Bidirectional press-fit die for embedded joint bearing

A joint bearing and die-matching technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of complex press-fitting steps, low symmetry accuracy, affecting service life, etc., and achieves improved efficiency, high symmetry accuracy, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

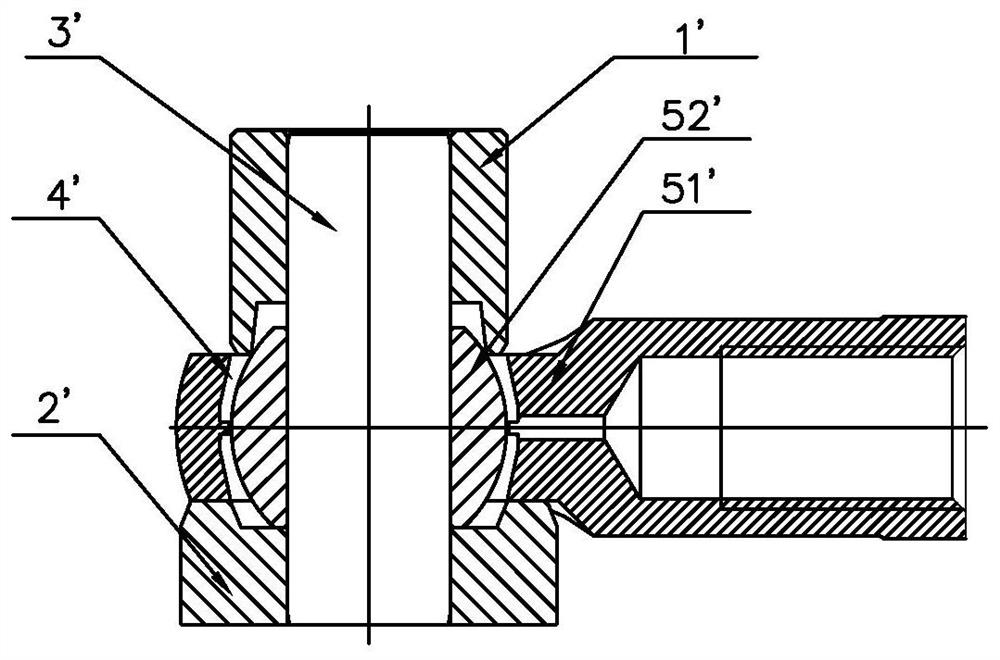

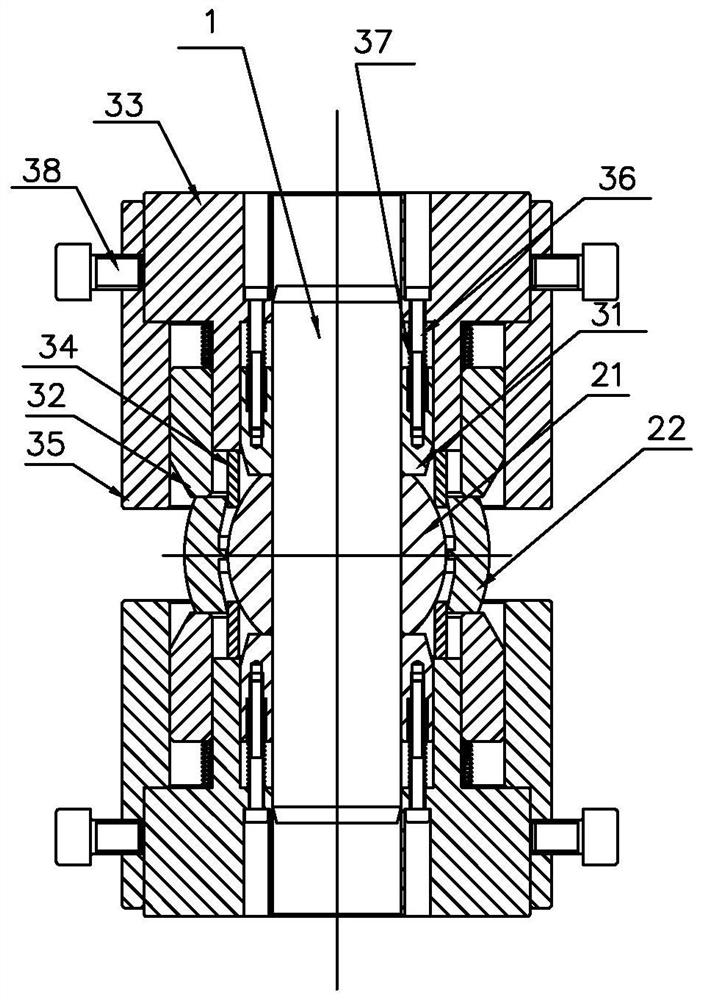

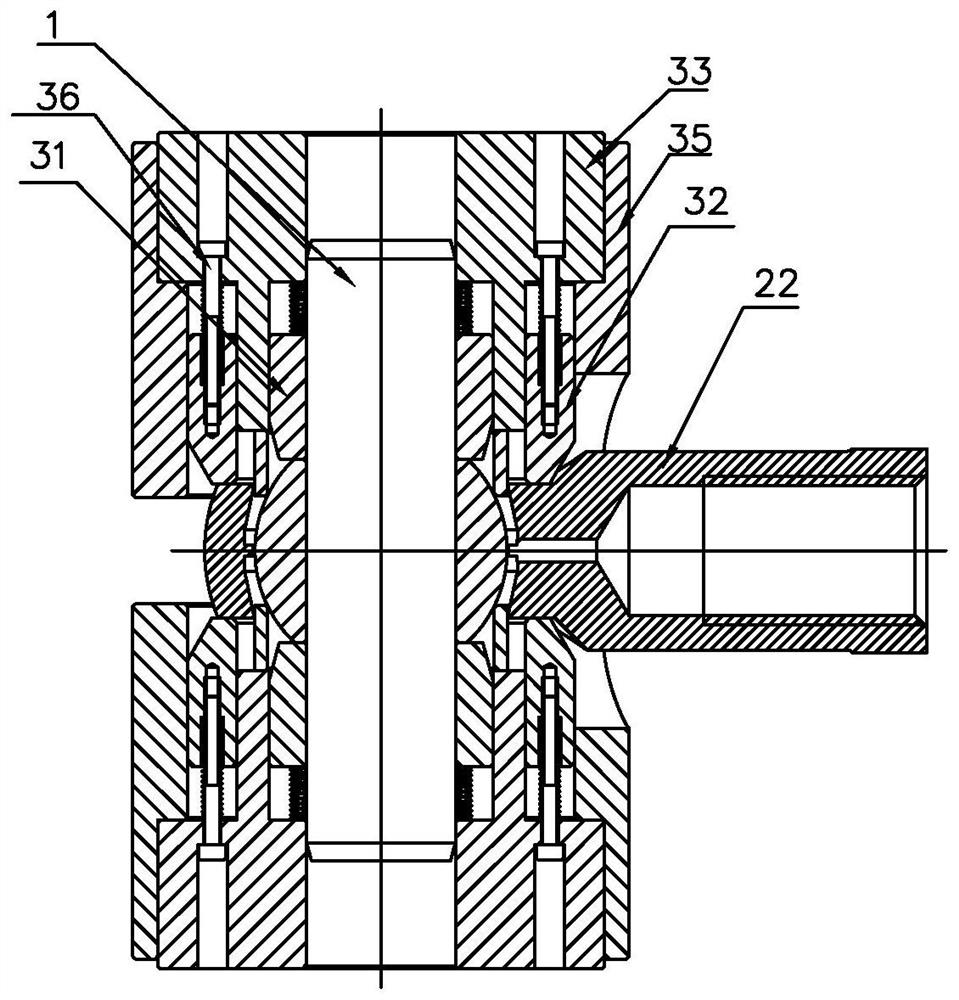

[0026] Examples, see figure 2 and image 3 As shown, a two-way press-fit die of an inlaid type joint bearing of the present invention is applied to the copper-inlaid liner of the rod end joint bearing. The inner ring 21 can be sleeved on the mandrel 1 , and each set of press-fit dies includes an inner ring stopper 31 , an outer ring stopper 32 , a press-fit base plate 33 , a binder sleeve 34 and a sheath 35 . The inner ring limiting block 31 has an inner ring limiting surface adapted to the end surface of the inner ring of the spherical plain bearing; the outer ring limiting block 32 has an outer ring limiting surface adapted to the end surface of the rod end eye; the press-fit base plate 33 It can be slidably connected between the inner ring limit block 31 and the outer ring limit block 32 ; the mandrel 1 can fit and slide in the press-fit base plate 33 .

[0027] In this embodiment, the outer ring limit block 32 and the inner ring limit block 31 are adjustablely connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com