Patents

Literature

64results about How to "Strong interface force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

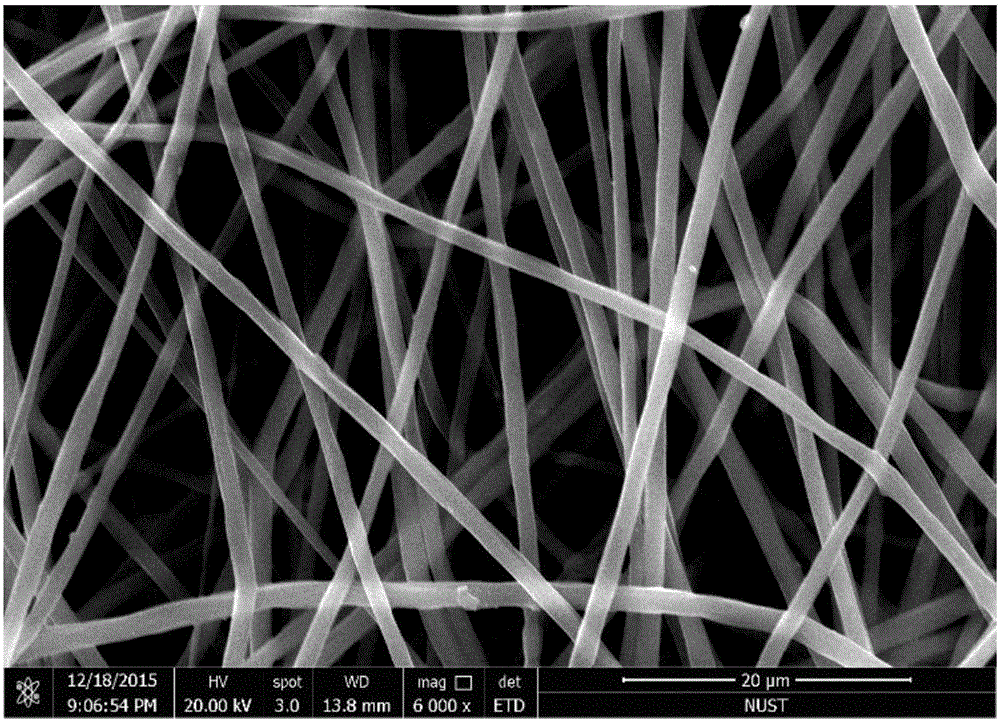

Reinforced heat-resistant polylactic acid electrostatic spun fibrous membrane and preparation method therefor

ActiveCN105755675AHigh strengthImprove heat resistanceElectro-spinningNon-woven fabricsFiberN dimethylformamide

The invention discloses a reinforced heat-resistant polylactic acid electrostatic spun fibrous membrane and a preparation method therefor. The electrostatic spun fibrous membrane comprises polylactic acid matrix resin and a composite reinforcing agent, wherein the composite reinforcing agent is a graphene oxide sheet with the surface loaded with a zeolite imidazate framework ZIF-8. The preparation method for the electrostatic spun fibrous membrane comprises the steps of mixing a polylactic acid solution with a certain concentration with an ultrasonic dispersion solution of N'N-dimethylformamide of the composite reinforcing agent according to a ratio by adopting a solution mixing method, and then performing electrostatic spinning under a certain process condition through an electrostatic spinning method to prepare the electrostatic spun fibrous membrane. Compared with a pure polylactic acid fibrous membrane, the electrostatic spun fibrous membrane has the advantages that both the tensile strength and break elongation rate of the polylactic acid fibrous membrane are remarkably improved; the heat resistance of the polylactic acid fibrous membrane is remarkably enhanced; and the electrostatic spun fibrous membrane is biodegradable, safe, reliable, odor-free and low in human body and environmental harm and pollution degree, thereby having wide application values in the fields of biomedicines, packages, textiles, traffic, electronics, electric equipment and the like.

Owner:NANJING UNIV OF SCI & TECH

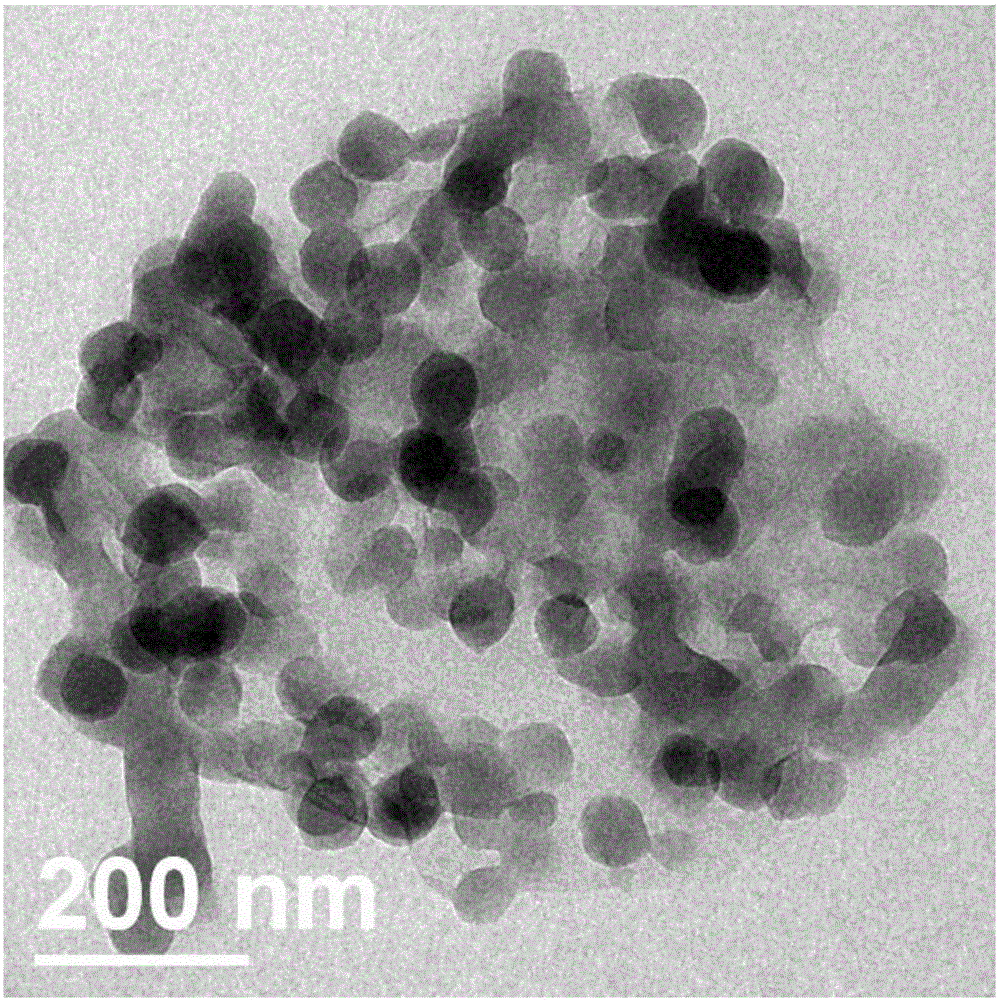

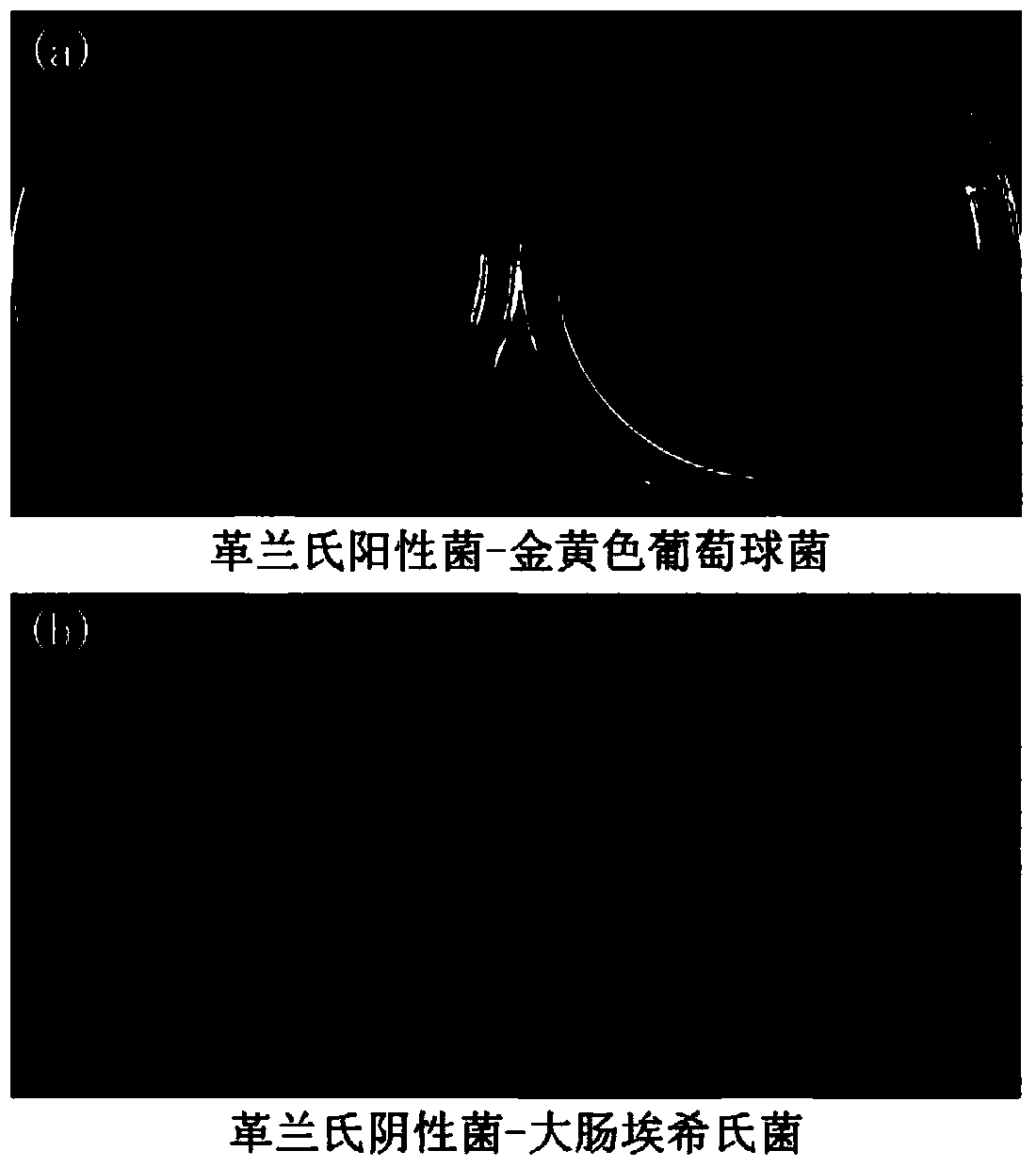

Polylactic acid/modified graphene oxide antibacterial plastic and preparation method

The invention discloses polylactic acid / modified graphene oxide antibacterial plastic and a preparation method. The antibacterial plastic is composed of polylactic acid matrix resin and a composite antibacterial agent. The composite antibacterial agent is graphene oxide sheets with the surfaces loaded with zinc oxide nano-particles. The preparation method of the antibacterial plastic comprises the following steps that a trichloromethane solution of polylactic acid and a trichloromethane dispersing solution of the composite antibacterial agent are blended according to a certain ratio with a solution blending method, a clean glass plate is coated with the mixed solution through an automatic coating machine, and the solution is naturally volatilized at a room temperature. The polylactic acid / modified graphene oxide antibacterial plastic is obvious in antibacterial effect, wide in antibacterial range, biodegradable, safe, reliable, free from peculiar smell, and low in degree of harm and pollution to the human body and the environment.

Owner:NANJING UNIV OF SCI & TECH

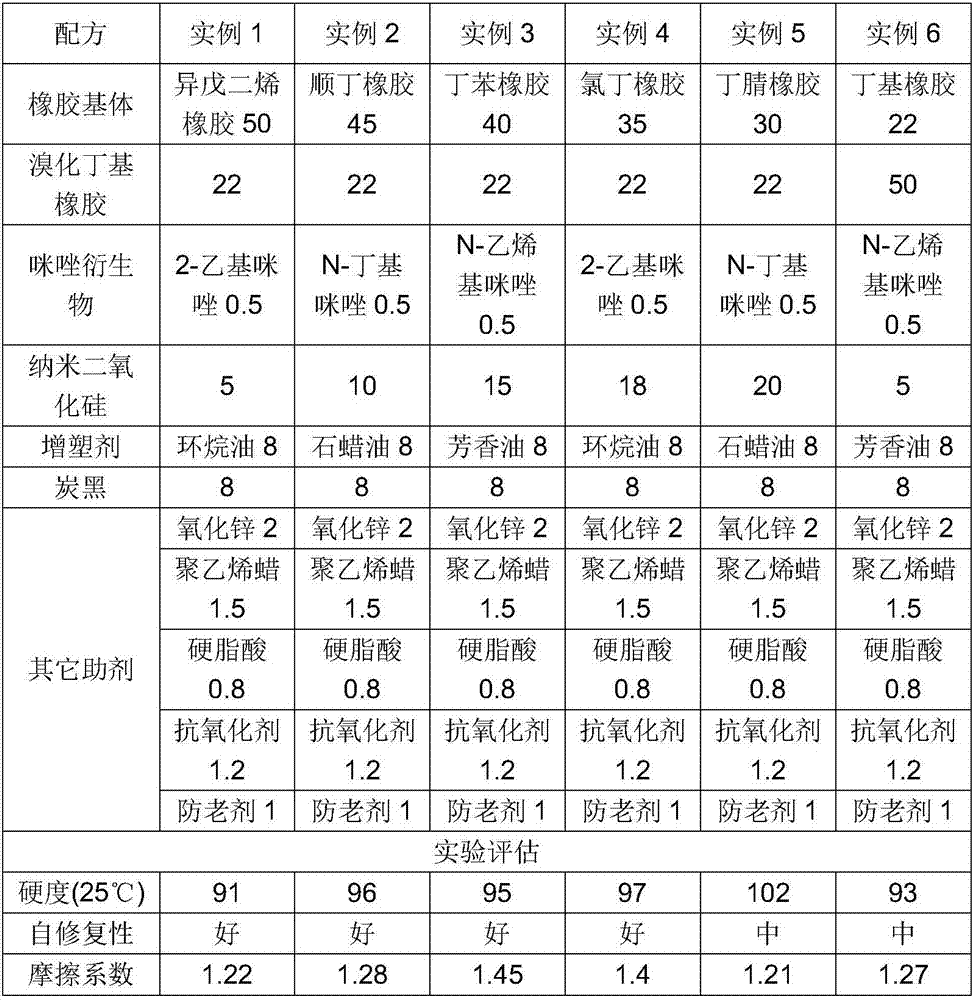

Self-healing antiskid unvulcanizedrubber material and preparation method thereof

The invention discloses a self-healing antiskid unvulcanized rubber material comprising the following components in percentage by weight: 20-50wt% of a rubber matrix, 1-50wt% of brominated butyl rubber, 0.1-0.5wt% of an imidazole derivative, 5-25wt% of nano silicon dioxide, 5-20wt% of a plasticizer, 5-10wt% of carbon black, and 1-5wt% of an auxiliary agent. The invention also discloses a preparation method. The self-healing antiskid unvulcanized rubber material disclosed by the invention has excellent weathering resistance, water tightness and air tightness, has good resistance to chemicals, oils, solvents and the like, can be used for manufacturing a sole material, automobile tires, and antiskid wear-resistant materials in various aspects of processing and manufacturing, and can also be used as a sealing ring and a waterproof material.

