Water-based anticorrosive coating applied to deep sea environment as well as preparation method and application of water-based anticorrosive coating

A technology for anti-corrosion coatings and deep-sea environments, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem of weakening the physical barrier effect of the sheet, and achieve the effect of improving physical shielding effect, improving mechanical properties, and fiber reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In some more specific embodiments, the preparation method of the titanium carbide nanosheet / nanocellulose composite includes: mixing titanium carbide nanosheets, nanocellulose and a solvent, and then undergoing ultrasonication, distillation, and freeze-drying to obtain The titanium carbide nanosheet / nanocellulose composite.

[0027] In some more specific embodiments, the water-based anti-corrosion coating includes: 80-90 wt% of component A and 10-20 wt% of component B.

[0028] Further, the distillation treatment method includes rotary evaporation treatment.

[0029] Further, the time of the rotary steaming treatment is 20-80 min, and the temperature is 20-80°C.

[0030] Further, the solvent includes any one or a combination of two or more of water, ethanol, and acetone, and is not limited thereto.

[0031] Further, the mass ratio of the titanium carbide nanosheets to the nanocellulose is 0.01-20:1. In some more specific embodiments, the titanium carbide nanosheets i...

Embodiment 1

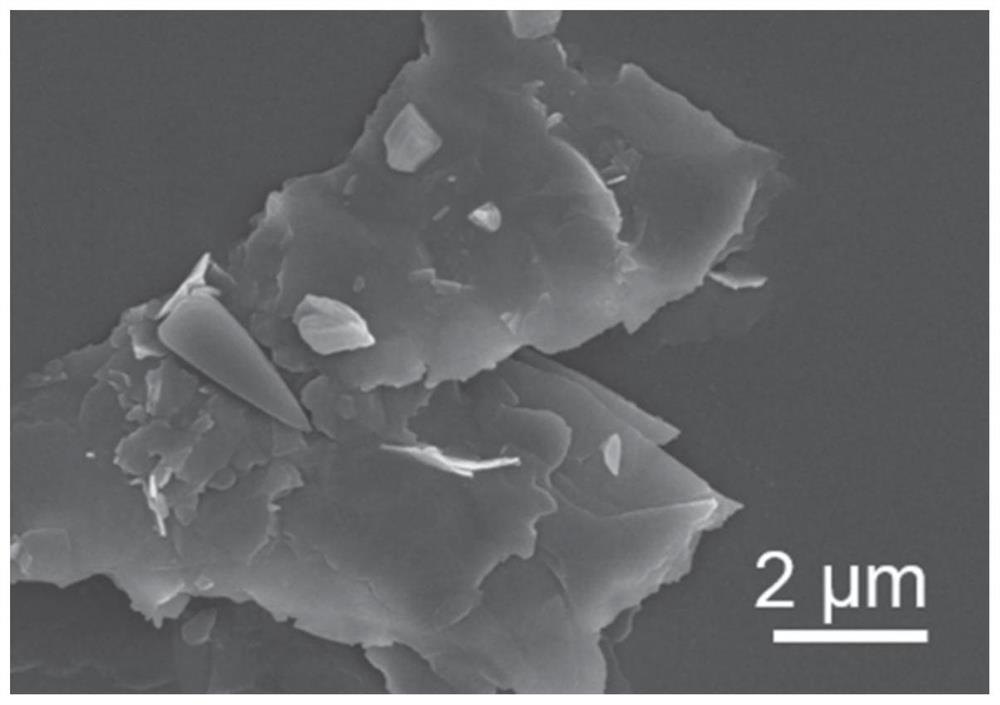

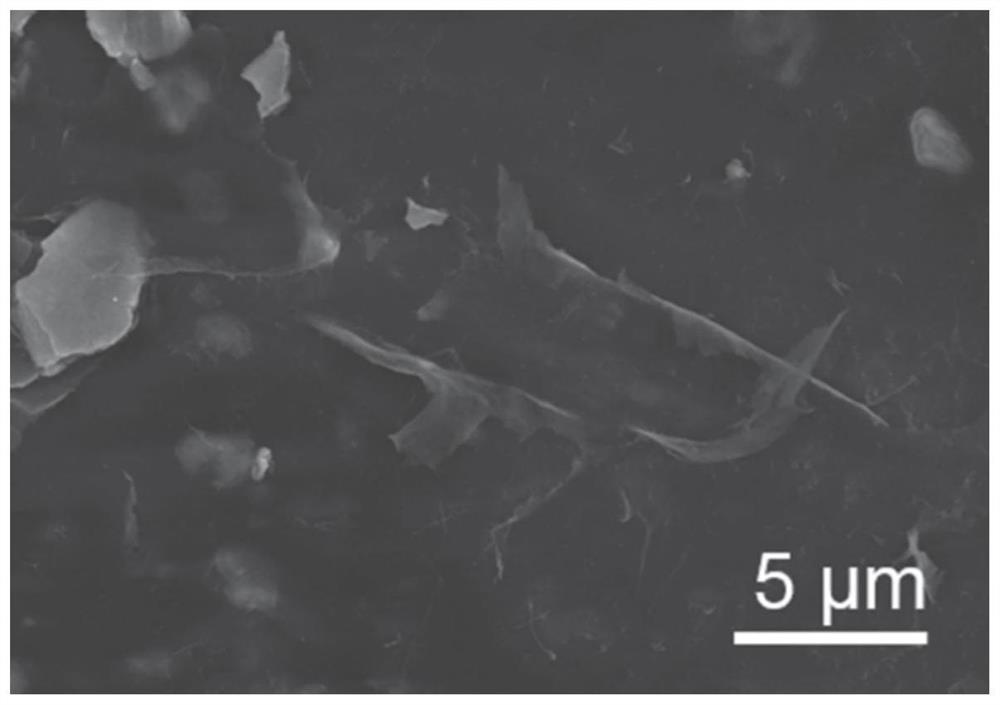

