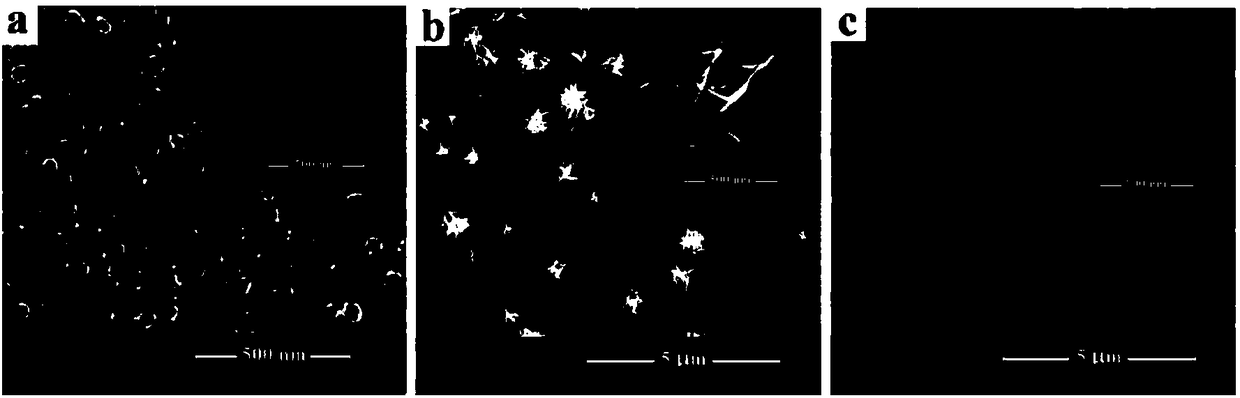

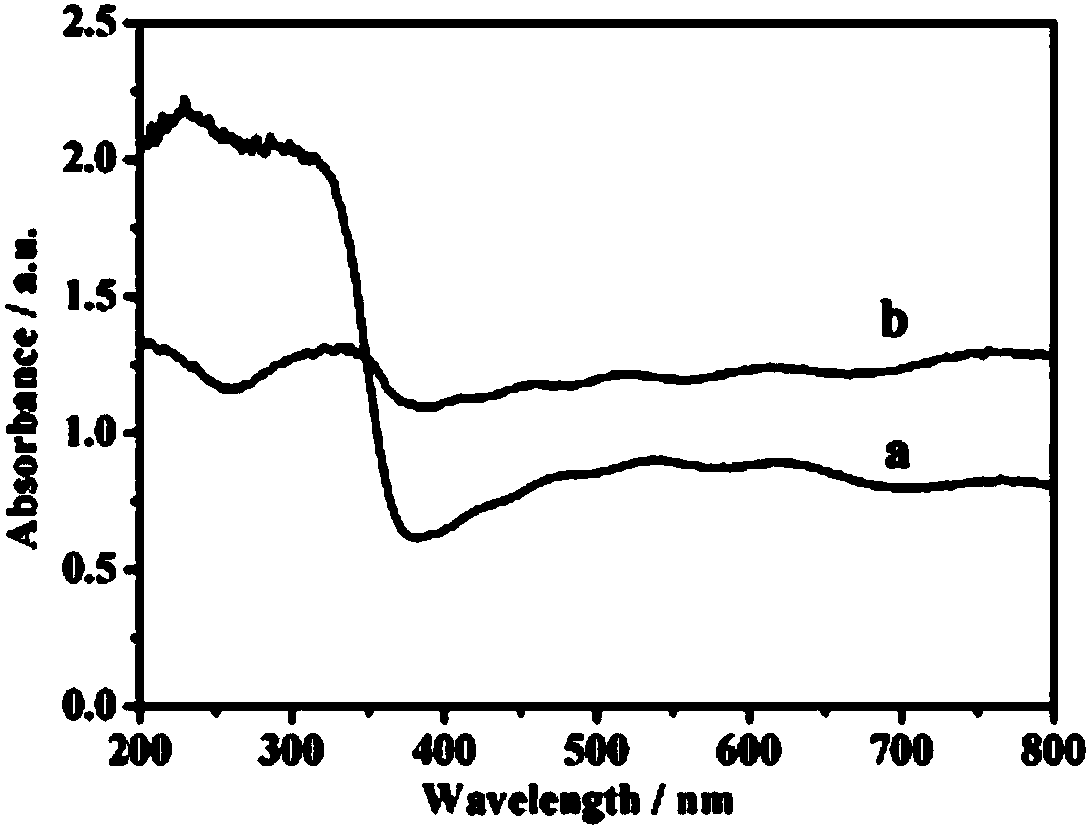

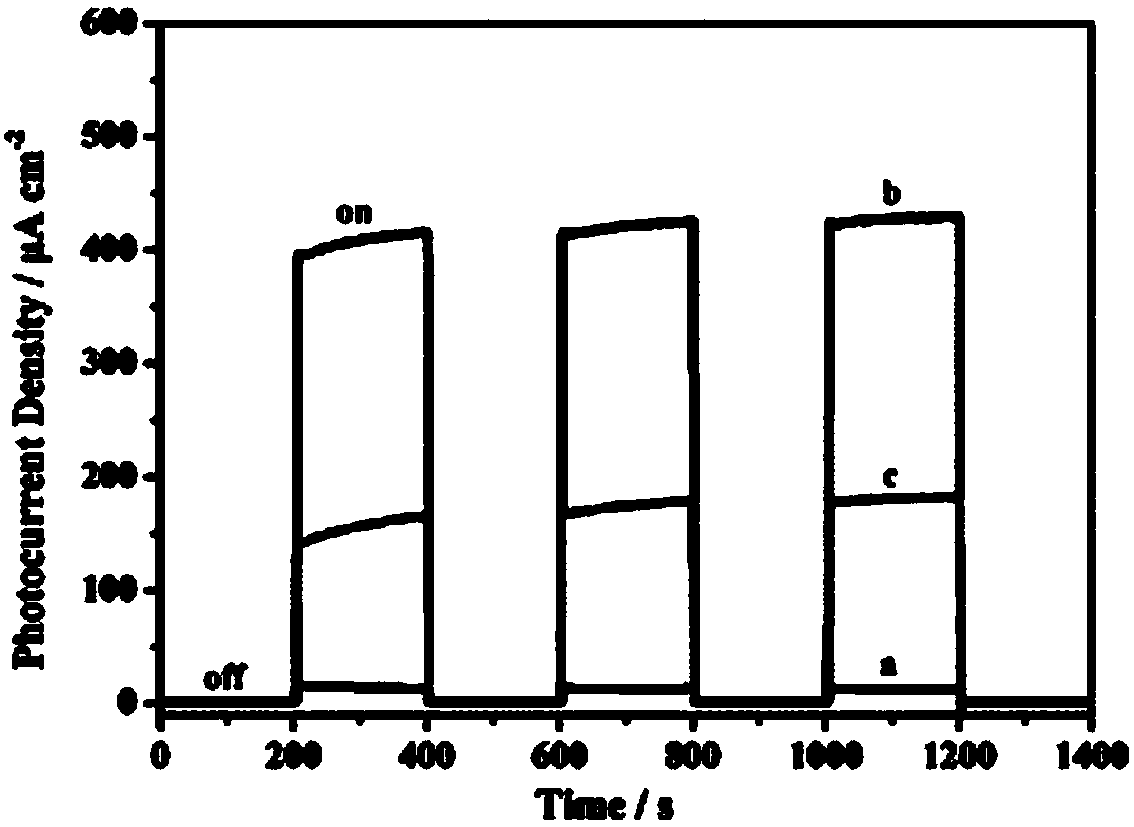

Bi2Se3/TiO2 nano composite film as well as preparation and application thereof

A nano-composite and nano-flower technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low utilization rate of sunlight, and achieve the promotion of separation efficiency, regular morphology, absorption, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Cut a commercially available titanium foil (purity >99.9%) into a titanium substrate sample of 0.3mm×10mm×40mm, and clean it alternately with deionized water and acetone for 10 minutes each time until the titanium substrate is removed. Soluble inorganic or organic matter on the surface of the base sample should be dried at room temperature for later use.

[0037] 2) Dissolve 0.45g of ammonium fluoride (NH 4 F), then add 6ml hydrogen peroxide (H 2 o 2 ) and 6ml concentrated nitric acid (concentrated HNO 3 ), stirred evenly with a glass rod to obtain a polishing solution. Put the treated titanium substrate sample into the polishing solution, and chemically polish until the surface of the titanium substrate sample is uniform, clean and smooth. After taking it out, alternately ultrasonically clean it with deionized water and absolute ethanol three times, each time for 5 minutes, to obtain a pretreated titanium substrate sample. Finally, it was stored in absolute eth...

Embodiment 2

[0046] 1) Cut a commercially available titanium foil (purity >99.9%) into a titanium substrate sample of 0.3mm×10mm×40mm, wash it with deionized water and acetone alternately and ultrasonically for 10 minutes each time, until the titanium is removed Soluble inorganic or organic matter on the surface of the base sample should be dried at room temperature for later use.

[0047] 2) Dissolve 0.45g of ammonium fluoride (NH 4 F), then add 6ml hydrogen peroxide (H 2 o 2 ) and 6ml concentrated nitric acid (concentrated HNO 3 ), stirred evenly with a glass rod to obtain a polishing solution. Put the treated titanium substrate sample into the polishing solution, and chemically polish until the surface of the titanium substrate sample is uniform, clean and smooth. After taking it out, alternately ultrasonically clean it with deionized water and absolute ethanol three times, each time for 5 minutes, to obtain a pretreated titanium substrate sample.

[0048] 3) Preparation of TiO on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pipe diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com