Owner:成都微熵科技有限公司

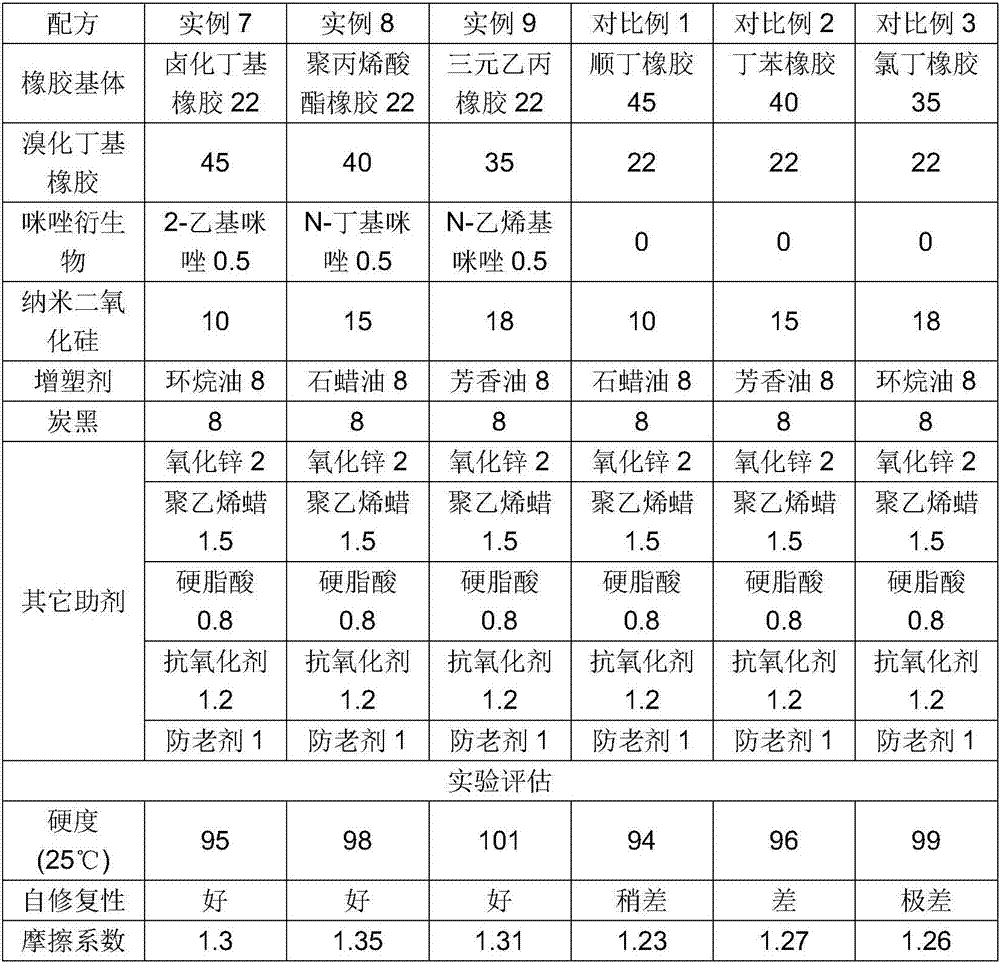

Modified carbon material as well as preparation method and application thereof

The invention relates to a modified carbon material as well as a preparation method and an application thereof, and belongs to the field of preparation of engineering materials. According to the technical scheme disclosed by the invention, modification of the carbon material comprises the following three steps: acidification of the carbon material; preparation of derivatives of chlorine of the carbon material; and amination of the carbon material. The method can be suitable for carbon materials with different shapes and structures, and the modified carbon material displays a good modification effect when being applied to modification of epoxy resin materials.

Owner:ORDOS JUNSHI TECH

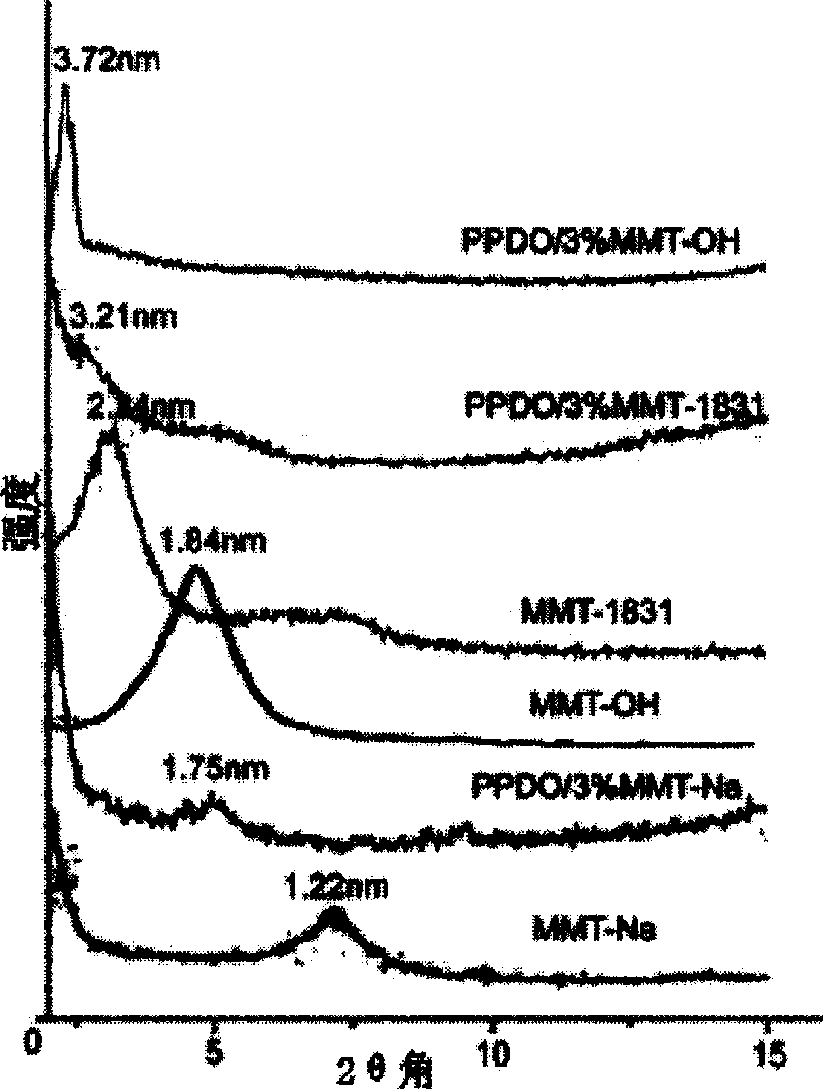

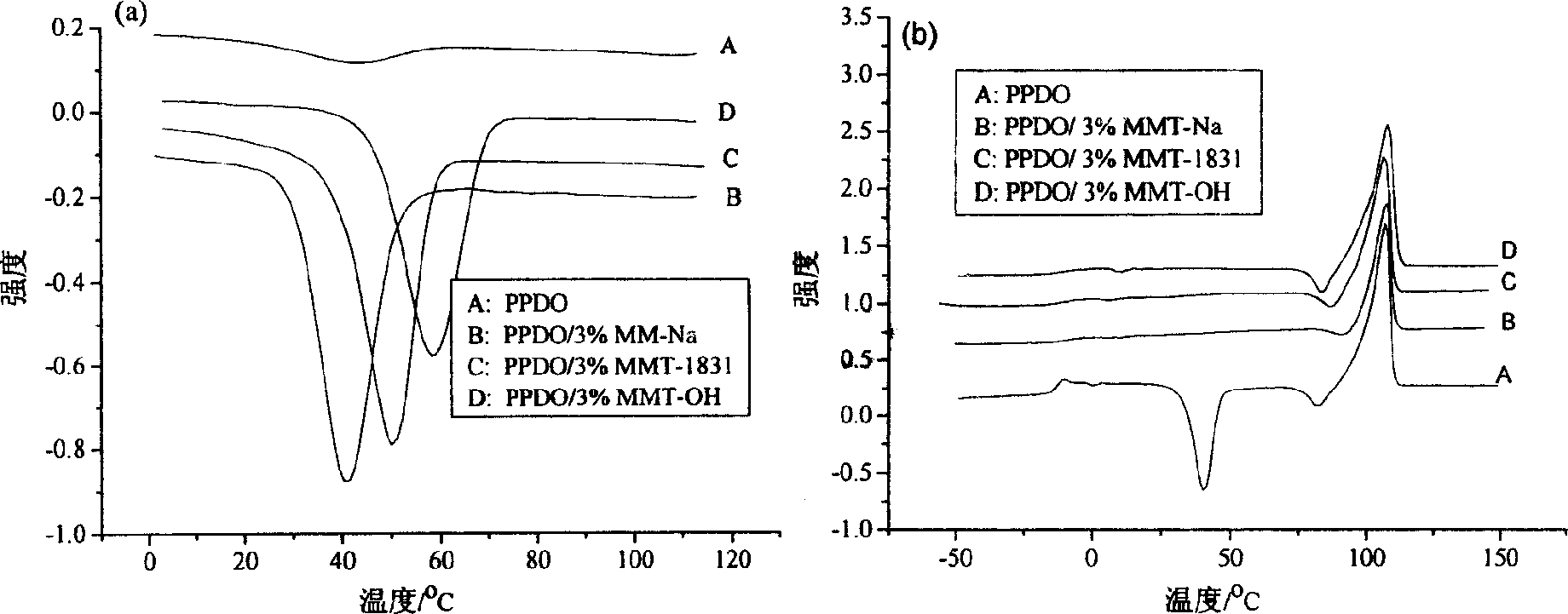

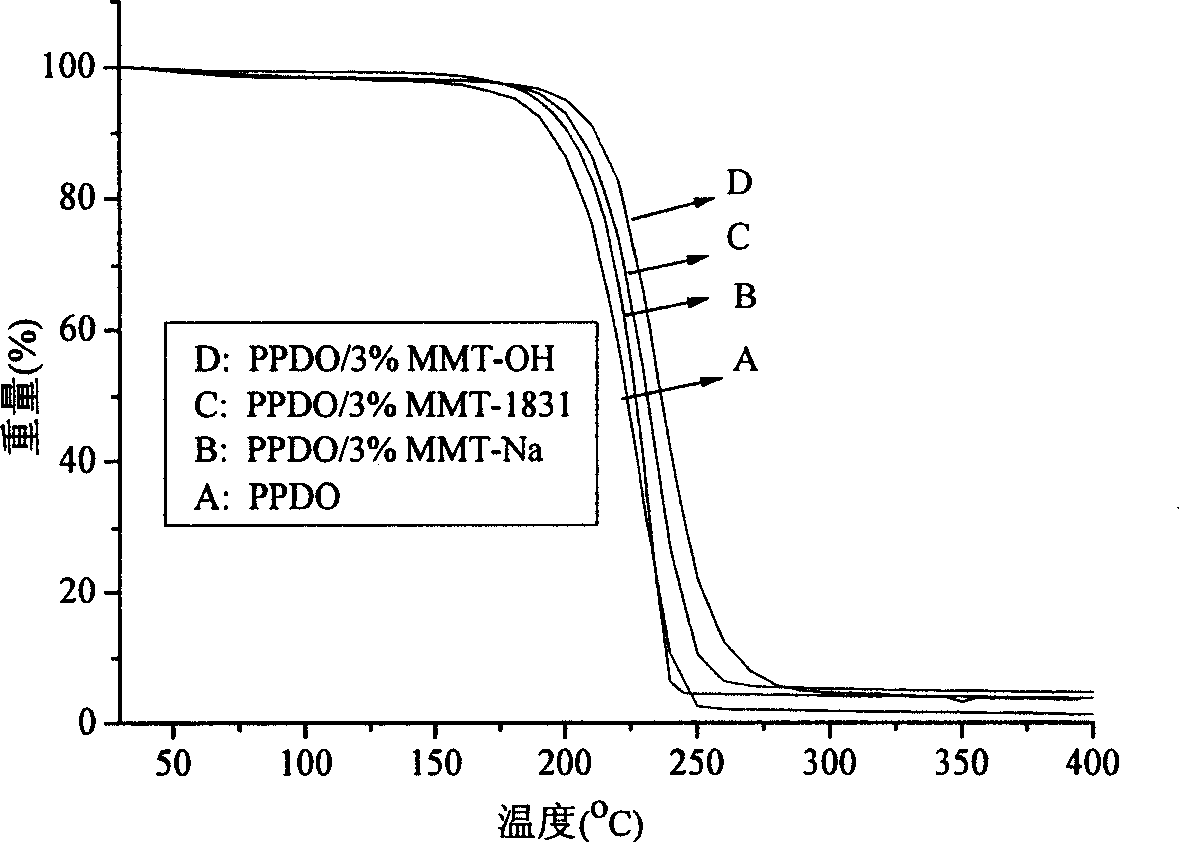

Polypara dioxocyclohexanone / montmorillonite nano-composite material and its preparation method

ActiveCN1651509AOvercome the defects that can not be blown film formingImprove mechanical propertiesPolymer scienceNanoparticle

A poly-p-dioxycyclohexanone / montmorillonite nano-composition is prepared from poly-P-dioxycyclohexanone and montmorillonite nanoparticles through proportionally mixing, stirring, heating, adding catalyst and reacting. Another preparing process is also disclosed. Said nano-composition features high mechanical and thermal performance, low reaction condition and high molecular weight.

