Patents

Literature

57results about How to "Reduce and prevent damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

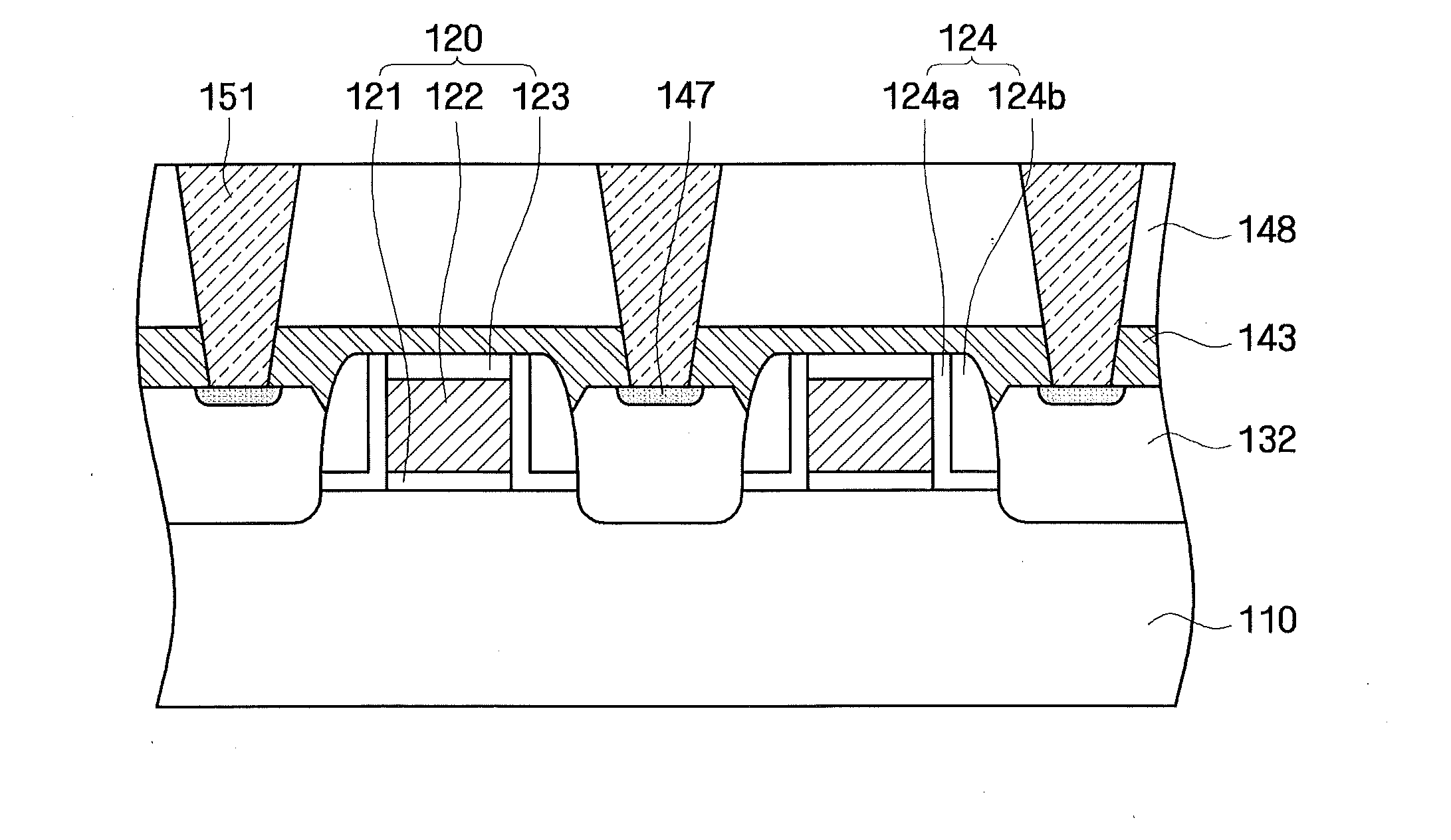

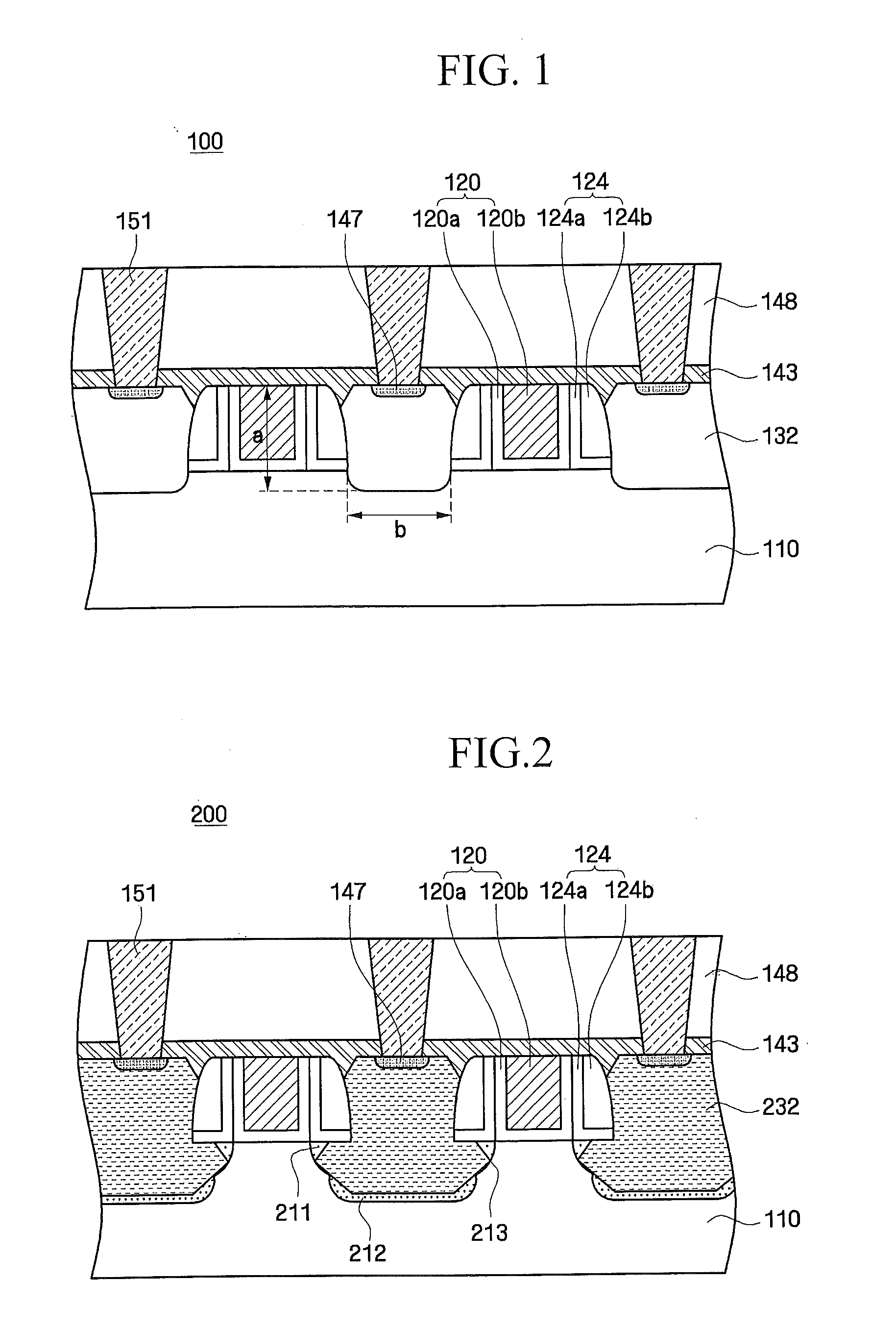

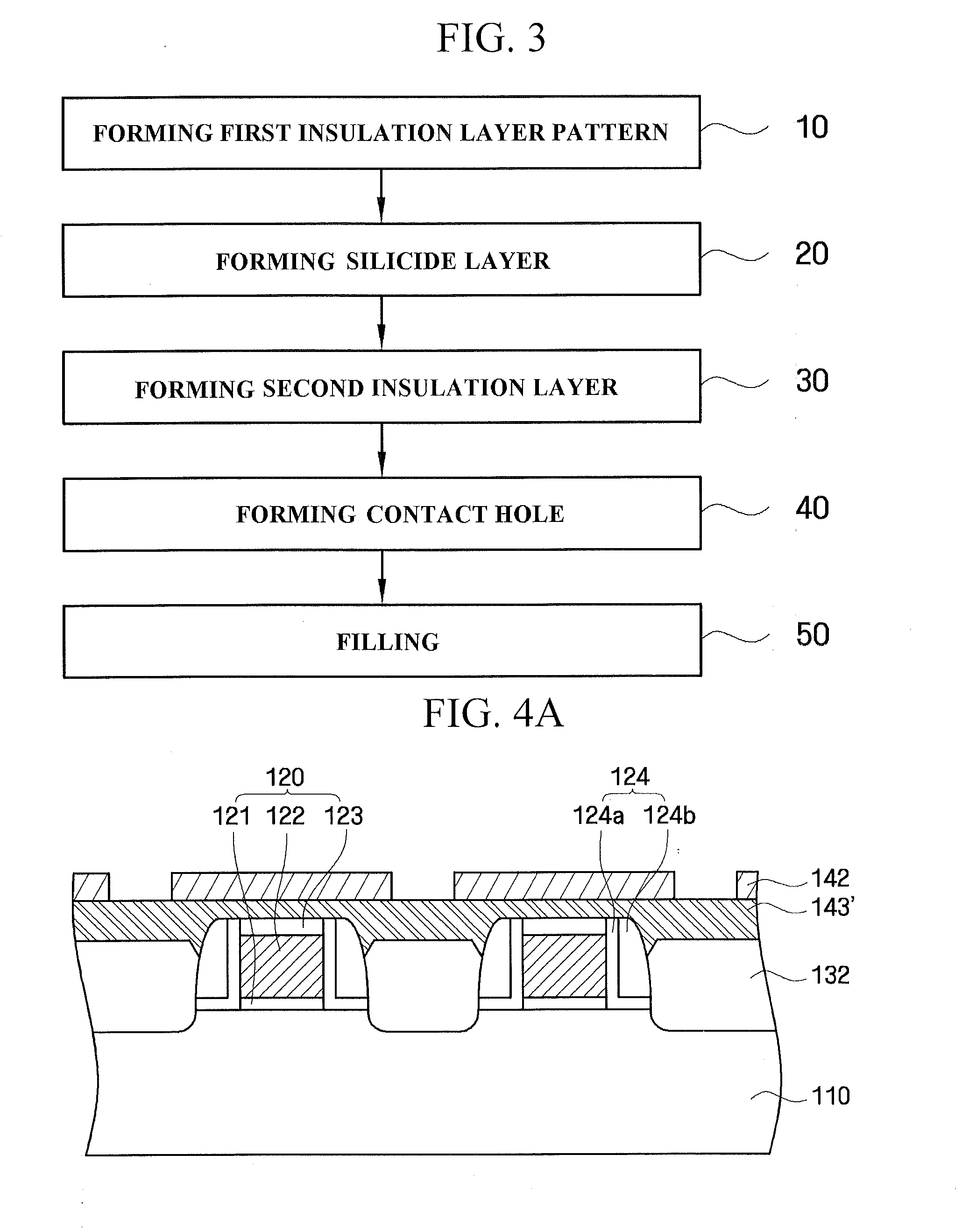

Semiconductor Devices and Methods of Manufacturing the Same

ActiveUS20120104514A1Difficult to depositReduce and prevent damageTransistorSemiconductor/solid-state device manufacturingEngineeringContact hole

Provided are a semiconductor device, which can facilitate a salicide process and can prevent a gate from being damaged due to misalign, and a method of manufacturing of the semiconductor device. The method includes forming a first insulation layer pattern on a substrate having a gate pattern and a source / drain region formed at both sides of the gate pattern, the first insulation layer pattern having an exposed portion of the source / drain region, forming a silicide layer on the exposed source / drain region, forming a second insulation layer on the entire surface of the substrate to cover the first insulation layer pattern and the silicide layer, and forming a contact hole in the second insulation layer to expose the silicide layer.

Owner:SAMSUNG ELECTRONICS CO LTD

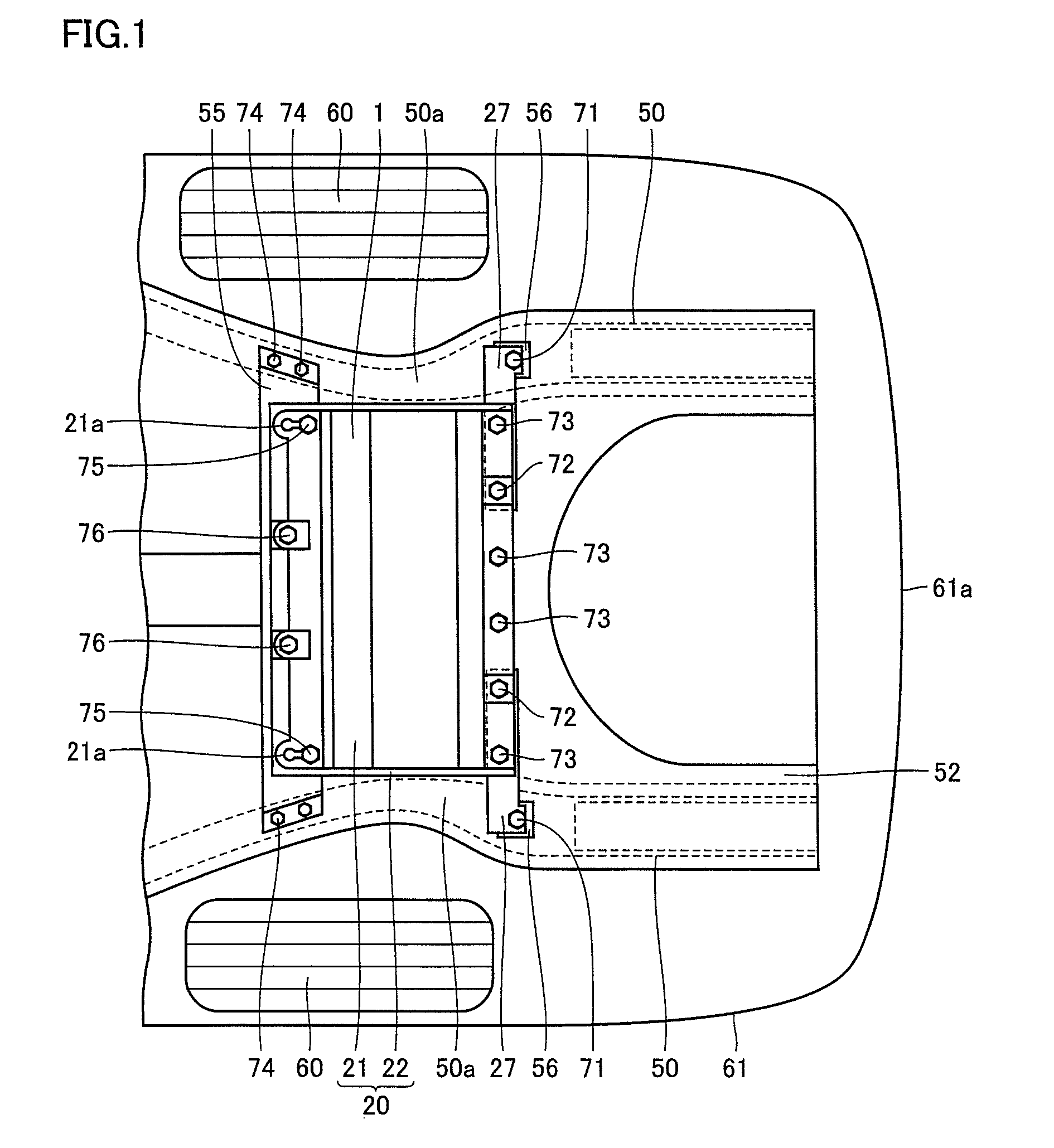

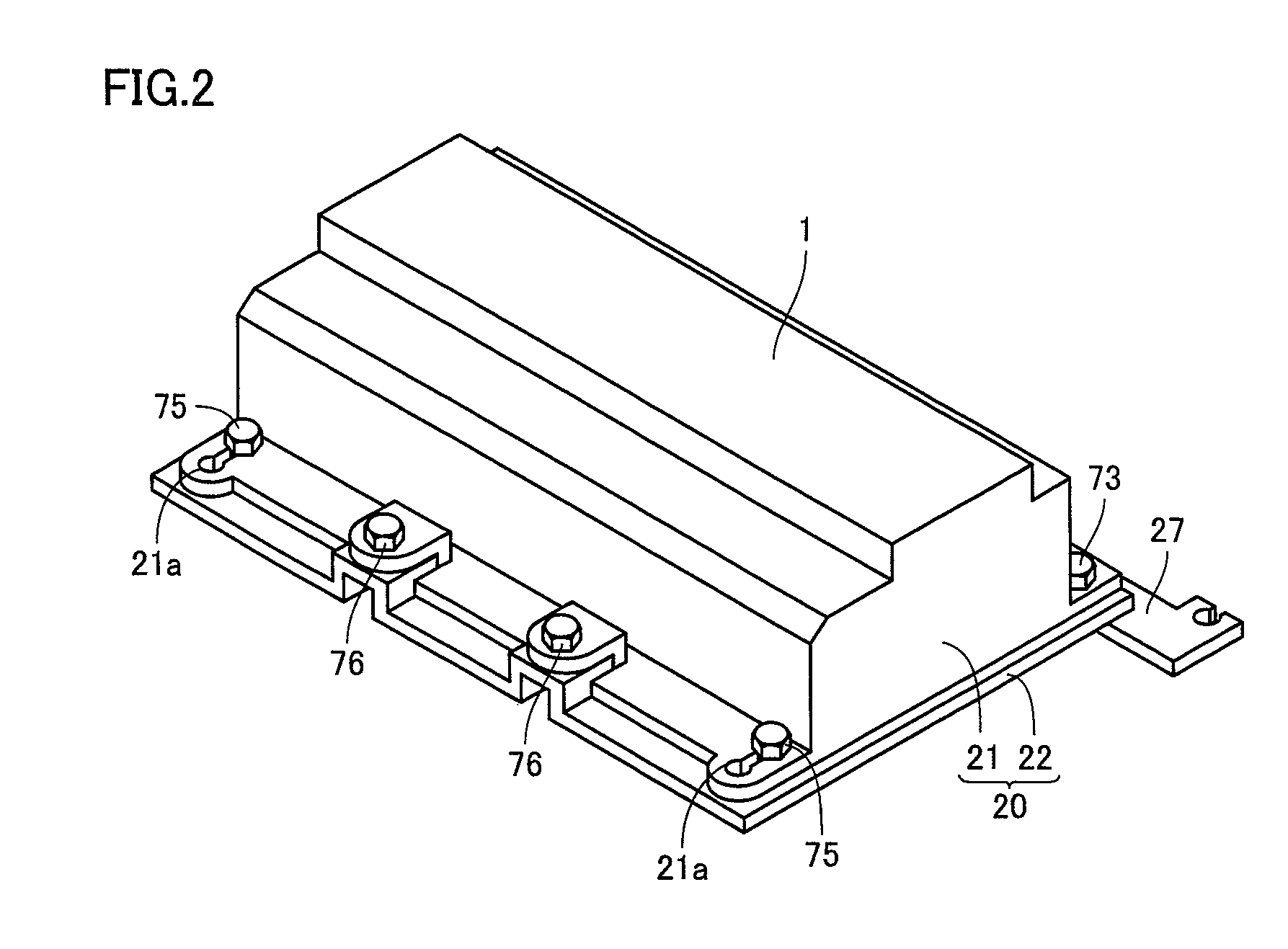

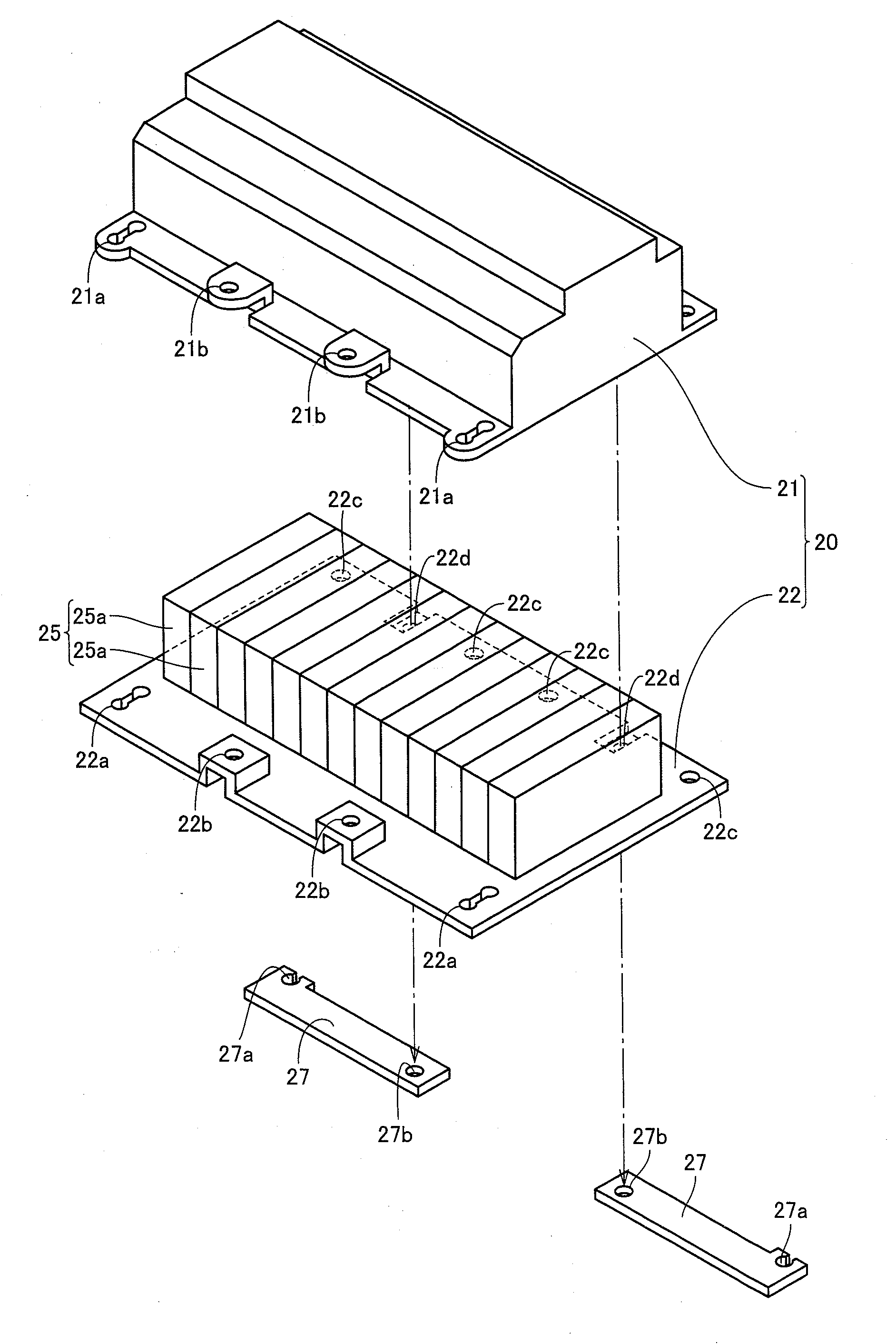

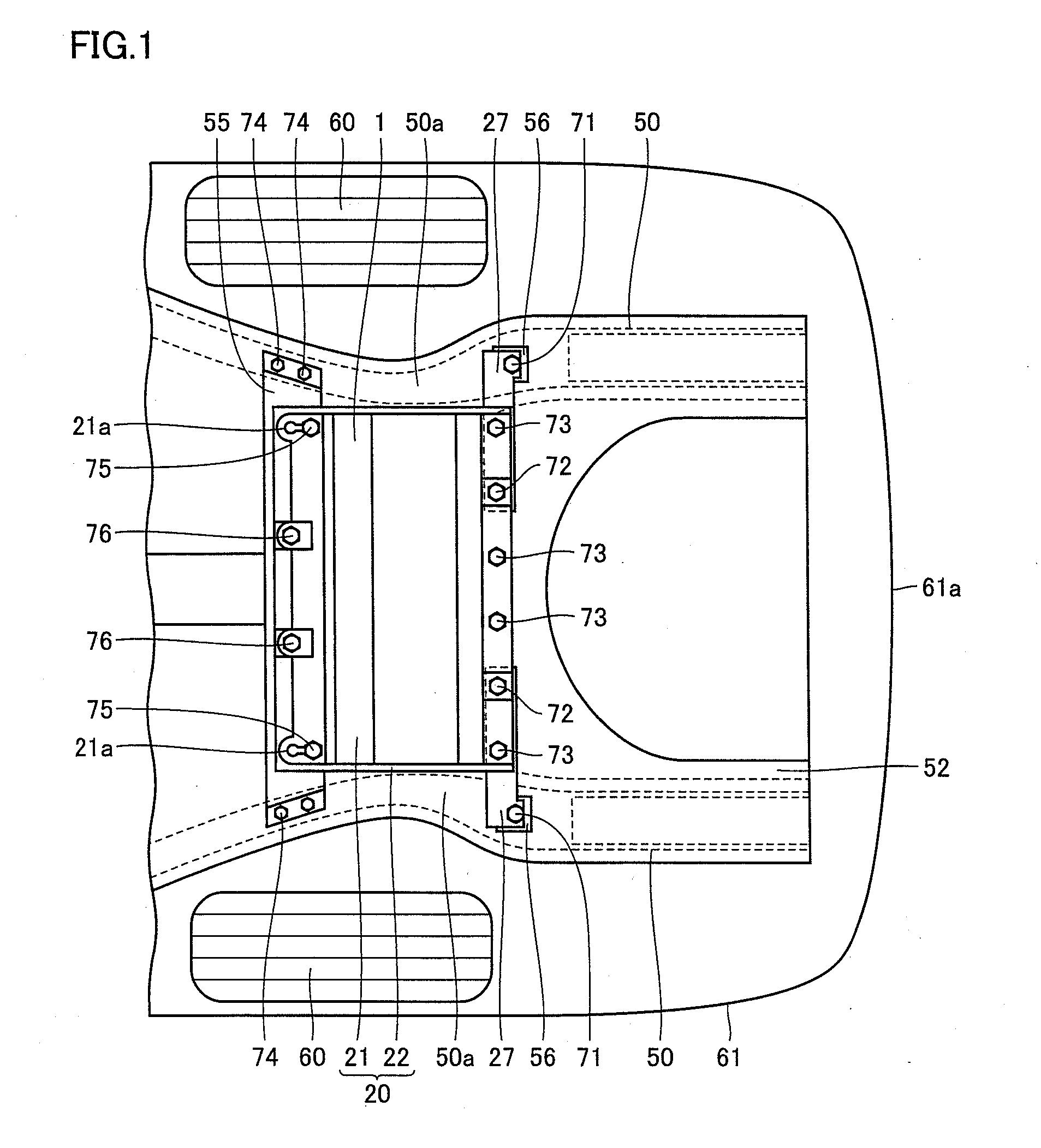

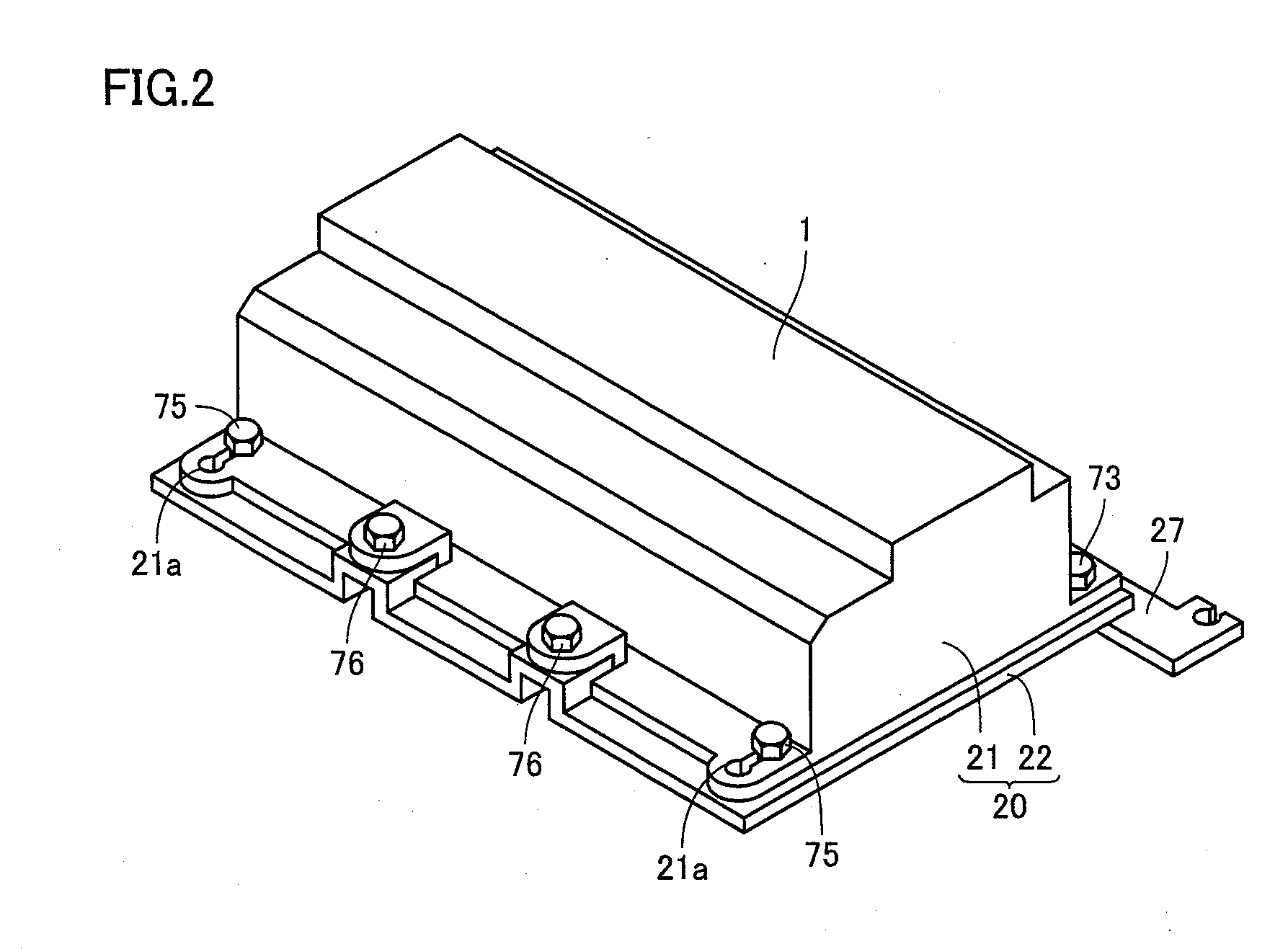

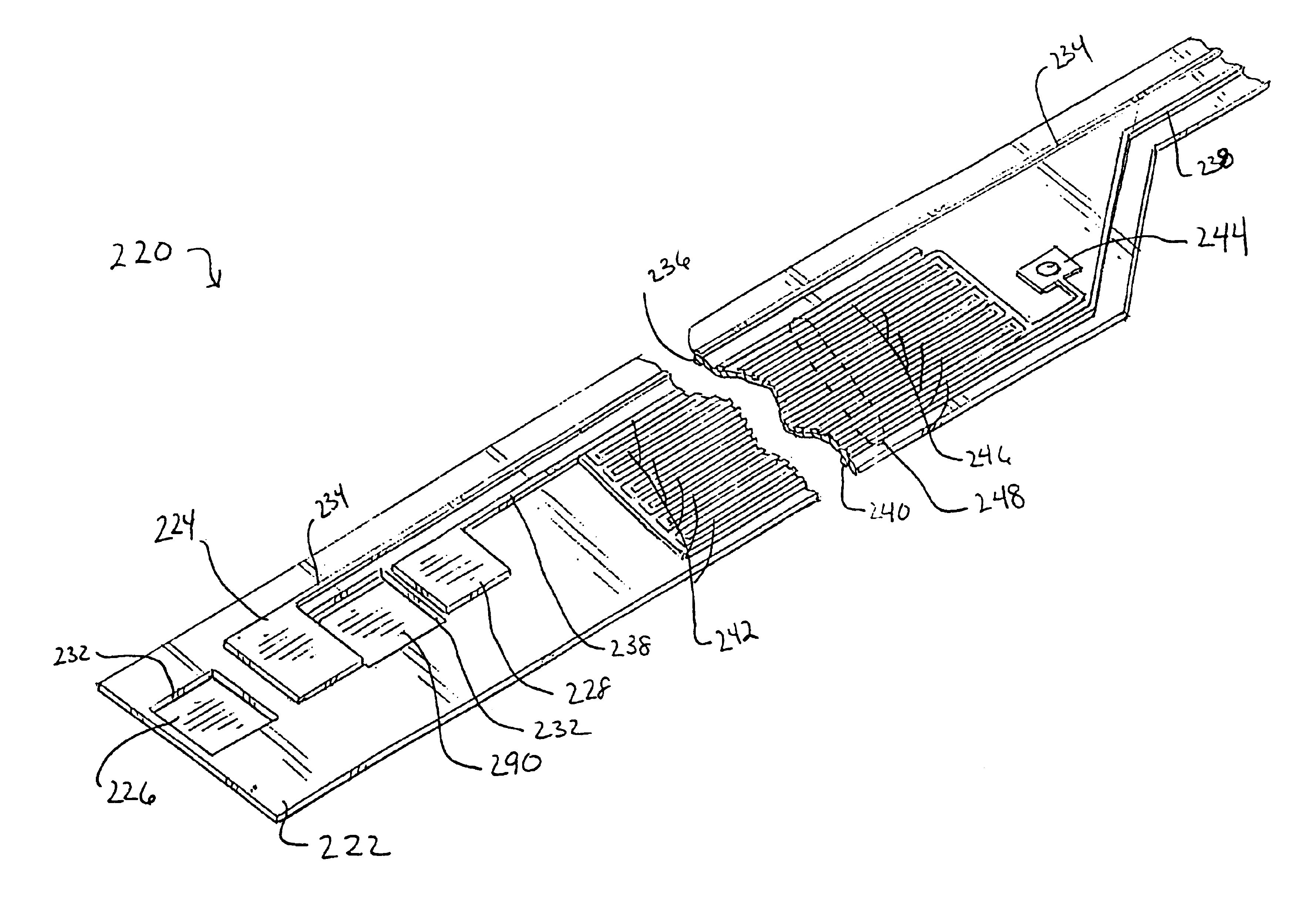

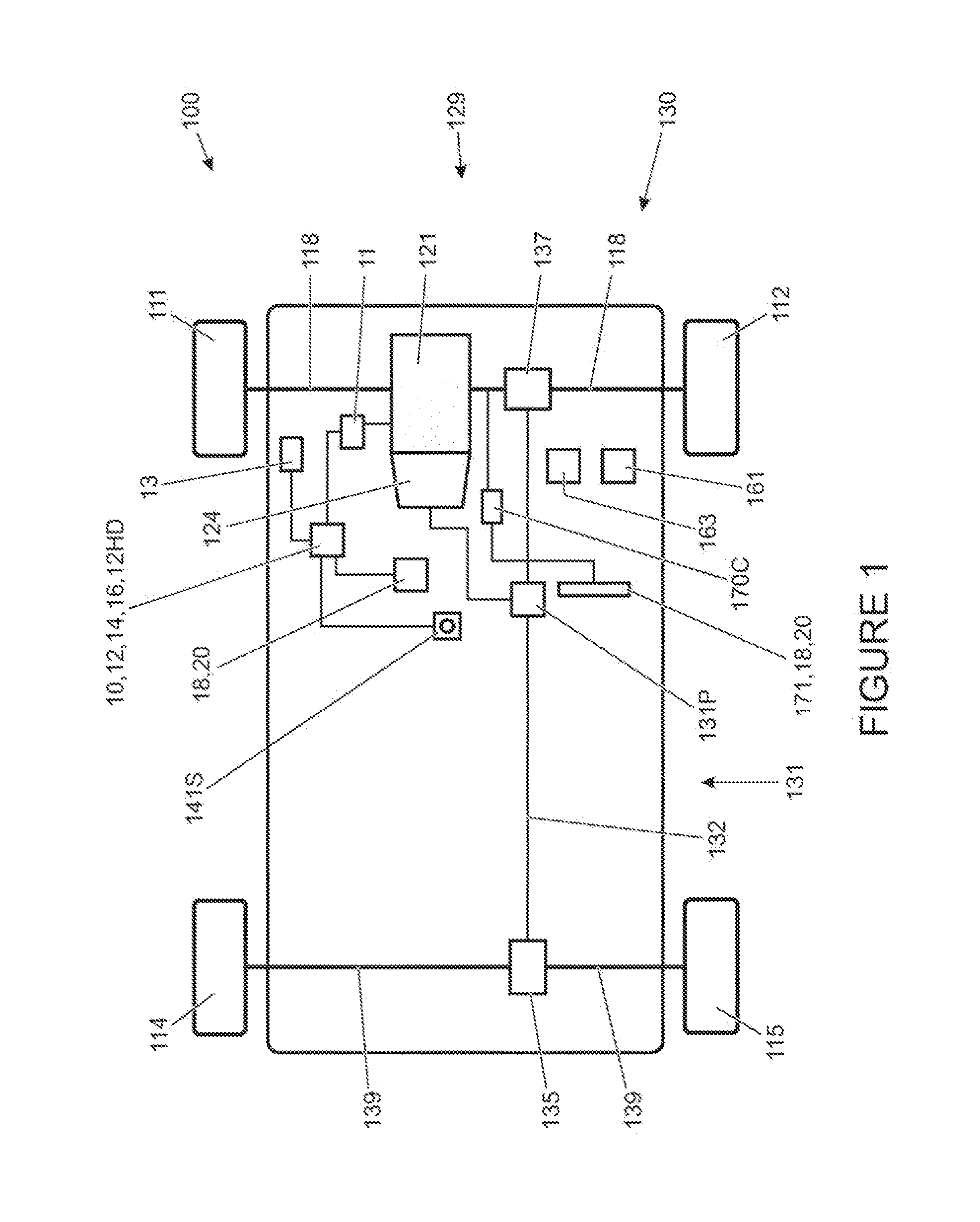

Structure mounting an electricity storage pack on a vehicle

ActiveUS8051934B2Reduce and prevent damageElectric devicesElectric propulsion mountingElectricityEngineering

There are included a side member formed to support a battery pack, and a rear bracket securing the battery pack to the side member. The rear bracket has one side pivotably coupled to the battery pack, and the other side pivotably coupled to the side member.

