Patents

Literature

586 results about "Hose clamp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hose clamp or hose clip or hose lock is a device used to attach and seal a hose onto a fitting such as a barb or nipple.

Outlet tube device for urinary drainage bag

InactiveUS6132407AReduce manufacturing costEasy to operateClosuresCheck valvesUrinary drainageResidual urine

An improved outlet tube device for a urinary drainage bag is disclosed wherein an outlet valve mechanism is contained with a rigid housing fixed securely to the drainage bag, rather than just being clamped to the outlet tubing, and thus cannot become separated from the bag. The outlet valve can be opened only by positive action on the part of the medical care personnel, thereby assuring that urine will be discharged only in a controlled manner. Further, because the valve mechanism does not require that a substantial length of tubing with a freely movable end be used in conjunction with the outlet port, there is no need to engage the free end of the tubing with a keeper. Thus the possibility of the tubing springing back to its straight configuration and flicking residual urine on the attending medical personnel is eliminated. In one embodiment the outlet tube device comprises a pinchcock-type valve which is fixedly mounted to the bag and which is normally operative to clamp off the outlet tube. In a second embodiment the outlet tube device comprises a syringetype fitting which is fixedly mounted to the bag. Depressing the syringe plunger closes the valve, and retracting the plunger opens the valve to permit fluid to be discharged through the outlet tube. In a third embodiment, a hose clamp is contained within a rigid housing and is selectively operative to clamp a hose to prevent fluid flow therethrough.

Owner:CR BARD INC

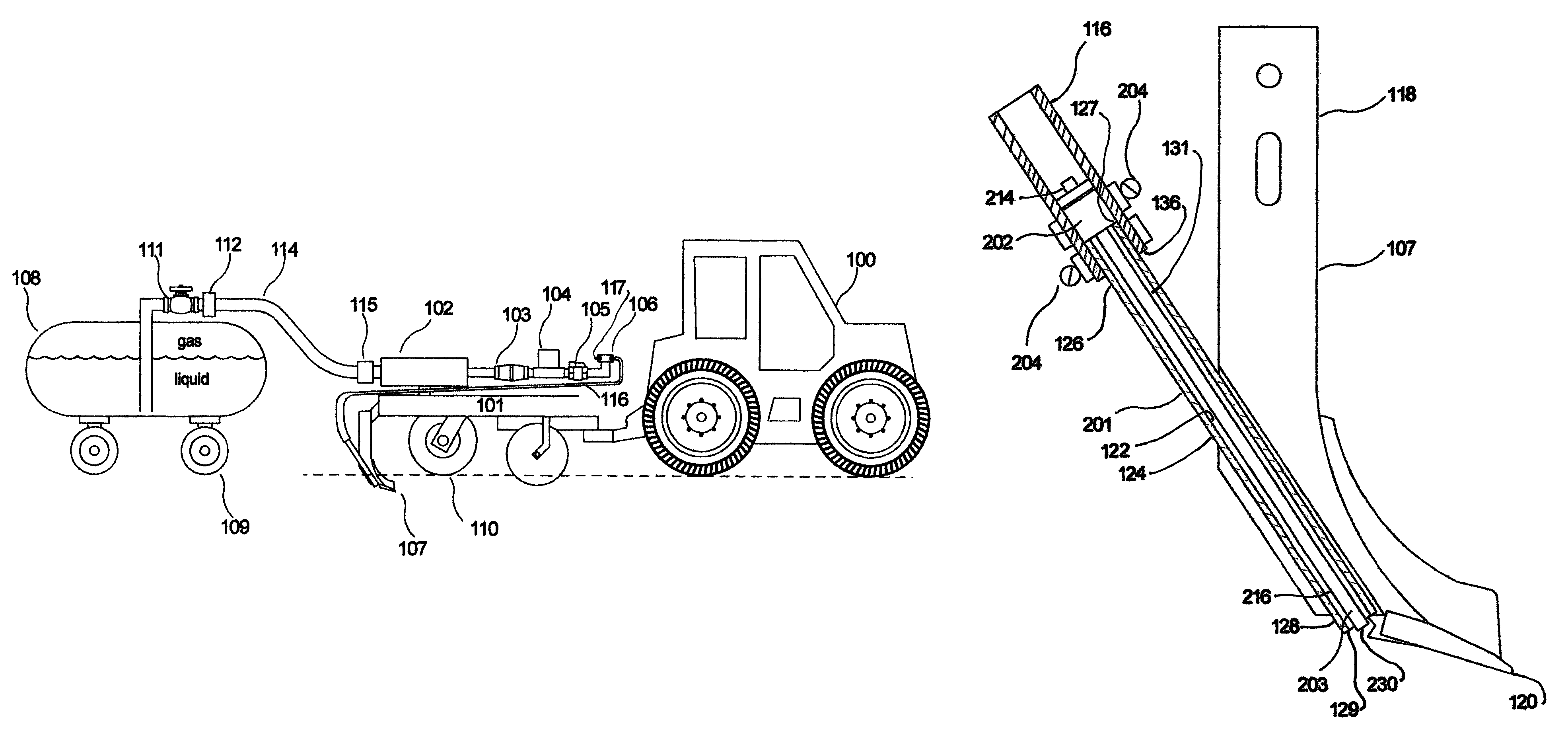

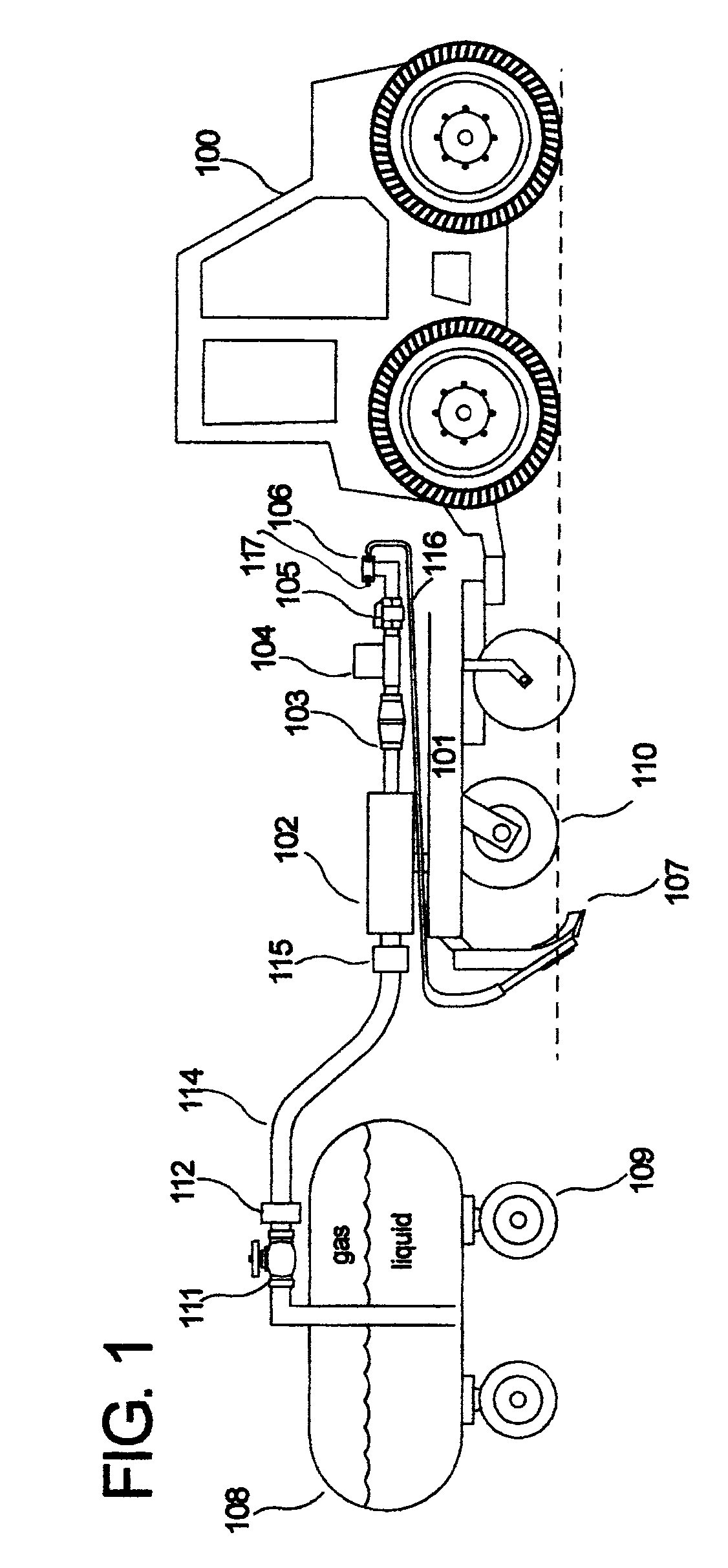

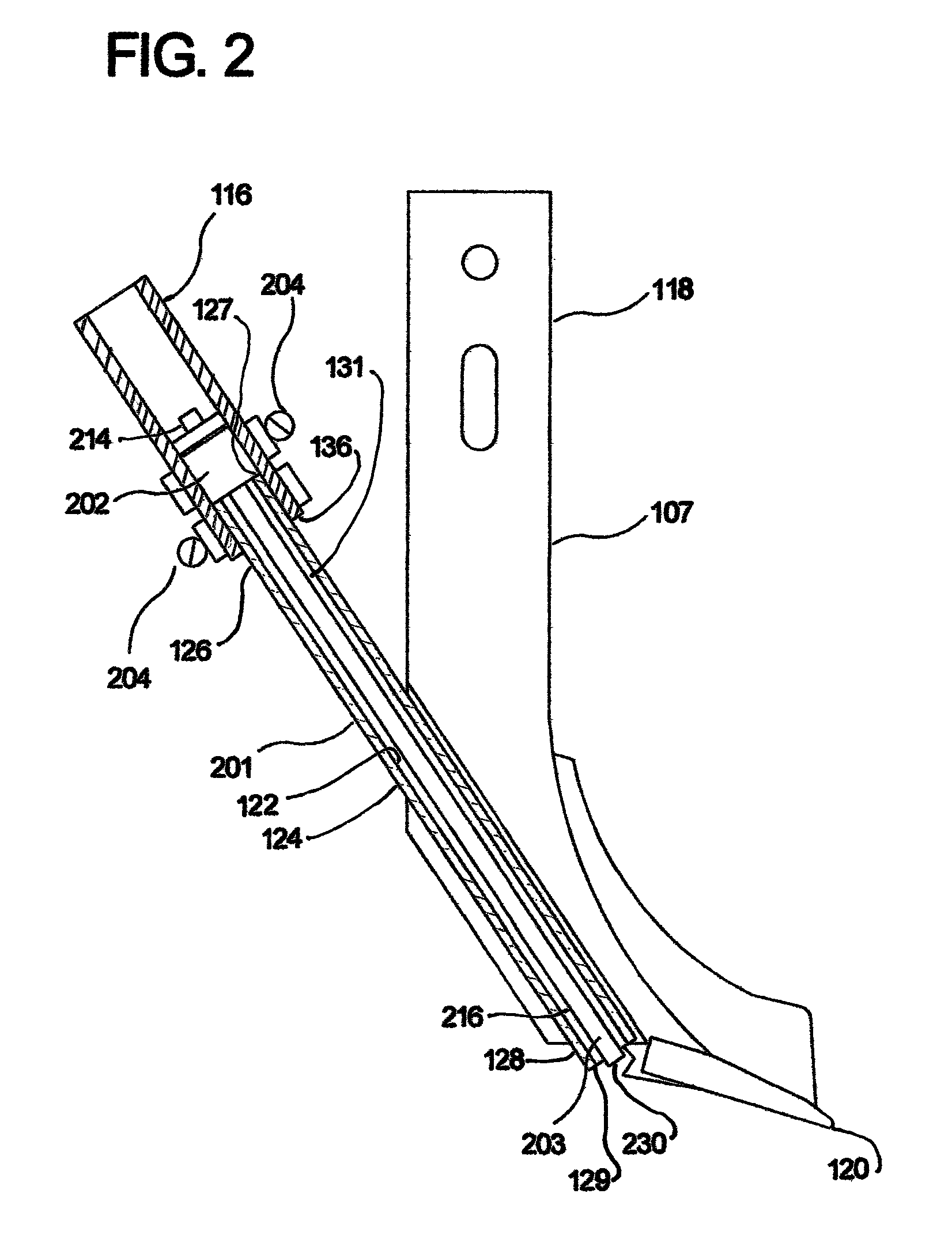

Apparatus for prevention of freezing of soil and crop residue to knife applying liquid anhydrous ammonia to the ground

InactiveUS7523709B1Reduce heat transferLow thermal conductivityPlantingLiquid fertiliser distributionCrop residueEngineering

A plastic discharge tube extends through a swaged cap bore through a metal swaged cap. A conical cap portion of the metal swaged cap is pressed into a retainer ring passage through a metal retainer ring. A swage surface in the retainer ring passage swages the conical portion of the metal swaged cap thereby fixing the position of the plastic discharge tube in the swaged cap bore and locking the swaged cap in the retainer ring passage. The plastic discharge tube is inserted into a steel injection tube fixed to a soil cutting knife. A ring bottom positioning surface contacts and injection tube upper end of the injection tube. A delivery hose is telescopically received on a plastic discharge tube retainer assembly and the steel injection tube. Hose clamps clamp the delivery hose to the retainer assembly and the injection tube.

Owner:360 YIELD CENT

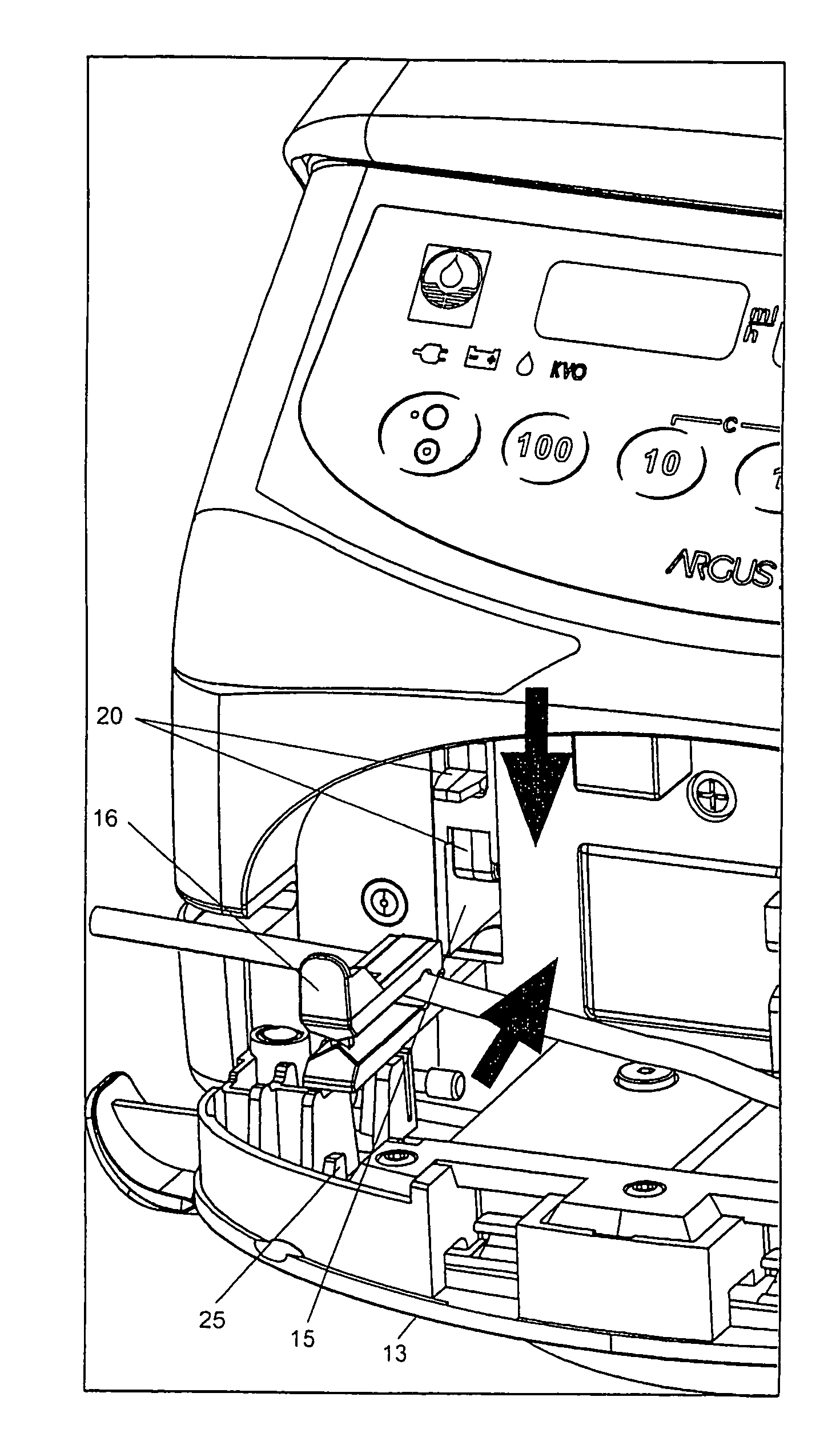

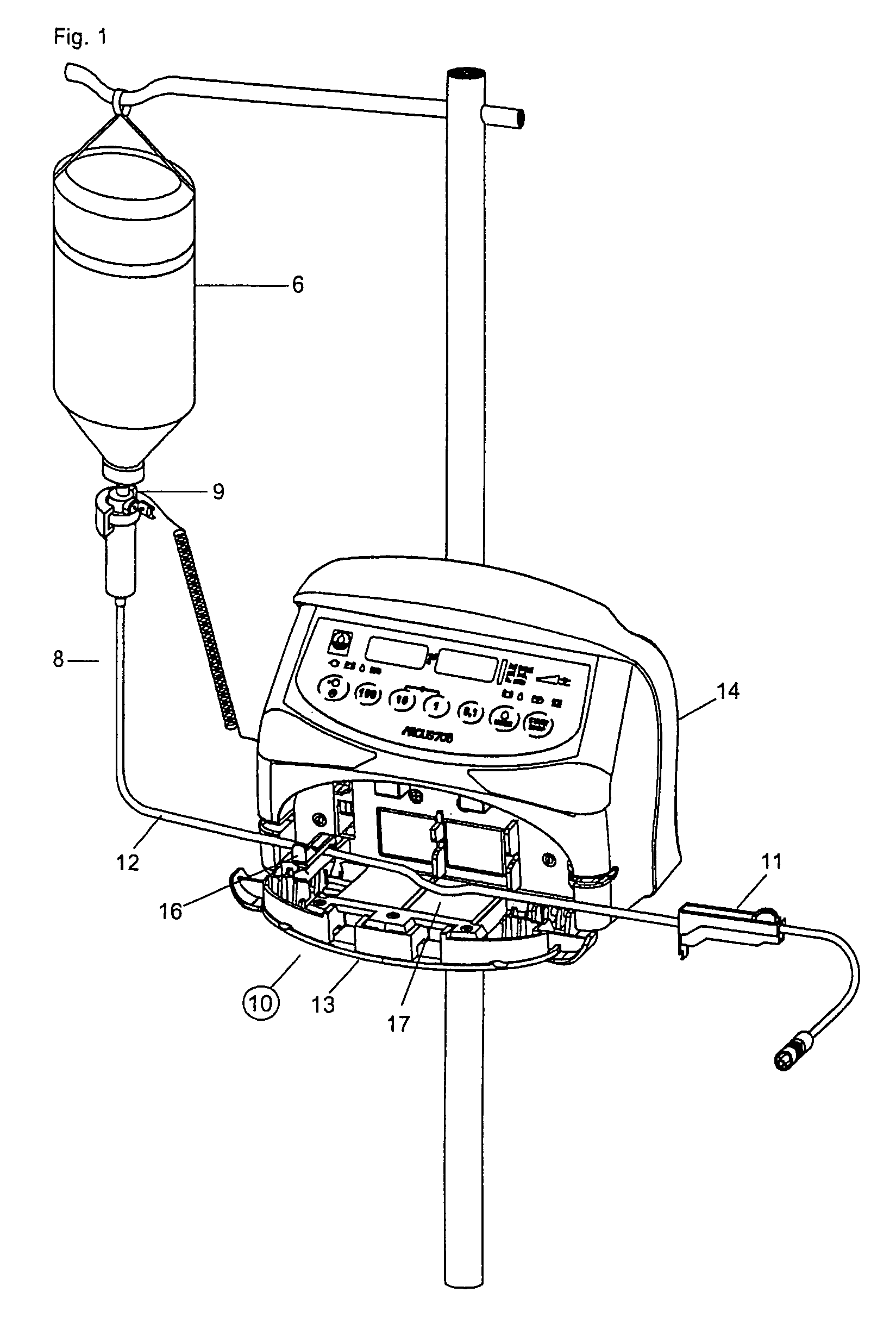

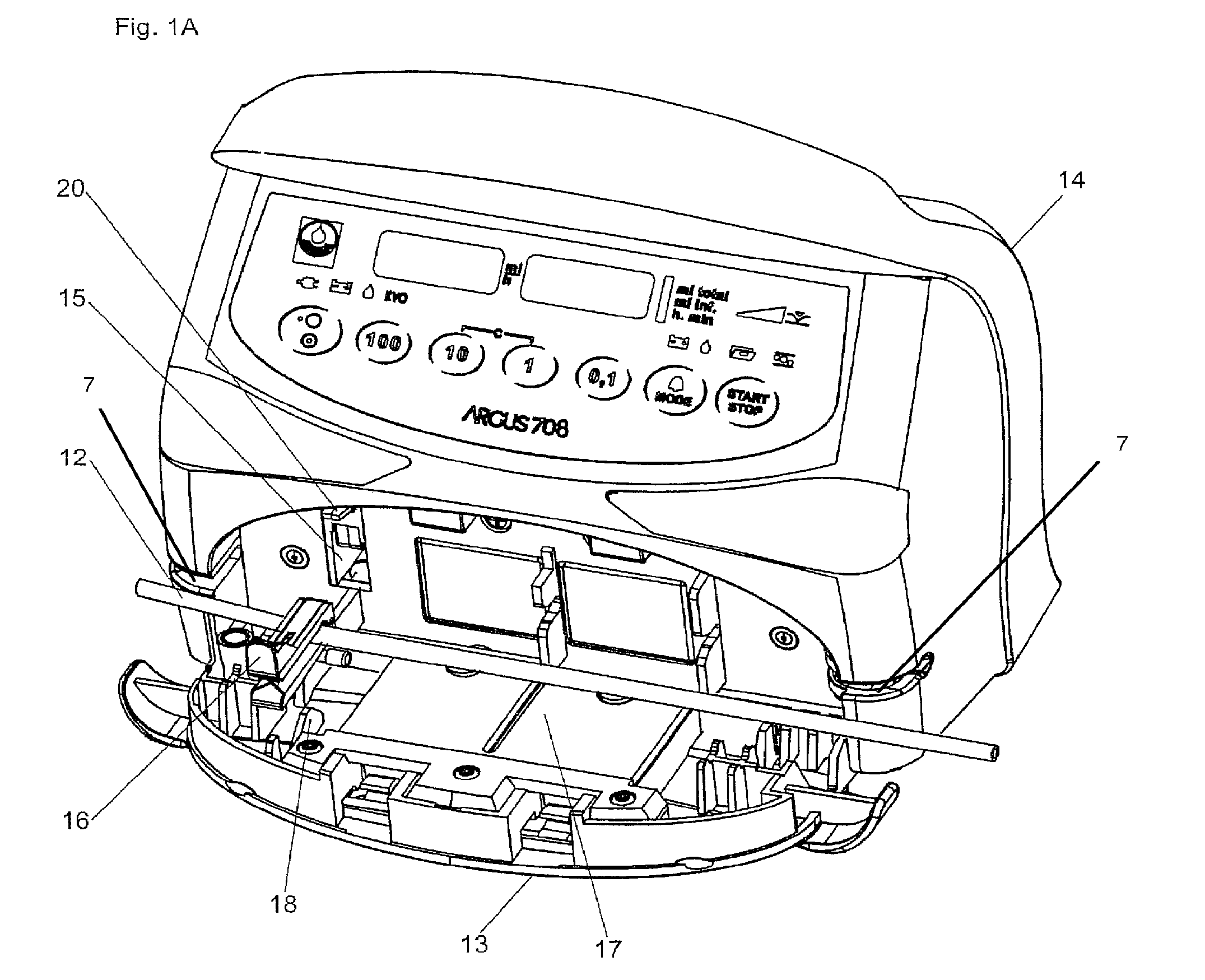

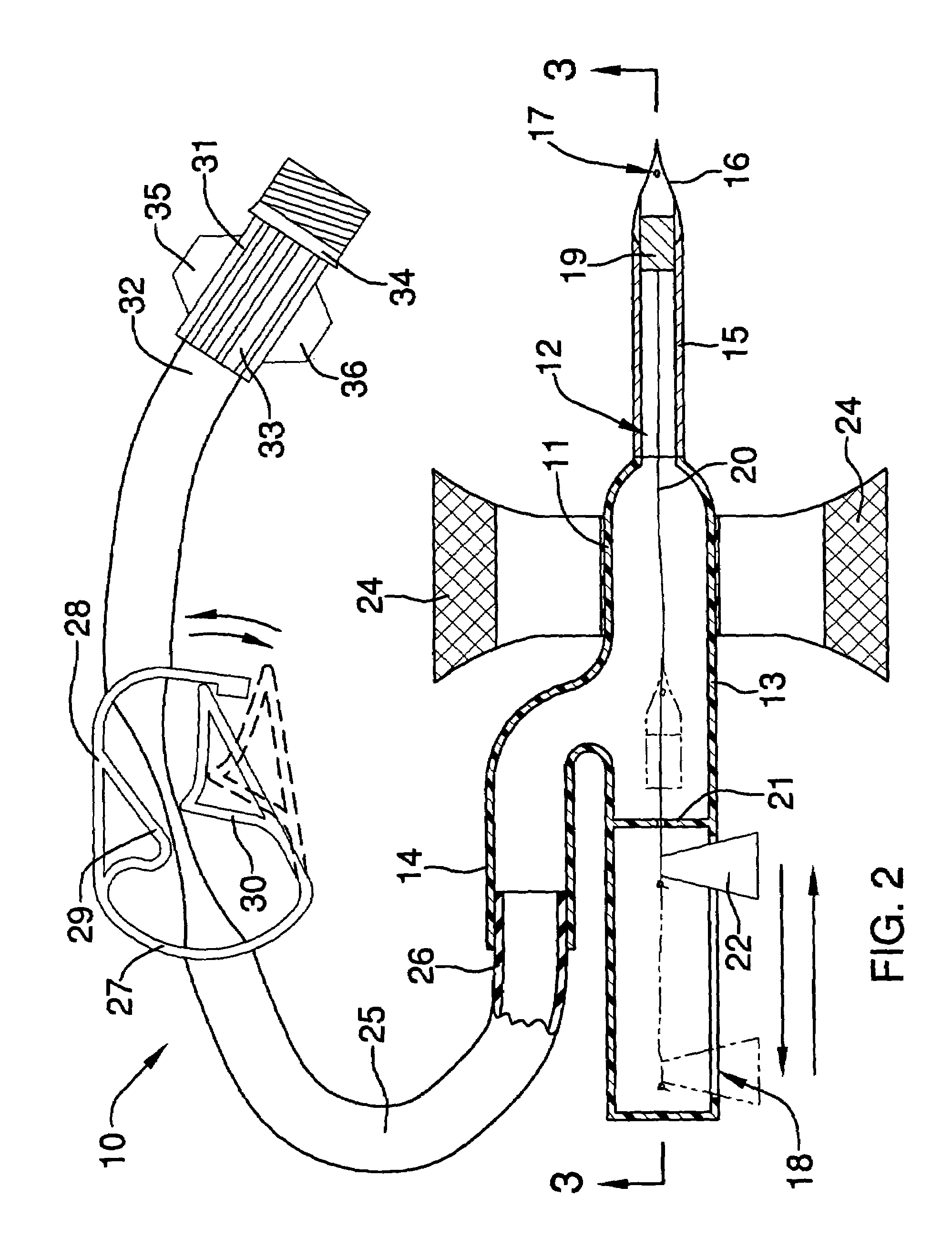

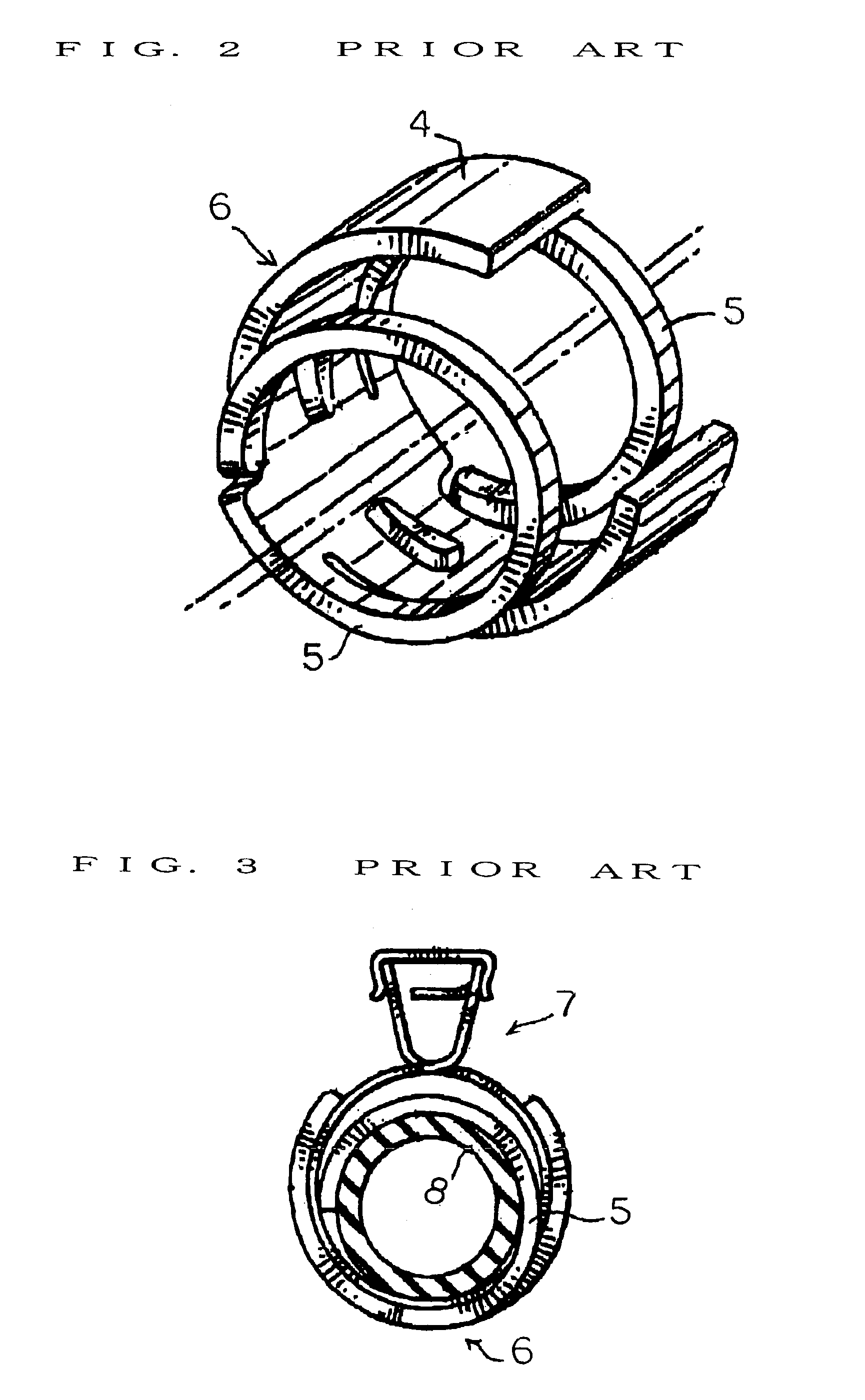

Arrangement for the coupling of an intravenous tube with infusion pump

The invention concerns an arrangement to couple an intravenous hose having a roller clamp with an infusion pump. A hose clamp has clamping surfaces in the form of legs which can move relative one another about a hinge, the legs being enveloped on their outside by a biased clamping spring, and the device is formed by an expander rib that is fastened on the inside of the door and can be brought into engagement with the legs of the hose clamp so to produce the open position after closing the door to expand the legs. The housing has a receiver, into which the hose clamp can be snapped, and that a locking device is present in the housing that prevents the closing of the door if the hose clamp is not inserted into the receiver and permits the closing of the door when the hose clamp is fully inserted.

