Patents

Literature

60results about How to "Excellent physical shielding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silane/graphene oxide composite passivation liquid and preparing method and application thereof

ActiveCN108642484AAchieve silane functionalizationImprove anti-corrosion performanceMetallic material coating processesWater basedSilanes

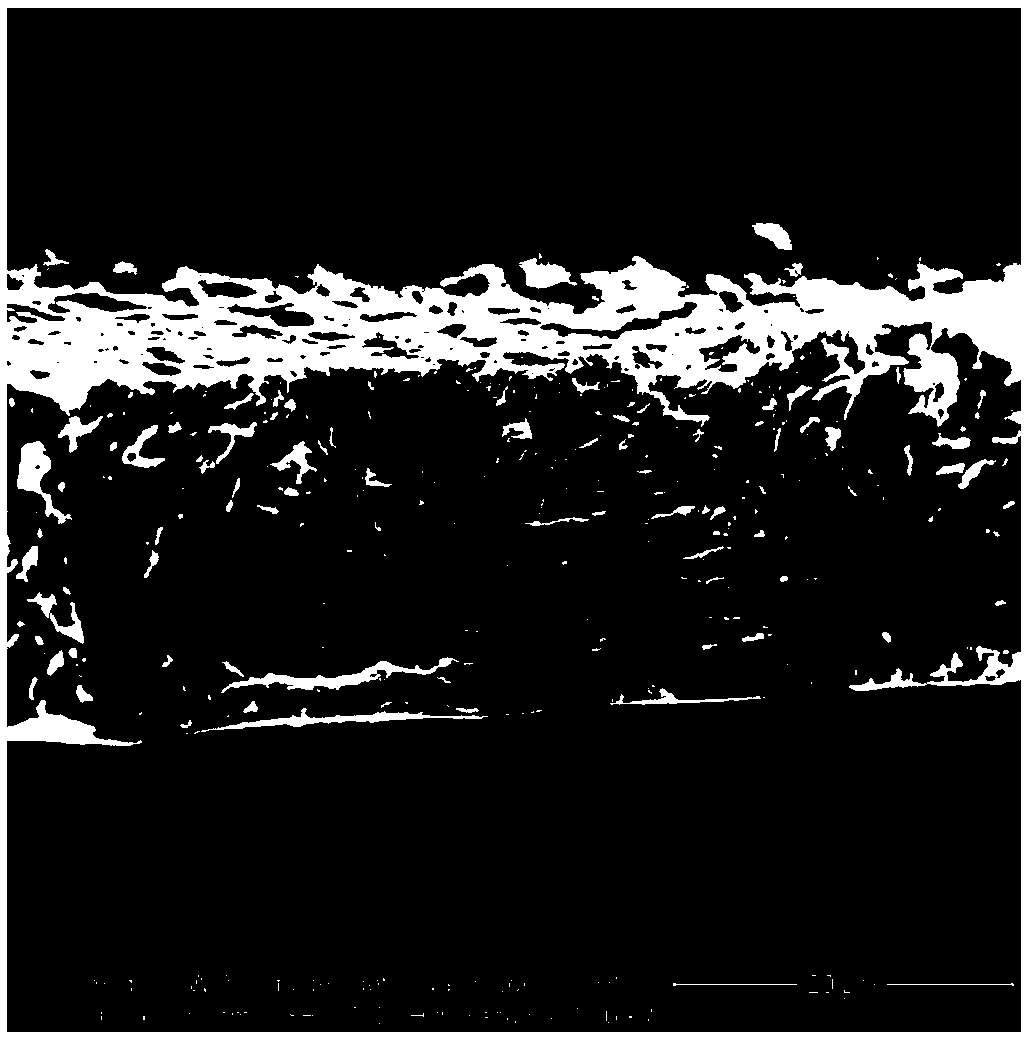

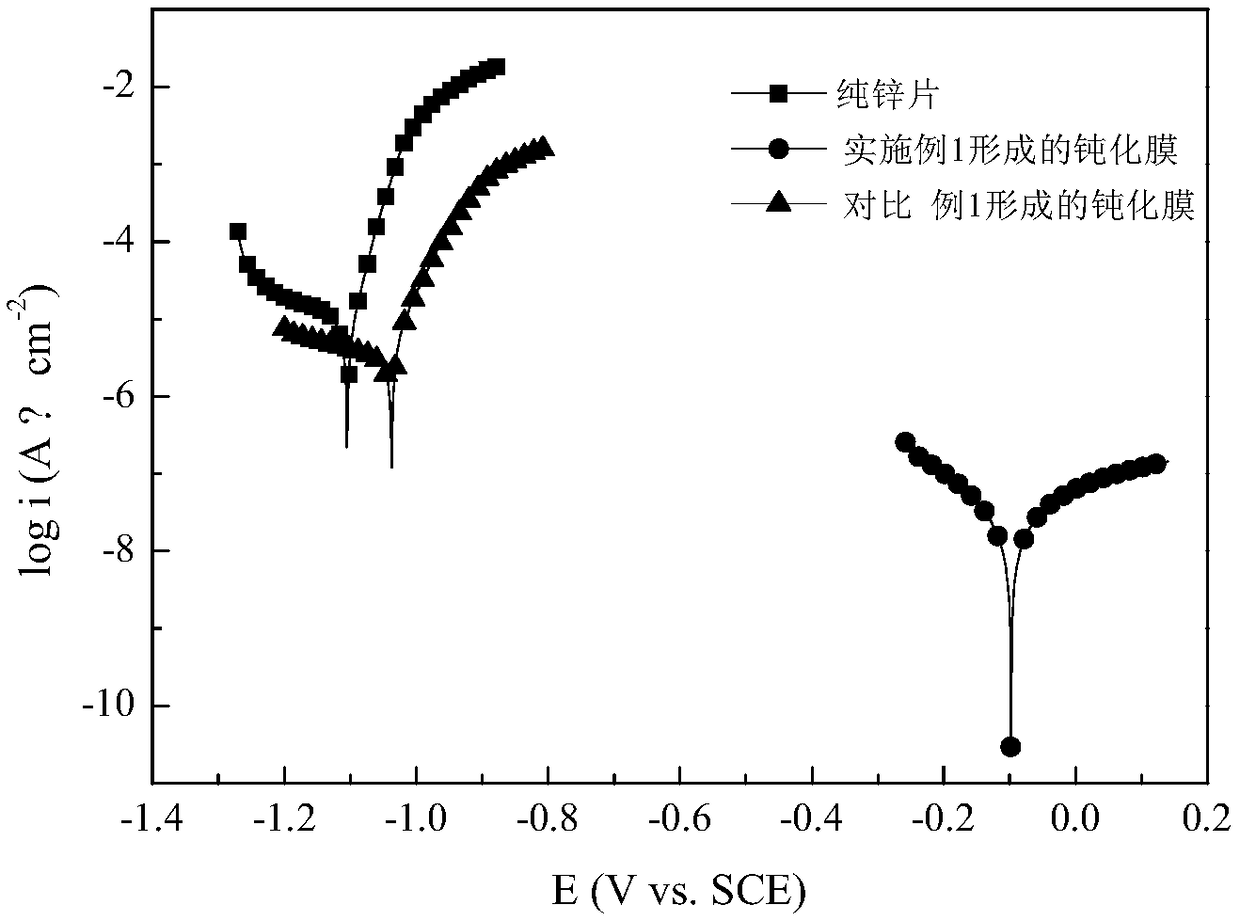

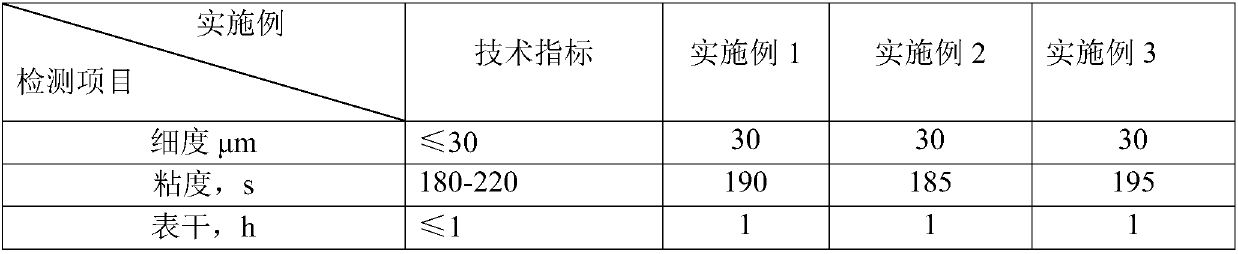

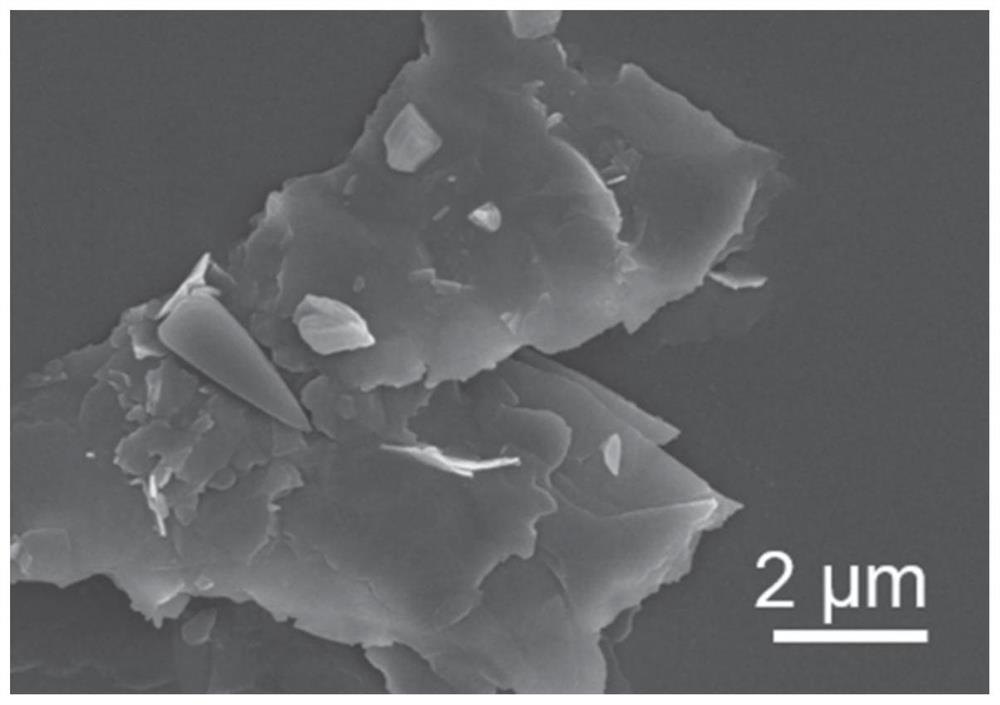

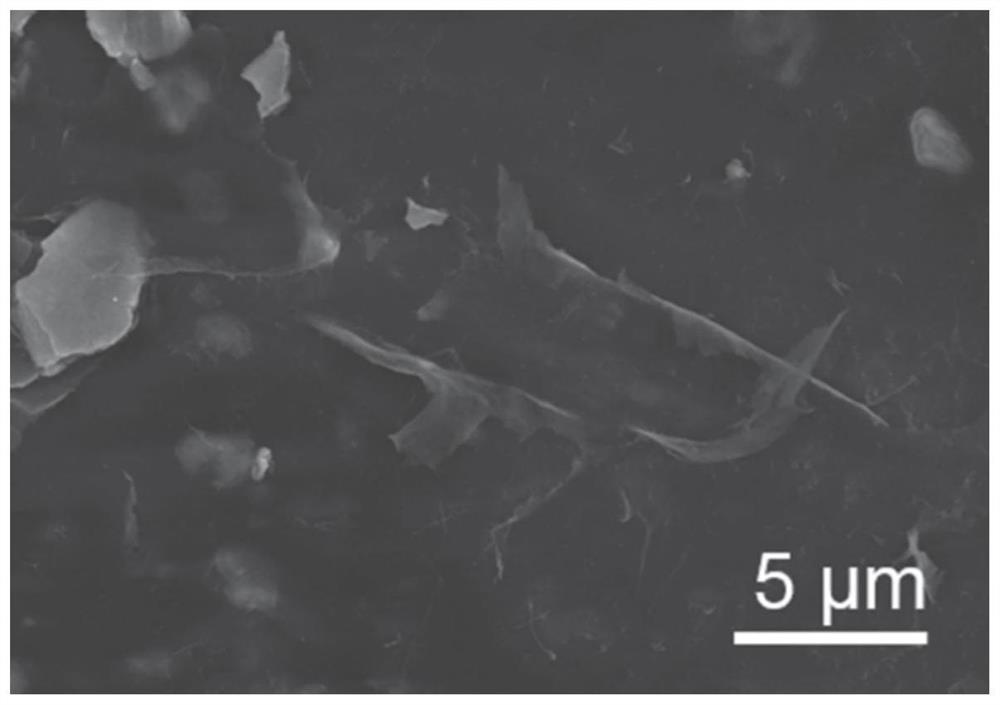

The invention relates to silane / graphene oxide composite passivation liquid and a preparing method and application thereof. The preparing method comprises the following steps that a water-based silanecoupling agent, water and alcohol are mixed according to the volume ratio being 1:(7-9):(0.8-1.2) to obtain mixing liquid; graphene oxide is added into the mixing liquid, and ultrasonic treatment iscarried out to obtain dispersion liquid; the pH value of the dispersion liquid is adjusted to be 2-4, and hydrolysis is carried out to obtain the silane / graphene oxide composite passivation liquid. The silane / graphene oxide composite passivation liquid and the preparing method of the silane / graphene oxide composite passivation liquid combine advantages of the graphene oxide and silane, the graphene oxide and the water-based silane coupling agent are used for joint hydrolysis, and the silane functionalization of the graphene oxide is achieved; and the silane coupling agent and a metal substrateform covalent bonds, the bonding force between a film layer and the metal substrate is improved, and the lamellar graphene oxide can strengthen the physic shielding property of the film layer on a corrosion medium.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Preparation method of anticorrosion epoxy resin embroidered coating containing coupled, dispersed and modified pigment fillings

InactiveCN107779052AGood dispersionImprove surface conditionFireproof paintsAnti-corrosive paintsEpoxySlurry

The invention discloses a preparation method of an anticorrosion epoxy resin embroidered coating containing coupled, dispersed and modified pigment fillings. The preparation method is characterized bycomprising the following steps: mixing talcum powder, iron oxide red, zinc phosphate and aluminum triphosphate, adding a dispersing agent, a titanate coupling agent and deionized water, dispersing, and grinding to obtain pigment slurry; adding a mixed solvent and KH550 into a graphene nanosheet, and carrying out uniform ultrasonic treatment, so as to obtain coupled and modified graphene nanosheetslurry; uniformly mixing KH560, ethyl orthosilicate and isopropanol, so as to obtain a component A; mixing isopropanol with deionized water, dropwise adding the mixed solution into the component A, and carrying out hydrolysis and polycondensation, so as to obtain hybridized silicon sol; dropwise adding diethanol amine and polyether amine into epoxy resin for reaction, dropwise adding glacial acetic acid for reaction, adding deionized water, stirring for emulsification so as to obtain an epoxy resin emulsion, mixing the epoxy resin emulsion with the obtained materials in foresaid steps, addinga polyurethane flatting agent, a film forming aid and a defoaming agent, uniformly mixing, and mechanically dispersing, so as to obtain the coating.

Owner:马鞍山天宇船舶制造有限公司

Graphene modified steel structure water-based anti-corrosive paint and preparation method thereof

InactiveCN107793865AImprove thermal stabilityGood chemical stabilityAnti-corrosive paintsWater basedEmulsion