Owner:成都普利铭医用材料科技有限责任公司

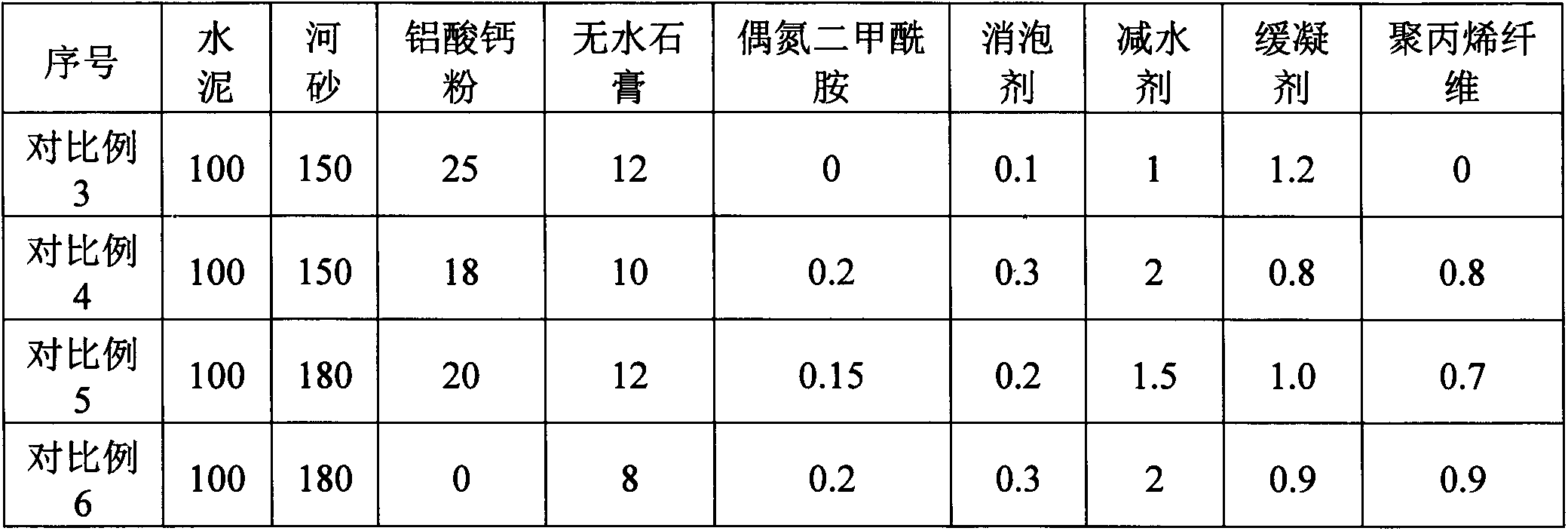

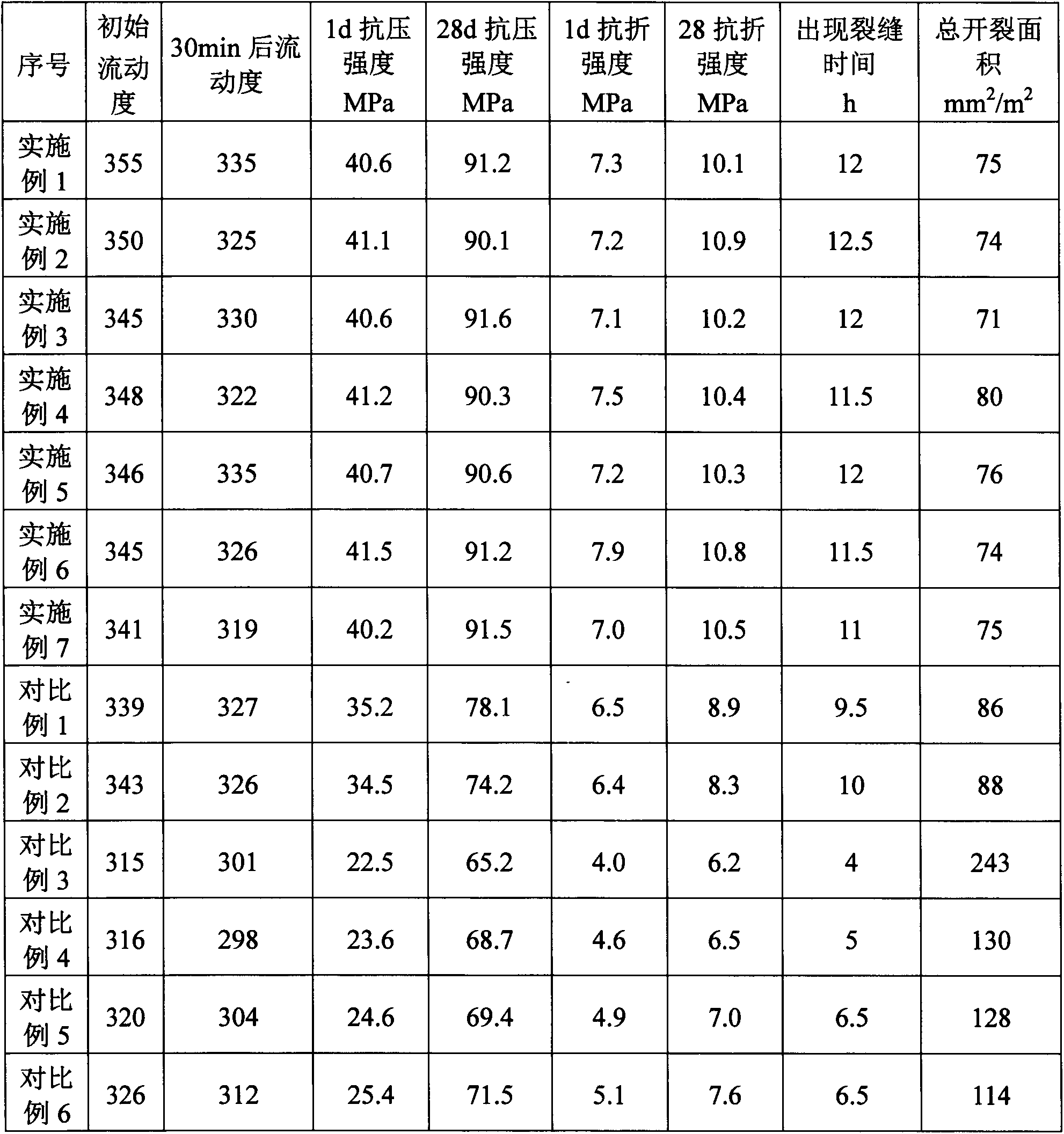

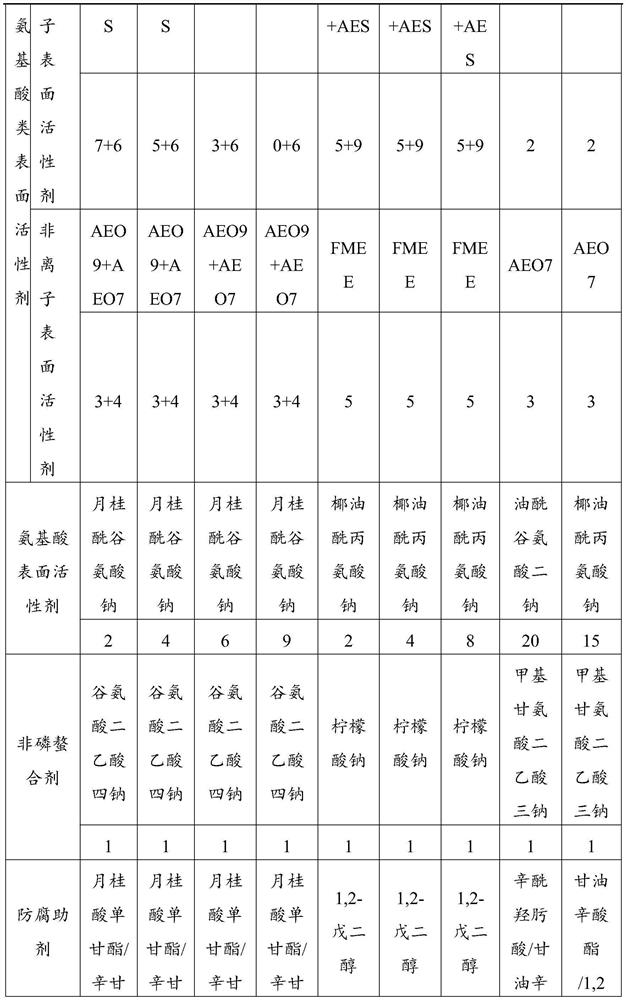

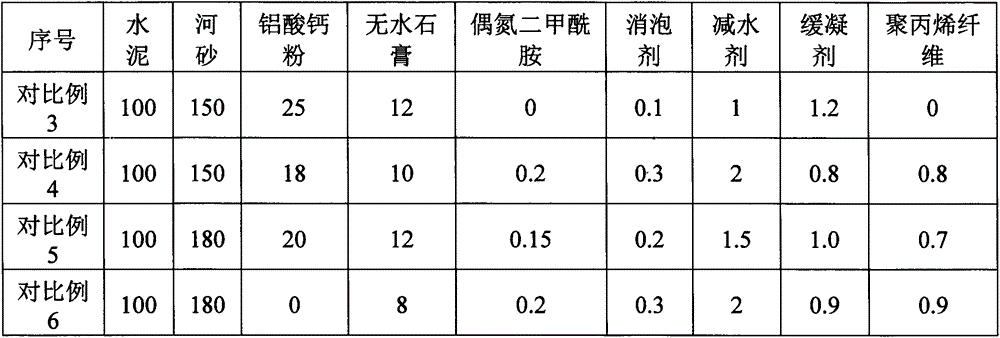

High-strength cement-based non-shrinkage grouting material

The invention discloses a high-strength cement-based non-shrinkage grouting material which is prepared from the following raw materials in parts by weight: 100 parts of cement, 150-180 parts of river sand, 1-2 parts of water reducing agent, 0.1-0.3 part of defoaming agent, 0.8-1.2 parts of retarder, 0.7-0.85 part of reinforcing agent and 0.2-0.35 part of hollow polymer microspheres through dry mixing. The microspheres adopted in the high-strength cement-based non-shrinkage grouting material can both make the cement base material be denser and improve the strength of the material, the components are reasonably matched, and the interface acting force is strong; the obtained grouting material has excellent liquidity and strength performance, thereby being capable of being applied in large equipment installation, bolt anchoring and structure reinforcement.

Owner:ZHENJIANG ATLANTIC MODULAR SYSTEM LIMITED

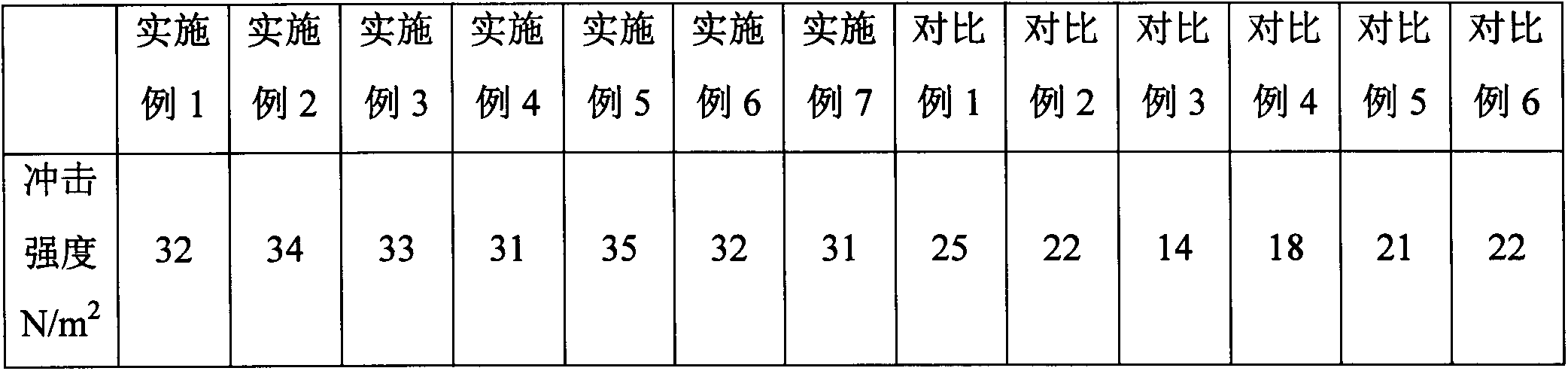

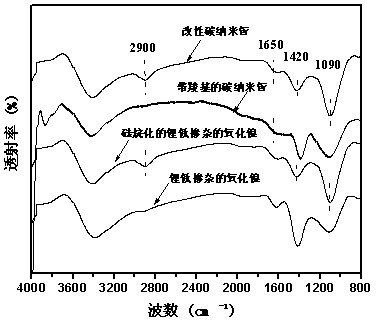

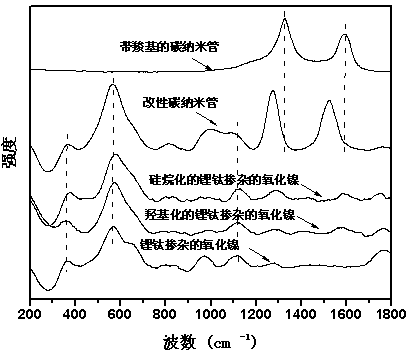

Modified carbon nano tube/thermosetting resin composite material and preparation method thereof

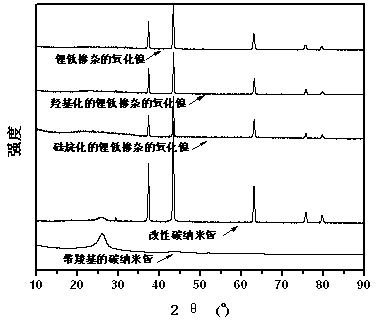

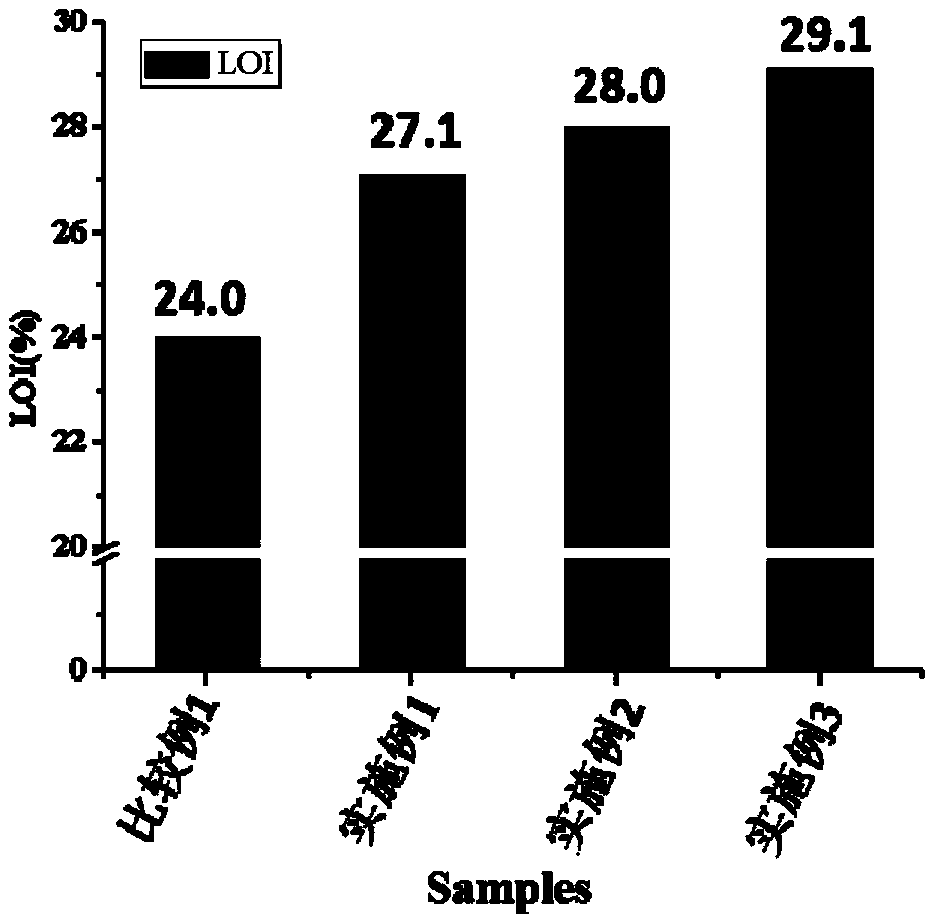

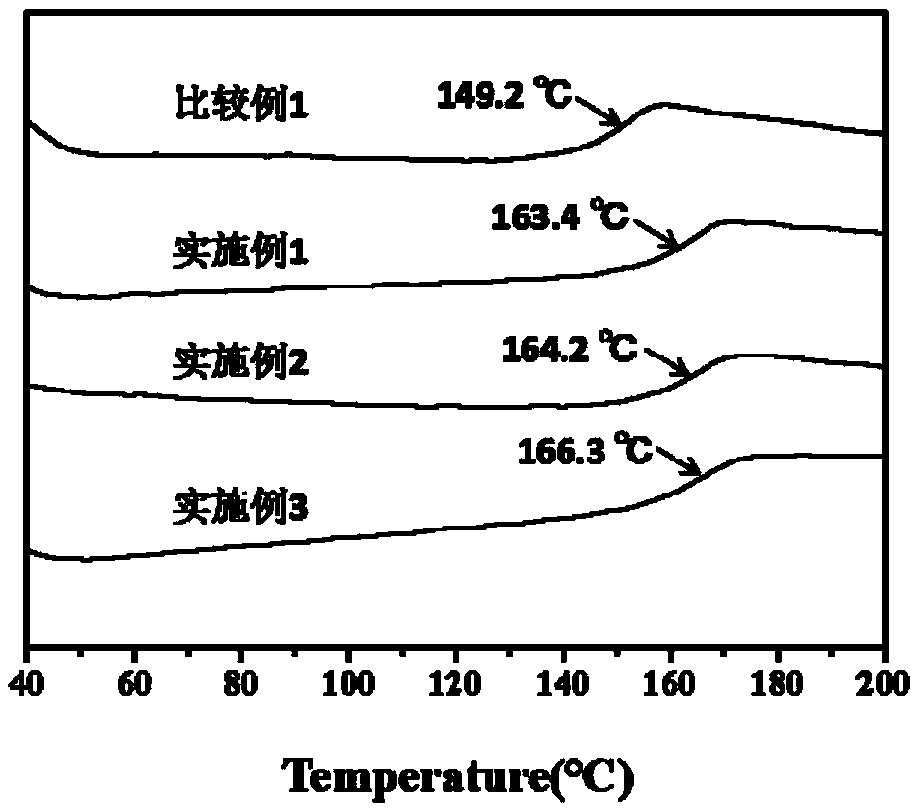

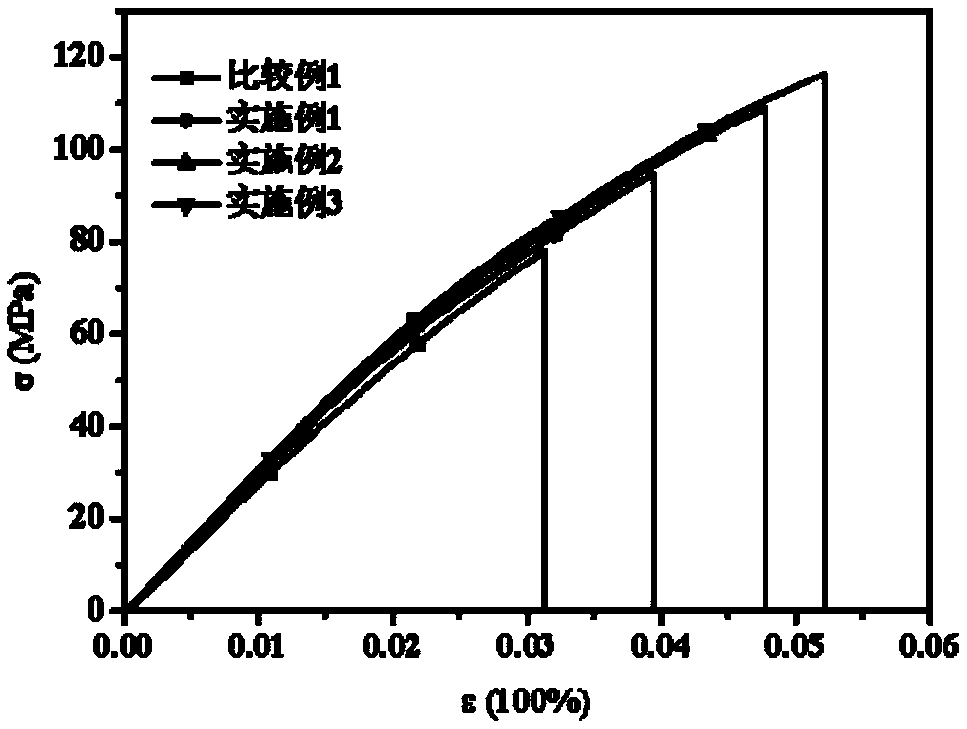

The invention discloses a modified carbon nano tube / thermosetting resin composite material and a preparation method thereof. The preparation method comprises the following steps: dispersing a carbon nano tube with carboxyl into N,N-dimethylformamide, then adding lithium-titanium-doped nickel oxide subjected to silanization to perform reaction, filtering, washing and drying to obtain a modified carbon nano tube; and uniformly mixing the modified carbon nano tube and molten thermal-curable resin and carrying out curing treatment to obtain the modified carbon nano tube / thermosetting resin composite material. The composite material has the characteristics of high dielectric constant and low dielectric loss. The surface of the modified carbon nano tube is grafted with the lithium-titanium-doped nickel oxide and by regulating content of the lithium-titanium-doped nickel oxide, control on dielectric property of the composite material can be realized. The composite material provided by the invention also has the characteristics of wide applicability of the preparation method and simple operation process.