Owner:CODAN HOLDING GMBH

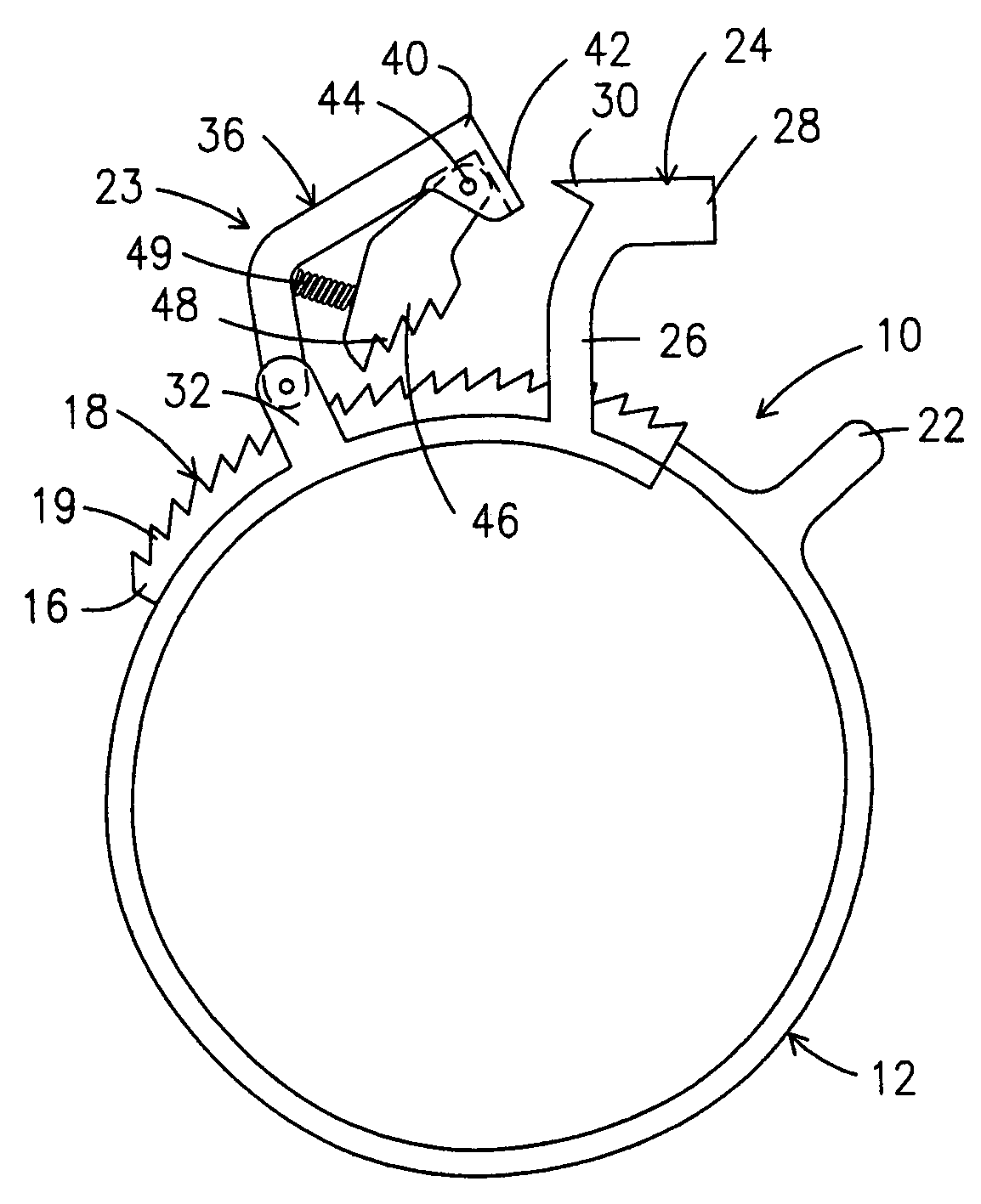

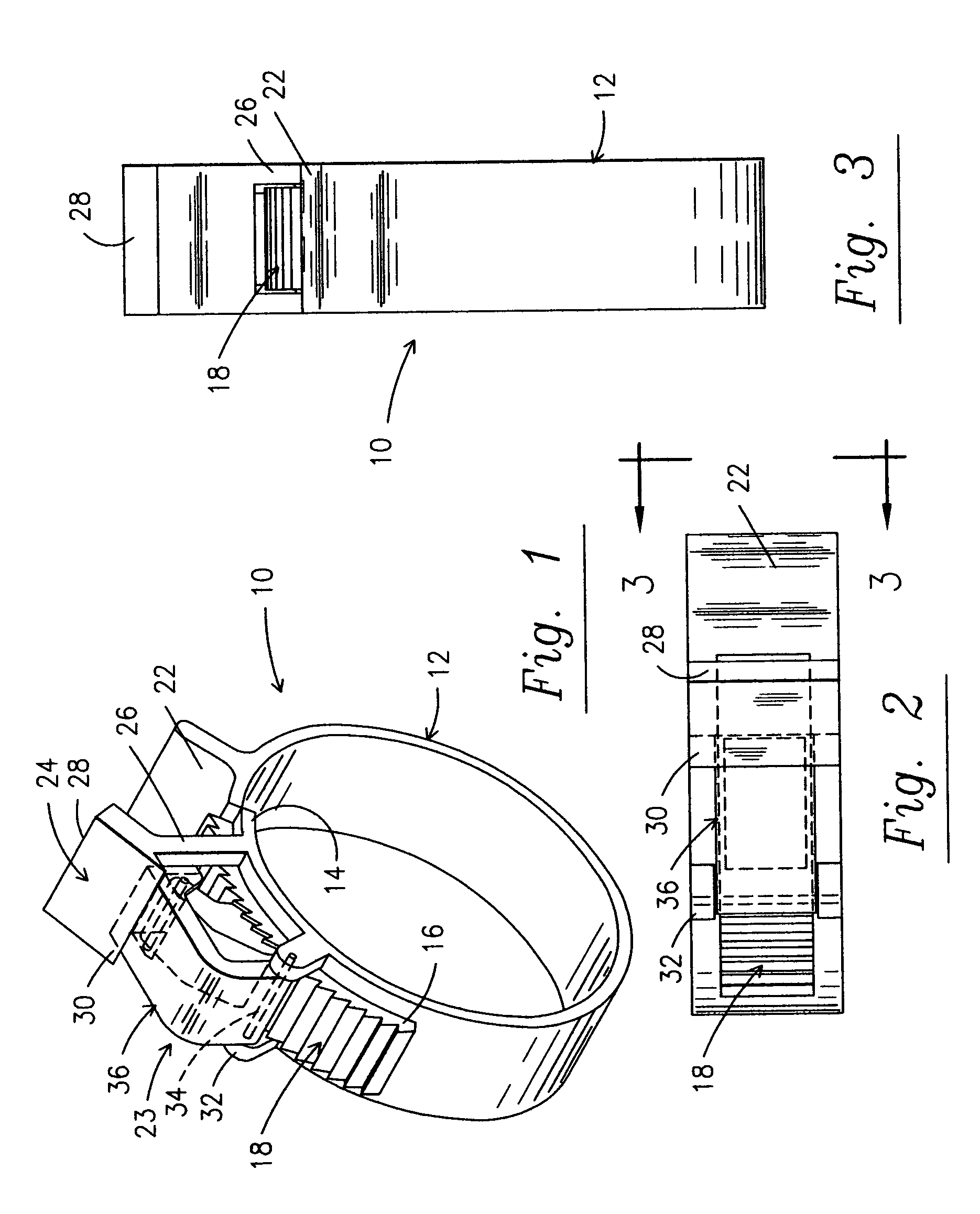

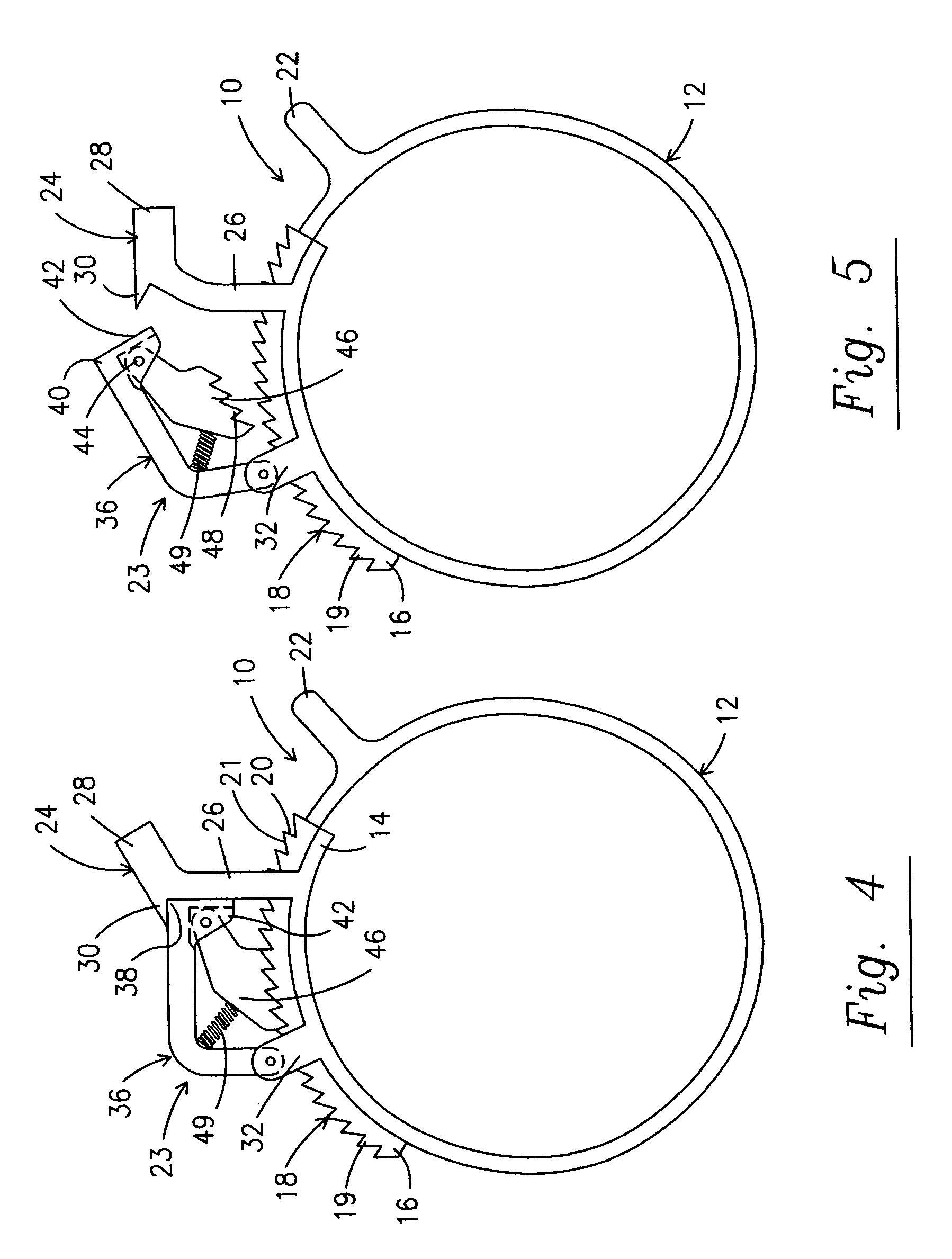

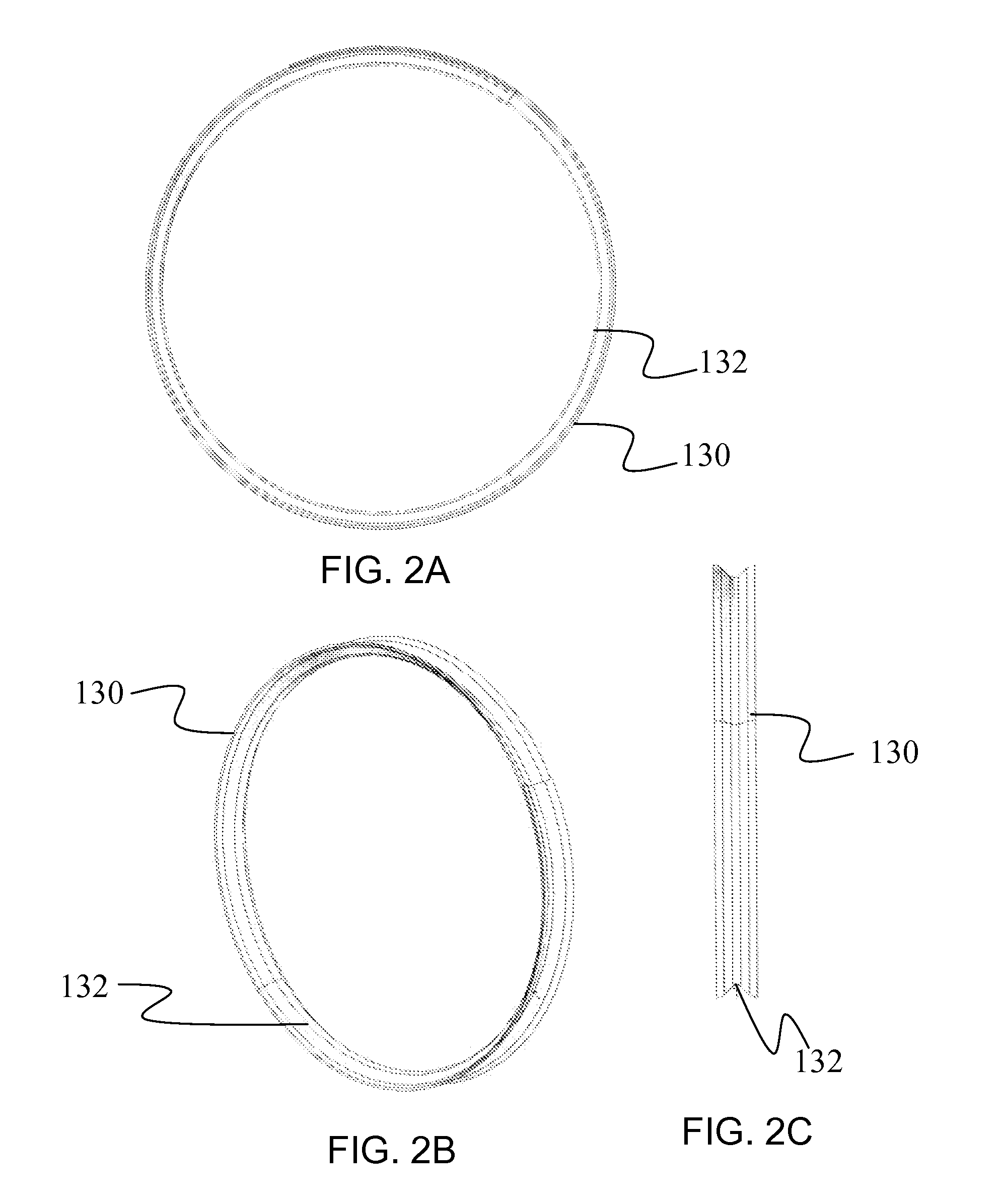

Hose clamp

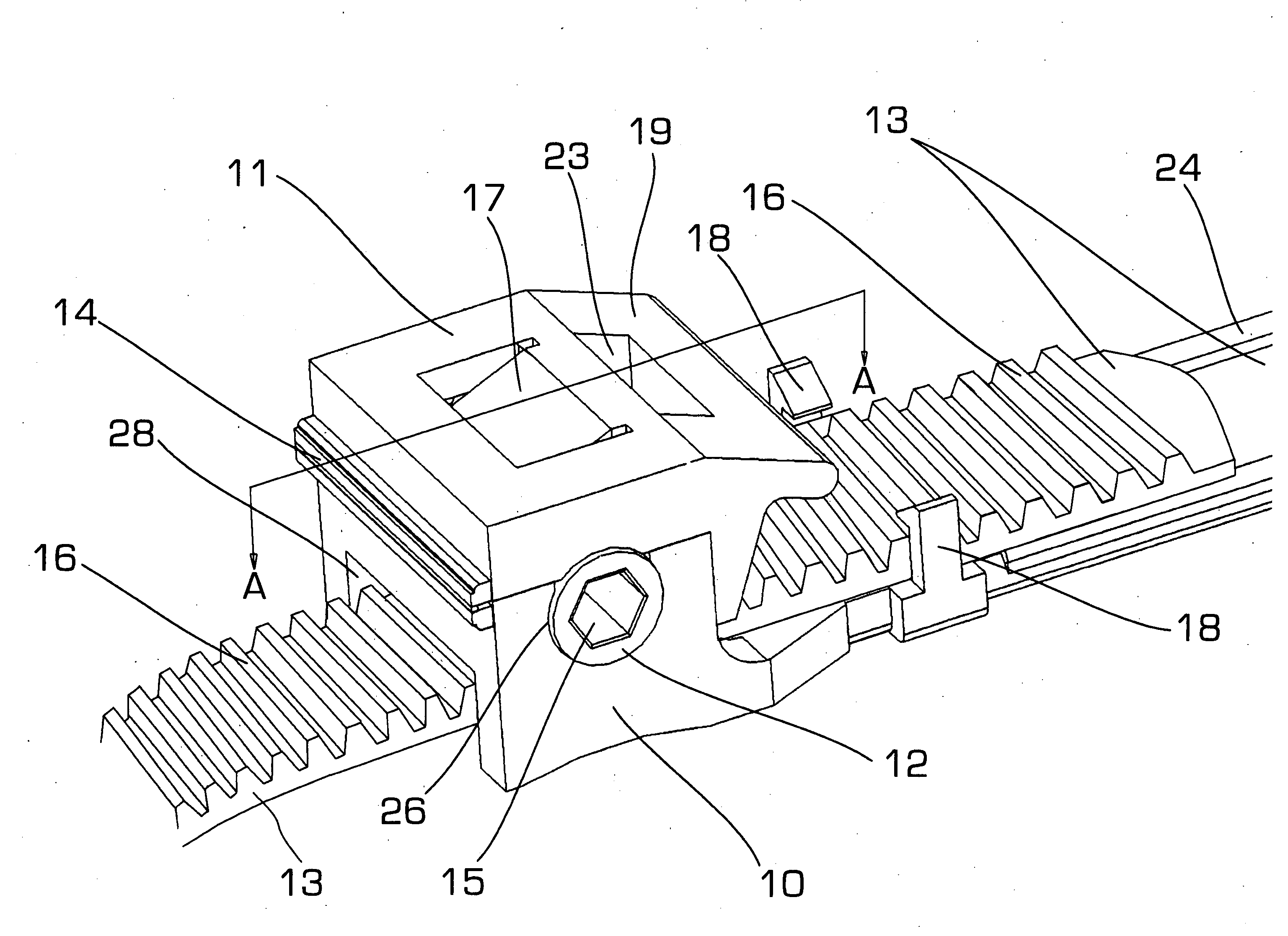

A hose clamp with overlapping ends, with the outer overlapping end having a toothed portion on the outer surface thereof and the overlapping end of the inner overlapping end having a locking arrangement thereon including a pivotable locking member with toothed projections thereon cooperable with the toothed portion on the outer end and the outer end has a graspable projection for tightening the clamp.

Owner:CHAREST SCOTT R

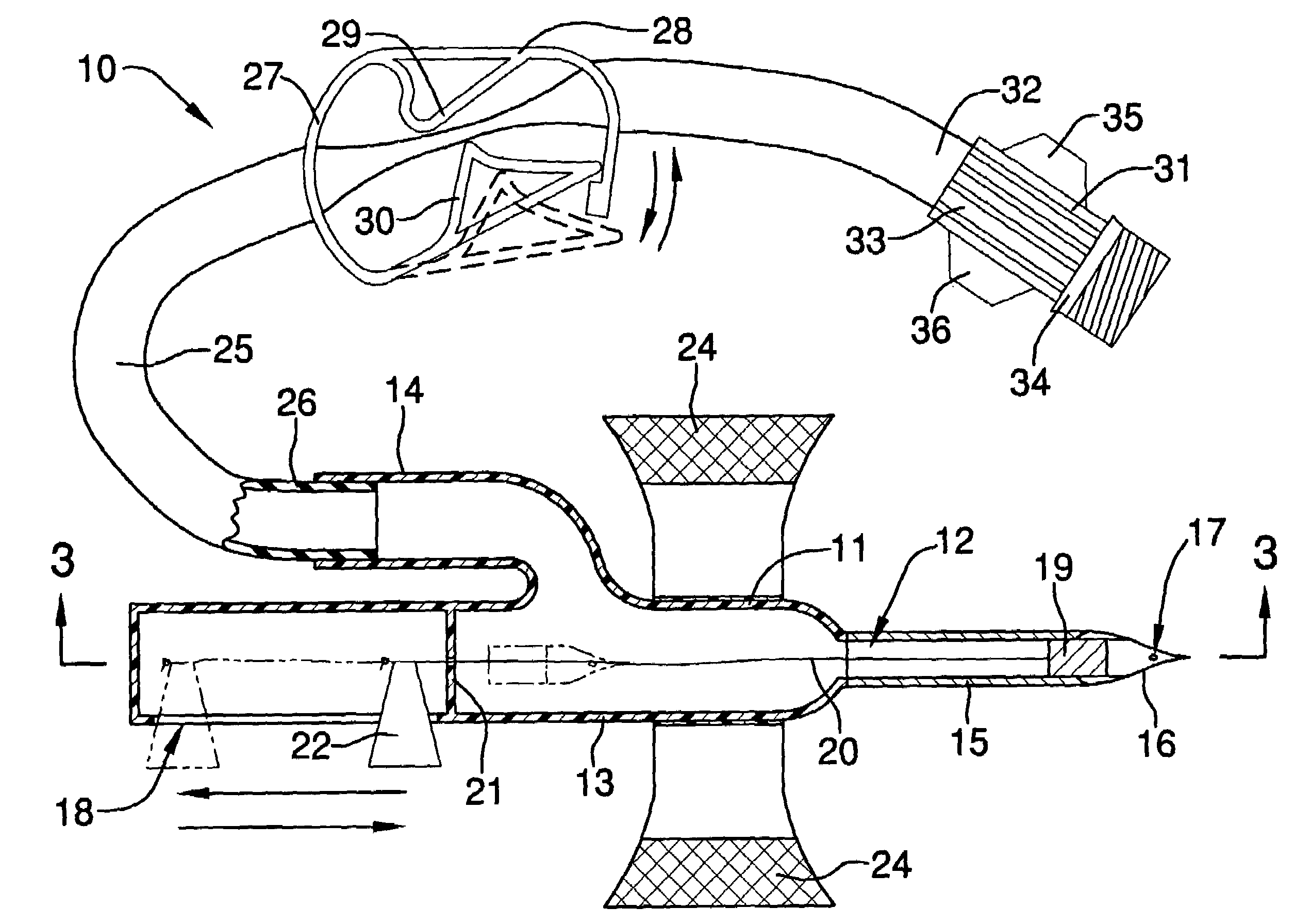

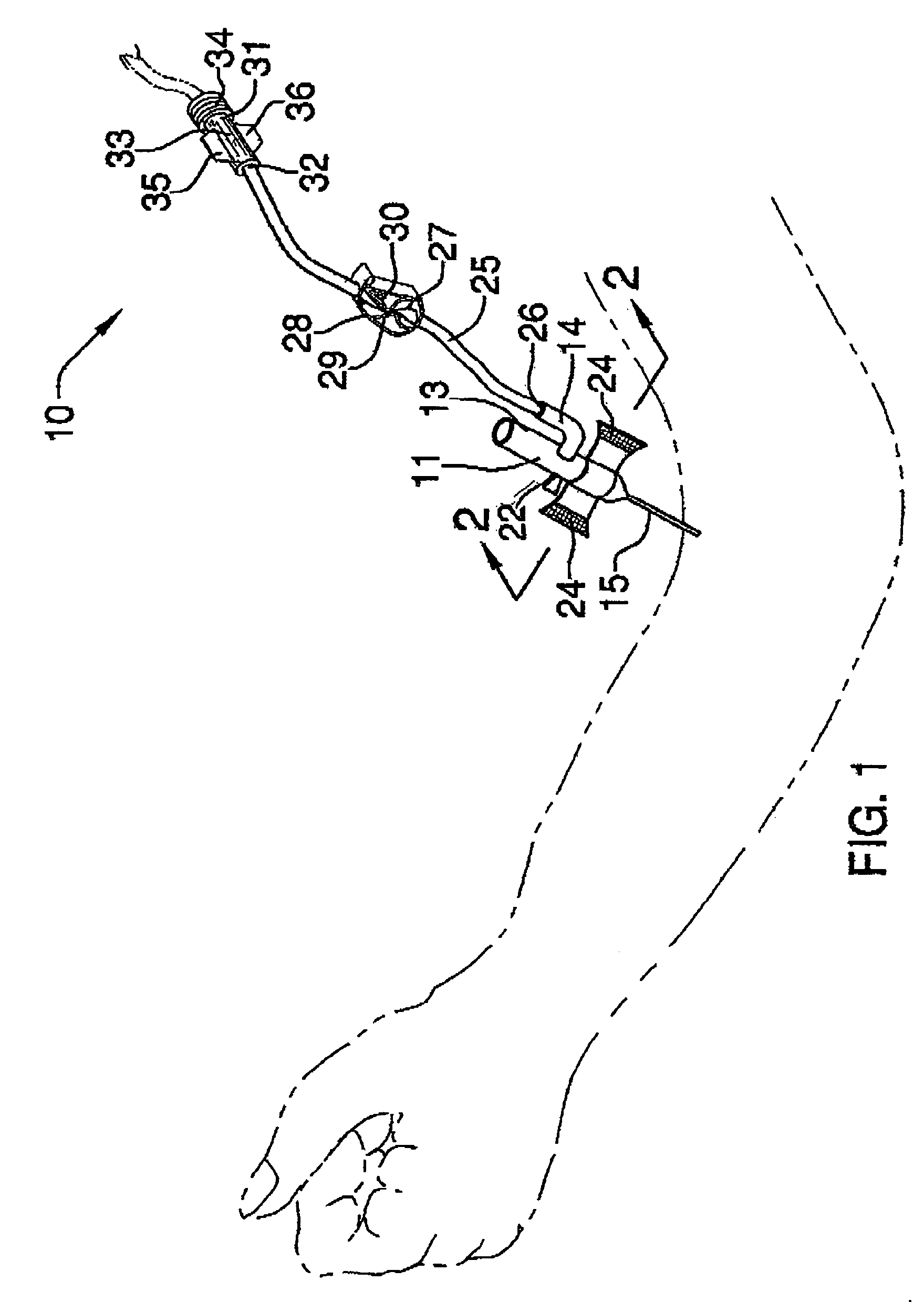

Dialysis procedure catheter

InactiveUS7060060B1Easy to useAccurately and facilitating insertionCatheterInfusion needlesGuide tubeDialysis patients

A dialysis procedure catheter for accurately facilitating insertion of a needle into a dialysis patient's body. The dialysis procedure catheter includes a tubular member having a bore being disposed therethrough, and also having an enlarged main portion and a branch portion, and further having a needle; and also includes a plug assembly including a plug member being removably disposed in the bore of the needle; and further includes a handle being attached to the enlarged main portion of the tubular member; and also includes a hose having a first end being attached to the branch portion; and further includes a hose clamp for crimping the hose; and also includes a hose connector being attached to a second end of the hose for connecting to a dialysis machine.

Owner:SIMPSON VICKI J +1

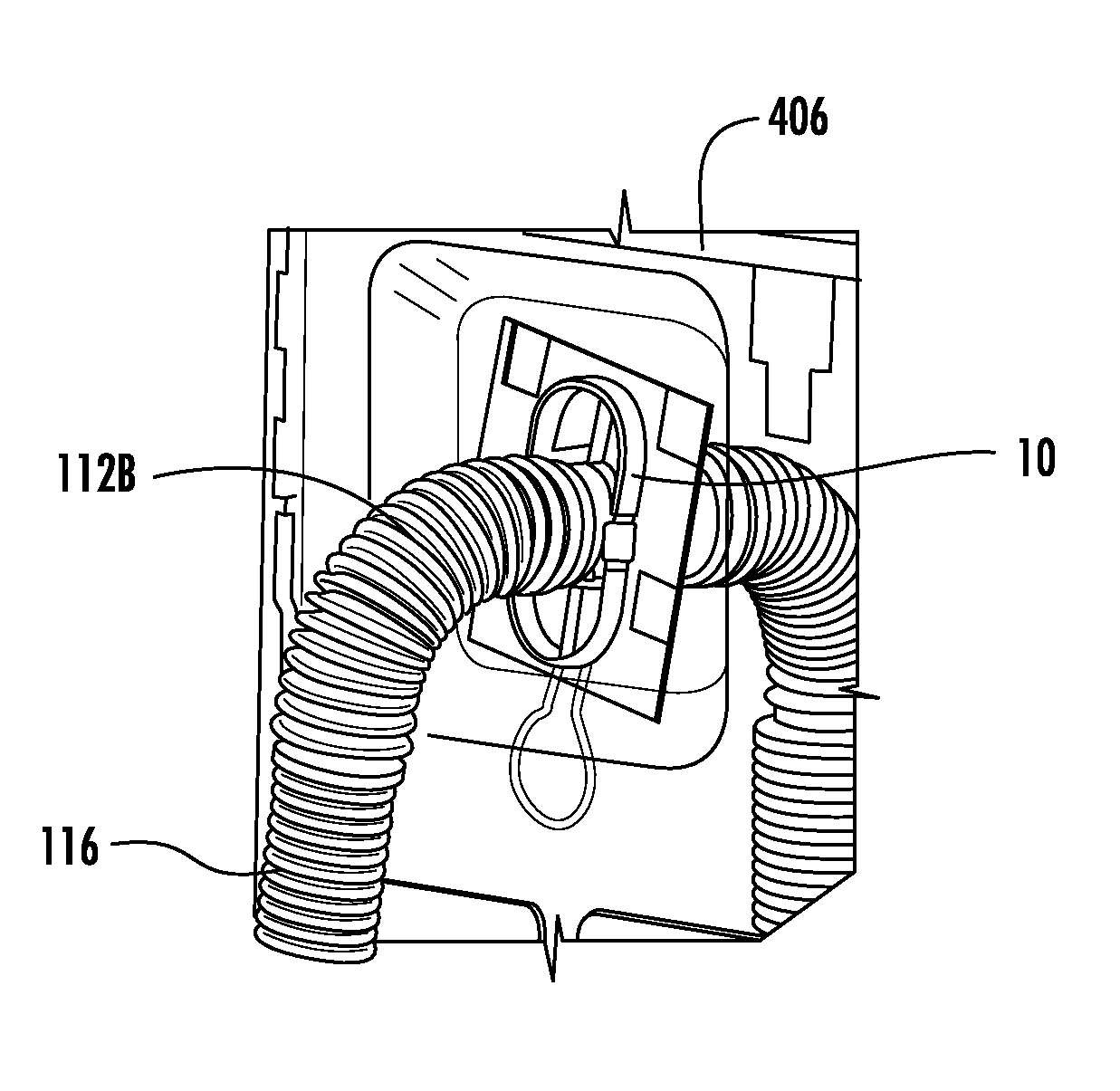

Drain hose clip for a washer

InactiveUS20120255330A1Precise positioningReduce and prevent damageOther washing machinesBranching pipesEngineeringHome appliance

A drain hose clip for securing a drain hose to a household appliance, and a household appliance having the drain hose clip and drain hose. The drain hose clip includes a body configured to be coupled to the drain hose and to secure the drain hose to the household appliance, and an orientation control feature on the body that engages a corresponding orientation control feature on the drain hose to maintain a fixed position of the drain hose with respect to the body of the drain hose clip.

