Polypara dioxocyclohexanone / montmorillonite nano-composite material and its preparation method

A technology of polydioxanone and nanocomposite materials, which is applied in the field of polydioxanone/montmorillonite nanocomposite materials and its preparation, and can solve the problems of slow crystallization speed of polymerization products, high production cost and limited Issues such as promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

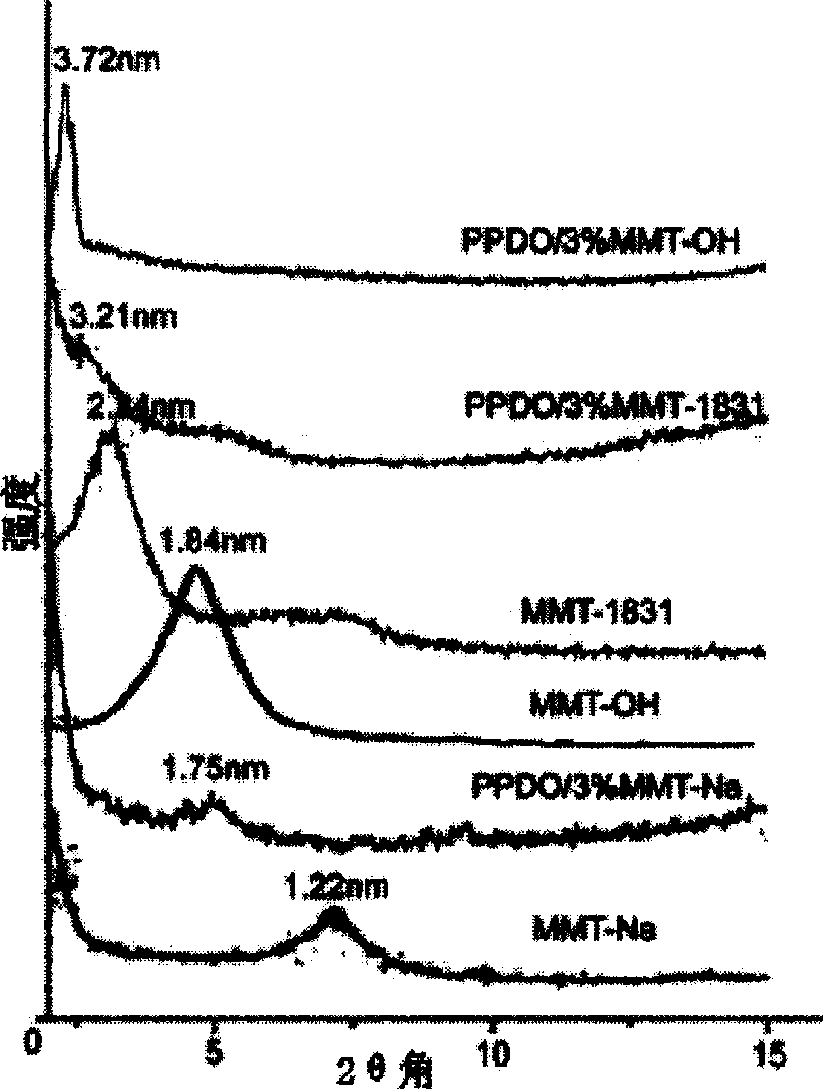

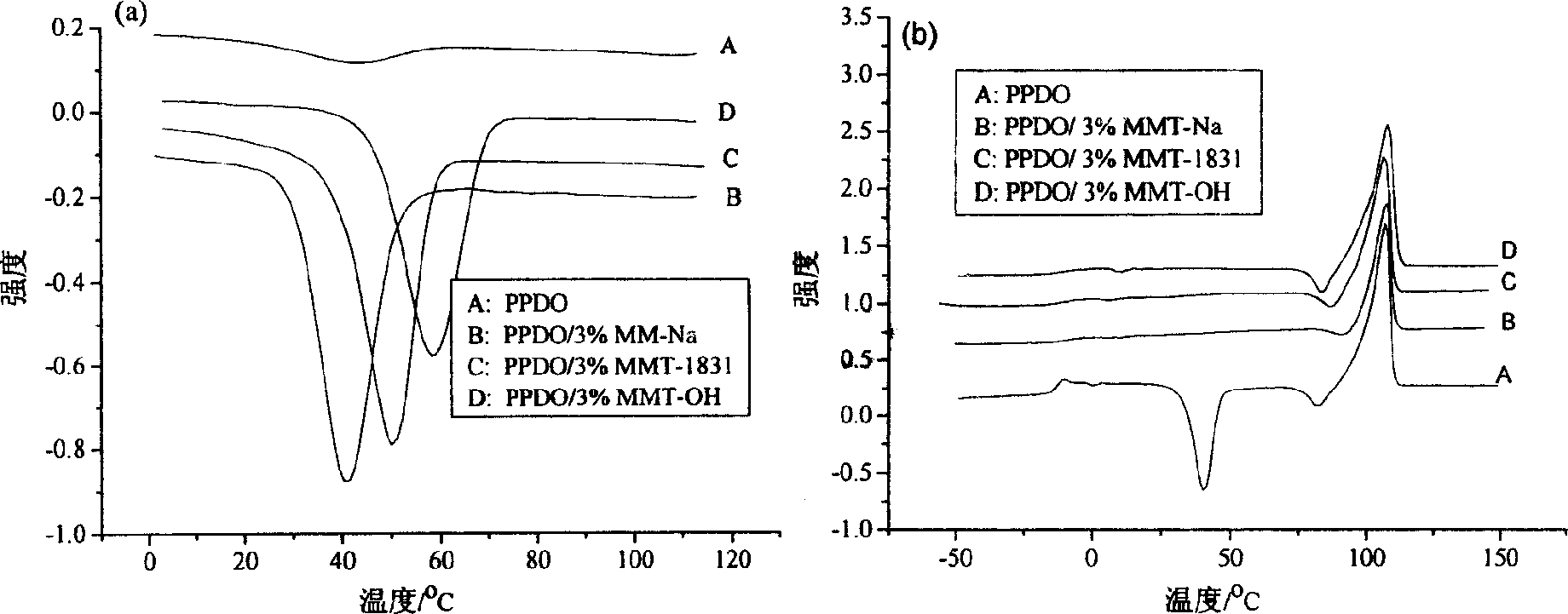

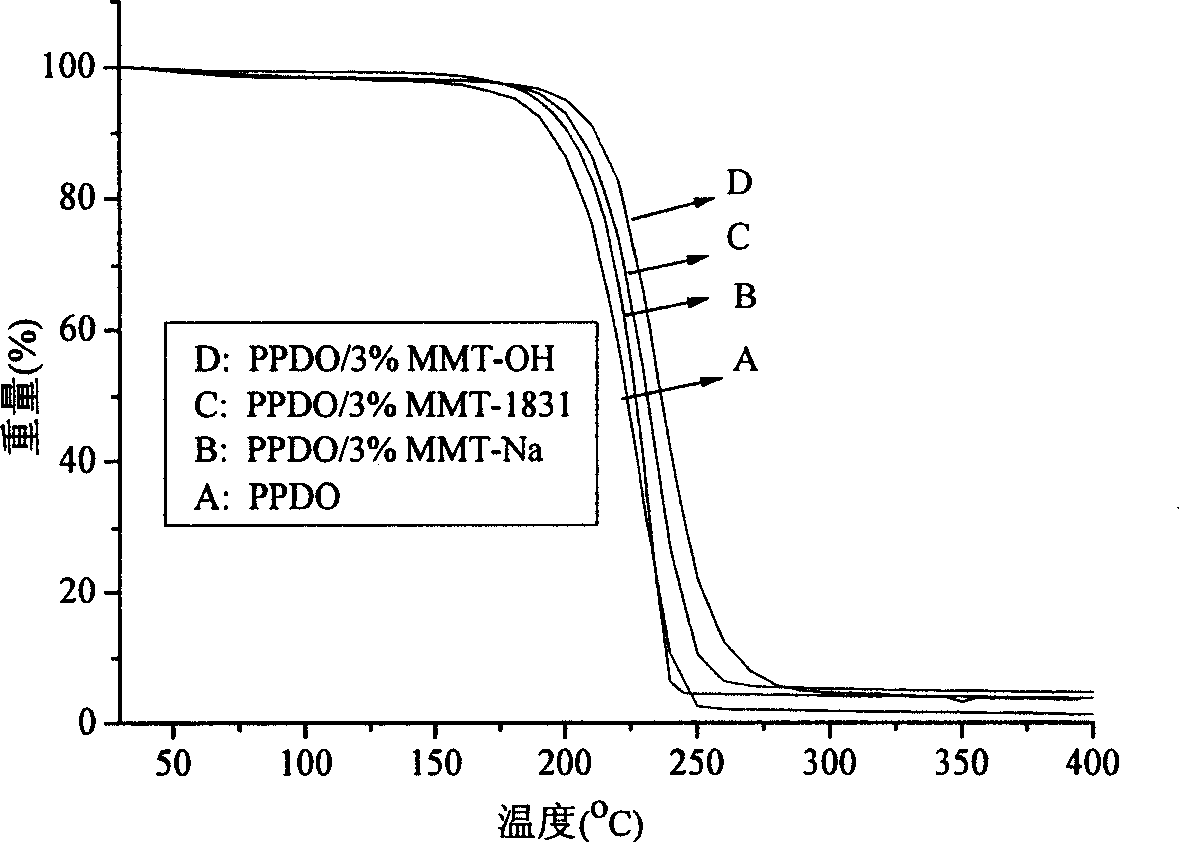

Method used

Image

Examples

Embodiment 1

[0013] (1) Place 20 g of Na-montmorillonite with a total cation exchange capacity of 100 meq / 100 g in 500 ml of distilled or deionized water, stir at high speed for 1 hour to form a stable suspension; then let it stand for 0.5 hours, and filter it with 400 mesh Cloth is used to filter the suspension to obtain the filtrate, which is set aside; dissolve 4g of octadecyltrimethylammonium chloride in 25ml of distilled water; heat the above filtrate to 50°C, add octadecyltrimethylammonium chloride solution, and stirred at 50°C for 10 hours to carry out ion exchange; then naturally cooled to room