Patents

Literature

91results about How to "Lower electrode potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

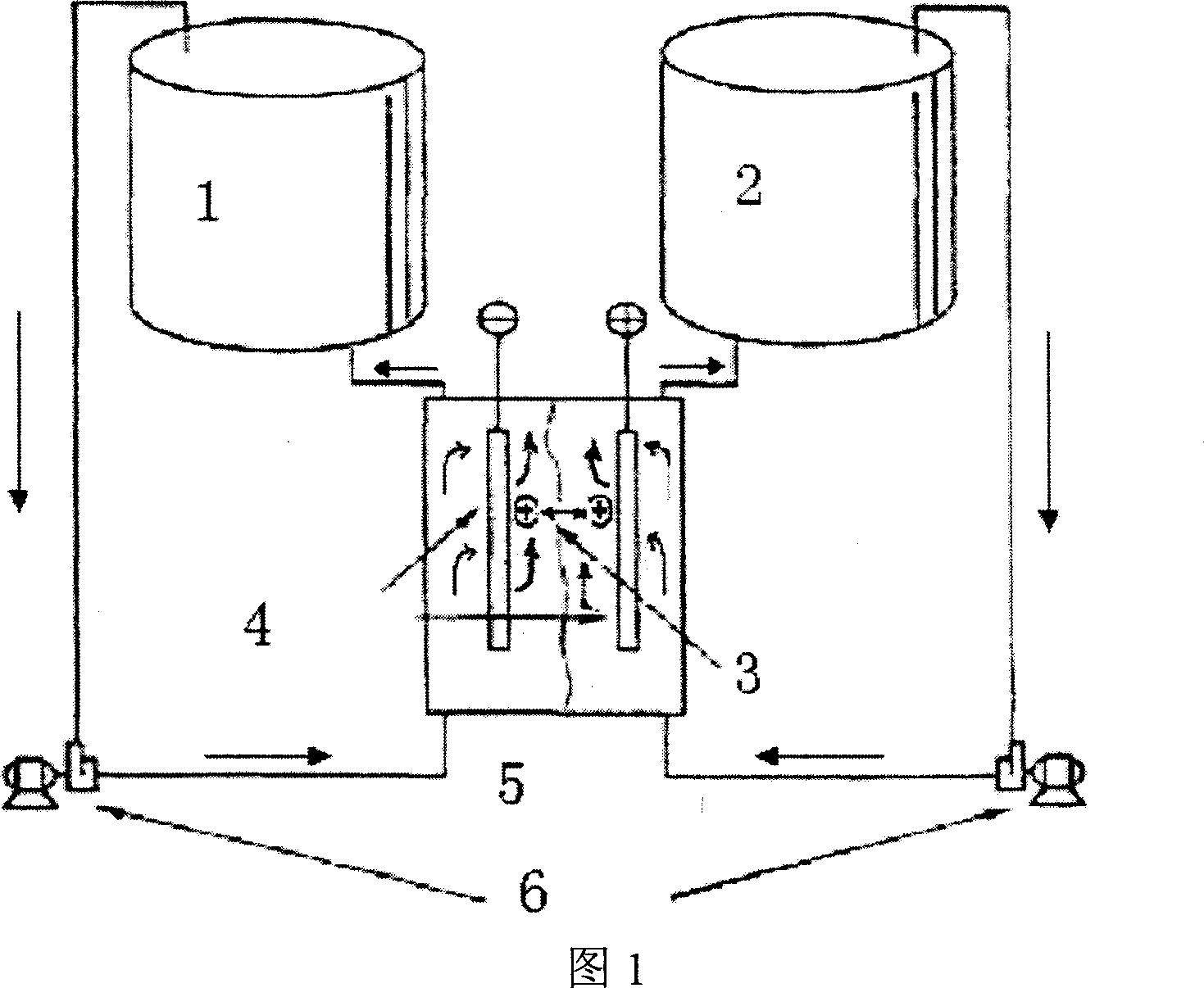

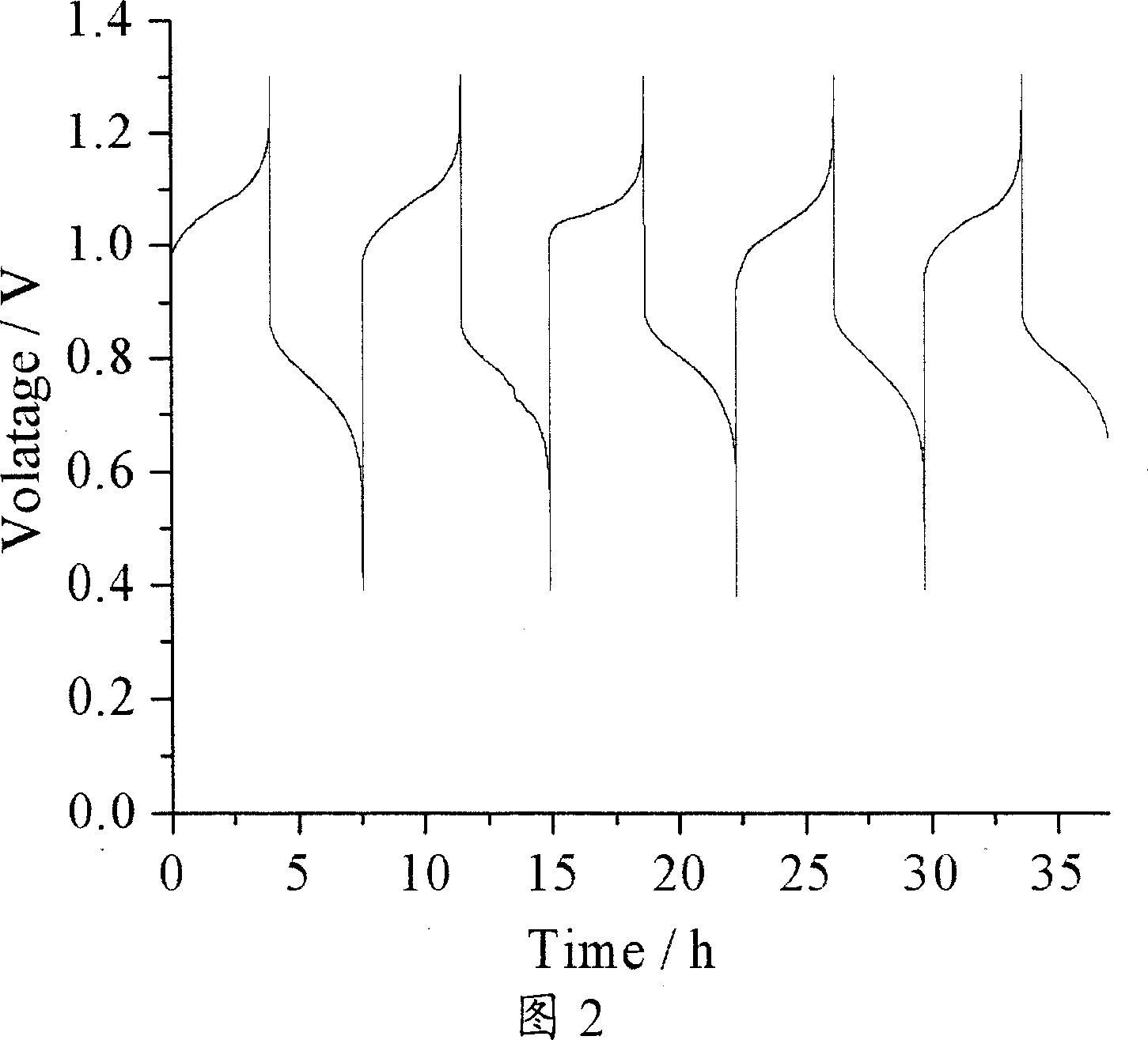

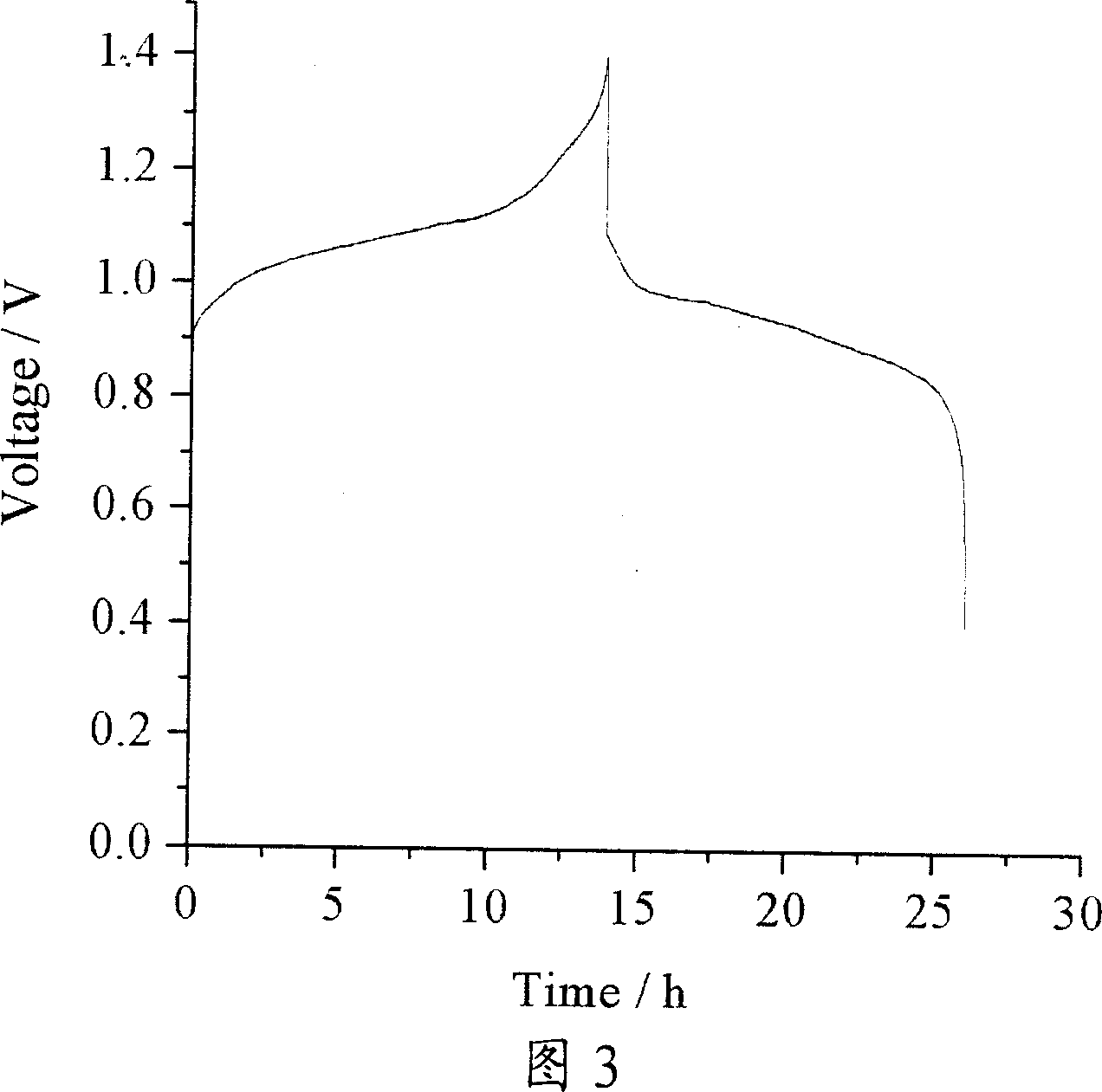

Iron composite/halogen electrochemical system for flow electric storage

InactiveCN101047261AReduce capacityImprove energy conversion efficiencyElectrolyte moving arrangementsCell electrodesElectricityHalogen

A Fe-matched matter-halogen electrochemical system used on liquid flow energy storage is prepared as separating positive / negative electrode electrolyte by positive ion exchange film and storing said electrolyte in external container, generating charge / discharge process by making oxidation / reduction reaction on inert carbon felt electrode through pump stream via battery, applying soluble Fe(III) / Fe(II) -matched matter oxidation / reduction electric pair as negative electrode and applying halogen oxidation / reduction electric pair as positive electrode.

