Accumulator

A technology of accumulator and shell, applied in the direction of accumulator device, actuator accumulator, fluid pressure actuating device, etc., can solve the problems of high rupture pressure and wrong valve opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Embodiments of the present invention will be described below with reference to the accompanying drawings.

no. 1 example

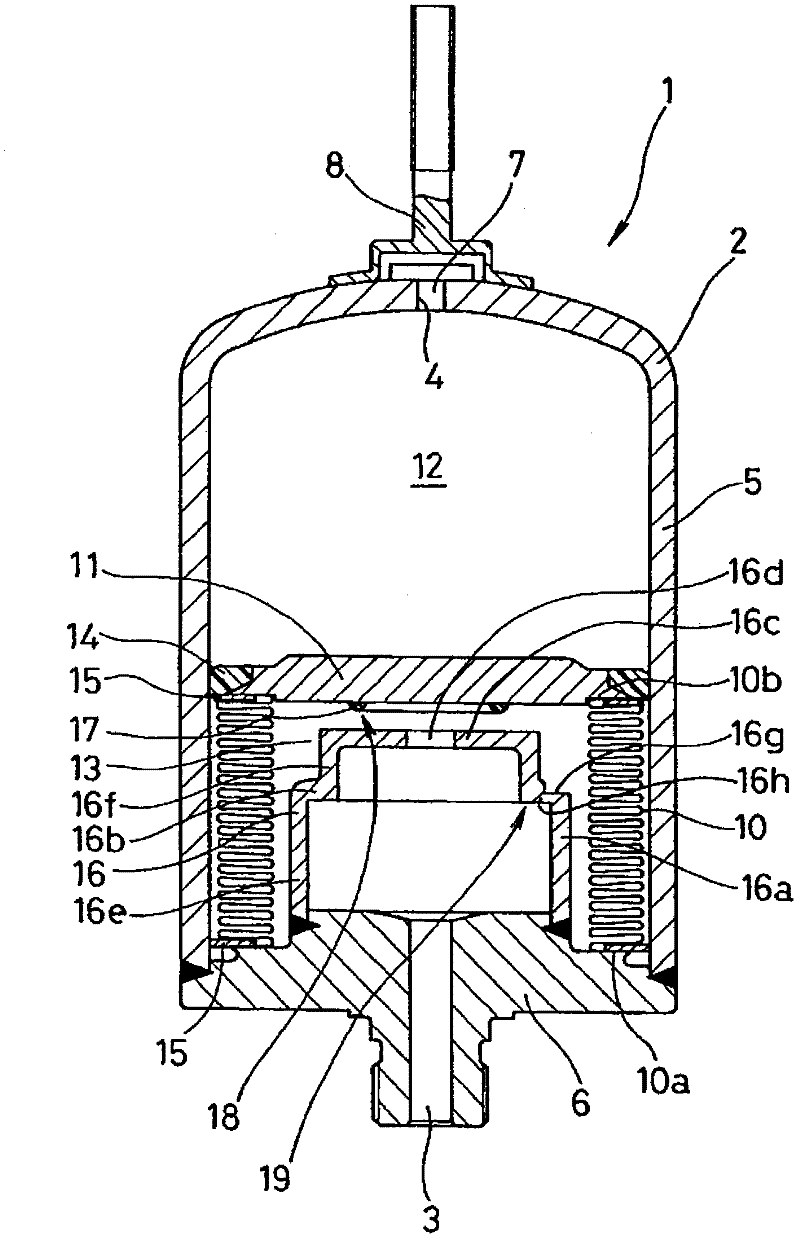

[0074] figure 1 A cross section of the accumulator 1 according to the first embodiment of the present invention is shown. The accumulator 1 according to this embodiment is a metal bellows type accumulator using a metal bellows as the bellows 10, and is configured as follows.

[0075] That is, firstly, an accumulator case 2 having one end (lower end in the figure) provided with an oil injection port 3 connected to a pressure pipe not shown in the figure, and the other end (upper end in the figure) provided with a gas inlet 4 is provided. A bellows 10 and a bellows cover 11 are arranged inside the housing 2, and the inner space of the housing 2 is divided into a gas chamber 12 filled with high-pressure gas (such as nitrogen) and a liquid chamber 13 communicating with the oil nozzle 3. Although it has been described that the housing 2 is composed of a bottomed cylindrical housing 5 and an oil nozzle member 6 fixed (welded) to an opening at one end of the housing 5, the componen...