Owner:BSH HOME APPLIANCES CORP

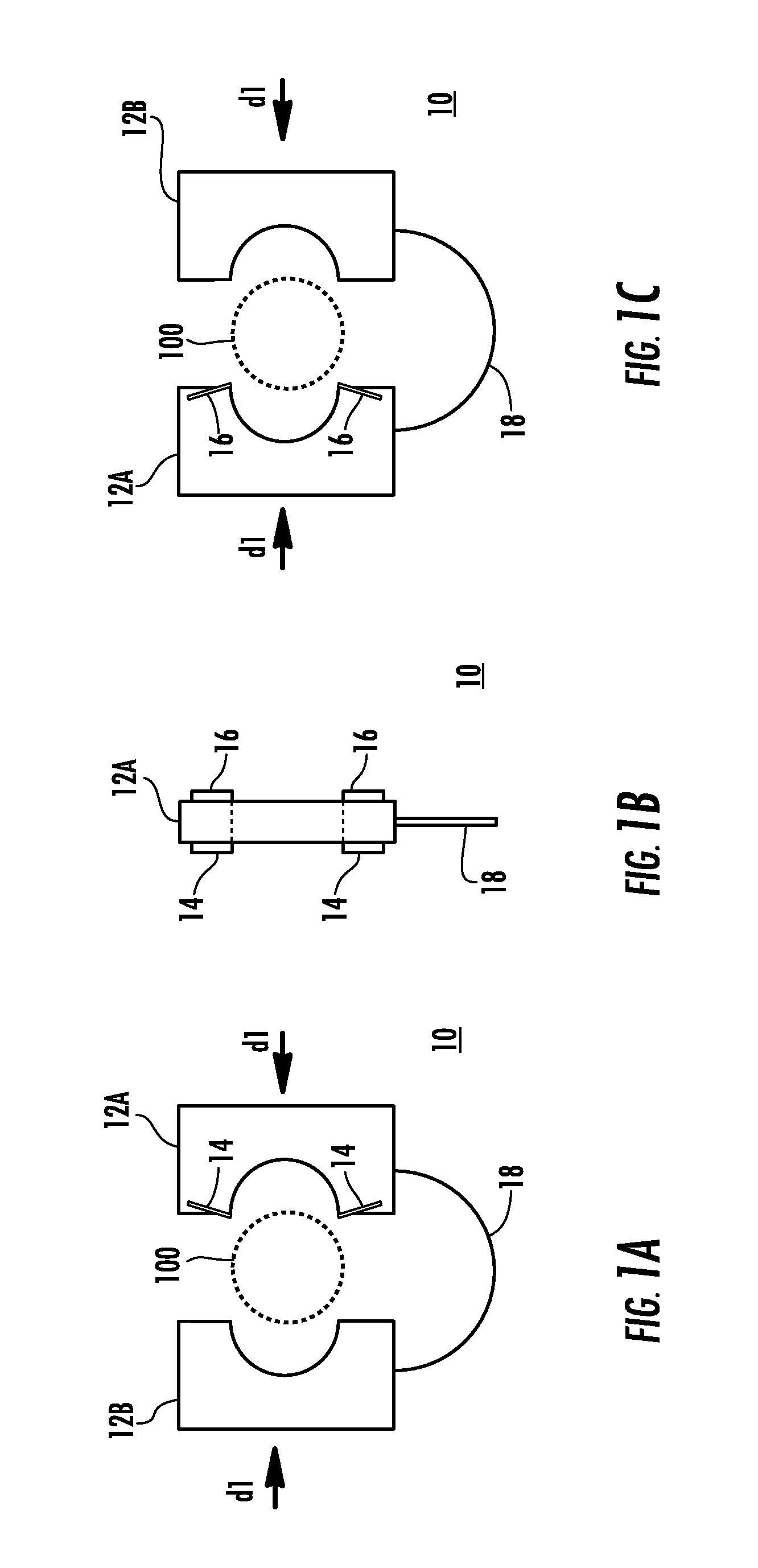

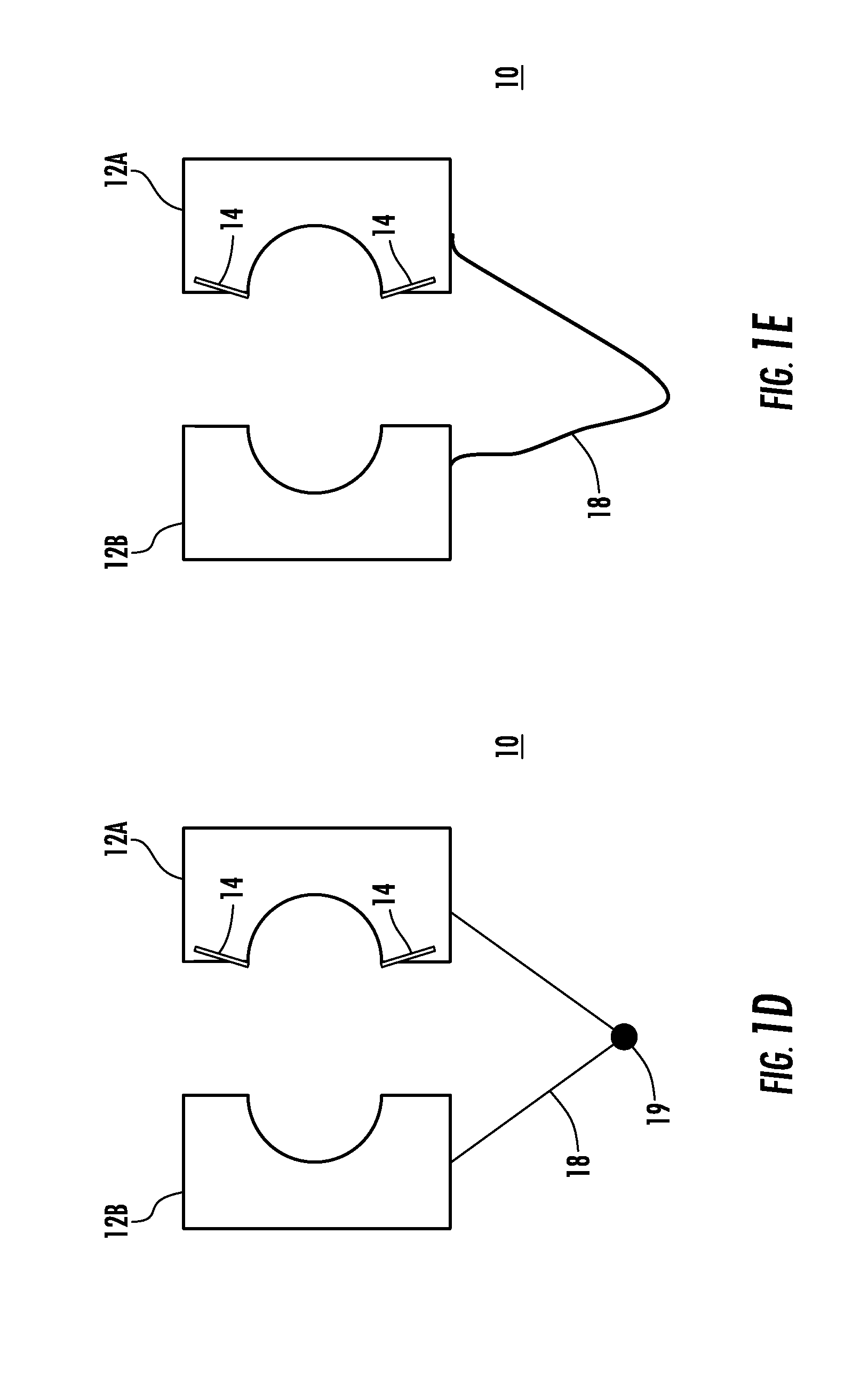

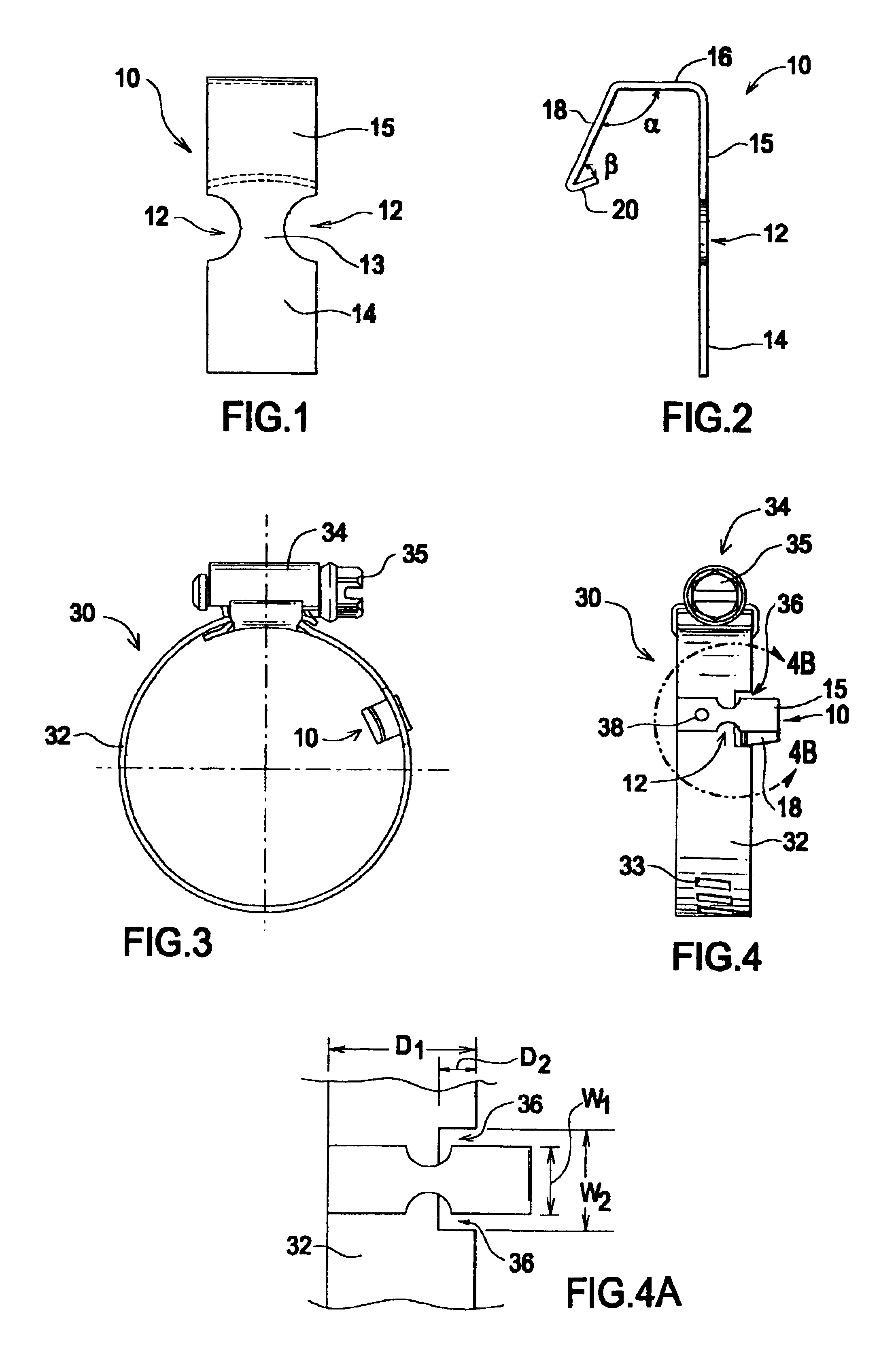

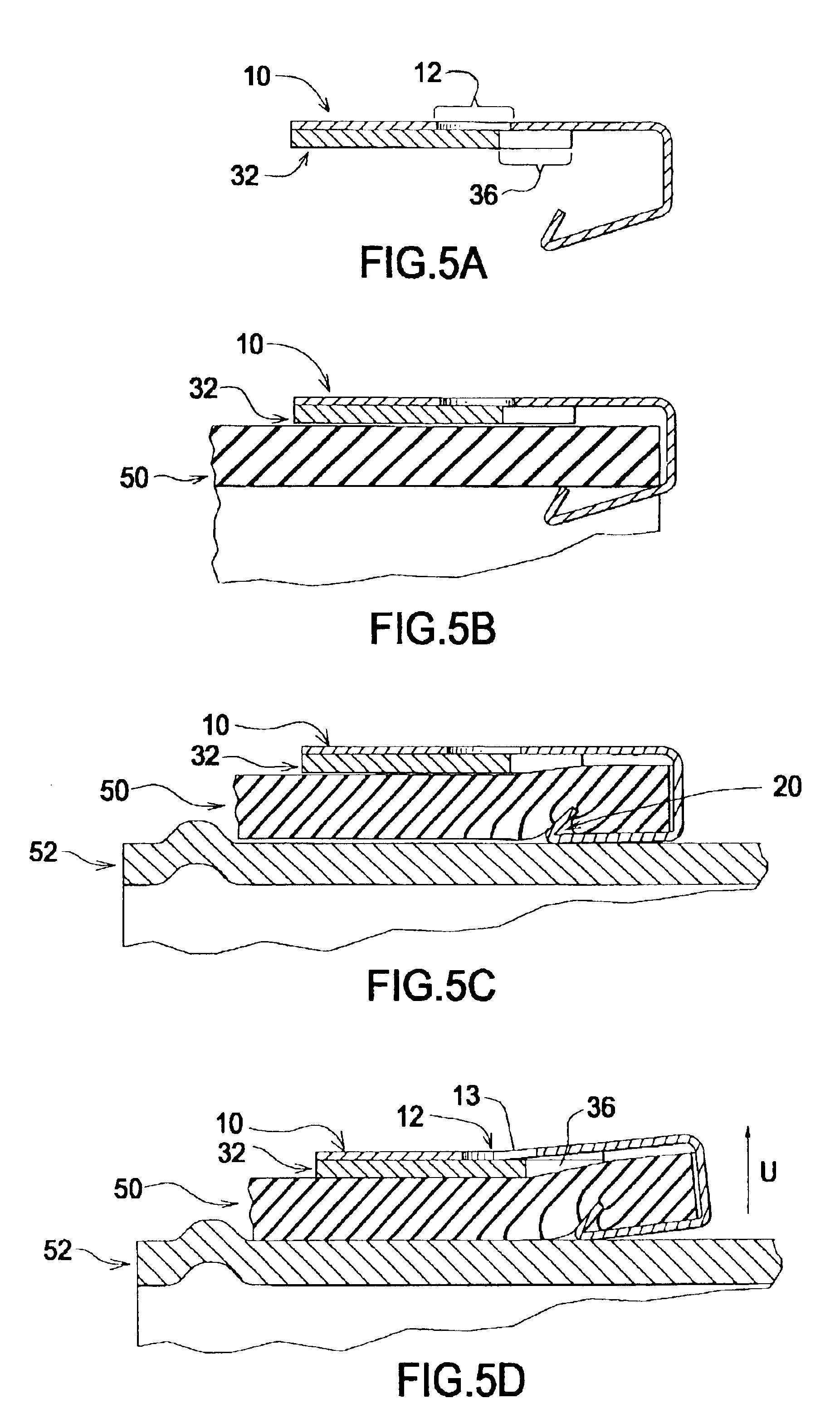

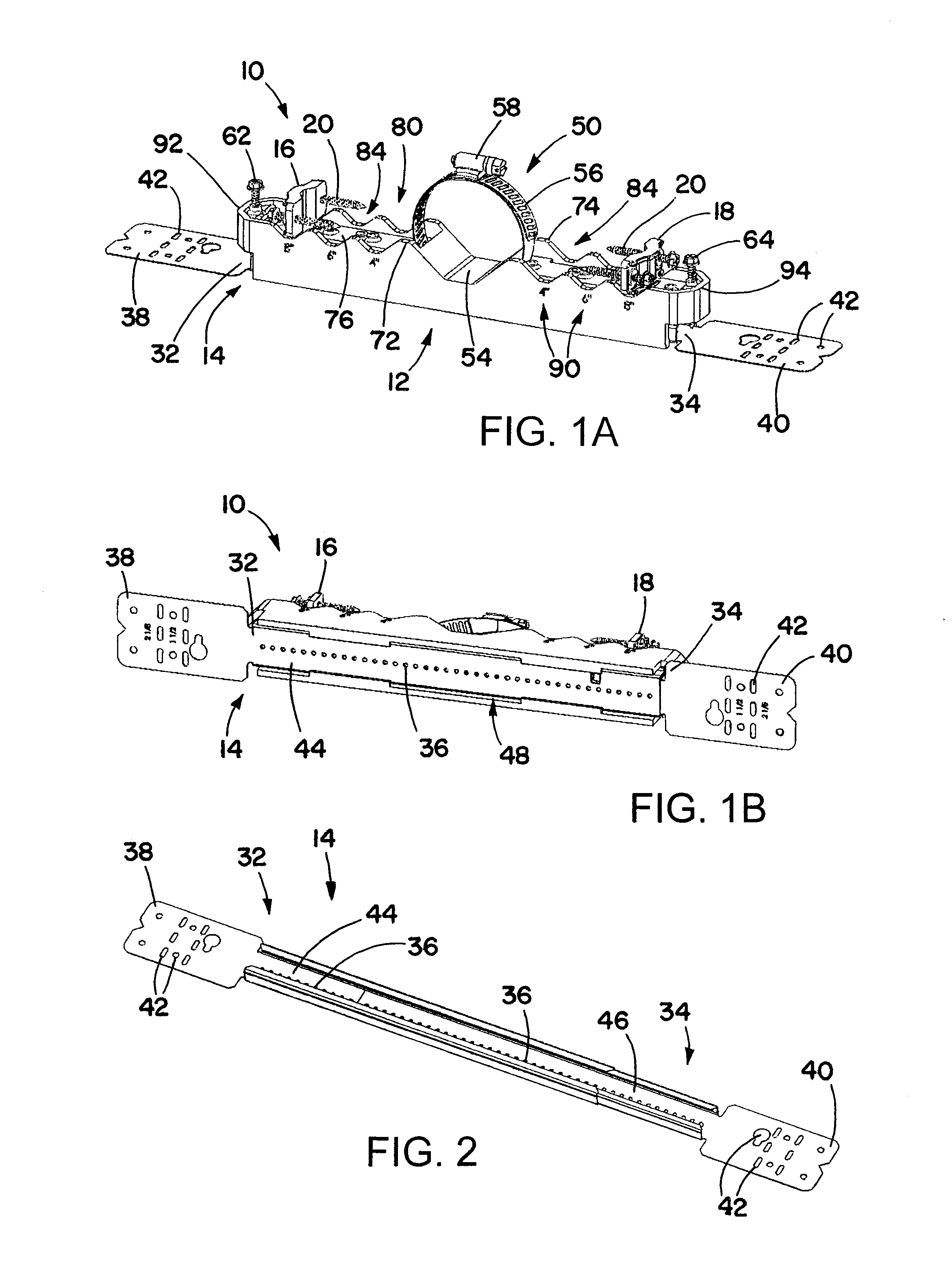

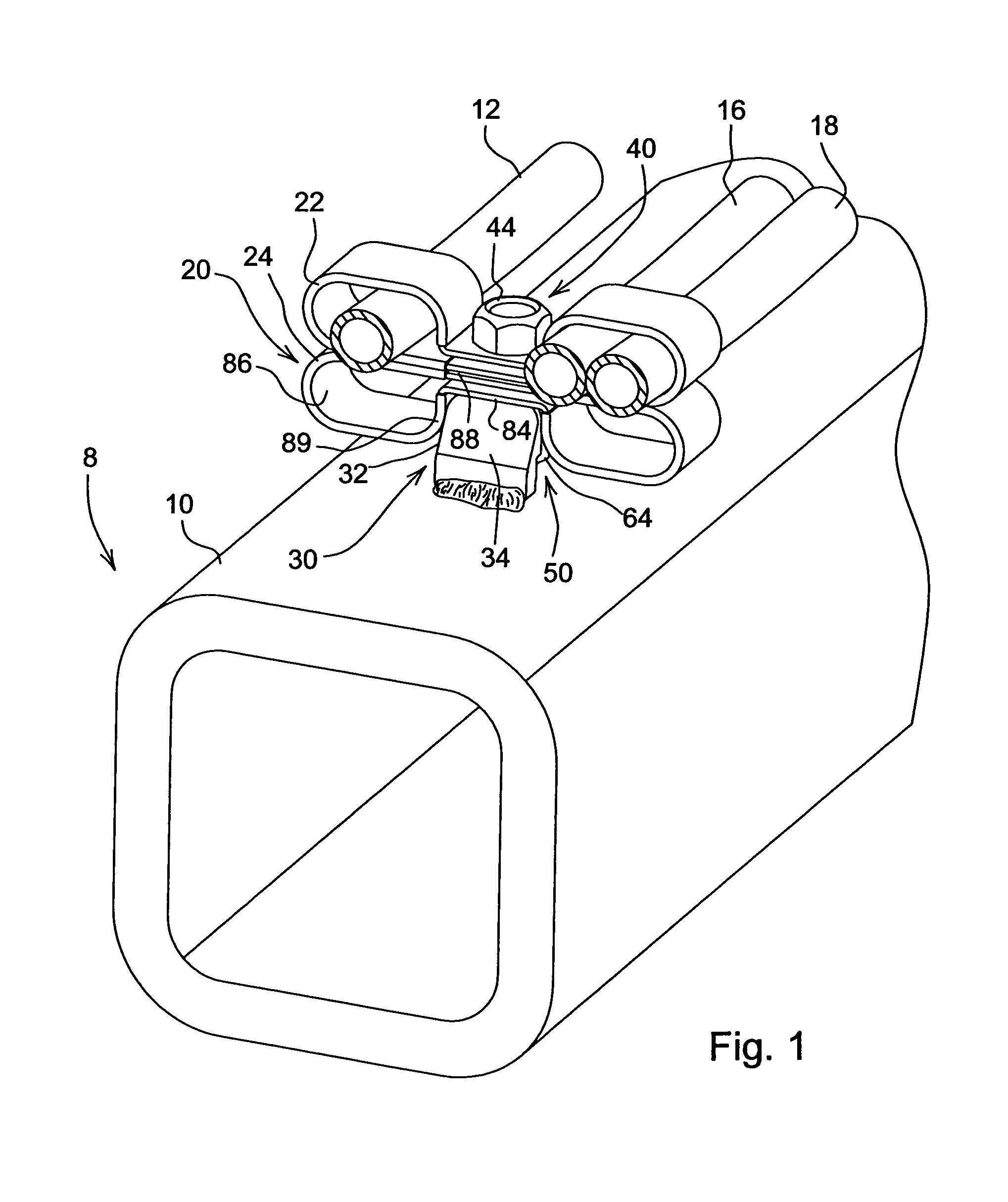

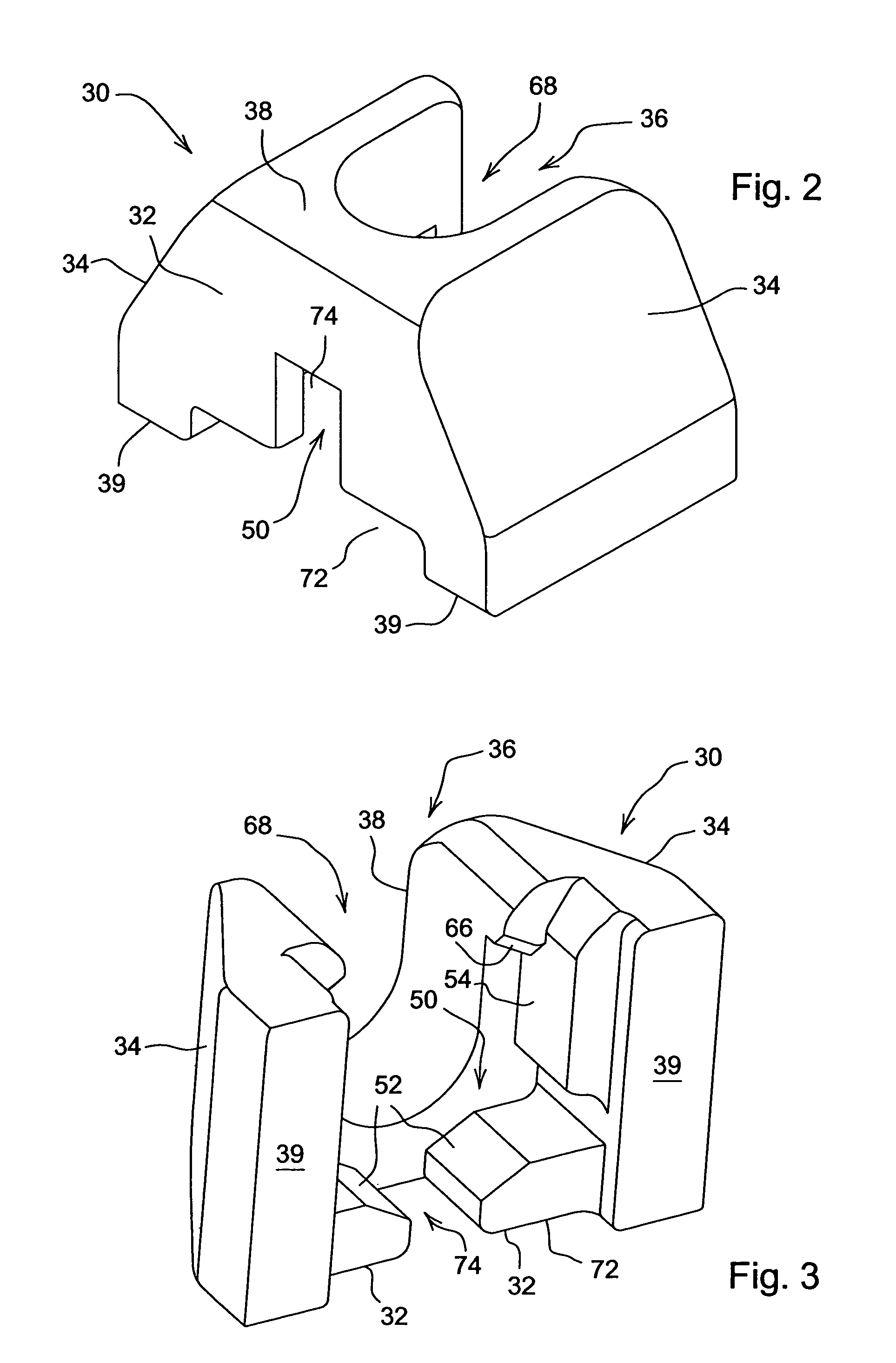

Locator tab and associated hose clamp

An improved locator and hose clamp configuration that is able to statically position a hose clamp in close proximity to the end of a hose, and resist substantial pull off loads. The improved hose clamp locator comprises a connection portion, a head portion, a deflecting portion having a reduced bending resistance positioned between the connection and head portion, an end portion extending angularly from the head portion, a clip portion extending angularly from the end portion, and a tooth portion disposed to engage an interior surface of a hose extending angularly from the clip portion. Also provided is an improved hose clamp assembly comprising a band provided with a partial aperture, an adjustor disposed to facilitate constriction of the band, and a clamp locator connected to the band and positioned adjacent the partial aperture. Additionally, a method of clamping a hose to a fitting comprising the steps of attaching a clamp locator being disposed to deflect under hose clamp operations to a hose clamp having a band describing a partial aperture, positioning the hose clamp around a hose, forcing the clamp locator to engage the hose, positioning the hose clamp and hose around a fitting, and tightening the hose clamp and allowing the clamp locator to deflect towards the partial aperture described by the hose clamp band.

