Two-dimensional titanium dioxide/graphene flaky modified self cleaning fabric and preparation method thereof

A graphene modification and titanium dioxide technology, applied in the field of textile materials, can solve problems such as rare research, and achieve the effects of simple preparation method, remarkable self-cleaning effect, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

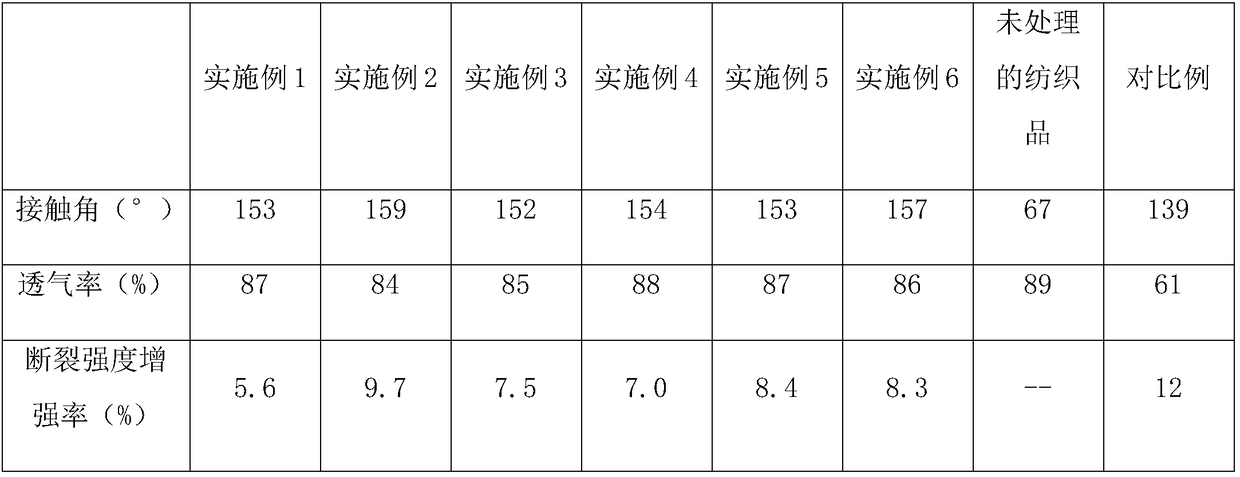

Examples

Embodiment 1

[0022] Add titanium tetrachloride and triblock polymer F127 with a mass ratio of 1:0.3 into the tetrahydrofuran solution, adjust the pH value to 2 with hydrochloric acid, and continue stirring until the solvent is completely evaporated to obtain a titanium source precursor gel, in which tetrahydrofuran The volume ratio with hydrochloric acid is 90:1.

[0023] According to the dosage ratio of 1g:50mL, the titanium source precursor gel is added to the mixed solution of ethanol / glycerol with a volume ratio of 1:3, after mixing evenly, the graphene oxide solution is added dropwise, mixed evenly, and transferred to In the hydrothermal reaction kettle, hydrothermal reaction was carried out at 800°C for 6 hours, centrifuged at 5000r / min for 3 minutes, and after cleaning, a graphene-modified two-dimensional titanium dioxide sheet material was obtained, wherein the graphene-modified two-dimensional titanium dioxide sheet The mass ratio of graphene to titanium dioxide in the shape mater...

Embodiment 2

[0026] Add n-butyl titanate and triblock polymer F127 with a mass ratio of 1:0.6 into the tetrahydrofuran solution, adjust the pH value to 4 with hydrochloric acid, and continue stirring until the solvent is completely evaporated to obtain a titanium source precursor gel, wherein The volume ratio of tetrahydrofuran to hydrochloric acid is 90:10.

[0027] According to the dosage ratio of 1g:50mL, the titanium source precursor gel is added to the mixed solution of glycerol / ethylene glycol with a volume ratio of 1:3, after mixing evenly, the graphene oxide solution is added dropwise, and the mixture is evenly mixed. Transfer to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 850°C for 8 hours, centrifuge at 8000r / min for 5 minutes, and after cleaning, obtain a graphene-modified two-dimensional titanium dioxide sheet material, wherein the graphene-modified two-dimensional The mass ratio of graphene to titanium dioxide in the titanium dioxide sheet material is 0....

Embodiment 3

[0030] Add isopropyl titanate and triblock polymer F127 with a mass ratio of 1:0.5 into the tetrahydrofuran solution, adjust the pH value to 2.5 with hydrochloric acid, and continue stirring until the solvent is completely evaporated to obtain a titanium source precursor gel, wherein The volume ratio of tetrahydrofuran to hydrochloric acid is 90:5.

[0031] According to the dosage ratio of 1g:50mL, the titanium source precursor gel is added to the mixed solution of ethanol / glycerol / diethylene glycol with a volume ratio of 1:3:1, and after mixing evenly, the graphene oxide solution is added dropwise , mixed evenly, transferred to a hydrothermal reaction kettle, hydrothermally reacted at 820°C for 6.5h, centrifuged at 6000r / min for 4min, and after cleaning, a graphene-modified two-dimensional titanium dioxide sheet material was obtained, wherein graphene The mass ratio of graphene to titanium dioxide in the modified two-dimensional titanium dioxide sheet material is 0.7:1, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com