A method for making L2 blind hole of high-density interconnection circuit board

A technology of high-density interconnection and second-order blind holes, which is applied to the removal of conductive materials by chemical/electrolytic methods, multilayer circuit manufacturing, printed circuit components, etc., can solve the problem of affecting the transmission effect of electrical signals between multilayer lines, Affecting the shape of second-order blind holes, many process steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

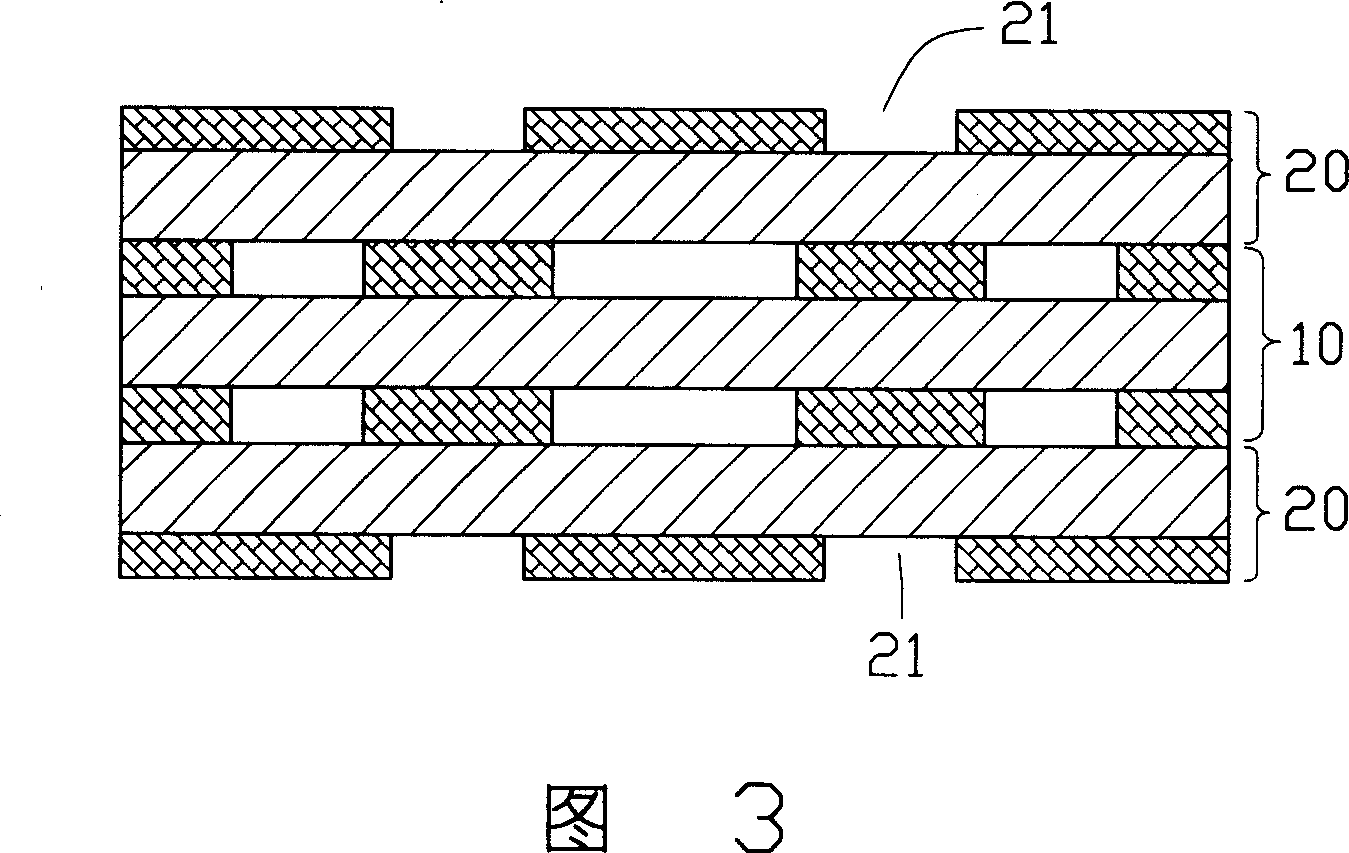

[0023] The method for manufacturing second-order blind holes of a high-density interconnection circuit board will be further described in detail below with reference to the accompanying drawings and embodiments.

[0024] This embodiment provides a method for manufacturing a second-order blind hole of a high-density interconnection circuit board, which includes the following steps:

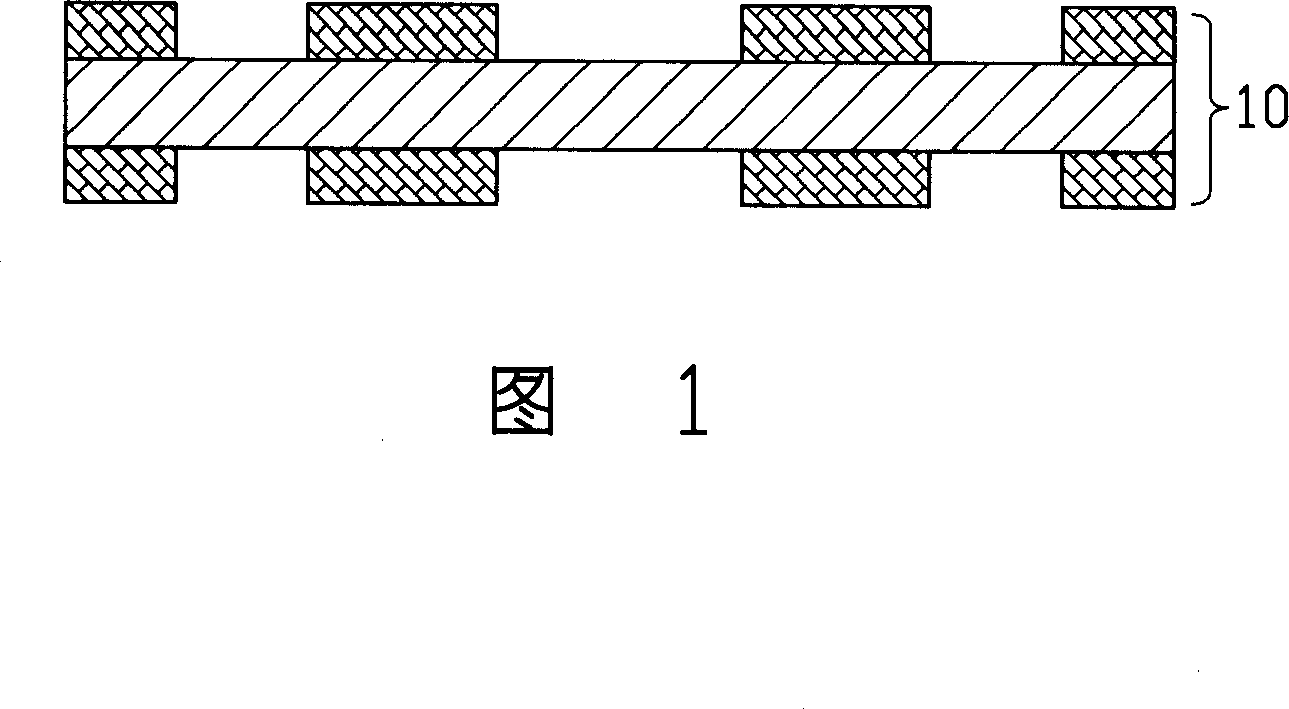

[0025] (a) providing a circuit board with a circuit on at least one side thereof;

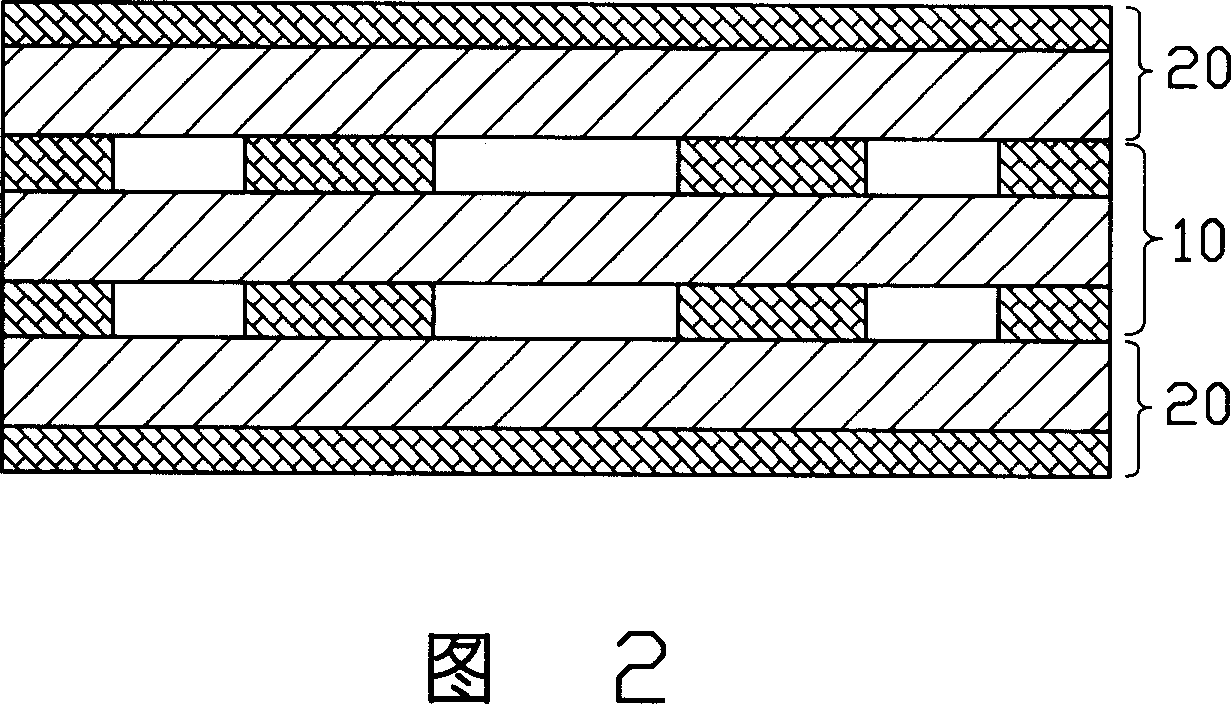

[0026] (b) forming a first adhesive-backed copper foil on the circuit surface;

[0027] (c) forming a plurality of first copper windows in the copper foil layer of the first adhesive-backed copper foil;

[0028] (d) forming a second adhesive copper foil on the surface of the first adhesive copper foil formed with the first copper window;

[0029] (e) using a first laser to form a plurality of second copper windows corresponding to the first copper windows in the copper foil layer of the second adhesive-backed copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com