The invention discloses a graphene modified steel structure water-based anti-corrosive paint and a preparation method thereof. The anti-corrosive paint is prepared from the components in percentage byweight: 10 to 20 percent of deionized water, 5 to 10 percent of graphene dispersion liquid, 30 to 40 percent of anionic acrylic emulsion, 5 to 13 percent of pigment, 20 to 30 percent of filler, 0.1 to 0.8 percent of wetting dispersant, 0.1 to 0.5 percent of defoaming agent, 0.2 to 0.5 percent of pH modifier, 0.3 to 0.6 percent of thickening agent, 0.2 to 0.5 percent of SiO2 hollow microspheres, 0.1 to 0.4 percent of RS preservative, and 2 to 5 percent of coalescing agents. The sum of the weight percent contents of the components in the graphene modified steel structure water-based anti-corrosive paint is 100 percent. Due to the interaction and the space effect among the graphene, the SiO2 hollow microspheres, the pigment and the filler, the defects of poor water fastness, weather fastnessand easiness of flash rust of a traditional water-based acrylic anti-corrosive paint are overcome, the hardness of a film is ensured on the basis of flexibility, and the paint has excellent storage and anti-corrosive performances.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

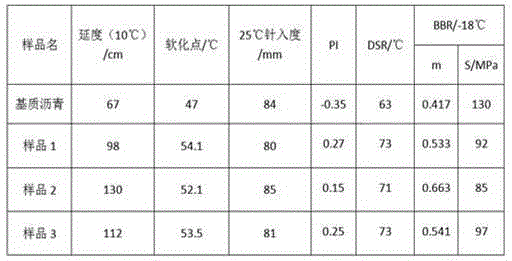

Environment-friendly elastomer modified asphalt waterproof material and preparation method thereof

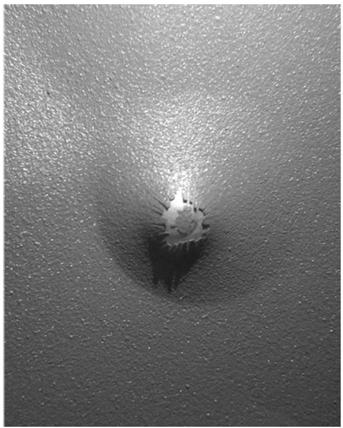

InactiveCN104312170AImproved performance against UV agingExcellent physical shielding effectBuilding insulationsElastomerBituminous waterproofing

The invention relates to an environment-friendly elastomer modified asphalt waterproof material which is prepared from the following components in parts by weight: 20-30 parts of 10# asphalt, 40-50 parts of 100# asphalt, 12-15 parts of an elastomer modifier, 10-15 parts of laminar bihydroxyl compound metal hydroxide, 17-25 parts of talcum powder, 5-10 parts of a stabilizer and 5-10 parts of packing. The softening point of asphalt is 45-50 DEG C and the elastomer modifier is a mixture of one or two of a linear styrene-butadiene-styrene triblock thermoplastic elastomer and a star-like styrene-butadiene-styrene triblock thermoplastic elastomer, wherein the elastomers are mixed in any proportions.

Owner:NANAN GUOGAO BUILDING MATERIAL TECH

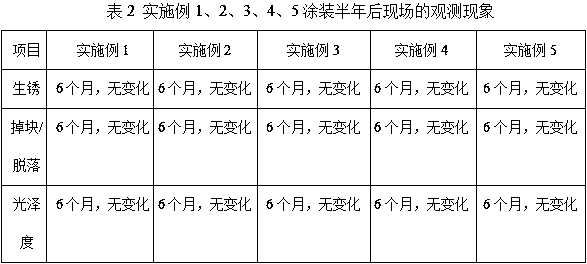

Zinc-alkene anticorrosive paint for steel structure anti-corrosion

InactiveCN108485476AImprove the effect of cathodic protectionReduce dosageAnti-corrosive paintsEpoxy resin coatingsPollutionDimethyl benzene

The invention discloses zinc-alkene anticorrosive paint for steel structure anti-corrosion. The zinc-alkene anticorrosive paint is prepared from, by weight, 10-40% of modified epoxide resin, 20-50% offunctional filler, 0.01-28% of zinc powder, 0.2-3% of graphene, 3-15% of surfactant, 5-25% of xylene and 5-25% of normal butanol. The waterproofness and fast electrical conductivity of nanometer two-dimensional flaky graphene are utilized to apply the graphene to the field of anti-corrosion of railway line bridge equipment steel structure workpieces. Because the used anticorrosive mechanism of the paint is good electrical conductivity of the graphene and lap joint characteristics of the flaky zinc powder, a good conductive layered network structure is formed on the coating surface, the immersion of a corrosive medium is hindered, the physical shielding effect is good, the steel structure workpieces are effectively protected, and the corrosion resistance of the surface of the steel structure workpieces is improved. In addition, the graphene is used to replace parts of zinc powder, not only does the coating have an excellent cathodic protection effect, but also the use amount of the zinc powder is reduced during the preparation of the paint, and the damage and pollution of zinc vapor to the human body are reduced during the processing of later welding.

