Patents

Literature

824results about "Actuator accumulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

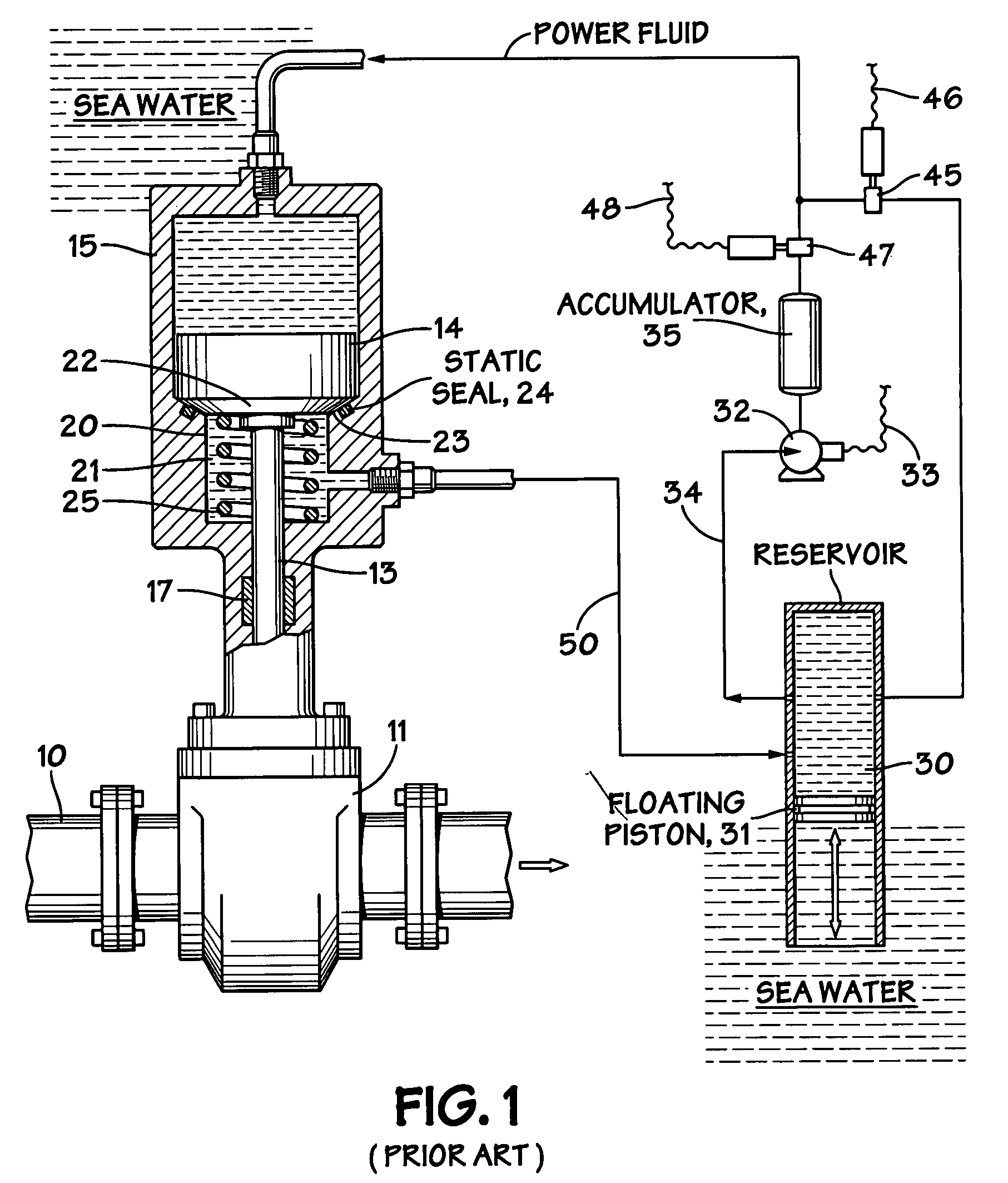

Subsea accumulator and method of operation of same

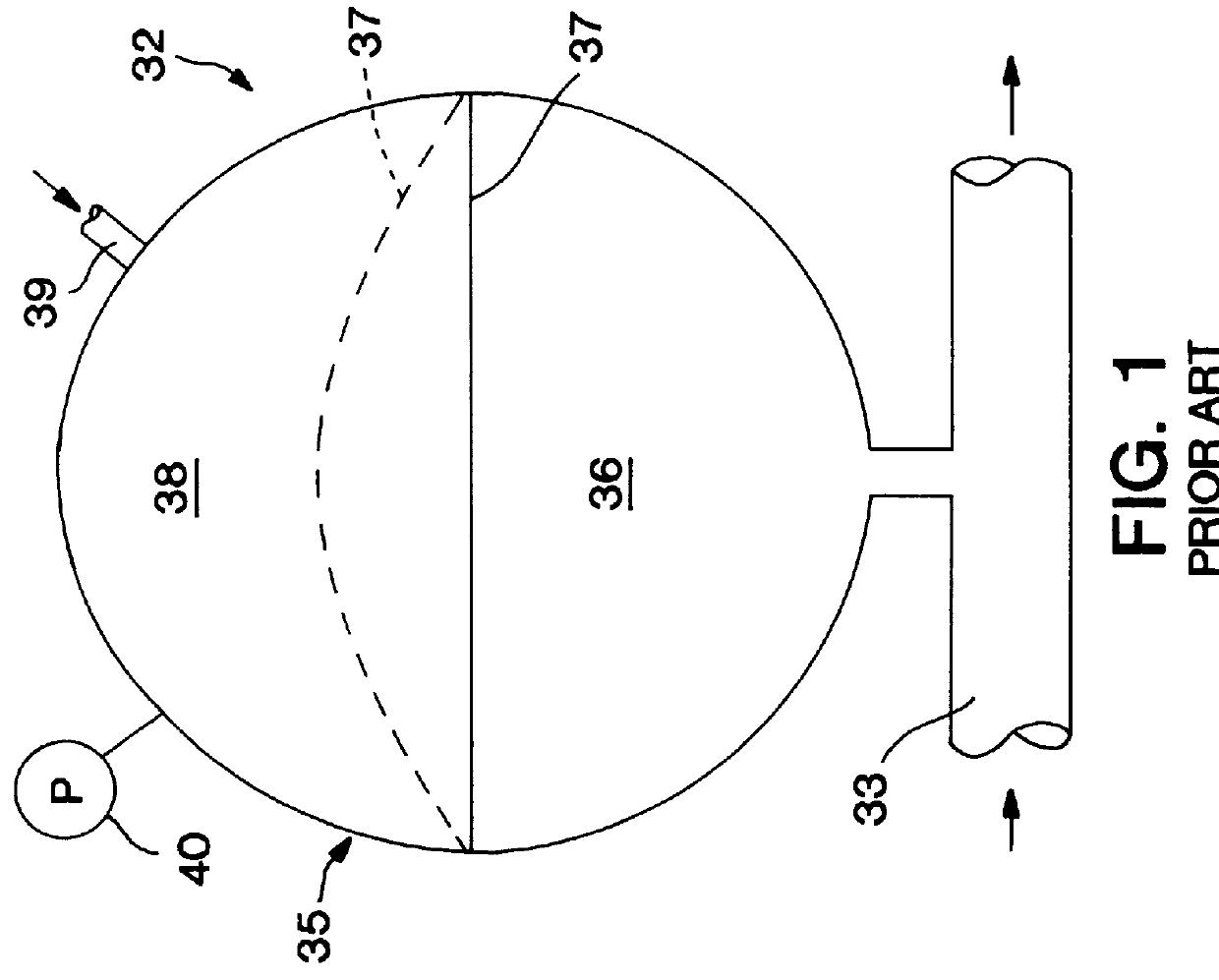

An accumulator for use in deepwater operational and control systems which uses a differential between a high pressure ambient pressure source such as sea water pressure and a low pressure source such as a chamber holding vacuum or atmospheric pressure to provide storage and delivery of hydraulic power for operation of equipment.

Owner:BAUGH BENTON F

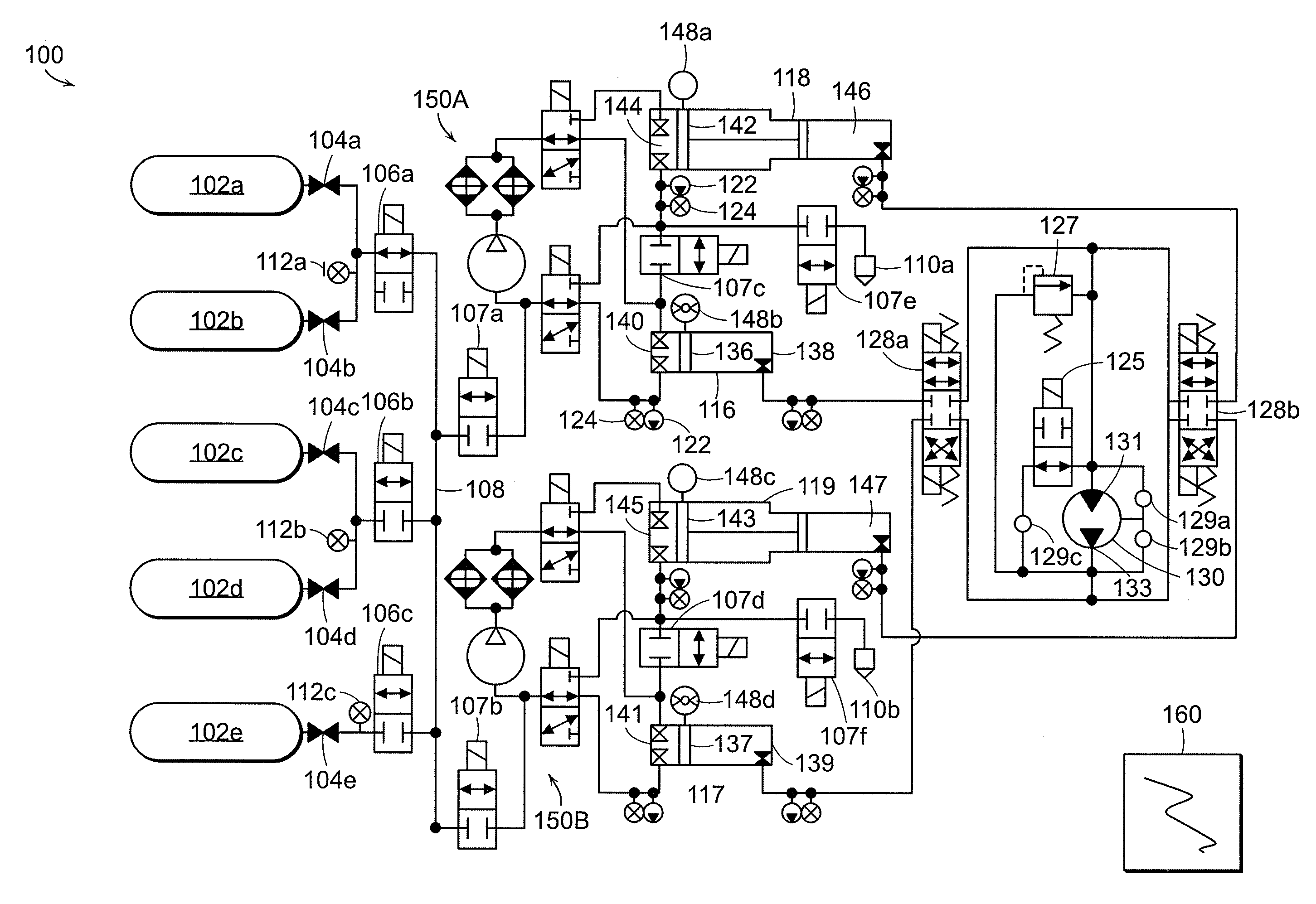

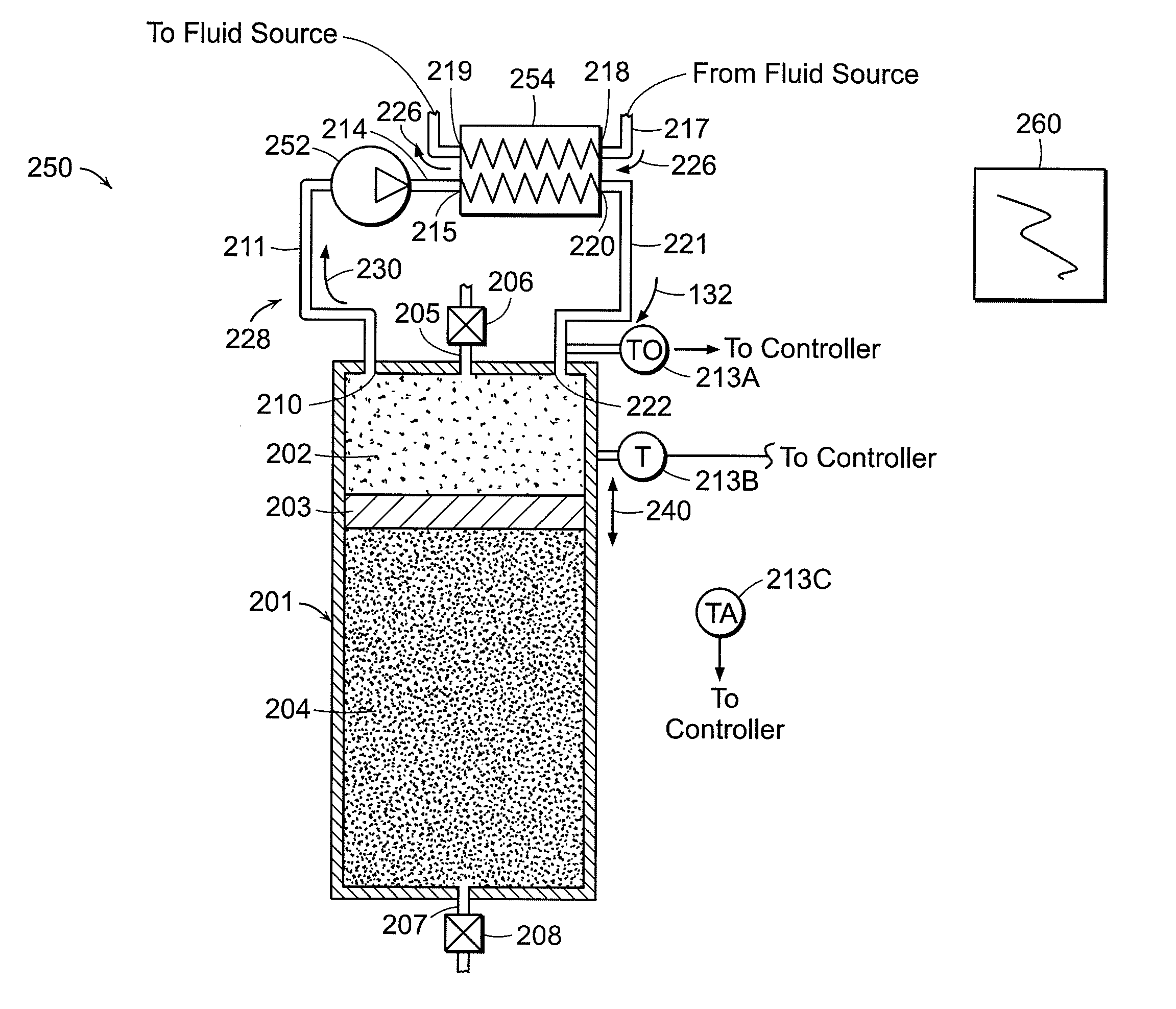

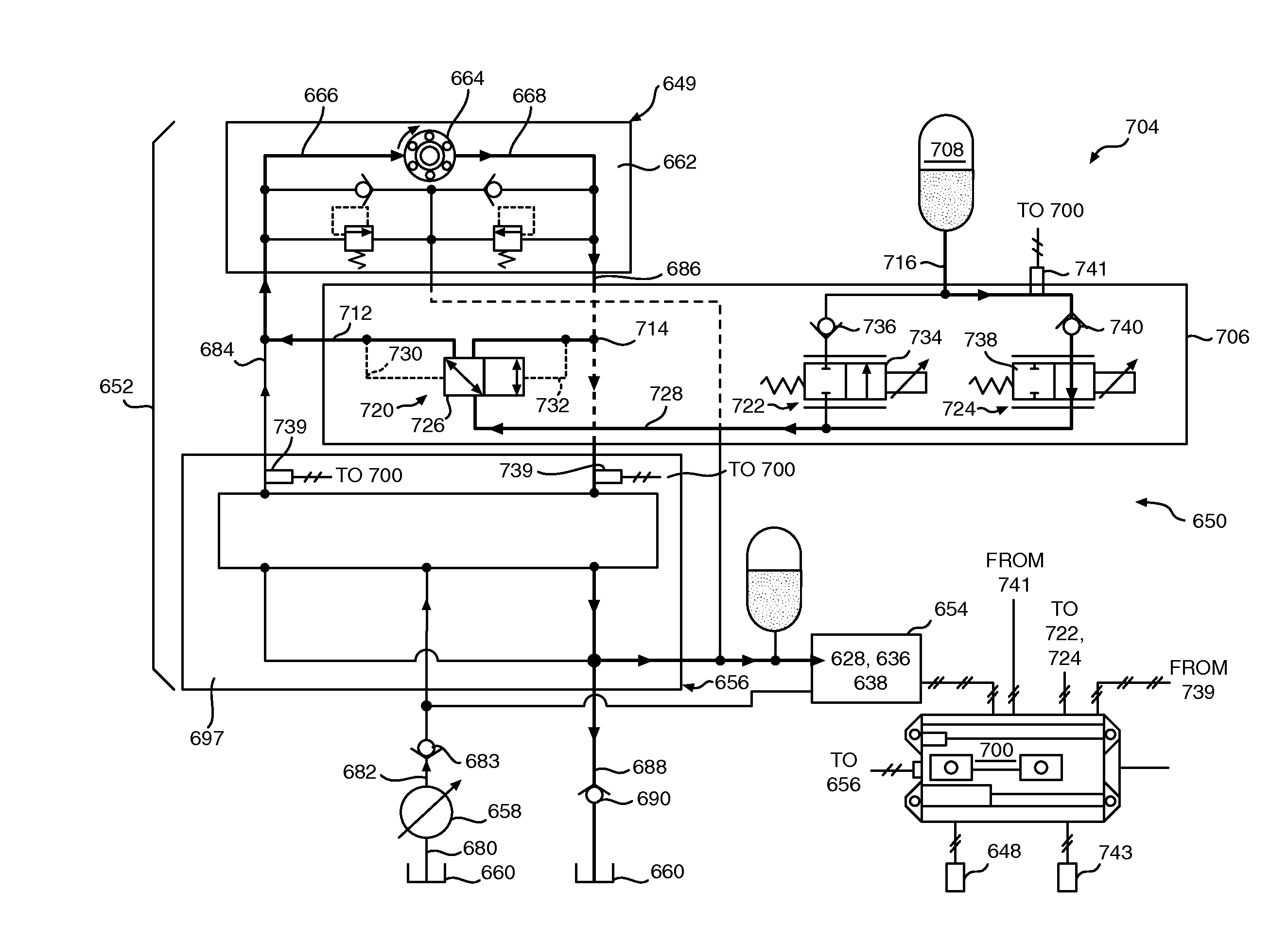

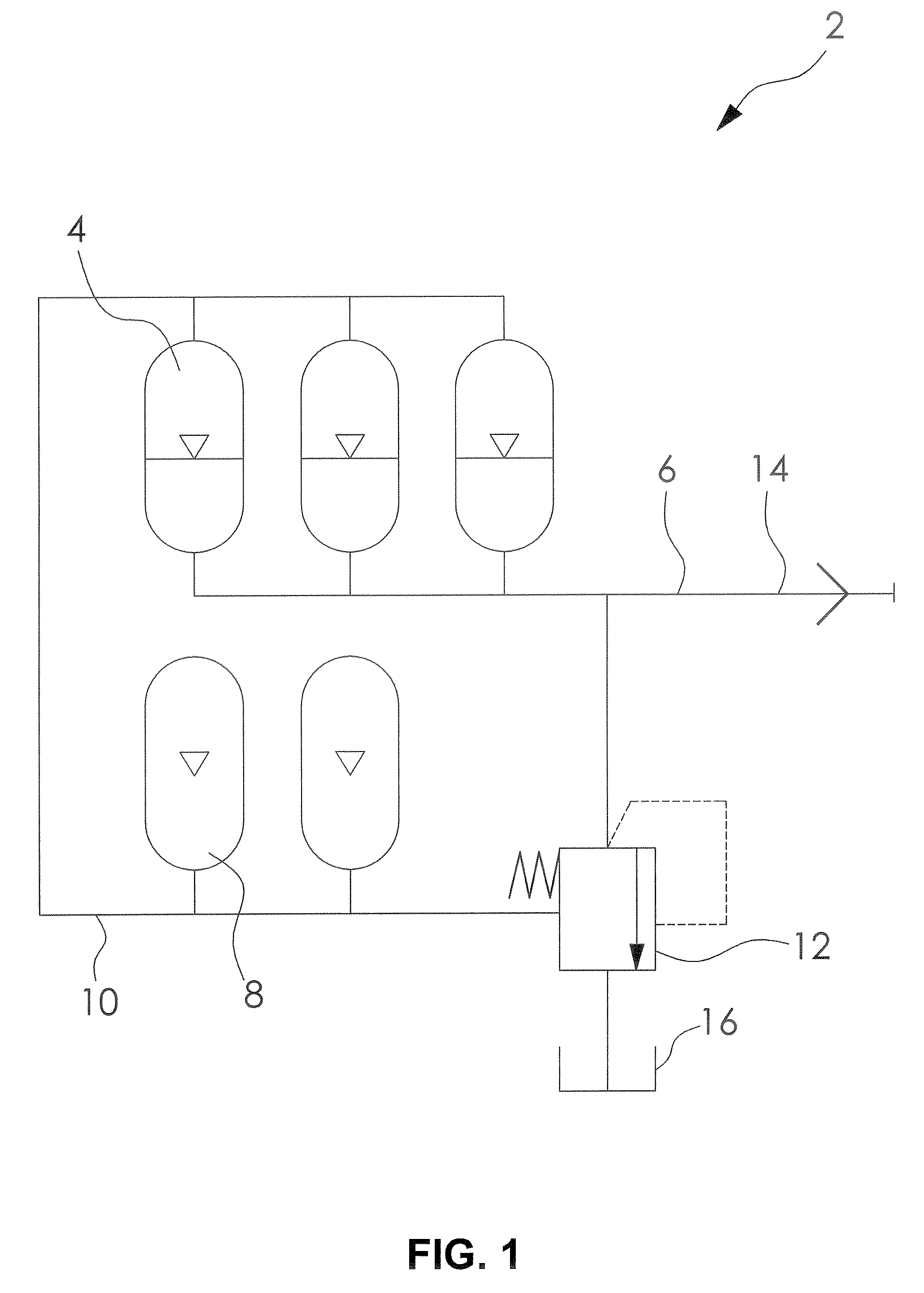

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

System and method for rapid isothermal gas expansion and compression for energy storage

InactiveUS7802426B2Overcome disadvantagesInhibit migrationElectrical storage systemServomotorsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

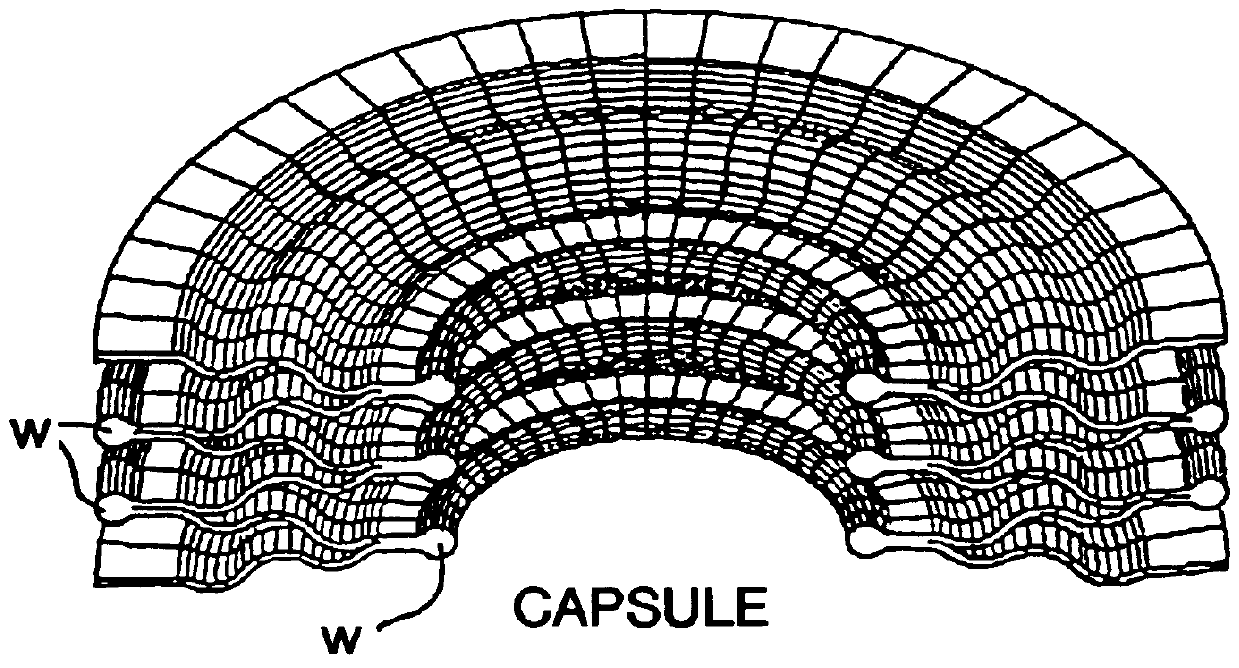

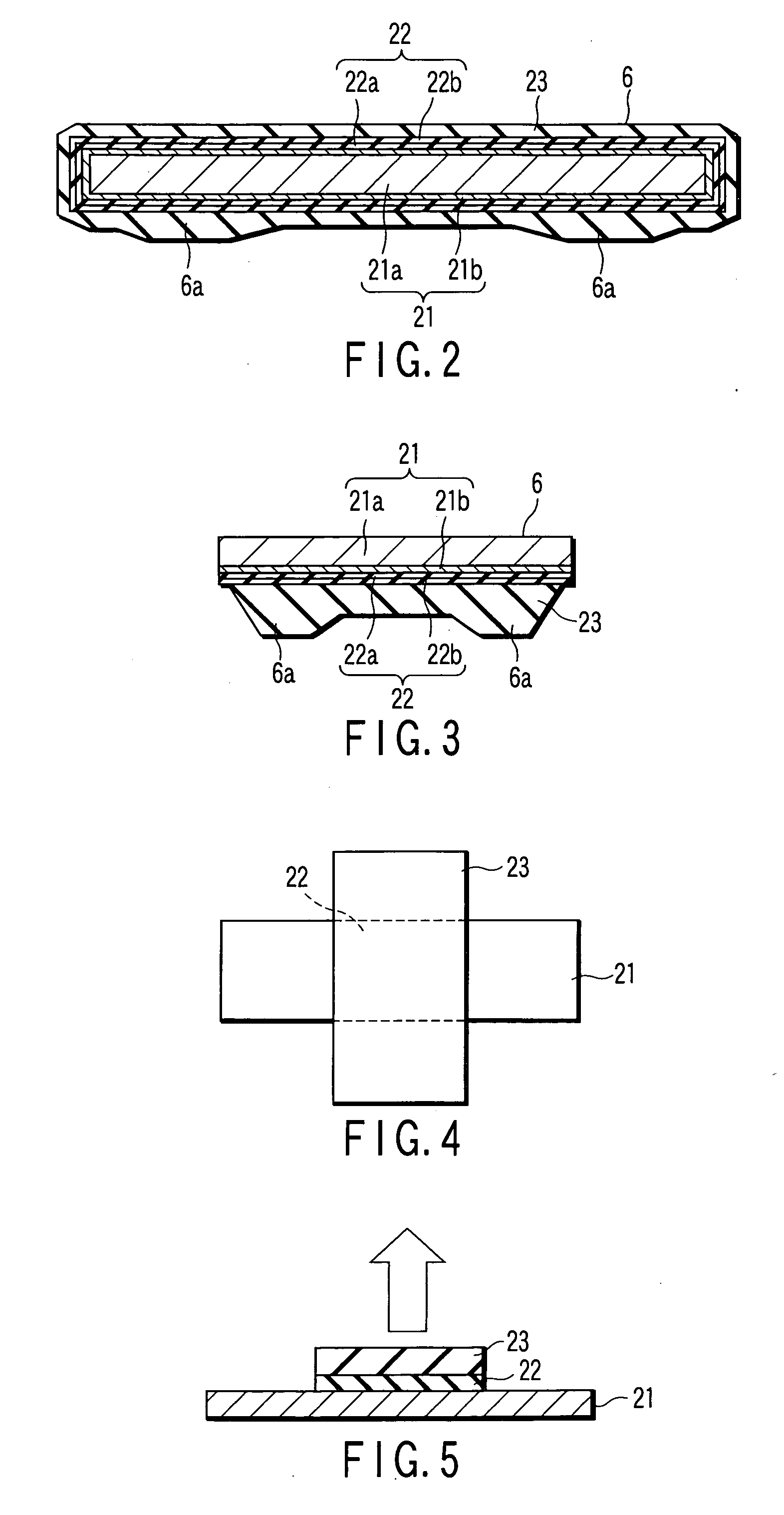

Thin wall, high pressure, volume compensator

Accumulators / compensators for pressurized fluent material systems are provided, in which a continuous substantially non-permeable, flexible membrane (like a bellows) surrounds or is surrounded by a non-gaseous support medium, all within a surrounding housing. Various combinations of support media, which may include internal gas-filled cavities, are described and illustrated.

Owner:SENIOR ENG INVESTMENTS

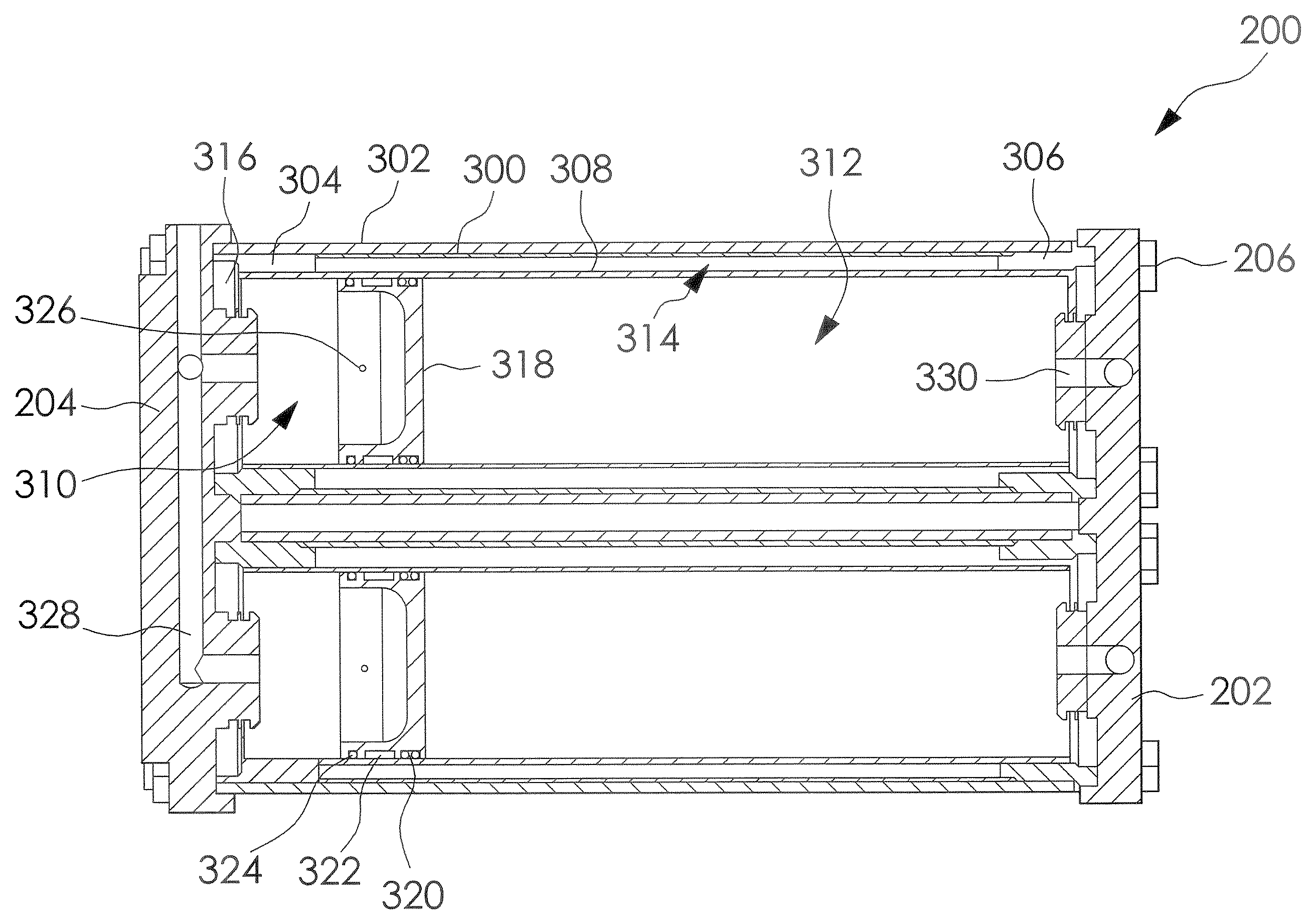

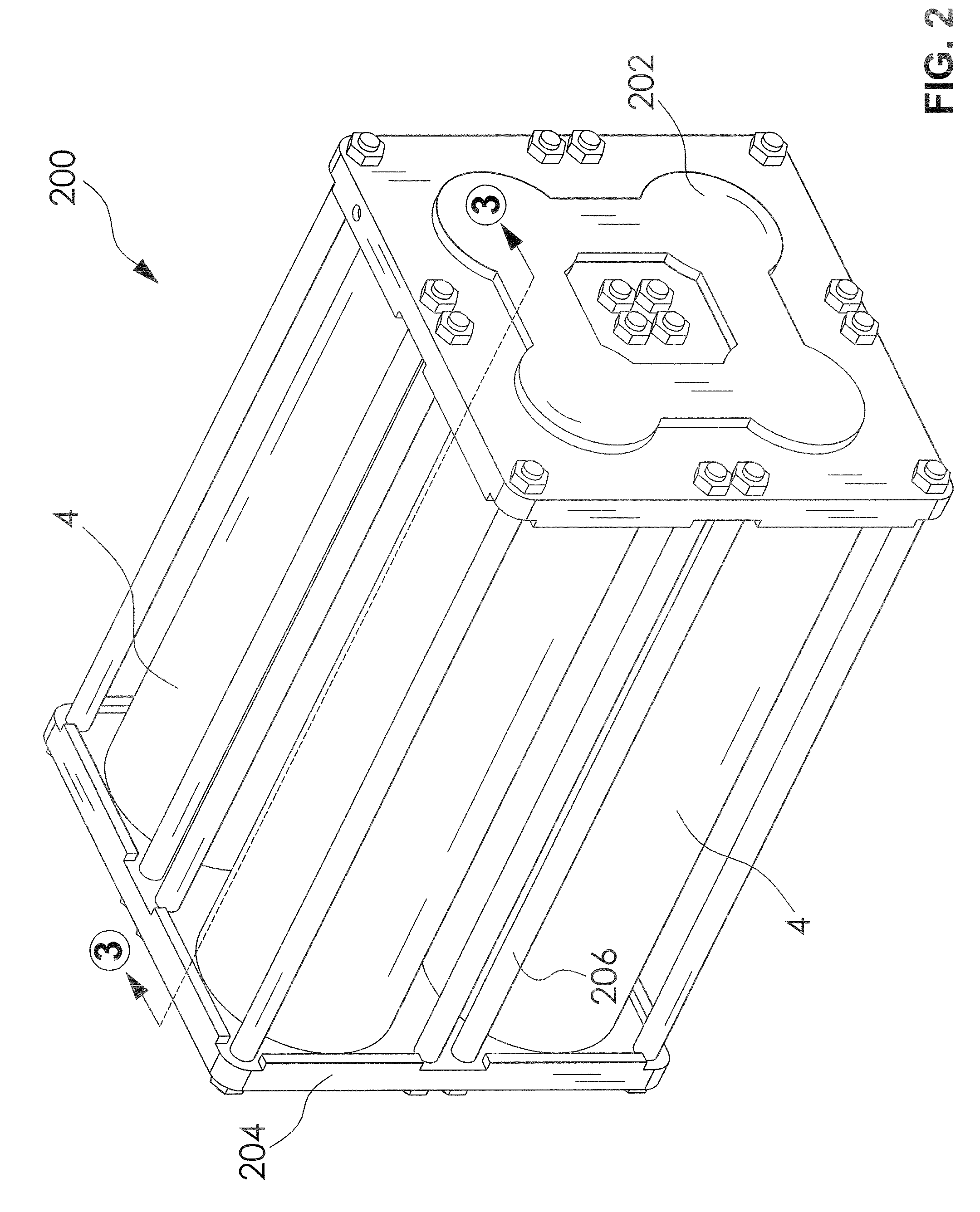

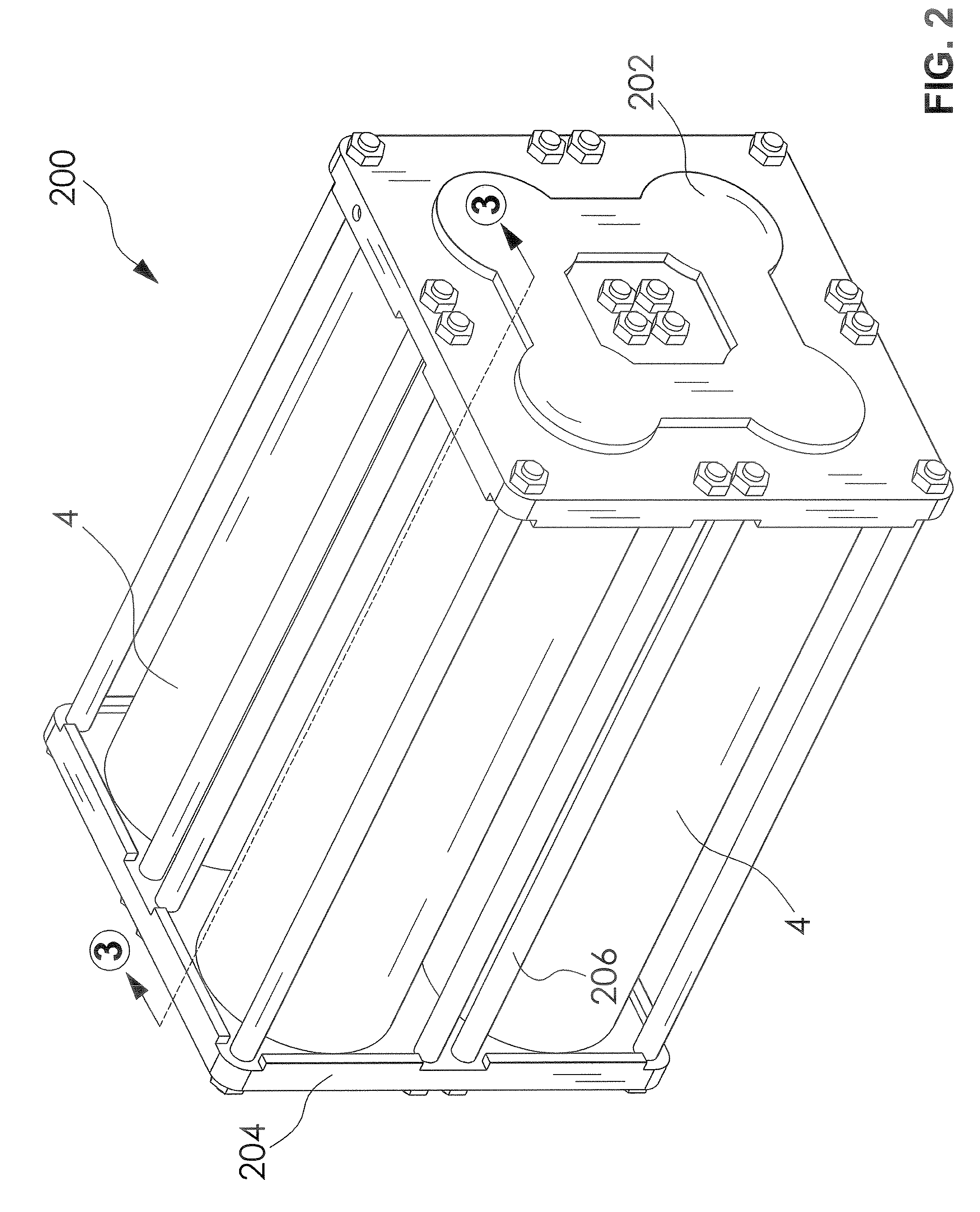

Compact hydraulic accumulator

InactiveUS20080308168A1Light weightEasy maintenanceFluid couplingsCheck valvesWorking fluidGas cylinder

A lightweight, optimally efficient, easily serviced, piston-in-sleeve high pressure accumulator is provided. The accumulator includes one or more cylindrical composite pressure vessel separate end cap manifolds. A piston slidably disposed in a thin impermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Gas is provided in a volume between the impermeable internal sleeve and the composite pressure vessel wall. Additional gas is optionally provided in gas cylinders. Further components are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle.

