Preparation method of epoxy zinc/graphene heavy-duty anticorrosive coating

A heavy-duty anti-corrosion and epoxy zinc technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems that affect the ability of the paint film to resist water penetration, reduce the utilization rate of zinc powder, and difficult to disperse the coating. Good physical shielding effect, improved interfacial compatibility, and low zinc powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

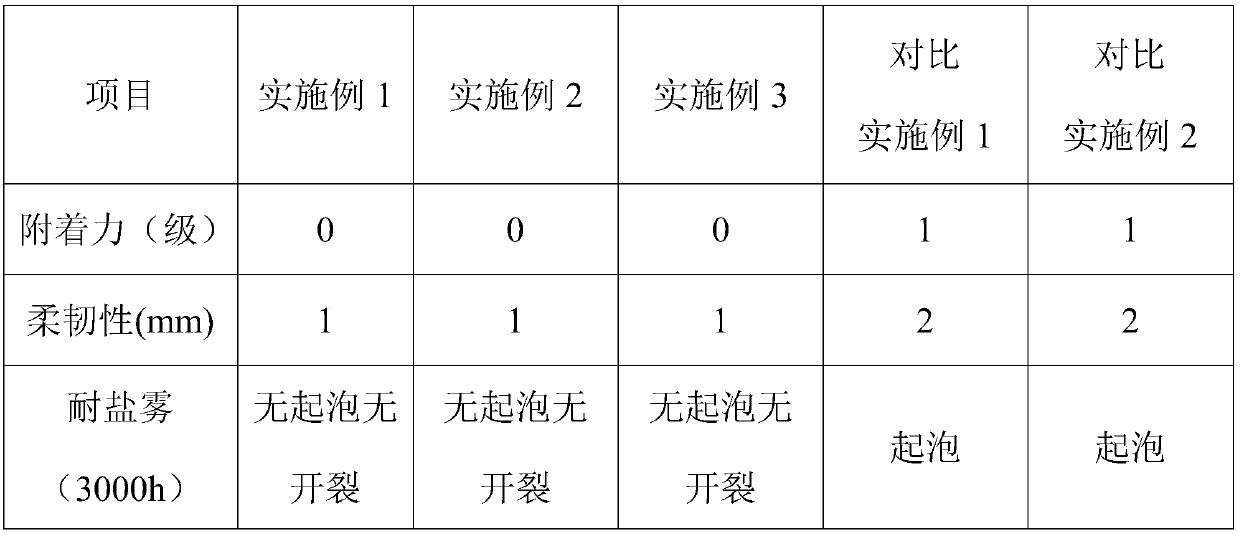

Examples

Embodiment 1

[0026] Step 1: Preparation of modified graphene-zinc composite powder

[0027] (1) According to the mass ratio of 1:25, graphene and zinc powder were weighed respectively, added to the ball mill jar successively, and ethanol was added, the ball mill jar was evacuated and filled with nitrogen, and the ball milled under the protection of nitrogen atmosphere for 2h and then discharged to obtain Slurry, the slurry is placed in a vacuum drying oven to dry, and the graphene-zinc composite powder is obtained after drying completely;

[0028] (2) Weigh 5g of graphene-zinc composite powder into a three-necked flask, add 30g of toluene diisocyanate and 80g of isopropanol, ultrasonically disperse for 15min under nitrogen protection, heat to 90°C after dispersion, stir for 1h, and filter with suction , put the filter residue into a vacuum drying oven, and dry it at 50° C. to obtain a modified graphene-zinc composite powder.

[0029] Step 2: Preparation of epoxy zincene heavy-duty anti-co...

Embodiment 2

[0035] Step 1: Preparation of modified graphene-zinc composite powder

[0036] (1) According to the mass ratio of 1:27, graphene and zinc powder were weighed respectively, added to the ball mill jar successively, and ethanol was added, the ball mill jar was evacuated and filled with nitrogen, and the ball mill was discharged for 3 hours under the protection of nitrogen atmosphere to obtain Slurry, the slurry is placed in a vacuum drying oven to dry, and the graphene-zinc composite powder is obtained after drying completely;

[0037] (2) Weigh 7g of graphene-zinc composite powder into a three-necked flask, add 40g of toluene diisocyanate and 100g of isopropanol, ultrasonically disperse for 17min under the protection of nitrogen, heat to 95°C after dispersion, stir for 1.5h, pump Filter to obtain the filter residue, put it in a vacuum drying oven, and dry it at 50° C. to obtain a modified graphene-zinc composite powder.

[0038] Step 2: Preparation of epoxy zincene heavy-duty a...

Embodiment 3

[0044] Step 1: Preparation of modified graphene-zinc composite powder

[0045] (1) According to the mass ratio of 1:30, graphene and zinc powder were weighed respectively, added to the ball mill jar successively, and ethanol was added, the ball mill jar was evacuated and filled with nitrogen, and the ball mill was discharged for 4 hours under the protection of nitrogen atmosphere to obtain Slurry, the slurry is placed in a vacuum drying oven to dry, and the graphene-zinc composite powder is obtained after drying completely;

[0046] (2) Weigh 10g of graphene-zinc composite powder into a three-necked flask, add 50g of toluene diisocyanate and 120g of isopropanol, ultrasonically disperse for 20min under nitrogen protection, heat to 100°C after dispersion, stir for 2h, and filter with suction , put the filter residue into a vacuum drying oven, and dry it at 50° C. to obtain a modified graphene-zinc composite powder.

[0047] Step 2: Preparation of epoxy zincene heavy-duty anti-cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com