no. 3 example

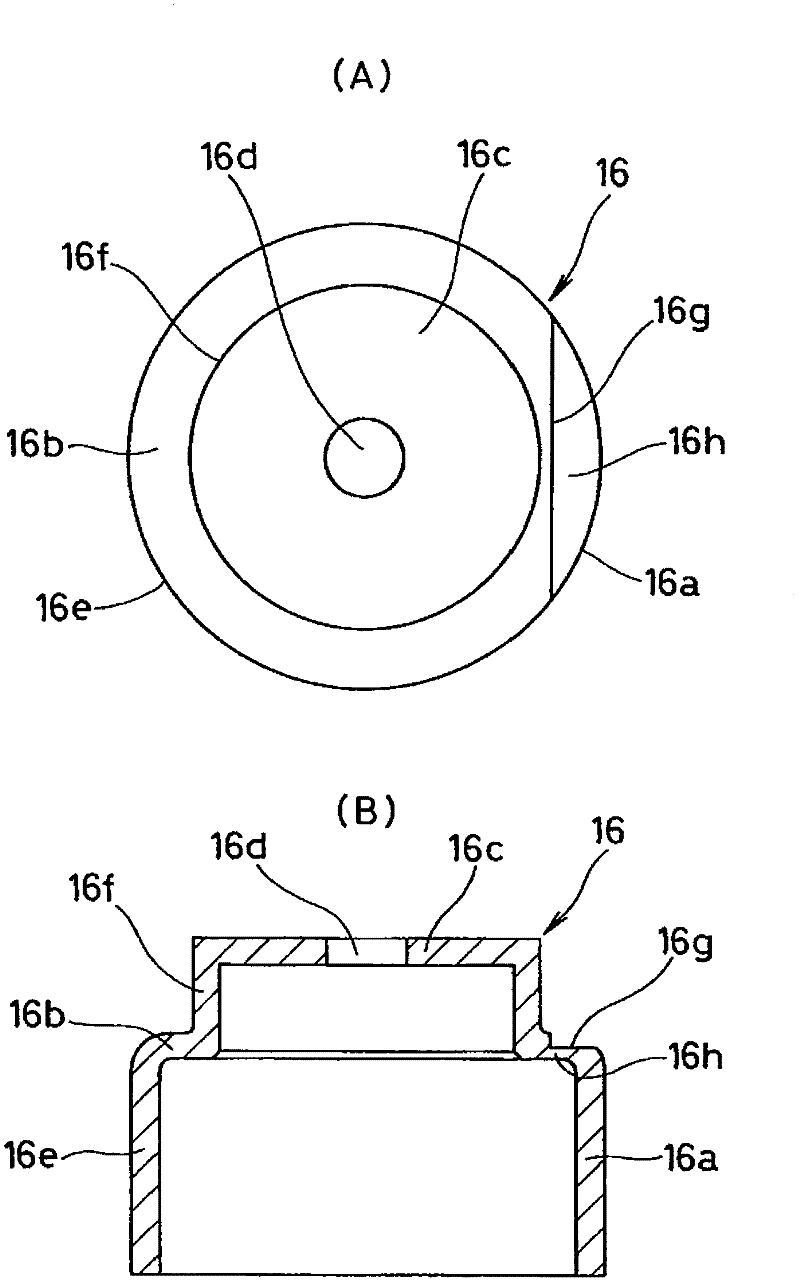

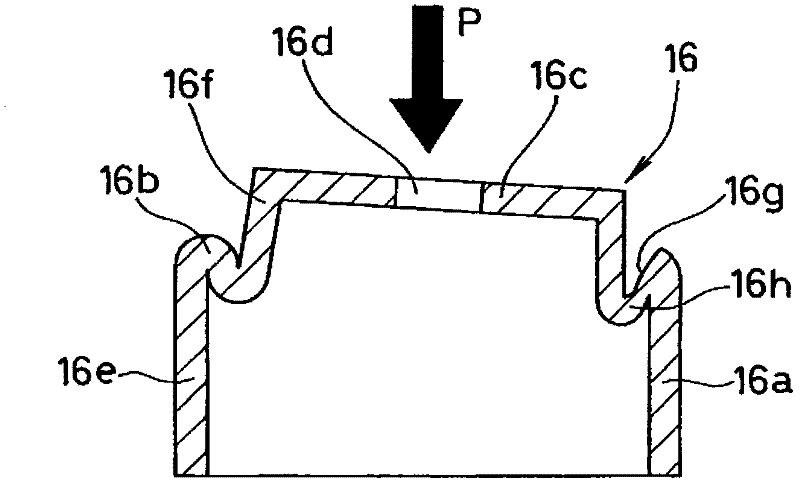

[0093] In addition, if figure 2 As shown in (A), in this embodiment, the planar shape of the notch portion 16g for forming a part of the thin wall portion 16h on the circumference is set to be arcuate, but, as Figure 4 As shown, as the second embodiment, it can also be set as a plane arc shape. In addition, in this embodiment, the notch portion 16g for forming the thin-walled portion 16h on a part of the circumference is provided on the outside (upper side) of the step difference 16b, however, as Figure 5 As shown, as the third embodiment, it may be installed on the inside (lower side) of the step difference 16b, or may be installed on both the outside (upper side) and the back side (lower side) of the step difference 16b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com