Preparation method of environment-friendly C9 fuel oil

A kind of fuel oil and environment-friendly technology, applied in the field of preparation of environment-friendly C9 fuel oil, can solve the problems of sludge carbon deposit and ash content, low degree of atomization, insufficient combustion, etc., to improve pollution, reduce maintenance and reduce sludge accumulation The effect of char and ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of environment-friendly C9 fuel oil, using ethylene cracking by-product C9 fraction with a distillation range of 80-190°C as raw material, adding extractant NMP and placing it in a constant temperature water bath at 30°C to stir and mix for 1 hour. The amount of extractant added is The volume ratio with the raw material is 1: 1, and the separation is allowed to separate for 1h. Add the additive oligomer to the separated oil phase and continue to stir for 1h to obtain the product. The amount of the oligomer added is 4-4% of the weight of the separated oil phase. 8%.

[0020] The additives include the following components and parts by weight: methane 90, isopropane 6, ethylene 1, cyclopentane 2, benzene 0.8.

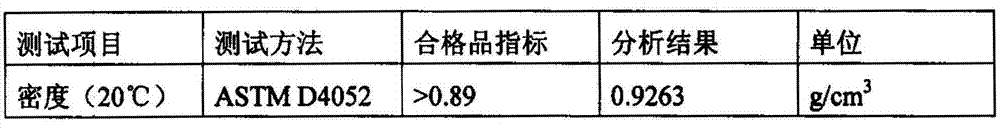

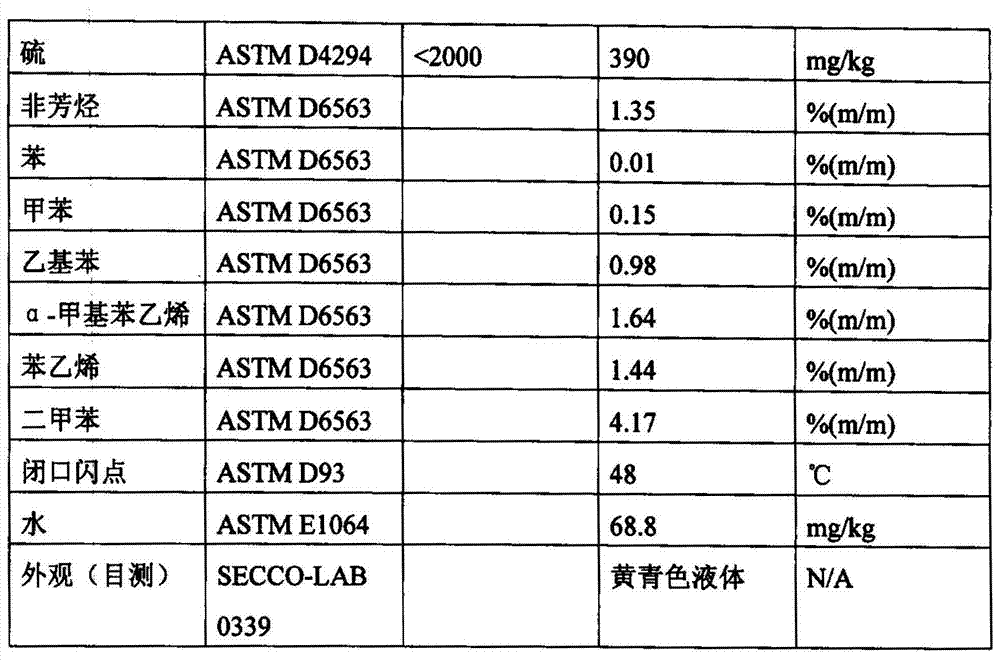

[0021] Gained C9 fuel oil is tested and the results are as follows:

[0022]

[0023]

Embodiment 2

[0025] A preparation method of environment-friendly C9 fuel oil, using ethylene cracking by-product C9 fraction with a distillation range of 80-190°C as the raw material, adding the extractant methanol and placing it in a constant temperature water bath at 30°C to stir and mix for 1 hour. The amount of the extractant added is The volume ratio with the raw material is 1: 1, and the separation is allowed to separate for 1h. Add the additive oligomer to the separated oil phase and continue to stir for 1h to obtain the product. The amount of the oligomer added is 4-4% of the weight of the separated oil phase. 8%.

[0026] The additives include the following components and parts by weight: 95 ethane, 3 isobutane, 2 butene, 1 cyclohexane, and 0.2 toluene.

Embodiment 3

[0028] A preparation method of environment-friendly C9 fuel oil, using ethylene cracking by-product C9 fraction with a distillation range of 80-190°C as raw material, adding extractant diethylene glycol and placing it in a constant temperature water bath at 30°C to stir and mix for 1 hour. The amount of addition is 1:1 with the volume ratio of the raw material, and the separation is allowed to separate for 1h. Add the additive oligomer to the separated oil phase and continue to stir for 1h to obtain the product. The amount of addition of the oligomer is the weight of the separated oil phase 4-8%.

[0029] The additives include the following components and parts by weight: 92 n-pentane, 5 isopentane, 1.8 propylene, 1.5 cyclopentane, and 0.5 ethylbenzene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com