Owner:DALIAN RONGKE POWER

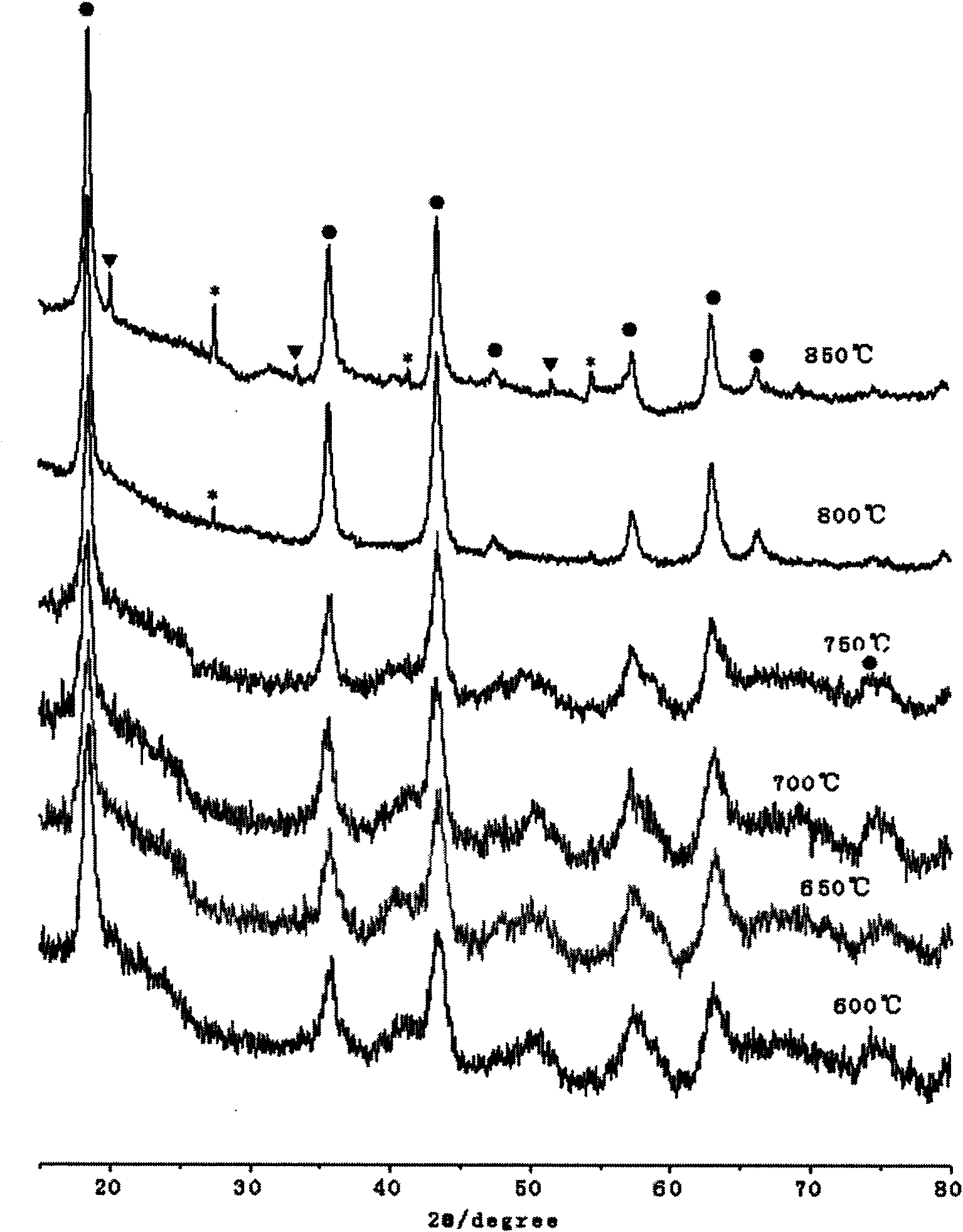

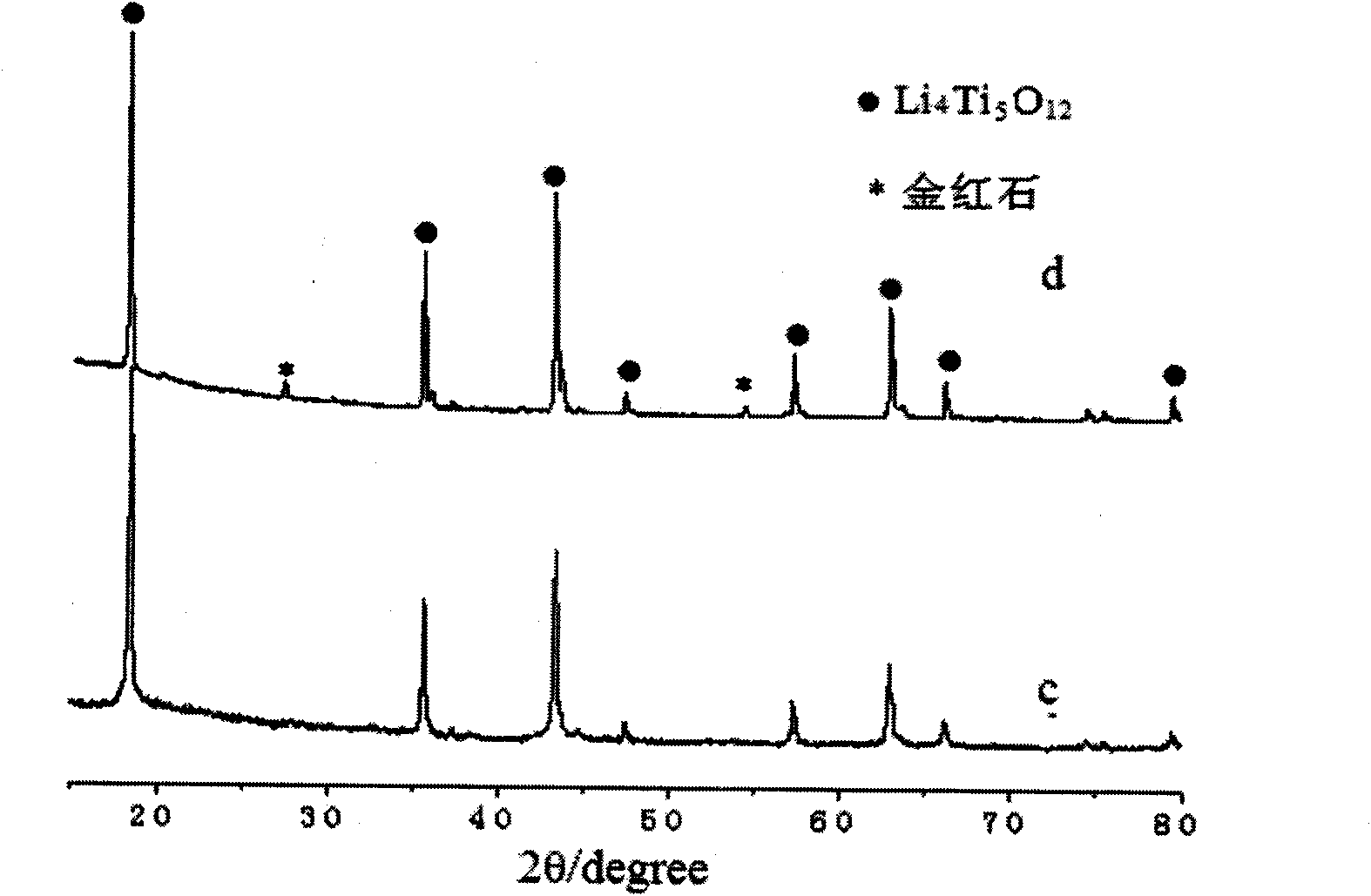

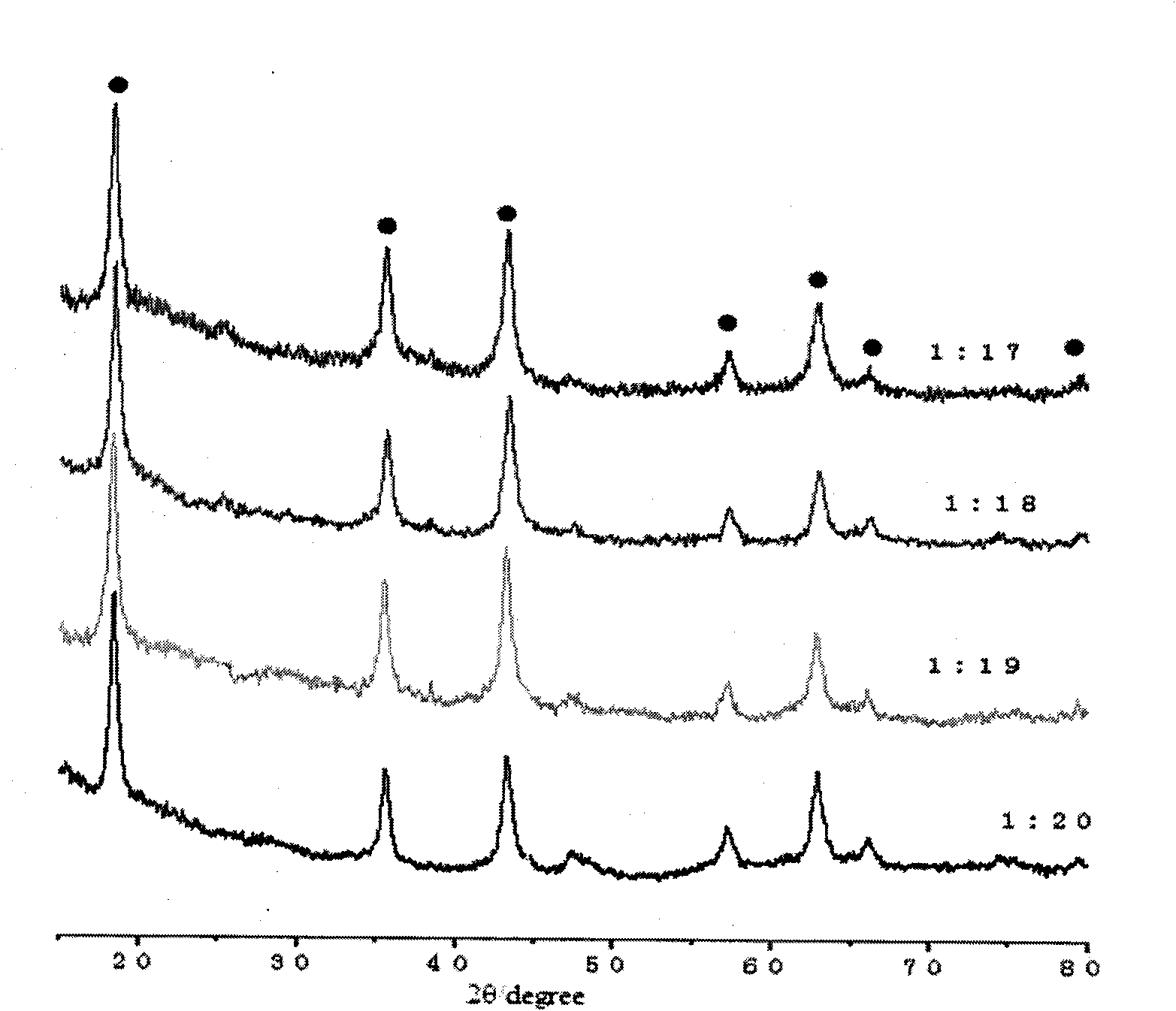

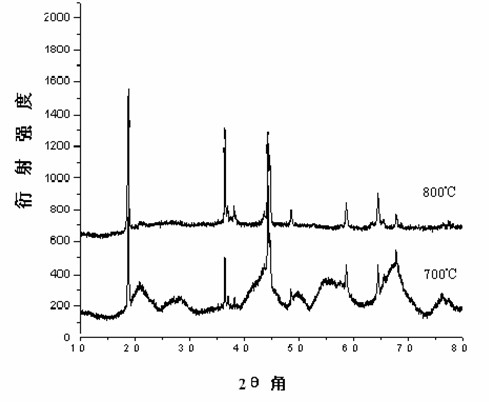

Method for preparing spinel lithium titanate of cathode material of lithium ion battery

InactiveCN101593830ALow costReduce energy consumptionElectrode manufacturing processesCombined methodMicroparticle

The invention relates to a method for preparing a cathode material Li4Ti5O12 of a high-performance lithium ion battery. The method comprises the following steps of: adopting the combined method of sol-gel and microwave treatment to prepare micro powder of nano-class Li4Ti5O12, and simultaneously modifying Li4Ti5O12 by carbon doping and metallic doping. The method utilizes the sol-gel method to effectively control chemical composition, phase composition and powder size of the Li4Ti5O12, thereby improving the uniformity and the electric conductivity of the Li4Ti5O12; simultaneously by utilizing the characteristics of the microwave technique of quick temperature rise, even heating and conglobation resistance, the high-power industrial microwave oven is used for treatment, so that the treatment time of the Li4Ti5O12 is greatly shortened, the yield is greatly improved, and the cost and the energy consumption of the material are reduced, the process is simplified, the efficiency on the industrialized production of the lithium ion battery is improved, and the industrialized application is easily achieved; and by doping carbon and metallic elements, the electric conductivity of lithium iron phosphate is greatly improved, and the charging and discharging capacities and the cycle index of the lithium iron phosphate are simultaneously and effectively increased.

Owner:ZHENGZHOU UNIV +1

Chemical tin plating liquor for copper and copper alloy

ActiveCN101403112ALower electrode potentialPrevent oxidationLiquid/solution decomposition chemical coatingChemical platingTin plating

The invention discloses a copper and a chemical plating tin liquor of copper alloys and each liter of chemical plating tin liquor consists of materials with the following components: organic mixed acid: 150g / 1 to 500g / 1; organic pink salt: 50g / 1 to 100g / 1; organic silver salt: 1g / 1 to 5g / 1; complex agent: 45g / 1 to 200g / 1; reducing agent: 30g / 1 to 60g / 1; stabilizing agent: 10g / 1 to 80g / 1; emulsifying agent: 5g / 1 to 20g / 1; brightening agent: 3g / 1 to 20g / 1 and de-ionized water as the rest. With the chemical plating tin liquor, the copper and alloy surfaces can simply and rapidly form a bright and flat tin layer which does not form tin whiskers and has a certain thickness only needing chemical tin plating treatment for 4 to 8 minutes. The copper and the chemical plating tin liquor are suitable for not only circuit boards which are coated with coppers or copper alloys but also tinning corrosion resistance of other copper materials, etc.

Owner:昆山成利焊锡制造有限公司

Chromium-free waterborne corrosion resistant coating used for surface of metal and preparation method thereof

ActiveCN101693811AImprove compactnessLower electrode potentialAnti-corrosive paintsChromium freeSolvent

The invention relates to a chromium-free waterborne corrosion resistant coating for the surface of metal and a preparation method thereof. The chromium-free waterborne corrosion resistant coating comprises the following components in percentage by mass: 15-33 flaked zinc powder, 2.5-8 flaked aluminium powder, 13.5-24 solvent, 0.2-2.5 assistant, 14-22 first silane coupling agent, 2-6 second silane coupling agent, 0.05-1.5 nano SiO2,0.03-1.2 nano TiO2, 0.02-1.5 nano ZrO2, 0.3-1 silver salt, 0.1-0.3 polyaniline, 0-0.6 tackifier and the balance of H2O, wherein the first silane coupling agent is a bi-[Gamma-(triethoxysilane) propyl] tetrasulfide; and the second silane coupling agent is a Gamma-aminopropyltriethoxysilane or Gamma-methacryloxypropyl trimethoxysilane. The coating contains no chromium and has corrosion resistance according with an international newest metal surface corrosion prevention technology.

Owner:CHANGZHOU JMT SURFACE ENG TECH

Water base non-chrome zinc-aluminium coating and methods for preparing and using same

ActiveCN102911534AMeet the requirements of environmental regulationsHydrogen embrittlement will notLiquid surface applicatorsCoatingsWater basedHazardous substance

The invention relates to a water base non-chrome zinc-aluminium coating and methods for preparing and using the same. The coating is prepared by proportionally mixing a component A and a component B; the component A contains 50-150g / L of lamellar metal powder, 145-290ml / L of organic solvent, 10-200ml / L of deionized water, 10-36ml / L of reducing agent and 5-15ml / L of wetting agent; and the component B contains 60-240ml / L of deionized water, 20-75ml / L of binding agent, 8-22ml / L of thickening agent, 4-8ml / L of silicon compound and the balance of the organic solvent. The method for preparing the water base non-chrome zinc-aluminium coating comprises the steps of: weighing the lamellar metal powder proportionally to be mixed uniformly, and then adding the organic solvent to be mixed uniformly for later use; mixing the reducing agent with the wetting agent, adding an appropriate amount of the deionized water to be mixed uniformly, and then adding the lamellar metal powder liquid to prepare the component A; proportionally weighing the thickening agent, the binding agent and the silicon compound, and adding the organic solvent to be mixed uniformly to prepare the component B; and mixing the prepared component A and the prepared component B according to the ratio of 2:1, and stirring unit uniform, thus obtaining the coating. The method for using the water base non-chrome zinc-aluminium coating is that the coating is coated on a part to be treated, and the baking temperature is increased to 360 DEG C so as to solidify and crosslink the coating to form a dense protective layer. The coating has the corrosion resistance which reaches 840 hours of a neutral salt spray test and over 96 hours of a heat resistance test, the usage amount of harmful substances is greatly reduced, and the working environment is improved.