[0066] (1) Cross-linking reaction of titanium carbide nanosheets and nanocellulose: titanium carbide nanosheets (Ti 3 C 2 ) and nanocellulose were added with distilled water for ultrasonic treatment, then rotary steamed at 50°C for 1 h, and then freeze-dried to obtain a titanium carbide nanosheet / nanocellulose composite; wherein the scanning electron microscope image of the titanium carbide nanosheet is as follows Figure 1a As shown, the scanning electron microscope image of the titanium carbide nanosheet / nanocellulose composite is as follows Figure 1b shown;

[0067] (2) Dispersion of titanium carbide nanosheets / nanocellulose composites: Add the titanium carbide nanosheets / nanocellulose composites obtained in step (1) into absolute ethanol and perform ultrasonic and magnetic stirring to obtain titanium carbide nanosheets. Sheet / nanocellulose composite dispersion;

[0068] (3) Preparation and coating of composite coating: Add PLR 609B water-based epoxy resin emulsion to t...

Embodiment 2

[0072] (1) Cross-linking reaction of titanium carbide nanosheets and nanocellulose: titanium carbide nanosheets (Ti 3 C 2 ) and nanocellulose were added with distilled water for ultrasonic treatment, then rotary steamed at 50° C. for 1 h, and then freeze-dried to obtain a titanium carbide nanosheet / nanocellulose composite;

[0073] (2) Dispersion of titanium carbide nanosheets / nanocellulose composites: Add the titanium carbide nanosheets / nanocellulose composites obtained in step (1) into absolute ethanol and perform ultrasonic and magnetic stirring to obtain titanium carbide nanosheets. Sheet / nanocellulose composite dispersion;

[0074] (3) Preparation and coating of composite coating: AB-EP-20 water-based epoxy resin emulsion is added to the titanium carbide nanosheet / nanocellulose composite dispersion obtained in step (2), and mixed by magnetic stirring For a uniform composite emulsion, the excess solvent is removed by vacuum treatment, and then AB-HZ water-based curing ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com