Owner:SUZHOU UNIV +1

Borate polymer@hexagonal boron nitride flame-retarding nanoparticles with core-shell structure as well as preparation method and application thereof

The invention provides borate polymer@hexagonal boron nitride flame-retarding nanoparticles with core-shell structure as well as a preparation method and application. The preparation method comprisesthe following steps: firstly, reacting one or two polyamines containing elements including phosphorus, nitrogen and the like with 4-formylphenylboronic acid and 3,4-dihydroxy benzaldehyde respectivelyto prepare multi-arm phenylboronic acid and multi-arm o-dihydroxybenzene; secondly, dispersing hexagonal boron nitride to obtain a uniform hexagonal boron nitride dispersion solution; then adding themulti-arm phenylboronic acid into the dispersion solution; after uniformly dispersing, slowly adding the multi-arm o-dihydroxybenzene; reacting for a period of time at room temperature; and carryingout condensation on the multi-arm phenylboronic acid and the multi-arm o-dihydroxybenzene on the surface of hexagonal boron nitride to form one layer of a borate polymer, so as to obtain the borate polymer@hexagonal boron nitride flame-retarding nanoparticles. The borate polymer@hexagonal boron nitride flame-retarding nanoparticles are uniformly mixed with epoxy resin; and a proper amount of a curing agent is added and high-temperature curing is carried out to obtain an epoxy resin composite material containing the borate polymer@hexagonal boron nitride flame-retarding nanoparticles.

Owner:XIAMEN UNIV

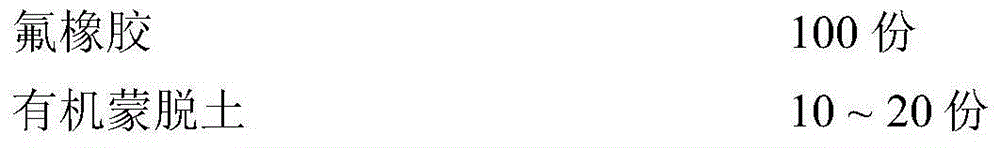

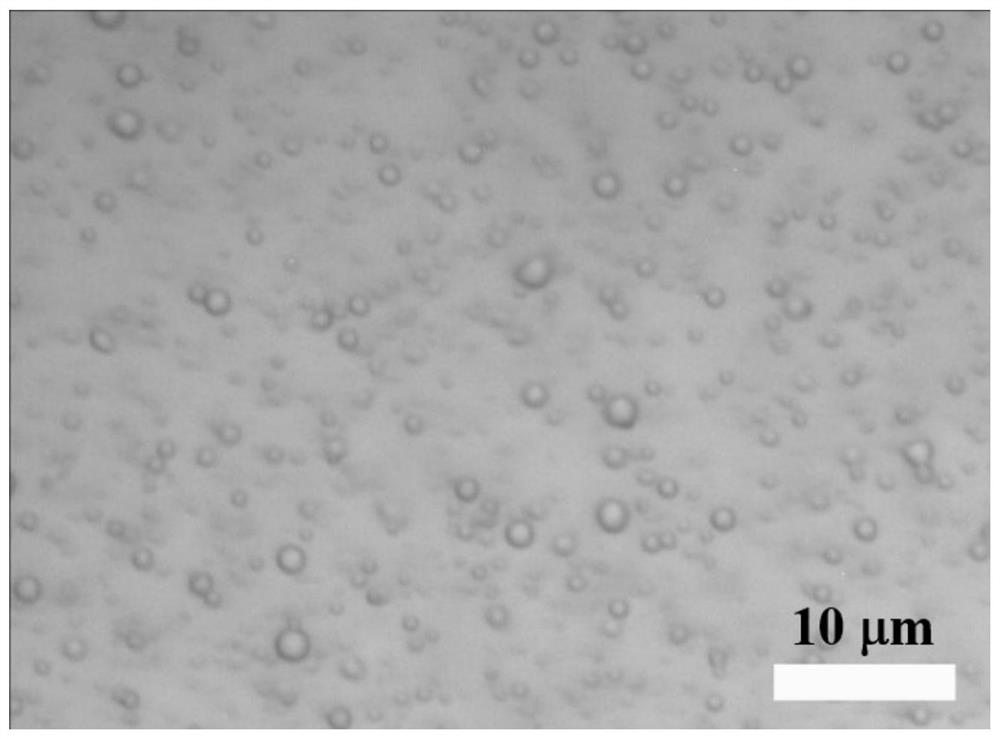

Grinding roller sealing ring materials and preparation method thereof

ActiveCN104530611ASolve difficult peelingSolve densityOther chemical processesMicrocrystalline waxBisphenol AF

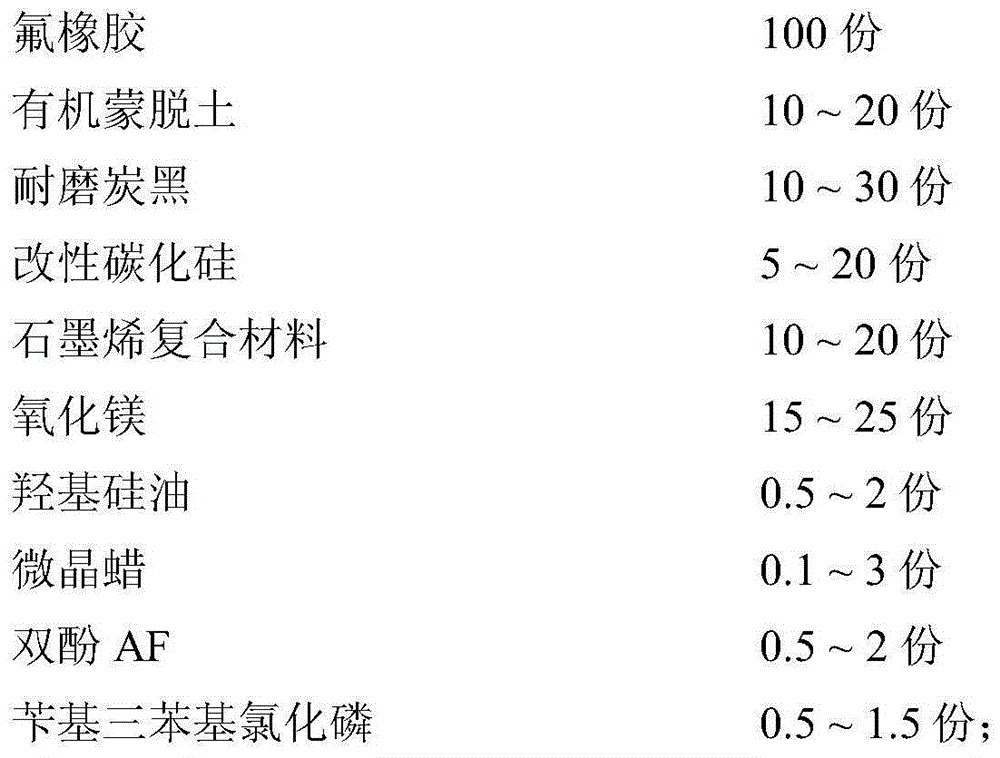

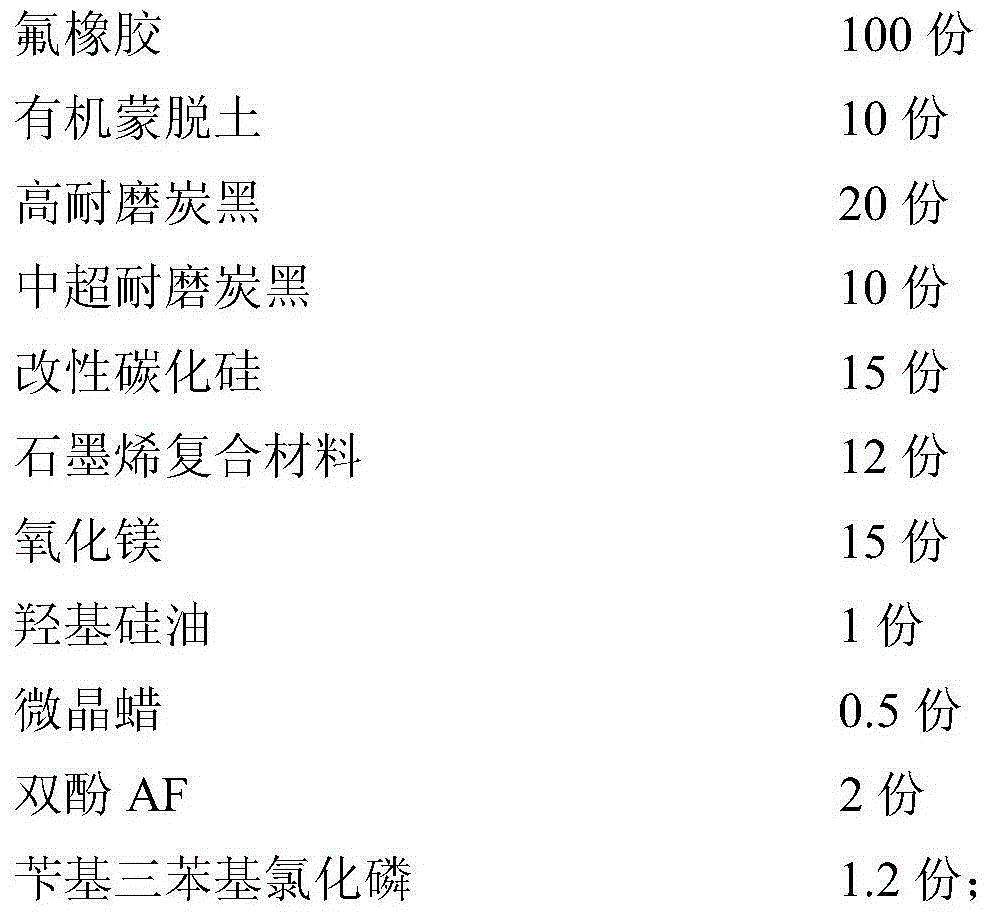

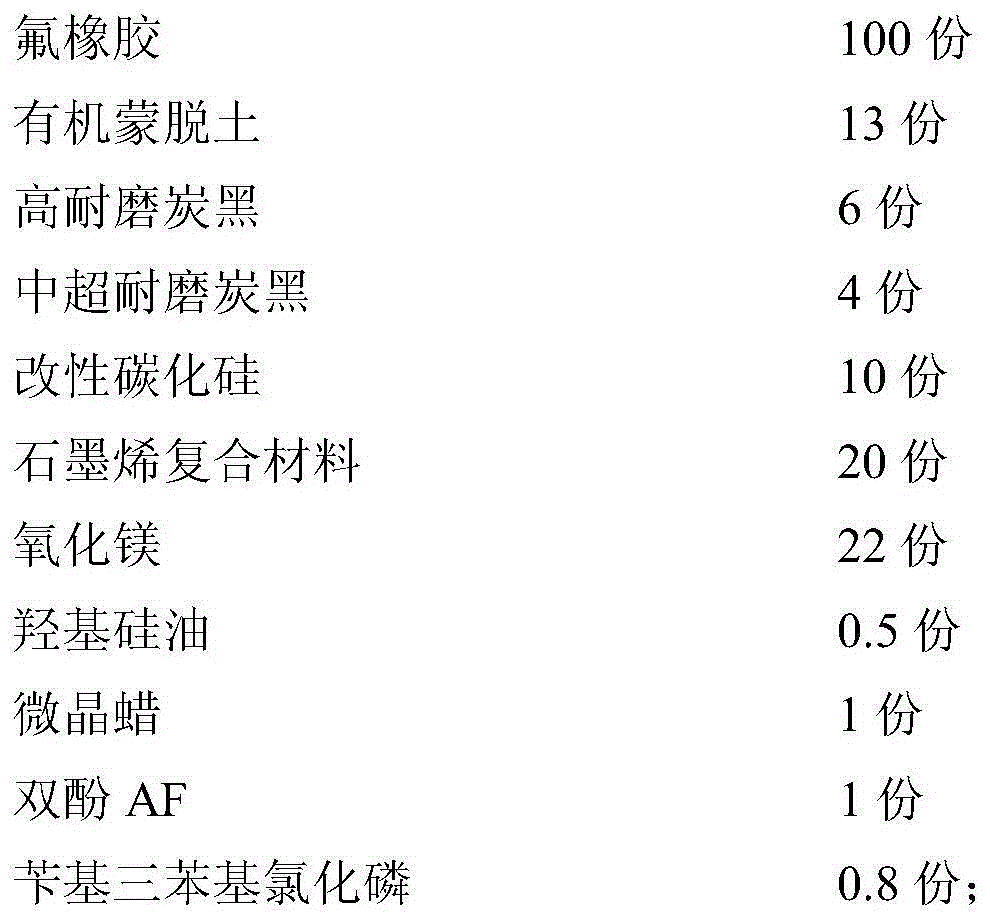

The invention relates to grinding roller sealing ring materials. The grinding roller sealing ring materials are characterized by comprising, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. The graphene composites are graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction. The graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the grinding roller sealing ring materials, the function of the graphene is fully played, and the wear resistance and heat resistance of the grinding roller sealing ring materials are effectively improved.

Owner:宁波佳乐特橡塑机电有限公司

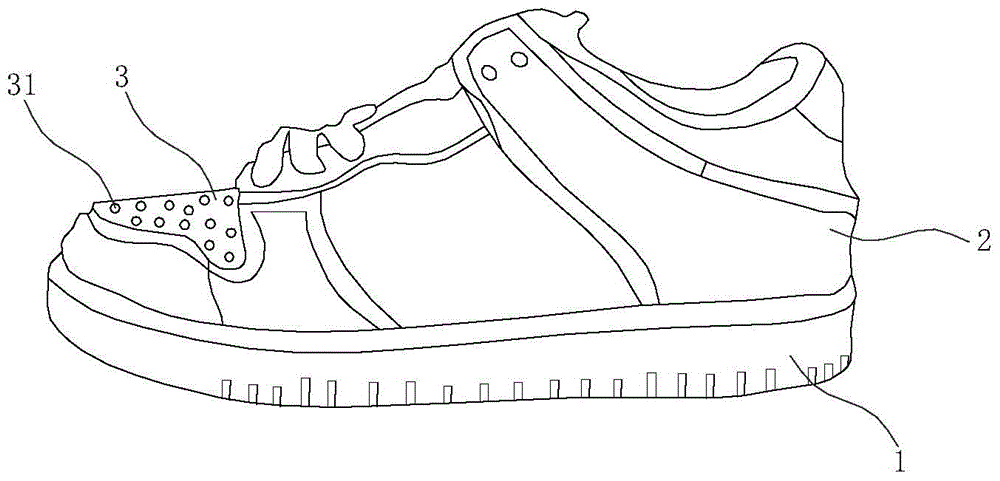

Wear-resisting climbing boot

The invention relates to a wear-resisting climbing boot. The wear-resisting climbing boot comprises a sole, an upper and a vamp, wherein the upper and the vamp are arranged on the sole, and a plurality of air-permeable holes are formed in the vamp at intervals. The wear-resisting climbing boot is characterized in that the materials of the sole comprise, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. Fluororubber rubber serves as the main materials, graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the sole materials, the function of the graphene is fully played, and the wear resistance of the sole materials is effectively improved.