Owner:翊鹏(湖北)实业有限公司

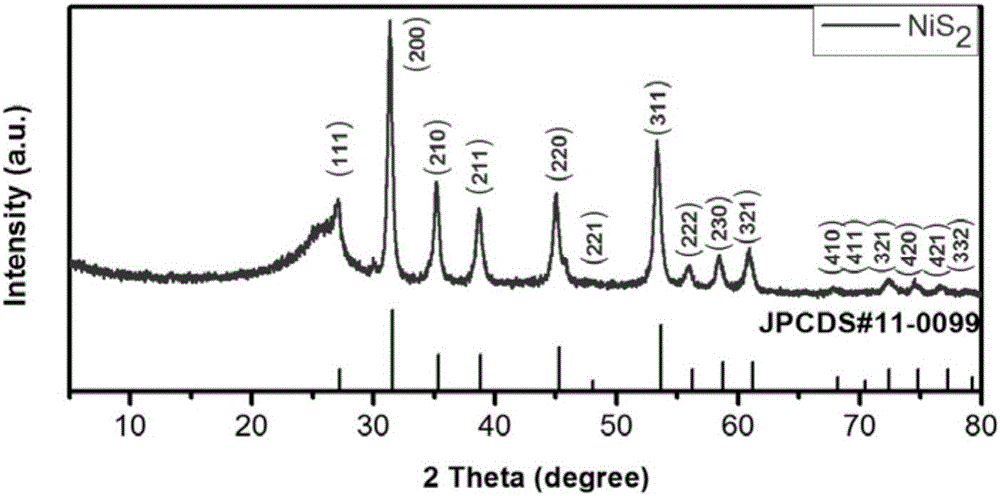

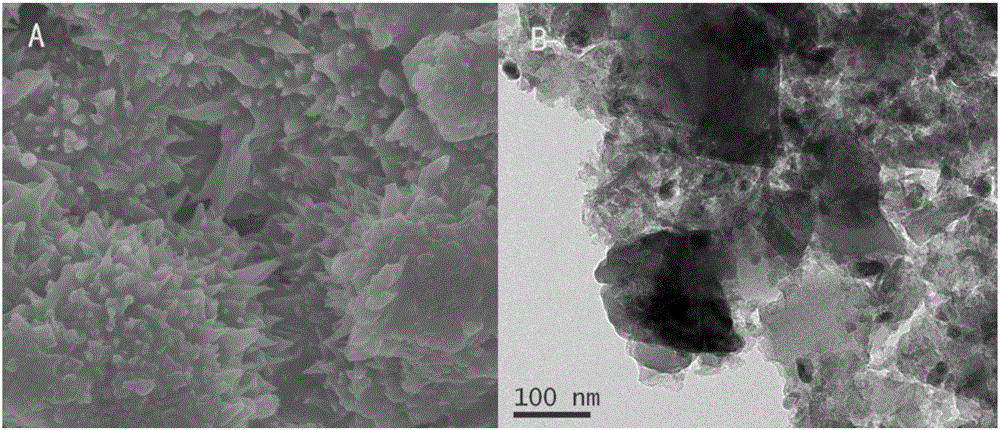

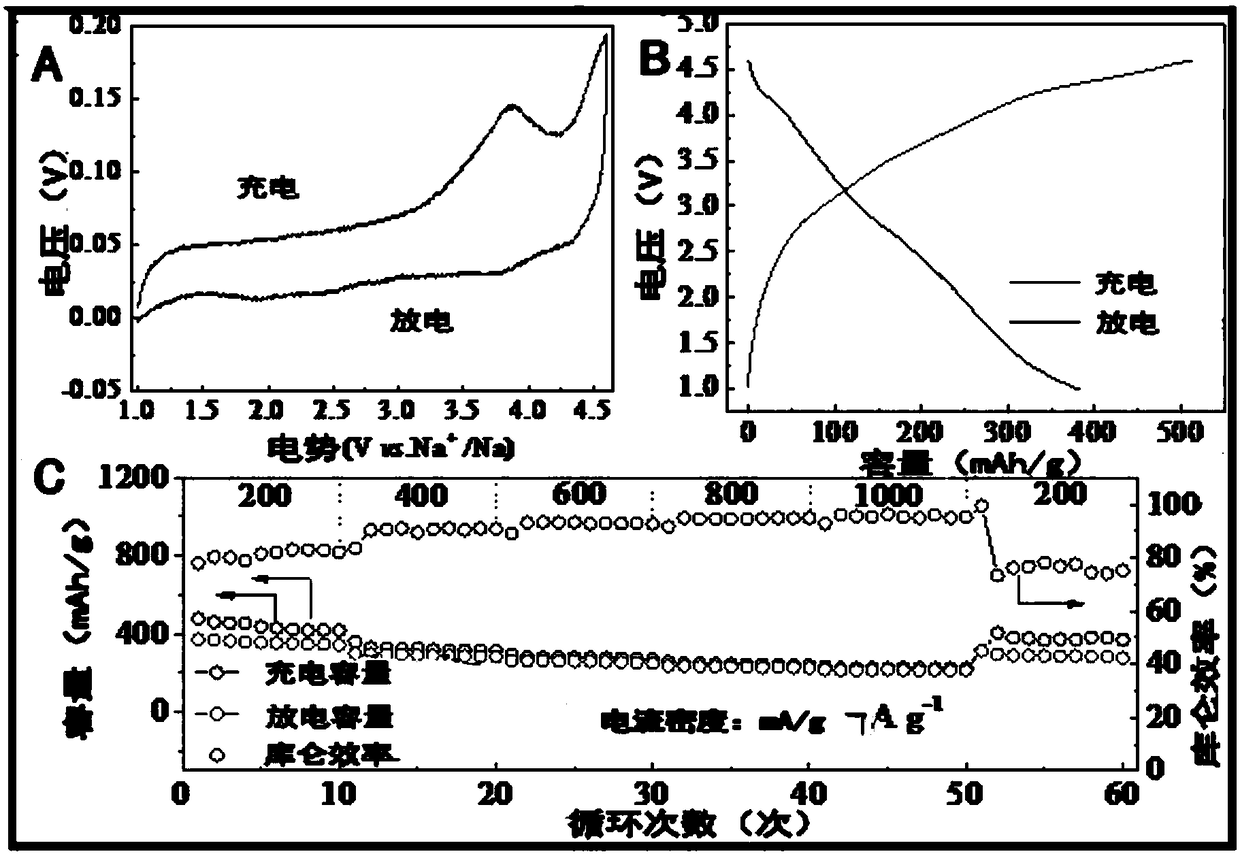

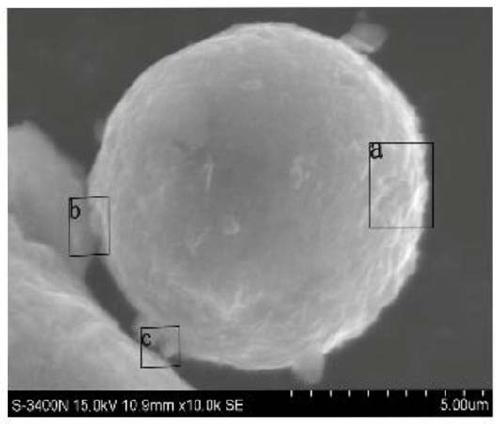

Preparation method of block NiS2 and application of block NiS2 to sodium-ion battery

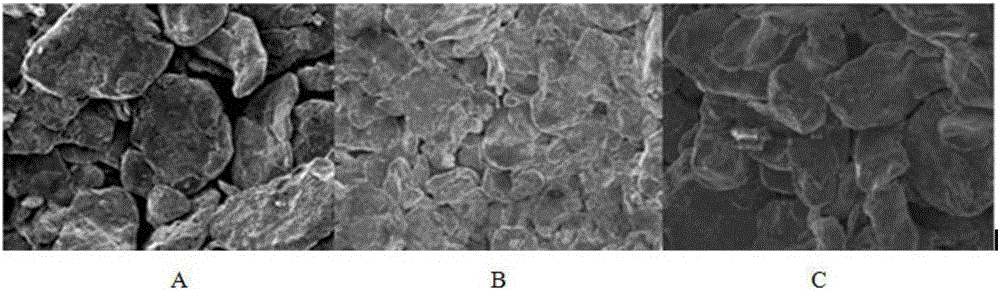

InactiveCN105883940AIncrease contact areaLower electrode potentialMaterial nanotechnologyCell electrodesNickel saltAlcohol

The invention discloses a preparation method of block NiS2 and an application of the block NiS2 to a sodium-ion battery. According to the method, a 2-methylimidazole alcohol solution is added to a nickel salt alcohol solution, the mixture is evenly mixed, left to stand, subjected to centrifugal separation and dried, and nickel precursors are obtained; the nickel precursors and sulfur powder are ground and mixed, the mixture is placed in a vacuum environment for heat treatment, and a block NiS2 material comprising high-purity NiS2 nano spherical small particles is obtained. The material is used as an anode material to be applied to the sodium-ion battery and shows excellent electrochemical properties such as the high specific capacity, the long cycle life and the like; the preparation method of the block NiS2 material is simple, the cost is low, and industrial production requirements are met.

