Patents

Literature

126results about How to "Improve the effect of cathodic protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

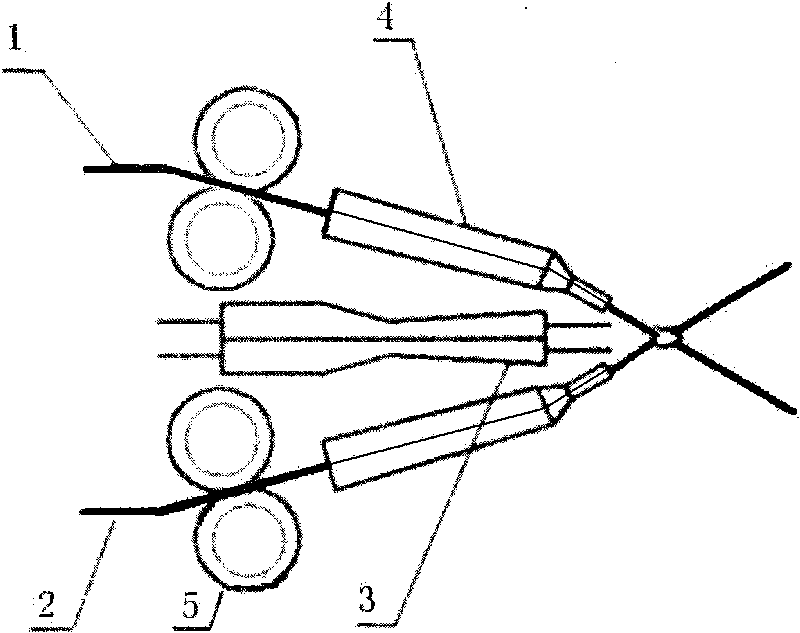

Rare earth aluminum alloy wire for thermal spraying

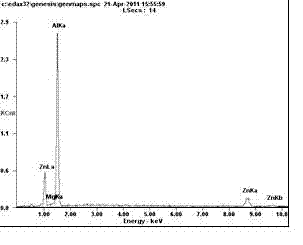

ActiveCN101906604AOptimizing Metal Crystal StructuresImprove corrosion resistanceMolten spray coatingCorrosion resistantMagnesium

The invention discloses a rare earth aluminum alloy wire for thermal spraying, which belongs to the technical field of thermal spraying. The wire contains aluminum, zinc, magnesium and the like, and also contains two or more than two rare earth metal elements, and the total weight of rare earth metal elements accounts for 0.51-5.00% of the total weight of the wire. The invention has the advantages that the processing and manufacturing process is convenient and the product coat cost is moderate; and the metal thermal spraying coating made from the wire has good adhering capability, good physical and mechanical property, good corrosion-resistant property, and moderate construction cost, and is favorable for popularization and application.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

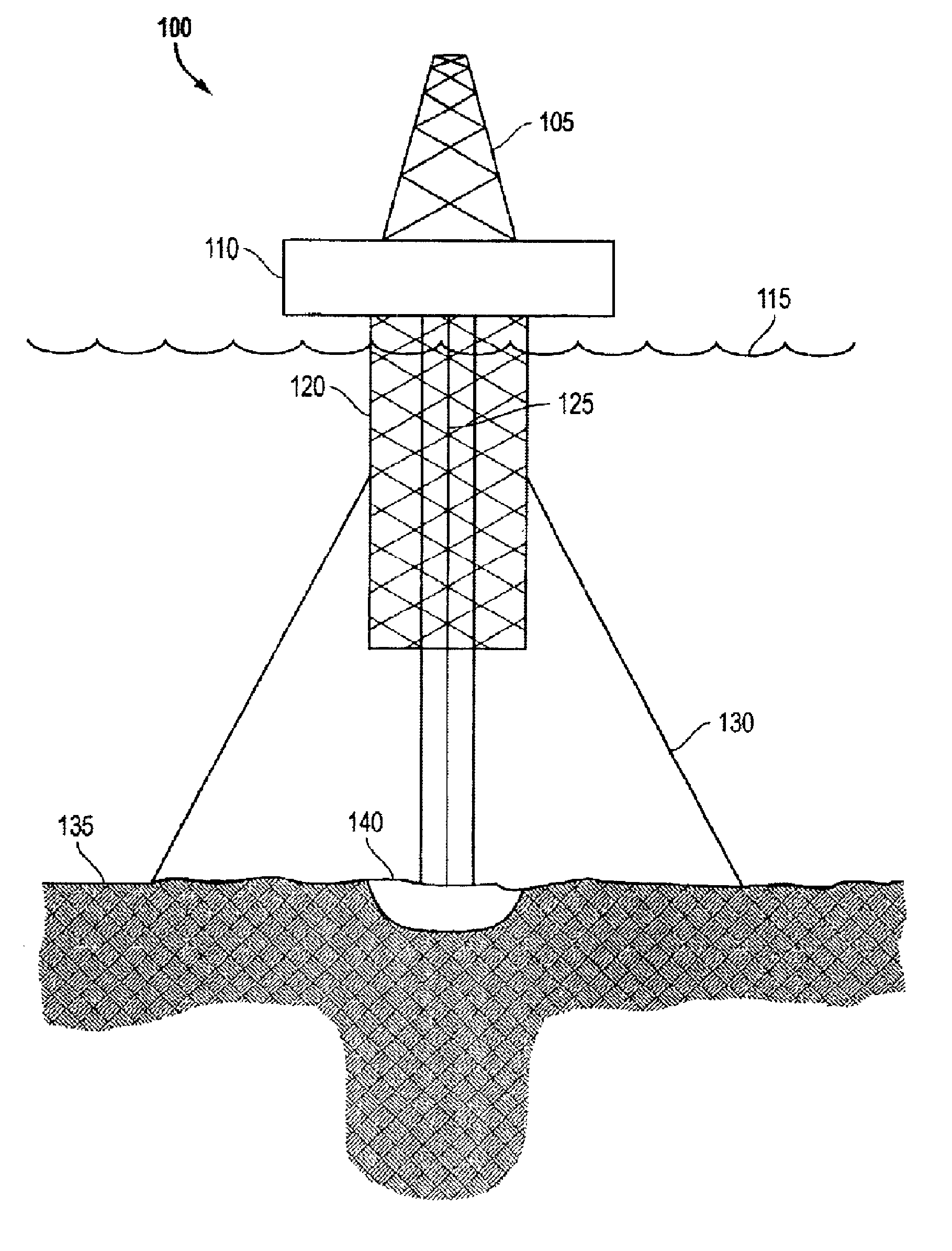

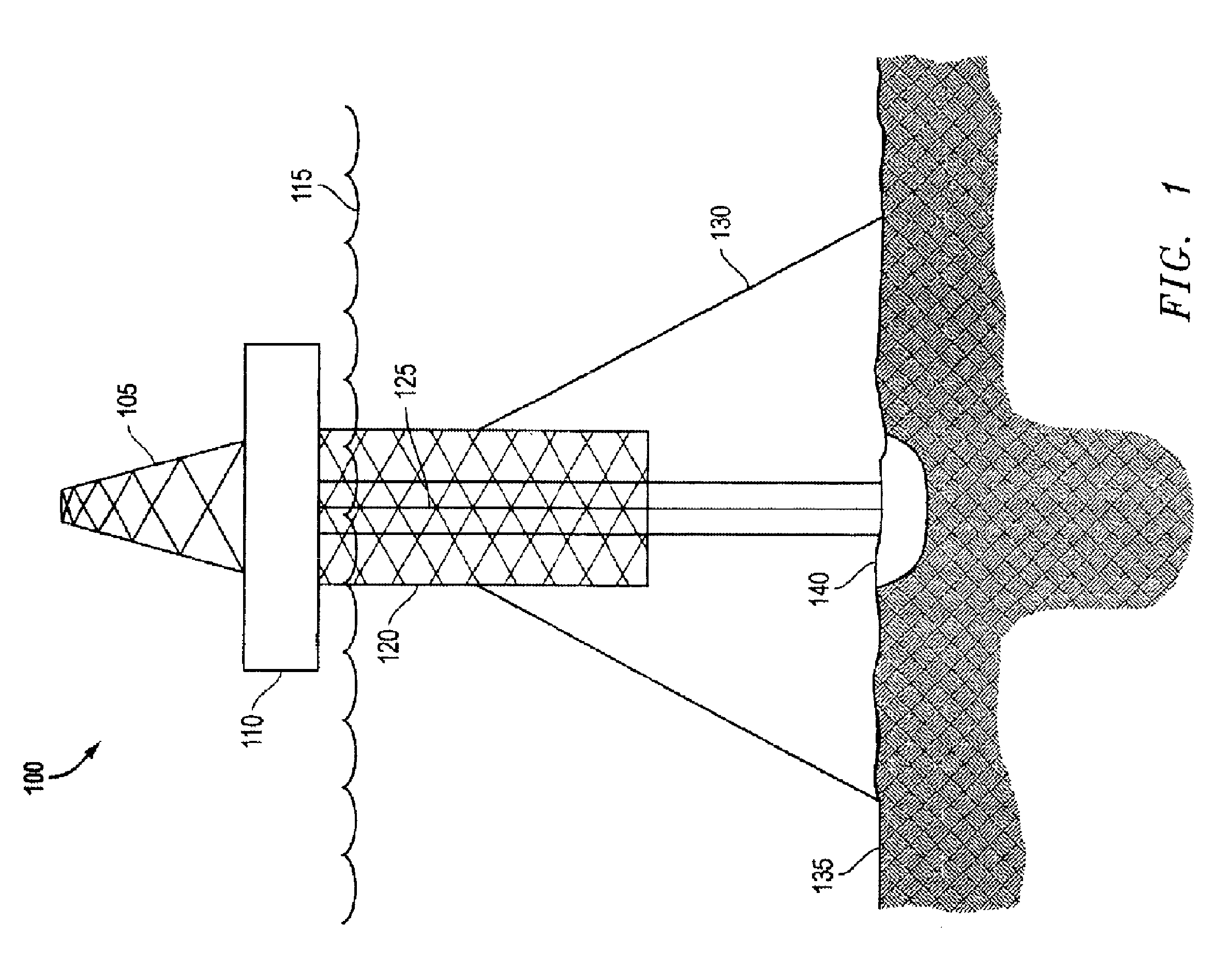

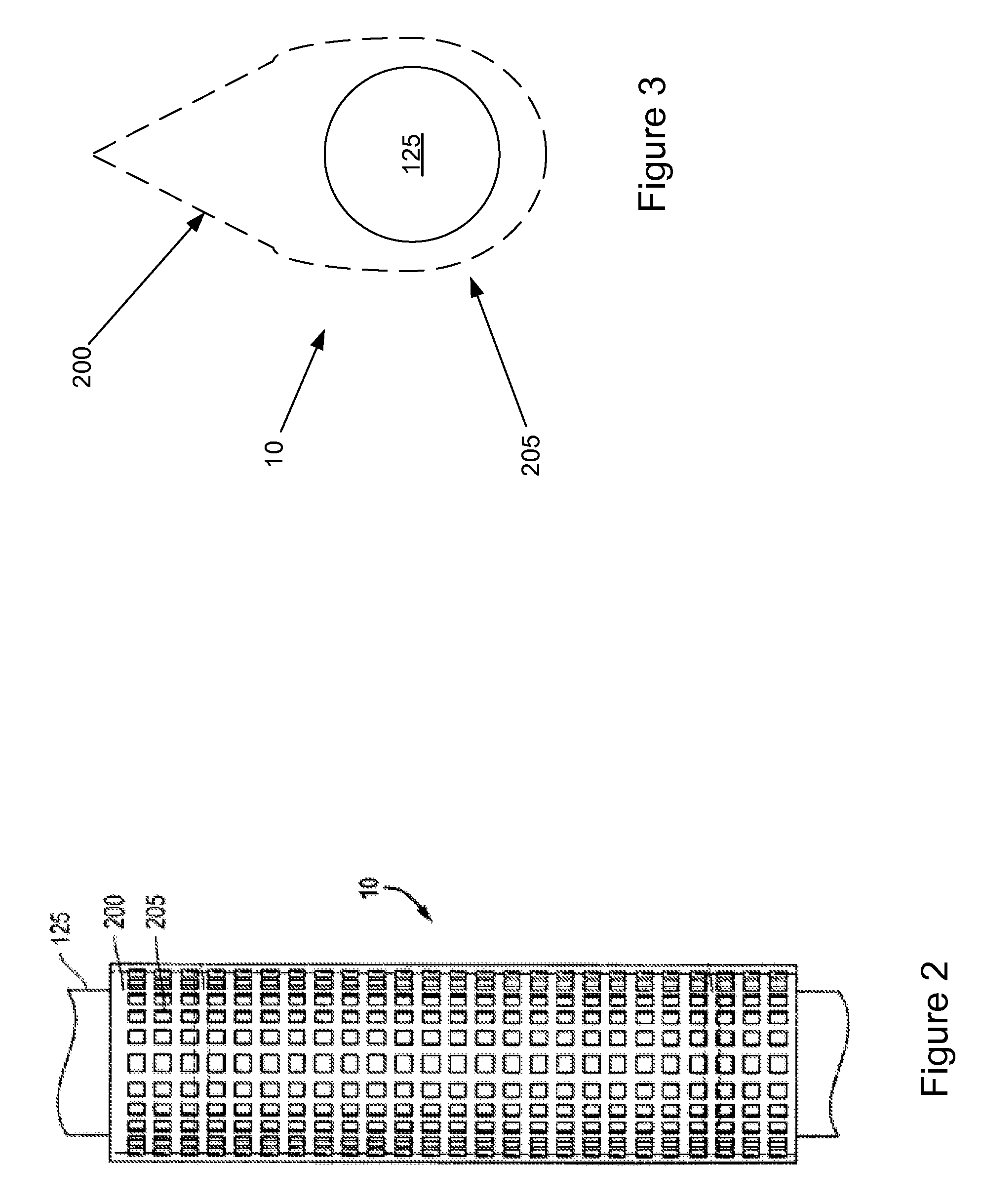

Systems and methods for reducing drag and/or vortex induced vibration

InactiveUS20070003372A1Reduce vibrationImproved VIV and/or drag reductionArtificial islandsDrilling rodsPorosityEngineering

There is disclosed a system for reducing drag and / or vortex induced vibration of a structure, the system comprising a fairing defining a plurality of perforations, wherein the fairing is suitable for placement around the structure, the perforations defining a porosity of the fairing of at least 1%.

Owner:SHELL OIL CO

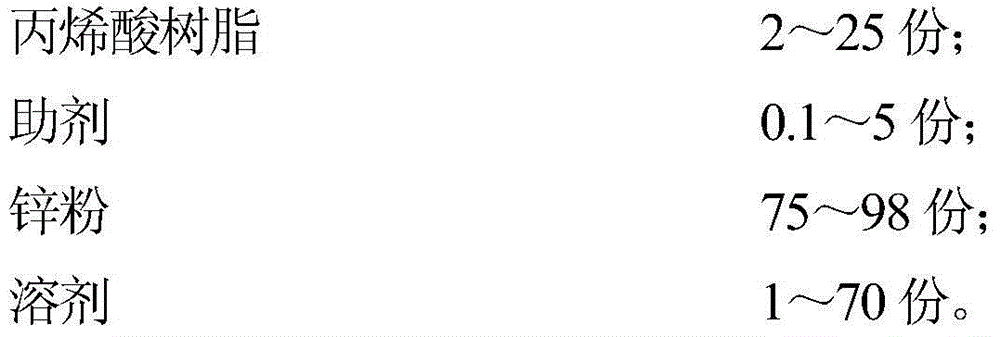

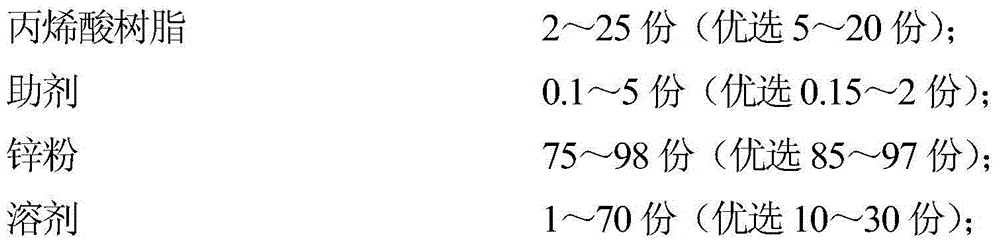

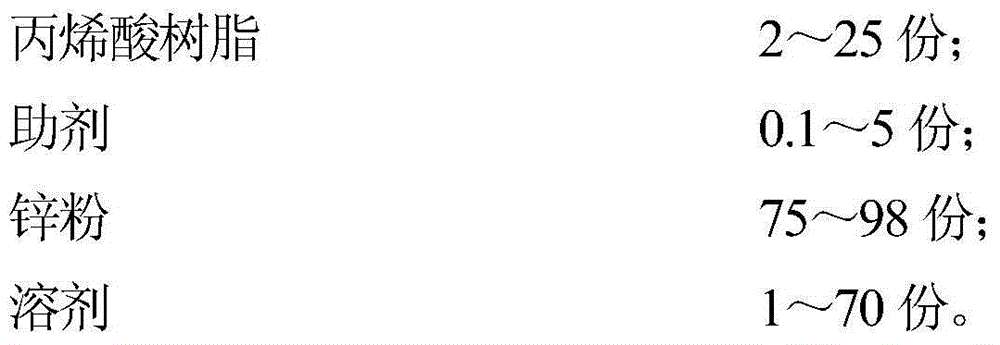

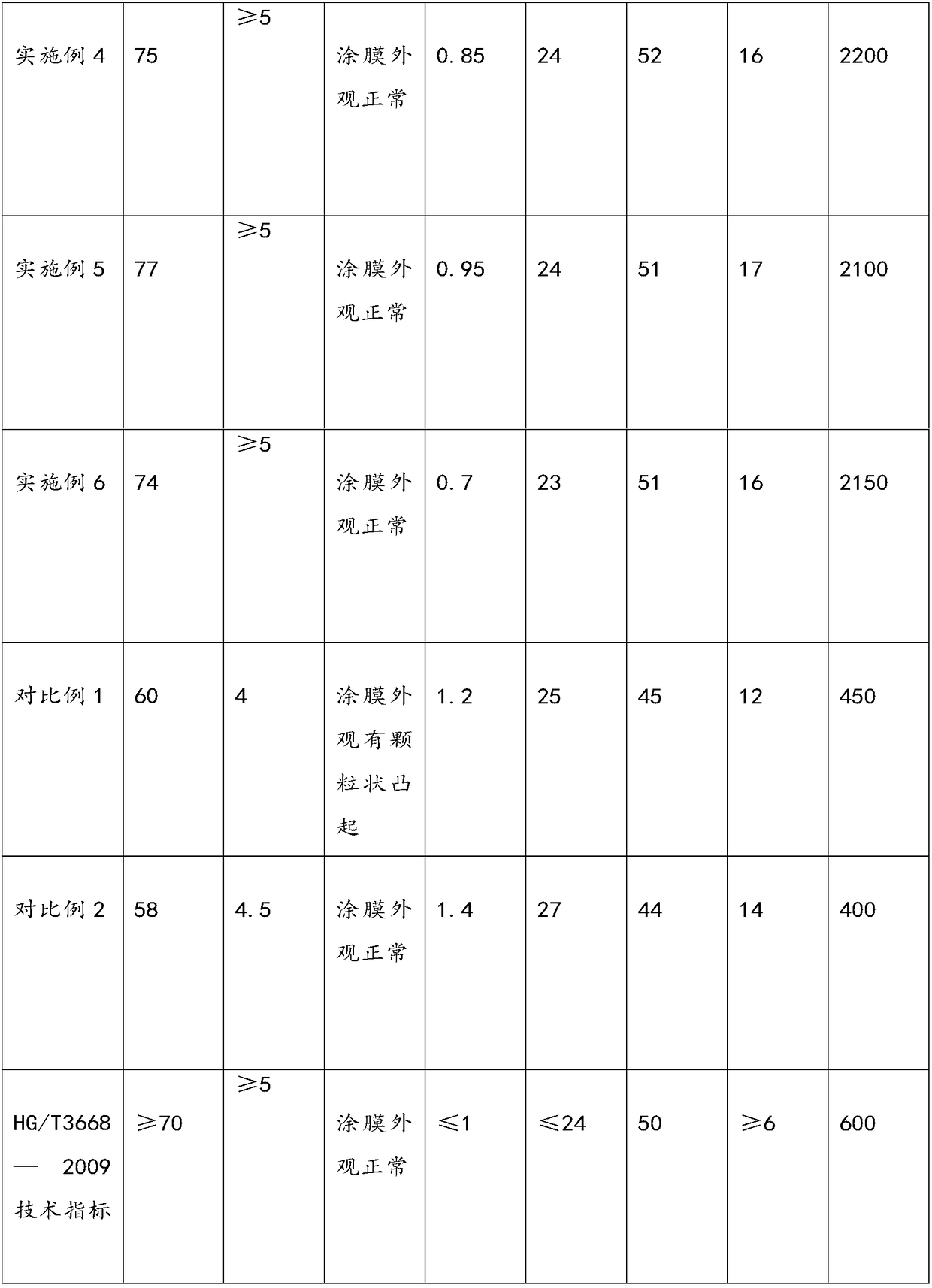

Nano composite cold galvanized coating and preparation method thereof

ActiveCN104449141AImprove dispersionImprove compatibilityAnti-corrosive paintsSolventHot-dip galvanization

The invention relates to a nano composite cold galvanized coating and a preparation method thereof and belongs to the field of nano coatings. The nano composite cold galvanized coating is prepared from the following raw materials in parts by weight: 2-25 parts of acrylic resin, 0.1-5 parts of an assistant, 75-98 parts of zinc powder and 1-70 parts of a solvent, wherein the zinc powder is a mixture of micro-scale zinc powder and nano-scale zinc powder modified by a fluorosilane coupling agent, so that the dispersity of the zinc powder is increased; the compatibility with resin is improved; the coat made of the nano composite cold galvanized coating has high hydrophobic property; the water contact angle is greater than or equal to 135 degrees; the porosity of the cold galvanized coating is significantly reduced; the corrosion resistance of the coating is improved; the nano composite cold galvanized coating disclosed by the invention can be widely applied to anti-corrosion engineering with a novel steel structure, old and new hot-dip galvanizing structures and an electric galvanized steel structure; and the difficulty in corrosion maintenance of transmission and substation facilities and substation equipments can be conveniently and rapidly solved.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST +1