Owner:NINGBO ZHONGDI SHOES

Preparation method for covalent crosslinking cladded type polyacrylate-based graphene nano composite finishing agent

The invention relates to a method. At present, researches about a cladded type polyacrylate-based graphene nano composite material prepared through covalent crosslinking are rarely reported. The method provided by the invention is realized through the following steps: firstly, taking sodium dodecyl sulfate and branched secondary alcohol ethoxylates as emulsifiers, taking butyl acrylate and methyl methacrylate as main monomers and taking diacetone acrylamide as a functional monomer; carrying out an emulsion polymerization method on the components to prepare carbonylated polyacrylate emulsion; then, enabling a graphene oxide water solution prepared by utilizing an improved Hummers method and adipic dihydrazide to react at 30 DEG C for 10h to 12h, so as to prepare aminated graphene oxide; and finally, enabling the carbonylated polyacrylate and the aminated graphene oxide to be subjected to a ketone-hydrazide crosslinking reaction under a weak acidic condition (wherein the pH (Potential of Hydrogen) is equal to 4 to 5), so as to prepare a covalent crosslinking cladded type polyacrylate-based graphene nano composite finishing agent. The covalent crosslinking cladded type polyacrylate-based graphene nano composite finishing agent is applied to leather finishing so that the wear-resisting performance of a finished leather sample is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Reinforced heat-resistant electrostatic-spinning/electret composite fiber membrane filtering material and preparing method thereof

InactiveCN106435766AGood storage stabilityImprove filtration efficiencyElectro-spinningMonocomponent synthetic polymer artificial filamentPolyetherimideSilicon monoxide

The invention discloses a reinforced heat-resistant electrostatic-spinning / electret composite fiber membrane filtering material. The reinforced heat-resistant electrostatic-spinning / electret composite fiber membrane filtering material is prepared from, by weight, 75-85 parts of polyetherimide, 7-13 parts of silicon monoxide, 10-16 parts of powdered activated carbon, 1-2 parts of a 3-aminopropyltriethoxysilane coupling agent, 0.8-2 parts of glacial acetic acid, a proper amount of deionized water, 2-6 parts of metatitanic acid, a proper quantity of a AgNO3 solution of 0.6 mol / L, a proper amount of N-methyl-pyrrolidone, 1-2 parts of oxidized graphene, 1-3 parts of zinc nitrate hexahydrate, 3-9 parts of dimethyl imidazole and 25-40 parts of methyl alcohol. According to the reinforced heat-resistant electrostatic-spinning / electret composite fiber membrane filtering material, silicon nanowires containing alpha-quartz are prepared, the electrostatic-spinning / electret composite fiber filtering material is prepared with the electrospinning technique, the excellent charge storage stability is achieved, and the filtering efficiency of the filtering material is greatly improved; in addition, nano-silver is added to load nanometer titania, the antibacterial durability of the filtering material is improved, and the long-time efficient filtering effect is achieved.

Owner:安徽名杰净化科技有限公司

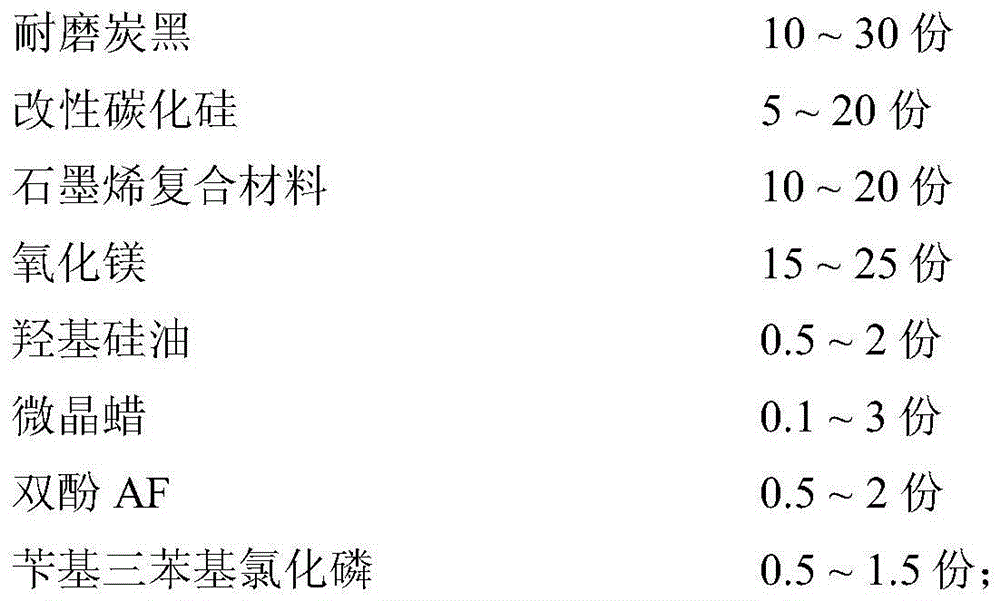

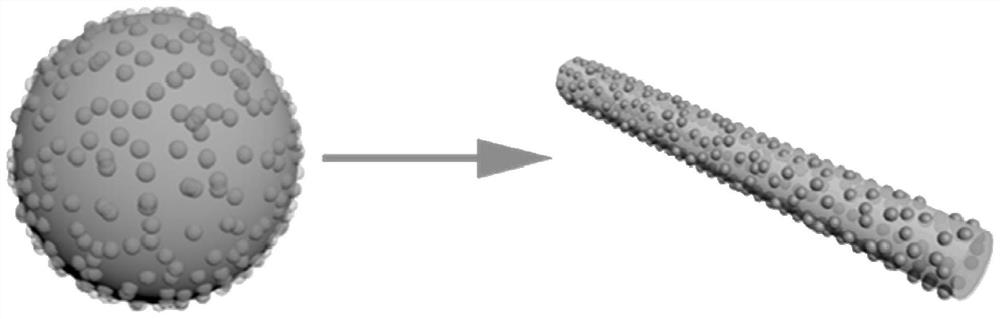

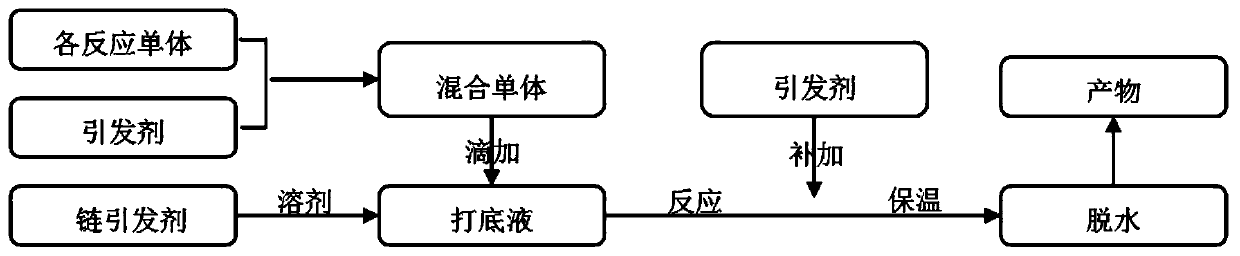

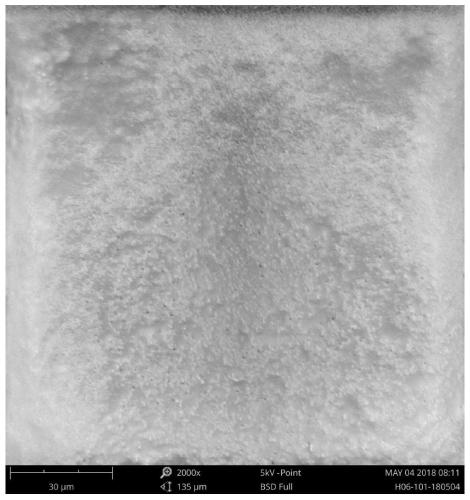

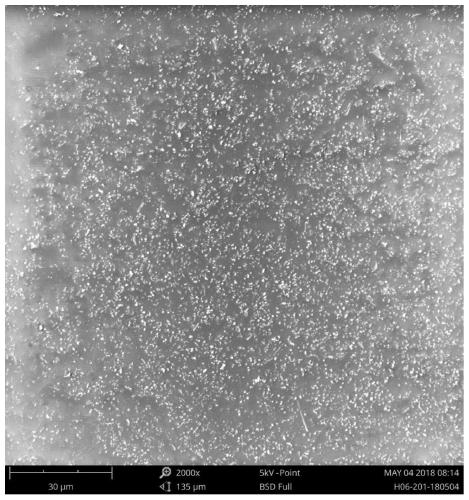

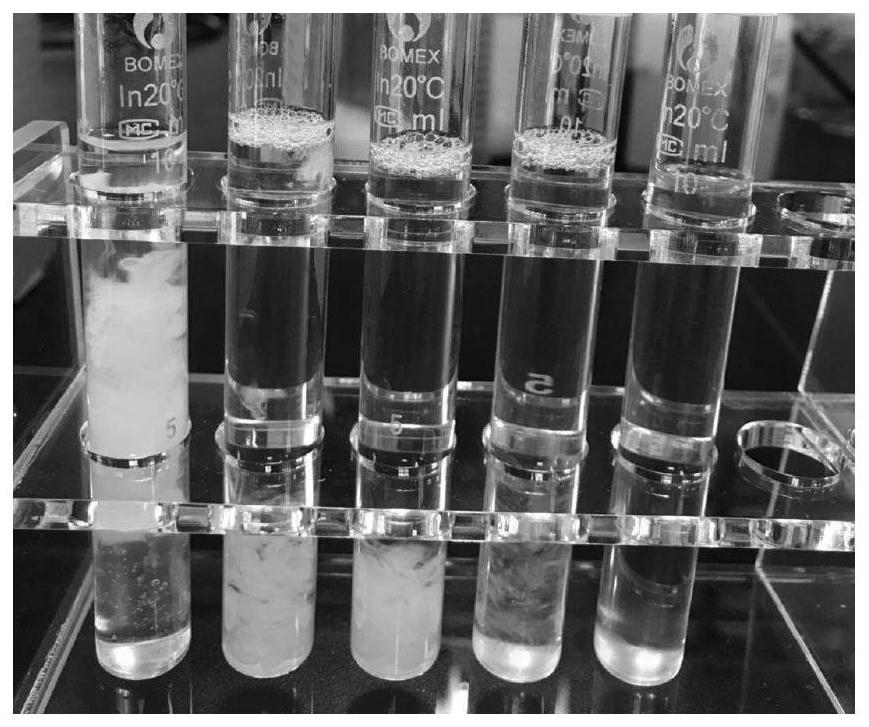

Preparation method of strawberry-shaped organic/inorganic crosslinked microsphere orientation filling enhanced chemical fibers

ActiveCN111850722AStrong interface forceLow interfacial forceMelt spinning methodsMonocomponent polyesters artificial filamentPolymer scienceMicrosphere

The invention discloses a preparation method of strawberry-shaped organic / inorganic crosslinked microsphere orientation filling enhanced chemical fibers. The preparation method includes the steps thatmonomer droplets are stabilized through pre-hydrolysed MPS and SiO2 nano-particles, and strawberry-shaped crosslinked composite microspheres are prepared through Pickering emulsion polymerization; and the microspheres and chemical slices are mixed, and after the processes such as melt spinning, drafting and winding, modified chemical fibers with the crosslinked composite microspheres for orientation filling enhancement are obtained. MPS pre-hydrolysed products for stabilizing the monomer droplets in Pickering emulsion are anchored on the surfaces of inorganic particles, and the interaction force between the inorganic particles and a polymer matrix is enhanced; and crosslinking structures in the microspheres provide deformation in the melt extrusion-stretching process for the composite microspheres, one-dimensional orientation micro-fiber structures are formed, the breaking strength of micro-fibers is enhanced, and radial mechanical defects are reduced.

