Patents

Literature

241results about How to "Improved performance against UV aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

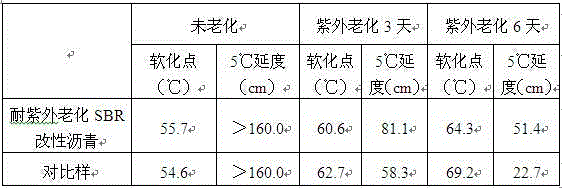

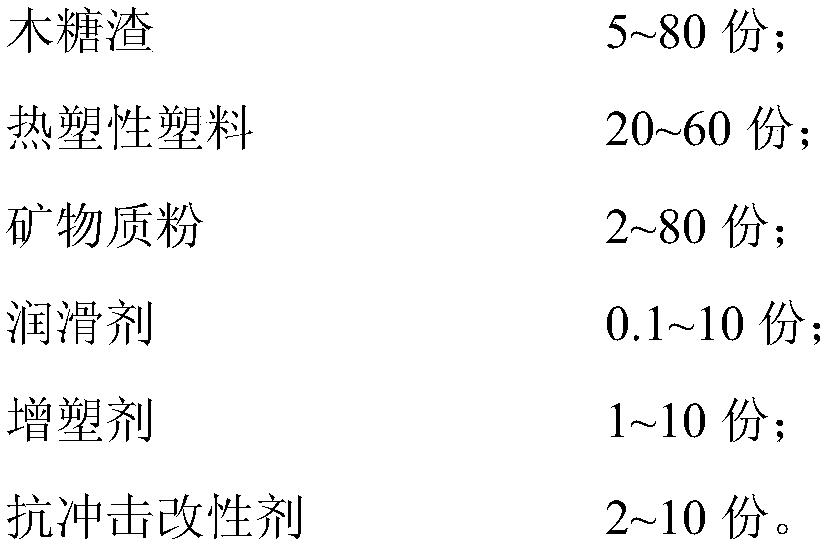

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

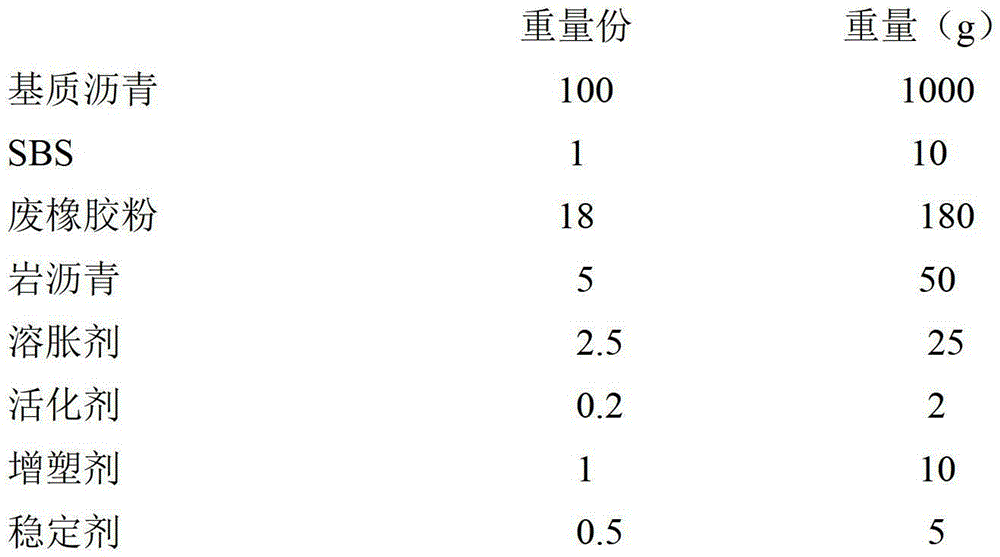

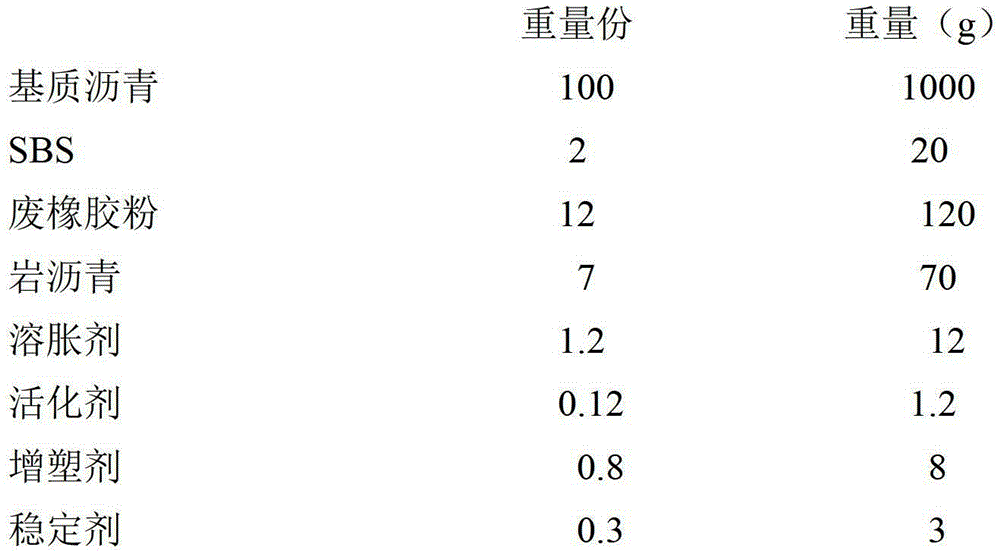

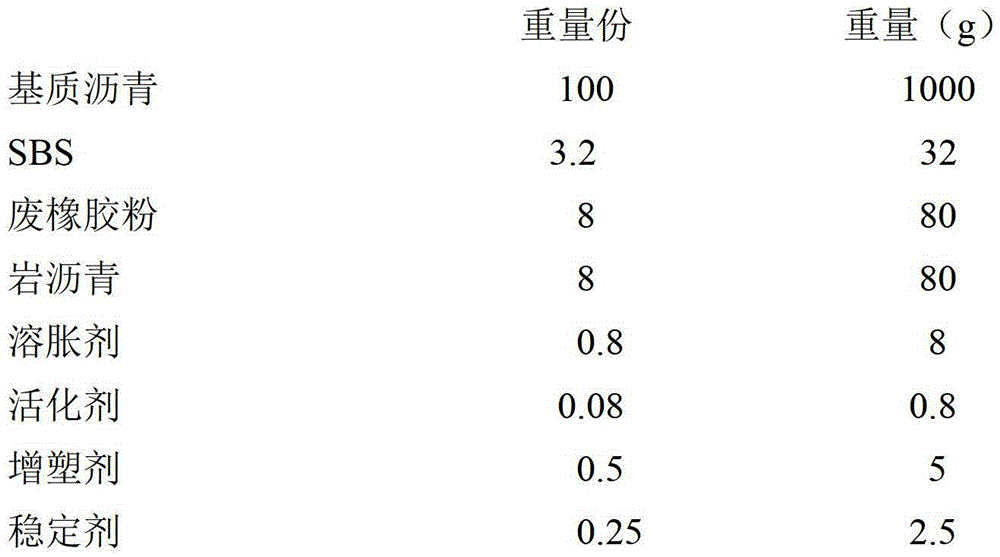

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

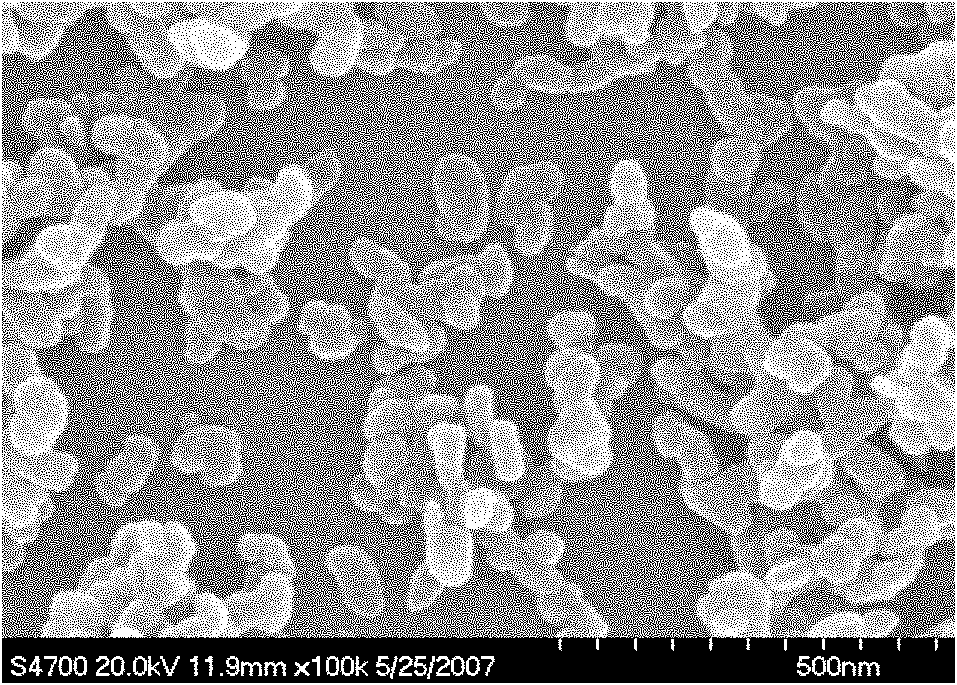

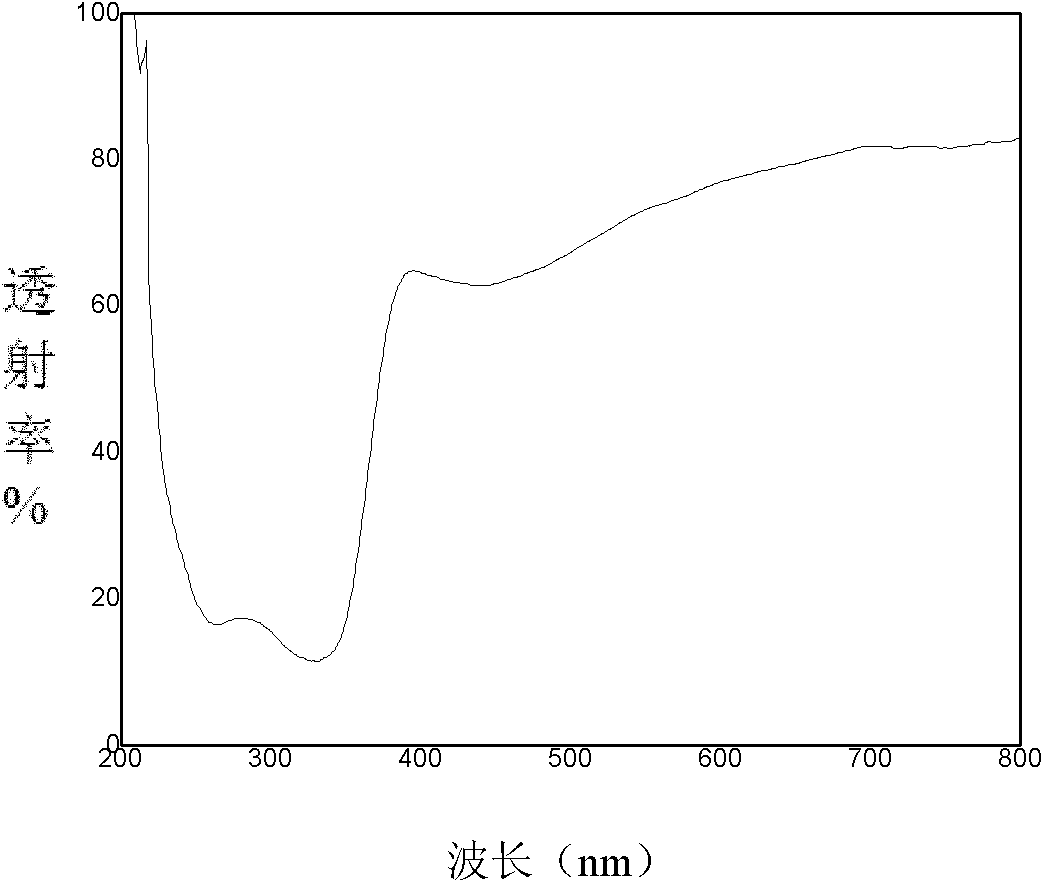

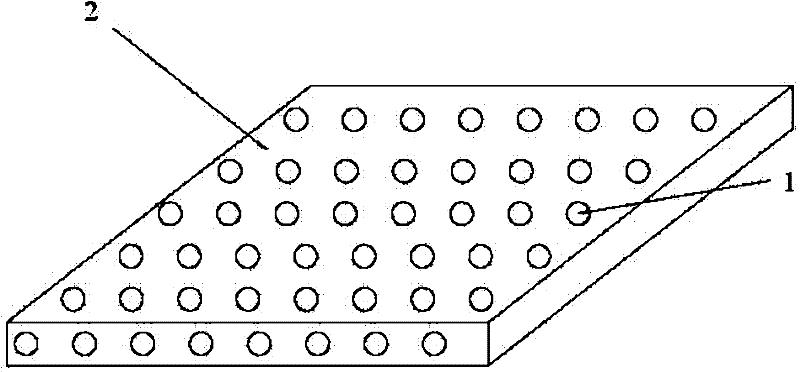

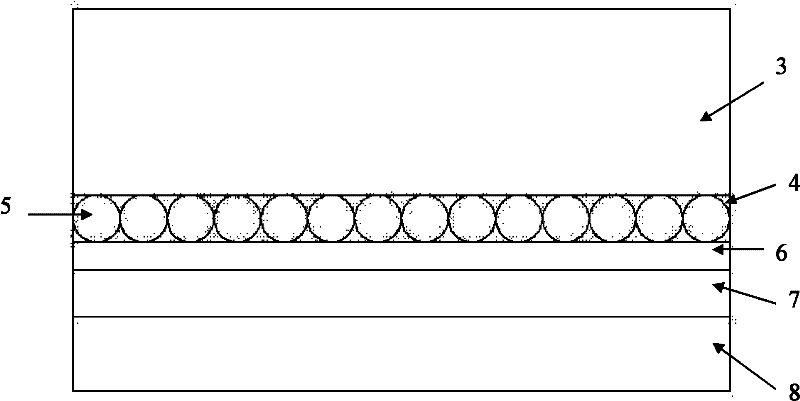

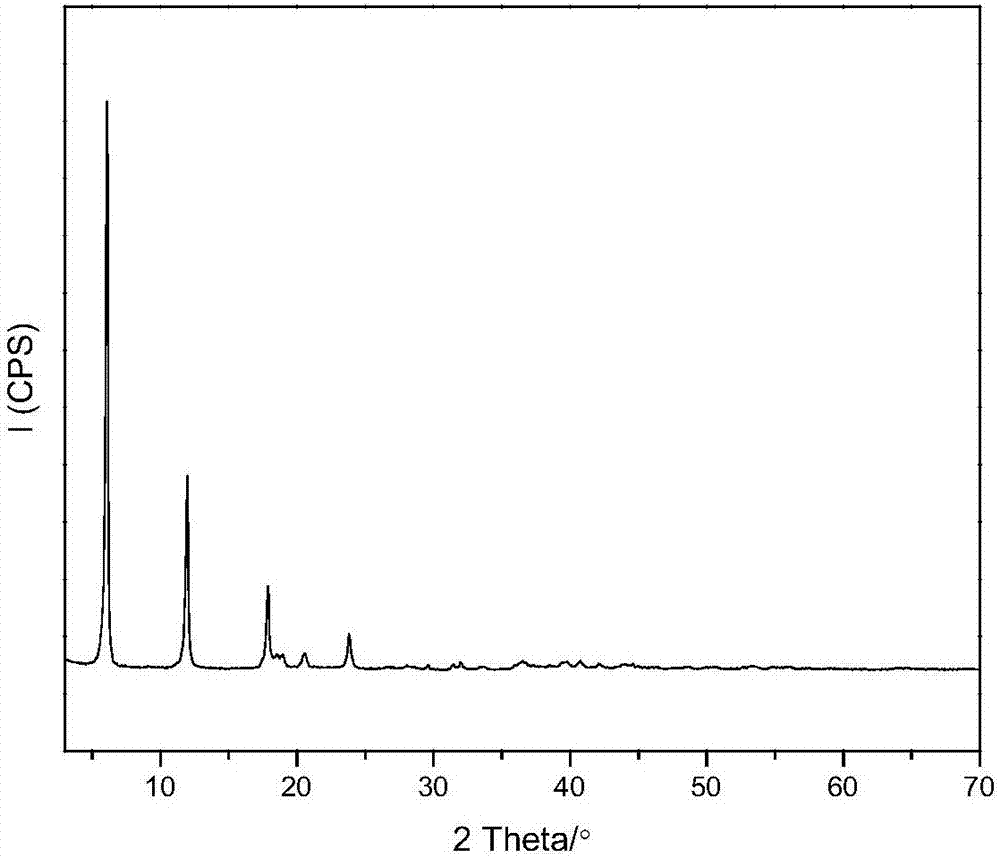

Magnelium base layer-shaped double-hydroxide ultraviolet barrier material used in anti-aging asphalt