Owner:NRG ENTERPRISES

Hydraulic accumulator health monitor

A system and method to diagnose the operational health of a hydraulic accumulator are provided. The system can include a hydraulic accumulator selectively coupled to a hydraulic actuator, such as a swing motor. The accumulator can be charged by movement of the actuator. A pressure sensor can be associated with the accumulator to determine an accumulator pressure. A controller can be connected to the pressure sensor. The controller can determine a charge curve based on a relationship between an actuator operational parameter associated with the actuator movement and the accumulator pressure. The controller can compare the charge curve to a previously defined charge curve or range to determine an error between the charge curve and the previously defined charge curve or range. The degree of the error can be associated with the operational health of the accumulator, and if too large, the operator may be notified of the status.

Owner:CATERPILLAR INC

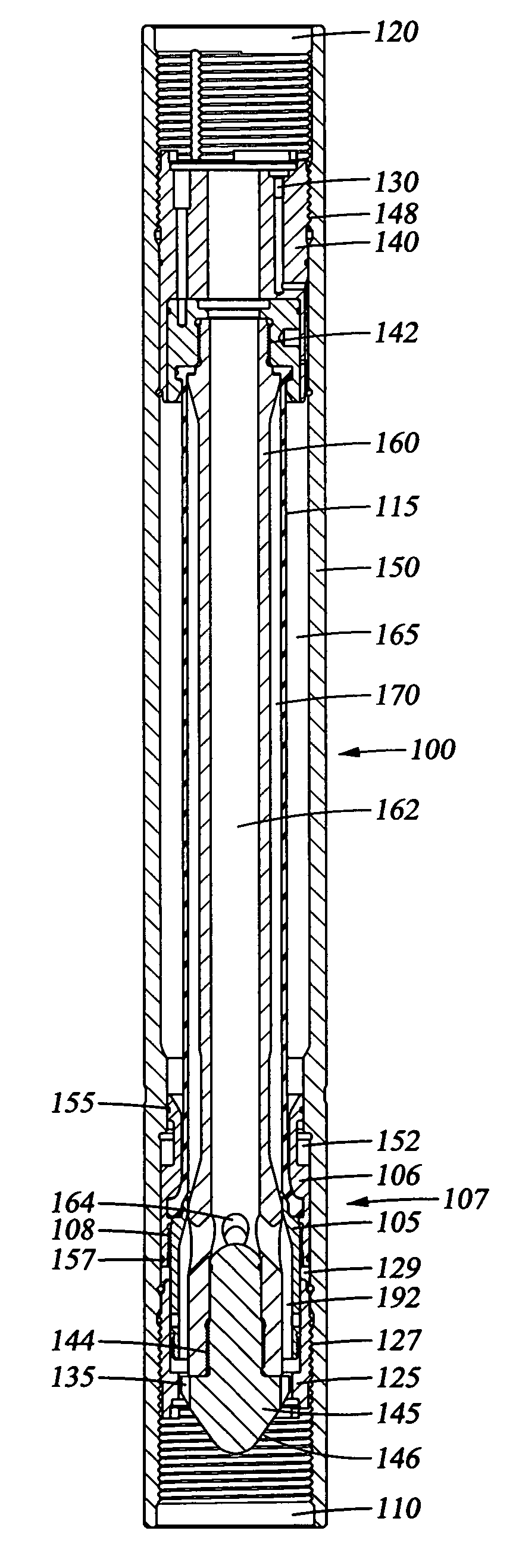

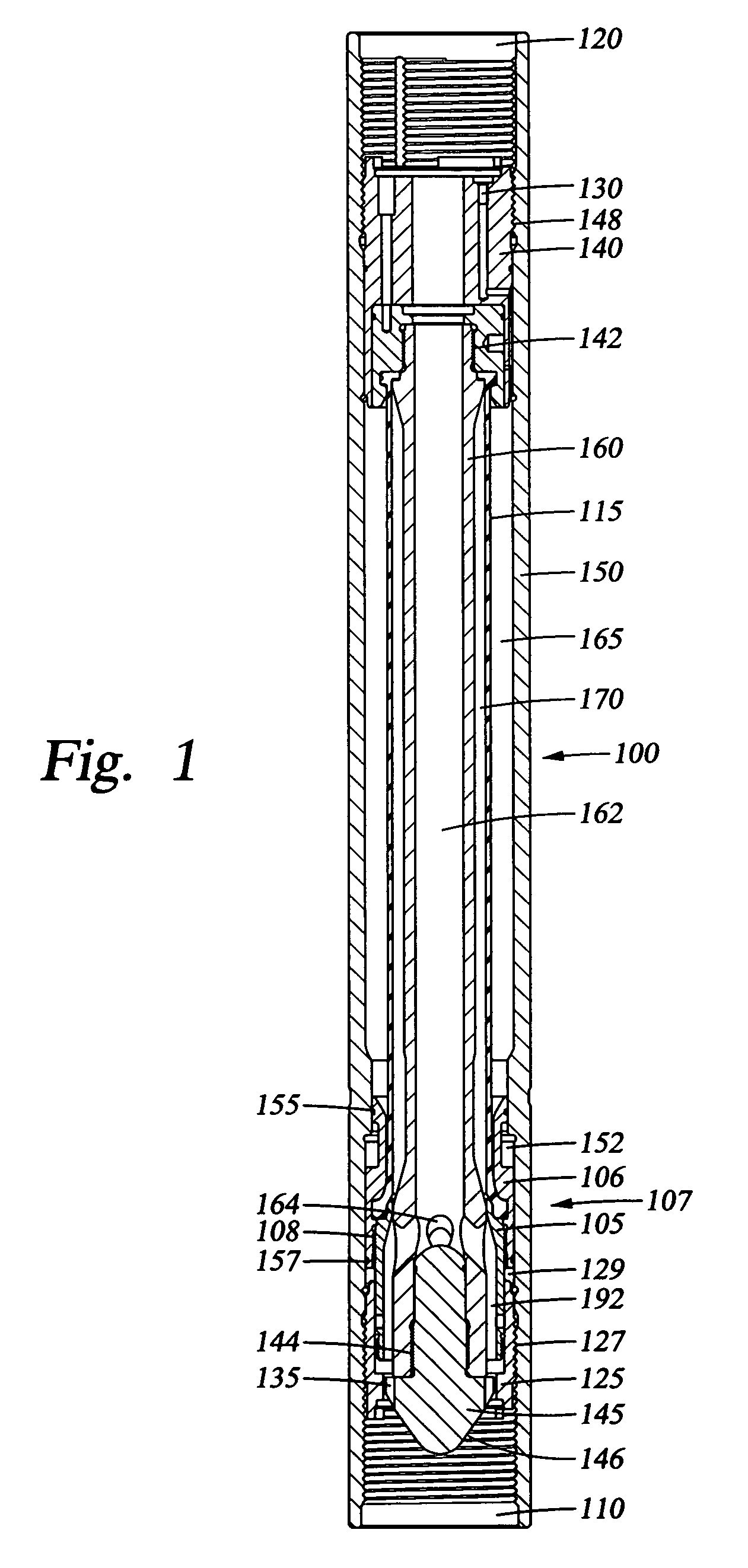

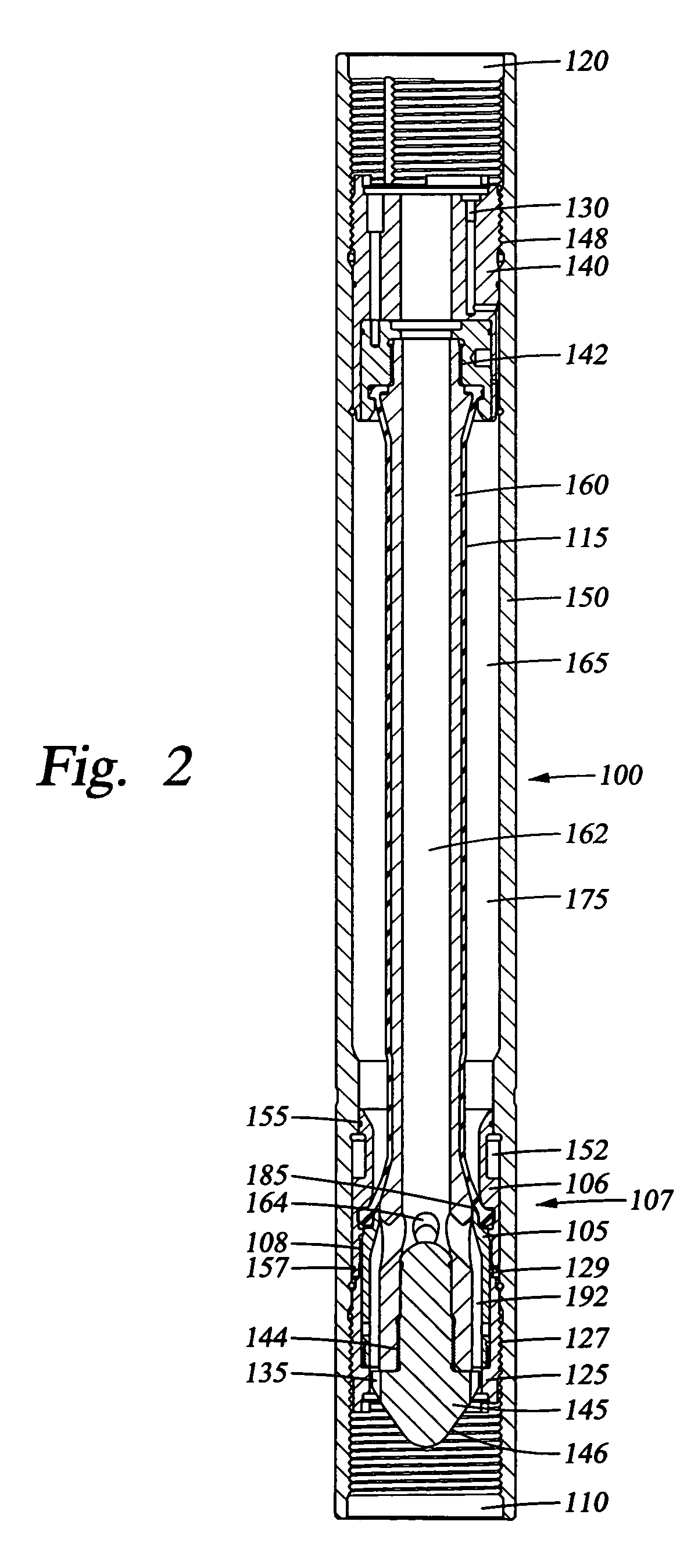

Inline bladder-type accumulator for downhole applications

InactiveUS7353845B2Good fluid performanceAccumulator installationsPressure pumpsFluid compartmentsEngineering

An accumulator comprises a housing connected to a hydraulic system, an elastomeric bladder separating a gas compartment from a fluid compartment, and an anti-extrusion device. A method for operating an accumulator comprises connecting the accumulator to a hydraulic system, injecting an inert gas into a gas compartment to a precharge pressure, moving an anti-extrusion device to prevent a bladder from extruding into the hydraulic system, running the accumulator and the hydraulic system downhole, moving the anti-extrusion device to allow fluid communication between the hydraulic system and a fluid compartment, generating pressure fluctuations within the hydraulic system, and expanding or contracting the bladder in response to the pressure fluctuations without moving the anti-extrusion device. A method of improving fluid hammer performance comprises connecting the fluid hammer to an accumulator that produces a greater delivered horsepower from the fluid hammer as compared to a baseline horsepower when operating without the accumulator.

Owner:SMITH INT INC

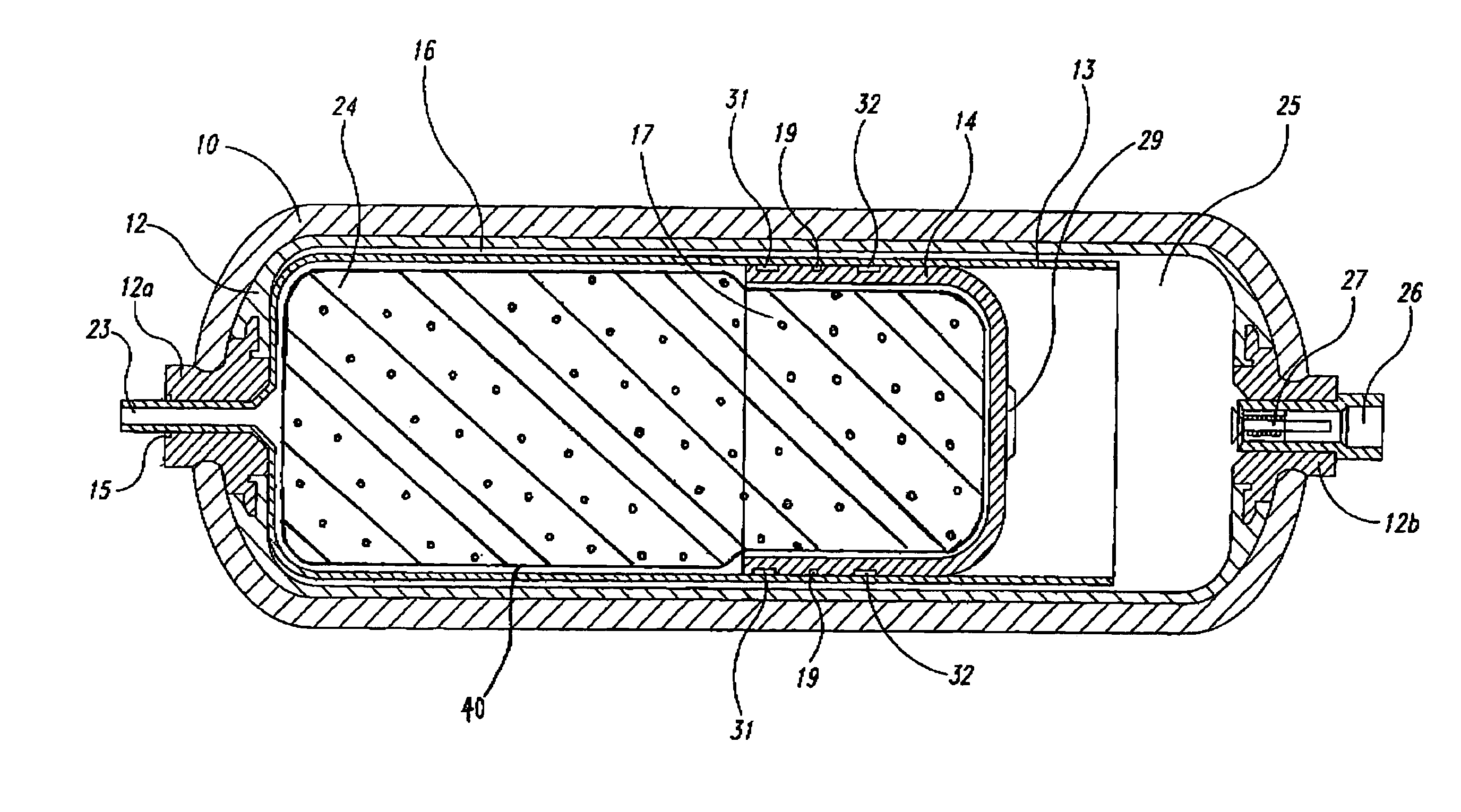

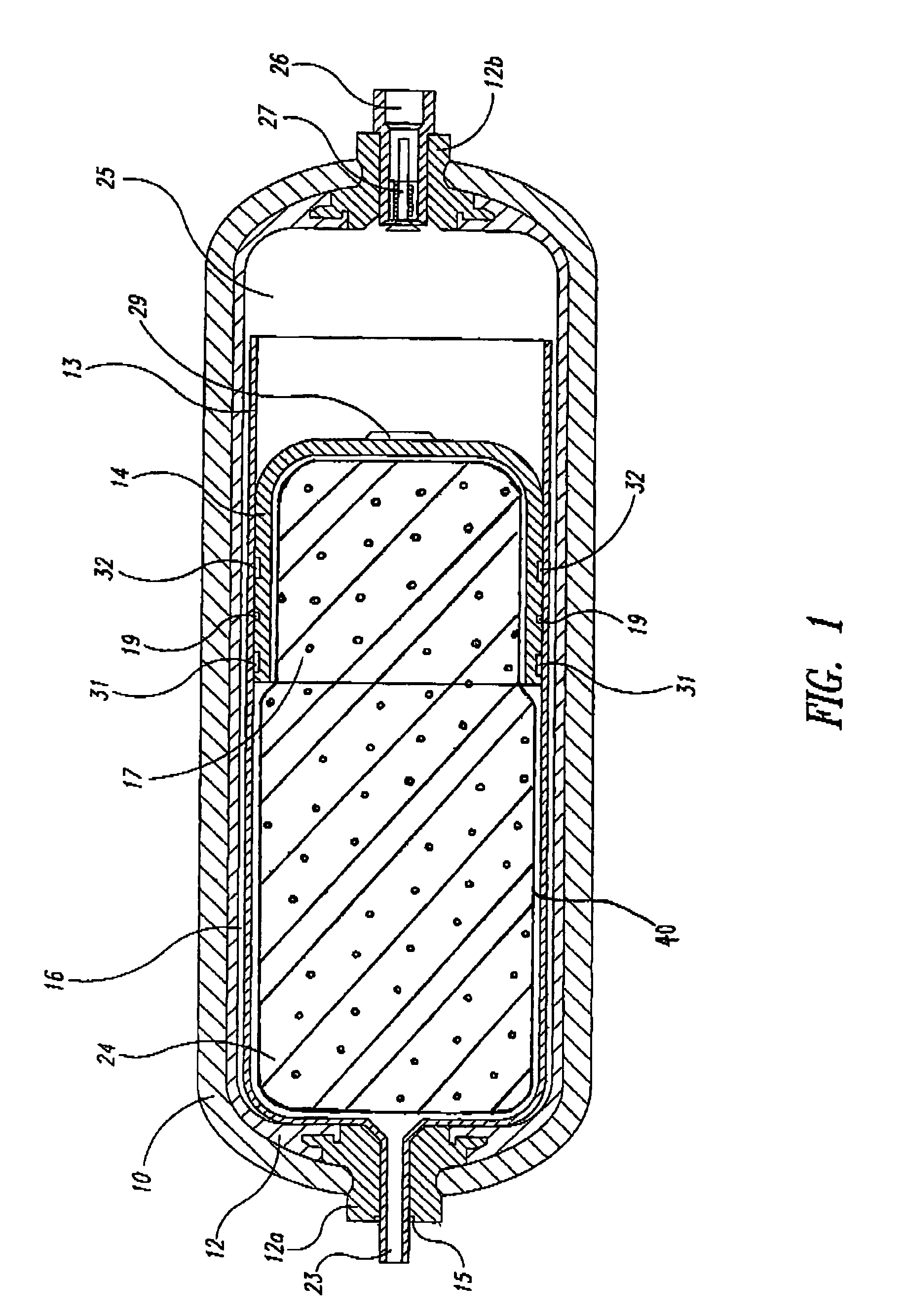

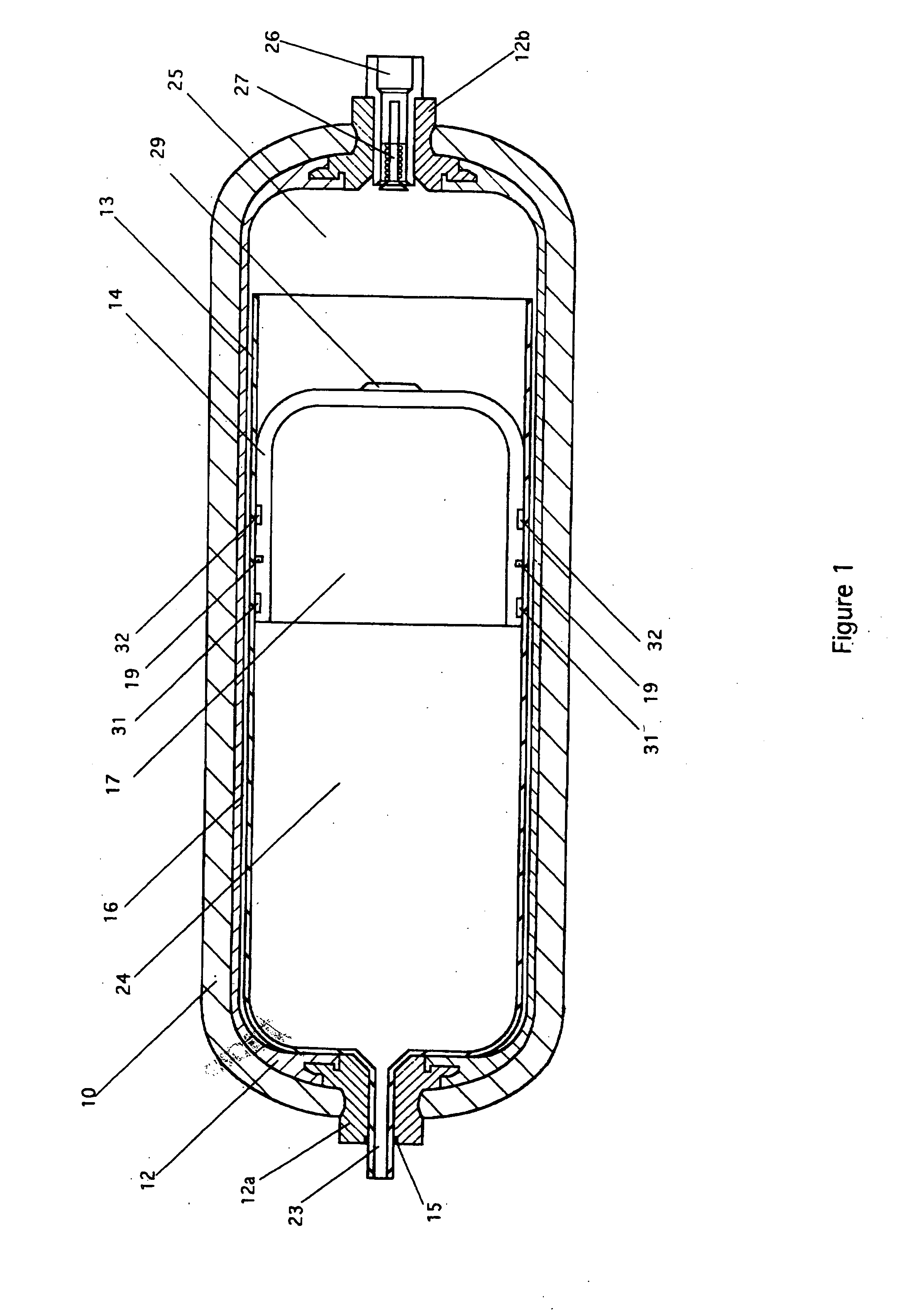

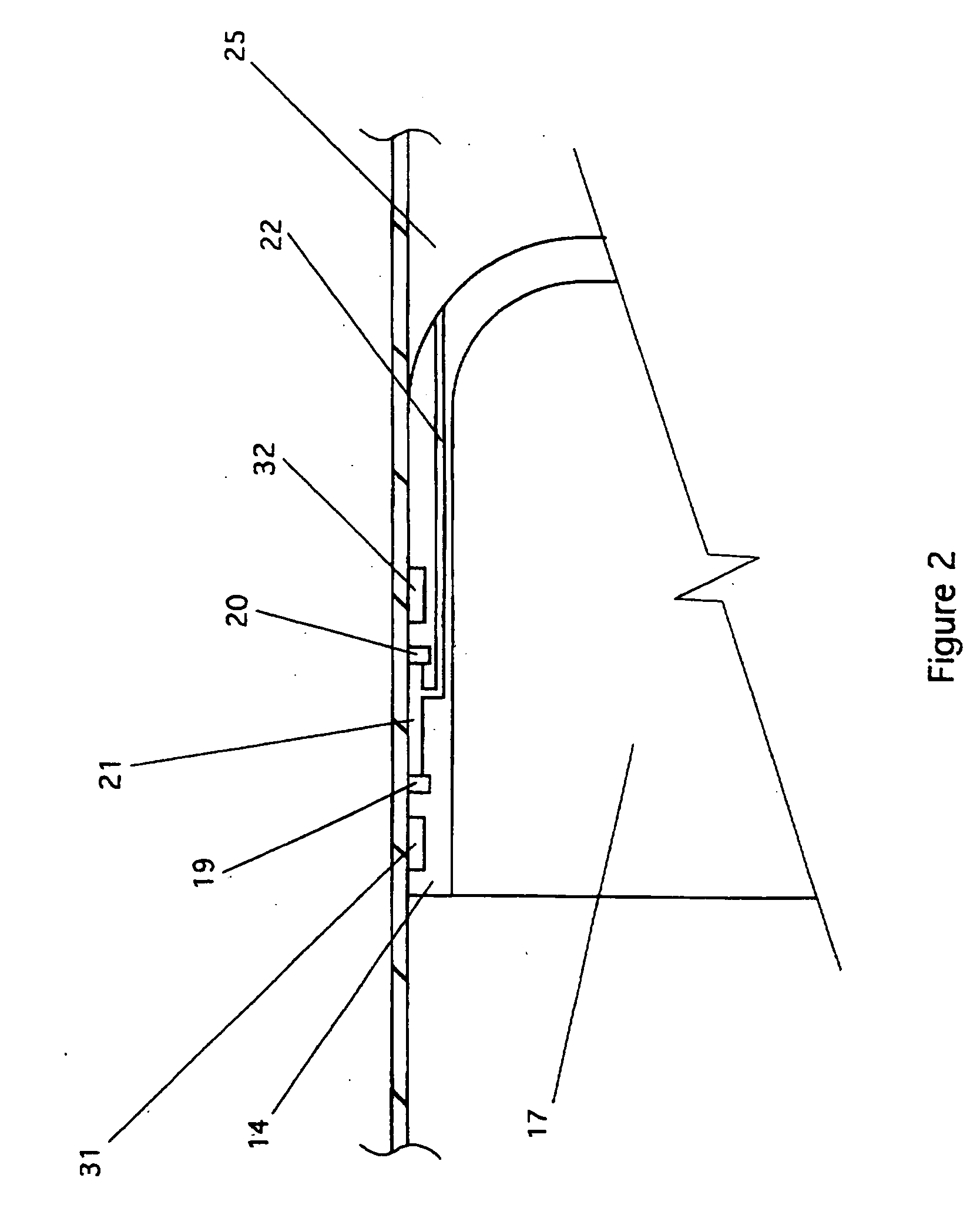

Lightweight low permeation piston-in-sleeve accumulator

Owner:UNITED STATES OF AMERICA

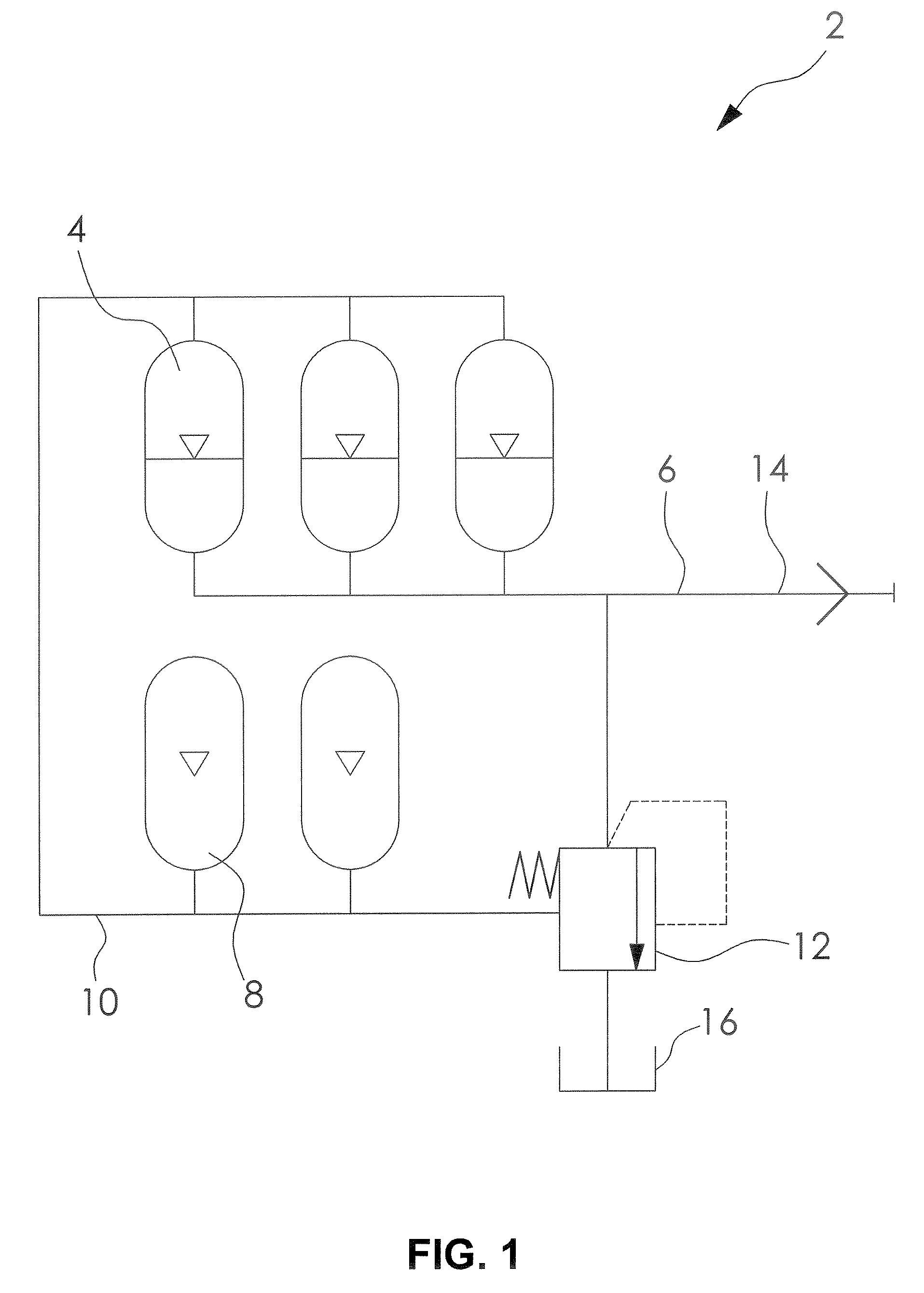

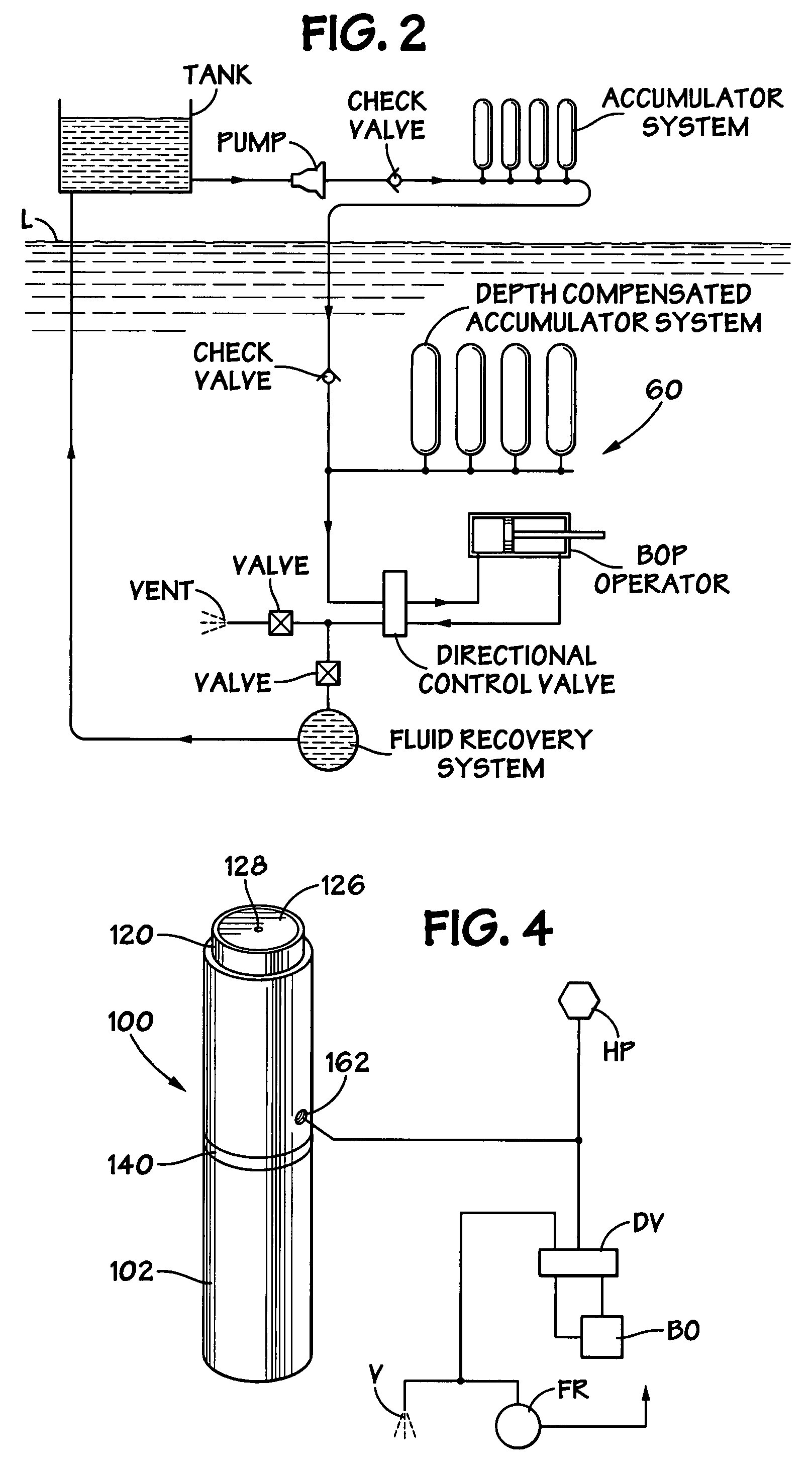

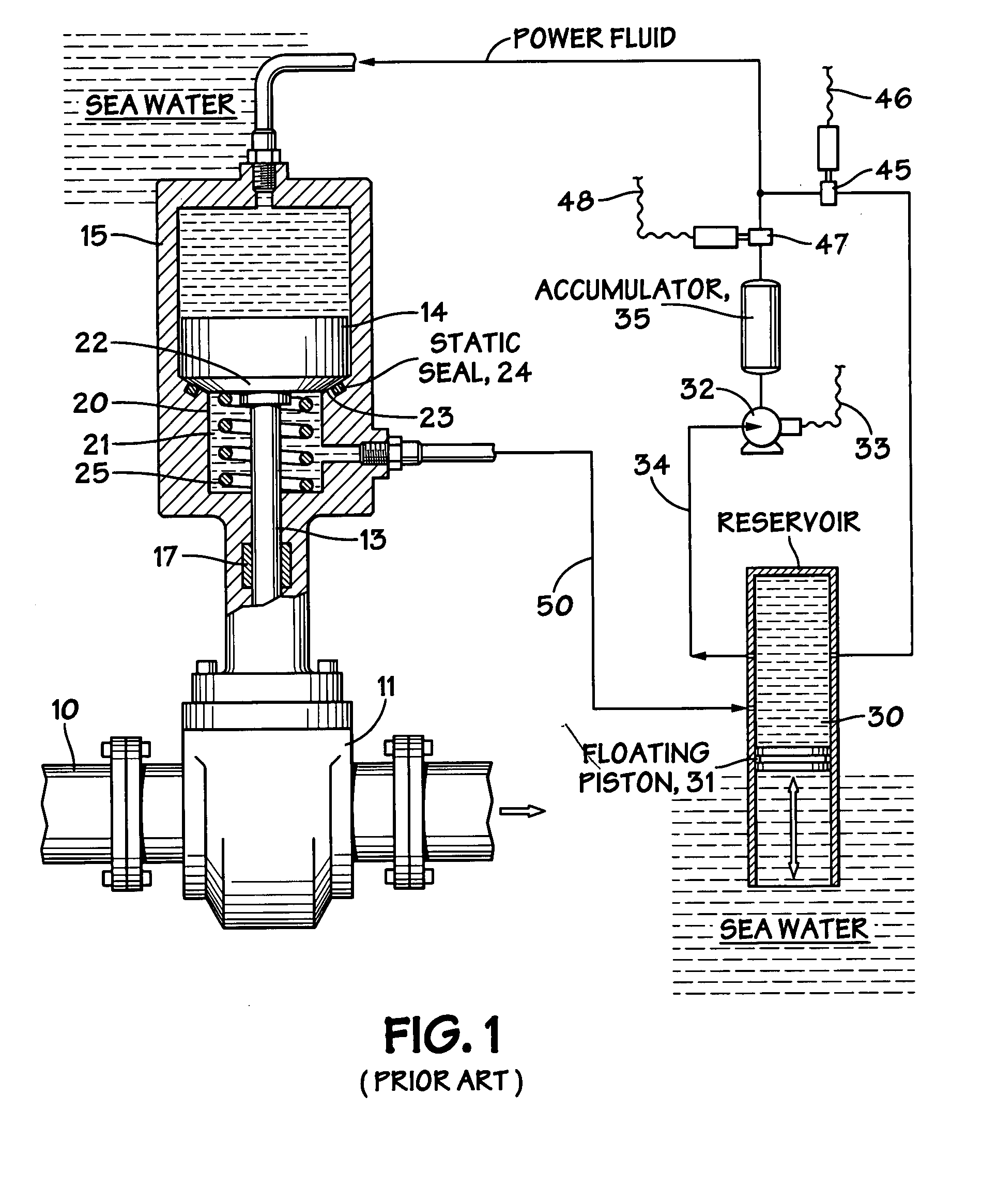

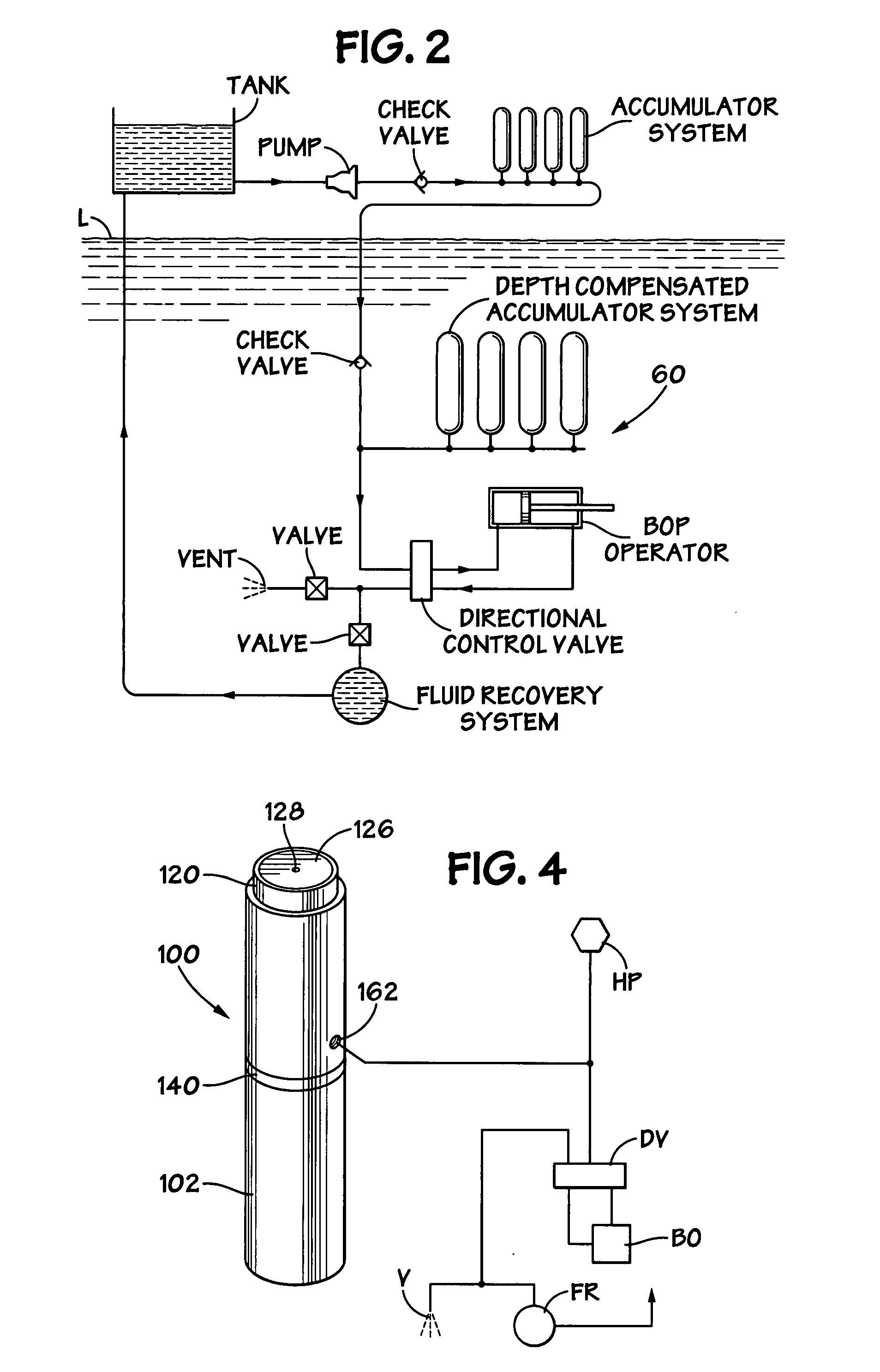

Subsea pressure accumulator systems

ActiveUS7520129B2Effective expansionReduce amountFluid couplingsActuator accumulatorsEngineeringMechanical engineering