Owner:ZHEJIANG SCI-TECH UNIV

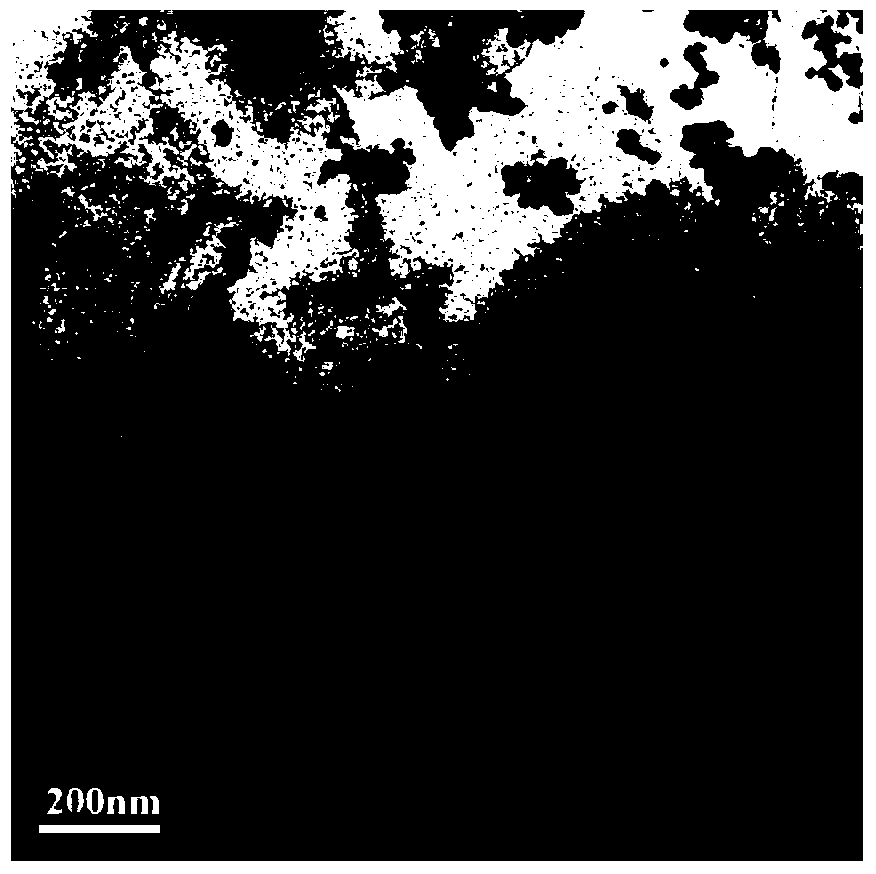

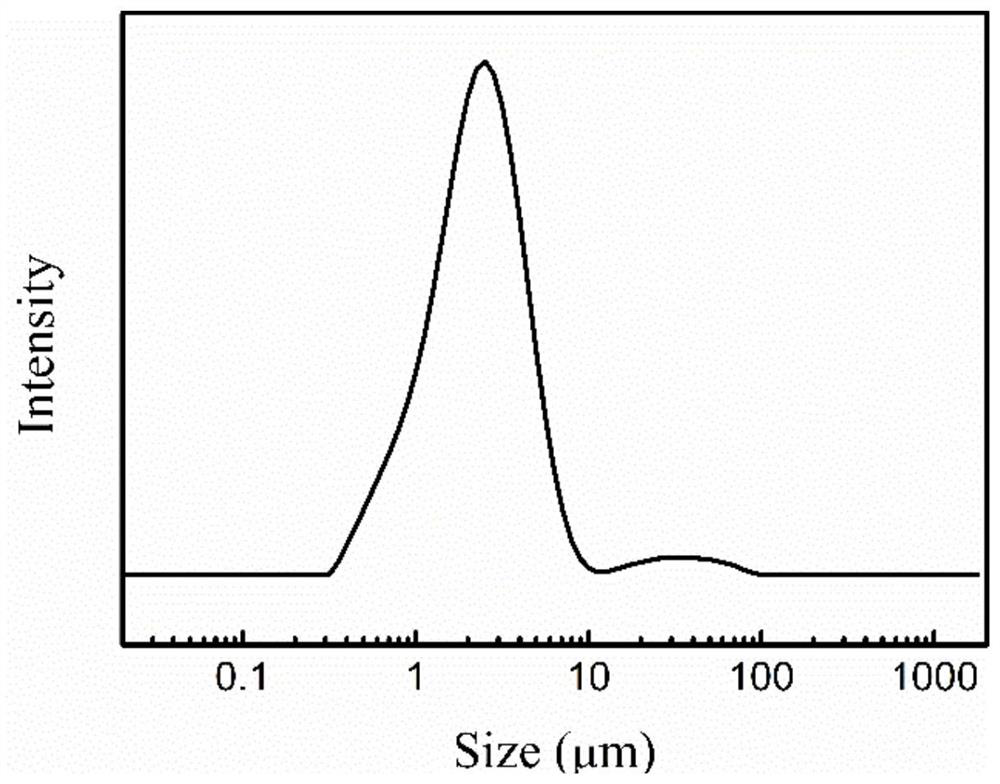

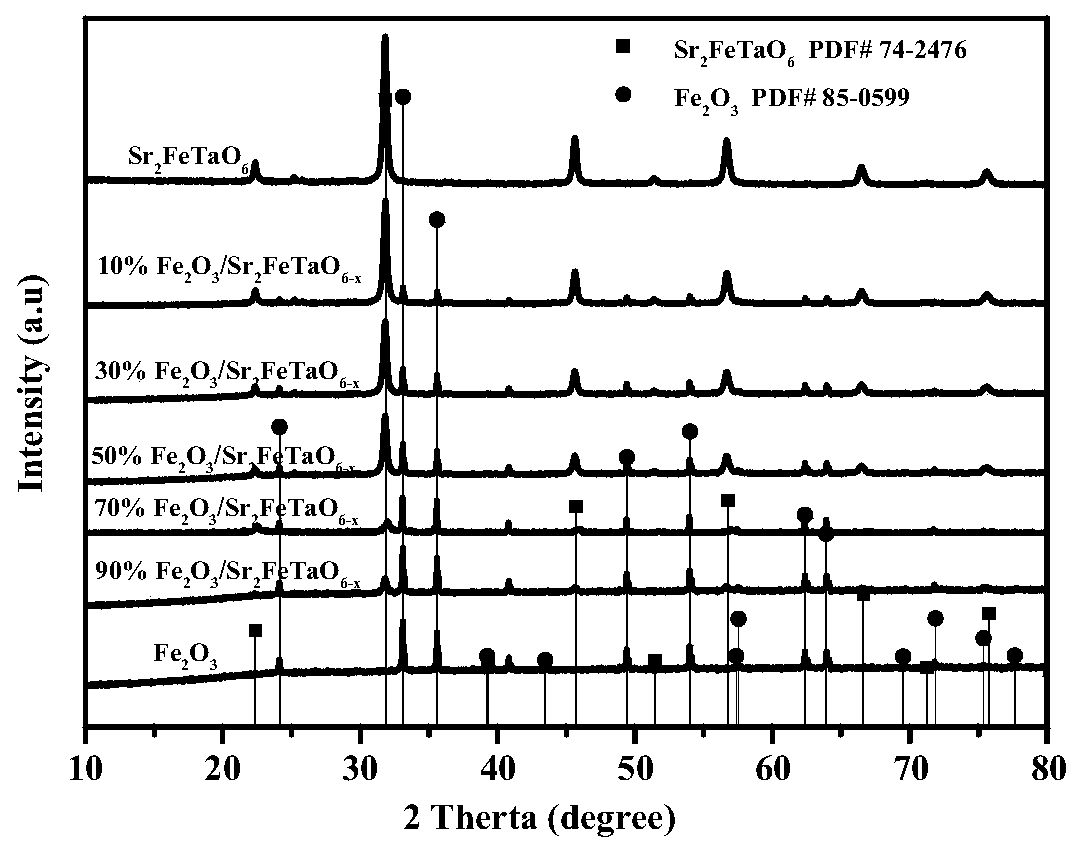

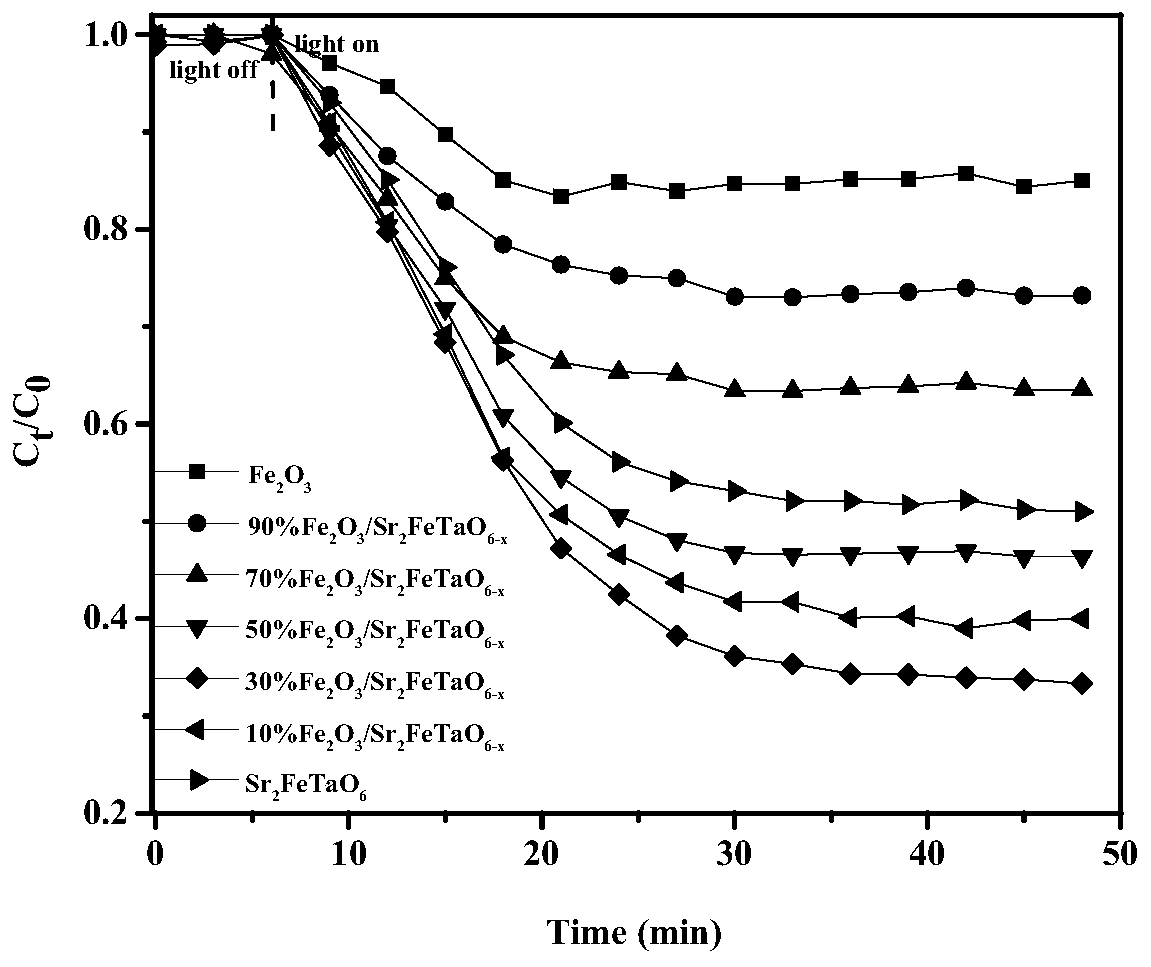

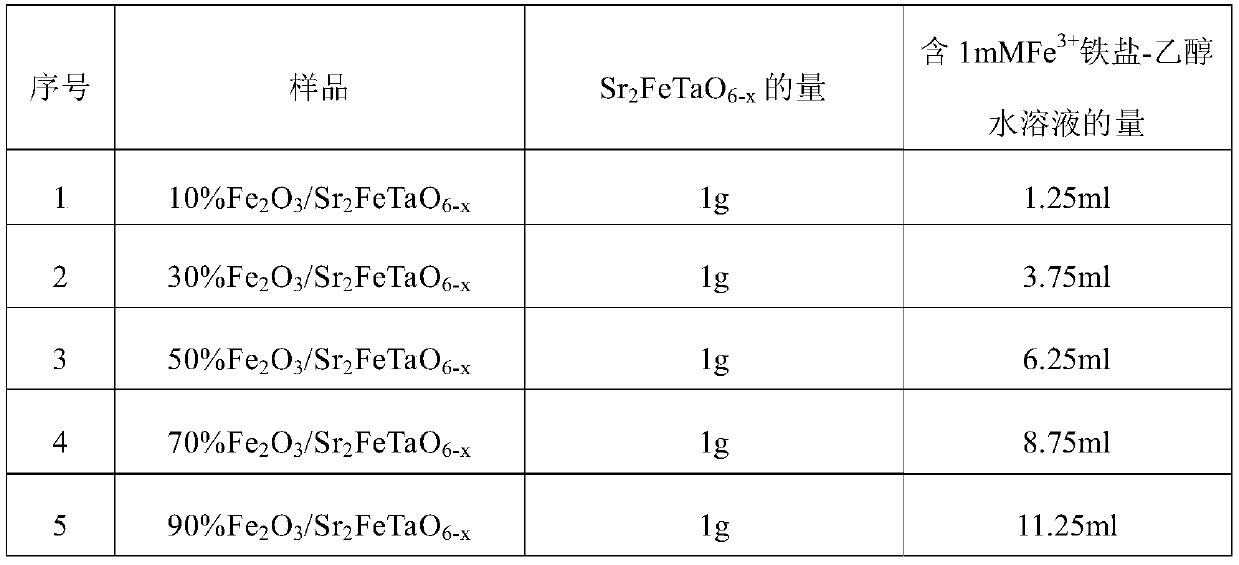

Fe2O3/Sr2FeTaO6-x photocatalyst, preparation method and application thereof

ActiveCN110860295APromote photocatalytic degradationStrong interface forceHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystNitric oxide

The invention discloses a Fe2O3 / Sr2FeTaO6-x photocatalyst, a preparation method and application thereof. The preparation method includes the steps of: dissolving oleic acid in anhydrous ethanol, adding sodium oleate, then adding tantalum pentachloride, an organic ferric salt and an organic strontium salt, performing stirring, then carrying out hydrothermal reaction, and then conducting flushing and drying to obtain Sr2FeTaO6 powder; mixing the Sr2FeTaO6 powder with calcium hydride, and conducting calcination to obtain dark red Sr2FeTaO6-x; preparing a ferric salt ethanol water solution, addingSr2FeTaO6-x, stirring the substances violently, carrying out hydrothermal reaction, then performing natural cooling, and conducting washing and drying to obtain the Fe2O3 / Sr2FeTaO6-x photocatalyst. The invention provides a brand-new preparation method of the photocatalyst on the basis of a hydrothermal-calcium hydride modification method, the Fe2O3 / Sr2FeTaO6-x composite semiconductor system withhigh interfacial force can be finally synthesized, and photocatalytic degradation of nitric oxide is greatly improved.

Owner:YANCHENG INST OF TECH

Abrasion resistance and impact resistance rubber sealing piece

InactiveCN106589627AHigh affinityMake up for the deficiencies of creepBuilding insulationsTriethylphosphiteTriethylamine phosphate

The invention discloses an abrasion resistance and impact resistance rubber sealing piece. The abrasion resistance and impact resistance rubber sealing piece comprises the following raw materials, by weight, of 20-50 parts of ethylene-propylene-diene monomer rubber, 10-20 parts of carboxyl-terminated butyronitrile rubber, 12-35 parts of chloroprene rubber, 1-2 parts of 1,1-double-(tertiary butyl peroxide) cyclohexane, 0.1-0.6 parts of dichromic acid sodium ammonium, 1-2 parts of titanate coupling agent TMC-TTS, 15-25 parts of nylon fibers, 2-6 parts of quartz powder, 10-20 parts of silicon carbide fibers, 2-8 parts of zirconia fibers, 1-2 parts of pine tar oil, 0.2-0.8 part of dioctyl phthalate, 1-2 parts of triethyl phosphate, 0.4-0.8 part of beeswax, 1-2 parts of vaseline and 1-3 parts of anti-aging agents. The abrasion resistance and impact resistance rubber sealing piece is good in toughness, excellent in impact resistance and abrasion resistance performance, good in corrosion resistance and aging-resistant performance, easily available in raw material and low in production cost.

Owner:安徽亚兰密封件股份有限公司

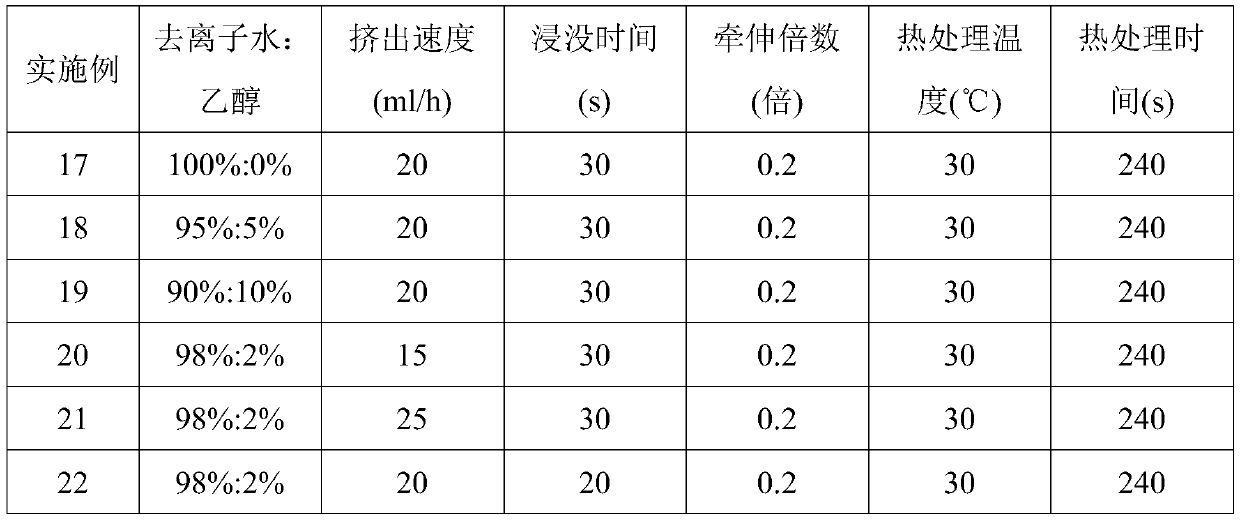

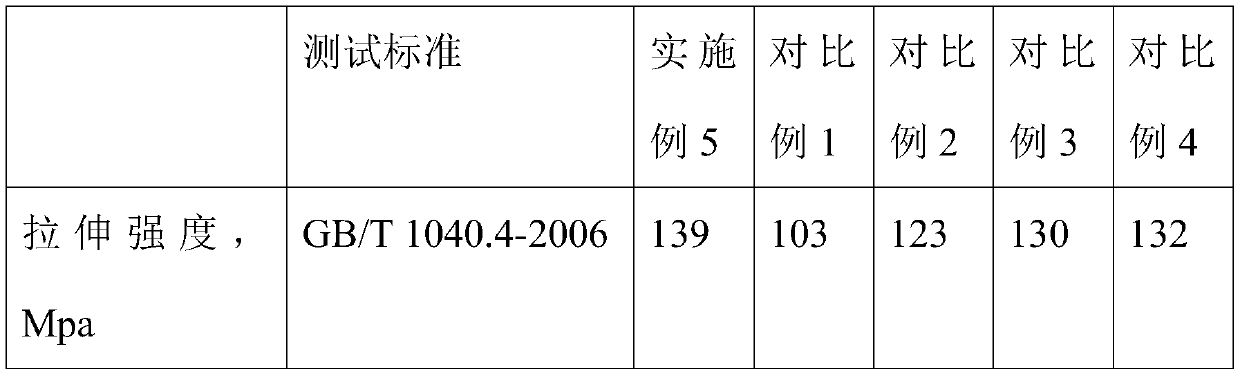

Preparation method of high-tenacity polyurethane composite fiber

ActiveCN110230121AIncrease the number of molecular chainsIncrease strainMonocomponent synthetic polymer artificial filamentArtifical filament manufactureSolventToluene

The invention discloses a preparation method of high-tenacity polyurethane composite fiber. The high-tenacity polyurethane composite fiber is prepared by adopting a solution spinning method, and comprises the steps of preparation of a spinning solution, preparation of coagulating bath, spinning and aftertreatment, wherein the preparation of a spinning solution adopts a mixed solvent method; methylbenzene and a good solvent of polyurethane are mixed, so as to obtain a binary mixed solvent; then polyurethane prepolymer and filler particles are added into the binary mixed solvent according to a certain mass ratio; the polyurethane prepolymer and the filler particles are mechanically mixed to be uniform and then are subjected to vacuum defoamation, so that a polyurethane composite fiber spinning solution with the solid content being 15 percent is formed; the spinning solution is extruded in a wet spinning frame, is cooled and formed through the coagulating bath, and is finally subjected tothermal treatment, so that the high-tenacity polyurethane composite fiber is obtained. The method obviously improves the interfacial compatibility between the filler particles and polyurethane through the preparation of the mixed solvent containing methylbenzene, so that structure regulation to polyurethane is realized, and the high-tenacity polyurethane composite fiber with an excellent functionis obtained.