Owner:TOYOTA JIDOSHA KK

Structure mounting an electricity storage pack on a vehicle

ActiveUS20090166116A1Reduce and prevent damageElectric devicesElectric propulsion mountingElectricityBattery pack

There are included a side member formed to support a battery pack, and a rear bracket securing the battery pack to the side member. The rear bracket has one side pivotably coupled to the battery pack, and the other side pivotably coupled to the side member.

Owner:TOYOTA JIDOSHA KK

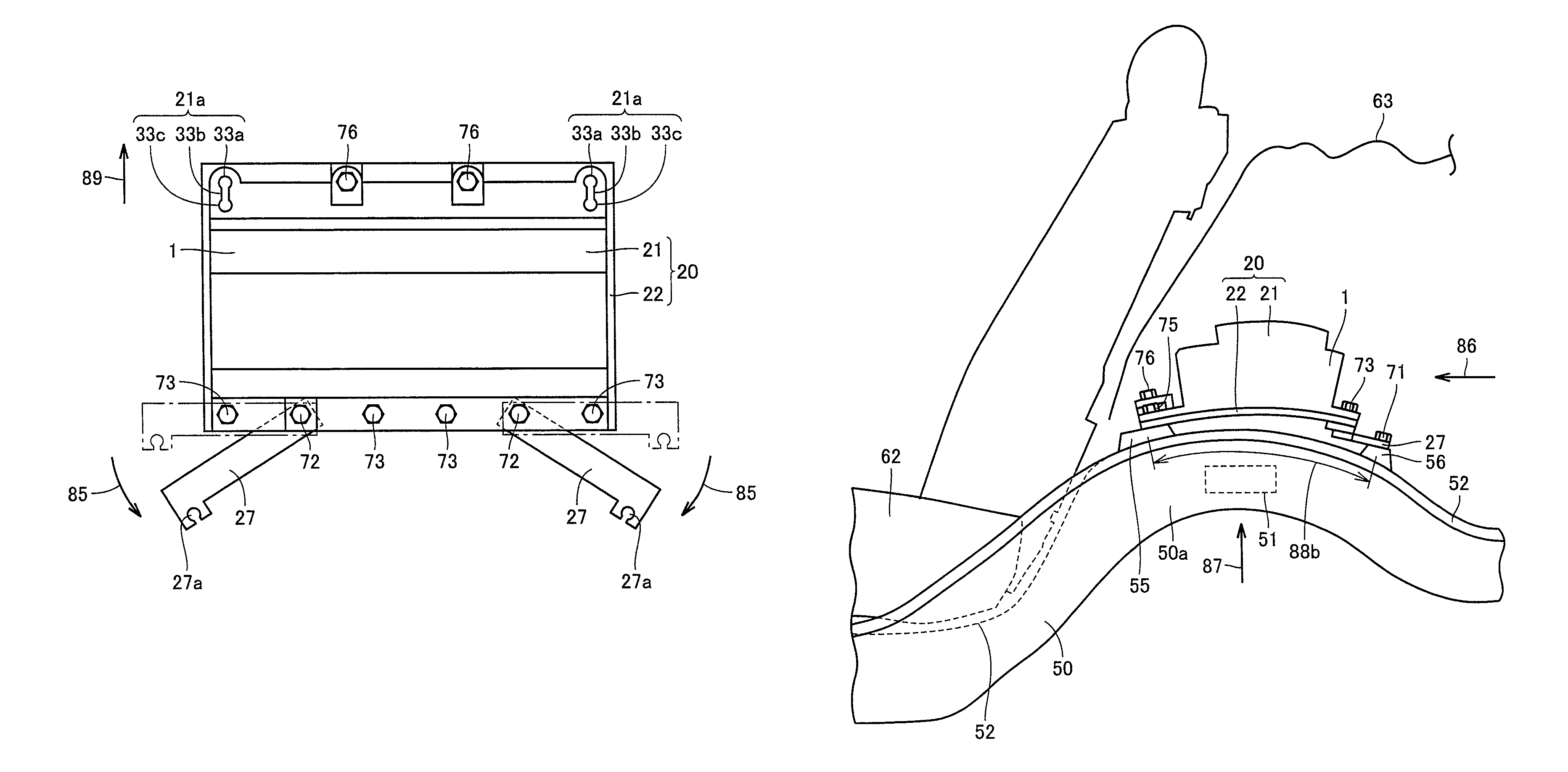

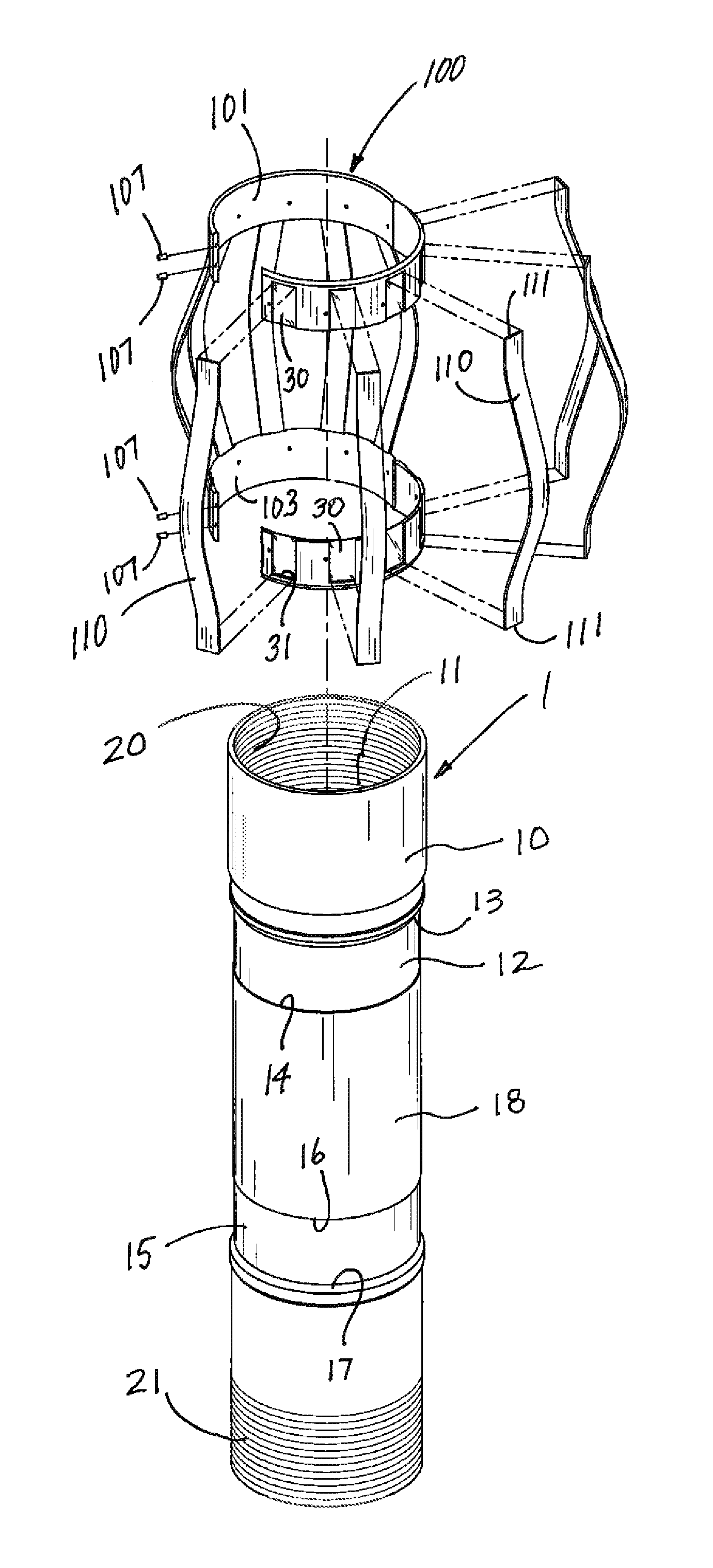

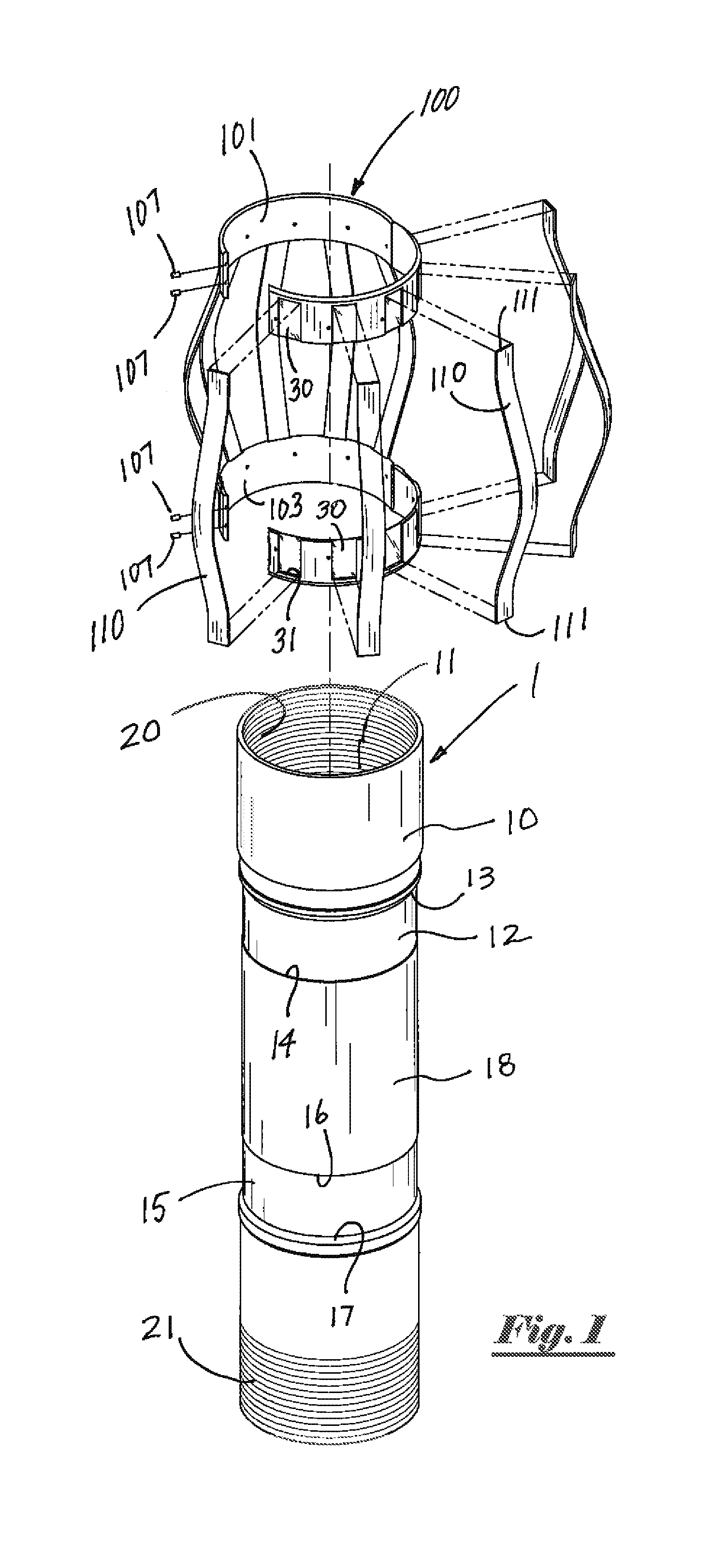

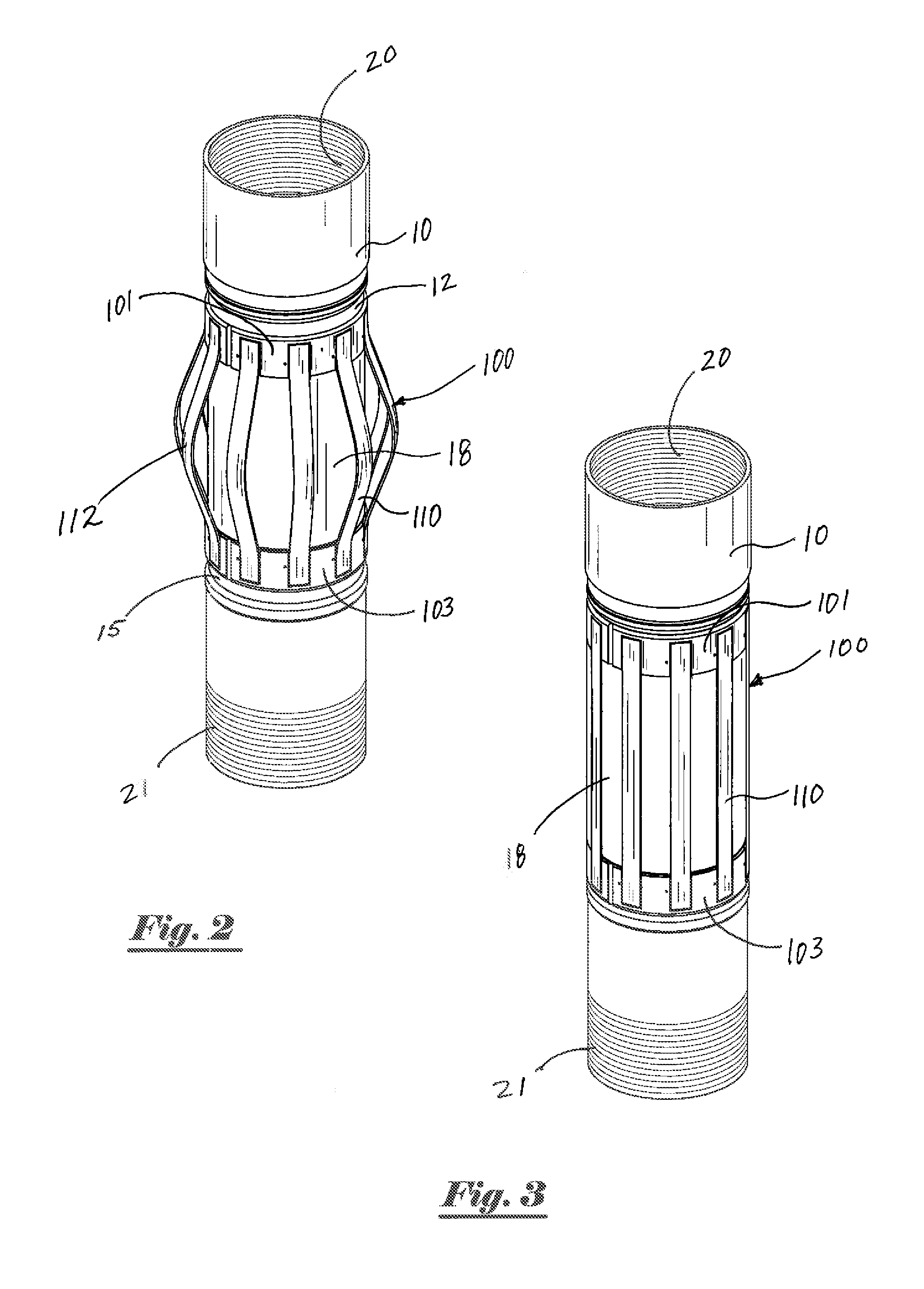

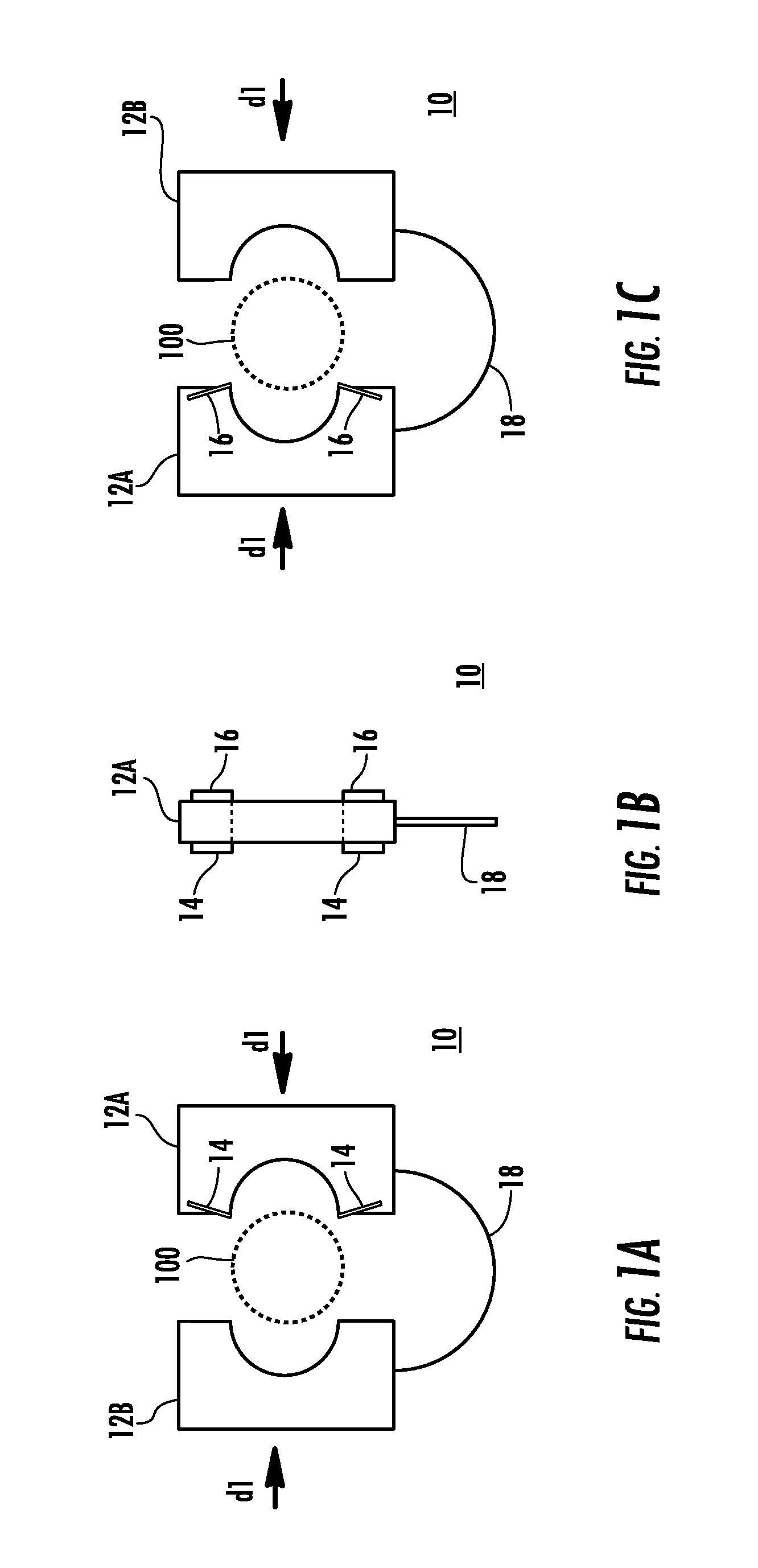

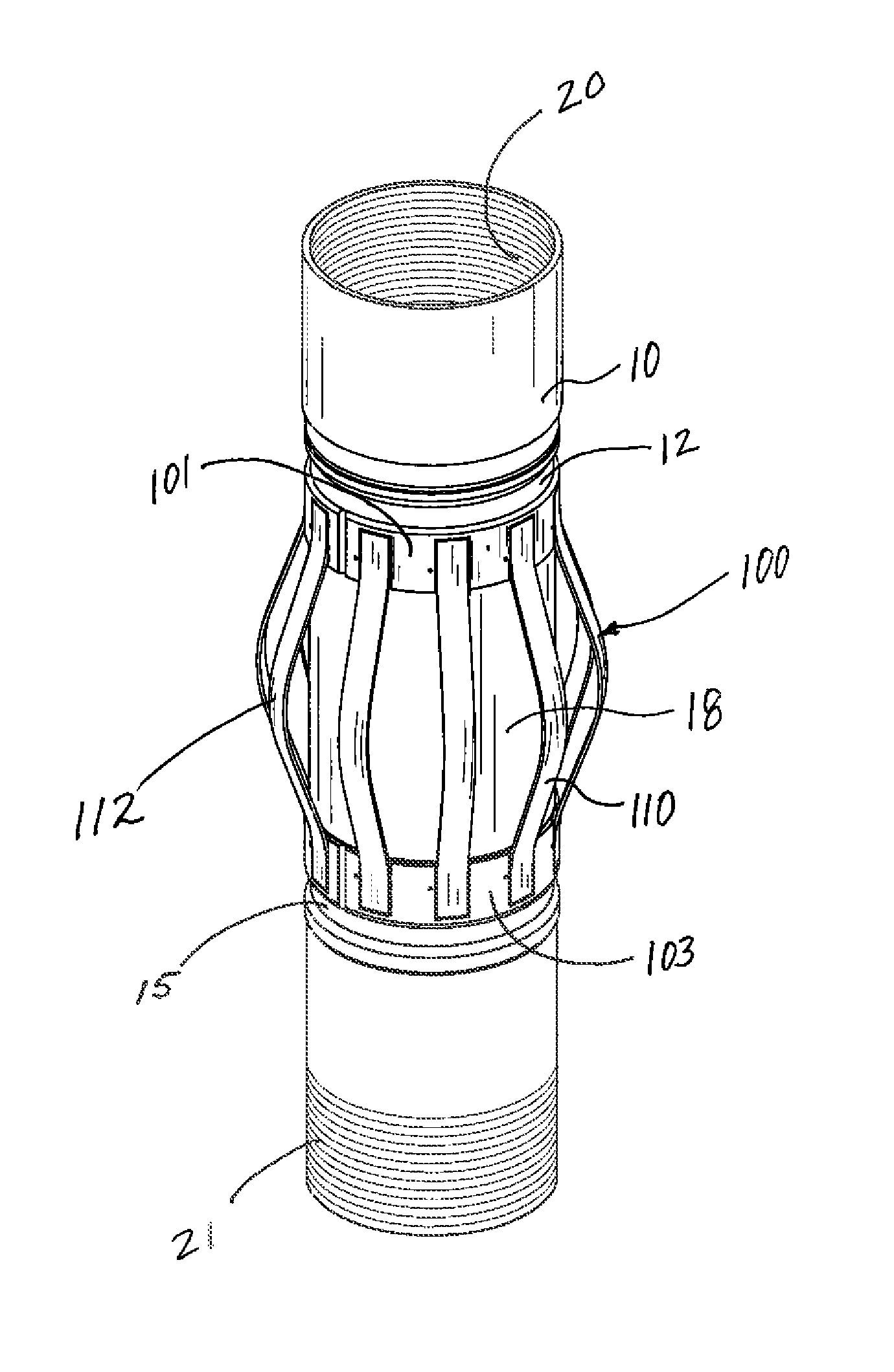

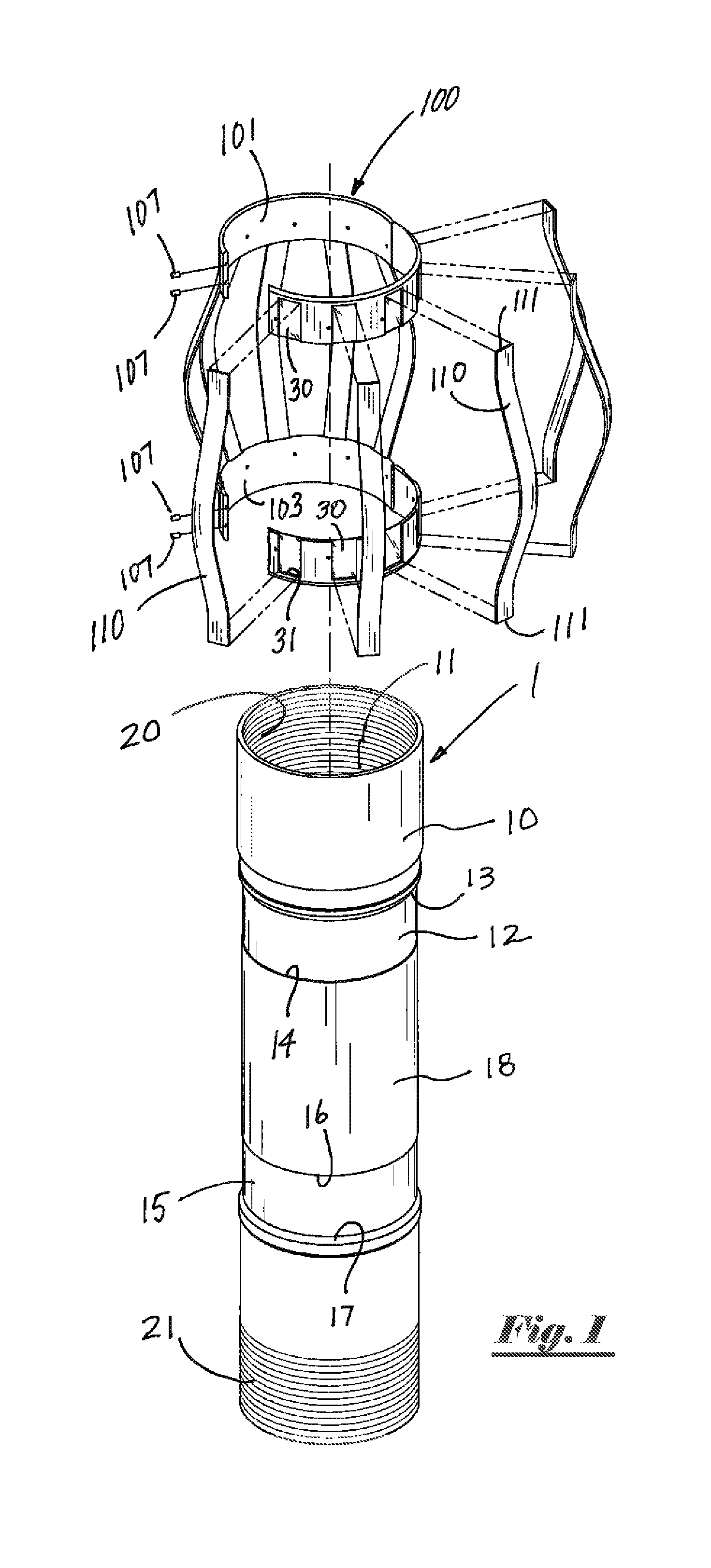

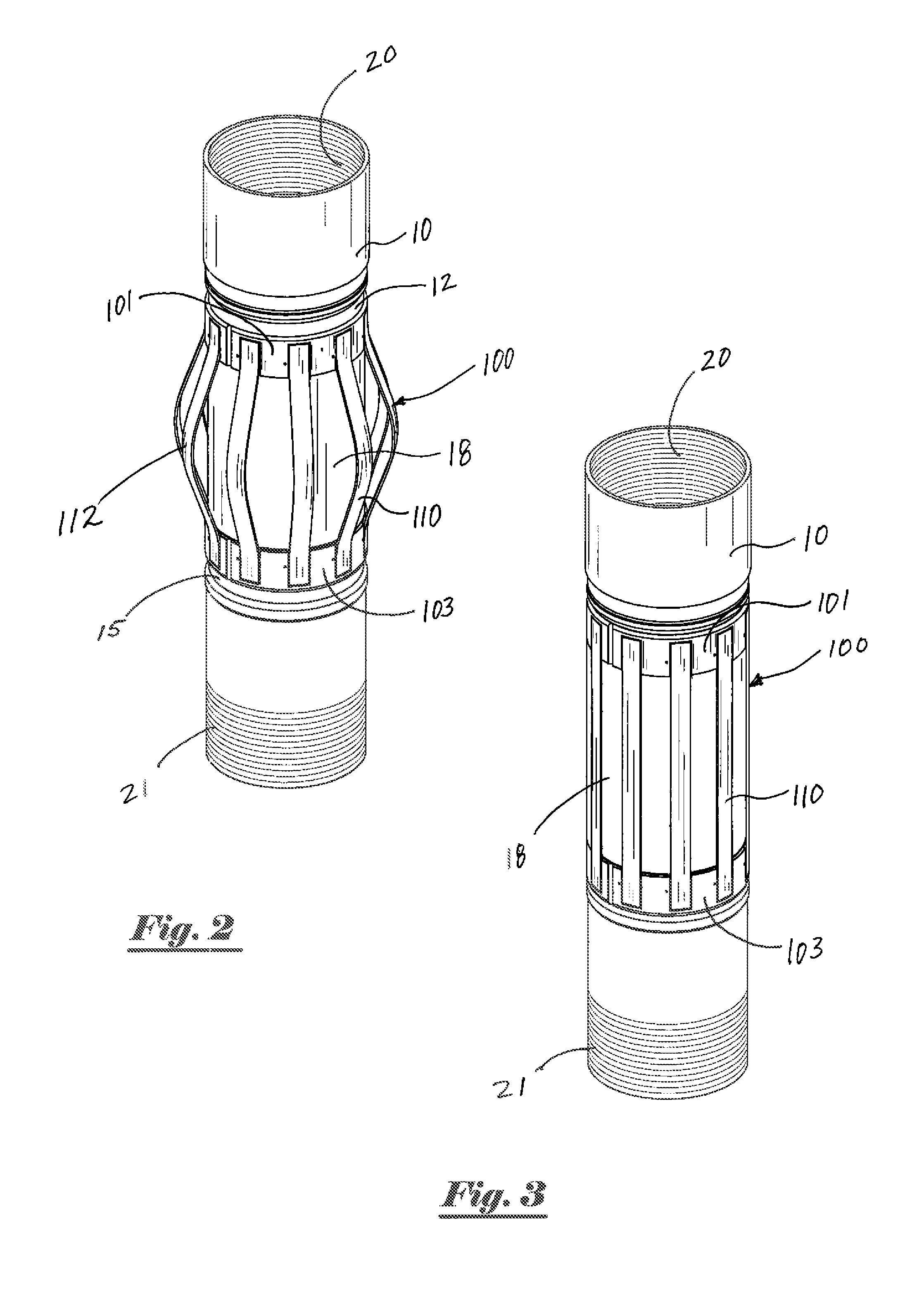

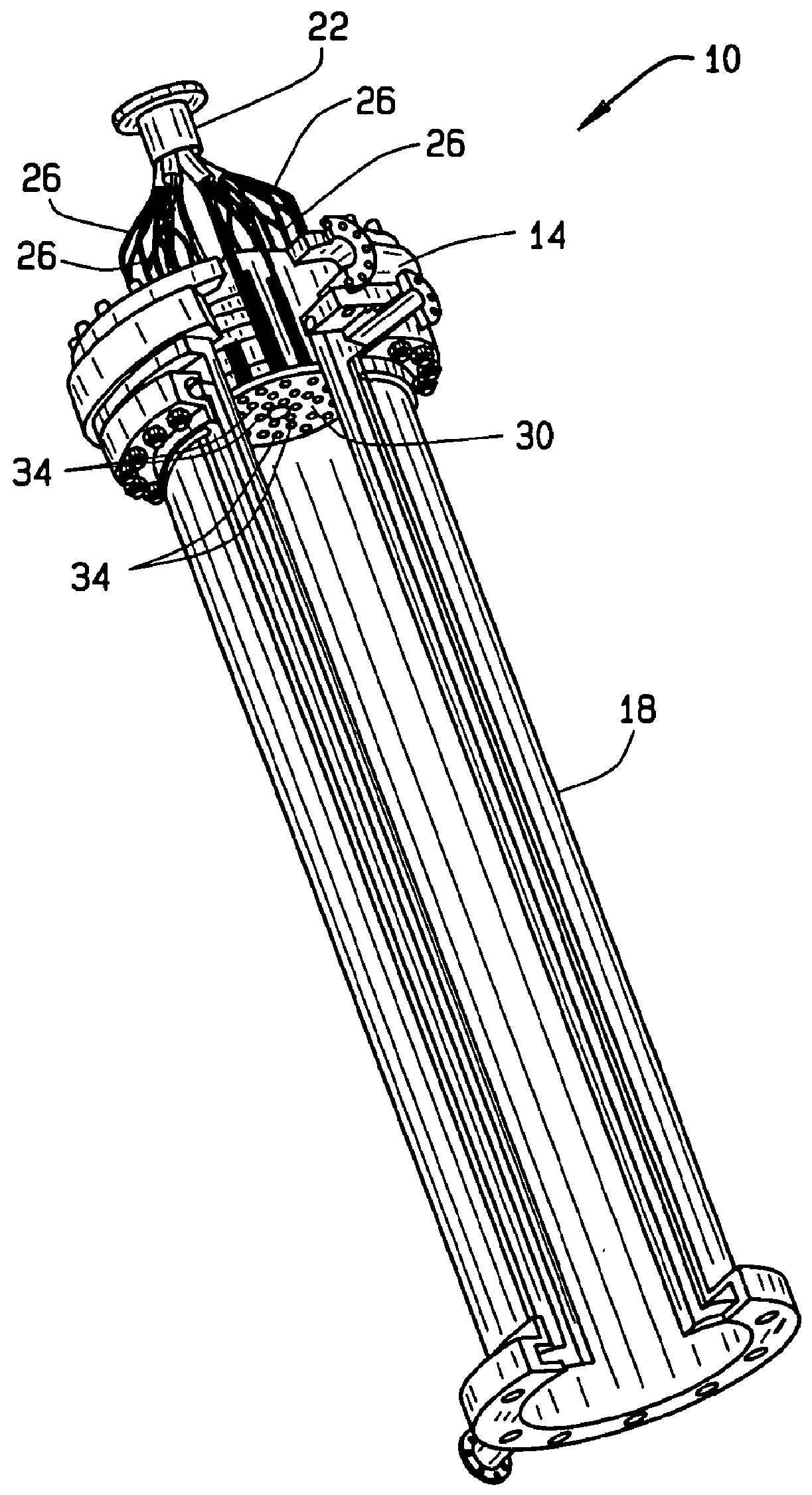

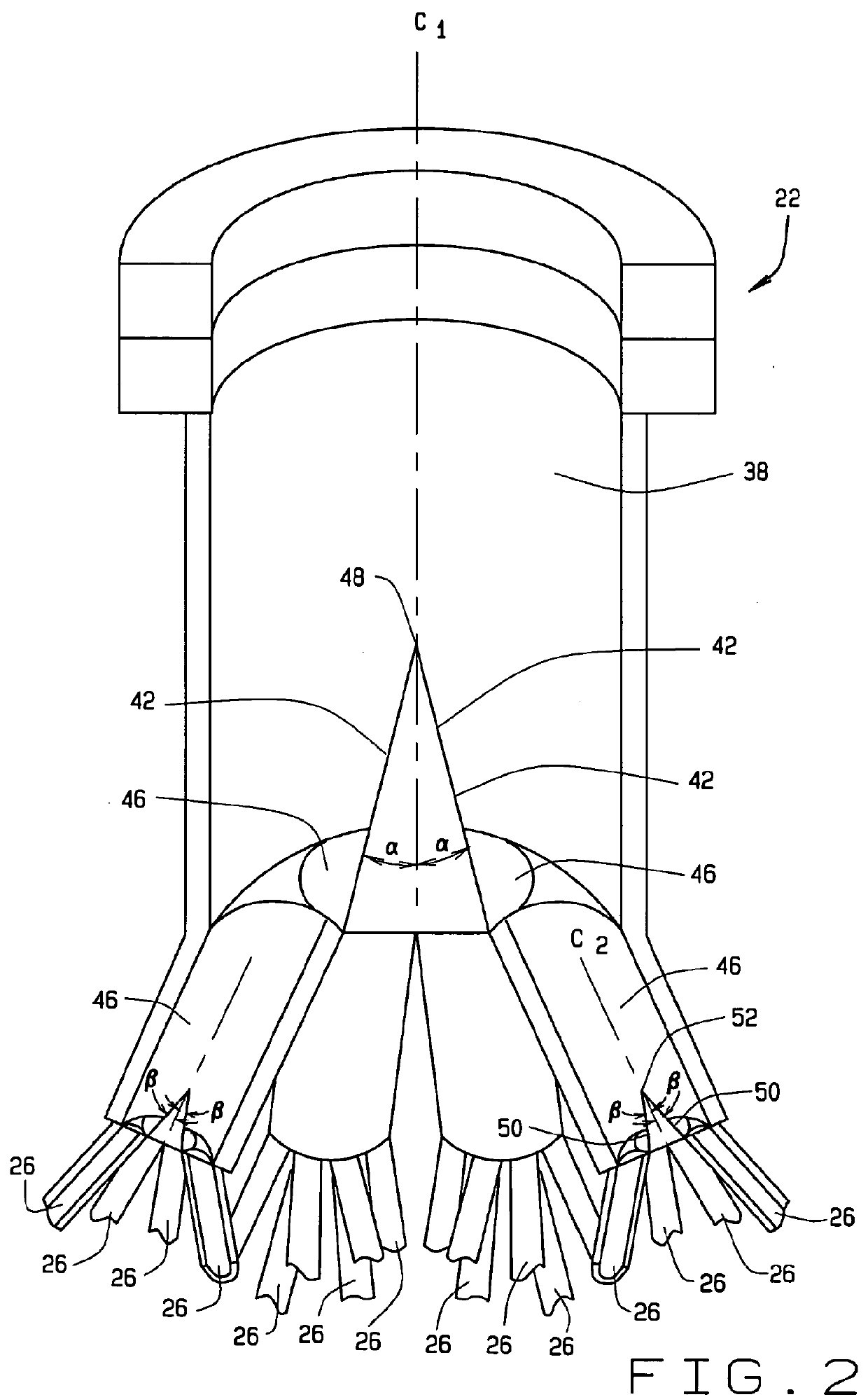

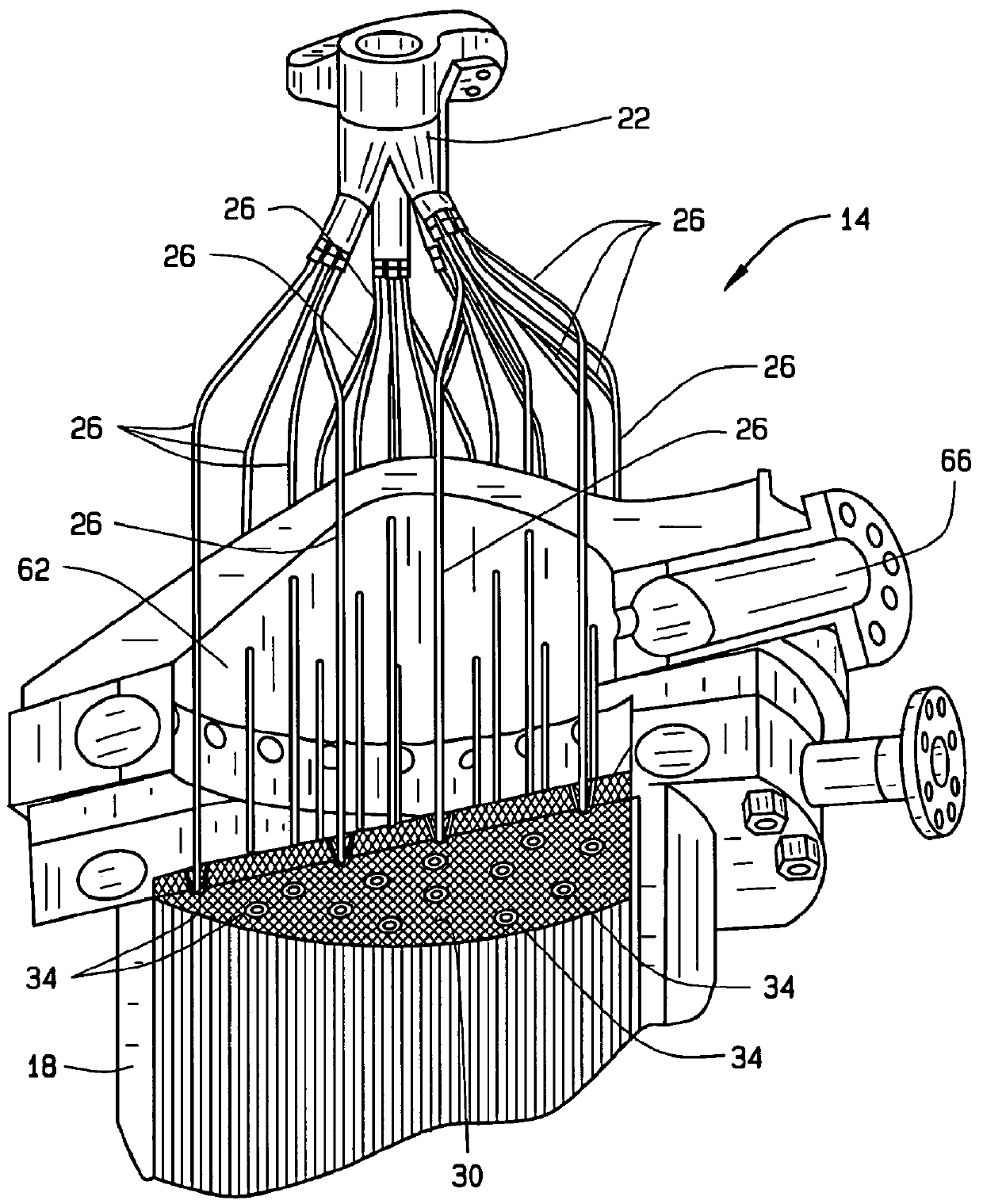

Well centralizer

ActiveUS20130248206A1Eliminate needReduce and prevent damageDrilling rodsFluid removalSurface mountingEngineering

A centralizer assembly having a tubular body member with upper and lower channels extending around the external surface of said central tubular body member. A bow spring assembly having bow spring members is installed around the outer surface of the tubular body member and can rotate about the outer surface of the central tubular body member. Bow spring heel supports prevent the bow spring members from contacting the outer surface of the central tubular member when compressed. Non-abrasive materials prevent damage to wellhead or other polished bore receptacles. A robust bolster frame protects the centralizer assembly during shipping, storage or other periods of non-use.