temperature, suction filtered, and repeatedly washed with distilled water several times, until no chloride ions were detected in the filtrate with 1mol / L silver nitrate solution; Finally, vacuum-dry at 50° C. for 20 hours until the montmorillonite has a constant weight, and grind it into a powder smaller than 100 microns.

[0014] (2) 100 g of p-dioxanone monomer and 3 g of organic montmoril...

Embodiment 2

[0016] (1) Put 20 g of H-montmorillonite with a total capacity of cation exchange of 80 meq / 100 g in 500 ml of distilled or deionized water, stir at high speed for 1 hour to form a stable suspension; Filter the suspension to obtain the filtrate for later use; dissolve 4g of octadecyltrimethylammonium chloride in 25ml of distilled water; heat the above-mentioned filtrate to 60°C, and add the octadecyltrimethylammonium chloride solution dropwise , and stirred at 60°C for 20 hours to carry out ion exchange; then naturally cooled to room temperature, suction filtered, and repeatedly washed with distilled water for several times, until no chloride ions were detected in the filtrate with 1mol / L silver nitrate solution; finally Vacuum dry at 50° C. for 20 hours until the montmorillonite has a constant weight, and grind it into a powder smaller than 100 microns.

[0017] (2) 100 g of p-dioxanone monomer and 5 g of organic montmorillonite prepared above were added successively into a r...

Embodiment 3

[0019] (1) Place 20 g of Mg-montmorillonite with a total cation exchange capacity of 120 meq / 100 g in 500 ml of distilled or deionized water, stir at high speed for 1 hour to form a stable suspension; Filter the suspension to obtain the filtrate for later use; dissolve 4g of octadecyltrimethylammonium chloride in 25ml of distilled water; heat the above-mentioned filtrate to 70°C, add the octadecyltrimethylammonium chloride solution dropwise , and stirred at a constant temperature of 70°C for 15 hours to carry out ion exchange; then naturally cooled to room temperature, suction filtered, and repeatedly washed with distilled water for several times, until no chloride ions were detected in the filtrate with 1mol / L silver nitrate solution; finally Vacuum dry at 50° C. for 20 hours until the montmorillonite has a constant weight, and grind it into a powder smaller than 100 microns.

[0020] (2) 100 g of p-dioxanone monomer and 10 g of organic montmorillonite prepared above were add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com