ActiveCN102180614AImproved performance against UV agingExtended service lifeMolecular compositionAging resistance

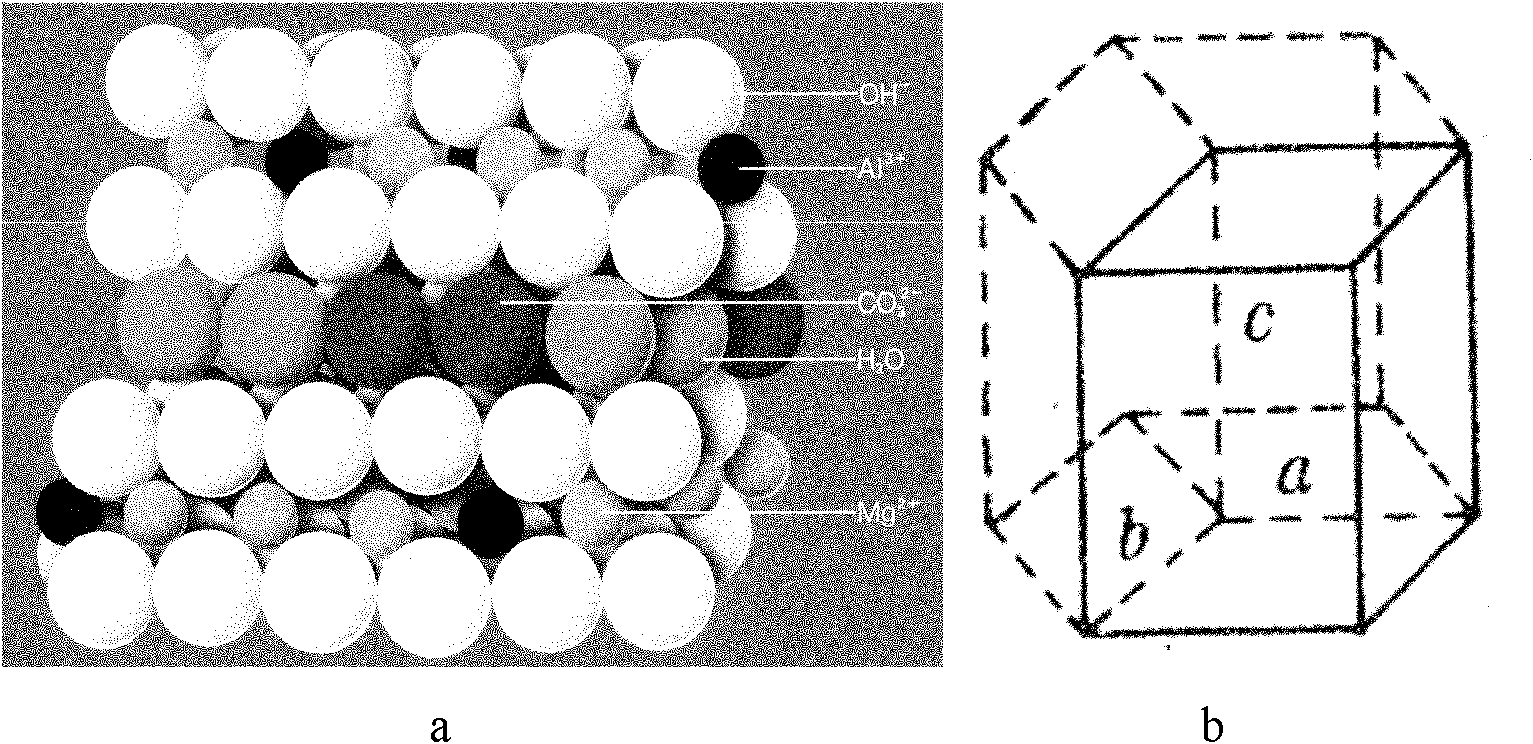

The invention relates to a magnelium base layer-shaped double-hydroxide ultraviolet barrier material used in anti-aging asphalt and a preparation method thereof. The magnelium base layer-shaped double-hydroxide ultra-violet barrier material has a laminated structure formed by magnelium double-hydroxide plywoods and interlayer carbonate through multi-stage superposition, and molecular composition is as follows: Mg1-xAlx (OH) 2 (CO3) x / 2 . mH2O. The inorganic plywoods of the material can play a role in physically shielding ultraviolet rays, and metal elements on the plywoods and interlayer anions can play a role in chemically absorbing the ultraviolet rays; in addition, by controlling the size and number of layers of the plywoods, multi-stage reflection and refraction occur on interfaces of the plywoods when the ultraviolet rays pass through the multi-stage plywoods, and multi-stage absorption occurs on the plywoods and interlayers, so as to play a role in blocking the ultraviolet rays. Due to the multi-stage multiple chemical absorption and physical shielding effect, the material has good ultraviolet blocking effect, and remarkably improves the ultraviolet aging resistance of asphalt when the material is used for preparing the anti-aging asphalt.

Owner:BEIJING UNIV OF CHEM TECH +1

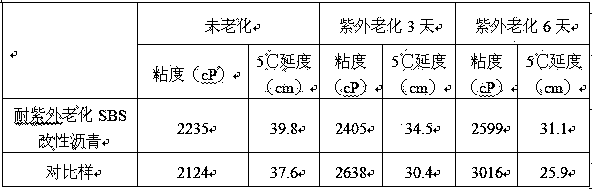

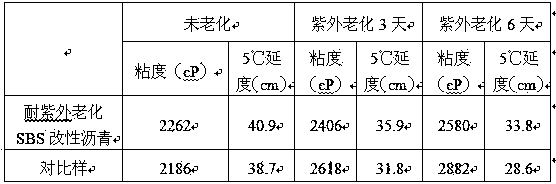

Magnesium-aluminum based layered double hydroxide aging resistant SBS (Styrene-Butadiene-Styrene Block Copolymer) modified asphalt and preparation method thereof

ActiveCN102174269AImproves UV resistanceImproved performance against UV agingBuilding insulationsAluminium oxides/hydroxidesPolymer modifiedAging resistance

The invention relates to aging resistant SBS (Styrene-Butadiene-Styrene Block Copolymer) modified asphalt and a preparation method thereof. The aging resistant SBS modified asphalt is a magnesium-aluminum based layered double hydroxide aging resistant SBS modified asphalt prepared from the following raw materials by weight percent: 86.7%-94.95% of base asphalt, 3%-5% of polymer modifier SBS, 2%-8% of magnesium-aluminum based layered double hydroxide and 0.05%-0.3% of vulcanizer. In the preparation method, the magnesium-aluminum based layered double hydroxide with the ultraviolet physical shielding and chemical absorption functions is mixed with the SBS modified asphalt so as to obviously increase the ultraviolet aging resistance of the SBS modified asphalt.

Owner:WUHAN UNIV OF TECH

Nano-composite polyurethane aircraft paint and its preparation method and application

InactiveCN1513930AFix compatibility issuesStorage stablePolyurea/polyurethane coatingsSolventAirplane

A nano-class composite polyurethane paint for airplane is composed of the modified synthetic resin and the solidifying agent. Said modified synthetic resin is prepared through sequentially adding nano slurry, solvent, assistant and pigment to synthetic resin, grinding and filtering. It is applied through mixing said modified synthetic resin with said solidifying agent to obtain paint, spraying antirust paint, and spraying said paint. Its advantage is high weatherability.

Owner:DALIAN YUXIANG TECH GRP

Ethylene-vinyl acetate adhesive film containing quantum dots as well as preparation method and application thereof

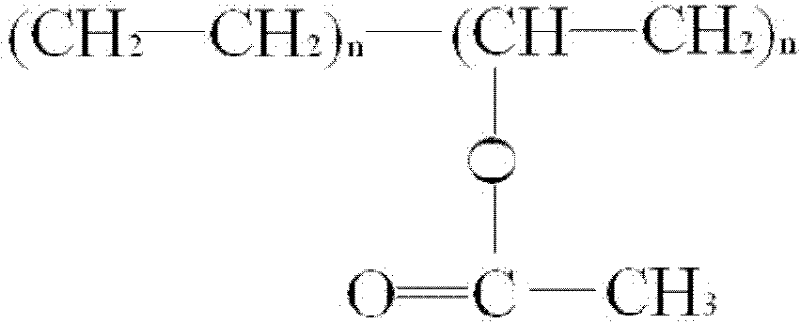

ActiveCN102226064AImprove efficiencyHigh fluorescence quantum efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesOperabilityCarvacryl acetate

The invention discloses a preparation method of an ethylene-vinyl acetate adhesive film containing quantum dots, which comprises the following steps: using a modifier to perform hydrophilic or lipophilic modification on the surfaces of the semiconductor quantum dots, further uniformly dispersing the semiconductor quantum dots after modification into a solvent for forming semiconductor quantum dotink, then mixing the semiconductor quantum dot ink, an ethylene-vinyl acetate copolymer and an assistant, and performing hot compression molding or extrusion molding for getting the ethylene-vinyl acetate adhesive film containing the semiconductor quantum dots. The preparation method is simple, good in controllability, strong in operability and easy for industrial production. The invention further discloses the ethylene-vinyl acetate adhesive film containing the quantum dots, which is applied in solar cells and can effectively improve the utilization efficiency of the solar cells.

Owner:ZHEJIANG UNIV

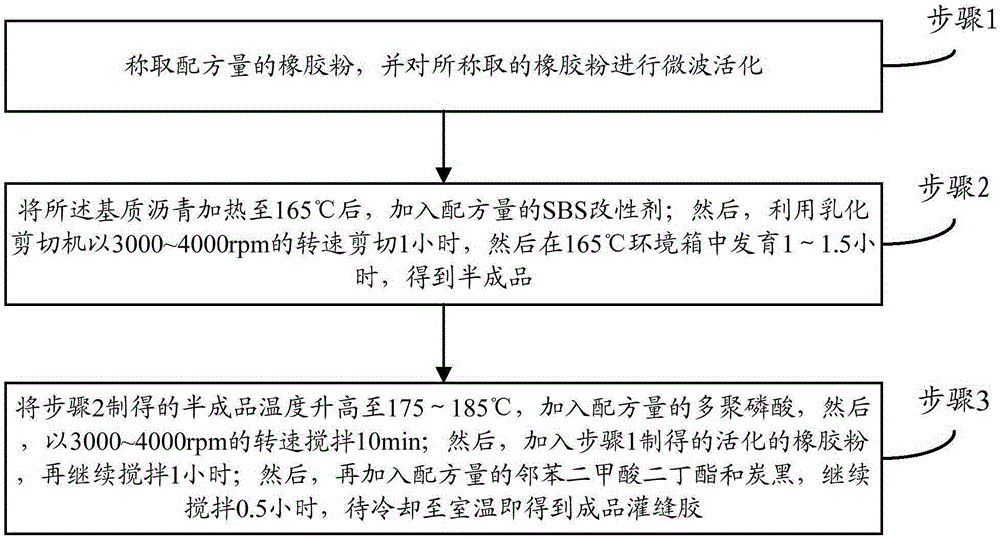

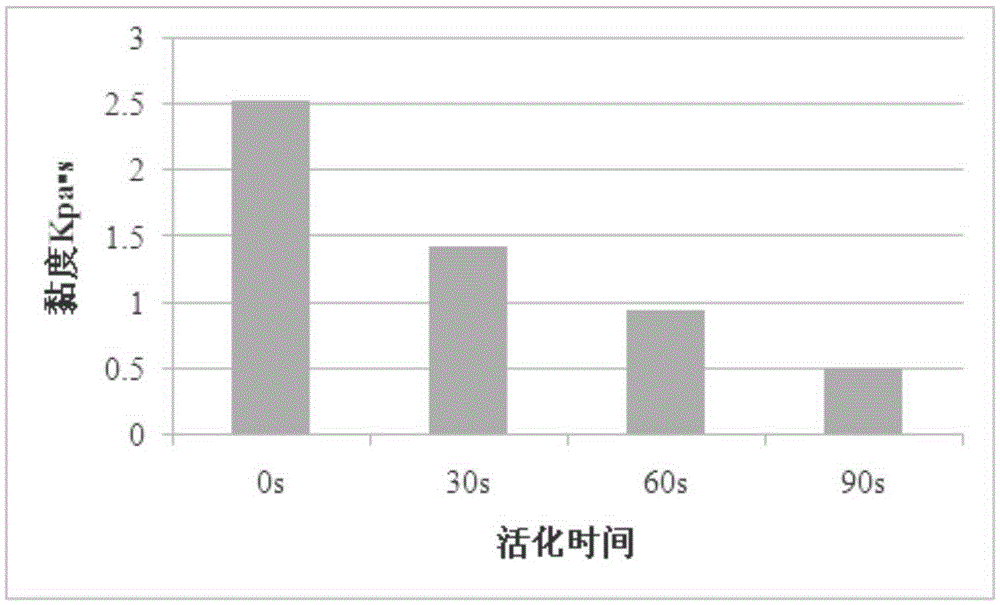

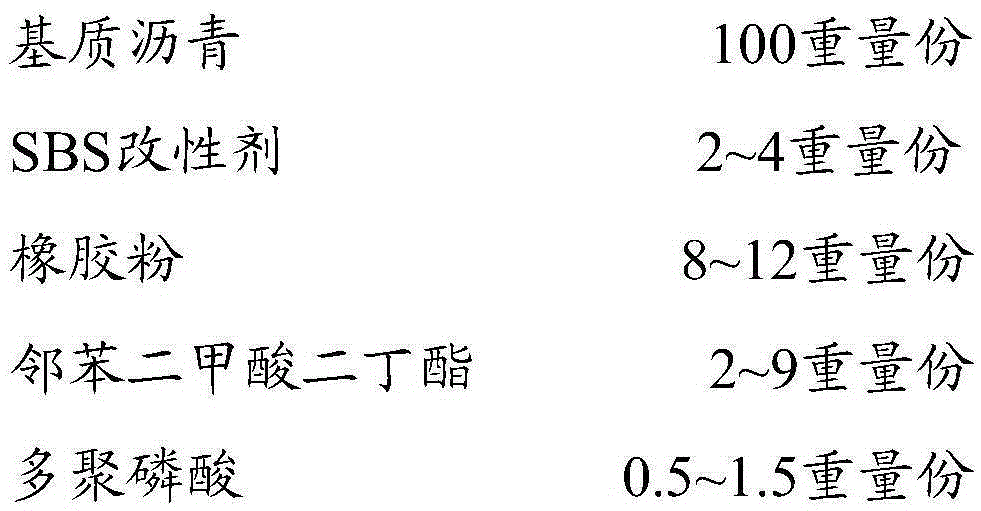

Ultraviolet-resistant bituminous pavement crack filling glue and preparation method thereof