Owner:FRANKS INT

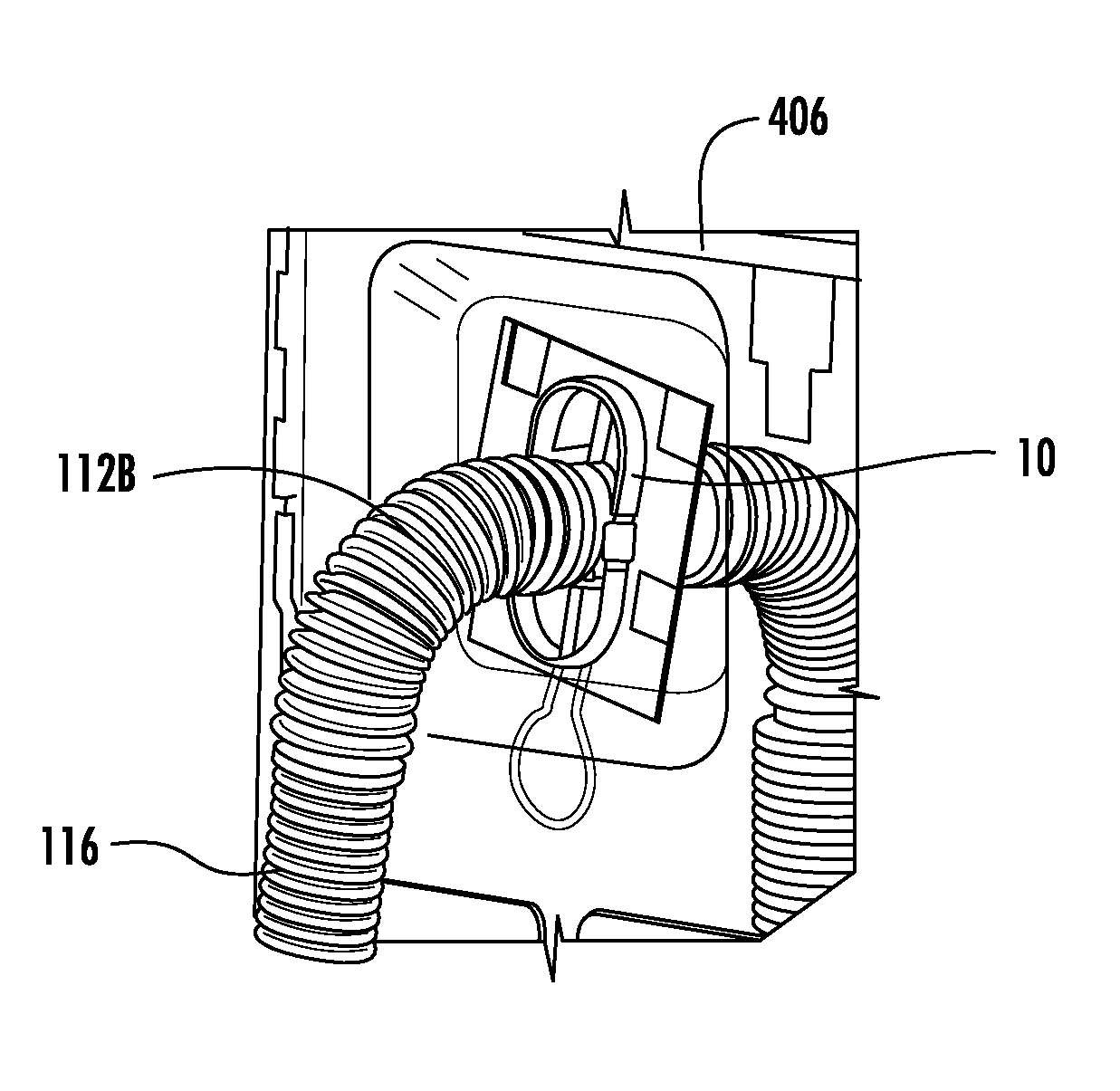

Drain hose clip for a washer

InactiveUS20120255330A1Precise positioningReduce and prevent damageOther washing machinesBranching pipesEngineeringHome appliance

A drain hose clip for securing a drain hose to a household appliance, and a household appliance having the drain hose clip and drain hose. The drain hose clip includes a body configured to be coupled to the drain hose and to secure the drain hose to the household appliance, and an orientation control feature on the body that engages a corresponding orientation control feature on the drain hose to maintain a fixed position of the drain hose with respect to the body of the drain hose clip.

Owner:BSH HOME APPLIANCES CORP

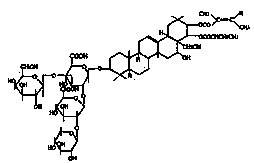

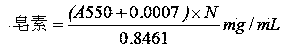

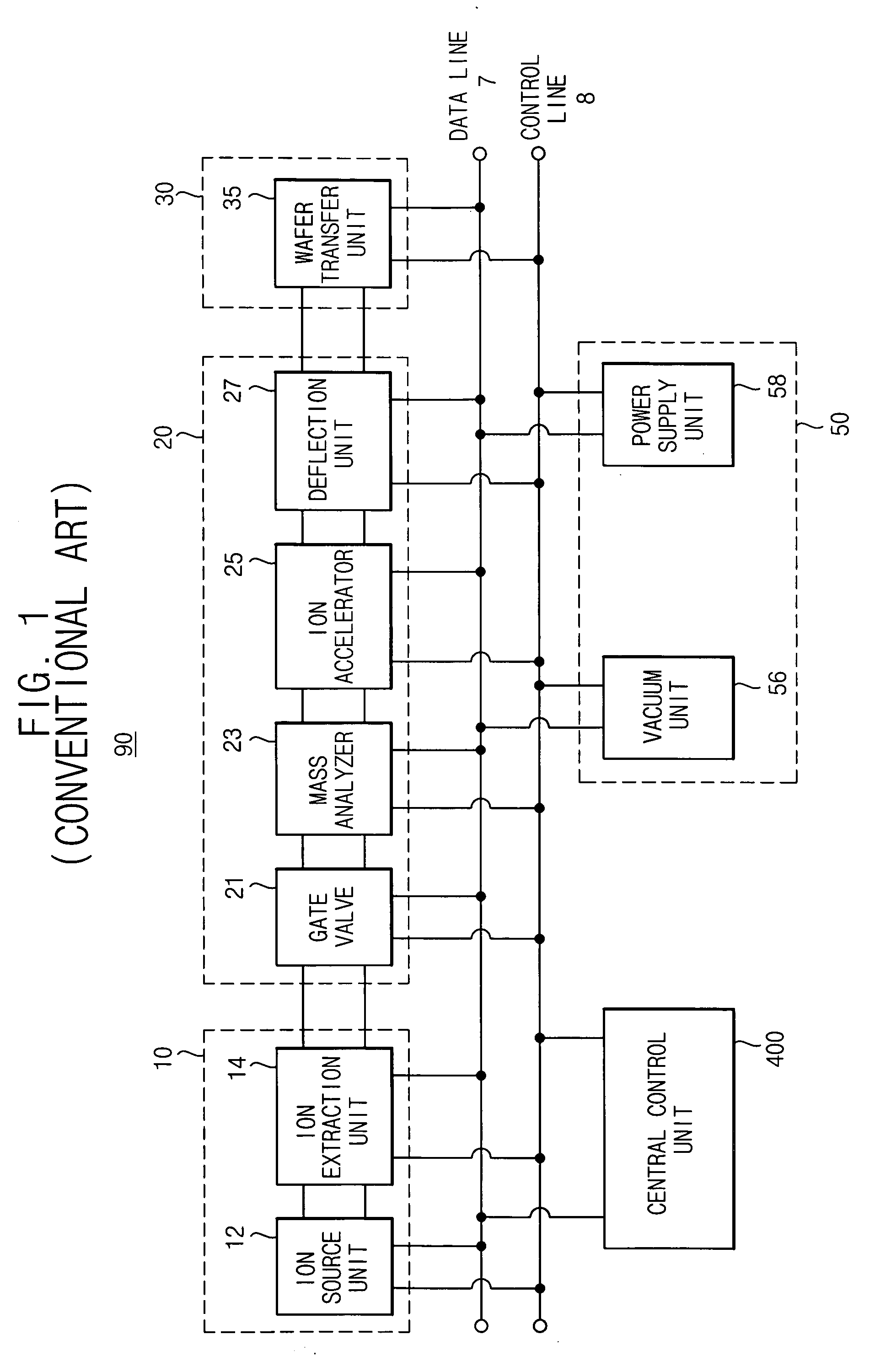

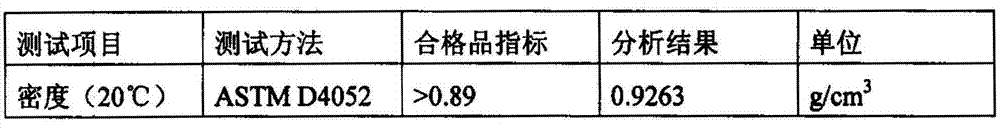

Sasanqua saponin concrete air entraining agent and preparation method thereof

The invention provides a sasanqua saponin concrete air entraining agent and a preparation method thereof. The air entraining agent is characterized by containing sasanqua saponin therein. The preparation method is characterized by extracting sasanqua as a raw material at normal temperature by hydrophilic solvent water solution, and filtering; removing large-molecule impurities from the filtrate by membrane separation under pressure, removing small-molecule impurities by membrane separation, concentrating to be concentrate with Baume degree of not lower than 10Be (60 DEG C), and spray-drying to form solid formulation; or adding a modifying agent to prepare the air entraining agent in liquid formulation. The idea is novel, the raw materials are abundant, the production efficiency is high, the energy consumption in the production is low, the production cost is low, the preparation method is simple in process, green and environment-friendly and is convenient to implement; when the air entraining agent is used in concrete engineering, the dosage of the air entraining agent is low, the air production rate is high, the aperture of the entrained air bubbles is small and the distance among the entrained air bubbles is small, and the air holes of the concrete are more even, more compact and non-communicated, therefore, the sasanqua saponin concrete air entraining agent is valuable for popularizing.

Owner:FUZHOU UNIV

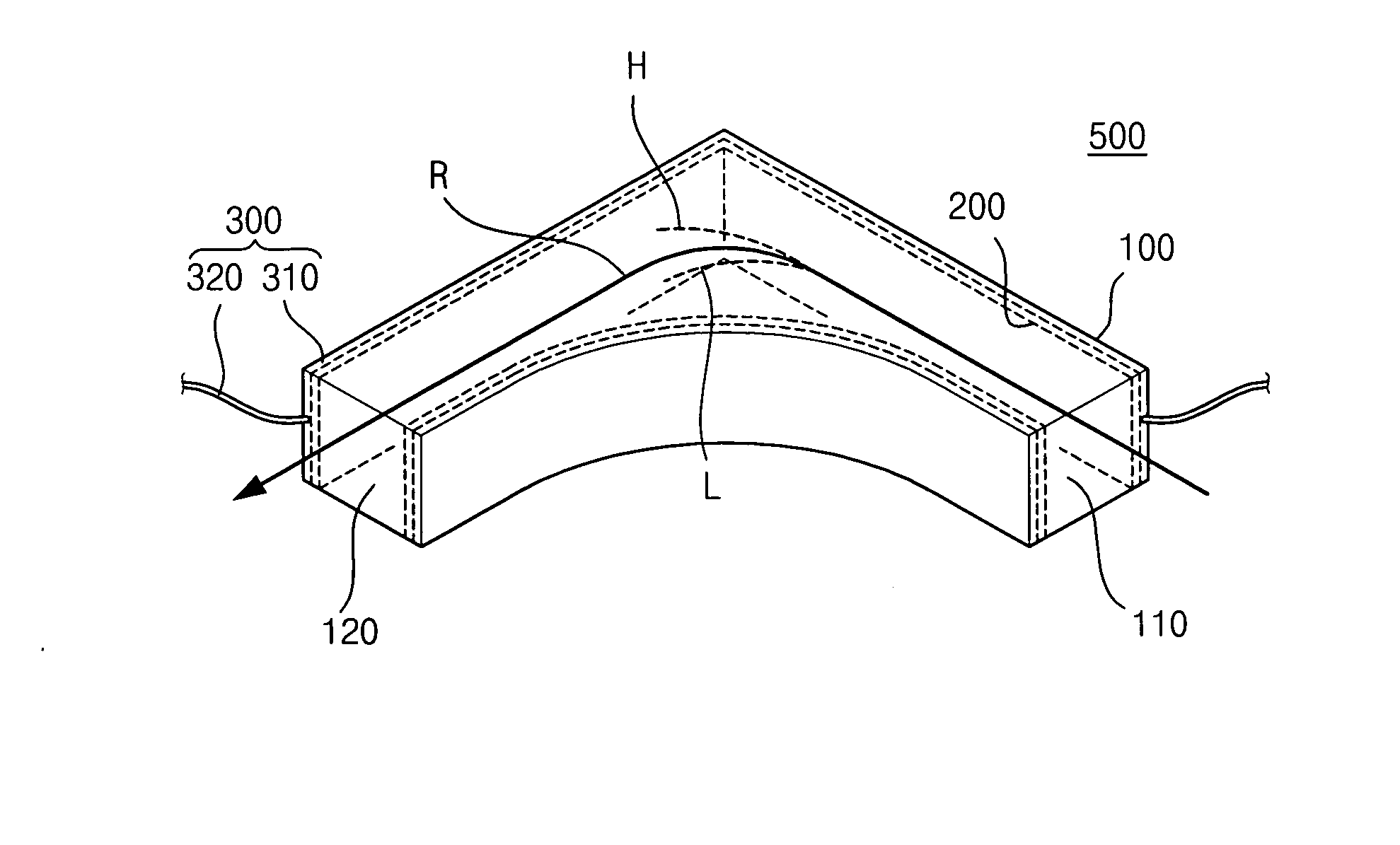

Analyzing chamber including a leakage ion beam detector and mass analyzer including the same

ActiveUS20070018093A1Avoid damageReduce and prevent damageSpectrometer detectorsMaterial analysis by electric/magnetic meansIon beamMass analyzer

In an analyzing chamber for a mass analyzer, a body of the analyzing chamber may include an inlet through which an ion beam enters and an outlet through which the ion beam leaves. A shielding section may be installed on a sidewall. The shielding section may prevent the ion beam traveling along a path in the body from causing damage to the sidewall of the body. A detector may be interposed between the sidewall of the body and the shielding section. The detector may detect an ion beam leaking through the shielding section. Accordingly, damage to the sidewall of the body may be sufficiently reduced and / or prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

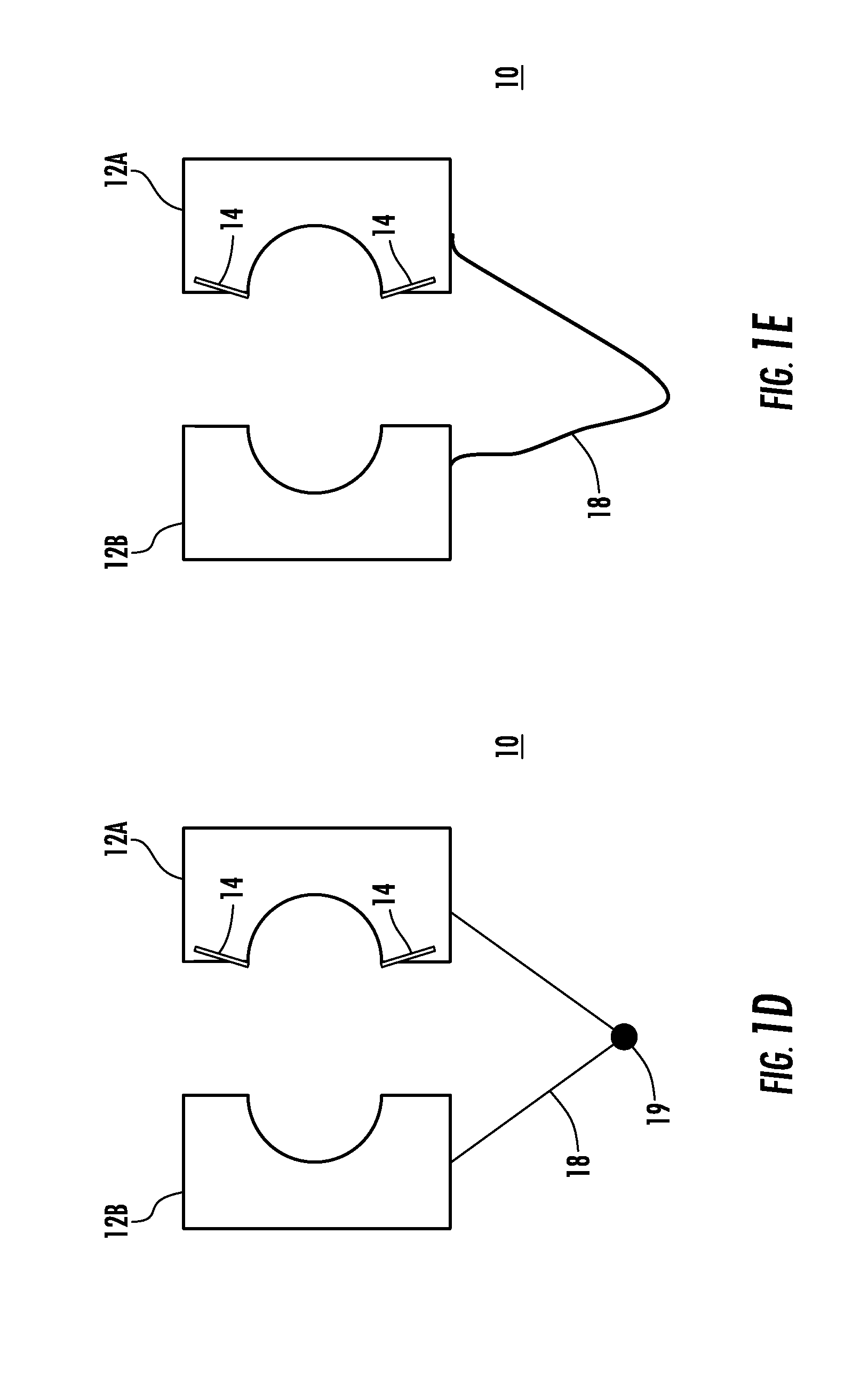

Valve assembly with magnetically coupled actuator

InactiveUS20080073606A1Reduce and prevent damageMaintenance be troublesomeOperating means/releasing devices for valvesMagnetEngineering

A valve assembly having a housing including a first and second port. A closure element is disposed within the housing and is selectively moveable between an open position wherein the first port is in fluid communication with the second port and a closed position wherein fluid communication between the first and second ports is blocked and / or controlled. A first magnet assembly is coupled to the closure element for actuating the closure element between the open and closed positions whereby the fluid communication is blocked and / or controlled. A second magnet assembly is magnetically coupled to the first magnet assembly for imparting movement to the first to provide fluid communication blocking and / or controlling. The drive mechanism is adapted to actuate the second magnetic assembly and is alternatively operable through a first and / or a second drive input. The first drive input is unable to drive the second drive input.

Owner:TARGET ROCK DIV OF CURTISS WRIGHT FLOW CONTROL

Electrical component and a shuntable/shunted electrical component and method for shunting and deshunting

InactiveUS6846991B2Reduce and prevent ESD/EOS damageReduce and prevent damagePrinted circuit aspectsHigh voltage circuit adaptationsEngineeringFlow diverter

Owner:APPLIED KINETICS

Vehicle speed control system

ActiveUS20160121862A1Guaranteed uptimeIncrease vehicle composure and occupant comfortVehicle fittingsDigital data processing detailsControl systemSpeed control system

A vehicle control system for a vehicle having a plurality of wheels, the vehicle speed control system being operable to receive an input signal corresponding to a rate of change of an angle of pitch of the vehicle, pitch rate, the system being operable to command a change in an amount of torque applied to at least one of the plurality of wheels in dependence on the pitch rate.

