Preparation method of graphene/CdTe-TiO2 composite membrane photo-anode

A technology of graphene and composite film, which is applied in the direction of electrolytic inorganic material coating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of low photoelectric efficiency, visible light cannot be effectively used, and visible light utilization rate is not high, so as to avoid The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Take a rectangular pure titanium foil with a thickness of 0.1 mm as a sample, which is 15 mm long and 10 mm wide. The surface of the sample was sequentially polished with 400-1500 grit sandpaper, and then ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes.

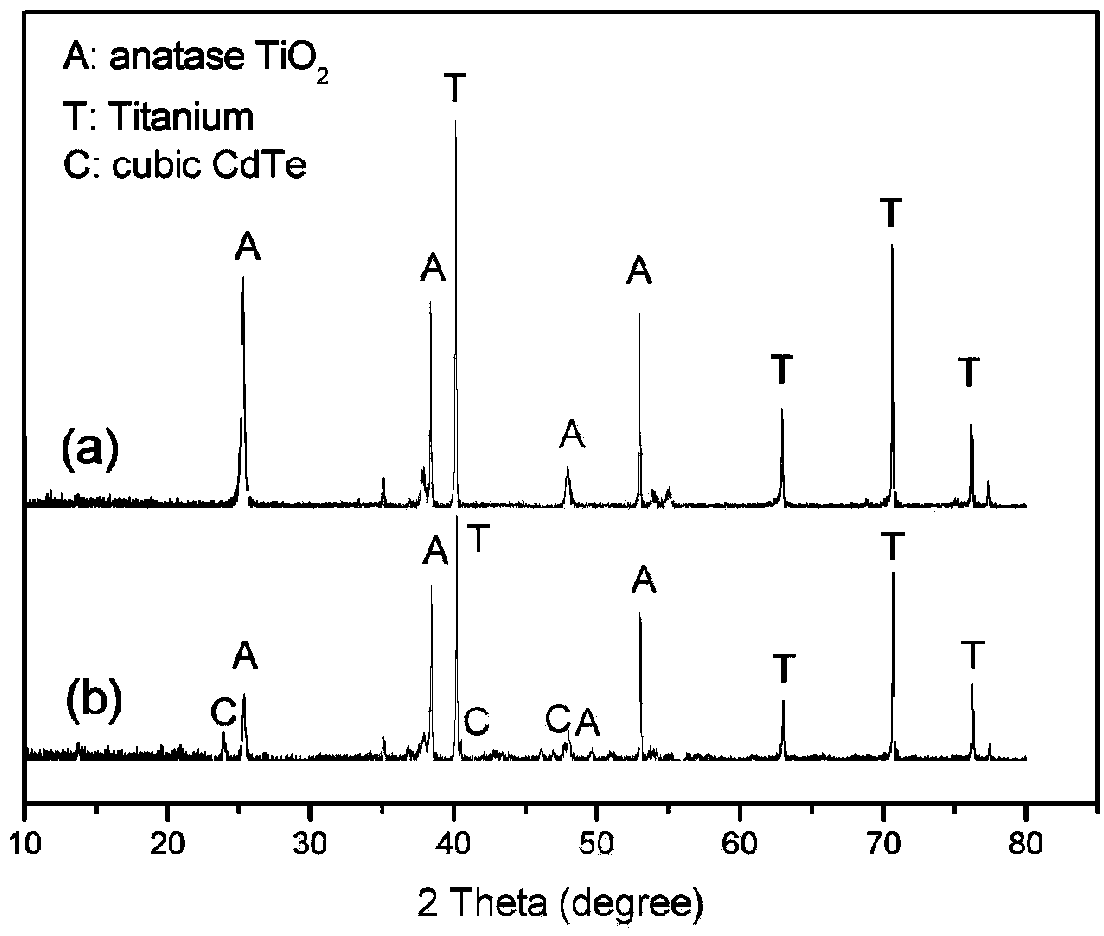

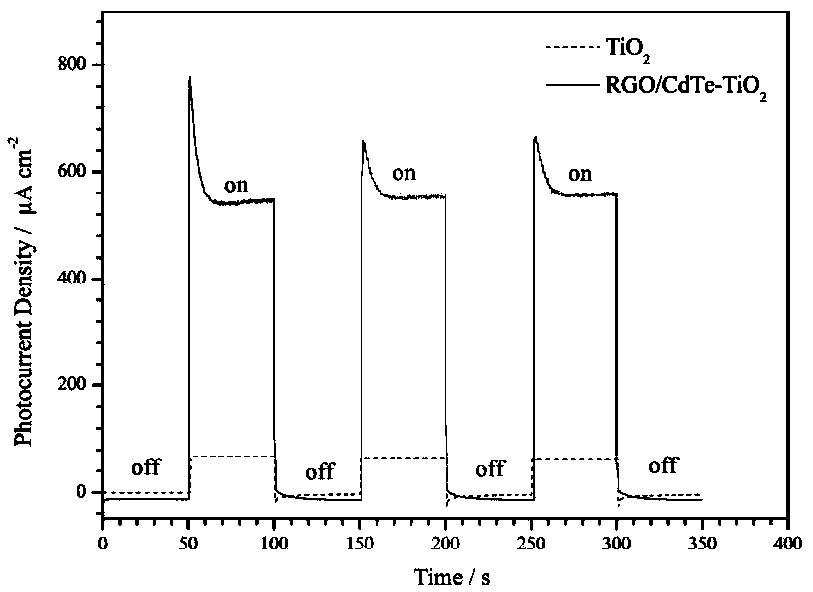

[0056] Measure 1 mL of hydrofluoric acid into 100 mL of deionized water to make a hydrofluoric acid solution. At room temperature, with the cleaned titanium foil substrate as the anode and the platinum sheet as the cathode, anodize at 30V for 30min in the above mixed solution. Then the sample was placed in a muffle furnace and calcined at 450 °C for 2 hours, and then cooled to room temperature with the furnace, that is, TiO was prepared on the surface of the titanium foil substrate. 2 nanotube array film.

[0057] Using cyclic voltammetry deposition method, first on TiO 2 Graphene quantum dots are deposited on the surface of the nanotube array film. 0.1 g of graphite oxide was...

Embodiment 2

[0063] Graphene / CdTe-TiO 2 Preparation method of composite film photoanode:

[0064] Take a rectangular pure titanium foil with a thickness of 0.1 mm as a sample, which is 15 mm long and 10 mm wide. The surface of the sample was sequentially polished with 400-1500 grit sandpaper, and then ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes.