Owner:胡延超

Anti-corrosion graphene coating and use method thereof

InactiveCN109181476AIncrease productivityIncrease salesFireproof paintsAnti-corrosive paintsEpoxySlurry

The invention discloses an anti-corrosion graphene coating. The anti-corrosion graphene coating is characterized by containing the following raw materials in parts by weight: epoxy resin, deionized water, graphene sheets, graphene dispersion liquid, a leveling agent, a wetting and dispersing agent, pigments, an ethanol solvent, an anionic acrylic emulsion, a defoaming agent, an Rs preservative, acuring agent, polyaniline, a film forming aid, isooctyl ester, a thickener, dimethyl fumarate, a mold release preservative, a toughening agent and a silane coupling agent. The preparation method comprises the following steps: (1) mixing, and stirring; (2) adding ingredients, and stirring at a high speed, so as to obtain slurry; (3) adding the slurry into a sand mill, and carrying out sand milling;and (4) putting the slurry into a size mixing tank, and stirring at a high speed, so as obtain the anti-corrosion graphene coating. By utilizing environment-friendly materials, the quality of a product is substantially improved; the time and the materials are saved, the anti-corrosion graphene coating is convenient to use only through thin coating and has excellent properties of water resistance,heat resistance, corrosion resistance, weather resistance, stability and the like.

Owner:EVERPOWER SHENG TIE (XIAMEN) GRAPHENE TECH CO LTD

Anti-aging plastomer modified asphalt coating materials and preparation method thereof

InactiveCN103421332APrevent agingLong-lasting and effective anti-aging propertiesBuilding insulationsAntioxidantUltraviolet

The invention relates to anti-aging plastomer modified asphalt coating materials and a preparation method of the anti-aging plastomer modified asphalt coating materials. The anti-aging plastomer modified asphalt coating materials are characterized by comprising, by mass, 50%-66% of asphalt, 8%-14% of plasticity modifying agents, 1%-6% of antioxidant intercalation magnalium base layer double-hydroxyl composite metal hydroxide and 25%-30% of padding. According to the anti-aging plastomer modified asphalt coating materials and the preparation method of the anti-aging plastomer modified asphalt coating materials, the prepared antioxidant intercalation magnalium base layer double-hydroxyl composite metal hydroxide is added into plastomer modified asphalt; due to the facts that the magnalium base layer double-hydroxyl composite metal hydroxide has the good physical shielding effect to ultraviolet rays, and interlayer antioxidants have the effect for blocking free radical chain reaction in the plastomer modified asphalt ageing process, the ultraviolet aging resistant capacity and thermo-oxidative aging resistant capacity of the plastomer modified asphalt coating materials are improved, and the anti-aging capacity of the prepared plastomer modified asphalt coating materials is significantly improved.

Owner:WUHAN UNIV OF TECH

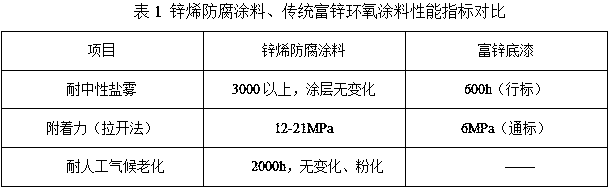

Preparation method of epoxy zinc/graphene heavy-duty anticorrosive coating

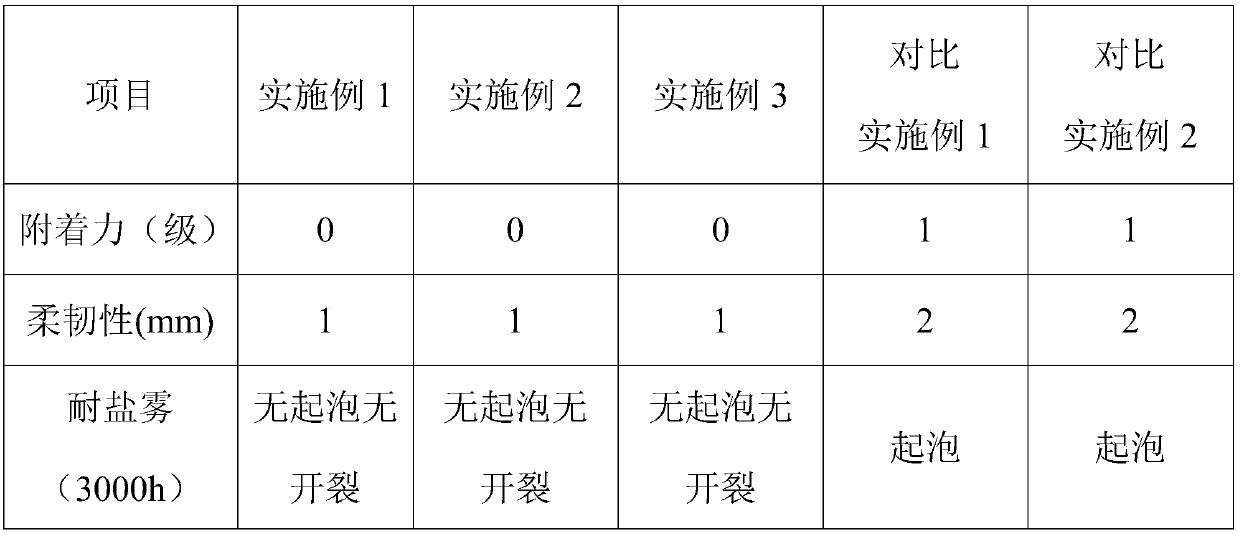

ActiveCN109836964AGood physical shielding effectImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsPliabilityToluene diisocyanate

The invention discloses a preparation method of an epoxy zinc / graphene heavy-duty anticorrosive coating and belongs to the technical field of coating preparation. Graphene and zinc dust are firstly ground and compounded to obtain a graphene-zinc composite powder, and the surface of the graphene-zinc composite powder is modified by the use of toluene diisocyanate. Agglomeration of graphene and zincdust in resin can be effectively prevented, and dispersity of the composite powder in resin is greatly improved. And then, anticorrosive effect of the graphene composite powder can be fully performed, and corrosion resistance of the epoxy resin coating is enhanced. Epoxy resin, a filter, modified graphene-zinc composite powder and other ingredients are mixed to obtain an ingredient A, a curing agent is used as an ingredient B, and the ingredient A and the ingredient B are mixed to obtain the epoxy zinc / graphene heavy-duty anticorrosive coating. The coating has good flexibility and good corrosion resistance, and salt spray resistance time can reach 3000 h and above.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

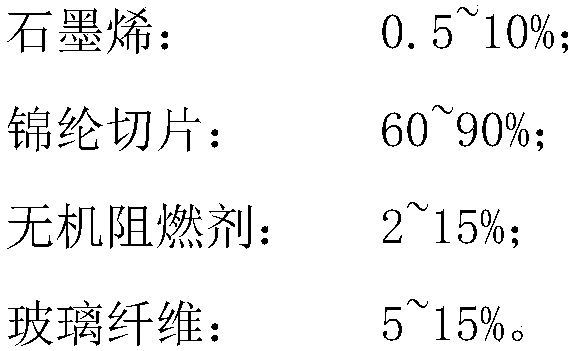

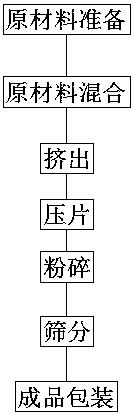

Preparation method of graphene flame retardant chinlon

InactiveCN107868990ALarge specific surface areaReduce usageFlame-proof filament manufactureMonocomponent polyamides artificial filamentAqueous ethanolPolyamide

The invention discloses a preparation method of graphene flame-retardant nylon, which belongs to the field of synthetic fibers and comprises the following steps: adding a coupling agent to 95% ethanol aqueous solution, adding graphene, an inorganic flame retardant, and glass fiber, And add ammonia water to adjust the pH value at 10-12, and stir at a high speed to obtain a graphene flame-retardant composite material; mechanically stir and evaporate at 80-90°C until the mixture is viscous, then dry at 50-60°C for 12 hours to obtain graphite Graphene-coated inorganic flame retardant composite material powder; Nylon chips and graphene-coated inorganic flame retardant composite material powder are mixed at high speed, twin-screw extruded and granulated; the composite masterbatch is spun and then slowly cooled Forming, oiling, stretching and winding, storage. The beneficial effect of the invention is: graphene has a high specific surface area, so that the inorganic flame retardant is evenly spread on the surface of the graphene instead of disordered stacking, so that the use of graphene can reduce the usage amount of the inorganic flame retardant.

Owner:福州市晋安区技智企业管理咨询有限公司

Graphene modified pure polyester powdery coating and preparation method thereof

InactiveCN109082212AImprove conductivityImprove chargeabilityAnti-corrosive paintsPowdery paintsPolyesterCvd graphene

Owner:CHANGZHOU NANOMEDIA INC LTD

Graphene super anticorrosive powdery paint, and preparation method thereof

InactiveCN107629625AGood weather resistanceIncrease polarityAnti-corrosive paintsPowdery paintsTO-18Graphene

The invention discloses a graphene super anticorrosive powdery paint, and a preparation method thereof. The graphene super anticorrosive powdery paint is prepared from 35 to 45 parts of polyphenol type glycidyl ether epoxy resin, 25 to 35 parts of hydantoin epoxy resin, 10 to 12 parts of graphene particle, 15 to 18 parts of glass bead, 2 to 3 parts of 2-methylimidazole, 8 to 10 parts of mica powder, 2 parts of a levelling agent, 5 to 8 parts of iron red, and 0.5 part of benzoin. The preparation method is capable of dispersing graphene in the graphene super anticorrosive powdery paint to be uniform, and the obtained graphene super anticorrosive powdery paint is excellent in effects.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

Environmentally-friendly solvent-free anticorrosive graphene coating and preparation method thereof

InactiveCN110358407ALarge specific surface areaImprove thermal conductivityAnti-corrosive paintsEpoxy resin coatingsEnvironmental resistanceSolvent free

The invention discloses an environmentally-friendly solvent-free anticorrosive graphene coating and a preparation method thereof. The coating of the invention is prepared from, by weight, 30-40 partsof epoxy resin, 15-20 parts of a reactive diluent, 0.15-0.2 part of graphene, 5-10 parts of an assistant, 20-25 parts of iron oxide red, 10-15 parts of mica powder, 0.4-0.8 part of fumed silica, 4-6 parts of barite, 6-10 parts of tripolyphosphate, 0.5-1.5 parts of a silane coupling agent and 7-15 parts of a phenolic amine epoxy resin curing agent. The product of the invention is a solvent-free coating, does not contain volatile organic solvents, has a solid content of 100% and a VOC content of zero, and is green and environmentally friendly; and the super large specific surface area, excellentbarrier property, high chemical stability and good electrical conducting property of the graphene are utilized, so the comprehensive properties of the anticorrosive composite coating are greatly improved.