Owner:JAGUAR LAND ROVER LTD

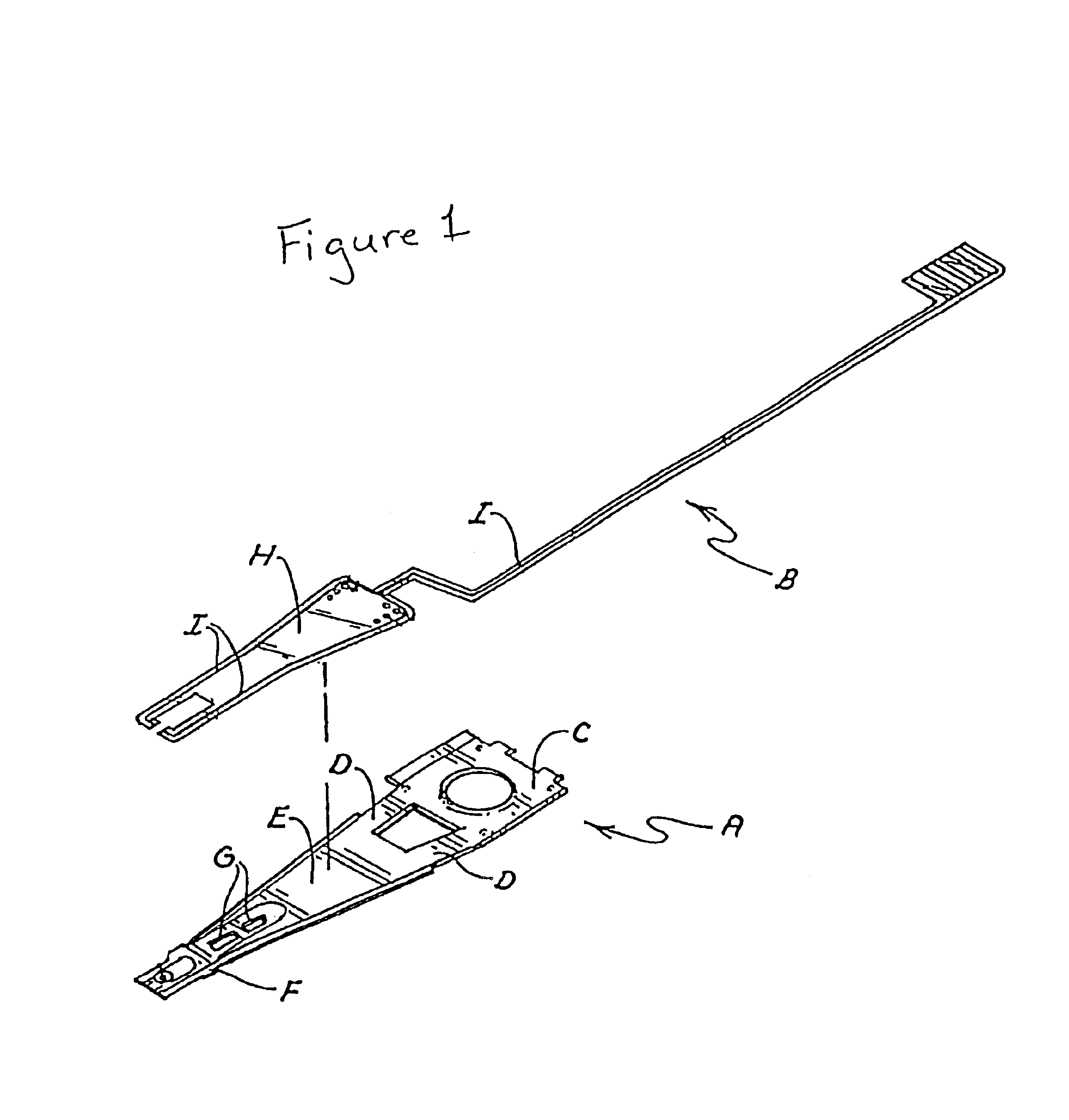

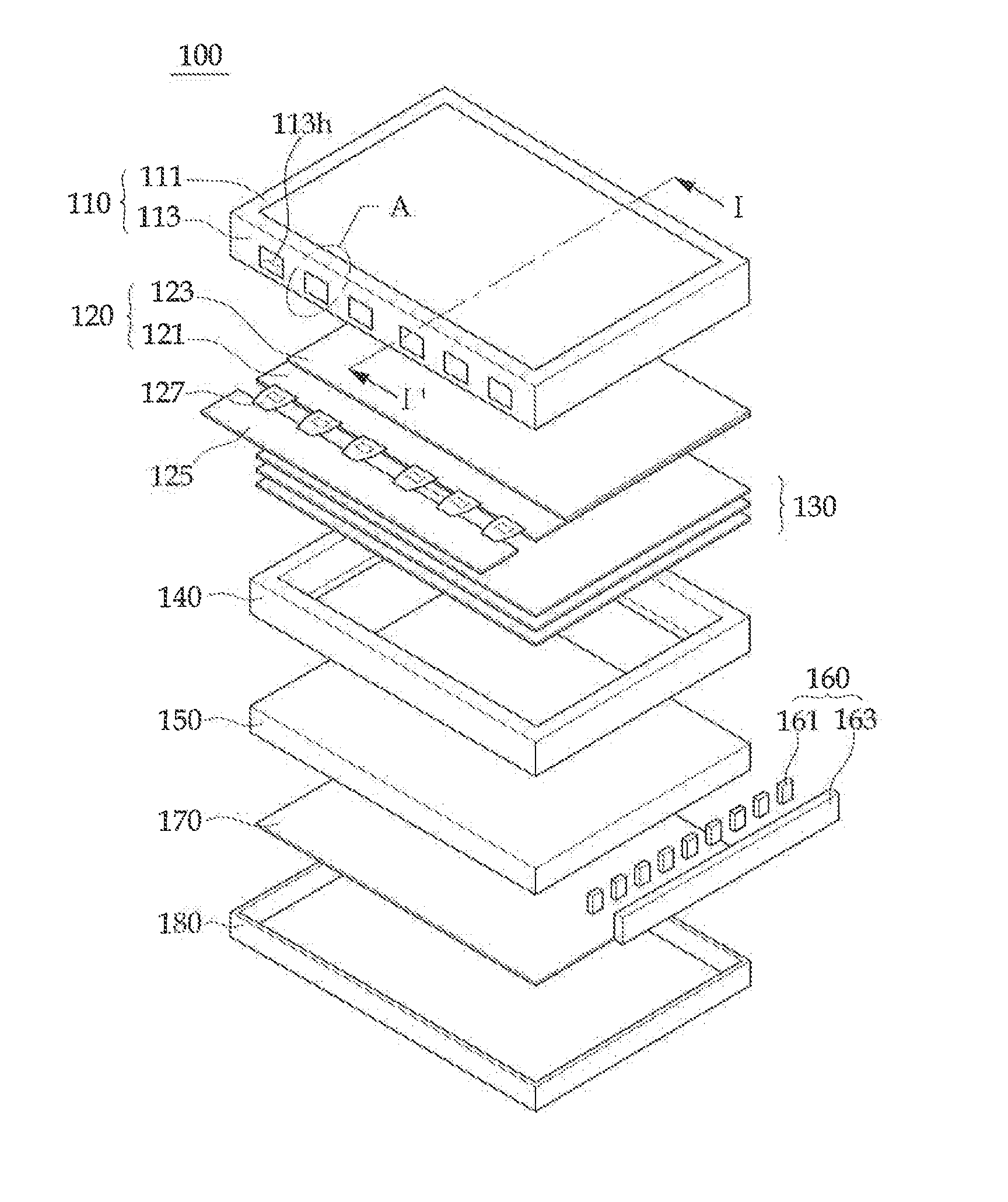

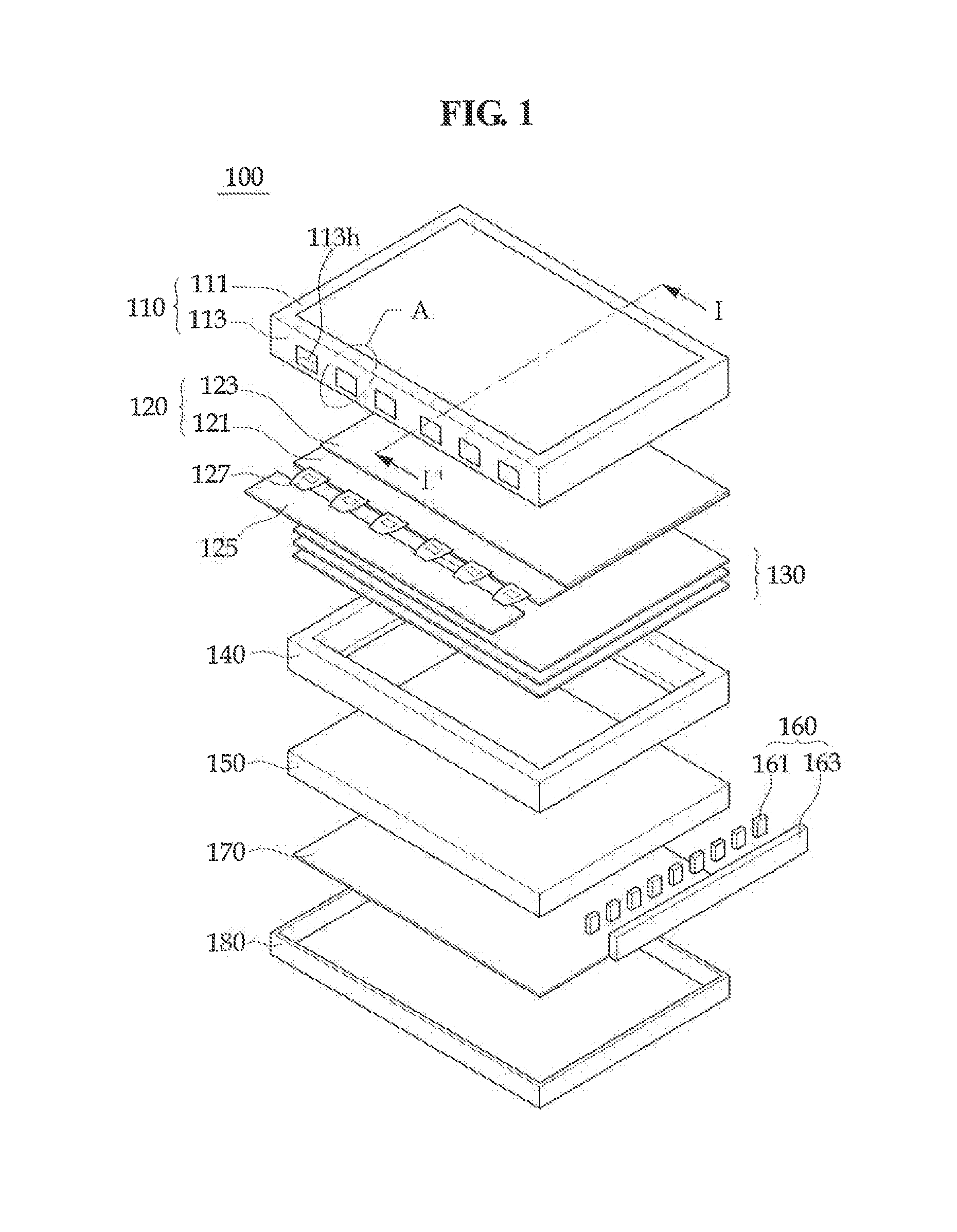

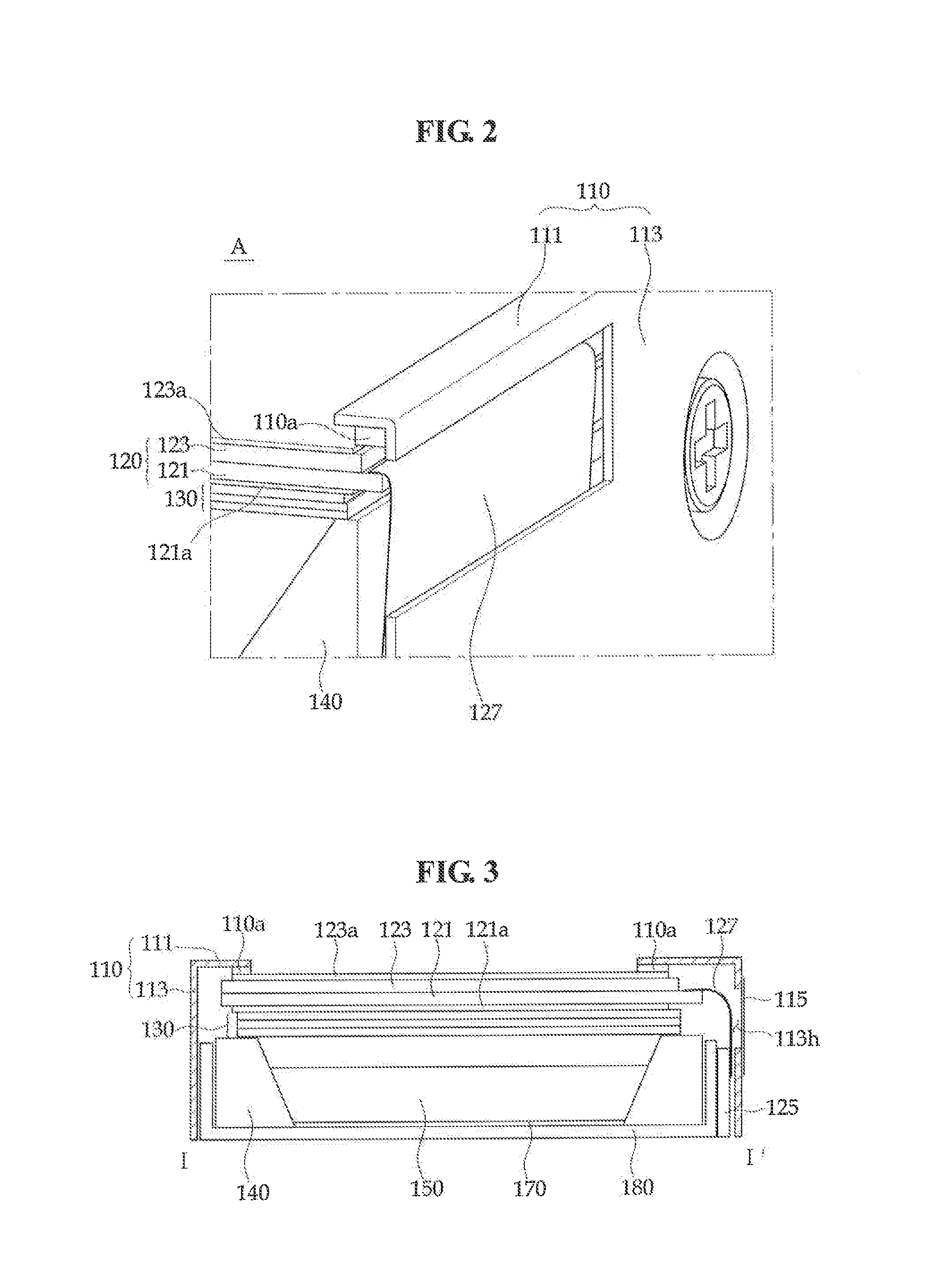

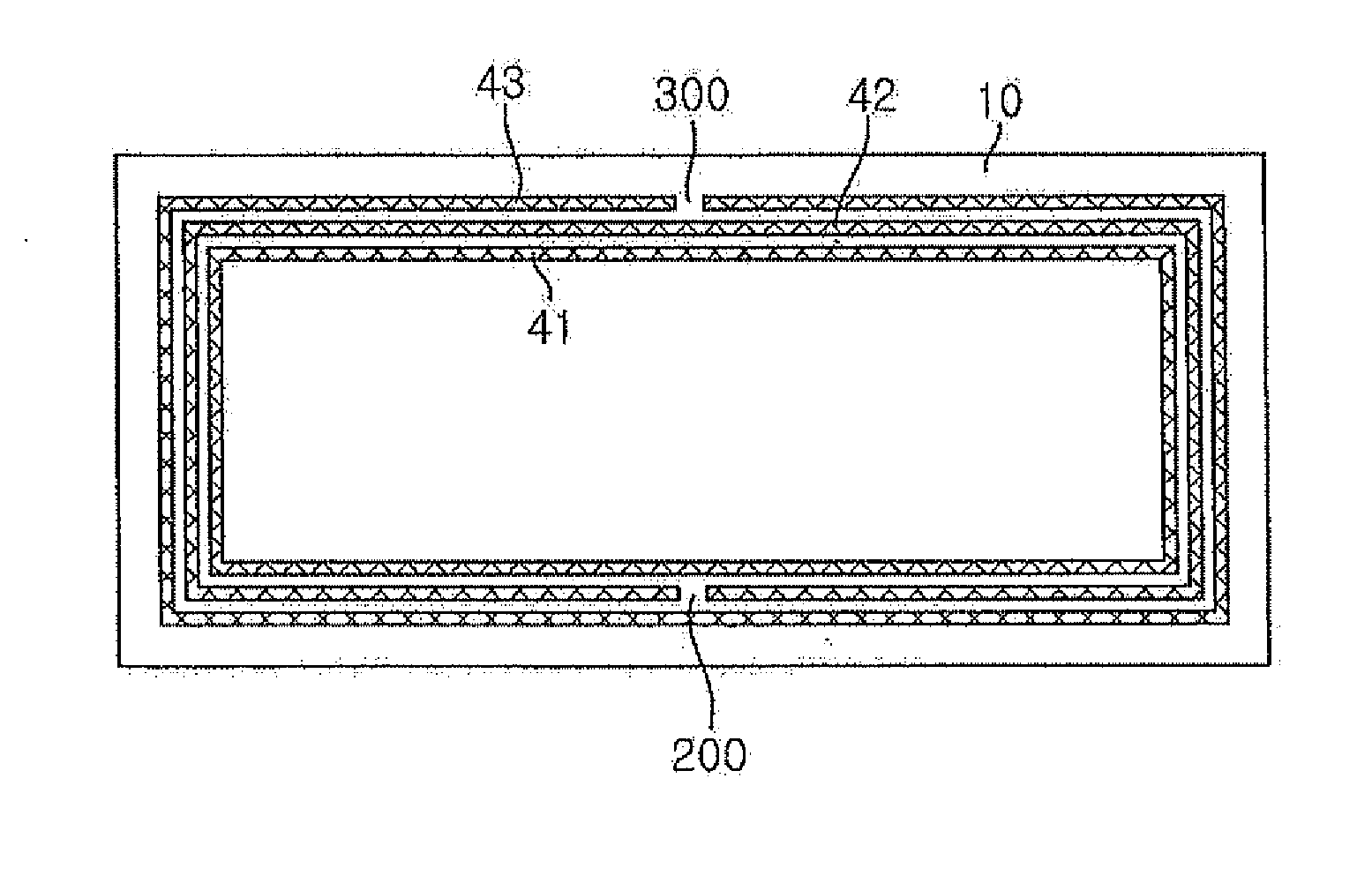

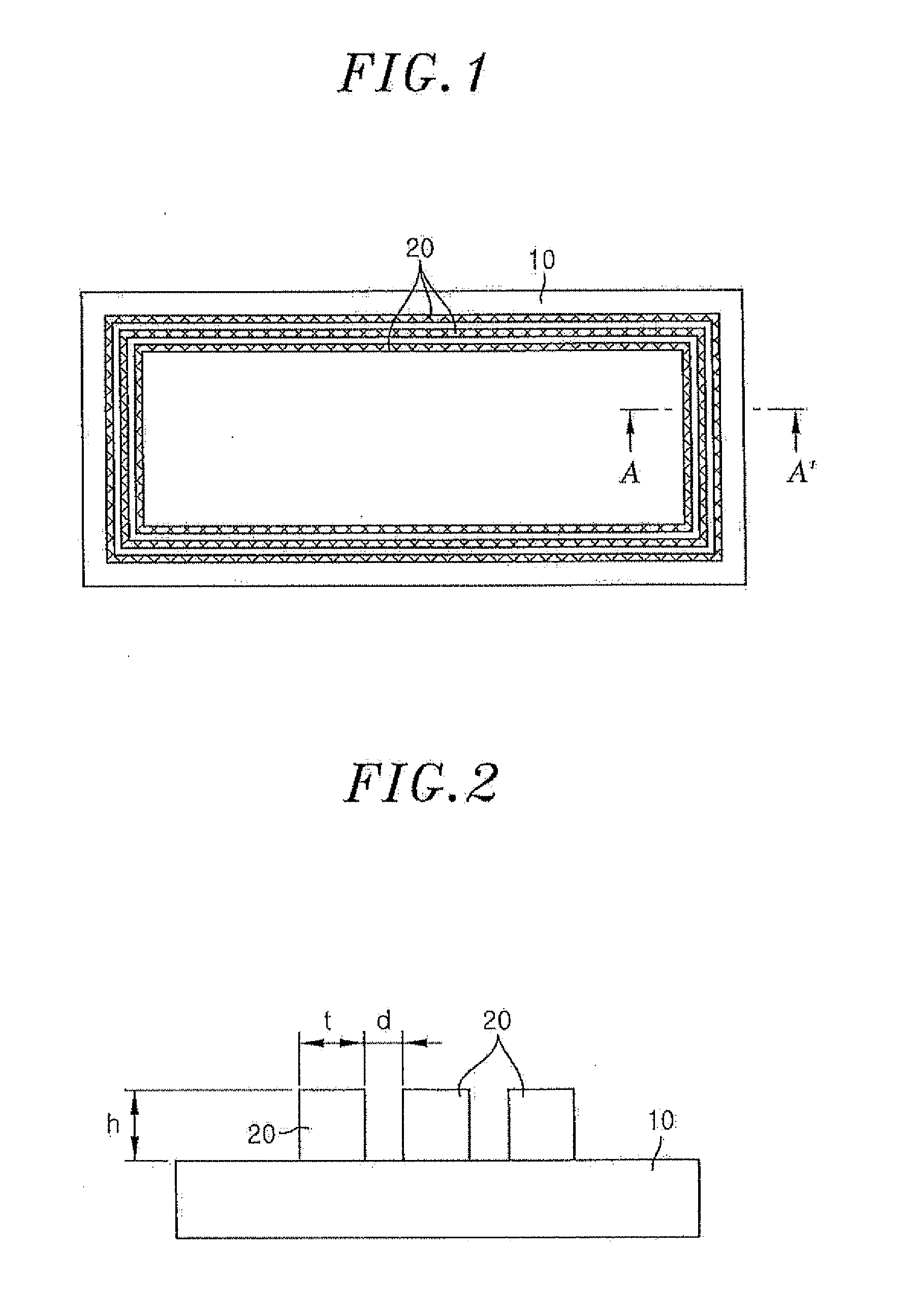

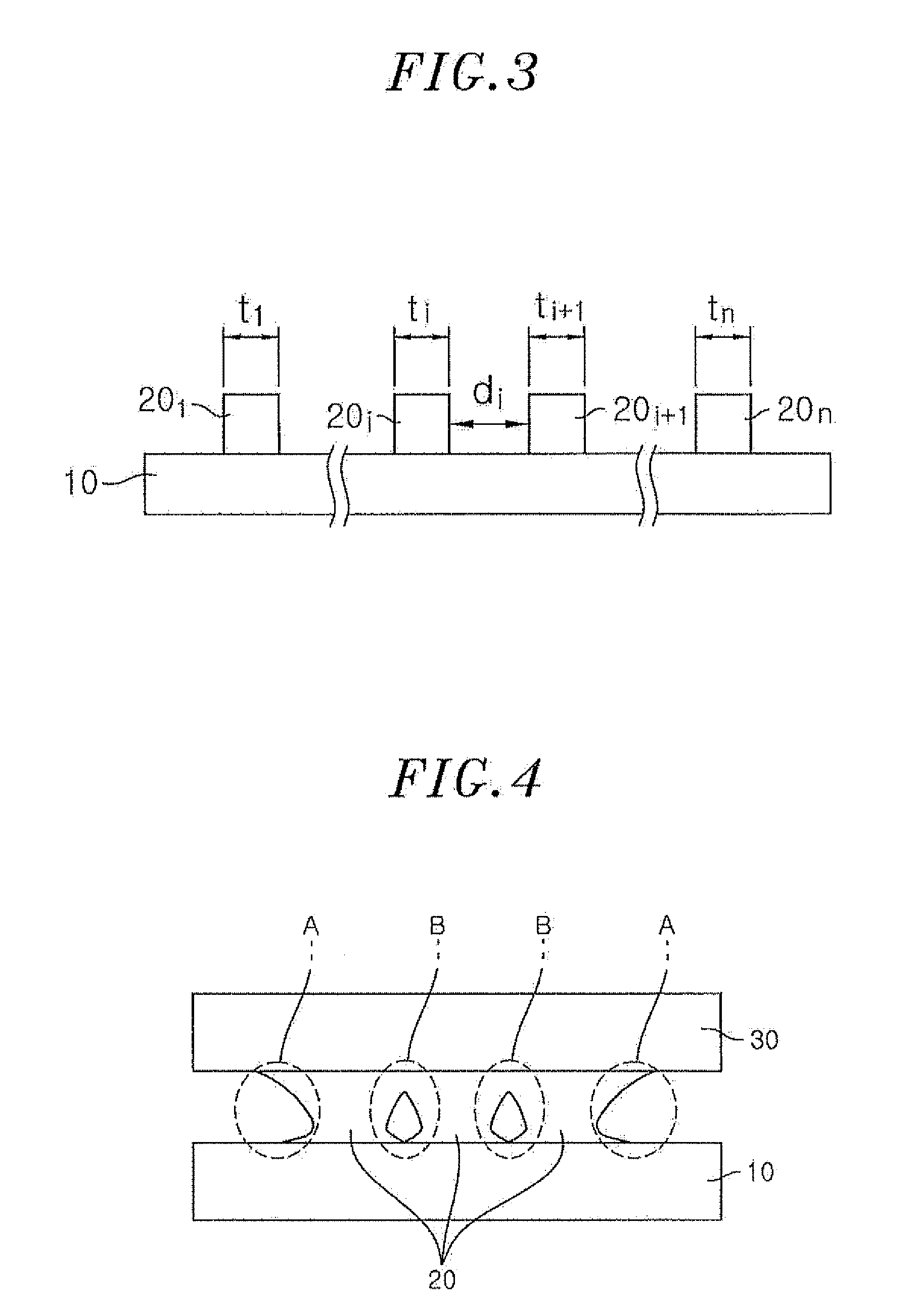

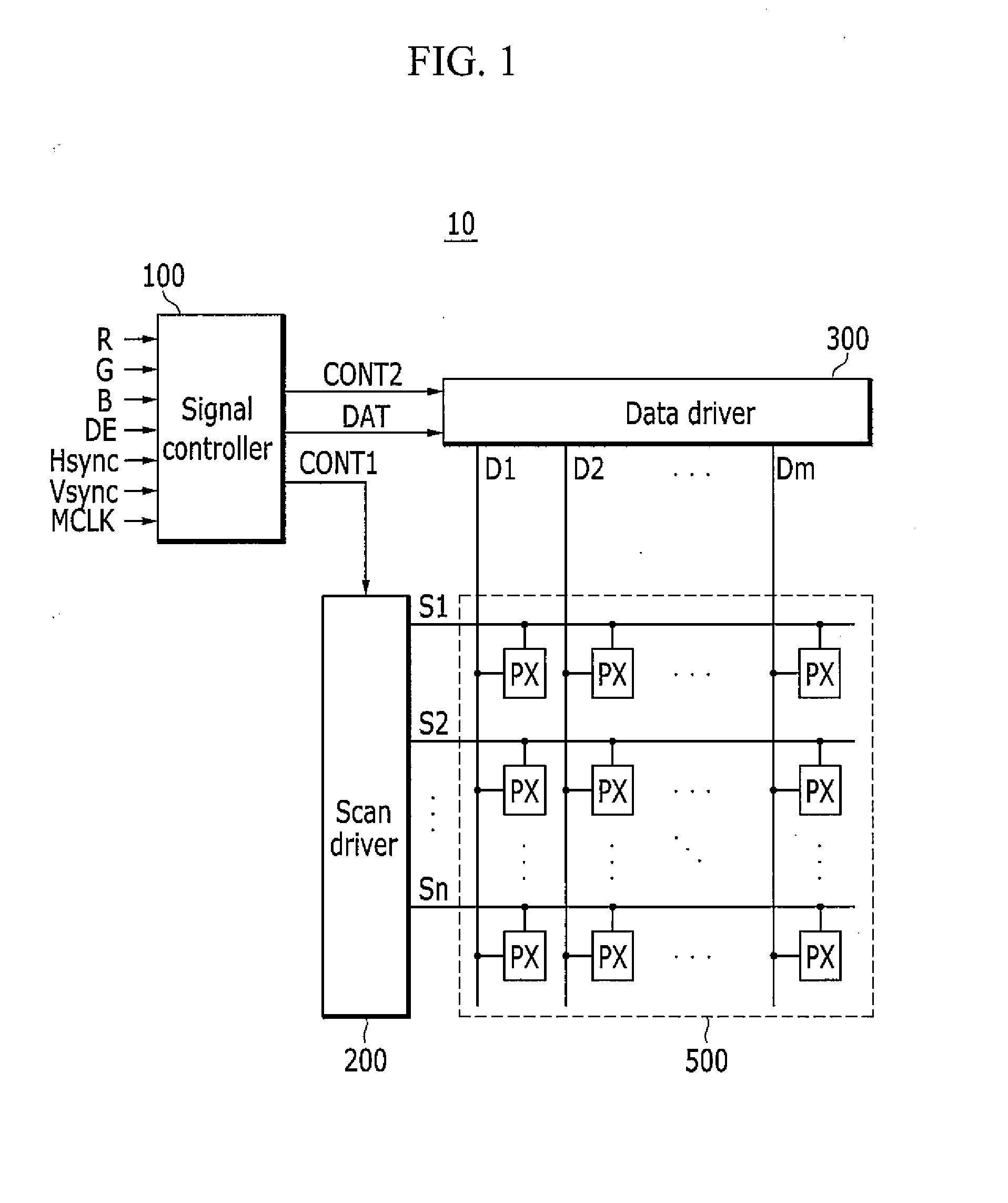

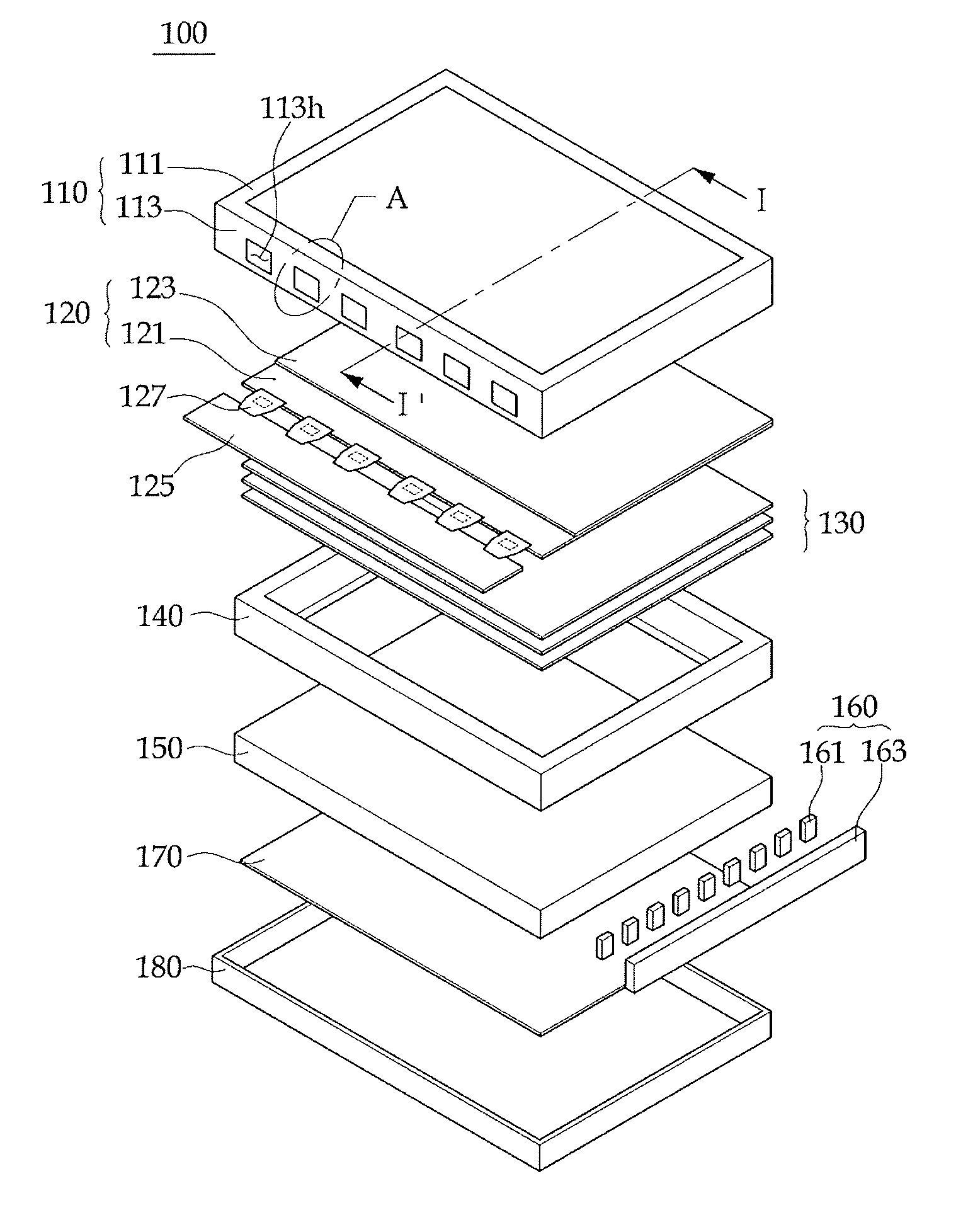

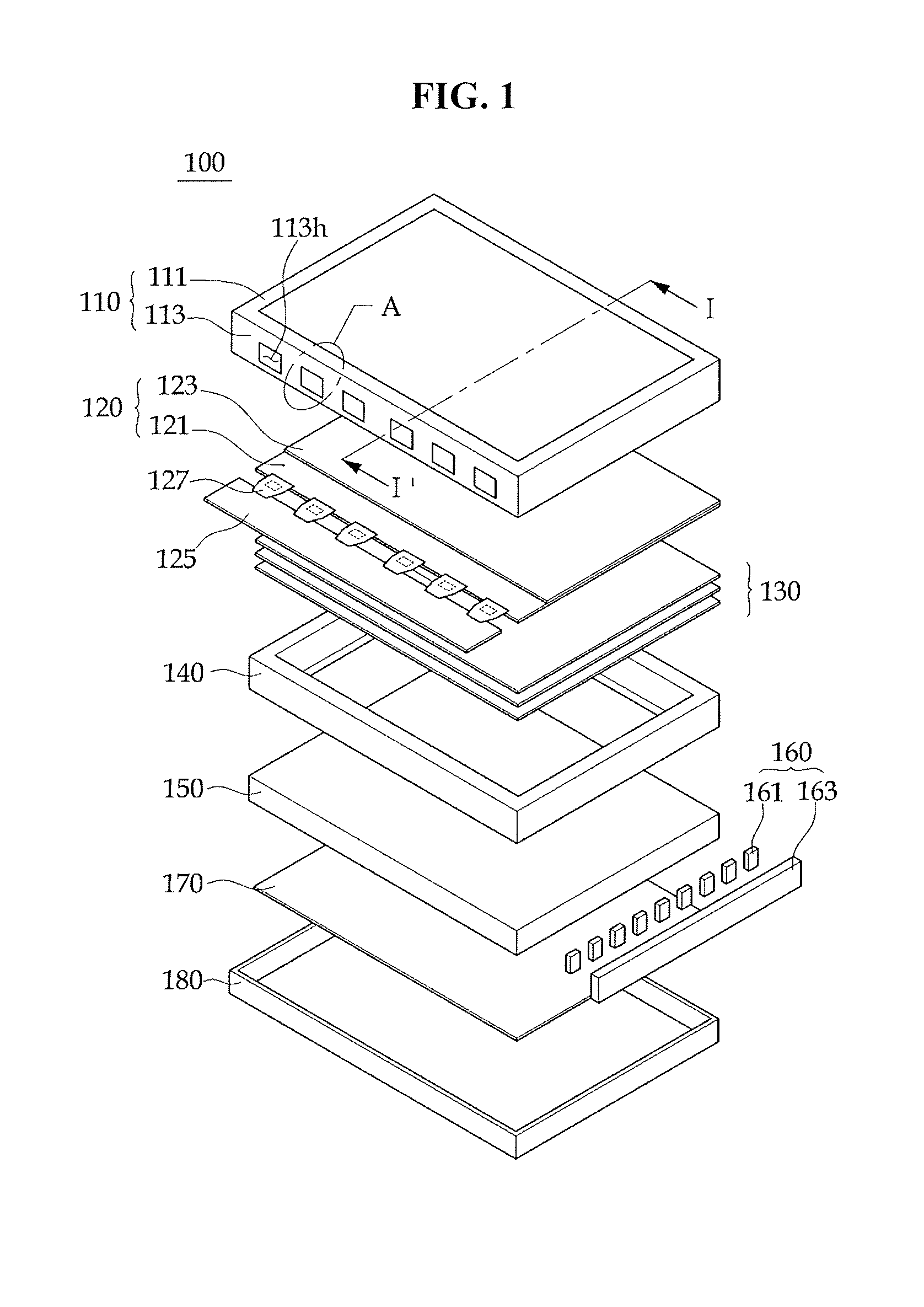

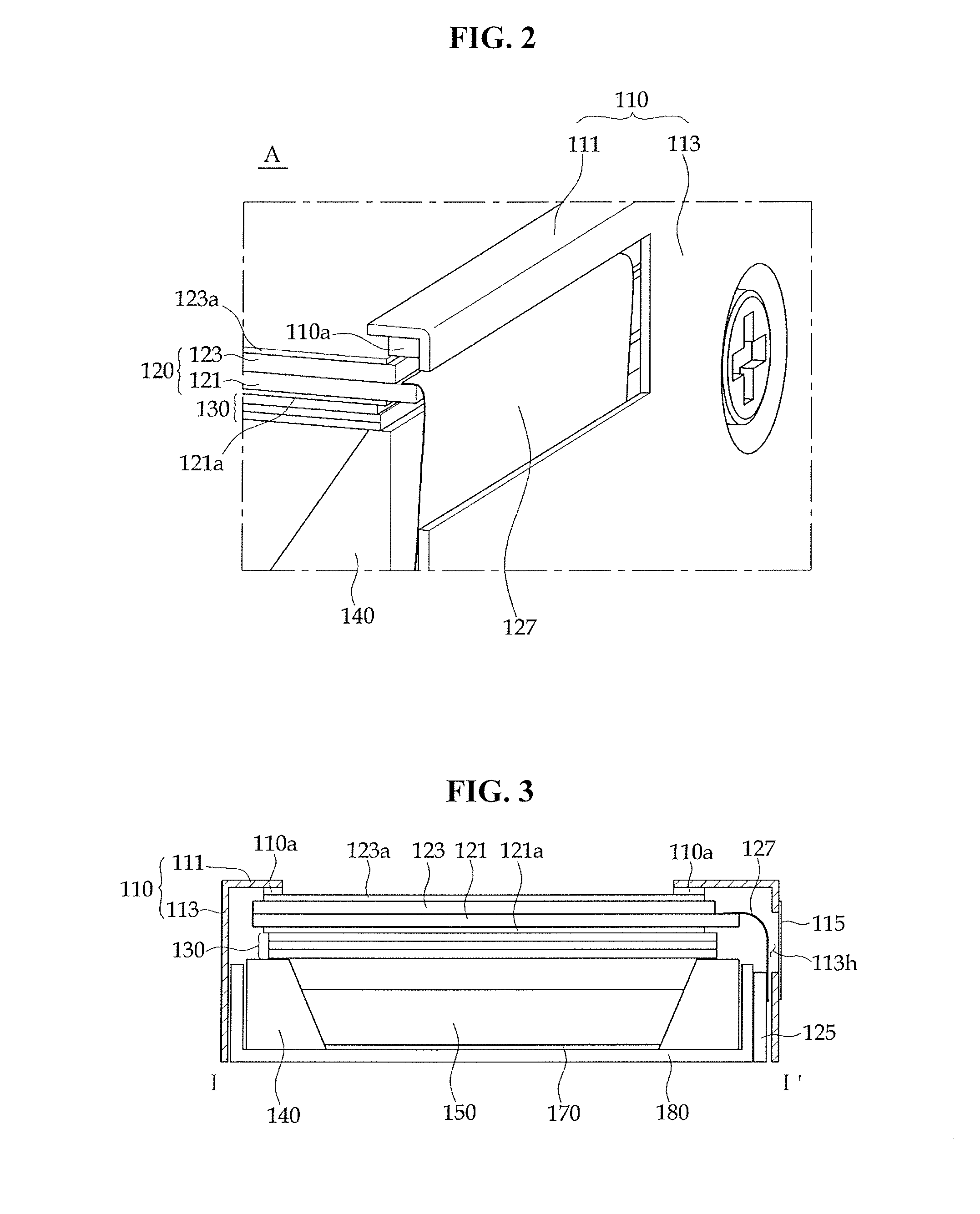

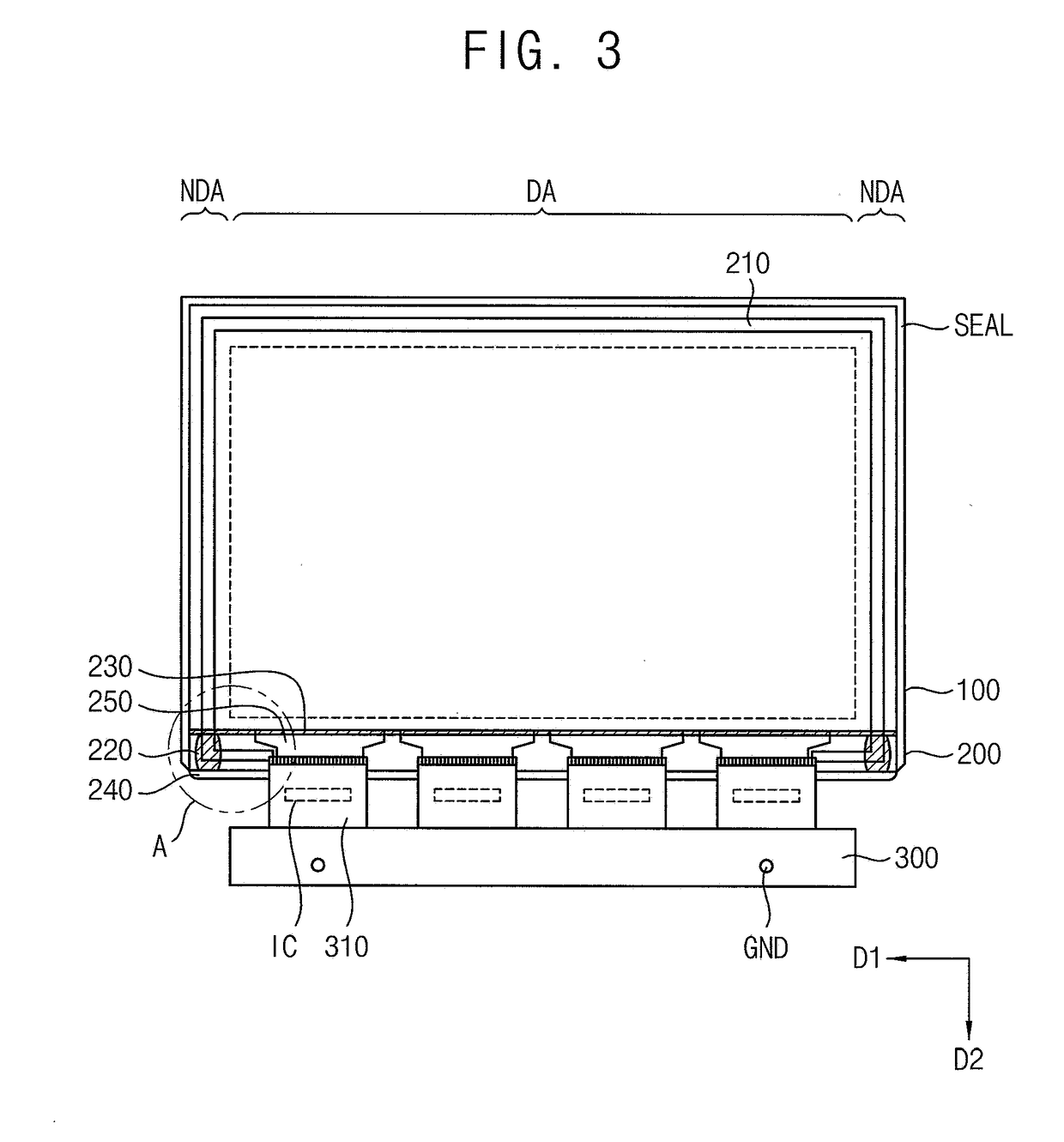

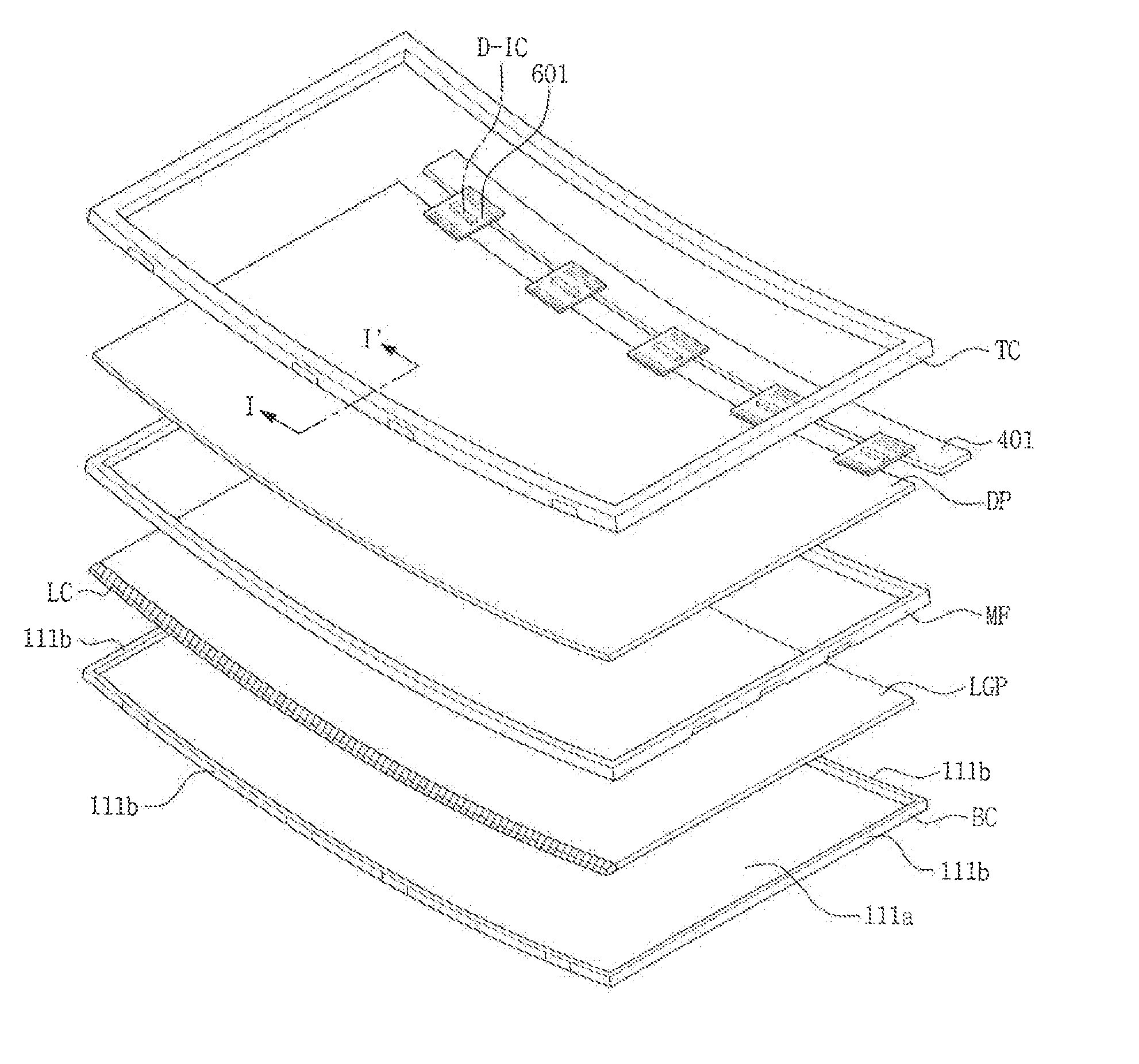

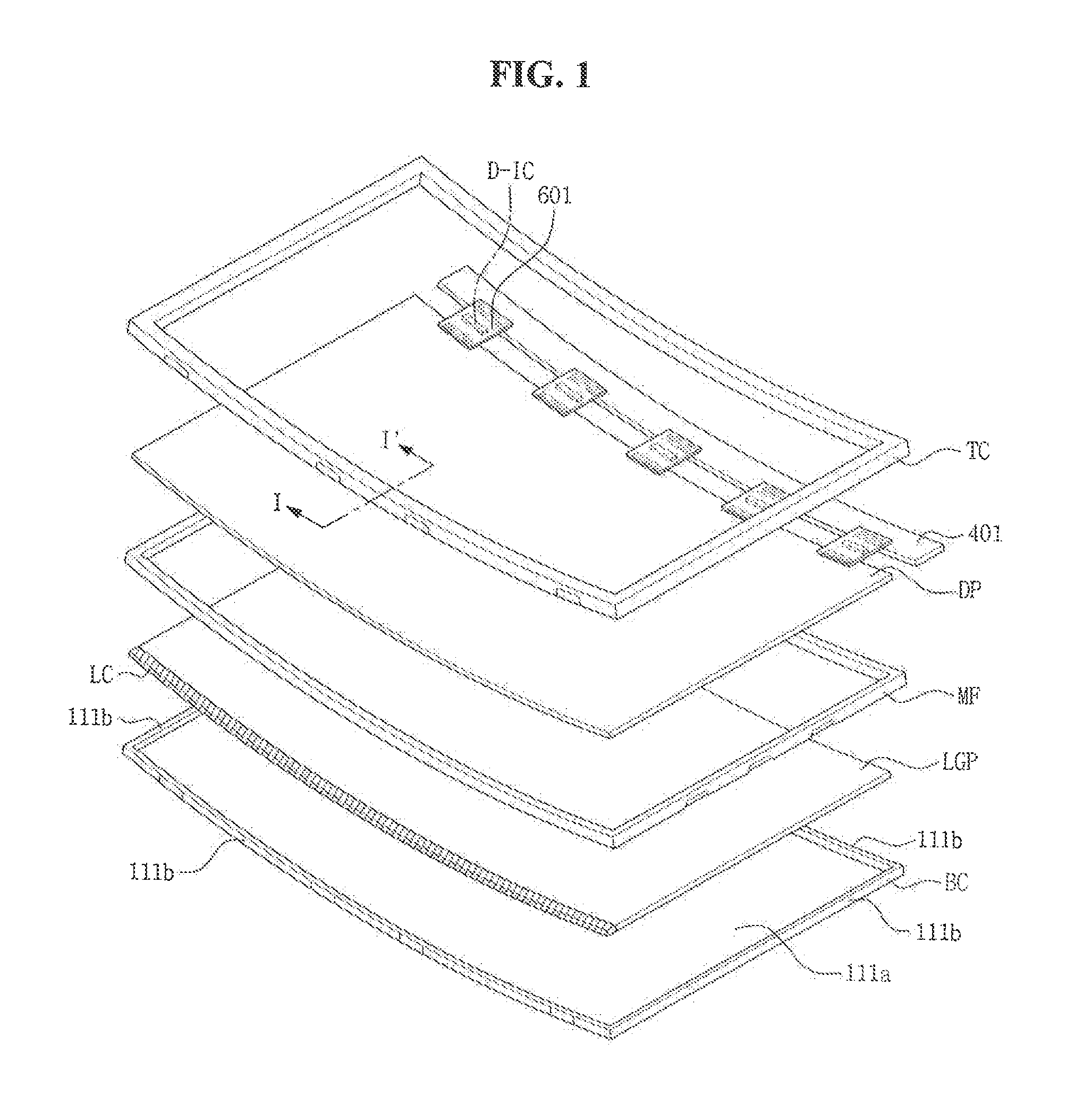

Display device and multi display device using the same

InactiveUS20160021773A1Reducing and preventing widthArea minimizationSide-by-side/stacked arrangementsCircuit arrangements on support structuresDisplay deviceFlexible electronics

A display device includes: a display panel; a bottom chassis in which the display panel is accommodated; a driving circuit substrate disposed on an outside surface of the bottom chassis; at least one flexible printed circuit board connecting the display panel to the driving circuit substrate; and a top chassis configured to cover an edge portion of a top surface and side surfaces of the display panel, wherein the top chassis has an opening formed in an area in contact with the flexible printed circuit board.

