Photo-anode composite film as well as preparation method and application of photo-anode composite film

A composite film, photoanode technology, applied in nanotechnology, liquid chemical plating, electrolytic coatings, etc. for materials and surface science, can solve the problem of uneven adhesion on the outer surface of nanotubes, low photoelectric conversion efficiency, and inability to adhere and other problems, to achieve the effect of good photogenerated cathodic protection effect, remarkable cathodic protection effect and strong stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of photoanode composite film comprises the following steps:

[0034]Take a rectangular pure titanium foil with a thickness of 0.1 mm. The purity of the titanium foil is greater than 99.7%, the length is 1.5 cm, and the width is 1.0 cm. It is ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 30 minutes to obtain a titanium matrix sample.

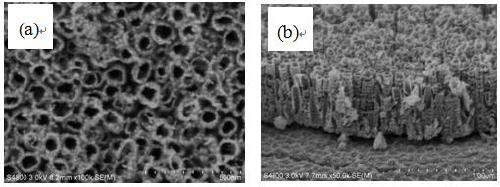

[0035] Preparation of TiO by anodic oxidation 2 Nanotube array film:

[0036] Prepare an electrolyte solution with ammonium fluoride, glycerol and water, the volume ratio of glycerol to water in the electrolyte solution is 3:2, and the mass fraction of ammonium fluoride is 0.5%; the titanium matrix sample obtained after treatment The anode is used as the anode, and the platinum sheet is used as the cathode. At room temperature, anodize at 20V for 1.0h. After the reaction, the prepared sample is washed with a large amount of deionized water, dried and calcined at 450°C for 120min in a m...

Embodiment 2

[0046] The preparation method of photoanode composite film comprises the following steps:

[0047] Take a rectangular pure titanium foil with a thickness of 0.05mm, the purity of the titanium foil is greater than 99.7%, the length is 1.0cm, and the width is 0.5cm, and it is ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 25 minutes successively to obtain a titanium matrix sample;

[0048] Preparation of TiO by anodic oxidation 2 Nanotube array membrane, ammonium fluoride, glycerol and water were used to prepare the electrolyte, the volume ratio of glycerol to water in the electrolyte solution was 3:1, and the mass fraction of ammonium fluoride was 0.55%. The titanium matrix sample obtained after treatment was used as the anode, and the platinum sheet was used as the cathode. At room temperature, it was anodized at 15V for 0.5h. After the reaction, the prepared sample was washed with a large amount of deionized water, dried and placed in a muffle fu...

Embodiment 3

[0052] The preparation method of photoanode composite film comprises the following steps:

[0053] Take a rectangular pure titanium foil with a thickness of 0.15mm, the purity of the titanium foil is greater than 99.7%, the length is 2.0cm, and the width is 1.5cm, and it is ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 40 minutes successively to obtain a titanium matrix sample;

[0054] Preparation of TiO by anodic oxidation 2 For the nanotube array membrane, ammonium fluoride, glycerol and water are used to prepare an electrolyte solution, the volume ratio of glycerol to water in the electrolyte solution is 3:3, and the mass fraction of ammonium fluoride is 0.45%. The treated titanium matrix sample was used as the anode, and the platinum sheet was used as the cathode. At room temperature, anodize at 25V for 1.5h. After the reaction, the prepared sample was washed with a large amount of deionized water, dried and placed in a muffle furnace. Calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com