ActiveCN105331330ALow costImprove anti-ultraviolet aging abilityNon-macromolecular adhesive additivesBituminous material adhesivesCarbon blackDibutyl phthalate

Owner:甘肃恒石公路检测科技有限公司

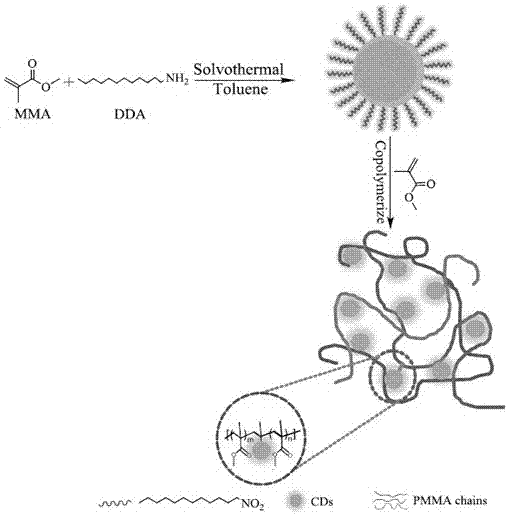

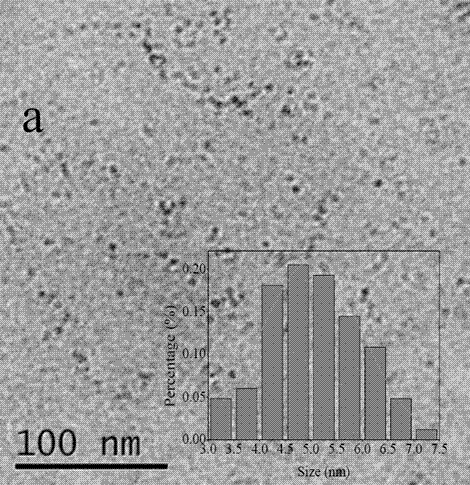

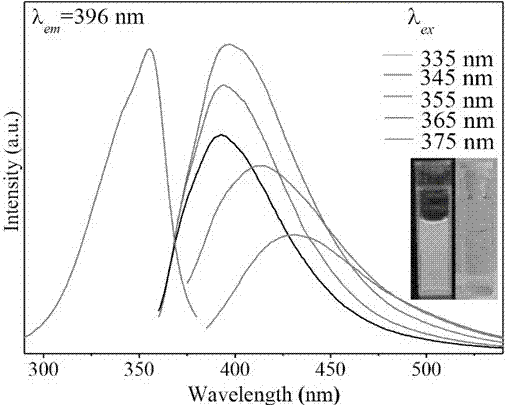

Oil-solubility carbon quantum dots (OCDs), PMMA-coated OOCDs, and preparation method and application thereof

InactiveCN106916587ASmall sizeHigh luminous intensityMaterial nanotechnologyNanoopticsTransmittanceIn situ polymerization

The invention relates to oil solubility carbon quantum dots (OCDs), PMMA-coated OOCDs, and a preparation method and an application thereof. The particle size of the oil solubility carbon quantum dots is 1-10 nm, and the surface non-saturated carbon bond contains 20-50%. The oil solubility carbon quantum dots synthesized by the method has good dispersibility and luminescence performance, can be taken as an age-proof probe of PMMA, a composite material obtained by in-situ polymerization of the oil solubility carbon quantum dots and the PMMA has excellent optical transparency (the transmittance can reach as high as more than 85%), the anti-ultraviolet aging performance of the PMMA can be increased by more than 10 times, the method solves the problems that the application of carbon quantum dots is existed in all-solid-state illumination in the prior art, and solves the problem that the PMMA cannot be widely used due to poor aging performance.

Owner:SHANGHAI UNIV

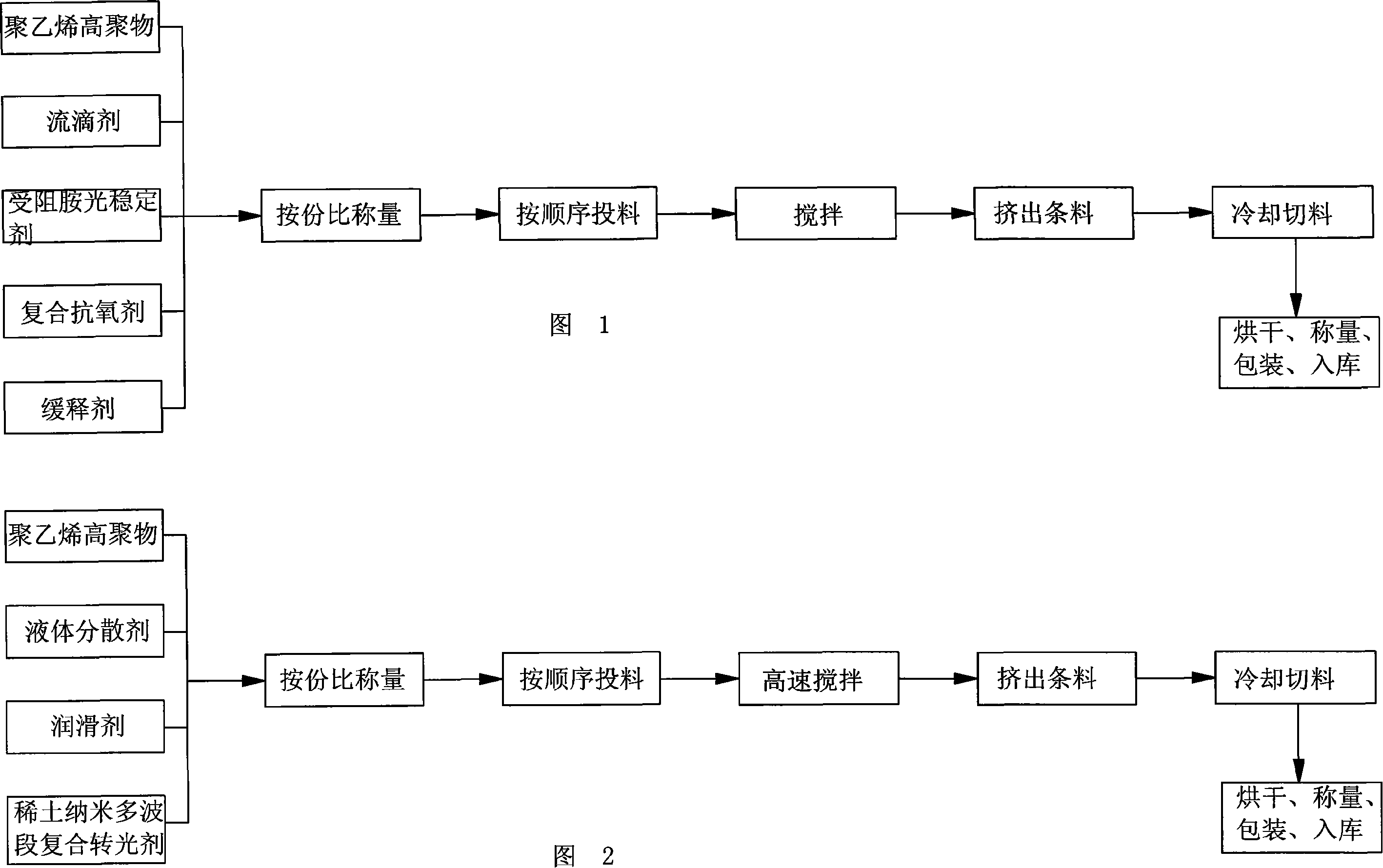

Improved light altering film for agriculture and method of processing the same

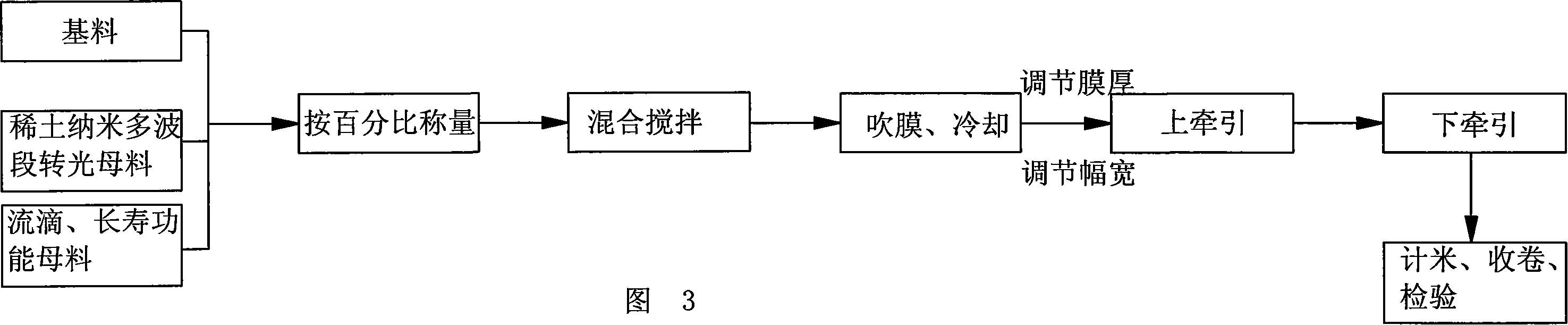

The present invention provides an improved light conversion agricultural membrane and the processing method. The agricultural membrane produced by the method has good dropping performances, excellent heat insulation and temperature-increasing performances, high transmittance, a plurality of colors for light conversion, long period of light conversion, and long service life of the agricultural membrane. An improved light conversion agricultural membrane is characterized in that the membrane comprises components of following weight percent: 8 percent to 12.5 percent of mother material of functions of dropping and long service life, 8 percent to 12.5 percent of rare earth nanometer multi-band light-conversion mother material, and 75.5 percent to 83 percent of base material. In the processing method of the light-conversion agricultural membrane, the concentrated mother material of functions of dropping and long service life, the rare earth nanometer multi-band light-conversion mother material and the base material are added into a mixing machine and stirred uniformly according to the proportion; the time is 5 minutes to 10 minutes; then the mixture is sent into a molding membrane-extruder; the diameter ratio is 30 to 1; the mould head is a type of feeding material from the center. The extruded membrane pipe is bulged, cooled, guided into an upper traction clamping roller and a lower traction roller by a human-held contraction frame, calculated by meter, fractured and rolled by double working positions, inspected, weighed, packaged and stored.

Owner:钱维均

Crude polypropylene fiber for concrete and preparation method thereof

InactiveCN101629332AHigh breaking strengthIncrease elasticityFilament manufactureArtificial filament heat treatmentWater bathsPolymer science

The invention relates to a crude polypropylene fiber for concrete and a preparation method thereof. The crude polypropylene fiber comprises polypropylene, a thermotropic liquid crystal polymer being 0.1-25 percent by weight of the polypropylene, a compatilizer being 0.1-5.0 percent by weight of the polypropylene, an antioxidant being 0.1-0.5 percent by weight of the polypropylene and an ultraviolet absorption agent being 0.1-0.3 percent by weight of the polypropylene. The preparation method comprises the following steps: drying the polypropylene, the thermotropic liquid crystal polymer and other components to constant weight and then uniformly mixing the components; extruding the dried components by a spinneret plate of a double-screw extruder and then cooling an obtained extruded material in a water bath; stretching the cooled material in different stages for multiple times at a temperature being higher than the vitrification temperature of the polypropylene; spraying a conventional oil agent used for polypropylene spinning on an obtained fiber bundle and carrying out thermal shaping; and then carrying out indentation processing on the surface of the fiber. The thermotropic liquid crystal polymer strengthens the crude polypropylene fiber in the form of a microfiber so as to greatly improve the mechanical property of the crude polypropylene fiber, thereby enhancing or improving the crude polypropylene fiber to enhance the performances of anti-cracking, permeability resistance, breaking resistance, toughness, impact resistance, freezing and thawing resistance, fire resistance, bursting resistance, and the like of the concrete.

Owner:JIANGSU SUBOTE MATERIAL +1

Weather resistant polypropylene composite material and its preparation method and uses

InactiveCN103509247AAvoid damageAvoid breakingForming/stuttering elementsGlass fiberPolypropylene composites

