High-strength cement-based non-shrinkage grouting material

A high-strength cement and non-shrinkage technology, applied in the field of cement-based materials, can solve the problems of great influence, accelerated decline in mechanical strength, and great influence on mechanical properties, etc., achieve strong interface force, improve mechanical strength, and avoid aging problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0042] Synthetic example 1 surface treatment of hollow polymethyl methacrylate microspheres

[0043]Mix hollow polymethyl methacrylate microspheres, deionized water, and methacrylic acid at a mass ratio of 1:100:25. The mixed solution is stirred on a magnetic stirrer and heated at 45°C for 30 minutes, and then Ultrasonic vibration treatment was performed for 15 minutes. After the treatment, it was placed in a vacuum oven at a temperature of 150° C. and baked for 2.5 hours to obtain surface-treated hollow polymethylmethacrylate microspheres.

Synthetic example 2

[0044] Preparation of Synthetic Example 2 Cyanate Resin Epoxy Resin Copolymer Fiber

[0045] Add bisphenol A type cyanate resin monomer and bisphenol A type epoxy resin monomer into the container at a mass ratio of 1:25, prepolymerize at 95°C for 15 minutes to obtain a prepolymer; then prepolymerize The polymer is dissolved in acetone to form a spinning solution with a concentration of 20%; the fiber material is prepared by conventional electrospinning, and its diameter is 0.09-0.14 microns;

[0046] The process parameters of electrospinning are: voltage 1-50 kV, receiving distance 1-50 cm, solution flow rate 0.01-20 mL / h.

Embodiment

[0048] According to the weight ratio shown in Table 1, each component is added into the dry powder mixer at one time, and the cement-based non-shrinkage grouting material can be obtained after thorough and uniform mixing.

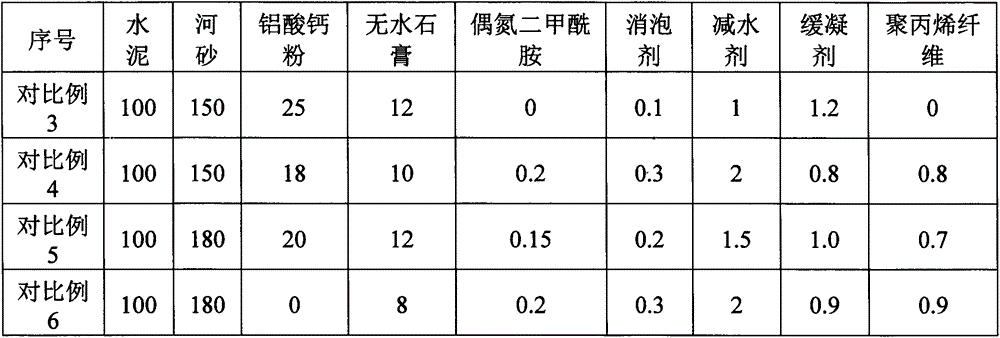

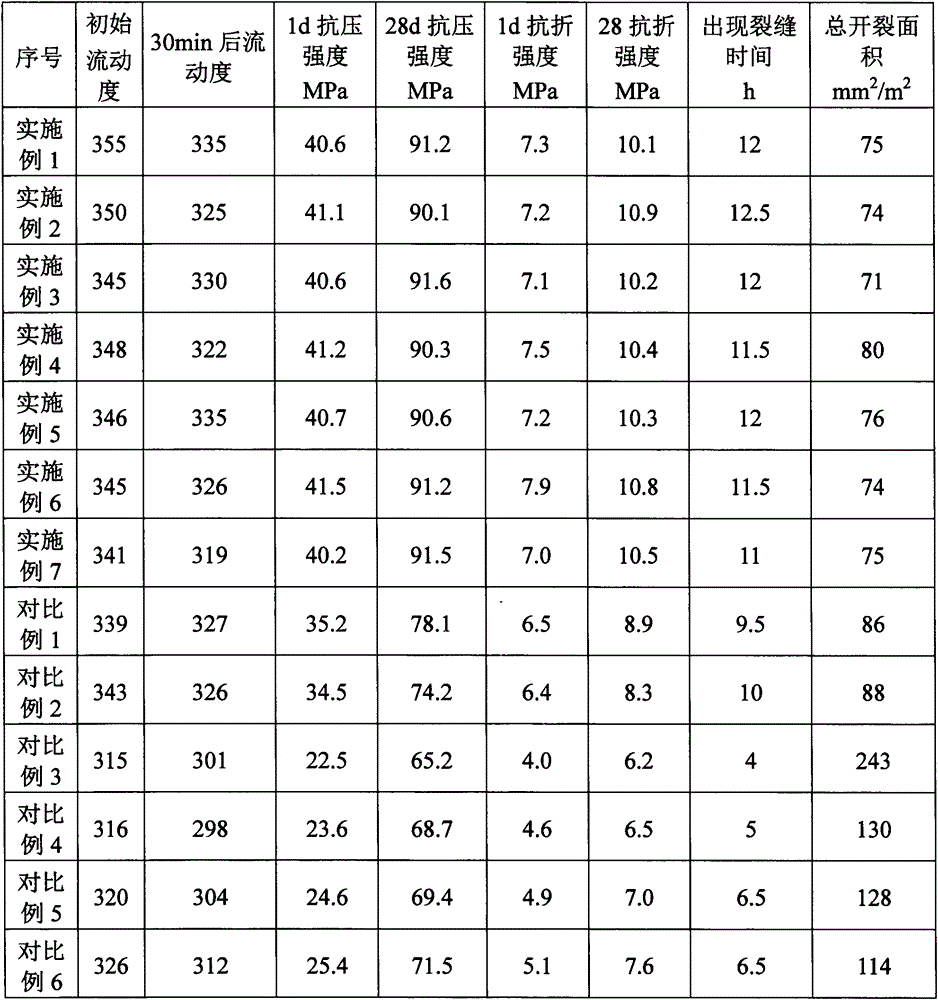

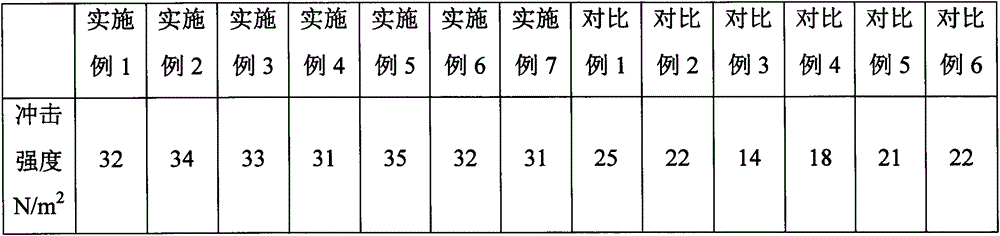

[0049] Table 1 Weight composition of cement-based non-shrinkage grouting material

[0050] serial number

[0051] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com