Heavy oil thermal recovery casing pipe testing device

A heavy oil thermal recovery casing and testing device technology, which is applied in the direction of measuring devices, fluid tightness testing, machine/structural component testing, etc. Thermal expansion and other issues to achieve the effect of increasing reliability and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with specific embodiments, and the given examples are only for clarifying the present invention, not for limiting the scope of the present invention.

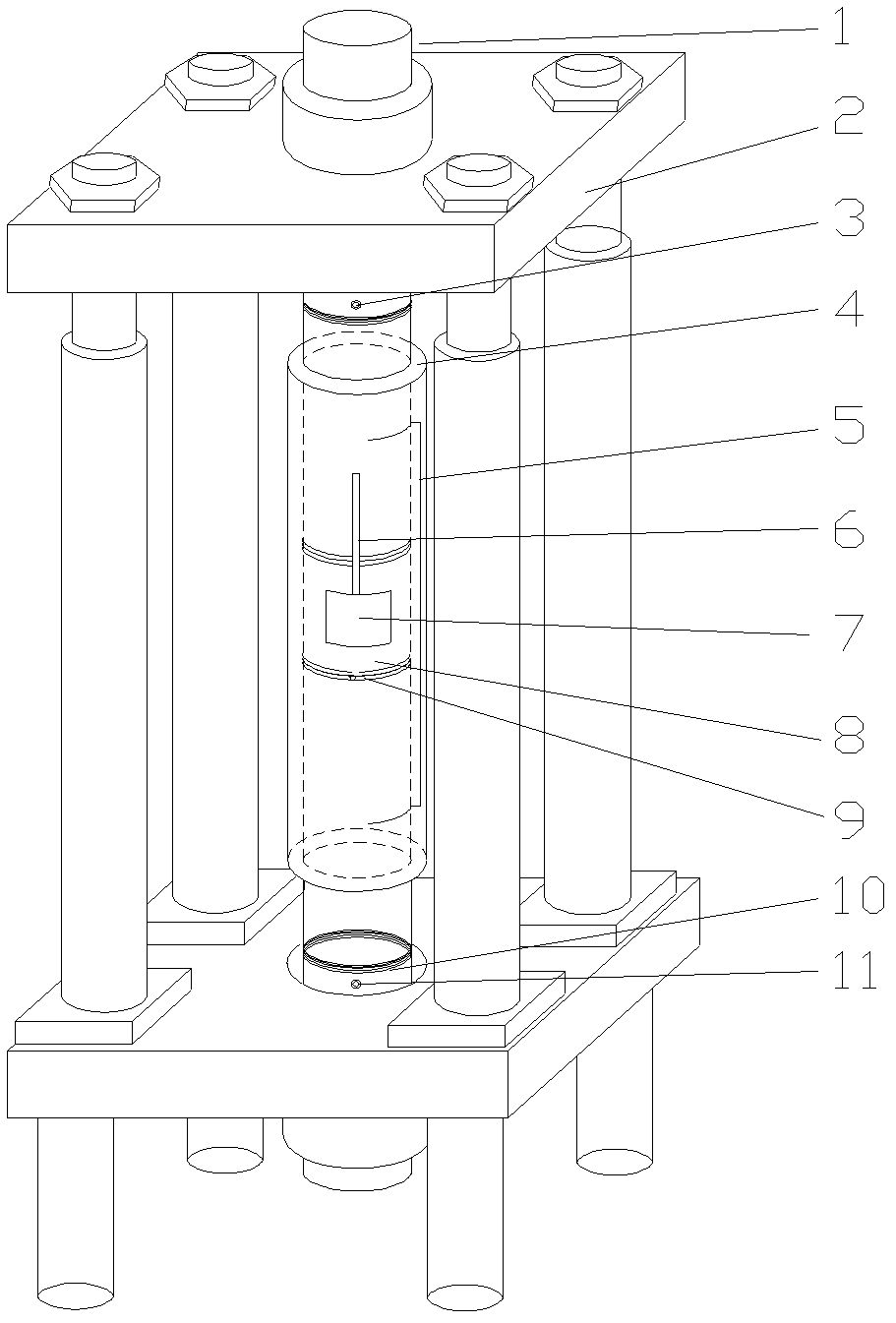

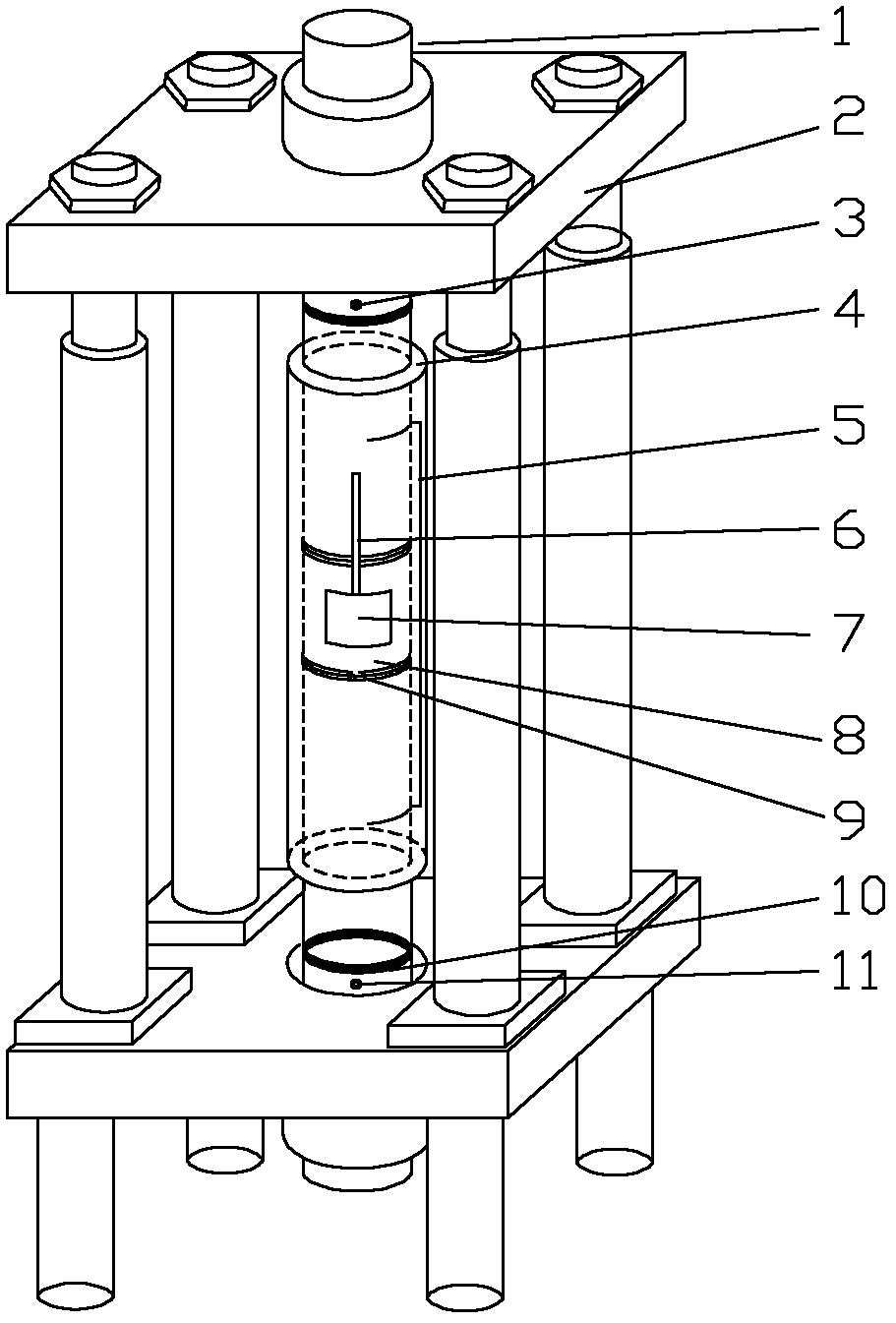

[0013] see figure 1 , the embodiment of the present invention provides a heavy oil thermal recovery casing testing device, which specifically includes the following components:

[0014] The mark 1 in the figure is the auxiliary rod, which plays the role of connecting the casing and the axial loading device 2, and at the same time plays the role of sealing the pipe end for the airtight test; 4 is the openable electric heating furnace, the electric heating furnace Wrapped on the surface of the casing, the electric heating furnace can wrap 3 / 4 of the length of the sample to increase the heat-affected area of the sample, and more effectively simulate the heating of the casing. Close the electric heating furnace when heating, and open the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com