Device for reducing and preventing hydrostatic extrusion breakdown blast-firing damages

A hydrostatic extrusion and extrusion cylinder technology, applied in the field of extrusion processing, can solve problems such as bending of finished products, and achieve the effect of preventing blasting damage, reducing and blasting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

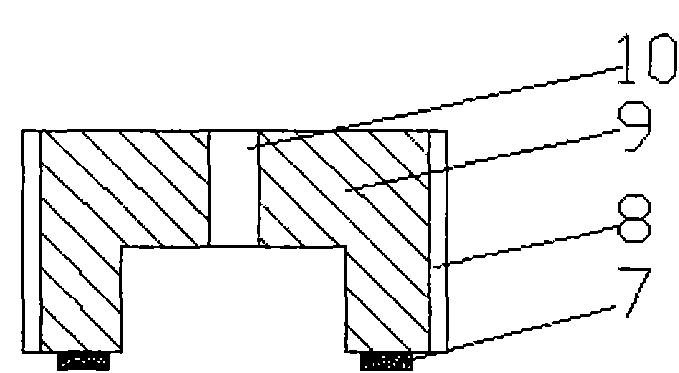

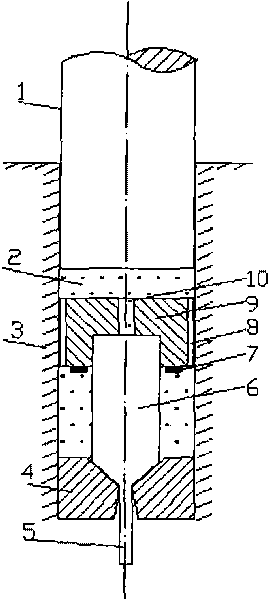

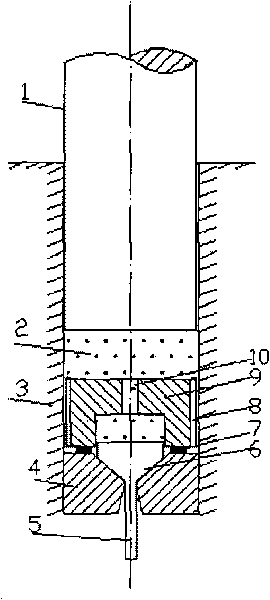

[0021] A device for reducing and preventing hydrostatic extrusion billet blasting damage, figure 1 It is a schematic diagram of the extrusion cap, and an extrusion cap 9 is placed in the extrusion cylinder 3. The extrusion cap 9 is made of metal materials such as carbon steel, alloy steel, copper alloy or aluminum alloy, and the inner diameter of the extrusion cap 9 is equal to that of the billet 6 The outer diameter of the extrusion cap 9 is not greater than the inner diameter of the extrusion cylinder 3, the extrusion cap 9 is tightly fitted with the blank 6, and the front section of the extrusion cap 9 has a sealing ring 7, and the sealing ring 7 is made of copper, aluminum, Made of soft metal such as lead or magnesium, rubber or plastic, the extruded cap 9 has a liquid channel 8 with a circular or polygonal cross-section. The liquid channel 8 is located outside the outer diameter of the sealing ring 7. The total liquid channel 8 The cross-sectional area accounts for 1-75% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com