Owner:EPICOR IND

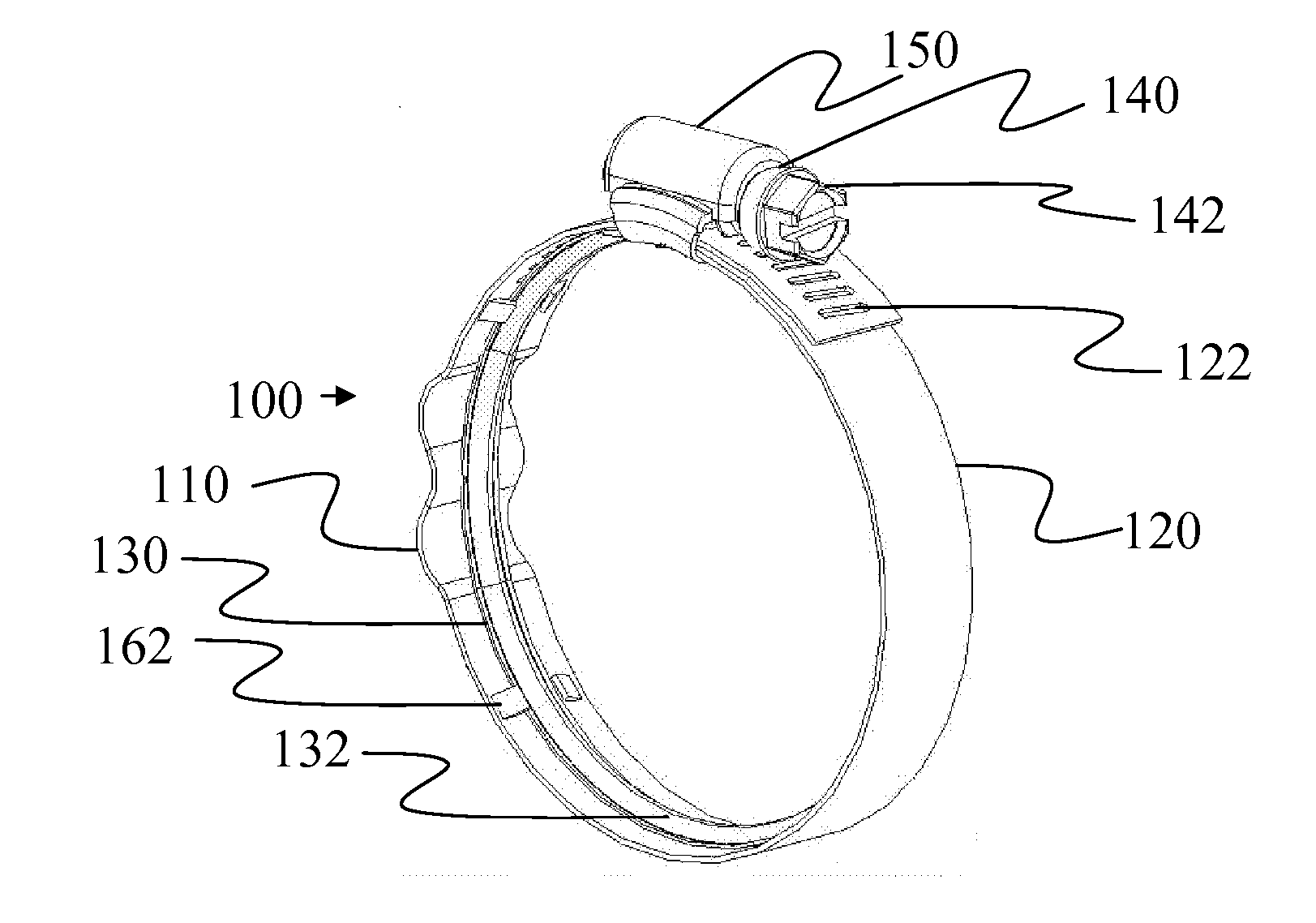

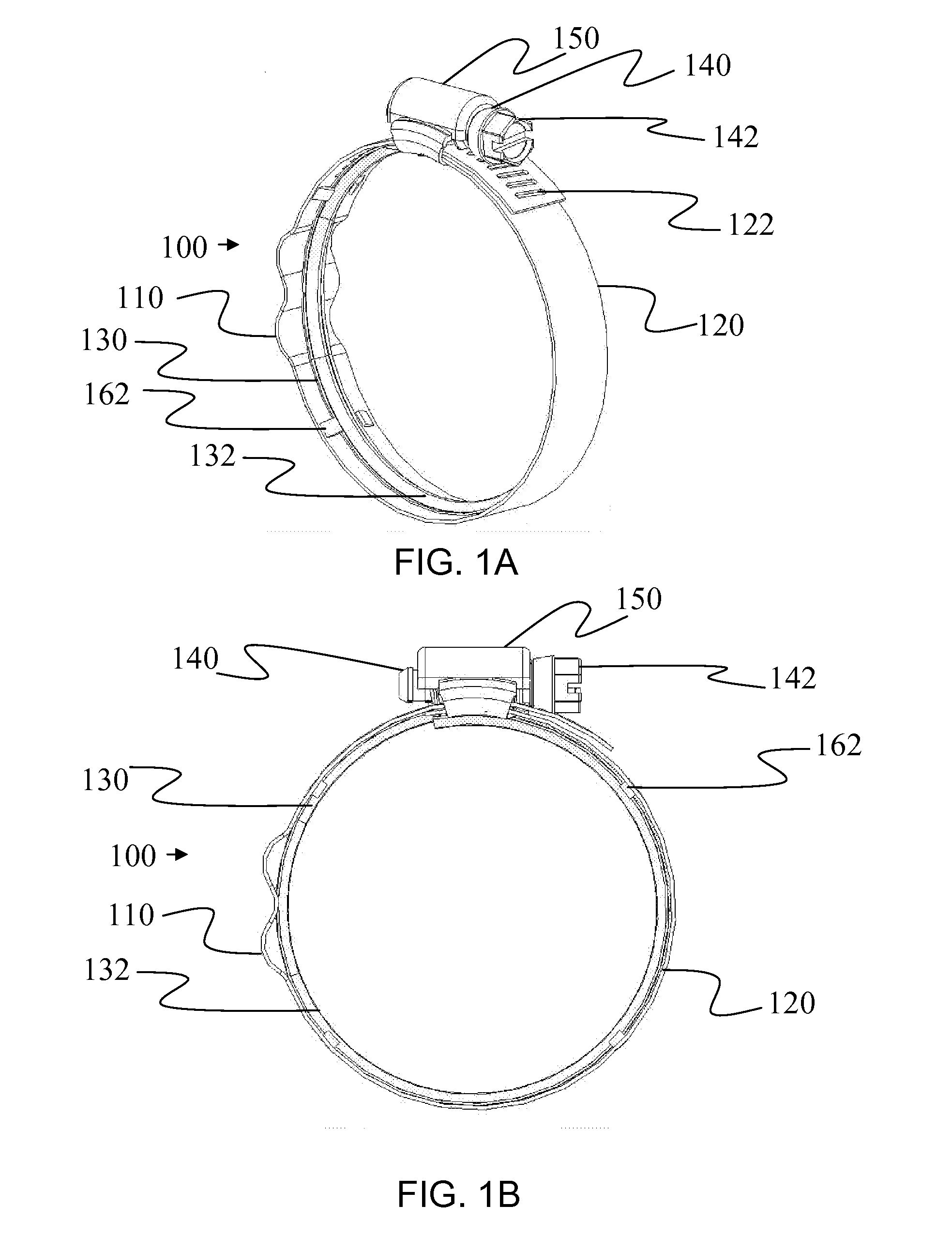

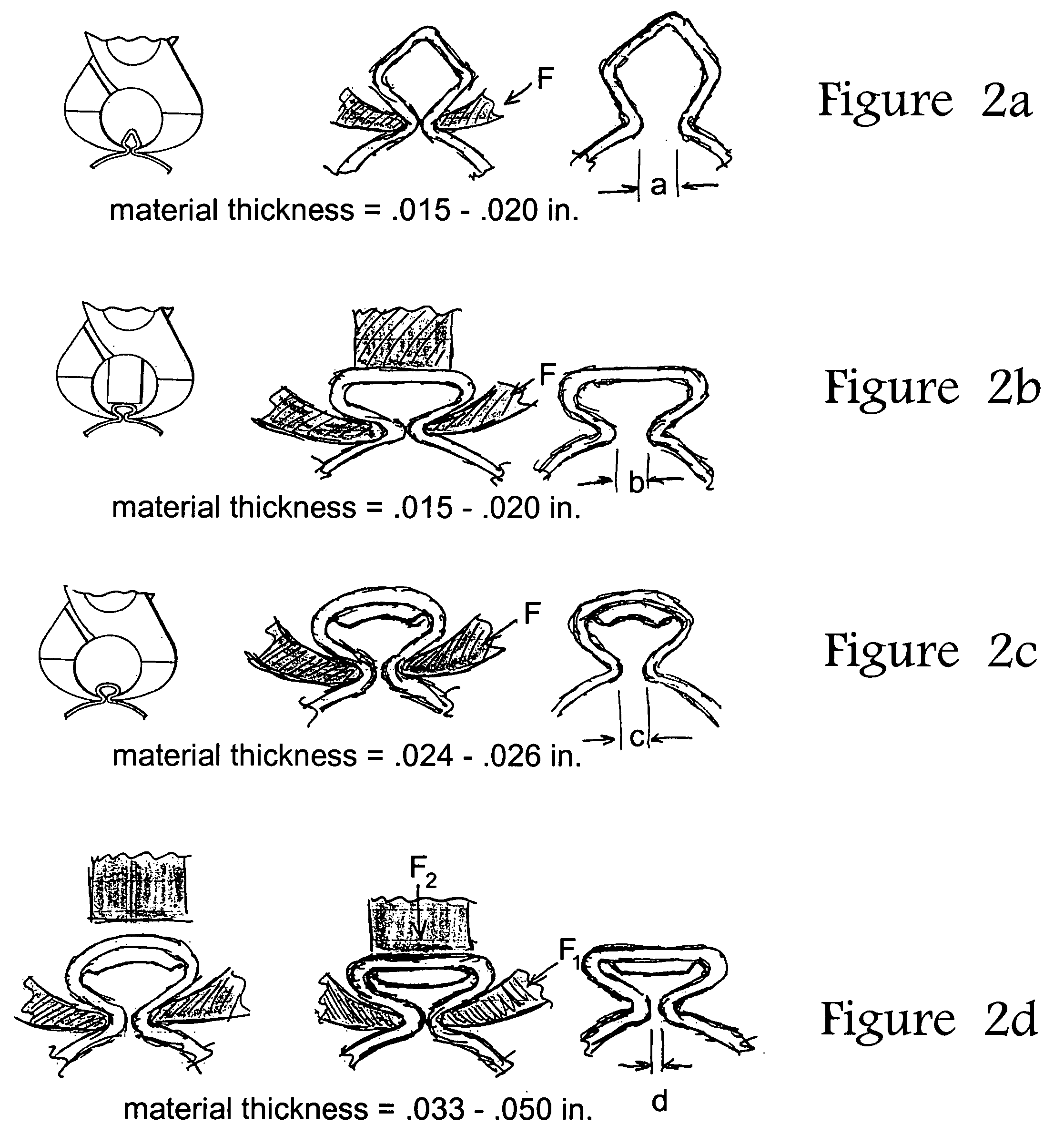

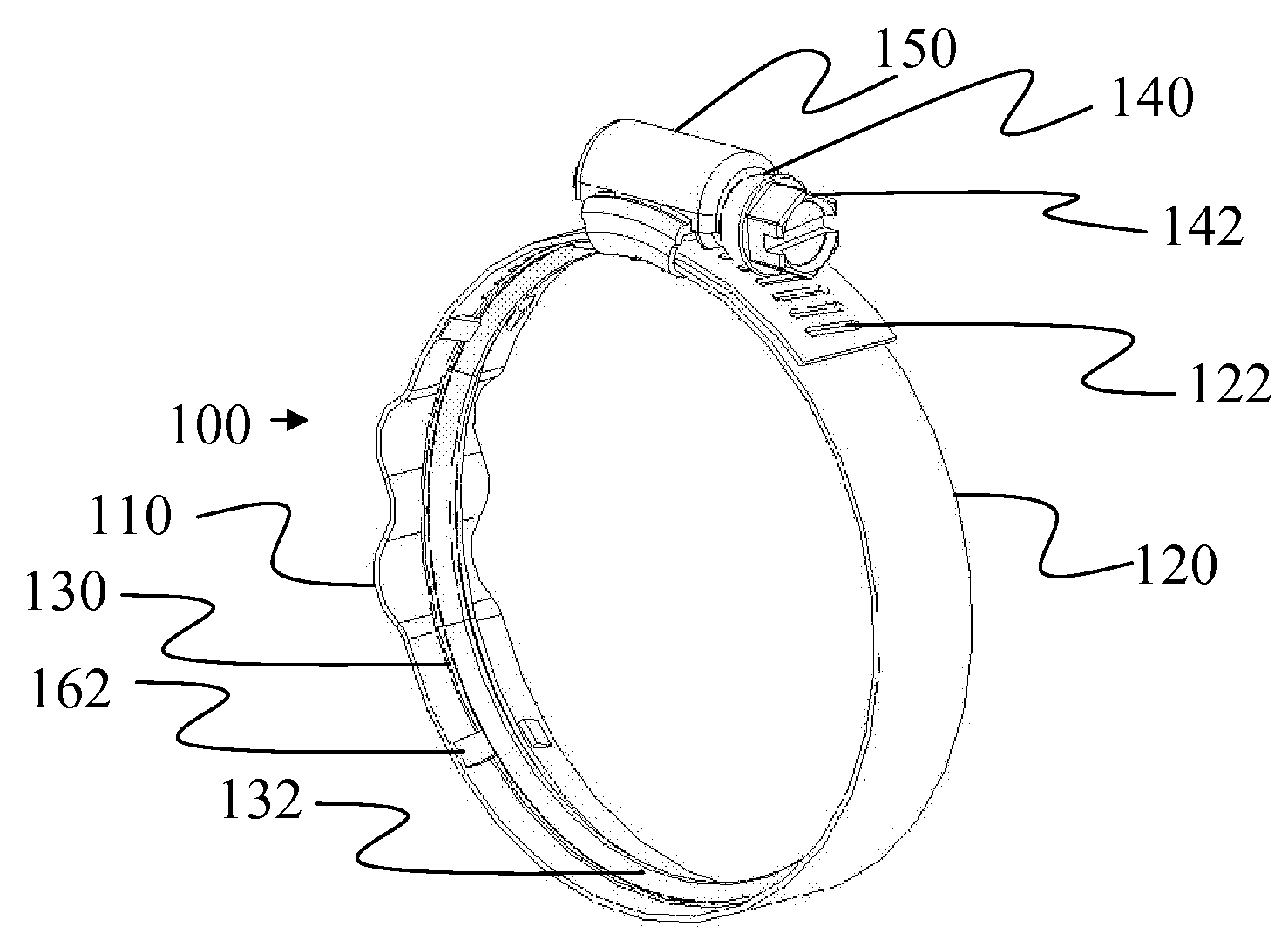

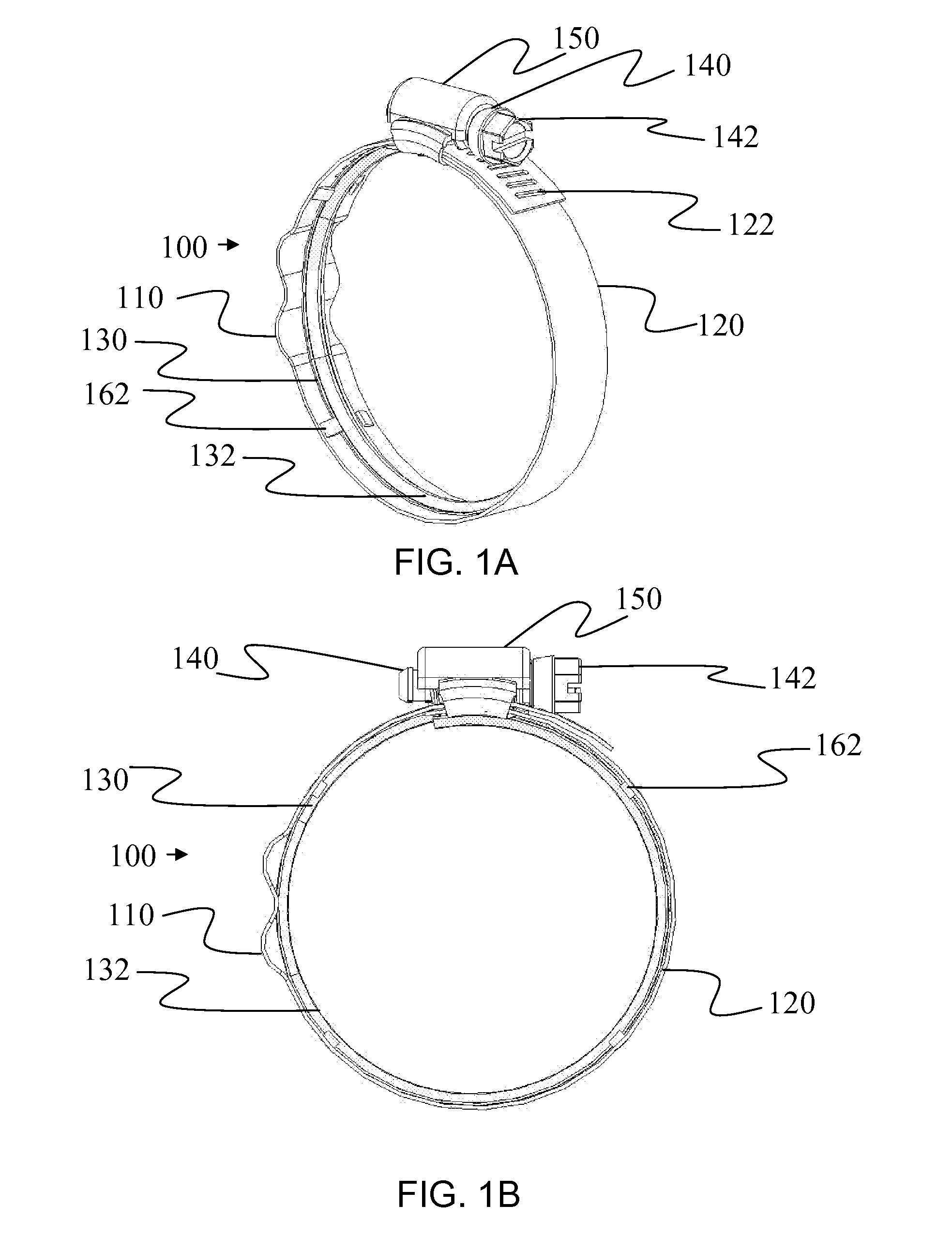

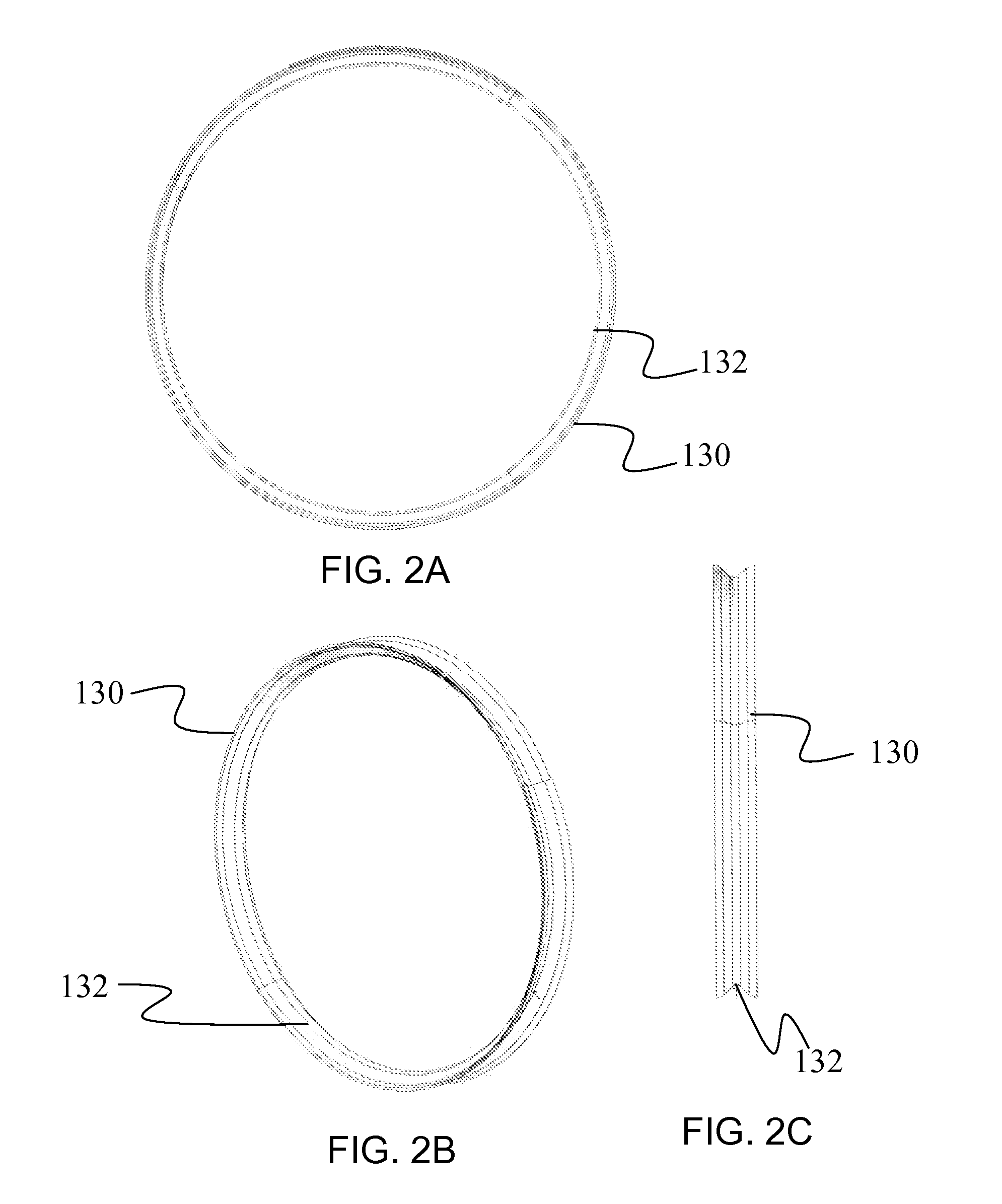

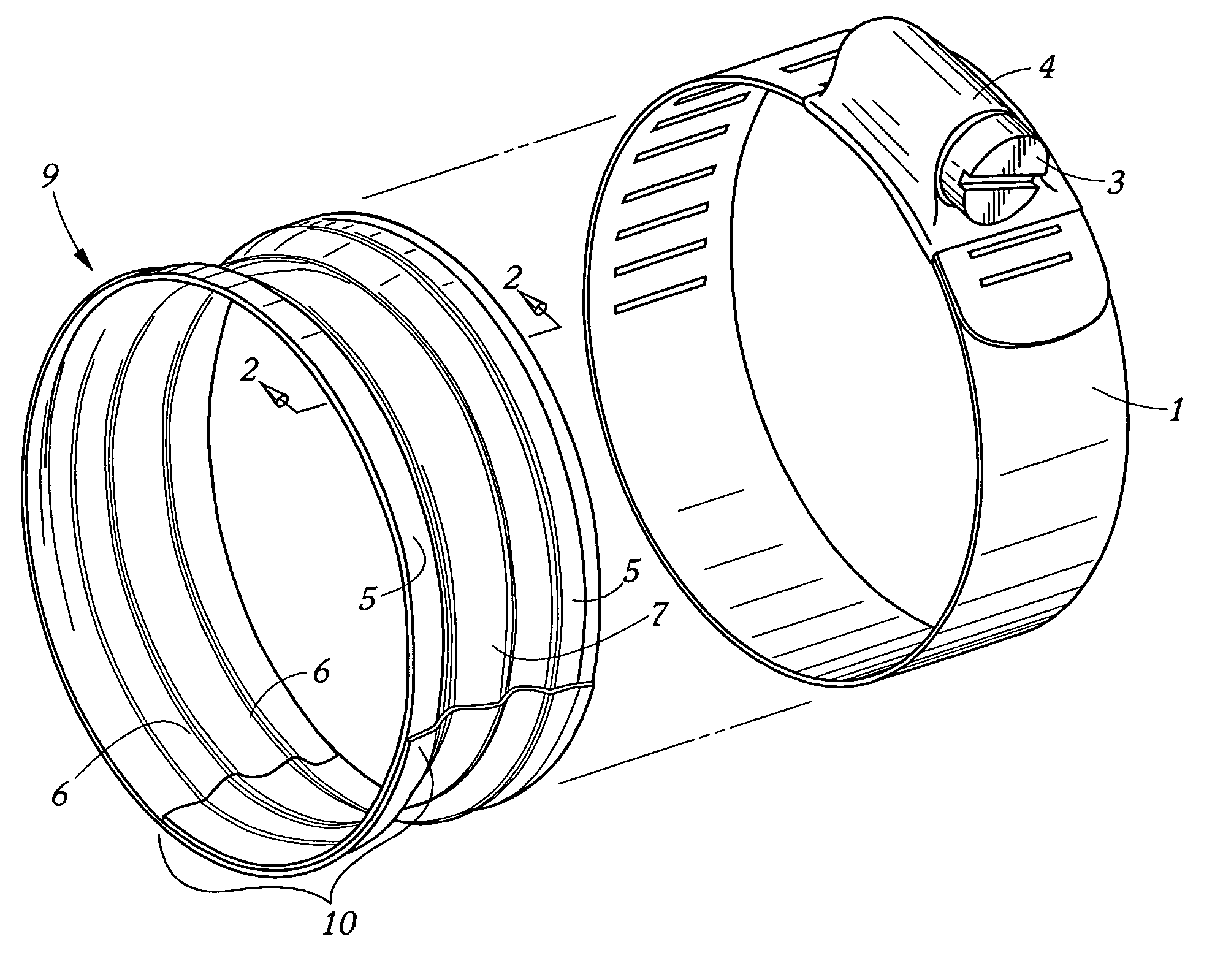

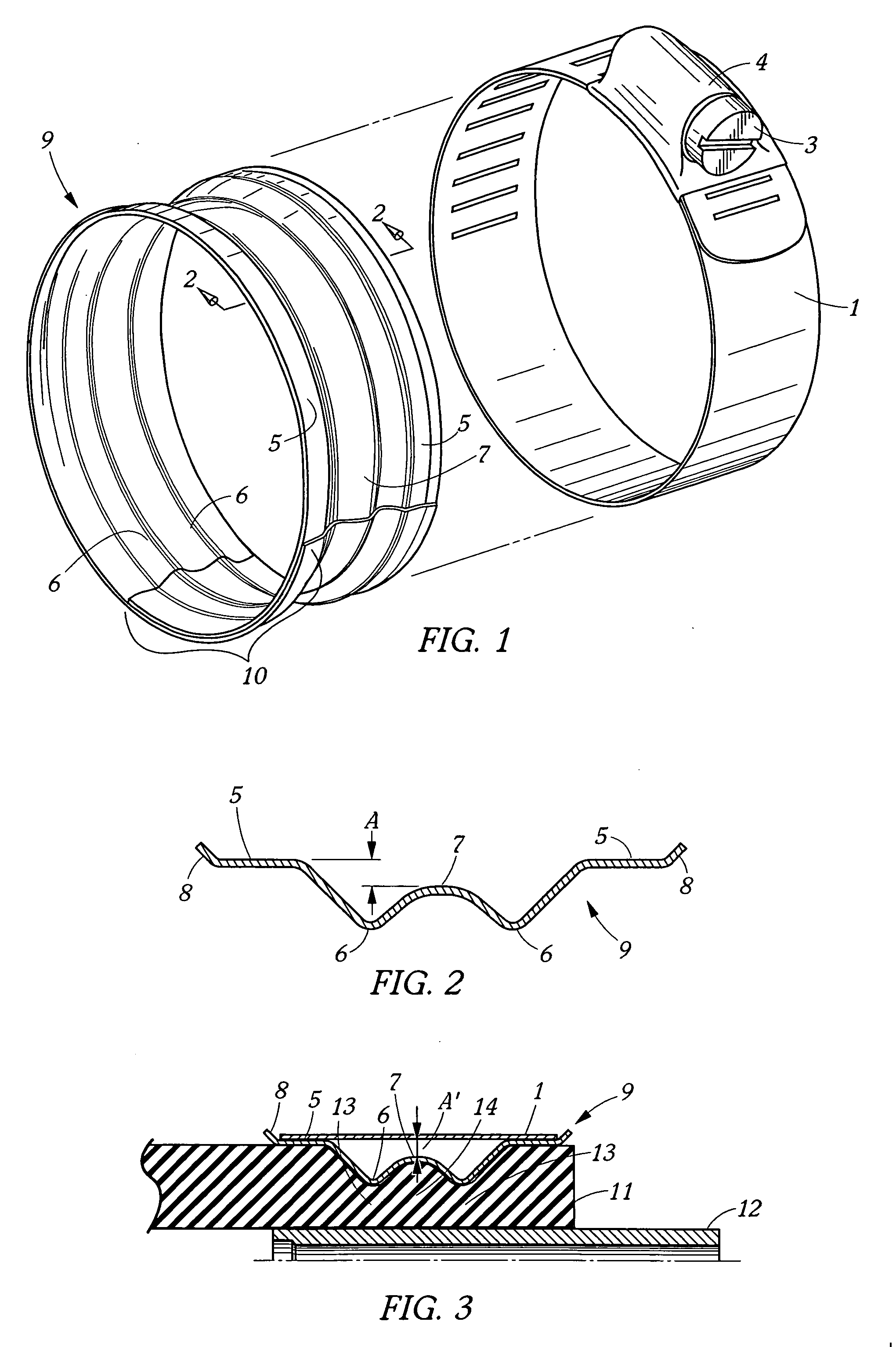

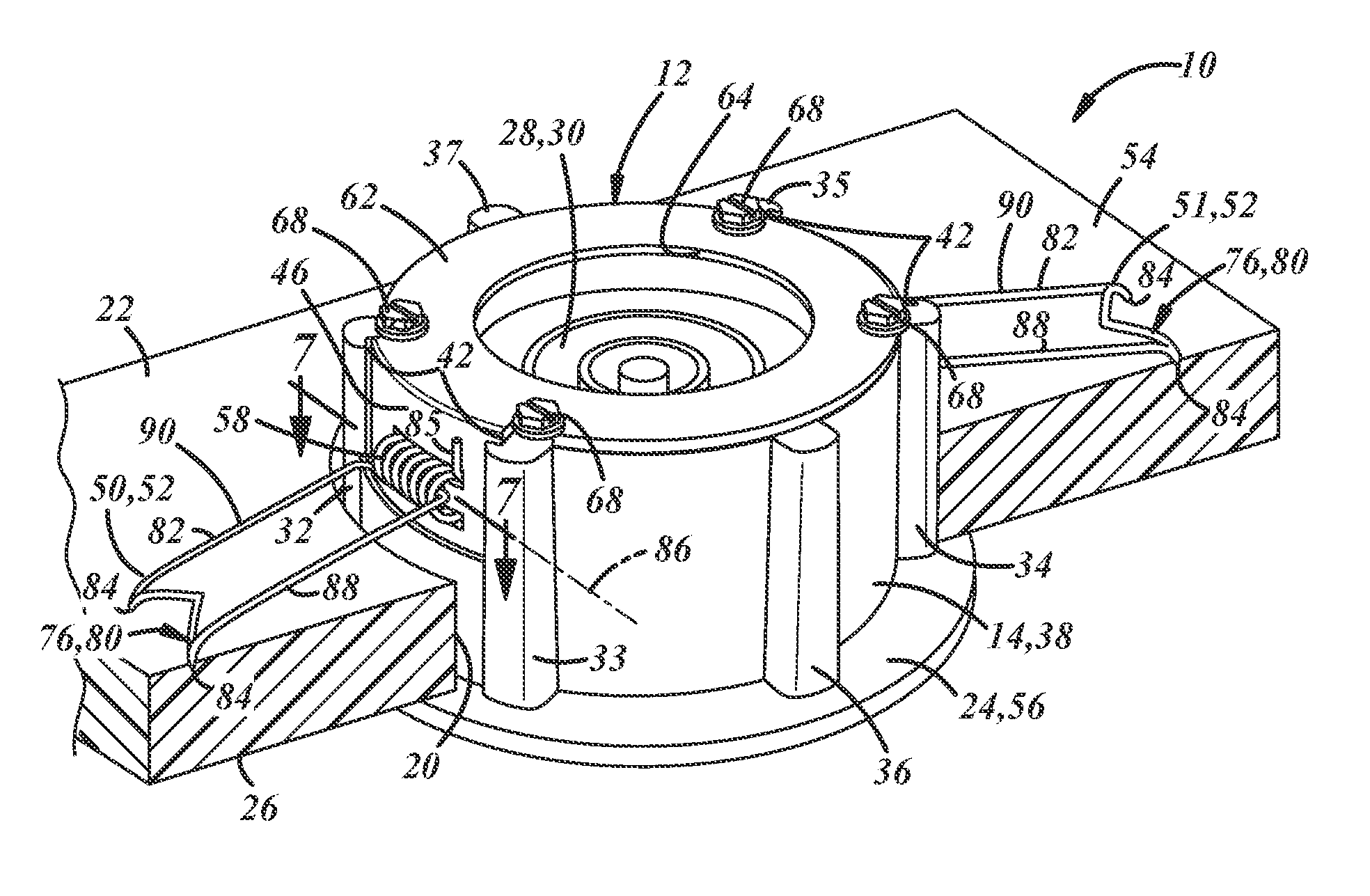

Compression Hose Clamp

A hose clamp 100 including a band 120 with an integrated wave-form 110 formed in the band 120 for spring compensation during thermal cycling and material aging, and notches 122 formed in the band 120; a housing 150; a worm gear screw 140 for tensioning the hose clamp; a compression liner 130 inserted in the inside circumference of the band 120 to increase clamp unit loading by concentrating the load radially inward around and through the circumference of the band120; and an attachment means to secure the compression liner 130 in place with the band 120.

Owner:EPICOR IND

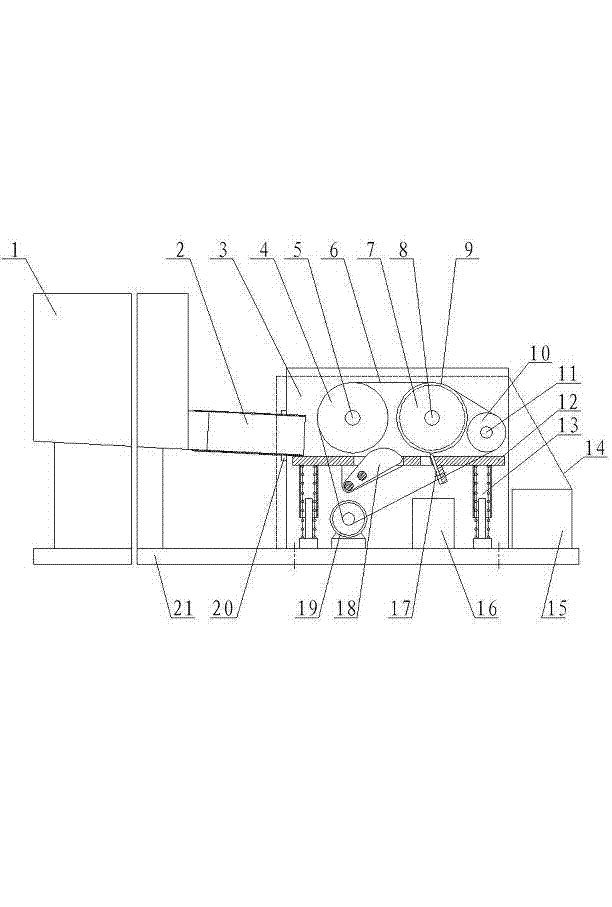

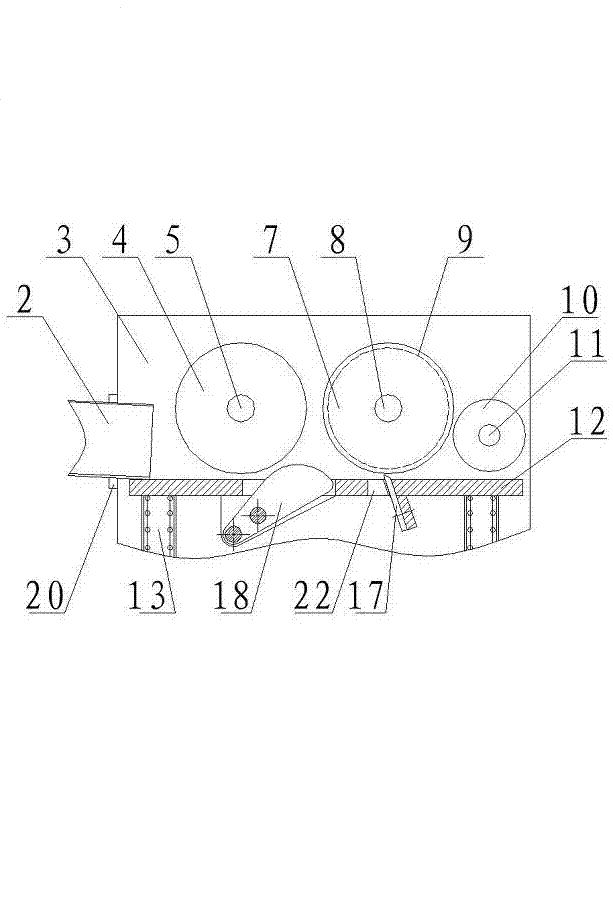

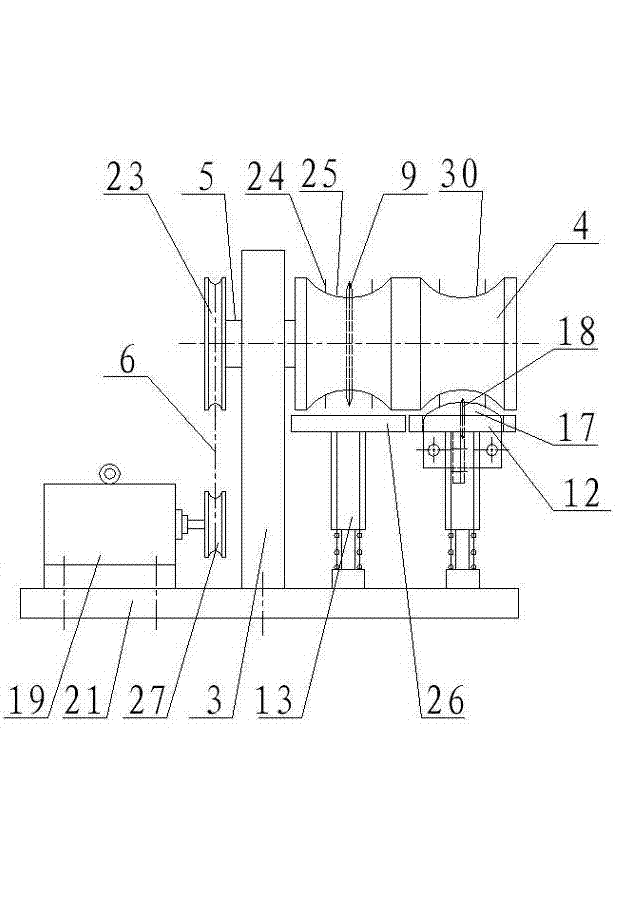

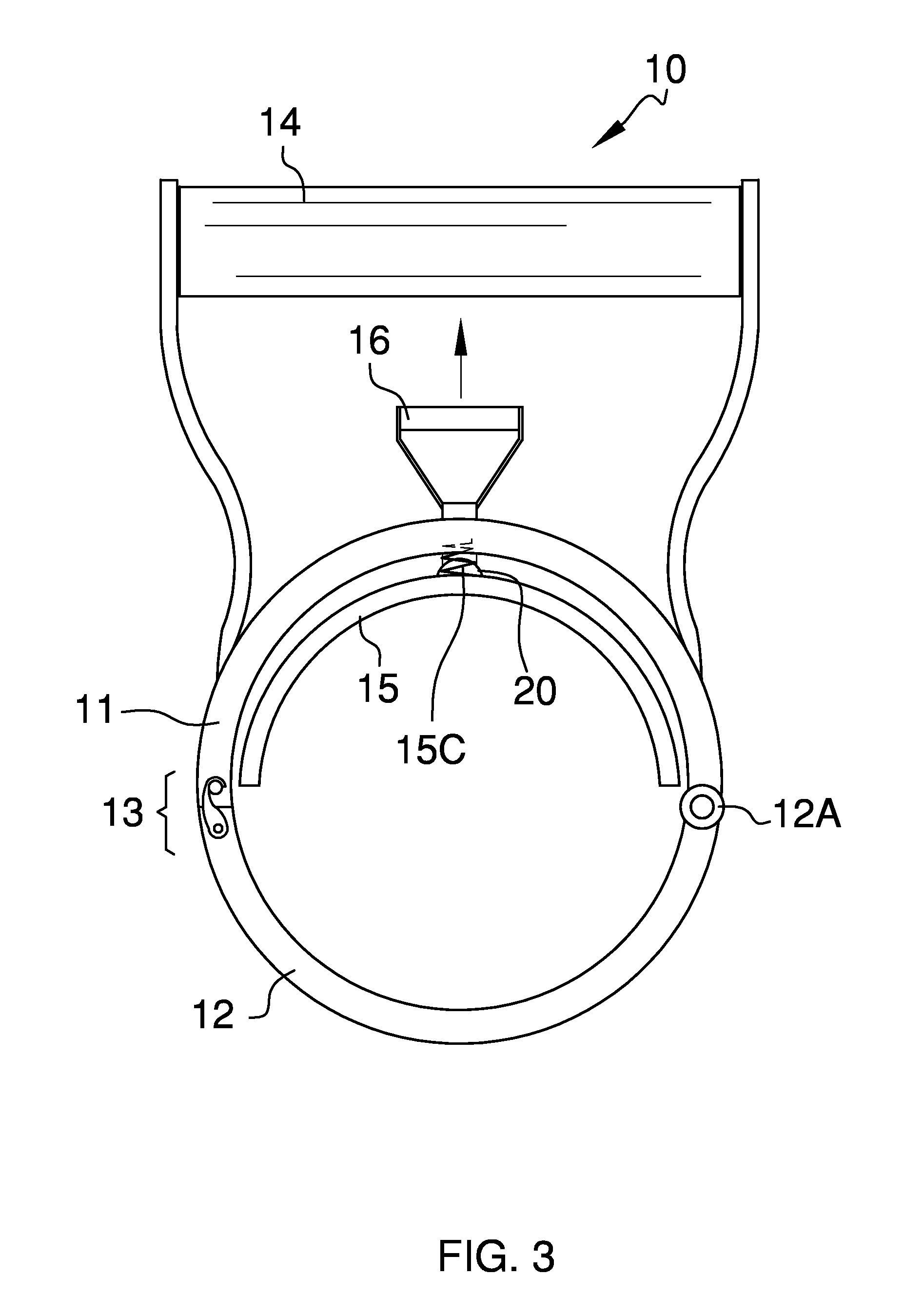

Eel and loach slaughtering machine

InactiveCN103168819ASolve the problemSolve the problem of missed killingPoultry/fish slaughtering/stunningAquatic productBack cutting

The invention relates to an eel and loach slaughtering machine which belongs to the field of an aquatic product processing machine. The eel and loach slaughtering machine is formed by a rack, a feeding barrel and a slaughtering device, wherein the feeding barrel is mounted at the one end of the rack and the slaughtering device is arranged at the other end of the rack; the feeding barrel and the slaughtering device are movably connected through a feeding hose and a hose clamp; and the slaughtering device is provided with a protection cover. The eel and loach slaughtering machine disclosed by the invention adopts a feeding roller to randomly grasp and convey eel and loach, the slaughtering speed is high, the slaughtering requirements on eel and loach with different sizes can be met, and the frequent problems that some eel and loach are not correctly slaughtered or are not slaughtered when an existing slaughtering machine is used for slaughtering eel and loach with different sizes are solved. When the eel and loach slaughtering machine disclosed by the invention is used for slaughtering eel and loach, eel and loach do not need to be classified according to specifications and sizes in advance, so that the labor intensity of workers is reduced and the working efficiency is improved; and eel and loach can be slaughtered from abdomens or from backs through the selection connection between the feeding hose and a back cutting supporting plate and between the feeding hose and an abdomen cutting supporting plate, and furthermore, the requirements on deep processing of eel and loach can be met.

Owner:李平

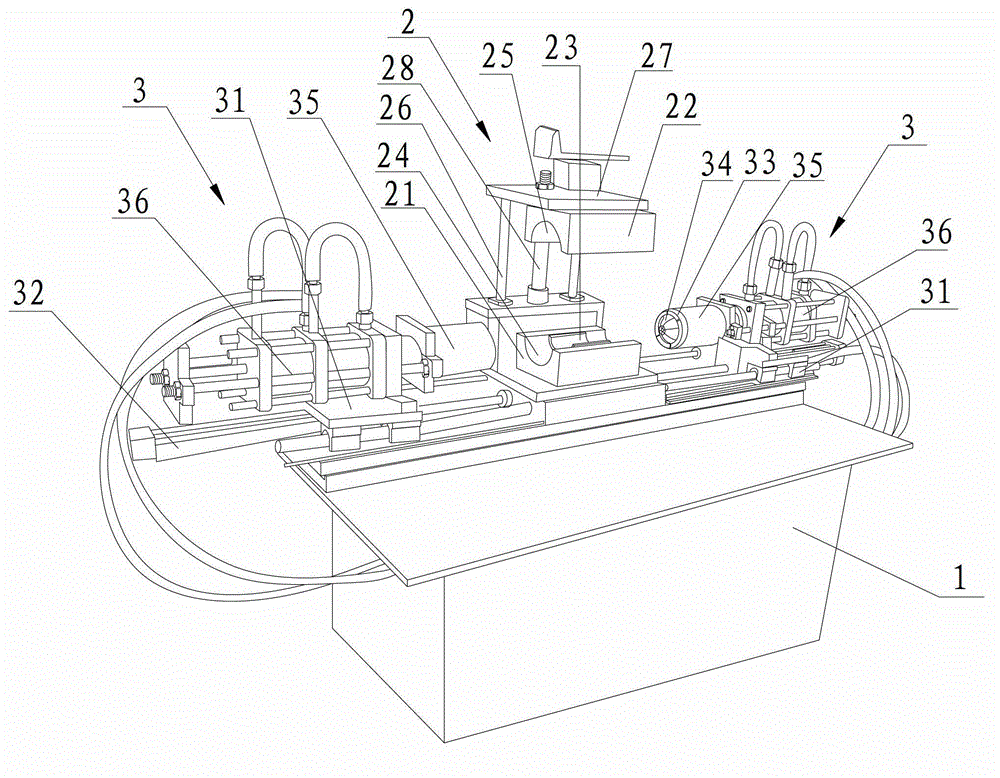

Automobile hose and coupling assembly equipment

ActiveCN102873527ASimple structureEasy to operateMetal working apparatusStructural engineeringHose coupling

The invention discloses automobile hose and coupling assembly equipment. A hose body of a hose is clamped by a hose clamping component of the automobile hose and coupling assembly equipment, tensioning and fastening compression devices are arranged on two sides of the hose clamping component, tensioning tubes and fastening tubes are arranged in the tensioning and fastening compression devices, ends of outer sides of the tensioning tubes and the fastening tubes can be opened or closed, the tensioning tubes can axially penetrate into a central through hole of the hose when the ends of the outer sides of the tensioning tubes are closed, and the fastening tubes can be axially sleeved on the periphery of the outer side of the hose when the ends of the outer sides of the fastening tubes are opened. When the tensioning and fastening compression devices are in a compression working state for compression assembly of the hose body of the hose and couplings, the ends of the outer sides of the fastening tubes are closed and fastened on the periphery of the outer side of the hose, and the ends of the outer sides of the tensioning tubes are opened and are abutted to the periphery of the inner side of the hose, so that internally tensioning and externally fastening compression force is exerted to joints of the hose body of the hose and the couplings, the couplings are compressed at ends of the hose body, and the hose and the couplings are assembled. The automobile hose and coupling assembly equipment is simple in structure and convenient to operate.

Owner:苏州市环宇汽车配件有限公司

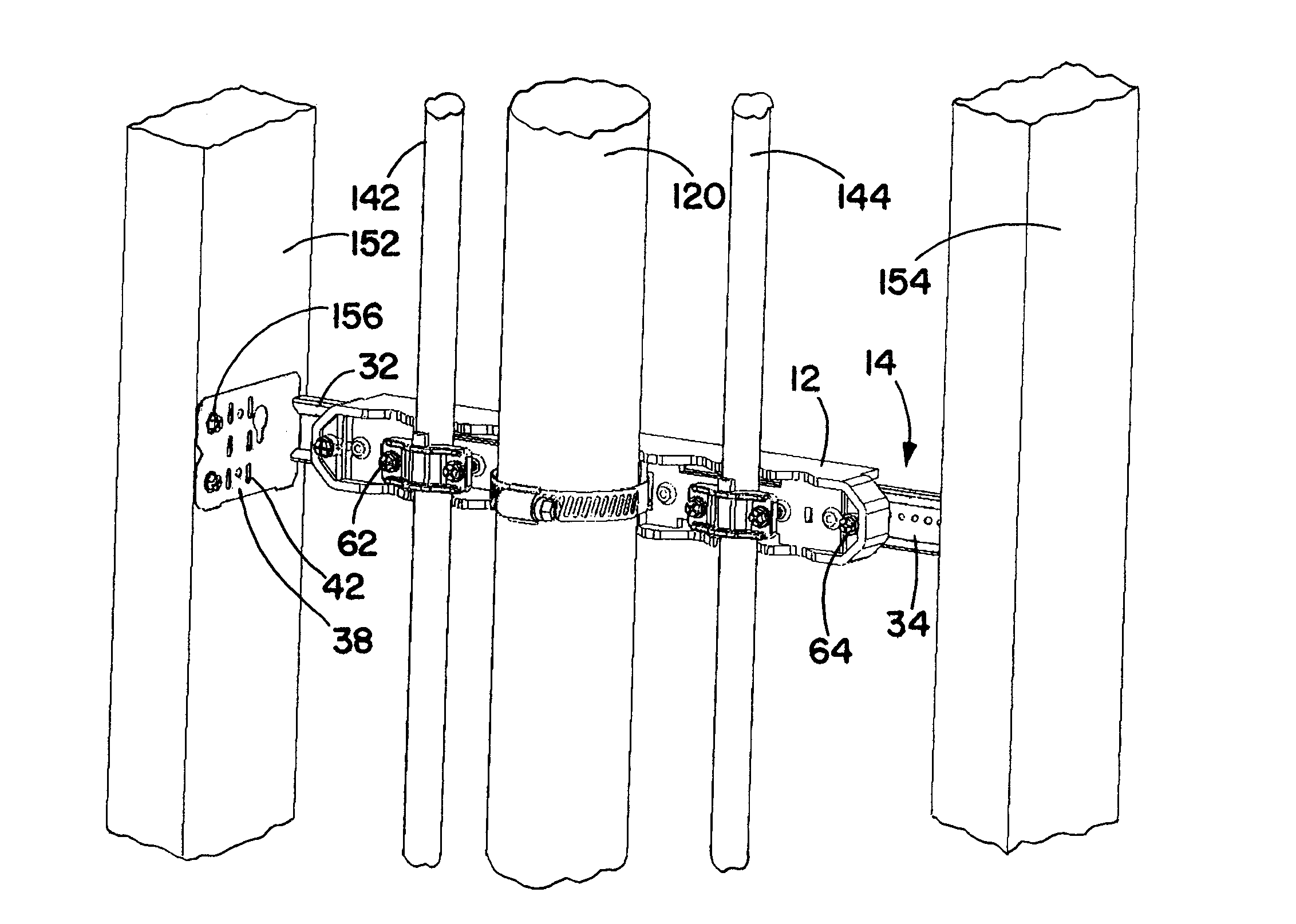

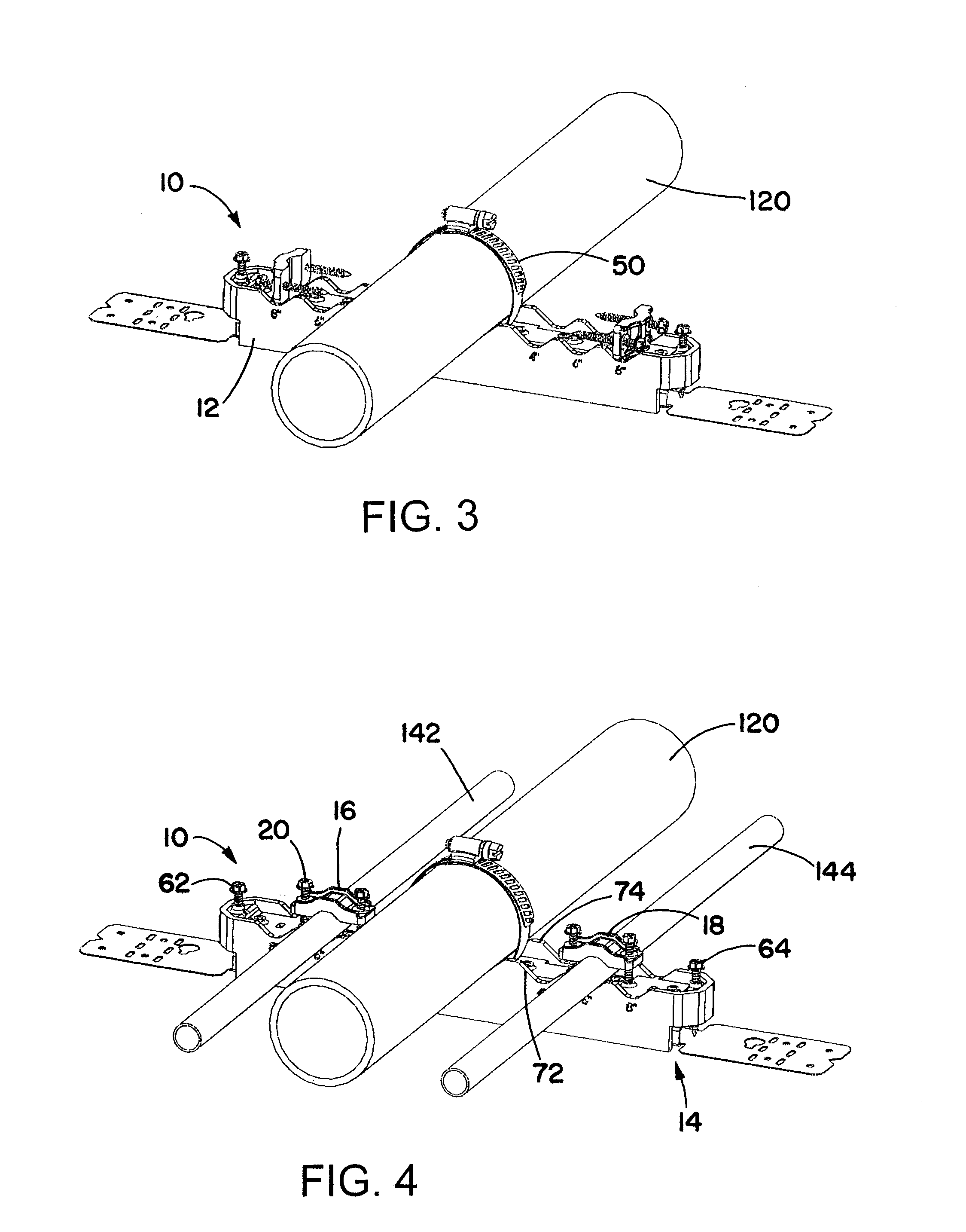

Plumbing bracket assembly

A plumbing bracket assembly has a plastic main bracket body and a telescoping bracket. The telescoping bracket runs through the main bracket body, and is able to extend to allow the bracket assembly to be secured to structure (such as studs) at both ends, over a range of distances between structure elements. The bracket body is initially able to slide along the telescoping bracket, for desired positioning, but may be locked in place using screws on the main bracket body. Hardware, such a hose clamp and multiple pipe clamps, is initially coupled to the main bracket body. The main bracket body may have a central depression for receiving a relatively large pipe run, and notches or depressions on opposite sides of the central depression, for receiving smaller pipe runs.

Owner:ERICO INT

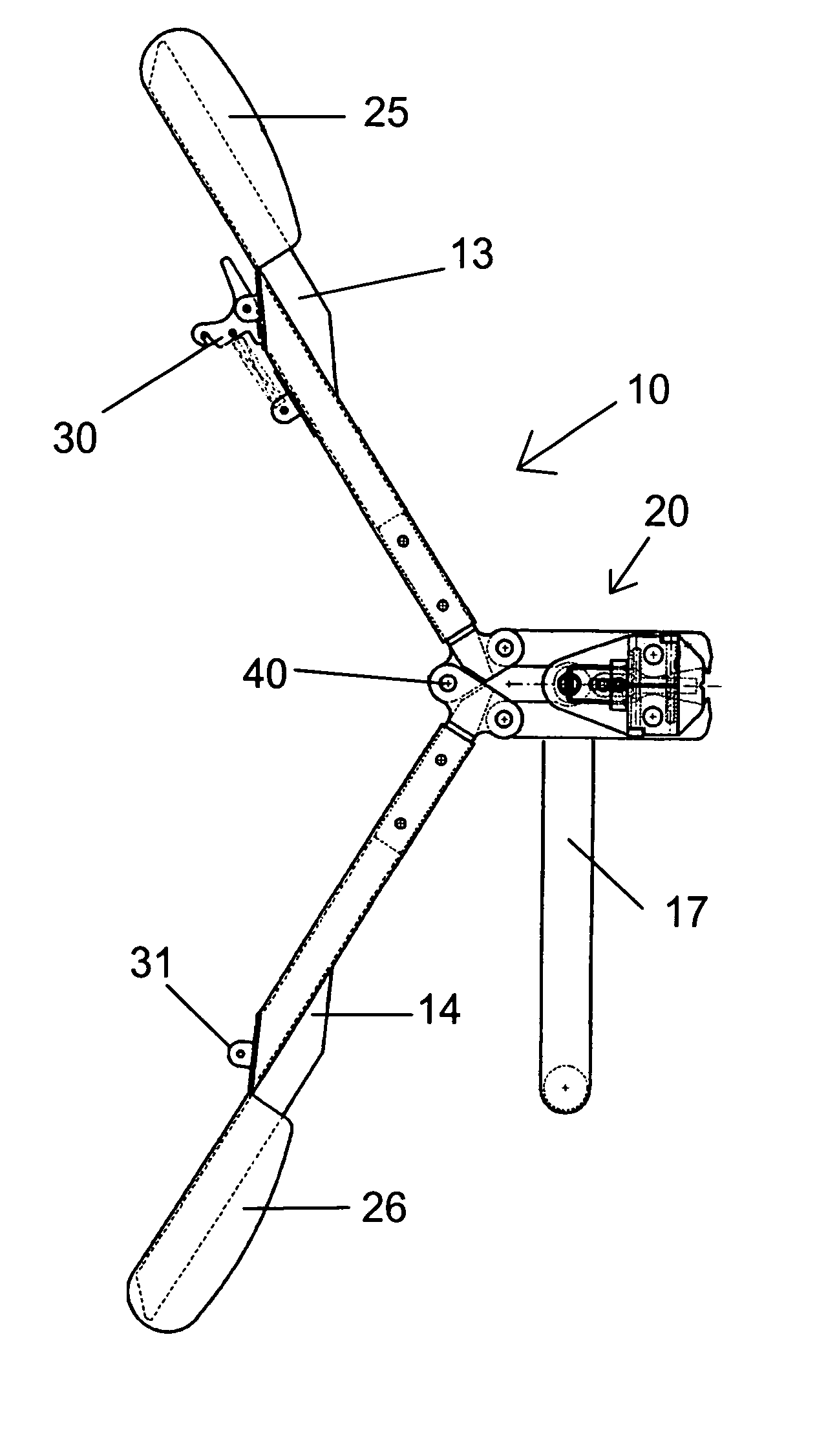

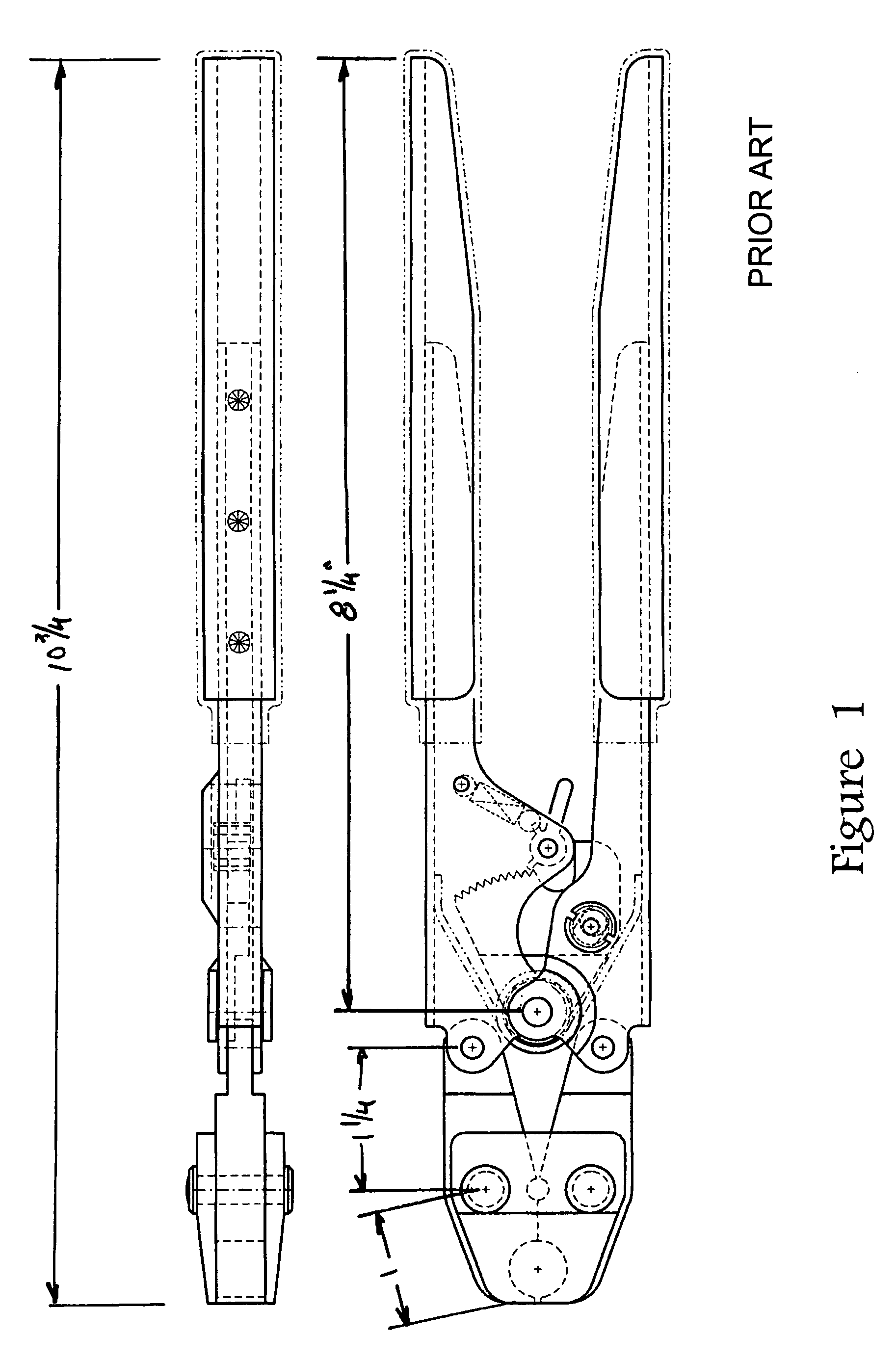

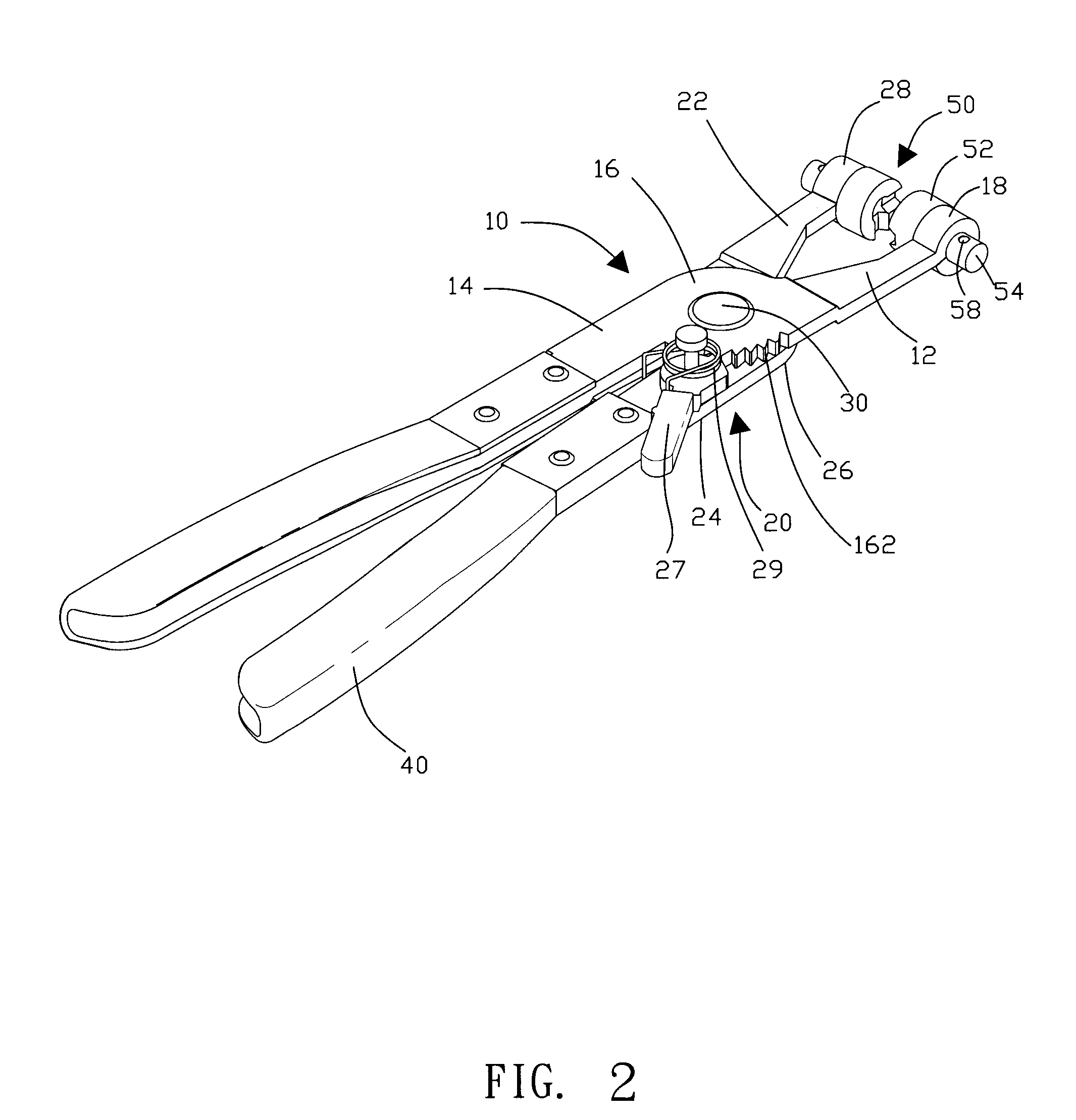

Heavy-duty PEX clamp installation tool

A heavy-duty hose clamp installation tool is described. A pair of lever arms operates a pair of jaw members to engage a pinch clamp ear. The installation tool includes a pair of jaw members with clamp edges forming a lip for receiving the clamp ears. A pair of extension arms connects the jaw members to a pair of lever arms. The extension arms are pivotally interconnected intermediate the jaw member section so that closing the handle ends of the lever arms translates the jaw members towards a closed position thereof, thus squeezing the clamp ear. Once the ear of the clamp is crimped, an auxiliary form punch is used to flatten the ear, resulting in a tighter clamp configuration.