Owner:CENT SOUTH UNIV

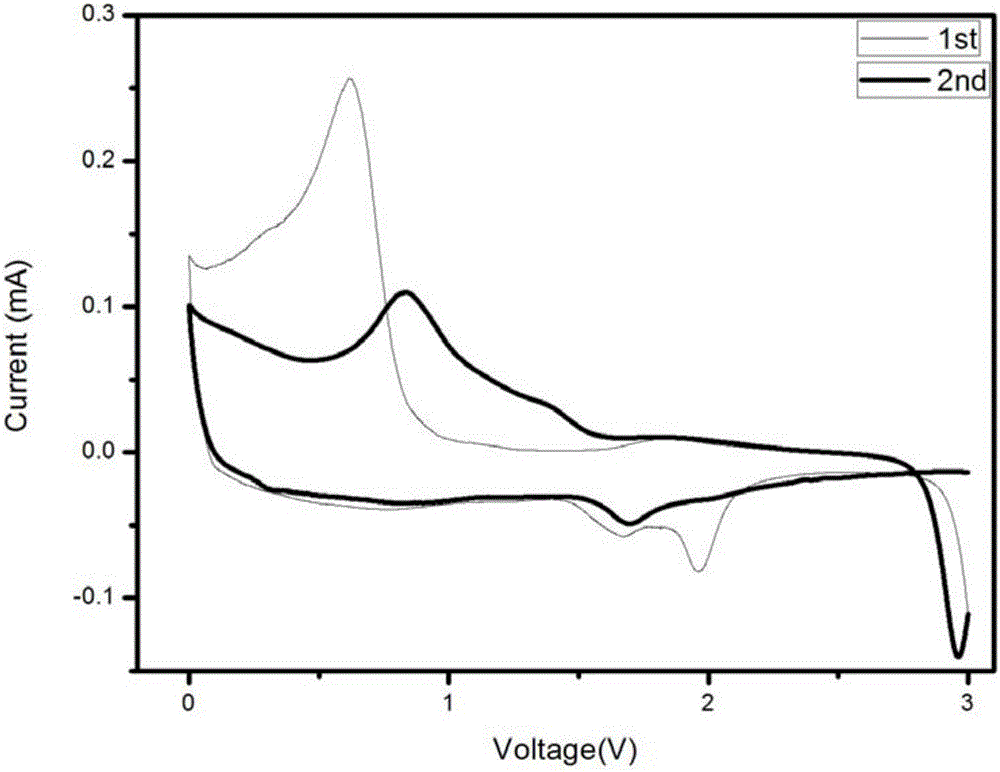

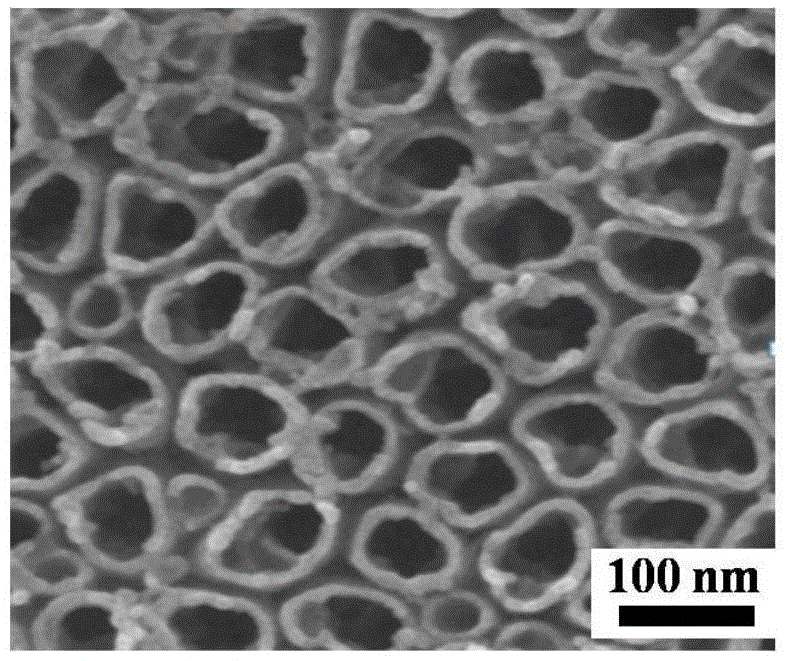

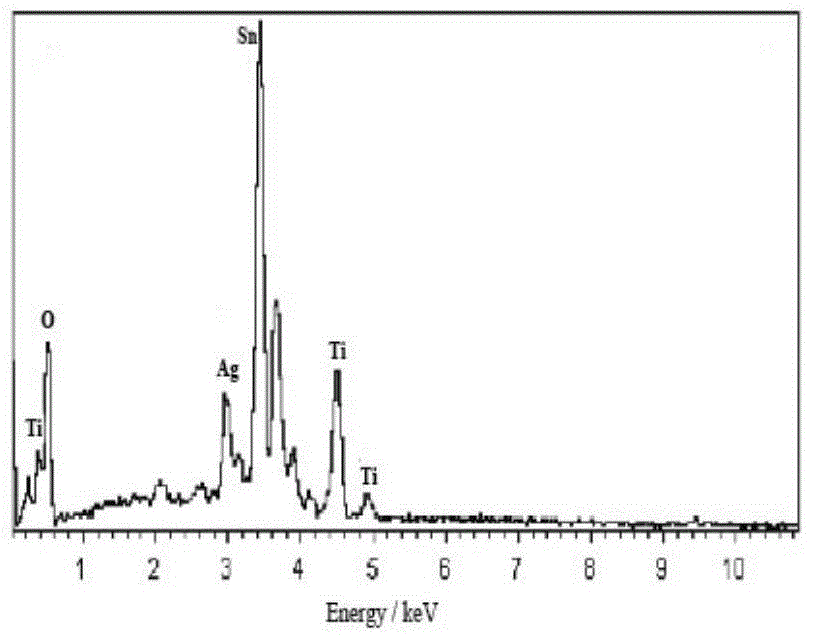

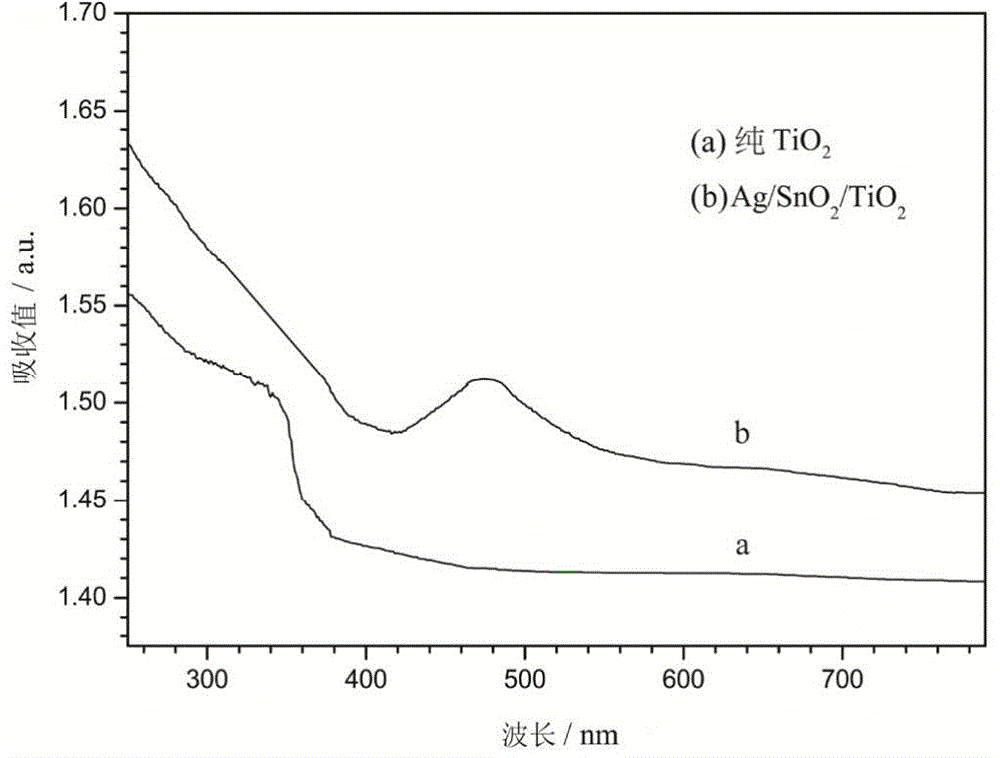

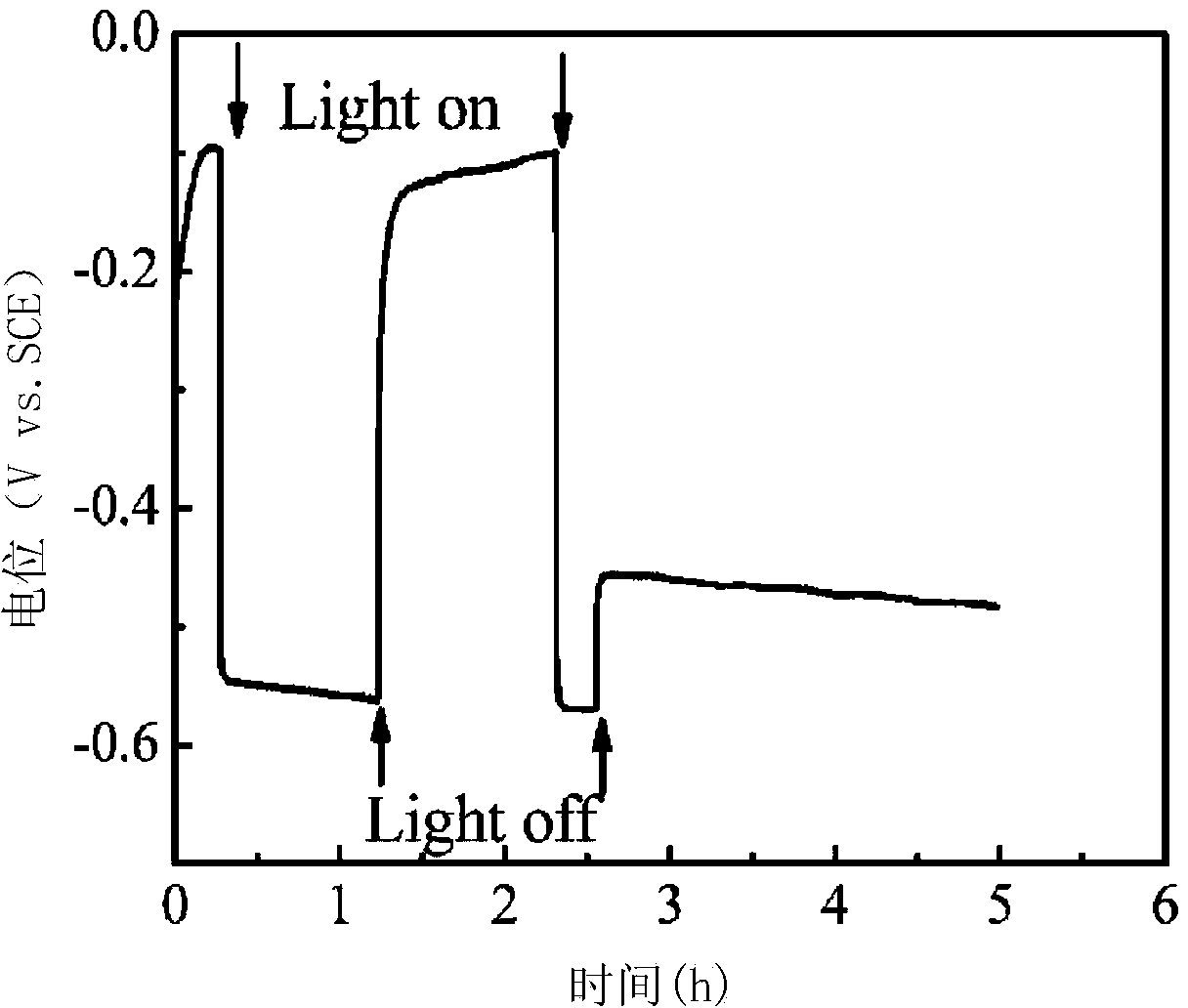

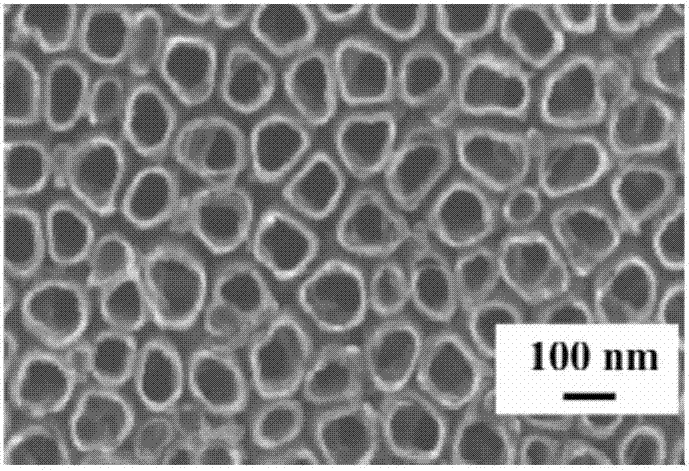

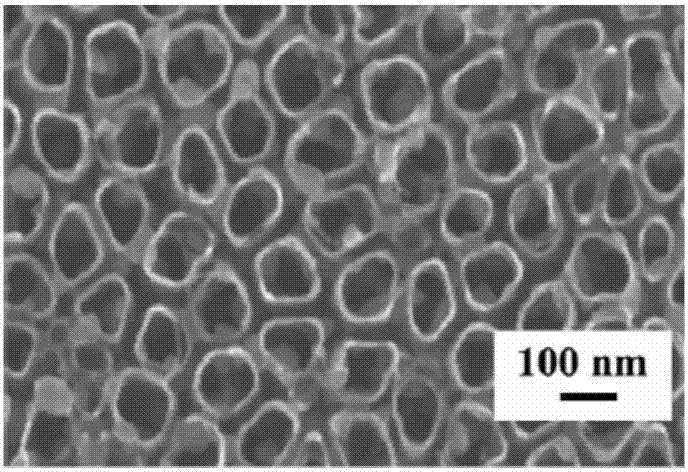

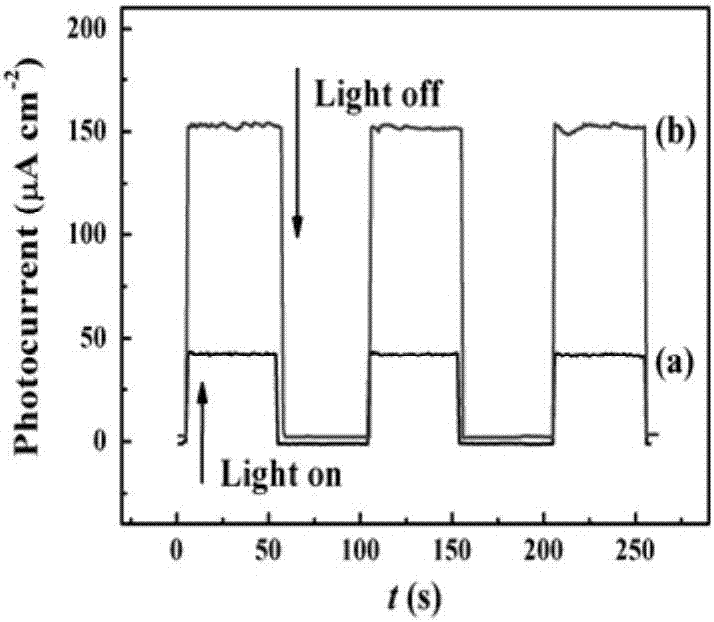

Preparation method for Ag/SnO2/TiO2 composite membrane photoanode used for photogenerated cathodic protection

ActiveCN103952708AUniform and complete coatingLower electrode potentialSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingTio2 nanotubeAcetone

The invention relates to preparation methods for an Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection, and relates to a composite membrane photoanode, and provides a preparation method for the efficient stable Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection. The preparation method comprises: 1) preparing a titanium substrate sample, specifically taking titanium foil as a substrate, and performing ultrasonic cleaning successively in acetone, absolute ethanol and deionized water to obtain a titanium substrate sample; 2) preparing a titanium-surface TiO2 nanotube array membrane, specifically dissolving NH4 in deionized water, adding glycol, mixing uniformly, taking platinum as a counter electrode, performing anodization, calcining the titanium substrate sample, and cooling to room temperature along the furnace, so as to obtain the TiO2 nanotube array membrane on the surface of titanium; and 3) preparing the Ag / SnO2 / TiO2 composite membrane, specifically preparing Ag and SnO2 nanometer particles on the surface of the TiO2 nanotube array membrane, so as to obtain the Ag / SnO2 / TiO2 photoanode used for photogenerated cathodic protection.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

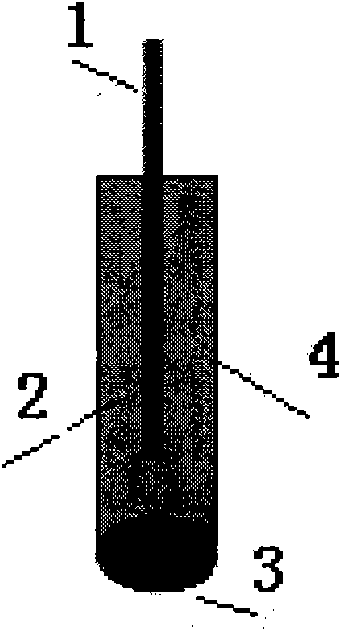

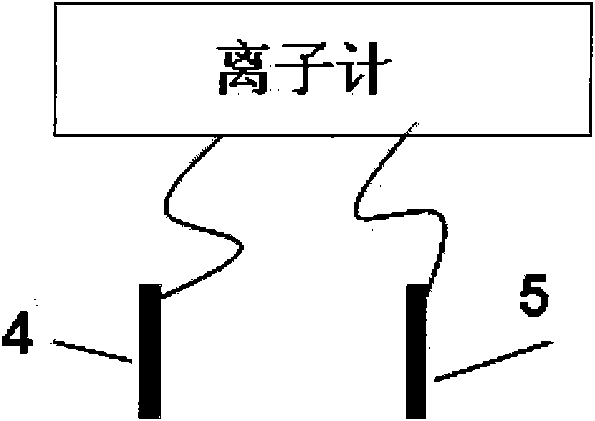

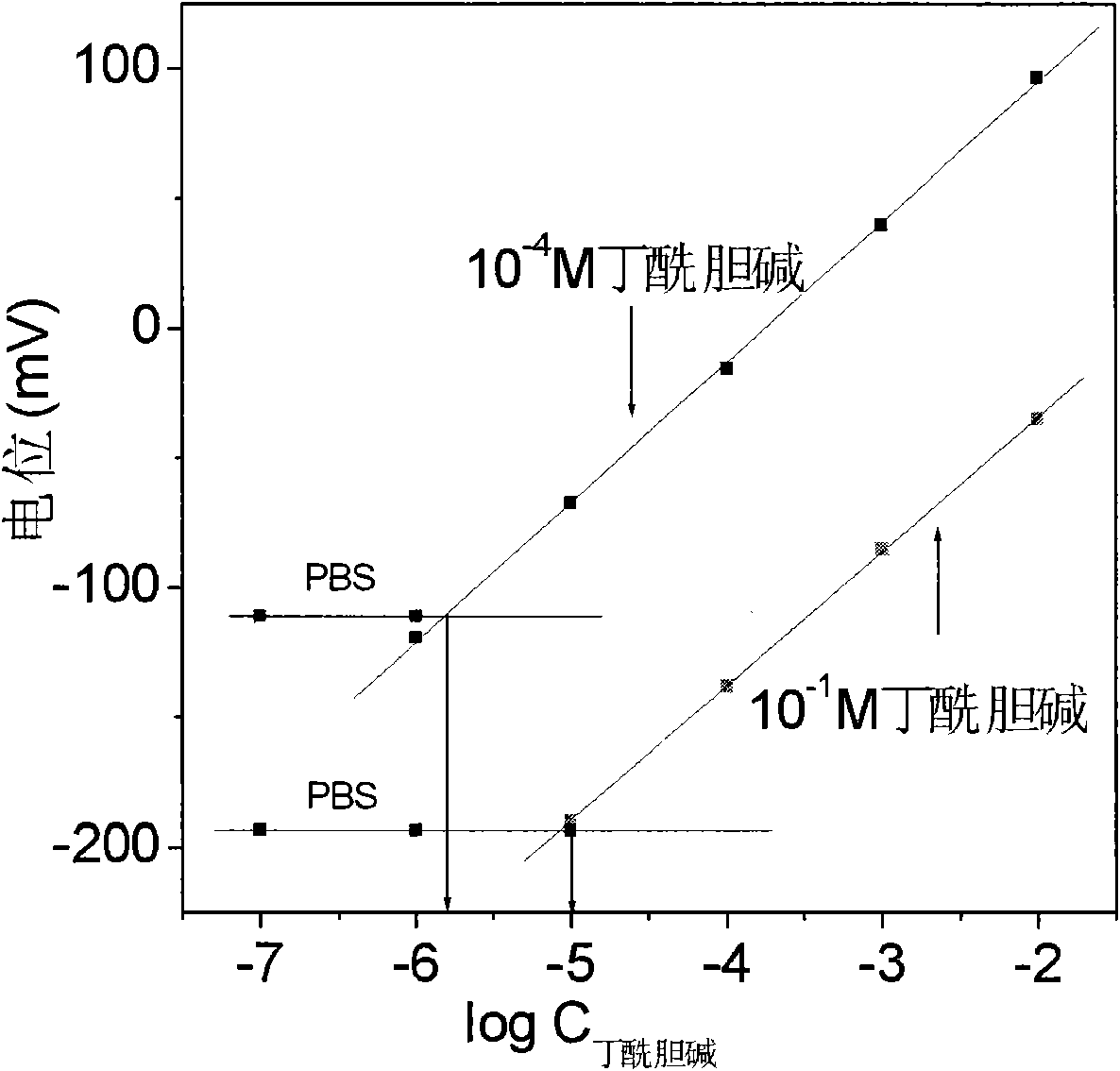

Method and device for detecting organic phosphorus pesticide

ActiveCN101685079ASimple and fast operationAvoid errorsMaterial electrochemical variablesButyrylcholinePotential difference

The invention relates to detection of organic phosphorus pesticide, in particular to a method and a device for detecting organic phosphorus pesticide. The method comprises the following concrete steps: inserting an ion selective electrode into a measuring pool and adopting seeped inner filling liquid during electrode detection as a substrate to generate a contrast signal; inserting the electrode into the measuring pool containing butyrylcholine esterase and standard pesticide and adopting the seeped inner filling liquid during electrode detection as the substrate to generate a standard signal; obtaining a standard curve by a potential difference of the standard signal and the contrast signal; finally inserting the electrode into the measuring pool containing butyrylcholine esterase and a sample to be detected and adopting the seeped inner filling liquid during electrode detection as the substrate to generate a sample signal; and obtaining the concentration of the organic phosphorus pesticide to be detected by the potential difference. The device adopts the structure that butyrylcholine inner filling liquid is contained in the electrode, an internal reference ratio electrode is inserted into the butyrylcholine inner filling liquid, and the bottom of the electrode is stuck with a polymer sensitive film. The electrode inner filling liquid can continuously seep, the enzyme substrate is generated at the original site of the surface of the electrode without manually adding the substrate, the operation is simple and convenient, and an error is prevented.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Preparation method of TiO2/SnO2 semiconductor two-layer composite film photo anode

ActiveCN104047043AUniform film layerLower electrode potentialElectrolytic coatingsVacuum evaporation coatingComposite filmPellicle membrane

The invention relates to a preparation method of a TiO2 / SnO2 semiconductor two-layer composite film photo anode and relates to a semiconductor photo anode. The invention provides the preparation method of the TiO2 / SnO2 semiconductor two-layer composite film photo anode with an efficient photo-induced cathodic protection effect. The preparation method comprises the following steps: 1) by using stainless steel as a matrix sample, grinding the surface of the matrix sample to a mirror surface, and then cleaning; 2) dissolving SnCl2.2H2O in water, then adding NaNO3 and nitric acid to prepare an electrolyte solution, and then adding water to fix the volume to 1000mL; by using platinum as a counter electrode and saturated mercurous chloride as a reference electrode and the matrix sample as a working electrode, in the electrolyte solution, electro-depositing and drying, namely electro-depositing a SnO2 film layer on the surface of the matrix sample; and 3) sputtering a TiO2 film on the surface of the SnO2 film layer obtained in the step 2), and then thermally treating to obtain the TiO2 / SnO2 semiconductor two-layer composite film photo anode. The photo-induced cathodic protection effect on metals by a TiO2 nano thin film in dark state is improved.

Owner:XIAMEN UNIV

Preparation method of energy storage tungsten trioxide/strontium titanate/titanium dioxide nanometer composite film photoanode

ActiveCN106894024AImprove photoelectric conversion efficiencyInhibitory complexElectrolytic inorganic material coatingSurface reaction electrolytic coatingComposite filmTio2 nanotube

The invention discloses a preparation method of an energy storage tungsten trioxide / strontium titanate / titanium dioxide nanometer composite film photoanode, and relates to a photoanode. A titanium foil is used as a basal body for ultrasonic operation in acetone, anhydrous ethanol and de-ionized water; a titanium basal body sample is used as an anode; a platinum piece is used as a cathode; after the anode is oxidized, a prepared sample is cleaned and dried to obtain a TiO2 nanotube array film; the TiO2 nanotube array film is put in a polytetrafluoroethylene reaction kettle; mixed solution containing Sr(COOH)2 and KOH is added for hydrothermal reaction; the sample is taken out to dip in HCl solution for cleaning, drying and calcining; and a SrTiO3 / TiO2 composite film is obtained. The SrTiO3 / TiO2 composite film is used as a working electrode; the platinum piece and a saturated calomel electrode are used as an auxiliary electrode and a reference electrode; constant potential is applied to an electrolytic cell for electric deposition to prepare WO3 on the surface of the SrTiO3 / TiO2 composite film; and the sample is flushed by de-ionized water, and is calcined after drying to obtain the photoanode.