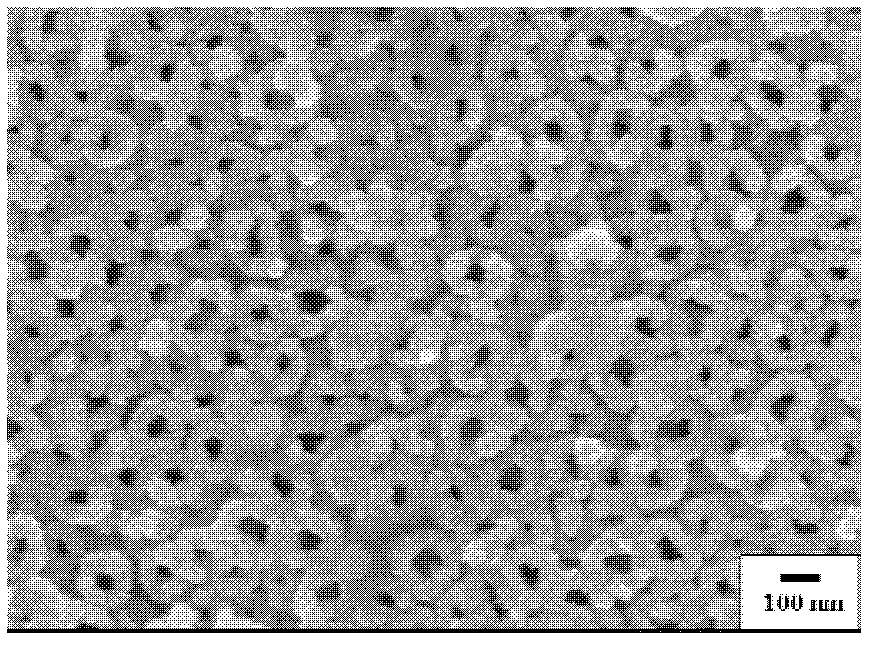

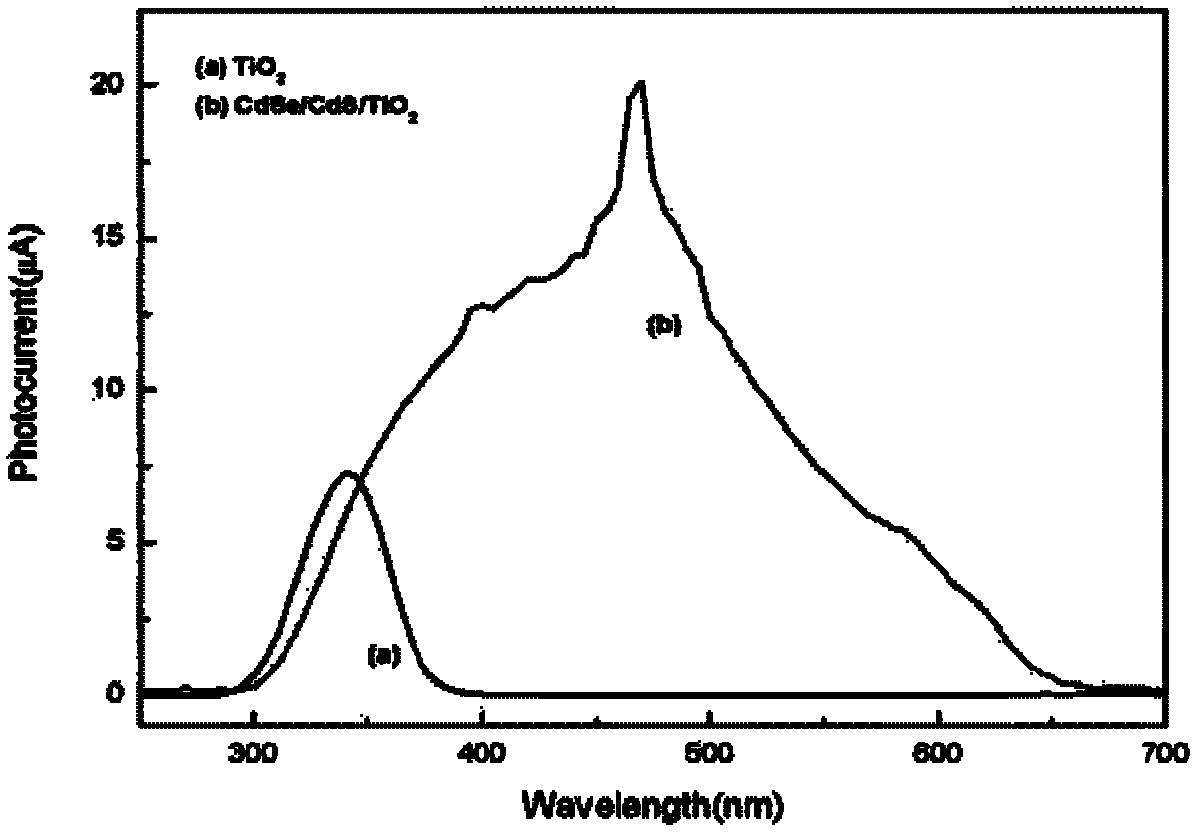

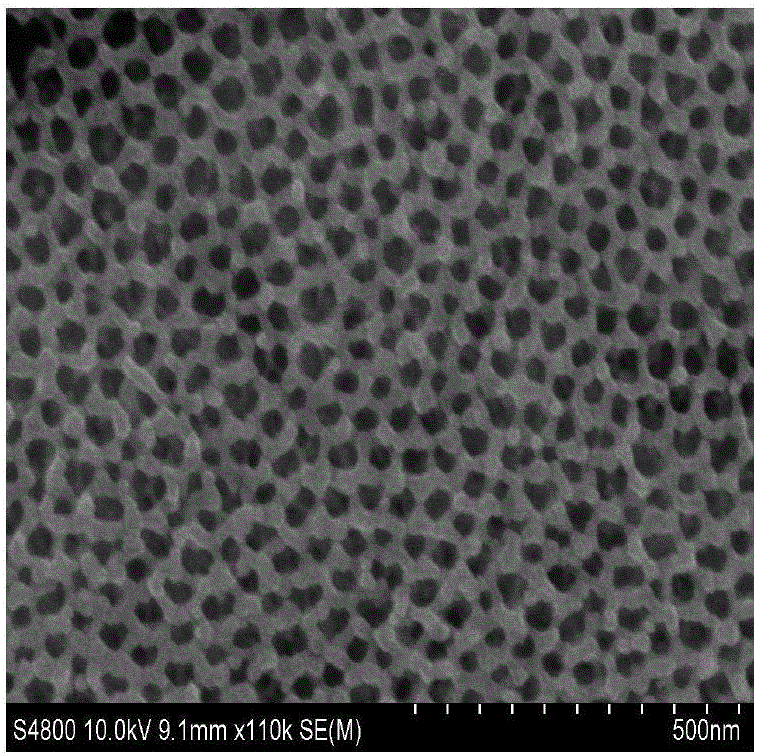

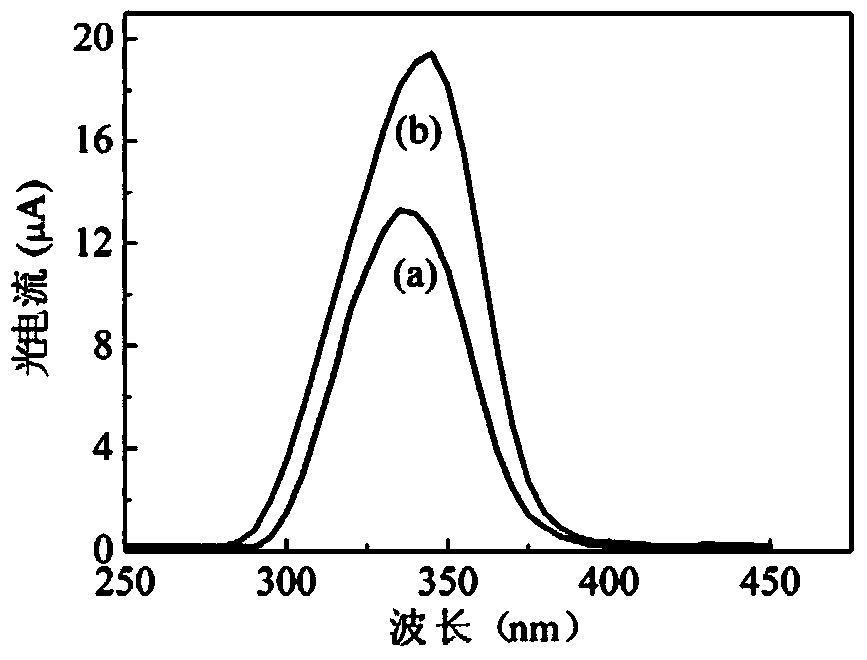

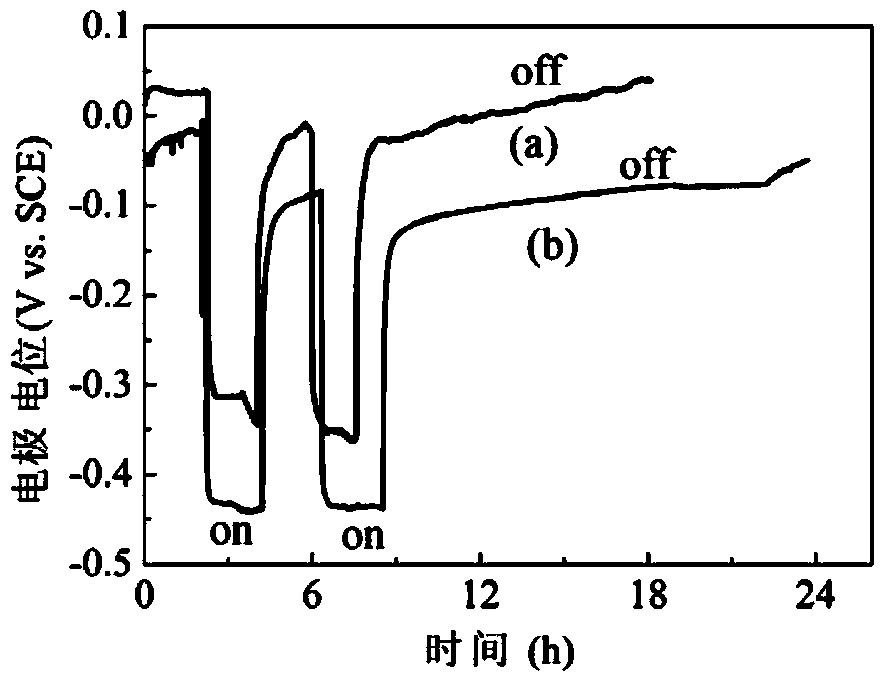

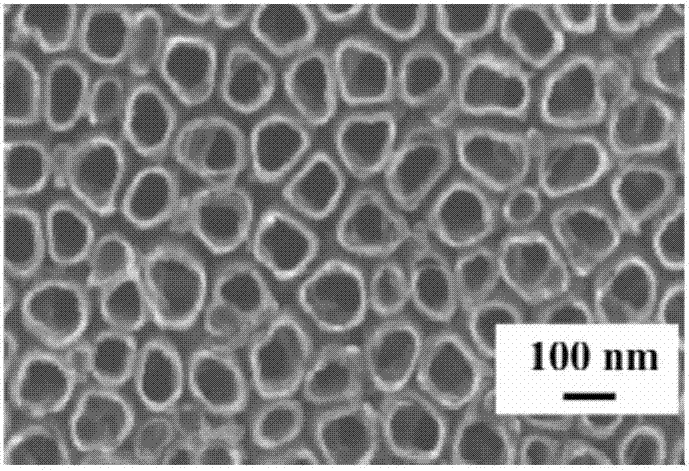

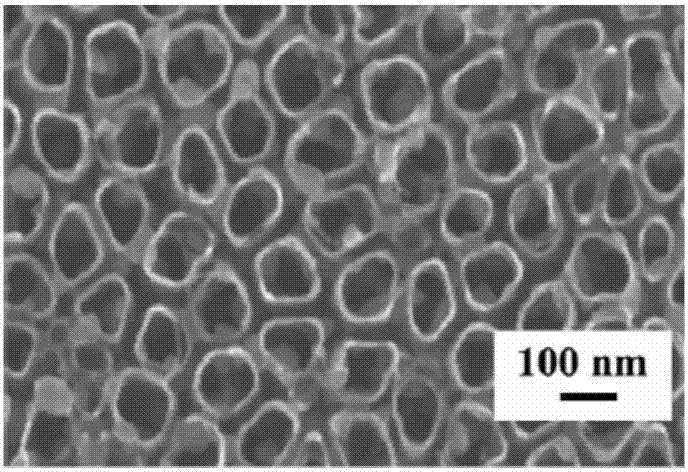

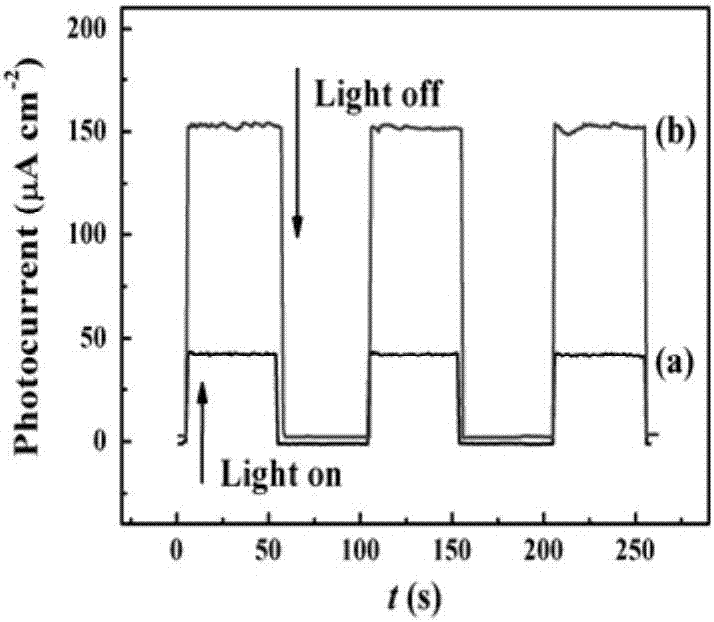

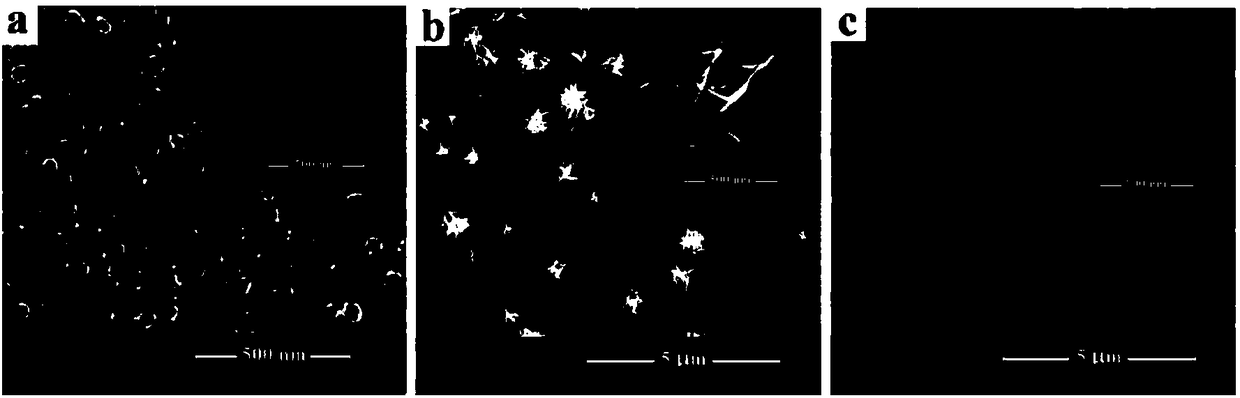

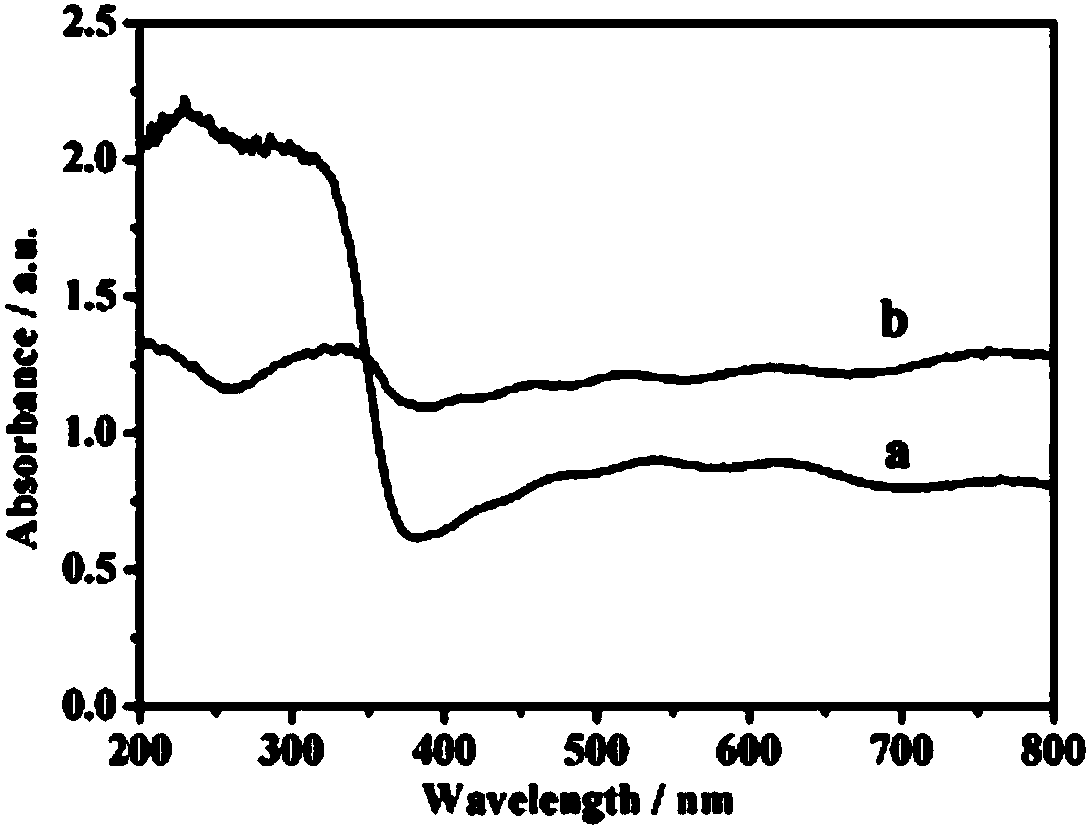

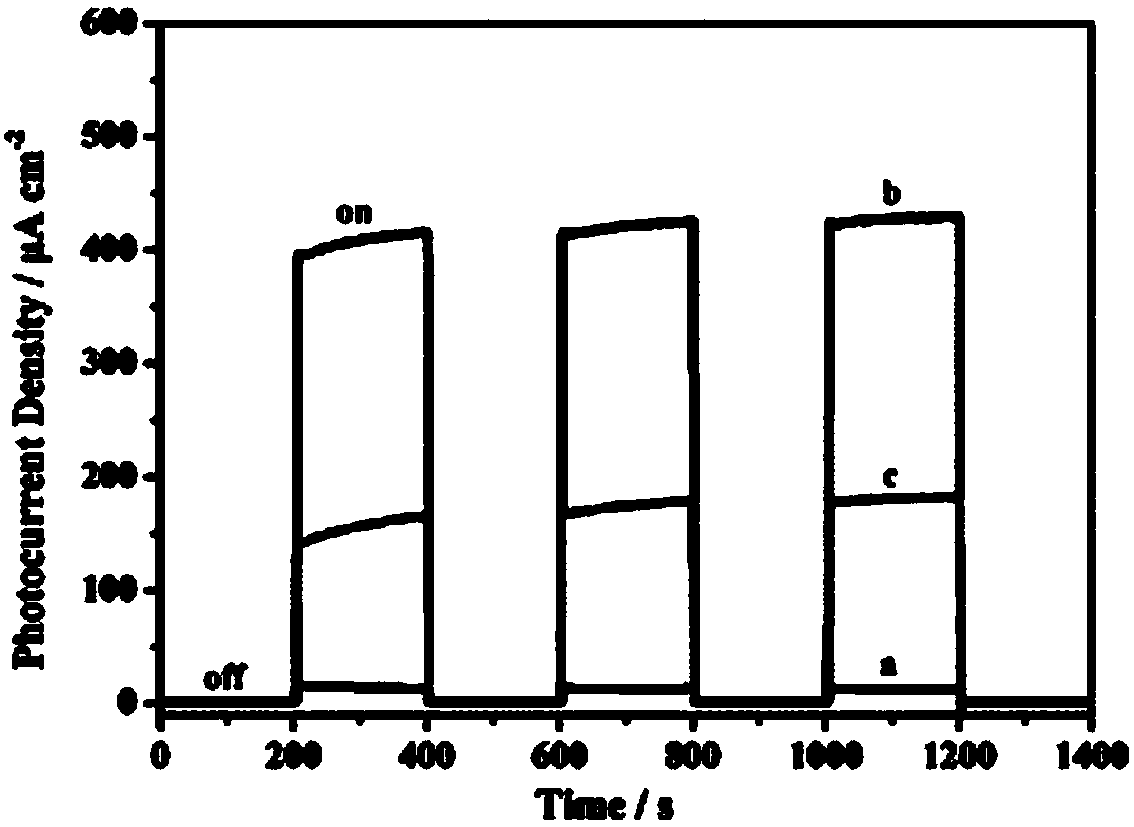

Preparation method of CdSe/CdS quantum dot sensitized TiO2 nanometer tube composite film

InactiveCN102352494AImprove photoelectrochemical performanceImprove the effect of cathodic protectionSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingIonQuantum dot

The invention provides a preparation method of a CdSe / CdS quantum dot sensitized TiO2 nanometer tube composite film, which relates to a nanometer tube composite film. A titanium foil is used as a substrate, ammonium fluoride is dissolved into deionized water, glycerin is added for carrying out calcination after the anode oxidation, CdS quantum dos are firstly deposited on the surface of a TiO2 nanometer tube array film, Cd(NO3)2 ethanol solution and Na2S methanol solution are respectively used as reaction solution, firstly, TiO2 nanometer tube array film samples are soaked in Cd<2+> ethanol solution, then, ethanol is used for flushing, next, the samples are soaked into methanol solution containing S<2-> and are than flushed by the ethanol, CdS / TiO2 composite films are obtained, the obtained CdS / TiO2 composite films are placed into mixed solution consisting of Na2SeSO3, Cd(NO3)2 and Na3NTA solution for carrying out deposition reaction, and the CdSe / CdS quantum dot sensitized TiO2 nanometer tube composite film is obtained.