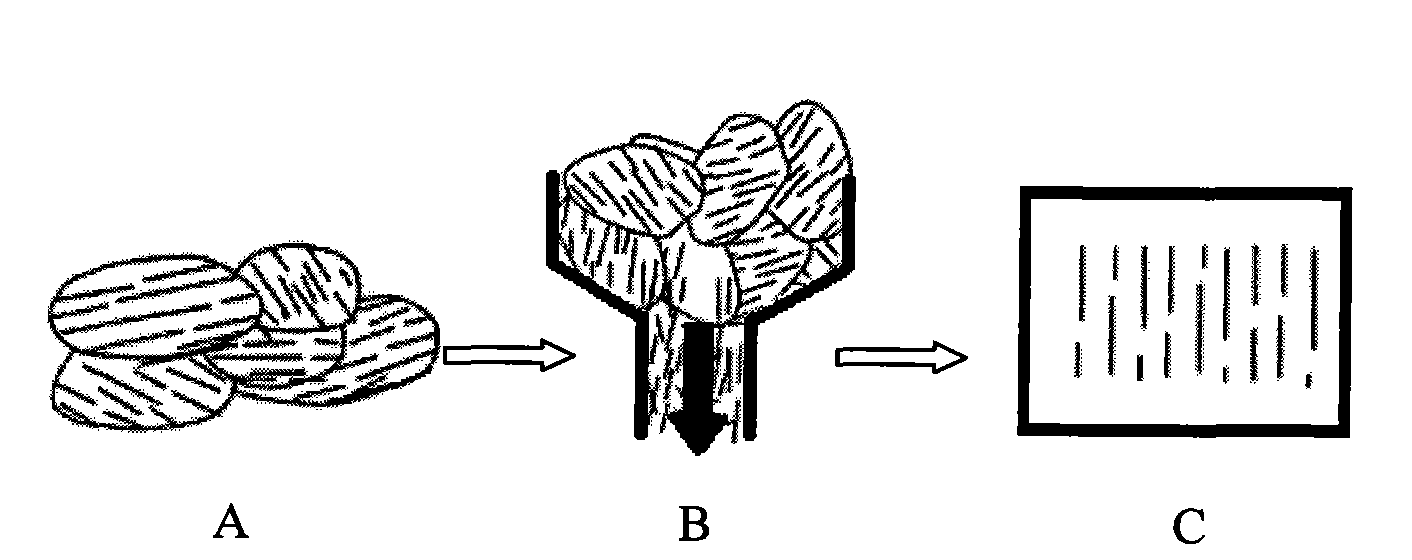

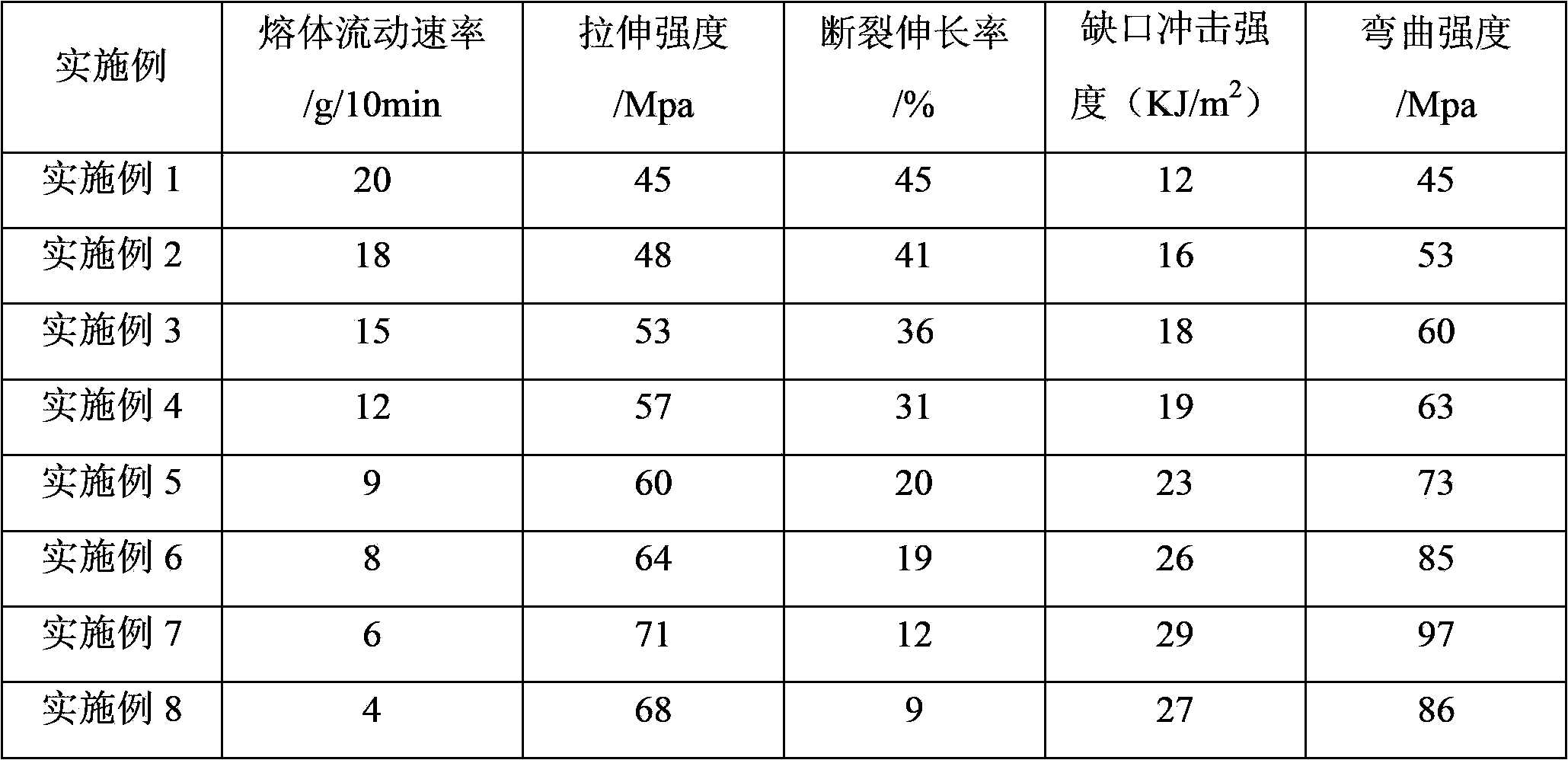

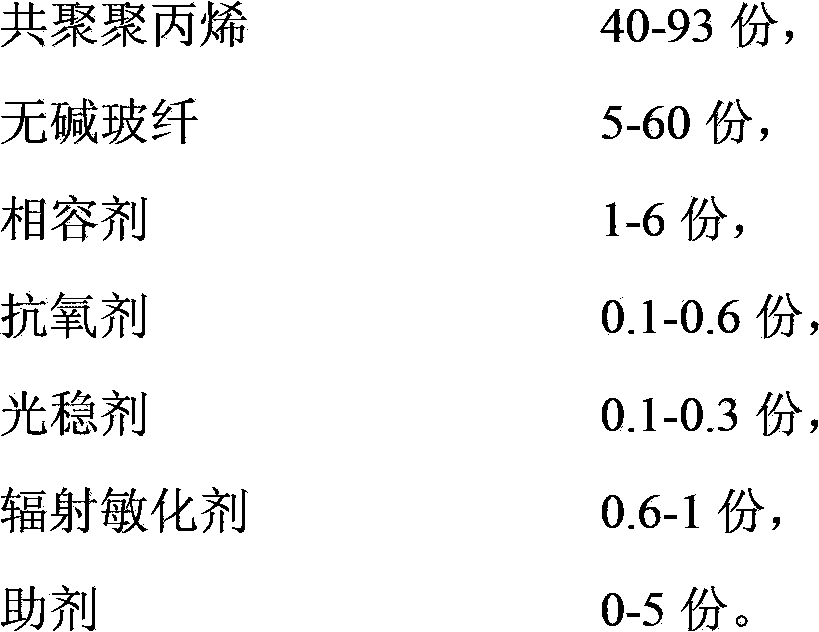

The invention belongs to the technical field of polymer composite materials, and relates to a polypropylene composite material and its preparing method and uses. The polypropylene composite material comprises the following components by weight: 40-93 parts of co-polypropylene, 5-60 parts of alkali free glass fiber, 1-6 parts of a compatible agent, 0.1-0.6 part of an antioxidant, 0.1-0.3 part of a light stabilizer, 0.6-1 part of a radiation sensitizing agent and 0-5 parts of an additive. Through cooperation of the functional additives, the high-strength, high-toughness and weather resistant composite material for building templates can be prepared, and the polypropylene composite material can be used for the preparation of various building templates and other outdoor equipment due to its excellent comprehensive properties.

Owner:HEFEI GENIUS NEW MATERIALS

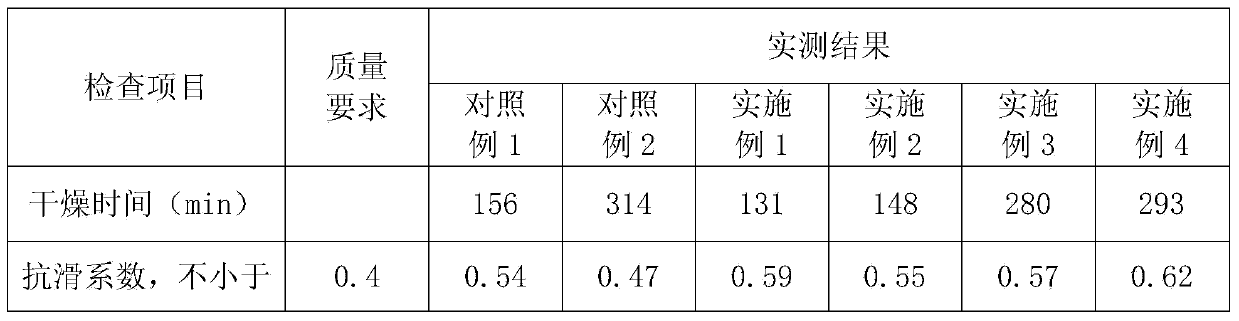

Water-based reinforced type fog sealing layer material for asphalt pavement, and preparation method and construction method of water-based reinforced type fog sealing layer material for asphalt pavement

InactiveCN104164818AImprove permeabilityLow costIn situ pavingsPaving gutters/kerbsWater basedOrganic solvent

The invention relates to the technical field of highway maintenance, and discloses a water-based reinforced type fog sealing layer material for an asphalt pavement, and a preparation method and a construction method of the water-based reinforced type fog sealing layer material for the asphalt pavement. The fog sealing layer material comprises a lower water-penetration-preventing sub-layer and an upper anti-skidding wear-resisting sub-layer, wherein materials for preparing the lower sub-layer contain an emulsifier, water, an organic solvent, a dispersant, an additive, a penetrating agent, a viscosifier and asphalt, and materials for preparing the upper sub-layer contain an emulsifier, water, an organic solvent, a dispersant, an additive, a penetrating agent, a viscosifier, an ultraviolet-resistant aging agent and asphalt. The construction method of the fog sealing layer material is a layered spreading method and comprises the following steps: mixing mixed liquor of the materials for preparing the lower sub-layer with a sand material to obtain a mixture, spreading the mixture on the asphalt pavement to form the lower water-penetration-preventing sub-layer, drying, spraying mixed liquor of materials for preparing the upper sub-layer on the lower water-penetration-preventing sub-layer, and spreading the sand material to form the upper anti-skidding wear-resisting sub-layer. The water-based reinforced type fog sealing layer material for the asphalt pavement, the preparation method and the construction method d of the water-based reinforced type fog sealing layer material for the asphalt pavement, disclosed by the invention, are used for pavement preventive maintenance, can improve the waterproof performance, anti-skidding performance, firmness and ultraviolet resistant aging performance, and are environmentally-friendly and economical.

Owner:CHANGAN UNIV

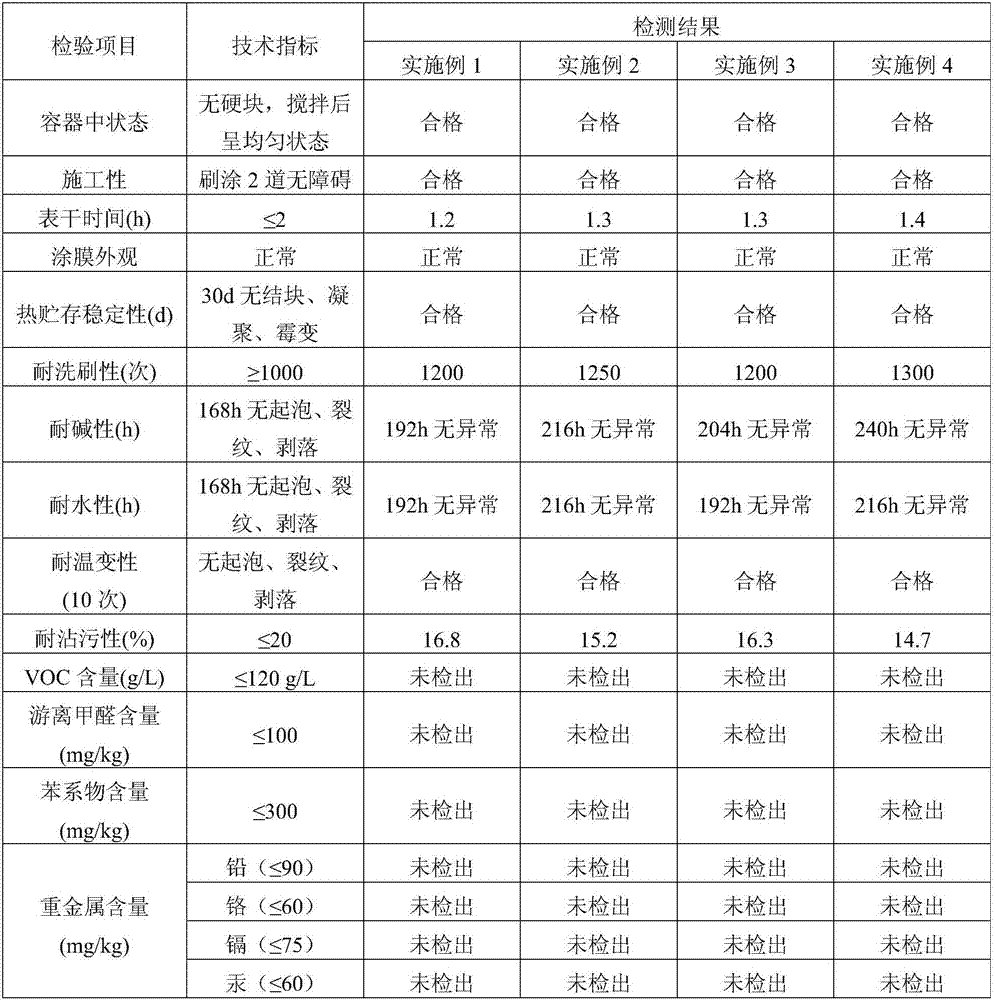

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

Ultraviolet aging resisting fiber-reinforced polymer base composite

The invention relates to an ultraviolet aging resisting fiber-reinforced polymer base composite which comprises the following raw materials in parts by weight: 0.1-10 parts of a compound ultraviolet aging resisting agent, 40-90 parts of matrix resin, 5-60 parts of reinforced fiber and 3-30 parts of a curing agent and an accelerating agent together. Through the addition of the compound ultraviolet aging resisting agent and the reinforced fiber, the ultraviolet aging resisting fiber-reinforced polymer base composite has good ultraviolet aging resisting performance and excellent mechanical performance, can be used for manufacturing outdoor large-sized composite products, and can effectively improve the weather resistance of the products and prolong the service life of the products; when the composite is irradiated under ultraviolet rays for 1000 h, the falling range of the mechanical strength is less than 3%.

Owner:孙仁华

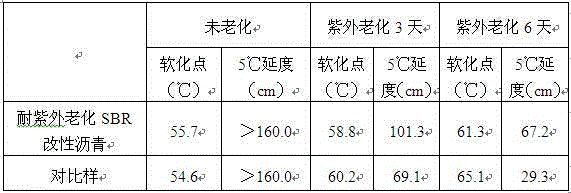

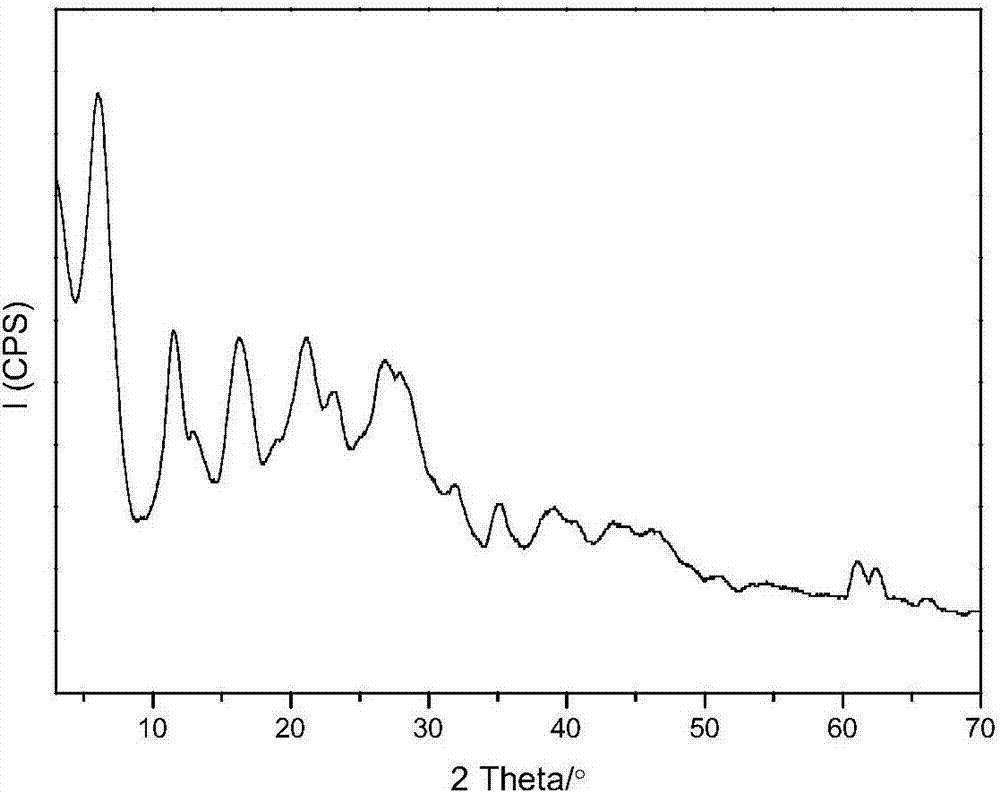

Magnesium-aluminum-based layered double hydroxide/SBR composite modifier, modified asphalt and preparation method of modifier

InactiveCN104140580AUniform and stable dispersionWon't settleBuilding insulationsAging resistanceAccelerant

The invention relates to a magnesium-aluminum-based layered double hydroxide / SBR composite modifier, modified asphalt and a preparation method of the modifier. The magnesium-aluminum-based layered double hydroxide / SBR composite modifier is prepared by mixing SBR, surface organic modified magnesium-aluminum-based layered double hydroxide, an accelerant and a compatilizer in a high speed, and performing extrusion pelleting. The ultraviolet aging resisting SBR modified asphalt is prepared by fusing and blending asphalt and the magnesium-aluminum-based layered double hydroxide / SBR composite modifier. The magnesium-aluminum-based layered double hydroxide / SBR composite modifier is prepared by performing composite reaction on the surface-modified magnesium-aluminum-based layered double hydroxide, the SBR, the accelerant and the compatilizer; after the composite modifier is added into the asphalt, the ultraviolet aging resistance of the SBR and the asphalt can be remarkably improved, long-term stable dispersion of the SBR and the magnesium-aluminum-based layered double hydroxide in the asphalt is achieved, and the prepared SBR modified asphalt is excellent in ultraviolet aging resistance.