Owner:四川芯美科技有限公司

Ultraviolet aging-resistant modified asphalt mixture and preparation method thereof

PendingCN109851282ASolving Difficult Difficult PuzzlesImproved performance against UV agingAging resistanceUltraviolet

The invention discloses an ultraviolet aging-resistant modified asphalt mixture and a preparation method thereof. The ultraviolet aging resistant-modified asphalt mixture is prepared from the following raw materials: coarse aggregate, fine aggregate, mineral powder and ultraviolet aging-resistant modified asphalt. The ultraviolet aging-resistant modified asphalt is prepared from the following rawmaterials: asphalt, SBS, surface organic modified magnesium-aluminum-based layered double hydroxide, an accelerant and a compatilizer. The preparation method comprises the following steps: selecting coarse aggregate, fine aggregate and mineral powder to prepare the ultraviolet aging-resistant modified asphalt; preheating the ultraviolet aging resistant modified asphalt, the coarse aggregate, the fine aggregate and the mineral powder; weighing the coarse aggregate, the fine aggregate, the mineral powder and the ultraviolet aging-resistant modified asphalt, and mixing all the components to obtain the ultraviolet aging-resistant modified asphalt mixture. Experimental results show that the ultraviolet aging-resistant modified asphalt mixture prepared by the preparation method disclosed by theinvention has very good ultraviolet aging resistance.

Owner:陶乐敏

Zinc-alkene anticorrosive coating for steel structure workpiece of railway track bridge equipment

InactiveCN107011767AImprove the effect of cathodic protectionReduce dosageAnti-corrosive paintsEpoxy resin coatingsLap jointN-Butyl Alcohol

The invention discloses a zinc-alkene anticorrosive coating for a steel structure workpiece of railway track bridge equipment. The zinc-alkene anticorrosive coating contains the following components in percentage by weight: 10%-40% of modified epoxide resin, 20%-50% of a functional filling, 0.01%-28% of zinc powder, 0.2%-3% of graphene, 3%-15% of a surfactant, 5%-25% of xylene and 5%-25% of n-butyl alcohol. The zinc-alkene anticorrosive coating is applied to the anticorrosion field of steel structure workpieces of the railway track bridge equipment by virtue of water repellency and rapid electrical conductivity of nanometer two-dimensional flake graphite. According to anticorrosion principles of the coating that the graphene has good electrical conductivity and flake zinc powder has a lap joint property, a good conductive layered network structure is formed on the surface of a coating layer to block immersing of corrosive mediums, so that the coating has a good physical shielding effect, the steel structure workpiece is effectively protected, and the corrosion resistance of the surface of the steel structure workpiece is enhanced. Besides, partial zinc powder is replaced with graphene, the coating has an excellent cathode protection effect, and furthermore, the use amount of the zinc powder is reduced in a preparation process of the coating, so that the harm and pollution caused by zinc steam to a human body and environments in a later weld machining process are alleviated.

Owner:郑州格莱菲高铁新材料科技有限公司

Passivation solution for stainless steel body of railway vehicle and preparation method therefor

ActiveCN113818017AEvenly dispersedExcellent physical shielding effectMetallic material coating processesHexagonal boron nitridePolyamide

The invention discloses a passivation solution for a stainless steel body of a railway vehicle and a preparation method therefor. The preparation method comprises four steps of preparation of hydroxylated boron nitride, preparation of amino modified boron nitride, preparation of titanate coupling agent modified montmorillonite, and preparation of the passivation solution. According to the invention, hexagonal boron nitride is modified by hydroxylation, then polyamidoamine is introduced through grafting; the dendritic structure of the polyamidoamine can enhance the physical shielding effect of boron nitride; the metal substrate is protected by prolonging the diffusion path of a corrosive medium, and the corrosion resistance of the passivation solution is improved; the polyamidoamine with the dendritic structure and montmorillonite with a layered structure are introduced, and the two structures cooperate with each other, so that the space barrier effect is enhanced together, diffusion of corrosive substances is retarded, and the anti-corrosion performance of a metal substrate is further improved.

Owner:WUHAN UNIV OF TECH +1

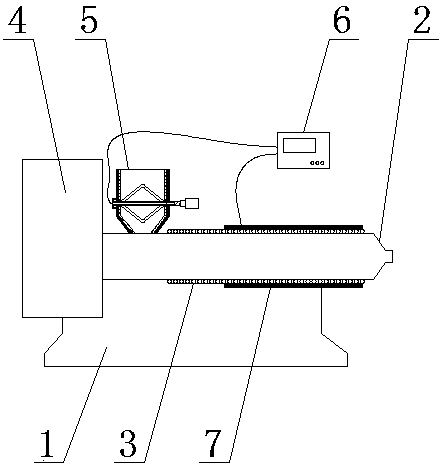

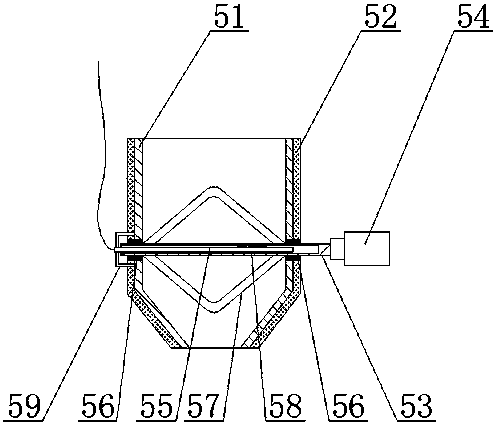

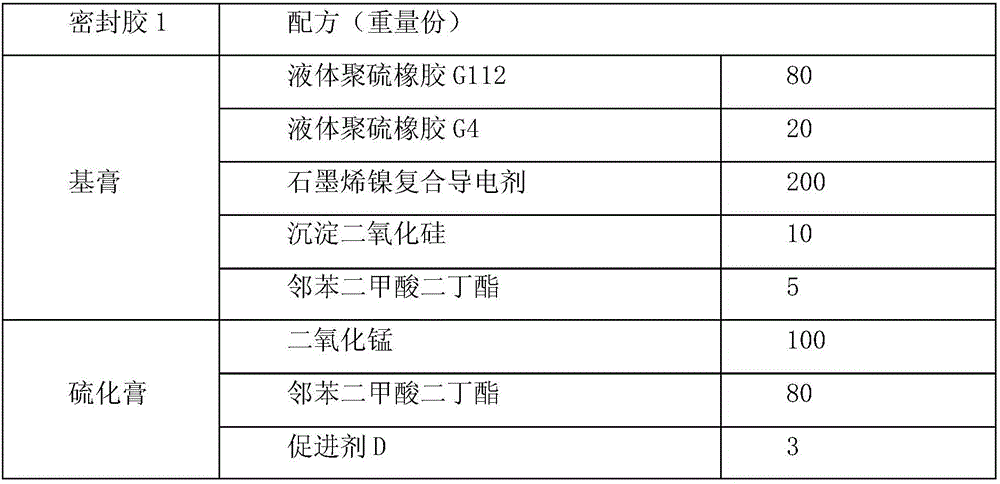

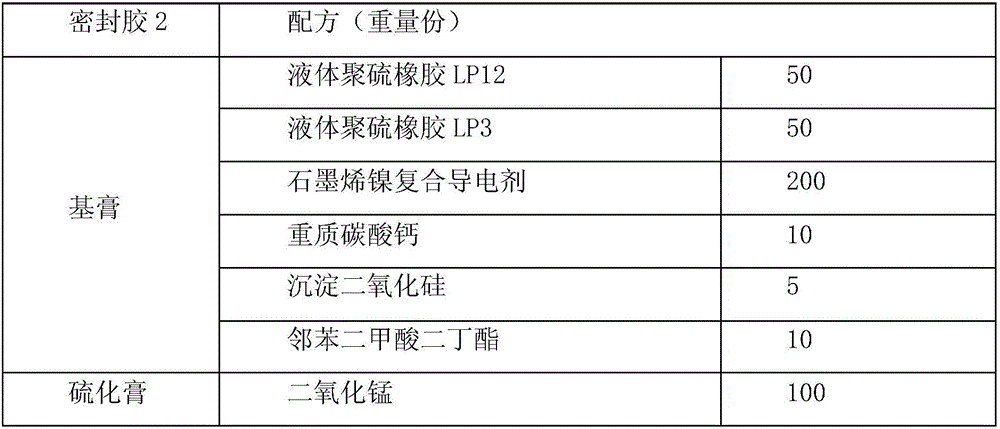

A graphene-nickel composite conductive anticorrosion polysulfide sealant

ActiveCN106520058AImprove conductivityImprove corrosion resistanceNon-macromolecular adhesive additivesElectrically-conducting adhesivesVulcanizationPolysulfide rubber

The invention belongs to the technical field of polymer material sealants, and relates to a graphene-nickel composite conductive anticorrosion polysulfide sealant. The polysulfide sealant includes a component A that is base paste and a component B that is vulcanization paste, wherein the component A is base paste and the component B is vulcanization paste. A graphene-nickel composite filler is adopted as a conductive agent and can allow the sealant to have a high conductivity. The sealant can have excellent corrosion resistance through adoption of the graphene. A coupling agent compositing technique is adopted to prepare the graphene-nickel composite conductive agent as a conductive filler of the sealant, a highly conductive composite material is prepared, agglomeration in a process of mixing graphene and liquid polysulfide rubber is overcome, and good dispersion and uniform distribution of the graphene in the liquid polysulfide rubber are achieved. The graphene is low in particle size, and can fill nickel powder well, thus increasing the conductive contact area. The high conductivity of the graphene is utilized, the graphene and the nickel powder form a conductive system, and the contact resistance is reduced from 0.8 to 0.03-0.01 omega.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