Owner:XIAMEN UNIV

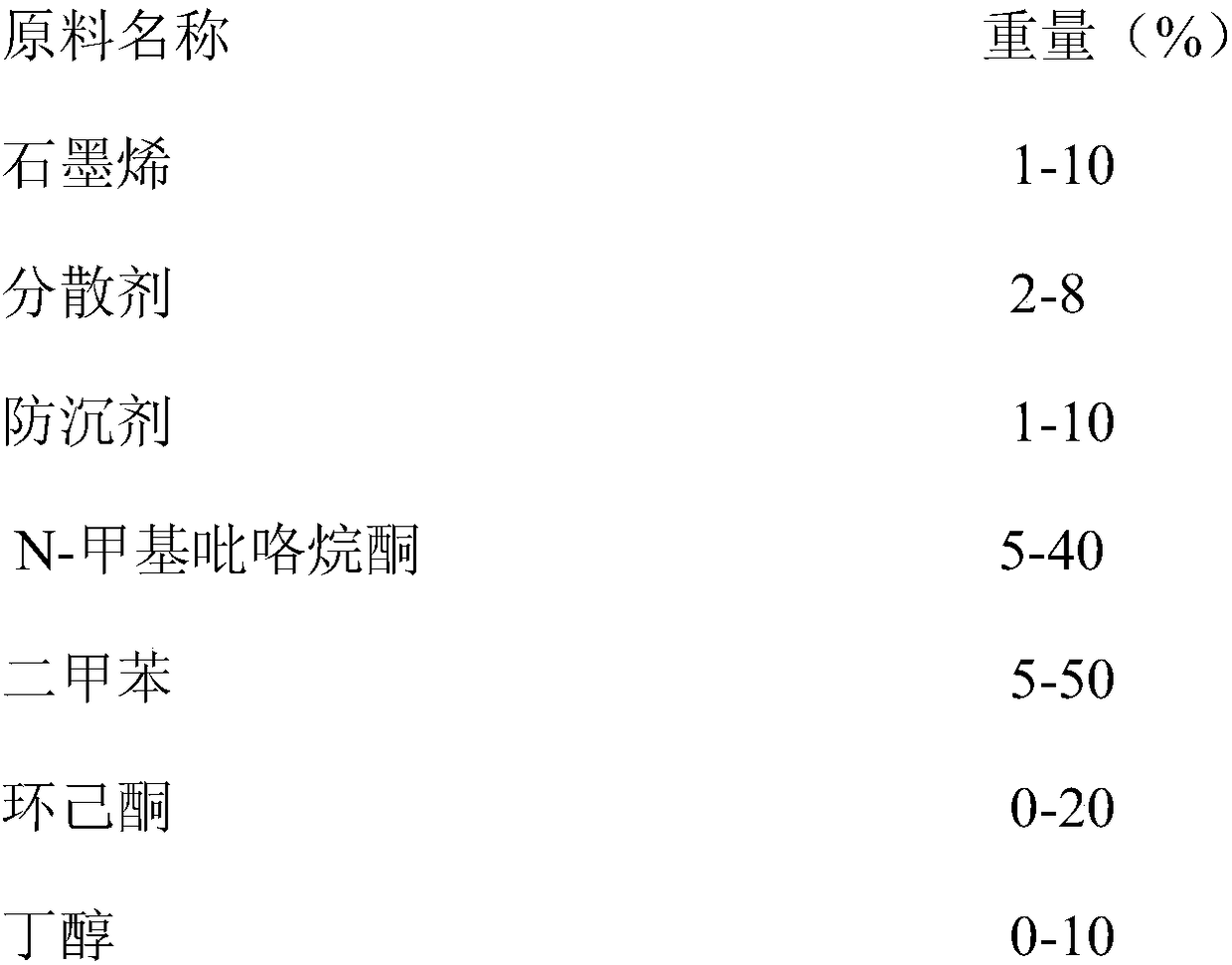

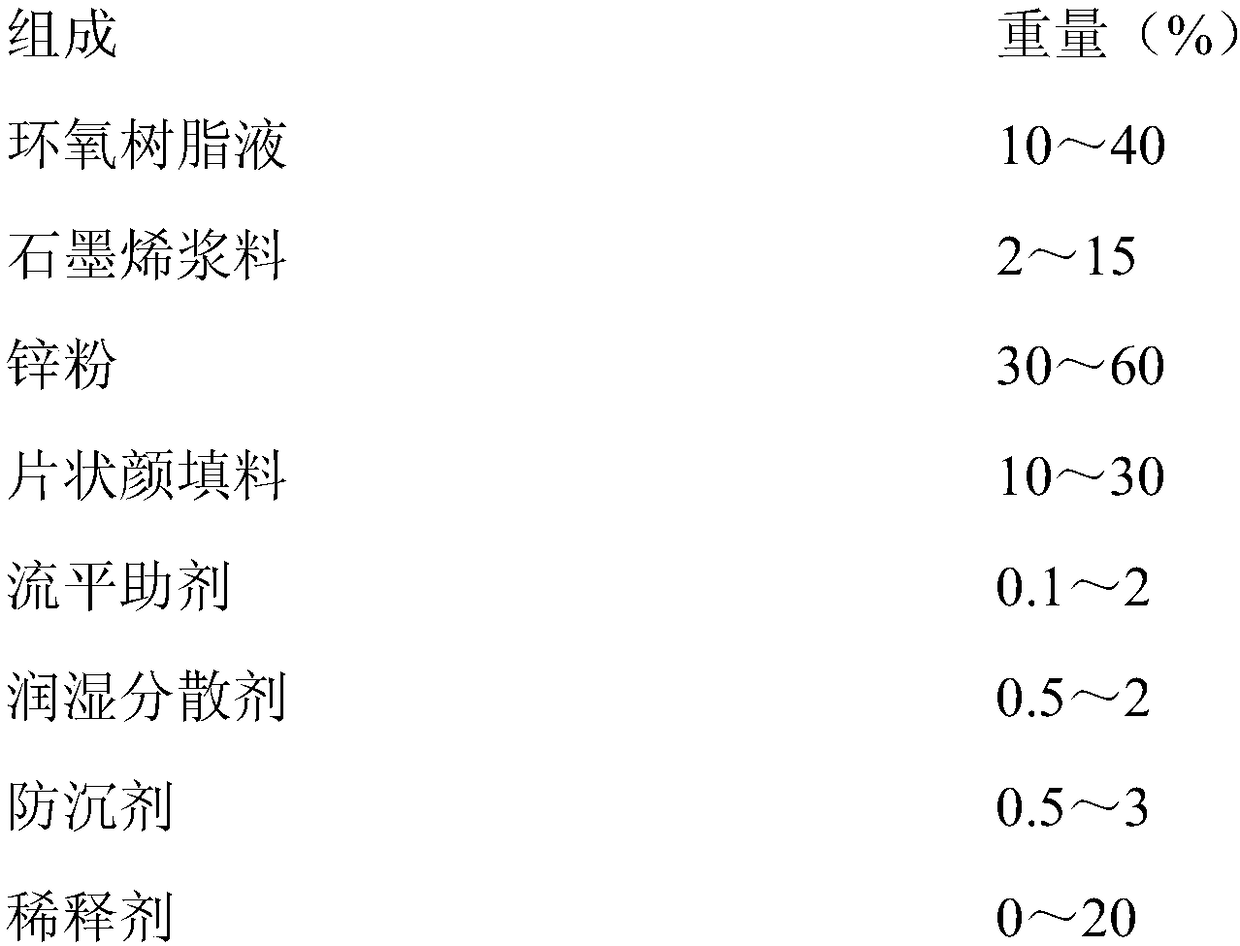

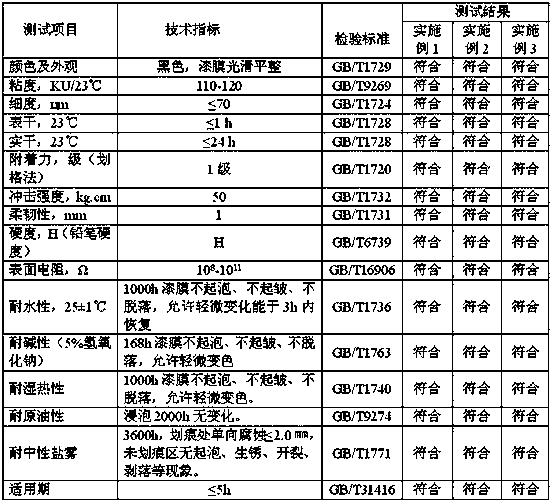

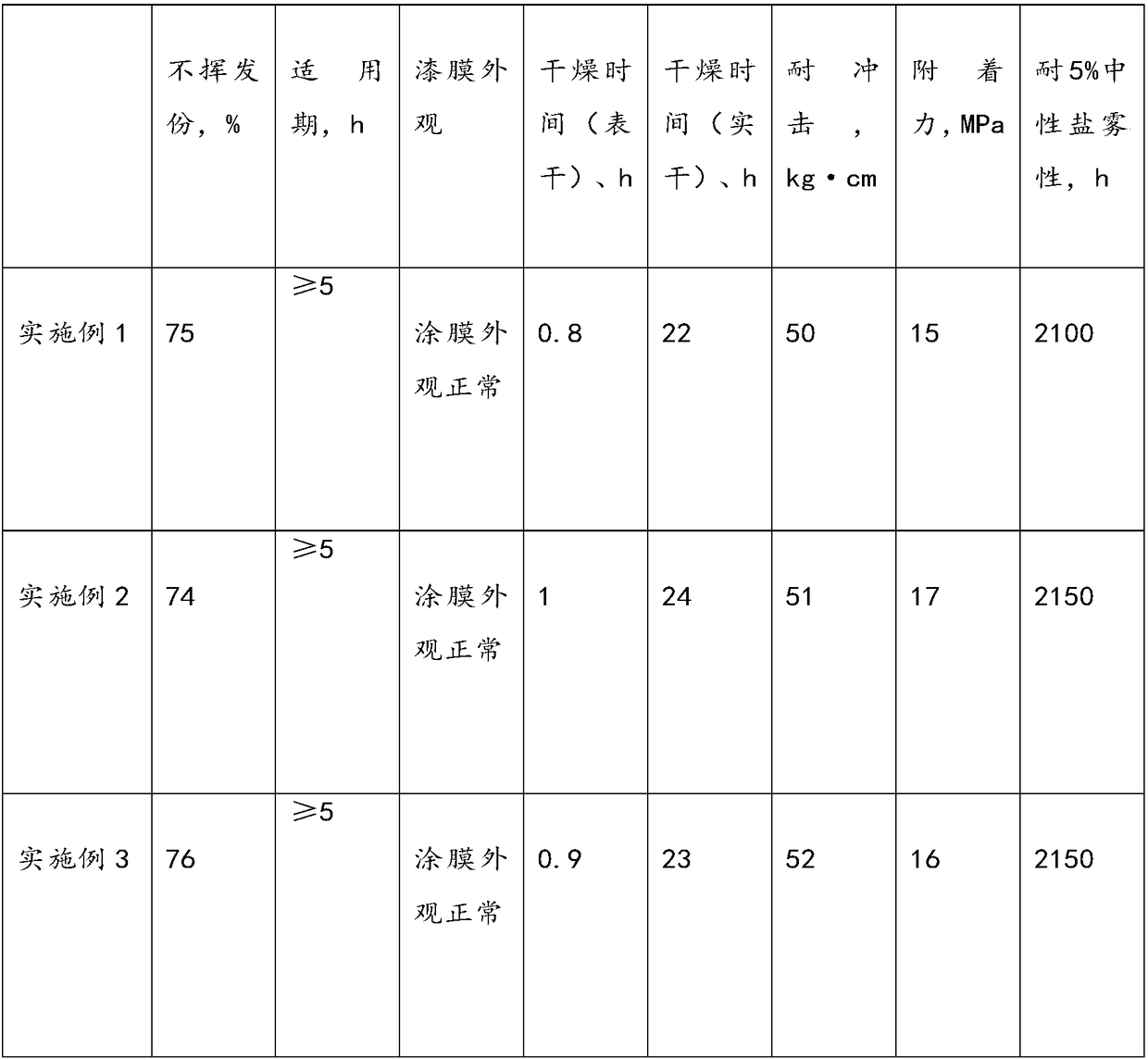

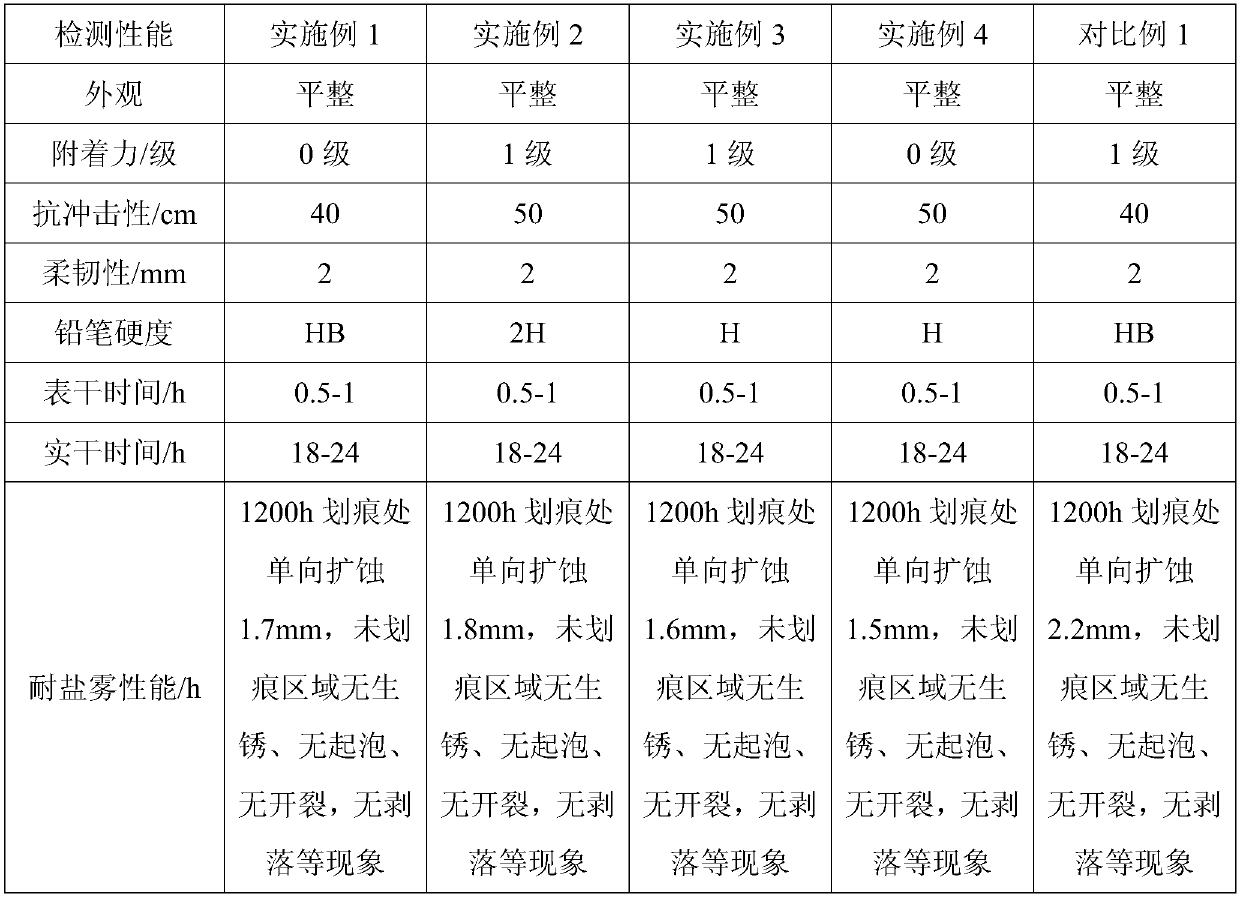

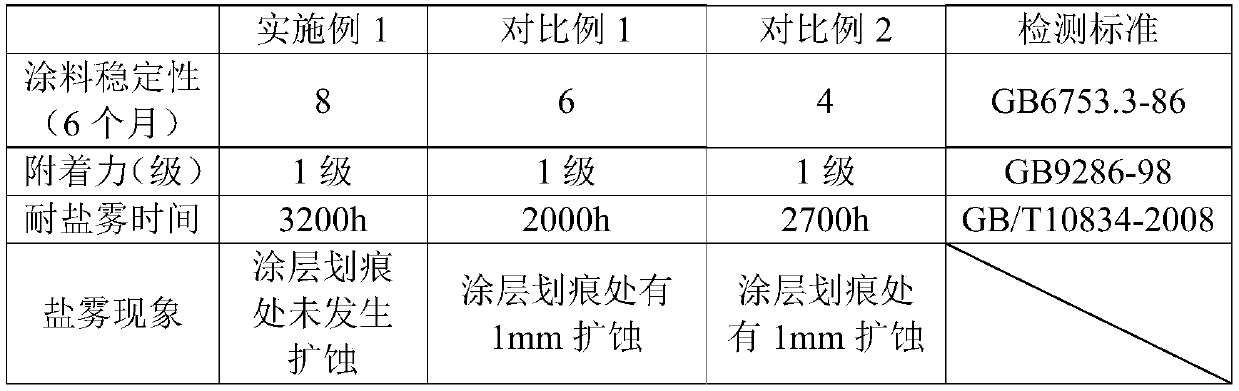

Thin-coating two-component anticorrosive coating for surface of precise steel structural part and preparation method thereof

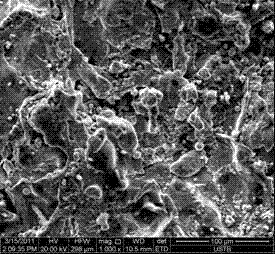

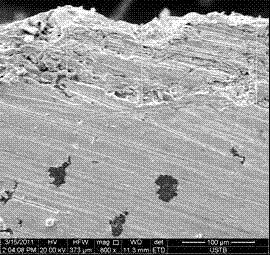

InactiveCN108300146AImprove the effect of cathodic protectionImprove anti-corrosion efficiencyAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The invention provides a thin-coating two-component anticorrosive coating for the surface of a precise steel structural part, wherein the two-component anticorrosive coating is composed of a componentA and a component B. The component A is composed of an epoxy resin liquid, graphene slurry, a zinc powder, flaky pigments and fillers, an auxiliary agent and a diluent. The component B is composed ofa polyamide curing agent and a mixture of xylene, n-butanol and cyclohexanone. The component A and the component B are evenly mixed according to the weight ratio of (5-15):1. The graphene slurry is prepared by adding powdery graphene and a dispersant into a mixed solvent under a stirring state, and dispersing in an ultrasonic oscillator to obtain the stable dispersed slurry. A coating layer has excellent cathodic protection effect, can be thin-coated to about 10-15 microns, still has good corrosion resistance, and can partly replace traditional phosphorization and oxidation processes.