Owner:SAMSUNG DISPLAY CO LTD

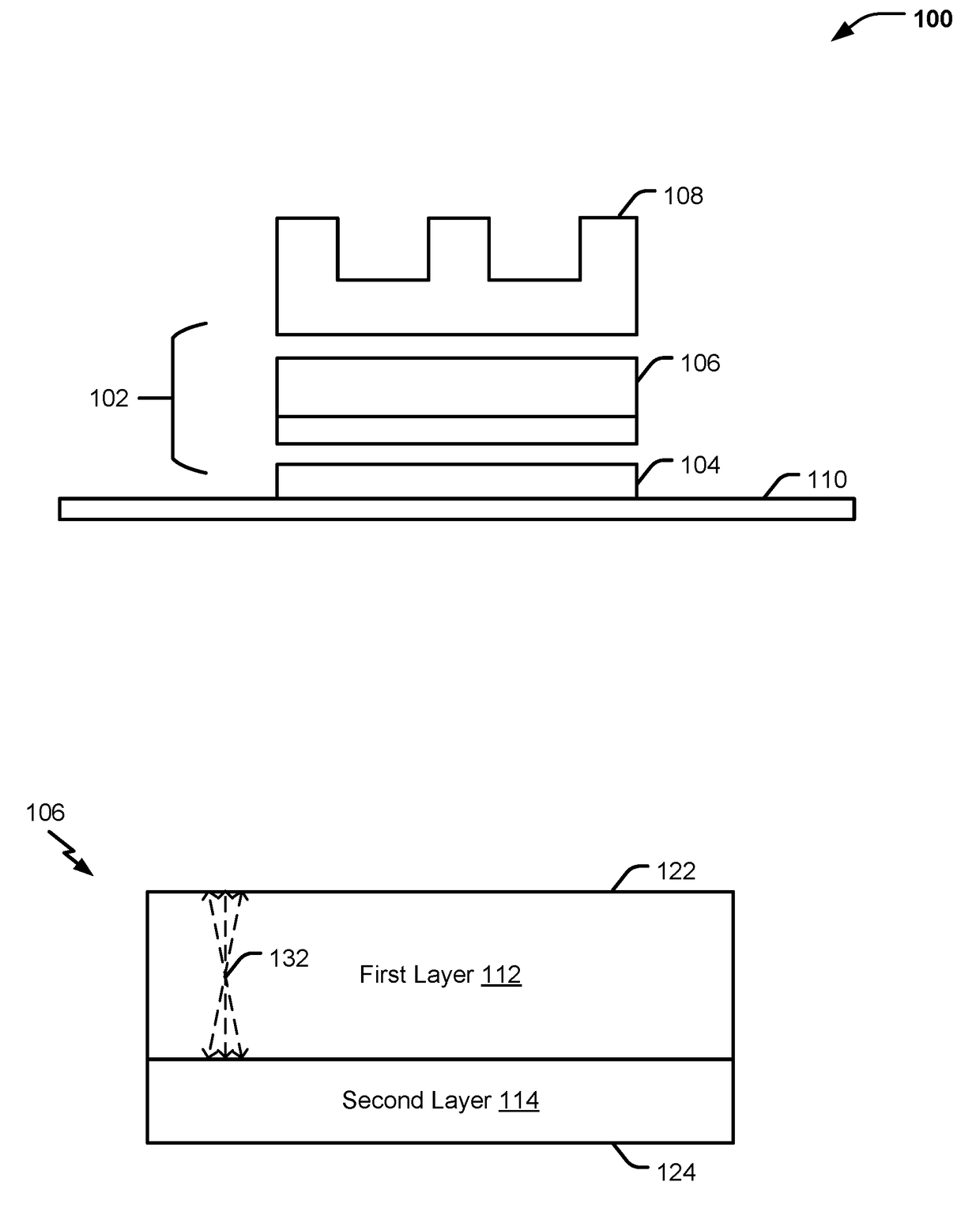

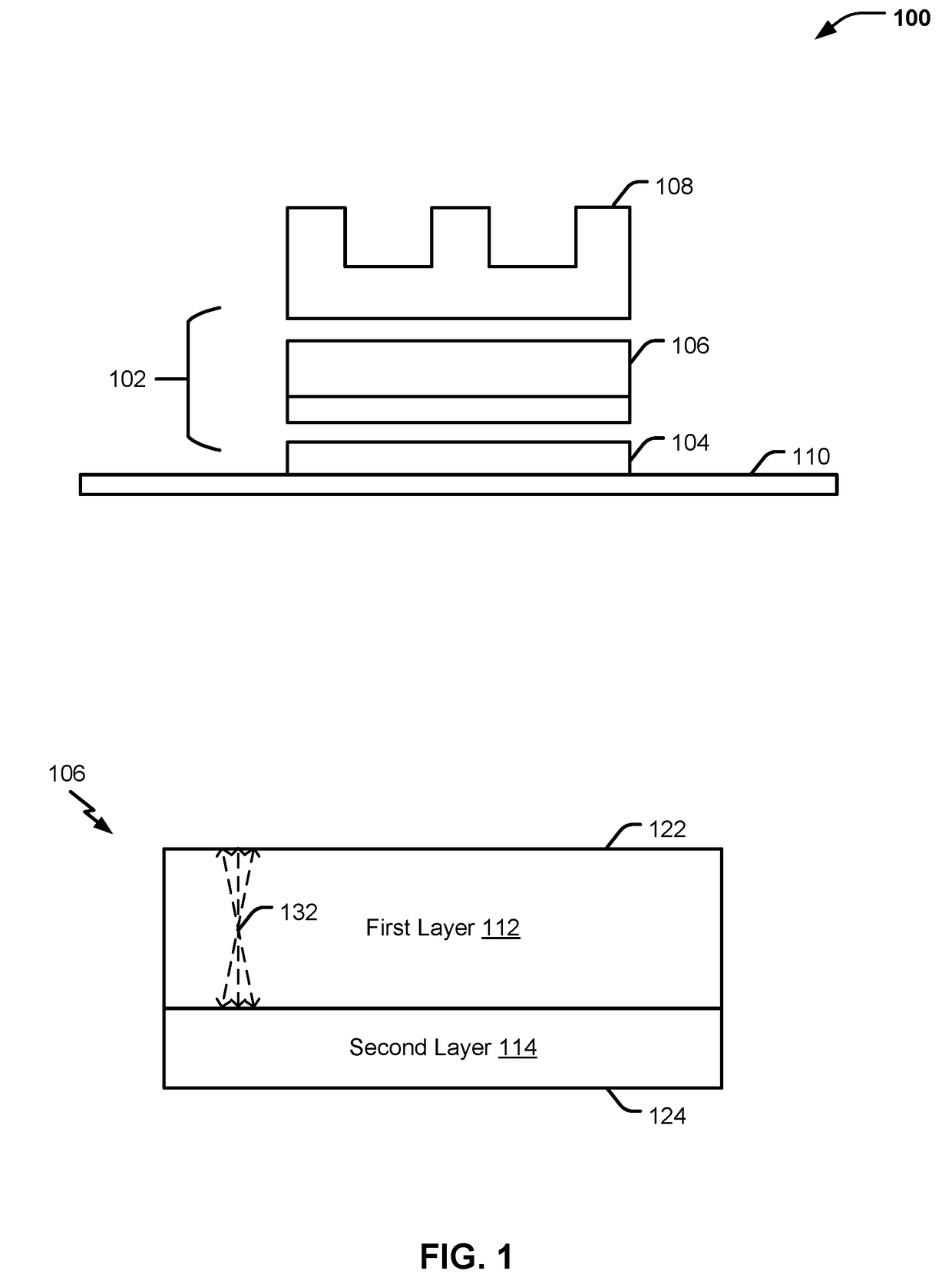

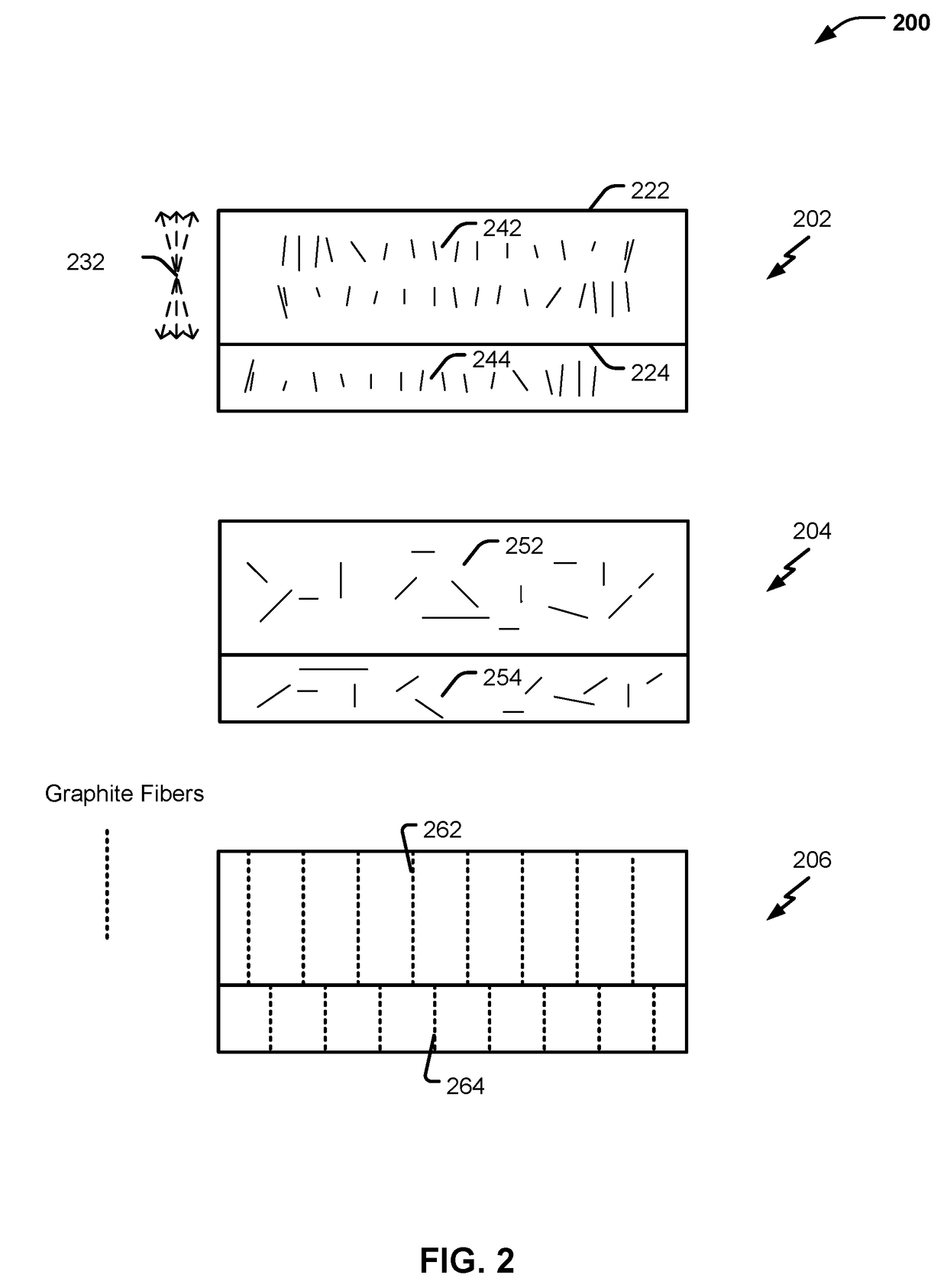

Composite thermal interface objects

ActiveUS20180027691A1High thermal conductivityReduce adhesionSemiconductor/solid-state device detailsDomestic articlesFiberGraphite

In an example, a composite thermal interface object includes a first layer including a first thermal interface material that has first compliance characteristics. The first layer includes first graphite fibers, and the first graphite fibers are aligned in a direction that is substantially orthogonal to a surface of the first layer. The composite thermal interface object further includes a second layer including a second thermal interface material that has second compliance characteristics that are different from the first compliance characteristics.

Owner:IBM CORP

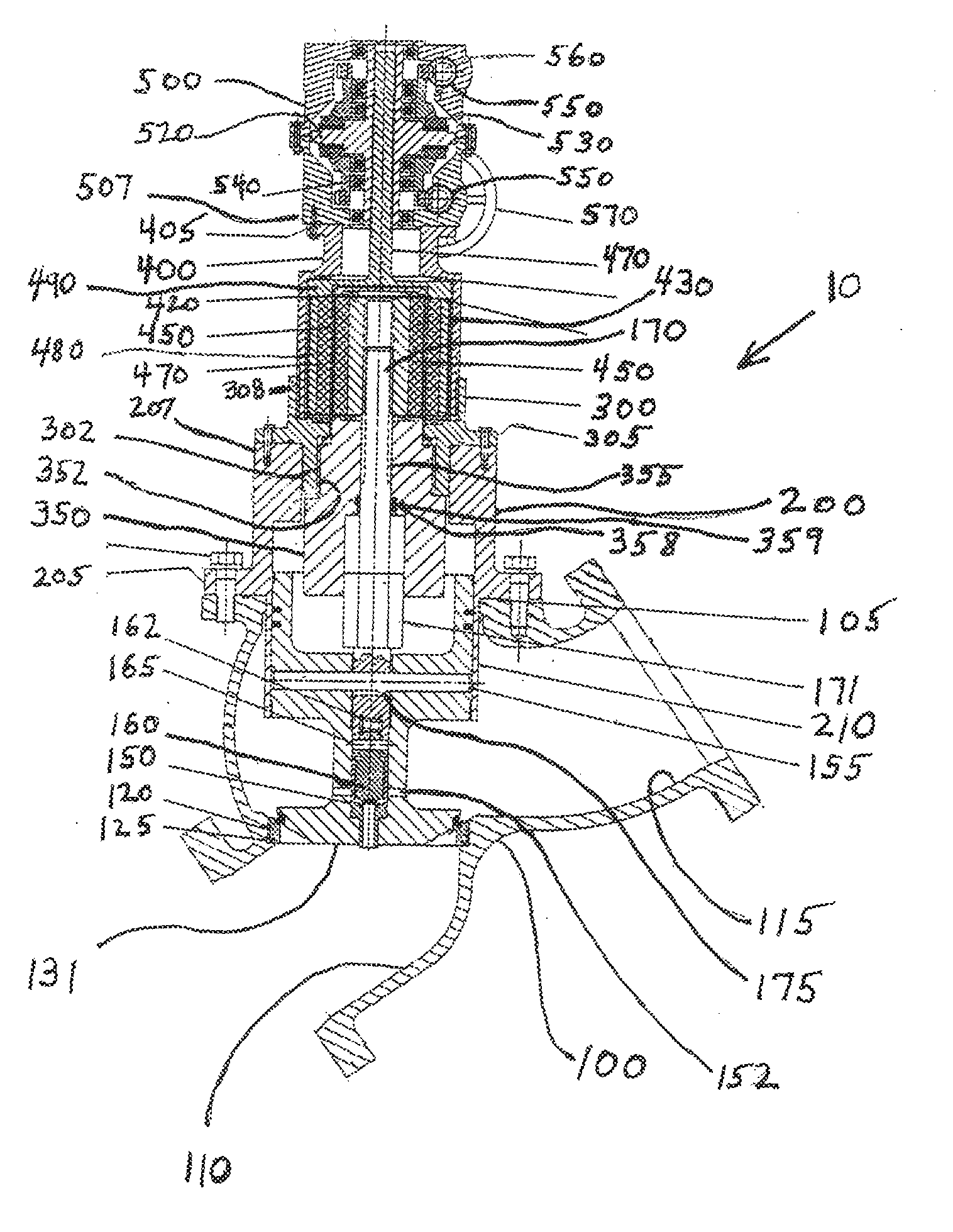

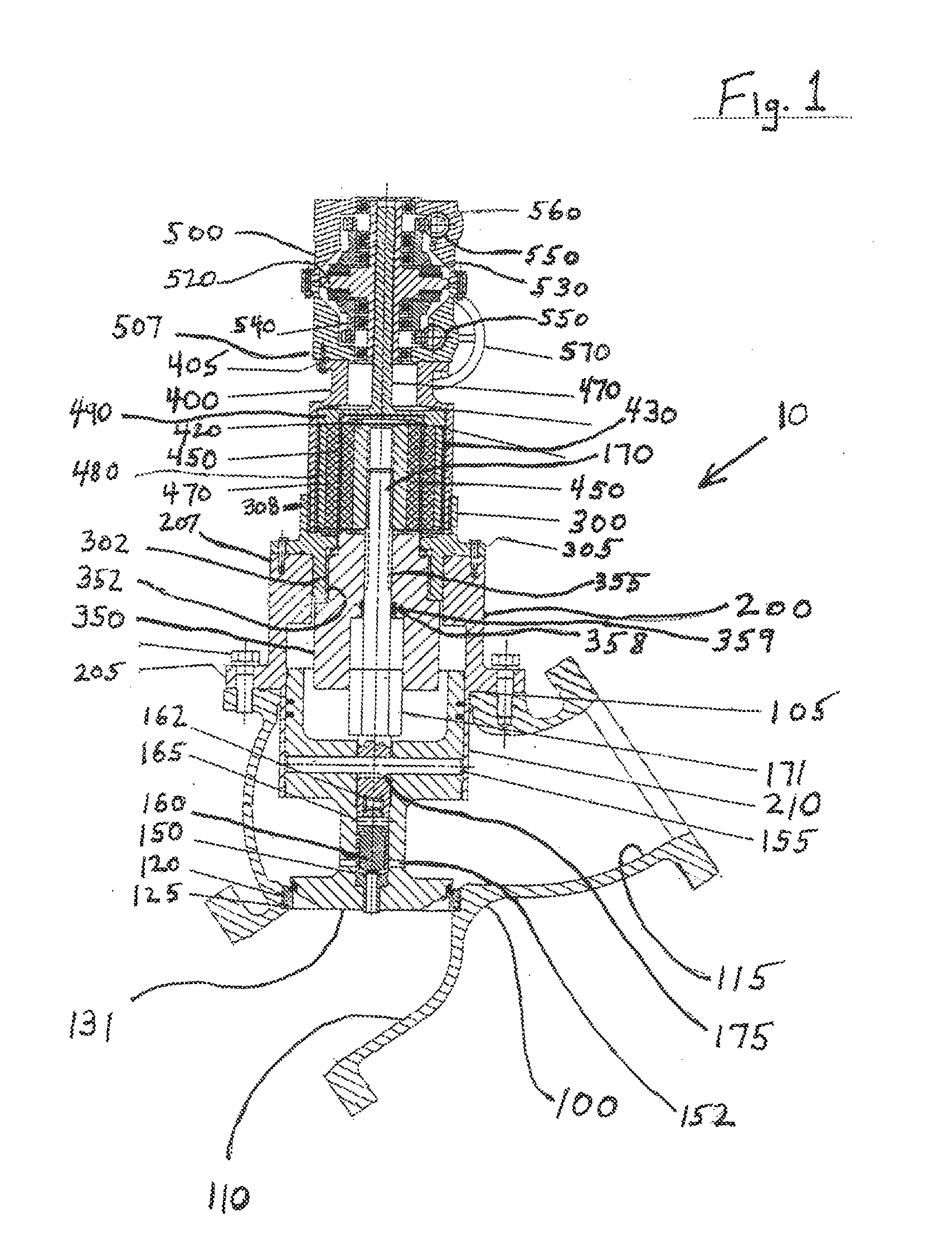

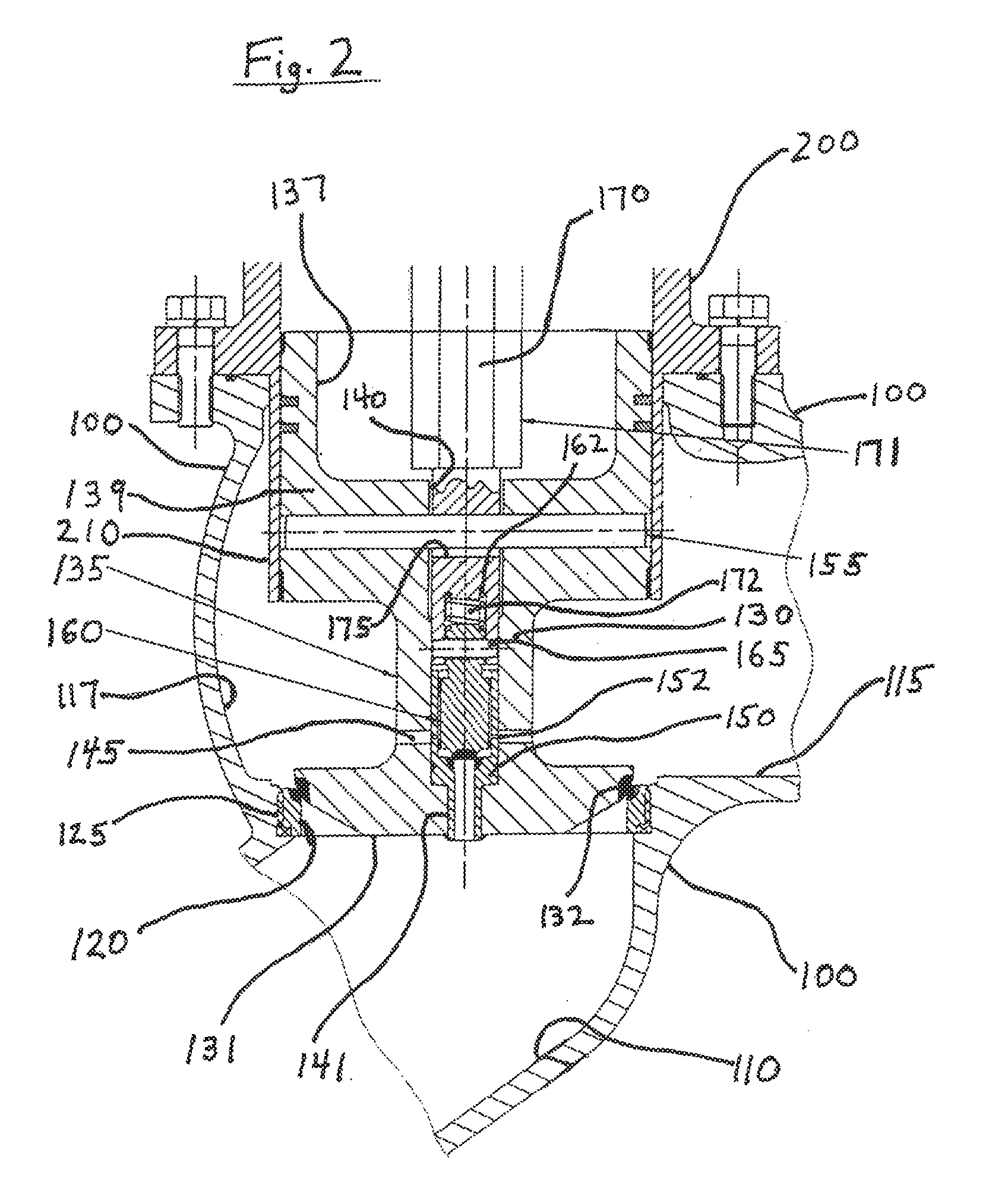

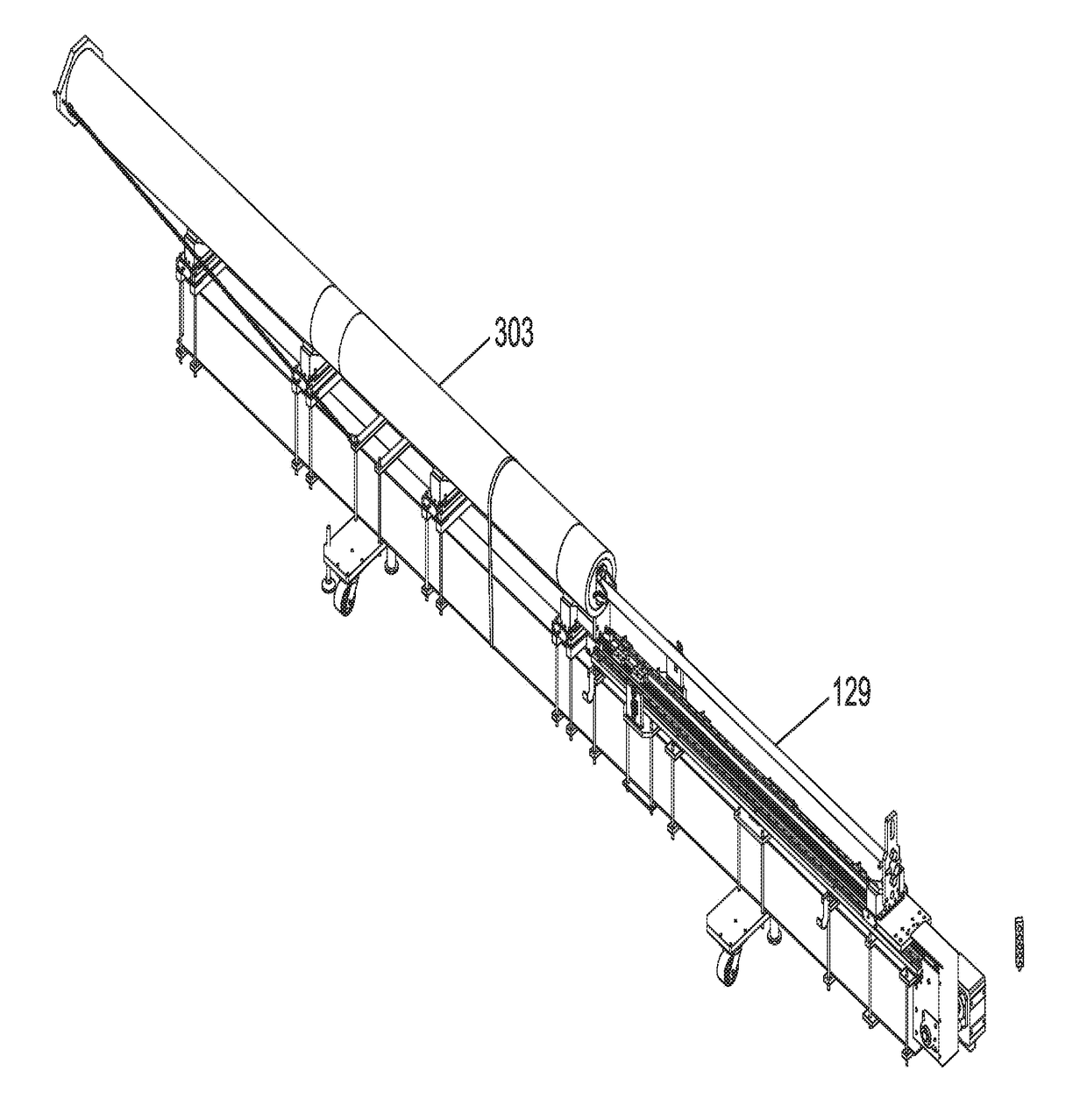

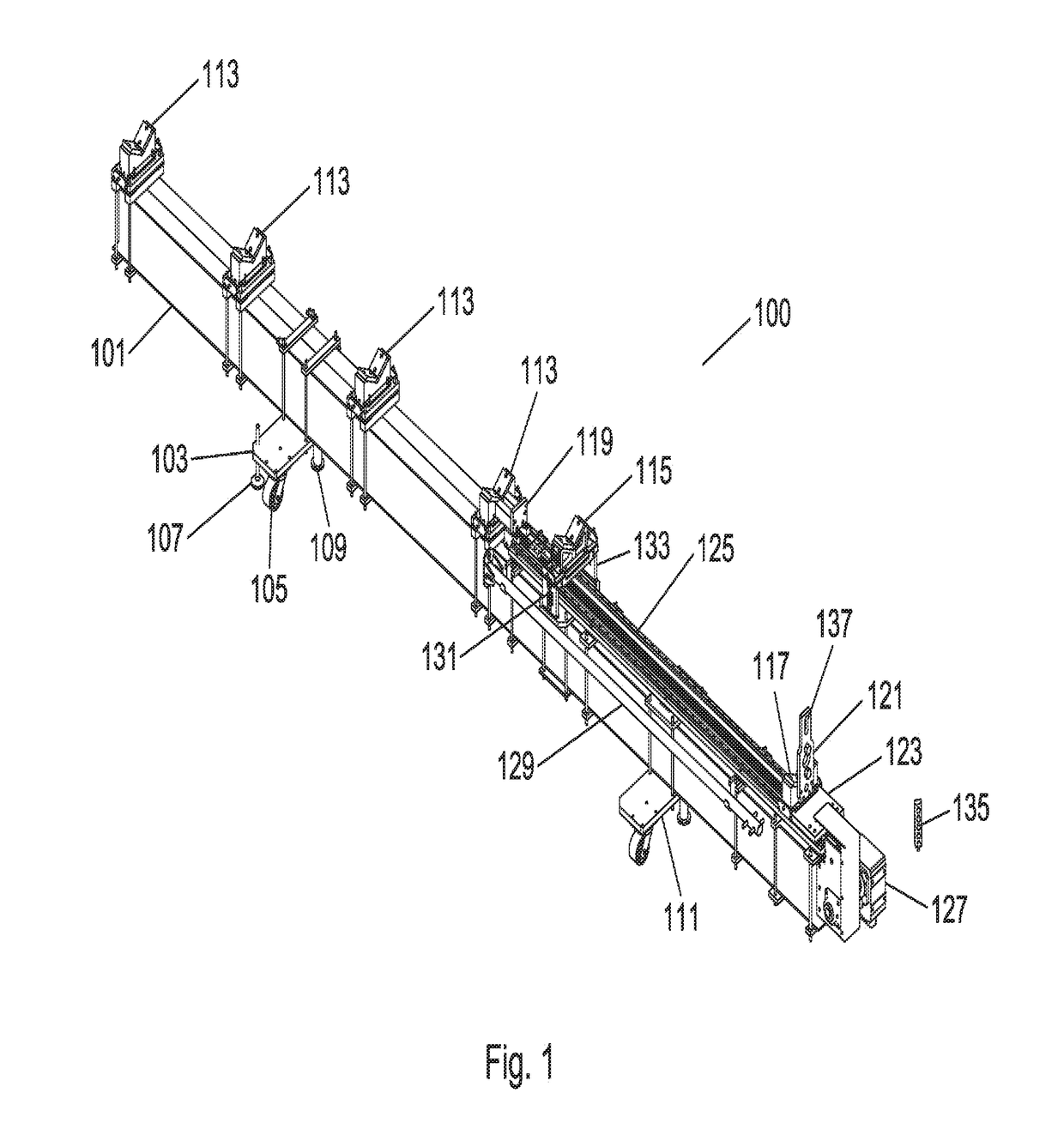

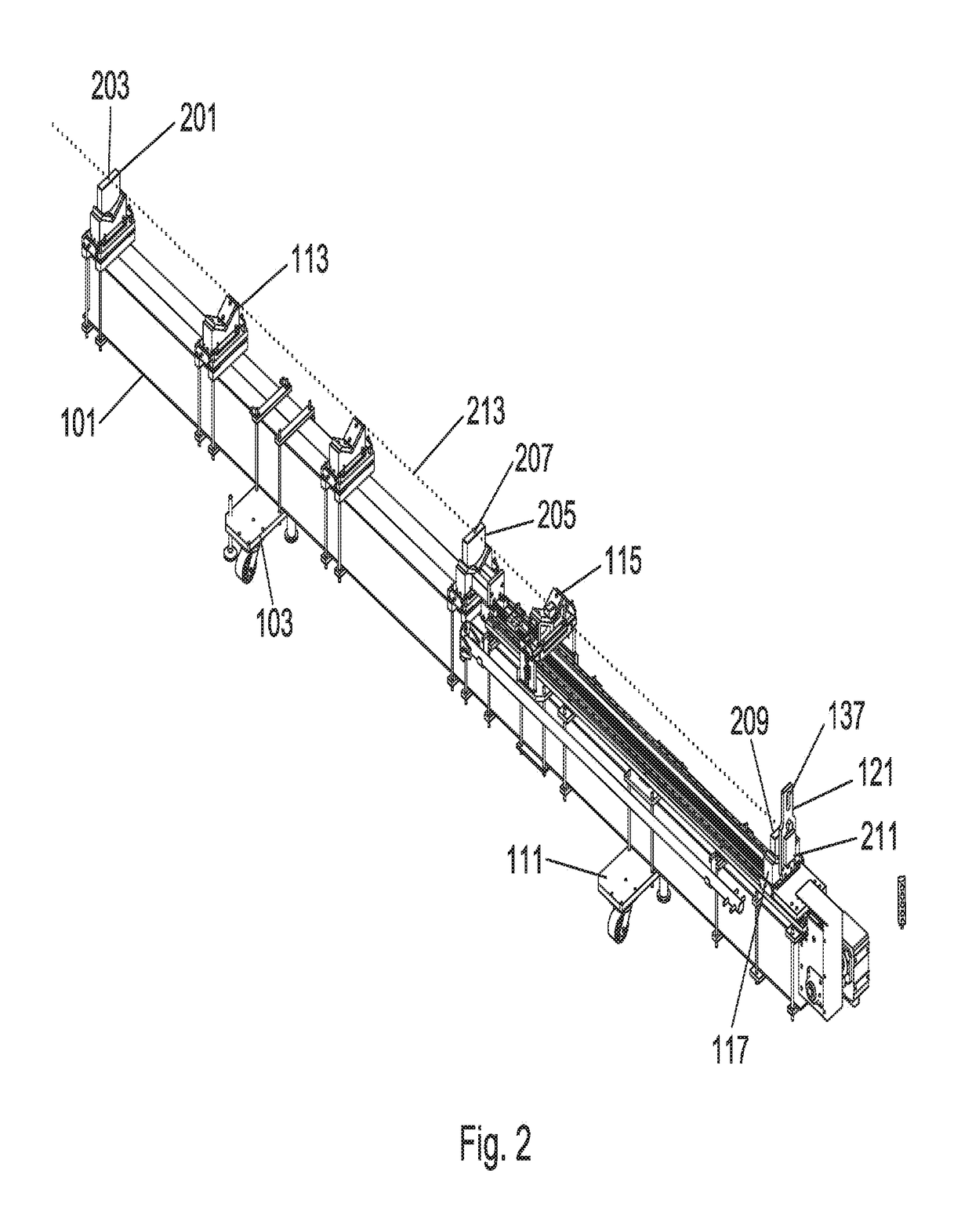

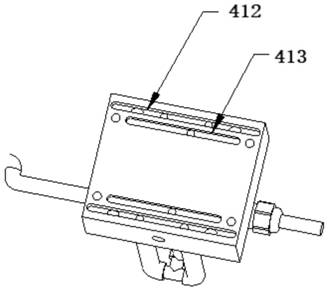

Accumulator assembly fixture

ActiveUS20180257186A1Reduce and prevent damageDurable and reliable constructionWork holdersActuator accumulatorsMechanical engineeringPiston

Owner:REEL POWER LICENSING

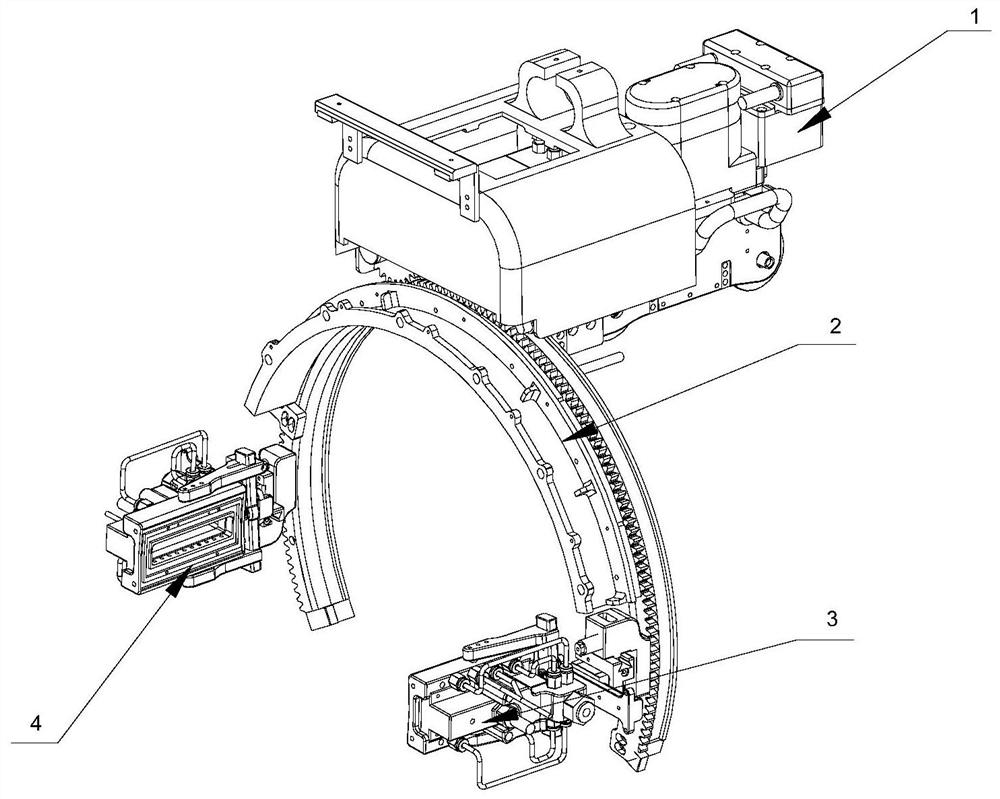

Workpiece surface ultrasonic phased array automatic detection device

InactiveCN112461928AAccurate detectionThe detection process is simpleAnalysing solids using sonic/ultrasonic/infrasonic wavesPhysicsEngineering

The invention discloses an automatic detection device for a workpiece surface ultrasonic phased array. The automatic detection device comprises a crawler, a scanning guide rail, an ultrasonic phased array instrument and a motion controller, wherein the crawler is arranged on a to-be-detected workpiece and can move on the to-be-detected workpiece, one end of the crawler is arranged on the scanningguide rail, an ultrasonic phased array instrument is arranged on the scanning guide rail, and the scanning guide rail is arranged on the surface of the to-be-detected workpiece and collects ultrasonicdetection data of the surface of the to-be-detected workpiece. According to the detection device provided by the invention, the pipeline crawl device drives the ultrasonic phased array probe to automatically detect, so that the safety condition of the pipeline can be better judged, and safety quality production can be better controlled; the liquid supply module and the liquid suction module workin cooperation to provide ultrasonic detection coupling water supply, meanwhile, overflowing coupling water is sucked away and filtered into the water supply water tank, and therefore cyclic utilization of the ultrasonic detection coupling water is achieved; consumption of ultrasonic detection coupling water is greatly reduced.