Owner:MURRAY CO

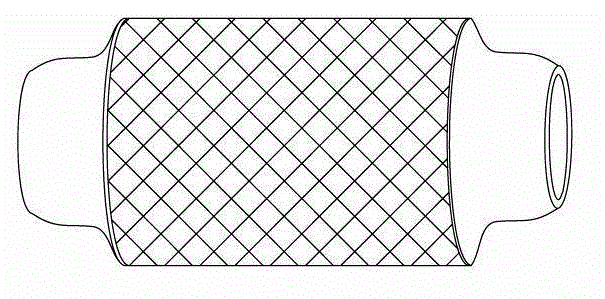

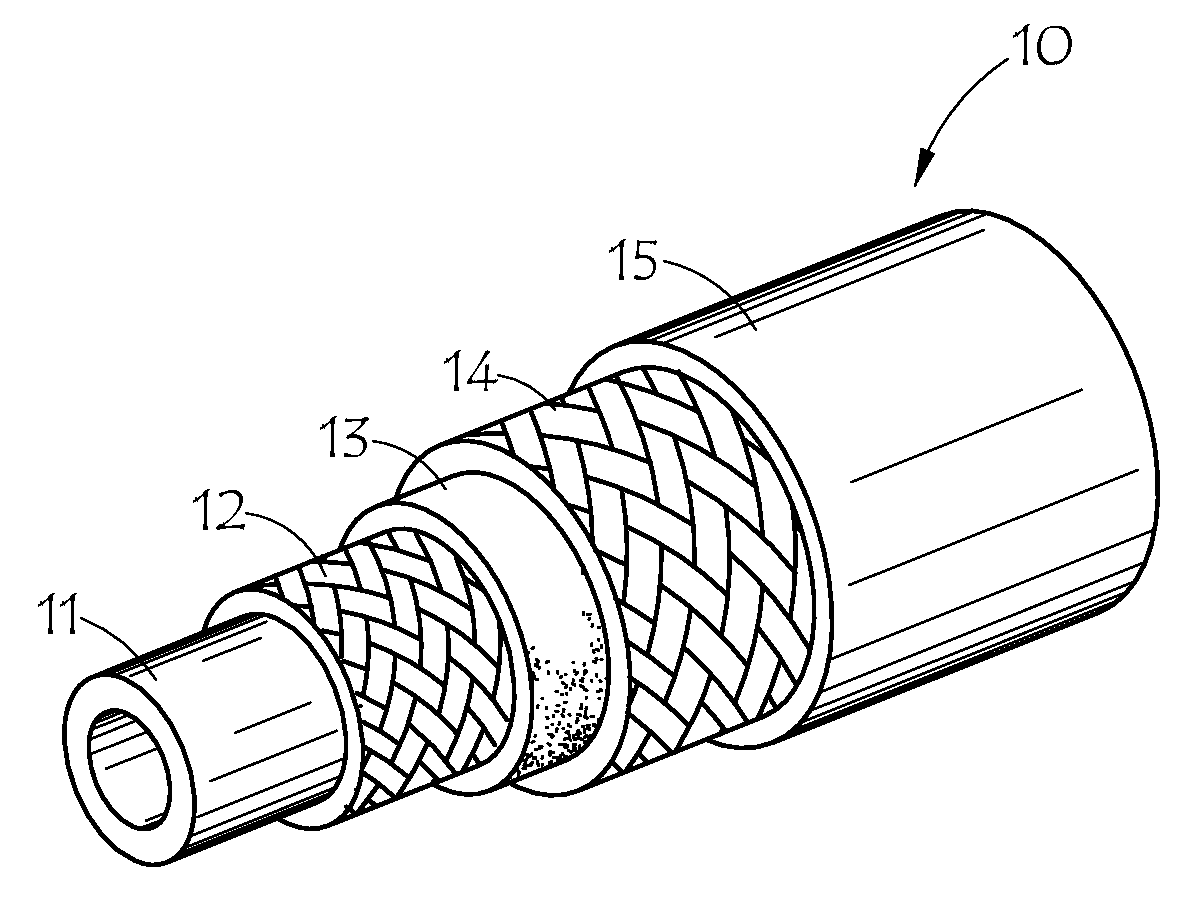

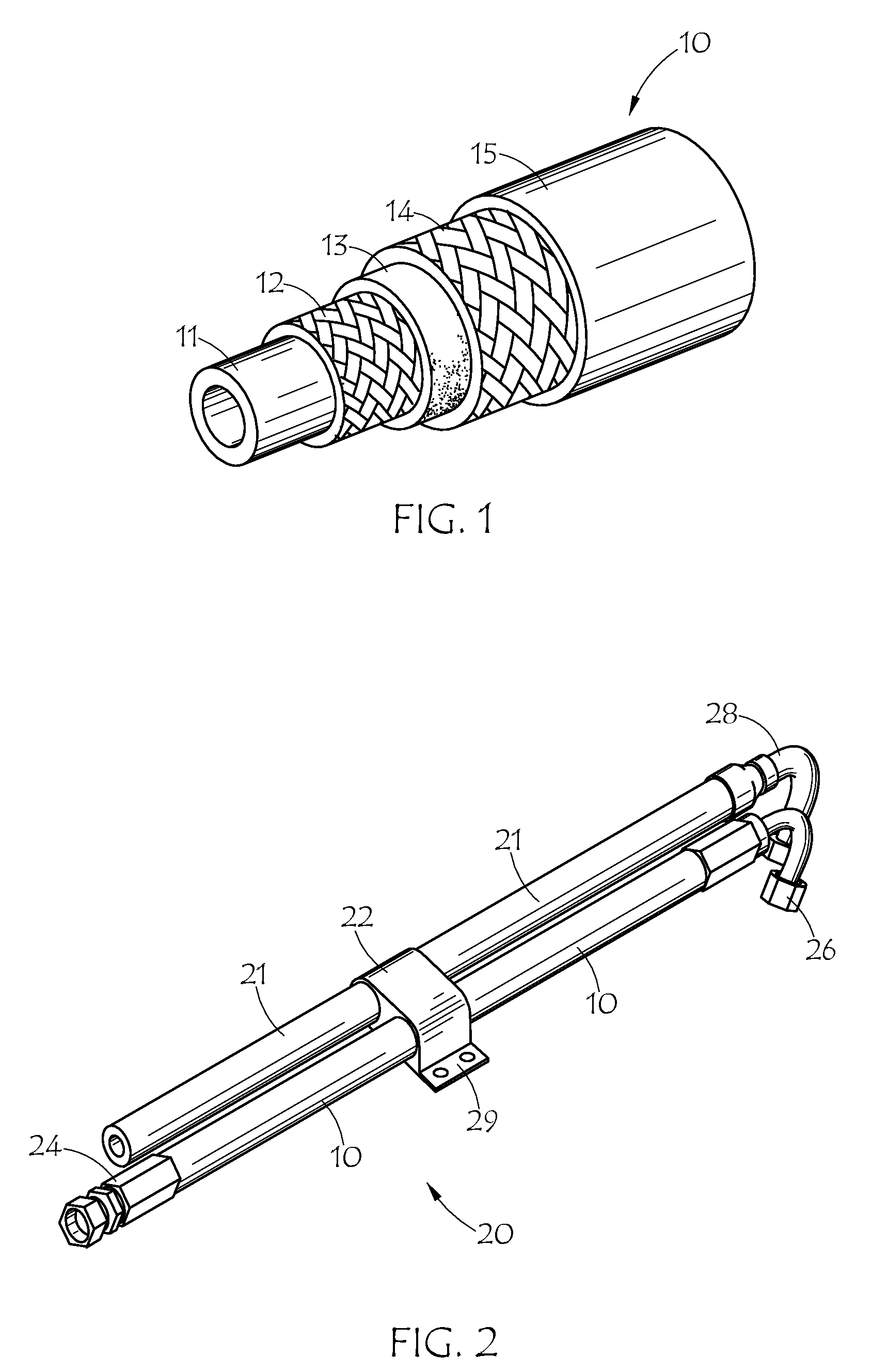

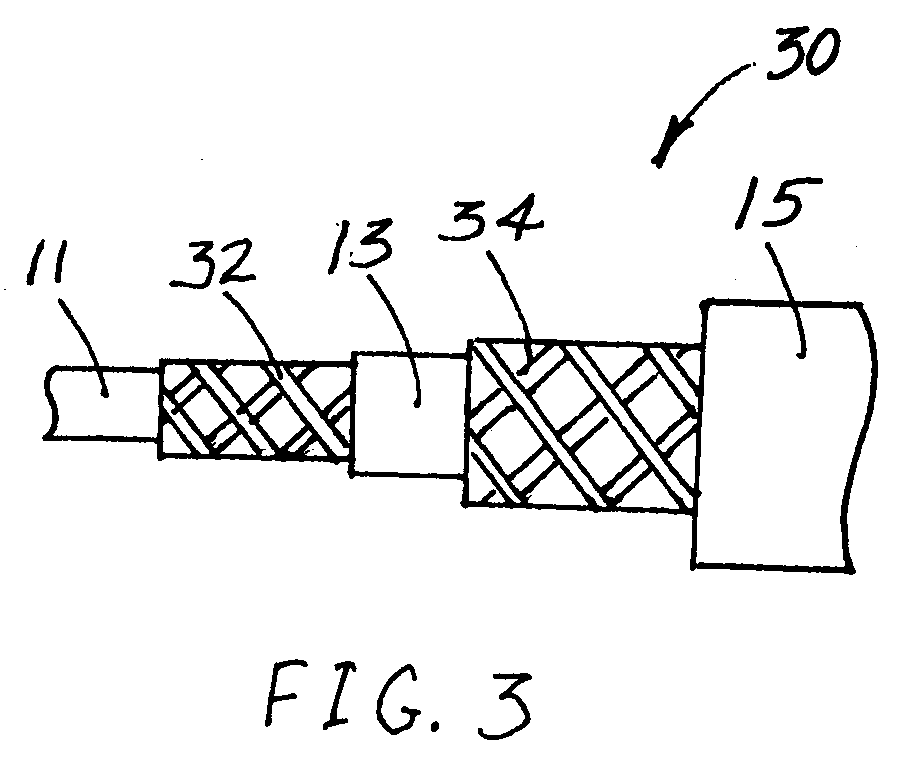

Controlled expansion hose

ActiveUS20090211660A1Reducing and smoothing pressure fluctuationImproved impulse fatigue resistance and burst pressureLayered productsPipe elementsYarnMaterial type

An expansion hose adapted for smoothing pressure fluctuations in a hydraulic system having an inner tube, a textile reinforcement, and an outer cover. The reinforcement includes a plurality of yarns, which in turn have a plurality of filaments of first fiber material type and a plurality of filaments of second fiber material type, with first fiber type having elongation at break higher than the second fiber type by at least about 4% elongation. The expansion hose may be part of an assembly including at least one fitting, coupling, bracket, hose clamp, or other hose.

Owner:THE GATES CORP

Compression hose clamp

A hose clamp 100 including a band 120 with an integrated wave-form 110 formed in the band 120 for spring compensation during thermal cycling and material aging, and notches 122 formed in the band 120; a housing 150; a worm gear screw 140 for tensioning the hose clamp; a compression liner 130 inserted in the inside circumference of the band 120 to increase clamp unit loading by concentrating the load radially inward around and through the circumference of the band 120; and an attachment means to secure the compression liner 130 in place with the band 120.

Owner:EPICOR IND

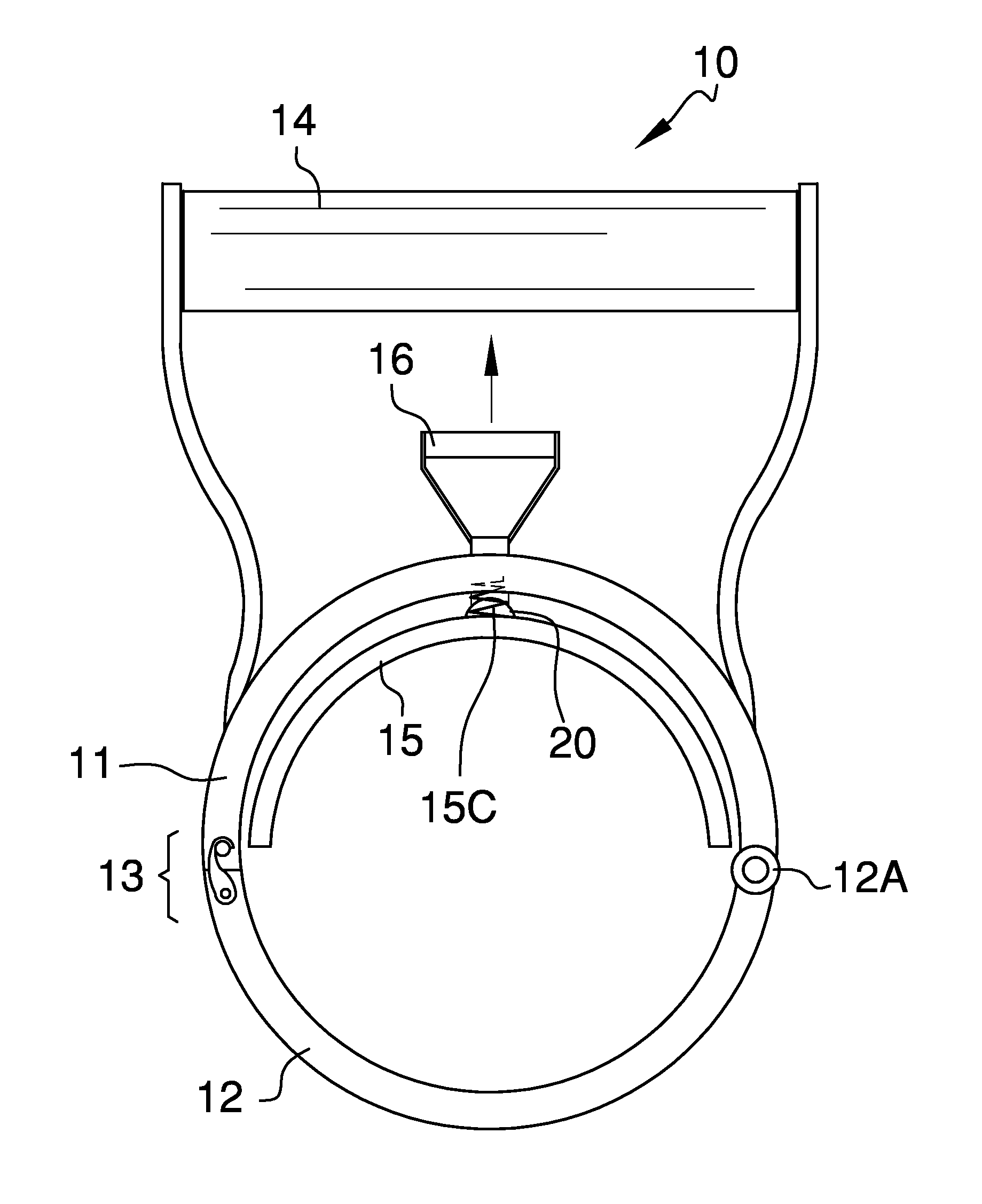

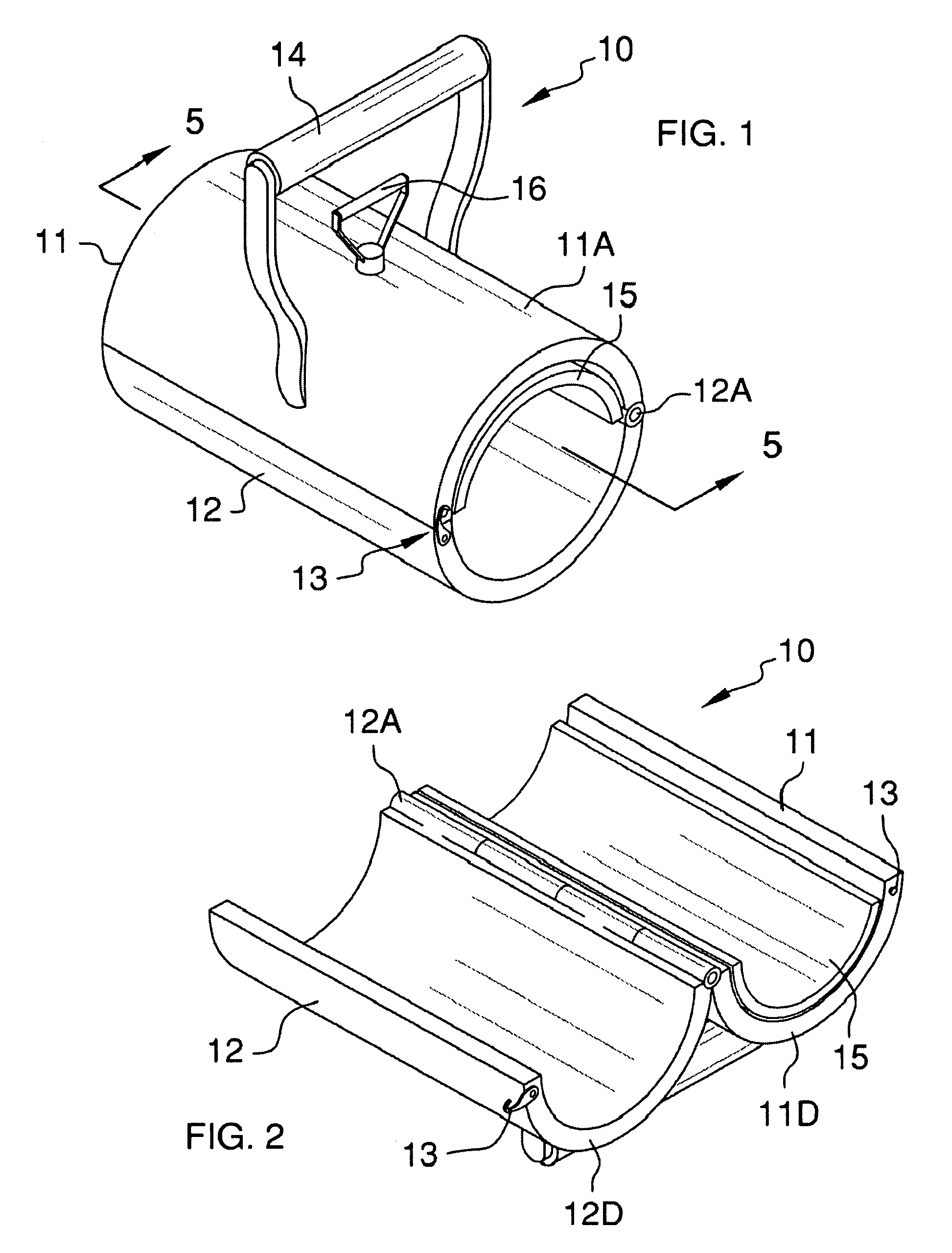

Fire hose holding apparatus

InactiveUS7730588B1Easy to installEasy to removeSnap fastenersTravelling carriersMechanical engineeringHose clamp

The invention is a fire hose holding apparatus that involves a hose clamp that involves two halves that are connected together via a hinge and a handle. Located along the interior of said two halves are rubber strips. The locking apparatus involves a locking clip on the opposite ends of the two halves and locking notch in the handle.

Owner:BERNIER CLAUDE

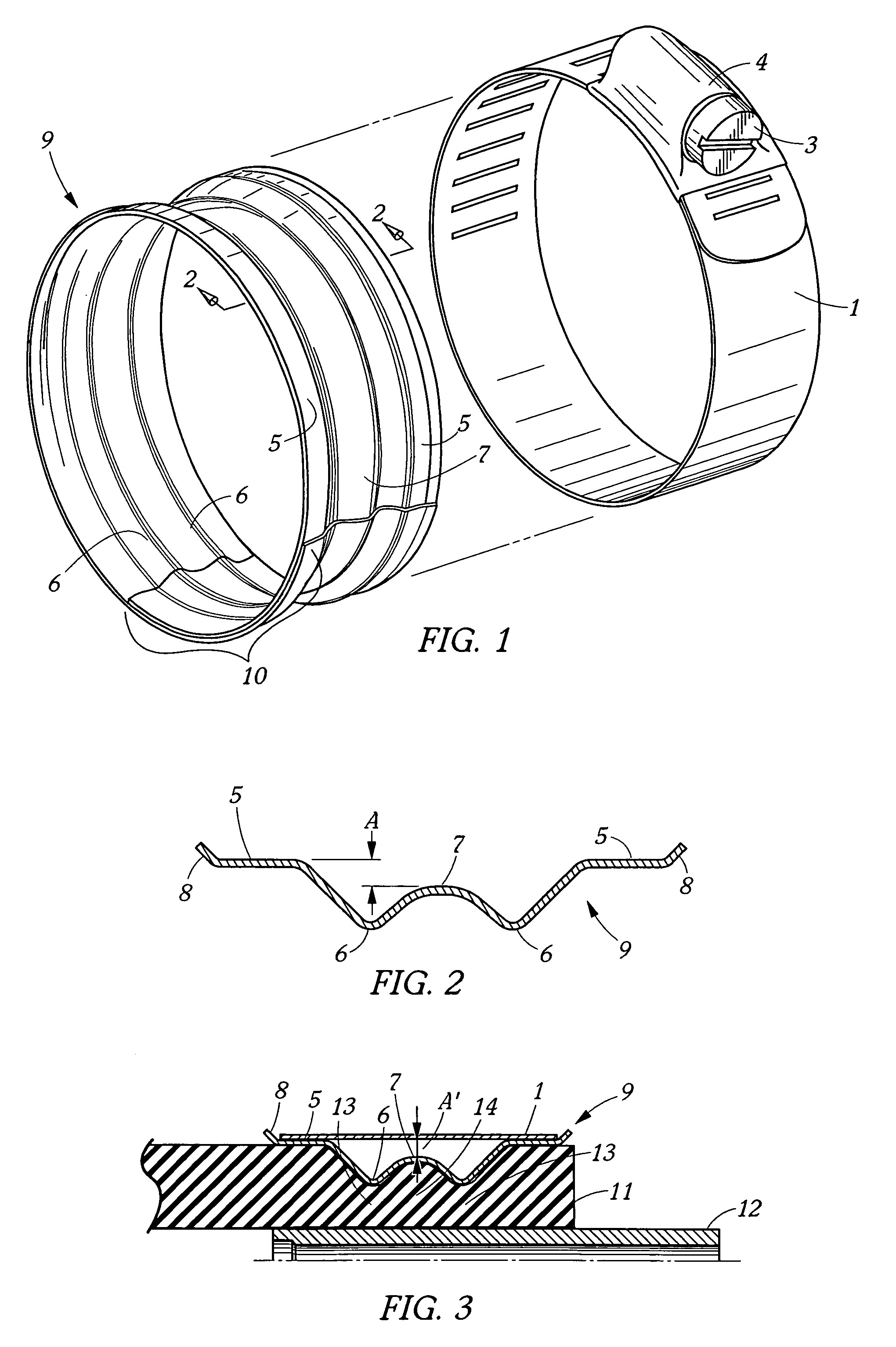

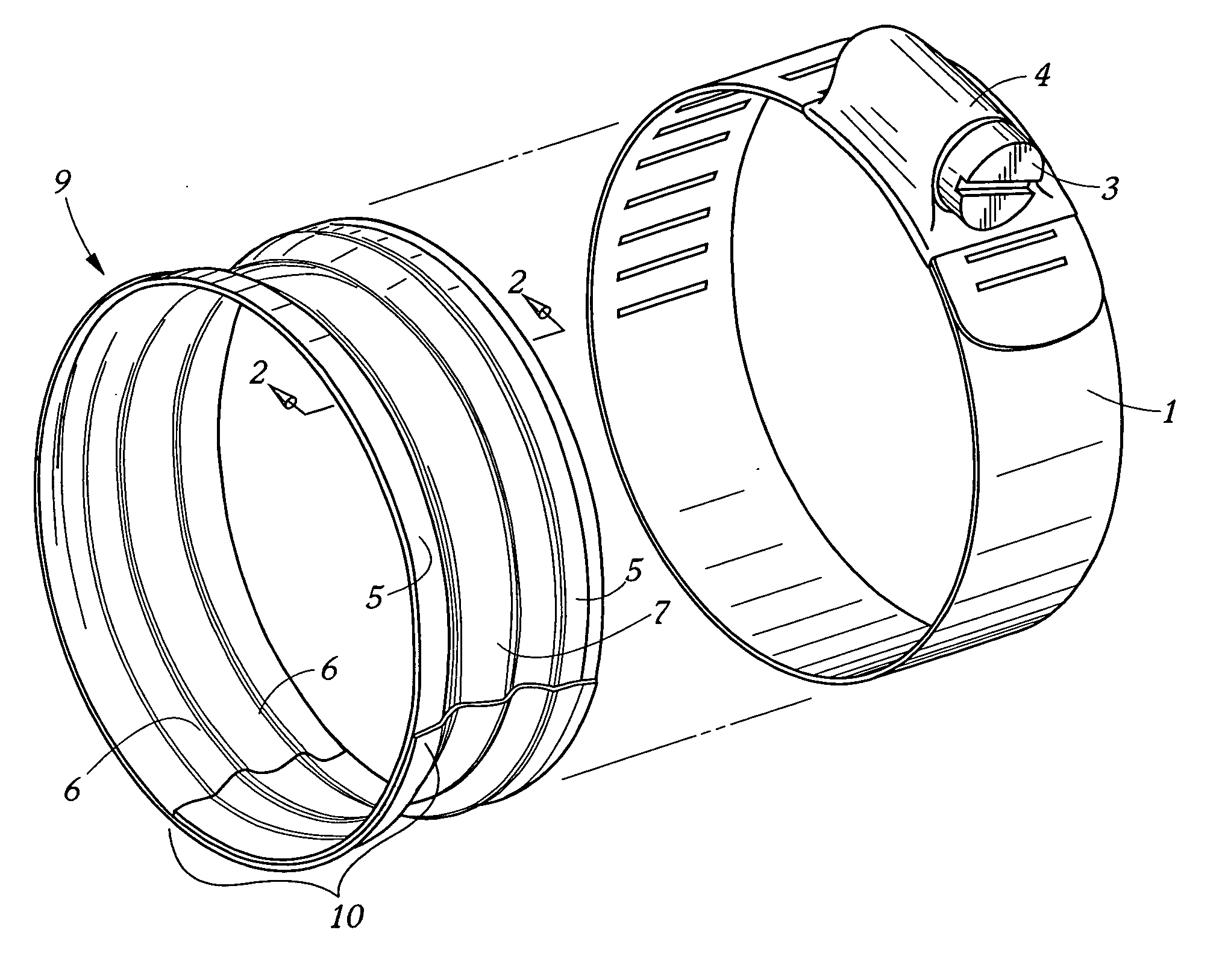

Hose clamp and spring liner

An improved hose clamp having an annular band with an inner face, tensioning means, and an annular spring liner. The spring liner includes an outwardly-projecting circumferential ridge; an inwardly-projecting circumferential ridge on each side of the outwardly-projecting ridge; and a circumferential shoulder near one or both circumferential edge of the spring liner; and at least one shoulder is adapted to abut the inner face.

Owner:EPICOR IND

Hose clamp and spring liner

An improved hose clamp comprising: an annular band having an inner face, tensioning means, and an annular spring liner; said spring liner comprising: an outwardly-projecting circumferential ridge; an inwardly-projecting circumferential ridge on each side of said outwardly-projecting ridge; and a circumferential shoulder near an edge of said spring liner; wherein at least one said shoulder is adapted to abut said inner face.

Owner:EPICOR IND

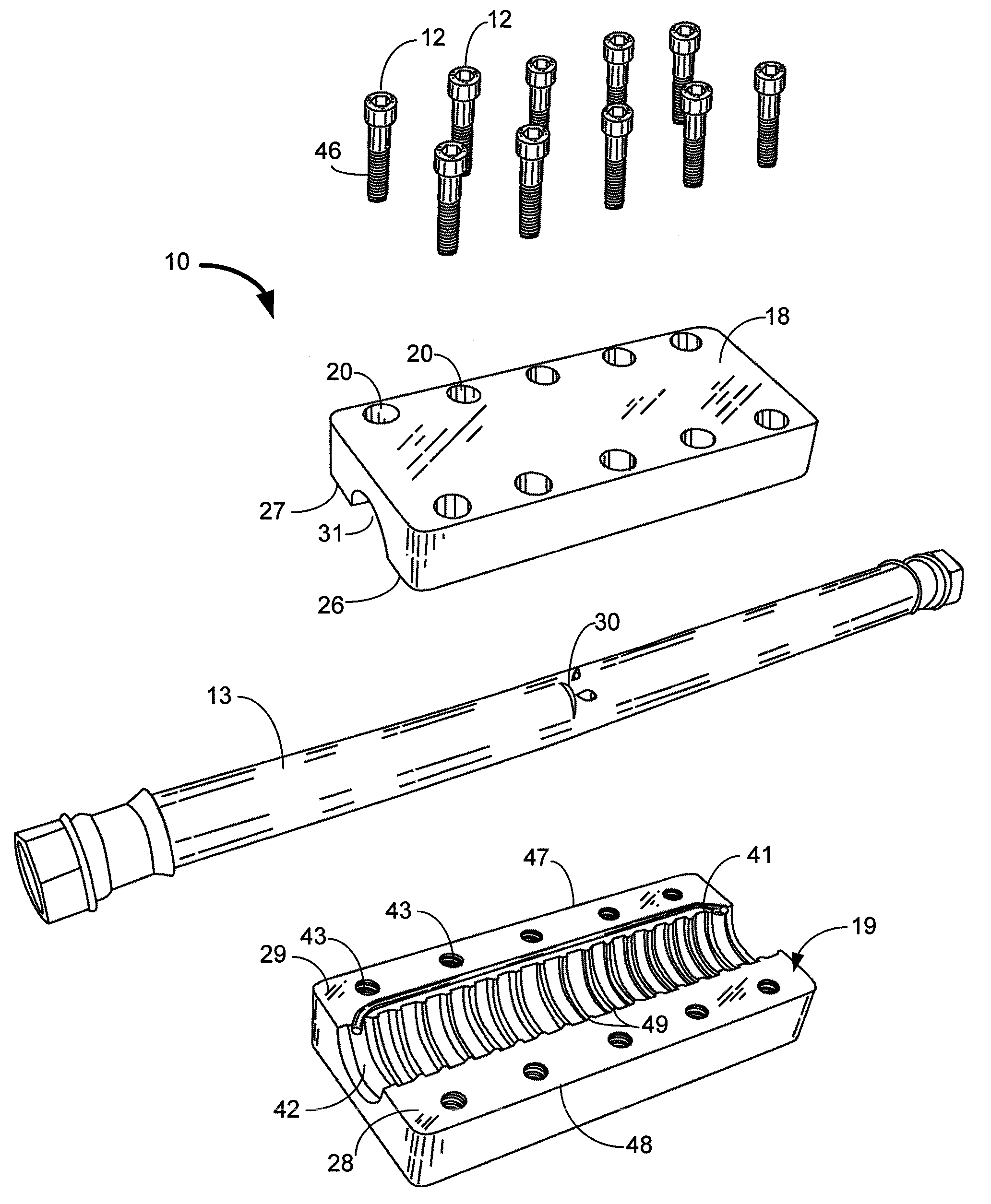

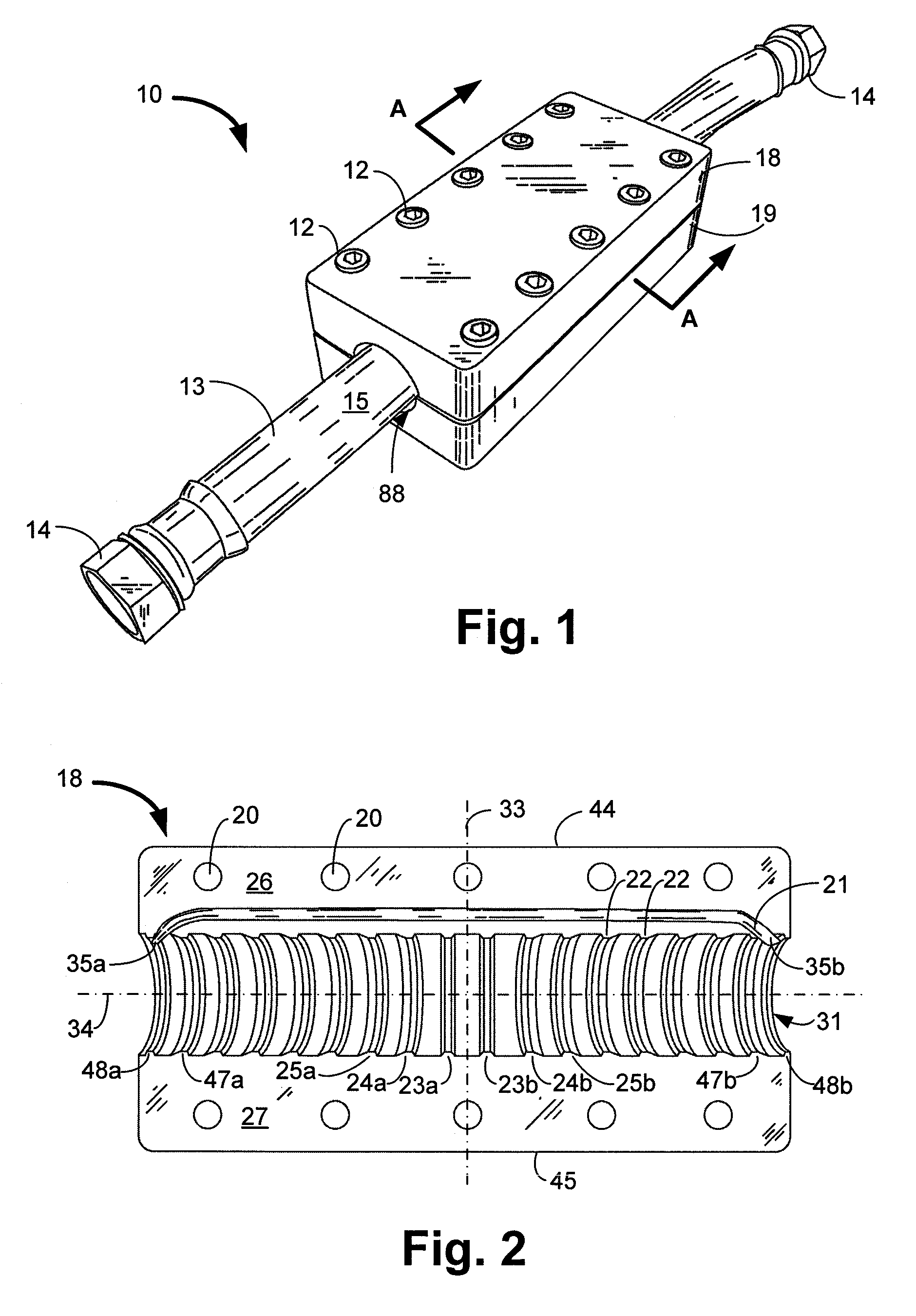

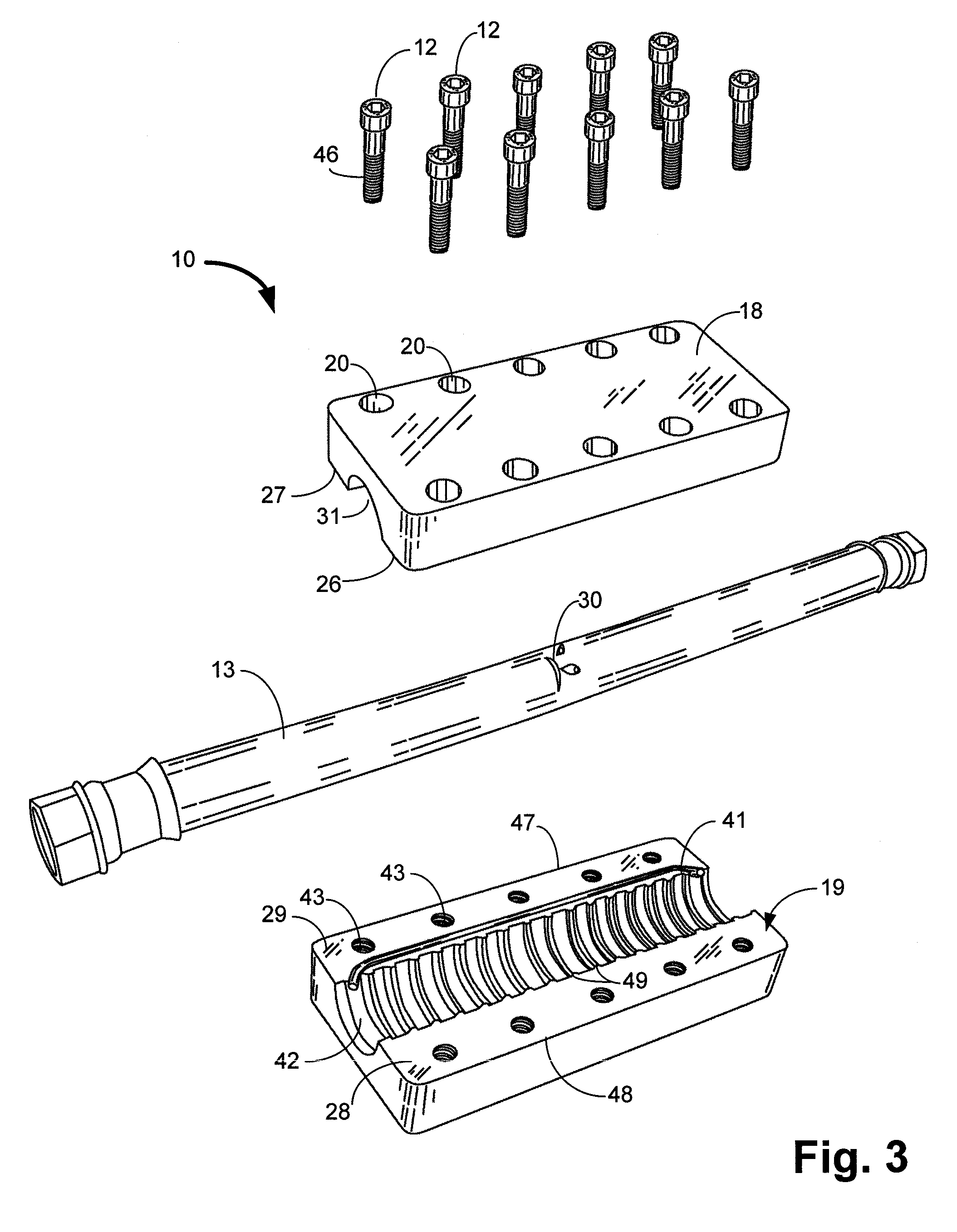

Hose Repair Clamp

A hose clamp for repairing high pressure hydraulic hoses comprises a first clamp portion mated to a second clamp portion around a hose. The first and second clamp portions each comprise a semi-cylindrical channel extending longitudinally along an inner surface of the clamp. The hose is received within the channel and a plurality of fasteners releasably affix the clamp portions together. A plurality of barbs extending circumferentially around the channel compress the hose to minimize leakage from the hose.