Owner:WUHAN UNIV OF TECH

Oil enhanced fog seal material for asphalt pavement and preparation method and construction method of oil enhanced fog seal material

InactiveCN104179107AImprove stabilityImprove skid resistanceIn situ pavingsBuilding insulationsRoad surfaceTackifier

The invention relates to the technical field of road maintenance and discloses an oil enhanced fog seal material for asphalt pavement and a preparation method and a construction method of the oil enhanced fog seal material. The fog seal material comprises a waterproof permeable lower sublayer and a non-slip wear-resistant upper sublayer, wherein the upper sublayer and the lower sublayer are respectively composed of emulsion materials and sand on the layers; the emulsion material on the lower sublayer contains petroleum asphalt, solvent oil, an oil penetrating agent, a tackifier and an additive; and the emulsion material on the upper sublayer contains petroleum asphalt, solvent oil, an oil penetrating agent, a tackifier, an additive and an ultraviolet aging-resistant agent. The construction method of the fog seal material refers to a layered spreading method, namely mixing the emulsion material and sand on the lower sublayer and then spreading the mixture on the asphalt pavement so as to form the waterproof permeable lower sublayer, spraying the emulsion material on the upper sublayer on the waterproof permeable lower sublayer after drying, and spreading the sand so as to form the non-slip wear-resistant upper sublayer. The fog seal material disclosed by the invention is used for preventive maintenance of roads, and the water resistance, skid resistance, firmness and ultraviolet aging resistance of the pavement can be improved.

Owner:CHANGAN UNIV

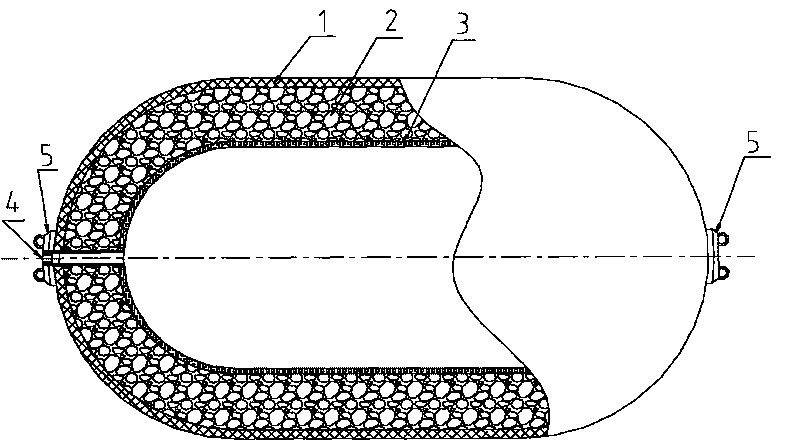

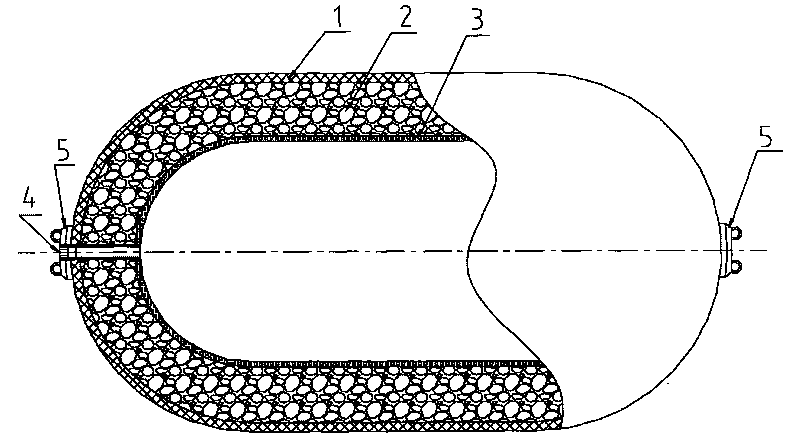

Combined type fender

InactiveCN101698424AAnti-agingExtended service lifeVessel cleaningClimate change adaptationEnergy absorptionEngineering

The invention relates to a combined type fender, which is a protective device to be used in docks, shipping and oceanographic engineering. The combined type fender is characterized by consisting of a shell, a buffering protective layer and a liner. The combined type fender integrates the advantages of various fenders, has the characteristics of toughness, extrusion resistance, fatigue resistance, ageing resistance and long service life of a fender taking rubber as a buffering medium, and avoids the disadvantages that the weight is large, the fender cannot float on a water surface, energy absorption is less and counter-force is large; the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force and pricking resistance which are possessed by a fender taking a foaming material as the buffering medium, and avoids the disadvantages of slow response speed and short service life; and in addition, the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force, quick response speed, capability to backpressure adjustment on the energy absorption and the counter-force and the like which are possessed by an air inflation type fender taking gas as the buffering medium, and avoids the defects that the combined type fender is easy for pricking, aging and air leakage, and needs to be maintained frequently.

Owner:钟爱民

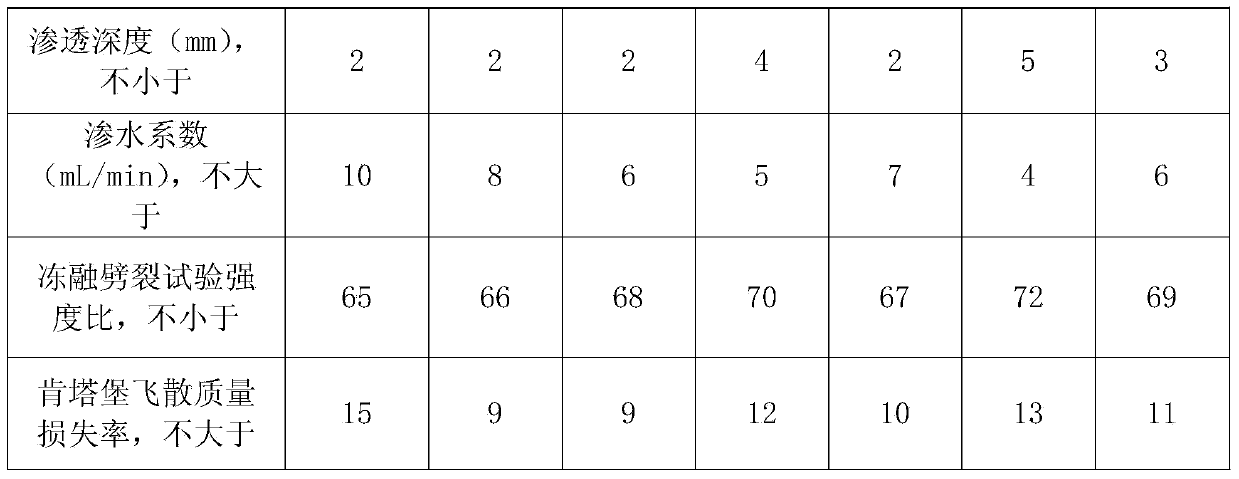

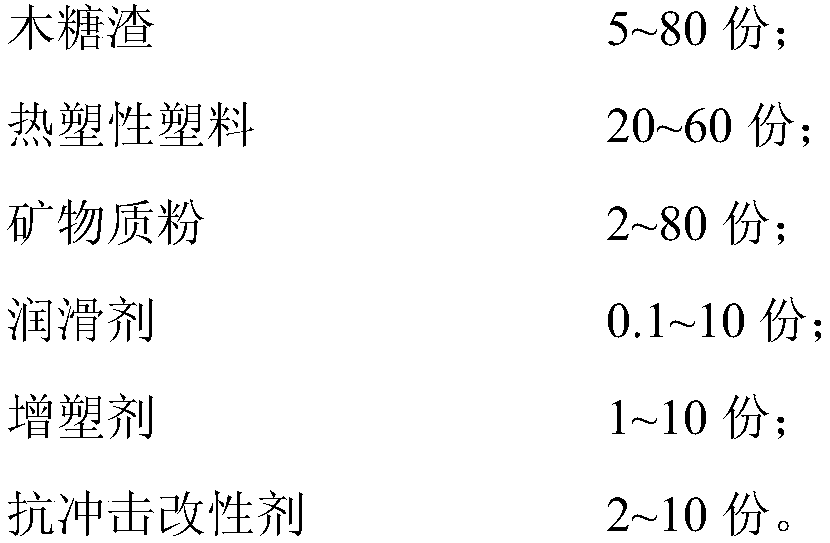

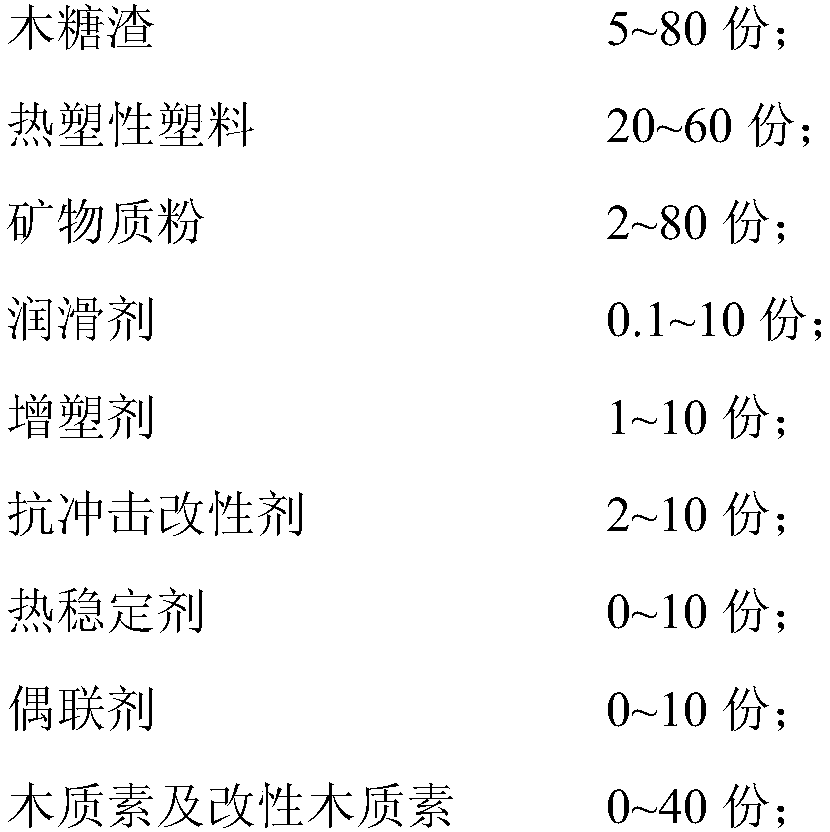

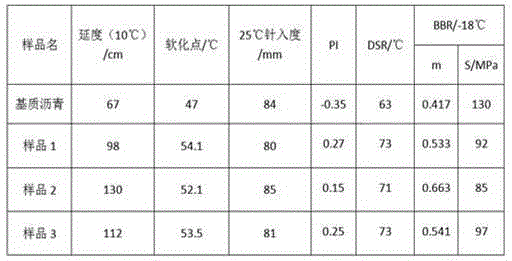

Application of xylose residue in preparation of wood plastic material

The invention discloses application of xylose residue in preparation of a wood plastic material. The wood plastic material includes 5-80 parts of xylose residue, 1-40 parts of lignin, 20-60 parts of thermoplastic, 2-80 parts of mineral powder, and 2-10 parts of an impact modifier. Compared with the prior art, the technical scheme of the invention utilizes xylose residue to prepare the wood plasticmaterial, and does not use wood flour, straw powder or other biomasses, can make full use of industrial xylose to produce waste, is economical, and is more environment-friendly. Moreover, the wood plastic material prepared from xylose residue has more excellent mechanical properties, thermal stability and UV aging resistance far exceeding the national standards, thus meeting the market demands.

Owner:NANJING UNIV OF TECH

Environment-friendly elastomer modified asphalt waterproof material and preparation method thereof

InactiveCN104312170AImproved performance against UV agingExcellent physical shielding effectBuilding insulationsElastomerBituminous waterproofing

The invention relates to an environment-friendly elastomer modified asphalt waterproof material which is prepared from the following components in parts by weight: 20-30 parts of 10# asphalt, 40-50 parts of 100# asphalt, 12-15 parts of an elastomer modifier, 10-15 parts of laminar bihydroxyl compound metal hydroxide, 17-25 parts of talcum powder, 5-10 parts of a stabilizer and 5-10 parts of packing. The softening point of asphalt is 45-50 DEG C and the elastomer modifier is a mixture of one or two of a linear styrene-butadiene-styrene triblock thermoplastic elastomer and a star-like styrene-butadiene-styrene triblock thermoplastic elastomer, wherein the elastomers are mixed in any proportions.

