Anti-fog self-cleaning film and method for preparing same

A self-cleaning film, anti-fog technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unsatisfactory anti-fog effect, high technical requirements for film sticking, and high price, and achieves increased specific surface area and cost. Low, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

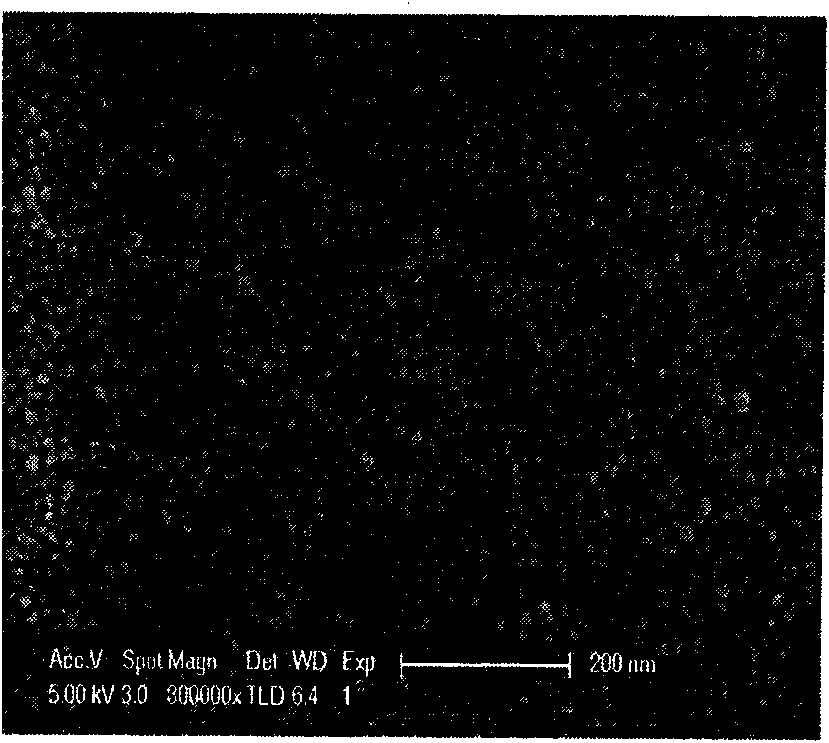

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of PEG400-Fe 2 o 3 / SiO 2 / TiO 2 Organic-ternary inorganic composite sol.

[0031] in TiO 2 Add 20% (mole percentage composition, with respect to pure TiO in the sol 2 , the same below) SiO 2 Sol, 0.25% Fe 2 o 3 Sol and 2.5g·L -1 PEG400, stirred to make it evenly mixed, let it stand for a day to obtain PEG400-Fe 2 o3 / SiO 2 / TiO 2 Organic-ternary inorganic composite sol. With glass as the base material, the impregnation-pulling method is adopted, with a temperature of 10mm·s -1 The pulling speed coats the glass surface with a film. After the coating film is completed, dry it in an oven at 100°C for 10 minutes, and then dry it in a muffle furnace at 1°C·min -1 The heating rate was set at 350°C for 7 hours to prepare the desired film, which was denoted as T1.

Embodiment 2

[0032] Embodiment 2: Preparation of PEG10000-Fe 2 o 3 / SiO 2 / TiO 2 Organic-ternary inorganic composite sol.

[0033] in TiO 2 Add 20% SiO to the sol 2 Sol, 0.25% Fe 2 o 3 Sol and 2.5g·L -1 PEG10000, stir vigorously to make it evenly mixed, and let it stand for a day to obtain PEG10000-Fe 2 o 3 / SiO 2 / TiO 2 Organic-ternary inorganic composite sol. Using the ceramic flat plate as the base material, the impregnation-pulling method was adopted, at 5mm·s -1 The pulling speed coats the glass surface with a film. After the coating film is completed, dry it in an oven at 80°C for 30 minutes, and then dry it in a muffle furnace at 3°C min -1 The heating rate is set at 400°C for 5 hours to prepare the desired film, which is denoted as T2.

Embodiment 3

[0034] Embodiment 3: Preparation of PEG1000-Fe 2 o 3 / SiO 2 / TiO 2 Organic-ternary inorganic composite sol.

[0035] in TiO 2 Add 20% SiO to the sol 2 Sol, 0.25% Fe 2 o 3 Sol and 2.5g·L -1 PEG1000, stir vigorously to make it evenly mixed, and let it stand for a day to obtain PEG1000-Fe 2 o 3 / SiO 2 / TiO 2 Organic-ternary inorganic composite sol. Using glass as the base material, using the dipping-pulling method, at 1mm·s -1 The pulling speed coats the glass surface with a film. After the coating is completed, dry it in a microwave oven on low heat for 5 minutes, and then place it in a muffle furnace at 5°C min -1 The heating rate is set at 500°C for 2 hours to prepare the desired film, which is denoted as T3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com