Owner:VARCO I P INC

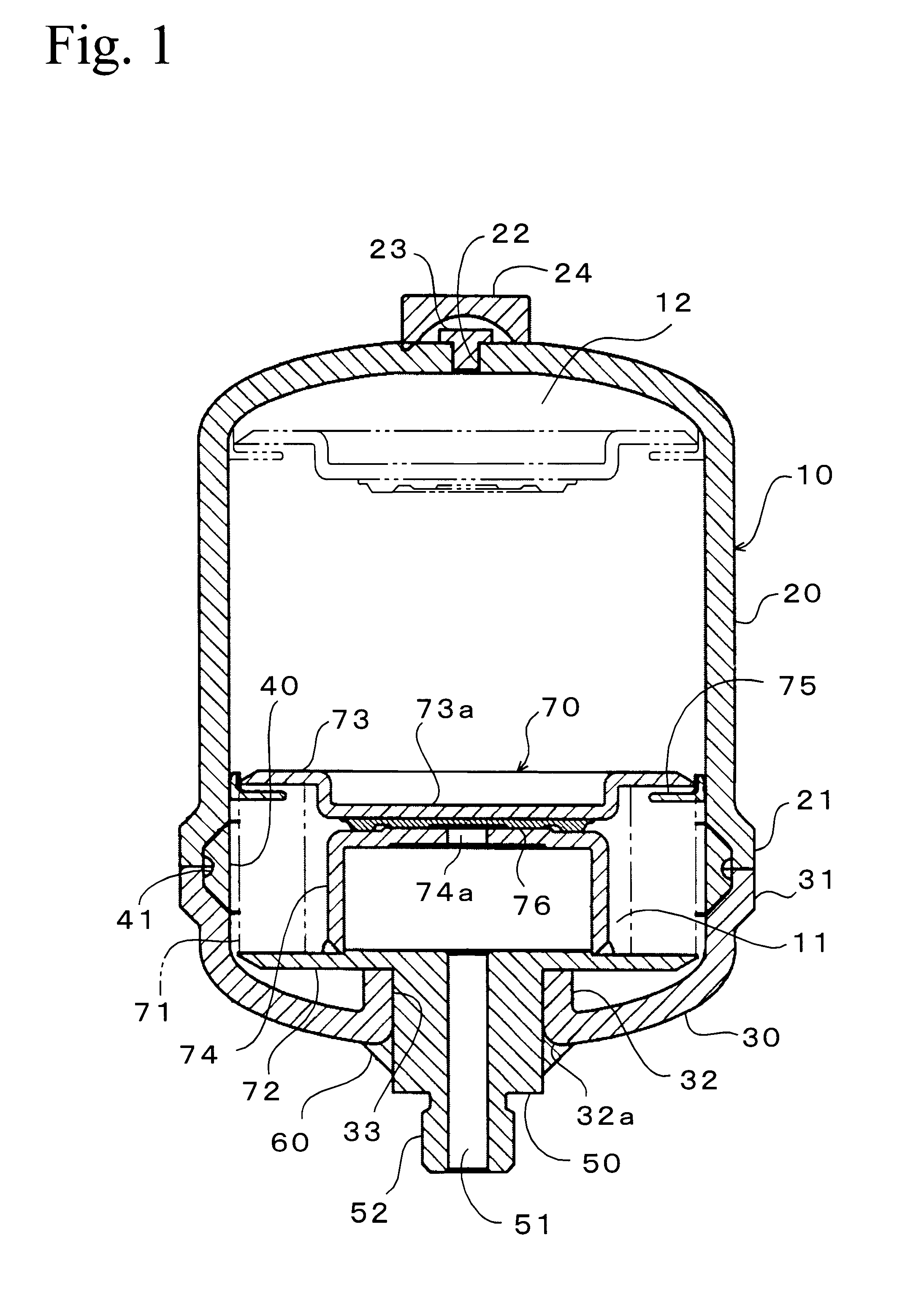

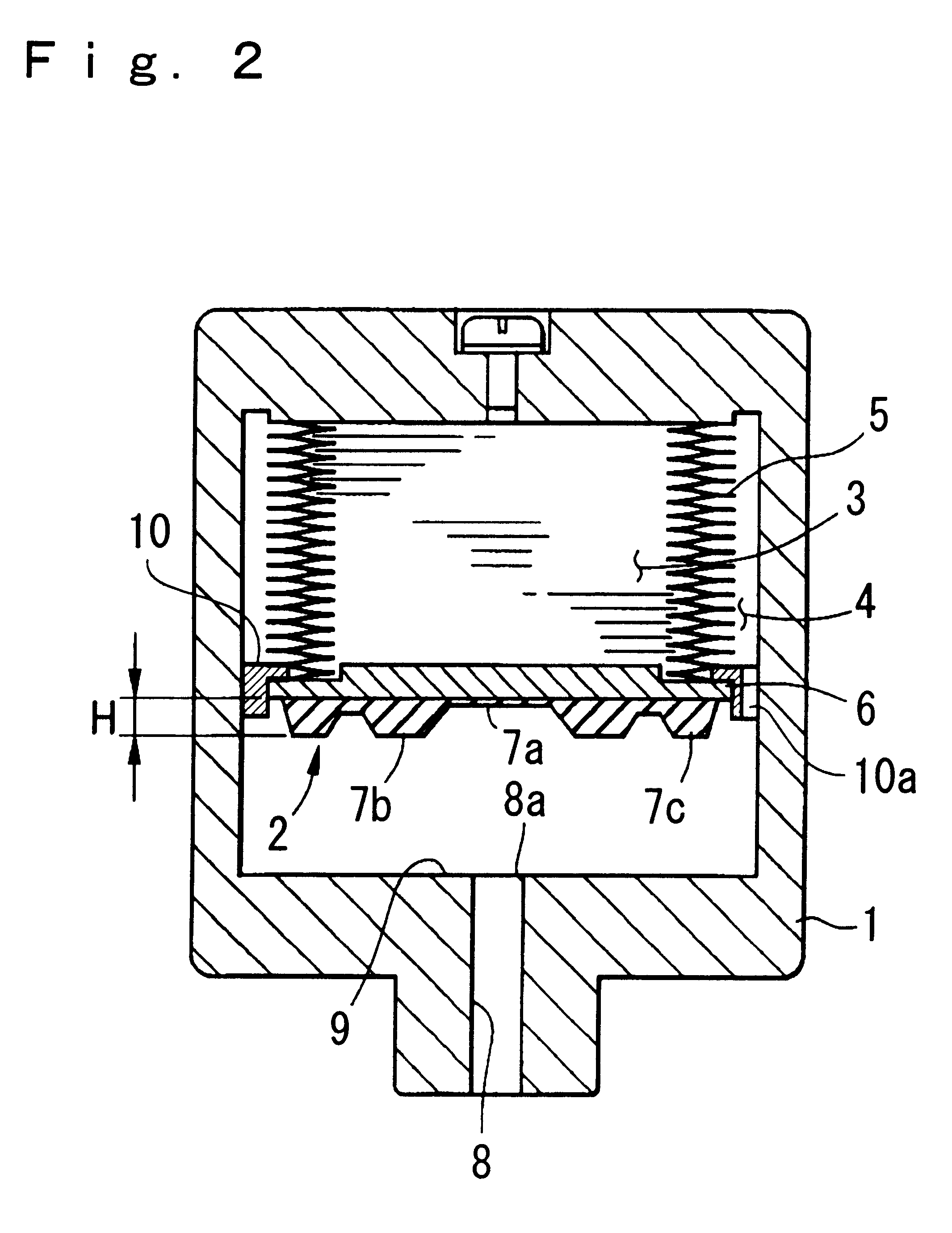

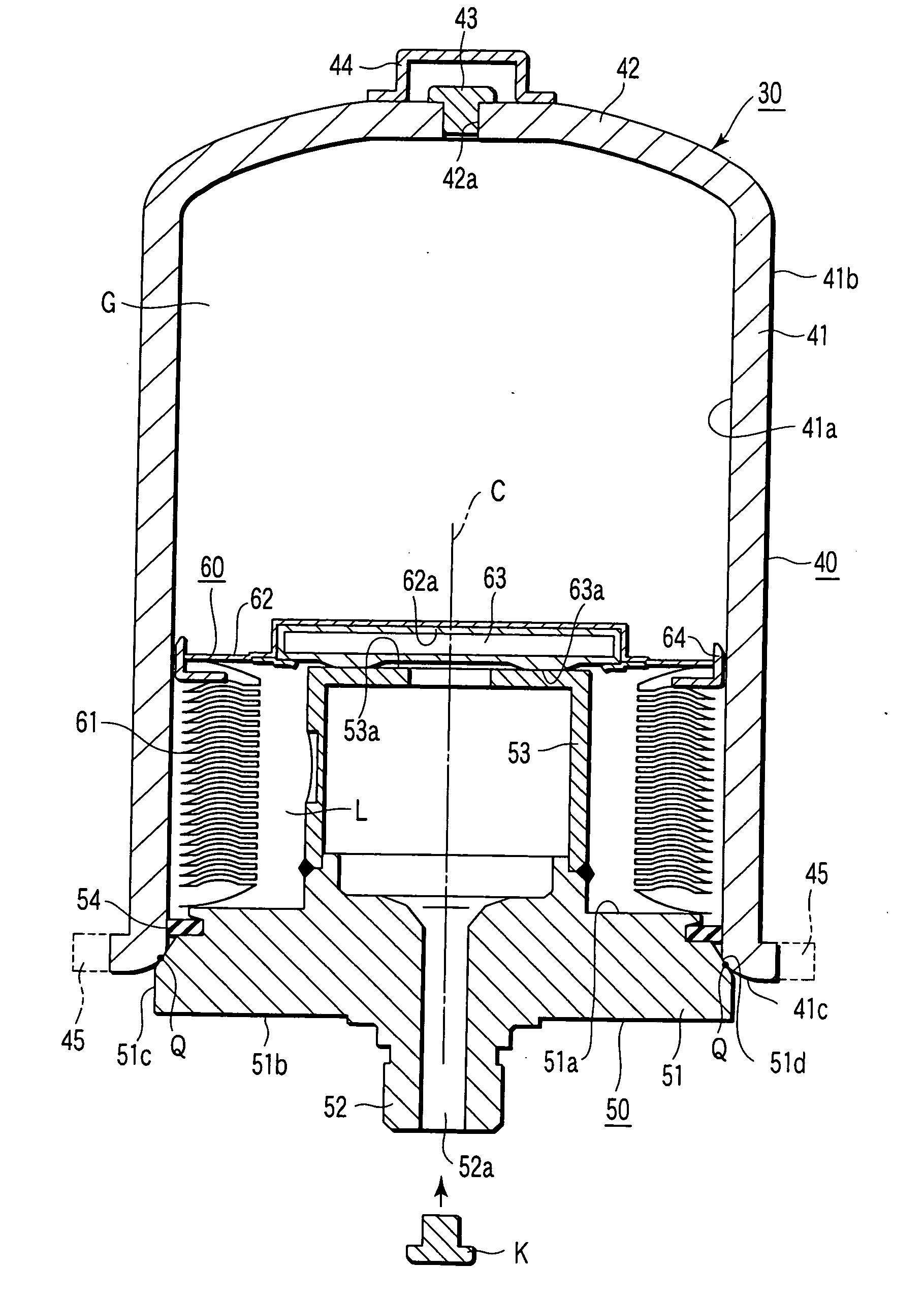

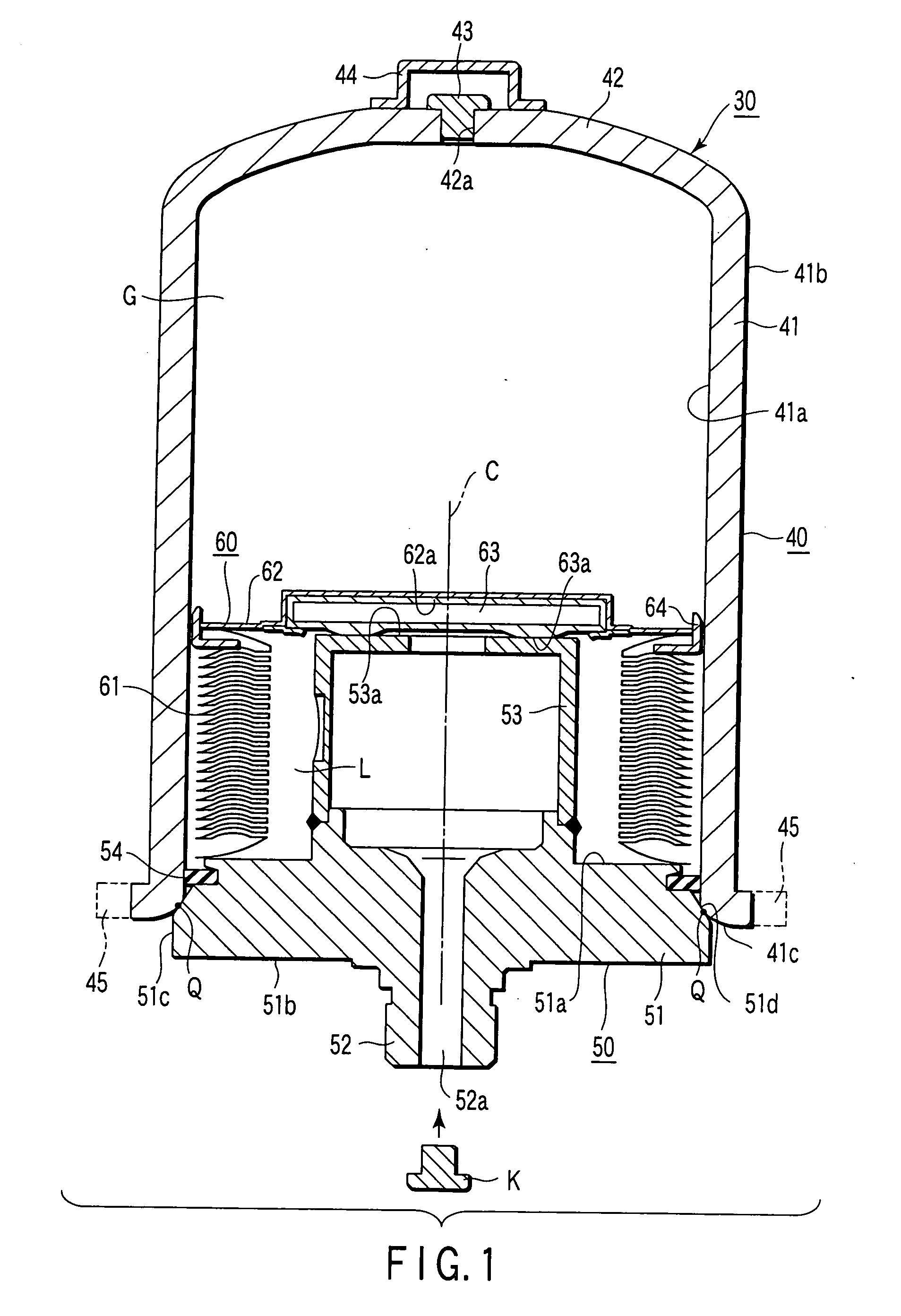

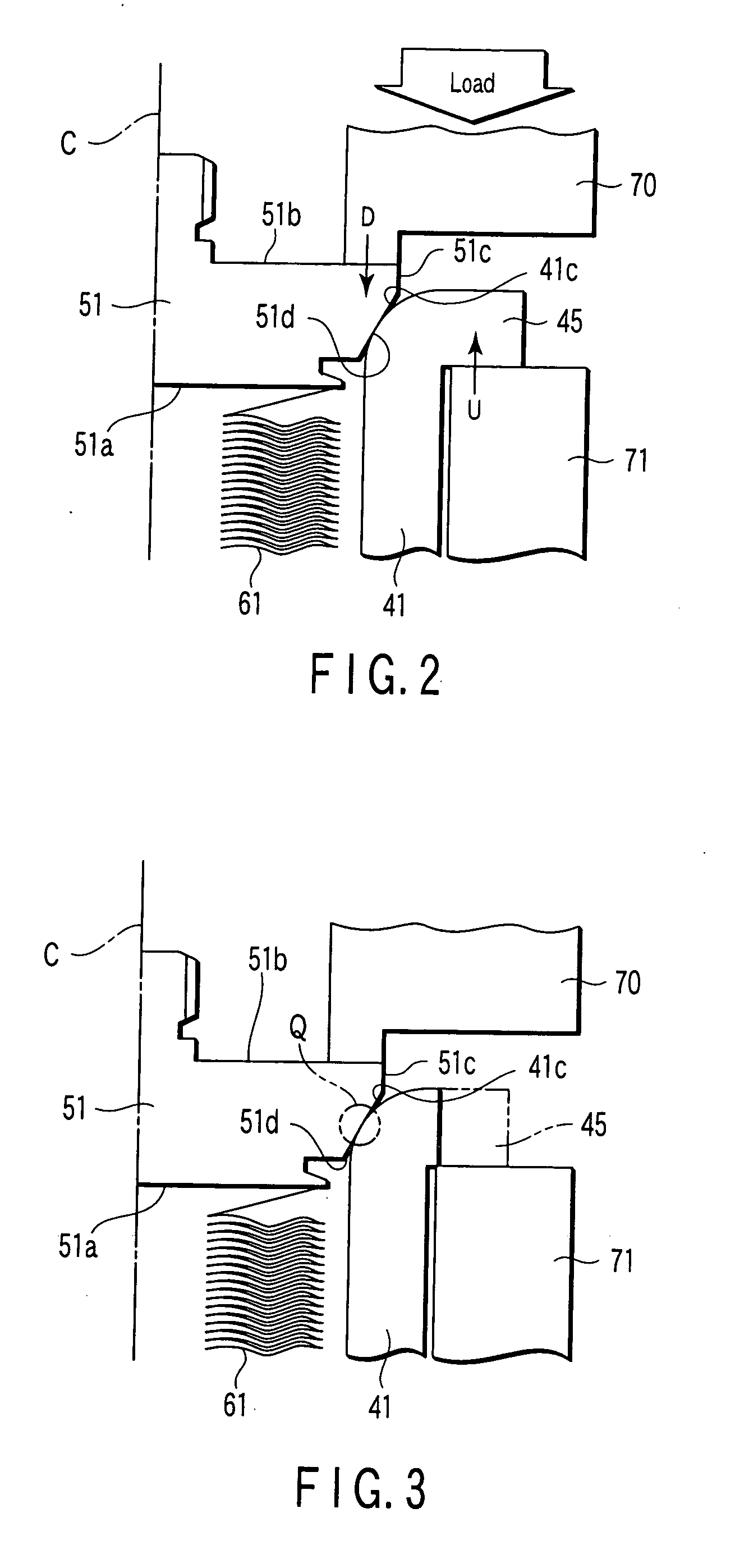

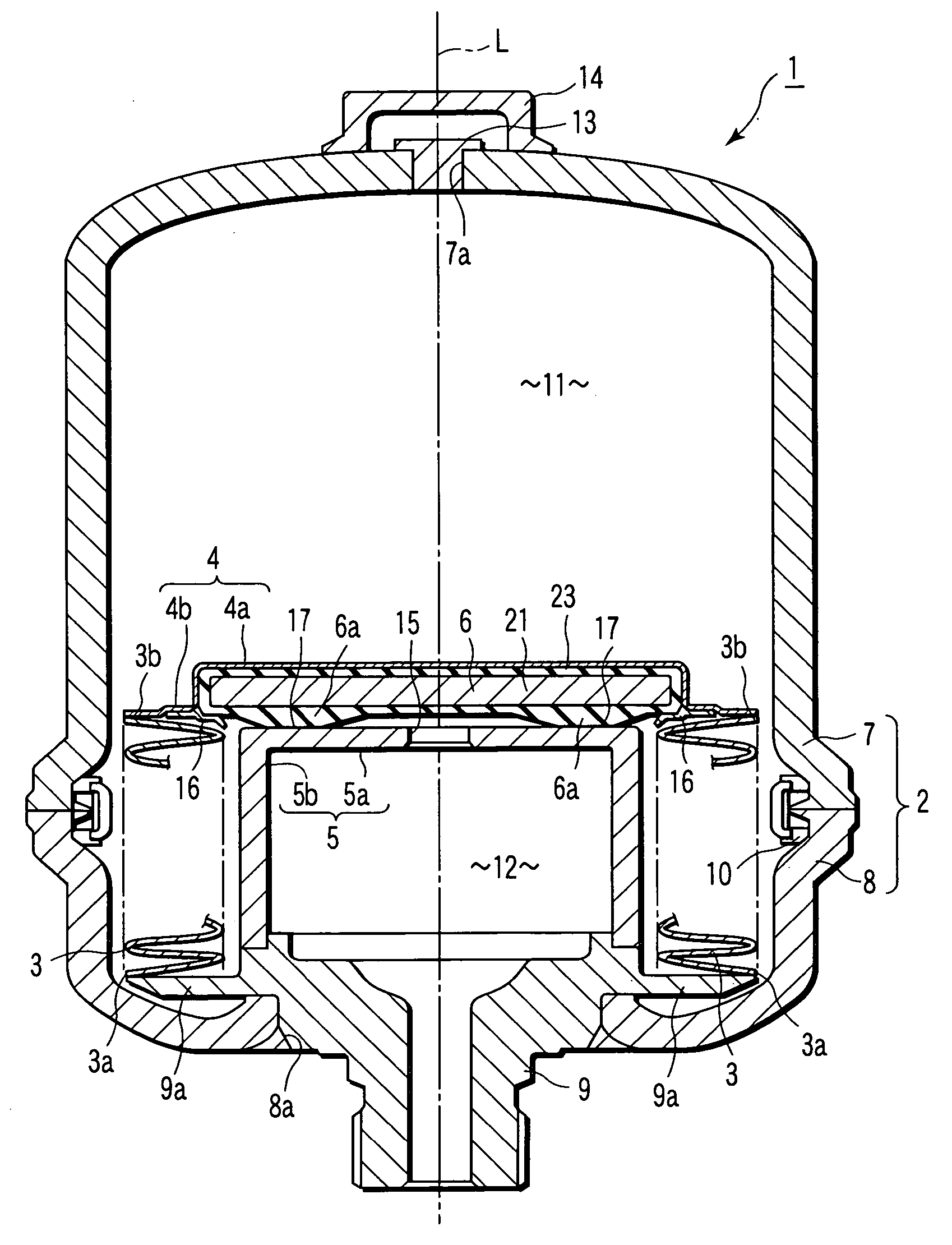

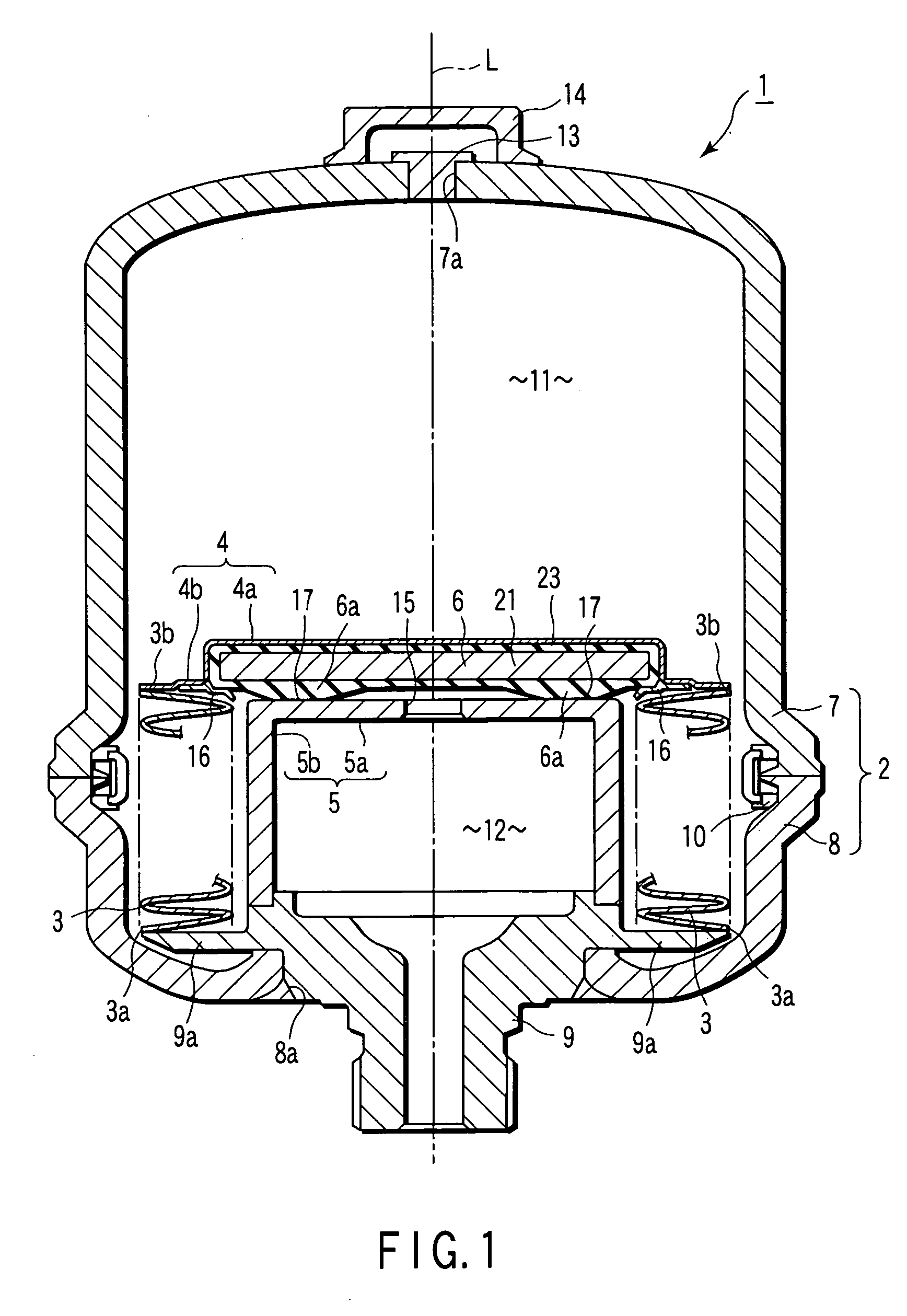

Accumulator

Disclosed is an accumulator comprising a cylindrical shell including a cylindrical portion, a partitioning member for partitioning the interior of the shell into a hydraulic chamber and a gas chamber, and a port including a hydraulic fluid flow path for communicating the exterior of the shell and the hydraulic chamber. The variation of the pressure of a hydraulic fluid flowing into the hydraulic chamber is accommodated by expansion and compression of a gas in the gas chamber according to expansion and contraction of the partitioning member. The port is approximately airtightly inserted into the cylindrical portion of the shell, and is welded to an outer circumference of the cylindrical portion by means of welding.