Owner:XIAMEN UNIV

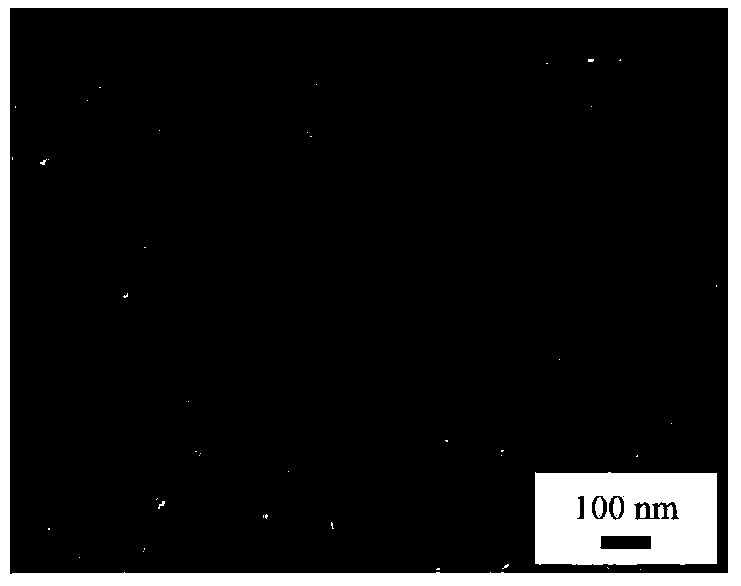

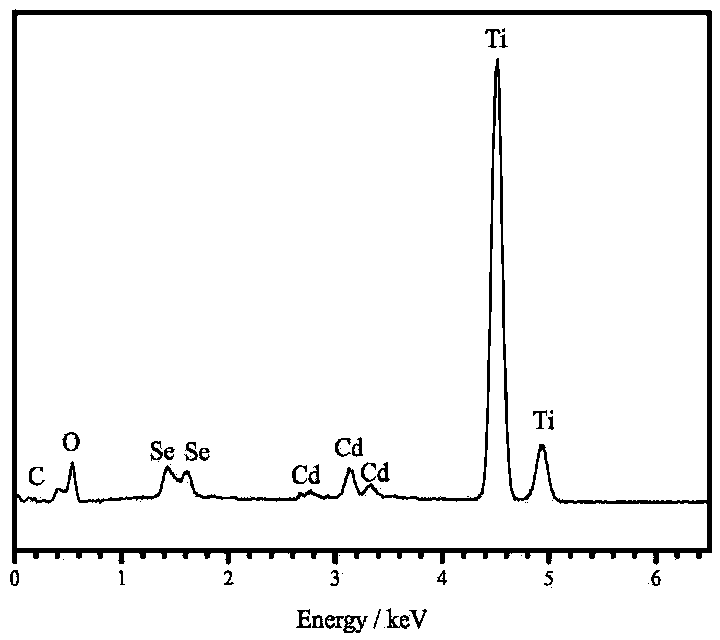

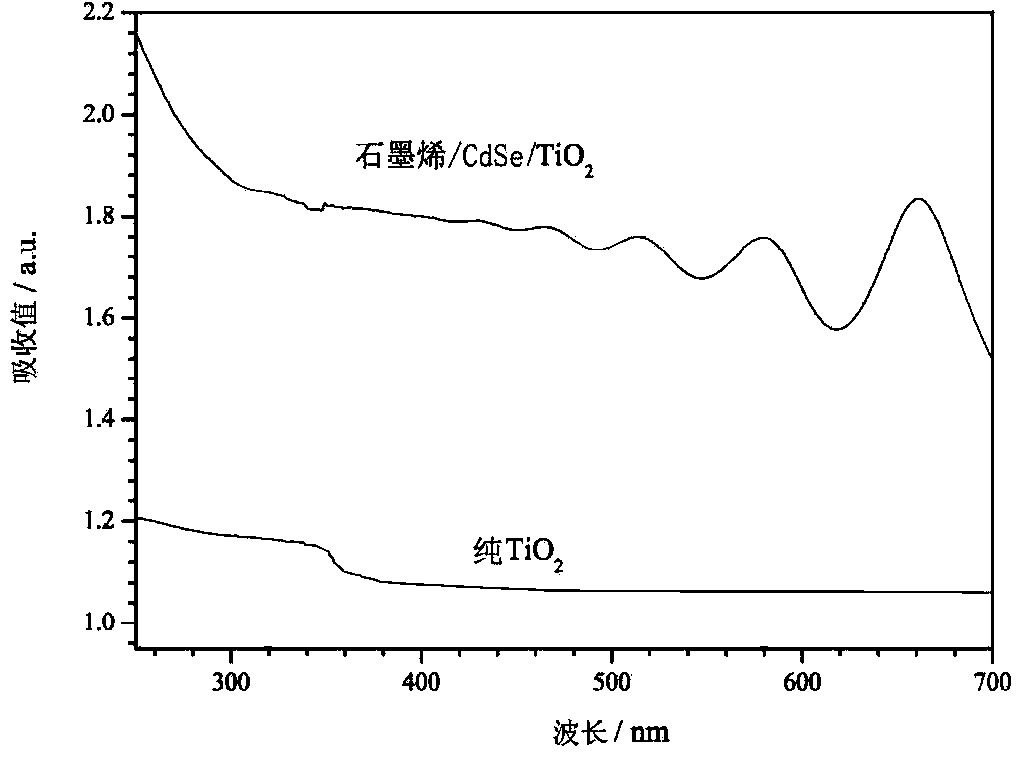

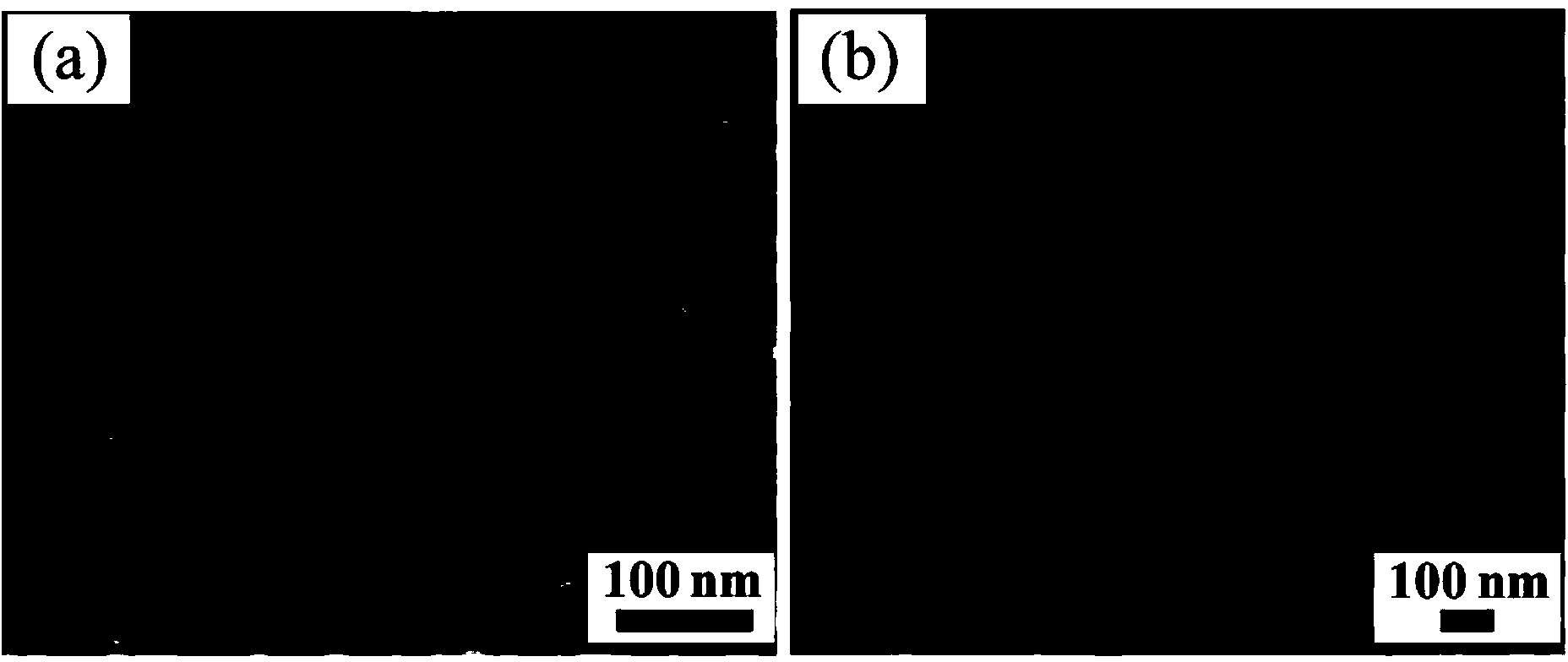

A preparing method of a graphene sensitized CdSe/TiO2 nanotube composite membrane

ActiveCN104164693AAvoid corrosionAchieve separationElectrolytic inorganic material coatingSurface reaction electrolytic coatingTio2 nanotubeCalcination

The invention relates to a nanotube composite membrane and particularly relates to a preparing method of a graphene sensitized CdSe / TiO2 nanotube composite membrane. The method includes: a step of performing anodic oxidation and then calcination by adopting titanium foil as a substrate, adopting a hydrofluoric acid solution as an electrolyte solution and adopting platinum as a counter electrode so as to prepare a TiO2 nanotube array membrane on the surfaces of titanium; a step of depositing graphene quantum dots onto the surfaces of the TiO2 nanotube array membrane by adoption of a cyclic voltammetry deposition method, namely a step of depositing graphene onto the surfaces of the TiO2 nanotube array membrane to prepare a graphene / TiO2 composite membrane by adopting a prepared graphene oxide solution as an electrolyte solution, adopting platinum as a counter electrode and adopting a saturated calomel electrode (SCE) as a reference electrode; and a step of depositing CdSe quantum dots onto the surfaces of the prepared graphene / TiO2 composite membrane, namely a step of depositing CdSe onto the surfaces of the graphene / TiO2 composite membrane to prepare the graphene sensitized CdSe / TiO2 nanotube composite membrane by adopting a mixed solution of SeO2, CdSO4 and sulfuric acid as an electrolyte solution, adopting platinum as a counter electrode and adopting a saturated calomel electrode (SCE) as a reference electrode.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

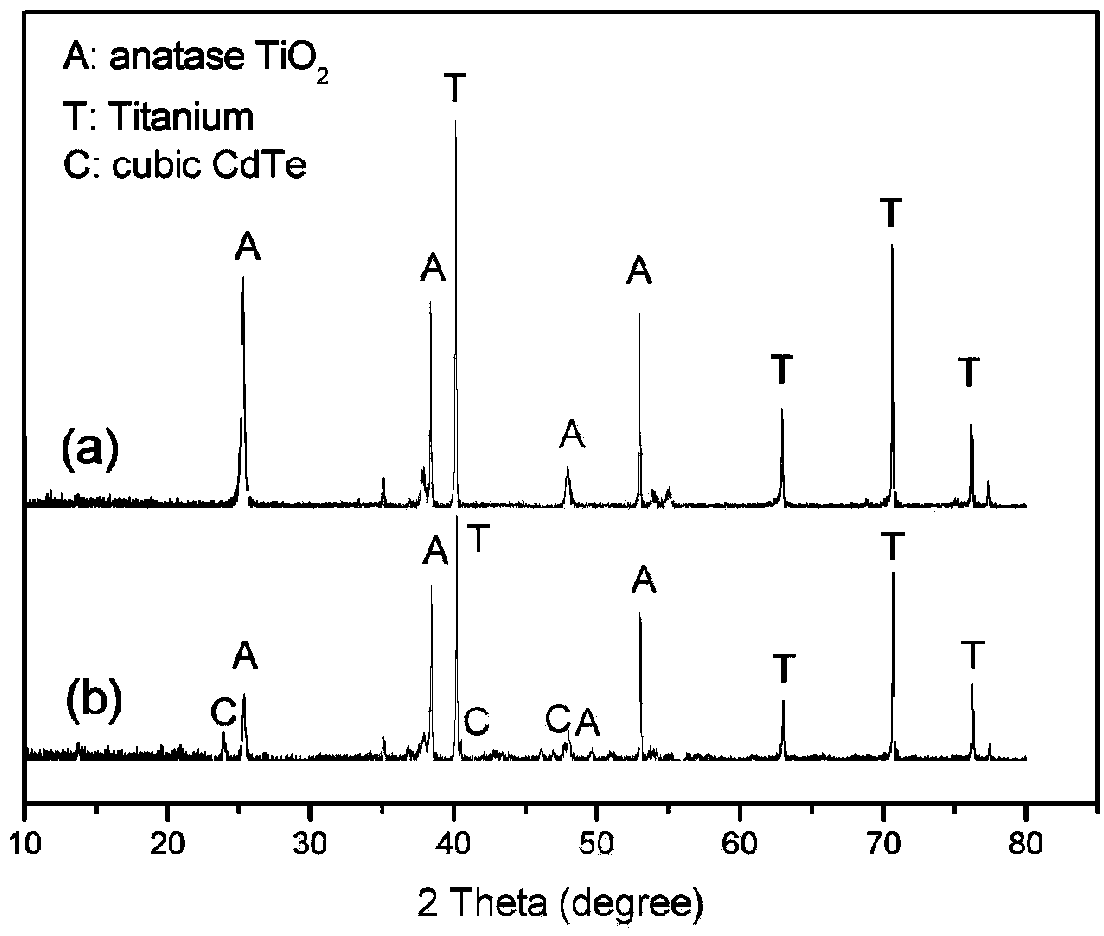

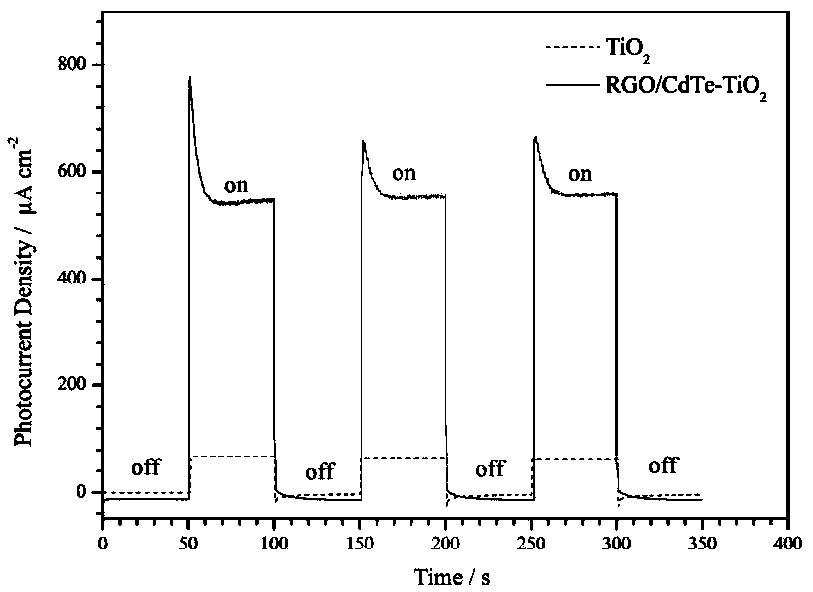

Preparation method of graphene/CdTe-TiO2 composite membrane photo-anode

ActiveCN104264158AAvoid corrosionAchieve separationElectrolytic inorganic material coatingSurface reaction electrolytic coatingTio2 nanotubeMaterials science

The invention relates to a preparation method of a graphene / CdTe-TiO2 composite membrane photo-anode for photo-induced cathodic protection and relates to a composite membrane photo-anode. The invention provides an efficient preparation method of the graphene / CdTe-TiO2 composite membrane photo-anode for photo-induced cathodic protection. The method comprises the following steps: sequentially carrying out anodic oxidation and calcining by taking a titanium foil as a matrix, taking a hydrofluoric solution as an electrolyte solution and taking platinum as a counter electrode, so that a TiO2 nanotube array membrane can be prepared on the titanium surface; firstly, by using a cyclic voltammetric deposition method, depositing graphene quantum dots on the surface of the TiO2 nanotube array membrane, and by taking a prepared graphene oxide solution as an electrolyte solution, taking platinum as a counter electrode and taking saturated calomel electrode (SCE) as a reference electrode, depositing graphene on the surface of the TiO2 nanotube array membrane, so that a graphene / TiO2 composite membrane is obtained; and then depositing CdTe quantum dots on the surface of the obtained graphene / TiO2 composite membrane, and by taking a mixed solution of TeO2, CdSO4 and a hydrochloric acid as an electrolyte solution, taking platinum as a counter electrode and taking a saturated calomel electrode (SCE) as a reference electrode, depositing CdTe on the surface of the graphene / TiO2 composite membrane, so that a graphene / CdTe-TiO2 composite membrane is prepared finally.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

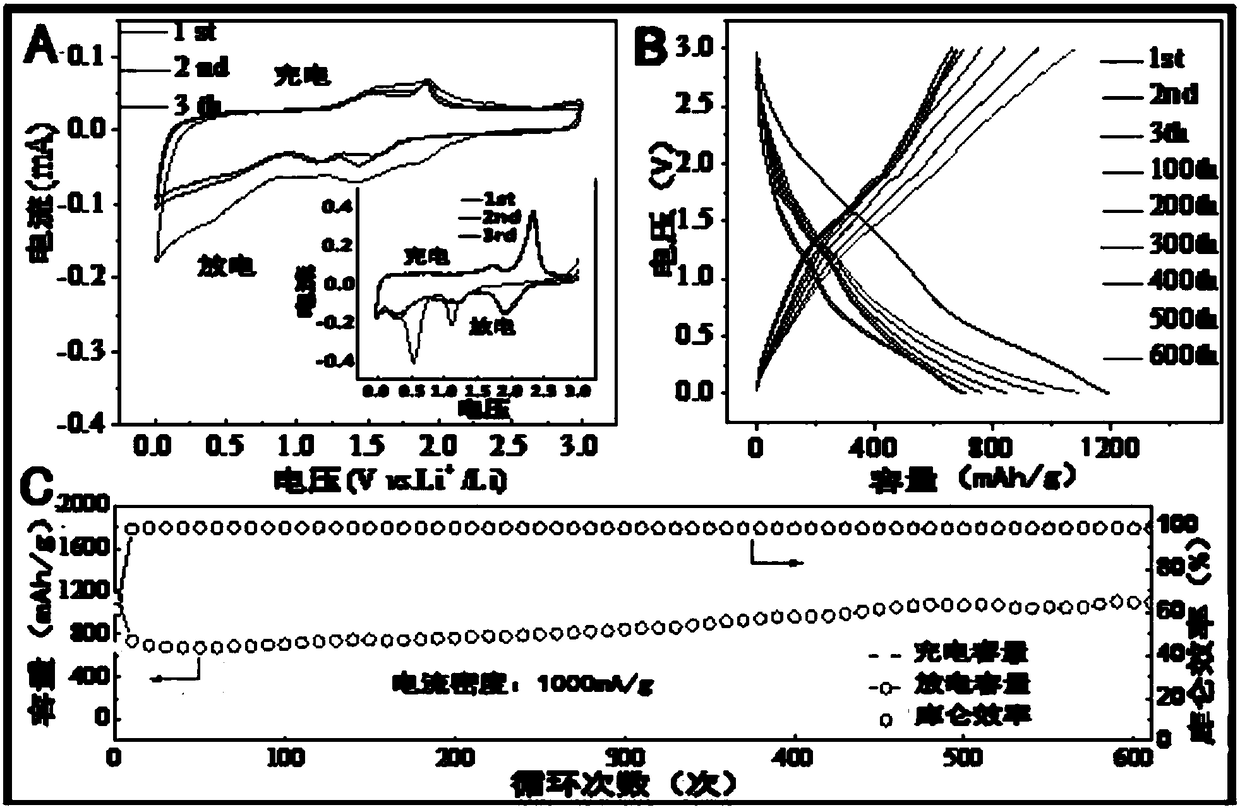

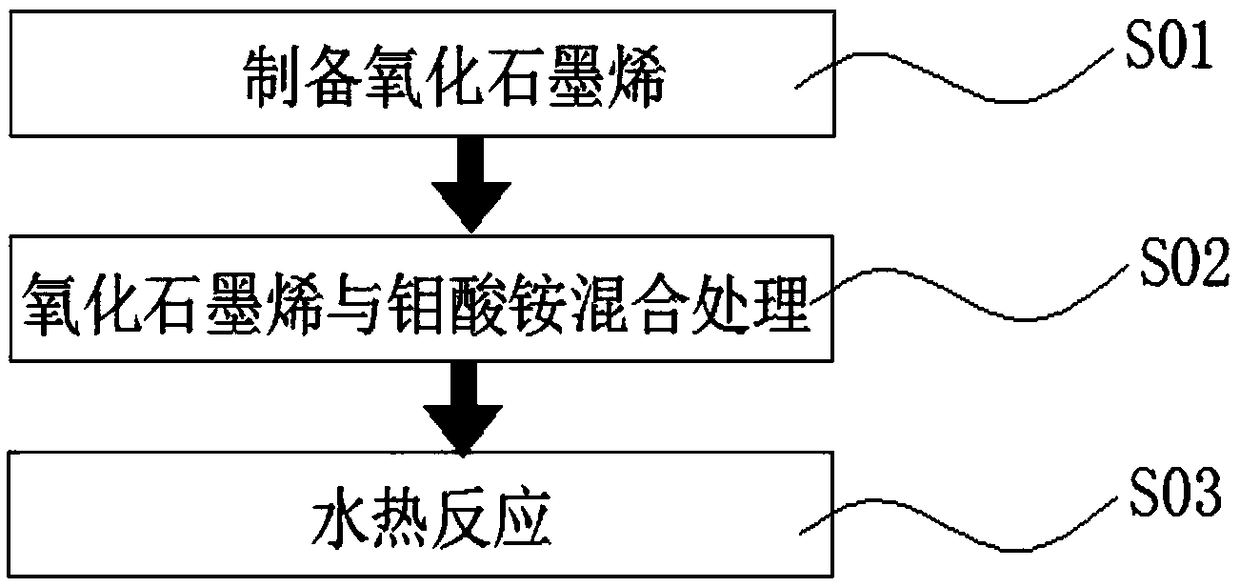

Preparation method of metalloid graphene negative electrode material and battery

InactiveCN108807835AImprove conductivityReduce rearrangementElectrode thermal treatmentNegative electrodesCvd grapheneAmmonium molybdate