Owner:广州多浦乐电子科技股份有限公司

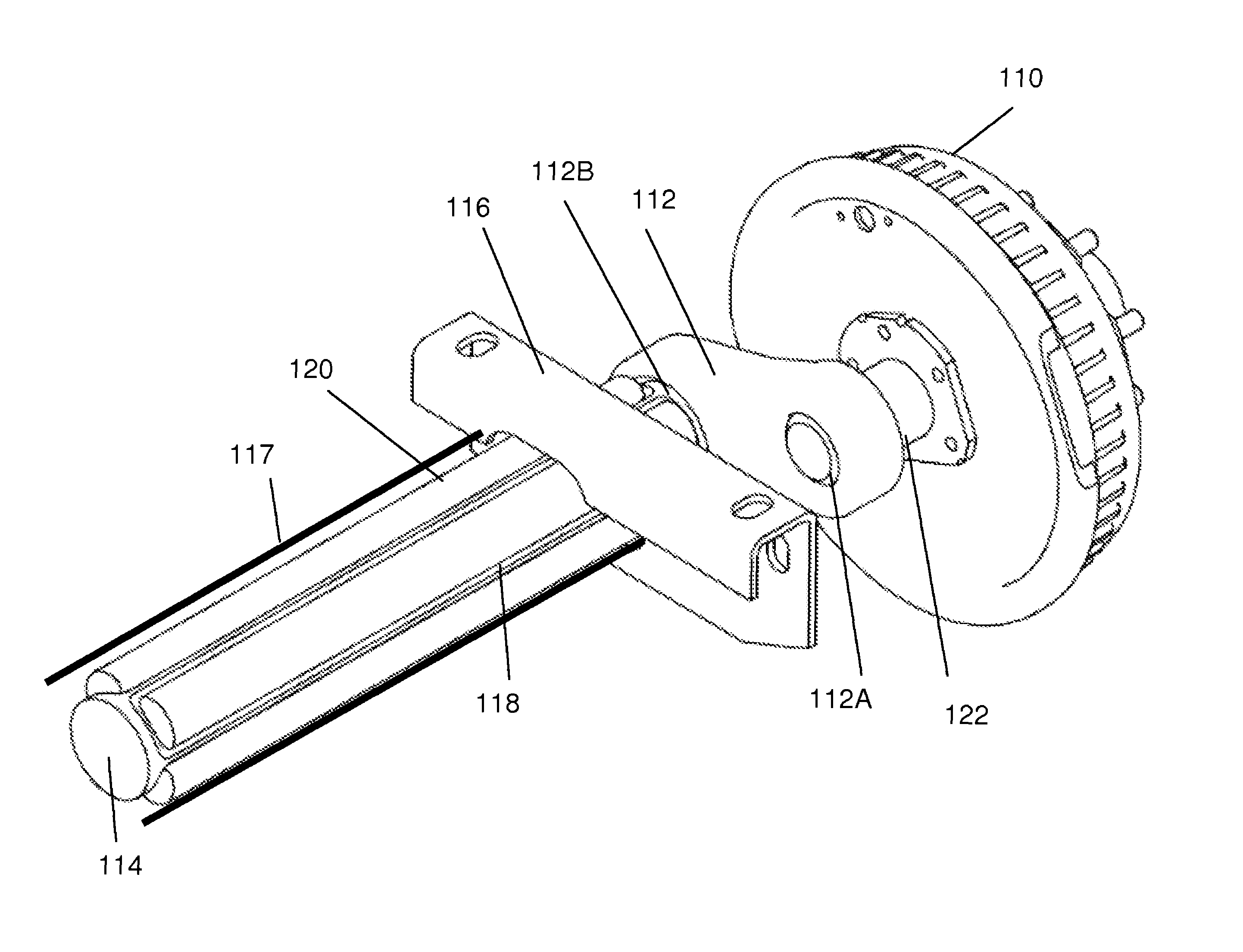

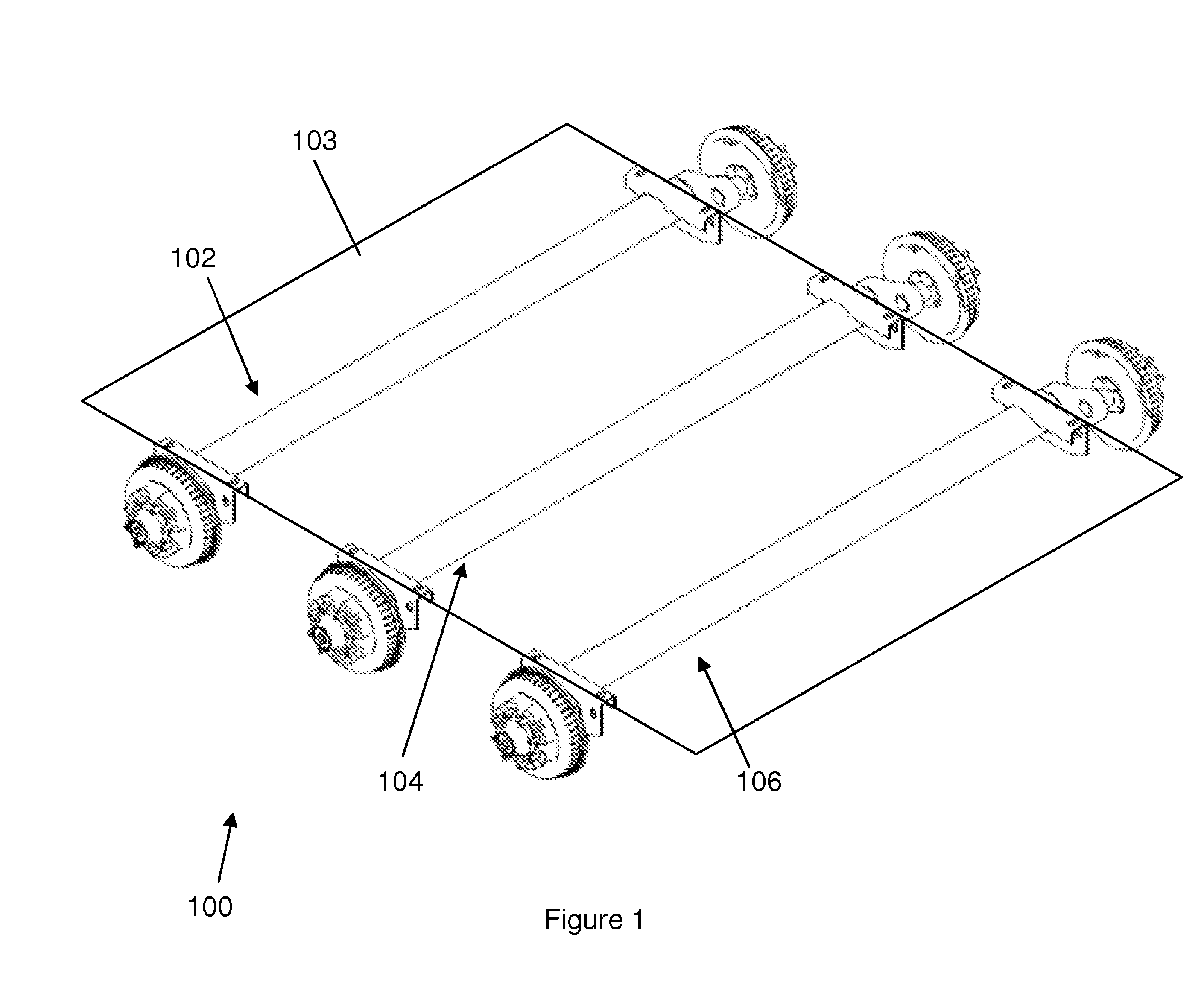

Triple axle with rubber torsion mechanism

ActiveUS8757650B2Improve stressReduce and prevent damageVehicle cleaning apparatusLoading/unloading vehicle arrangmentMedial axisEngineering

Owner:DEXTER AXLE CO LLC

Preparation method of gelatin

A process for preparing gelatin features use of membrane technology and includes such steps as regulating the pH value of extracted gelatin solution to 5.5-6.5 in the condition of sealing system, andthe gelatin solution flowing through a combined membrane unit for filtering, concentrating, and removing bacteria at 50-60 deg.C. The resultant gelatin features high viscosity and coagulating and freezing strength, and low cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

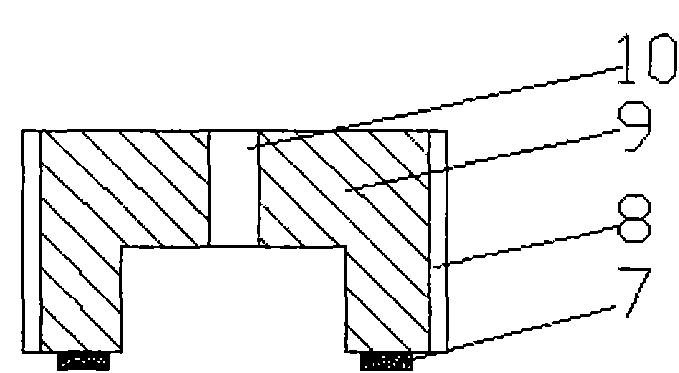

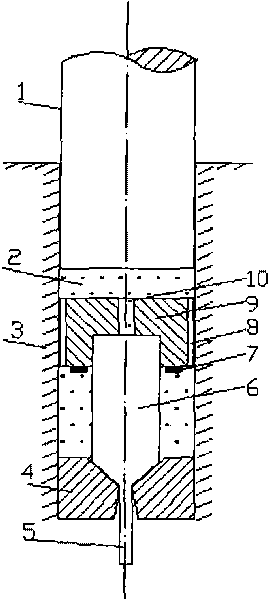

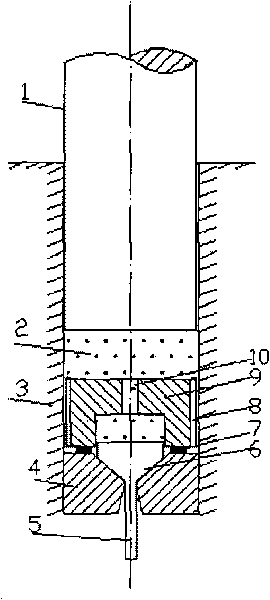

Device for reducing and preventing hydrostatic extrusion breakdown blast-firing damages

InactiveCN101745558AReduce and blast damagePrevent blastingRams/plungersMechanical engineeringExtrusion

The invention discloses a device for reducing and preventing hydrostatic extrusion breakdown blast-firing damages, which belongs to the technical field of extrusion processing, an extrusion cap is placed in an extrusion cylinder, the extrusion cap and a blank are in tight fit and assembly, a seal ring is arranged at the front section of the extrusion cap, a liquid channel is arranged on the outer circle of the extrusion cap, a damping hole is arranged at the bottom of the extrusion cap, extrusion liquid is filled between an extrusion rod and a mold, and the blank is extruded for obtaining a finished product. The extrusion cap moves along with the blank during the extrusion process, and the extrusion liquid can fill the whole extrusion cylinder through the liquid channel; when the extrusion is close to the end, the seal ring at the front section of the extrusion cap is in contact with the upper end surface of the mold for playing the sealing role, and then the extrusion liquid can only impose the pressure to the blank through the damping hole of the extrusion cap, thereby achieving the purpose of reducing the speed of the blank. The adoption of the device can effectively reduce and prevent the hydrostatic extrusion breakdown blast-firing damages.

Owner:有研科技集团有限公司

Joining structure and a substrate-joining method using the same

InactiveUS20100327443A1Reduce and prevent damagePrevent and reduce damagePrinted circuit assemblingSemiconductor/solid-state device detailsAerospace engineeringEngineering

Owner:BARUN ELECTRONICS CO LTD

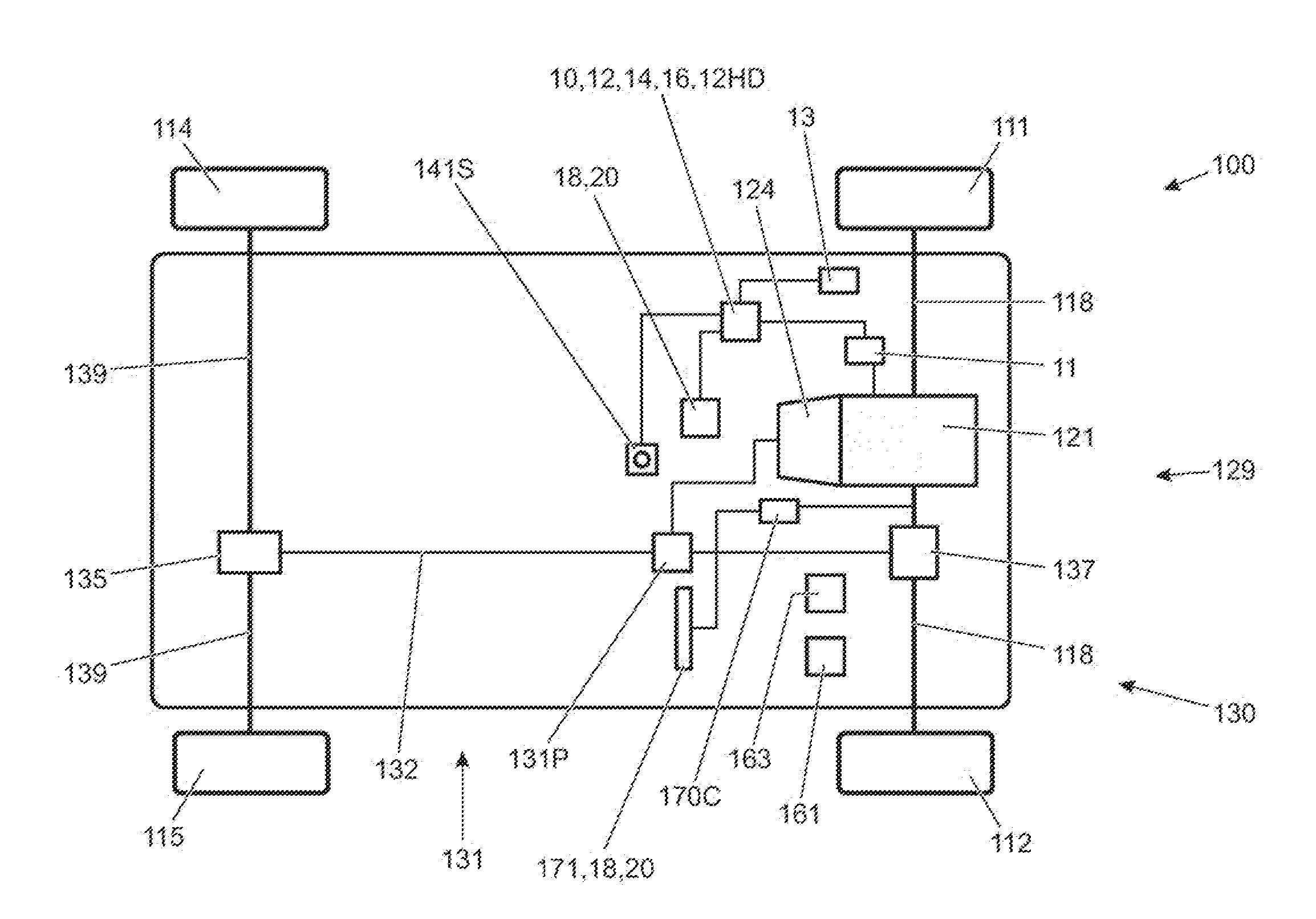

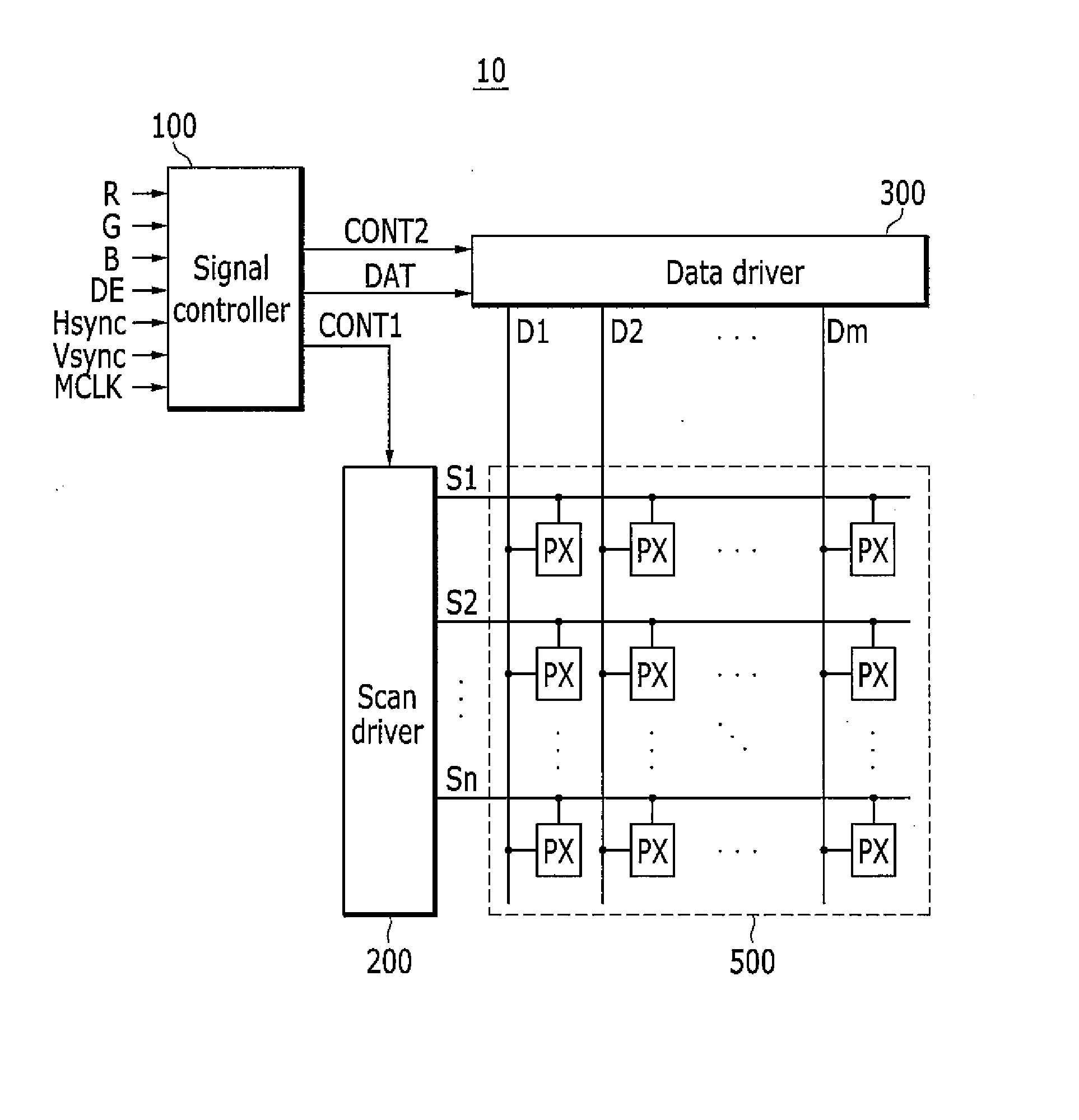

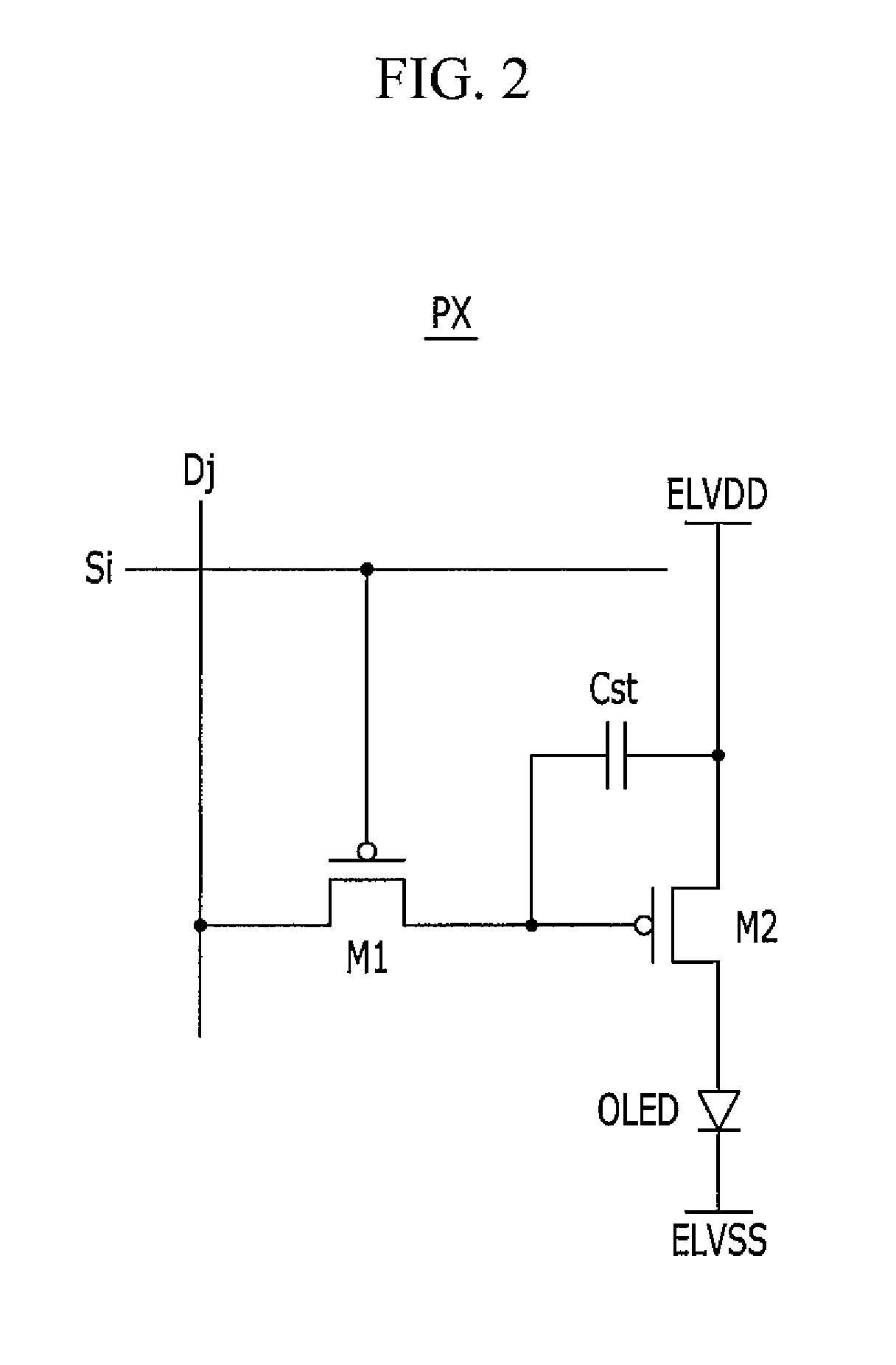

Display device, scan driving device and driving method thereof

ActiveUS20140333596A1Reduce and prevent damageReduce and prevent and operationCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceTransistor

A scan driver includes scan-driving blocks, each including a first transistor having a gate coupled to a first node to supply a first power to an output terminal, a second transistor having a gate coupled to a second node to couple a second clock to the output terminal, a third transistor having a gate coupled to a first input to supply the first power to the first node, a fourth transistor having a gate coupled to a second input to supply a second power to the first node, and a fifth transistor having a gate coupled to a first clock to couple the first input to the second node. A first scan-driving block further includes a sixth transistor coupled between the second input and the fourth transistor gate, and a NOT gate configured to invert the first input signal and to supply the inverted signal to the sixth transistor gate.

Owner:SAMSUNG DISPLAY CO LTD

Well centralizer

A centralizer assembly having a tubular body member with upper and lower channels extending around the external surface of said central tubular body member. A bow spring assembly having bow spring members is installed around the outer surface of the tubular body member and can rotate about the outer surface of the central tubular body member. Bow spring heel supports prevent the bow spring members from contacting the outer surface of the central tubular member when compressed. Non-abrasive materials prevent damage to wellhead or other polished bore receptacles. A robust bolster frame protects the centralizer assembly during shipping, storage or other periods of non-use.

Owner:FRANKS INT

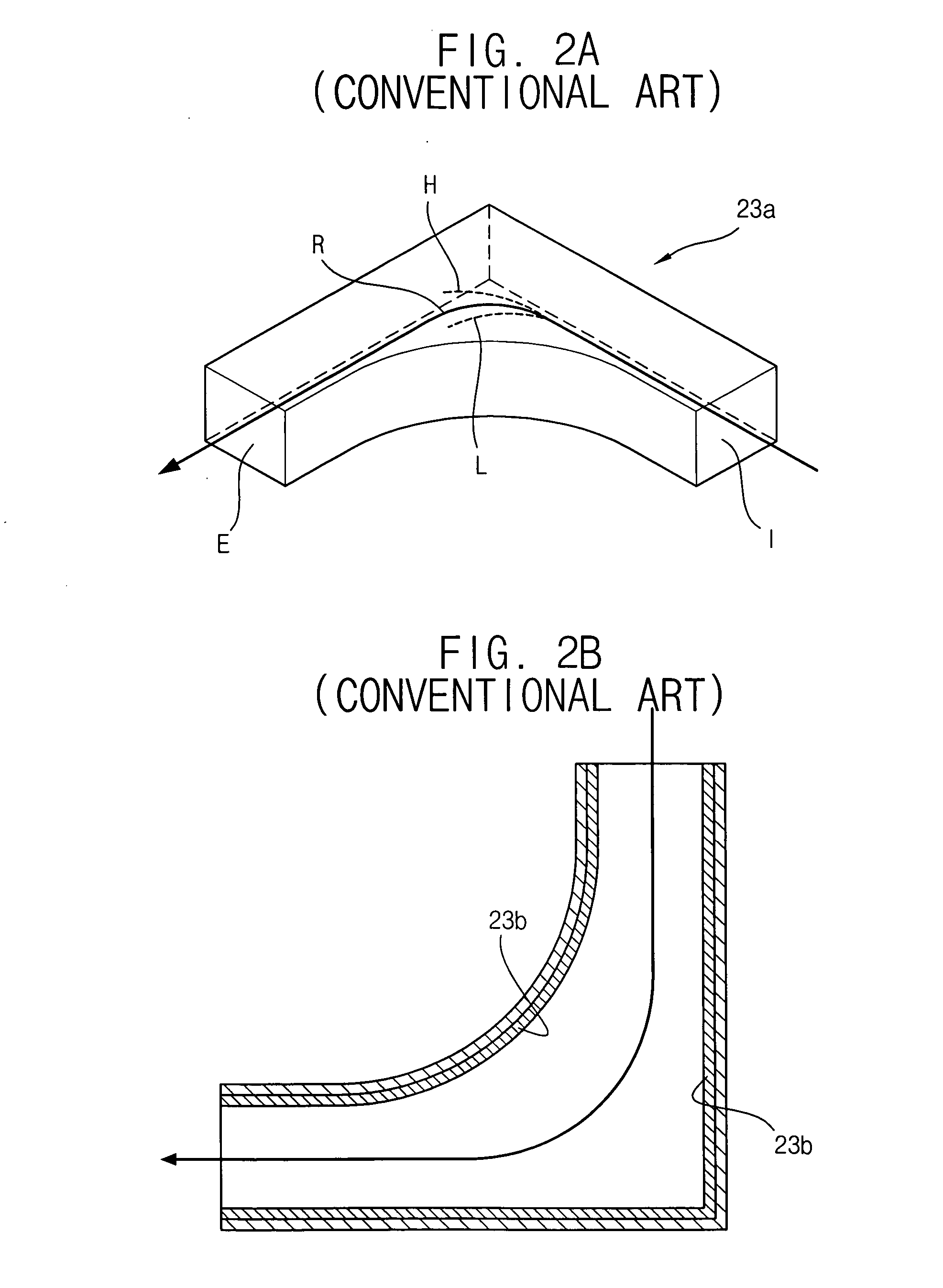

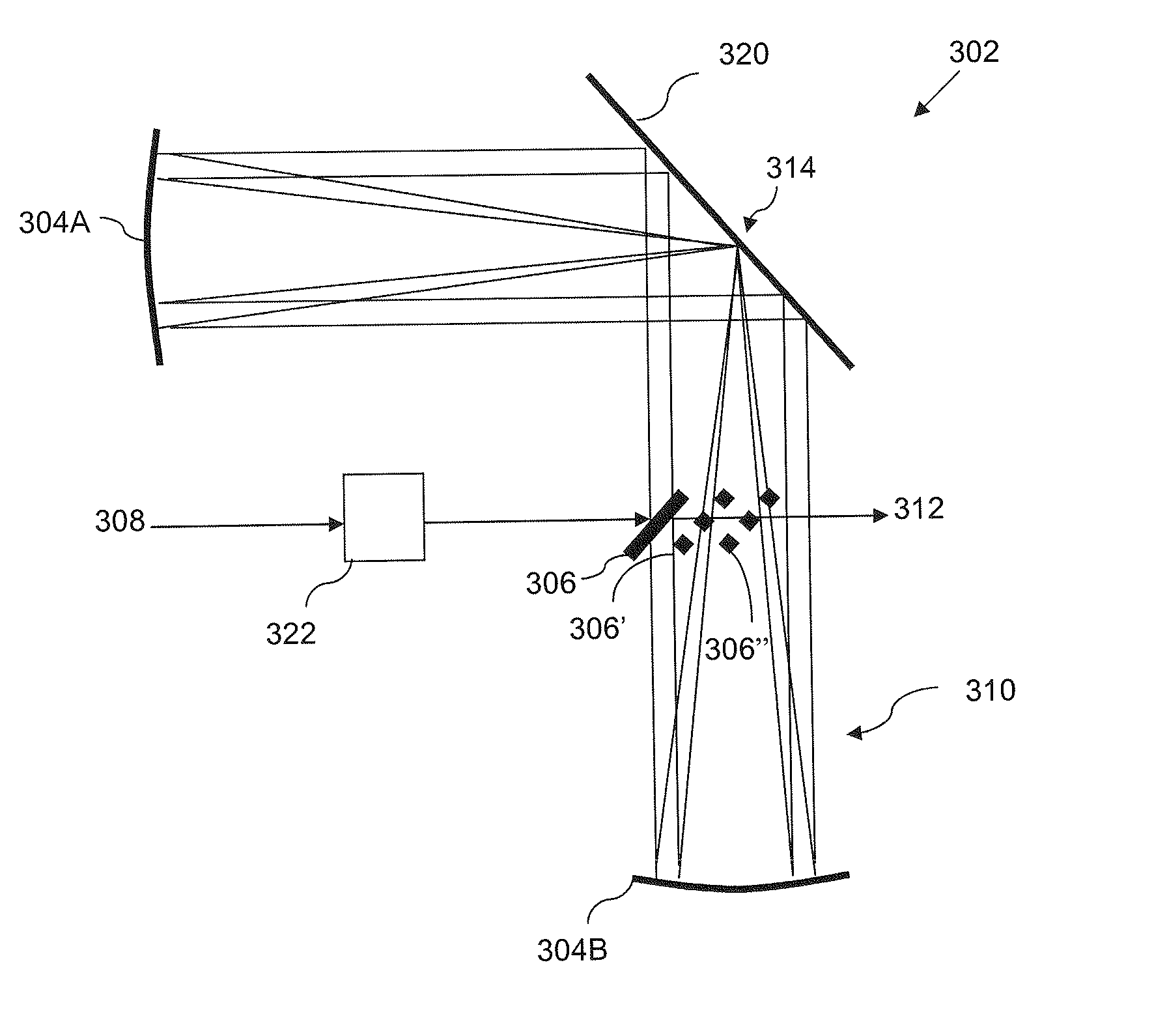

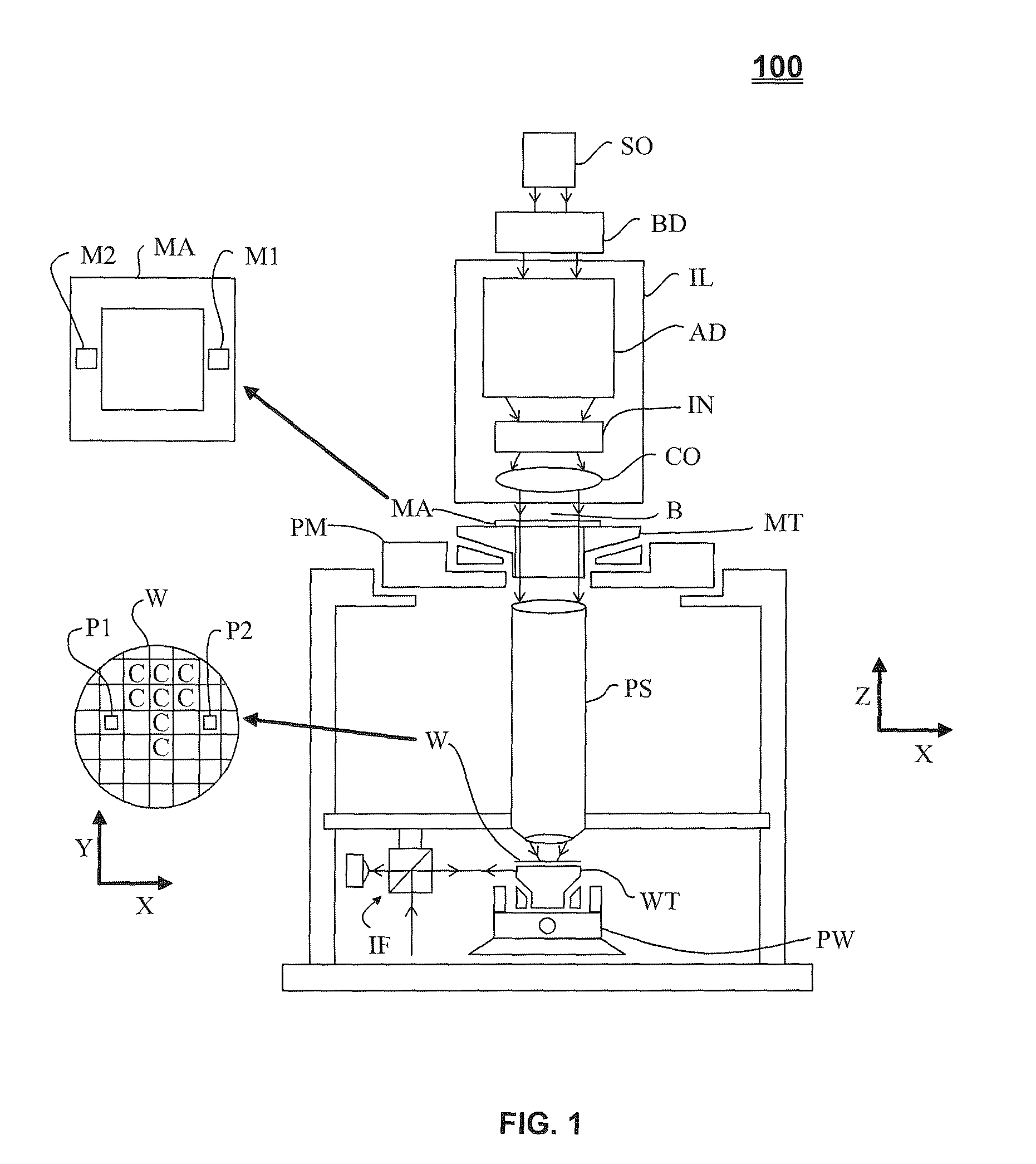

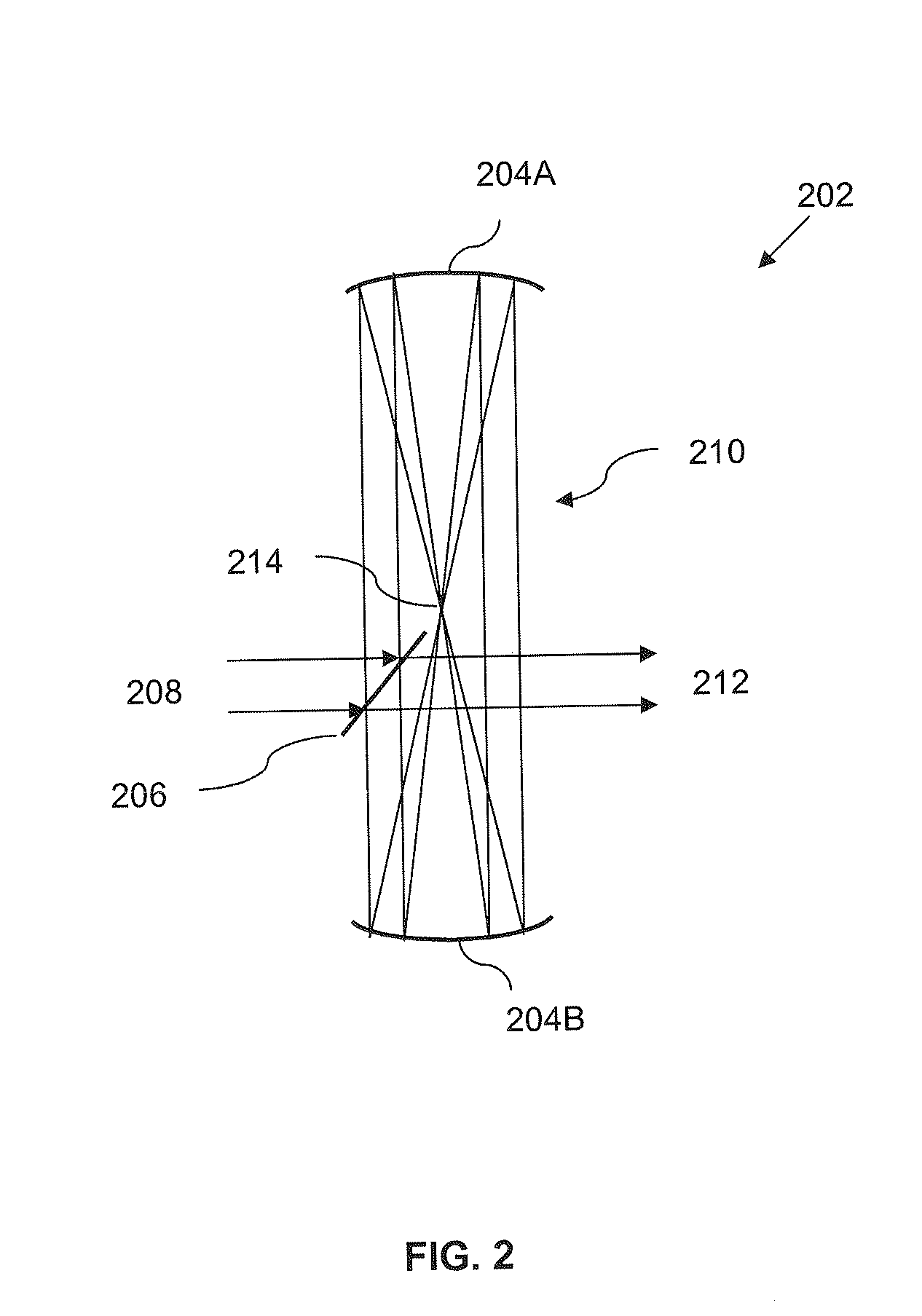

Pulse Stretcher with Reduced Energy Density on Optical Components

ActiveUS20100302522A1Reduce and prevent damageIncrease energy densitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusBeam splitterLight beam

A pulse stretcher includes a beam splitter configured to split an input light beam into first and second beams, a con-focal resonator including first and second con-focal mirrors, and a fold mirror. The beam splitter, con-focal resonator, and fold mirror are optically arranged such that at least a portion of the first beam is recombined with the second beam into a modified beam after an optical delay of the first beam caused by the optical arrangement. The apparatus further includes one or more optical elements in an optical path of the input light beam prior to the beam splitter such that a focal point of the first beam is foamed at a distance away from the fold mirror preventing energy density-related damage to the fold mirror. The apparatus can further include one or more additional optical elements to provide re-conditioning of the modified beam. A related method is also disclosed.