Owner:NANAN GUOGAO BUILDING MATERIAL TECH

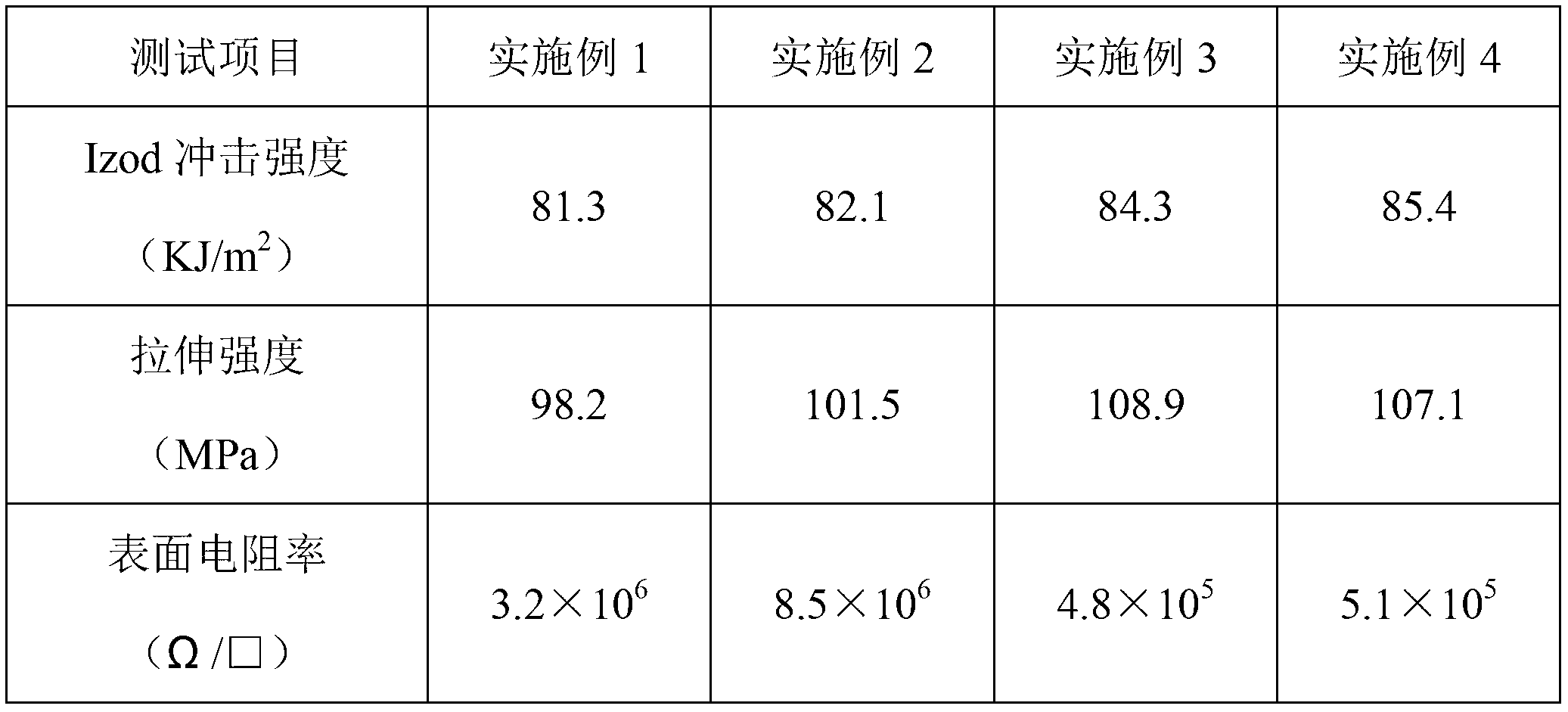

Conductive PBT composite material

The invention relates to the field of polymer materials, and particularly relates to a conductive PBT composite material. The PBT composite material is composed of, by weight, 80-100 parts of polyethylene terephthalate, 15-20 parts of conductive masterbatch, 1-5 parts of a toughening agent, 1-2 parts of a light shielding agent and 0.2-0.8 part of an antioxidant, wherein the conductive masterbatch is composed of 68% of graphene, 22% of a dispersant and 10% of a coupling agent. The conductive masterbatch is used as a conductive additive. The addition of the conductive masterbatch increases the addition amount of the graphene, thereby effectively reducing surface resistivity of a PBT matrix; and the addition of other auxiliary agents increase comprehensive performance of the composite material.

Owner:SUZHOU SUNWAY POLYMER

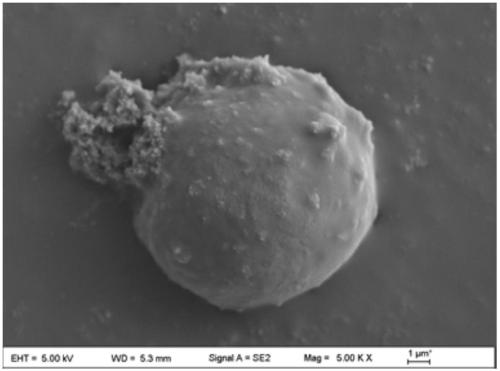

Intercalated hydrotalcite anti-ultraviolet aging agent for rubber as well as preparation method and usage method thereof

The invention discloses an intercalated hydrotalcite anti-ultraviolet aging agent for rubber as well as a preparation method and a usage method thereof, and belongs to the technical field of inorganic functional materials. According to intercalated hydrotalcite provided by the invention, a cross-linking agent is introduced into an interlayer of hydrotalcite by utilizing the characteristic that a guest molecule of the interlayer can be exchanged, and is enabled to generate a chain reaction with a molecular chain of the rubber to produce a cross bond; the anti-ultraviolet aging performance of vulcanized rubber is enhanced; the hydrotalcite which is small and further uniform in particle size and is spherical in morphology is obtained through a template agent, and owns a larger specific surface area; the ultraviolet shielding effect of the hydrotalcite is enhanced. The intercalated hydrotalcite can be also modified by using a modifying agent and etched; the interfacial action between the hydrotalcite and the rubber is ameliorated; the dispersity and the uniformity in the rubber are promoted and the physical and mechanical properties of the rubber are improved; the hysteresis loss and the heat generation under dynamic deformation are decreased.

Owner:BEIJING UNIV OF CHEM TECH

Anti-aging plastomer modified asphalt coating materials and preparation method thereof

InactiveCN103421332APrevent agingLong-lasting and effective anti-aging propertiesBuilding insulationsAntioxidantUltraviolet

The invention relates to anti-aging plastomer modified asphalt coating materials and a preparation method of the anti-aging plastomer modified asphalt coating materials. The anti-aging plastomer modified asphalt coating materials are characterized by comprising, by mass, 50%-66% of asphalt, 8%-14% of plasticity modifying agents, 1%-6% of antioxidant intercalation magnalium base layer double-hydroxyl composite metal hydroxide and 25%-30% of padding. According to the anti-aging plastomer modified asphalt coating materials and the preparation method of the anti-aging plastomer modified asphalt coating materials, the prepared antioxidant intercalation magnalium base layer double-hydroxyl composite metal hydroxide is added into plastomer modified asphalt; due to the facts that the magnalium base layer double-hydroxyl composite metal hydroxide has the good physical shielding effect to ultraviolet rays, and interlayer antioxidants have the effect for blocking free radical chain reaction in the plastomer modified asphalt ageing process, the ultraviolet aging resistant capacity and thermo-oxidative aging resistant capacity of the plastomer modified asphalt coating materials are improved, and the anti-aging capacity of the prepared plastomer modified asphalt coating materials is significantly improved.

Owner:WUHAN UNIV OF TECH

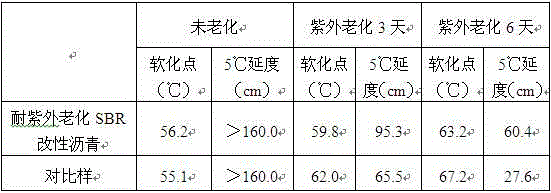

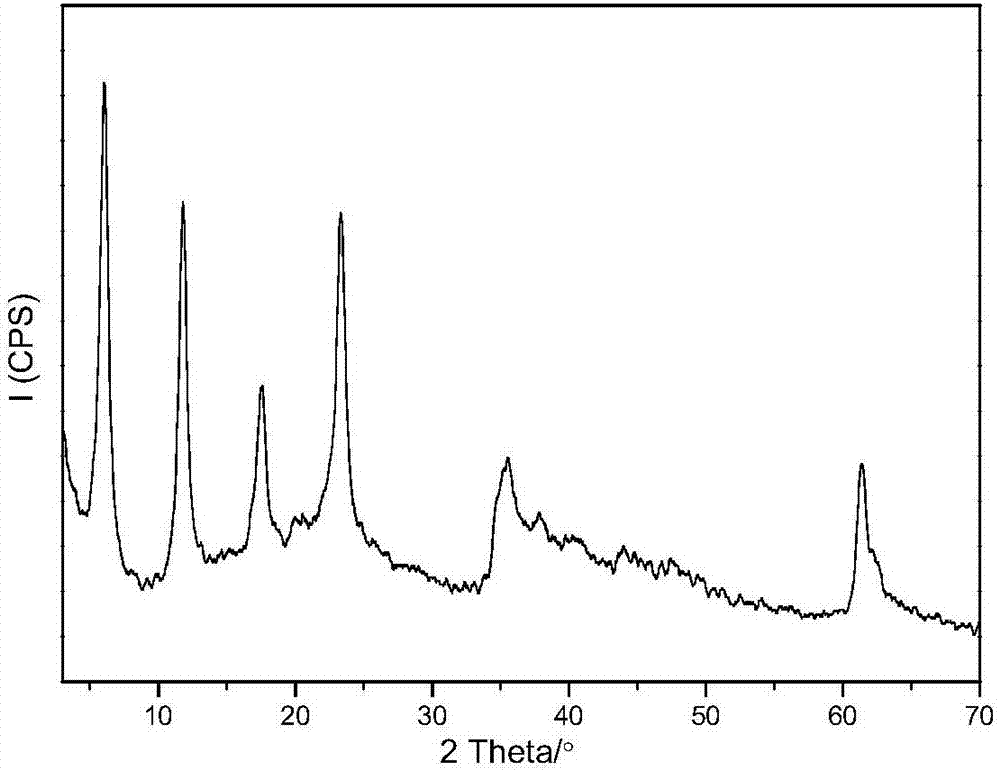

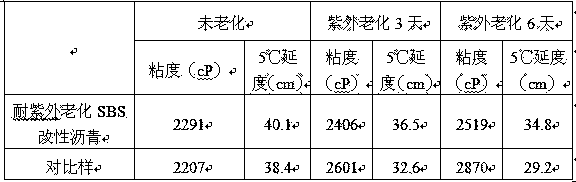

Magnalium-based layered double-hydroxide/SBS composite modifier, modified asphalt and preparation method of magnalium-based layered double-hydroxide/SBS composite modifier

The invention relates to magnalium-based layered double-hydroxide / SBS composite modifier, modified asphalt and a preparation method of the magnalium-based layered double-hydroxide / SBS composite modifier. The composite modifier is prepared by mixing SBS, surface organic modified magnalium-based layered double-hydroxide, an accelerant and a compatilizer at high speed, extruding and pelleting. The ultraviolet aging-resisting SBS modified asphalt is prepared by melting and commixing asphalt, the magnalium-based layered double-hydroxide / SBS composite modifier and a stabilizer. The magnalium-based layered double-hydroxide / SBS composite modifier is prepared by compounding and reacting the magnalium-based layered double-hydroxide, SBS, the accelerant and the compatilizer, the ultraviolet aging resistance of SBS and asphalt can be remarkably improved after the composite modifier is added into asphalt, long-term stable dispersion of SBS and magnalium-based layered double-hydroxide in asphalt is achieved, and the prepared SBS modified asphalt is excellent in ultraviolet aging resistance.