The invention discloses a preparation method of a metalloid graphene negative electrode material and a battery. The method includes the steps: preparing oxidized graphene; mixing the prepared oxidizedgraphene with ammonium molybdate; performing hydrothermal reaction on mixture to obtain a 1T-MoS2 / graphene composite material with a layered three-dimensional structure. The 1T-MoS2 / graphene composite material is provided with an atomic-scale sandwiched three-layer nanostructure with a good interface, is a vertically stacked ultrathin two-dimensional layered graphene sheet / two-dimensional 1T-MoS2layered heterogeneous material, serves as a lithium / sodium ion battery and lithium / sodium double-ion battery negative electrode material and has high reversible capacity, ultra-long cycle life, excellent coulombic efficiency and high rate performance.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

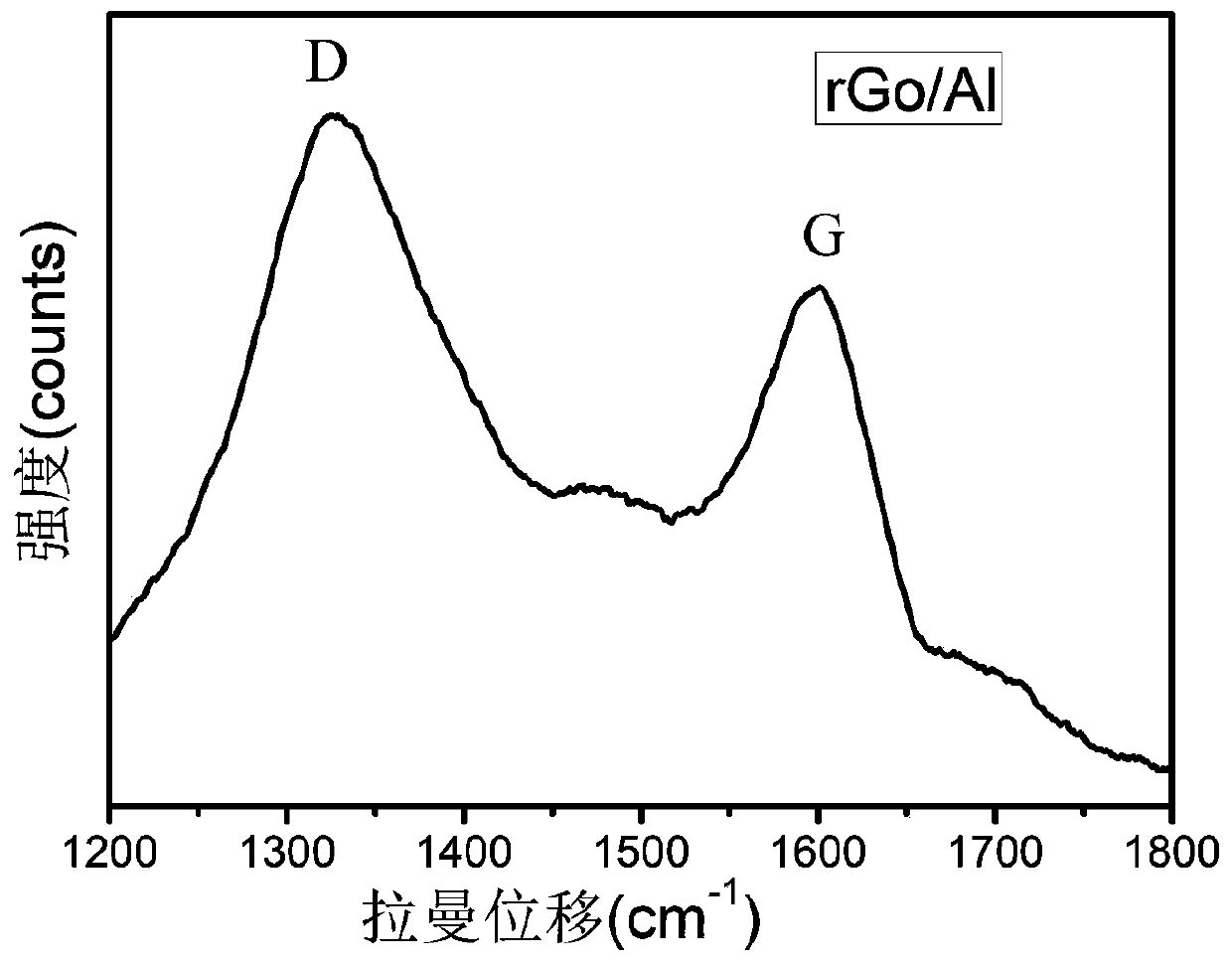

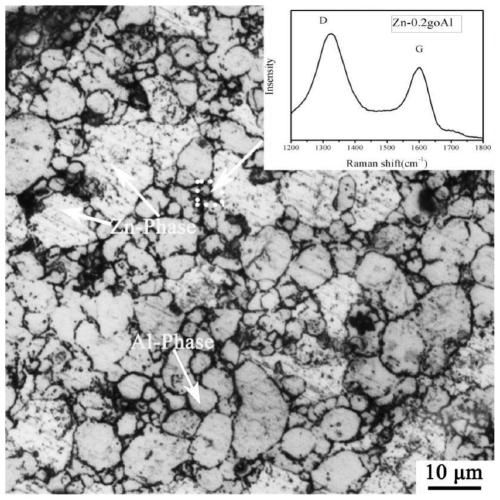

Zinc-based composite coating with rapid repairing capability as well as preparation method and application thereof

ActiveCN110144579AStrong cathodic protectionImprove repair abilityTransportation and packagingMetal-working apparatusElectrode potentialElectrical battery

The invention belongs to the technical field of metal surface treatment, and discloses a zinc-based composite coating with rapid repairing capability as well as a preparation method and application thereof. The zinc-based composite coating is prepared through the following steps that reduced graphene oxide coated aluminum powder and zinc powder are adopted, a cold spraying method is adopted for deposit a feed on the surface of a substrate, and reduced graphene oxide is uniformly dispersed in the zinc-aluminum phase interface. The thickness of the zinc-based composite coating is 0.05-1 mm. Thecomposite coating has lower electrode potential, a stable corrosion product layer can be quickly generated when the coating is complete, the consumption rate of the coating is reduced, and the protection life of the coating is prolonged. When the coating is damaged and the substrate is exposed, the coating and the substrate form an original battery to serve as an anode to form cathode protection on the substrate, so that a compact corrosion product can be quickly generated to fill a defect of the coating, so that a corrosion medium is prevented from damaging the substrate, and the coating canbe applied to the field of cathode protection of carbon steel.

Owner:GUANGDONG UNIV OF TECH

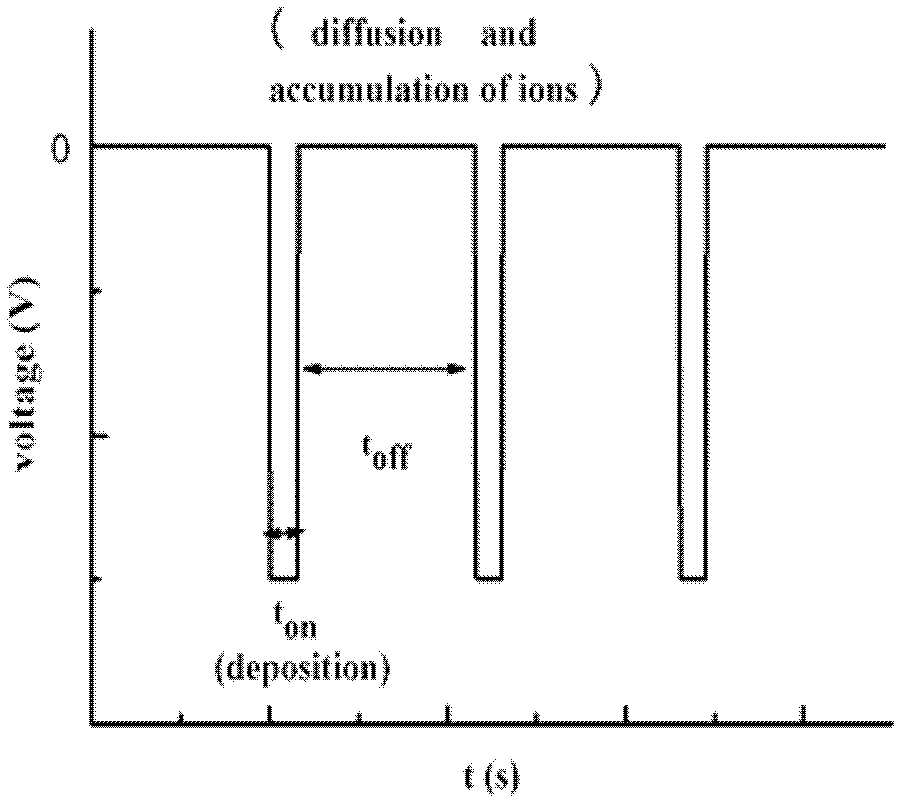

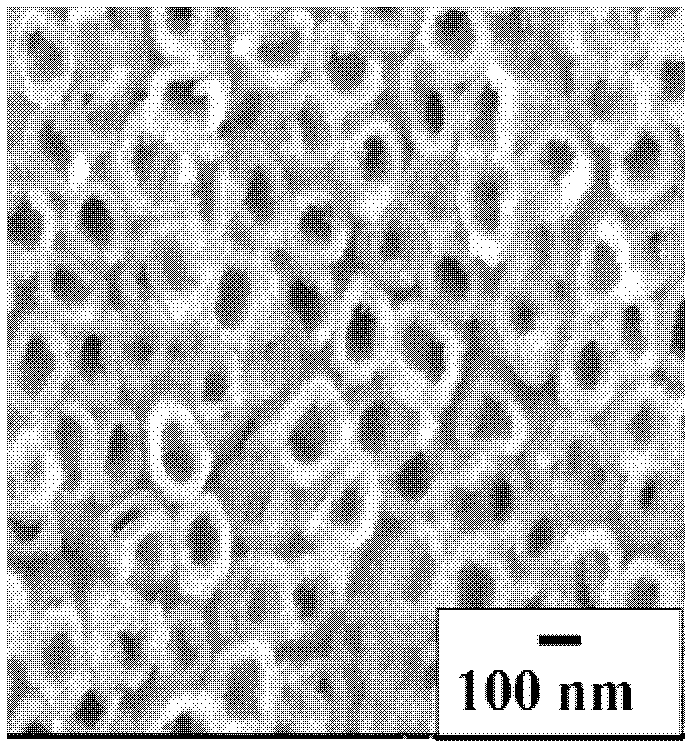

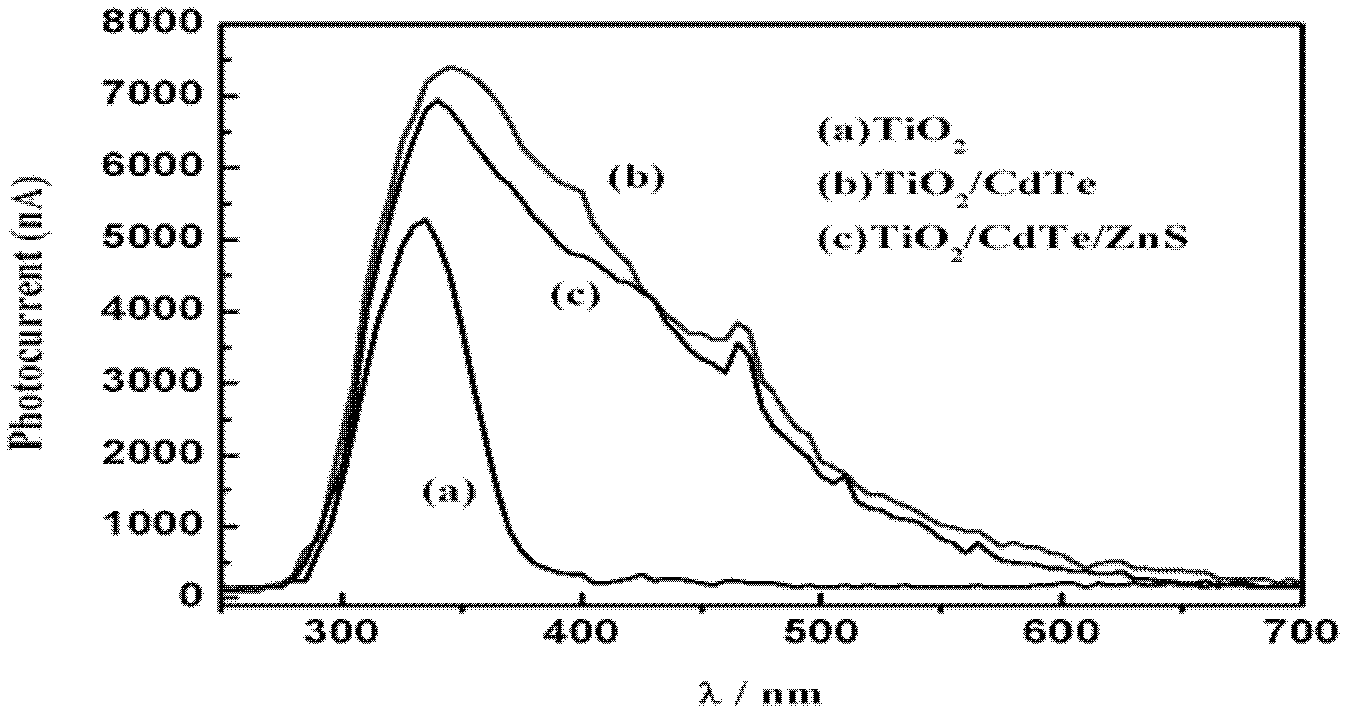

Preparation method of zinc sulfide (ZnS)/cadmium telluride (CdTe) quantum dot sensitization titanium dioxide (TiO2) nano film

InactiveCN102543457AReduce defect densityHigh crystallinityLight-sensitive devicesSolid-state devicesElectrode potentialCathode

The invention discloses a preparation method of zinc sulfide (ZnS) / cadmium telluride (CdTe) quantum dot sensitization titanium dioxide (TiO2) nano film, and relates to a TiO2 nano film. The method comprises the following steps: preparing a titanium matrix sample, preparing a TiO2 nano-tube array film at the surface of the sample, preparing a CdTe quantum dot sensitization TiO2 nano film, and finally preparing a ZnS / CdTe quantum dot sensitization TiO2 nano film. Under irradiation of white light, the film enables an electrode potential of connected metals like stainless steel to be greatly reduced in corrosive medium, and can protect good cathode of metals like stainless steel continuously for a long time in a dark state. And the nano film prepared by using the method has an efficient photoproduction cathode protection effect.