Owner:ASML HLDG NV

Display device and multi display device using the same

ActiveUS20160327827A1Area minimizationReduce and prevent damageSide-by-side/stacked arrangementsCircuit arrangements on support structuresDisplay deviceEngineering

A display device includes: a display panel; a bottom chassis in which the display panel is accommodated; a driving circuit substrate disposed on an outside surface of the bottom chassis; at least one flexible printed circuit board connecting the display panel to the driving circuit substrate; and a top chassis configured to cover an edge portion of a top surface and side surfaces of the display panel, wherein the top chassis has an opening formed in an area in contact with the flexible printed circuit board.

Owner:SAMSUNG DISPLAY CO LTD

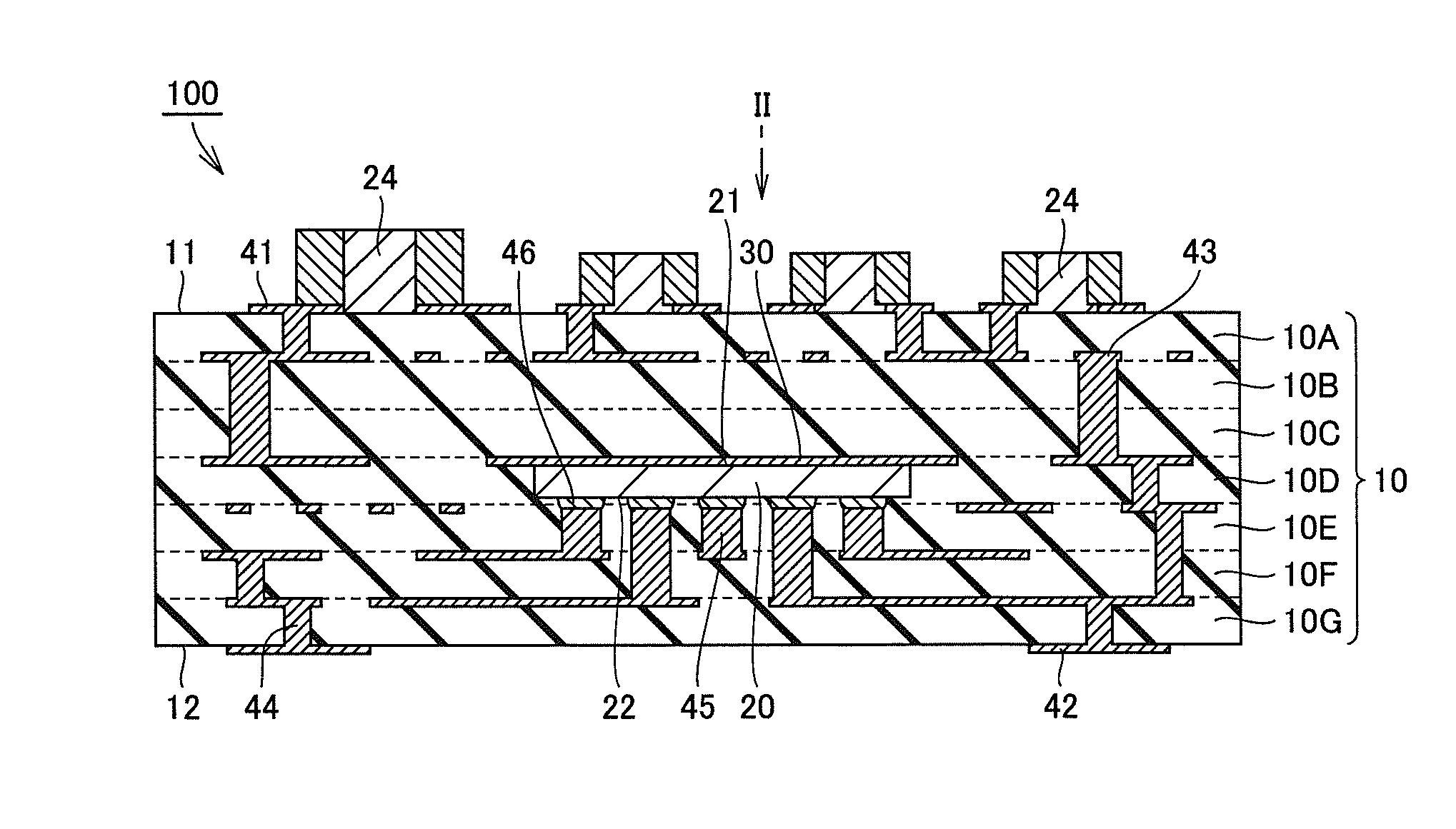

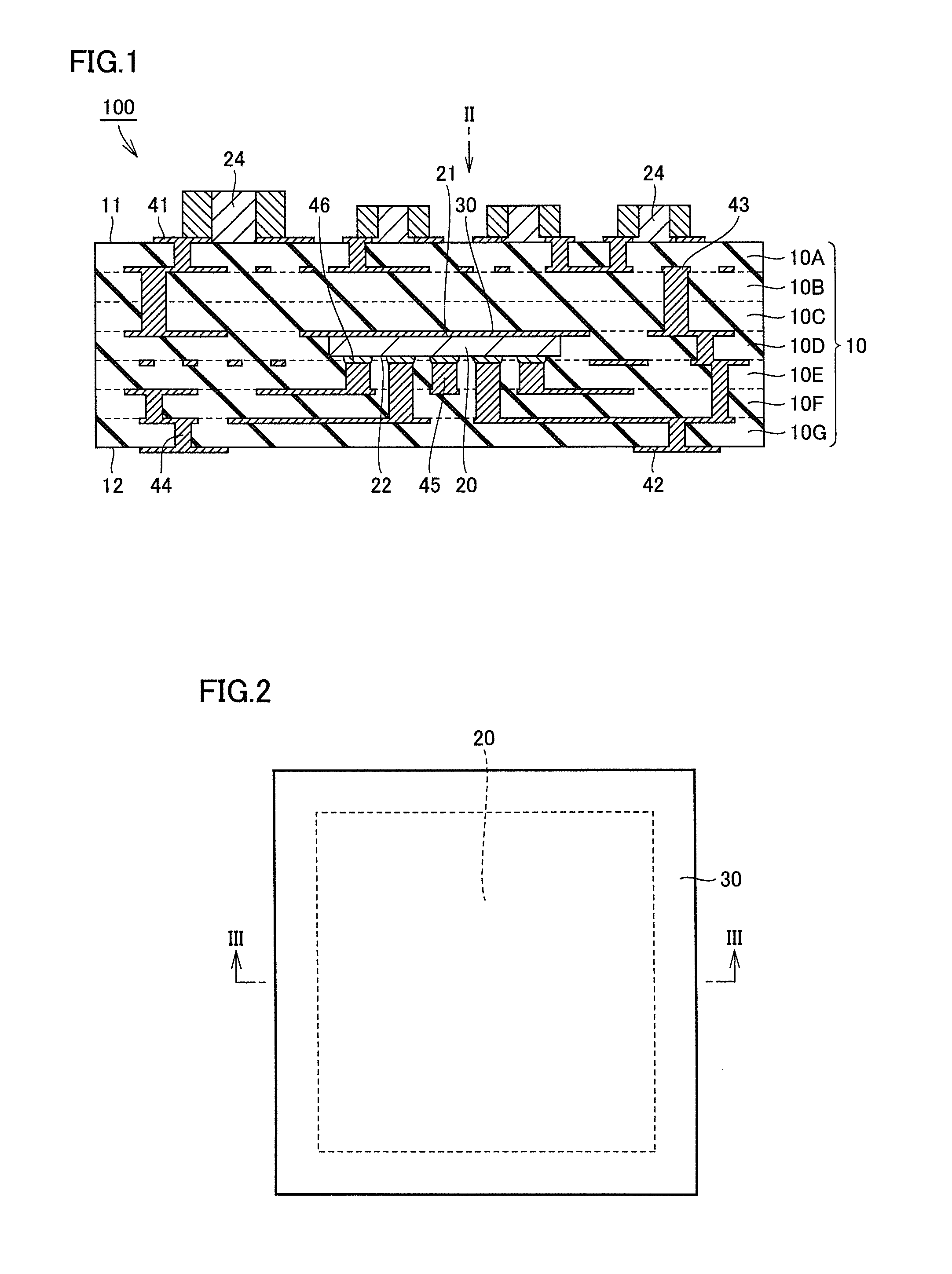

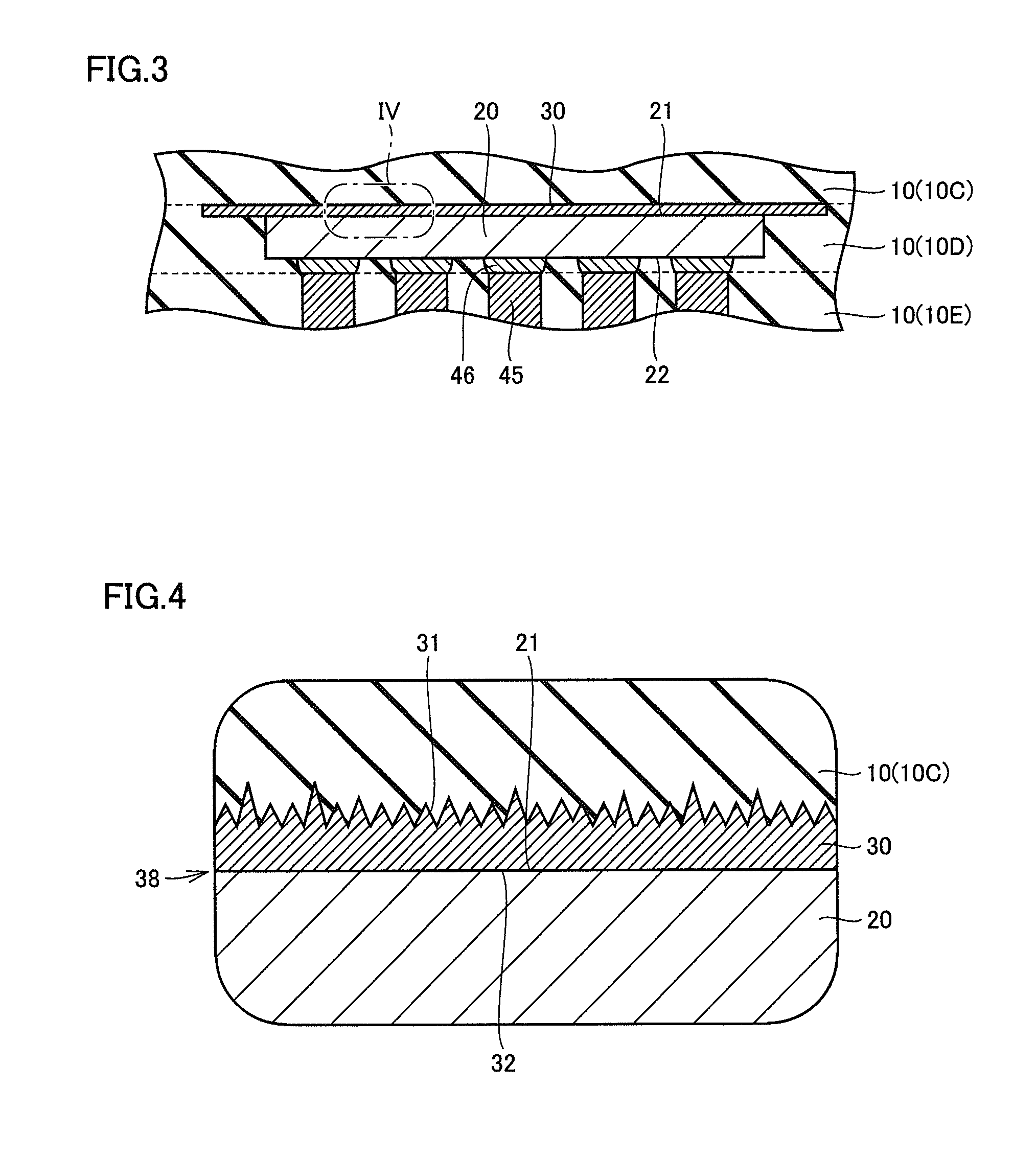

Electric element-embedded multilayer substrate and method for manufacturing the same

ActiveUS20140003011A1Reducing and preventing damageAvoid disconnectionPrinted circuit assemblingSemiconductor/solid-state device detailsEngineering

An electric element-embedded multilayer substrate, which is a multilayer substrate including an electric element embedded therein and a plurality of base material layers having flexibility, the electric element including a main surface and being embedded in the multilayer substrate to be sandwiched between the base material layers, and a slide member provided between the main surface of the electric element and the base material layer.

Owner:MURATA MFG CO LTD

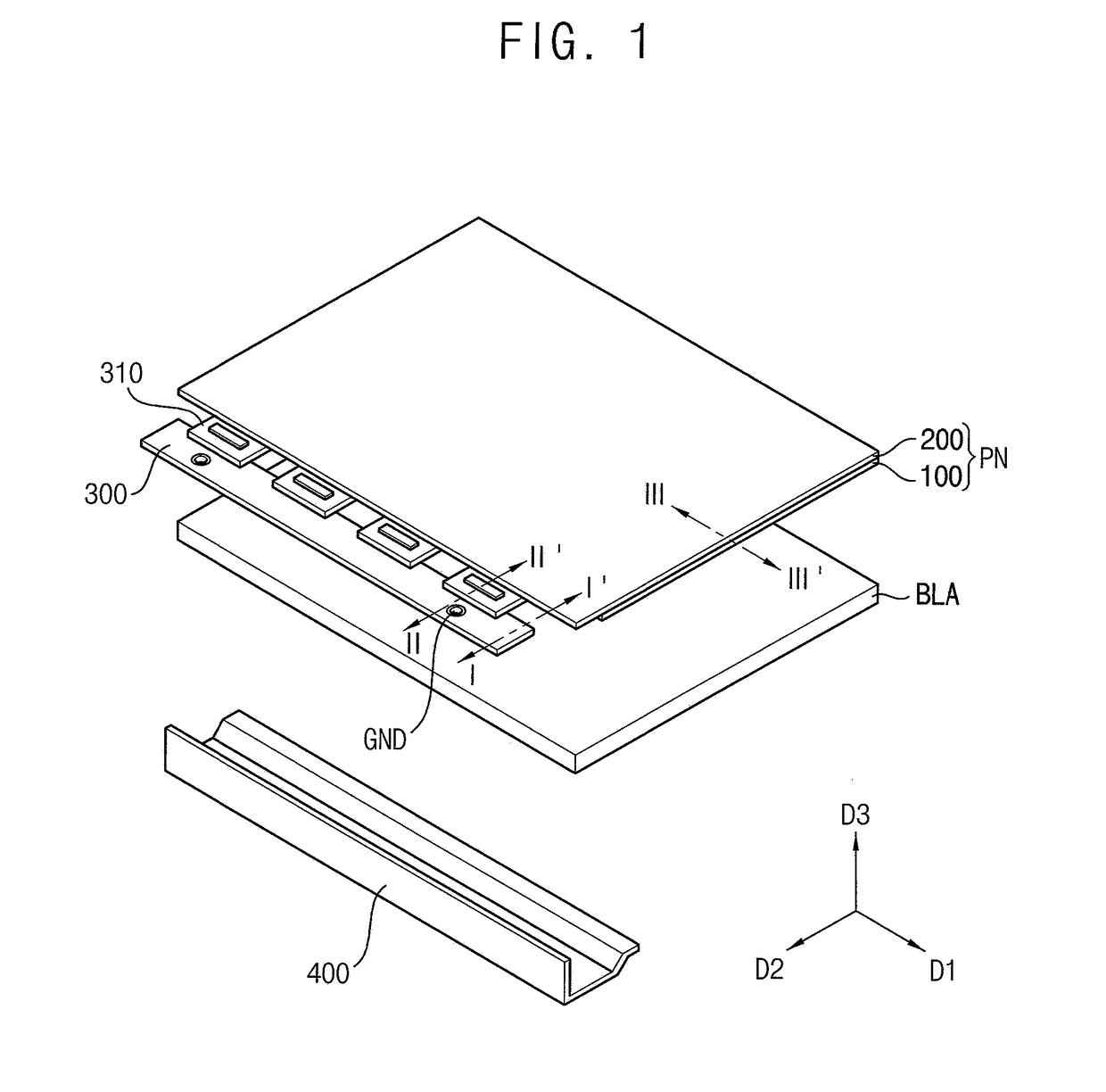

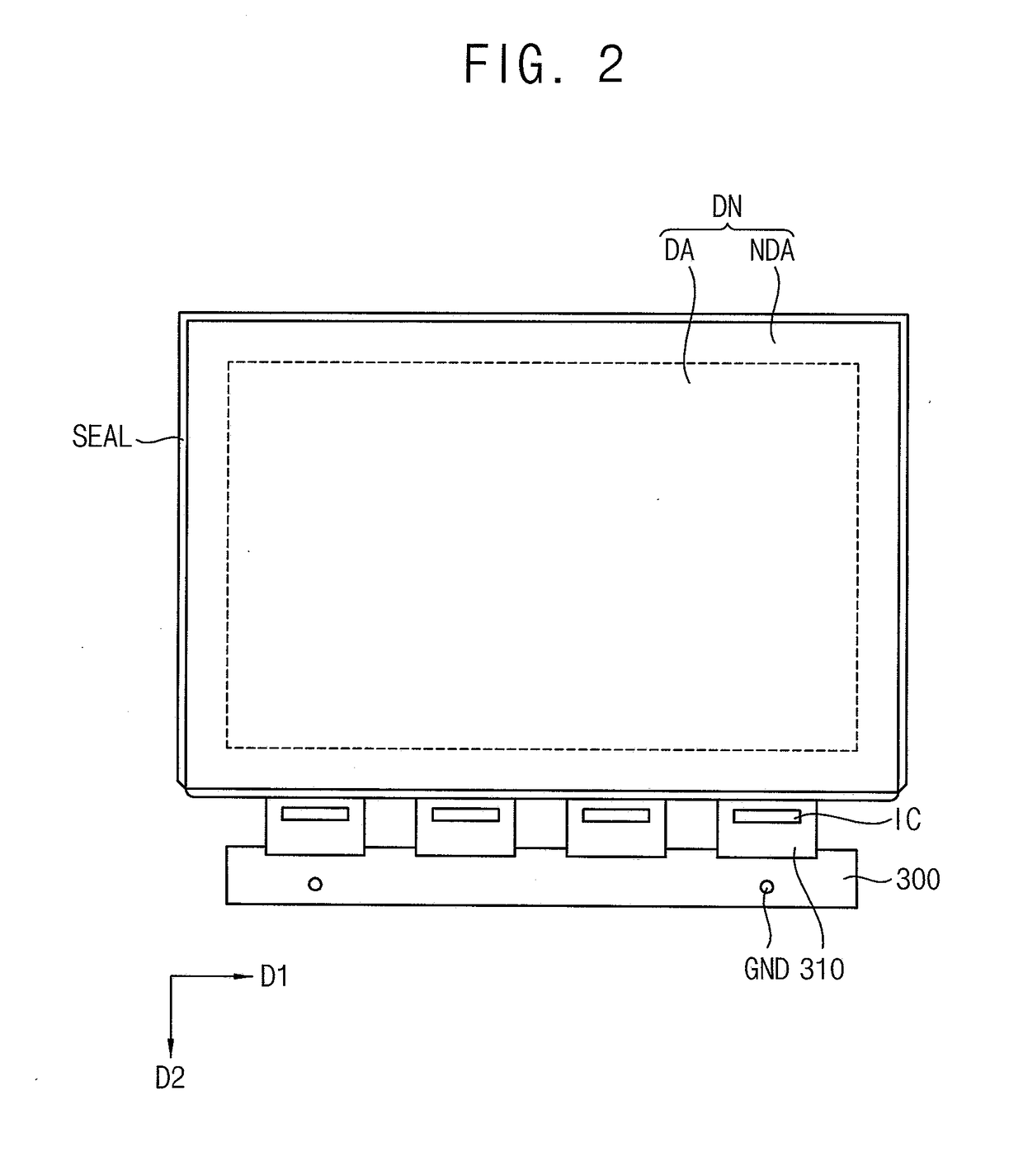

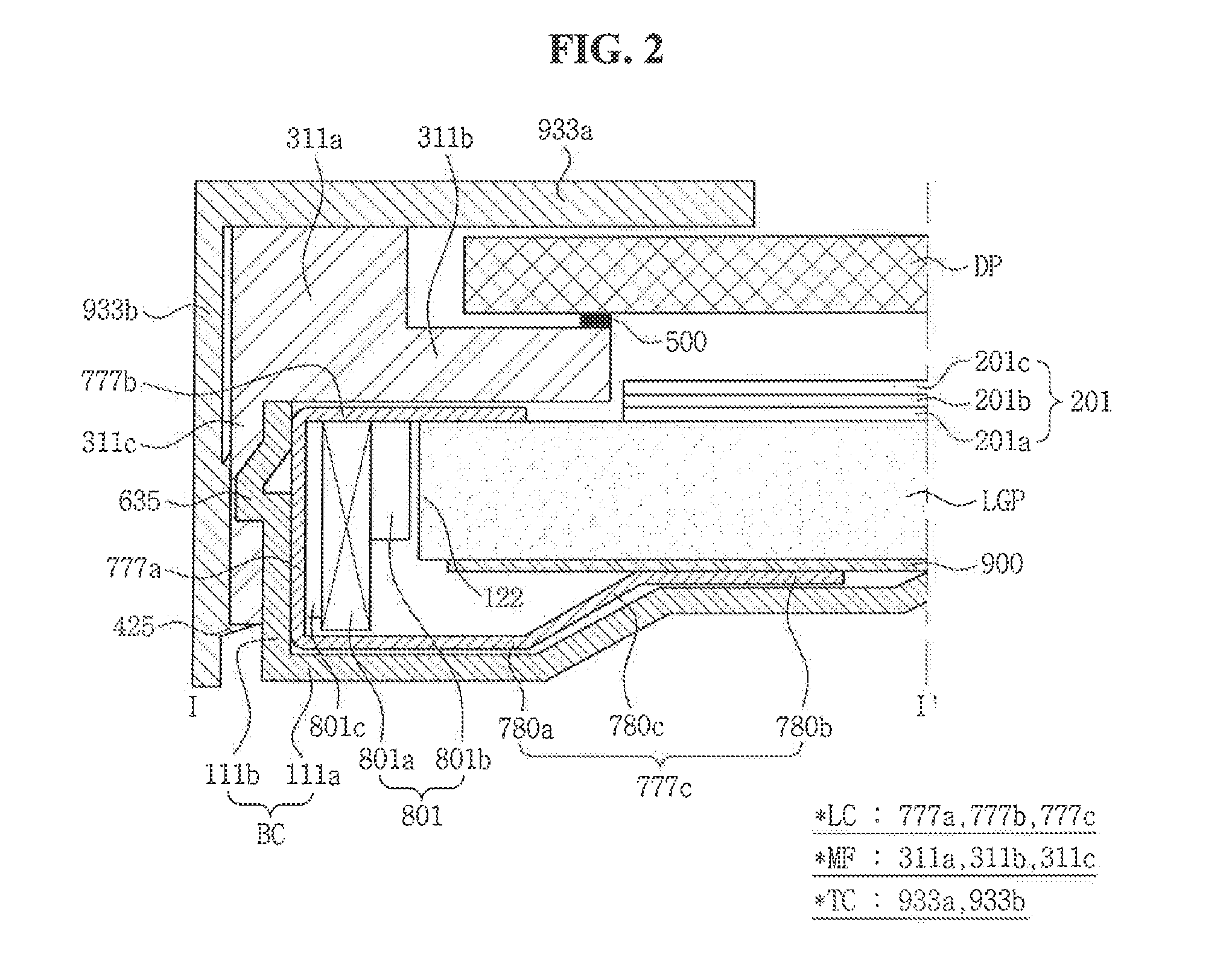

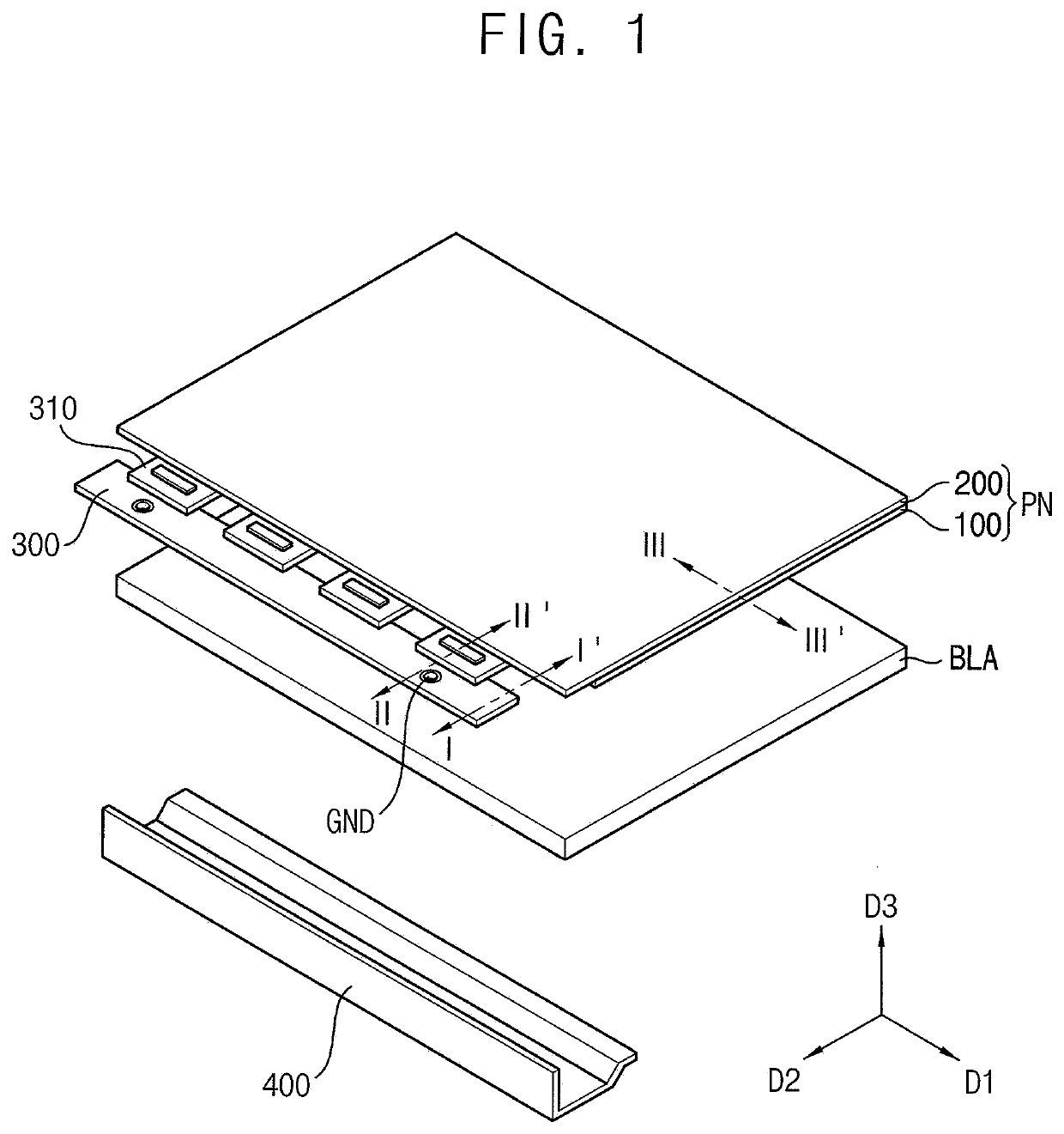

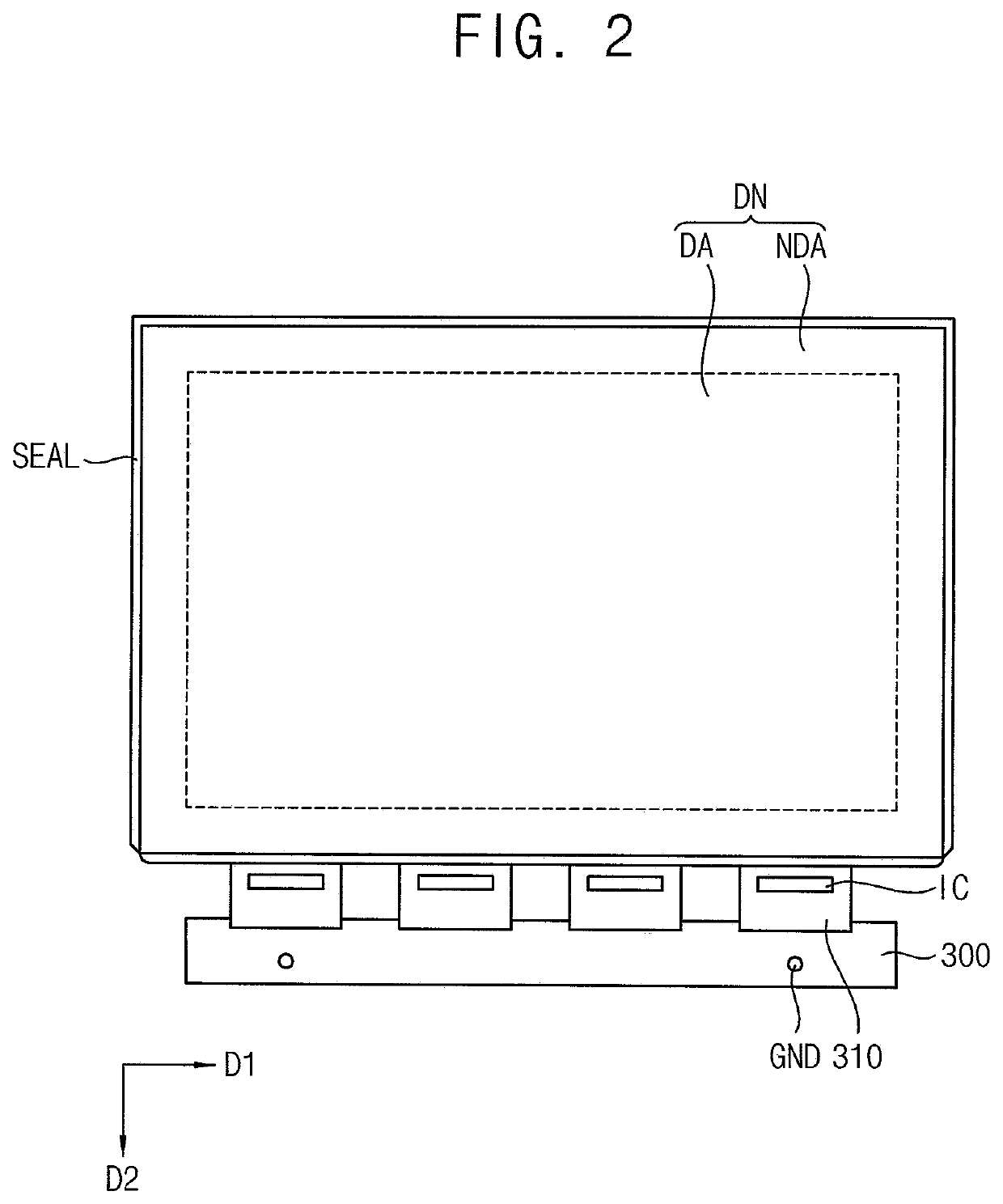

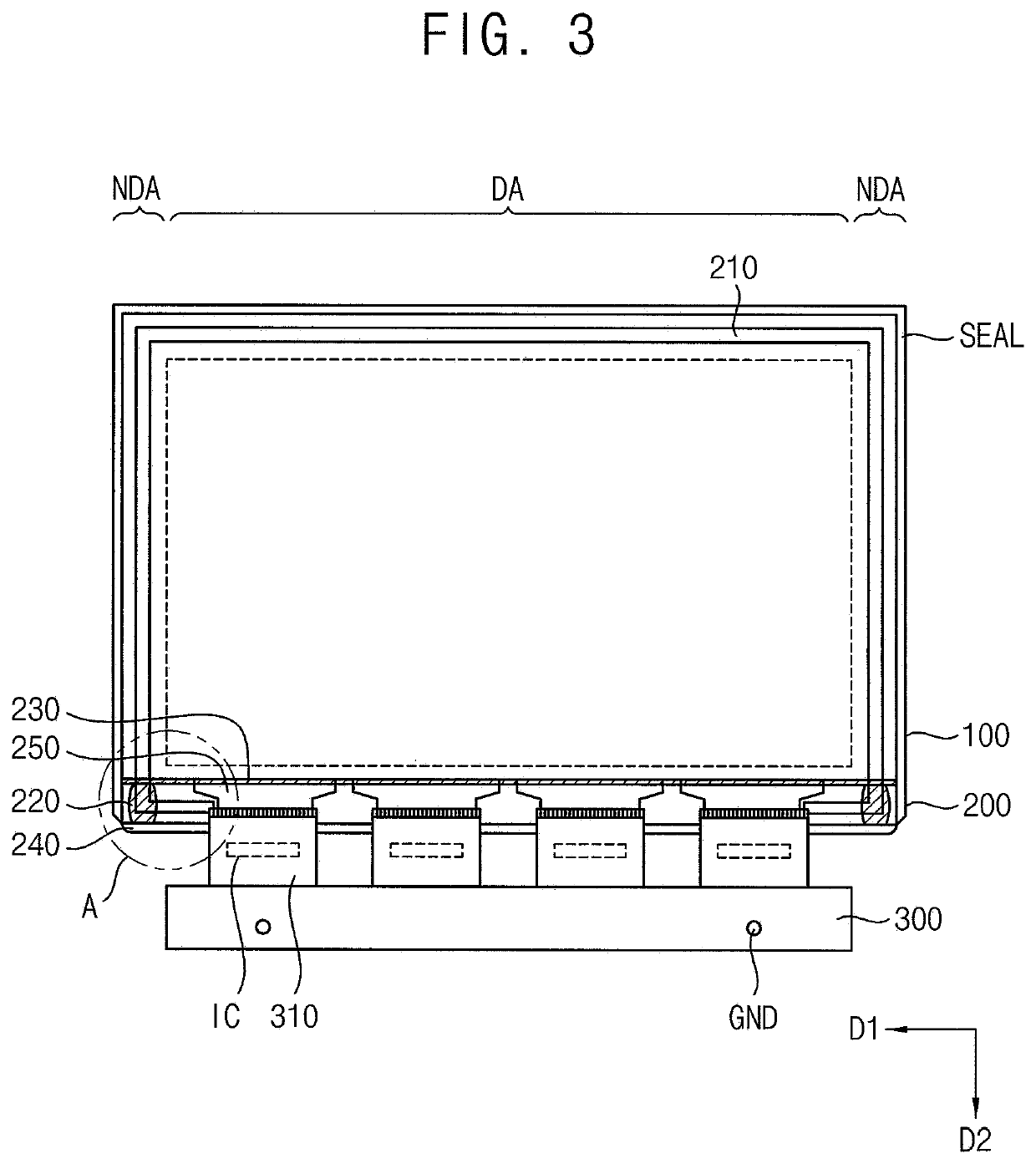

Display apparatus including a backlight assembly

ActiveUS20180356696A1Narrow bezelReduce and prevent damageStatic indicating devicesNon-linear opticsEngineeringTransistor

A display apparatus includes first and second substrates, a first side sealing layer, a ground connecting part, a flexible film, a driving circuit substrate, and a backlight assembly. The first substrate includes sides extending in a first and a second direction. The second substrate is disposed opposite to the first substrate and is larger in the second direction. The second substrate includes a thin film transistor, a ground wiring and first to fourth side surfaces. The first side sealing layer is disposed on the fourth side surface. The ground connecting part is disposed on the second substrate and is electrically connected to the ground wiring and the first side sealing layer. The flexible film is connected to the second substrate. The driving circuit substrate is connected to the flexible film. The backlight assembly is disposed between the driving circuit substrate and the first substrate.

