Petroleum drilling trajectory-controlled harmonic gear transmission device

A trajectory control, harmonic gear technology, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problem of inability to meet the stepless adjustable wellbore trajectory control tool, low transmission efficiency of underground work, reduction mechanism Large volume and other problems, to achieve the effect of light weight, high fatigue resistance, and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

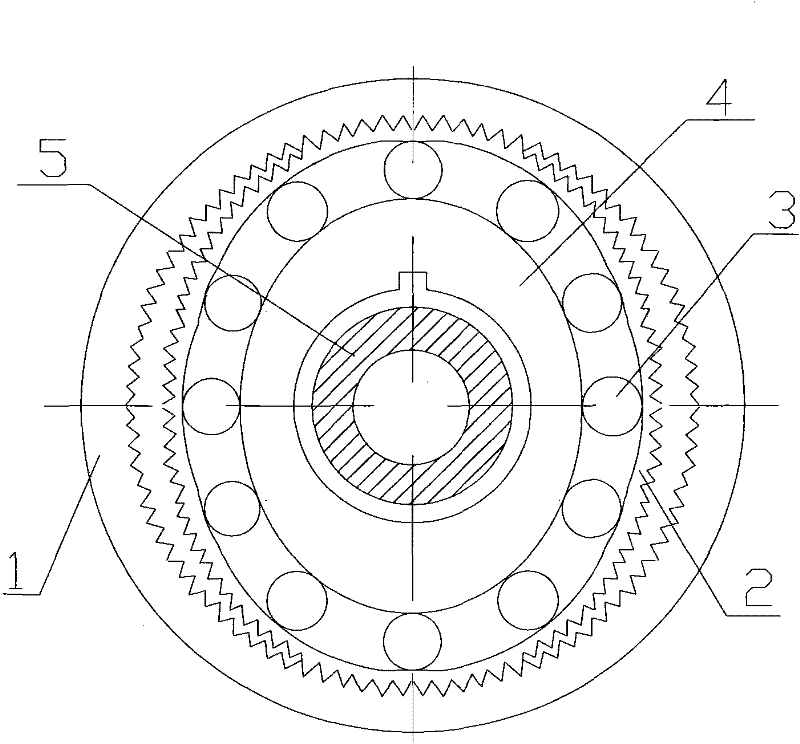

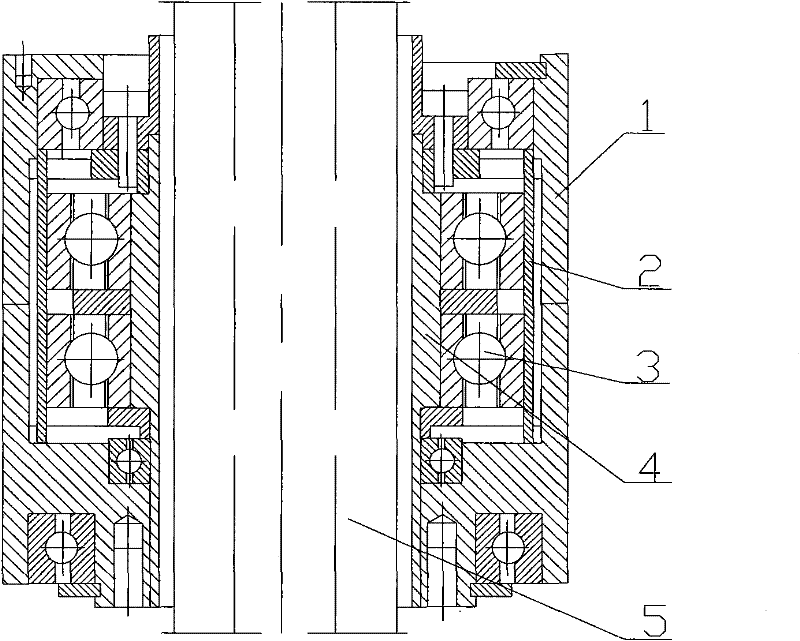

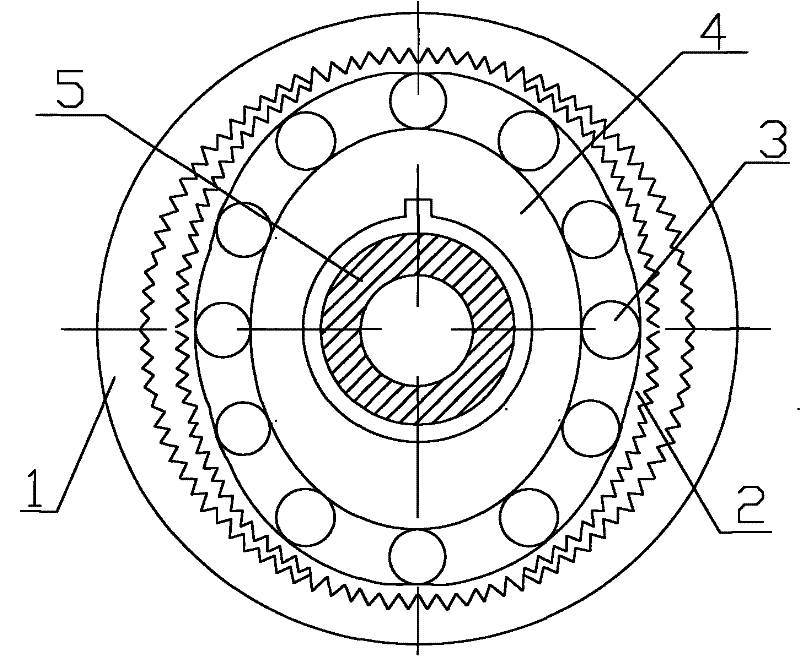

[0013] The present invention is a kind of harmonic gear transmission device for oil drilling track control, which is composed of rigid gear 1, flexible gear 2, bearing 3, wave generator 4, hollow shaft 5; rigid gear 1 has an inner gear, which is equivalent to The center wheel in the planetary system; the flexible gear 2 has an outer ring gear, which is equivalent to a planetary gear, and can produce deformation; the wave generator 4 is an elliptical cam, which is equivalent to a planet carrier; the wave generator 4 is installed on the hollow shaft 5, A bearing 3 is installed between the wave generator 4 and the flexible gear 2; a rigid gear 1 is installed on the outer ring of the flexible gear 2; the number of teeth of the flexible gear 2 is 2 less than that of the rigid gear 1; , Corrosion-resistant 30 chromium manganese silicon material processing.

[0014] The wave generator 4 is the input end, and the rigid gear 1 is the output end, which can realize deceleration and obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com