Owner:HOSEBEE

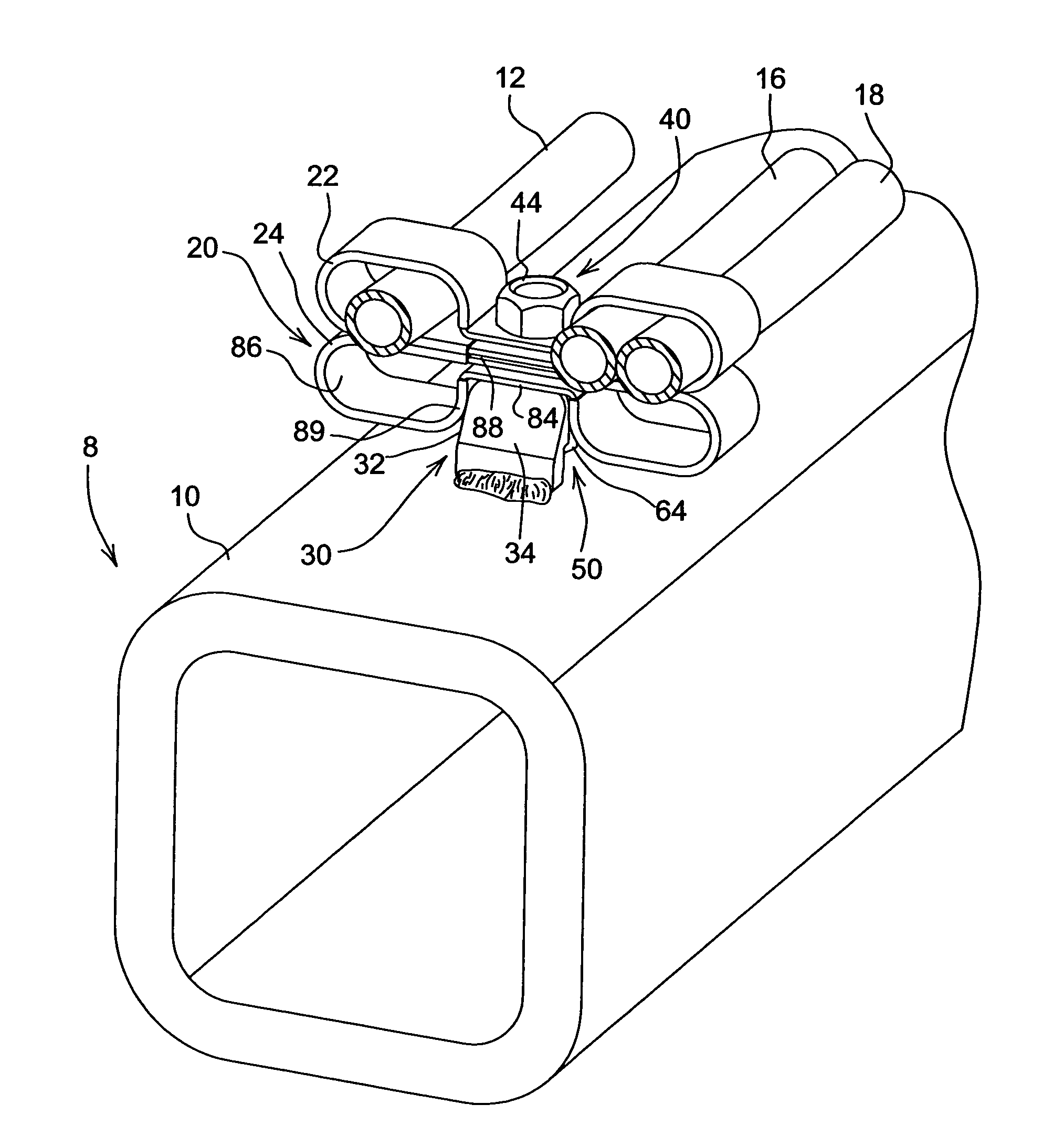

Pipe joint restraint

ActiveUS20100244437A1Sleeve/socket jointsFluid pressure sealed jointsEngineeringMechanical engineering

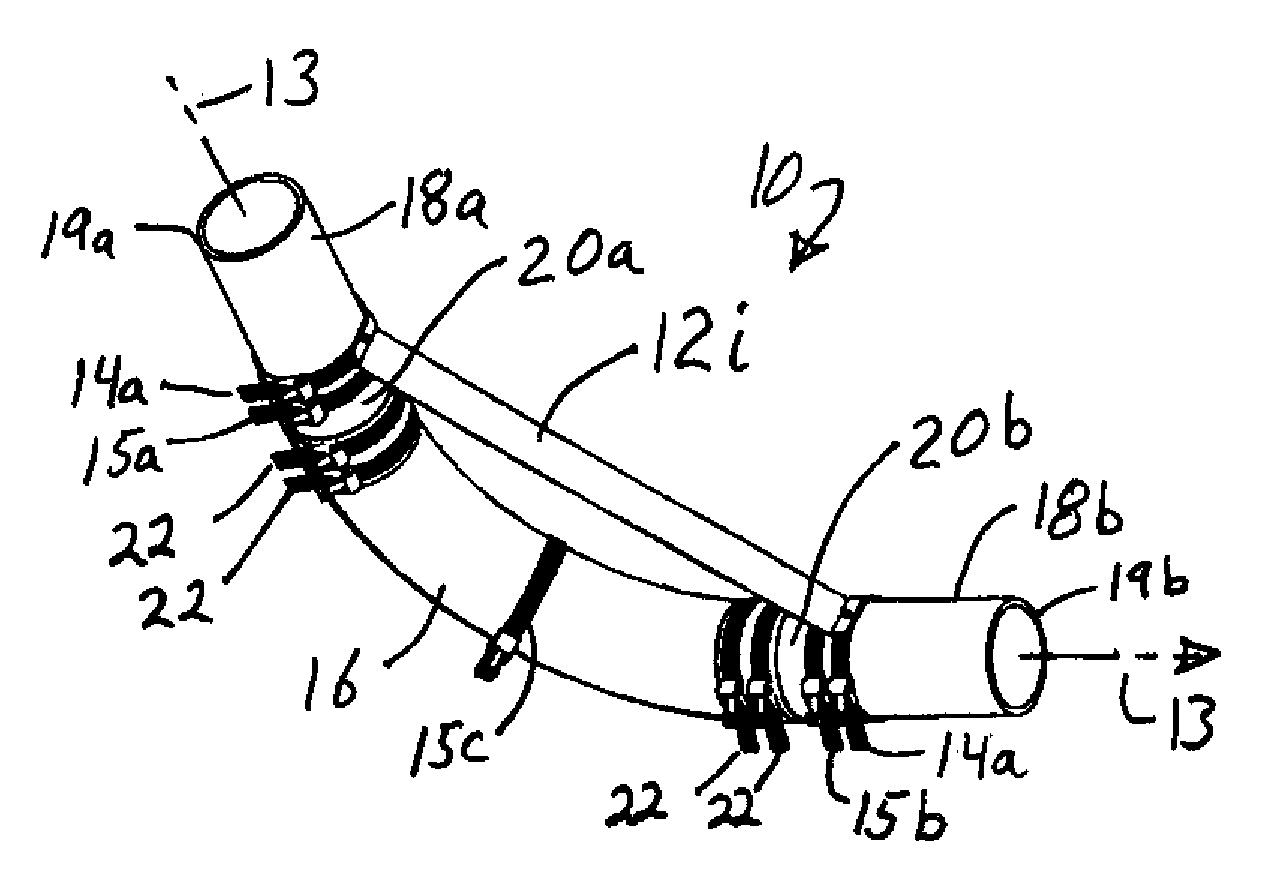

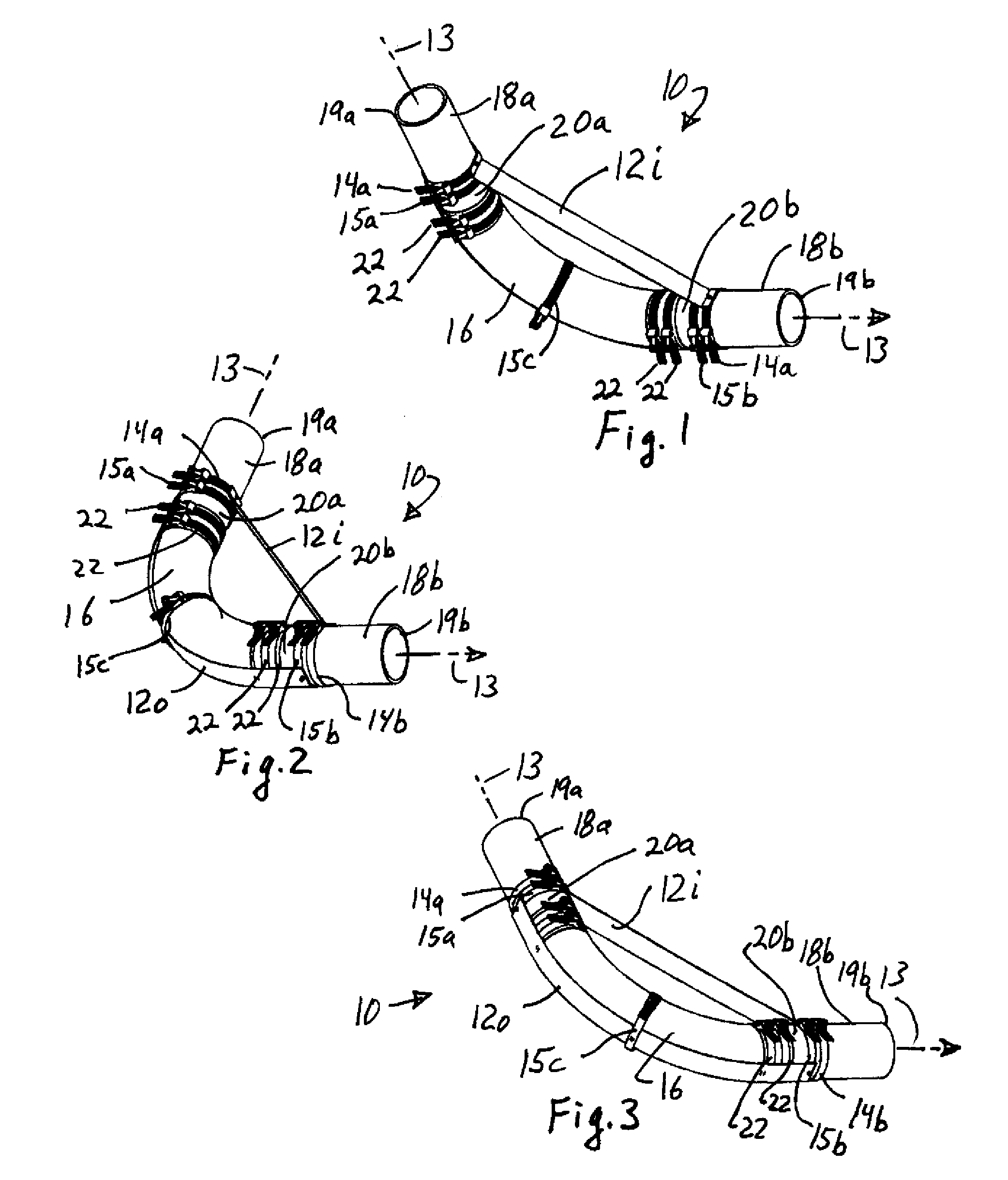

A joint restraint is provided for a curved pipe joint having a curved pipe section joining two adjacent pipe sections. The pipes are joined using tubular sleeves held by hose clamps to form fluid tight seals, with two clamps on each end of the curved pipe sections and two clamps on each proximal end of the adjacent pipe sections. An inner strap extends between and fastens to one of the clamps on each adjacent pipe section forming a chord of an arc. An outer strap extends along an outer periphery of the joined pipes and fastens to the other clamps on each adjacent pipe section. The straps are in a plane through a center of the flow path of the joined pipes