Owner:SAMSUNG DISPLAY CO LTD

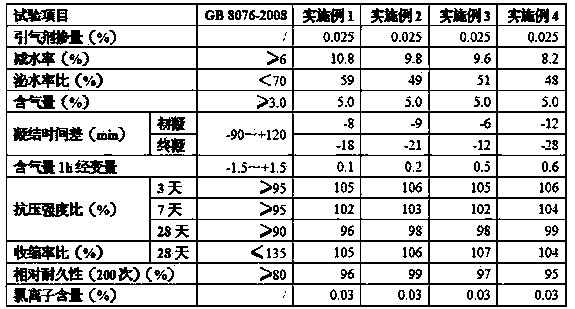

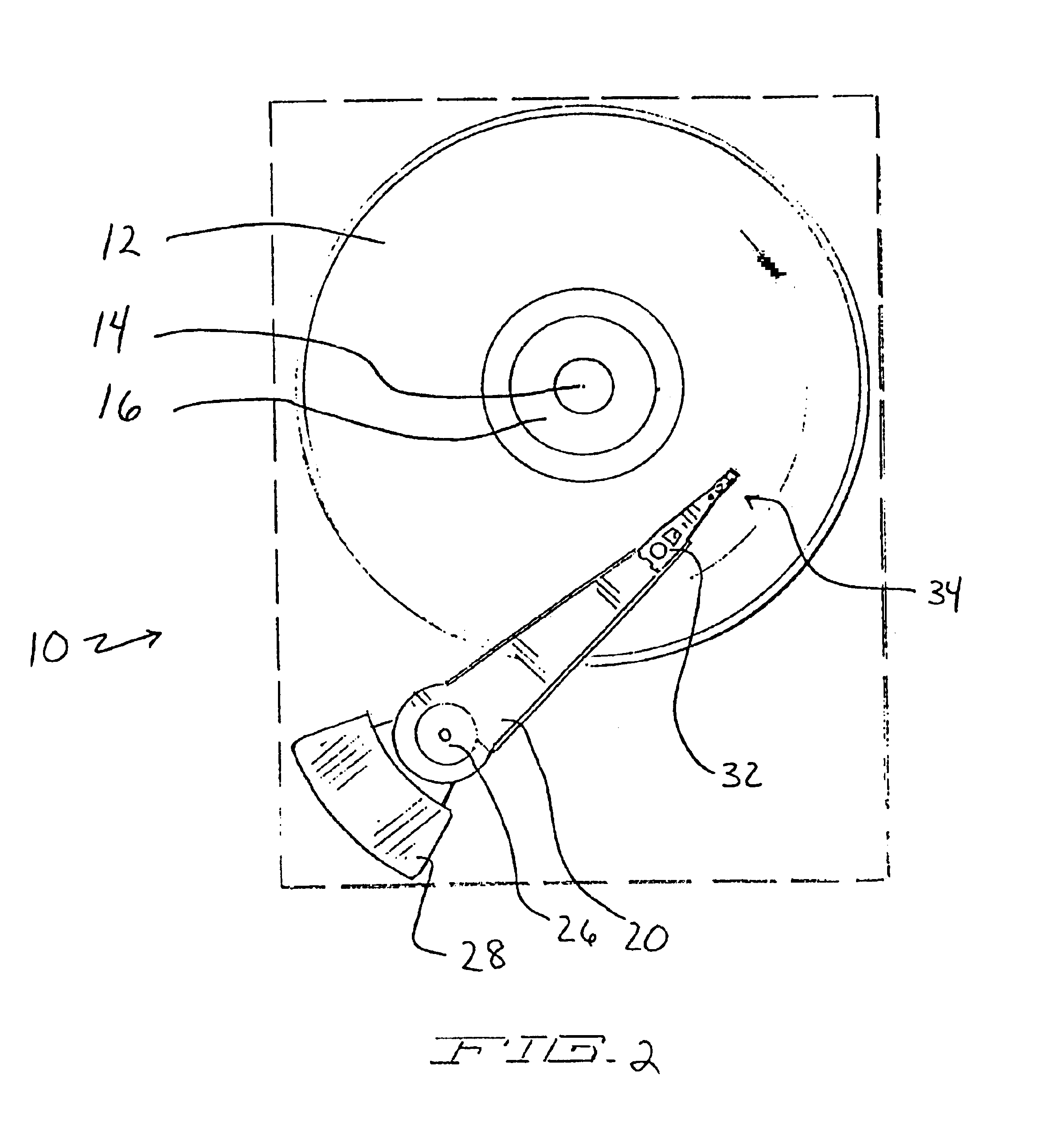

Display device and method for fabricating the same

ActiveUS20160091746A1Reduce and prevent damageStress induced on the carrier may be reduced or preventedElectrically conductive connectionsCircuit arrangements on support structuresCurve shapeDisplay device

A display panel includes a display panel having a curved shape and a printed circuit hoard (PCB). At least one carrier connects the display panel and the PCB. At least one driving integrated circuit (driving IC) is disposed on each carrier. Each carrier includes a body and at least one connector extending from the body. Each connector is spaced apart from each other connector.

Owner:SAMSUNG DISPLAY CO LTD

Gasifier injector

Owner:GAS TECH INST +1

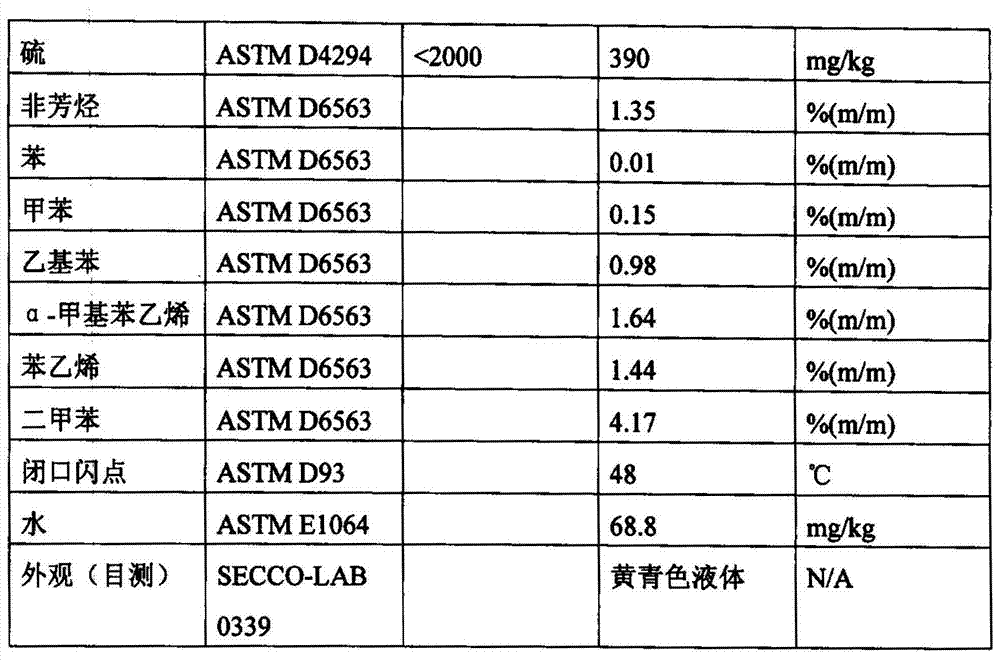

Preparation method of environment-friendly C9 fuel oil

InactiveCN103173244AReduce pollutionImprove pollutionTreatment with plural serial refining stagesWater bathsFuel oil

The invention relates to a preparation method of environment-friendly C9 fuel oil. The preparation method of the environment-friendly C9 fuel oil comprises the following steps of: based on a fraction with the boiling range of 80 to 190 DEG C in the byproduct C9 fraction from ethylene cracking as a raw material, adding an extraction agent, placing in a water bath with the constant temperature of 30 DEG C, stirring for 1h, standing and layering for 1h, adding an additive in the separated oil, and continuing stirring for 1h to obtain the environment-friendly C9 fuel oil. In comparison with the prior art, the environment-friendly C9 fuel oil has the advantages of less sulphur content, good dispersibility and the like.

Owner:SHANGHAI BOHUI CHEM

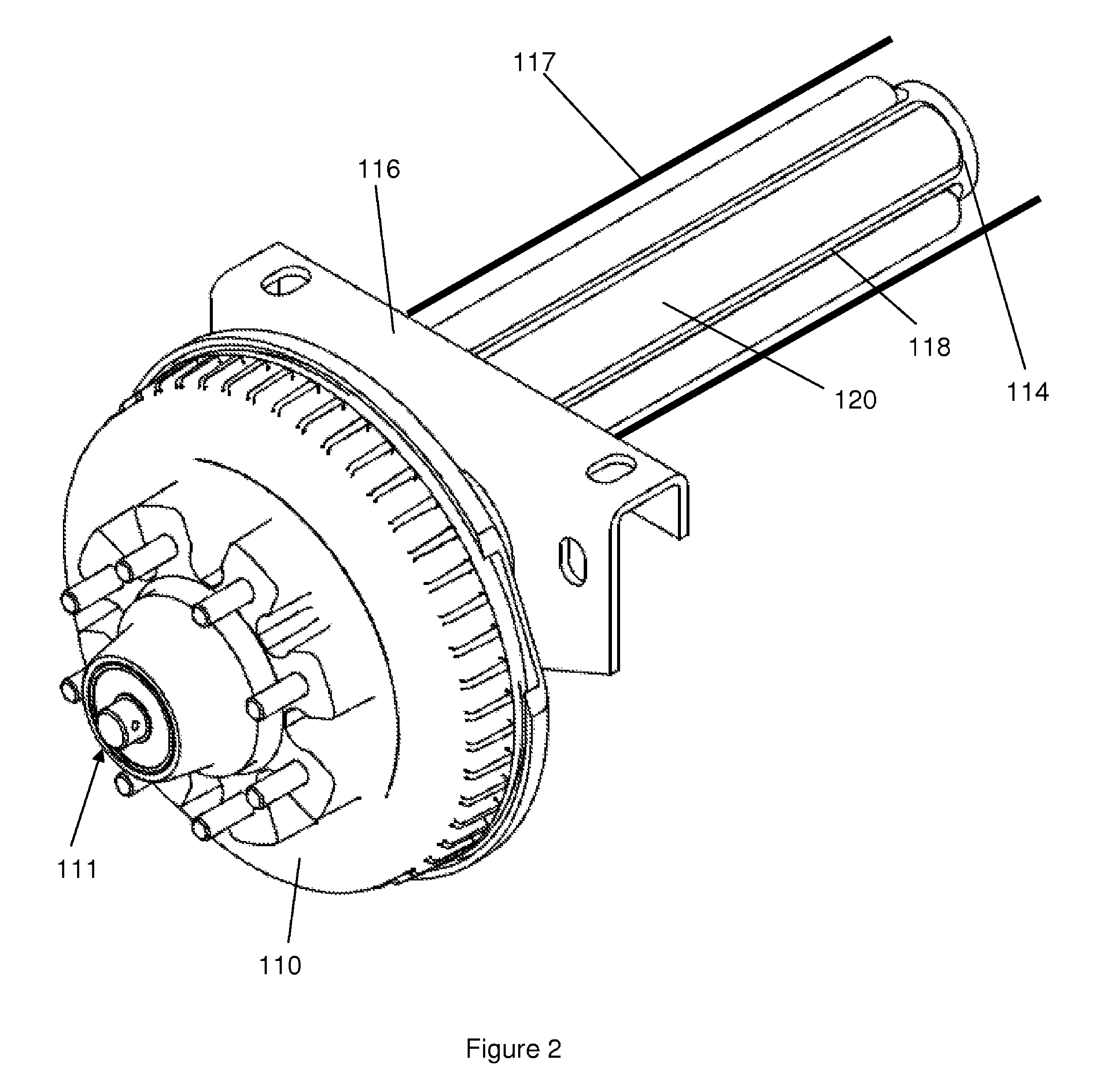

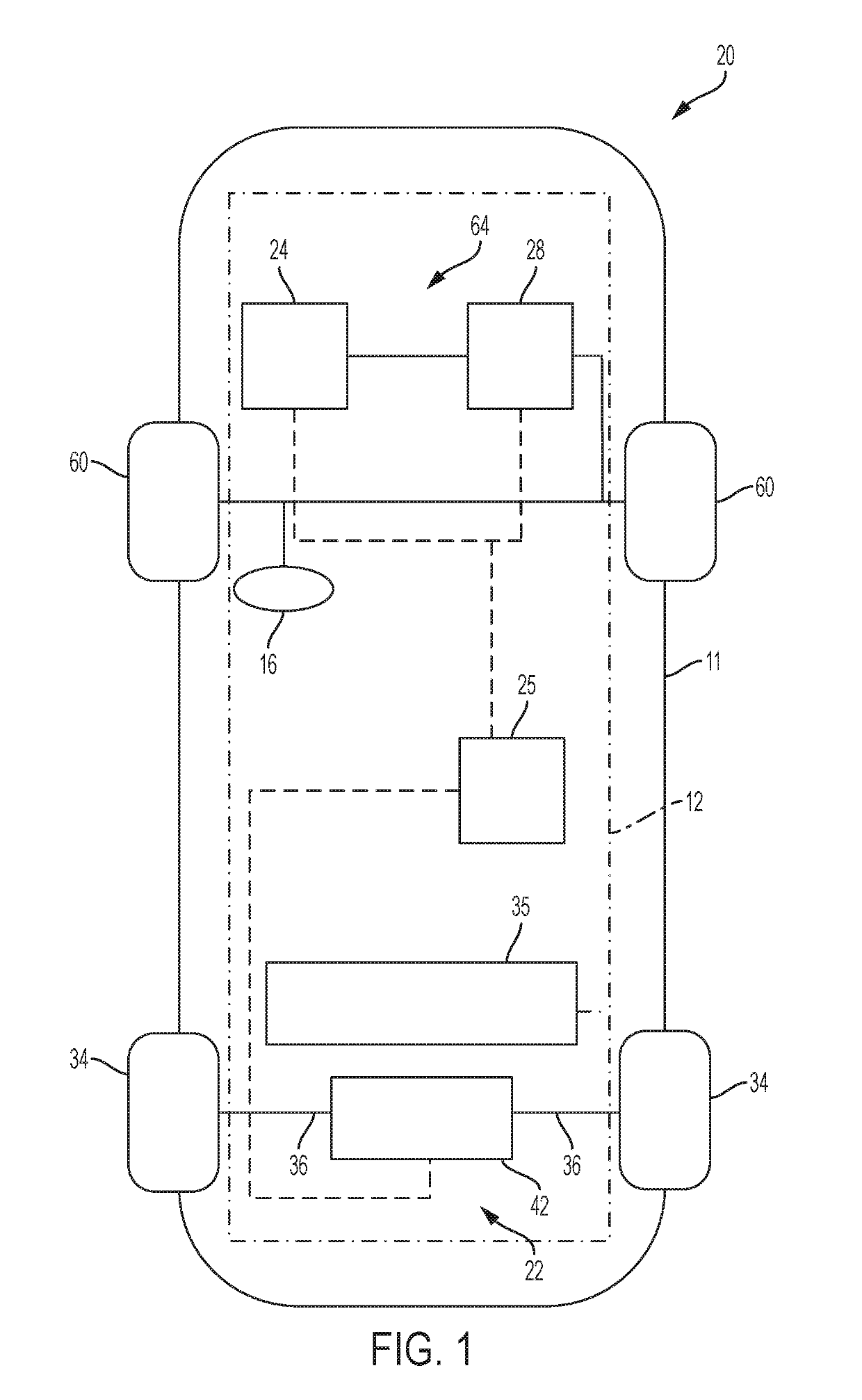

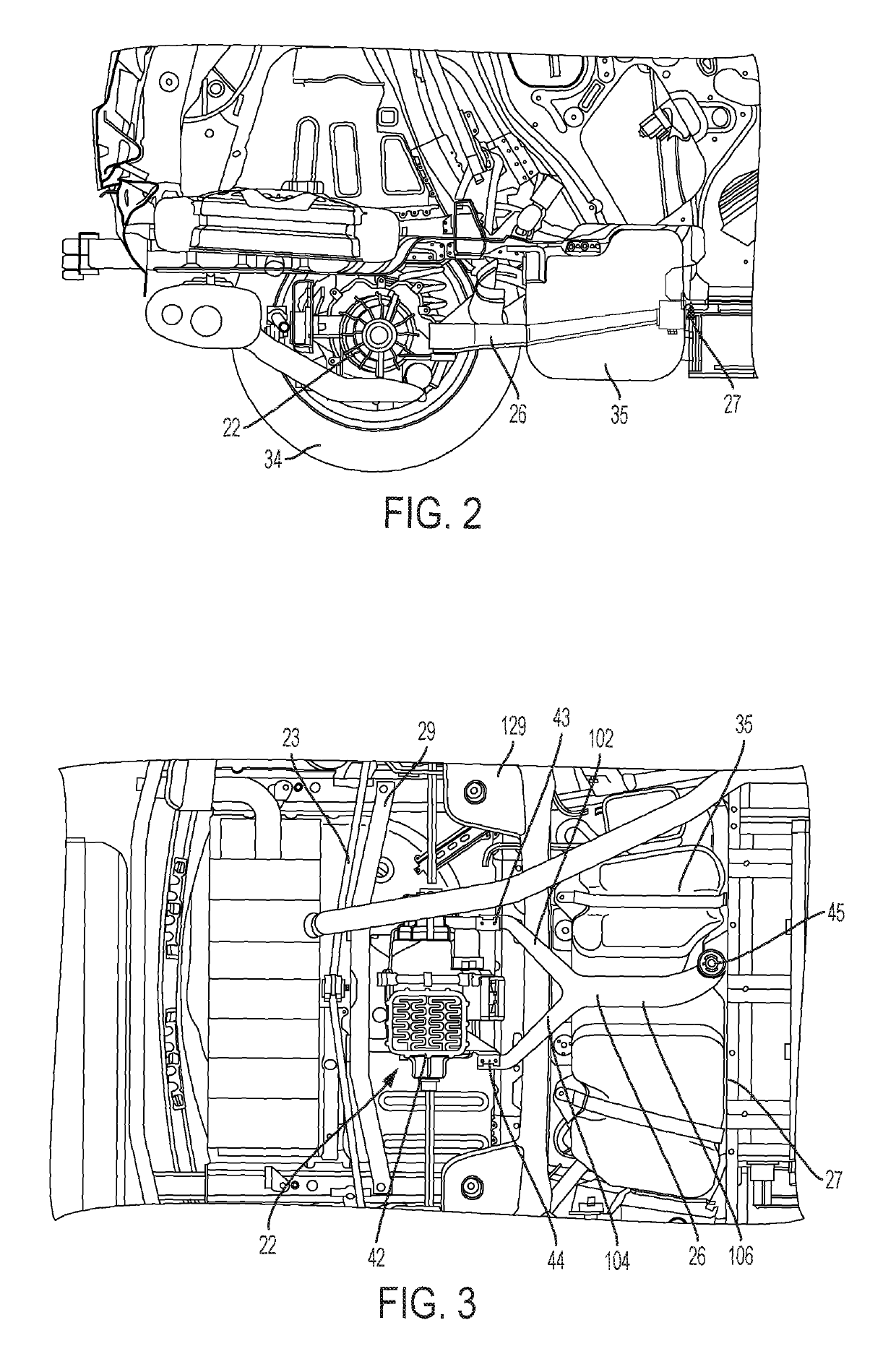

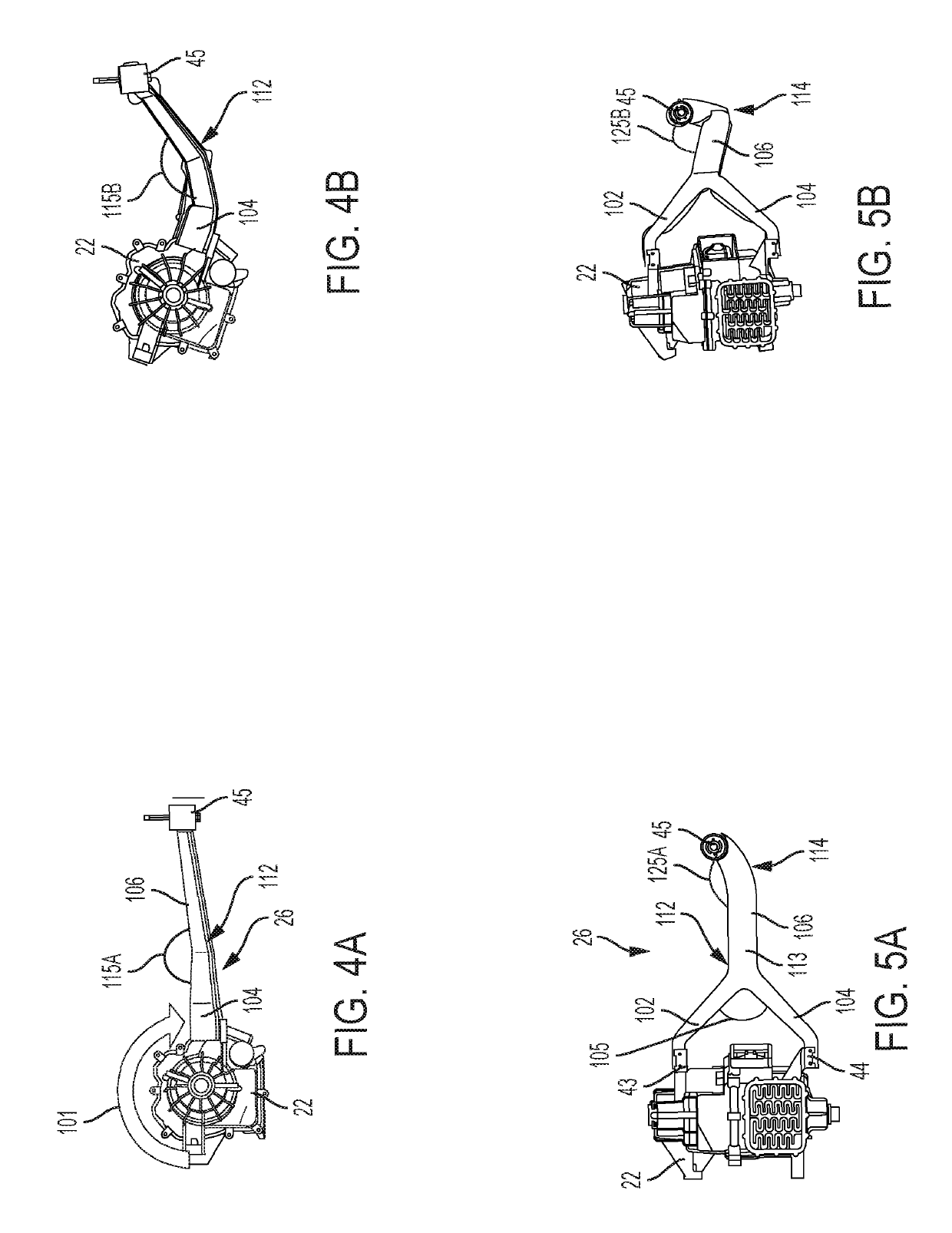

Torque reaction frame for mitigation of rear impact effects

InactiveUS10246132B2Reduce and prevent damageAvoid collisionElectric propulsion mountingVehicle sub-unit featuresRear impactMechanical engineering

A device for rear impact mitigation of a vehicle is disclosed herein. In some embodiments, the device includes a Y-shaped frame having a first leg, a second leg, and a reaction member, the reaction member having a first end and a second end, the first leg and the second leg extending from the first end of the reaction member at a first area and defining an angle therebetween, the reaction member having a straight portion proximate the first end and a curved portion defining a second area proximate the second end, wherein the frame is configured to deform at one or more of the first area and the second area upon application of a force from a rear impact event to the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

Display apparatus including a backlight assembly

A display apparatus includes first and second substrates, a first side sealing layer, a ground connecting part, a flexible film, a driving circuit substrate, and a backlight assembly. The first substrate includes sides extending in a first and a second direction. The second substrate is disposed opposite to the first substrate and is larger in the second direction. The second substrate includes a thin film transistor, a ground wiring and first to fourth side surfaces. The first side sealing layer is disposed on the fourth side surface. The ground connecting part is disposed on the second substrate and is electrically connected to the ground wiring and the first side sealing layer. The flexible film is connected to the second substrate. The driving circuit substrate is connected to the flexible film. The backlight assembly is disposed between the driving circuit substrate and the first substrate.

Owner:SAMSUNG DISPLAY CO LTD

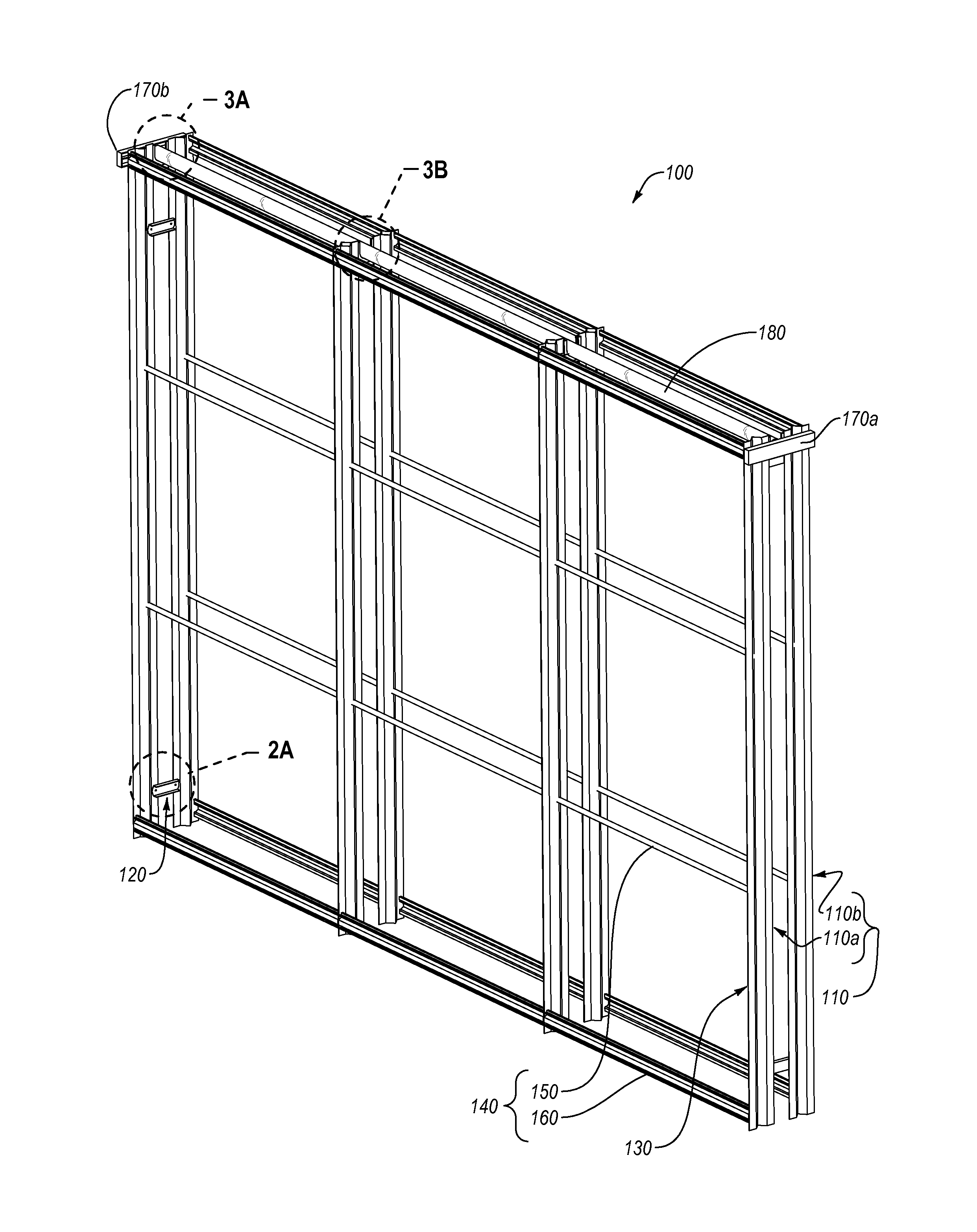

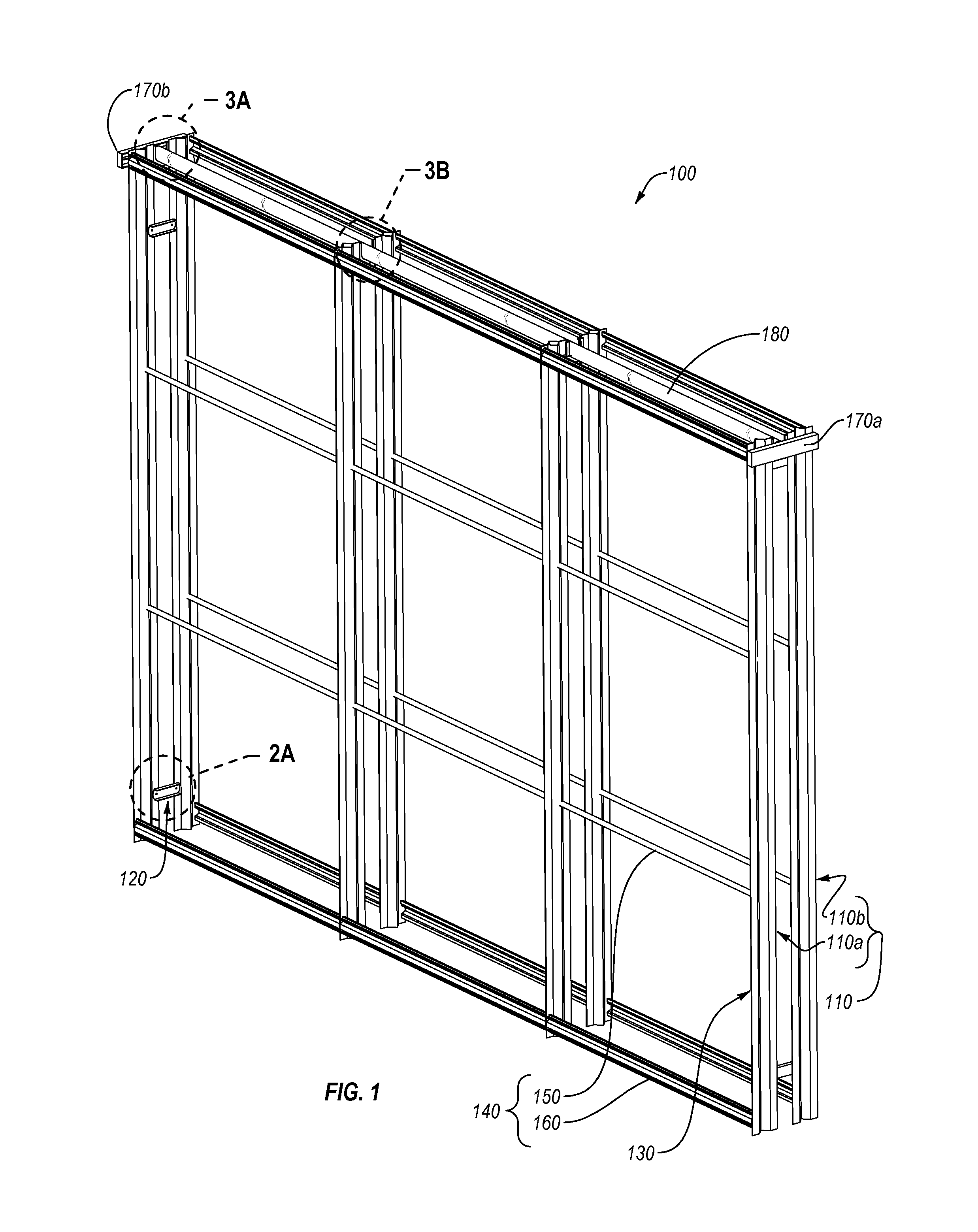

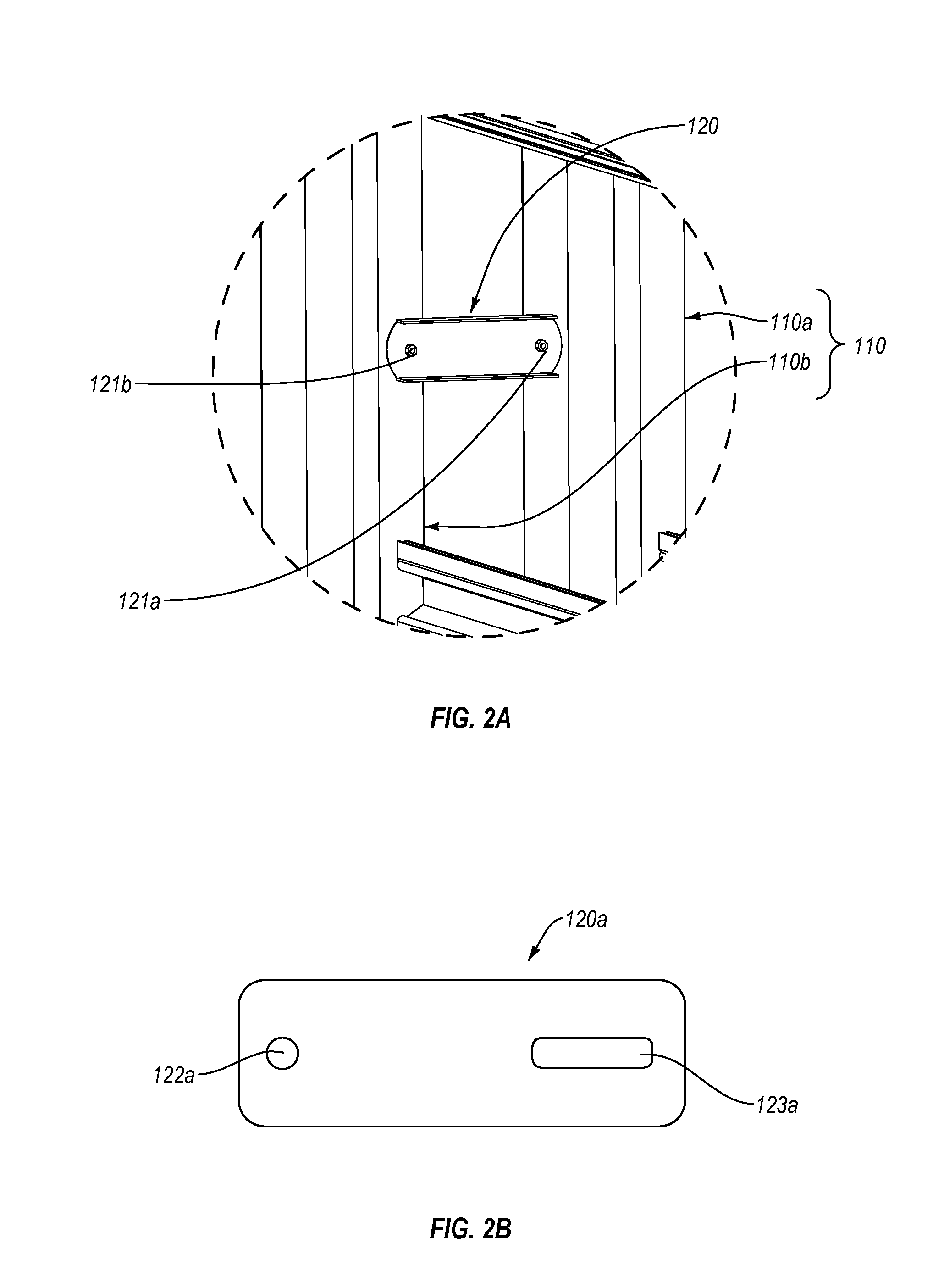

Modular walls with seismic-shiftability

ActiveUS20150211229A1Reduce and prevent damageImprove structural strengthWallsBuilding repairsComputer moduleModularity

Owner:DIRTT ENVIRONMENTAL SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com