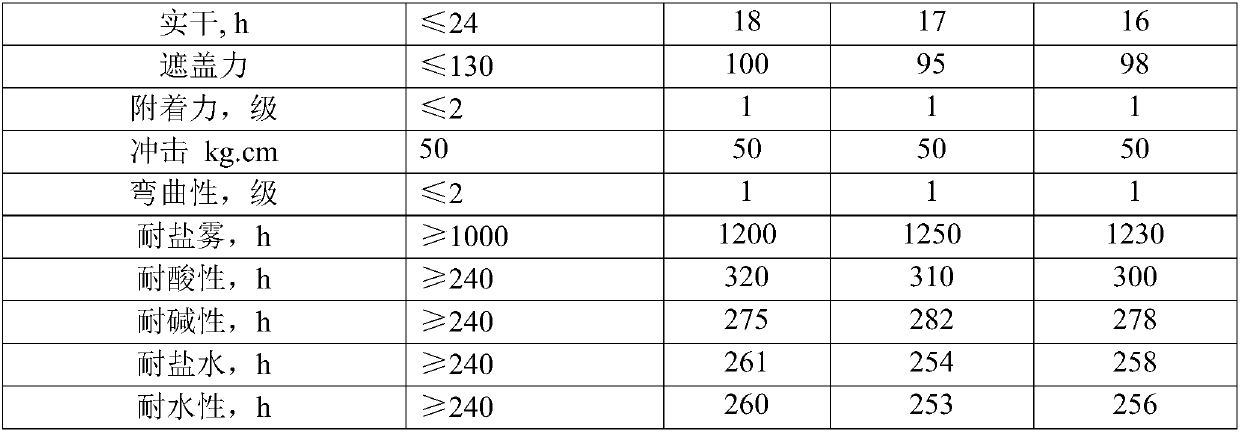

Waterborne weather-resisting anticorrosive coating and preparation method thereof

ActiveCN109762455AAvoid pollutionThe preparation process is easy to operateAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceChemistry

The invention relates to waterborne weather-resisting anticorrosive coating and a preparation method thereof and relates to the field of waterborne anticorrosive coating. The coating is prepared by uniformly mixing and stirring a resin component and an isocyanato curing agent component, wherein the resin component contains fluorocarbon resin, and the ratio of the hydroxyl mol number of the fluorocarbon resin to the isocyanato mol number of the isocyanato curing agent component is 1 to (1.02 to 1.05); the resin component also contains graphene powder which accounts for 0.1 to 5.0 percent of thetotal weight of the coating; the coating can be used for effectively improving the water resistance, acid resistance, alkali resistance, temperature and heat resistance, salt mist resistance and weather resistance of a whole body, so that the safe, green, environment-friendly and pollution-free utilization requirements on the coating in the market can be effectively met.

Owner:赵娜

Water-based fluorocarbon coating for communication iron tower and preparation method thereof

InactiveCN110804349AGood dispersionGood combinationAntifouling/underwater paintsPaints with biocidesFluorocarbon ResinsChemistry

The invention discloses a water-based fluorocarbon coating for communication towers and a preparation method thereof. The water-based fluorocarbon coating is prepared from the following raw materialsin parts by weight: 25-35 parts of water-based fluorocarbon resin, 8-16 parts of hydrophilic graphene dispersion, 15-25 parts of hydroxyl acrylic resin, 0.5-1 part of alcohol ester, 5-8 parts of alkydresin, 5-8 parts of water-based polyurethane, 0.5-1.5 parts of an environment-friendly water-based flash rust inhibitor, 5-10 parts of superfine wollastonite powder, 5-10 parts of modified nano calcium carbonate and 5-15 parts of deionized water. The water-based fluorocarbon coating uses water-based film-forming raw materials and uses water as a dispersion medium, can effectively avoid environmental pollution caused by toxic solvents in the oily coating, and at the same time may not cause harm to the health of construction personnel. Moreover, the prepared coating has excellent water resistance, salt fog resistance, weather resistance and physical and mechanical properties, and when used on iron towers, the service life of the iron towers can be effectively prolonged.

Owner:广西凯威铁塔有限公司

Environment-friendly high polymer uvioresistant coating and preparing method thereof

The invention relates to an environment-friendly high polymer uvioresistant coating and a preparing method thereof. The coating comprises polypropionate emulsion, a coalescing agent, an anti-foaming agent, a dispersing agent and the like. The environment-friendly water-based nanometer anti-ageing building coating is low in cost, little in pollution, little in harm to the human body, good in rub-off resistance, high in ageing resistance, capable of being coated through scraping, rolling and spraying, and suitable for application of a building. The added polyurethane elastomer has superior abrasion resisting and oil resisting performance, and belongs to the polarity polymer capable of being organically combined with polypropylene, and the mechanical performance of the polypropylene can be effectively improved. The added fluororubber has the characteristics of high temperature resisting and oil resisting, and other added filler can have other physical performance and processing performance. The laminated double hydroxy composite metal hydroxide forms a multi-level superposed laminated structure through a laminated subject double metal hydroxide laminate and an interlamination object negative ions, a good physical shielding function is achieved on ultraviolet rays, and the uvioresistant ageing resistance can be effectively improved.

Owner:CHANGZHOU NUOJIN PRECISION MACHINERY

Anti-ultraviolet calcium silicate board prepared from industrial waste residue and production process thereof

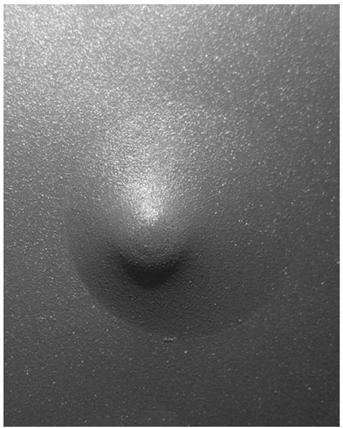

InactiveCN105174884AReduce pollutionExcellent physical shielding effectSolid waste managementCalcium silicateDry weight

The invention relates to the technical field of calcium silicate board preparation, in particular to a calcium silicate board prepared from industrial waste residue and a production process thereof. The raw materials for preparation of the calcium silicate board from industrial waste residue include, by dry weight percentage, 35-45 parts of blast furnace steel slag; 5-15 parts of fly ash; 10-25 parts of desulfurization gypsum; 1-5 parts of mica powder; 20-35 parts of an anti-ultraviolet ageing agent; 5-10 parts of sanding powder; 0.05-0.1 part of polyacetamide. The raw materials are prepared into a mixed material. Specifically, the blast furnace steel slag, fly ash and desulfurization gypsum are all solid wastes discharged from smelting plants. The calcium silicate board product made by the process provided by the invention meets the various index requirements of the national standard, not only can reduce the pollution of industrial solid waste discharge to the environment, but also can achieve the economic and social benefits of turning "waste" into wealth. Layered dihydroxyl composite metal hydroxide is a multistage superimposed layer structure composed of a layered host double hydroxide laminate and interlayer guest anions, has excellent physical shielding effect to ultraviolet, and can effectively improve the anti-ultraviolet aging properties.

Owner:CHANGZHOU NUOJIN PRECISION MACHINERY

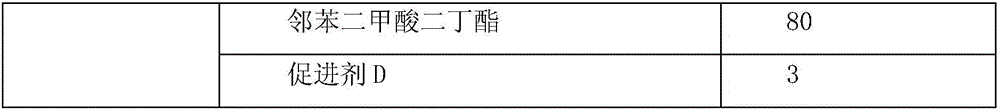

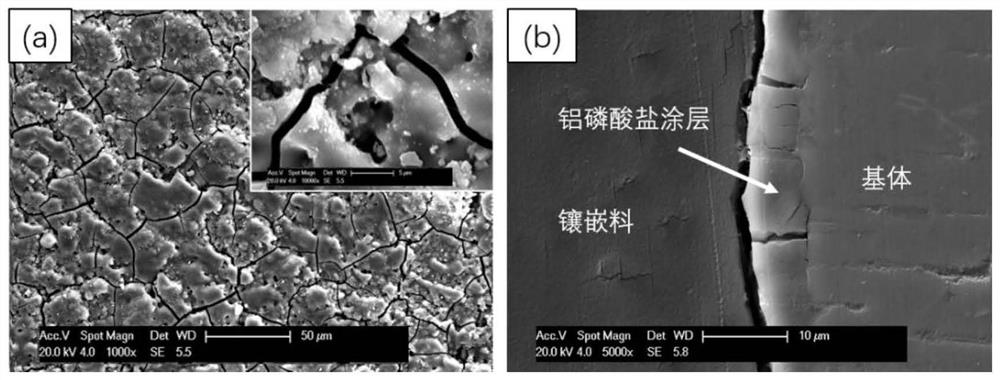

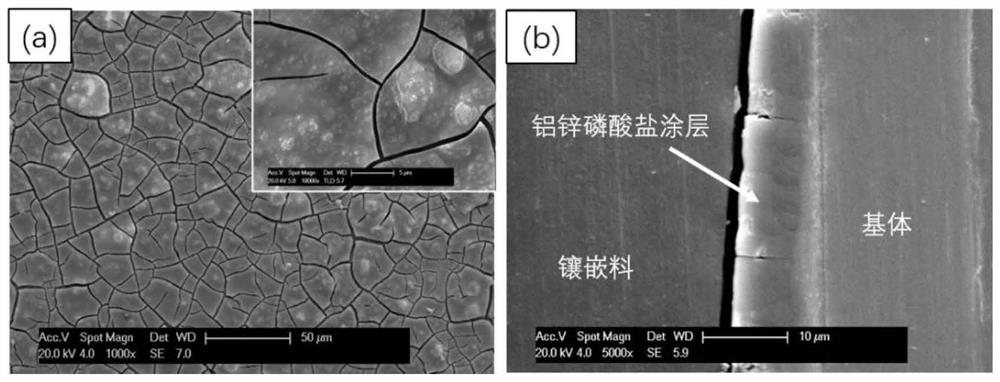

Aluminum-zinc phosphate coating and use method thereof

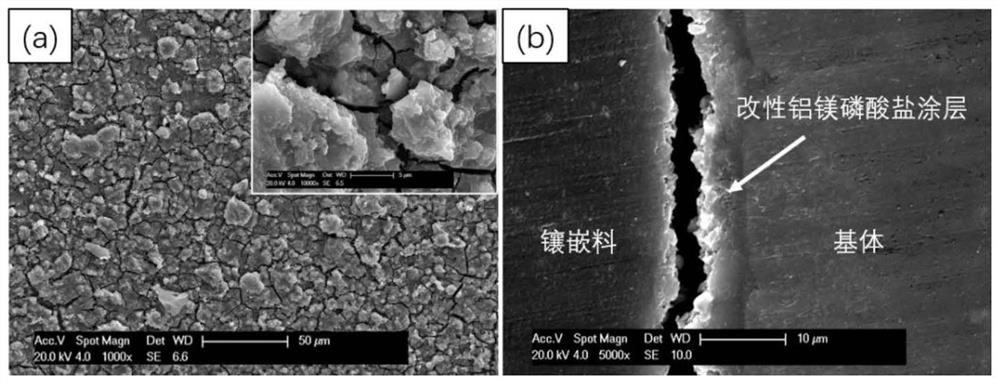

ActiveCN113174150AHigh reactivityIncrease crosslink densityAnti-corrosive paintsZinc phosphatePhysical chemistry

The invention discloses an aluminum-zinc phosphate coating and a use method thereof. The coating is prepared from the following components in parts by weight: 10 to 50 parts of Al(H2PO4)3, 1 to 20 parts of Zn(H2PO4)3, 1 to 10 parts of TEOS, 60 to 90 parts of H2O and 10 to 70 parts of Al2O3 powder. The modified aluminum-zinc phosphate coating is prepared on the surface of a cast aluminum alloy through a steam-assisted heat treatment method. According to the invention, Al(H2PO4)3 and Zn(H2PO4)3 are used as composite binders, so the reaction activity of the coating and a cast aluminum matrix is improved; as the TEOS is added as a modifier, the compatibility of nano-SiO2 and the composite binders can be improved, and the crosslinking density of the coating is improved; and the prepared modified aluminum zinc phosphate coating is uniform and flat, is tightly combined with the matrix, mainly comprises Zn3(PO4)2, AlPO4, AlPO4. 2H2O and SiO2, and can remarkably improve the corrosion resistance of an aluminum alloy casting.