Owner:NHK SPRING CO LTD

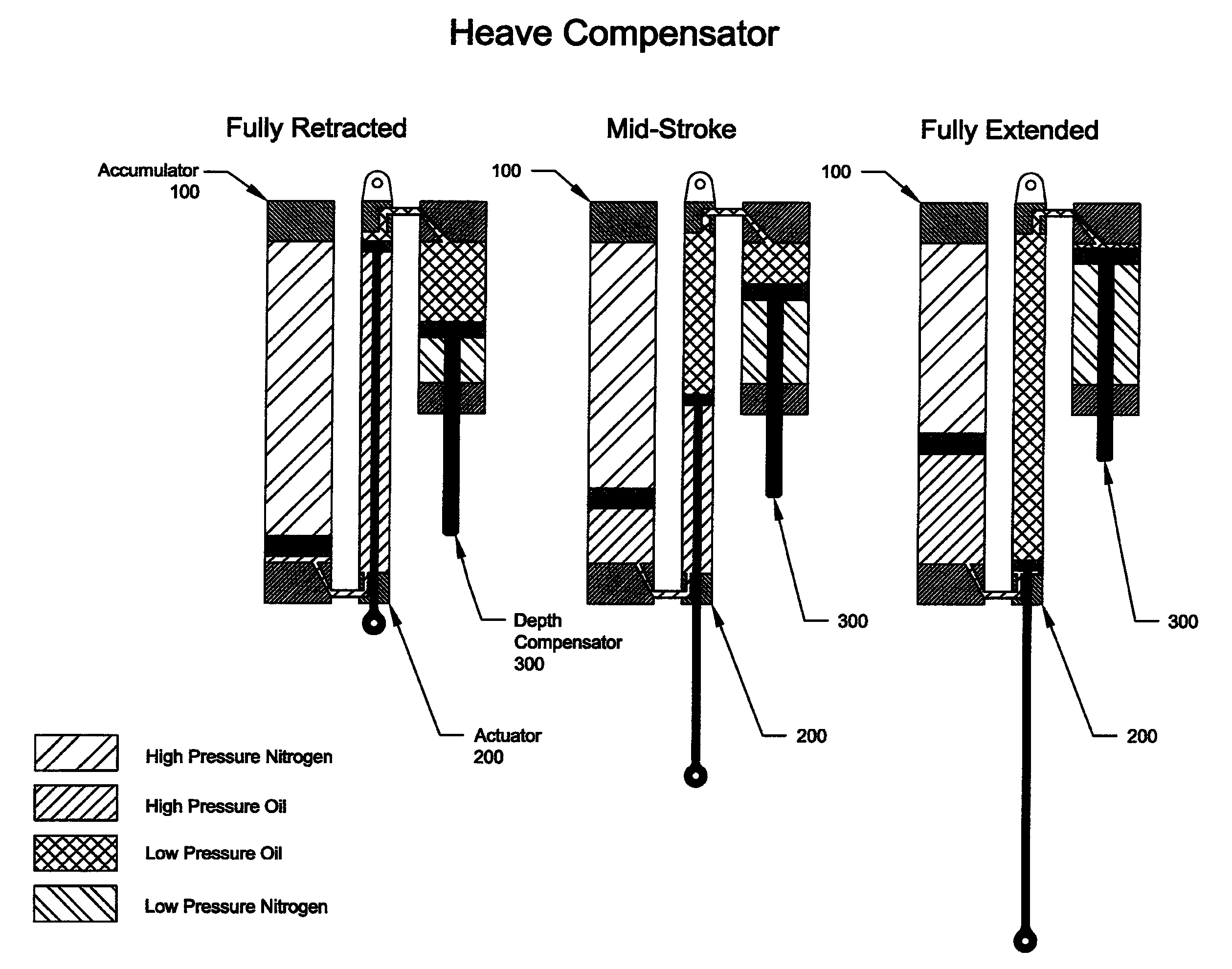

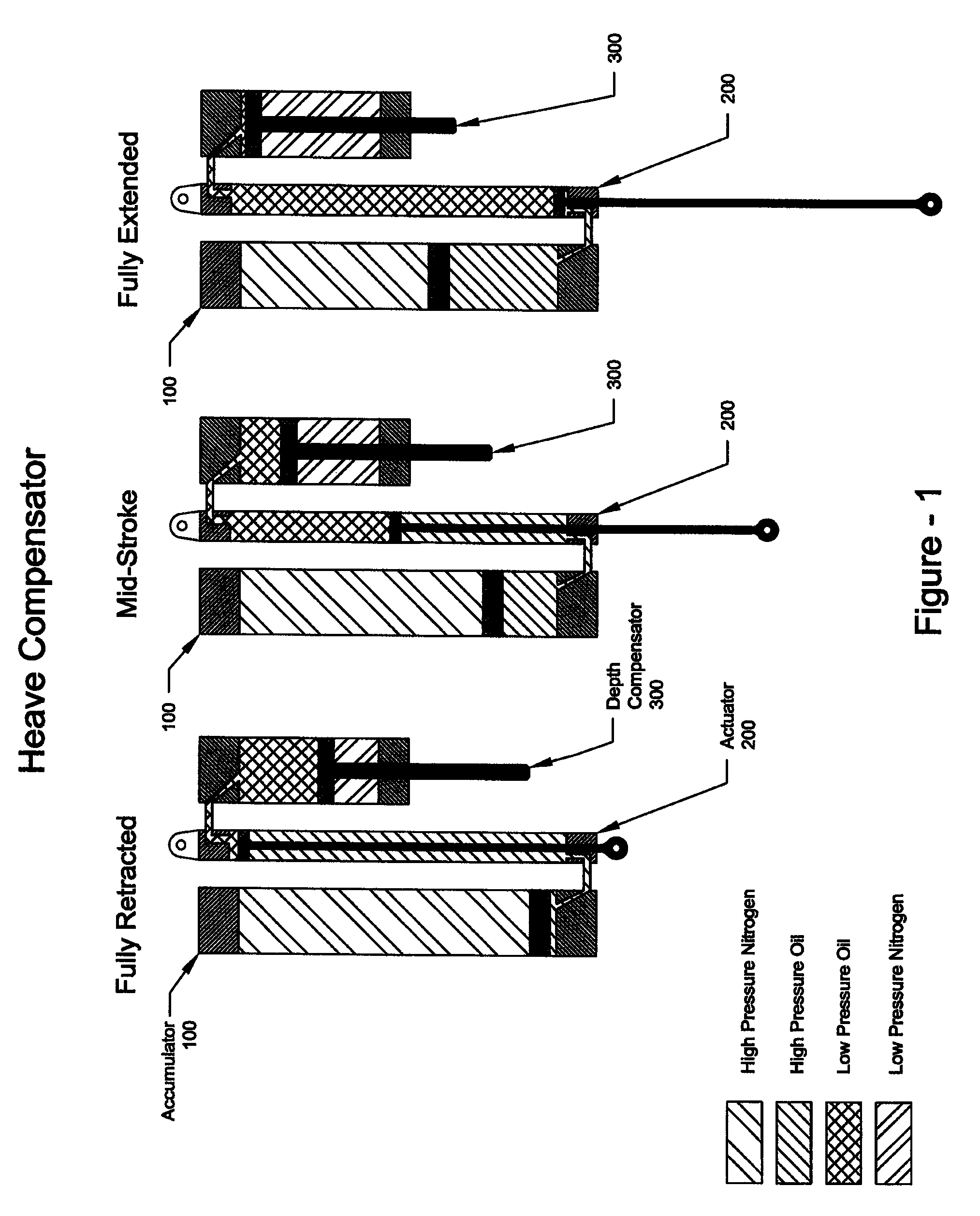

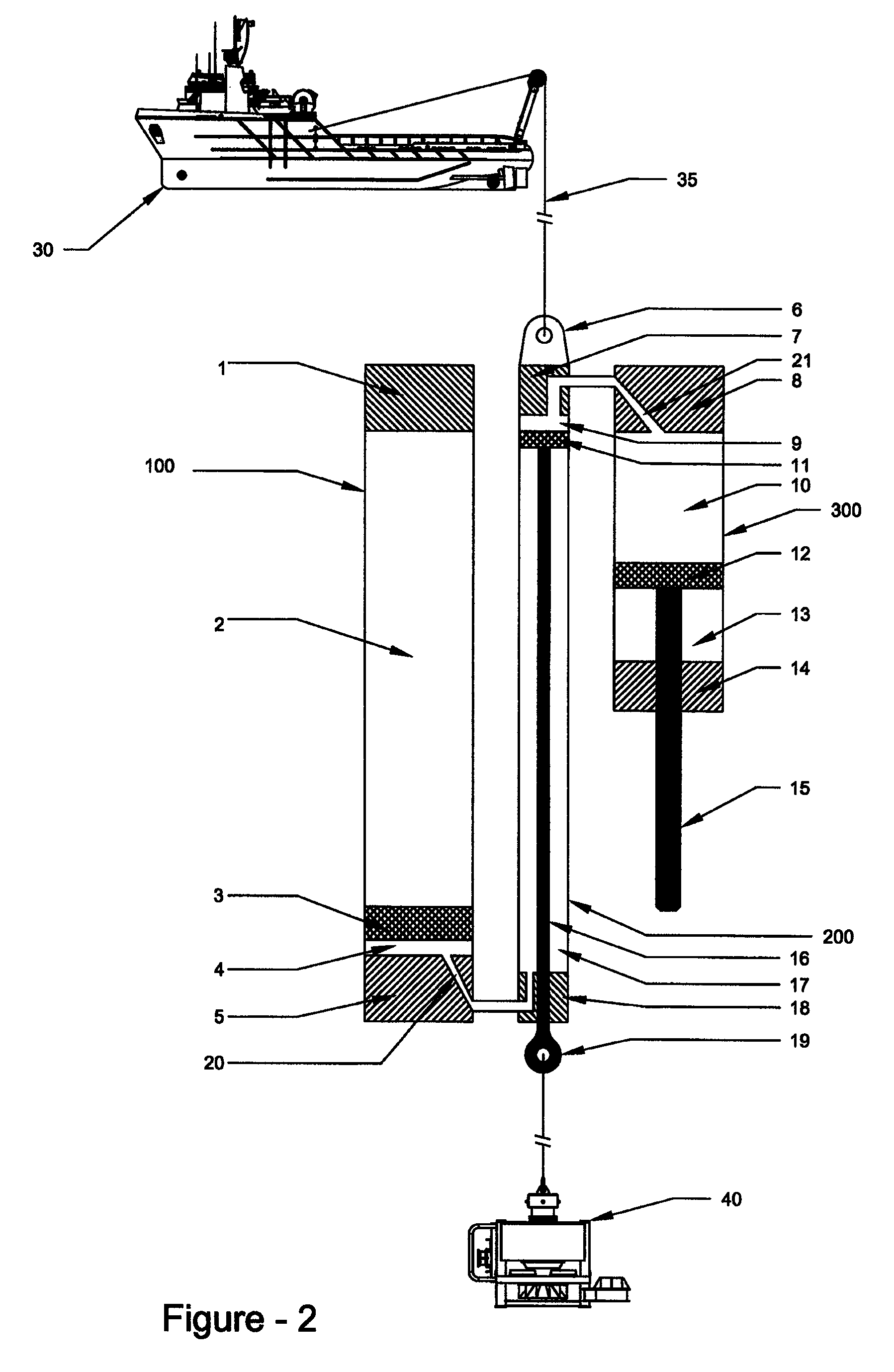

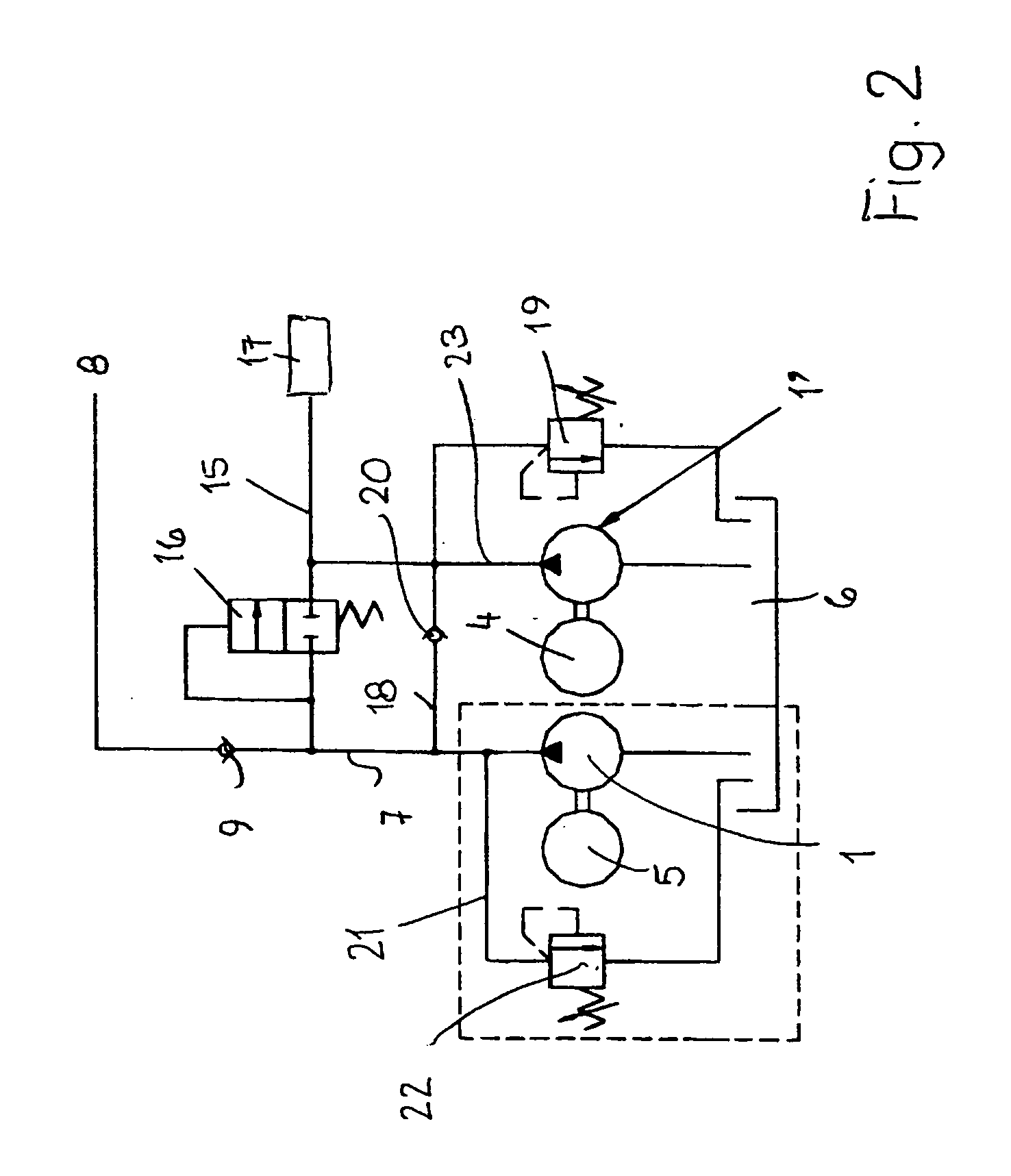

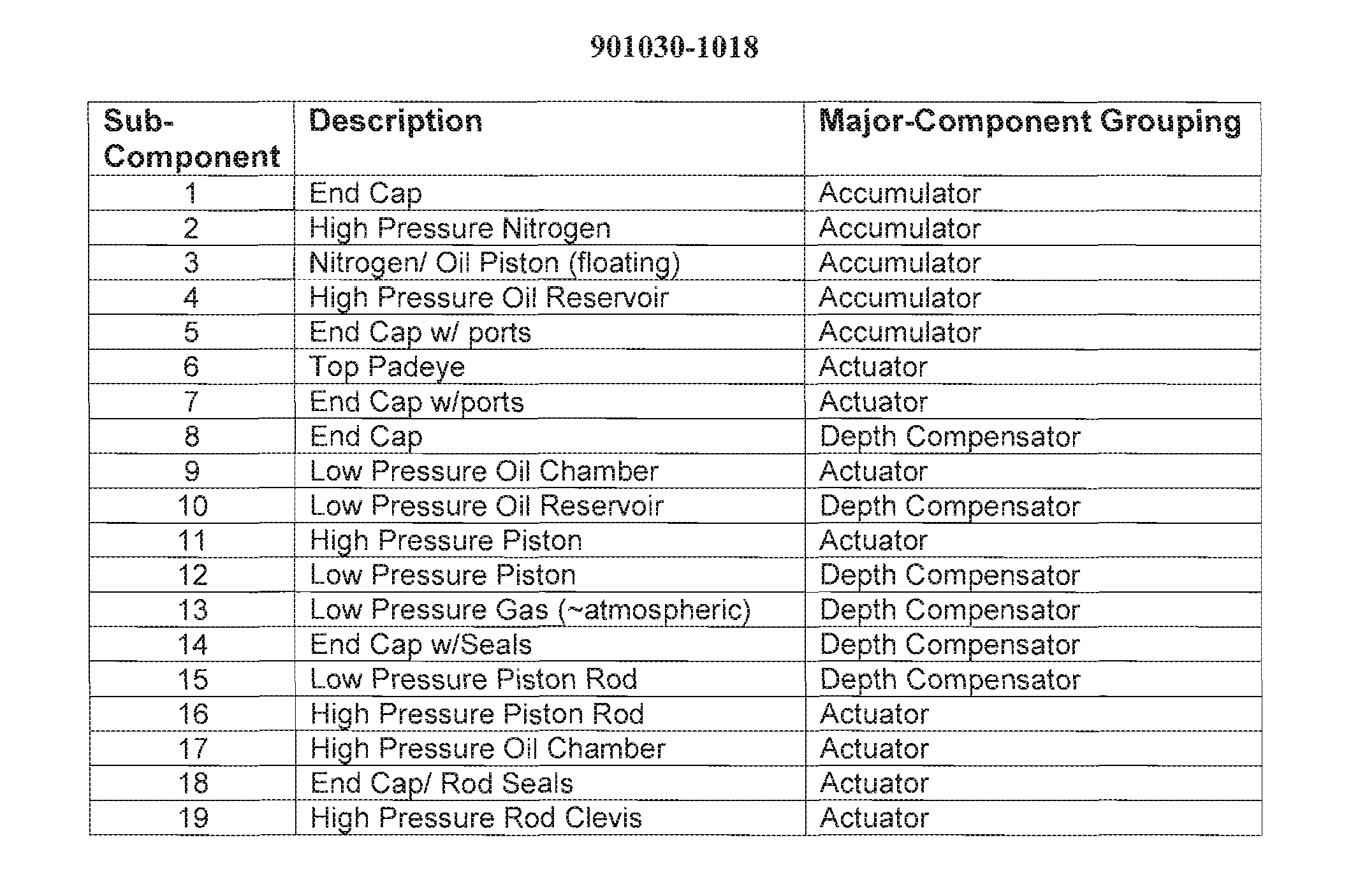

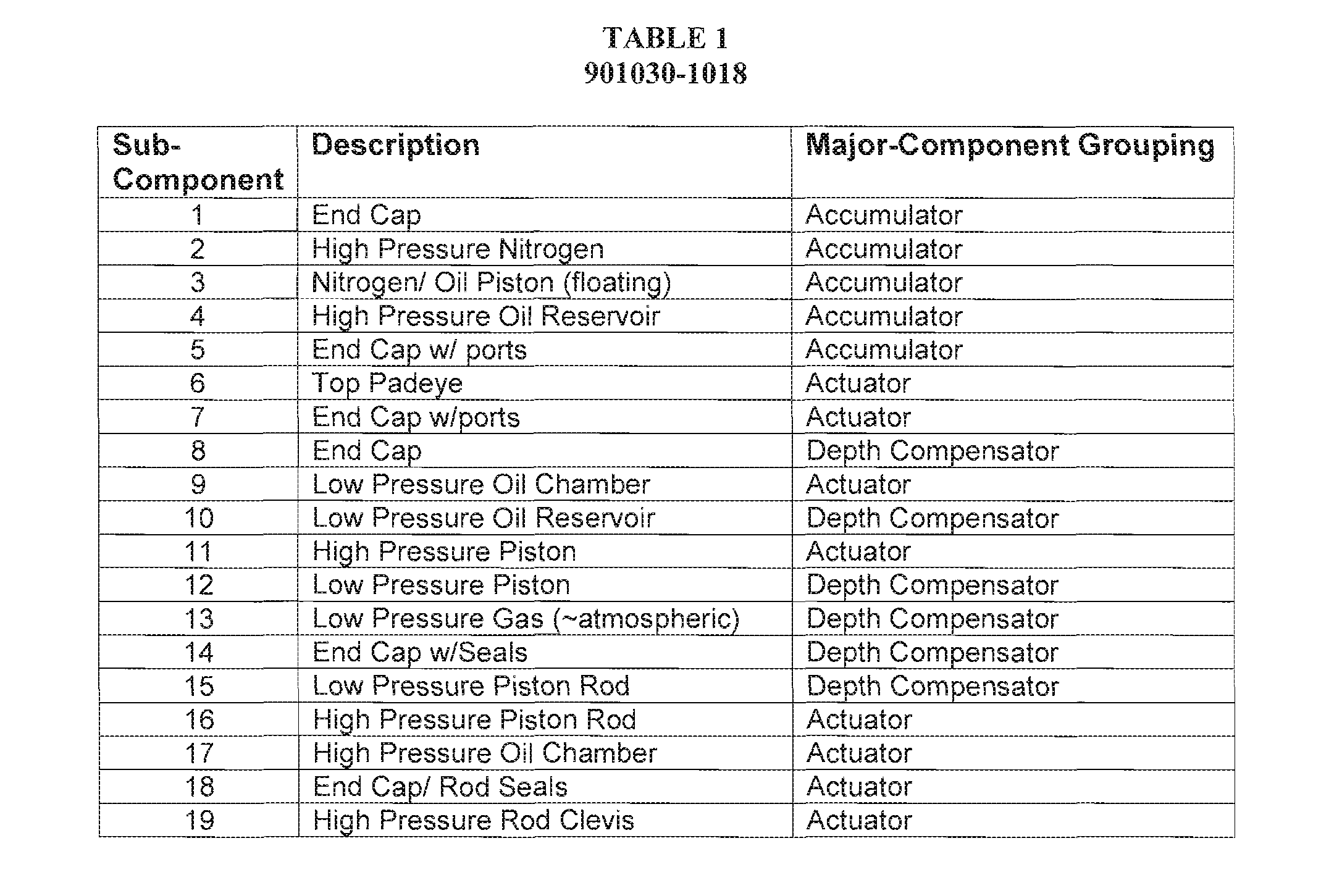

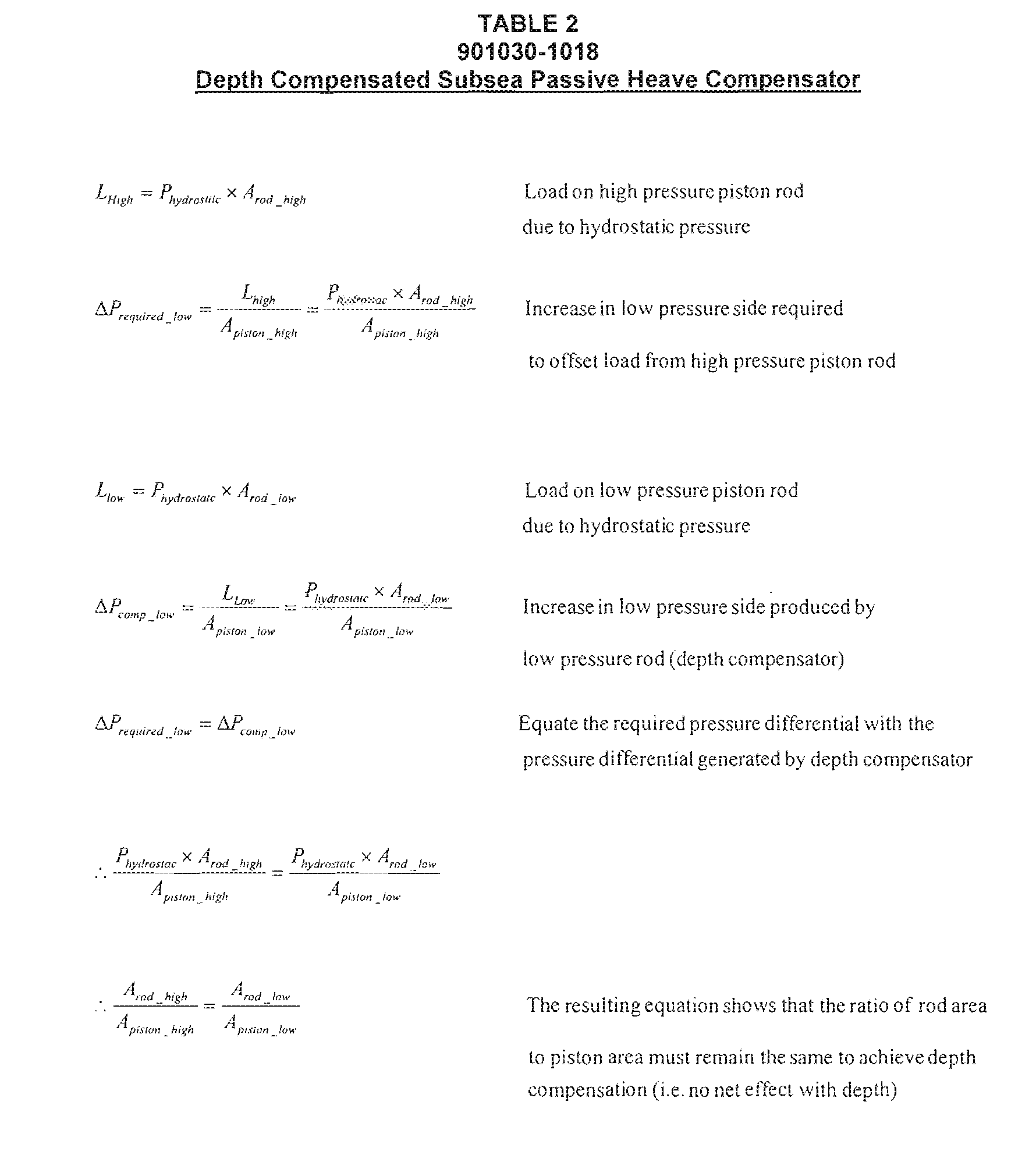

Depth compensated subsea passive heave compensator

ActiveUS7934561B2Mitigate/eliminate the depth effectEliminate the effects ofDrilling rodsDerricks/mastsEngineeringPiston rod

A depth compensated passive eave compensator comprises a first cylinder connected at its upper end to a vessel. A piston rod extends from a piston located within the first cylinder through the lower end thereof and is connected to subsea equipment. A second cylinder contains a compressed gas which maintains pressure beneath the piston of the first cylinder. The upper end of the first cylinder is connected to the upper end of a third cylinder having a piston mounted therein. A piston rod extending from the piston of third cylinder extends through the lower end thereof thereby applying the pressure of the sea to the piston of the third cylinder.

Owner:INTERMOOR

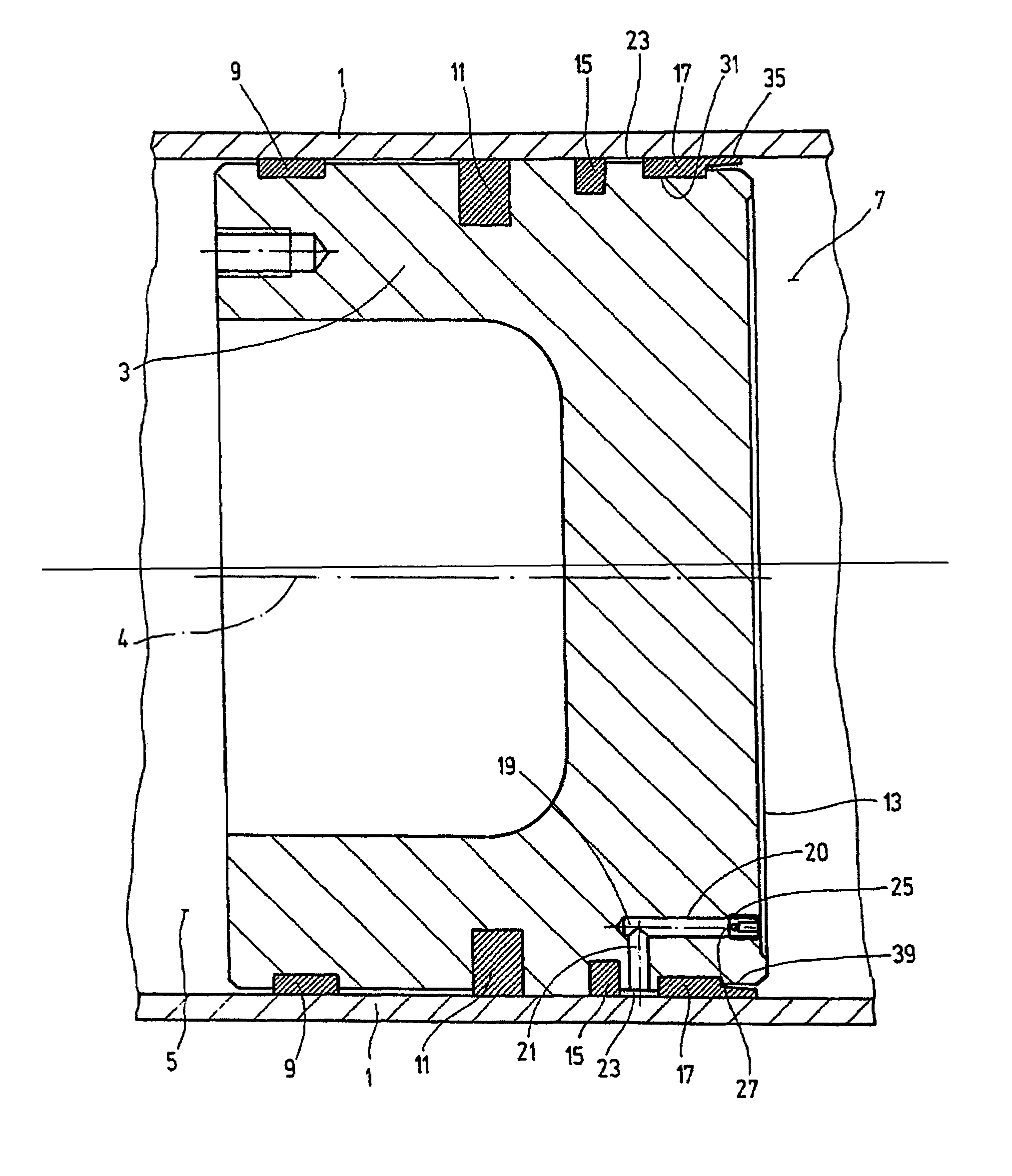

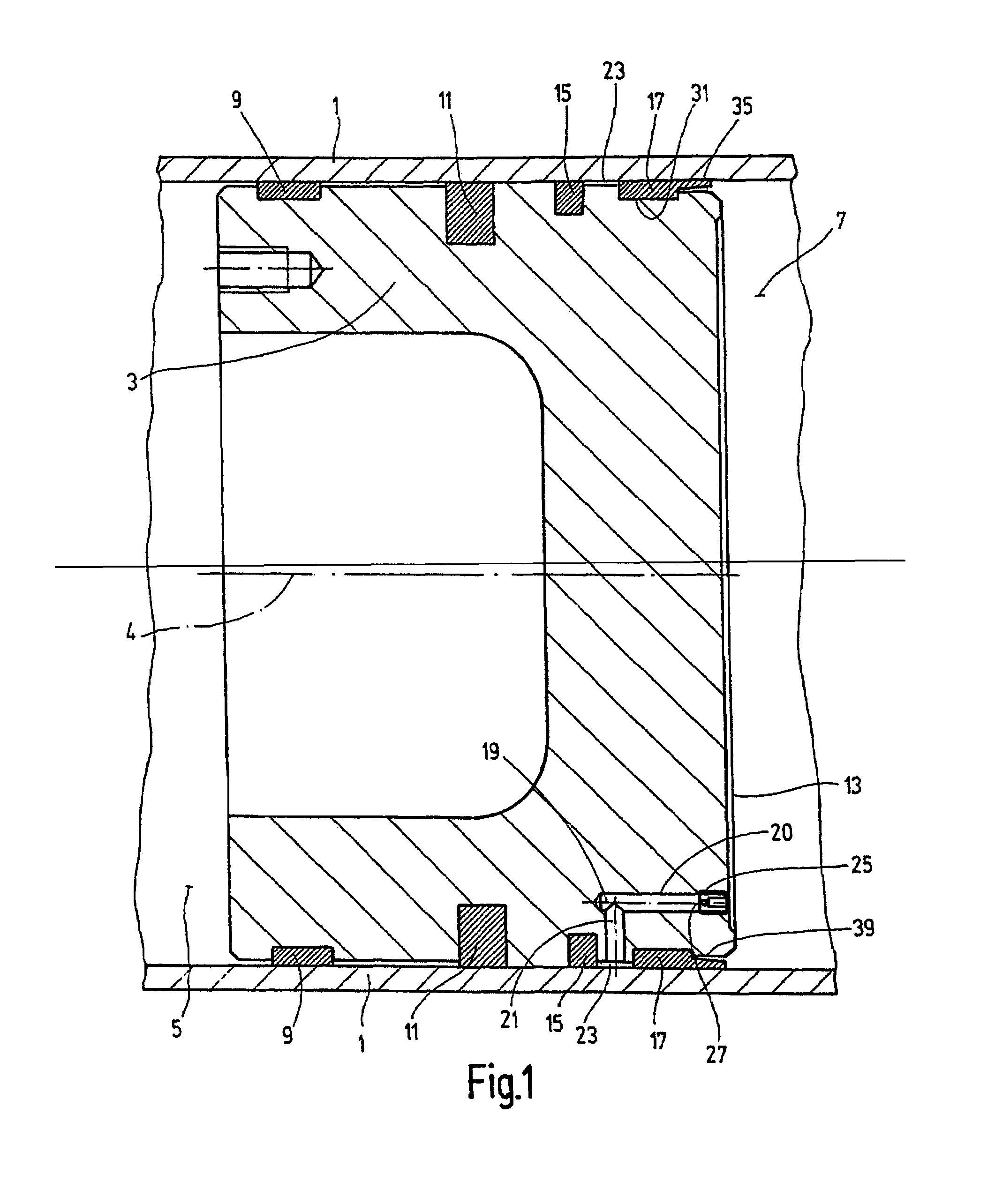

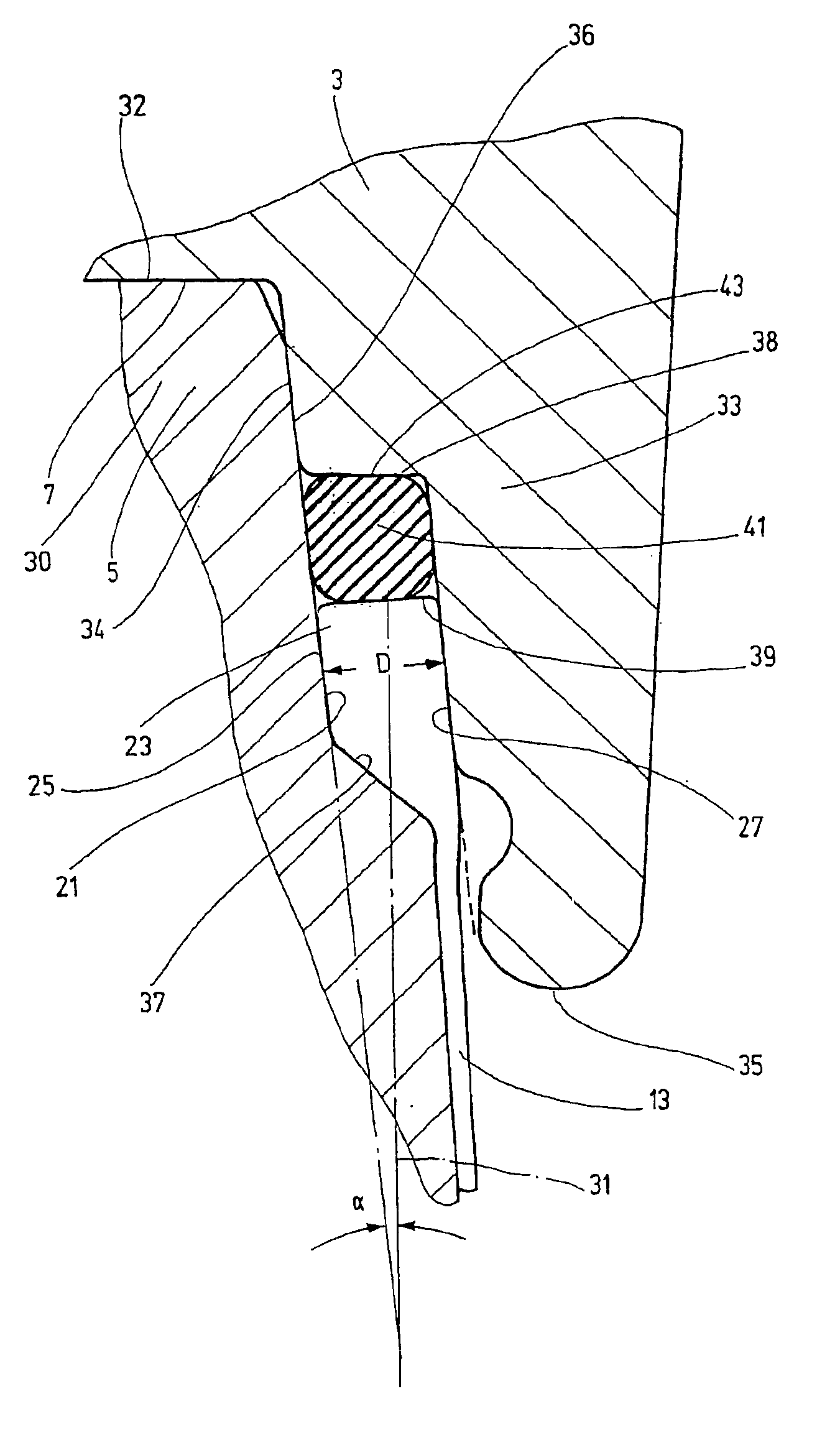

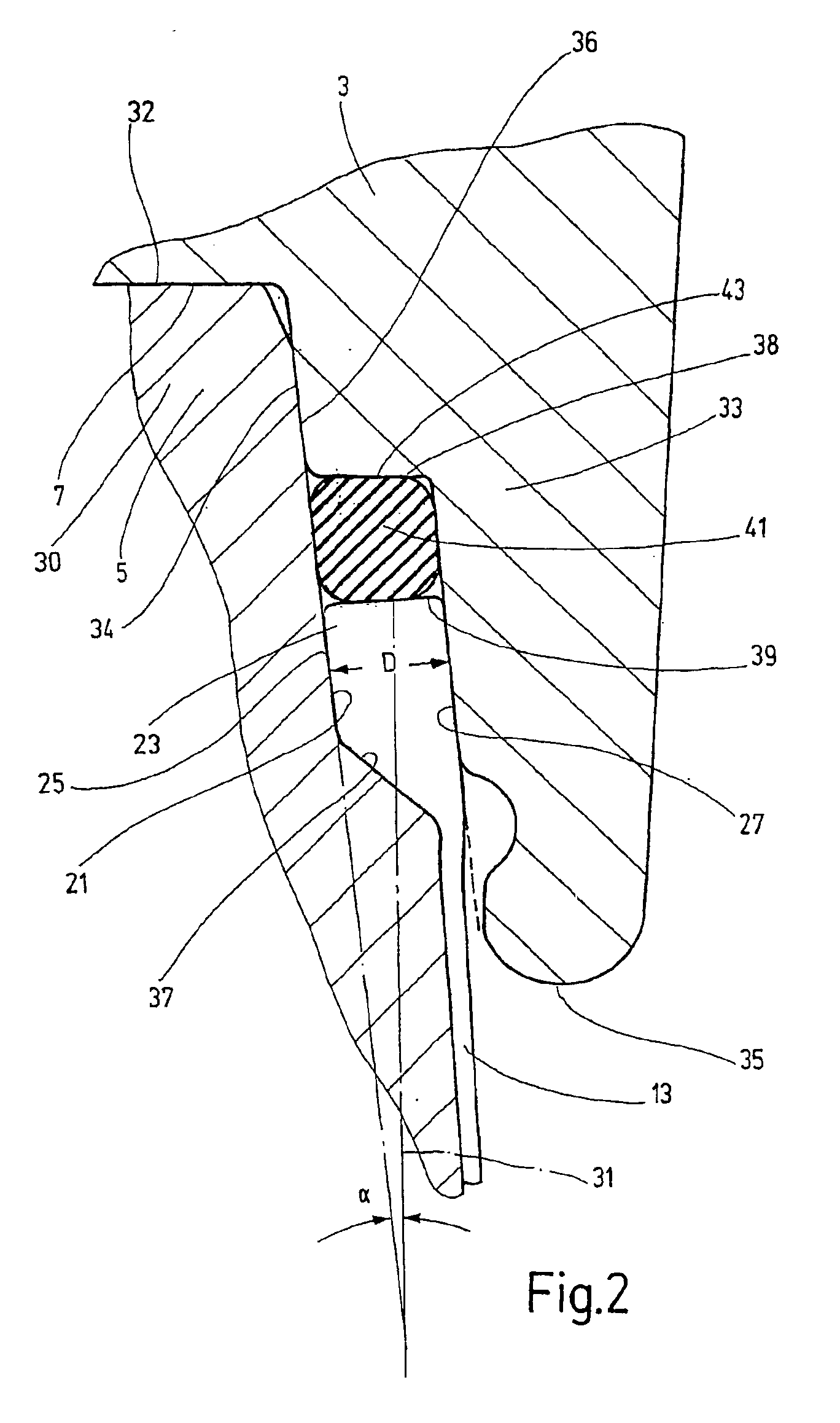

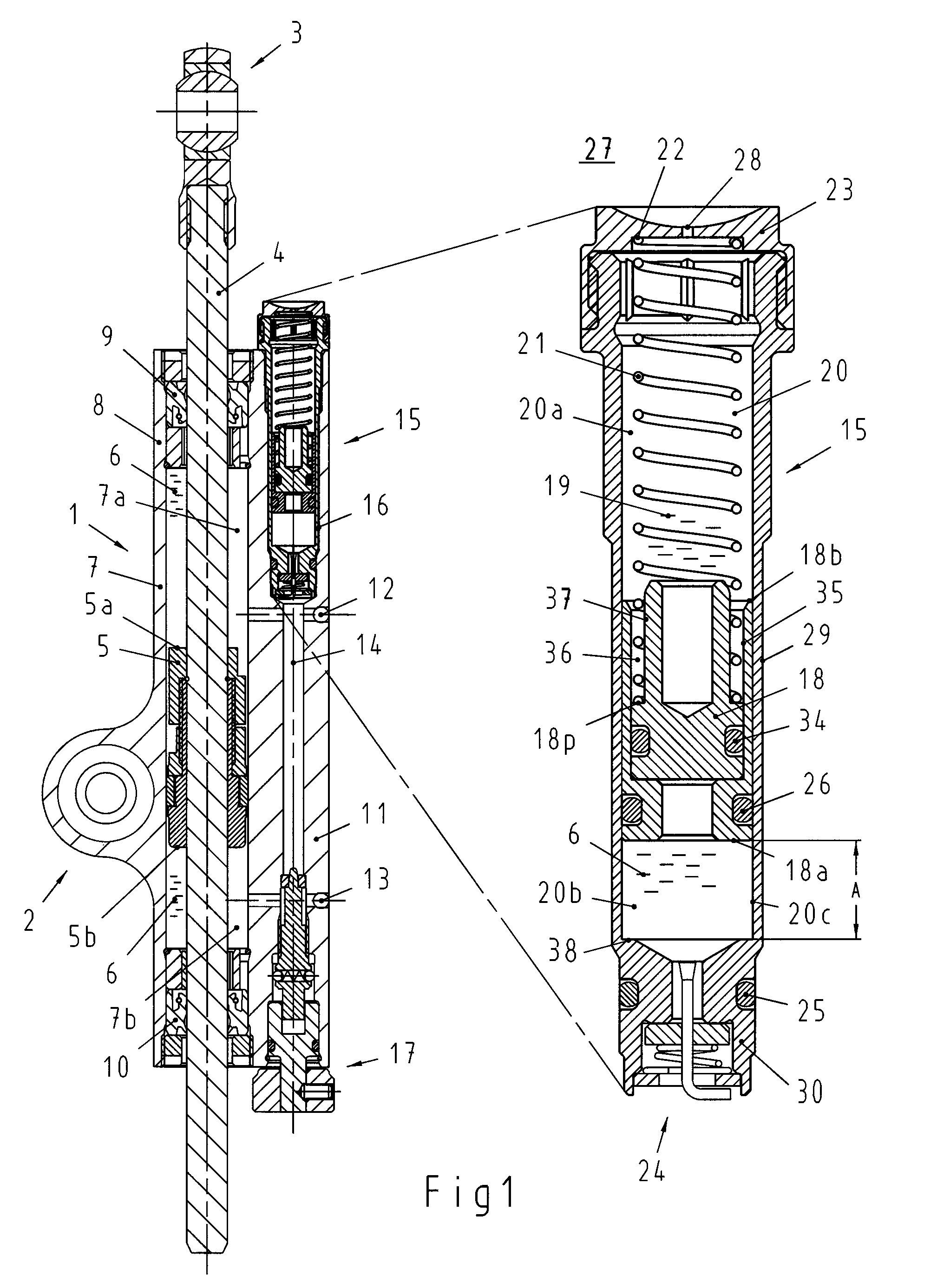

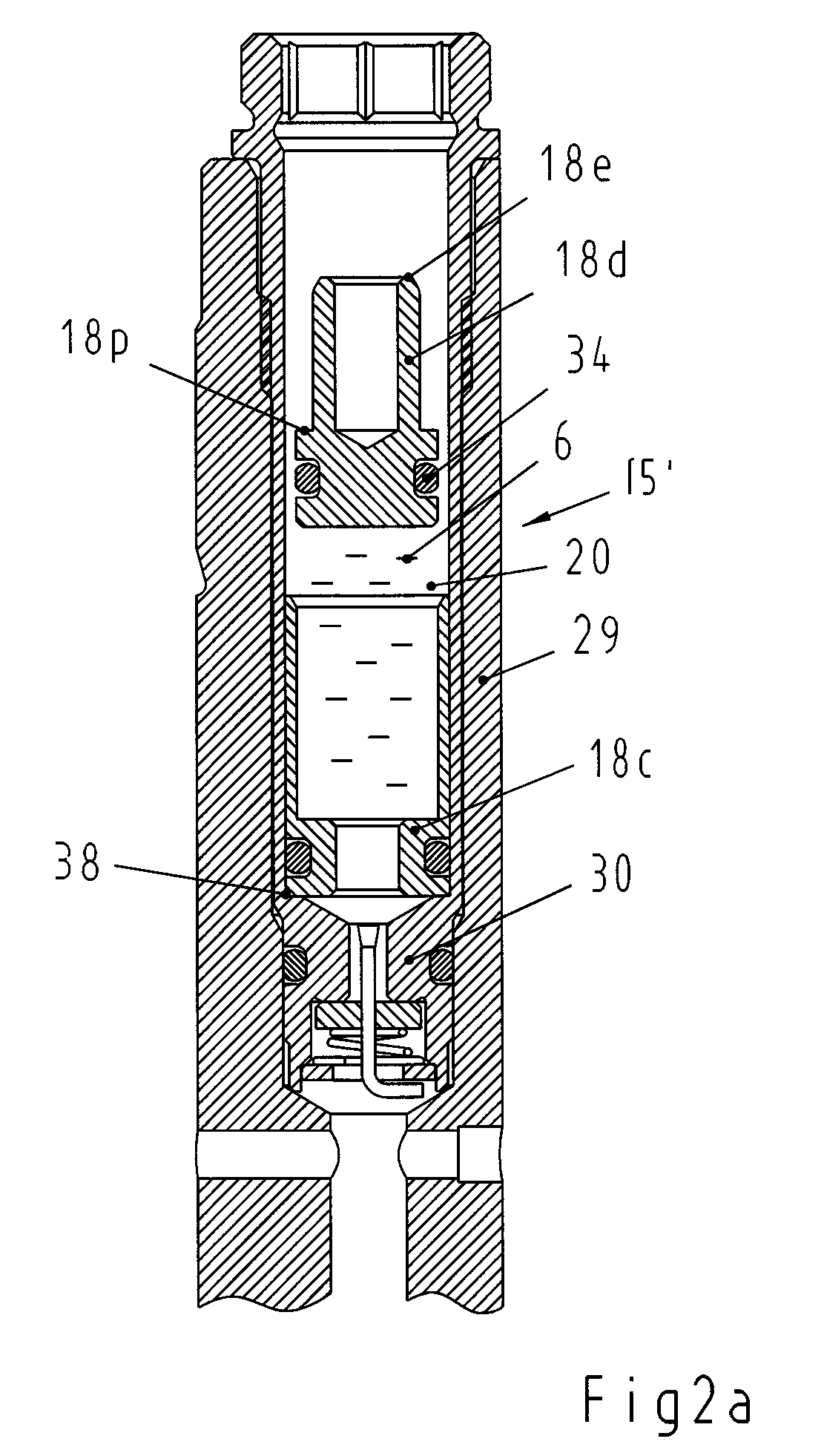

Hydraulic accumulator

ActiveUS7322377B2Guaranteed long-term operationReduction of the passage cross-sectionPiston ringsBraking action transmissionMechanical engineeringPiston

A hydraulic accumulator includes a piston (3) capable of moving in an accumulator housing (1) in its axial direction and separating a gas side (5) from a liquid side (7) of the accumulator housing (1). Guide elements (9, 17) designed to co-operate with the accumulator housing wall (1), as well as at least one sealing element (15), are arranged at the periphery of the piston. The sealing element is arranged offset in the axial direction relative to the guide elements (9, 17), and is located between the guide elements. In the piston (3), a pressure compensating channel (19) forms, at the piston periphery, a liquid flow path between the liquid side (7) and a space (2) located between the guide element (17) nearest to the liquid side (7) and the sealing element immediately next in the axial direction. A device (25) reducing the cross-section of the passage of the pressure compensating channel (19) is located in it.