Owner:WUHAN UNIV OF TECH

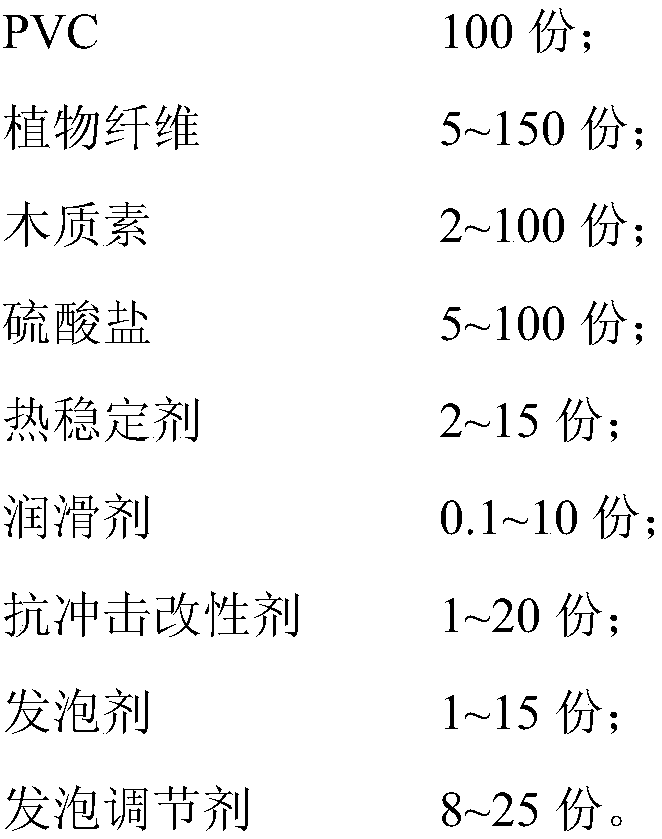

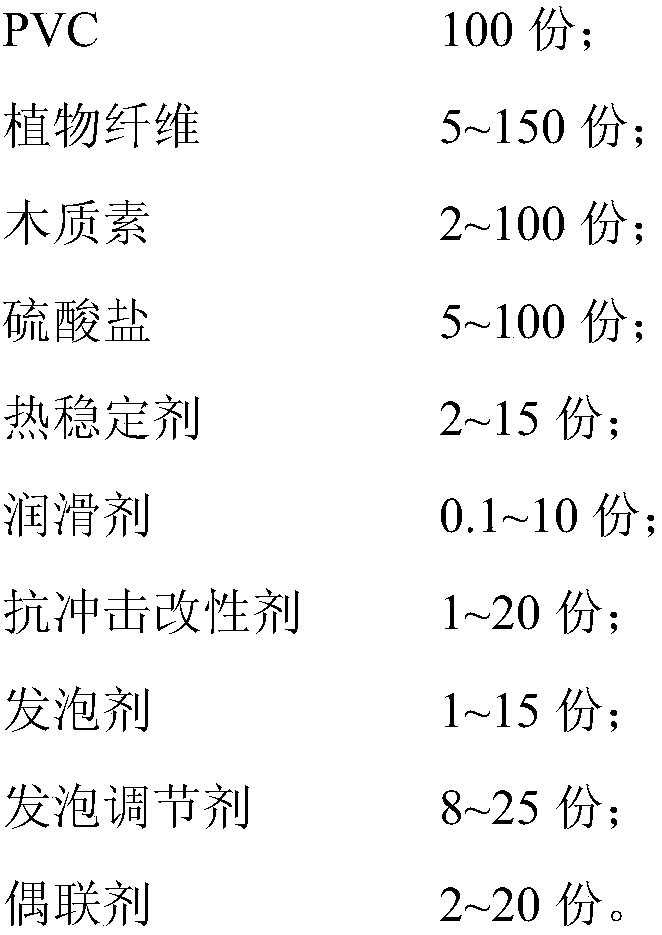

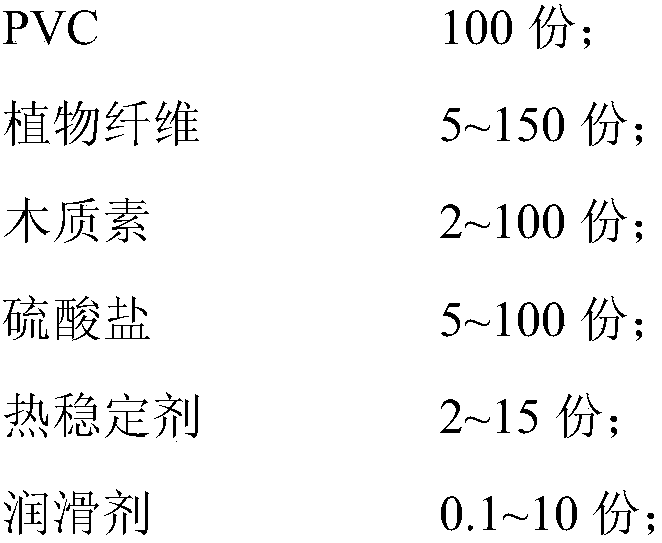

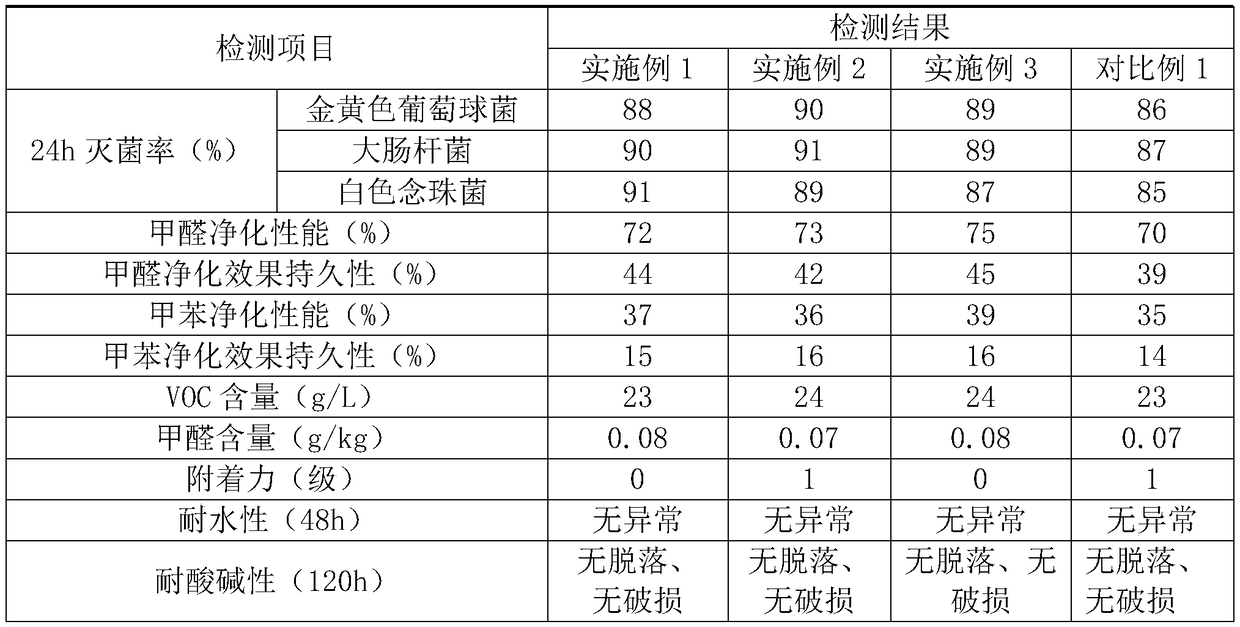

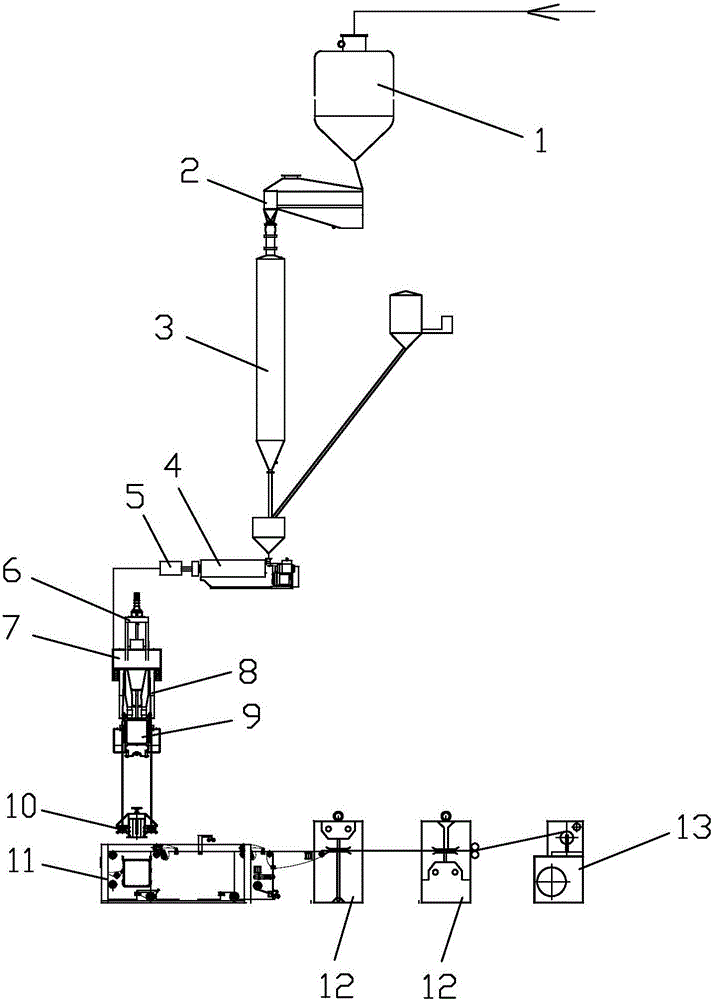

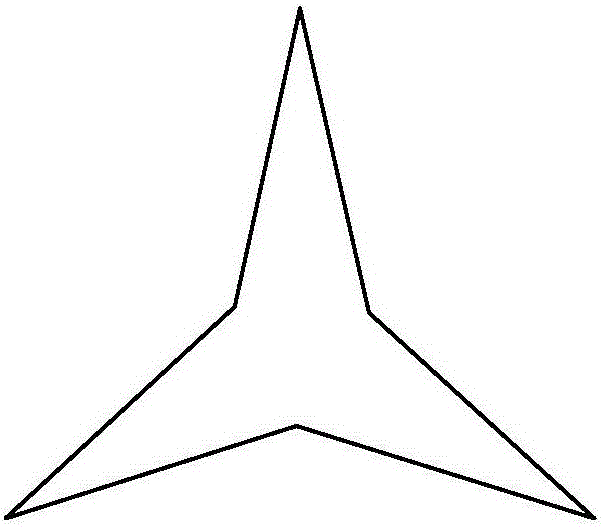

PVC (Polyvinyl Chloride)-lignin-sulfate wood-plastic composite material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride)-lignin-sulfate wood-plastic composite material and a preparation method thereof and belongs to the field of high molecular composite materials. The wood-plastic composite material is prepared from one or more of plant fibers, lignin, sulfate, PVC, a thermal stabilizer, a lubricant, a plasticizer, an anti-impact modifier, a coupling agent, a foaming agent and a foaming regulator, and is extruded and processed through a screw rod. Compared with the prior art, the lignin and the sulfate are added into the wood-plastic composite material at the same time, the flowability is improved and the mutual effect between molecules is improved, so that the filling amount of the plant fibers is improved, and the mechanical property, thermal stability property, and anti-ultraviolet, anti-ageing and bacterium corrosion resisting properties of the wood-plastic composite material are improved.

Owner:NANJING TECH UNIV

Water-based wood coating with antibacterial, anti-fouling, mosquito-repellent and insect-repellent effects, and preparation method thereof

InactiveCN108997876AImprove water resistanceImprove stain resistanceFireproof paintsAntifouling/underwater paintsWater basedSolvent

The invention discloses a water-based wood coating with antibacterial, anti-fouling, mosquito-repellent and insect-repellent effects, and preparation method thereof. The water-based wood coating comprises, by weight, 24-30 parts of water-based polyacrylate, 7-12 parts of water-based polyurethane, 1.5-2.5 parts of water-based fluorocarbon resin, 0.5-0.8 part of a cosolvent, 3-6 parts of deionized water, 1.0-2.5 parts of silicone oil, 0.1-0.3 part of nanometer zinc oxide, 0.6-1.0 part of multiply modified nanometer titanium dioxide, 0.05-0.15 part of a surfactant and 0.6-1.8 parts of anhydrous ethanol. The water-based wood coating of the invention has good antibacterial, anti-fouling, anti-insect and mosquito-repellent effects; and a paint film formed by the coating also has good adhesion, toughness, water resistance, wear resistance, weather resistance and the like.

Owner:CHENGDU POLYTECHNIC

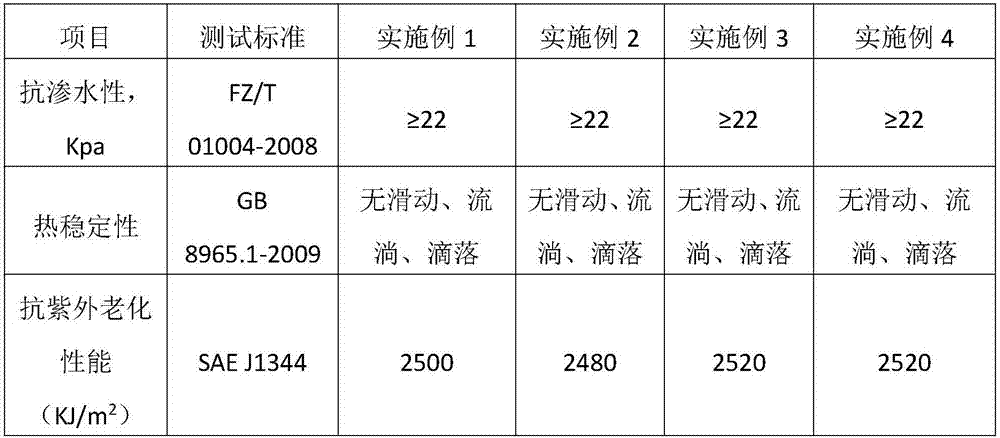

Preparation method of ultraviolet aging resistant polyester spunbonded needle-punched geotextile

InactiveCN106087255AImprove dispersion effectImproves UV aging resistanceSpinning solution de-aeratingGeotextilesGeotextilePolyester

The invention discloses a preparation method of an ultraviolet aging resistant polyester spunbonded needle-punched geotextile. The preparation method includes steps of preparation of ultraviolet aging resistant masterbatch and preparation of a spunbonded needle-punched geotextile. Specifically, the step of preparation of the ultraviolet aging resistant masterbatch includes: preparation of polyester chips and functional auxiliaries, high-speed mixing, twin-screw extrusion, pulling, water cooling, pelletizing and drying, wherein the functional auxiliaries include a light stabilizer; the step of preparation of the spunbonded needle-punched geotextile includes: polyester chip feeding, pre-crystallizing, drying, mixing with the ultraviolet aging resistant masterbatch, screw extrusion, prefiltering, melt spinning, cross air blowing, air drawing, yarn swaying for net forming, needling for reinforcement and winding for cloth forming. By mixing of various ultraviolet aging resistant auxiliaries, synergistic effects are achieved, and ultraviolet aging resistance is improved; in addition, by the method, a dispersion effect of the ultraviolet aging resistant auxiliaries in fibers is effectively improved, and accordingly ultraviolet aging resistance of a product is improved, service life of the product is prolonged greatly, and utilization requirements are met.

Owner:FOSHAN S L P SPECIAL MATERIALS

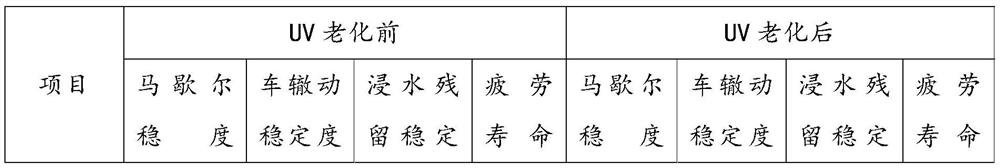

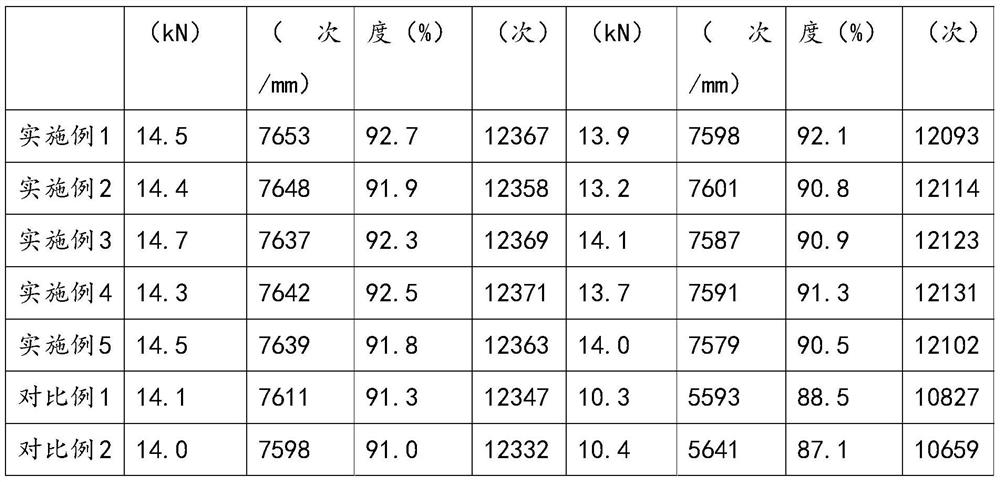

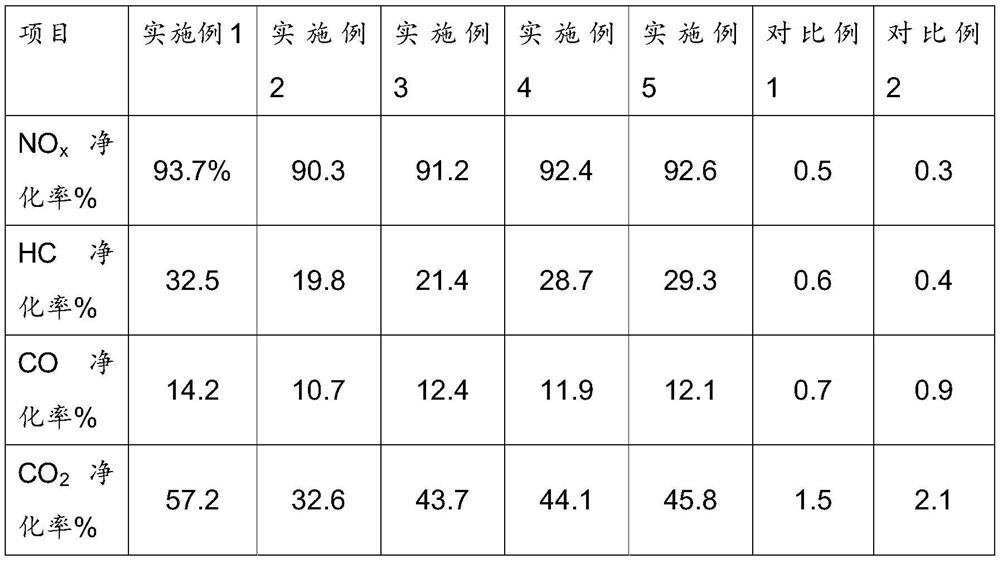

Basalt fiber reinforced asphalt concrete and preparation method thereof

InactiveCN111689719AImproved performance against UV agingGood physical and mechanical propertiesBasalt fiberSilica fume

The invention provides basalt fiber reinforced asphalt concrete and a preparation method thereof. The basalt fiber reinforced asphalt concrete comprises the following components in percentage by mass:13-25% of matrix asphalt, 53-65% of a coarse aggregate, 11-20% of a fine aggregate, 1-2% of silica fume, 2-5% of mineral powder and 6-13% of modified basalt fibers. The modified basalt fibers are basalt fibers coated with nano titanium dioxide, the modified basalt fibers are used as a reinforcing agent of the asphalt concrete, and the prepared asphalt concrete has excellent mechanical propertiesand ultraviolet aging resistance when used for asphalt pavements, and can help to absorb and degrade automobile exhaust.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD +1

Preventive maintenance material for asphalt pavement

InactiveCN102153315AStrong anti-ultraviolet aging abilityImproved performance against UV agingSolid waste managementAging resistanceWaste rubber

The invention belongs to the technical field of road maintenance, and particularly relates to a preventive maintenance material for an asphalt pavement. The preventive maintenance material for an asphalt pavement is characterized by mainly comprising the following raw materials in percentage by weight: 30-60% of organic silicon resin, 0-2% of ultraviolet absorbent, 3-5% of silane coupling agent, 30-50% of fine stone dust and 4-20% of waste rubber powder. The maintenance material can enhance the ultraviolet aging resistance and skid resistance of the asphalt pavement.