Owner:SOUTHEAST UNIV

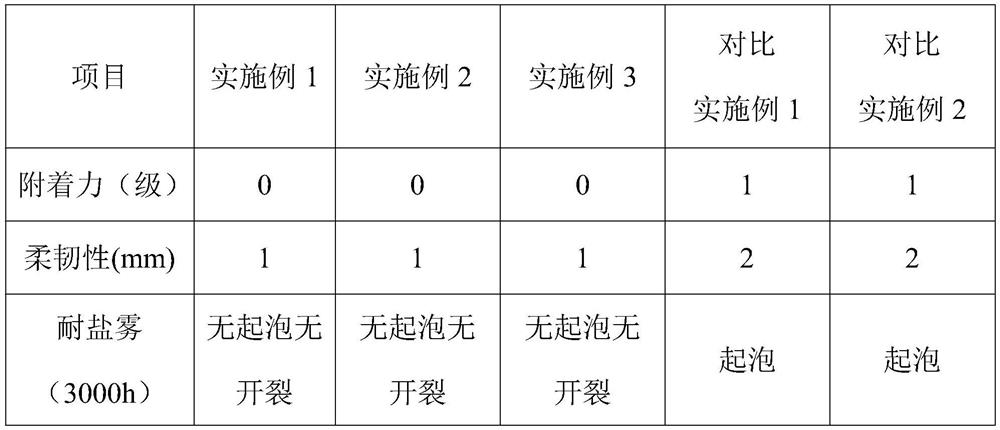

A kind of preparation method of epoxy zinc olefin heavy-duty anti-corrosion coating

ActiveCN109836964BReduce reunionIncrease profitAnti-corrosive paintsEpoxy resin coatingsToluene diisocyanateFirming agent

The invention discloses a preparation method of epoxy zincene heavy-duty anti-corrosion paint, which belongs to the technical field of paint preparation. In the present invention, graphene and zinc powder are first ground and compounded to obtain graphene-zinc composite powder, and the surface of graphene-zinc composite powder is modified by toluene diisocyanate, which can effectively prevent graphene and zinc powder from being deposited on the resin The reunion in the medium greatly improves the dispersibility of the composite powder in the resin, thereby fully exerting the anticorrosion effect of the graphene composite powder and enhancing the anticorrosion of the epoxy resin coating. Component A is obtained after mixing ethylene-zinc composite powder and other components, and the curing agent is used as component B. After mixing, epoxy zinc ene heavy-duty anti-corrosion coating is obtained. The coating has good flexibility, good anti-corrosion performance, and the salt spray resistance time is long. Reach more than 3000h.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Anticorrosive inner coating film for inner layer of steel drum

InactiveCN113943517AAct as a physical shieldReduce corrosion rateAnti-corrosive paintsEpoxy resin coatingsActive agentFirming agent

The invention belongs to the technical field of anticorrosive coatings, and relates to an anticorrosive inner coating film for an inner layer of a steel drum. The anticorrosive inner coating film mainly comprises the following components in percentage by weight: 60-70% of modified epoxy resin emulsion; 1-5% of a coalescing agent; 3-15% of anticorrosive pigment and filler; 2-8% of a surfactant; 4-10% of a coupling agent; 10-15% of a curing agent; 0.1-2% of a defoaming agent; 0.1-2% of a leveling agent; 0.1%-0.6% of a corrosion inhibitor; and 10-50% of water. The modified epoxy resin emulsion is adopted, so that a formed coating plays a role in physically shielding various corrosive media; the corrosion inhibitor is added, so that the corrosion rate of steel is greatly reduced; and a pigment and filler are modified to form the anticorrosive pigment and filler, the dispersity of the pigment and filler in epoxy resin is improved, and a phase interface between the pigment and filler and the resin is eliminated, so that the shielding property and the corrosion resistance of a colored paint film are improved on the premise of ensuring high hardness and high adhesive force of the paint.

Owner:荆州市先隆包装制品有限公司

Water-based anticorrosive coating applied to deep sea environment as well as preparation method and application of water-based anticorrosive coating

ActiveCN113549386AGood dispersionFill microporous defectsAnti-corrosive paintsEpoxy resin coatingsTitanium carbideMaterials science

The invention discloses a water-based anticorrosive coating applied to a deep sea environment as well as a preparation method and application of the water-based anticorrosive coating. The water-based anticorrosive coating comprises a component A and a component B, wherein the component A comprises a titanium carbide nanosheet / nanocellulose compound, a water-based resin emulsion and a dispersing solvent; the component B comprises a water-based curing agent; and the titanium carbide nanosheet / nanocellulose compound is prepared by carrying out a cross-linking reaction on titanium carbide nanosheets and nanocellulose. The titanium carbide nanosheet / nanocellulose compound in the prepared water-based anticorrosive coating can be stably dispersed in the water-based resin emulsion, so micropore defects formed in the rapid curing process of the water-based resin can be effectively filled, and thus, the compactness and integrity of the coating are improved; and meanwhile, by adding the titanium carbide nanosheet / nanocellulose compound, the physical shielding effect, the mechanical property and the corrosion resistance of the coating can be improved, and the coating can be widely applied to a complex deep sea alternating pressure environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Graphene reinforced epoxy resin anticorrosion coating and preparation method thereof

InactiveCN106349867AGood compatibilityExcellent physical shielding effectCarboxyl rubber coatingsAnti-corrosive paintsEpoxyAniline

The invention discloses a graphene reinforced epoxy resin anticorrosion coating which is characterized by being prepared from the following raw materials: epoxy resin E51, butadiene rubber, n-hexane, maleic anhydride, dicumyl peroxide, tetrahydrofuran, methanol, p-xylylenediamine, dibutyltin dilaurate, graphene oxide, aniline, hydrochloric acid, an ammonium persulfate solution, octaphenyl polyoxyethyiene, carboxymethyl cellulose, a proper amount of acetone and a proper amount of deionized water. The graphene reinforced epoxy resin anticorrosion coating disclosed by the invention has the advantages of being good in salt water resistance, good in corrosion resistance, free of toxin, good in environmental friendliness and the like.

Owner:马鞍山采石矶涂料有限公司

Silicate reinforced polyurethane coating and preparation method thereof

InactiveCN108774453AHigh strengthImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatings1-Butyl-3-methylimidazolium hexafluorophosphateP-Phenylenediamine

A silicate-reinforced polyurethane coating is characterized in that the polyurethane coating is prepared from the following ingredients in parts by weight: acetone, sodium hydroxide solution, anhydrous zinc chloride, n-butylaldehyde, cyclohexane, anhydrous magnesium sulfate, benzenetetracarboxylic anhydride, 1,2-propylene glycol, terephthalic acid, montmorillonite, talcum powder, sodium tripolyphosphate, silane coupler KH-560, absolute ethyl alcohol, butanediamine, acrylonitrile, ferric chloride, 1-butyl-3-methylimidazolium hexafluorophosphate, N-phenyl-N'-isopropyl-p-phenylenediamine, propylene glycol butyl ether, N,N'-lutidine, triethylamine, methylene diphenyl diisocyanate, appropriate amount of hydrochloric acid solution and appropriate amount of deionized water. The polyurethane coating hereof has the advantages of firm coating bonding, uniform thickness, strong salt water resistance, good wear resistance, good anti-corrosion performance, non-toxicity and environmental protectionand the like.

Owner:黄春梅

Outer ultraviolet-resistant polyethylene wallboard prepared from waste brick dregs and production method of wallboard

InactiveCN105060767ASolve processing problemsLow thermal conductivitySolid waste managementBrickAging resistance

The invention discloses an outer ultraviolet-resistant polyethylene wallboard prepared from waste brick dregs and a production method of the wallboard. The wallboard is prepared from raw materials in parts by weight as follows: 70-75 parts of the waste brick dregs and the like. The outer wallboard takes ceramic waste as a main raw material, the clay resource is saved, the production cost is reduced, the problem about treatment of the ceramic waste is also solved, and environmental pollution caused by the ceramic waste is avoided; laminated dihydroxy composite metal hydroxide adopts a multi-level overlapped laminated structure comprising main laminated bodies, namely, double metal hydroxide laminates, and interlamination objects, namely, anions, and the laminated dihydroxy composite metal hydroxide has the excellent physical shielding effect on ultraviolet rays and can effectively improve the ultraviolet aging resistance.