Owner:HYDAC TECH GMBH

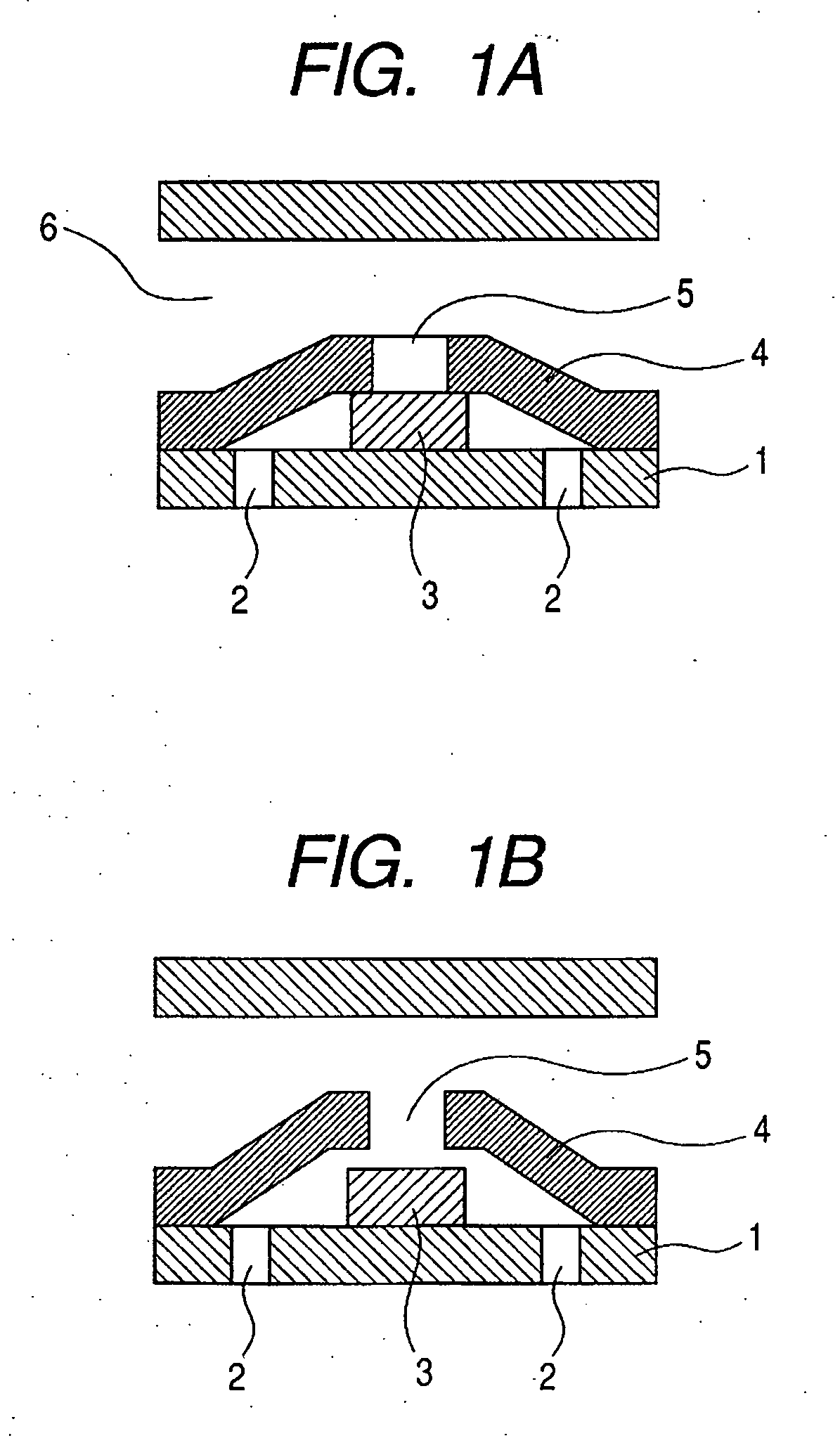

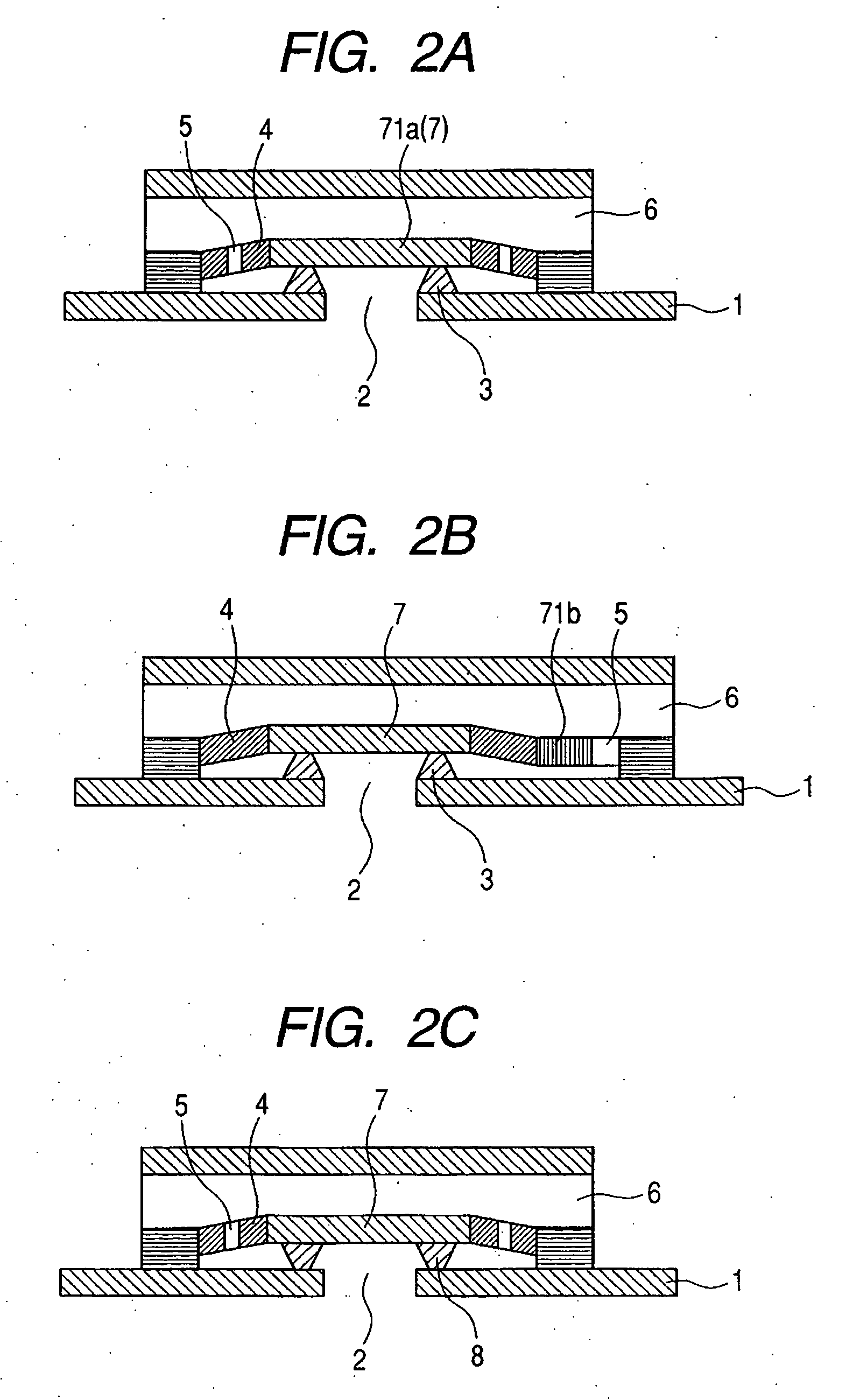

Relief valve, method of manufacturing relief valve, and fuel cell

InactiveUS20070026269A1Small sizeSimple structureFinal product manufactureFuel cell auxillariesFuel cellsDifferential pressure

Provided is a relief valve that is small in size and has a simple structure in which a flow path is provided so as to penetrate a diaphragm or a support portion of the diaphragm, and an outlet is located at an opposite side of an inlet through the diaphragm. The relief valve for pressure adjustment is made of a semiconductor wafer and operates in a case where a pressure at a fluid inlet is higher than a pressure at a fluid outlet by a pressure higher than a set pressure value, the relief valve including a flow path communicating the fluid inlet with the fluid outlet and a diaphragm for opening and closing the flow path by deformation utilizing a differential pressure between the fluid inlet and the fluid outlet, wherein the flow path penetrates the diaphragm or is disposed at a side surface of the diaphragm, the diaphragm and the valve seat are in contact with each other, and the flow path is opened and closed by deformation of the diaphragm.

Owner:CANON KK

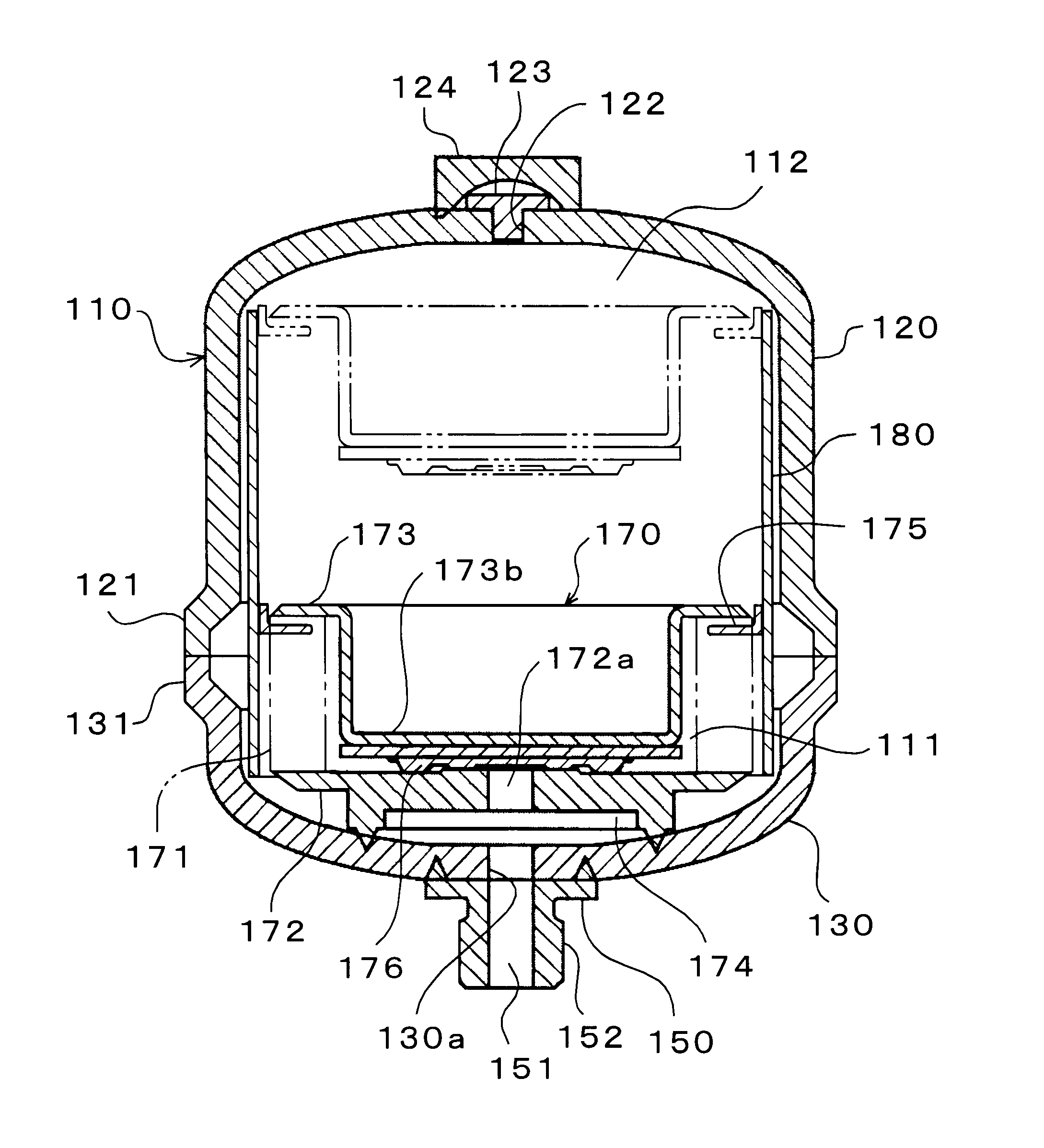

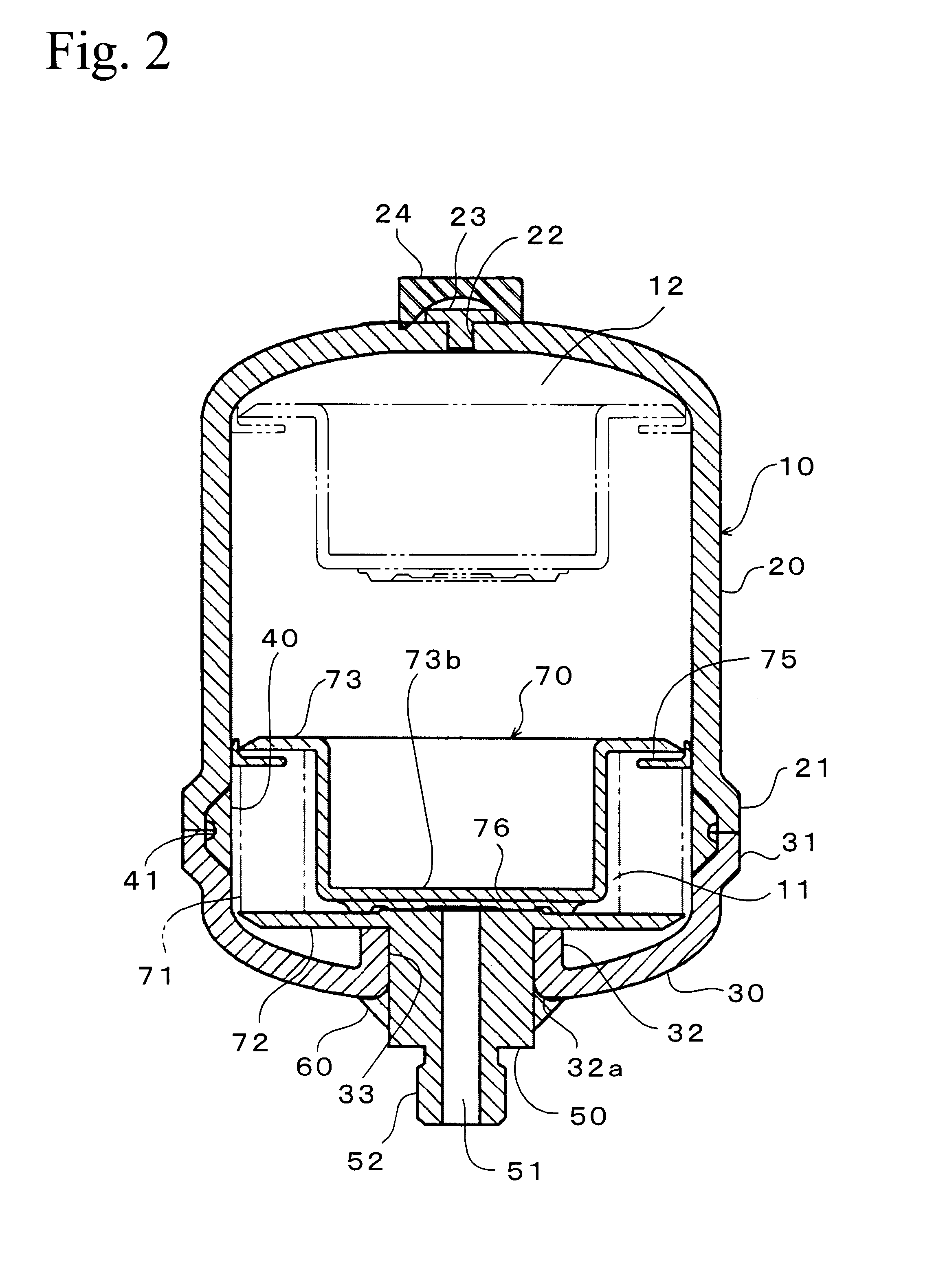

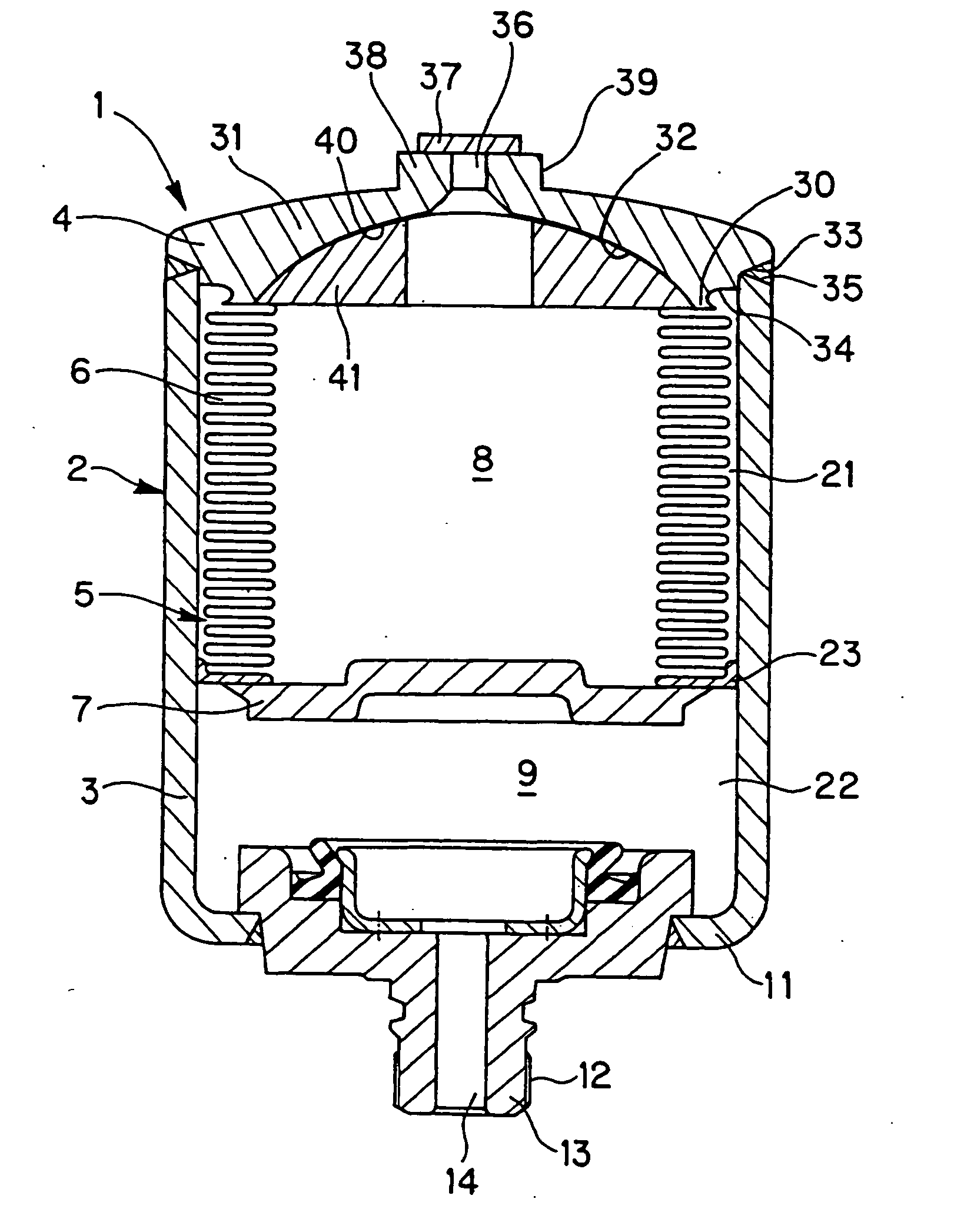

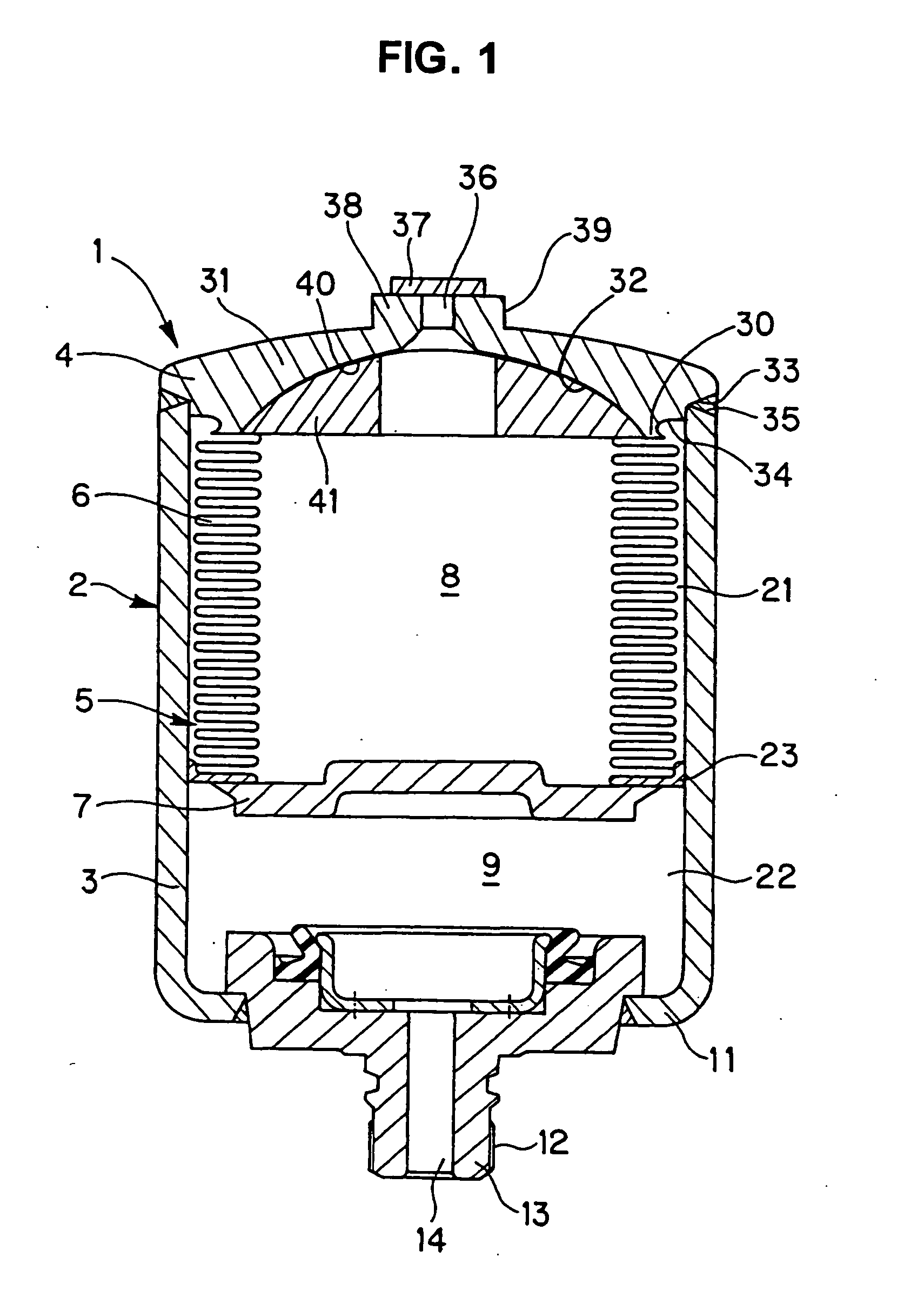

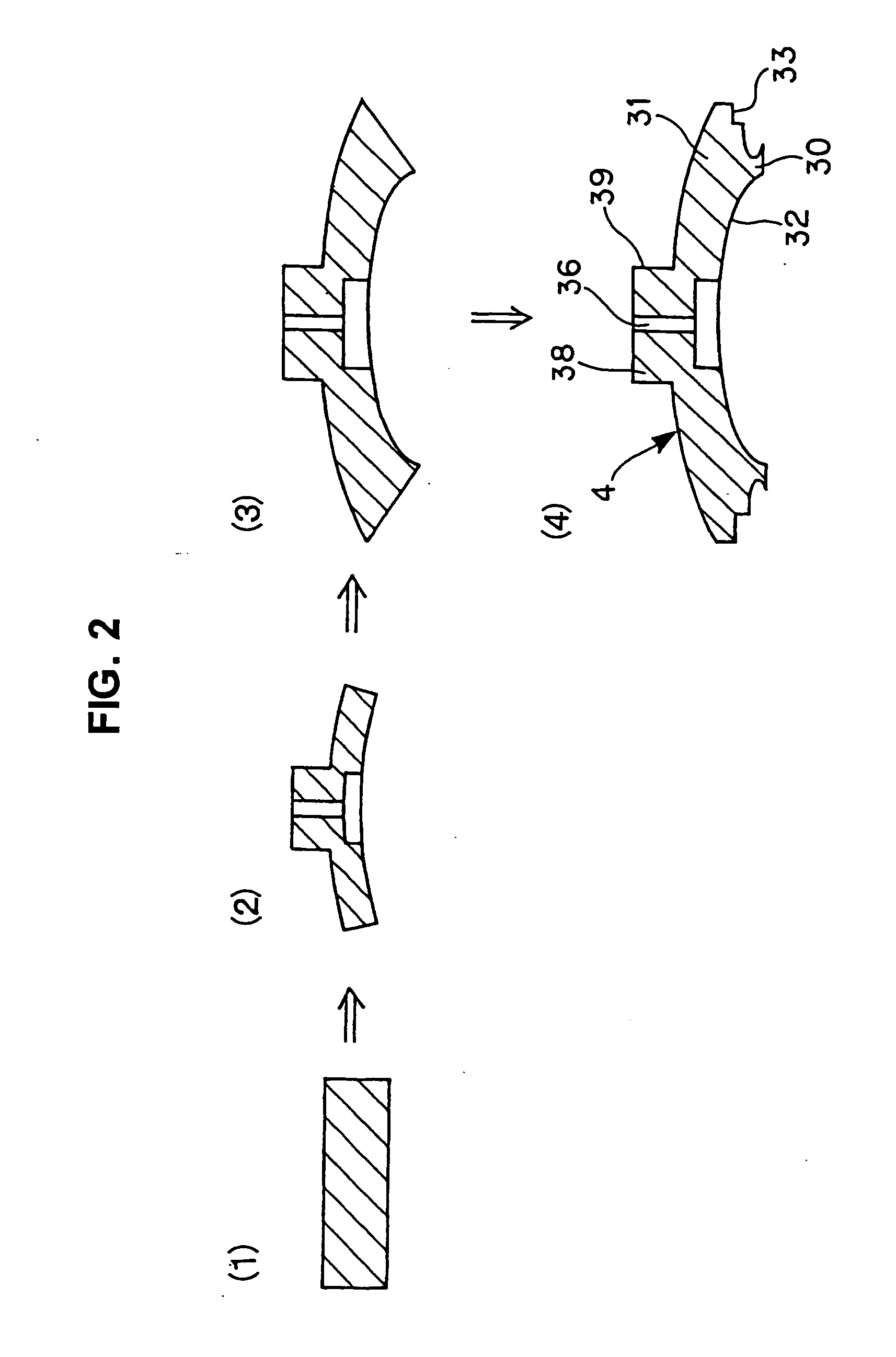

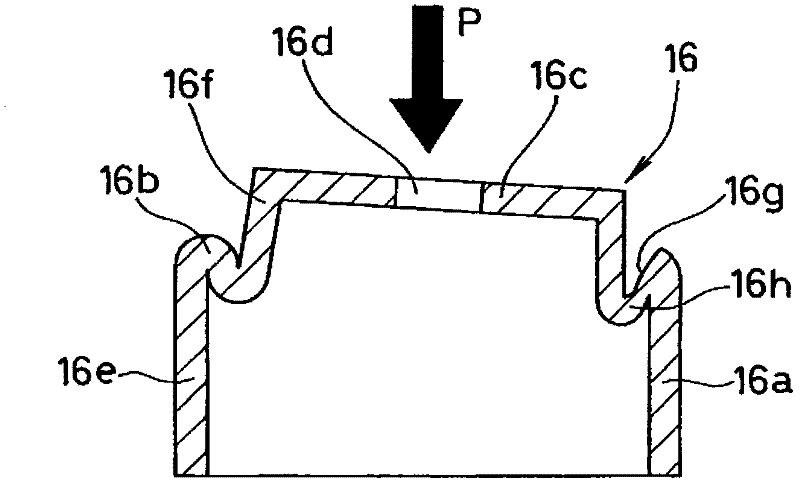

Accumulator and manufacturing process thereof

InactiveUS6286552B1Optimize timingImprove mass production efficiencyAccumulator installationsPipe elementsEngineeringGas chamber

Disclosed is an accumulator comprising: a pressure vessel; an elastic bellows in which a compressed gas is sealed, an end of the bellows being fixed to an interior of the pressure vessel; a flow path having an opening communicating with the interior and an exterior of the pressure vessel; a valve connected to a movable end of the bellows to operatively close the opening according to elastic motion of the bellows; and a hydraulic chamber partitioned from a gas chamber formed in an interior of the bellows containing the compressed gas. The valve comprises an upper surface which can cover the opening, and plural circular protrusions which surround the entire circumference of the opening and can closely contact the circumference of the opening.

Owner:NHK SPRING CO LTD

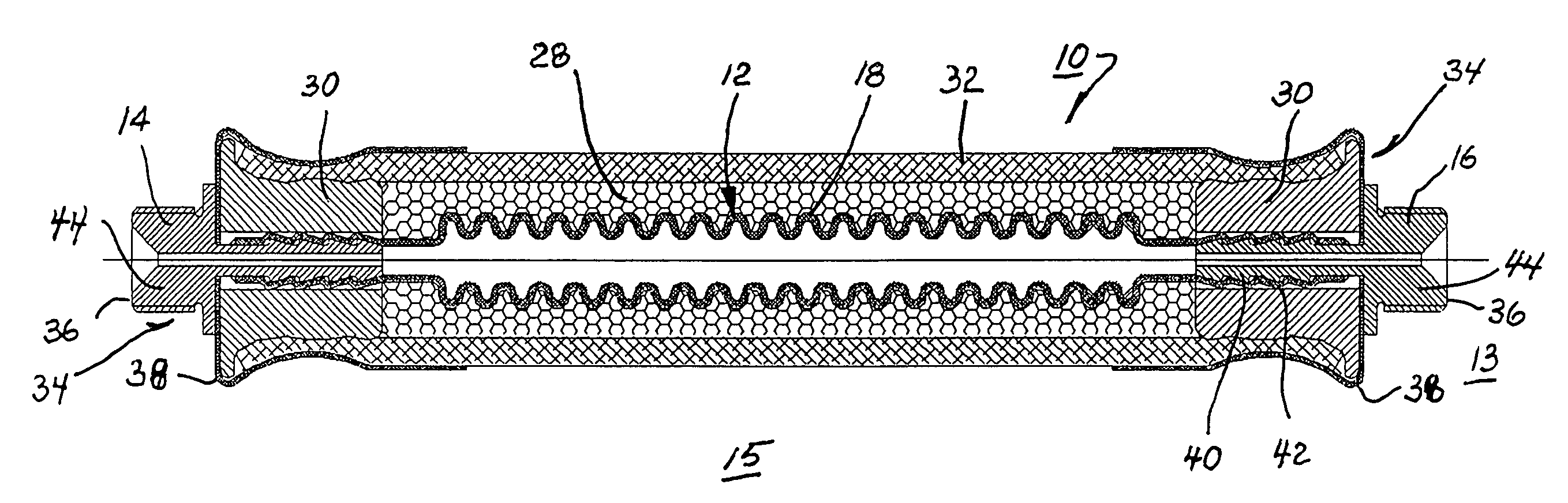

Inline pulsation damper system

A hydraulic pulsation damper system for installation into an otherwise rigid hydraulic system to absorb and extinguish pressure pulsations being transmitted through the system by hydraulic fluid contained therein. The system is useful in suppressing pulsations in automotive fuel lines supplying fuel to fuel injection systems. The system includes fuel-conducting tubing made of flexible, non-permeable material that includes a convoluted central portion capable of expanding and contracting in response to pulsations in the fuel. Resilient foam is molded around the convoluted portion for controlling expansion of the convolutions. The foam and convoluted tubing are contained within a housing made from a larger-diameter hose having ends sealed as by swaged connectors. The damper system may be bent to accommodate installation with a fuel line in an engine and can conveniently provide a sound-deadening link in the fuel line of a vehicle between a body-mounted portion and an engine-mounted portion thereof.

Owner:DELPHI TECH INC

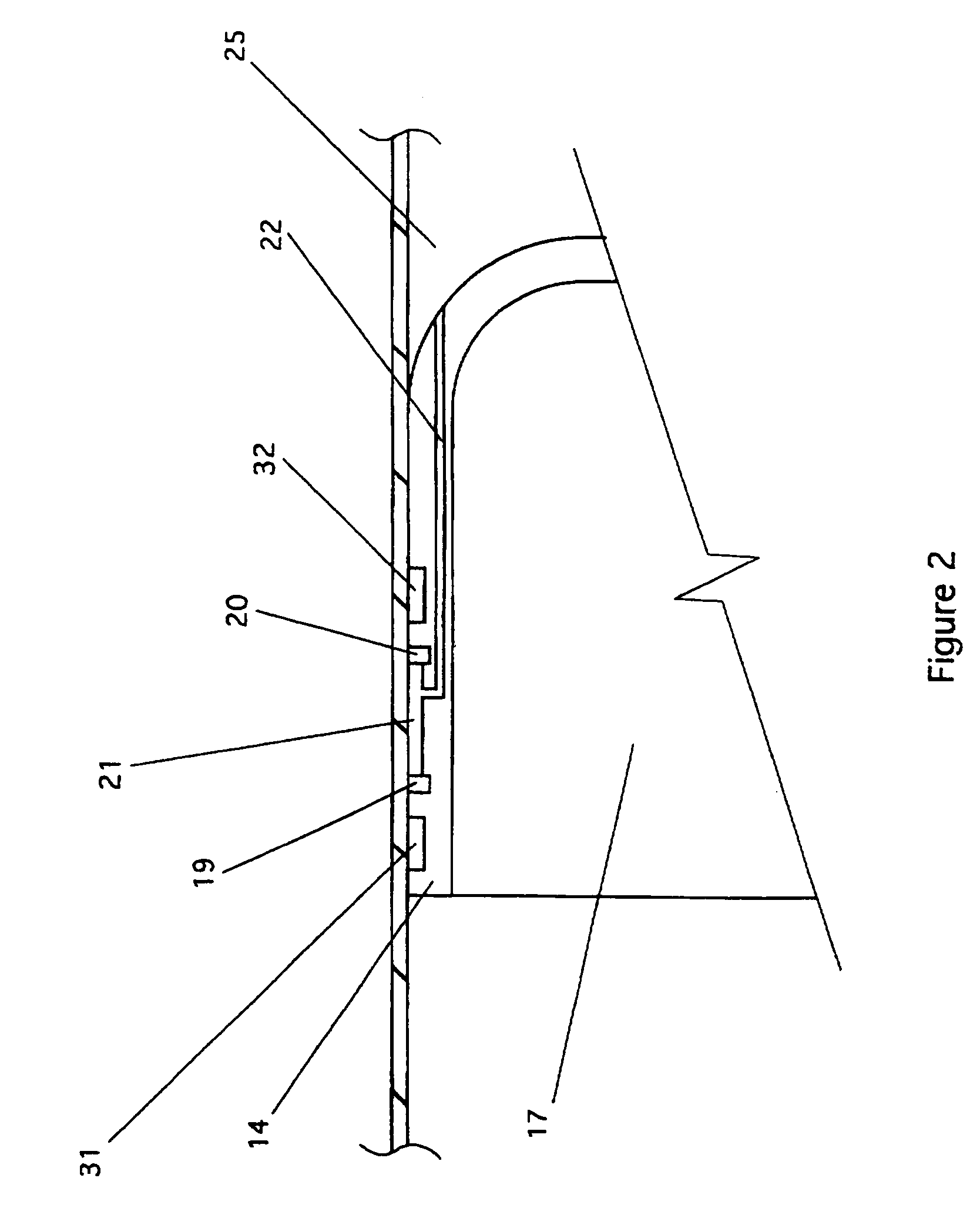

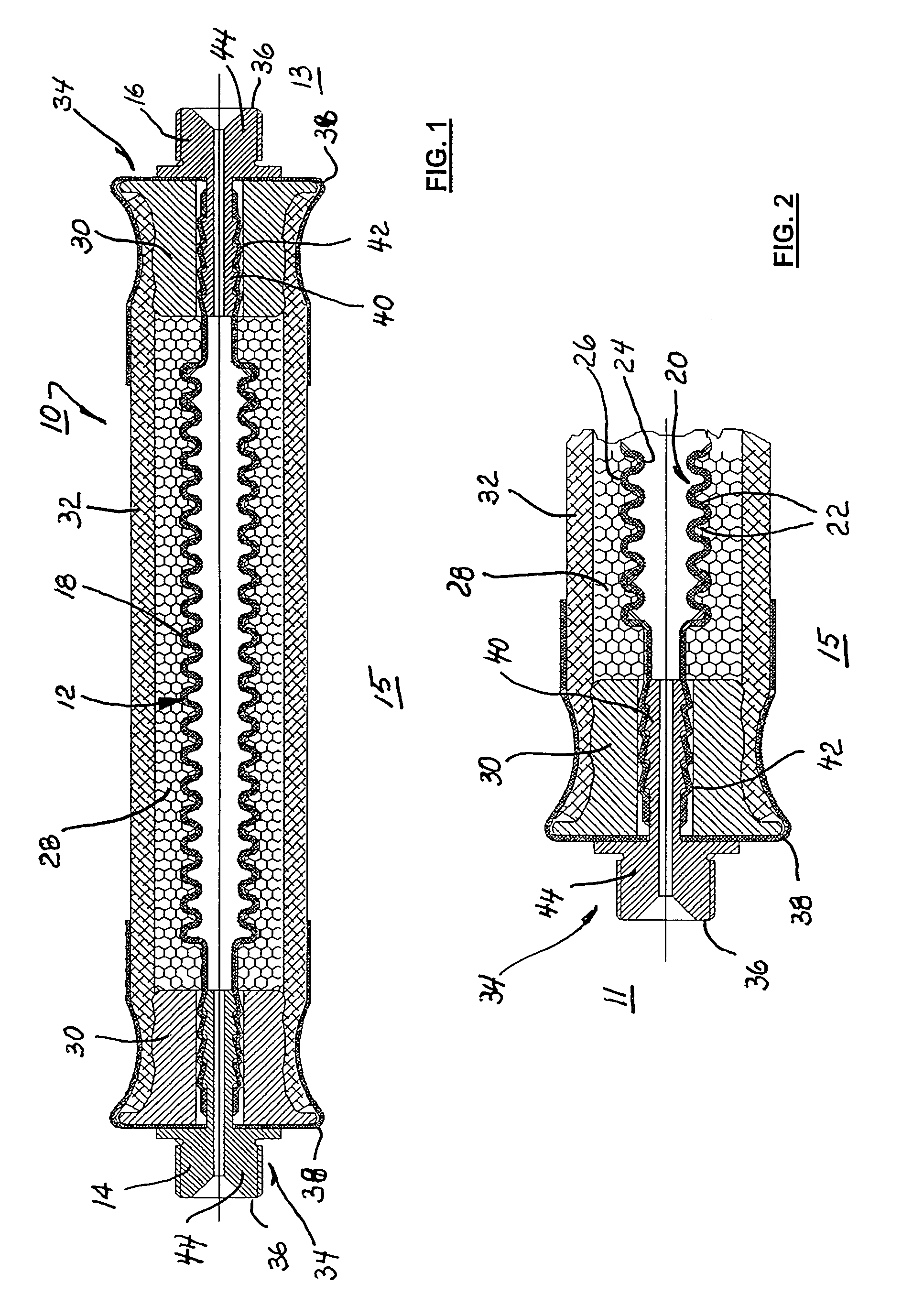

Lightweight low permeation piston-in-sleeve accumulator

InactiveUS20050194054A1Increase pressureMass productionAccumulator installationsPipe elementsWorking fluidPre-charge

A lightweight, low permeation, piston-in-sleeve high pressure accumulator is provided. The accumulator includes a cylindrical composite pressure vessel with two integral rounded ends. A piston slidably disposed in a thin nonpermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Working fluid is provided in a volume between the nonpermeable internal sleeve and the composite pressure vessel wall. Further means are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle. A method for pre-charging the device is also presented.

Owner:UNITED STATES OF AMERICA

Control device for at least one consumer, such as a camshaft adjuster, automatic transmsion and the like, of motor vehicles

InactiveUS20050072397A1Increase supplyFluid-pressure actuator safetyValve arrangementsMobile vehicleAutomatic transmission

A control device for at least one consumer of a motor vehicle, having an engine and at least one pump for supplying a medium via at least one pressure line to the at least one consumer, is configured to supply the medium to the at least one consumer before the engine is started. The pump can be driven by an electric motor or by the engine of the motor vehicle or alternatingly by the electric motor and the engine.

Owner:HYDRAULIK RING

Depth compensated subsea passive heave compensator

ActiveUS20080251980A1Extended maintenance periodGreat spring isolationDrilling rodsDerricks/mastsOcean bottomEngineering

A depth compensated passive eave compensator comprises a first cylinder connected at its upper end to a vessel. A piston rod extends from a piston located within the first cylinder through the lower end thereof and is connected to subsea equipment. A second cylinder contains a compressed gas which maintains pressure beneath the piston of the first cylinder. The upper end of the first cylinder is connected to the upper end of a third cylinder having a piston mounted therein. A piston rod extending from the piston of third cylinder extends through the lower end thereof thereby applying the pressure of the sea to the piston of the third cylinder.