Owner:MARINE CHEM RES INST +1

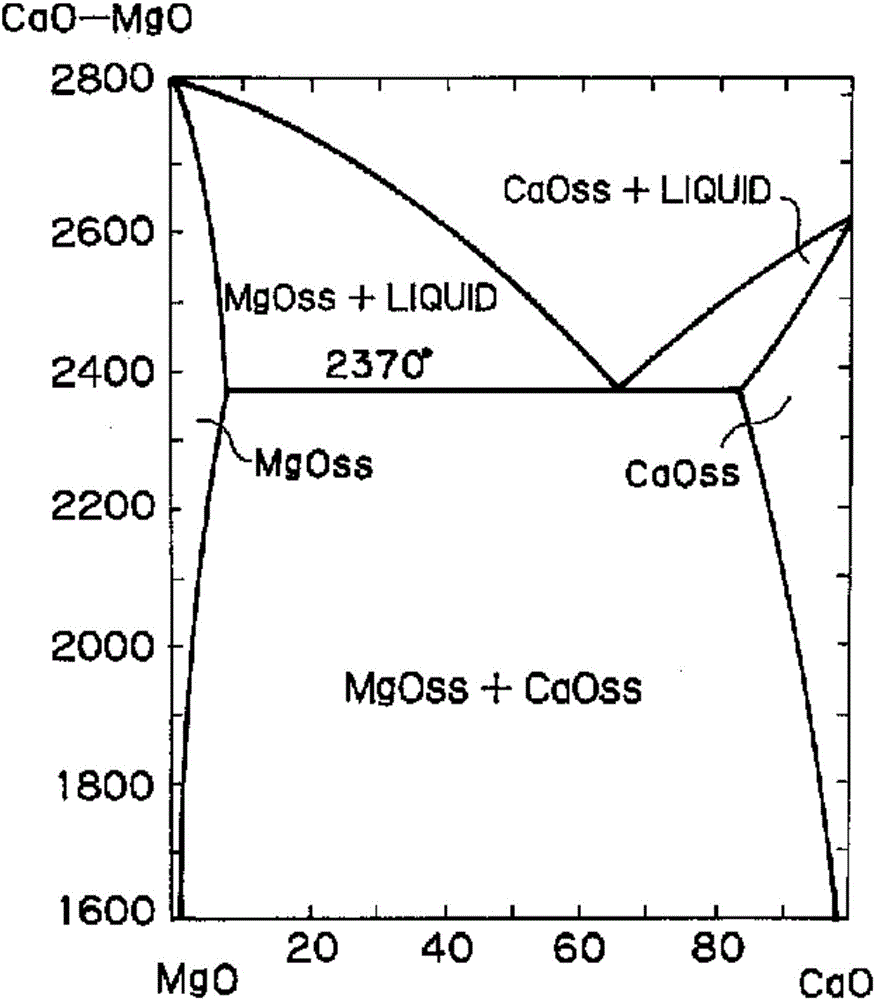

Magnalium special metal coating and preparation method thereof

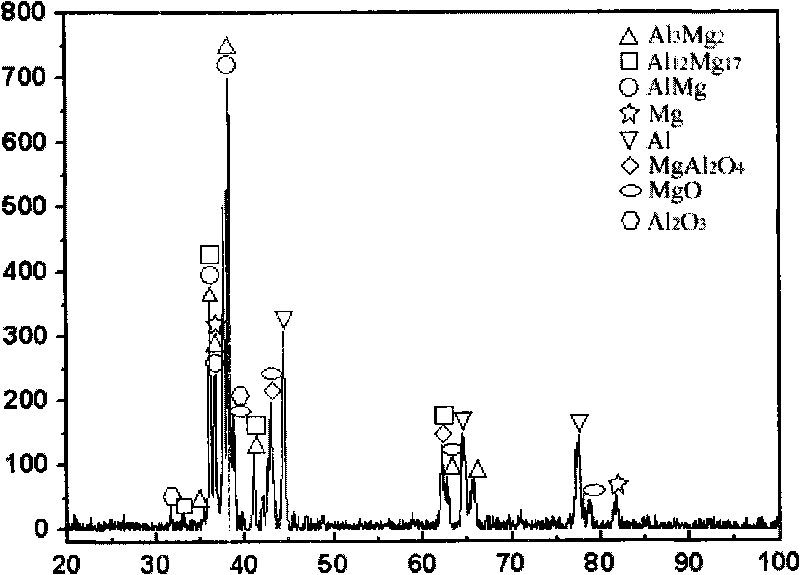

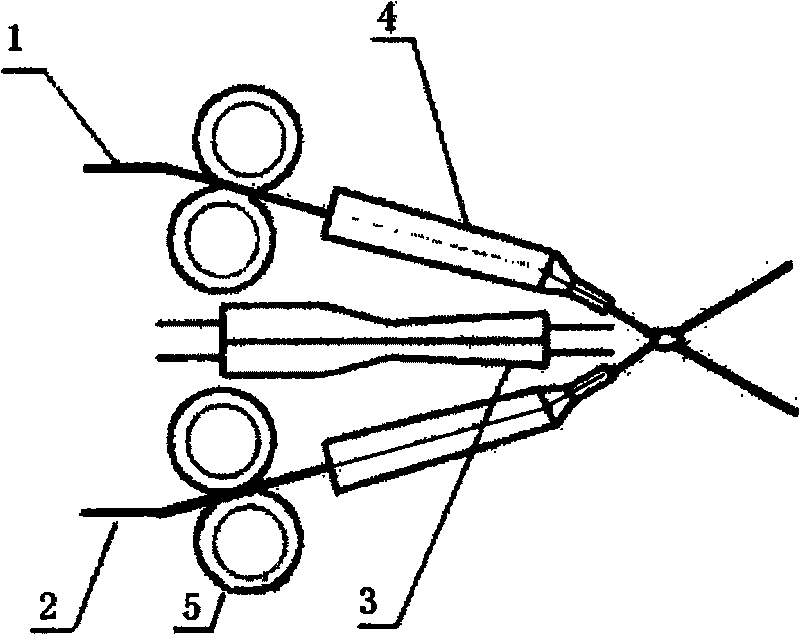

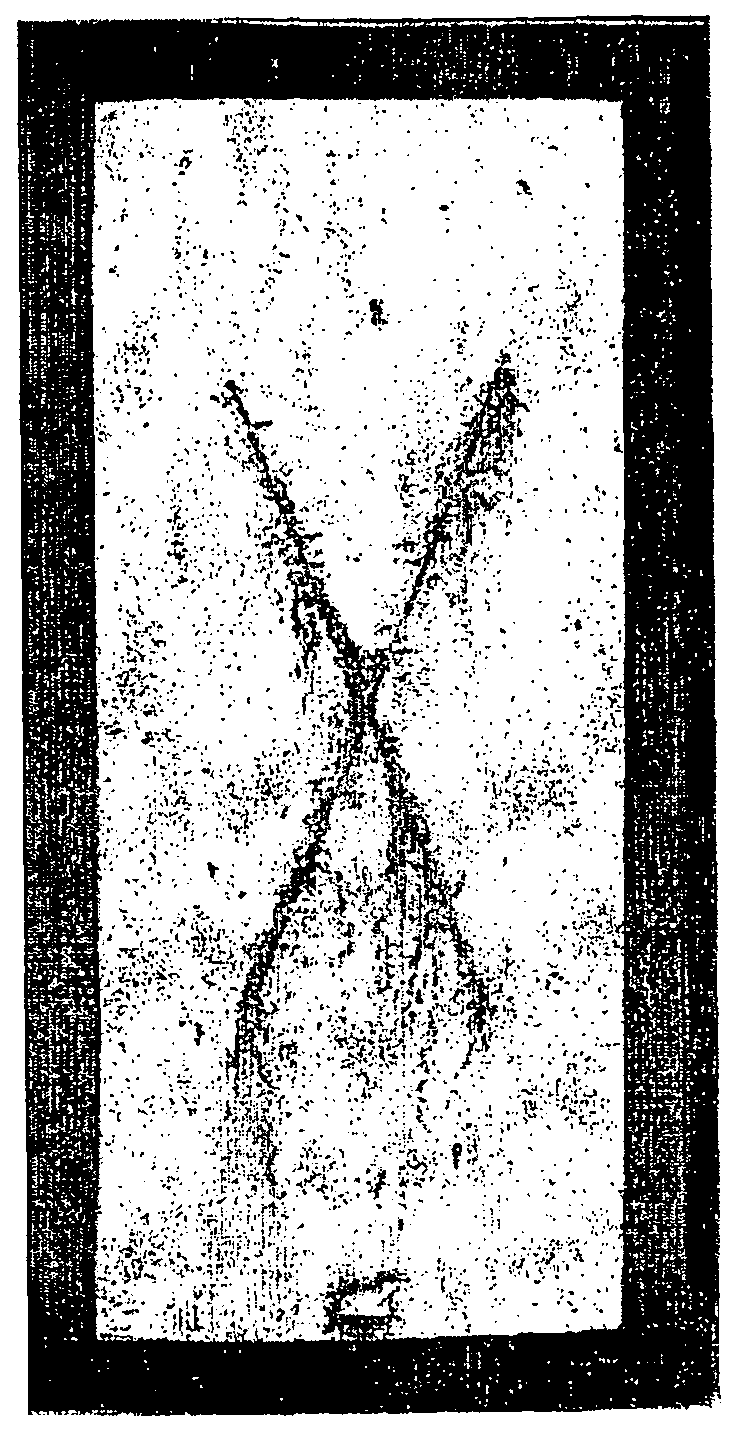

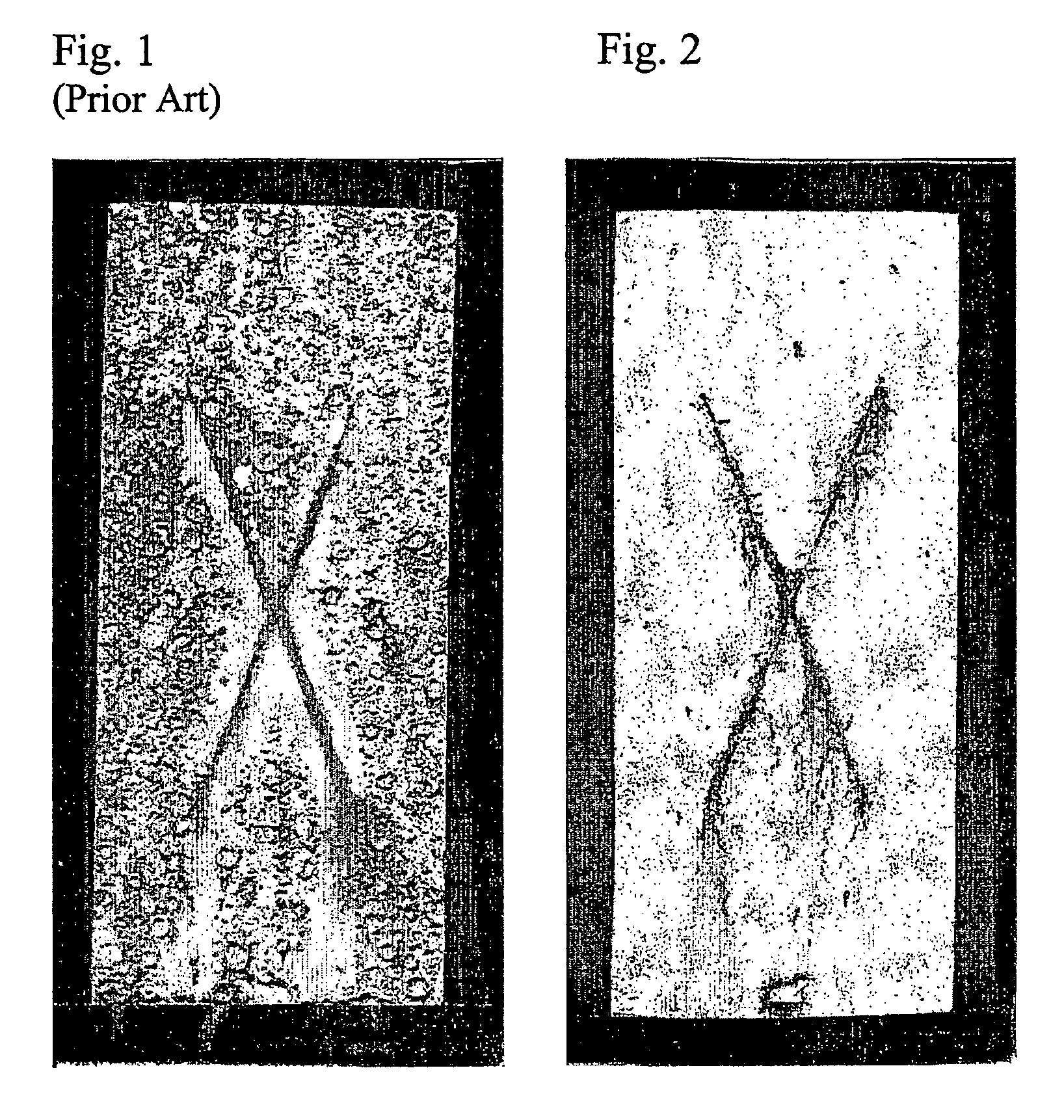

InactiveCN101709448AImprove corrosion resistanceHigh hardnessMolten spray coatingElectrode potentialMetal coating

The invention belongs to the technical field of hot spraying, and relates to a preparation method of a special metal coating. The preparation method comprises the following steps: adopting electric arc spraying, plasma spraying or ultrasonic flame spraying; and performing electric arc spraying on magnesium wire or aluminum wire serving as two electrodes in the diameter ratio of 1:1-1:3, or performing plasma spraying or ultrasonic flame spraying on a mixture of magnesium powder with the particle size between 0.2 and 100mu m and aluminum powder serving as raw materials in a ratio of 1:1-1:9 to obtain the coating, wherein the coating comprises the following components by weight: 5.5 to 40.0 percent of Mg, 55.0 to 93.0 percent of Al and less than or equal to 10 percent of other components. The special coating has the advantages of having good cathode protection effect on steel and metals with lower electrode potential such as aluminum, zinc and the like. After being subjected to heat treatment at the temperature of between 200 and 470 DEG C for 30 to 150 minutes, the coating is rich in Al12Mg17 phase and Al3Mg2 phase, thereby further improving the rigidity and corrosion resistance of the coating.

Owner:DALIAN UNIV OF TECH

Cathodic protection compounds

ActiveUS7794626B2Improve the effect of cathodic protectionLess expensiveMaterial nanotechnologyConductive materialCompound aMetallurgy

A cathodic protection compound is disclosed. The coating includes sacrificial metallic particles less noble than metal in the metal substrate to be protected. The coating also includes inherently conductive polymer in an amount of less than 1 weight percent of total solids of the coating. A concentrate of the metallic particles and inherently conductive polymer can also be prepared.

Owner:AVIENT CORP

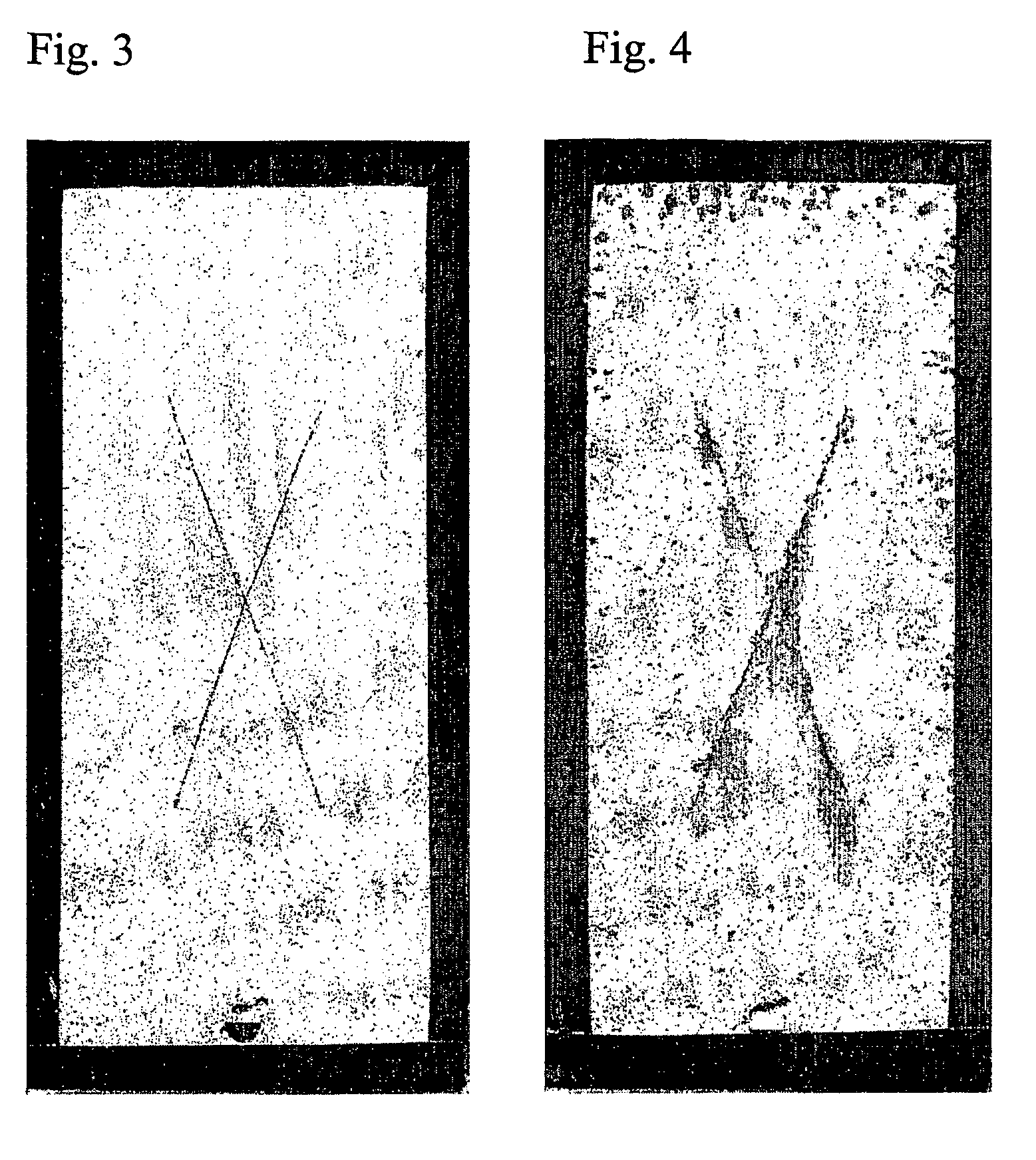

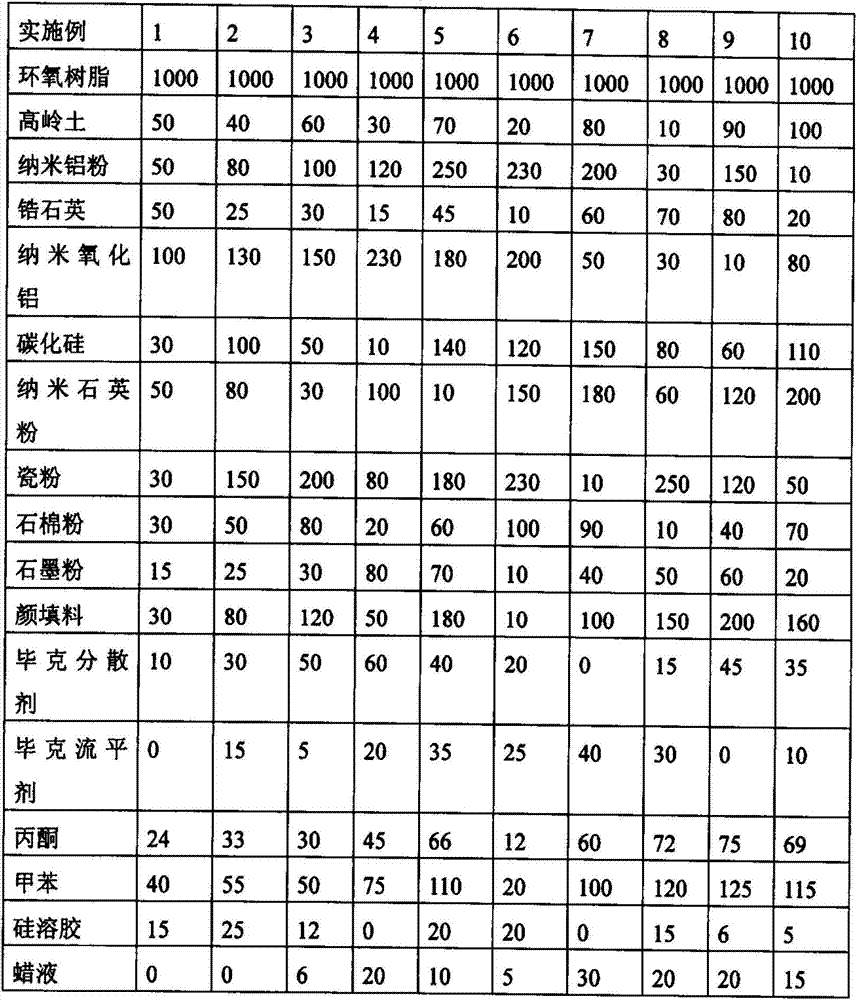

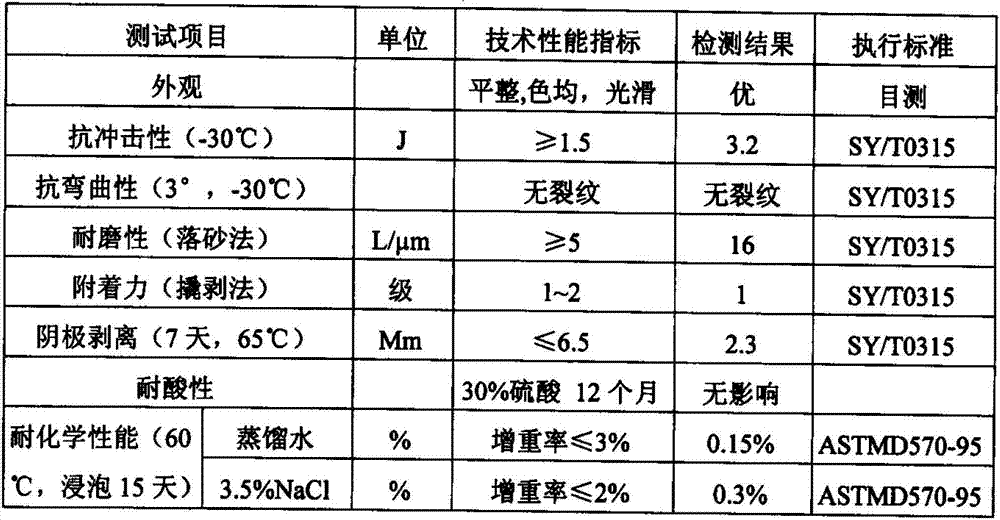

Manufacturing method of metal ceramic anticorrosive paint

ActiveCN103589273AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

A metal ceramic anticorrosive paint mainly includes kaolin, nanometer aluminium powder, nano alumina, silicon carbide, nano quartz powder, ceramic powder, asbestos powder, graphite powder, a pigment, a filler, epoxy resin, an additive and a mixed organic solvent. The solid powders are subjected to nano ultrafine treatment to reach a granularity of 20-200 nm. The paint provided by the invention is a single-component paint, which is simple in manufacturing process, economical and environment-friendly. The coating of the paint does not require a primer and can be used alone without adding special finish. The coating has excellent wear resistance, corrosion resistance, impact resistance, stability, strong adhesion, compactness and stability, and can effectively prevent erosion by acid, alkali, salt and seawater. In addition, the paint can be widely applied to oil pipeline, oil storage tank, chemical equipment, ships, bridges, offshore platforms and other steel structure buildings.