Owner:RELIANCE WORLDWIDE CORP

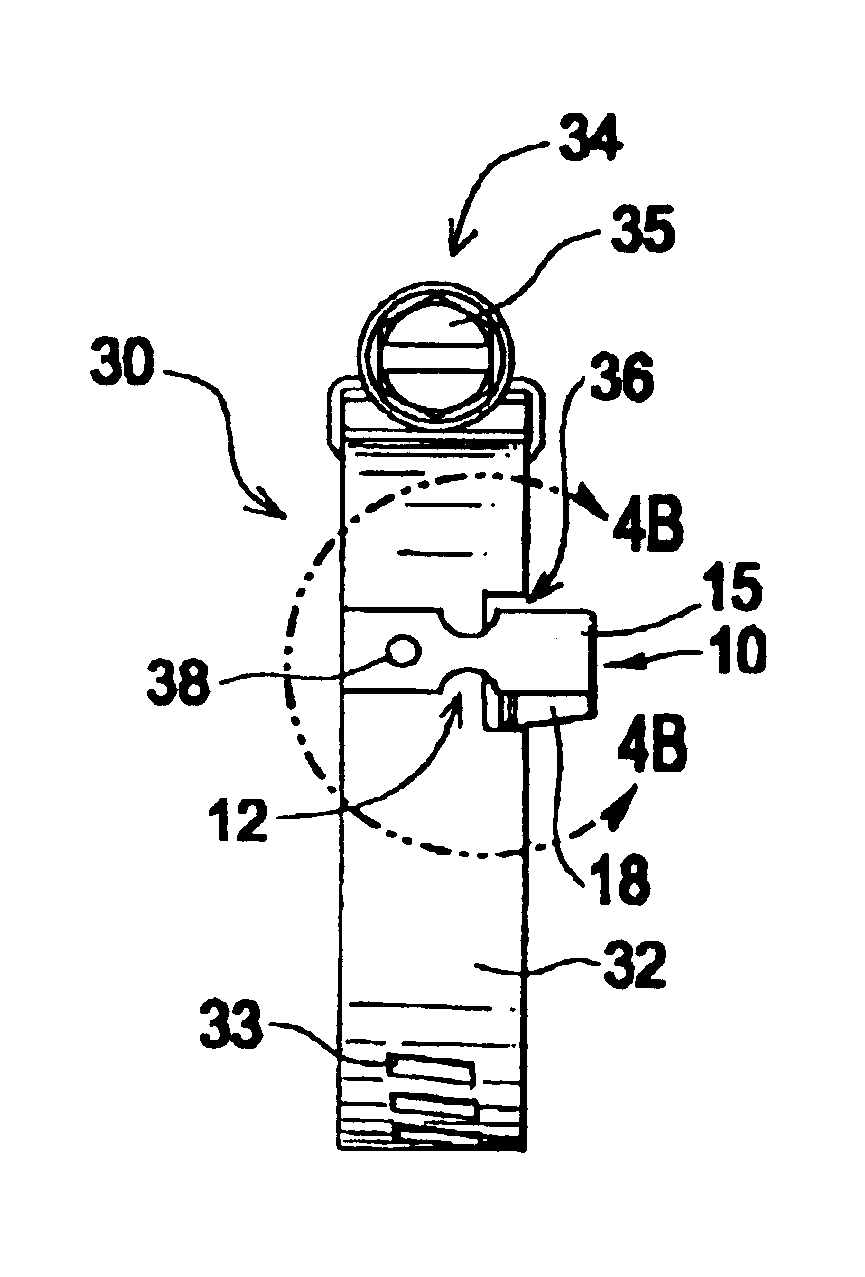

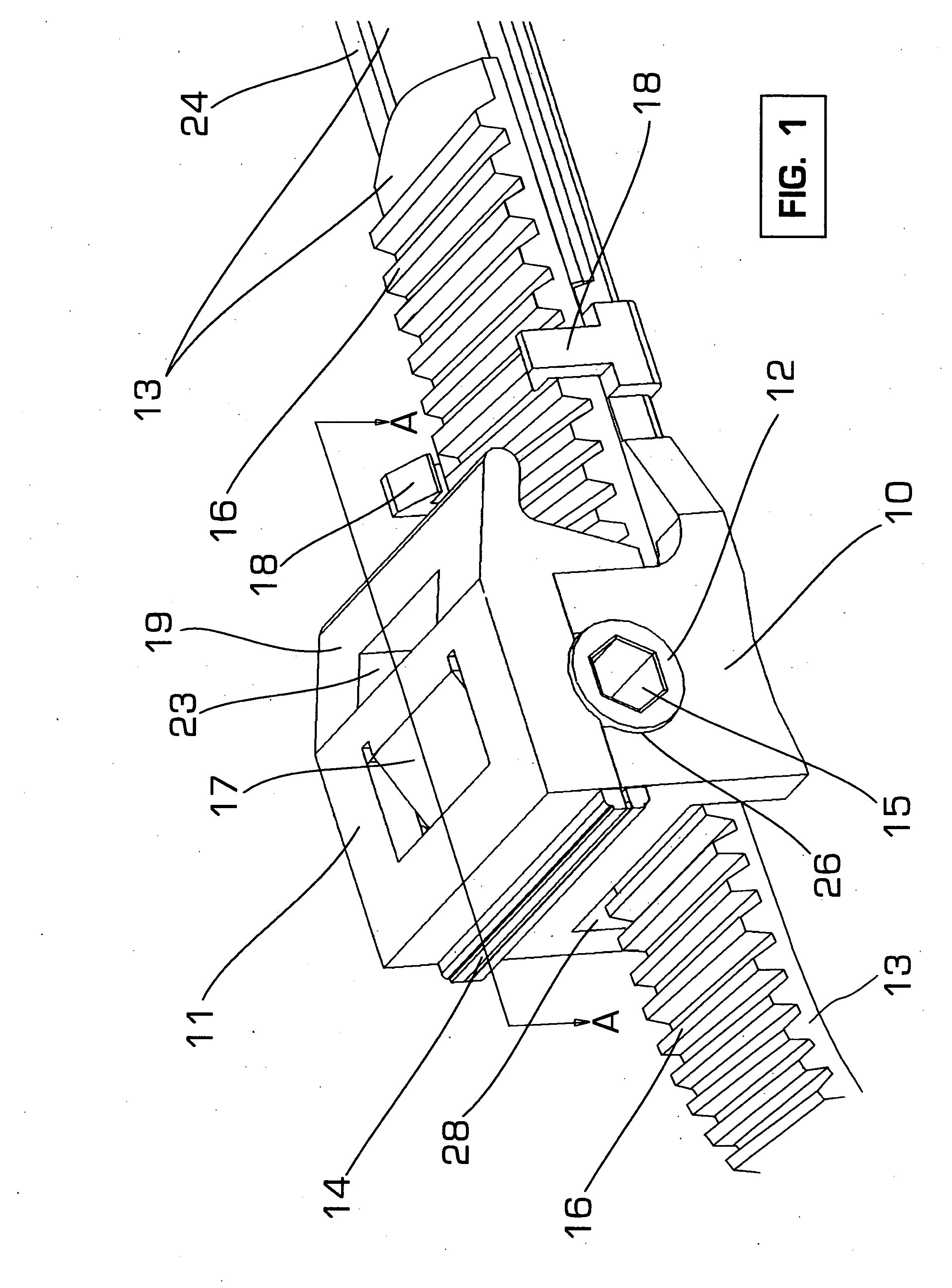

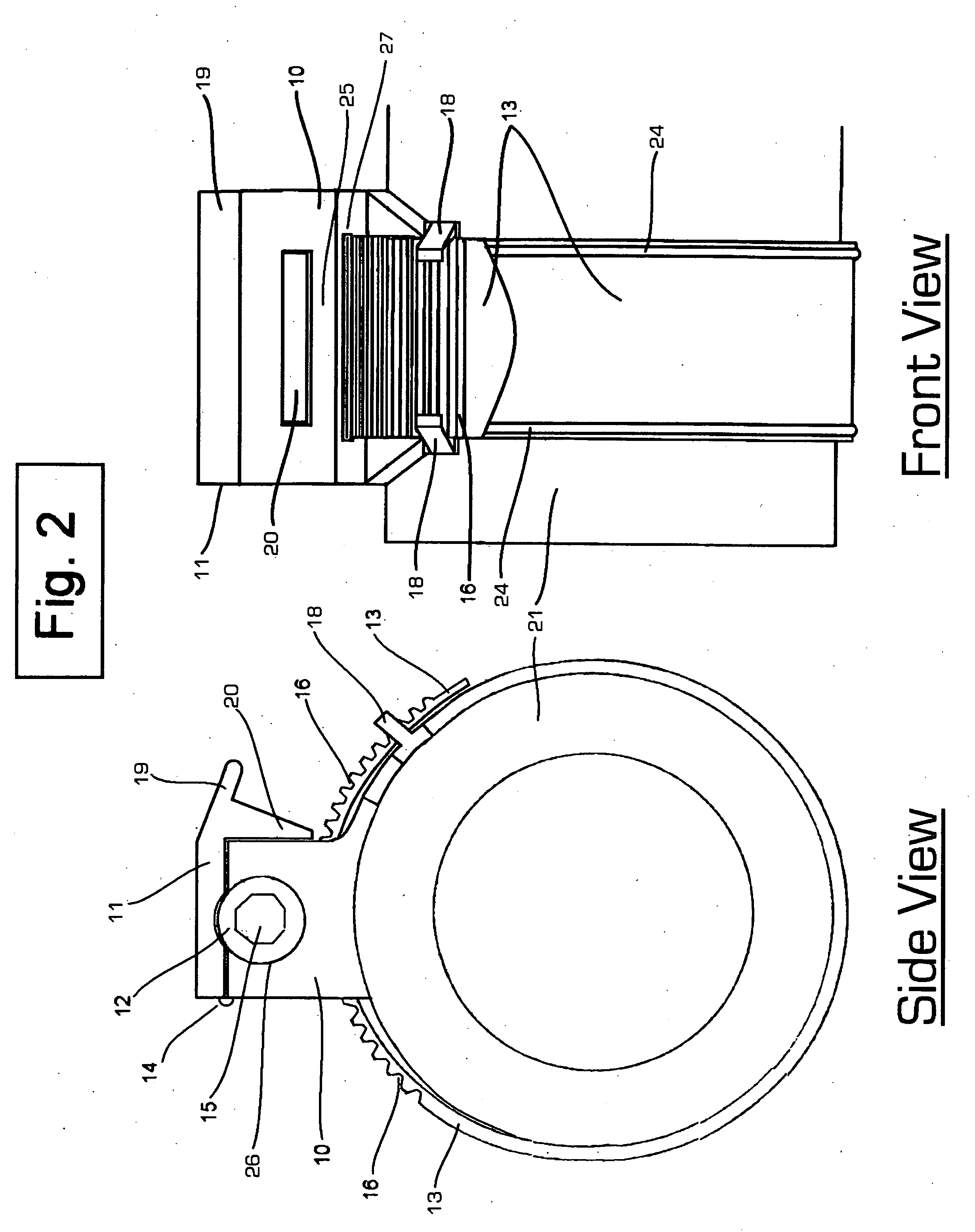

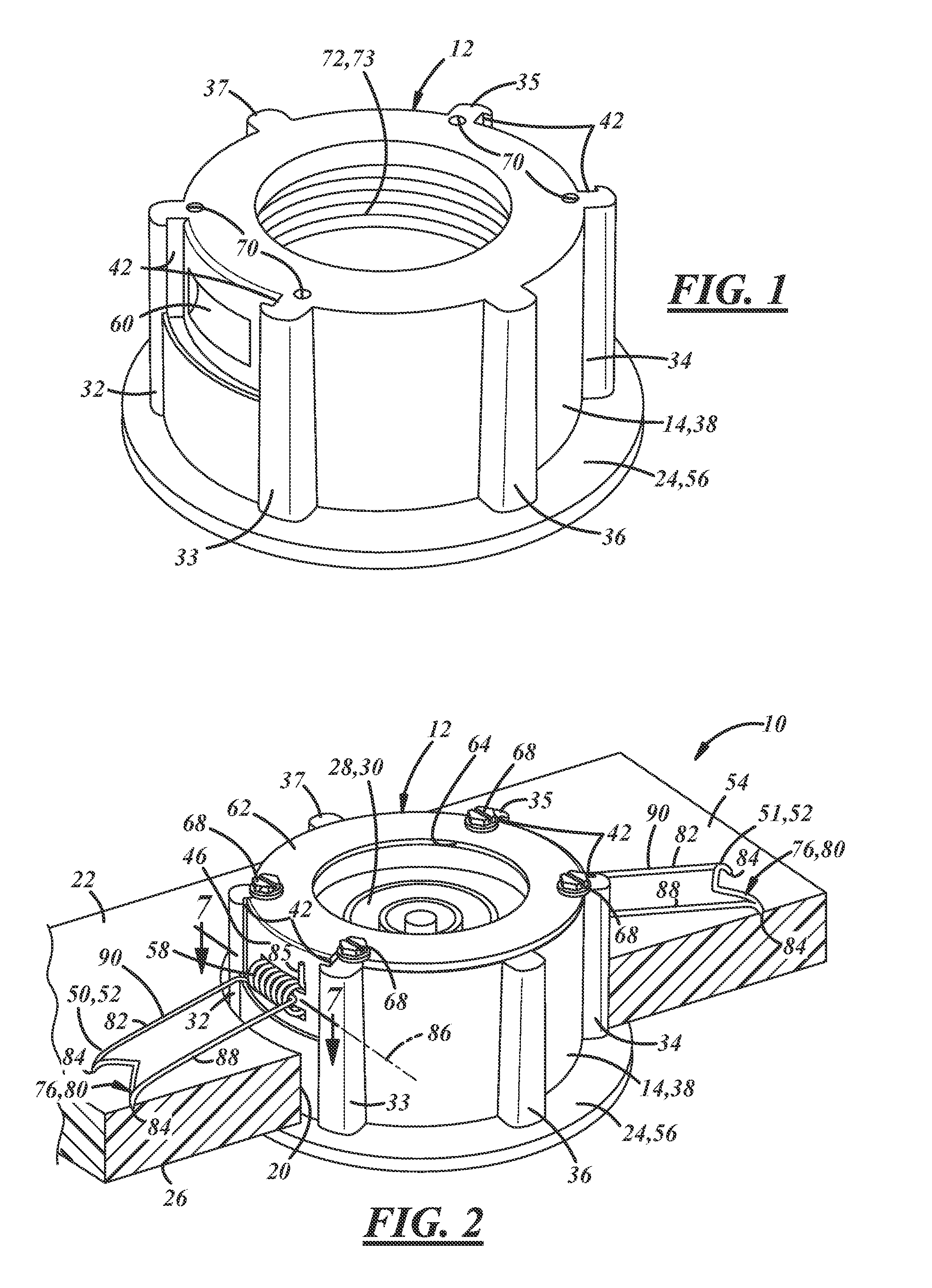

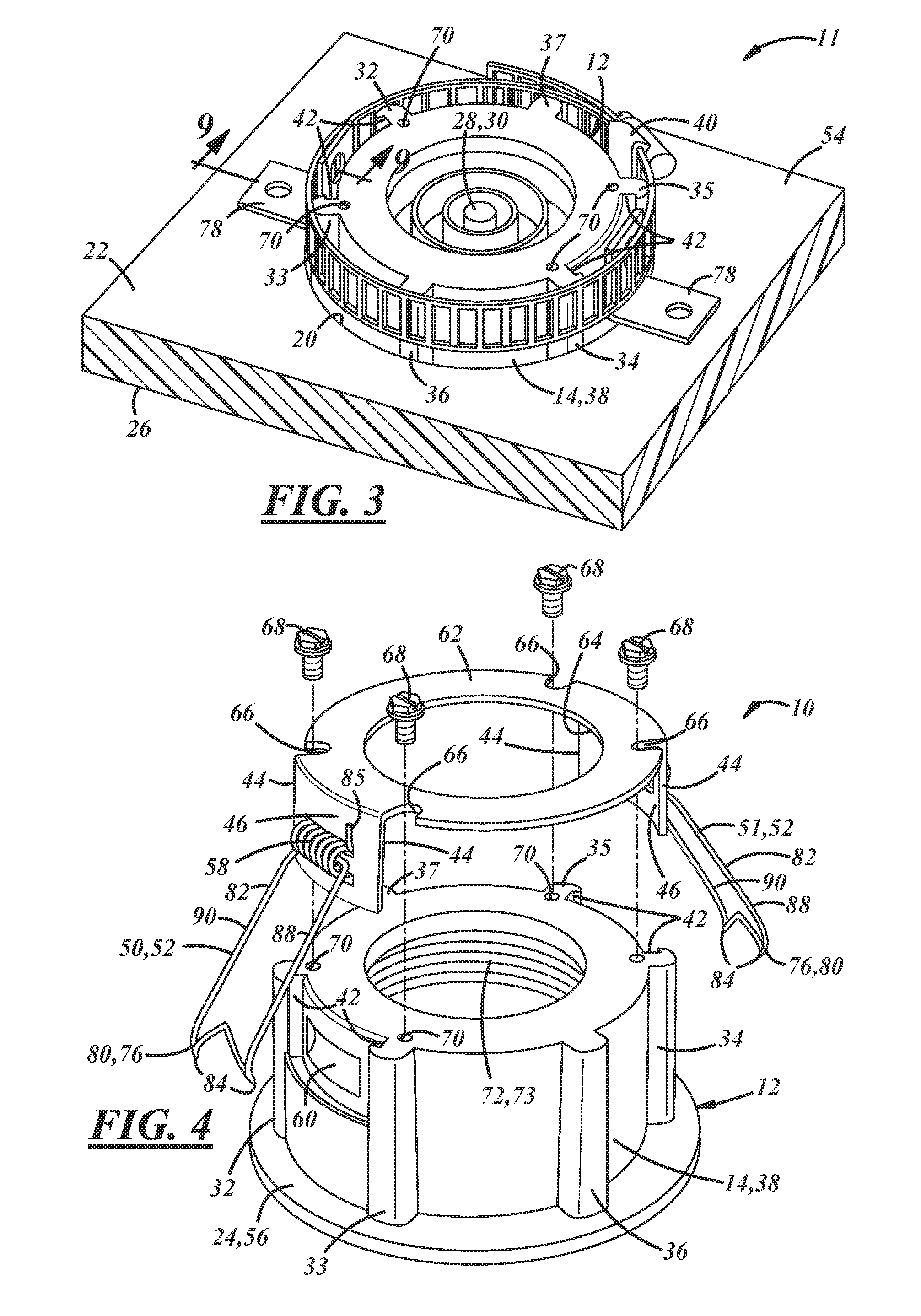

Hose clamp with parallel tightening and rapid release

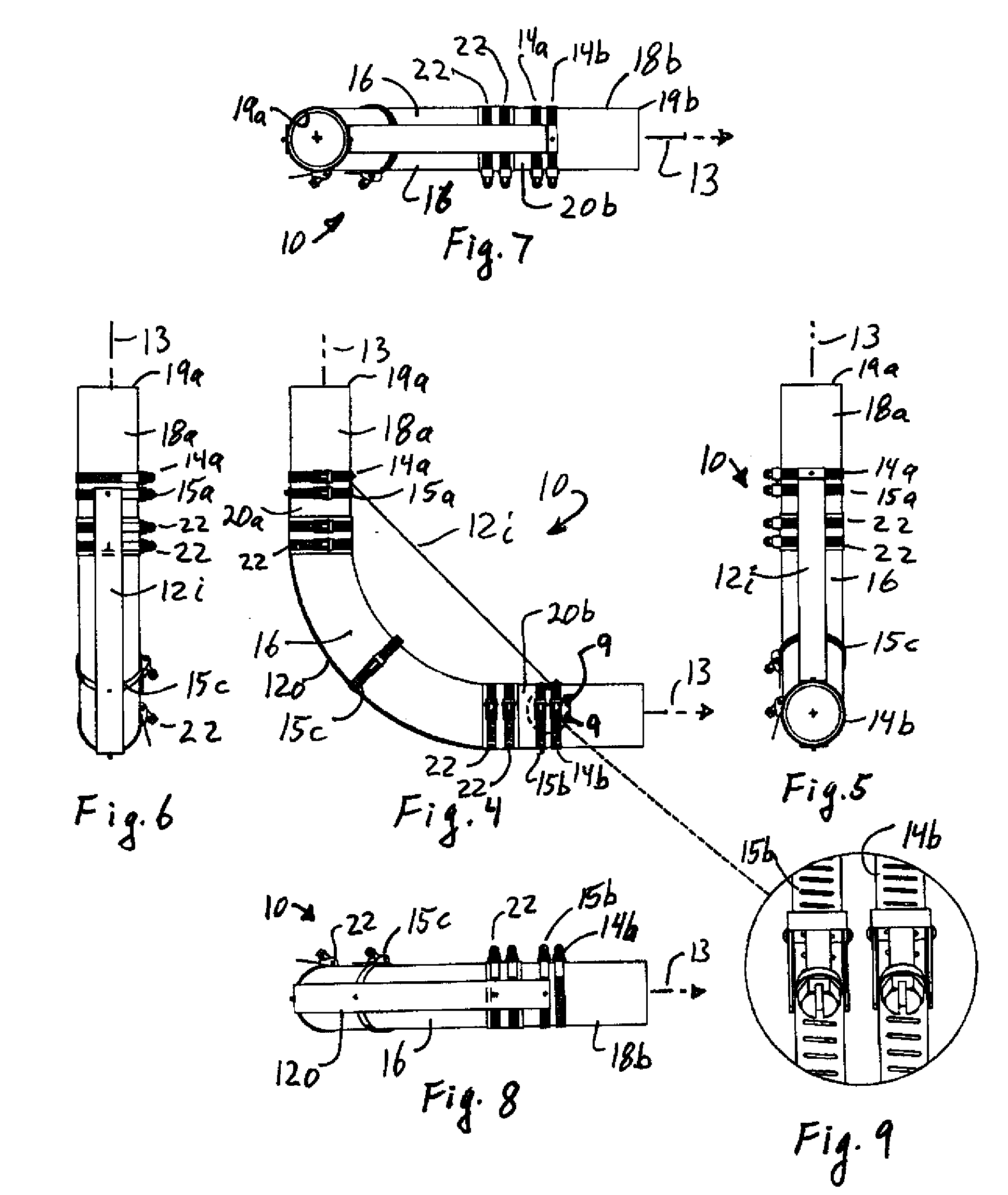

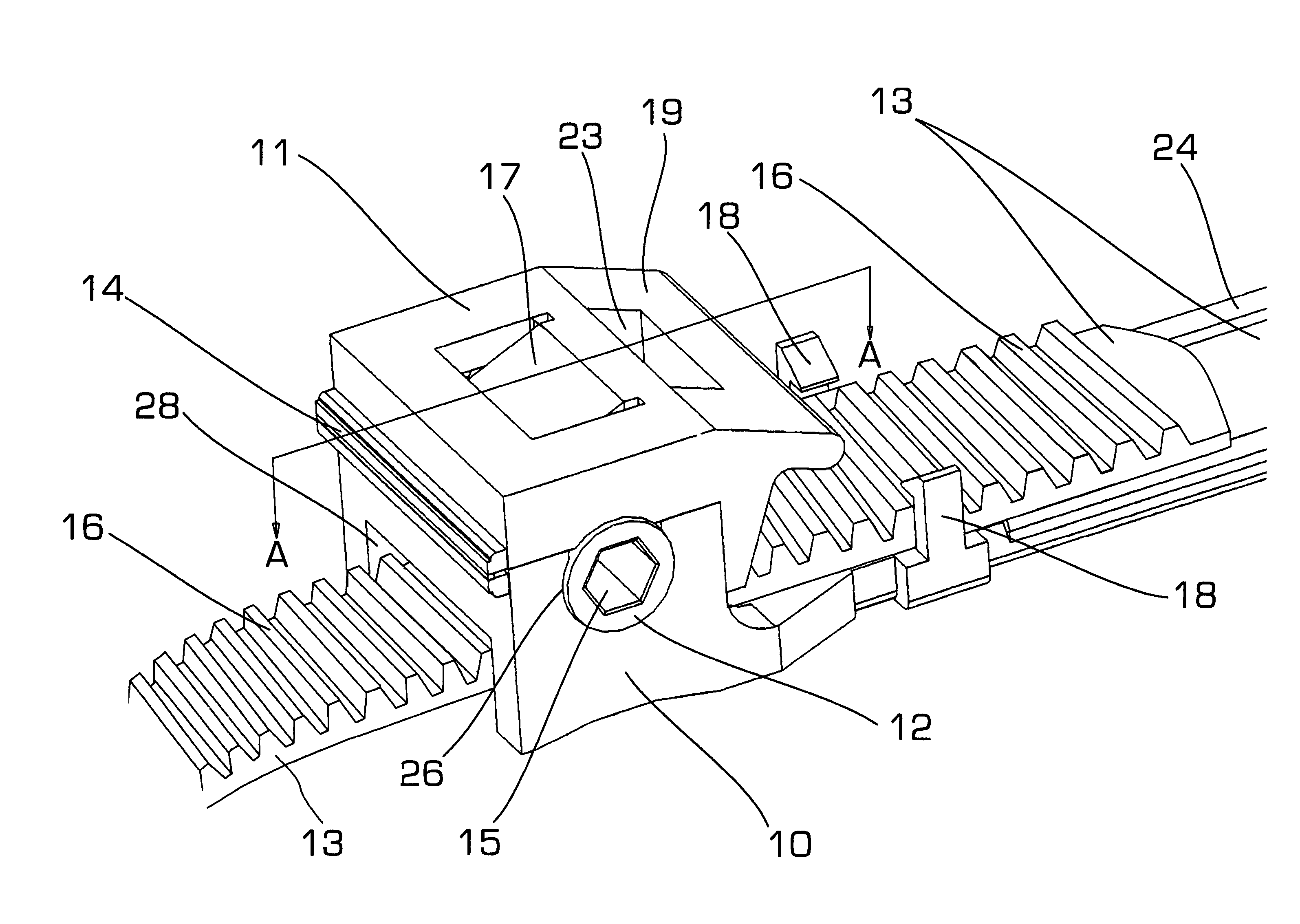

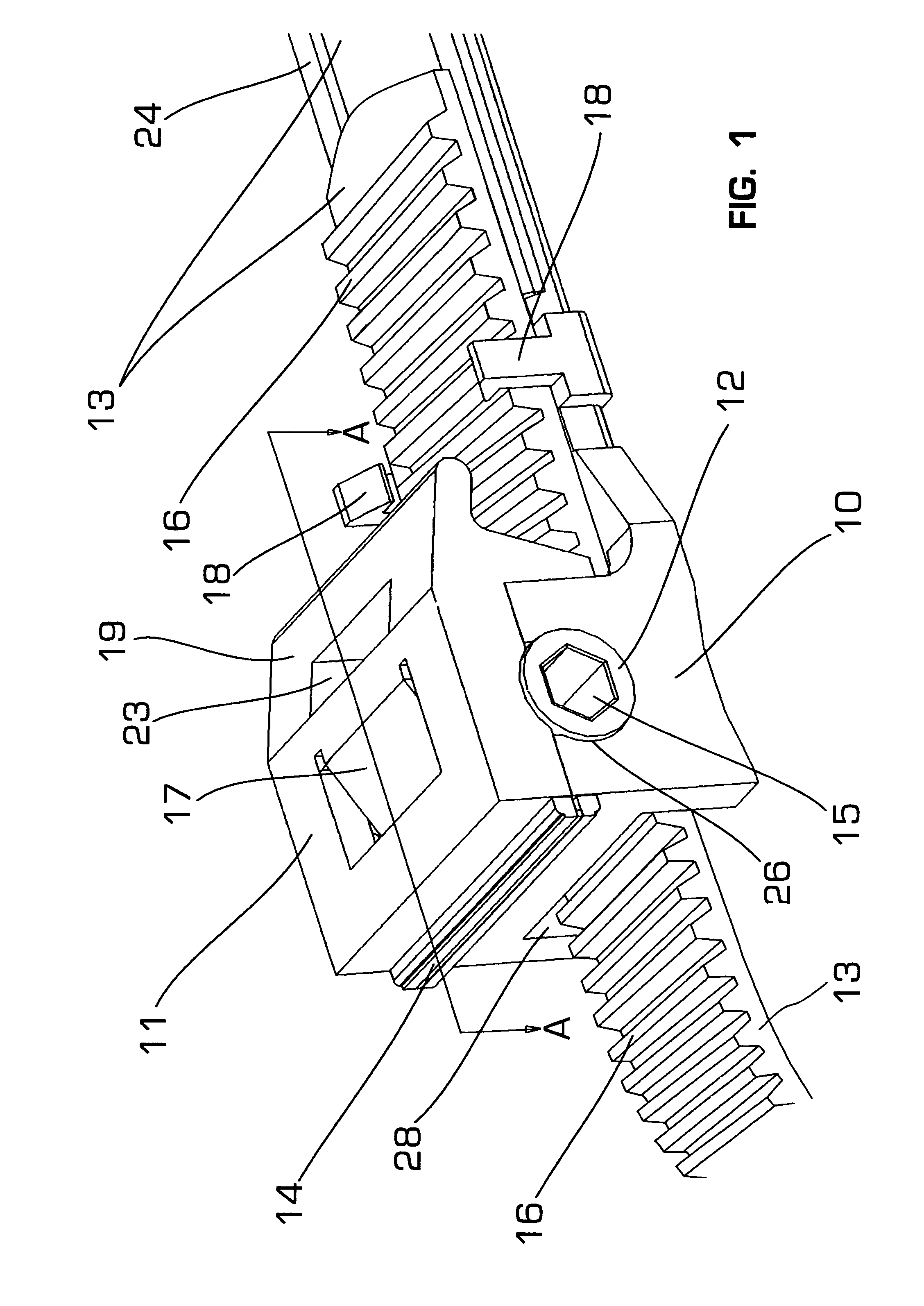

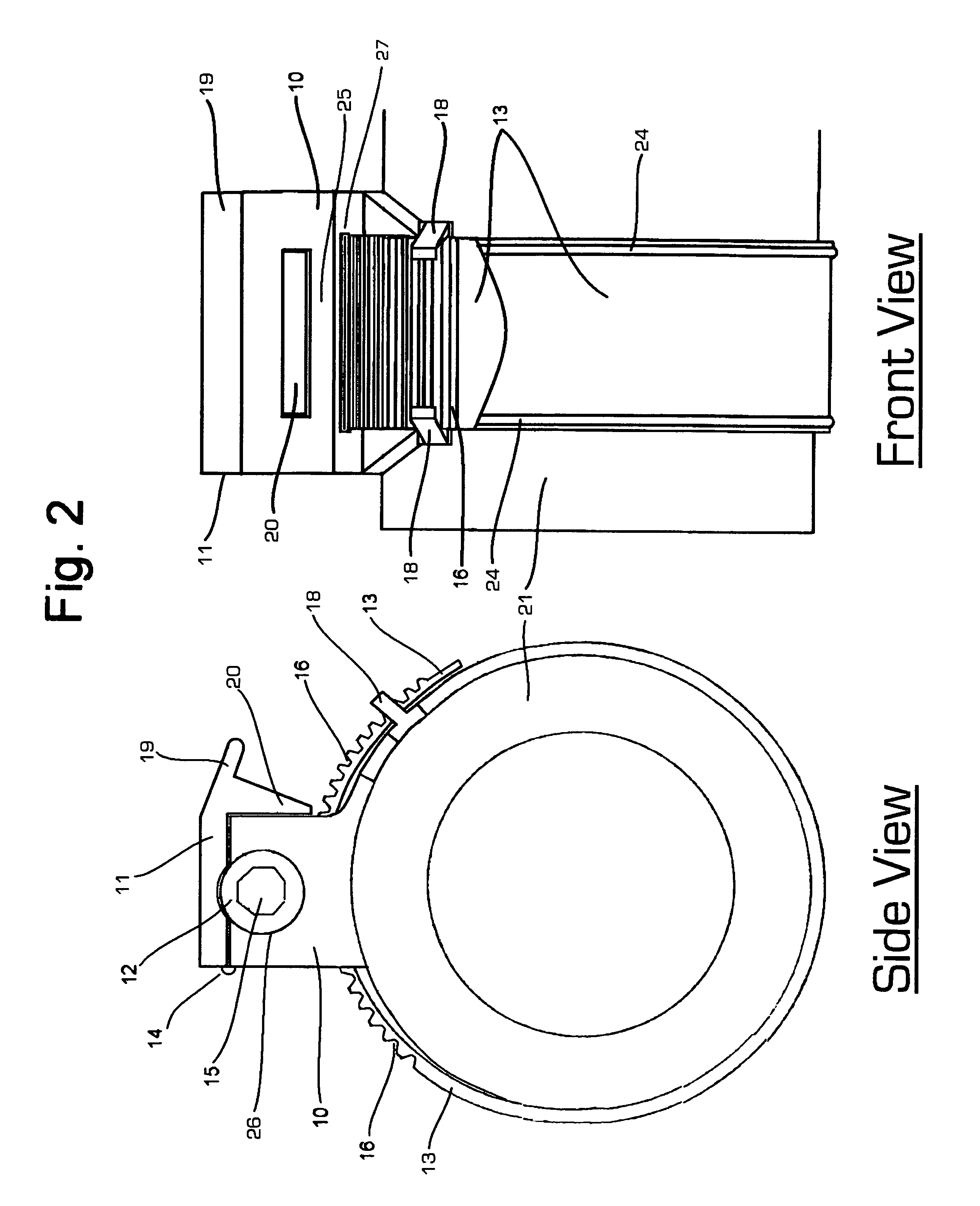

An improved clamp constricting objects to be held in place including hoses wires tubes. One embodiment having some or all plastic molded parts one of which is a support base (10) to one side is attached a partially grooved or fully flexible grooved band strap (13) where as the other end is free to enter a band strap entrance port (26) thereby contact is made with a matching grooved rotating cylinder (12) held by two bearings. The band strap (13) advances encircling objects to be held. The support base top (11) is closed and locked by the rapid release hold down top lock (20) confining the grooved molded rotating cylinder (12) engaging a flexible paw (17) allowing advancing rotation only, preventing the grooved molded band strap (13) from retracting. Six sided wrench or tool is inserted into the cylinder cavity (15) forcefully rotating the grooved rotating cylinder (12) advancing the flexible grooved band strap (13) through exit port (27) being held down by band strap retainers (18). A rapid release finger grip (19) releases a rapid release hold down top lock (20) lifting the molded support base top (11) disengaging the flexible paw (17) from the grooved molded rotating cylinder (12) allowing counter rotation of the grooved molded rotating cylinder (12) retracting the flexible grooved band strap (13) freeing the constricted objects.

Owner:POSNER SAMUEL LEWIS

Clamp holder

InactiveUS7093808B2Easy to packAvoid damageSnap fastenersPipe supportsEngineeringMechanical engineering

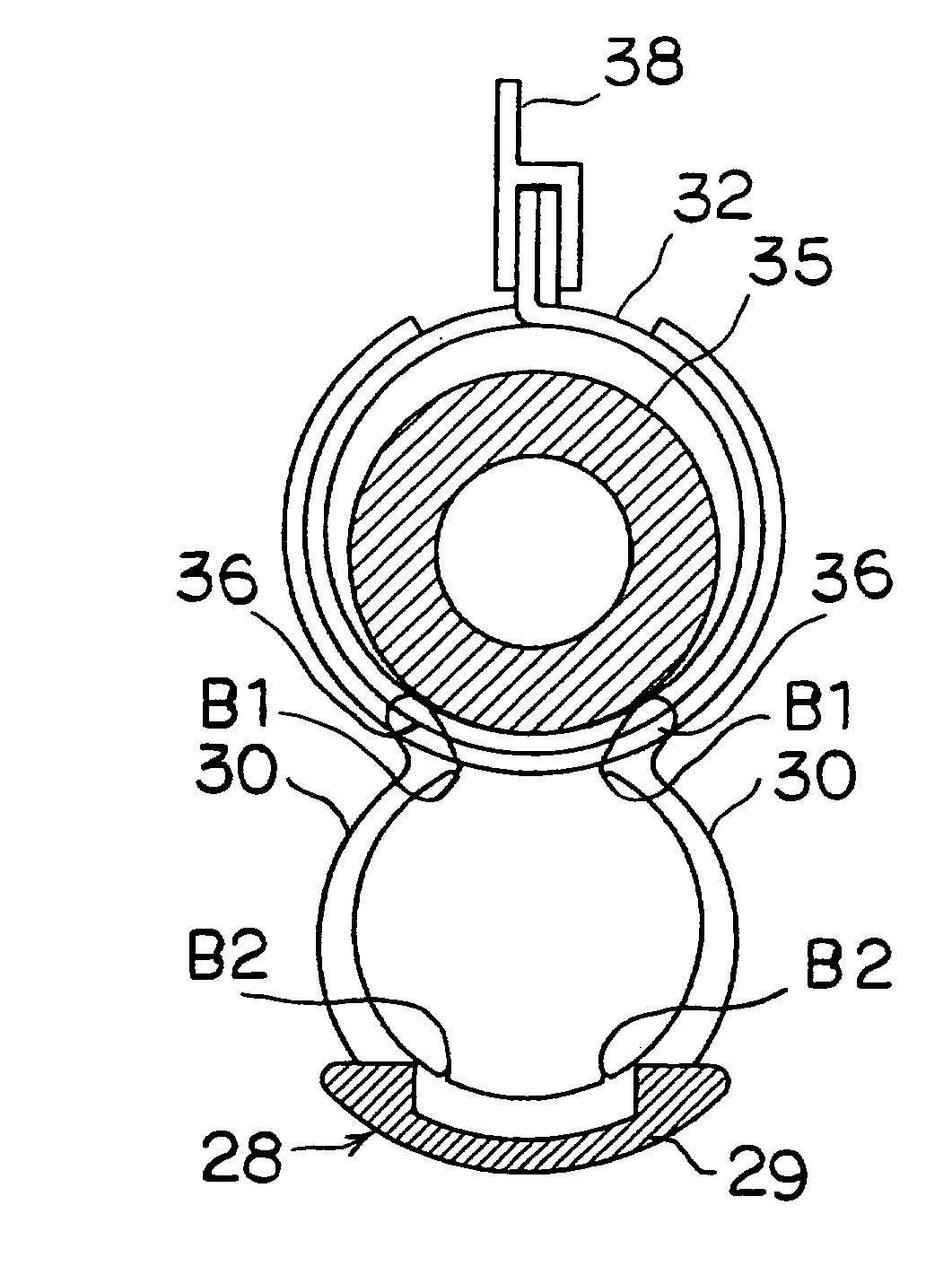

In a holder having a holder base and holding arms and used for holding a hose clamp in position, the holder base is so constructed as to be capable of being positioned on the outer periphery of an annular hose clamp and a pair of holding arms protrude from each of a pair of opposite lateral edges of the holder base. Each pair of holding arms are so shaped as to define a pair of opposed arcs extending along a circumference A having a diameter somewhat smaller than the outside diameter of a hose. Each holding arm has a sharp projection B1 formed on its inner peripheral surface at its distal end and directed substantially toward the center of the circumference A, or more inwardly than it. The clamp holder facilitates the preliminary holding of a hose clamp in position on a hose without damaging the hose, and without slipping off the hose or being displaced easily.

Owner:SUMITOMO RIKO CO LTD

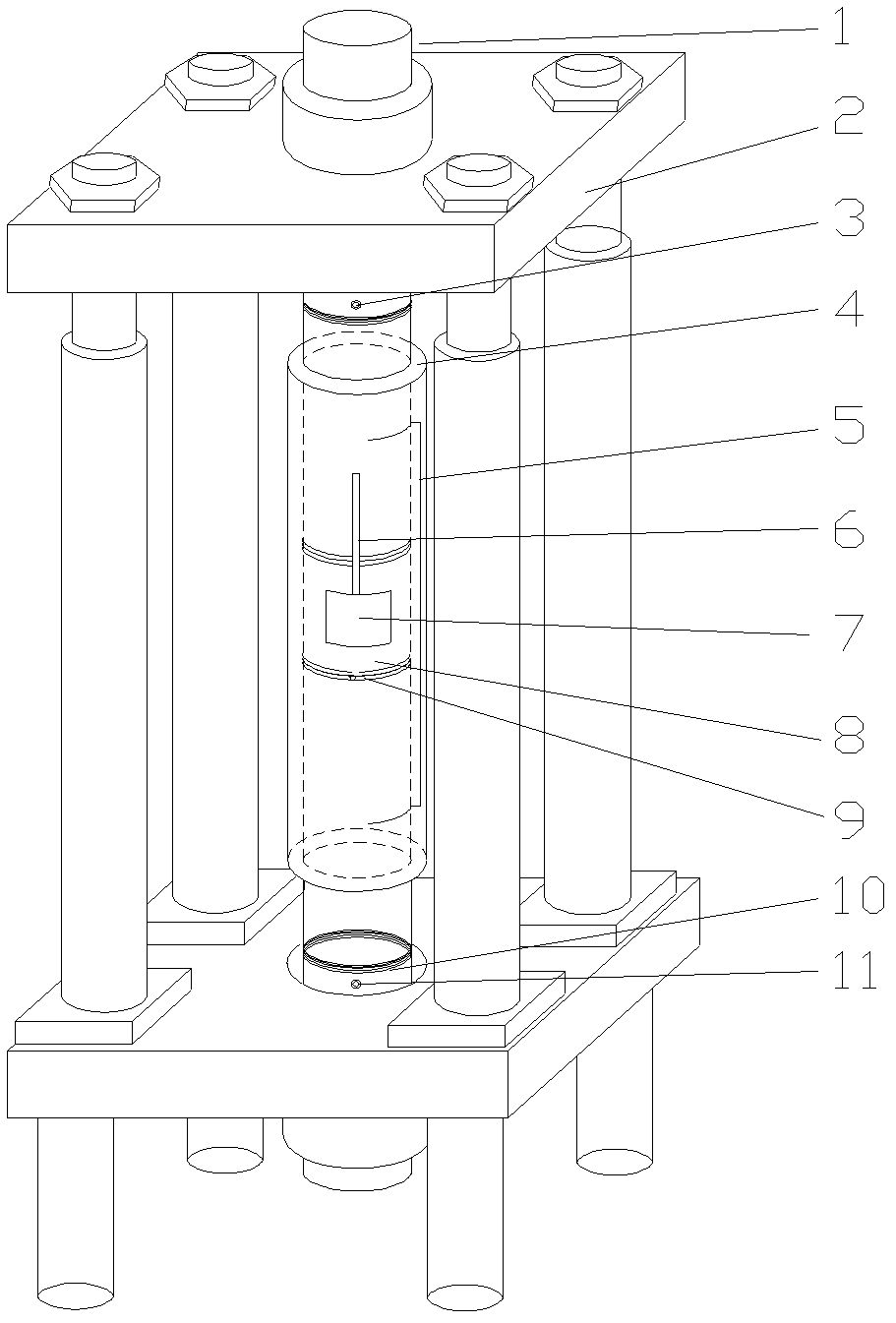

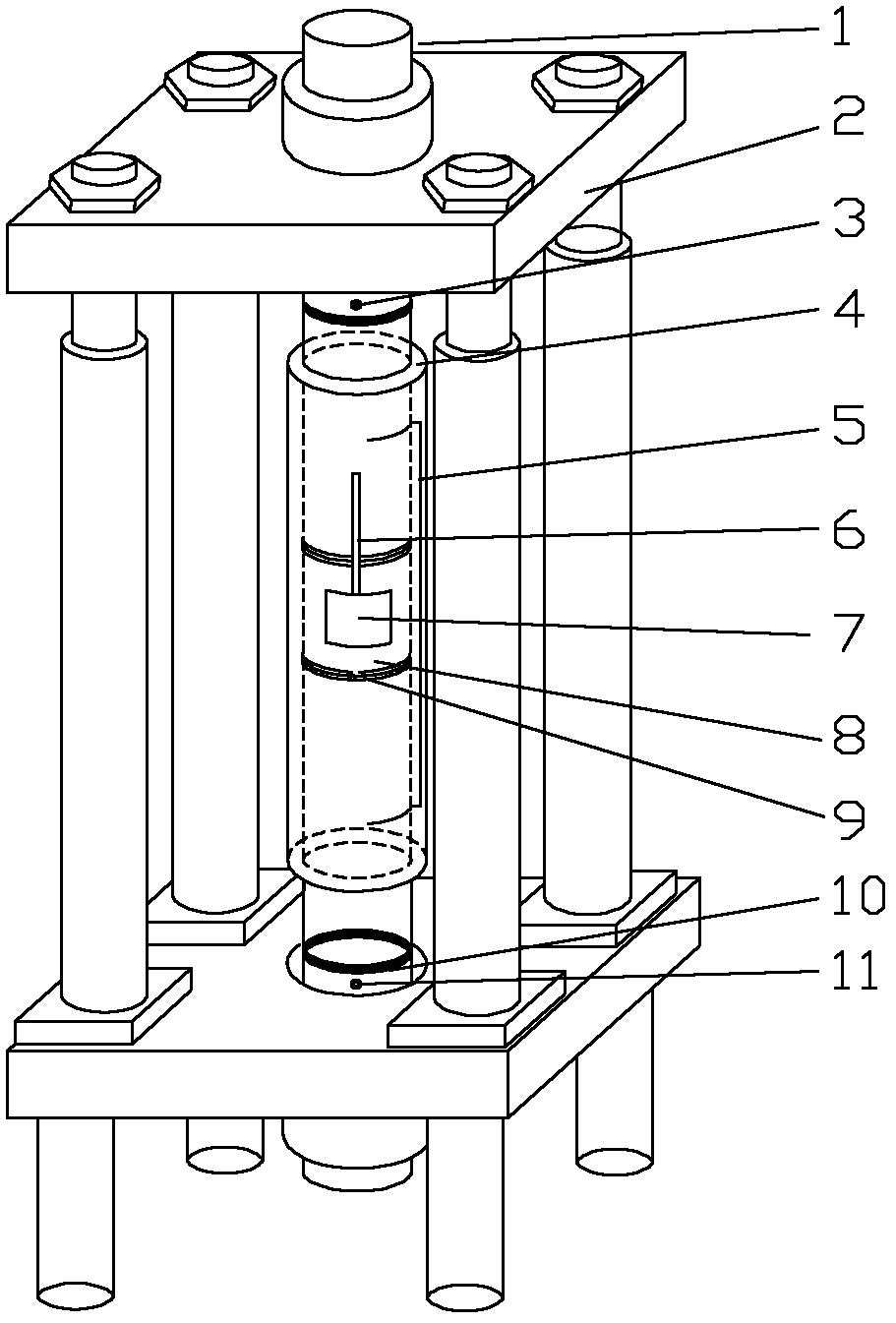

Heavy oil thermal recovery casing pipe testing device

InactiveCN102589990AImprove reliabilityEasy to useFluid-tightness measurementMaterial strength using repeated/pulsating forcesInternal pressureCoupling

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

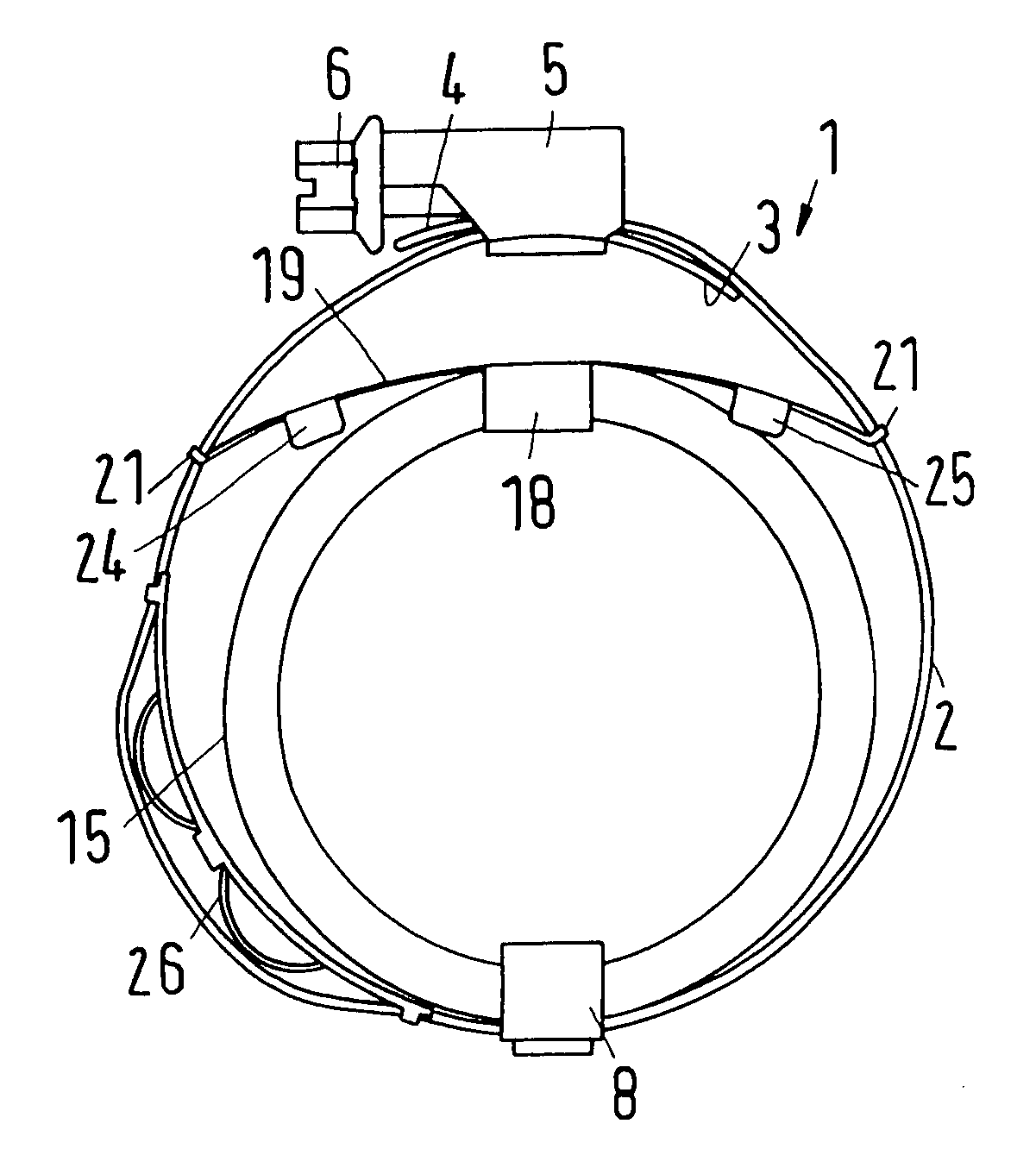

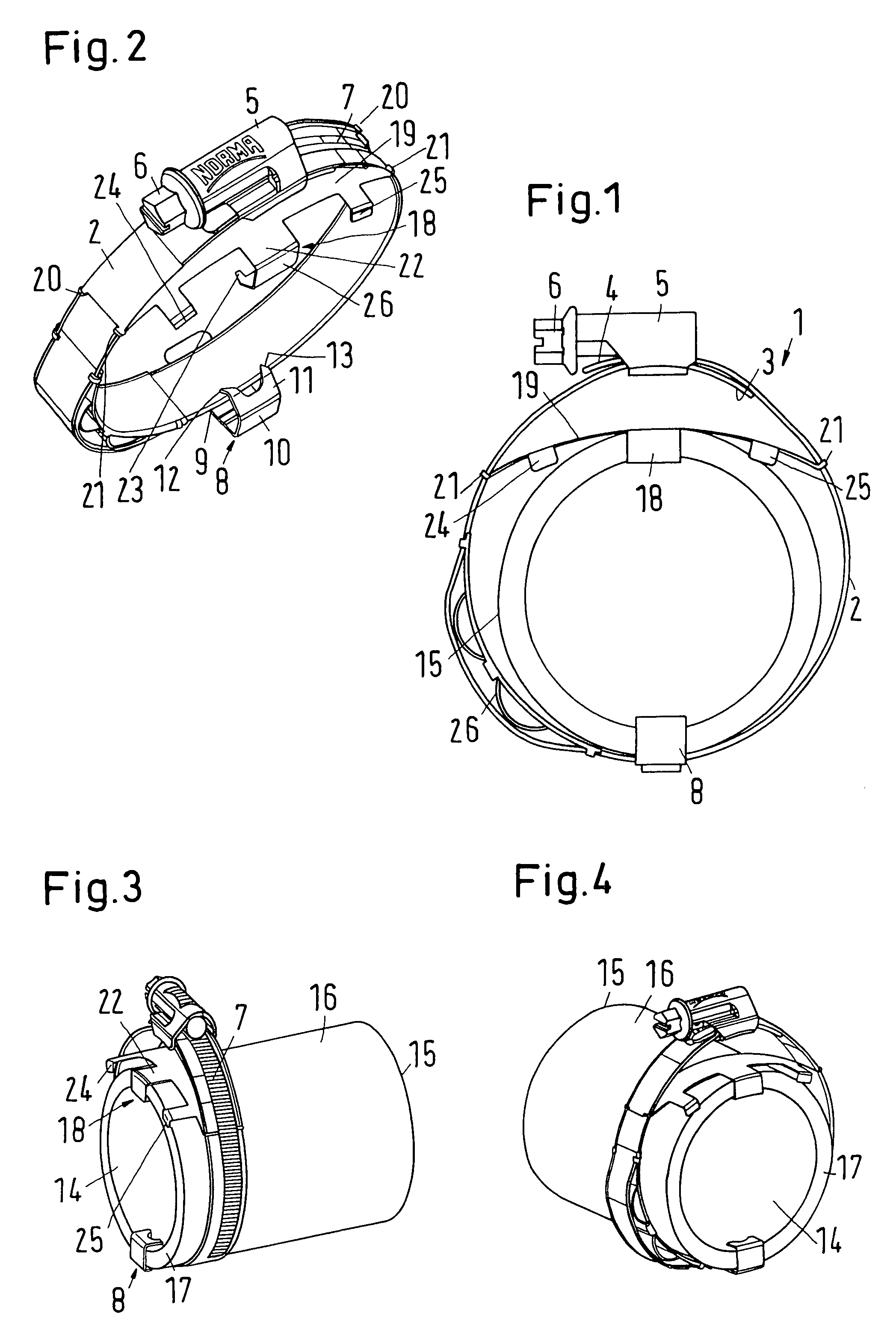

Hose clamp

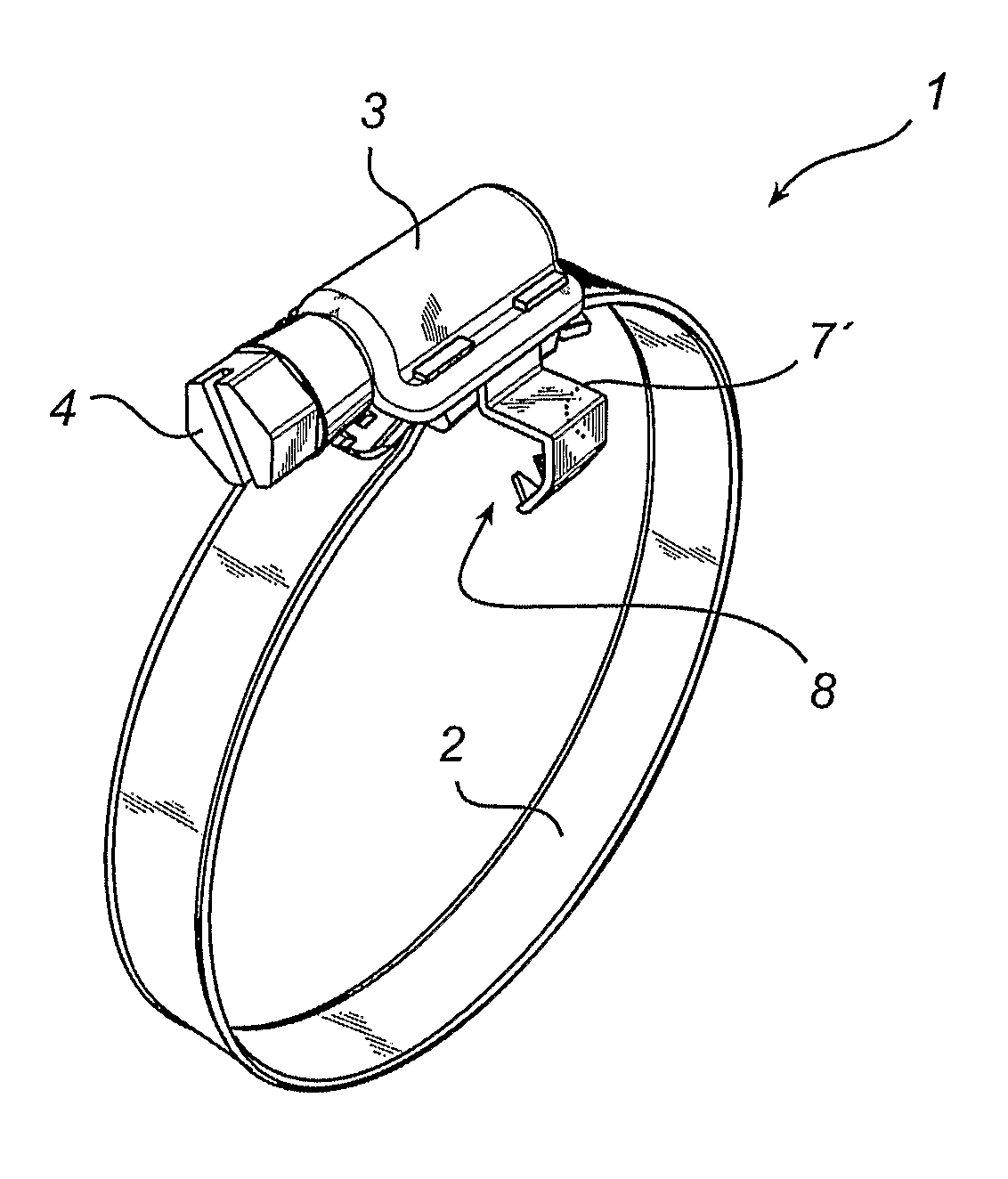

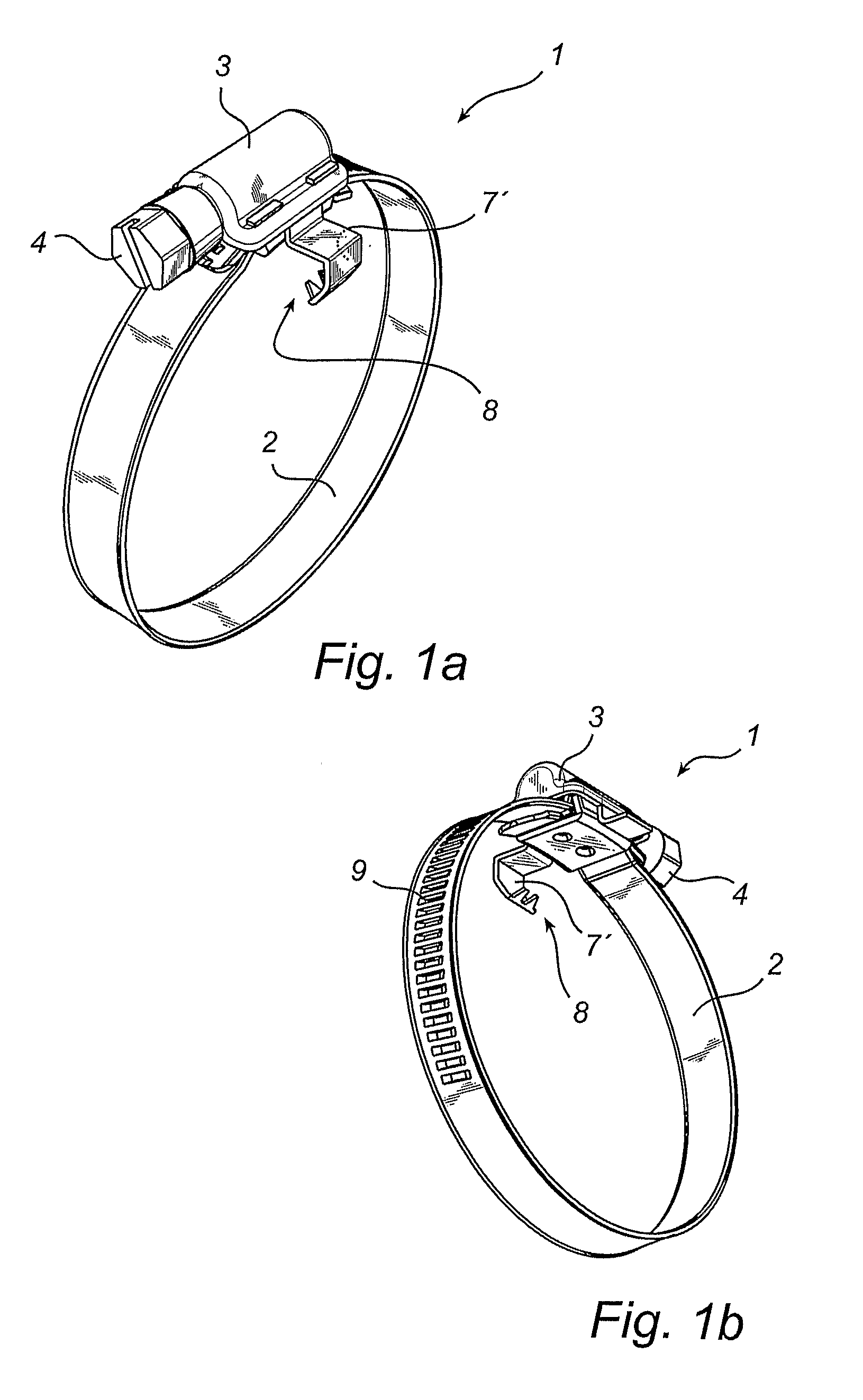

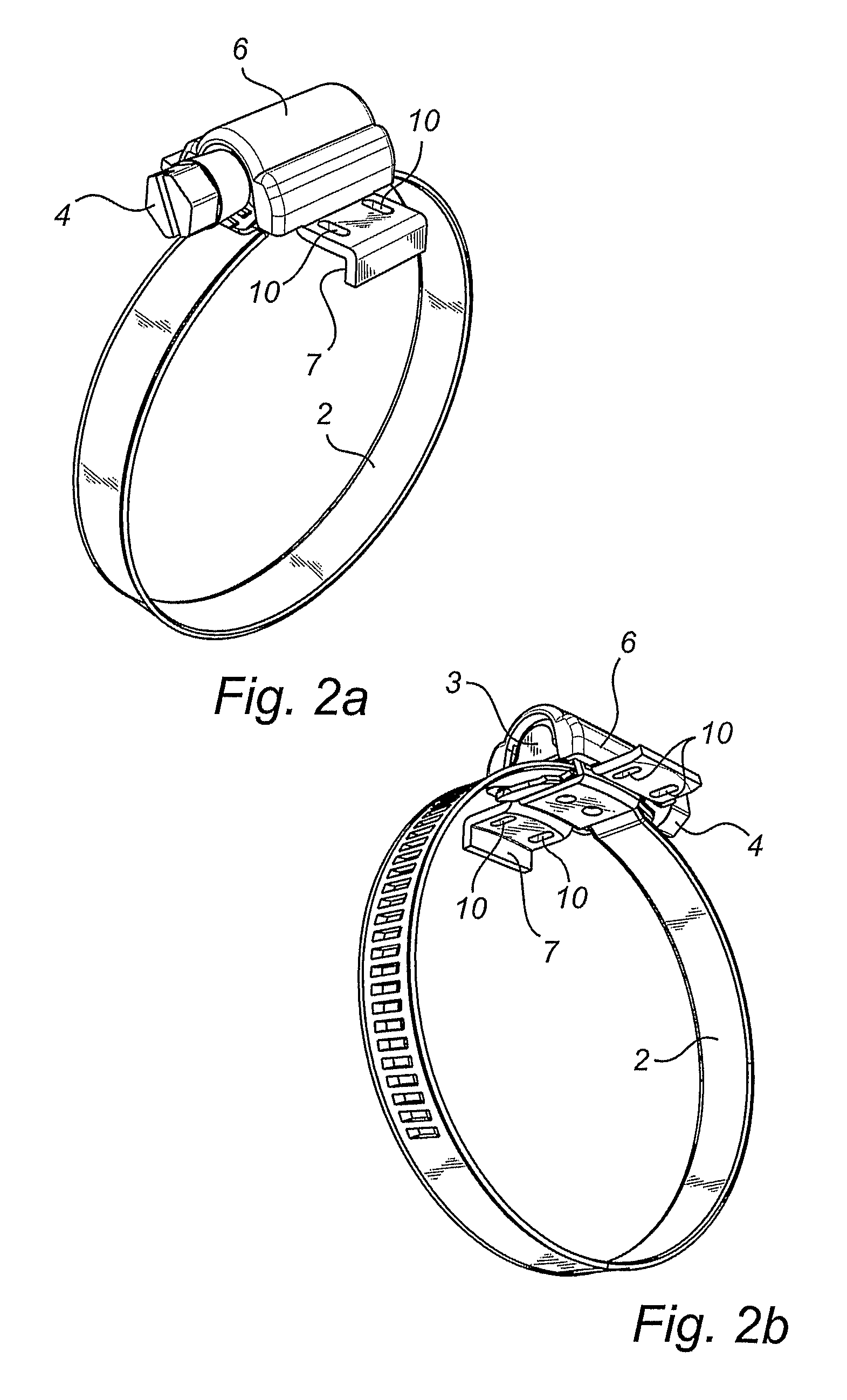

ActiveUS7761962B2Inaccurate tightening can be preventedLess careSnap fastenersFlexible elementsElectrical and Electronics engineeringHose clamp

A hose clamp includes a clamping band, a tensioning device and a positioning arrangement for positioning the hose clamp on a hose. The positioning arrangement includes at least two positioners. The two positioners may be arranged at a distance from each other in a circumferential direction of at least 120°. Axial stops may be arranged on both sides in a circumferential direction of at least one of the positioners.