Owner:CHANGZHOU CITY WUJIN DISTRICT KAILIDA ELECTRONICS

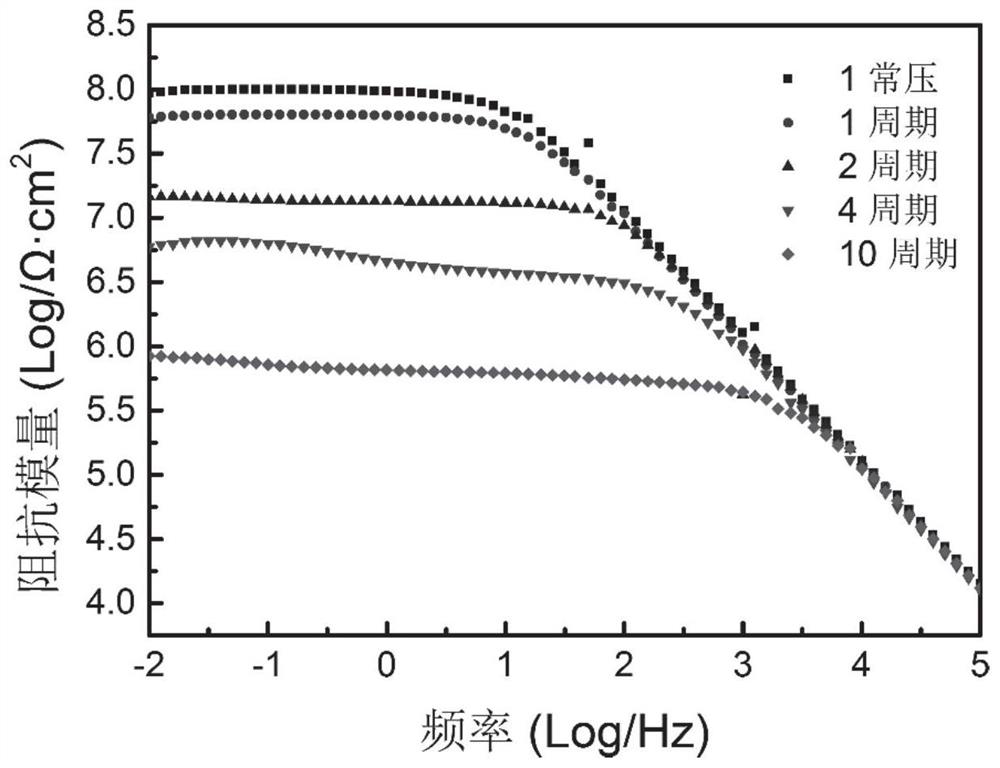

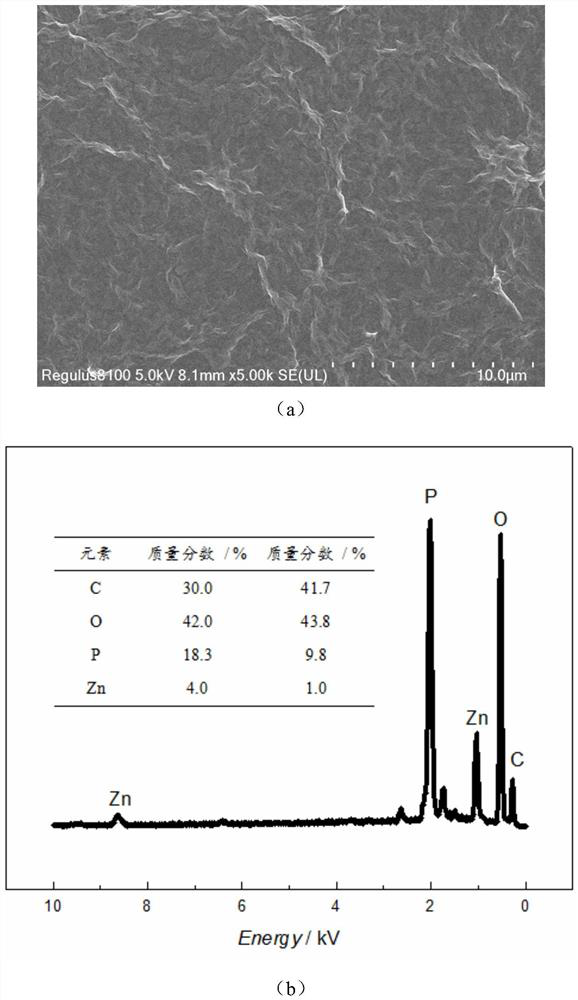

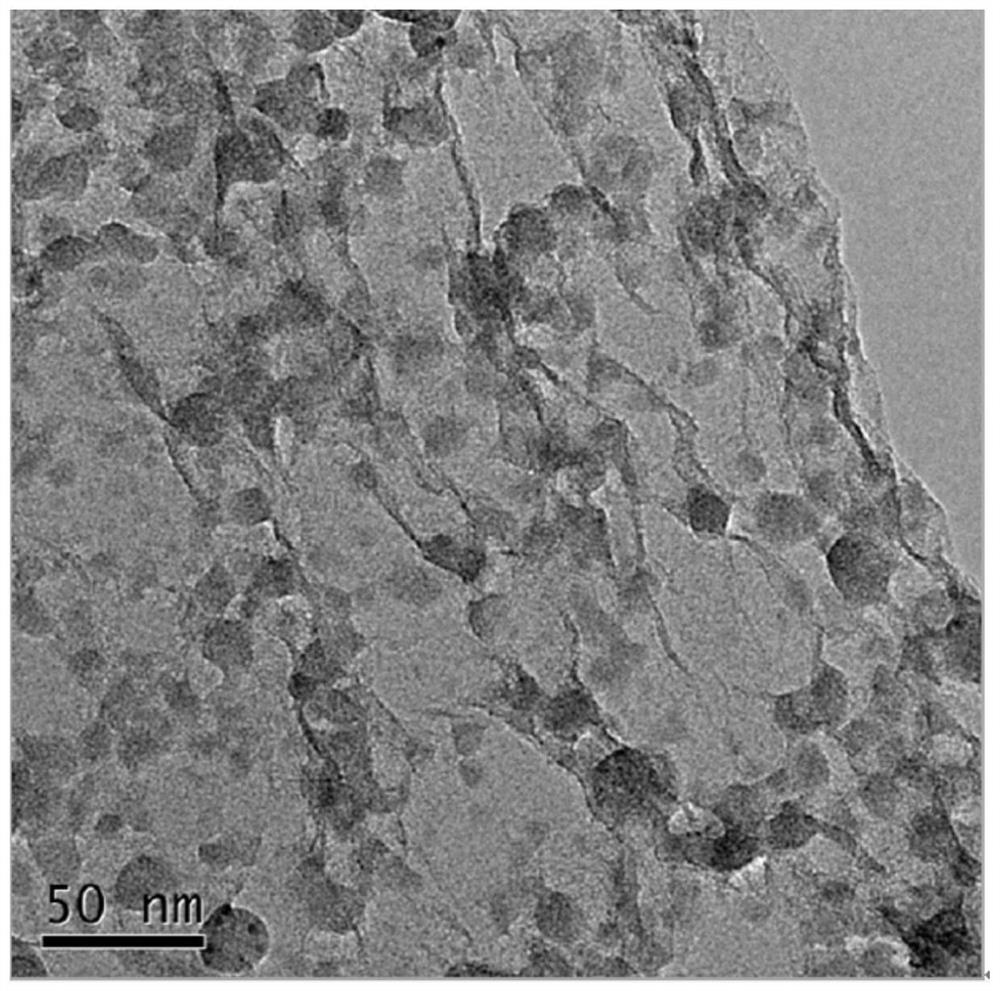

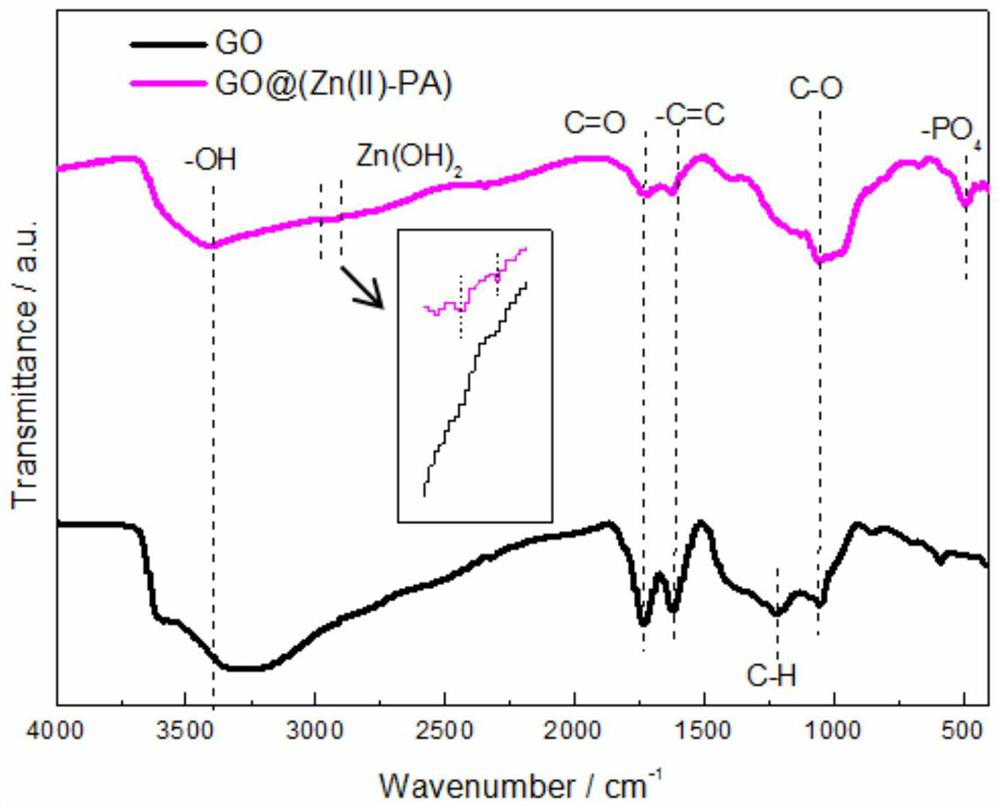

Anticorrosive waterborne epoxy coating based on divalent zinc ions and phytic acid modified graphene oxide and preparation method of anticorrosive waterborne epoxy coating

The invention discloses an anti-corrosion water-based epoxy coating based on divalent zinc ions and phytic acid modified graphene oxide and a preparation method of the anti-corrosion water-based epoxy coating, and belongs to the technical field of anti-corrosion water-based epoxy coatings. The preparation method comprises the following steps: adjusting the pH value of a solution, selecting zinc nitrate hexahydrate and phytic acid as precursors, loading phytic acid functional groups and divalent zinc ions on graphene oxide, adding a modified graphene oxide filler into waterborne epoxy and a curing agent, mixing, and curing to obtain the waterborne epoxy coating. In a 3.5% wt. NaCl solution, compared with a blank waterborne epoxy coating, the corrosion resistance of the coating is improved by more than 5 times, the corrosion current density is reduced to an order of magnitude, and the chloride ion corrosion resistance of the coating is greatly enhanced. According to the graphene oxide loaded with phytic acid functional groups and divalent zinc ions, the dispersity of the graphene oxide in a water-based epoxy coating is improved, and the corrosion resistance of the water-based epoxy coating in a seawater environment is remarkably enhanced.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

A kind of heat-resisting thermal insulation coating and preparation method thereof

ActiveCN107201067BImprove thermal conductivityImprove insulation effectFireproof paintsAlkali metal silicate coatingsCarboxymethyl celluloseCellulose