Owner:SHANGHAI JIANYE TECH ENG

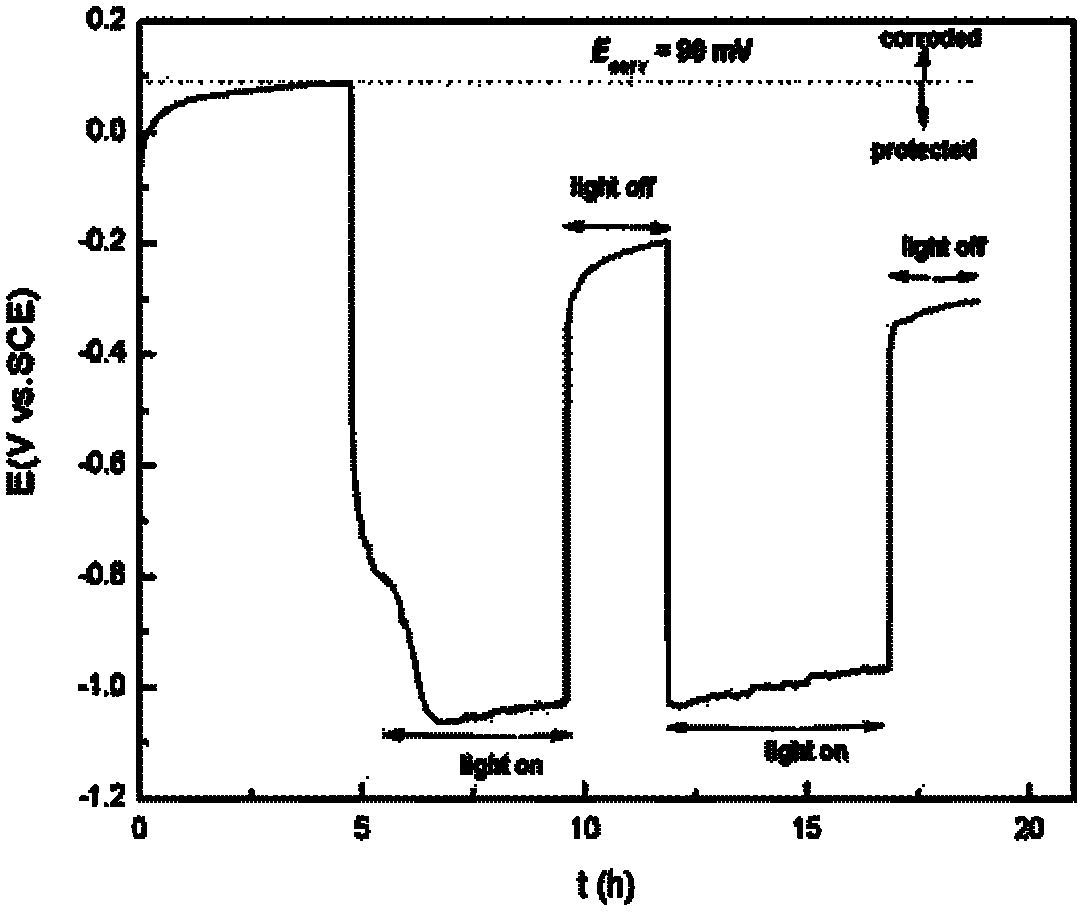

Method for preparing nanotube composite membrane photo-anode through hydrothermal method

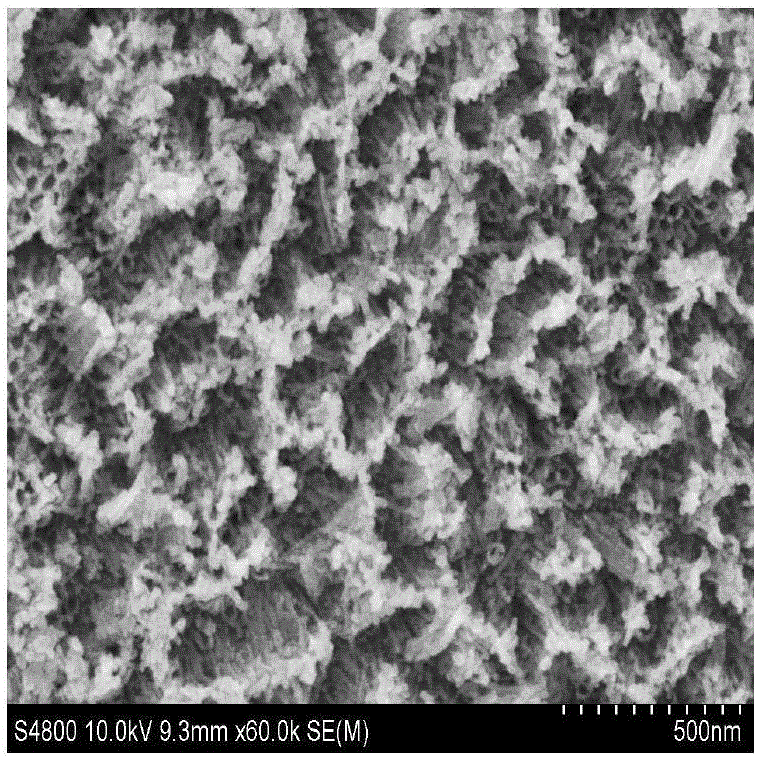

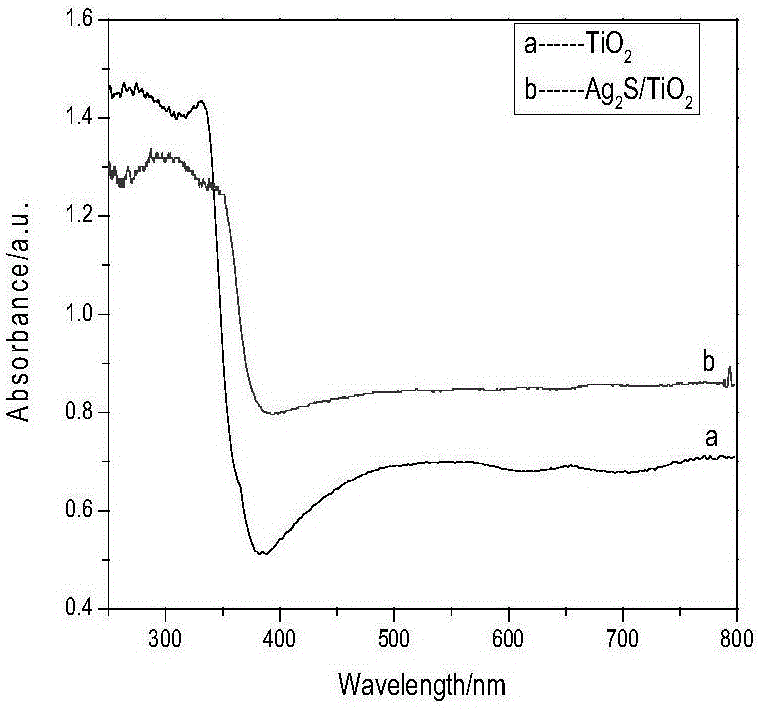

The invention relates to a composite membrane photo-anode used for photo-production cathode protection, in particular to a method for preparing an Ag2S / TiO2 composite membrane photo-anode through a hydrothermal method. The method comprises the steps that ammonium fluoride is dissolved in ultrapure water, ethylene glycol is added, an electrolytic solution is prepared after uniform mixing, a cleaned titanium substrate serves as an anode, a platinum sheet serves as a counter electrode, the cleaned titanium substrate is cooled to the room temperature after being subjected to two-step anodic oxidation in the electrolytic solution and calcination in a muffle furnace, and then, a TiO2 nanotube can be obtained on the surface of the titanium substrate; and the obtained TiO2 nanotube is subjected to hydrothermal treatment under the action of a sulfur source and a silver source, so that Ag2S is loaded on the TiO2 nanotube, and the Ag2S / TiO2 composite membrane photo-anode is obtained. The composite membrane photo-anode prepared through the method has an excellent photo-production cathode protection effect and can enable the electric potential of 304 stainless steel connected with the composite membrane photo-anode to be reduced to 700 mv or lower through visible light irradiation in a 0.1 mol / L Na2S solution.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

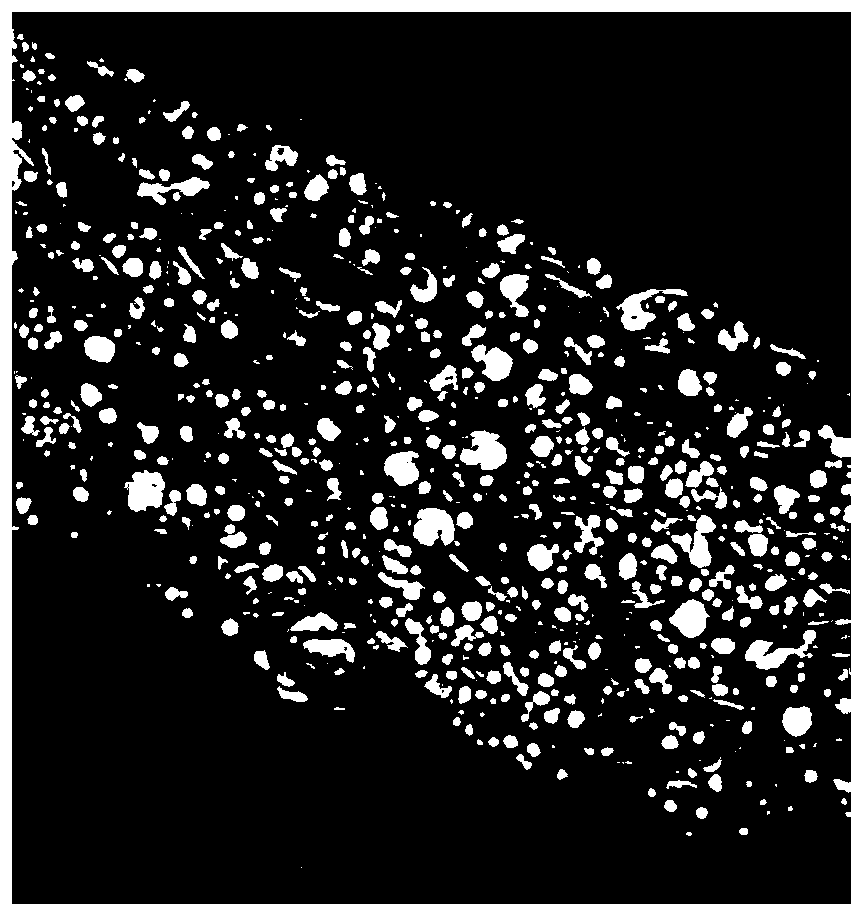

Multicomponent alloy composite anticorrosive coating for metal pipe/pipe fitting

InactiveCN102418831AReduce porosityImprove anti-corrosion performanceCorrosion preventionPipe protection against corrosion/incrustationPorosityPipe fitting

The invention discloses a multicomponent alloy composite anticorrosive coating for a metal pipe / pipe fitting, which comprises a Zn-Al-Mg-RE multicomponent alloy layer and a hole-sealing finishing layer, wherein the hole-sealing finishing layer is coated on the surface of the Zn-Al-Mg-RE multicomponent alloy layer, the Zn-Al-Mg-RE multicomponent alloy layer comprises the following components by weight percentage: 56-83% of Zn, 16-41% of Al, 0.05-2.0% of Mg and 0.05-1.0% of Re, and the hole sealing finishing layer is an organic or inorganic coating layer. The multicomponent alloy composite anticorrosive coating disclosed by the invention has the advantages of low porosity, good anticorrosive property and the like.

Owner:XINXING DUCTILE IRON PIPES CO LTD

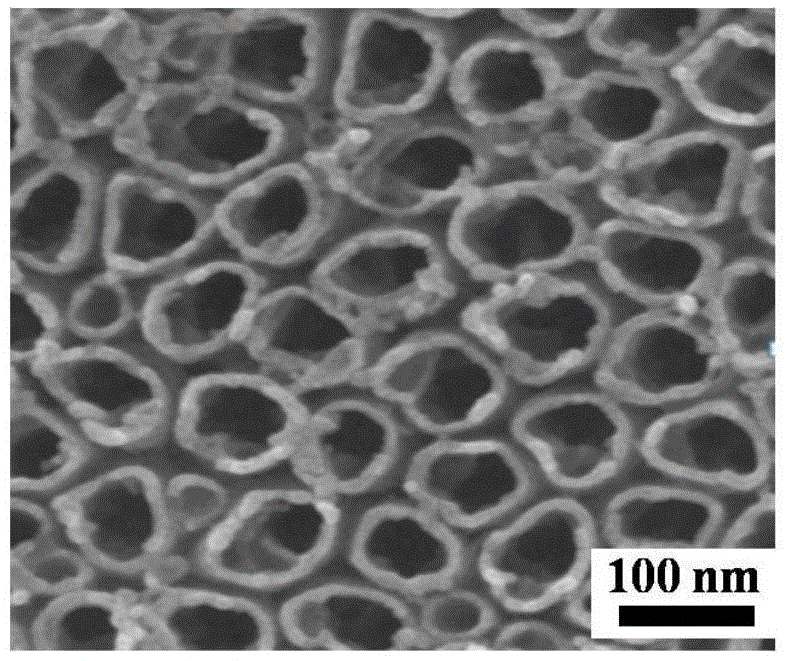

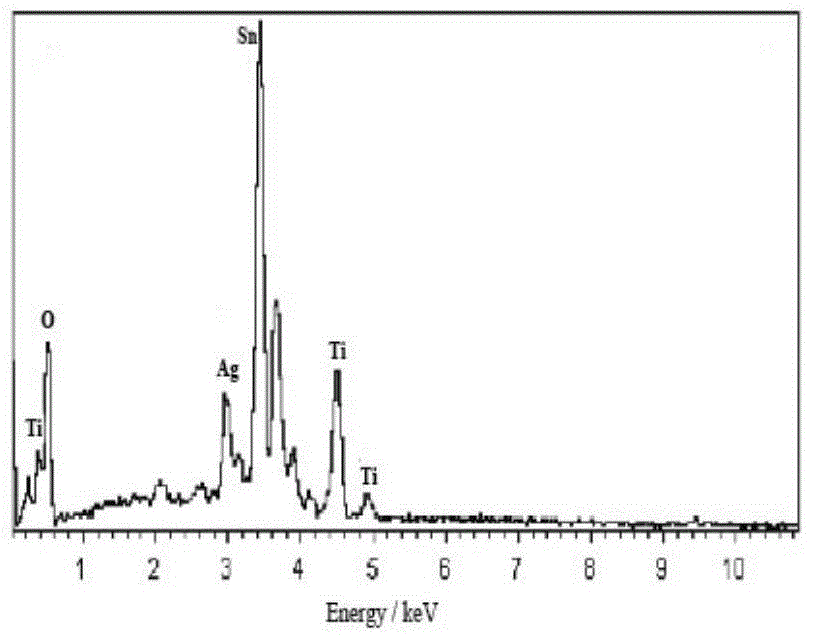

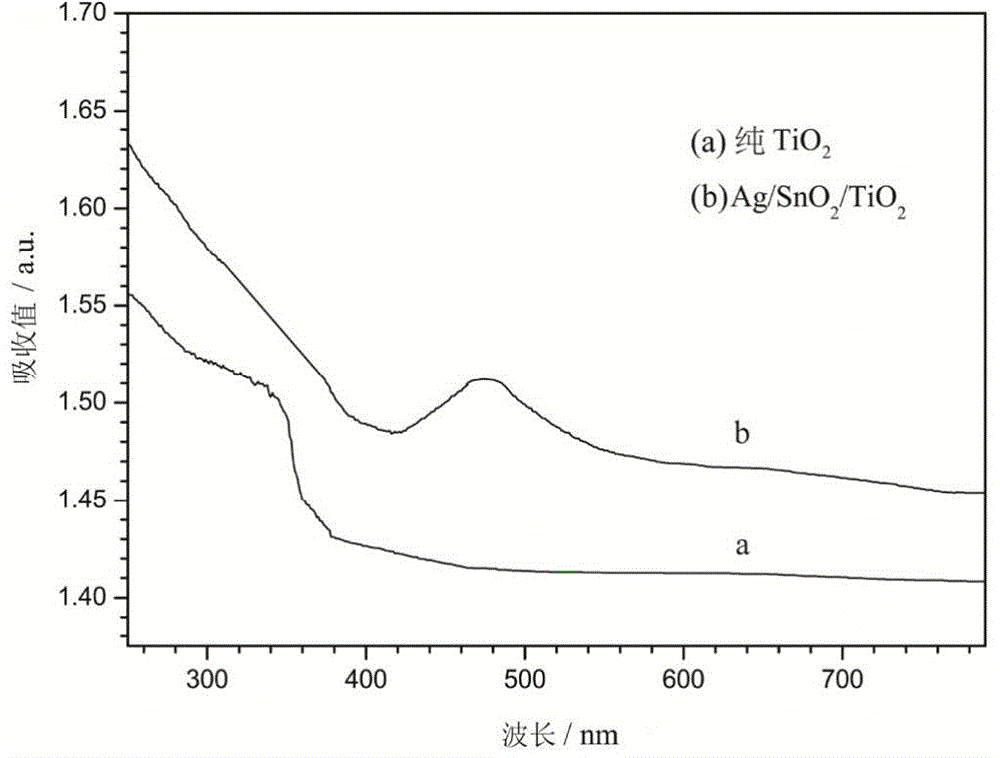

Preparation method for Ag/SnO2/TiO2 composite membrane photoanode used for photogenerated cathodic protection

ActiveCN103952708AUniform and complete coatingLower electrode potentialSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingTio2 nanotubeAcetone

The invention relates to preparation methods for an Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection, and relates to a composite membrane photoanode, and provides a preparation method for the efficient stable Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection. The preparation method comprises: 1) preparing a titanium substrate sample, specifically taking titanium foil as a substrate, and performing ultrasonic cleaning successively in acetone, absolute ethanol and deionized water to obtain a titanium substrate sample; 2) preparing a titanium-surface TiO2 nanotube array membrane, specifically dissolving NH4 in deionized water, adding glycol, mixing uniformly, taking platinum as a counter electrode, performing anodization, calcining the titanium substrate sample, and cooling to room temperature along the furnace, so as to obtain the TiO2 nanotube array membrane on the surface of titanium; and 3) preparing the Ag / SnO2 / TiO2 composite membrane, specifically preparing Ag and SnO2 nanometer particles on the surface of the TiO2 nanotube array membrane, so as to obtain the Ag / SnO2 / TiO2 photoanode used for photogenerated cathodic protection.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Heavy-duty graphene primer for ocean ships and preparation method thereof

InactiveCN108997889AStrong adhesionWide applicabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The present invention provides a heavy-duty graphene primer for ocean ships and a preparation method thereof. The primer is prepared by mixing a plurality of antirust pigments, fillers and solvents, such as modified epoxide resin, additives, nanoscale graphene, zinc powder and diphenyl guanidine chromate, with a modified amine and a polyamide, and has long-term corrosion resistance and also advantages unmatched by other graphene primers, including wide scope of application, convenience in construction, excellent electrical conductivity, and good self-repair performance and hydrophobic and oleophobic properties of the coating. In addition, the primer is air-dried at normal temperature, thereby saving energy and facilitating industrialization thereof.

Owner:HUNAN JINHAI SCI & TECH

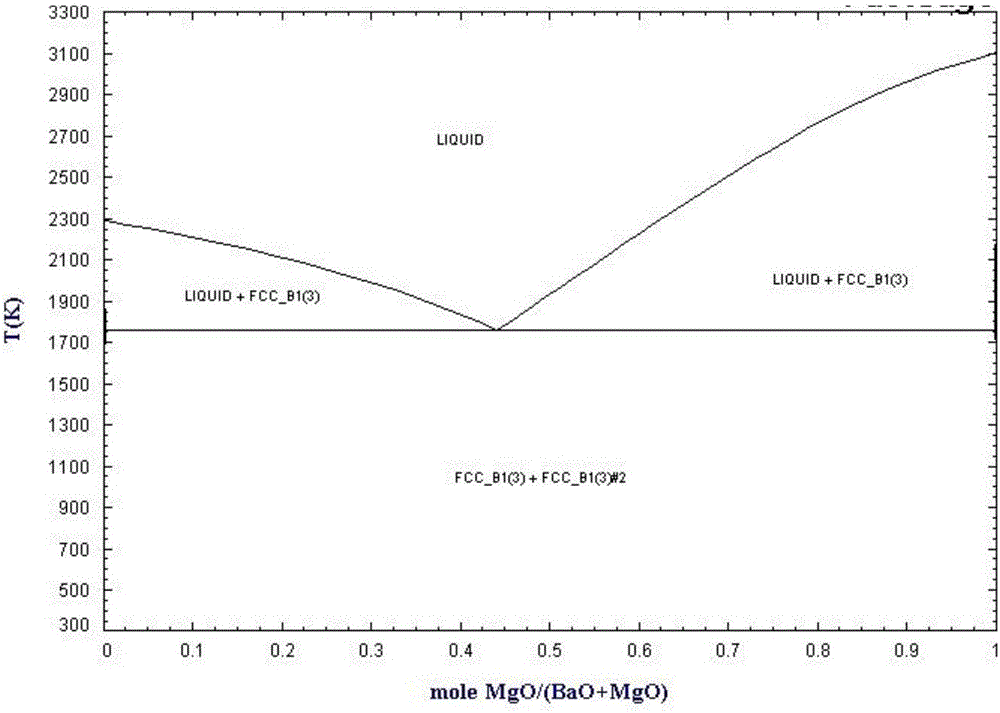

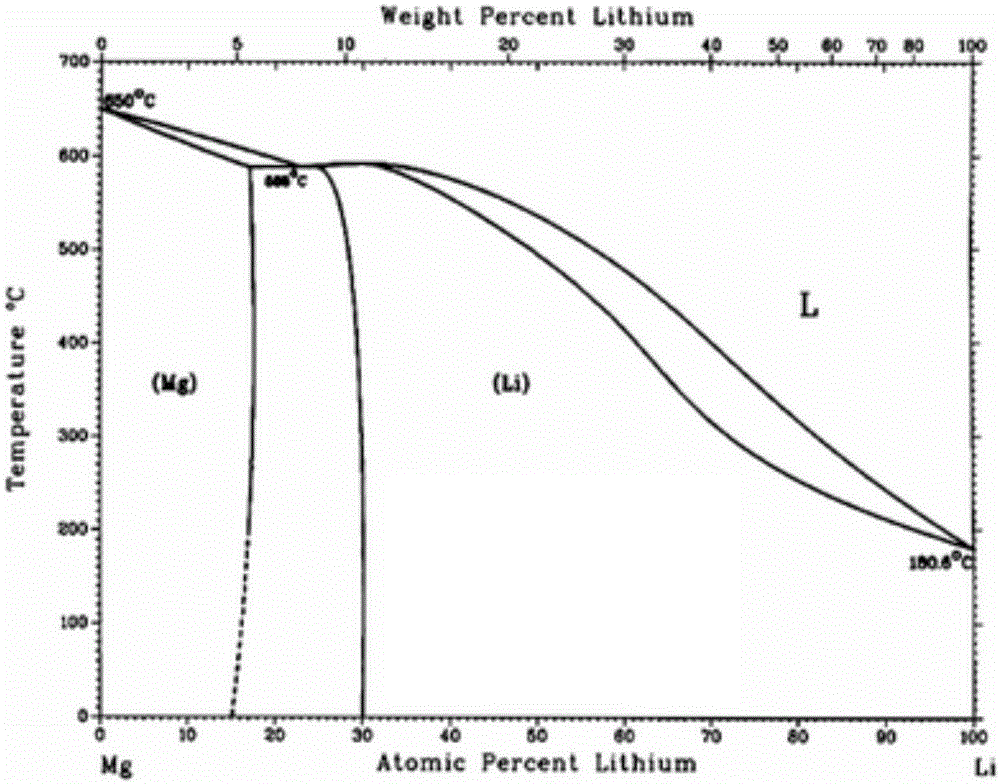

Hot dipping steel and manufacturing method thereof

ActiveCN105671469AImprove cathodic protection capabilityOptimizing the Hot Dip Plating ProcessHot-dipping/immersion processesAlloy elementAluminium

The invention provides hot dipping steel and a manufacturing method thereof. The hot dipping steel comprises a steel substrate and a zinc-aluminum-magnesium coating formed on the steel substrate. The zinc-aluminum-magnesium coating comprises, by the total weight of the coating, 1%-4% of Mg, 1%-4% of Al, 0.01%-0.1% of Ca and / or Ba, 0.1%-0.4% of Li, 0.1%-10% by volume of Zn-Mg phase and / or Zn-Mg-Al phase. According the hot dipping steel and the manufacturing method thereof, in order to avoid coating flow lines and blackening defects, a small number of other alloy elements are added to a plating bath, so that cathode protection ability is improved, and the hot dipping process is optimized. Therefore, the hot dipping steel which has good cathode protection performance for an aluminum plate and a good coating appearance is obtained, and the corrosion resistance is improved to a certain extent.