Owner:INTERMOOR

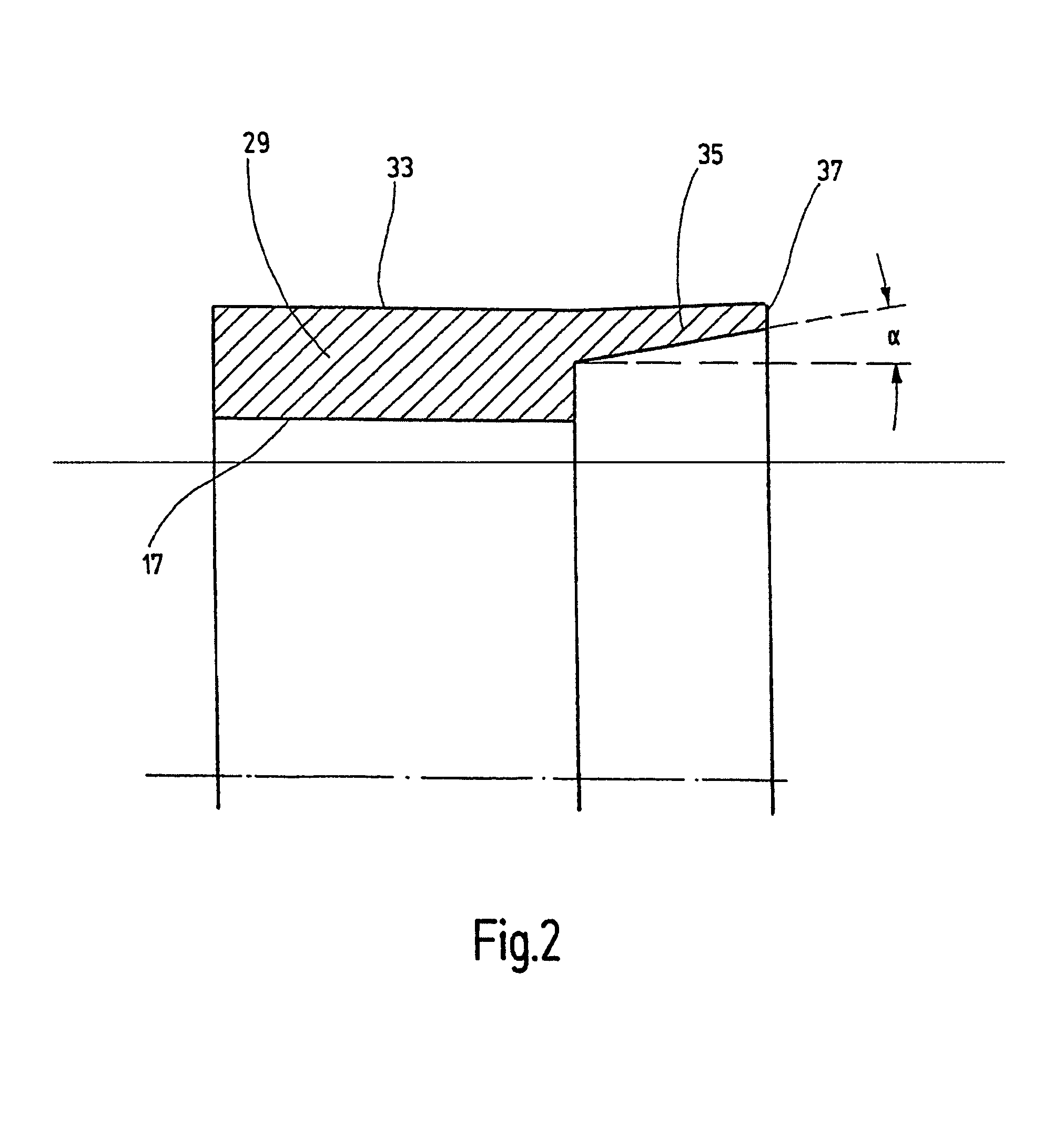

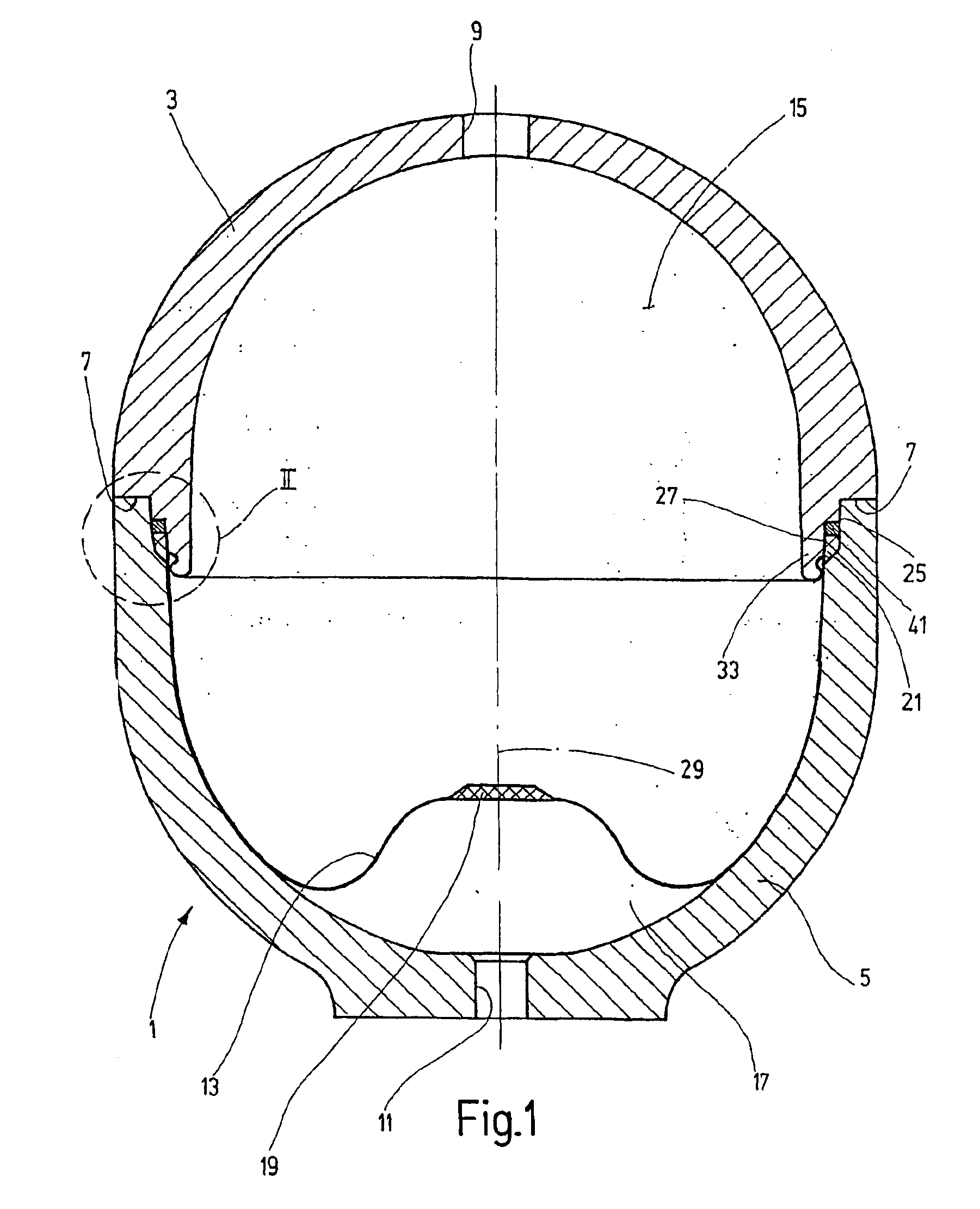

Hydropneumatic pressure reservoir

InactiveUS6857450B2Easy to assembleAvoid disadvantagesAccumulator installationsPipe elementsEngineeringBoundary region

A hydropneumatic pressure reservoir (1) forms a housing from at least two housing shells (3, 5) connected together. At least the end region of the one housing shell (5) includes an outwardly-extending, funnel-like guide surface between its free end and a sealing element for bringing together the two housing shells (3, 5). At least on elastic sealing element (41) is provided on at least one retaining surface for generation of a tensioning force on the boundary region (21) of the membrane (13). A simplified construction with improved sealing in the critical connection of the pressure reservoir is achieved.

Owner:HYDAC TECH GMBH

Method for arranging a separating piston in a cavity and a device with such a separating piston

ActiveUS7975814B2Facilitate non-critical settingKeep the pressureSpringsAccumulator installationsDashpotControl theory

A steering damper system and method of regulating the fluid pressure of such a system are provided. The system can comprise a piston rod, a cylinder, a passage, and a damper portion. The damper portion can comprise a damper cavity, an outer piston, an inner piston, and a biasing component. The damper cavity can be in fluid communication with the passage. The outer piston can be slidably disposed in the damper cavity and define a chamber and a duct that is in fluid communication with the chamber and the passage. The inner piston can be slidably disposed in the chamber of the outer piston. The biasing component can exert an axial biasing force against the inner piston for regulating the pressure of fluid disposed in the system passing intermediate the passage, the damper cavity, and the chamber of the outer piston.