Owner:WUHAN TEXTILE UNIV

Ethylene propylene diene monomer sealing element

The invention discloses an ethylene propylene diene monomer sealing element, prepared from the following raw materials in parts by weight: 40-60 parts of ethylene propylene diene monomer, 20-40 parts of styrene-butadiene rubber, 15-25 parts of polyurethane rubber, 20-30 parts of polypropylene fibers, 4-10 parts of glass fibers, 15-25 parts of alumina whiskers, 4-8 parts of sepiolite powder, 2-4 parts of naphthenic oil, 2-4 parts of a silane coupling agent, 2-4 parts of dimethyl phosphite, 1-2 parts of chlorinated paraffin, 0.5-1.3 parts of dibutyl phthalate, 2-4 parts of phenolic resin, 0.3-0.9 part of sodium persulfate, 1.5-2.5 parts of 1,1,3,3-tetramethylbutyl hydroperoxide and 2-5 parts of an anti-aging agent. The ethylene propylene diene monomer sealing element has good toughness, excellent shock and abrasion resistance, good corrosion and aging resistance, easily available raw materials and low production cost.

Owner:安徽亚兰密封件股份有限公司

High-ductility high-strength polyamide material and preparation method thereof

The invention discloses a high-ductility and high-strength polyamide material. The polyamide composite material is prepared from the following raw materials in parts by weight: 70 to 90 parts of polyamide composite master batch, 15 to 25 parts of low-density polyethylene, 2 to 6 parts of maleic anhydride grafted polyethylene, 5 to 10 parts of polypropylene fiber, 6 to 12 parts of nano cellulose whisker, 1 to 2 parts of a toughening agent, 1 to 3 parts of coupling agent, 1 to 2 parts of an antioxidant, 1 to 2 parts of a coloring agent and 1 to 2 parts of a lubricant. Wherein the polyamide composite master batch is a polyamide material grafted by activated multi-walled carbon nanotubes. The invention further discloses a preparation method of the high-ductility and high-strength polyamide material. The obtained composite polyamide material is excellent in mechanical property and high in ductility, and the application range of the polyamide material is widened.

Owner:江门市融泰新材料科技有限公司

Polyphenylene-oxide-filled (PPO-filled) aligned carbon nanotube bundle (ACNTB)/thermosetting resin and preparation method thereof

ActiveCN106221212AImprove mechanical propertiesModifiable mechanical propertiesHeat resistanceCarbon nanotube

The invention relates to a polyphenylene-oxide-filled (PPO-filled) aligned carbon nanotube bundle (ACNTB) / thermosetting resin and a preparation method thereof. The preparation method comprises the following steps: adding PPO-filled ACNTB particles into a cyanate ester (CE) resin system, and curing to obtain the high-performance CE composite material system. The PPO is filled into the gaps between carbon tubes in the ACNTB, so that the mechanical properties of the ACNTB are enhanced; the PPO-filled ACNTB particles are added into the CE resin; and curing treatment is carried out to obtain the high-performance CE resin system composite material. The PPO-filled (ACNTB) / thermosetting resin has the advantages of excellent mechanical properties, excellent heat resistance, excellent flame retardancy and the like. The preparation method has the characteristics of wide applicability and simple operating technique. The resin system can be used for preparing high-performance composite materials, electronic devices and the like for aerospace.

Owner:重庆辰鸿实业发展有限公司

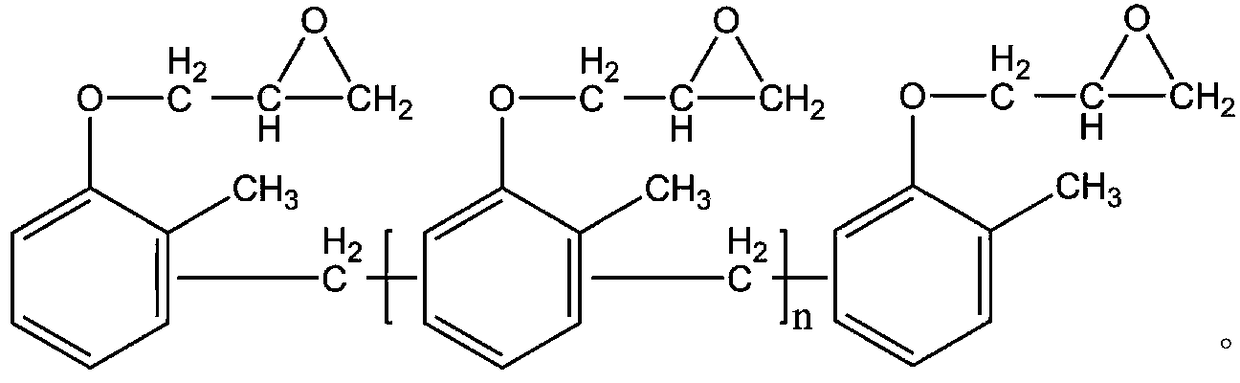

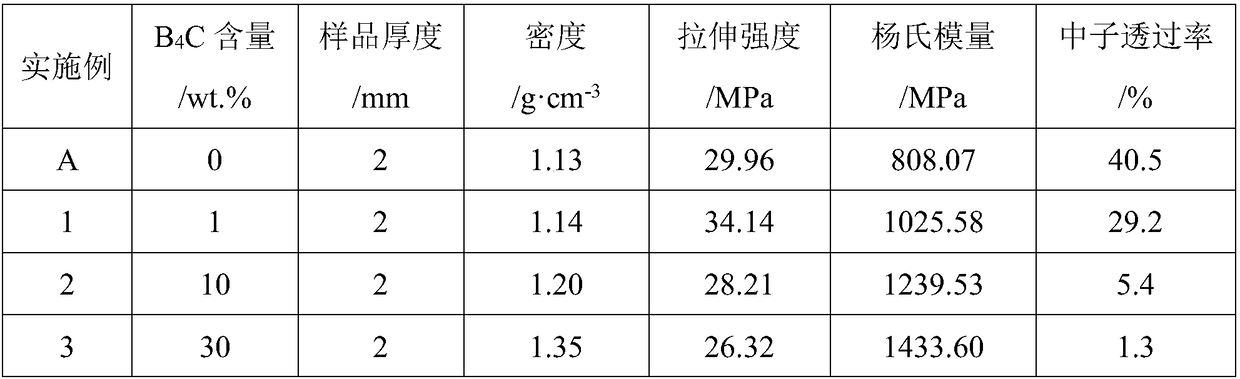

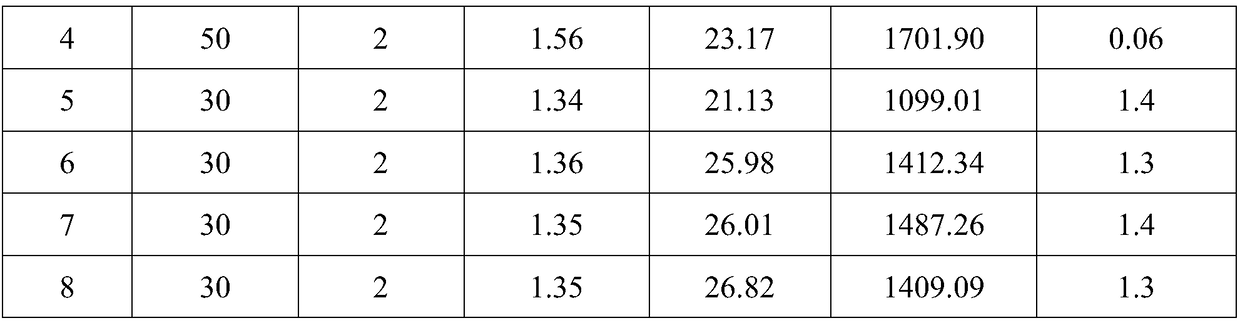

Epoxy-resin-based neutron shielding material and method for preparing same

The invention discloses an epoxy-resin-based neutron shielding material and a method for preparing the same. The epoxy-resin-based neutron shielding material is prepared from epoxy resin matrix composite boron carbide fillers. Epoxy resin for the epoxy-resin-based neutron shielding material is o-cresol-formaldehyde epoxy resin, a curing agent is phenolic resin, and a curing accelerator is imidazole or an imidazole compound. The epoxy-resin-based neutron shielding material and the method have the advantages that the epoxy-resin-based neutron shielding material which is an epoxy resin / boron carbide composite material prepared by the aid of the method is excellent in neutron shielding performance; processes are easy to operate and popularize and low in cost.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Automotive dashboard material capable of improving antistatic property through modified graphene

InactiveCN105802011AImprove descriptiveImproved absorption of impact energyN dimethylformamidePolyvinyl alcohol

The invention discloses an automotive dashboard material capable of improving the antistatic property through modified graphene. The automotive dashboard material is prepared from raw materials in parts by weight as follows: 100-105 parts of polypropylene powder, 20-22 parts of methyl methacrylate, 30-32 parts of polycarbonate powder, 10-11.5 parts of 200-mesh kaolin, 0.6-0.7 parts of polyvinyl alcohol, 3-3.5 parts of divinyl benzene, 0.2-0.22 parts of tween 80, an appropriate amount of distilled water, an appropriate quantity of sodium chloride aqueous solutions with the concentration being 10wt%, 1.5-2 parts of ethoxylated alkyl acid amide, 3-4 parts of white oil, 100-105 parts of N,N-dimethylformamide, 5-6 parts of graphite oxide, 5-6 parts of hydrazine hydrate, an appropriate amount of ammonia water and 10-12 parts of isophorone diisocyanate. The manufactured automotive dashboard has excellent toughness, strength and antistatic and dustproof functions and a good self-cleaning effect.

Owner:ANHUI AICS SCI & TECH GROUP

Environment-friendly composite mattress containing bamboo fibers and preparation method of environment-friendly composite mattress

PendingCN112457554AExtended service lifePerformance is not affectedStuffed mattressesSpring mattressesLow-density polyethyleneFiber

The invention discloses an environment-friendly composite mattress containing bamboo fibers, and relates to the field of articles for daily use. The environment-friendly composite mattress containingthe bamboo fibers is prepared from the following raw material components in parts by weight: 70-80 parts of low-density polyethylene, 10-20 parts of modified bamboo fibers, 12-18 parts of attapulgite,3-6 parts of a foaming agent, 0.5-0.8 part of a coupling agent, 0.4-0.8 part of a foaming shrinkage aid, 0.1-0.4 part of a foam stabilizer, 3-5 parts of a surfactant and 150-300 parts of a modified liquid. Attapulgite is added into a low-density polyethylene foam material, and the low-density polyethylene foam material is modified and then mixed with bamboo fibers subjected to surface treatment for injection molding. The environment-friendly composite mattress containing the bamboo fibers is low in cost, moderate in hardness and good in bearing performance, has excellent strength, toughness,air permeability and heat dissipation performance, and is proper in softness and resilience; and the mattress can be adjusted according to different parts of a human body to achieve the comfort degreeof people, the performance due to the use time process cannot be influenced, and the service life of the mattress is prolonged.

Owner:湖南省爱意缘家居有限公司

Coating and self-spraying paint

ActiveCN111040539AImproved chemical resistanceImprove oil resistanceAnti-corrosive paintsAirplaneInorganic matrix

The invention relates to a coating and a self-spraying paint. The coating comprises a film-forming substance, an antirust filler, a pigment, an auxiliary agent and a solvent, wherein the film-formingsubstance is polysulfide thermoplastic acrylic resin, and the structural formula of the polysulfide thermoplastic acrylic resin comprises a sulfydryl functional group. The sulfydryl functional group can endow the thermoplastic acrylic resin with good flexibility, solvent resistance, stress relaxation and other properties, and can obviously enhance the oil resistance of a paint film formed by the coating and the adhesive force on aluminum, zinc and other inorganic matrixes. Therefore, the coating and the self-spraying paint comprising the paint can be suitable for spraying of equipment making contact with gasoline or organic solvents, such as automobiles and motorcycles, and can also be suitable for spraying of aircrafts with high requirements for paint film performances, such as aircrafts,and realizes rapid repairing of paint films of aircrafts such as airplanes.

Owner:ZHEJIANG TRANSFER PAINT CO LTD

Method for producing stair armrests with eucalyptus cores as raw material

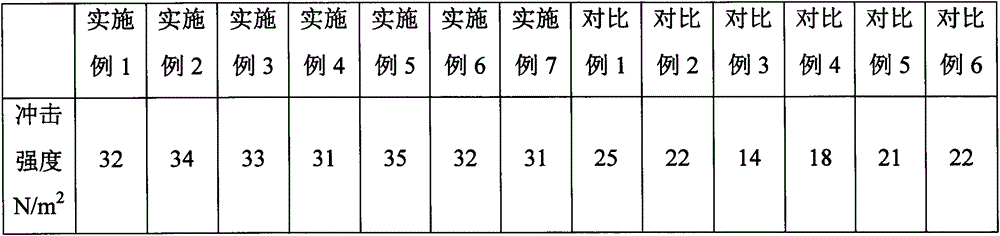

InactiveCN106272851AStrong interface forceStrong adhesionOther plywood/veneer working apparatusWood veneer joiningPulp and paper industryMelamine

The invention relates to the technical field of decorative materials, in particular to a method for producing stair armrests with eucalyptus cores as a raw material. The method comprises the technological steps of primary eucalyptus core maintaining, drying, secondary eucalyptus core maintaining, section cutting, splicing, repairing assembly, prepressing, hot pressing, cutting molding, melamine impregnated adhesive film paper pasting, abrasion resistant paper gluing and the like. According to the method, the eucalyptus cores are used as the raw material to produce the stair armrests, so that the eucalyptus cores are sufficiently utilized, the waste material is turned into things of value, energy sources are saved, and meanwhile the production cost of the stair armrests is greatly reduced; and in addition, the stair armrests produced through the method are good in quality and stability, resistant to abrasion and moisture, high in impact resistance and not prone to deforming.

Owner:GUANGXI BINWEI DECORATION MATERIAL

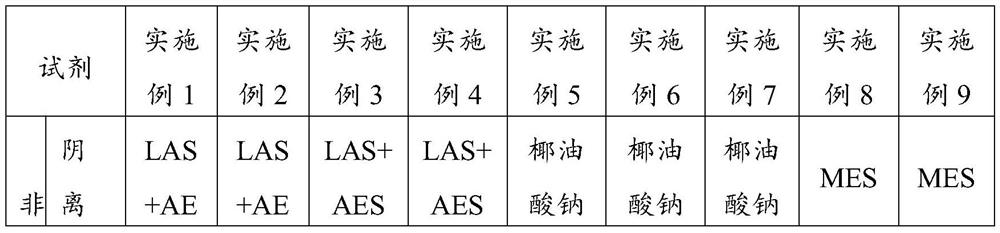

Mild laundry detergent and preparation method thereof

InactiveCN112080352ALess irritatingImprove adsorption capacityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActive agentIrritation

The invention provides a mild laundry detergent and a preparation method thereof, and belongs to the technical field of daily chemical products. The mild laundry detergent provided by the invention isprepared from the following components in percentage by mass: 1 to 25 percent of amino acid surfactant, 1 to 25 percent of multi-element surfactant, 1 to 10 percent of preservative aid, 0.1 to 5 percent of non-phosphorus chelating agent, 0.1 to 1 percent of thickening agent and the balance of water. According to the invention, the amino acid surfactant contains amide groups, has strong interfacial force and strong adsorption capacity to protein stains, and can efficiently remove the protein stains in clothes. No preservative or protease is added into the raw materials of the mild laundry detergent provided by the invention, so that the mild laundry detergent is mild and small in irritation to a human body and does not easily cause allergy.

