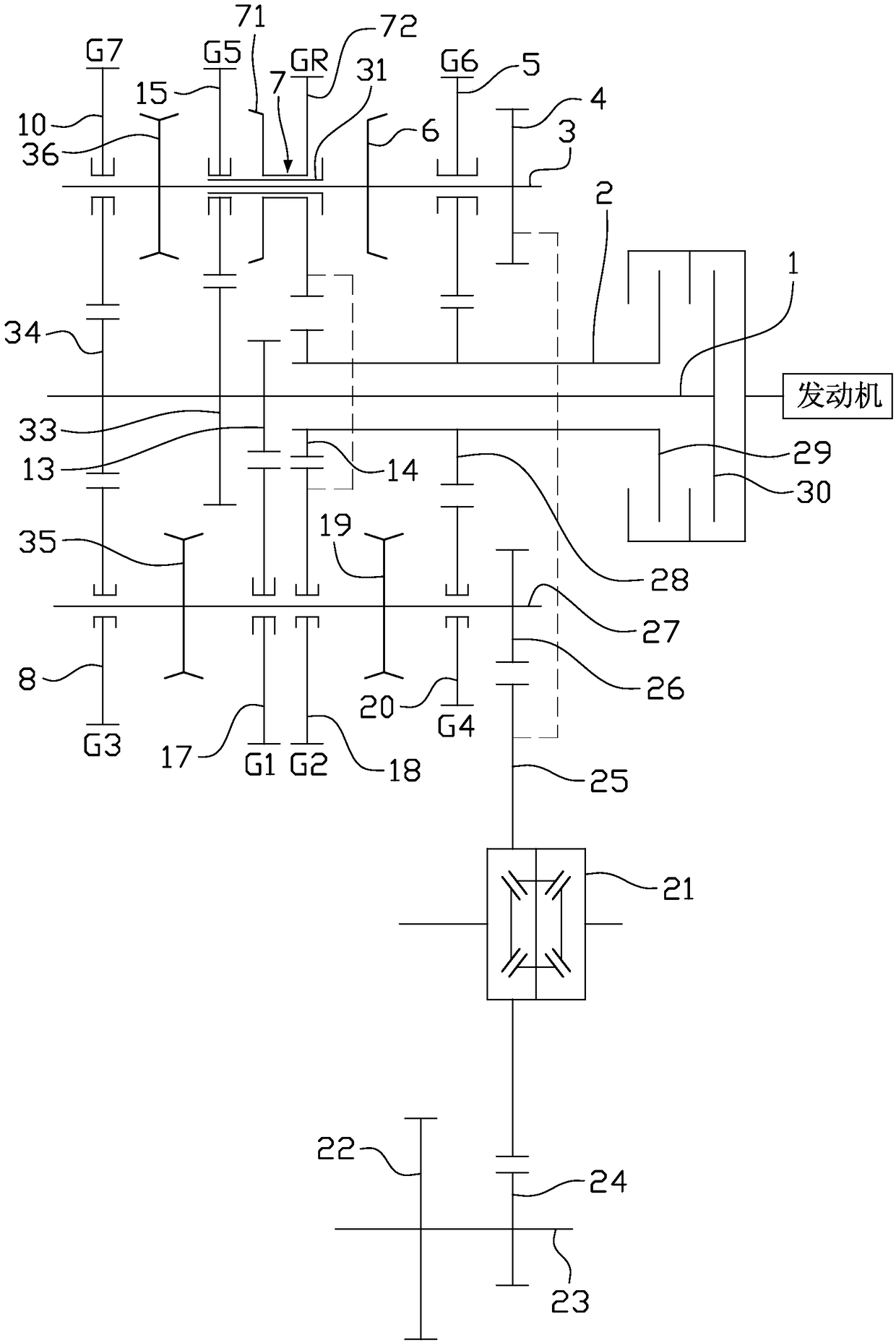

[0068] image 3 It is a structural schematic diagram of the dual-clutch transmission of the second embodiment of the present invention, please refer to image 3 The difference between the speed changer of this embodiment and the speed changer of the first embodiment is that the third gear and the fifth gear are interchanged. Therefore, the first gear driving gear 13 and the fifth gear driving gear are fixed on the inner input shaft 1 from one end close to the power source. 33 and the third and seventh gears driving gear 34, four and six gears driving gear 28 and the second gear driving gear 14 are fixed on the outer input shaft 2 from one end near the power source, and there are empty sleeves on the first output shaft 27 from one end near the power source The fourth gear driven gear 20, the second gear driven gear 18, the first gear driven gear 17 and the third gear driven gear 8, the second output shaft 3 has a sixth gear driven gear 5, which is empty from one end close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com