Owner:北京志盛威华化工有限公司

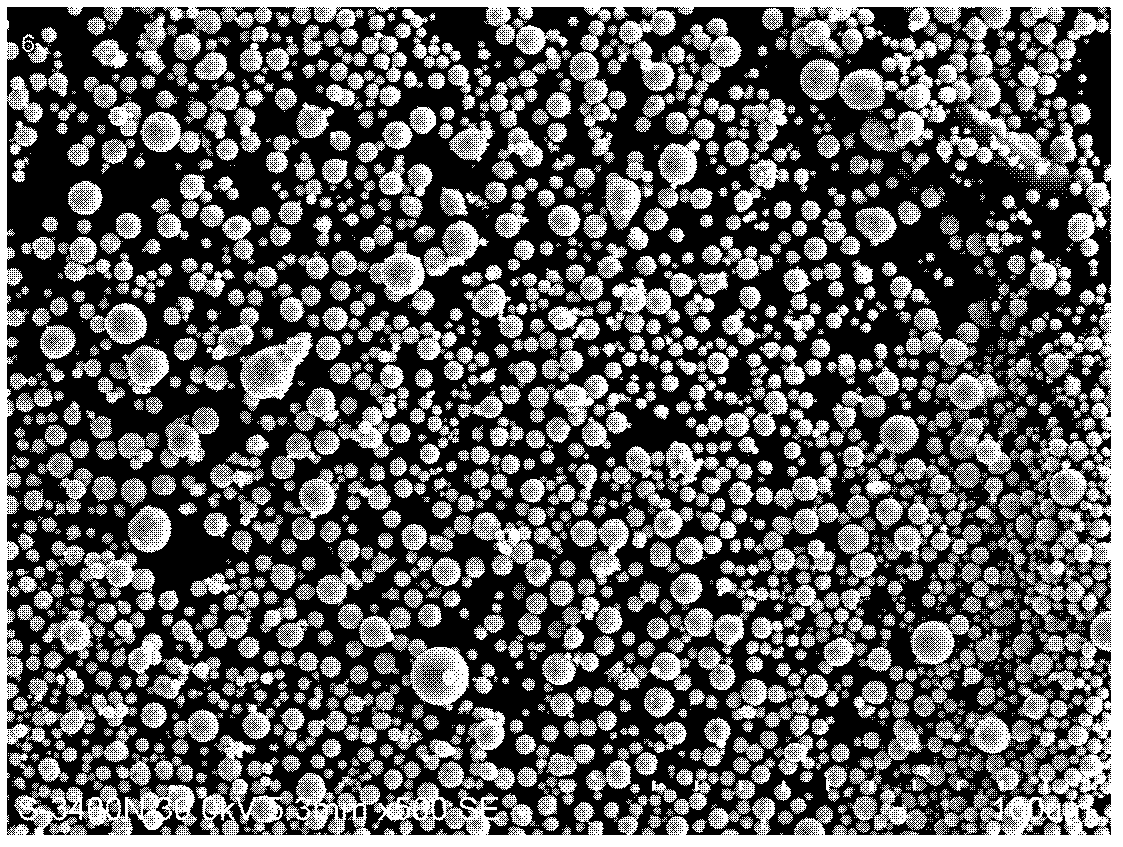

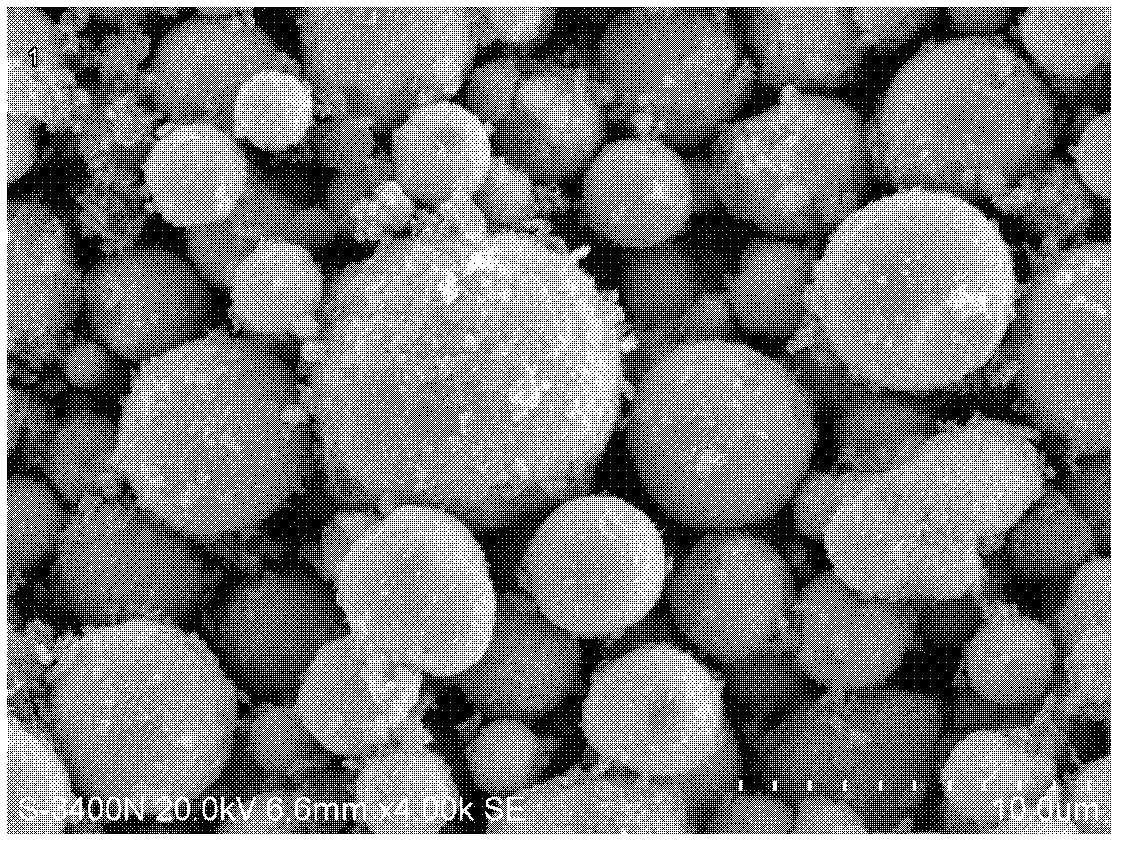

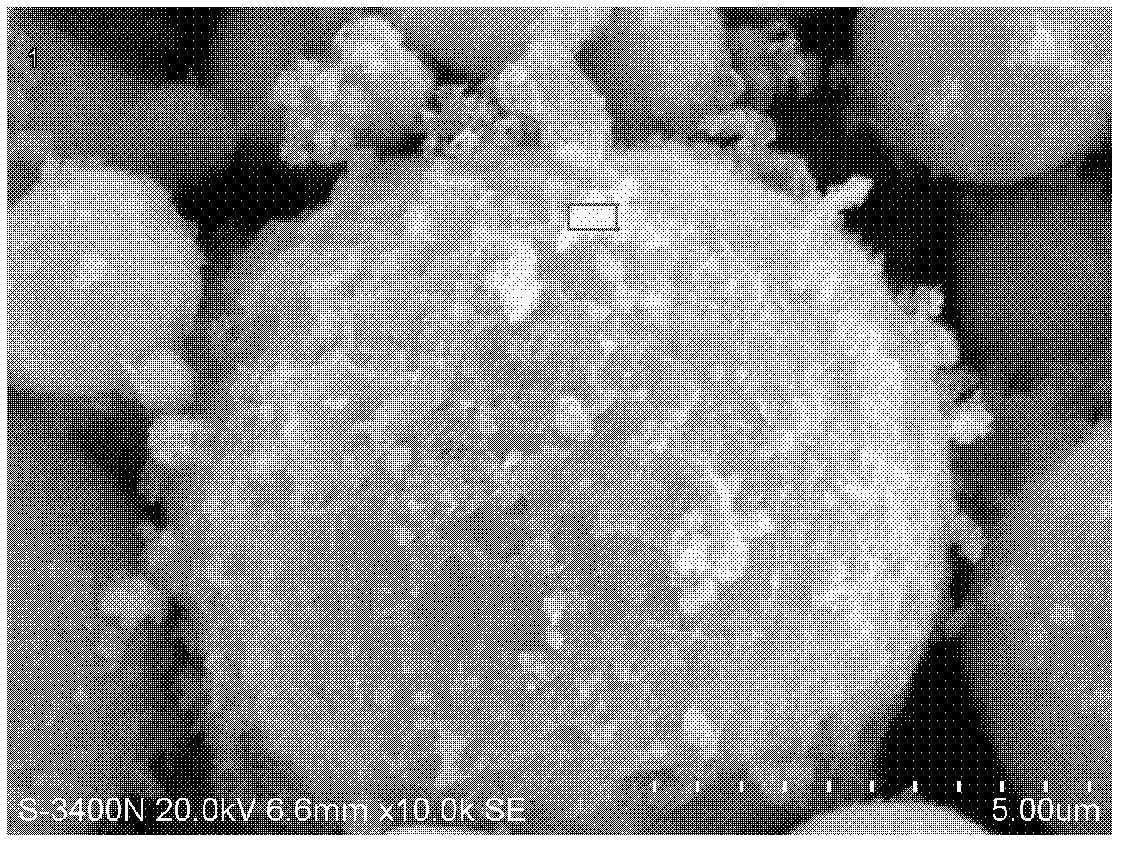

Organic substance bonding-type zinc powder and preparation method thereof

InactiveCN102672157AExcellent physical shielding effectImprove early chemical anti-rust performanceAnti-corrosive paintsPaints with free metalsSocial benefitsChemical reaction

The invention discloses an organic substance bonding-type zinc powder and a preparation method thereof. The zinc powder is prepared from the following raw materials in parts by weight: 10 to 12 parts of spherical zinc powder, 2 to 6 parts of organic amine and 3 to 15 parts of water. The preparation method comprises the following steps: adding spherical zinc powder into an aqueous solution of organic amine in a reaction kettle, allowing reactions to take place for 20 to 40 min at room temperature or in a low temperature heating condition (35 DEG C to 60 DEG C), filtering, recovering the filtrate, washing the zinc powder until neutral, drying and grinding to obtain the final product of organic substance bonding-type zinc powder. According to the organic substance bonding-type zinc powder obtained by the preparation method, the physical shielding performance of spherical zinc powder is enhanced, the early corrosion prevention performance of spherical zinc powder coating is improved, the electric conductivity of the original zinc powder is not changed, and the overall anti-rust performance is improved. The preparation method has the advantages of no strict requirement for reaction conditions, simple process, convenience for operation and industrial production, recycling of the filtrate, low production cost, and good economic and social benefits.

Owner:GUANGXI UNIV FOR NATITIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com