Owner:湖北环宇化工有限公司 +1

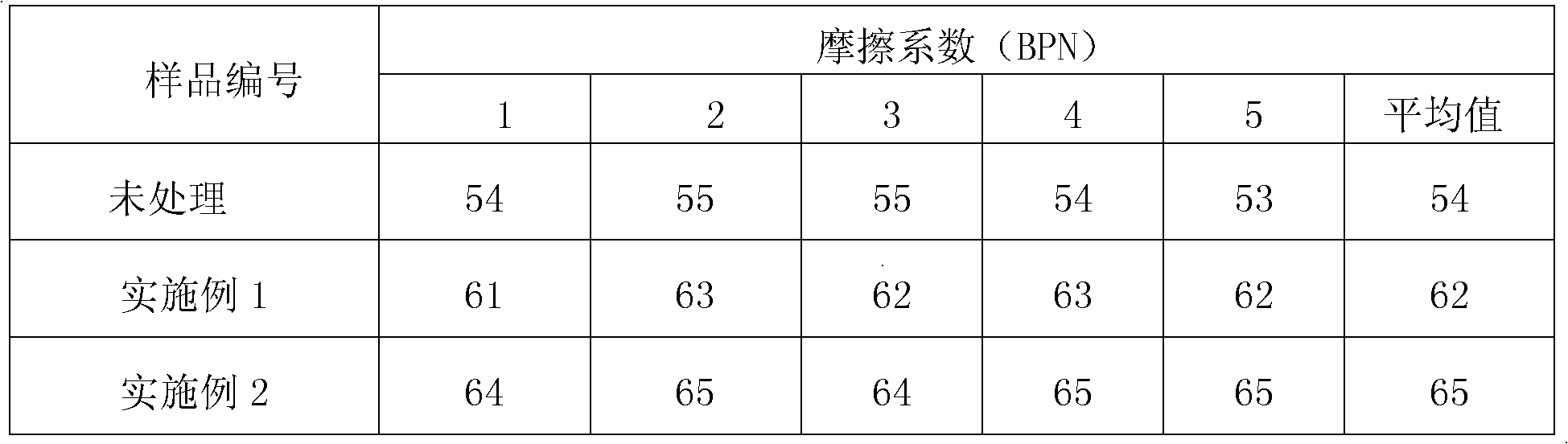

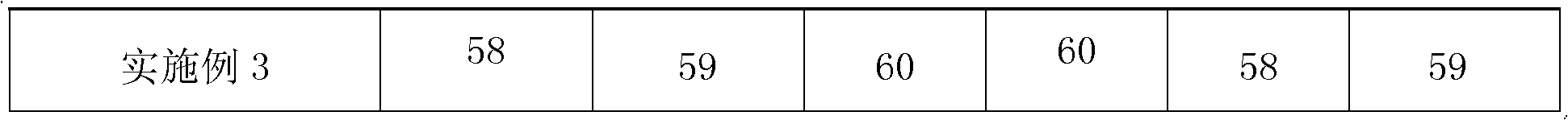

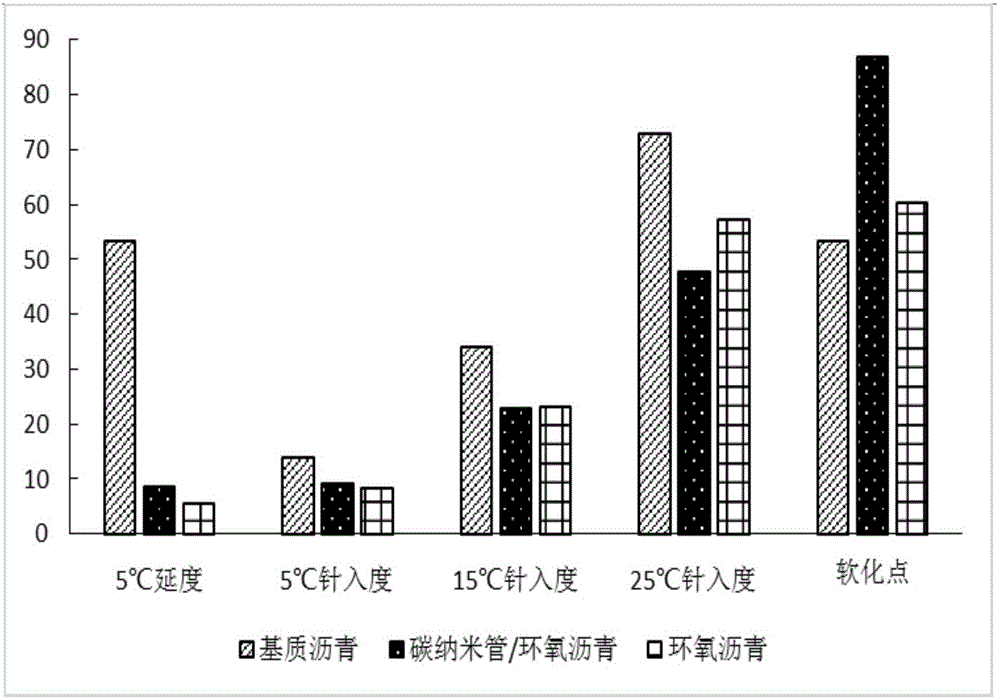

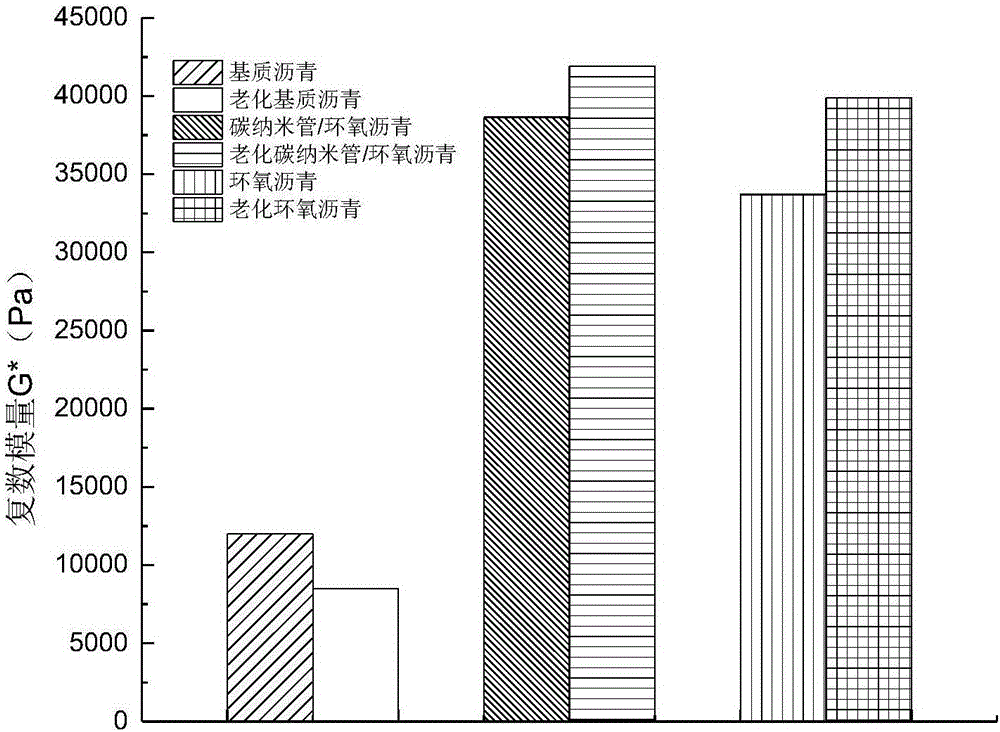

Carbonnano-tube reinforced epoxy asphalt composite material and preparation method of material

The invention discloses a carbonnano-tube reinforced epoxy asphalt composite material and a preparation method of the material. The preparation method comprises the steps of using concentrated acid solution to modify the carbonnano-tube under the condition of microwave heating and reflux, conducting ultrasonic combination of the modified carbon nano-tube and epoxy resin in ethanol, after drying the ethanol by distillation, adding the combined carbon nano-tube and epoxy resin into melted asphalt substrate, adding curing agent, stirring to acquire the carbon nano-tube / epoxy resin composite material. The method not only is beneficial to overcome the bottleneck problems such as easy agglomeration of carbon nano-tube and inferior compatibility, and enhance the strengthening effect of the carbon nano-tube, but also uses no additive, has simple preparation process and low cost, therefore being beneficial for industrial production. The method provides an effective preparation method for the preparation of high performance road surface material.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-temperature-resistant self-adhesive waterproofing coiled material and preparation method thereof

InactiveCN107216823ASimple preparation processRaw materials are easy to getNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention discloses a high-temperature-resistant self-adhesive waterproofing coiled material and a preparation method thereof. The high-temperature-resistant self-adhesive waterproofing coiled material is formed by sequentially compounding five layers of an isolating membrane layer, a high-temperature-resistant self-adhesive waterproofing glue layer, a carrier film layer, the high-temperature-resistant self-adhesive waterproofing glue layer and the isolating membrane layer from top to bottom, wherein the high-temperature-resistant self-adhesive waterproofing glue is prepared from the following raw materials of epichlorohydrin rubber, a softening agent, benzotriazole-modified zinc oxide, polyformaldehyde, organic silicon elastomers for daily use, petroleum asphalt and natural asphalt; the benzotriazole-modified zinc oxide is prepared by adopting a special preparation method; the total thickness of the waterproofing coiled material is 1.5 to 5.0mm; the thickness of the carrier film layer is 1.0 to 3.5mm. The waterproofing coiled material disclosed by the invention has the advantages of excellent waterproofing property, excellent high temperature resistance and excellent ageing resistance.

Owner:ZHEJIANG DIHENG IND CO LTD

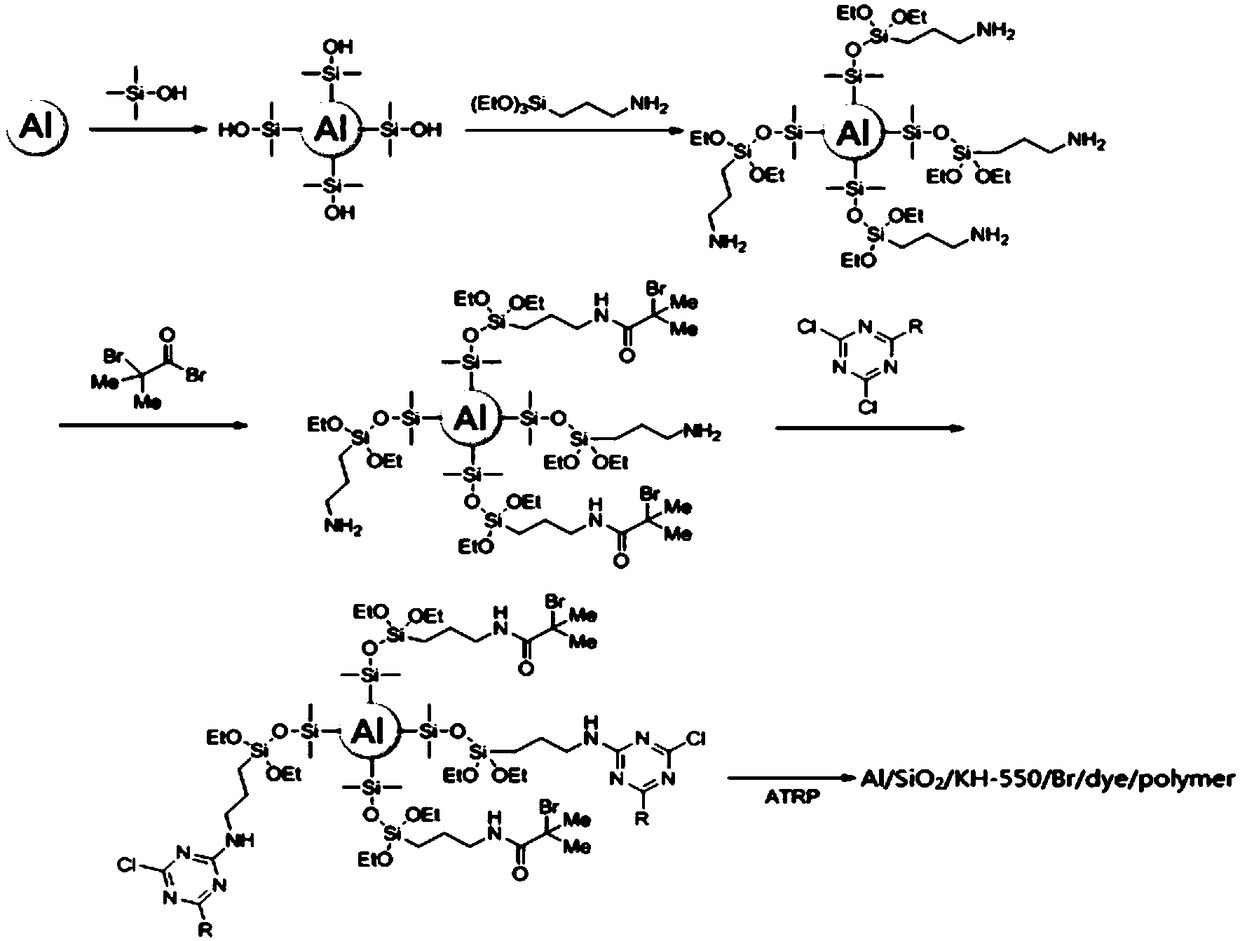

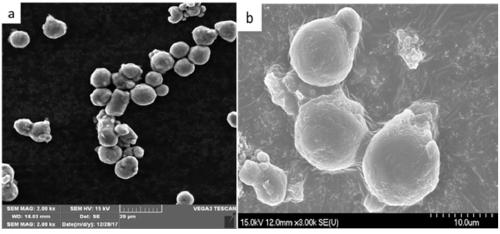

Preparation method of corrosion resisting UV aging resistant coating modified aluminum pigment

ActiveCN108929576AAvoid contactImprove corrosion resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsAl powderUltraviolet

The invention relates to the pigment field, and discloses a preparation method of a corrosion resisting UV aging resistant coating modified aluminum pigment. The preparation method comprises followingsteps: utilizing a sol-gel method to prepare SiO2 coated Al particles, then utilizing a silane coupling agent to modify active hydroxyl groups on the surface of SiO2 coated Al powder to synthesize Al / SiO2 / silane coupling agent composite particles with an amino containing surface; then reacting part of amino groups with 2-bromoisobutyryl bromide to synthesize a composite particle initiator with bromine terminals, adjusting the ratio of composite to pigment molecules, carrying out substitution reactions between the other part of amino groups and melamine dye molecules to anchor the pigment molecules onto the surface of SiO2 particles, and finally generating the polymer coating aluminum pigment (Al / SiO2 / silane coupling agent / Br / dye / polymer) with a core-shell structure by an atom transfer radical polymerization method. The provided preparation method effectively improves the comprehensive performances of the aluminum pigment such as alkali resistance, acid resistance, UV resistance, and the like.

Owner:YIWU WADOU PICTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com