Owner:SHOUGANG CORPORATION

Preparation method of SrTiO3 nano composite film photoanode

InactiveCN103474517AUniform and complete coatingImprove the effect of cathodic protectionFinal product manufactureNanotechnologyPlatinumTio2 nanotube

The invention relates to a photoanode, particularly a preparation method of a SrTiO3 nano composite film photoanode. The invention provides a preparation method of a SrTiO3 nano composite film photoanode with efficient photogenerated cathode protection effect. The preparation method comprises the following steps: 1) preparation of titanium base: applying ultrasonic on a titanium foil used as a base to obtain a titanium base; 2) preparation of TiO2 nanotube array film: carrying out anodization reaction by using the titanium base as an anode and a platinum sheet as a cathode, cleaning, drying and calcining to obtain a TiO2 nanotube array film on the titanium base; and 3) preparation of SrTiO3 nano composite film photoanode: putting the titanium base coated with the TiO2 nanotube array film prepared in the step 2) into a teflon reaction kettle, adding a Sr(OH)2 solution, reacting, immersing in a HCl solution, cleaning, drying, and calcining to obtain the SrTiO3 nano composite film photoanode. The SrTiO3 nano composite film photoanode is a SrTiO3 / TiO2 composite material in a P-N heterostructure.

Owner:XIAMEN UNIV

Water-based heavy-duty anti-corrosive coating and preparation method thereof

InactiveCN108441077AImprove the effect of cathodic protectionReduce usageAnti-corrosive paintsEpoxy resin coatingsWater basedSlurry

The invention relates to the coating field, in particular to a water-based heavy-duty anti-corrosive coating and a preparation method thereof. The water-based heavy-duty anti-corrosive coating comprises a component A and a component B in the weight ratio being (2-6):1. The component A comprises, in parts by weight, 12-40 parts of zinc powder, 0.2-5 parts of graphene slurry, 20-65 parts of an antirust pigment and 8-25 parts of a hydrophilic epoxy curing agent. A layered netted conductive structure can be formed in the coating by adding uniformly dispersed graphene, the zinc powder can be fullyand effectively utilized, the cathodic protection function of the zinc powder can be improved, the protection of the coating for a base material is strengthened, the shielding performance of a coatingfilm is improved, and the usage amount of the zinc powder is substantially reduced.

Owner:常州市润金木环保科技有限公司

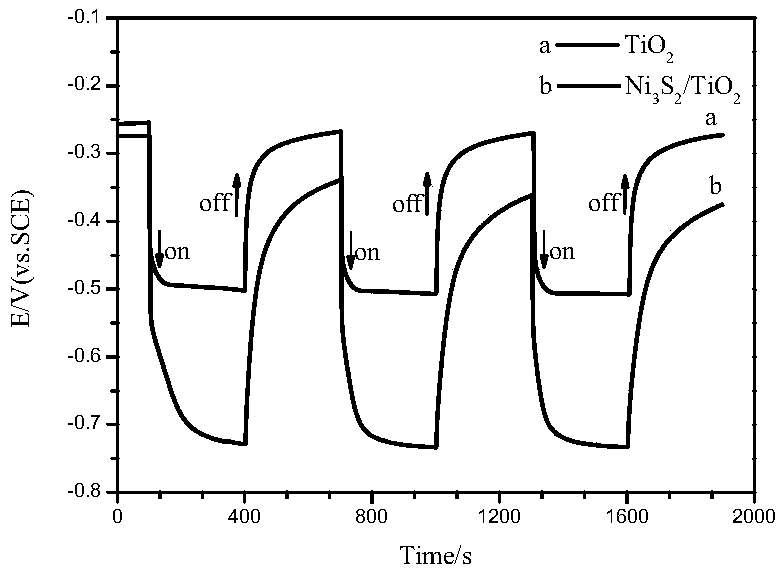

Hydrothermal preparation method of Ni3/S2 nanotube composite membrane photo-anode

The invention relates to a composite membrane photo-anode for photo-induced cathodic protection, and especially relates to a hydrothermal preparation method of a Ni3S2 / TiO2 nanotube composite membranephoto-anode. The method comprises following steps: (1) preparing a TiO2 nanotube array membrane precursor: adopting an anodic oxidation method, taking a titanium foil as the work electrode and a platinum foil as the counter electrode, carrying out oxidation in work electrolyte under a constant voltage, and burning to form a TiO2 nanotube array membrane precursor on the platinum foil substrate, wherein the nanotube diameters are uniform, the nanotube wall thicknesses are even, and the morphology of the precursor is regular; and (2) preparing a Ni3S2 / TiO2 composite membrane: under the action ofa sulfur source and a nickel source, subjecting the obtained TiO2 nanotube precursor to a hydrothermal treatment so as to load Ni3S2 onto the TiO2 nanotubes to obtain the Ni3S2 / TiO2 composite membrane photo-anode. The obtained composite membrane has a good photo-induced cathodic protection effect, moreover, the operation is simple and easy to perform, the method is safe and reliable, and the properties of the photo-anode are stable.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

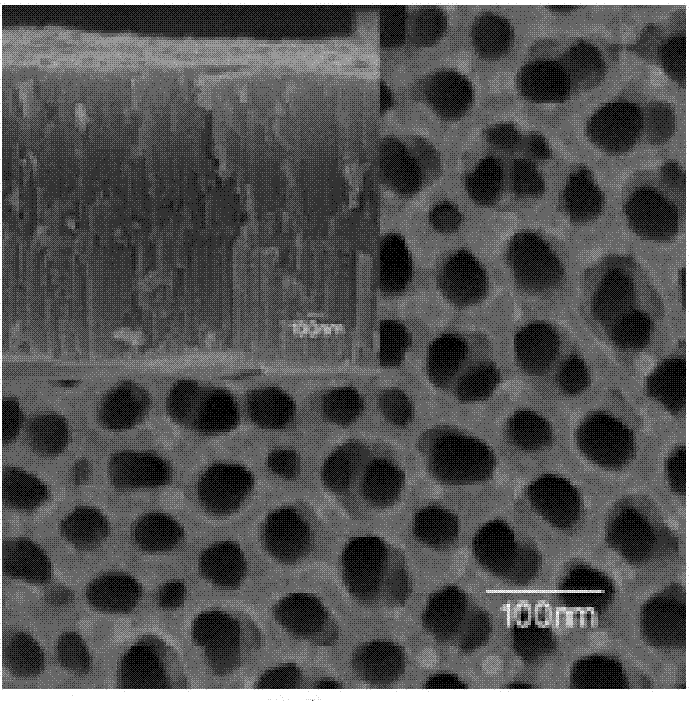

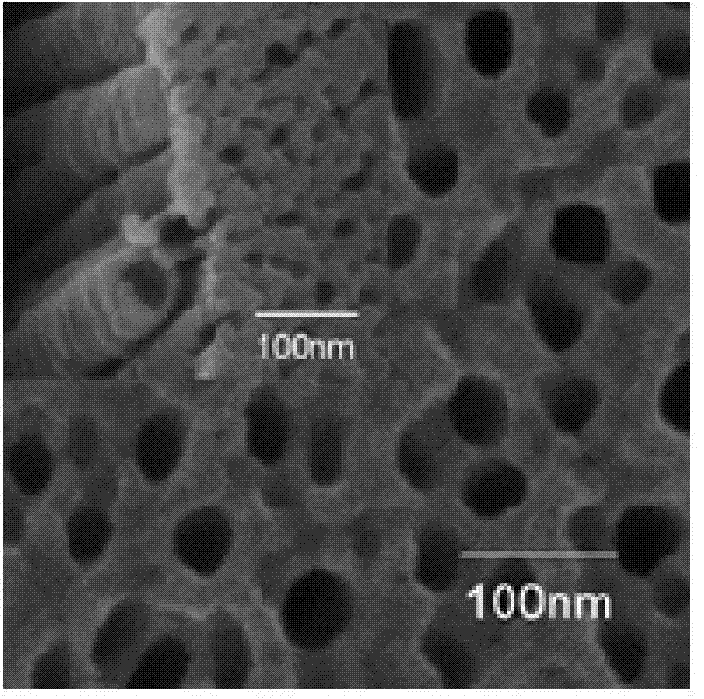

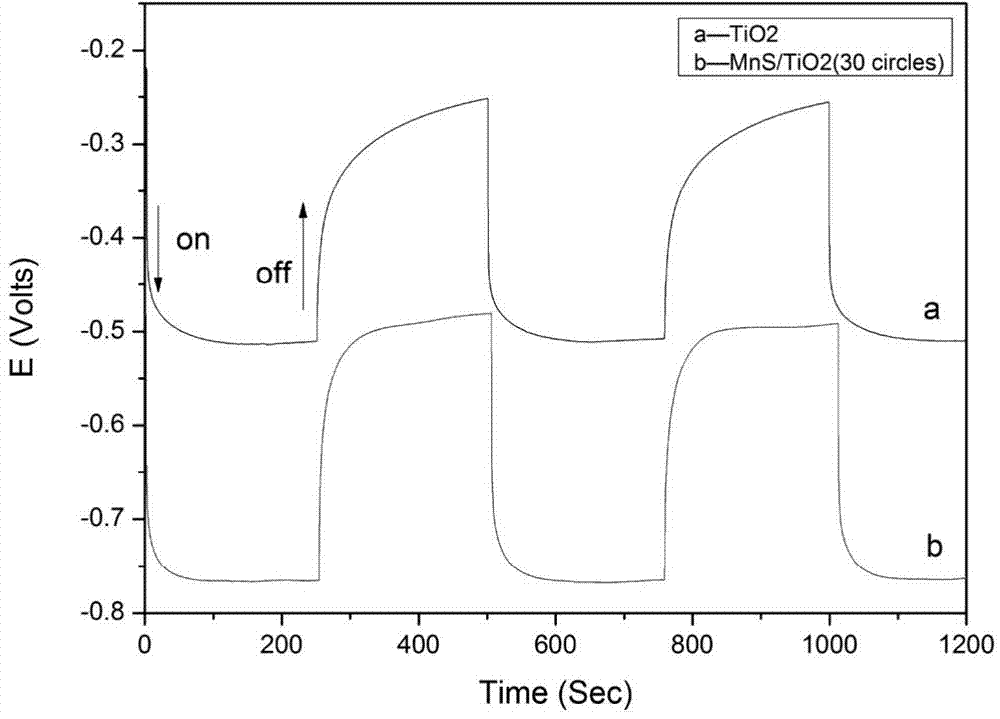

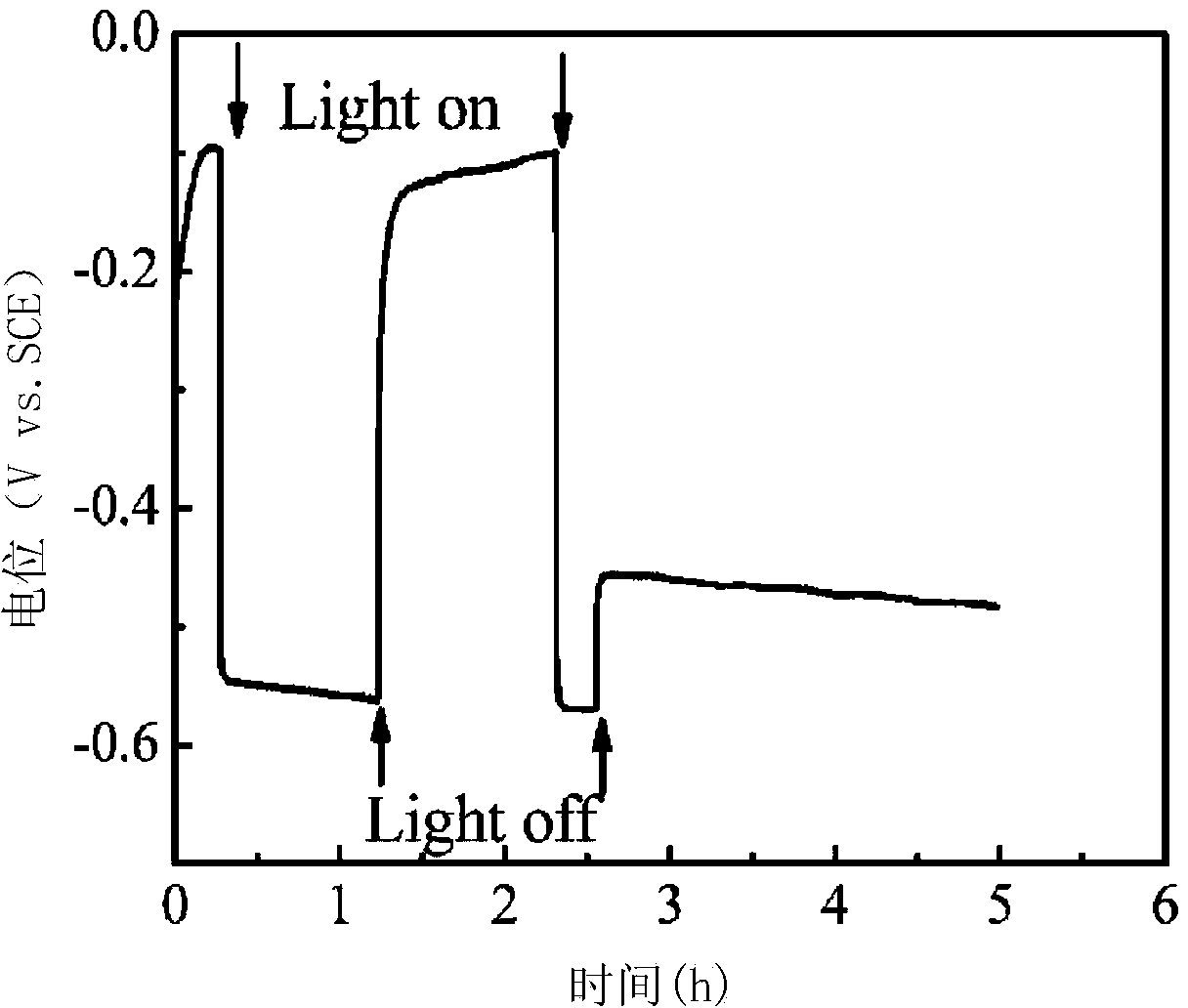

MnS/TiO2 composite nanotube array film for photo-induced cathodic protection and preparation and application thereof

The invention discloses a MnS / TiO2 composite nanotube array film for photo-induced cathodic protection and preparation and an application thereof, and relates to a composite nanotube photo-anode. The method includes the following steps: 1) substrate pretreatment: selecting a titanium foil as a substrate, carrying out ultrasonic cleaning successively in acetone, absolute ethyl alcohol and deionized water; 2) preparation of a TiO2 nanotube array thin film: adopting a two-step anodic oxidation method, with a platinum sheet as a counter electrode, in a working fluid, carrying out oxidization and calcination treatment on a titanium sheet, and generating a regular-morphology TiO2 nanotube array thin film on the substrate surface; and 3) preparation of the MnS / TiO2 composite film: adopting a continuous ionic layer adsorption reaction method, modifying TiO2 with MnS, and then carrying out calcination treatment to obtain the MnS / TiO2 nanotube array composite photo-anode. The method can significantly reduce the corrosion potential of 304 stainless steel, and has the characteristics of simple, feasible, safe and reliable operations, and high photoelectric conversion efficiency and stable performance of the product.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparation method of TiO2/SnO2 semiconductor two-layer composite film photo anode

ActiveCN104047043AUniform film layerLower electrode potentialElectrolytic coatingsVacuum evaporation coatingComposite filmPellicle membrane

The invention relates to a preparation method of a TiO2 / SnO2 semiconductor two-layer composite film photo anode and relates to a semiconductor photo anode. The invention provides the preparation method of the TiO2 / SnO2 semiconductor two-layer composite film photo anode with an efficient photo-induced cathodic protection effect. The preparation method comprises the following steps: 1) by using stainless steel as a matrix sample, grinding the surface of the matrix sample to a mirror surface, and then cleaning; 2) dissolving SnCl2.2H2O in water, then adding NaNO3 and nitric acid to prepare an electrolyte solution, and then adding water to fix the volume to 1000mL; by using platinum as a counter electrode and saturated mercurous chloride as a reference electrode and the matrix sample as a working electrode, in the electrolyte solution, electro-depositing and drying, namely electro-depositing a SnO2 film layer on the surface of the matrix sample; and 3) sputtering a TiO2 film on the surface of the SnO2 film layer obtained in the step 2), and then thermally treating to obtain the TiO2 / SnO2 semiconductor two-layer composite film photo anode. The photo-induced cathodic protection effect on metals by a TiO2 nano thin film in dark state is improved.

Owner:XIAMEN UNIV

Preparation method of energy storage tungsten trioxide/strontium titanate/titanium dioxide nanometer composite film photoanode

ActiveCN106894024AImprove photoelectric conversion efficiencyInhibitory complexElectrolytic inorganic material coatingSurface reaction electrolytic coatingComposite filmTio2 nanotube

The invention discloses a preparation method of an energy storage tungsten trioxide / strontium titanate / titanium dioxide nanometer composite film photoanode, and relates to a photoanode. A titanium foil is used as a basal body for ultrasonic operation in acetone, anhydrous ethanol and de-ionized water; a titanium basal body sample is used as an anode; a platinum piece is used as a cathode; after the anode is oxidized, a prepared sample is cleaned and dried to obtain a TiO2 nanotube array film; the TiO2 nanotube array film is put in a polytetrafluoroethylene reaction kettle; mixed solution containing Sr(COOH)2 and KOH is added for hydrothermal reaction; the sample is taken out to dip in HCl solution for cleaning, drying and calcining; and a SrTiO3 / TiO2 composite film is obtained. The SrTiO3 / TiO2 composite film is used as a working electrode; the platinum piece and a saturated calomel electrode are used as an auxiliary electrode and a reference electrode; constant potential is applied to an electrolytic cell for electric deposition to prepare WO3 on the surface of the SrTiO3 / TiO2 composite film; and the sample is flushed by de-ionized water, and is calcined after drying to obtain the photoanode.