[0065] Measure 1 mL of hydrofluoric acid into 100 mL of deionized water to make a hydrofluoric acid solution. At room temperature, with the cleaned titanium foil substrate as the anode and the platinum sheet as the cathode, anodize at 30V for 30min in the above mixed solution. Then the sample was placed in a muffle furnace and calcined at 450 °C for 2 hours, and then cooled to room temperature with the furnace, that is, TiO was prepared on the surface of the titanium foil substrate. 2 nanotube array film.

[0066] Using cyclic voltammetry deposition method, first on TiO 2 Graphene quantum dots are d...

Embodiment 3

[0072] Graphene / CdTe-TiO 2 Preparation method of composite film photoanode:

[0073] Take a rectangular pure titanium foil with a thickness of 0.1 mm as a sample, which is 15 mm long and 10 mm wide. The surface of the sample was sequentially polished with 400-1500 grit sandpaper, and then ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes.

[0074] Measure 1 mL of hydrofluoric acid into 100 mL of deionized water to make a hydrofluoric acid solution. At room temperature, with the cleaned titanium foil substrate as the anode and the platinum sheet as the cathode, anodize at 30V for 30min in the above mixed solution. Then the sample was placed in a muffle furnace and calcined at 450 °C for 2 hours, and then cooled to room temperature with the furnace, that is, TiO was prepared on the surface of the titanium foil substrate. 2 nanotube array film.

[0075] Using cyclic voltammetry deposition method, first on TiO 2 Graphene quantum dots are d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com