Owner:SHANGHAI BAIMAO

High-strength cement-based non-shrinkage grouting material

ActiveCN103482928BCompensation for shrinkage defectsHigh mechanical strengthMicrosphereSuperplasticizer

The invention discloses a high-strength cement-based non-shrinkage grouting material, which is prepared by dry mixing the following raw materials in the weight ratio: 100 parts of cement; 150-180 parts of river sand; 1-2 parts of water reducing agent; defoaming 0.1-0.3 parts of agent; 0.8-1.2 parts of retarder; 0.7-0.85 parts of reinforcing agent; 0.2-0.35 parts of hollow polymer microspheres. The microspheres used in the present invention can not only make the cement base material denser but also improve the strength of the material. The distribution ratio of each component is reasonable and the interface force is strong. The obtained grouting material has excellent fluidity and strength performance and can be used for large-scale equipment installation , Bolt anchoring and structural reinforcement.

Owner:ZHENJIANG ATLANTIC MODULAR SYSTEM LIMITED

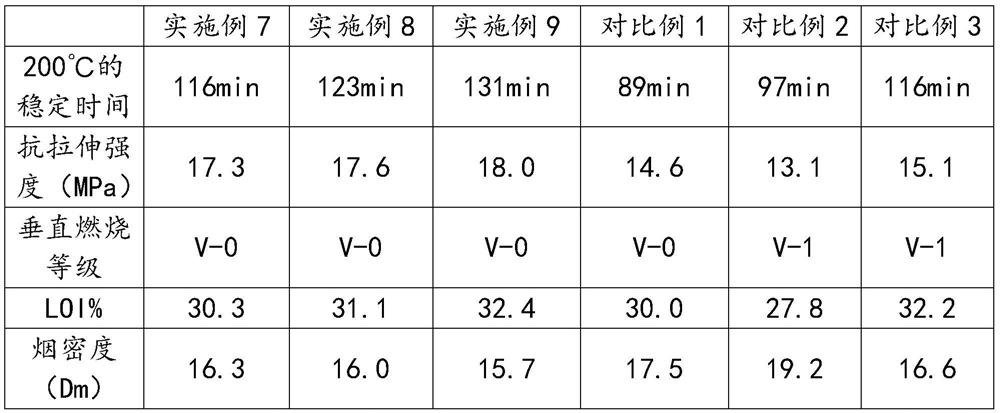

High-flame-retardant photoelectric composite cable sheath material with good processability and preparation method thereof

The invention relates to a high-flame-retardant photoelectric composite cable sheath material with good processability and a preparation method thereof, and belongs to the technical field of cable sheath materials. The high-flame-retardant photoelectric composite cable sheath material comprises the following raw materials: a resin base material, a compatilizer, a composite flame retardant, a synergistic flame retardant, an antioxidant, modified glass fibers and a lubricant. The resin base material, the compatilizer, the composite flame retardant, the synergistic flame retardant, the antioxidant, the modified glass fiber and the lubricant are uniformly mixed and then extruded and granulated to prepare the flame-retardant resin. According to the invention, the composite flame retardant and the modified glass fiber are introduced and are scientifically proportioned with other raw materials, so that the high-flame-retardant photoelectric composite cable sheath material with good processability is obtained; the halogen-free flame-retardant low-smoke halogen-free flame-retardant halogen-free halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant halogen-free flame-retardant

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Preparation method of large biological coating containing tea bioactive component

InactiveCN113388320AImprove performanceImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesSurface modificationEngineering

The invention provides a preparation method of a large biological coating containing a tea bioactive component, and relates to the technical field of large biological coatings. The large biological coating containing the tea bioactive component is prepared through the steps of extraction of tea polyphenol, graphene modification, preparation of the large biological coating containing the tea bioactive component and the like. According to the invention, tea polyphenol molecules are utilized to perform surface modification on graphene, so that the agglomeration problem of graphene is solved, and the performance of the large biological coating containing tea bioactive component is remarkably improved. Meanwhile, the method provided by the invention is simple in process and low in cost, and has a good industrial production prospect and a relatively high economic value.

Owner:百草春天大生物科技(青岛)有限公司 +1

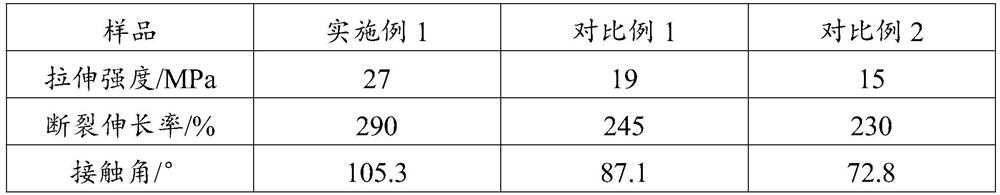

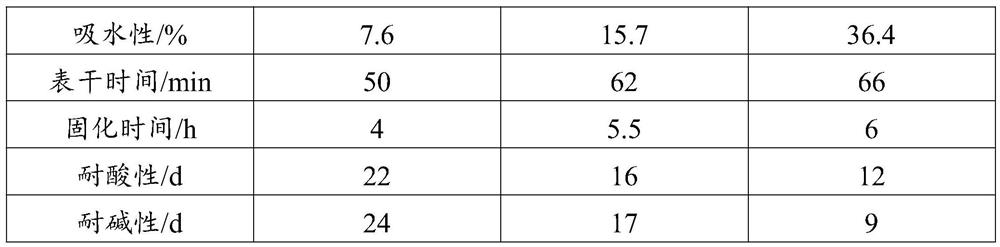

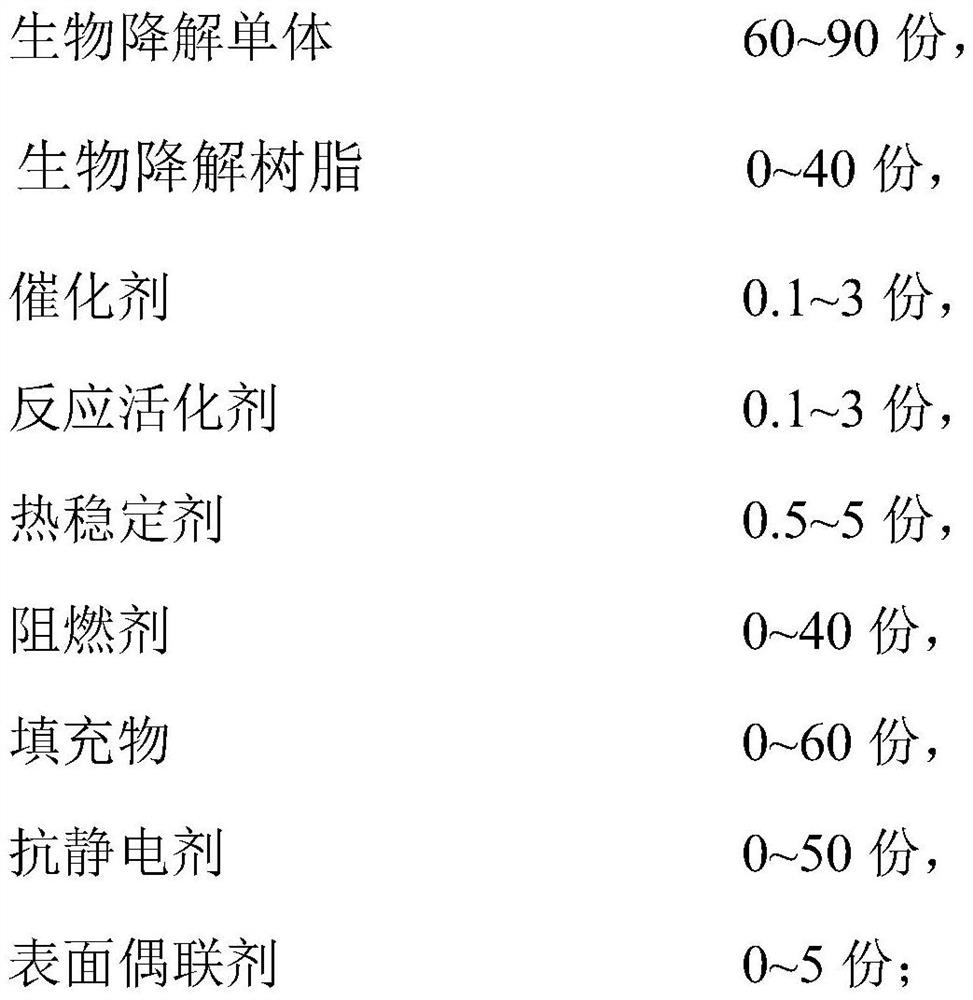

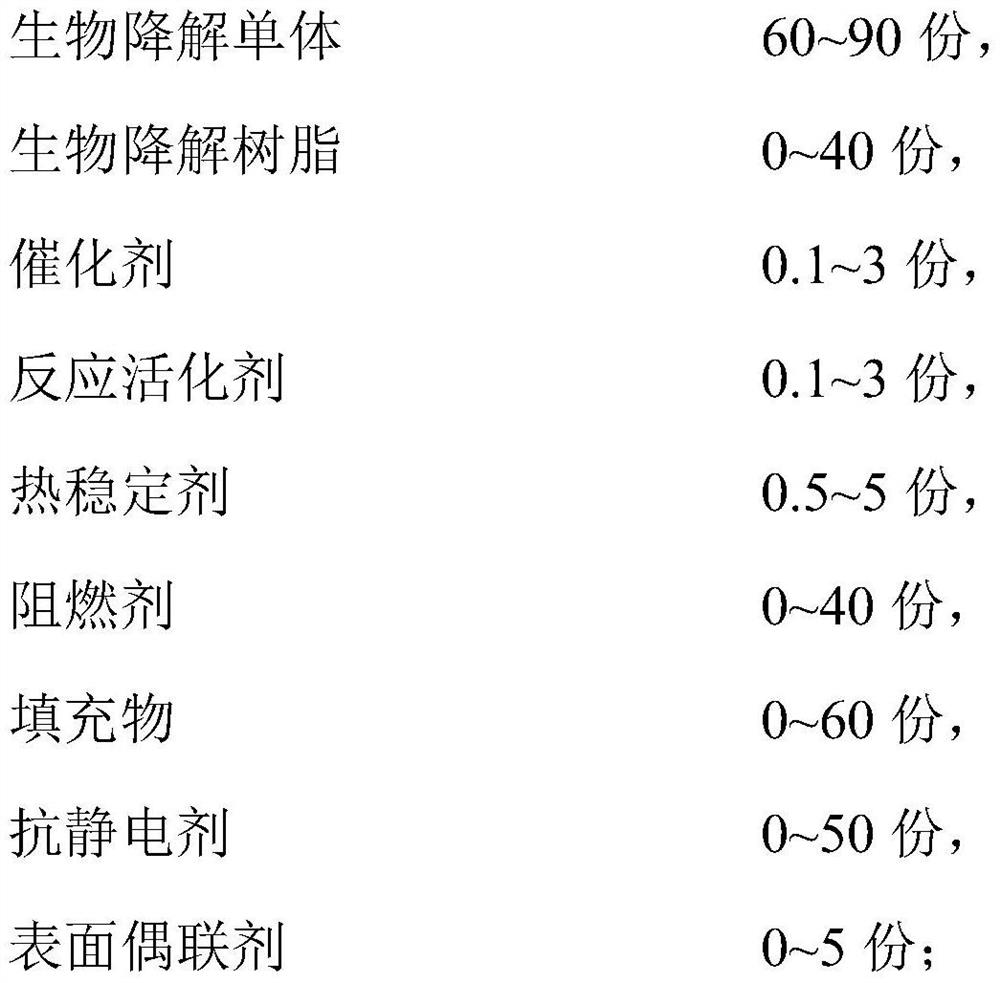

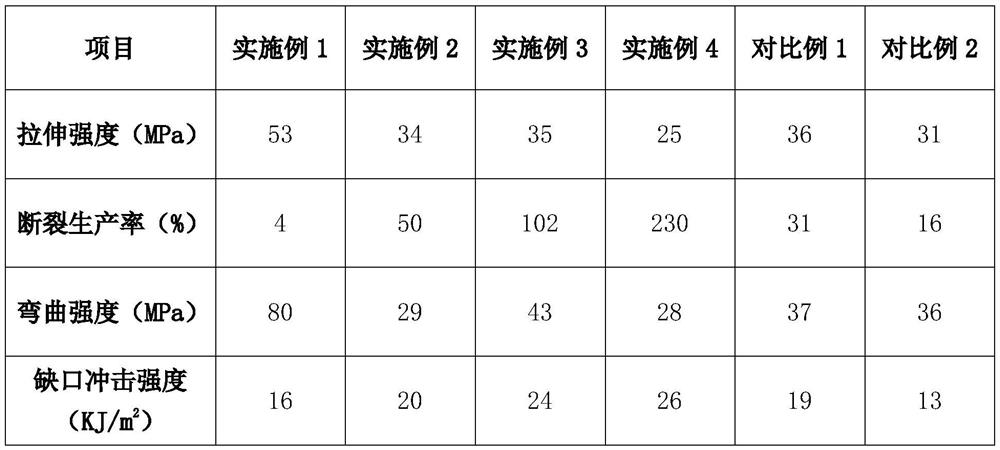

Full-biodegradable plastic alloy and preparation method thereof

The invention discloses a full-biodegradable plastic alloy and a preparation method thereof, the plastic alloy comprises the following raw material components: a biodegradable monomer, a catalyst, a reaction activator, a heat stabilizer, a flame retardant, a filler, an antistatic agent, a surface coupling agent and the like, all the raw material components are dissolved or mixed in a cyclic ester biodegradable monomer, and polymerizing and molding are carried out to obtain the full-biodegradable plastic alloy. According to the plastic alloy disclosed by the invention, not only is the biodegradability ensured, but also good compatibility and flowability among the components in the preparation process are ensured on the basis that no solvent is not used, so that the components of the obtained plastic alloy material are uniformly dispersed, excellent performance is obtained, the preparation process route is shortened, the cost is reduced, and industrial application is easy.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Carbon nanotube-titanium dioxide filling modified wear-resistant anti-ageing type composition material and preparation method thereof

InactiveCN107828133AImprove mechanical propertiesImproved performance against UV agingLow speedWear resistant

The invention discloses a carbon nanotube-titanium dioxide filling modified wear-resistant anti-ageing type composition material. The carbon nanotube-titanium dioxide filling modified wear-resistant anti-ageing type composition material is characterized by being prepared by the following steps: drying titanium dioxide powder, putting the dried powder into a high-speed mixing machine to stir uniformly, mixing a coupling agent and acetone, spraying the mixture on the powder for many times and performing modification treatment; adding aqua regia into a carbon nantotube, heating by oil bath, electromagnetically stirring at low speed and refluxing, cooling, adding distilled water with the same volume to dilute, filtering under reduced pressure and drying to obtain an oxidized carbon nano-tube;drying microcrystalline white mica powder and nano-silicon dioxide; mixing distilled water and absolute ethanol to obtain a diluent; mixing KH550 and the diluent to obtain a modifier; putting the dried powder and the modifier into a high-speed mixing machine, and mixing and modifying to obtain modified powder; and uniformly mixing polypropylene resin, PA6, maleic anhydride grated polyethylene andthe obtained materials, mixing on a double-roller mixing machine, performing extruding and mixing on an extruding machine, and performing preheating and hot-pressing forming on a plate vulcanizing machine to obtain the composite material.

Owner:ANHUI HONGSHI OPTOELECTRONICS HIGH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com