Owner:XIAMEN UNIV

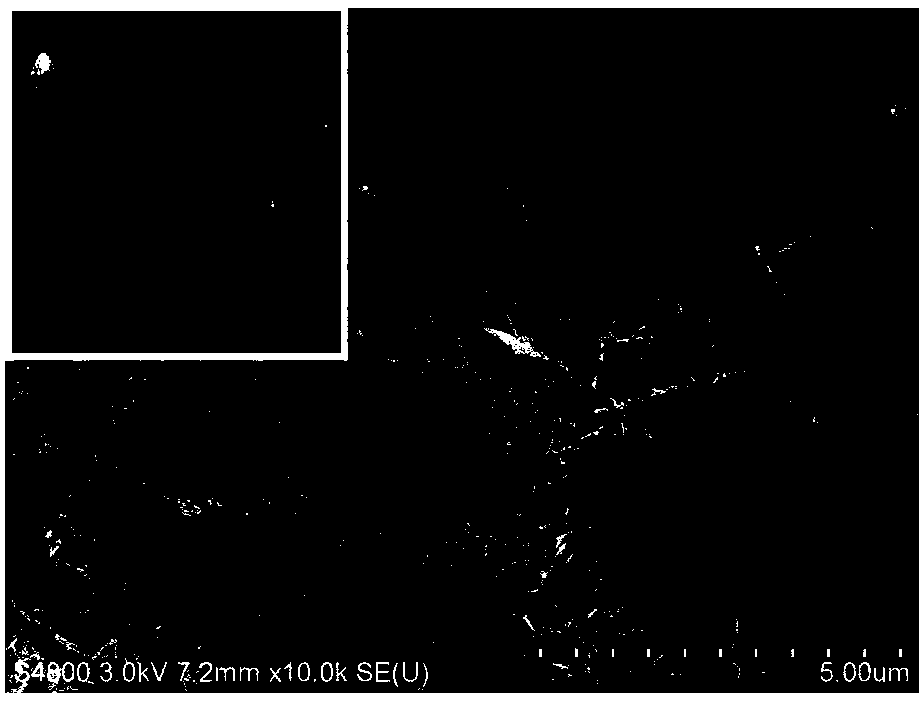

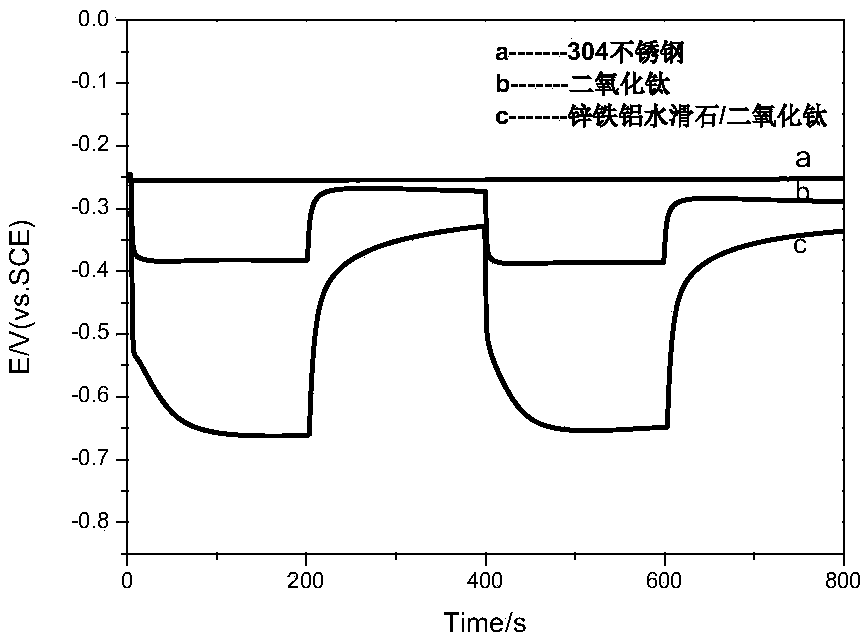

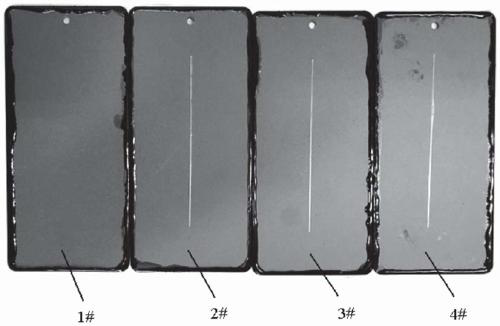

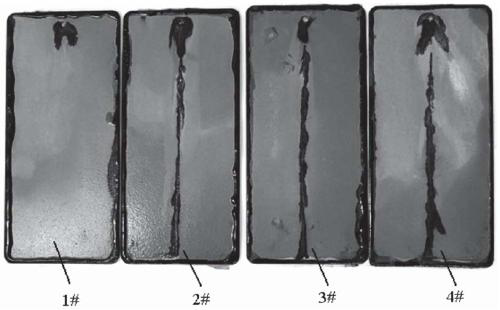

Preparation method of zinc-iron-aluminum hydrotalcite/titanium dioxide composite film photo-anode for photoproduction cathode protection

ActiveCN107699901ABroaden the range of light absorptionEnhanced photogenerated cathodic protection propertiesSurface reaction electrolytic coatingElectron holeComposite film

The invention discloses a preparation method of a zinc-iron-aluminum hydrotalcite / titanium dioxide composite film photo-anode for photoproduction cathode protection and relates to composite film photo-anodes. The zinc-iron-aluminum hydrotalcite / titanium dioxide composite film photo-anode is prepared by loading a titanium dioxide nanotube with zinc-iron-aluminum hydrotalcite of a unique interlayerstructure. The visible light adsorbing performance of titanium dioxide is enhanced by loading the zinc-iron-aluminum hydrotalcite, and the separation efficiency of photoproduction electrons and electron holes can be improved due to the unique interlayer structure. Compared with pure titanium dioxide nanotubes, the composite film photo-anode prepared through the method has higher photocurrent density and potential fall and can effectively relieve corrosion to stainless steel.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Waterborne epoxy graphene zinc anticorrosive coating and preparation method and application thereof

InactiveCN109762446AIncrease the conductive pathIncrease profitAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses a waterborne epoxy graphene zinc anticorrosive coating. The waterborne epoxy graphene zinc anticorrosive coating comprises a first component and a second component, wherein thefirst component is prepared from the following components in parts by weight: 5-10 parts of a waterborne epoxy resin curing agent, 0.5-1 part of a dispersant, 1-3 parts of an anti-settling agent, 1-3parts of a coalescing agent, 10-15 parts of body pigment, 42-65 parts of zinc powder and 4.5-5 parts of graphene dispersion slurry. The second component is prepared from the following components in parts by weight: 30-40 parts of aqueous epoxy emulsion, 1-2 parts of an anti-flash rust agent, 5-15 parts of water and 0.2-0.8 part of a defoaming agent. The waterborne epoxy graphene zinc anticorrosive coating has high utilization rate of zinc powder and is easy to prepare, and the formed coating has excellent comprehensive properties, such as good compactness, excellent cathodic protection performance and shielding performance, anticorrosive performance is remarkably improved, and the waterborne epoxy graphene zinc anticorrosive coating has wide application prospects in the field of marine equipment anticorrosion.

Owner:宁波中科银亿新材料有限公司 +1

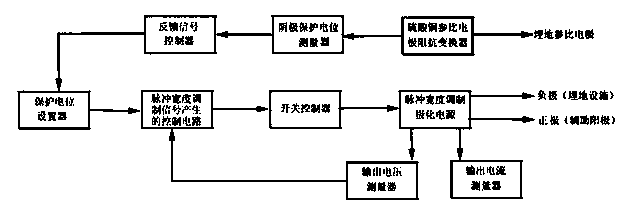

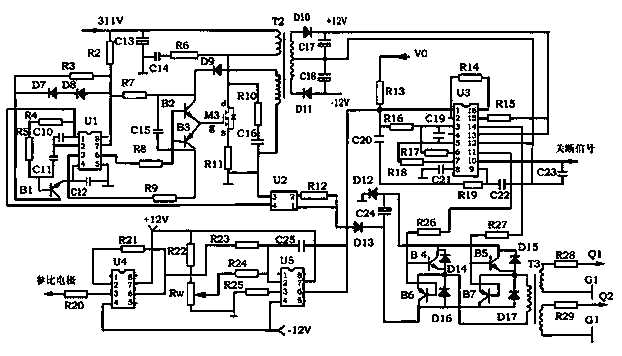

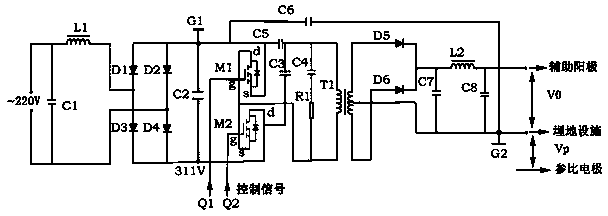

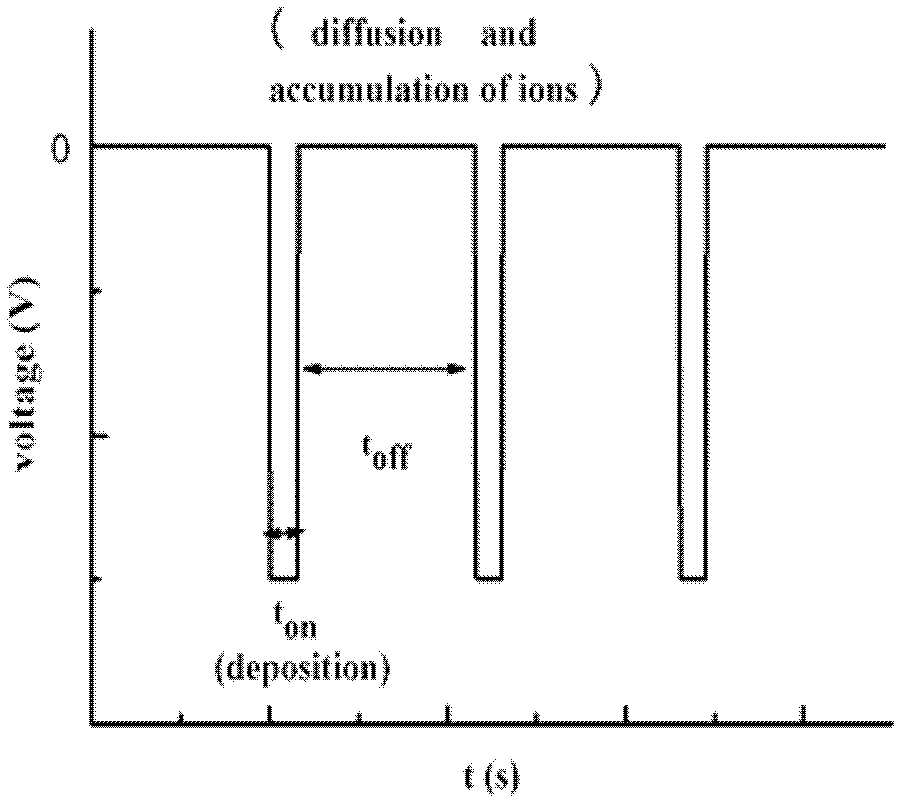

Pulse width modulation based cathode protection method and protector thereof

InactiveCN103849880AIncrease the output voltageIncrease the pulse widthImpedance ConverterSulphate Ion

The invention relates to a pulse width modulation based cathode protection method. The pulse width modulation based cathode protection method comprises the following steps: firstly, connecting a buried pipeline facility by adopting a pulse width modulation polarization power supply; secondly, setting a cathode protective potential to a predetermined value; thirdly, generating a pulse width modulation signal according to cathode protective potential value; fourthly, driving the pulse width modulation polarization power supply by the pulse width modulation signal; fifthly, measuring output voltage of the pulse width modulation polarization power supply, measuring output current of the pulse width modulation polarization power supply; sixthly, measuring cathode protective potential, relative to a reference electrode, of the buried pipeline facility; a pulse width modulation based cathode protection device is characterized in that the pulse width modulation polarization power supply is connected with an output current measuring device and an output voltage measuring device, the pulse width modulation polarization power supply is connected with a buried facility, an auxiliary anode and an on-off controller, a control circuit is connected with a feedback signal controller by virtue of a protective potential setting device, and a cathode protective potential measuring device is connected with a buried reference electrode by virtue of a copper sulphate reference electrode impedance converter, so that size is small and control accuracy is high.

Owner:XI'AN PETROLEUM UNIVERSITY

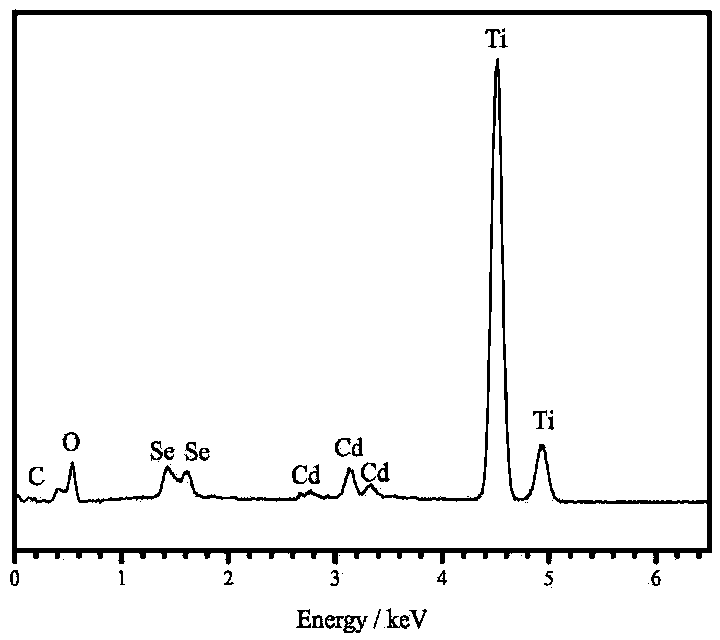

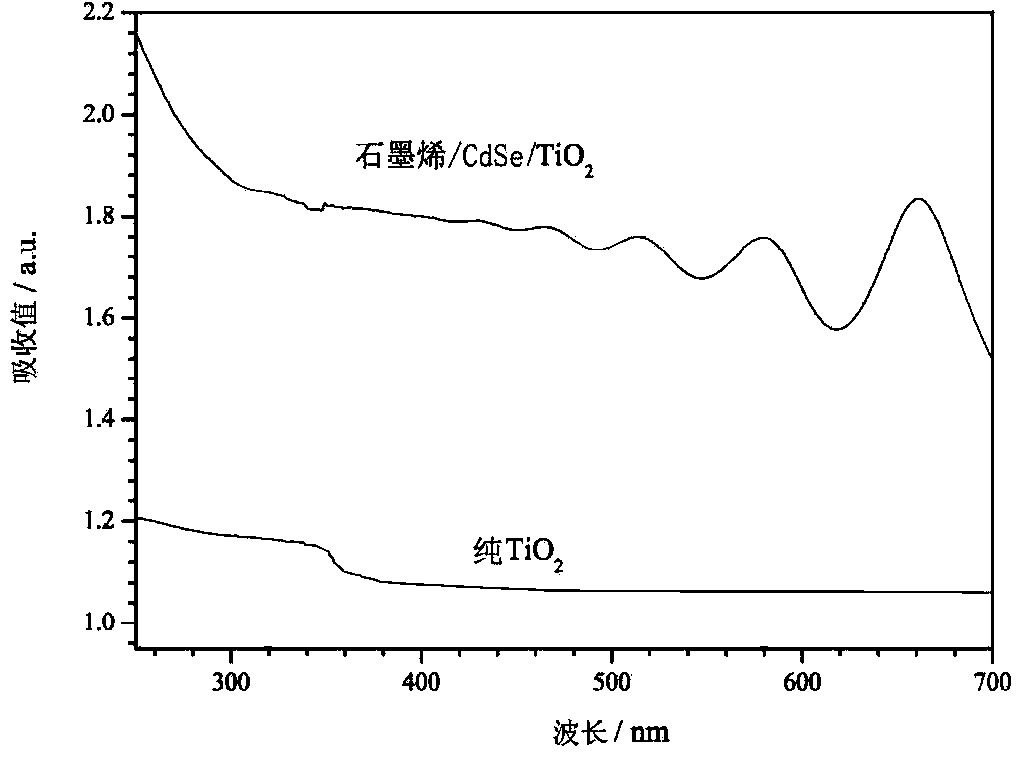

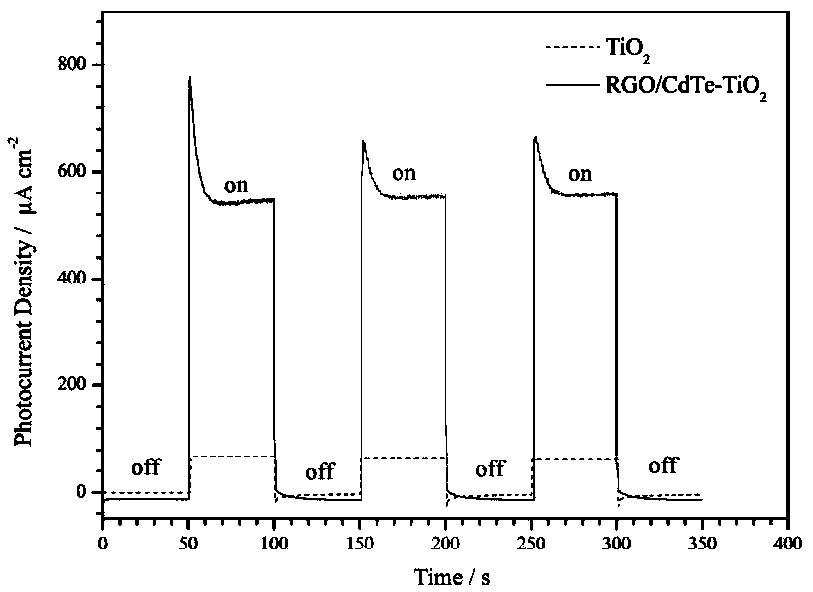

A preparing method of a graphene sensitized CdSe/TiO2 nanotube composite membrane

ActiveCN104164693AAvoid corrosionAchieve separationElectrolytic inorganic material coatingSurface reaction electrolytic coatingTio2 nanotubeCalcination

The invention relates to a nanotube composite membrane and particularly relates to a preparing method of a graphene sensitized CdSe / TiO2 nanotube composite membrane. The method includes: a step of performing anodic oxidation and then calcination by adopting titanium foil as a substrate, adopting a hydrofluoric acid solution as an electrolyte solution and adopting platinum as a counter electrode so as to prepare a TiO2 nanotube array membrane on the surfaces of titanium; a step of depositing graphene quantum dots onto the surfaces of the TiO2 nanotube array membrane by adoption of a cyclic voltammetry deposition method, namely a step of depositing graphene onto the surfaces of the TiO2 nanotube array membrane to prepare a graphene / TiO2 composite membrane by adopting a prepared graphene oxide solution as an electrolyte solution, adopting platinum as a counter electrode and adopting a saturated calomel electrode (SCE) as a reference electrode; and a step of depositing CdSe quantum dots onto the surfaces of the prepared graphene / TiO2 composite membrane, namely a step of depositing CdSe onto the surfaces of the graphene / TiO2 composite membrane to prepare the graphene sensitized CdSe / TiO2 nanotube composite membrane by adopting a mixed solution of SeO2, CdSO4 and sulfuric acid as an electrolyte solution, adopting platinum as a counter electrode and adopting a saturated calomel electrode (SCE) as a reference electrode.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

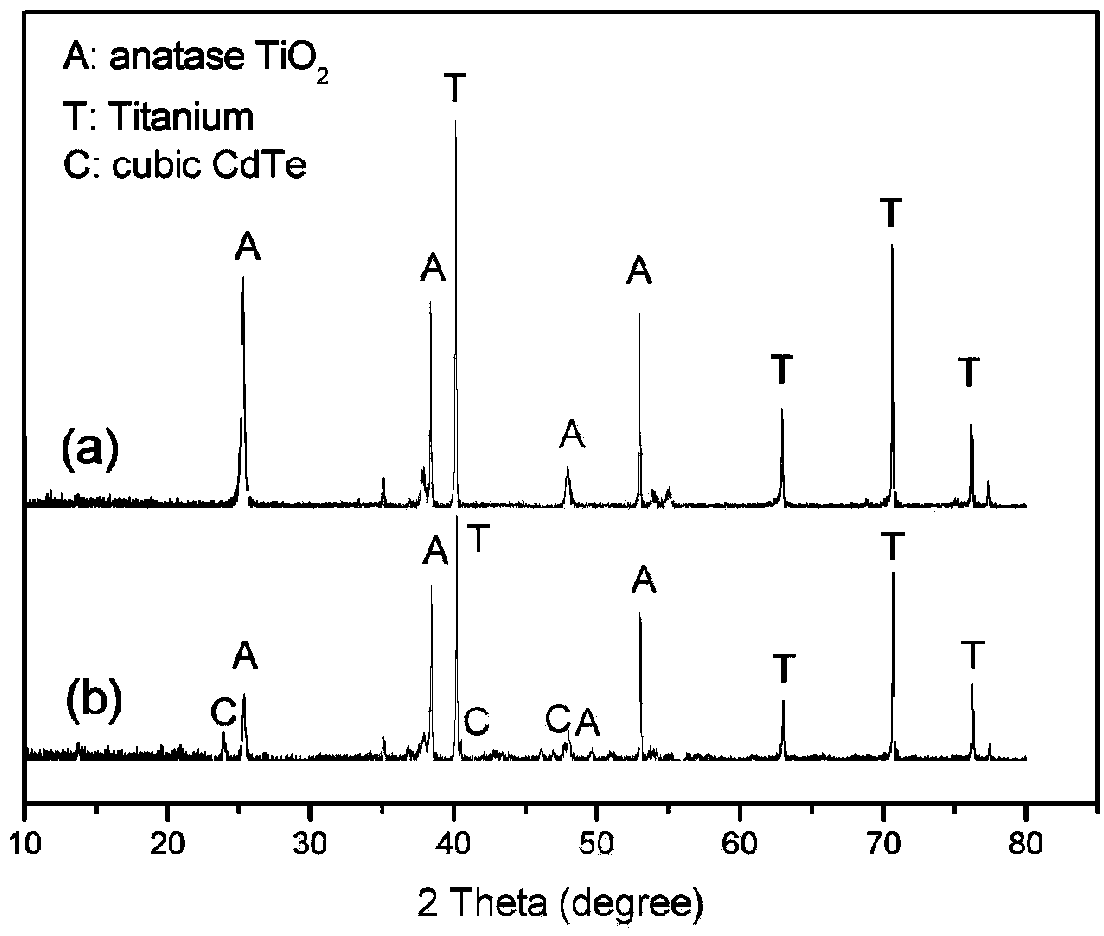

Preparation method of graphene/CdTe-TiO2 composite membrane photo-anode

ActiveCN104264158AAvoid corrosionAchieve separationElectrolytic inorganic material coatingSurface reaction electrolytic coatingTio2 nanotubeMaterials science

The invention relates to a preparation method of a graphene / CdTe-TiO2 composite membrane photo-anode for photo-induced cathodic protection and relates to a composite membrane photo-anode. The invention provides an efficient preparation method of the graphene / CdTe-TiO2 composite membrane photo-anode for photo-induced cathodic protection. The method comprises the following steps: sequentially carrying out anodic oxidation and calcining by taking a titanium foil as a matrix, taking a hydrofluoric solution as an electrolyte solution and taking platinum as a counter electrode, so that a TiO2 nanotube array membrane can be prepared on the titanium surface; firstly, by using a cyclic voltammetric deposition method, depositing graphene quantum dots on the surface of the TiO2 nanotube array membrane, and by taking a prepared graphene oxide solution as an electrolyte solution, taking platinum as a counter electrode and taking saturated calomel electrode (SCE) as a reference electrode, depositing graphene on the surface of the TiO2 nanotube array membrane, so that a graphene / TiO2 composite membrane is obtained; and then depositing CdTe quantum dots on the surface of the obtained graphene / TiO2 composite membrane, and by taking a mixed solution of TeO2, CdSO4 and a hydrochloric acid as an electrolyte solution, taking platinum as a counter electrode and taking a saturated calomel electrode (SCE) as a reference electrode, depositing CdTe on the surface of the graphene / TiO2 composite membrane, so that a graphene / CdTe-TiO2 composite membrane is prepared finally.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

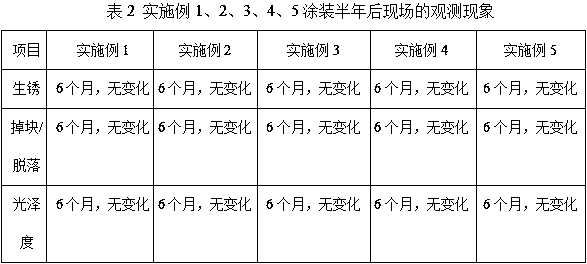

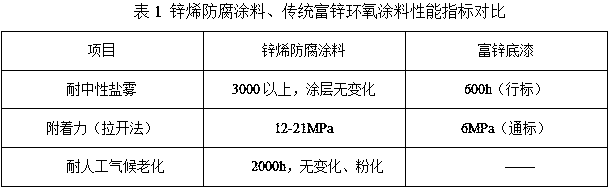

Zinc-alkene anticorrosive paint for steel structure anti-corrosion

InactiveCN108485476AImprove the effect of cathodic protectionReduce dosageAnti-corrosive paintsEpoxy resin coatingsPollutionDimethyl benzene

The invention discloses zinc-alkene anticorrosive paint for steel structure anti-corrosion. The zinc-alkene anticorrosive paint is prepared from, by weight, 10-40% of modified epoxide resin, 20-50% offunctional filler, 0.01-28% of zinc powder, 0.2-3% of graphene, 3-15% of surfactant, 5-25% of xylene and 5-25% of normal butanol. The waterproofness and fast electrical conductivity of nanometer two-dimensional flaky graphene are utilized to apply the graphene to the field of anti-corrosion of railway line bridge equipment steel structure workpieces. Because the used anticorrosive mechanism of the paint is good electrical conductivity of the graphene and lap joint characteristics of the flaky zinc powder, a good conductive layered network structure is formed on the coating surface, the immersion of a corrosive medium is hindered, the physical shielding effect is good, the steel structure workpieces are effectively protected, and the corrosion resistance of the surface of the steel structure workpieces is improved. In addition, the graphene is used to replace parts of zinc powder, not only does the coating have an excellent cathodic protection effect, but also the use amount of the zinc powder is reduced during the preparation of the paint, and the damage and pollution of zinc vapor to the human body are reduced during the processing of later welding.