Owner:XIAMEN UNIV

Rare-earth modification anode type zinc-aluminum alloy wire material for thermal spraying

InactiveCN103205666AImprove corrosion resistanceExtended service lifeMolten spray coatingRare-earth elementElectrode potential

The invention relates to a rare-earth modification anode type zinc-aluminum alloy wire material for thermal spraying which belongs to the technical field of metal alloys and thermal spraying. The wire material comprises the following components: 3-8% of Zn, 0.5-1.5% of Mg, 0.1-0.5% of Re, 0.05-0.2% of Ti, 0.01-0.17% of M, impurities of which the total amount is less than 0.5%, and the balance of Al, wherein Re is a rare-earth material, and M is any one or the combination of In, Sn and Ga. The wire material combines respective advantages of zinc and aluminum, an alloy coating is modified by adding rare-earth elements, the electrode potential of the coating is reduced by adding elements such as indium, tin, gallium and the like, and the current efficiency of the coating is improved, so that a compact coating with a good cathode protection function and a certain self-sealing function is obtained; and meanwhile the occurrence of corrosive pitting is avoided, therefore steel is effectively prevented from corrosion of corrosive media, and the service life of a steel structure is prolonged.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Method for separating vanadium from vanadium-chromium waste residue

ActiveCN110358920ALower electrode potentialLow leaching rateProcess efficiency improvementLiquid ratioHydrogen

The invention relates to a method for separating vanadium from vanadium-chromium waste residue. According to the technical scheme, the method comprises the steps: sodium sulfite and sodium hydrogen sulfite are mixed according to the mass ratio of (1 to 4):1, and a reducing agent is obtained; vanadium-chromium waste residue powder and water are mixed according to the solid-to-liquid ratio of 1: (1to 2) Kg / L, and slurry is obtained; the slurry is added into a closed reactor, then the reducing agent is added into the closed reactor, stirring is conducted for 30-60 min under the conditions of 20-40 DEG C and 100-200 r / min, and reduced slurry is obtained, wherein the adding amount of the reducing agent is 3-9 wt% that of the vanadium-chromium waste residue powder; concentrated sulfuric acid isadded into the reduced slurry according to the ratio that 0.02-0.040 L of the concentrated sulfuric acid is added into the vanadium-chromium waste residue powder per kilogram, stirring is conducted for 1-4 h under the conditions of 20-40 DEG C and 200-400 r / min, and slurry after a reaction is obtained; and the slurry after the reaction is subjected to solid-liquid separation, and vanadium-rich liquid and chromium-containing leach residue are obtained. The method has the characteristics of high vanadium leaching rate, good vanadium-chromium separation effect and low energy consumption.

Owner:WUHAN UNIV OF SCI & TECH

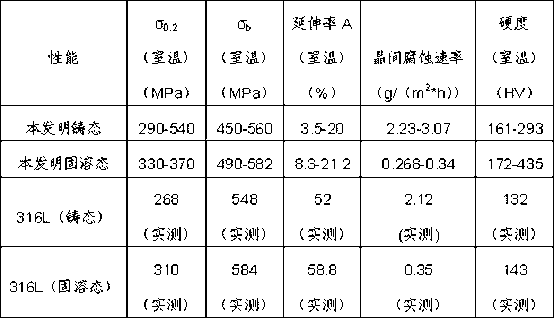

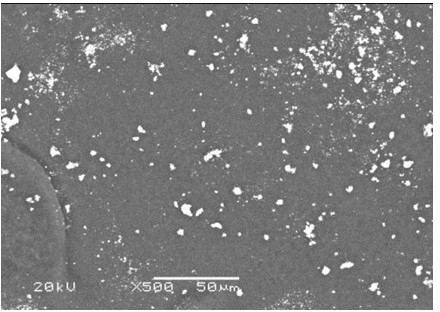

High-alumina 316L stainless steel and preparation method thereof

InactiveCN103266286ALower electrode potentialPromote passivationSolution treatmentSS - Stainless steel

The invention discloses high-alumina 316L stainless steel and a preparation method thereof. The high-alumina 316L stainless steel comprises the following ingredients by mass percent: 12.00-16.00% of Ni, 16.00-19.00% of Cr, no more than 1.0% of Si, no more than 0.035% of P, no more than 0.03% of S, no more than 0.03% of C, 1.8-2.5% of Mo, no more than 2.0% of Mn, 1.5-3.0% of Al, and the balance of Fe. The preparation method comprises the steps of (1) preparing materials according to the ingredients according to claim 1, wherein the furnace charge is a 316L stainless steel plate and industrial aluminum ingots; (2) heating the furnace charge to 700 DEG C under an atmosphere environment, carrying out heat preservation for half an hour; then heating until the melting temperature is 1540 DEG C, and carrying out heat preservation for 20 minutes; (3) pouring molten steel into a cast mold; and (4) carrying out solution treatment method, namely heating cast alloy to 1050 DEG C in a chamber electric furnace, carrying out heat preservation for 30 minutes, and then carrying out water-cooling treatment.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

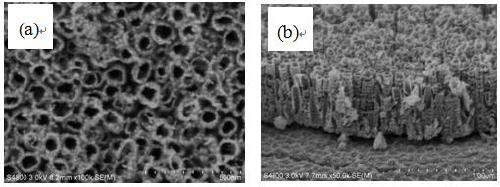

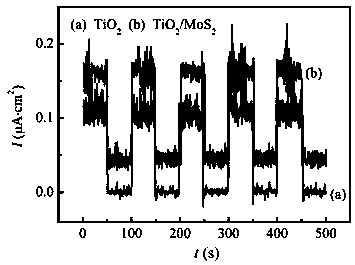

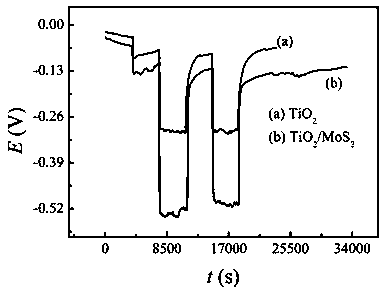

Photo-anode composite film as well as preparation method and application of photo-anode composite film

ActiveCN110042452AGood repeatabilityImprove stabilityMaterial nanotechnologySurface reaction electrolytic coatingElectron holeTio2 nanotube

The invention discloses a photo-anode composite film as well as a preparation method and application of the photo-anode composite film, and belongs to the technical field of metal corrosion and protection. The photo-anode composite film which is a TiO2 nanotube arrayed composite film with MoS2 nano particles attached to the inner surfaces and the outer surfaces of TiO2 nanotubes. According to thephoto-anode composite film as well as the preparation method and the application of the photo-anode composite film, TiO2 nanotube arrayed film prepared on the surface of a titanium foil through an anodic oxidation method is taken as the basis, a layer of MoS2 nano particles with visible light absorption capacity is deposited on each of the inner surface and the outer surface of each TiO2 nanotubethrough a hydrothermal method, so that the TiO2 / MoS2 nano-composite film is obtained; the photoinduced electron-hole composite probability of the TiO2 / MoS2 nano-composite film is relatively lower, thelight absorption range is expanded, and the photoelectric conversion efficiency is remarkably improved; and the photo-anode composite film has very good photoinduced cathode protection effect on stainless steel.

Owner:BINZHOU UNIV

Automobile heat dissipation fin aluminum foil prepared from aluminum alloy XR348and preparation method of automobile heat dissipation fin aluminum foil

ActiveCN107299259AHigh strength after weldingImprove corrosion resistanceHeat exchange apparatusMetal rolling arrangementsManganeseImpurity

The invention relates to an automobile heat dissipation fin aluminum foil prepared from an aluminum alloy XR348. The aluminum alloy XR348 is prepared from the following components: 1.1 to 1.4 weight percent of manganese, 1.0 to 1.2 weight percent of silicon, 0.9 to 1.1 weight percent of iron, 0.8 to 1.0 weight percent of zinc, 0.21 to 0.30 weight percent of zirconium, 0 to 0.05 weight percent of titanium, 0 to 0.03 weight percent of copper, 0 to 0.01 weight percent of magnesium, 0 to 0.03 weight percent of a single unavoidable impurity, 0 to 0.10 weight percent of all unavoidable impurities and the balance of aluminum. The preparation method of the automobile heat dissipation fin aluminum foil comprises a step of performing continuous casting-rolling on the aluminum alloy XR348, so as to obtain the automobile heat dissipation fin aluminum foil. The preparation method disclosed by the invention is short in flow and high in quality; after being subjected to high-temperature soldering, the aluminum foil is extremely high in postwelding strength and high in corrosion resistance; diffusion of silicon atoms on a soldered layer can be prevented, so that the hang-down resistance property of a material is improved; therefore, the aluminum foil and the preparation method which are disclosed by the invention are extremely high in performance.

Owner:江阴新仁铝箔科技有限公司

Chemical immersion tin plating solution and preparation method thereof

InactiveCN109055921AUniform and dense coatingGood solderability of the coatingLiquid/solution decomposition chemical coatingEnvironmental chemistryCompound (substance)

The invention relates to a chemical immersion tin plating solution and a preparation method thereof. The chemical immersion tin plating solution is composed of tin salt, an accelerant, a wetting agentand a stabilizer, wherein the mass concentration of the tin salt is 5-20 g / L, the mass concentration of the accelerant is 30-200 g / L, the mass concentration of the wetting agent is 0.1-0.5 g / L, the mass concentration of the stabilizer is 50-170 g / L. Under reasonable concentration proportioning and the synergistic effect of all the components, the chemical immersion tin plating solution is very stable, the plating layer is uniform, compact and semi-bright, moreover, the used working temperature is not high, the temperature is 35-45 DEG C, plating is carried out for 10-15 minutes, the thicknessof the plating layer can reach about 1.5-2 microns, and the plating layer is good in weldability.

Owner:CHONGQING LIDAO SURFACE TECH

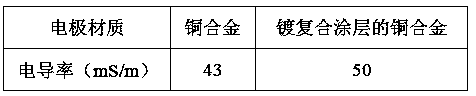

Preparation method of corrosion-resistance and high-electroconductibility composite coating for electrode

ActiveCN109402586AReduce usageEnhance film bindingVacuum evaporation coatingSputtering coatingComposite ceramicAlloy

The invention relates to a preparation method of a corrosion-resistance and high-electroconductibility composite coating for an electrode. The electrode is a Cu alloy electrode, and the composite coating comprises a Ti thin film and a titanium oxide coating thin film which coat the surface of the Cu alloy electrode in sequence. The method comprises the following specific steps that the Cu alloy electrode is taken, deoxidized and subjected to impurity removal; titanium oxide powder and Ti powder are weighed according to the weight ratio of 98:2-99:1, mixed, then put into a sintering furnace andsintered into composite ceramic blocks, and a composite target material is prepared; a magnetron sputtering coating machine is used for making the surface of the Cu alloy electrode coated with the Tithin film, and the thickness of the Ti thin film is 40-100 nm; the magnetron sputtering coating machine is used for making the surface of the Ti thin film coated with the titanium oxide thin film, and the thickness of the titanium oxide thin film is 2-5 microns. According to the preparation method, the surface of the Cu alloy material is coated with the Ti coating and the titanium oxide coating,the service life of the Cu alloy material is prolonged, the material cost is lowered, and accordingly the electrode material has high corrosion resistance and electroconductibility.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

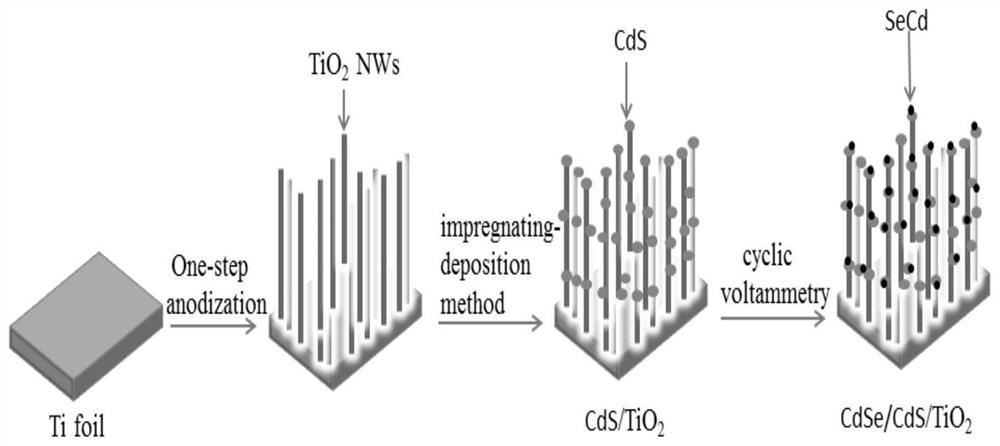

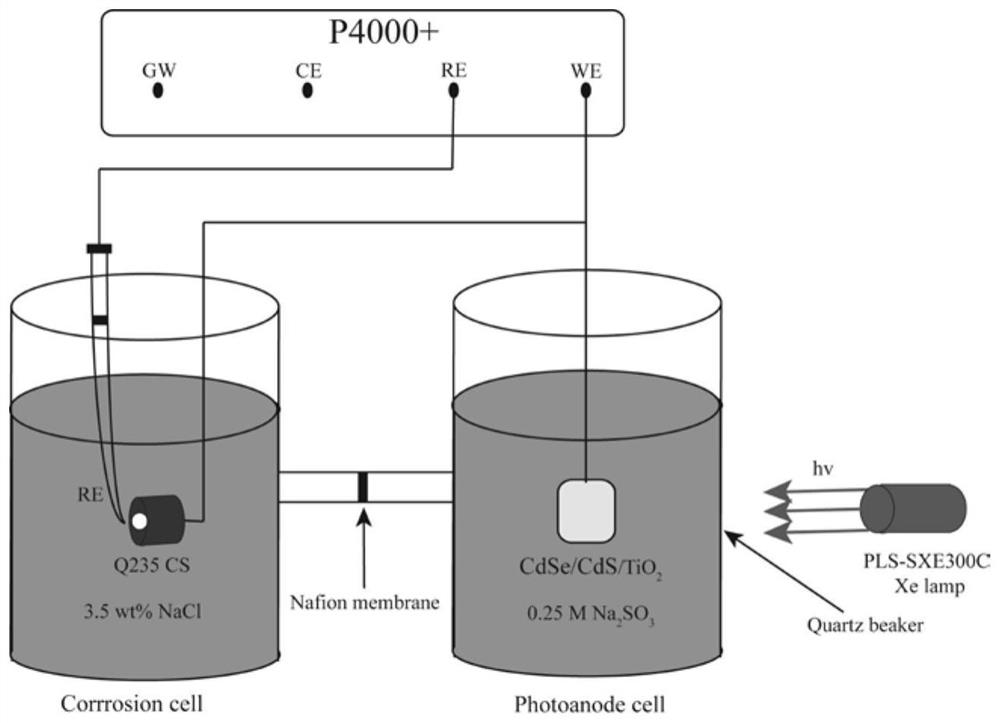

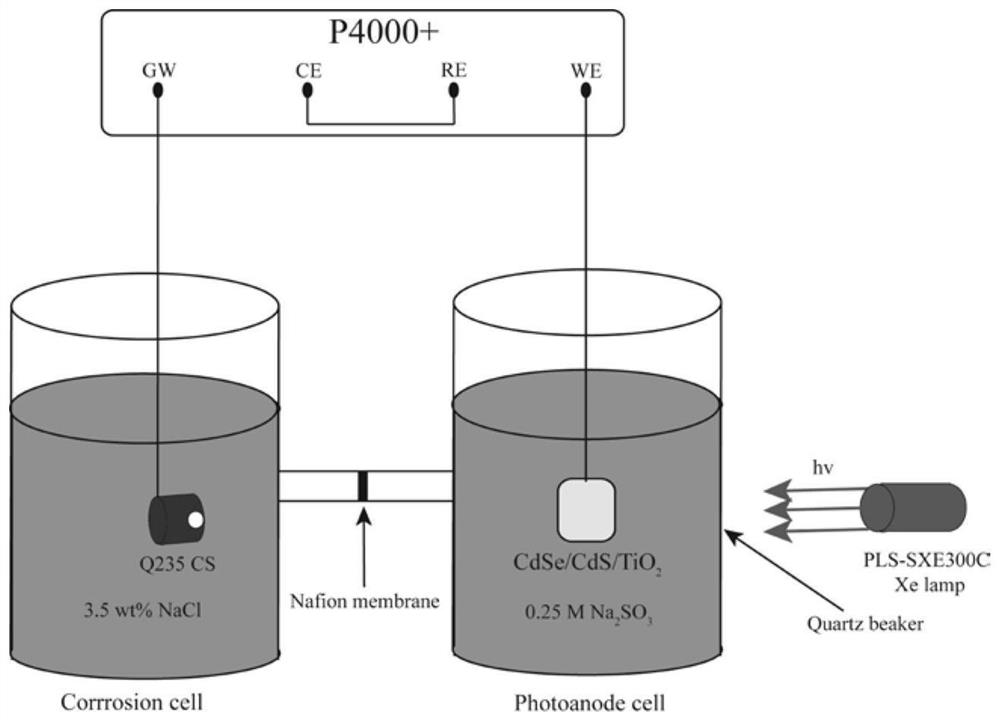

Photo-anode composite membrane material and application thereof

ActiveCN112779542ABroaden the response rangeIncrease profitMaterial nanotechnologyElectrolytic inorganic material coatingElectrode potentialNanowire

The invention relates to a photo-anode material, in particular to a photo-anode nano composite membrane material (CdSe / CdS / TiO2 composite membrane photo-anode) prepared by adopting an impregnation-deposition method and a cyclic voltammetry and application. CdSe and CdS nano particles are compounded on the surface of a TiO2 nanowire by adopting the impregnation-deposition method and the cyclic voltammetry to prepare the CdSe / CdS / TiO2 nano composite membrane photo-anode material. When the composite membrane is used as a photo-anode material for cathodic protection, compared with a pure TiO2 material, the photo-anode nano composite membrane material has the advantages that the visible light utilization rate of TiO2 and the separation rate of photo-induced electron-hole pairs are remarkably improved, the electrode potential of Q235 carbon steel is reduced, the corrosion rate is reduced, and the photo-induced cathodic protection performance of TiO2 on Q235 carbon steel is effectively improved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Epoxy alloy industry anti-corrosion paint

InactiveCN101265388ALong stable timeLower electrode potentialAnti-corrosive paintsEpoxy resin coatingsEpoxyIsophorone

The invention relates to an epoxy alloy industrial anti-corrosive paint, which consists of an ethoxyline resin with high molecular weight, alloy of zinc, magnesium and aluminum, and isophorone diamine. The epoxy alloy industrial anti-corrosive paint is applicable to corrosion prevention of metal in air in coastlands, and is characterized by lower cost than the epoxy zinc-rich paint, long performance life, excellent appearance, and capability of being used as a finish coat alone.