Owner:OHLINS

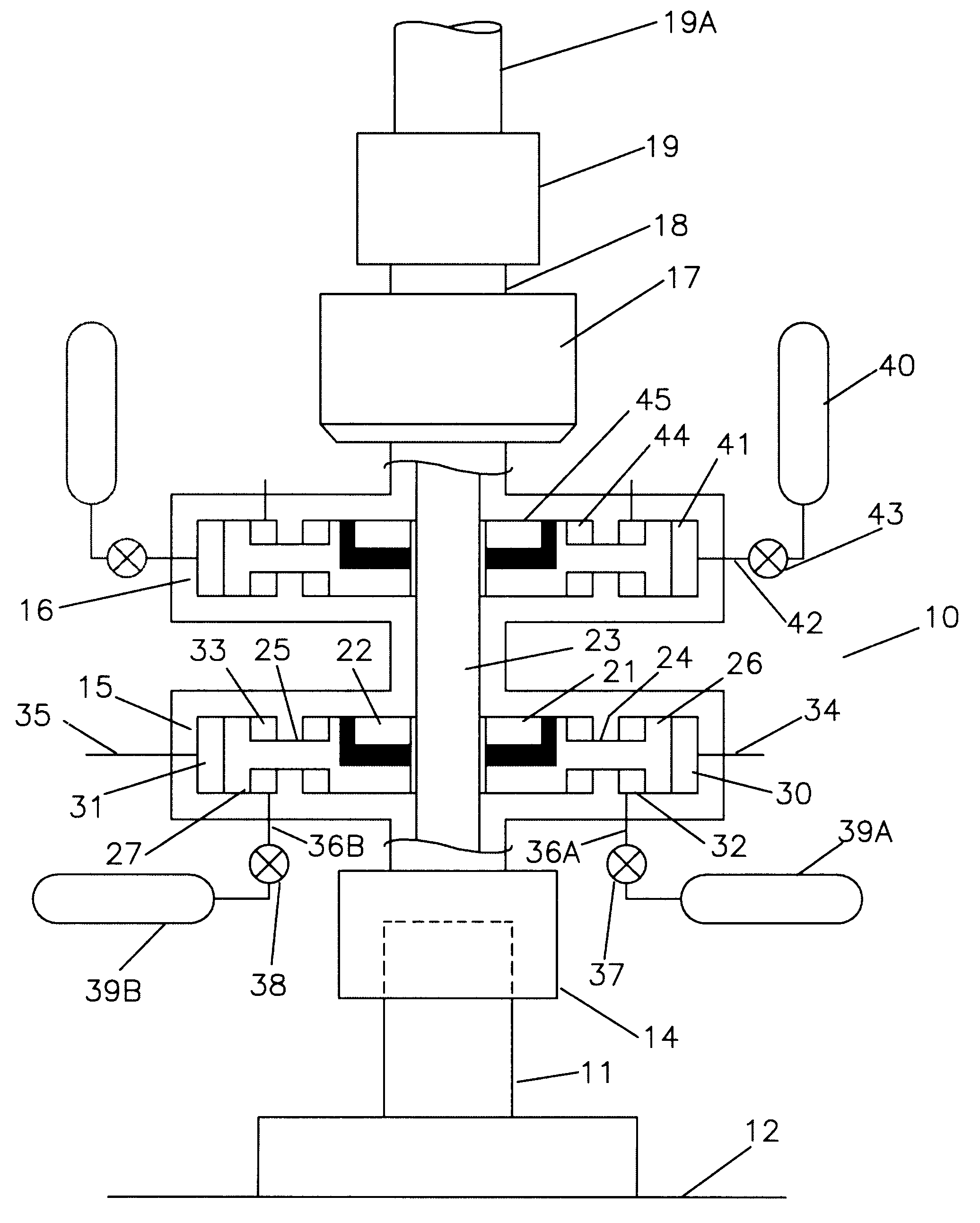

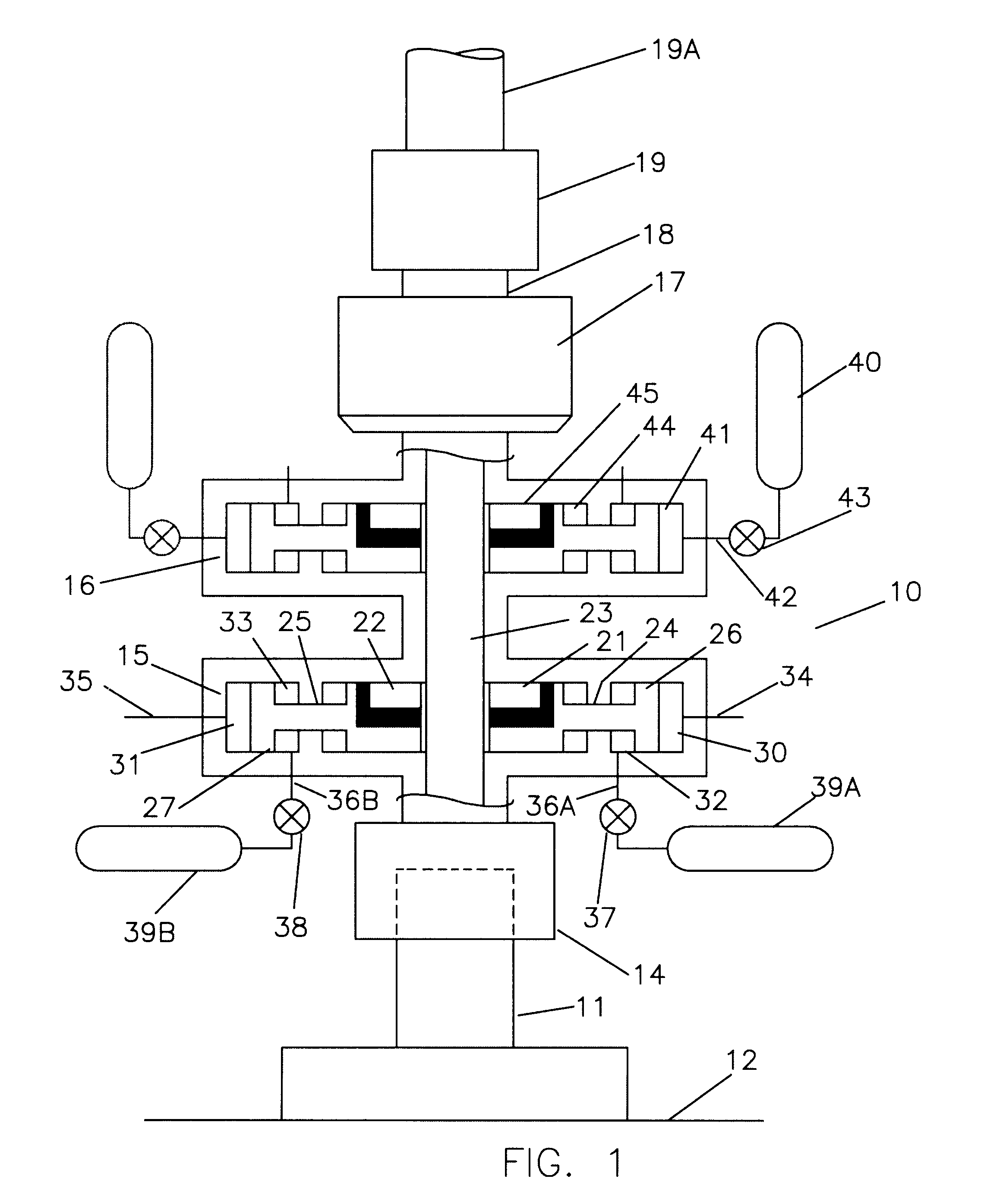

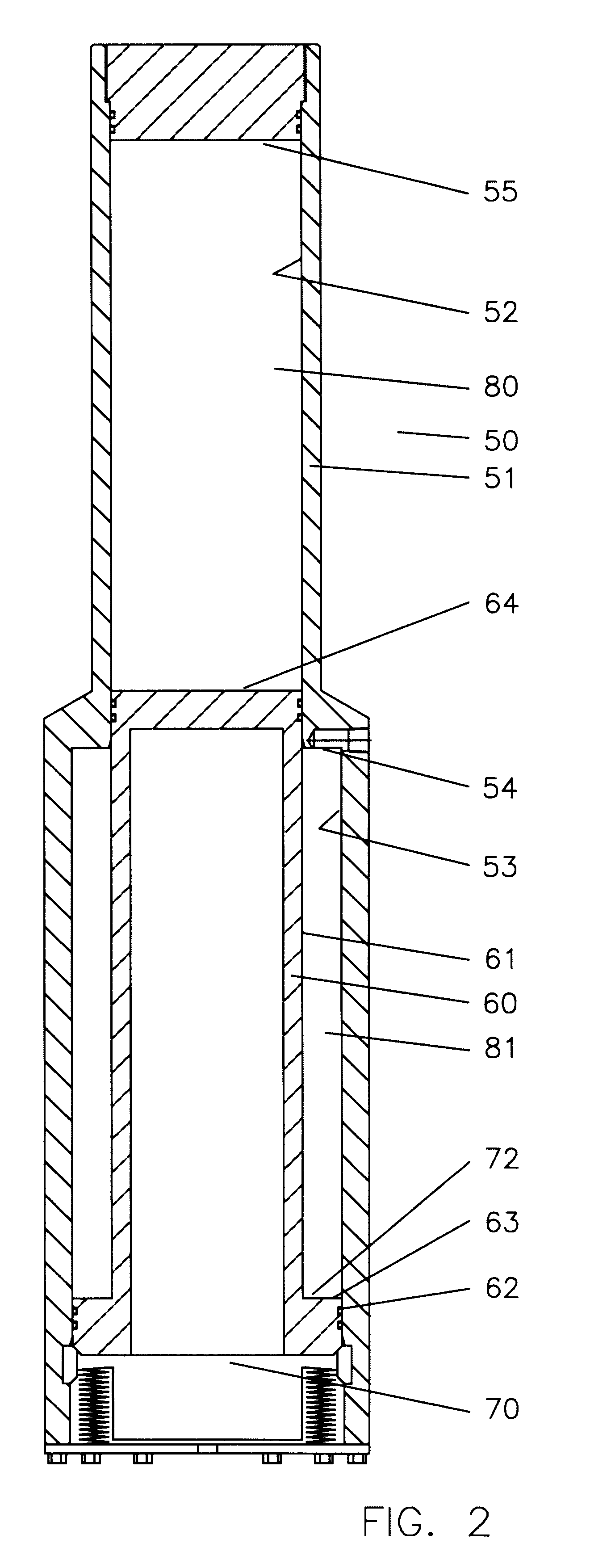

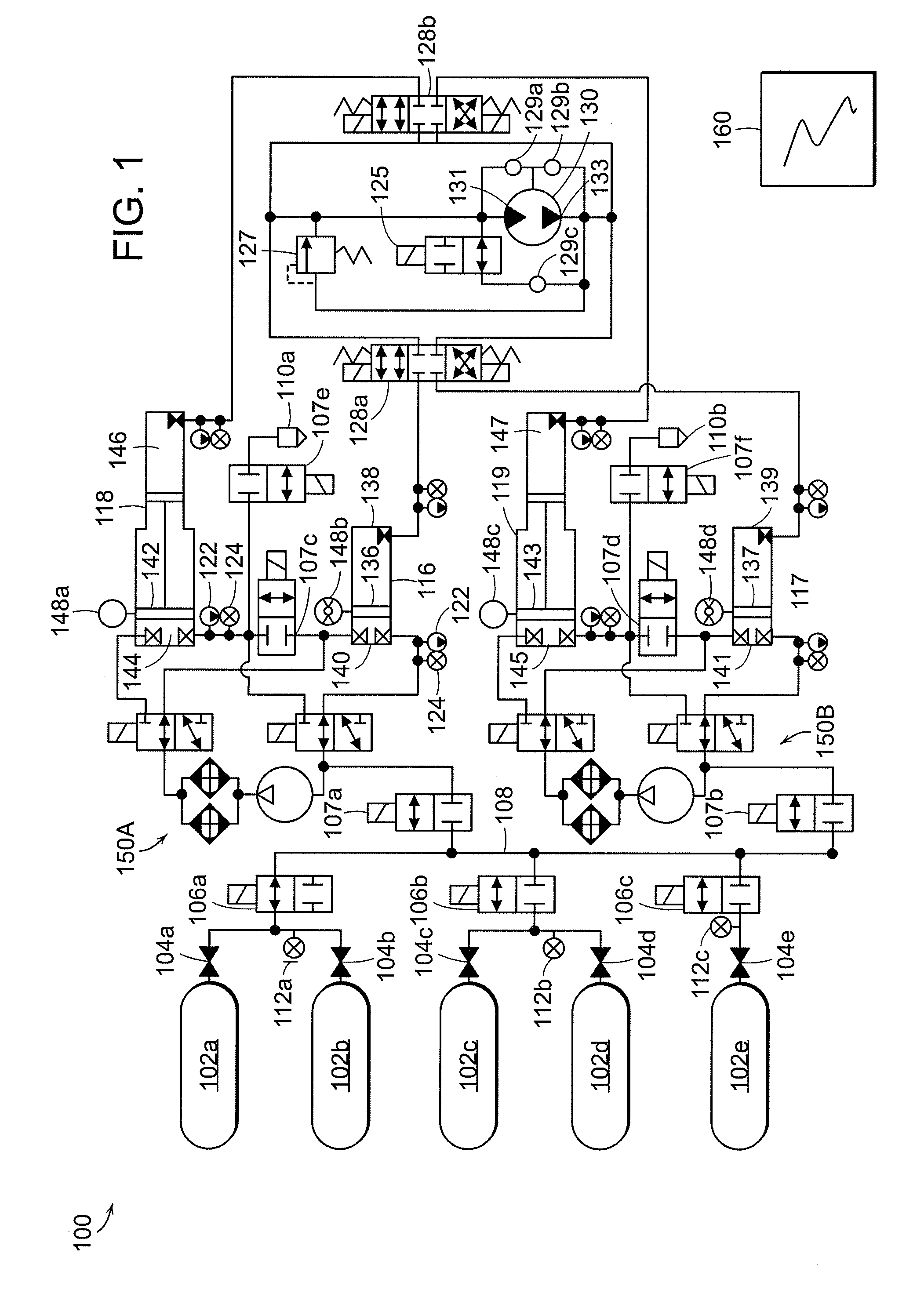

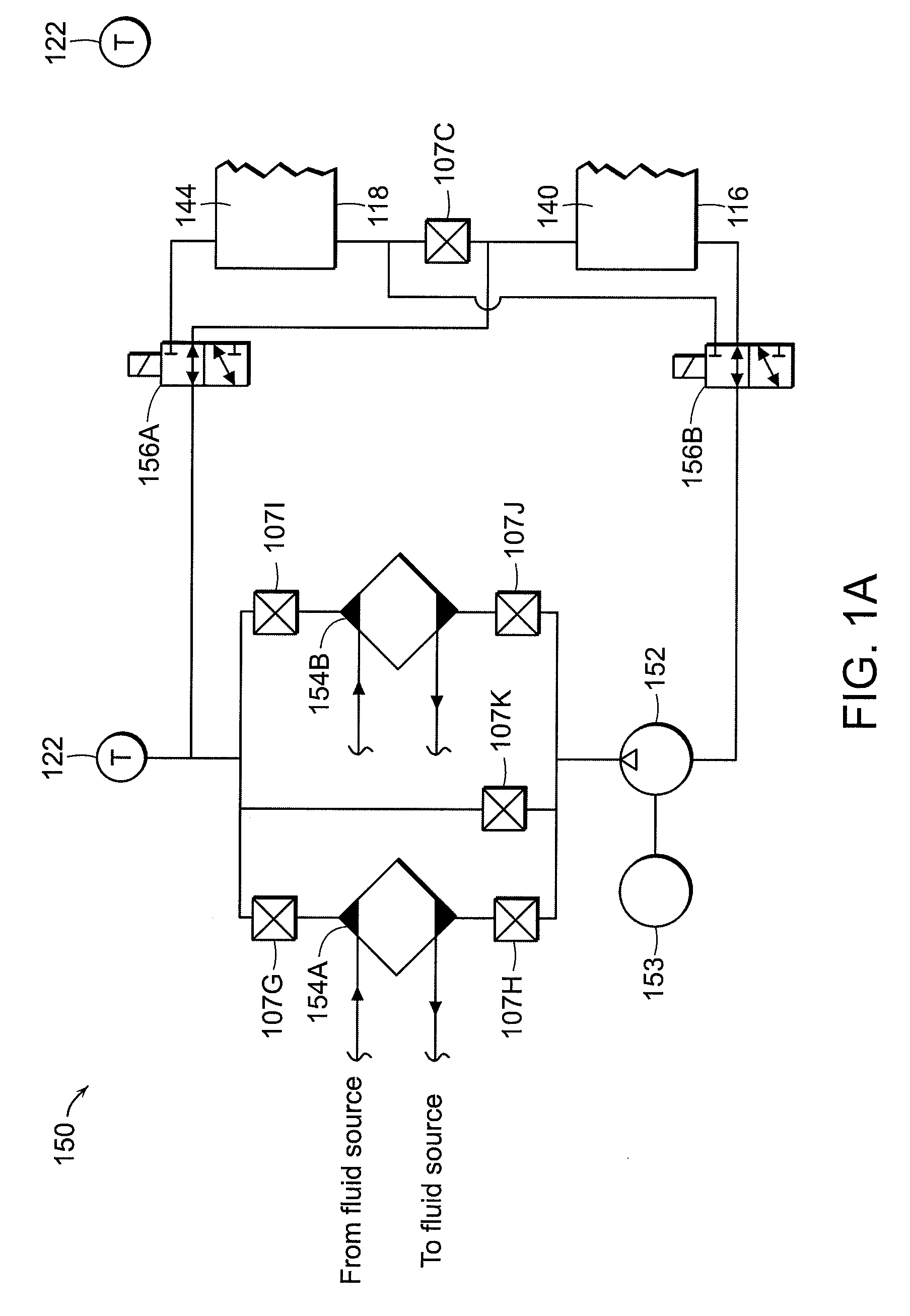

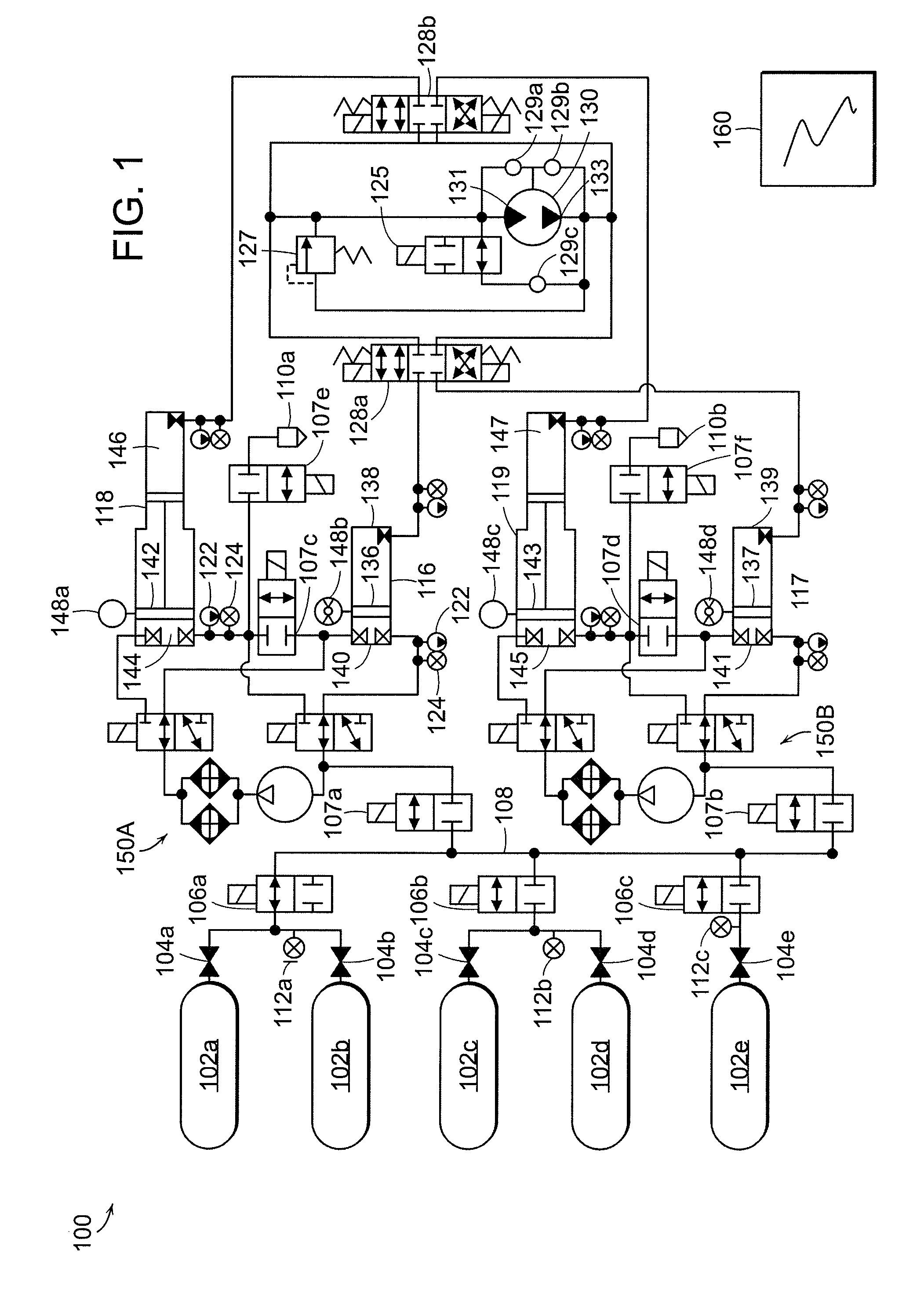

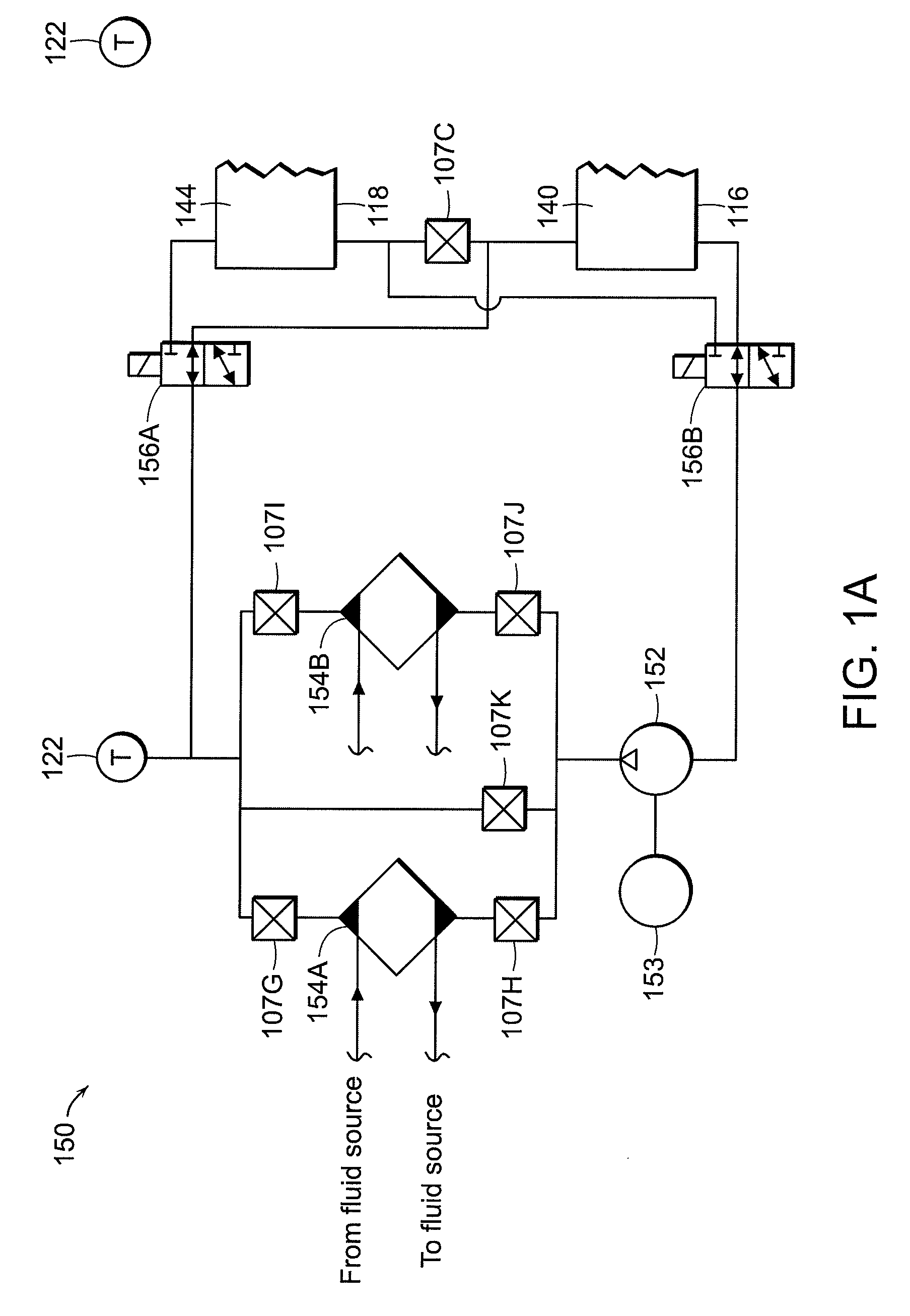

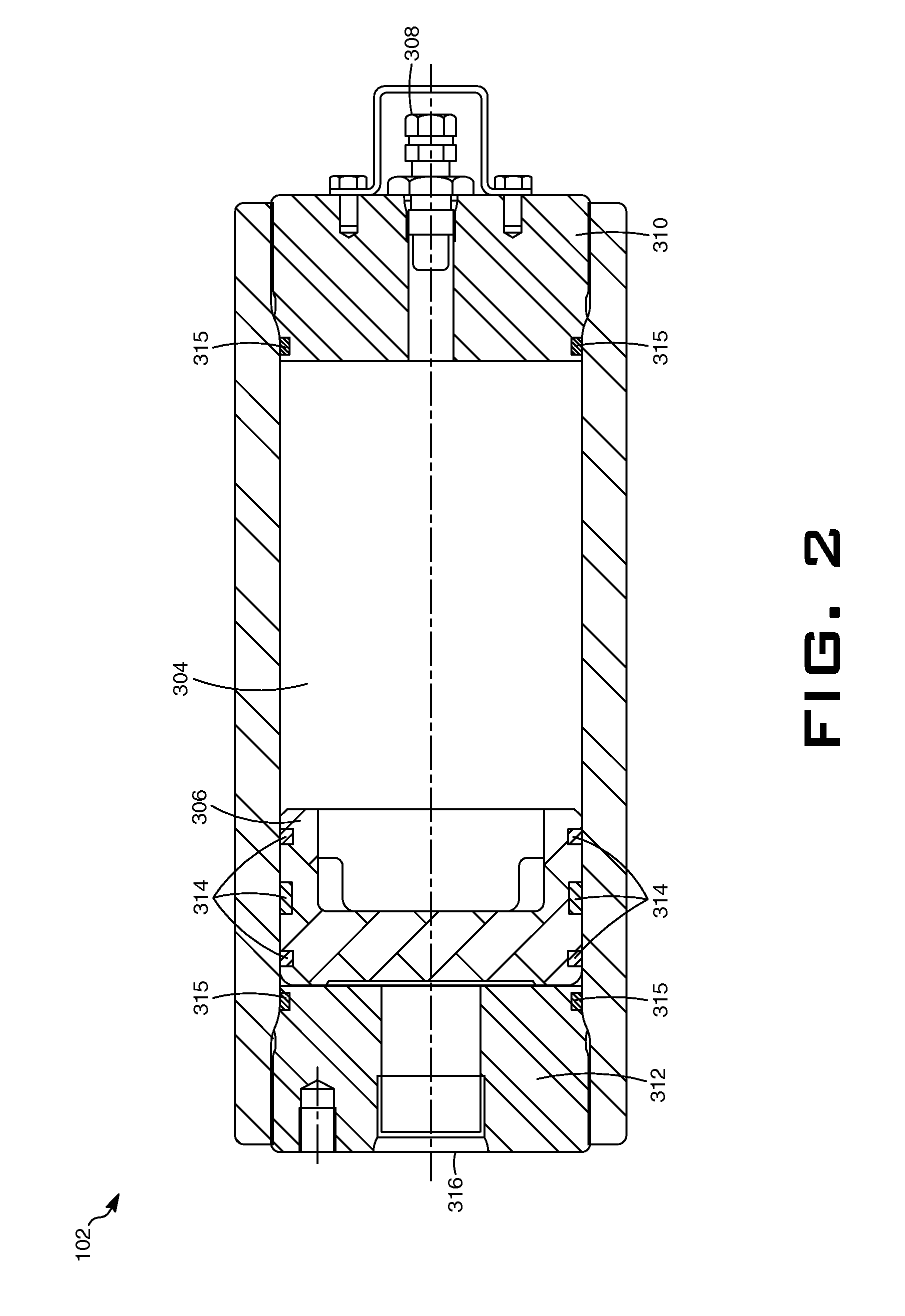

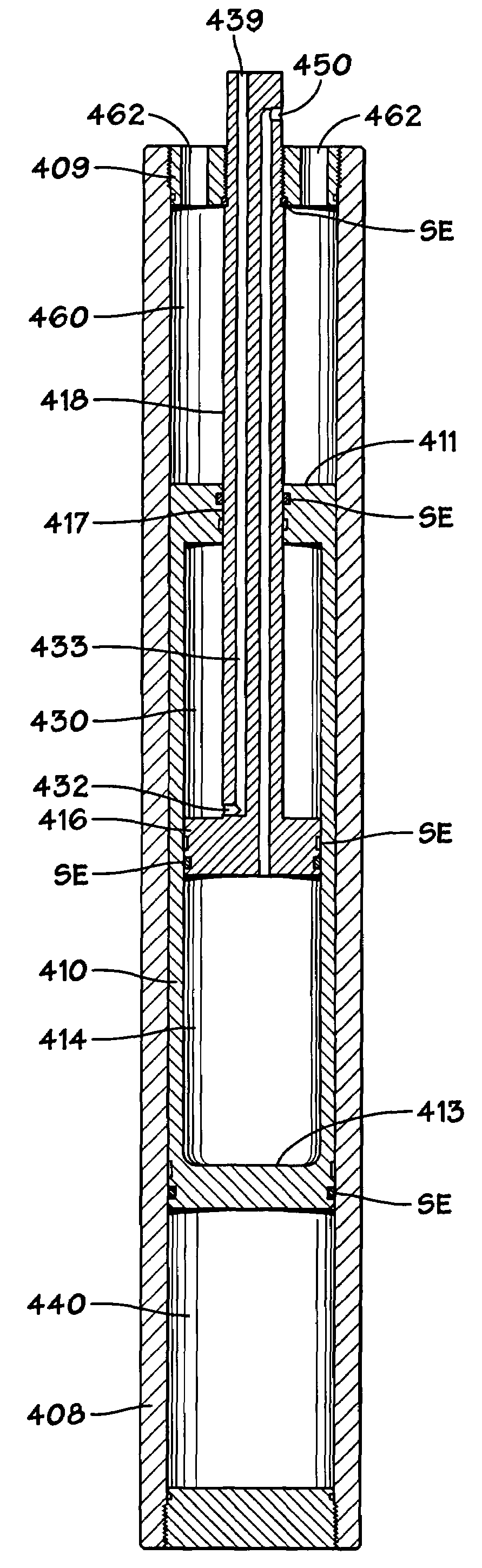

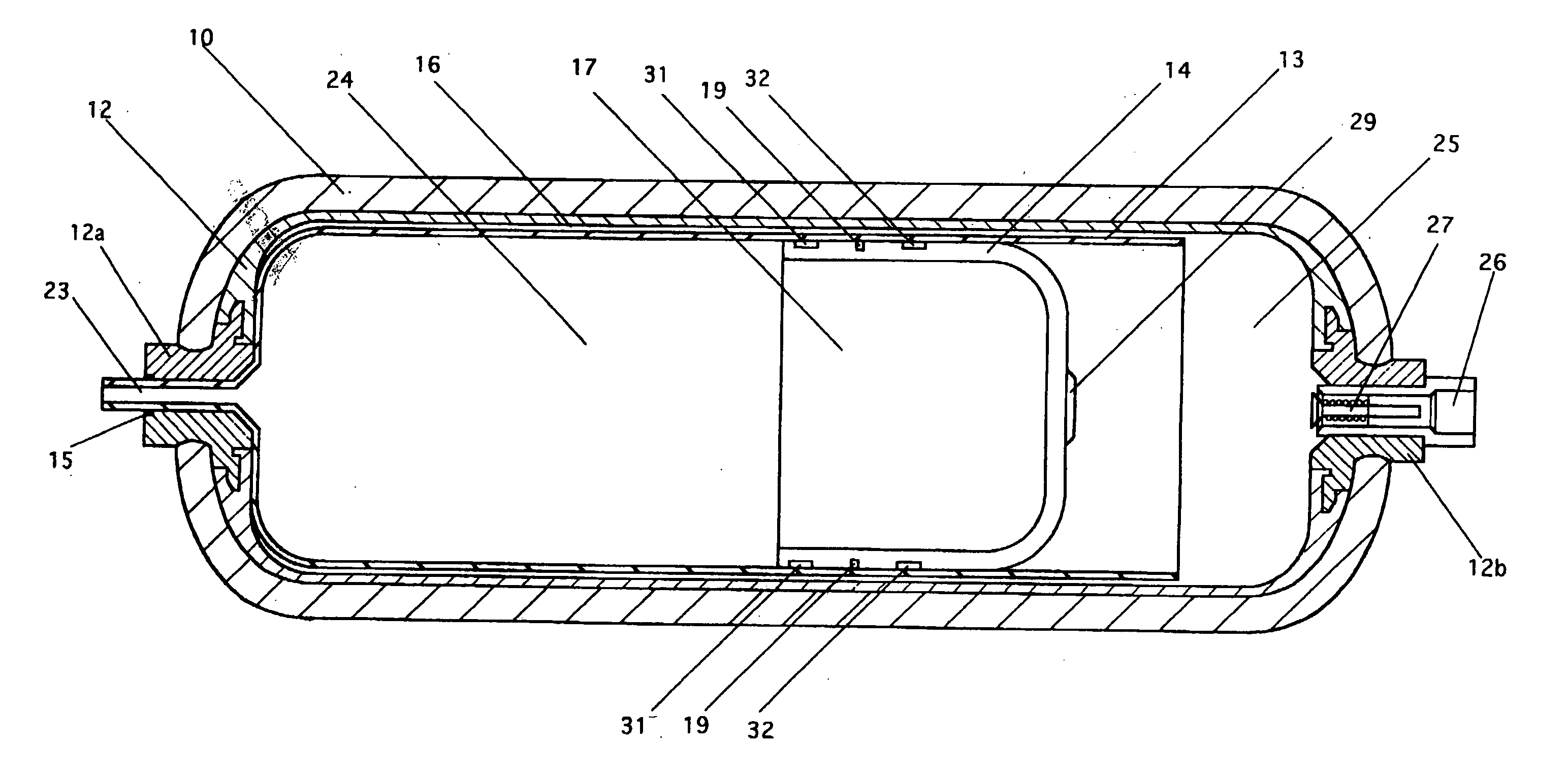

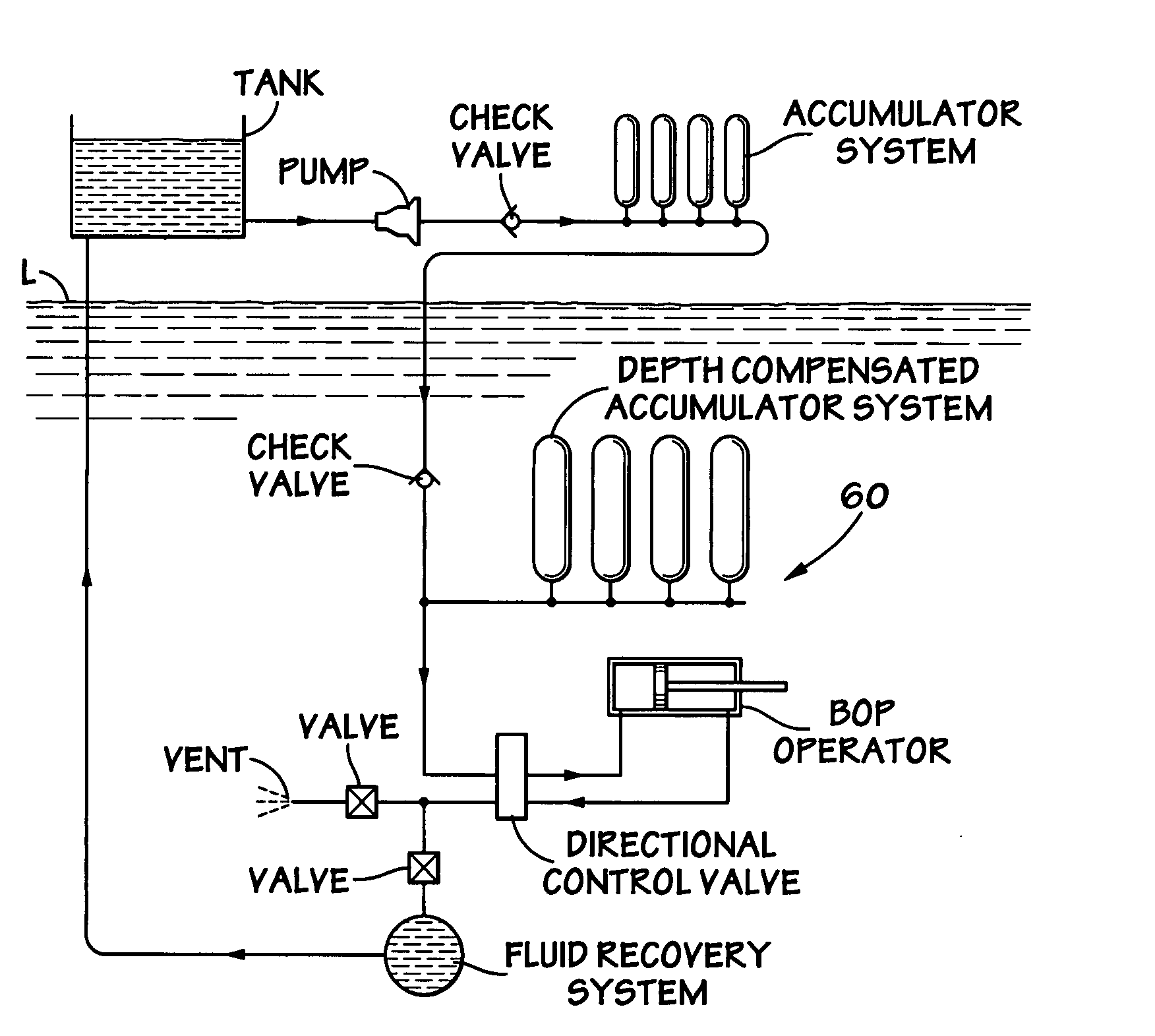

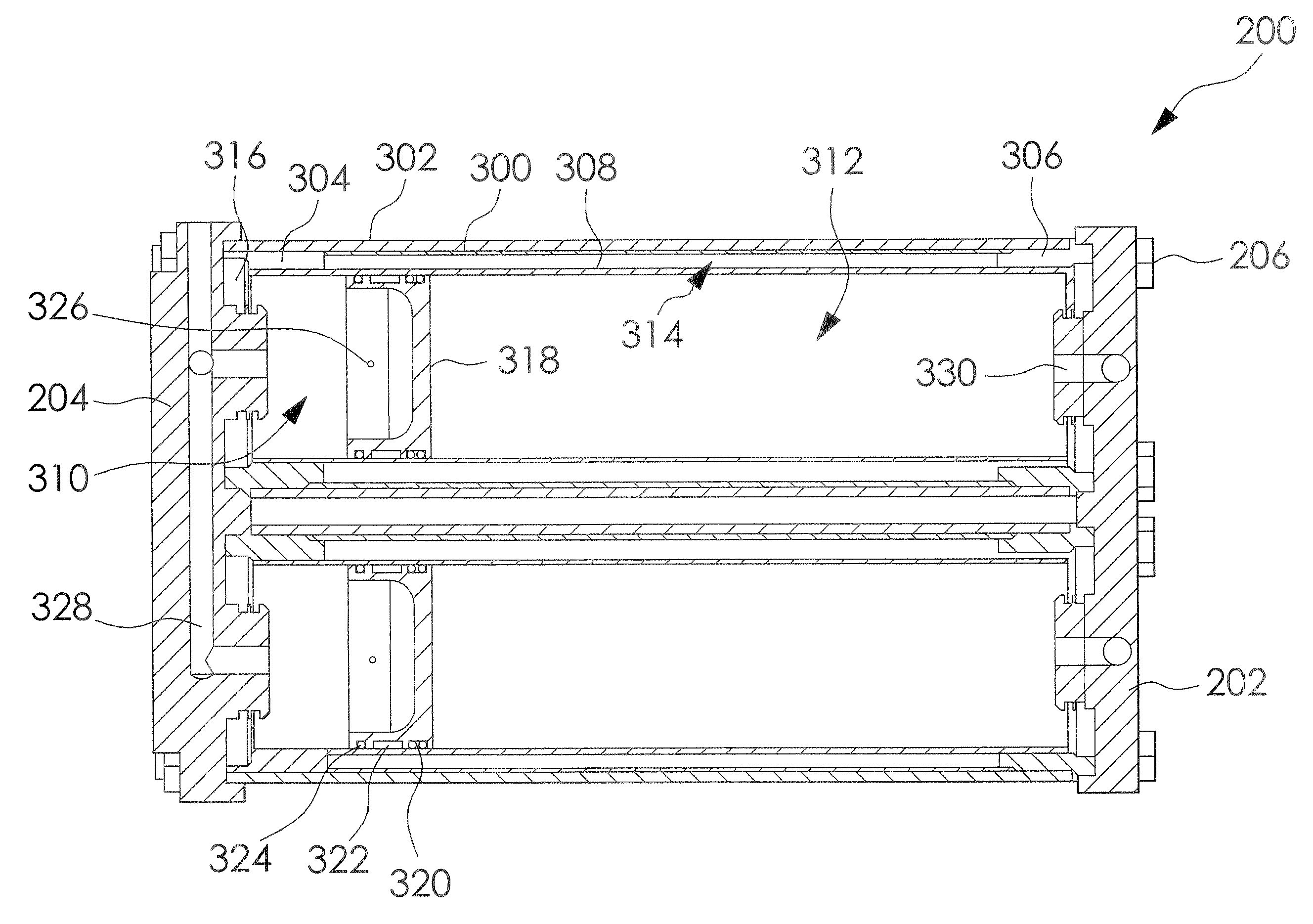

Subsea pressure accumulator systems

ActiveUS20080104951A1Effective expansionReduce amountFluid couplingsActuator accumulatorsEngineeringMechanical engineering

An accumulator system which, in certain aspects, has a body with three (or more) interior chambers, e.g. in one aspect first, second, and third chambers, the body having a first body end with a first opening, and a second body end with a second opening, an amount of operational power fluid in the first chamber, an amount of pressurized gas in the second chamber for moving a piston assembly for moving power fluid from the body to operate an apparatus, the piston assembly having a cavity within a piston end for containing additional pressurized gas for moving the piston assembly.

Owner:VARCO I P INC

Pressure container and pressure accumulating/buffer apparatus

A pressure container has a steel pipe and an end plate that is formed with a joint portion by allowing its tapered surface to touch a tapered surface of an opening end of the steel pipe so as to block the opening end. The steel pipe has a flange portion which can be cut at the opening end of the steel pipe, and the joint portion is allowed to touch the flange portion. The flange portion is pressed against the opening end along an axial direction so as to touch the end plate, and while the end plate is being pressed against the steel pipe along the axial direction, an electric current is applied so that welding is carried out.

Owner:NHK SPRING CO LTD

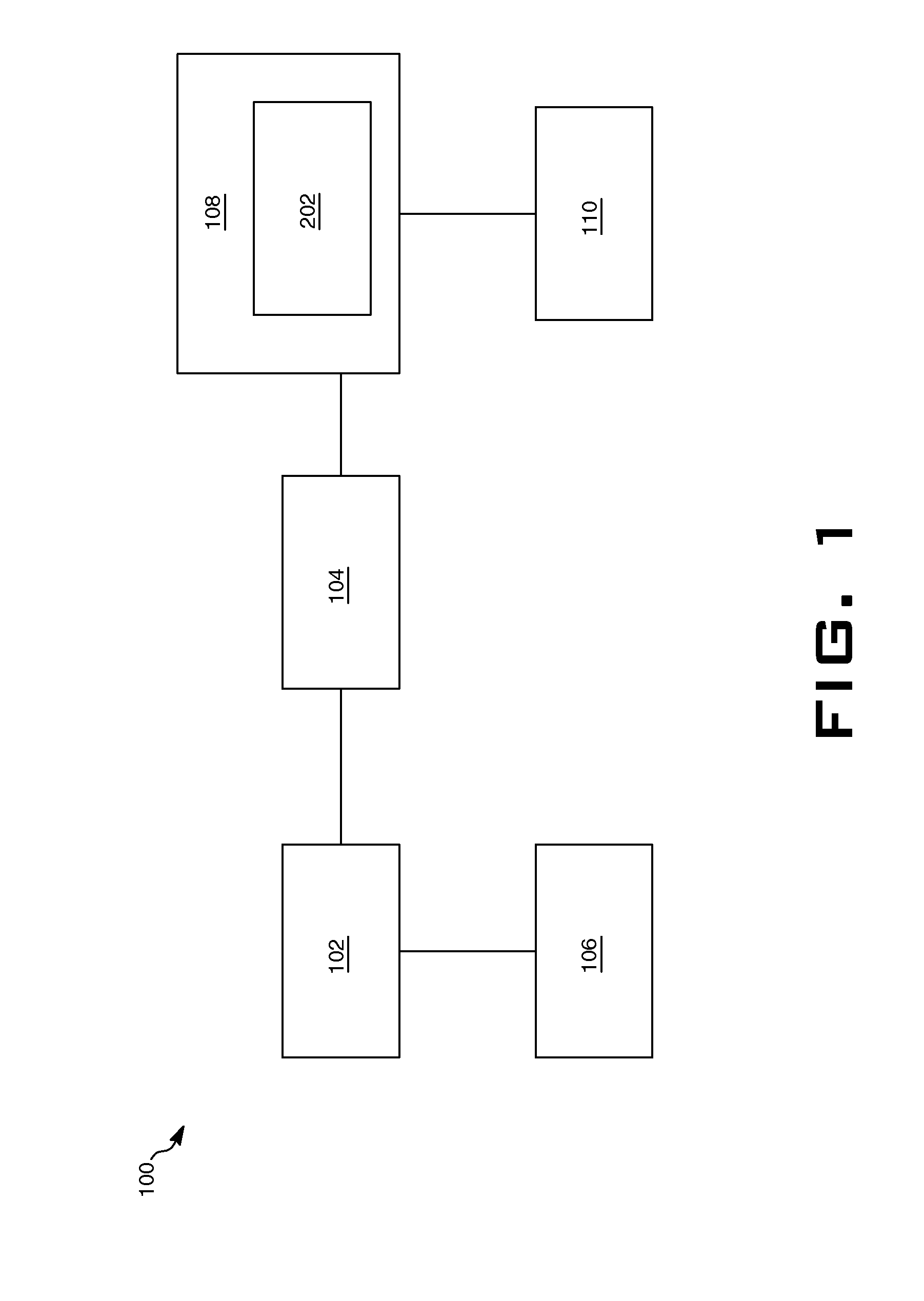

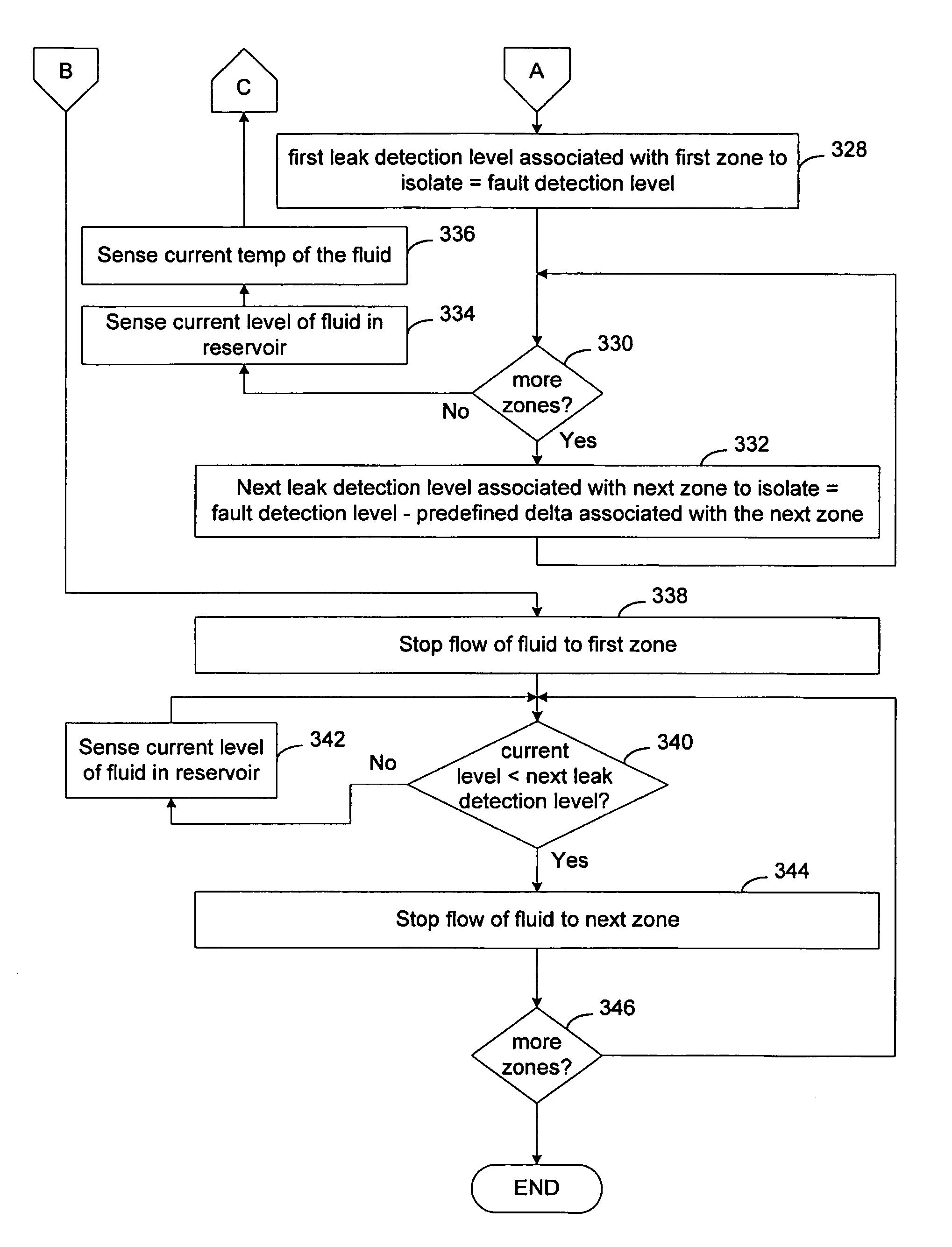

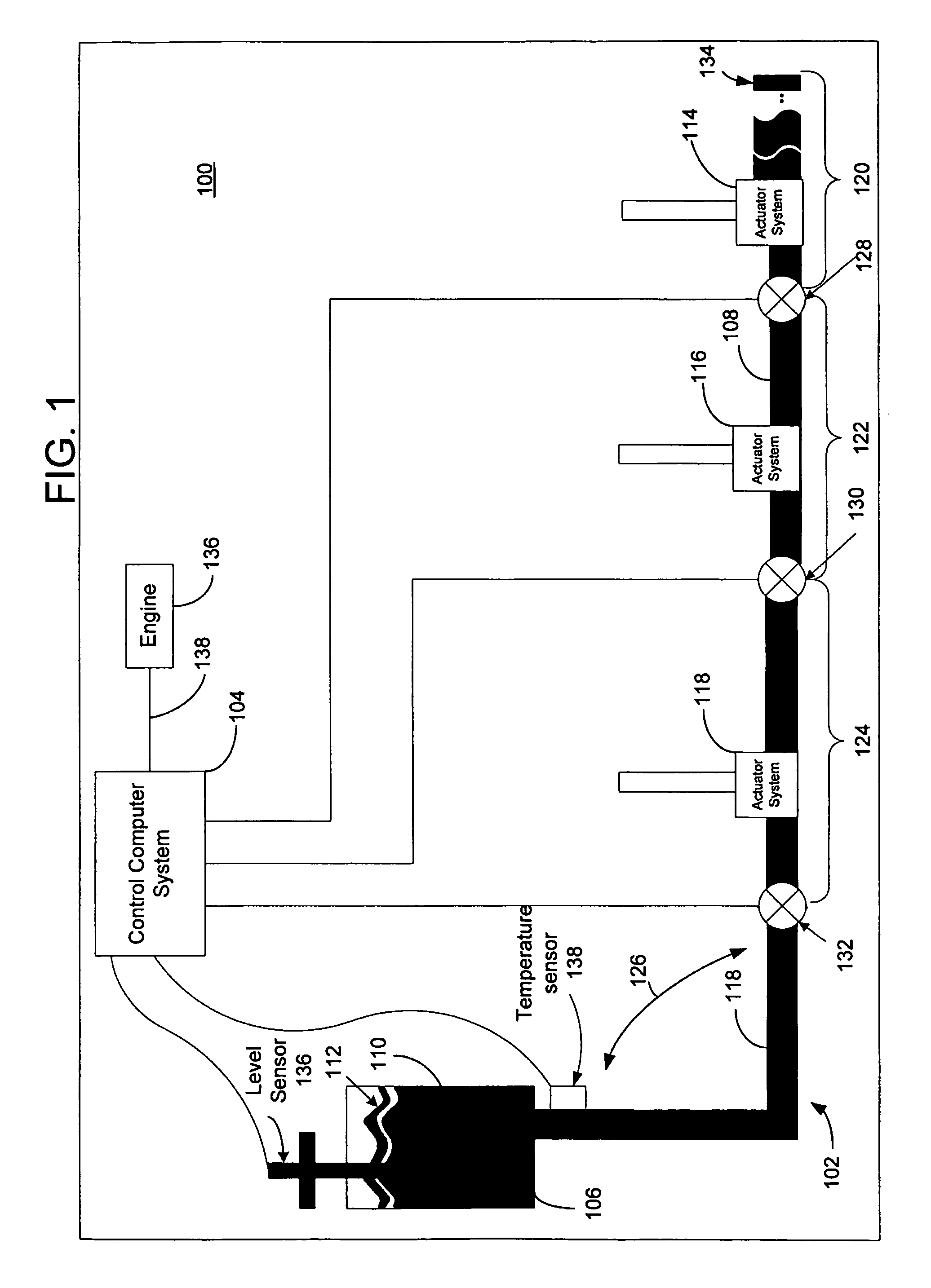

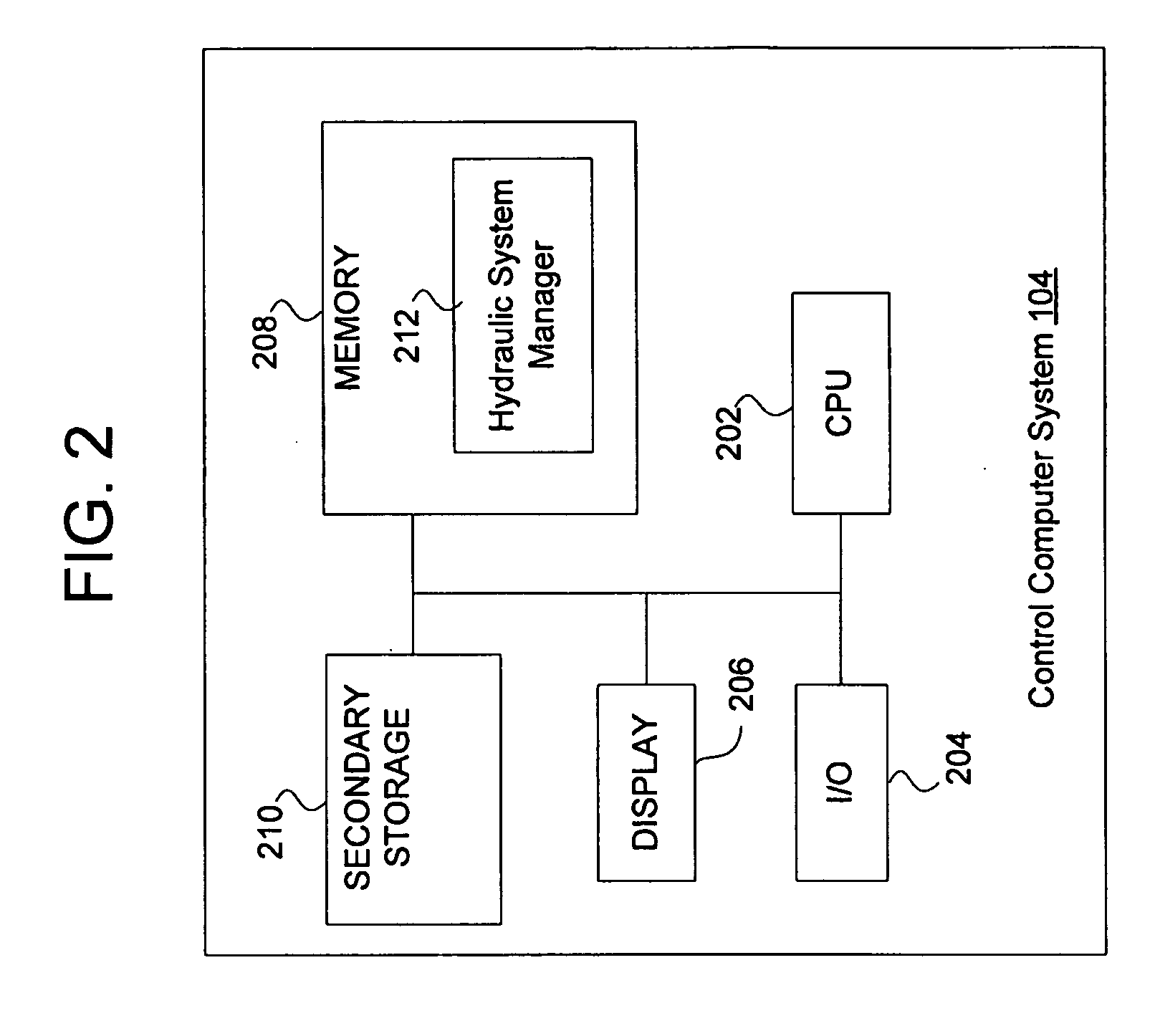

System and method for detecting a leak in a hydraulic fluid system

ActiveUS20070028674A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringThermal expansion

Methods, systems, and articles of manufacture consistent with the present invention provide for detecting a leak in a hydraulic fluid system having a reservoir and a conduit operatively connected to the reservoir. The fluid may reside in the reservoir, the conduit, or both. A current level of the fluid in the reservoir is sensed. A determination is made as to whether the current level is less than a leak detection level. When it is determined that the current level is greater than the leak detection level, a current temperature of the fluid is sensed and the leak detection level is updated based on the current temperature of the fluid so that thermal expansion of the fluid in the system is considered in detecting and isolating a leak.

Owner:THE BOEING CO

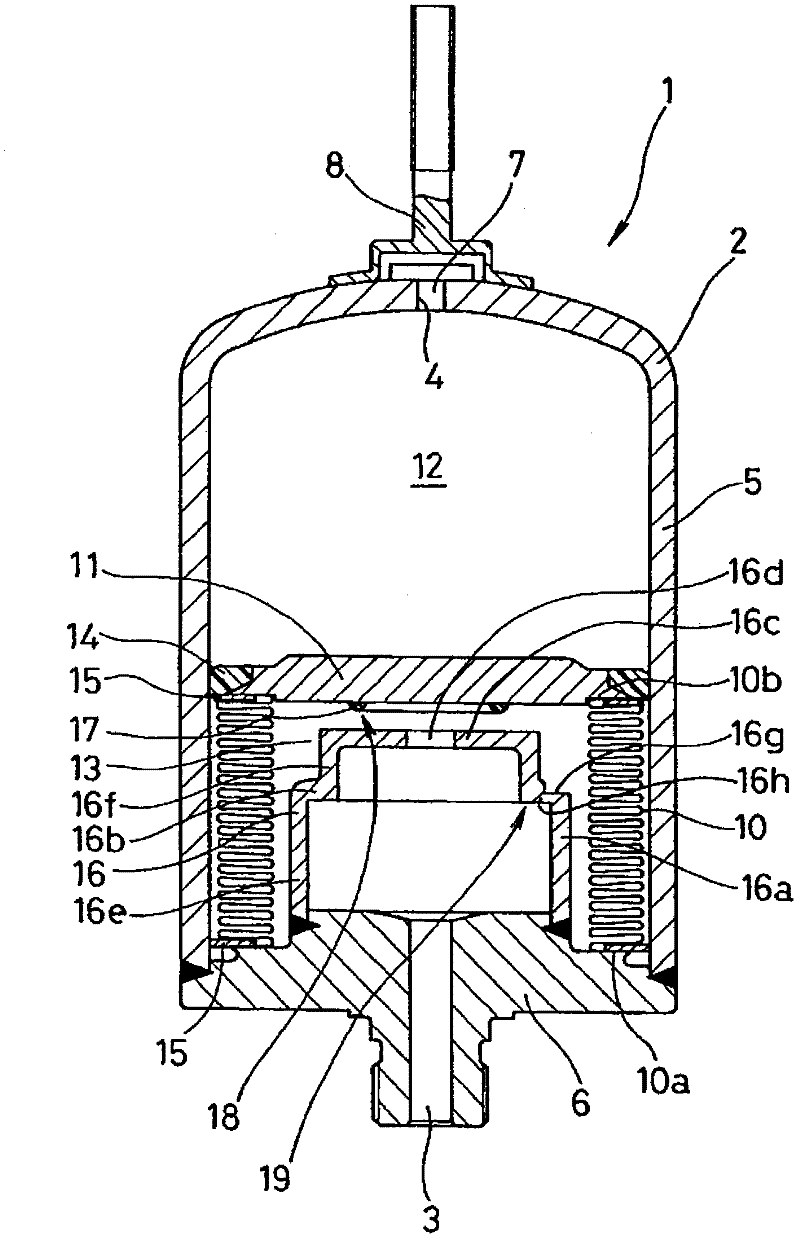

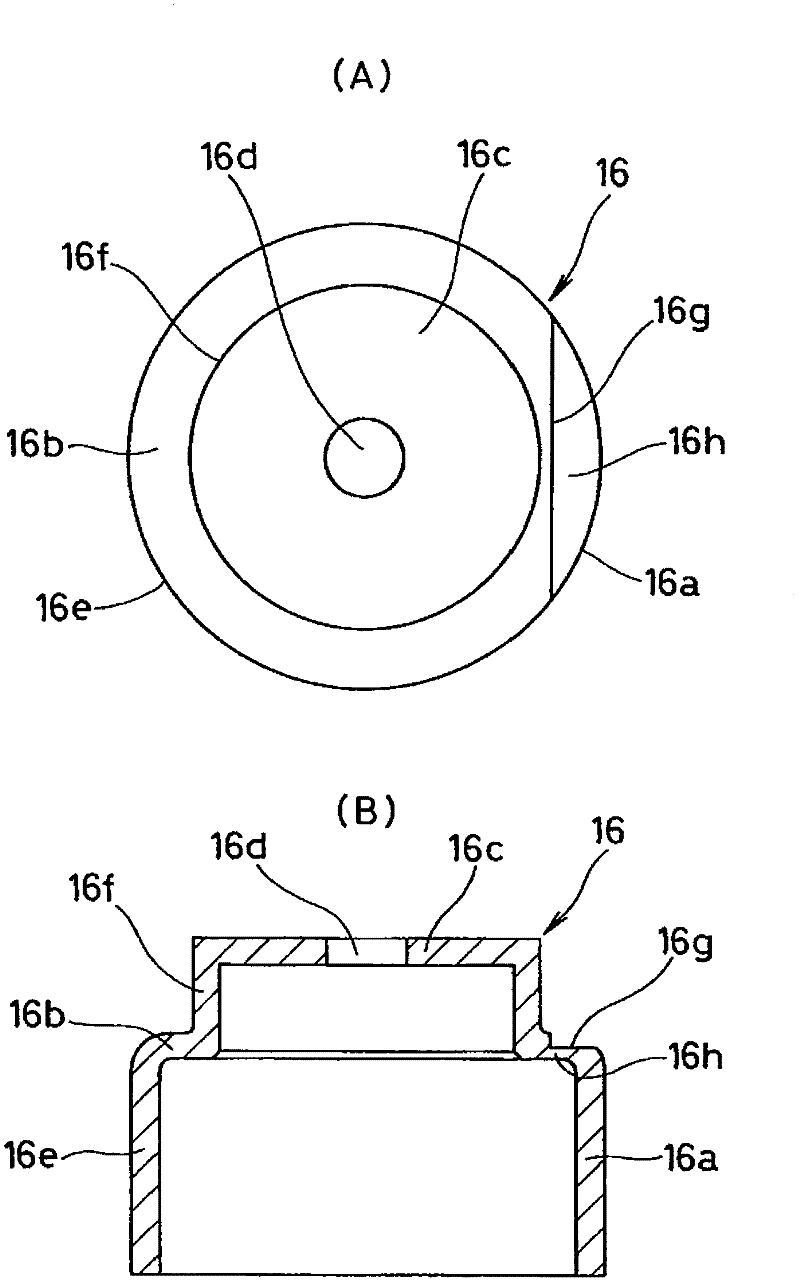

Accumulator, process and apparatus for making the same

A shell is constructed by an outer shell and an end plate. The end plate has a port into a liquid champer and a gas champer. A bladder divides an internal space of the shell into a liquid champer and a gas champer. A gas is introduced into the gas chamber without the provision of a gas inlet hole in the outer shell located on the side of the gas champer. For example, an accumulator is assembled by combining the outer shell, the end plate and bladder under atmosphere of a high pressure gas.