Owner:NORMA GERMANY GMBH

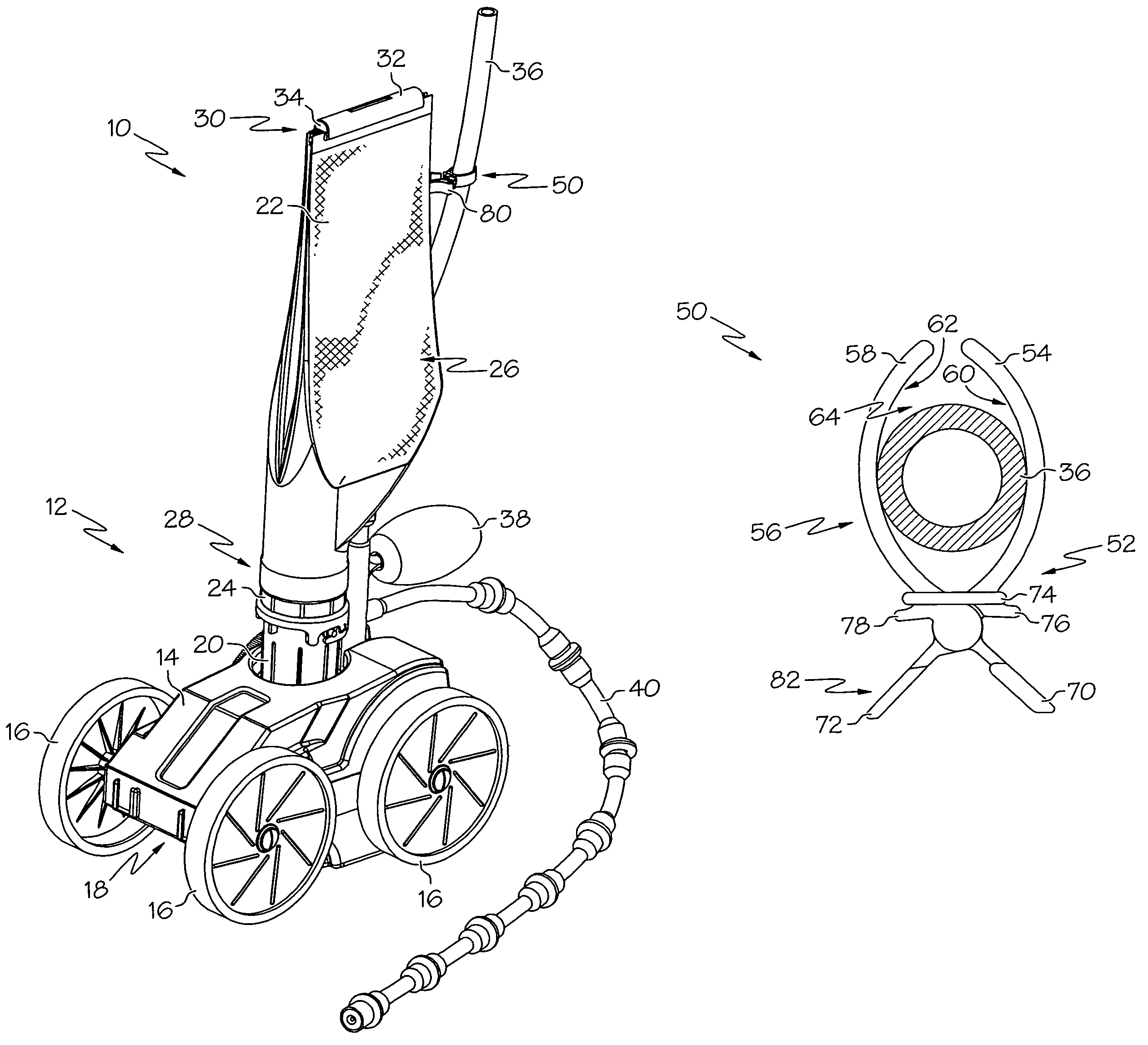

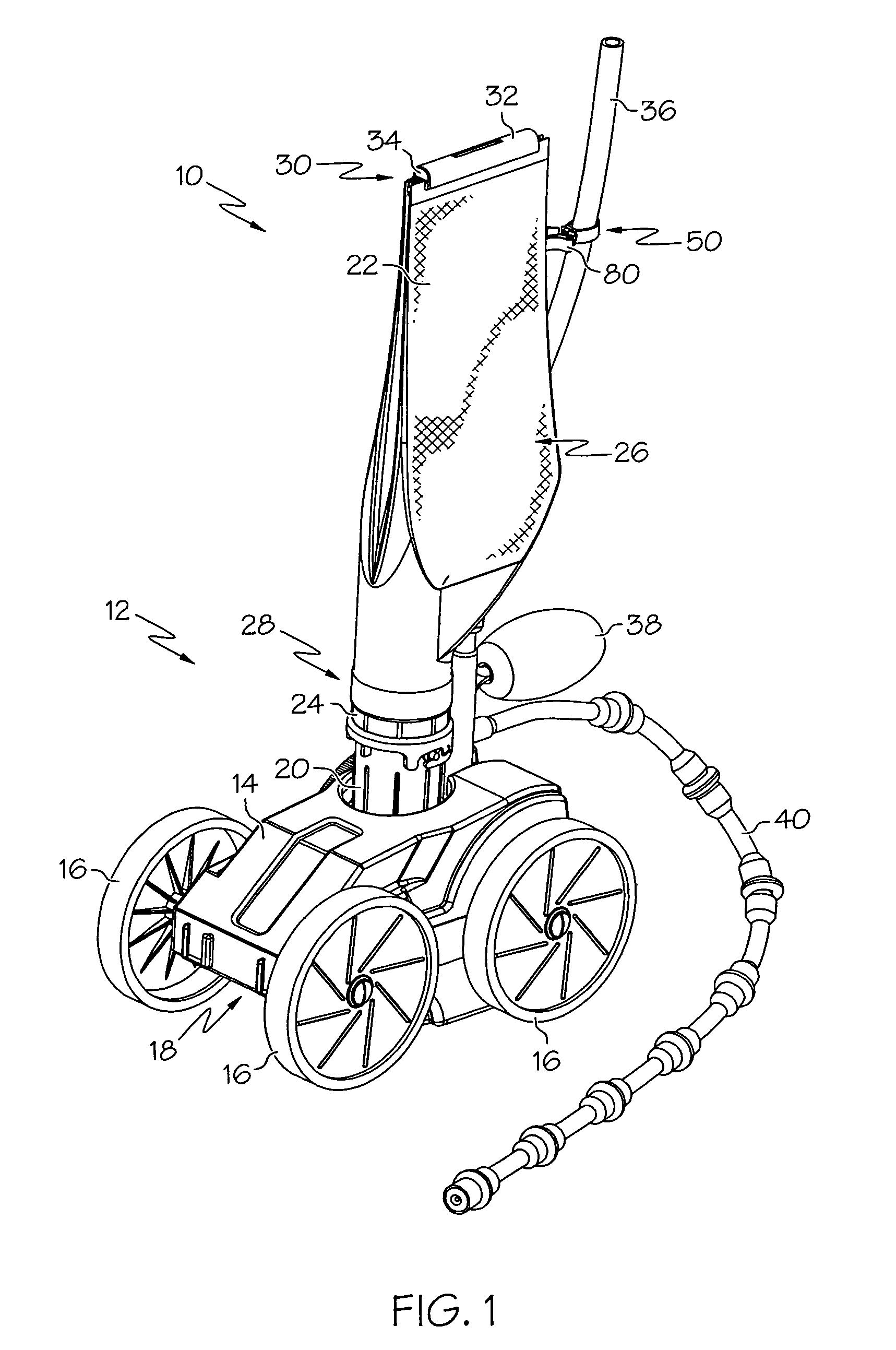

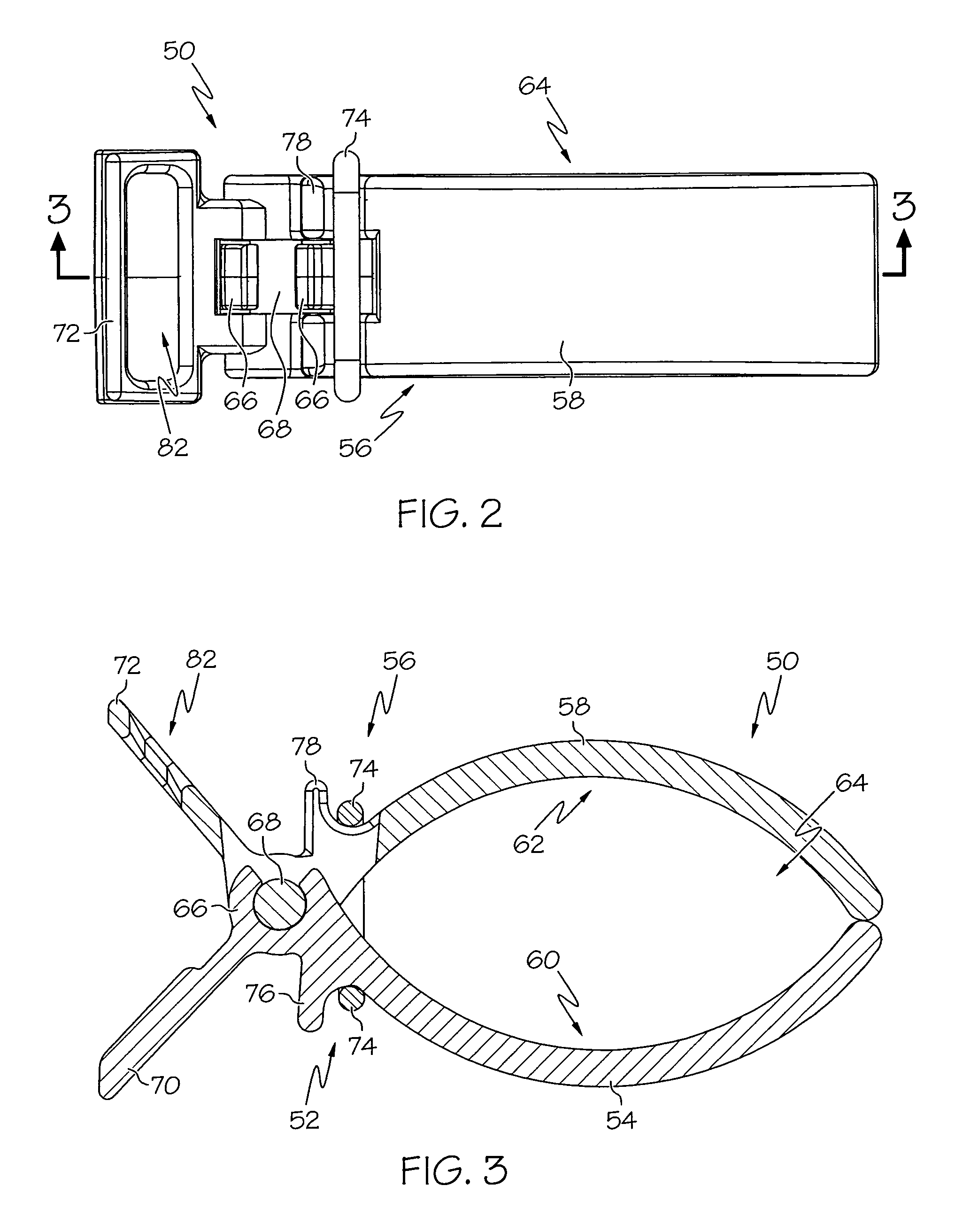

Adjustable hose clip

An adjustable hose clip is provided for use with a pool cleaner debris bag, including a first member having a retaining arm and a second member having a retaining arm. The hose clip also includes means for connecting the hose clip to a pool cleaner debris bag and resilient means for resiliently biasing the retaining arms towards each other such that at least a portion of a pool hose can be retained between the retaining arms. In one example, the resilient means is adapted to automatically adjust the distance between the retaining arms to accommodate various pool hoses having various diameters within the range of a minimum diameter to a maximum diameter at least 50% larger than the minimum diameter. In addition or alternatively, an arrangement for cleaning a swimming pool can include an automatic pool cleaner, a debris bag, a hose and an adjustable hose clip.

Owner:PENTAIR WATER POOL & SPA INC

Fixing device for hose clamp

ActiveUS8060991B2Prevent movementClosuresInternal framesEngineeringElectrical and Electronics engineering

A hose clamp (1) to be fastened to a hose (5), which hose clamp (1) comprises a band (2) which forms an open ring. The ends of the open ring are arranged adjacent to a locking portion (3), adjacent to which locking portion (3) a means (4) is arranged to vary the diameter of the ring and to hold the ends of the ring of the band together. Parts, which are substantially immovably connected to the locking portion (3), are arranged for fixed attachment to said hose (5).

Owner:NORMA SWEDEN AB

Frame mounted hose clamp

A hose clamp retainer assembly for an implement includes a retainer welded to the implement and having an apertured wall leading into a cavity. A bolt having a headed end is slidably received within through the apertured wall for support within the cavity. A hose clamp received by the bolt includes a projecting portion abutting the second wall and preventing the headed end from sliding out of the cavity through the apertured wall. The bolt can be easily replaced if damaged.

Owner:DEERE & CO

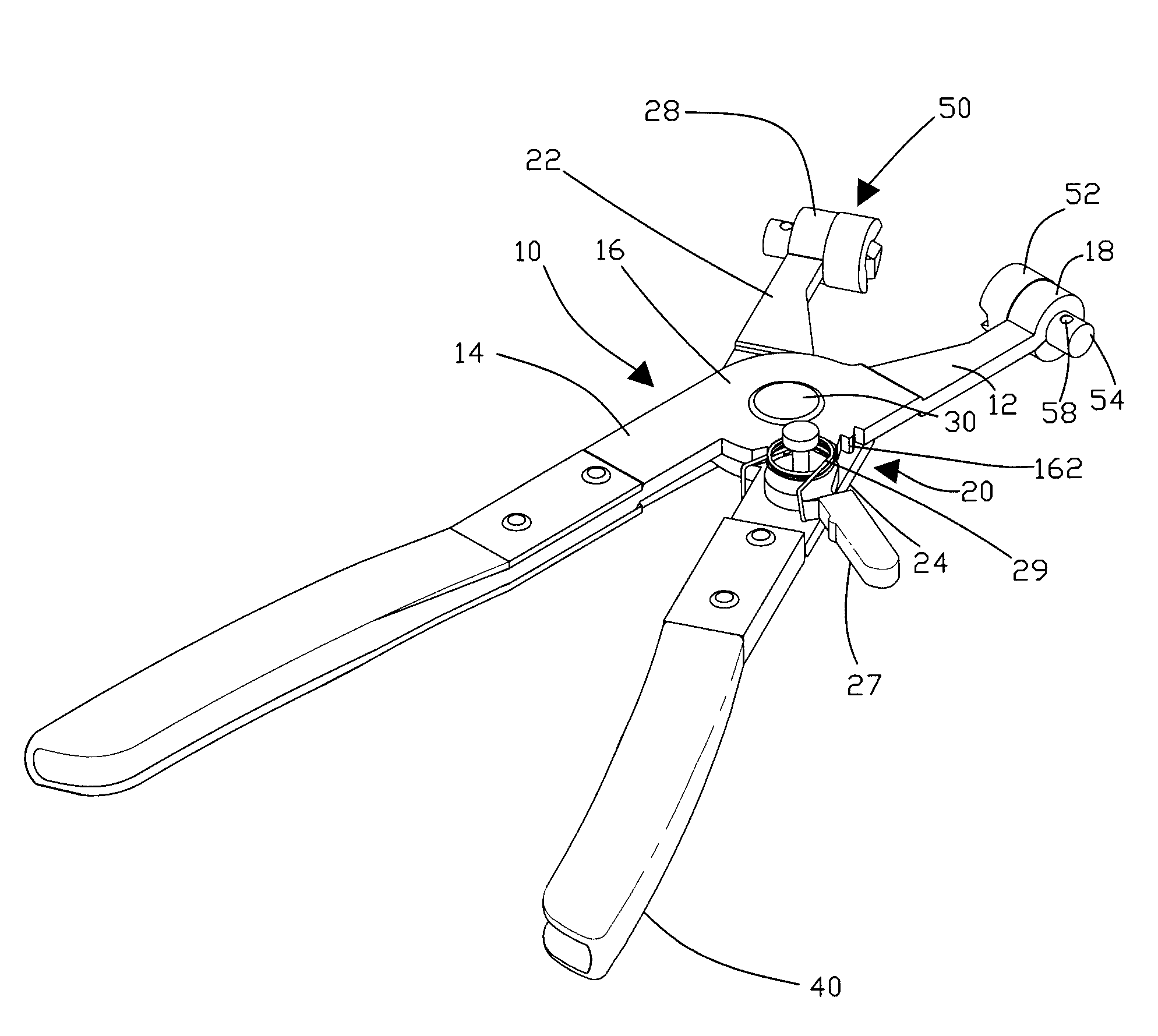

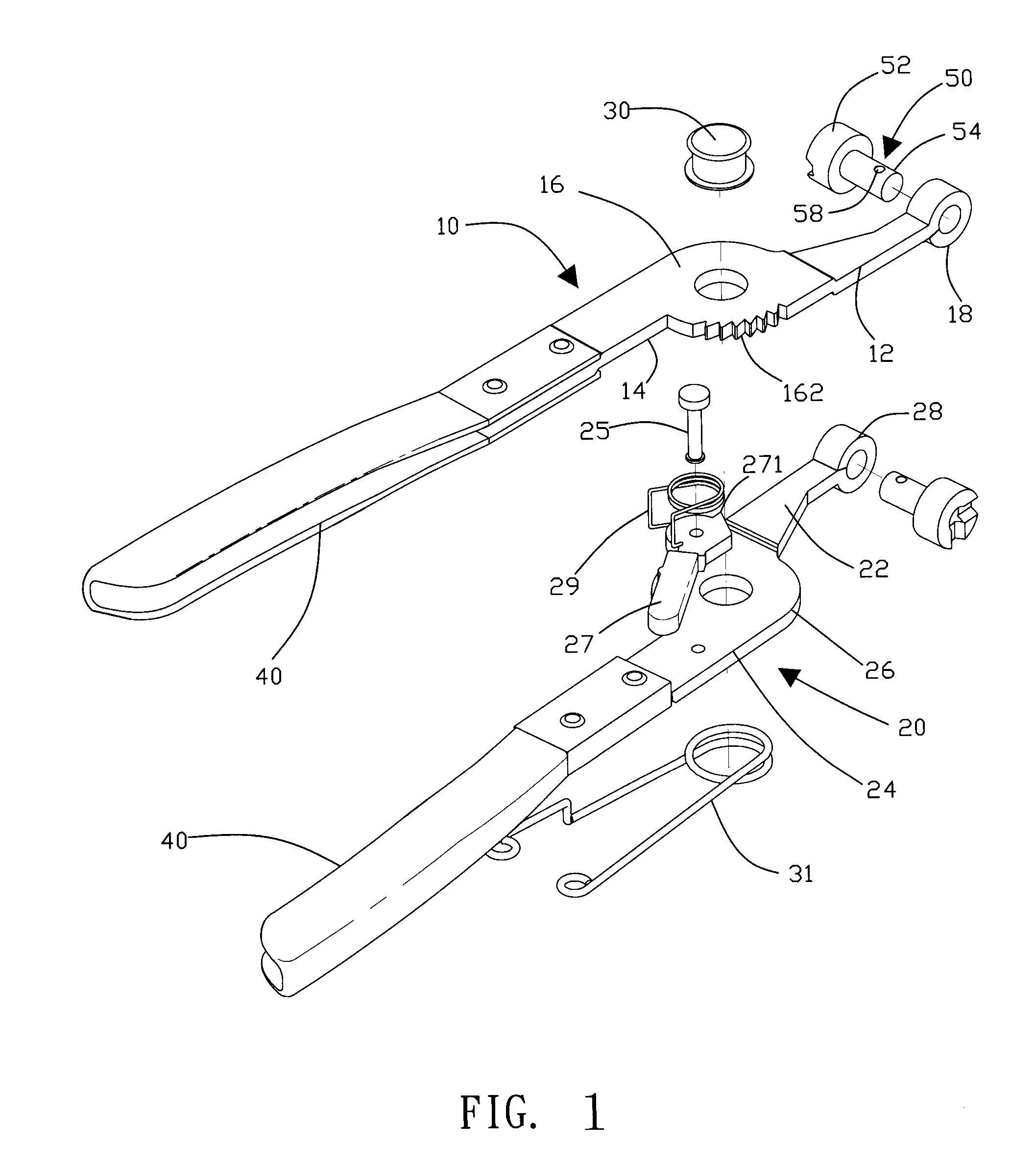

Hose clamp pliers

InactiveUS20090064823A1Quick installationQuick removalWire toolsMetal-working hand toolsEngineeringVariospora

A hose clamp pliers comprises first and second pliers bodies axially combined together by a pivot pillar for forming operating segments and working segments thereon including fitting seats disposed on the front ends thereof for fitting clamping members therein individually, the clamping members including positioning portions for accommodation various types of hose members mounted on one ends thereof, and including shanks with smaller diameters coupled on another ends thereof and inserting through the fitting seats respectively, the inner end surfaces of the positioning portions being biased against the inner end surfaces of the fitting seats respectively, and one ends of the shanks projecting out of the outer end surfaces of the fitting seats, the shanks including holes formed therein for receiving compression springs including balls placed on the free ends thereof and pushed out of the shanks thereby for being retained on the outer end surface of the fitting seats respectively, thus quickly replacing different sizes or shapes of clamping members.

Owner:HUANG CHUAN MAO

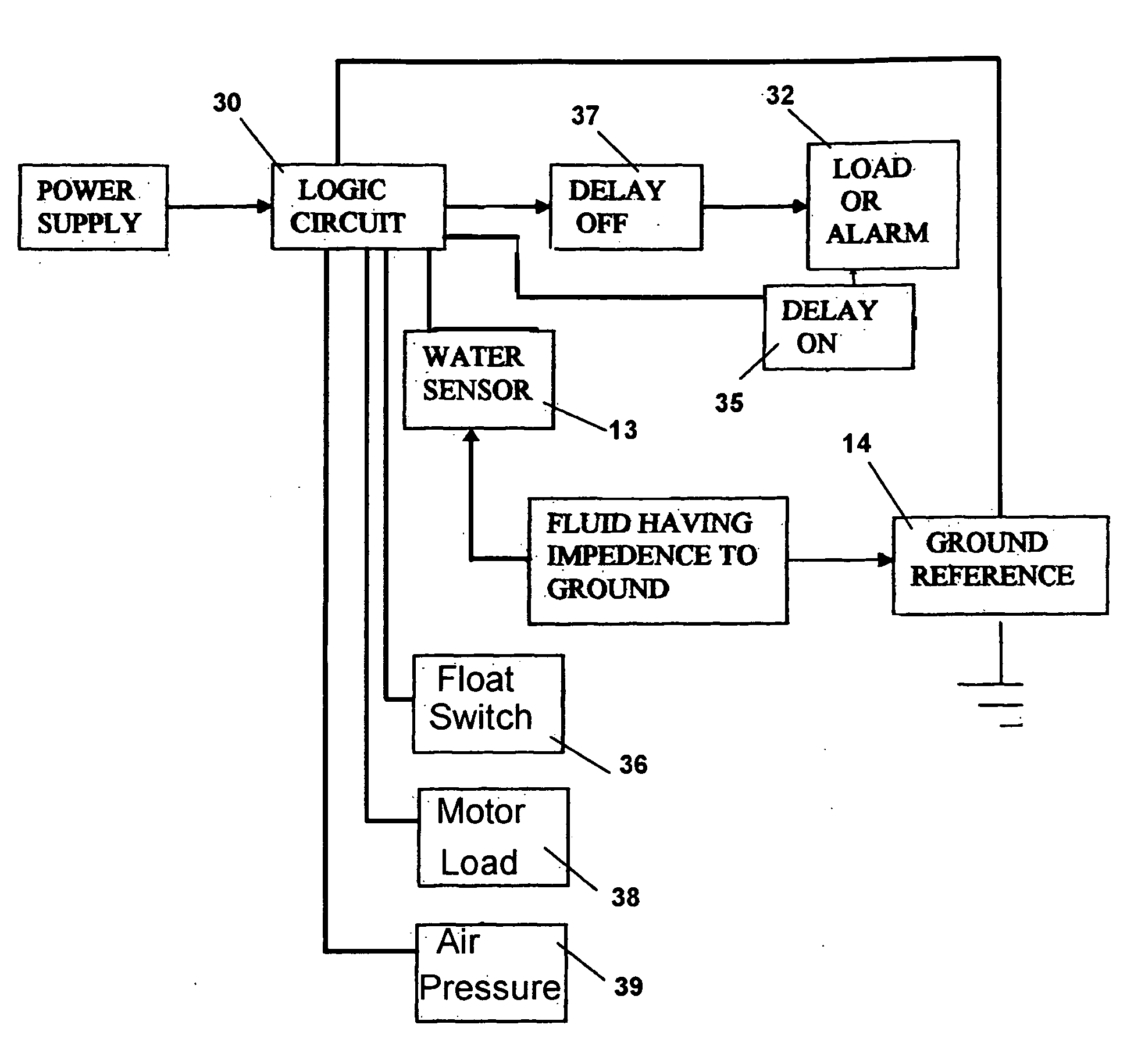

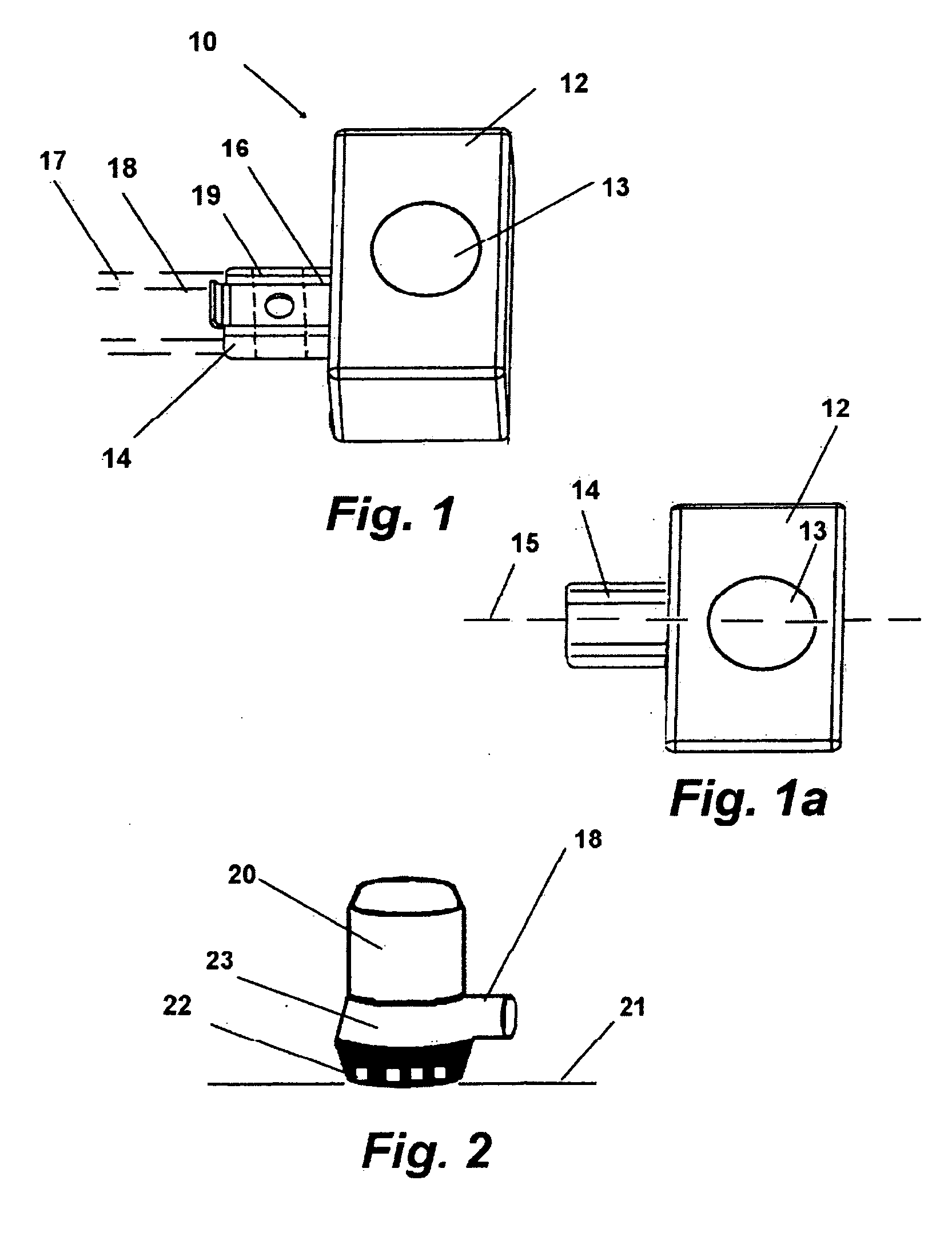

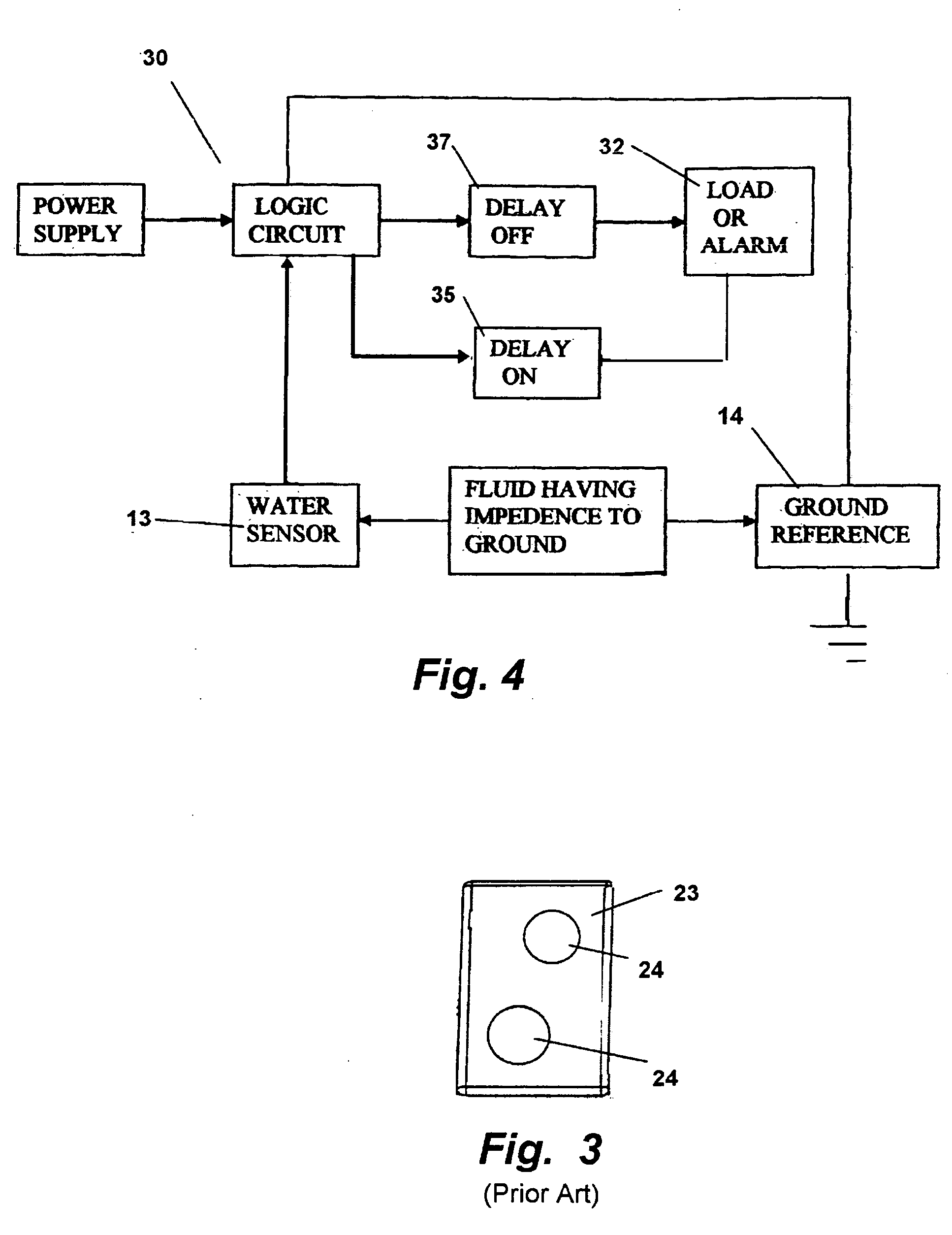

Sump pump activation switch

InactiveUS20090123295A1Improve performanceFor easy referencePump controlPositive-displacement liquid enginesFluid levelBiological activation

A switching device for submersed sump pump. The switching device employs an internal logic circuit inside a housing having a metallic member extending therefrom for mounting. The member is adapted to engage with the curved surface of a hose and hose clamp engaged to the sump pump. The member is engaged to the electrical ground to communicate a reference ground to the fluid in the sump to allow an impedance sensor to discern the fluid level and cause the logic circuit to energize or de-energize the sump pump.

Owner:ABBOTT BRYAN L

Hose clamp with parallel tightening and rapid release

An improved clamp constricting objects to be held in place including hoses wires tubes. One embodiment having some or all plastic molded parts one of which is a support base (10) to one side is attached a partially grooved or fully flexible grooved band strap (13) where as the other end is free to enter a band strap entrance port (26) thereby contact is made with a matching grooved rotating cylinder (12) held by two bearings. The band strap (13) advances encircling objects to be held. The support base top (11) is closed and locked by the rapid release hold down top lock (20) confining the grooved molded rotating cylinder (12) engaging a flexible paw (17) allowing advancing rotation only, preventing the grooved molded band strap (13) from retracting. Six sided wrench or tool is inserted into the cylinder cavity (15) forcefully rotating the grooved rotating cylinder (12) advancing the flexible grooved band strap (13) through exit port (27) being held down by band strap retainers (18). A rapid release finger grip (19) releases a rapid release hold down top lock (20) lifting the molded support base top (11) disengaging the flexible paw (17) from the grooved molded rotating cylinder (12) allowing counter rotation of the grooved molded rotating cylinder (12) retracting the flexible grooved band strap (13) freeing the constricted objects.

Owner:POSNER SAMUEL LEWIS

Light Fixture Mounting Assembly

A light fixture mounting assembly that includes a lamp housing having a sidewall and an opening defined by a rim at one end of the sidewall and a detent extending outward from the sidewall in a position to engage an outer surface of a panel when the housing is in an installed position. A lamp module is carried within the lamp housing and comprises a lamp positioned to emit light through the housing opening. The lamp housing is configured to carry either a spring clip-type retainer or a hose clamp-type retainer to hold the lamp housing in the installed position.

Owner:MAN D TEC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com