Owner:胡延超

Bi2Se3/TiO2 nano composite film as well as preparation and application thereof

ActiveCN108546970AReduced band gapImprove separation efficiencyMaterial nanotechnologySurface reaction electrolytic coatingComposite filmDiffuse reflection

The invention belongs to the technical field of nanometer materials and particularly relates to a Bi2Se3 / TiO2 nano composite film as well as preparation and application of the Bi2Se3 / TiO2 nano composite film in photoproduction cathodic protection. Preparation of the Bi2Se3 / TiO2 nano composite film comprises the following steps: at first, the anodic oxidation method is adopted to prepare a TiO2 nanotube array film on the surface of a pretreated titanium substrate sample, then, the chemical bath sedimentation method is adopted to prepare Bi2Se3 nanoflowers on the surface of TiO2, and the obtained TiO2 nanotube array film and Bi2Se3 nanoflowers uniformly distributed on the surface of the TiO2 nanotube array film constitute the Bi2Se3 / TiO2 nano composite film with the NN type heterostructure.The ultraviolet visible diffuse reflection absorption spectrum of the Bi2Se3 / TiO2 nano composite film indicates that the Bi2Se3 / TiO2 nano composite film has the visible light absorption effect betterthan that of TiO2. After the Bi2Se3 / TiO2 nano composite film is coupled with stainless steel 304, the open circuit potential-time curve indicates that the open circuit potential of stainless steel 304reaches -996mV, indicating that stainless steel 304 has already entered an excellent cathodic protection state.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

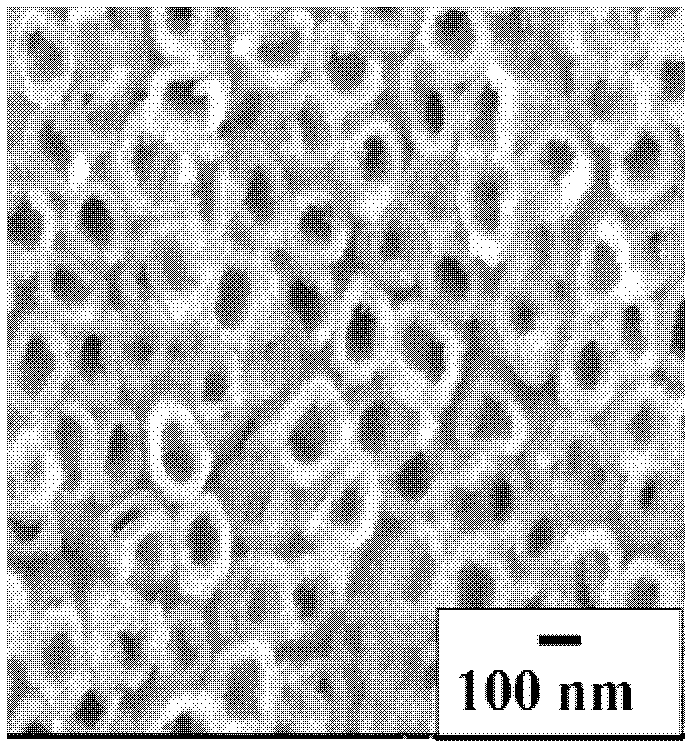

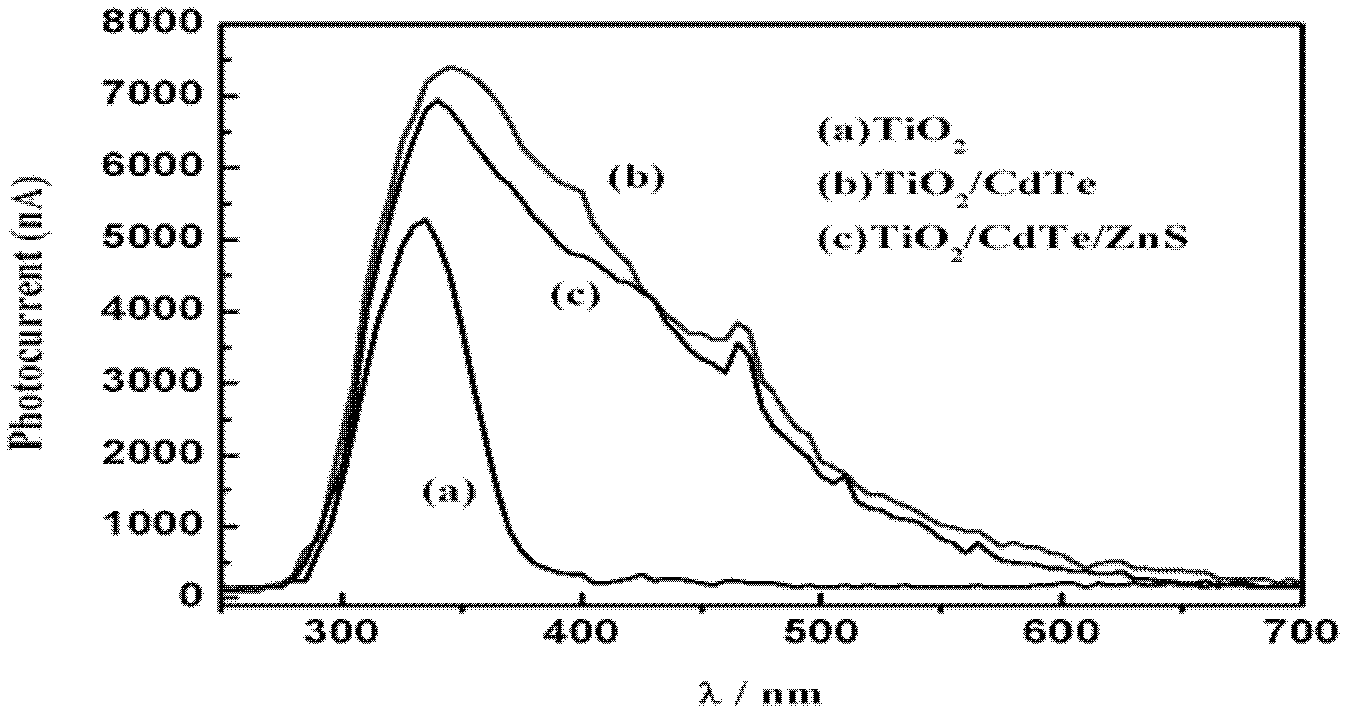

Preparation method of zinc sulfide (ZnS)/cadmium telluride (CdTe) quantum dot sensitization titanium dioxide (TiO2) nano film

InactiveCN102543457AReduce defect densityHigh crystallinityLight-sensitive devicesSolid-state devicesElectrode potentialCathode

The invention discloses a preparation method of zinc sulfide (ZnS) / cadmium telluride (CdTe) quantum dot sensitization titanium dioxide (TiO2) nano film, and relates to a TiO2 nano film. The method comprises the following steps: preparing a titanium matrix sample, preparing a TiO2 nano-tube array film at the surface of the sample, preparing a CdTe quantum dot sensitization TiO2 nano film, and finally preparing a ZnS / CdTe quantum dot sensitization TiO2 nano film. Under irradiation of white light, the film enables an electrode potential of connected metals like stainless steel to be greatly reduced in corrosive medium, and can protect good cathode of metals like stainless steel continuously for a long time in a dark state. And the nano film prepared by using the method has an efficient photoproduction cathode protection effect.

Owner:XIAMEN UNIV

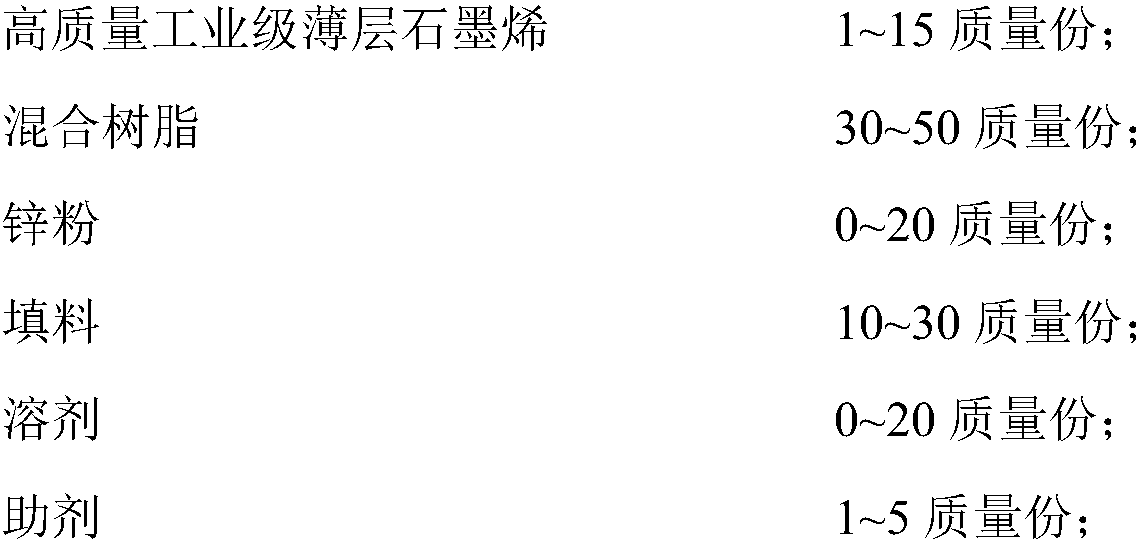

Environment-friendly graphene low-zinc heavy-duty anticorrosive paint for highway facilities and preparation method

PendingCN109971230AImprove thermal stabilityGood weather resistanceAnti-corrosive paintsPowdery paintsEpoxyAcrylic resin

The invention relates to a graphene low-zinc heavy-duty anticorrosive paint, which includes a component A and a component B. The component B contains a curing agent, and the component A is composed ofthe following components by mass percentage: 1-15 parts of graphene, 30-50 parts of mixed resin, 0-20 parts of a basic solvent, 0-20 parts of zinc powder, 10-30 parts of filler and 1-5 parts of an assistant. Specifically, the mixed basis resin is a mixed aqueous dispersion of hydroxyl acrylic resin, acrylic resin and amino resin, or one of or a mixture of several of epoxy resin, polyester resin,polyurethane resin and alkyd resin. The paint provided by the invention has the characteristics of high weather resistance and abrasion resistance, and can be widely applied to the outer protection ofbalustrades, stand columns and other highway guardrail facilities and related traffic supporting facilities, and also can be used for protection of large engineering machinery, power transmission andtransformation facilities and other outdoor steel structures.

Owner:JIANGNAN GRAPHENE RES INST +2

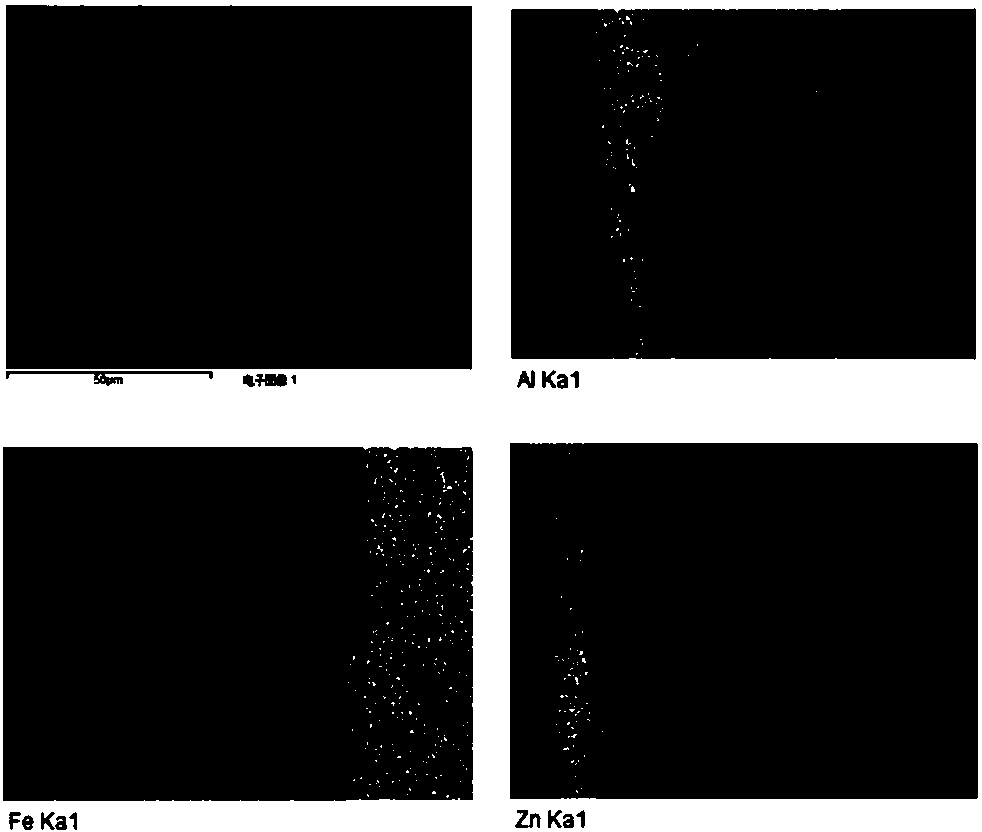

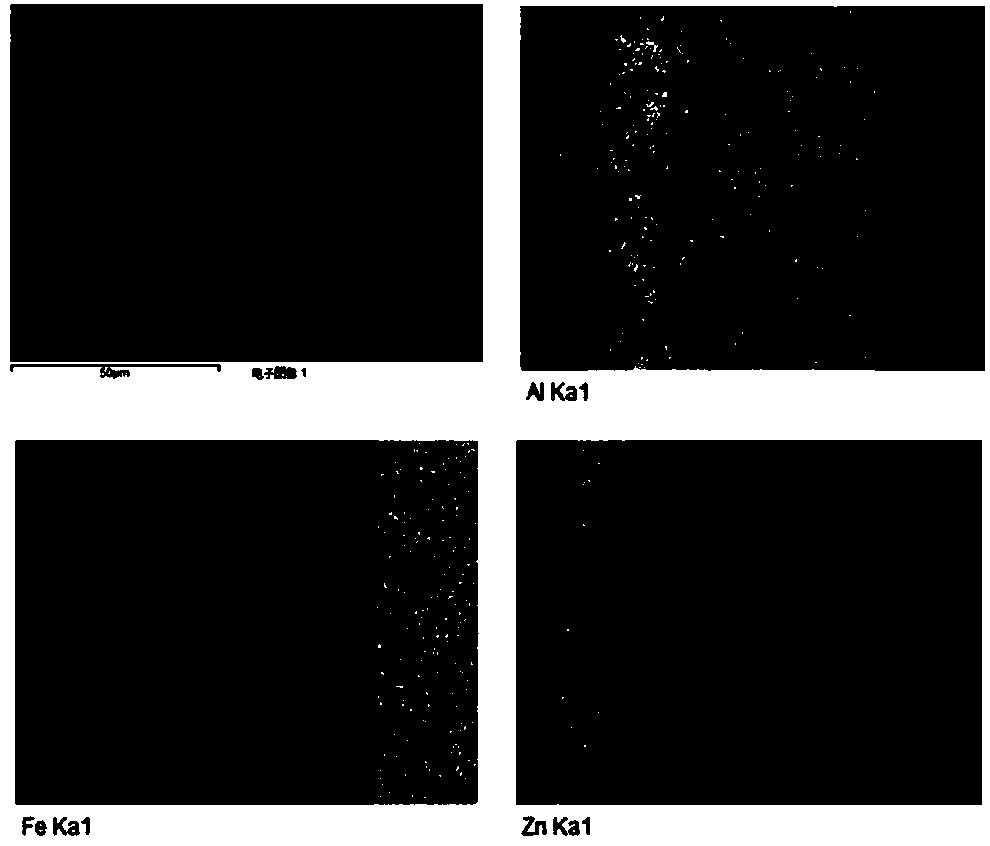

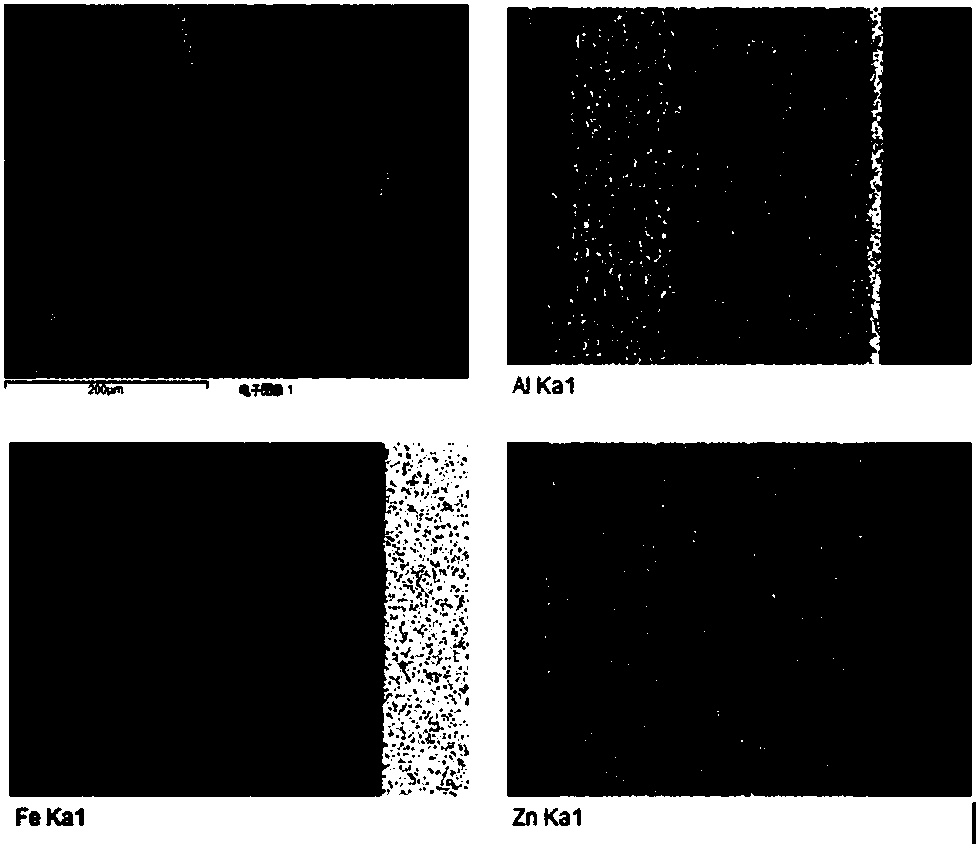

Method for carrying out hot-dipping on aluminum-zinc alloy on steel surface

InactiveCN104178719AImprove corrosion resistanceImprove the effect of cathodic protectionHot-dipping/immersion processesCeriumZinc alloys

The invention relates to a method for carrying out hot-dipping on an aluminum-zinc alloy on a steel surface, and belongs to the technical field of steel hot-dipping processes. According to the method, hot-dipping temperature is melting point Tm+(80-100) DEG C, and hot-dipping time is 30-200 seconds; and an adopted dip plating solution comprises the following materials in percentage by weight: 3%-15% of aluminum, 1%-5% of magnesium, 0.05%-0.5% of cerium-containing mixed rare earth, less than 0.5% of optional one or more optional additional elements and the balance of zinc. According to the method, an obtained alloy layer structurally comprises a zinc-aluminum alloy layer and an aluminum-zinc-iron alloy layer sequentially from outside to inside. Compared with the structure and thickness of a plating layer of the traditional hot-dipping zinc-aluminum alloy, the plating layer takes the aluminum-zinc-iron alloy layer as a main part; and the total thickness of the plating layer is relatively thinner, and the thickness of the plating layer is more stable and is not greatly changed along with dipping time.

Owner:STATE GRID CORP OF CHINA +1

Inorganic graphene antibacterial alga-resistant zinc-rich anticorrosive coating and preparation method thereof

InactiveCN110527329AAdd release pathImprove conduction efficiencyAntifouling/underwater paintsAlkali metal silicate coatingsEmulsionGraphene

The invention discloses an inorganic graphene antibacterial alga-resistant zinc-rich anticorrosive coating and a preparation method thereof. The inorganic graphene antibacterial alga-resistant zinc-rich anticorrosive coating comprises 30-50 wt% of a stable high-modulus silicate, 0.1-2 wt % of graphene, 40-69 wt% of zinc powder, 0.1-5 wt% of a modified composite antibacterial alga-resistant agent,and 0.1-3 wt% of a coating auxiliary agent, wherein the stable high-modulus silicate is prepared by carrying out a reaction of a silicate, a silane coupling agent and a silicone-acrylic emulsion, themodulus of the silicate is 4.5-7.0, the zinc powder is flake zinc powder and granular zinc powder, the modified composite antibacterial alga-resistant agent is prepared by modifying a composite antibacterial alga-resistant agent with a surface modifier, the surface modifier is an organic silane coupling agent, and the compound antibacterial alga-resistant agent is formed by loading an antibacterial alga-resistant agent on an inorganic porous carrier. By adding anticorrosive fillers such as graphene, the flake zinc powder and the granular zinc powder, and the composite antibacterial alga-resistant agent functional filler, a formed coating layer of the coating is dense, and has relatively few pores, and improvement of a service life of the anticorrosive coating is realized.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com