Owner:NOK CORP

Vehicular brake system component

ActiveUS20050061379A1Peel strengthHigh peel strengthAccumulator installationsPipe elementsBrake fluidBraking system

Owner:NHK SPRING CO LTD +2

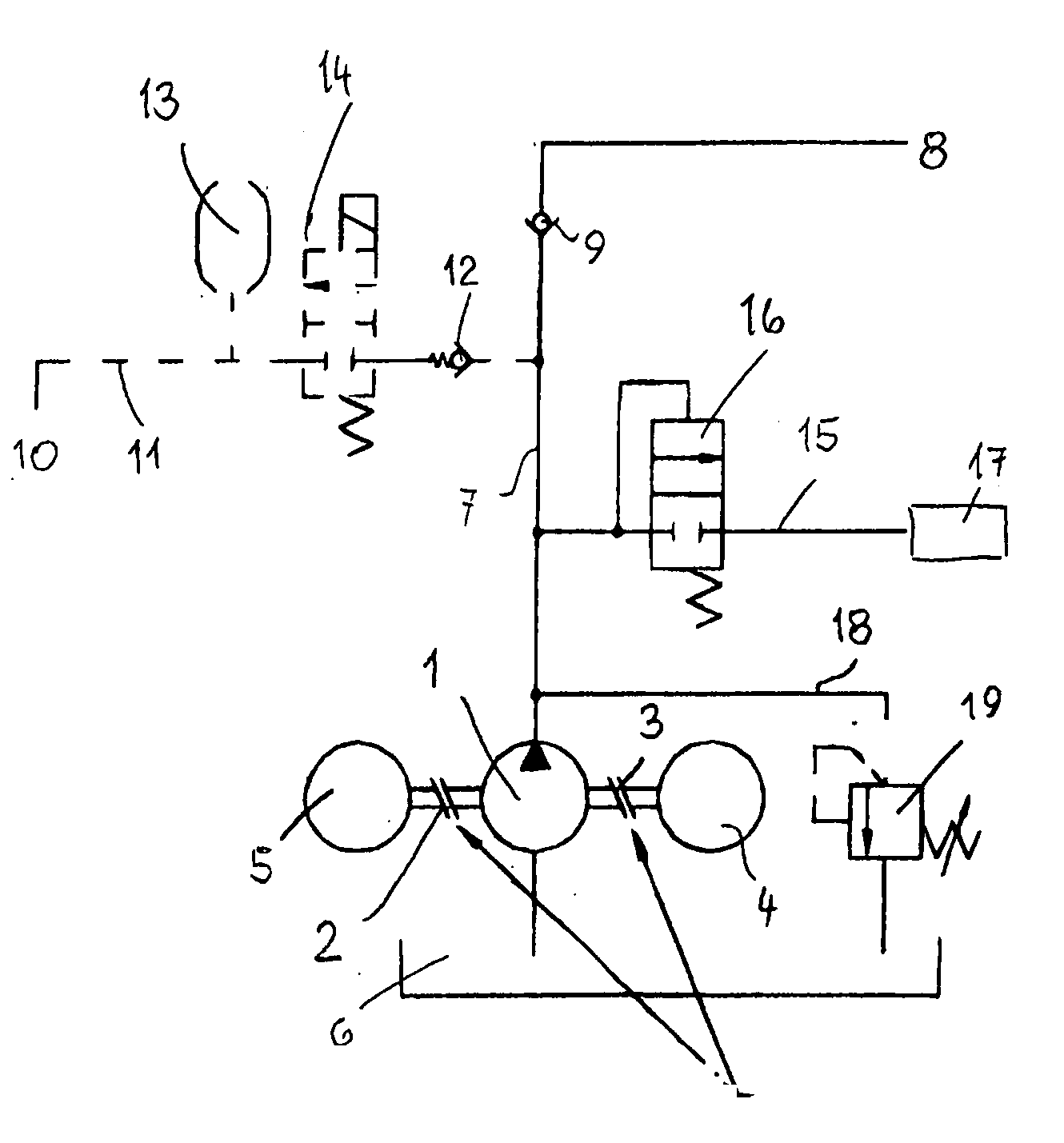

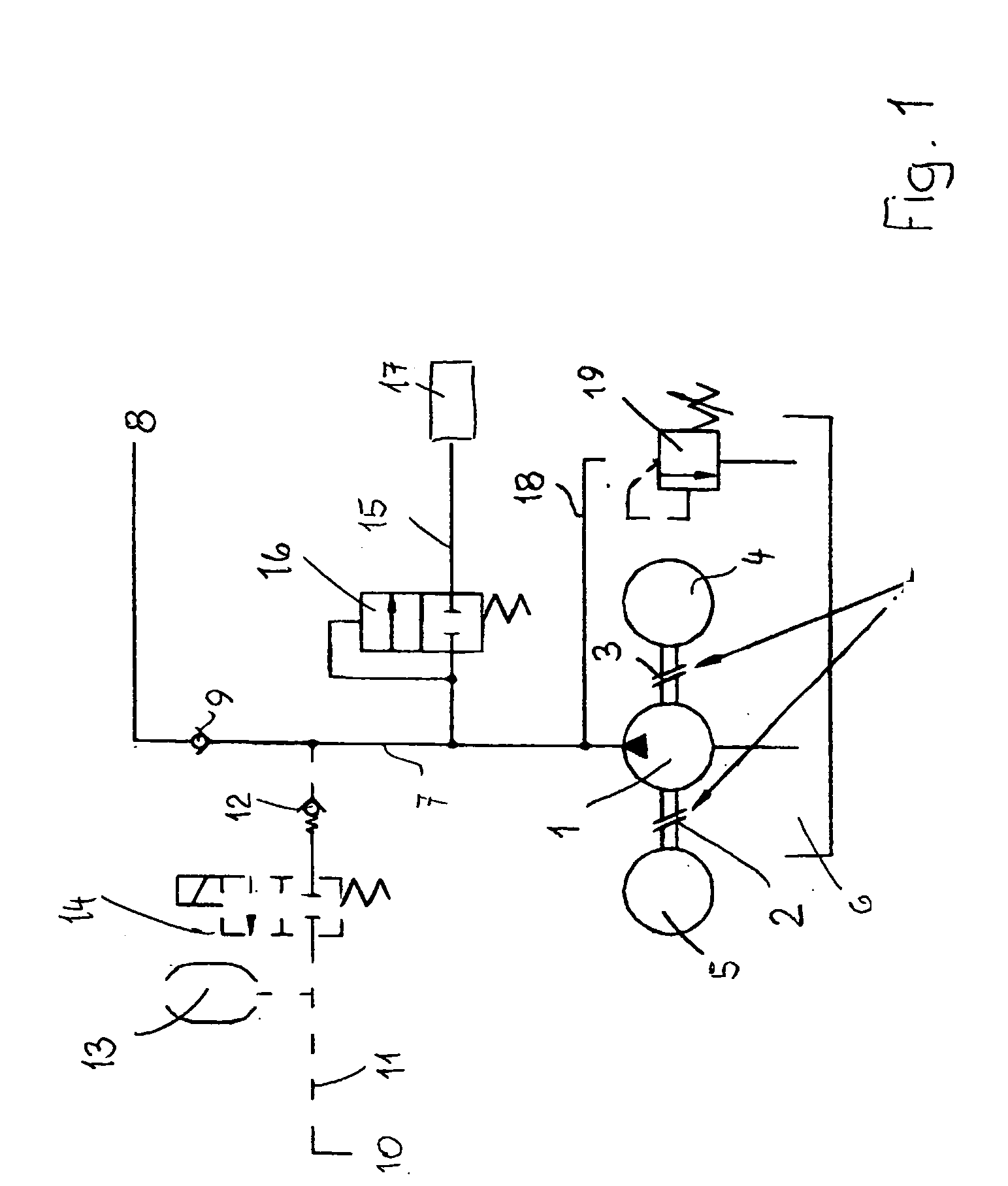

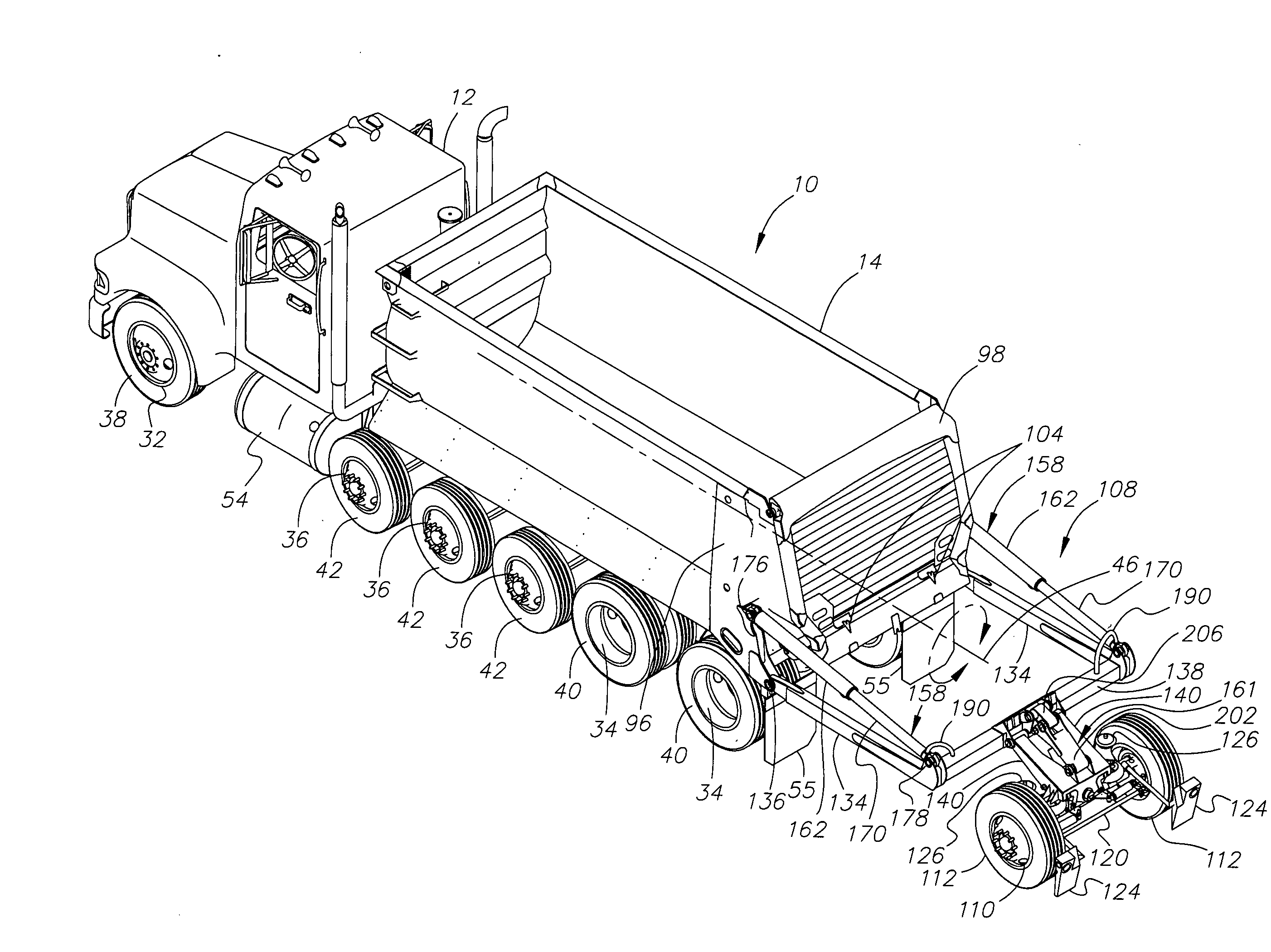

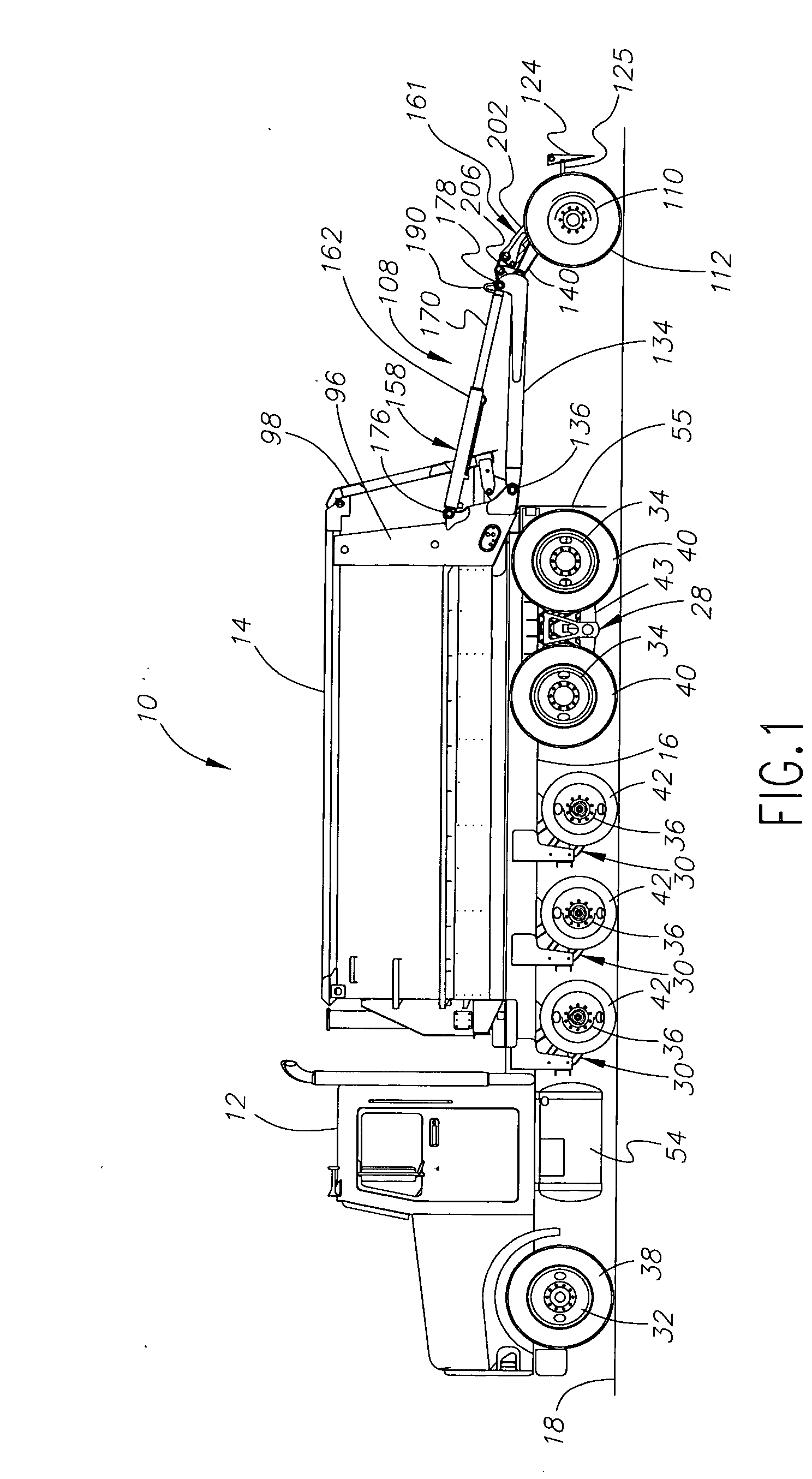

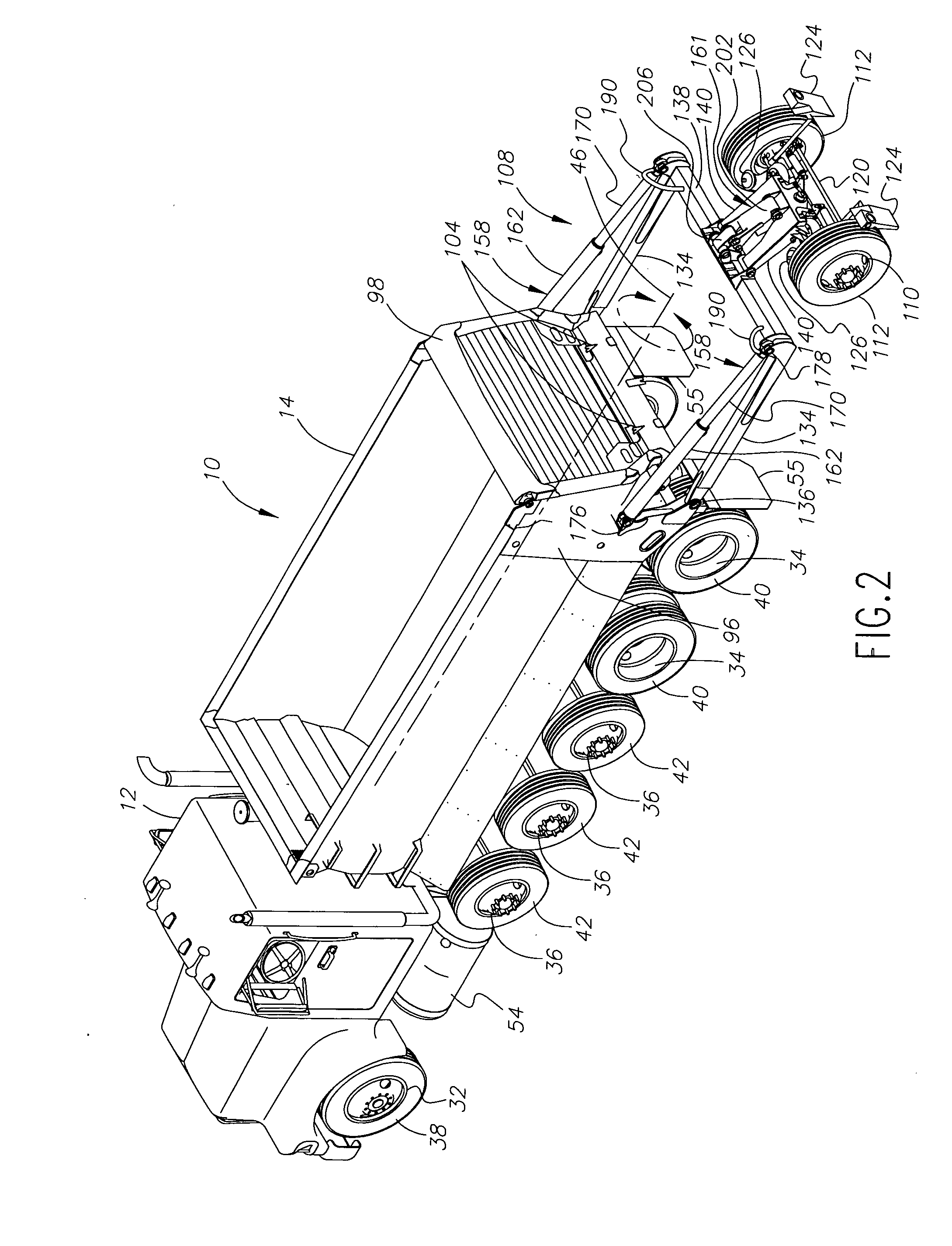

Tag axle operating system

An operating system for a tag axle having wheels with tires and air brakes wherein the tag axle is suspended from a motor vehicle and is raised and lowered by pivotal movement about a first axis by operation of parallel-arranged hydraulically-operated actuators and can also pivot about a second axis located equidistant from the tag axle wheels and laying in a plane at right angles to the first axis. The system comprises a closed gas circuit that is charged with a gas at a prescribed pressure and a hydraulic circuit that is adapted to delivery hydraulic fluid under pressure to the actuators to raise and establish the tag axle in an inactive condition and to lower and establish the tag axle in an active condition. The hydraulic circuit is adapted when the tag axle is in the active condition to establish a prescribed hydraulic operating pressure opposing the gas pressure and a resulting force on the tag axle forcing the tires to bear against a road surface and the tag axle to accept a predetermined load. A brake valve is adapted to allow air under pressure to be delivered to operate the air brakes while the prescribed hydraulic operating pressure is maintained and to prevent such delivery to thereby disable the air brakes when the prescribed hydraulic operating pressure is relieved. And the hydraulic circuit is adapted while the tag axle is in the active condition to relieve the prescribed hydraulic operating pressure and thereby relieve the force on the tag axle and disable the air brakes when the tag axle experiences a predetermined tilt angle when pivoting about the second axis.

Owner:STRONG BROOKS

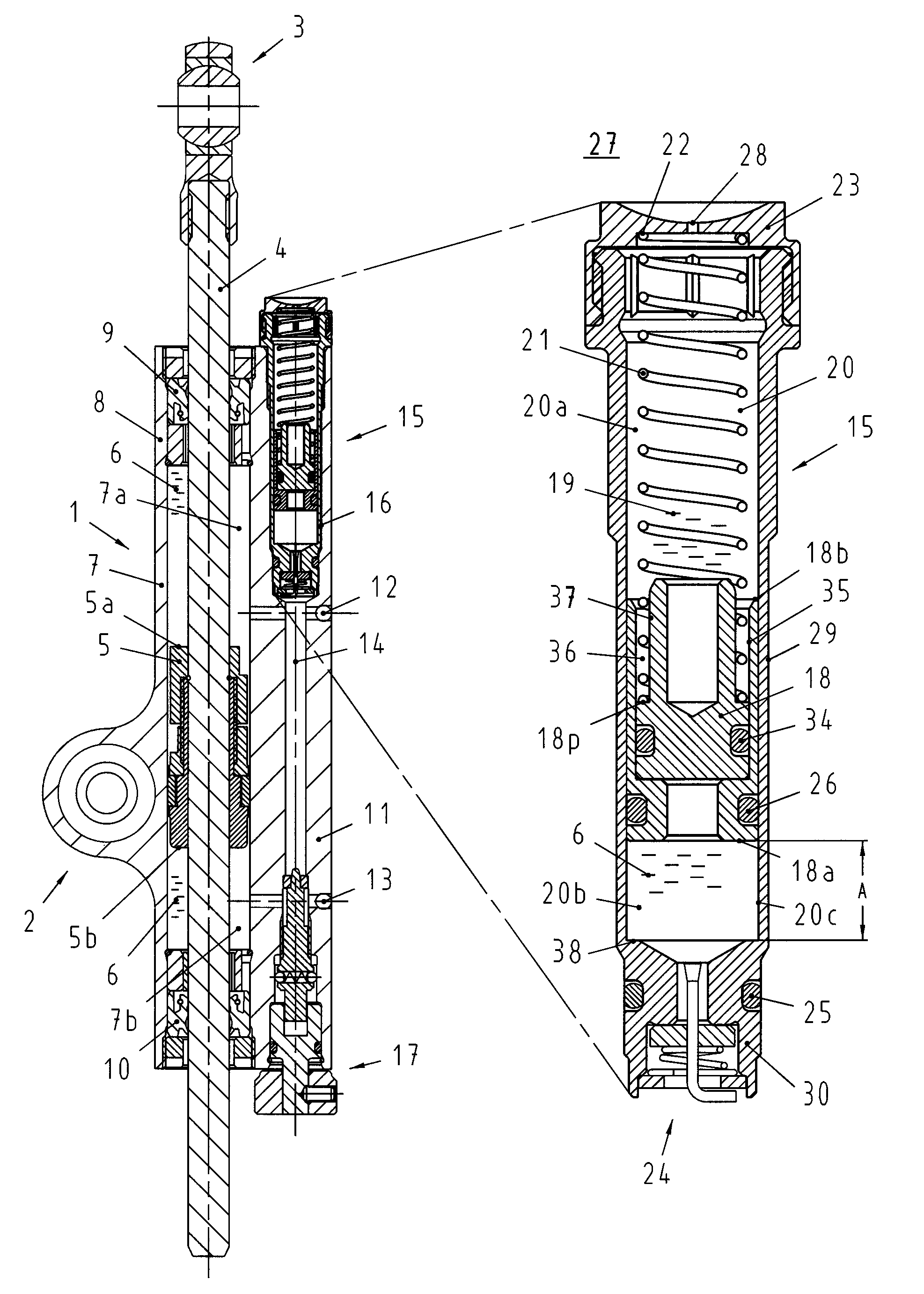

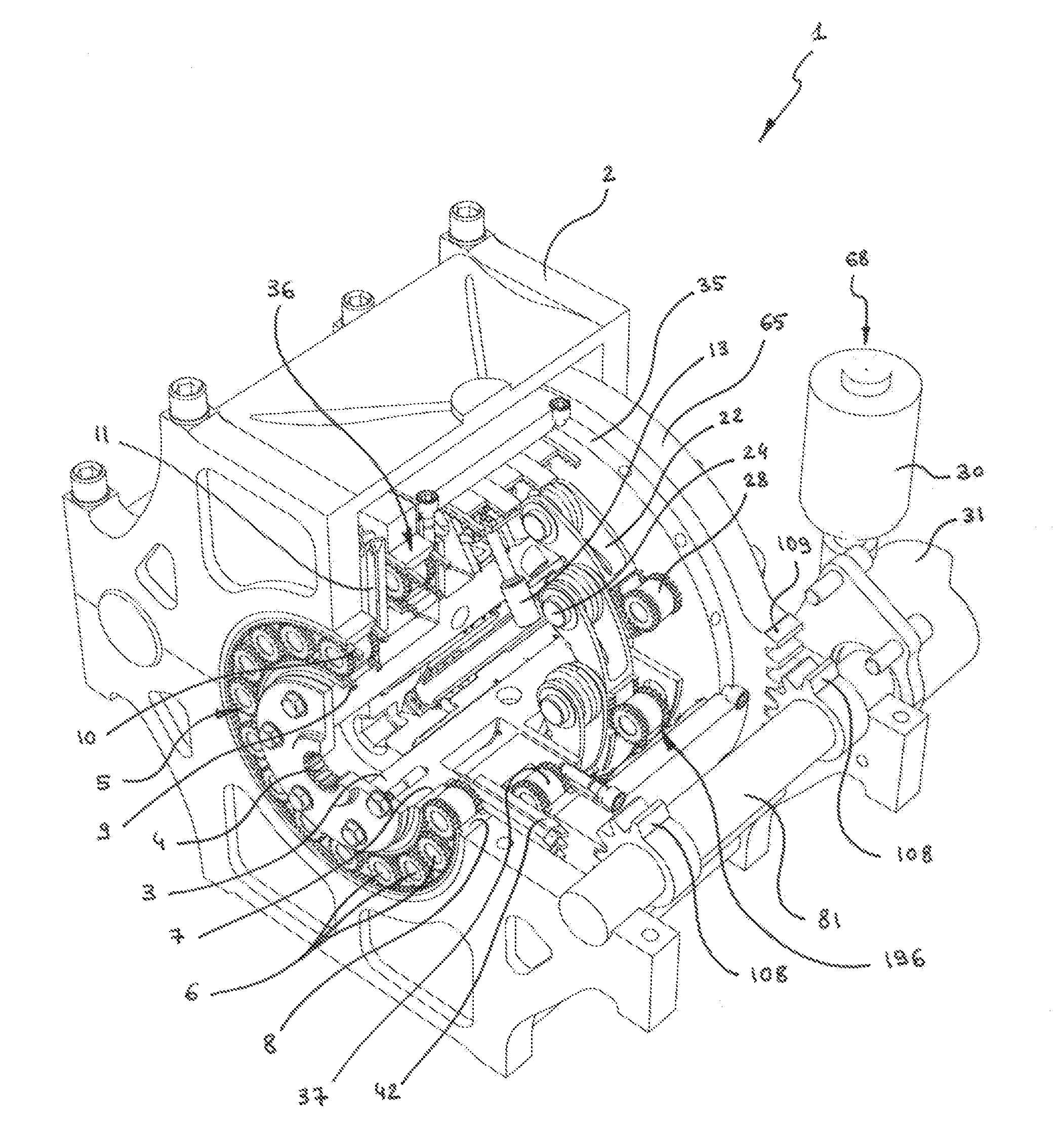

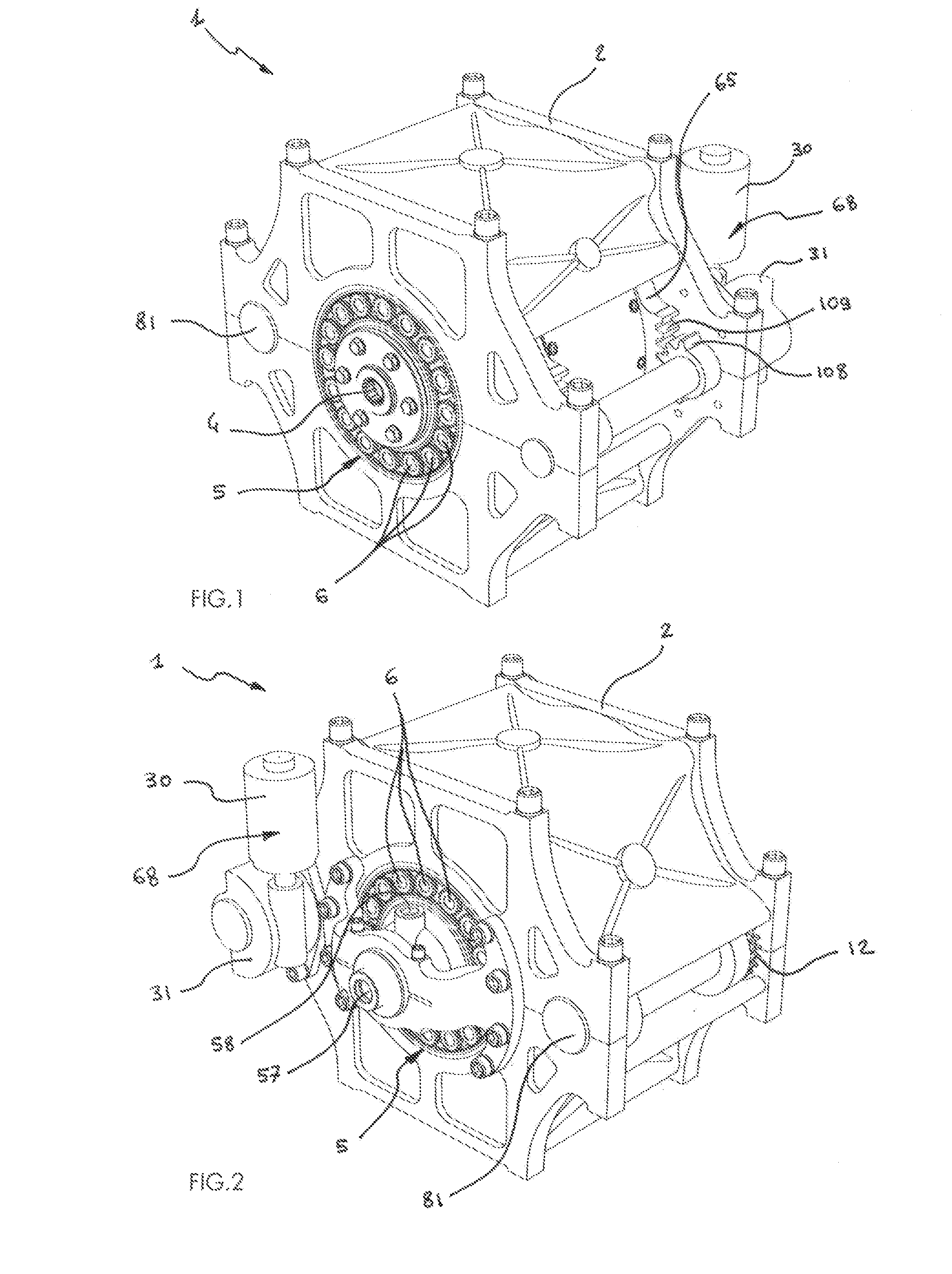

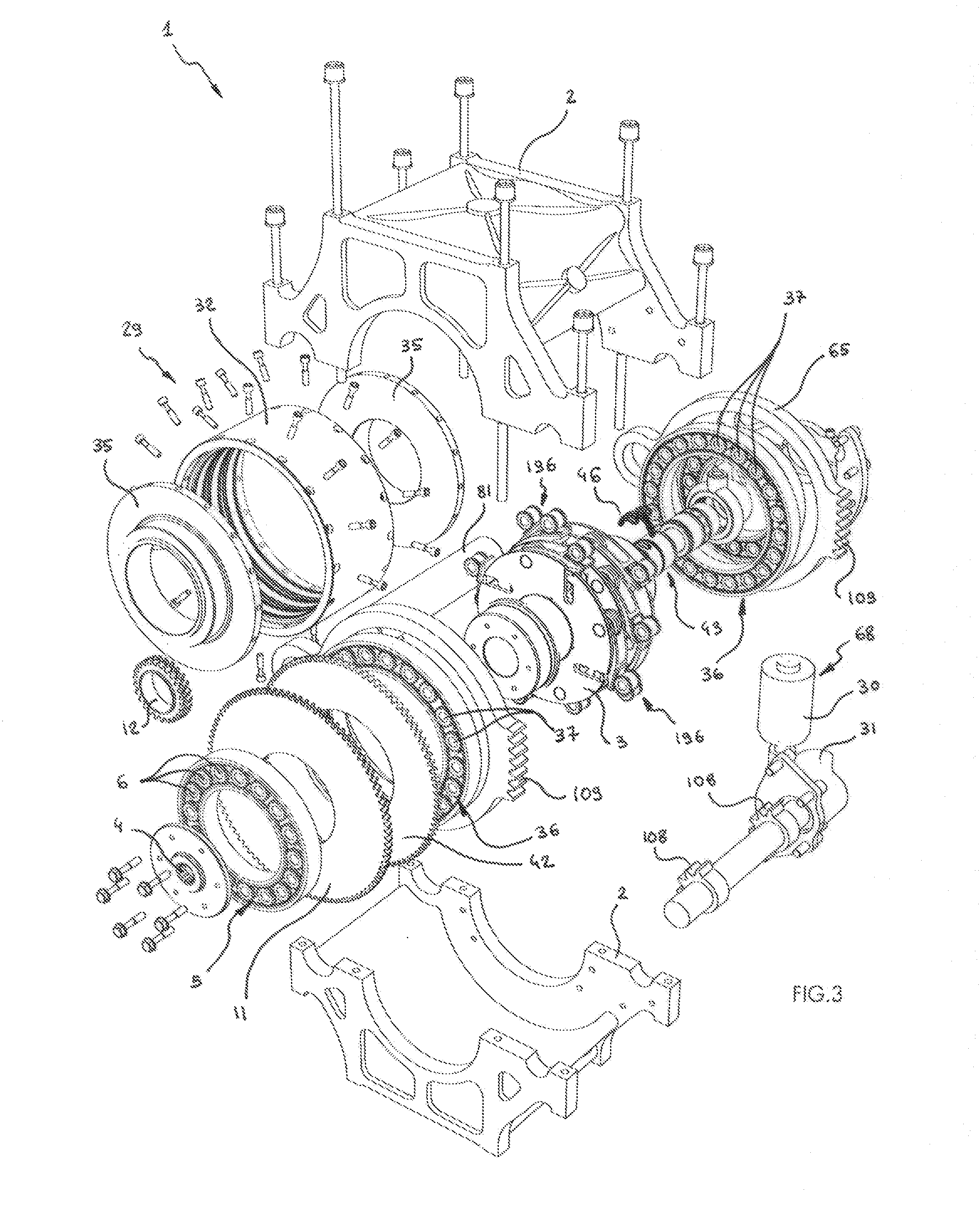

Hydraulic motor-pump with fixed or variable displacement

The fixed or variable displacement hydraulic motor-pump (1) includes a motor-pump central rotor (3) in which a hydraulic cylinder (14) is arranged, the rotor (3) being in sealed contact with an input-output spool valve (43) connecting the cylinder (14) with a motor-pump frame (2) while a hydraulic piston (13) moves in the cylinder (14) to push, using a hydraulic piston guided plunger (18), a tangential arm (22) articulated in the central rotor (3), and a tangential arm antifriction roller (28) on a motor-pump peripheral rotor (29) synchronized in rotation with the motor-pump central rotor (3).

Owner:RABHI VIANNEY

Compact hydraulic accumulator

A lightweight, optimally efficient, easily serviced, piston-in-sleeve high pressure accumulator is provided. The accumulator includes one or more cylindrical composite pressure vessel separate end cap manifolds. A piston slidably disposed in a thin impermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Gas is provided in a volume between the impermeable internal sleeve and the composite pressure vessel wall. Additional gas is optionally provided in gas cylinders. Further components are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle.

Owner:NRG ENTERPRISES

Accumulator

InactiveUS20070102052A1Made smallSolve large capacityAccumulator installationsPipe elementsEngineeringWeld penetration

An accumulator in which a pressure sealed chamber and a pressure flow-in chamber are formed by an operation member including a metallic bellows provided within a housing constituted by a gas end cover and a bottomed tubular shell, wherein a cross sectional inner outline of a peripheral edge portion of the gas end cover is an oval shape which is concave to the pressure sealed chamber side, and a dead space is not formed, so that a capacity of a volume adjusting spacer is reduced by eliminating a dead space, a working step is reduced by simplifying a shape of the gas end cover, and a margin of welding penetration depth is increased by thickening of a backing metal portion.

Owner:NOK CORP

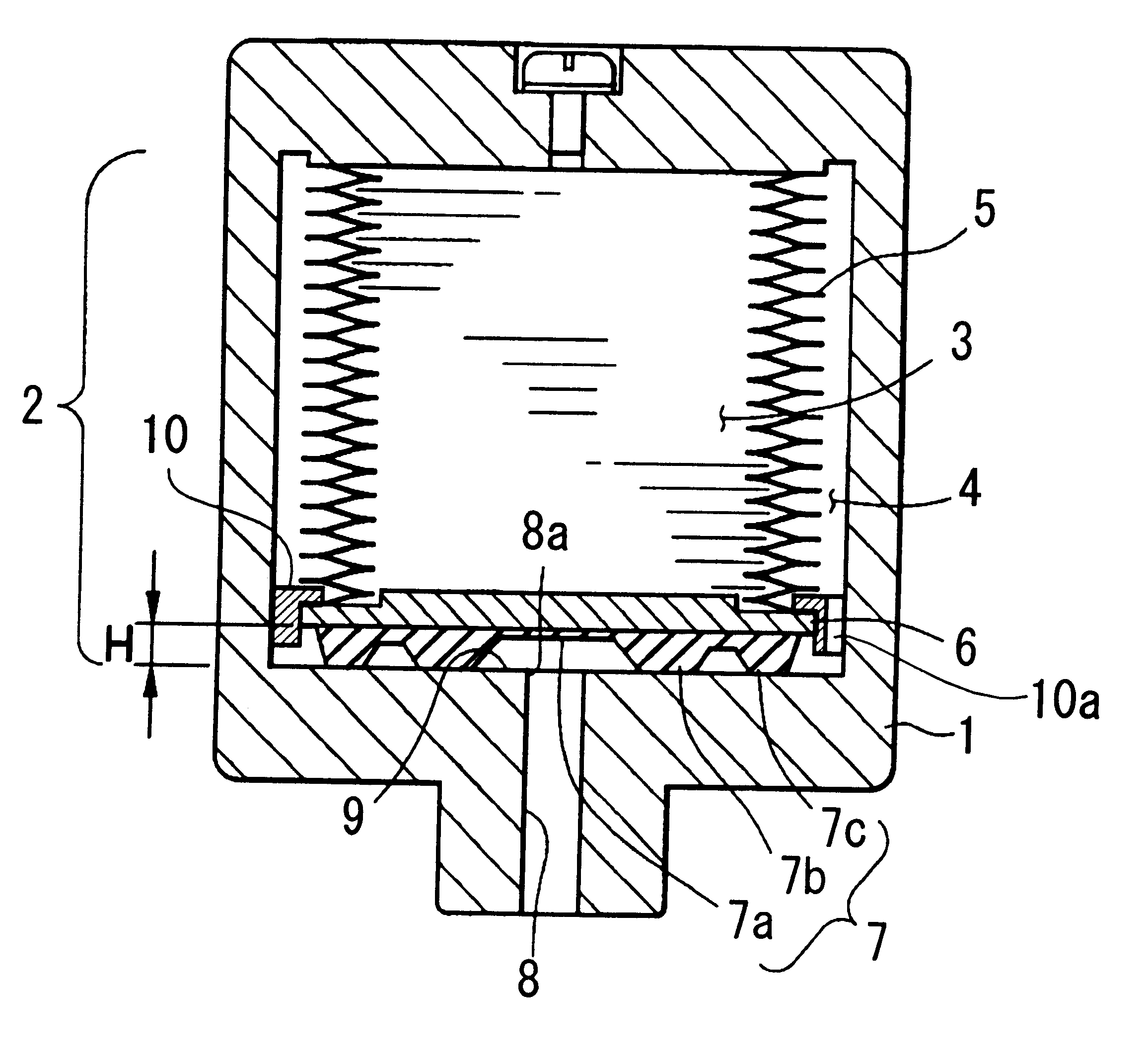

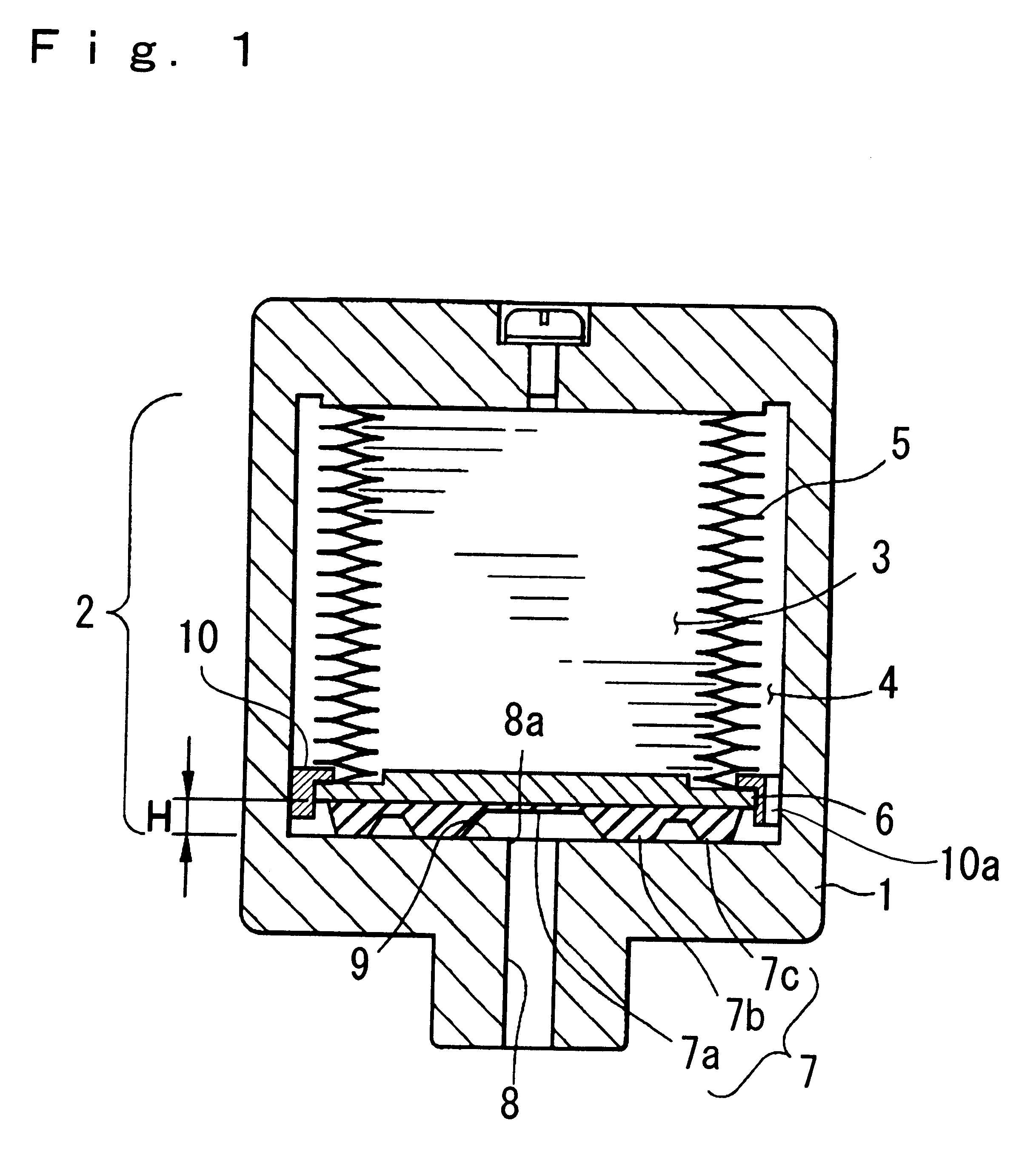

Accumulator

ActiveCN102227563AAccurateImprove securityFluid-pressure actuator safetyAccumulator installationsEngineeringHigh pressure

An accumulator provided with an emergency safety mechanism capable of being activated at a pressure lower than the pressure in the case in which a stay is provided with a rupture plate. In order to achieve the object, an accumulator comprises: an accumulator housing; a stay having a liquid inlet / outlet provided in the end surface of the tip of a stepped tubular section of the stay; a bellows equipped with a bellows cap; a safety mechanism provided in preparation for pressure reduction; and an emergency safety mechanism configured in such a manner that, in an emergency such as occurrence of a fire, the bellows cap or a member held by the bellows cap is caused to press the stay by the pressure in the housing, said pressure being high due to the occurrence of a fire, to cause the stay to be buckled at the step, opening a liquid chamber. A thin-walled section is provided at a circumferential part of the step of the stay so that, in an emergency, the end surface of the stay can easily tilt when the stay is pressed by the bellows cap to be buckled at the step.

Owner:EAGLE INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com