Owner:于沛洲

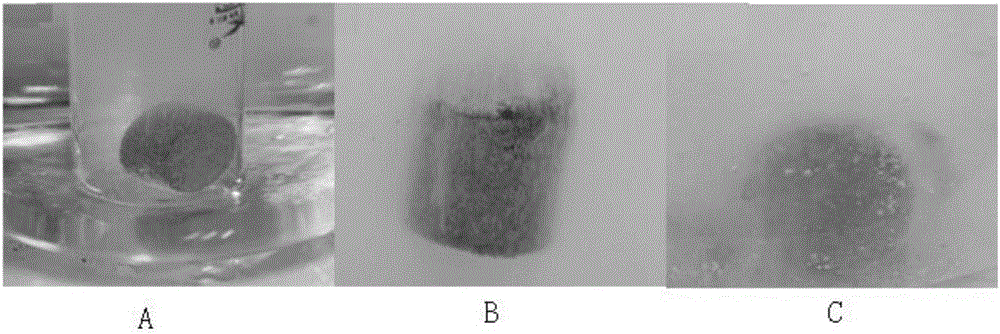

Iron-containing magnesium-based composite material as well as preparation method and application thereof

InactiveCN105177383ASolve storage problemsNo pollution in the processFluid removalHydrogen productionPorosityGeneration rate

The invention discloses an iron-containing magnesium-based composite material as well as a preparation method and an application thereof. The mass fraction of Fe in the composite material is 0.01 to 10 percent, and the balance is magnesium, and the material density is 1.37 to 2.35g / cm<3>. The preparation method of the iron-containing magnesium-based composite material comprises the following steps: (1) ball milling magnesium powder and iron powder to form a uniform mixture, wherein the mass fraction of the Fe powder in the mixture is 0.01 to 10 percent, and the balance is magnesium powder; (2) placing the uniform mixture processed in the step 1 into a forming mold, and pre-pressing and forming under the conditions that the temperature is 25 to 150 DEG C and the pressure is 50 to 300 MPa; and (3) sintering the material pressed and formed in the step (2) under the argon protection condition, wherein the sintering temperature is 580 to 600 DEG C, the sintering time is 2 to 5 hours, and the pressure is 100 to 300 MPa. The iron-containing magnesium-based composite material can be used as a hydrogen evolution reaction raw material and a fracturing ball during the petroleum exploitation process. The iron-containing magnesium-based composite material is simple in preparation process and high in hydrogen generation and dissolving rate; and moreover, the hydrogen generation rate can be controlled by virtue of porosity and the surface area, and the application of the product produces no pollution.

Owner:CHONGQING UNIV

Preparation method of rare earth doped LiNi0.5 Mn1.5O4 as anode material for super capacitor

InactiveCN102324322ALow costReduce energy consumptionElectrolytic capacitorsSupercapacitorAqueous solution

The invention provides a preparation method of rare earth doped LiNi0.5 Mn1.5O4 as an anode material for a super capacitor. The preparation method comprises the following steps of: respectively taking compounds of Ni, Mn and Li according to the mole ratio that Ni to Mn to Li to rare earth is 1:3.0:(2.05-2.24):(0.003-0.02), adding the compounds of Ni, Mn and Li in a reaction pot and adding pure water to obtain a mixed solution A; based on a target product, respectively taking 6-30% of citric acid, 300-600% of pure water and 0.002-0.01% of dispersing agent, adding the citric acid and the dispersing agent to the pure water, and uniformly stirring; and then adding the rare earth to the aqueous solution of citric acid to obtain a solution B; adding the solution B to the solution A to obtain a solution C; adjusting the pH value of the solution C to 5-7, heating the solution C in a water bath manner to obtain a precursor; and putting the precursor in a metal container and carrying out microwave baking on the precursor to obtain the target product. According to the invention, the conductivity of LiNi0.5 Mn1.5O4 and the energy density of the super capacitor are improved greatly, the preparation process is simplified by adopting a microwave treatment technology, and thus the preparation method is easy for industrial implementation.

Owner:HENAN COAL CHEM IND GROUP INST +1

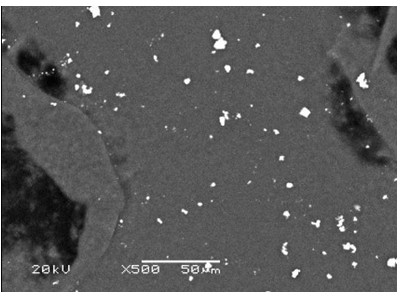

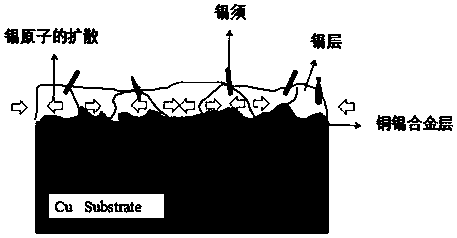

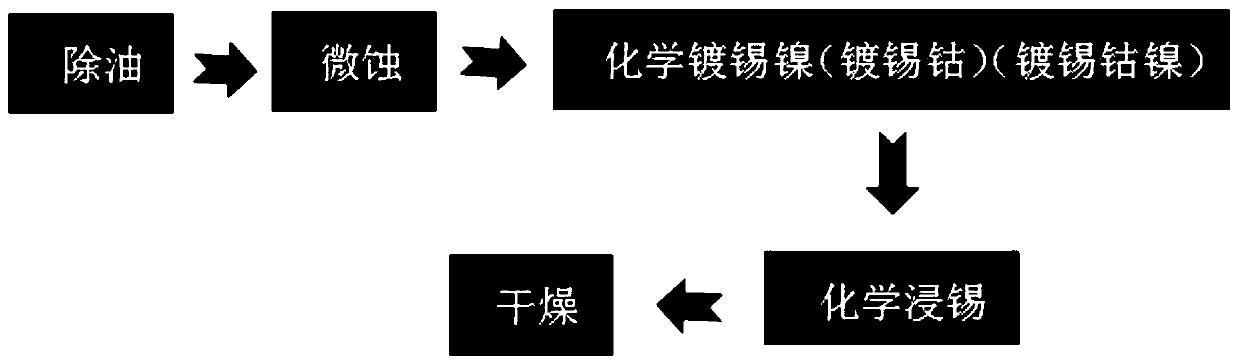

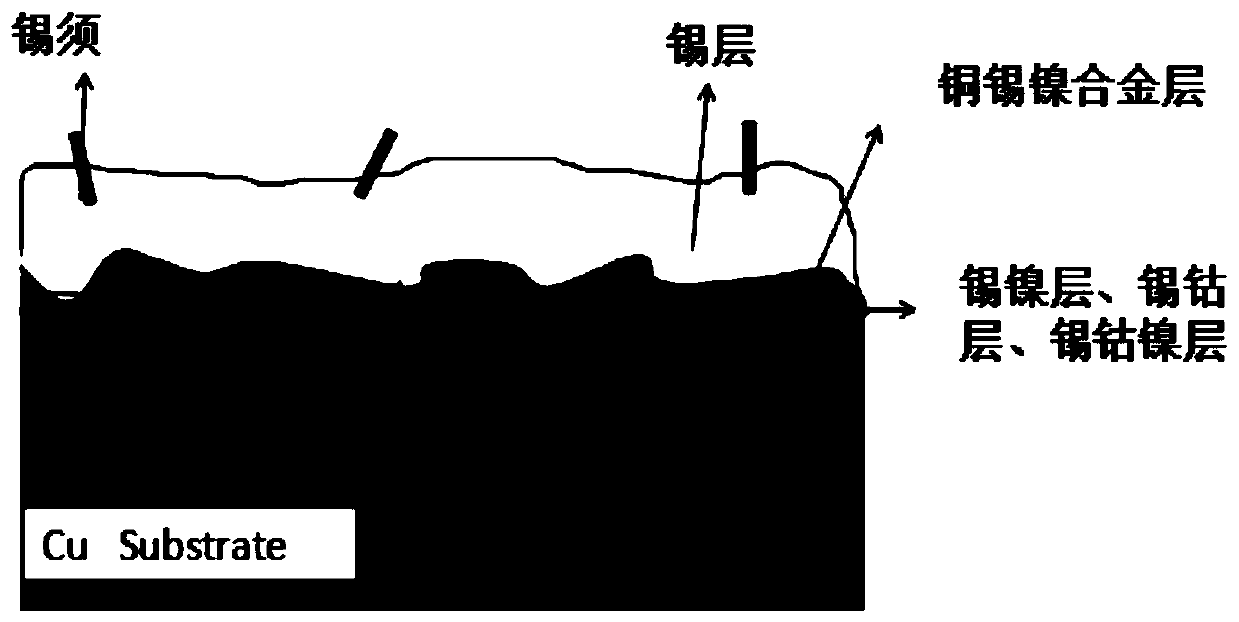

Chemical tin immersion plating solution used for suppressing tin whisker growth of printed circuit board and plating method

ActiveCN110004434AReduce manufacturing costReduced growth rateLiquid/solution decomposition chemical coatingSurface finishNickel salt

The invention belongs to the field of printed circuit board preparation, and provides a chemical tin immersion plating solution used for suppressing tin whisker growth of a printed circuit board and aplating method. Through metal achieving the function of blocking through deposition in the chemical tin immersion process, generation of a copper-tine alloy is suppressed, and the aim of eliminatingtin whiskers is achieved. The chemical tin immersion plating solution comprises at least one kind in tin salt with the concentration ranging from 20 g / L to 30 g / L, nickel salt with the concentration ranging from 10 g / L to 40 g / L and cobalt salt, a reducing agent with the concentration ranging from 20 g / L to 50 g / L, a complexing agent with the concentration ranging from 0.1 g / L to 50 g / L, a stabilizer with the concentration ranging from 1 g / L to 10 g / L and a pH adjusting agent. Compared with a traditional printed circuit board surface finishing technology, by means of the chemical tin immersionplating solution, the growth rate of the tin whiskers can be greatly reduced, the aim of suppressing tin whisker growth is achieved, growth of tin whiskers on the surfaces of devices is greatly reduced, and good application prospects are achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Antirust UV-cured water-based paint

The invention relates to the field of paints, especially to an antirust UV-cured water-based paint. The antirust UV-cured water-based paint comprises the following raw materials by weight: 45 to 55 parts of water-borne anion acrylic resin, 20 to 25 parts of inositol hexaphosphate, 10 to 15 parts of graphene fiber, 3 to 8 parts of zinc dust, 2 to 4 parts of a photoinitiator, 3 to 8 parts of a wetting dispersant, 0.3 to 0.6 part of a leveling agent, 5 to 10 parts of a cosolvent, 0.2 to 0.5 part of an anti-settling agent, 1 to 1.5 parts of an antifoaming agent and 150 to 250 parts of water. The antirust UV-cured water-based paint realizes antirust in a plurality of means at the same time, improves antirust capability of a rust-resisting paint and guarantees the characteristics of adhesion, durability, crack resistance, scrubbing resistance and the like of the rust-resisting paint.

Owner:CHENGDU NASHUO TECH

Agricultural waste fuel cell

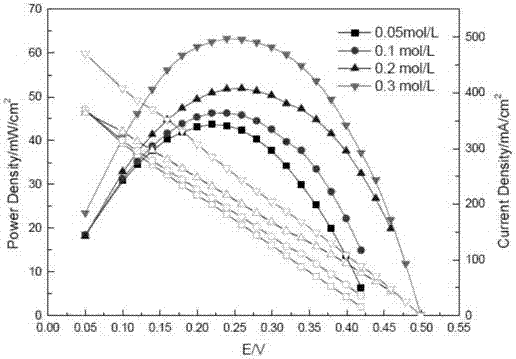

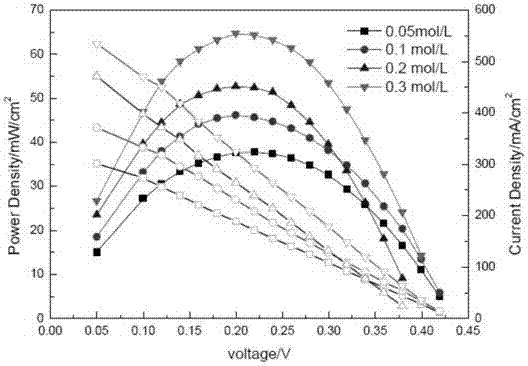

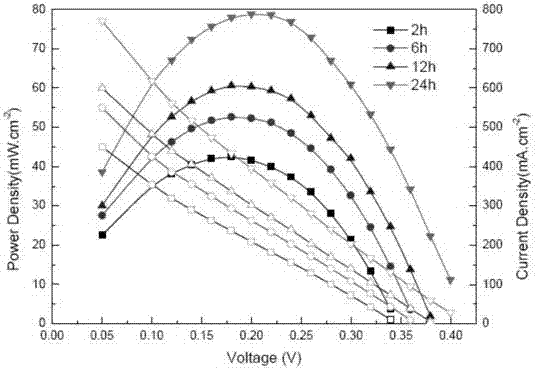

InactiveCN107342432ALower electrode potentialIncrease the output voltageBiochemical fuel cellsAgricultural engineeringMaterial transfer

The invention relates to an agricultural waste fuel cell. The agricultural waste fuel cell is characterized by comprising a positive electrode side composition material, a positive electrode circulation system, a proton exchange membrane, a negative electrode side composition material and a negative electrode circulation system, wherein the proton exchange membrane is placed between the negative electrode circulation system and the positive electrode circulation system; the positive electrode side composition material is stored in the positive electrode circulation system; the negative electrode side composition material is stored in the negative electrode circulation system; the materials on the two sides are isolated by the proton exchange membrane; the positive electrode side composition material transfers the carried electrons to an external circuit through the positive electrode circulation system; and the proton exchange membrane is combined with the negative electrode side composition material which is pumped through the negative electrode circulation system and external circuit electrons to generate water. By virtue of the agricultural waste fuel cell provided by the invention, the chemical energy of the organic matters in the agricultural waste can be converted into electric energy directly and efficiently at a low temperature; and meanwhile, the agricultural waste fuel cell has the advantages of environmental protection, high electric energy output power density and high electrochemical efficiency.

Owner:GUODIAN NEW ENERGY TECH INST

Antirust ultraviolet-curing paint

InactiveCN104910721AInhibit corrosionExcellent anti-rustAnti-corrosive paintsPhotoinitiatorDefoaming Agents

The invention relates to the field of paints, particularly an antirust ultraviolet-curing paint which is prepared from the following raw materials in parts by weight: 55-65 parts of acrylic resin, 10-15 parts of graphene, 10-15 parts of phytate, 5-10 parts of zinc powder, 3-5 parts of photoinitiator, 7-12 parts of reactive diluent, 0.3-0.6 part of leveling agent, 0.2-0.5 part of anti-settling agent and 1-1.5 parts of defoaming agent. Multiple antirust methods are performed at the same time, thereby enhancing the antirust capacity of the antirust paint and ensuring the adhesive force, durability, cracking resistance, scrub resistance and other characteristics.

Owner:CHENGDU NASHUO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com